Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

897results about How to "Increase late strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lightweight high-performance foam concrete and preparation method thereof

ActiveCN104108912AHigh CaO contentHigh glass bead contentSolid waste managementCeramicwareFoam concreteFiber

The invention discloses a lightweight high-performance foam concrete, which is composed of the following components in parts by weight: 50 to 60 parts of cement, 20 to 35 parts of mineral slag, 15 to 20 parts of fly ash, 5 to 10 parts of gypsum, 60 to 80 parts of fine aggregate, 2.7 to 7.3 parts of additive, 0.1 to 0.2 part of fiber, 32 to 45 parts of water, and 5 to 25 parts of foam. The invention also discloses a preparation method of the foam concrete. The foam concrete has the advantages of small volume-weight, high strength, low water absorption, and small contraction rate, and has the waterproof and anti-cracking functions at the same time.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

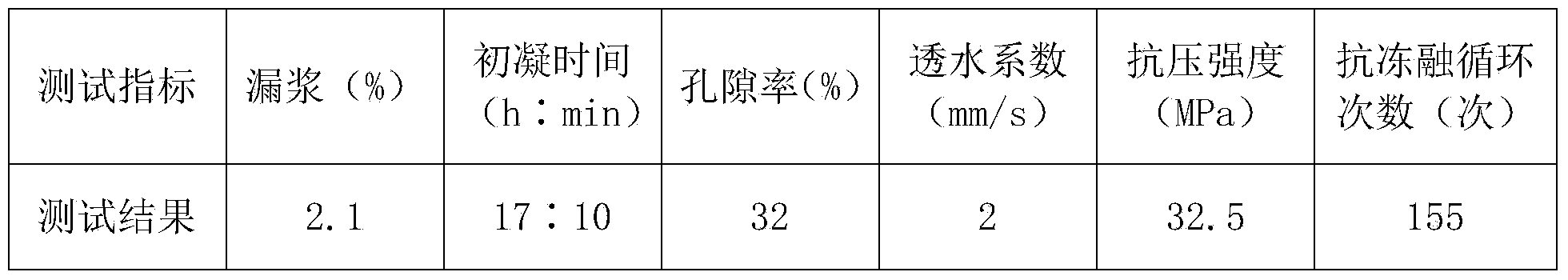

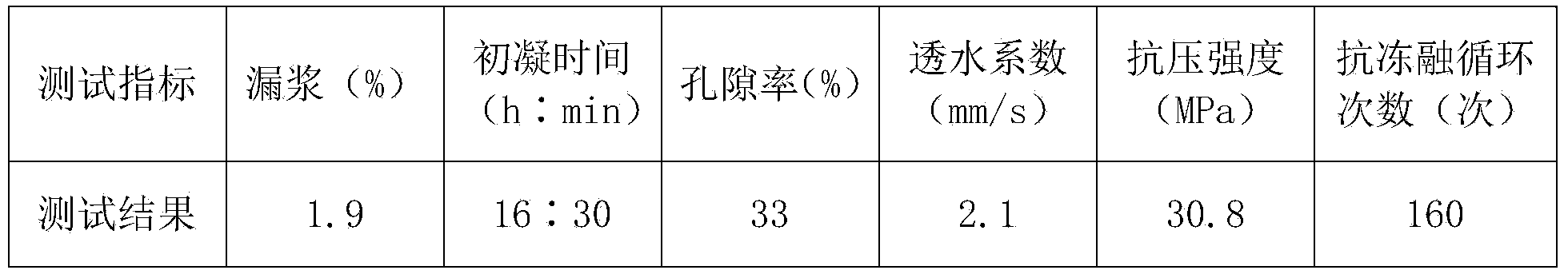

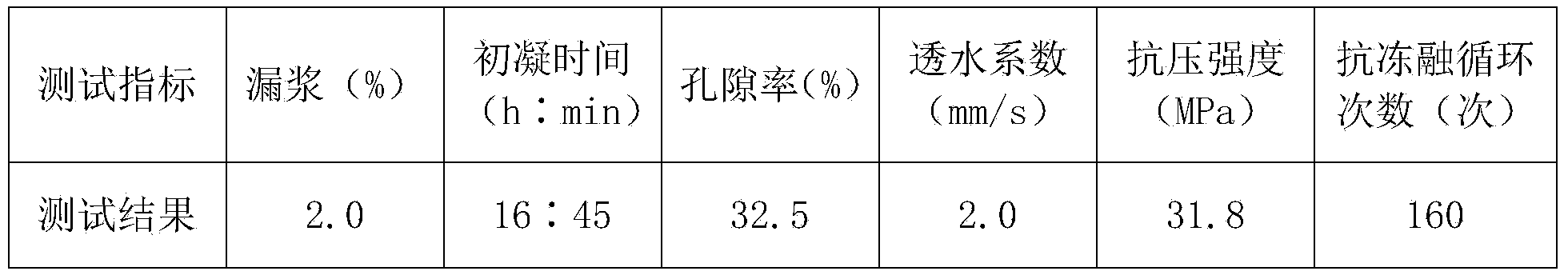

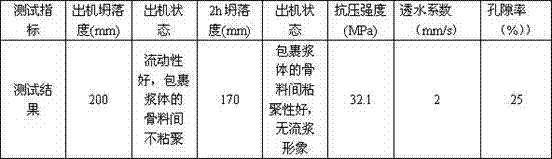

Additive for pervious concrete and application thereof

The invention discloses an additive for pervious concrete. The additive for the pervious concrete comprises a water reducer, a retarder, a viscosity modifier, an entraining agent and water, wherein the mass ratio of the water reducer to the retarder to the viscosity modifier to the entraining agent to the water is (30-50): (1-3): (0.5-3): (0.3-1.5): (42-60). The invention further discloses the application of the additive for the pervious concrete. The additive for the pervious concrete has the advantages that for the application requirement of the pervious concrete, the additive special for the pervious concrete is provided; after the additive is added to the pervious concrete to be used, the fluidity of the pervious concrete can be improved, premature drying and condensation can be avoided, unloading is facilitated, and the durability and the long-term strength of the previous concrete are improved.

Owner:JIANGSU MINGHE GRP

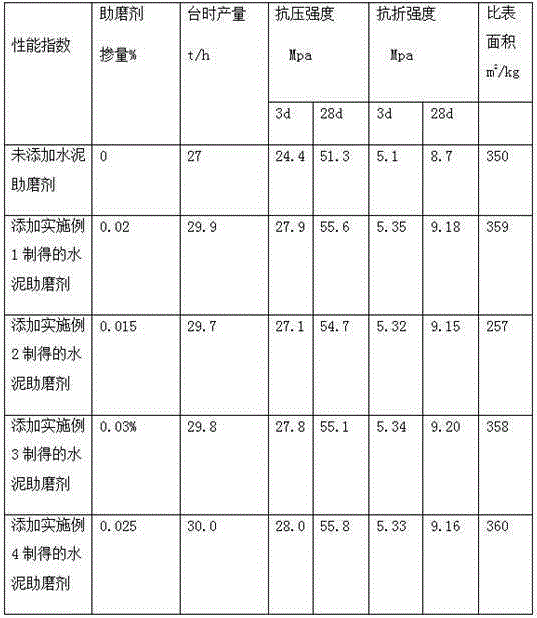

Cement grinding aid and preparation method thereof

The invention relates to a cement grinding aid, in particular to a cement grinding aid and a preparation method thereof. The cement grinding aid is prepared from, by weight, 13-18 parts of polymeric polylol, 8-12 parts of tri-isopropanolamine, 12-15 parts of polyol ether, 15-20 parts of ethanediol, 25-30 parts of triethanolamine, 15-18 parts of molasses, 13-15 parts of lignin, 0.03-0.06 part of sodium chloride, 0.5-1 part of silane coupling agents and 40-45 parts of water. By means of the obtained cement grinding aid, in the cement production process, the phenomena of clinker fine particle aggregation and ball pasting can be effectively improved, mobility of clinker particles is enhanced, thereby the pulverization effect of grinding media in a grinding machine for materials is enhanced, grinding efficiency can be improved by 15-20%, the cement machine-hour yield is increased, electricity consumption is greatly lowered, production cost is lowered, in addition, strength of cement at different ages can be remarkably improved, and flowability of the cement is improved.

Owner:内蒙古同佳技术发展有限公司

Method for preparing novel sulfamic acid high-efficiency concrete water reducing agent

The invention relates to a method for preparing novel sulfamic acid high-efficiency concrete water reducing agent, which is carried out according to the steps of: (1) hydroxymethylation: adding formaldehyde with the mass ratio of 3-6 with melamine into melamine solution, adjusting the pH value to be 10-12, and carrying out heat preservation for 1-5h at the temperature of 65-95 DEG C; wherein the formaldehyde is polyformaldehyde or 30-40% of formaldehyde water solution; (2) sulfonation: adding p-amino benzene sulfonic acid sodium with the mass ratio of 1-3 with melamine into the melamine solution treated by hydroxymethylation, maintaining the pH value to be 10-12, and keeping the temperature of 70-85 DEG C for 1-3h; (3) etherification reaction: adjusting the pH value to be 3.5-6, and reacting for 1-6h at the temperature of 70-95 DEG C; and (4) neutralization: adding alkali and adjusting the pH value to be 7-9. The high-efficiency concrete water reducing agent prepared by the method can be separately used when the solid doping quantity is 4%, has the water reducing rate of 24% and increases the later period strength of concrete to be 140%.

Owner:JIANG SU TMS CONCRETE ADDITION AGENT

Inorganic composite heat insulation material and preparation method thereof

ActiveCN102093030ADecreased volumetric water absorptionStable physical and chemical propertiesFiberCellulose

The invention relates to an inorganic composite heat insulation material, which is prepared from the following raw materials in part by weight: 100 parts of common silicate cement, 10 to 30 parts of quick hardening sulfate aluminum cement, 10 to 30 parts of gypsum powder, 10 to 40 parts of admixture, 20 to 40 parts of mineral fiber, 150 to 200 parts of vitrified micro bubbles, 4 to 8 parts of re-dispersible latex powder, 2 to 4 parts of cellulose ether, 0.1 to 0.3 part of starch ether, 0.2 to 1.0 part of water reducing agent, 0.2 to 0.6 part of retarder, 1 to 3 parts of early strength agent, 0.5 to 3 parts of water repellent, and 0.02 to 0.06 part of air entraining agent. The raw materials are mixed uniformly to prepare dry powder, and the dry powder and water are mixed in a weight ratio of 1: (0.8-1.2) and stirred to form slurry for use. The inorganic composite heat insulation material has good workability, quick strength development, high construction efficiency, good adhesive property, low drying shrinkage, heat insulation, hydrophobic property, fire resistance and durability.

