Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1688 results about "Steel fibre" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fiber reinforced high-strength mortar used for concrete structure repair

ActiveCN101580369AExcellent structural repair comprehensive performanceIncreasing the thicknessSolid waste managementChemical admixtureCement mortar

The invention relates to a fiber reinforced high-strength mortar used for concrete structure repair, belonging to the technical field of building materials. The mortar is characterized in that the mortar is formed by mixing cement, activated and inert mineral admixtures, expanding agents, micro steel fibers, chemical admixtures, sand and the like based on a certain proportion. At the constructionfields or concrete batching plants, the mortar is added with right amount of water and the mixture is stirred evenly, transported to the construction sites and poured by hand spreading or pumping. Thefiber reinforced high-strength mortar has high strength, good volume stability and durability and large deformability, can be free of vibrating and self-leveling construction, and is convenient, fastand flexible in construction. The structure repair combination property of the fiber reinforced high-strength mortar is greatly superior to that of the current commonly used fine gravel concrete or steel wire mesh-polymer cement mortar system.

Owner:TSINGHUA UNIV

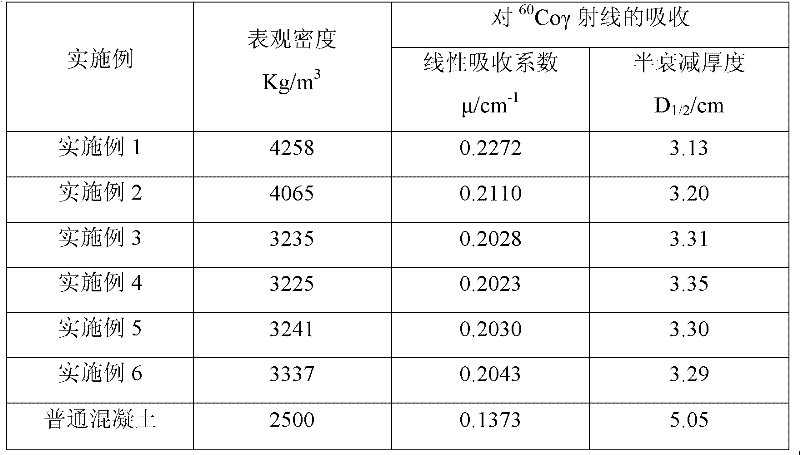

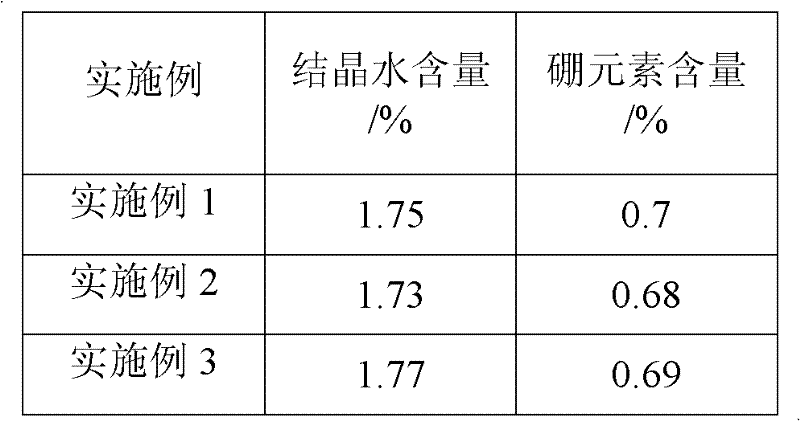

Radiation shield concrete and preparation method thereof

InactiveCN102219459AReduce water-cement ratioLow shrinkageSolid waste managementShieldingSlagSuperplasticizer

The invention relates to radiation shield concrete and a preparation method thereof. The radiation shield concrete is characterized by comprising a cementing material, coarse aggregates, fine aggregates, steel fibre, a high-efficiency slushing agent and water; the cementing material is composed of ordinary portland cement and inorganic mineral admixtures; the inorganic mineral admixtures are siliceous dust and coal ash; the fine aggregates are natural sand, boron glass powder and steel slag powder; the coarse aggregates are steel sections or a mixture of the steel sections and steel slag; the proportions of various types of components are as follows: 500 kg / m<3> of cementing material, 1400-2215 kg / m<3> of coarse aggregates, 750-950 kg / m<3> of fine aggregates, and 155-200 kg / m<3> of water; the high-efficiency slushing agent is 0.5-1.0% of the total weight of the cementing material by weight; and the steel fibre is 1.0-1.5% of the total volume of the concrete by volume. The radiation shield concrete has good mechanical property and lasting quality, good shielding effect on gamma rays, good effect on shielding neutron rays, can be used or comprehensively recycling wastes and has low cost.

Owner:WUHAN UNIV OF TECH

Dedicated pouring material for cement kiln outlet and jetting coal pipe and preparation method thereof

InactiveCN101445379AImprove thermal shock performanceGood alkali resistanceCarbide siliconCement factory

The invention discloses a dedicated pouring material for a cement kiln outlet and a jetting coal pipe, which comprises the following components by the weight percentage: 20 to 30 percent of sintered plate-shaped corundum, 20 to 30 percent of sintered and synthesized mullite, 10 to 15 percent of chrome corundum, 5 to 10 percent of silicon carbide, 3 to 5 percent of silicon carbide superfine powder, 3 to 5 percent of magnesia alumina spinel, 5 to 8 percent of zircon sand, 2 to 5 percent of activated Al2O3 micro powder, 2 to 5 percent of silicon micro powder, 3 to 5 percent of pure calcium aluminate cement, 1 to 2 percent of stainless steel fiber, 5 to 10 percent of synthesized zirconium mullite grinding powder, 0.1 to 0.15 percent of composite additives and 0.01 to 0.1 percent of explosion proof fiber. The invention further discloses a method for preparing the pouring material. The pouring material is applicable to the dry-process cement kiln outlets and the jetting coal pipes in large-scale cement plants and has the advantages of high wear resistance, good anti-stripping resistance and long service life.

