Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Lower beam height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

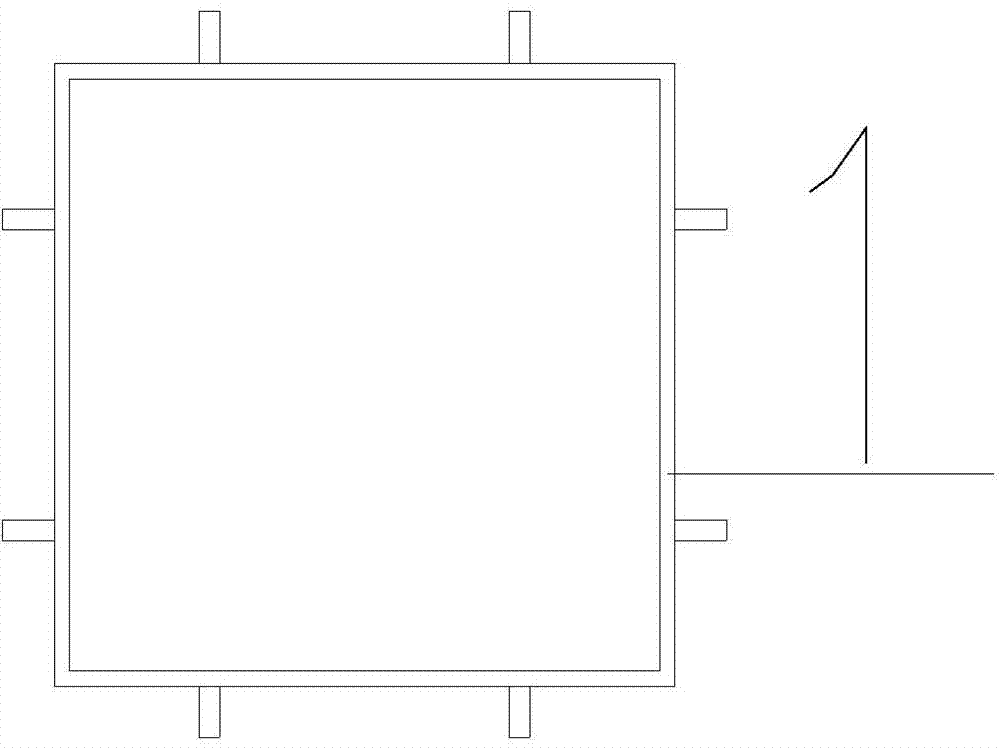

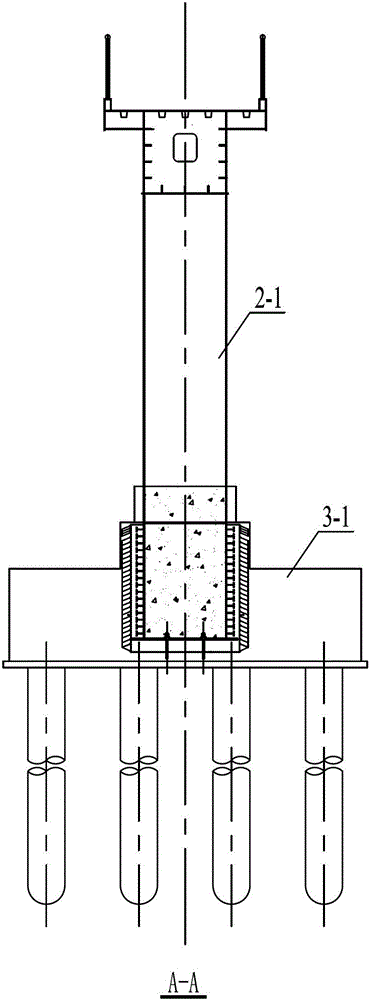

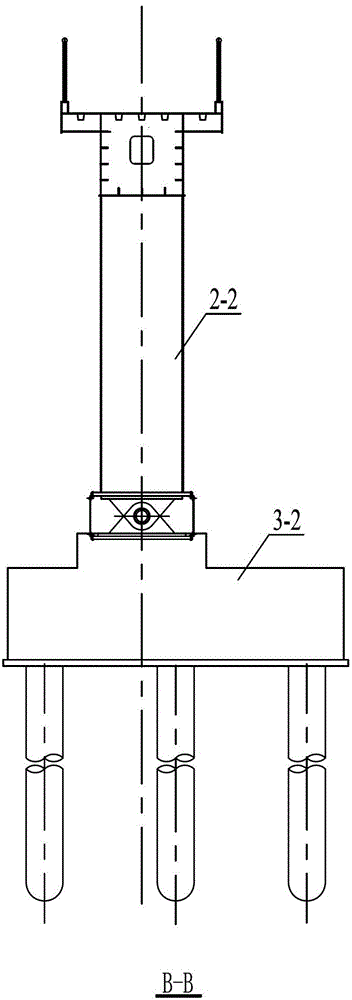

Integral assembling type building system and installing method

InactiveCN105649360AImprove quality controlEasy to installBuilding material handlingDwelling buildingTime of usePrecast concrete

The invention belongs to the technical field of building engineering and particularly relates to an integral assembling type building system and an installing method. The integral assembling type building system is characterized by comprising prefabricated steel reinforced concrete combination columns, prefabricated steel reinforced concrete combination beams, prefabricated reinforced concrete slabs, a prefabricated light integral inner wall and a prefabricated concrete heat preservation outer wall which are assembled together. The building system has the beneficial effects that all the members are prefabricated in a factory, quality is controlled conveniently, and the construction difficulty caused by outdoor weather changes can be reduced. Moreover, splicing is carried out on site, and installing is safe, fast and convenient. The recycle rate of formworks is high, work for the formworks and frame pipes on site is avoided, the number of times of use and consumption of the formworks and frame pipes are reduced, on-site labor is saved, the on-site dust raise phenomenon is improved substantially, the influence on the environment is small, and environmental pollution is reduced.

Owner:SHANDONG YUANBO BUILDING TECH CO LTD

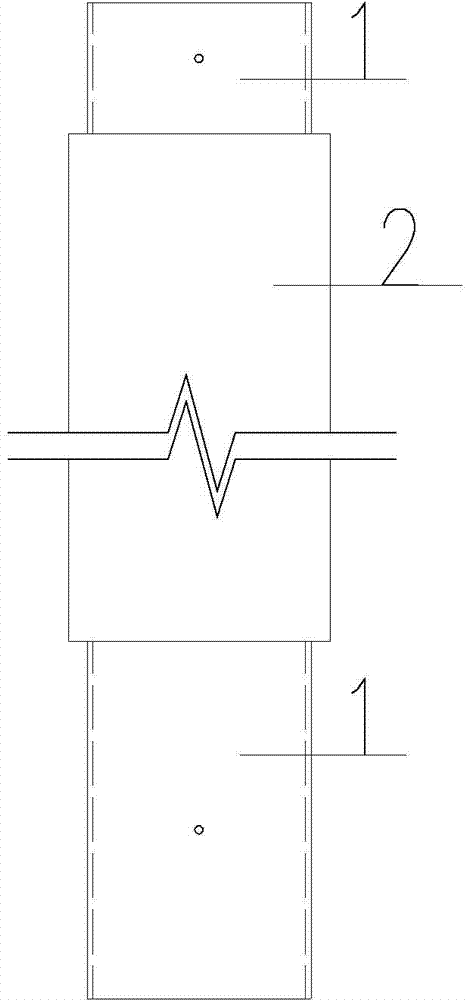

Square steel pipe fabricated column-prefabricated superposed beam integrally-fabricated frame and construction method

InactiveCN104499568ALabor savingImprove product qualityClimate change adaptationBuilding material handlingSteel tubeHigh performance concrete

The invention discloses a square steel pipe fabricated column-prefabricated superposed beam integrally-fabricated frame and a construction method. The frame comprises a square steel pipe with inner and outer ribs, a square steel pipe casing with connecting wing plates and a prefabricated superposed beam. The square steel pipe is formed by rolling once, a thin centrifugally-produced concrete protective wall is arranged inside the square steel pipe, and high-performance concrete wraps the square steel pipe, so that a square steel pipe fabricated column is formed. The square steel pipe casing with the connecting wing plates is used for vertical connection between one upper square steel pipe fabricated column and one lower square steel pipe fabricated column as well as connection between the prefabricated superposed beam and the square steel pipe fabricated column. Short I-beams are arranged at the ends of the prefabricated superposed beam, and the prefabricated superposed beam is connected with the connecting wing plates on the square steel pipe casing through high-strength bolts. An engineered cementitious composite or fiber reinforced cement composite is poured in beam-column joint connection areas. The concrete fabricated superposed beam is connected with prefabricated floor slabs as well as the prefabricated floor slabs are connected both through fiber reinforced composite plastic boards. A prefabricated house has the advantages of reasonable stress, convenience in construction, high joint ductility, good endurance and anti-seismic performance and the like.

Owner:SOUTHEAST UNIV

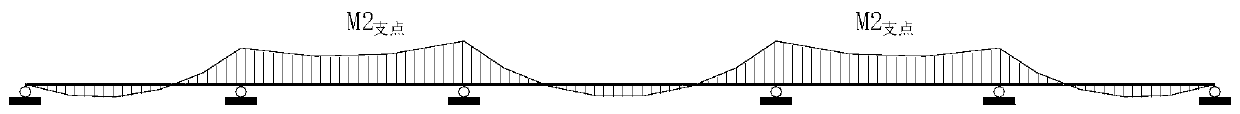

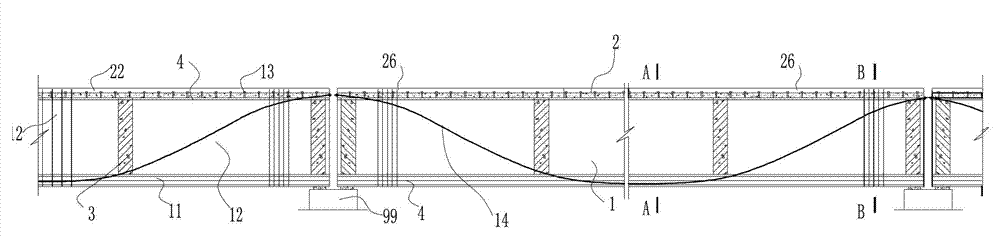

Prestressed concrete-corrugated web steel box connecting beam hybrid beam structural system

InactiveCN106400666ASolve crackingReduce the weight of the structureBridge structural detailsBridge materialsCrazingPre stress

The invention discloses a novel hybrid beam structural system. The novel hybrid beam structural system comprises a corrugated web steel box connecting beam segment and prestressed concrete box beam segments. The prestressed concrete box beam segments are located on the two sides of the corrugated web steel box connecting beam segment. The novel hybrid beam structural system is mainly used for a continuous beam bridge or a rigid frame bridge. The midspan part of a main span is the corrugated web steel box connecting beam, the rest part of the main span and sidespans are prestressed concrete box beams, and steel-concrete composite segments are used for connection transition between the prestressed concrete box beams and the corrugated web steel box connecting beam. The novel hybrid beam structural system overcomes the defects of a traditional prestressed concrete box beam unitary system and defects of a traditional steel box beam unitary system, and has the beneficial effects of being good in stress performance and economical efficiency, high in span capacity and the like. According to the structural system, the dead load is effectively reduced, the span capacity is improved, the midspan deflection can be reduced, and the defects that the continuous downwarping and crazing of the midspan of the prestressed concrete box beam, poor stability of an ordinary steel box beam web and poor durability of bridge deck pavement are avoided.