Owner:辽宁际洲环保节能建材有限公司

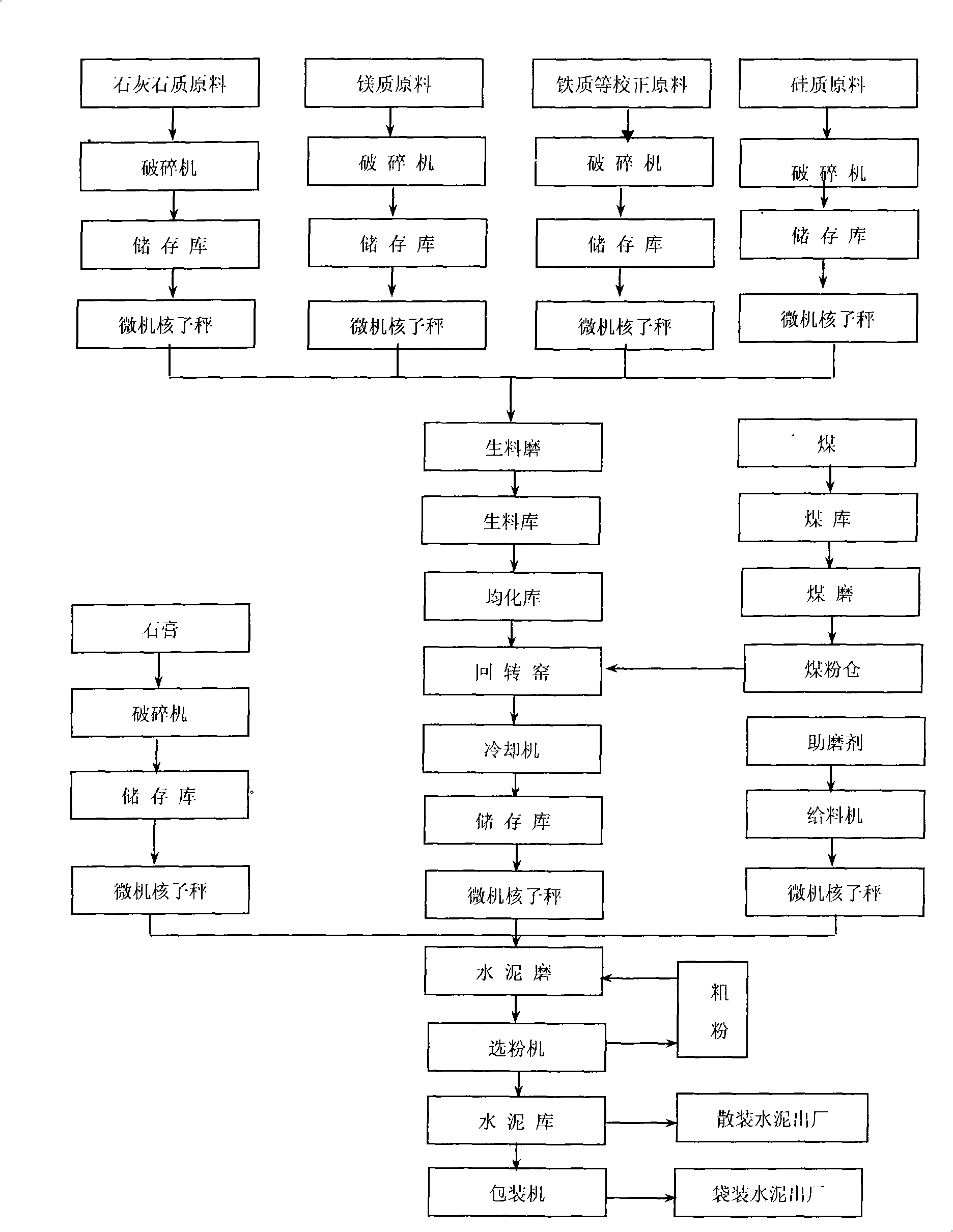

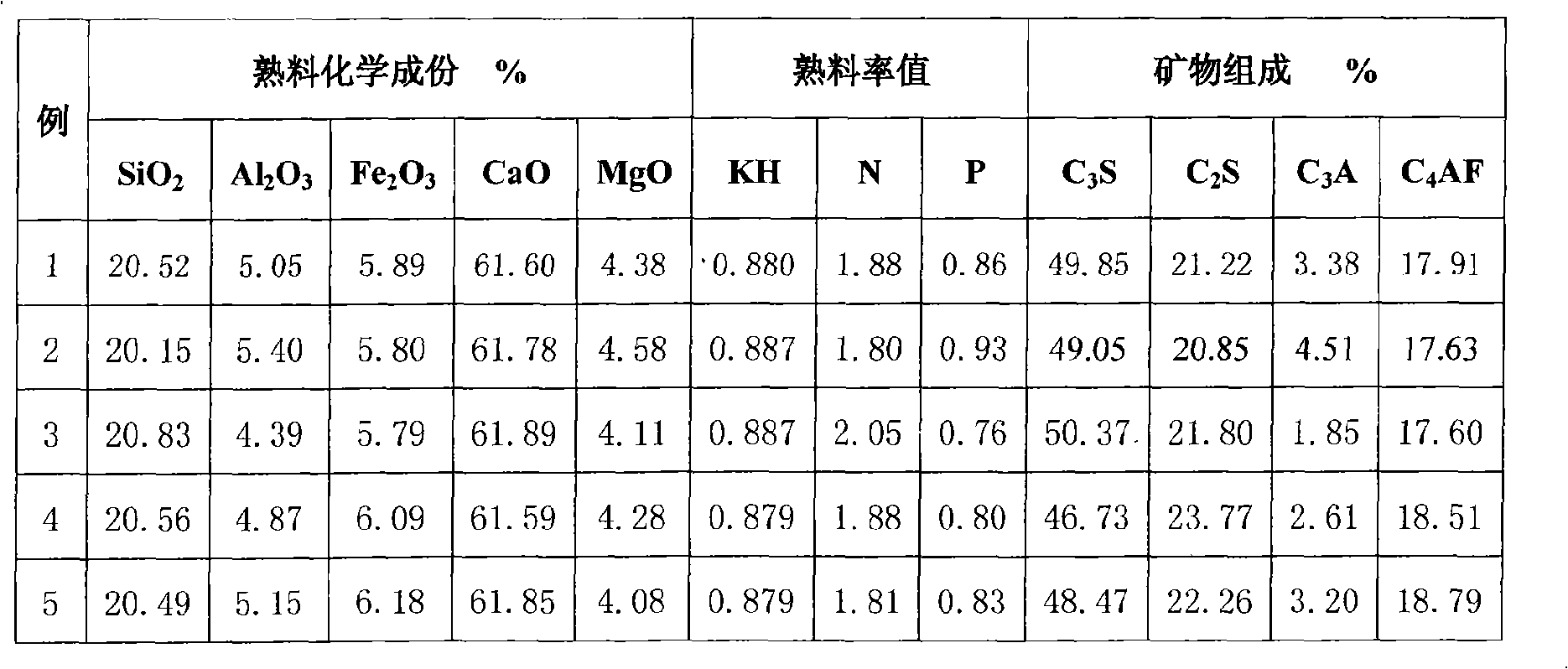

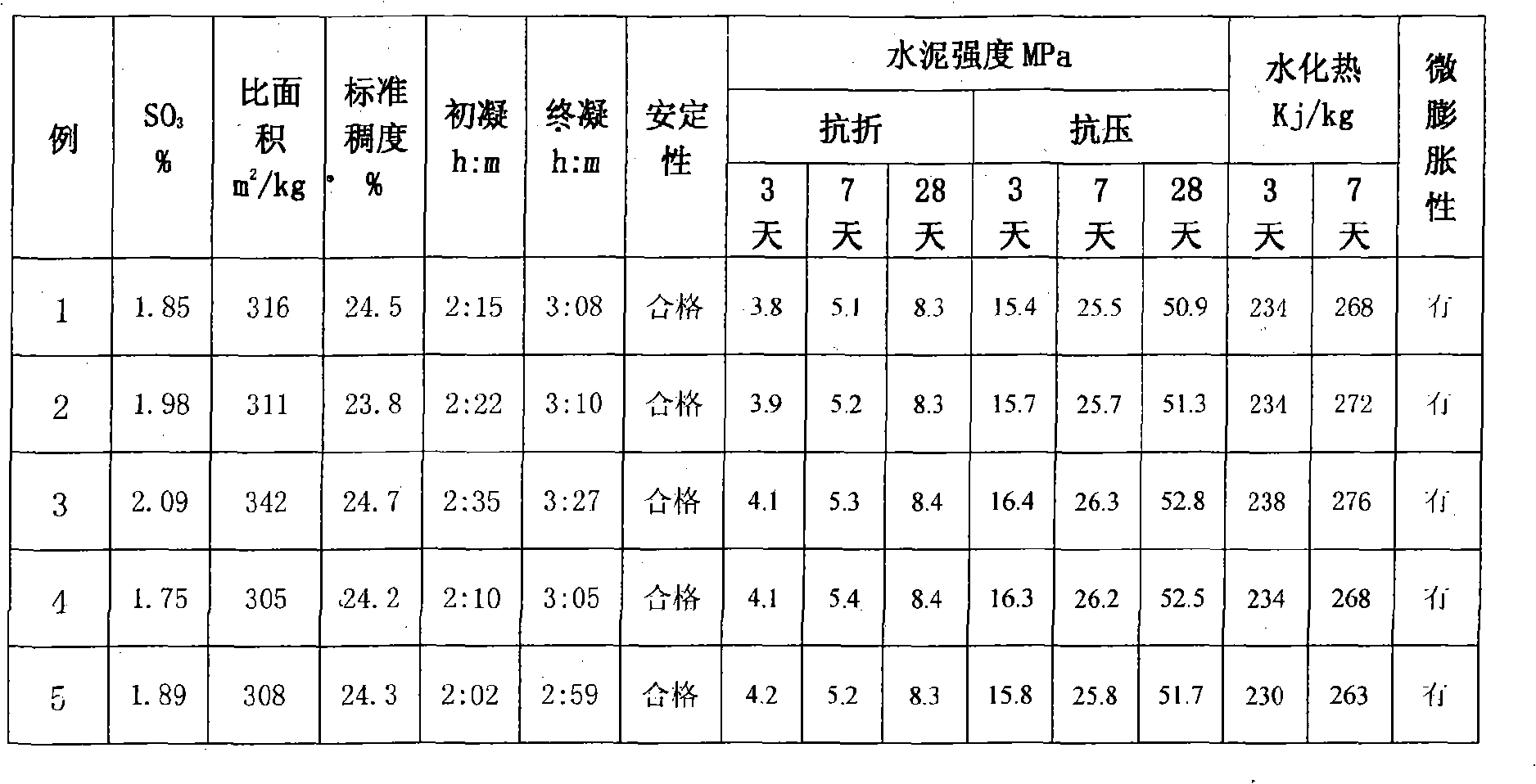

High-magnesium moderate-heat portland cement and production method thereof

InactiveCN101353231AReduce water demandThe micro-expansion property hasClinker productionHigh magnesiumPortland cement

The invention relates to a high-magnesium moderate heat portland cement, which is characterized in that (1) the contents of MgO and SO3 in the cement are 3.0-6.5% and 1.4-2.2% respectively; (2) the weight percentages of the mineral composition for grinding cement clinker are 35-55% of C3S, 15-35% of C2S, 1-6% of C3A and 10-25% of C4AF; and the content of MgO in the cement clinker is 3.0-6.5%; (3) in the raw materials for calcining the clinker, the contents of MgO, CaO and Fe2O3 are respectively controlled at a certain value within the ranges of 2.5-3.8%, 38.0-42.0% and 3.5-4.5%, and the variation ranges thereof are respectively controlled within plus or minus 0.10%, plus or minus 0.20% and plus or minus 0.15%. The production method of the cement mainly comprises three procedures of raw material milling, clinker calcining and cement grinding, namely, 'two grinding and one calcining'. The concrete made from the cement is characterized by good fluidity, low water requirement, moderate cement heat, high later strength, good durability, microdilatancy performance, and the like; compared with the conventional portland cement and moderate heat portland cement, the high-magnesium moderate heat portland cement is more favorable for realizing high performance of the concrete.

