Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1092 results about "High strength concrete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

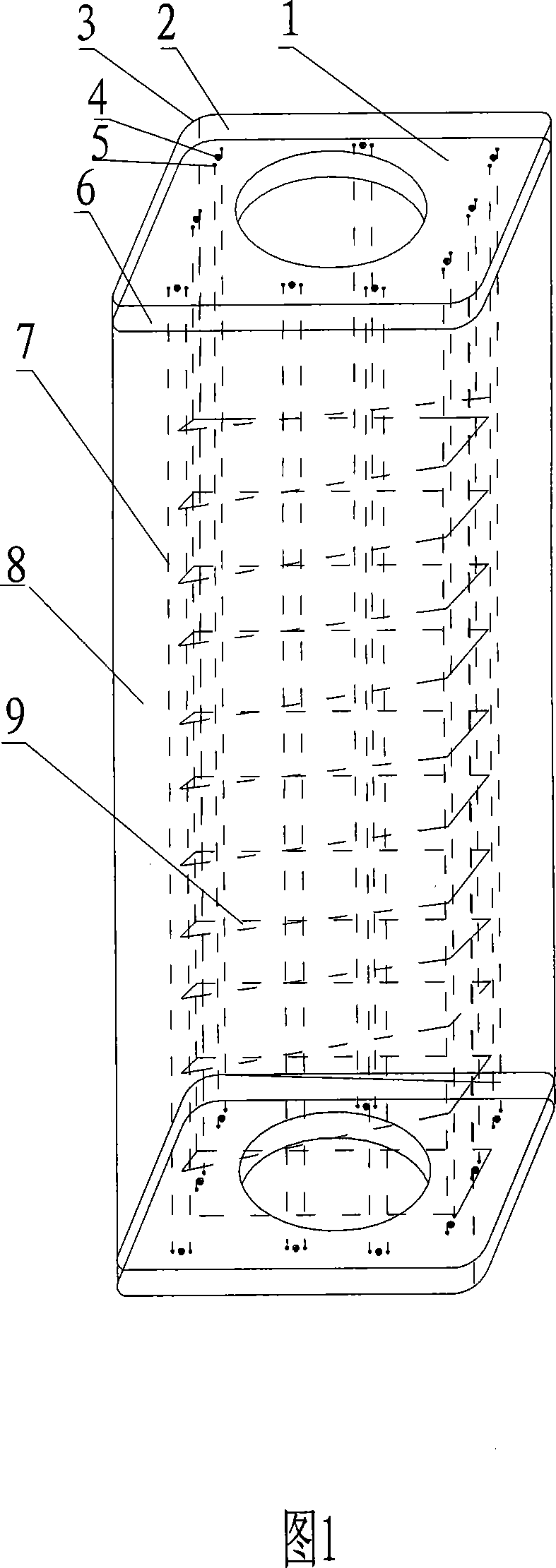

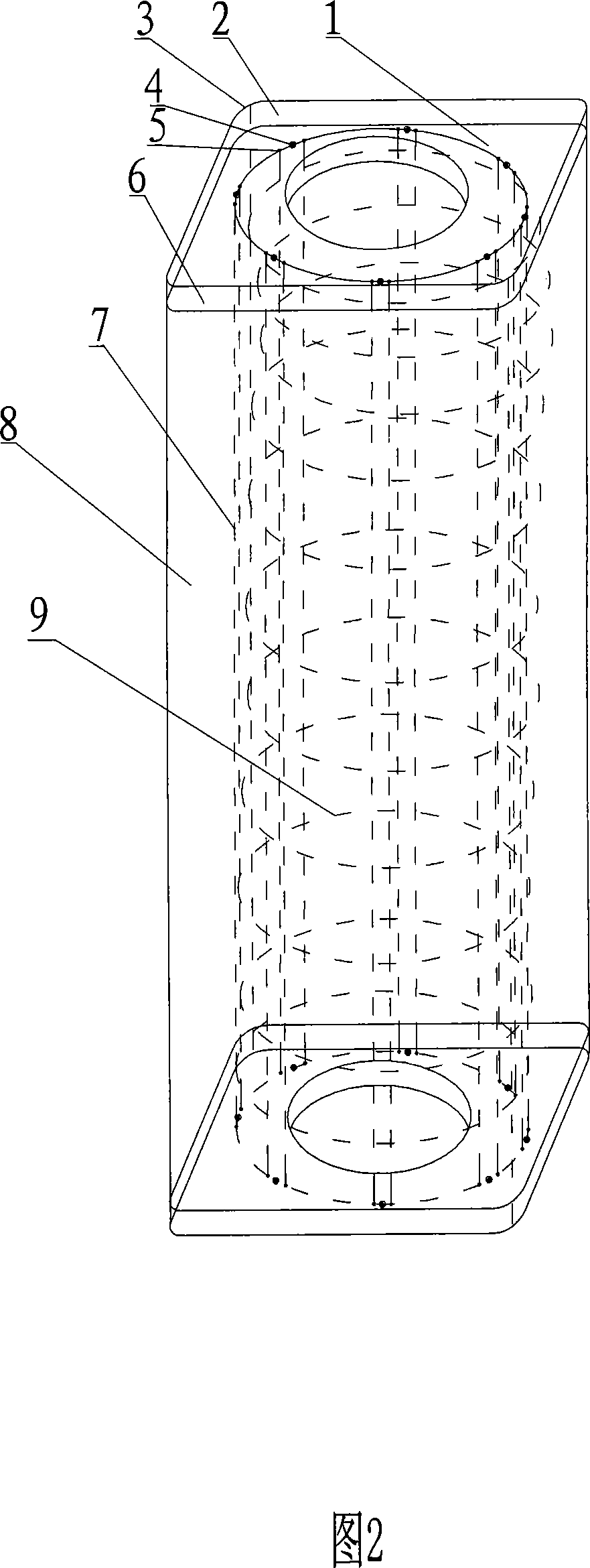

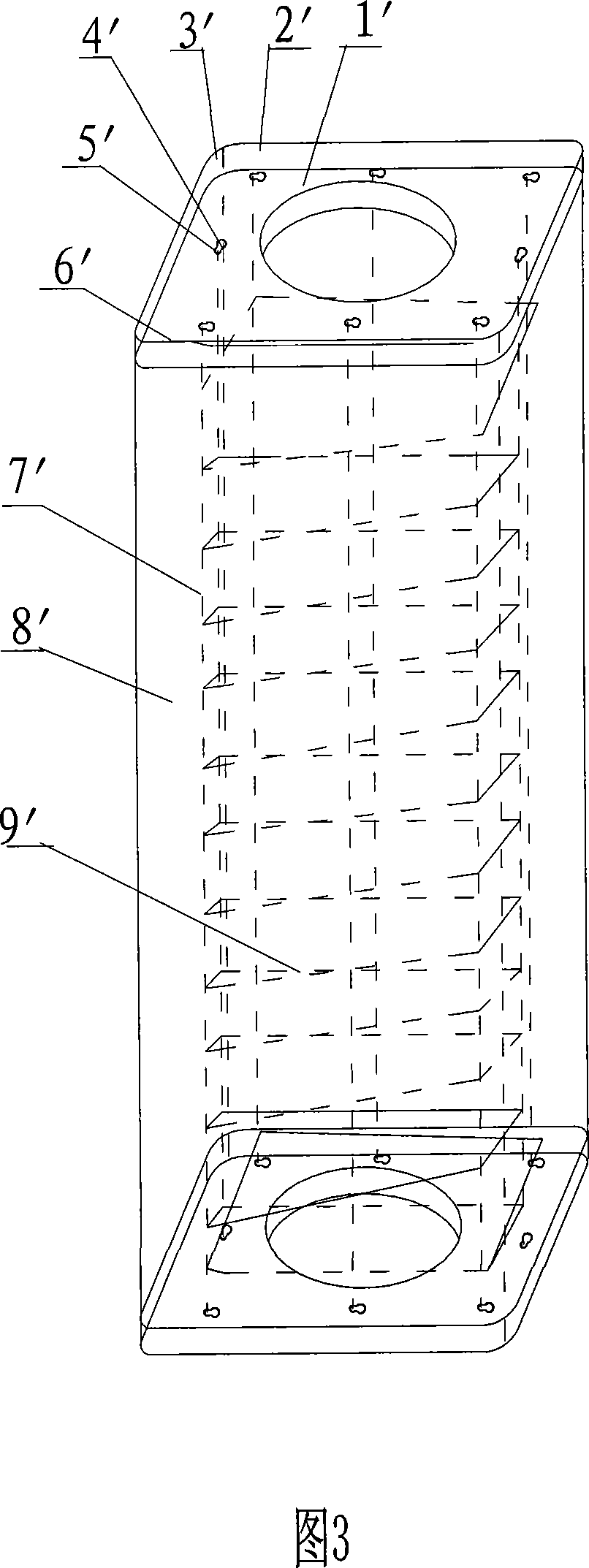

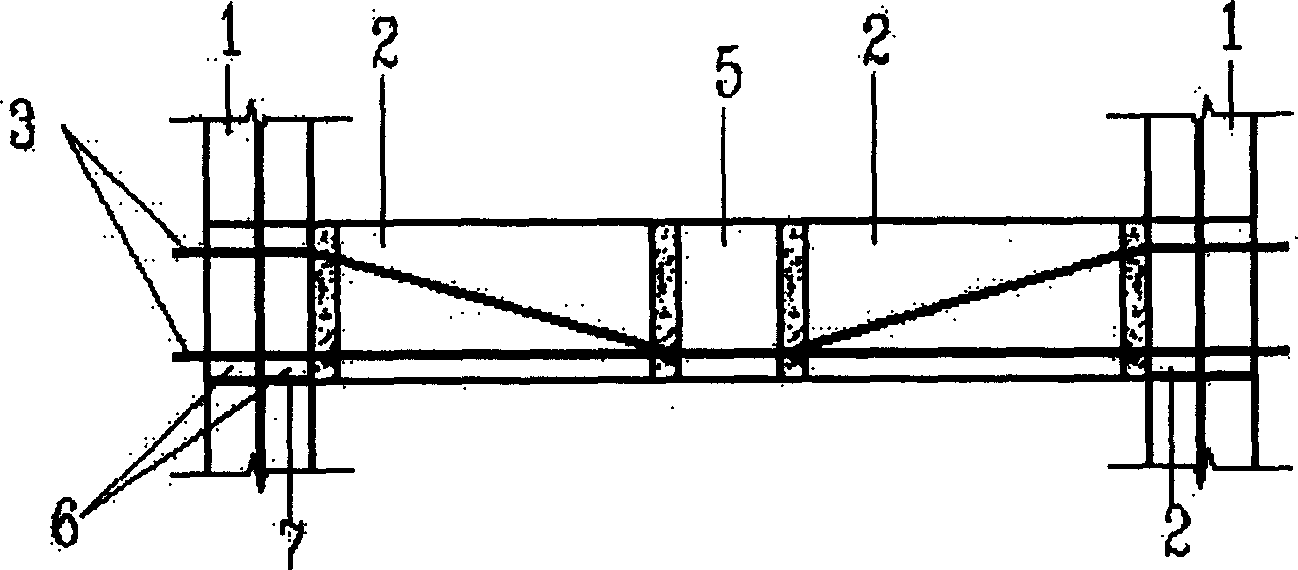

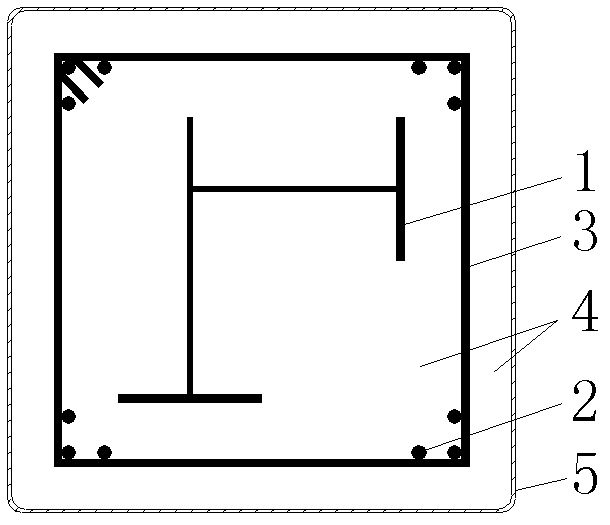

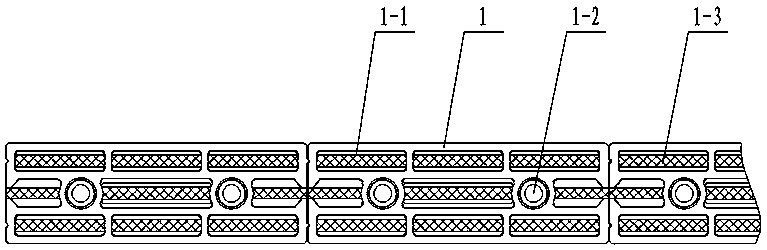

Prestress high intensity concrete square pile and its production method and moulding die

InactiveCN101054800AHigh pile rateIncrease profitCeramic shaping apparatusBulkheads/pilesHigh strength concretePre stress

The invention belongs to the architecture field, which relates to an improvement with the foundation pile shape and the structure and the manufacturing method of the foundation pile and the foundation pile shaper in the architecture field, in particular the invention is a prestressing force high strength concrete square pile and the manufacturing method thereof and the shaping device. In the invention a square terminal plate is disposed on the two ends of the square pile, and the four sides of the terminal plate is provided with a groove, while the center is equipped with a circular hole, and between the circular hole and the four sides, a strain hole and a threading hole are arranged symmetrically; a stirrp of a reinforcement cage in a twist is welded on the principal reinforcement continuously, wherein the principal reinforcement is the steel strand or the steel bar; the concrete square pile and the four-side corners of the terminal plate are in a stress elimination arc, and the pile core is a columnar mid level outlet having the same diameter with the terminal plate central circular hole. The manufacturing method is characterized in that, the principal reinforcement has the fix ed length and blanking, and the stirrp of the reinforcement cage is welded in the seam welder with the high degree of mechanisation; the principal reinforcement is stretched in a group of a whole pile fixed value, wherein the stretching performance is good and the balance is consistent; the disposable high pressure has short shaping time, low energy consumption, high product grade; the die design meets with the shaping requirement of the shape, which is convenient to use.

