Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

14019results about "Floors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

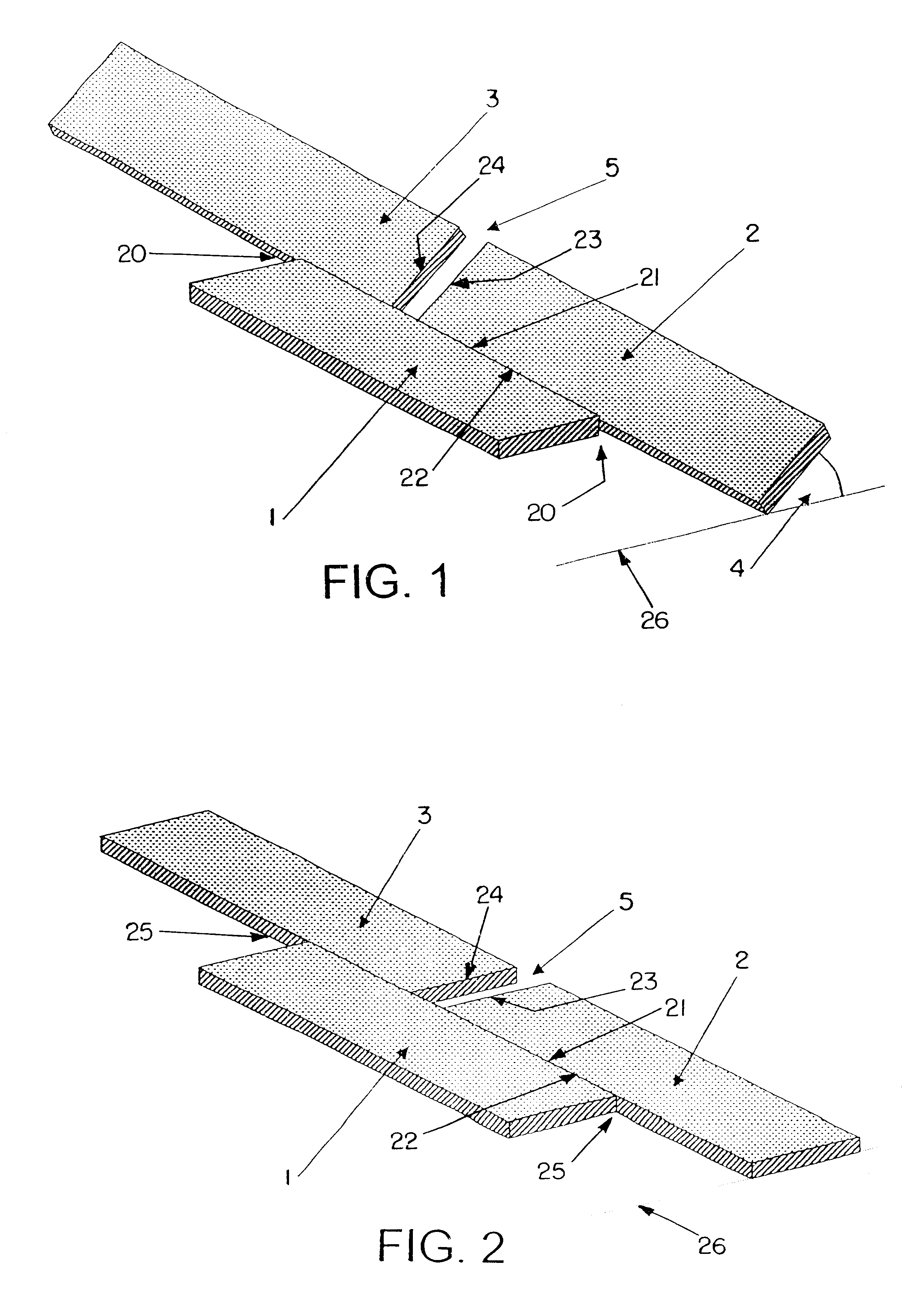

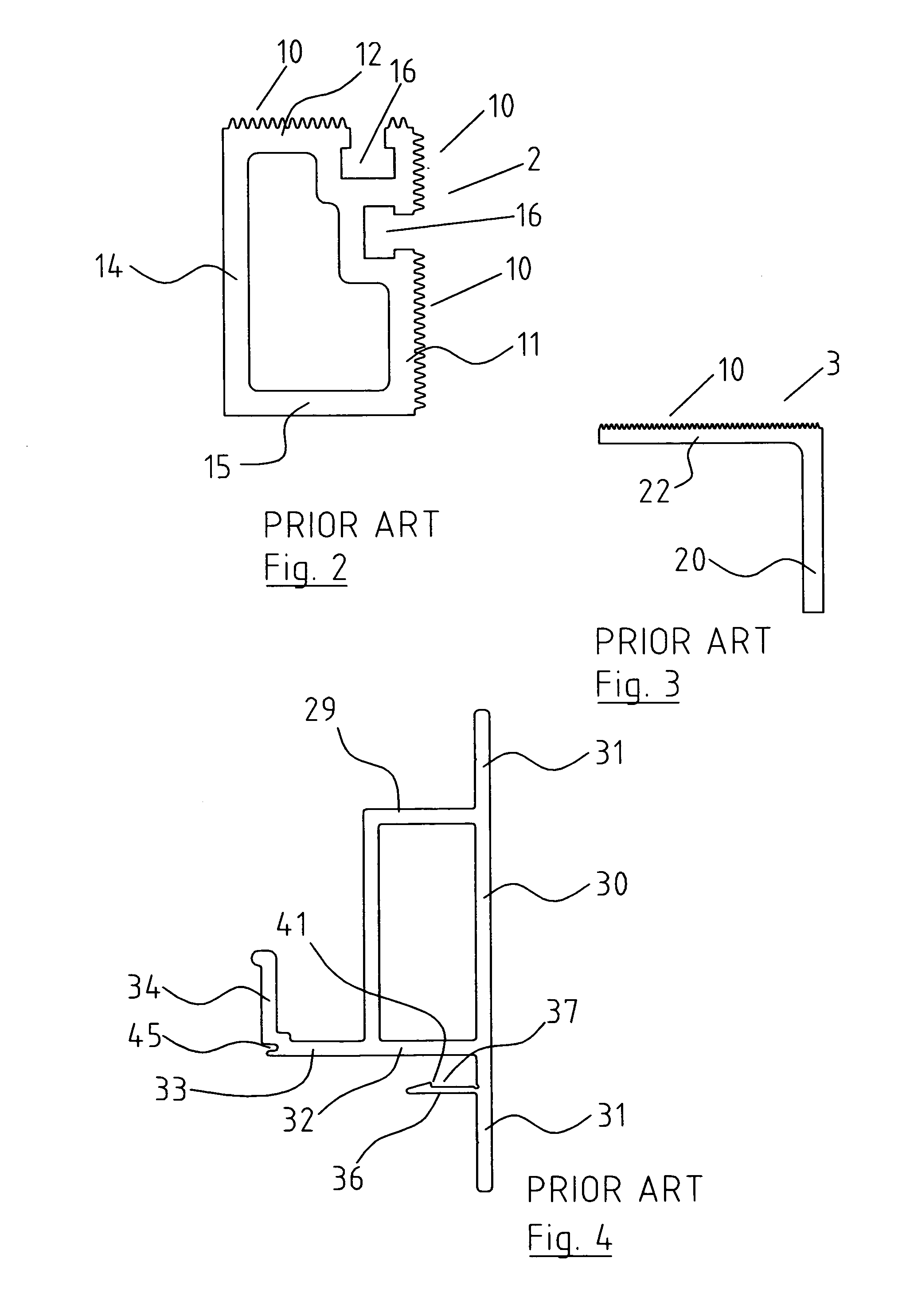

Joint for panels

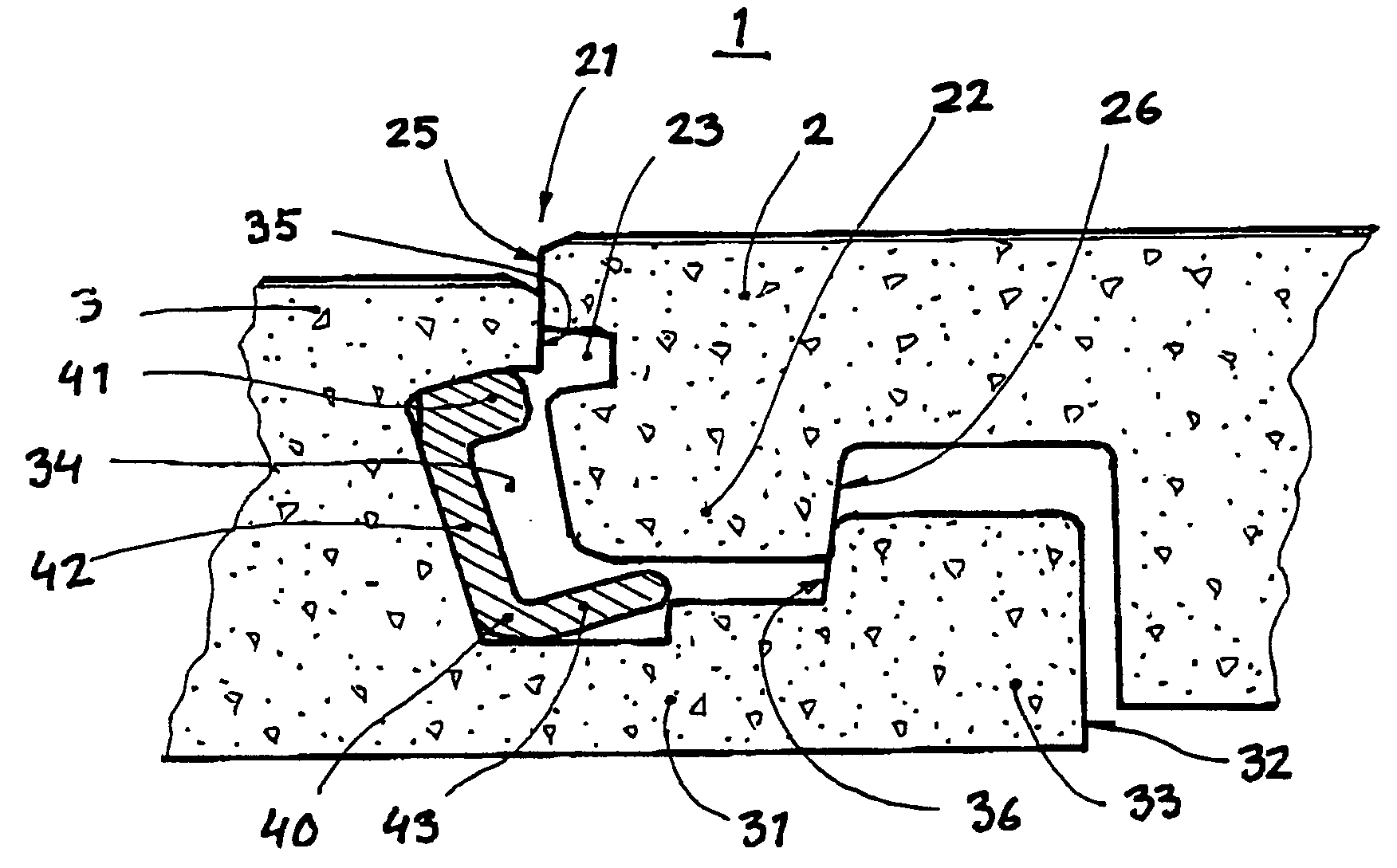

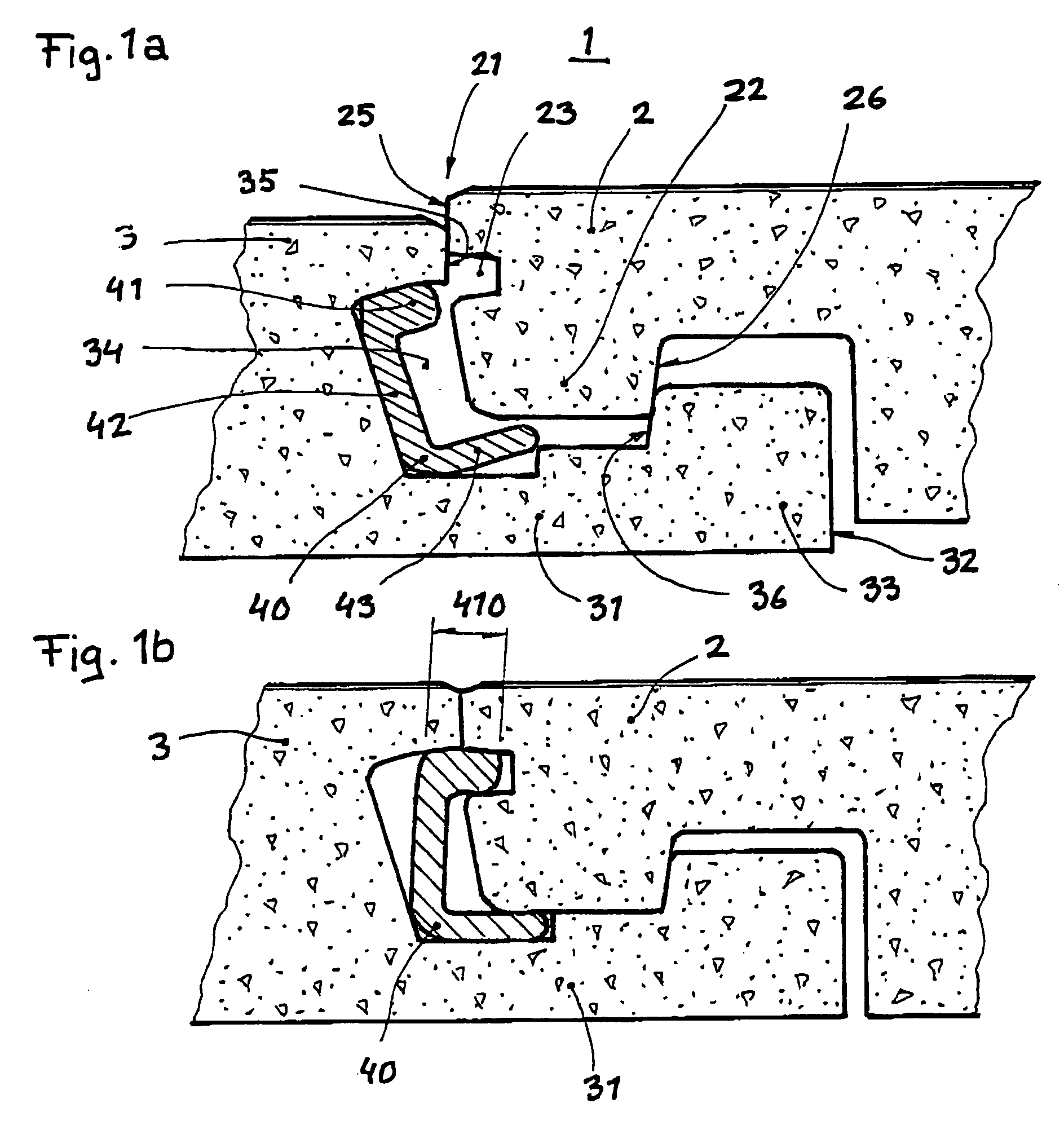

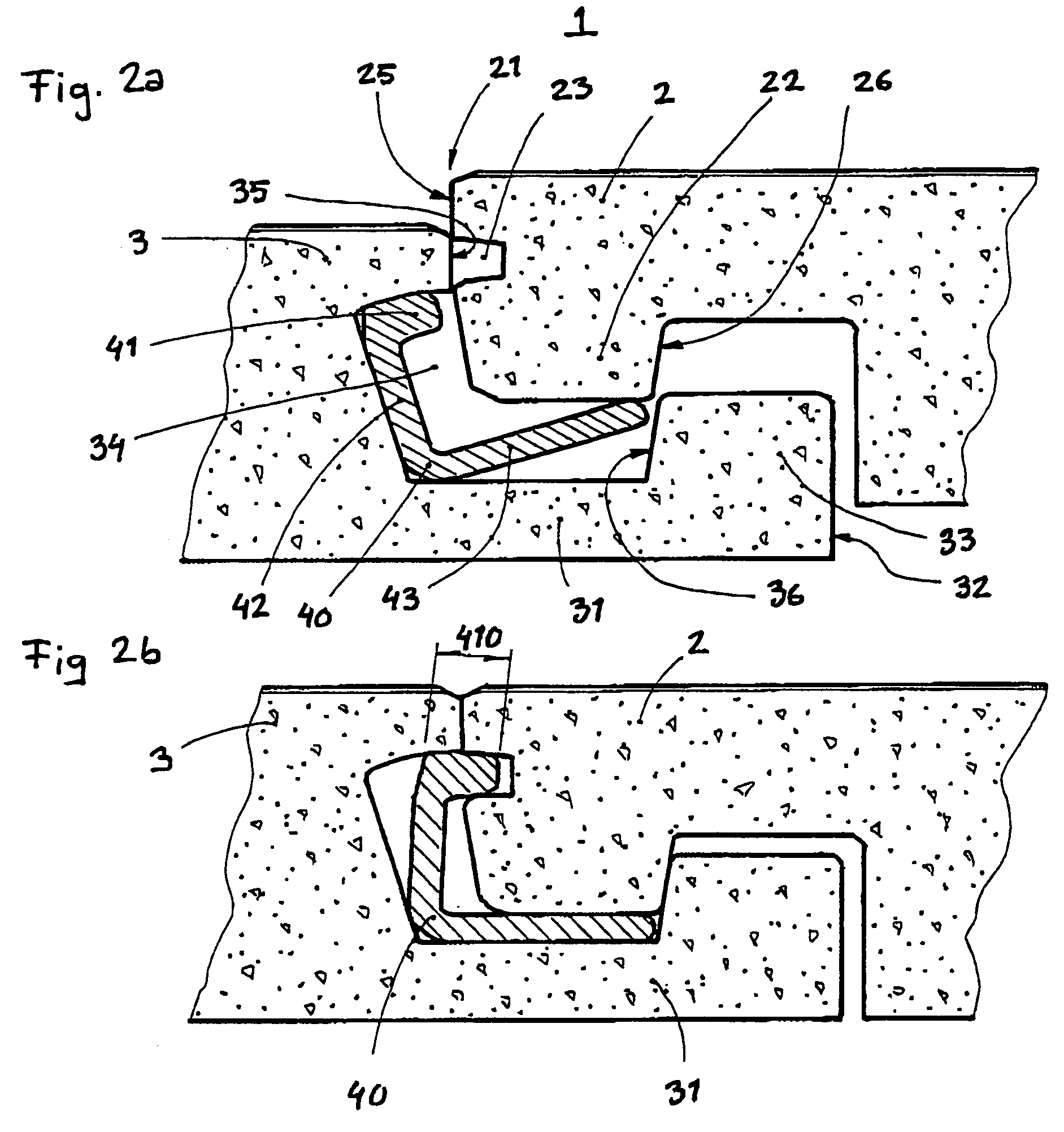

A joint (1) having a first edge (2) and a second edge (3), the first edge (2) being provided with a distal edge (21) and a downwards protruding heel (22) The distal edge (21) is further provided with an upper joint edge (25) beneath which a groove (23) is arranged. The second edge (3) is provided with lower cheek (31) having a distal end (32) at which an upwards protruding lower cheek heel (33) is arranged. The second edge (3) is further provided with an upper joining edge (35) beneath which an undercut (34) is arranged. A moveable locking element (40) is arranged in the space created by the undercut (34). The moveable locking element (40) have a locking tongue (41), a locking tongue leg (42) and a manoeuvring leg (43).