Owner:JIANGSU GUOHAO REFRACTORY TECH

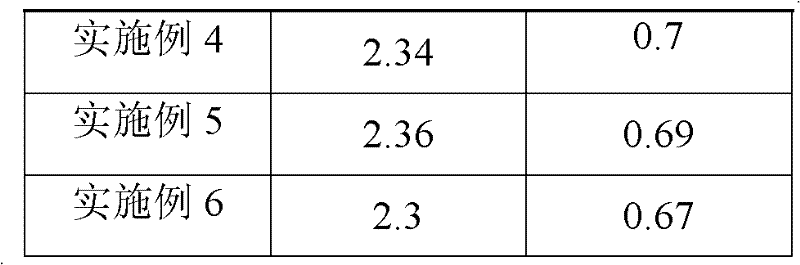

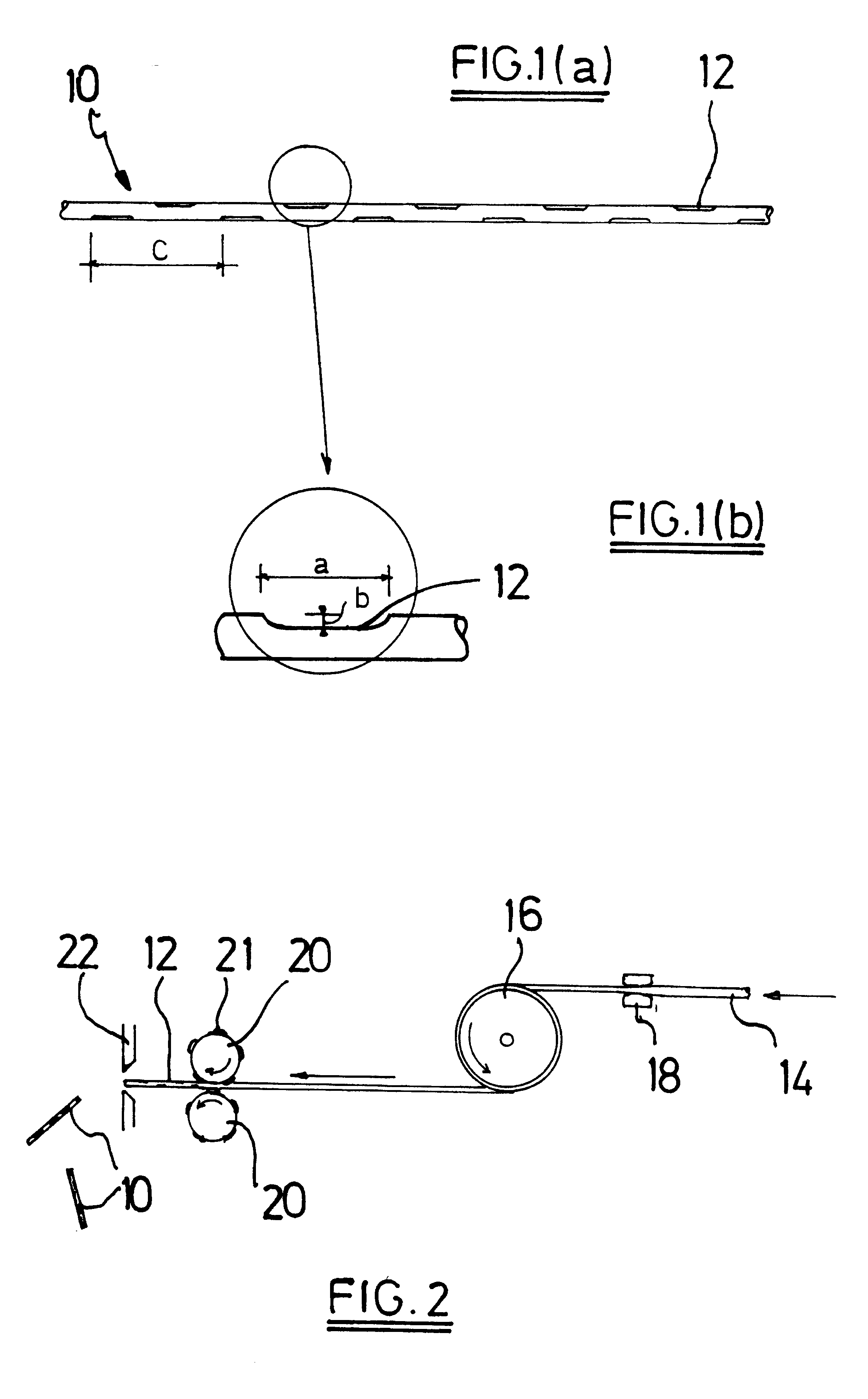

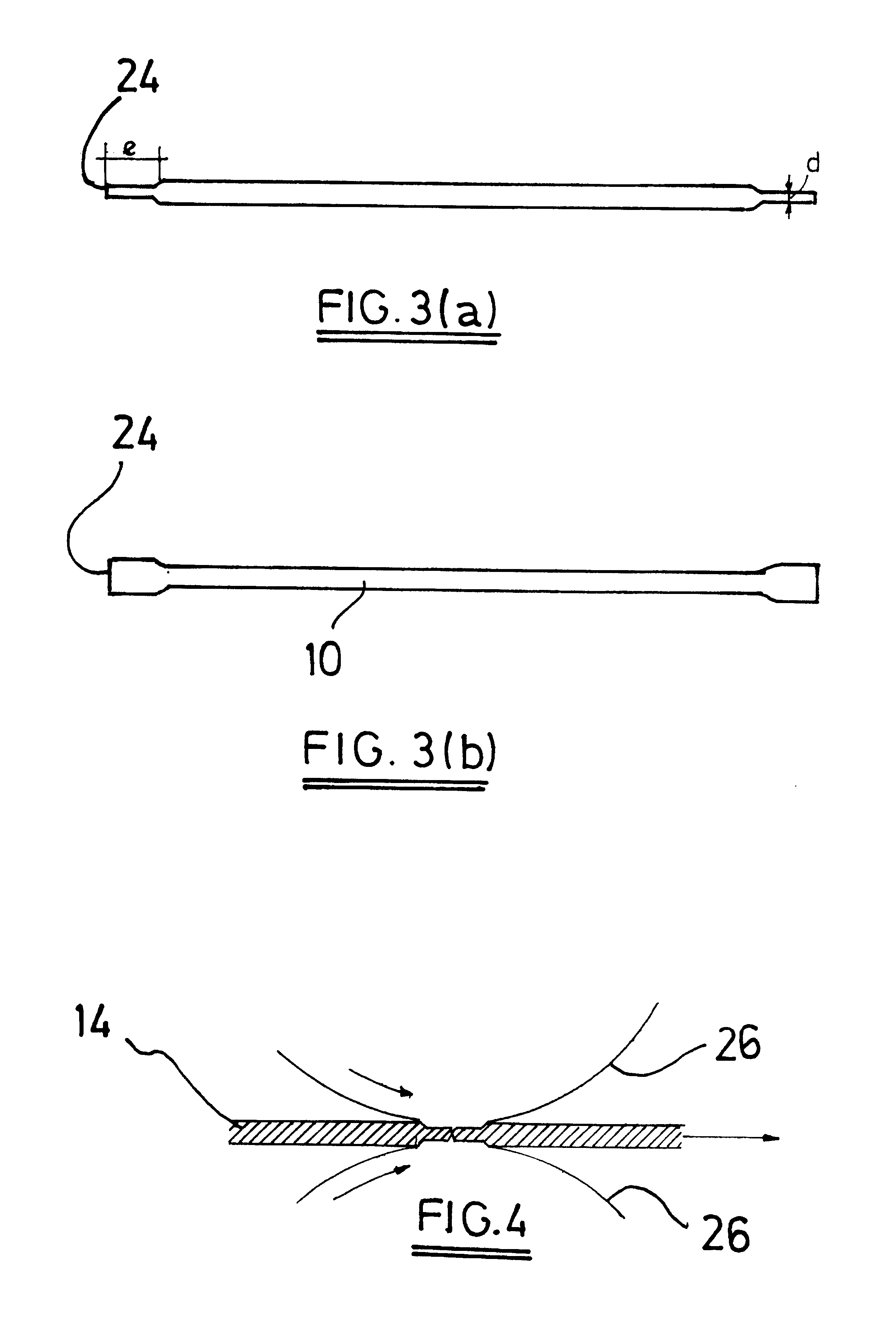

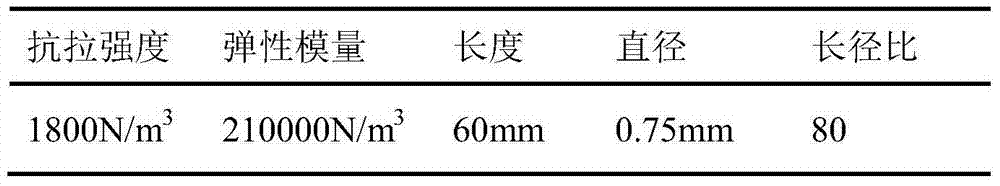

Steel fiber for reinforcement of high-performance concrete

InactiveUS6235108B1Reduce decreaseIncrease anchorageBuilding reinforcementsYarnMetallurgySteel fibre

A steel fiber (10) for reinforcement of high-performance concrete or mortar has a length ranging from 3 mm to 30 mm, a thickness ranging from 0.08 mm to 0.30 mm, and a tensile strength greater than 2000 MPa. The steel fiber is provided with anchorages (12,24) the dimension of which in a direction perpendicular to the longitudinal axis of the steel fiber is maximum 50% of the thickness. These anchorages provide an effective staying in the high-performance concrete without influencing the mixability of the steel fibers in a negative way.

Owner:NV BEKAERT SA

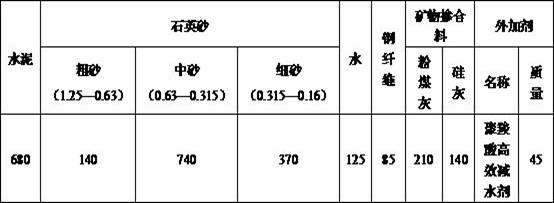

High-strength active powder concrete and preparation method

InactiveCN102320789AImprove performanceImprove uniformityCeramic shaping apparatusDry mixingWater reducer

The invention discloses a cement-based composite material - high-strength active powder concrete which comprises the following raw materials by weight: 40-55 parts of quartz sand, 25-30 parts of cement, 0-10 parts of fly ash, 0-7 parts of silica fume, 1-4 parts of steel fibers, 1-2 parts of water reducers, and 2-7 parts of water; in the components, the particle size of quartz sand is less than 1.25 mm, wherein the weight content of SiO2 is 97%. The mixing preparation comprises the following steps: weighing quartz sand and steel fibers according to the mixing ratios, adding into a stirring pot, performing dry mixing for 2 min; weighing cement and a special composite admixture according to the mixing ratios, adding into the stirring pot, performing dry mixing with quartz sand and steel fibers for 2 min; finally adding the high-efficient water reducer and water together, stirring for 6 min; after the stirring of the concrete, blanking and molding. The concrete of the invention has ultrahigh strength, low brittleness, high durability, and high compactness, brings into better play of the excellent performance of the active powder concrete, and reaches the purposes of less maintenance or free of maintenance, and prolongation of structure service life.

Owner:SICHUAN SOUTHWEST JIAOTONG UNIV RAILWAY DEV

Basalt fiber high temperature compositing filter material

InactiveCN101053718AImprove high temperature resistanceMeeting the needs of the high temperature filtration industryFiltration separationThermal energyIndustrial gas

The invention provides a basalt fibre high-temperature composite filter material. The high-temperature composite filter material is formed by weaving or needling, using the basalt fibre or the mixture of basalt fibre and other high temperature material which is one or more of the glass fibre, stainless-steel fibre and ceramic fibre. The invention can effectively improve the resistance to high temperature of filter material, extending the useful life, and also recycle heat energy, which saves energy source, has a excellent filter effect, and meet the need in the industry of industrial gases filter in high temperature.

Owner:江苏正大森源集团

Self-compacting fiber reinforcement active powder concrete and method for making same

ActiveCN101139192AImprove liquidityNo need to vibrateSolid waste managementCompressive strengthUltimate tensile strength

The present invention belongs to the building material technology field, in particular to relate to a self-compact strengthened fibre active concrete and the corresponding preparation method. The present invention is made of cement, silicon ash, quartz powder, quartz sand, water reducer and steel fibre or polypropylene fibre or the mixing fibre between the steel fibre and the polypropylene fibre according to the weight ratio. By using the new type water reducer, the present invention makes the concrete not need any vibration when being molded and the concrete can rely on the self weight to be filled in each angle of the building mould. Besides, the concrete can rely on the self weight to reach the compact situation. By using the rational fibre, both the compression strength and the folding strength can be enhanced greatly, especially for the folding strength, the enhanced degree is much greater. And moreover, the tenacity of the RPC is also enhanced greatly. The self-compact strengthened fibre active concrete in the present invention can simplify the manufacturing process greatly and provide much wider application foreground for manufacturing thin-wall products, slight components or other components with novel structure shape.

Owner:广东利盈投资集团有限公司

Composite fire resistant pouring material

The invention relates to an organic-inorganic composite combined advanced monolithic refractory which has the formula of 40 to 56 percent of 5-1mm corundum or bauxite, 12 to 30 percent of 1-0.0088mm corundum or bauxite, 16 to 25 percent of corundum or bauxite with d90 less than 0.088mm, 0 to 5 percent of alpha alumina micropowder, 1 to 8 percent of hydratable alumina, 1 to 6 percent of siliceous dust, 0 to 2 percent of calcium aluminate cement, 0.05 to 0.4 percent of external efficient water reducing agents (polycarboxylic acid plus sulfonation naphthaldehyde polymer plus sulfonation melamine polymer), 1 to 6 percent of latex of the system of external polyacrylic acid, 1 to 6 percent of external water and 0 to 3 percent of external heat-resistant steel fiber. Casting materials of the invention have excellent performances of condensation, hardening, demoulding, drying and heating and are suitable for high-temperature furnace projects with changeful field conditions.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

Green environmentally-friendly powder reinforced concrete water delivery pipe

ActiveCN103224356ALow costReduce pollution treatment costsCeramic shaping apparatusSlagMesh reinforcement

The invention belongs to the field of water delivery engineering and relates to a green environmentally-friendly powder reinforced concrete water delivery pipe. The green environmentally-friendly powder reinforced concrete water delivery pipe is manufactured by uniform distribution of concrete on a reinforcement mat. The concrete is prepared from 450 to 500 weight parts of ordinary portland cement or low-alkaline portland cement having the average grain diameter of 30 to 60 microns, 90 to 130 weight parts of silica fume having the average grain diameter of 0.18 microns and SiO2 content greater than or equal to 85%, 100 to 130 weight parts of I-grade coal ash having the average grain diameter of 10 to 20 microns, 130 to 160 weight parts of more than S95 grade of slag powder having the average grain diameter of 10 to 30 microns, 520 to 600 weight parts of quartz sand having the grain diameter of 0.16 to 1.63 millimeters, 800 to 880 weight parts of crushed stone having the grain diameter of 5 to 14 millimeters, 12 to 20 weight parts of a composite high-efficiency water reducer having a water-reducing rate more than 30%, 7 to 12 weight parts of a corrosion inhibitor, 45 to 50 weight parts of a high-efficiency expanding agent, 130 to 150 weight parts of water, 0.8 to 1.2 weight parts of polypropylene fibers, and 80 to 160 weight parts of copper-coated steel fibers having the diameter of 0.18 to 0.25 millimeters and the length of 10 to 15 millimeters. The reinforcement mat is manufactured by weaving hard-drawn wires having the diameter of 4.0 to 6.0 millimeters as reinforcements and cold-rolled ribbed bars having the diameter of 5.0 to 10.0 millimeters as hoop reinforcements.