Owner:湖南石门特种水泥有限公司

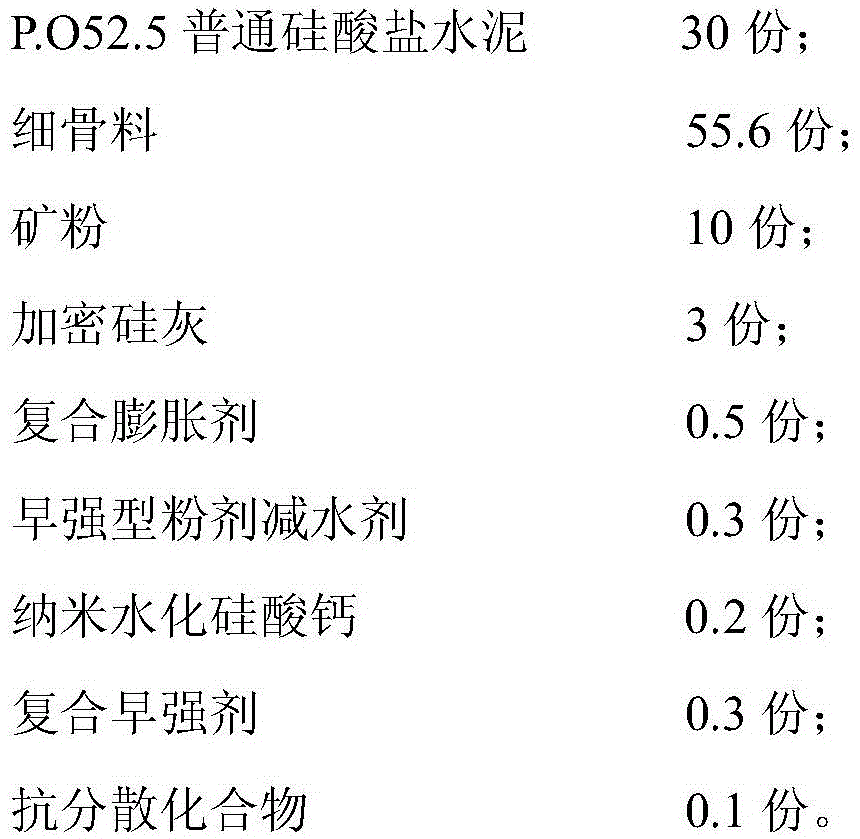

Low-temperature early-strength high-strength underwater grouting material

ActiveCN105622006AEnhance early compressive strengthImprove early strengthCalcium silicateWater reducer

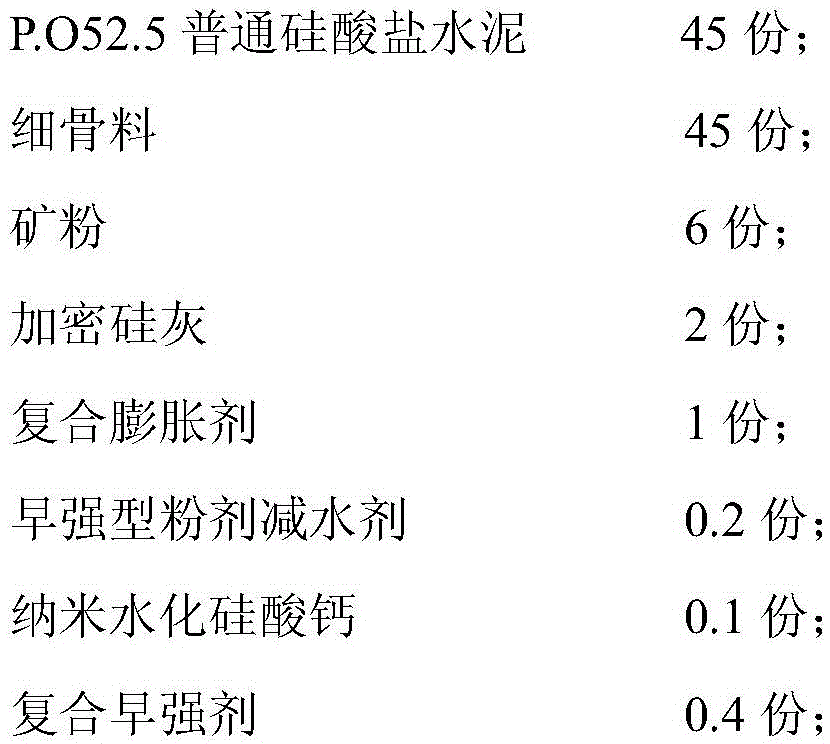

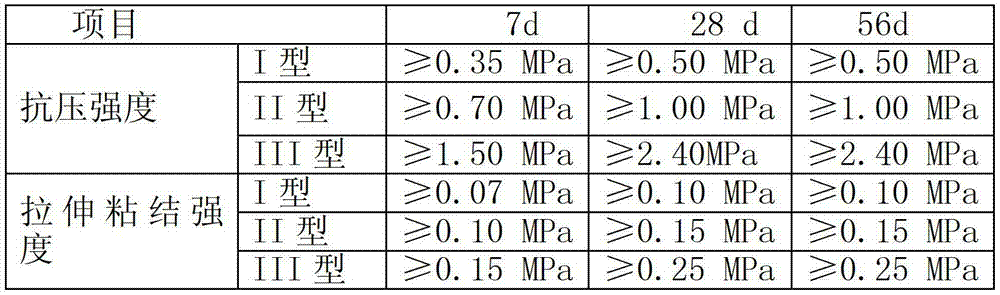

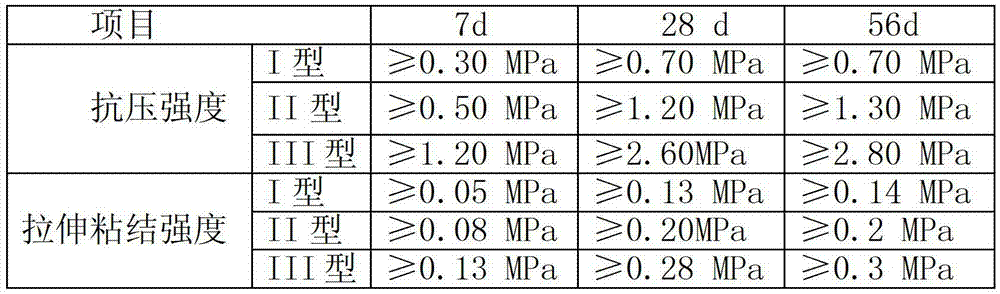

The invention provides a low-temperature early-strength high-strength underwater grouting material. The low-temperature early-strength high-strength underwater grouting material consists of the following ingredients in parts by weight: 30-45 parts of ordinary Portland cement, 45-60 parts of fine aggregate, 5-10 parts of mineral powder, 2-4 parts of encryption silica fume, 0.5-1 part of a compound expanding agent, 0.2-0.5 part of an early-strength powdery water reducer, 0.1-0.5 part of nano hydrated calcium silicate, 0.3-0.5 part of a compound early-strength agent and 0.1-0.3 part of a dispersion-resistant compound. The low-temperature early-strength, low-temperature high-strength and dispersion resistant properties of the low-temperature early-strength high-strength underwater grouting material in water are improved at the same time in the four aspects of reducing the void ratio of the aggregate, optimizing the expanding components and improving the nano early strength and the dispersion resistance, the construction performance, such as the water holding performance and the viscosity, of the grouting material are remarkably improved, the 1d strength and the 28d strength of the grouting material under the undersea low-temperature condition are effectively improved, and the underwater dispersion resistance of the grouting material can be greatly improved. The low-temperature early-strength high-strength underwater grouting material has favorable low-temperature early-strength, low-temperature high-strength and underwater dispersion resistant functions.

Owner:JIANGSU SOBUTE NEW MATERIALS

Cement grinding aid and preparation method thereof

InactiveCN101125742AImprove grinding efficiencyReduce grinding power consumptionCement grindingTriisopropanolamine

The invention discloses a cement grinding aid and a preparation method thereof. Raw materials of the cement grinding aid consists of 10-30 percent of triethanolamine, 12-30 percent of tirisopropanolamine, 5-20 percent of ethylene glycol, 3-10 percent of propanediol, 15-40 percent of water, 1-5 percent of sodium dodecyl benzene sulfonate, 3-10 percent of lignin and 2-5 percent of anhydrous sodium sulfate; water is poured into a reactor and heated to 40-50 DEG C to be reserved; the sodium dodecyl benzene sulfonate is added to be stirred for 15min; the anhydrous sodium sulfate is added and stirred for 10min, then the lignin is added and stirred for 30min; materials in the reactor are filtered by a 150 mesh screen; the ethylene glycol and the propanediol are added and stirred for 20min; the triethanolamine and the tirisopropanolamine are added and stirred for 30min and the grinding aid products are obtained. The cement grinding aid can improve grinding efficiency and early and later strength of cement and reduce cement cost.

