Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4373 results about "Butanol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Butanol (also called butyl alcohol) is a four-carbon alcohol with a formula of C₄H₉OH, which occurs in five isomeric structures (four structural isomers), from a straight-chain primary alcohol to a branched-chain tertiary alcohol; all are a butyl or isobutyl group linked to a hydroxyl group (sometimes represented as BuOH, n-BuOH, i-BuOH, and t-BuOH). These are n-butanol, 2 stereoisomers of sec-butanol, isobutanol and tert-butanol. Butanol is primarily used as a solvent, as an intermediate in chemical synthesis, and as a fuel. It is sometimes also called biobutanol when produced biologically and petrobutanol when produced from petroleum; those two names refer to the same substance, but highlight their different origins.

Fermentive production of four carbon alcohols

Owner:GEVO INC

Fermentive production of four carbon alcohols

Methods for the fermentive production of four carbon alcohols are provided. Specifically, butanol, preferably 2-butanol is produced by the fermentive growth of a recombinant bacteria expressing a 2-butanol biosynthetic pathway. The recombinant microorganisms and methods of the invention can also be adapted to produce 2-butanone, an intermediate in the 2-butanol biosynthetic pathways disclosed herein.

Owner:GEVO INC

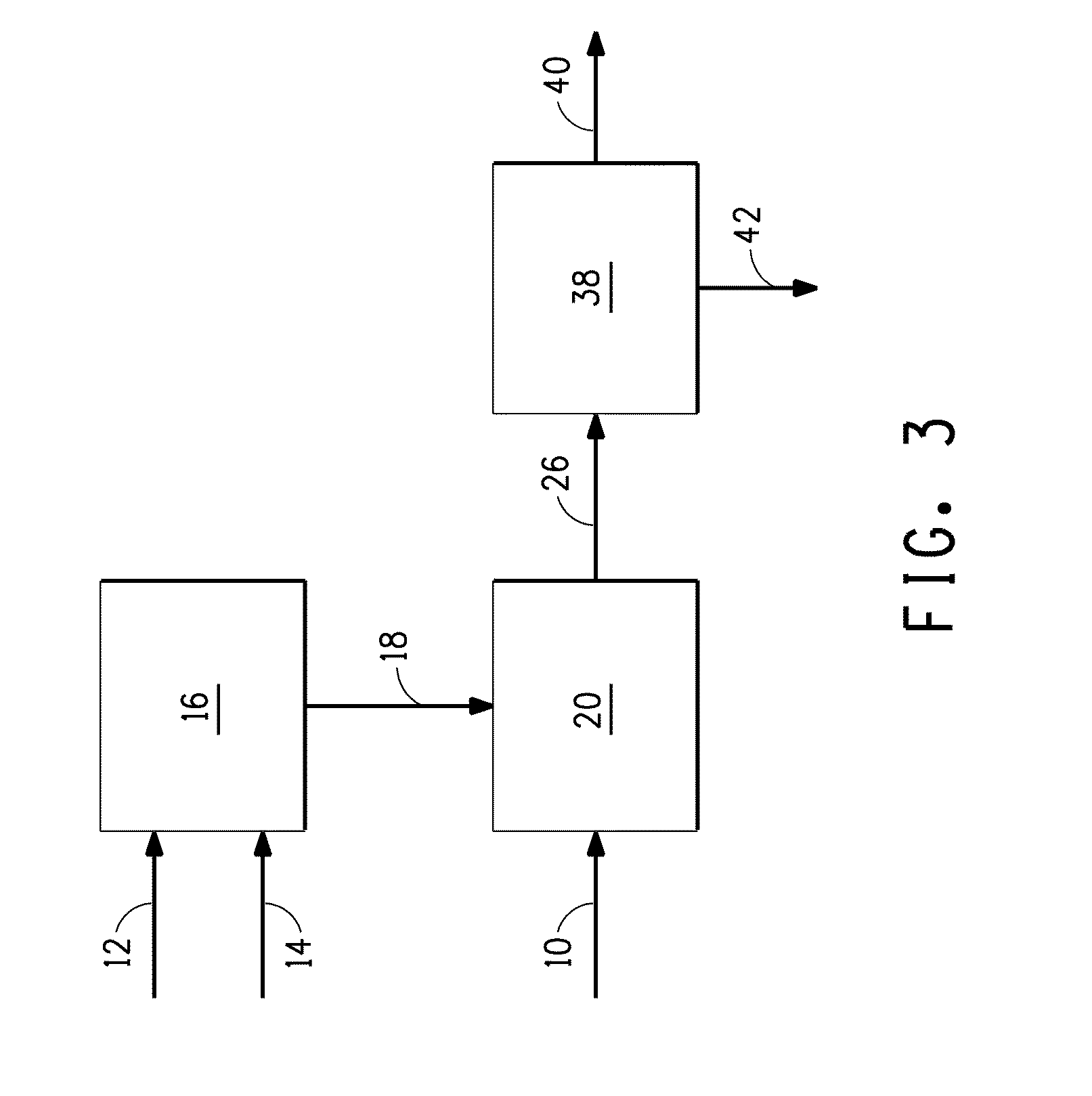

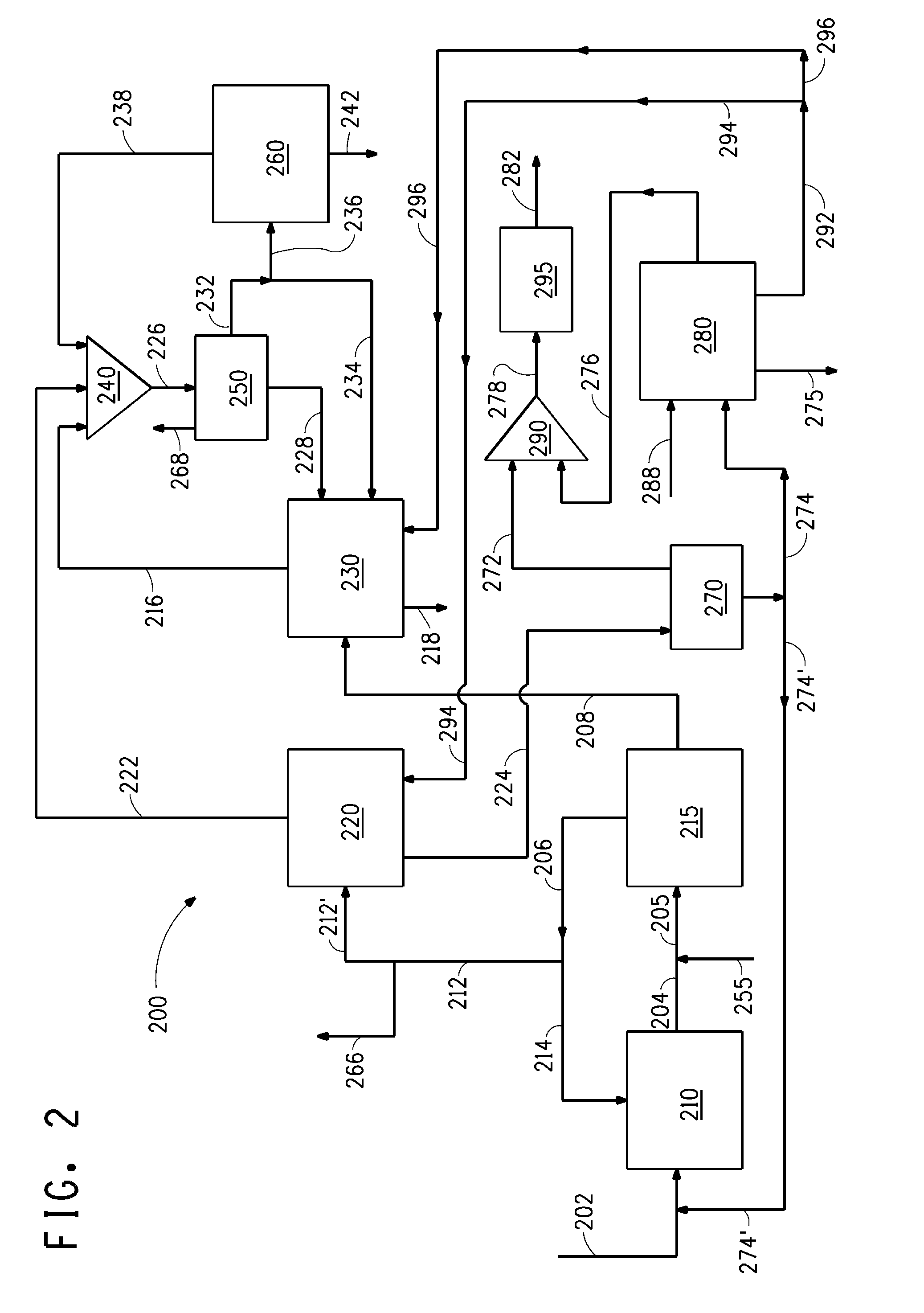

Method for producing butanol using two-phase extractive fermentation

InactiveUS20090305370A1Reformed easilyAvoid impactOrganic compound preparationBiofuelsMicroorganismMicrobiology

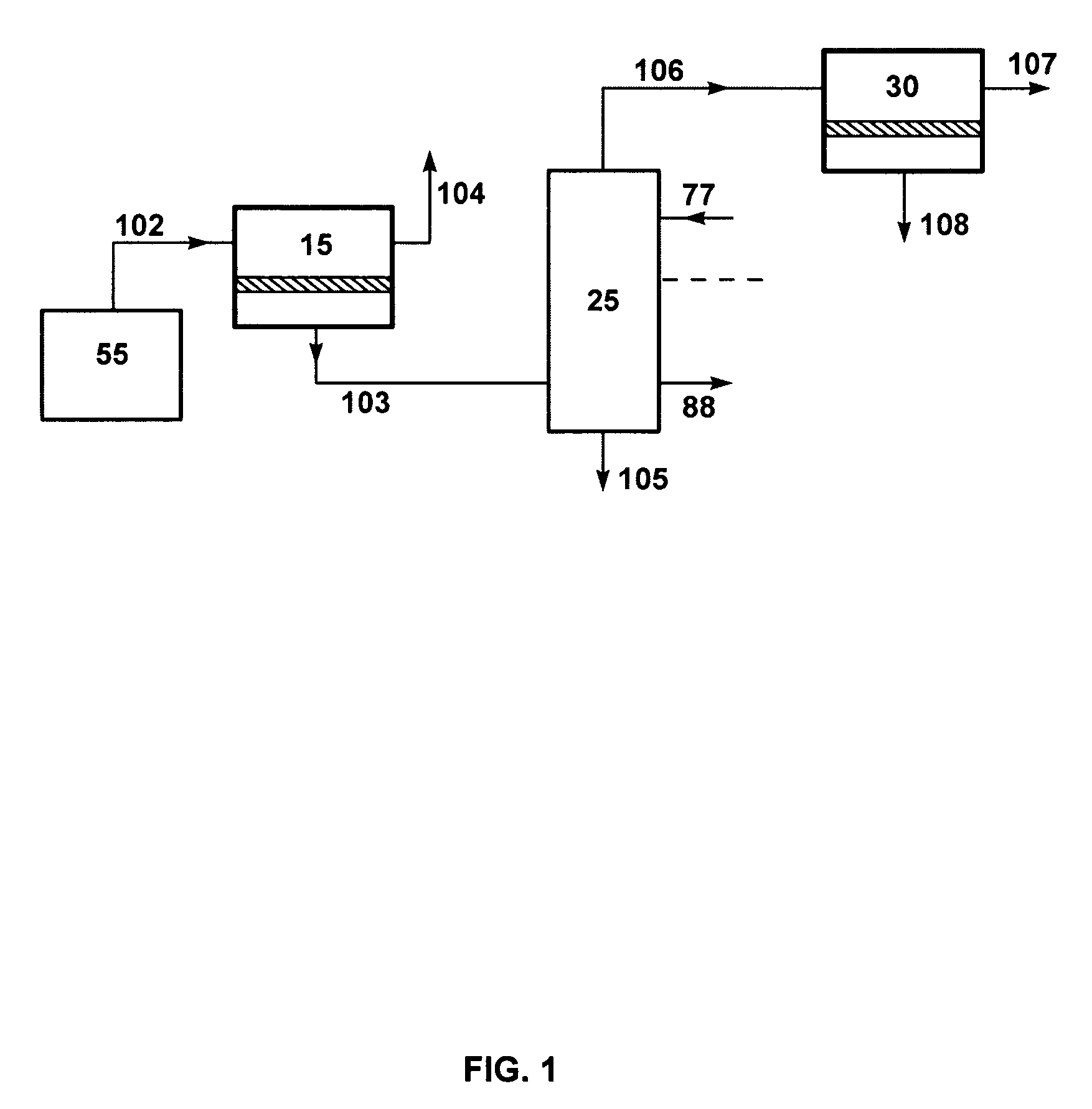

A method of making butanol from at least one fermentable carbon source that overcomes the issues of toxicity resulting in an increase in the effective titer, the effective rate, and the effective yield of butanol production by fermentation utilizing a recombinant microbial host wherein the butanol is extracted into specific organic extractants during fermentation

Owner:BUTAMAXTM ADVANCED BIOFUELS

Ethanol recovery process

ActiveUS20070031954A1Permeate pressureSimple equipmentMembranesFermented solutions distillation/rectificationAlcoholFractionation

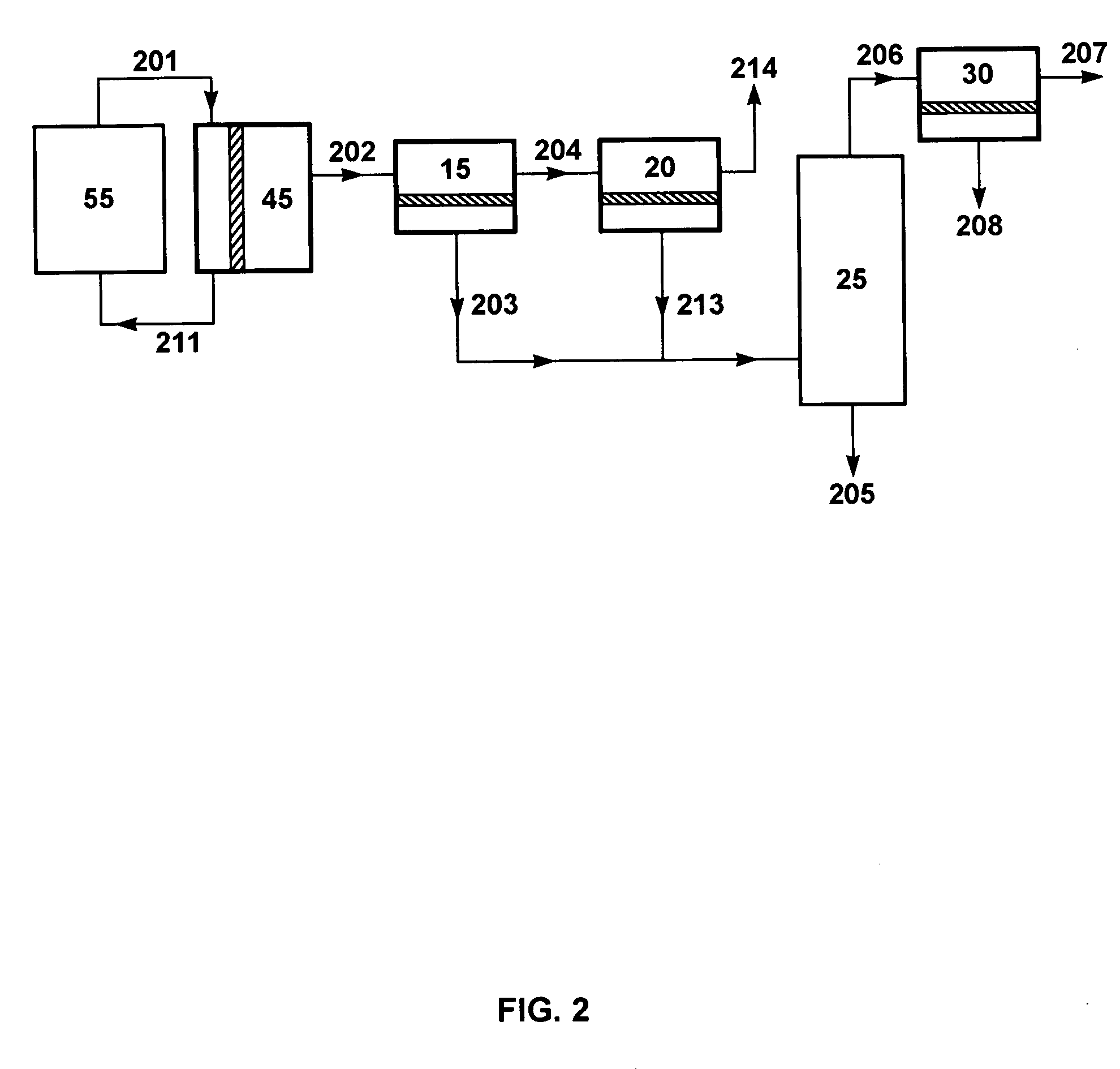

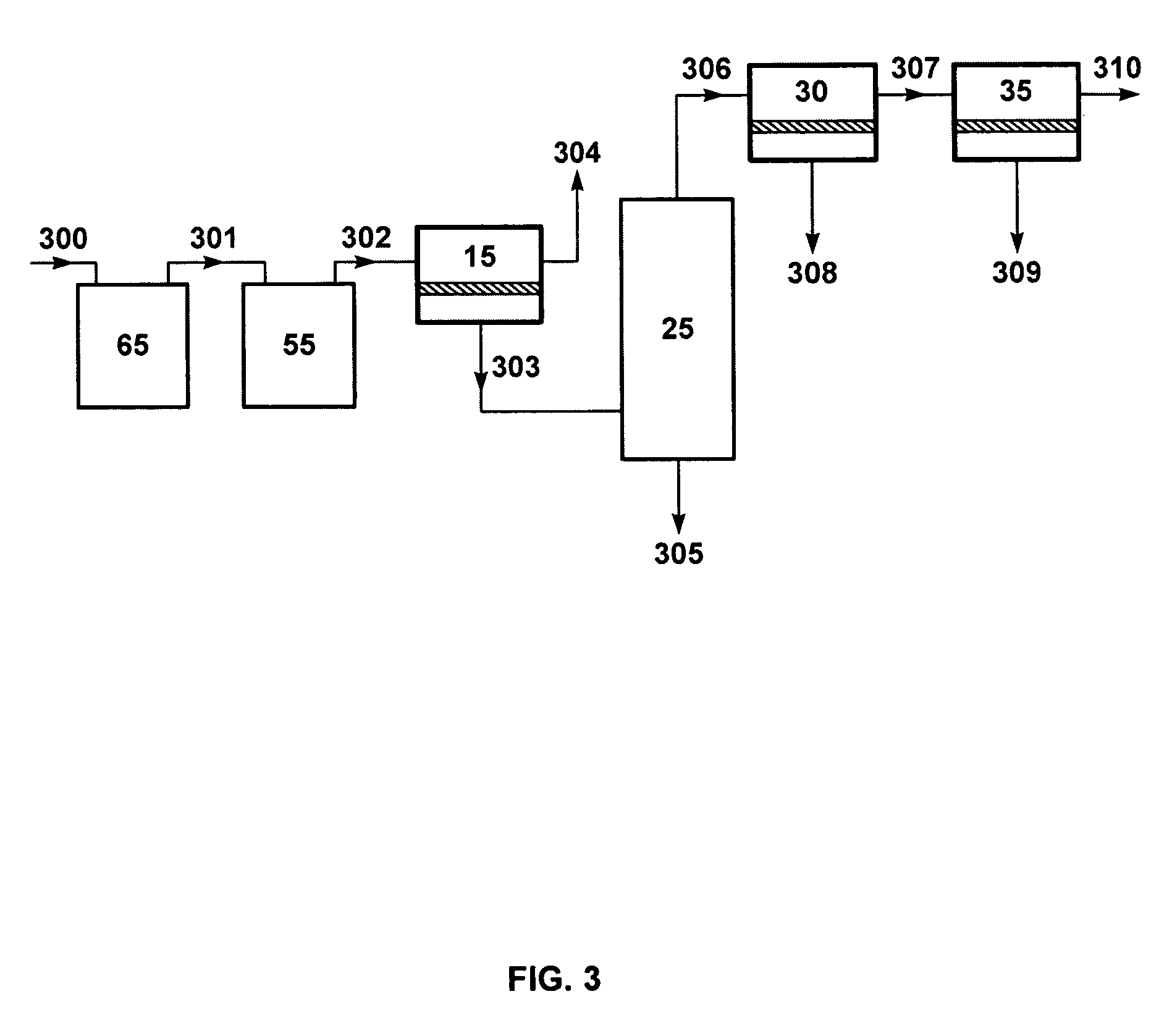

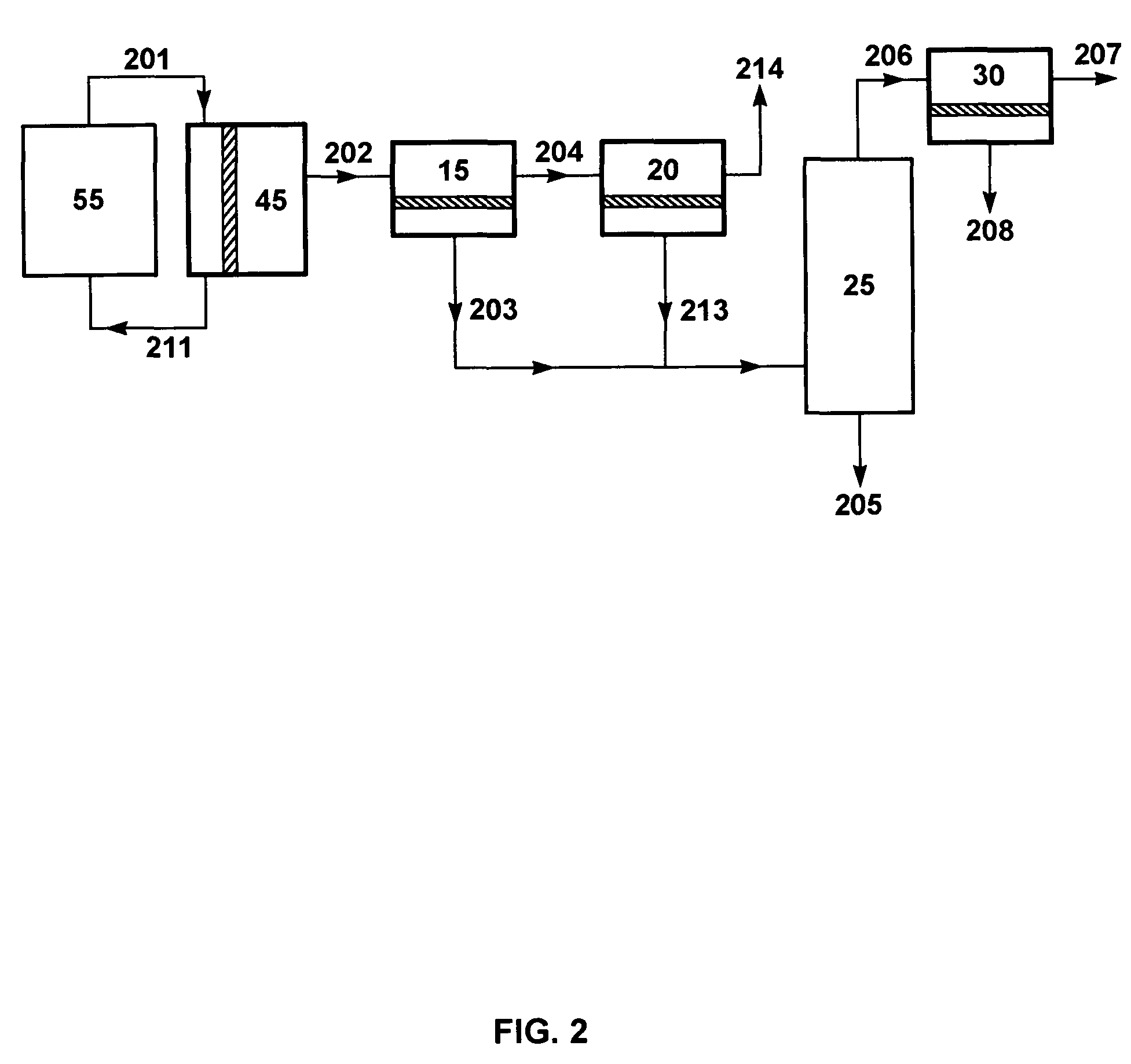

A process for producing and recovering light alcohols, particularly ethanol, alcohol mixtures containing ethanol, and ABE mixtures (alcohol mixtures containing acetone, butanol and ethanol), using a combination of steps including fermentation, first membrane separation, dephlegmation and dehydration by second membrane separation.

