Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

135results about How to "Uniform force transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

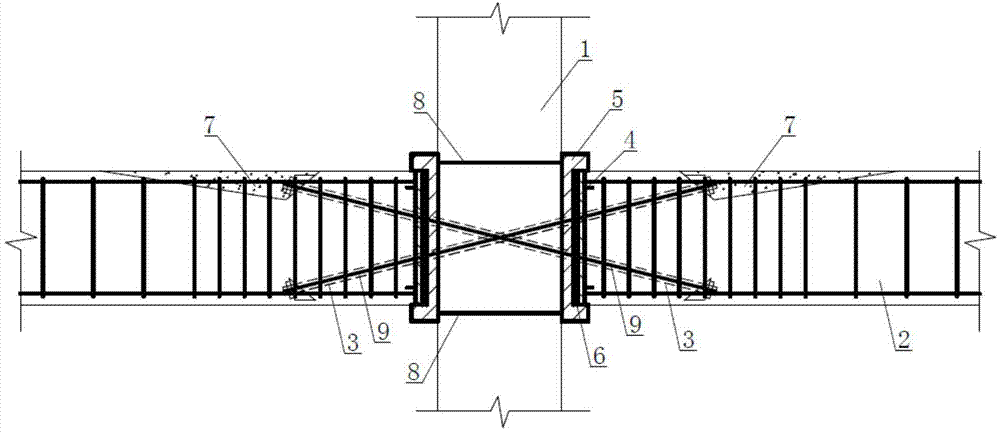

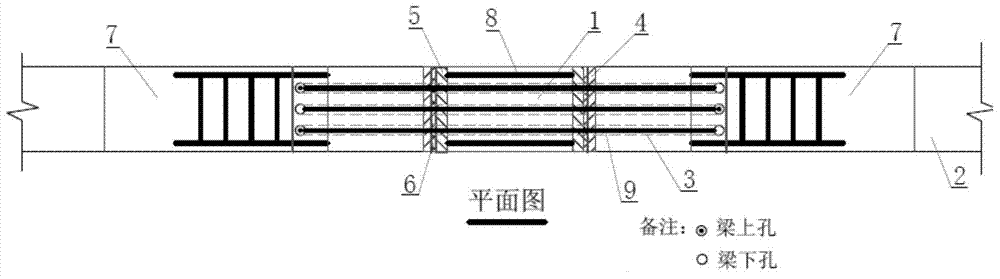

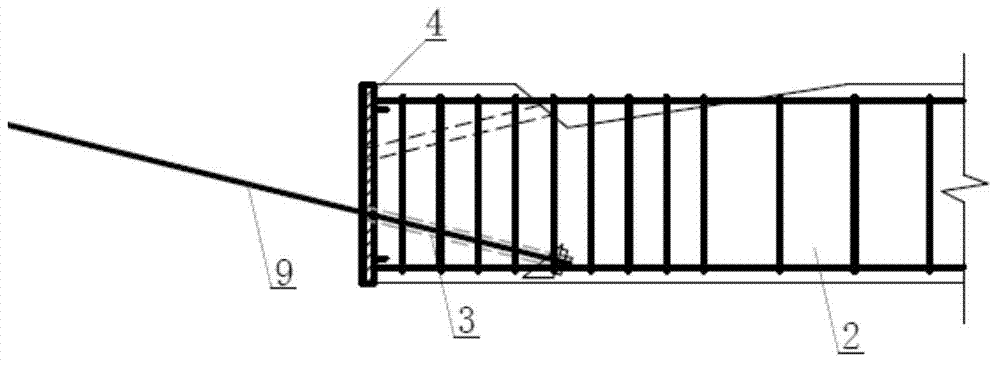

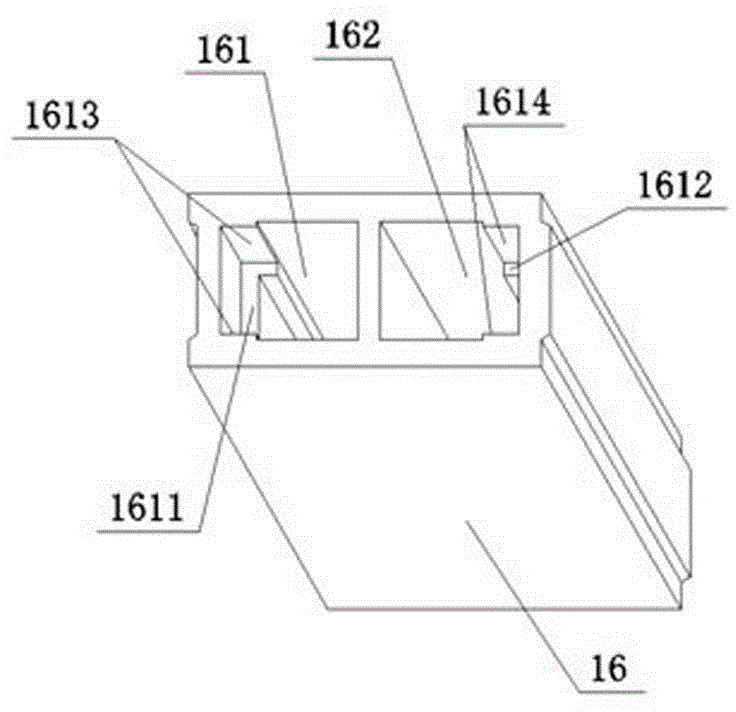

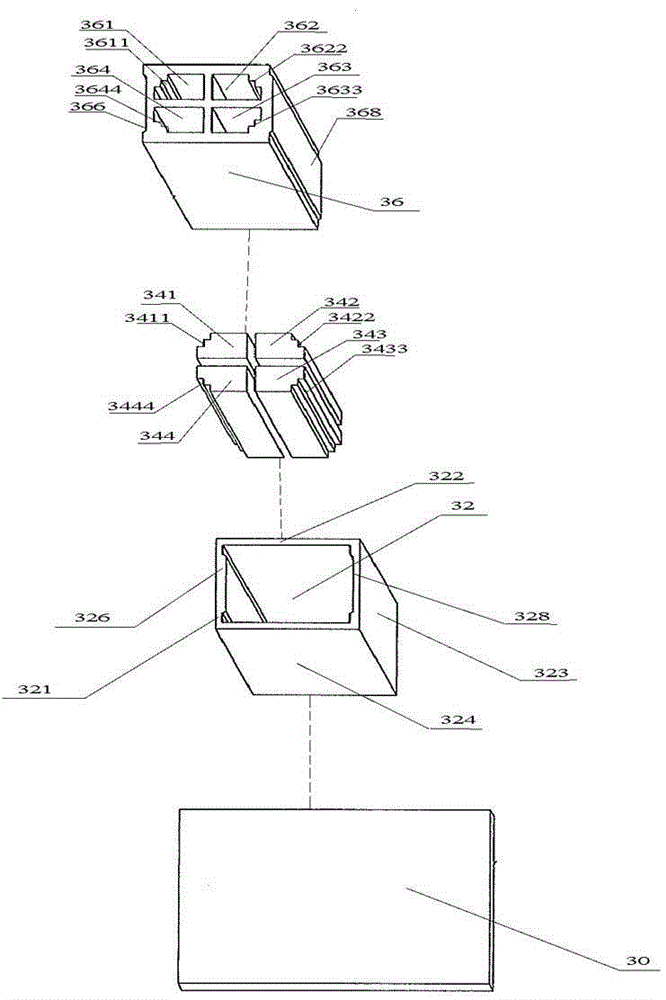

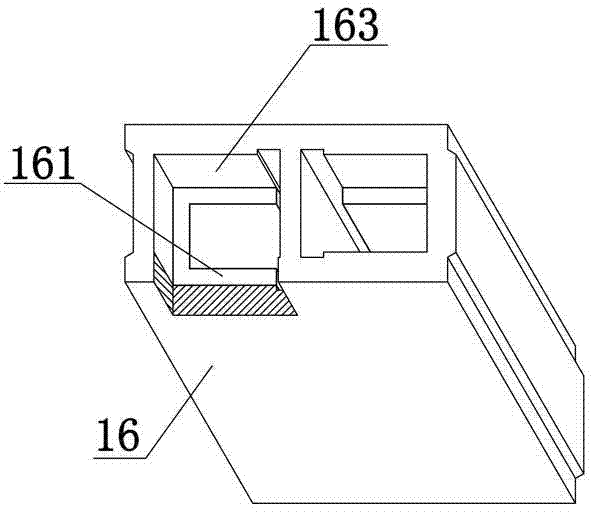

Prestress assembled concrete beam column joint structure and construction method thereof

InactiveCN104727441AArrangement length is shortSmall loss of prestressBuilding constructionsPre stressConcrete beams

The invention relates to a prestress assembled concrete beam column joint structure and a construction method thereof. The prestress assembled concrete beam column joint structure comprises a prefabricated column and a prefabricated beam. The prefabricated beam and the prefabricated column are in prepressing connection through the prestress formed by tensioning prestressed reinforced steel bars. The bottom of the beam end on one side of a joint is connected with the top of the beam end on the other side of the joint through the prestressed reinforced steel bars, and the prestressed reinforced steel bars are symmetrically crossed on a vertical face. When the prefabricated beam is manufactured, the prestressed reinforced steel bars and anchoring parts of the prestressed reinforced steel bars are pre-buried at the bottom of the beam end, prestressed reinforced steel bar pore channels and an anchoring area are reserved in the top of the beam end, and open type stirrups are adopted in the anchoring area. A force transmission steel plate is arranged on the cross section part of the beam end by the way that the cross section part of the beam end is welded with longitudinal bars. Slant prestressed reinforced steel bar pore channels are reserved in a prefabricated column joint area, groove-shaped steel plates are pre-buried on the two sides of the joint of the column, and high damping rubber layers are attached to the insides of the groove-shaped steel plates. In the connecting process, the beam is clamped into channel steel, and the prestressed reinforced steel bars penetrate through a joint core area to the top of the beam end on the other side of the joint and are anchored after being tensioned to be at the designed stress. According to the prestress assembled concrete beam column joint structure and the construction method thereof, assembling construction is convenient, and high shear-bearing capacity, energy-dissipating capacity and self-resetting capacity of the connecting joint can be achieved.

