Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

939 results about "Industrial gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Industrial gases are the gaseous materials that are manufactured for use in industry. The principal gases provided are nitrogen, oxygen, carbon dioxide, argon, hydrogen, helium and acetylene; although a huge variety of gases and mixtures are available in gas cylinders. The industry producing these gases is also known as industrial gas, which is seen as also encompassing the supply of equipment and technology to produce and use the gases. Their production is a part of the wider chemical Industry (where industrial gases are often seen as "specialty chemicals").

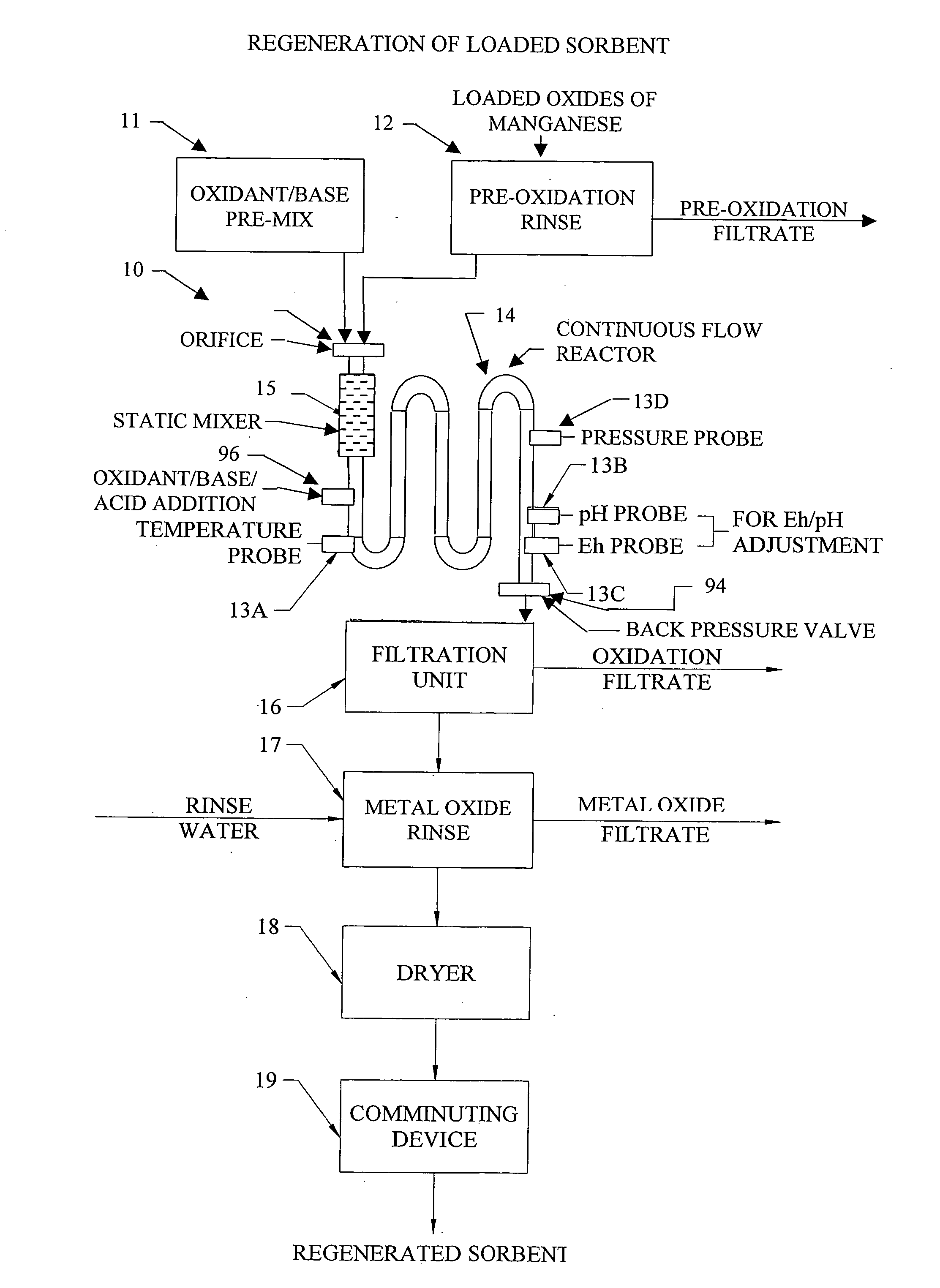

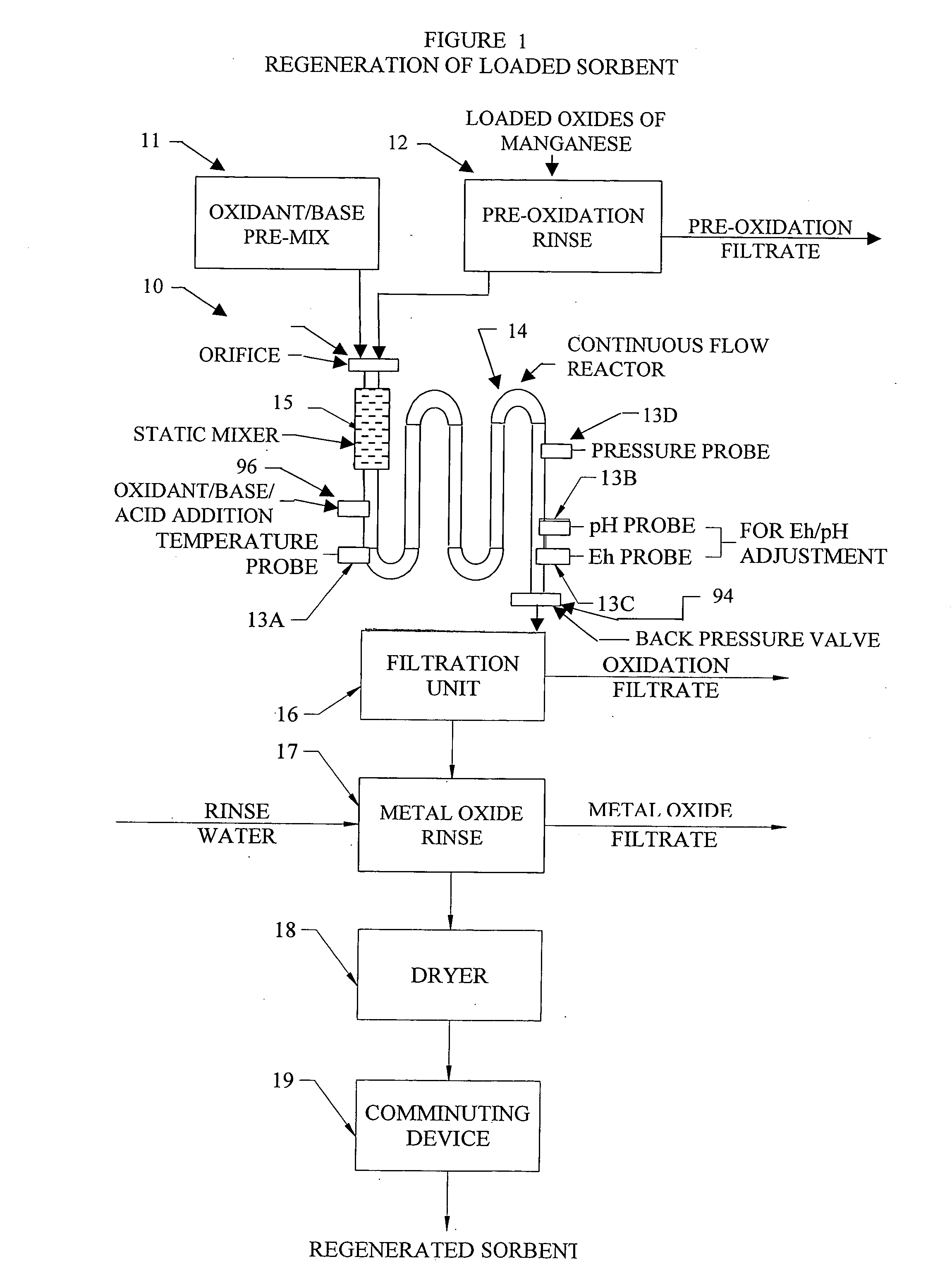

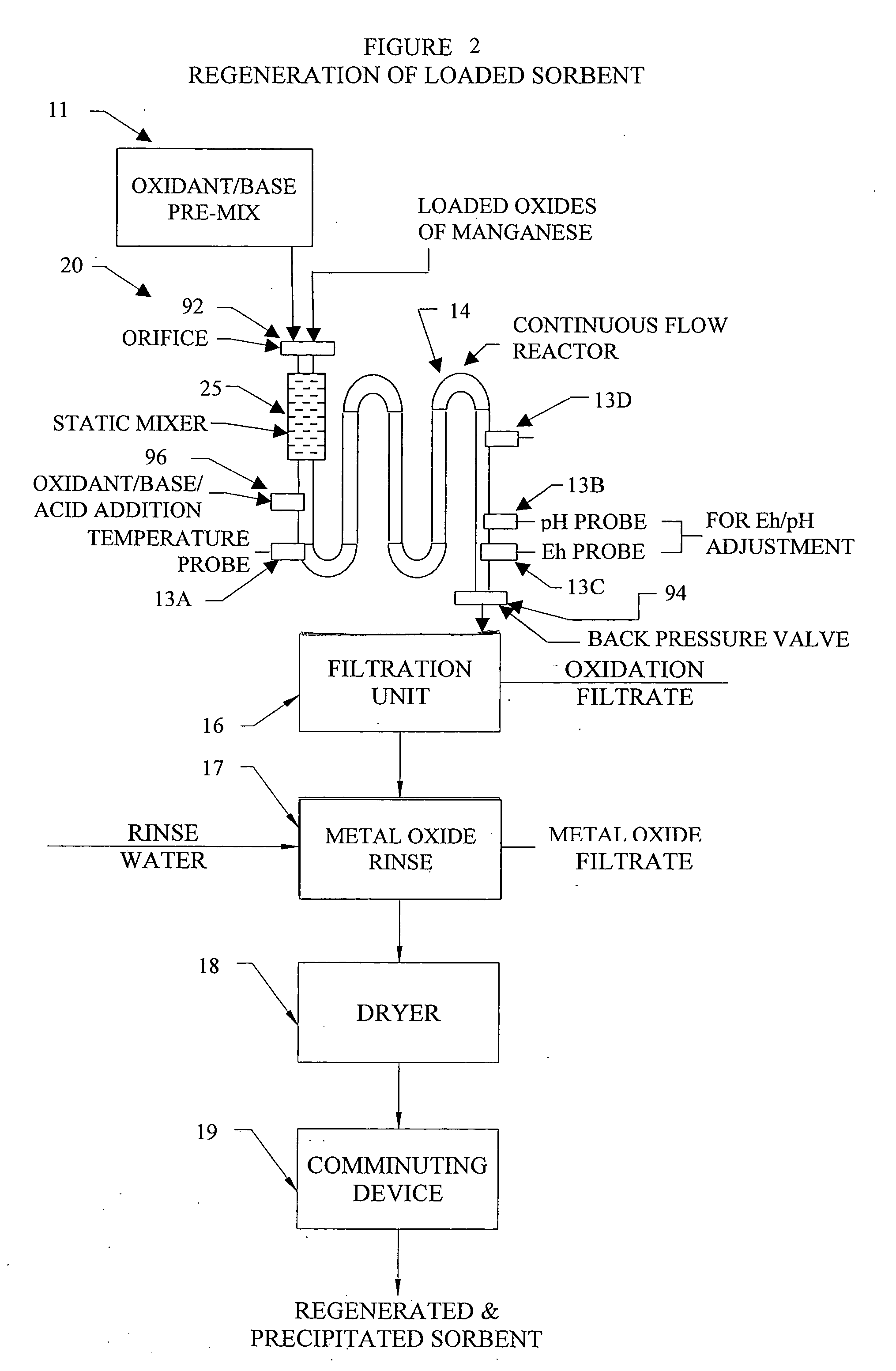

Metal oxide processing methods and systems

InactiveUS20050074380A1Move quicklyIncrease load capacityCombination devicesTemperatue controlIndustrial gasBatch processing

Methods and systems for processing metal oxides from metal containing solutions. Metal containing solutions are mixed with heated aqueous oxidizing solutions and processed in a continuous process reactor or batch processing system. Combinations of temperature, pressure, molarity, Eh value, and pH value of the mixed solution are monitored and adjusted so as to maintain solution conditions within a desired stability area during processing. This results in metal oxides having high or increased pollutant loading capacities and / or oxidation states. These metal oxides may be processed according to the invention to produce co-precipitated oxides of two or more metals, metal oxides incorporating foreign cations, metal oxides precipitated on active and inactive substrates, or combinations of any or all of these forms. Metal oxides thus produced are, amongst other uses; suitable for use as a sorbent for capturing or removing target pollutants from industrial gas streams or drinking water or aqueous streams or for personal protective respirators.

