Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6006 results about "Wire cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In wire electrical discharge machining (WEDM), also known as wire-cut EDM and wire cutting, a thin single-strand metal wire, usually brass, is fed through the workpiece, submerged in a tank of dielectric fluid, typically deionized water. Wire-cut EDM is typically used to cut plates as thick as 300mm and to make punches, tools, and dies from hard metals that are difficult to machine with other ...

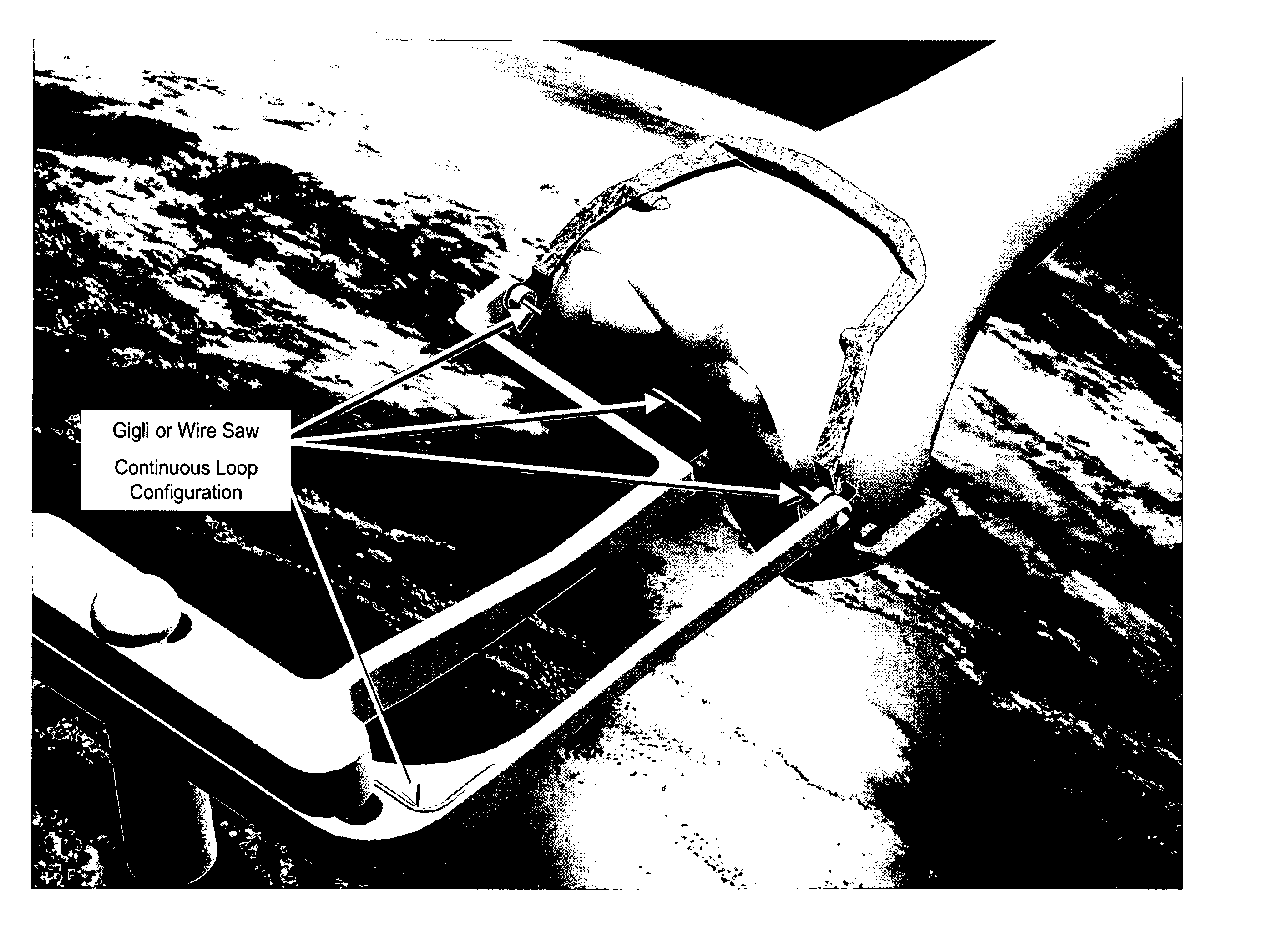

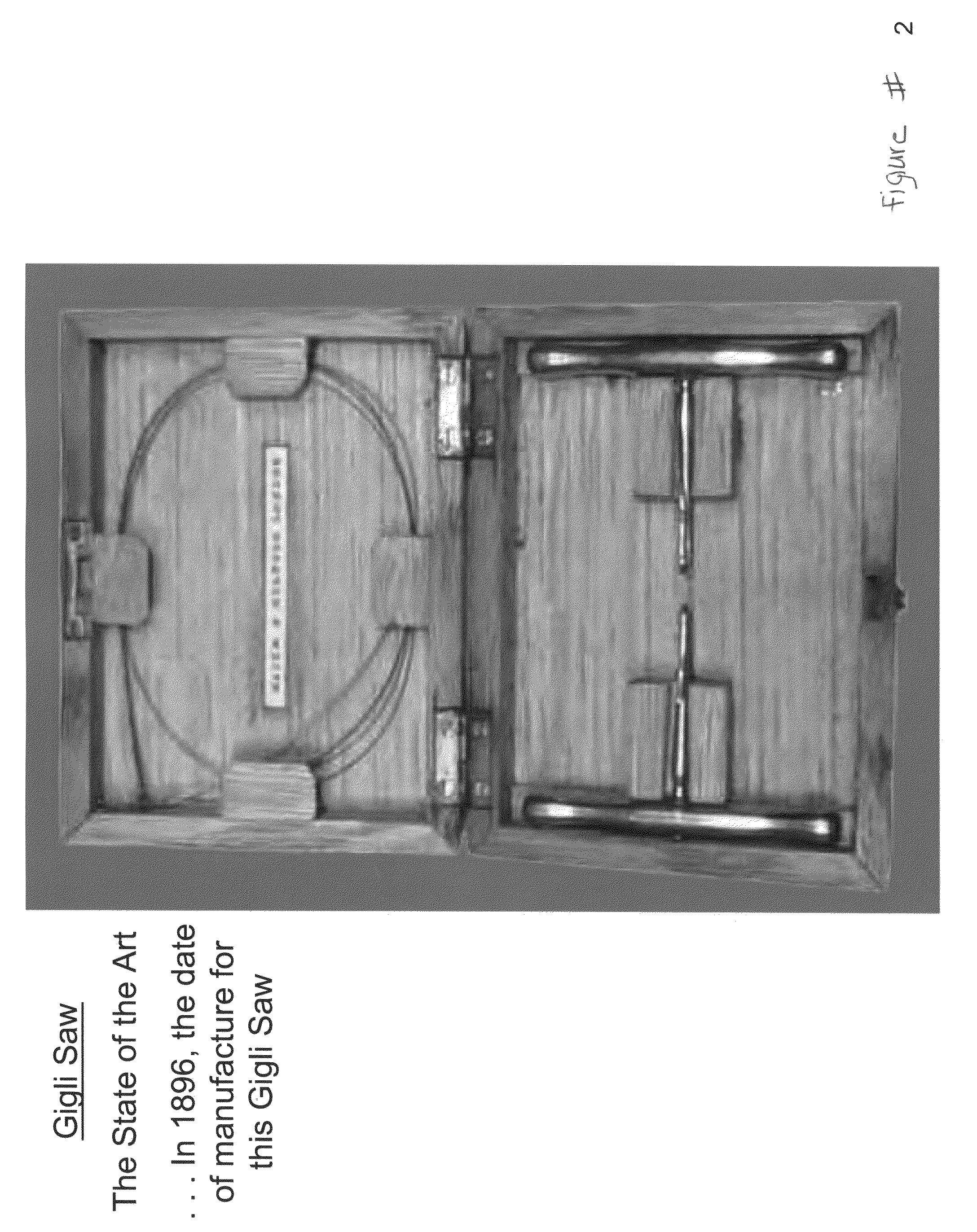

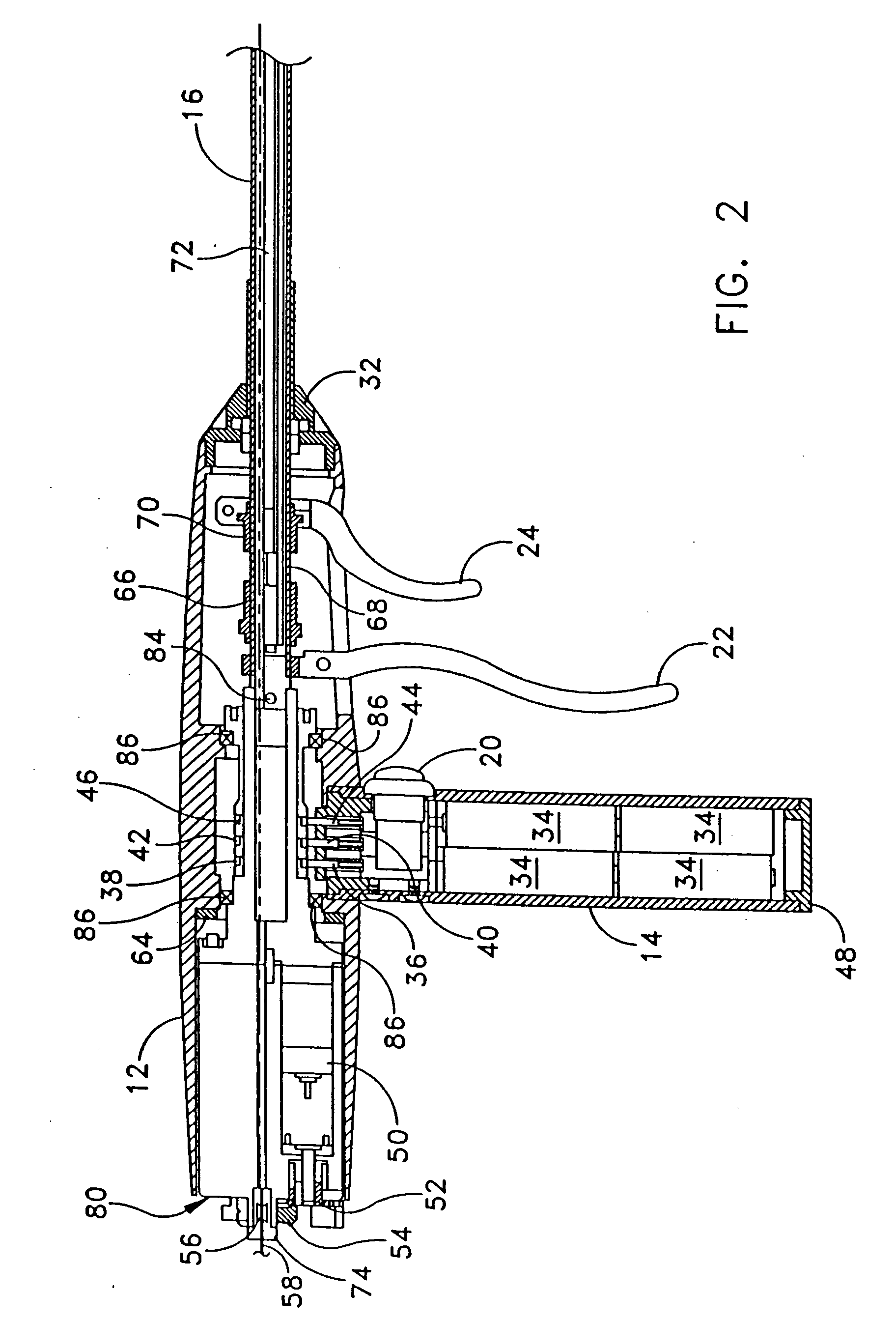

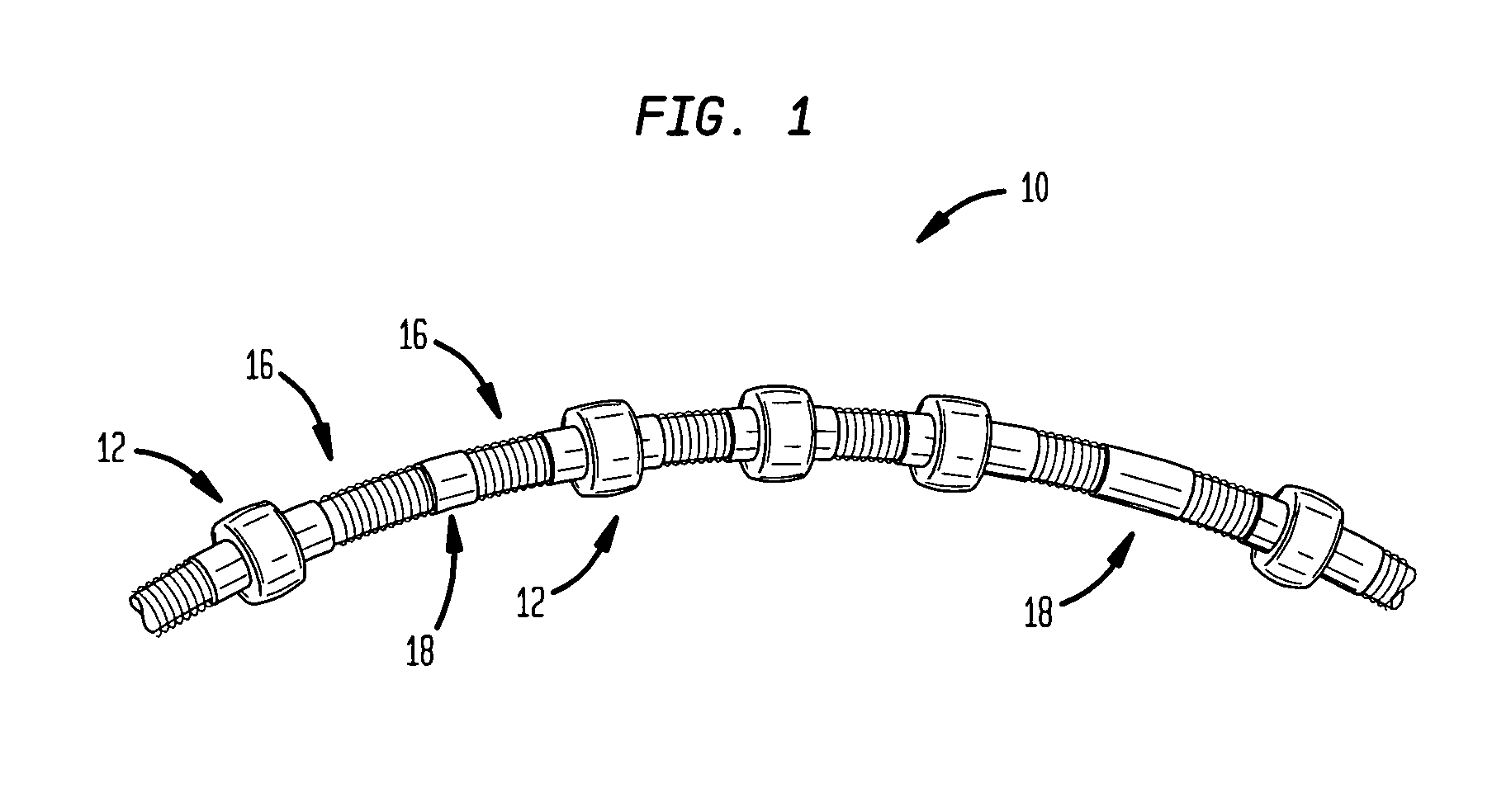

Methods and apparatus for wireplasty bone resection

InactiveUS20060030854A1Thin cutting profileMinimize size of incisionSurgical sawsProsthesisBone tissueWire cutting

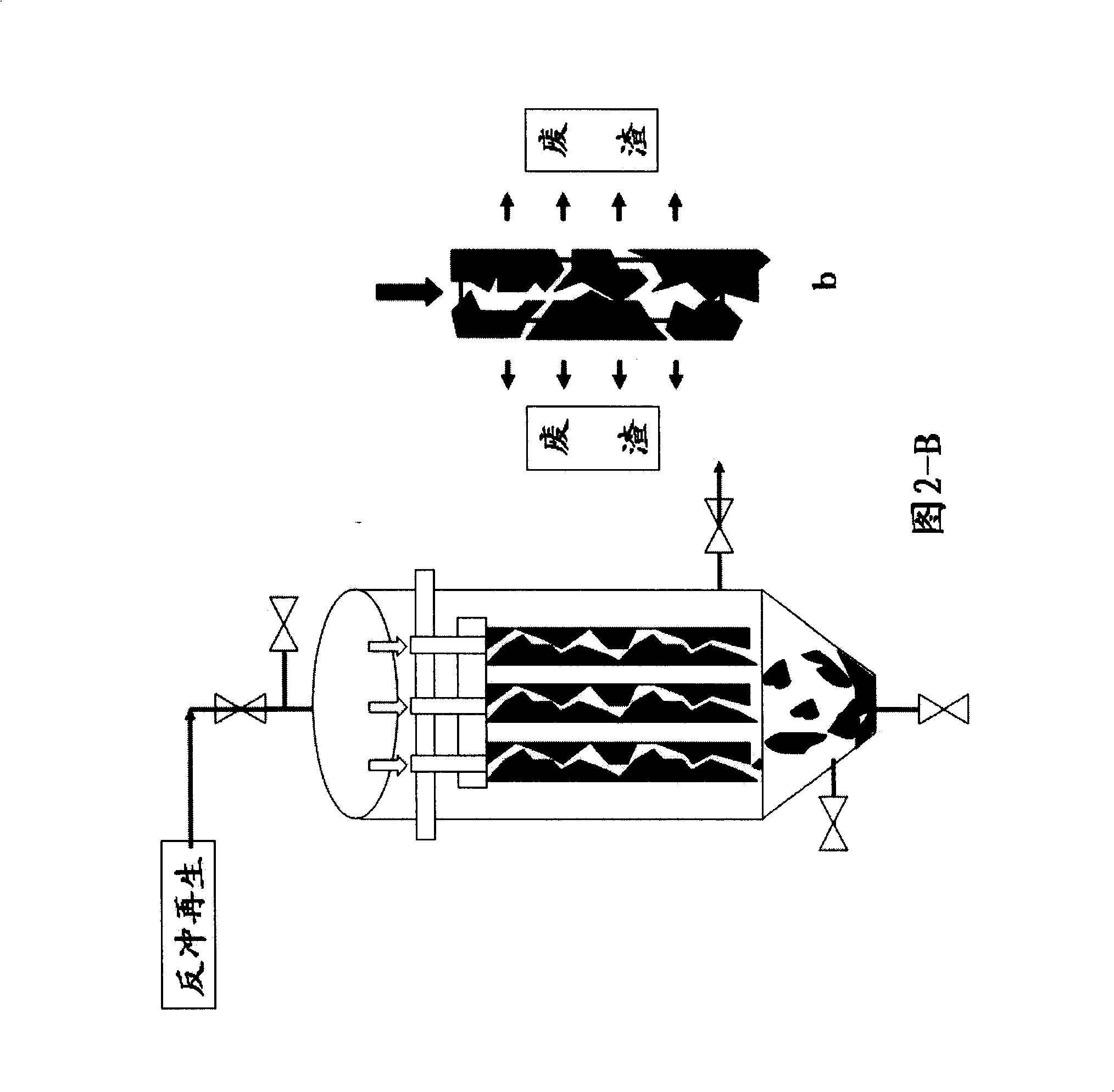

A cutting tool to be utilized in the resection or removal of bone tissue from patients includes a handle that tensions a wire or cable-like cutting member with a small diameter between at least two features on the handle to present a thin cutting profile. The design of the cutting tool includes features that protect against soft tissue damage and minimize the incision size necessary to utilize the tool. Some embodiments feature details of the cutting tool that interface with a surgical cutting guide system. Other embodiments describe a cutting tool with a selectively changeable length of the cutting profile of the wire cutting member. In one embodiment, the wire cutting member of the cutting tool is energized by mechanical energy in the form of a unidirectional rotation of the cutting member, a mechanical vibration of the cutting member, or an oscillating movement of the wire cutting member.