Owner:PERGO

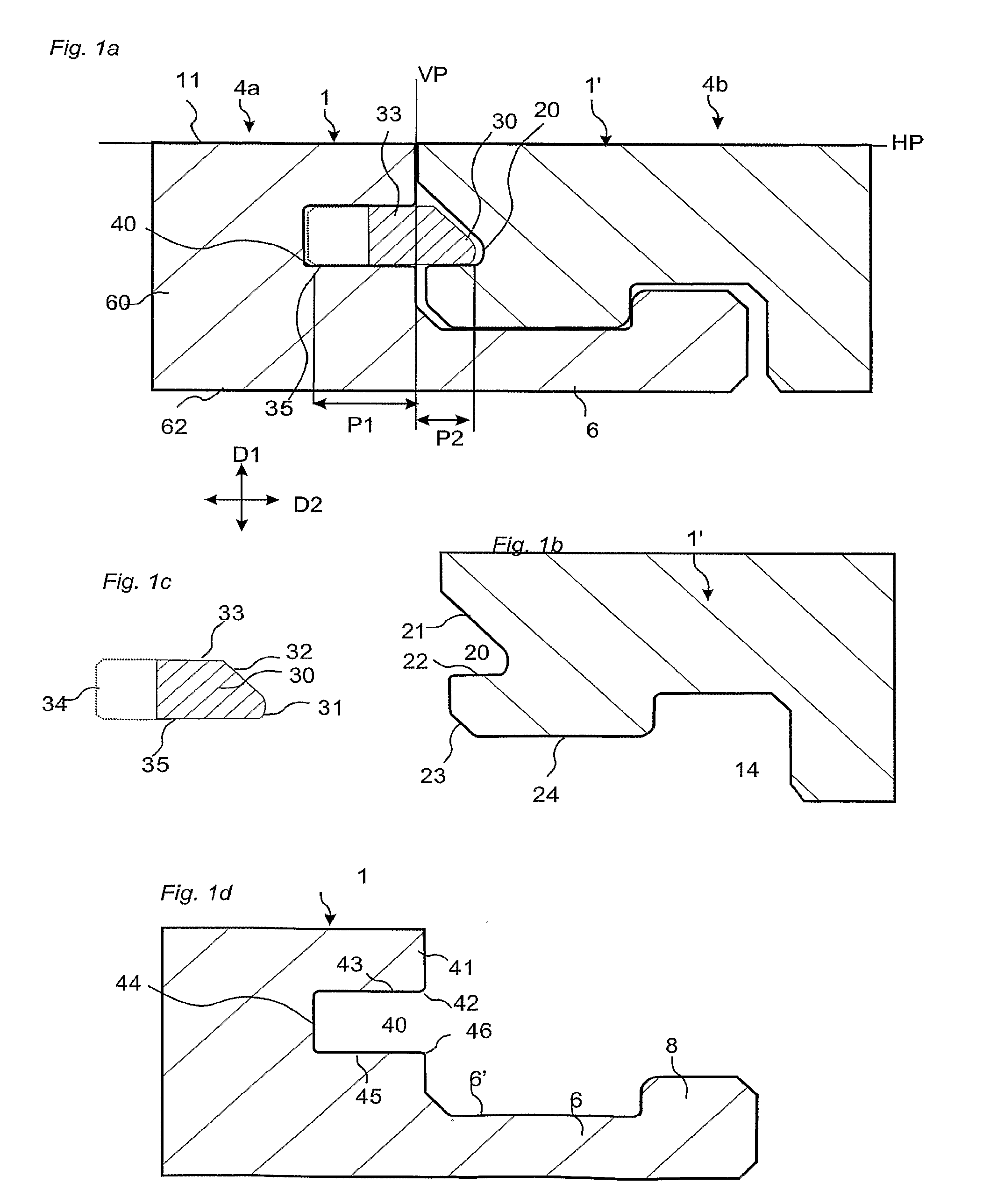

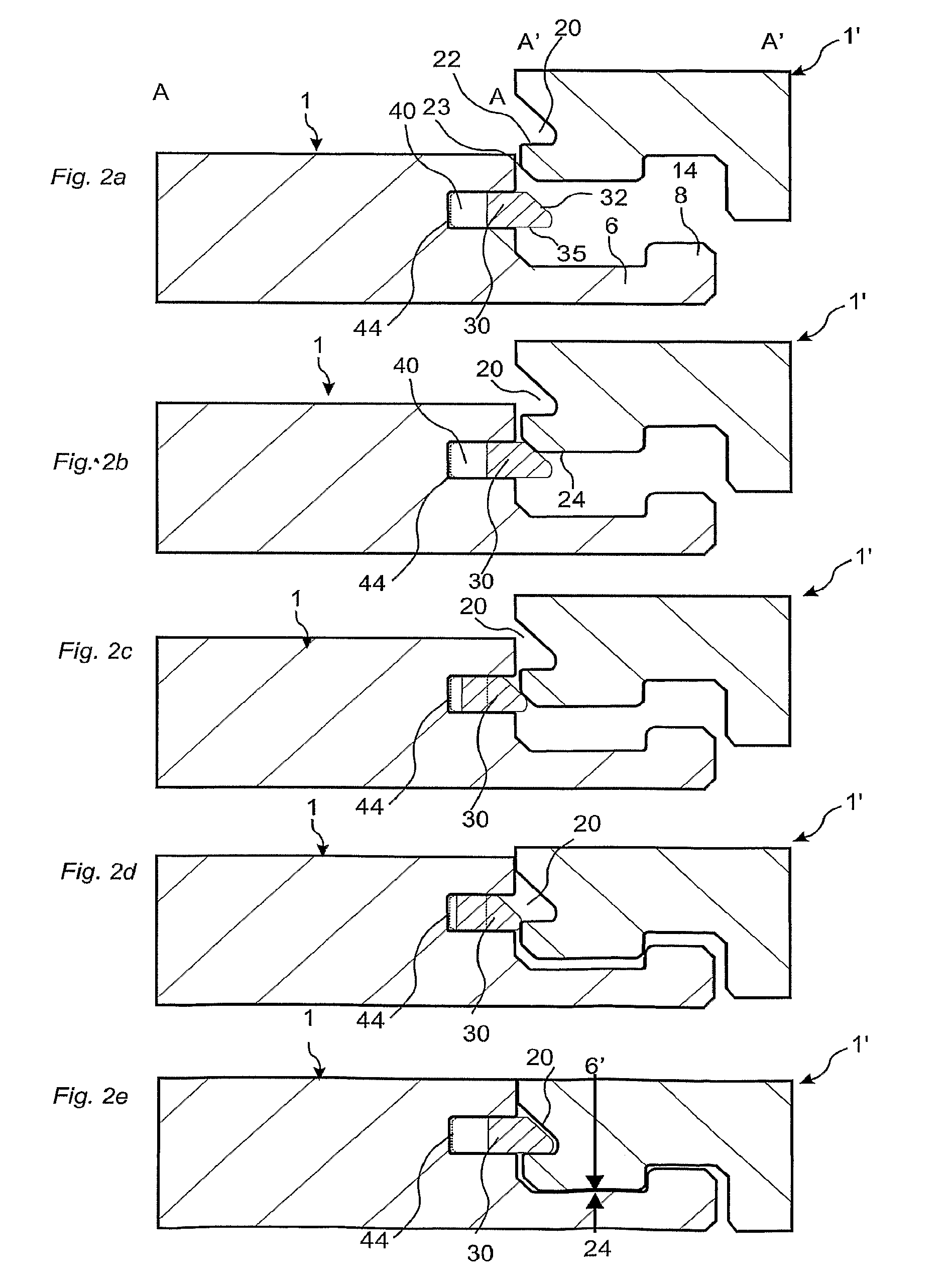

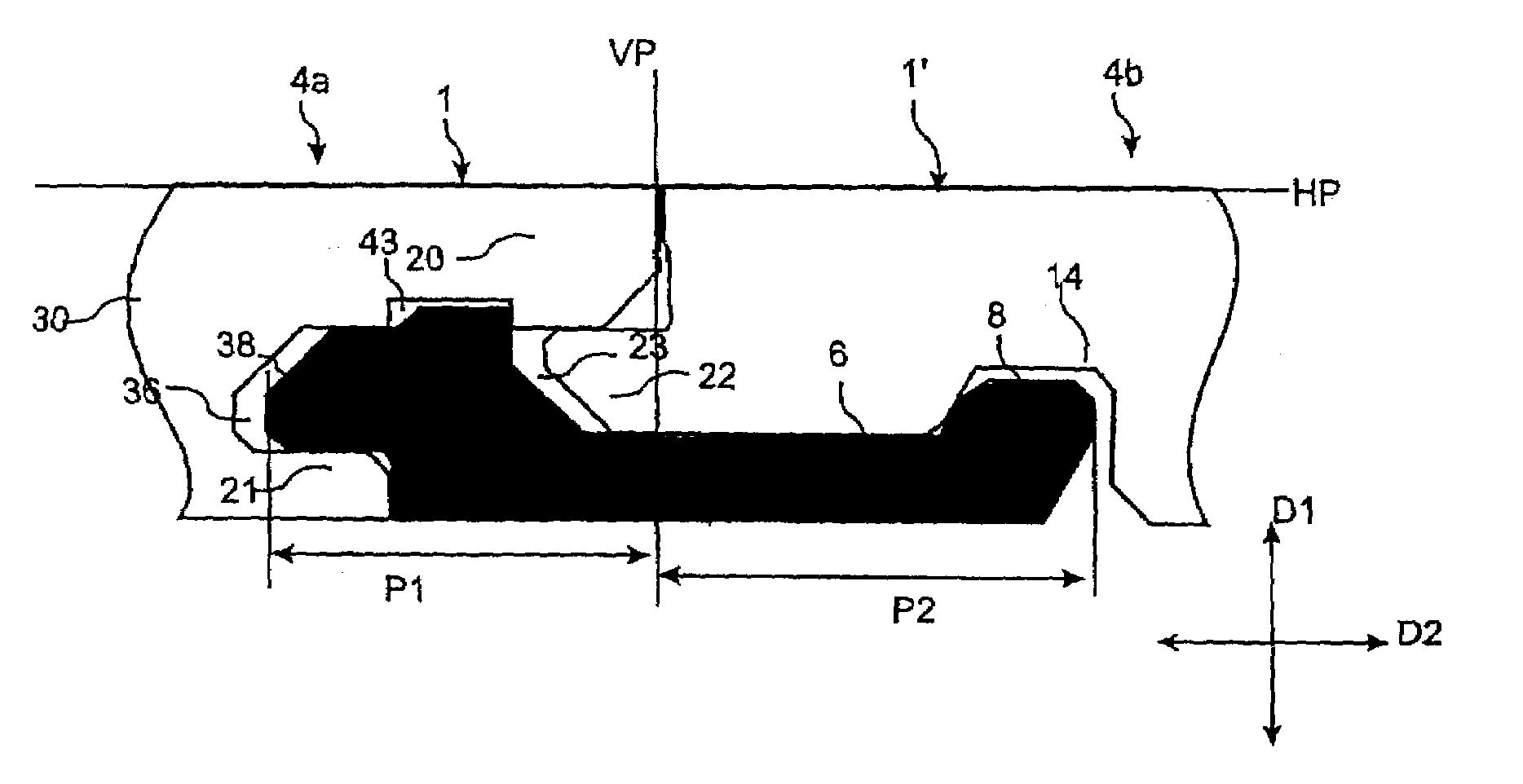

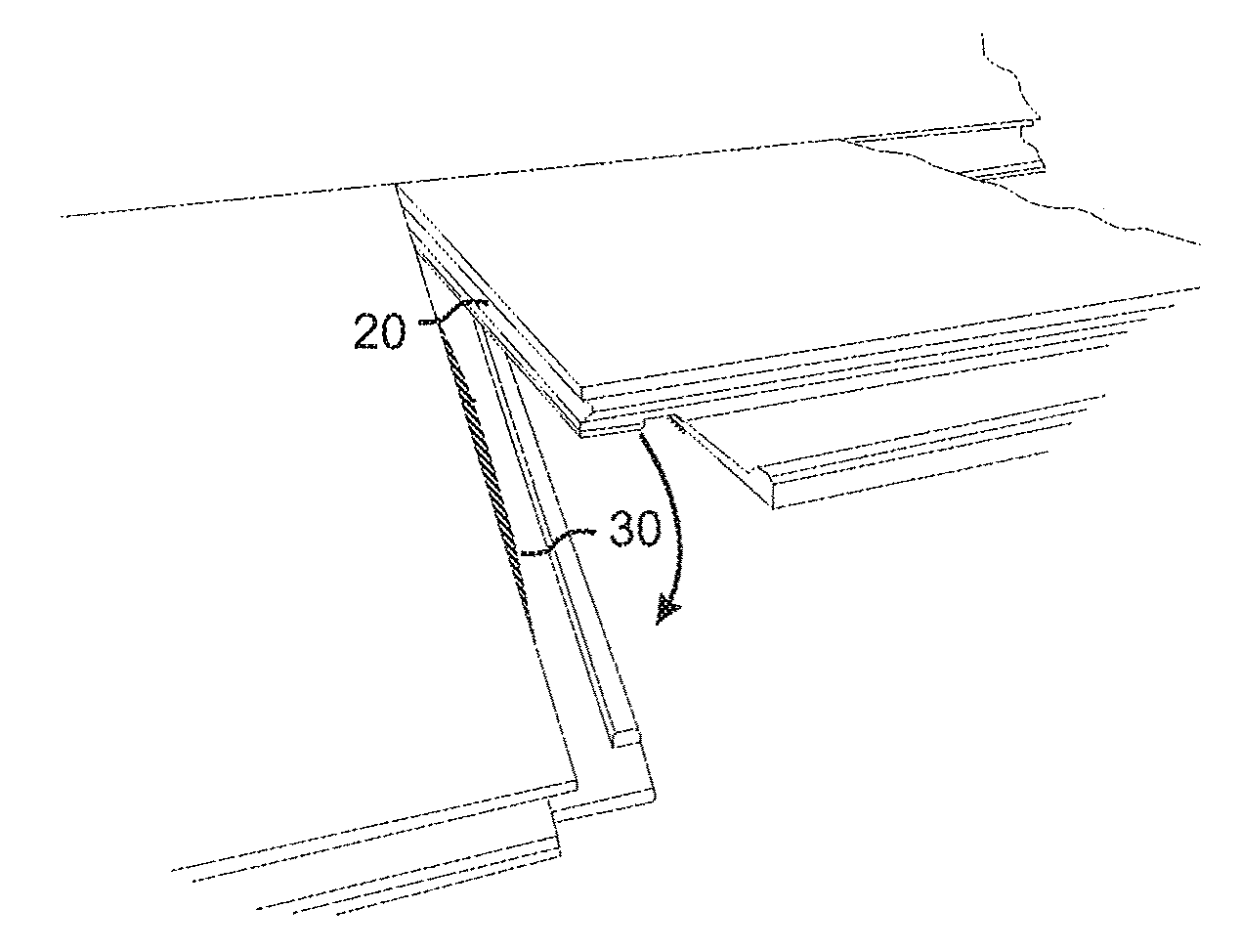

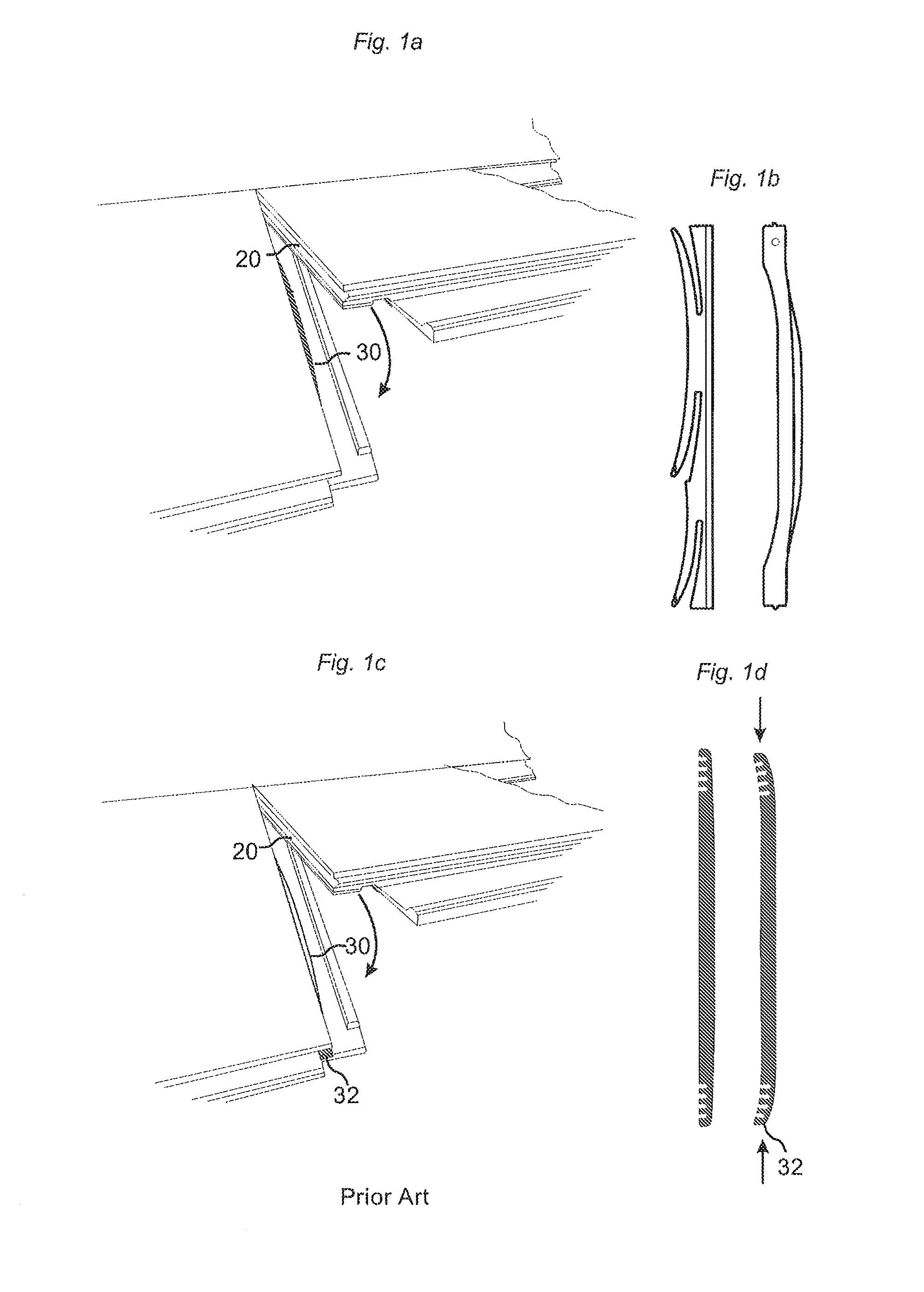

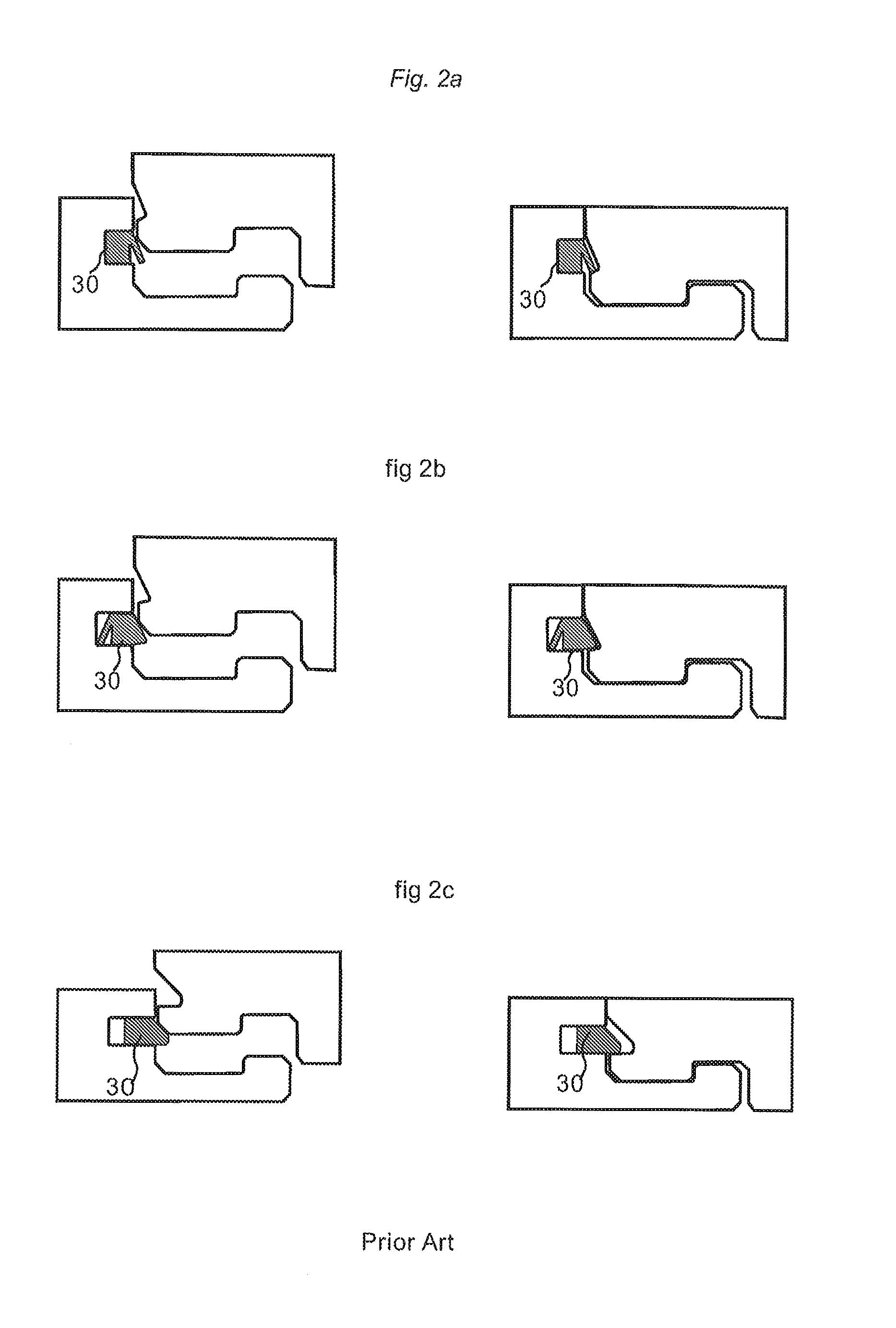

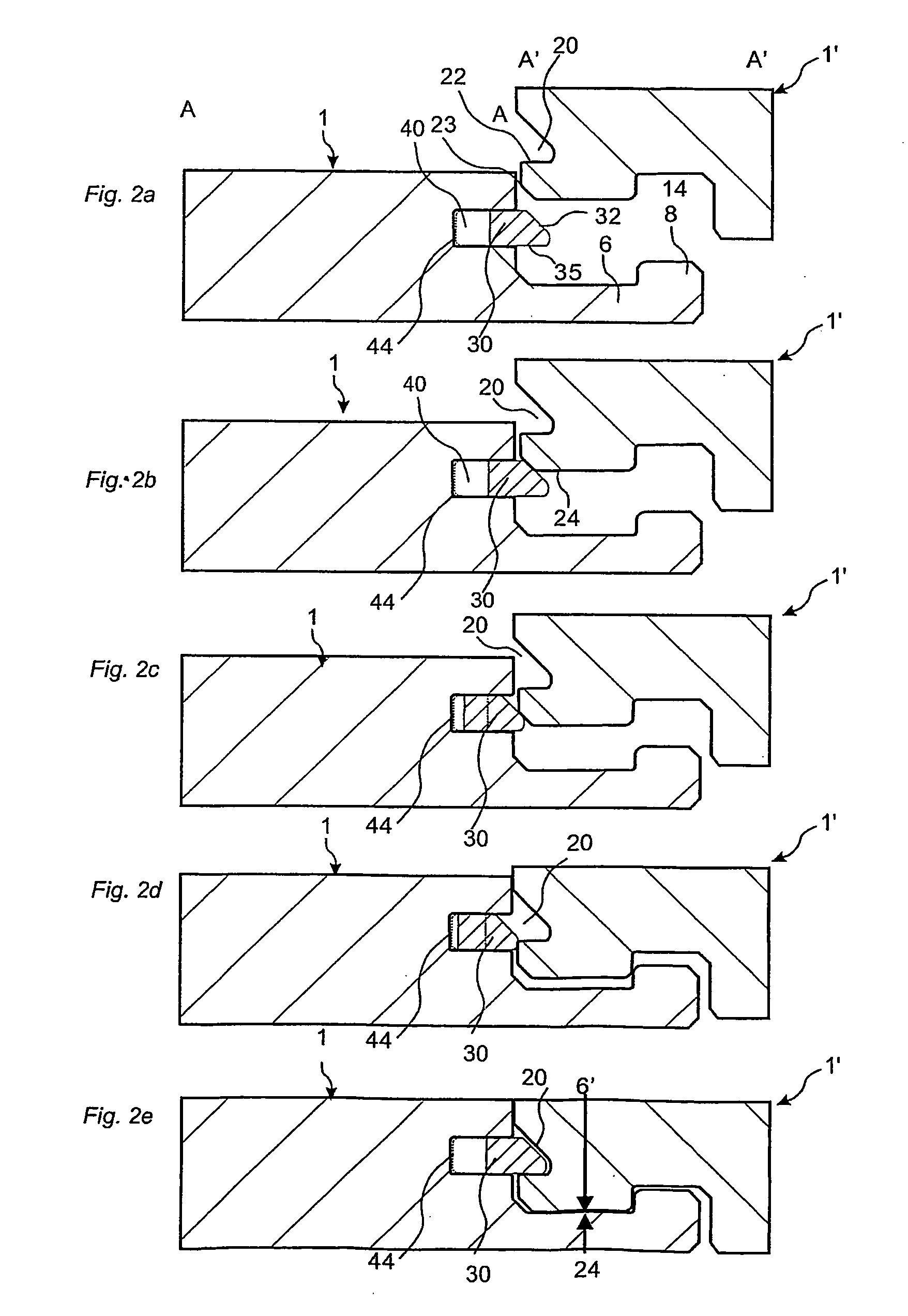

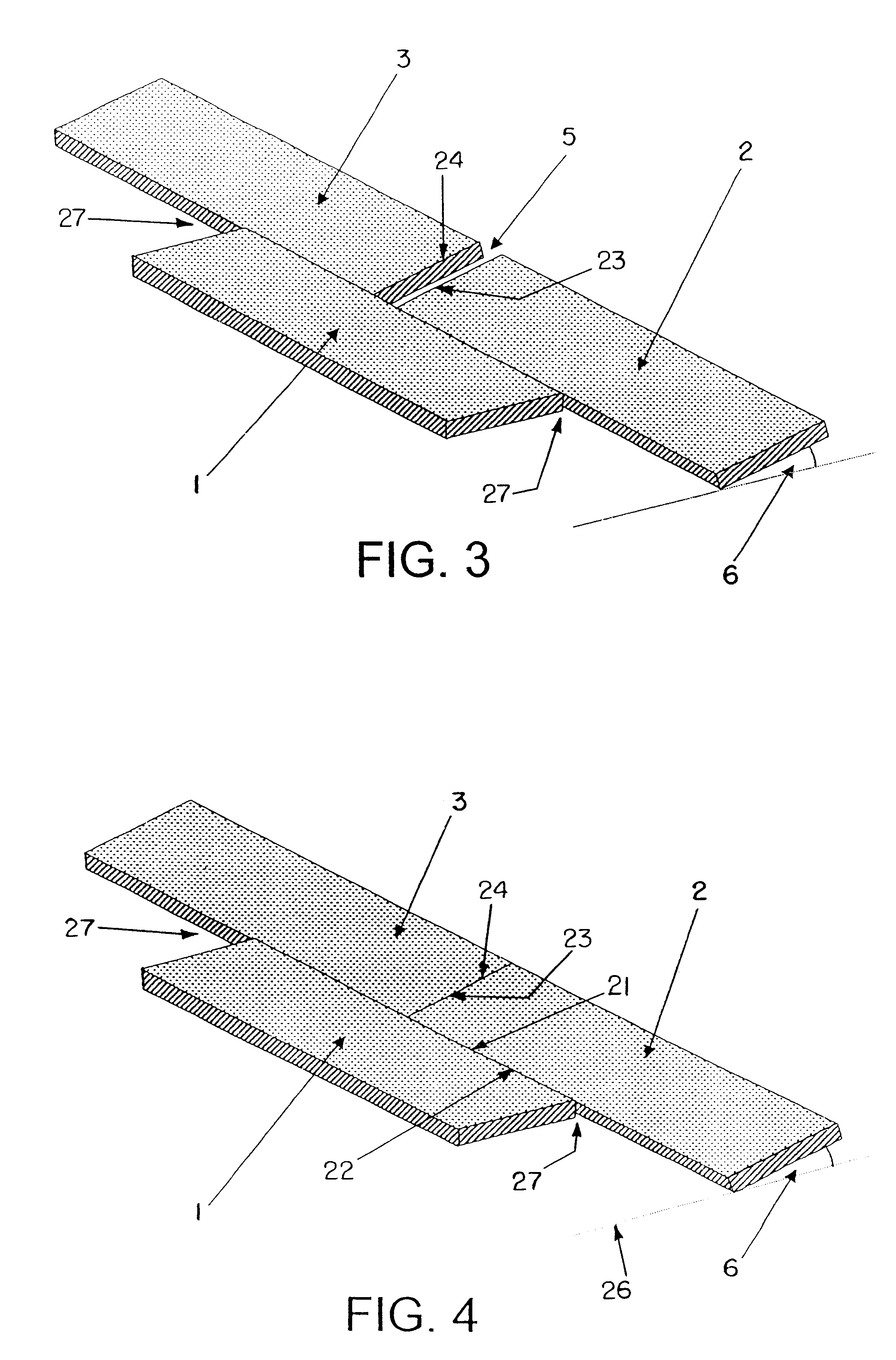

Mechanical Locking of Floor Panels With a Flexible Tongue

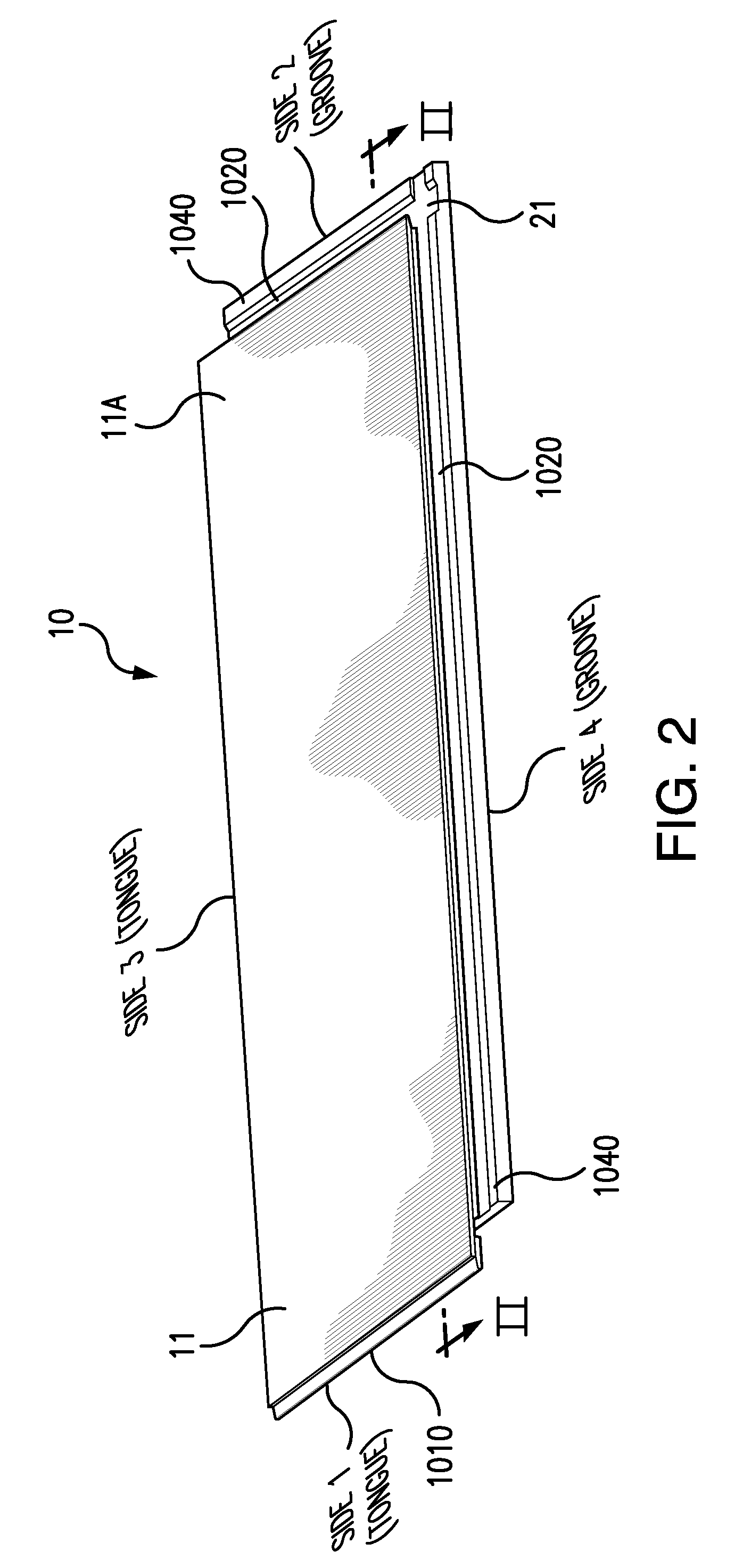

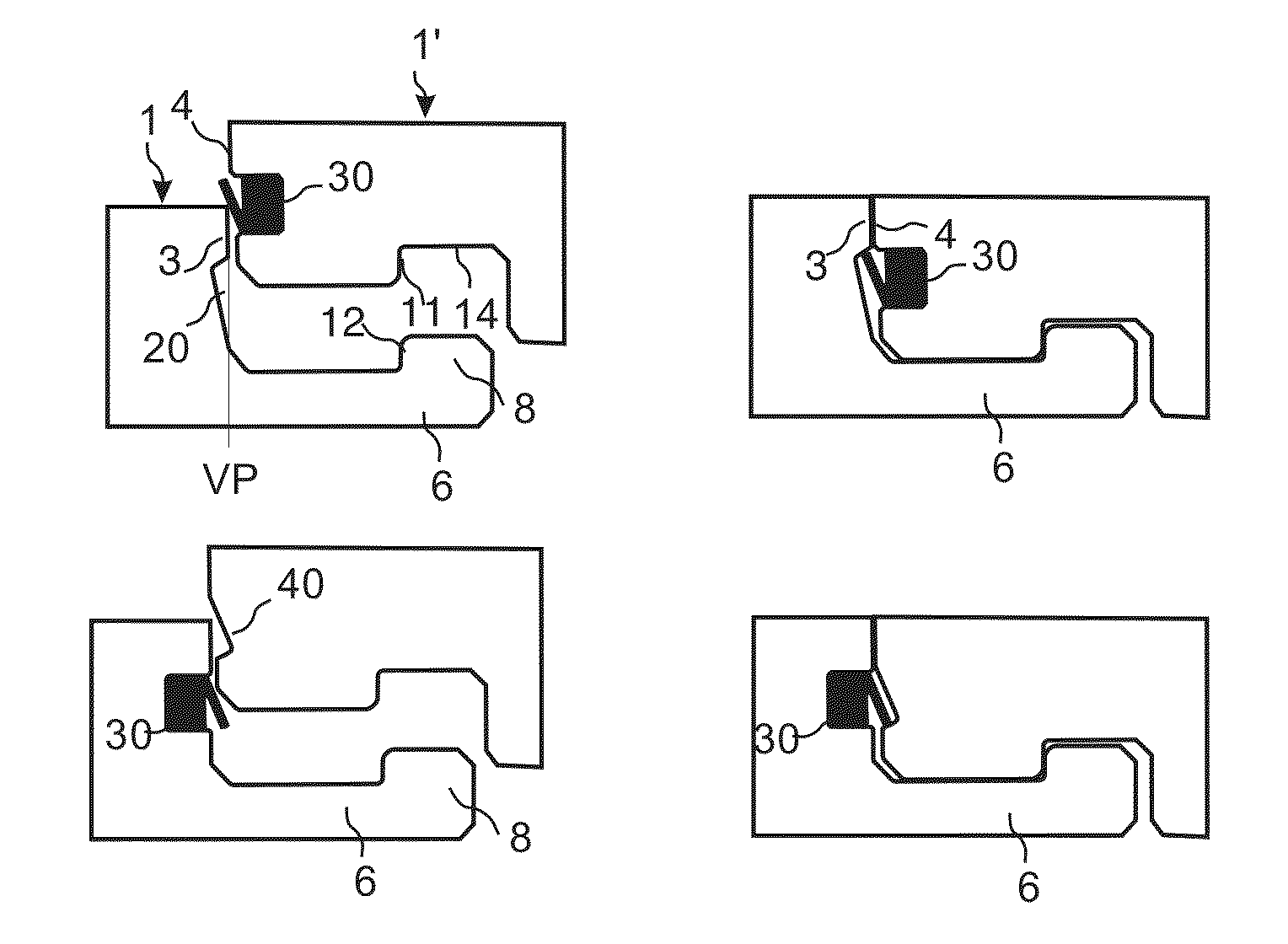

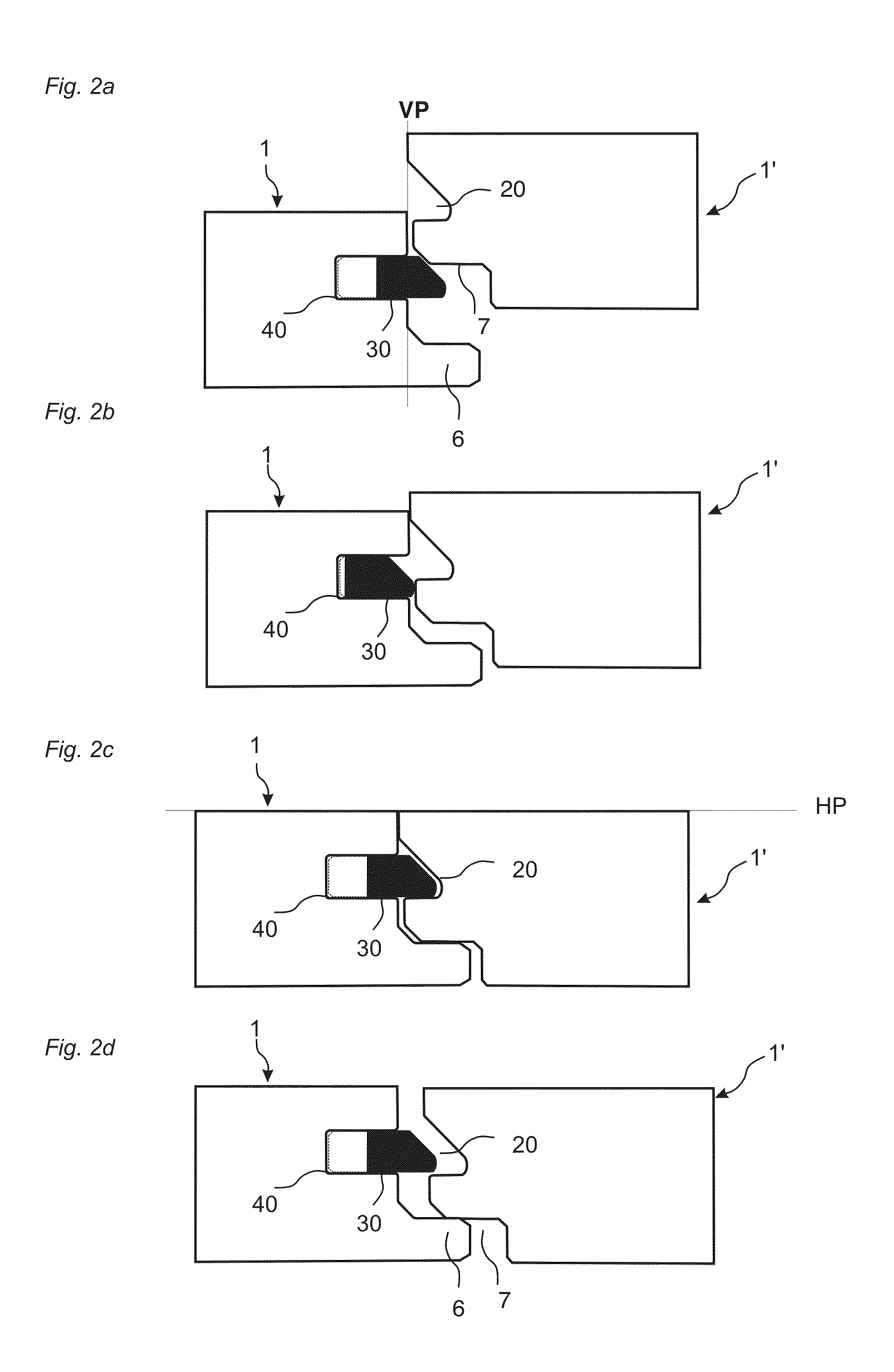

Floor panels (1, 1′) are shown, which are provided with a mechanical locking system having a flexible tongue (30) in a displacement groove (40), which during a vertical folding motion is displaced. Moreover, a tongue blank (50), a production method and an installation method are shown.

Owner:VÄLINGE INNOVATION AB

Locking System And Flooring Board

InactiveUS20080028707A1Good orientationCost of waste differsCeilingsStrutsEngineeringMechanical engineering

Owner:VÄLINGE INNOVATION AB

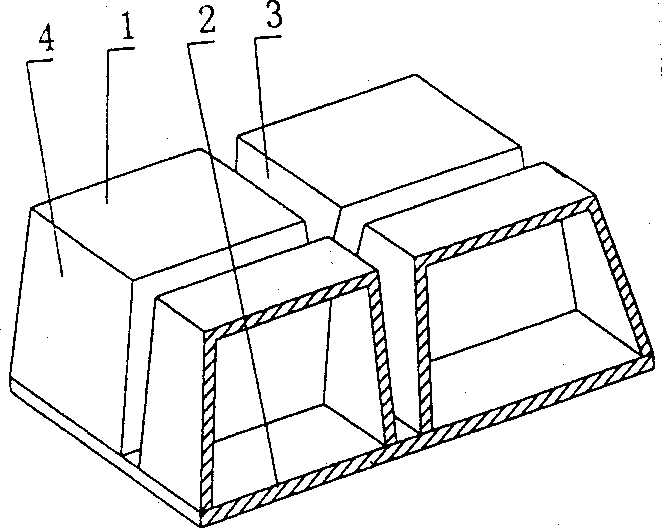

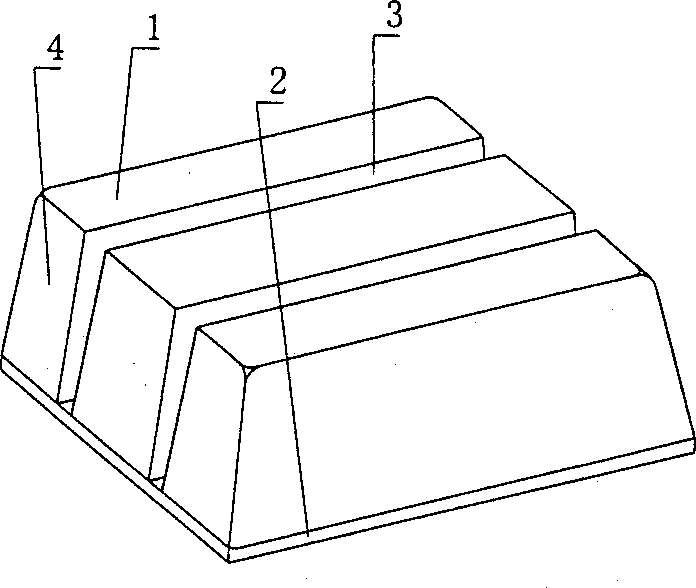

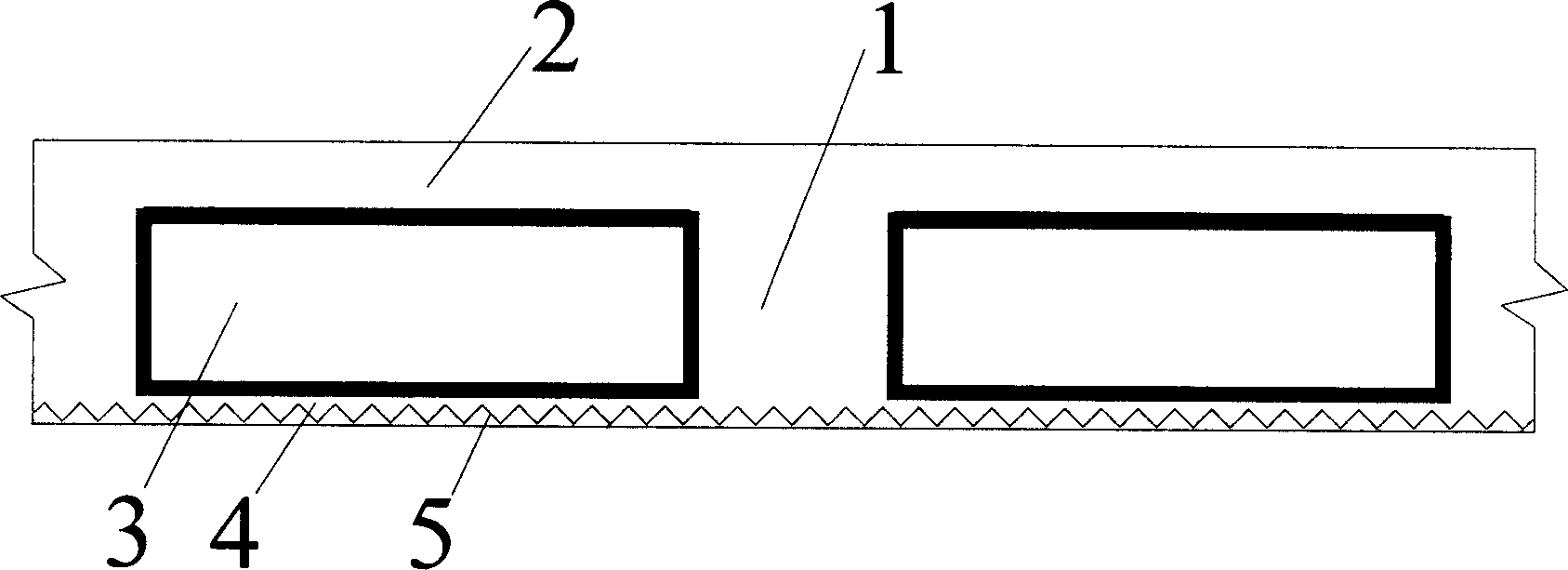

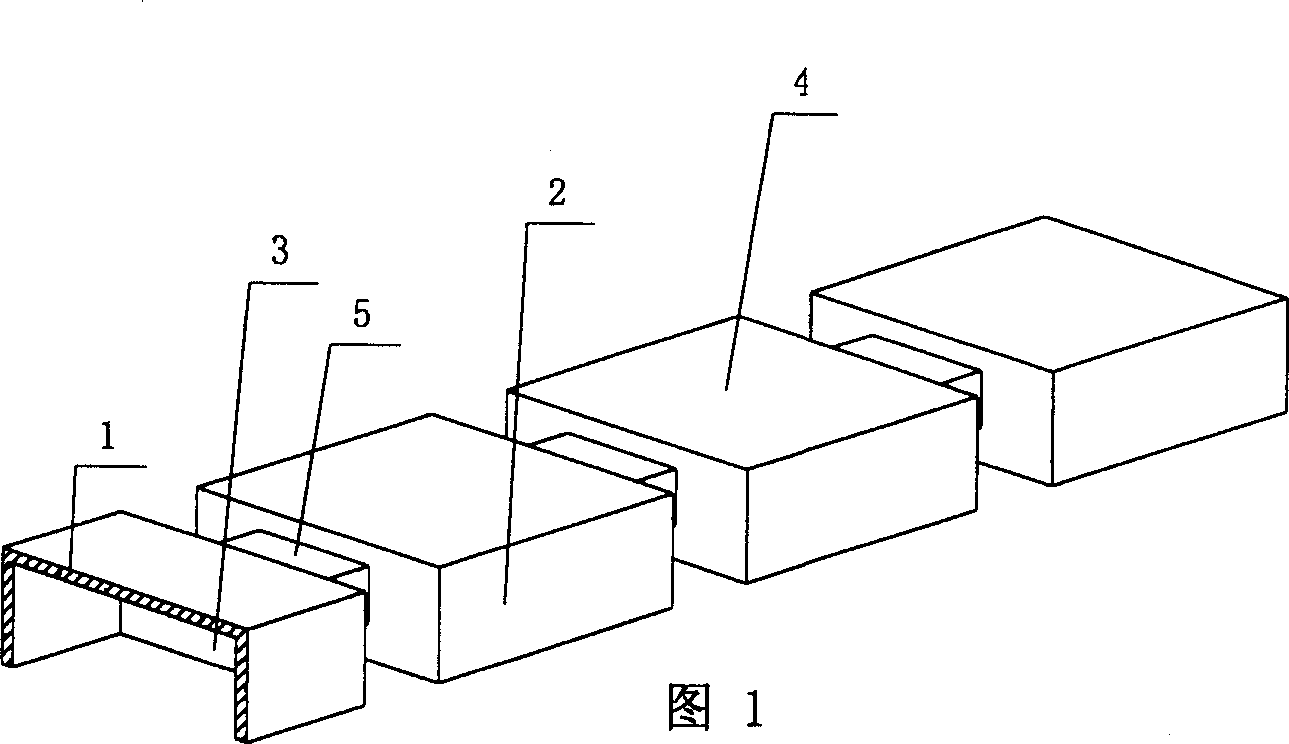

Comobined ribbed cavity member for spatial structure roof

A combined-rib cavity member for space-structure flooring includes cavity form and structure bottom plate, which are connected into one integral whole. It is characterized by that there are at least two cavity forms arranged alternate with each other on the structure bottom plate, its side forms with the structure bottle plate at least one subrit form cavity of casti-in-situ structure, and other other sides of the cavity form forms the side fromboard of main rib or beam or wall for cast-in-situ structure. By this, the subrib of cast-in-situ structure can be formed in the sub-rib form cavity on the structure battom plate, the sub-rib participates in load bearing of structural bottom slat, cast-in-situ main rib, cast-in-sita upper slab so to a load-bearing space structure, improved mechanical property, raise integrity and anti-shock property, decrease structural wt. lower cost and make construction be convenient.

Owner:湖南邱则有专利战略策划有限公司

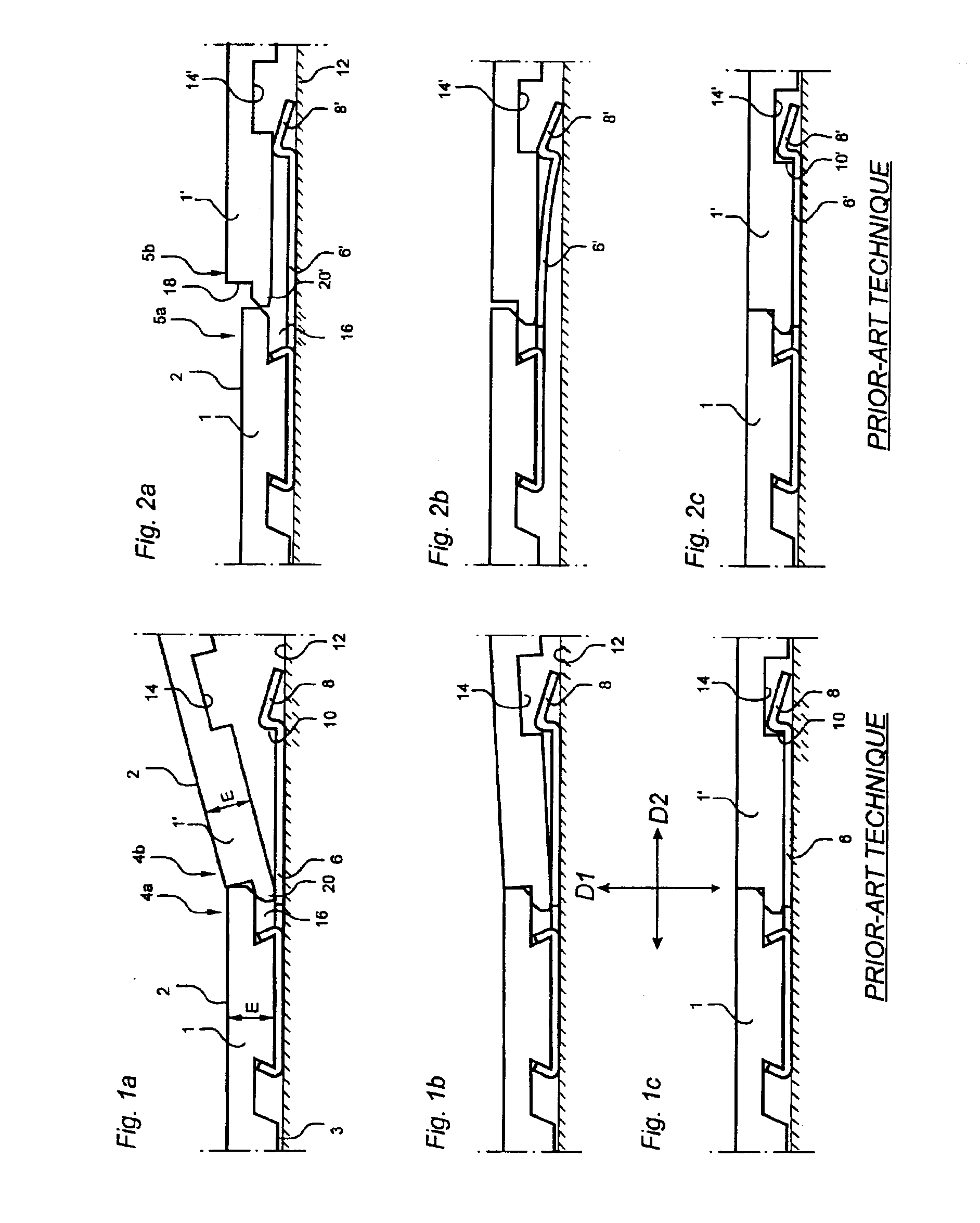

Mechanical locking system for floating floor

InactiveUS7051486B2Rational and cost-efficientReduce the amount requiredStrutsTreadsEngineeringFloating floor

Floorboards with a mechanical locking system having a separately machined strip which is mechanically joined with the floorboard.

Owner:VÄLINGE INNOVATION AB

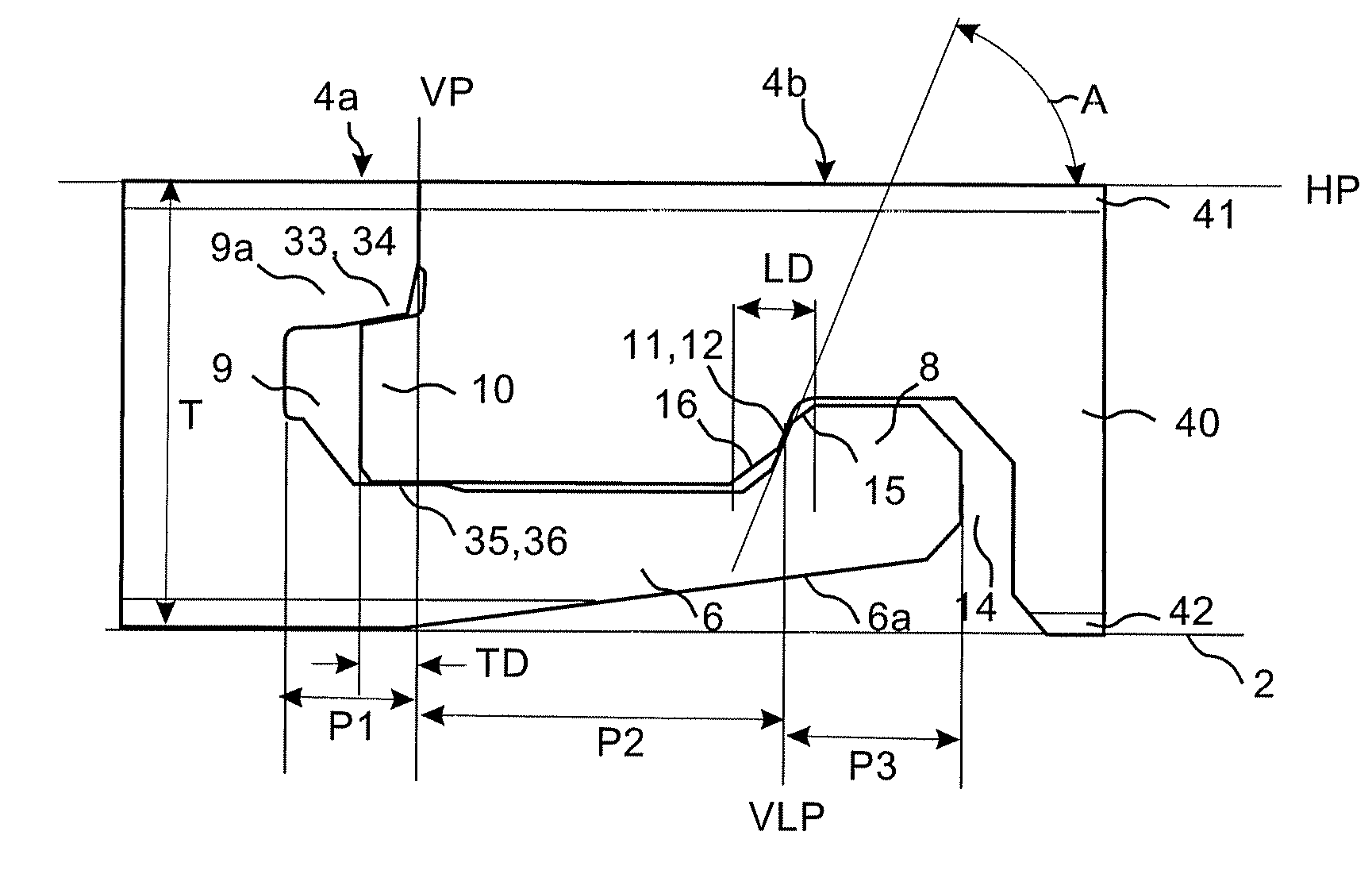

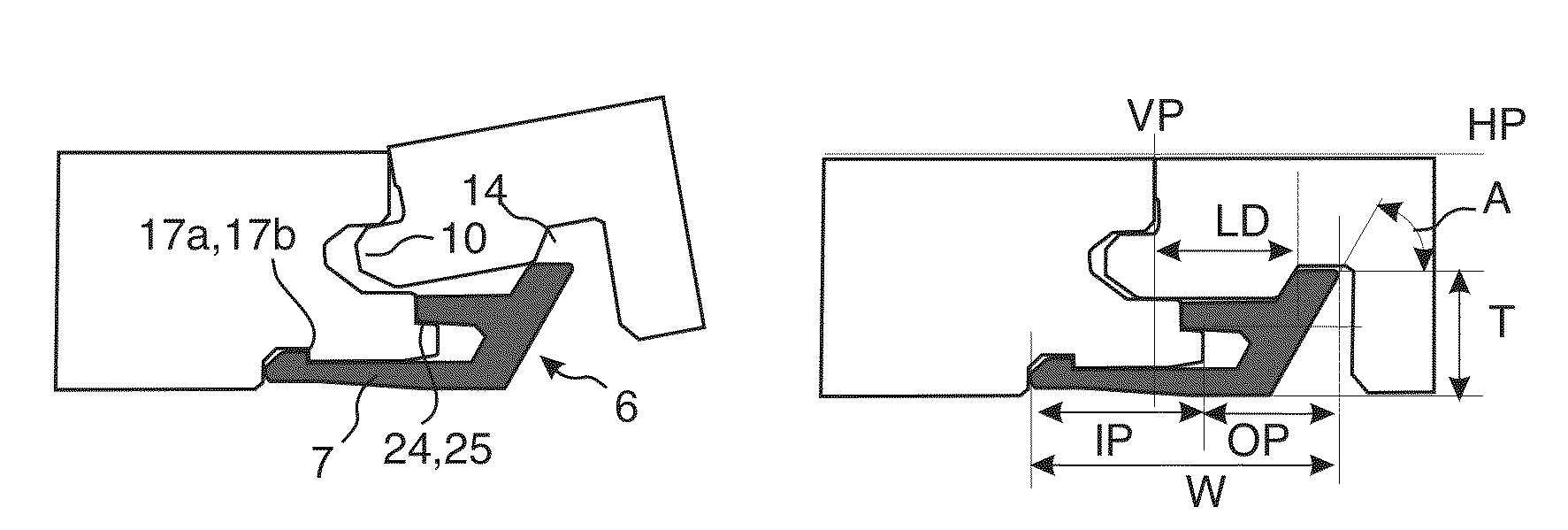

Mechanical locking system for panels and method of installing same

ActiveUS20080034708A1Simple horizontal displacementReduces snapping resistanceCovering/liningsWallsMechanical engineeringEngineering