Owner:ENVIROSCRUB TECH CORP

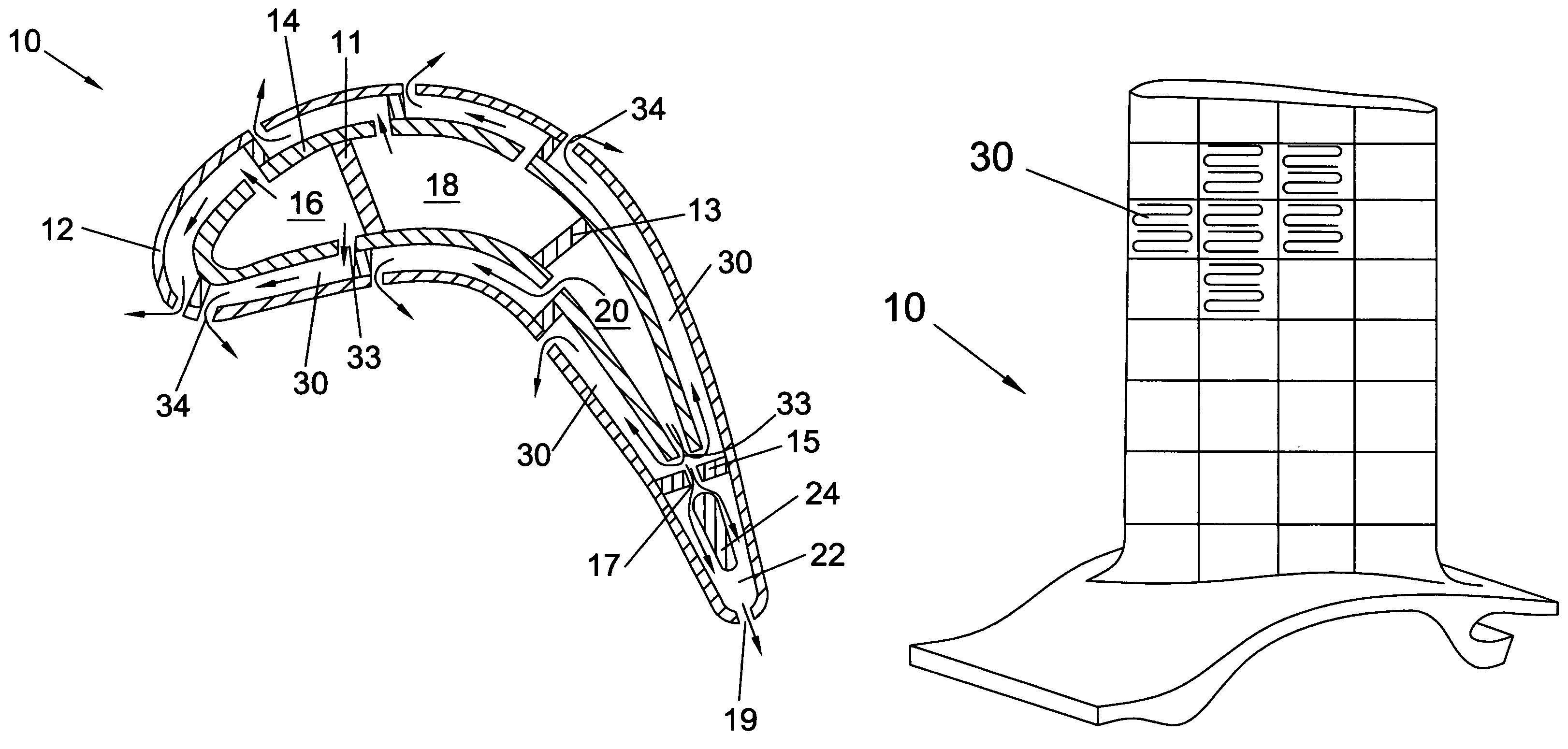

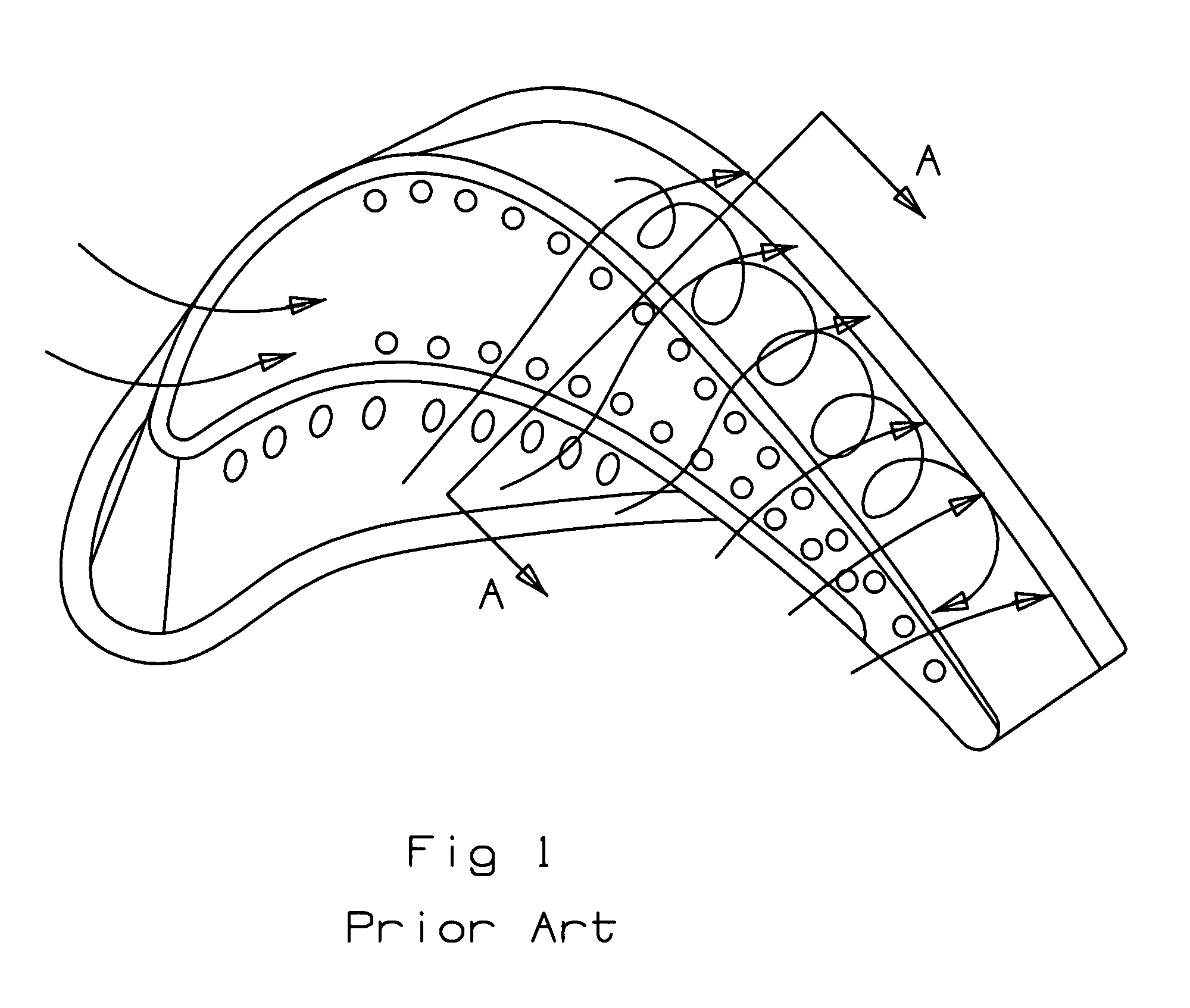

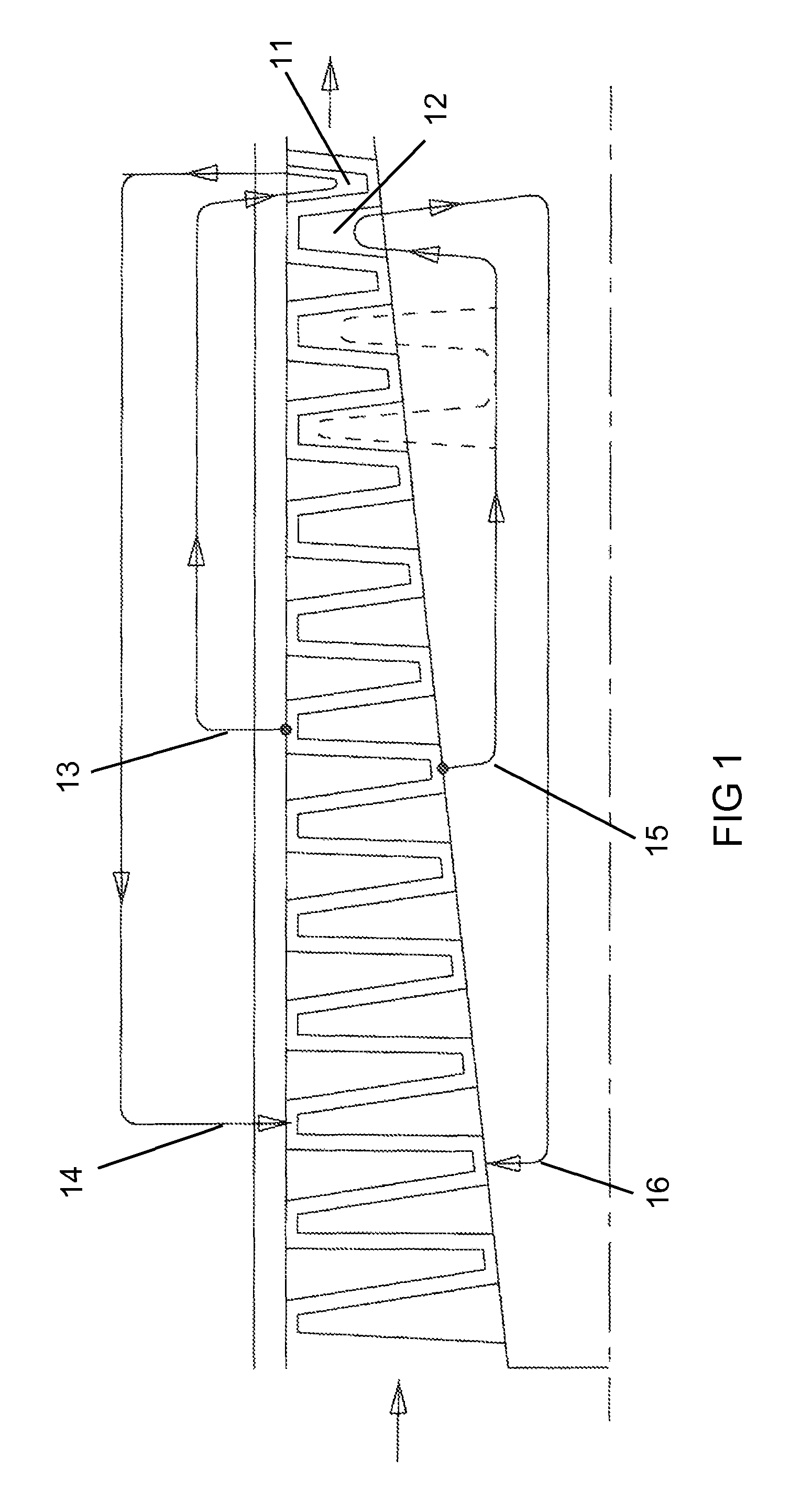

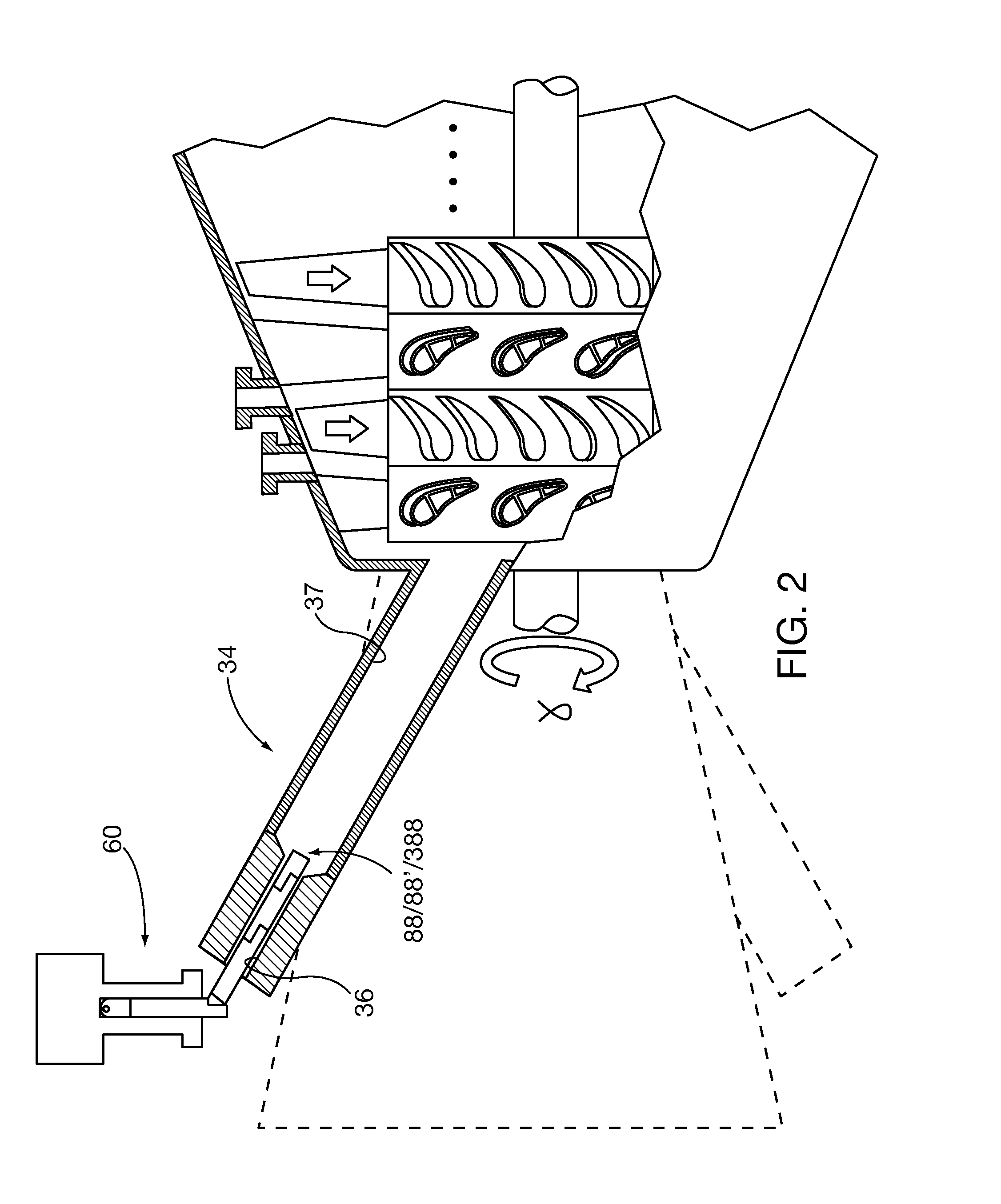

Turbine airfoil with mini-serpentine cooling passages

InactiveUS7527474B1Maximize useHigh internal convection cooing effectivenessPropellersEngine manufactureIndustrial gasTurbine

An airfoil used in a gas turbine engine, especially a large rotor blade in an industrial gas turbine engine, the airfoil having at least one cooling air supply cavity formed by an inner wall of the airfoil to supply cooling air to the airfoil, and a plurality of mini-serpentine cooling modules formed between the inner wall and the outer wall surface of the airfoil providing near-wall cooling for the airfoil. The modules includes three-pass or five-pass serpentine cooling channels with an inlet in fluid communication with the cooling air supply cavity and an outlet opening onto the airfoil surface to provide film cooling to the airfoil. The length of a straight section of the passage is about 5 to 10 mm and about 1 mm in diameter. A plurality of supply cavities are formed within the inner wall and separated by ribs. A plurality of mini-serpentine cooling modules is arranged along a chordwise length of the airfoil and each is in fluid communication with the nearest supply cavity.