Owner:MEMBRANE TECH & RES

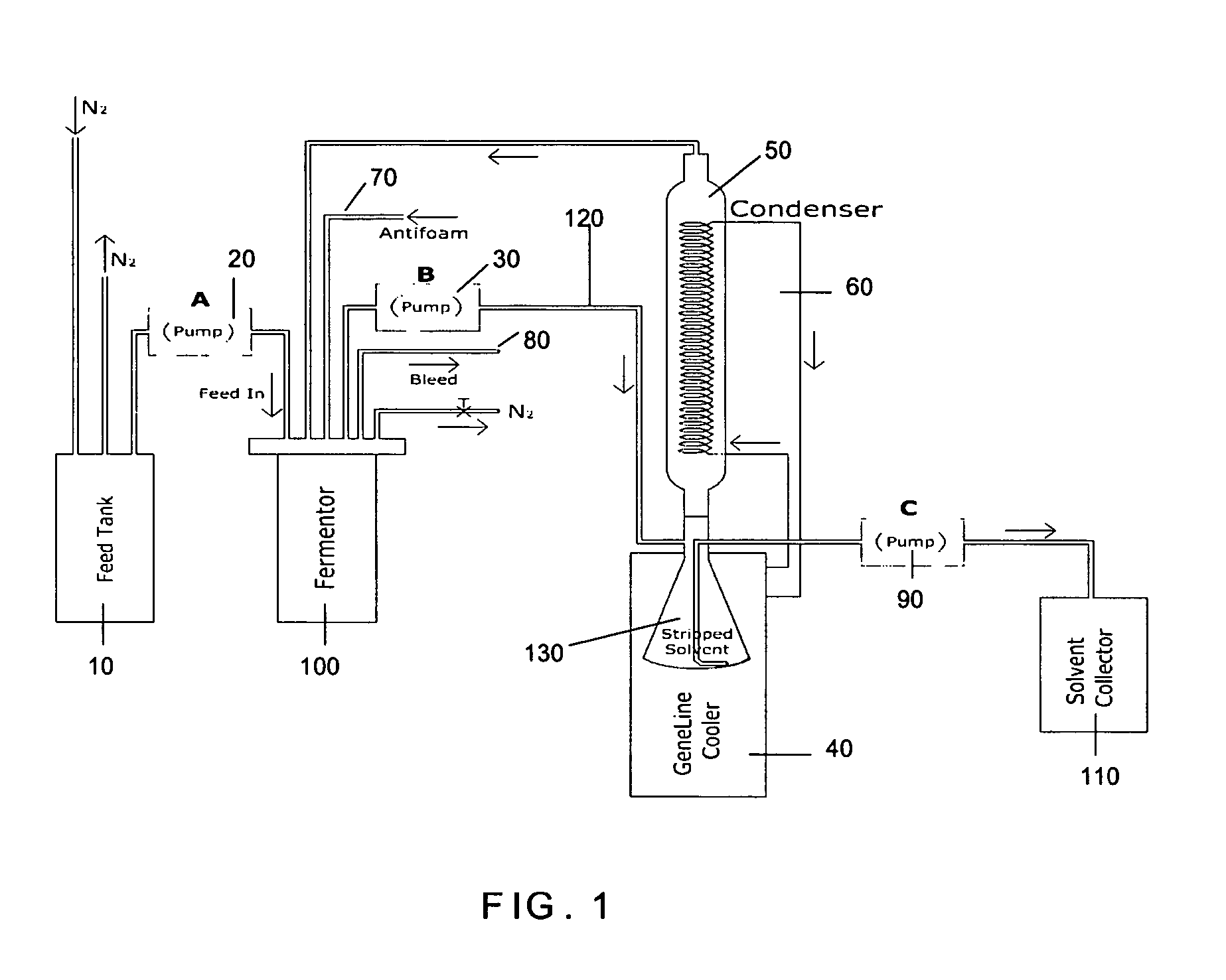

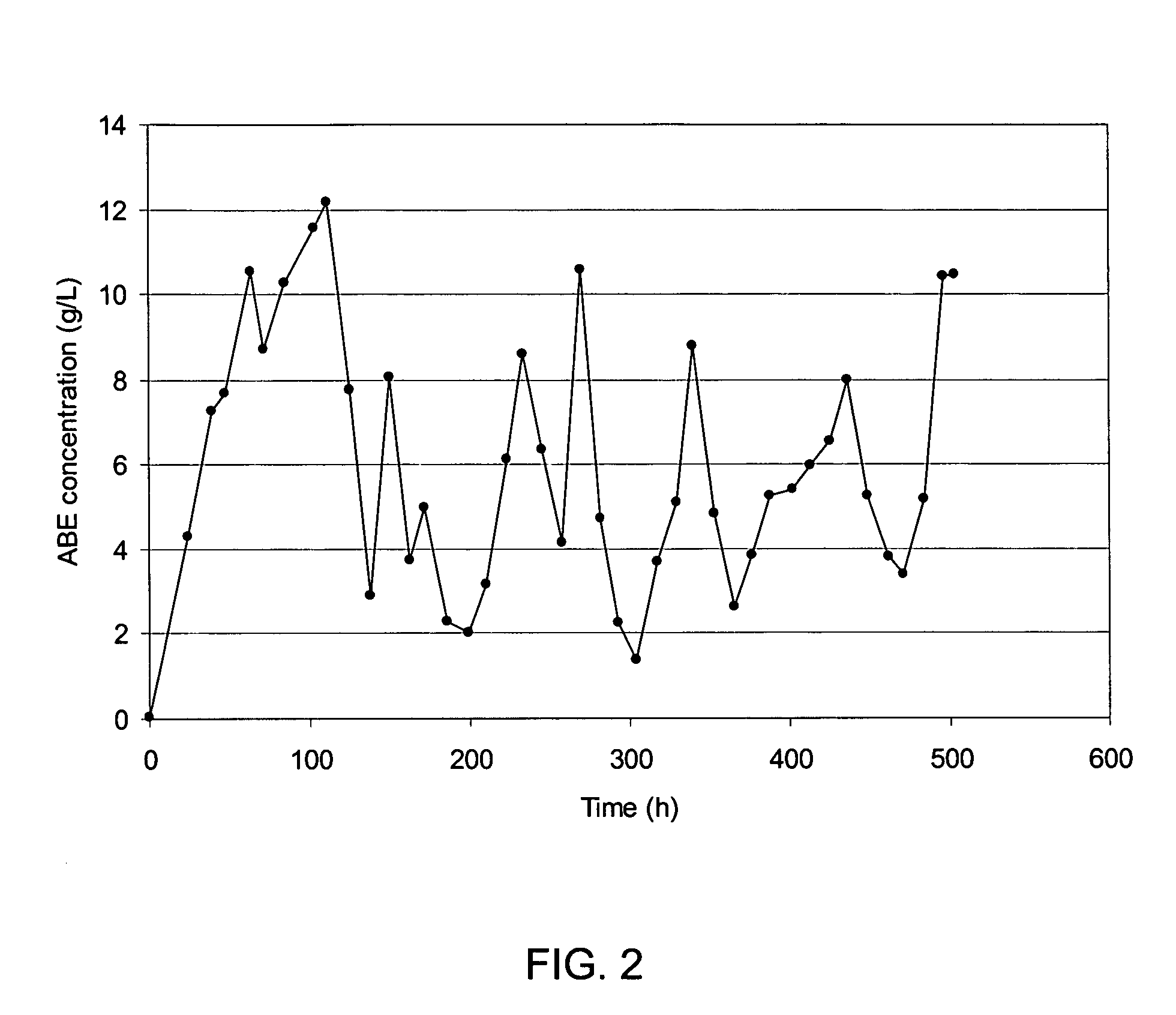

Process for continuous solvent production

InactiveUS20050089979A1High solventProducing strainBioreactor/fermenter combinationsBiological substance pretreatmentsMicrobial inoculationSolvent

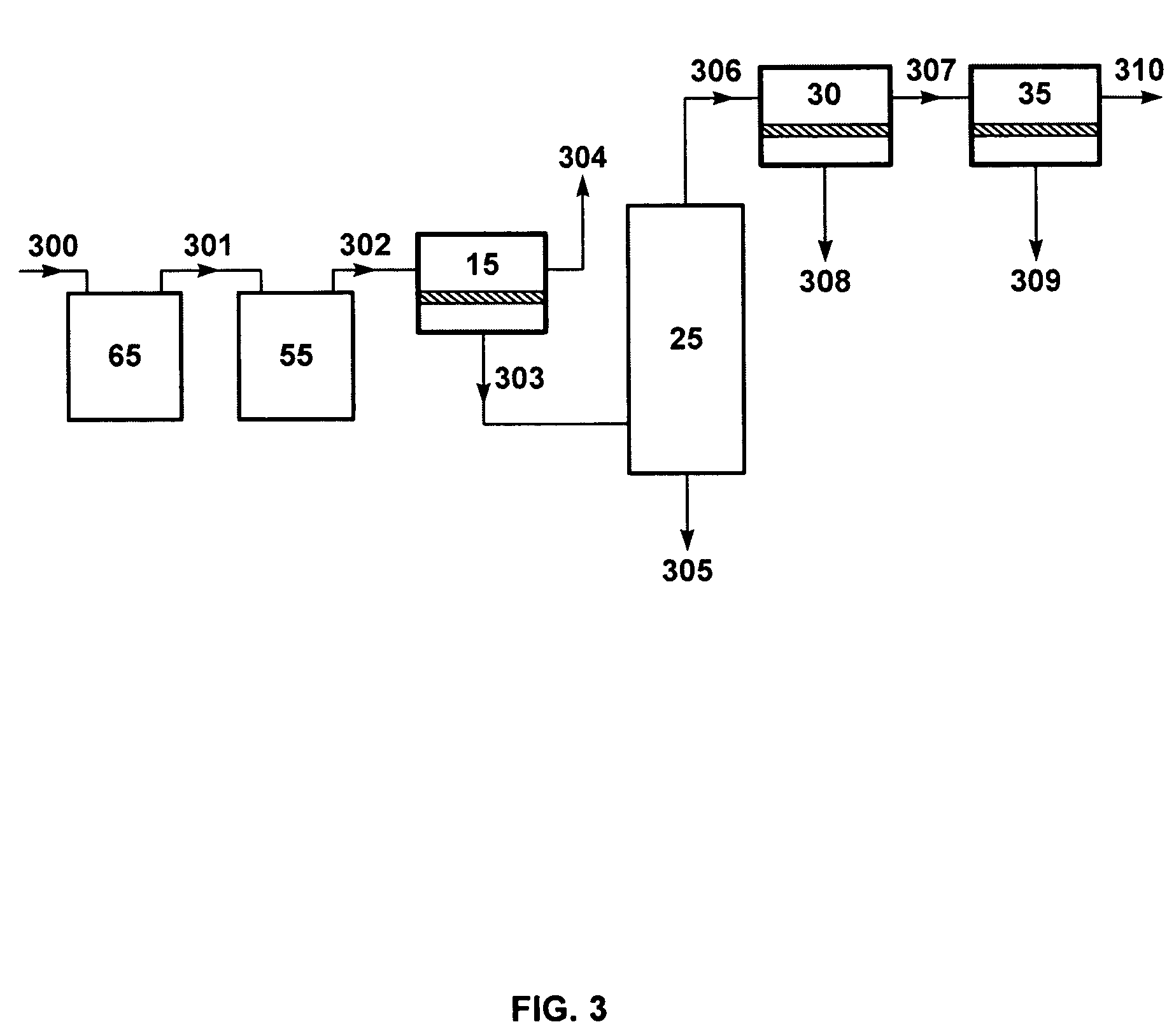

A continuous process for production of solvents, particularly acetone-butanol-ethanol (ABE) using fermentation of solventogenic microorganisms and gas stripping is provided. The solventogenic microorganisms are inoculated in a nutrient medium containing assimilable carbohydrates (substrate) and optional other additives. Control of the solventogenic microorganism concentration in the fermentor (cell concentration) and the assimilable carbohydrate concentration in the fermentor, along with removal of solvents formed results in a continuous process for production of solvents.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Ethanol recovery process

ActiveUS7732173B2Reduce stressSimple equipmentMembranesFermented solutions distillation/rectificationAlcoholMedicinal chemistry

A process for producing and recovering light alcohols, particularly ethanol, alcohol mixtures containing ethanol, and ABE mixtures (alcohol mixtures containing acetone, butanol and ethanol), using a combination of steps including fermentation, first membrane separation, dephlegmation and dehydration by second membrane separation.

Owner:MEMBRANE TECH & RES

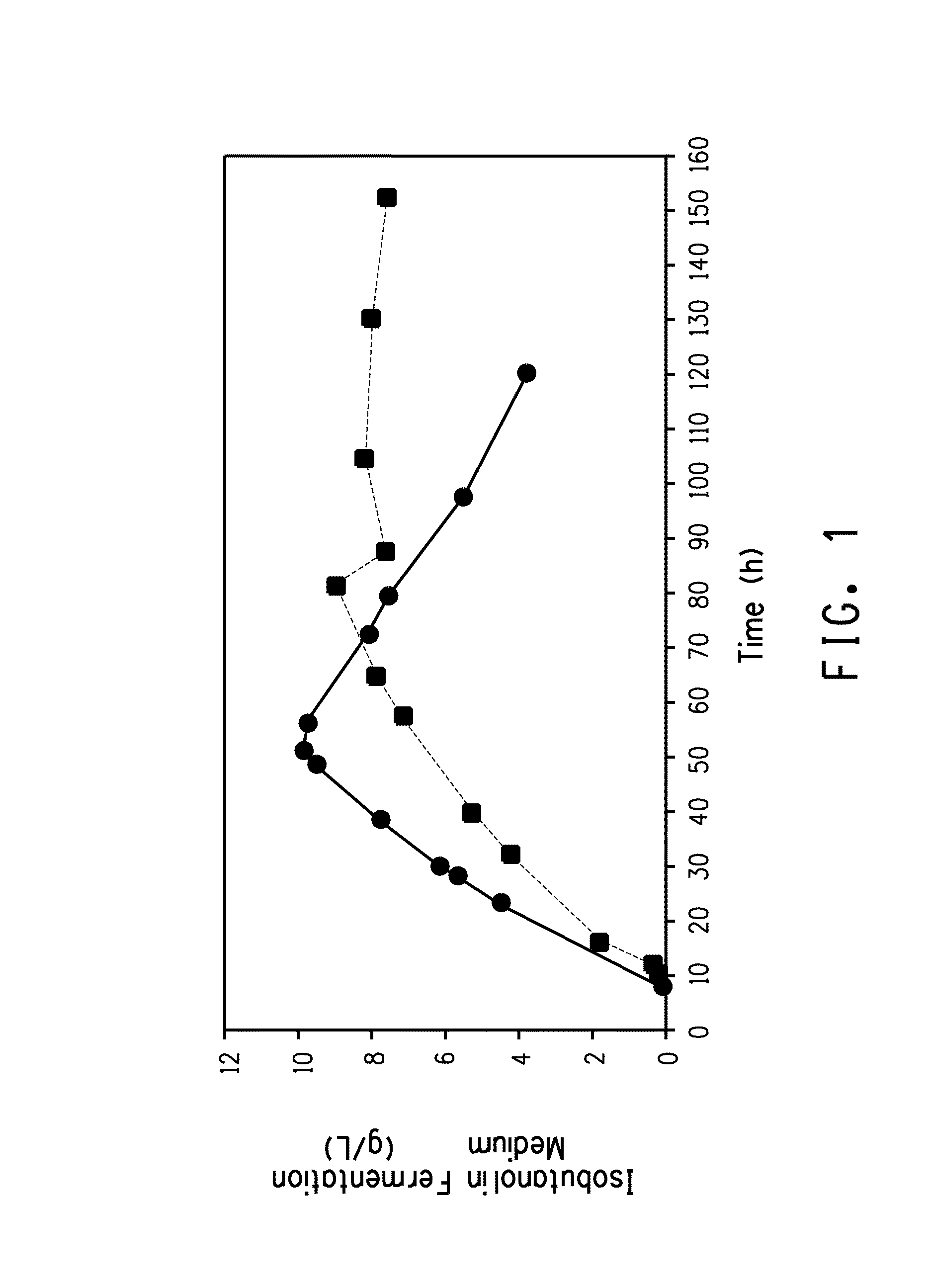

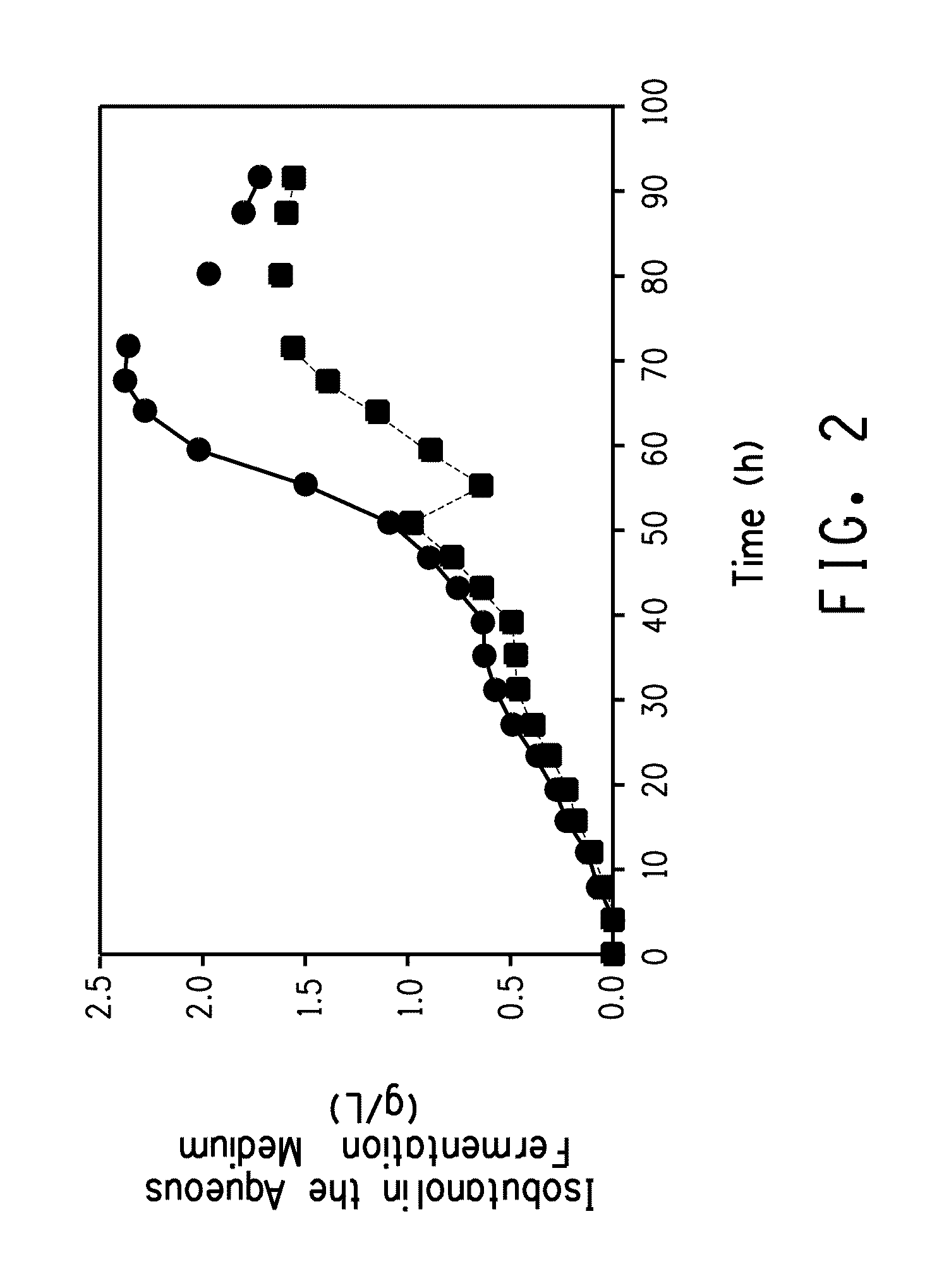

Method for the production of isobutanol

InactiveUS20080274526A1Reduce the temperatureRobust toleranceBiofuelsOxidoreductasesIsobutanolFermentation

A method for the production of isobutanol by fermentation using a microbial production host is disclosed. The method employs a reduction in temperature during the fermentation process that results in a more robust tolerance of the production host to the butanol product.

Owner:BUTAMAXTM ADVANCED BIOFUELS

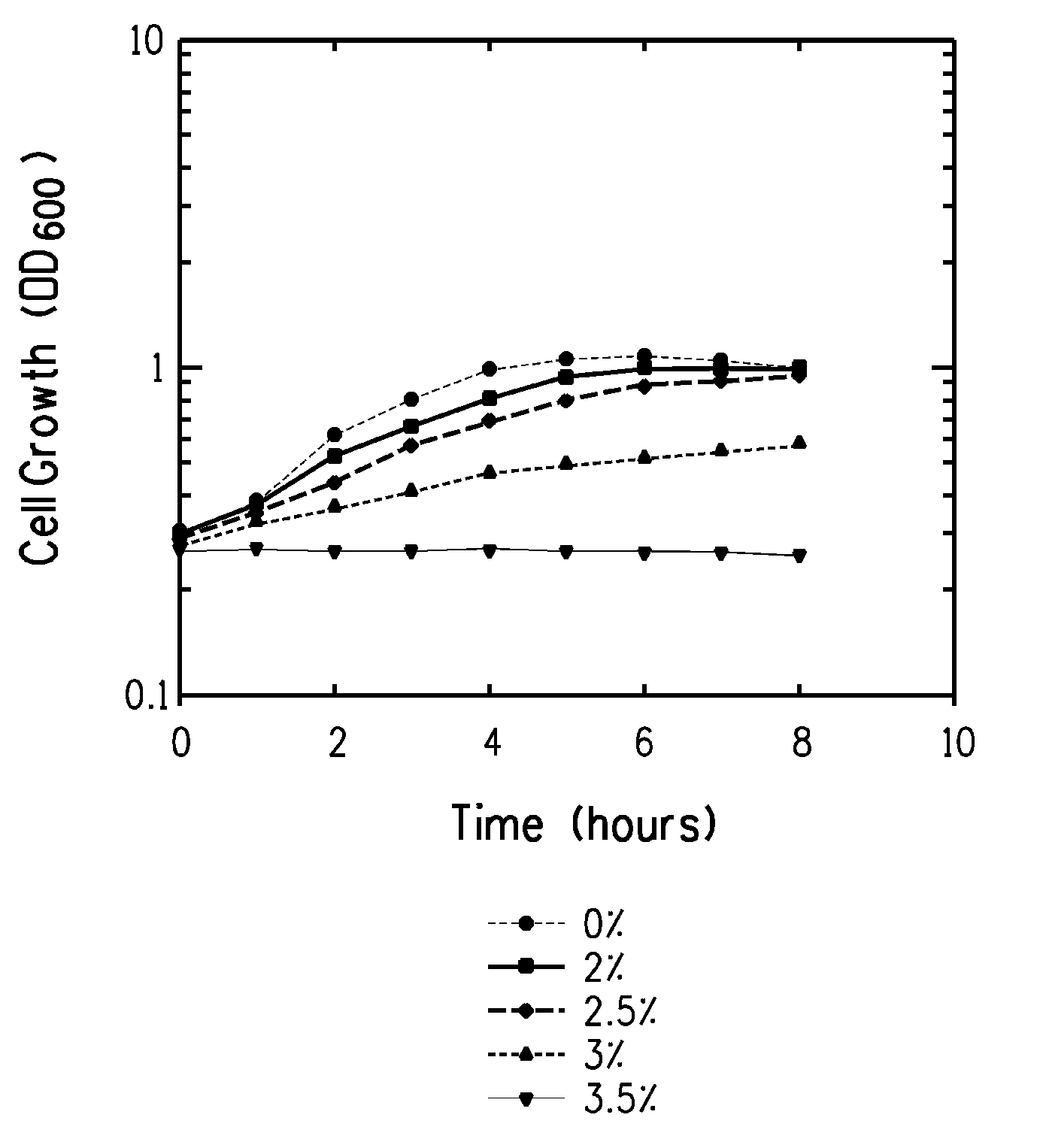

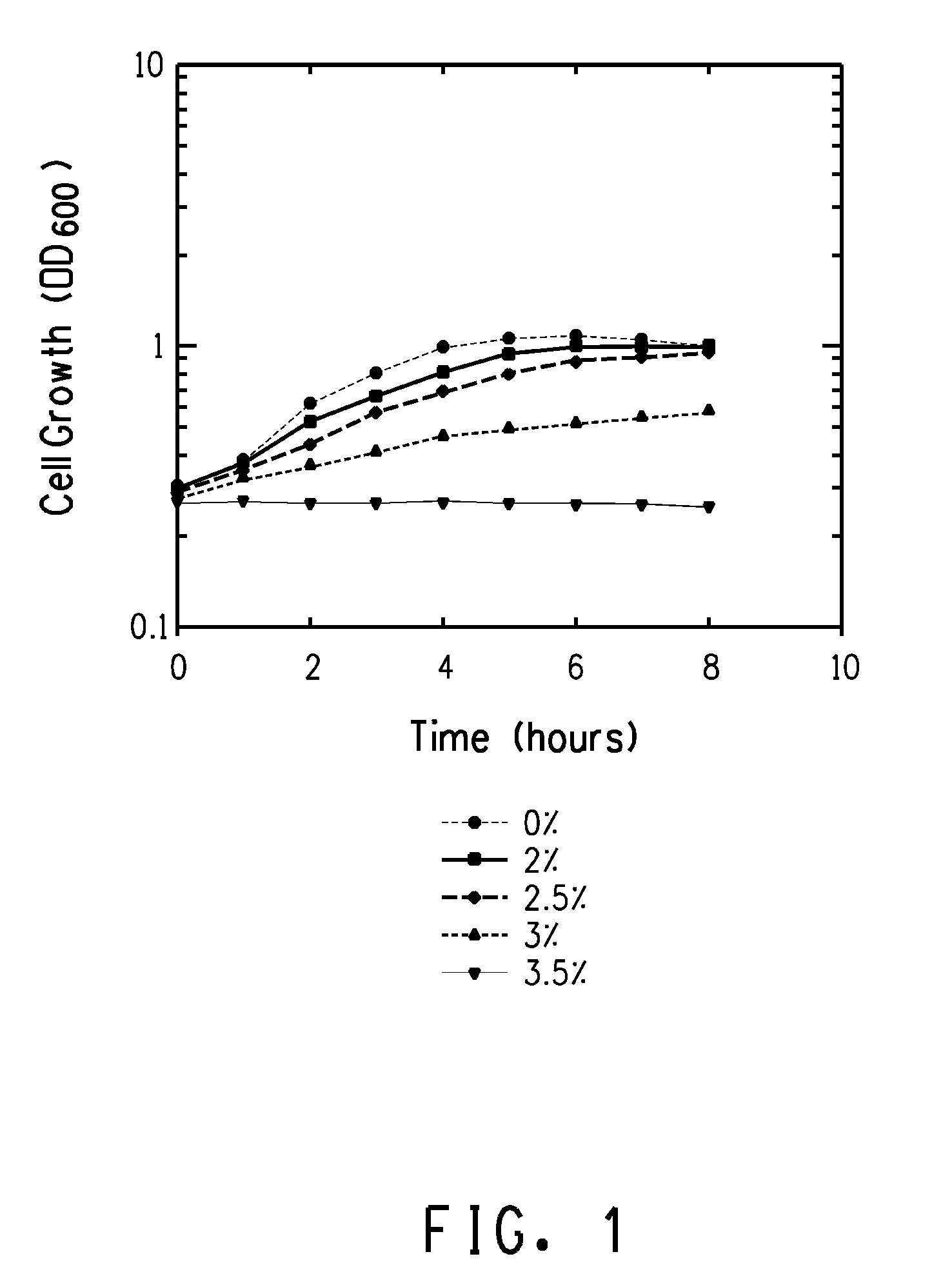

Solvent tolerant microorganisms

Pediococcus bacteria having enhanced tolerance to butanols have been isolated. The bacteria are useful for the fermentative production of butanol.

Owner:GEVO INC

Methods and compositions for producing solvents

Described herein are methods, compositions and synthetic biology approaches for solvent production, including but not limited to butanol production. Described herein are recombinant bacteria and yeast strains which may be used in production of a solvent, including but not limited to butanol, from lignocellulosic and other plant-based feedstocks. Described herein are methods of producing solvents, including but not limited to butanol, using bacteria and yeast strains. Described herein are methods of producing organisms that display highly efficient butanol production.

Owner:EASTMAN RENEWABLE MATERIALS LLC +1

Recombinant microorganism having butanol production capacity and butanol production method

This invention relates to a recombinant microorganism having improved butanol production capacity and butanol production with the use of such recombinant microorganism with good efficiency. In this invention, the acetoacetyl-CoA synthase gene encoding an enzyme capable of synthesizing acetoacetyl-CoA from malonyl-CoA and acetyl-CoA and a group of genes involved in butanol biosynthesis that enables synthesis of butanol from acetoacetyl-CoA are introduced into a host microorganism.

