Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

459results about How to "Reduce frictional heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

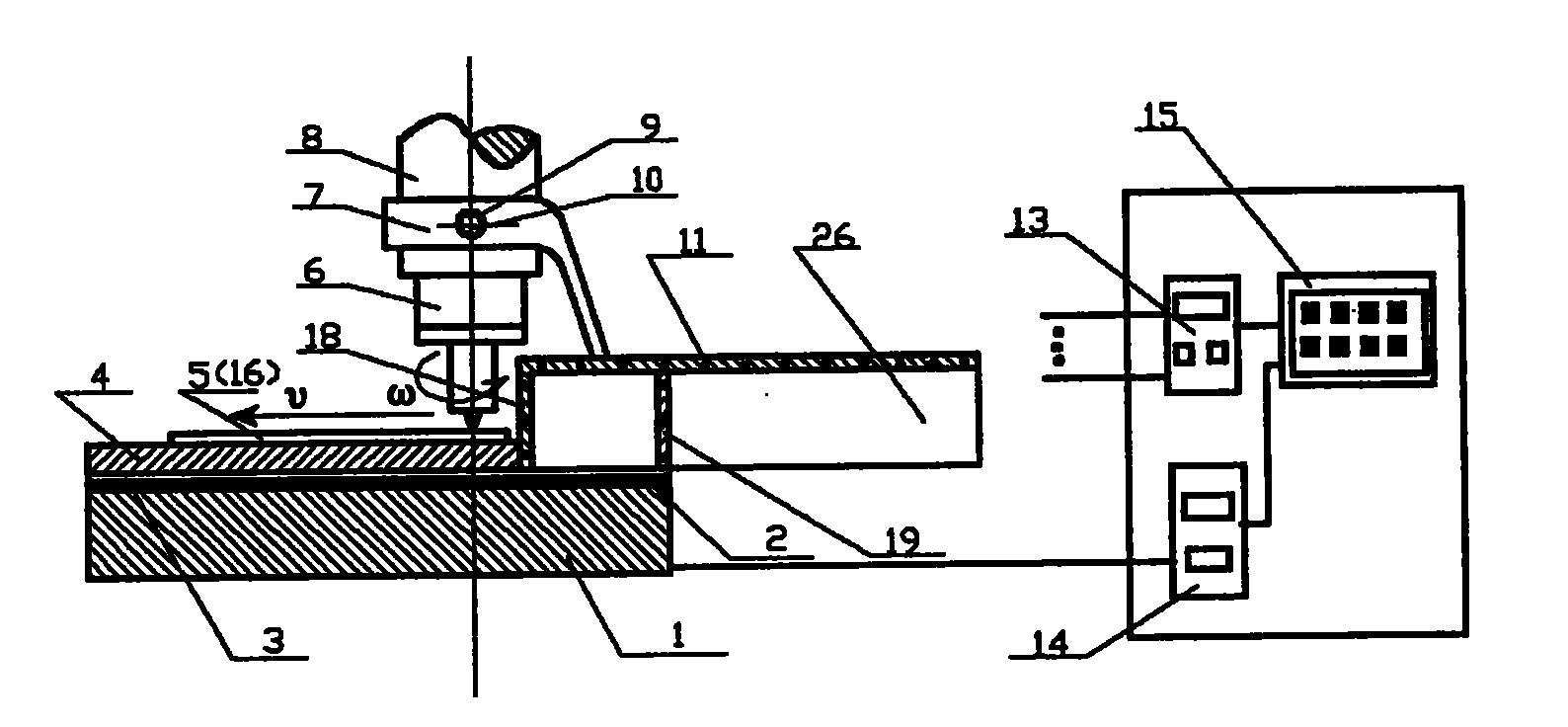

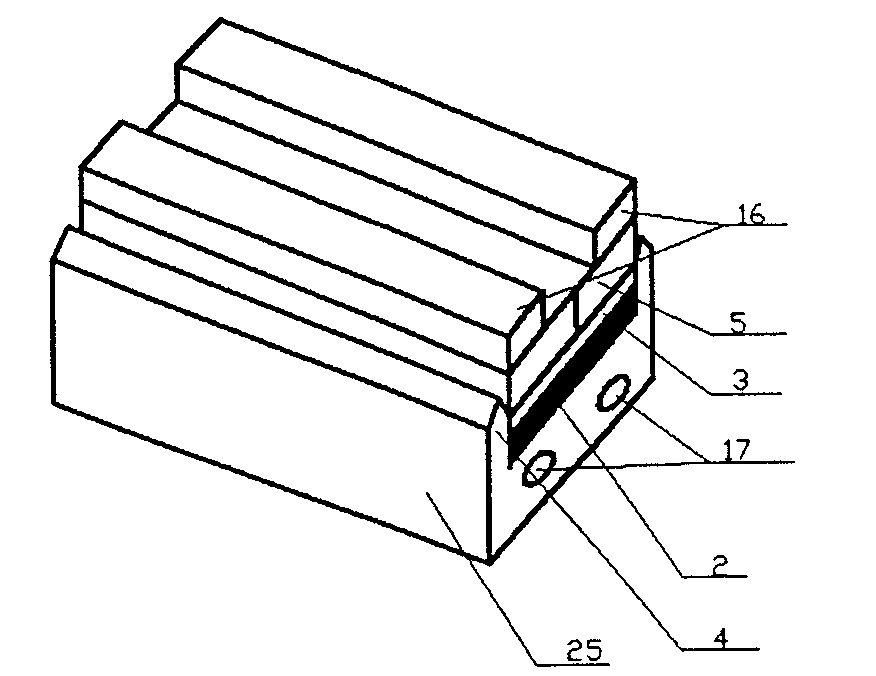

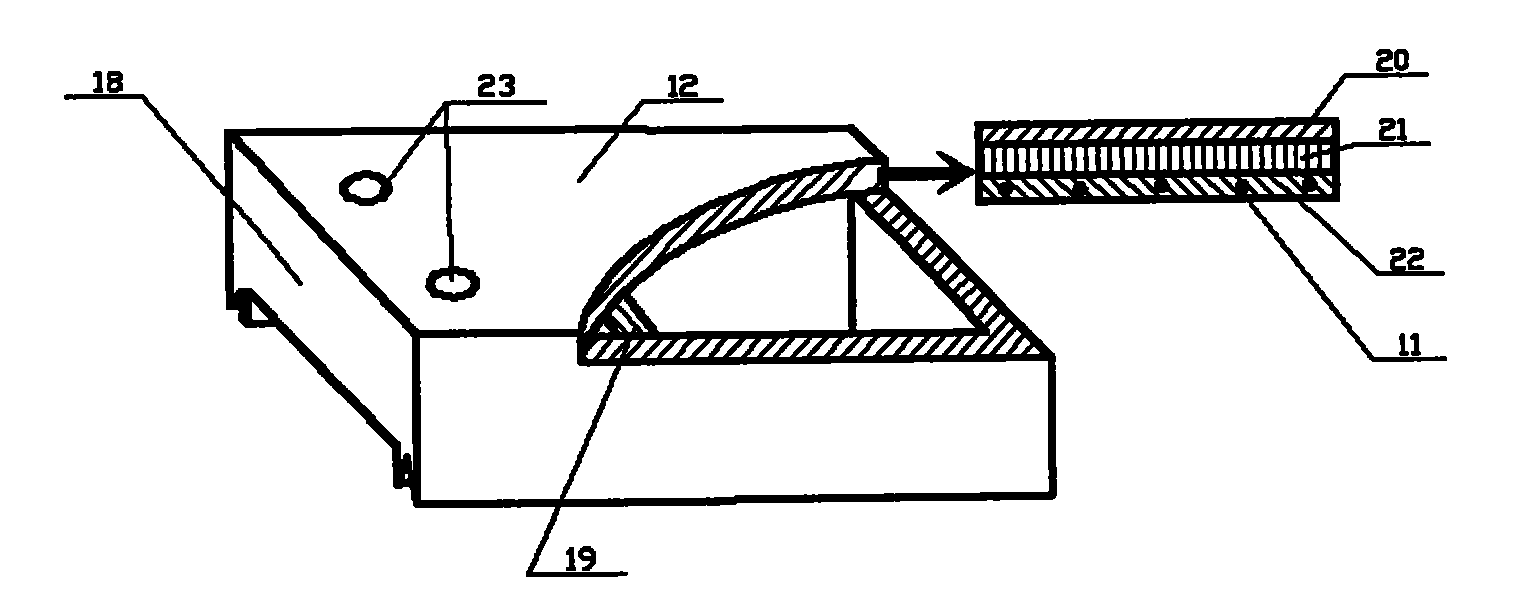

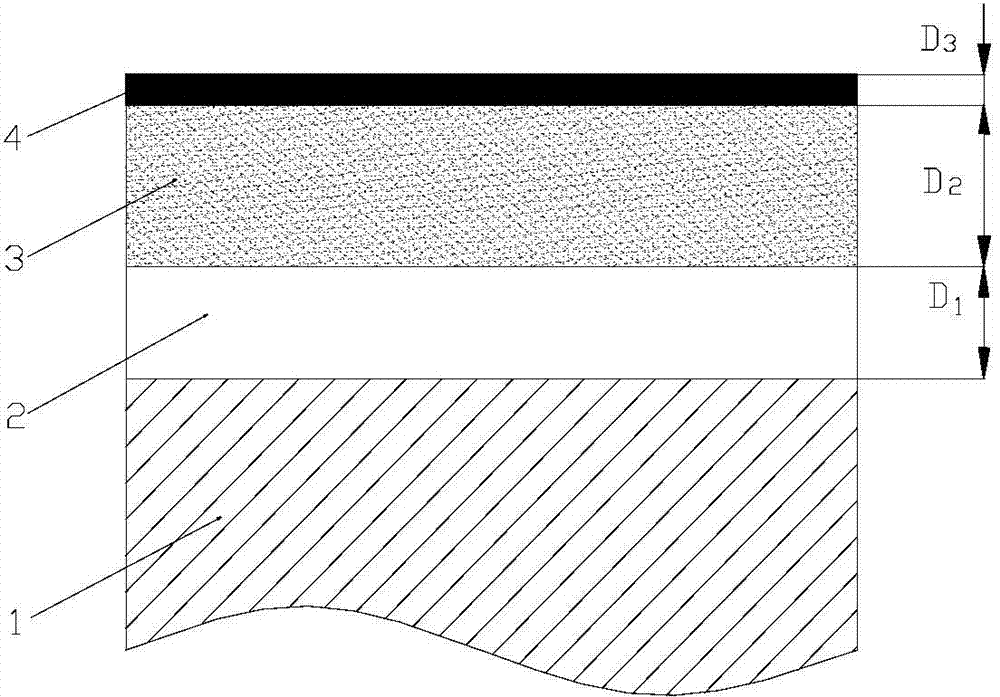

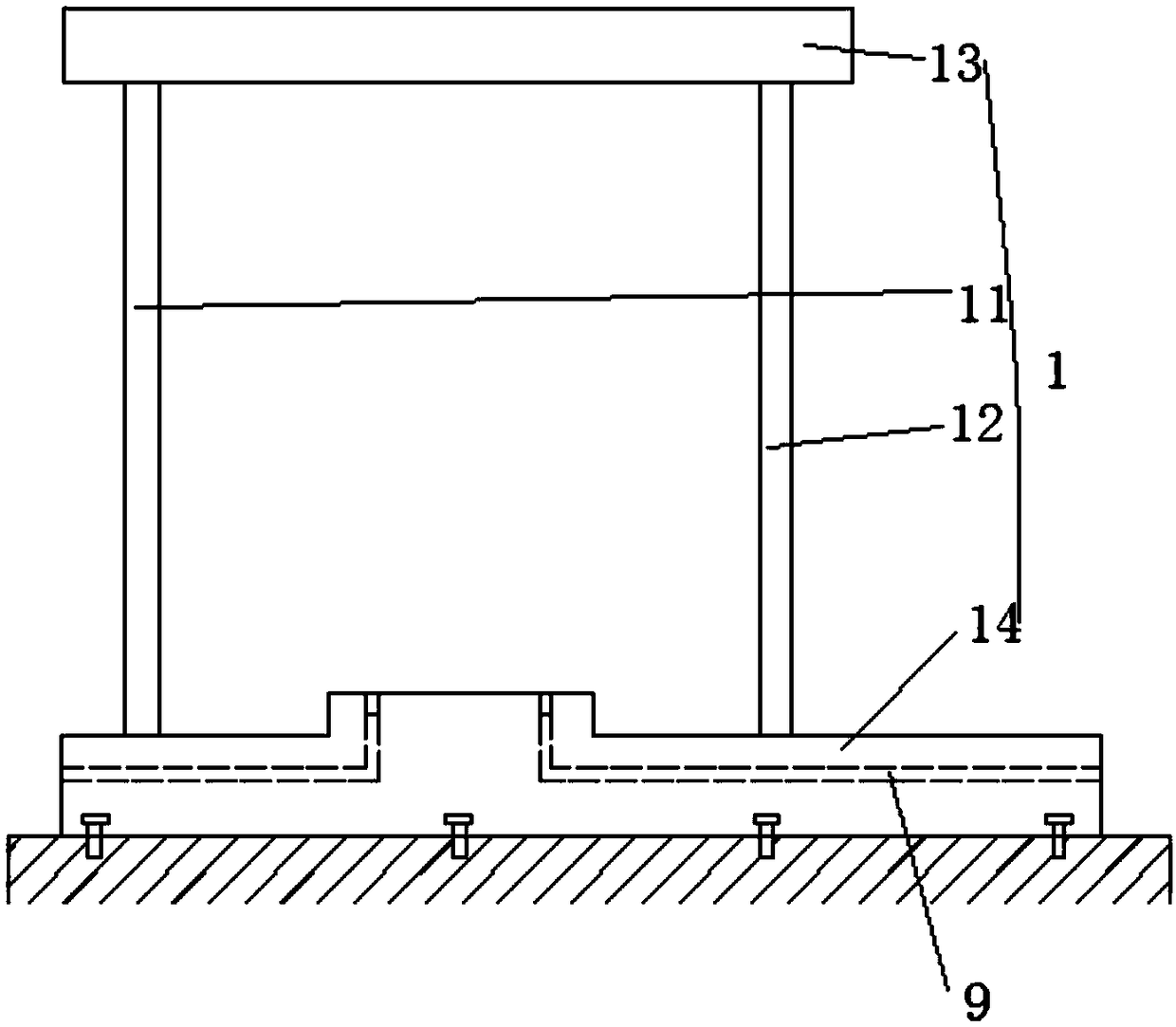

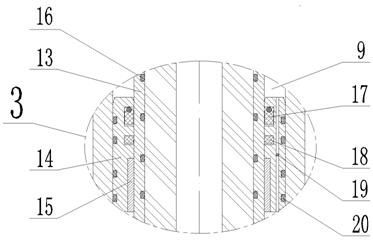

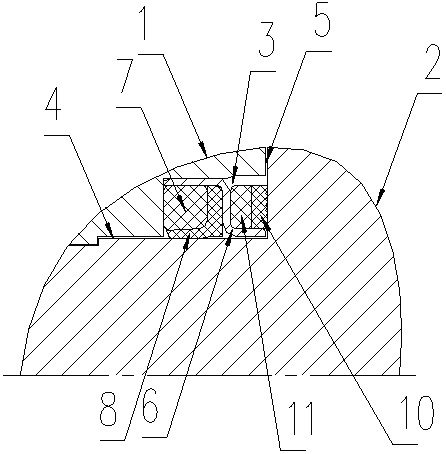

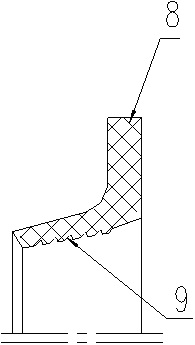

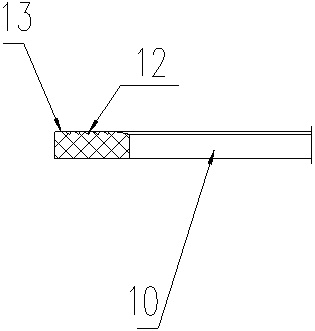

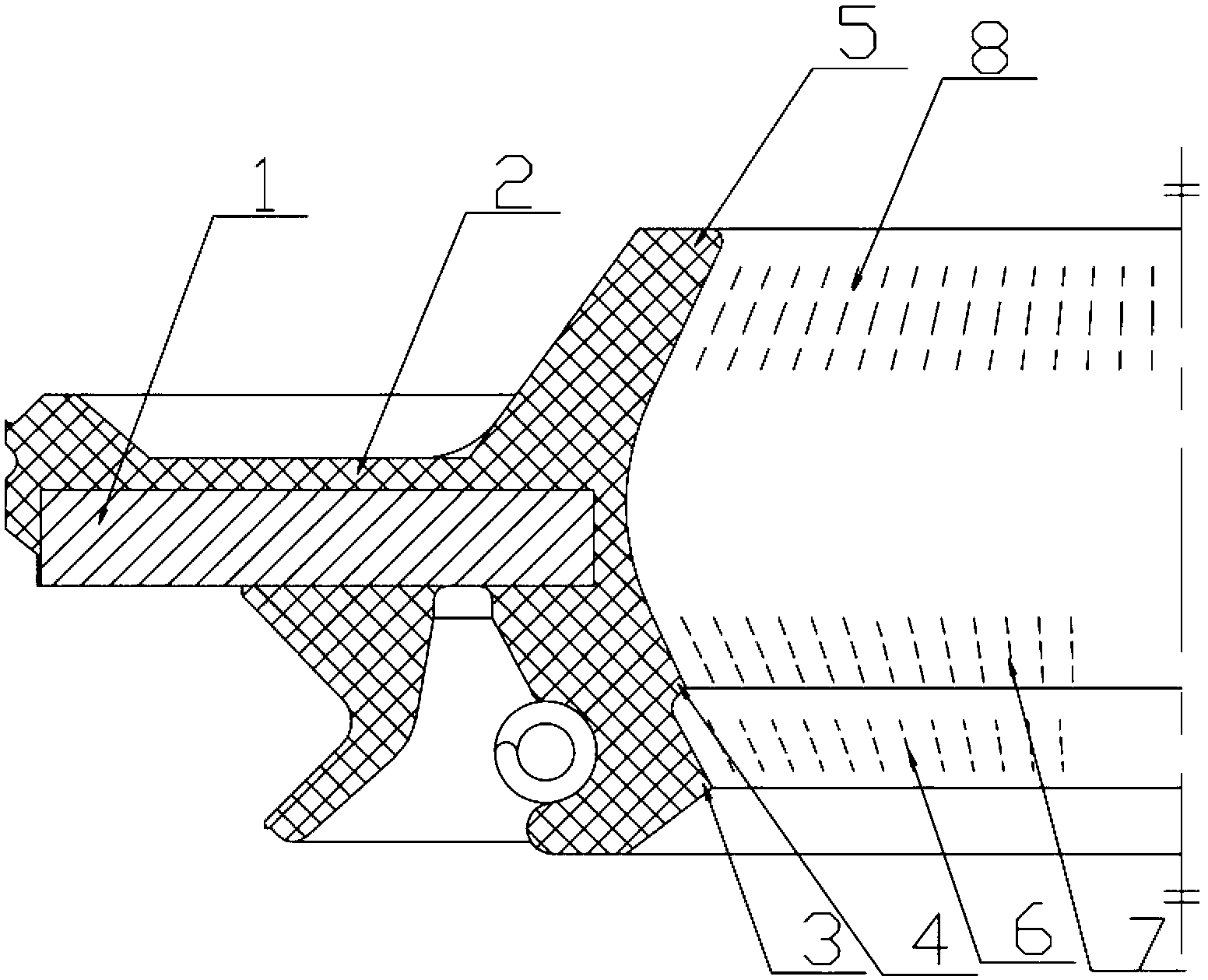

Method and device for controlling residual stress on stir friction welding surface

InactiveCN101774079AAvoid Welding Quality DeteriorationRealize full CNC controlNon-electric welding apparatusEngineeringControl equipment

The invention relates to a method and a device for controlling a residual stress on a stir friction welding surface. According to the method, an insulation box capable of moving along a stirring head is adopted to insulate the weld joint and parent metal after welding, and then furnace cooling is performed so as to reduce the residual stress on the stir friction welding surface. The device mainly comprises a sucking-disc type fixture, the insulation box and control equipment, wherein the insulation material mainly comprises fire bricks, asbestos and steel plates. During welding, the insulation box moves along the stirring head and insulates the welded workpiece continuously; and after the welding, the whole workpiece enters the insulation box to be insulated and is cooled with the furnace after being insulated for a certain time so as to control the residual stress on the welding surface and the deformation, wherein the insulating temperature is the critical temperature of the heat treatment of the materials. The device realizes full automation in the whole welding process and avoids the reduction in the welding quality due to a human factor. The method and the device have the advantages of simple device, convenient operation, high technical economic benefit, and high welding quality of the stir friction welding.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Metal-based self-lubricating composite coating and preparation method thereof

ActiveCN104746071AHigh friction and noise reduction performanceReduce frictional heatMolten spray coatingVacuum evaporation coatingFriction reductionBase metal

The invention discloses a metal-based self-lubricating composite coating; the metal-based self-lubricating composite coating comprises a thermal barrier transition layer, a self-lubricating interlayer and a self-lubricating working layer which are sequentially coated from the surface of base metal; the thermal barrier transition layer comprises 83-88% of a mixture P, 10-15% of nano Cr powder and 2% of Y2O3; the mixture P comprises 45-50% of zirconium oxide, 12-20% of aluminium oxide, 2-4% of palladium oxide and 26-41% of Ni powder; the self-lubricating interlayer comprises 91-98% of NiCrSiB-401 and 2-9% of carbon fibre; and the self-lubricating working layer comprises 2-8% of Cr, 0.2-5% of Y, 0.3-5% of Ce, 0.2-6% of Ta and the balance of C. The metal-based self-lubricating composite coating disclosed by the invention has the advantages of being high in thermal barrier property, self-lubricating property, friction reduction and noise reduction properties and the like.