Owner:FLORIDA TURBINE TECH

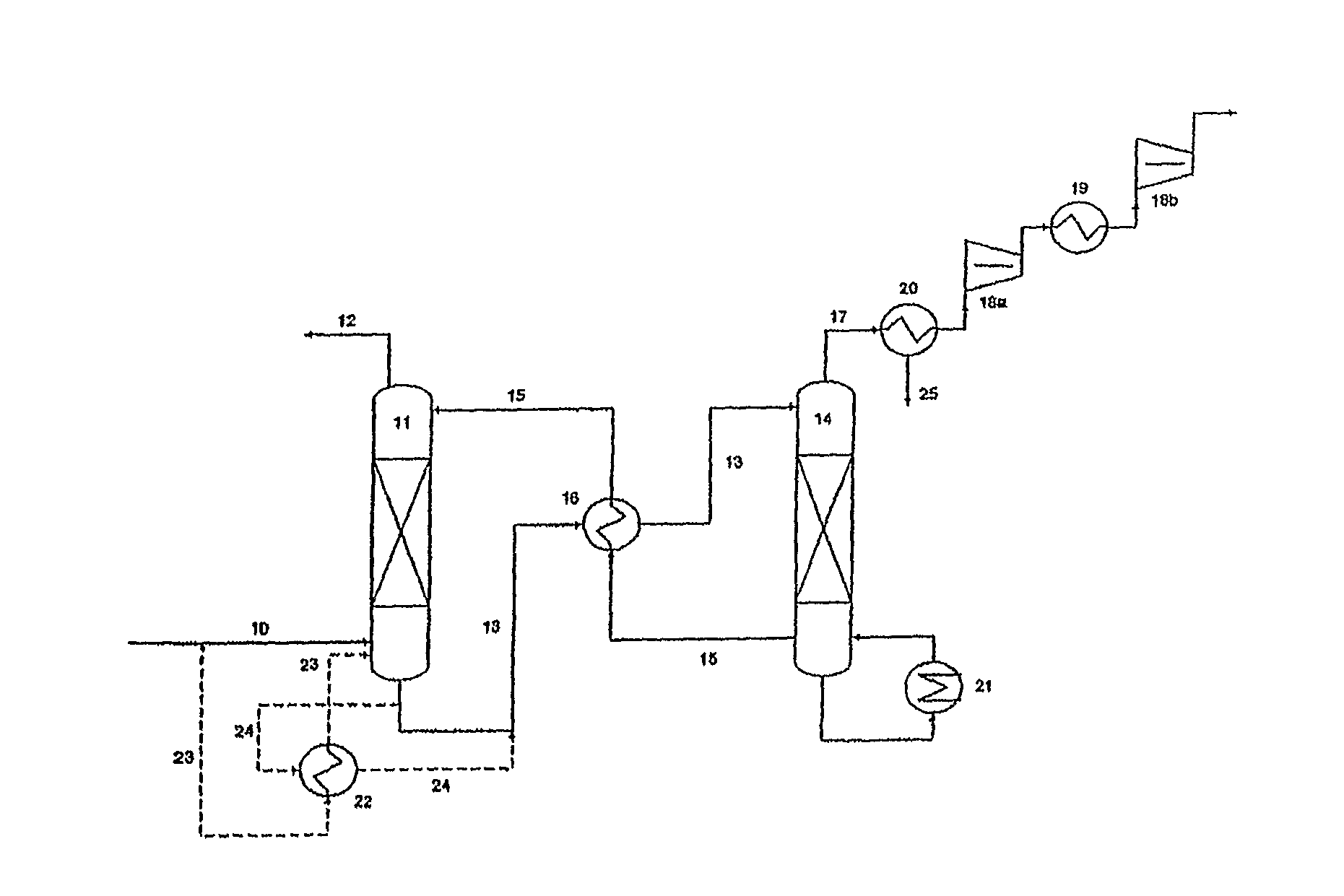

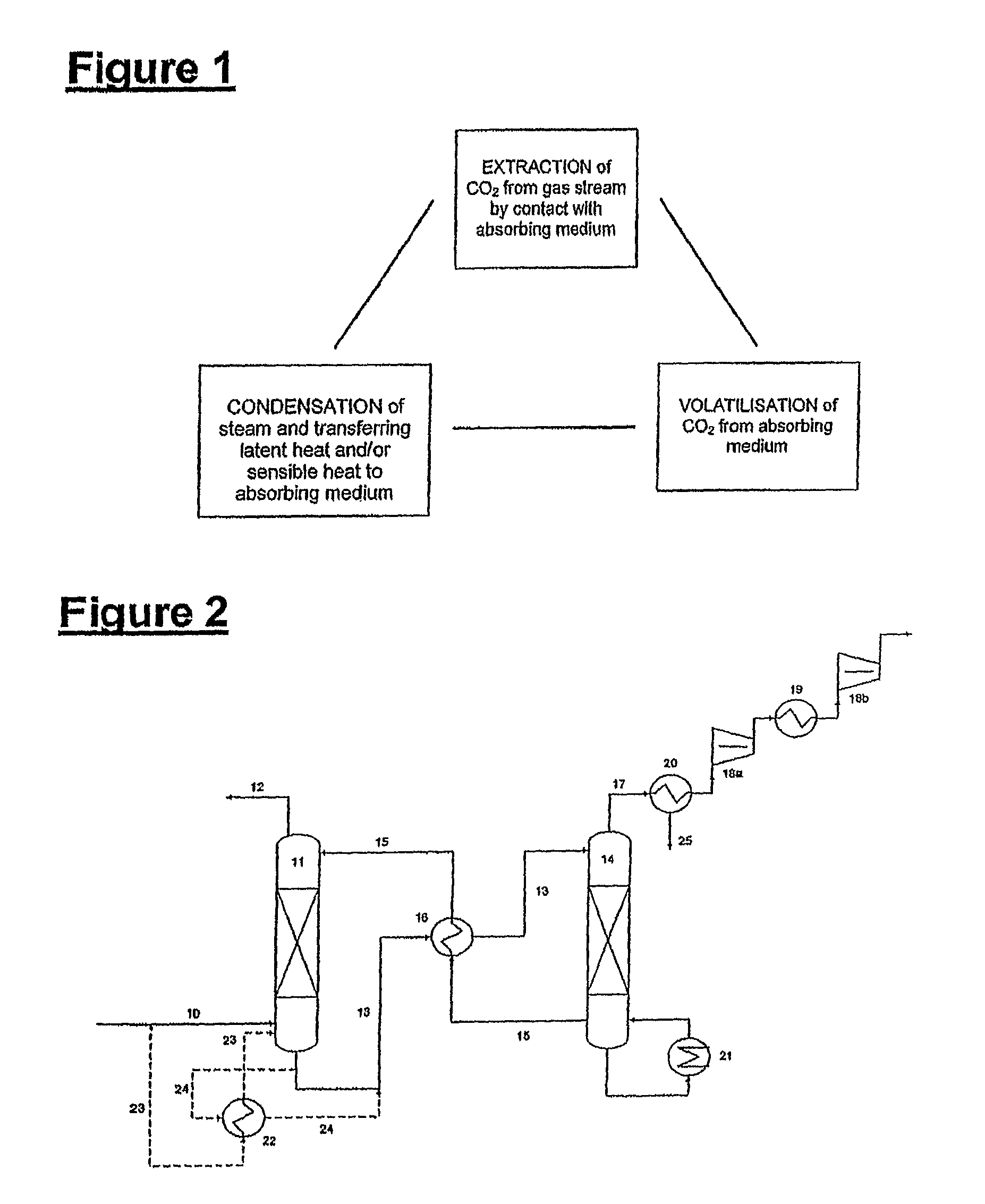

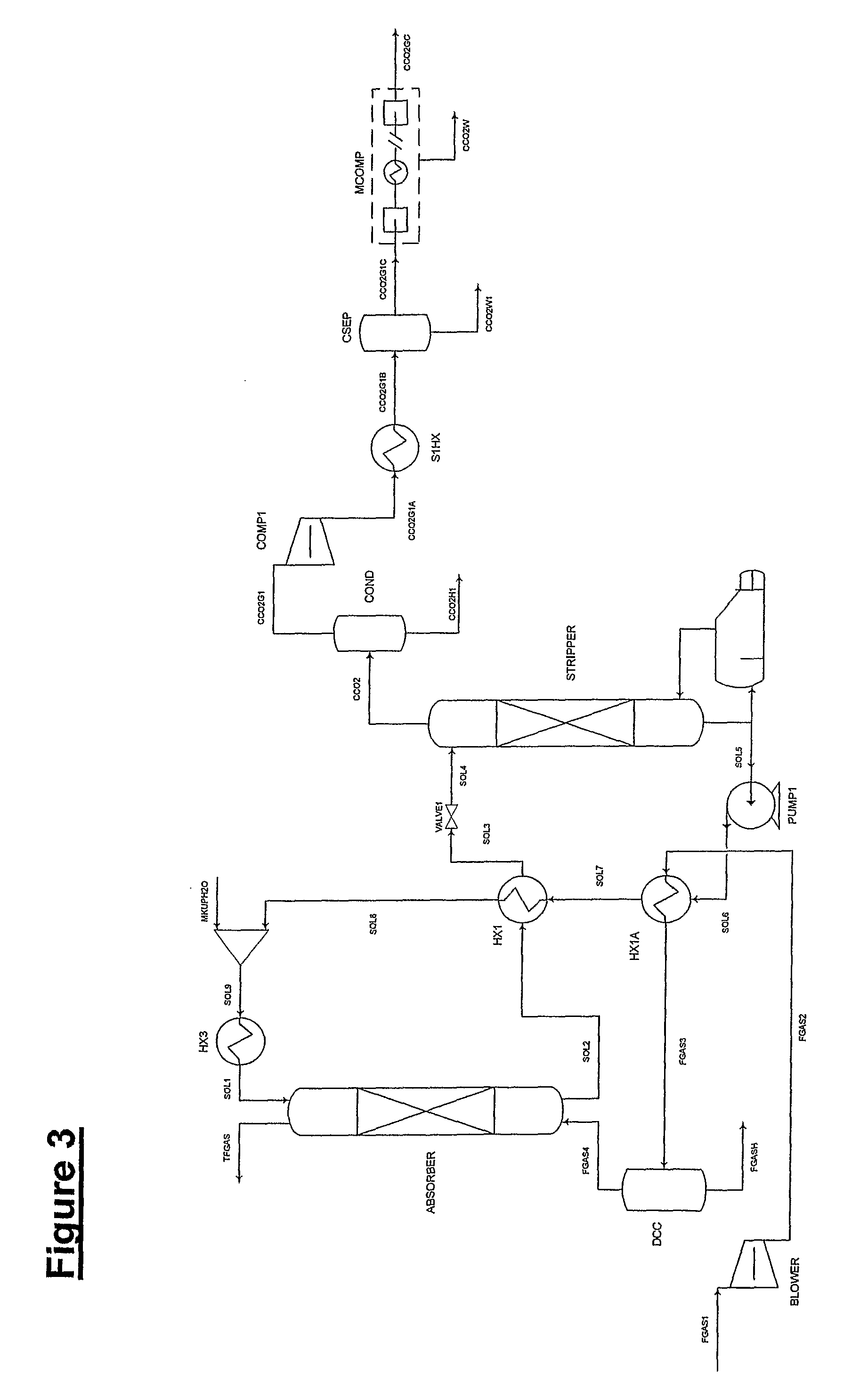

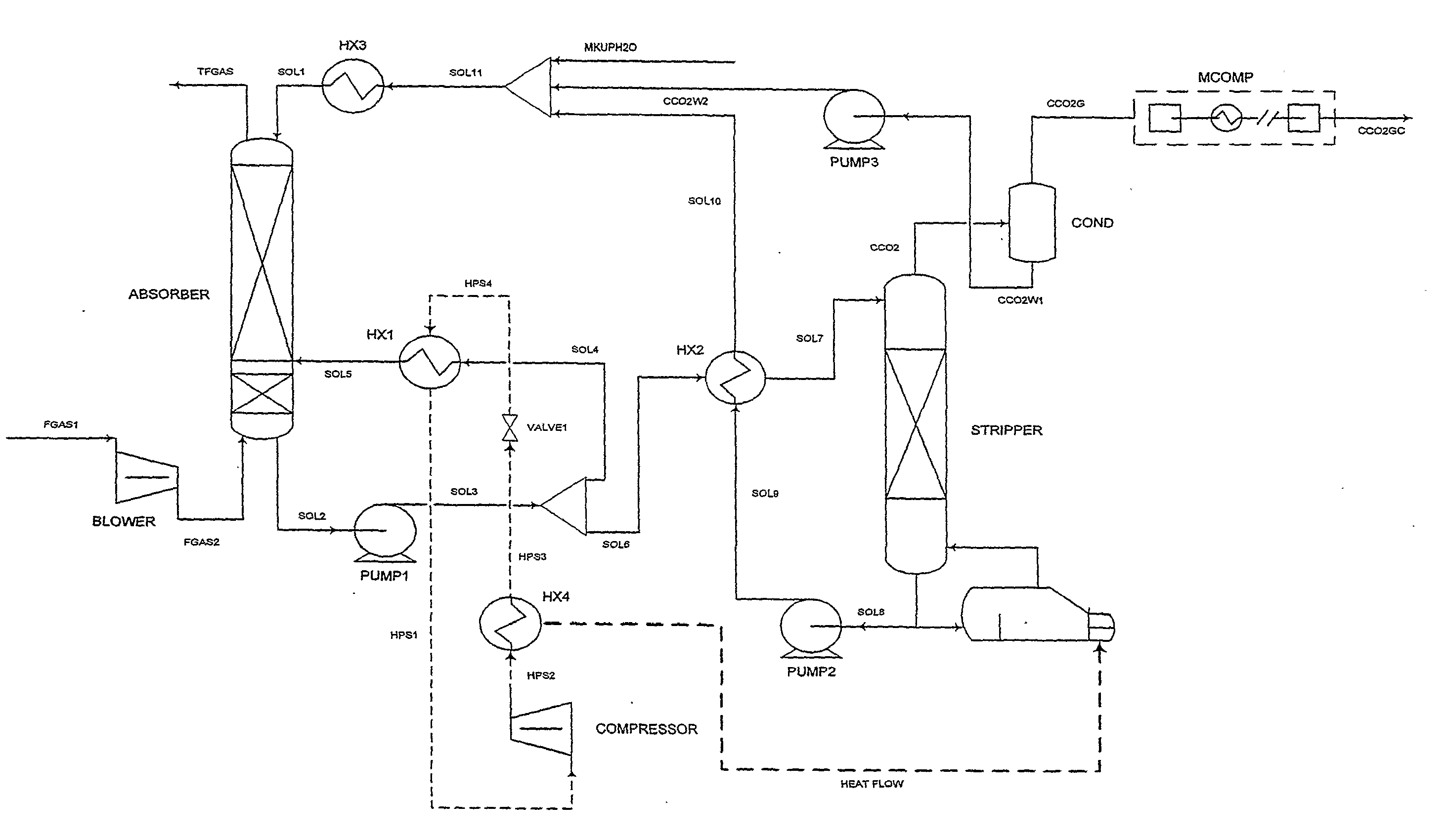

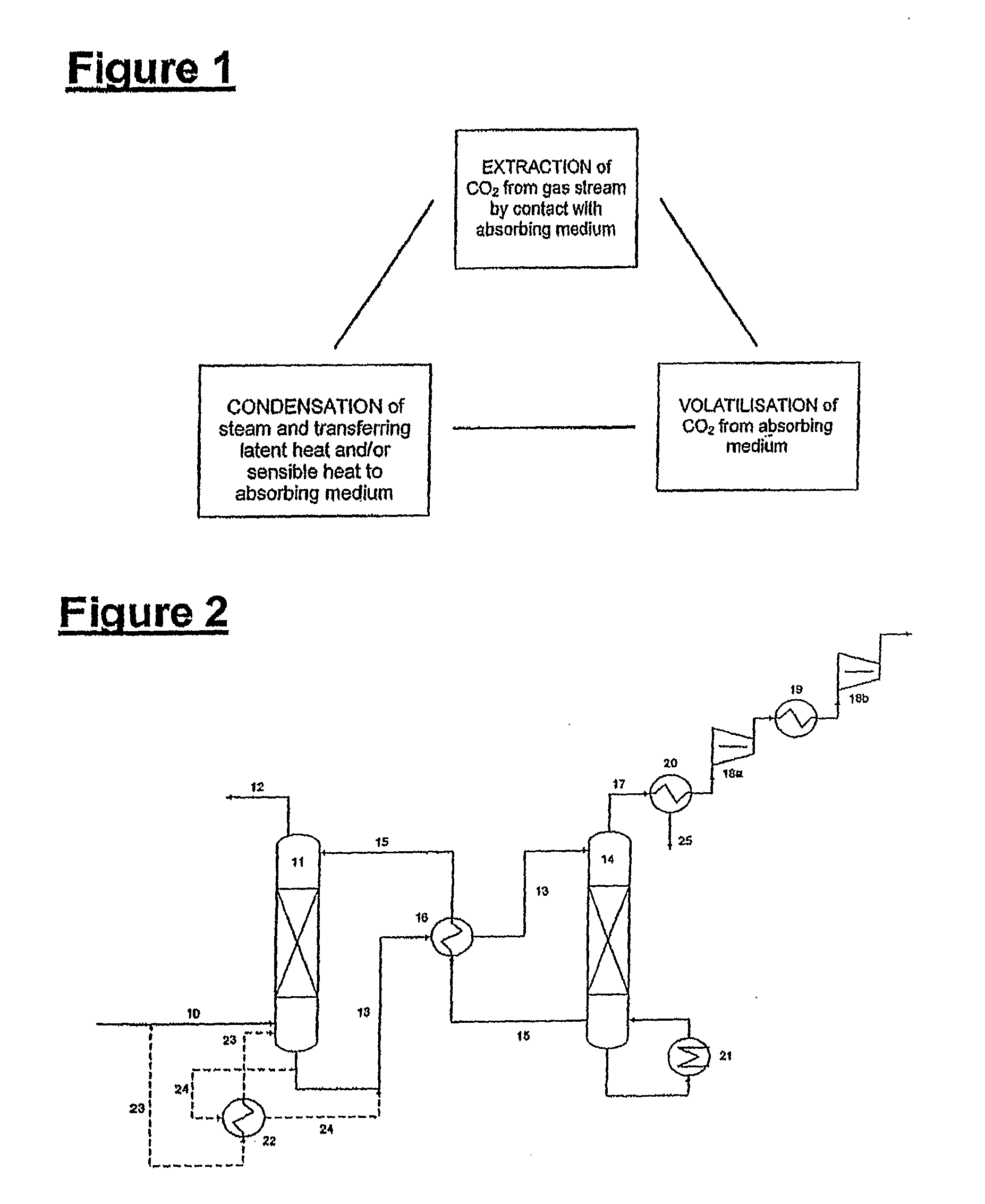

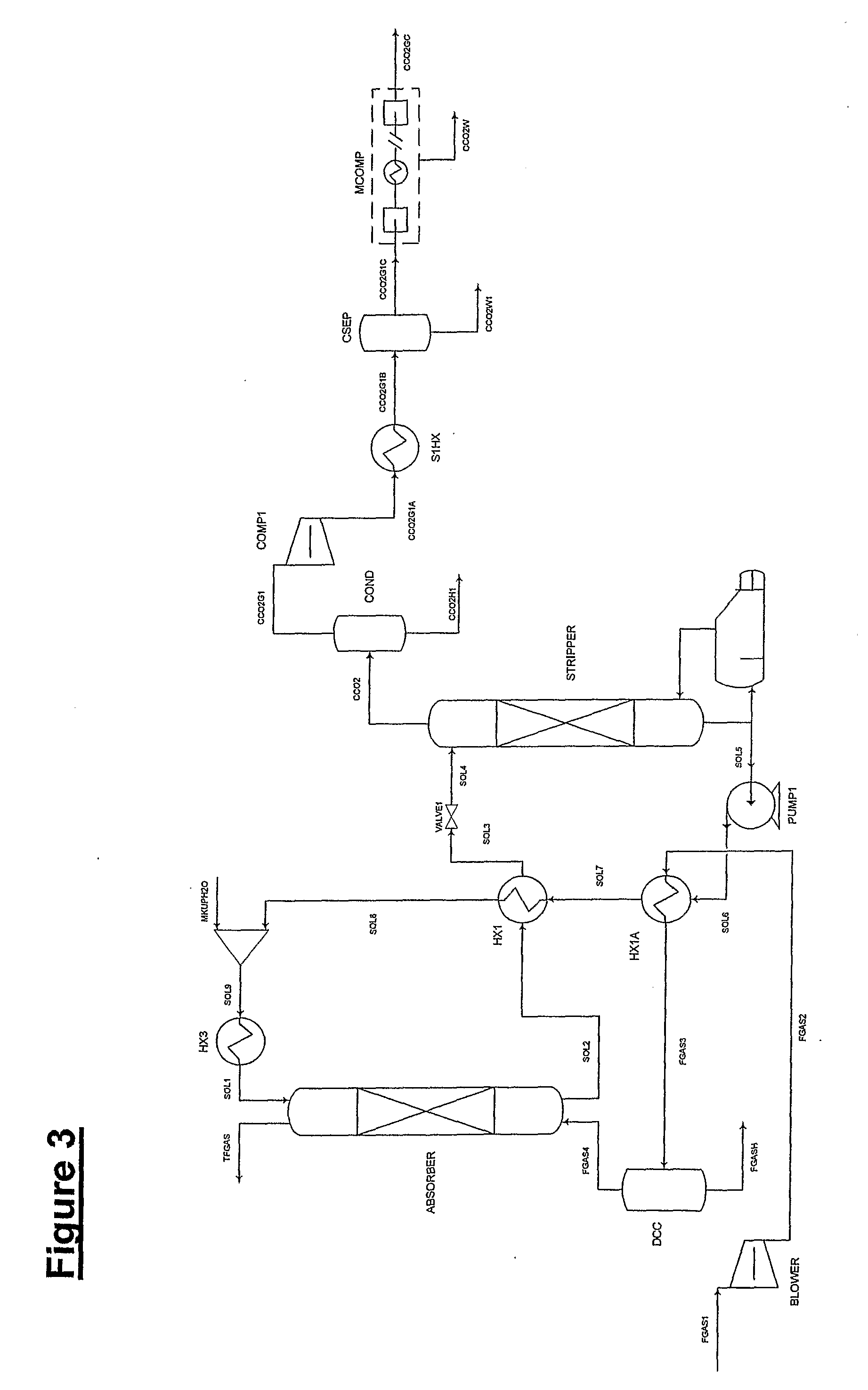

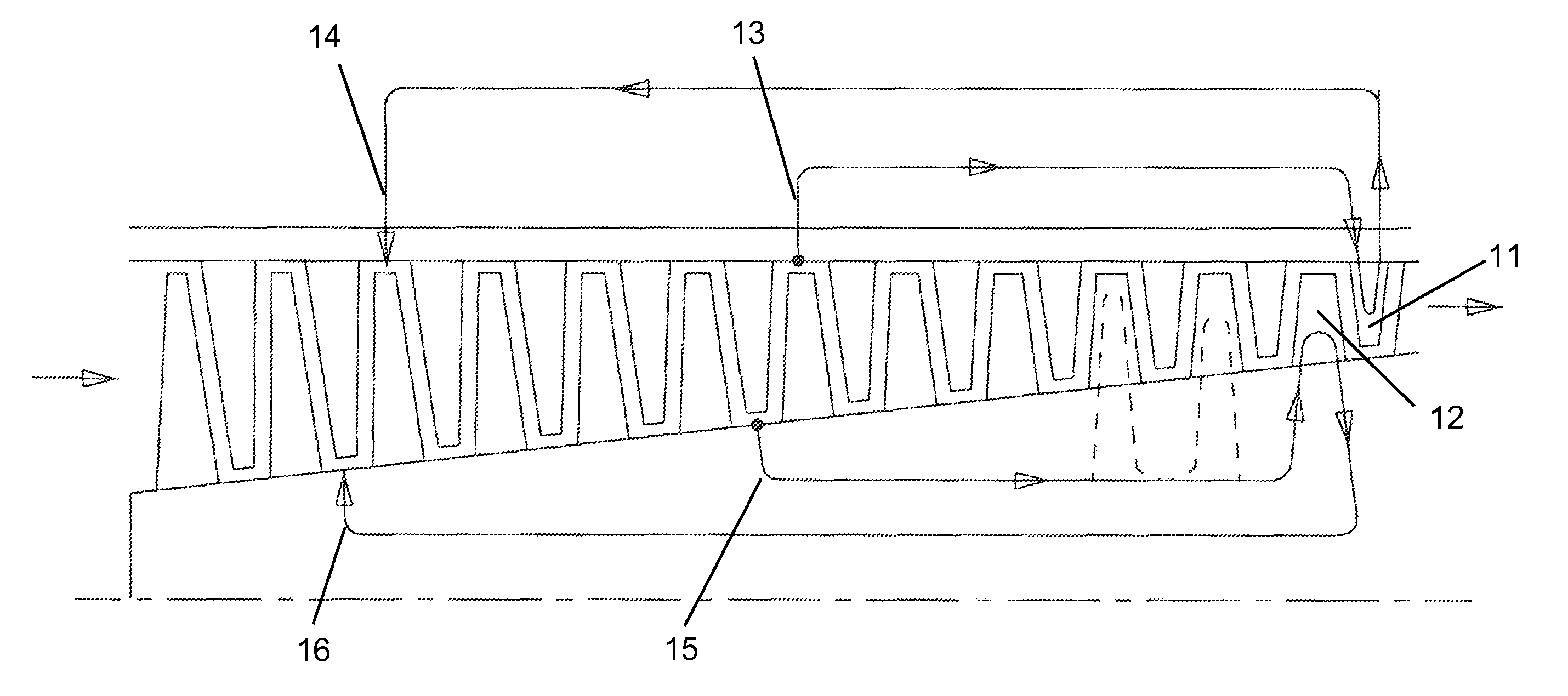

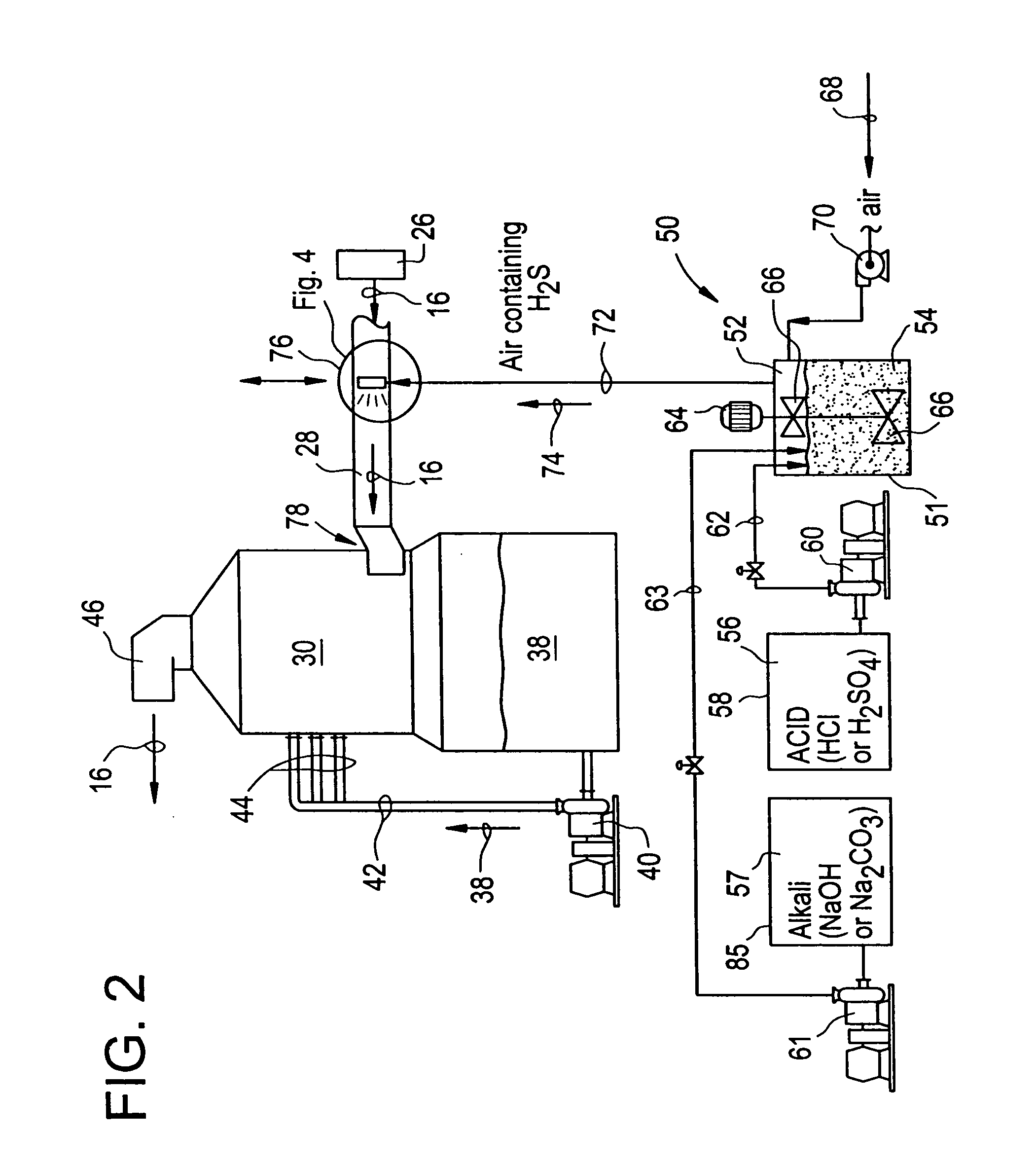

Plant and process for removing carbon dioxide from gas streams

ActiveUS7976803B2Minimizing overall energy requiredAssist in volatilizationFluidized bed combustionIndirect heat exchangersComponents of crude oilCoal

Owner:KC8 CAPTURE TECH LTD

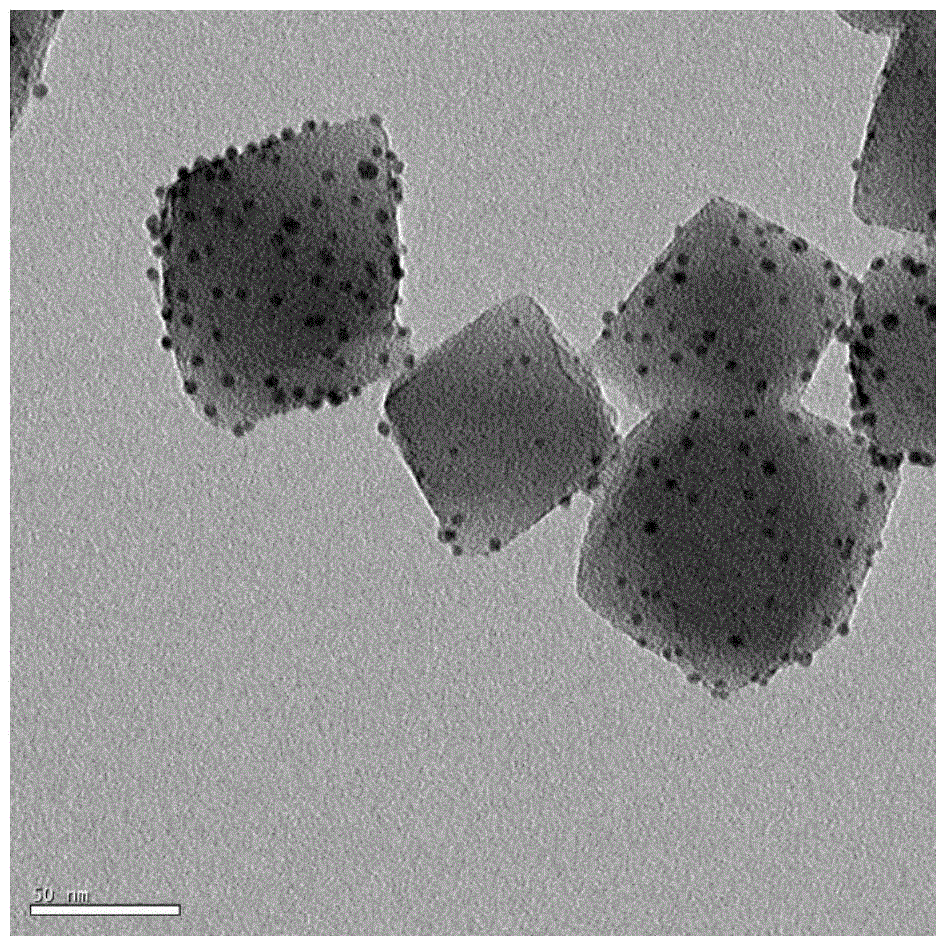

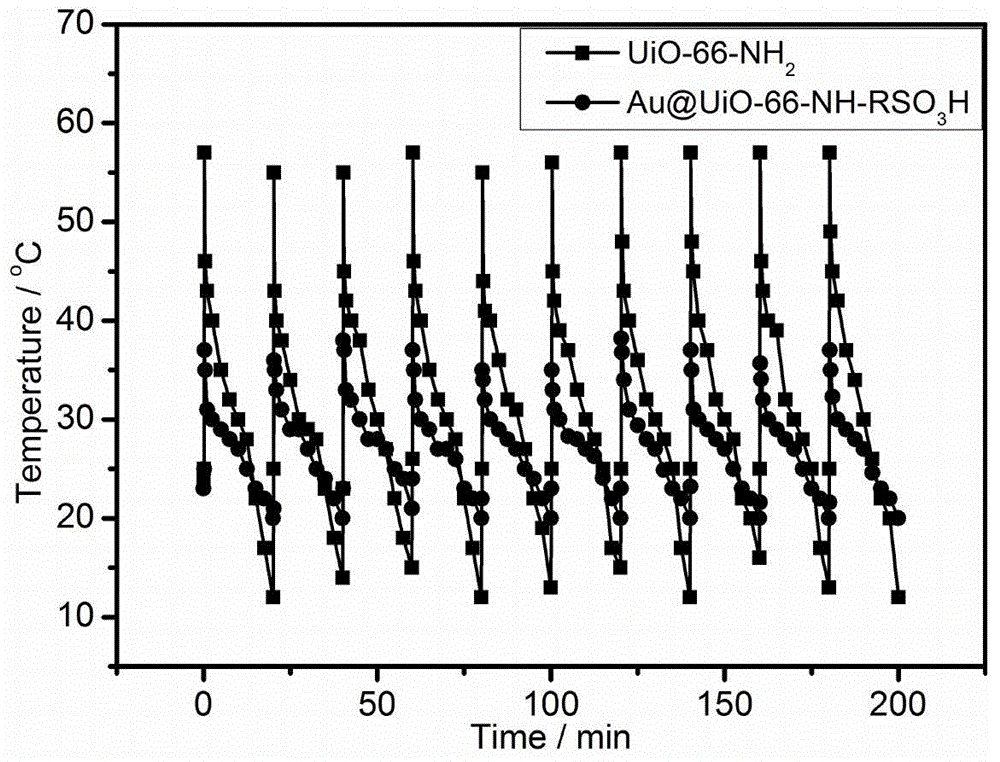

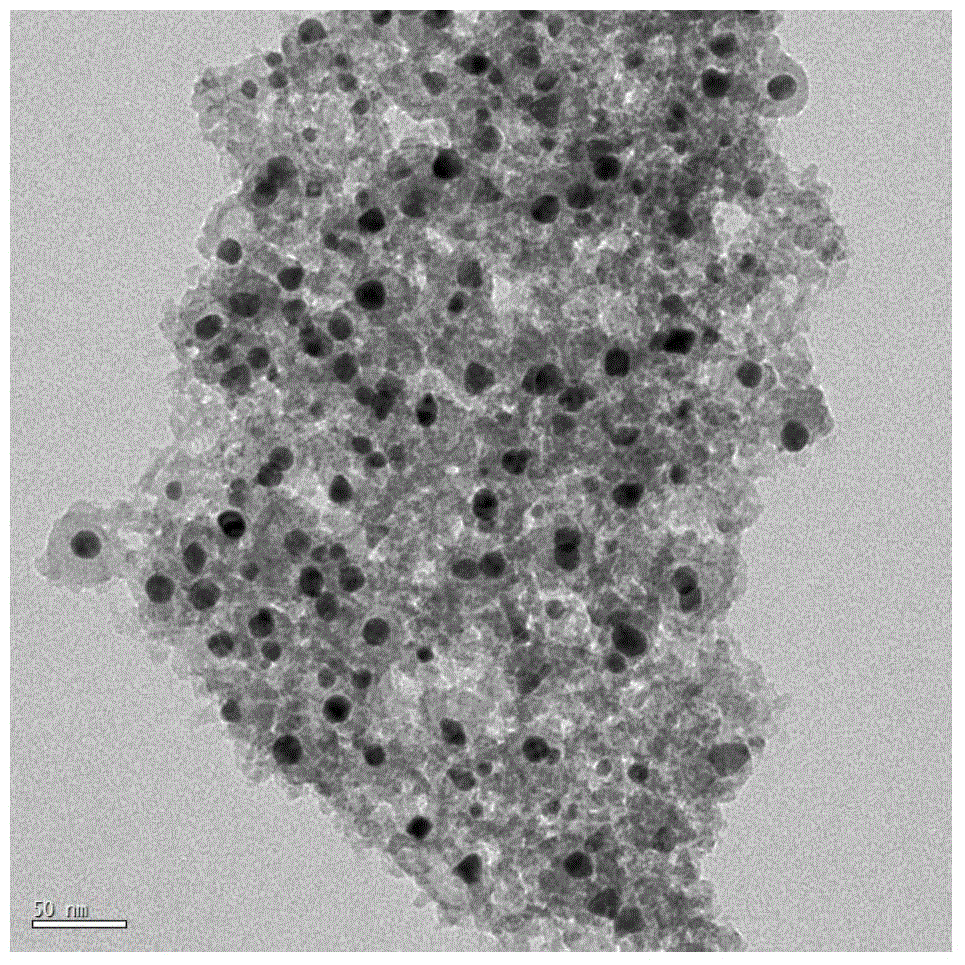

Preparation method of thermal conduction enhanced metal organic framework gas storage material

ActiveCN104624160AImprove adsorption capacityHigh thermal conductivityOther chemical processesGroup 4/14 organic compounds without C-metal linkagesIndustrial gasSorbent

The invention relates to a preparation method of a thermal conduction enhanced metal organic framework gas storage material and belongs to the field of nanocomposites. The preparation method comprises the following steps: firstly selectively preparing a metal organic framework material with a large surface area and a high micropore proportion; performing synthesis post-modification on the metal organic framework material by a 'one-pot' method, regulating the polarity and contained functional groups of pores, immobilizing metal nanoparticles inside the pores to enhance the thermal conduction property of the metal organic framework material; adsorbing industrial gas by utilizing the ultra-large specific surface area and the nano duct structure of the metal organic framework material, wherein the thermal conduction enhanced adsorption material can be used for quickly transmitting the heat generated in the adsorption and desorption process of the industrial gas. The metal organic framework industrial gas adsorber prepared by the invention can be used for efficiently adsorbing and desorbing the industrial gas and effectively improving the thermal conduction property of the adsorber, and avoiding the influence of the heat effect on the adsorption quantity in the adsorption and desorption process. The preparation method provided by the invention has the advantages of use of readily available and inexpensive raw materials, simple process, and mild reaction conditions and is suitable for large-scale production.

Owner:UNIV OF SCI & TECH BEIJING

Turbine blade with blade tip cooling passages

InactiveUS7922451B1Eliminate the problemEngine manufacturePump componentsIndustrial gasTurbine blade

A turbine blade for use in an industrial gas turbine engine, the blade having a squealer pocket with a plurality of discrete curved cooling channels to cool the blade tip and to reduce the hot gas flow leakage across the tip. The curved cooling channels include a side wall cooling channel, a tip rail crown cooling channel and an inner tip rail wall cooling channel all discharging cooling air from a cooling supply channel within the airfoil. Both the pressure side and suction side tip rails include this arrangement of cooling channels.

Owner:FLORIDA TURBINE TECH

Plant And Process For Removing Carbon Dioxide From Gas Streams

ActiveUS20080317651A1Minimizing overall energy requiredAssist in volatilizationExhaust apparatusDispersed particle separationBy-productChemistry

The present invention is based on the realization that the carbon dioxide component of industrial gas streams also containing steam can be processed so to utilize either as latent and / or sensible heat the heat available from the steam component to assist in separating carbon dioxide from the remainder of the gas stream. For example, flue gases produced by power stations burning brown coal, black coal or natural gas inherently contain a useful amount of energy that can be harnessed according to the present invention. According to particular preferred forms of the invention, nitrogen and sulphur constituent such as SOx and NOx, H2S and other nitrogen containing compounds may also be removed from the gas stream through direct contact with the absorbing medium and used to produce by-products such as fertiliser material.