Owner:SOUTHEAST UNIV

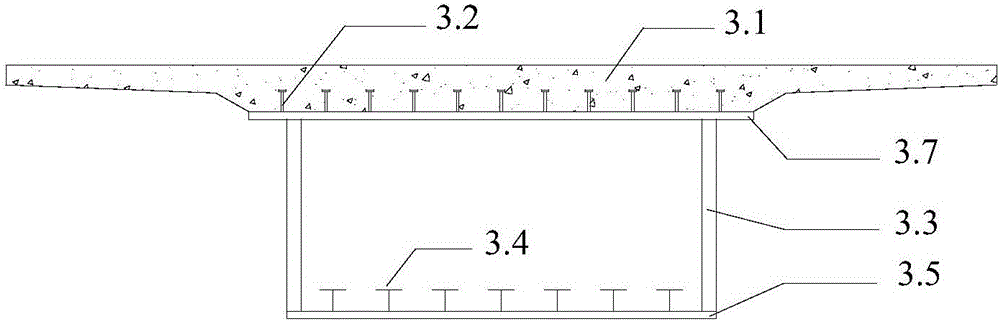

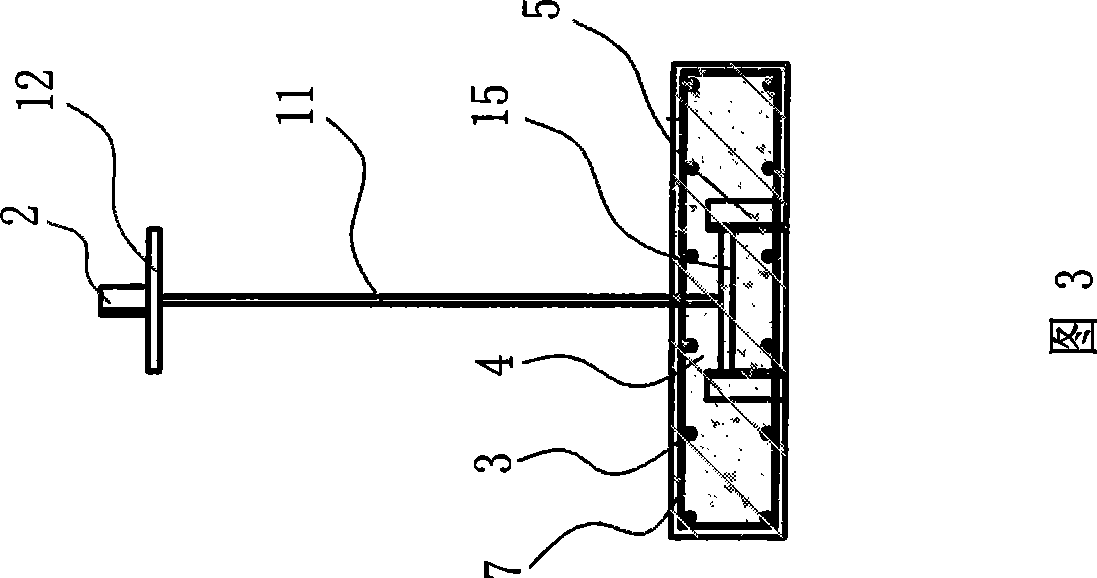

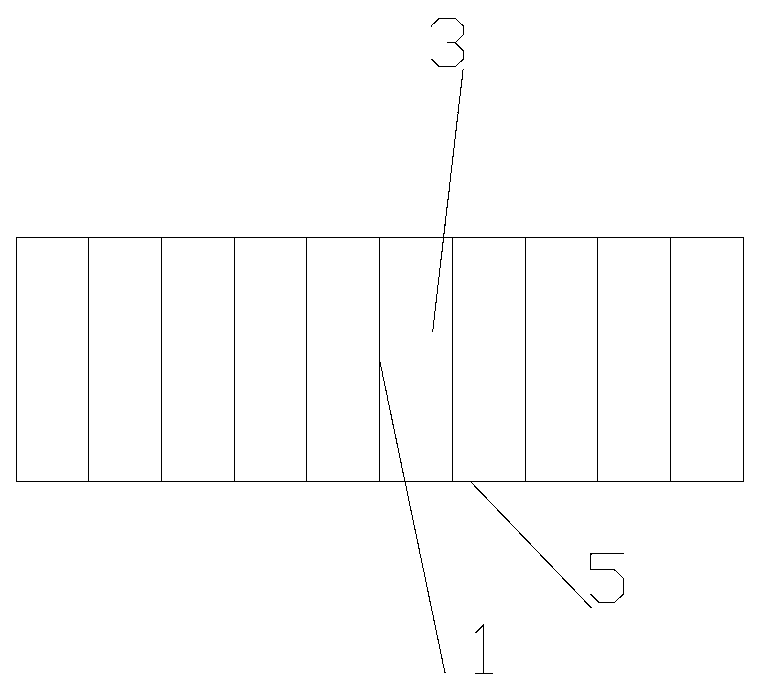

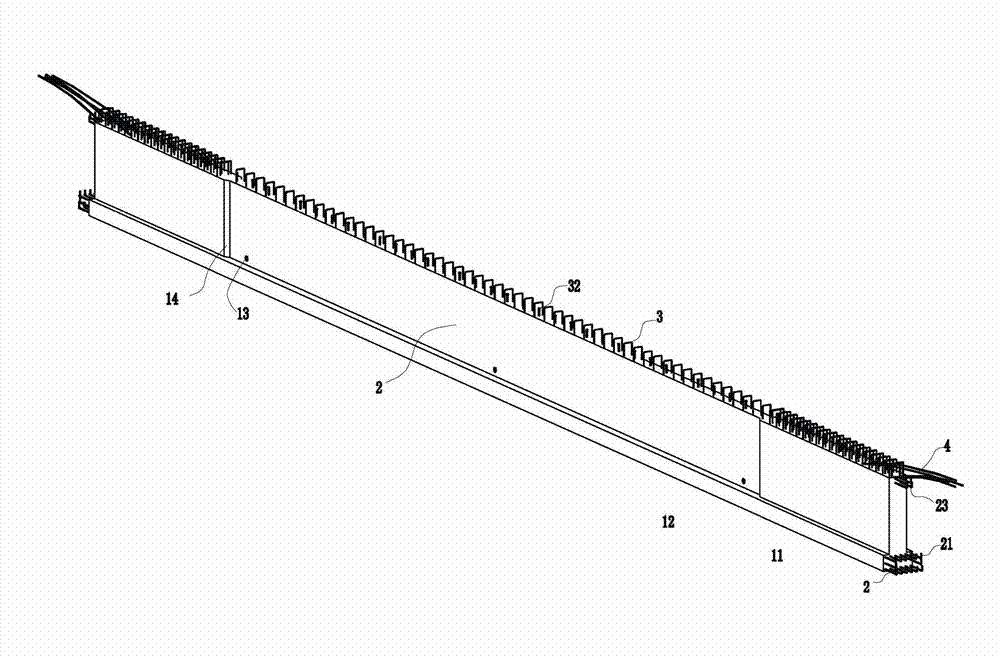

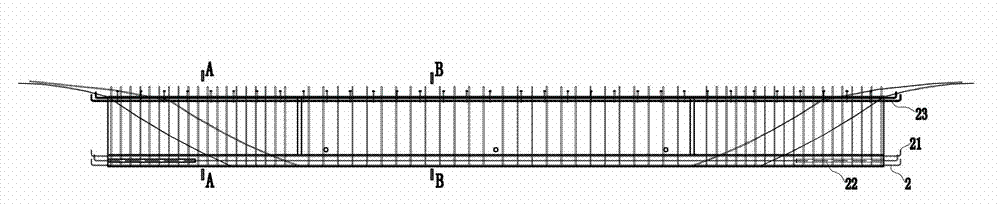

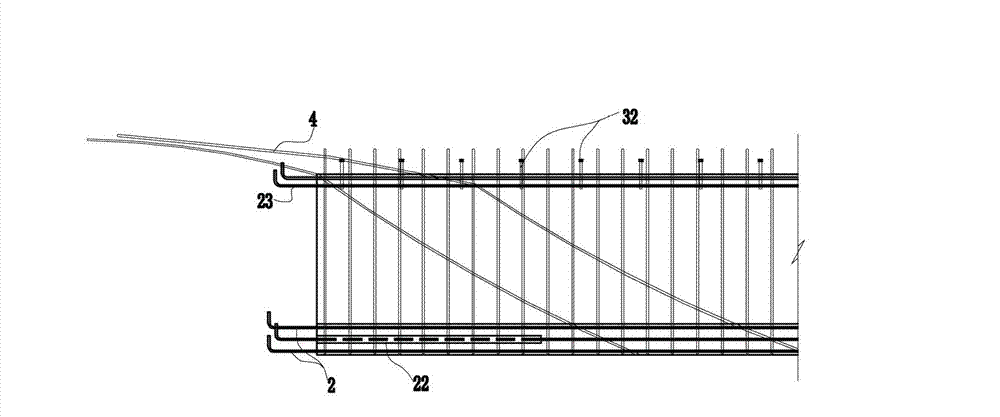

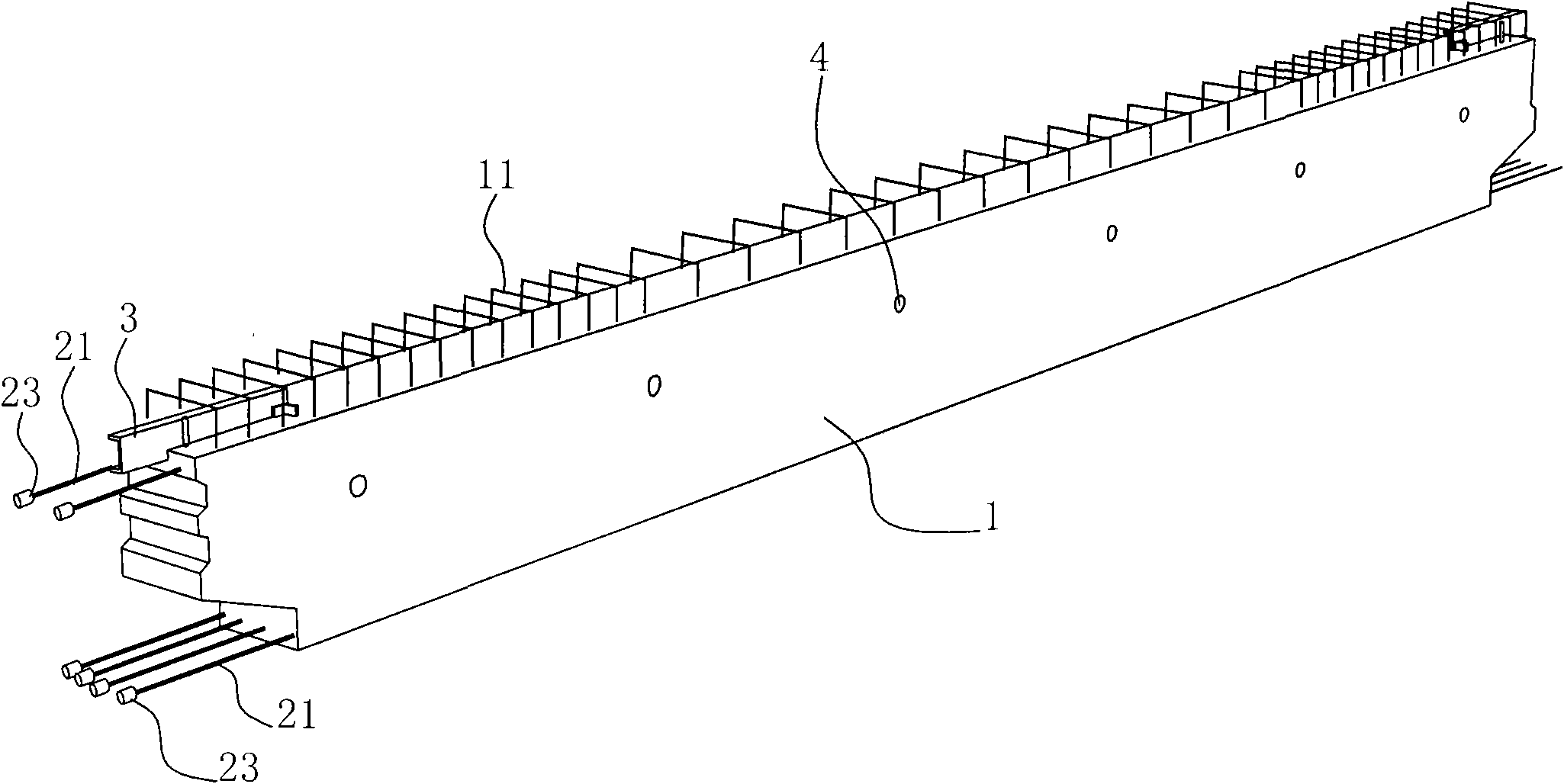

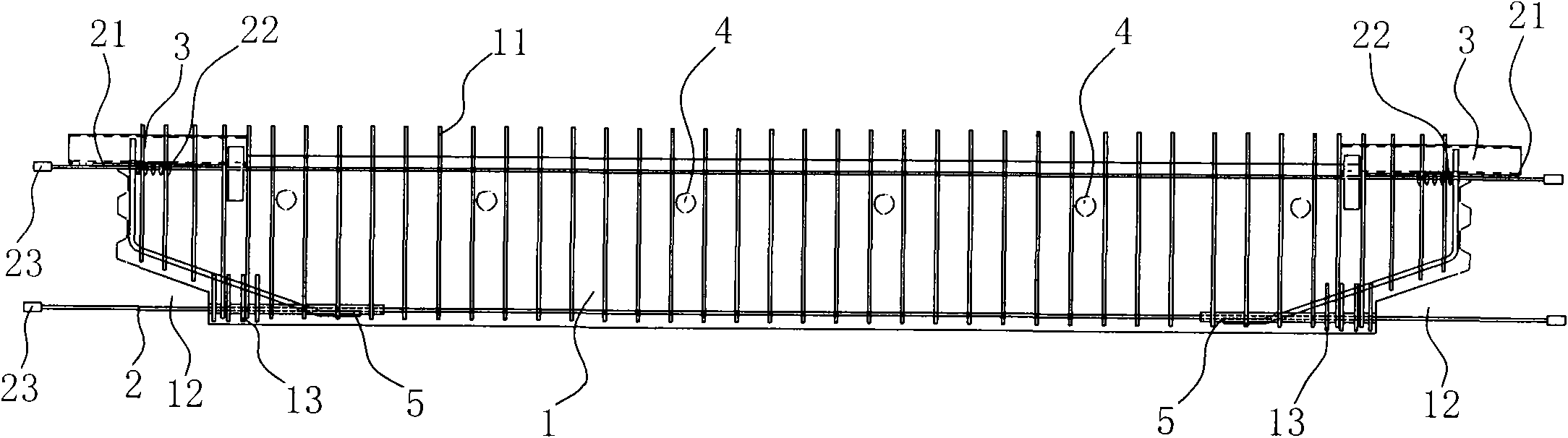

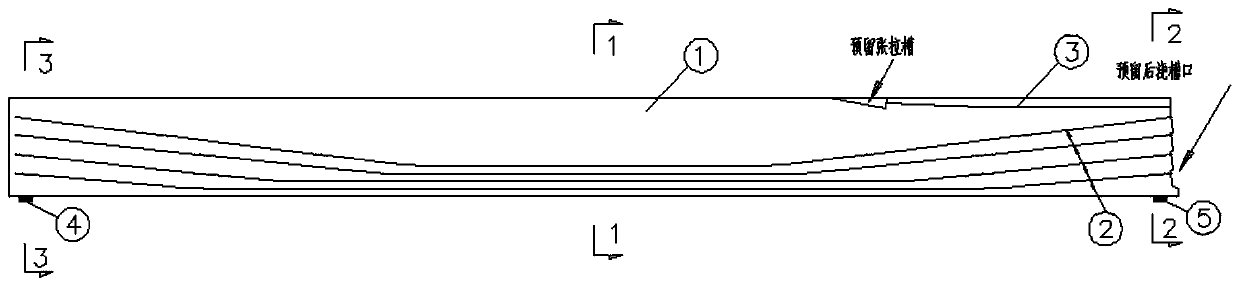

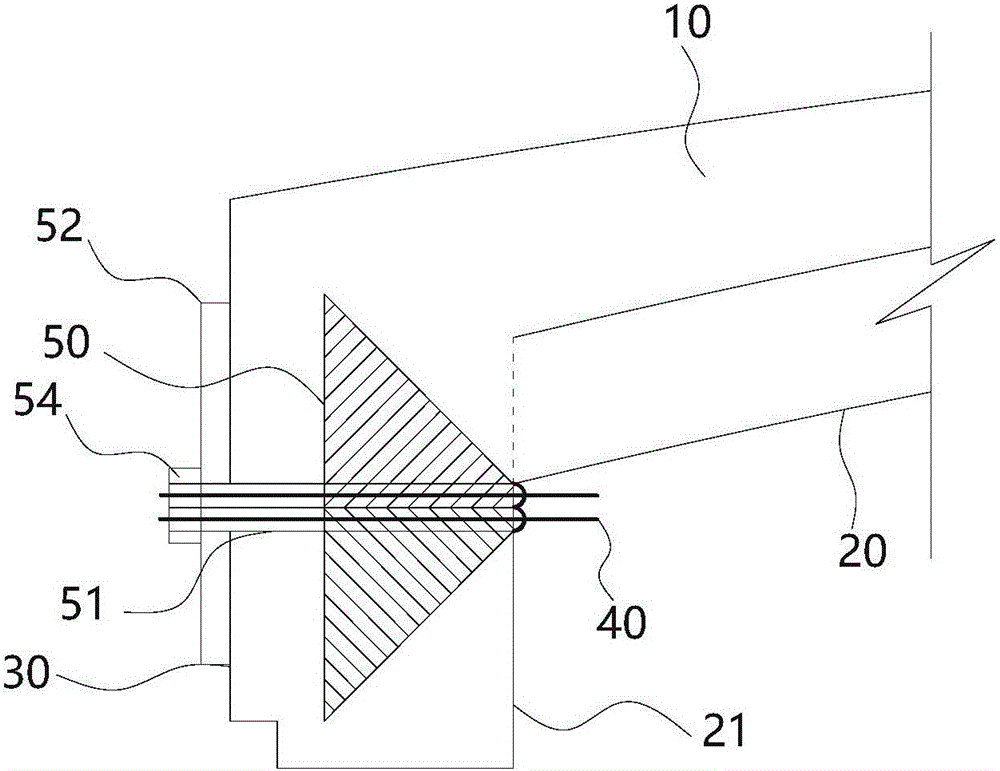

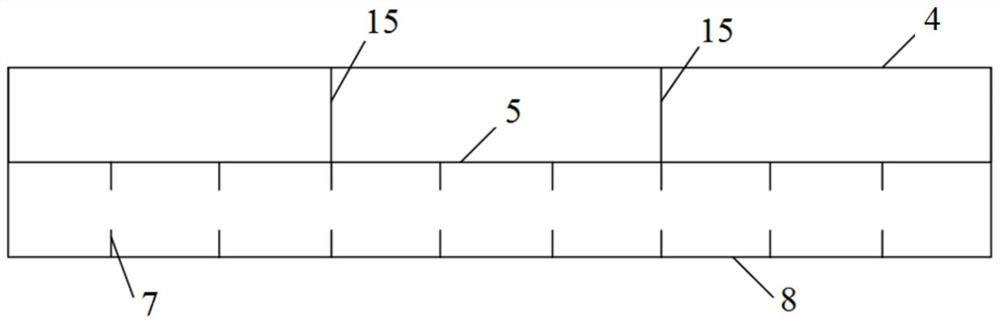

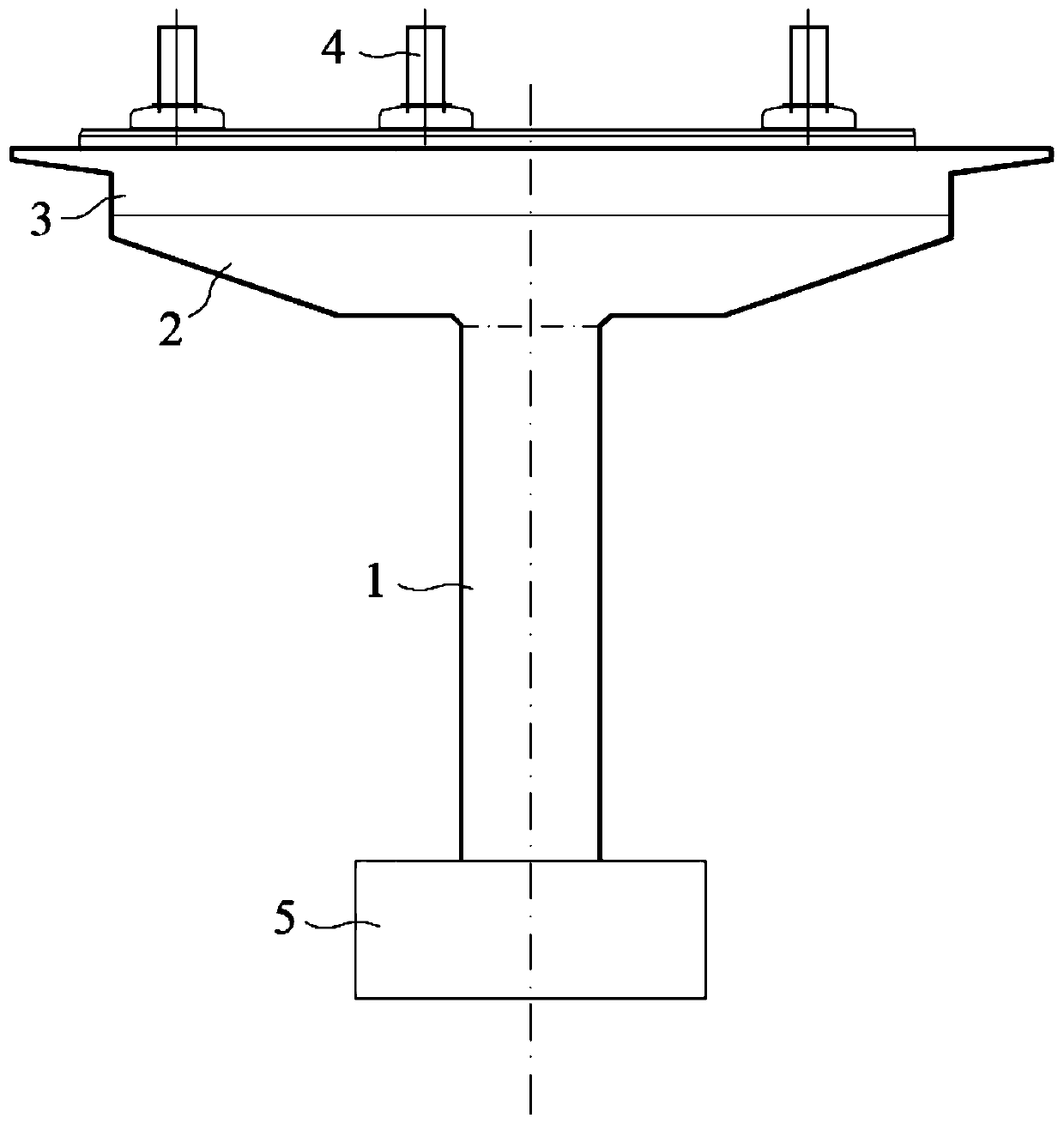

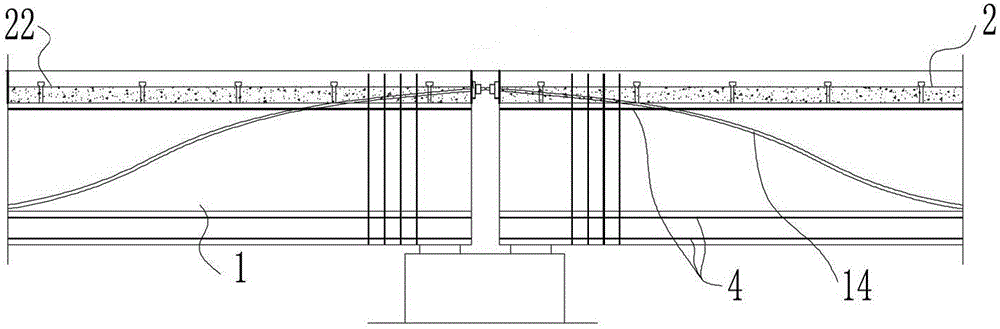

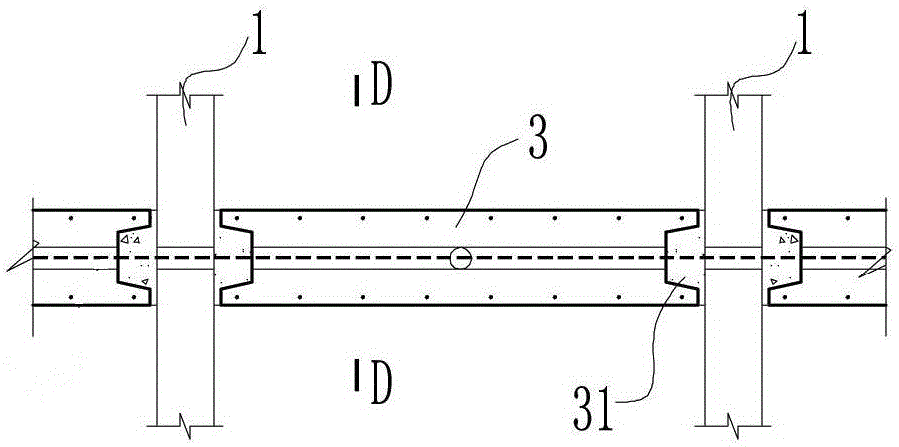

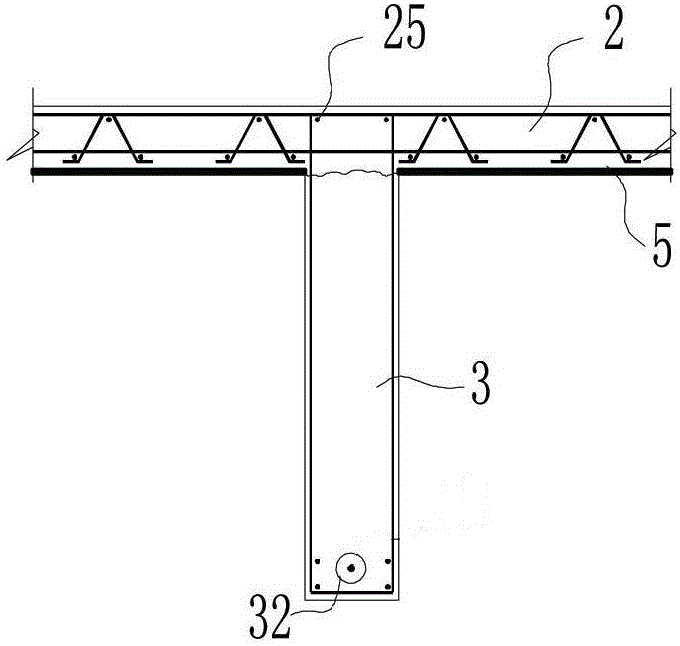

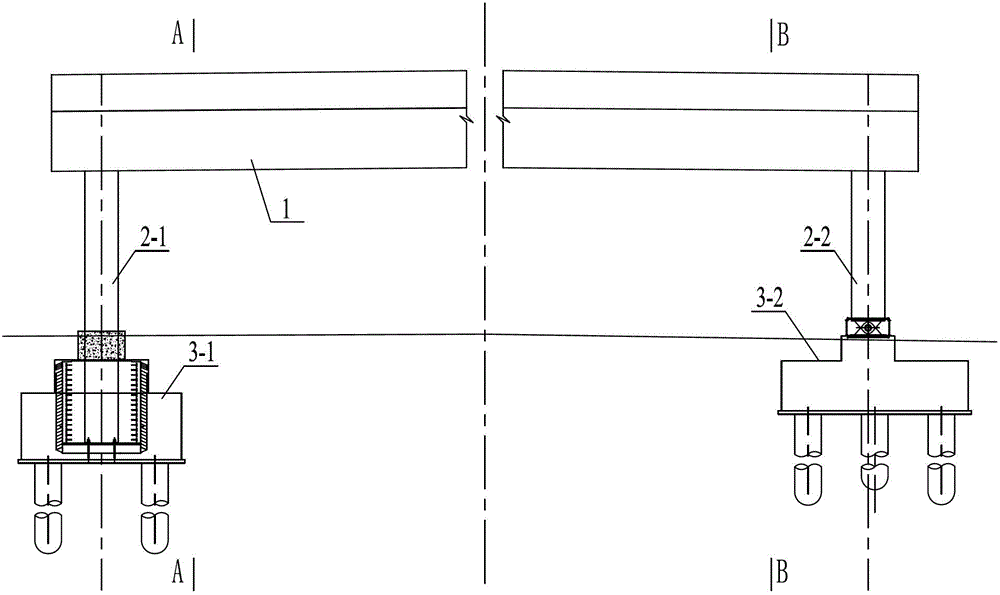

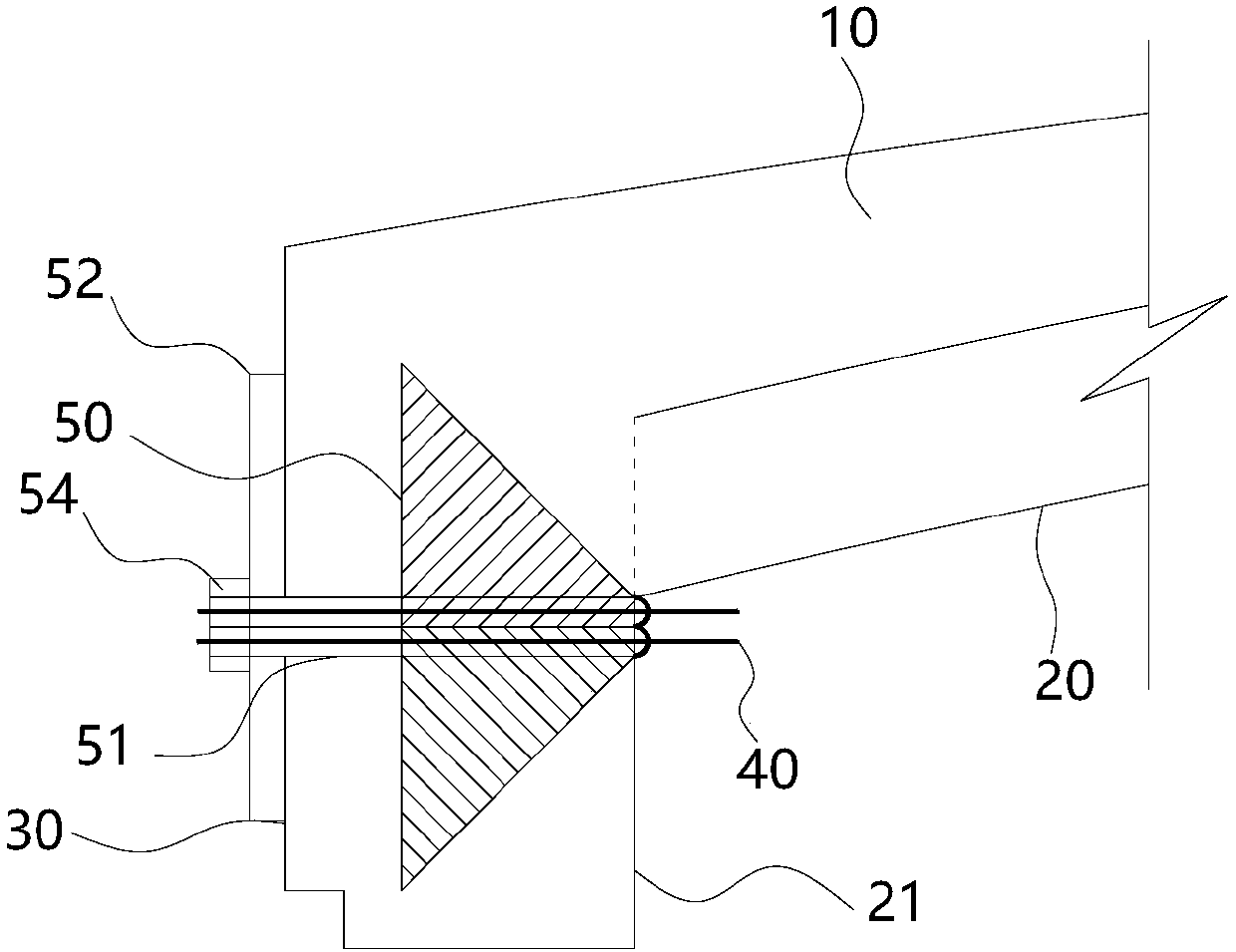

Pretensioned prestressing composite girder and method for producing the same

ActiveCN101418630ASmall beam heightReduce the overall heightLoad-supporting elementsBuilding material handlingShaped beamSheet steel

Provided is a pre-tensioned prestressed composite beam, which is an I-shaped beam composed of H-shaped steel and concrete, the web plate of the H-shaped steel is provided with trapezoidal holes (14) at intervals, the upper flange and the lower flange of the H-shaped steel are welded with shearing nails, the outer periphery of the lower flange is enclosed with concrete to form a steel-concrete lower flange (4), and the inside of the steel-concrete lower flange is embedded with prestressed steel twisted wire by pretensioning method. The manufacturing method of the composite beam is that: a steel plate is cut into two tooth-shaped plates along tooth-shaped line to be respectively as the trapezoidal hole plates of the H-shaped steel flange, the trapezoidal hole plates are welded with steel plates to form the web plate, the web plate is welded with the upper flange and the lower flange to form the H-shaped steel (1) having trapezoidal holes, the H-shaped steel is put on a base surface with the lower flange downward, the two sides of the lower flange are provided with side molds, a stirrup (7) is arranged and steel twisted wires (3) are longitudinally fastened between the two side molds, the steel twisted wire is tensioned to