Owner:TOYOTA JIDOSHA KK

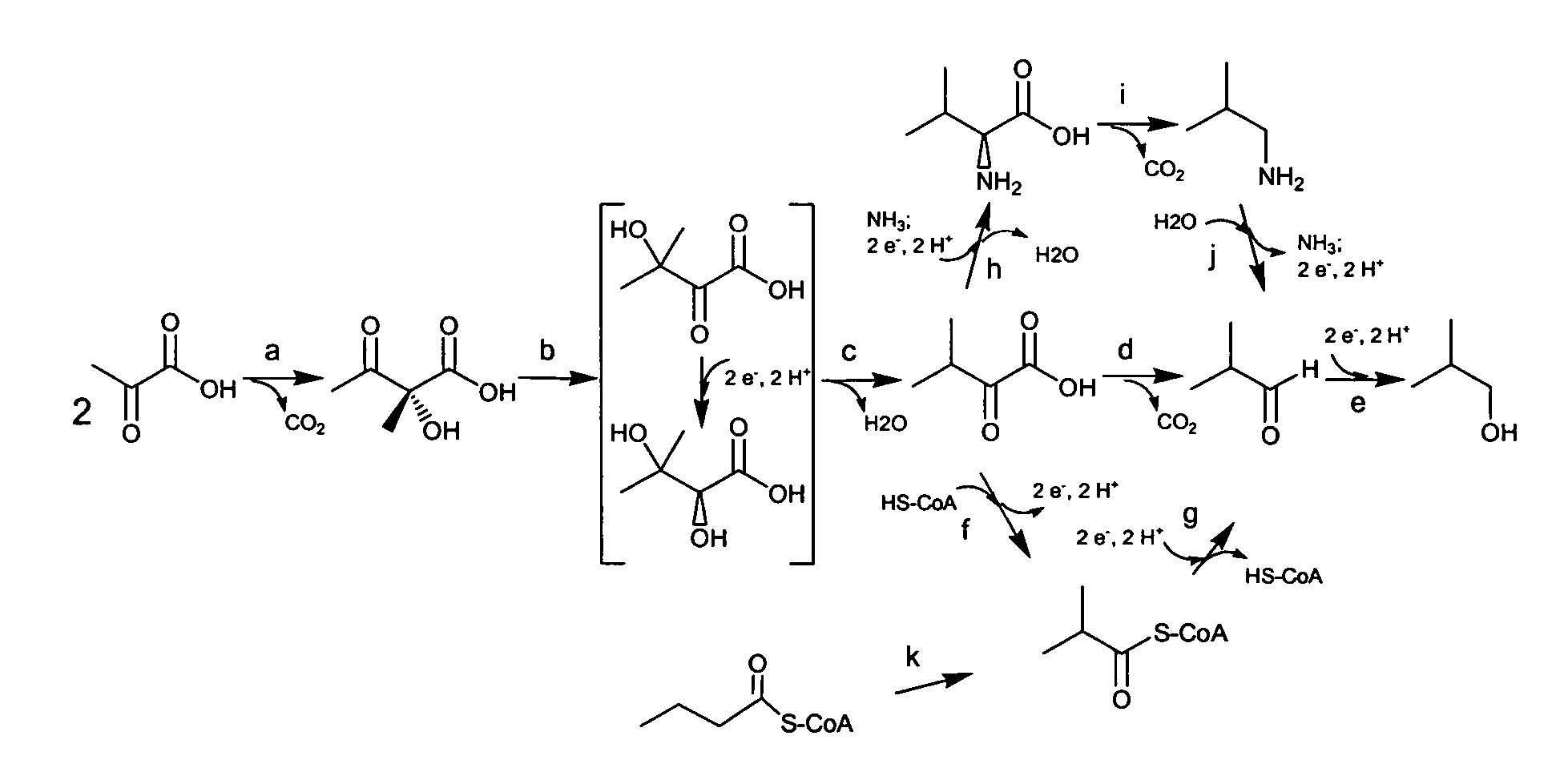

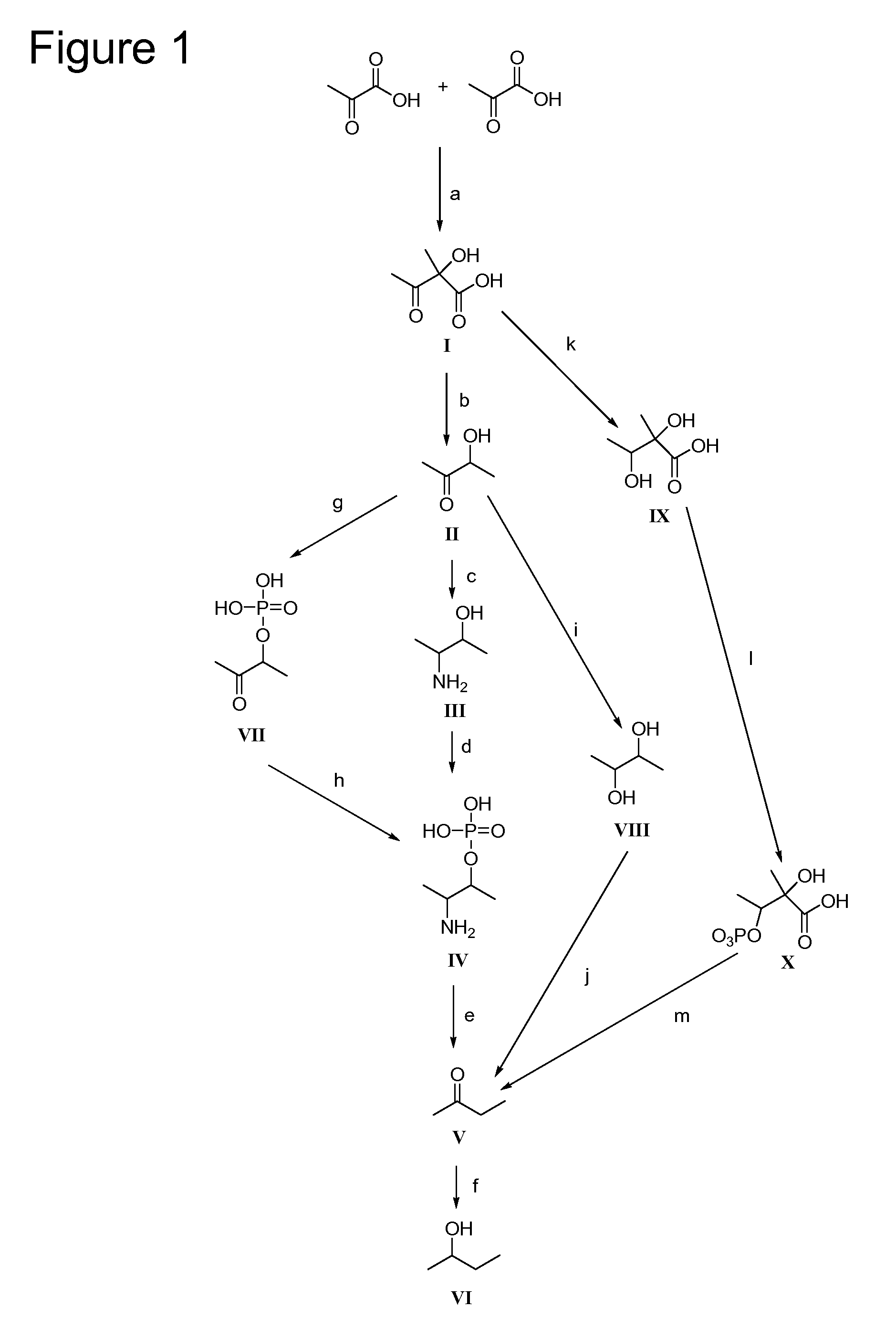

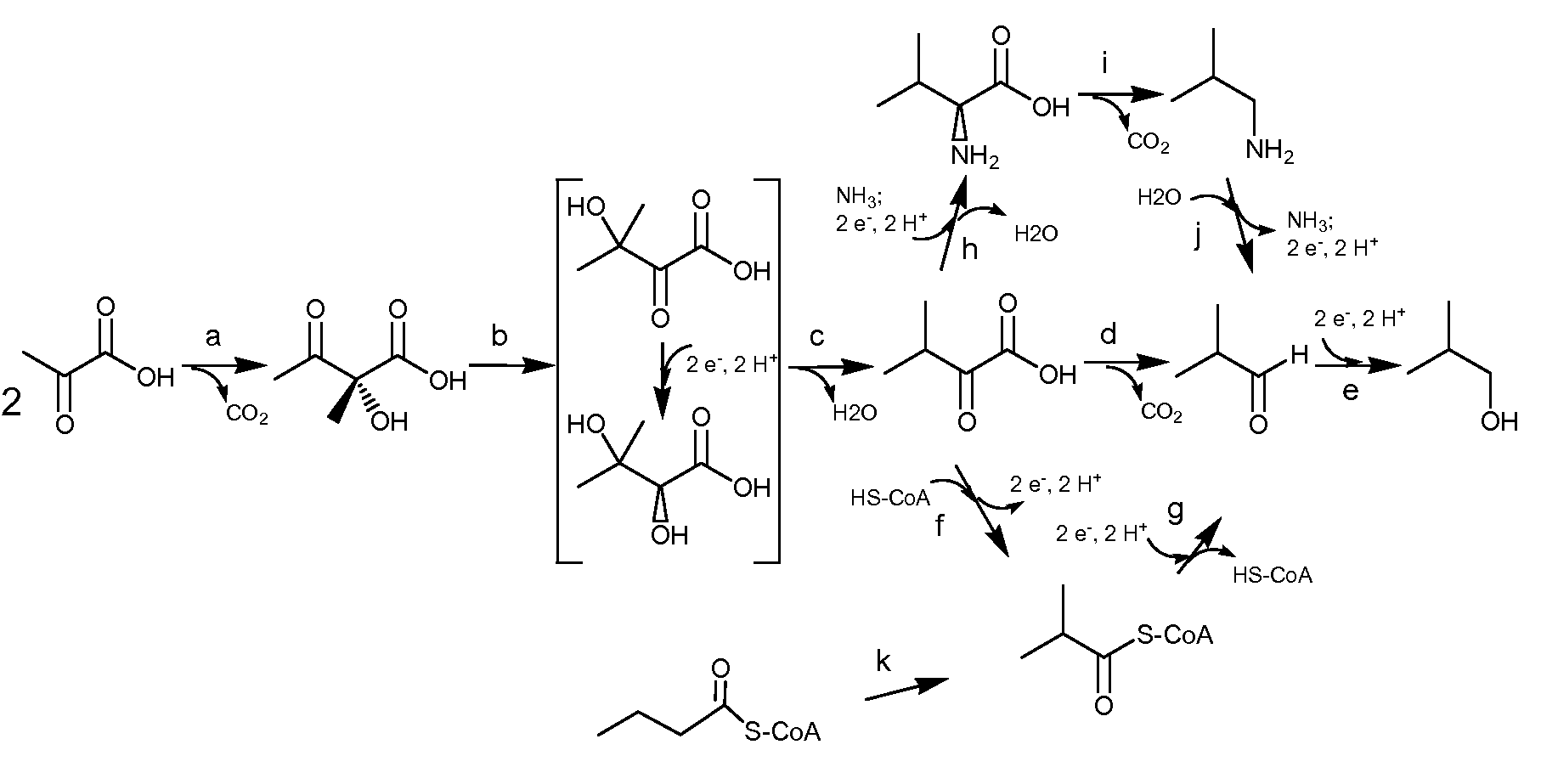

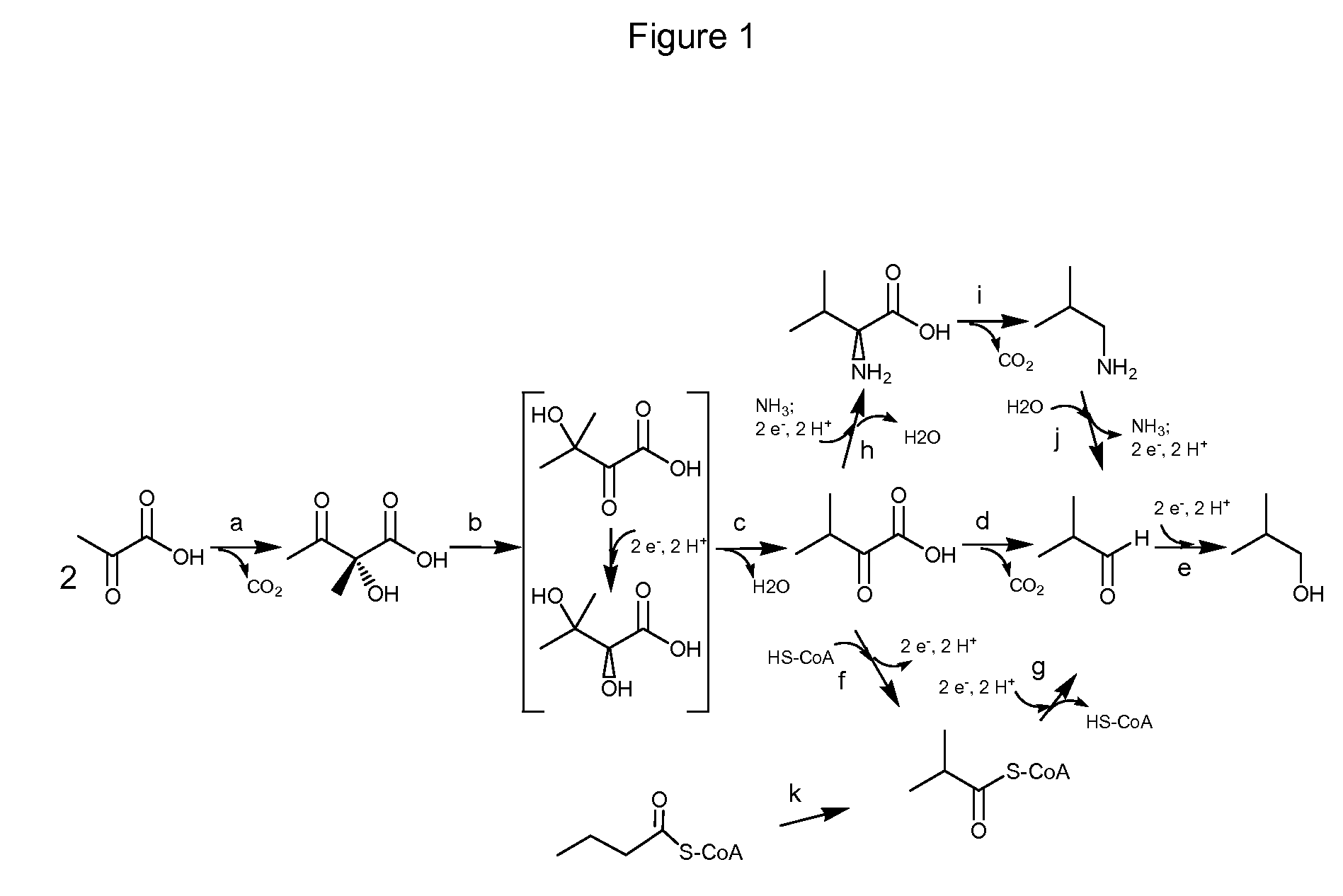

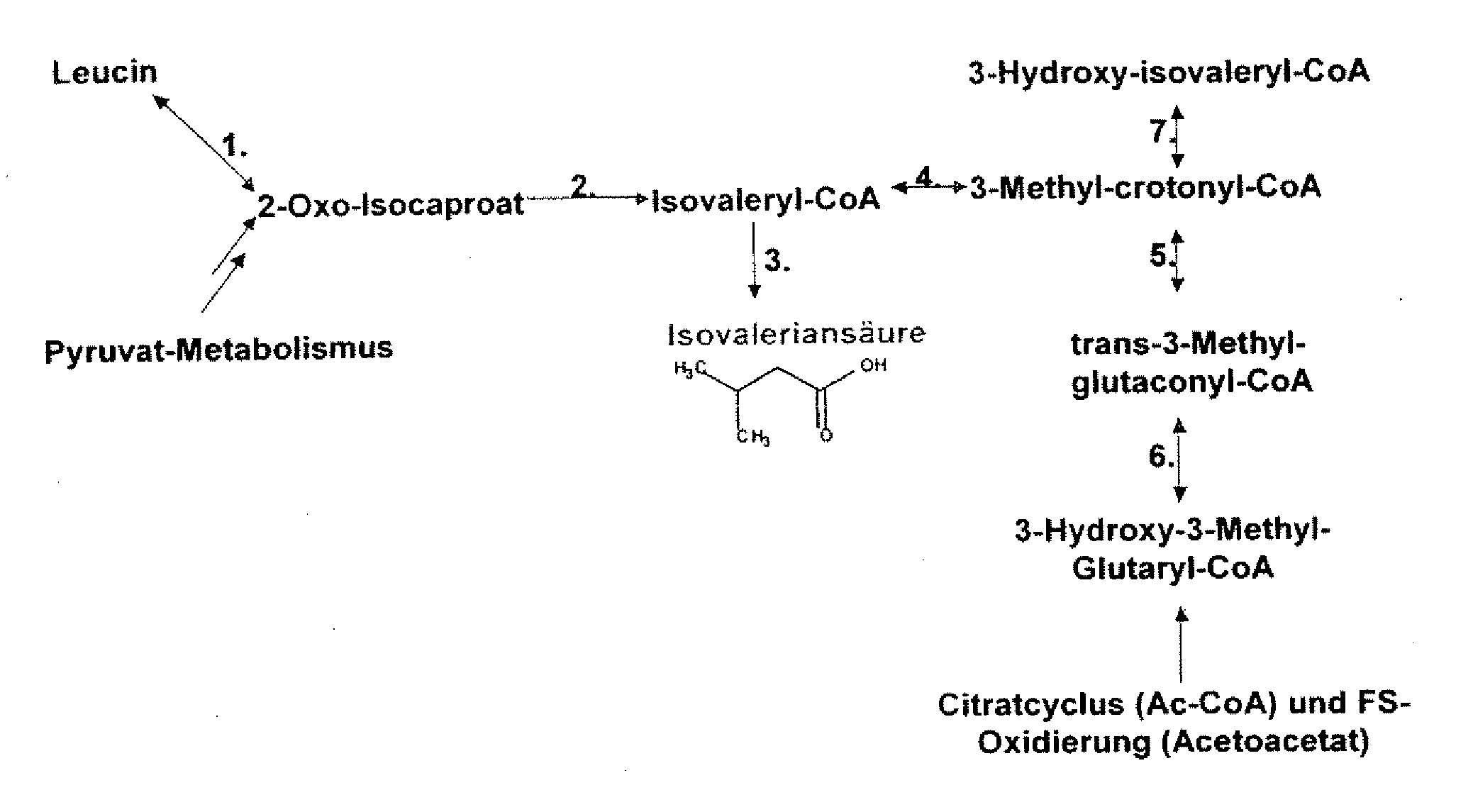

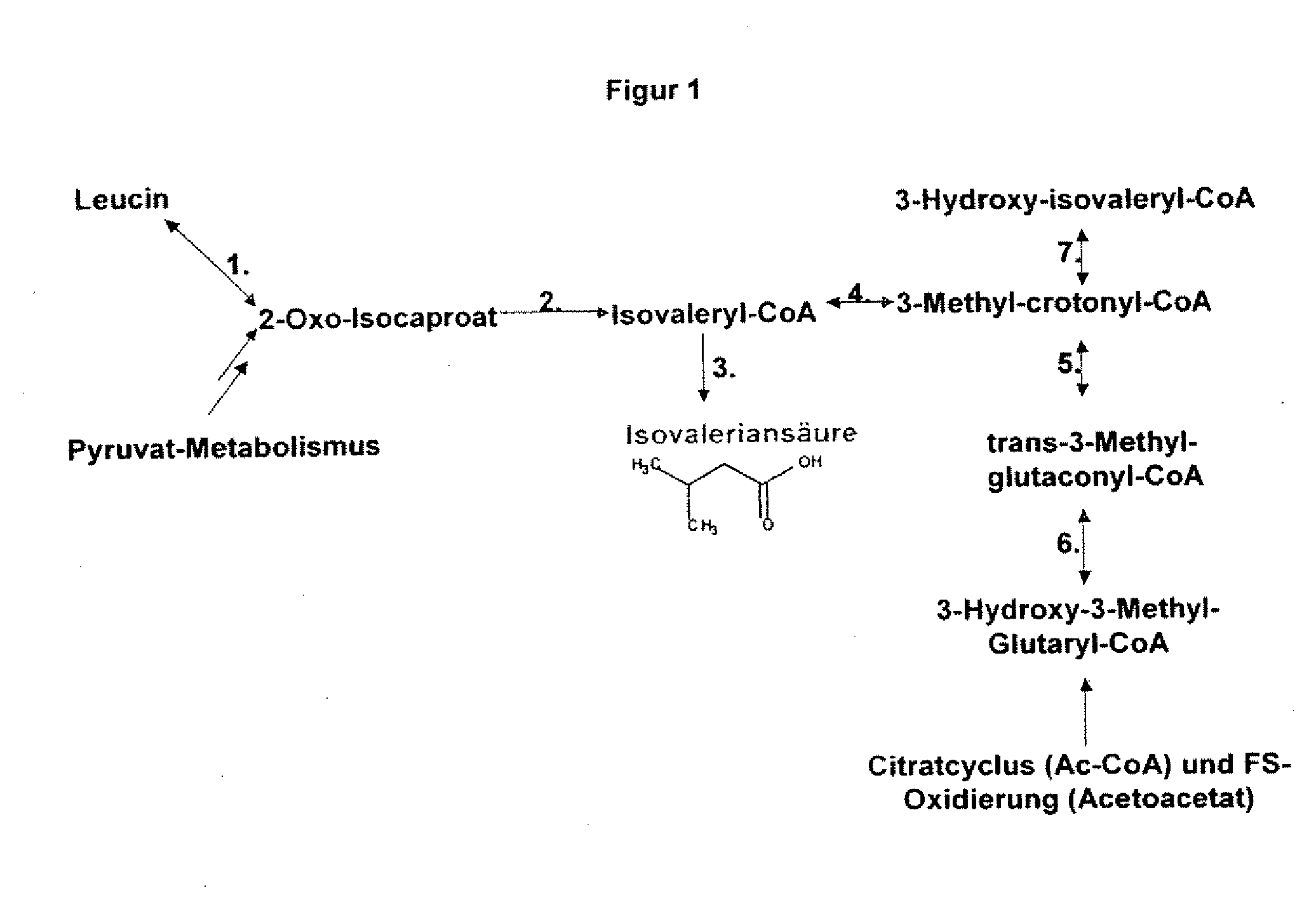

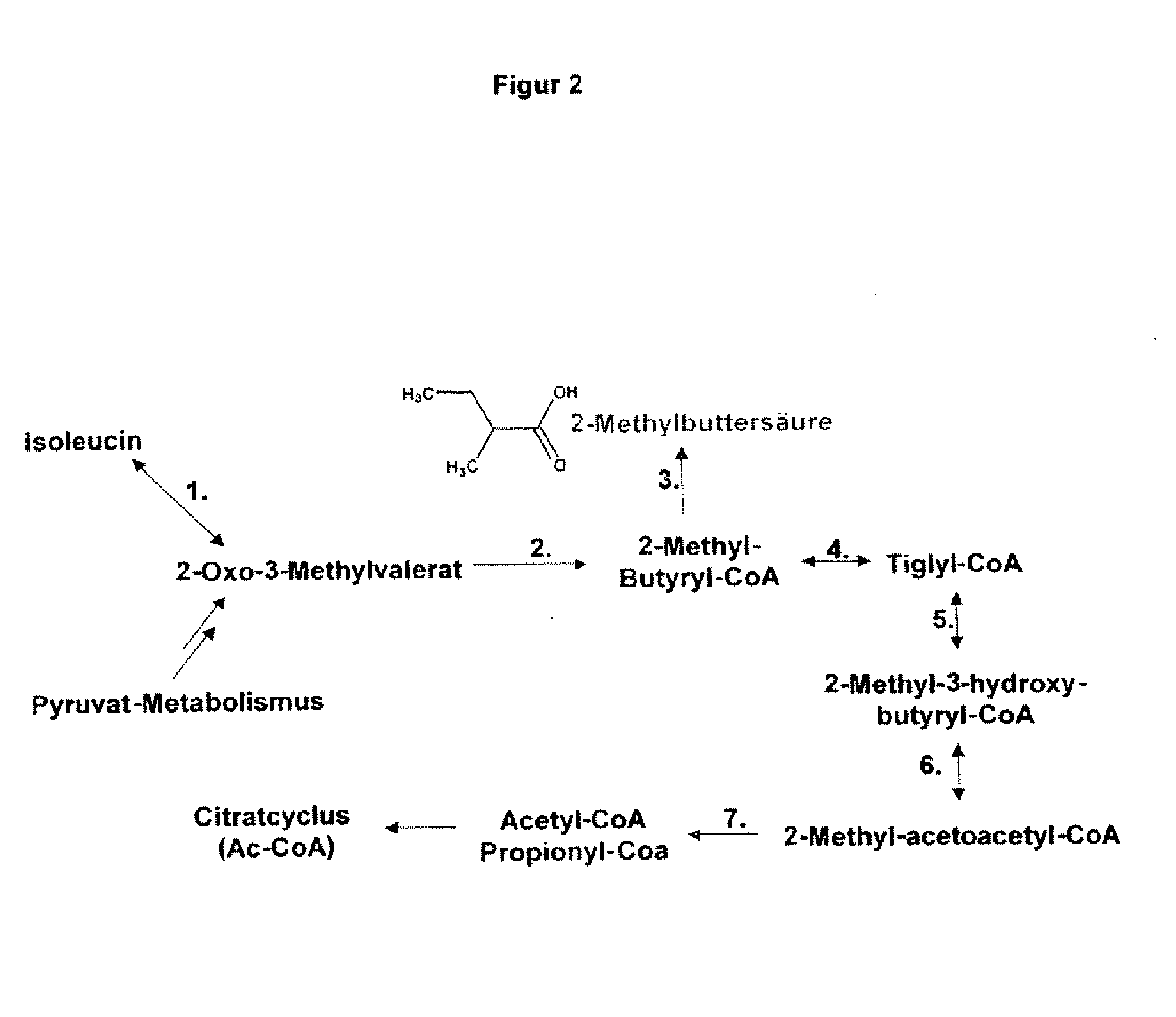

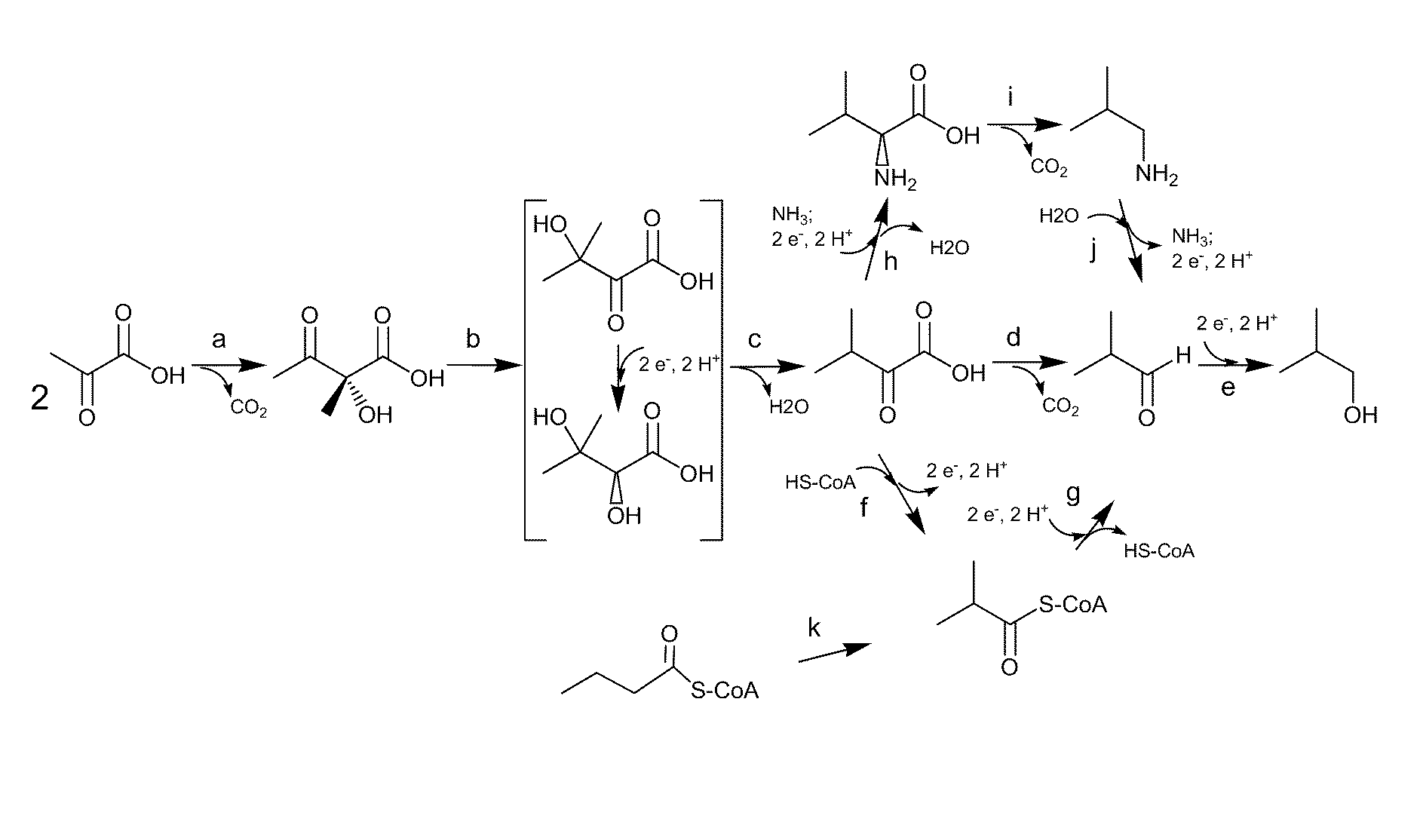

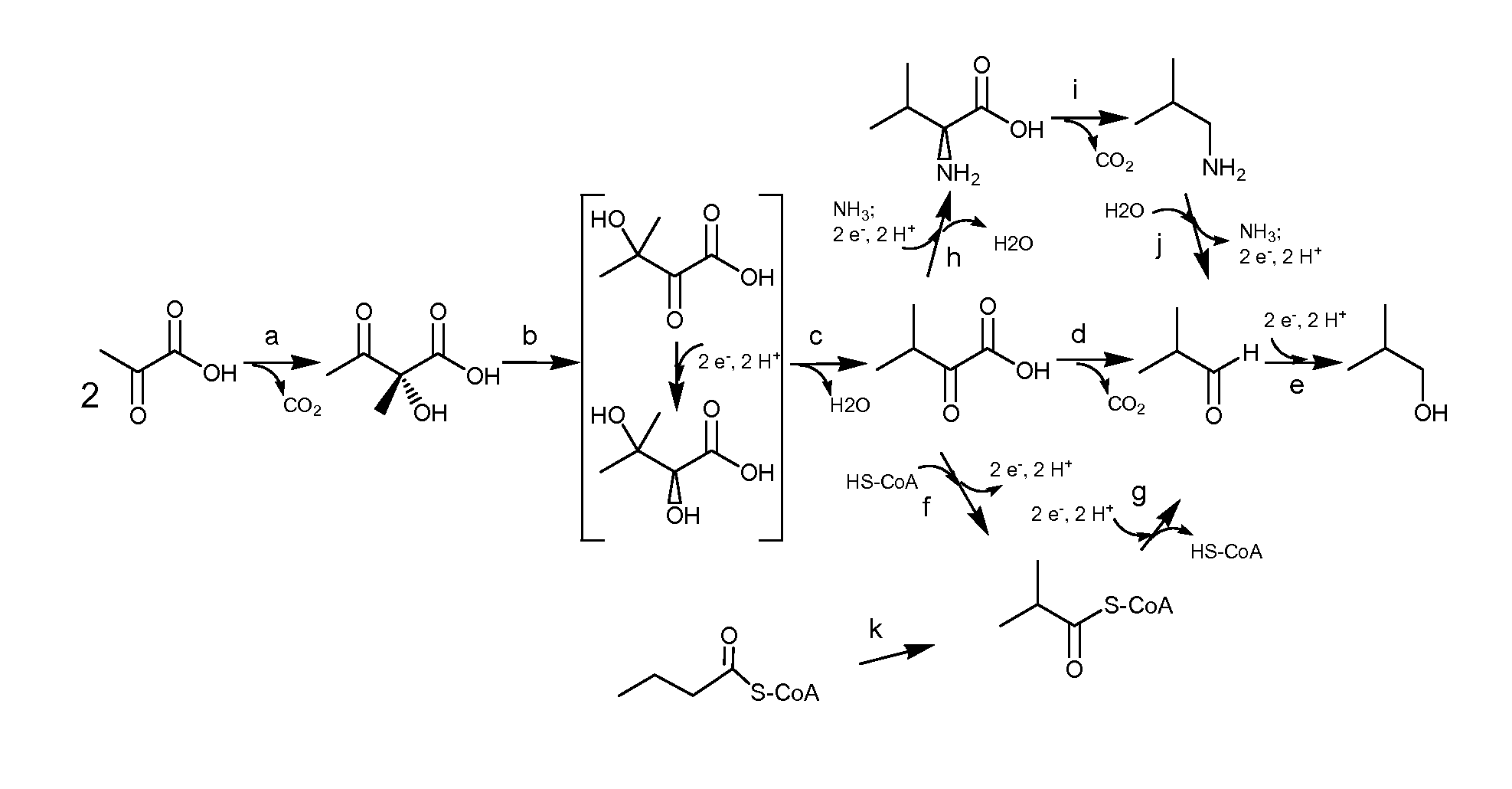

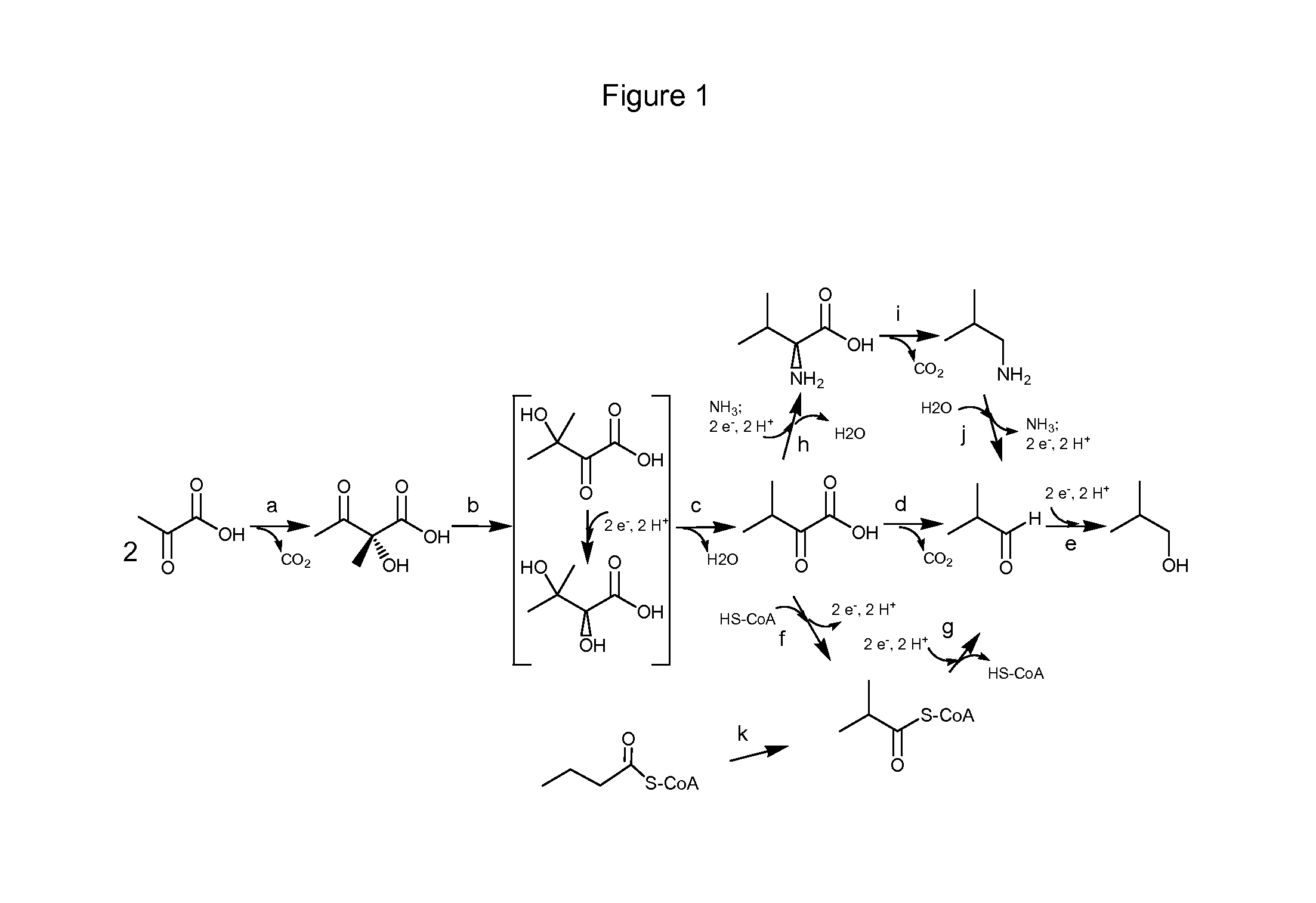

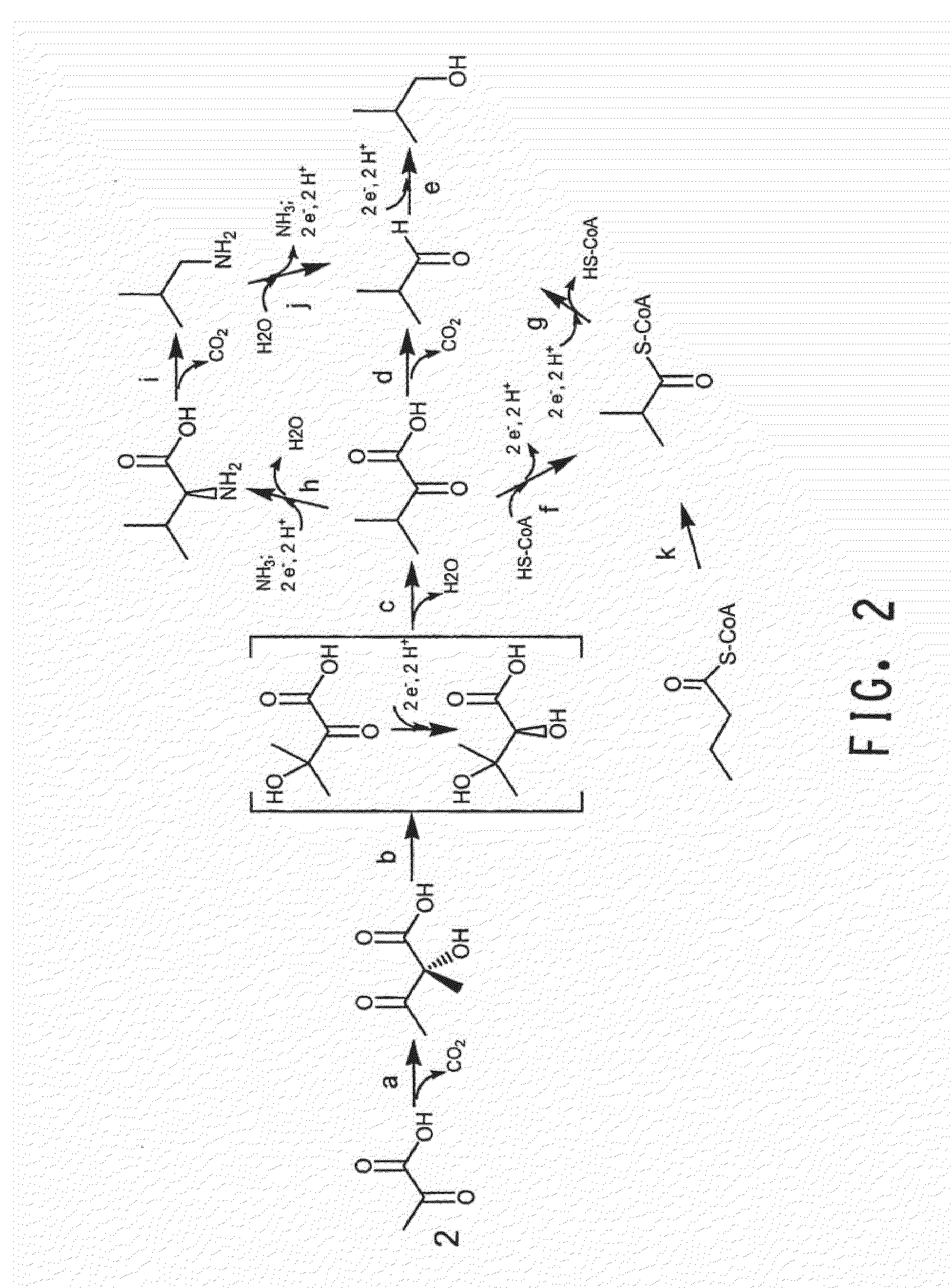

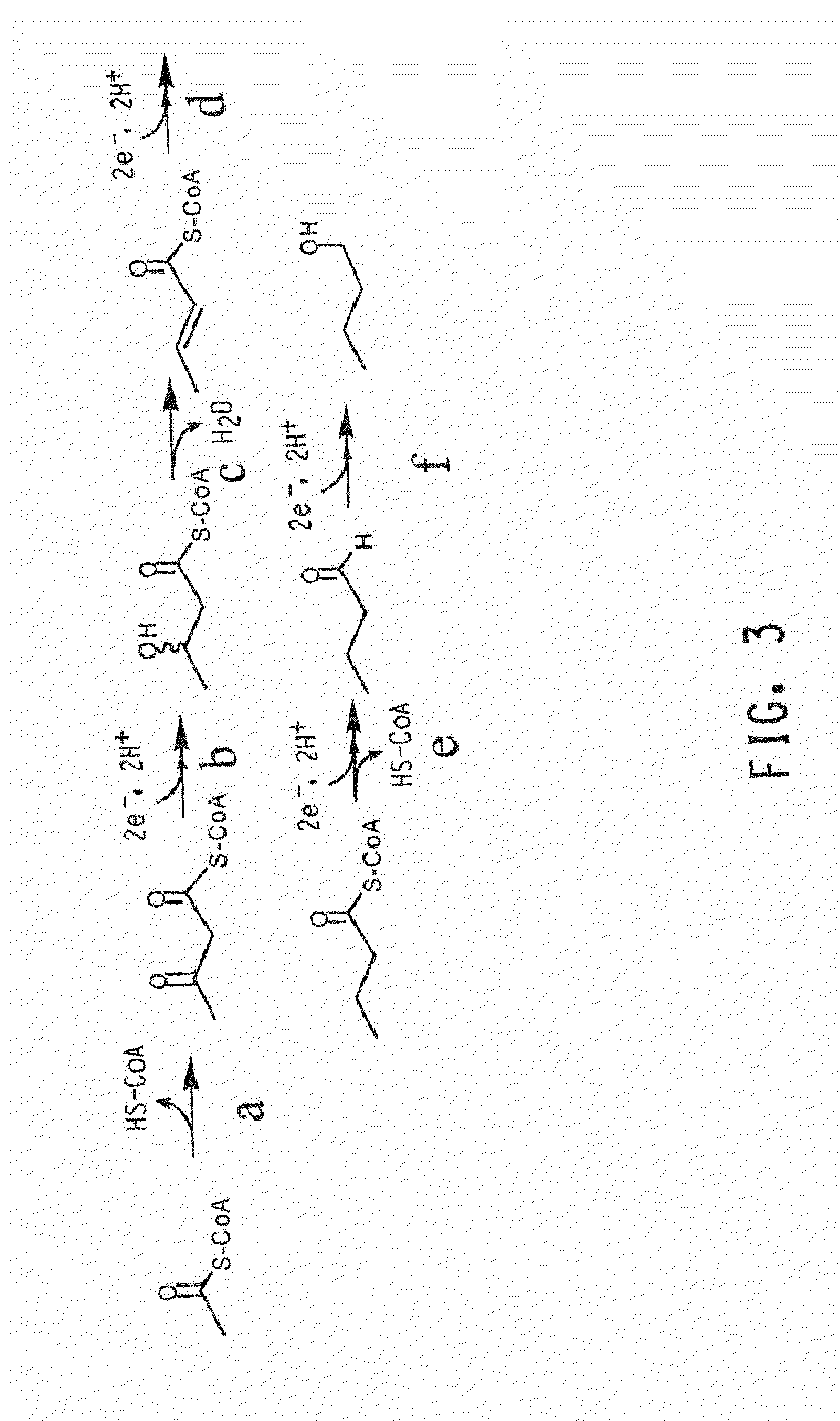

Gene products of bacillus licheniformis which form odorous substances and improved biotechnological production methods based thereon

InactiveUS20070190605A1Reduce formationImprove filtering effectBacteriaHydrolasesBacillus licheniformisPropanoic acid

The present invention relates to 25 hitherto undescribed genes of B. licheniformis and gene products derived therefrom and all sufficiently homologous nucleic acids and proteins thereof. They occur in five different metabolic pathways for the formation of odorous substances. The metabolic pathways in question are for the synthesis of: 1) isovalerian acid (as part of the catabolism of leucine), 2) 2-methylbutyric acid and / or isobutyric acid (as part of the catabolism of valine and / or isoleucine), 3) butanol and / or butyric acid (as part of the metabolism of butyric acid), 4) propyl acid (as part of the metabolism of propionate) and / or 5) cadaverine and / or putrescine (as parts of the catabolism of lysine and / or arginine). The identification of these genes allows biotechnological production methods to be developed that are improved to the extent that, to assist