Owner:PUGET BIOVENTURES

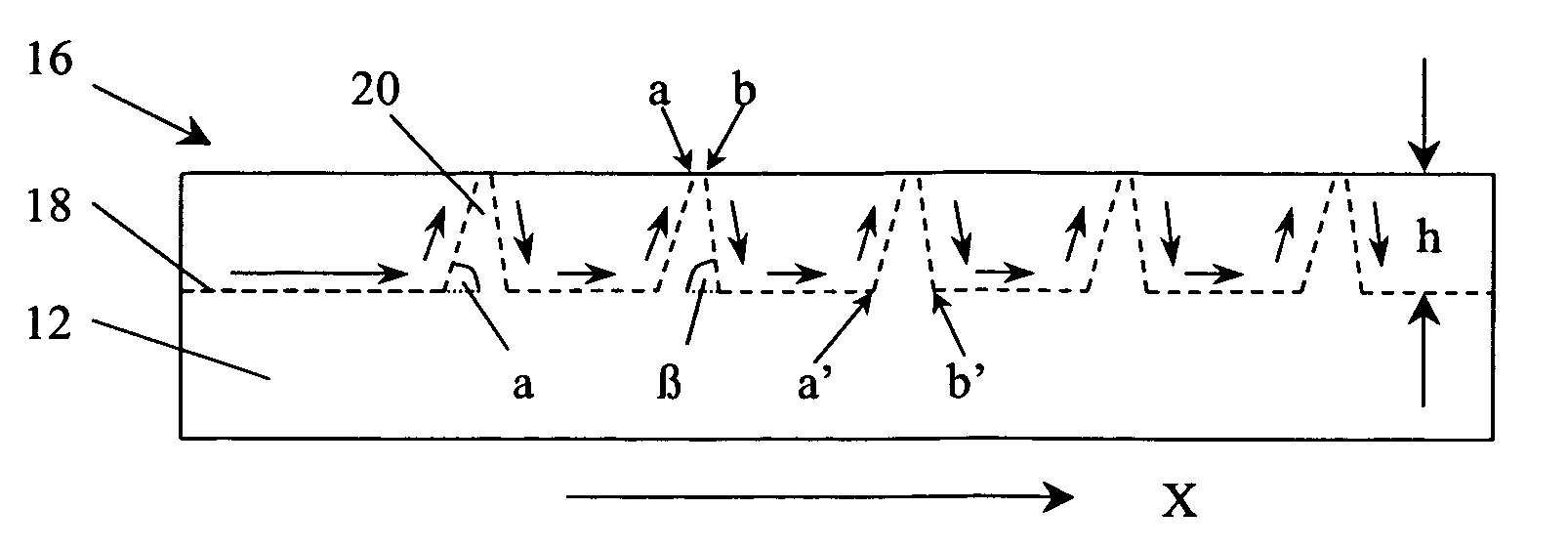

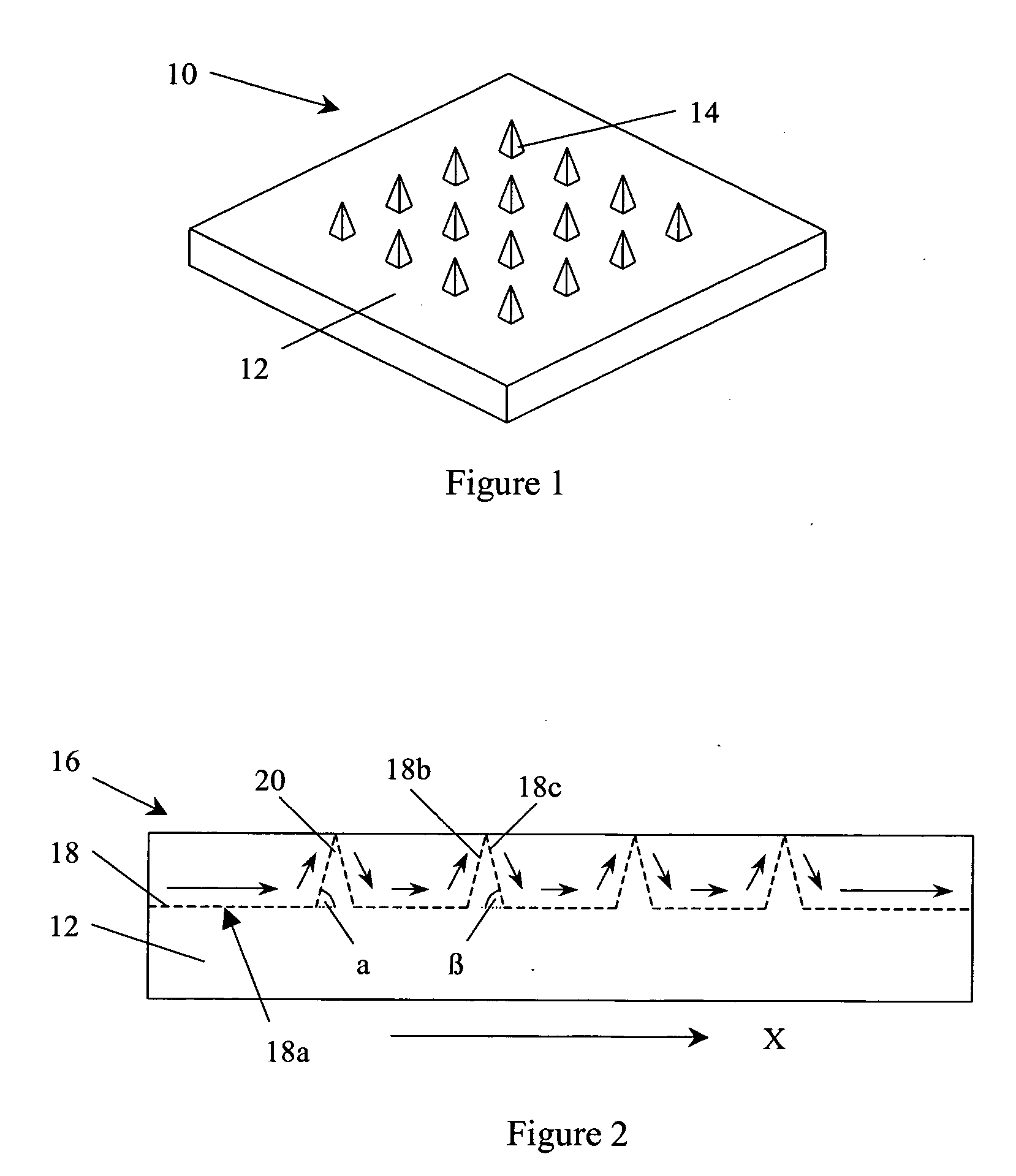

Microneedles and microneedle fabrication

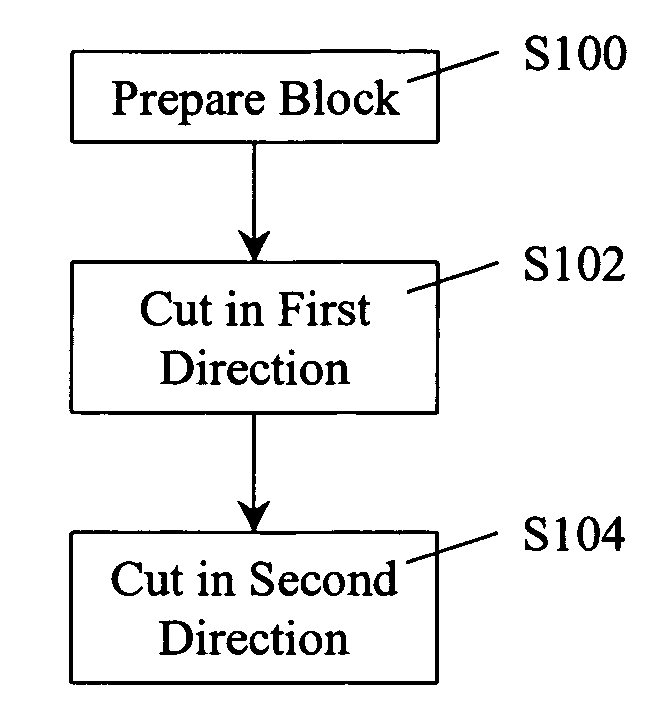

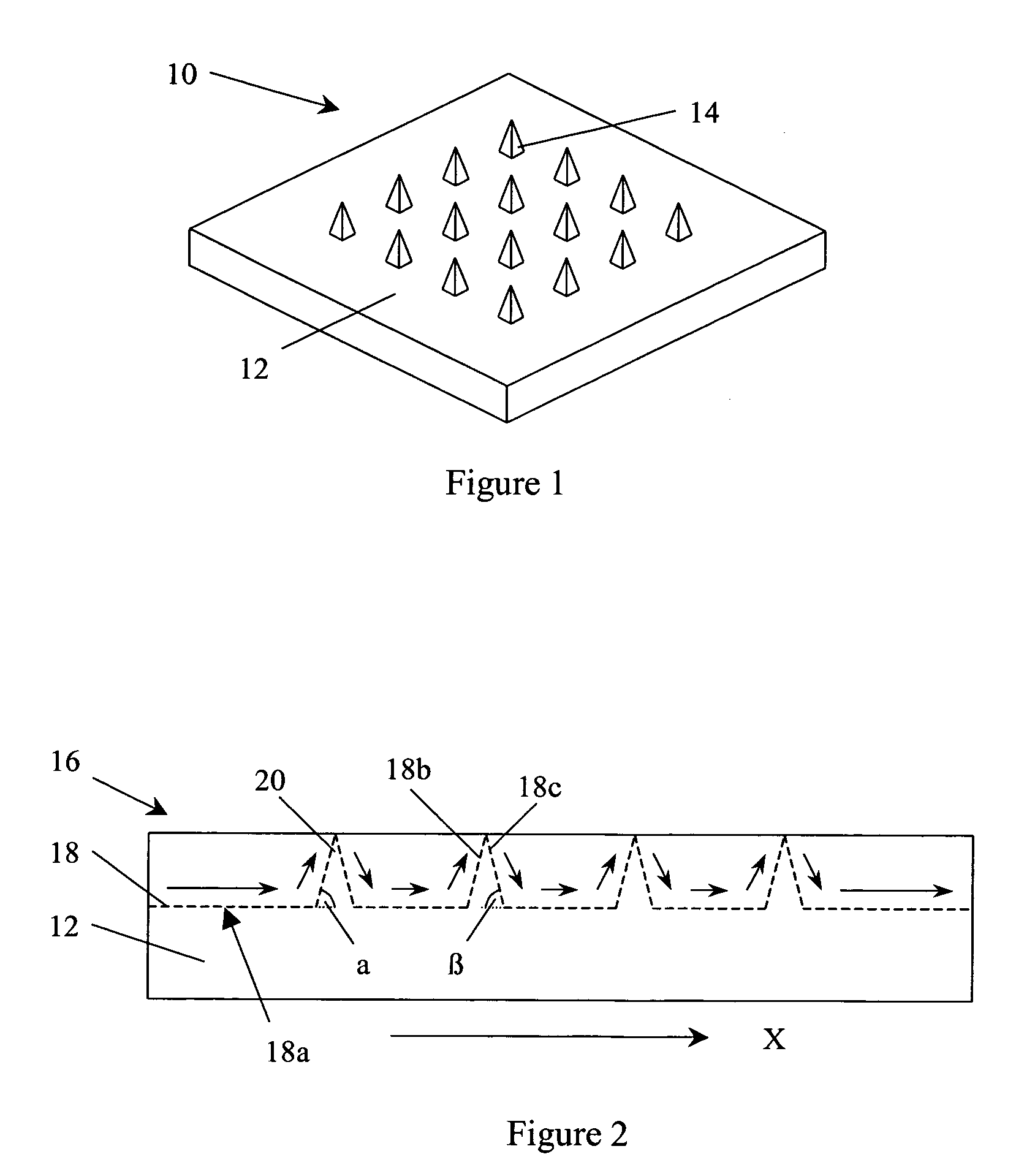

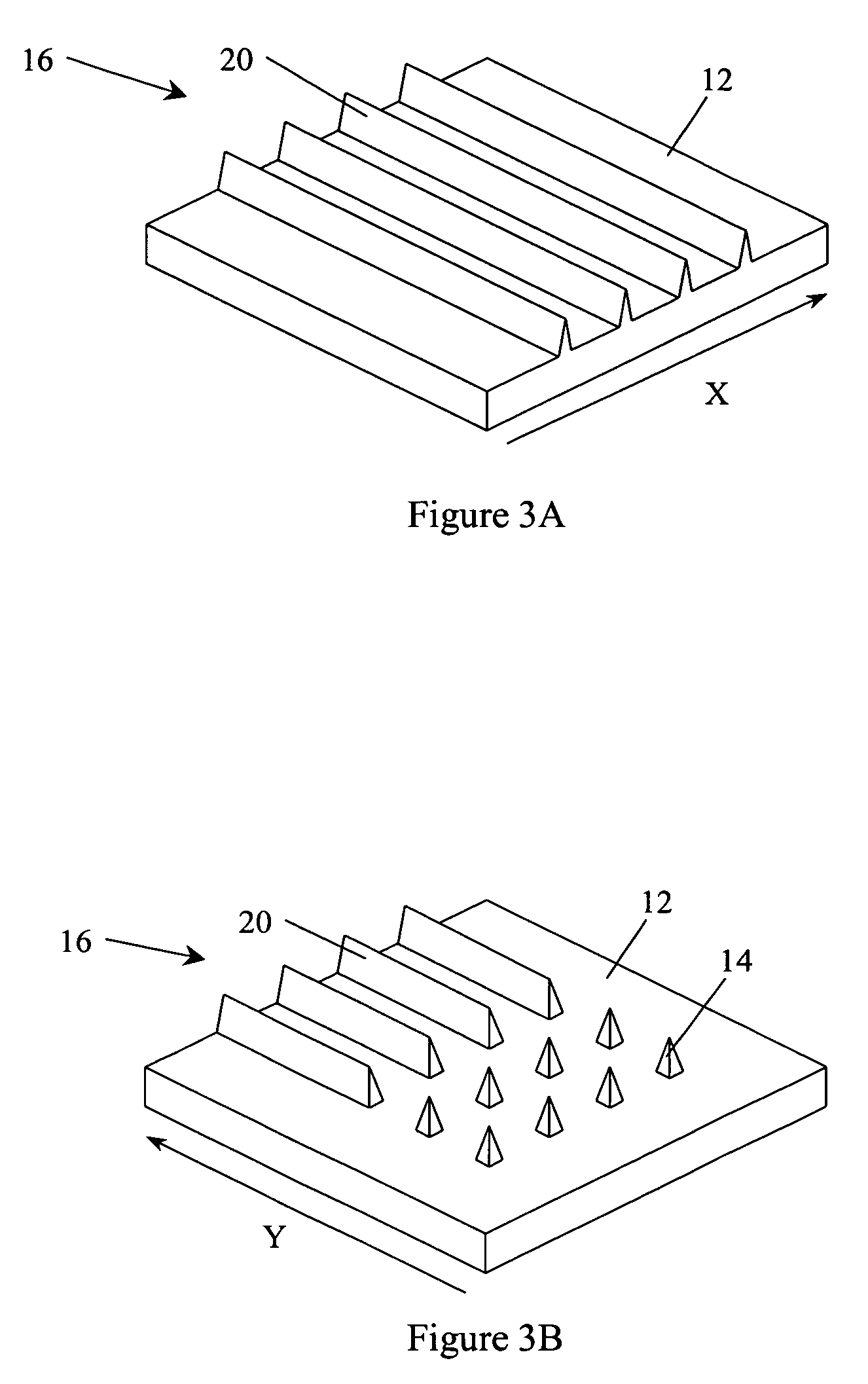

A master mould is made by wire cutting a plate in two or more directions to provide a base with an array of master mould needles protruding therefrom. The size and shape of the master mould needles can readily be varied by varying the angles of upward and downward cuts in the two or more directions. The master mould is used to make a secondary mould by hot embossing a secondary mould plate onto the master mould. This forms through-holes in the secondary mould. The secondary mould is plated with a layer of metal, which forms a microneedle array.

Owner:AGENCY FOR SCI TECH & RES

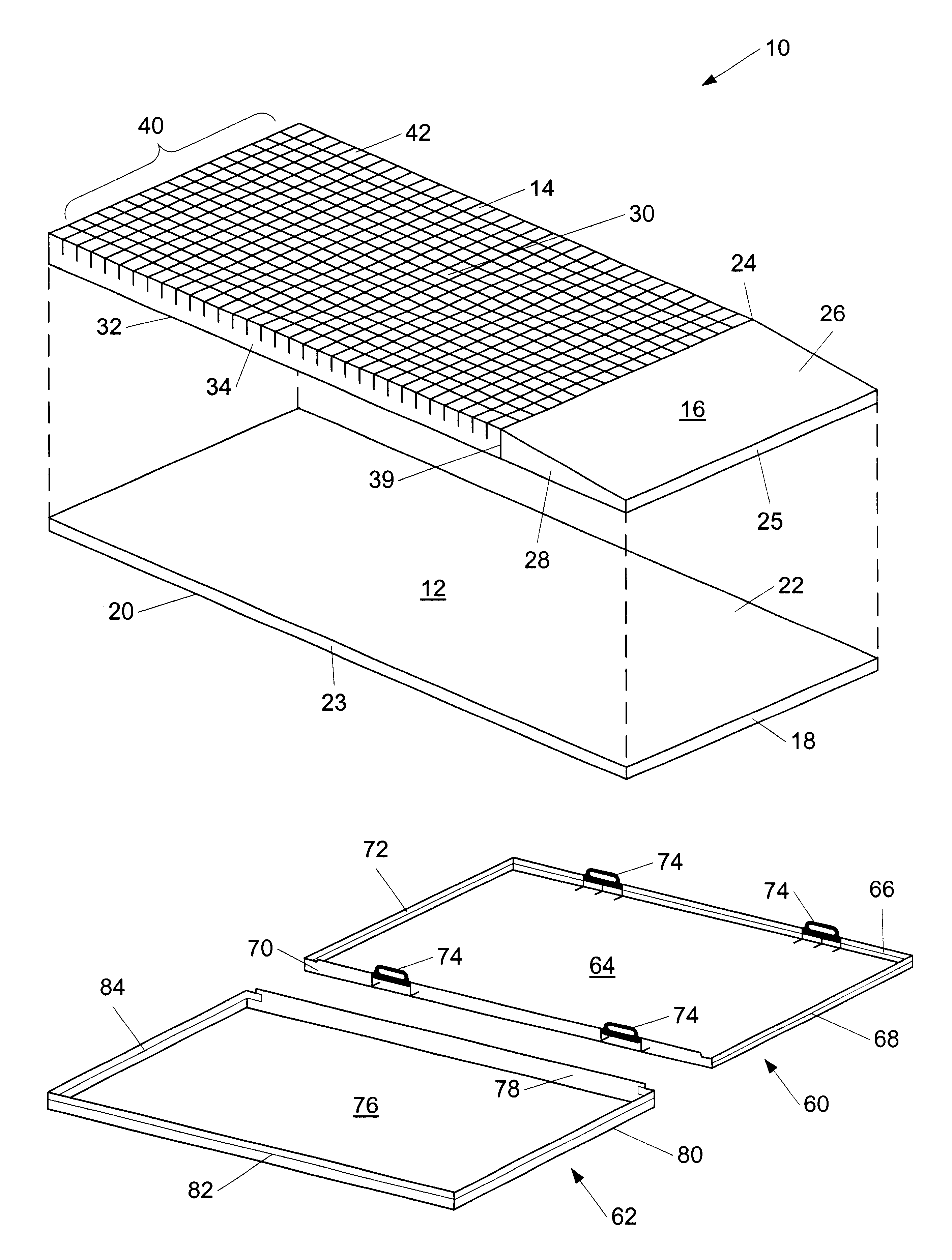

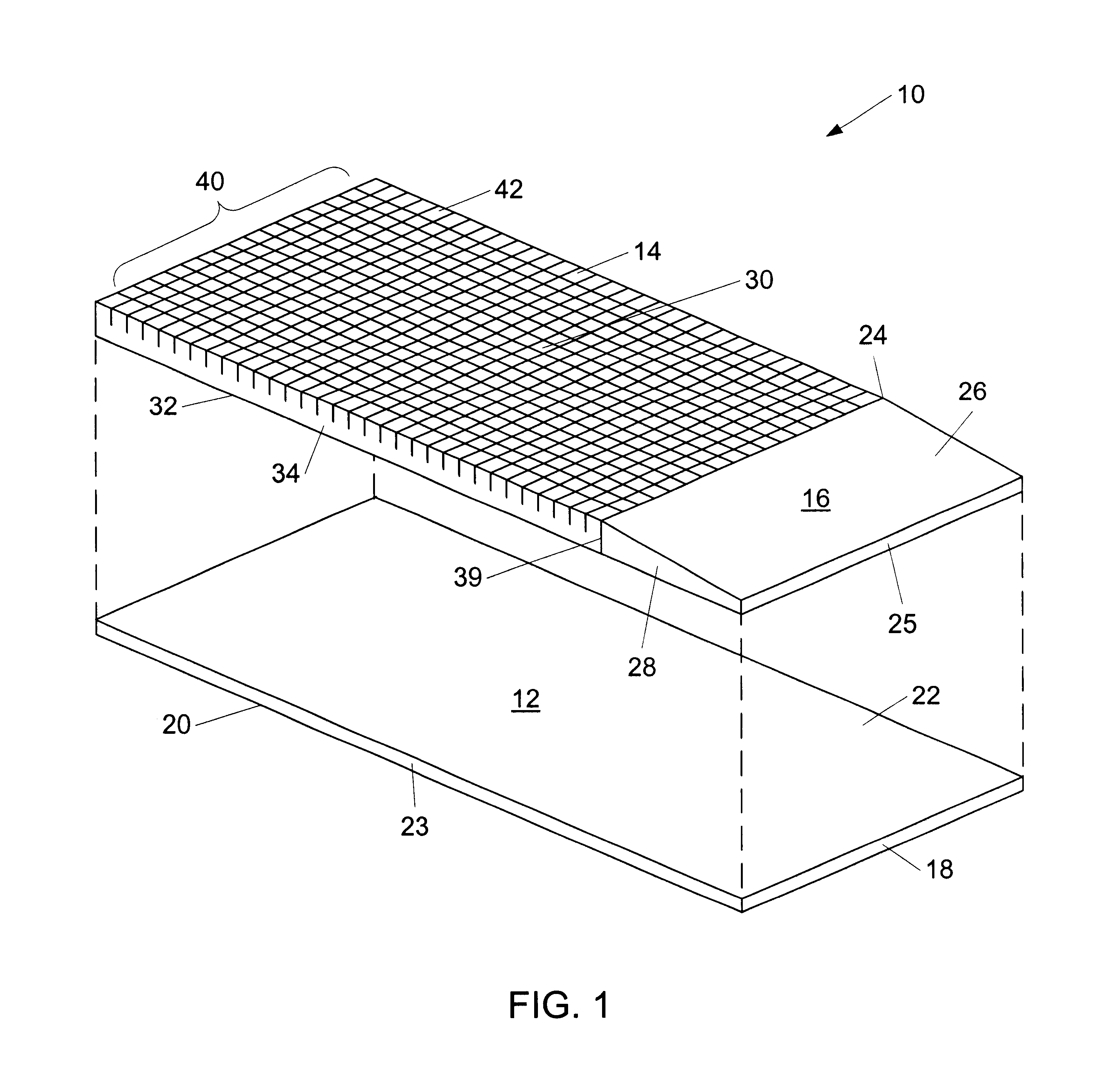

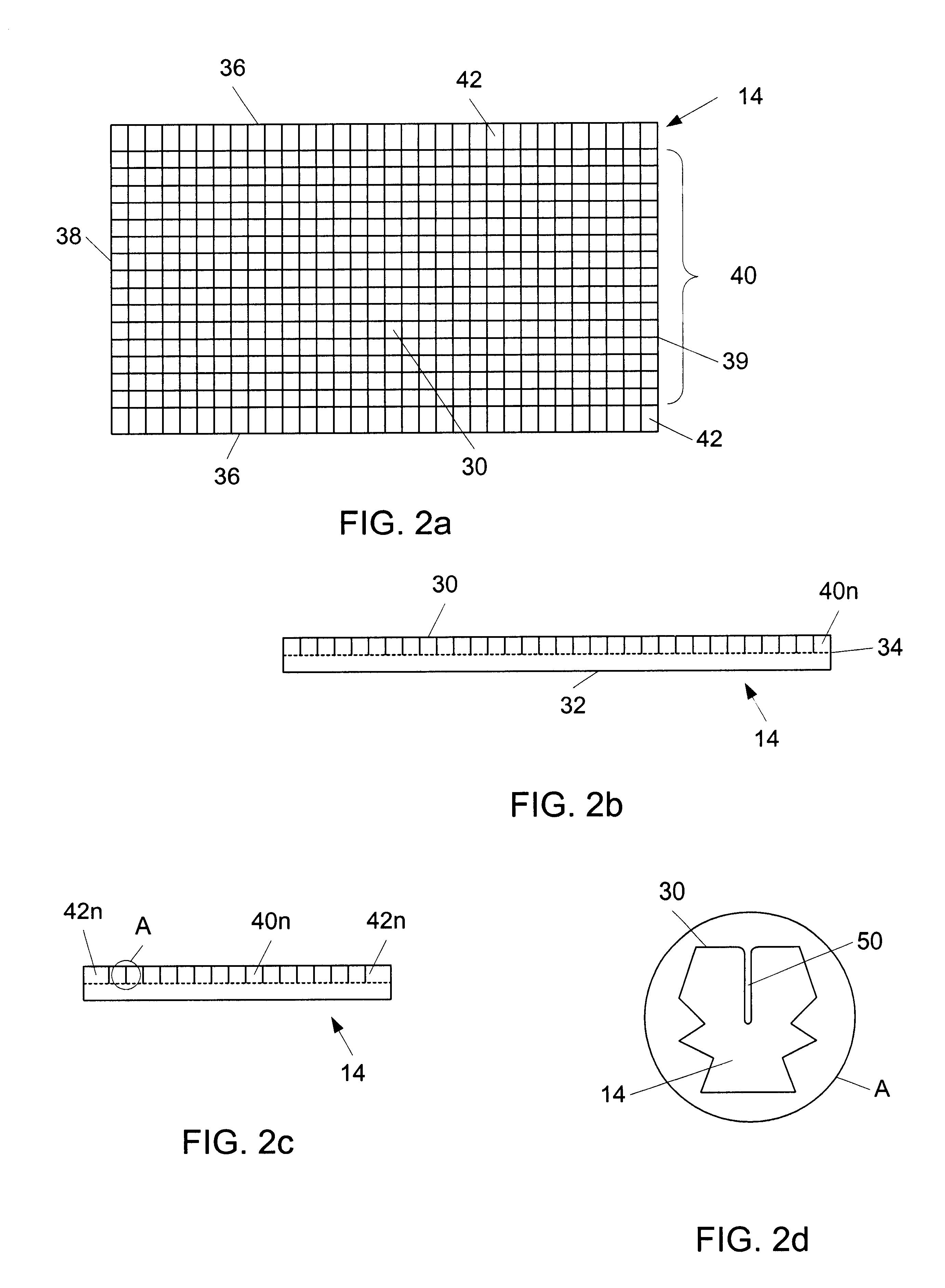

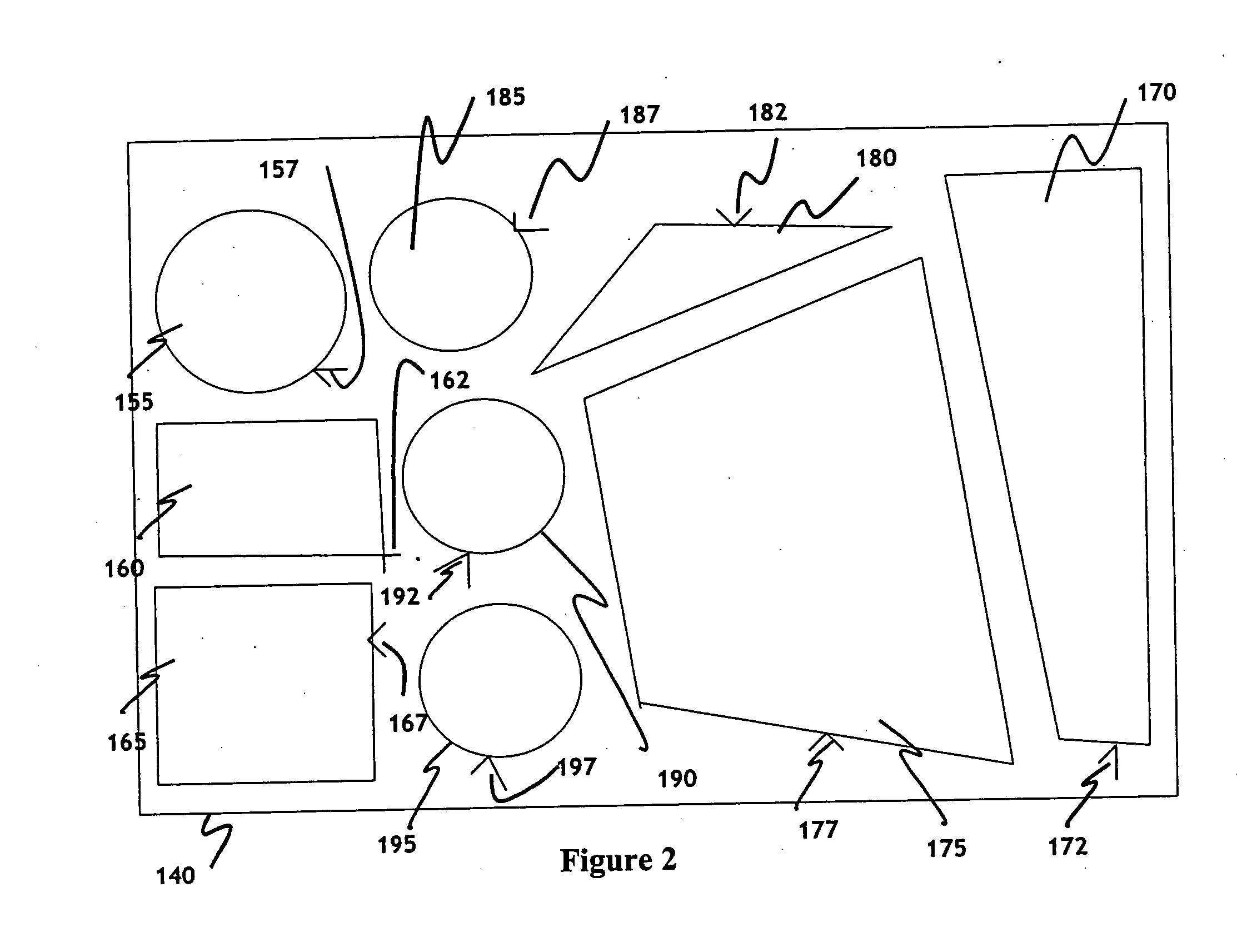

Mattress with semi-independent pressure relieving pillars

InactiveUS6874185B1Easy and relatively affordable to manufactureReduce generationStuffed mattressesSpring mattressesCushioningFoot cushion

A foam core cushion mattress assembly provides semi-independent foam pillars on the upper surface of the mattress. The mattress may be unitary, or comprise multiple cushioning components, possibly base, body support and foot cushions. The body support cushion is constructed from a flat, rectangular solid, foam element whose upper surface is cut into an array of rectangular solid pillars, preferably by a hot wire cutting method. The array of rectangular solid pillars is grouped into a central array comprising pillars with generally square top surfaces and edge rows of rectangular solid pillars having rectangular top surfaces. The depth of the hot wire cuts into the surface of the body support cushion is preferably approximately one-half the overall thickness of the body support cushion or approximately three fourths of the length of the shortest face of the pillar. A zippered fabric cover removeably envelops the assembled cushioning components. The resultant structure defines a plurality of semi-independently compressible pillars that support a reclining, or supine patient. The pillars may also be cut into the top and bottom surfaces of the cushion for enhanced pressure relieving effects. Methods of manufacture, and treatment and alleviation of decubitus ulcer formation are also presented.