tensioning state, the concrete for enclosing the H-shaped lower flange is poured and tamped between the two side molds, the steel-concrete lower flange (4) is formed after demolding, and the steel twisted wire at tensioning state is loosened after the concrete reached to predetermined strength and is cut off at predetermined position. The invention is suitable for beams of buildings.

Owner:杨峰

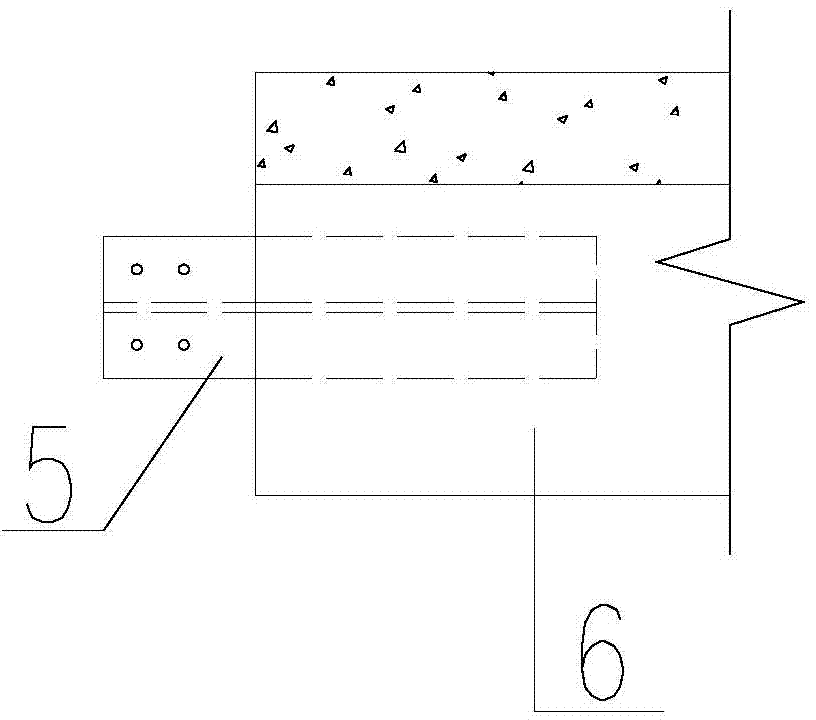

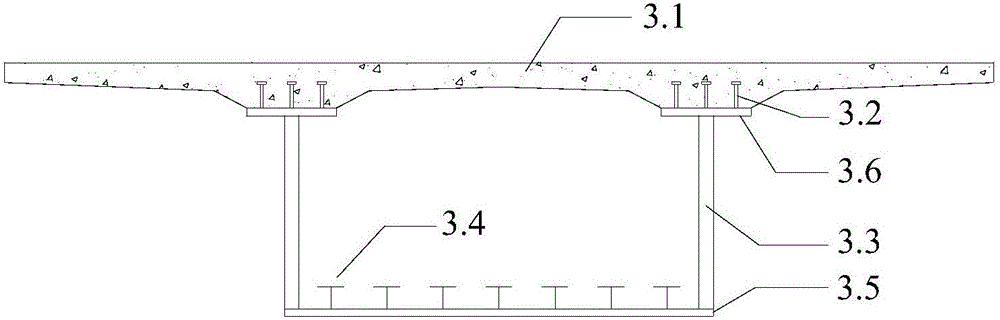

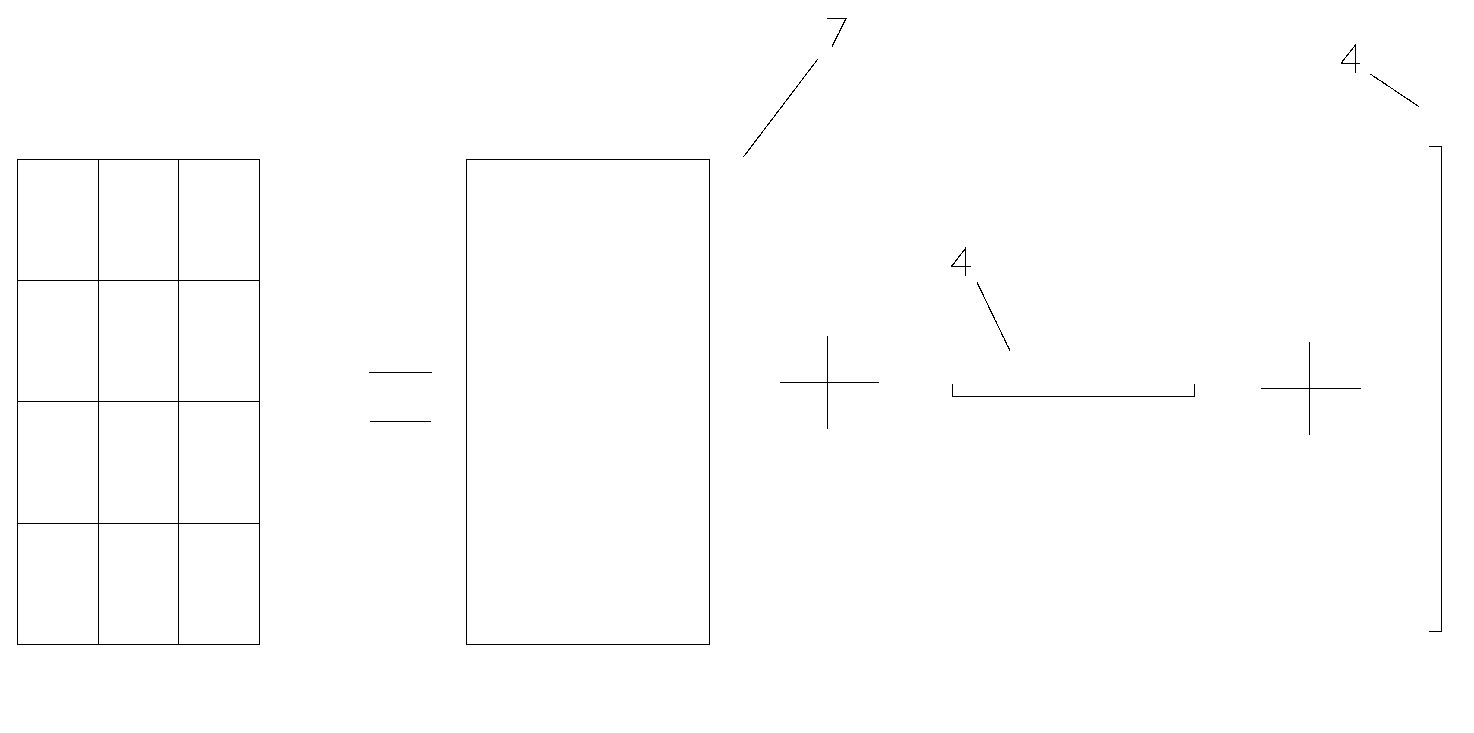

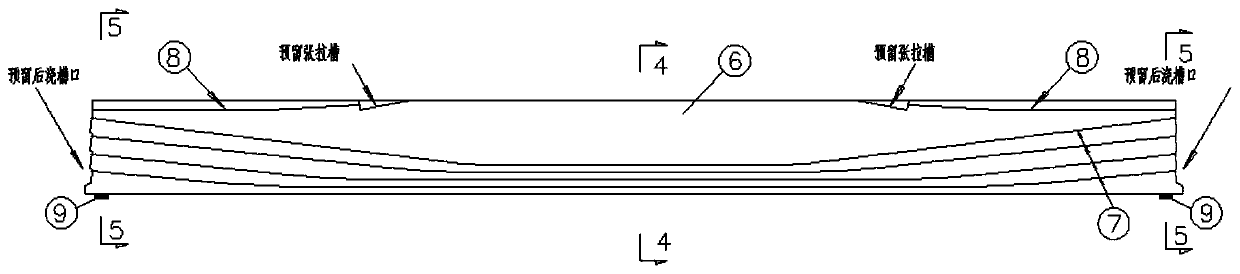

Large span prefabricated monolithic casting structure and construction method

ActiveCN103046645AImprove shear resistanceSmall floor spanBuilding material handlingShaped beamFloor slab

Disclosed is a large span prefabricated monolithic casting structure. The large span prefabricated monolithic casting structure comprises a floorslab, a superposed beam and a column, the superposed beam and the column are used for supporting the floorslab, the superposed beam is divided into a short frame main beam, a long frame beam and an auxiliary beam, the auxiliary beam is connected with the main beam, the superposed beam comprises a prestress prefabricated beam and a cast-in-situ portion, the prestress prefabricated beam comprises a beam body and a pre-stressed steel strand which is buried in the beam body and serves as a main rib, two ends of the short frame main beam and the long frame beam are connected with the column, cross sections of prefabricated beam portions of the long frame beam and the auxiliary beam are invertedly T-shaped, the superposed beam after monolithic casting is an I-shaped beam connected with the floorslab, and the auxiliary beam and the long frame beam utilize the inverted T-shaped prestress prefabricated beams with small intervals. The large span prefabricated monolithic casting structure has the advantages that the span, the thickness and the self weight of the floorslab are small, heights of the beams are reduced, reinforcing bars are reduced, and the short main beam which uses a superposed rectangular beam is good in shear resistance and convenient to connect with the auxiliary beam.