Owner:东台市五烈镇乡镇企业集体资产经营有限公司

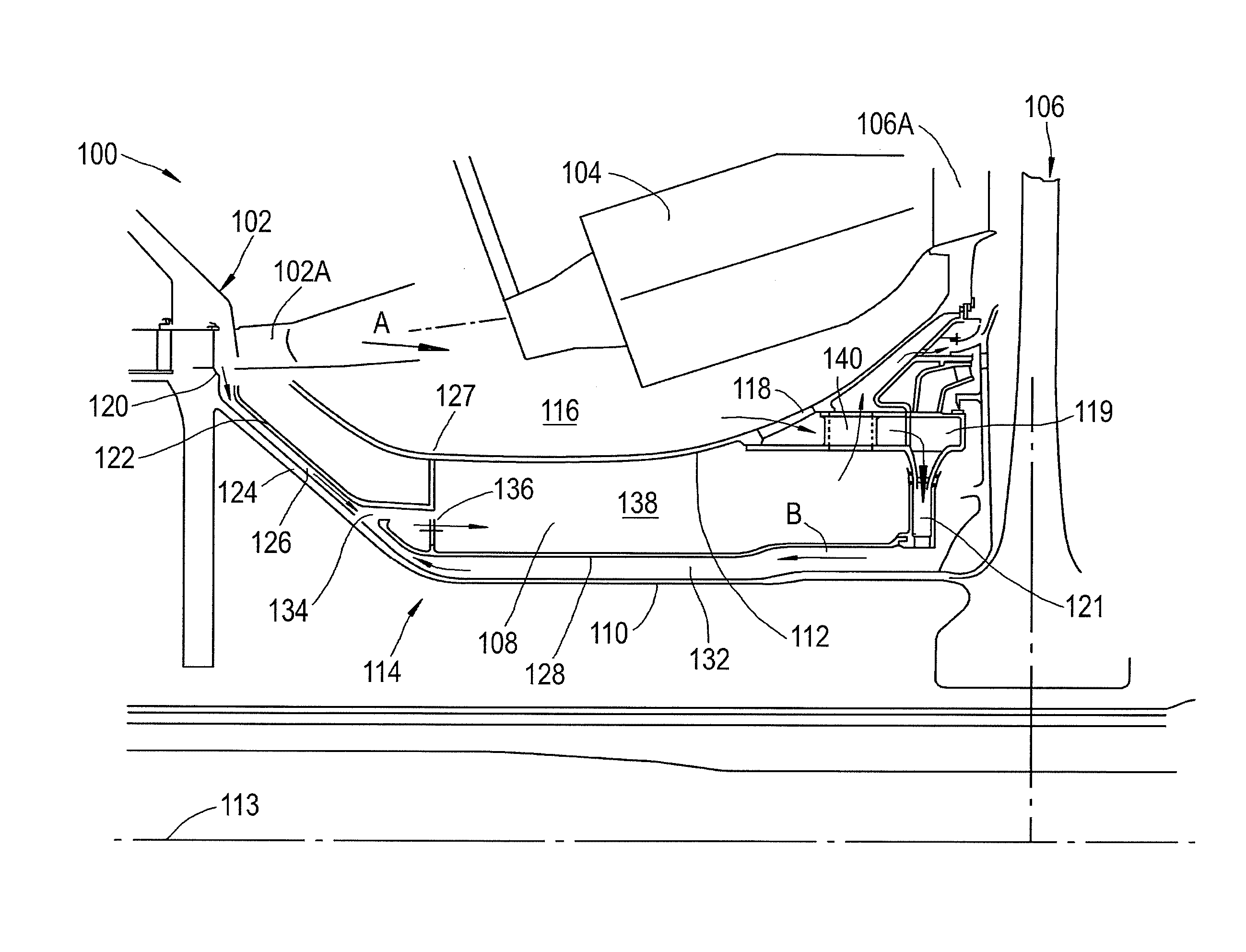

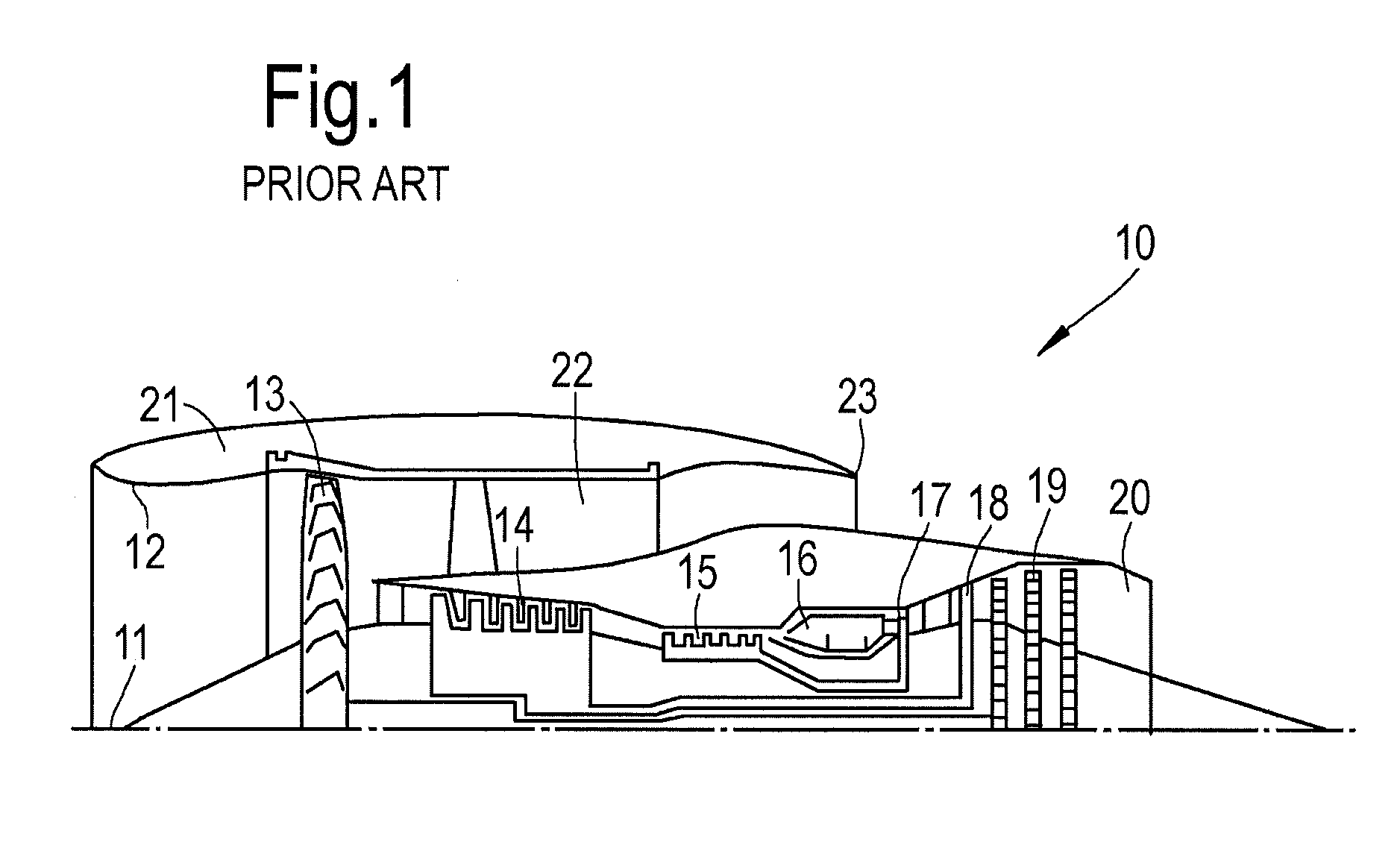

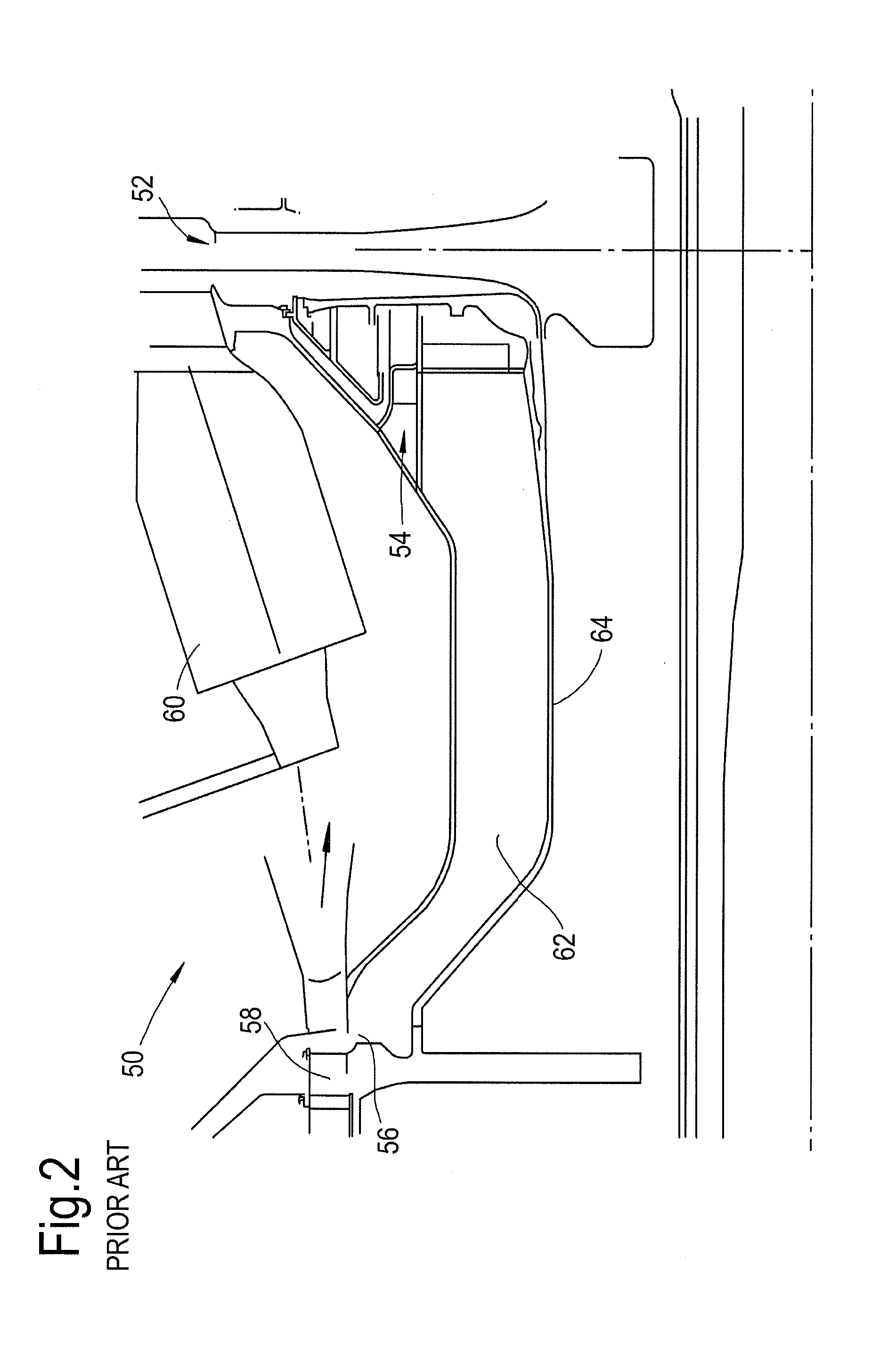

Axial flow machine cooling system

ActiveUS20150047359A1Reduce heat loadIncrease tangential speedEngine fuctionsTurbine/propulsion engine coolingCombustorTurbine

This invention concerns a system for cooling components in a gas turbine engine, the gas turbine engine including a compressor for driving a primary gas flow to a combustor and a turbine arranged to be driven by combustion gases from the combustor, wherein the system includes: an annular cooling flow passage arranged for fluid communication between the compressor and the turbine, the flow passage having a first inlet arranged to receive gas from the primary gas flow downstream of compressor, and a second inlet located upstream of the first inlet, wherein the annular cooling flow passage has at least one internal wall for guiding airflow from the first inlet towards the airflow from the second inlet, the airflow from the first and second inlets coalesce within the annular flow passage prior to passing along the passage in a direction from the compressor to the turbine.

Owner:ROLLS ROYCE PLC

Wear-resistant mechanical sealing structure on end face

ActiveCN1818434AExtended service lifeStrong hydrodynamic effectEngine sealsWear resistantEngineering

A wear-proof mechanical end face sealing structure comprises mechanical sealing movable and fixed rings, on the end faces of which are machined microlugs arranged a girdle according to the centre of the end face. Beside the girdle is disposed a ring sealing dam with a smooth surface symmetrically about the centre of the end face and there is at least one ring sealing dam on the end face. The parametric range of the microlug structure is that, the aspect ratio or the breadth depth ratio is 0.5~30, the height is 2~500 mu m, the area density is 0.1~0.7 and the distance between the section axile wires of the adjacent microlugs is 0.05~1.0 mm.

Owner:ZHEJIANG UNIV OF TECH

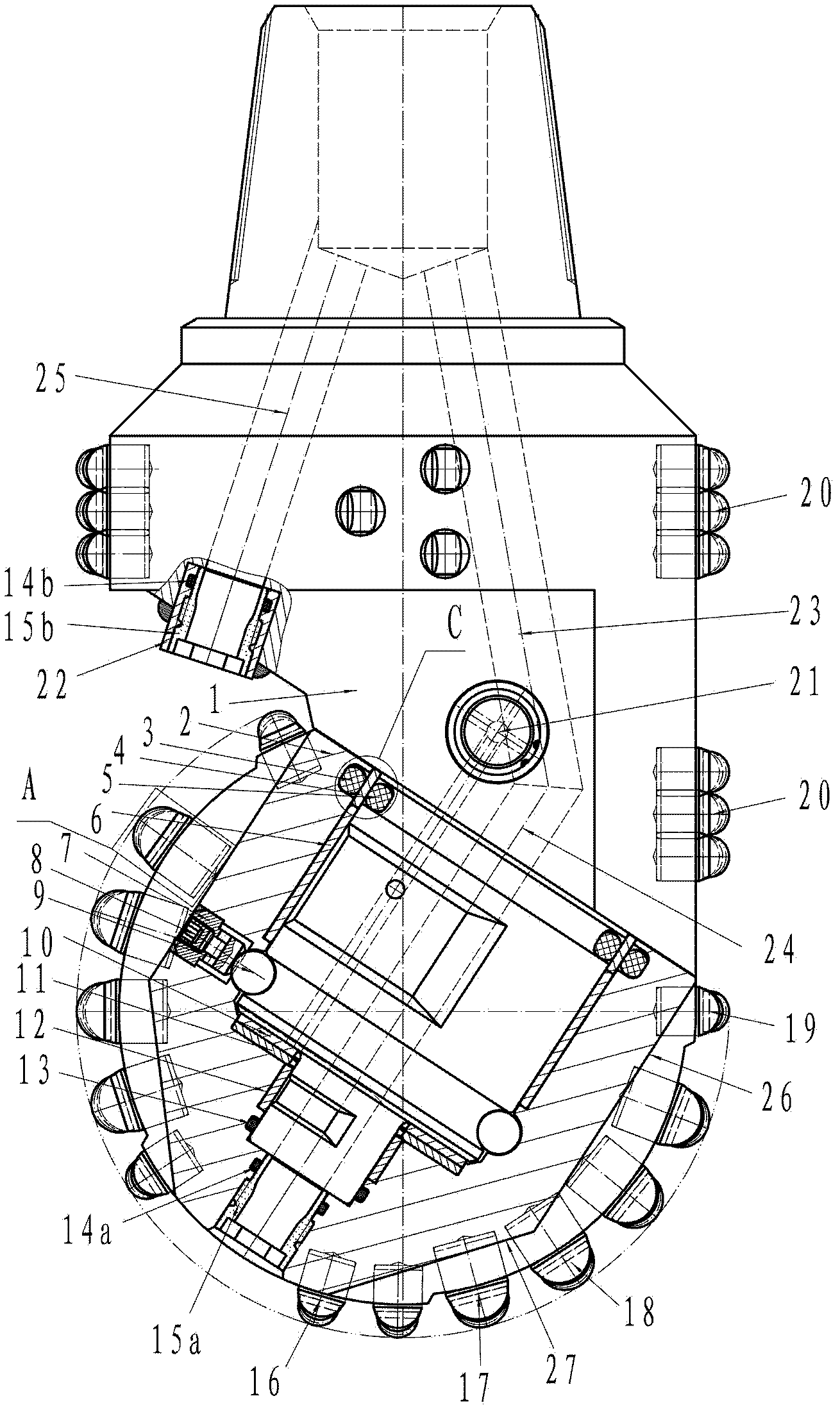

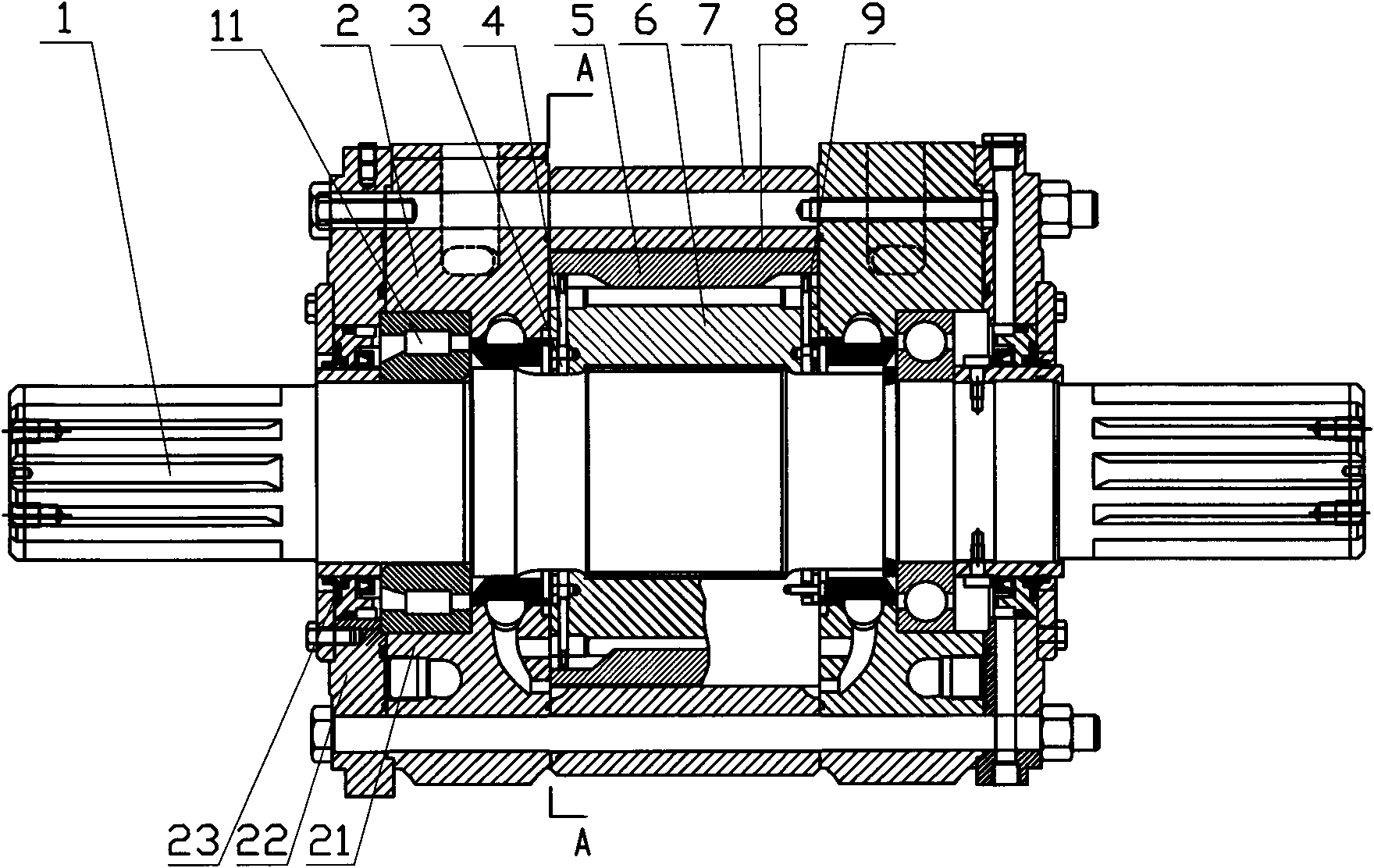

Single-roller bit with PDC (polycrystalline diamond compact) composite plates

ActiveCN102536124AReduce frictional heatExtend your lifeDrill bitsConstructionsWork performanceWell drilling

The invention discloses a single-roller bit with PDC (polycrystalline diamond compact) composite plates, which is characterized in that diamond PDC plates are brazed on a toothed column and then are embedded on a roller, a bearing is sealed with a metal ring in a combined manner by two O-shaped rings, high-speed rotating radial combined sealing of a roller groove diameter and a ring outer diameter and high-speed rotating radial combined sealing of a ring inner diameter and a shaft groove diameter are respectively realized alternatively by the aid of the two O-shaped rings, the sealing life of each single O-shaped ring is prolonged, and bearing abrasion speed is reduced by the aid of double thrust cushions; gauge protection ability and work stability of the bit are increased by two-stage gauge protection; and high-speed slurry sprayed out via a hydraulic jetting system cleans rocks of a shaft bottom, a surface of the roller and PDC teeth and carries rock scraps at the shaft bottom to return upwards, the multiple groups of gauge protection PDC composite plates are arranged reasonably, work indexes of the bit are greatly increased under the condition of ultra-high rotation speed, well drilling cost is reduced, the rotation speed of the bit and torque of the PDC plates are reduced as compared with a PDC bit, damage to the PDC plates due to rotation is reduced, and work performances of the single-roller bit can be greatly improved.

Owner:陕西金刚石油机械有限公司

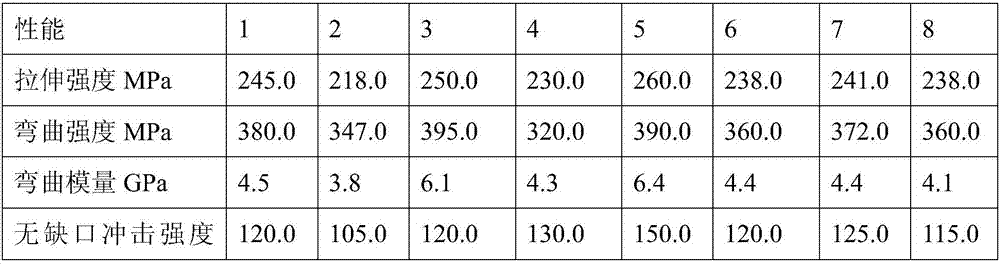

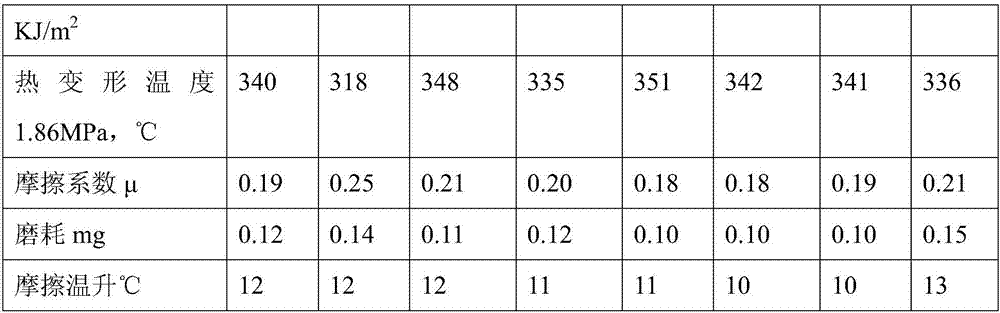

Heat-resistant and wear-resistant composite material and preparation method and application thereof

The invention discloses a heat-resistant and wear-resistant composite material and a preparation method and an application thereof and belongs to the field of high polymer wear-resistant materials. The heat-resistant and wear-resistant composite material is prepared from the following raw materials in parts by weight: 100 parts of thermoplastic resin, 10-40 parts of carbon fiber, 40-100 parts of a wear-resistant material, 0.1-1.0 part of a heat conduction material, 0.5-2.0 parts of a coupling agent, 0.2-1.0 part of an antioxidant and 0.5-5.0 parts of a lubricant. The heat-resistant and wear-resistant composite material has the characteristics of light specific gravity and high strength, the properties, such as the wear resistance, the corrosion resistance and the ageing resistance, are improved, and the heat-resistant and wear-resistant composite material is a composite material with excellent overall performance and can effectively replace metal alloy and ceramic materials.

Owner:长沙五犇新材料科技有限公司

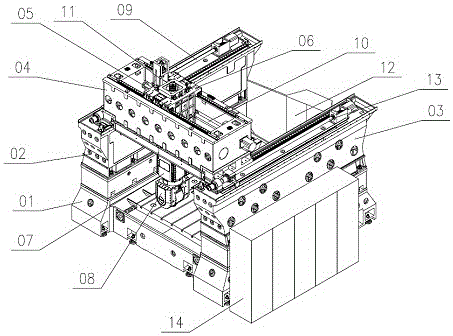

Thermal deformation suppression middle type high-speed crown block gantry five-axis machining center

InactiveCN106736799AImprove machining accuracyWide range of processingFeeding apparatusLarge fixed membersStructural deformationThermal deformation

The invention discloses a thermal deformation suppression middle type high-speed crown block gantry five-axis machining center. A workbench is directly cast on a base; a left bridge and a right bridge are installed on the two sides of the base; linear guide rails are installed on the left bridge and the right bridge correspondingly; a cross beam is installed on the left bridge and the right bridge through X-axis sliding blocks on the two sides; the middle of the cross beam is hollowed-out; four guide rails are arranged on the upper side and the lower side of the cross beam; and a left sliding base and a right sliding base are installed in the middle of the cross beam through the sliding blocks. A left ram and a right ram are connected into a whole through a Y-axis sliding block and a connection board, four linear guide rails are arranged on the rams, and the rams are installed in the middle of the left sliding base and the right sliding base through Z-axis sliding blocks. The middle type design of the movement components in the thermal deformation suppression middle type high-speed crown block gantry five-axis machining center effectively conduct temperature rise generated by movement, so that structural deformation is uniform and influence of thermal deformation on the precision machining of products is reduced. The thermal deformation suppression middle type high-speed crown block gantry five-axis machining center is stable in operation and performance and suitable for precision machining in the automotive die field.