Owner:黄贺明

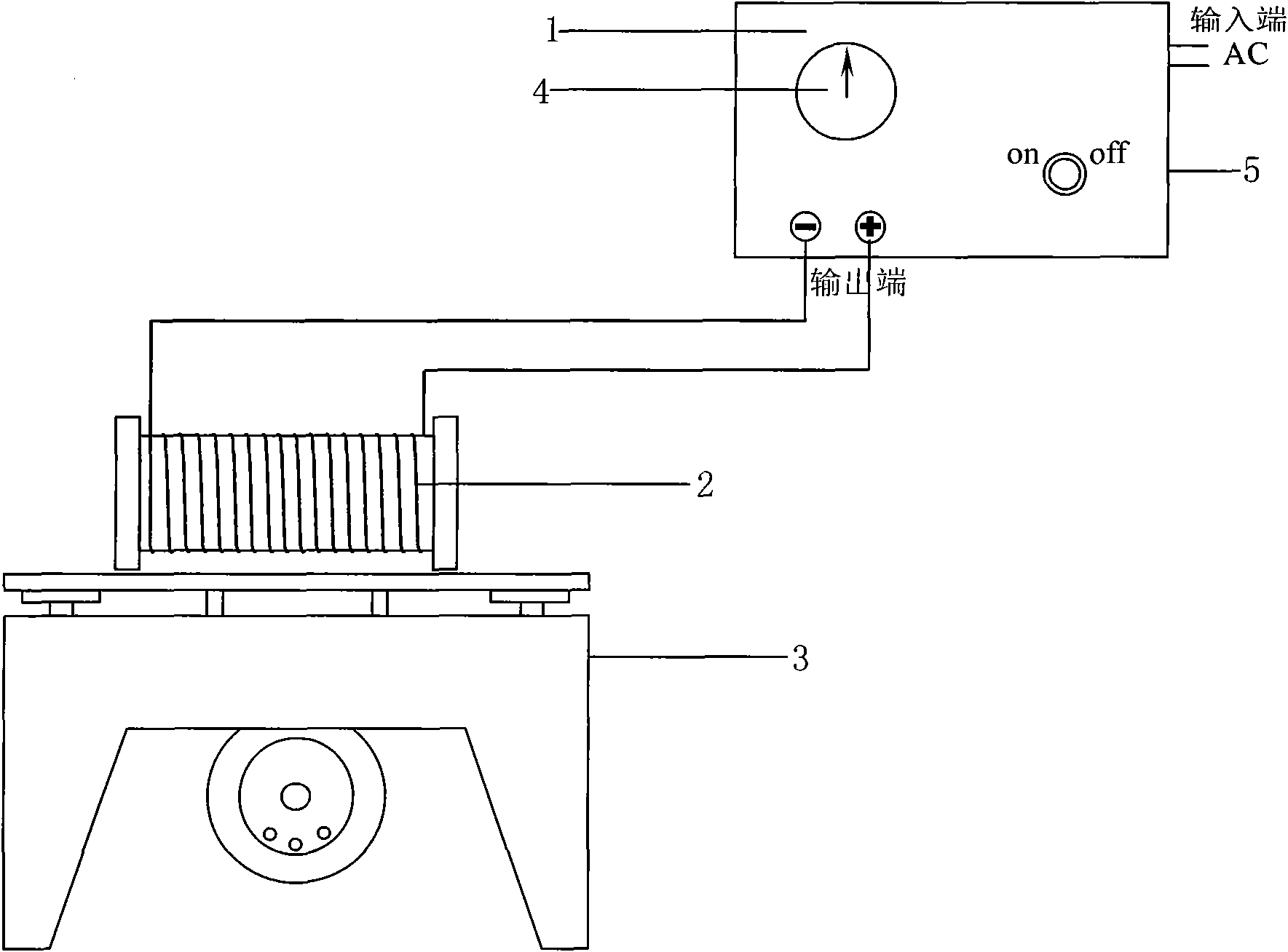

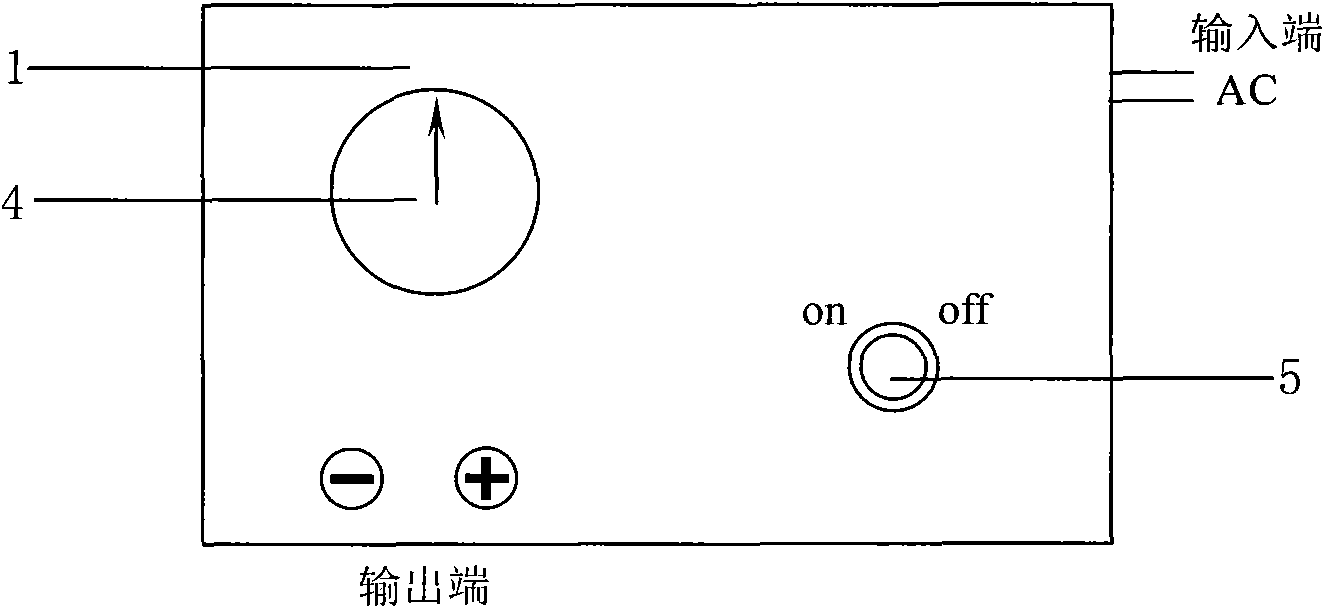

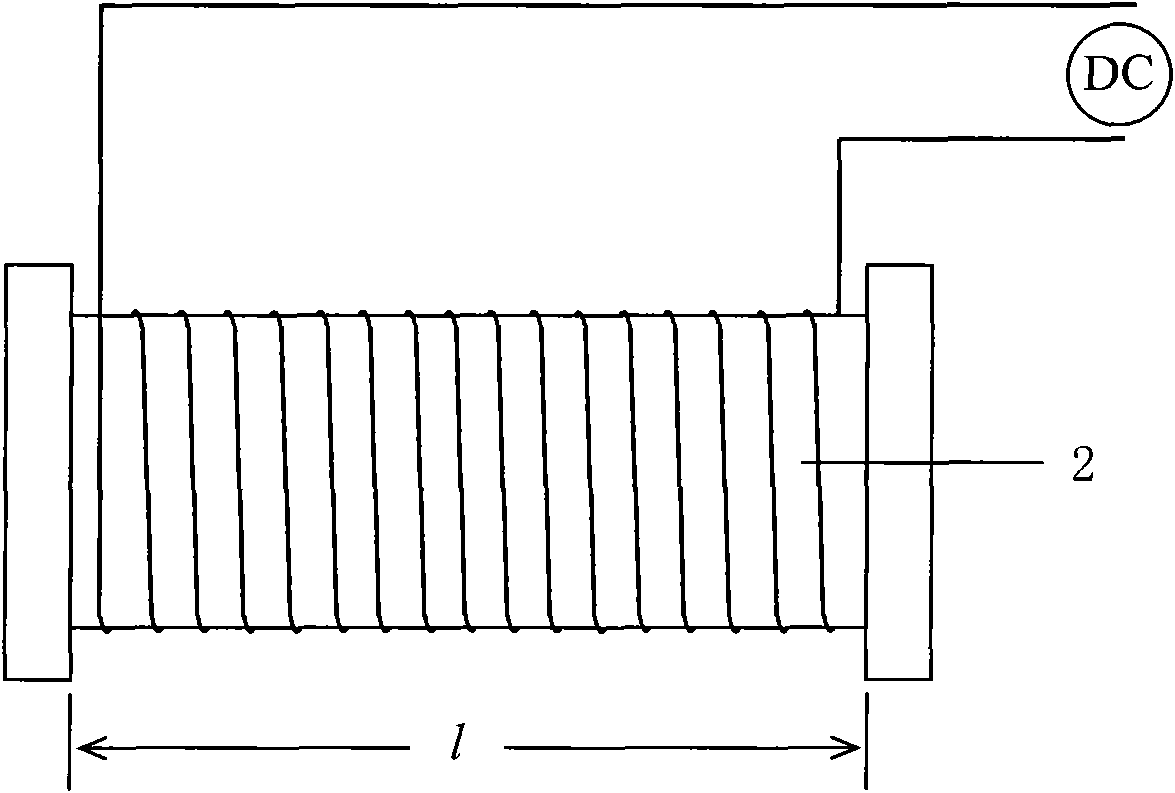

Method and special equipment for preparing unidirectionally-distributed steel fiber reinforced concrete

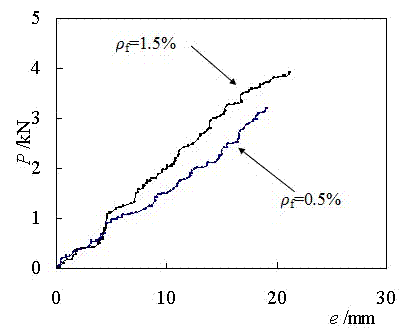

ActiveCN101913188AHighlight substantiveReduce dosageCeramic shaping apparatusBreaking strengthUltimate tensile strength

The invention discloses a method and special equipment for preparing unidirectionally-distributed steel fiber reinforced concrete and relates to fiber reinforced concrete. The method comprises the following key steps of: pouring a prepared steel fiber concrete mixture into a nonmetallic test mold and putting the test mold into a cavity in a framework of a coil of the special equipment for preparing the unidirectionally-distributed steel fiber reinforced concrete; putting the coil and the test mold on a vibrating table of the special equipment; switching on a direct current power supply of the special equipment to electrify the coil so as to form a magnetic field; applying the magnetic field to the prepared steel fiber concrete mixture so as to orient steel fiber; and keeping the direction of the magnetic field accordant with that of pulling stress during test piece testing or in a working state, wherein the special equipment consists of the vibrating table, the coil and the direct current power supply. Compared with steel fiber reinforced concrete prepared by the conventional method, the unidirectionally-distributed steel fiber reinforced concrete prepared by the method and the special equipment of the invention has breaking strength increased by 25 to 100 percent or saves the steel fiber by 25 to 60 percent.

Owner:HEBEI UNIV OF TECH

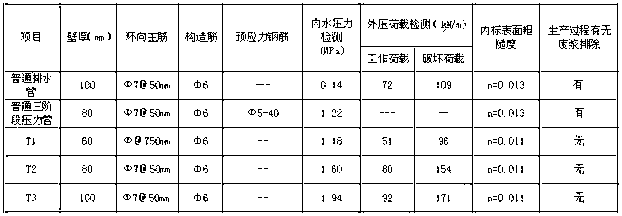

High-durability high-activity powder concrete electrical pole

InactiveCN101033658ANo lossImprove impermeabilitySolid waste managementMixing operation control apparatusPattern matchingPre stress

The invention relates to a RPC electric pole. Percentage of its quality quotient is: 100-140 portion thin round steel fiber with a diameter of 0.22mm, a length of 12-15mm and copperized surface, 21-25 portion water reducing agent, 170-190 portion water and 1110-1190 portion slender quartz grain with a grain size of 0.16-1.25mm. The steel fiber and slender quartz grain are added into agitator for homogenization, add cement and silicon powder for homogenization, then, add water reducing agent and residue water for homogenization to get RPC. Prime RPC into pattern matching prestressed reinforcement and centrifugate it. The finishsed product is conserved in 70-80deg.C steam for 48 hours and demould to achieve high endurance high intensity RPC electric pole. Its compression strength is above 200MPa, tensile strength is 15MPa and impermeability is above P16.

Owner:NORTHEAST DIANLI UNIVERSITY

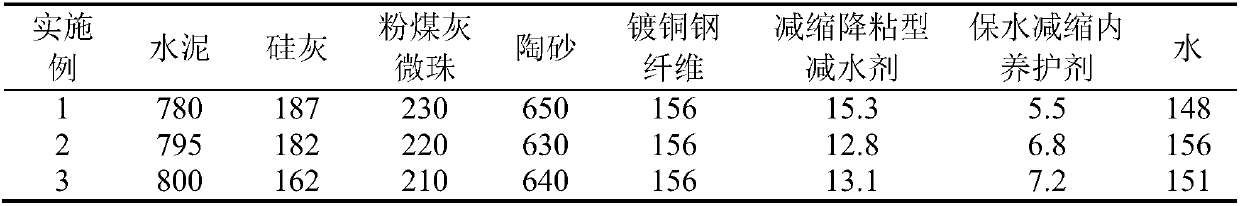

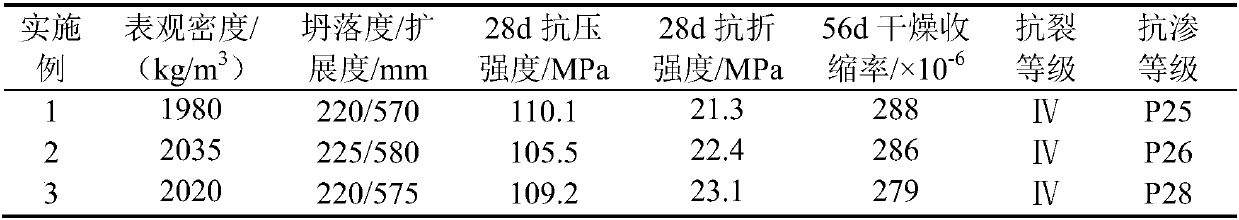

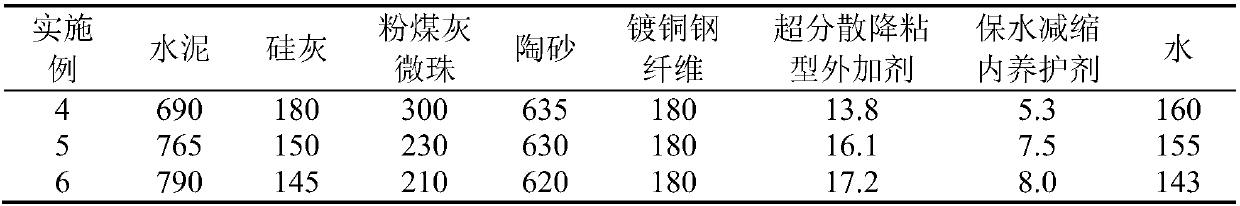

Light low-shrinkage super-high performance concrete and preparation method thereof

The invention discloses light low-shrinkage super-high performance concrete which is prepared from cement, coal ash beads, silica fume, pottery sand, a brass coated steel fiber, shrinkage and viscosity reduction type water reduction agent, a water-retention shrinkage-reduction inner curing agent and water as main raw materials. According to the concrete, the pottery sand is adopted as aggregate, the self weight of the concrete is reduced, and a high-strength and dense 'arch housing' interface area is formed on the surface of the pottery sand by using a pre-mixing process, so that the interfacestrength is improved, and the mechanical properties and the anti-penetrability performance of the concrete are improved; due to the adoption of the shrinkage and viscosity reduction type water reduction agent and the coal ash beads, the working performance and the density of the concrete are improved; due to the adoption of the pre-wetted pottery sand and the developed water-retention shrinkage-reduction inner curing agent, reduction of wetness inside the concrete is retarded, the self-shrinkage and the drying shrinkage of the concrete are reduced, and the volume stability of the concrete isimproved. While the self weight of the concrete is reduced, the light low-shrinkage super-high performance concrete disclosed by the invention is good in working performance, mechanical property, anti-penetrability and durability, and has significant practical application values.