Owner:WUHAN UNIV OF TECH

Articulated yoke, method for the production of a supporting surface enabling an even distribution and bearing arrangement

InactiveUS6923726B1Uniform force transmissionLow design and production engineering inputYielding couplingBearing assemblyPropellerRoller bearing

The invention relates to a yoke (4) which is used in universal-joint propeller shafts, having at least one leg member (7) which is connected to an input or output part of a machine element comprising at least one bearing part (8) surrounding a bore (9). Said bore (9) forms a supporting surface (10) at least one partial zone of a roller-bearing arrangement (11) for the positioning of a journal (6) of a differential-pinion shaft (3). The invention is characterized in that the supporting surface has at least one local recess (20) in the region of the rolling elements (14)) of the roller-bearing arrangement (11) which is subjected to maximum tensile stress during the transmission of the torque.

Owner:VOITH TURBO GMBH & CO KG

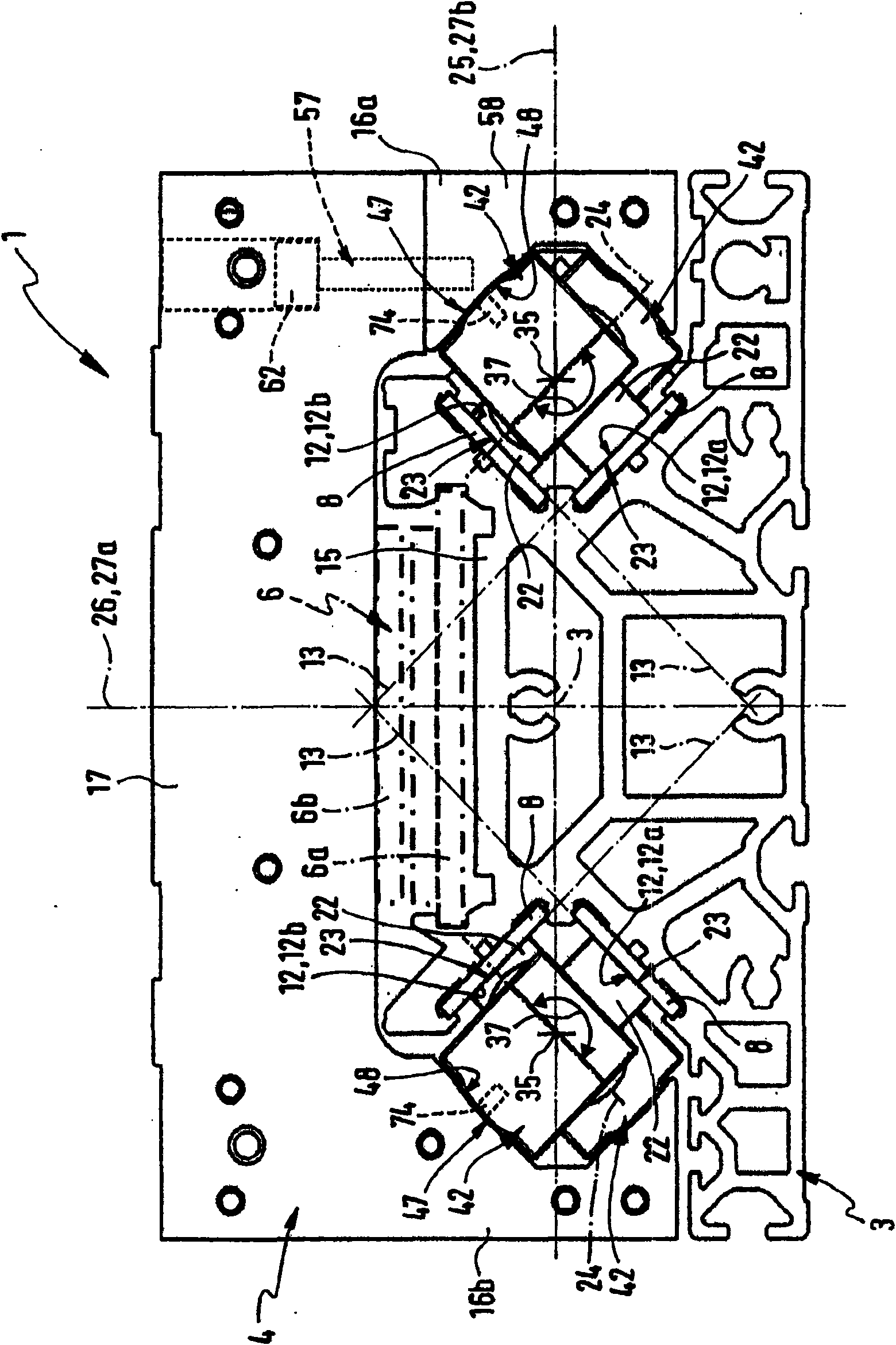

Linear unit

InactiveCN101629600AUniform force transmissionReduce wearLinear bearingsFluid-pressure actuatorsKinematic couplingBearing surface