Owner:HUNTLEIGH TECH LTD

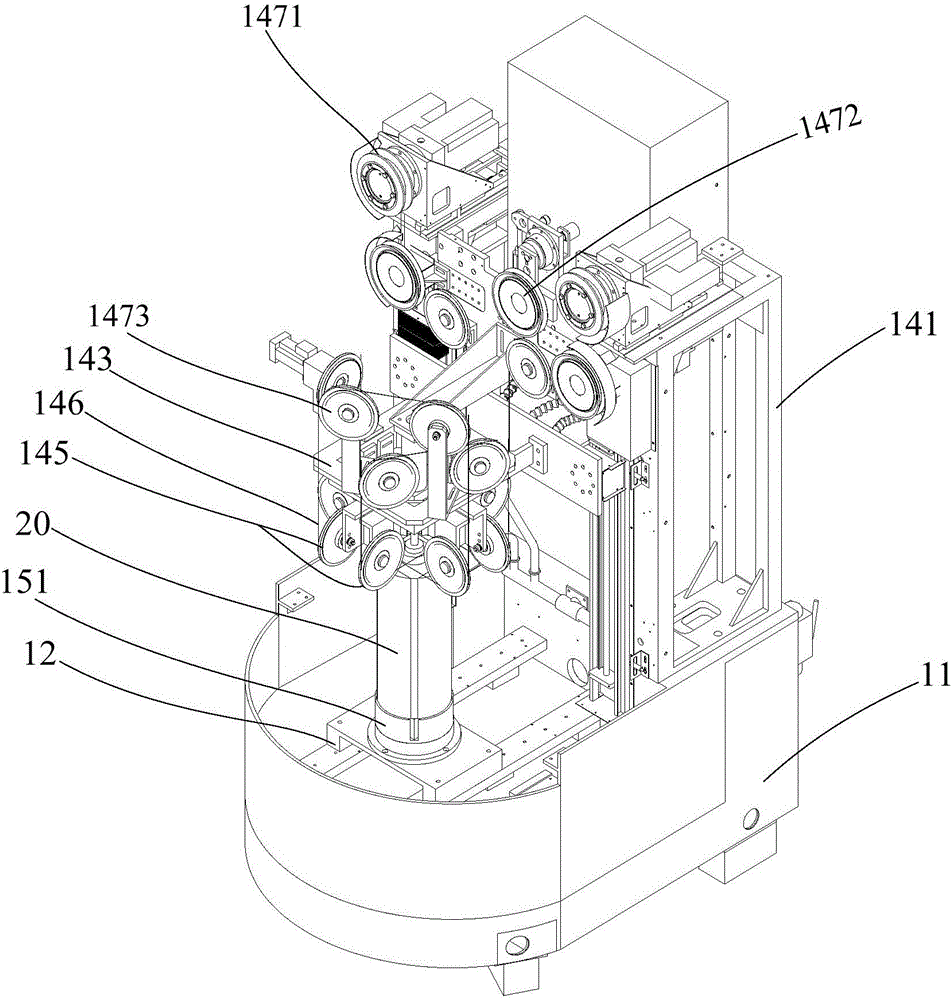

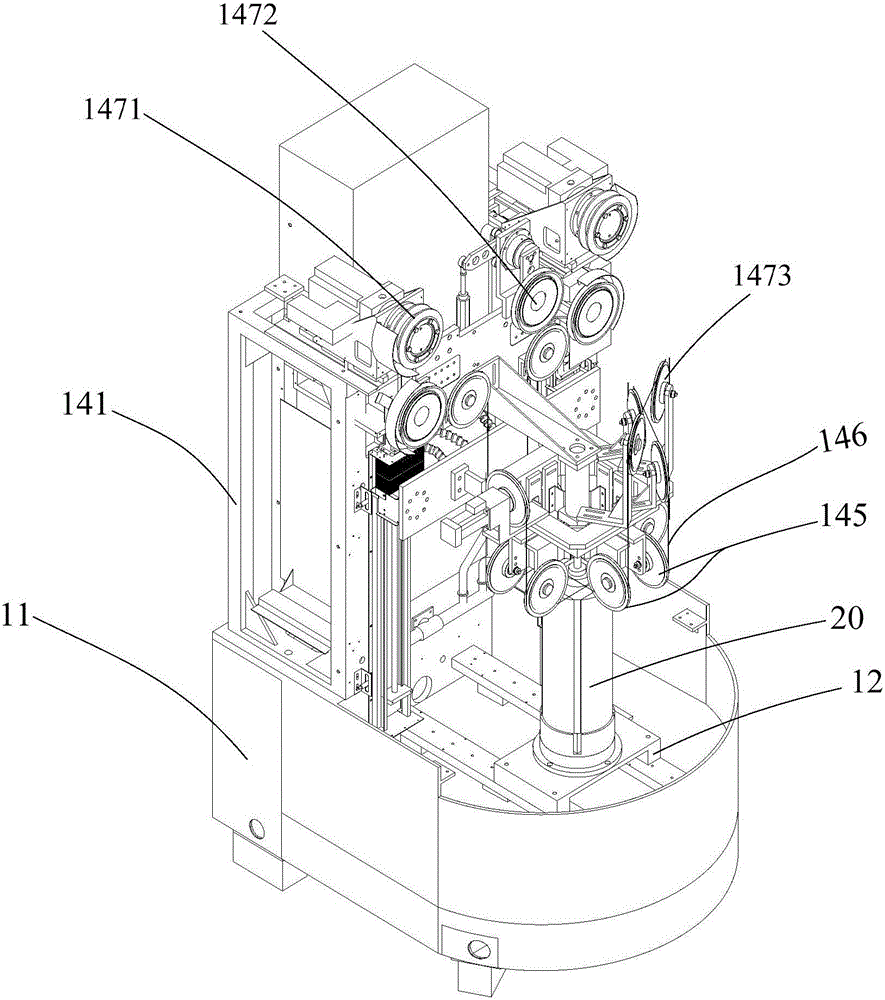

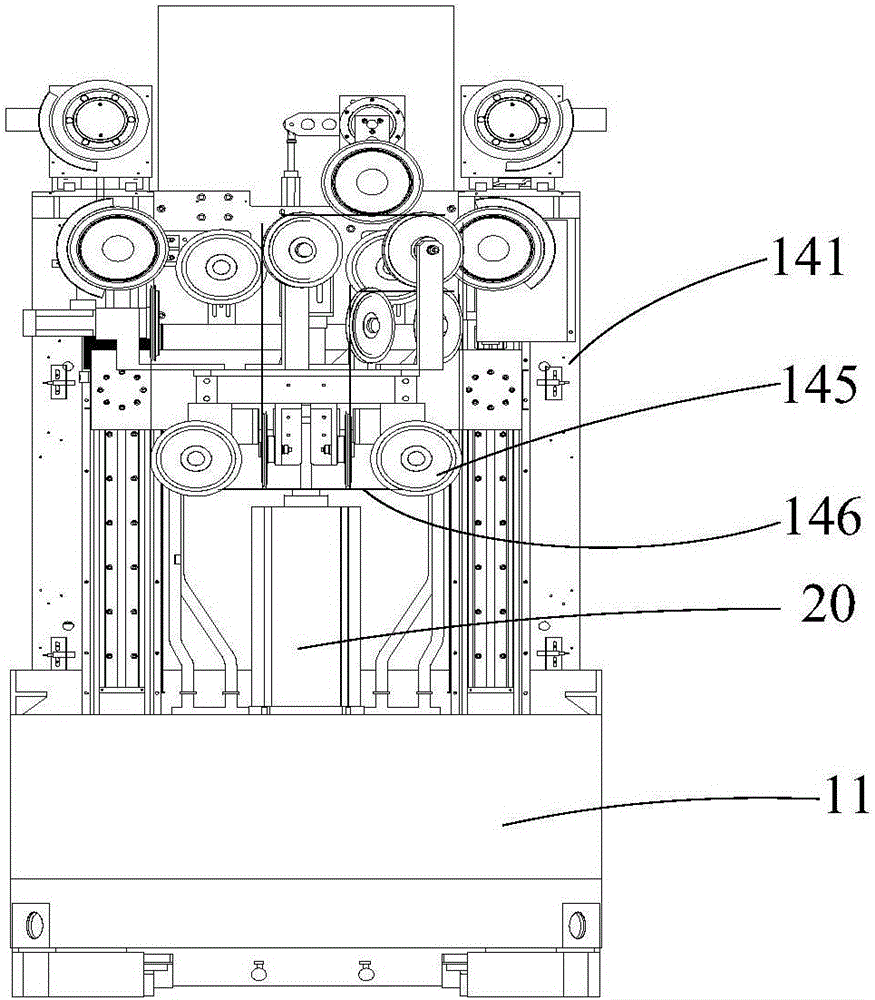

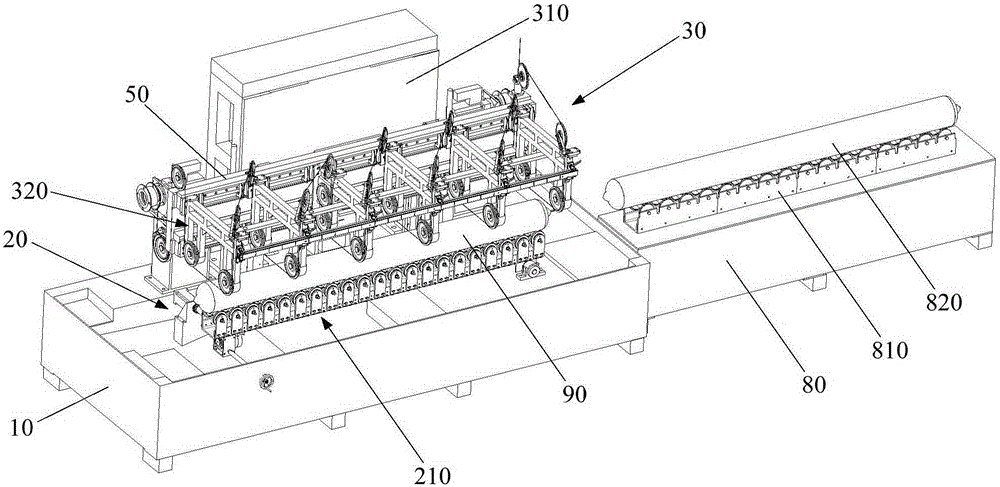

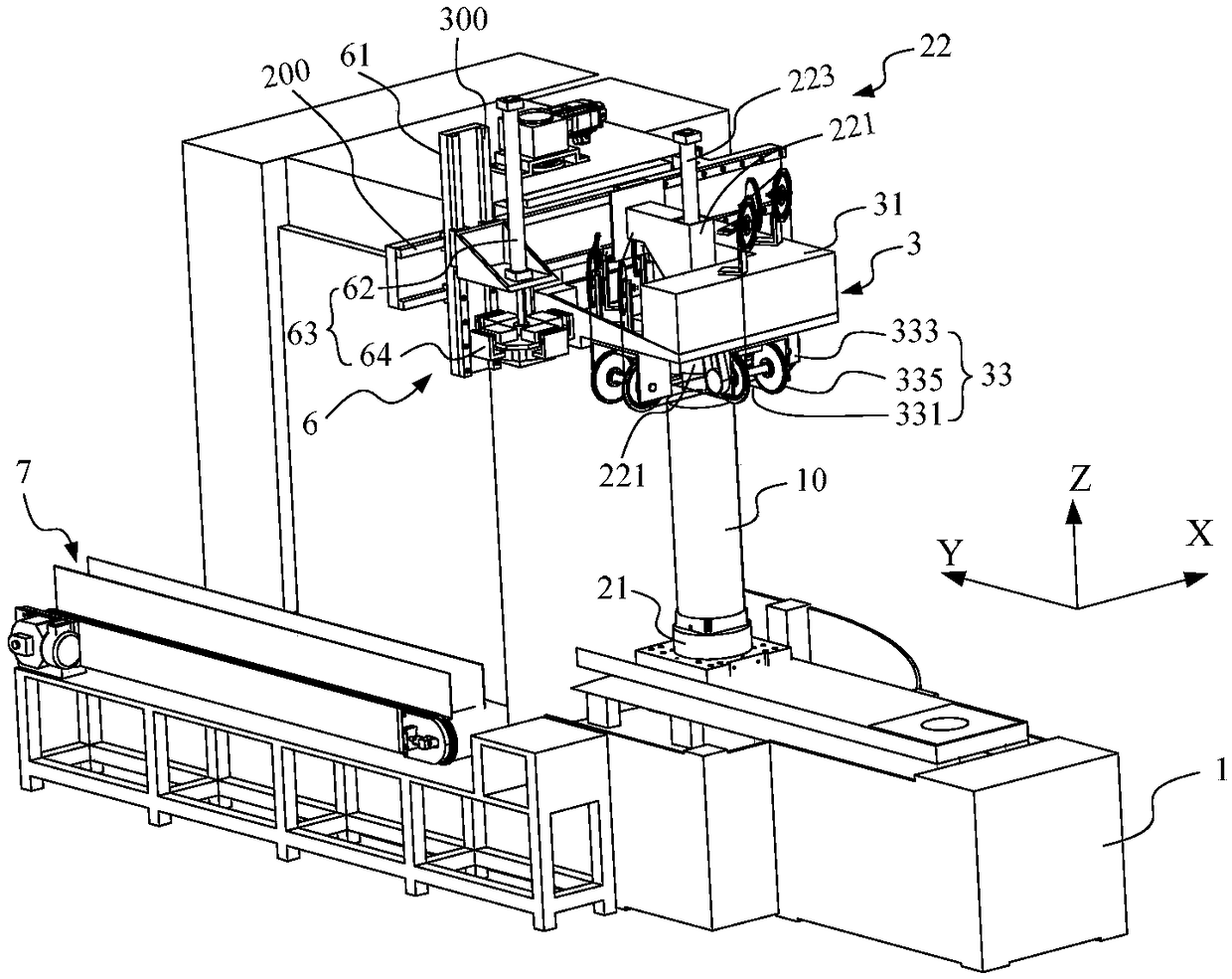

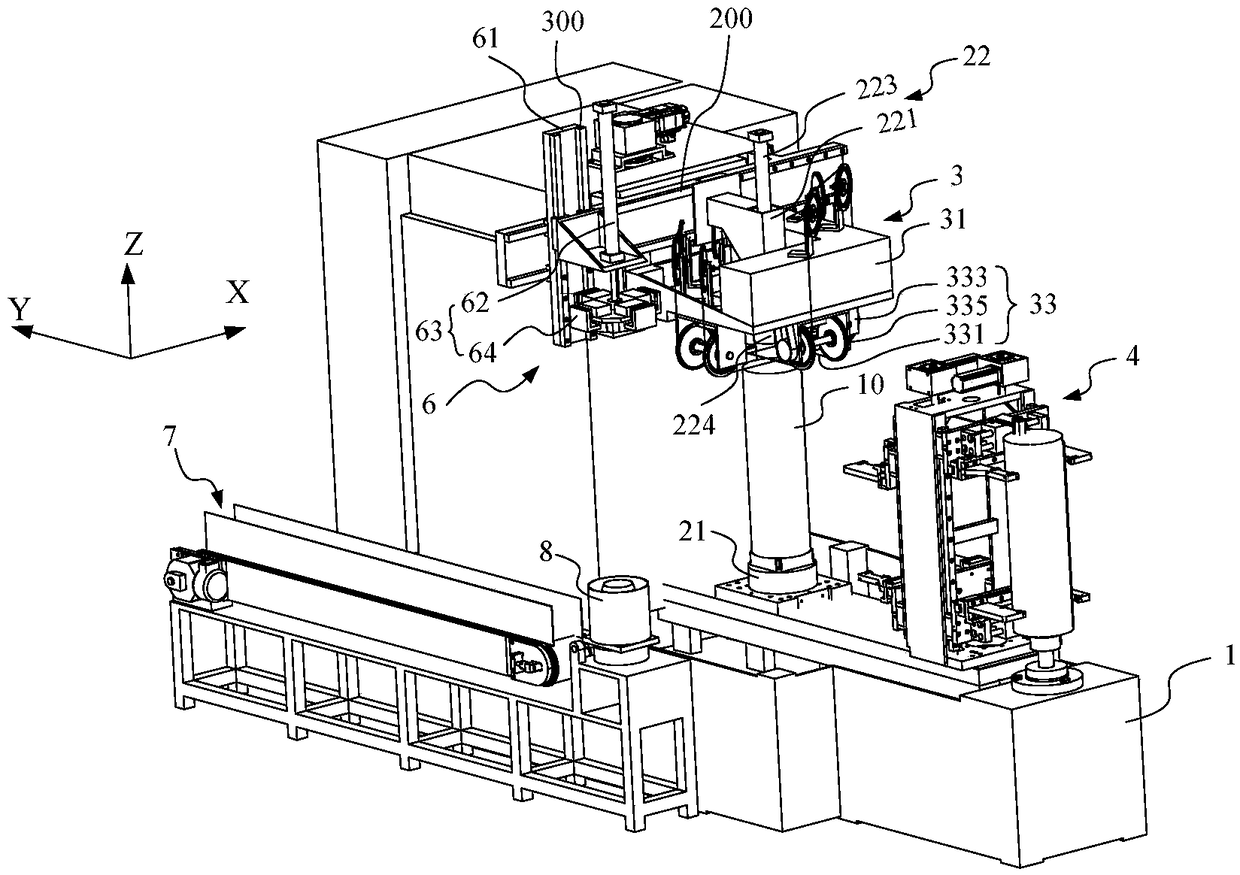

Silicon rod squarer

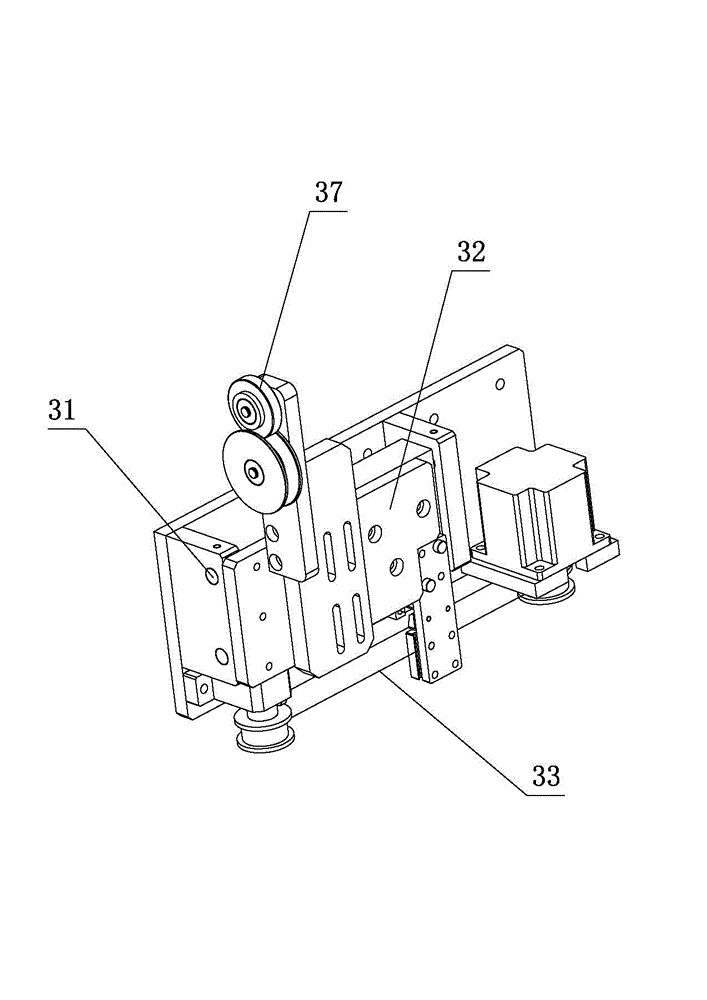

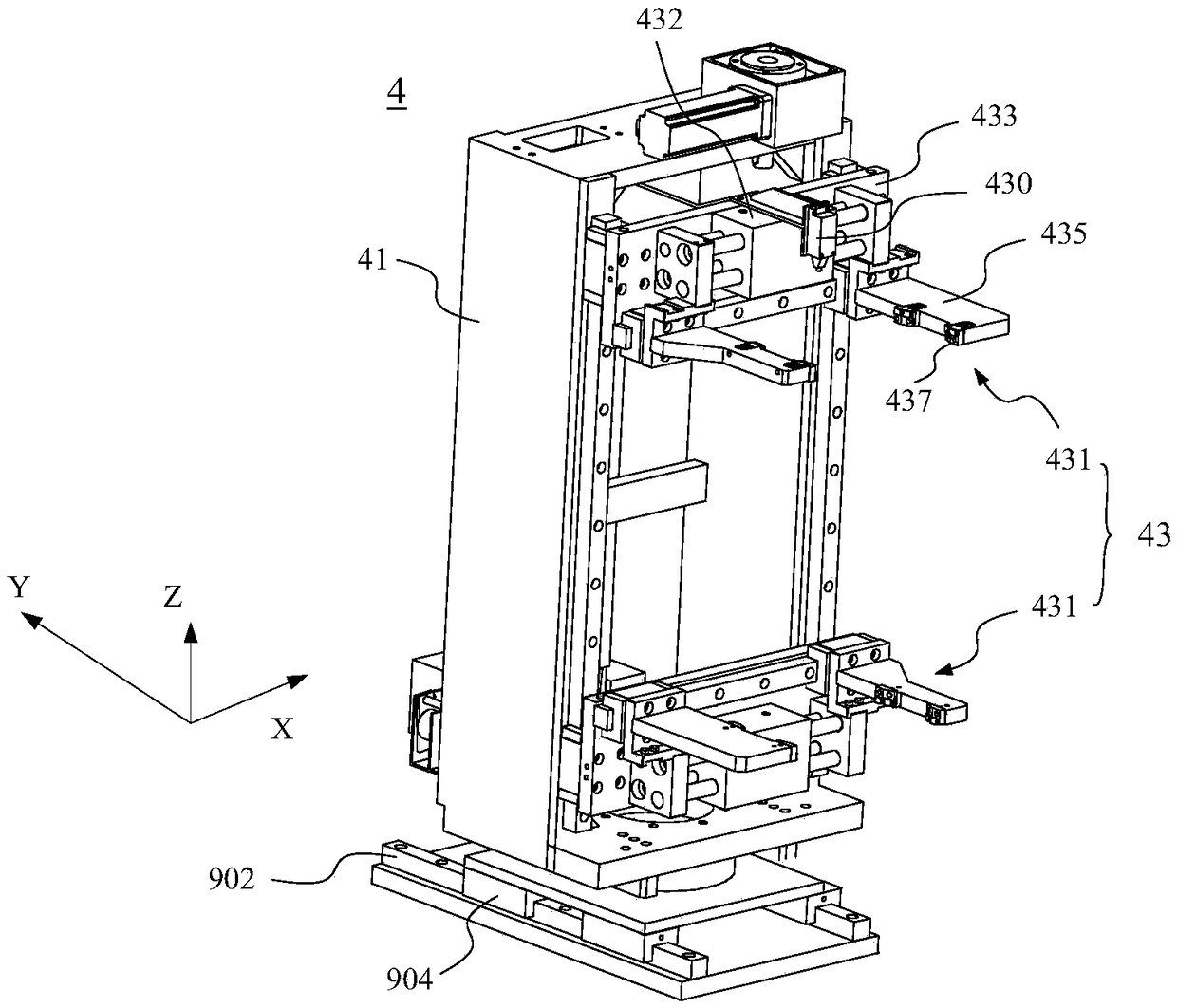

InactiveCN105818285AReduce labor costsIncrease productivityWorking accessoriesFine working devicesWire cuttingIngot

The invention provides a silicon rod squaring machine, comprising: a machine base with a square cutting area; a bearing platform arranged on the machine base and located in the square cutting area for carrying vertically placed silicon rods; The wire cutting equipment on the machine base includes: a cutting frame, which is arranged on the machine base and adjacent to the bearing table; The cut lines that form the cut line mesh. Compared with the prior art, the silicon ingot squaring machine of the present invention uses the supporting platform to carry the vertically placed silicon ingots, and cuts the silicon ingots below in a straight line through the wire cutting equipment, which can realize automatic cutting and complete the silicon ingot squaring operation. Save labor cost and improve production efficiency.

Owner:TDG NISSIN PRECISION MACHINERY CO LTD

Silicon rod cutter and cutting method

The invention discloses a silicon rod cutter and a cutting method. The silicon rod cutter comprises a feeder device, a cutting device, a silicon rod conveyor table, an axis adjusting mechanism and a plurality of wire cutting units, wherein the feeder device is used for conveying a to-be-cut silicon rod to a to-be-loaded region; the cutting device is connected to the feeder device for performing a cutting operation on the to-be-cut silicon rod which is conveyed from the to-be-loaded region by the feeder device; the cutting device comprises a base; the silicon rod conveyor table is arranged on the base for carrying the to-be-cut silicon rod and driving the silicon rod to be conveyed along the axial direction of the silicon rod; the axis adjusting mechanism is arranged on the silicon rod conveyor table for adjusting the axis of the silicon rod to a horizontal state; and the plurality of wire cutting units are arranged on the base and are arranged above the silicon conveyor table in a liftable manner for cutting the to-be-cut silicon rod into a plurality of silicon rod sections. The to-be-cut silicon rod is conveyed to the to-be-loaded region through the feeder device, the plurality of wire cutting units can cut the to-be-cut silicon rod into the plurality of sections simultaneously, and the plurality of the silicon rod sections are removed from the silicon rod conveyor table to a material receiving table to be sequentially unloaded.