Owner:WUHAN UNIV OF TECH

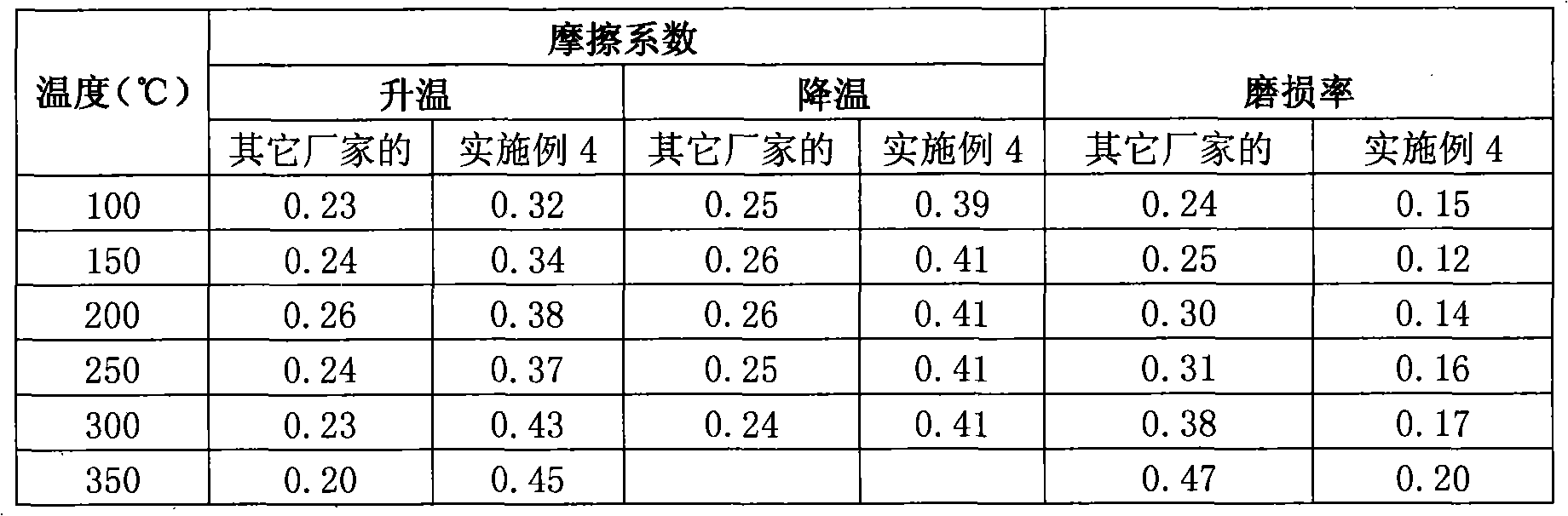

High-performance semi-metallic brake pad

ActiveCN101555915ASensitive brakesReduce brake noiseFriction liningGraphite particleAluminium silicate

A high-performance semi-metallic brake pad comprises the following components according to weight percentages: 4-6% of nitrile rubber powder, 2-4% of tyre powder, 3-5% of crystalline flake graphite, 6-9% of foam iron powder, 9-13% of boron containing phenolic resin, 8-12% of chopped steel fibre, 2-4% of alumina fibre, 8-11% of red copper fibre, 2-5% of cashew nut oil friction powder, 2-3% of graphite particle, 2-3% of calcined petroleum coke, 7-13% of barite, 3-4% of chromite, 2-3% of magnetite, 2-4% of diatomite, 7-10% of glued aluminium silicate fibre, 3-5% of flake aluminium powder, 2-4% of molybdenum disulfide, 0.2-0.5% of zinc stearate, 0.7-1% of antimony sulphide, 0.5-1% of copper sulphide, and 0.3-0.5% of tungsten carbide. After the brake pad is used, the car brake is sensitive, brake noise is low and comfort performance is good. The brake drum or brake disc has no damage in long-term use.

Owner:摩擦一号制动科技(仙桃)有限公司

Cement-based nanocomposite material and preparation method thereof

The invention relates to an inorganic nanocomposite material and a preparation method thereof and in particular relates to a cement-based nanocomposite material and a preparation method thereof. The invention provides a cement-based nanocomposite material in order to improve the mechanical property of a cement-based material. The cement-based nanocomposite material comprises the following raw materials in parts by weight: 1 part of silicate cement, 0.15-0.25 part of silicon ash, 0.003-0.006 part of nano CaO, 0.01-0.02 part of nano CaCO3, 0.005-0.01 part of nano Al2O3, 0.01-0.02 part of fibrous nano calcium silicate or 0.001-0.002 part of carbon nanofibers, 0.3-0.4 part of 325-mesh quartz powder or glass powder, 0.45-0.55 part of quartz sand with a particle diameter of 0.4-0.6mm, 0.4-0.6 part of steel fiber, 0.015-0.025 part of a high-performance water reducer and 0.18-0.25 part of water. The mechanical property of the cement-based nanocomposite material is improved to a great extent.