The linear unit (1) has a base element, at which a carriage (4) is mounted in a linear movable manner in axial direction of a main axis (3). The base element has multiple longitudinal guide paths (12,12a,12b) extended to the main axis. A supporting roller (22) is fixed with a carriage body (14) of a carriage. The supporting roller is movement-coupled with circumferential-sided circular-cylindrical bearing surface (23) such that supporting roller is unrolled during the linear movement of the carriage on the assigned guide paths.

Owner:FESTO AG & CO KG

Detachable reused single-pore clamping piece type anchor rope anchorage device

The invention relates to a detachable reused single-pore clamping piece type anchor rope anchorage device which comprises a large tray, a primary anchor plate, a clamping piece and an anchor rope. The anchor rope is arranged in the middle, the clamping piece is arranged on the outer side of the anchor rope, the primary anchor plate is arranged on the outer side of the clamping piece, the large tray is arranged at the front end of the primary anchor plate, the anchor rope penetrates through a through hole of the large tray, and the primary anchor plate is formed by two oppositely open conical barrel. A secondary anchor plate is sleeved on the outer surface of the primary anchor plate, and the secondary anchor plate and the primary anchor plate are provided with limiting devices. The detachable reused single-pore clamping piece type anchor rope anchorage device has lock component detachable reused functions and is safe and convenient to dismantle, firm, reliable and easy to process, an installing method and device have no changes in comparison with conventional locks, a tray transmission force is uniform, material sources are wide, yielding anchoring of a soft rock roadway and post-exploitation retracement of a gate road support of a coal face can be achieved.

