Thermal deformation suppression middle type high-speed crown block gantry five-axis machining center

A five-axis machining center, mid-mounted technology, used in manufacturing tools, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of small processing range and low precision, achieve high processing precision, fast response speed, eliminate gap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

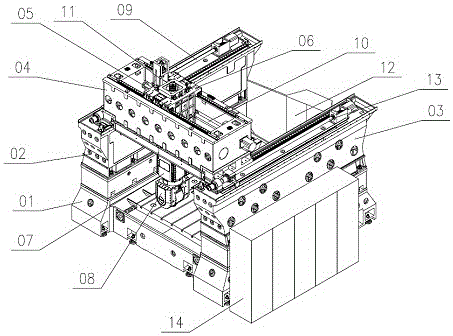

[0033] Such as figure 1 As shown, a middle-mounted high-speed crane gantry five-axis machining center for suppressing thermal deformation of the present invention includes 01 base, 02 left bridge, 03 right bridge, 04 beam, 05 left sliding seat, 06 right sliding seat, 07 sliding Pillow, 08 AC double swing head, 09 X-axis left transmission assembly, 10 Y-axis transmission assembly, 11 Z-axis transmission assembly, 12 tool magazine, 13 X-axis right transmission assembly, 14 CNC system, etc., five-axis machining center The X-axis is driven by dual motors, the YZ-axis is driven by a single motor, and the three-axis transmission components are all cooled by hollow screw and nut circulation.

[0034] The workbench is directly cast on the base 01, and the left bridge 02 and the right bridge 03 are fixedly installed on both sides of the base 01, and linear guide rails are respectively installed on the left bridge 02 and the right bridge 03, and the crossbeam 04 passes through the X-axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com