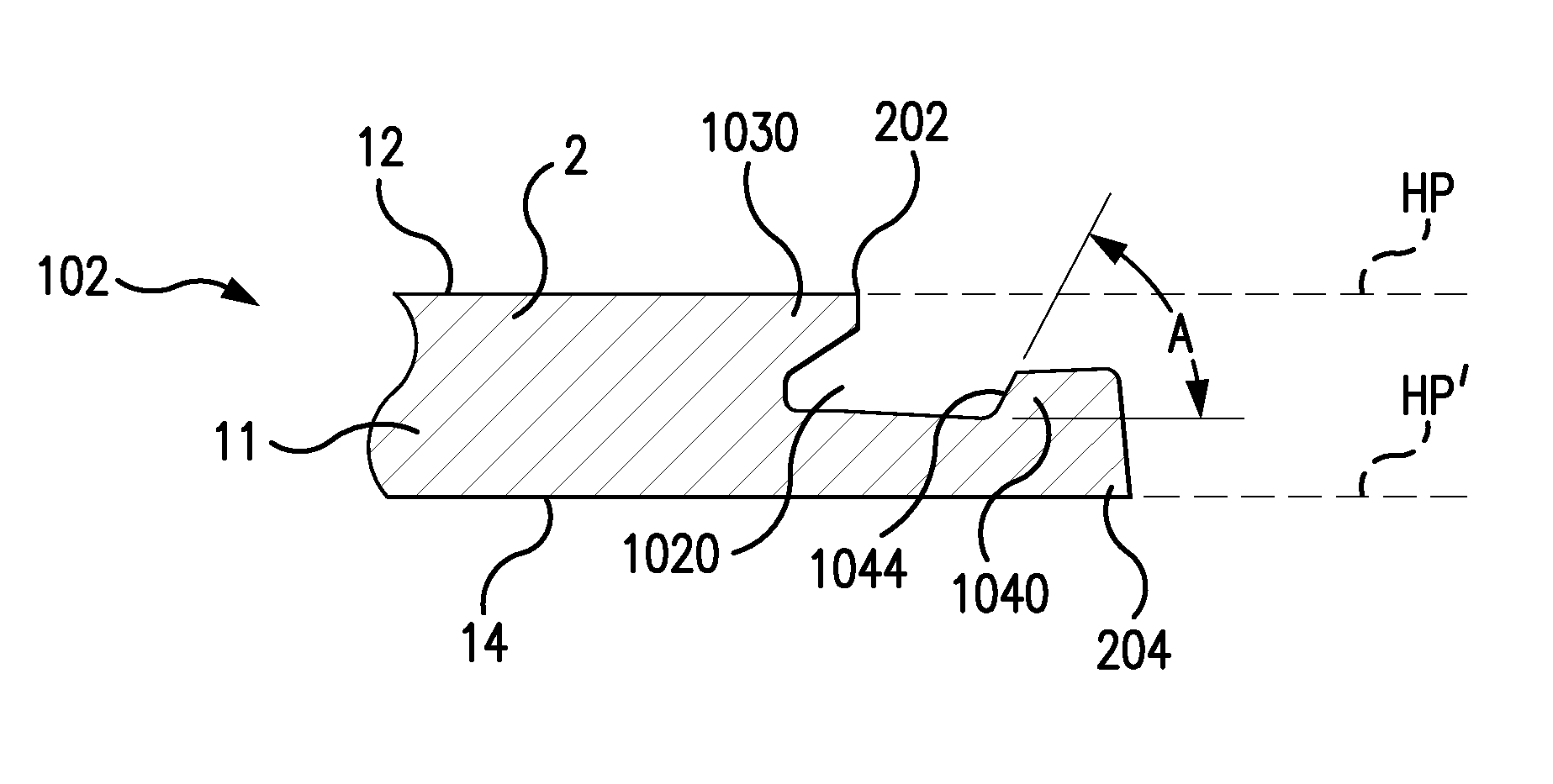

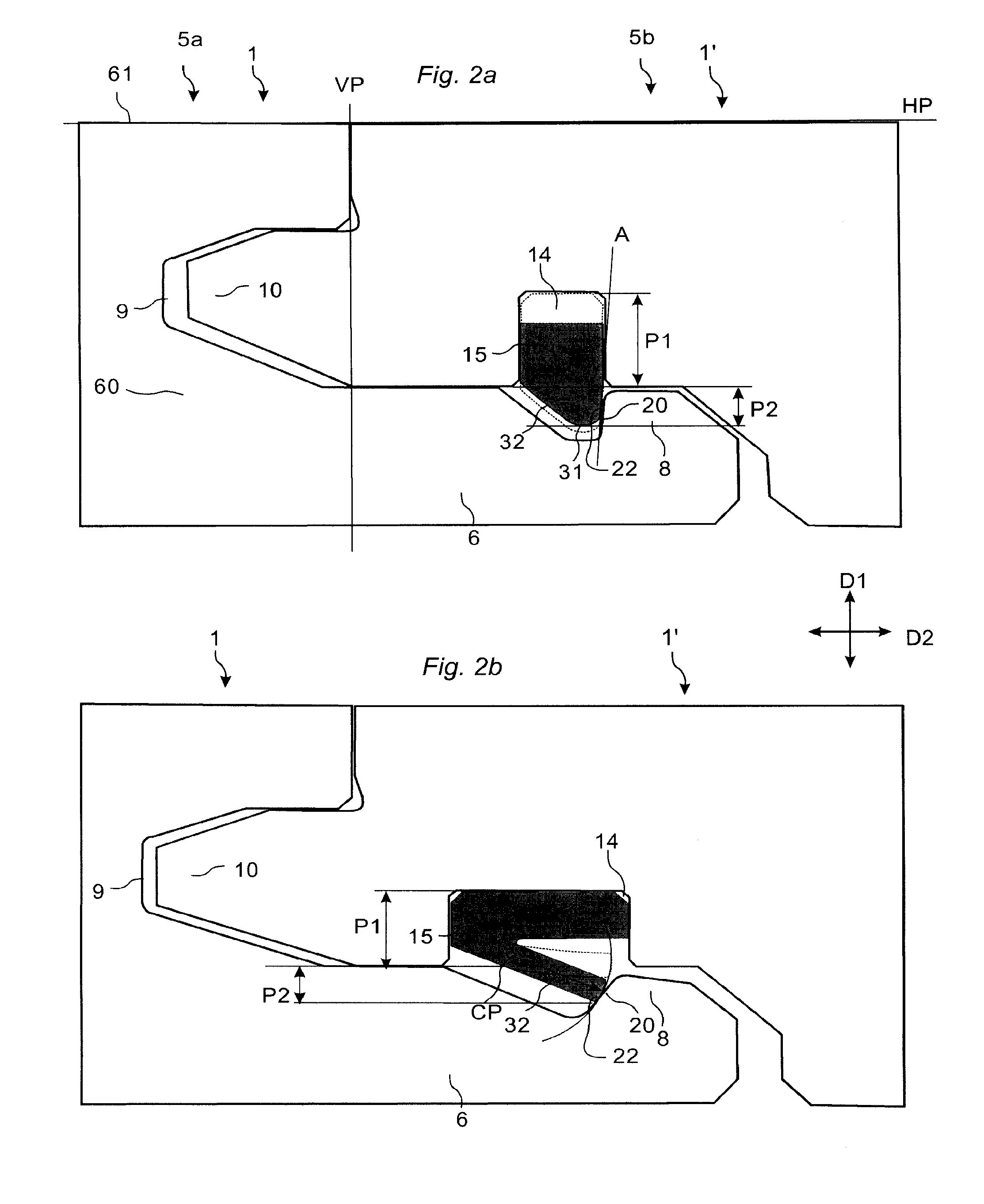

Floor panels ( 1, 1 ') are provided with a mechanical locking system including a flexible locking element 15 in a locking groove 14 which during a horizontal motion is displaced vertically.

Owner:VÄLINGE INNOVATION AB

Extrusion devices for mounting wall panels

InactiveUS6588165B1Easy to insertImprove grip strengthCeilingsRoof covering using tiles/slatesEngineeringEdge space

An extrusion device for mounting a wall panel has an outer cap extending to an edge on at least one side which is positioned against an outer surface of a wall panel, having a pair of spaced-apart insertion fingers, and a receiver base having a planar mounting portion and a pair of angled receiver flanges projecting upwardly to receive the insertion fingers therein. The two-piece extrusion permits wall panels to be mounted or removed from the underlying wall structure in on-sequential order. The receiver base and cap can be provided on both sides to form an "H" type extrusion, or on only one side in a "J" type extrusion. Preferably, the outer cap is made of metal, and the tips of the insertion fingers are beveled at a slight angle of about 7° to 14° to allow easy insertion into the receiver flanges. The cap has compound water-shedding edges formed with a rounded rain-drip edge spaced in close proximity to a sharply inclined knife edge. In another variation, a one-piece extrusion device has a rear base portion and a front cover portion forming a pocket therewith, and a ramp formed on the base portion within the width of the front cover portion for gradually forcing the edge of a wall panel inserted in the pocket toward the front cover portion clear of the heads of screws used to mount the base portion to the underlying wall structure. The base portion is formed with a hook indentation on a back side of the ramp on a rear surface of the base portion, and interconnects with a "Z" type extrusion having a hook end to form a right angle connection. The one-piece extrusion may be formed as a "J" (one-sided), "H" (two sided), "C" (corner), or other suitable types.

Owner:WRIGHT JOHN T

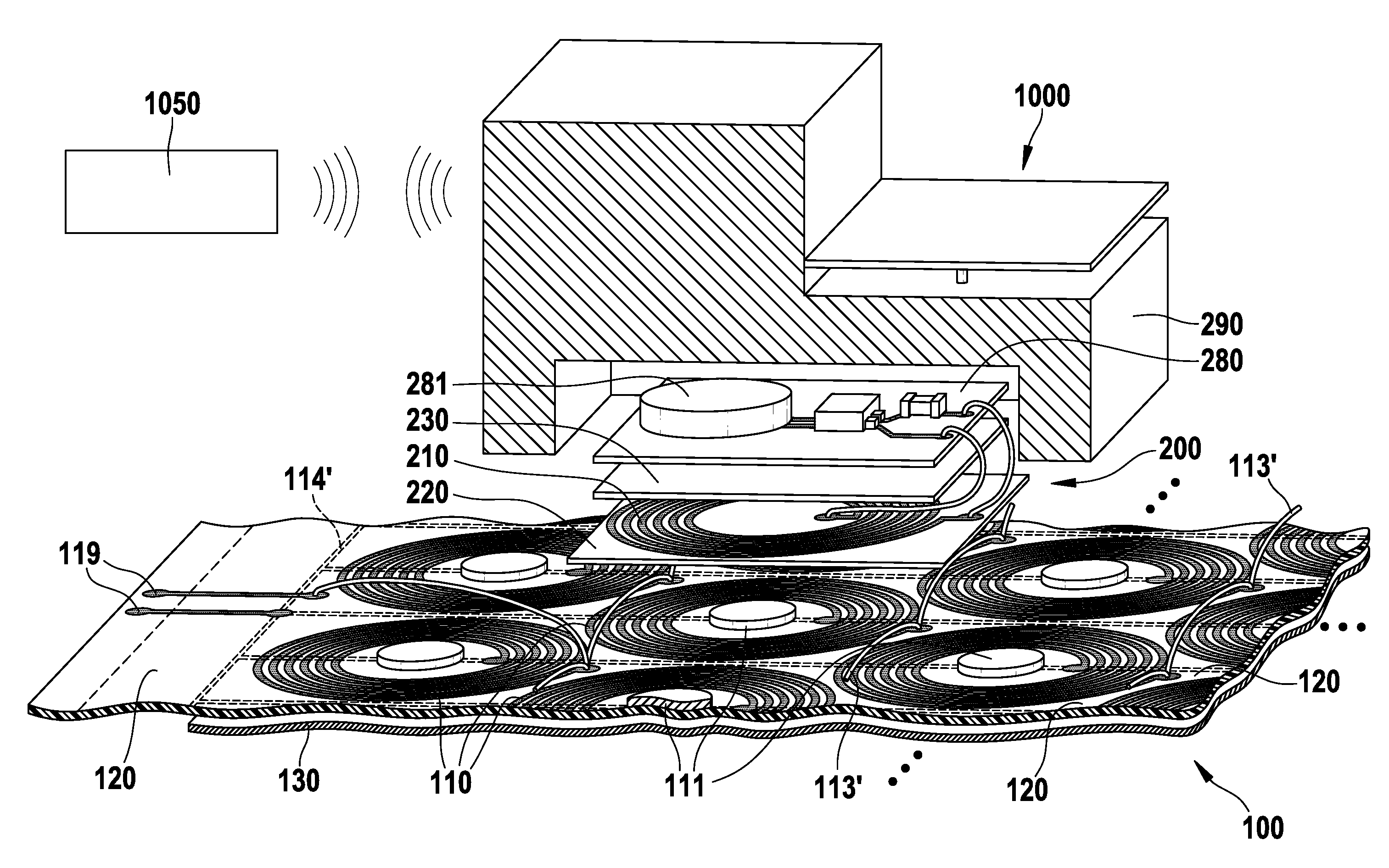

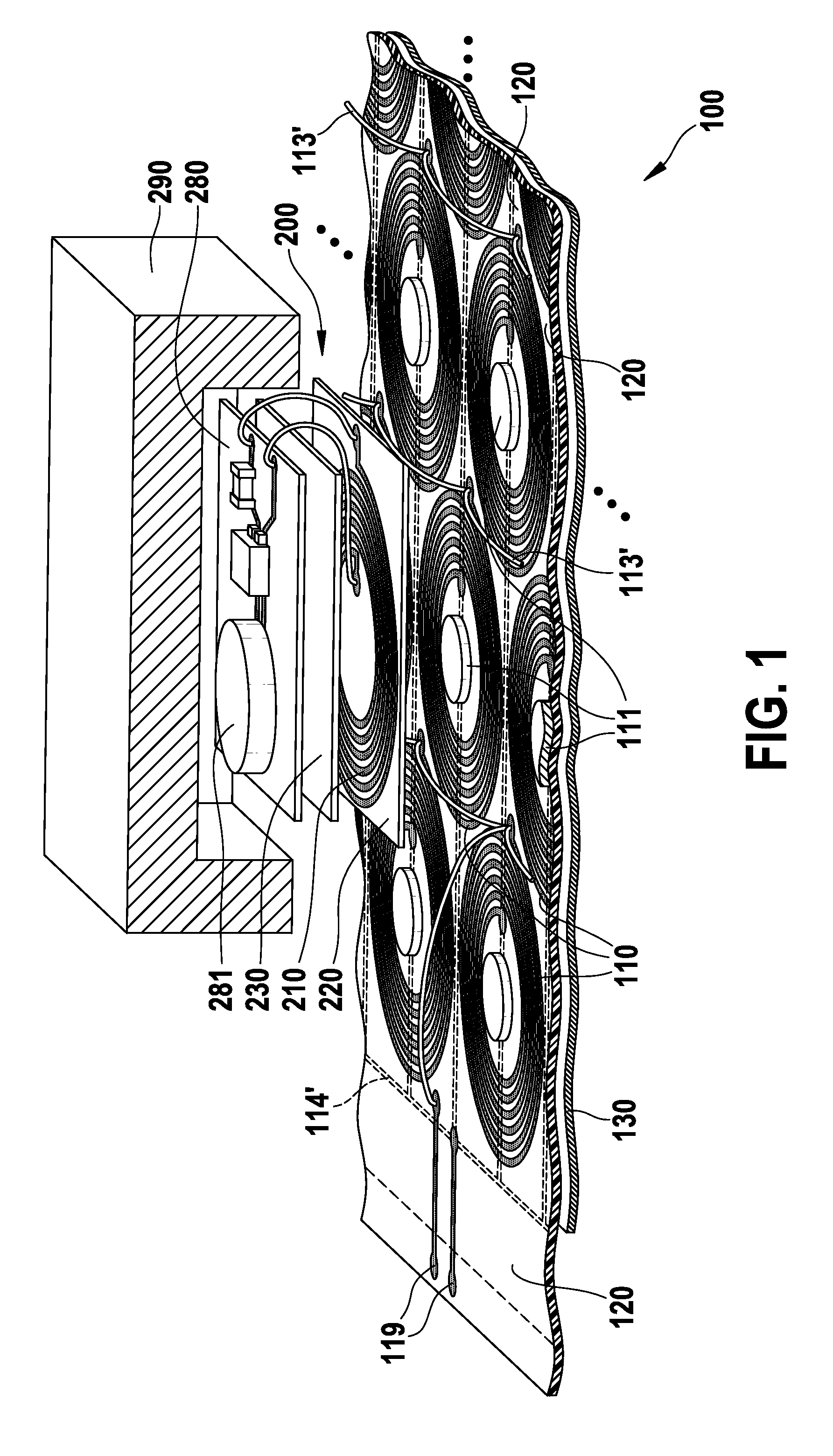

Floor covering and inductive power system

InactiveUS20100314946A1Improving magnetic couplingPrevent short-circuitingRoof covering using slabs/sheetsBatteries circuit arrangementsCharge currentEngineering

The invention relates to a floor covering (100) comprising: a plurality of coils (110), each coil (110) being operable to supply inductive energy to a power receiver circuit (200); wherein the plurality of coils comprises a transmitter area occupying the largest area of the floor covering (100); and a charging current through the coils is operable to generate said inductive energy.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

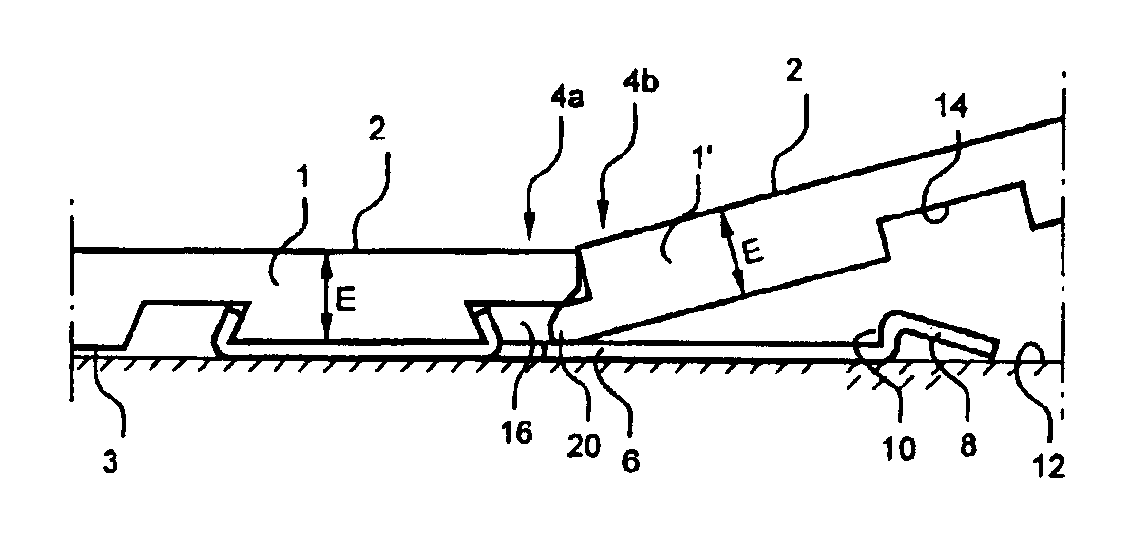

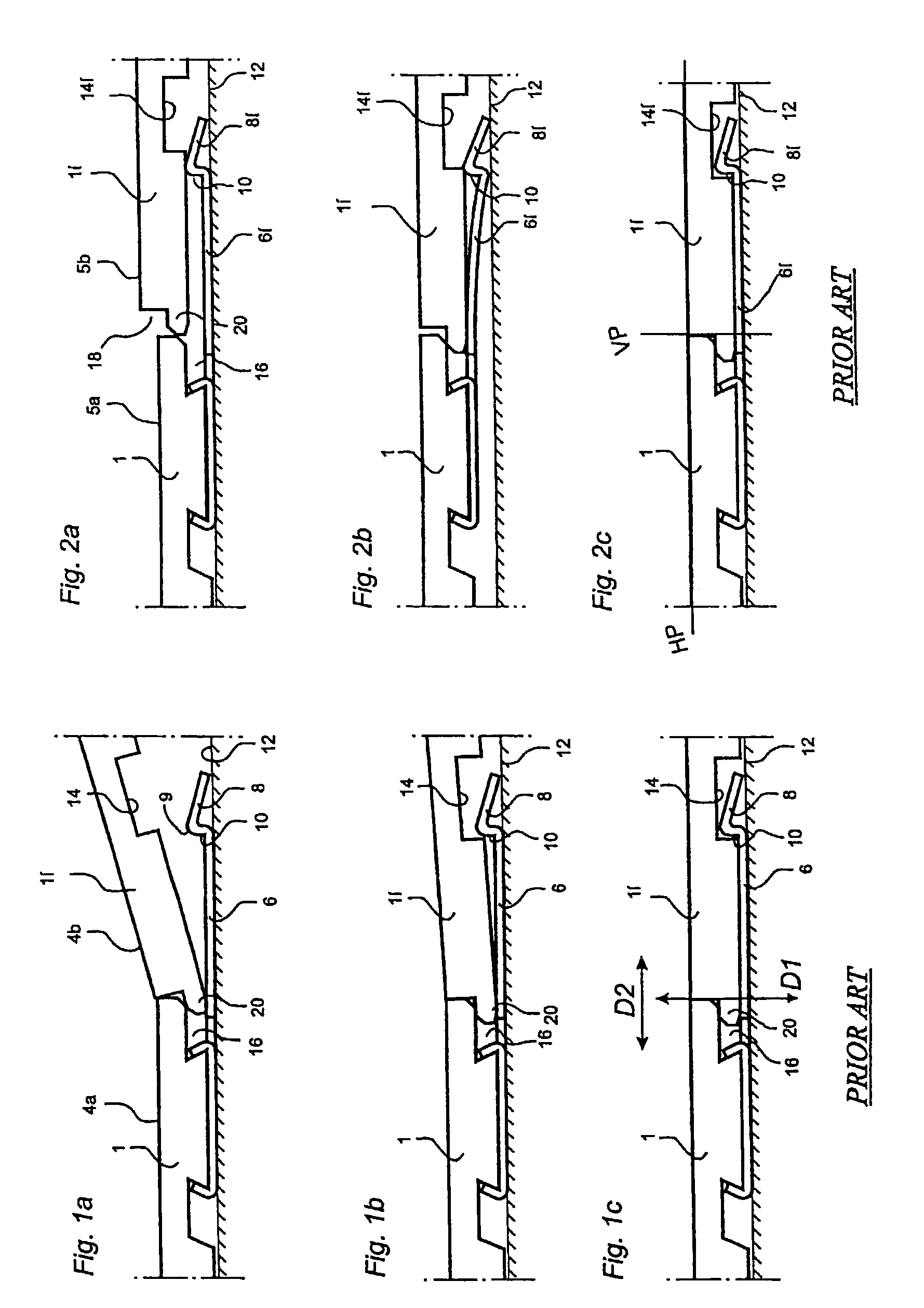

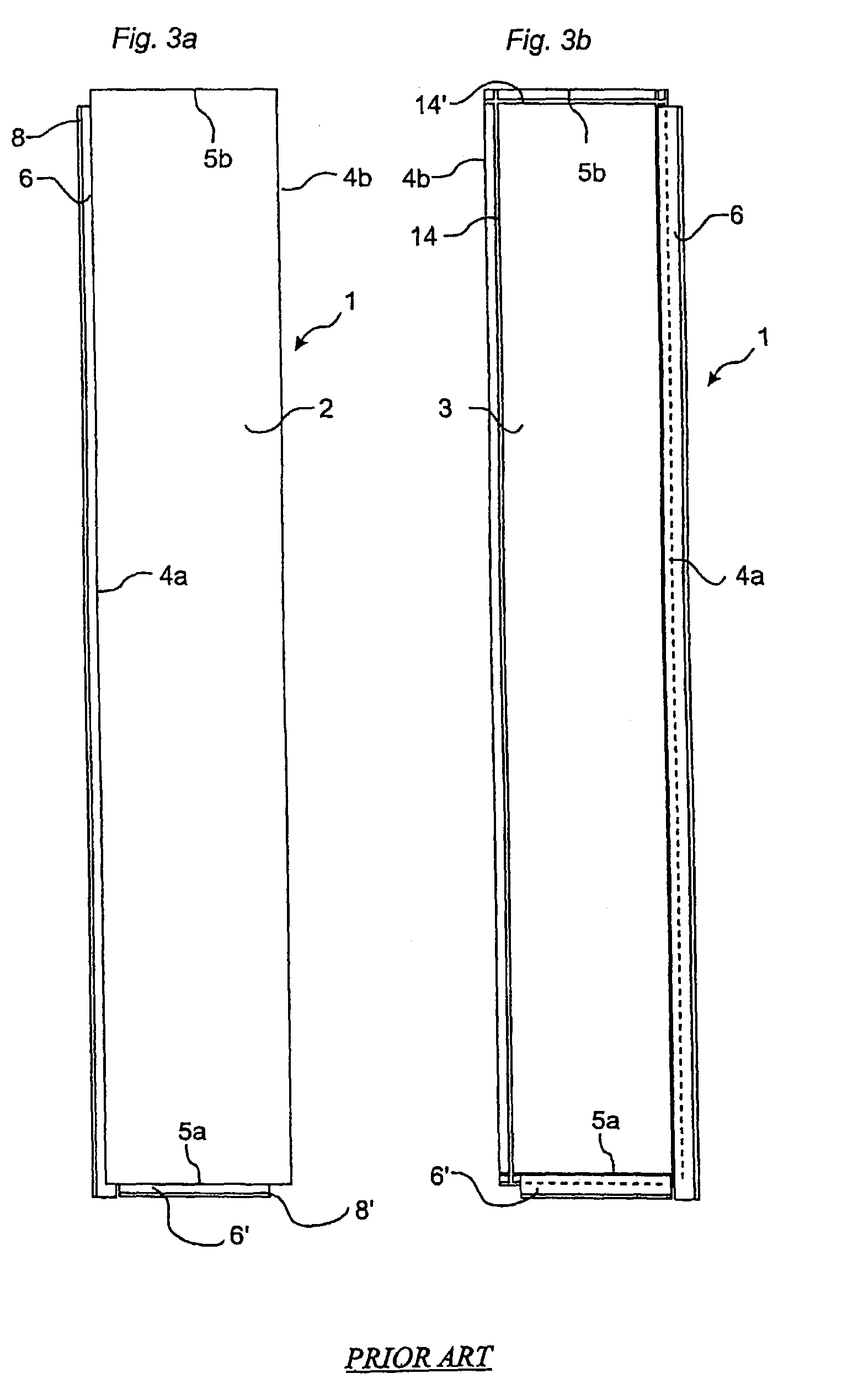

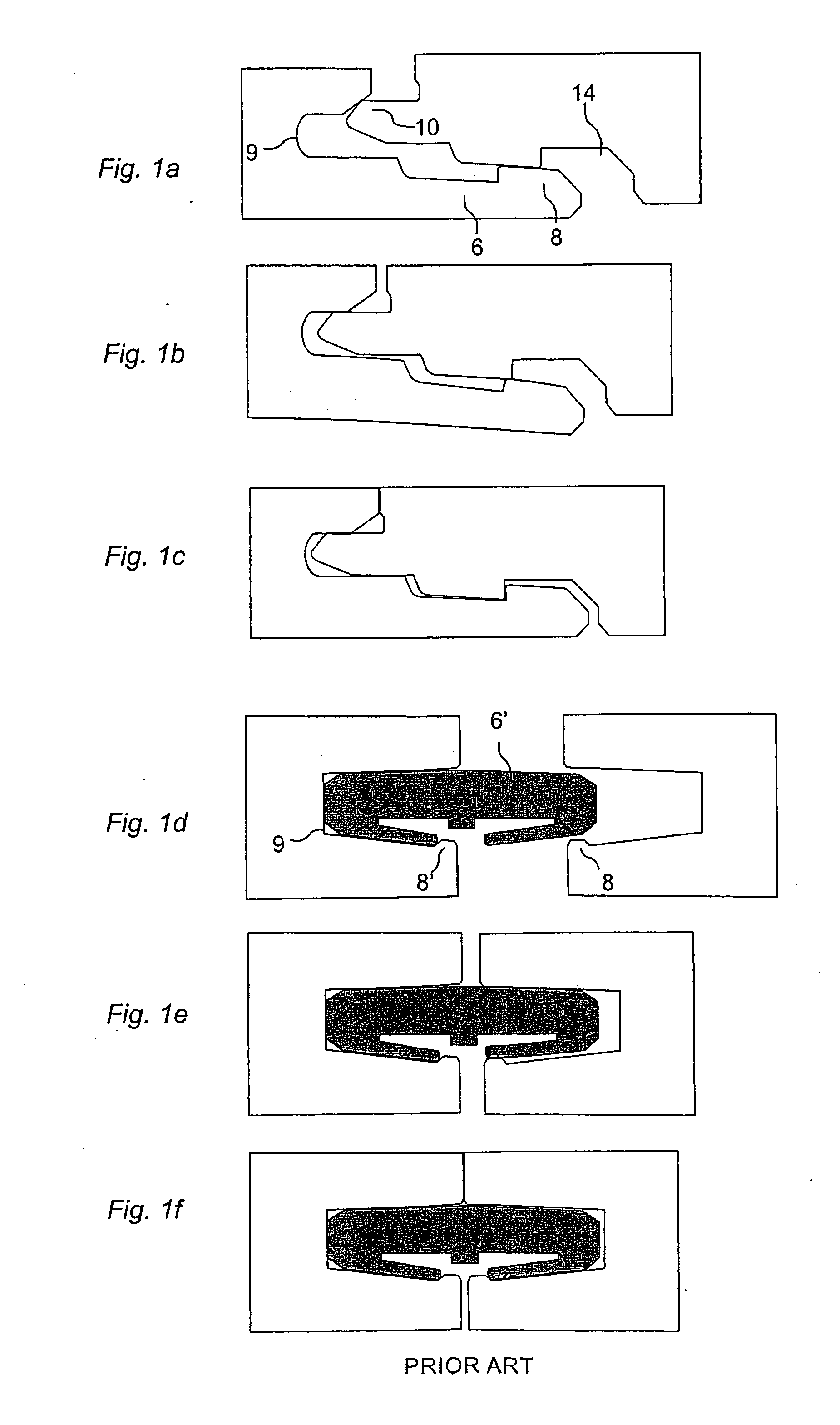

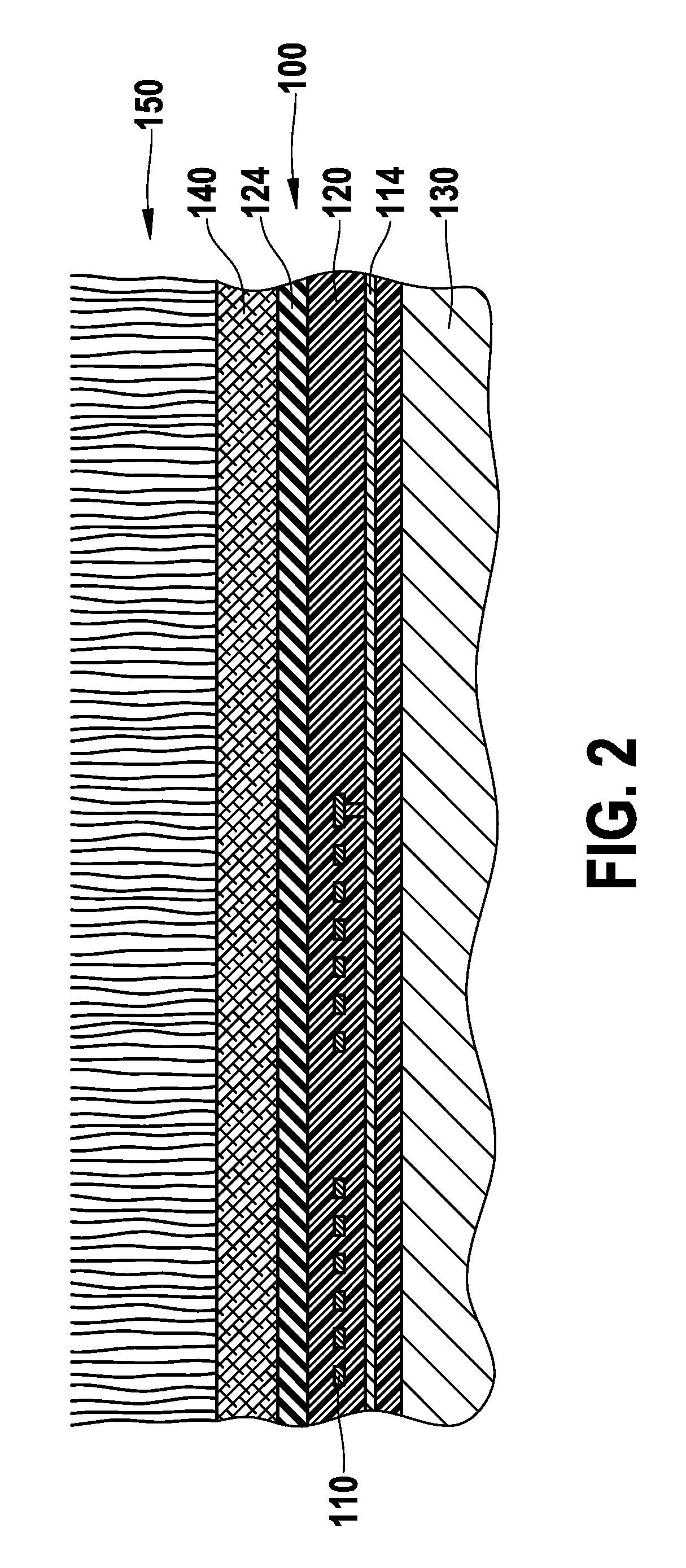

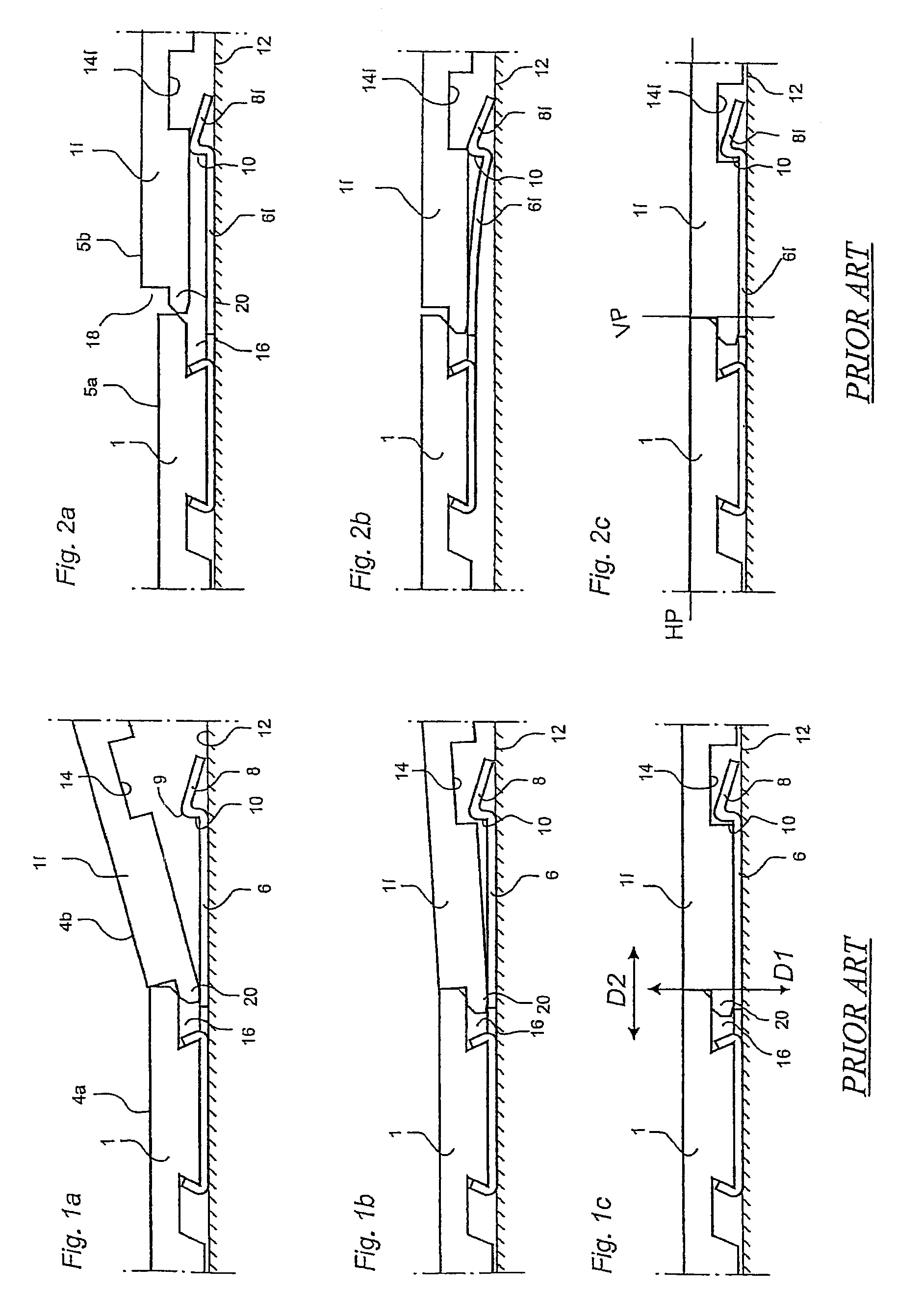

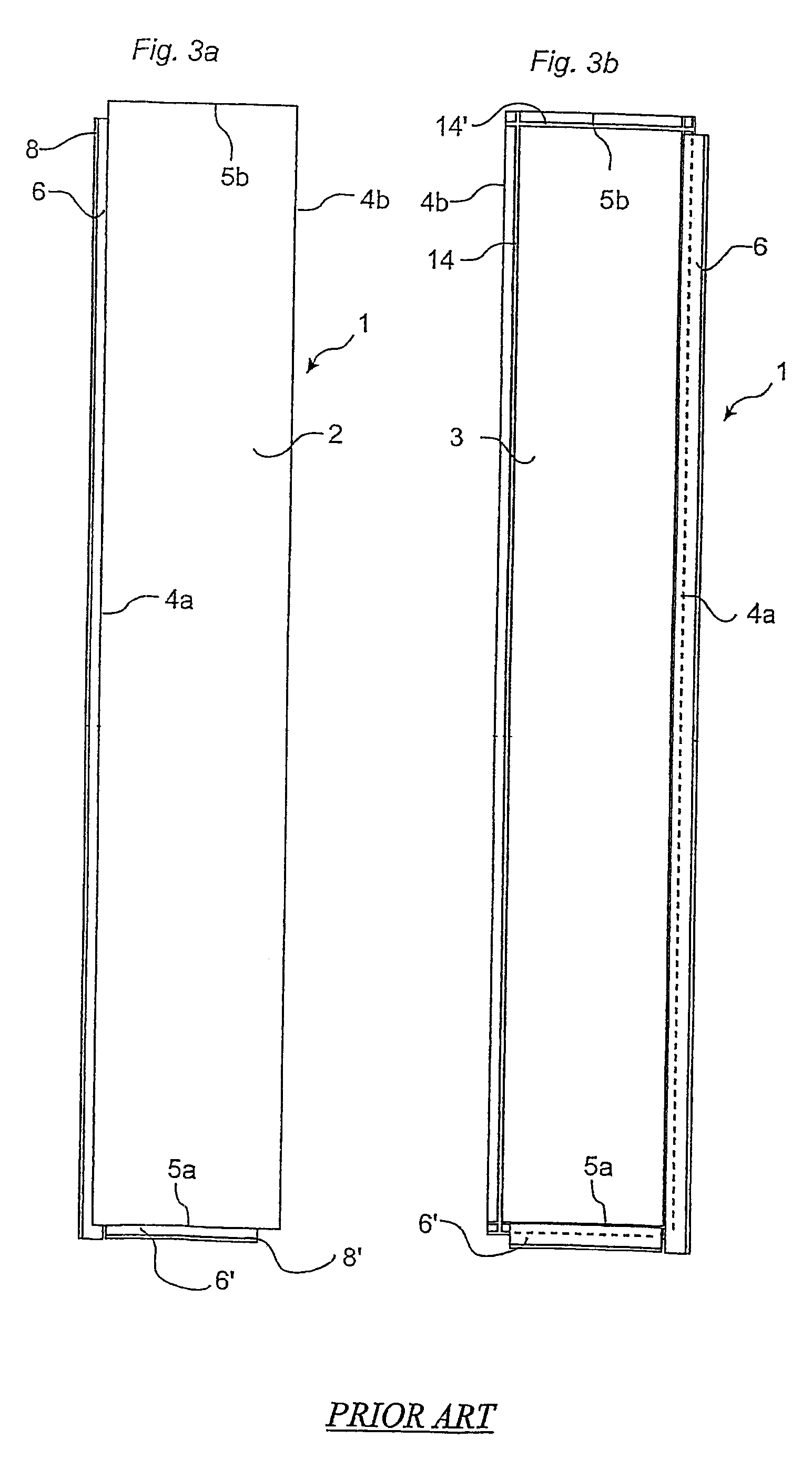

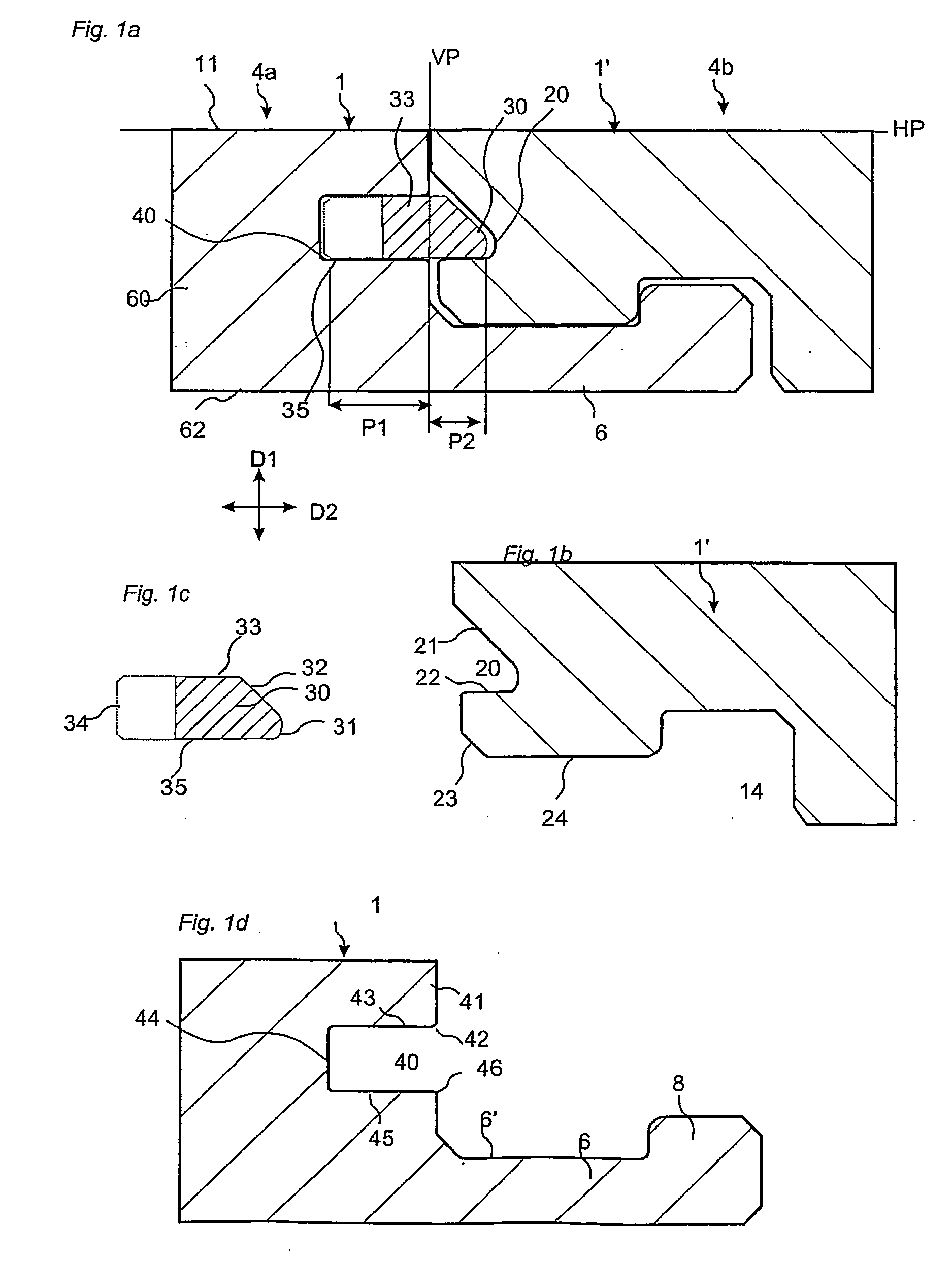

Mechanical locking system for floorboards

InactiveUS20060070333A1High strength requirementsCost advantageTongue/grooves making apparatusWallsEngineeringMechanical engineering