Owner:洛阳万顺建材有限公司

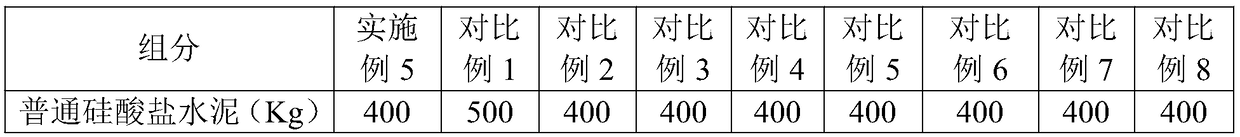

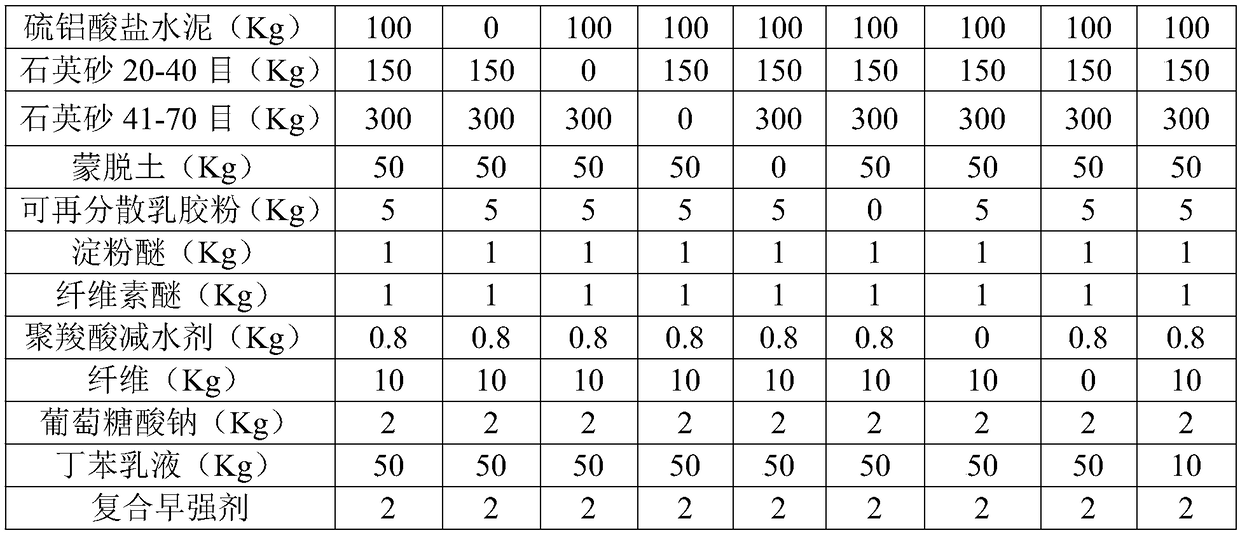

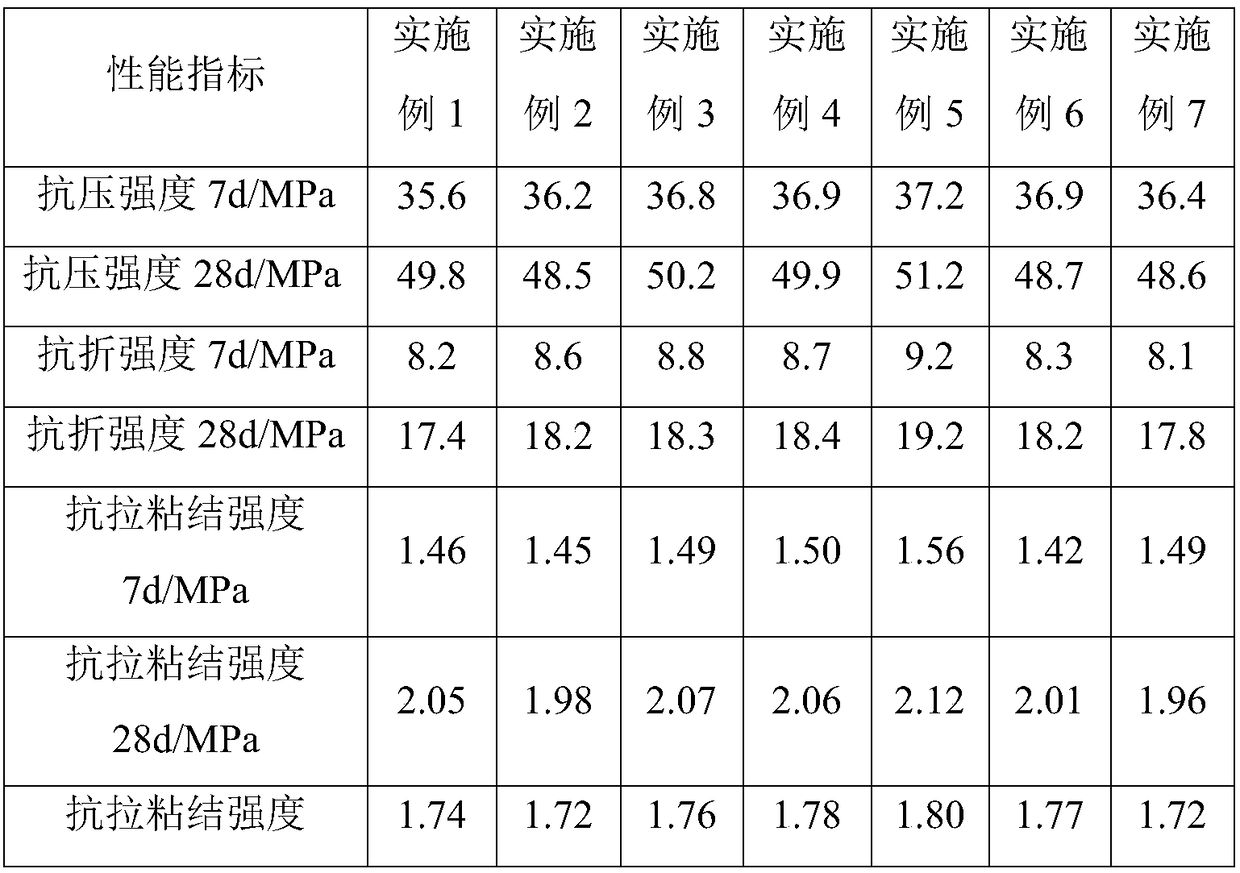

Special repair mortar for structure and preparation method thereof

The invention discloses special repair mortar for a structure. The mortar is prepared from the following components in parts by weight: 350-500 parts of common silicate cement, 50-150 parts of sulphate aluminum cement, 100-200 parts of 20-40-mesh quartz sand, 300-350 parts of 41-70-mesh quartz sand, 20-50 parts of montmorillonite, 30-50 parts of a styrene-butadiene rubber latex, 1-10 parts of redispersible latex powder, 1-5 parts of starch ether, 1-5 parts of cellulose ether, 0.5-2 parts of a polycarboxylate superplasticizer, 1-3 parts of a retarder, 1-10 parts of fibers and 1-5 parts of a compound early strength agent. According to the special repair mortar for the structure, by selecting and proportioning the components in proportion, comprehensively excellent utilizing performance of the components, the components draw on strengths of each other and act jointly, so that the shrinking percentage of the mortar is low. Mechanical properties of relatively high bonding strength, tensileand crush resistances and the like are obtained, and the cost performance is high.

Owner:GUANGDONG FUTE NEW MATERIALS TECH CO LTD

Composite low-heat-release high-active superfine powder concrete admixture and making method thereof

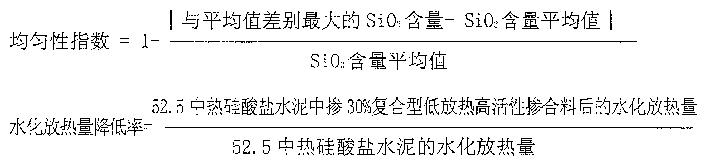

InactiveCN1401607ALow exotherm High hydration reactivityIncreased hydration reactivitySolid waste managementSlagHomogeneity index

A high-activity superfine additive for concrete is prepared from at least two of steel slag, flyash, granular slag of blast furnace and phosphur slag, and gypsum through grinding, proportional mixing and further pulverizing. Its advantages are high specific surface area (more than 400 sq.m / kg), high activity, and low heat release.

Owner:CHINA BUILDING MATERIALS ACAD +2

3D printing mortar and preparation method thereof

The invention relates to 3D printing mortar and a preparation method thereof and belongs to the field of building materials. The mortar is mainly composed of 70-90% of compound cement, 5-20% of quartz sand, 0.2-2% of lime, 1-5% of coagulant, 0-3% of water reducing agent, 0-3% of defoaming agent, 0-0.5% of thickener and 0.2-0.8% of fiber. The mortar can be quickly hardened and is good in thixotropy and flowability, initial setting time can be within 2 min at least, the requirement that the 3D printing mortar is quickly dried and hardened can be met, and later strength is high.

Owner:WUHAN UNIV OF TECH

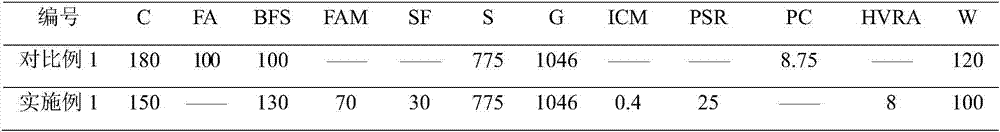

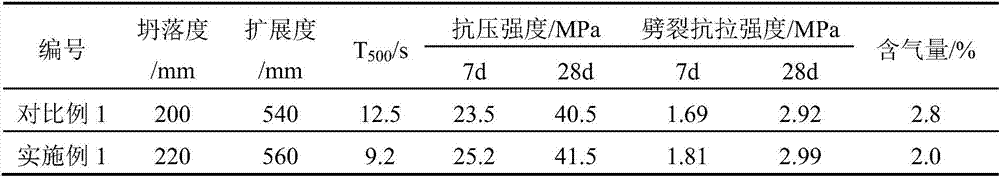

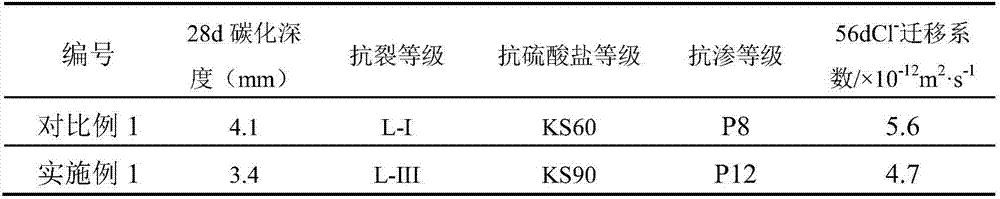

Graphene oxide ultra-high performance concrete with low cement consumption and preparation method thereof

InactiveCN111377687AImprove early strengthIncrease late strengthBreaking strengthUltimate tensile strength

The invention provides graphene oxide ultra-high performance concrete with low cement consumption, which belongs to the technical field of building materials. The concrete comprises the following components in parts by weight: 100 parts of cement, 30-50 parts of silica fume, 60-120 parts of fly ash, 10-50 parts of slag powder, 80-120 parts of quartz sand, 30-50 parts of water, 20-50 parts of steelfiber, 2-10 parts of a water reducing agent and 1-10 parts of graphene oxide. The invention also provides a preparation method of the ultra-high performance concrete. The graphene oxide is compoundedwith the steel fiber concrete doped with the mineral fine powder, and the graphene oxide can promote cement hydration, improve the early and later strength of the concrete, improve the interface conditions of a matrix and steel fibers and improve the binding strength of the matrix and the steel fibers, so that the breaking strength of the concrete is improved. The graphene oxide can improve the pore structure of the concrete, so that the concrete is denser, the strength of the concrete is improved, concrete strength shrinkage caused by steam curing is avoided, and the durability of the concrete is further improved.