Owner:HUNAN MINGXIANG TECH DEV

Fibre-polymer compound toughened concrete and preparation method for same

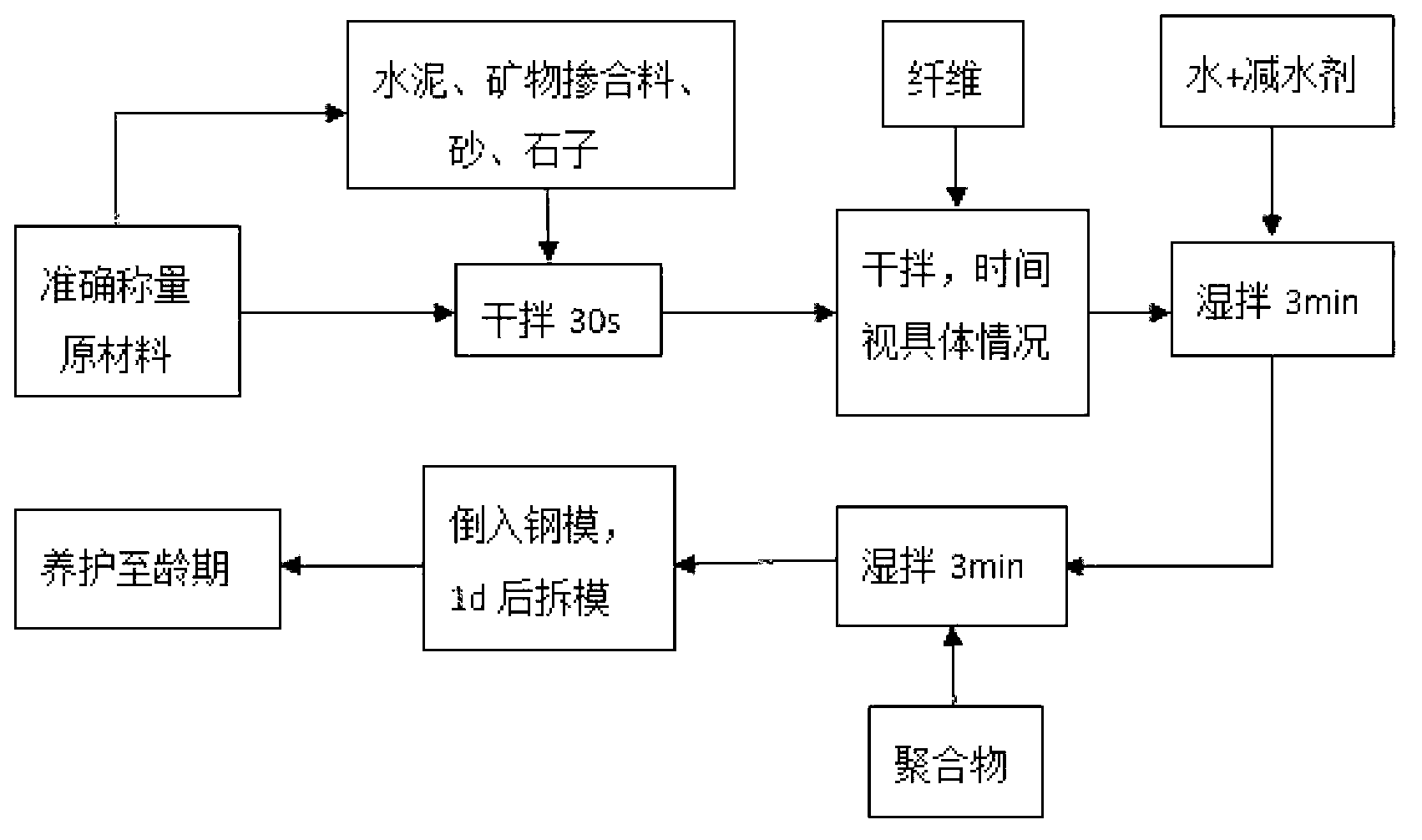

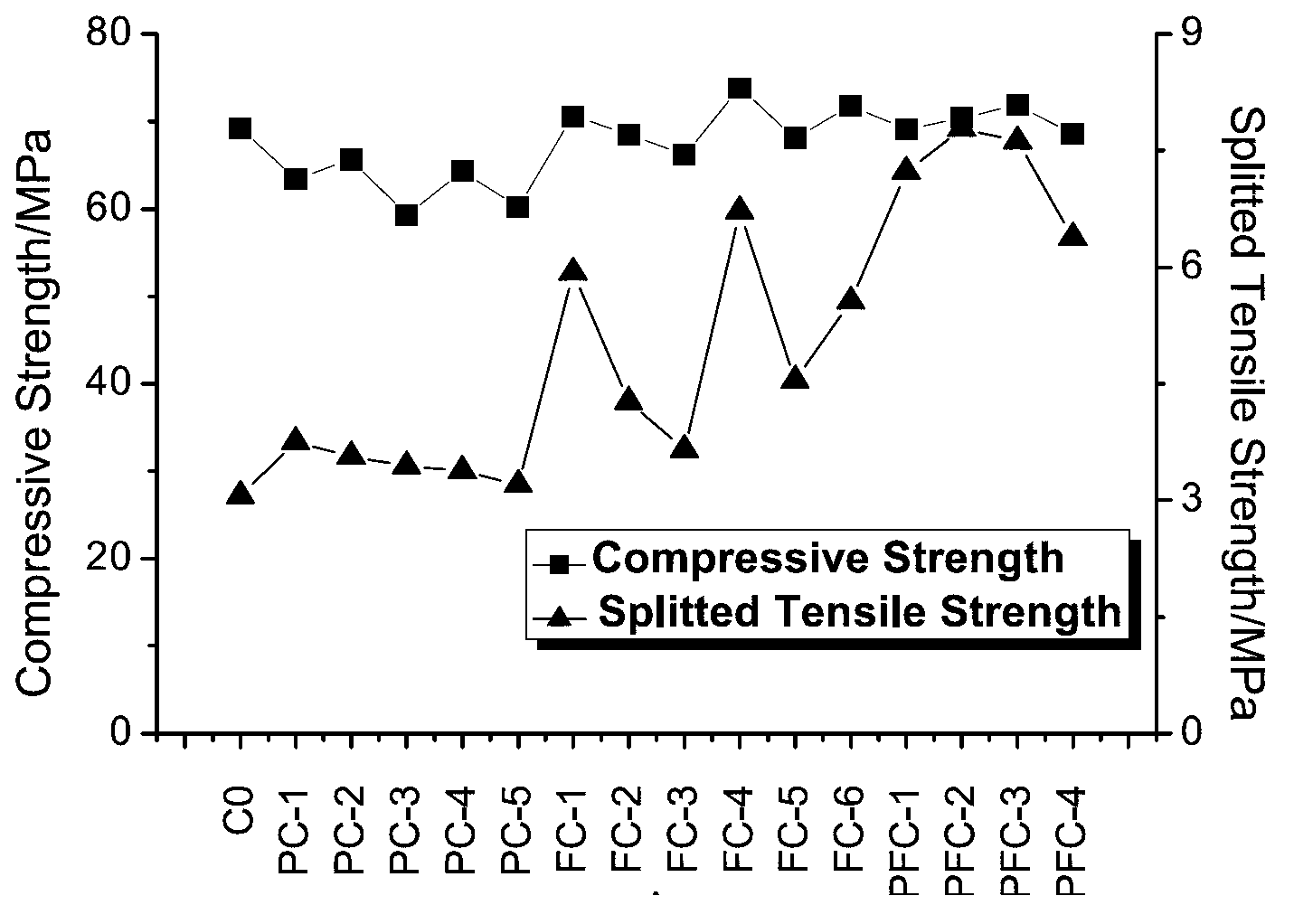

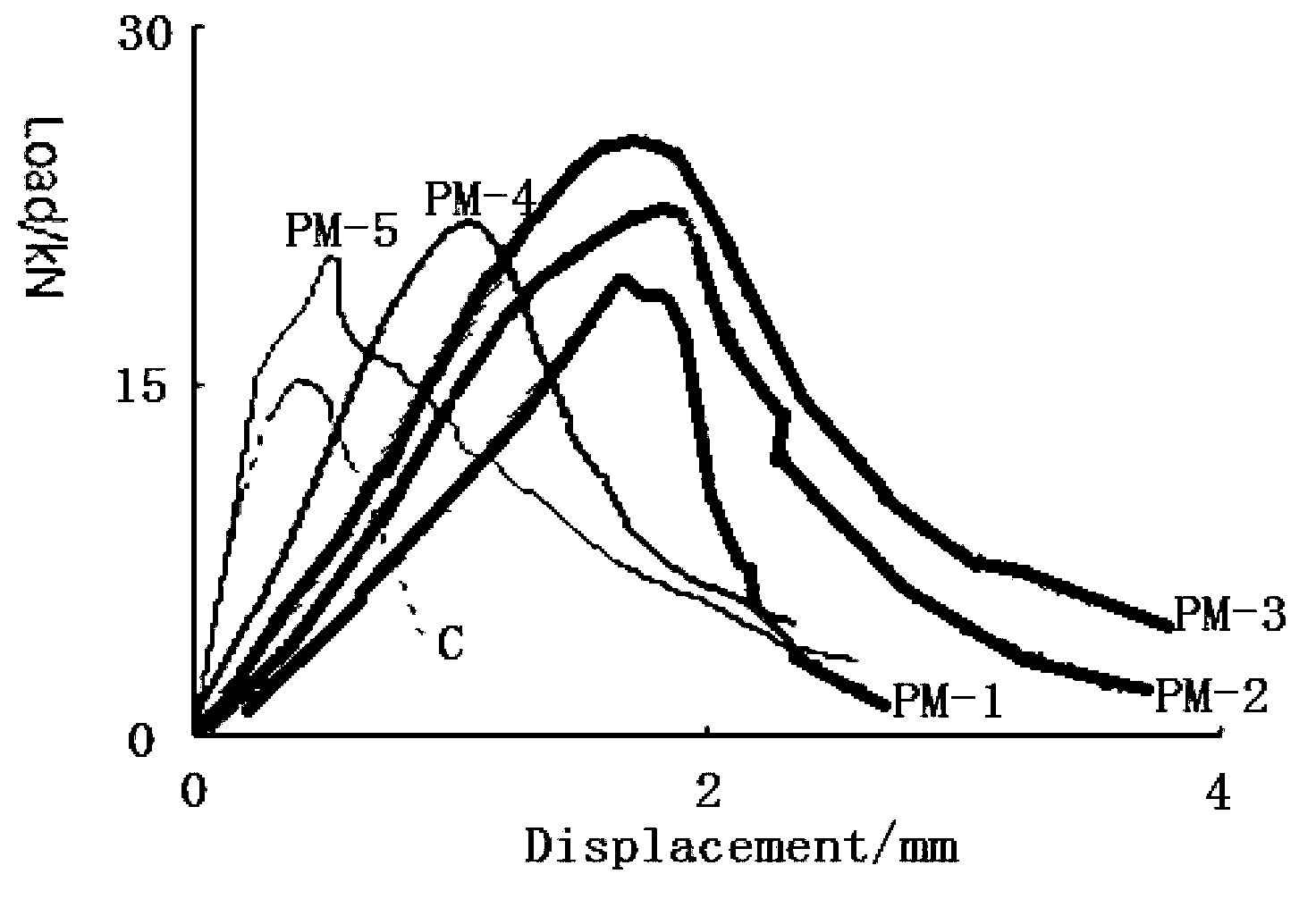

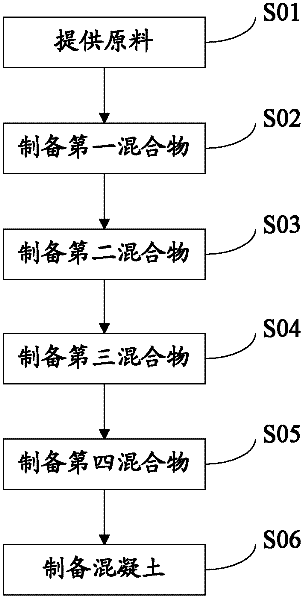

The invention discloses a fibre-polymer compound toughened concrete and a preparation method for the same. The basic raw materials of the concrete are coarse aggregate, fine aggregate, portland cement, fly ash and a polycarboxylic water reducer; moreover, fibres and a polymer are added, the fibres are any one of end-hook type steel fibres, superfine type steel fibres, modified polyester fibres, polyvinyl alcohol fibres, basalt fibres and cellulose fibres, and are doped in a ratio that the volume doped amount in per 1 m<3> concrete is 0.08%; and the polymer is any one of ethylene-vinyl acetate copolymer, ethyl acrylate, styrene-acrylate copolymer, vinyl acetate-acrylate copolymer and organosilicone acrylate, and the doped amount of each polymer is 10% based on the mass of the portland cement and the fly ash. The preparation method comprises the following steps of: pouring stone, sand, a gelling material, fibres, and water dissolved with a water reducer, and then stirring according to a blending mode of pouring dry materials at first and then pouring wet materials; and pouring the polymer, and stirring and forming.

Owner:SOUTHEAST UNIV

Refractory pouring material used for melten iron desulfur agitator

The present invention discloses a refractory pouring material for molten iron desulfurization stirrer. It is formed from pouring material base material and proper quantity of additive. The composition of the base material of pouring material includes (by wt%) 55-65% of general electrofused mullite 3-10% of jiaobaoshi, 3-7% of silicon micropowder, 5-10% of alpha-Al2O3 micropowder, 3-10% of pure calcium aluminate cement and 1.5-2.5% of compact corundum fine powder, and the described additive is formed from heat-resistant steel fibre, aluminium lactate and / or metal aluminium powder and sodium triphosphate and / or trimeric cyanamide.

Owner:武钢集团有限公司

Concrete and preparation method thereof

The invention is applicable to the technical field of building materials, and provides a concrete and a preparation method of the concrete. The concrete comprises a cementing material, river sands, a super plasticizer, water, steel fibers and polypropylene fibers. The concrete of the invention has a gradation synergetic effect by utilizing mixed graded steel fibers, so as to greatly improve compressive strength and bending strength, crack resistance and impact resistance of concrete; and the concrete overcomes early-stage microcrack problem of concrete via fine polypropylene fibers, and mainly improves toughness of concrete via coarse polypropylene fibers, so as to realize the advantages of concrete such as high compressive strength and bending strength, high crack resistance, and good durability. The concrete preparation method is easy in operation and low in cost, and is very suitable for industrial production.

Owner:黄贺明

Reactive powder concrete for reinforcing buildings as well as preparation method and construction method thereof

ActiveCN103274652AHigh compressive strengthHigh bonding strengthMicrosphereUltimate tensile strength

The invention discloses a reactive powder concrete for reinforcing buildings as well as a preparation method and the construction method thereof. The reactive powder concrete comprises the following raw material constituents in parts by weight: 50 to 80 parts of cement, 15 to 40 parts of fly ash microsphere, 5 to 13 parts of silica fume, 35 to 80 parts of river sand, 20 to 65 parts of quartz sand, 10 to 20 parts of water, 10 to 30 parts of steel fibre and 1 to 2 parts of chemical additive. The reactive powder concrete has the advantages of good fluidity, strong plasticity, good cohesive property with an existing structure, similar linear expansion coefficient with an existing concrete structure, high strength, wide raw material source, reliable technology, durable service, low in cost and simple construction technology. In addition, the RPC material poured at later stage and the existing structure are closely integrated as a whole, resulting from contraction performance of the reactive powder concrete during the process of hardening, and the integrity of the structure is enhanced; all that is needed is to carry out conventional maintenance on the reactive powder concrete after forming, the prospective reinforcement effect can be achieved, and curing condition is the same as that of the normal premixed concrete.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD +1

Light thermal-shield refractory castable

InactiveCN101792294ALight weightImproved thermal shock stabilitySolid waste managementCapacitanceMullite

The invention relates to a light thermal-shield refractory castable comprising the following components in percentage by weight: 40-60% of light aggregate, 10-20% of capacitance mullite, 5-10% of kyanite powder, 5-10% of high-aluminium clinker powder, 3-8% of silica micro powder, 3-8% of alpha-Al2O3 micro powder, 5-10% of high-aluminium cement, 0.5-10% of high-aluminium refractory fibre containing zirconium, 1.5-4% of thermal-shield steel fibre, 0.1-1% of melamine and 0.05-0.1% of organic anti-explosion fibre, wherein the granularity of the capacitance mullite is less than or equal to 1 mm, both the granularity of the silica micro powder and the granularity of the alpha-Al2O3 micro powder are less than or equal to 5 mu m, and the chemical modified light aggregate is obtained by drying after the light aggregate is dipped in inorganic chemical solution or sol. The light thermal-shield refractory castable of the invention can improve the service life of a furnace roller, lowers production consumption cost, reduces non-working hours caused by exchanging rollers and improves production efficiency.

Owner:武钢集团有限公司

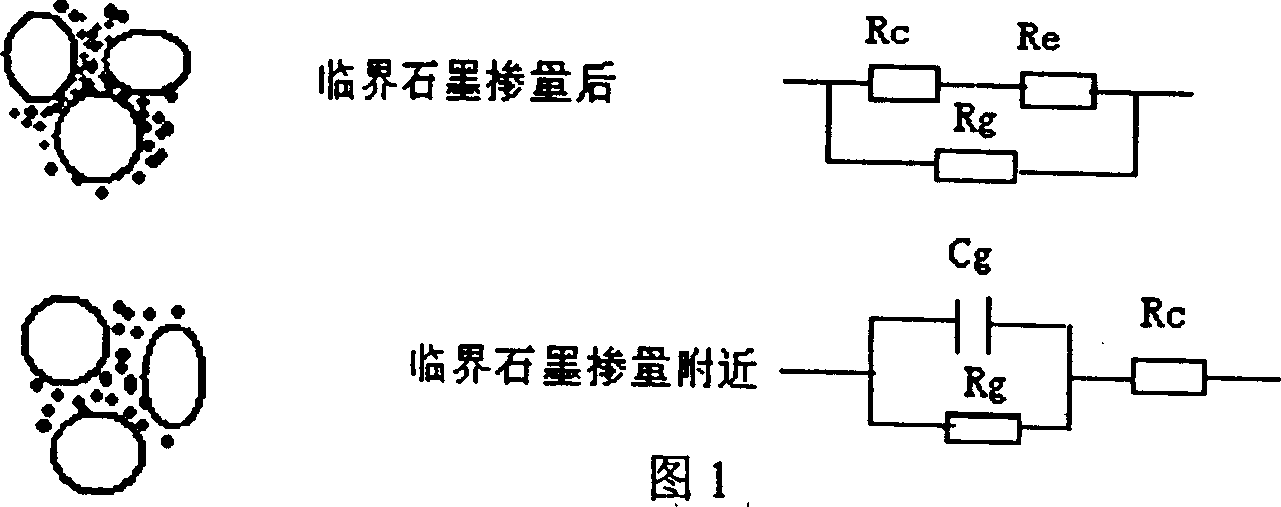

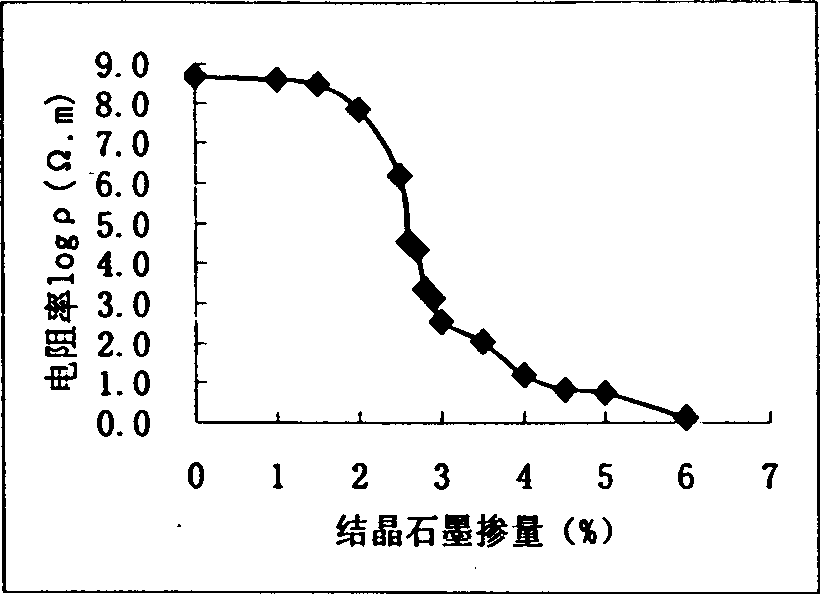

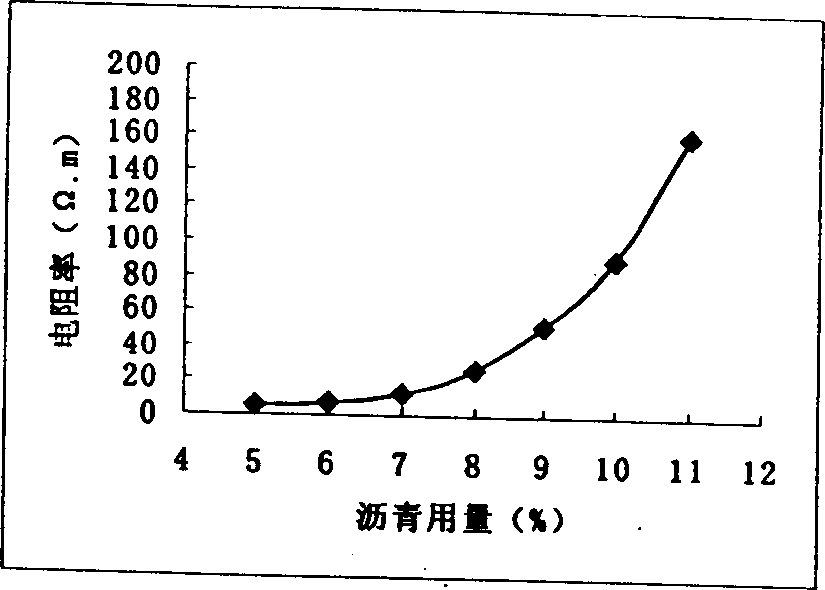

Conducting asphalt concrete and its prepn process

InactiveCN1403401AImprove electrical performanceImprove road performanceNon-conductive material with dispersed conductive materialFiberCarbon fibers

The conducting asphalt concrete consists of coarse aggregate, fine aggregate, slag powder filler, asphalt, and graphite powder, carbon fiber or steel fiber as conducting material. The preparation process includes heating aggregate and asphalt to 170 deg.c and mixing, mixing with other material, compacting via Marshall process or rolling to form. The present invention improves the electrical performance and other performance of asphalt road.