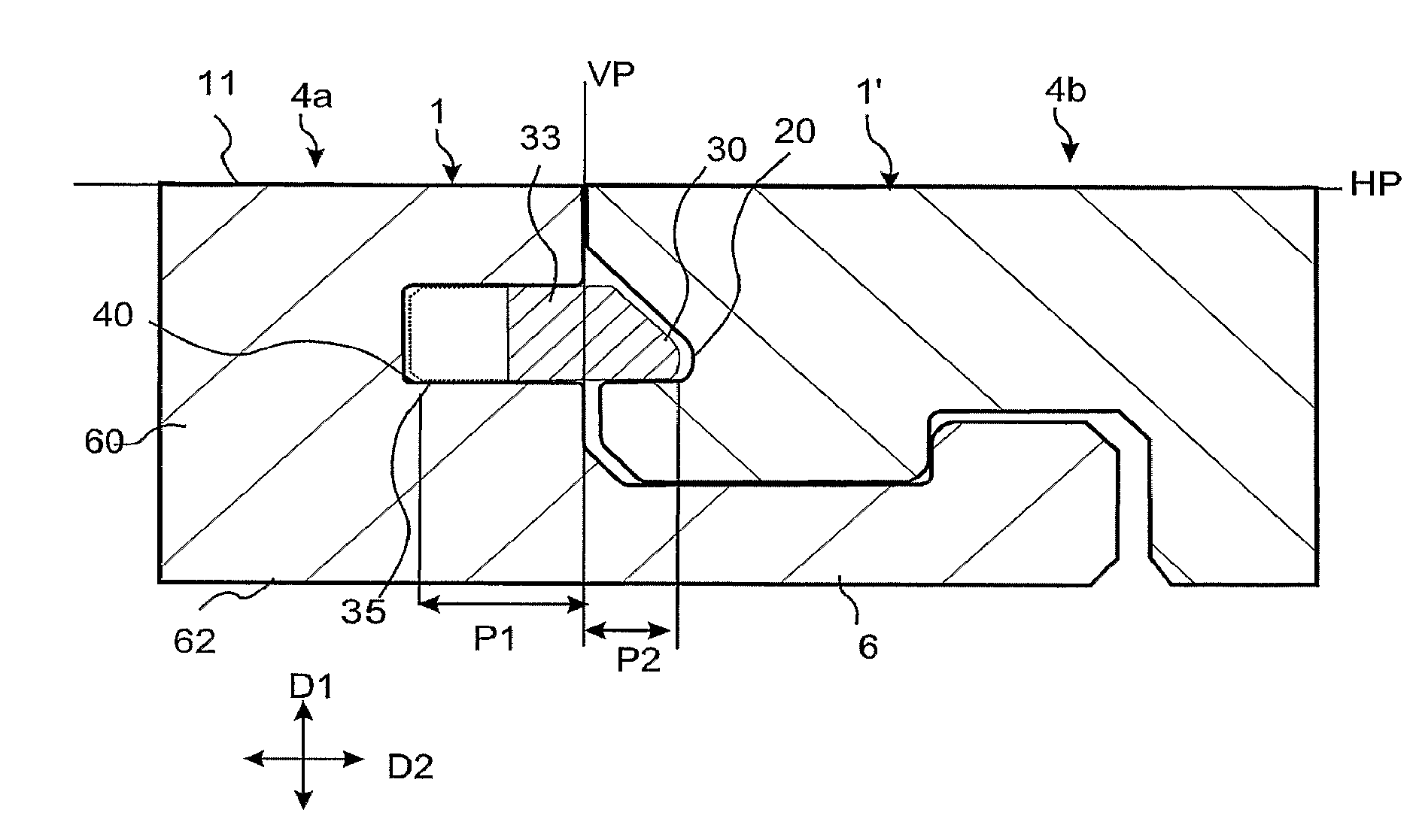

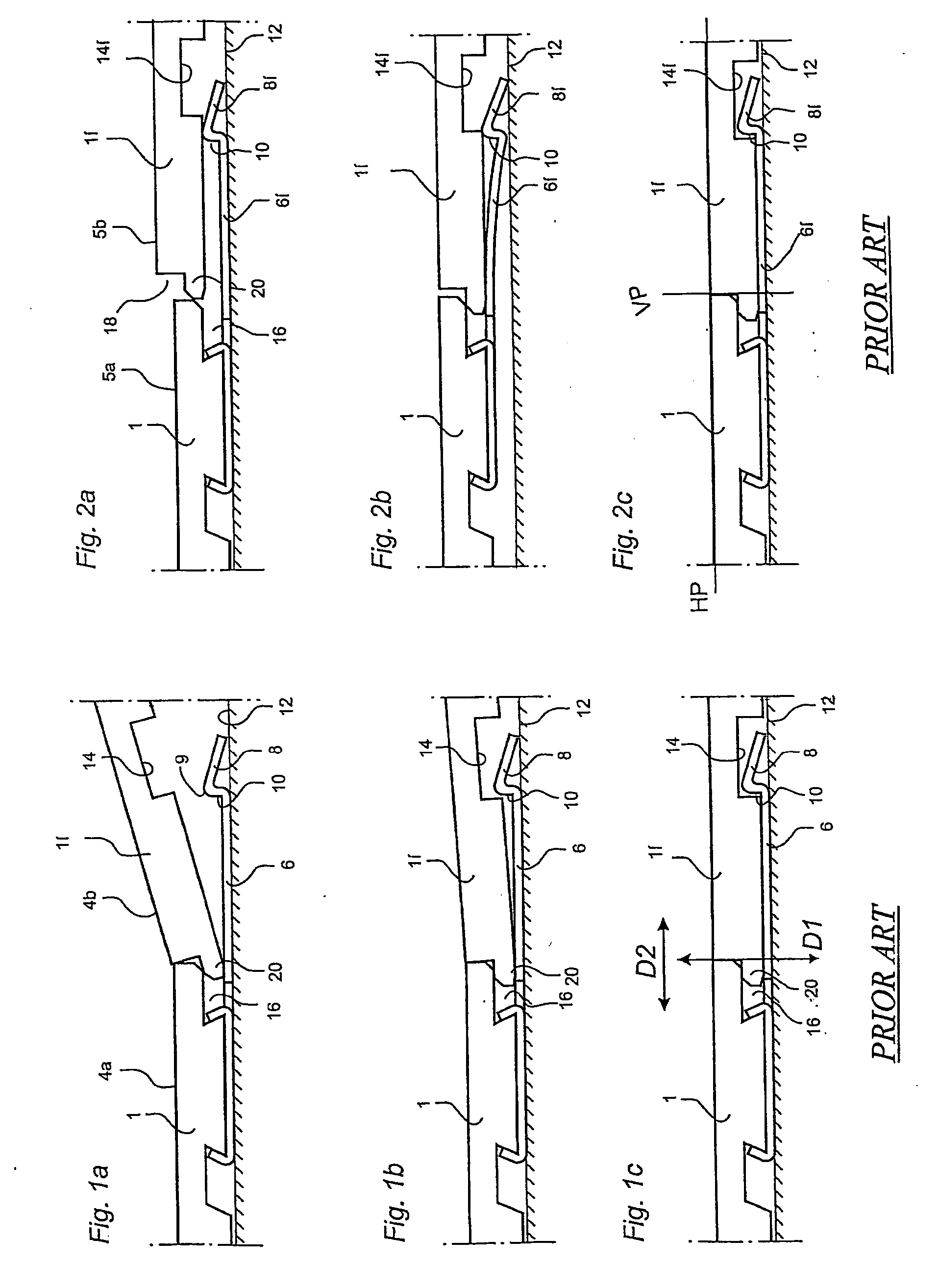

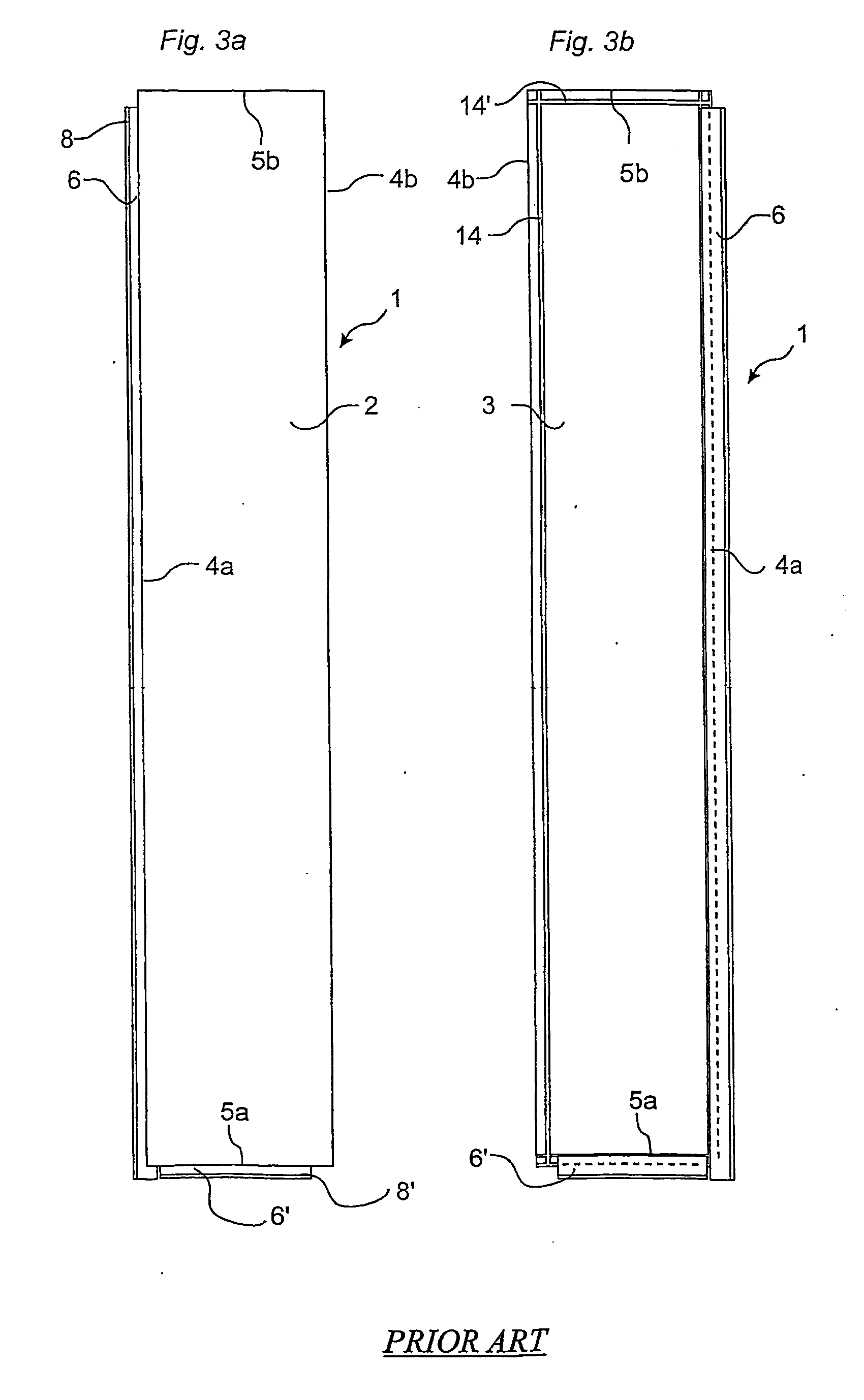

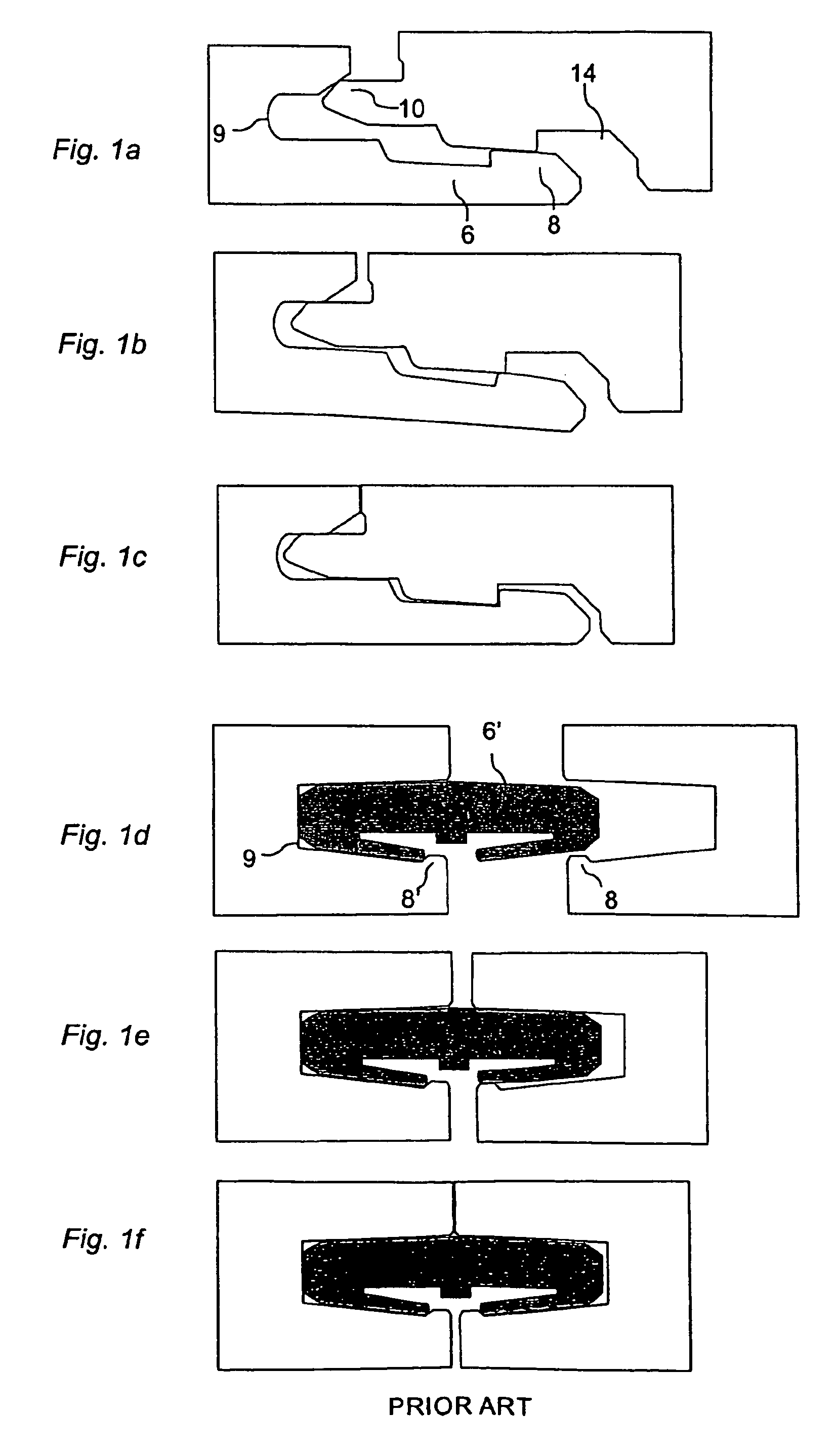

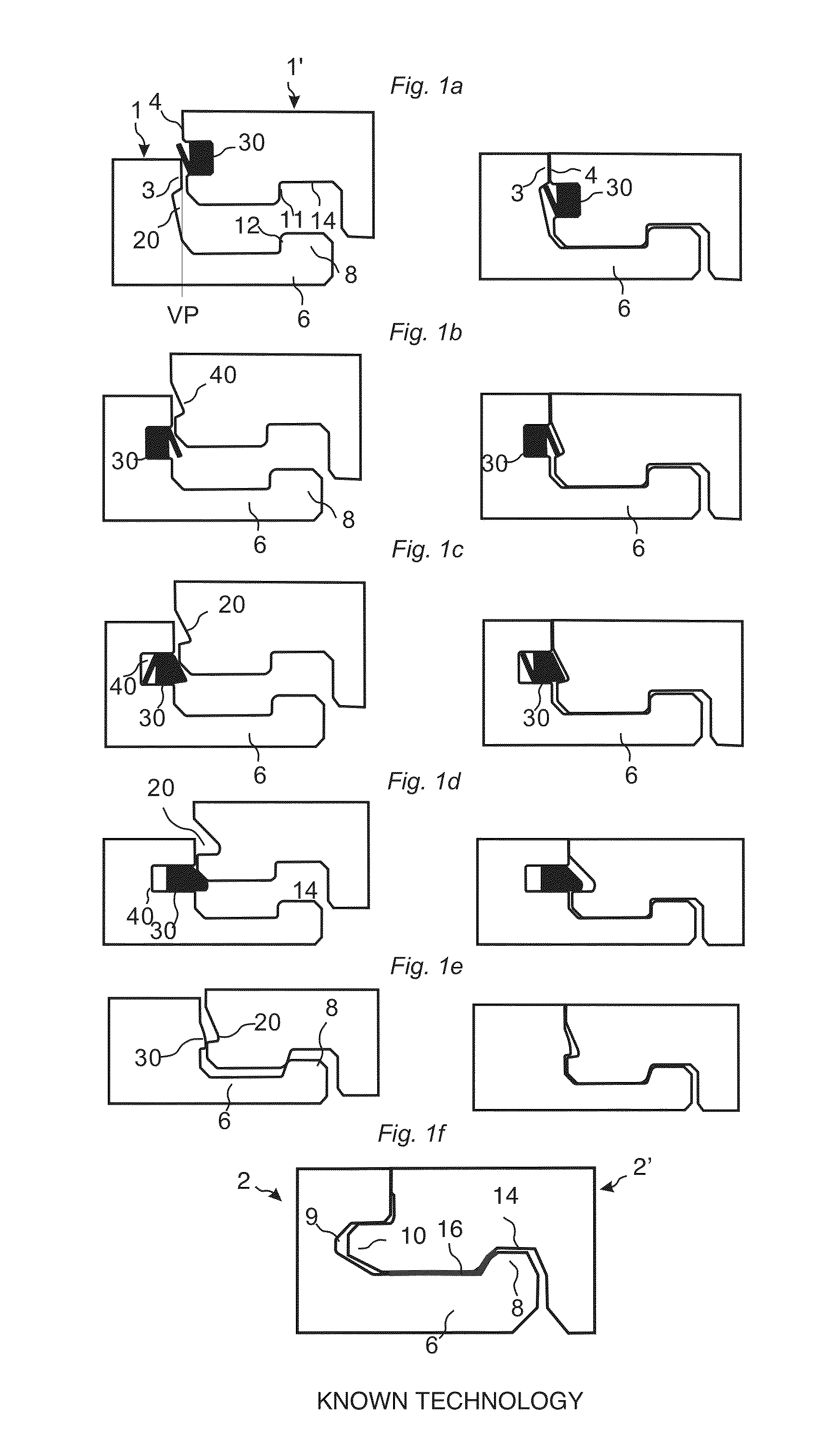

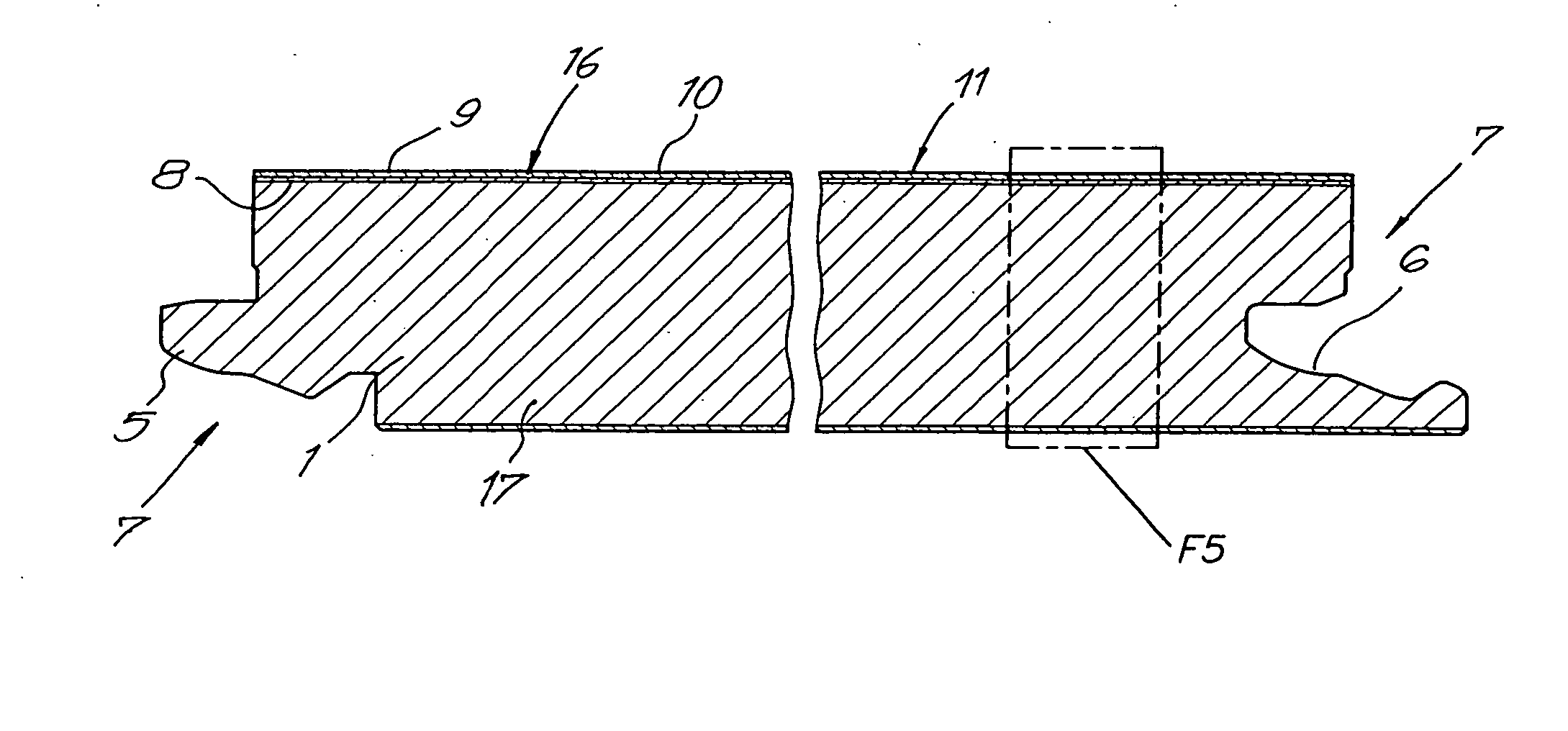

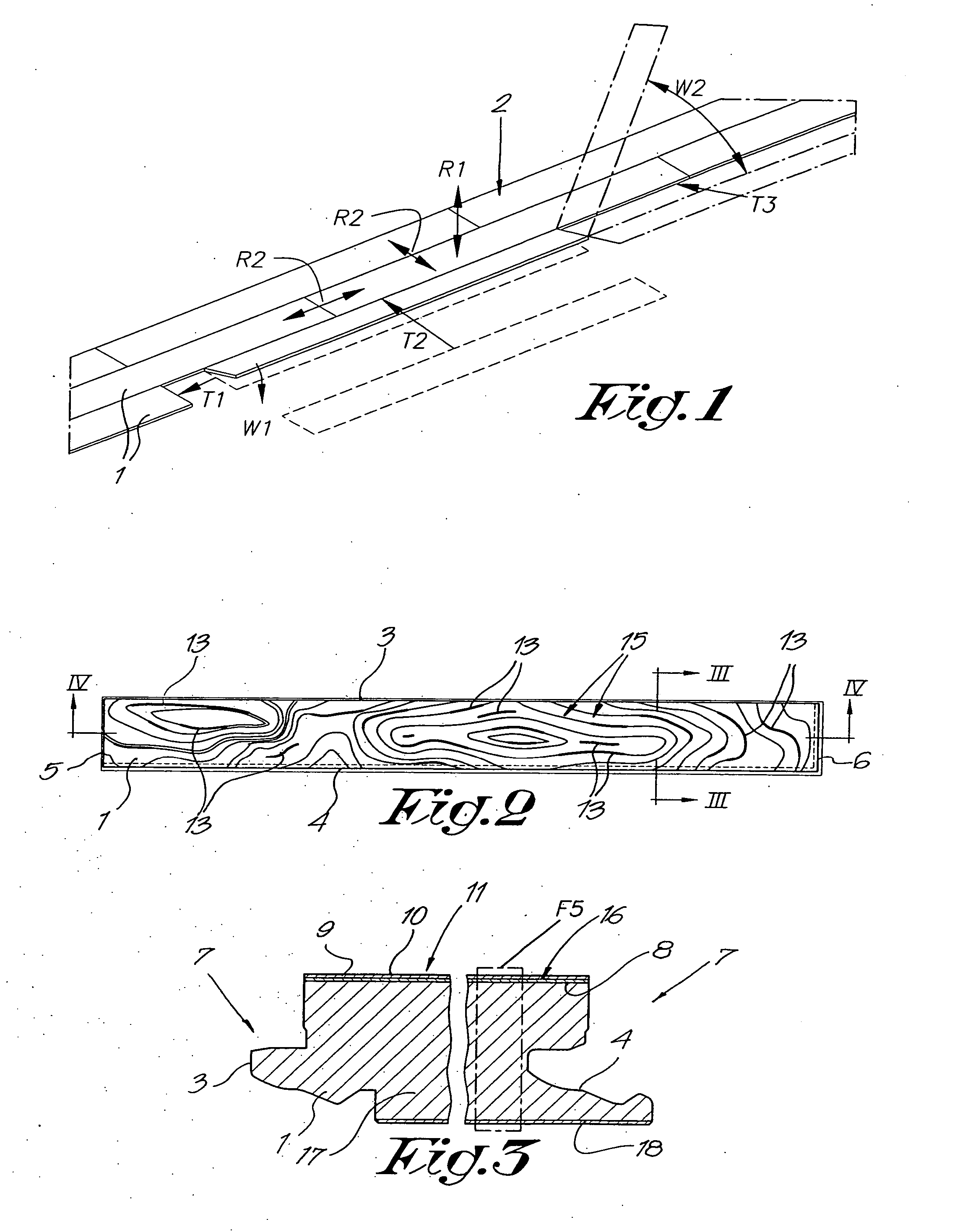

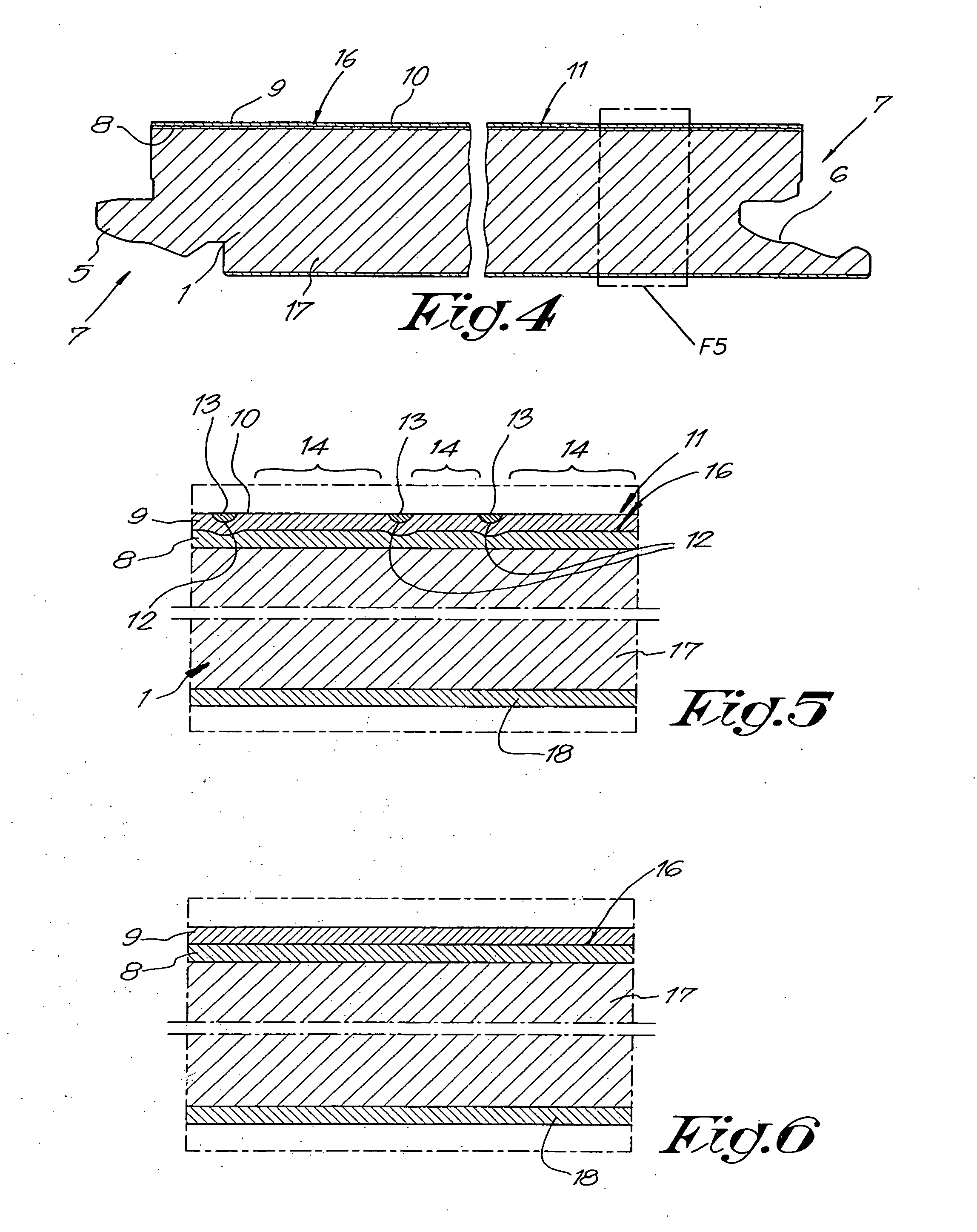

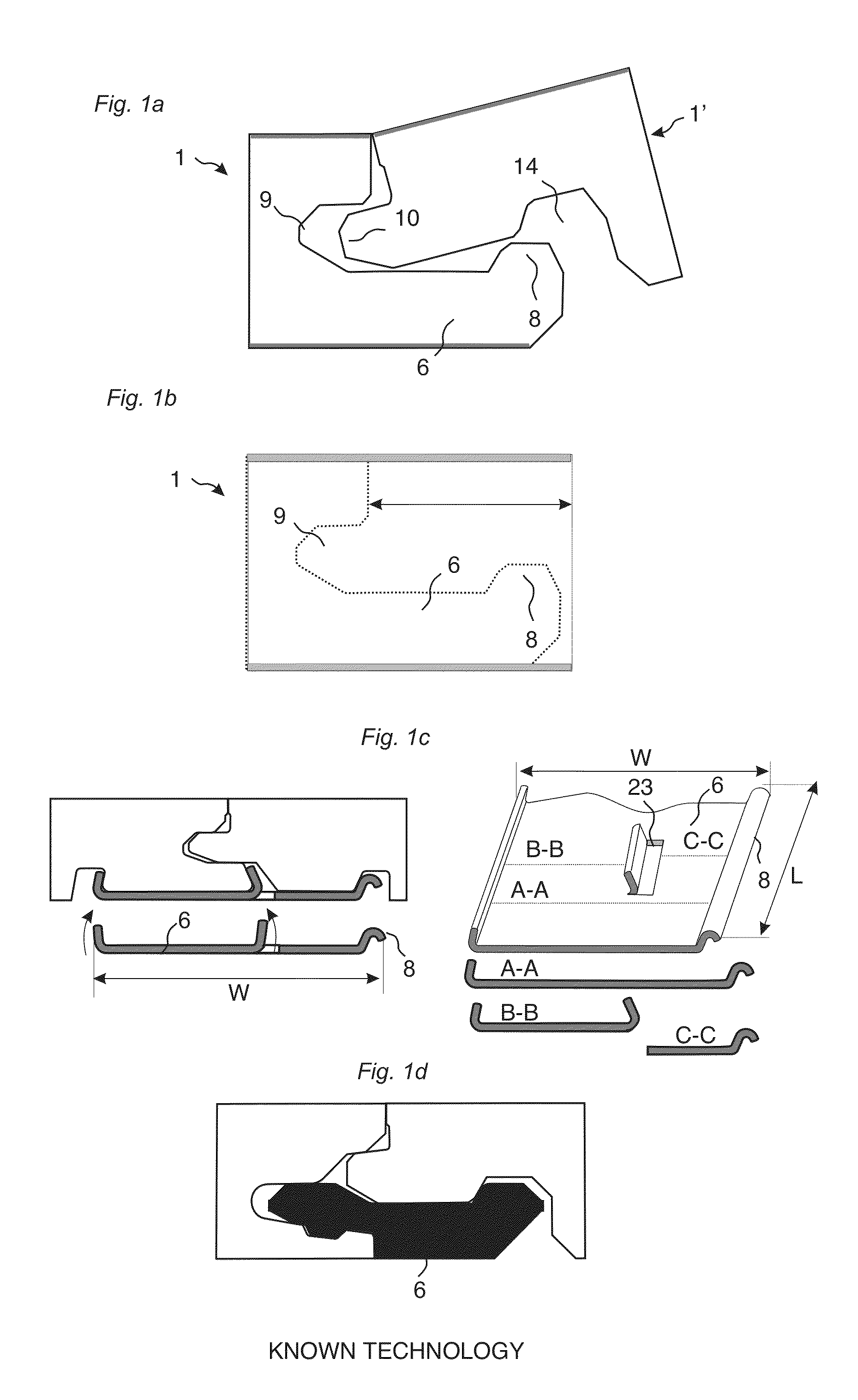

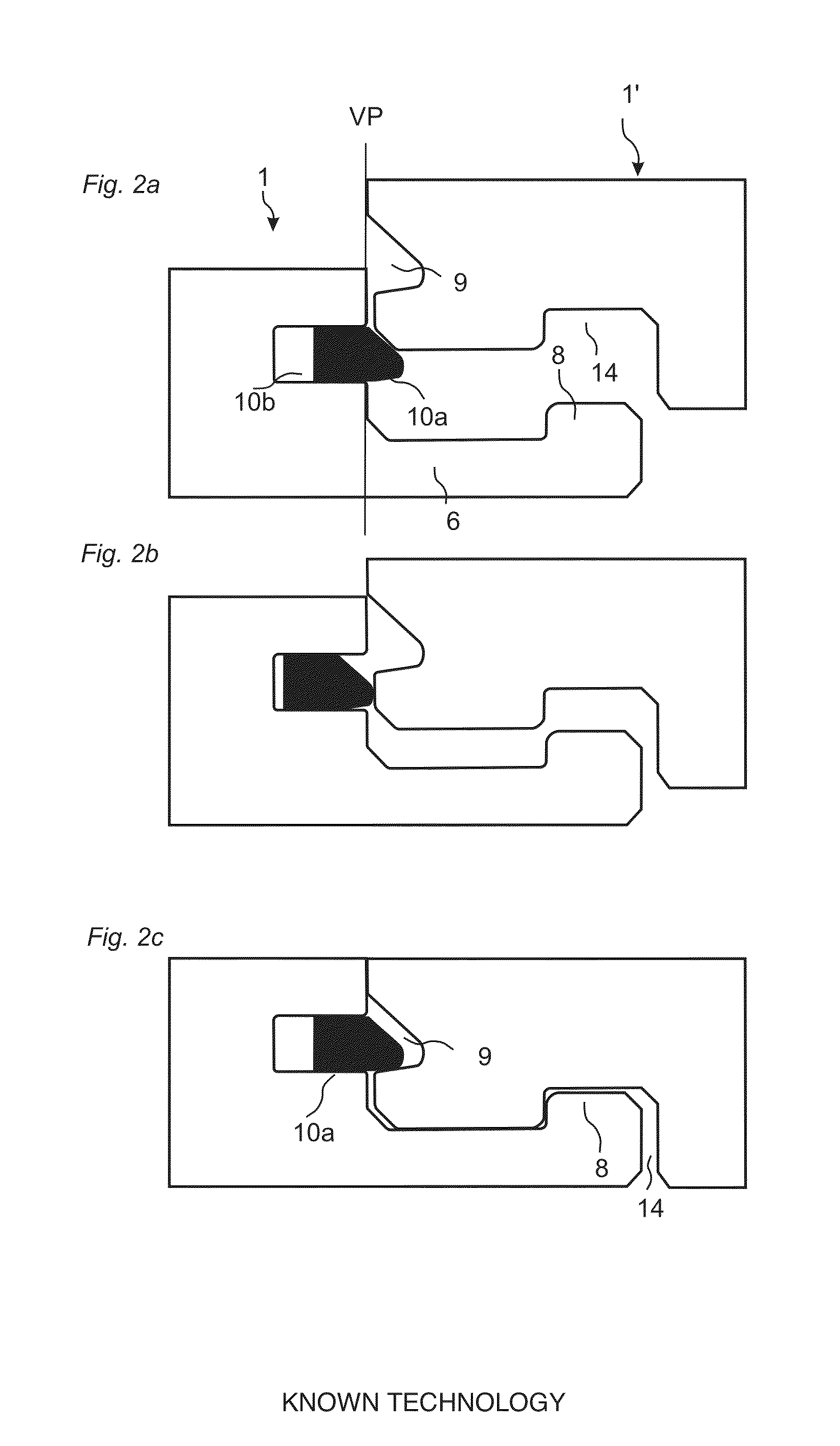

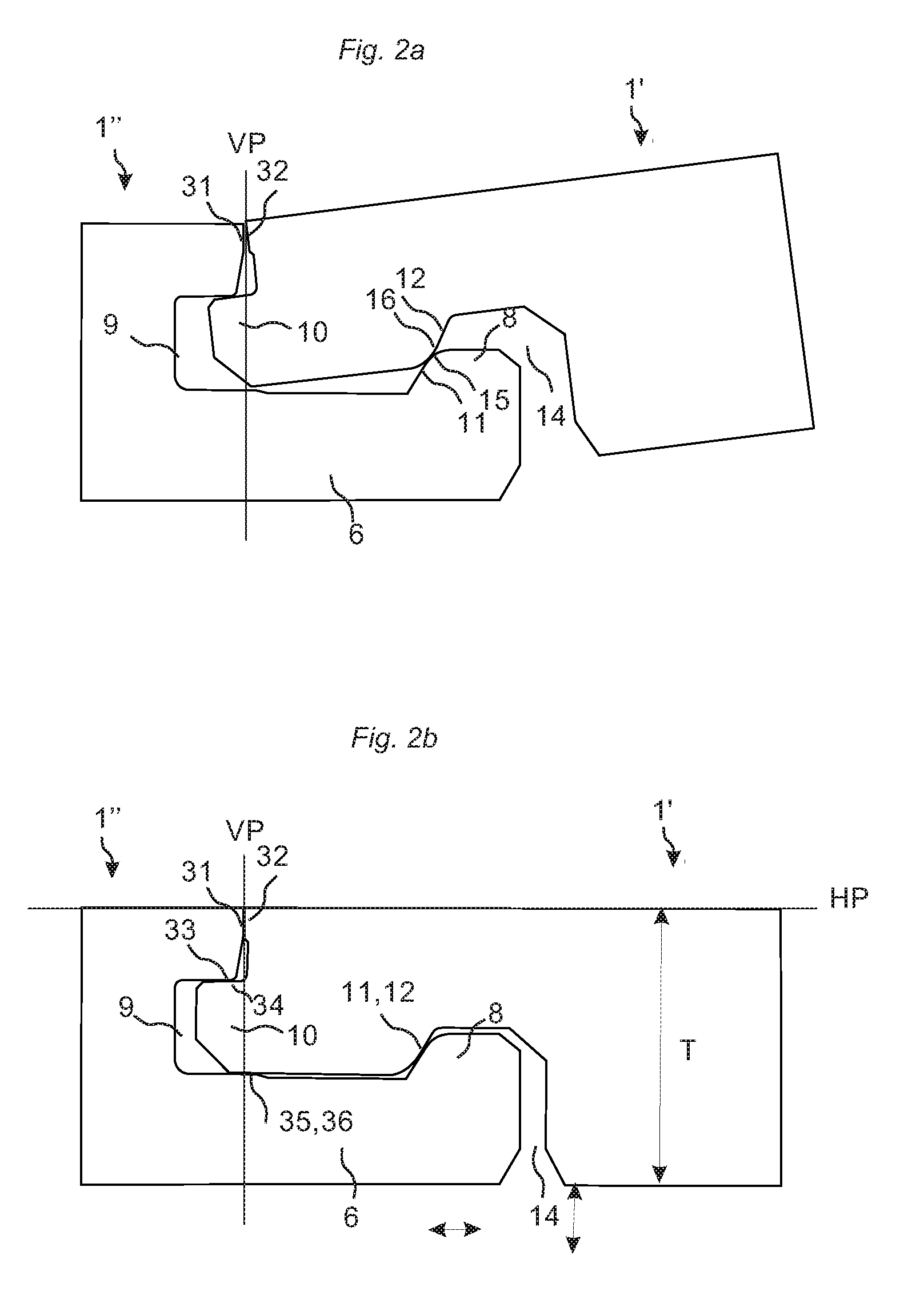

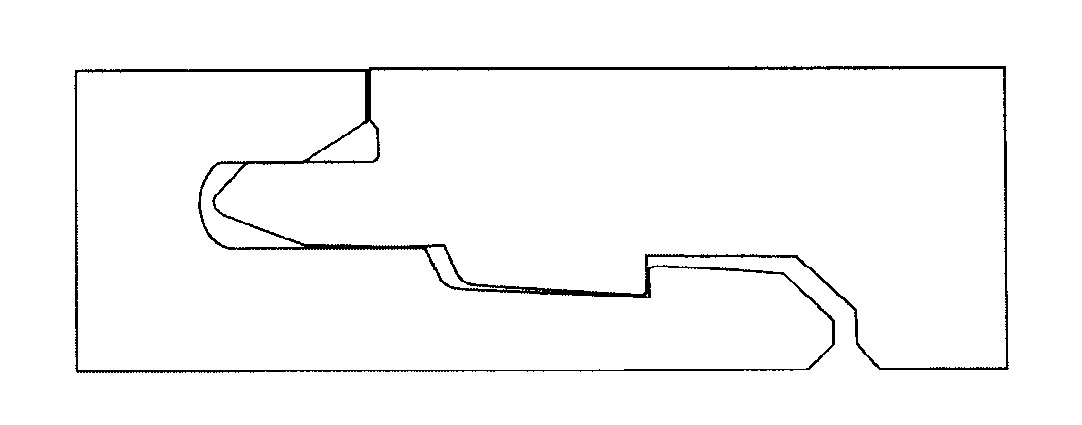

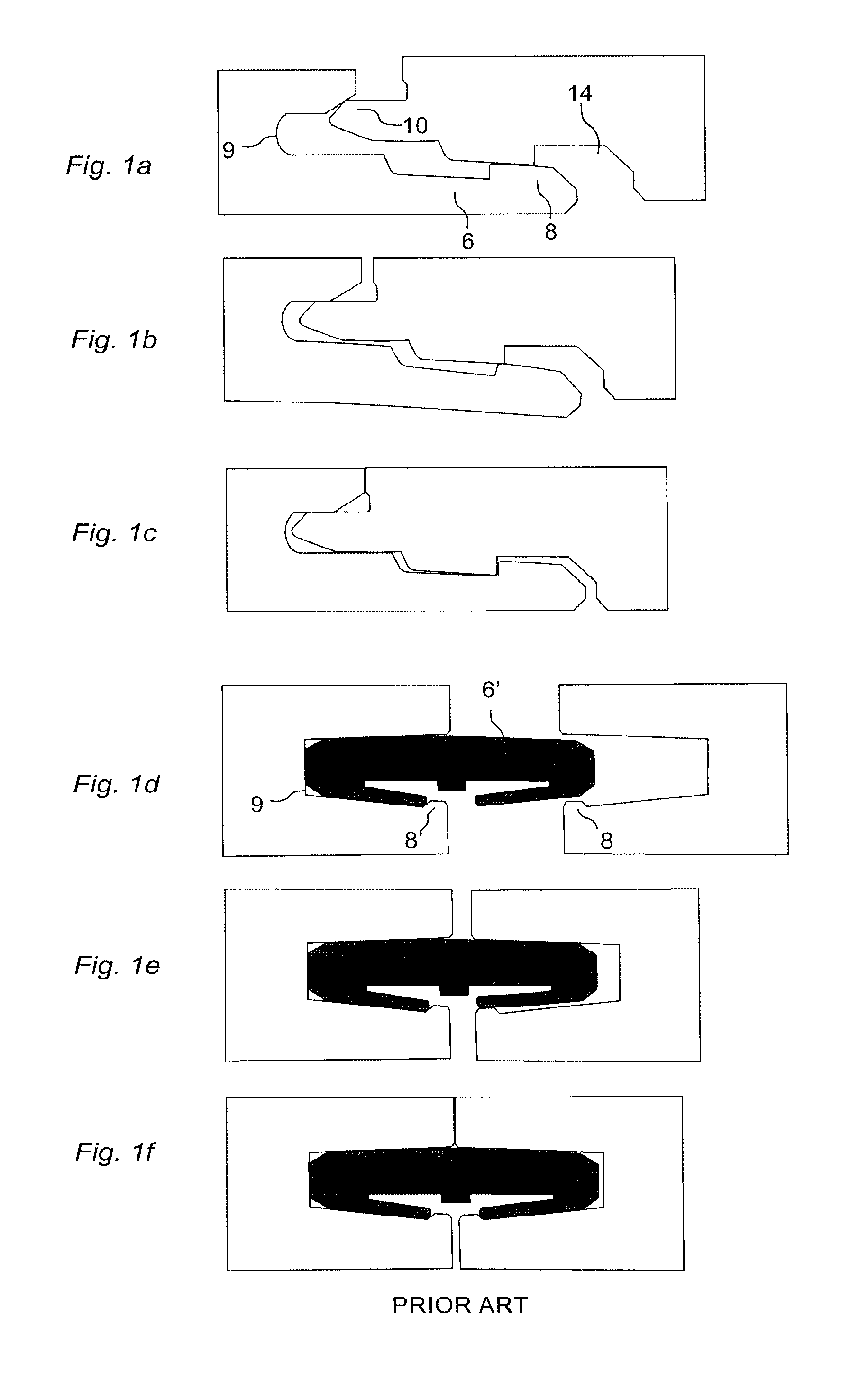

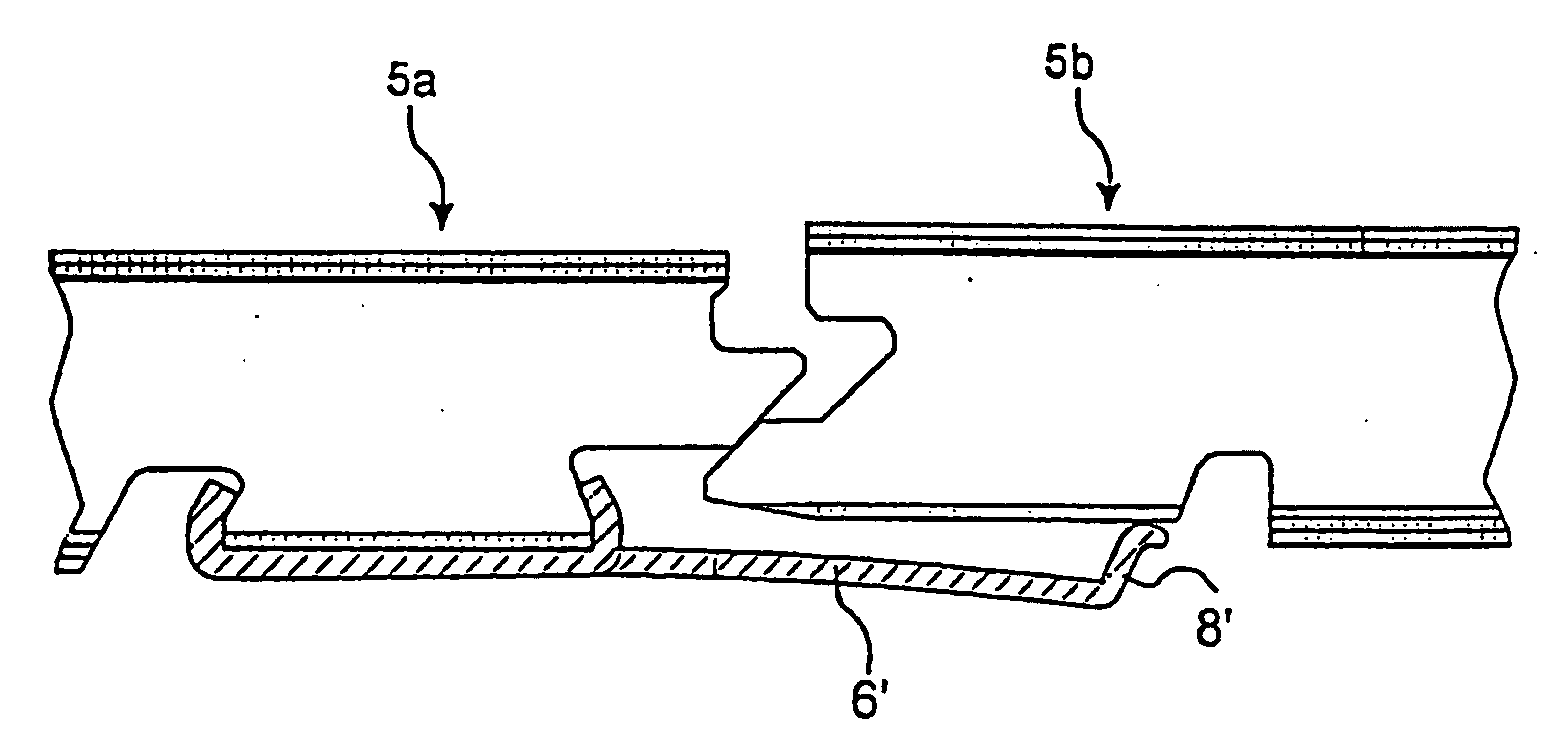

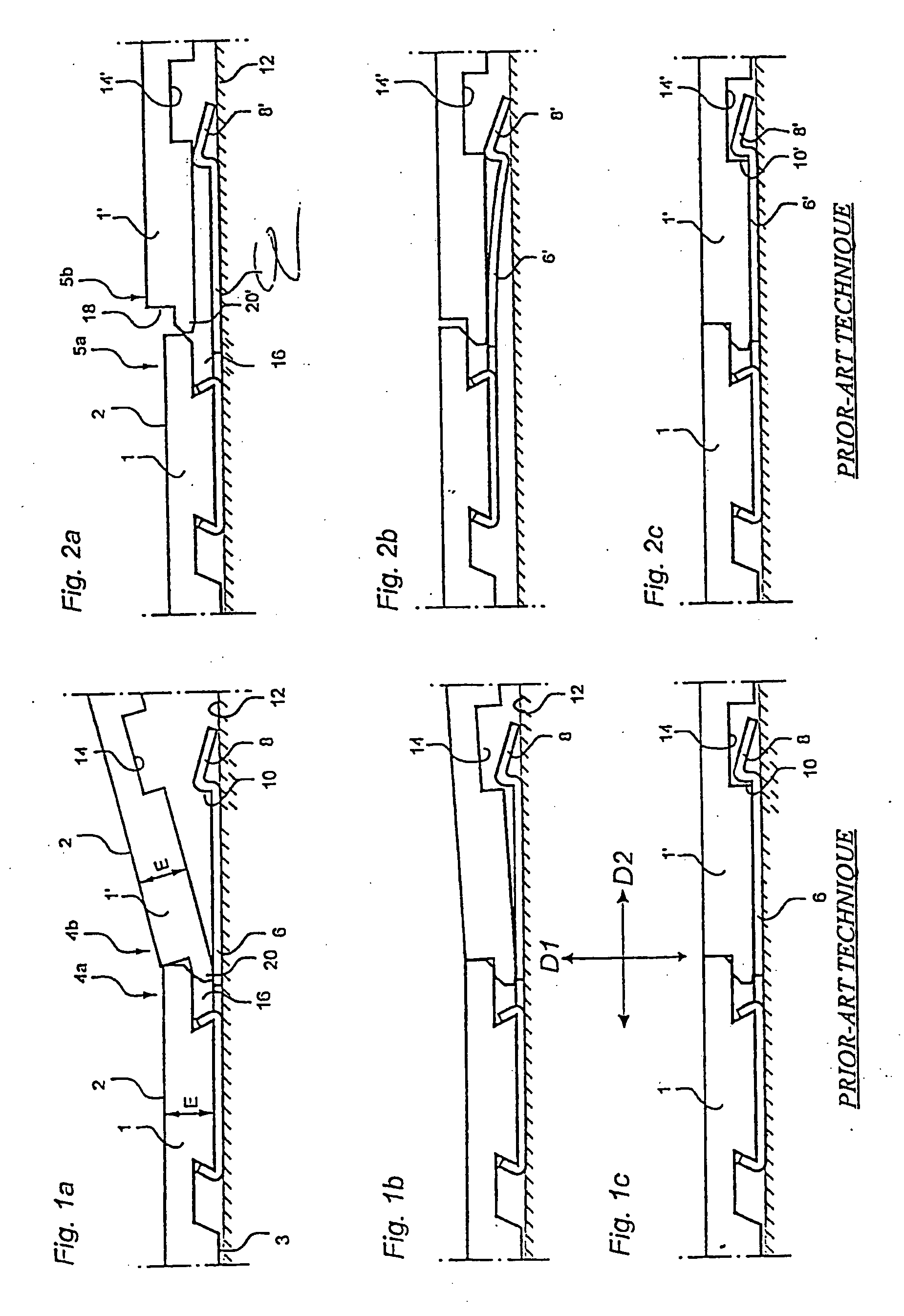

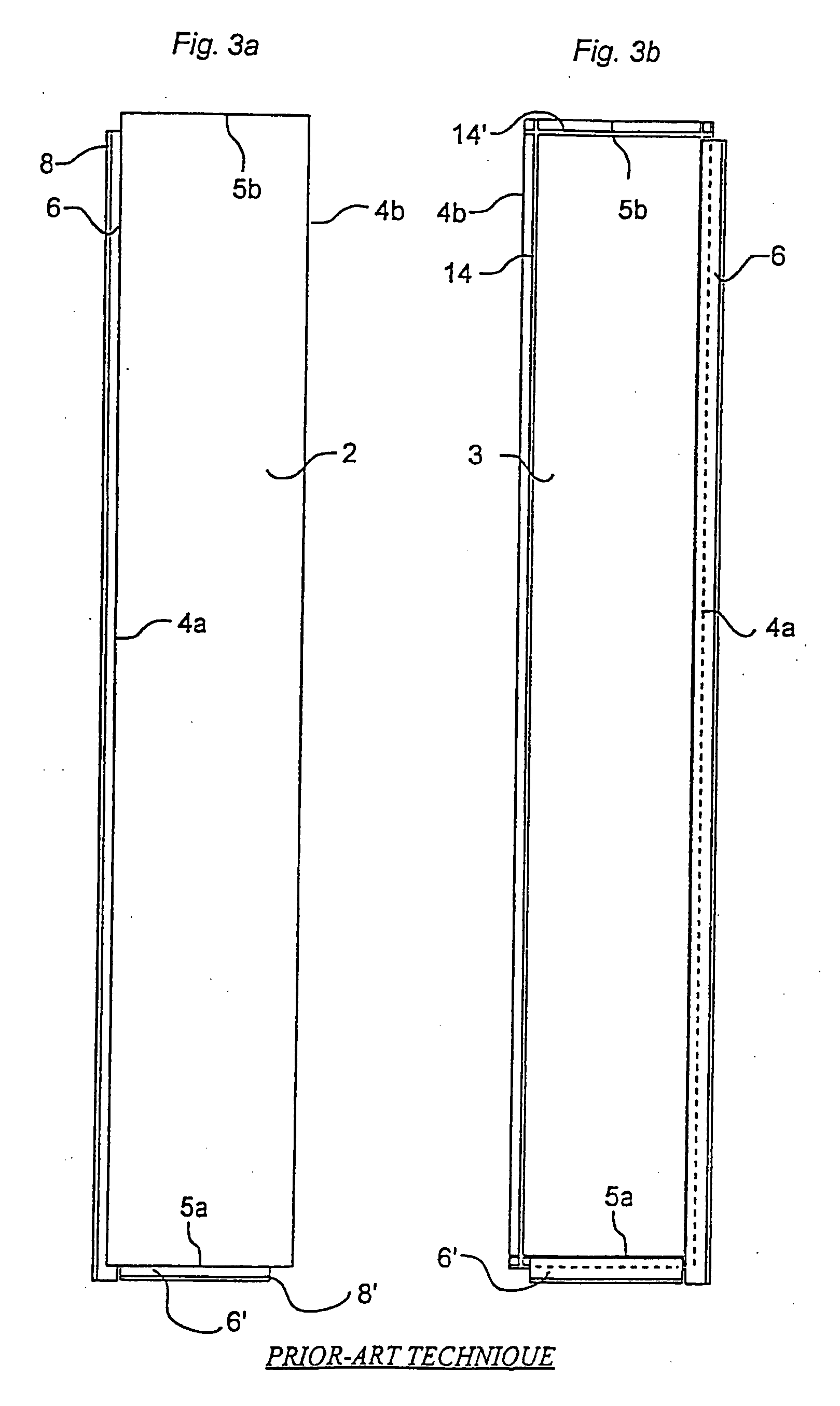

Floorboards (1, 1′) are shown, which are provided with a mechanical locking system consisting of a separately machined locking strip (6) which is mechanically joined with the floorboard (1), the locking strip (6) being designed for mechanical fixing to the floorboard (1) by means of a joint, which is operable by snapping-in and / or inward angling, and the locking strip (6) being designed to connect the floorboard (1) with the essentially identical floorboard (1′) by at least inward angling. Moreover, a locking strip, a strip blank, a set of parts for making a floorboard and methods for manufacturing a floorboard and a locking strip, respectively, are shown.

Owner:VÄLINGE INNOVATION AB

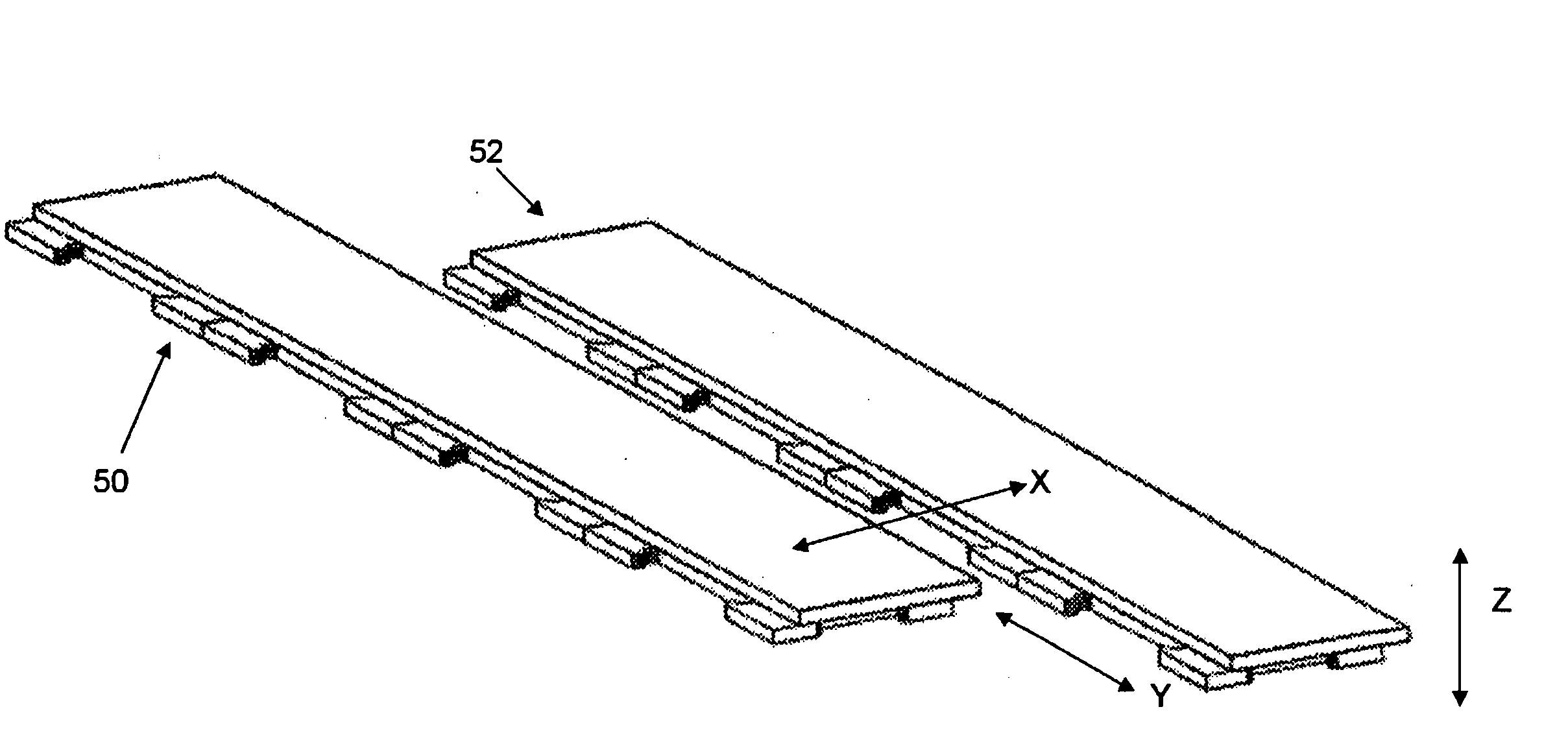

Mechanical locking of floor panels, methods to install and uninstall panels, a method and an equipement to produce the locking system, a method to connect a displaceable tongue to a panel and a tongue blank

ActiveUS20110030303A1Avoid resistanceAvoid separationCovering/liningsTongue/grooves making apparatusTongue and grooveFace sheet

Floor panels are shown, which are provided with a mechanical locking system including tongue and grooves provided with protrusions and cavities which are displaceable in relation to each other and configured such that the protrusions can obtain a vertically unlocked position where they match the cavities and a vertically locked position where the protrusions overlap each other.

Owner:VÄLINGE INNOVATION AB

Mechanical locking system for floorboards

InactiveUS20080041008A1Rational and cost-efficientTongue/grooves making apparatusFloorsClassical mechanicsEngineering