Owner:宁波优造建筑科技有限公司

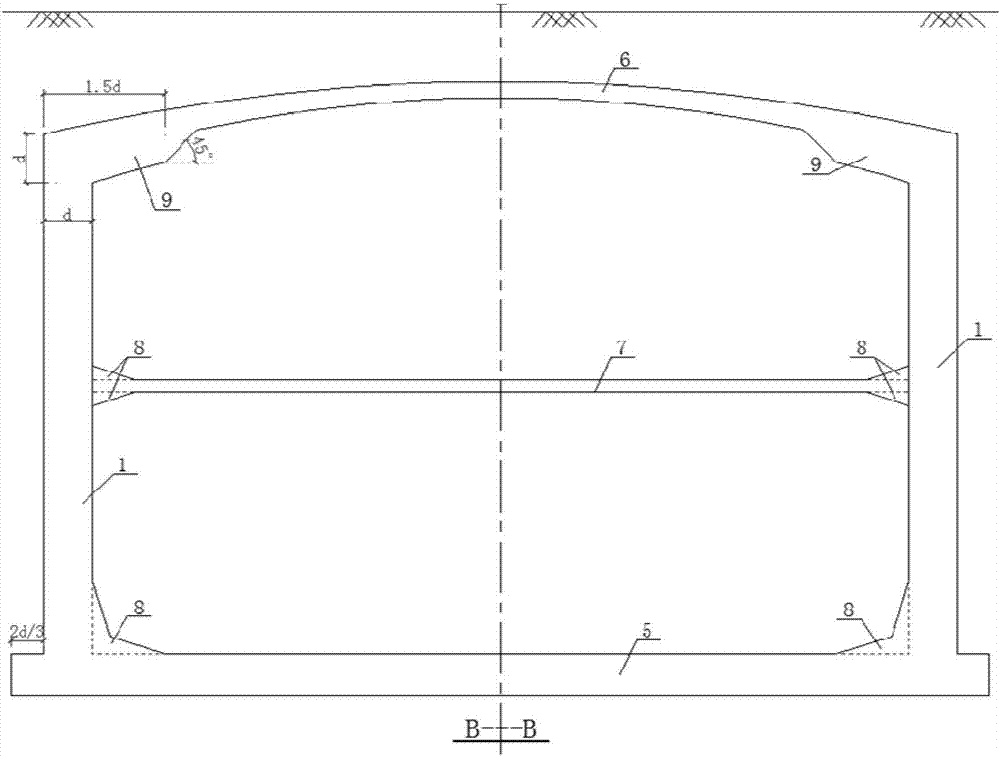

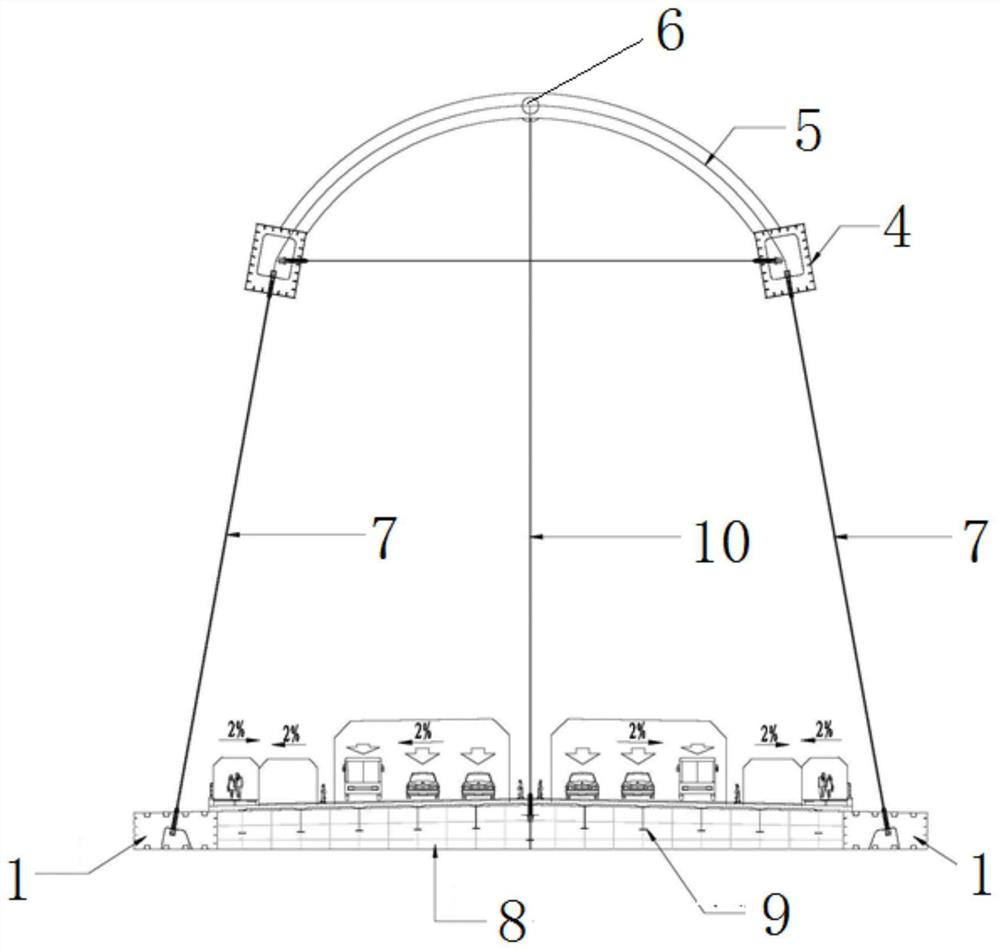

Open-cut type non-column large-span arched subway station structure as well as design and construction method

InactiveCN106869170AGive full play to resistanceThe force of the joint structure is clear and reasonableArtificial islandsUnderwater structuresSubway stationBearing capacity

The invention discloses an open-cut type non-column large-span arched subway station structure as well as a design and construction method and relates to the field of subway and underground engineering as well as underground pipe gallery construction. The structure comprises a bottom plate, side walls, middle plates, middle beams, arched plates, arched beams, reinforcing tips and prestressed cables; the two side walls in parallel are oppositely arranged on the bottom plate; the multiple arched beams are evenly arranged in the passage direction; one arched plate is arranged between every two arched beams; the arched plates located on two sides of the same arched beam are connected with each other; one prestressed cable is arranged between two arch feet of the same arched beam; the middle beams are arranged in the middles of the two side walls; and one middle plate is arranged between the every two adjacent middle beams. The method is as follows: the prestressed cables are anchored and tensioned among the bottom plate, the side walls and the middle plates, among the middle beams, the side walls and the arched beams, among the arched plates, among the reinforcing tips and top ends of the side walls. With the structure and the method, the carrying force of end weak areas and the overall rigidity are improved, the lost height of the arched beams is increased, the beam height is reduced, the dead weight is reduced, and the phenomena of concrete cracking on lower edges and crushing on upper edges of the beams are avoided.

Owner:JIAN YAN FOUND ENG

Double beam floor structure

Owner:杨大刚

Long-span steel-concrete composite bridge structure and construction process thereof

PendingCN110344315AImprove support strengthRealize a large spanBridge structural detailsBridge erection/assemblyBridge deckPrefabrication

The invention discloses a long-span steel-concrete composite bridge structure and construction process thereof. Thus, the problems in the prior art of restricted bridge span and large integral steel using amount of bridges can be solved. The bridge structure and construction process can realize factory prefabrication and have beneficial effects of saving construction periods and steel using amount. The schemes include as follows: the bridge structure includes a steel main beam, a concrete bridge deck and bridge piers; the steel main beam includes multiple sections which can be assembled; the steel main beam adopts a box type section structure in a width direction; the two sides of the box type section structure are provided with outer longitudinal beams connected to the box type section structure; the concrete bridge deck is arranged on the top of the steel main beam and connected to the steel main beam; and steel diagonal bracings are arranged between the bridge piers and the steel main beam.

Owner:SHANDONG TRAFFIC PLANNING DESIGN INST

High-strength reinforcing steel bar self-compaction steel fiber ultrahigh-strength concrete transfer girder

The invention provides a high-strength reinforcing steel bar self-compaction steel fiber ultrahigh-strength concrete transfer girder and relates to a reinforcing steel bar concrete transfer girder. The high-strength reinforcing steel bar self-compaction steel fiber ultrahigh-strength concrete transfer girder overcomes the defect that the common reinforced concrete transfer girder has high self-weight, is difficult to construct and cannot apply the high-strength reinforcing steel bar, the defects that a profile steel concrete transfer girder and a combined transfer girder cannot apply the high-strength reinforcing steel bar and has complex connecting nodes with a concrete frame supporting column, and the defect that the wing edge of a steel girder is easy to buckle under the negative bending moment action of the combined transfer girder. The high-strength reinforcing steel bar self-compaction steel fiber ultrahigh-strength concrete transfer girder consists of a high-strength longitudinal reinforcing steel bar, a high-strength closed hooping and self-compaction steel fiber ultrahigh-strength concrete, restrains the hooping spacing of the whole concrete comprising a concrete protective layer to be 60 to 80 mm, and restrains the hooping spacing of the longitudinal reinforcing steel bar to be 80 to 150 mm, wherein the outer surface of the whole concrete is in level with the outer surface of the transfer girder. The high-strength reinforcing steel bar self-compaction steel fiber ultrahigh-strength concrete transfer girder organically combines the self-compaction steel fiber ultrahigh-strength concrete, the high-strength hooping and the high-strength longitudinal reinforcing steel bar and completely exerts the advantages of different materials, so that the earthquake resistance of the transfer girder is greatly improved and the transfer girder has a wide application prospect in high-rise and super high-rise structures.

Owner:贵州中建伟业建设(集团)有限责任公司

Irregular-shaped precast beam used for bridges

An irregular-shaped precast beam used for bridges comprises a reversed T-shaped beam body and a prestress steel strand which is embedded in the middle of the beam body and serves as a main reinforcing-bar. The beam body comprises a web, wherein a stirrup is arranged on a bottom flange web, and the stirrup extends out of the upper surface of the beam body. The irregular-shaped precast beam used for bridges is characterized in that through holes traversing partition board main reinforcing-bars are arranged on the lower portion of the beam body web along the longitudinal direction at intervals. The cross sections are simple in shape, and templates with single specifications and strong generality can be adopted to manufacture, thereby greatly lowering mold cost.