Owner:海宁市日进科技有限公司

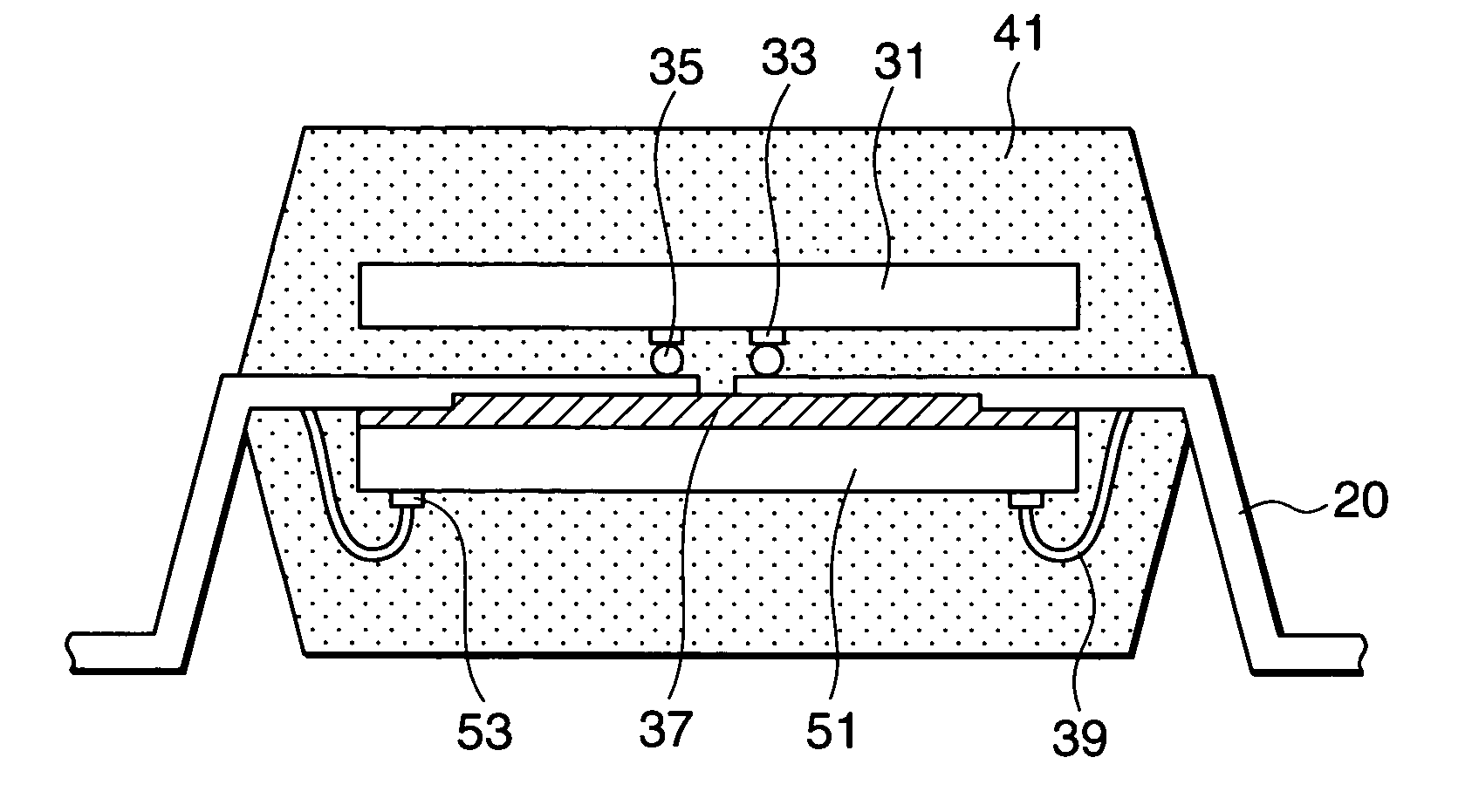

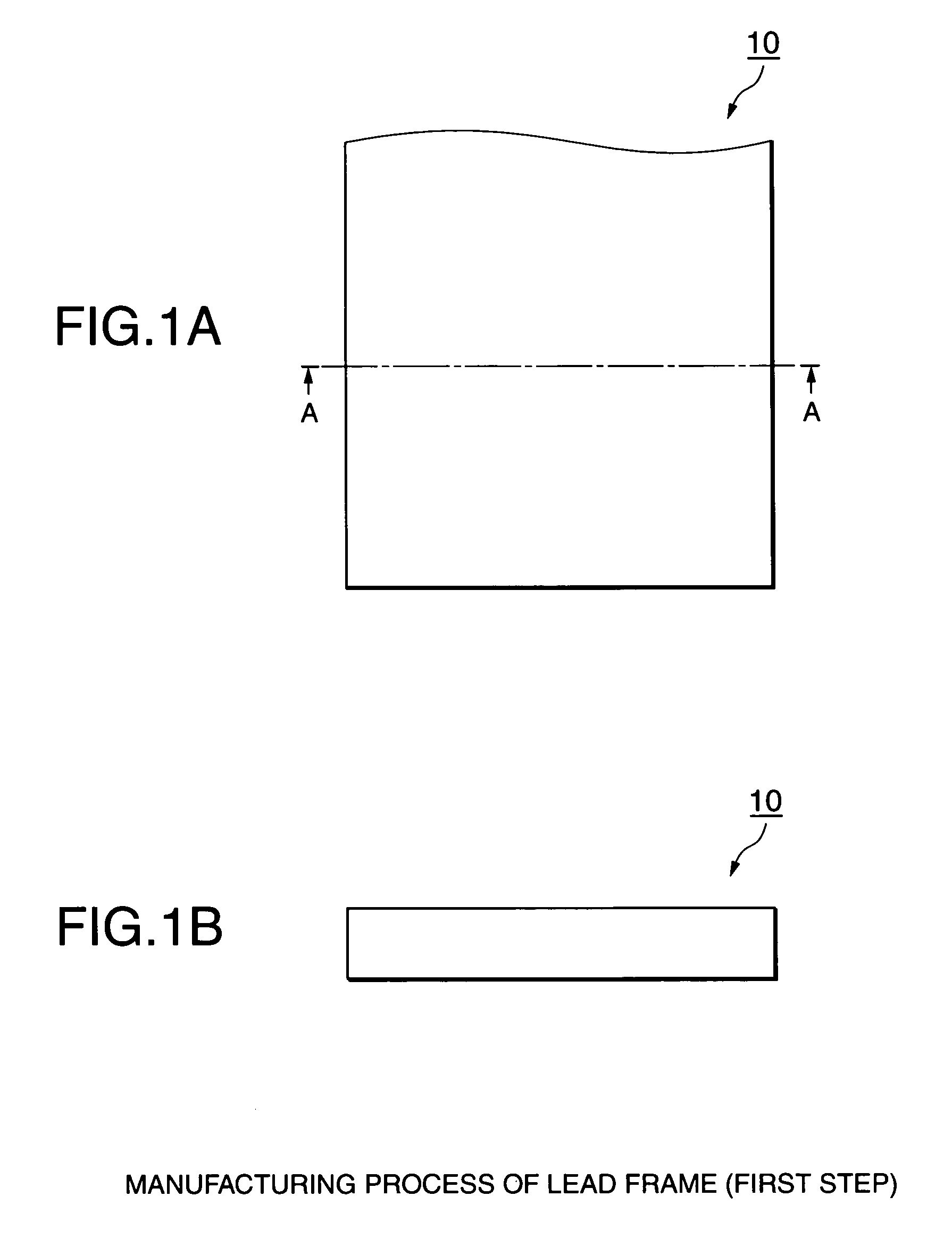

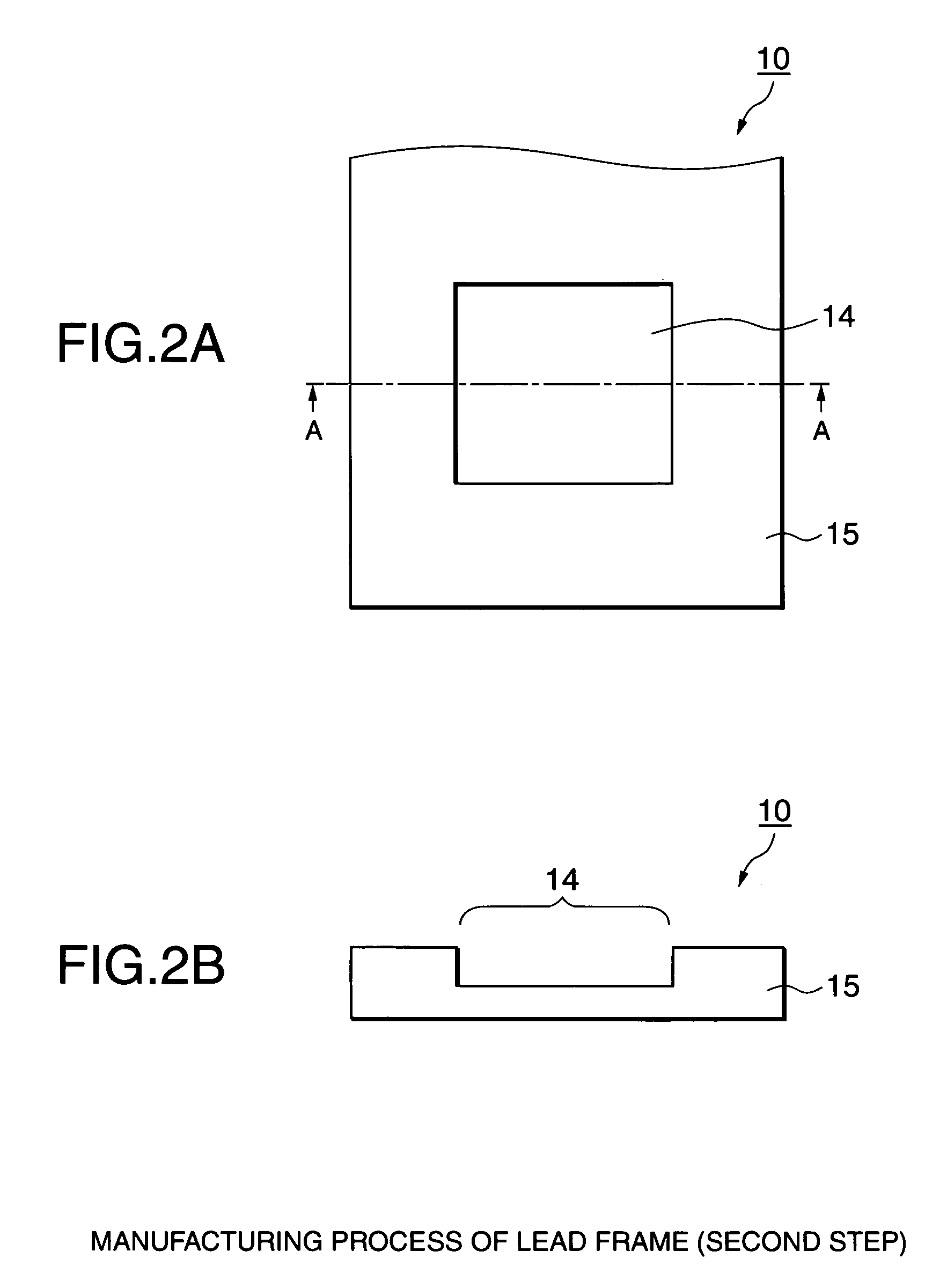

Lead frame, manufacturing method of the same, and semiconductor device using the same

InactiveUS7102210B2Reduce spacingSemiconductor/solid-state device detailsSolid-state devicesWire cuttingLead frame

Owner:LAPIS SEMICON CO LTD

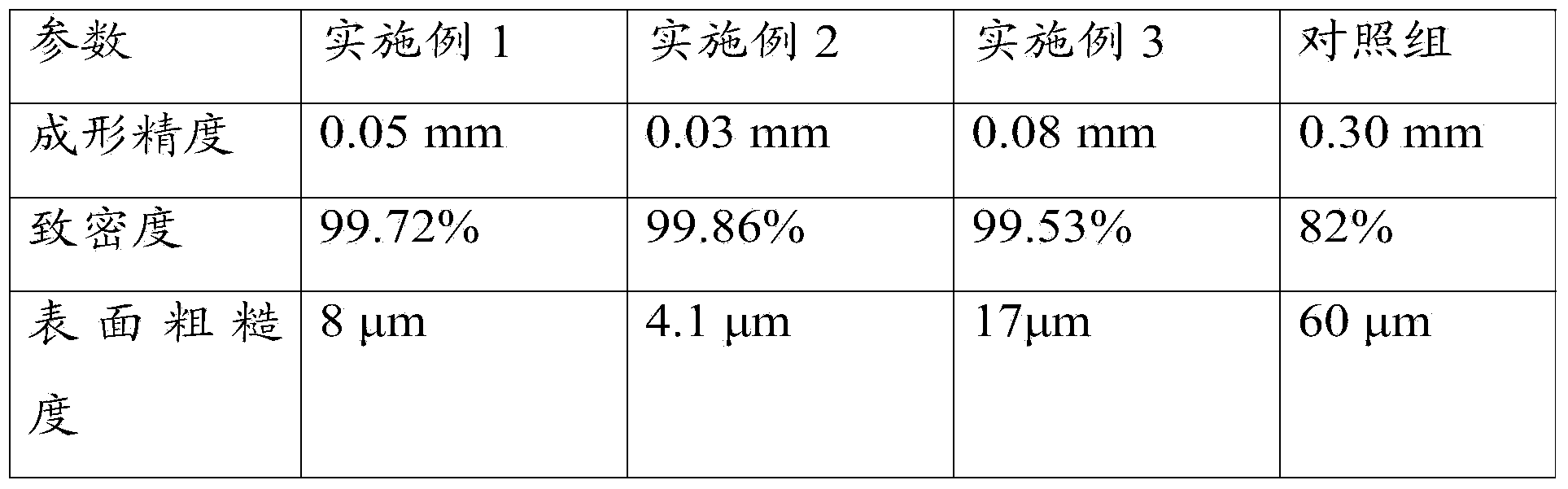

Method for producing titanium alloy artware by adopting selective laser melting

ActiveCN104259459AHigh precisionImprove forming qualityIncreasing energy efficiencySelective laser meltingSelective laser sintering

The invention relates to the field of material preparation, in particular to a method for producing titanium alloy artware by adopting selective laser melting. The method includes the steps: creating two-dimensional slicing data of a part structure to be produced and importing the two-dimensional slicing data into a metal powder laser melting system; setting processing technological parameters of the metal powder laser melting system; taking titanium alloy powder and spreading the titanium alloy powder on the metal powder laser melting system, and sequentially performing laser melting, powder sieving, heat treatment, wire cutting, cleaning, sand blasting, polishing and the like under the protection of inert gas to obtain the titanium alloy artware. According to the method, specific titanium alloy types and specification parameters are selected, and the processing technological parameters of the metal powder laser melting system are optimized for multiple times, so that the produced titanium alloy artware is high in precision, stable in shaping quality, small in distortion, excellent in mechanical property and good in surface smoothness through follow-up processing and has great artistic value.

Owner:飞而康快速制造科技有限责任公司

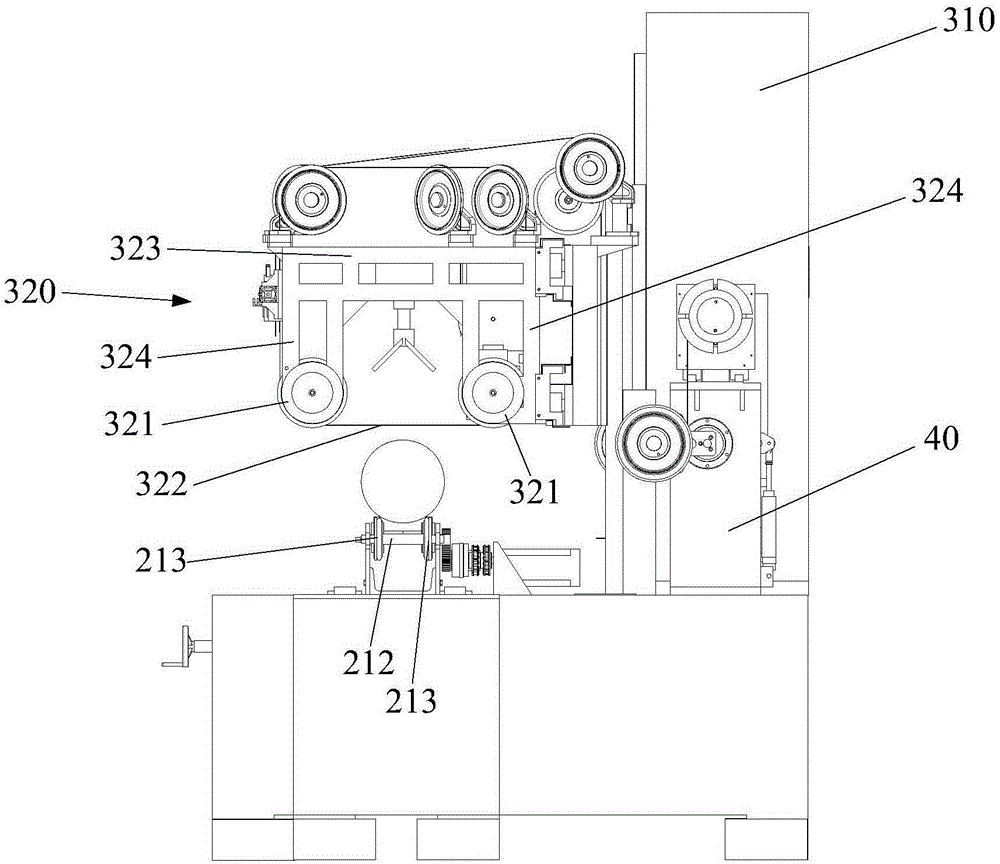

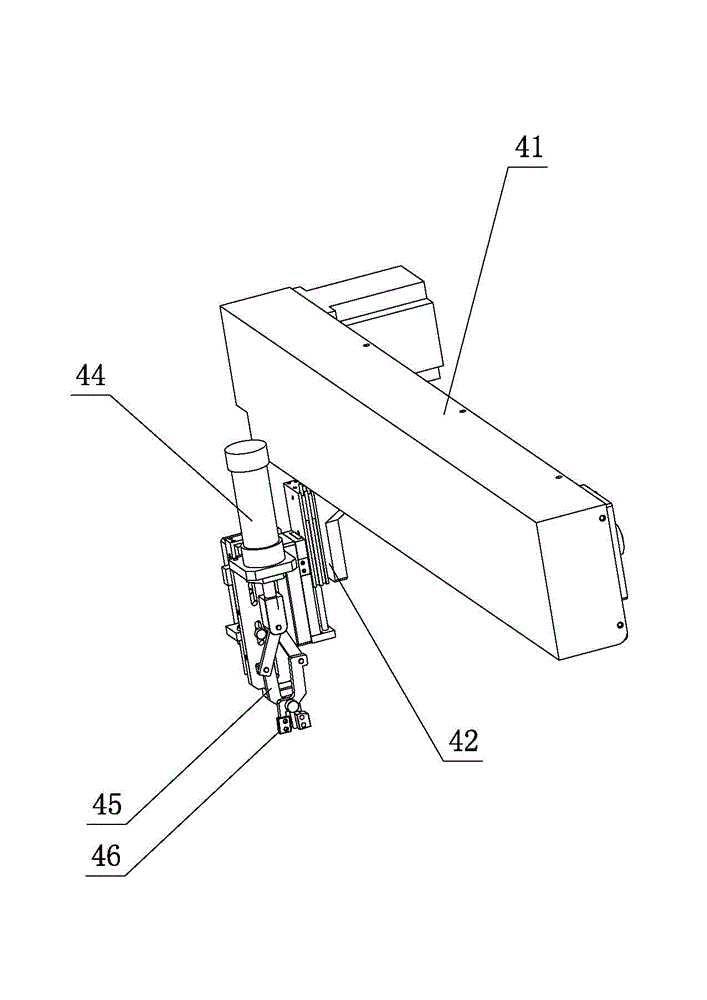

Single crystal silicon rod cutting-off machine and single crystal silicon rod cutting-off method

The invention discloses a single crystal silicon rod cutting-off machine and a single crystal silicon rod cutting-off method. The single crystal silicon rod cutting-off machine comprises a machine base, a material conveying table arranged on the machine base and used for bearing single crystal silicon rods to be cut and driving the single crystal silicon rods to be conveyed in the axial directions of the single crystal silicon rods, and a multi-wire cutting device comprises a machine frame arranged on the machine base and multiple wire cutting units arranged on the machine frame and arranged above the material conveying table through a lifting mechanism in a liftable mode. The multiple wire cutting units synchronously descend to the material conveying table under the control of the lifting mechanism and meanwhile cut the single crystal silicon rods into multiple single crystal silicon sections, and then the multiple single crystal silicon sections formed after cutting are sequentially discharged through the material conveying table. The single crystal silicon rod cutting-off machine can synchronously cut the single crystal silicon rods to be cut into the multiple single crystal silicon sections through the multi-wire cutting device, is high in cutting speed, moves the single crystal silicon sections formed through cutting from the material conveying table to a material receiving table in a sectioned mode for sequential discharge and ensures that the single crystal silicon sections do not bump.

Owner:海宁市日进科技有限公司

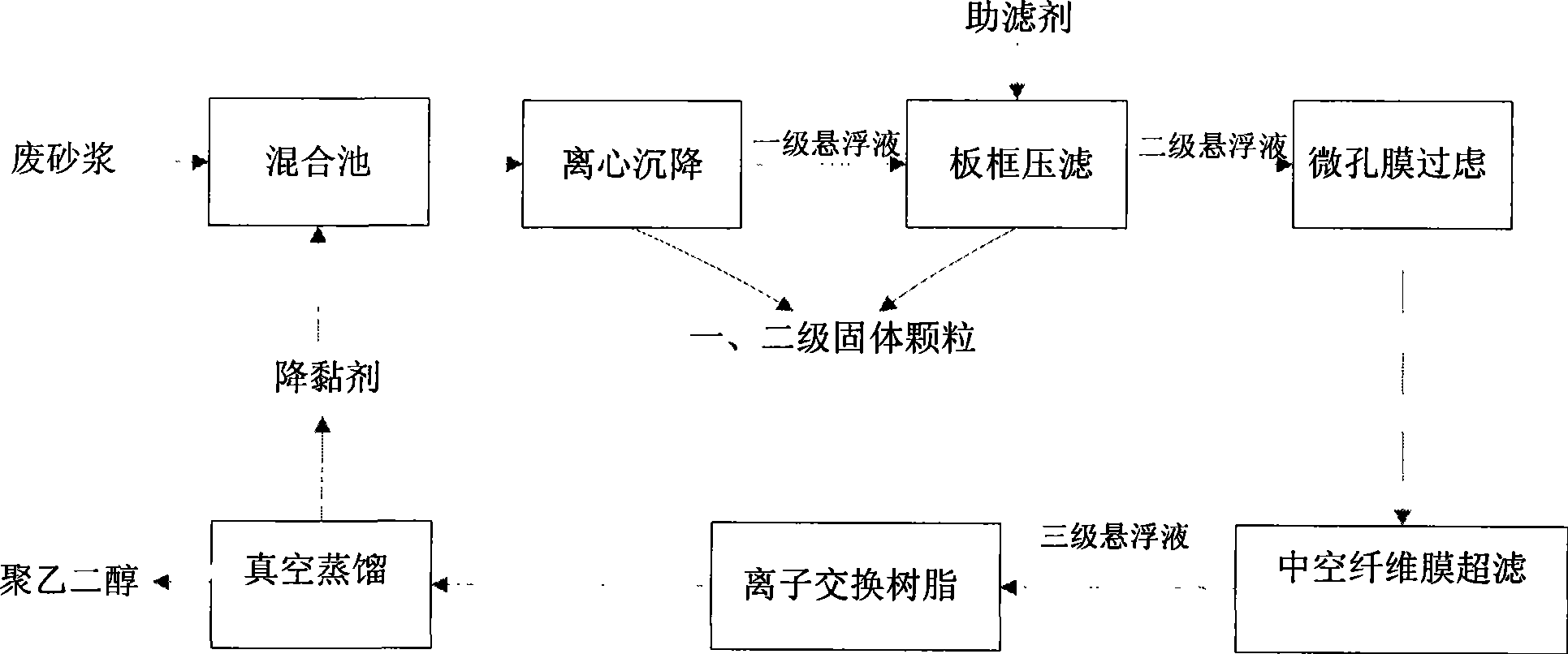

Mortar recovery technique for cutting single-crystal and polycrystalline silicon wire

InactiveCN101327622APhysical properties unchangedSlicing works wellWorking accessoriesFine working devicesFiltrationWire cutting

