Device and method for automatically detecting and sorting light emitting diodes (LEDs)

A technology of automatic detection and detection device, which is used in sorting and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

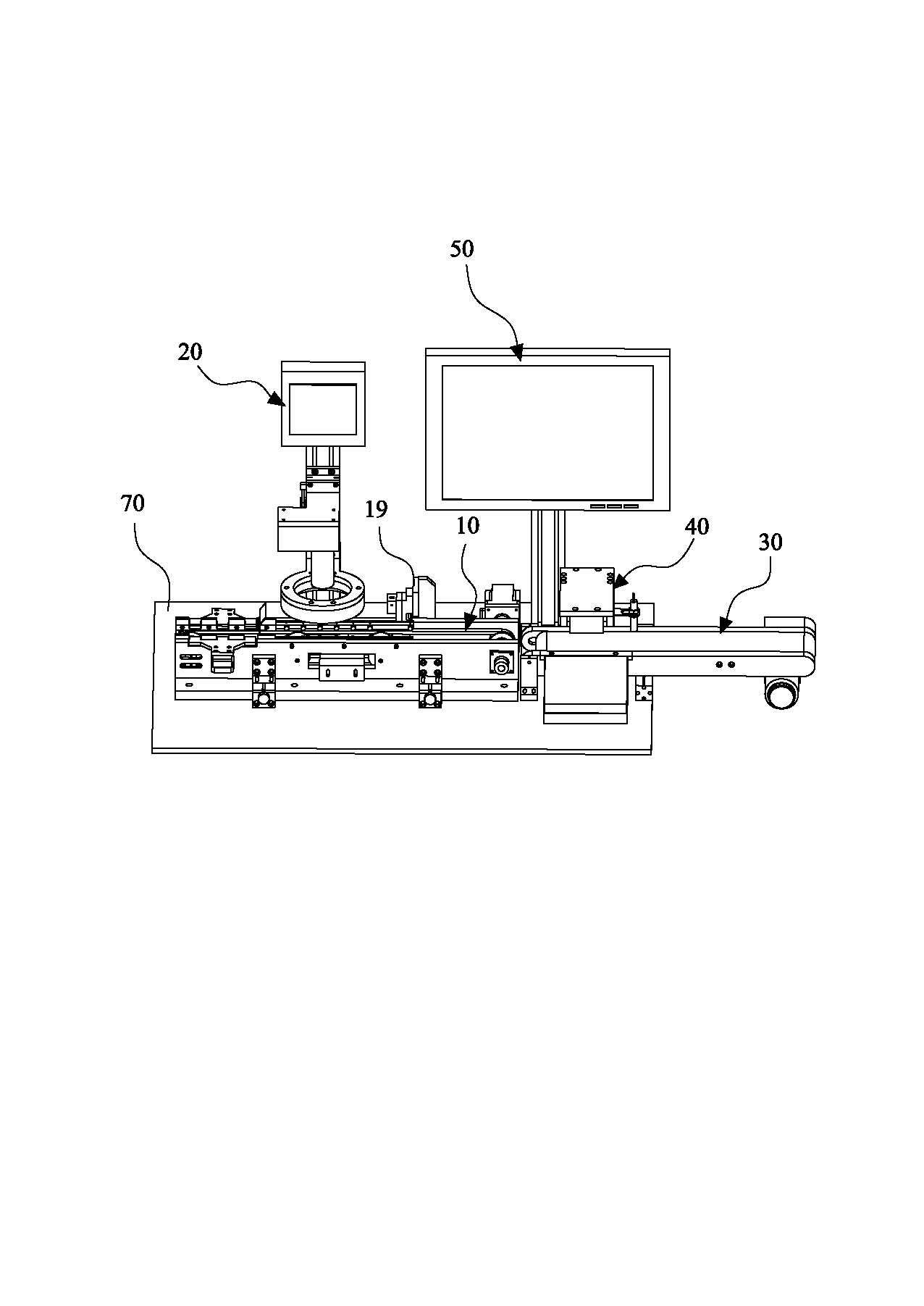

[0066] Please refer to Figure 1 to Figure 8 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a working platform 70 and the first conveying device 10 installed on the working platform 70, the detection device 20, the second conveying device 30, the sorting The device 40 and the display device 50 also include a control device 60 , the aforementioned devices are all connected to the control device 60 , and controlled by the control device 60 to make each device automatically operate.