Owner:杨众 +1

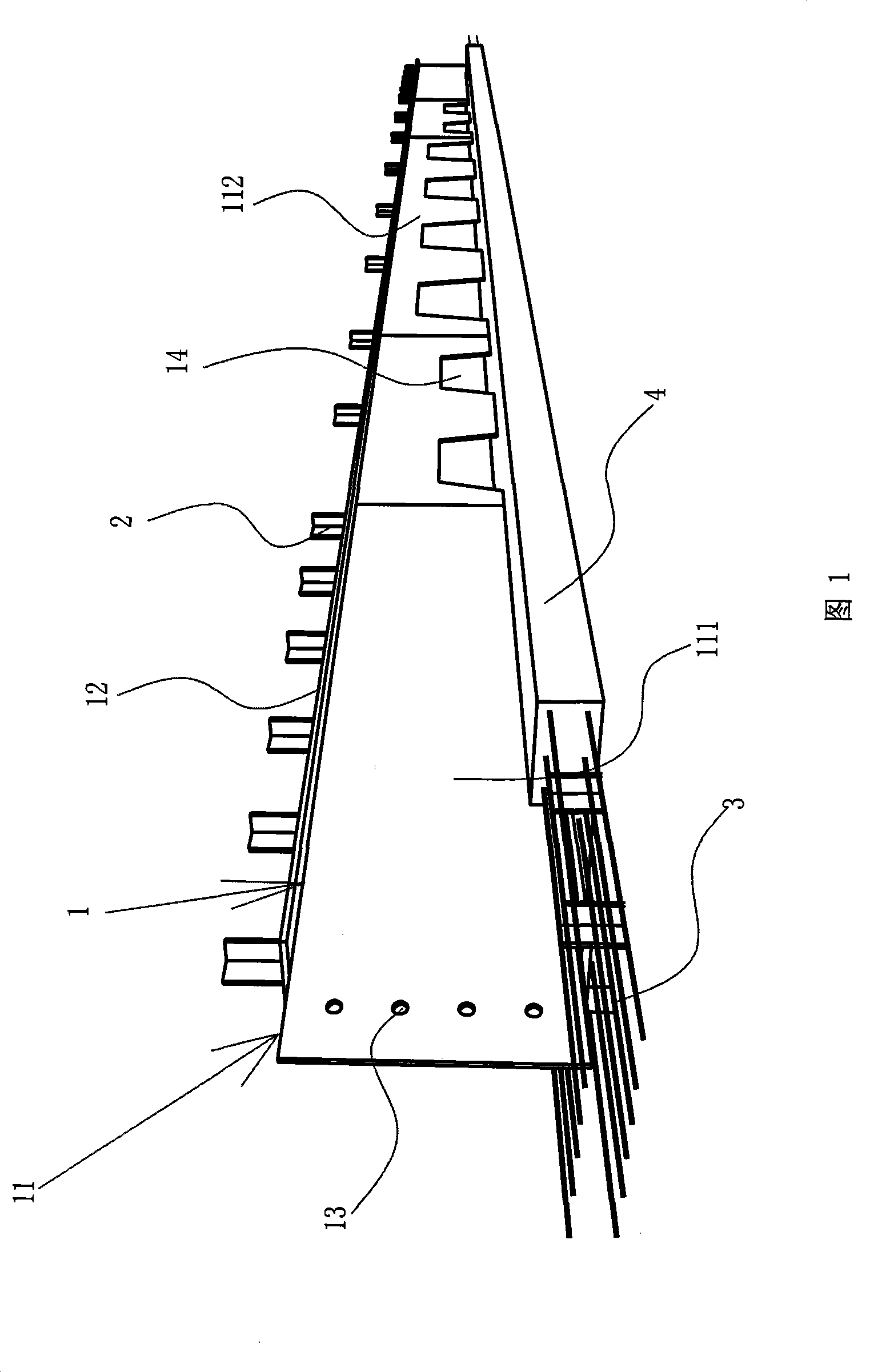

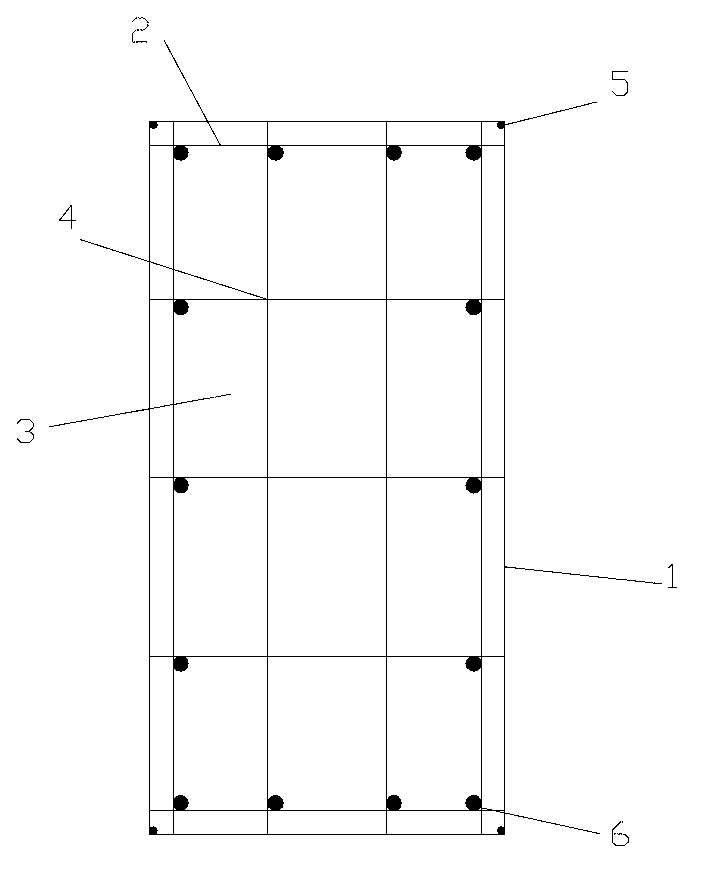

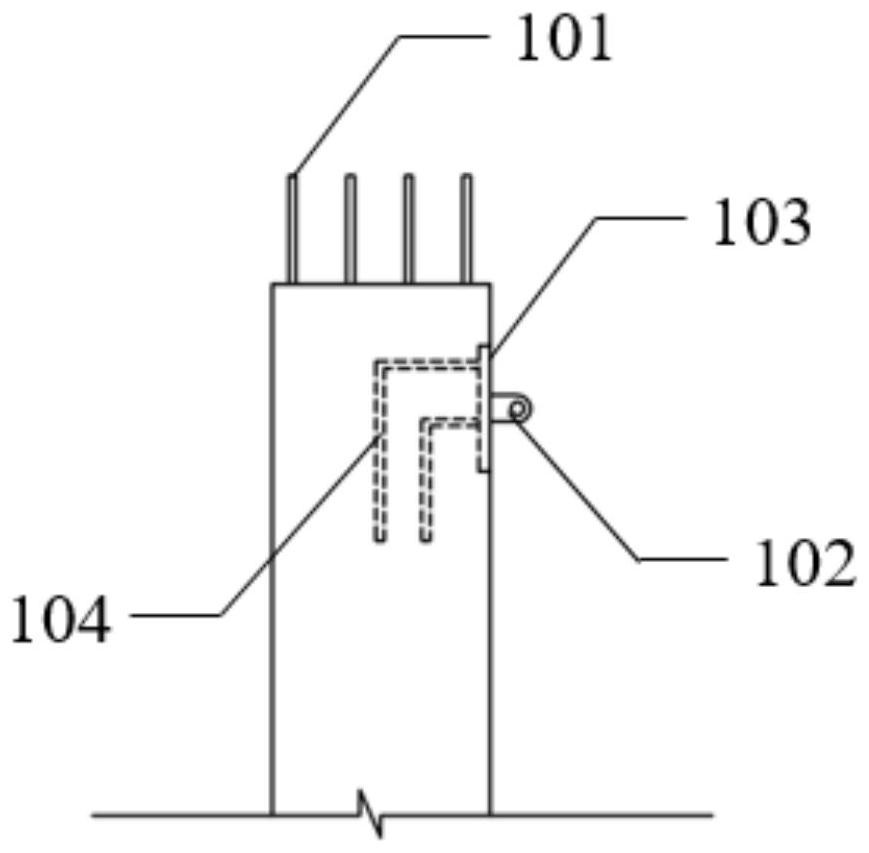

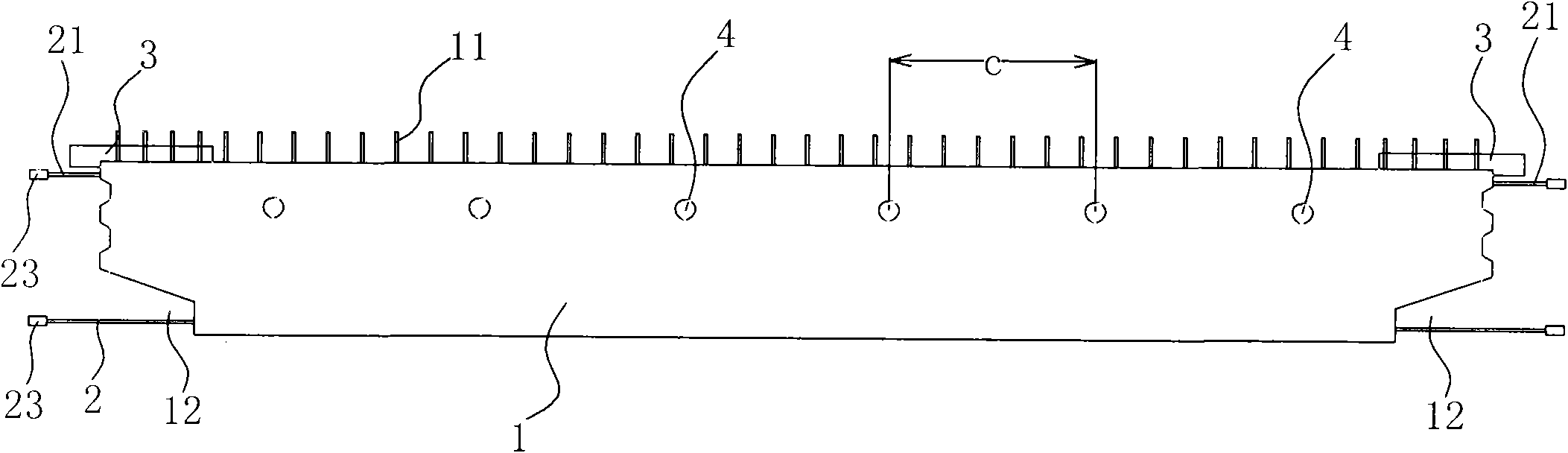

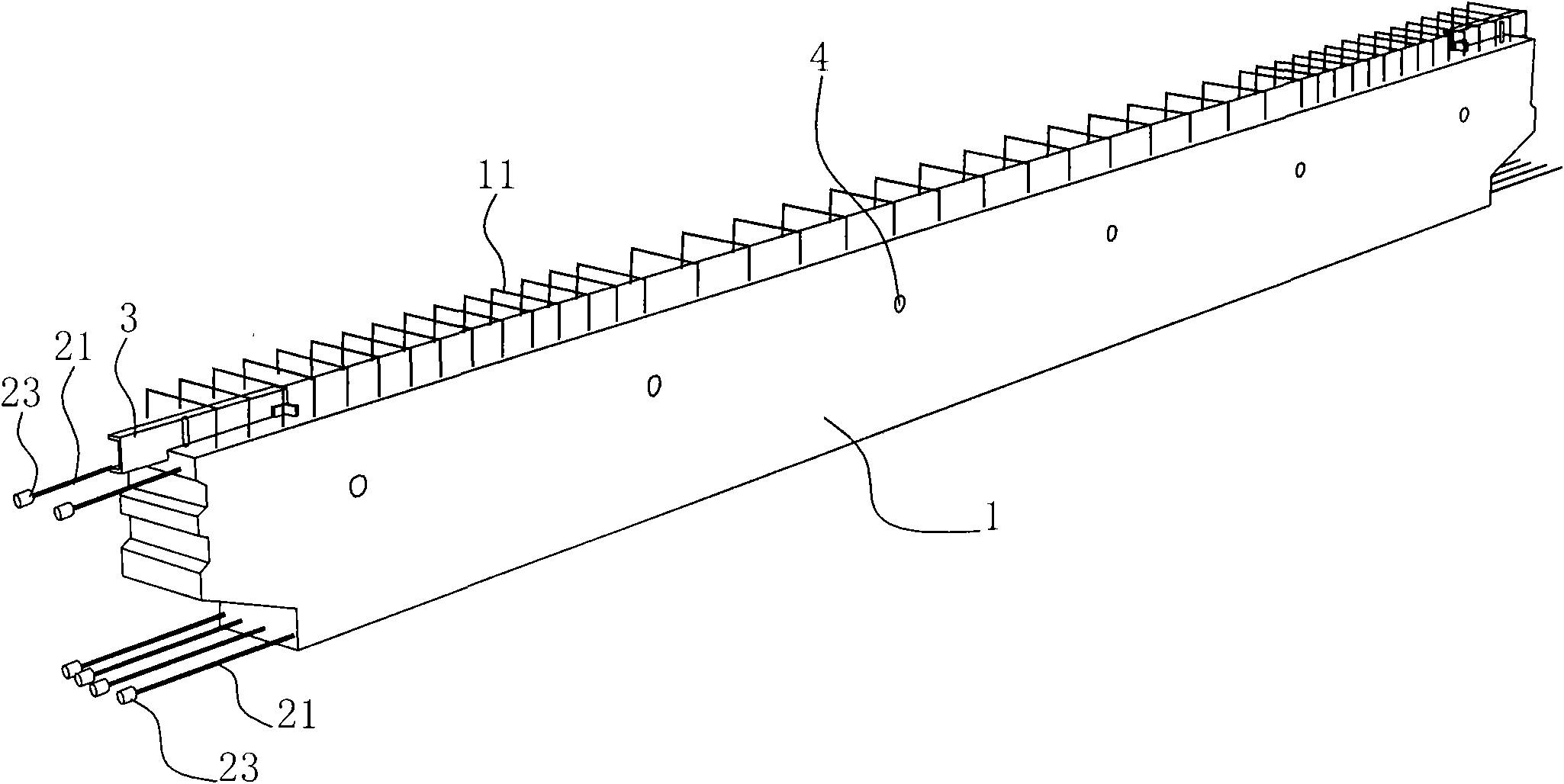

Pre-tensioned prestressed reinforced concrete precast beam

ActiveCN102418402AReduce steel consumptionReduce deflectionGirdersJoistsReinforced concreteEngineering

The invention relates to a pre-tensioned prestressed reinforced concrete precast beam which comprises a beam body and prestressed steel strands which are buried in the beam body and serve as main bars, wherein the beam body is provided with stirrups, the stirrup parts extend out of the upper surface of the beam body, at least one end part of the beam body is provided with section steel which is suitable for being connected with an external structure, the section steel part is buried in the beam body, the other parts are exposed at the end part of the beam body, and a plurality of support formwork holes are arranged on at least one side wall of the beam body along the longitudinal direction. The section steel is arranged at the end part of the precast beam, thereby being conductive to mounting of the precast beam; the section steel can also serve as a member for combining new concrete with old concrete or a mounting shelving member of a column or a beam; and simultaneously, the support formwork holes are arranged on the beam body, and the support formwork holes can enable the beam to be used as a load-bearing member during the construction stage for bearing the dead weight of the concrete, thereby omitting a landing load-bearing frame.

Owner:杨峰

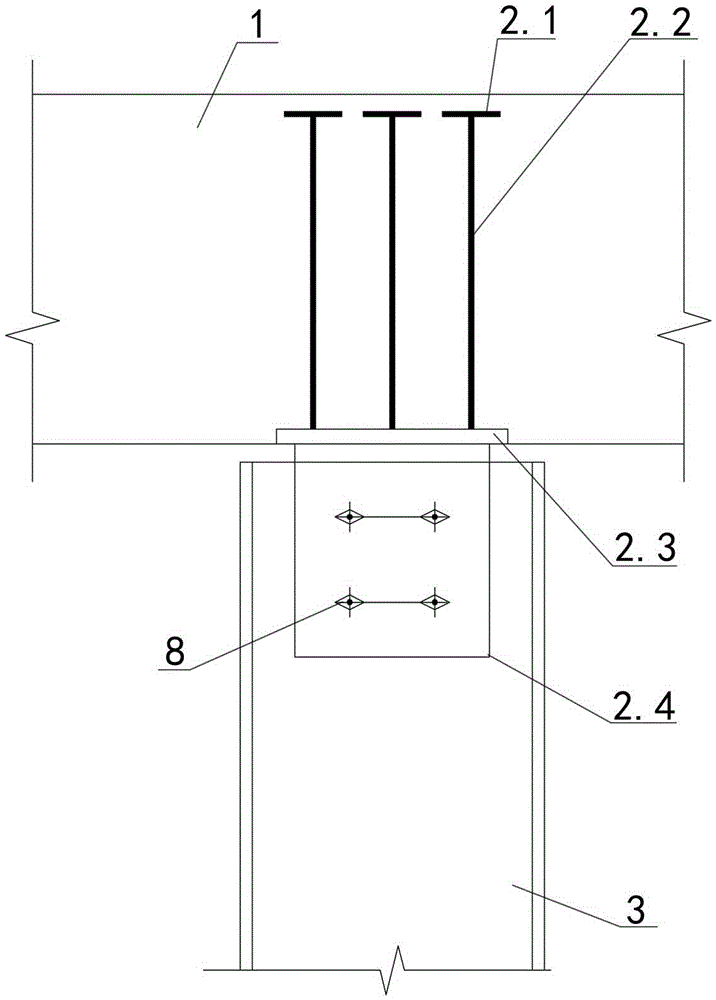

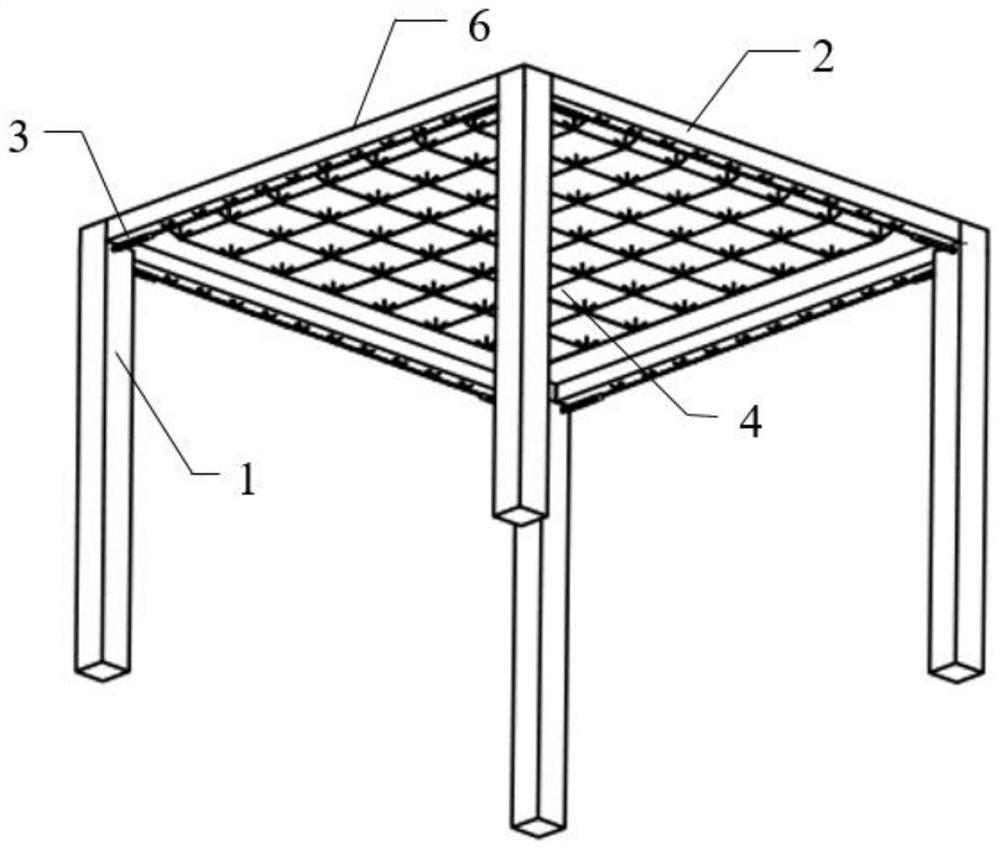

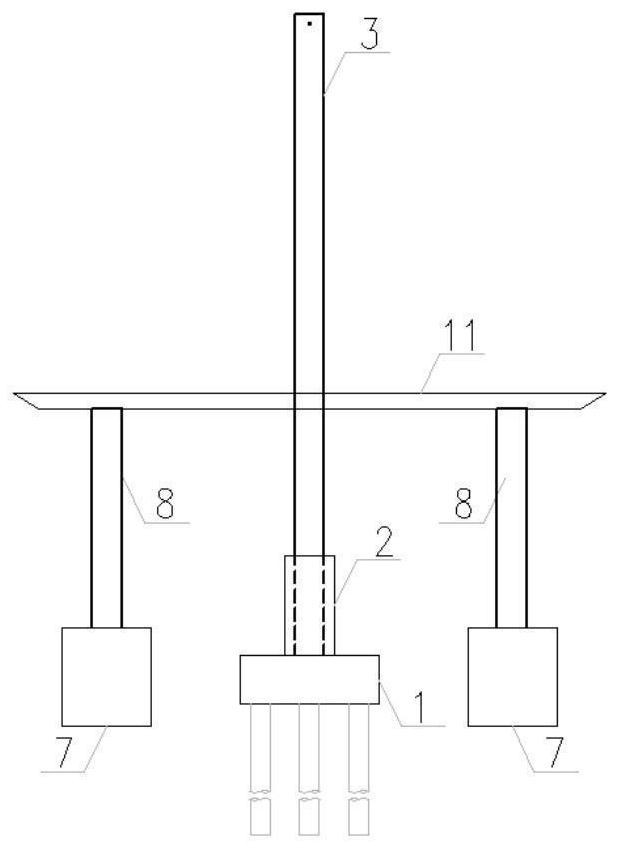

Hung interlayer structure and construction method thereof

ActiveCN105421638ALower beam heightIncrease the effective heightFloorsBuilding material handlingFloor slabUpper floor

The invention discloses a hung interlayer structure and a construction method thereof. The hung interlayer structure comprises an upper layer structure component, a hung fitting and an interlayer floor. The upper end of the hung fitting is connected with the upper layer structure component through an upper connecting device. The lower end of the hung fitting is fixedly connected with the interlayer floor in a hung mode through a lower connecting deice. A hole matched with the contour of a frame column, makes the frame column penetrate through the interlayer floor and keeps the frame column and the interlayer floor separated is reserved in the interlayer floor. A gap between the hole and the frame column is filled with a buffer material. The construction method includes the steps of determining the interlayer scheme and the interlayer load, manufacturing the upper connecting device and the hung fitting, reserving the hole in the interlayer floor, connecting the hung fitting with the interlayer floor, filling the gap between the interlayer floor and the frame column with the buffer material and the like. By means of the hung interlayer structure and the construction method, the structure design is simplified, design difficulty is lowered, the disadvantageous anti-seismic factors caused by sudden changes of rigidity and bearing capacity of the upper floor and the lower floor are avoided, cost is reduced, and work efficiency is improved.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

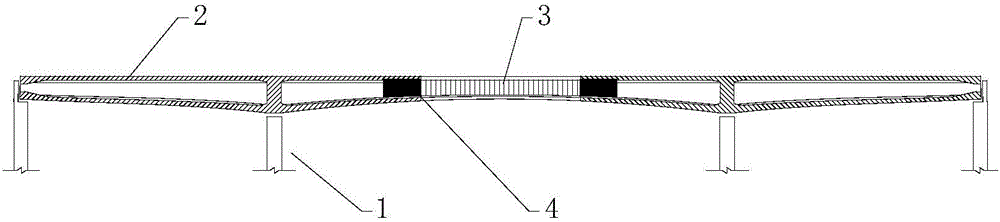

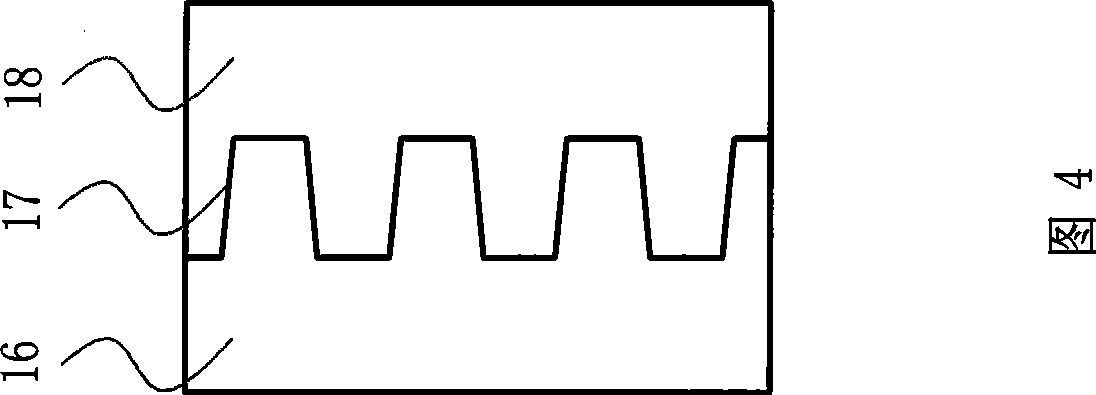

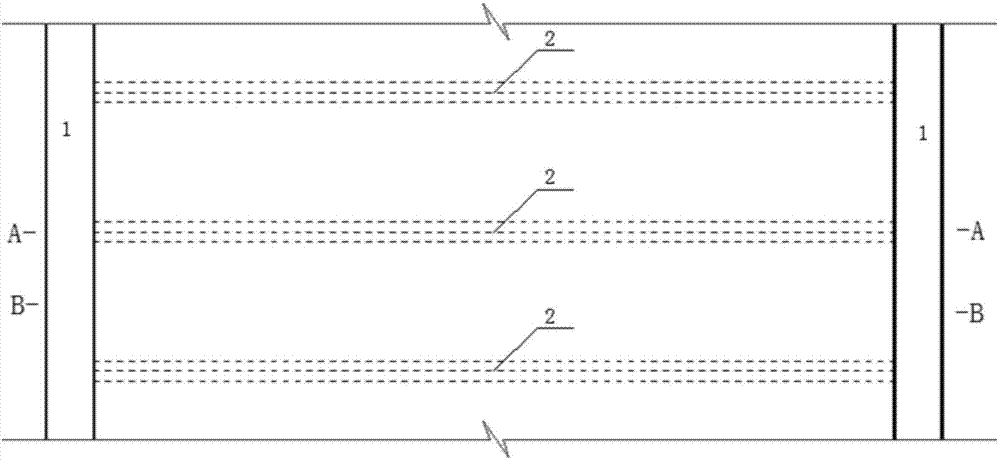

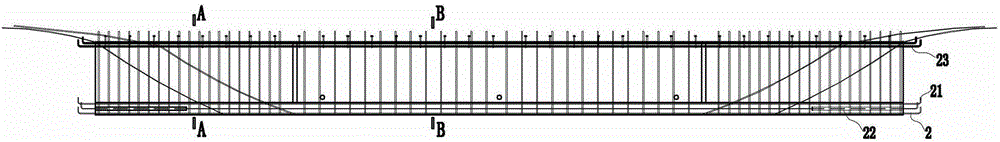

Simply supported prefabricated integrally-cast superposed bridge and construction method thereof

ActiveCN102808372ALight weightEasy to transport and installBridge erection/assemblyPre stressInverted t

The invention discloses a simply supported prefabricated integrally-cast superposed bridge. The prefabricated integrally-cast superposed bridge comprises inverted T-shaped prestressed prefabricated beam parts, cast-in-situ parts and horizontal baffles, and is characterized in that each cast-in-situ part comprises a cast-in-situ plate and a cast-in-situ superposed part at the upper part of the beam part; pretensioned prestressed steel strands are embedded in the upper parts of a web plate and a lower flange of each inverted T-shaped prestressed prefabricated beam part; the horizontal baffles adopt prefabricated plates, and are longitudinally arranged at intervals between the web plates of the adjacent prefabricated beam parts at the two ends of each beam part and positioned above the flanges of the prefabricated beam parts; and the inverted T-shaped prestressed prefabricated beam parts adopt manufacturing moulds commonly used with buildings, and mould plates are good in commonality, convenient to mount and dismount, high in working efficiency and low in amortized cost.