Owner:NANTONG GUOSHENG INTELLIGENCE TECH GRP CO LTD

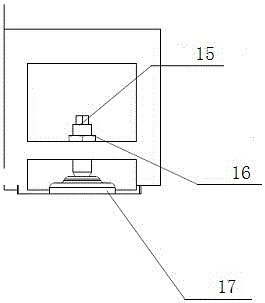

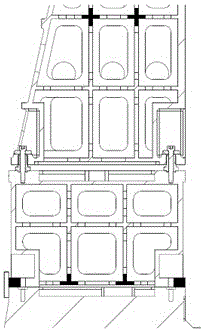

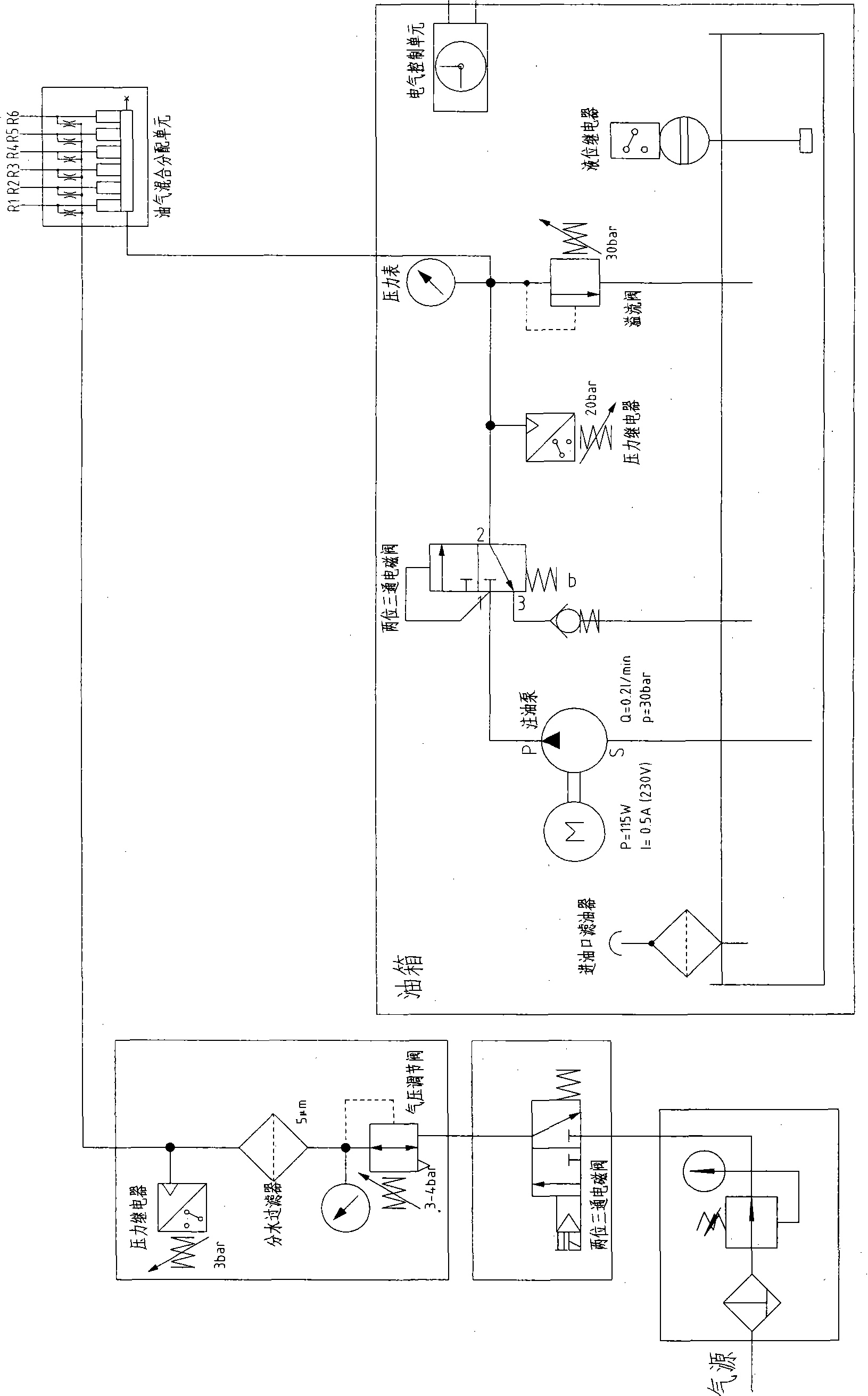

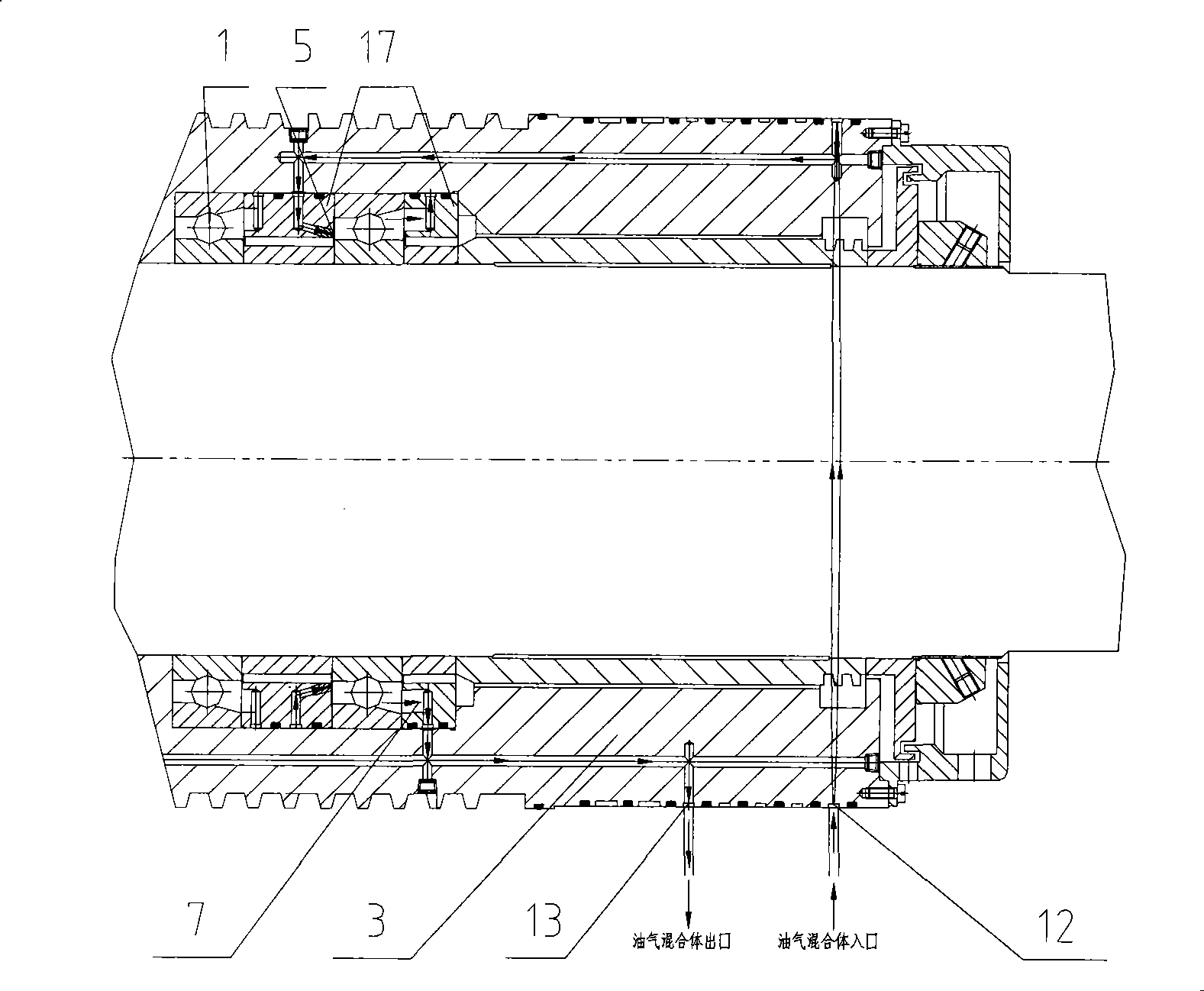

Large-size horizontal machining-center high-speed main-axle oil gas lubricating system

InactiveCN101362300ALow calorific valueSlow heatingMaintainance and safety accessoriesGas lubricationControl signal

The invention relates to an oil-gas lubrication system for a high speed main shaft in a large scale horizontal machining center. The oil-gas lubrication is adopted for the high speed main shaft with the diameter of large than 160 mm, and an external gas source and an external oil tank are arranged. The oil-gas lubrication system is characterized in that the system is composed of an oil-gas generating device and an oil-gas delivery mechanism, wherein, the lubrication circulation and the operation of an oil-filling pump are controlled through the program of an electric control unit inside the oil-gas generating device, the electric control unit is connected with the control system of a machining center through a connecting terminal, and the output of a control signal and the remote control of the oil-gas lubrication are realized; the gas source pipeline of the oil-gas generating device and the oil tank are respectively provided with an inductor and a pressure valve, and the pump is communicated with an oil-gas mixing and distribution unit inside the oil-gas generating device; a plurality of delivery pipelines of the oil-gas mixing and distribution unit are respectively connected with an oil-gas connector arranged at the bottom of a main shaft box, the oil-gas connector is communicated with an oil-gas channel on the bearing sleeve of the main shaft and the oil-gas channel on an annular outer sleeve gasket, and an oil-gas circulation delivery channel from entering the main shaft to being discharged out of the main shaft is formed. The friction coefficient between the inner / outer sleeve gasket and balls of the bearing system can be as low as 0.001 or even lower, simultaneously, the bearing of the main shaft is ensured to run in the required temperature range, the self control design can also ensure that once the running of the lubrication system is abnormal, the automatic shutdown of the machine tool can be implemented.

Owner:ZHONGJIE MACHINE TOOL

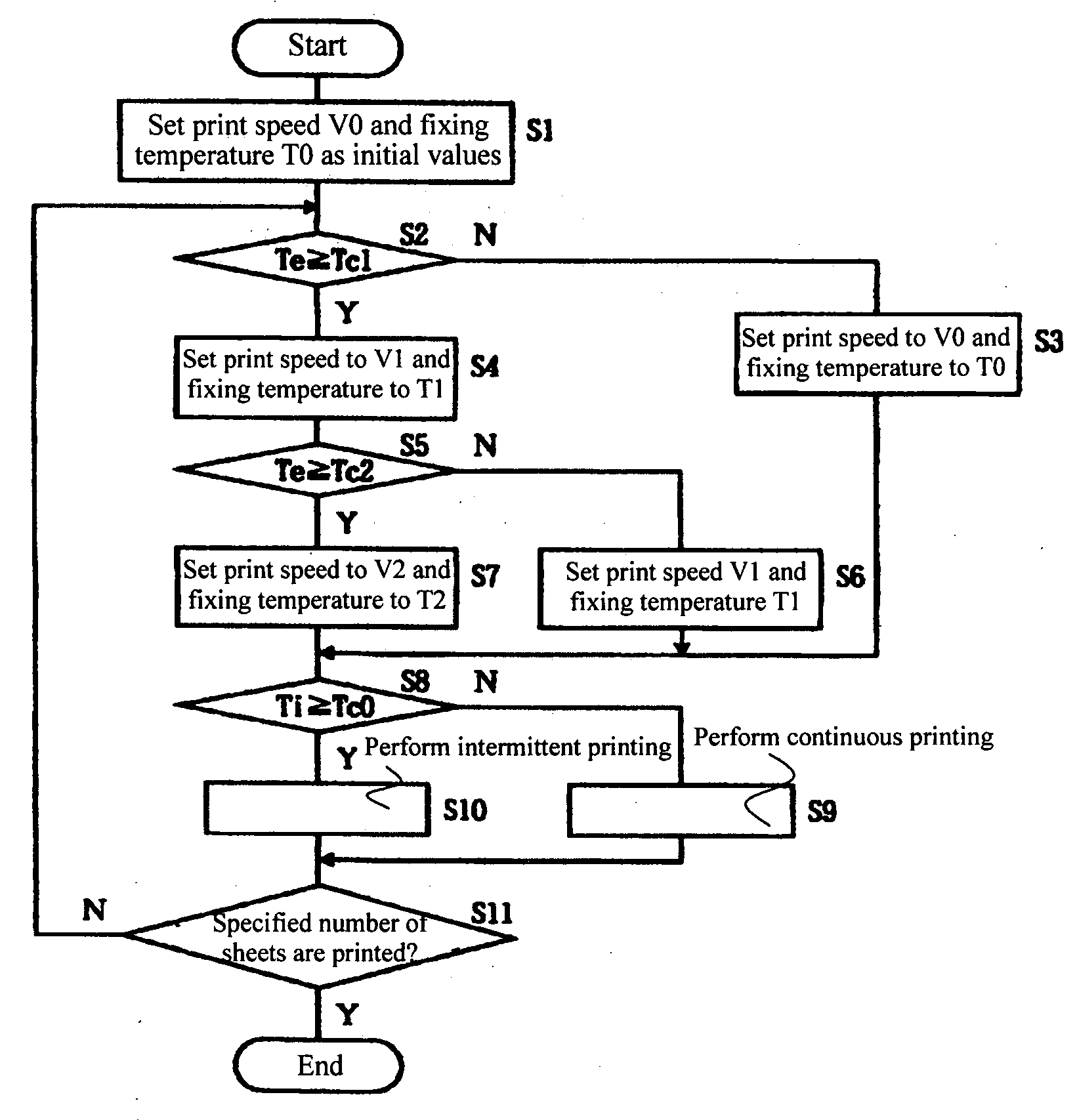

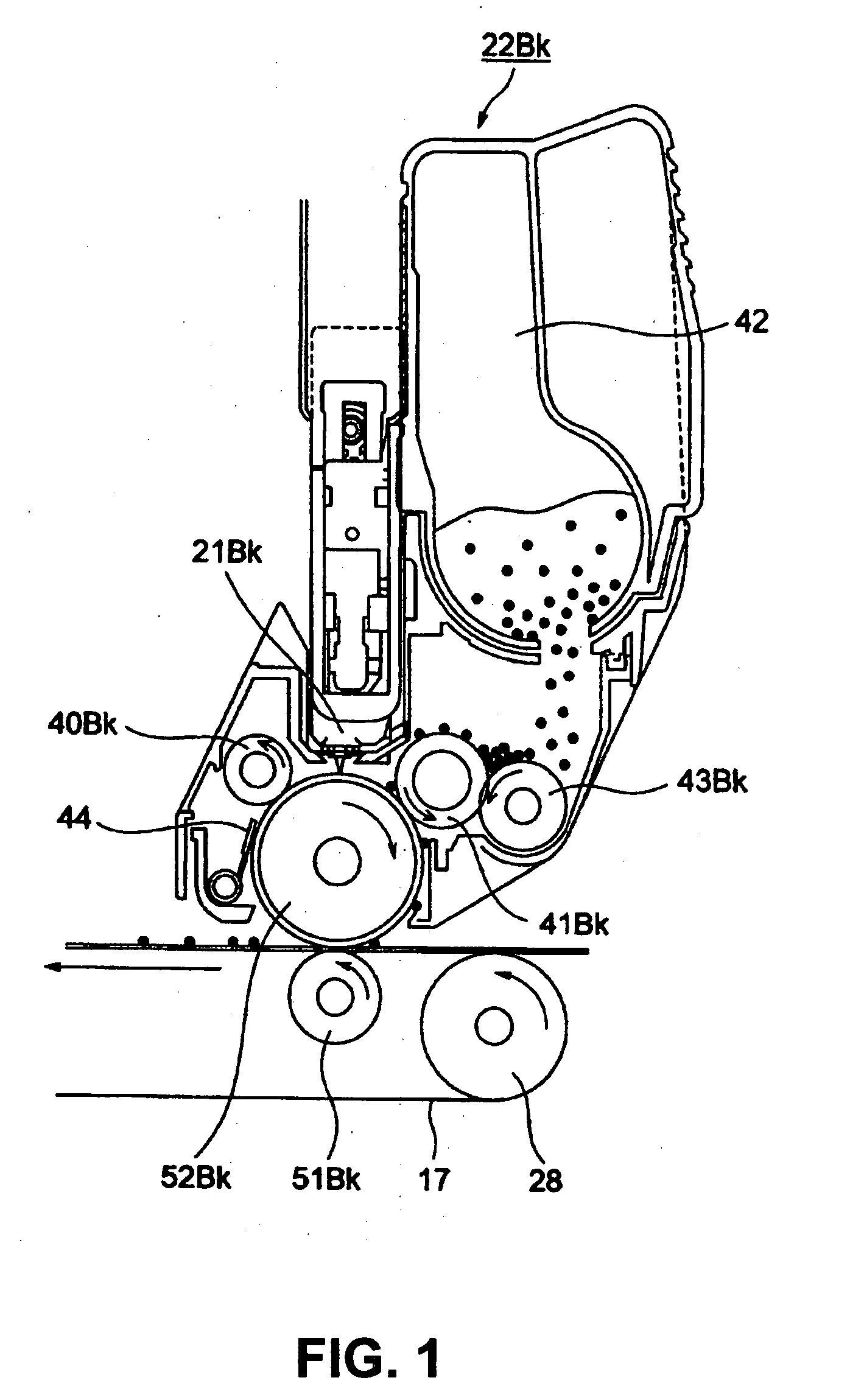

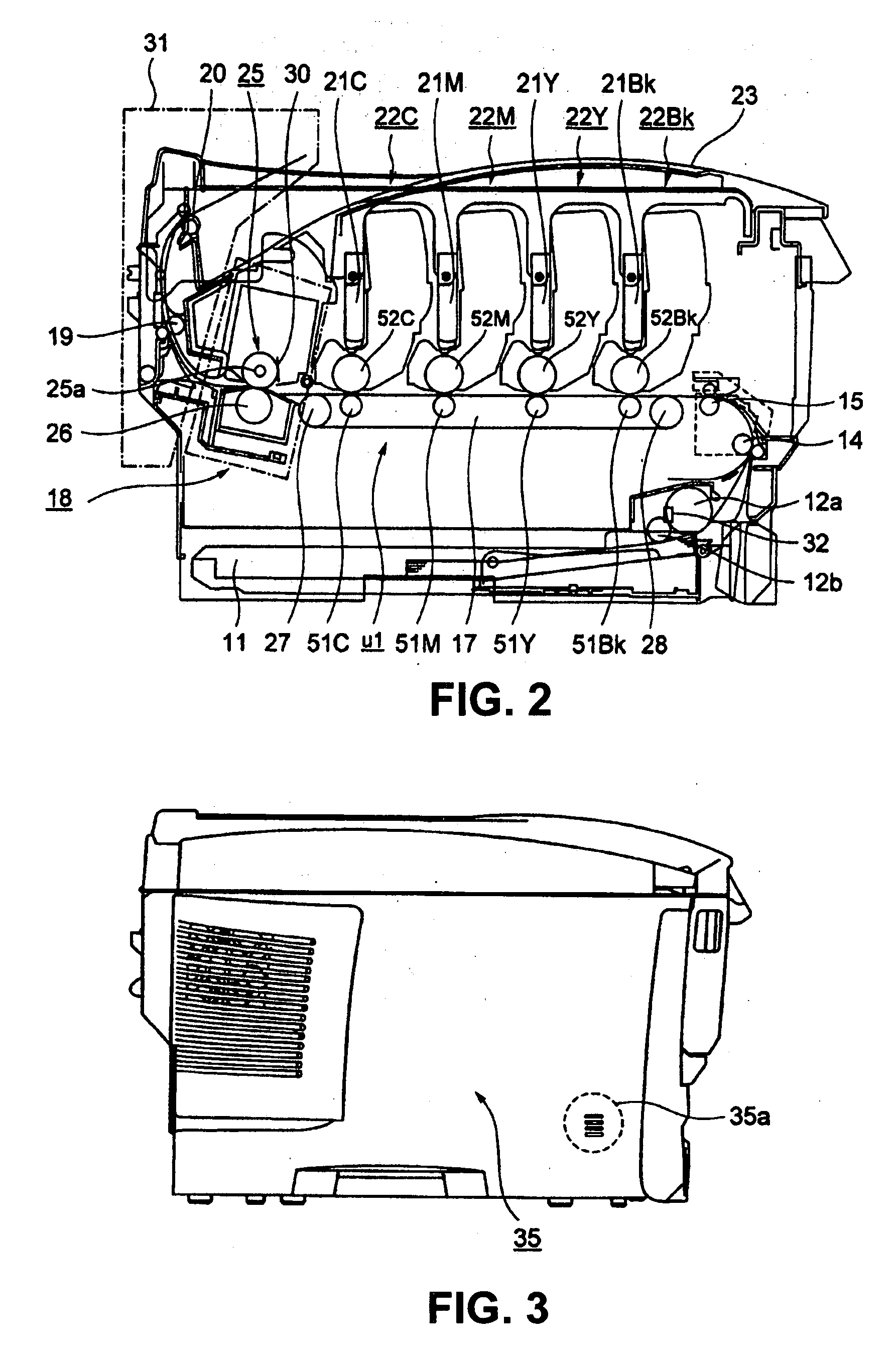

Image forming apparatus

InactiveUS20070212083A1Avoid flowReduce frictional heatElectrographic process apparatusImage formationMechanical engineering

An image forming apparatus includes an image supporting member; a developer supporting member for attaching developer to the image supporting member to form a developer image; a transfer unit for transferring the developer image to a recording medium; a driving unit for driving at least one of the image supporting member, the developer supporting member, and the transfer unit; an external temperature detection unit for detecting an environmental temperature outside the image forming apparatus; and a control unit for setting a driving speed of the driving unit according to the environmental temperature.

Owner:OKI DATA CORP

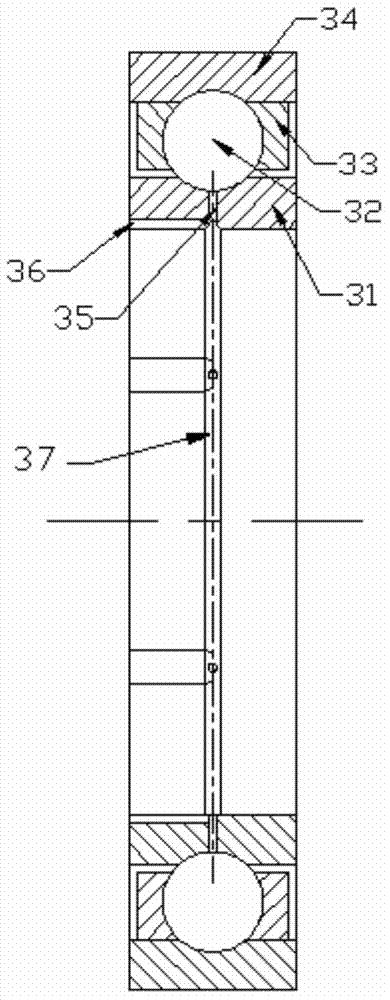

High-speed lower lubricating device for bearing ring

InactiveCN104747602ACause delay in deliveryEfficient collectionBearing componentsEngineeringPetroleum engineering

The invention discloses a high-speed lower lubricating device for a bearing ring. The high-speed lower lubricating device comprises an oil gathering sleeve, wherein an inner ring of a bearing and the oil gathering sleeve rotate synchronously; the inner wall of the inner ring of the bearing is respectively provided with a lubricating oil groove in an axial direction and a radial oil hole in a radial direction; one end of the radial oil hole is communicated with the lubricating oil groove, and the other end of the radial oil hole is communicated with a raceway of the inner ring of the bearing; the oil gathering sleeve and the inner ring of the bearing coaxially and fixedly sleeve a main shaft; the oil gathering sleeve is divided into two parts along the axial direction, the inner part of one part is provided with axial oil grooves butted with the lubricating oil groove, and the other part is radially provided with oil gathering passages which are in one-to-one butt joint with the axial oil grooves; the oil gathering passages are separated by a plurality of oil gathering blades distributed in the radial direction; an outer ring of the bearing is fixedly arranged on a shaft shell; the parts, which correspond to the oil gathering passages, of the shaft shell are provided with nozzles connected with a lubricating oil system. The high-speed lower lubricating device is capable of improving the bearing lubricating efficiency, reducing the lubricating oil quantity, further reducing the internal friction heat of the bearing and ensuring that sufficient oil film thickness exists in the raceway during high-speed rotation of the bearing.