Owner:重庆高途新材料科技有限公司

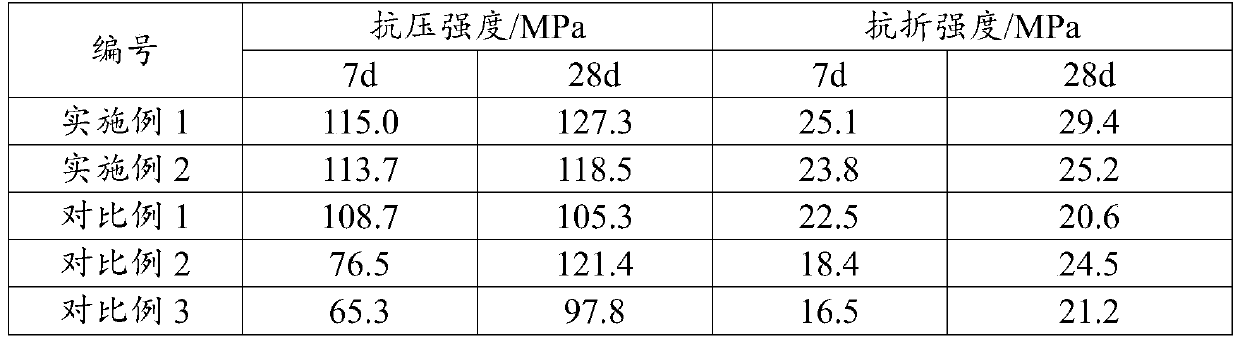

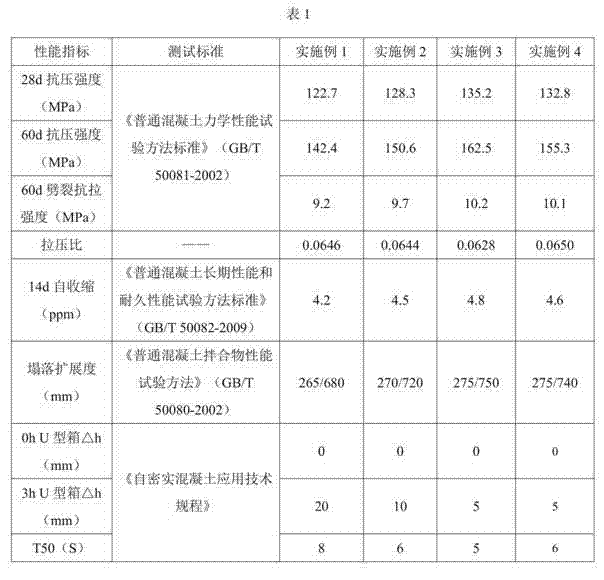

Ultrahigh-strength concrete and preparation method thereof

The invention discloses ultrahigh-strength concrete which comprises the following components in parts by weight: 300-350 parts of cement, 270-315 parts of composite mineral admixture, 30-35 parts of composite expanding agent, 96-112 parts of water, 680-720 parts of river sand, 1012-1080 parts of gravel, 13.2-14.0 parts of polycarboxylic acid high-efficiency water reducing agent, 4.4-4.7 parts of plastic retaining agent and 0.18-0.21 part of defoaming agent, wherein the composite mineral admixture is prepared from 42-49 parts of ore powder, 150-175 parts of fly ash, 30-35 parts of silica fume, 18-21 parts of zeolite powder and 30-35 parts of wollastonite powder. The invention is characterized in that the 60d concrete compression strength is 140-160 MPa, the 60d splitting tensile strength is 9.2-10.2 MPa, extruded concrete can achieve self-compaction effect within 3 hours, and the 14d self-shrinkage value is less than 0.05%.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

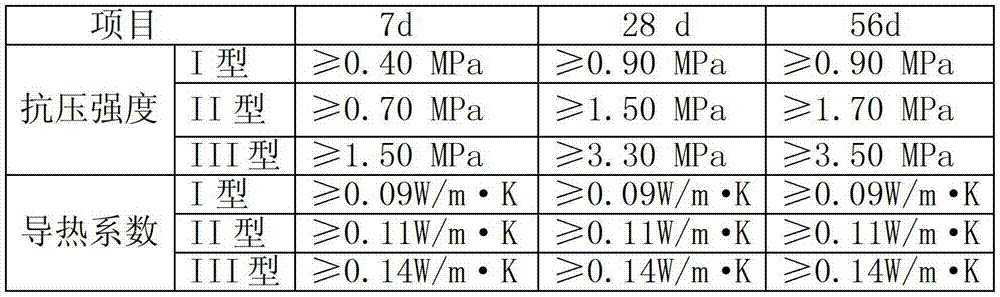

Method for preparing micro expanded inorganic heat insulation mortar

ActiveCN102010166AWide variety of sourcesLow priceSolid waste managementCeramicwareMethyl celluloseEther

The invention discloses a method for preparing micro expanded inorganic heat insulation mortar. Materials such as common silicate cement, desulfuration ash, calcium carbonate powder, re-dispersible latex powder, hydroxypropyl methyl cellulose ether, wood fiber, polypropylene fiber, surfactant, foam stabilizer, water, vitrified micro bubbles and the like are adopted; and the mortar is obtained by adopting the steps of stirring, mixing, shaping, curing and the like. The method has the advantages of low cost, early micro expansion, low later linear shrinkage rate, fire resistance, durability and the like, is easy to construct, and achieves good effect of preparing the I-type building heat insulation mortar by using the III-class vitrified micro bubbles.

Owner:CHONGQING SIBEIKEN ENERGY SAVING TECH DEV +1

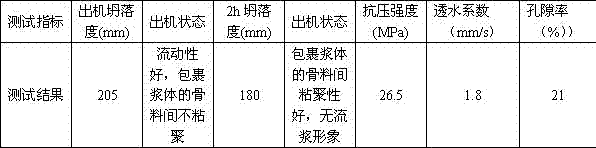

Specialadmixture for pervious concrete and application ofspecialadmixture

The invention discloses a specialadmixture for pervious concrete and application of the specialadmixture. Thespecial admixture comprises the following materials in weight percent: 5 to 15 percent (solid content) of a water reducing agent; 0.1 to 1 percent of a retarder; 0.1 to 1 percent of a thickener; 15 to 25 percent of an early strength agent; 25 to 50 percent of a water-repellent agent; 25 to 50 percent of rubber powder. The admixture overcomes the problem that the existing pervious concrete is not easy to transport bya tanker, and ensures that the phenomenon of blocking cannot occur when the pervious concrete is put into a tanker after the admixture is used, has excellent service behavior after the pervious concrete is discharged from the tanker, and has excellent cohesiveness, without phenomena of bottom sealing and hole blocking.

Owner:SICHUAN HUASHI GREEN HOMELAND BUILDING MATERIALS

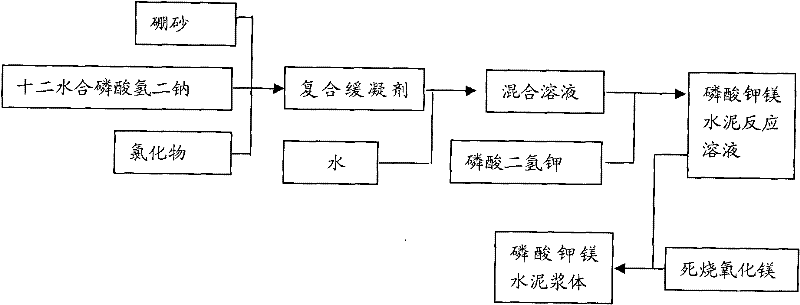

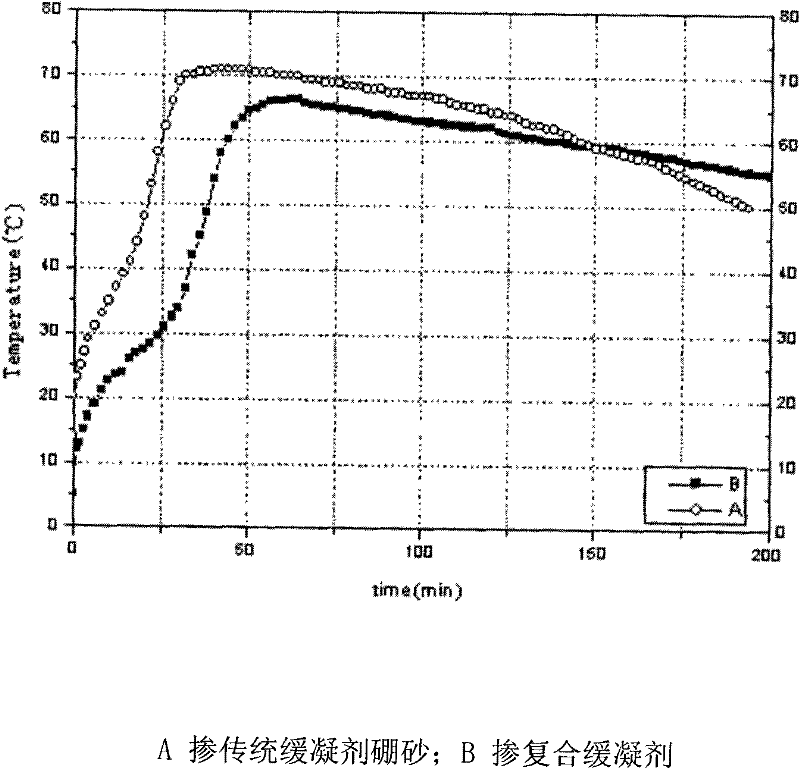

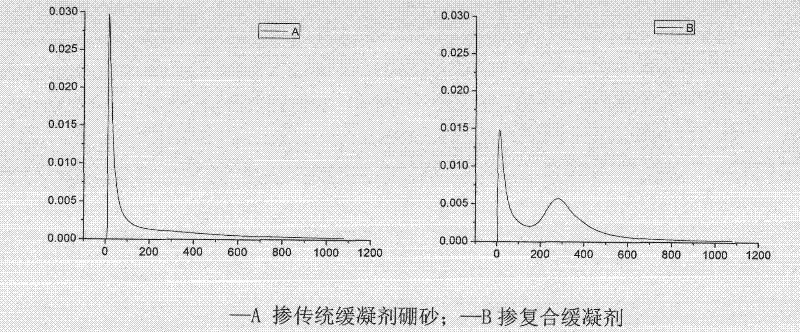

Method for controlling setting time and early hydration speed of magnesium potassium phosphate cement

InactiveCN102234200AEffective adjustment of clotting timeEffective control of clotting timeControl setOperability

The invention relates to a method for controlling the setting time and early hydration speed of magnesium potassium phosphate cement, and belongs to an early strength quick hardening cement cementing material. A composite retarder can effectively adjust the setting time of magnesium potassium phosphate cement slurry, and the setting time of the magnesium potassium phosphate cement slurry can be effectively controlled in the range of 10 minutes to 6 hours by adjusting the content of chloride and disodium hydrogen phosphate dodecahydrate in the composite retarder, so that the problems of a limited retarding effect, low operability and the like are solved; the composite retarder can change the hydration heat release characteristic of the magnesium potassium phosphate cement, the magnesium potassium phosphate cement slurry doped with the conventional retarder borax has a hydration heat release peak at the initial reaction stage and has a high heat release speed and large heat release amount, and the magnesium potassium phosphate cement doped with the composite retarder has two hydration heat release peaks and has small hydration heat release amount at the initial hydration stage; and the doped composite retarder improves the microstructure and later strength of a hardened magnesium potassium phosphate cement body, so that enough construction operable time can be ensured while the magnesium potassium phosphate cement slurry has early strength and is quickly hardened.