Owner:KC8 CAPTURE TECH LTD

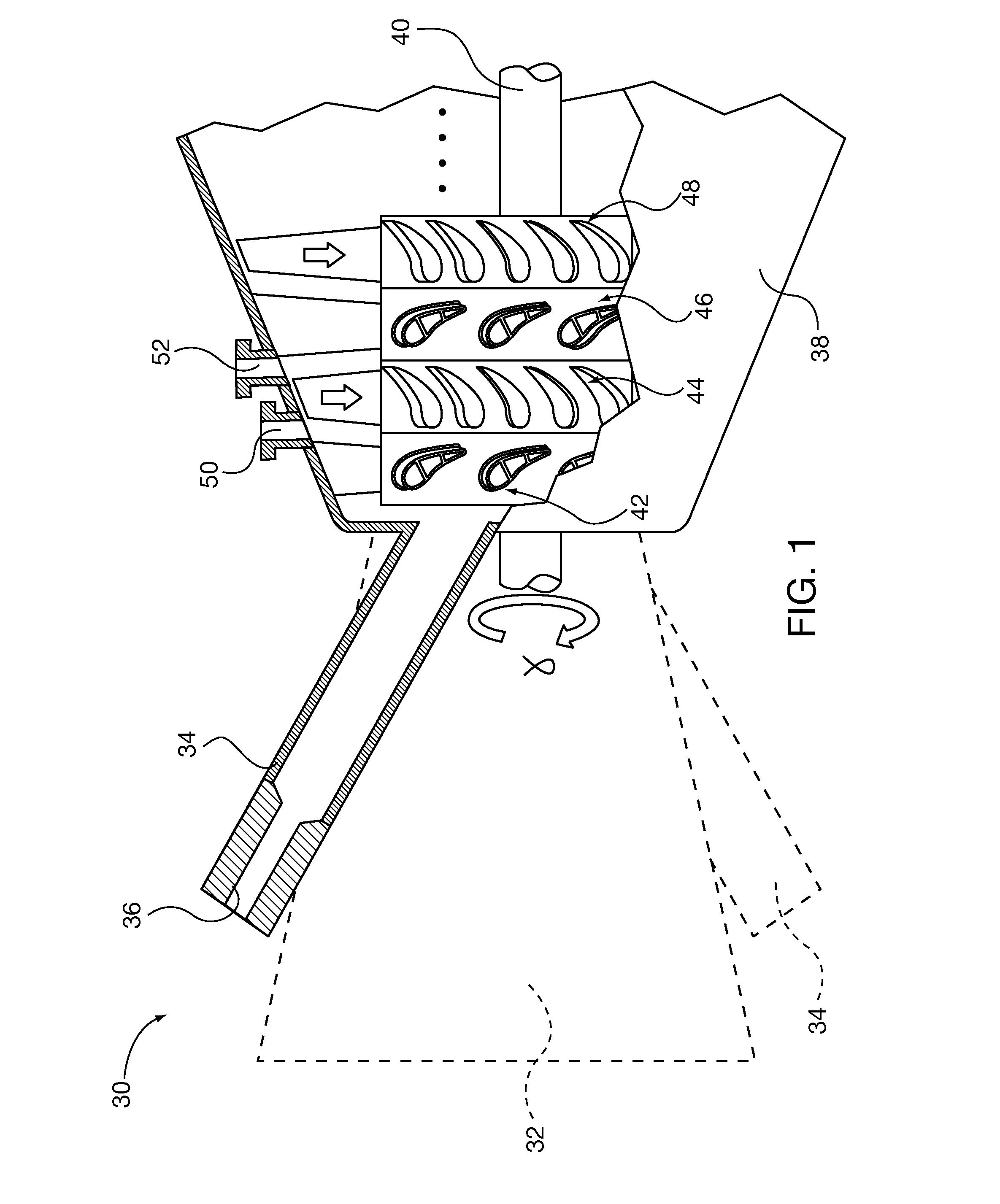

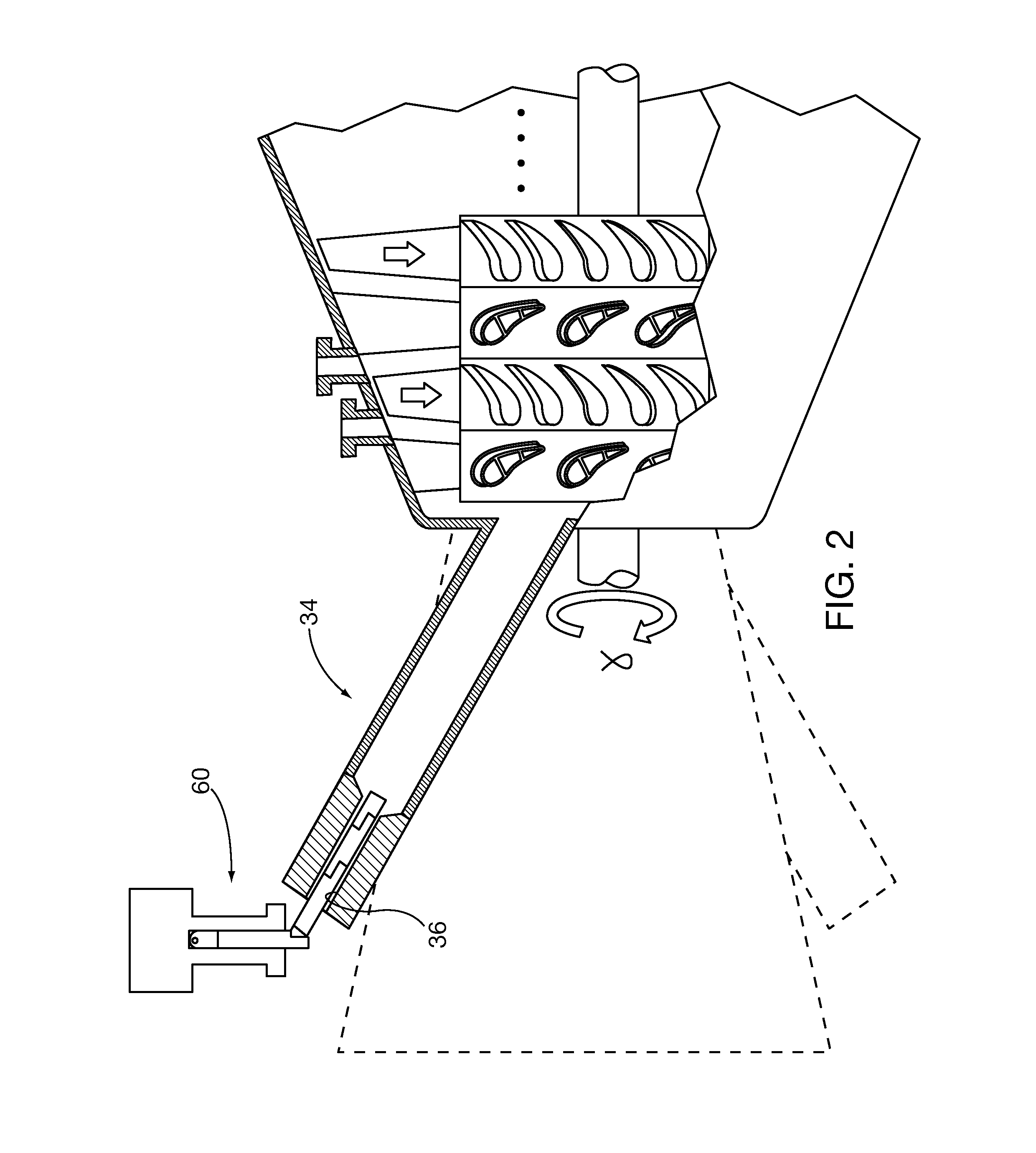

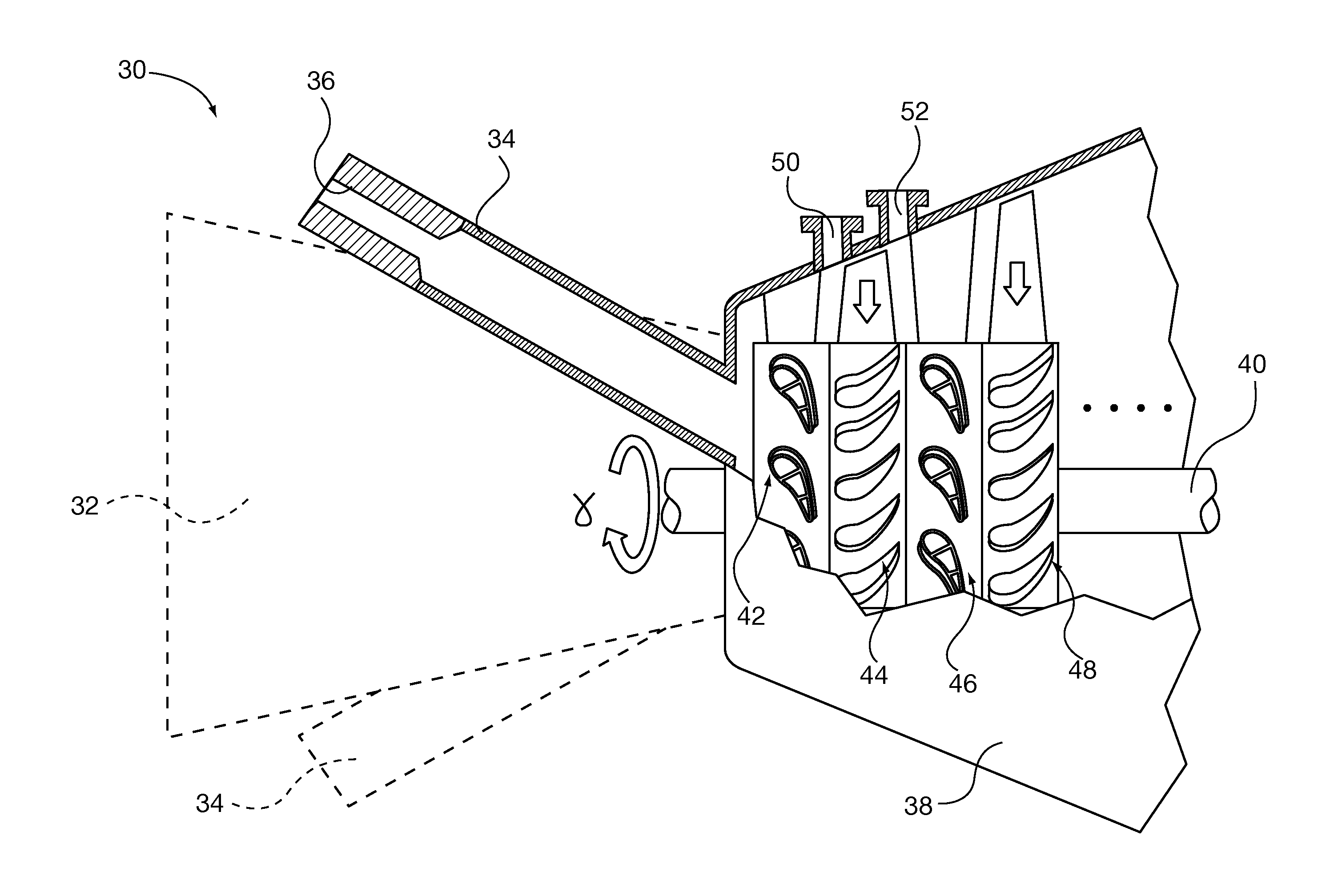

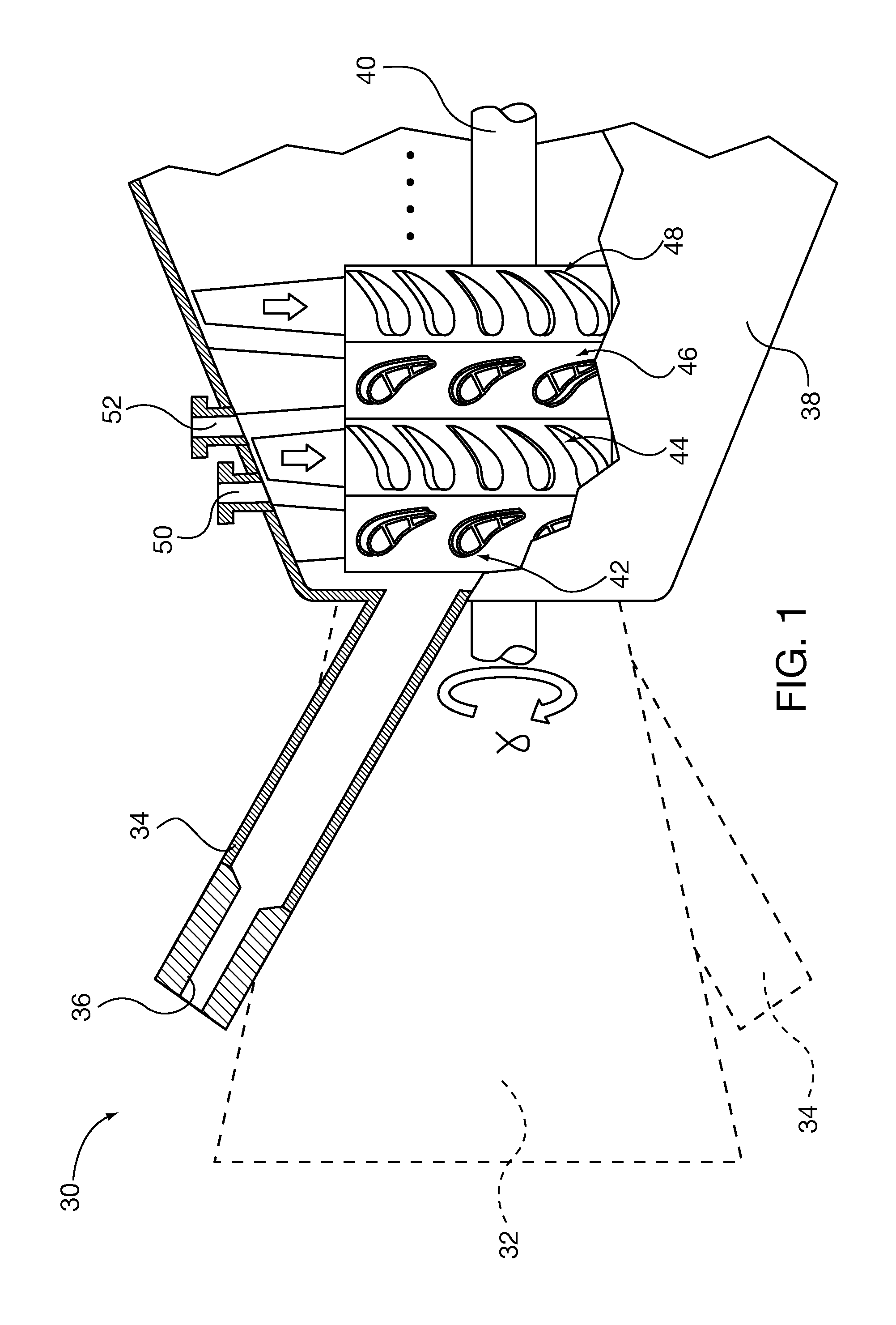

Process for retrofitting an industrial gas turbine engine for increased power and efficiency

InactiveUS20170241336A1Raise the firing temperatureImprove efficiencyTurbine/propulsion engine coolingEngine fuctionsClosed loopEngineering

A process for retrofitting an industrial gas turbine engine of a power plant where an old industrial engine with a high spool has a new low spool with a low pressure turbine that drives a low pressure compressor using exhaust gas from the high pressure turbine, and where the new low pressure compressor delivers compressed air through a new compressed air line to the high pressure compressor through a new inlet added to the high pressure compressor. The old electric generator is replaced with a new generator having around twice the electrical power production. One or more stages of vanes and blades are removed from the high pressure compressor to optimally match a pressure ratio split. Closed loop cooling of one or more new stages of vanes and blades in the high pressure turbine is added and the spent cooling air is discharged into the combustor.

Owner:JONES RUSSELL B +3

Multiple staged compressor with last stage airfoil cooling

An industrial gas turbine engine in which a compressor includes later stage airfoils that are cooled using a coolant from an external closed loop cooling circuit or from a heat recovery steam generator. Cooling air compressed by a compressor external to the IGT engine can be used for cooling of the main compressor airfoils with a heat exchanger to preheat a fuel used in the combustor. Or, water and steam from a heat recover steam generator can be used to cool the compressor airfoils in which steam can be bled off from the steam generator for cooling and then reintroduced into the HRSG at a downstream stage. Steam is used to cool the rotor blades while water is used to cool the stator vanes.