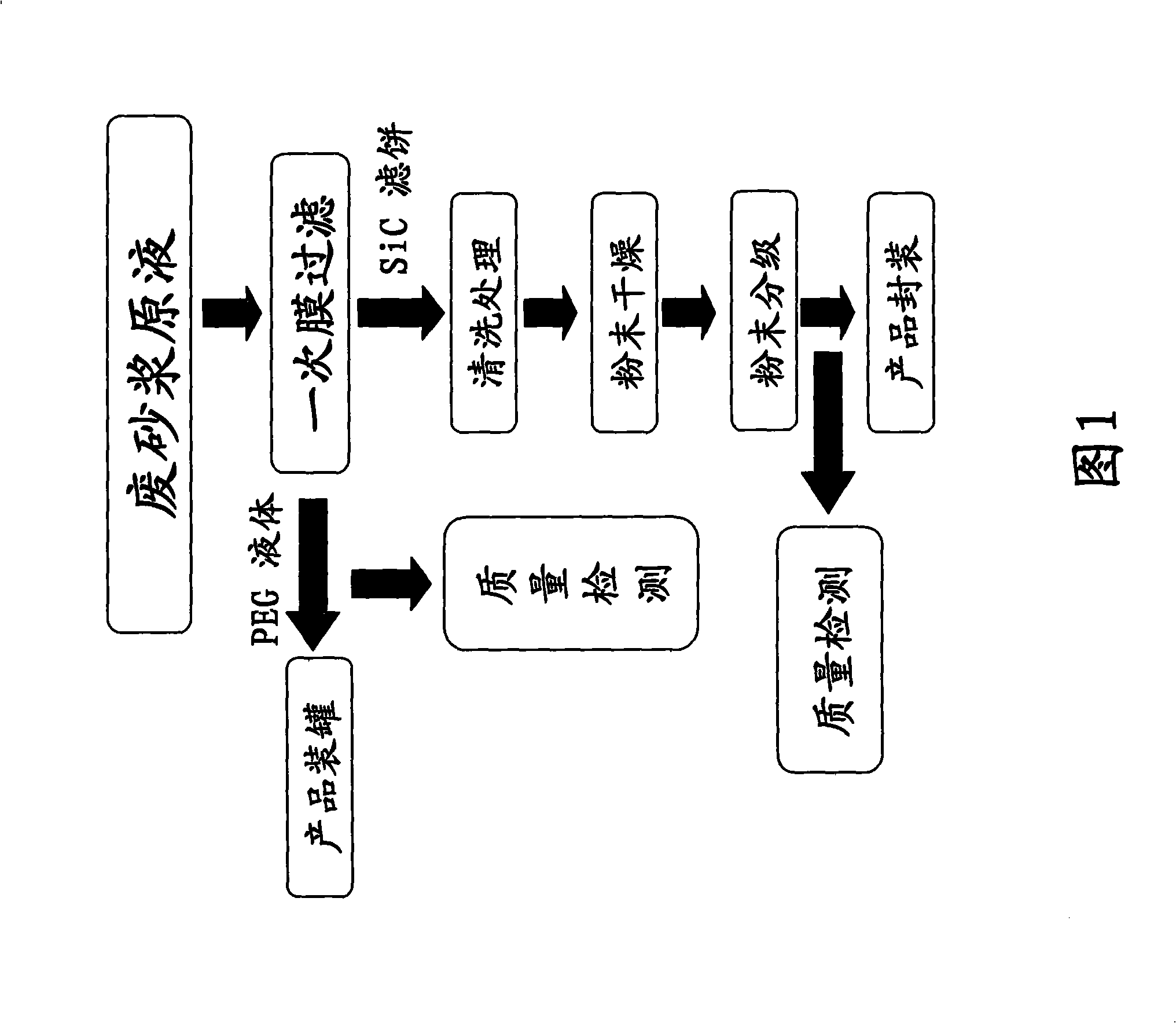

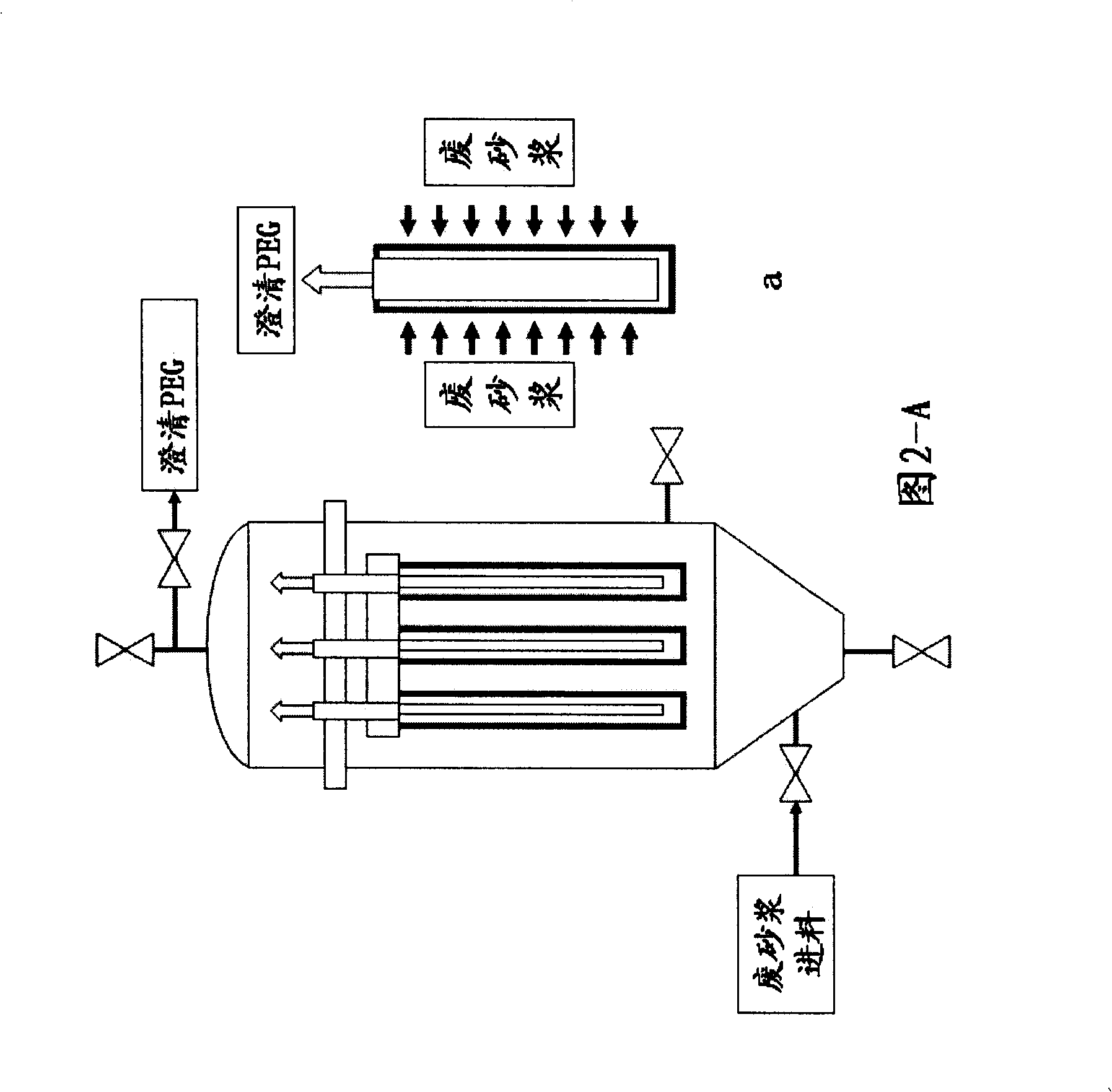

The present invention relates to a technique of recovering mortar used in the wire cutting of monocrystalline silicon or polycrystalline silicon. Silicon is an important material for solar batteries, semiconductors, liquid crystal displays, etc. A silicon rod is cut into silicon wafers by the wire cutting technique, and in the process, a wire-cutting machine needs to be added with cutting liquid mortar, which is mainly composed of liquid phase polyethylene glycol and solid phase silicon carbide powder. When the wire-cutting machine cuts the silicon rod, the solid particles in the mortar are changed into waste mortar as the silicon carbide grinds the silicon rod and a steel wire. If the waste mortar is discharged directly, environment is polluted, and the raw material is wasted. The present invention adopts the mortar-recovering technique to recover the waste mortar, so that the waste mortar can be reused and the discharging of the three wastes can be reduced, so while reducing production cost, the mortar-recovering technique can protect environment. The technique of recovering mortar used in the wire cutting includes the following flow: waste mortar dope, one-step membrane filtration and PEG liquid; waste mortar dope, one-step membrane filtration, cleaning, powder drying, powder classification and SiC powder.

Owner:正申科技(北京)有限公司

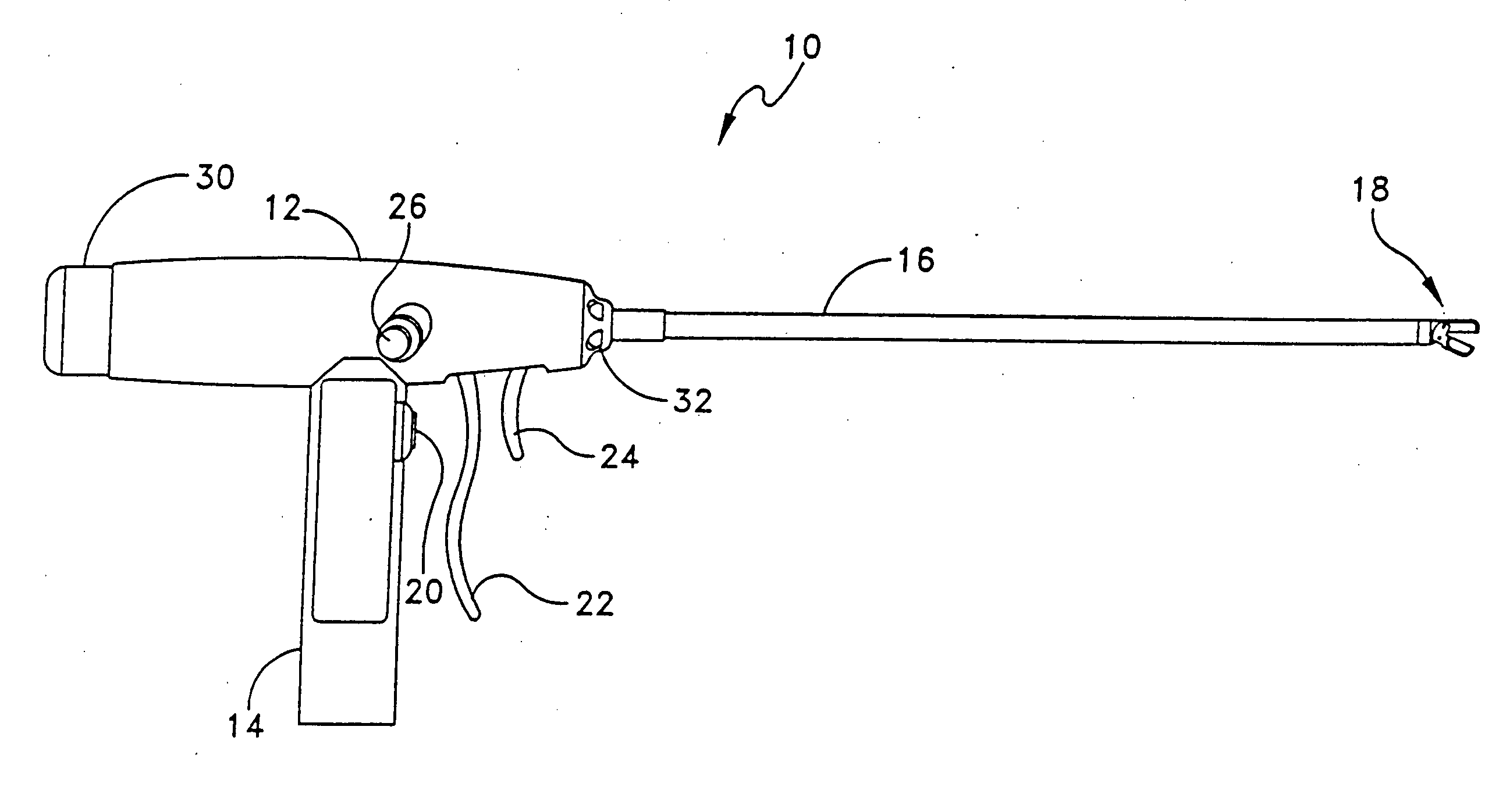

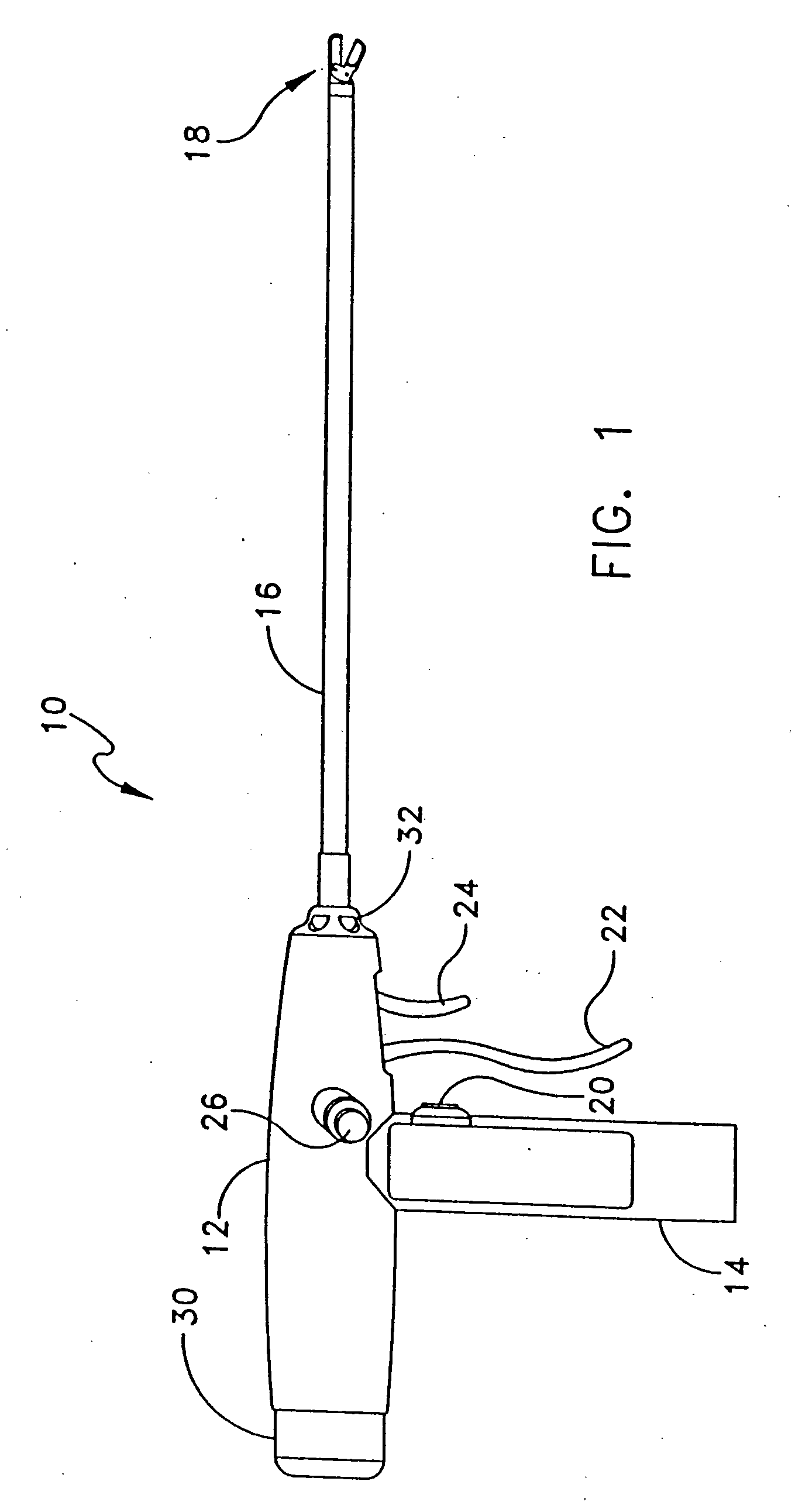

Method and apparatus for wireplasty bone resection

InactiveUS20090082773A1Low profileAvoid soft tissue damageNon-surgical orthopedic devicesSurgical sawsBone tissueMechanical energy

A cutting tool to be utilized in the resection or removal of bone tissue from patients includes a handle that tensions a wire or cable-like cutting member with a small diameter between at least two features on the handle to present a thin cutting profile. The design of the cutting tool includes features that protect against soft tissue damage and minimize the incision size necessary to utilize the tool. Some embodiments feature details of the cutting tool that interface with a surgical cutting guide system. Other embodiments describe a cutting tool with a selectively changeable length of the cutting profile of the wire cutting member. In one embodiment, the wire cutting member of the cutting tool is energized by mechanical energy in the form of a unidirectional rotation of the cutting member, a mechanical vibration of the cutting member, or an oscillating movement of the wire cutting member.

Owner:BIOMET MFG CORP

Surgical suturing instrument and method of use

A device is disclosed for joining a first layer of material to a second layer of material, the device comprising a handle, a first jaw and a second jaw mounted on the handle, at least one of the first jaw and the second jaw being moveable relative to the other; the first jaw defining therein: a first channel for retaining a wire guide; a second channel extending from the first channel for supporting a suture wire extending from the wire guide; and a passageway for retaining a cutting bar; the second channel being curved to impart a looping configuration to portions of the suture wire passed therethrough; a wire advancing actuator mounted on the handle for moving the suture wire through the second channel and through the first and second layers of material in the looping configuration; and a wire cutting actuator mounted on the handle for moving the cutting bar into cutting engagement with the suture wire, wherein the suture wire in the looping configuration joins the first layer of material to the second layer of material.

Owner:DVL ACQUISITION SUB

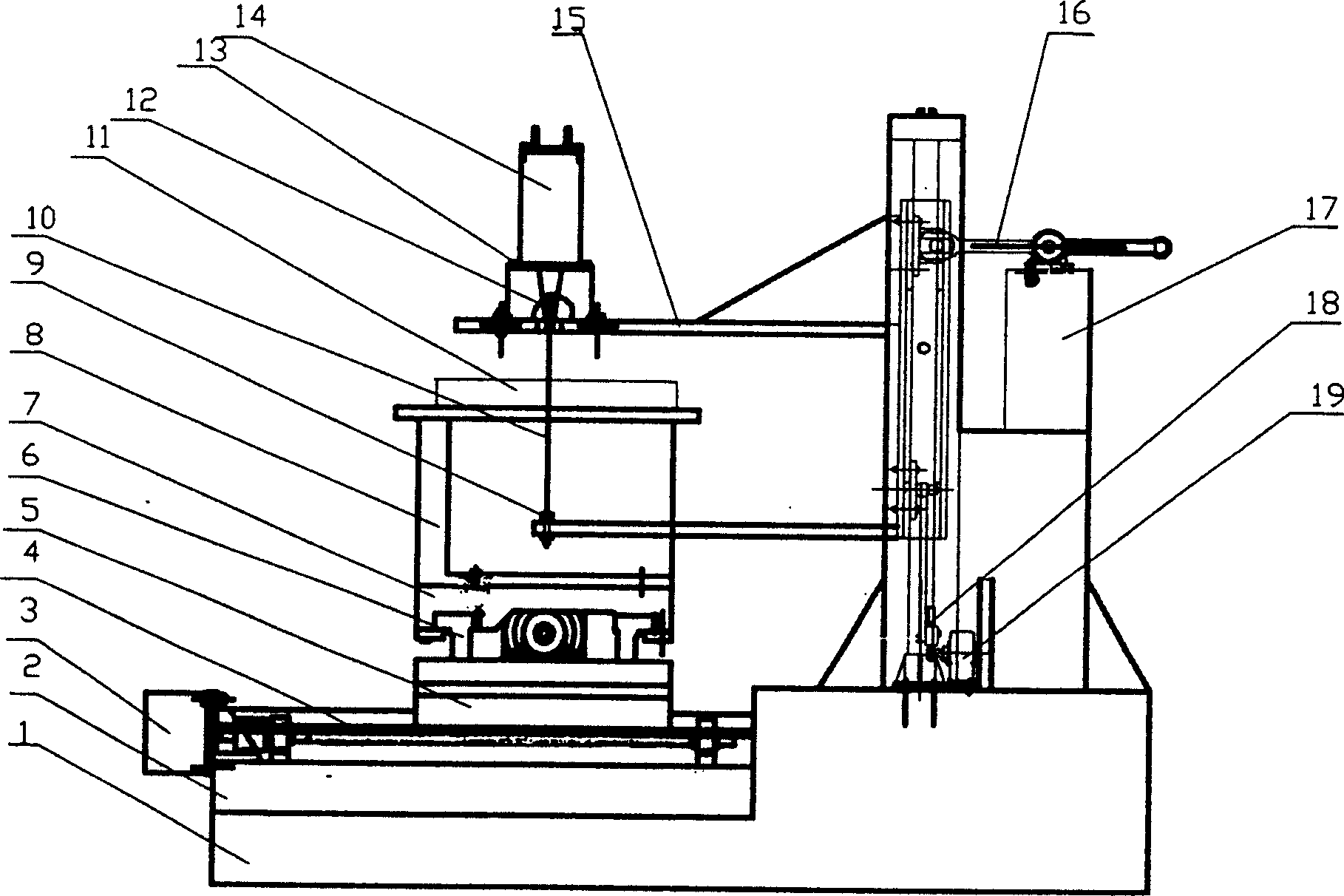

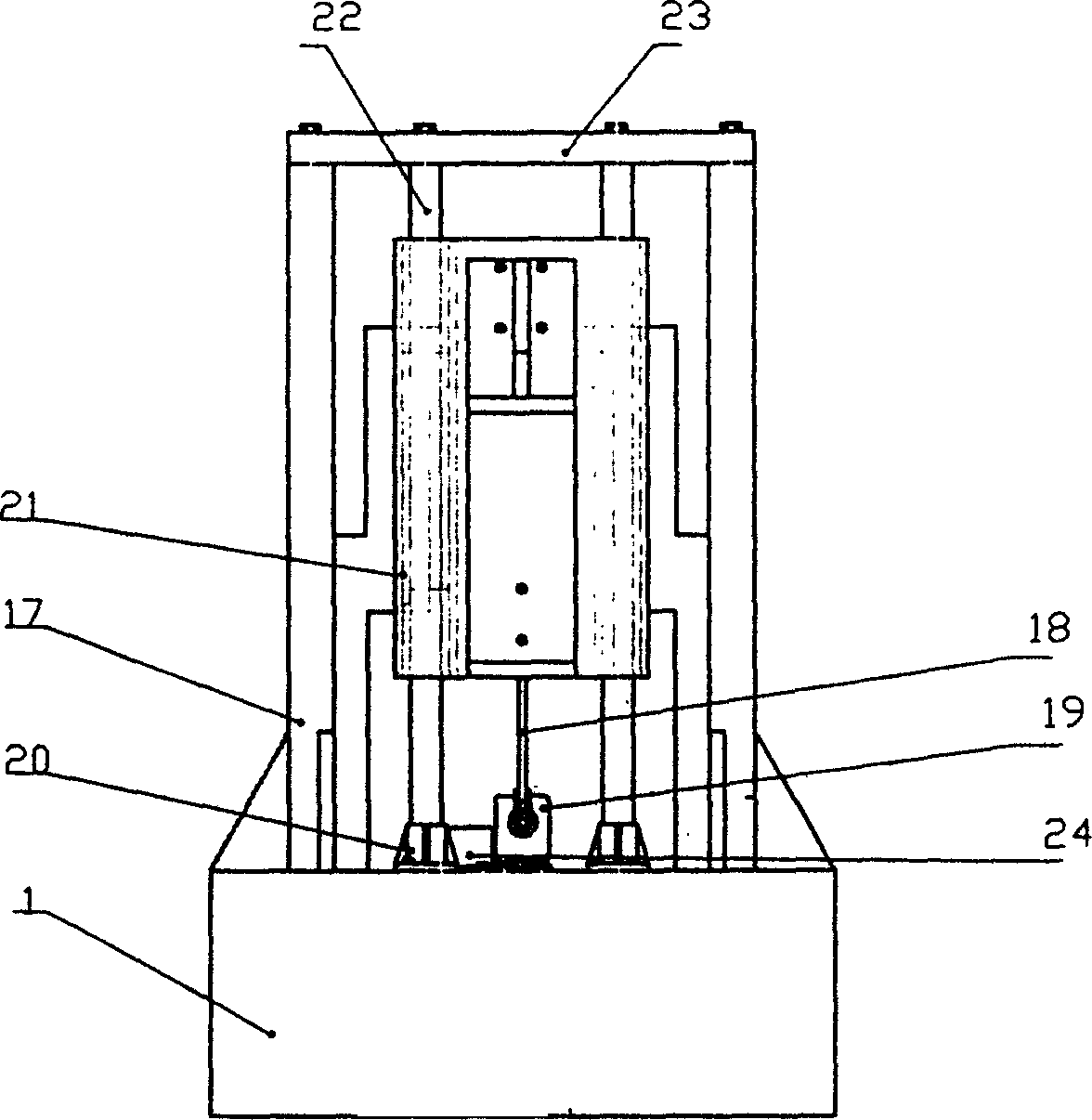

Ultrasonic wire cutting saw for hard-fragile material processing

InactiveCN1488480ASimple structureIncrease productivityStone-like material working toolsWire cuttingEngineering

The invention is a kind of supersonic wave tangent line saw for hard and crisp material, which comprises the bed, longitudinal working slide flat, transversal work slide flat, piece bracket, diamond line saw, supersonic wave vibrating device, saw reciprocating motion mechanism and electricity control device, the supersonic vibrating device is fixed on the upper arm of the C type work bracket through screw, the electrical signal is transformed into mechanical vibration, and enlarges the amplitude through a pole, the diamond saw vibrates as wave, it generates reciprocating motion through cranked rod, C type work bracket, slide flat seat. The saw is in linear high frequency vibration state and reciprocating motion; the invention is simple and has a high productivity.

Owner:沈阳工业学院

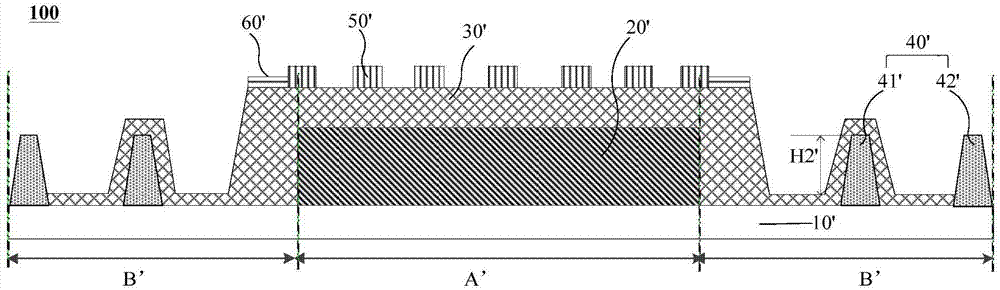

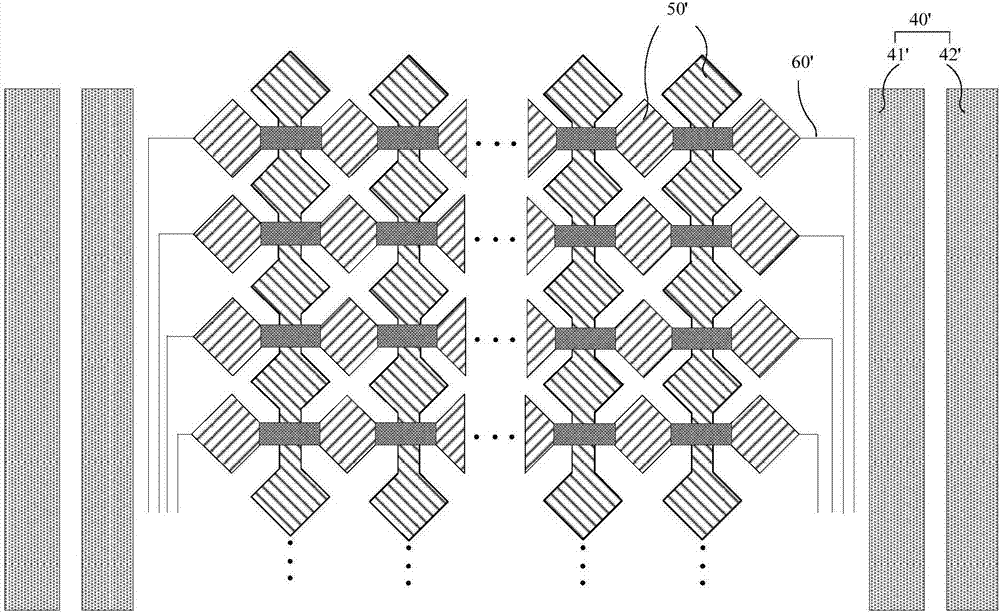

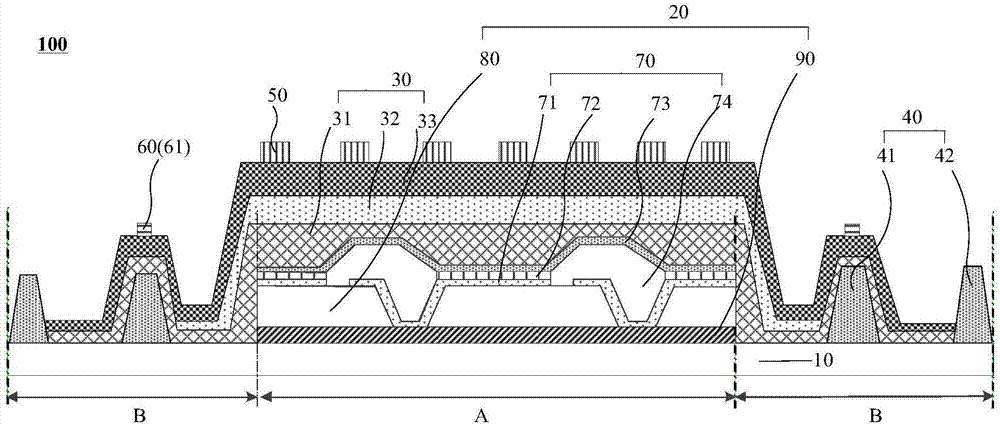

Touch control display panel and touch control display device

ActiveCN106873839AReduce border areaAchieving Narrow BezelsInput/output processes for data processingMicrometerOrganic light emitting device