Owner:苏州诚开新材料有限公司

High fluidization micro expansive high-strength grouting material

ActiveCN104402345AReduce physical water consumptionImprove early strengthSolid waste managementChemical admixtureSlag

The invention discloses a high fluidization micro expansive high-strength grouting material which comprises the following raw materials by mass percentage: 23-34% of cement, 3-5% of microbead, 5-7.5% of phosphorus slag composite powder, 2.5-3.5% of silica fume, 2.5-3.5% of quartz powder, 46-55% of fine aggregate, 0.7-1% of water reducer, 0.01-0.03% of defoaming agent, 2.5-3.5% of expanding agent and 0.5-1% of early strength agent. The grouting material has the advantages of high strength in the early stage and later stage, good flowing property and adjustable expansiveness by taking the cement as a major binding material and employing the silica fume, the microbead and the phosphorus slag composite powder with different hydration activities together with a chemical additive matched with a binding material system and an aggregate system with reasonable gradation, and is particularly applicable to high precision equipment mounting, secondary grouting of an equipment foundation, bolt anchoring, crack repairing, duct grouting and the like.

Owner:中建西部建设西南有限公司

Concrete nano water-reducing super high-early-strength agent

The invention discloses a concrete nano water-reducing super high-early-strength agent which is capable of remarkably increasing early and late strength of concrete and shortening construction period and simultaneously has good water-reducing performance, plastic retaining performance, corrosion inhibiting performance and stability. The agent comprises the following ingredients: 46-52 wt% of early strength components, 26-32 wt% of water reducing components, 6-15 wt% of corrosion inhibiting components, 4-5 wt% of retarding components, and 6-8 wt% of adjustment components, wherein the early strength components comprise three or four selected from magnesium sulfate, sodium sulfate, sodium nitrite, triethanolamine, sodium thiosulfate, triisopropanolamine, and calcium formate, the water reducing components comprise one selected from naphthalene sulfonic acid high-efficiency water reducer and carboxylic acid water reducer, the corrosion inhibiting components comprise one selected from calcium nitrite, calcium nitrate, potassium chromate, and stannous chloride, the retarding components comprise one selected from sodium gluconate and citric acid, and the adjustment components comprise nano ground calcium carbonate.

Owner:DALIAN KEYKOWN TECH CO LTD +1

Non-sintered ceramic aggregate with stone coal vanadium extraction tailings as main raw material and preparation method thereof

InactiveCN102617097AEffective way to useExpand sourceSolid waste managementThermal insulationExpanded clay aggregate

The invention relates to a non-sintered ceramic aggregate with stone coal vanadium extraction tailings as a main raw material and a preparation method thereof. The non-sintered ceramic aggregate comprises the following raw material components in percentage by weight: 45-60 percent of stone coal vanadium extraction tailings, 10-30 percent of fly ash, 7-15 percent of solid alkali exciter, 5-10 percent of cement, 5-10 percent of quick lime, 2-5 percent of gypsum and 5-15 percent of water. The preparation method comprises the following steps of: according to the raw materials and the contents thereof, uniformly mixing the stone coal vanadium extraction tailings and the solid alkali exciter and grinding to be below 0.074 mm to prepare a prefabricated material; adding the fly ash, the cement, the quick lime, the gypsum and the water into the prefabricated material and uniformly stirring to prepare a mixture; aging the mixture for 1-3 hours; pelletizing; aging for 3-7 days; holding in an autoclave; and autoclaving under the condition of 0.8-1.2 MPa for 6-10 hours. The non-sintered ceramic aggregate has the advantages of environmental friendliness, simple process, low energy consumption and high utilization rate of tailings; and a prepared non-sintered ceramic aggregate product has high strength and good thermal insulation performance.

Owner:WUHAN UNIV OF SCI & TECH

Water-permeable agent for water-permeable bricks or water permeable concrete and application of water-permeable agent

The invention discloses a water-permeable agent for water-permeable bricks or water permeable concrete and application of the water-permeable agent. The water-permeable agent comprises, by weight, 75-110 parts of water reducing agent, 150-300 parts of retarder, 100-150 parts of binder, 55-70 parts of air entraining agent and 55-100 parts of water. The water-permeable agent has the advantages that the water-permeable agent can increase the workability of a water-permeable layer, increase water permeability and increase the durability and later strength of the water-permeable bricks and is low in adding amount and low in cost. The water-permeable bricks have the advatnages that the bricks use haycite and regenerated porous coarse aggregate as the aggregate of the water-permeable layer and use the water-permeable agent, the features of porosity, good water absorption performance and high strength of the aggregate and the good performance of the water-permeable agent are utilized to increase the strength and water permeability of the water-permeable bricks, and the bricks are lightweight and convenient to carry.

Owner:SHANDONG JINYI GARDEN SHARES CO LTD

Composite curing agent for dredged silt in watercourse

InactiveCN102060480AHigh strengthSpeed up the reaction processSludge treatmentSolid waste managementPolyvinyl alcoholCompressive strength

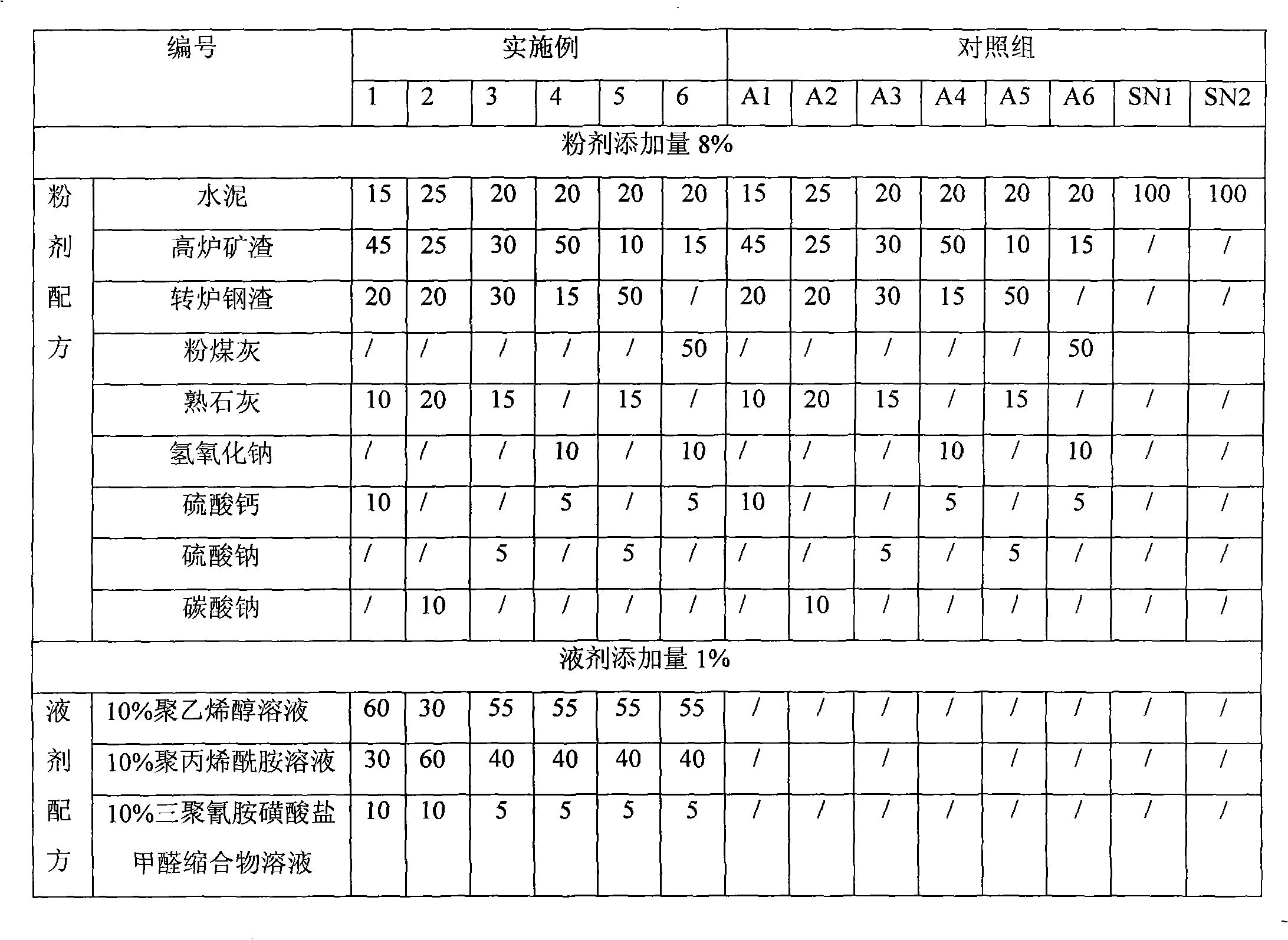

The invention discloses a composite curing agent for dredged silt in a watercourse, comprising a powdered agent and a liquid agent, wherein the powdered agent consists of the following components on the basis of 100 percent of the total mass fraction: 15-25 percent of cement, 45-65 percent of pozzolanic material, 10-20 percent of alkali activator and 5-10 percent of salt activator; and the liquid agent consists of the following components on the basis of 100 percent of the total mass fraction: 2-7 percent of polyvinyl alcohol, 2-7 percent of polyacrylamide, 0.5-1 percent of melamine sulfonate formaldehyde condensate and the balance of water. The dredged silt has high compressive strength after being solidified by the composite curing agent for the watercourse silt, and can meet the requirements of road construction.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI +1

Functional diatomite putty powder and preparation method thereof

InactiveCN105949863AImprove efficiencyShorten the timeFilling pastesInorganic pigmentsMaterials science

The invention relates to putty powder, in particular to functional diatomite putty powder and a preparation method thereof, wherein the putty powder includes in percent by weight: 10-50% of high-temperature activated diatomite, 5-30% of an inorganic binder, 30-70% of an inorganic filler, 0.01-2% of a functional aid, 0.1-5% of an inorganic pigment, 0.5-5% of an organic binder, and 0.5-5% of an organic aid. The functional diatomite putty powder meets the related standard requirements of putty powder and diatomite, and has qualified constructability and functionality, namely having standard-meeting properties such as humidity regulation, formaldehyde clarifying performance, long duration of formaldehyde purifying performance, mold-proof performance, and mold durability.