Owner:LIUZHOU HUAWEI FORCE MACHINERY

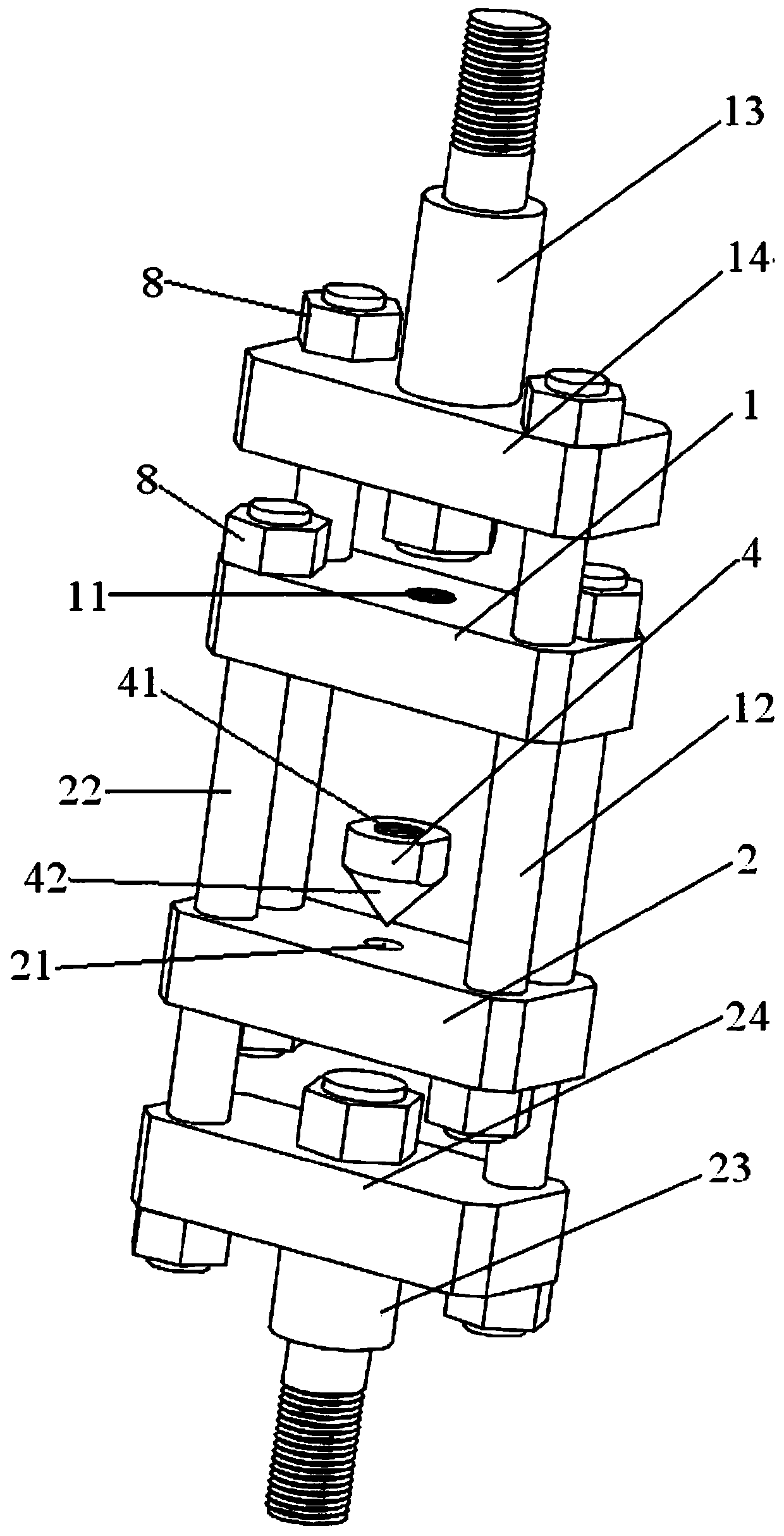

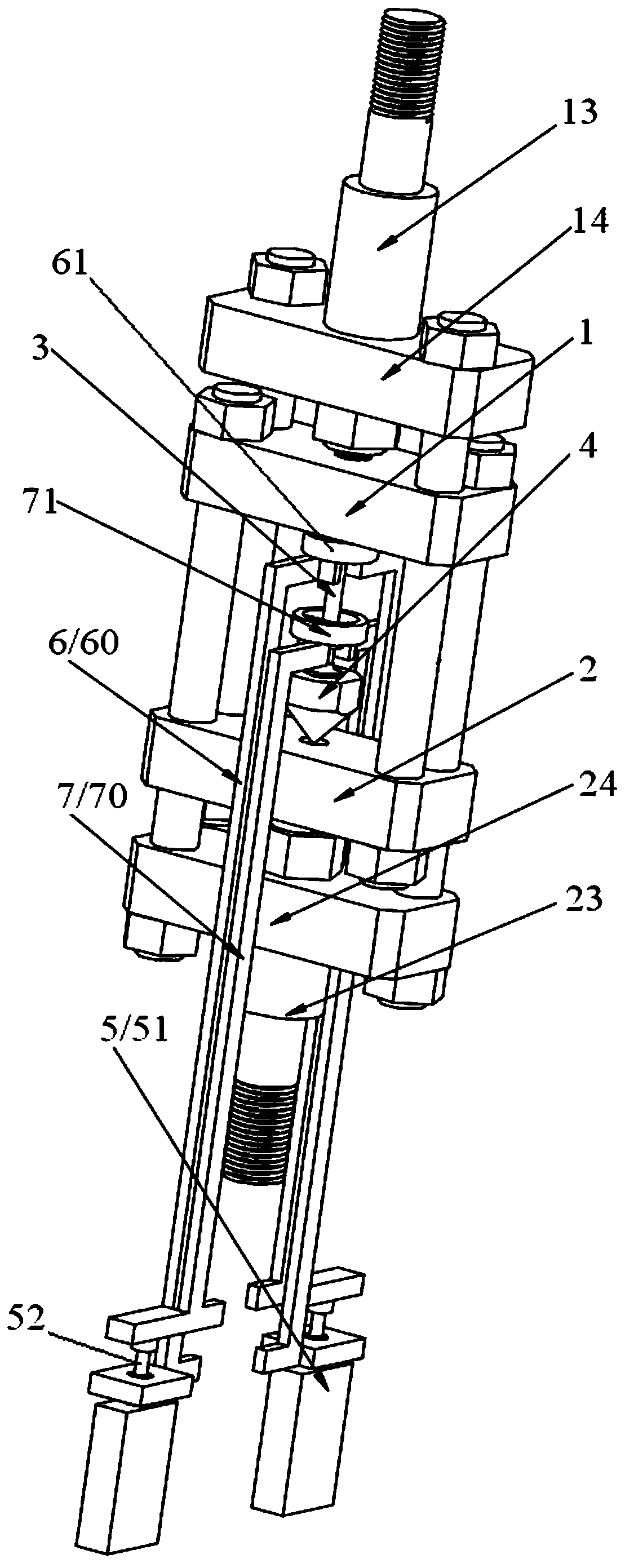

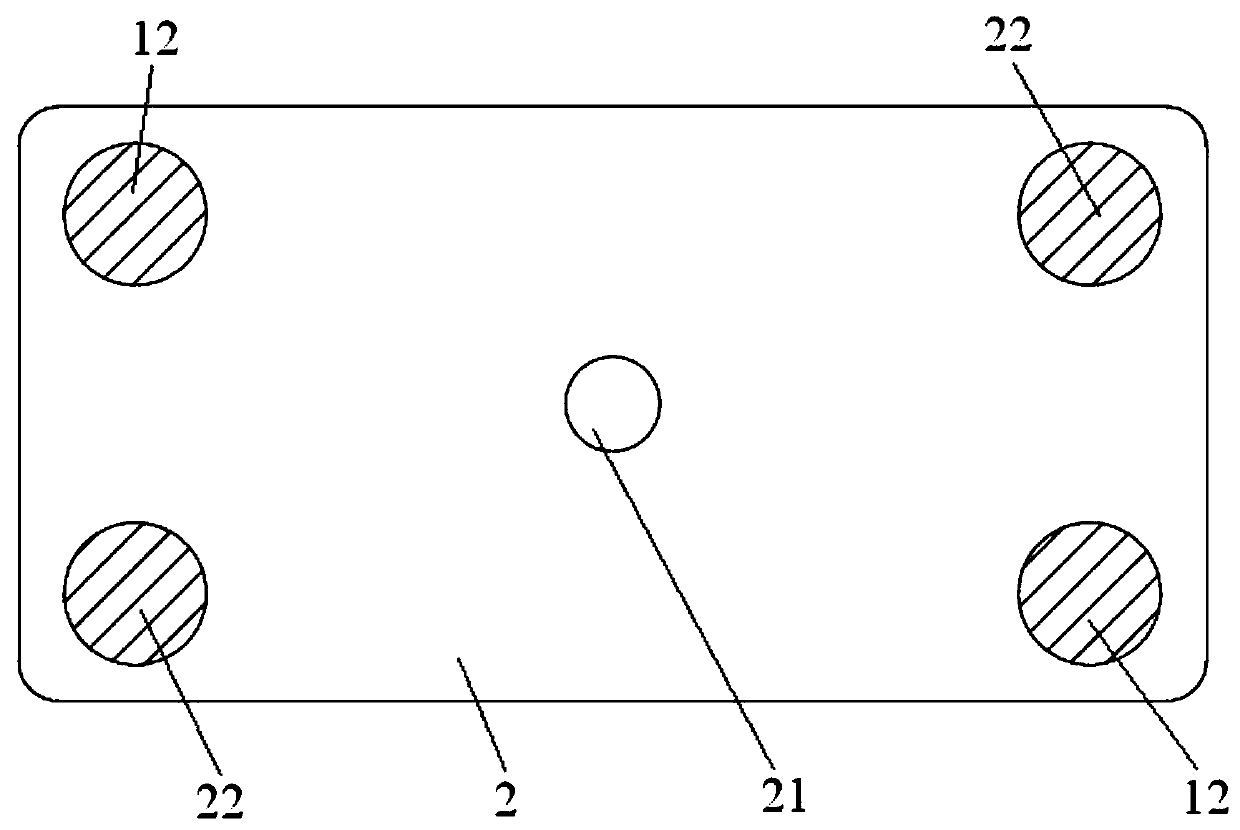

Creep compression experimental apparatus

ActiveCN109870371ANeutral goodReduce risk of damageInvestigating material ductilityNuclear energy generationUniaxial compressionTest sample

The invention provides a creep compression experimental apparatus. The creep compression experimental apparatus comprises an installation frame connected between an upper stretching rod and a lower stretching rod of a creep test machine, wherein the installation frame comprises an upper pressure block and a lower pressure block, the upper pressure block is provided with a threaded hole A, the lower pressure is provided with a conical hole coaxial with the threaded hole A, one end of a test sample is fixed in the threaded hole A, the other end is located in the conical hole by virtue of a conical head of a conical positioning device, and when the conical head is matched with the conical hole, the threaded hole A, the conical head, the conical hole and the test sample are coaxial. The auto-positioning function is realized by virtue of a conical surface contact of the conical positioning device, so that the test sample can be well centralized in the single-axis compression process, and the instability bending possibility of the test sample can be reduced. By virtue of the reversely-arranged extension rod, the rebound displacement of a precompressed sensor measuring head in the reset process is taken as the compression creep deformation of a sample, so that the occurrence of overstroke of the sensor measuring head and damage to the displacement sensor can be effectively avoided.