Owner:SHANGHAI ZHONGJI PILE IND

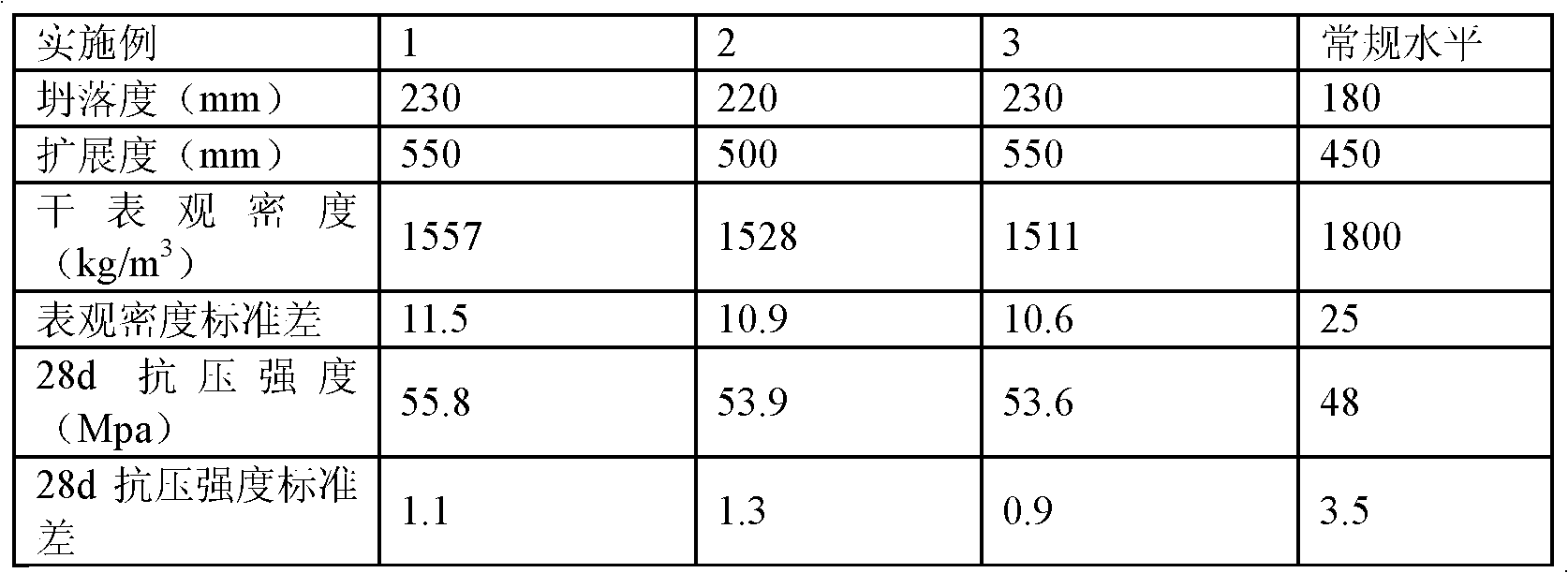

Light high-strength concrete and preparation method thereof

The invention discloses light high-strength concrete, which is prepared from the following raw materials in percentage by weight: 10 to 15 percent of silicate cement, 8 to 12 percent of mineral powder, 6 to 10 percent of coal ash, 2 to 6 percent of wollastonite, 20 to 30 percent of ceramsite,25 to 35 percent of ceramic sand, 0.2 to 0.8 percent of high-performance water reducing agent, 0.05 to 0.3 percent of exciting agent, 0.05 to 0.8 percent of tackifier and 8 to 12 percent of water. The light high-strength concrete has the advantages that compact accumulation is realized by optimizing the grain composition of cementing materials; the mineral powder is subjected to ultrafine grinding, so that the hydrated activity of the mineral powder is improved substantially; and the using quantity of the low-density cementing materials can be increased, and the cohesiveness of slurry is improved by combining the high-performance water reducing agent, the exciting agent and the tackifier, so that the concrete slurry is high in working performance and is not segregable, and the aim of reducing the volume weight of the hardened slurry substantially is fulfilled on the basis of ensuring the mechanical property of the hardened slurry.

Owner:JIANGSU MINGHE GRP

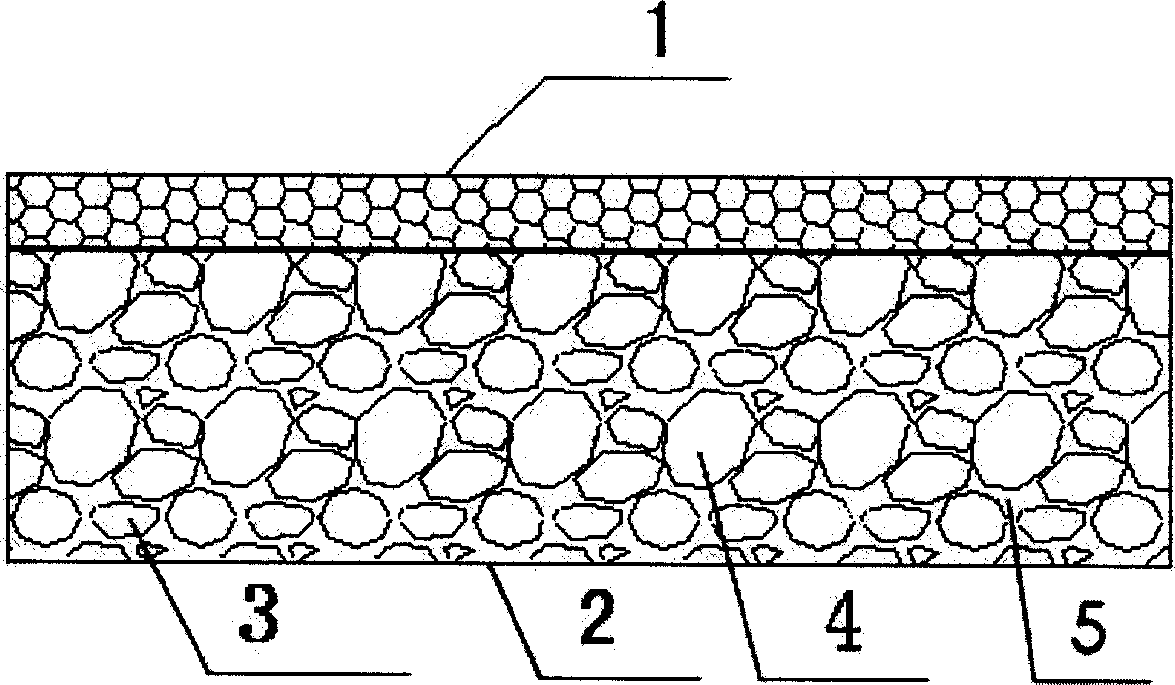

High-strength water-permeable concrete floor brick and its production method

The production process of permeable high-strength concrete paver includes the steps of: the first making base layer via mixing cement 18-21 wt%, small rubble of 3-5 mm size 50-55 wt%, large rubble of 7-10 mm size 18-21 wt%, admixture 0.1-6 wt% and water in 0.2-0.23 weight of cement, molding and vibrating to form; and the subsequent making facing layer via mixing cement 15-22 wt%, quartzite 76-85 wt%, admixture 0.1-6 wt%, dispersible latex powder 0.2-0.6 wt% and water in 0.24-0.26 weight of cement, pouring the mixture onto freshly formed base layer, and vibrating to form; demolding; and curing to obtain the finished product. The permeable high-strength concrete paver has high strength, high water permeability and no need of baking, and may be used widely.

Owner:潘英豪

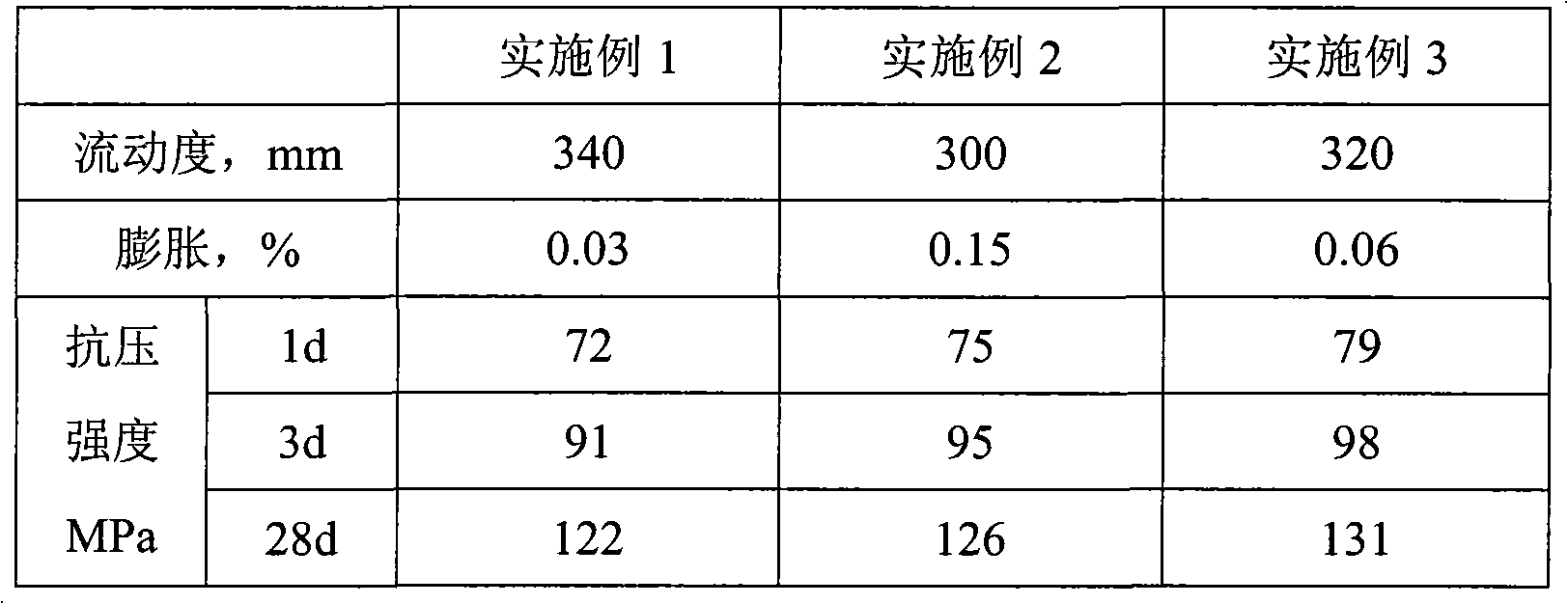

Cement-based ultra-high strength contraction-free grouting concrete

The invention provides a cement-based ultra-high strength contraction-free grouting concrete which is composed of cement, quartz sand, water reducer, swelling agent, defoamer, anti-settling agent, steel fiber, retarder and water-retaining agent in parts by weight: 100 parts of cement, 5-10 parts of swelling agent, 50-100 parts of quartz sand, 0.5-2.5 parts of water reducer, 0.3-1.0 part of defoamer, 0.1-0.3 part of anti-settling agent, 5-30 parts of steel fiber, 0-1.0 part of retarder and 0.1-0.3 part of water-retaining agent. The invention has the following beneficial effects: (1) at the normal temperature, the 1d compression strength of the cement-based grouting concrete is improved to be above 70 MPa; (2) at the normal temperature, the 28d compression strength of the cement-based grouting concrete is improved to be above 120 MPa; and (3) the cement-based ultra-high strength contraction-free grouting concrete can be used for installing large, ultra-large equipment basis, and can be used for occasions, such as bolt anchoring, structure fastening, road repair and the like which have high requirements on the compression strength of grouting concrete.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