Floorboards (1, 1′) are shown, which are provided with a mechanical locking system consisting of a separately machined locking strip (6) which is mechanically joined with the floorboard (1), the locking strip (6) being designed for mechanical fixing to the floorboard (1) by means of a joint, which is operable by snapping-in and / or inward angling, and the locking strip (6) being designed to connect the floorboard (1) with the essentially identical floorboard (1′) by at least inward angling. Moreover, a locking strip, a strip blank, a set of parts for making a floorboard and methods for manufacturing a floorboard and a locking strip, respectively, are shown.

Owner:VÄLINGE INNOVATION AB

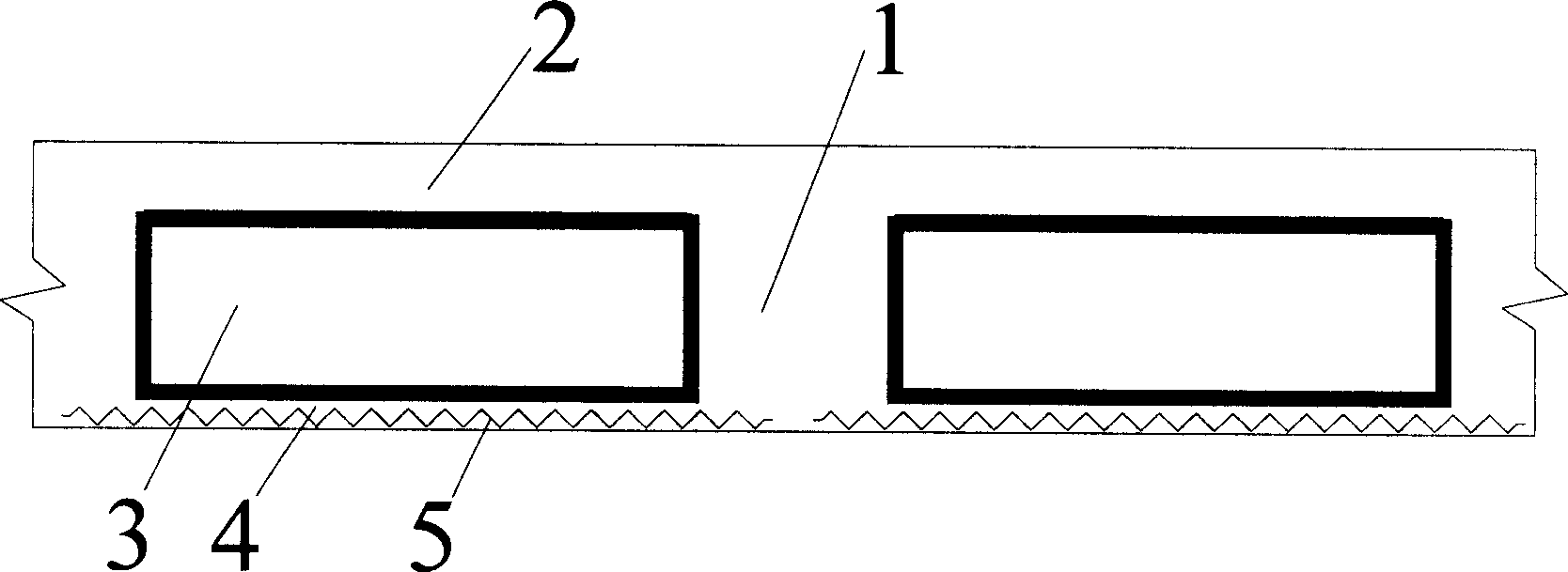

Hollow floor slab with small dense ribs and its production process

InactiveCN1637217ALarge spanSafe and reliable structureFloorsForms/shuttering/falseworksFloor slabLine tubing

The hollow floor slab includes column, solid belt, solid reinforced beam with dense ribs, reinforced facing board, and composite box with lower thin bottom board. The production process includes: a) laying and tying reinforcing steel bar in the floor slab formwork; b) laying the steel wire net and other reinforcing material; c) setting and fixing made composite thin box; d) tying reinforcing steel bar for the facing board; e) fixing reinforcing bars with iron wire; and f) embedding prefabricated pipeline inside the facing board and the dense ribs. The present invention may produce flat sealed floor slab cavity with dense ribs in once deposition.

Owner:HUNAN BDF ENERGY SAVING TECH

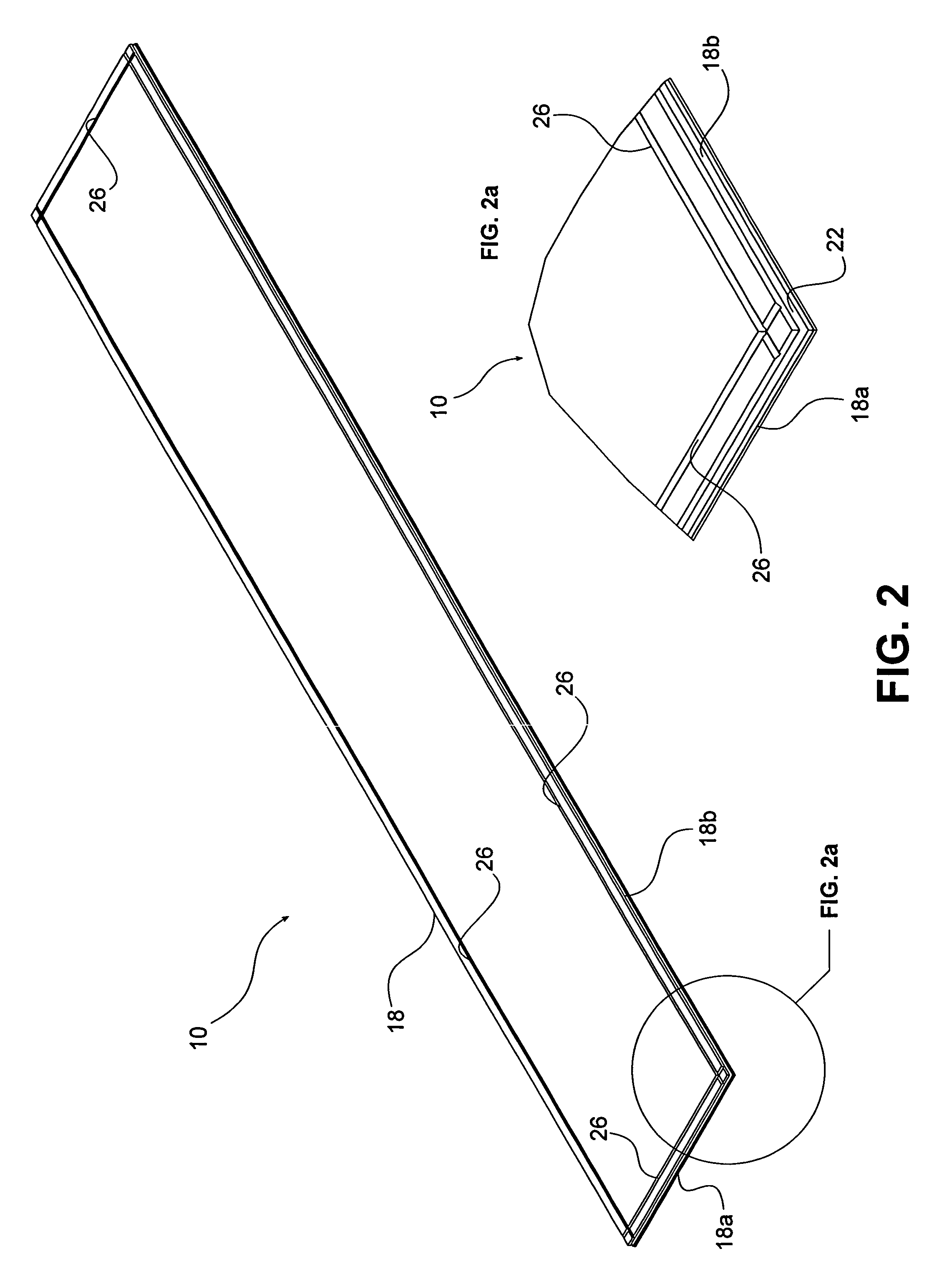

Glider bar for flooring system

A flooring system for use with floating floors is described which includes a glider bar having base portions including extending rails in the form of dovetail protrusions. The bases and rails are longitudinally moveable relative to anchoring plates, which anchoring plates are affixed to a subflooring. Flush finished floor moldings are slid longitudinally along the rails and are glued or mechanically fixed, at one side only, to the adjacent floating laminate flooring. By this assembly, smooth transitions between adjacent floating floors, or where floating floors meet another hard floor covering, or carpet, can be achieved. The system can also be used with flush stair nosing elements.