Owner:CENT SOUTH UNIV +1

Sea sand anti-corrosion marine concrete and preparation method thereof

The invention discloses sea sand anti-corrosion marine concrete. By adjusting the proportion of binding materials, cement, mineral powder, silicon ash and fly ash micro-spheres are uniformly distributed, and adsorption of corrosive ions is increased by hydration reaction of high-aluminum minerals and chemical curing of Cl- ions in sea sand. Transmission paths of the Cl- ions in the sea sand and the corrosive ions in a marine environment can be effectively inhibited by pore structure adjustment and corrosive ion transmission inhibitors, and reinforcing steel corrosion is decreased. Micro-expansion and water retention components in internal maintenance materials can effectively avoid cracking of the inside of the concrete due to excessive shrinkage under the moisture coupling action of a marine environment, and the working performance and the compactness of the concrete can be improved by special ball effects of ultra-dispersed shrinkage additives and the fly ash micro-spheres. The sea sand anti-corrosion marine concrete can effectively solve the problem of river sand resource shortage, resource application of the sea sand is realized, and the sea sand anti-corrosion marine concrete more effectively serves a severe marine environment and has an important engineering application value.

Owner:HAINAN RUIZE NEW BUILDING MATERIAL +2

Phosphogypsum-base wall material for cast-in-place wall

The invention discloses a phosphogypsum-base wall material for a cast-in-place wall. The invention is characterized in that the material is prepared from the following raw materials in percentage by weight: 60-80% of beta-phosphogypsum, 10-20% of mineral admixture, 5-25% of cement, 0.25-0.5% of retarder, 0.05-0.15% of defoaming agent, 0.05-0.2% of thickener and 0.5-1% of water reducer. The raw materials are uniformly mixed to obtain the phosphogypsum-base cast-in-place wall material; and the material and water are mixed uniformly in a water / material ratio of 0.4-0.5 to obtain a slurry, and the slurry is cast in place and molded. The phosphogypsum-base wall material has the advantages of controllable setting time, low flowing loss rate, high utilization ratio of solid waste, low material cost and high strength, is convenient for construction, and can be widely used for frame-structure infilled internal walls of commercial and civil buildings.

Owner:WUHAN UNIV OF TECH

Special thin anti-crack plastering mortar for autoclaved aerated concrete

The invention discloses a special thin anti-crack plastering mortar for autoclaved aerated concrete and belongs to the technical field of building materials. According to the special thin anti-crack plastering mortar disclosed by the invention, a dry material is added with water by a mass ratio that water to dry material ratio is equal to 1:4, and then stirred for 3-5 minutes to prepare mortar, wherein the dry material consists of the following components in mass by percentage: 20%-35% of cement, 10%-30% of 40-70-mesh quartz sand, 30%-50% of 80-100-mesh quartz sand, 2%-7% of 200-mesh coarse whiting powder, 1.5%-4% of redispersible emulsion powder; 0.15%-0.5% of water-retaining agent; 0.2%-0.7% of wood fiber and 0.11%-0.45% of short fiber. Being prepared by adopting quartz sand of 40-70 meshes or 80-100 meshes, the special thin anti-crack plastering mortar for the autoclaved aerated concrete disclosed by the invention has an excellent anti-crack performance, realizes effective control on contraction percentage of the mortar, causes no cracks during large-area construction, achieves good caking property, and realizes organic combination between the mortar and the surface layer of the autoclaved aerated concrete.

Owner:山东高阳建材有限公司

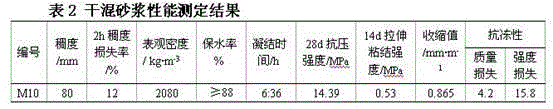

Industrial waste residue dry-mixed mortar

The invention discloses an industrial waste residue dry-mixed mortar. The industrial waste residue dry-mixed mortar takes cement, phosphorus slag powder, fly ash, composite activators, composite additives and sand as raw materials and is prepared after all the raw materials are mixed evenly. The industrial waste residue dry-mixed mortar comprises, by weight, 18-22 parts of cement, 35-45 parts of phosphorus slag powder, 35-45 parts of fly ash, 0-20 parts of composite activators, 0.1-7.5 parts of composite additives and 65-85 parts of sand. The industrial waste residue dry-mixed mortar can take a large number of phosphorus slag and fly ash as raw materials and is advantaged by low production cost, low energy consumption, less pollution, good workability, good mechanical properties, good durability, reliable quality and wide adaptability.

Owner:GUIZHOU UNIV

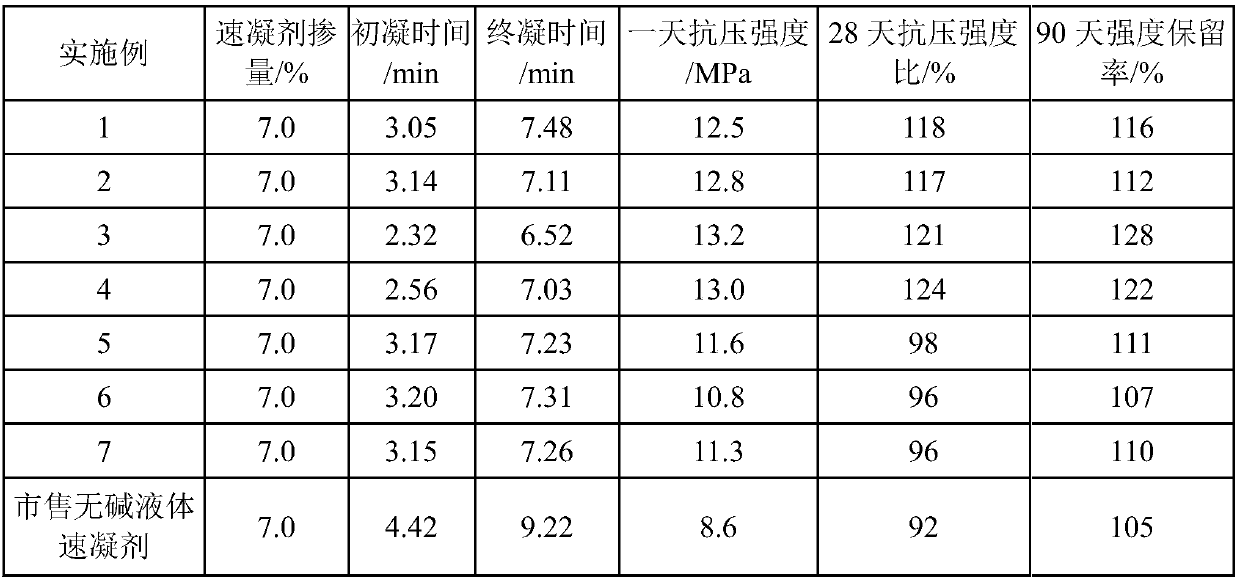

Alkali-free liquid accelerator and preparation method thereof

The invention provides an alkali-free liquid accelerator and a preparation method thereof and belongs to the technical field of concrete admixtures. The alkali-free liquid accelerator is prepared fromthe following raw materials: aluminum sulfate, ferrous sulfate, sodium fluoride, magnesium fluosilicate, precipitated hydrated magnesium silicate, diethanol amine and water. The alkali-free liquid accelerator has a good rapid hardening effect, can effectively shorten the coagulating and final setting time of concrete, and effectively improves the early strength and the later strength of concrete.The preparation method of the alkali-free liquid accelerator comprises the following steps: stirring water and precipitated hydrated magnesium silicate for 15-20 min at 40 DEG C; then adding ferroussulfate and sodium fluoride, and performing mixing and stirring for 8-15 min; after that, adding aluminum sulfate; performing heating up to 75-85 DEG C; after a reaction for 1 h, adding magnesium fluosilicate, and performing stirring for 20-40 min; and at last, adding diethanol amine, performing stirring for 18-25 min to prepare the alkali-free liquid accelerator. The preparation method is simple,the reaction is safe, and the prepared accelerator has good dispersibility.

Owner:PANZHIHUA CITY JIYUAN TECH

Polycrystal inorganic lightweight aggregate thermal insulation mortar

InactiveCN103172314AImprove the defect of insufficient penetration gripImprove adhesionThermal insulationEther

The invention discloses a polycrystal inorganic lightweight aggregate thermal insulation mortar. The polycrystal inorganic lightweight aggregate thermal insulation mortar comprises cement, redispersible latex powder, hydroxymethyl propyl cellulose ether,air entraining agent, organosilicone water repellent, closed perlite or glass beads. 98% of the thermal insulation mortar is an inorganic incombustible material; the thermal insulation mortar has integrative functions of heat insulation, decoration, fire retardance, water retardance, climatic change resistance and the like; moreover, the process is simple and easy to operate; quality problems caused by construction technique can be reduced; the development cost is lowered; and large-range promotion and application are promoted.