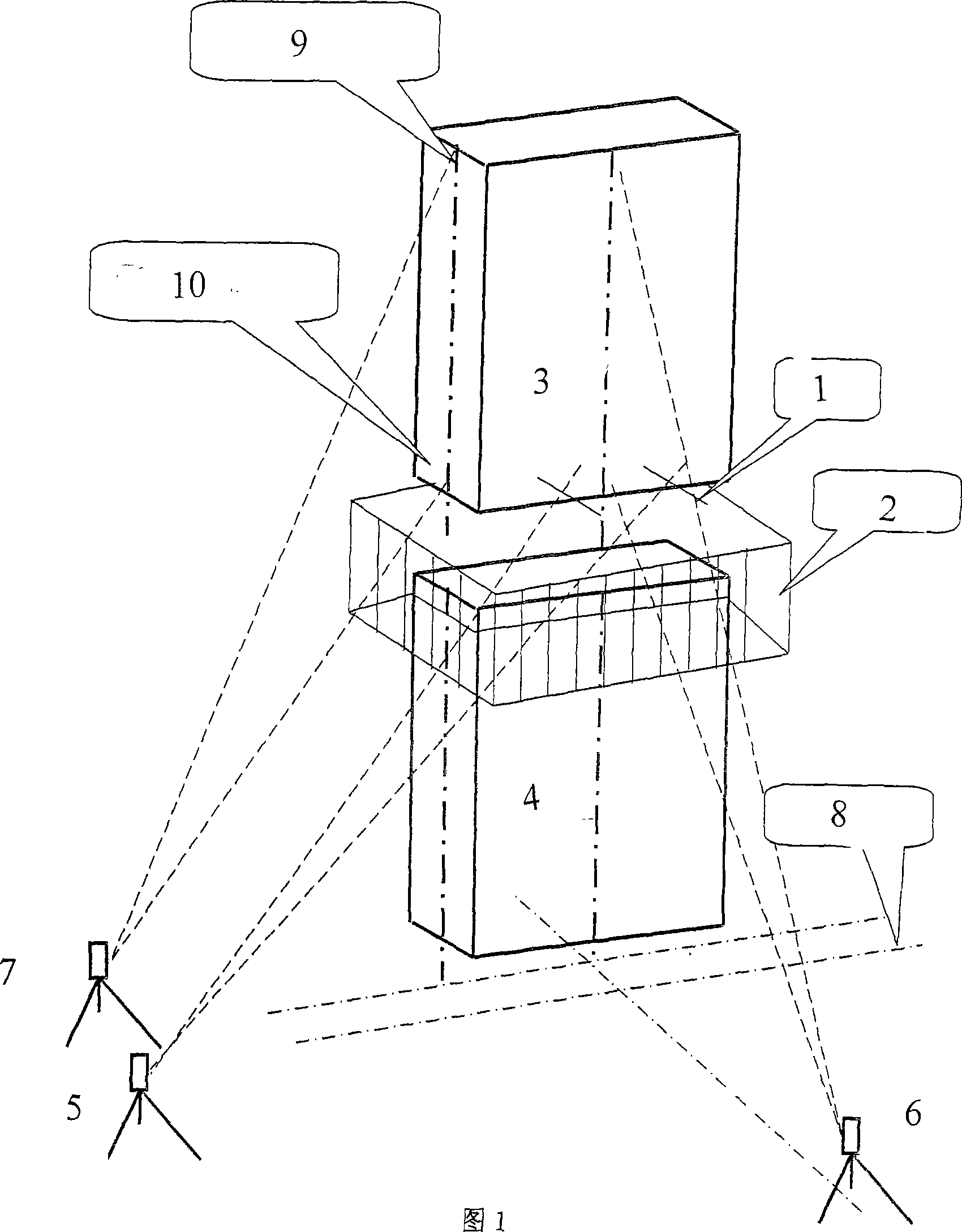

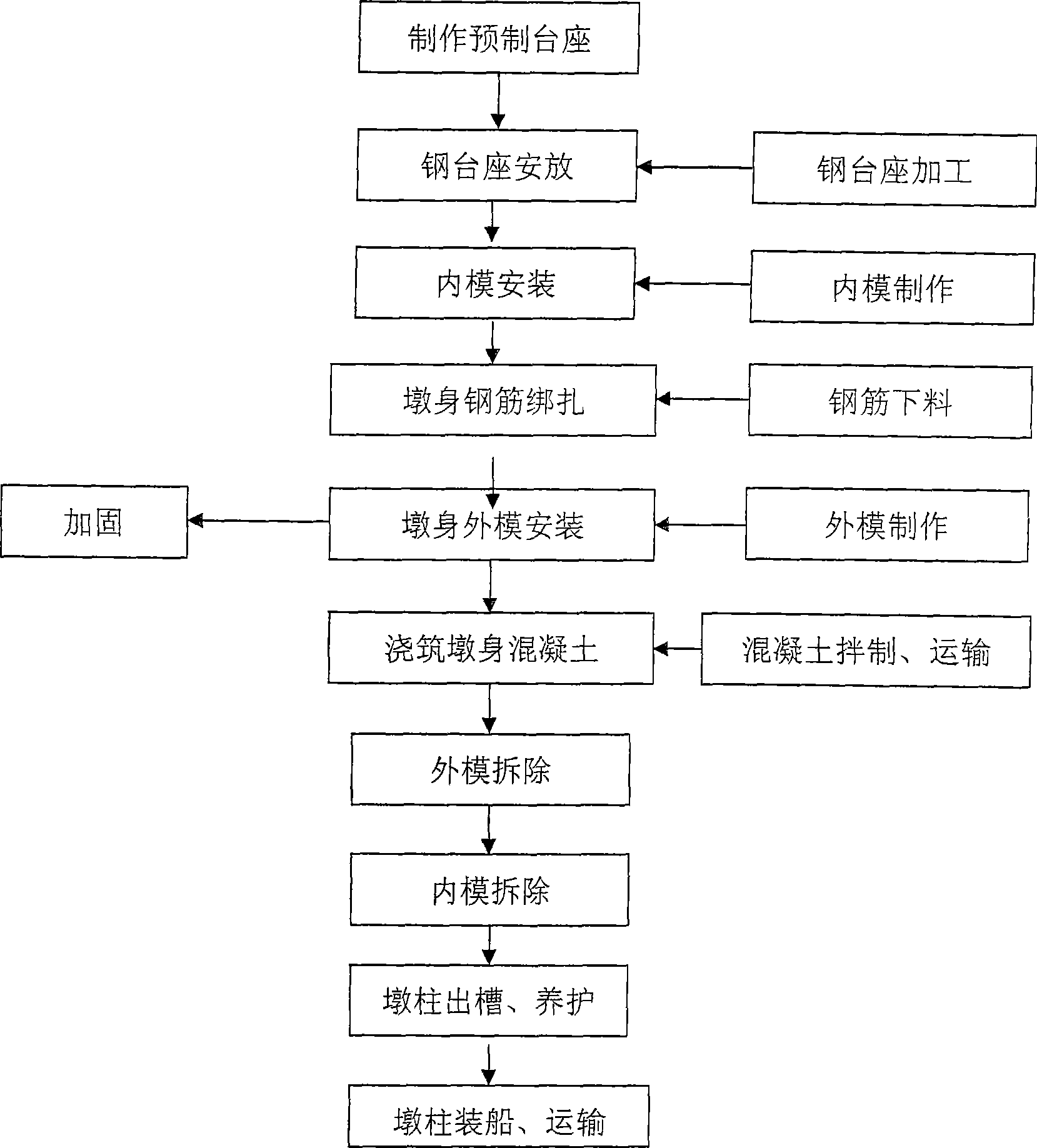

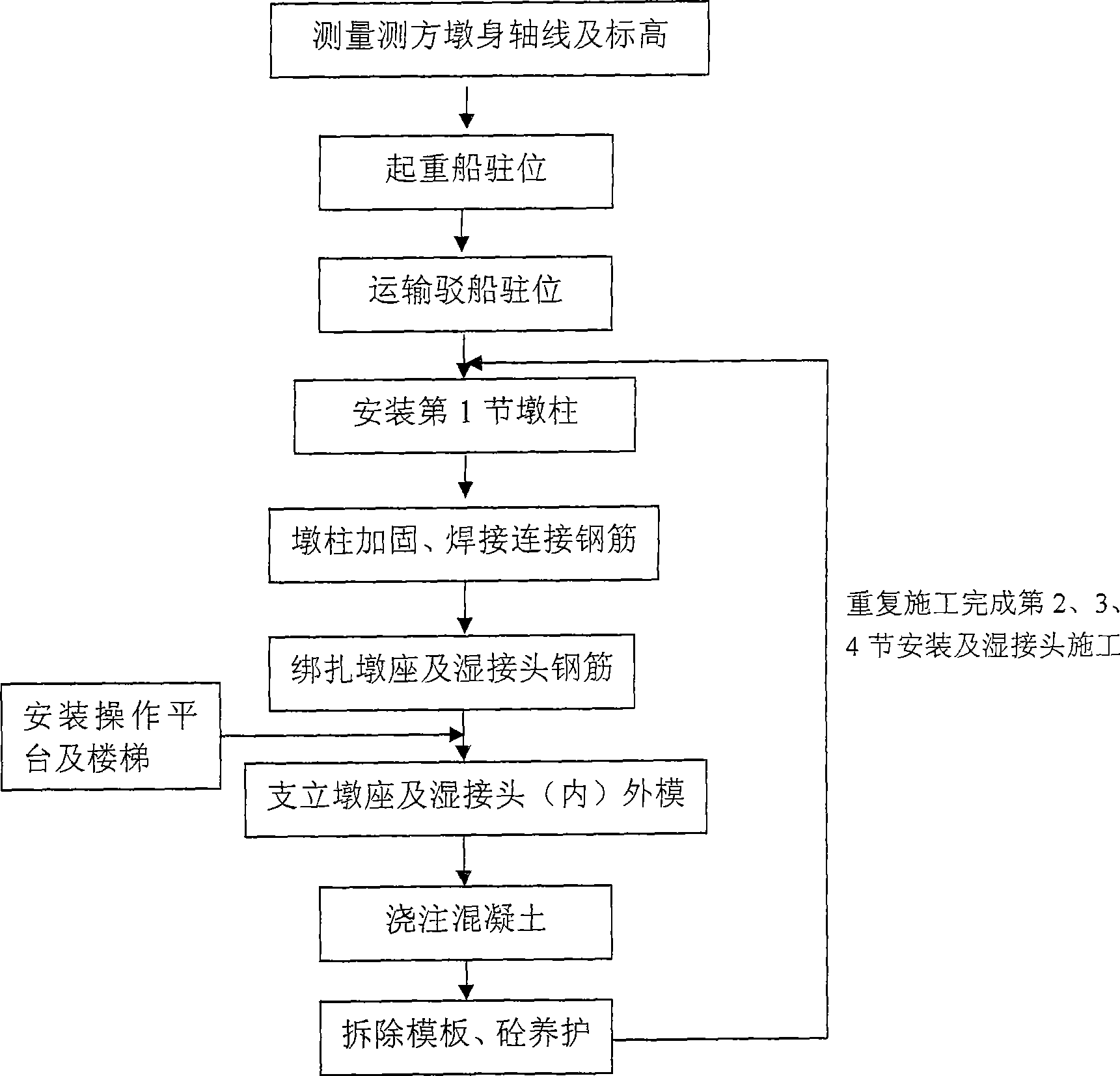

Pier column prefabrication splicing building technology

ActiveCN101429752AInspection is easy to implementImprove construction qualityBridge structural detailsBridge erection/assemblyHigh strength concreteBridge engineering

Owner:NO 1 ENG COMPANY CO LTD OF CCCC FIRST HARBOR ENG COMPANY +1

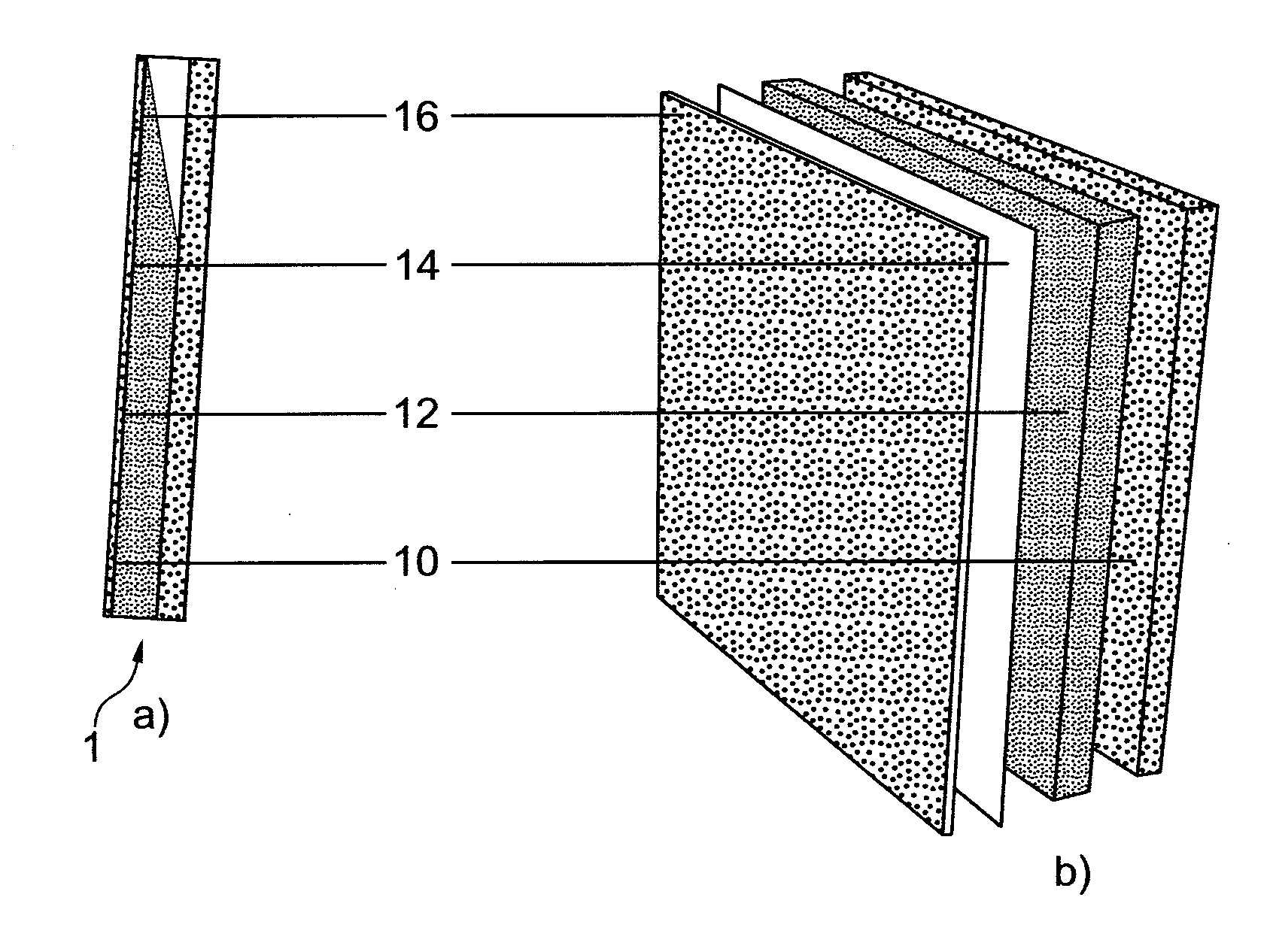

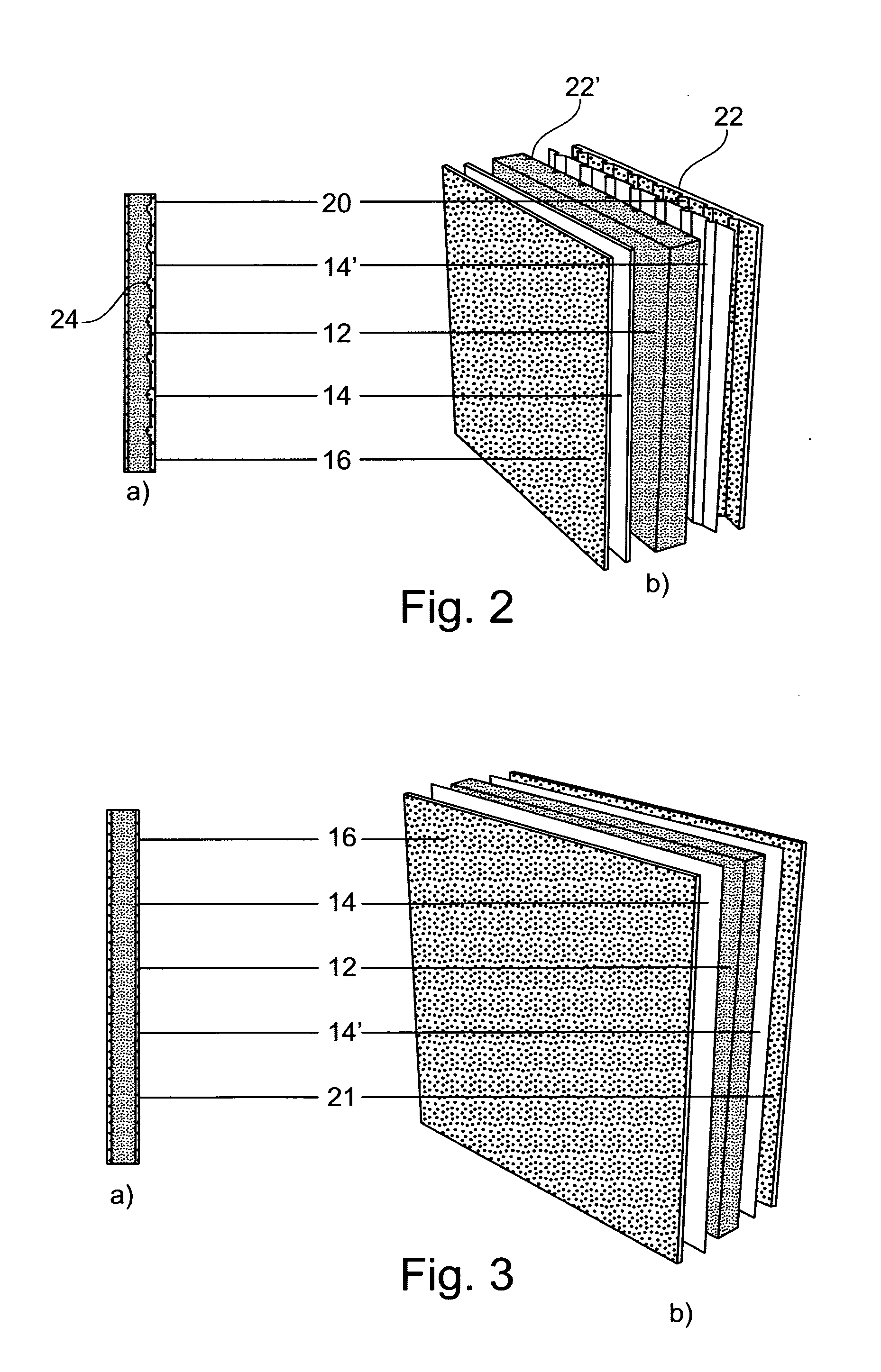

Composite Sandwich Panel

InactiveUS20120058299A1Increase resistanceSynthetic resin layered productsLaminationHigh strength concreteHigh intensity

Constructional panel having a front side suitable to be exposed to outside weather conditions, comprising a front side element, a rear side element and an insulating material arranged between said front and rear side elements, where the front side element is made from a high strength concrete, and where the insulating material is adhered to the rear side of said front and rear side elements.