Owner:PERGO

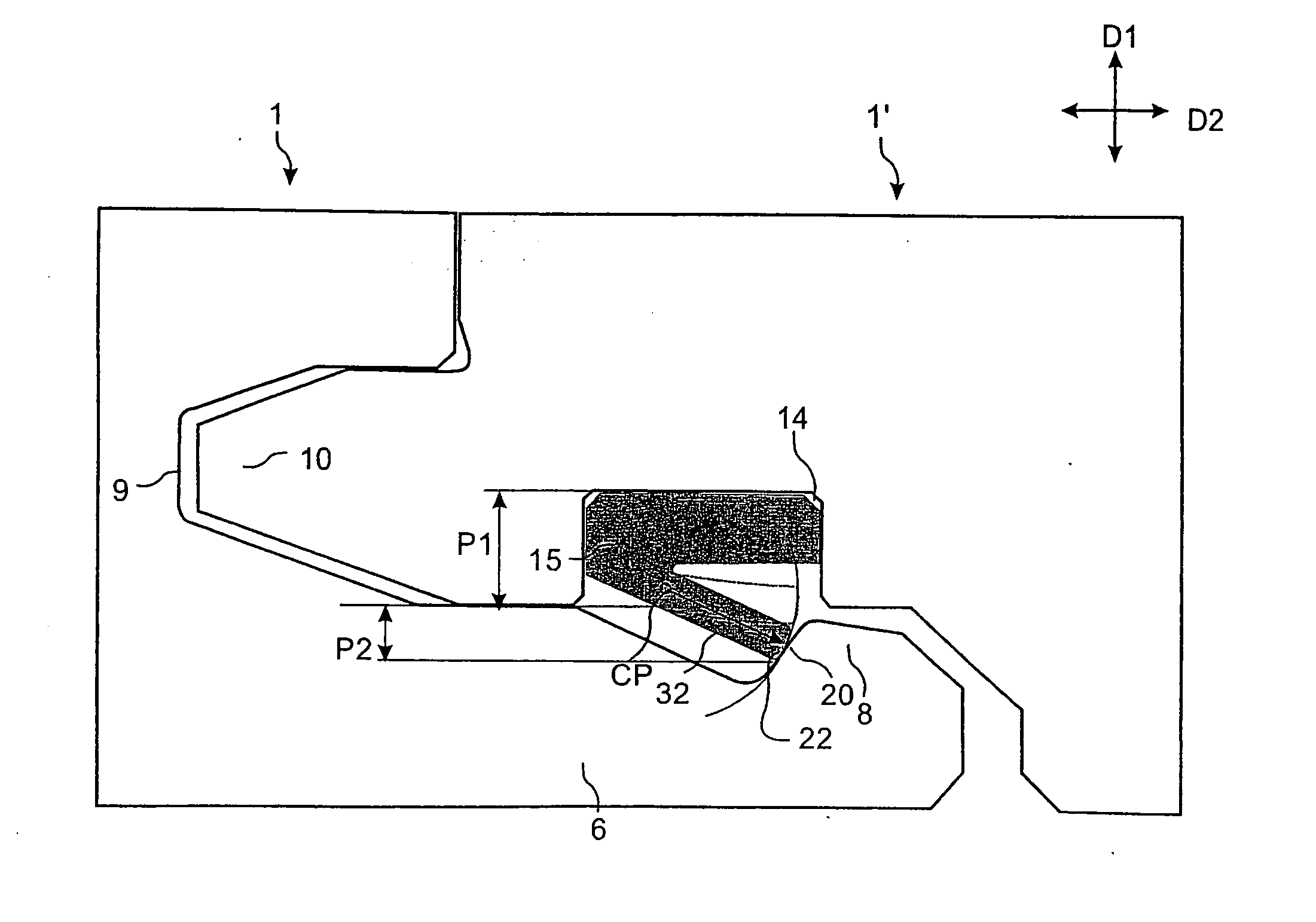

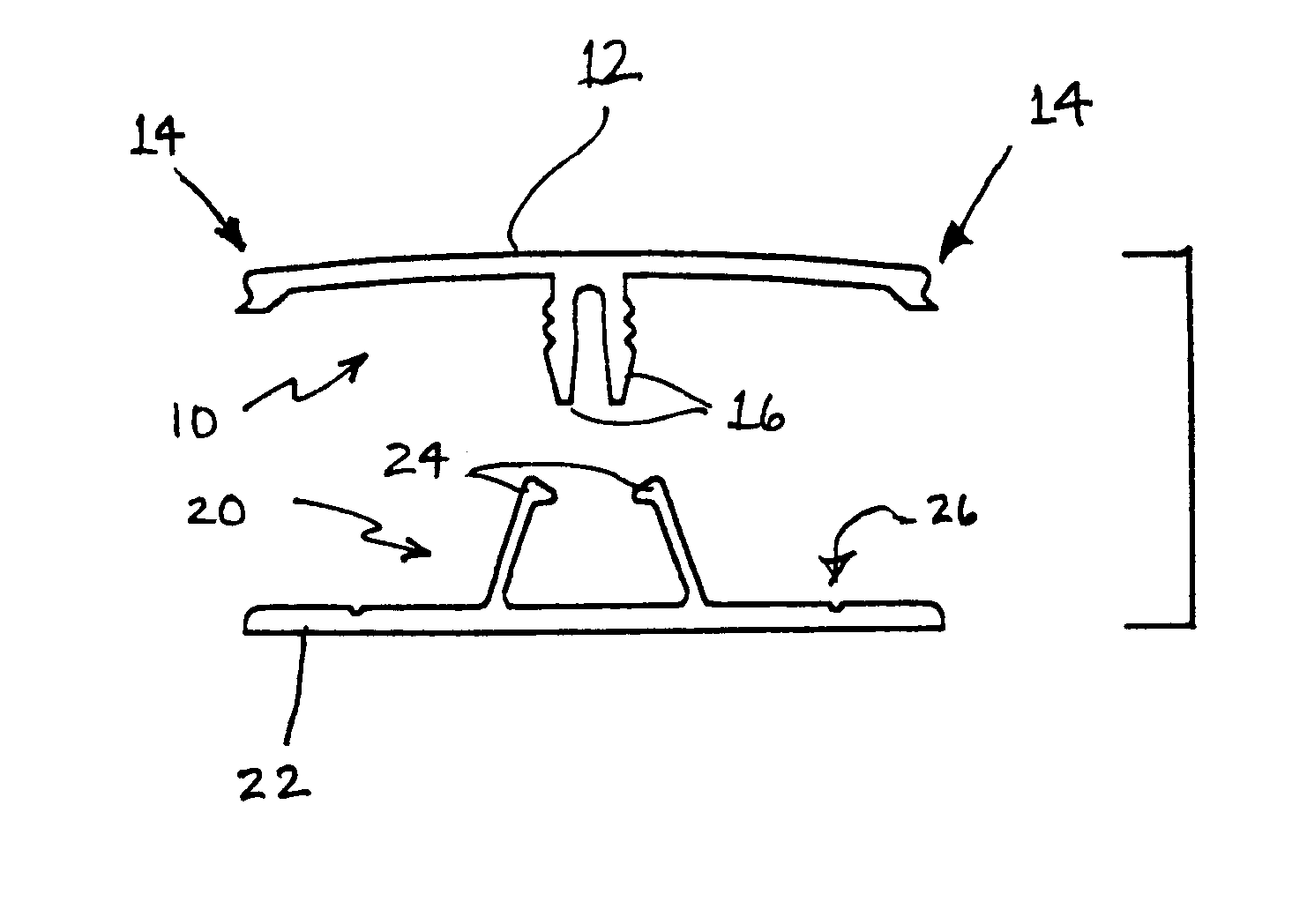

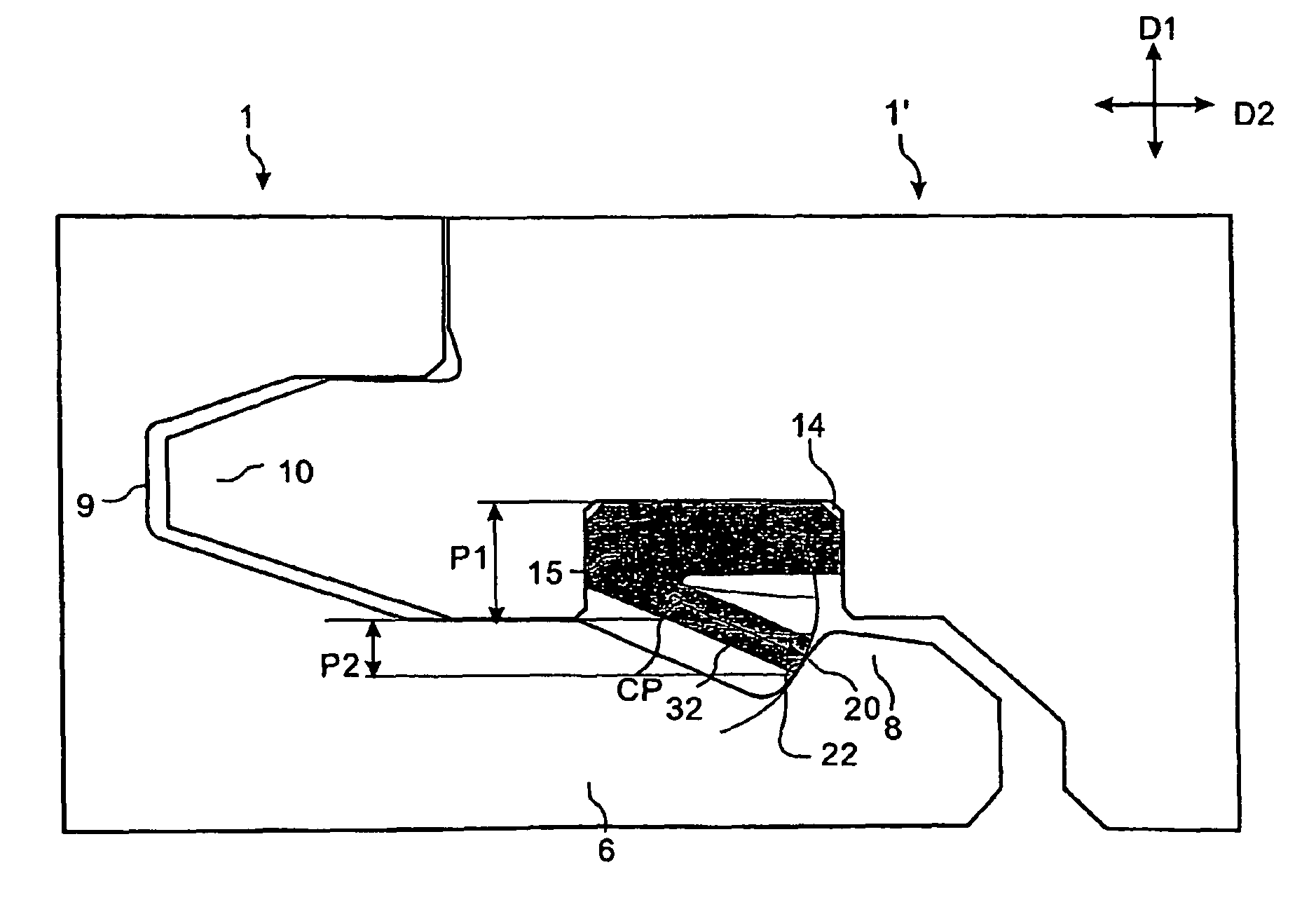

Mechanical locking system for panels and method of installing same

ActiveUS7841145B2Function increaseLower resistanceCovering/liningsWallsEngineeringMechanical engineering

Floor panels are provided with a mechanical locking system including a flexible locking element in a locking groove, which during a horizontal motion is displaced vertically.

Owner:VÄLINGE INNOVATION AB

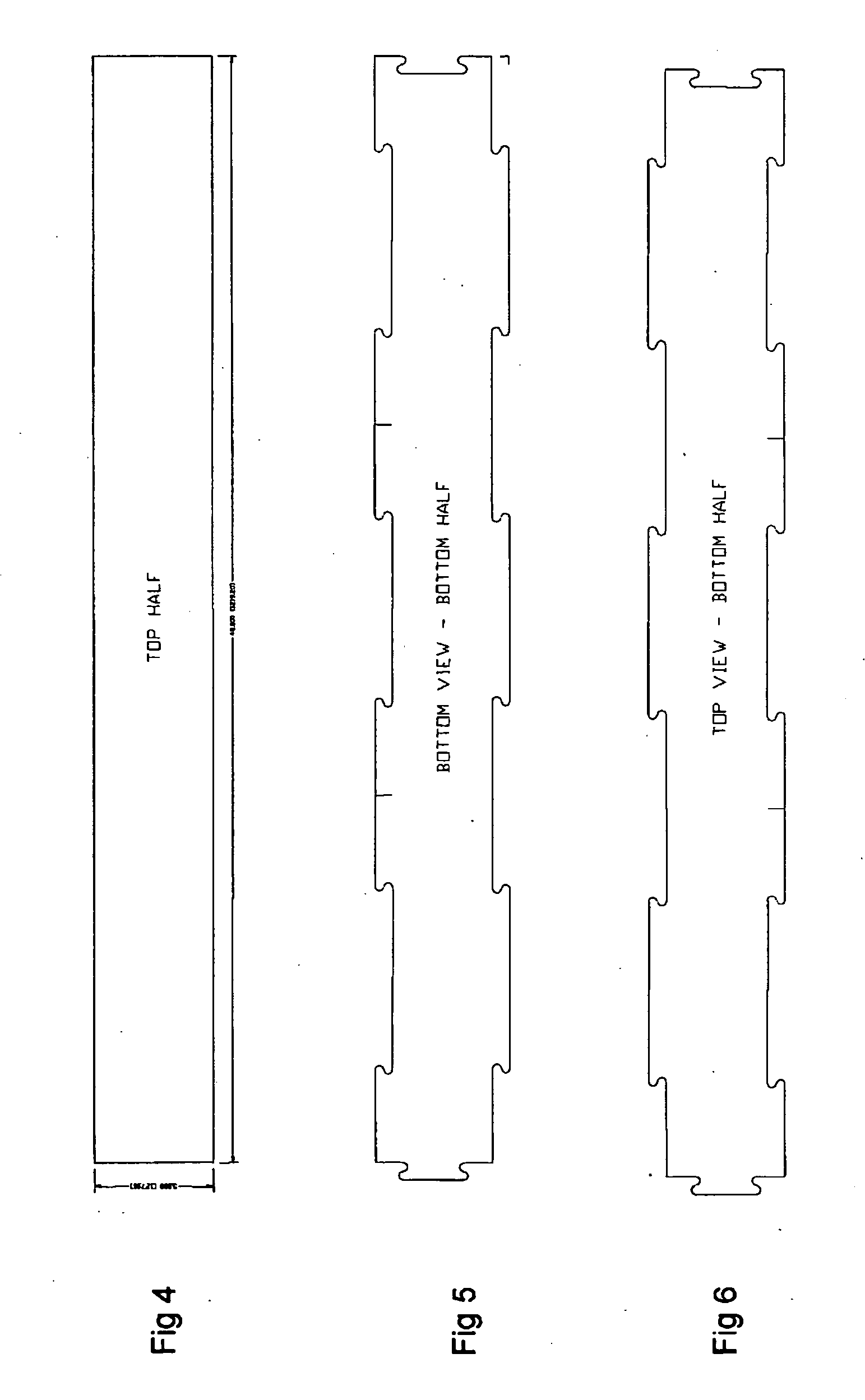

Floor Covering With Interlocking Design

Surface coverings, such as floor coverings, with an interlocking design are described. Methods of making the surface coverings are further described.

Owner:VÄLINGE INNOVATION AB

Mechanical locking of floor panels with a flexible tongue

Floor panels are shown which are provided with a mechanical locking system consisting of an extruded flexible tongue in a sidewardly open groove which during a vertical folding motion is bent horizontally.

Owner:VÄLINGE INNOVATION AB

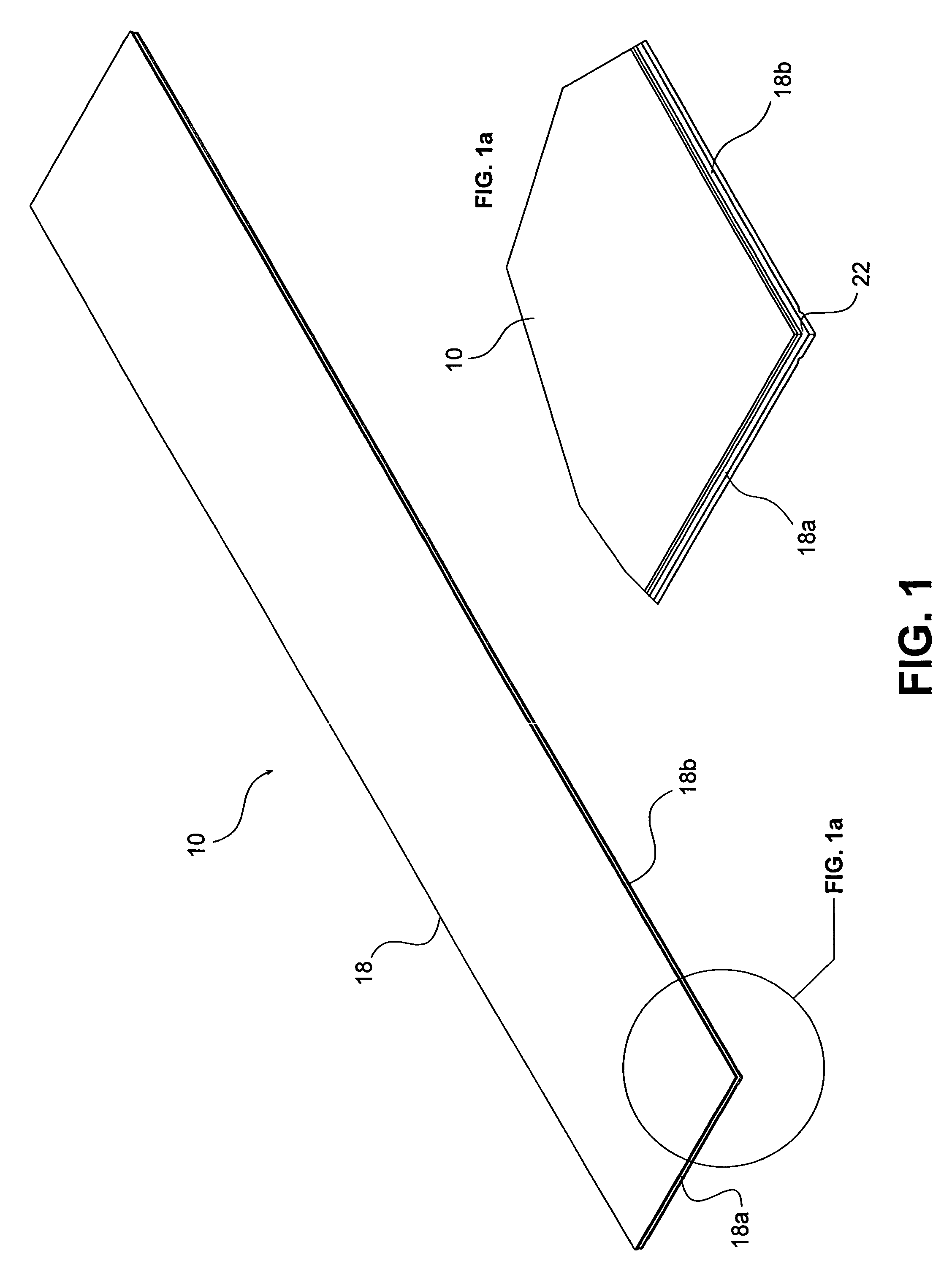

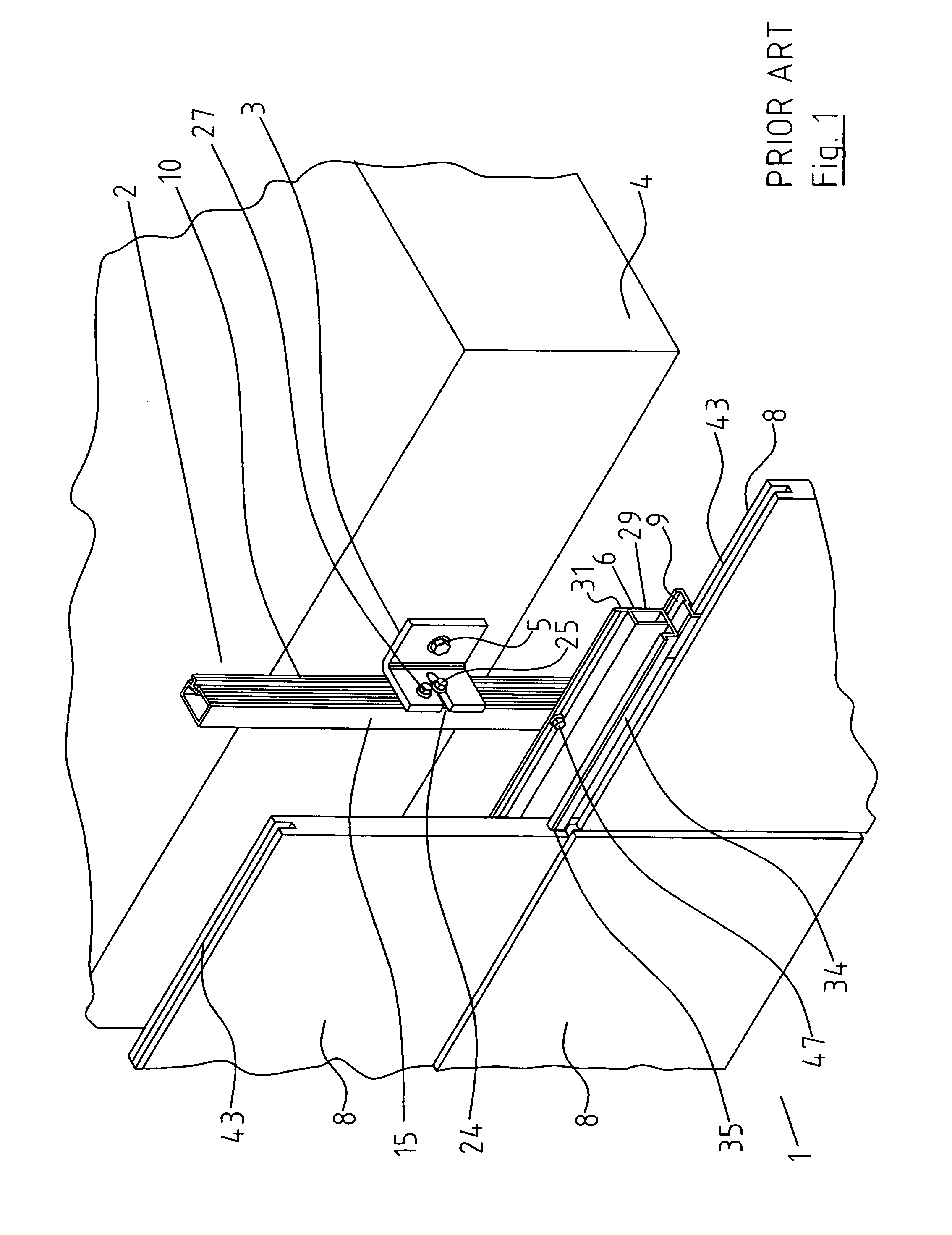

Method of laying panels

InactiveUS6546691B2Increase displacementAvoid the needRoof covering using tiles/slatesWallsEngineeringMutual position

The present invention provides a method of laying and mechanically joining panels, especially floor panels. In a first step a first panel is already located in a first row. A second panel is positioned in a second row in a first position in relation to the first panel. A third panel is now brought into the second row and into the first position in relation to the first panel. In this position, there is a mutual distance between the adjacent edges of the second and third panel. In a second step the second and third panel are angled into the third mutual position in relation to the first panel. Thereby, the second and third panel each achieve the possibility of easy displacement in the third direction in relation to the first panel. In a third step one or both of the second and third panel are moved in relation to the first panel. By this displacement the second and third panel get in a second position in relation to each other. An additional intermediate step may be employed between the first and the second step. In this intermediate step the second and third panel are angled down into the second mutual position in relation to the first panel.

Owner:KRONOSPAN TECHN

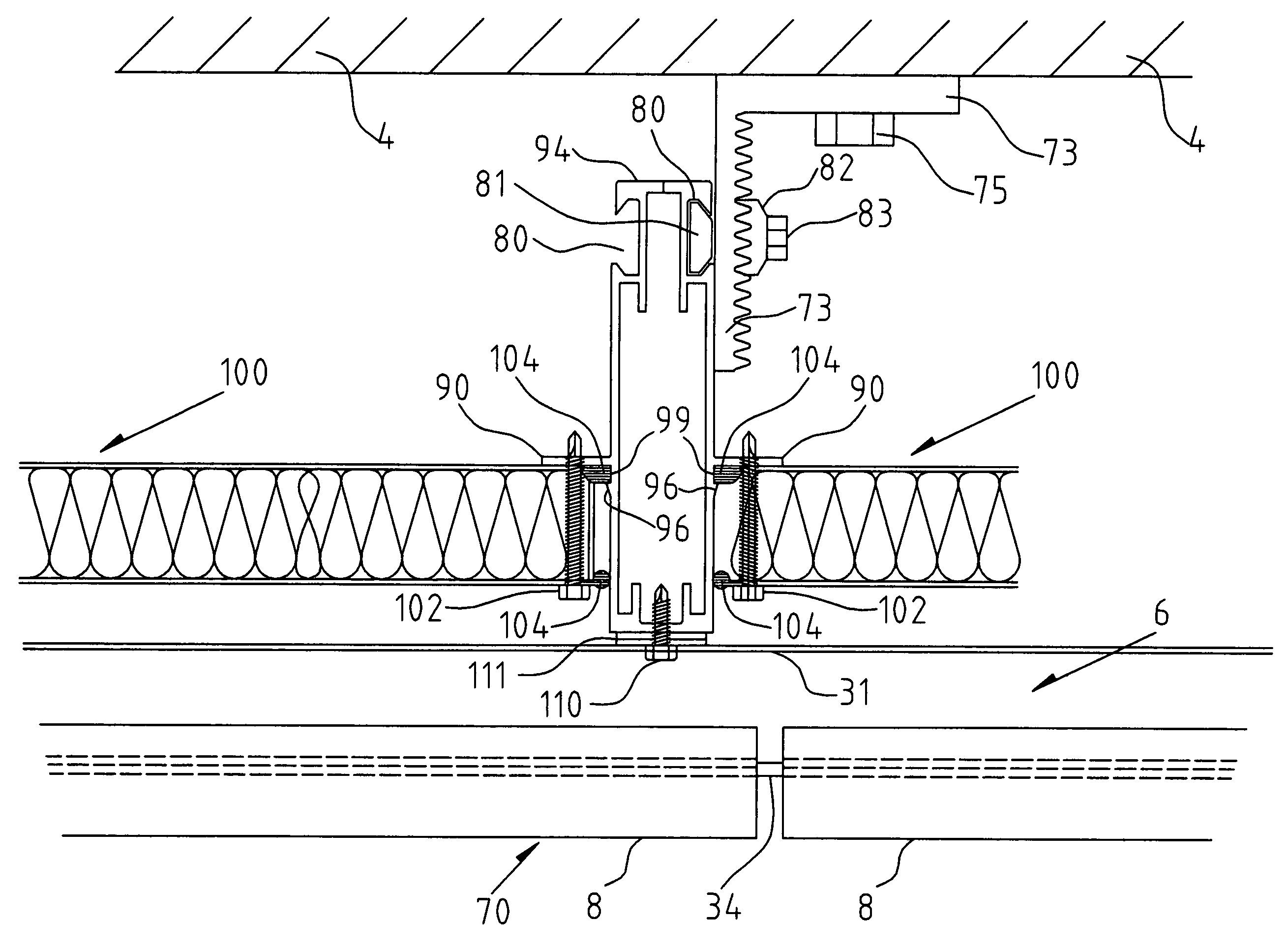

Laminate flooring

InactiveUS7614197B2Improve the immunityCeilingsRoof covering using tiles/slatesEngineeringSurface plate

A disengageable connector for interconnecting panels includes a longitudinally extending connector body. The connector body including a base and a projection extending from the base. The base includes a top surface and a bottom surface, and at least one footing member extending downwardly from the bottom surface of the base. The footing member is shaped and dimensioned to compress the upper surface of a resilient pad positioned beneath the connector and the panels. The connector is used in conjunction with an interlocking flooring system. The interlocking flooring system includes a plurality of flooring panels, each flooring panel including a plurality of edges. A first connecting member is provided for connecting adjacent flooring panels and a second connecting member is provided for connecting adjacent flooring panels. The first connecting member is the same as the connector described above and is different from the second connecting member. The first connecting member provides greater resistance to disengagement of adjacent flooring panels when compared to the second connecting member.

Owner:WILSONART

Cladding system

InactiveUS7043884B2Readily and easily and quickly mounted on and removedEasy constructionCeilingsCovering/liningsBraced frameArchitectural engineering

A stone cladding system for building has a support frame formed by a plurality of spaced-apart upright mullions fixed to an exterior of a building by anchor bracket's with a number of horizontal cladding panel support rails mounted in vertically spaced apart rows on the mullions. Each stone cladding panel is mounted between at adjacent pair of vertically spaced-apart rails with a bottom of the cladding panel seated on the lowermost rail and a top of the cladding panel secured to the uppermost rail by a pair of retaining clips. A bottom of each stone cladding panel is fully supported along its length by the lowermost rail.

Owner:CRONOS 2000

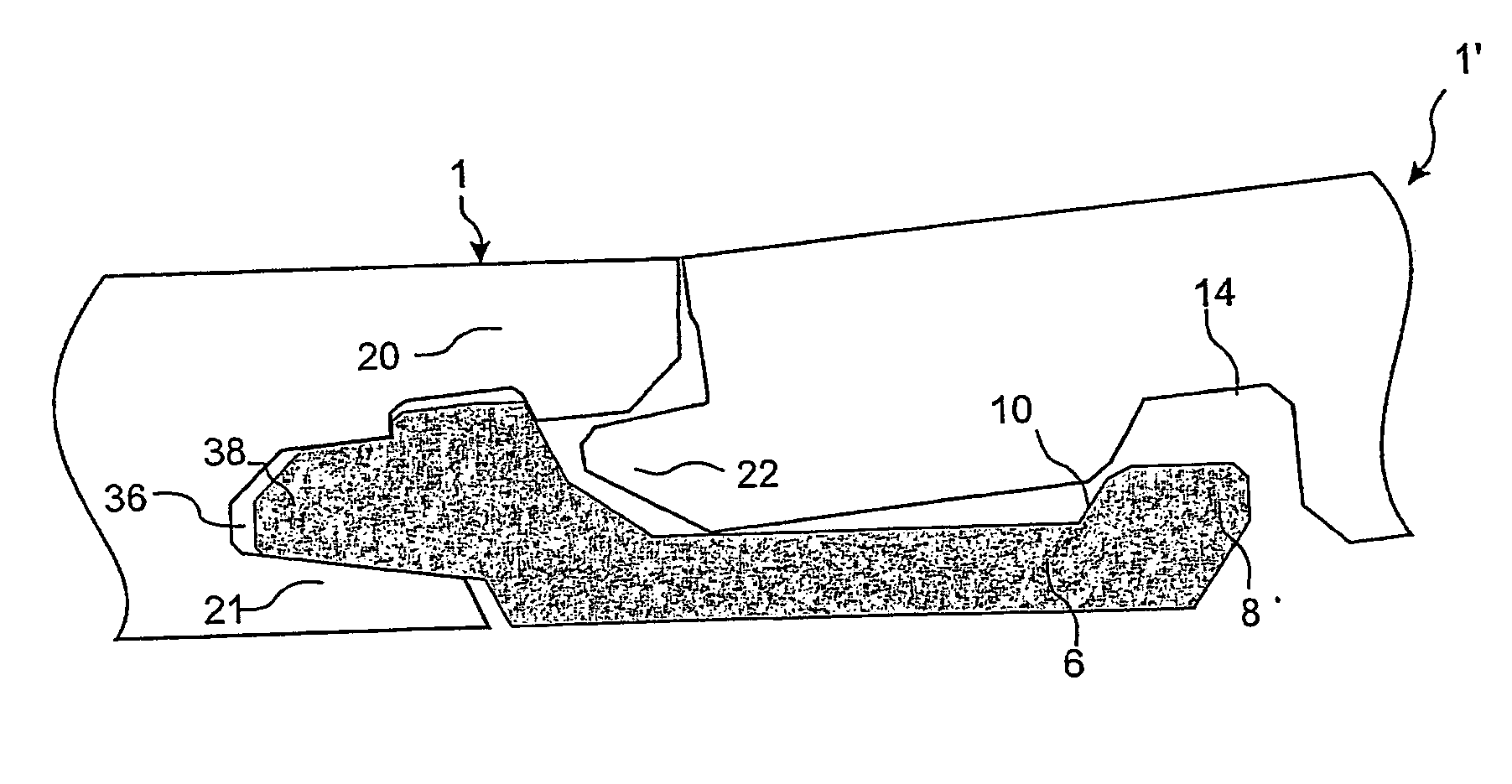

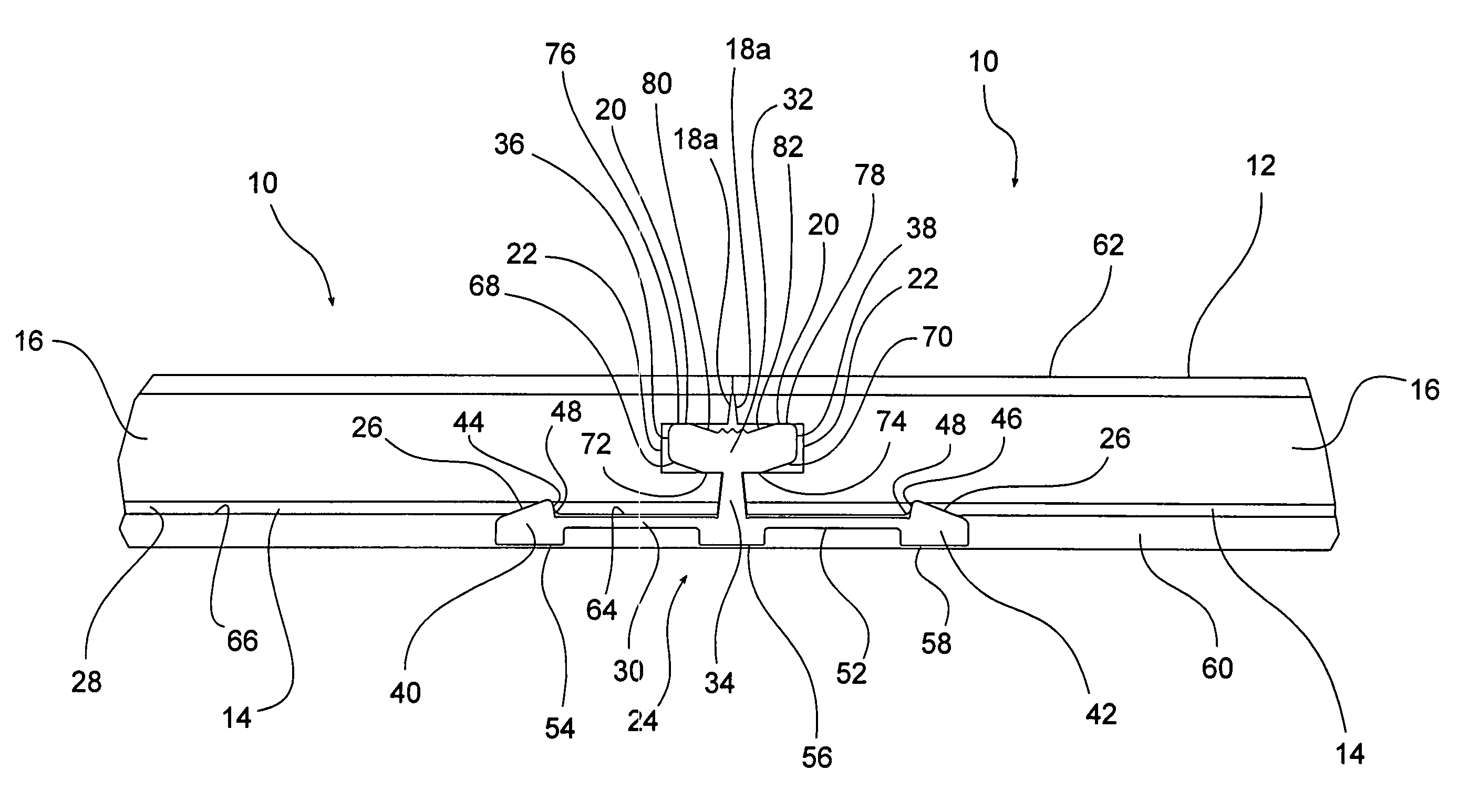

Floor panel and method for manufacturing such floor panels

Floor panel, of the type consisting of a laminate panel which comprises at least a printed decorative layer (8) and a top layer (9) forming the upper surface (10) of the floor panel (1), more particularly a so-called overlay, whereby this top layer (9), or, thus, overlay, is realized on the basis of a thermosetting resin, characterized in that in the upper side (11) of the floor panel (1), indentations (12) are formed and in that at last in a number of these indentations (12), a component (13) is provided, which is obtained in that it has been provided in those indentations (12) after the provision of the indentations (12).

Owner:FLOORING IND LTD

Mechanical locking system for floor panels

Building panels, especially floor panels are shown, which are provided with a locking system including several separate strip parts connected to the panel edge.

Owner:CERALOC INNOVATION AB

Floor Covering With Interlocking Design

InactiveUS20090031662A1Thin thicknessEasy to assembleCovering/liningsWallsFloor coveringManufacturing engineering

Surface coverings, such as floor coverings, with an interlocking design are described. Methods of making the surface coverings are further described.

Owner:NOVALIS HLDG +1

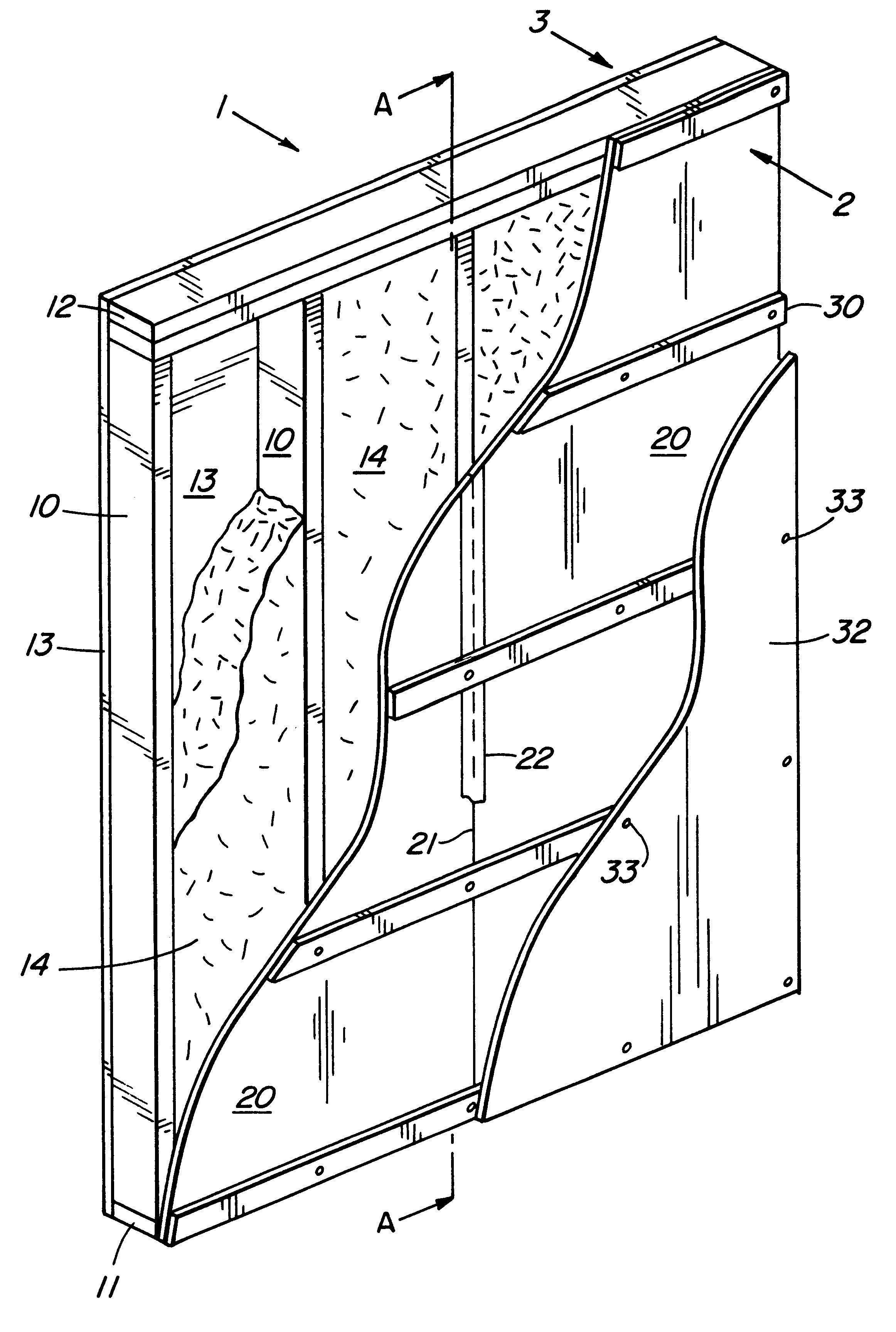

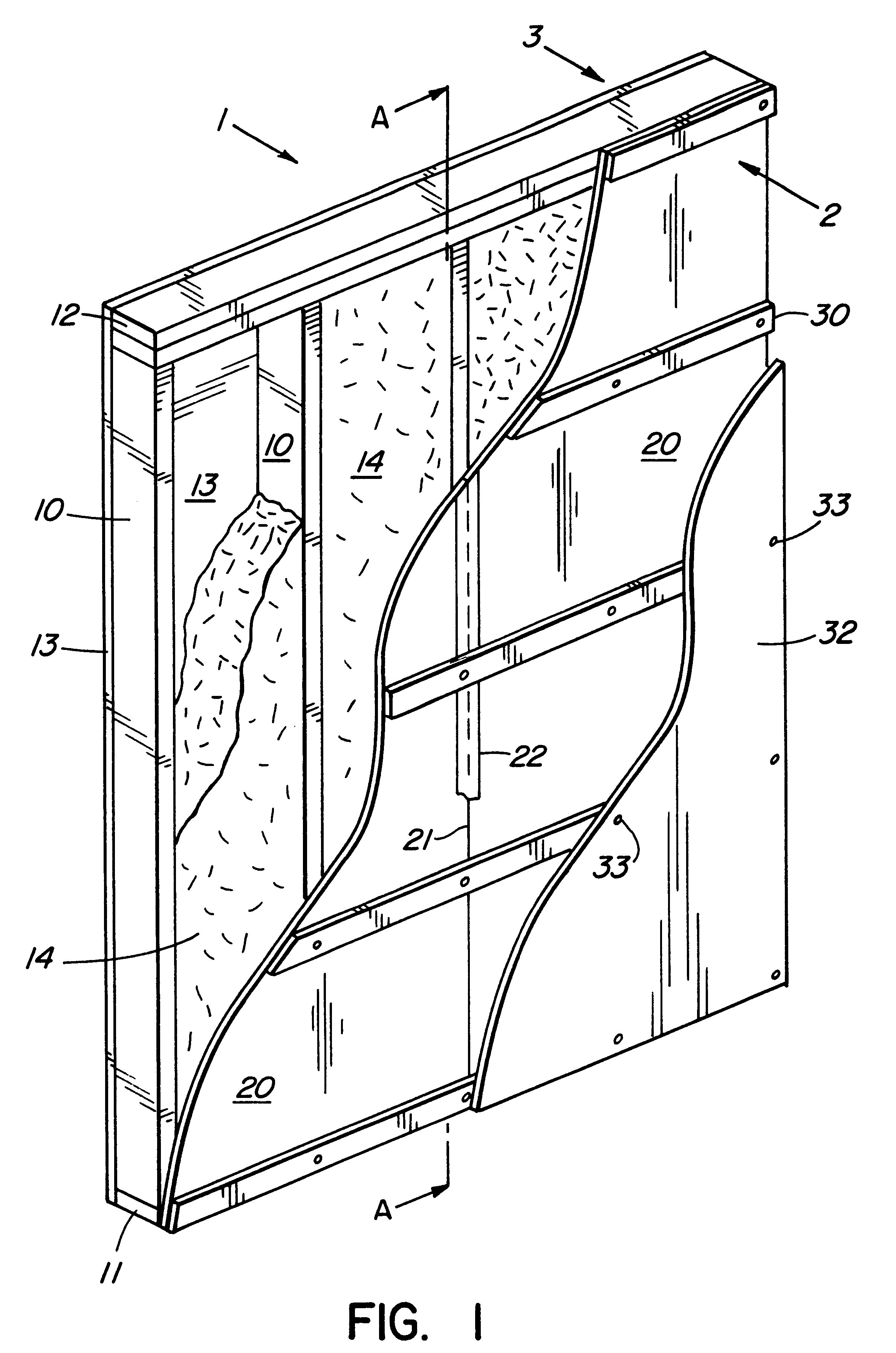

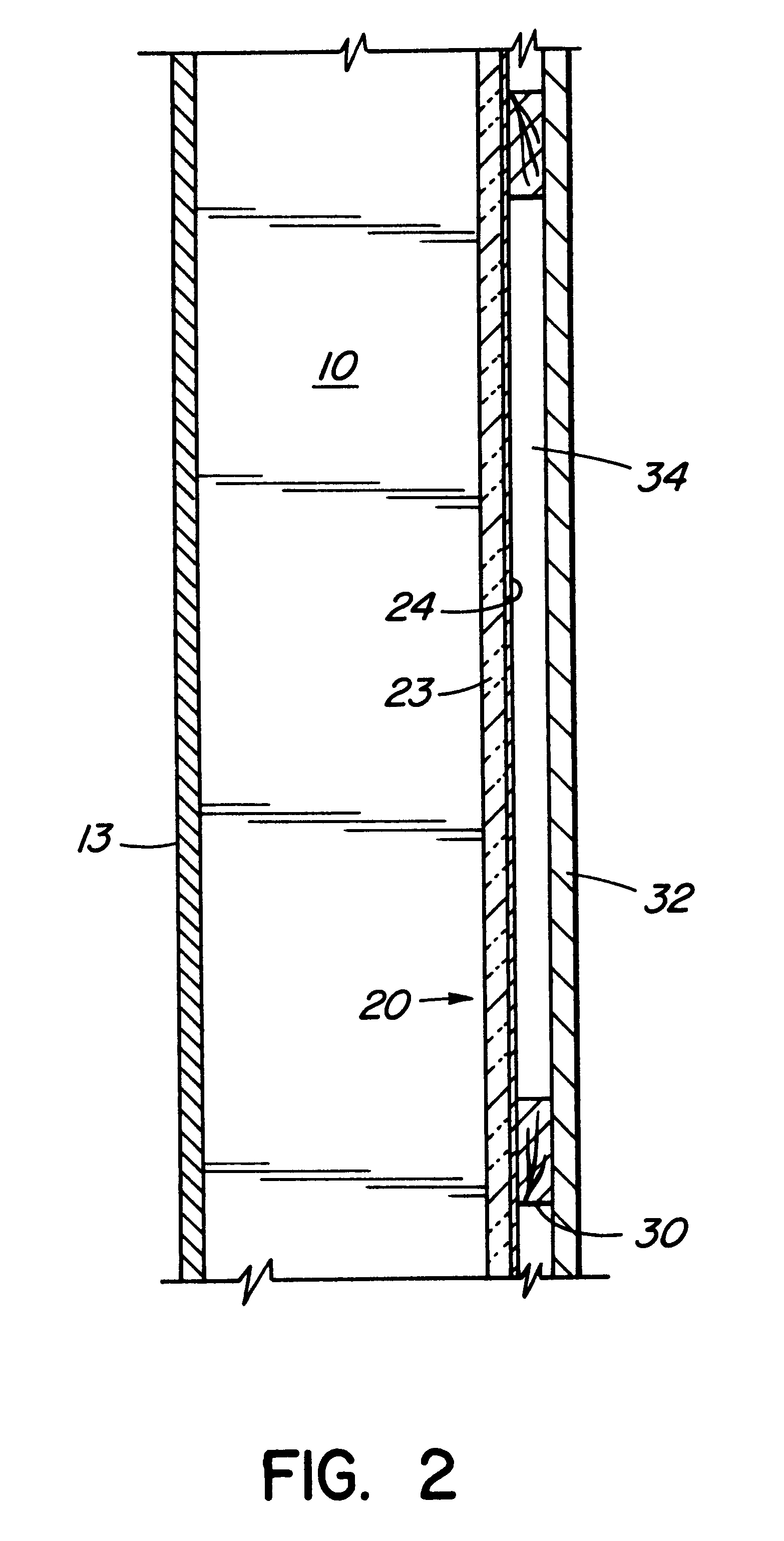

Composite vapor barrier panel

A fibreboard, insulating, wall panel includes an integral air and vapor barrier of metal foil or metallized plastic film adhered to one surface of the panel. Panels are attached to a stud wall frame. Abutting panel joints are taped to provide a continuance vapor barrier. Increased thermal and acoustic insulation as well as structural integrity of the barrier is provided by the panel.