Owner:CENT SOUTH UNIV

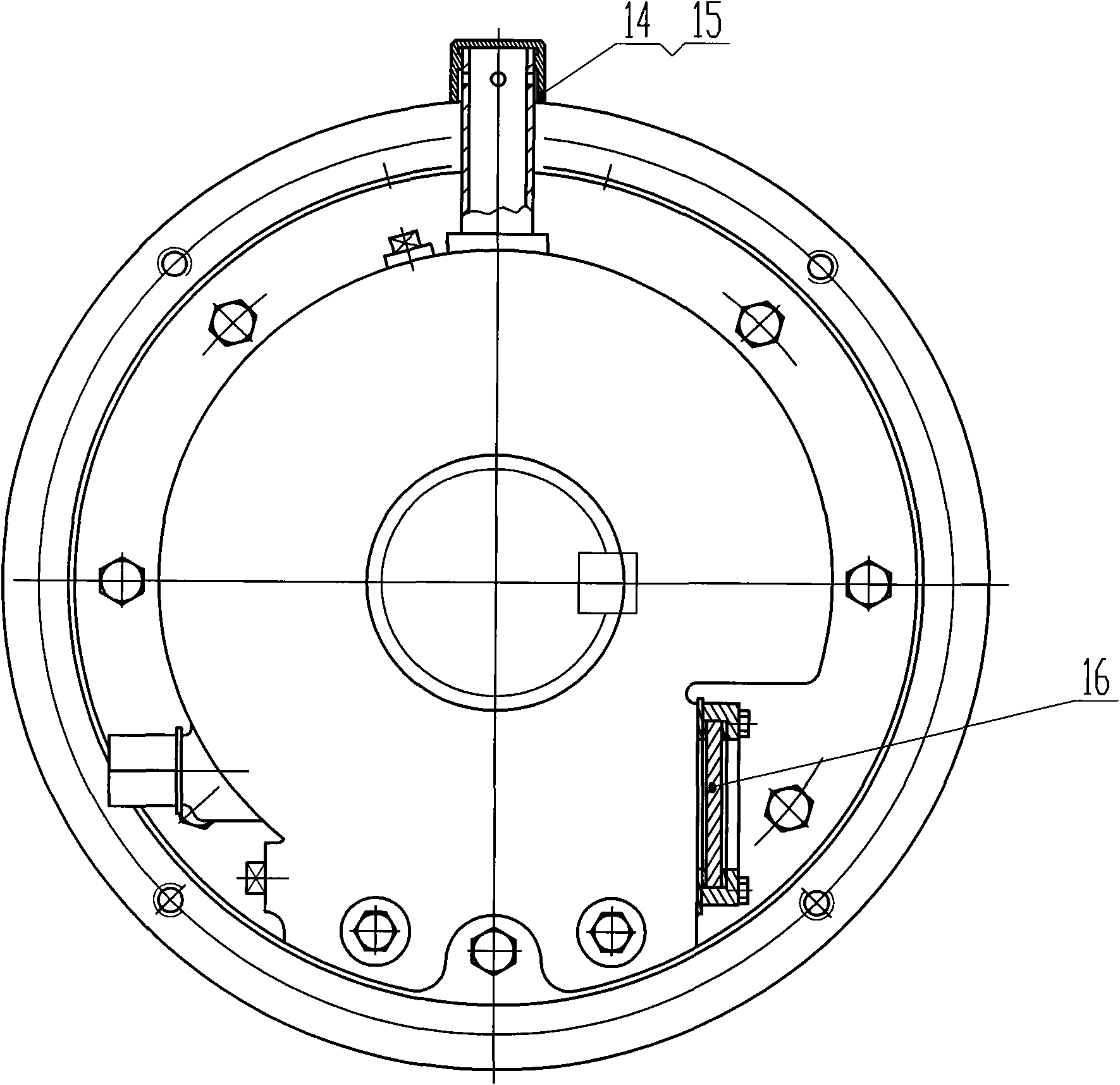

Vertical shearing surface annular shearing testing instrument capable of exerting confining pressure

ActiveCN108801804AStable normal stressAchieve shear failureMaterial strength using steady shearing forcesLandslideEngineering

The invention discloses a vertical shearing surface annular shearing testing instrument capable of exerting confining pressure. The testing instrument comprises a frame, a frame support shearing box,a hydraulic servo loading system, a monitoring sensing system and a shearing power system, wherein the shearing box comprises an inner shearing box and an outer shearing box; the inner shearing box issteady without movement; the outer shearing box is capable of rotating annularly; the shearing power system is connected with the outer shearing box and is capable of driving the outer shearing box to rotate annularly; the hydraulic servo loading system comprises a normal pressurizing device and an annular force conduction plate; the normal pressurizing device is vertically inserted in the middleof the inner shearing box and is used for providing normal stress; the annular force conduction plate is mounted above the shearing box and is used for conducting vertical confining pressure; the monitoring sensing system is used for sensing shearing data of a soil sample in real time and used for transmitting the shearing data to a control device; the control device is used for qualitatively controlling the normal stress of the normal pressurizing device and the vertical confining pressure of the annular force conduction plate. The testing instrument has great significances in studying shearing resistance properties of long-runout landslide slip soil and revealing evolutionary process and mechanisms of landslide.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Staple fibre rubber composite material for manufacturing transmission belt

The present invention discloses a short fibre / rubber composite for manufacturing driving belt, comprising hydrogenized nitrile rubber, styrene butadiene rubber, short fibre made from the reinforcement cord of the worn-out driving belt, chloroprene rubber, vulcanizing agent, coupling agent and phenol-formaldehyde resin. The driving belt of the invention made from the composite has a good thermal endurance, self- lubricity, oil resistance and durability. And the reinforcement cord and the special binding agent are unused to manufacture the driving belt, which economizes the cost of manufacture, prolongs the service life of the driving belt greatly, and raises the drive efficiency.

Owner:ZHEJIANG SOUTHEAST RUBBER CORP

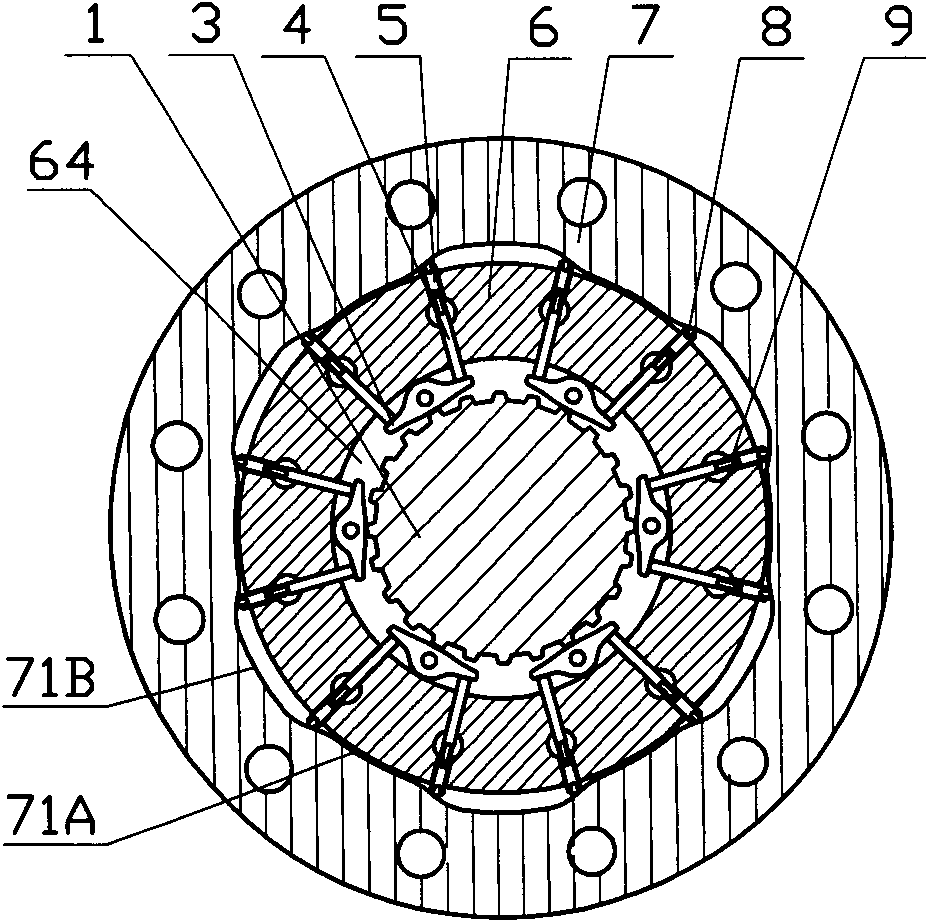

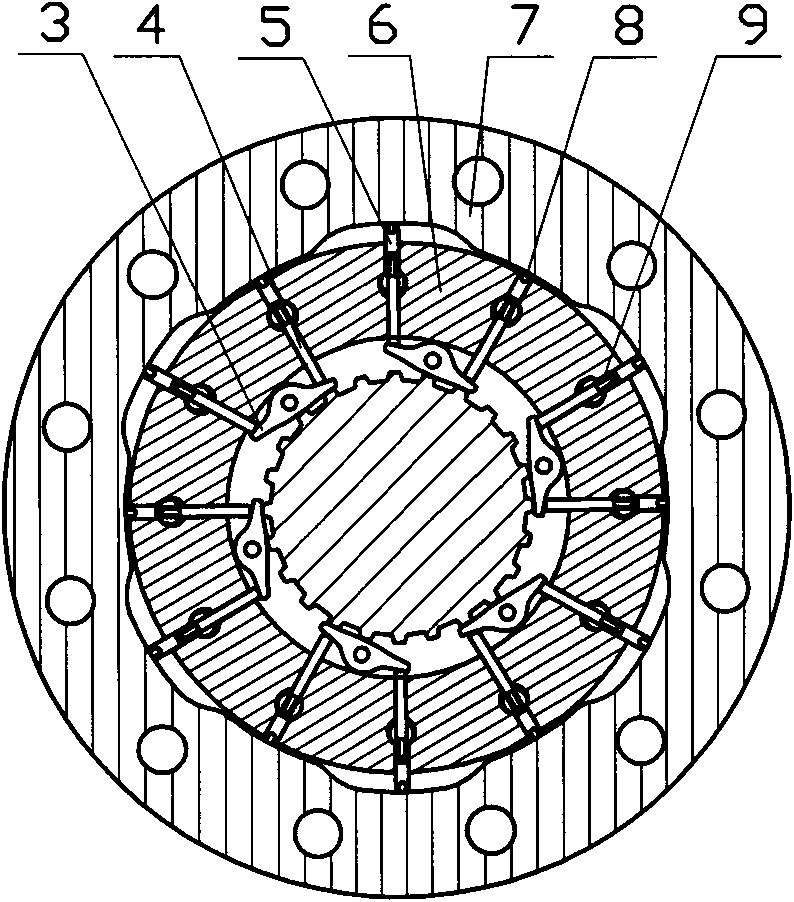

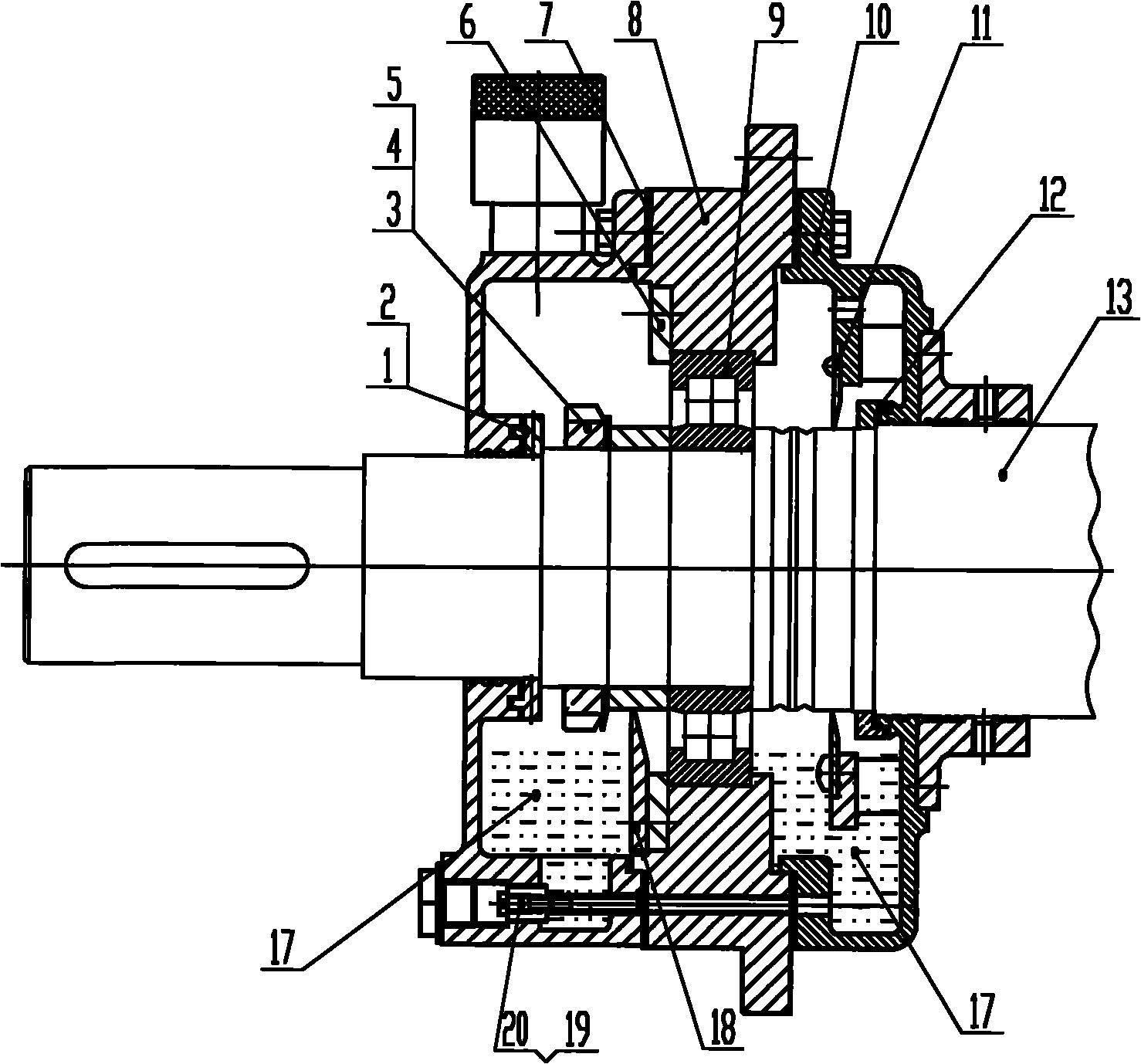

Blade type hydraulic motor with rocker arm structure

ActiveCN102174901AImprove performanceCooperate wellEngine componentsRotary piston enginesHydraulic motorEngineering

The invention discloses a blade type hydraulic motor with a rocker arm structure. The hydraulic motor comprises an end cover, an oil distribution disc, a stator, a rotor and a rotating shaft, wherein the rotor is connected with the rotating shaft by a spline; a plurality of blade grooves are uniformly formed on the rotor; two layers of rocker arm beams are arranged in circular grooves at the two ends of the rotor, each layer comprises a plurality of rocker arm beams, holes are formed in the centers of the rocker arm beams; pin shafts pass through the holes to rotationally connect the rocker arm beams with the rotor; circular cavities are formed at the two ends of each blade groove; through holes which are intersected with the circular cavities along the radial direction are formed below the circular cavities; pull rods and springs are arranged in the through holes sequentially; the bottom surfaces of the pull rods are contacted with the arms of the rocker arm beams; blades are arranged in the blade grooves; the bottom ends of the blades are contacted with the springs; the springs are positioned in the circular cavities; an oil circuit is communicated with the circular cavities; grooves are formed on the tops of the blades; and blade heads are inserted into the grooves, are tightly matched with the blades, are higher than the tops of the blades and are contacted with the inner curve surface of the stator. The hydraulic motor has high sealing performance between the blades and the stator, small abrasion during rotation, higher efficiency and longer service life.

