Cement-based ultra-high strength contraction-free grouting concrete

A non-shrinkage, grouting material technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems that cement-based grouting materials cannot meet the requirements, materials do not have fluidity, and do not have on-site application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Select 100kg of aluminate cement, 5kg of calcium oxide expansion agent, 50kg of 1-3mm quartz sand, 0.9kg of polycarboxylate superplasticizer, 0.3kg of polyether modified silicon, 0.1kg of fumed silica, ordinary steel fiber (diameter 0.5 mm, length 6mm) 8kg, tartaric acid 0.5kg, hydroxyethyl methyl cellulose ether 0.1kg. Mix the above-mentioned various raw materials evenly to obtain a cement-based ultra-high-strength non-shrinkage grouting material with high fluidity.

Embodiment 2

[0022] Select 100kg of Portland cement, 10kg of ettringite expansion agent, 100kg of 1-3mm quartz sand, 0.5kg of melamine water reducer, 1kg of dimethyl silicone oil defoamer, 0.3kg of modified bentonite, indented steel fiber (diameter 0.8 mm, length 9mm) 30kg, sodium gluconate 0.02kg, low viscosity methyl cellulose ether 0.15kg. Mix the above-mentioned various raw materials evenly to obtain a cement-based super high-strength non-shrinkage grouting material with large expansion.

Embodiment 3

[0024] Select 20kg of aluminate cement, 80kg of Portland cement, 6kg of ettringite expansion agent, 80kg of 0.5-3mm quartz sand, 1.0kg of polycarboxylate superplasticizer, 0.4kg of polyether modified silicon, and 0.2kg of modified bentonite. Ordinary steel fiber (diameter 0.2mm, length 5mm) 10kg, tartaric acid 1kg, low viscosity methyl cellulose ether 0.3kg. By mixing the above-mentioned various raw materials evenly, a cement-based ultra-high-strength non-shrinkage grouting material with moderate fluidity, moderate expansion and the highest compressive strength can be obtained.

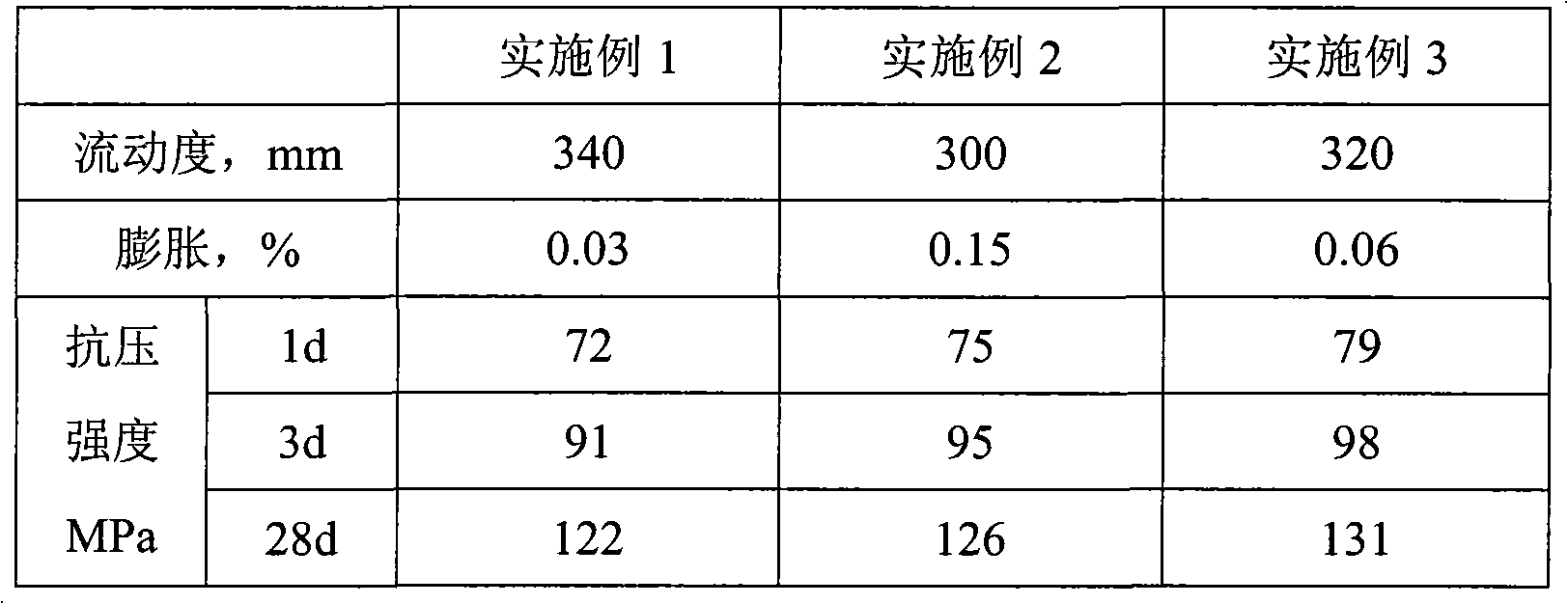

[0025] The various index performances of embodiment 1-3 are as follows

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com