Hollow floor slab with small dense ribs and its production process

A technology of small dense ribs and fasting, which is applied in the field of fasting small dense ribbed floors and its manufacturing, can solve the problems of low hollowness ratio, small span, and low bearing capacity of the floor, and achieve clear bidirectional force, safe and reliable structure, and reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

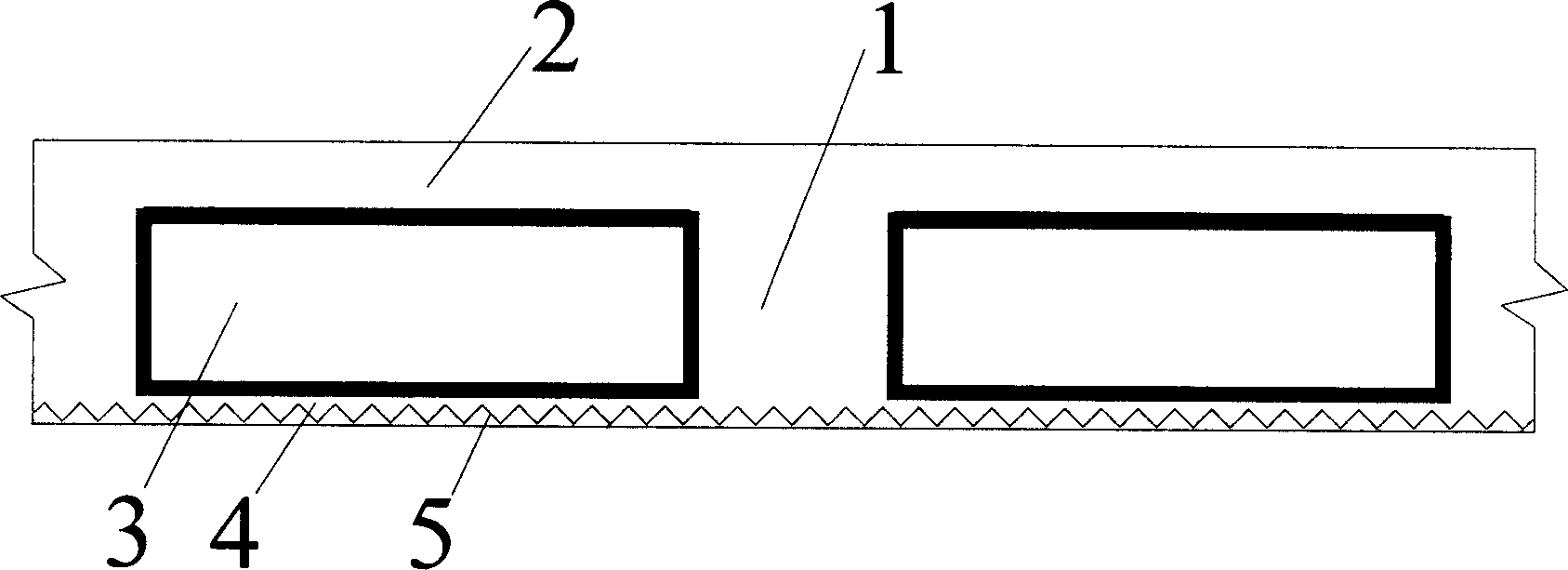

[0033] Such as figure 1 As shown, the fasting small ribbed floor of the present invention includes a solid densely ribbed beam 1 with reinforced concrete, a panel 2 with reinforced concrete, a composite thin-walled box 3, and a thin bottom plate 4 integrated at the lower end of the box 3 , the thin bottom plate 4 is a board formed by diamond-shaped steel wire mesh or other shaped steel wire mesh, alkali-resistant glass fiber cloth or alkali-resistant glass fiber cloth or plastic mesh cloth and cement mortar 5, when the reinforced concrete hollow ribbed floor When cast-in-place, the bottom plate of the composite thin-walled box 3 and the reinforcing material 5, under the action of the vibrator, make the cement mortar infiltrate into the bottom of the composite thin-walled box, and the bottom panel of the composite thin-walled box 3 and the infiltrated cement mortar Organically combined to form a thin bottom plate 4 that closes the cavities of the ribs. And because the newly fo...