Owner:宁波恒通诺达液压股份有限公司

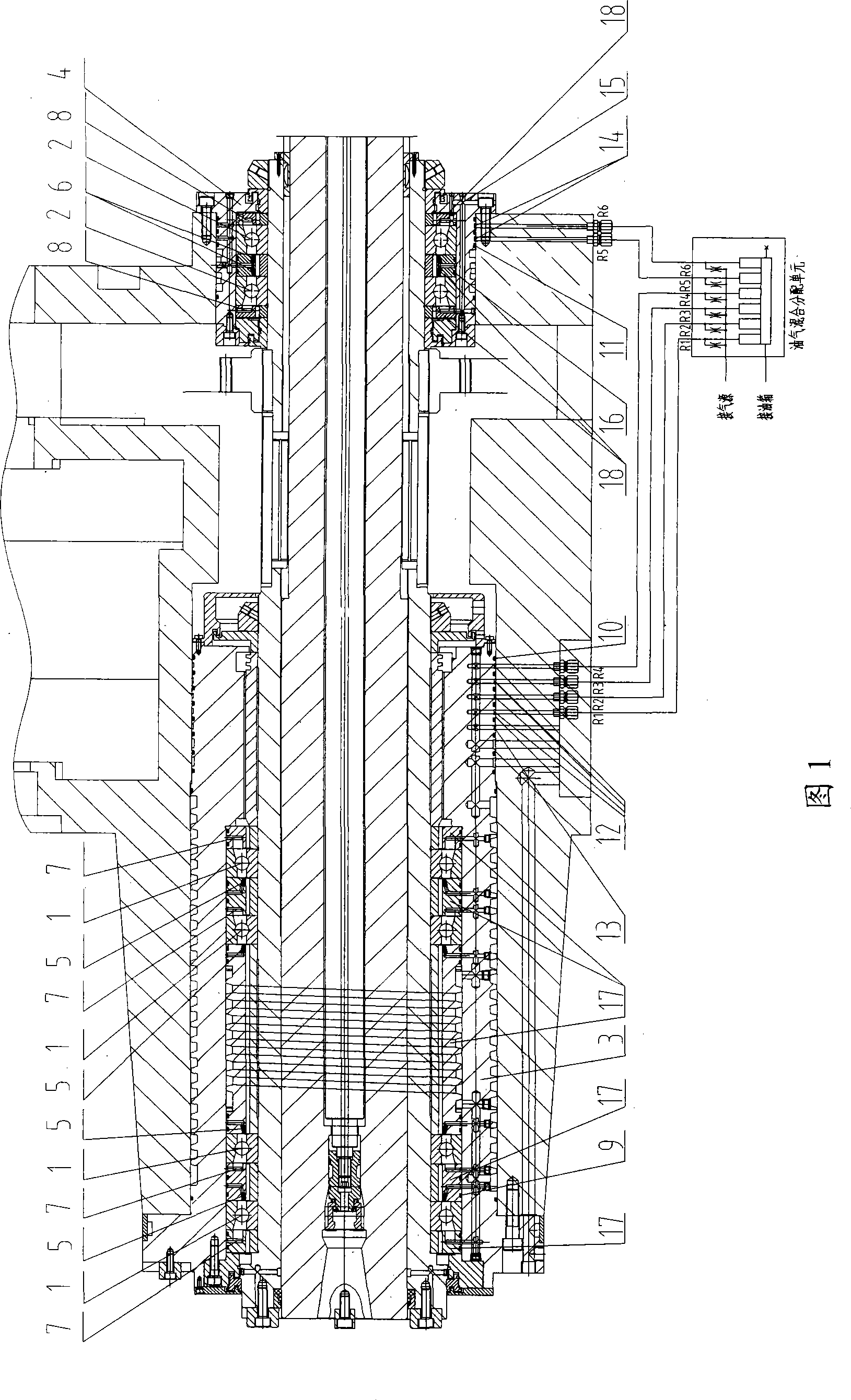

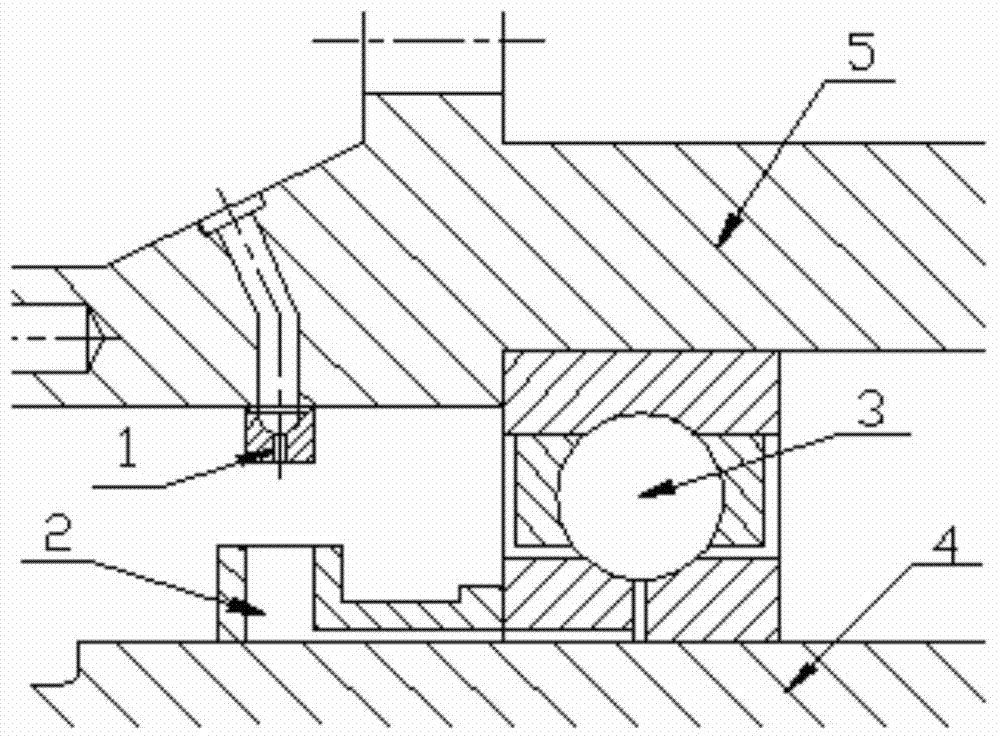

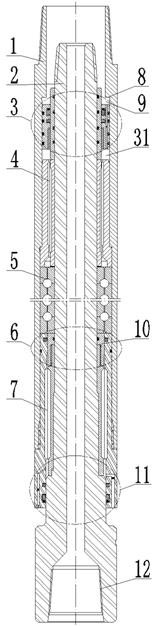

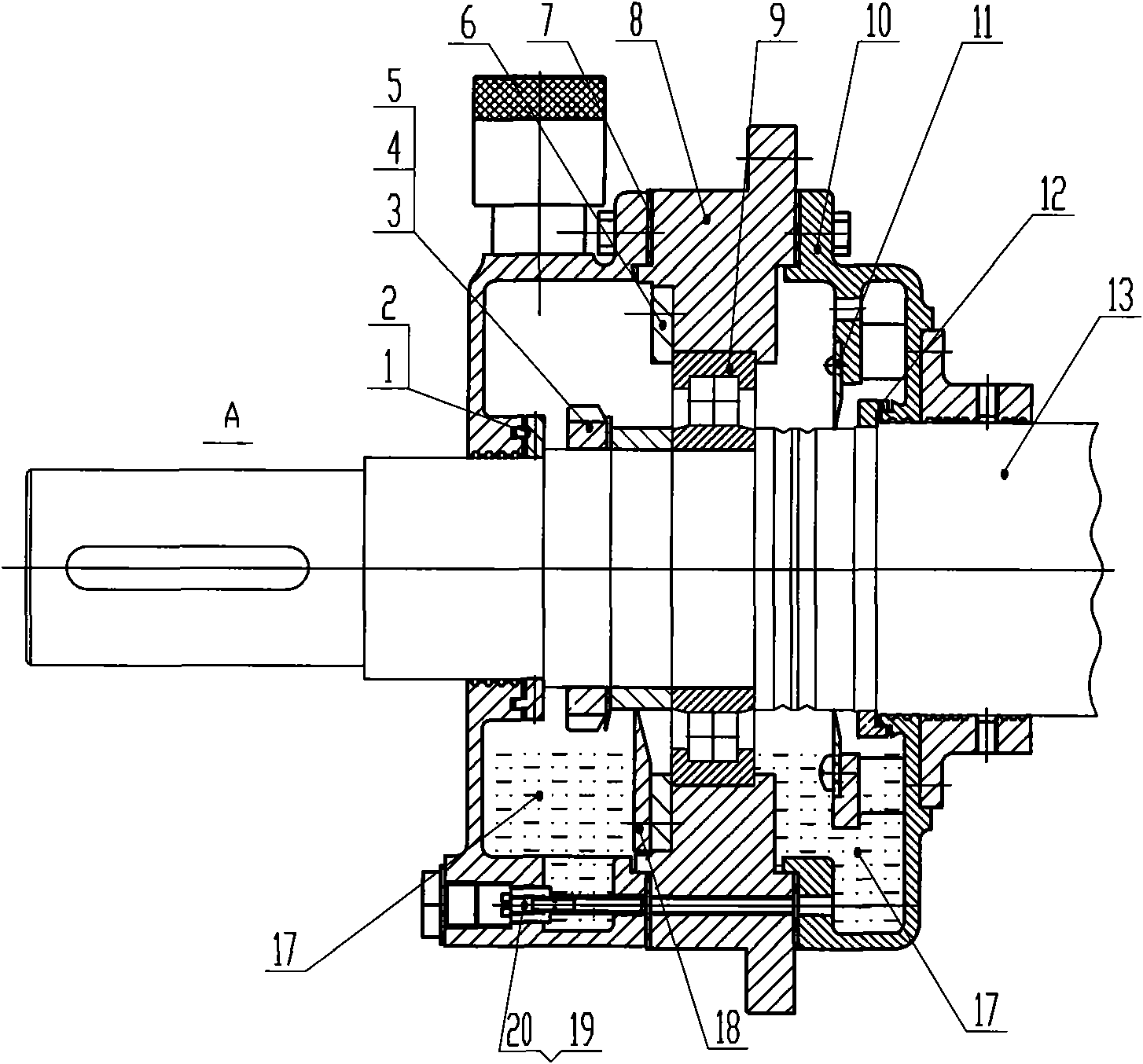

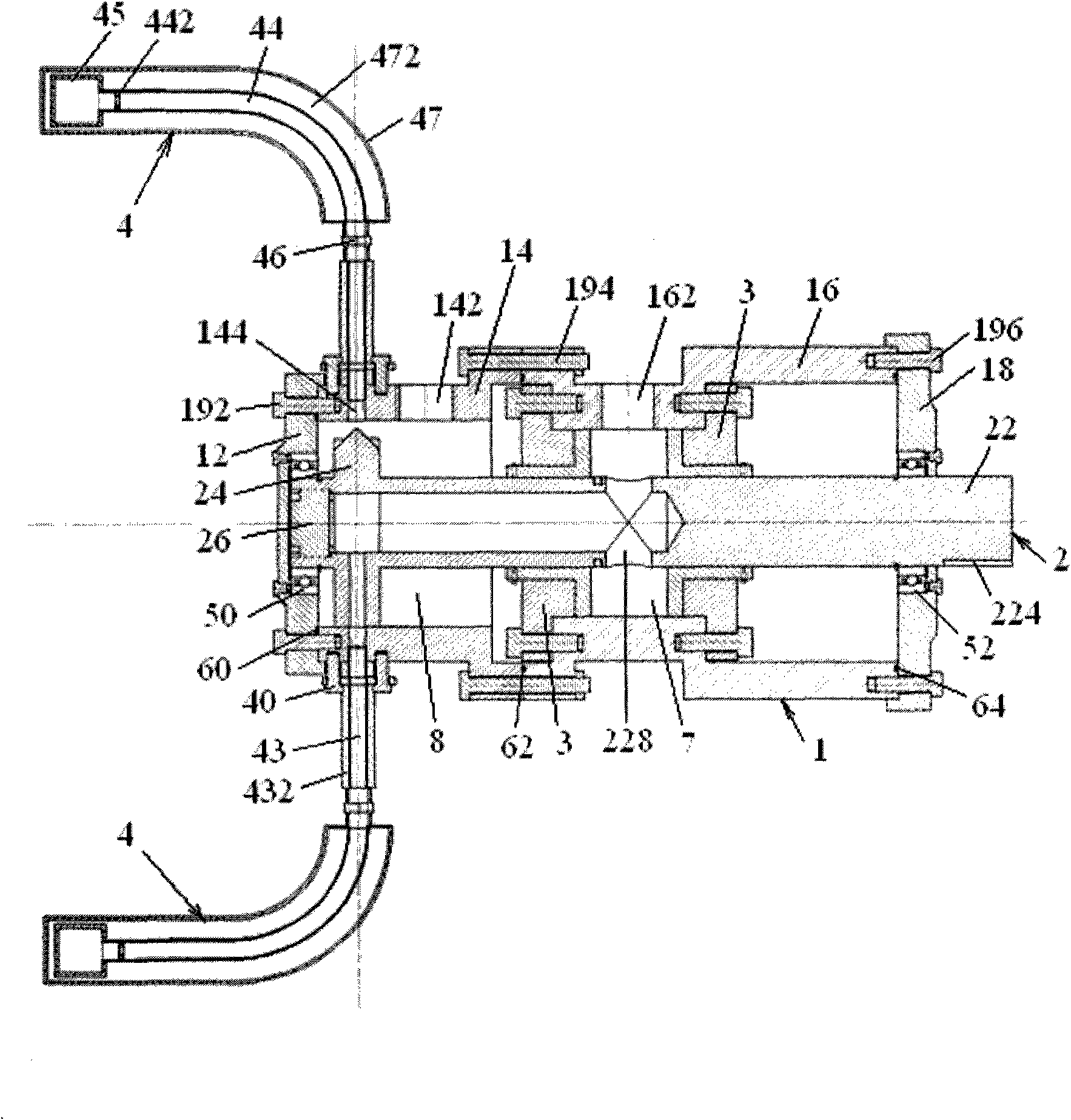

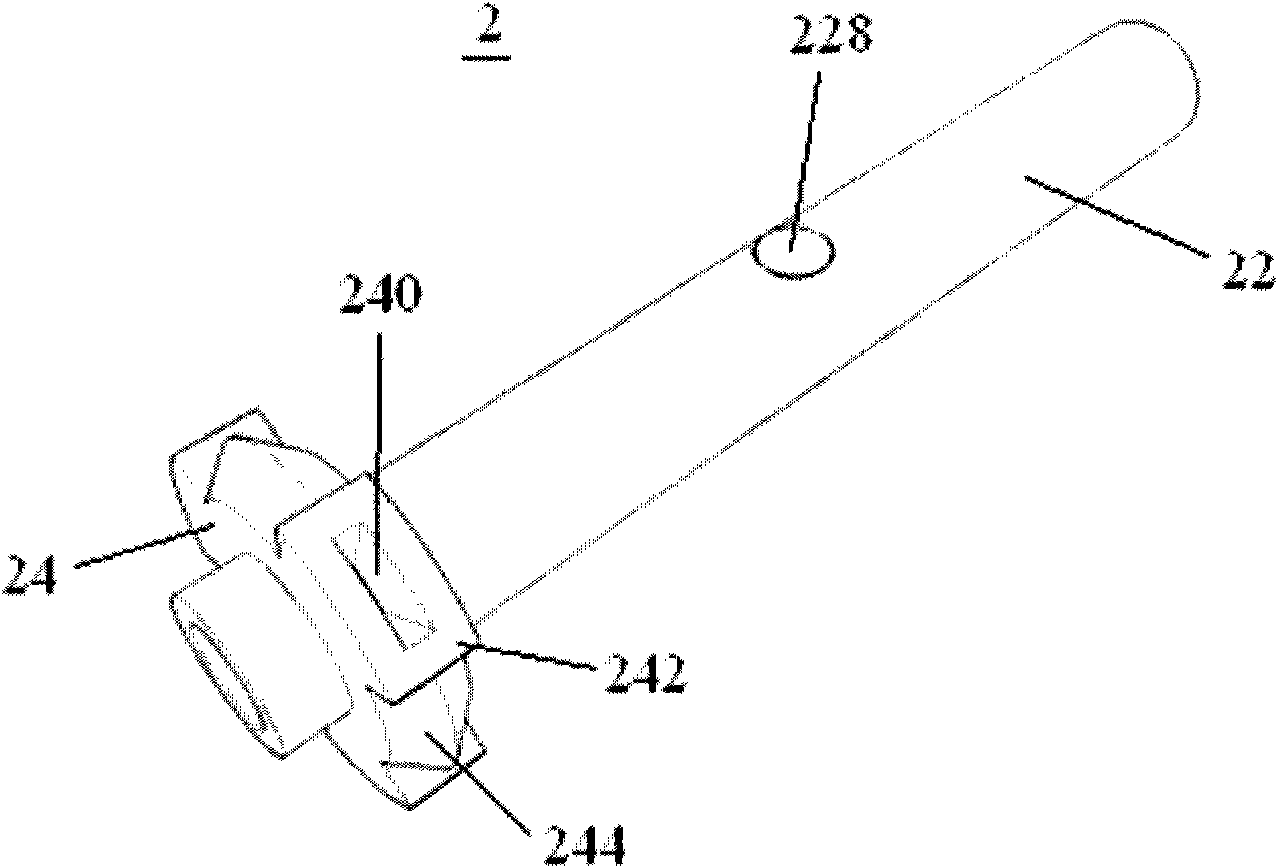

An oil-sealed cavity pressure-balanced screw drilling tool transmission shaft assembly

InactiveCN102296928AImprove the lubrication effectGood sealing pressureEngine sealsDrilling rodsEngineeringPressure balance

The invention relates to a driving shaft assembly of a screw drilling tool capable of maintaining the pressure balance of an oil seal chamber for oil and gas drilling. The technical solution is: oil seal chamber pressure balance screw drilling tool transmission shaft assembly includes upper seal assembly, middle seal assembly and lower seal assembly, etc.; upper seal assembly and middle seal assembly, middle seal assembly and lower seal assembly The cavity between the sealing assemblies is filled with lubricating oil; the upper sealing assembly includes the annular cavity, the piston cylinder and the upper sealing check valve, etc., and the lower sealing device includes the flow channel, the piston chamber, the piston and the lower sealing check valve. Valves, etc.; the balance between the pressure in the sealing cavity and the external drilling fluid pressure is controlled by the up and down sliding of the piston cylinder and the piston, and the opening and closing of the upper sealing check valve and the lower sealing check valve. The invention has the advantages of good sealing performance, long service life, high temperature and high pressure resistance, small friction coefficient and simple structure, and can be used in gas drilling and mud medium drilling with high temperature and strong vibration.

Owner:SOUTHWEST PETROLEUM UNIV

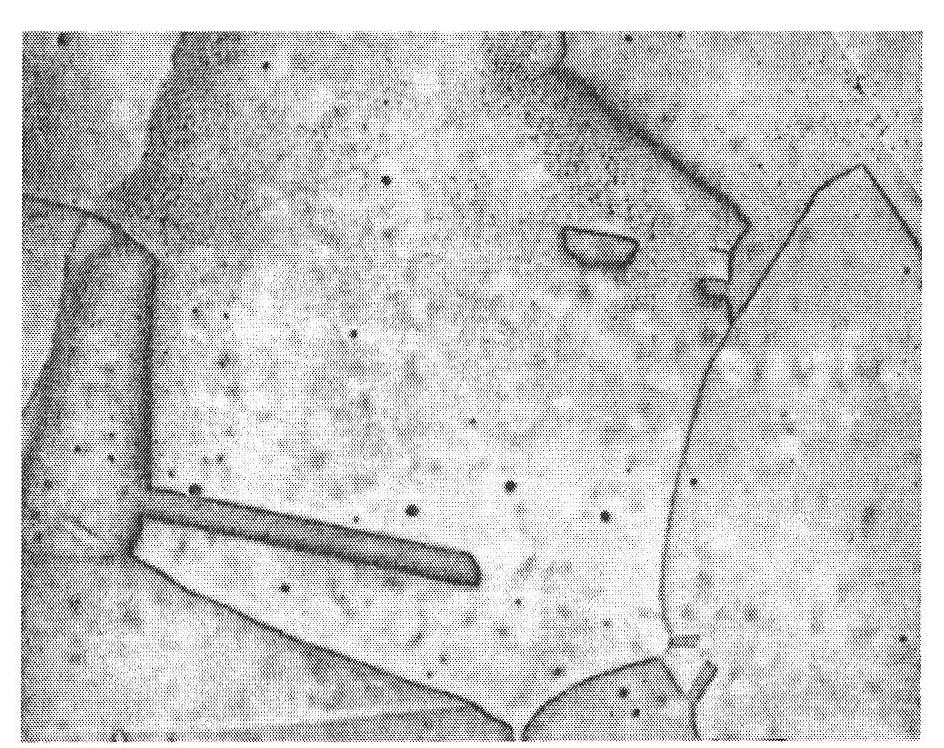

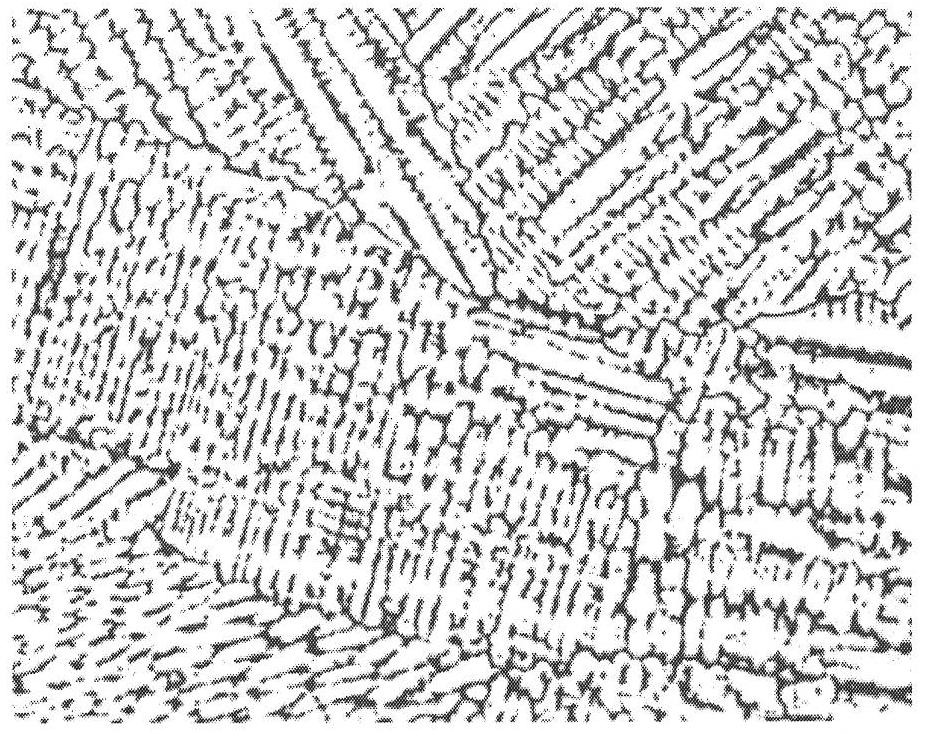

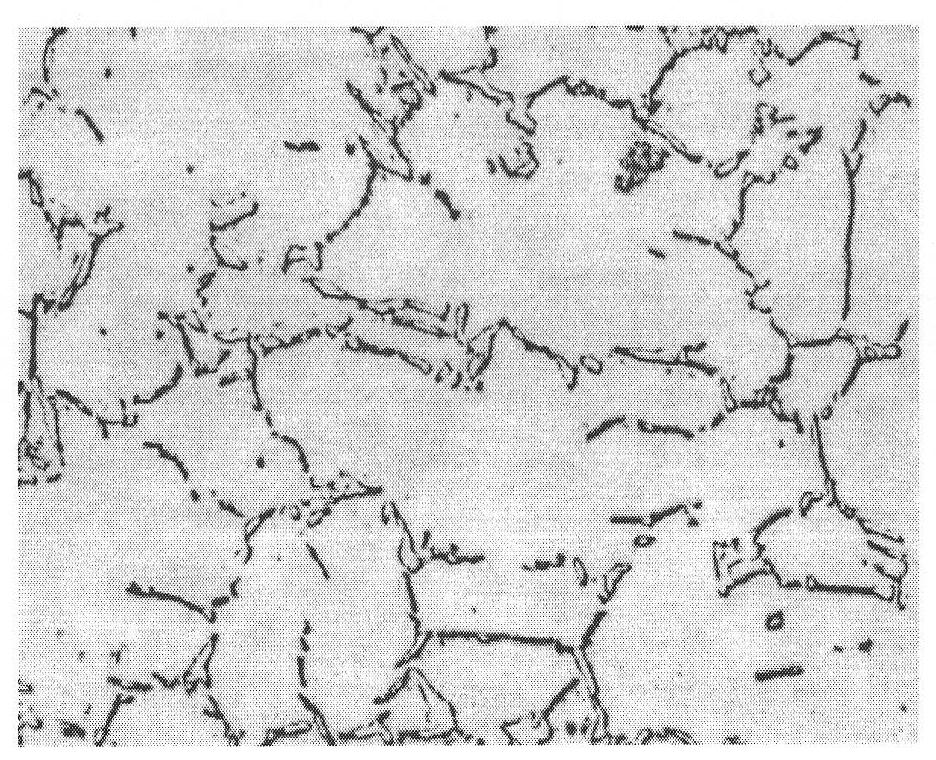

Method for preparing lead and lead alloy metallic phase samples and exposing texture

ActiveCN101788413ADeformation will not appearShort processPreparing sample for investigationAlcoholMaterial consumption

The invention discloses a method for preparing lead and lead alloy metallic phase samples and exposing texture. The method comprises a wet grinding step in which a fine-tooth flat file is used, a mechanical polishing step, a chemical polishing step and a texture exposing step, wherein in the chemical polishing step, chemical polishing solution consisting of absolute ethyl alcohol, glycerin, hydrogen peroxide and lactic acid is used; and in the texture exposing step, an etching agent consisting of the absolute ethyl alcohol, the glycerin and the hydrogen peroxide is used, so the sample for observing a metallic phase is successfully prepared. The method has the characteristics of simple and convenient operation, short sample preparing time and low material consumption, high texture exposing definition of the prepared sample, and is particularly suitable for preparing the lead and lead alloy metallic phase samples and exposing the texture.

Owner:NINGBO HUASUN ALUMINUM +1

Rotary graphene stripping device, graphene production system and production method

The invention discloses a rotary graphene stripping device including a rotary cylinder body; a top cover is arranged above the rotary cylinder body, a bottom cover is arranged below the rotary cylinder body, the top of the top cover is provided with a feed inlet, the bottom of the bottom cover is provided with a discharge port, and the feed inlet is communicated with the interior of the rotary cylinder body; the outer side of the rotary cylinder body is provided with a first motor, and is used for driving the rotary cylinder body to horizontally rotate; the rotary cylinder body is also internally provided with an inner cylinder, and a second motor used for driving the inner cylinder to horizontally rotate in a direction opposite to the rotating direction of the rotary cylinder body is arranged below the rotary cylinder body; the upper part of the inner cylinder is shrunk in a certain angle, and a material storage space is left between the upper part of the inner cylinder and the upper part of the rotary cylinder body; the lower part of the inner cylinder and the lower part of the rotary cylinder body are in clearance fit to be used for grinding graphite sheets, and a clearance between the lower part of the inner cylinder and the lower part of the rotary cylinder body is successively decreased downward along the axial direction of the rotary cylinder body. The rotary graphene stripping device can achieve successful stripping of graphene. The invention also relates to a graphene production system containing the rotary graphene stripping device and a graphene production method.

Owner:江苏碳谷二维世界科技有限公司

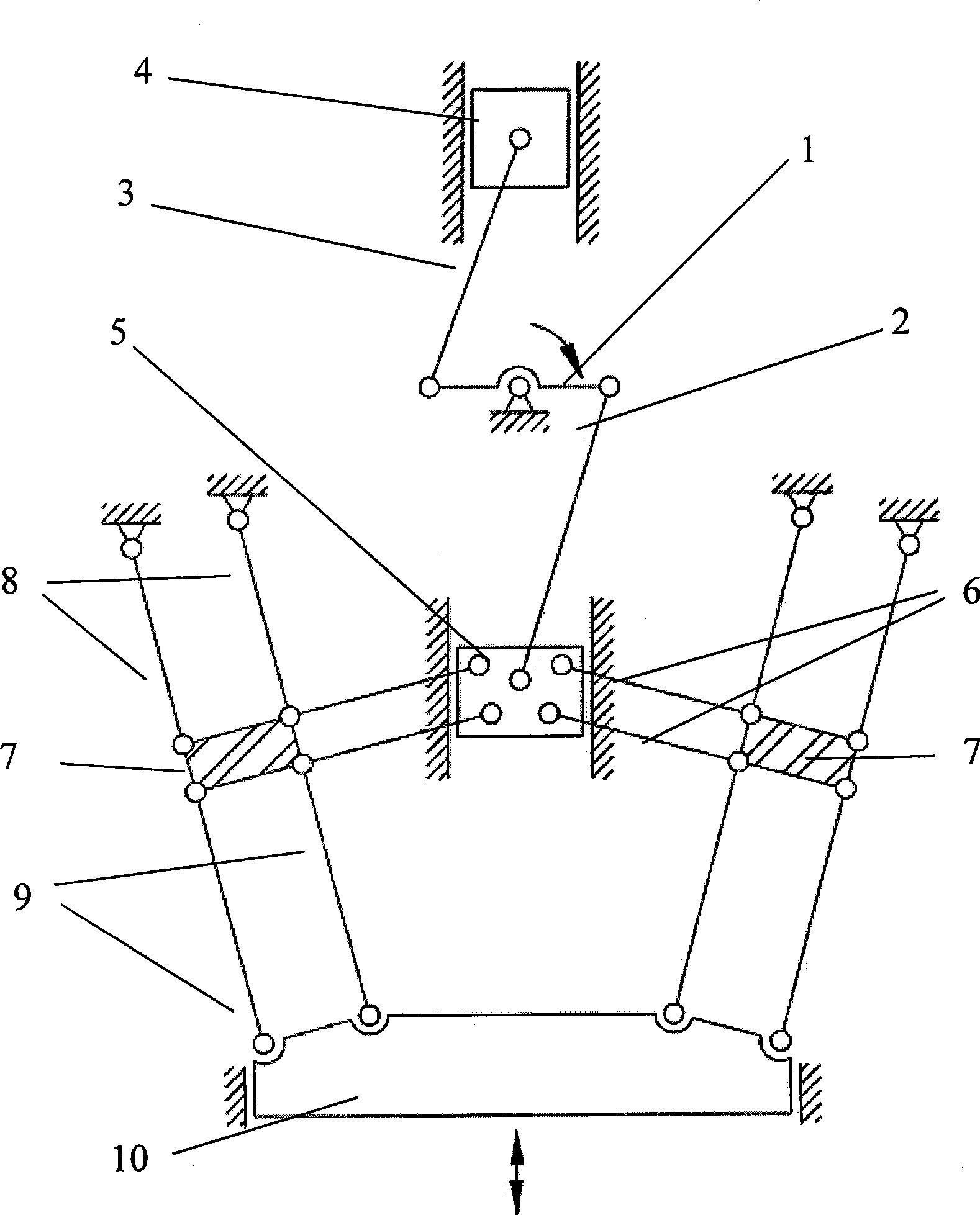

High-speed fine press

InactiveCN101543858AImprove the ability to resist partial loadReduce forcePress ramMachine pressEngineering

The invention discloses a high-speed fine press having a structure that one end of a double-crank rod which has 180-degree phase difference is connected with a movable slide block by a main connecting rod, the other end of the double-crank rod is connected with an auxiliary slide block by an auxiliary connecting rod, same multiple-rod branch chains are symmetrically arranged at the left sides and the right sides of the movable slide block and a pressing slide block so as to connect the movable slide block and the pressing slide block together; the movable slide block makes reciprocation movement up and down under the drive of the double-crank rod and the main connecting rod so as to push a lower connecting rod, an upper connecting rod and a swinging block to swing at two sides through the push of push rods of the two multiple-rod branch chains, and the pressing slide block is further driven to do reciprocation movement up and down, and a workpiece is placed under the pressing slide block, therefore, the pressing processing of metal or nonmetal workpieces is completed. A parallelogram structure of a movable branch chain of the invention can ensure that the pressing slide block is always kept in a horizontal position and the force at horizontal direction of the pressing slide block can be balanced by a mechanism, thereby the capability of uneven loading resistance and the machining precision of the press are enhanced.