Owner:杨众 +1

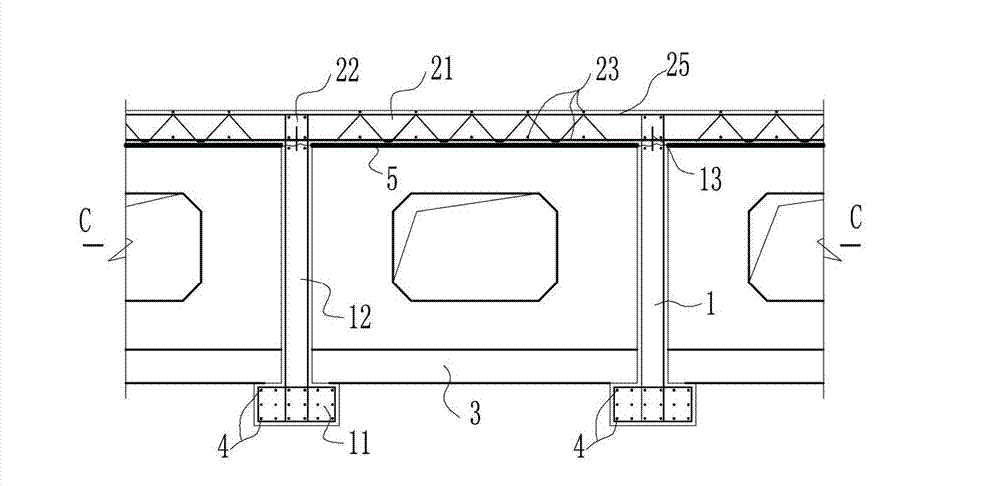

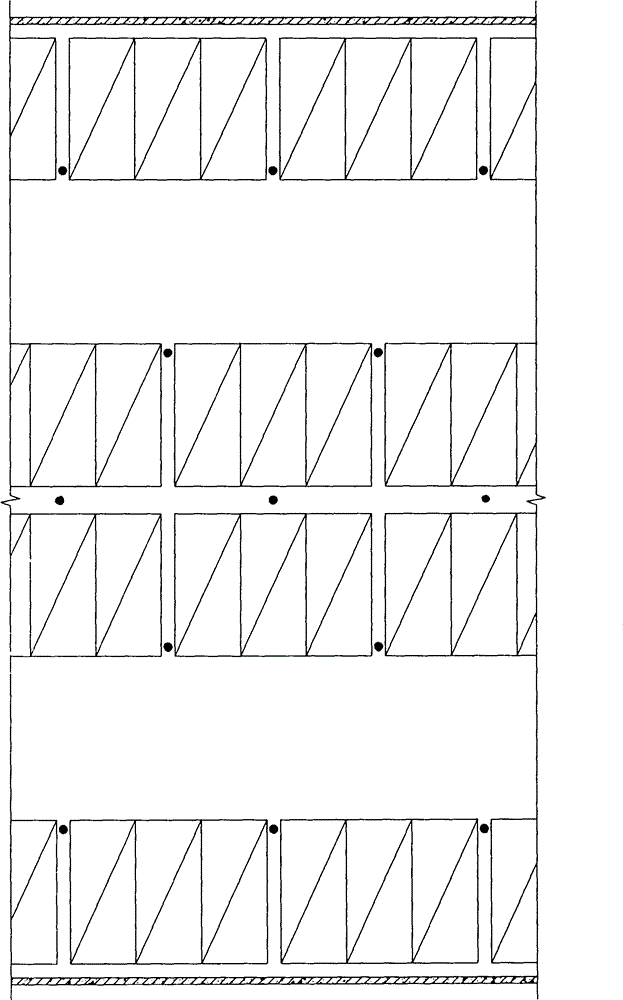

Prefabricated concrete frame system with exposed flat grid floor slabs and exposed truss girders

The invention discloses a prefabricated concrete frame system with exposed flat grid floor slabs and exposed truss girders, and belongs to the technical field of constructional engineering. The prefabricated concrete frame system comprises a prefabricated concrete column, an exposed truss superposed beam, an energy dissipation damper, an exposed flat grid composite slab bottom plate, a temporary support and a post-cast concrete layer, wherein a space truss is exposed out of the superposed beam, and the exposed truss is connected with the prefabricated concrete column through the energy dissipation damper; and a flat grid is exposed out of the bottom of a composite slab, the composite slab is placed on the temporary support, and the purpose of few supports is achieved. According to the prefabricated concrete frame system disclosed by the invention, the space truss and the flat grid are exposed, so that the beam height and the plate thickness are reduced, and the manufacturing cost is reduced; and the temporary support is placed on the space truss, so that the number of the supports is reduced, and the construction speed is increased.

Owner:CHONGQING UNIV

Prefabricated prestressed concrete stair

The invention belongs to the field of construction engineering and relates to a prefabricated prestressed concrete stair in prefabricated structure. The prefabricated prestressed concrete stair comprises stair steps, ladder slabs and ribbed beams under the ladder slabs, wherein the ladder slabs comprises inclined ladder segments and platform segments, and the ribbed beams are internally provided with prestressed steel bars. The technical problem that the self-weight of the ladder slabs in a plate-type stair is larger or the ribbed beams in a beam-type stair are higher is solved.

Owner:EAST CHINA ARCHITECTURAL DESIGN & RES INST

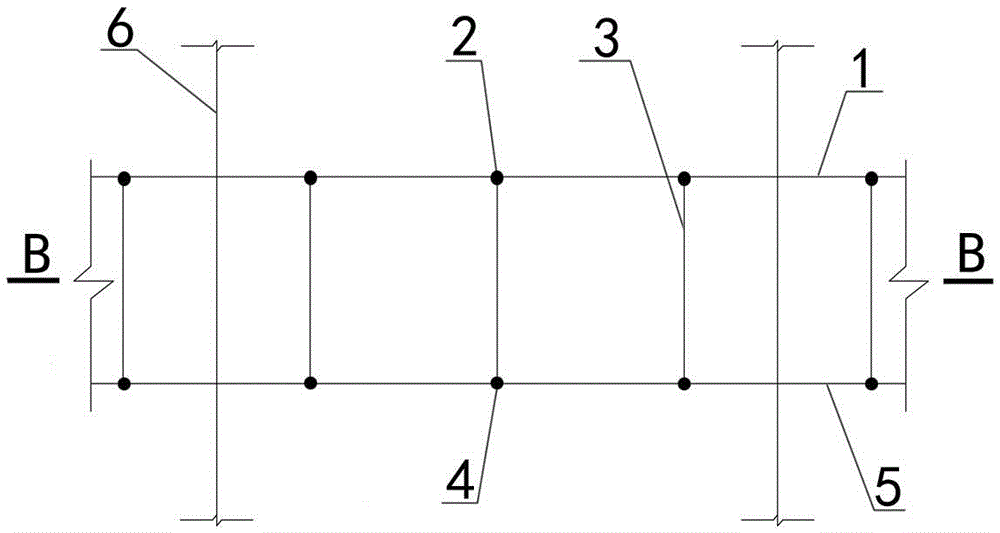

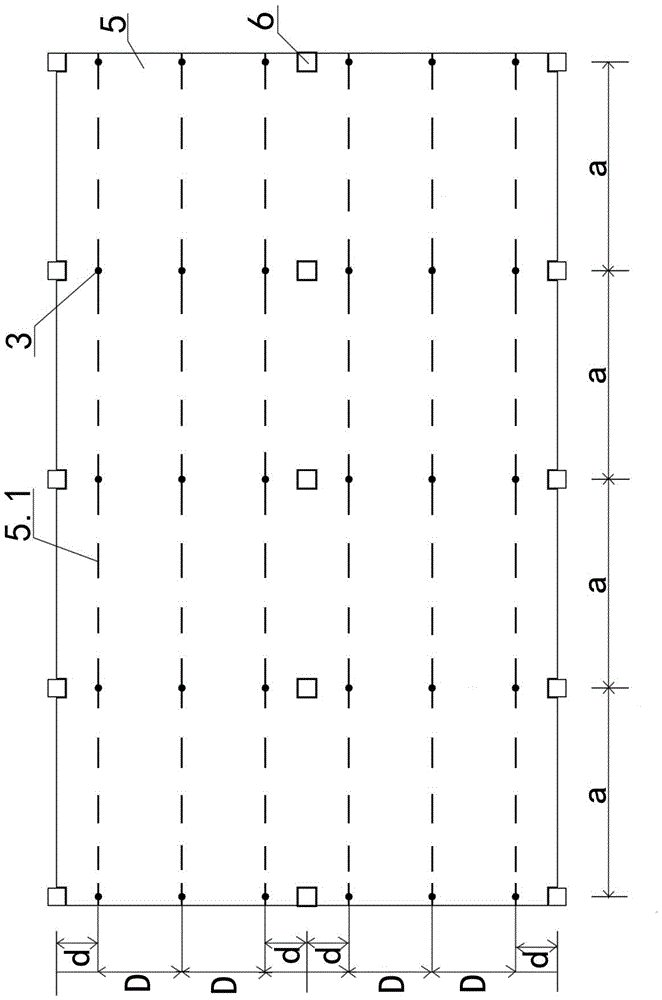

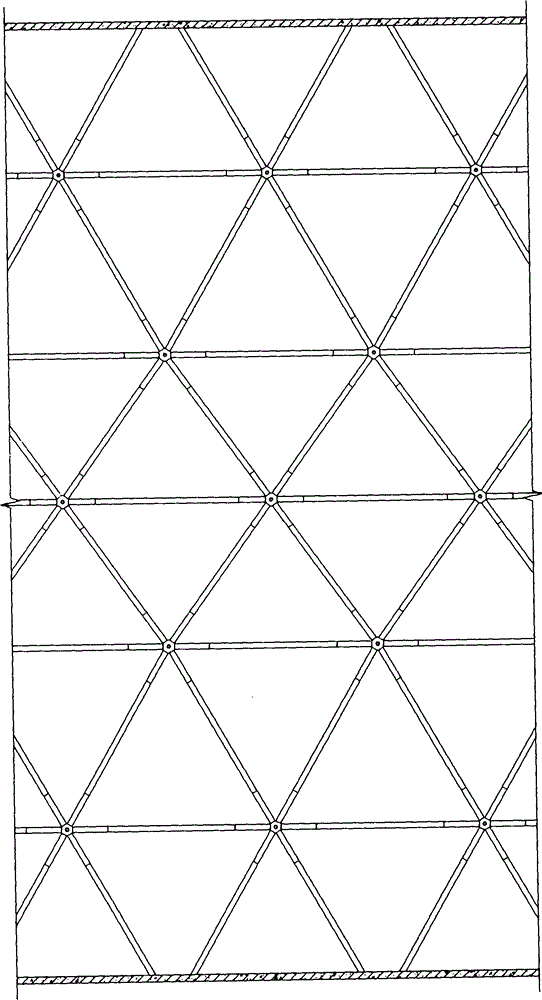

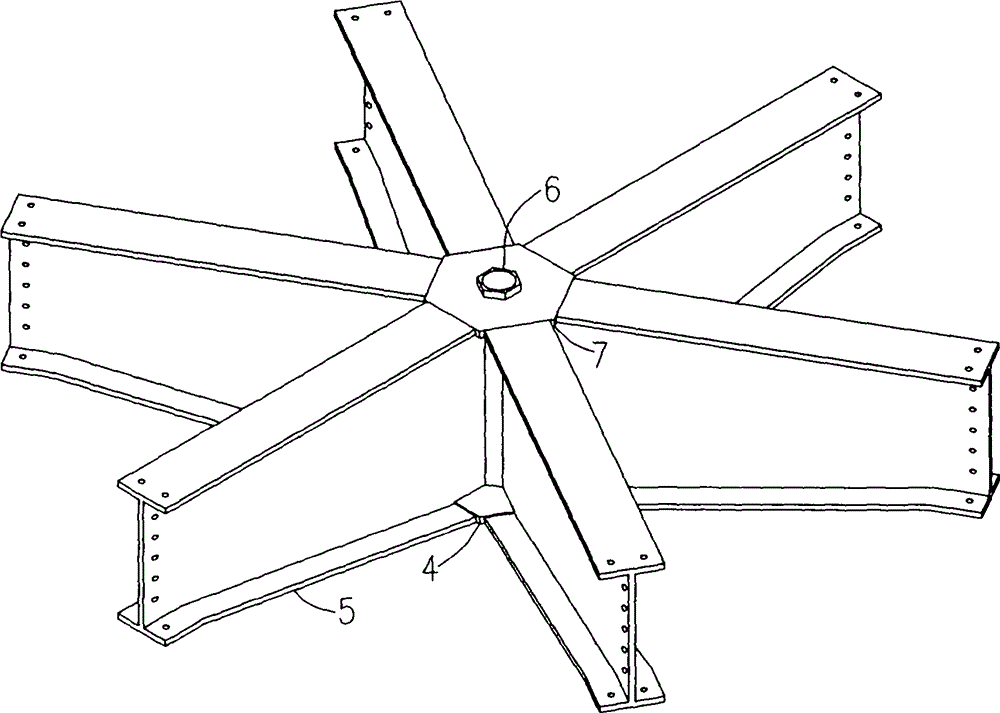

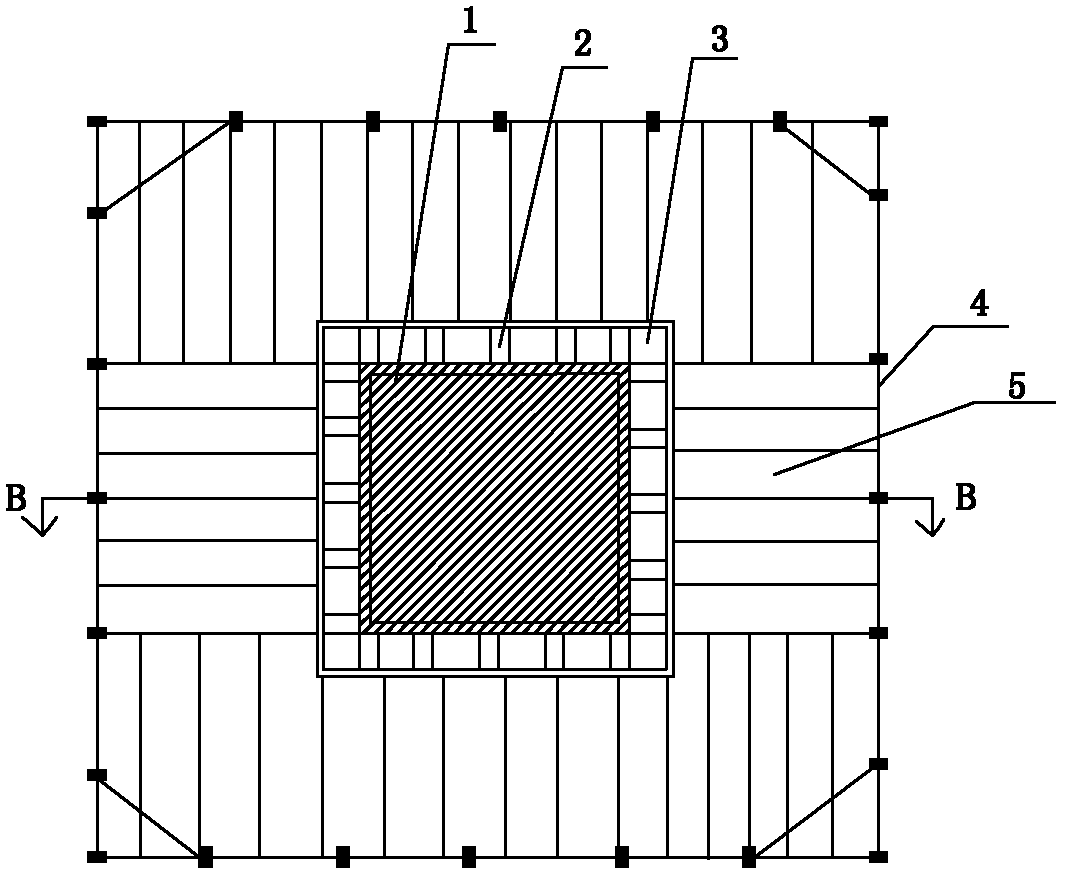

Garage arrangement mode and structure system thereof

InactiveCN106285093AEasy to recycleLower beam heightArtificial islandsBuilding constructionsPlate columnStructure system

The invention relates to a garage arrangement mode and a structure system thereof which are applied to underground garage construction. The existing underground garage structure system comprises a common frame beam plate structure system, a plate column structure system and a hollow beamless floor structure system, wherein column grid systems of the three structure systems are in rectangular arrangement and column grids align with each other longitudinally and transversely. The column arrangement of the structure system disclosed by the invention is triangular arrangement; columns adopts concrete-filled steel pipe columns; beams adopt H-shaped steel beams; main beams are in triangular arrangement and secondary beams are avoided, so power is transmitted directly; and floors are divided into triangles correspondingly. Compared with the existing structure system, the structure system provided by the invention has the advantages that beam height is effectively reduced; component node standardized and industrialized production is realized; field splice is realized; templates are not needed during construction; cost, land and floor height can be effectively saved and construction period can be shortened.

Owner:杨大刚

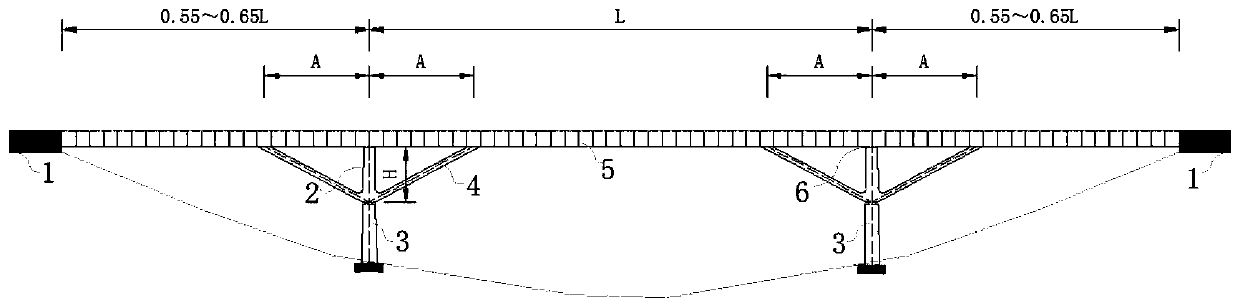

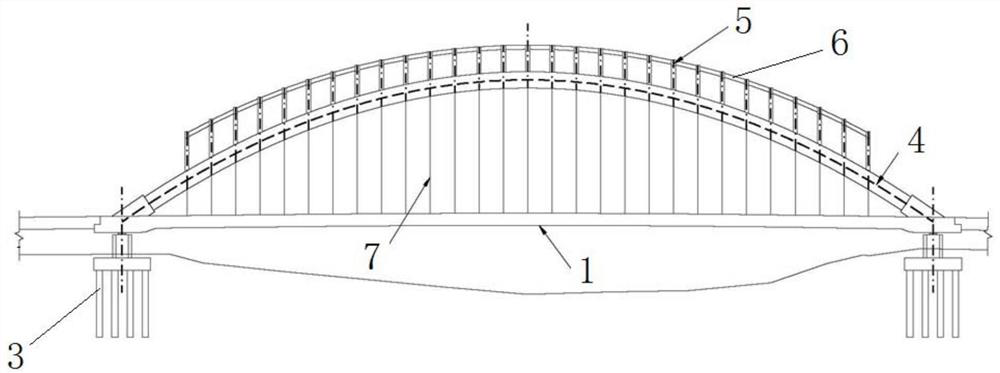

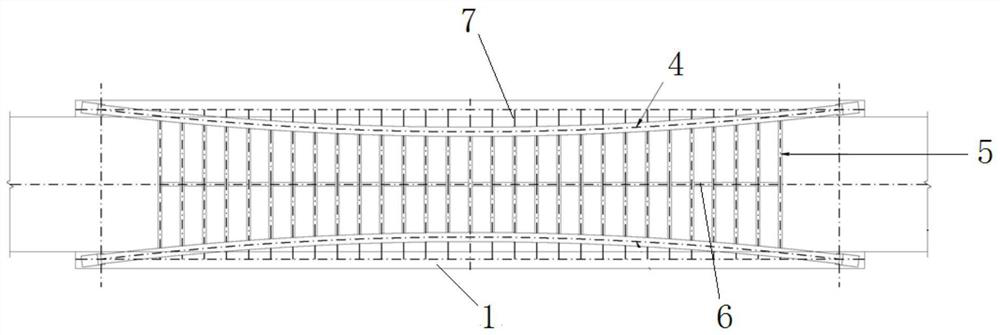

Novel two-way curved arch bridge

ActiveCN109763416AThe stress is reasonableOptimize the vertical forceArch-type bridgeStructural engineeringWide bridge

The invention relates to a novel two-way curved arch bridge. The novel two-way curved arch bridge comprises a main beam, main arch ribs, auxiliary arch ribs, a side hanging rods and middle hanging rods, wherein one parabolic main arch rib is arranged on each of the two sides of the main beam; a plurality of parabolic auxiliary arch ribs are arranged between the two main arch ribs; the two ends (namely arch feet) of the main arch ribs are positioned above middle piers respectively; the two ends of the auxiliary arch ribs are fixed to the two main arch ribs respectively. Compared with the priorart, the novel two-way curved arch bridge provided by the invention has the advantages as follows: due to the actions of the hanging rods and the auxiliary arch ribs which are added between the parabolic main arch ribs, stress on a cross beam is reduced for a wide bridge, so that reduction on the beam height of the cross beam and control of the height of a wide bridge structure are facilitated.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

High-rise and ultrahigh-rise floor system

The invention discloses a high-rise and ultrahigh-rise floor system, which comprises a core cylinder (1) constructed on a foundation and penetrating all floors, a core cylinder peripheral steel structure (4) around the core cylinder (1) and a combined floor (5). The floor system is characterized in that a plurality of cantilever beams (2) are arranged on the floors of the core cylinder (1) at intervals, and the cantilever beams (2) on the same floor form a cantilever floor (3) by pouring reinforced concrete; and the combined floor (5) is arranged between the cantilever floor (3) and the core cylinder peripheral steel structure (4). By using the cantilever floor (3), nodes of the combined floor (5), which are connected with the core cylinder (1), are outwards shifted from the outer edge of the core cylinder (1) to the outer edge of the cantilever floor (3), so that steel consumption in the combined floor (5) and the core cylinder peripheral steel structure (4) can be reduced, the heights of the floors are reduced, and the floor system is convenient to construct.