Owner:CENT SOUTH UNIV

Pure stalk fermentation biogas preparation process and apparatus based on composite strain degradation

InactiveCN101497893AEasy to useEasy to transportBio-organic fraction processingClimate change adaptationMicroorganismPhysical separation

The invention relates to a technique for preparing methane through straw stalks fermentation only based on multi-microorganism degradation, which comprises the following steps: A. physical and biologic comprehensive pretreatment is carried out on biomass straw stalk raw materials; B. the biomass straw stalk raw materials which are comprehensively pretreated are thoroughly degraded and thrown into an anaerobic fermentation reactor together with fermentation inoculation strains for anaerobic reaction and methane preparation; C. the output methane of the step B is desulfurized, enters into a gas-storing device and is delivered to users through a transmission pipeline network; D. methane residues and methane liquid of the step B after the anaerobic reaction are discharged, the methane residues can be used as solid organic fertilizer through physical separation, and the methane liquid refluxes to the anaerobic fermentation reactor for reutilization. The invention also discloses a device for preparing the methane through straw stalks fermentation only based on multi-microorganism degradation. The time of traditional technique for straw stalks pretreatment is 10-15 days; however, the time of the technique for straw stalks pretreatment is only 5 days and the degradation efficiency of the technique is 1.3-1.5 times as high as that of the traditional technique.