these nucleic acids, the formation of the odorous substances synthesized via these metabolic pathways can be reduced by deactivating the corresponding genes in the micro-organism used for the biotechnological production. In addition, these gene products are thus available for preparing reactions or for methods according to their respective biochemical properties.

Owner:BASF AG

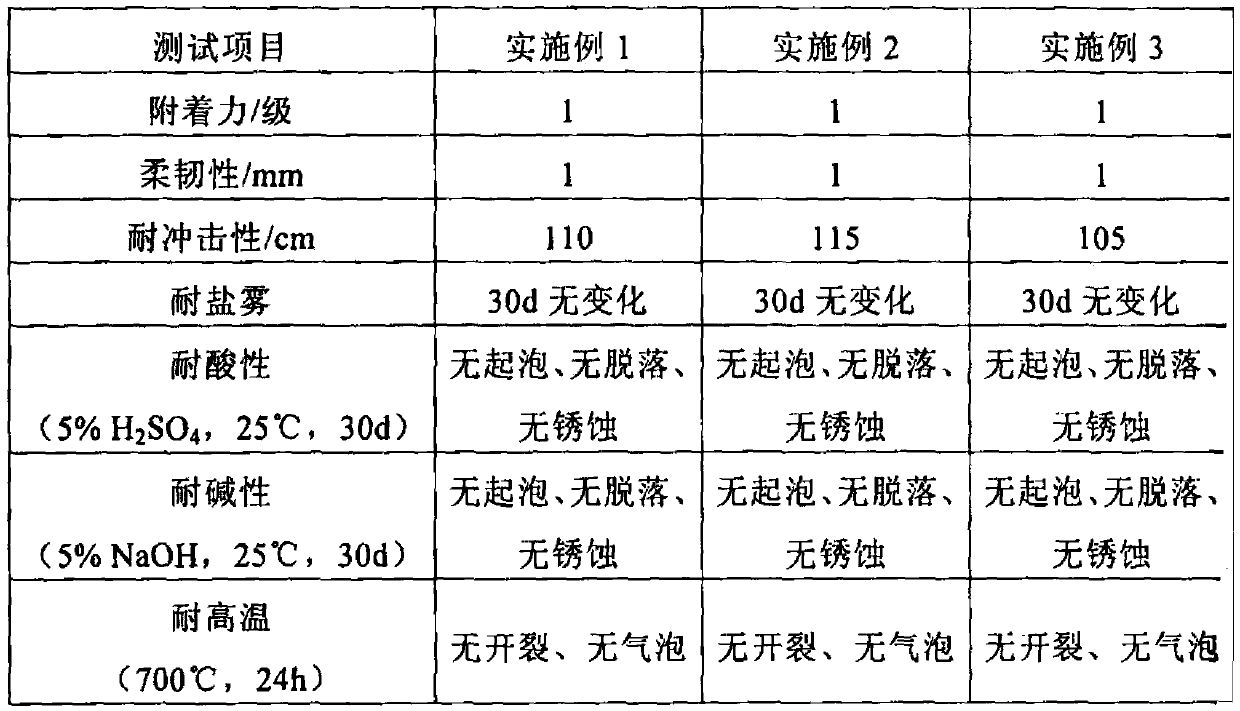

High temperature resistant anticorrosion coating based on graphene and preparation method thereof

InactiveCN103589281AImprove high temperature resistanceImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxySodium Bentonite

The invention relates to a high temperature resistant anticorrosion coating based on graphene and a preparation method thereof. The high temperature anticorrosion coating comprises the following components by the mass percentage: 5-60% of epoxy resin, 3-30% of polyphenylene sulfide resin, 3-30% of amino resin, 1-10% of a pigment, 1-20% of graphene, 3-50% of n-butyl alcohol, 0.1-0.3% of a defoaming agent, 0.1-10% of polyhydroxy acid sodium salt, 0.1-5% of benzenedicarboxylic acid dibutyl ester, 0.5-1.0% of bentonite, and 0.2-0.5% of a leveling agent. Compared with the prior art, the prepared coating has the advantages of quite excellent waterproof and anticorrosion performance, high temperature resistance, weather resistance, alkali resistance, impact resistance, artificial aging resistance and the like, and the preparation method has the advantages of good controllability, simple operation, low production cost, and easy industrialized production.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