Owner:CONNOVATE

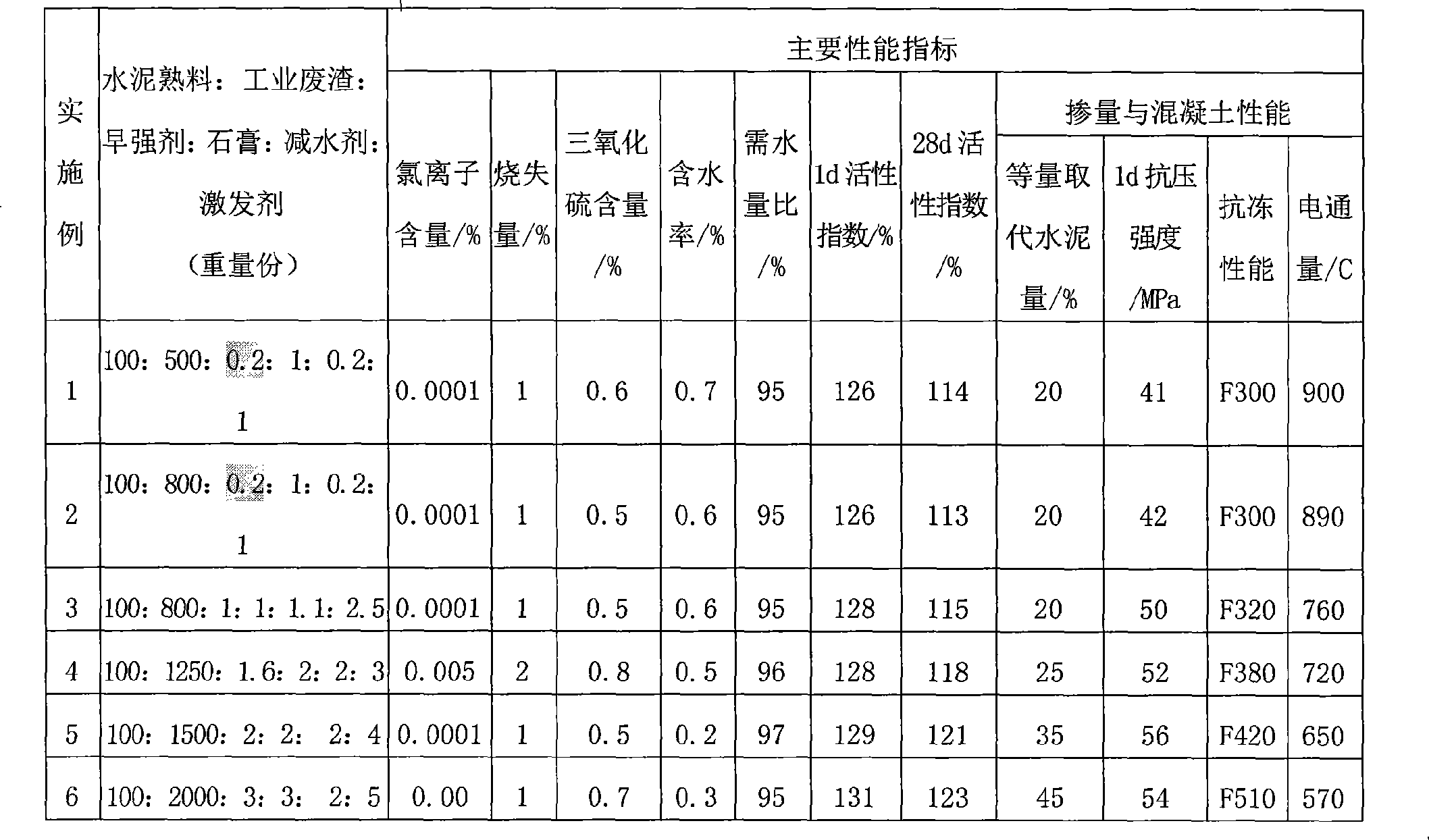

Blending material for high-early-strength concrete

InactiveCN101508557AImprovement of early strength and high strengthReduce dosageSolid waste managementHigh strength concreteCalcium formate

The invention relates to an admixture for high early strength of concrete, characterized in that the admixture is formed by mixing and stirring cement clinkers, industrial residues, early strength agents, plaster, water reducing agents and excitants. The parts by weight of the components are as follows: 100 parts of cement clinkers, 500-2000 parts of industrial residues, 0.2-3 parts of early strength agents, 1-3 parts of plaster, 0.2-2 parts of water reducing agents and 1-5 parts of excitants. The excitant is the mixture of aluminum hydroxide, calcium nitrite and calcium nitrate; wherein, the aluminum hydroxide accounts for 50% of the mixture while the calcium nitrite and the calcium nitrate are in any proportion; the early strength agent is the mixture of trolamine, lithium carbonate and calcium formate, wherein, the trolamine accounts for 50% of the mixture while the lithium carbonate and the calcium formate are in any proportion. The admixture for concrete provided by the invention has high activity index and low content of harmful ions. Adding the admixture can obviously improve the demoulding strength, long-term mechanical property and durability of the concrete.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

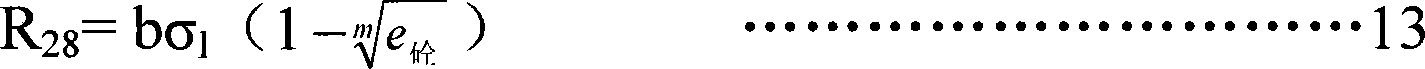

Confecting method of modern concrete and the mixing proportion thereof

InactiveCN101081527AMixing operation control apparatusCement mixing apparatusHigh strength concreteHigh intensity

The present invention is one kind of completely new concrete compounding process suitable for compounding various kinds of concrete, including high strength concrete and penetrative concrete. The present invention compounds concrete through optimizing the material proportion and size proportion of concrete without altering available concrete construction process and by means of the concrete theory of the present inventor. The compounded concrete has theoretic strength as high as 4.1466-5.4624 times the compression strength of the cement, and infinite theoretic service life similar to stone. The concrete compounding process is simple, practical, reliable, controllable in strength, low in cost and environment friendly.

Owner:王昱海

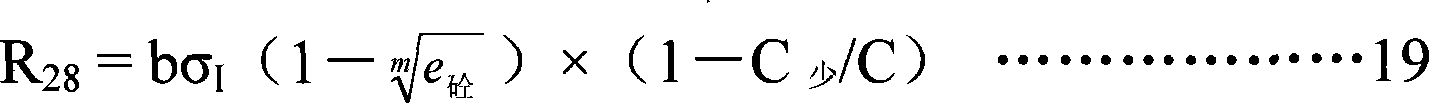

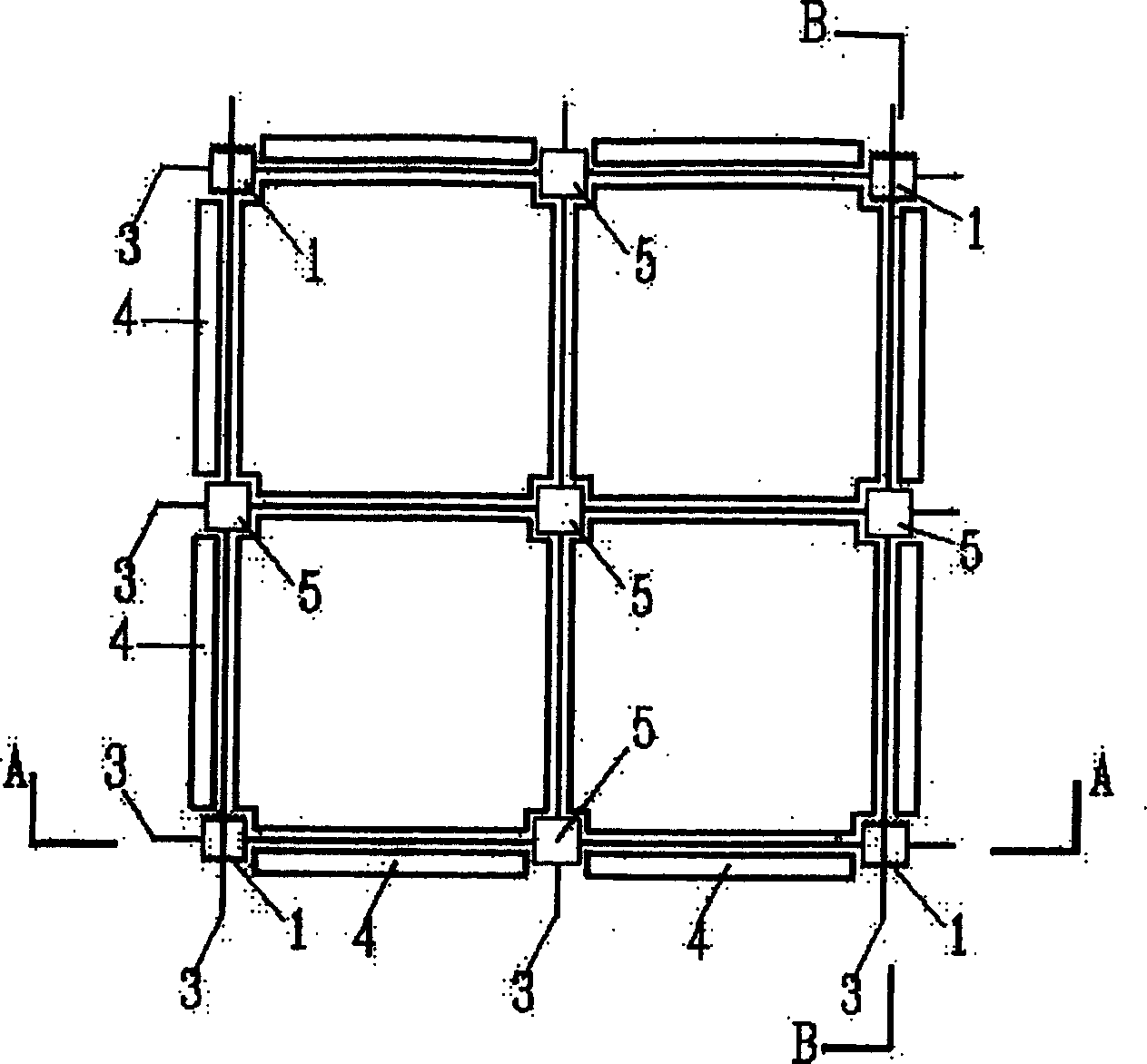

Steel-steel concrete fully prefabricated assembling structure

InactiveCN1554839AEnsure safetyImprove bearing capacityBuilding constructionsHigh strength concreteFloor slab

The fully prefabricated assembled steel-steel concrete structure includes two kinds of assembling forms. The first one is fully prefabricated assembled steel column-steel concrete structure, and its prefabricated steel column consists of H-shaped steel column, reinforcing concrete ribs, supporting steel plate and prestress-shearing force friction nodes with shear resisting strips. The second one is fully prefabricated assembled prefabricated steel pipe-concrete column-steel concrete structure, and the prefabricated steel pipe-concrete column consists of steel pipe with square cross section, micro expanding high strength concrete cast inside the steel pipe and shear resisting strips attached to the outer wall of the steel pipe to form preshearing force-friction type nodes. The present invention has raised antiseismic performance, area utilization, construction efficiency, fireproof performance, low cost and small member size, and is suitable for various buildings.

Owner:KUNMING UNIV OF SCI & TECH

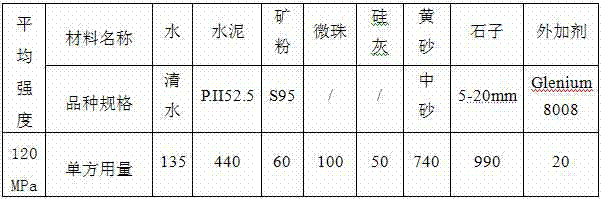

Low-viscosity easy-to-pump ultrahigh-strength concrete with average strength of 120MPa

ActiveCN103613348ALow viscosityEase of pumping performance requirementsHigh strength concreteMicrosphere

The invention relates to low-viscosity easy-to-pump ultrahigh-strength concrete with average strength of 120MPa. The concrete comprises the following components at single-prescription dosage ratio of kg / m<3>: 400-440 parts of cement, 40-60 parts of silica fume, 60-80 parts of slag micro powder, 100-120 parts of microspheres, 700-750 parts of natural sand with fineness modulus of 2.8-3.2, 980-1,000 parts of stone, 19.5-22.75 parts of additive and 130-135 parts of mixing water, wherein the additive is a polycarboxylate-type high-performance water reducing agent Glenium 8008 and has high water reducing rate, strong viscosity reducing property and high slump retaining property; the expansion degree of the ultrahigh-strength concrete is kept at 700+ / -50mm within 4 hours, the back taper time is controlled at 3-8 seconds, the viscosity is kept at 28-35Pa.s, and ultrahigh pumping of 300m and higher is easy to realize. The concrete provided by the invention can meet the performance requirements for ultrahigh concrete pumping of 500m and higher in terms of high slump retaining property, self-compaction property, strength property, low-viscosity property and the like.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD +1

High efficiency aliphatic sulfonate water reducing agent and method for preparing same

InactiveCN1634794AExcellent water reducing rateImprove performanceHigh strength concreteSuperplasticizer

The present invention relates to a high efficiency water reducing agent for manufacturing high performance cement based material such as high-strength concrete, fluid state and / or pumping concrete, etc. and method for preparing same. The invention takes ketones compound and aldehydes as condensation monomer, and sulphite as sulphonating agent, and take condensation reaction in alkaline aqueous solution. Then a water-soluble high-polymer condensate containing hydrophilic group such as sulfonic group, carboxy, hydroxyl, etc. in molecule with molecular weight ranging from 3000 to 10000 is obtained. By changing the matching, charging sequence of raw material, the technological process is simplified, the reaction time is shortened, and burst boiling and geling phenomena are also avoided at the same time. By controlling charging rate and condensation temperature, the condensation product is made with required molecular weight and can meet application performance. The fatty group sulphonate condensation compound made by the invention can be served as high efficiency water reducing agent of cement concrete, the water reducing, dispersion and reinforcing effects are better than the traditional albocarbon group high efficiency water reducing agent. The water reducing agent provided by the invention has the advantages of wide raw material source, simple synthesizing process, clean and suitable for industrial production.