Owner:FLORIDA TURBINE TECH

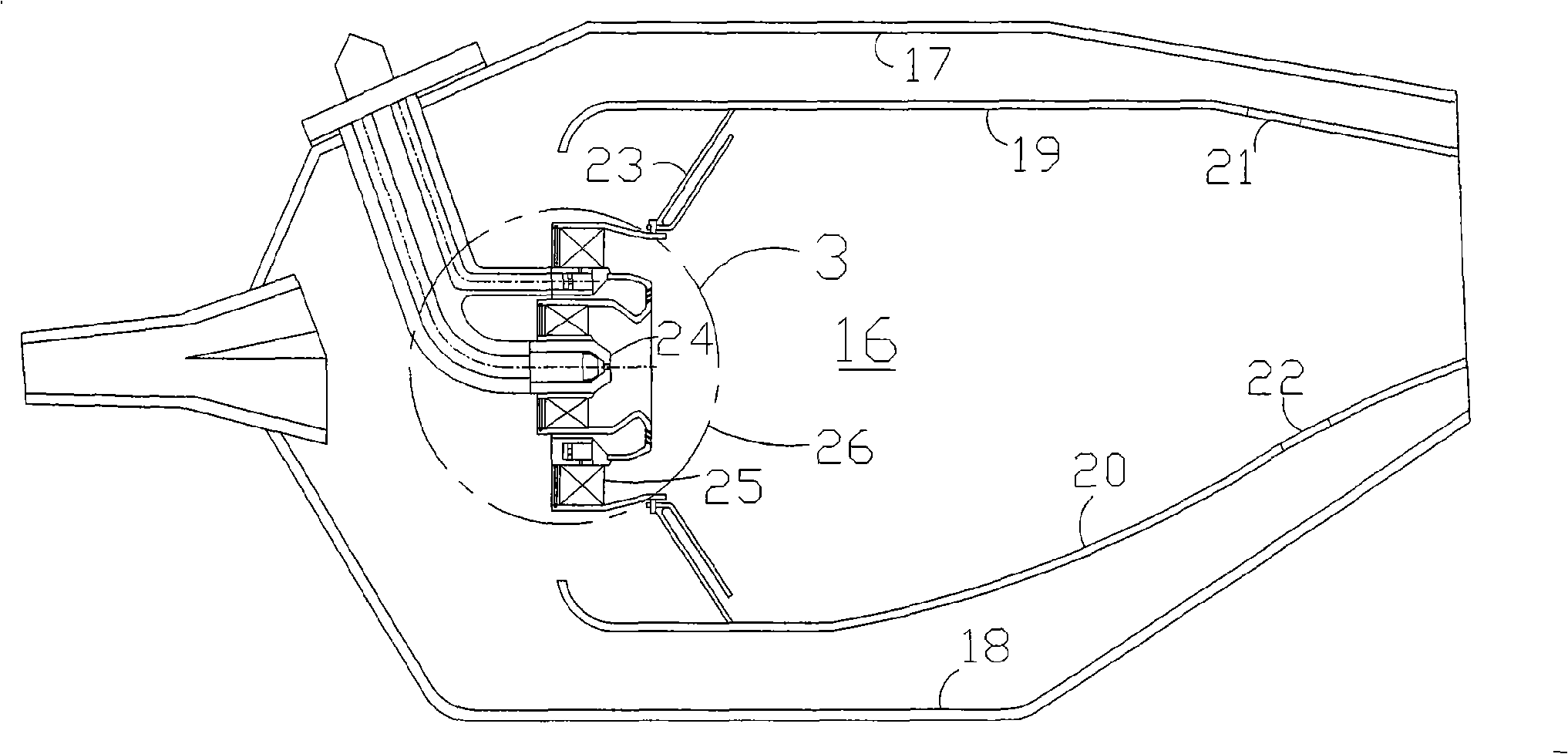

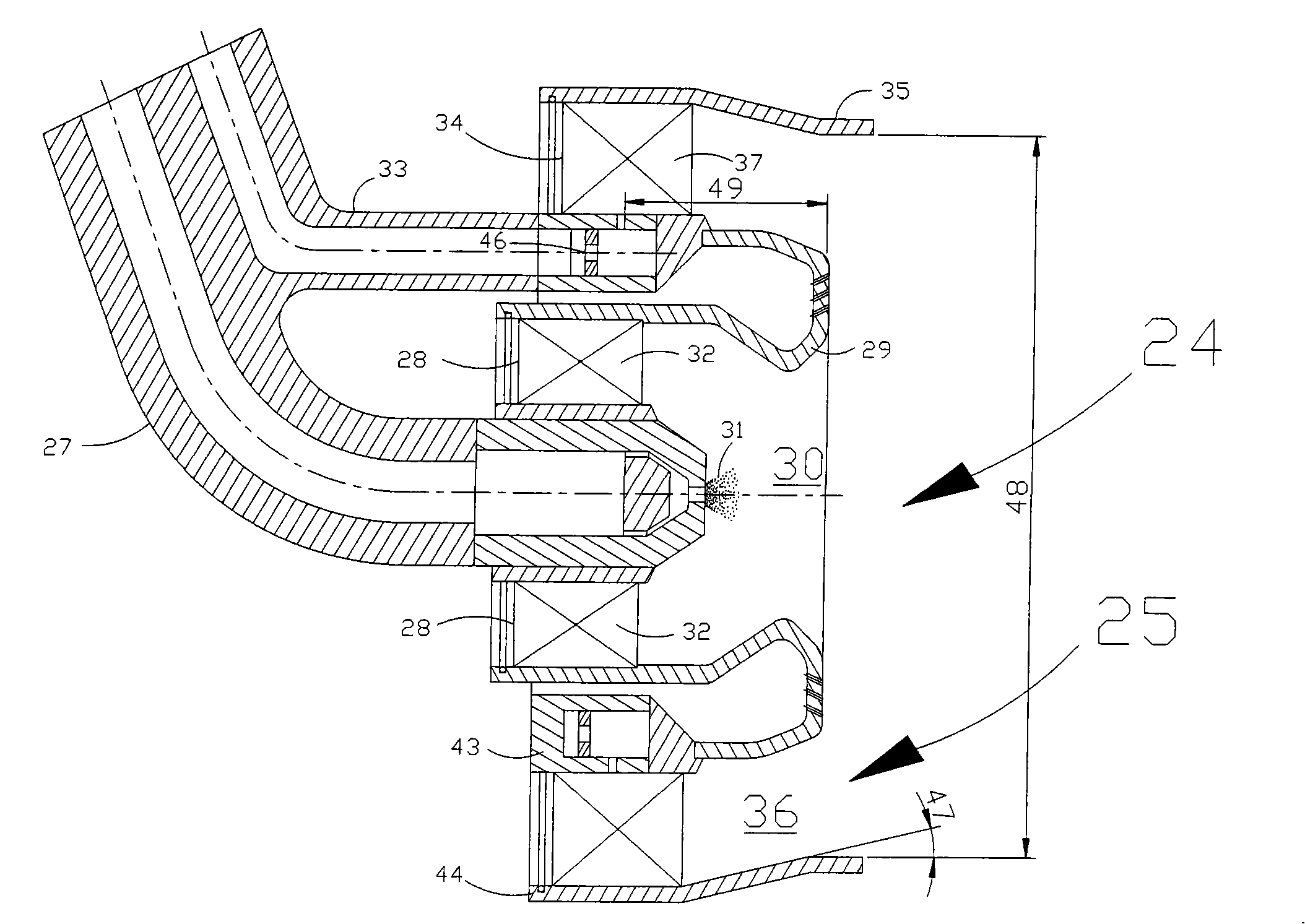

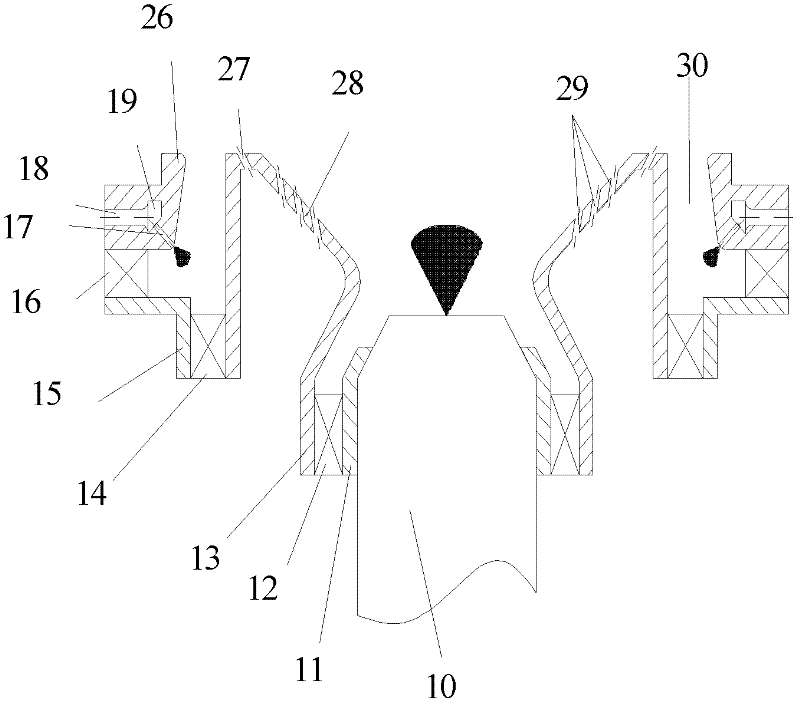

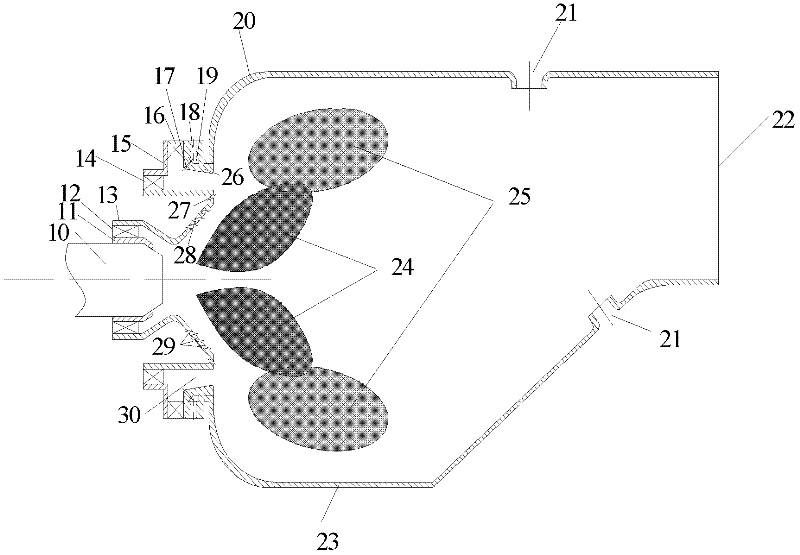

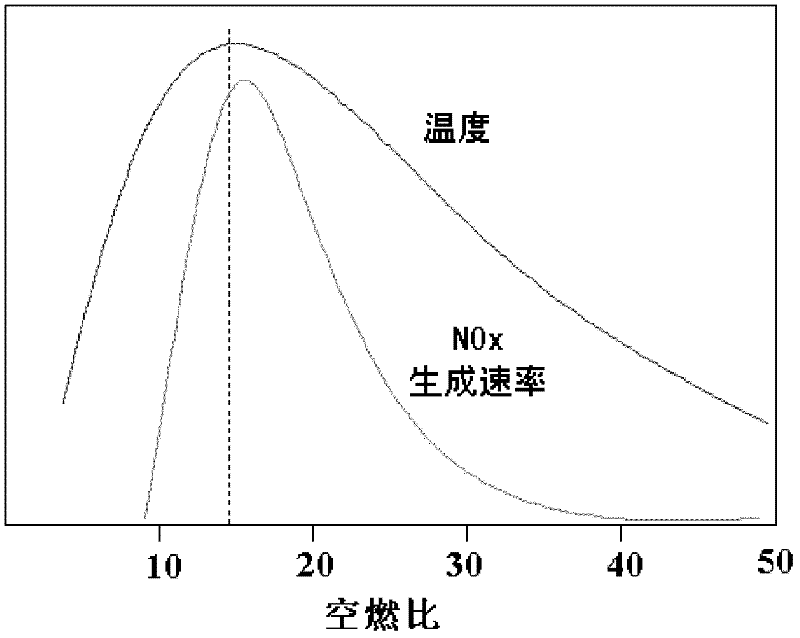

Radial swirler turning zone direct injection premixing and prevapourising low pollution burning chamber

InactiveCN101275750AShorten the lengthWell mixedContinuous combustion chamberIndustrial gasCombustion chamber

Disclosed is a radial swirler turning area direct injection premixing pre-evaporation firebox, wherein the firebox composed of a burner head and a flame tube is a single ring structure. The burner head includes a preburning level in the center and a main burning level at the outer ring; Using the direct injection project in the back turning area of the main burning level radial swirler, the main burning level fuel forms the premixing pre-evaporation gas-oil mixture to enter the burning area for burning under the action of the swirling gas of the main burning lever radial swirler, wherein the burning way can effecctively reduce the discharge of the pollutants in the burning chamber, meanwhile, the direct injection in the back turning area and the turning flow for the main burning level radial swirler of the main burning level fuel can reduce the length of the burning chamber; the invention is mainly used in the airmortor firebox, also can be used in the firebox of the industrial gas turbine and the ship gas turbine.

Owner:BEIHANG UNIV

Cooled turbine stator vane

InactiveUS7921654B1Increase air temperaturePump componentsTurbine/propulsion engine coolingLeading edgeIndustrial gas

A first stage turbine stator vane used in an industrial gas turbine engine, the vane having an outer endwall and an inner endwall with the airfoil extending between the two endwalls. A showerhead arrangement of film cooling holes is located along the leading edge region, and a row of exit cooling air slots is located along the trailing edge of the airfoil. A slanted rib extends from the outer endwall to the inner endwall and separates the vane into a forward cavity and an aft cavity. A leading edge impingement tube is secured within the forward cavity to provide impingement cooling to the leading edge walls of the airfoil. The leading edge impingement tube includes a cooling air inlet section extending out from the inner endwall so that a vena contractor forms in the tube entrance before the impingement holes begin. The leading edge impingement tube narrows in the cooling air flow direction. The trailing edge impingement tube has similar construction but has the cooling air inlet extending out from the outer endwall. With this design, the first stage vane can use both impingement cooling of the leading edge region and showerhead film cooling of the leading edge airfoil surface to allow for a higher gas flow temperature across the vane.

Owner:FLORIDA TURBINE TECH

Agglomerated adsorbent, process for the production thereof and use thereof for the non-cryogenic separation of industrial gases

InactiveUS6652626B1Reduce the burden onReduce consumptionIsotope separationHydrogen/synthetic gas productionLithiumIndustrial gas

A description is given of agglomerates of faujasite X with an Si / Al ratio of 1, the inert binder of which, on the one hand, has been converted to active zeolite by conversion to zeolite in an alkaline liquor, and which have been subjected, on the other hand, to an exhaustive lithium exchange. These adsorbents develop a nitrogen adsorption capacity (1 bar / 25° C.) of at least 26 cm<3> / g, which makes them excellent adsorbents for the non-cryogenic separation of gases from air and for the purification of hydrogen.

Owner:ARKEMA FRANCE SA

Device for Removing Particulate, Various Acids, and Other Contaminants from Industrial Gases

InactiveUS20070251393A1Reducing emission of nitrous oxideReduce gas volumeCombination devicesAuxillary pretreatmentIndustrial gasParticulates

Owner:ARTEC 1

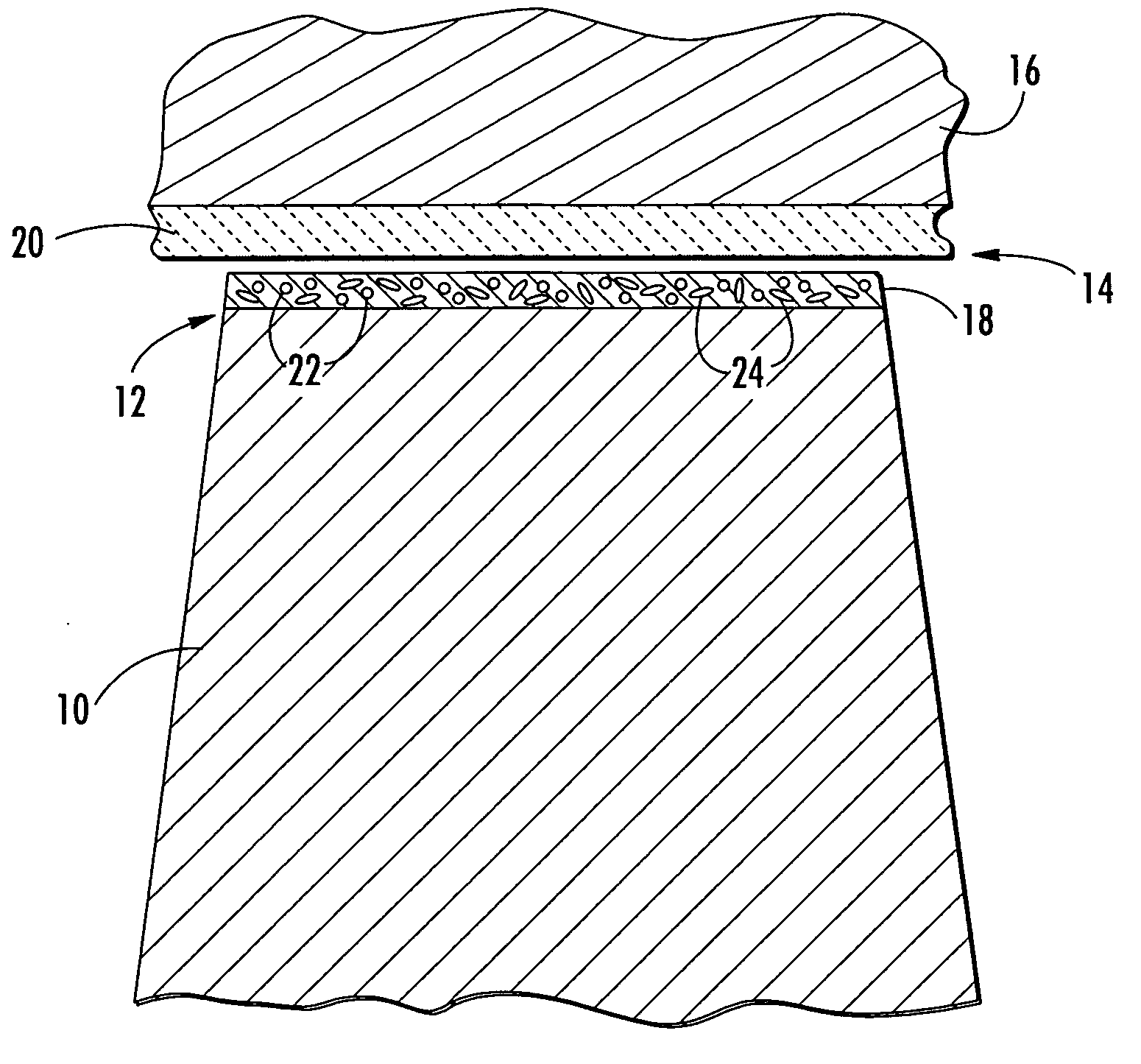

Turbine blade tip with optimized abrasive

InactiveUS20050129511A1Improved blade tip clearance controlImprove engine efficiencyElectrolytic coatingsPump componentsIndustrial gasTurbine blade

A new abrasive blade tip treatment is disclosed with the potential to provide improved blade tip clearance control in the turbine section of modern industrial gas turbines (IGT's). This blade tip treatment is composed of a unique combination of abrasive compounds that result in improved resistance to thermal degradation while retaining desirable initial cutting capacity.

Owner:SIEMENS ENERGY INC

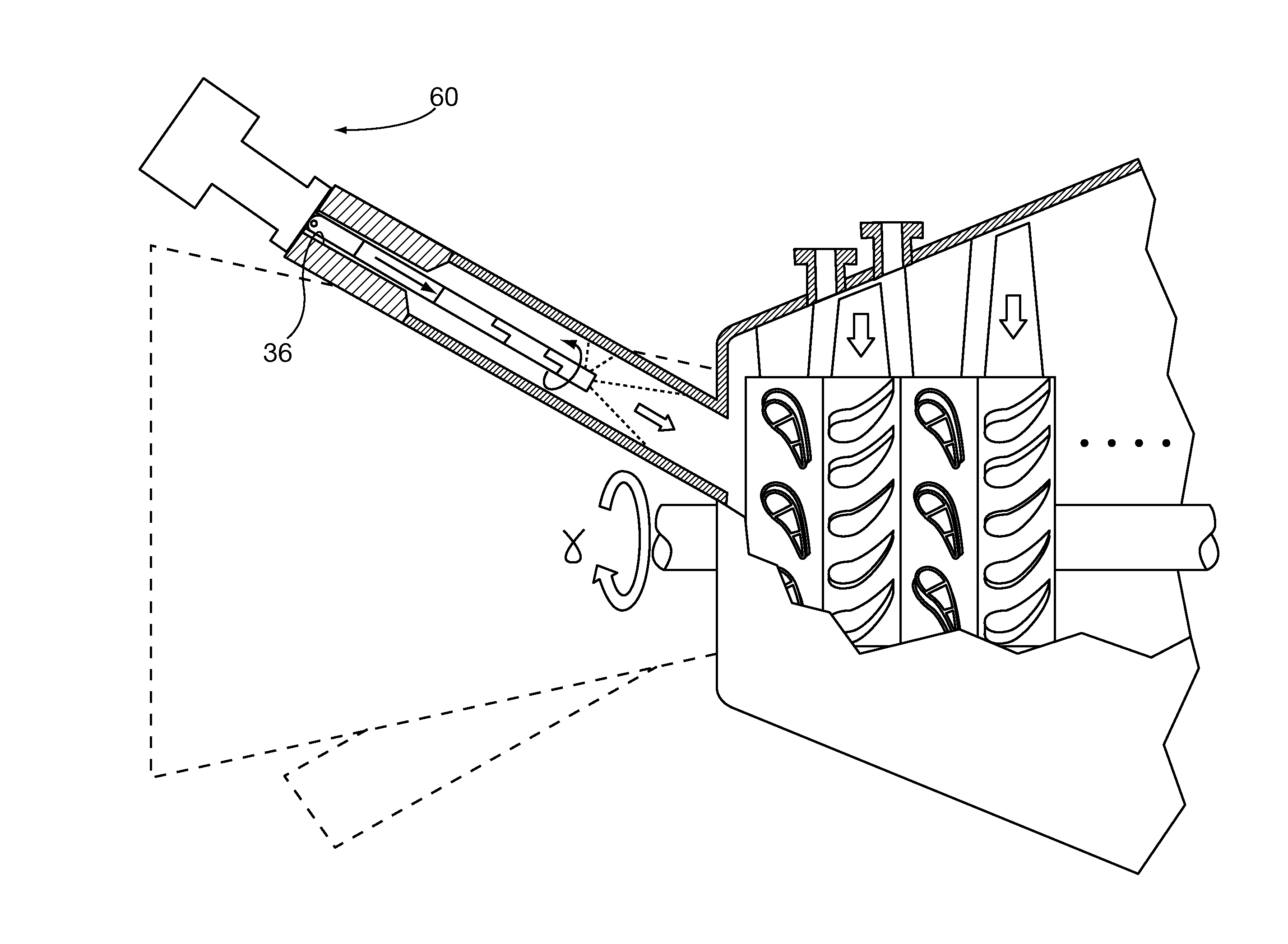

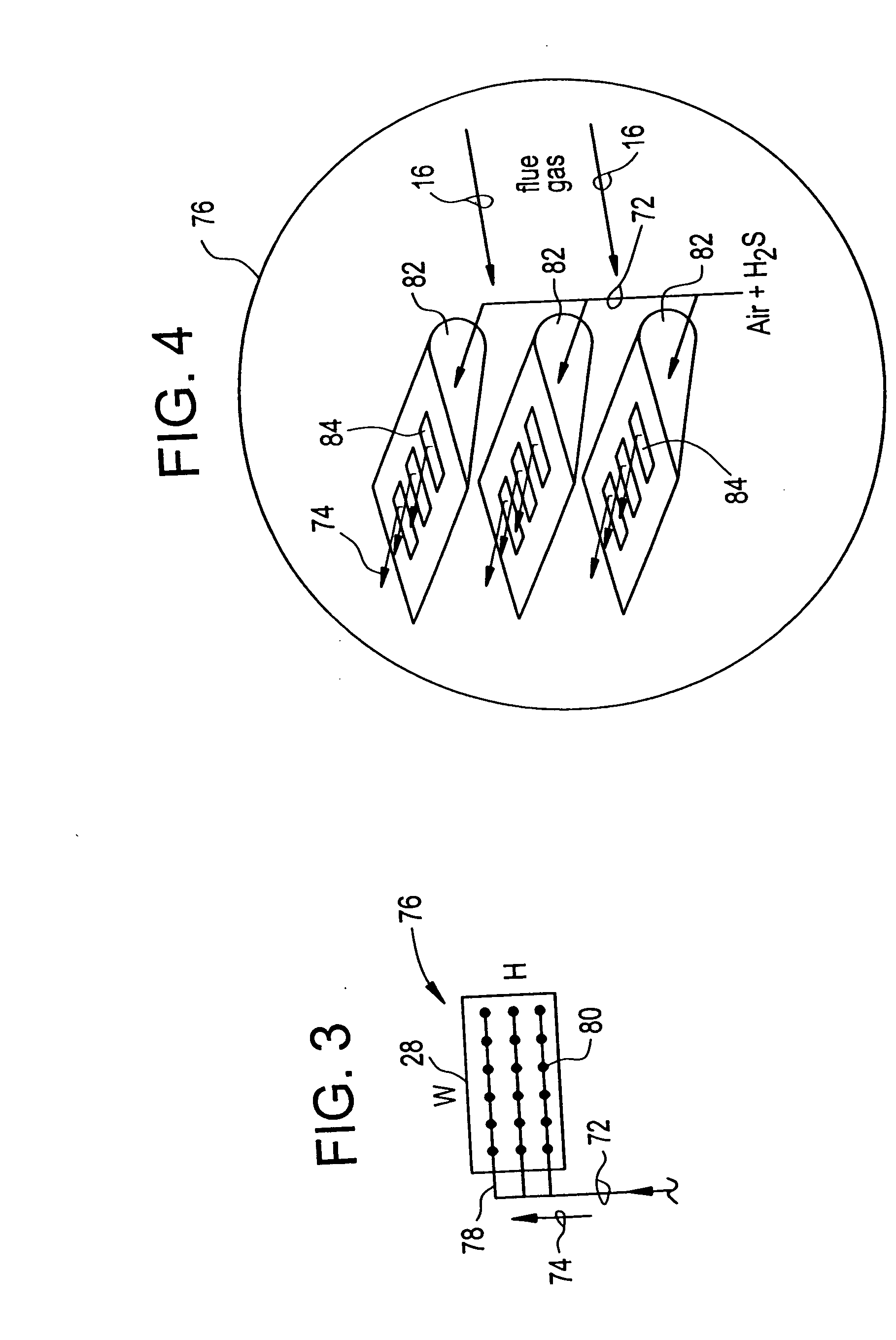

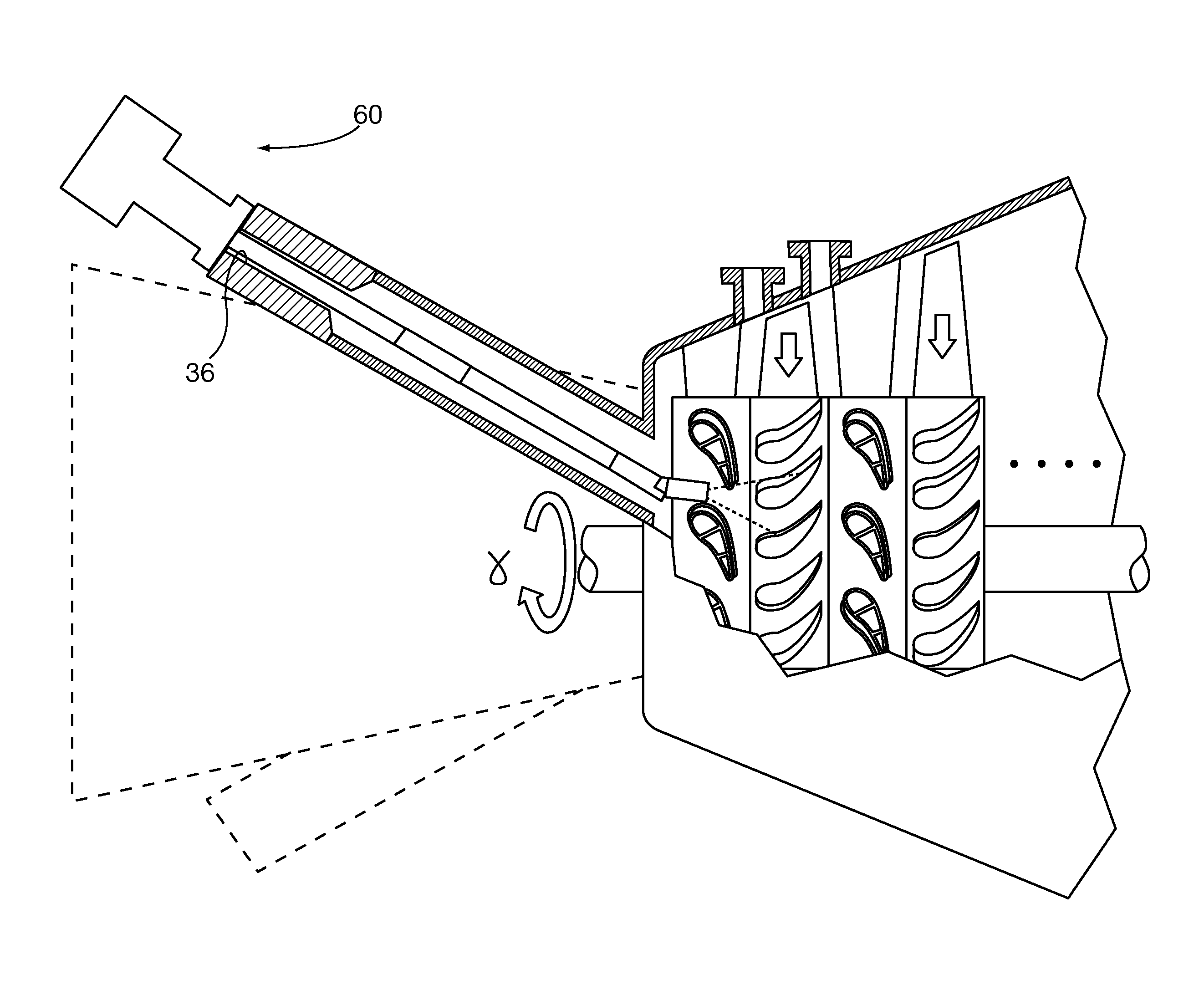

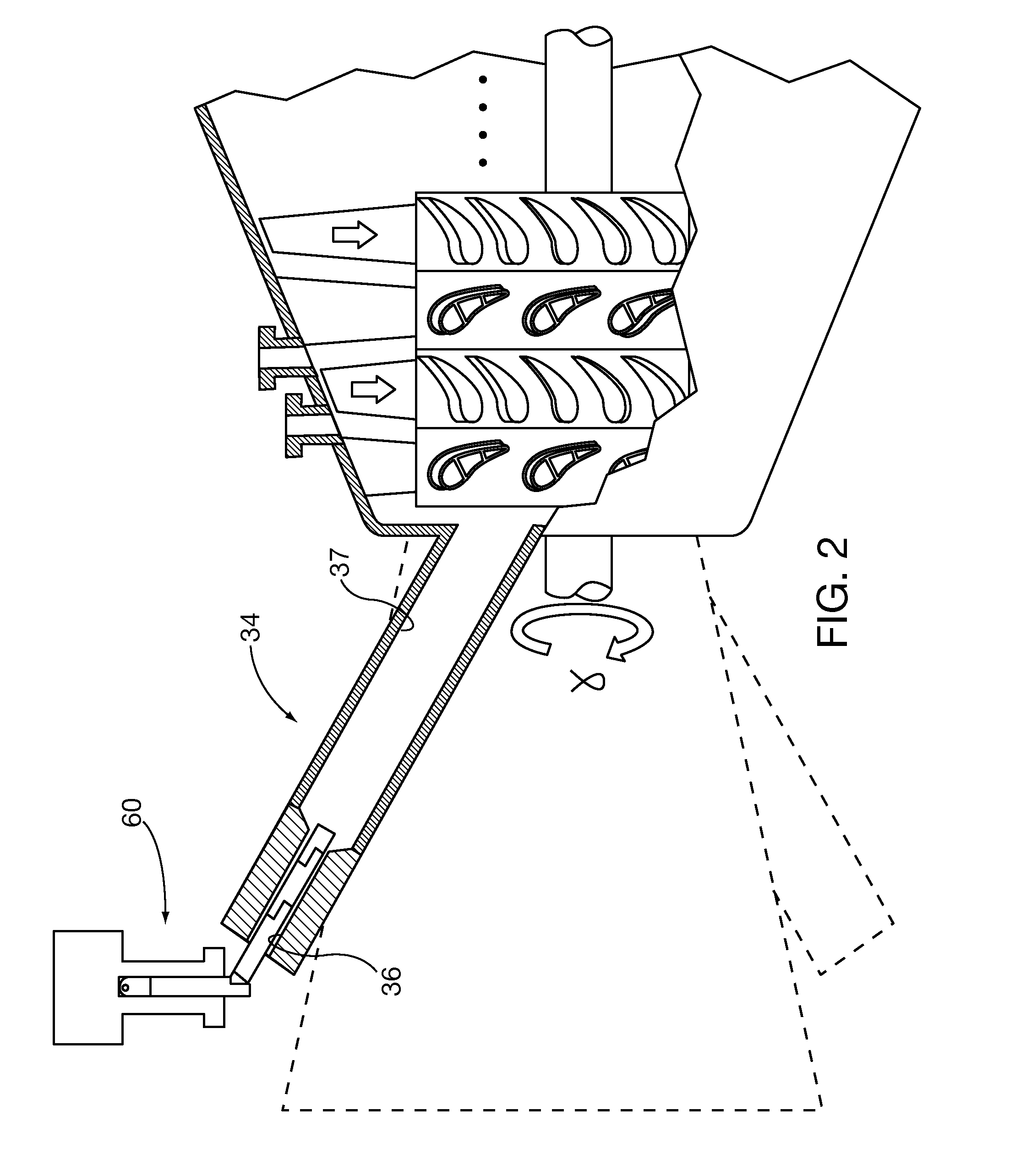

System and method for automated optical inspection of industrial gas turbines and other power generation machinery