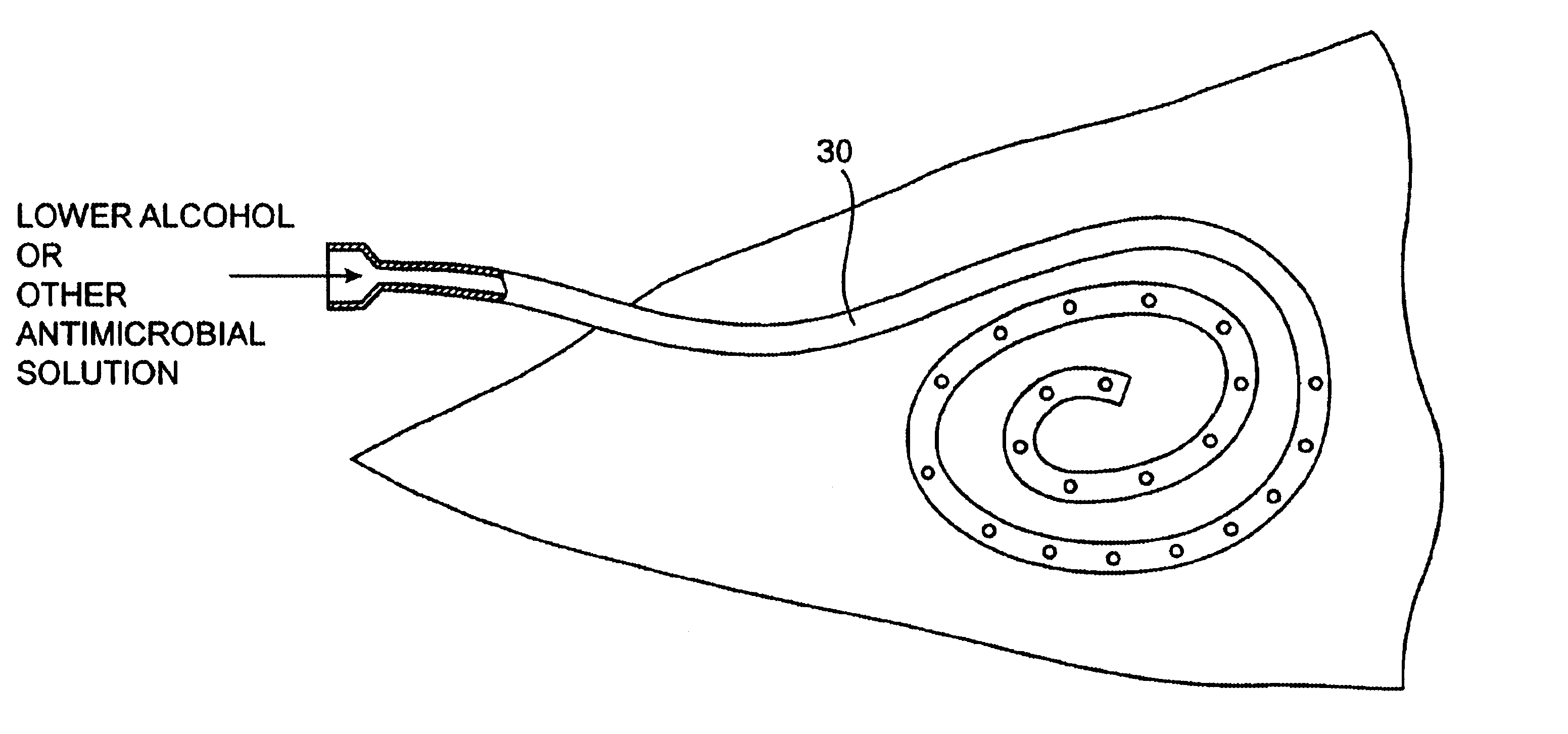

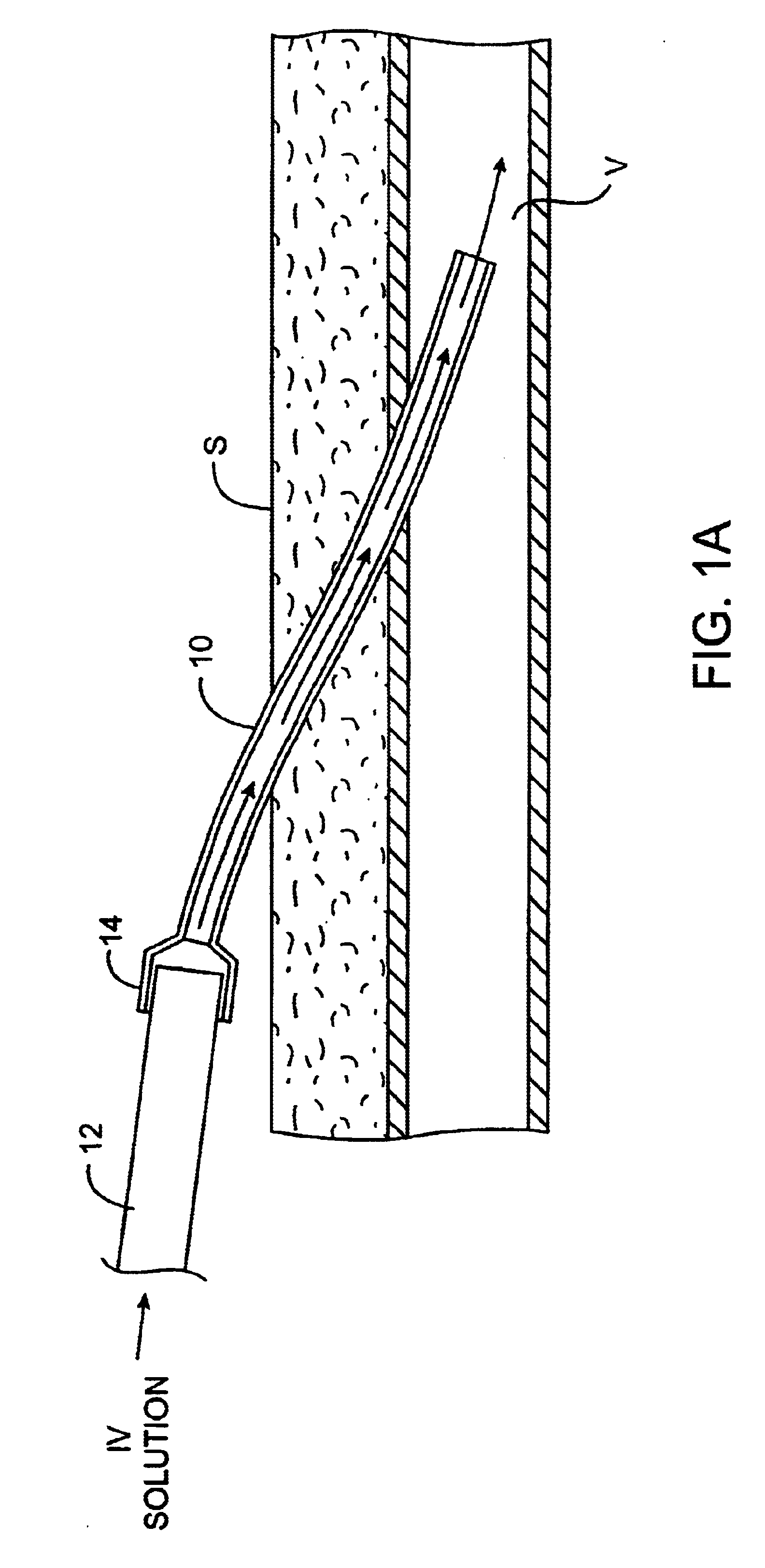

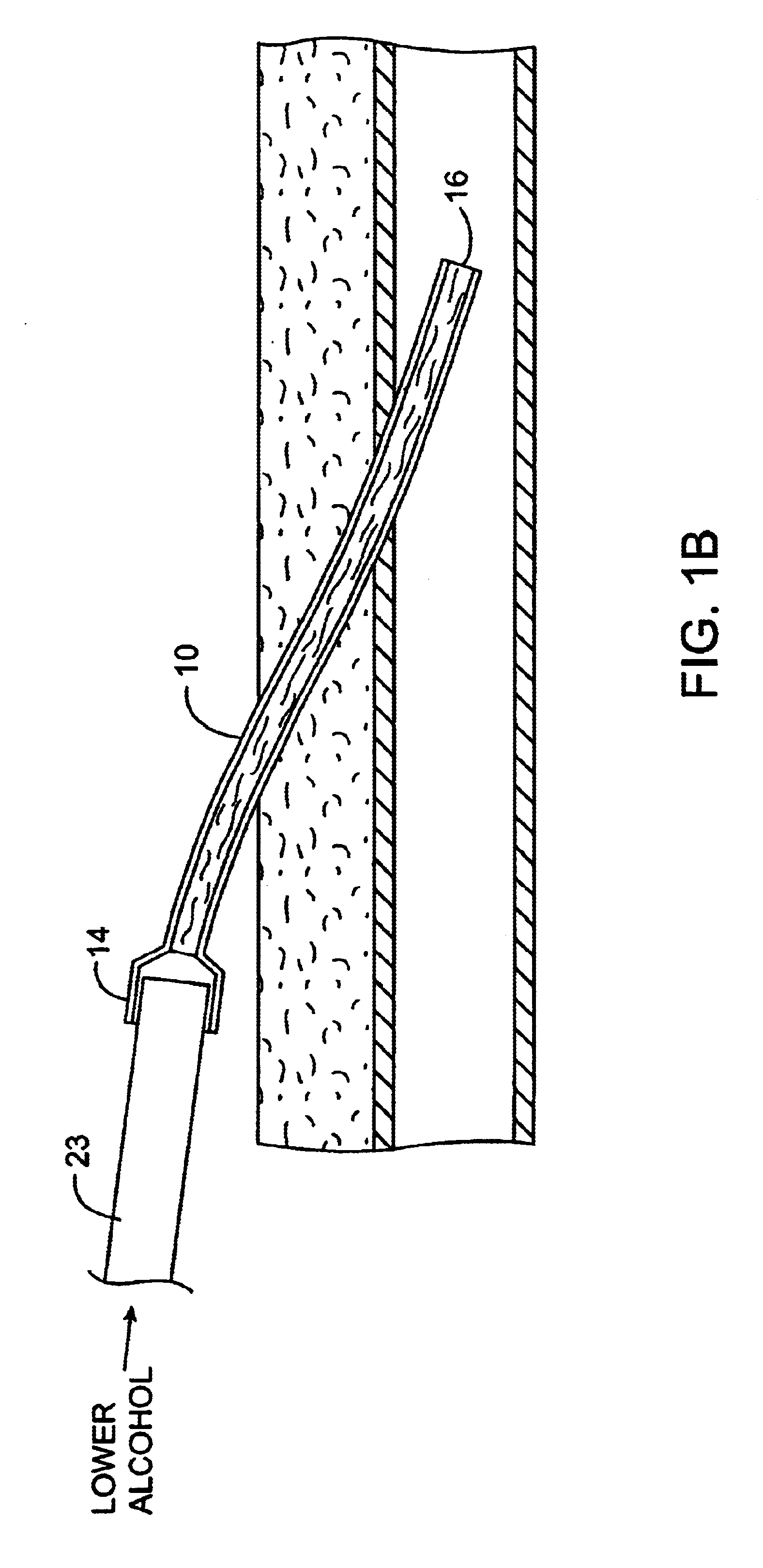

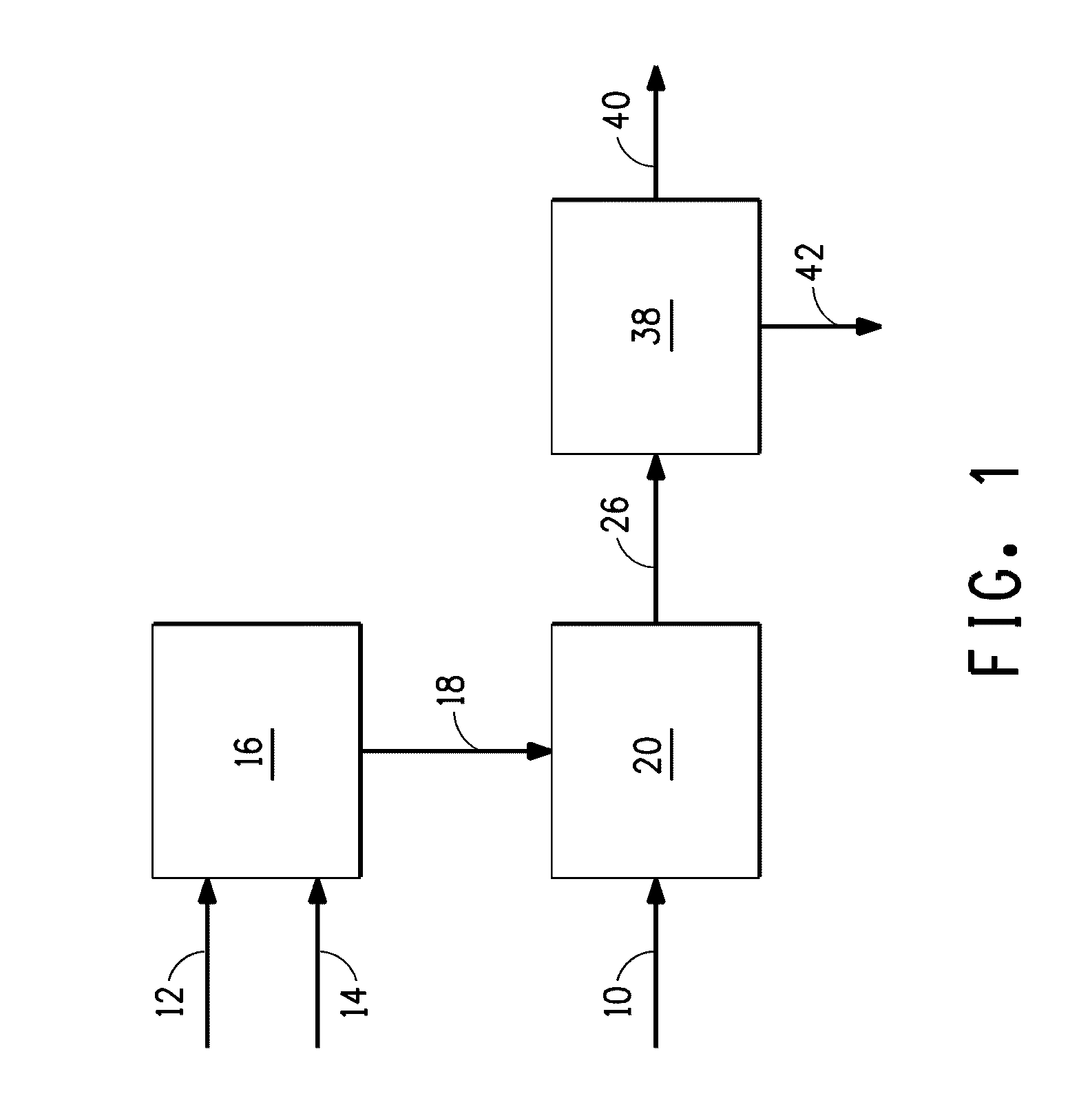

Methods and kits for locking and disinfecting implanted catheters

InactiveUS6685694B2Reduce riskInhibiting fouling and plugging of the lumenDialysis systemsMedical devicesTriclosanThrombus

Implanted catheters are locked with a solution comprising a lower alcohol, typically ethanol, propanol, or butanol, in a range from 1% to 99% by volume, and an additive in a range from 1% to 99% by volume, the additive comprising an anti-microbial, typically taurolidine or triclosan, or an anti-coagulant, typically riboflavin, sodium citrate, ethylene diamine tetraacetic acid, or citric acid. The use of an alcohol and additive solution can effectively reduce fouling of the catheter, particularly clotting and thrombus in intravascular catheters, as well as eradicate existing infections and / or reduce the risk of potential infections. Existing infections and / or potential infections can be further reduced by employing a catheter body which permits an anti-microbial solution to penetrate into the catheter body and preferably through the catheter into tissue surrounding the implanted catheter.

Owner:EXCELSIOR MEDICAL

Method for producing butanol using extractive fermentation

InactiveUS20110097773A1Less corrosiveOrganic compound preparationMicroorganismsAlcoholCarboxylic acid

A method for producing butanol through microbial fermentation, in which the butanol product is removed by extraction into a water-immiscible extractant composition comprising a first solvent and a second solvent, is provided. The first solvent is selected from the group consisting of C12 to C22 fatty alcohols, C12 to C22 fatty acids, esters of C12 to C22 fatty acids, C12 to C22 fatty aldehydes, C12 to C22 fatty amides and mixtures thereof. The second solvent is selected from the group consisting of C7 to C11 alcohols, C7 to C11carboxylic acids, esters of C7 to C11 carboxylic acids, C7 to C11 aldehydes, and mixtures thereof. Also provided is a method for recovering butanol from a fermentation medium.

Owner:BUTAMAXTM ADVANCED BIOFUELS

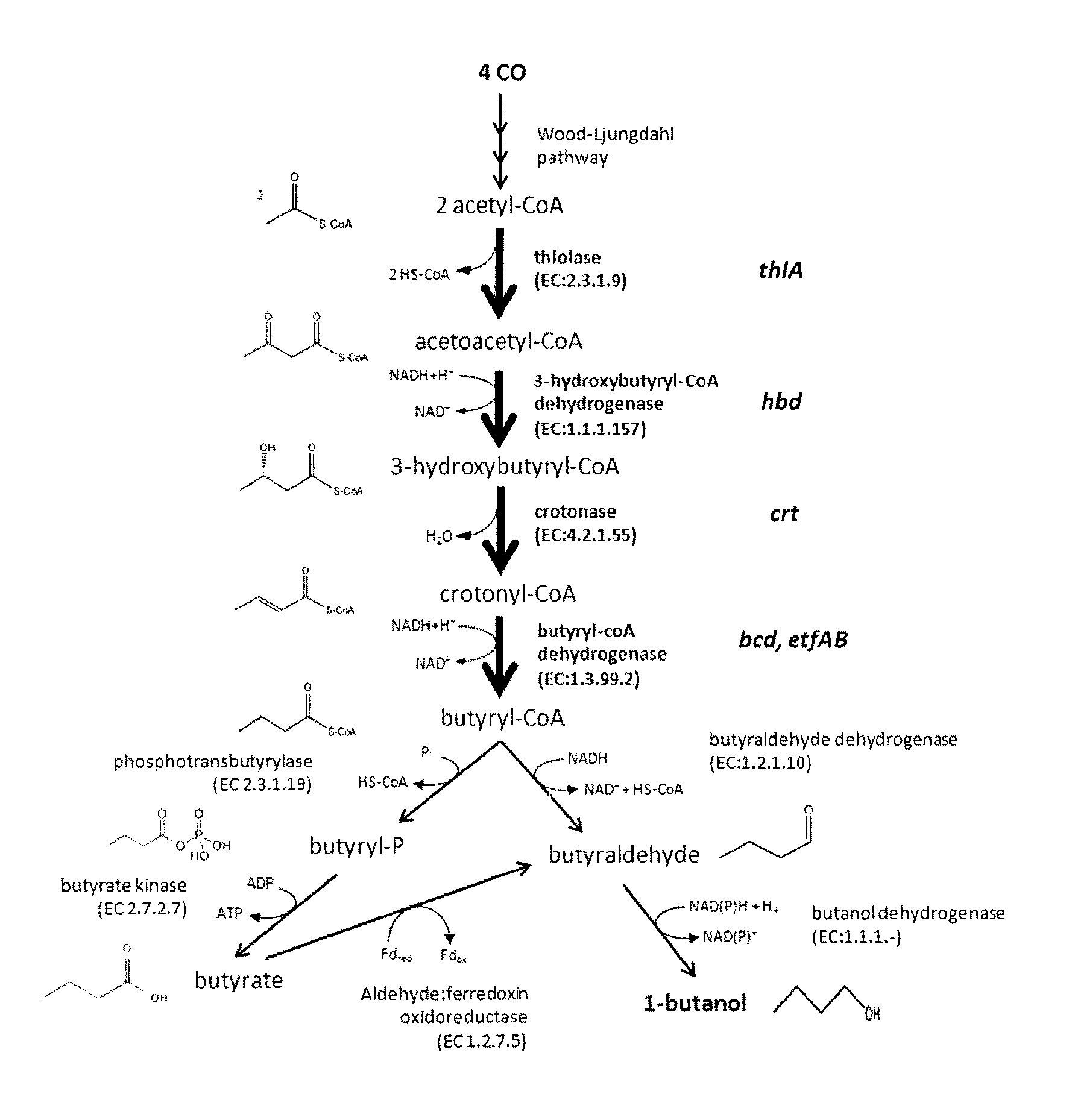

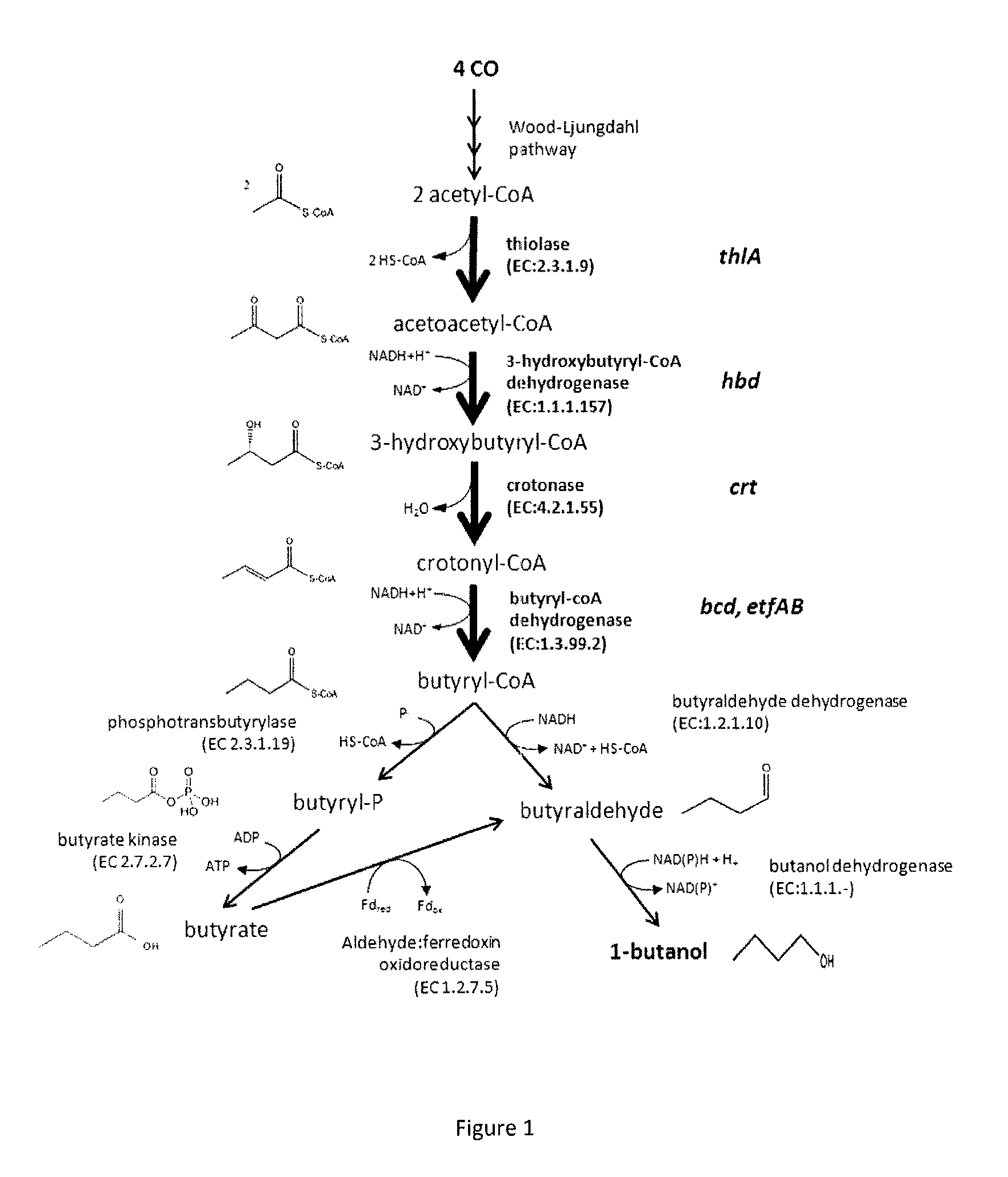

Recombinant microorganism and methods of production thereof

A novel genetically modified microorganisms capable of using CO to produce 1-butanol and / or a precursor thereof, novel methyltransferases and nucleic acids encoding same, methods for producing genetically modified microorganisms using said novel methyltransferases, and methods of producing 1-butanol and / or a precursor thereof by microbial fermentation.

Owner:LANZATECH NZ INC

Fuels for internal combustion engines

InactiveUS6858048B1Emission reductionSafer land environmentLiquid carbonaceous fuelsFuel additivesKeroseneOctanol

Mixed alcohols can be used as a fuel additive in gasoline, diesel, jet fuel or as a neat fuel in and of itself. The mixed alcohols can contain C1-C5 alcohols, or in the alternative, C1-C8, or higher, alcohols in order to boost energy content. The C1-C5 mixed alcohols contain more ethanol than methanol with amounts of propanol, butanol and pentanol. C1-C8 mixed alcohols contain the same, with amounts of hexanol, heptanol and octanol. A gasoline-based fuel includes gasoline and the mixed alcohols. A diesel based fuel includes diesel and the mixed alcohols. A jet fuel includes kerosene and the mixed alcohols. The neat fuel of the mixed alcohols has an octane number of at least 109 and the Reid Vapor Pressure is no greater than 5 psi. The gross heat of combustion is at least 12,000 BTU's / lb.

Owner:STANDARD ALCOHOL COMPANY OF AMERICA

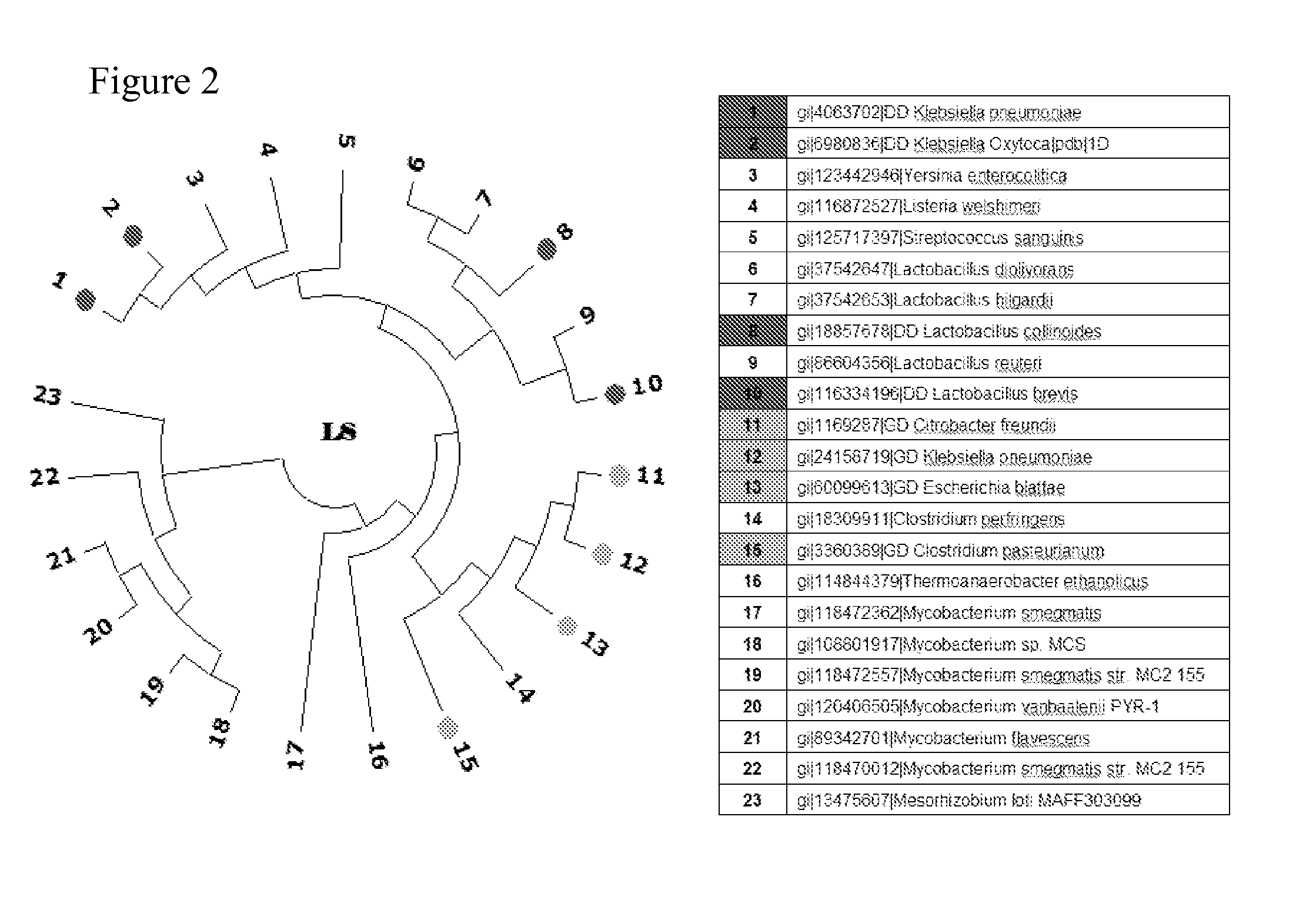

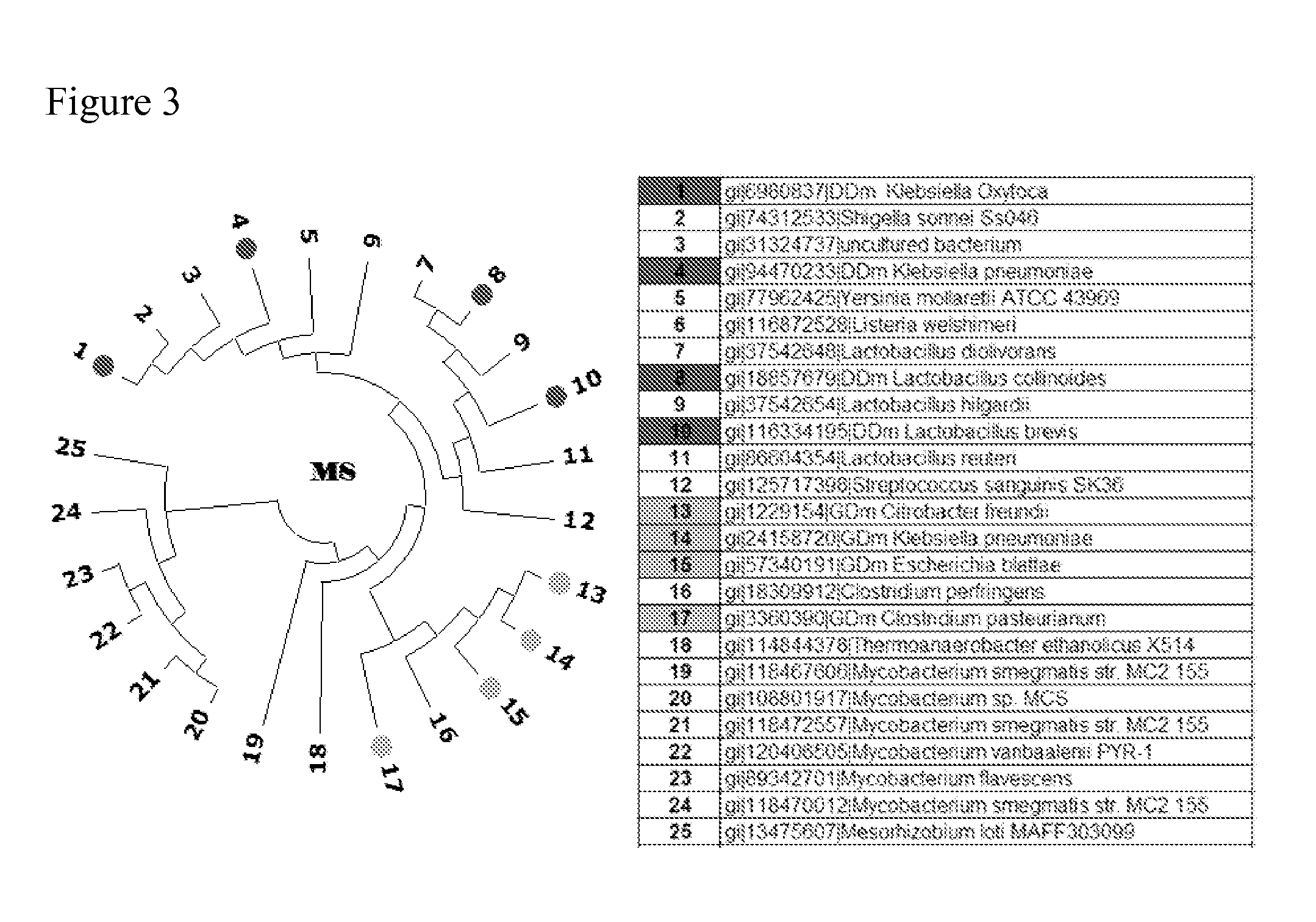

Solvent tolerant microorganisms and methods of isolation

Lactobacillus bacteria having enhanced tolerance to butanols have been isolated. The bacteria are useful for the fermentive production of butanol. New methods for the isolation of butanol tolerant Lactobacillus are also provided.

Owner:GEVO INC

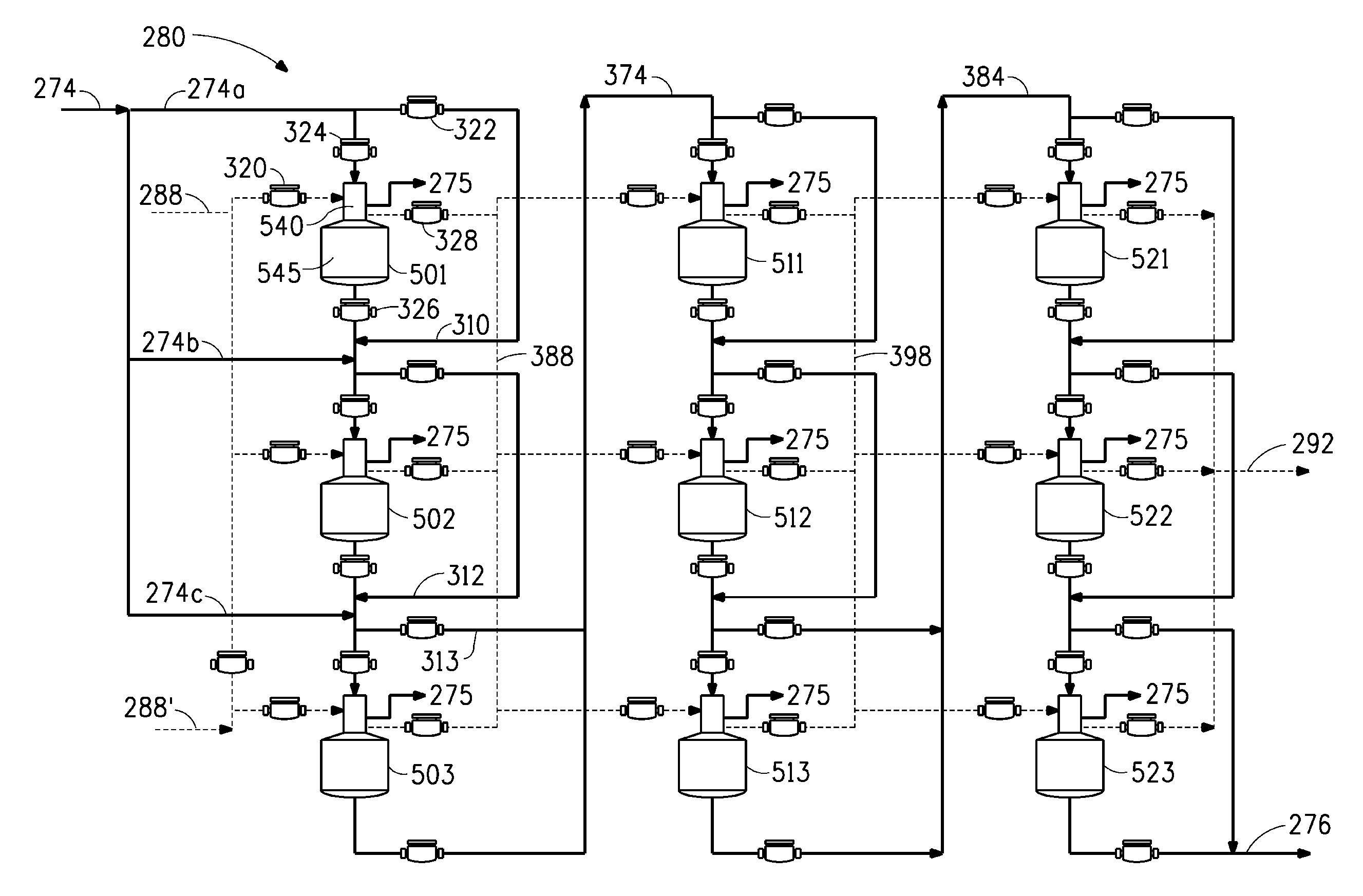

Systems and methods for alcohol recovery and concentration of stillage by-products

ActiveUS20110315541A1Efficient use ofHydrocarbon purification/separationHydroxy compound preparationAlcoholDistillation

Systems and methods for separating an alcohol, and in particular butanol, from a fermented feed and concentrating thin stillage into syrup includes operation of one or more alcohol recovery distillation columns using the heat supplied by steam generated from concentration of the thin stillage in a multi-train, multi-effect evaporation system.