Owner:SHANDONG UNIV

Anti-buckling steel plate shear wall with combined vertical seams

InactiveCN106436974ARestoration workload after minor earthquakeImprove energy consumptionWallsProtective buildings/sheltersSteel plate shear wallMaterials science

The invention discloses an anti-buckling steel plate shear wall with combined vertical seams. The anti-buckling steel plate shear wall comprises a plurality of layers of low-yield point steel plates, and a plurality of groups of vertical seams in different lengths are formed in each of the steel plates. The anti-buckling steel plate shear wall further comprises a constraint component, and the lower part of each of the steel plates is inserted in the constraint component; an antifriction layer is arranged on the surface of each of the steel plates, a cushion block continuously arranged in the horizontal direction is arranged between each of the upper end and the lower end of each of the steel plates and the adjacent steel plate or the constraint component, and the part between each of the steel plates and the adjacent steel plate or the constraint component is filled with mortar; a connecting piece is arranged at each of the upper end and the lower end of the two sides of the shear wall, and connects and fixes the shear wall and a concrete frame beam through a fastening part. The anti-buckling steel plate shear wall disclosed by the invention has the benefits that by utilizing good plastic properties of the low-yield point steel plates, the anti-buckling steel plate shear wall with the structure has better energy dissipation capacity and ductility performance as compared with a traditional steel plate shear wall; by forming the vertical seams in different lengths in each of the low-yield point steel plates, a moderate and major earthquake multi-stage yielding energy dissipation mechanism can be formed, a weak link in the structure is formed, and the effect of a structure fuse is achieved.