ActiveUS20130194413A1Shorten the timeMore power generationTelevision system detailsMaterial analysis by optical meansIndustrial gasEngineering

Internal components of power generation machinery, such as gas and steam turbines are inspected with an optical camera inspection system that is capable of automatically positioning the camera field of view (FOV) to an area of interest within the machinery along a pre-designated navigation path and capturing images without human intervention. Automatic camera positioning and image capture can be initiated automatically or after receipt of operator permission. The pre-designated navigation path can be defined by operator manual positioning of an inspection scope within the power machine or a similar one of the same type and recording of positioning steps for future replication. The navigation path can also be defined by virtual simulation.

Owner:SIEMENS ENERGY INC

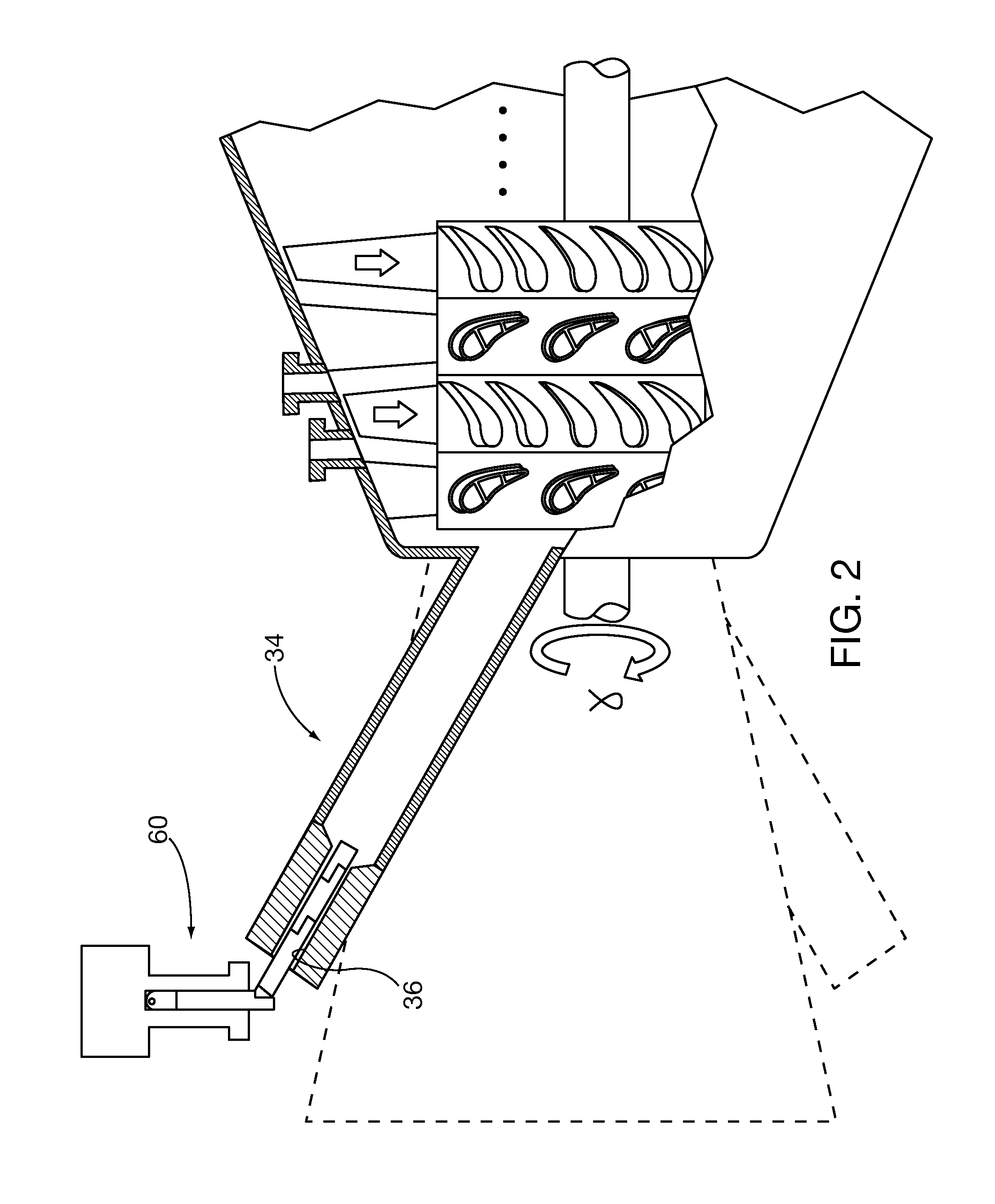

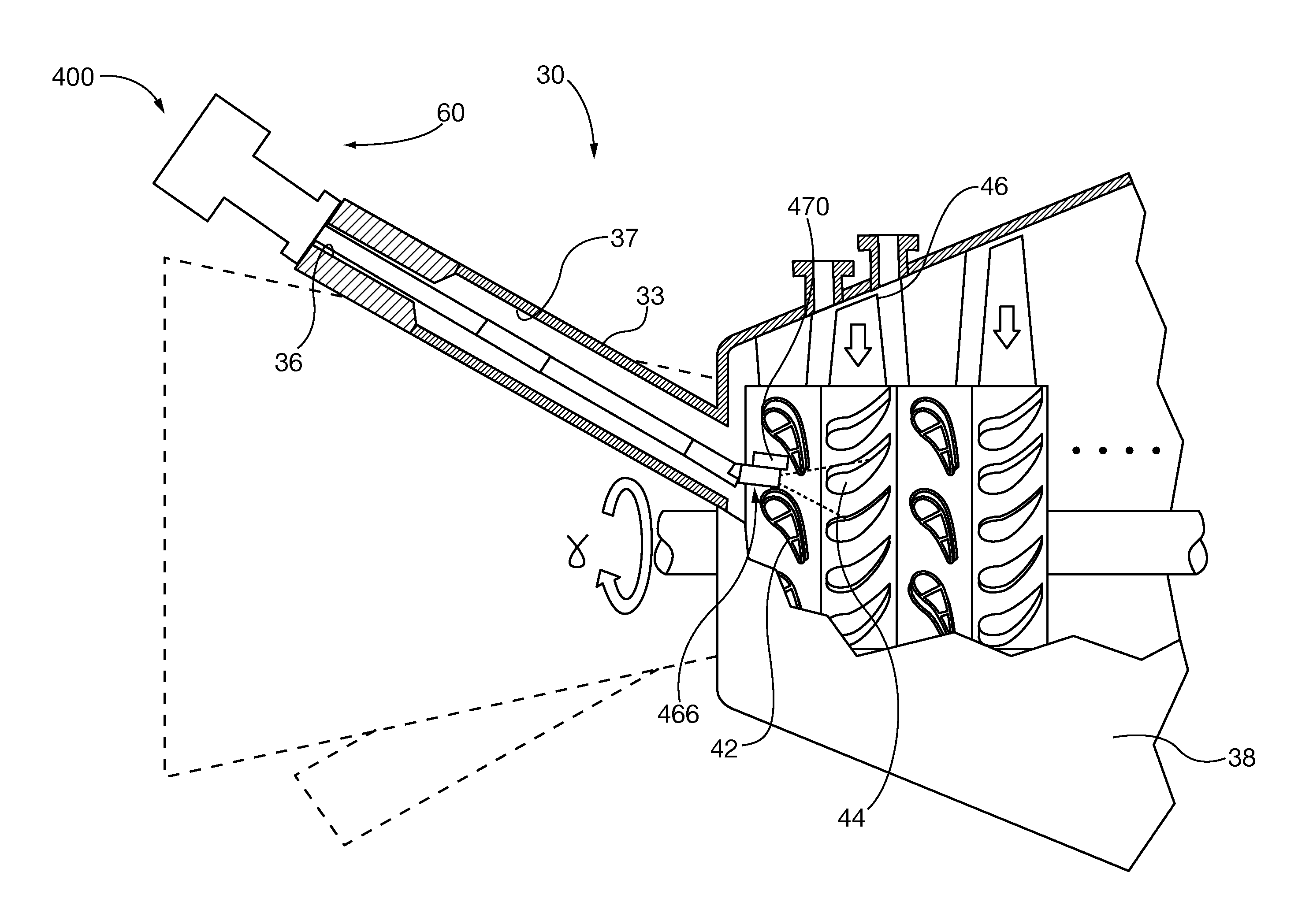

Method and system for surface profile inspection of off-line industrial gas turbines and other power generation machinery

ActiveUS20150300920A1Facilitates of dimensionalGathering informationGas-turbine engine testingMaterial analysis by optical meansIndustrial gasTime profile

Internal components of power generation machines, such as gas or steam turbines, are inspected with a laser profilometer inspection system that is inserted and positioned within the turbine, for example through an inspection port that is in communication with an open inter-row spacing volume between an opposing turbine vane and turbine blade row. Component surface profile scans are performed to determine relative profile heights along a two-dimensional scan line generated by the profilometer. Three-dimensional profile information is obtained by translating the scan line across the surface. Real time profile information is gathered without physical contact, which is helpful for extracting off-line engineering information about component surface conditions, including surface spallation, perforation, and gaps between components. The system is capable of determining blade tip gap between a turbine blade tip and its opposing abradable surface in the turbine casing.

Owner:SIEMENS ENERGY INC

Basalt fiber high temperature compositing filter material

InactiveCN101053718AImprove high temperature resistanceMeeting the needs of the high temperature filtration industryFiltration separationThermal energyIndustrial gas

The invention provides a basalt fibre high-temperature composite filter material. The high-temperature composite filter material is formed by weaving or needling, using the basalt fibre or the mixture of basalt fibre and other high temperature material which is one or more of the glass fibre, stainless-steel fibre and ceramic fibre. The invention can effectively improve the resistance to high temperature of filter material, extending the useful life, and also recycle heat energy, which saves energy source, has a excellent filter effect, and meet the need in the industry of industrial gases filter in high temperature.

Owner:江苏正大森源集团

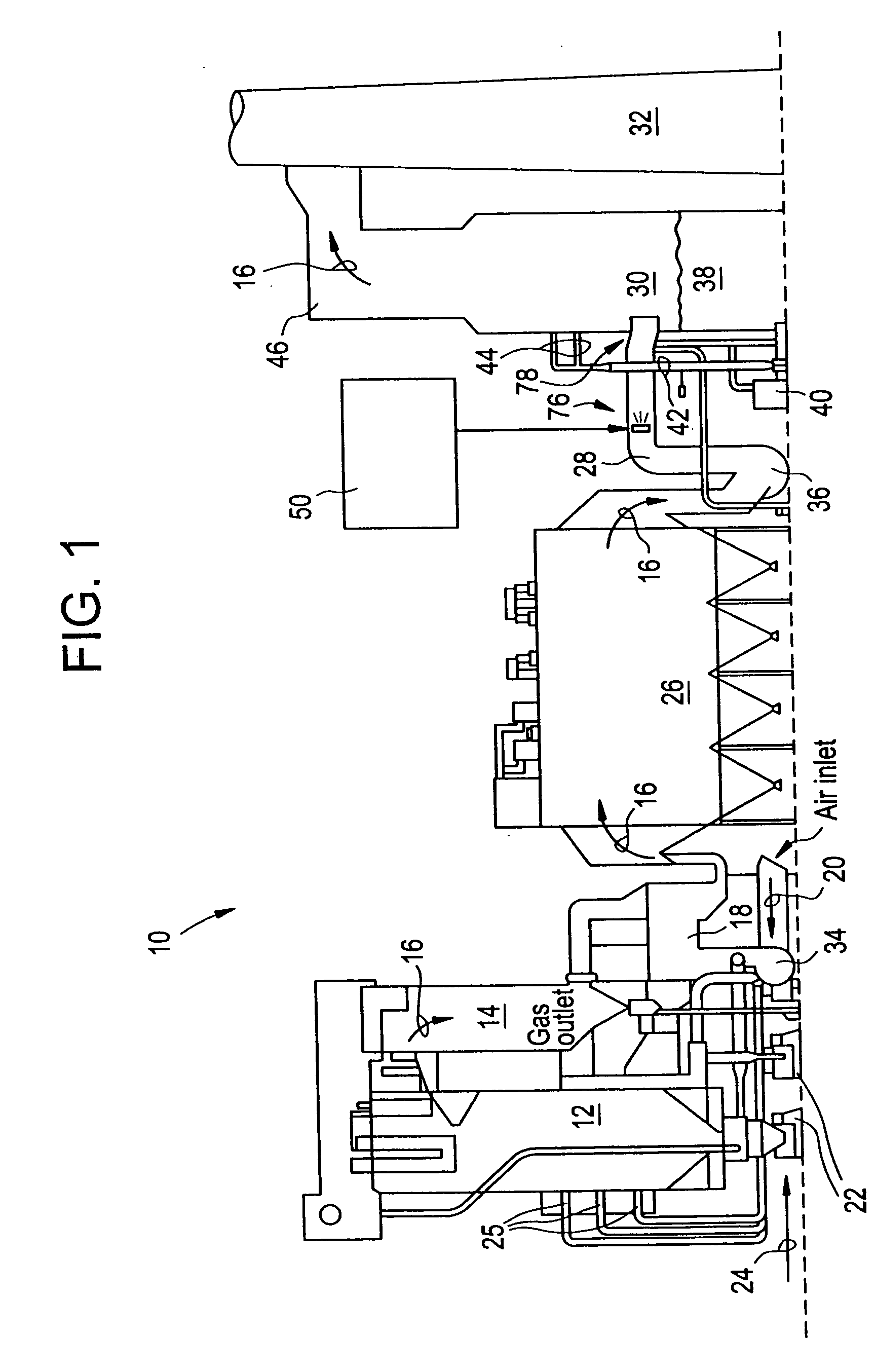

Method for control of mercury

InactiveUS20050169824A1Inherent safety advantageEfficient removalUsing liquid separation agentEmission preventionCoalWet scrubber

A method and apparatus for reducing mercury in industrial gases such as the flue gas produced by the combustion of fossil fuels such as coal adds hydrogen sulfide to the flue gas in or just before a scrubber of the industrial process which contains the wet scrubber. The method and apparatus of the present invention is applicable to installations employing either wet or dry scrubber flue gas desulfurization systems. The present invention uses kraft green liquor as a source for hydrogen sulfide and / or the injection of mineral acids into the green liquor to release vaporous hydrogen sulfide in order to form mercury sulfide solids.

Owner:DOWNS WILLIAM +1

System and method for automated optical inspection of industrial gas turbines and other power generation machinery with articulated multi-axis inspection scope

ActiveUS20130194412A1Minimize damageEqualize levelGas-turbine engine testingMaterial analysis by optical meansEngineeringVideo camera

Internal components of power generation machinery, such as gas and steam turbines are inspected with an optical camera inspection system that is capable of automatically positioning the camera field of view (FOV) to an area of interest within the machinery along a pre-designated navigation path and capturing images without human intervention. Automatic camera positioning and image capture can be initiated automatically or after receipt of operator permission. The pre-designated navigation path can be defined by operator manual positioning of an inspection scope within the power machine or a similar one of the same type and recording of positioning steps for future replication. The navigation path can also be defined by virtual simulation. The inspection system includes an articulated multi-axis inspection scope.

Owner:SIEMENS ENERGY INC

System and method for automated optical inspection of industrial gas turbines and other power generation machinery with multi-axis inspection scope

ActiveUS20130192353A1Shorten the timeMore power generationGas-turbine engine testingMaterial analysis by optical meansReceiptVideo camera

Owner:SIEMENS ENERGY INC

System and method for visual inspection and 3D white light scanning of off-line industrial gas turbines and other power generation machinery

ActiveUS20130335530A1Shorten the timeMore power generationEngine testingMaterial analysis by optical meansEngineeringVisual perception

Internal components of gas or steam turbines are inspected with a 3D scanning camera inspection system that is inserted and positioned within the turbine, for example through a gas turbine combustor nozzle port. Three dimensional internal component measurements are performed using projected light patterns generated by a stripe projector and a 3D white light matrix camera. Real time dimensional information is gathered without physical contact, which is helpful for extracting off-line engineering information about the scanned structures. Exemplary 3D scans, preferably with additional visual images, are performed of the gas path side of a gas turbine combustor support housing, combustor basket and transition with or without human intervention.