Owner:HAIDA CONSTR GRP

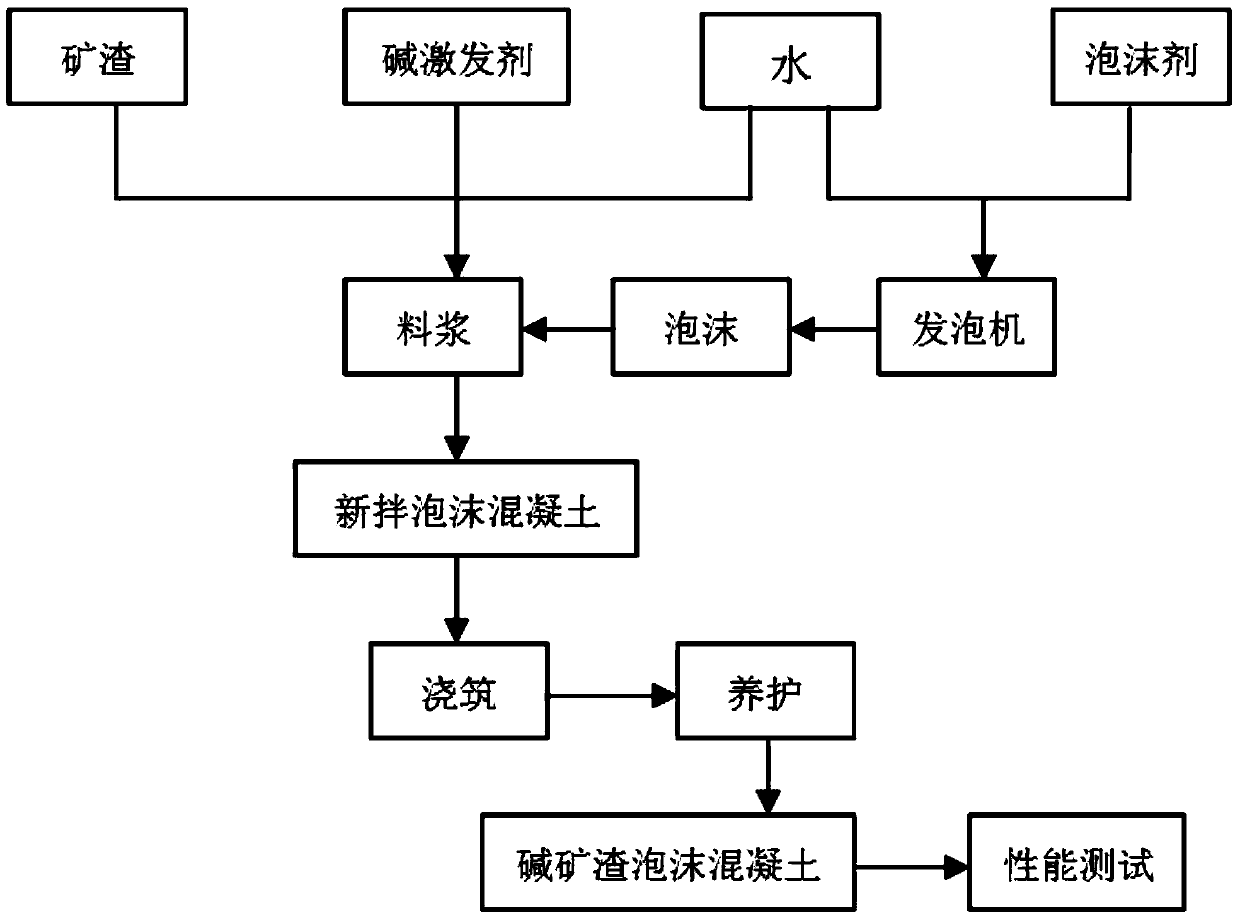

Alkali slag foamed concrete

The invention discloses an alkali slag foamed concrete which comprises slag and an alkali activator, wherein the alkali activator is sodium hydroxide or water glass. When the alkali activator is sodium hydroxide, the alkali slag foamed concrete is composed of the following components in parts by mass: 59-65 parts of slag, 5-6% of NaOH, 23-26 parts of water and 4.8-12.2 parts of foaming agent. When the alkali activator is water glass, the alkali slag foamed concrete is composed of the following components in parts by mass: 56-61 parts of slag, 9-11 parts of water glass, 21-25 parts of water and 5.0-12.2 parts of foaming agent. The volume weight of the foamed concrete is 290-610 kg / m<3>. The alkali slag foamed concrete has the advantages of short setting time, quick strength development, higher later strength, excellent water resistance and excellent weather resistance, and can be used for a long time.

Owner:CHONGQING UNIV

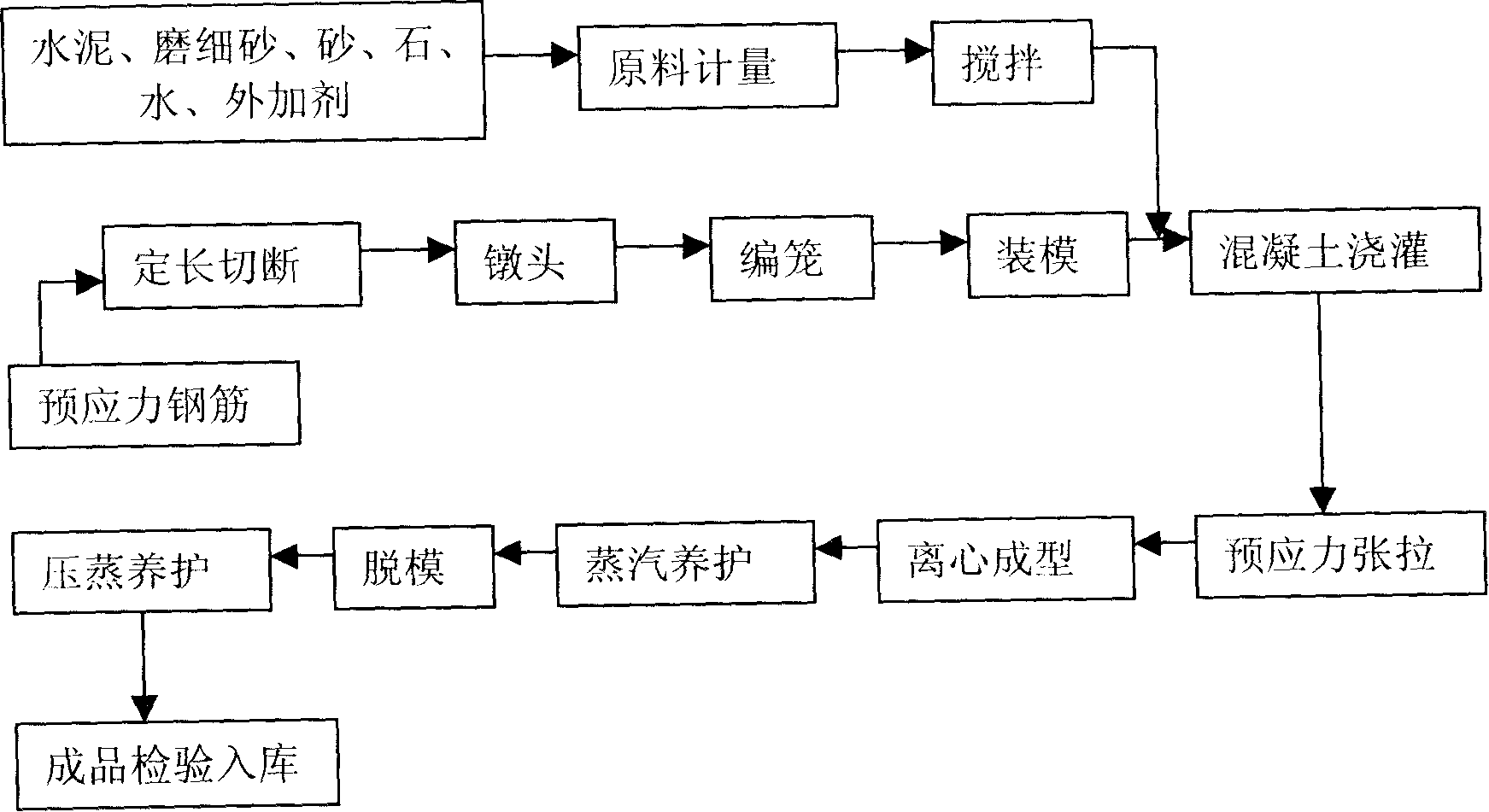

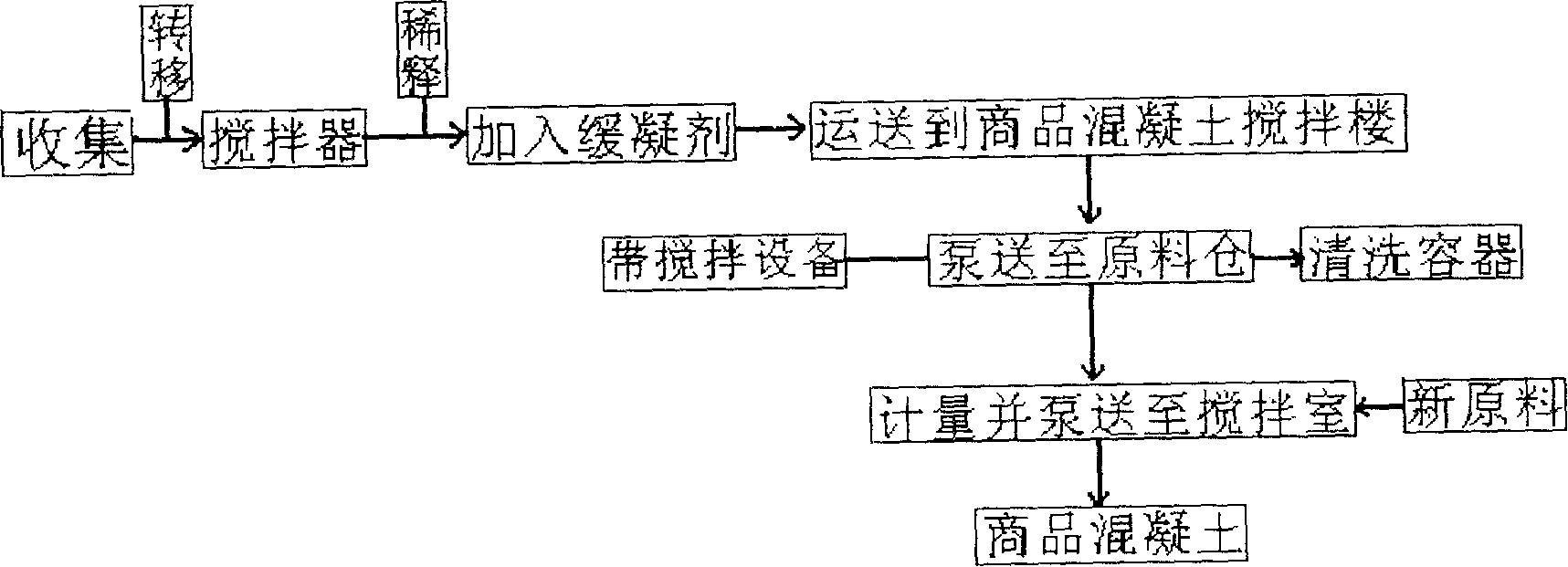

Method for producing concrete by reclaiming and reusing PHC pipe pile residual slurry

InactiveCN101168266AReduce pollutionWork lessMixing operation control apparatusCement mixing apparatusCentrifugationSlurry

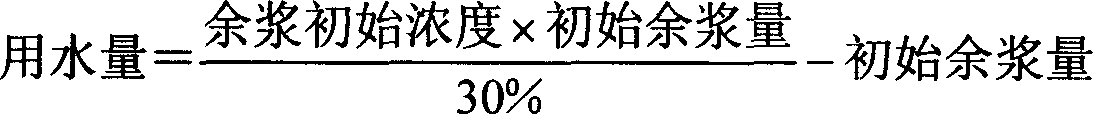

The invention discloses a process for preparing concrete by recycling and utilizing PHC pile tube surplus slurry, which comprises collecting the surplus slurry produced by the centrifugation of the PHC pile tube in a ware, then calculating the proportion of the surplus slurry X and calculating solidity Y of the surplus slurry according to the mathematical formula Y=AX-B, and according to the solidity value of original surplus slurry, adding water into the surplus slurry for mixing and diluting into a fixed density or solidity, adding retarder into the surplus slurry and controlling the coagulation time of the surplus slurry in 4-6 hours, then adding the surplus slurry and the row material of commodity concrete into the blender for producing the mixture fitting for the relative strength gradation, and conducting commodity concrete production to the mixture with manufacturing technique of commodity concrete. The process for preparing concrete by recycling and utilizing PHC pile tube surplus slurry enables the effective components of the surplus slurry to be reutilized, which not only reduces the environmental contamination and saves resource, but also substantially improves both the service performance and the early strength and later strength of the produced commodity concrete.

Owner:富春控股集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com