Owner:深圳市华筑工程设计有限公司

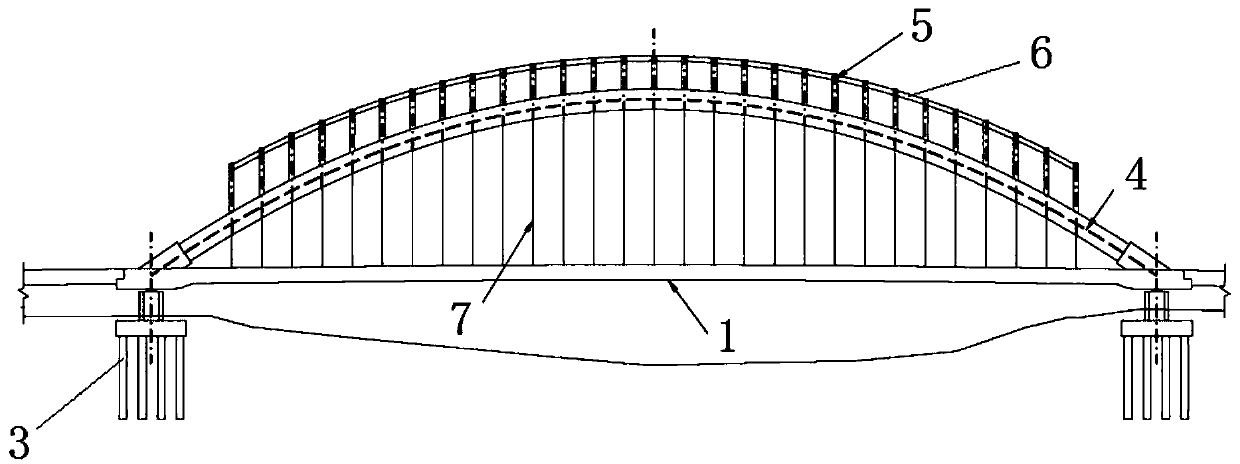

Suspension cable-arch combined system bridge structure and assembly construction method thereof

InactiveCN112160230AReduce thrustSmall horizontal spanBridge erection/assemblyArchitectural engineeringAxial force

The invention discloses a suspension cable-arch combined system bridge structure and an assembly construction method thereof. Arch ribs are arranged below a main beam of a suspension bridge, arch columns are arranged on the arch ribs, the upper ends of the arch rib columns are connected with the main beam, the lower ends of the arch rib columns are connected with the arch ribs, and the two ends ofthe arch ribs are fixed to arch rib foundations which are independent foundations; the arch rib foundations are arranged below the main beam; the arch ribs comprise a plurality of prefabricated archrib sections, and the prefabricated arch rib sections are fixedly connected. Arch rib main arches and main cable surfaces are not coplanar, so that the main beam forms a continuous structure in the transverse direction to reduce the height of the main beam; the axial force level of a bridge cable bent tower and a main cable of the suspension cable-arch combined system is lower, so that a lighter structural size can be made, and the construction control difficulty is also reduced; compared with a common arch bridge, the load level of the arch ring and the arch foot of the suspension cable-archcombined system bridge is low, the size of the structure can be reduced, the axial force of the cable bent tower can be reduced, and the horizontal thrust of the main arch ring can be greatly reduced.

Owner:XIAN MUNICIPAL ENG DESIGN & RES INST

Prefabricated assembled narrow-web combined box girder structure and construction method thereof

ActiveCN111501518ALower beam heightSolve the situation where the beam height is limitedBridge erection/assemblyArchitectural engineeringBridge deck

The invention discloses a prefabricated assembled narrow-web combined box girder structure which comprises a box girder body and two side longitudinal beams arranged at the two ends of the box girderbody respectively, and a bridge deck slab is arranged on the top face of the box girder body. An anti-collision area is arranged on the side, close to the bridge deck slab, of the upper portion of each side longitudinal beam. The anti-collision area comprises a sealing plate, an anti-collision panel and an anti-collision K support fixedly connected with a side plate of the edge longitudinal beam,the anti-collision panel is located on the side, away from the edge longitudinal beam, of the anti-collision K support, the sealing plate is located above the anti-collision K support, and the anti-collision panel and the edge longitudinal beam are fixedly connected with the sealing plate. According to the prefabricated assembled narrow-web combined box girder structure and the construction methodthereof, the structure is simple, assembling is convenient, and the requirement for rapid construction of urban bridges can be met.

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST

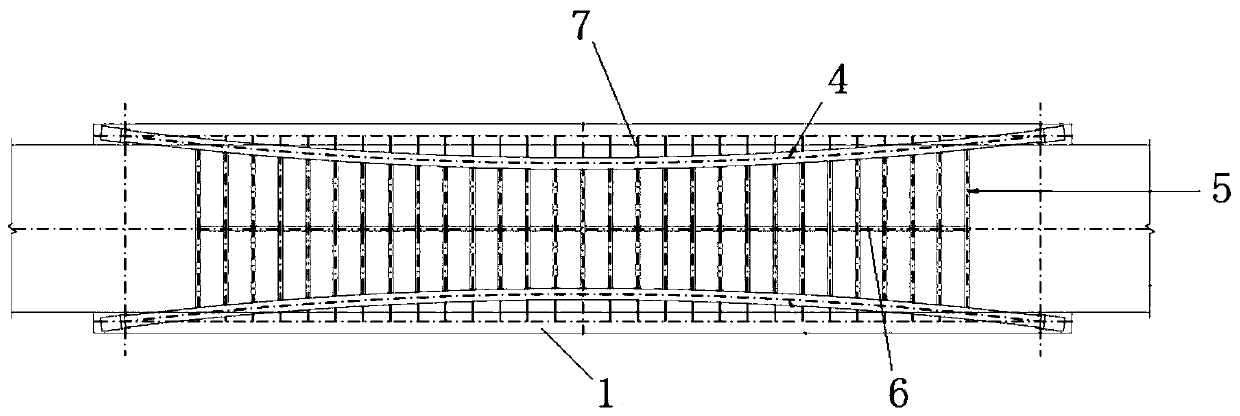

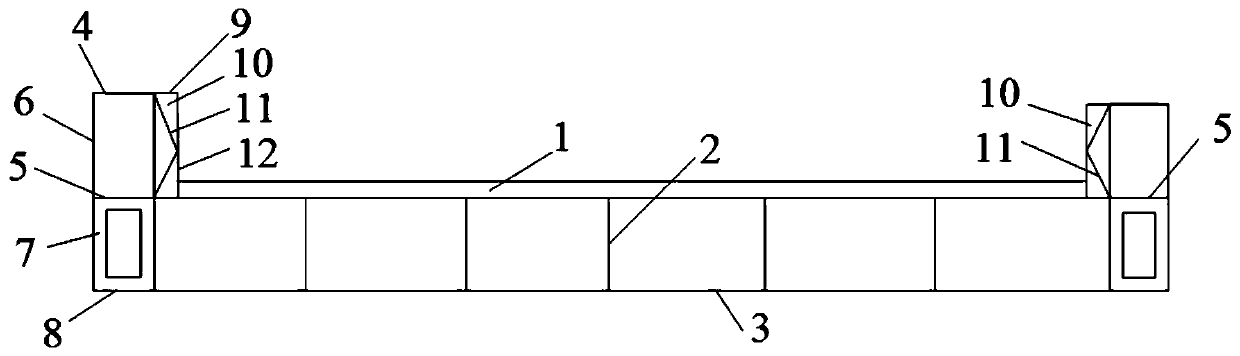

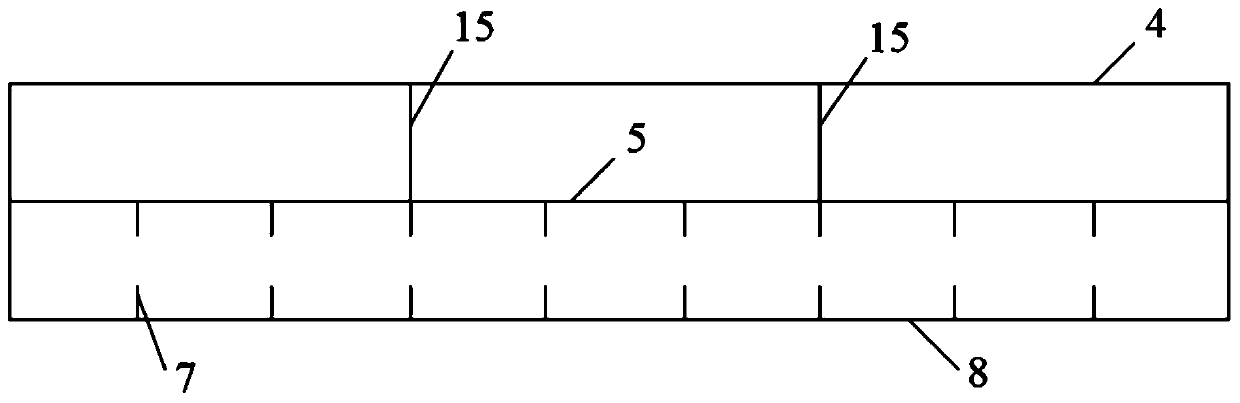

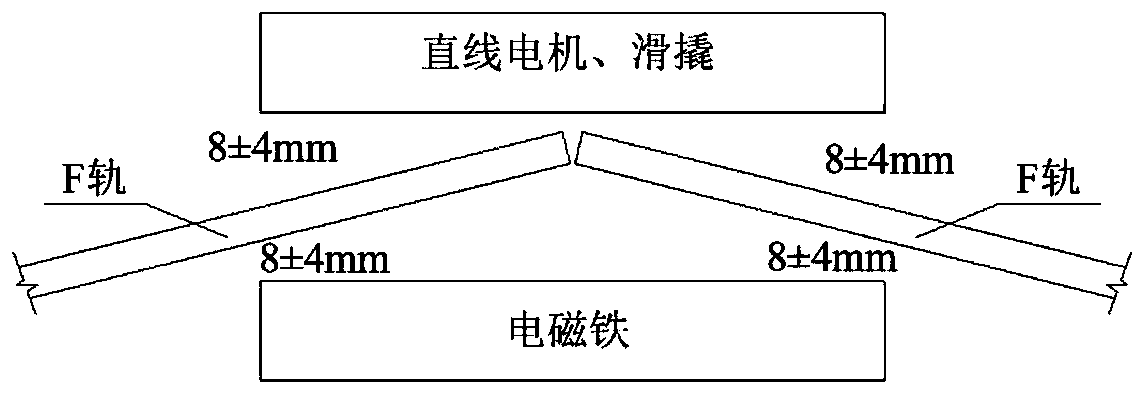

Simply-supported-continuous large full-span box girder with medium-lower-speed maglev double lines and construction method

PendingCN110029566AImprove ride comfort performanceSmooth dynamic track surfaceRailway tracksBridge erection/assemblyPre stressPre stressing

The invention discloses a simply-supported-continuous large full-span box girder with medium-lower-speed maglev double lines. The simply-supported-continuous large full-span box girder comprises sidehole girders arranged at two ends of a route and a plurality of middle hole girders arranged between the side hole girders, wherein the side hole girders and the middle hole girders are of a concentric-squares-shaped cross-section structure, and the two sides of the top surfaces of the side hole girders and the middle hole girders extend outwards to form bridge wing plates; each side hole girder comprises a side hole girder concrete girder (1), and side hole girder simply-supported-continuous longitudinal pre-stressed tendons (3) are arranged on the upper edges of the ends, adjacent to the middle hole girders, of the side hole girder concrete girders (1); and each the middle hole girder comprises a middle hole girder concrete girder (6), and middle hole girder simply-supported-continuous longitudinal pre-stressed tendons (8) are arranged on the upper edges of the two ends of the middle hole girder concrete girders (6). The invention further discloses a construction method of the simply-supported-continuous large full-span box girder. According to the simply-supported-continuous large full-span box girder, simply-supported girders of a regular and standard span medium-lower-speed maglev bridge structure is changed to simply-supported-continuous girders, and the break angle rail surface irregularity, formed along with bridge deformation, of girder seam positions of two adjacent spans of simply-supported girders is greatly reduced.

Owner:CHINA RAILWAY MAGLEV TRANSPORTATION INVESTMENT CONSTR CO LTD

A special-shaped prefabricated beam for bridges

An irregular-shaped precast beam used for bridges comprises a reversed T-shaped beam body and a prestress steel strand which is embedded in the middle of the beam body and serves as a main reinforcing-bar. The beam body comprises a web, wherein a stirrup is arranged on a bottom flange web, and the stirrup extends out of the upper surface of the beam body. The irregular-shaped precast beam used for bridges is characterized in that through holes traversing partition board main reinforcing-bars are arranged on the lower portion of the beam body web along the longitudinal direction at intervals. The cross sections are simple in shape, and templates with single specifications and strong generality can be adopted to manufacture, thereby greatly lowering mold cost.