Owner:GEVO INC

Alternative fuel and fuel additive compositions

InactiveUS20090013591A1Reduce concentrationReduce severityBiofuelsLiquid carbonaceous fuelsParticulatesAlternative fuels

Alternative gasoline, diesel fuel, marine diesel fuel, jet fuel, and flexible fuel compositions are disclosed. The compositions include an alcohol and / or a glycerol ether or mixture of glycerol ethers, which can be derived from renewable resources. When combined with gasoline / ethanol blends, the glycerol ethers can reduce the vapor pressure of the ethanol and increasing the fuel economy. When added to diesel fuel / alcohol blends, glycerol ethers improve the cetane value of the blends. All or part of the diesel fuel in the compositions described herein can be biodiesel fuel and / or synthetic fuel derived from a Fischer-Tropsch synthesis process. Fischer-Tropsch synthesis can also use feedstocks derived from sources other than crude oil, such as methane, methanol, ethanol, lignin and glycerol, which can further reduce reliance on foreign sources of crude oil. When used in jet fuel, glycerol ethers can replace all or part of conventional deicing additives, thus lowering skin toxicity, and glycerol ethers ability to reduce particulate emissions can lower the appearance of contrails. When used in marine diesel, the reduction in particulate emissions can be environmentally significant. In another embodiment, the alternative compositions comprise gasoline, ethanol, and n-butanol, and in one aspect, the ethanol and / or n-butanol can be derived from renewable resources. Fuel additive compositions, including glycerol ethers and hydrocarbons and / or alcohols, are also disclosed.

Owner:BRADIN DAVID +2

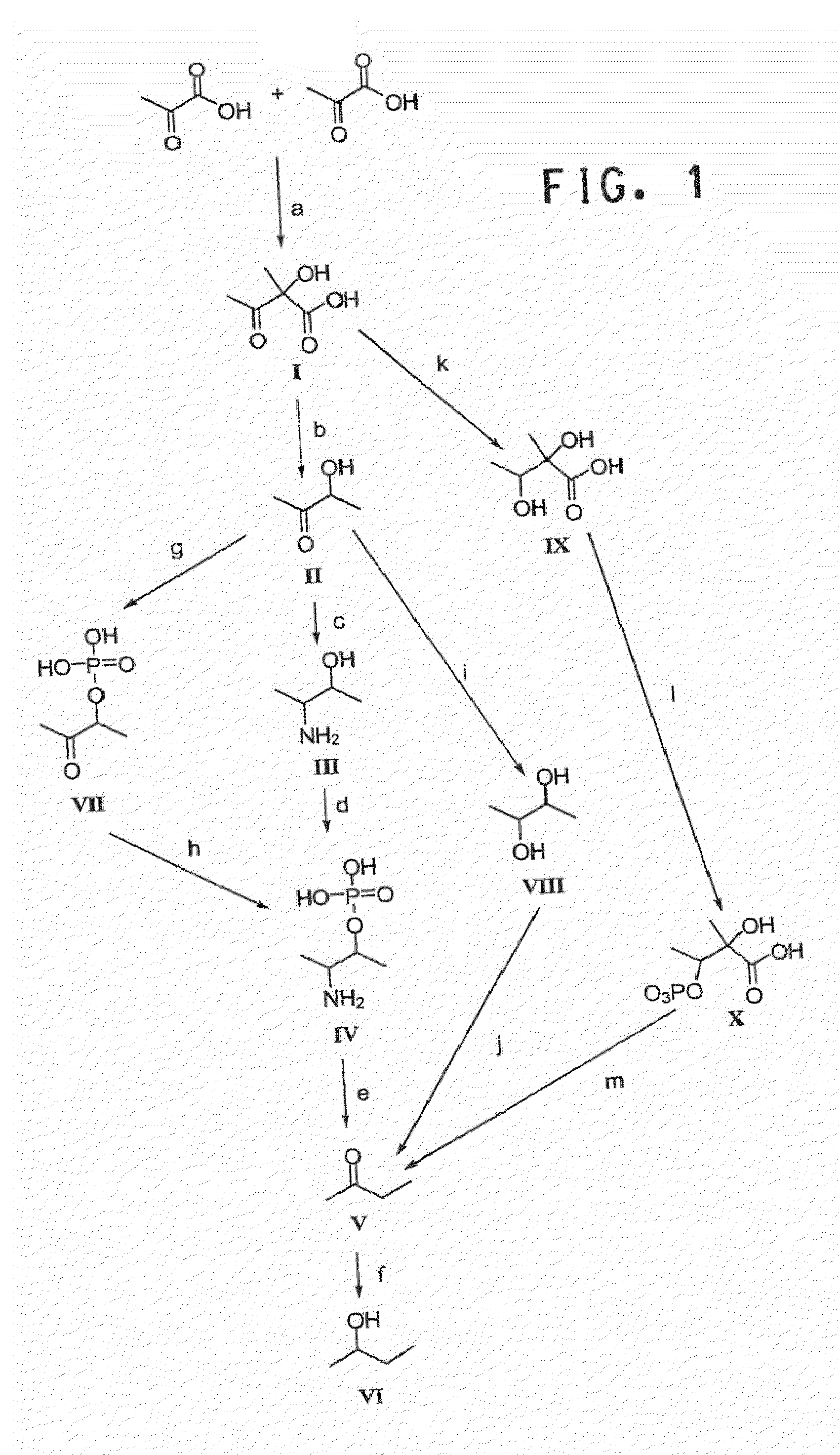

Fermentive production of four carbon alcohols

Methods for the fermentative production of four carbon alcohols is provided. Specifically, butanol, preferably isobutanol is produced by the fermentative growth of a recombinant bacterium expressing an isobutanol biosynthetic pathway.

Owner:GEVO INC

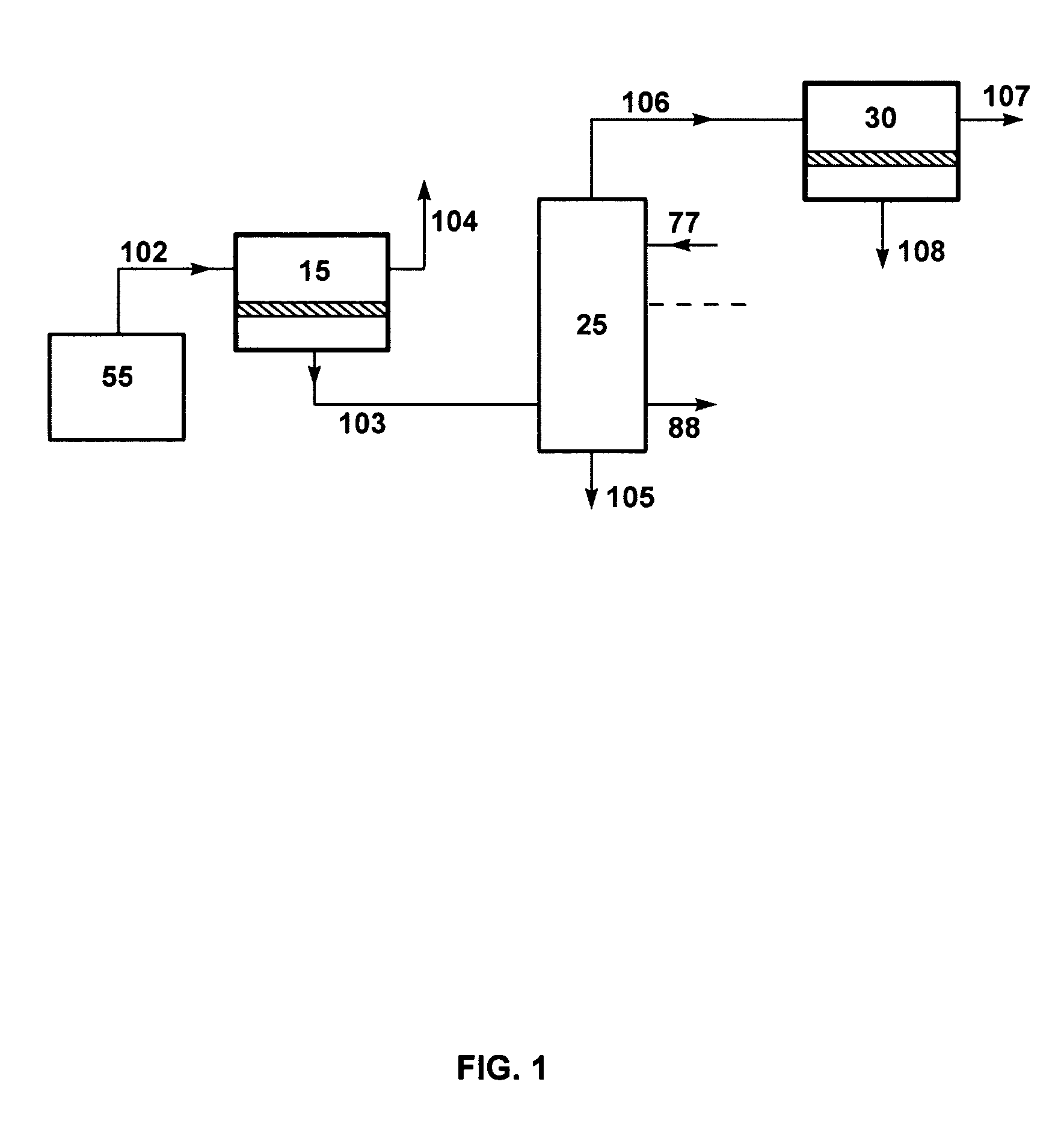

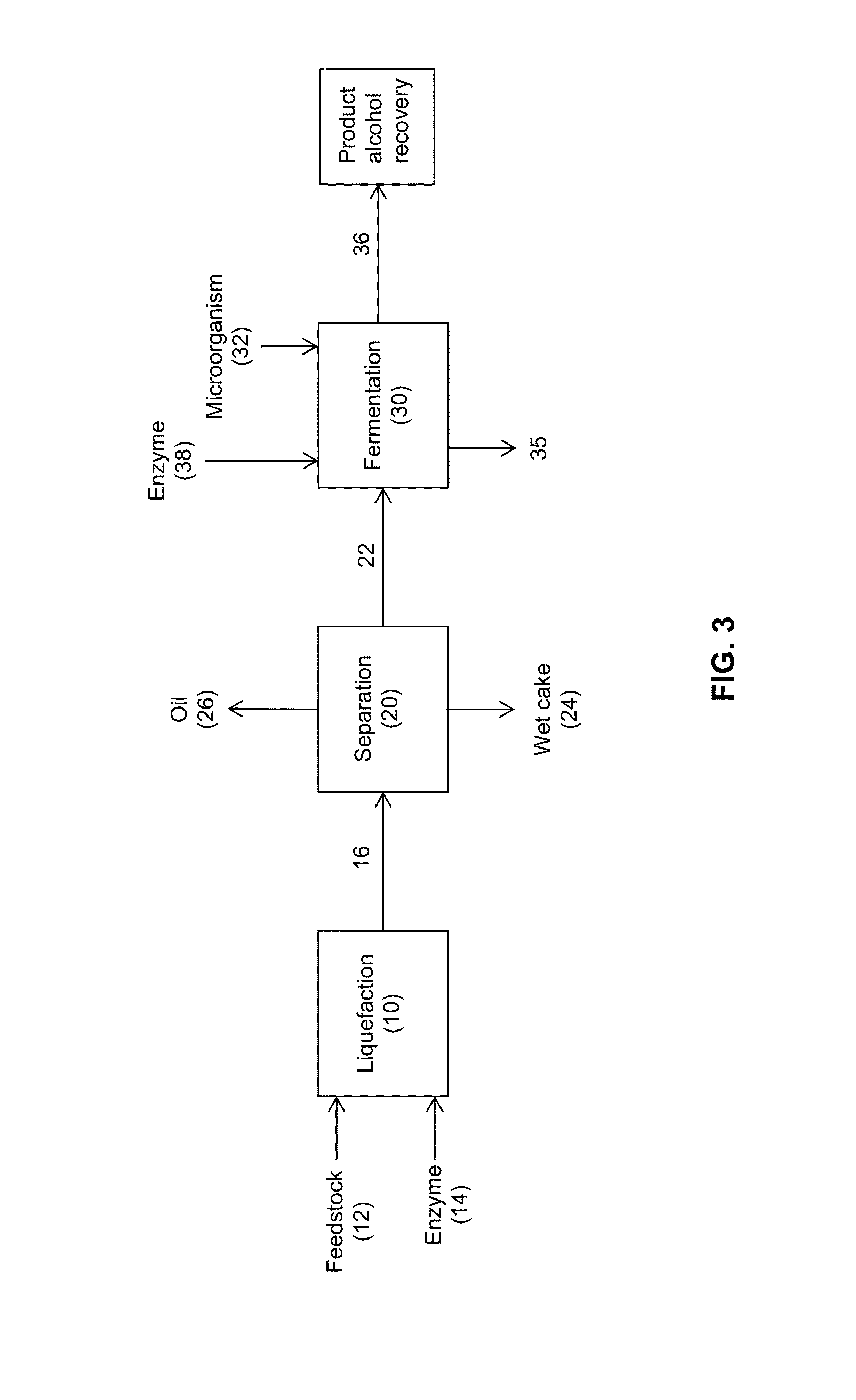

Extraction solvents derived from oil for alcohol removal in extractive fermentation

ActiveUS20110312044A1Reduce the amount requiredReduce decreaseFatty oils/acids recovery from wasteOxygen-containing compound preparationSolventFatty alcohol

In an alcohol fermentation process, oil derived from biomass is chemically converted into an extractant available for in situ removal of a product alcohol such as butanol from a fermentation broth. The glycerides in the oil can be chemically converted into a reaction product, such as fatty acids, fatty alcohols, fatty amides, fatty acid methyl esters, fatty acid glycol esters, and hydroxylated triglycerides, and mixtures thereof, which forms a fermentation product extractant having a partition coefficient for a product alcohol greater than a partition coefficient of the oil of the biomass for the product alcohol. Oil derived from a feedstock of an alcohol fermentation process can be chemically converting into the fermentation product extractant. The oil can be separated from the feedstock prior to the feedstock being fed to a fermentation vessel, and the separated oil can be chemically converted to a fermentation product extractant, which can then contacted with a fermentation product comprising a product alcohol, whereby the product alcohol is separated from the fermentation product.

Owner:GEVO INC

Solvent tolerant microorganisms and methods of isolation

Lactobacillus bacteria having enhanced tolerance to butanols have been isolated. The bacteria are useful for the fermentive production of butanol. New methods for the isolation of butanol tolerant Lactobacillus are also provided.