Owner:葛洲坝武汉道路材料有限公司

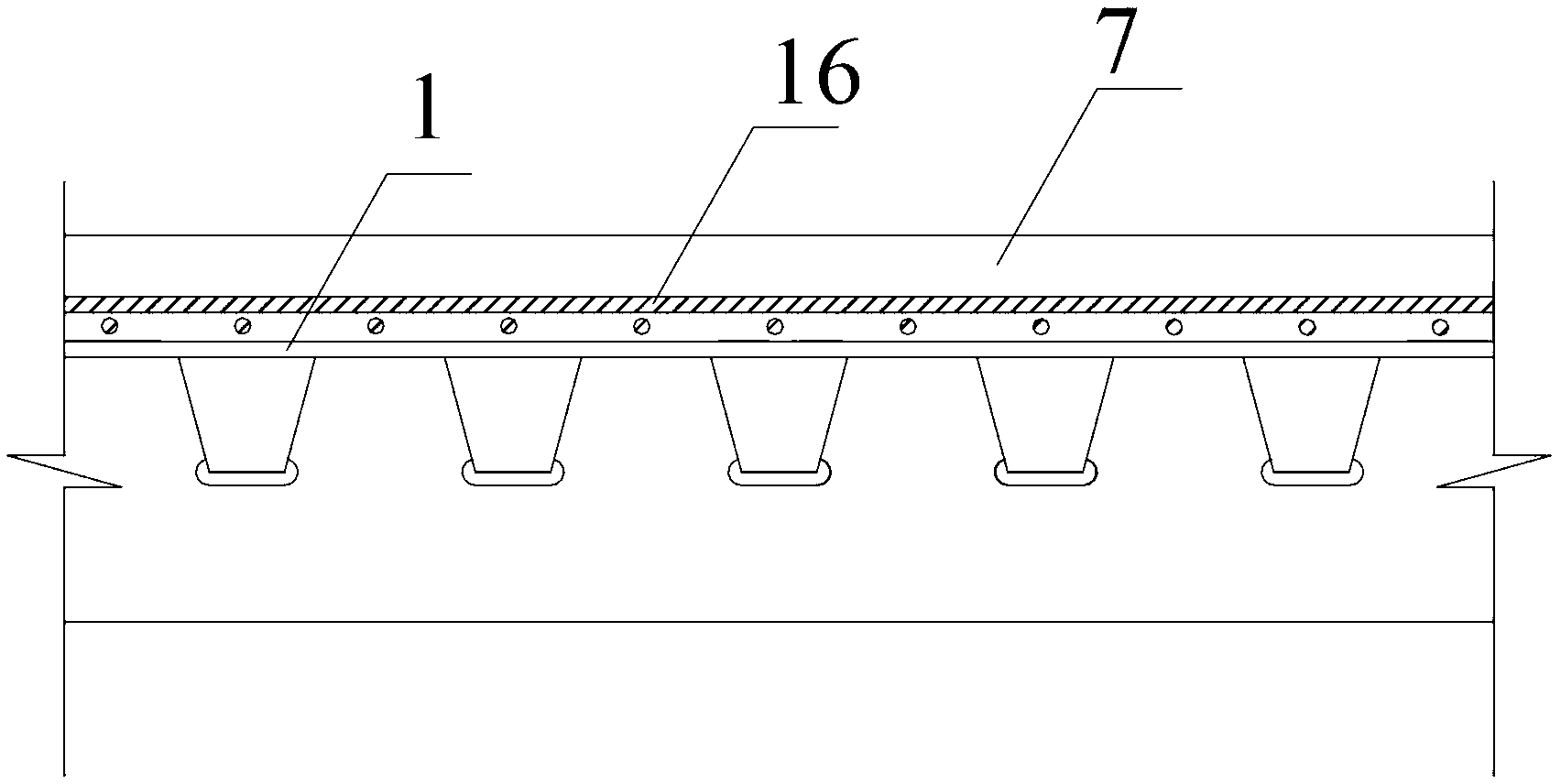

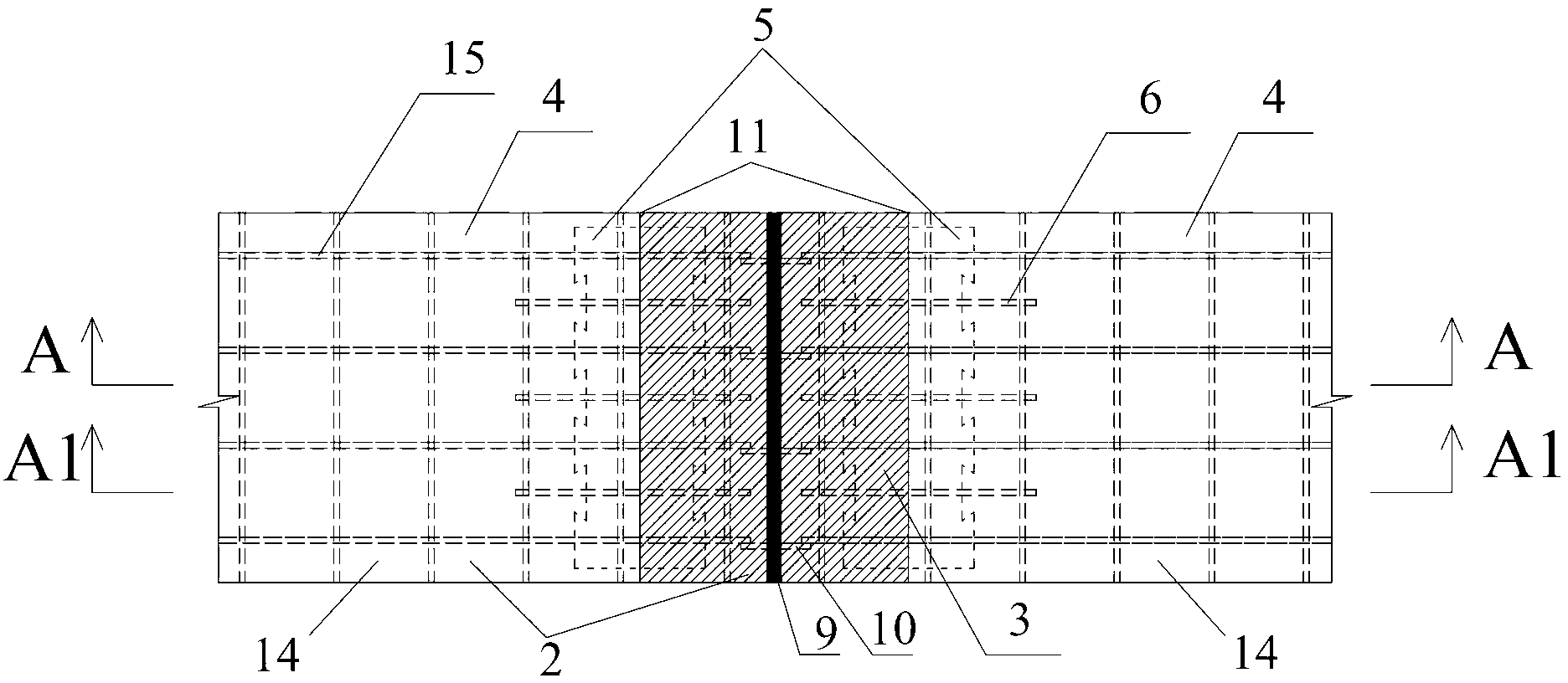

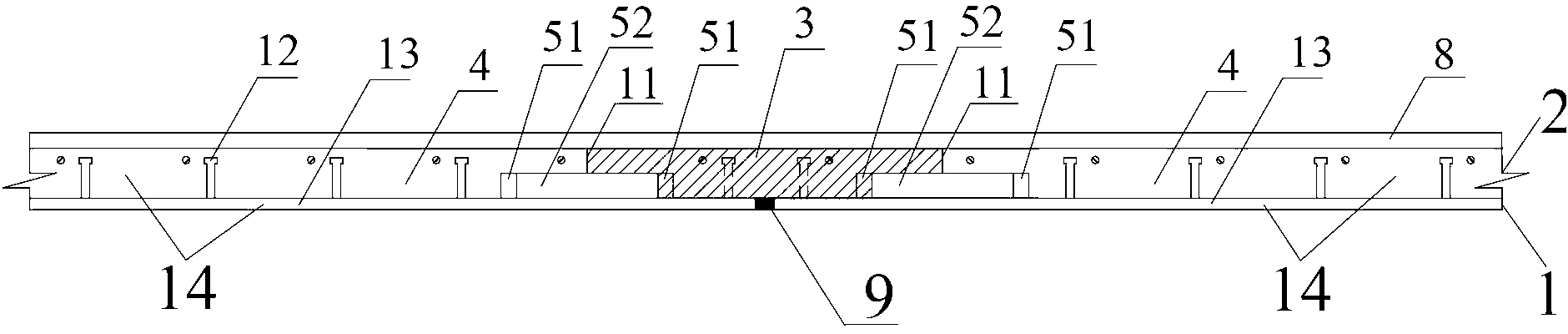

Steel-fiber concrete combined bridge deck structure with reinforced joints and construction method of steel-fiber concrete combined bridge deck structure

ActiveCN102704394AReduce adverse effectsEasy constructionBridge structural detailsBridge erection/assemblyButt jointArchitectural engineering

The invention discloses a steel-fiber concrete combined bridge deck structure with reinforced joints. The steel-fiber concrete combined bridge deck structure is mainly formed by assembling a plurality of steel plate-fiber concrete combined components, each component comprises a steel bridge deck plate and a prefabricated fiber concrete element cast on the steel bridge deck plate, reinforced joint structures are arranged in butt joint regions of two adjacent components and comprise cast-in-situ concrete elements and steel plate reinforcing components, the steel plate reinforcing components are covered by prefabricated fiber concrete elements and cast-in-situ fiber concrete elements, the steel plate reinforcing components and the prefabricated concrete elements are connected in a tongue-and-groove engaging mode for forming an integral fiber concrete layer, and the adjacent steel bridge deck plates are welded into an integral steel bridge deck plate layer. A construction method provided by the invention comprises the following steps that the steel-fiber concrete combined components are firstly manufactured, then, the combination and split joint is carried out, and next, the repeated sequential assembly is carried out. The steel-fiber concrete combined bridge deck structure and the construction method have the advantages that the tensile strength and the rigidity of local parts of the combined bridge deck structure can be improved, the joint seam stress is reduced, and the generation of cracks of paving layers is prevented.