Owner:杨众 +1

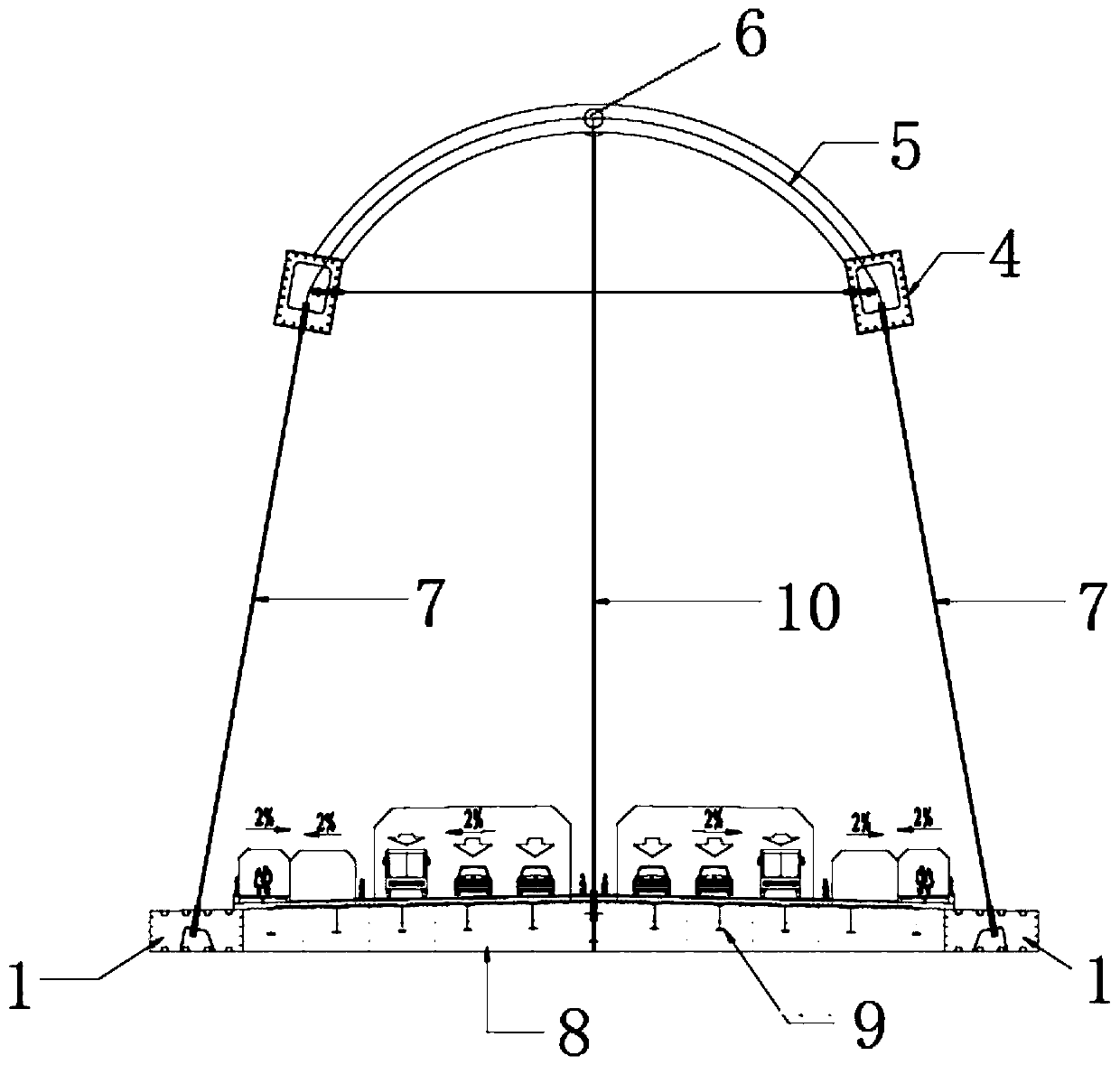

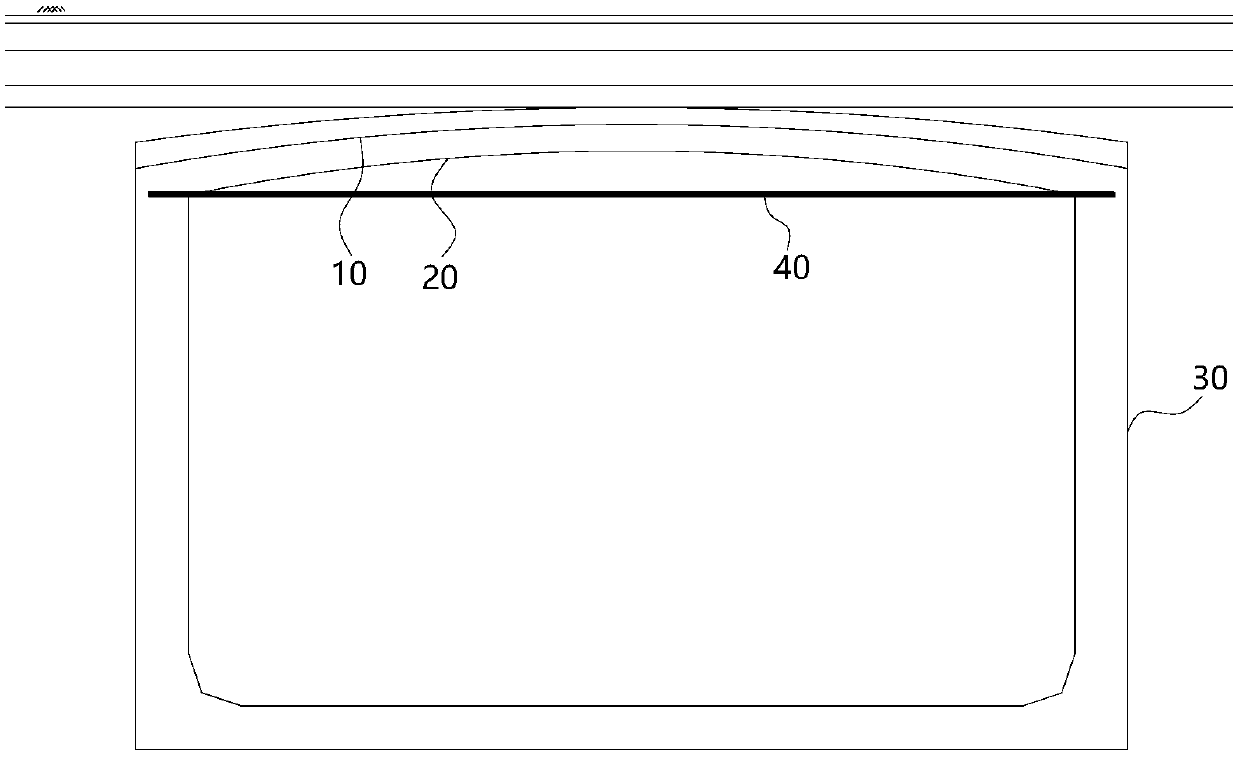

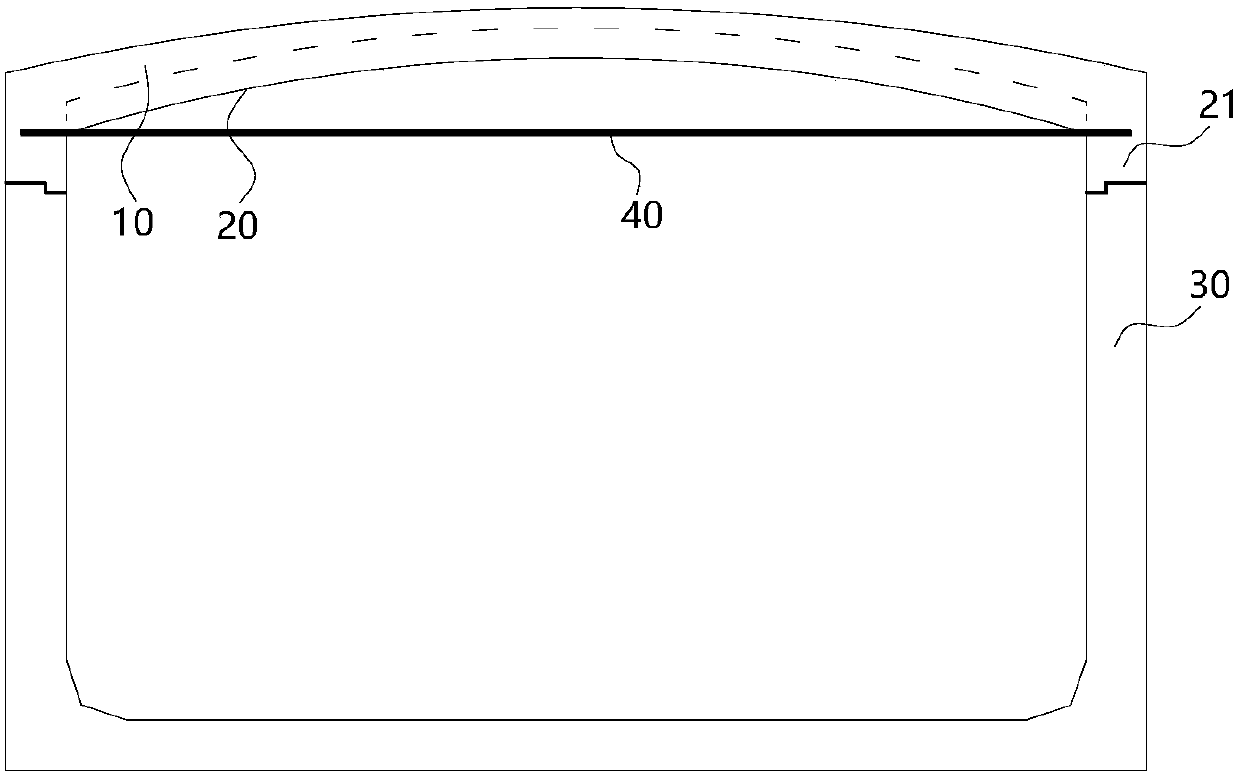

Non-column large-span repairable prestressed cable-arch combined structure of open-cut subway station

ActiveCN106049661AGive full play to resistanceThe force is clear and reasonableBuilding roofsArtificial islandsPre stressSubway station

The invention provides a non-column large-span repairable prestressed cable-arch combined structure of an open-cut subway station. The non-column large-span repairable prestressed cable-arch combined structure of the open-cut subway station comprises side walls, arched girders, a top plate and prestressed cables, wherein the side walls are arranged on the two sides of a subway tunnel; the arched girders are of an arc structure and are supported at the top end of the subway tunnel through the side walls on the two sides, and the span of the arched girders is at least 20 meters; the top plate is of an arc structure and is arranged on the upper portions of the arched girders and used for sealing the top of the subway channel; and the prestressed cables are arranged below the arched girders and used for connecting two arch legs of each arched girder so that horizontal tension can be applied to the arch legs. According to the non-column large-span repairable prestressed cable-arch combined structure of the open-cut subway station, the arched girders can bear external loads and pressure stress generated by the weight of the arched girder, the prestressed cables enable the rise of the arched girders to be increased by applying stress, and the pressure resistance characteristic of a concrete material is brought into full play. The combined structure is clear and reasonable in stress, simple in structure, repairable, convenient to construct, feasible in construction and the like, the resistance characteristics of the cable and the arch are brought into full play, and the purpose of achieving a large-space structure in an underground structure is achieved.

Owner:JIAN YAN FOUND ENG

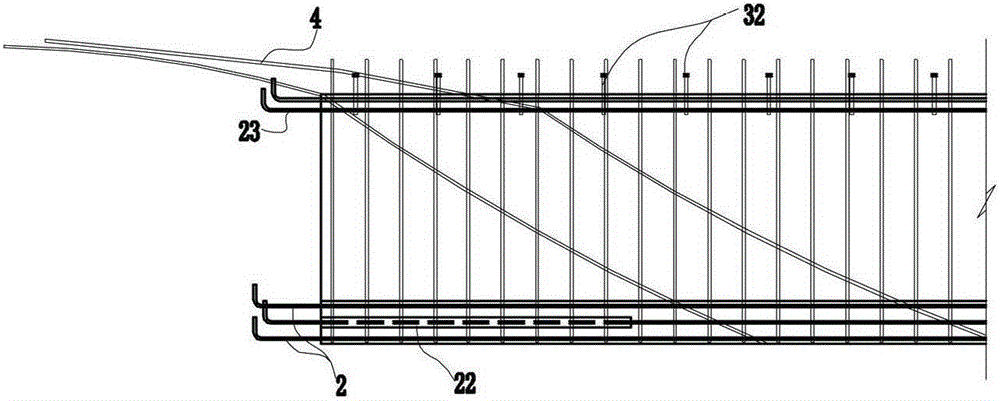

Pre-tensioned prestressed reinforced concrete precast beam

ActiveCN102418402BReduce steel consumptionReduce deflectionGirdersJoistsReinforced concreteEngineering

The invention relates to a pre-tensioned prestressed reinforced concrete precast beam which comprises a beam body and prestressed steel strands which are buried in the beam body and serve as main bars, wherein the beam body is provided with stirrups, the stirrup parts extend out of the upper surface of the beam body, at least one end part of the beam body is provided with section steel which is suitable for being connected with an external structure, the section steel part is buried in the beam body, the other parts are exposed at the end part of the beam body, and a plurality of support formwork holes are arranged on at least one side wall of the beam body along the longitudinal direction. The section steel is arranged at the end part of the precast beam, thereby being conductive to mounting of the precast beam; the section steel can also serve as a member for combining new concrete with old concrete or a mounting shelving member of a column or a beam; and simultaneously, the support formwork holes are arranged on the beam body, and the support formwork holes can enable the beam to be used as a load-bearing member during the construction stage for bearing the dead weight of the concrete, thereby omitting a landing load-bearing frame.

Owner:杨峰

A prefabricated assembled narrow-web composite box girder structure and its construction method

ActiveCN111501518BLower beam heightSolve the situation where the beam height is limitedBridge erection/assemblyArchitectural engineeringBridge deck

The invention discloses a prefabricated and assembled narrow-web combined box girder structure, which comprises a box girder body and two side longitudinal beams respectively arranged at both ends of the box girder body, and a bridge deck is arranged on the top surface of the box girder body; An anti-collision zone is provided on the side of the upper part of each side stringer close to the bridge deck, and the crash zone includes a sealing plate, an anti-collision panel and an anti-collision zone fixedly connected with the side plate of the side stringer. Collision K brace, the anti-collision panel is located on the side of the anti-collision K brace away from the side longitudinal beam, the sealing plate is located above the anti-collision K brace, the anti-collision panel and the side longitudinal beam The beams are fixedly connected to the sealing plates respectively. The prefabricated and assembled narrow-web composite box girder structure and its construction method of the present invention have simple structure and convenient assembly, and can meet the requirements of rapid construction of urban bridges.

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST

A new double-curved arch bridge

ActiveCN109763416BThe stress is reasonableOptimize the vertical forceArch-type bridgeClassical mechanicsEngineering

The invention relates to a novel double-curved arch bridge. The arch bridge includes a main girder, a main arch rib, an auxiliary arch rib, a side suspender and a middle suspender. Both sides of the main girder are provided with a parabolic main arch rib. There are multiple parabolic auxiliary arch ribs between the two main arch ribs, the two ends of the main arch ribs (i.e. The main arch rib is fixed. Compared with the prior art, the present invention reduces the stress on the beam for wide bridges due to the addition of suspenders and auxiliary arch ribs between the parabolic main arch ribs, which is beneficial to reduce the height of the beam and control the width of the wide bridge. structure height.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

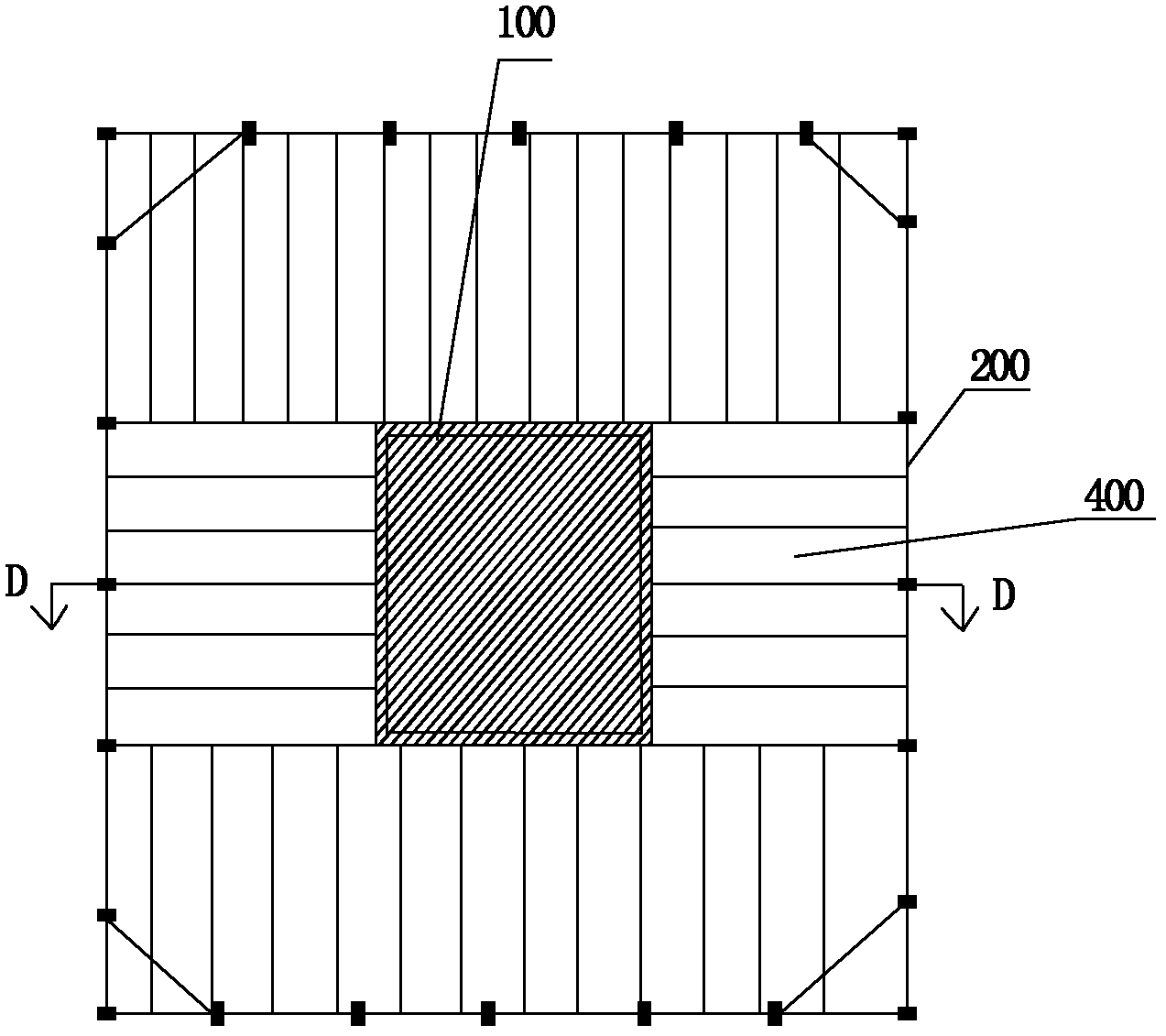

Turnout support system applicable to straddle type monorail

PendingCN109763386ALower the altitudeReduce the difficulty of settingRailway tracksSupporting systemStraddle

The invention discloses a turnout support system applicable to a straddle type monorail and belongs to related technical fields of straddle monorails. A continuous rigid frame in a longitudinal direction and a plurality of support units which are arranged below the continuous rigid frame at intervals in the longitudinal direction are arranged, the continuous rigid frame is fixedly connected with apier cover beam at the top of the support units, then a rigid system with synergetic stress is formed, and a turnout system can be stably supported effectively on premise that the setup height of a support system is reduced. The turnout support system applicable to the straddle type monorail, which is disclosed by the invention, is simple in structure, simple and convenient to set, small in construction difficulty and high in construction efficiency, a straddle type monorail turnout system can be effectively and stably supported, the height of the cover beam and the overall height of the turnover system are reduced, the construction cost is reduced, great flexibility is provided for design of stations and rails of the straddle type monorail, good application prospects and popularization and application values can be made, and popularization and application of the straddle type monorail can be effectively promoted.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

A simple-supported prefabricated monolithic composite bridge and its construction method

ActiveCN102808372BLight weightEasy to transport and installBridge erection/assemblyPre stressEngineering

The invention discloses a simply supported prefabricated integrally-cast superposed bridge. The prefabricated integrally-cast superposed bridge comprises inverted T-shaped prestressed prefabricated beam parts, cast-in-situ parts and horizontal baffles, and is characterized in that each cast-in-situ part comprises a cast-in-situ plate and a cast-in-situ superposed part at the upper part of the beam part; pretensioned prestressed steel strands are embedded in the upper parts of a web plate and a lower flange of each inverted T-shaped prestressed prefabricated beam part; the horizontal baffles adopt prefabricated plates, and are longitudinally arranged at intervals between the web plates of the adjacent prefabricated beam parts at the two ends of each beam part and positioned above the flanges of the prefabricated beam parts; and the inverted T-shaped prestressed prefabricated beam parts adopt manufacturing moulds commonly used with buildings, and mould plates are good in commonality, convenient to mount and dismount, high in working efficiency and low in amortized cost.

Owner:杨众 +1

Steel-structured passenger foot bridge

ActiveCN102864737BMeet landscape requirementsHigh base frequencyBridge structural detailsBridge erection/assemblyReliable transmissionEngineering

The invention discloses a portal frame overbridge structure and a construction method thereof; two ends of a main beam are supported on a 1# pier column and a 2# pier column respectively; the main beam is solidified with the 1# pier column and the 2# pier column; the connecting position of the 1# pier column and a 1# concrete bearing platform is a solidification construction; the connecting position of the 2# pier column and a 2# concrete bearing platform is an articulation construction; the depth-span ratio of the portal frame overbridge structure disclosed by the invention reaches to 1 / 28-1 / 35 and belongs to typical ultrathin beams; about 1 / 20-1 / 22 conventional depth-span ratio of a simply-supported steel case beam passenger foot bridge is broken greatly; the landscape demand of urban passenger foot bridge is satisfied; the base frequency of a foot bridge is improved greatly, thus, passengers feel more safely, more stably and more comfortably. According to the invention, the portal frame overbridge structure is characterized by simple construction and reliable transmission force and has good antifatigue performance and good durability; engineering investment is reduced; structural design, construction and application can be more reasonable; in addition, a structure has relatively strong comprehensive economic indicators in a full-life period and has wide application prospect.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

Large-span and column-free repairable prestressed cable-arch combined structure in open-cut subway station

ActiveCN106049661BGive full play to resistanceThe force is clear and reasonableBuilding roofsArtificial islandsPre stressSubway station

The invention provides a non-column large-span repairable prestressed cable-arch combined structure of an open-cut subway station. The non-column large-span repairable prestressed cable-arch combined structure of the open-cut subway station comprises side walls, arched girders, a top plate and prestressed cables, wherein the side walls are arranged on the two sides of a subway tunnel; the arched girders are of an arc structure and are supported at the top end of the subway tunnel through the side walls on the two sides, and the span of the arched girders is at least 20 meters; the top plate is of an arc structure and is arranged on the upper portions of the arched girders and used for sealing the top of the subway channel; and the prestressed cables are arranged below the arched girders and used for connecting two arch legs of each arched girder so that horizontal tension can be applied to the arch legs. According to the non-column large-span repairable prestressed cable-arch combined structure of the open-cut subway station, the arched girders can bear external loads and pressure stress generated by the weight of the arched girder, the prestressed cables enable the rise of the arched girders to be increased by applying stress, and the pressure resistance characteristic of a concrete material is brought into full play. The combined structure is clear and reasonable in stress, simple in structure, repairable, convenient to construct, feasible in construction and the like, the resistance characteristics of the cable and the arch are brought into full play, and the purpose of achieving a large-space structure in an underground structure is achieved.

Owner:JIAN YAN FOUND ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com