Owner:BUILDING PROD OF CANADA CORP

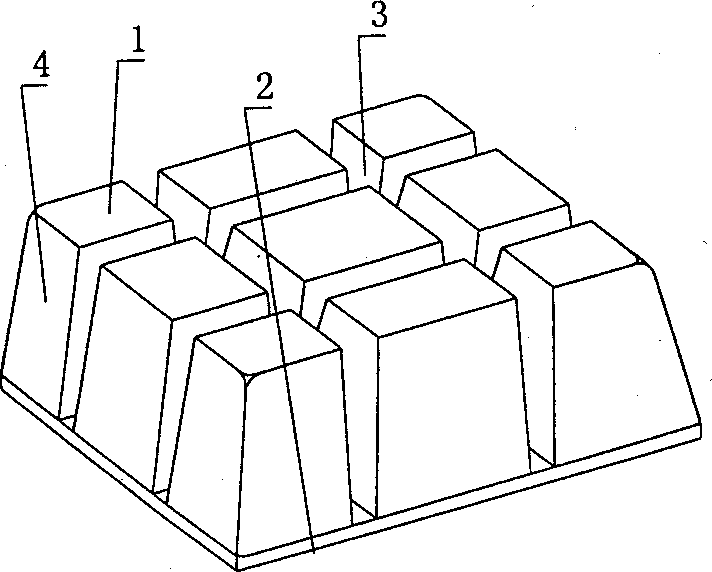

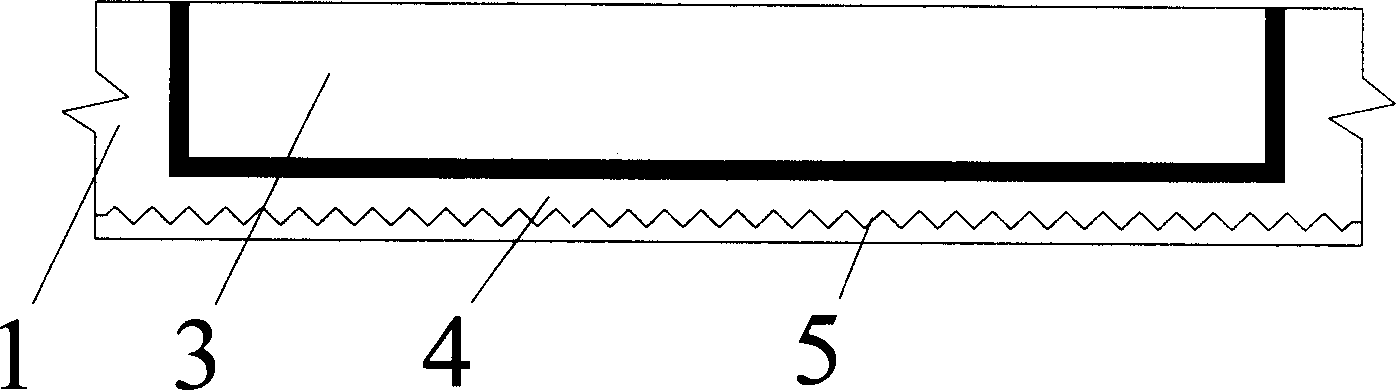

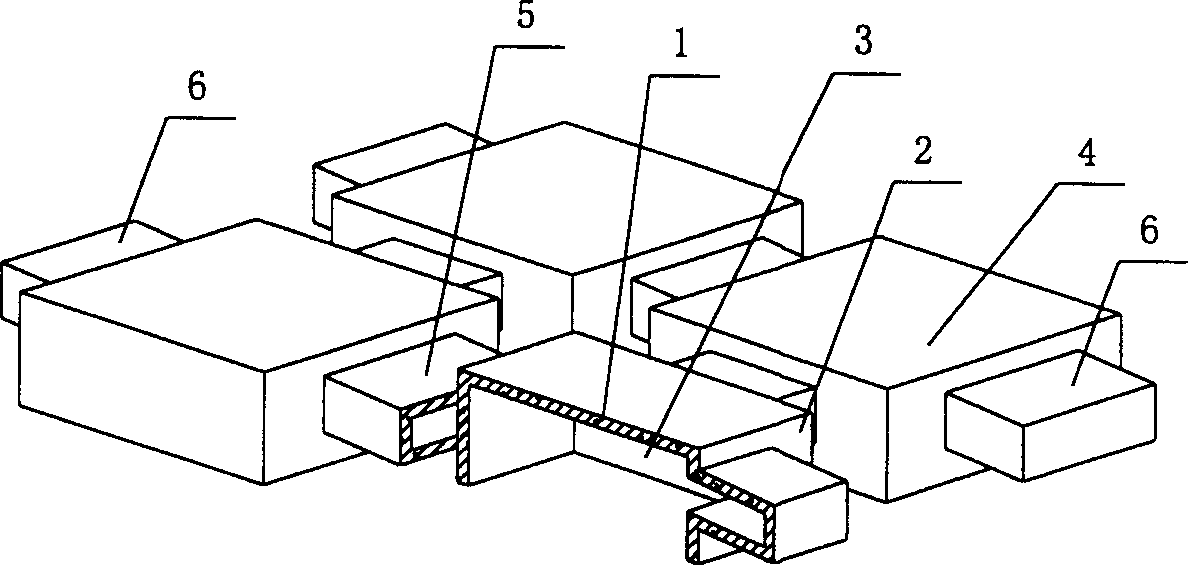

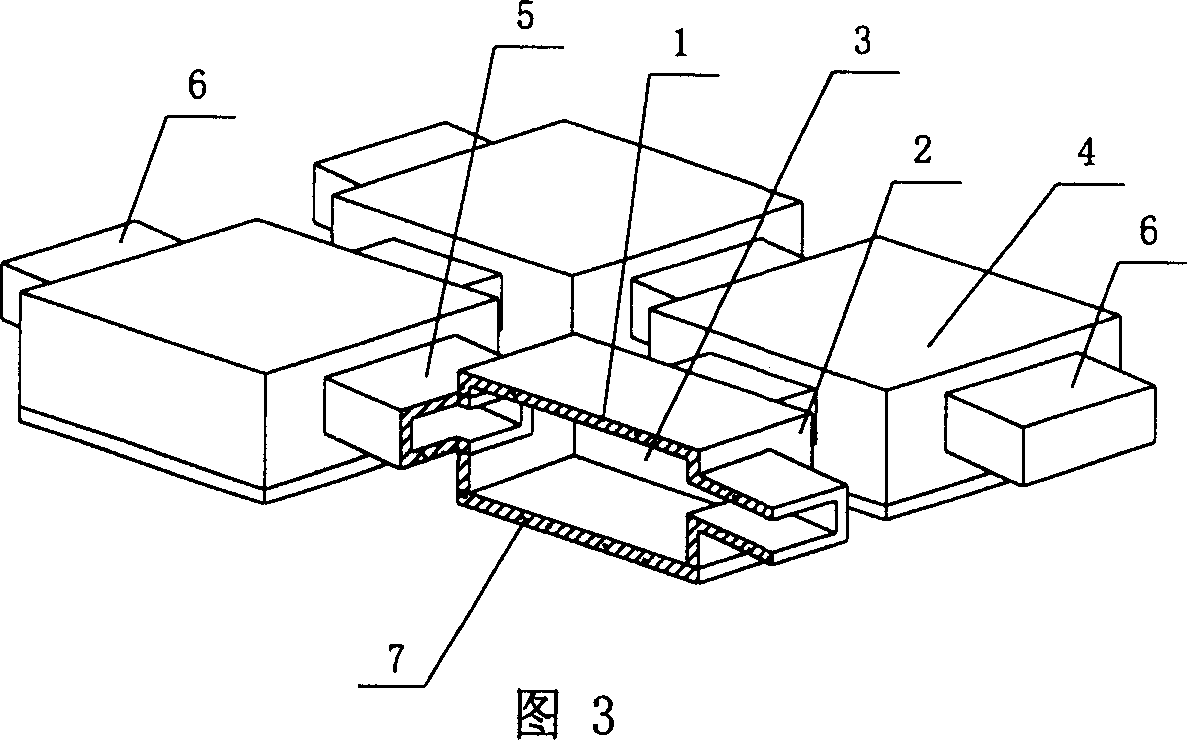

Modular formwork members

InactiveCN1403667ASimple designIncrease production capacityFloorsReinforced concreteUltimate tensile strength

The modular formwork member includes top plate and side walls to constitute cavity formwork. The present invention features that there is at least one connection tube between the adjacent walls of two formworks. When the modular formwork members are used in hollow stringboard, there will be vertical rib formed around the connection tube via in-situ cast and shearing bonding formed in the empty part between the formwork members, so that the hollow stringboard can form reinforced concrete-shearing bonding type bi-directional hollow large board in only once deposition. The present invention has simple formwork, simple construction, low cost and short construction period, and the member has high strength, simple structure, low cost and easy construction.

Owner:湖南邱则有专利战略策划有限公司

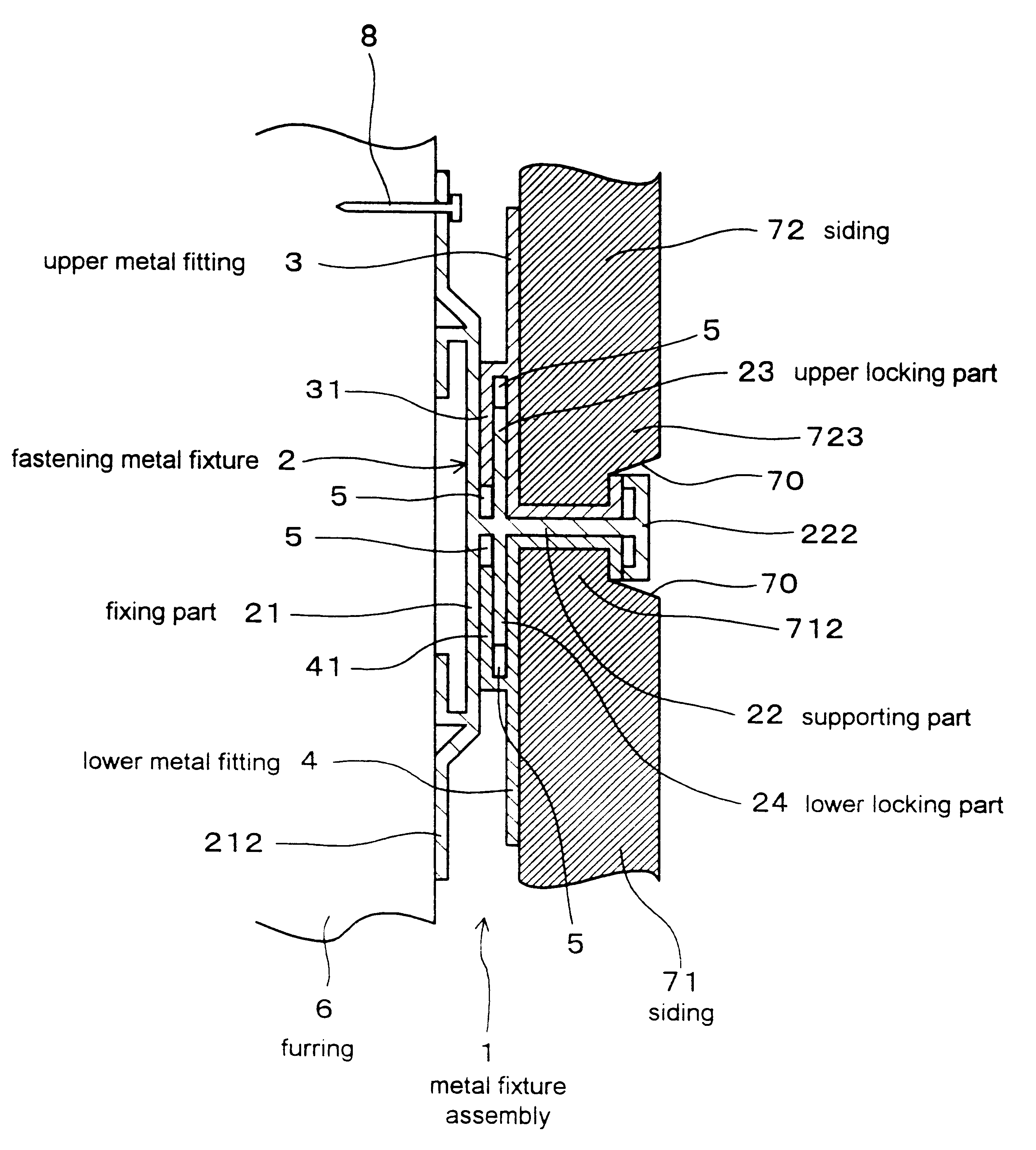

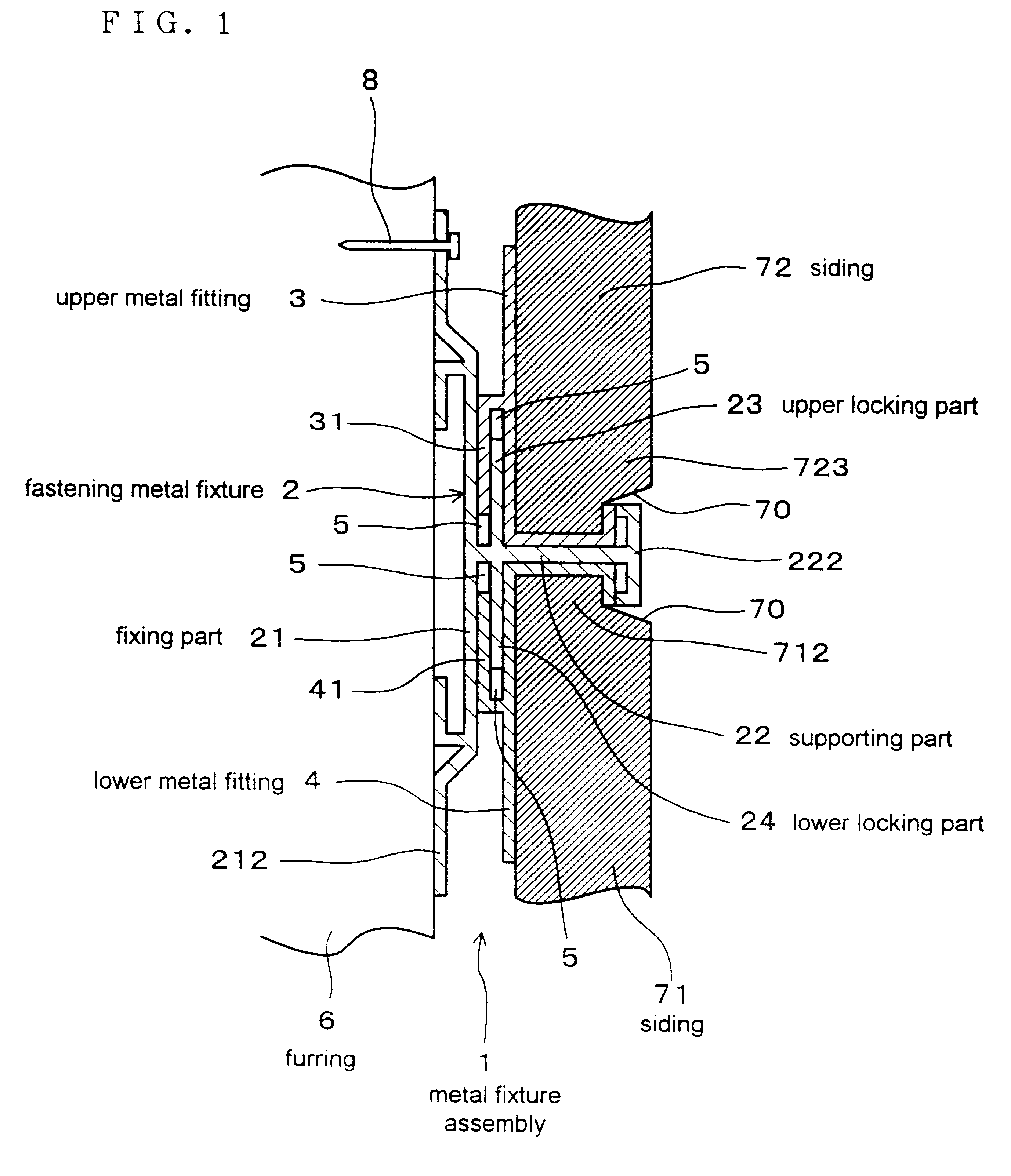

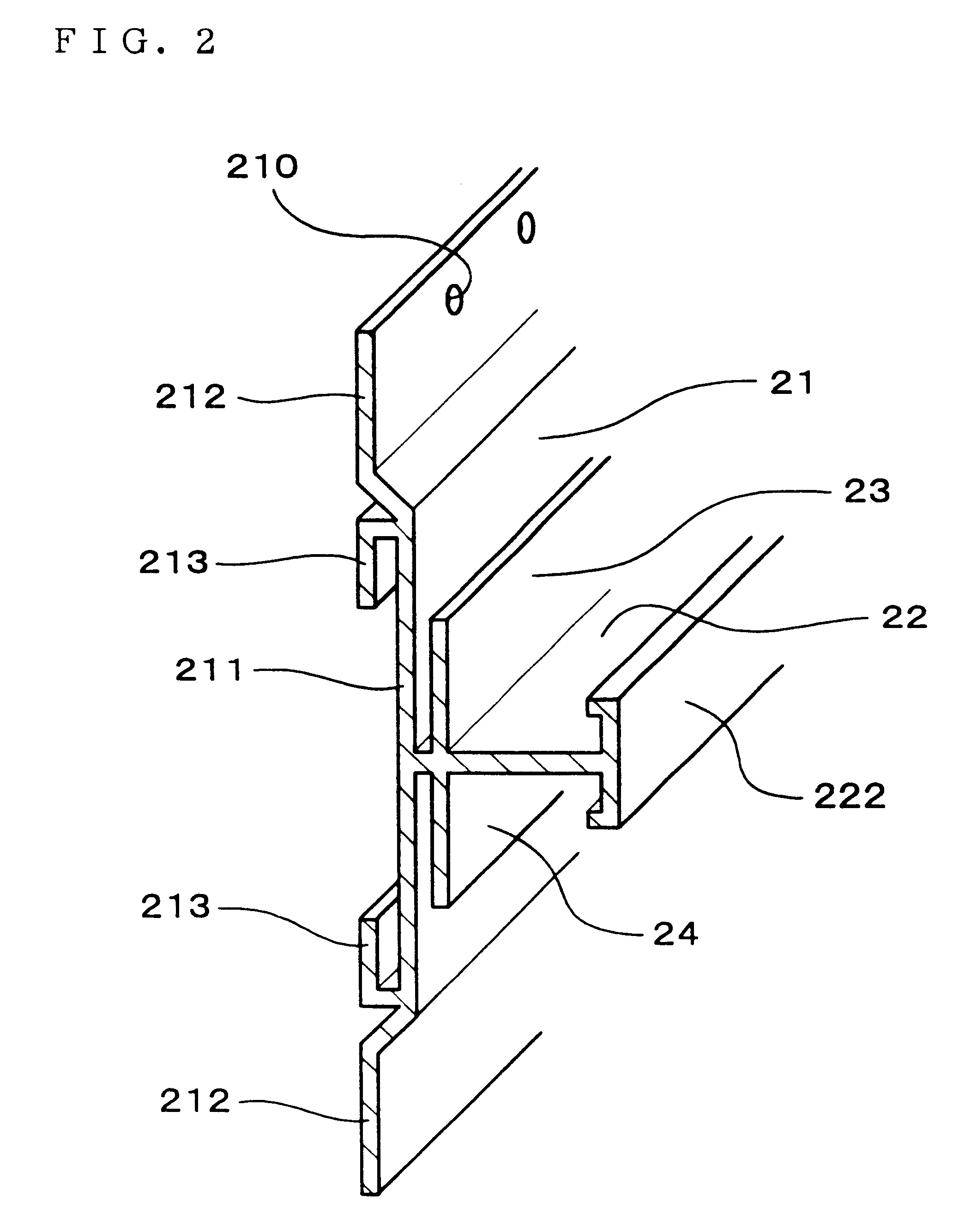

Metal fixture assembly for installation of vertical sidings, construction and method of installation

InactiveUS6289646B1Safe installationGood lookingCeilingsRoof covering using tiles/slatesArchitectural engineeringFurring

A metal fixture assembly for installation of vertical sidings to fix the siding to a furring, which is capable of providing a construction of the installation having excellent appearance and weathering, and a method using the metal fixture assembly to facilitate the installation. A metal fixture assembly for installation of a vertical lower siding and a vertical upper siding vertically adjacent to each other on a furring is positioned therebetween. The metal fixture assembly includes a fastening metal fixture to be fixed to the furring, an upper metal fitting provided between the fastening metal fixture and the upper siding and fittingly fixed on a bottom portion thereof, and a lower metal fitting provided between the fastening metal fixture and the lower siding and fittingly fixed on a top portion thereof. The fastening metal fixture has a fixing part to be fixed to the furring, a supporting part projecting from the fixing part to support the lower and upper sidings, an upper locking part provided between the fixing part and the supporting part and locking the upper metal fitting thereto, and a lower locking part provided between the fixing part and the supporting part and locking the lower metal fitting thereto.