The invention discloses a touch control display panel and a touch control display device. The panel comprises a substrate, an organic luminescent device, at least one baffles, wherein the width of the at least one baffle is 30-200 micrometers, a thin film encapsulation layer, wherein the thin film encapsulation layer covers the at least one baffle, and difference between the baffle 30 and baffle 40 of the thin film encapsulation layer between the first baffle 41 and a display area A is 0-3 micrometers, electrode wires which are located at least at the non-display area of the substrate, and at least part of the electrode wires are located at the side away from the baffle, of the thin film encapsulation layer, and are arranged in the extension direction of the baffle. The projection of the electrode wires on the substrate is located in the range of the projection of the baffle on the substrate. According to the touch control display panel, at least part of electrode wires are located at the side away from the baffle, of the thin film encapsulation layer, and arranged in the extension direction of the baffle, therefore the side frame area of the baffle location is fully utilized to achieve narrow side frames and the lowering of wire cutting-off risk.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

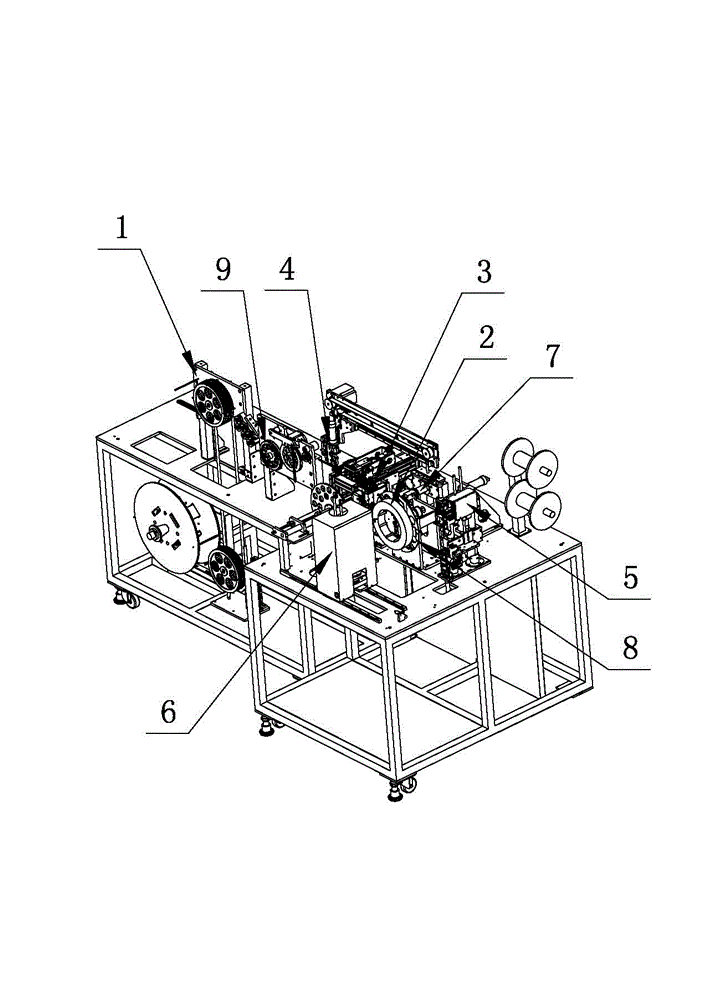

Automatic wire winding, binding and cutting integrated machine and automatic winding, binding and cutting method thereof

InactiveCN102941936AReduce manufacturing costFilament handlingBundling machine detailsWire rodWire cutting

The invention relates to the technical field of mechanical automation production devices, in particular to an automatic wire winding, binding and cutting integrated machine and automatic winding, binding and cutting method thereof. The integrated machine comprises a frame, a wire releasing device, a wire feeding device, a wire winding device, a ribbon tightening device, a ribbon contour device and a ribbon cutting device are arranged on the frame, a wire is pulled to the wire winding device through the wire feeding device and is automatically clamped, fixed and wound by the wire winding device, an annular wire coil is formed after the wire is wound, a ribbon cut off by the ribbon cutting device is conveyed to the wire coil by the ribbon contour device and is further tightened onto the wire coil by the ribbon tightening device, the wire is cut off by the wire feeding device, the wire coil is automatically unloaded by a wire clamping and coil unloading device, the winding, binding and cutting process of the whole wire coil is finished, the wire can be peeled and accuracy of the length of the wire coil can be controlled according to requirements of a customer, fully automatic unmanned operation of wire winding / length counting, wire binding, compensation, wire cutting, peeling and coil unloading is realized, and the manufacturing cost of an enterprise is reduced.

Owner:温增璟

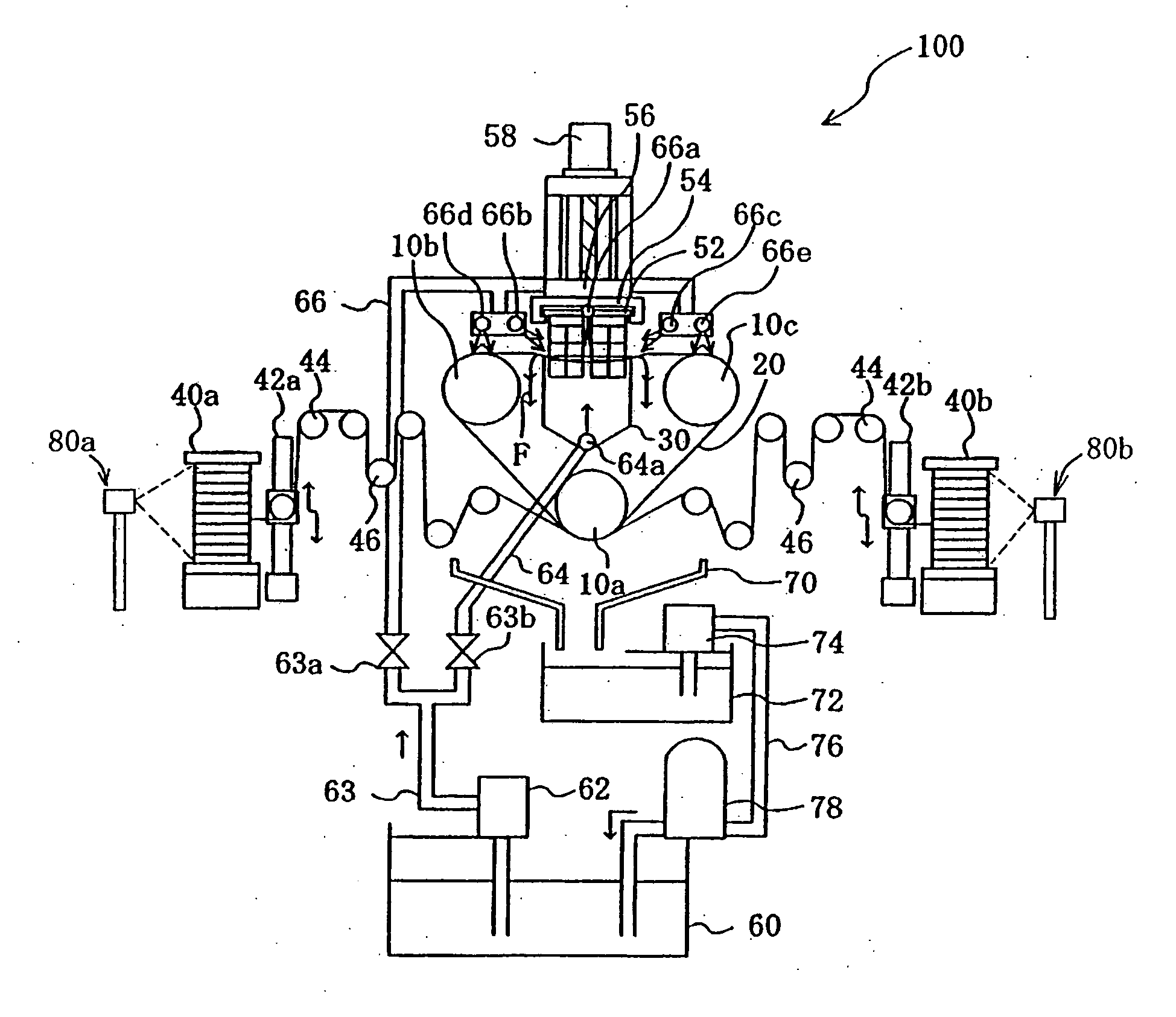

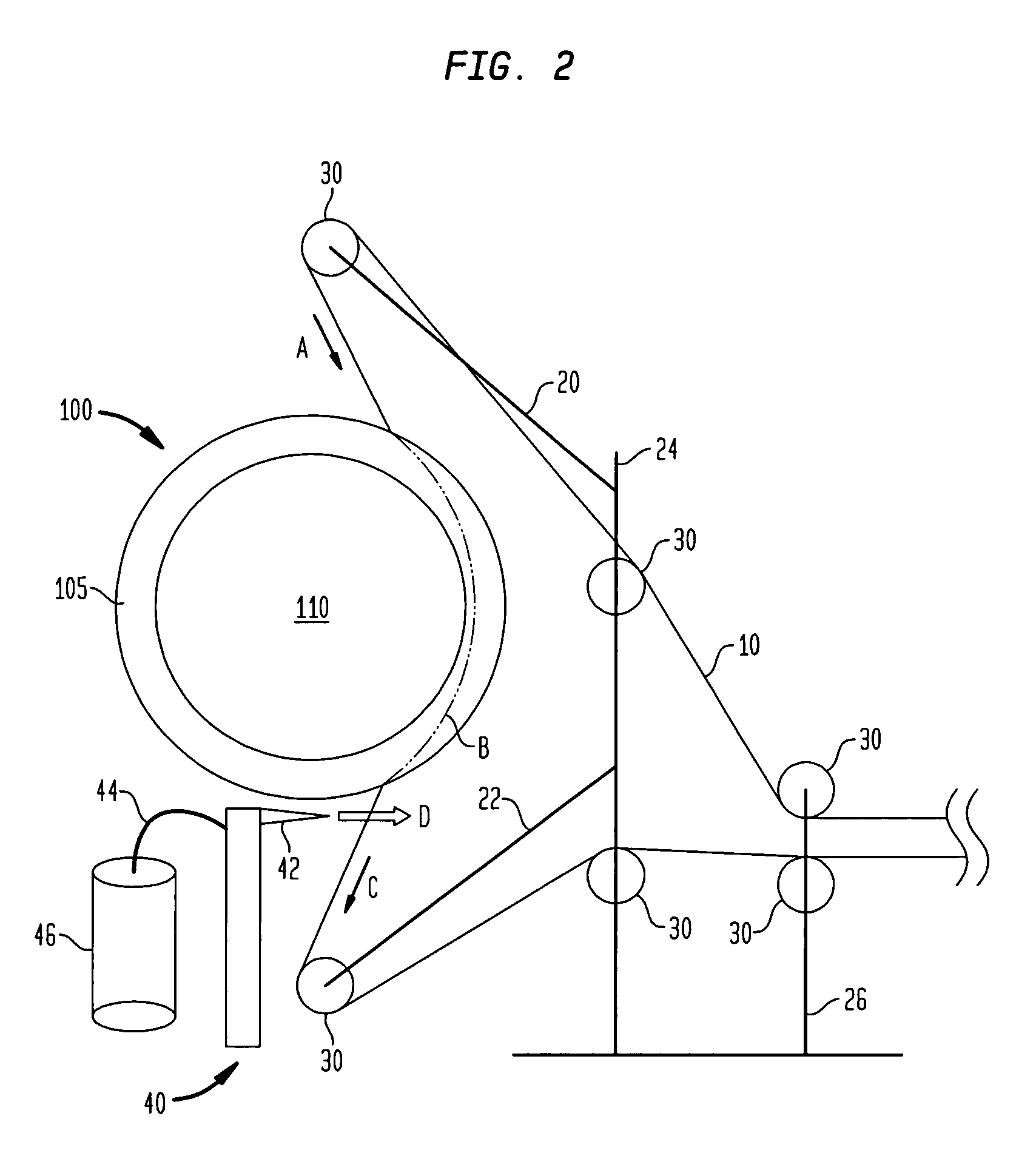

Cutting method using wire saw, wire saw device, and method of manufacturing rare-earth magnet

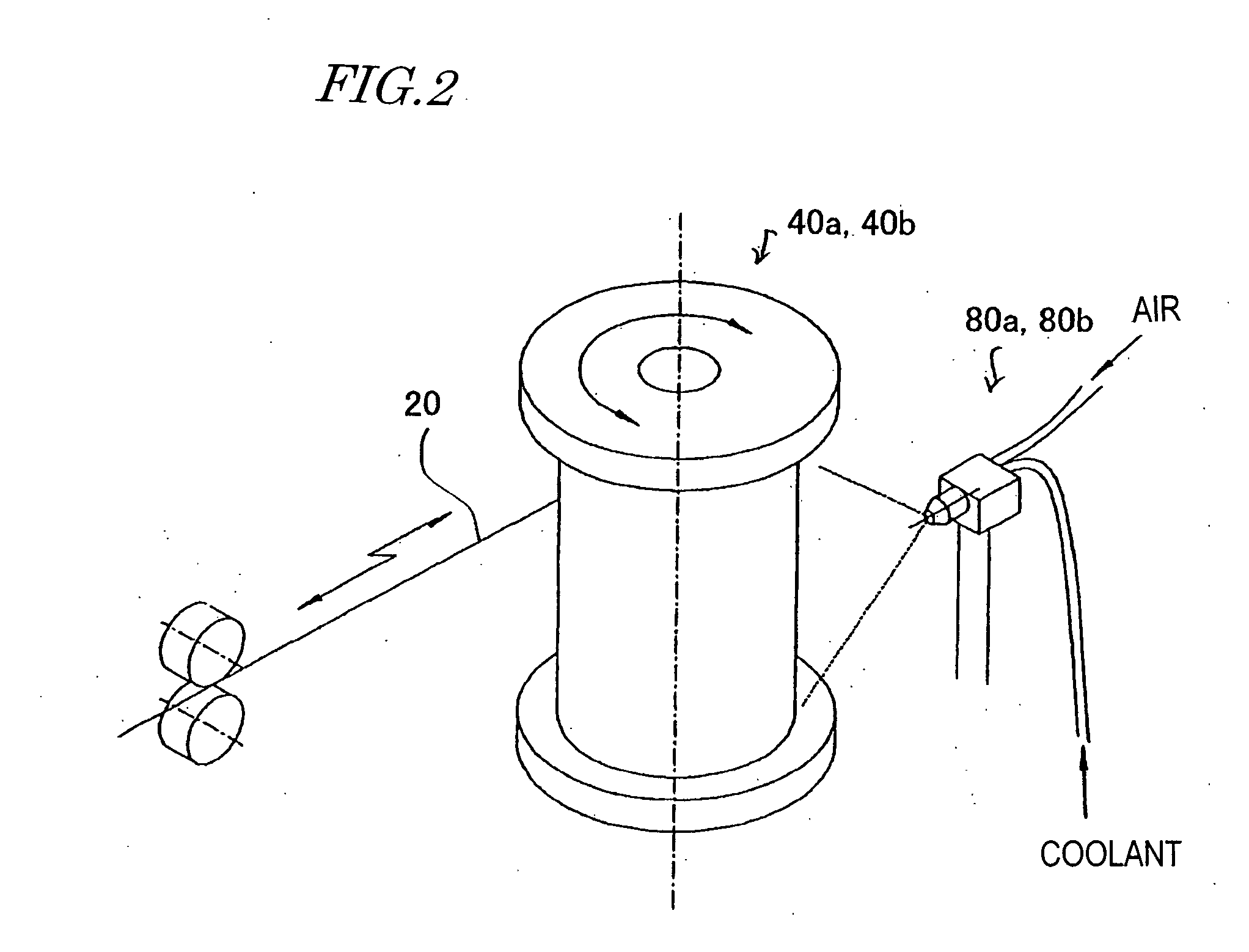

A method of cutting a rare-earth alloy with a wire 20, on which abrasive grains are fixed with a resin layer provided on the outer surface of a core wire, includes the steps of: providing a wire, of which the surface is coated with a lubricant including a glycol, by reeling the wire up in a pair of reel bobbins 40a and 40b; reeling the wire off one of the reel bobbins and letting the wire travel on a plurality of rollers 10a, 10b and 10c; and cutting the rare-earth alloy with the traveling wire while a portion of the rare-earth alloy being cut with the wire is supplied with a first coolant which is mainly composed of water. As a result, the life of a wire can be extended when a rare-earth alloy is cut with a wire saw machine using a coolant which is mainly composed of water.

Owner:HITACHI METALS LTD

Microneedles and microneedle fabrication

A master mould is made by wire cutting a plate in two or more directions to provide a base with an array of master mould needles protruding therefrom. The size and shape of the master mould needles can readily be varied by varying the angles of upward and downward cuts in the two or more directions. The master mould is used to make a secondary mould by hot embossing a secondary mould plate onto the master mould. This forms through-holes in the secondary mould. The secondary mould is plated with a layer of metal, which forms a microneedle array.

Owner:AGENCY FOR SCI TECH & RES

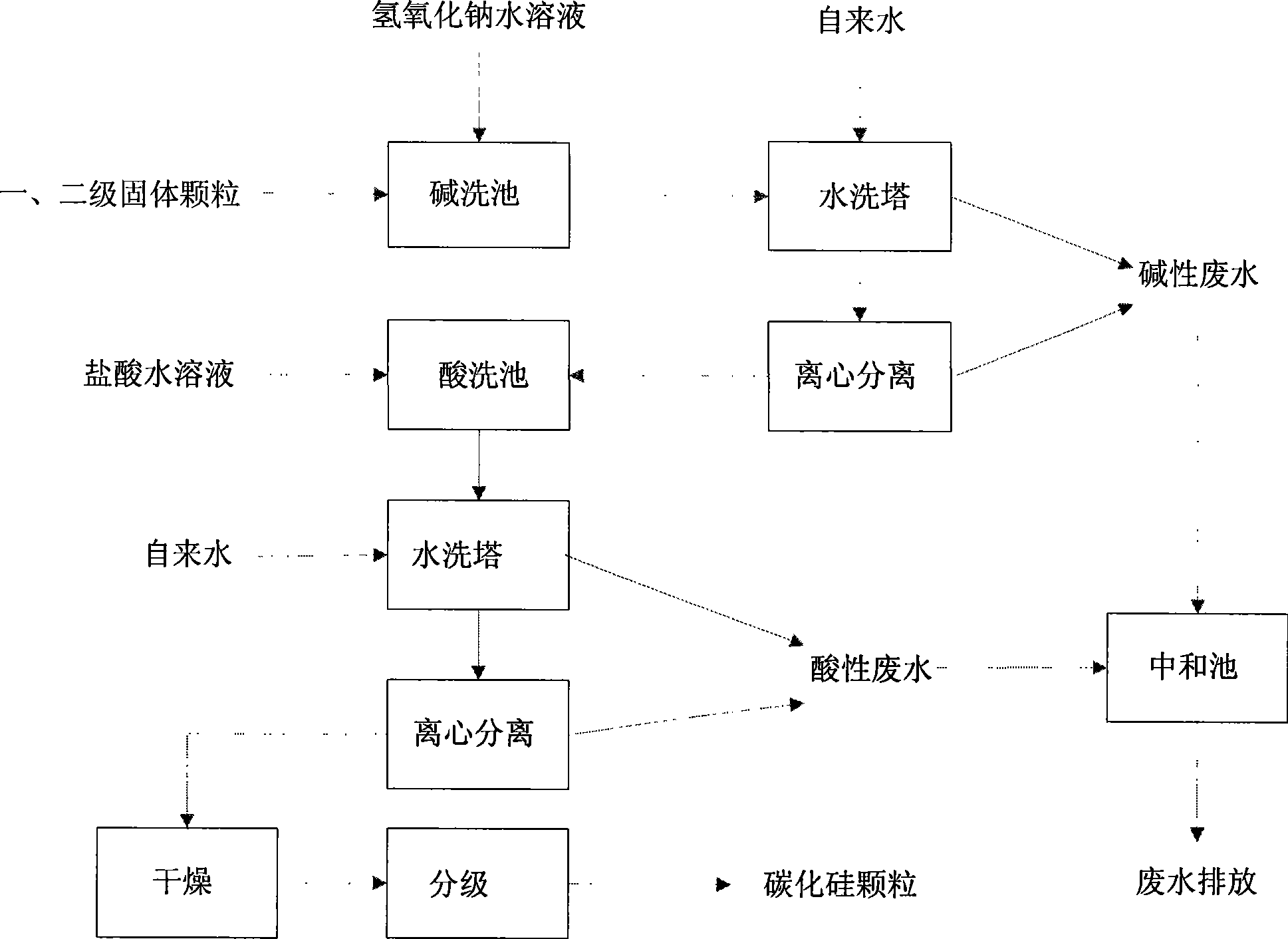

Process for recovering polyethylene glycol and silicon carbide in waste mortar from silicon wafer wire cutting

InactiveCN101474511AFacilitates flocculation and filtrationAvoid pollutionPlastic recyclingFiltration circuitsFiberHollow fibre

The invention relates to the field of silicon wafer wire-electrode cutting and discloses a method for recycling carborundum and cutting polyethyleneglycol in waste mortar by silicon wafer wire-electrode cutting. In monocrystalline silicon piece processing technique, a viscosity reduction agent is firstly added before waste mortar linear cutting, and then a suspending liquid part and a solid particles part are obtained by the solid-liquid separation; The suspending liquid part is added with a filter aid, then filter pressing with a plate frame, micro porous filtration, hyper filtration with hollow fiber and ion exchange are carried out sequentially, and finally, the suspending liquid is distillated in vacuum and polyethyleneglycol is recycled. Alkali reaction cleaning, water scrubber washing, centrifugalization, acid reaction cleaning, the second water scrubber washing, the second centrifugalization, the second acid reaction cleaning, drying and drying classification are carried out on the solid particles in sequence, and finally, recyclable silicon carbide particles are obtained.

Owner:西安通鑫半导体辅料有限公司

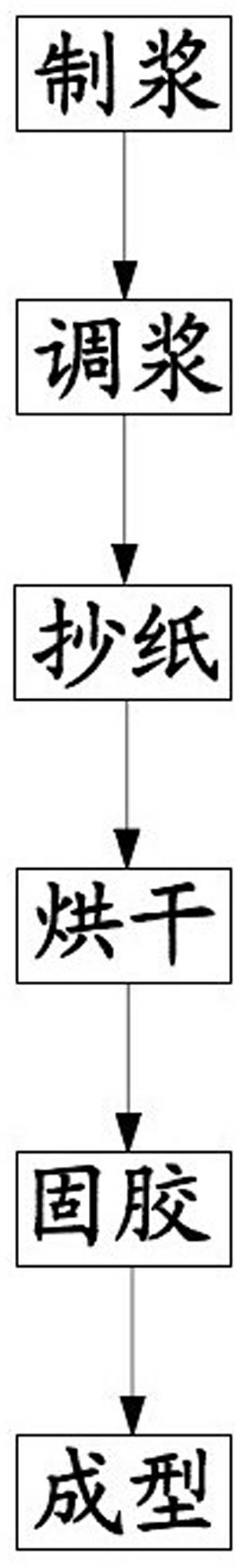

Filter paper for cooling system in wire electrical discharge machining (WEDM) and production method of filter paper

InactiveCN102444054AReduce the maximum apertureReduce the average pore sizeNon-fibrous pulp additionPaper/cardboardPolyesterGlass fiber

The invention relates to filter paper for a cooling system in wire electrical discharge machining (WEDM), which comprises the following components in percent by weight: 18-25 percent of phenolic resin, 0.5-5 percent of glass fiber, 0.5-5 percent of polyester fiber and 65-82 percent of wood pulp fiber. A production method of the filter paper comprises the steps of pulping, pulp mixing, paper making, drying, glue setting and forming. The filter paper adopts the wood pulp fiber as the main material which is matched with a proportion of glass fiber and polyester fiber, so that the bore diameter of the filter paper can be reduced, and the filtering accuracy can be improved; and in addition, since the polyester is chemically-synthesized fiber and has high strength, the bursting strength of the filter paper is improved, and the service life of the filter paper is prolonged. In the production process of the filter paper, thermosetting phenolic resin is introduced by dipping setting glue, and the size stability, the high temperature resistance and the water resistance of the filter paper are further improved. When being applied to a cooling liquid circulating system in WEDM, the filter paper is not deformed or expanded and has good strength in water, and the phenomena of water jetting and black water generating due to bursting are avoided.