Owner:GEVO INC

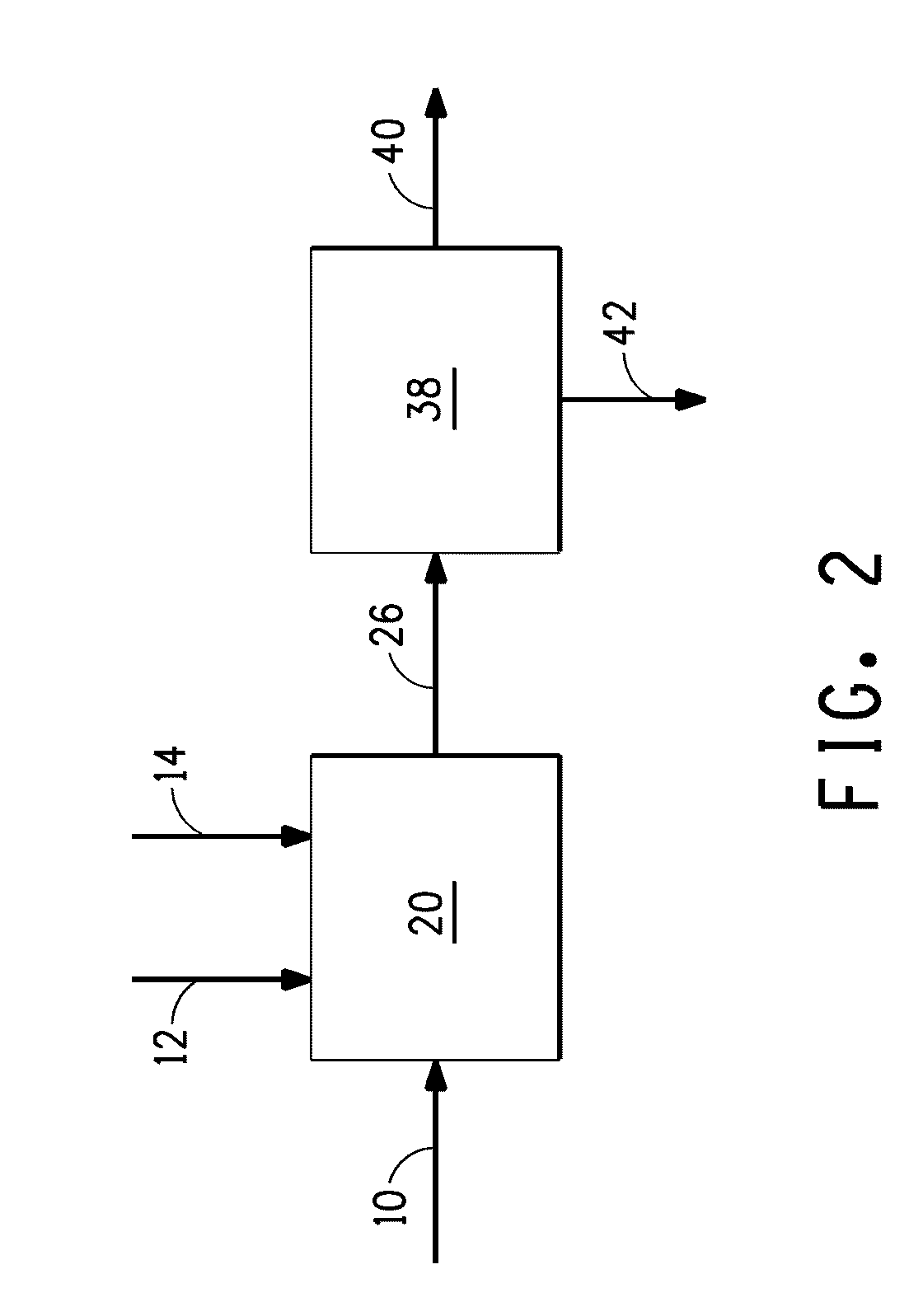

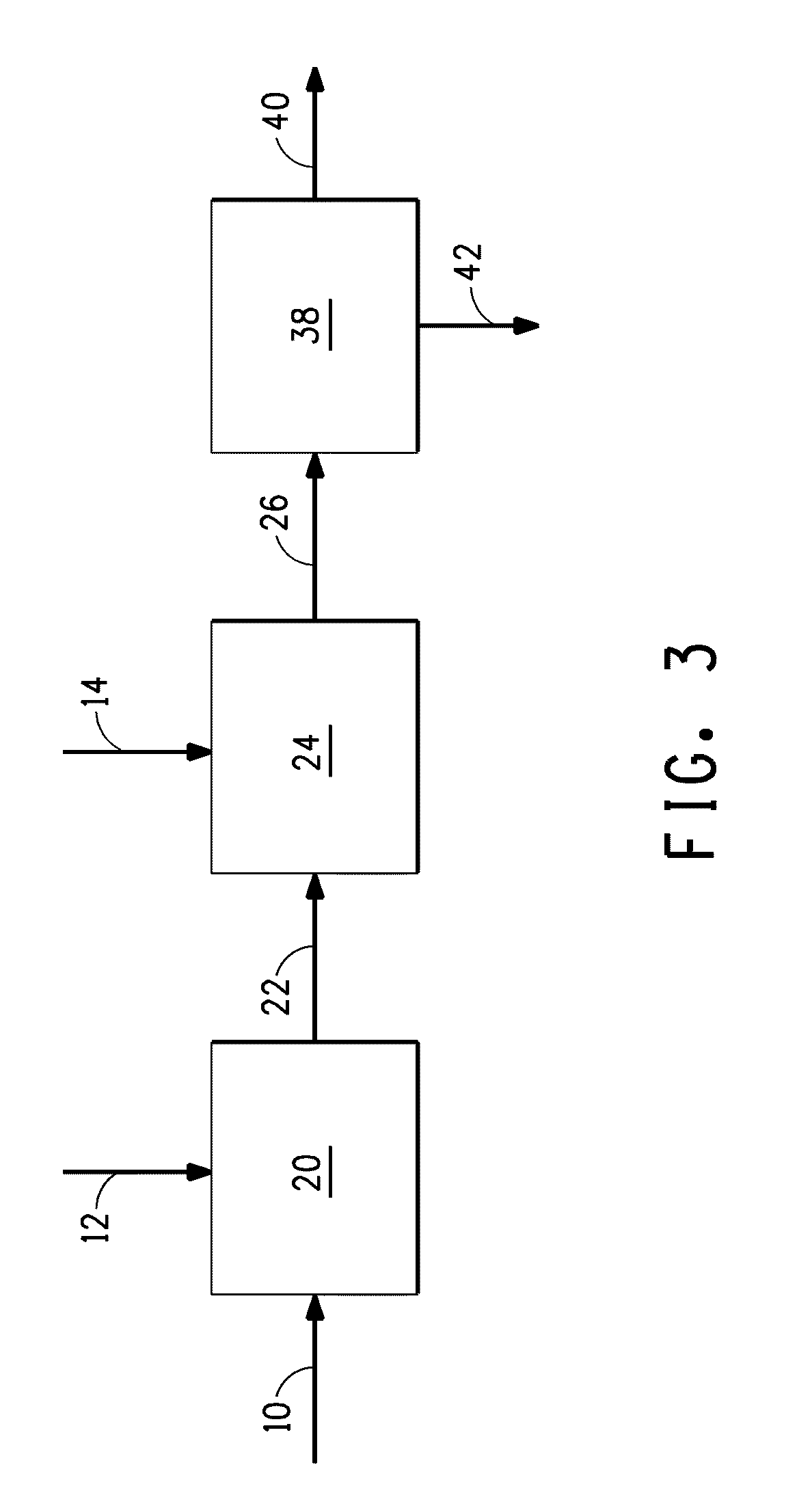

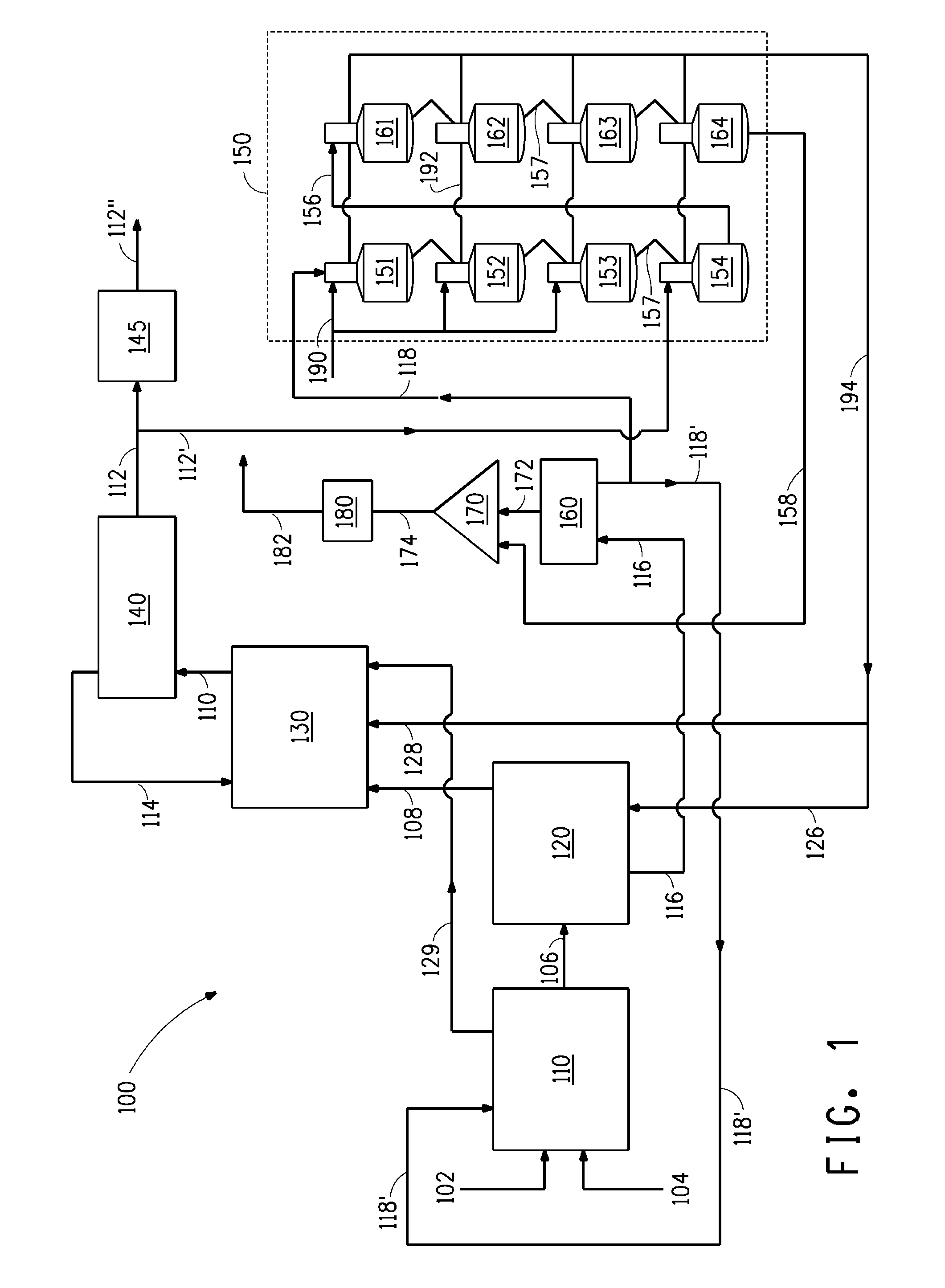

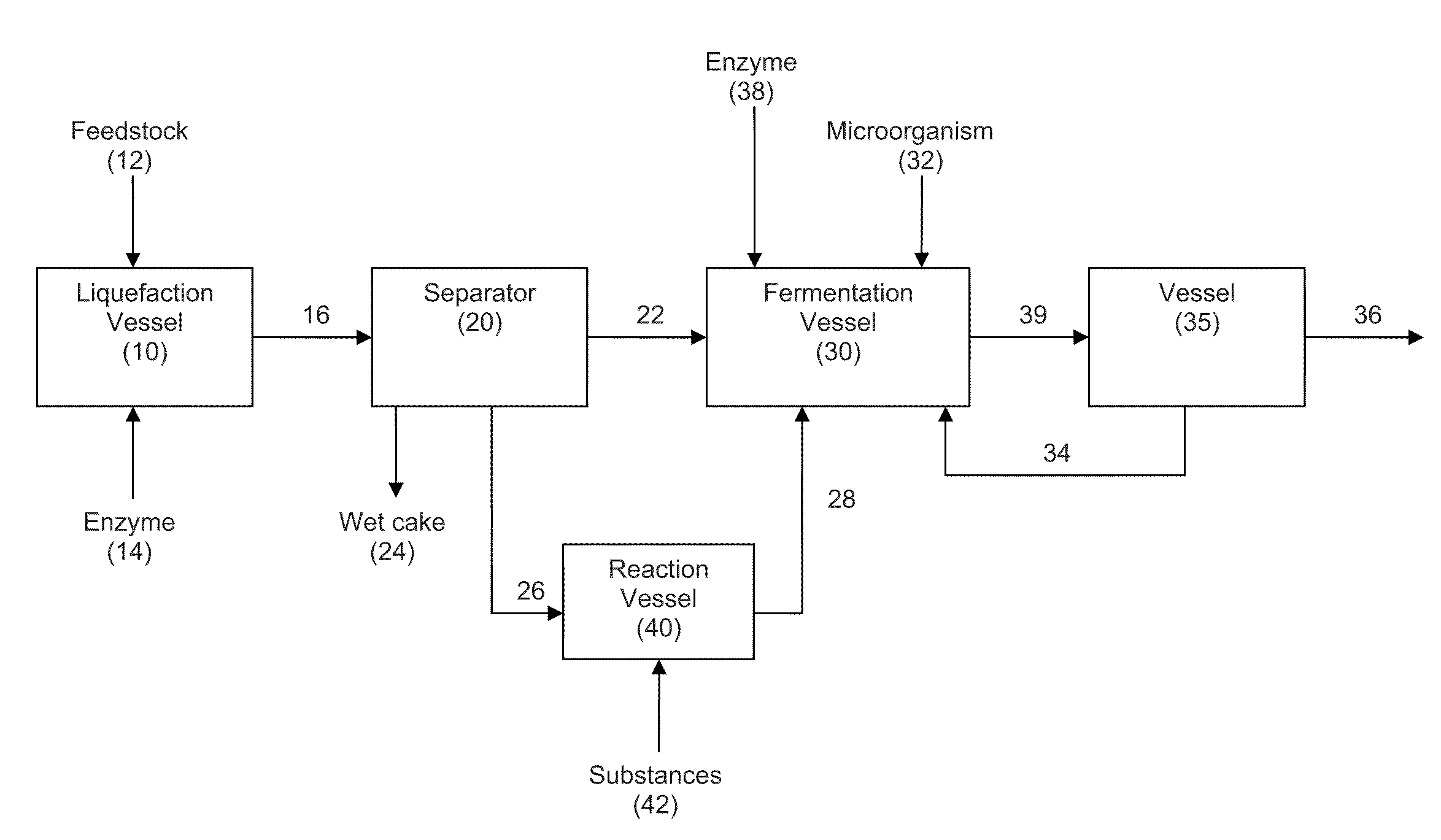

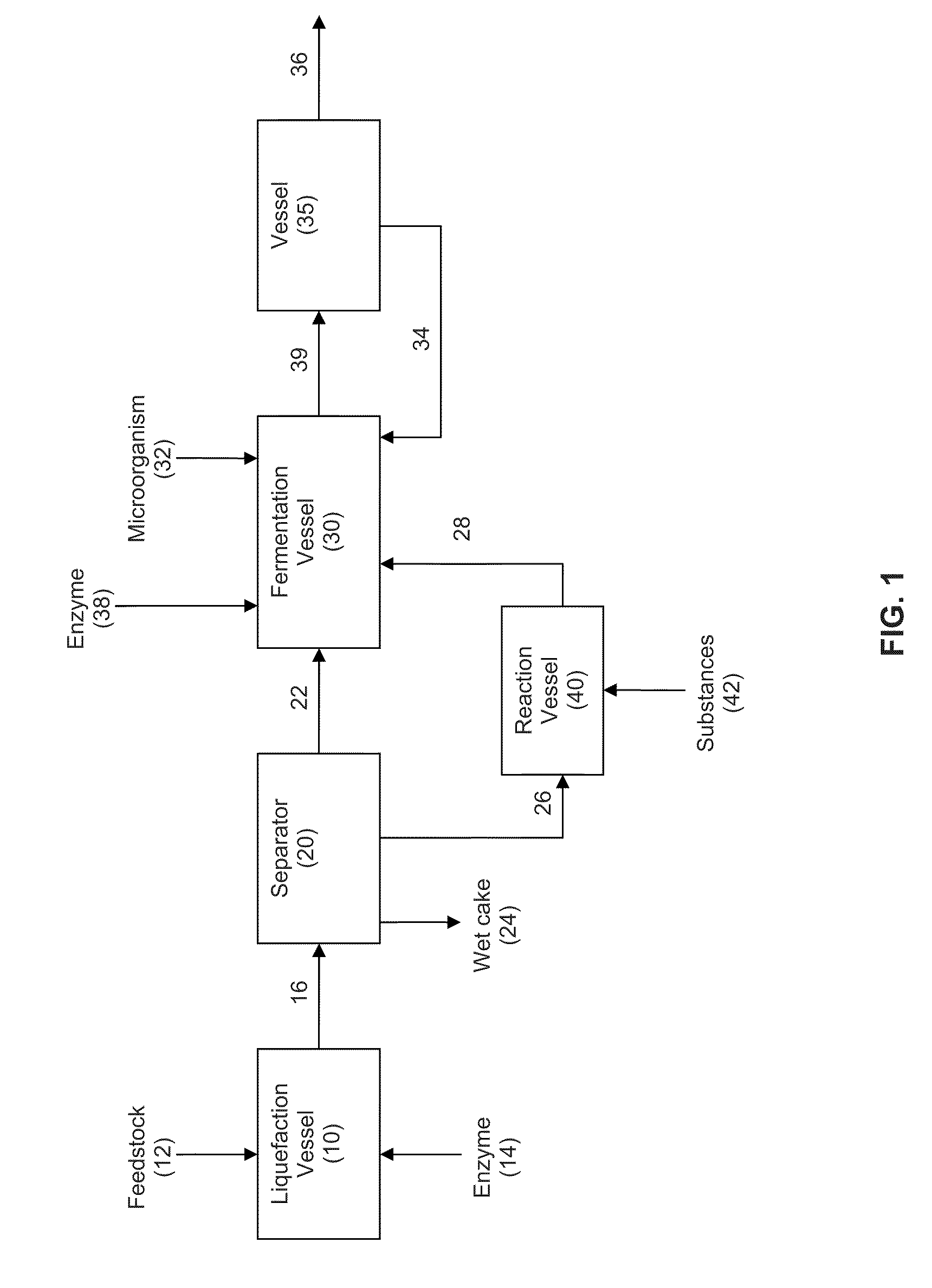

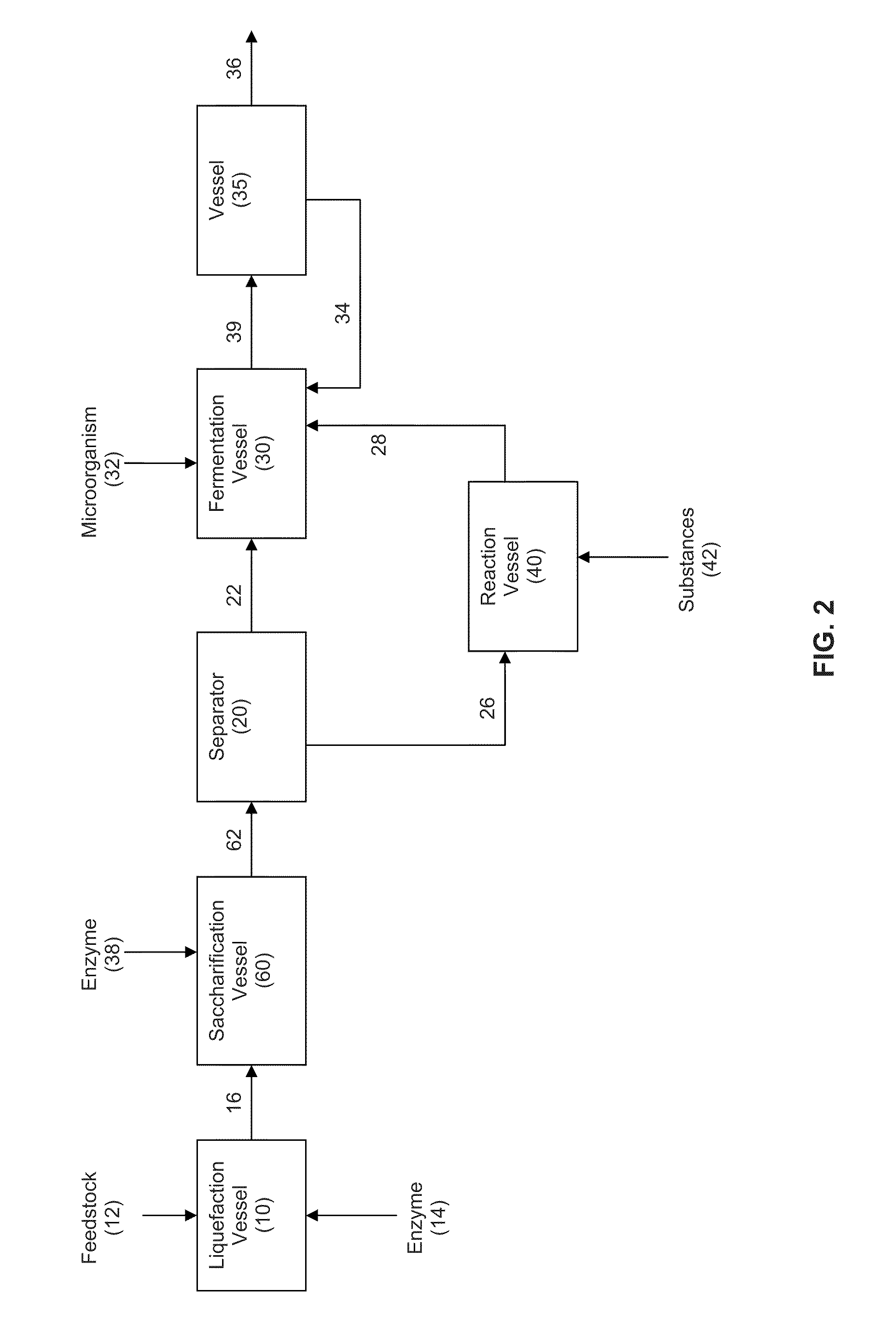

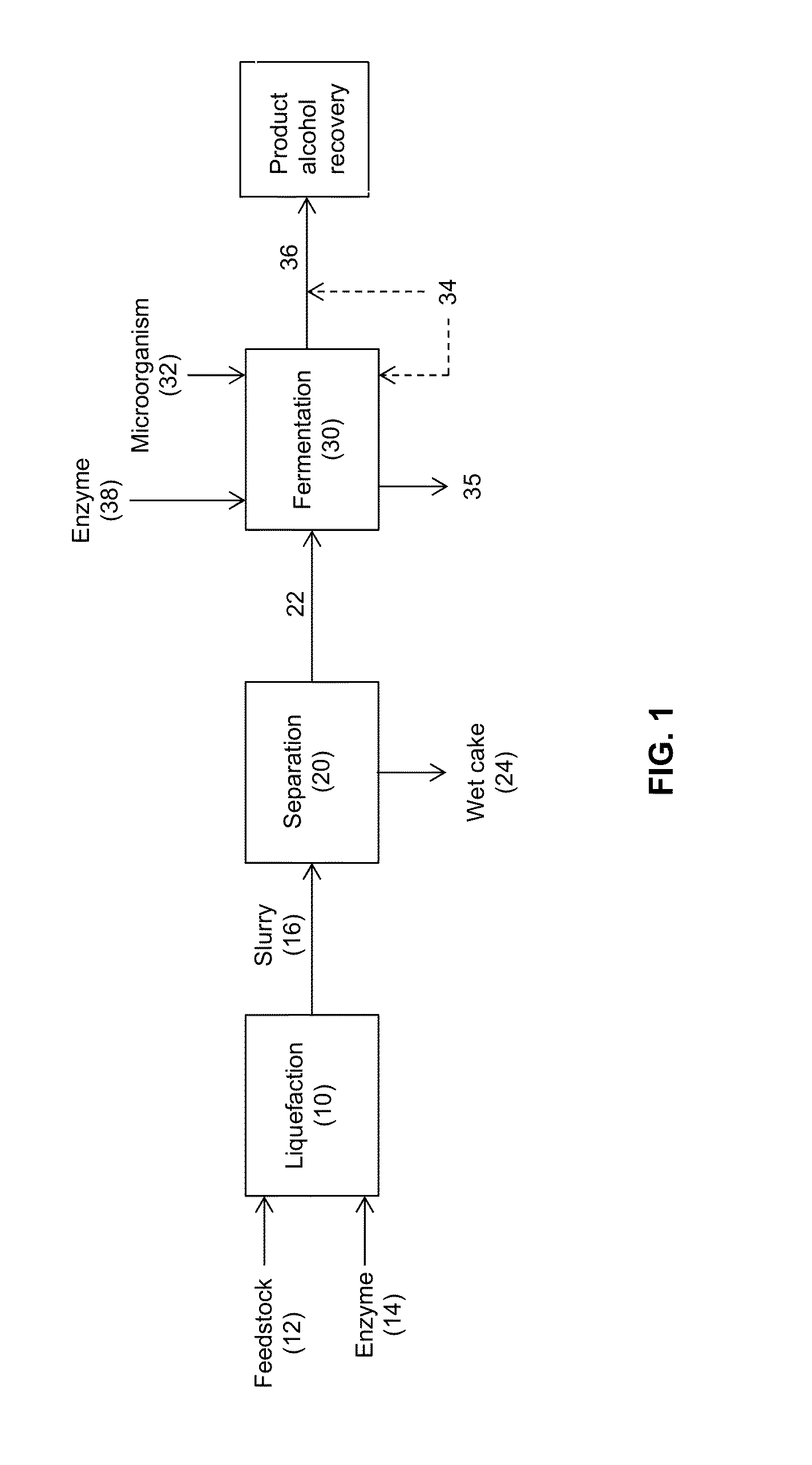

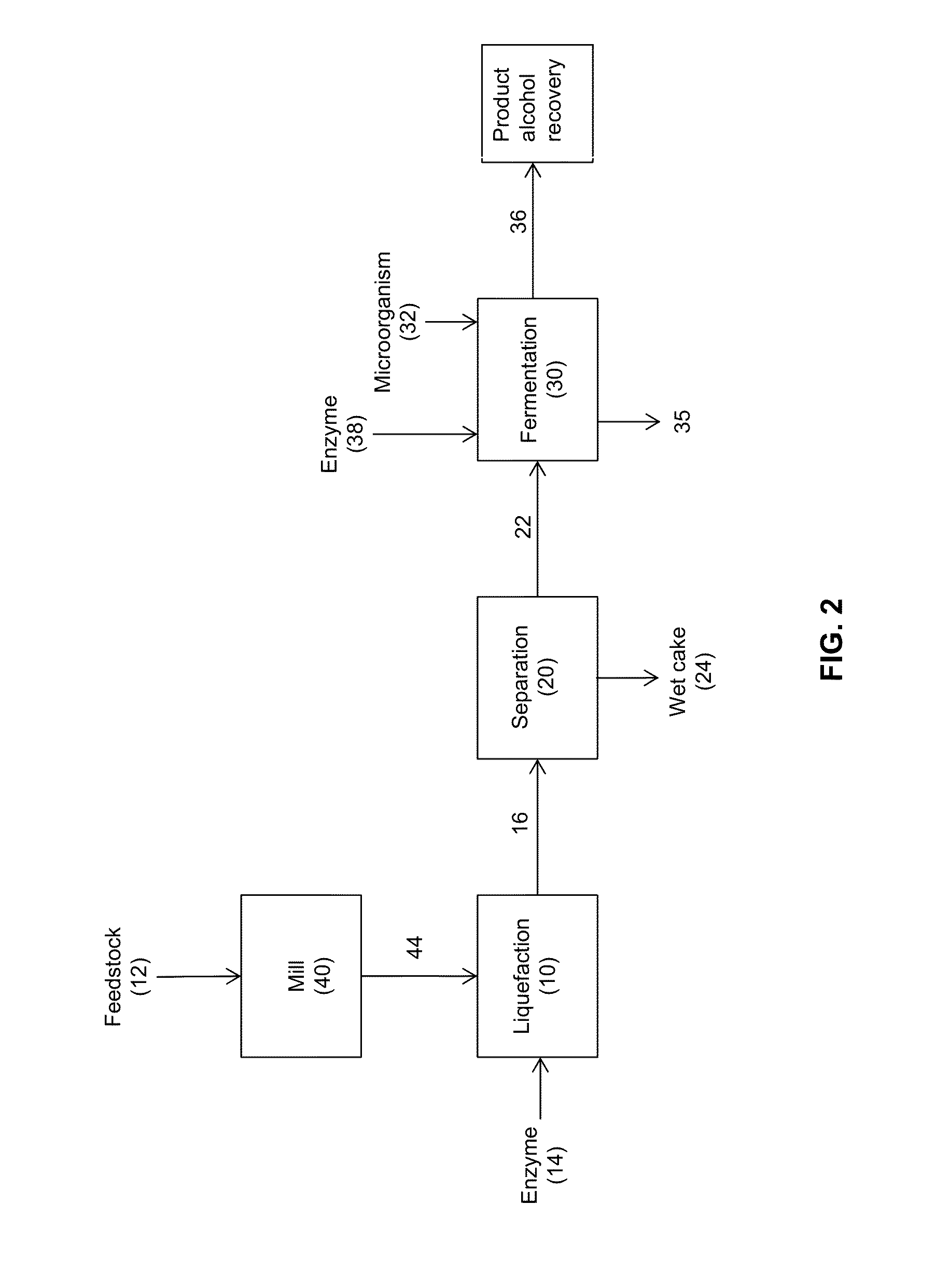

Processes and systems for the production of fermentative alcohols

InactiveUS20140024064A1Increasing biomass processing productivityImproving alcohol fermentation co-product profileBioreactor/fermenter combinationsBiological substance pretreatmentsAlcoholButanol

The present invention relates to processes and systems for the production of fermentative alcohols such as ethanol and butanol. The present invention also provides methods for separating feed stream components for improved biomass processing and productivity.

Owner:BUTAMAXTM ADVANCED BIOFUELS

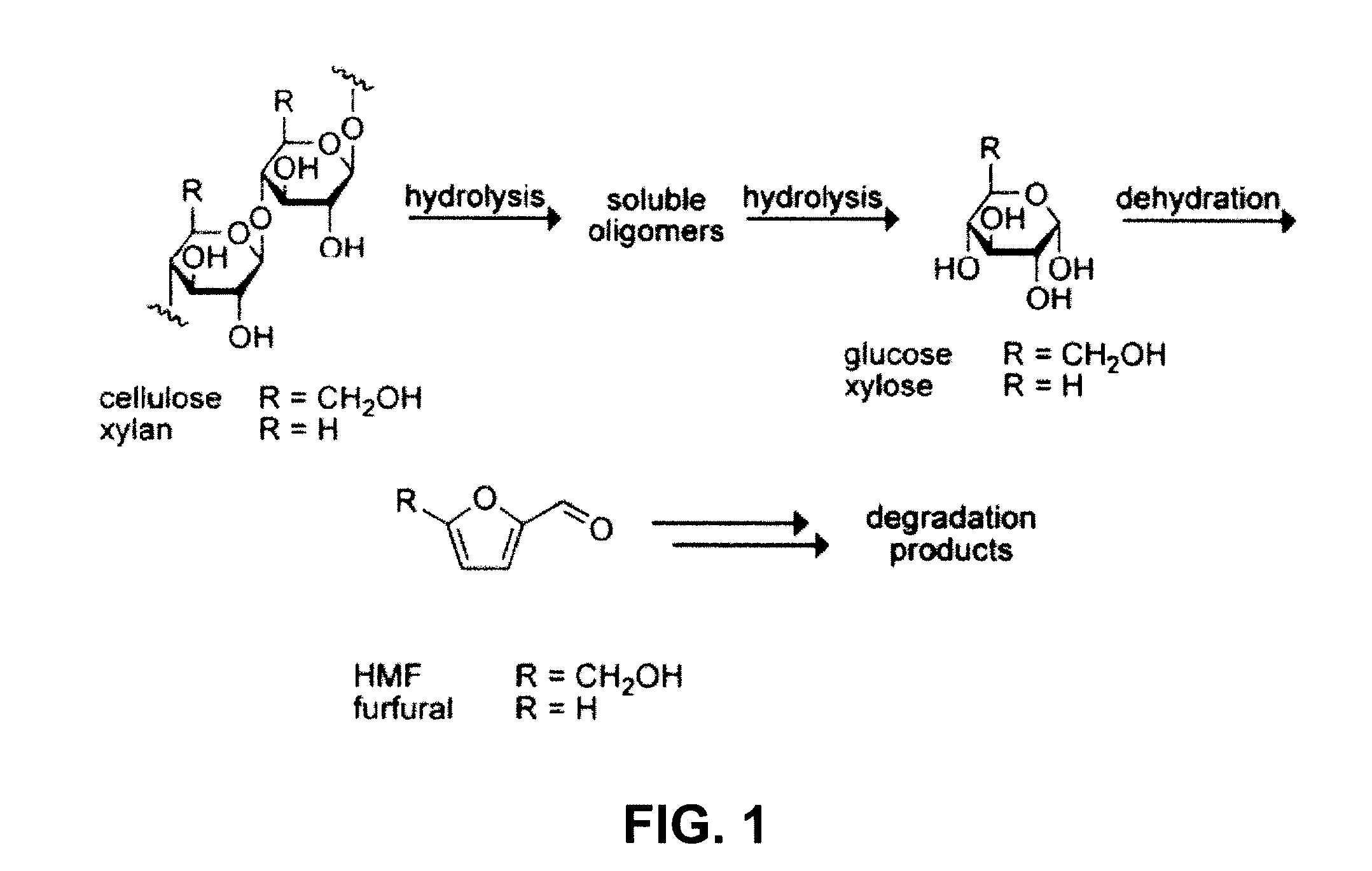

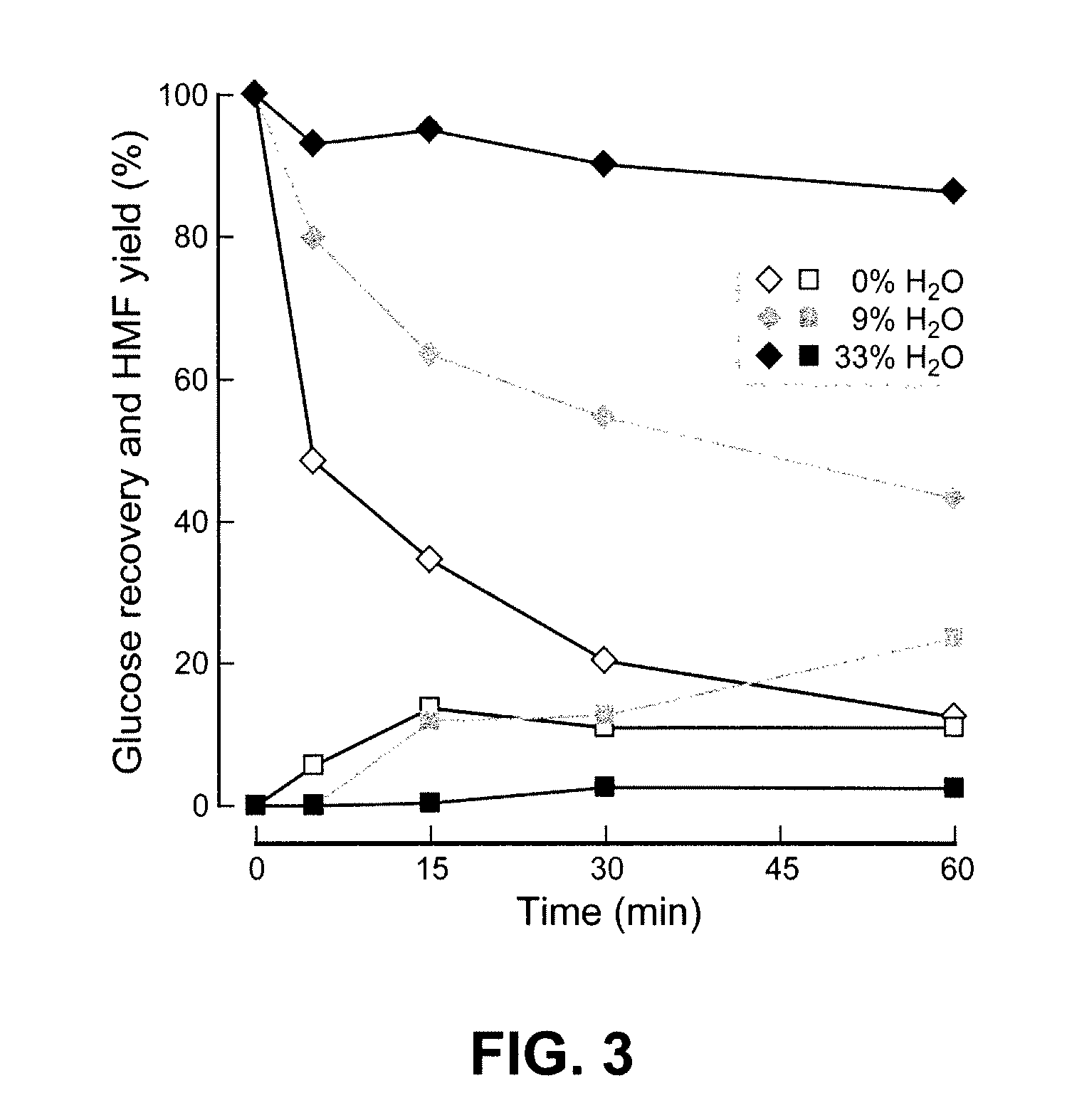

Biomass hydrolysis

ActiveUS20110065159A1Facilitate enhanced yield of glucoseImprove glucose yieldSugar derivativesOrganic-compounds/hydrides/coordination-complexes catalystsCelluloseHydrolysate

High-yielding method for chemical hydrolysis of lignocellulose into monosaccharides. The process of the invention can additionally be applied to cellulose, xylan and related biomass polysaccharides, such as galactan, mannan, or arabinan. The method is employed for hydrolysis of a biomass polysaccharide substrate. The process is carried out in an ionic liquid in which cellulose is soluble in the presence of catalytic acid at a temperature sufficiently high to initiate hydrolysis. Water is added to the reaction mixture after initiation of hydrolysis at a rate controlled to avoid precipitation yet avoid undesired sugar dehydration products such ad HMF. Hydrolysis product is useful as feedstock for fermentations including fermentation processes for ethanol, butanol and other fuels.

Owner:WISCONSIN ALUMNI RES FOUND

Fermentive production of four carbon alcohols

Methods for the fermentative production of four carbon alcohols is provided. Specifically, butanol, preferably isobutanol is produced by the fermentative growth of a recombinant bacterium expressing an isobutanol biosynthetic pathway.

