Recombinant microorganism and methods of production thereof

a technology of recombinant microorganisms and biofuels, applied in the field of biofuel production methods, can solve the problems of limited greenhouse gas reductions that can be achieved, unsustainable first-generation biofuels, and synthesis process that requires non-renewable resources, and achieves the effect of improving the overall efficiency of alcohol production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0293]The invention will now be described in more detail with reference to the following non-limiting examples.

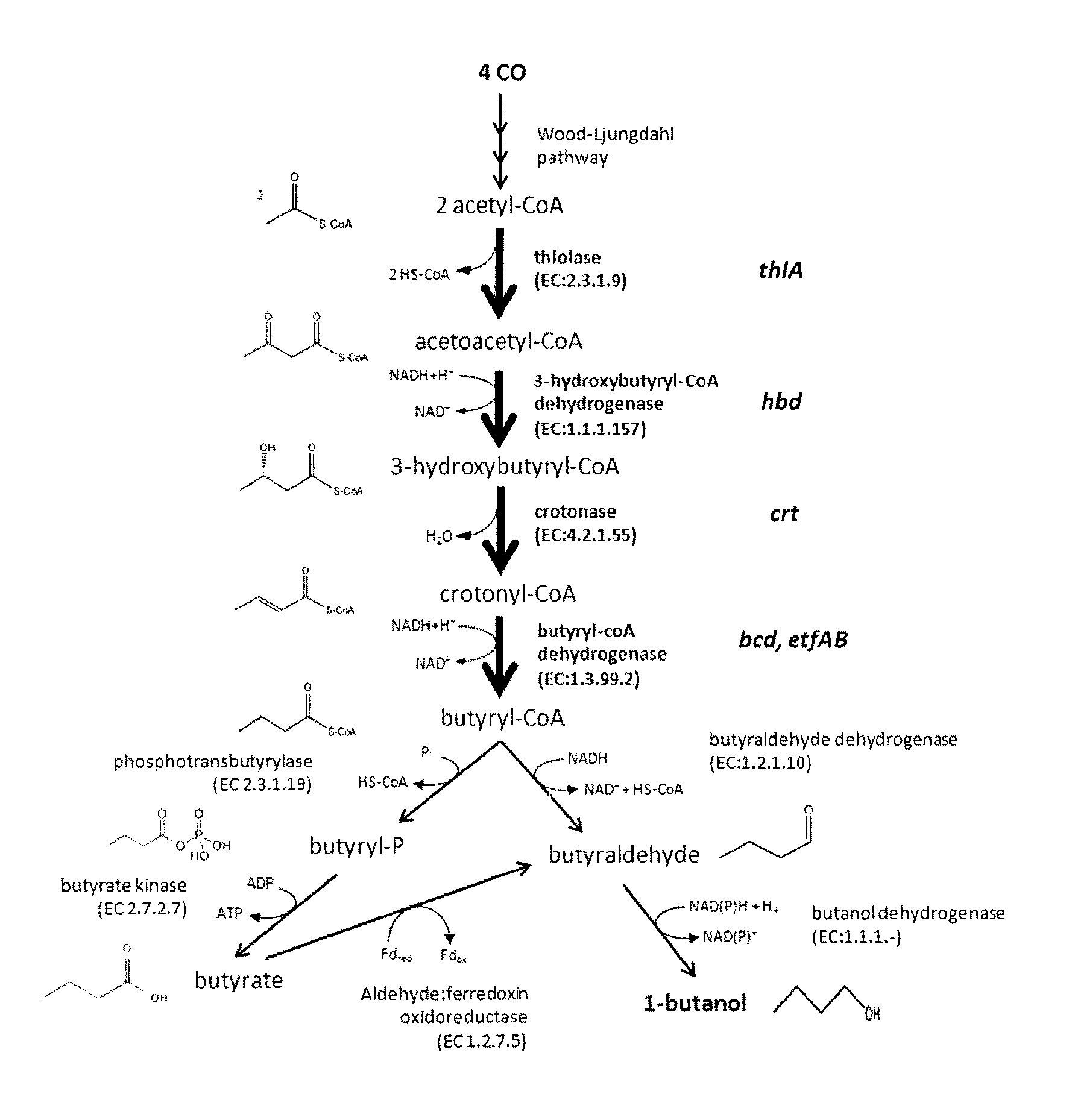

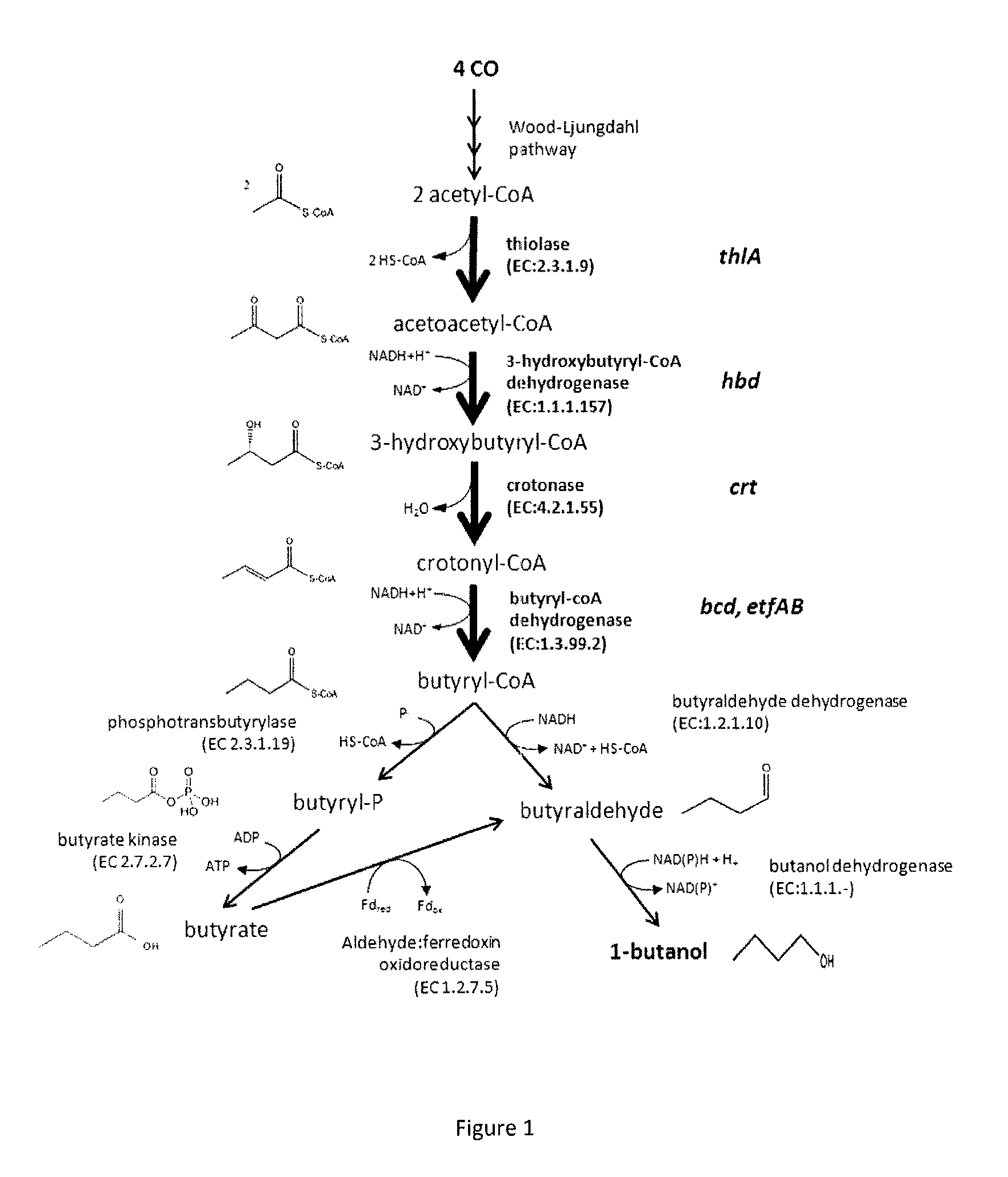

[0294]Genetic modifications were carried out using a plasmid containing a synthetic operon consisting of a strong, native C. autoethanogenum promoter controlling a thiolase, 3-hydroxybutyryl-CoA dehydrogenase, crotonase, butyryl-CoA dehydrogenase, and 2 electron transferring flavoproteins genes from C. acetobutylicum (FIG. 1-2). This plasmid was methylated in vivo using a novel methyltransferase and then transformed into C. autoethanogenum DSM23693. Production of 1-butanol as the main fermentation product was shown on different industrial gas streams (steel mill waste gas, syngas).

Construction of Expression Plasmid:

[0295]Standard Recombinant DNA and molecular cloning techniques were used in this invention and are described by Sambrook et al, 1989 and Ausubel et al, 1987. DNA sequences of butanol biosynthetic genes of Clostridium acetobutylicum ATCC824 used were obtained fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com