Square steel pipe fabricated column-prefabricated superposed beam integrally-fabricated frame and construction method

A technology of square steel pipes and laminated beams, applied in climate change adaptation, architecture, building construction, etc., can solve the problems of crack resistance and integrity, seismic performance, and poor reliability of structures that are difficult to meet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings.

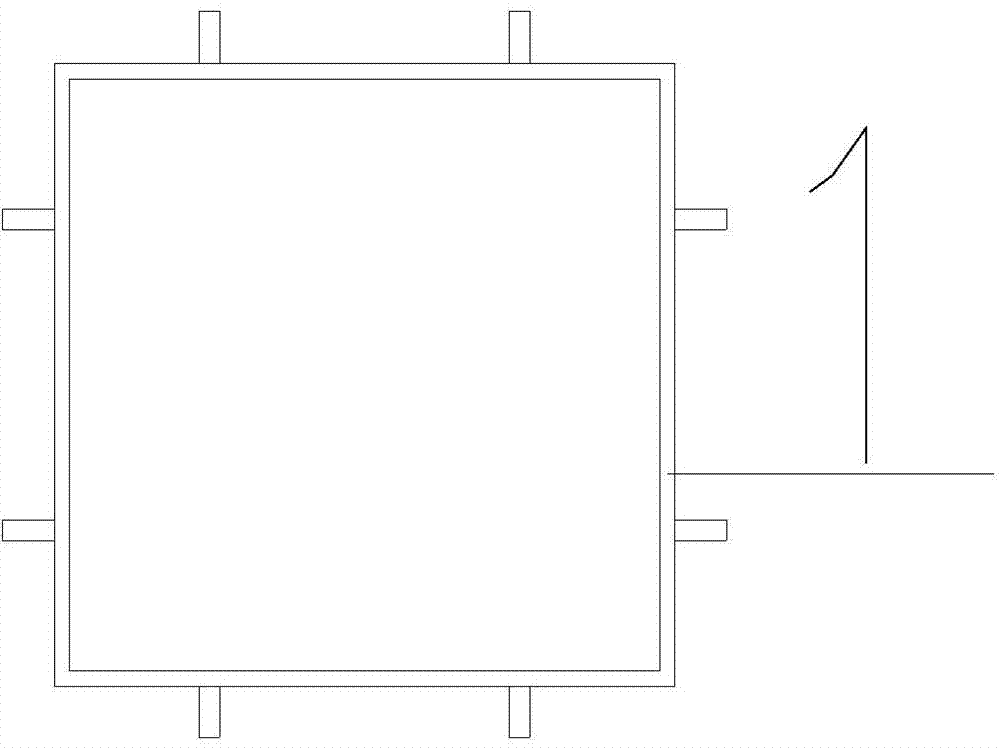

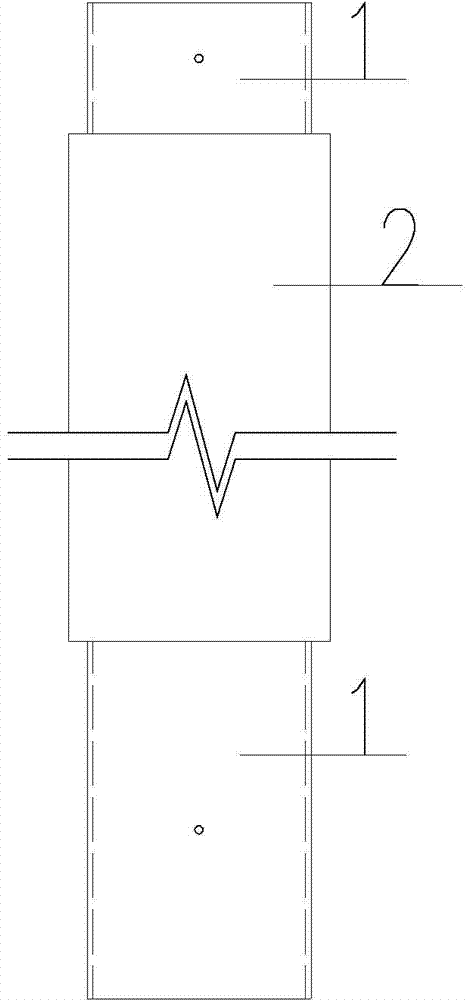

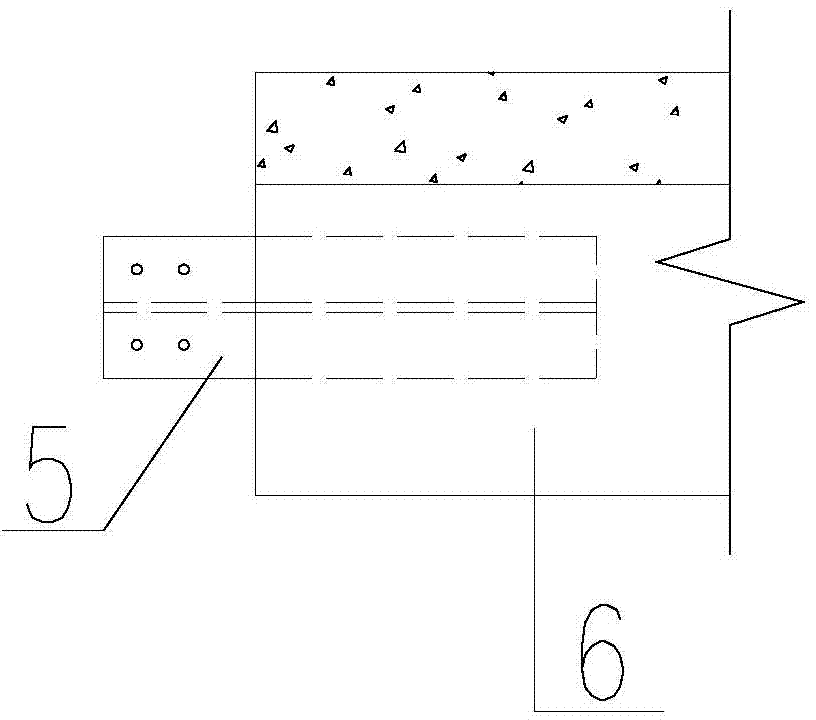

[0051] Such as Figure 1-8 As shown, the present invention provides a square steel pipe prefabricated column-prefabricated composite beam assembly integral frame, which includes a square steel pipe 1 with internal and external ribs, a square steel pipe prefabricated column 2 respectively arranged inside and outside the square steel pipe, Node square steel pipe casing 4 with connecting flange 3, prefabricated composite beam 6 with short I-beam 5, prefabricated floor groove 7, fiber reinforced composite plastic plate 8, engineering cement-based composite material or fiber-reinforced cement-based composite material 9 , prefabricated floor slab 10;

[0052] The square steel pipe prefabricated column 2 and the prefabricated composite beam 6 are connected by the node square steel pipe casing 4 with the connecting flange 3 to form an integral frame beam-column node; There a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com