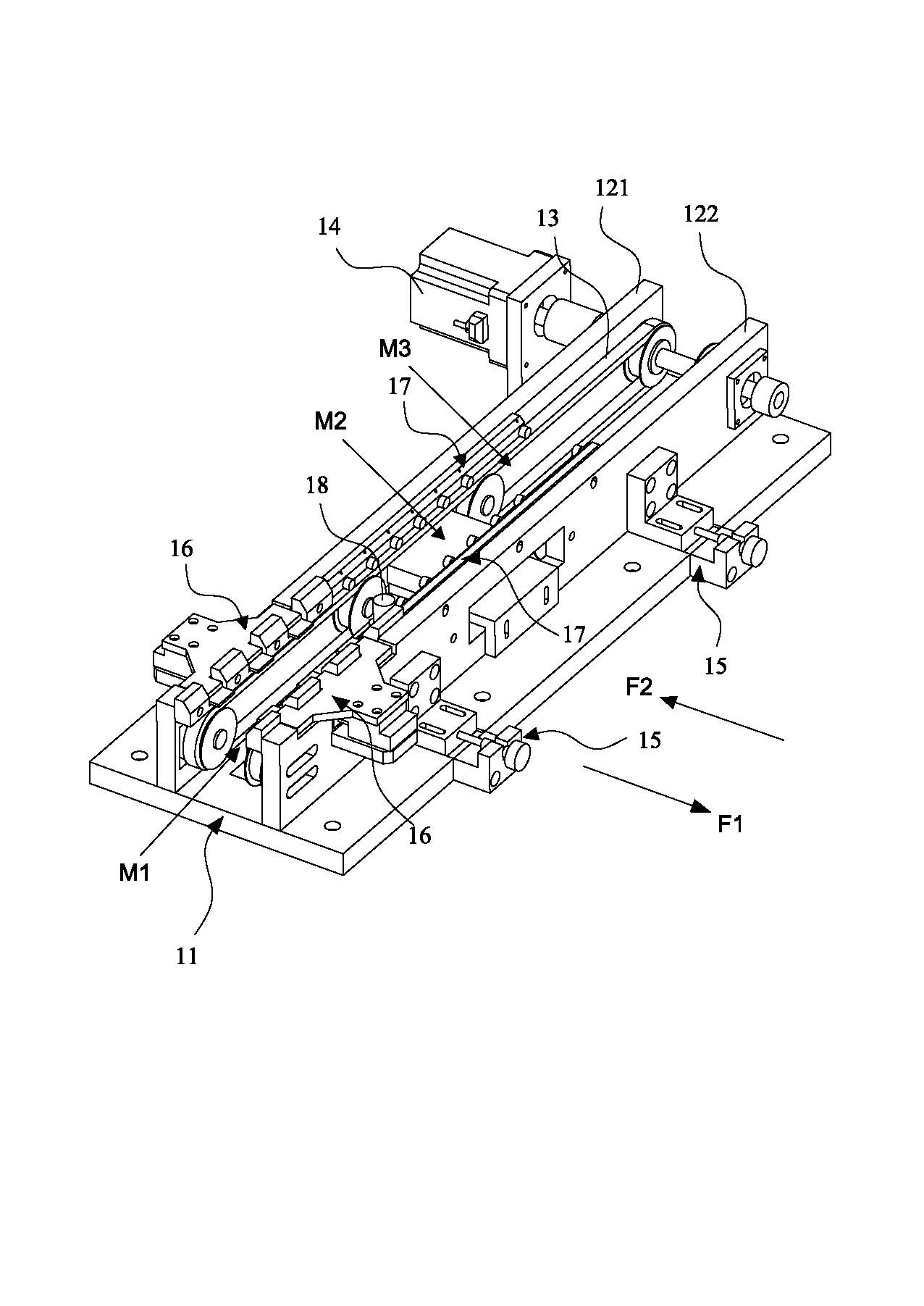

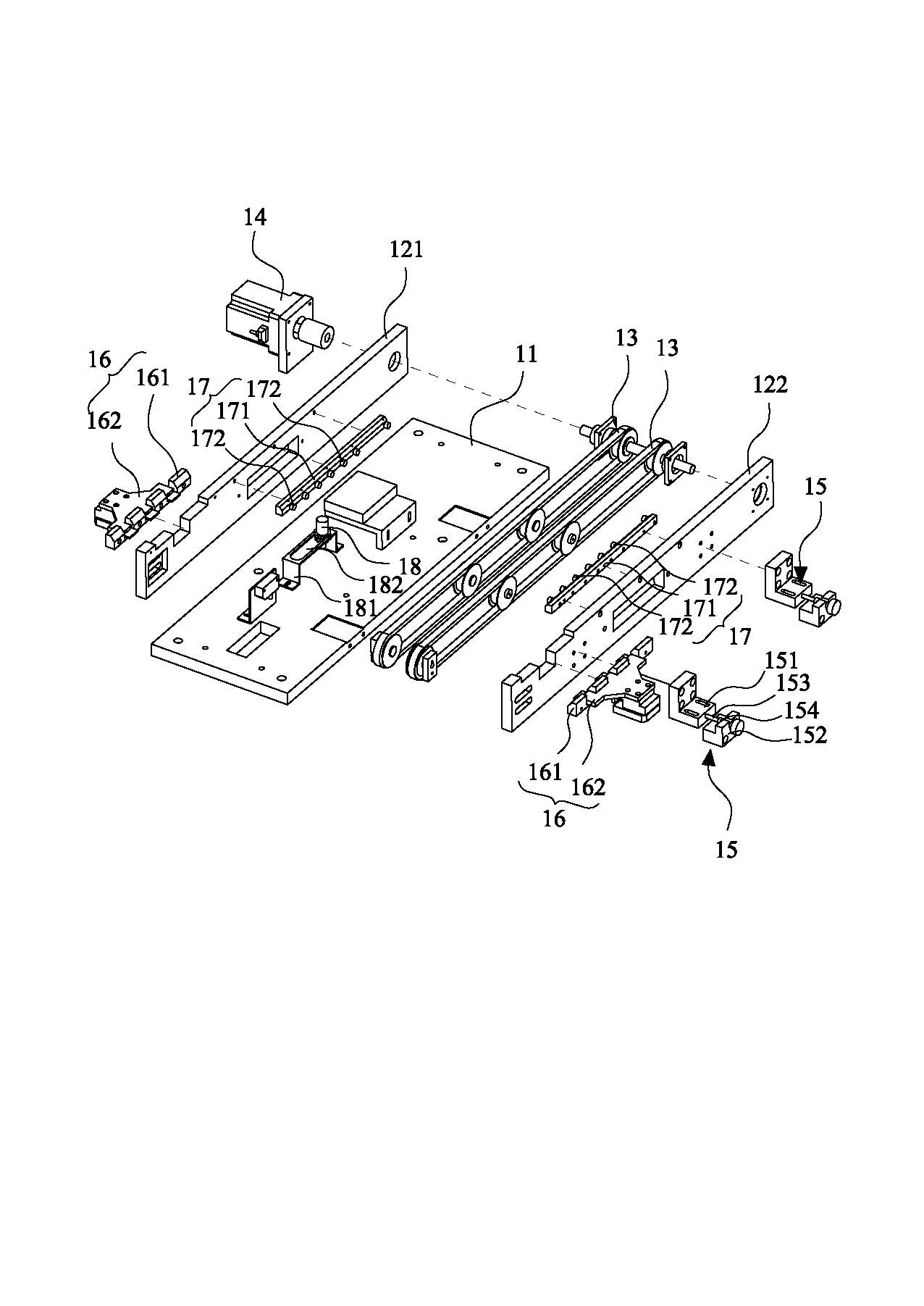

[0067] Among them, such as figure 2 with image 3 As shown, the first conveying device 10 includes a bottom plate 11 , two positioning brackets 121 , 122 , a first motor 14 disposed between the two positioning brackets 121 , 122 , and two first conveyor belts 13 . Specifically, the base plate 11 is fixed on the aforementioned work platform 70, and the two positioning brackets refer to a first positioning bracket 121 and a second positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com