Owner:SIEMENS ENERGY INC

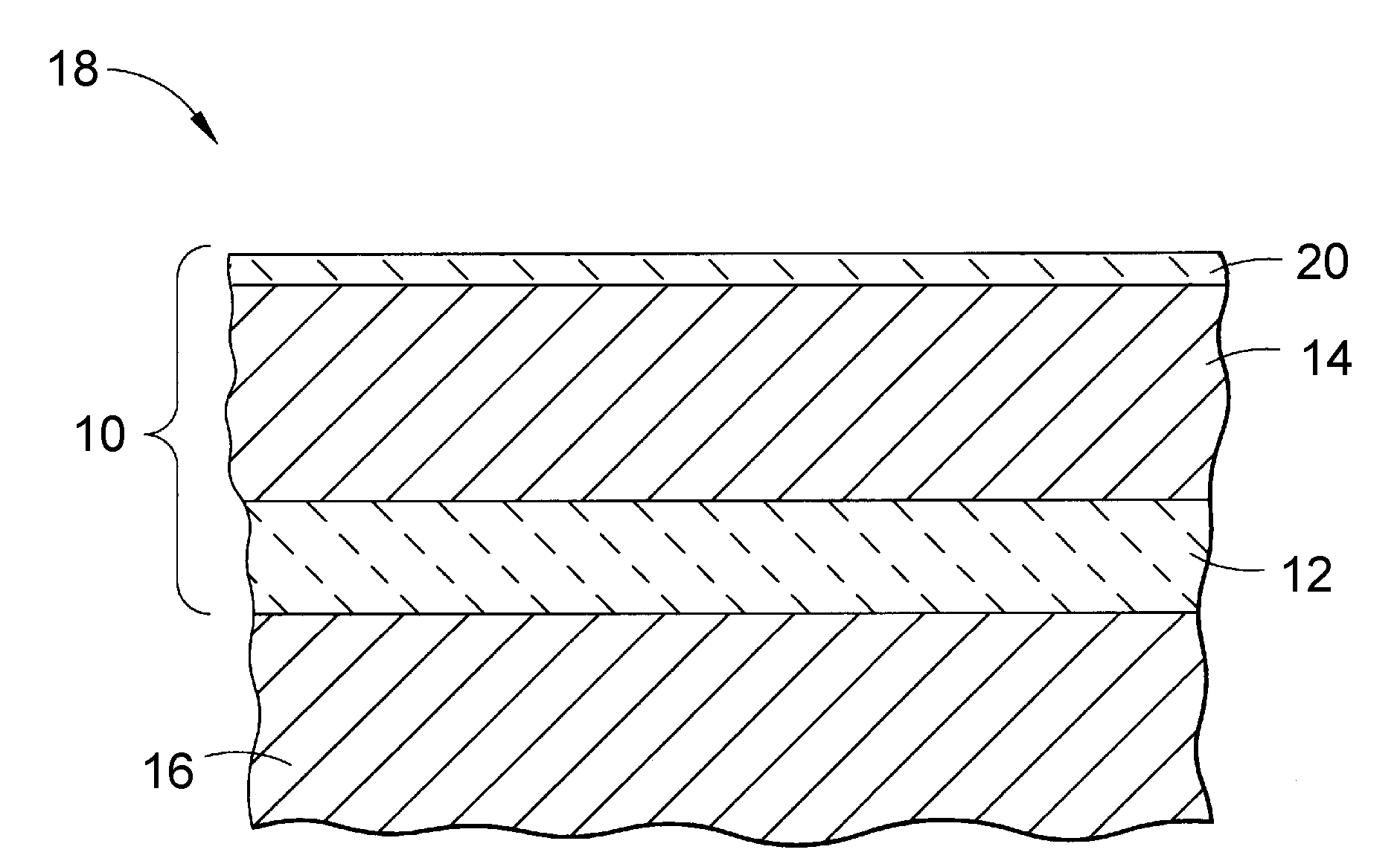

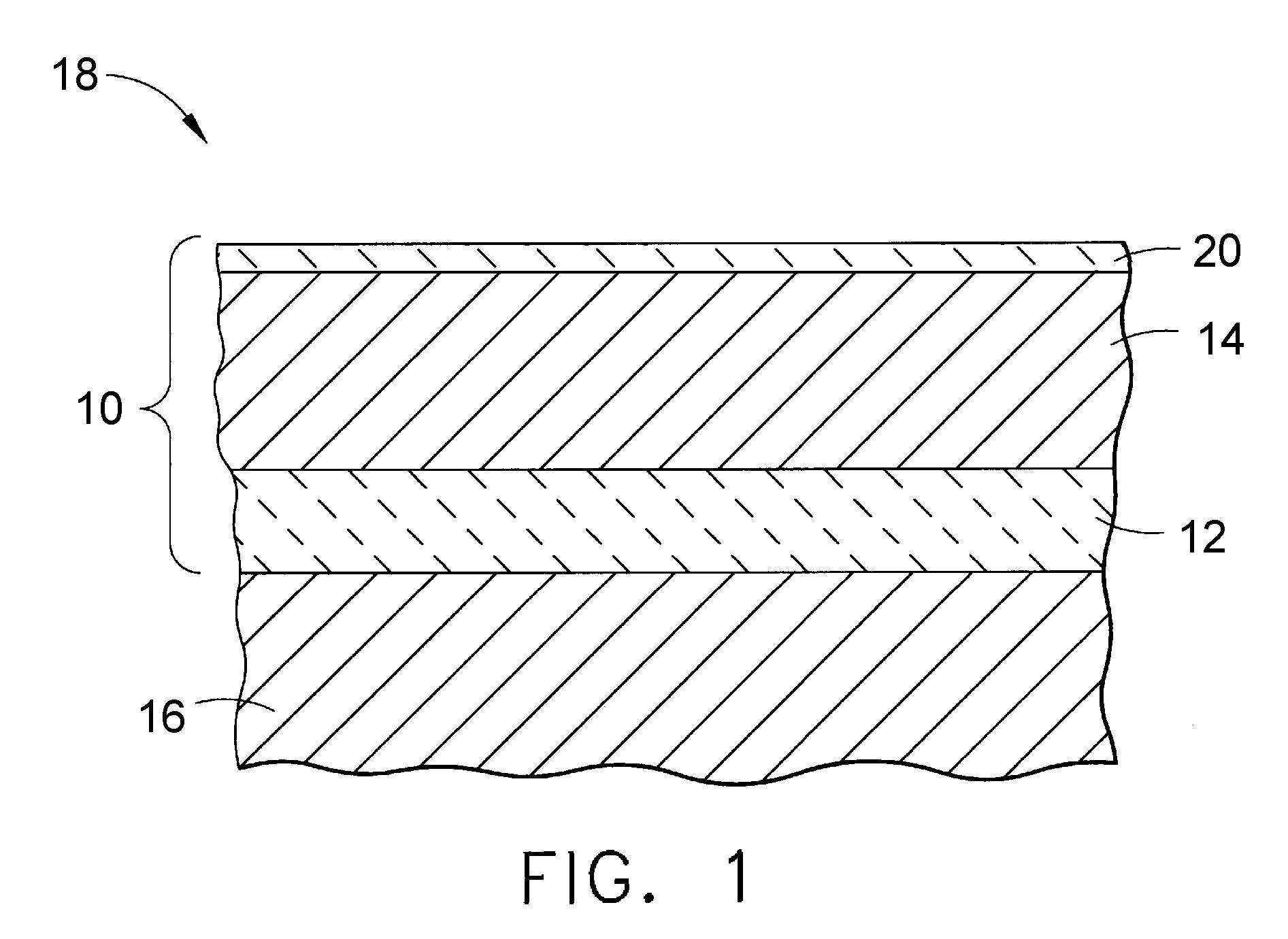

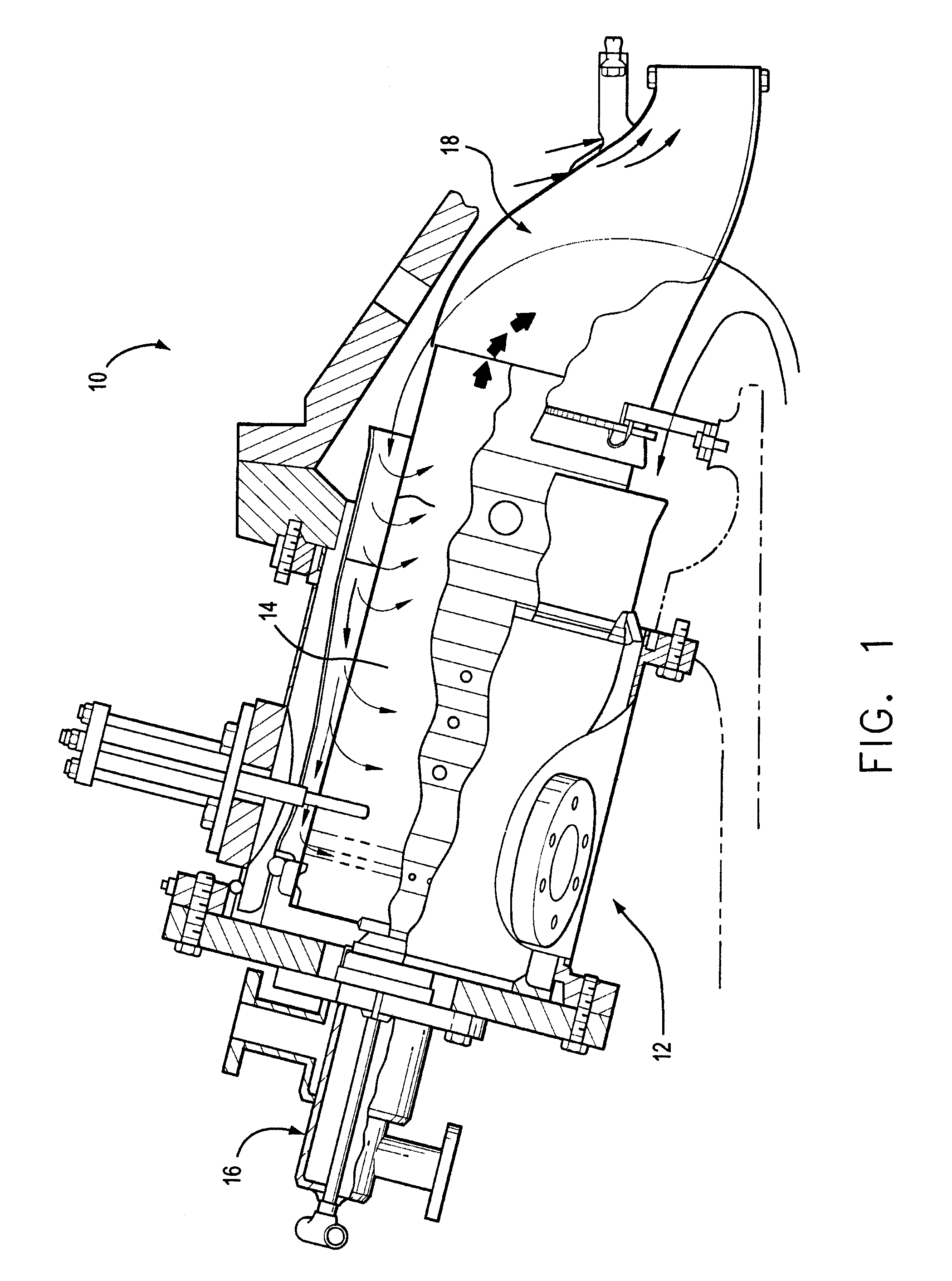

Erosion and corrosion-resistant coating system and process therefor

InactiveUS20090176110A1Improving solid particle and water droplet erosion characteristicImprove corrosion resistanceMolten spray coatingEngine fuctionsThermal sprayingCoating system

A coating system and process capable of providing erosion and corrosion-resistance to a component, particularly a steel compressor blade of an industrial gas turbine. The coating system includes a metallic sacrificial undercoat on a surface of the component substrate, and a ceramic topcoat deposited by thermal spray on the undercoat. The undercoat contains a metal or metal alloy that is more active in the galvanic series than iron, and electrically contacts the surface of the substrate. The ceramic topcoat consists essentially of a ceramic material chosen from the group consisting of mixtures of alumina and titania, mixtures of chromia and silica, mixtures of chromia and titania, mixtures of chromia, silica, and titania, and mixtures of zirconia, titania, and yttria.

Owner:GENERAL ELECTRIC CO

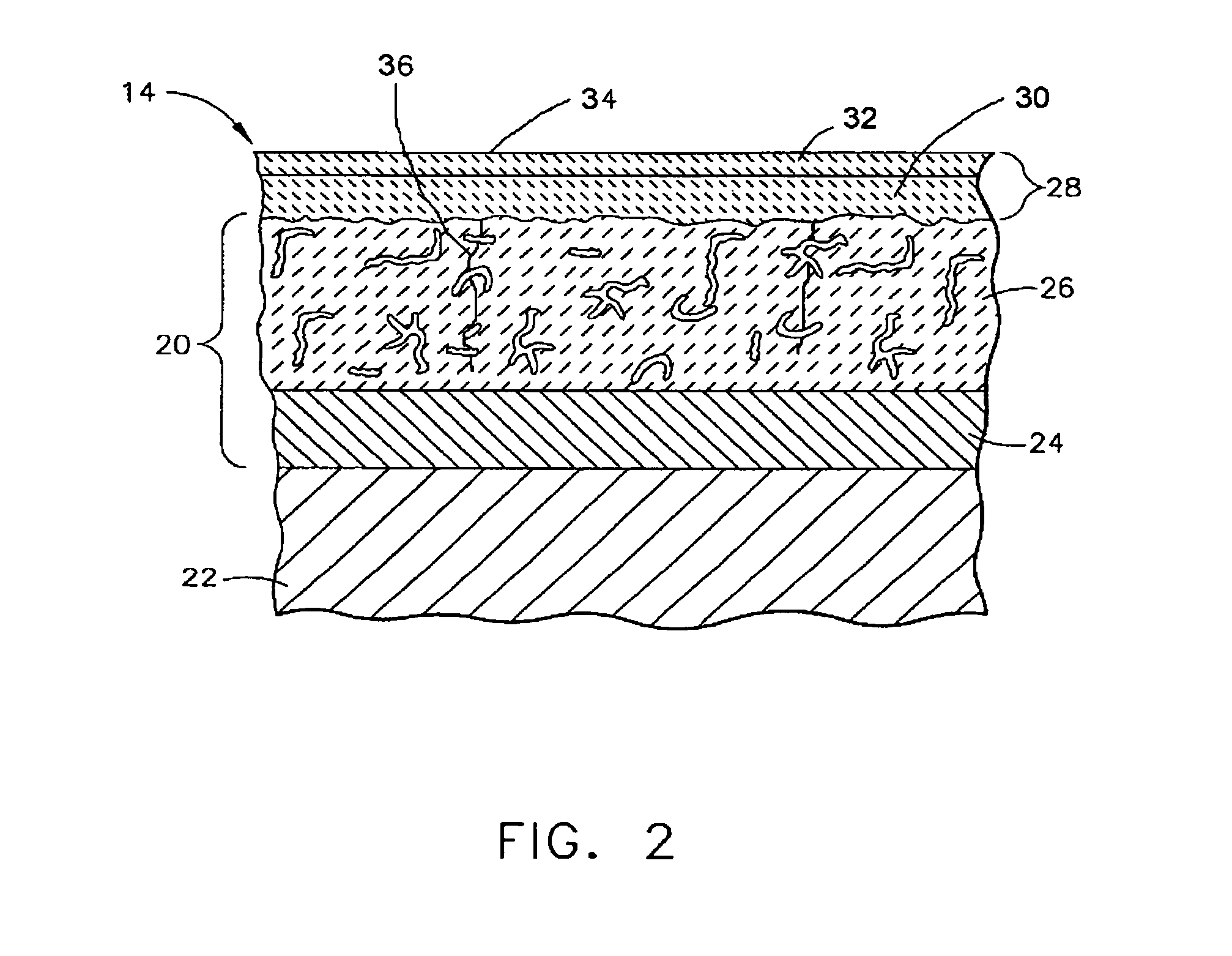

Smooth outer coating for combustor components and coating method therefor

InactiveUS7368164B2Suppresses component temperature riseReduce transferMolten spray coatingPropellersZinc titanateSilica matrix

A coating and method for overcoating a TBC on a component used in a high-temperature environment, such as the combustor section of an industrial gas turbine. The coating defines the outermost surface of the component and is formed of at least two layers having different compositions. An inner layer of the coating contains alumina in a first silica-containing matrix material that is free of zinc titanate. An outer layer of the coating contains alumina, a glass material, and zinc titanate in a second silica-containing matrix material. The outer layer of the coating has a surface roughness of not greater than three micrometers Ra and forms the outermost surface of the component. The coating reduces the component temperature by reducing the convective and radiant heat transfer thereto.

Owner:GENERAL ELECTRIC CO

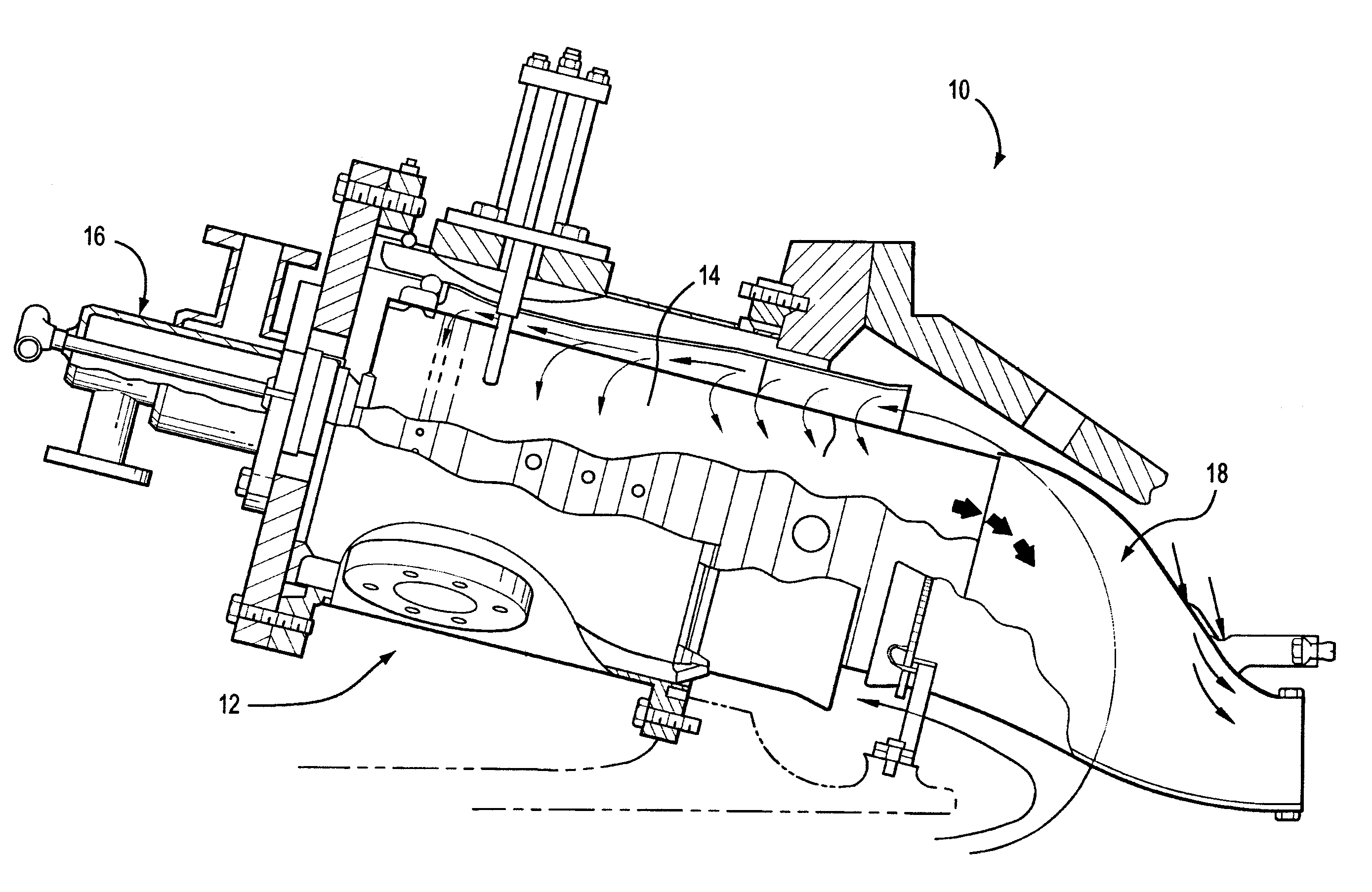

Turbine inter-stage gap cooling and sealing arrangement

InactiveUS8240980B1Limitation on injectionAvoid crackingPump componentsEngine fuctionsIndustrial gasTurbine

An industrial gas turbine engine having a first stage rotor blade with a outer segmented shroud forming a blade outer air seal with the blade tips and a second stage stator vane assembly which forms an axial inter-stage gap between an isolation ring that supports the outer shroud segment and the outer endwall of the vane. The isolation ring and the outer endwall both include a circumferential rail extending into the gap to form a serpentine flow passage in the gap. The outer shroud segment includes an aft edge extending outward to form the serpentine flow passage within the gap. Cooling air holes in the aft edge of the outer shroud segment discharge cooling air from the impingement cavity located above the shroud segment into a continuous slot opening into the inner end of the serpentine flow passage in the gap.

Owner:FLORIDA TURBINE TECH

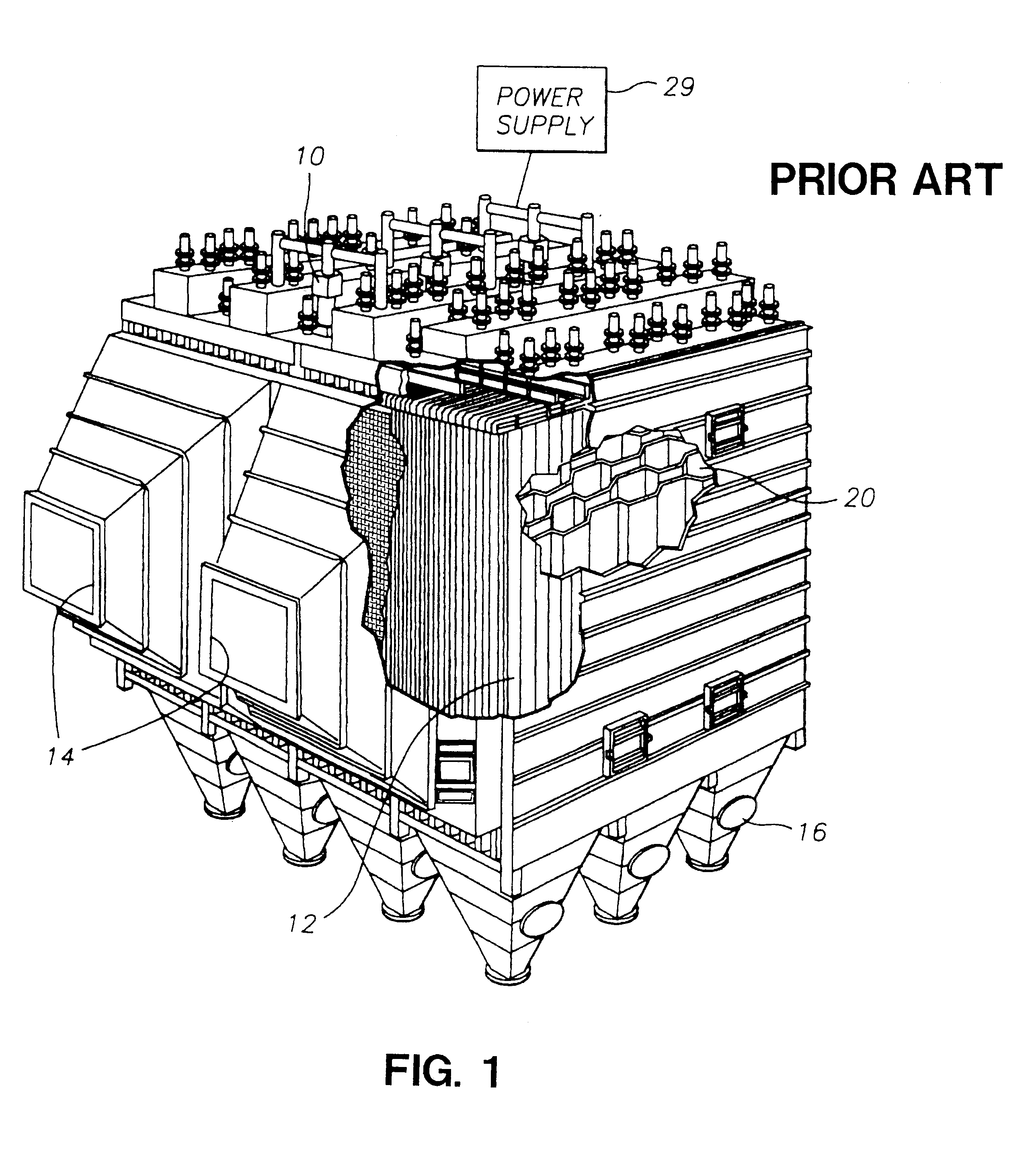

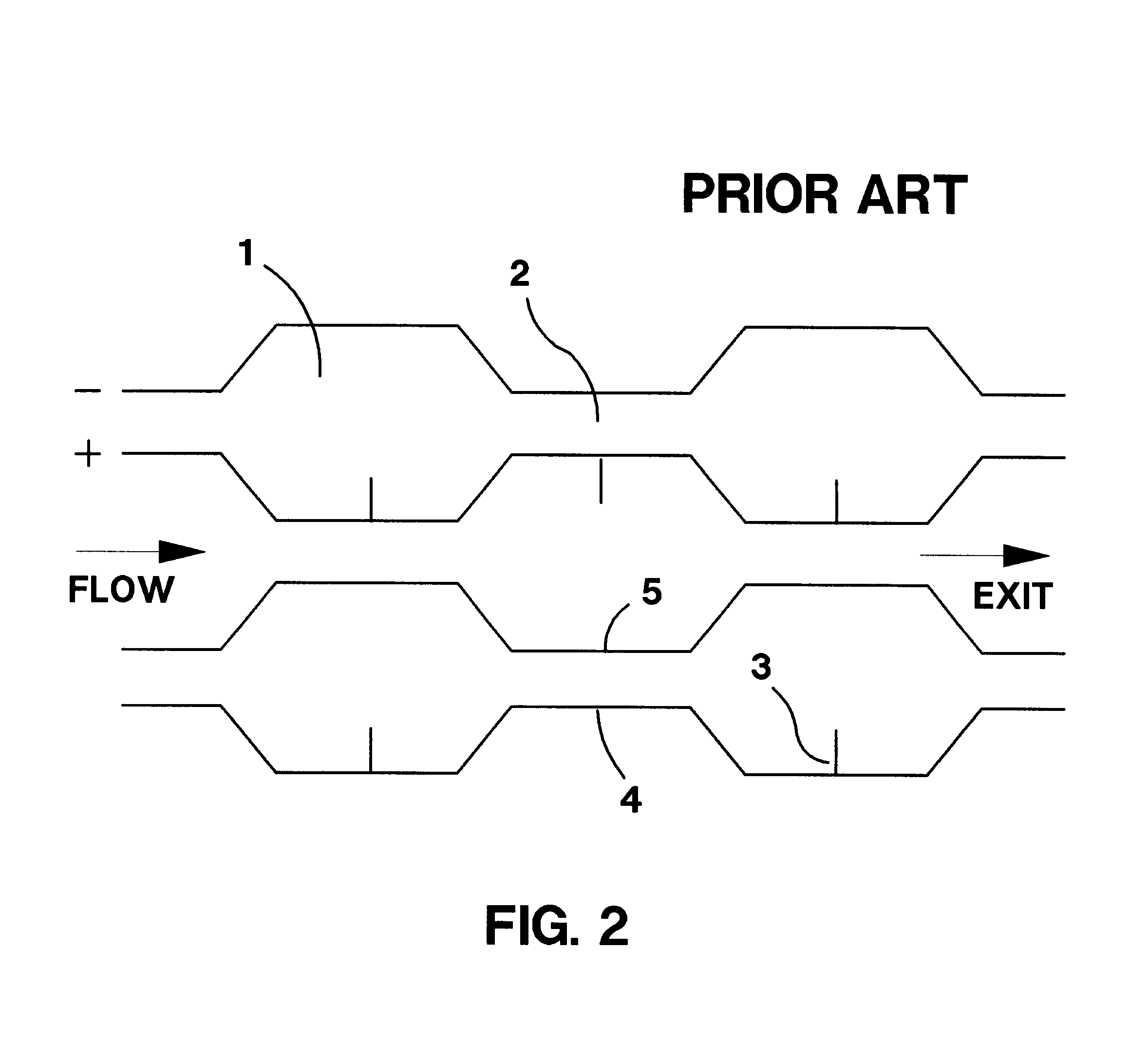

Multi-stage particulate matter collector

InactiveUS6524369B1Improve collection efficiencyIncrease the areaDispersed particle filtrationParticle charging/ionising stationsParticulatesParallel plate

A multi-stage particulate matter collector of the type used to collect particles from waste industrial gas. The collector can contain multiple narrow and wide zones formed by a plurality of parallel corrugated plates. Contained in the narrow zones are elongated electrodes with sharp leading and / or trailing edges. These electrodes provide a non-uniform electric field near their sharp edges leading to corona discharge. The corona discharge causes particulate matter in the gas flow to become charged. The region in narrow zones away from the sharp edges of the electrodes resembles a parallel plate capacitor with relatively uniform electric field. In this region, particles can be collected on the plates and on the electrode. Wide regions can contain barrier filters (bag filters) with conductive surfaces. The electric field is also relatively uniform in this region causing electrostatic collection on the plates and filter surface. Gas exits the array through the sides of the barrier filters which provides additional highly efficient filtering.