Owner:NICHIHA CORP

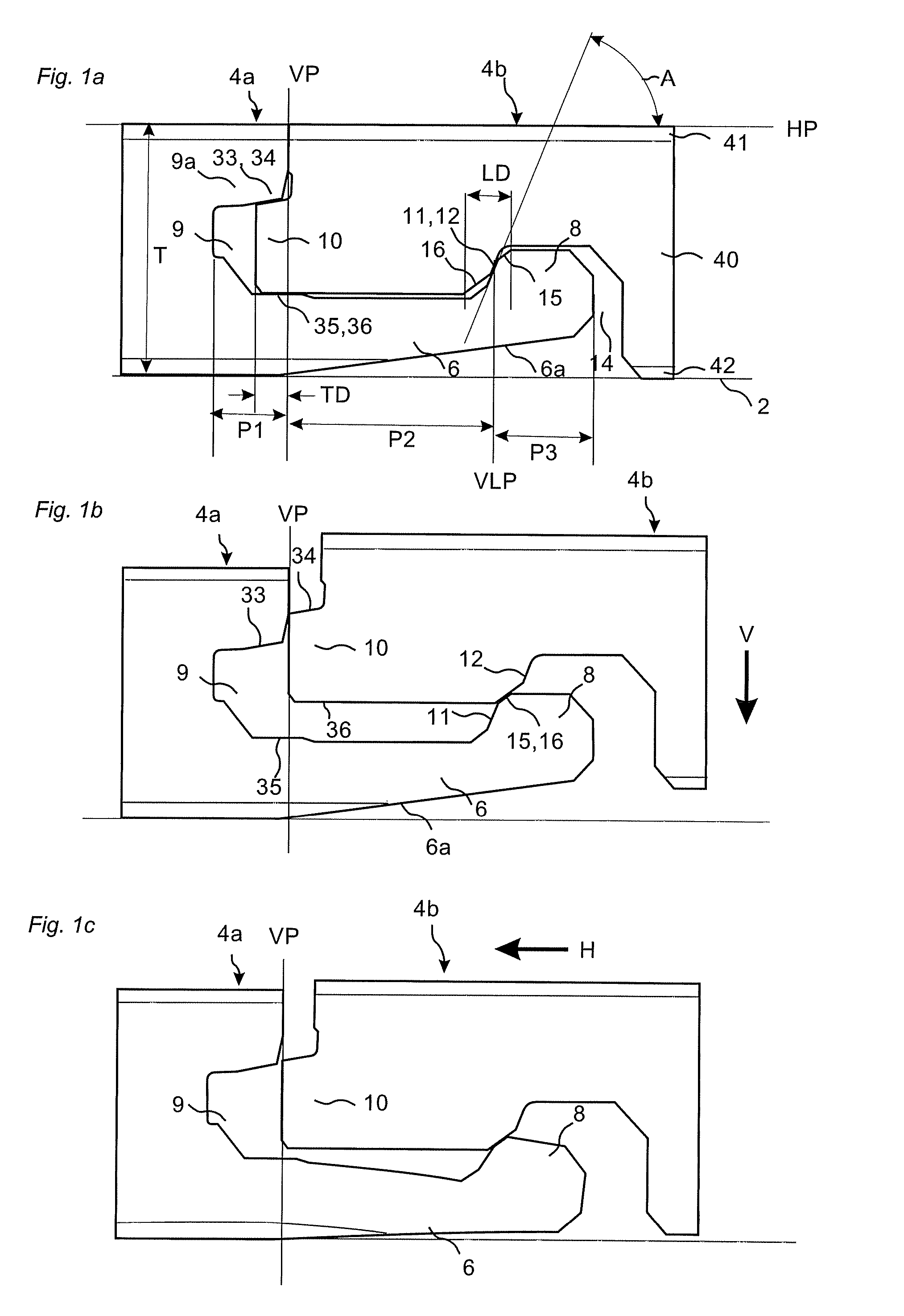

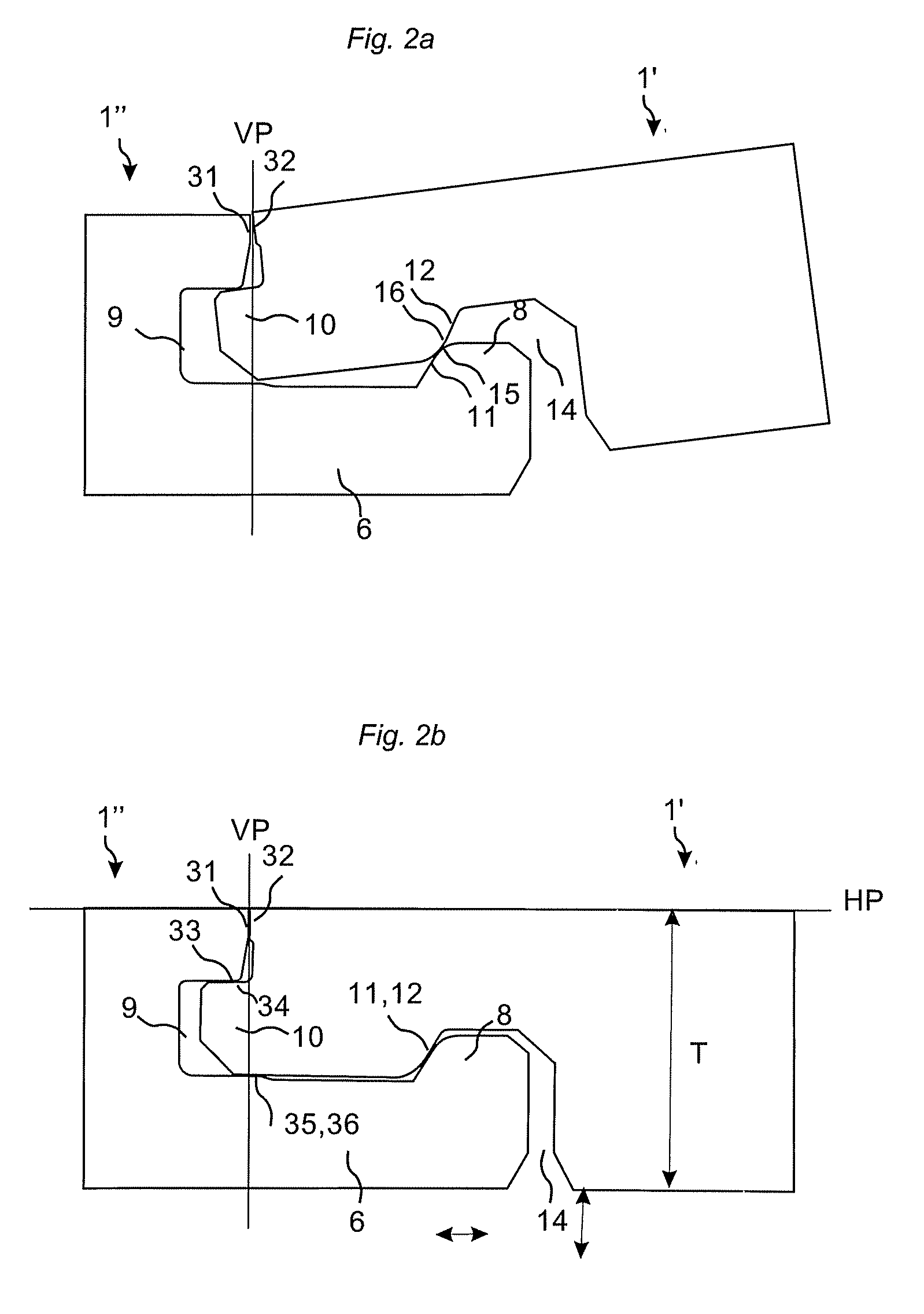

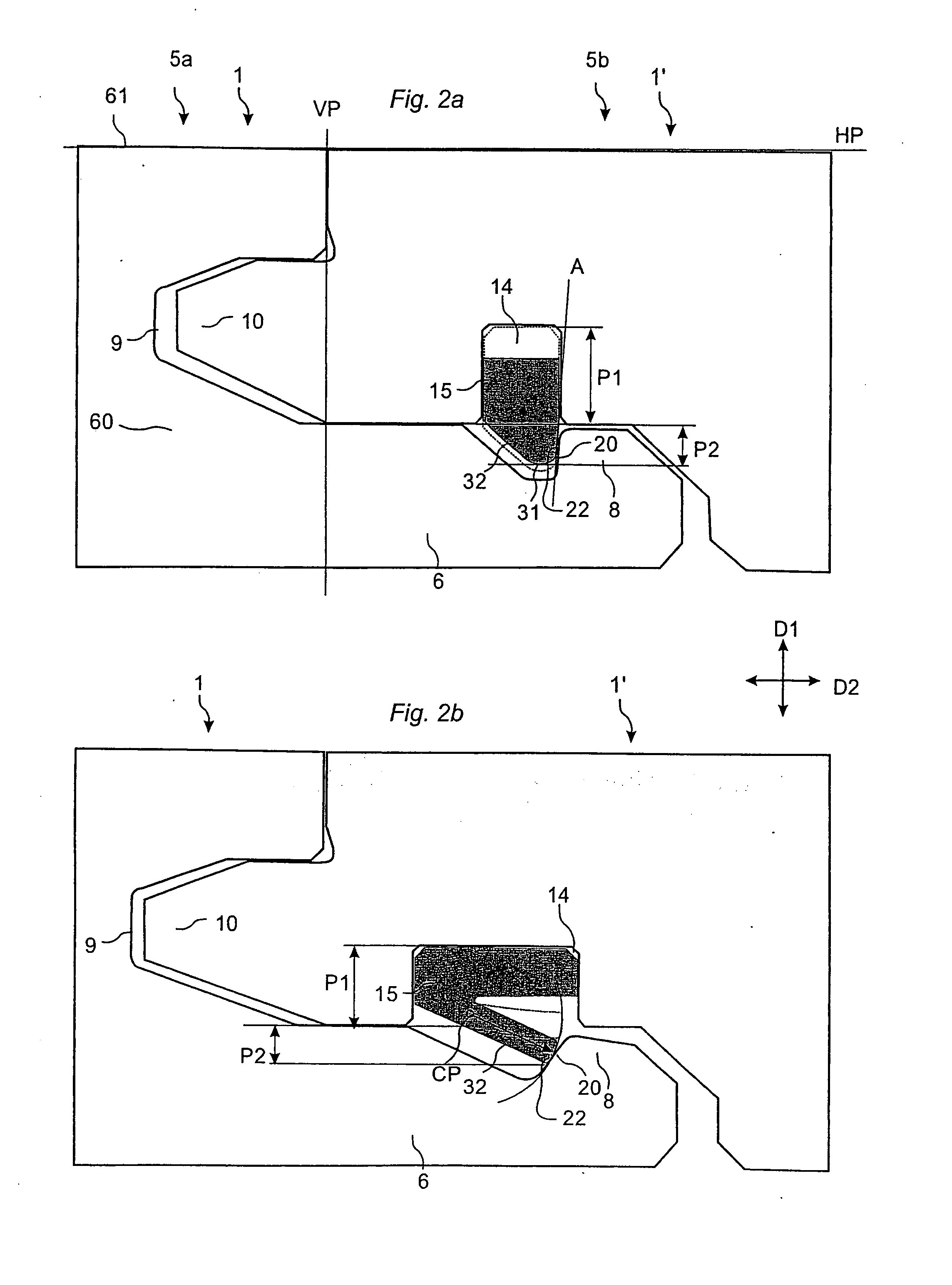

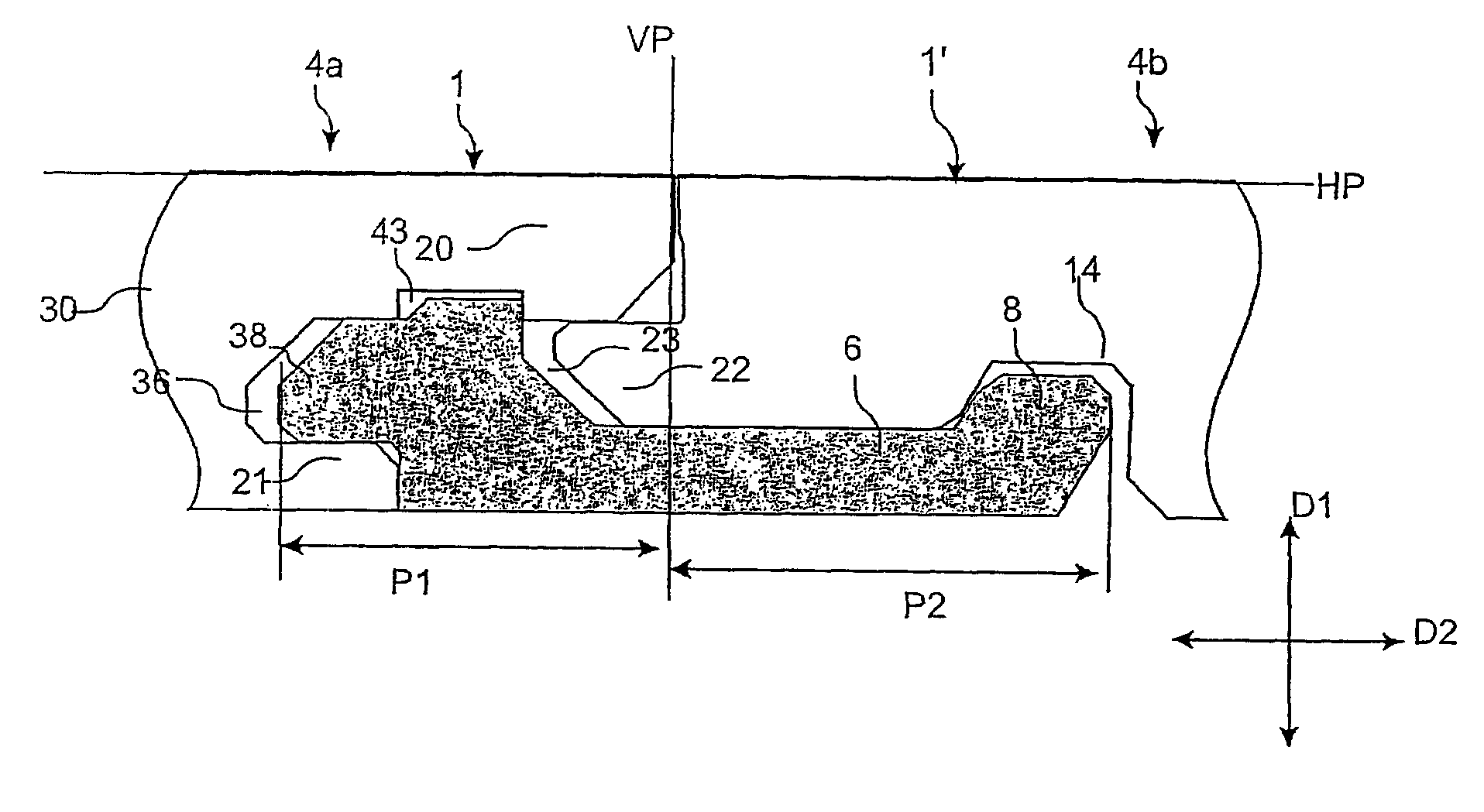

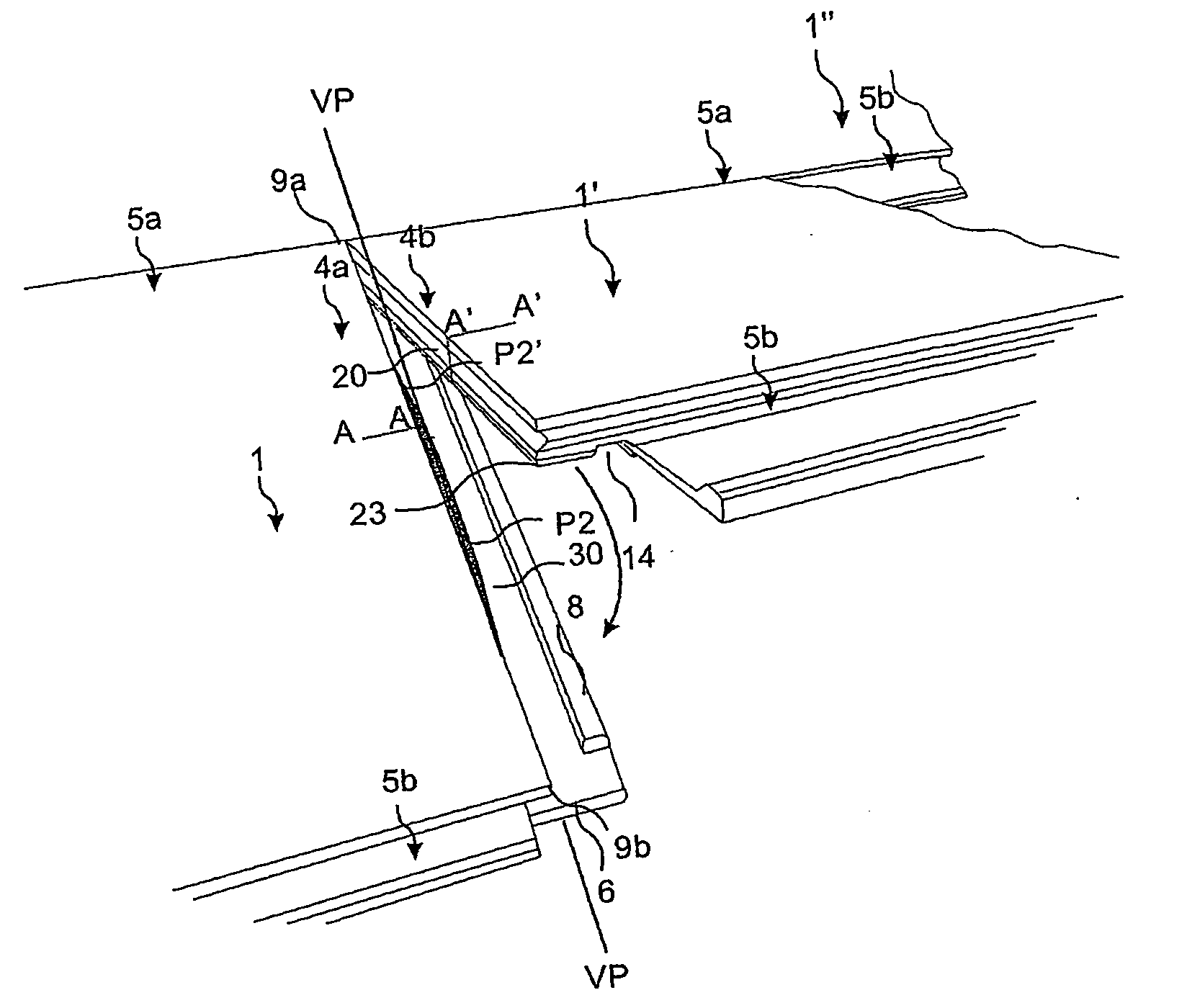

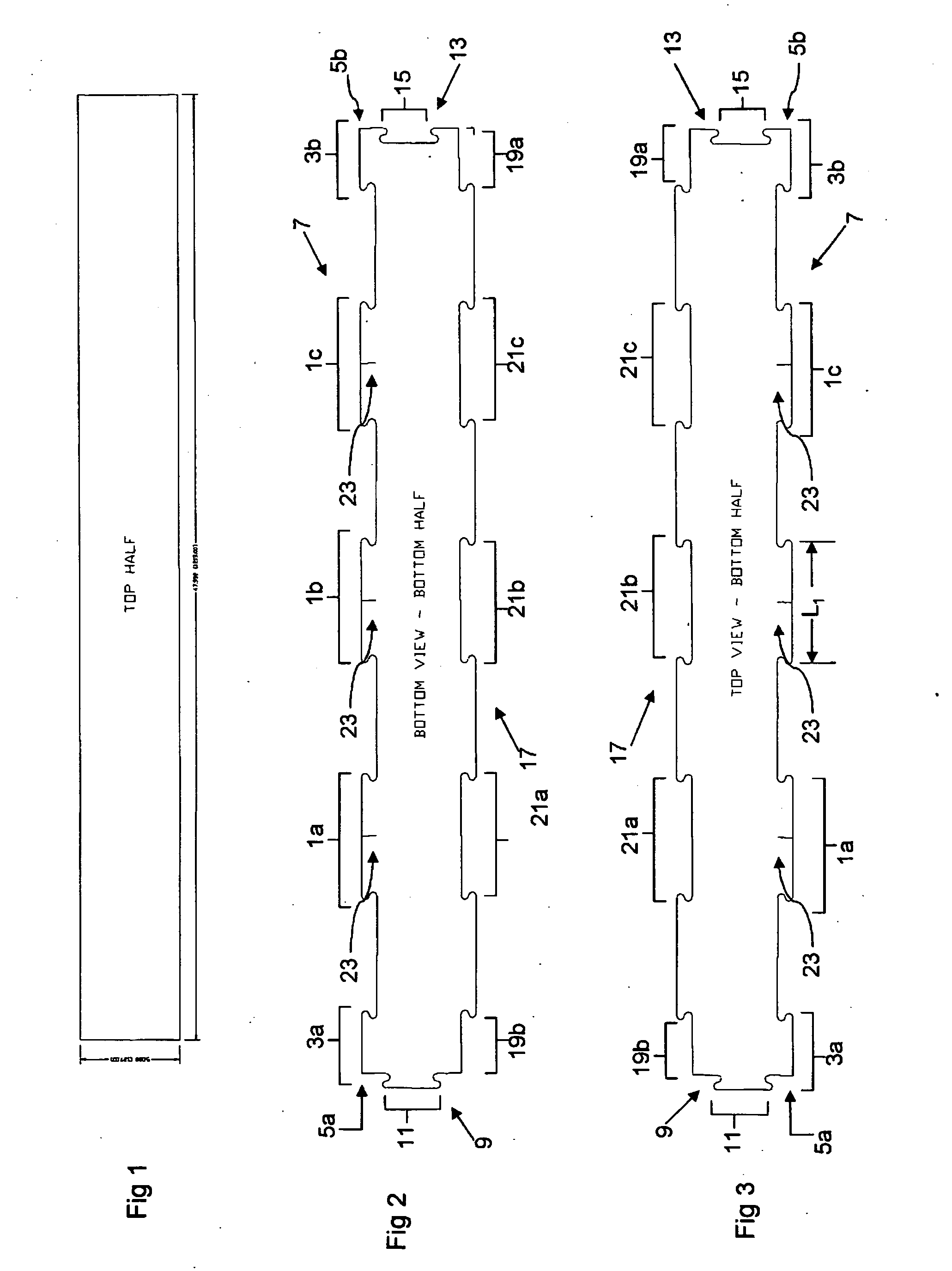

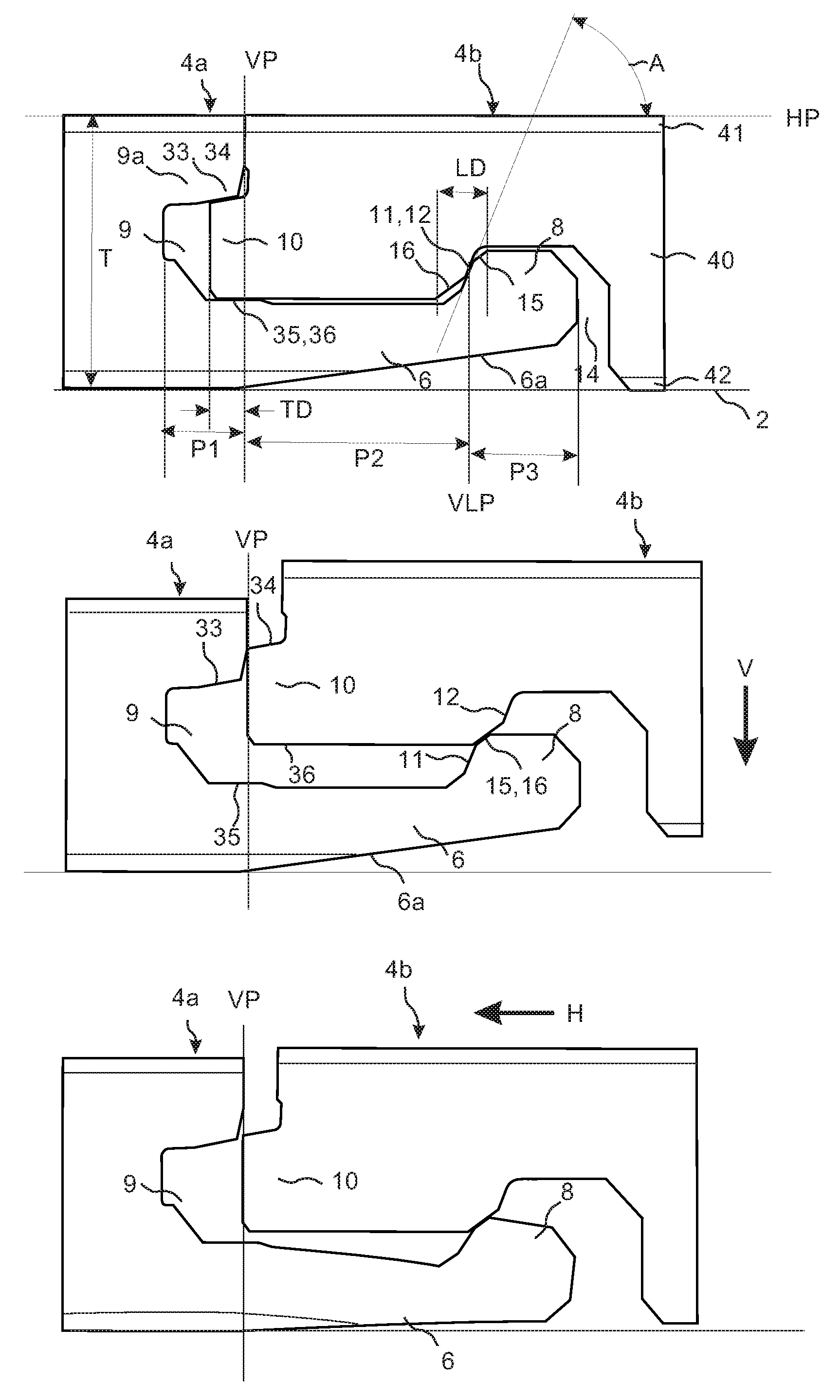

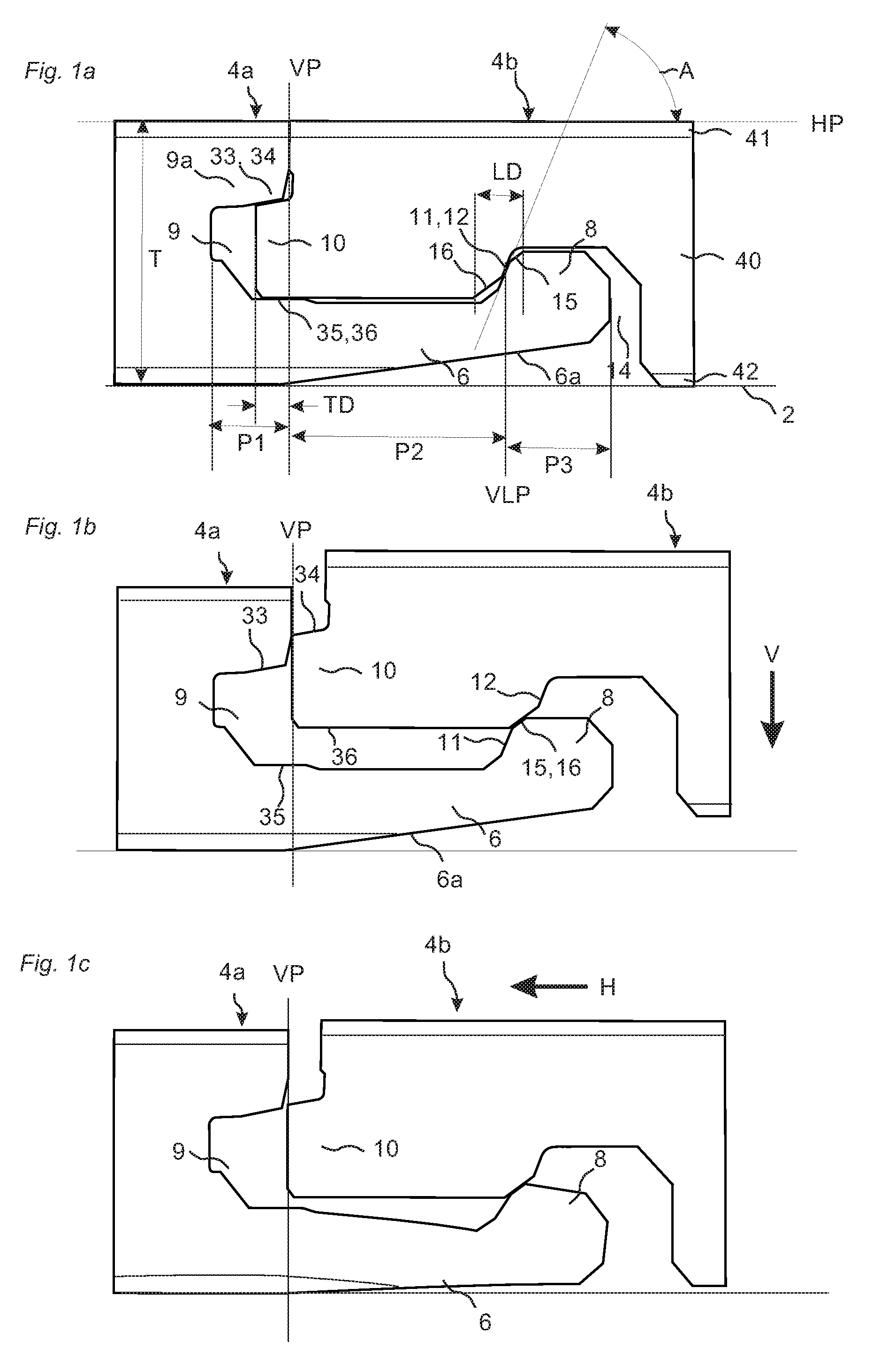

Mechanical locking of floor panels with vertical snap folding and an installation method to connect such panels

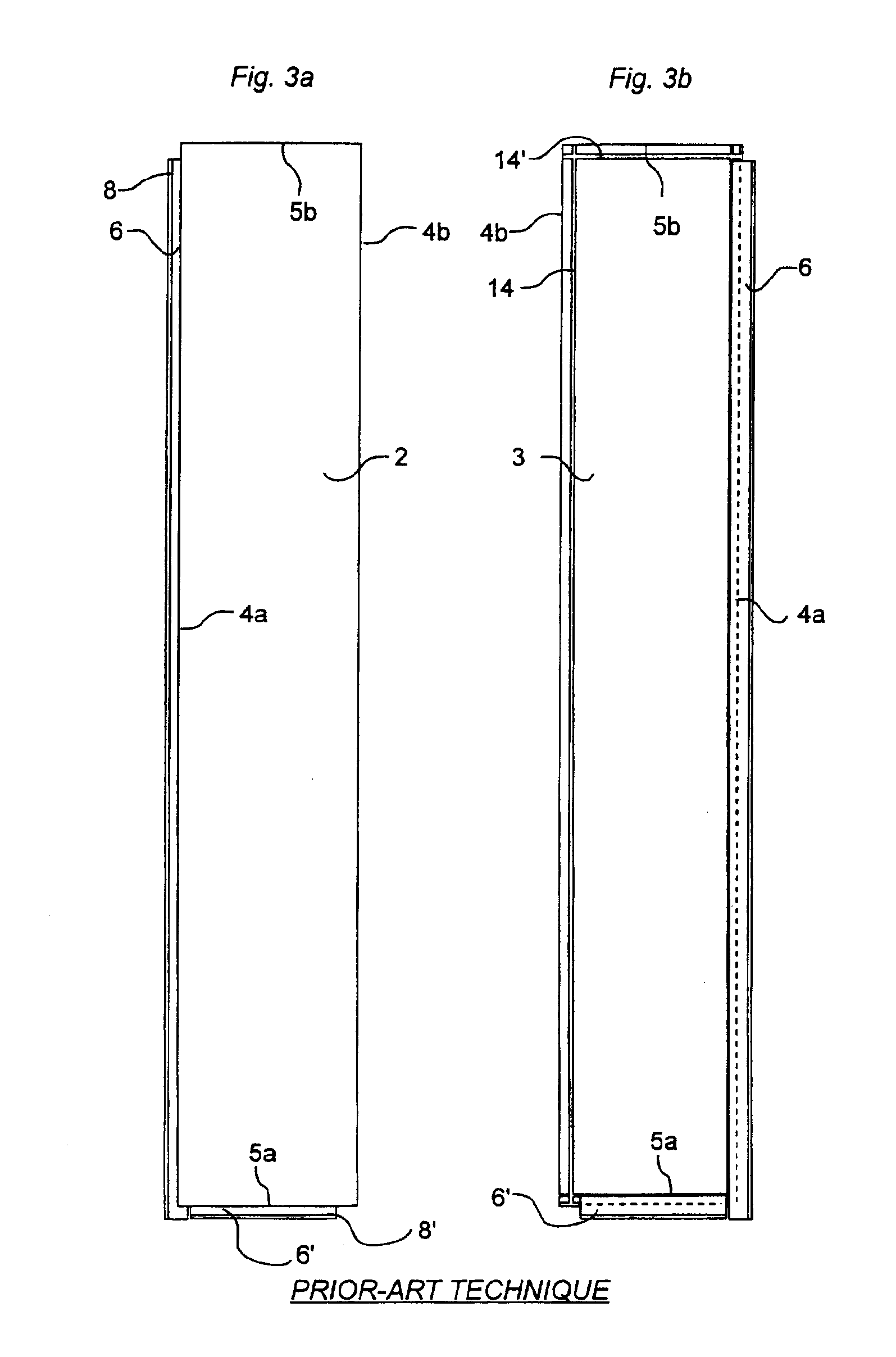

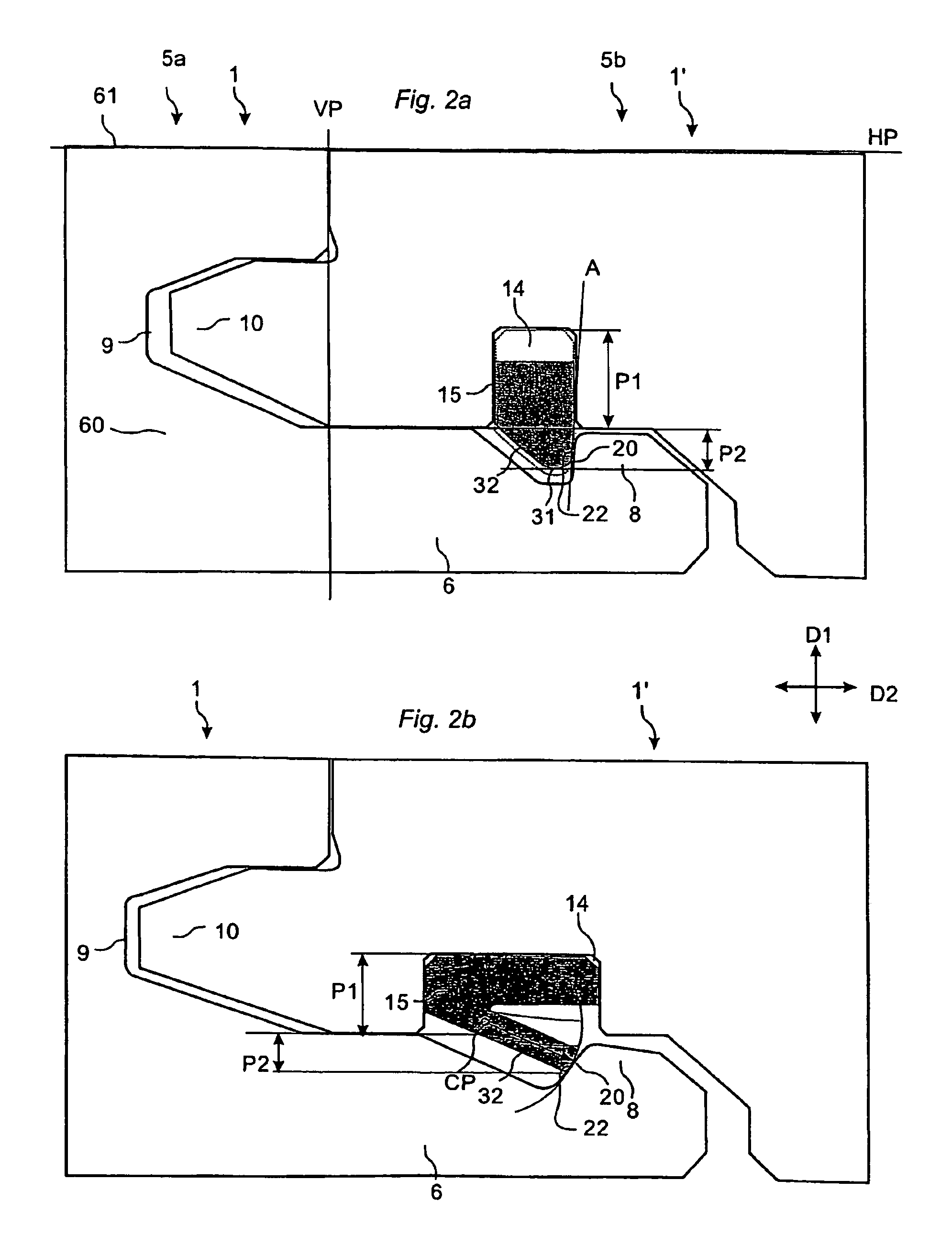

Floor panels (1, 1′) are shown, which are provided with a mechanical locking system on long and short edges (5a, 5b, 4a, 4b) allowing installation with vertical snap folding that could be accomplished automatically without tools and where the short edge (4a, 4b) locking system comprises a tongue (10) made in one piece with the panel.

Owner:VÄLINGE INNOVATION AB

Mechanical locking system for panels and method of installing same

ActiveUS20080155930A1Function increaseLower resistanceCovering/liningsFloorsEngineeringMechanical engineering

Floor panels are provided with a mechanical locking system including a flexible locking element in a locking groove, which during a horizontal motion is displaced vertically.

Owner:VÄLINGE INNOVATION AB

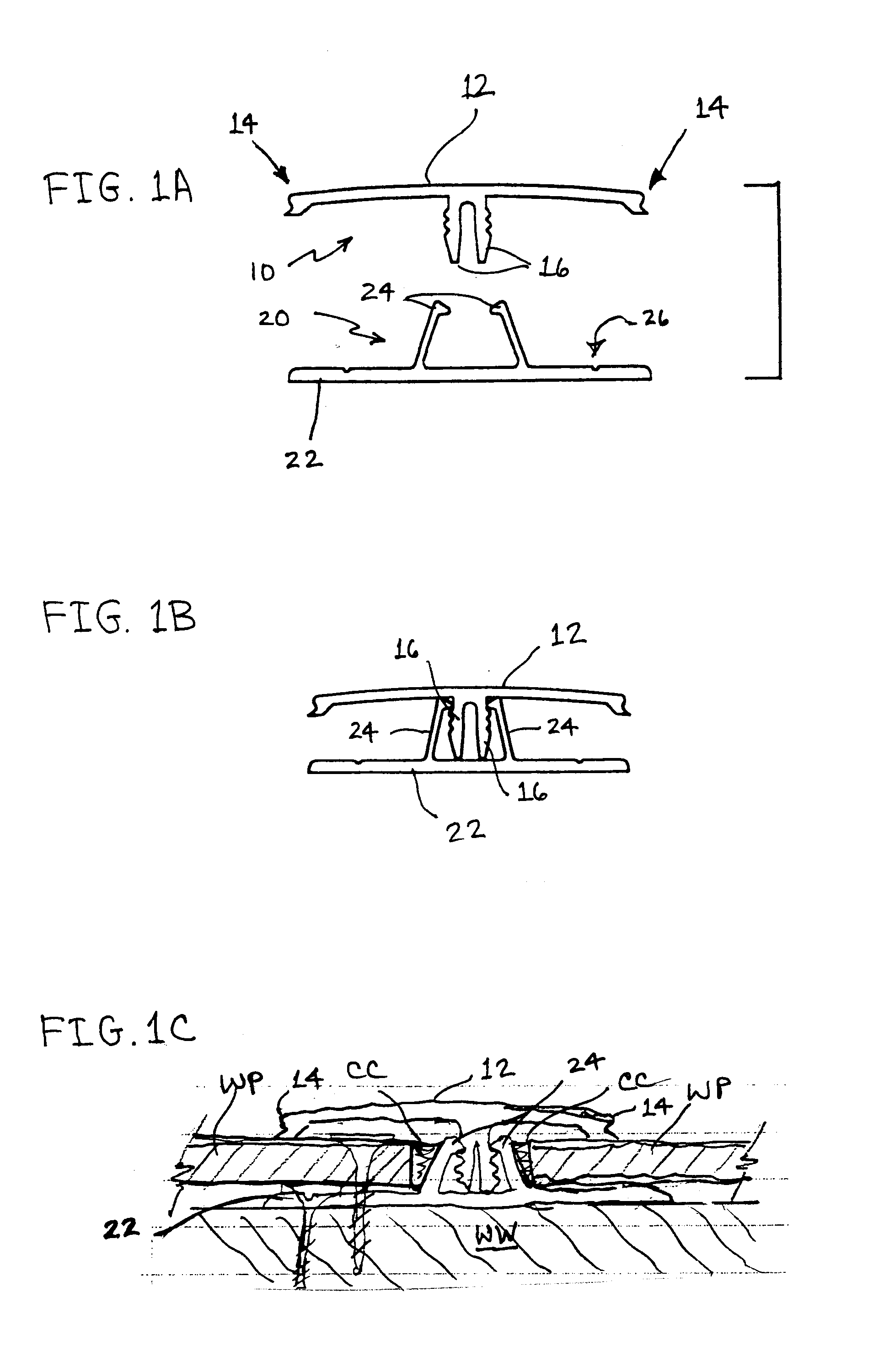

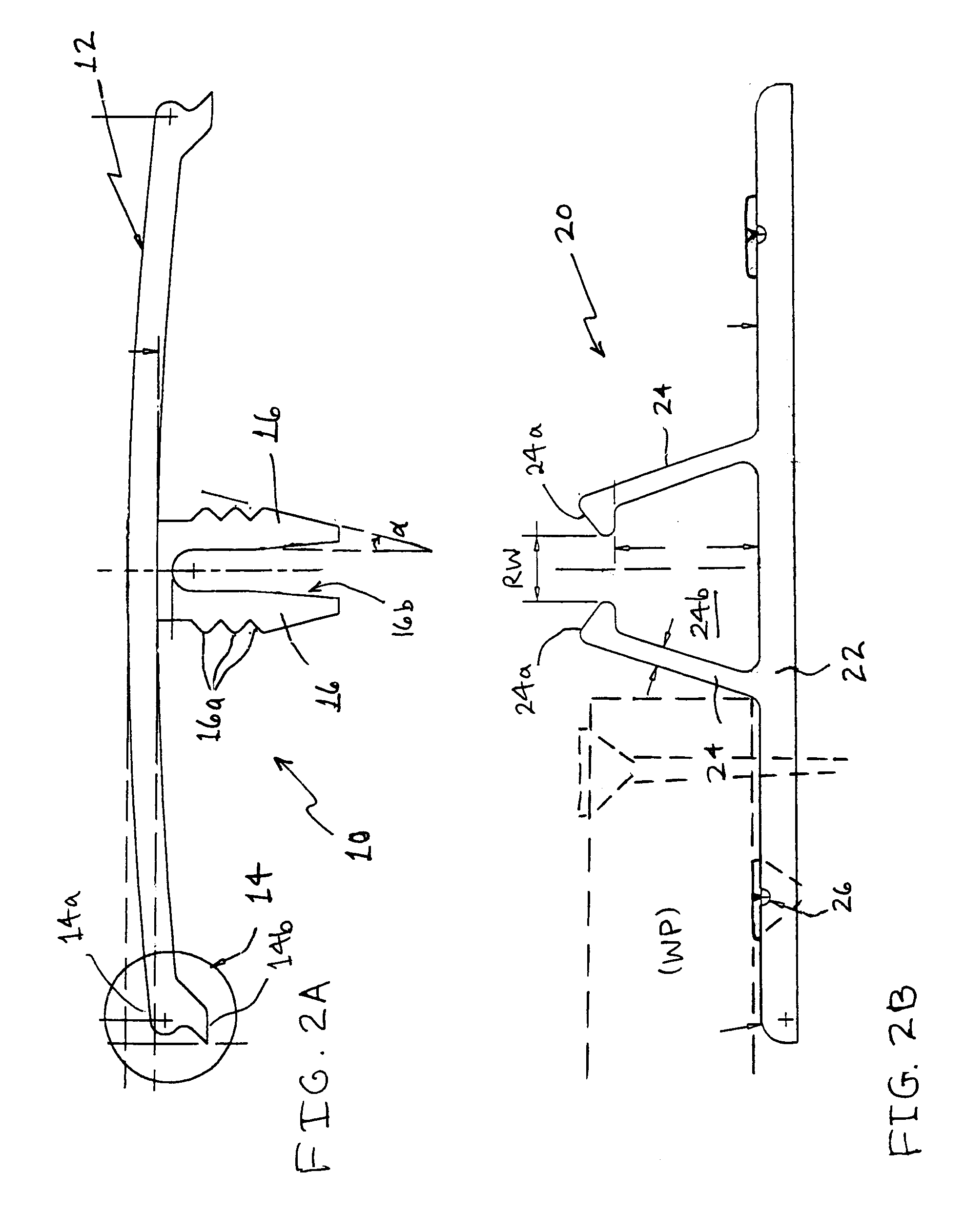

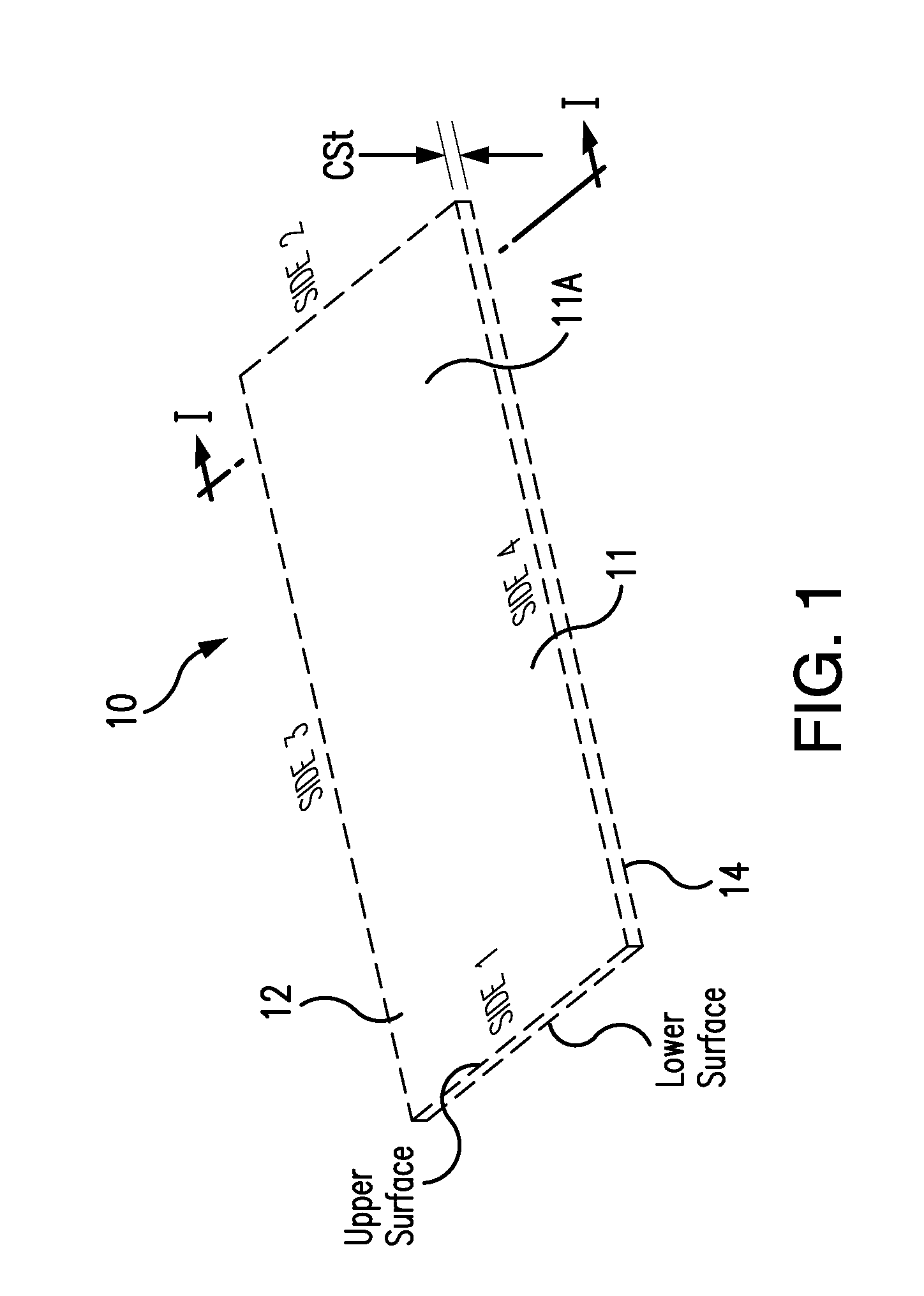

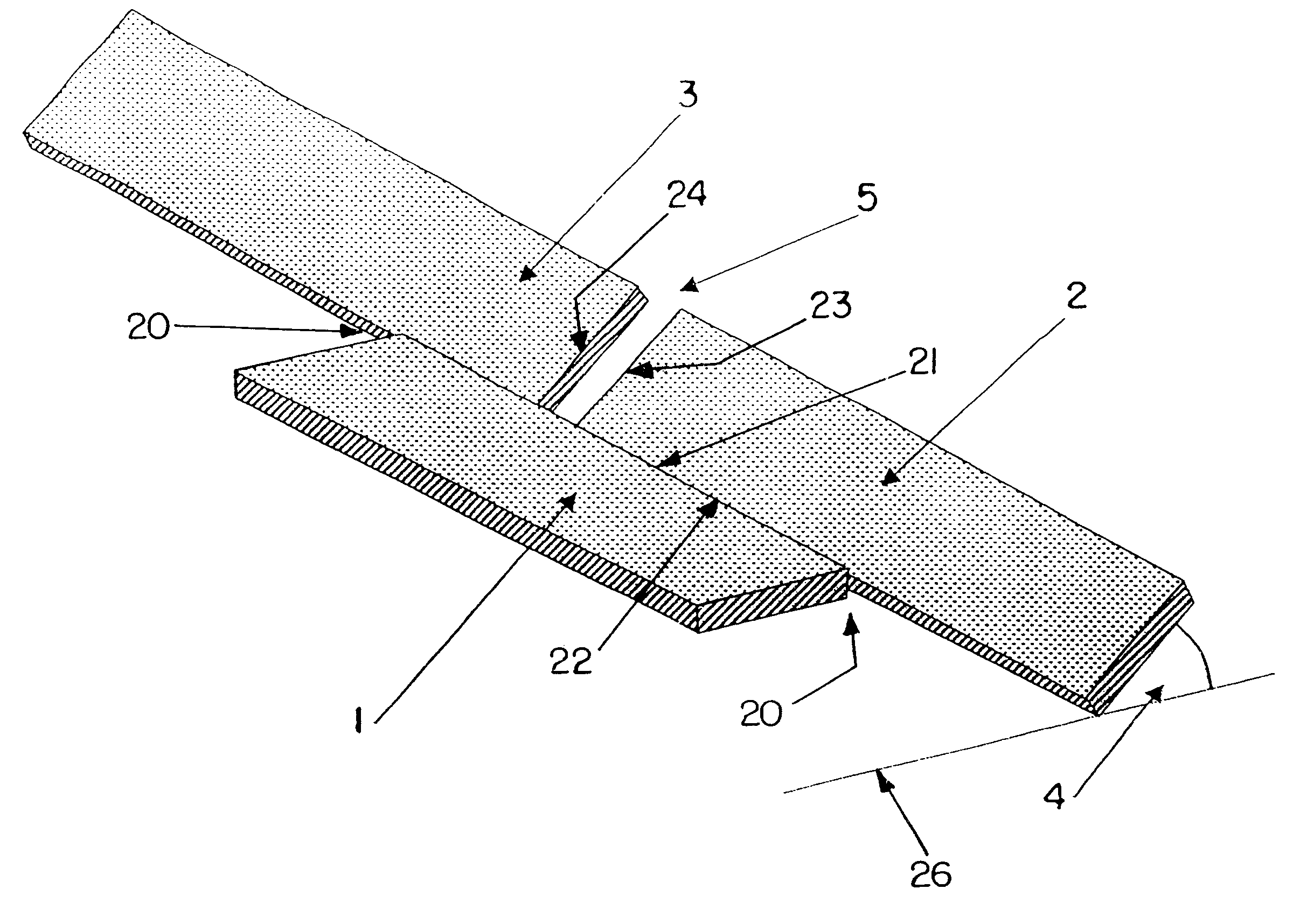

Locking system and flooring board

A locking system for mechanical joining of floorboards. For horizontal mechanical joining there is a projecting portion with a locking element which cooperates with a locking groove in an adjacent board. A tongue-and-groove joint for vertical mechanical joining has cooperating upper abutment surfaces and cooperating lower abutment surfaces which are essentially parallel with the principal plane of the floorboards and of which the lower abutment surfaces are positioned essentially outside the outer vertical plane, i.e. displaced relative to the upper abutment surfaces. The tongue is movable at an angle into the groove and the locking element is insertable into the locking groove by mutual angular movement of the boards about the joint edges.

Owner:VÄLINGE INNOVATION AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com