Embodiment 2

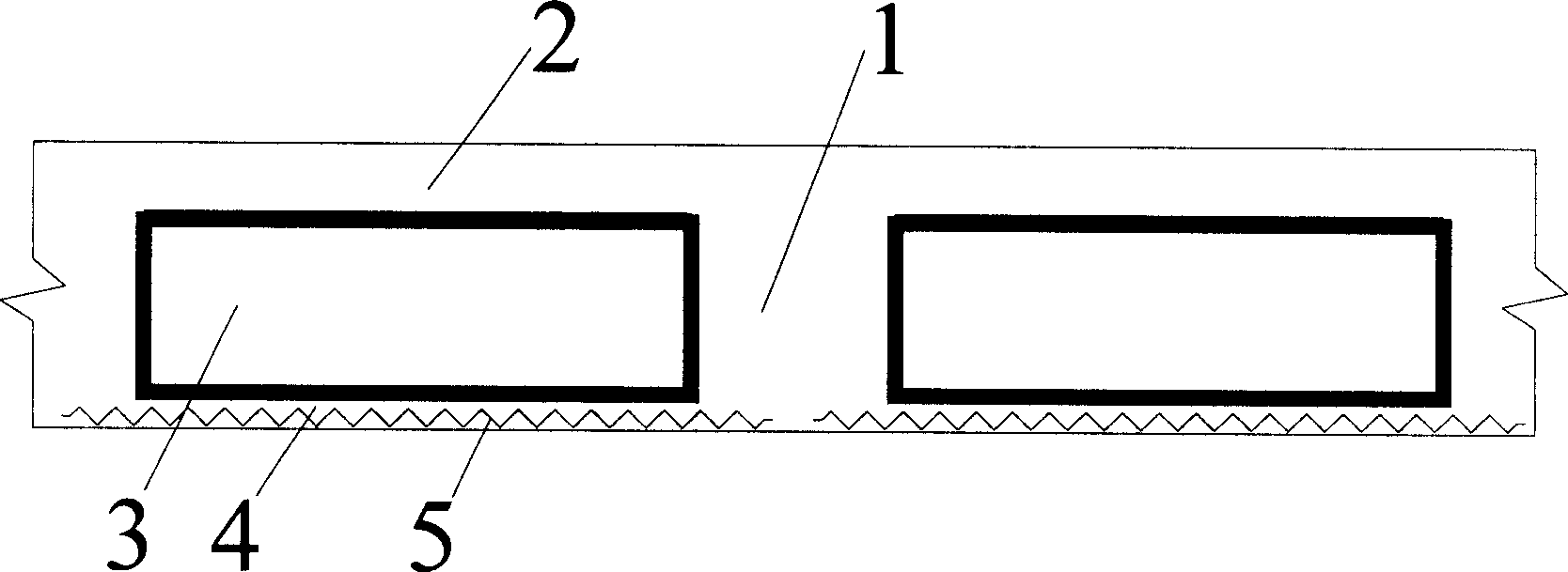

[0036] Such as figure 2 As shown, on the same basis as Embodiment 1, the difference of this embodiment is that the water chestnut of the composite thin-walled box body 3 is an inverted water chestnut (such as Pic 4-1 , 4-2 Shown), the book base plate 4 that is arranged on casing 3 lower ends is segmental type, only is provided with by this type book base plate 4 at the lower end corresponding position of each casing 3, saves material again while reaching the object of the present invention.

Embodiment 3

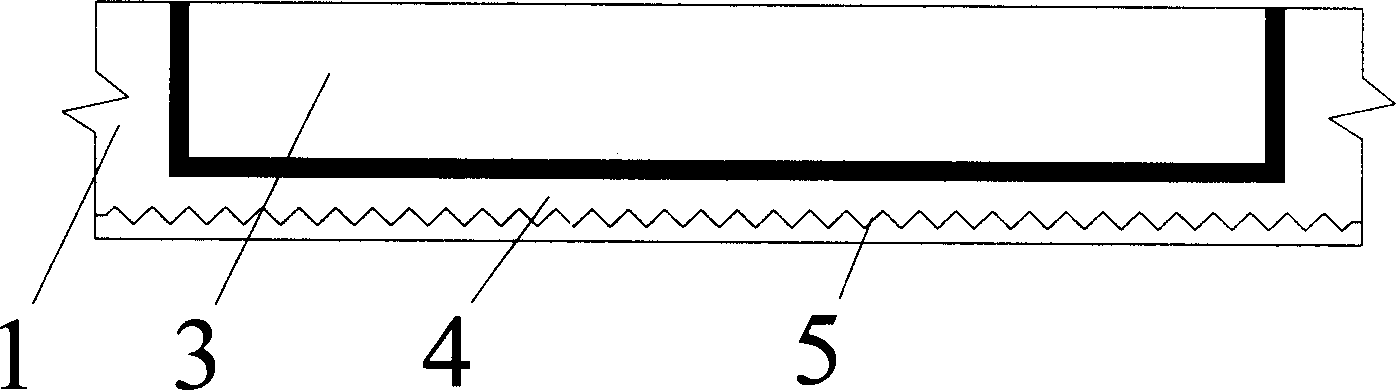

[0038] Such as image 3 As shown, on the same basis as that of Embodiment 1, the difference of this embodiment is that the box body 3 is an integral box body, and the water chestnut of the composite thin-walled box body is an inverted water chestnut, as Figure 4-3 shown.

[0039] The manufacturing method of the above-mentioned embodiment mainly includes the following steps

[0040] a) Beams, columns and small ribbed steel bars laid and bound on the floor formwork;

[0041] b) At the same time, lay diamond-shaped or other shaped steel wire mesh and other reinforcing materials for the bottom panel;

[0042] c) Place and fix the manufactured composite thin-walled box;

[0043] d) Binding panel reinforcement;

[0044] e) When the buoyancy is generated, use 12# iron wire to tie the steel bar at the bottom of the densely ribbed beam through the formwork and tie it to the support rod, or use 12# iron wire to tie the support rod, penetrate the formwork, and tie it to the bottom s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com