Owner:SUZHOU XINYE PAPER - MAKING

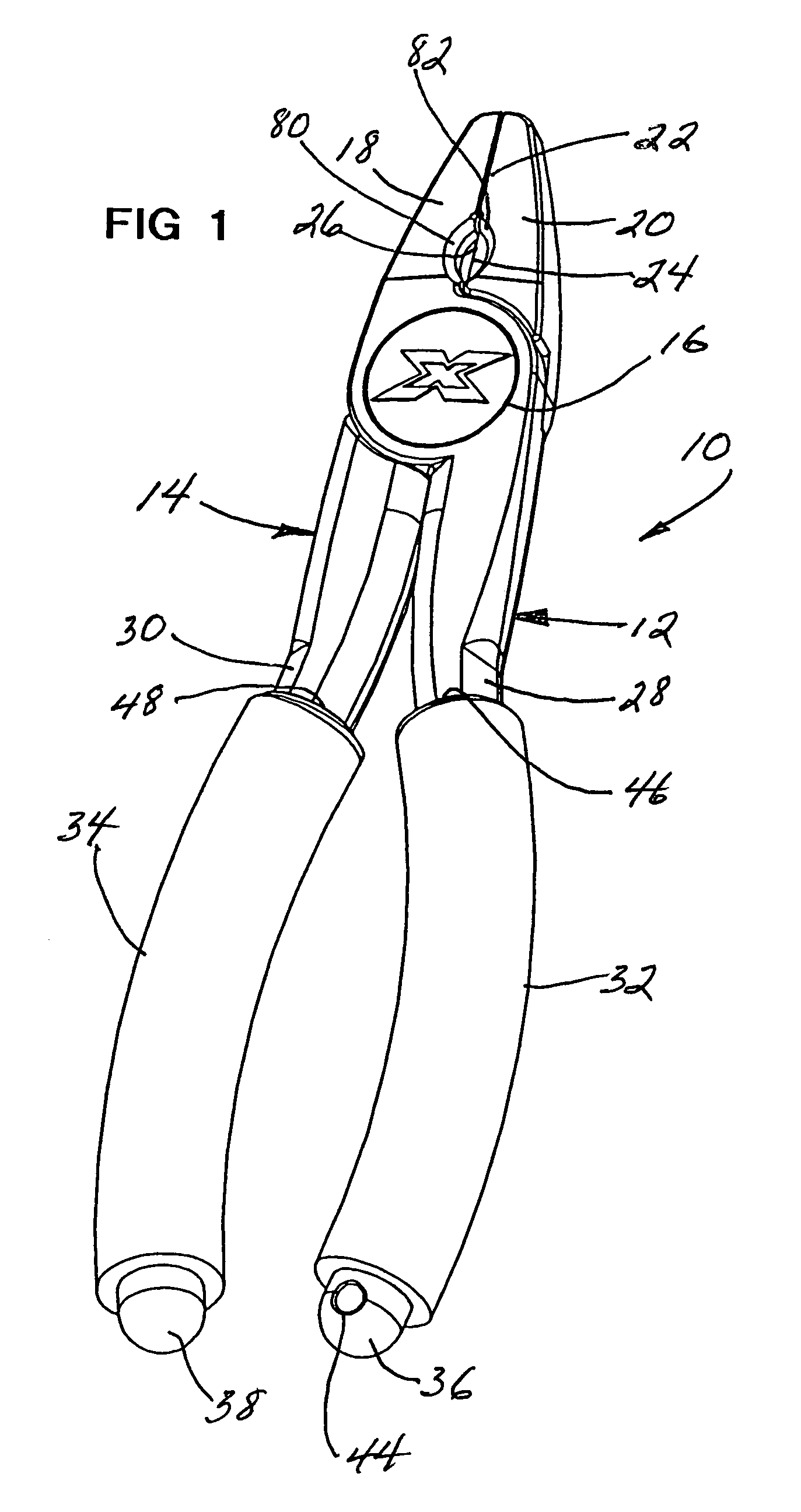

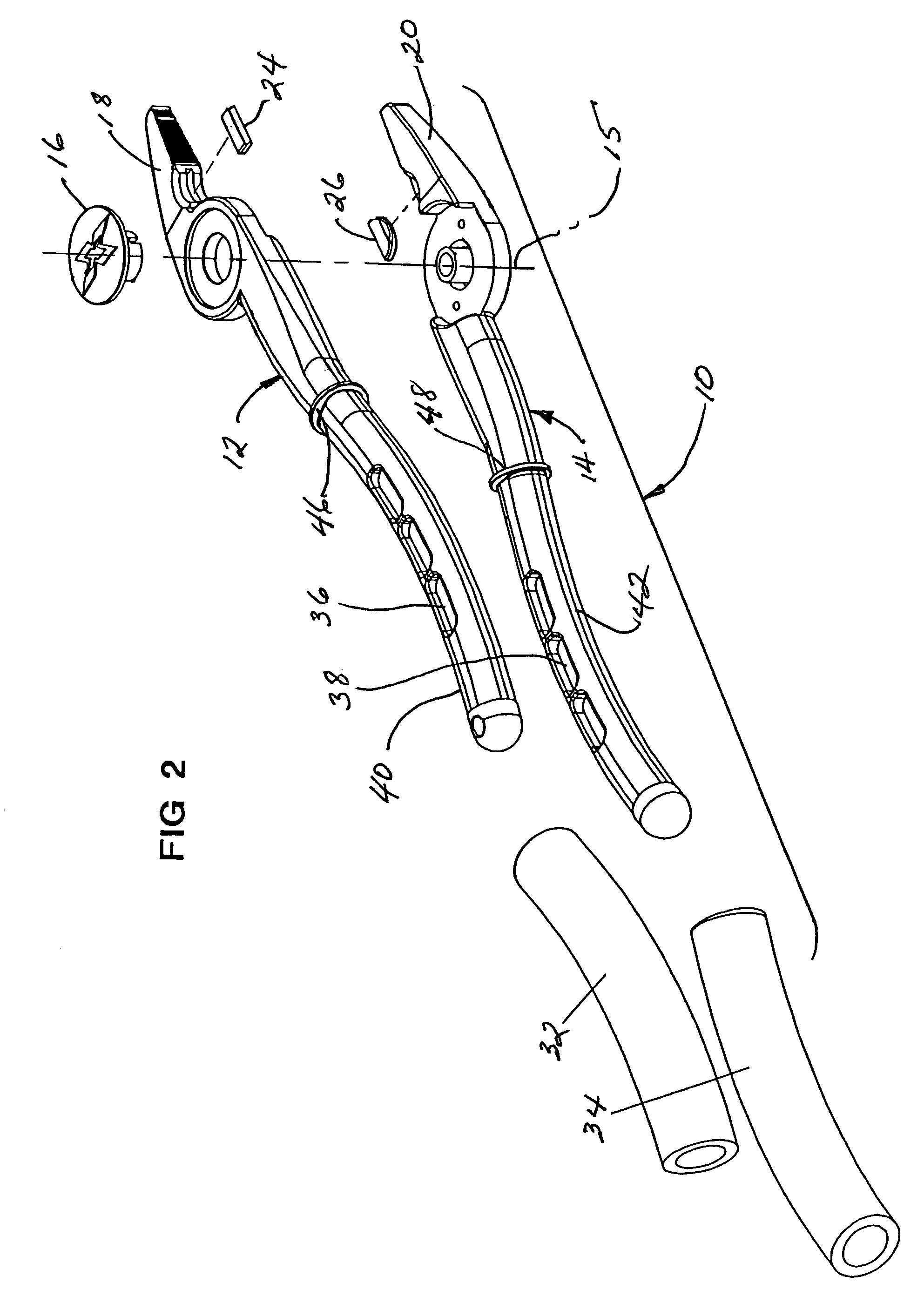

Non-metallic hand pliers with wire cutter

InactiveUS6966244B2Efficient arrangementReduce arrangementPliersMetal working apparatusEffective densityWire cutting

A pair of preferably substantially buoyant-in-water hand pliers comprising a pair of non-metallic lever members each having a handle portion and a jaw portion and formed of material preferably having a density greater than water. The lever members are pivotally connected together at common central portions between the jaw and handle portions. Each handle portion preferably has one or more outwardly opening cavities formed into a side surface of the handle portions. An elongated tubular sheath preferably formed of material buoyant in water covers and sealingly encloses the cavities whereby the effective density of the pliers is less than that of water. An effective, durable, non-corrosive wire cutting arrangement is also provided, the components uniquely configured and supported in the non-metallic jaw portions.

Owner:SHAKESPEARE CO

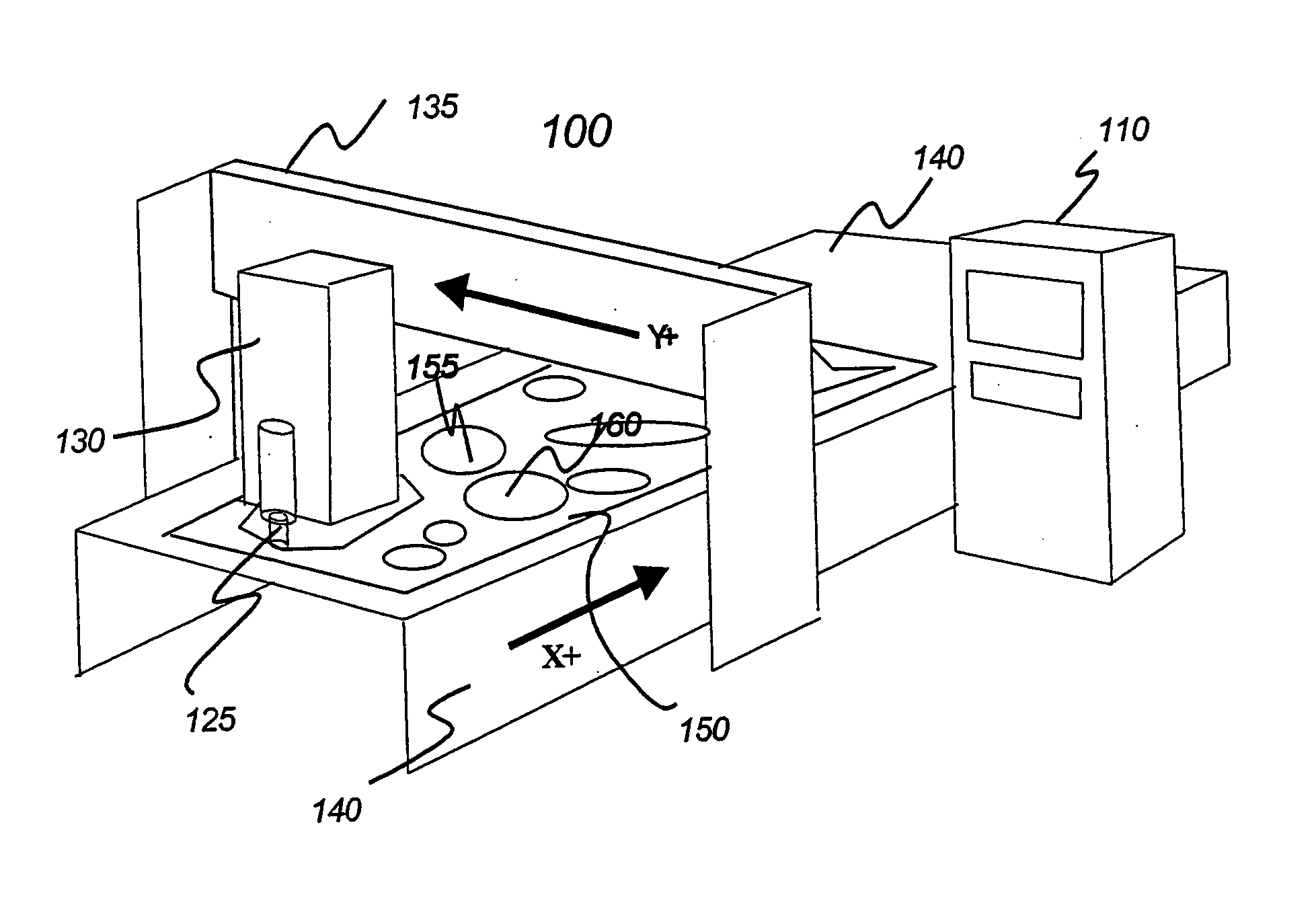

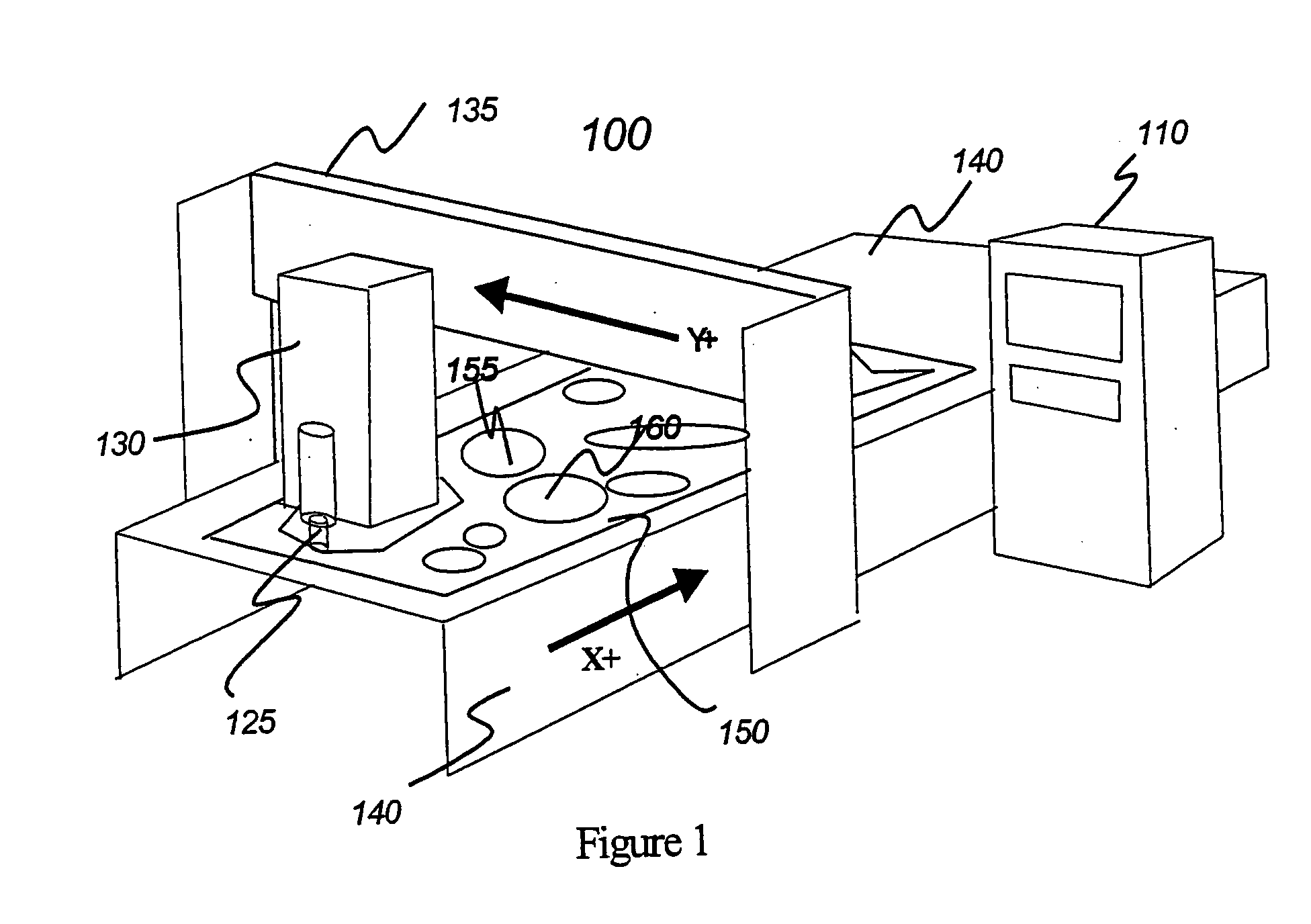

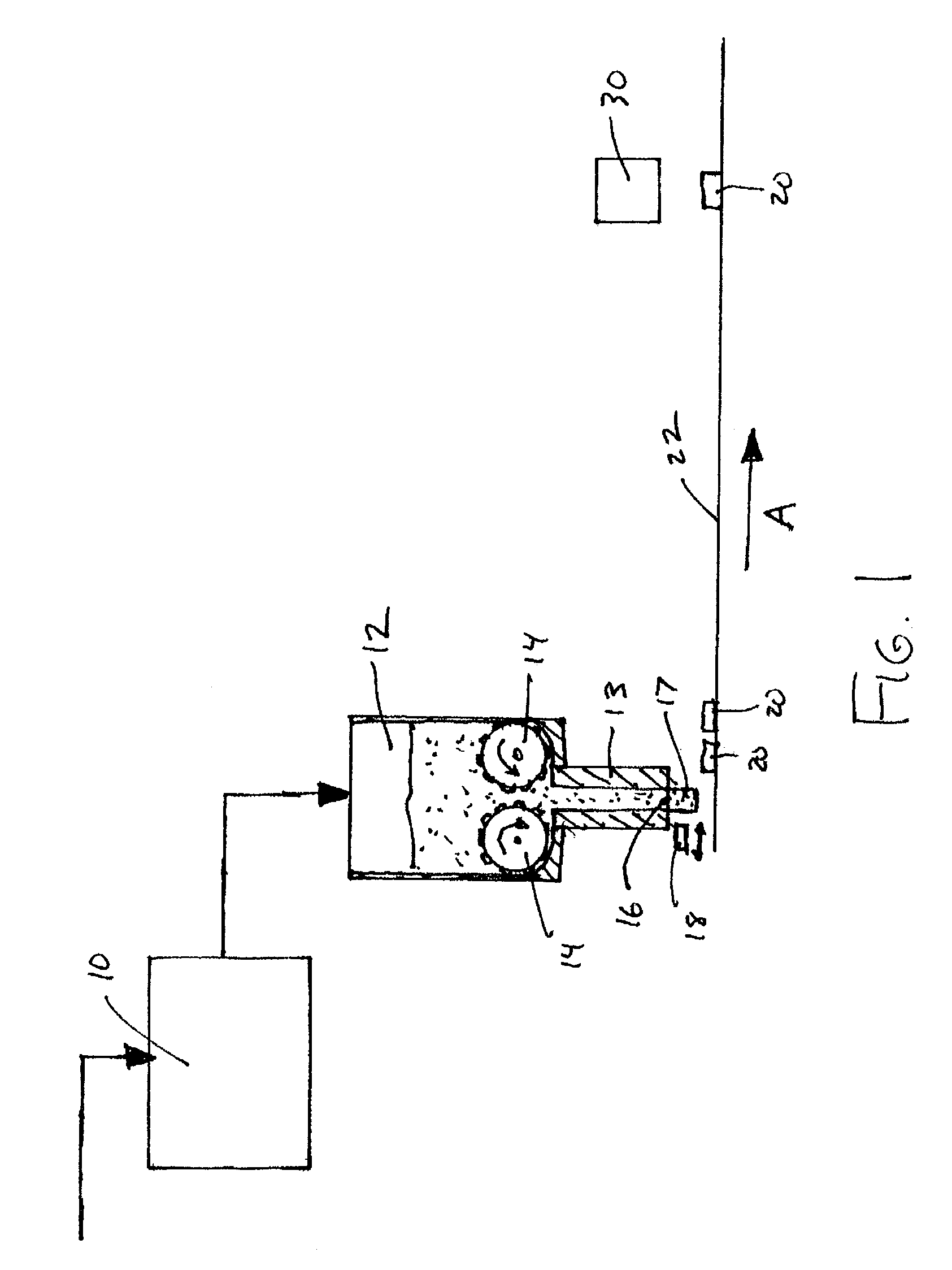

Method and system for eliminating external piercing in NC cutting of nested parts

ActiveUS20050172764A1Programme controlWelding/cutting auxillary devicesEngineeringManufacturing engineering

This invention pertains to machinery and methods for cutting a workpiece utilizing a cutting tool into at least two parts having prescribed shapes from a metal plate comprising the steps of: identifying each of the parts by one or more contour lines; cutting a workpiece along one of the identifying contour lines into one of the parts; creating at least one path diversion, wherein the diversion has an associated bounded region or opportunity; cutting the workpiece along a contour line associated with the opportunity; resuming the cutting of the part along the identifying contour line with minimal damage to the part being cut; finishing the cutting of the part and then moving the cutting tool to the opportunity and thence to an associated adjacent identifying contour line and then repeating the process until all parts have been manufactured.

Owner:FAGAN MATTHEW

Cooling liquid for diamond wire cutting technology

ActiveCN103184094AImprove the lubrication effectImprove cooling effectWorking accessoriesLubricant compositionSurface finishPreservative

The invention relates to cooling liquid for diamond wire cutting technology, which mainly comprises a lubricant, an emulsifier, an antirust agent, a dispersant, a preservative, and deionized water, wherein the mass percents of the components are 5-50% of the lubricant, 0.05-10% of the emulsifier, 0.1-5% of the antirust agent, 0-10% of the dispersant, 0-5% of the preservative, and the balance being deionized water. The cooling liquid has excellent lubricity and dispersibility, is easy to clean, suitable for cutting of hard and brittle materials such as crystal silicon, sapphire, and the like, can not only meet requirements for diamond wire high-speed cutting, but also realize good surface finish of cut pieces, and can significantly increase product qualified rates.

Owner:LIAONING OXIRANCHEM INC

Method for making sweet cookie dough having an imprinted surface

ActiveUS7067167B2Rapid and efficient and systematic processConfectioneryCeramic shaping apparatusWire cuttingEngineering

Rapid, efficient, and systematic processes and apparatuses for making repeatable imprints on multiple, individual sweet dough pieces are provided. An advantage of the process is the ease of making uniform imprints that are aligned with the individual dough pieces as formed and deposited. Such provides the ability to create a three-dimensional pattern on the surface of a sweet dough piece, particularly a soft cookie dough piece. The methods can be accomplished by high-speed wire cutting production methods as well as other dough piece depositing apparatuses, such as roller-type depositors.

Owner:GENERAL MILLS INC

Water-based response type multifunctional metal machining liquid and preparation method thereof

InactiveCN101519622AImprove cooling effectImprove the lubrication effectLubricant compositionChemistryTriethanolamine

The invention relates to a water-based response type multifunctional metal machining liquid, the composition formula of which comprises a surfactant, a solvent, plant oleic acid, triethanolamine, sodium salts with a corrosion inhibitive function, an inhibiter, dimeric dibasic acid, a defoamer, a preservative, deionized water, defoamer 903, preservative 1227, deionized water, and the like. The metal machining liquid is nontoxic, harmless and pollution-free, has no harm to human bodies or corrosion to metal surfaces, has no abnormal taste or deterioration after long time usage, and has superior auxiliary machining functions of cooling, lubricating, cleaning, extreme pressure, rust prevention, and the like. The metal machining liquid can be used for the metal working of devices for machining, milling, planning, drilling, boring, punching, wire-electrode cutting, and the like, and is especially suitable for high-grade numerical control machines. The machining liquid has high physical stability and small surface mightiness, and can effectively reduce the machining temperature, reduce the thermal deformation of workpieces and cutting tools, increase the abrasion resistance of the cutting tools, increase the machining precision and the surface finish quality of the workpieces to a great extent, effectively remove dirt on the surfaces of the workpieces, and prolong the natural antirust time of the processed workpieces to be longer than 45 days.

Owner:天津市澳路浦润滑科技股份有限公司

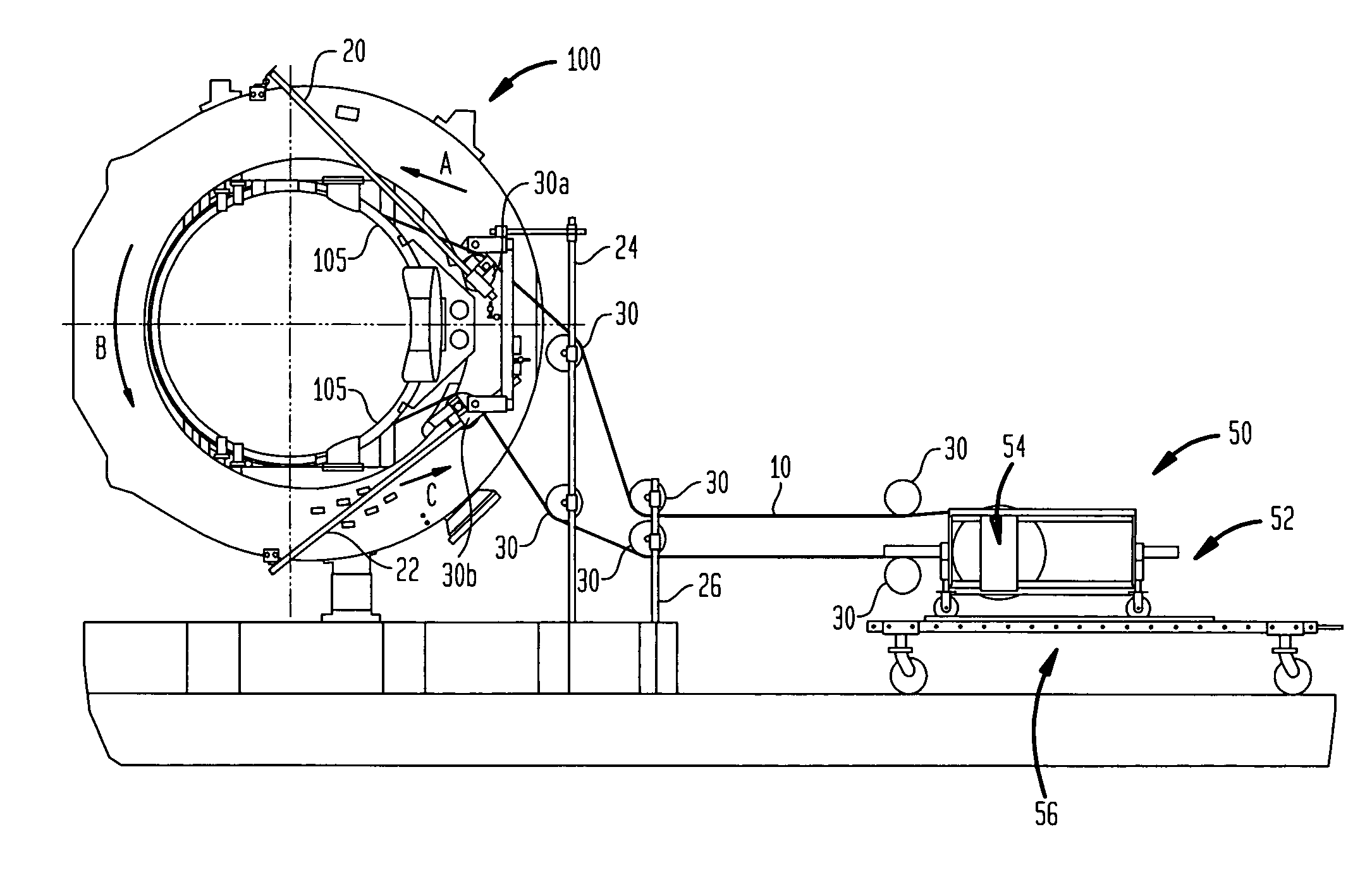

Method and apparatus for diamond wire cutting of metal structures

InactiveUS6881131B2Reduce breakageAbsorb energyMetal sawing devicesMetal sawing accessoriesNuclear reactorDiamond wire saw

A method and apparatus for diamond wire cutting of metal structures, such as nuclear reactor vessels, is provided. A diamond wire saw having a plurality of diamond beads with beveled or chamfered edges is provided for sawing into the walls of the metal structure. The diamond wire is guided by a plurality of support structures allowing for a multitude of different cuts. The diamond wire is cleaned and cooled by CO2 during the cutting process to prevent breakage of the wire and provide efficient cutting. Concrete can be provided within the metal structure to enhance cutting efficiency and reduce airborne contaminants. The invention can be remotely controlled to reduce exposure of workers to radioactivity and other hazards.