Owner:NANJING UNIV OF SCI & TECH

Novel roller bit sealing ring

ActiveCN102628338AReduced service lifeExtended service lifeConstructionsThermodynamicsMetal framework

The invention discloses a novel roller bit sealing ring, which belongs to the field of bearing sealing. The novel roller bit sealing ring is disposed in a sealing groove between a bearing shaft hole and a tooth palm journal. Both ends of the sealing groove are respectively communicated with an inside lubricating oil channel and an outside drilling fluid channel. The novel roller bit sealing ring comprises a metal framework fixed in the sealing groove, the metal framework separates the sealing groove into a lubricating oil sealing groove communicated with the inside lubricating oil channel and a drilling fluid sealing groove communicated with the outside drilling fluid channel. A lubricating oil sealing part is disposed in the lubricating oil sealing groove and completely seals and separates the inside lubricating oil channel together with the metal framework. A drilling fluid sealing part is disposed in the drilling fluid sealing groove and completely seals and separates the outside drilling fluid channel together with the metal framework. The novel roller bit sealing ring is more suitable for severe environment of drilling work, and capable of more effectively and simultaneously separating lubricating oil and drilling fluid, rock debris and the like. Separation of lubricating oil and separation of drilling fluid do not affect each other, and service life of a sealing device is prolonged.

Owner:CHENGDU SHENGBANG SEALS

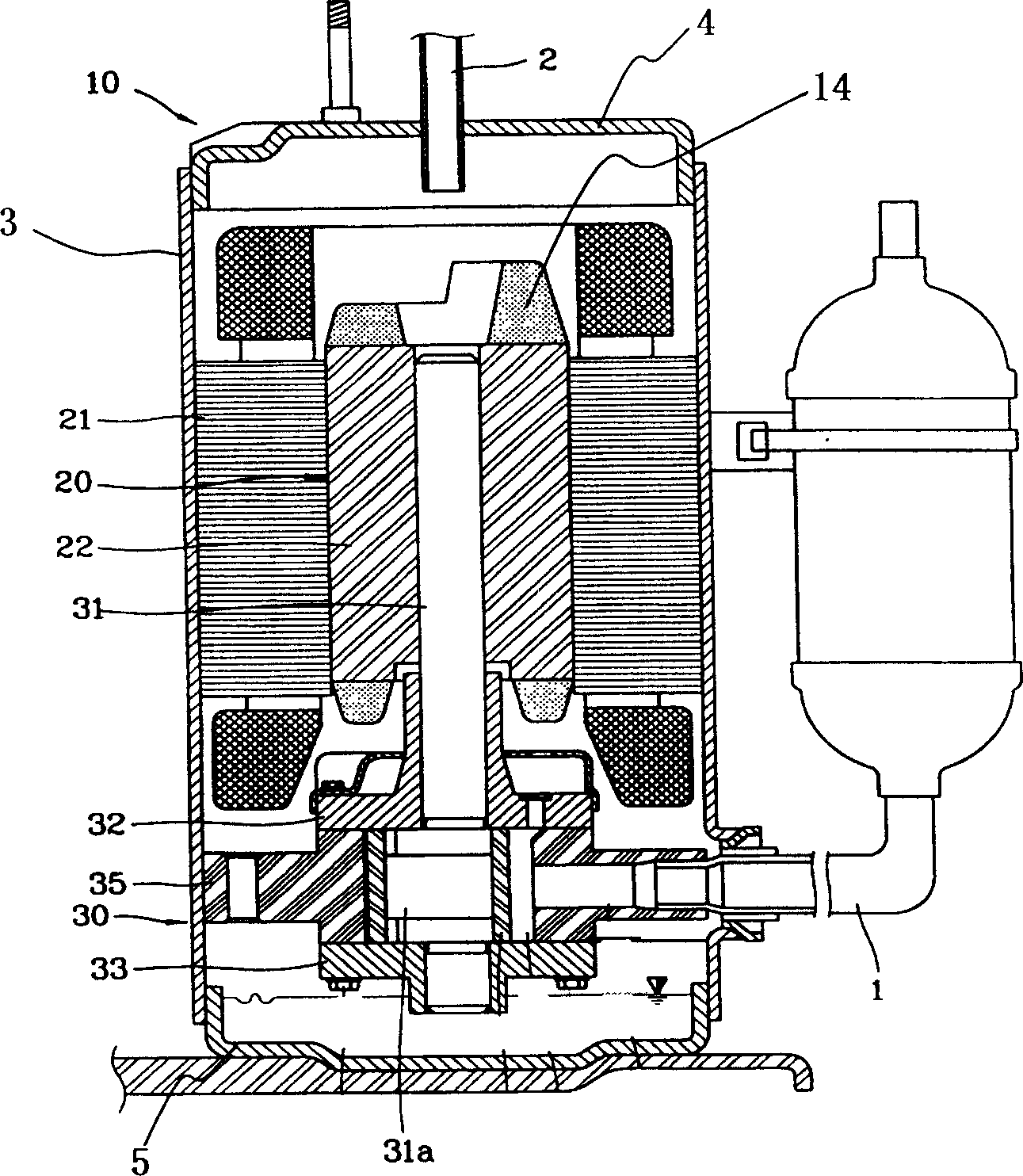

Thin oil-lubricated bearing device for horizontal motor

InactiveCN101924412ALow viscosityGuaranteed lubrication effectBearing componentsSupports/enclosures/casingsFixed bearingRespirator

The invention relates to a thin oil-lubricated bearing device for a horizontal motor. The thin oil-lubricated bearing device for the horizontal motor is characterized in that: a motor shaft is arranged in a bearing bush; a gasket, a respirator, a respiratory tube and an oil duct are arranged on an outer cover of a bearing; a fixed bearing retainer ring, the outer cover of the bearing, an inner cover of a bearing, and a semi-ring are arranged on the bearing bush; a fixed baffle plate is arranged on the inner cover of the bearing; and an outer cover oil throwing disk, a rolling bearing, a round nut, a sleeve and an inner cover oil throwing disk are fixed on the motor shaft sequentially. The thin oil-lubricated bearing device for the horizontal motor has the advantages of completely guaranteeing the lubricating of the bearing of the horizontal motor with heavy load and high rotating speed due to thin oil lubrication and effectively improving the permissible working rotating speed of the motor bearing and prolonging the service life of the motor bearing, along with compact and reasonable structure.

Owner:WUXI ZHONGDA MOTORS

Motor rotor counterbalance structure for compressor

InactiveCN1862919AImprove vortex situationImprove performanceMechanical energy handlingElectric machineEngineering

The invention discloses the electric machine rotor balance block frame of the compressor, the balance block is fixed on the above end of the electric machine rotor composed by the rotor iron core and the above and the bottom end casting aluminum in the cavity of the compressor, it can be used to balance the electric machine rotor, the frame of the balance block is showed below, the windward face of the side of the balance block and the other side of the balance block are arc streamline ladder frames. The invention processes the windward face of the balance block of the electric machine rotor to the streamline round angle, the friction between the balance block and the medium such as the cold intermediary when the electric machine rotating can be reduced to the least, the heat produced form the friction and the importing power can be reduces to advance the capability of compressor. The leeward face of the balance block can also be produced to the round arc streamline ladder frame to amend the complexion of producing the bow wave when cold intermediary flow passes.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

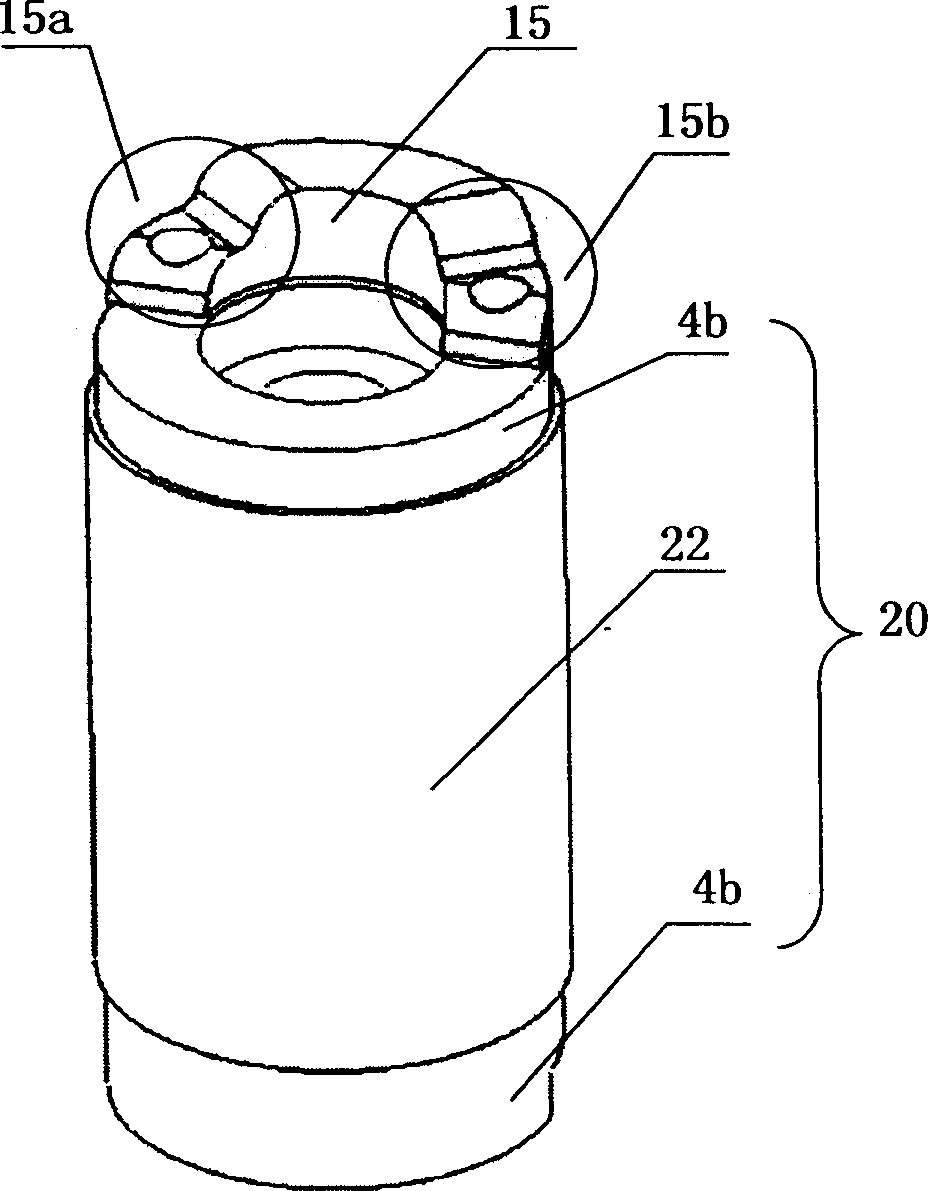

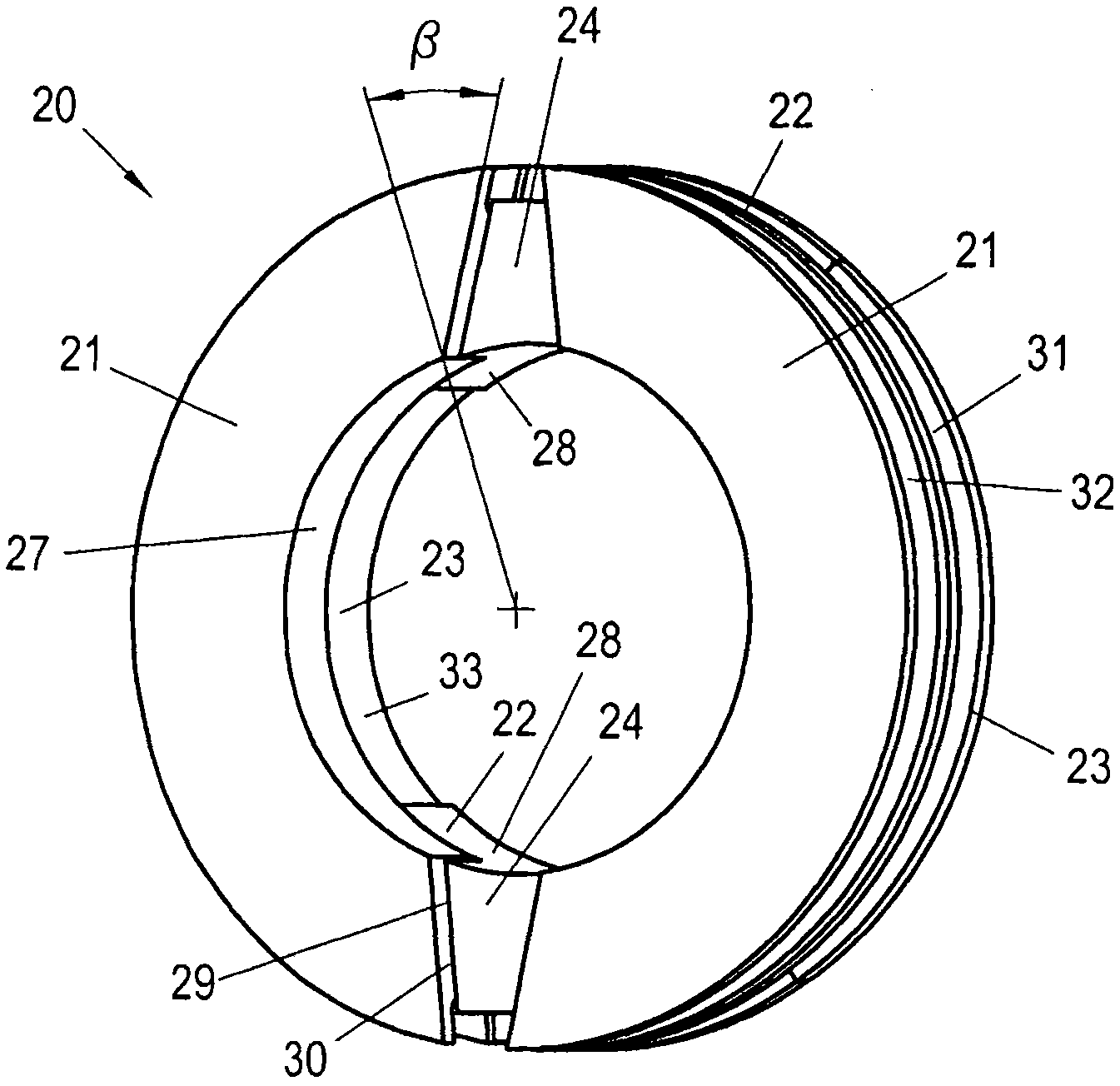

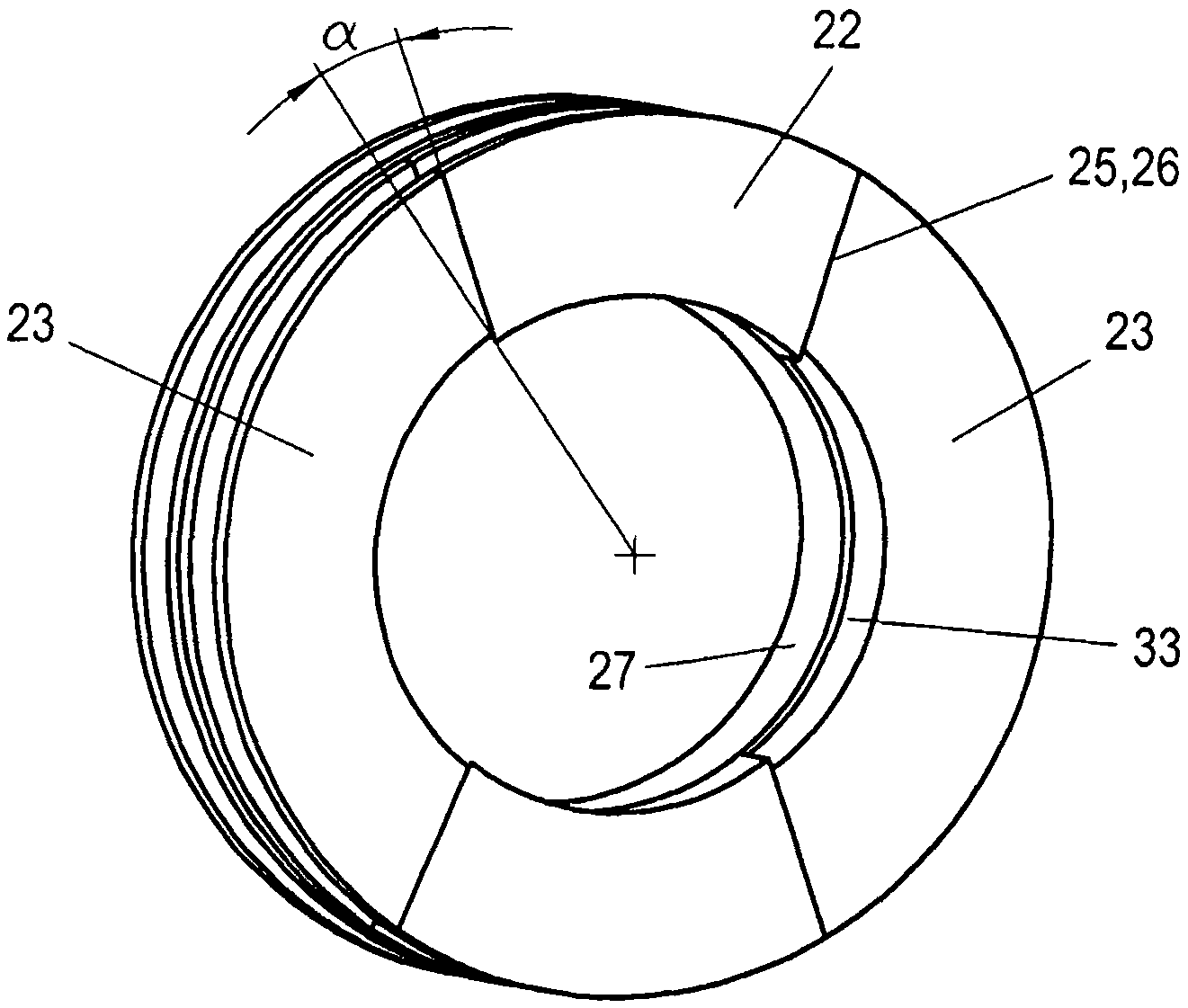

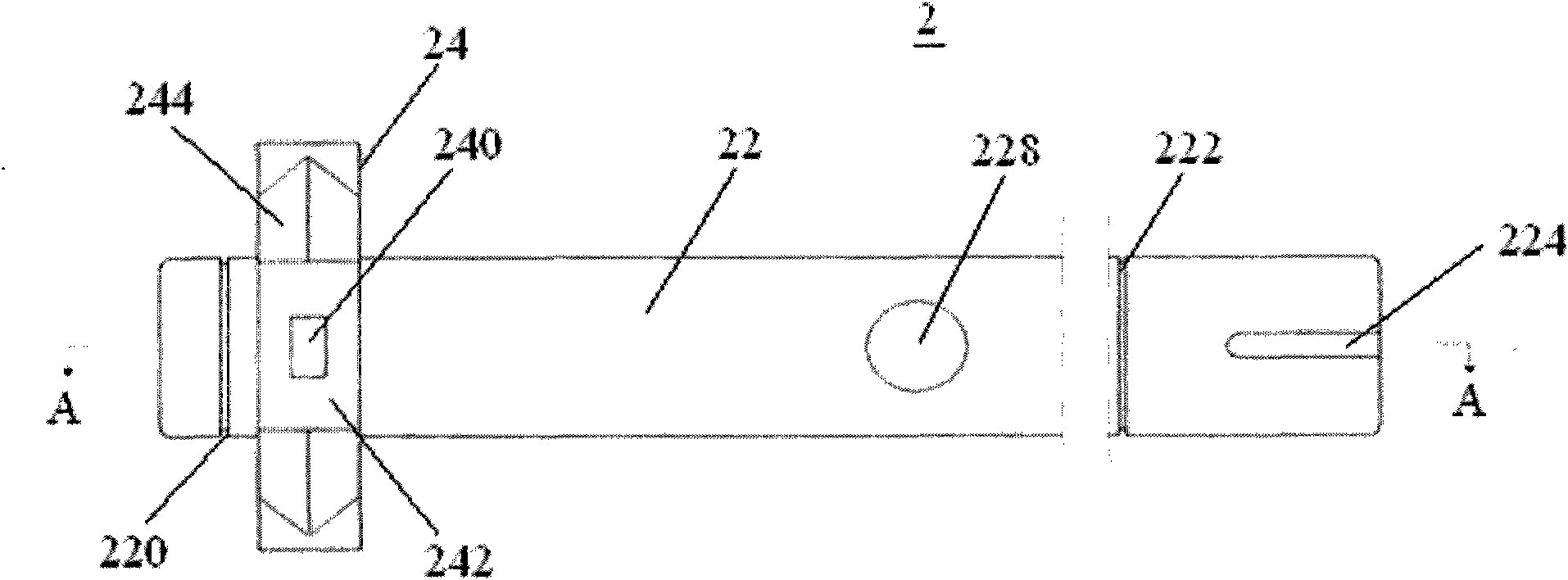

Segmented packing ring

InactiveCN101793325AReduce wear (speed) rateImprove sealingEngine sealsStructural engineeringMechanical engineering

A segmented packing ring 20 includes a number of first sealing segments 21, a number of second sealing segments 22, and a number of support segments 23, the support segments 23 and the second sealing segments 22 being arranged in an alternating successively abutting manner in the circumferential direction, and the first sealing segments 21 being arranged in a manner axially abutting the second sealing segments 22 and the support segments 23, and including a nose 24 extending axially on the second sealing segments 22, which is arranged in the circumferential direction between two adjacent first sealing segments 21.