Owner:HUNAN UNIV

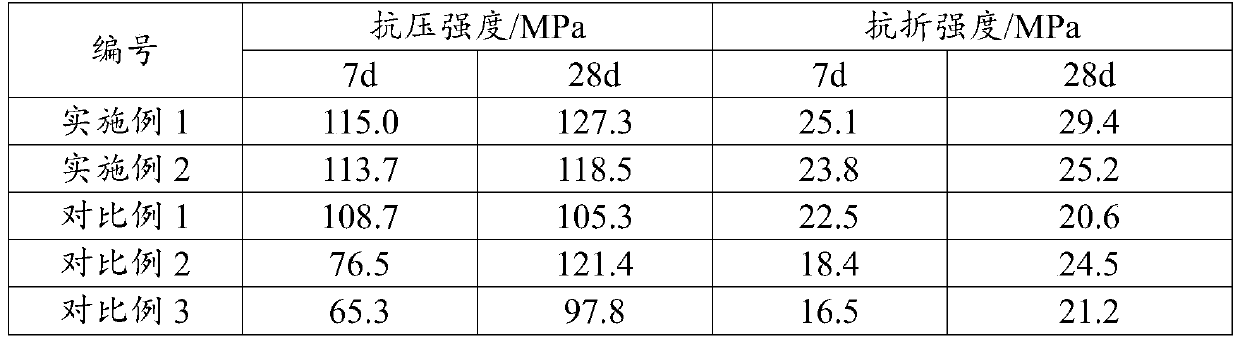

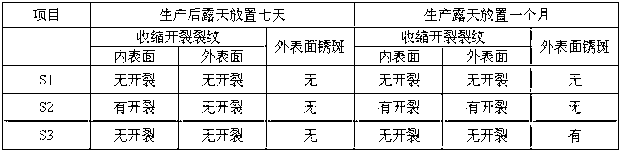

Graphene oxide ultra-high performance concrete with low cement consumption and preparation method thereof

InactiveCN111377687AImprove early strengthIncrease late strengthBreaking strengthUltimate tensile strength

The invention provides graphene oxide ultra-high performance concrete with low cement consumption, which belongs to the technical field of building materials. The concrete comprises the following components in parts by weight: 100 parts of cement, 30-50 parts of silica fume, 60-120 parts of fly ash, 10-50 parts of slag powder, 80-120 parts of quartz sand, 30-50 parts of water, 20-50 parts of steelfiber, 2-10 parts of a water reducing agent and 1-10 parts of graphene oxide. The invention also provides a preparation method of the ultra-high performance concrete. The graphene oxide is compoundedwith the steel fiber concrete doped with the mineral fine powder, and the graphene oxide can promote cement hydration, improve the early and later strength of the concrete, improve the interface conditions of a matrix and steel fibers and improve the binding strength of the matrix and the steel fibers, so that the breaking strength of the concrete is improved. The graphene oxide can improve the pore structure of the concrete, so that the concrete is denser, the strength of the concrete is improved, concrete strength shrinkage caused by steam curing is avoided, and the durability of the concrete is further improved.

Owner:重庆高途新材料科技有限公司

Environment-friendly concrete pole

ActiveCN103225439ASmall electric fluxNo weight lossCeramic shaping apparatusTowersSlagMesh reinforcement

The invention relates to the field of transmission equipment, in particular to a concrete pole. Concrete is uniformly distributed on a reinforcing steel bar mesh, so that the pole is formed. The concrete comprises raw materials in parts by mass as follows: 480-550 parts of low-alkaline Portland cement or ordinary Portland cement with an average grain diameter of 30-60 mu m, 120-140 parts of silica fume with an average grain diameter of 0.18 mu m and the SiO2 content of no less than 85%, 80-110 parts of I-level pulverized fuel ash with an average grain diameter of 10-20 mu m, 110-140 parts of slag powder with the level higher than S95 and an average grain diameter of 10-30 mu m, 510-550 parts of quartz sand with a grain diameter of 0.16-1.63 mm, 860-920 parts of cobbles with a grain diameter of 5-14 mm, 14-18 parts of a compound high-efficiency slushing agent with a water-reducing rate higher than 30%, 7-12 parts of a corrosion inhibitor, 120-140 parts of water, 70-110 parts of a copper plating steel fiber with a diameter of 0.18-0.25 mm and a length of 10-15 mm and 0.8-1.5 parts of a polypropylene fiber. Prestressed wires with a diameter of 4.8-10.7 mm and taken as main bars and high-strength hard-drawn wires with a diameter of 3.0-5.0 mm and taken as circular structural bars are woven, so that the reinforcing steel bar mesh is formed.

Owner:黄贺明

Asbestos-free small mount of metal disk brake lining used in vehicle and manufacture method therefor

The invention discloses a kind of disk brake staff facing used in cars with none asbestos and little metal and the production technology. Its friction material includes bed charge and plus material. The bed charge includes: mineral fiber 35~50%, barite powder 10~20%, heavy calcium carbonate 10-20%, the oil of cashew shell phenol-formaldehyde resin modified 20~30%, flour acrylonitrile butadiene rubber 2~15%. The match of plus material: kaflar fiber 0.1~3%, steel fiber 20~35%, copper fiber 1~5%, particle graphite 6~18%, oil coke blacking 5~15%, the oil of cashew shell friction-type mix 2~8%, sericite in powder 5~10%, antimony trisulfide 0.5~5%, heavy calcium carbonate 2-8%, barite powder 10~20%, flour acrylonitrile butadiene rubber 2~6%, the oil of cashew shell phenol-formaldehyde resin modified 6~15%. After made the bed charge and the plus material weight them in proportion then chill-pressing confectioning and heat pressing confectioning steps and so on and then rivet accessory at last treatment make up the products. It needs low abrasion and has no noise.

Owner:福建冠良汽车配件工业有限公司

Testing method of steel fiber reinforced concrete fracture test crack initiation load

ActiveCN103760036AReduce test costsLower requirementMaterial strength using steady bending forcesStress intensity factorClassical mechanics

The invention relates to a testing method of steel fiber reinforced concrete fracture test crack initiation load, and belongs to the technical field of concrete cracking parameter testing. The testing method provided by the invention is characterized in that when a steel fiber reinforced concrete coped beam specimen cracks, a stress intensity factor of a prefabrication crack front edge achieves concrete fracture toughness, and the steel fibre blocking action is not exerted; the stress intensity factor generated by external load and concrete cracking toughness(i)K( / i) IC are equal, the external load value which is corresponding to a numerical value (i)K( / i)IC of the stress intensity factor generated by the external load can be used for determining the crack initiation load according to the curve relation graph of the external load and the stress intensity factor (i)K generated by the external load (img file='2014100081259100004dest_path_image002.TIF'wi='8'he='21' / )( / i)-(i)P( / i) curve relational graph. The testing method provided by the invenytion has the advantages that the required equipment, analyzing and processing method are simple, the cost is low, and the precision is high.

Owner:YELLOW RIVER INST OF HYDRAULIC RES YELLOW RIVER CONSERVANCY COMMISSION

Concrete material and preparation method thereof

The invention provides a concrete material, comprising the following components with corresponding proportions: cement, fine aggregate, coarse aggregate, fly ash, silica fume, carbon nanotube, nano silica, ceramsite, polyphenyl particles, steel fibers, nano kaolin particles, ultrafine natural zeolite powder, gypsum, polymer emulsion, a diol compound, modified lignosulfonate, a layered silicate mineral material, polysiloxane, oxalic acid, styrene acrylic emulsion, crystalline hydrated magnesium aluminum silicate minerals, water, a super plasticizer, a barium-containing naphthalene superplasticizer, an organic polymer plastic retaining agent, a composite retarder and an air entraining agent. The invention further relates to a preparation method of the concrete material. Compared with the existing concrete, various properties of the concrete material provided by the invention are greatly improved. The concrete material has a wide application range, a significant practical engineering value and remarkable technical and economic significance.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

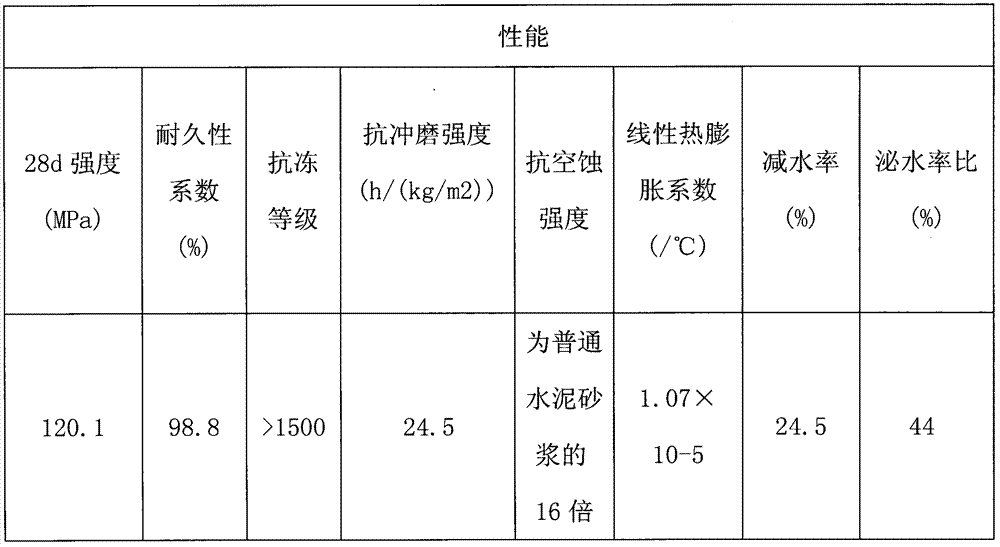

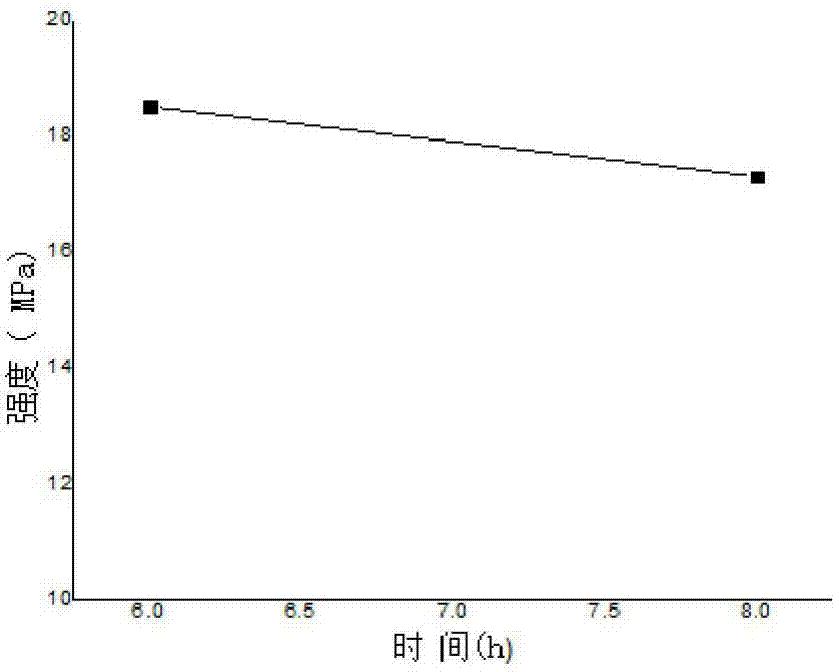

Steam-curing-free early-strength steel fiber concrete pipe segment and preparation method thereof

InactiveCN104773988AHarden fastSimplify maintenanceSolid waste managementFiberCALCIUM HYDROXIDE SOLUTION

The invention discloses a steam-curing-free early-strength steel fiber concrete pipe segment comprising ordinary Portland cement, early-strength sulphoaluminate cement, fly ash, slag, fine aggregate, coarse aggregate, water, a polycarboxylic acid type water reducer and end hook type steel fibers. The invention also discloses a preparation method of the steam-curing-free early-strength steel fiber concrete pipe segment. The steam-curing-free early-strength steel fiber concrete pipe segment is quick in coagulation and hardening and high in early strength, can reach the strength of 15MPa required by pipe segment demolding in 6-8 hours, and can be prepared into a concrete pipe segment for an underground structure by performing water curing in a 20 DEG C saturated calcium hydroxide solution for 24 hours and then performing natural curing for 28 days. The steam-curing-free early-strength steel fiber concrete pipe segment does not need steam curing, so that the curing mode of the pipe segment can be simplified, the curing time is shortened, a lot of manpower and resources are saved, and the popularization and application values are high.

Owner:SOUTHEAST UNIV +1

Multi-scale fiber-reinforced high-performance cement-based composite material and preparation method thereof

The invention relates to a multi-scale fiber-reinforced high-performance cement-based composite material and a preparation method of the multi-scale fiber-reinforced high-performance cement-based composite material, and belongs to the technical field of fiber-reinforced cement-based composite materials. The multi-scale fiber-reinforced high-performance cement-based composite material comprises a base body and a multi-scale fiber system, wherein the base body comprises cement and sand, the multi-scale fiber system comprises steel fibres, polyvinyl alcohol fibers (PVA fibres) and calcium carbonate whiskers, the dosage of the multi-scale fiber system accounts for 2.4-5.6 vol.% of the volume of the fibre-reinforced cement-based material, and the volume ratio of the steel fibres to the PVA fibres to the calcium carbonate whiskers is 1 to (0.1-1.2) to (0.3-5.3). The multi-scale fiber-reinforced high-performance cement-based composite material and the preparation method provided by the invention have the advantages that the manufacturing technique is simple, special equipment is not needed, the multi-scale fiber-reinforced high-performance cement-based composite material is as the same as the common cement-based material, the source of materials is wide, the finished product price is low, the industrialized production is realized, the multi-scale fiber-reinforced high-performance cement-based composite material with different properties is obtained by adjusting the ratio, and the product can be used for manufacturing a cast-in-place structure and a cladding material and also can be prefabricated into a product.

Owner:DALIAN UNIV OF TECH

Grinder of bullet train tread cleaner and production method thereof

ActiveCN102432978AAvoid stressAvoid heat cracksOther chemical processesVehicle cleaningIron powderGraphite

The invention provides a grinder of a bullet train tread cleaner, wherein the grinder is made of a composite material; the composite materials comprises modified phenolic resin 6818, iron powder, copper fibres, steel fibres, sepiolite, potassium feldspar, graphite, cryolite and aluminium oxide; the invention further provides a production method of the grinder.