Owner:吴霖秀 +2

Massive security barriers having tie-bars in tunnels

ActiveUS7654768B1Reduce manufacturing costInexpensive to deployPasturing equipmentTraffic restrictionsHigh strength concreteCoupling

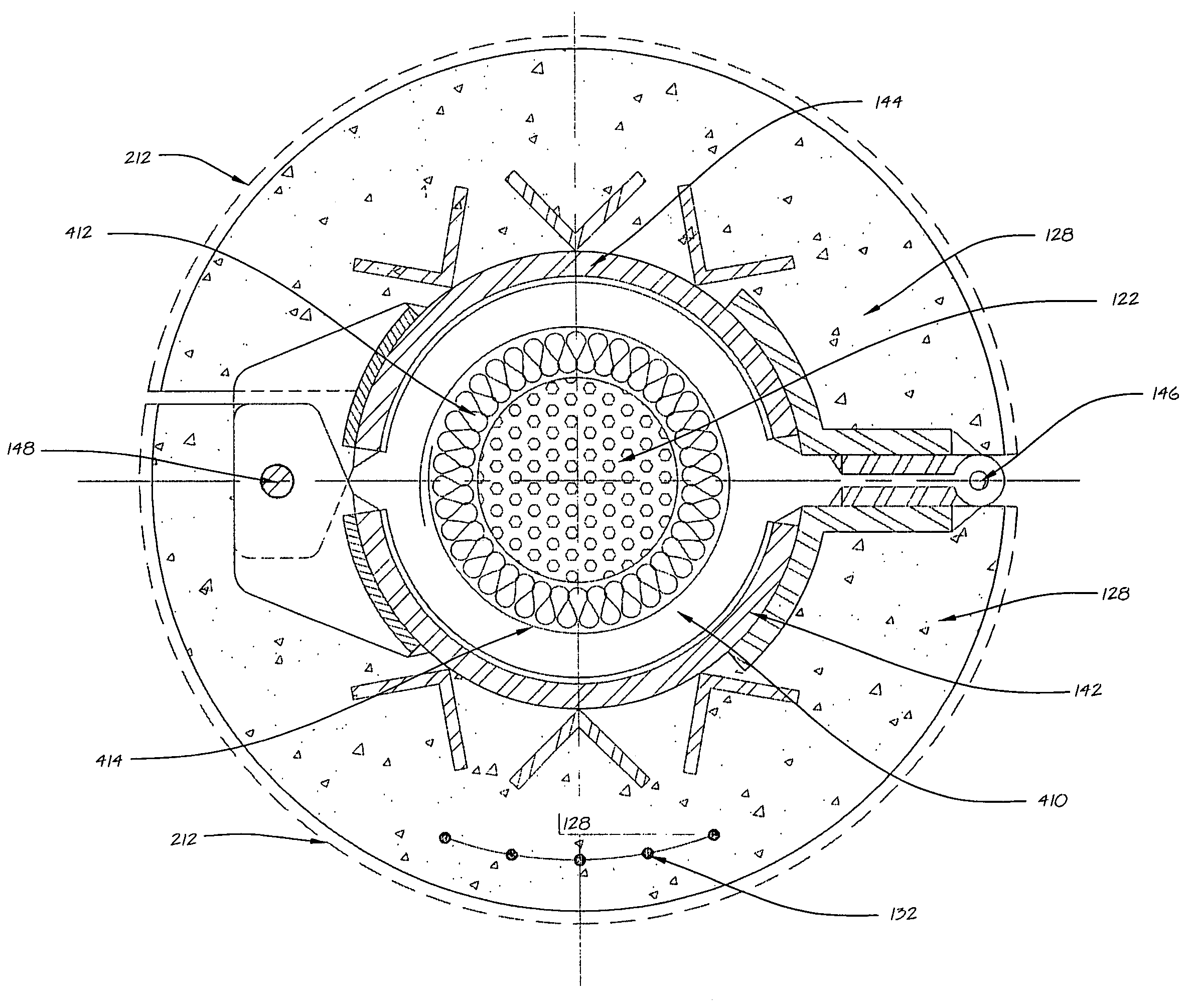

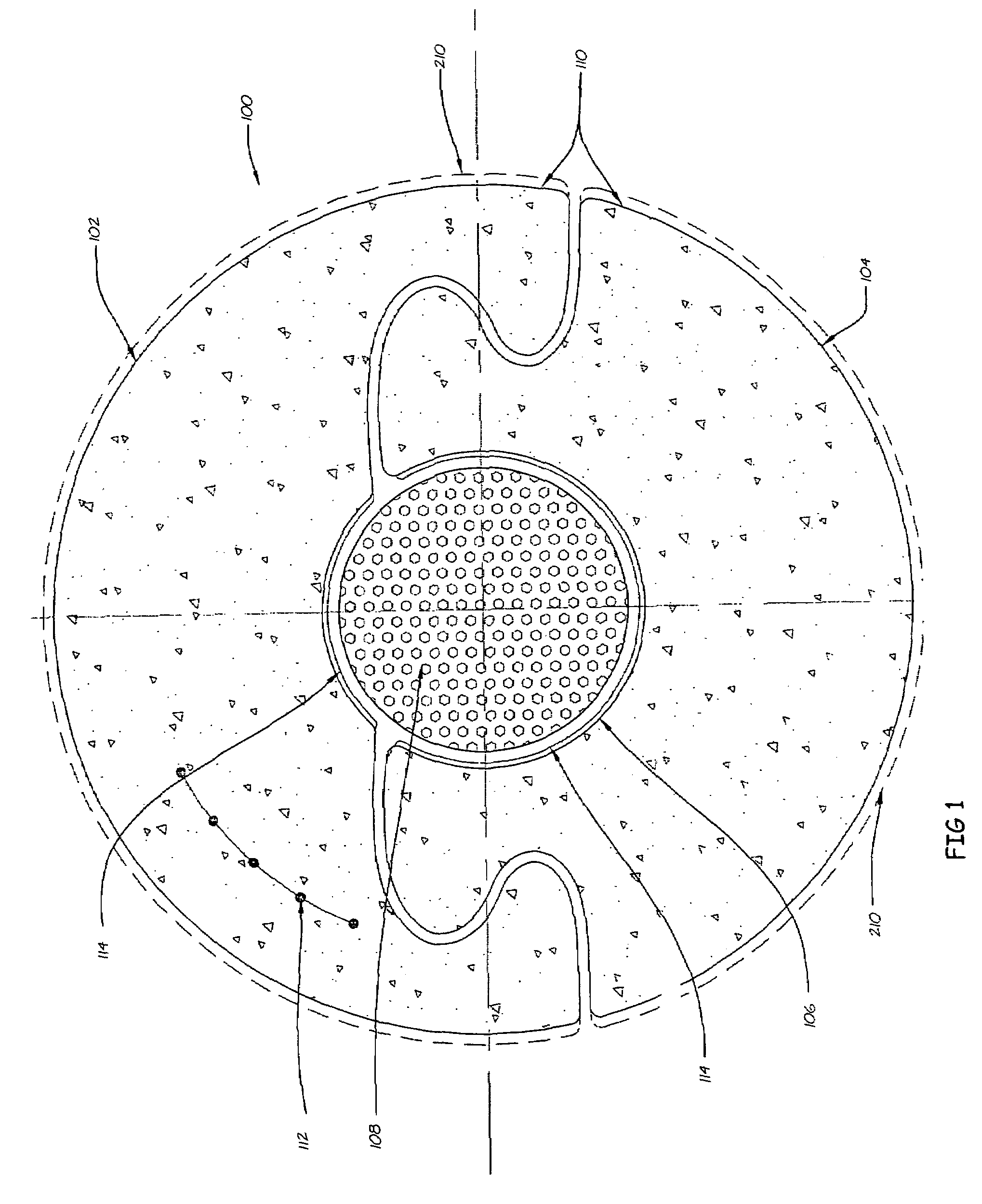

Barrier elements provide security from terrorist threats by ability to withstand both vehicle collisions and explosive blasts. Each barrier element is prefabricated to include a massive block of durable material, preferably of high strength concrete, with at least one tunnel extending at least partially between respective cavities in two opposite sides of the block. Each barrier element also includes at least one beam that is preferably made of steel and extends through one such tunnel. Multiple blocks are positionable slidably on top of the ground side-against-side with their beams coupled longitudinally to one another at least approximately end-to-end. Retainer means can be used to block coupling means from entry into the tunnels. Forces from a vehicle collision or an explosive blast can cause barrier elements to rotate relative to one-another when the couplings between beams hinge or bend as the durable material that interferes with the rotation breaks away.