Owner:HOERBIGER KOMPRESSORTECHNIK HLDG GMBH

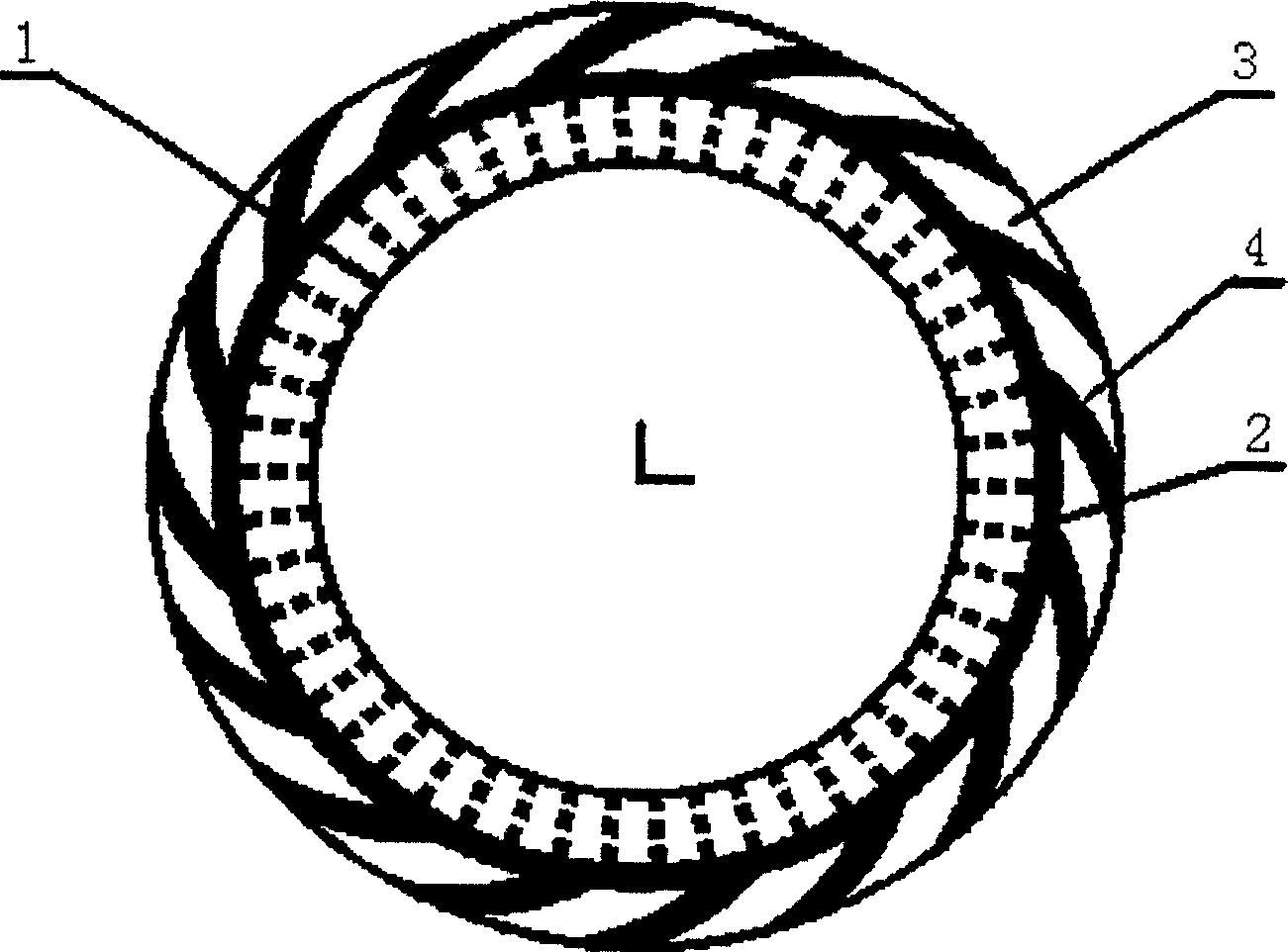

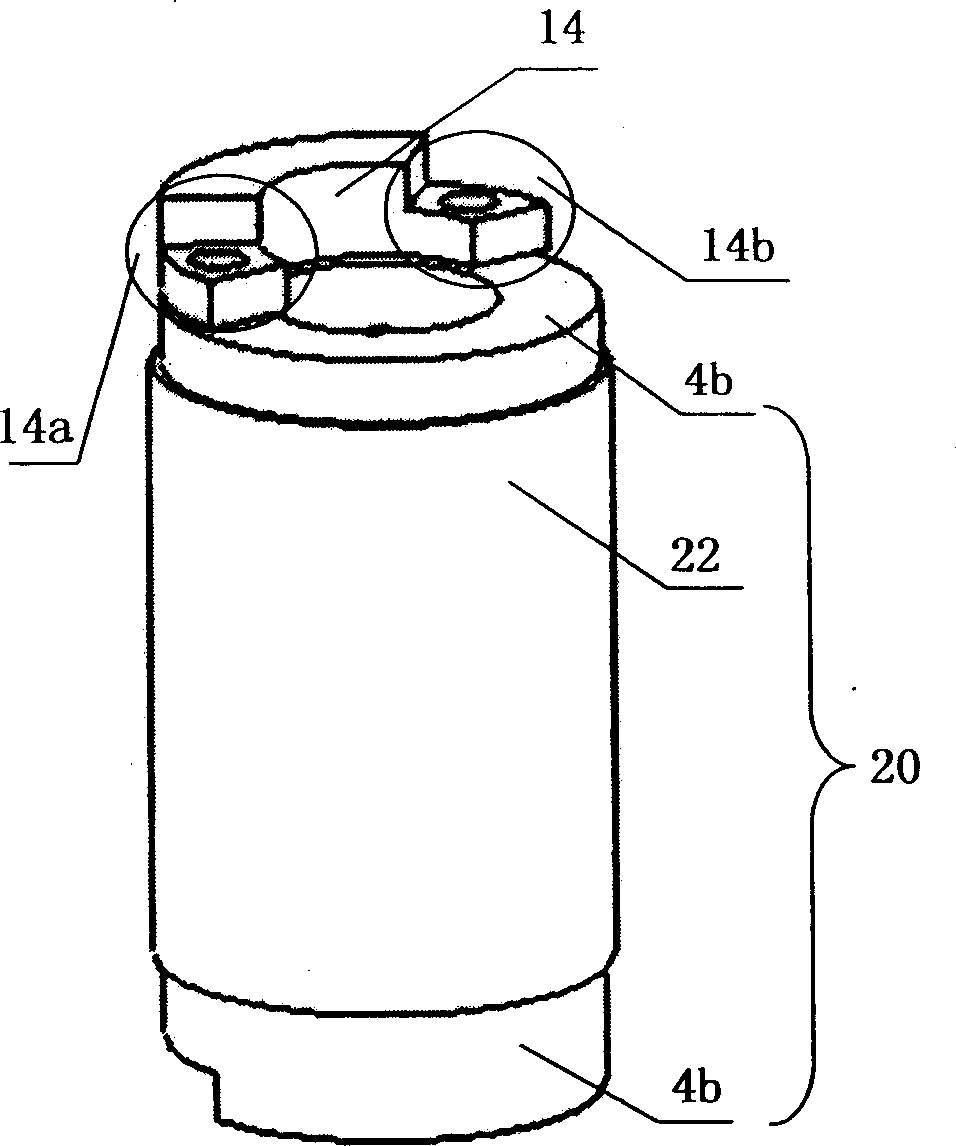

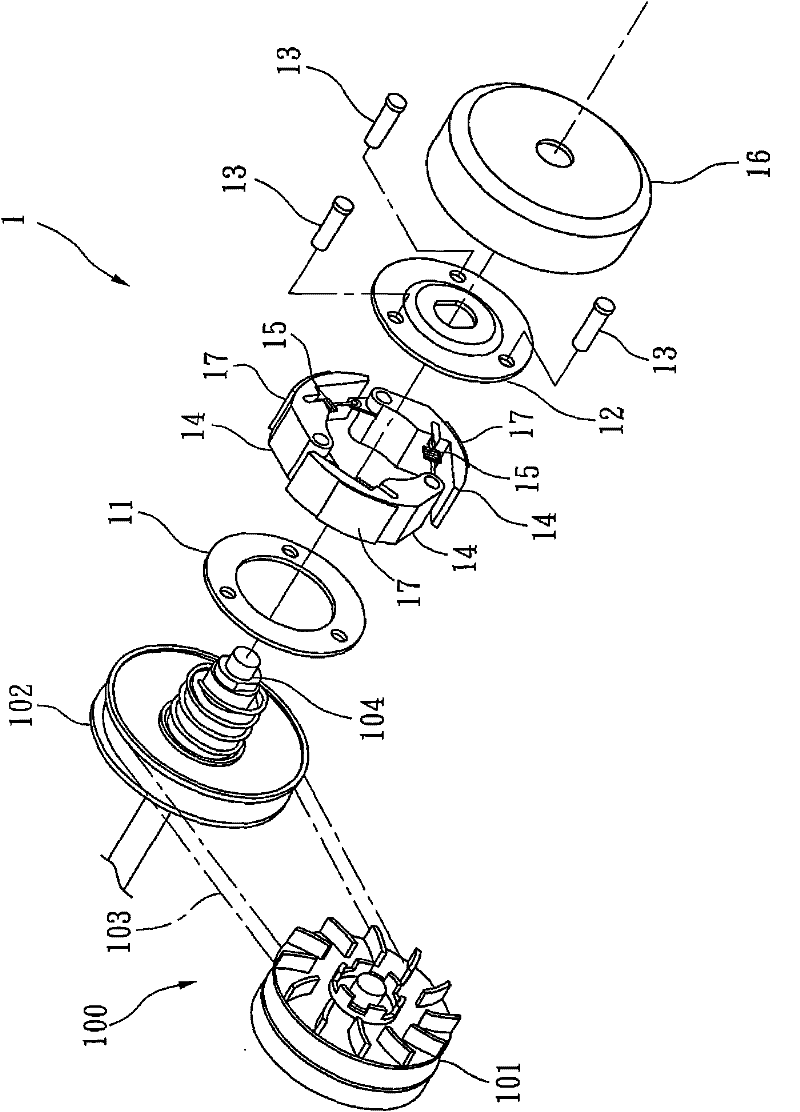

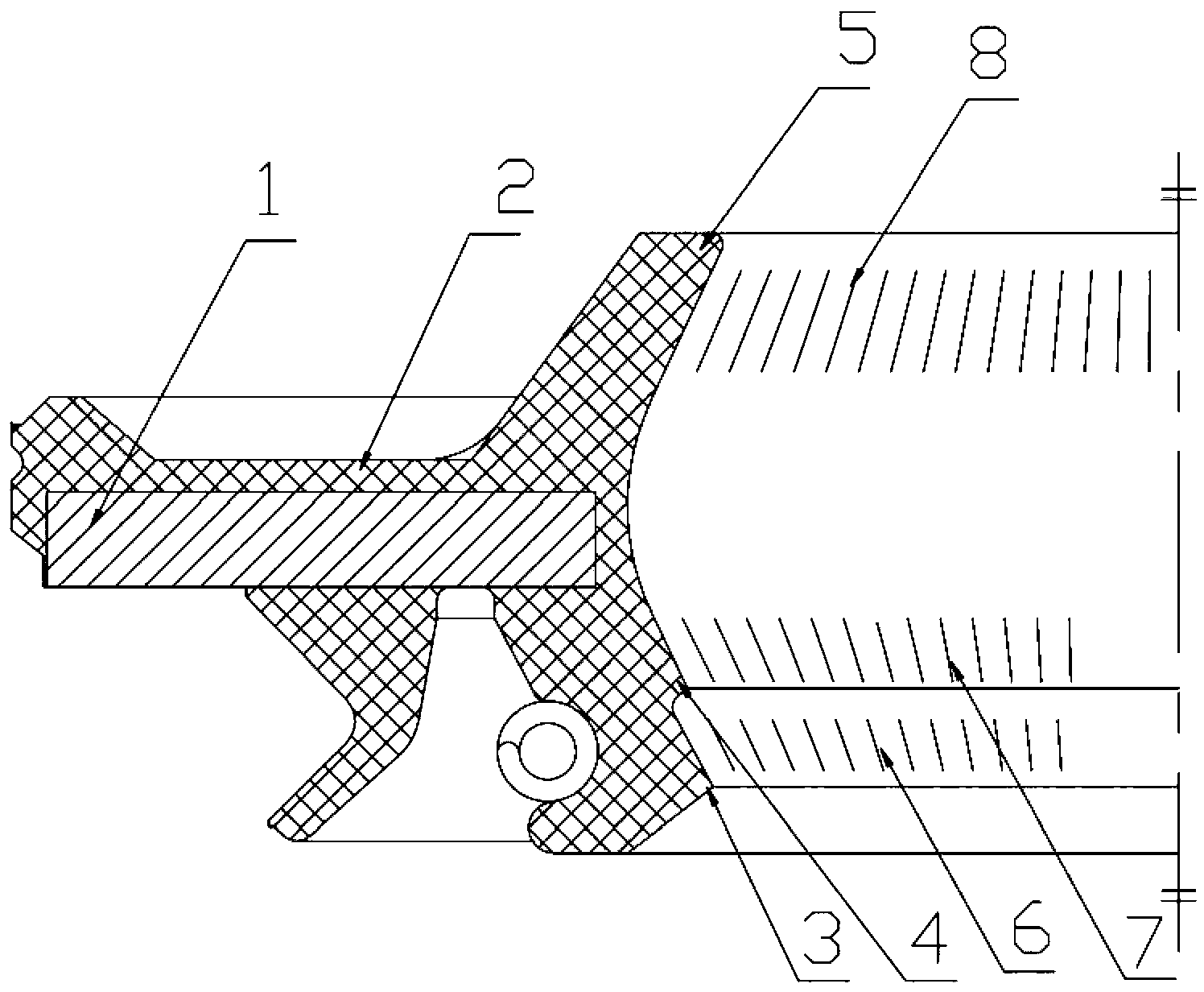

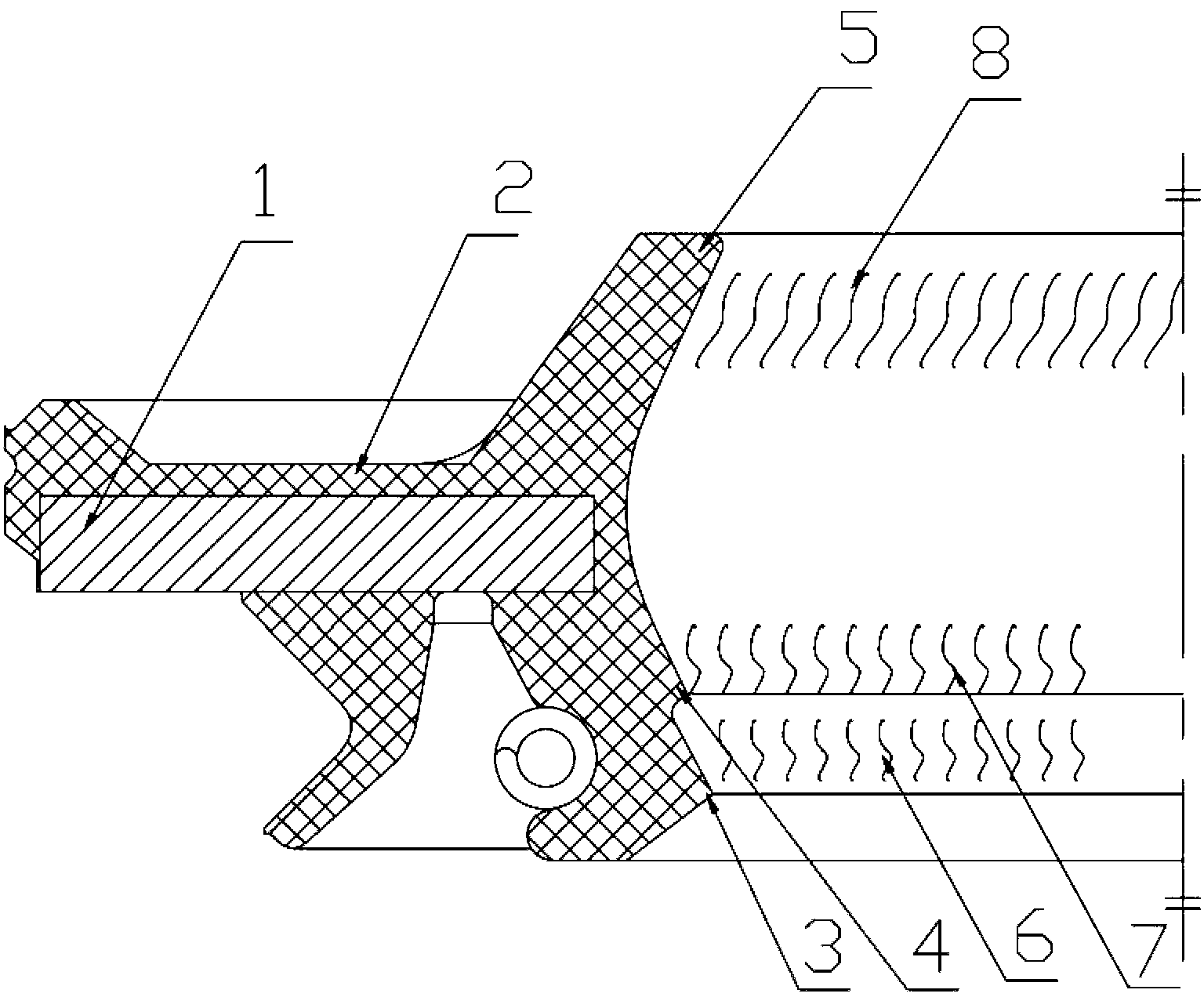

Bearing structure and wind power generator

InactiveCN101715520ASlow down the sliding speedReduce frictional heatRoller bearingsBearing assemblyEngineeringLubricant

The invention provides a bearing structure which reduces the relative sliding speed between a seal ring (20) and contact surfaces and suppresses relative deformation due to a difference between the temperatures of inner and outer rings (11, 12). Rolling elements (14) are disposed in a space portion (16) formed between the inner ring (11) and the outer rings (12) to relatively rotate the inner ring (11) or the outer rings (12) via the rolling elements (14). The sliding portions of the surfaces of the rolling bodies (14) and the inner surface of the space portion (16) are cooled with a lubricant supplied into the space portion (16). The axial end opening of the space portion (16) is covered with the seal ring (20) attached to the retainer (13) retaining the rolling elements (14).

Owner:MITSUBISHI HEAVY IND LTD

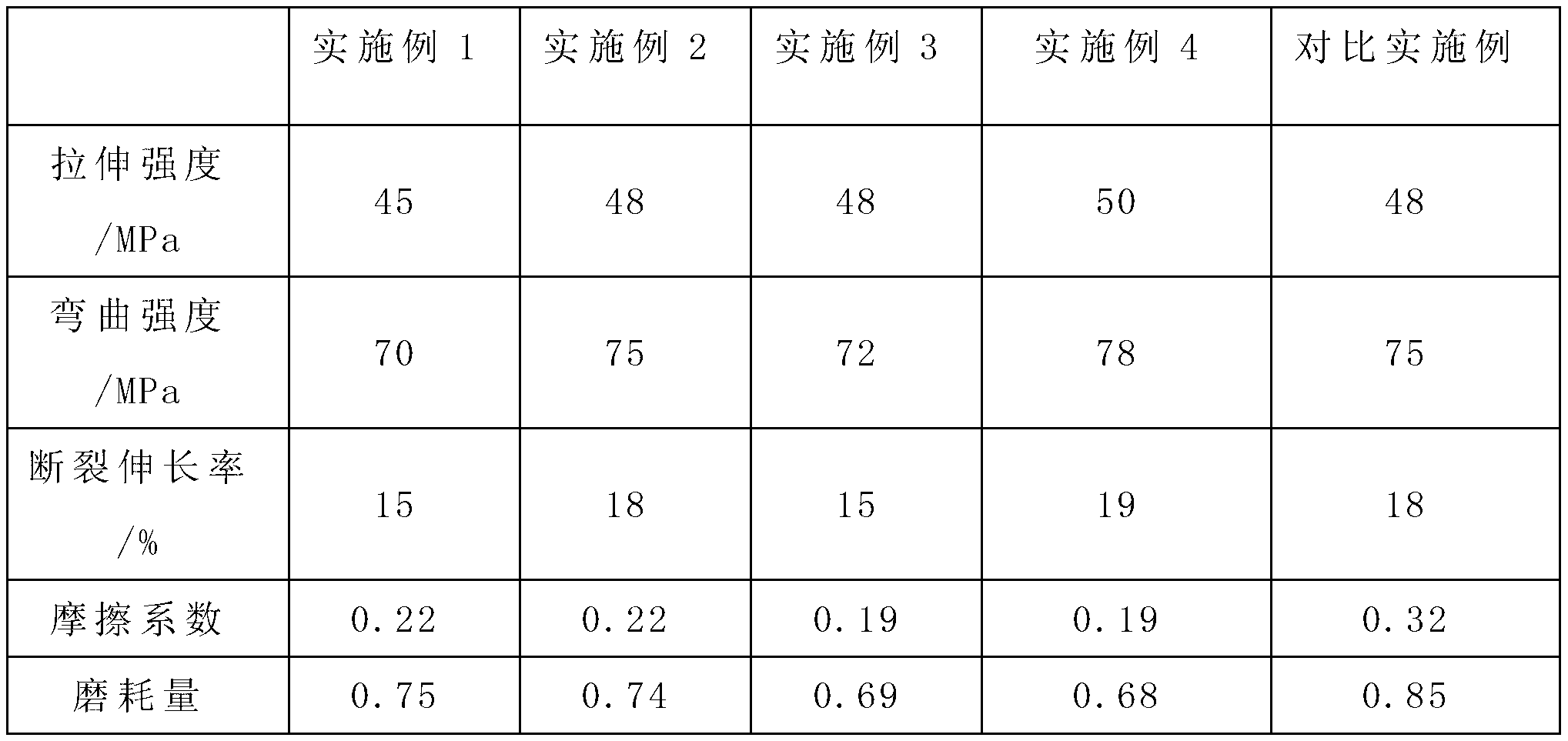

Graphene/carbon fiber enhanced nylon composite wear-resistant material and preparation method and application thereof

Disclosed are a graphene / carbon fiber enhanced nylon composite wear-resistant material and a preparation method and application thereof. The material includes a nylon resin, carbon fibers, graphene / nylon 6 master batch, an organic lubricant, an inorganic solid lubricant, a coupling agent and an anti-oxidant. The method comprises: (1) coupling the inorganic solid lubricant with the coupling agent to obtain a coupled inorganic solid lubricant; (2) mixing graphene / nylon 6 master batch, the organic lubricant, the coupled inorganic solid lubricant and the anti-oxidant; and (3) sending the nylon resin and a mixing auxiliary agent to an extruder, adding carbon fibers, performing mixing extrusion, and performing strap stretching, cooling, drying, and grain-sized dicing to obtain the material. The material is used for lubricating bearings and joint bearings of automobiles, and transmission gears of textile, food and packaging machinery or joint bearings of robots. The material is high in strength, good in thermal conductivity, self-lubrication, and wear resistance, and is long in service life. The method is simple and is suitable for industrial production.