Owner:BEIJING RAILWELD NEW MATERIAL TECH CO LTD +1

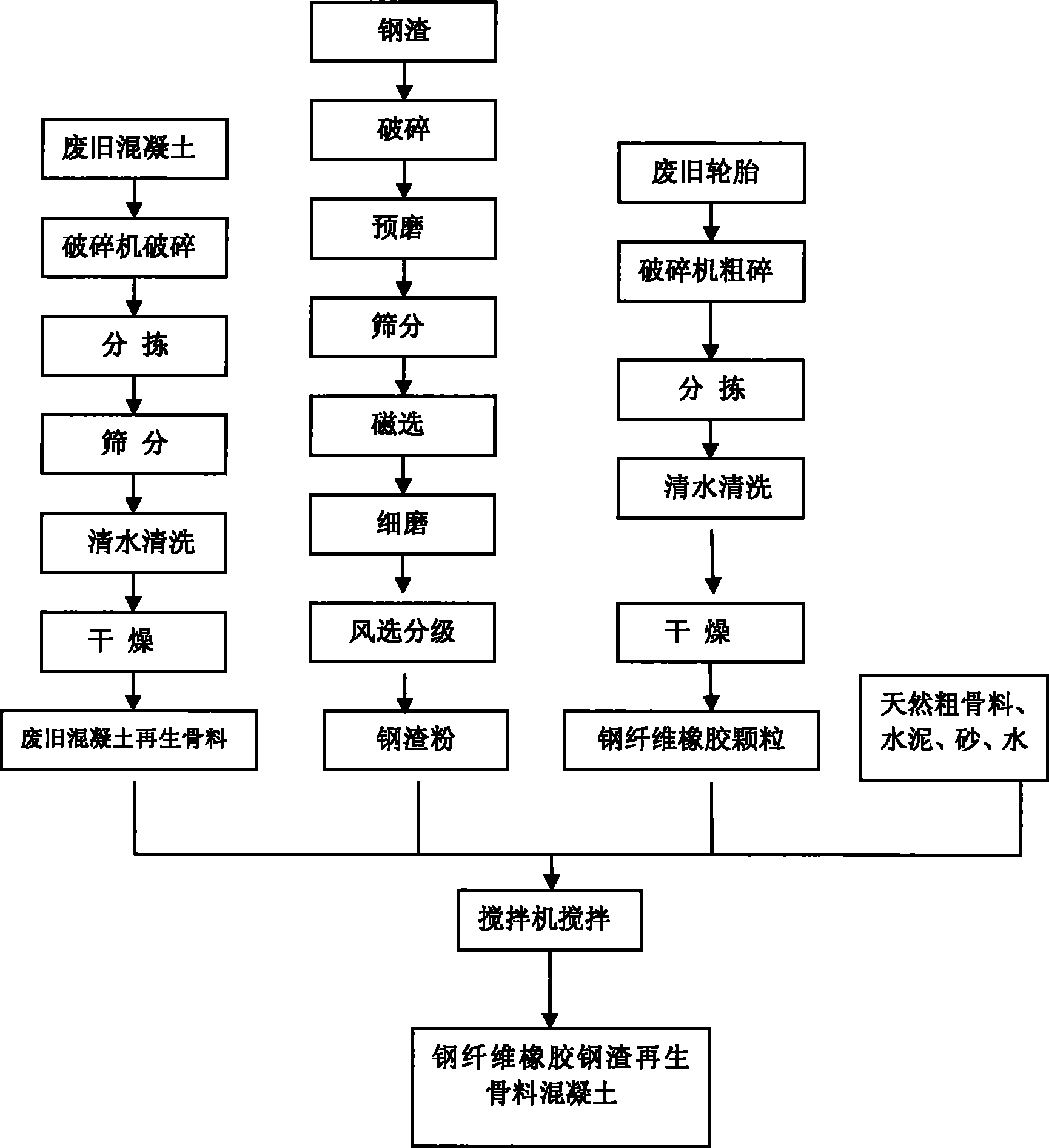

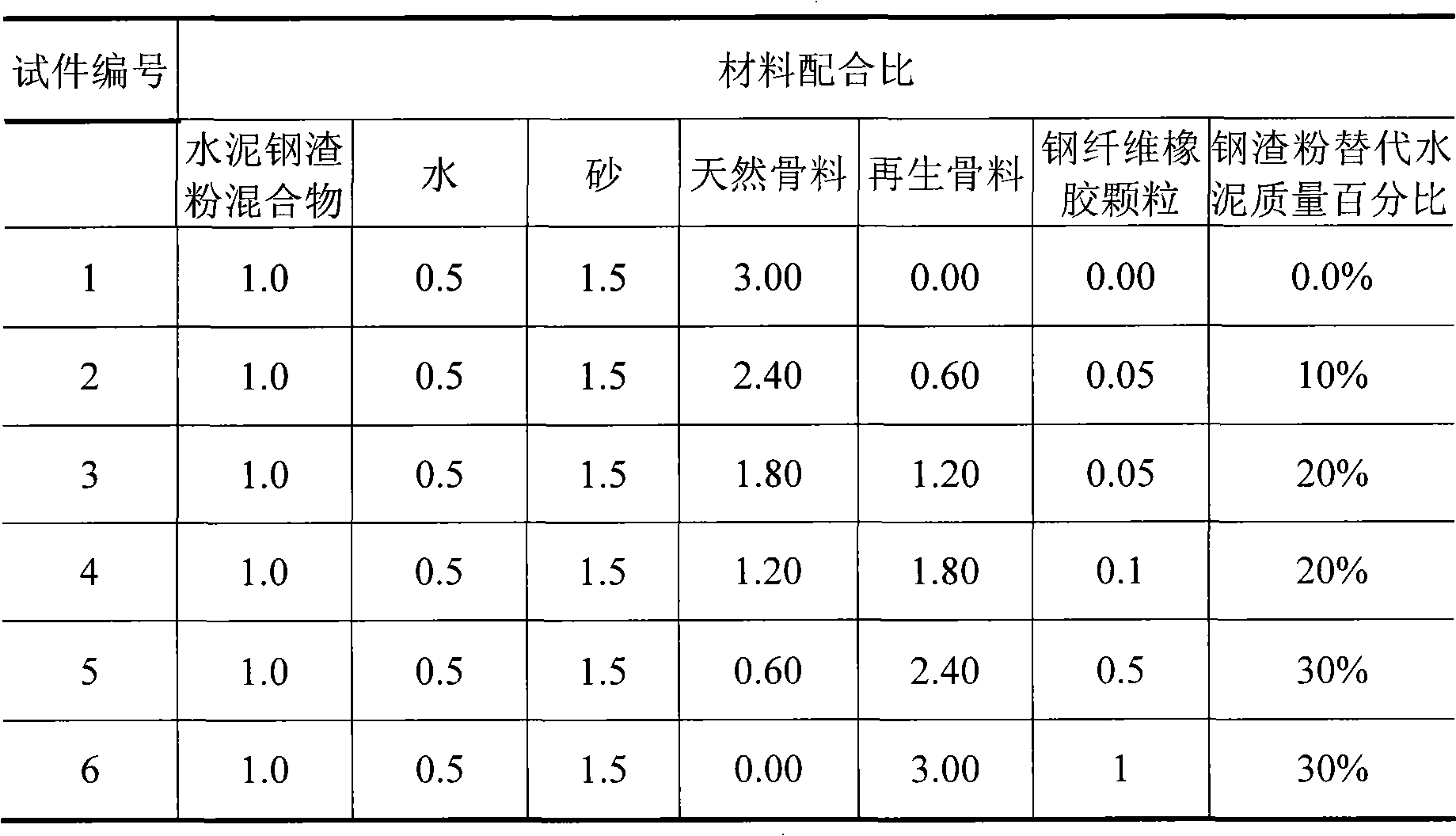

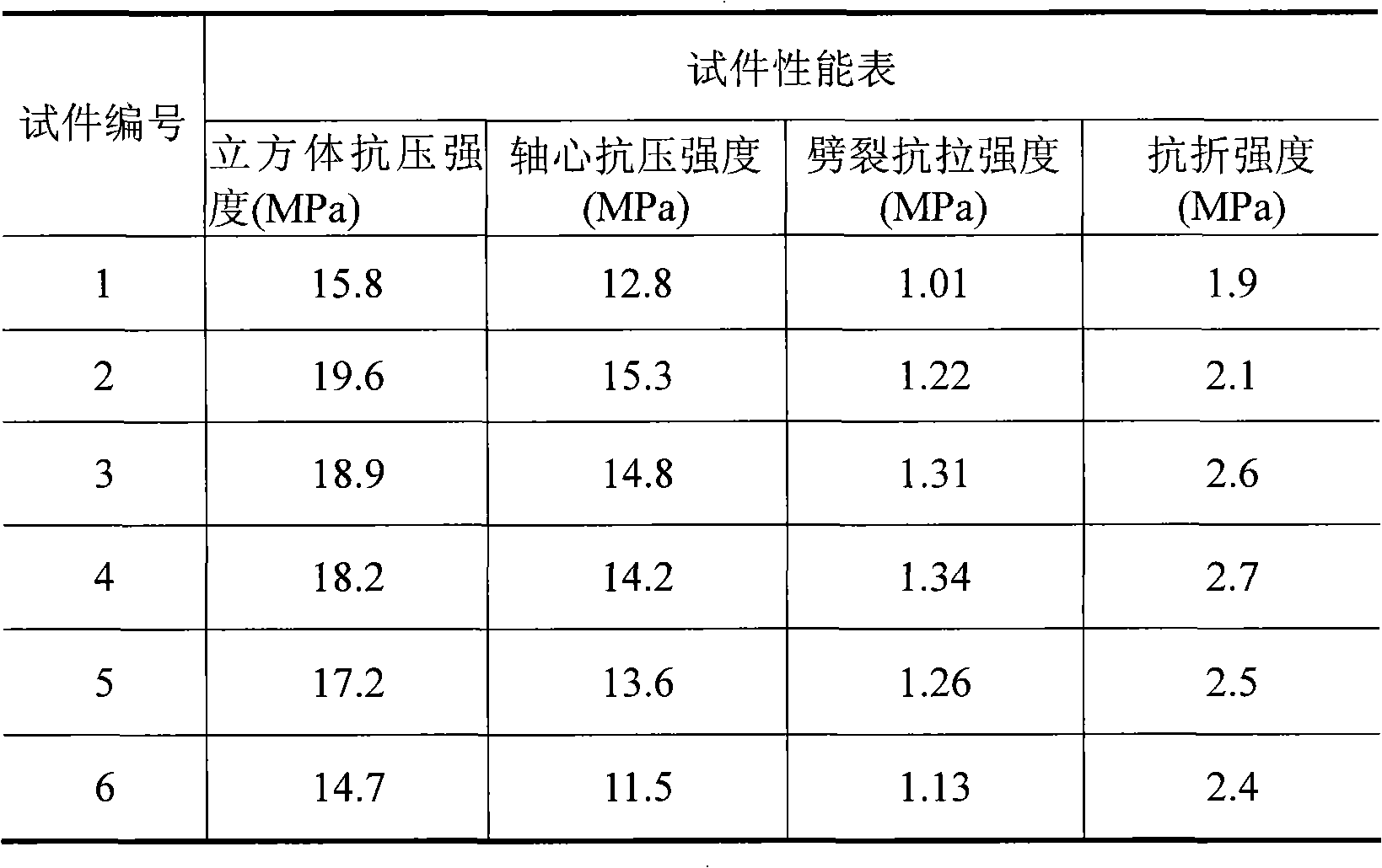

Method for preparing recycled aggregate concrete from steel fiber rubber and slag

ActiveCN101774223AImprove crack resistanceImprove insulation effectSolid waste managementClimate change adaptationCrack resistancePowder mixture

The invention discloses a method for preparing recycled aggregate concrete from steel fiber rubber and slag. The method comprises the following steps: waste concrete is crushed, separated, screened, washed and dried to obtain waste concrete recycled aggregate; waste tires are coarsely crushed, separated, washed and dried to obtain steel fiber rubber particles; the slag is crushed, screened, magnetically separated and classified by air to obtain slag powder; the waste concrete recycled aggregate, the steel fiber rubber particles, cement slag powder mixture, natural coarse aggregate, sands and water are stirred in proportion; the cracking resistance, thermal insulation performance and energy absorbing and noise reducing performance of the recycled aggregate concrete can be effectively improved by modifying the steel fiber rubber particles; the working performance of green concrete and contraction performance of the concrete in each curing time can be improved by modifying the slag powder; and the infiltration resistance and carbonization resistance can be effectively improved and chloride ion diffusion velocity of the concrete can be effectively reduced. The material is a cycled economical building material, and can improve the material performance on the basis of not increasing cost.

Owner:GUANGDONG DIANBAI CONSTR GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com