Owner:KONTEK INDS

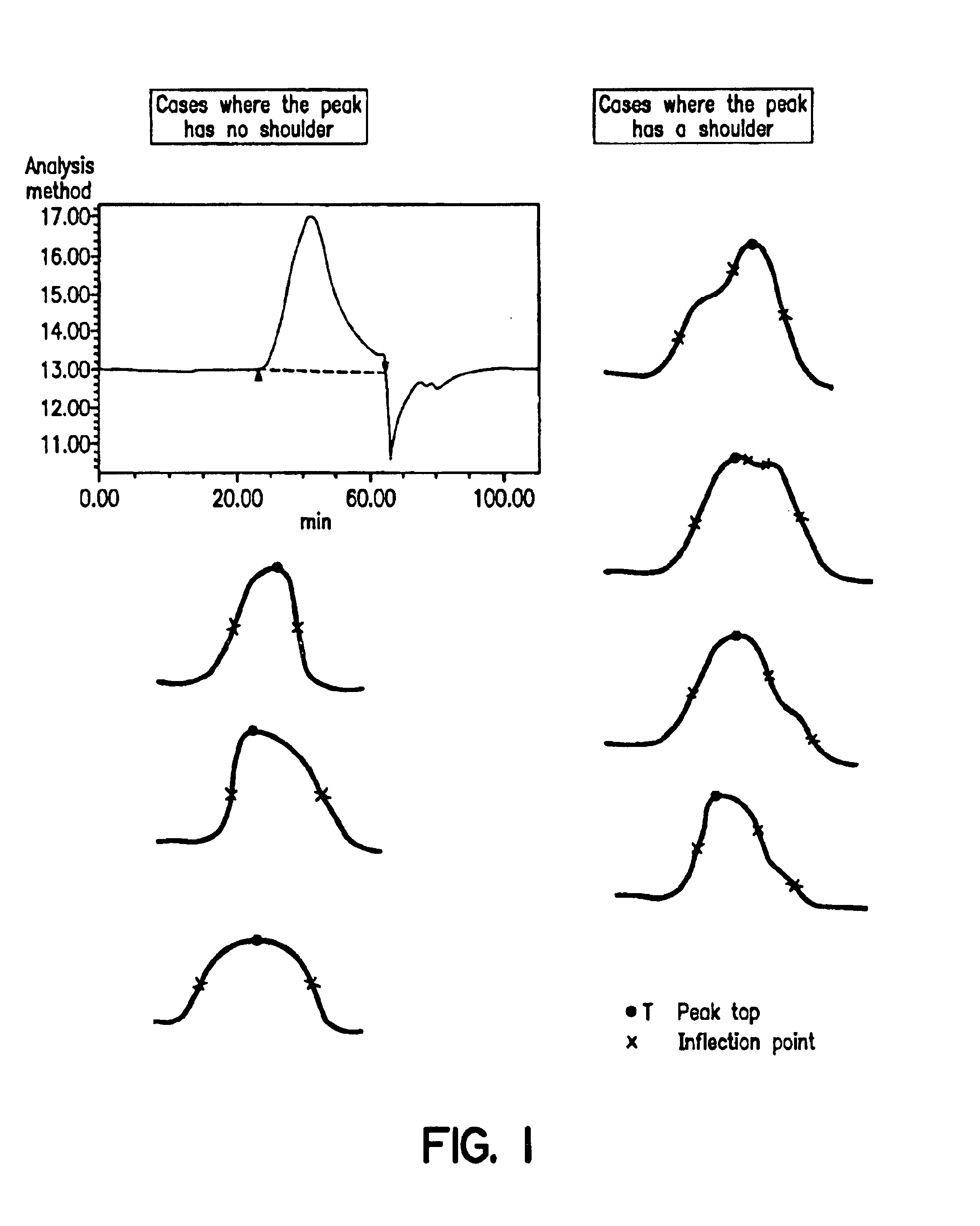

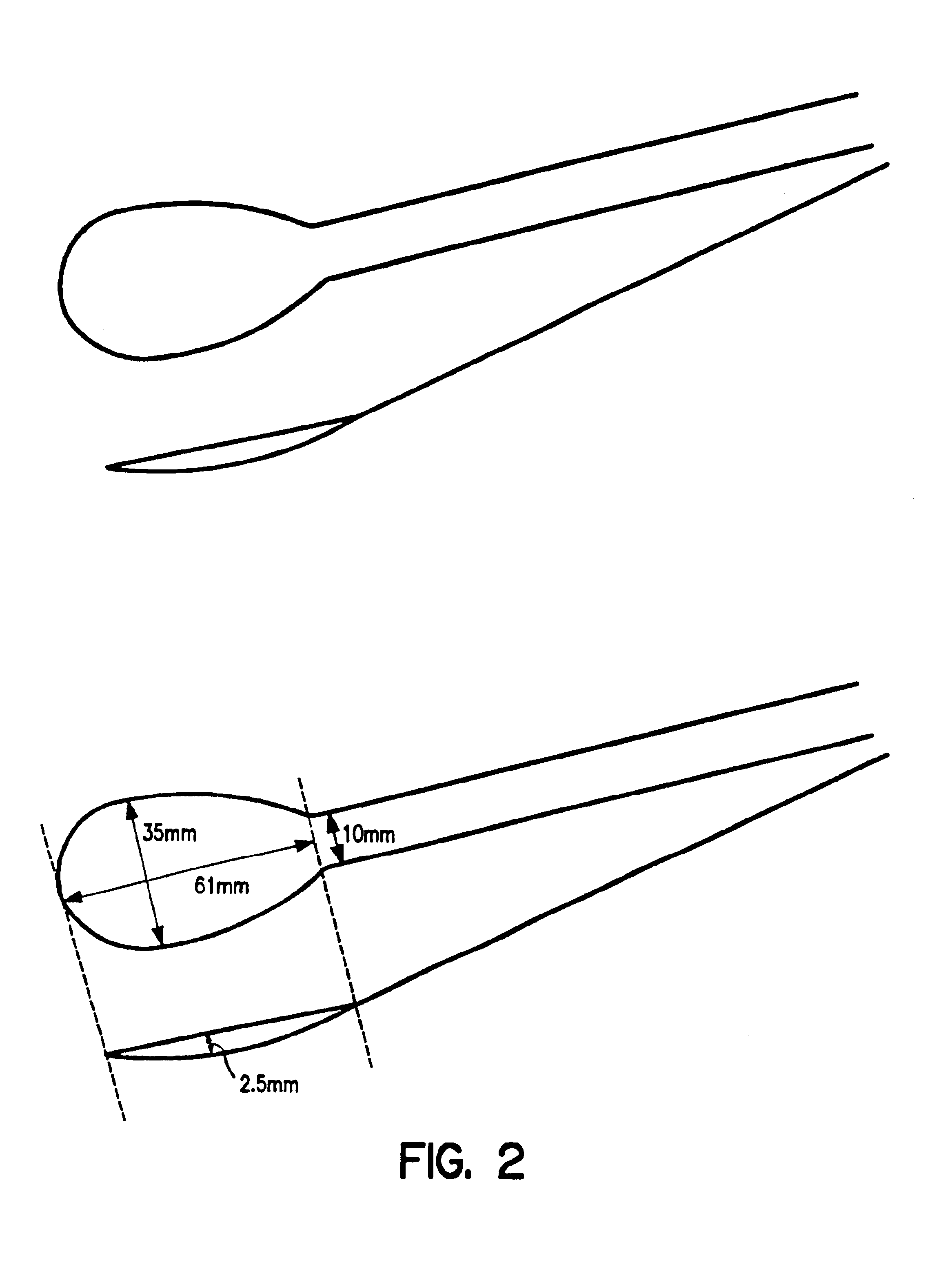

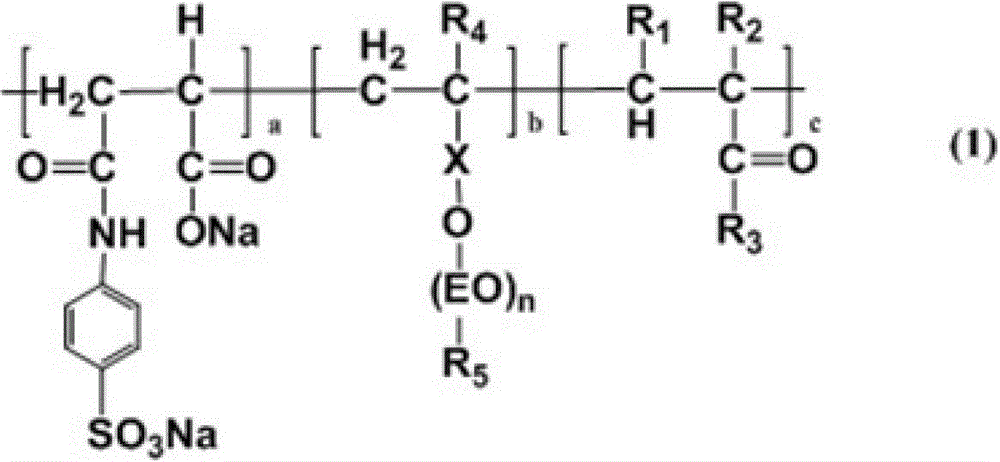

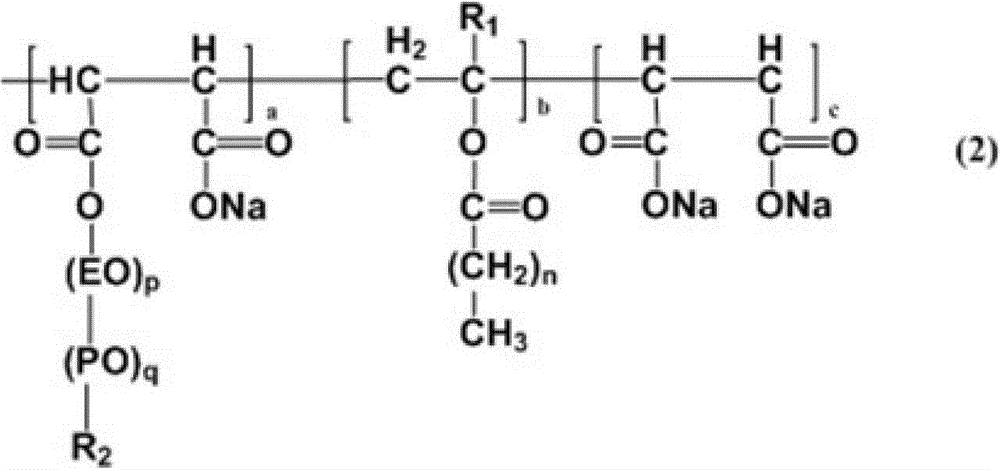

Polycarboxylic acid copolymer, production method and use thereof

InactiveUS6864337B2Improves water reducing capacityImprove workabilityHigh strength concreteUltimate tensile strength

It is an object of the present invention to provide a polycarboxylic acid copolymer which improves the water reducing capacity and workability of cement compositions and the like and making them easier to handle when the fluidity and water reducing capacity are at the same levels, a method of producing the copolymer, and a cement additive and a cement composition comprising the copolymer. The present invention is further to provide a polycarboxylic acid copolymer and a cement additive which are capable of improving the strength and durability of hardening products of cement compositions, hence can advantageously be used in ultrahigh strength concrete. The present invention is still further to provide a method of producing polycarboxylic acid copolymers having high water reducing capacity, reducing the viscosity of cement compositions and improving the workability in applying cement.The present invention is directed to a polycarboxylic acid copolymer which is obtained by copolymerization of monomer components comprising a polyalkyleneimine unsaturated monomer (A1) and an unsaturated carboxylic acid monomer (B).

Owner:NIPPON SHOKUBAI CO LTD

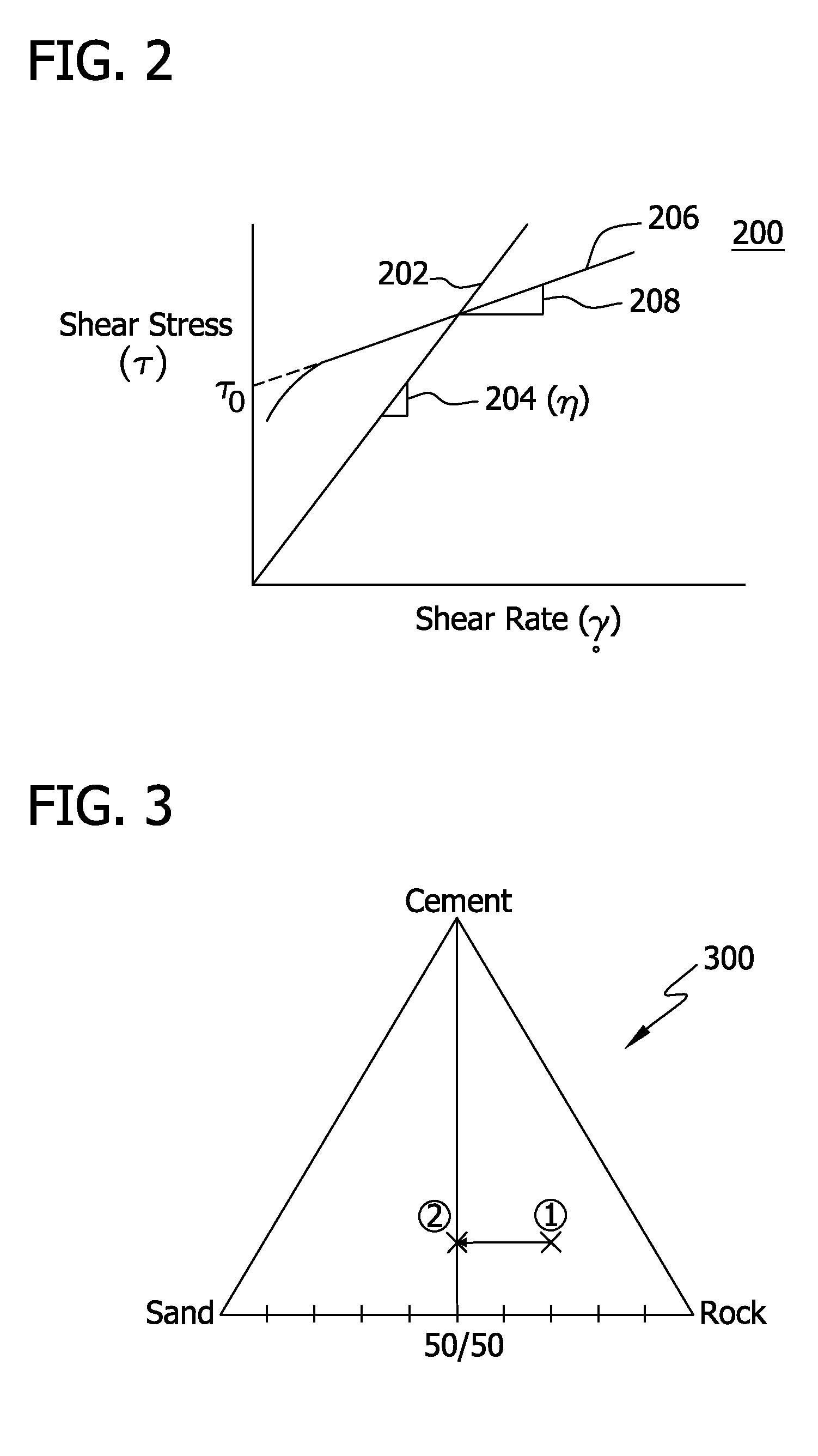

Highly workable concrete compositions having minimal bleeding and segregation

InactiveUS20090158960A1Accurate measurementAccurate predictorAntifouling/underwater paintsPaints with biocidesHigh strength concreteHigh intensity

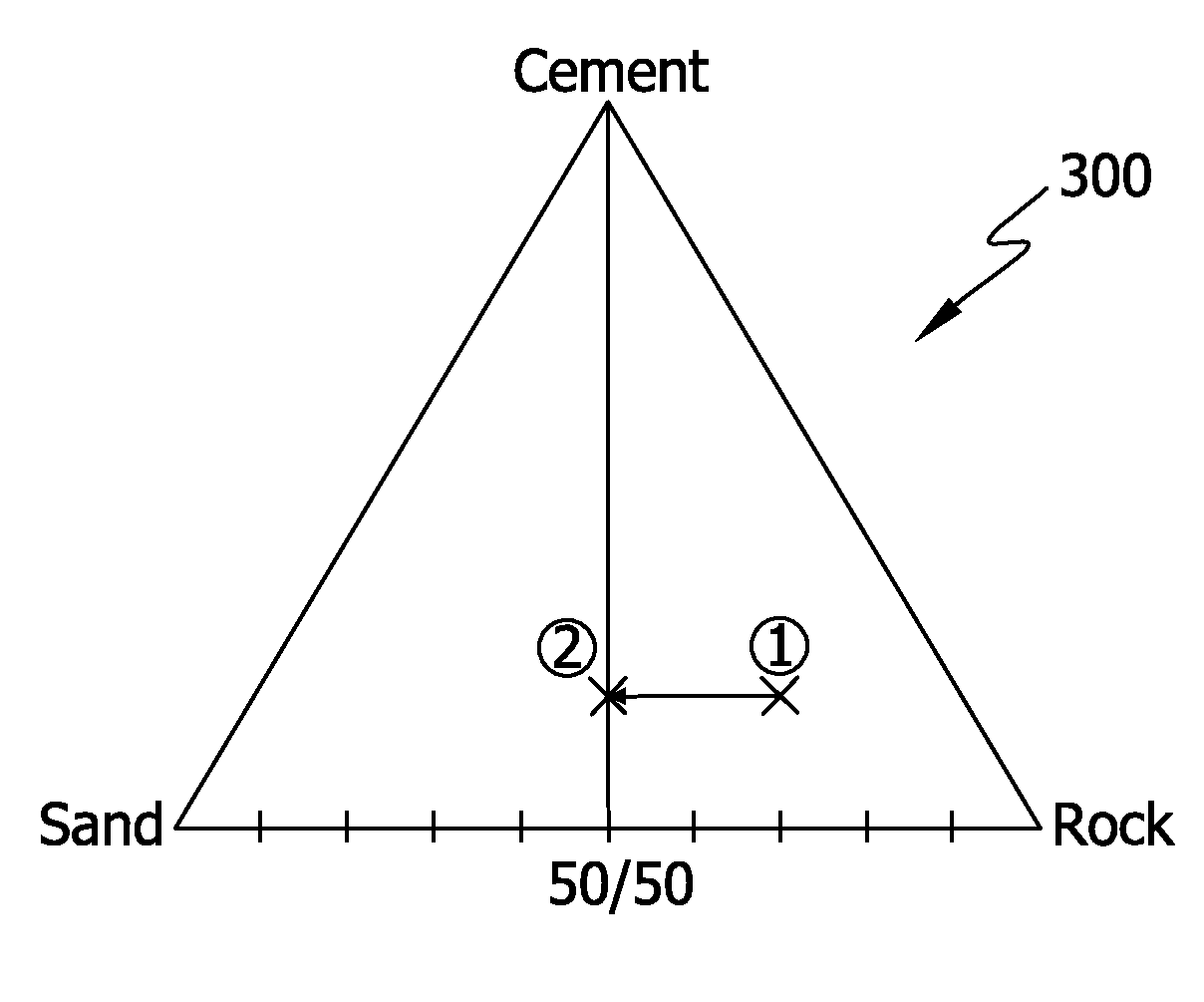

Concrete compositions have a fine-to-coarse aggregate ratio optimized for increased workability with minimal segregation and bleeding. The concrete compositions include at least water, cement, coarse aggregate, and fine aggregate and have a slump of at least 1 inch and a 28-day compressive strength of at least about 1500 psi. Workability is improved by minimizing the viscosity as a function of the aggregate content, while minimizing segregation and bleeding. To improve workability, the concrete compositions include between 45% and 65% fine aggregate and between 35% and 55% coarse aggregate as a function of total aggregate volume. For relatively low strength concrete (1500-4500 psi), the fine aggregate is 55-65% of the total aggregate volume. For medium strength concrete (4500-8000 psi), the fine aggregate is 50-60% of the total aggregate volume. For high strength concrete (>8000 psi), the fine aggregate is 45-55% of the total aggregate volume. Overall workability can be maintained or improved even if slump is decreased.