Owner:KRIGMONT HENRY V

Method for producing vanadium trioxide

A process for preparing V2O3 includes such steps as adding the powdered ammonium vanadate or V2O5 into the furnace pipe of an externally heated fluidized furnace, filling industrial gas in the furnace pipe while heating it to 600-650 deg.C, reducing reaction for 3-9 min, and cooling in the condition of isolating air.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Integral fuel jet axial swirler pre-mixing preevaporated low pollution combustion-chamber

InactiveCN101285592AShorten the lengthReduce distanceContinuous combustion chamberCombustion chamberAtmospheric air

The invention discloses a combustion cavity of an integral fuel oil ejecting axial hydrocyclone with functions of premixing, pre-evaporation and low pollution. The combustion cavity has a single ring cavity structure, and consists of a combustion cavity head and a flame tube. The combustion cavity head comprises a precombustion stage positioned at the center and a main combustion stage positioned at the peripheral. The main combustion stage comprises a direct jet type air atomizer spray nozzle and a main combustion stage axial hydrocyclone. The technical proposal that the jetting of the main combustion stage fuel oil and the main combustion stage axial hydrocyclone are integrated is adopted. The main combustion stage fuel oil ejected by the direct jet type air atomizer spray nozzle enters into a main combustion stage axial hydrocyclone vane channel of a main combustion stage axial hydrocyclone vane, and the fuel oil is mixed with the rotary flow air of the main combustion stage axial hydrocyclone. A premixed oil-gas mixture enters into a combustion zone through a main combustion stage mixing cavity to be combusted. The combustion mode can effectively reduce pollutant emission in the combustion cavity and reduce the length of the combustion cavity. The combustion cavity is mainly used for an aerial engine combustion cavity, and also can be used for the combustion cavity of industrial gas turbines and ship gas turbines so as to reduce pollutant discharged into atmosphere.

Owner:BEIHANG UNIV

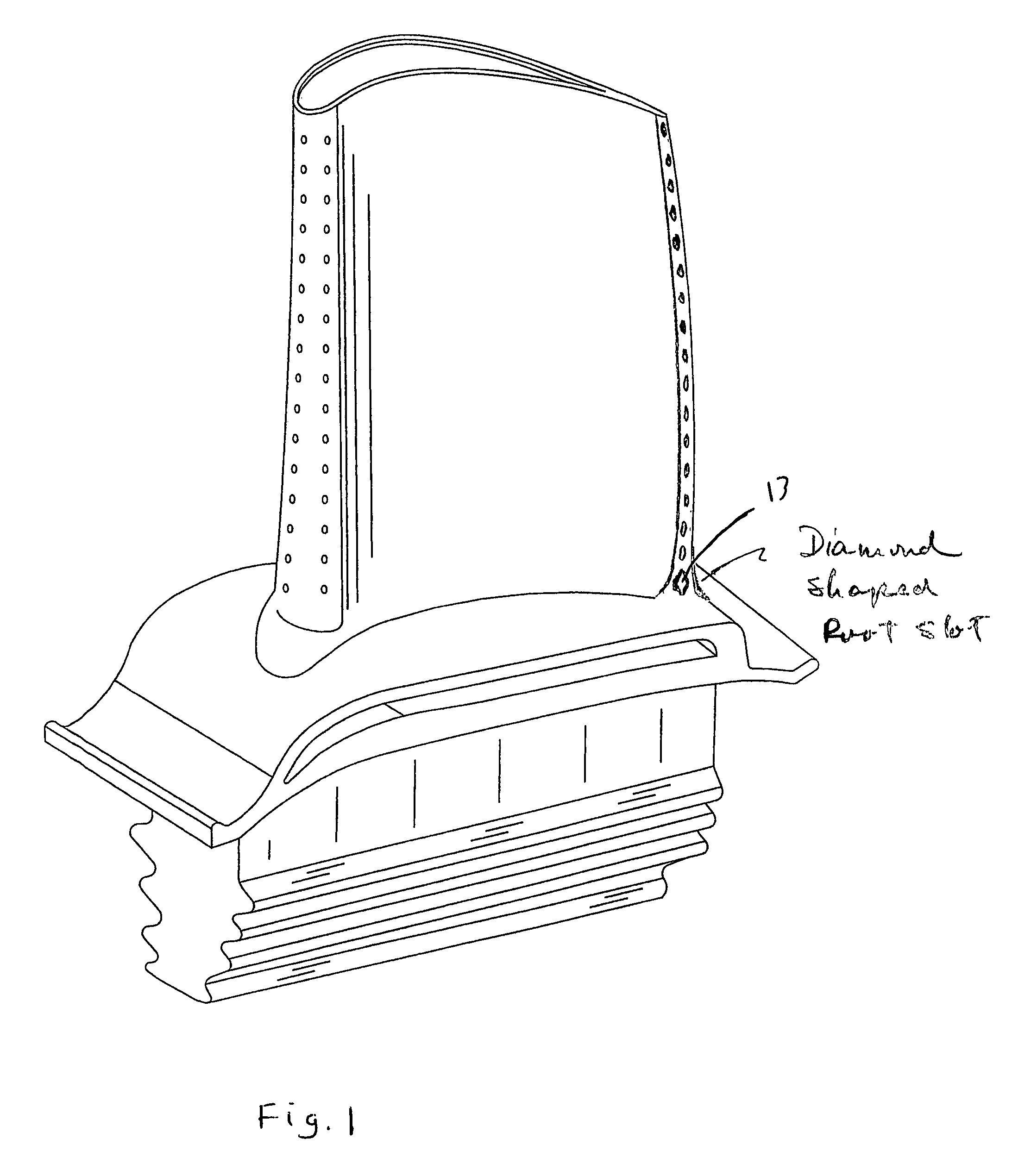

Turbine blade with trailing edge root slot

InactiveUS8047787B1Minimizes high stressIncrease pressureEngine manufactureEngine fuctionsIndustrial gasStress concentration

A turbine rotor blade for use in an industrial gas turbine engine in which the blade includes a root section with a fillet region formed between the root and the platform of the blade. The platform region includes a diamond shaped root slot to discharge cooling air from the internal cooling passage out through the trailing edge of the blade. The diamond shaped cooling slot of the present invention comprises a smaller radius at the upper and lower corners and a much larger radius at the mid section of the slot. The cooling slot is positioned in the trailing edge root section where the upper corner is positioned above the fillet run out location. The diamond shaped cooling slot thus minimizes the high stresses induced by the stress concentration from the cooling slot and the fillet run out location.

Owner:FLORIDA TURBINE TECH

Fuel and air mixing device for low-pollution burning chamber of gas turbine

ActiveCN102506446AFast evaporationQuick blendContinuous combustion chamberIndustrial gasCombustion chamber

The invention discloses a fuel and air mixing device for a low-pollution burning chamber of a gas turbine. Fuel comprises a main burning level and a duty burning level; and air is supplied by a three-stage cyclone. The fuel and air mixing device is characterized in that the central duty level adopts diffusive burning, and the peripheral main burning level adopts premixing or semi-premixing burning. The central duty level consists of a centrifugal atomizing nozzle and first-stage cyclone air; and the rotating directions of the first-stage cyclone air and second-stage cyclone air are opposite. The fuel of the main burning level is supplied by a multipoint direct-injection type nozzle, the air is respectively supplied by the second-stage cyclone air and third-stage cyclone air, and the rotating directions of the second-stage cyclone air and third-stage cyclone air are opposite. The central duty level is used when in low working conditions such as starting and slowing and the like, so that the stable burning range can be widened, the burning efficiency can be improved and the emission of CO and UHC is reduced; and when in large working conditions, the duty level and the main burning level work simultaneously, the duty level provides a stable ignition source for the main burning level, a main burning area is in a lean-oil state, and the temperature is far lower than the temperatureof insulated flame, so that the emission of NOx under the large working conditions can be obviously reduced. The fuel and air mixing device can be used for an aerial gas turbine engine or an industrial gas turbine.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Asymetric membrane FeAl intermetallic compound porosint filter element and application thereof

ActiveCN101524609AGood degree of pore structure controlWide range of regulationIncreasing energy efficiencyManufacturing convertersPorosityVulcanization

The invention belongs to the field of inorganic porosint and particularly relates to an asymetric membrane FeAl intermetallic compound porosint filter element and the application thereof. The filter element of the invention consists of a multiaperture support body and complex film; wherein, the multiaperture support body is in tubular shape or platy shape, the complex film is made in the following steps: a compound sizing agent is coated on outer surface of a single side of the multiaperture support body; and degreasing, bias diffusion, reaction synthesis and sintering are carried out to form thin-layer complex film with millipores. The millipores on the surface of the filter element is small and uniform, porosity is high, no dust is blocked inside filter material, filtering gas circuit is smooth, and resistance is small; in addition, the element has good resistance to high temperature oxidation / vulcanization and good normal temperature and high temperature mechanical properties. The element can directly carry out solid-gas separation on industrial gasses, bear top load and high-pressure and high-speed back washing, thus saving relative cooling devices, saving a large amount of water resources, avoiding cooling water treatment, lowering energy loss, shortening process flow and improving work efficiency.

Owner:CHENGDU INTERMENT TECH

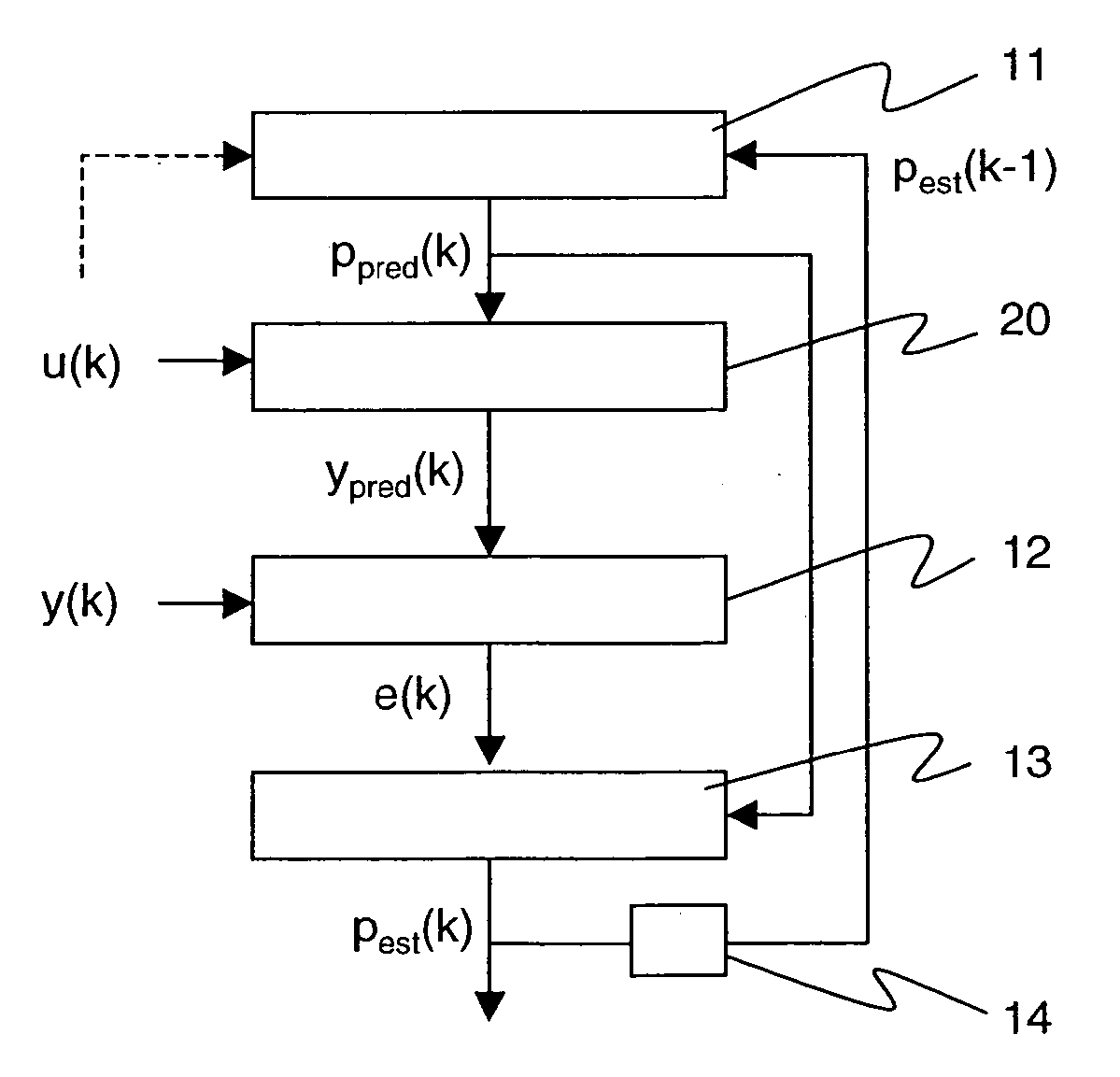

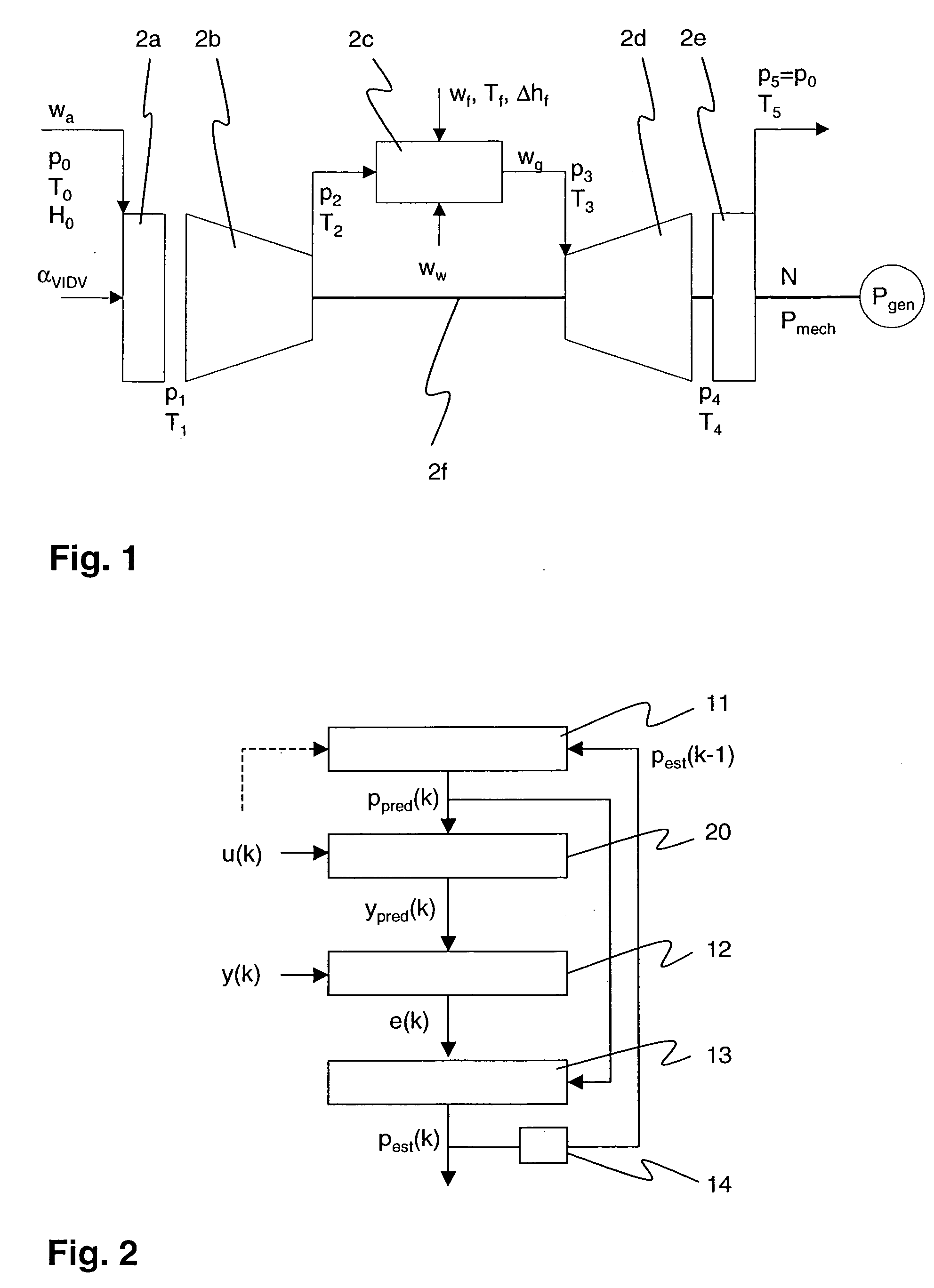

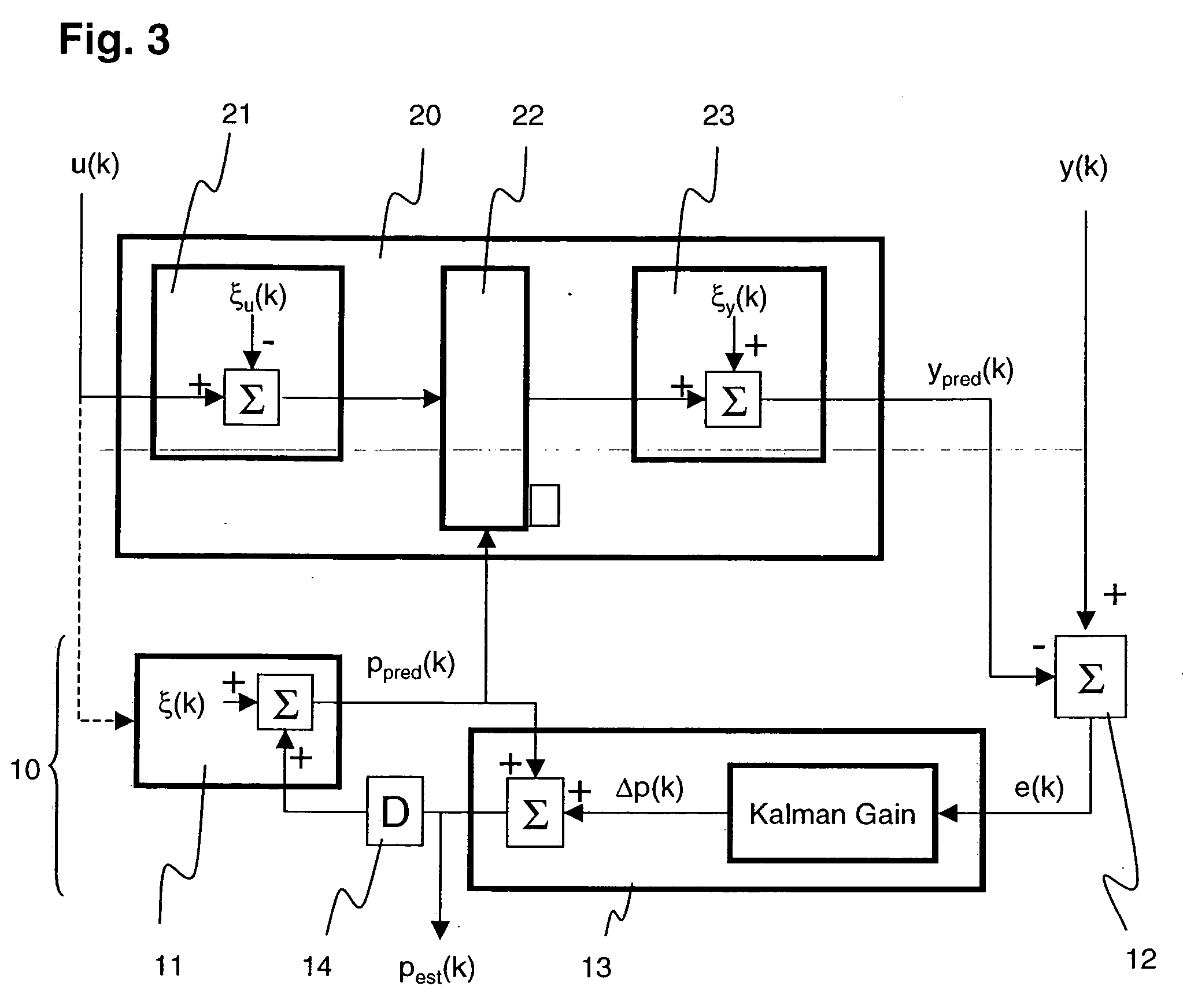

Estimating health parameters or symptoms of a degrading system

The present invention is concerned with the estimation of health parameters p(k) representing symptoms of a slowly degrading system, in particular industrial gas turbines. According to the invention, an estimation of a true health or independent parameter vector at time step k uses the estimation of the true health or parameter vector at a previous time step k−1 as a starting value for the production of a predicted health parameter vector at time step k. Based on the latter and a set of measured values of input variables of an extended model of the system, a prediction of output variables of the model is produced. This predicted model output is compared with measured values of the output variables to yield an error. From this error, a health parameter estimator in turn produces a health parameter estimate as a revision of the predicted health parameters. Preferably, the estimation of a true health or independent parameter vector at time step k includes a generalised process noise representing stochastic uncertainty and / or a-priori knowledge of an evolution of the health parameters.

Owner:ABB RES LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com