Owner:THE TRUSTEES FOR PRINCETON UNIV

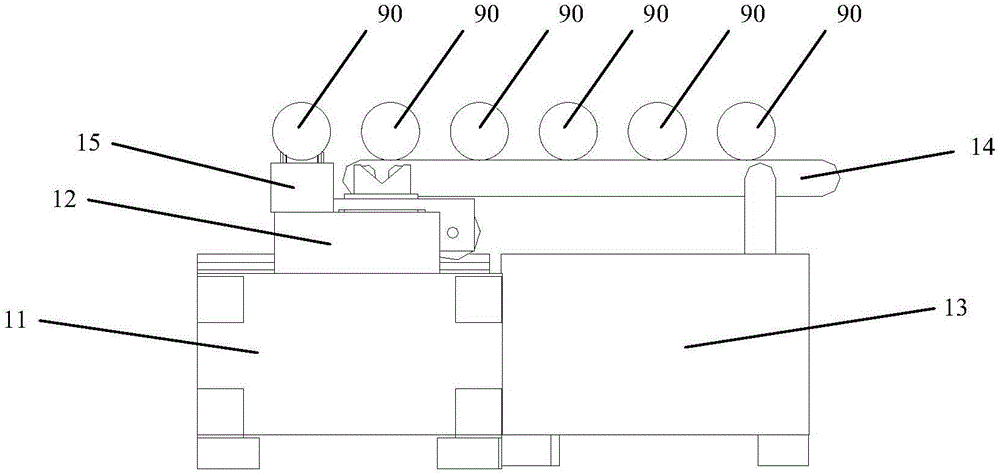

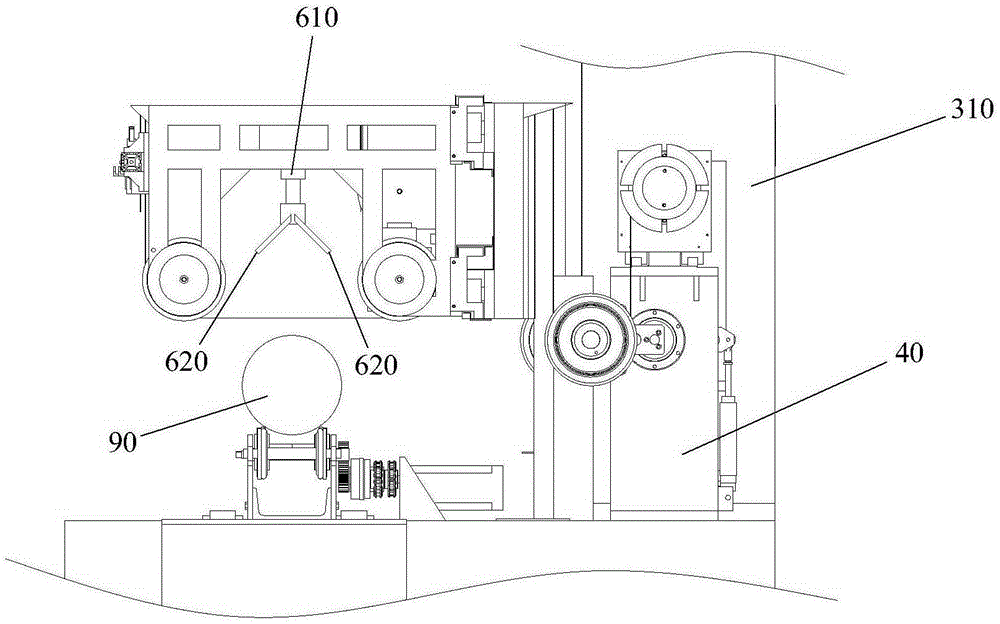

Silicon rod squaring equipment, silicon rod squaring method and flaw piece unloading device

PendingCN109129947AImprove efficiencyImprove work efficiencyWorking accessoriesFine working devicesEngineeringMechanical engineering

The invention discloses silicon rod squaring equipment, a silicon rod squaring method and a flaw piece unloading device. The silicon rod squaring equipment comprises a silicon rod bearing device, a linear cutting device and the flaw piece unloading device. The linear cutting device comprises a linear cutting support and a linear cutting unit. A cutting line segment is arranged in the linear cutting unit, the cutting line segment in the linear cutting unit penetrates through a to-be-cut silicon rod by driving the linear cutting support to descend, and the cut silicon rod and a flaw piece are formed. The flaw piece unloading device comprises a flaw piece lifting mechanism and a line thumbing mechanism. The line thumbing mechanism thumbs the cutting line segment to expand outwards, so that interference between the cutting line segment and the cut silicon rod is avoided. According to the technical scheme, the flaw piece can be stably lifted under the condition that it is guaranteed that the cutting line segment does not interfere with the cut silicon rod, thus, the efficiency of squaring cutting work of the silicon rod can be improved, the squared flaw piece is lifted in an unobstructed manner and then unloaded, operation is convenient, and the overall working efficiency is improved.

Owner:TDG NISSIN PRECISION MACHINERY CO LTD

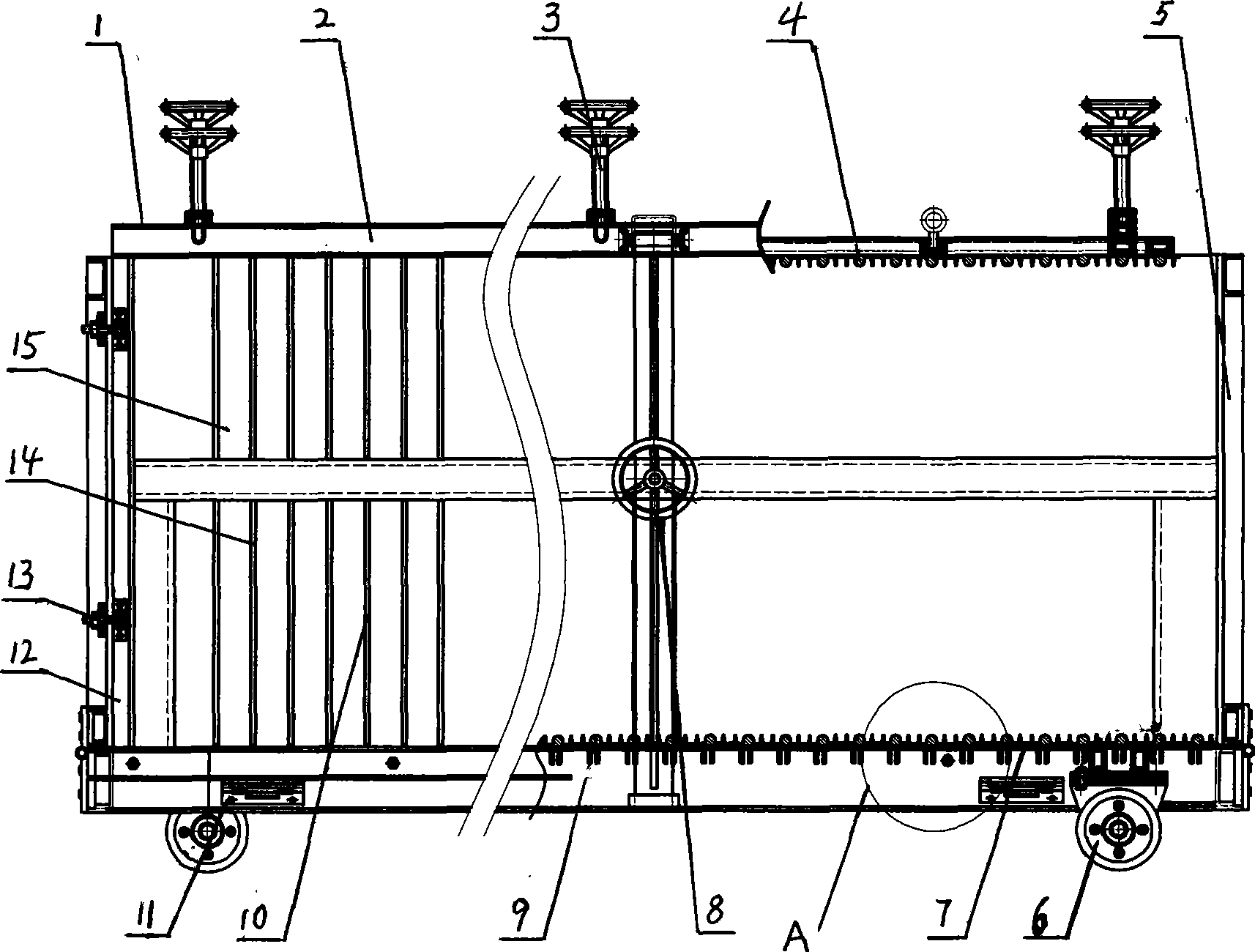

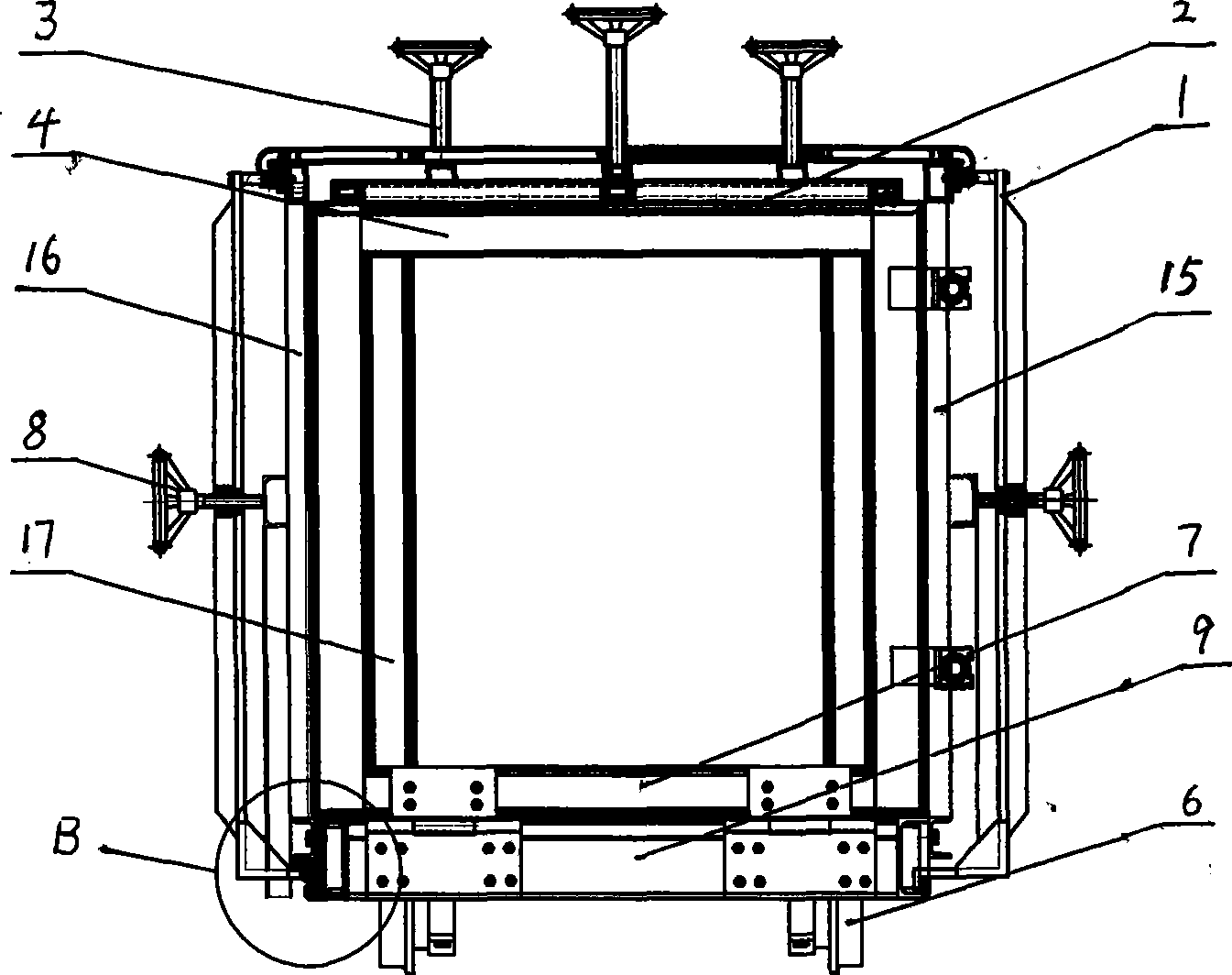

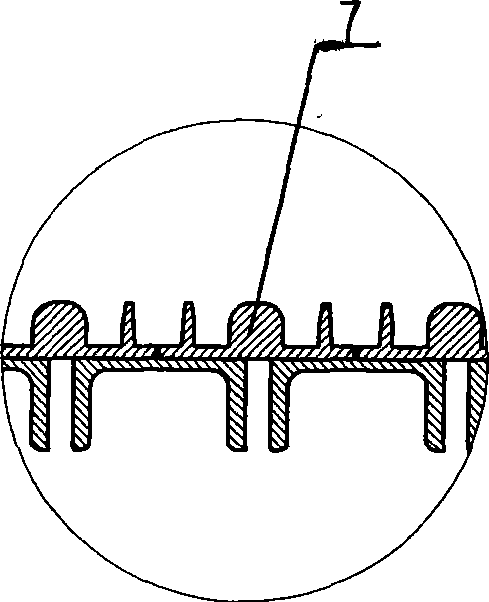

Method for pouring and molding large scale disposal wallboard and mould carriage thereof

InactiveCN101439553AHigh strengthImprove product qualityDischarging arrangementMould separation apparatusWire cuttingSlurry

The invention discloses a method for one-time wallboard perfusion moulding on a large scale and a pan car thereof. A die of the bottom plate of a wallboard is fixed inward the internal part of the bottom plate of the pan car at equal distance; dies of the side wall of the wallboard are respectively fixed inward the front side plate and the back side plate of the pan car at equal distance; therefore, after the case of the pan car is fully filled with pasty slurries, a vibrator leads to the vibration of the whole case on the front side plate and the back side plate; after the vibration, a finished product is obtained after initial setting, wallboard cutting, steam curing, pan car removal of shuttering and other processes; therefore, 20-200 wallboards are processed in one time. The wallboard cutting is realized in the form of steel wire cutting or clapboard partition; a steel wire netting is embedded in the wallboard, so as to greatly enhance the strength of the wallboard; therefore, the invention has the advantages that the inner wallboard of the pan car is formed by large-scale one-time injection moulding by using the die, the precision of the die is high, the product quality is reliable, the injection amount is large, the production efficiency is greatly improved and the cost is saved.

Owner:朱春生

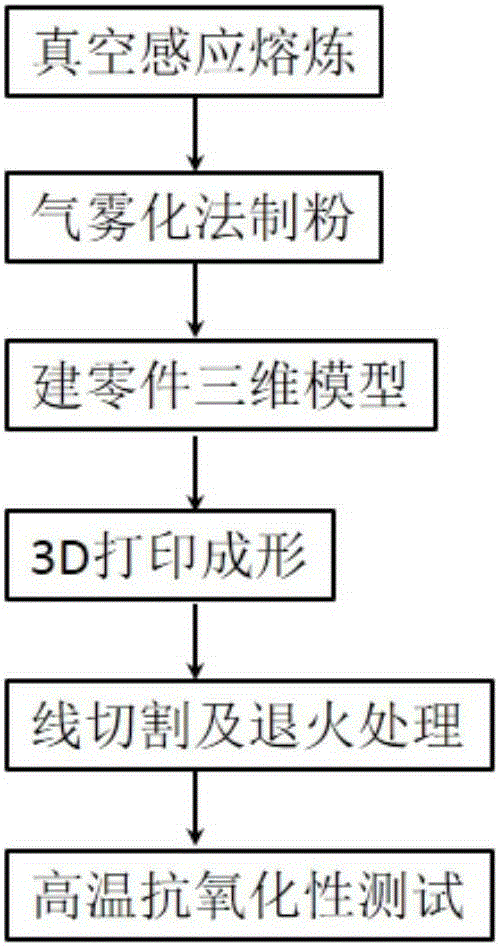

Method for preparing high temperature titanium alloy by adopting selective laser melting rapid formation technique

ActiveCN105154701AIncrease the content of low melting point elementsIncrease the content of melting point elementsIncreasing energy efficiencyManufacturing cost reductionSelective laser melting

The invention discloses a method for preparing high temperature titanium alloy by adopting a selective laser melting rapid formation technique. The method comprises the following steps: (1), preparing powder of elements in nominal chemical components of titanium alloy according to the mass proportion of all the elements, then carrying out vacuum induction melting; (2), milling titanium alloy formed by melting by adopting a gas atomization milling method; (3), establishing a part three-dimensional model, and importing the part three-dimensional model into selective laser melting rapid formation equipment; (4), placing powder into the selective laser melting rapid formation equipment, and carrying out part forming on a substrate; (5), separating the formed part from the substrate by adopting a wire cutting process, annealing the part, so as to improve the plasticity and the toughness of titanium alloy; (6), performing a high temperature oxidation test on the part, so as to determine the high temperature oxidation resistance of the novel titanium alloy. According to the method for preparing high temperature titanium alloy by adopting the selective laser melting rapid formation technique, provided by the invention, a high temperature titanium alloy part with a complex structural shape is quickly formed, and the characteristics of rapid manufacturing, accurate manufacturing and reduction of manufacturing cost and the like are achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

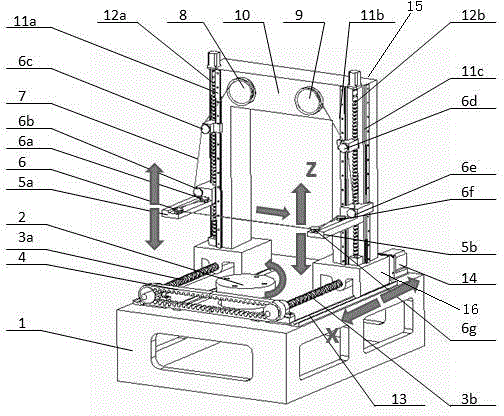

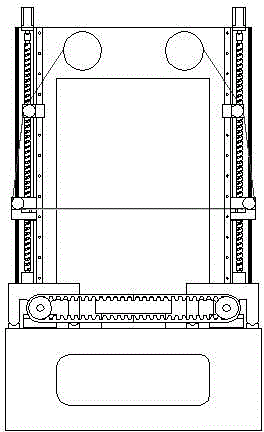

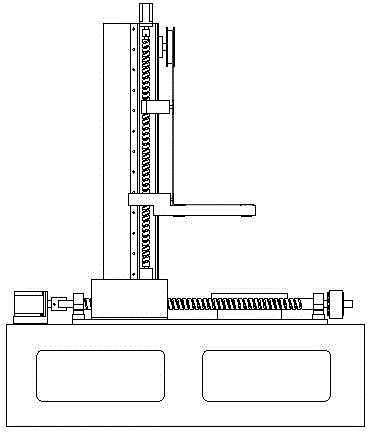

Horizontal diamond wire cutting machine tool

ActiveCN104890036AEasy clampingAvoid breakingMetal working apparatusStone-like material working toolsWire cuttingEngineering

Disclosed is a horizontal diamond wire cutting machine tool. The horizontal diamond wire cutting machine tool comprises a tool body (1), the tool body (1) is provided with a rotary worktable (2) for fixing workpieces, a portal frame (15), and a guide wheel group on the portal frame (15), wherein the portal frame (15) can be driven by an X-direction transmission mechanism on the tool body to move in an X direction. The horizontal diamond wire cutting machine tool is characterized in that the beam (10) of the portal frame (15) is provided with a pay-off drum (8) and a take-up drum (9), the stand columns on both sides of the portal frame (15) are respectively provided with an extending plate, and the cantilever end of each extending plate is provided with a cantilever end guide wheel; the extending plates on both sides are driven by the same or a separated Z-direction transmission mechanism to move up and down along the stand columns to control the height and accordingly to maintain a horizontal state so that a diamond wire on the cantilever end guide wheels on the cantilever ends can maintain a horizontal state and participate in cutting of the workpieces. The horizontal diamond wire cutting machine tool is convenient to fixe and high in machining efficiency and yield rate.

Owner:TAIZHOU CHEN HONG NC EQUIP MFG CO LTD +2

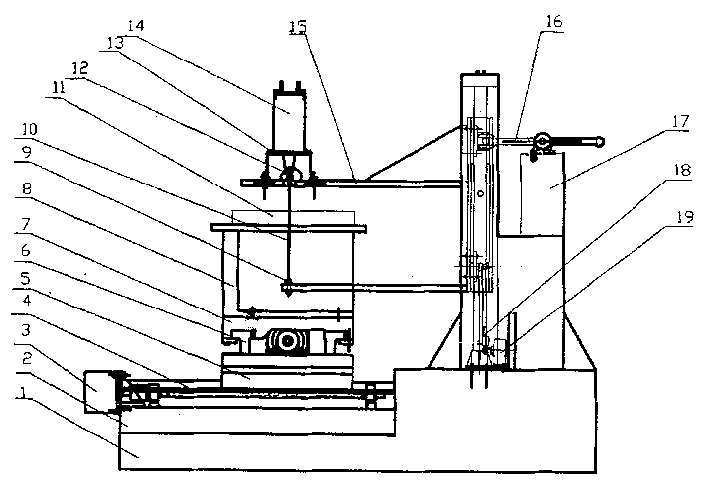

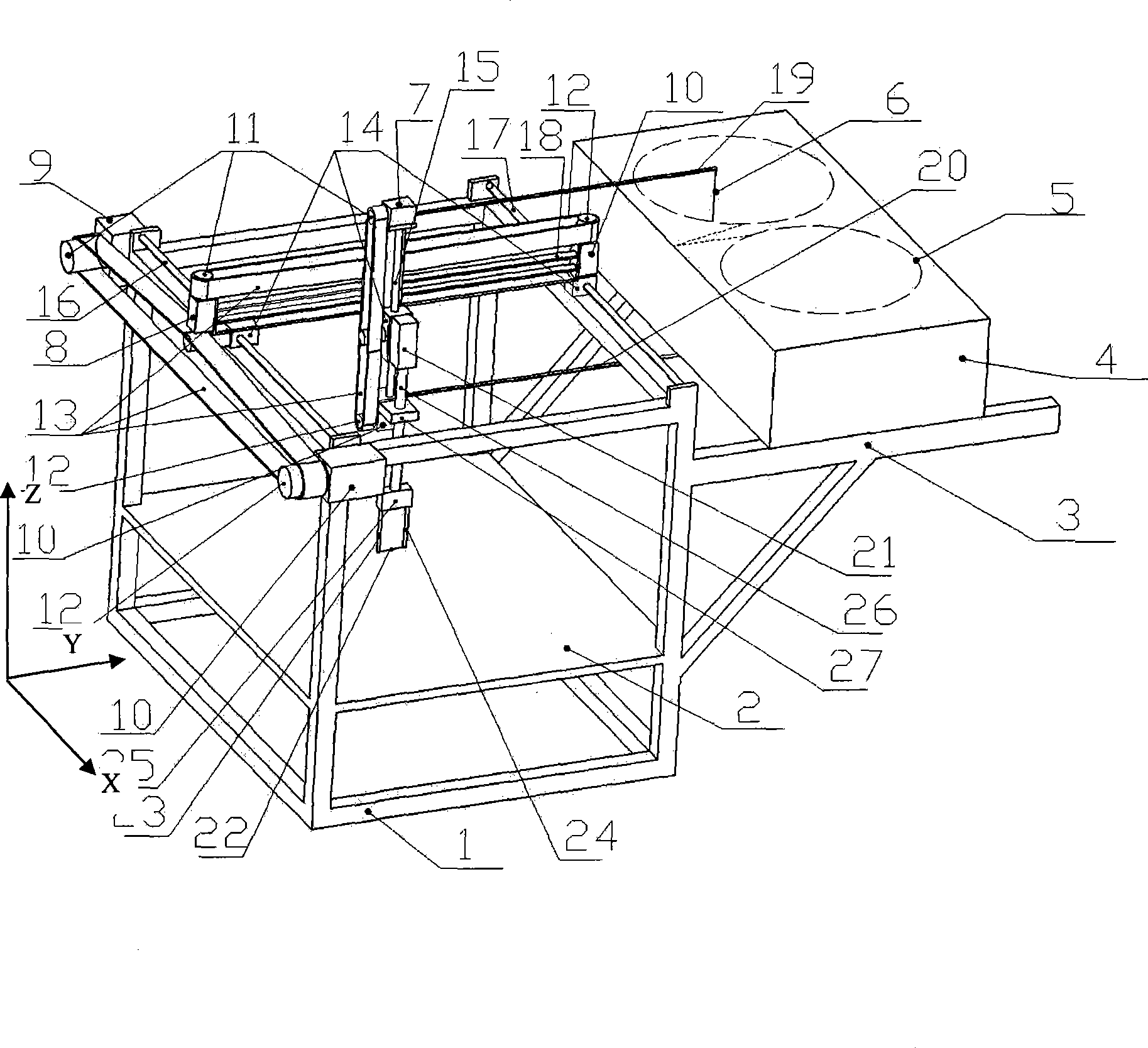

Lost foam wire cutting numerical control machining shaping mill

InactiveCN101474803AFast preparationAutomatic productionMetal working apparatusAxis cylinderNumerical control

A vanishing mould digital control linear cutting processing forming machine belongs to automatic machining device, and overcomes the problems of low forming speed and singular function of prior vanishing mould digital control linear cutting processing forming machine. The vanishing mould digital control linear cutting processing forming machine is composed of a mechanical part and a control part. The mechanical part comprises a frame, a tray, an X-axis motor, a Y-axis motor, a Z-axis motor, a X-axis left cylinder slide way, a X-axis right cylinder slide way, a Y-axis cylinder slide way, a Z-axis cylinder slide way, a main shaft motor and the main shaft. The right side of frame is fixed with a bracket. Two ends of Z-direction vertical girder are fixed with an upper cantilever and a lower cantilever. A baiting cutting line is connected between the end of upper cantilever and the end of lower cantilever. An installation plate is installed on the end of main shaft. The installation plate is fixed with a left supporting arm and a right supporting arm. A processing cutting line is connected between the end of left supporting arm and the end of right supporting arm. The vanishing mould digital control linear cutting processing forming machine of the invention has the advantages of compact structure, complete function, excellent economy and excellent practicality. The vanishing mould digital control linear cutting processing forming machine integrates the functions of baiting, blocking, etc. The manufacturing of vanishing moulds with middle or small quantity is quickly, economically and automatically / semi-automatically completed. The vanishing mould digital control linear cutting processing forming machine can also be used for manufacturing foam pad with middle or small quantity.

Owner:HUAZHONG UNIV OF SCI & TECH

Great diameter SiC monocrystal cutting method

ActiveCN1739927ARealize continuous cuttingReduce lossesMetal working apparatusWire cuttingSingle crystal

The great diameter SiC monocrystal cutting method belongs to crystal material processing technology. SiC monocrystal is cut by means of diamond wire cutting machine with cutting wire of 150-450 micron diameter and coated with diamond grains. The diamond wire cutting wire in high speed reciprocation cuts great diameter SiC monocrystal. The present invention has the following advantages: capacity of cutting SiC monocrystal of size ove 2 in, less cutting loss, shallow cutting trace, less damage to cut chip, capacity of cutting chip with thickness as small as 200 micron, saving in cost, homogeneous thickness and less deformation of the cut chip, and simple cutting process.

Owner:SICC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com