Owner:ICRETE LLC

Concrete compositions optimized for high workability

Concrete compositions have a fine-to-coarse aggregate ratio optimized for decreased viscosity and increased workability. The concrete compositions include at least water, cement, coarse aggregate, and fine aggregate and have a slump of at least 1 inch and a 28-day compressive strength of at least about 1500 psi. Workability is improved by minimizing the viscosity as a function of the aggregate content. To improve workability, the concrete compositions include between 45% and 65% fine aggregate and between 35% and 55% coarse aggregate as a function of total aggregate volume. For relatively low strength concrete (1500-4500 psi), the fine aggregate is 55-65% of the total aggregate volume. For medium strength concrete (4500-8000 psi), the fine aggregate is 50-60% of the total aggregate volume. For high strength concrete (>8000 psi), the fine aggregate is 45-55% of the total aggregate volume. Overall workability can be maintained or improved even if slump is decreased.

Owner:ICRETE LLC

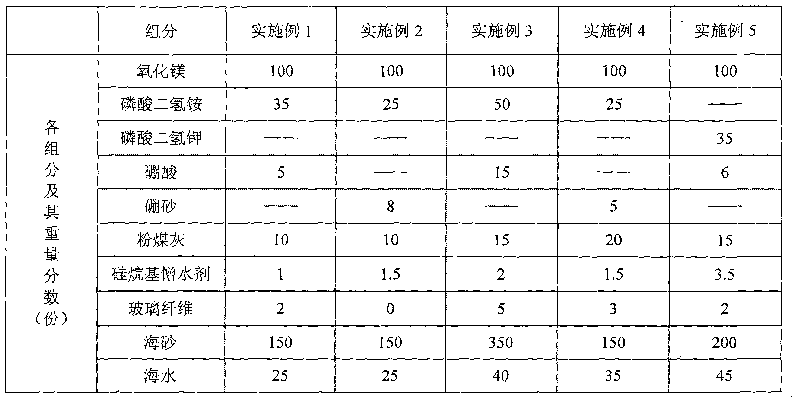

Quick-hardening high-early strength concrete-based composite material for maritime work

InactiveCN101708985ATake advantage ofReduce transport volumeSolid waste managementHigh strength concreteGlass fiber

The invention discloses a quick-hardening high-early strength concrete-based composite material for a maritime work, which mainly comprises the following components in parts by weight: 100 parts of magnesium oxide, 25-50 parts of phosphate, 5-15 parts of retarder, 0.5-3.5 parts of siloyl group moisture repellent, 10-20 parts of flyash, 0-5 parts of glass fibre, 150-350 parts of sea sands and 25-50 parts of seawater. The invention takes the sea sands without desalting treatment as aggregate and the seawater as mixing water, thereby fully utilizing island resources such as sea sands, seawater, and the like, greatly reducing traffic capacity, saving cost. In addition, the invention has the advantages of quick setting and hardening, high early strength, good seawater erosion capability, and the like, thereby being widely applied to quick repatching and building in projects such as island roads, landingstrips, docks, and the like.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

High-temperature-resistant super retarder with favorable dispersibility and preparation method thereof

InactiveCN103449749ASolve high temperature adaptabilityGood retarding effectHigh strength concreteRetention time

The invention relates to a high-temperature-resistant super retarder with favorable dispersibility and a preparation method thereof. The invention aims to provide a high-temperature-resistant super retarder with favorable dispersibility adaptable to high temperature in summer and a preparation method thereof. The high-temperature-resistant super retarder with favorable dispersibility comprises the following components in parts by weight: 300-450 parts of organophosphorous acid or organic phosphorus salt, 150-300 parts of dispersant and 15-25 parts of surfactant. The preparation method comprises the following steps: proportionally adding raw materials into a reaction kettle, uniformly mixing and stirring, adding 300-400 parts by weight of water, and dissolving by stirring to obtain the product. The high-temperature-resistant super retarder provided by the invention solves the problem of high temperature adaptability of the retarder, is convenient for construction in summer, can adapt to multiple water reducers, is applicable to C40 above high-strength concrete, can prolong the retention time of concrete flowability by more than 0.5 hour, is convenient for concrete transportation, and has the advantages of simple production technique and low cost.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

Polycarboxylic water reducer with viscosity reducing and slump retaining functions, and preparation method thereof

InactiveCN109021181AReduce the hydrophilic-lipophilic balanceReduce generationHigh strength concreteWork performance

The invention discloses a polycarboxylic water reducer with viscosity reducing and slump retaining functions, and a preparation method thereof, and belongs to the technical field of building materials. The polycarboxylic water reducer is prepared through the following steps: free radical polymerization of an unsaturated polyether monomer I, an unsaturated block modified polyether monomer II, an unsaturated carboxylic acid monomer, an unsaturated carboxylic acid alkyl ester, an unsaturated phosphate ester monomer, a chain transfer agent, an oxidant, a reducing agent and deionized water in an aqueous solution at 15-30 DEG C, addition of an alkali solution to adjust the pH value, and water supplementation. The water reducer can meet the requirements of the water-reducing and slump-retaining performances of high-strength concrete, and also can greatly reduce the viscosity of the concrete and significantly improve the working performances of the high-strength concrete, so the problems of fast slump loss and excessive viscosity of existing polycarboxylic water reducers are solved. The preparation method can be carried out at normal temperature without a heat source, so the preparation method has the advantages of simple production device, reasonable process, simplicity in operation, high production efficiency, and suitableness for industrial production and promotion.

Owner:SICHUAN TONGZHOU CHEM TECH

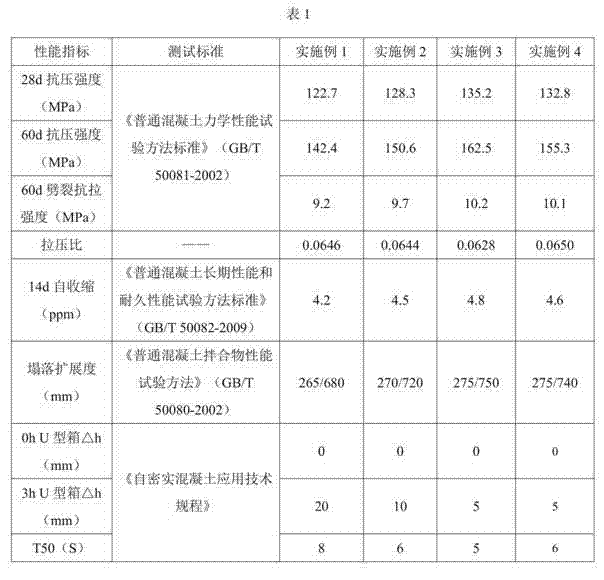

Ultrahigh-strength concrete and preparation method thereof

The invention discloses ultrahigh-strength concrete which comprises the following components in parts by weight: 300-350 parts of cement, 270-315 parts of composite mineral admixture, 30-35 parts of composite expanding agent, 96-112 parts of water, 680-720 parts of river sand, 1012-1080 parts of gravel, 13.2-14.0 parts of polycarboxylic acid high-efficiency water reducing agent, 4.4-4.7 parts of plastic retaining agent and 0.18-0.21 part of defoaming agent, wherein the composite mineral admixture is prepared from 42-49 parts of ore powder, 150-175 parts of fly ash, 30-35 parts of silica fume, 18-21 parts of zeolite powder and 30-35 parts of wollastonite powder. The invention is characterized in that the 60d concrete compression strength is 140-160 MPa, the 60d splitting tensile strength is 9.2-10.2 MPa, extruded concrete can achieve self-compaction effect within 3 hours, and the 14d self-shrinkage value is less than 0.05%.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

Concrete mixture for PHC (Prestressed High-strength Concrete) pipe pile and PHC pipe pile prepared therefrom

ActiveCN103145390ALow maintenance energy consumptionImprove automationHigh strength concreteCombustion

The invention discloses a concrete mixture for a PHC (Prestressed High-strength Concrete) pipe pile. The concrete mixture comprises the following raw materials: 400-520kg / m<3> of cementing material, 120-145kg / m<3> of water, 675-870kg / m<3> of sand, 1050-1110kg / m<3> of gravel and a polycarboxylate water reducing agent, wherein the usage amount of the polycarboxylate water reducing agent by mass is 1.0-1.5% the mass of the cementing material, and the cementing material is prepared from the following ingredients in percentage by mass: 80-95% of cement and 5-20% of mineral admixture. According to the concrete mixture, after centrifugal molding, the concrete mixture can be over 80MPa only through normal-pressure steam curing and short-time natural curing and can be over 85 MPa through 28-day natural curing, a high-pressure steam curing process is not needed, the production cycle is shortened, and approximately 70% of the consumption of standard combustion coal for the production of every one meter of the pipe pile can be reduced.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Concrete reinforced column for steel framework of hybrid FRP (Fiber Reinforced Plastic) pipe

ActiveCN102635202ADelay or inhibit oblique fissureDelay or weaken bond failureStrutsPillarsHigh strength concreteFiber

The invention provides a concrete reinforced column for a steel framework of a hybrid FRP (Fiber Reinforced Plastic) pipe and belongs to the field of buildings. The concrete reinforced column comprises a steel framework, a hybrid FRP pipe and concrete filled between the steel framework and the hybrid FRP pipe. Compared with the traditional steel pipe concrete reinforced column and a steel pipe high-strength concrete reinforced column, the concrete reinforced column can be used for improving the bearing force, the transformation capacity and the anti-vibration property. The concrete reinforced column provided by the invention is applicable to the technical field of structures of concrete reinforced columns, so that the concrete reinforced column not only can be used for a new construction structure but also can be used for reinforcing and hoisting engineering of the steel framework concrete reinforced column.

Owner:徐州新南湖科技有限公司

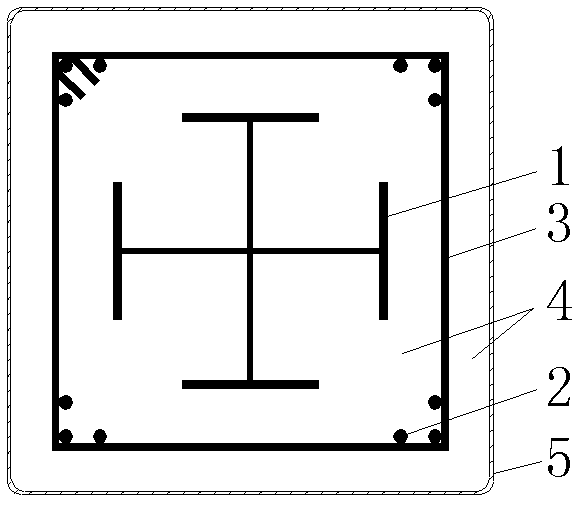

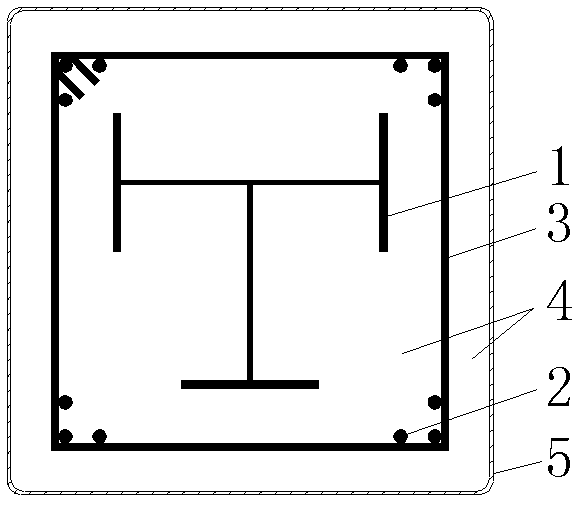

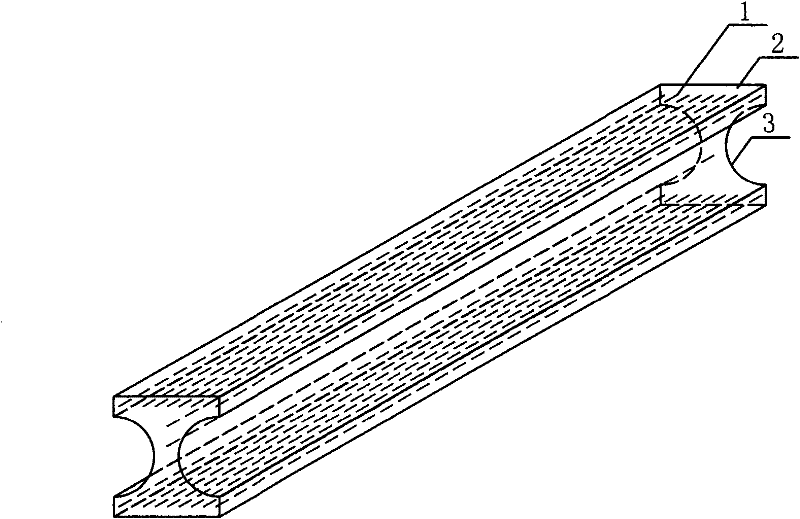

A kind of open high-strength concrete prefabricated pile and its pile form, centrifugal manufacturing method

InactiveCN102261065AImprove bearing capacityReduce the cross-sectional areaMouldsBulkheads/pilesHigh strength concreteCentrifugation

The invention relates to an open high-strength concrete prefabricated pile in the field of pile foundation engineering, a pile form thereof, and a centrifugal manufacturing method. 1) The outer high-strength concrete prefabricated pile body (2), and on the side of the high-strength concrete prefabricated pile body (2), there is a concave surface (3) with a centrifugally formed cross-section and an arc-shaped cross-section, depending on the shape of the cross-section. , proposed pile types such as H-type piles, groove piles, corner piles, open cylindrical piles, star piles, etc., and then put forward the pile mold and forming method of one-time centrifugal forming multi-section piles, and proposed open high-strength concrete precast piles and cement The structural composition and construction method of the PMW earth-retaining and water-stop pile combined with soil piles, the open high-strength concrete prefabricated pile of the present invention has high material strength, good flexural performance, small pile driving effect, and can greatly save the cost of pile foundation engineering. , the environmental protection benefits are outstanding.

Owner:张继红

High strength concrete and preparation method thereof

InactiveCN105367026AHigh strengthSolution to short lifeSolid waste managementHigh strength concreteAggregate (composite)

The invention discloses high strength concrete and its preparation method, and relates to the technical field of building materials. 1 m<3> of the high strength concrete comprises the following ingredients: 200-300 kg of ordinary Portland cement, 40-50 kg of mineral powder, 15-30 kg of rubber particles, 500-800 kg of fine aggregate, 600-900 kg of coarse aggregate, 20-60 kg of a concrete composite additive, 50-100 kg of polypropylene fiber, 100-200 kg of water, 45-90 kg of phosphorous slag powder, 2-3 kg of a corrosion inhibitor, 5-10 kg of a water reducing agent, and 10-20 kg of a reinforcing agent. According to the prepared concrete product, compressive strength is remarkably raised, cracks are minimized, and life of concrete structures is prolonged. In addition, the preparation method is simple, and production efficiency is high.