Owner:GEVO INC

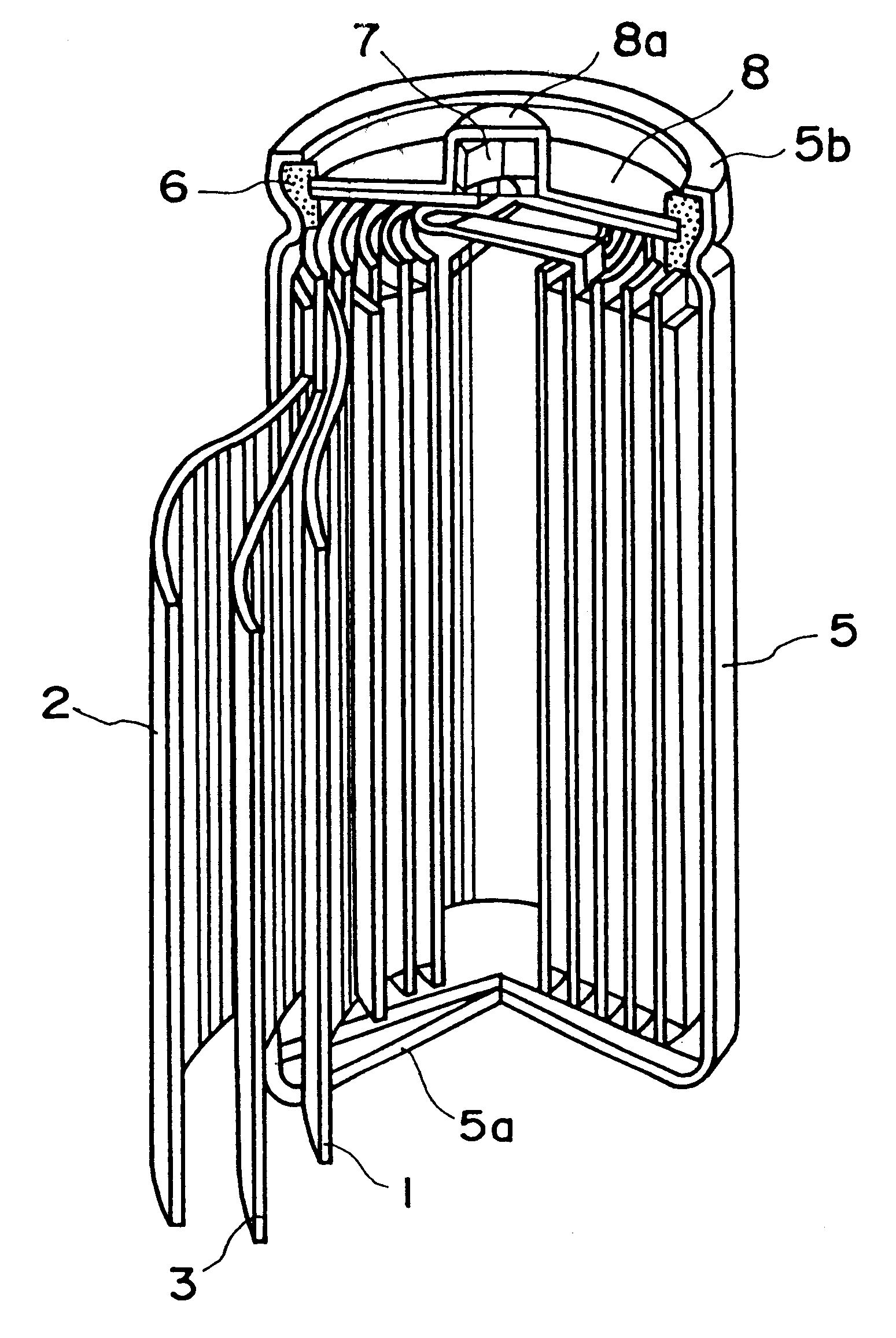

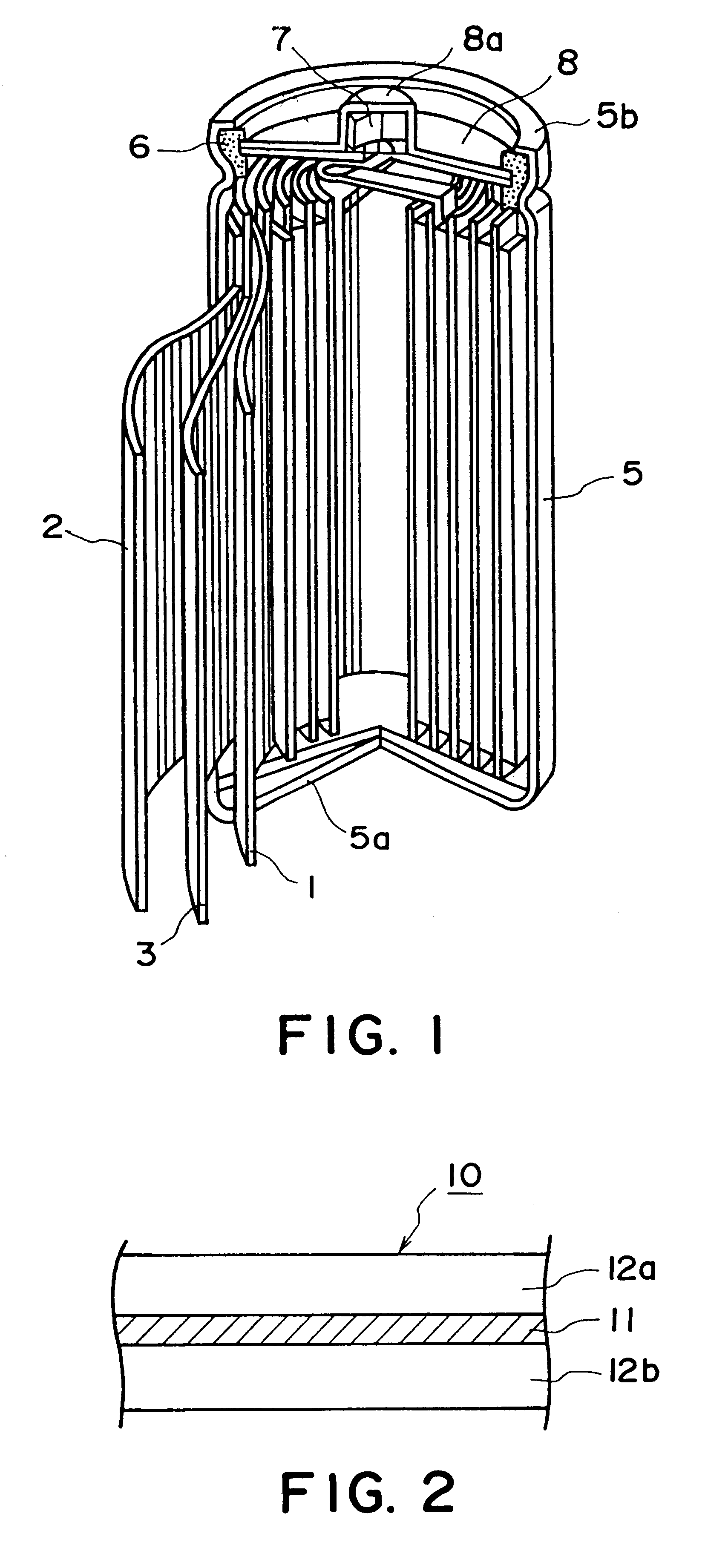

Carbonaceous electrode material for non-aqueous secondary battery

InactiveUS6335122B1Large de-doping capacityLarge doping and de-doping capacityNon-aqueous electrolyte accumulatorsActive material electrodesElement analysisVolumetric Mass Density

A carbonaceous electrode having improved capacities for doping and dedoping of a cell active substance, such as lithium, and suitable for a non-aqueous solvent secondary battery, is constituted by a carbonaceous material having a true density as measured by a butanol substitution method of at most 1.46 g / cm3, a true density as measured by a helium substitution method of at least 1.7 g / cm3, a hydrogen-to-carbon atomic ratio H / C of at most 0.15 as measured according to elementary analysis, a BET specific surface area of at most 50 m2 / g as measured by nitrogen adsorption BET method, and a carbon dioxide adsorption capacity of at least 10 ml / g. The carbonaceous material is advantageously produced by carbonizing an organic material originated from bamboo genera of family Gramineae, particularly genus Pleioblastus or Bambusa, at 1000-1400° C. under a reduced pressure or under a flowing inert gas stream to provide an appropriate porous structure.

Owner:TOHOKU MURATA MFG CO LTD +1

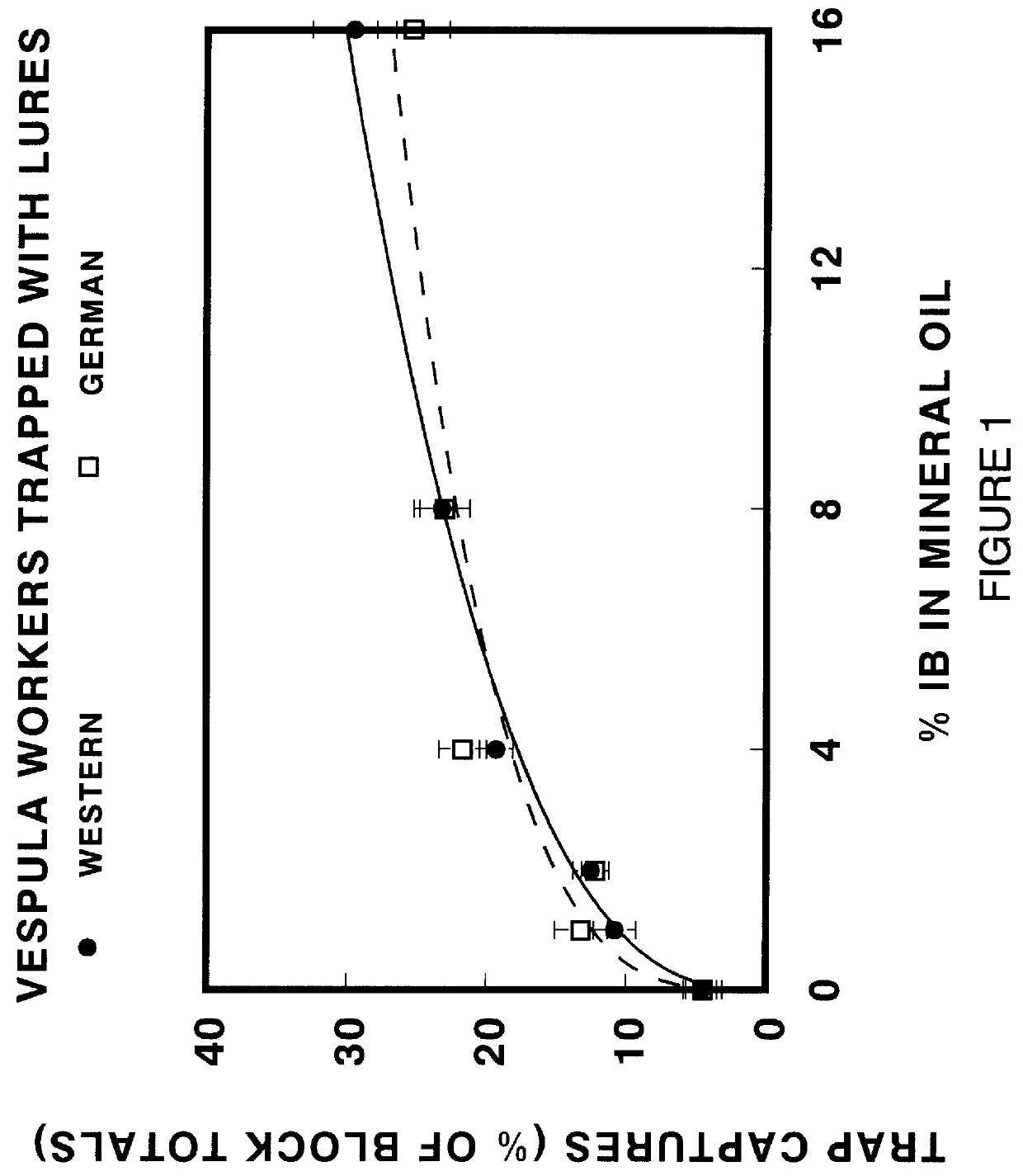

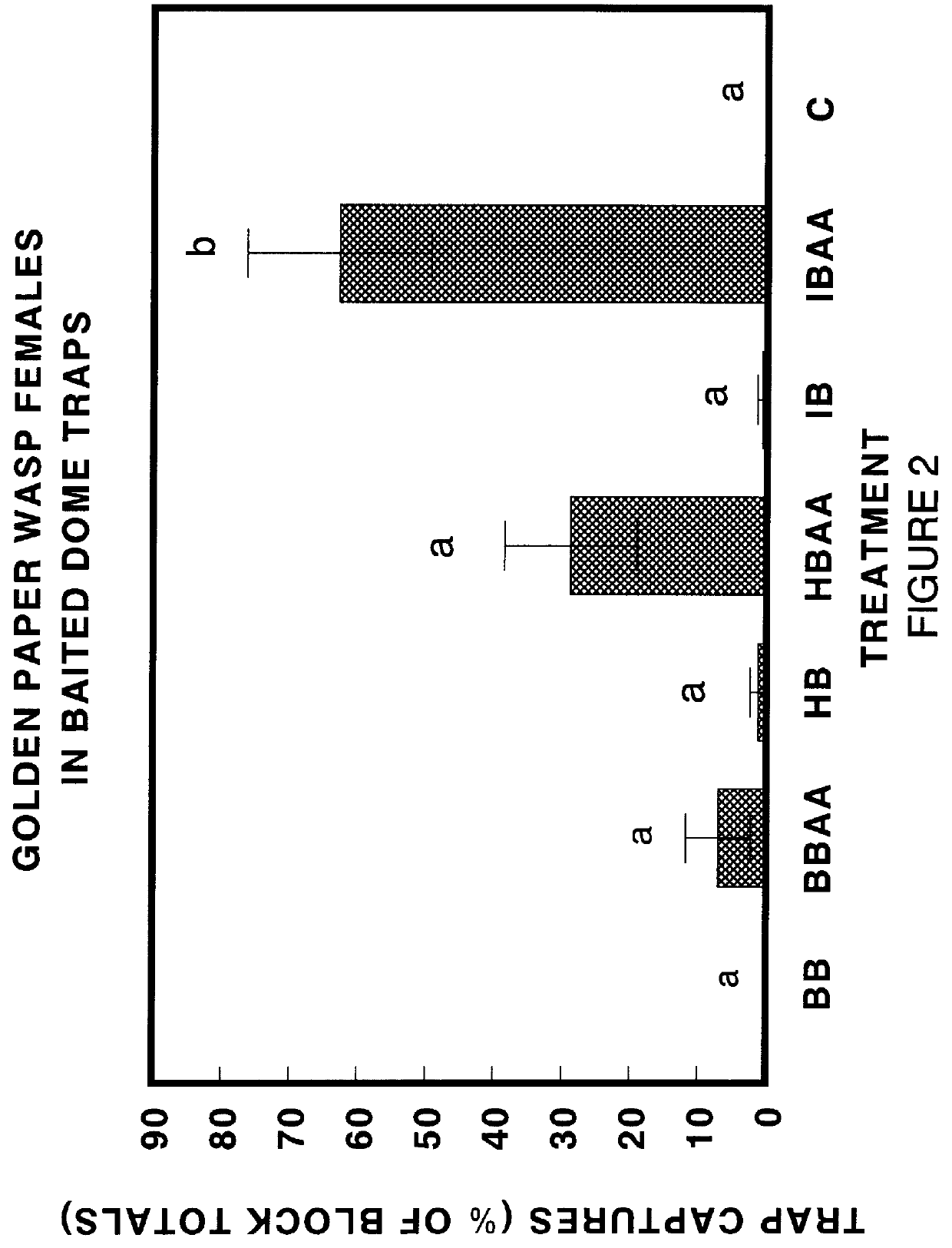

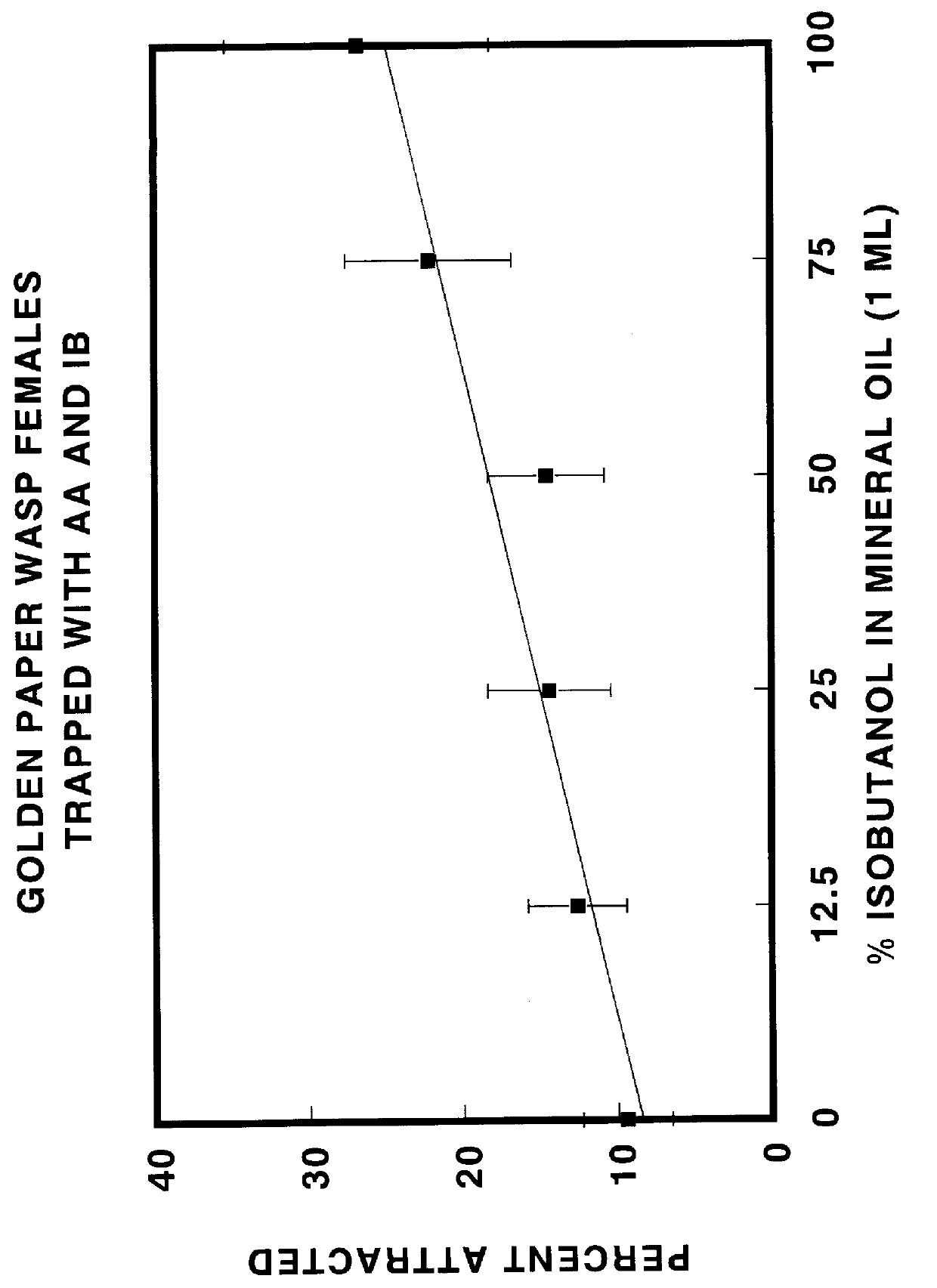

Chemical attractants for yellowjackets and paper wasps

InactiveUS6083498AEnhanced informationEfficient methodBiocidePeptide/protein ingredientsIsobutanolPropanol

Compositions and lures are described which provide vapor blends of acetic acid and one or more compounds selected from the group consisting of isobutanol, racemic 2-methyl-1-butanol, S-(-)-2-methyl-1-butanol, 2-methyl-2-propanol, heptyl butyrate, and butyl butyrate which function as highly effective attractants for yellowjacket wasps and paper wasps. By attracting wasps to traps or baits, the chemical attractants provide a means for detecting, surveying, monitoring, and controlling the wasps.

Owner:US SEC AGRI

Yeast production culture for the production of butanol

High cell density cultures of yeast were found to have higher tolerance for butanol in the medium. The high cell density yeast cultures had greater survival and higher glucose utilization than cultures with low cell densities. Production of butanol using yeast in high cell density cultures is thus beneficial for improving butanol production.

Owner:BUTAMAXTM ADVANCED BIOFUELS

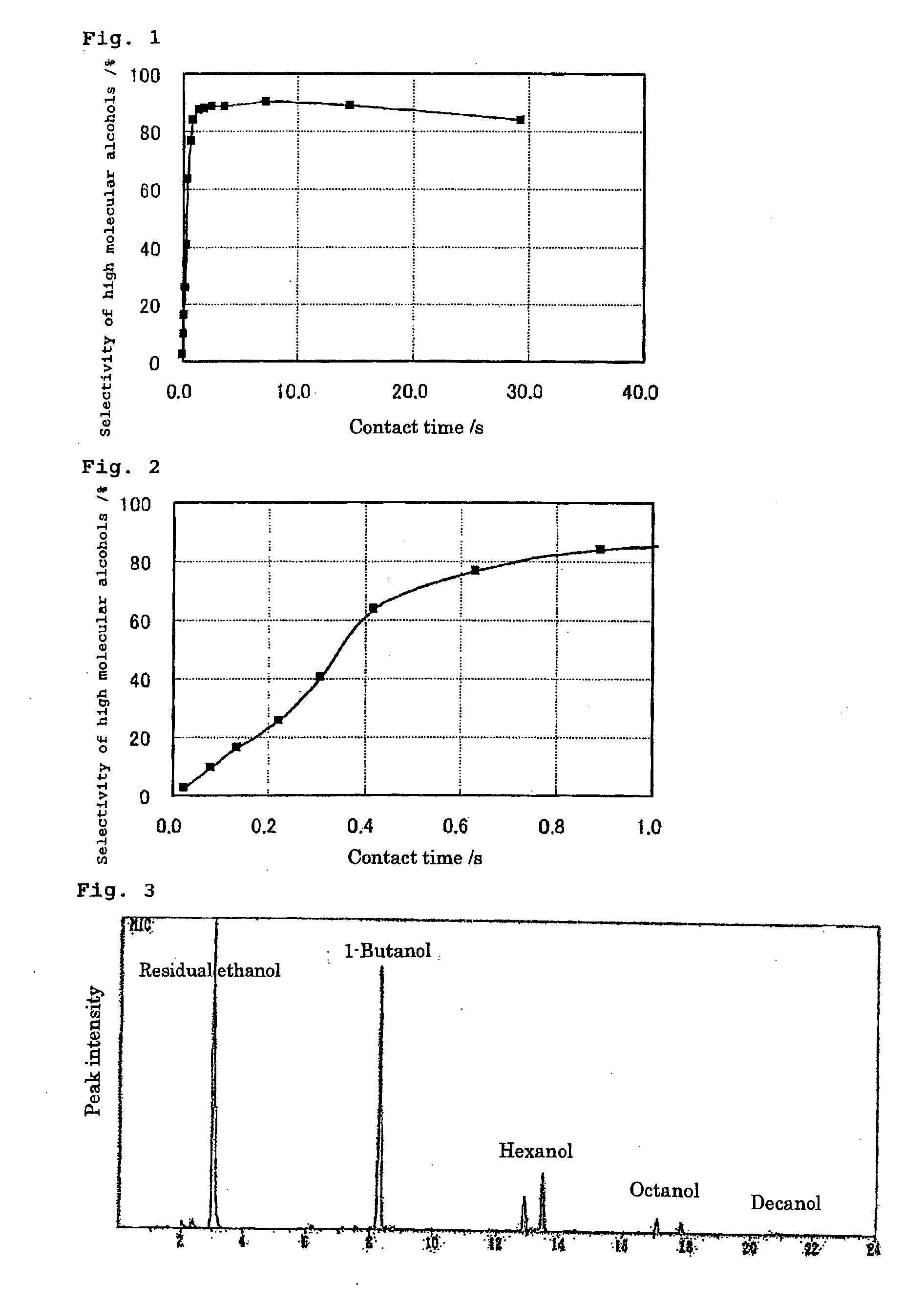

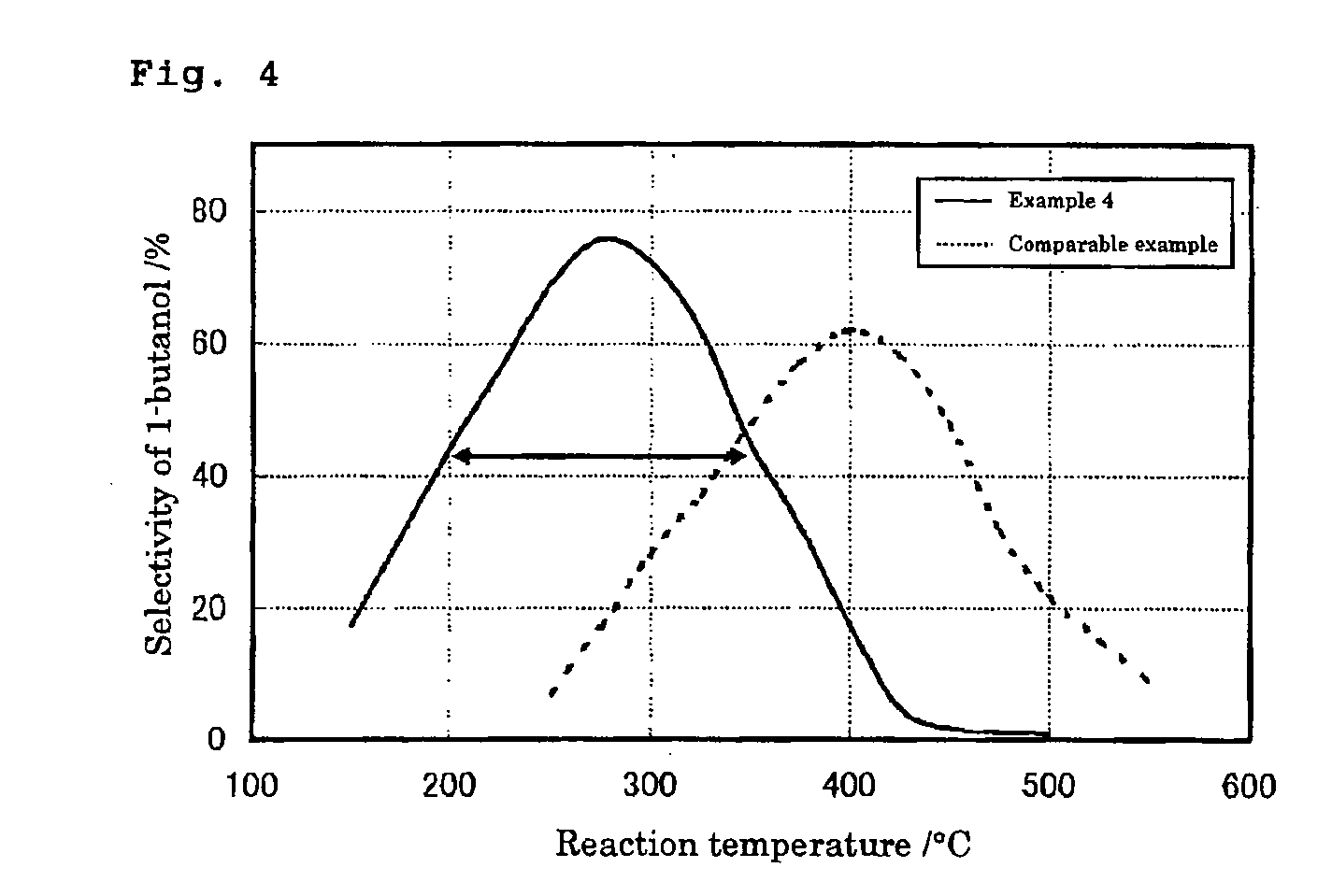

Method of Synthesizing Higher-Molecular Alcohol

ActiveUS20070255079A1Efficient collectionIncreased ethanol productionOxygen-containing compound preparationOrganic compound preparationOctanolSynthetic Polymeric Macromolecules

The present invention provides a production method with which high molecular alcohols having an even number of carbon atoms such as 1-butanol, hexanol, octanol and decanol, and a mixture of these are efficiently collected through clean processes with the use of ethanol as a raw material. High molecular alcohols are produced from ethanol by using calcium phosphate-based compounds such as hydroxyapatite Ca10(PO4)6(OH)2, tricalcium phosphate Ca3(PO4)2, calcium monohydrogen phosphate CaHPO4.(0˜2)H2O, calcium diphosphate Ca2P2O7, octacalcium phosphate Ca8H2(PO4)6.5H2O, tetracalcium phosphate Ca4(PO4)2O or amorphous calcium phosphate Ca3(PO4)2.nH2O as a catalyst, using ethanol as a starting material, and setting a contact time at 0.4 second or longer.

Owner:SANGI CO LTD

Complex oxide catalysts and process for producing (meth) acrolein and (meth) acrylic acid

InactiveUS6383973B1Good reproducibilityHigh activityOrganic compound preparationOrganic chemistry methodsNitrate anionAlkaline earth metal

Complex oxide catalysts represented by the formula,(in which A is Ni or Co; B is Na, K, Rb, Cs or Tl; C is an alkaline earth metal; D is P, Te, Sb, Sn, Ce, Pb, Nb, Mn, As, B or Zn; E is Si, Al, Ti or Zr; and where a is 12, 0<=b<=10, 0<c<=10, 0<d<=10, 2<=e<=15, 0<f<=10, 0<=g<=10, 0<=h<=4 and 0<=i<=30)are provided. The catalysts are characterized in that the molar ratio of the total nitrate anions to the molybdenum at the time of catalyst preparation is more than 1 but not more than 1.8. When used in the reaction for producing (meth)acrolein and (meth)acrylic acid by vapor-phase oxidation of at least a compound selected from propylene, isobutylene, t-butanol and methyl-t-butyl ether, the catalysts exhibit excellent activity and selectivity and maintain stable performance over prolonged period.

Owner:NIPPON SHOKUBAI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com