Wear-resistant mechanical sealing structure on end face

An end face sealing and wear-resistant technology, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of cold welding, easy to generate howling sound, and difficult end face processing, so as to achieve small frictional heat and improve Reliable, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A wear-resistant mechanical end face seal structure, including a moving ring 5 and a static ring 6 of the mechanical seal, micro-protrusions 1 are processed on the end faces of the moving ring or the static ring, and the micro-protrusions 1 are arranged in a ring according to the center of the end face The ring belt is provided with an annular seal dam 2 symmetrical to the center of the end face, the end face of the seal dam is a smooth surface, and there is an annular seal dam on the end face.

[0040] The microprojections gradually increase along the leakage direction of the sealing medium, and their maximum height does not exceed the height of the adjacent sealing dam, and the density of the microprojections decreases slightly along the leakage direction of the sealing medium.

[0041] The structural parameters of microprojections range from: aspect ratio or aspect ratio α is 1 to 10; height is 2 to 200 μm; area density is 0.1 to 0.7; the distance between the cross-se...

Embodiment 2

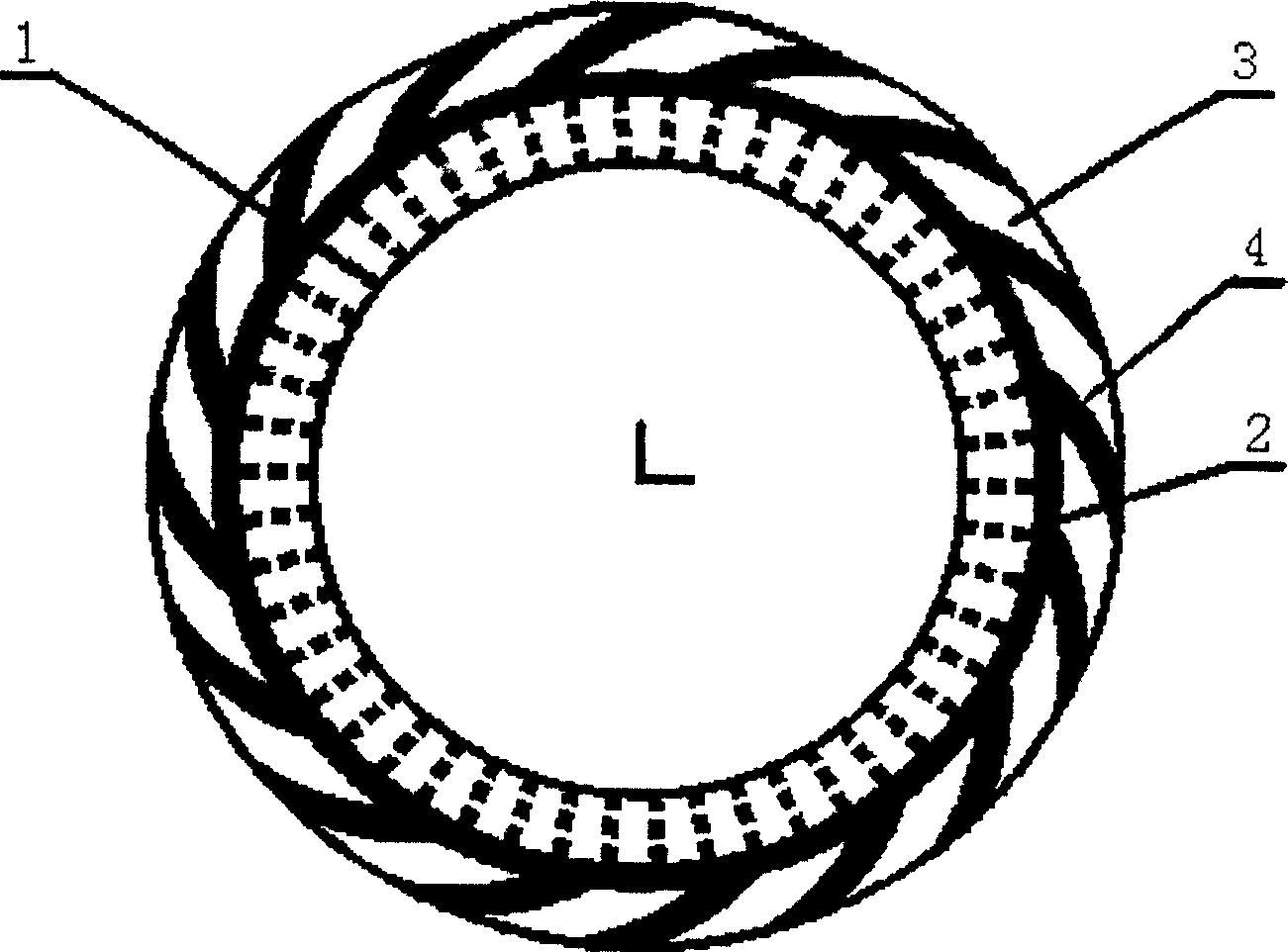

[0045] A wear-resistant mechanical end face seal structure, including a moving ring 5 and a static ring 6 of the mechanical seal, micro-protrusions 1 are processed upstream of the end face of the moving ring or the static ring, and the micro-protrusions are arranged in an annular band according to the center of the end face , there is an annular sealing dam 2 symmetrical to the center of the end face next to the ring belt, the end face of the sealing dam is a smooth surface, the height of the sealing dam 2 is equal to the height of the micro-protrusion 1, and the downstream of the end face is also processed according to the end face A micro-groove 3 symmetrical to the center, the sealing weir 4 of the micro-groove is as high as the sealing dam 2, and there is an annular sealing dam on the end face, and the sealing dam 2 is located between the micro-protrusion 1 and the micro-groove 3.

[0046] The microprojections have the same height along the radial direction of the end face....

Embodiment 3

[0050] A wear-resistant mechanical end face seal structure, including a moving ring 5 and a static ring 6 of the mechanical seal, micro-protrusions 1 are processed downstream of the end face of the moving ring or the static ring, and the micro-protrusions 1 are arranged in a ring according to the center of the end face The ring belt is provided with an annular seal dam 2 symmetrical to the center of the end face. The end face of the seal dam is a smooth surface. The upstream of the end face is also processed with a micro-groove 3 symmetrical to the center of the end face. The micro-groove The sealing weir 4 is as high as the sealing dam 2, and there is an annular sealing dam 2 on the end face, and the sealing dam 2 is located between the microprotrusion 1 and the microgroove 3.

[0051] The microprotrusions 1 gradually increase along the leakage direction of the sealing medium, and their maximum height does not exceed the height of the adjacent sealing dam 2, and the density of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com