Owner:长沙五犇新材料科技有限公司

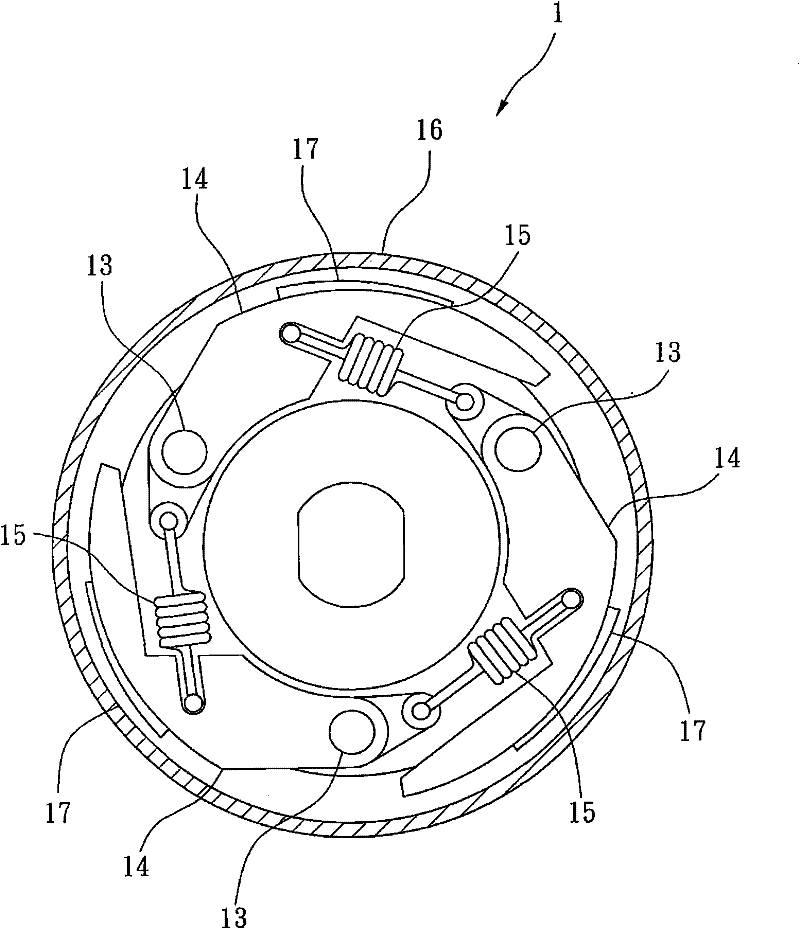

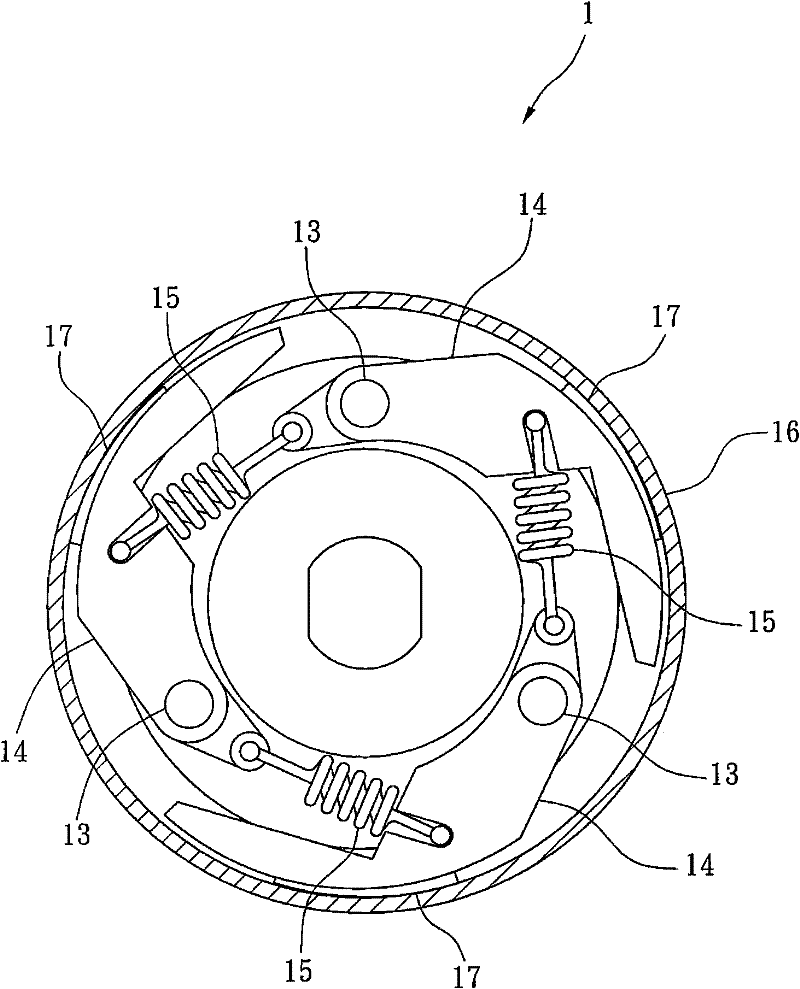

Centrifugal clutch

InactiveCN102444678APrevent slippingReduce frictional heatAutomatic clutchesCentrifugal clutchFriction reduction

Owner:KYMCO

Gas wave refrigerator

InactiveCN101571326AImprove sealingReduce manufacturing difficultyEngine sealsCompression machinesFriction reductionEngineering

The embodiment of the invention discloses a gas wave refrigerator, comprising an engine body, a bearing, a turning wheel distributor, a sealing structure and a receiving pipe; the engine body is provided with an air inlet and an air outlet; the sealing structure is arranged between the air inlet and the air outlet on the engine body; the engine body is provided with a receiving pipe connector, the receiving pipe is inserted into the receiving pipe connector; the sealing structure comprises a moving ring which can rotate along with the turning wheel distributor and a stationary ring which can not rotate along with the turning wheel distributor but can slightly move axially corresponding to the turning wheel distributor and the moving ring, and the stationary ring is arranged beside the moving ring; the receiving pipe is externally encircled with a shell, the shell forms a refrigeration cavity. The gas wave refrigerator of the invention features improved sealing effect due to the sealing structure thereof, reduced difficulty of manufacturing and assembly, greatly reduced heat generated by frictions, arrangement of the refrigeration cavity outside the receiving pipe which fast reduces temperature inside the receiving pipe, thus obviously improving refrigerating efficiency of the gas wave refrigerator.

Owner:SHENZHEN LK SCI&TECH

Wear-resistant and heat-resistant modified polyformaldehyde composite material and preparation method thereof

The invention discloses a wear-resistant and heat-resistant modified polyformaldehyde composite material comprising the following components in parts by weight: 50-80 parts of polyformaldehyde, 10-20 parts of polytetrafluoroethylene, 2-6 parts of MoS2, 0.1-1 part of formaldehyde absorbent, 2-10 parts of compatilizer, 0.3-1 part of antioxidant, 0.1-0.8 parts of coupling agent, and 0.1-0.5 parts of other auxiliary agents. A little of MoS2 and the polytetrafluoroethylene are added to the polyformaldehyde, so that the solubility of the product can be reduced; the size stability and temperature resistance of the product are improved; meanwhile, the effect of friction heat is reduced; and the improved composite material has excellent mechanical property and wear resistance, and has high application prospect in the field of gears with high manufacturing demands and self-lubricating property.

Owner:SUZHOU SUNWAY POLYMER

Lubricant sheet for making hole and method of making hole with drill

InactiveUS6753300B2Reduce frictional heatQuality improvementThread cutting machinesPrinted circuit aspectsMetal foilPolyethylene glycol

A lubricant sheet for making a hole used for a printed circuit board, comprising an organic substance layer having a thickness of 0.02 to 3.0 mm and formed of a mixture (a) or a mixture (b) and a metal foil having a thickness of 0.05 to 0.5 mm,said organic substance layer being formed on one surface of said metal foil,said mixture (a) being a mixture containing polyether ester (I), a solid water-soluble lubricant (II) and polyethylene glycol (III) having a number average molecular weight of 200 to 600, andsaid mixture (b) being a mixture containing said polyether ester (I), said solid water-soluble lubricant (II) and a liquid water-soluble lubricant (IV), and a method of making a hole which uses the lubricant sheet.

Owner:MITSUBISHI GAS CHEM CO INC

Low-friction oil seal for shock absorber

ActiveCN103244686AReduce coefficient of frictionKeep radial force constantEngine sealsEngineeringShock absorber

The invention relates to a sealing element, in particular to a low-friction oil seal for a shock absorber. The oil seal comprises a framework and an oil seal body. The oil seal body comprises at least one sealing lip and a dust-proof lip. The oil seal is characterized in that axial parallel veins are arranged on annular sealing surfaces formed by the sealing lips. The sealing lips comprise a first sealing lip and a second sealing lip, and first axial parallel veins and second axial parallel veins are arranged on the annular sealing surfaces formed by the first sealing lip and the second sealing lip respectively. Third axial parallel veins are arranged on an annular sealing surface formed by the dust-proof lip. The low-friction oil seal has the advantages that forming of critical lubricating oil film between contact surfaces of the sealing surfaces and a shock absorber shaft is facilitated, so that the contact area is reduced; and lubricating oil can be stored between the axial veins conveniently, so that the friction coefficient between the oil seal and the shock absorber shaft is reduced, the friction between the oil seal and the shock absorber shaft is reduced on the premise that the radial sealing force is not changed, and the service life of the oil seal is increased.

Owner:YANTAI RUNFUXIANG OIL SEAL

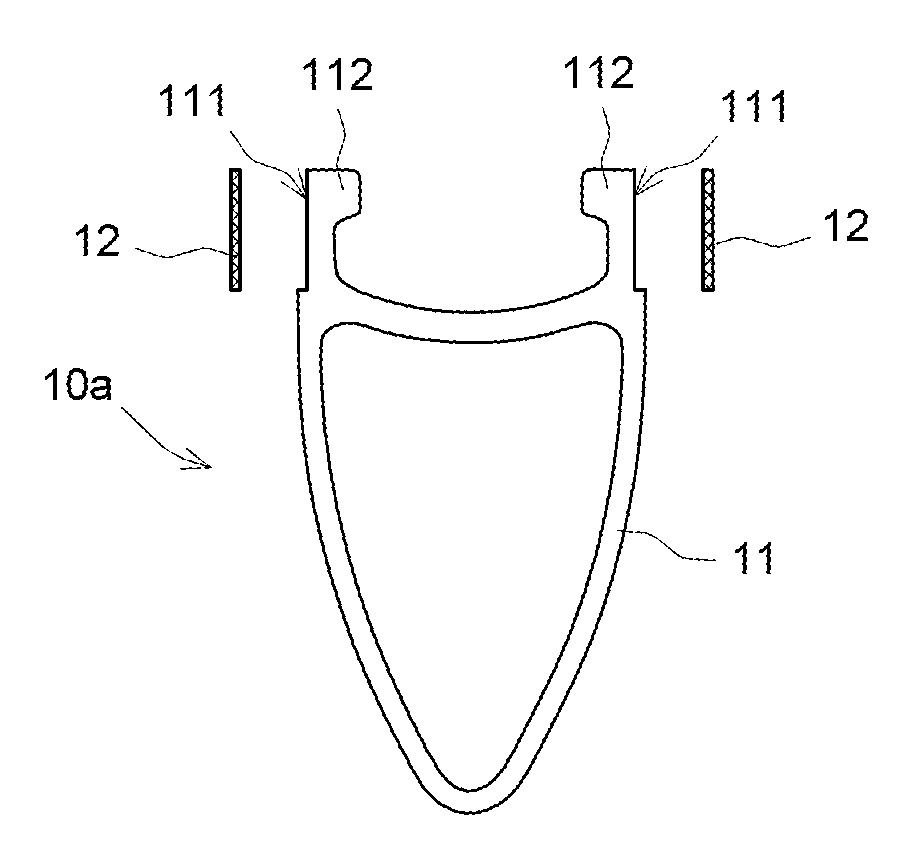

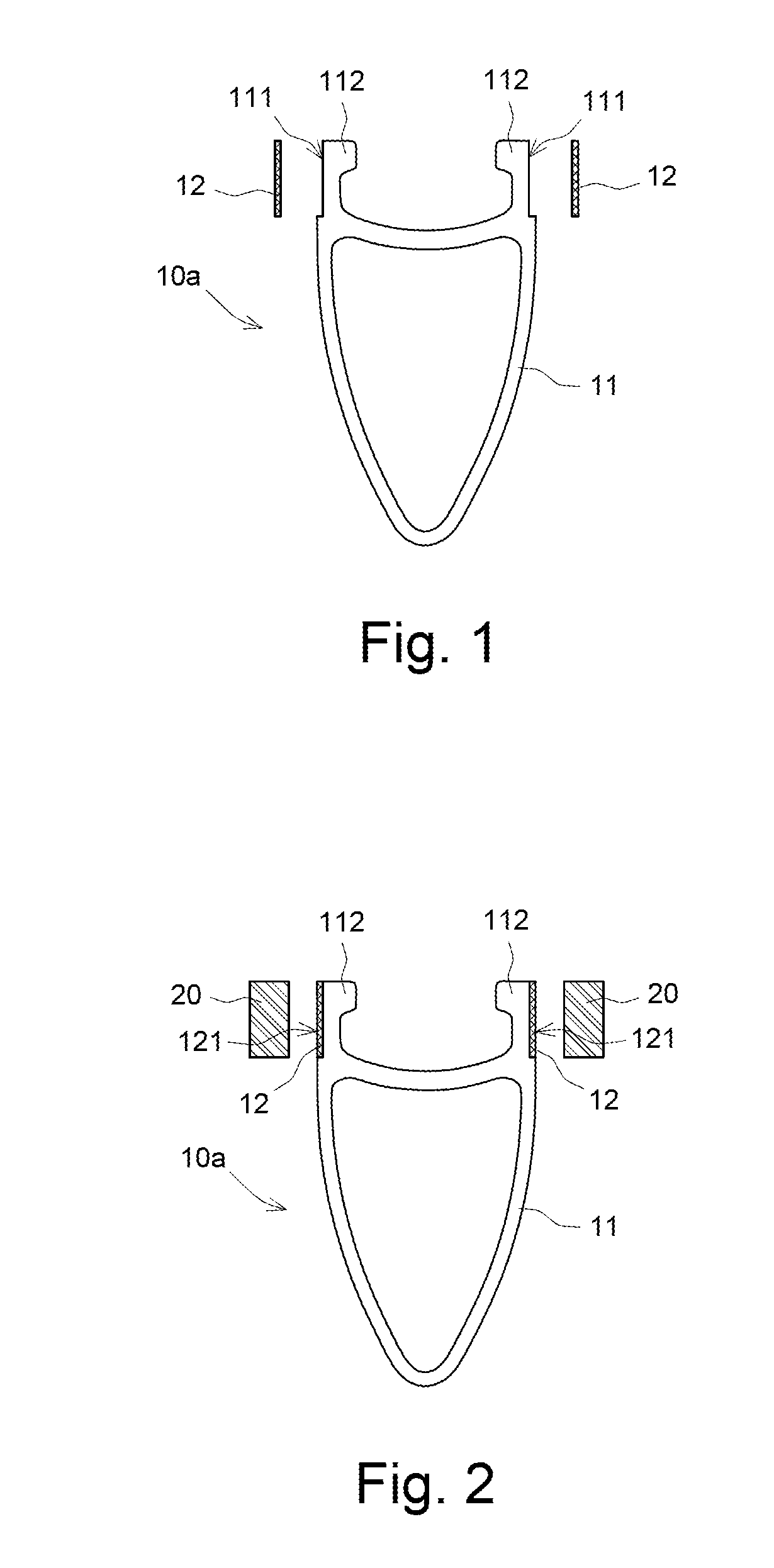

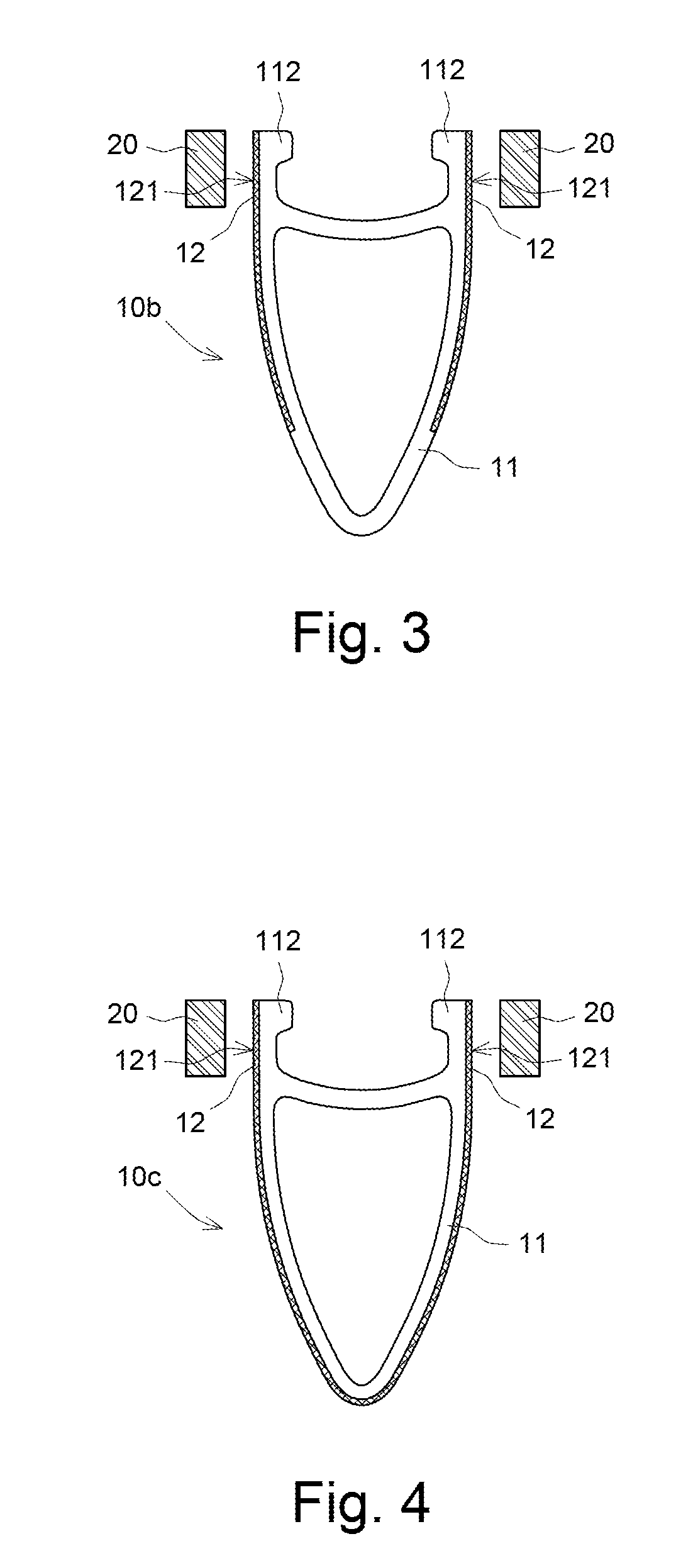

Carbon fiber rim, bicycle including the same and manufacture method thereof

InactiveUS20140167384A1Avoid distortionReduce frictional heatPassenger cyclesChildren cyclesFiberEngineering

A carbon fiber rim comprises a circular rim and a heat conduction layer. The circular rim comprises carbon fiber composites, and has two opposite side surfaces facing two brake pads and two opposite hooks extending outward radially to hold tires. The heat conduction layer is arranged on the side surface of the circular rim for forming a braking region facing the brake pad. The heat conduction layer comprises a porous or mesh heat conduction material. A bicycle including the aforementioned carbon fiber rim and the manufacturing method of the carbon fiber rim are also disclosed here. The carbon fiber rim can prevent distortion due to frictional heat when braking.

Owner:AWISE FIBER TECH

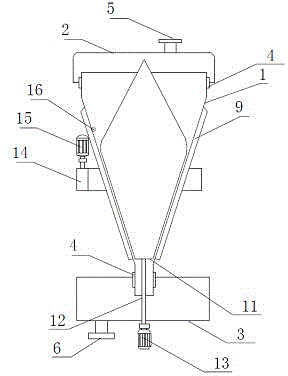

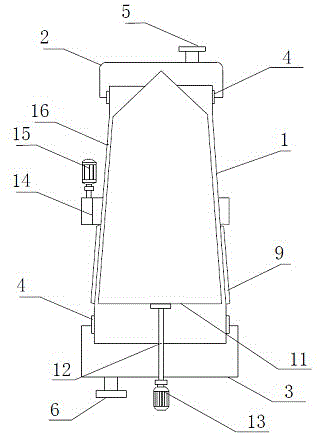

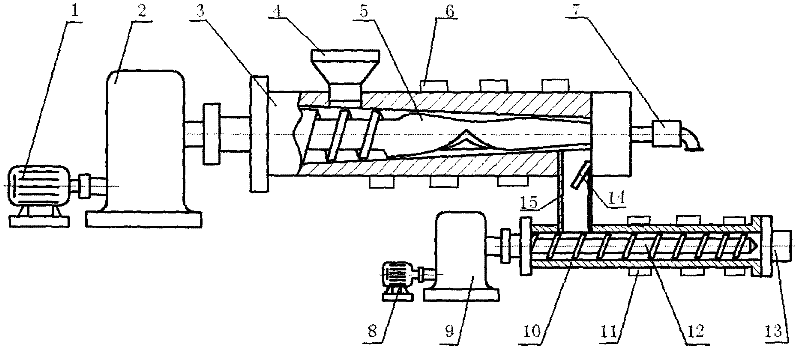

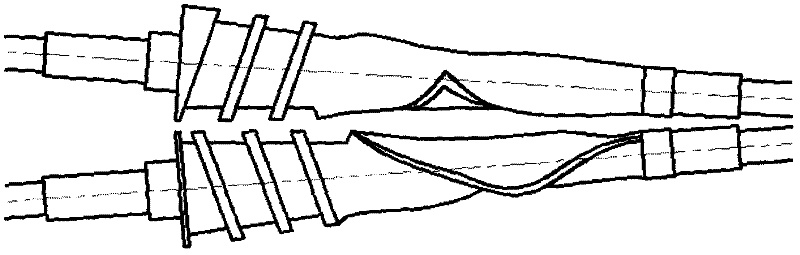

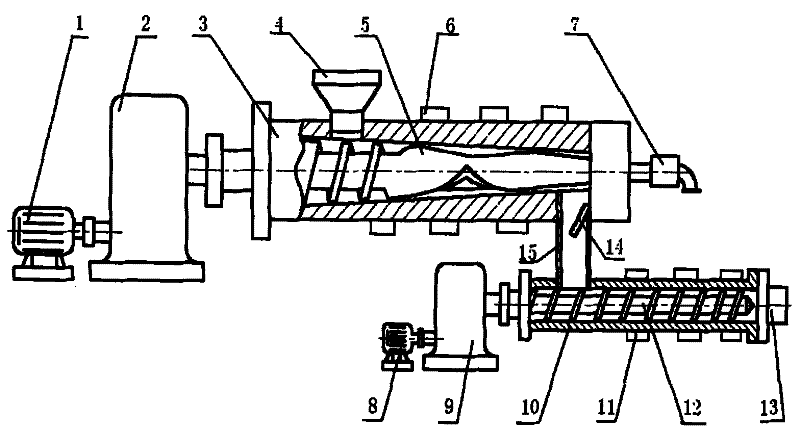

Double-conical-rotor continuous mixing unit

The invention provides a double-conical-rotor continuous mixing unit. The mixing unit mainly comprises a mixing part and a discharging part and can adopt a single-band or dual-band mode; wherein the mixing part mainly comprises a charging device, a cylinder, conical rotors, heating and cooling devices and a transmission device; the two mixing rotors are conical and the center lines of the two rotors form a certain angle when the two rotors are installed; the outer diameter outline of each mixing rotor is gradually reduced and is conical; the mixing rotors are provided with charging segments and mixing segments; the rotors on the charging segments adopt screw conveying structure; seen from the angle vertical to the conical surfaces of the outer outlines of the rotors, the structures of the mixing segments have the typical rotor characteristics such as cam shape, S shape or four-wing shape; when the mixing unit adopts the single-band mode, the tail ends of the rotors adopt the screw structure and pressure is created to convey the materials to the head; and when the mixing unit adopts the dual-band mode, the mixed materials enter into next band of screw extruder via a valve and pressure is created to convey the materials to the head; the mixing unit in any one of the two modes adopts the head fit for the cavity for pelleting or forming; a melt pump can be connected in front of the head; and two rotors can rotate at the same speed or different speed and form a plurality of shearing, drawing and kneading zones during rotation, and exchange of materials among the rotors is more frequent, thus effectively improving the plasticating, melting and dispersing properties of equipment, shortening the processing time and improving the yield. The mixing unit can be used in such processes as mixing, pelleting and the like during processing rubbers, coatings, propellants, explosives, paper pulp, plastics, food, medicaments, feeds and the like.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com