Owner:张进

Decorative layer for brown high-strength concrete decorative hanging plate

InactiveCN106013683AIncrease slumpClosely connectedCovering/liningsCeramic shaping apparatusHigh strength concreteIron oxide

The invention relates to external wall decoration of a building and specifically relates to a decorative layer for a brown high-strength concrete decorative hanging plate. According to the scheme, the decorative layer is prepared from the following raw materials in parts by weight: 400-800 parts of cement, 710-950 parts of 10-40-mesh sand, 160-240 parts of 70-140-mesh sand, 110-260 parts of 325-mesh sand, 45-110 parts of a water reducer, 120-160 parts of water and 0-4 parts of pigment iron oxide brown. On the basis of the prior part, the matching form of cement base stock and multi-level specific sand is adopted, and the decorative layer can be tightly connected with the structural layer of an external wall hanging plate, so that the connecting strength can be greatly increased and the stripping can be avoided.

Owner:CHINA MINGSHENG DRAWIN TECH INVESTMENT CO LTD

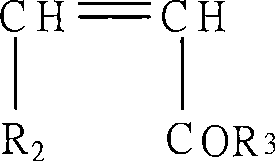

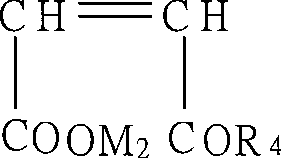

Allyl polyglycol ether type polycarboxylic acid series dehydragent and preparation method thereof

InactiveCN101386490AMolecular structure changeableImprove performanceHigh strength concretePolyethylene glycol

The invention discloses an allyloxypolyethyleneglycol type polycarboxylate water reducing agent and a method for preparing the same, wherein the water reducing agent is a polymer obtained through polymerization; the polymer comprises the following components in weight percentage: 30 to 50 percent of unsaturated polyoxyalkylene group ether monomer(a), 5 to 20 percent of unsaturated monocarboxylic acid and derivative monomer(b) of unsaturated monocarboxylic acid, 1 to 20 percent of unsaturated dicarboxylic acid(c) and 40 to 60 percent of water; the components undergo polymerization in a water solution at a temperature of between 45 and 70 DEG C in the presence of a redox initiator to form the water reducing agent. The polycarboxylate water reducing agent has the advantages of high conversion rate of reaction product, good cohesiveness and super high dispersibility and excellent performance when applied to high strength concrete.

Owner:上饶市天佳新型材料有限公司

High-performance reinforced mortar suitable for thick-layer spraying and preparation method thereof

InactiveCN102718447AMeet reinforcement requirementsEnhanced pumpabilityHigh strength concreteCellulose

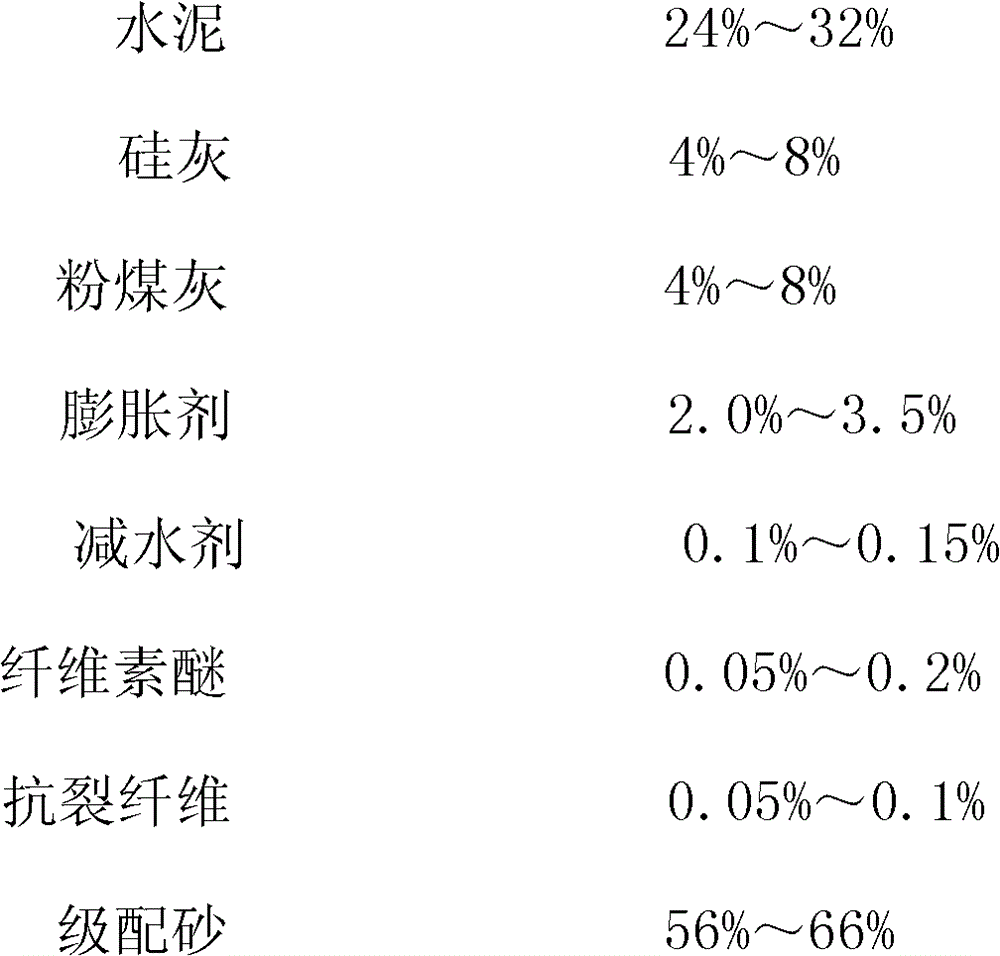

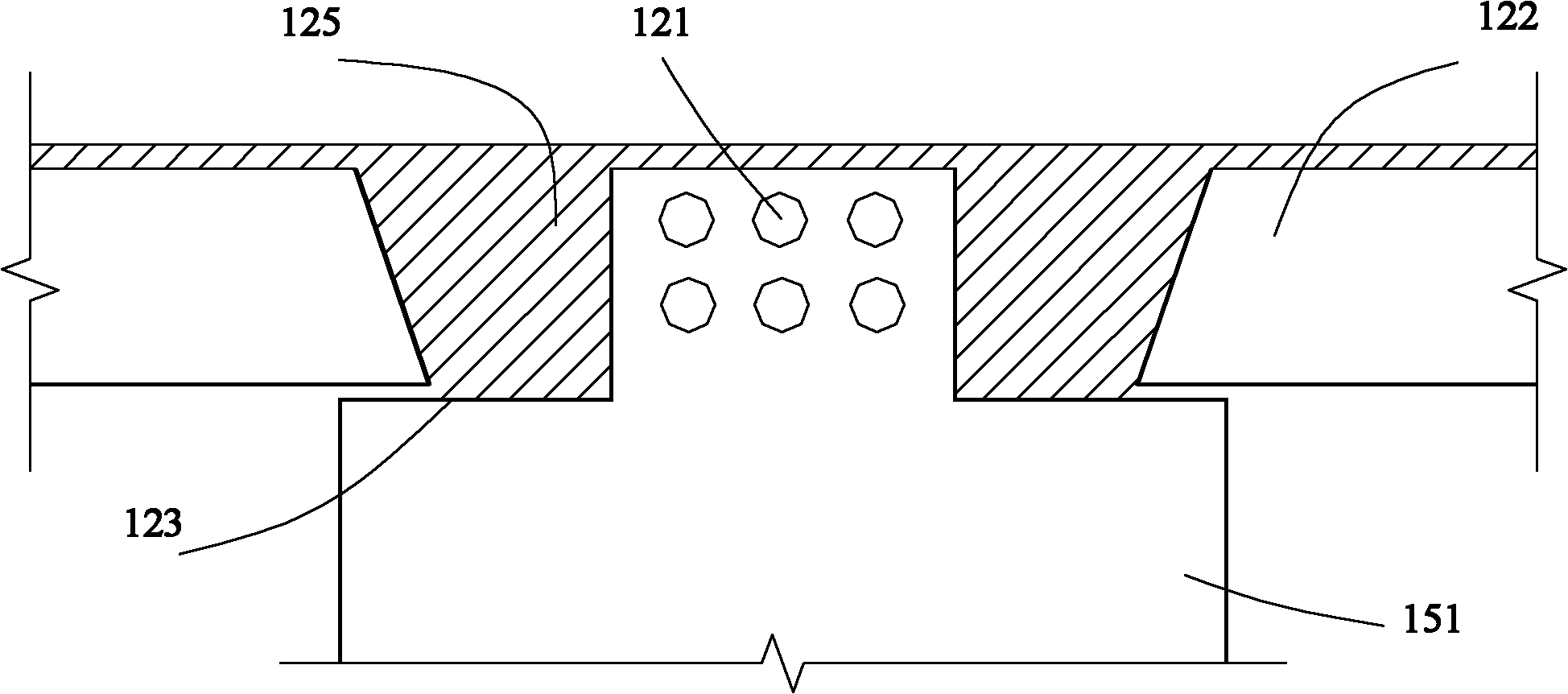

The invention discloses a high-performance reinforced mortar suitable for thick-layer spraying and a preparation method thereof. The high-performance reinforced mortar is mainly prepared from ordinary portland cement, silica fume, coal ash, an expanding agent, a water reducing agent, cellulose ether, anti-crack fibers, and graded sand in a certain mass percent, wherein the mass percent of each composition is as follows: the cement 24%-32%, the silica fume 4%-8%, the coal ash 4%-8%, the expanding agent 2.0%-3.5%, the water reducing agent 0.1%-0.15%, the cellulose ether 0.05%-0.2%, the anti-crack fibers 0.05%-0.1%, and the graded sand 56%-66%. The high-performance reinforced mortar of the invention has strength of M60-M80, and can be used to meet reinforcing requirements of high strength concrete of strength grade C60. The high-performance reinforced mortar has good pumping performance, and is suitable for mechanized spraying construction. Moreover, the high-performance reinforced mortar has excellent substituted performance and a single spraying construction thickness of 40mm, and can be used to meet construction requirements of large-size members and thick-layer reinforcement.

Owner:陈明中

Shielding for structural support elements

A shield for shielding a structural member from an explosive blast or accidental or malicious destruction is provided. The shield includes a plurality of shield members which include cast ultra high strength concrete, wherein the shield members are capable of being assembled to enclose at least a portion of the structural member to provide protection to the enclosed portion from, for example, an explosive blast. In one embodiment, the shield members include a chassis, at least one ballistic liner disposed on the energy absorbing layer, and a concrete-integrating structure.

Owner:HALLISSY GERALD +1

Bridge erection method

InactiveCN102021889AReduce the overall heightLow costBridge structural detailsBridge erection/assemblyHigh strength concretePre stress

The invention discloses a bridge erection method, which is a prefabricated pier-top beam method. The bridge erection method comprises the following steps of: casting at least two pier columns at intervals; prefabricating pier-top beams, and arranging transverse prestressing tendons in the prefabricated pier-top beams; after the setting of concrete, tensioning the transverse prestressing tendons; arranging supports at the tops of piers, hoisting the pier-top beams, arranging the pier-top beams at the tops of the piers, and temporarily fixedly connecting the pier-top beams and the pier columns by using steel plates and reinforcing steel bars; erecting prefabricated longitudinal deck beams on the pier-top beams; casting in-situ concrete joint surfaces on the end faces of the longitudinal deck beams and the lateral surfaces of the pier-top beams, and casting in-situ early-strength and high-strength concrete in the joint surfaces; after the setting of the concrete in the joint surfaces, tensioning longitudinal prestressing tendons of the longitudinal beams; and removing the steel plates and the reinforcing steel bars. The method greatly reduces the height of a structural building and reduces the deck elevation; and a freely supported structure is changed into a continuous structure by the cast-in-situ concrete so as to improve the integrity of a bridge, prolong the service life of the bridge, solve the problem of stress in construction stages and reduce the cost of engineering construction.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

Apparatus for incinerating rice husk and producing SiO2 rice husk ash with nano structure therefor

InactiveCN1559897ASolve the problem of limited stack volumeEfficient take awaySilicaSolid waste disposalHigh strength concreteNano structuring

The invention is a rice hull burning device and the nano structural SiO2 rice hull ashes produced by it, and the device includes a burning container, where the bottom board is distributed with many small hole, the inside of the container is distributed with heat exchange water pipes, it regulates the distribution density of these water pipes to control the burning temperature under 600 deg.C in the rice hulls, thus able to ensure the produced rice hull ashes are nano structural rice hull ashes, using the produced heat energy in burning course, and simultaneously solving the problem of limitation to the bulk of a rice hull pile; the produced nano structural SiO2 rice hull ashes contain many about 50 nm-sized SiO2 particles loosely bound together and many holes, where the content of SiO2 exceeds 90%, and has superhigh activity of volcanic ash and strong reinforcement action on ordinary concrete and high-strength concrete, and when the quantity of replacing the cement is 5-20%, can heighten the pressive strength of high-strength concrete by above 10MPa.

Owner:JINAN UNIVERSITY

Heat-preservation precast wall body and assembled house

InactiveCN105908859ANo thermal bridgingImprove insulation effectWallsHeat proofingHigh strength concreteSteel bar

The invention relates to a heat-preservation precast wall body and an assembled house, and belongs to the technical field of walls of fixed buildings. The heat-preservation precast wall body is a wall body which is built in advance by building blocks from bottom to top before conventional wall building construction, each building block is provided with cavities and small column holes, which penetrate through the corresponding building block body in the height direction, and the cavities and the small column holes in each layer of building blocks separately penetrate through the cavities and the small column holes in the adjacent layer of building blocks which are built up and down; a stand column steel pipe or a stand column reinforcing bar is mounted in each cavity, or a heat-preservation sheet is clamped in each cavity, concrete is stuffed in each cavity in which the stand column steel pipe or the stand column reinforcing bar is mounted so that a core column is formed; multi-layer building blocks which are built up and down are mutually fixed into a whole in a manner that high strength concrete is poured in the small column holes which are partially penetrated; one or more reinforcing bars which are used for hoisting and assembling the wall body are arranged in the wall body, and are mounted, inserted and fixed in the high strength concrete in the small column holes. The heat-preservation precast wall body and the assembled house are safe and firm in structure, and besides, have the functions of heat preservation and noise elimination.

Owner:SUZHOU SHIHAO BUILDING MATERIAL NEW TECH ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com