Cooling liquid for diamond wire cutting technology

A technology of diamond wire and coolant, which is applied in the field of coolant, can solve problems such as the difficulty in satisfying the lubricity of cutting fluid, and achieve the effects of improving the surface quality and yield of slices, easy cleaning, and excellent lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Prepare 1000g of cooling liquid, take polyoxyethylene polyoxypropylene butanol ether (number average molecular weight 600) 400g, sulfonated oil 100g, nonylphenol polyoxyethylene ether (NP10) 50g, sodium dodecylsulfonate 50g, acrylic acid - 100 g of maleic acid copolymer (weight average molecular weight: 10,000), 50 g of barium petroleum sulfonate, 25 g of potassium sorbate, and 225 g of water.

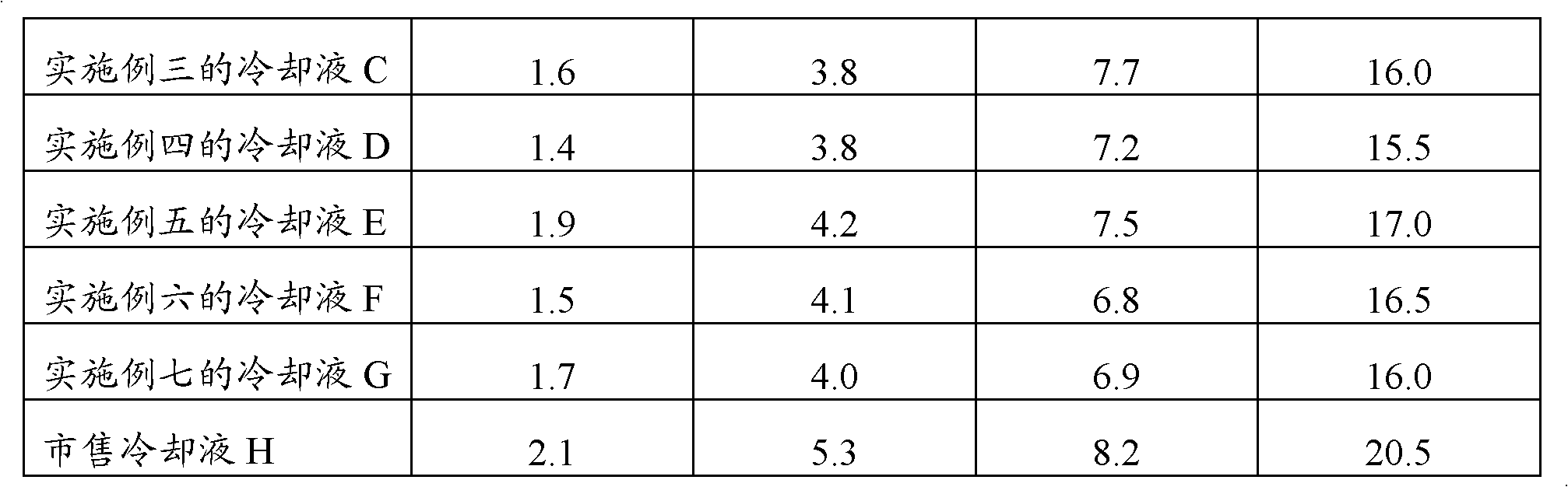

[0068] Slowly add the above amounts of polyoxyethylene polyoxypropylene butanol ether, sulfonated oil, nonylphenol polyoxyethylene ether, sodium dodecylsulfonate, acrylic acid-maleic acid copolymer in the water under continuous stirring , barium petroleum sulfonate, and potassium sorbate, and stirred for 30 minutes to obtain diamond wire coolant A. For its performance index, see Tables 1-3 below.

Embodiment 2

[0070] Prepare 1000g cooling liquid, get polyethylene glycol (number average molecular weight 2000) 200g, sodium silicate 80g, cetyltrimethylammonium chloride 30g, sodium molybdate 10g, sodium benzoate 50g, water 630g.

[0071] Slowly add polyethylene glycol, sodium silicate, sodium molybdate, cetyltrimethylammonium chloride, and sodium benzoate in the above-mentioned quantities into water under continuous stirring, and stir for 30 minutes to obtain diamond wire cooling solution B . For its performance index, see Tables 1-3 below.

Embodiment 3

[0073] To prepare 1000g of cooling liquid, take octyldiamine polyoxyethylene ether (number average molecular weight 1000) 300g, isooctyl oleate 100g, octylphenol polyoxyethylene ether (OP10) 100g, polyacrylamide 80g, triethanolamine 30g, water 390g.

[0074] Slowly add the above-mentioned amount of octyldiamine polyoxyethylene ether, isooctyl oleate, octylphenol polyoxyethylene ether, polyacrylamide, and triethanolamine to the water under continuous stirring, and stir for 30 minutes to obtain diamond wire cooling. Liquid C. For its performance index, see Tables 1-3 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com