Owner:FUJIAN UNIV OF TECH

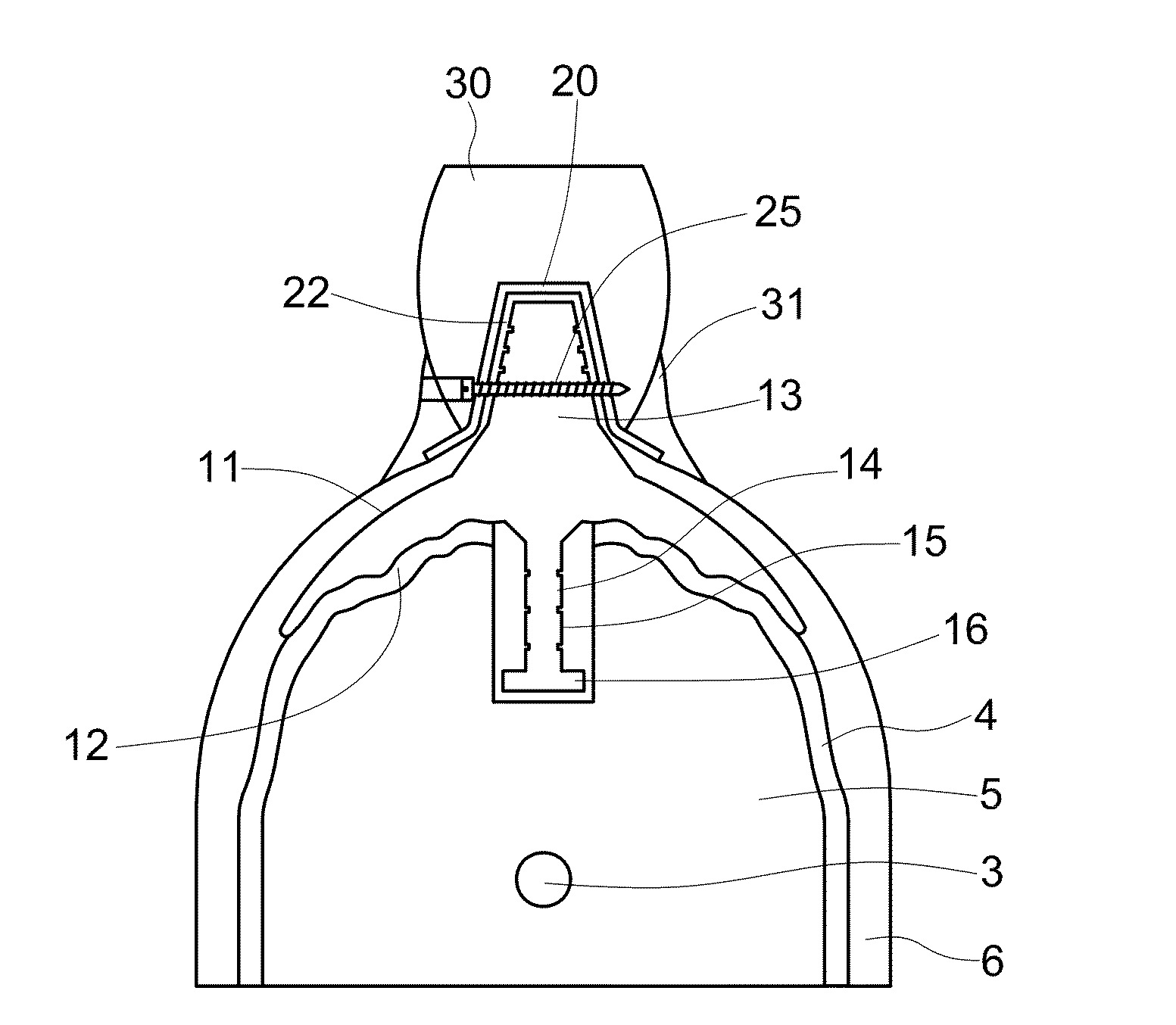

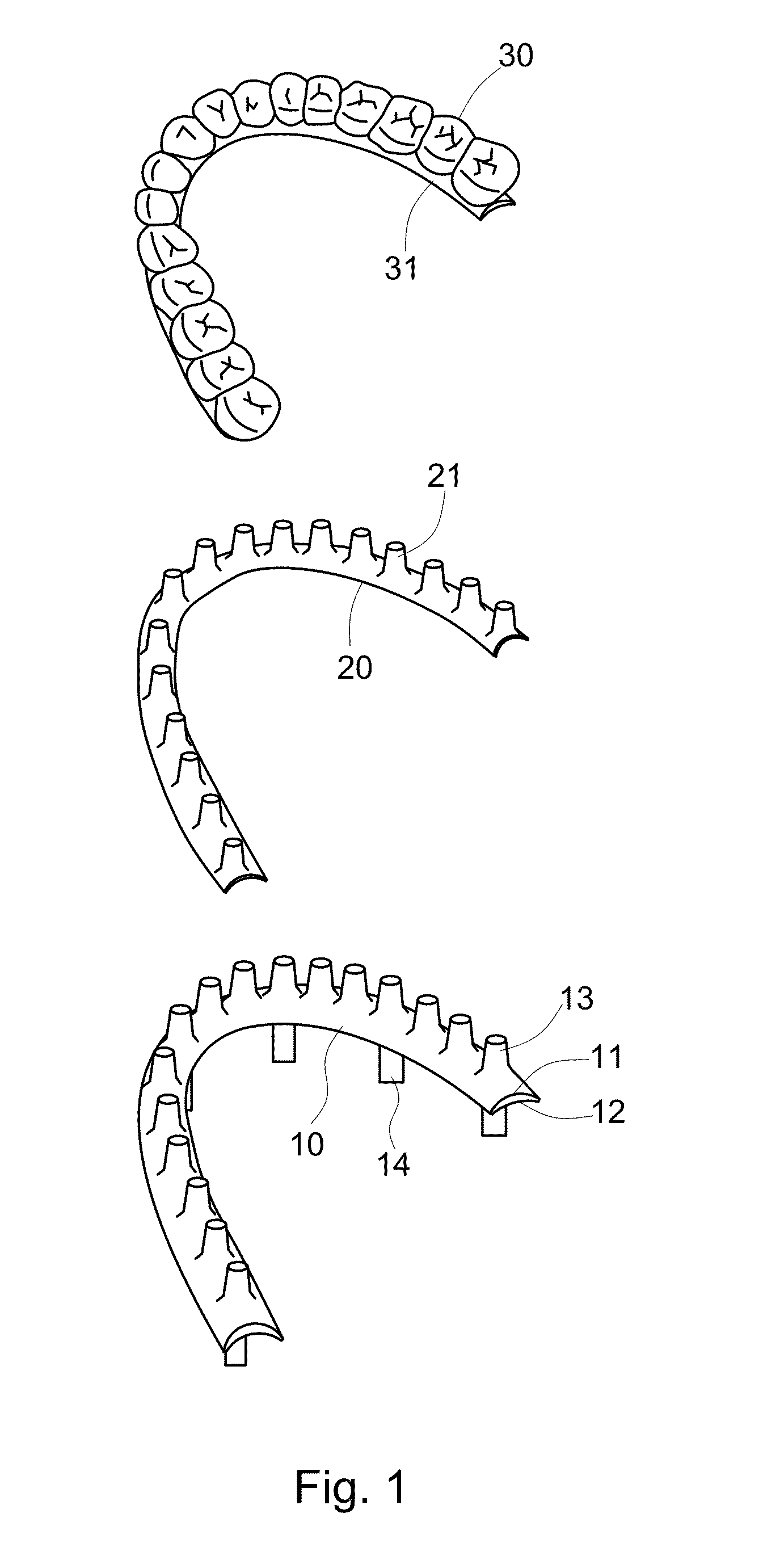

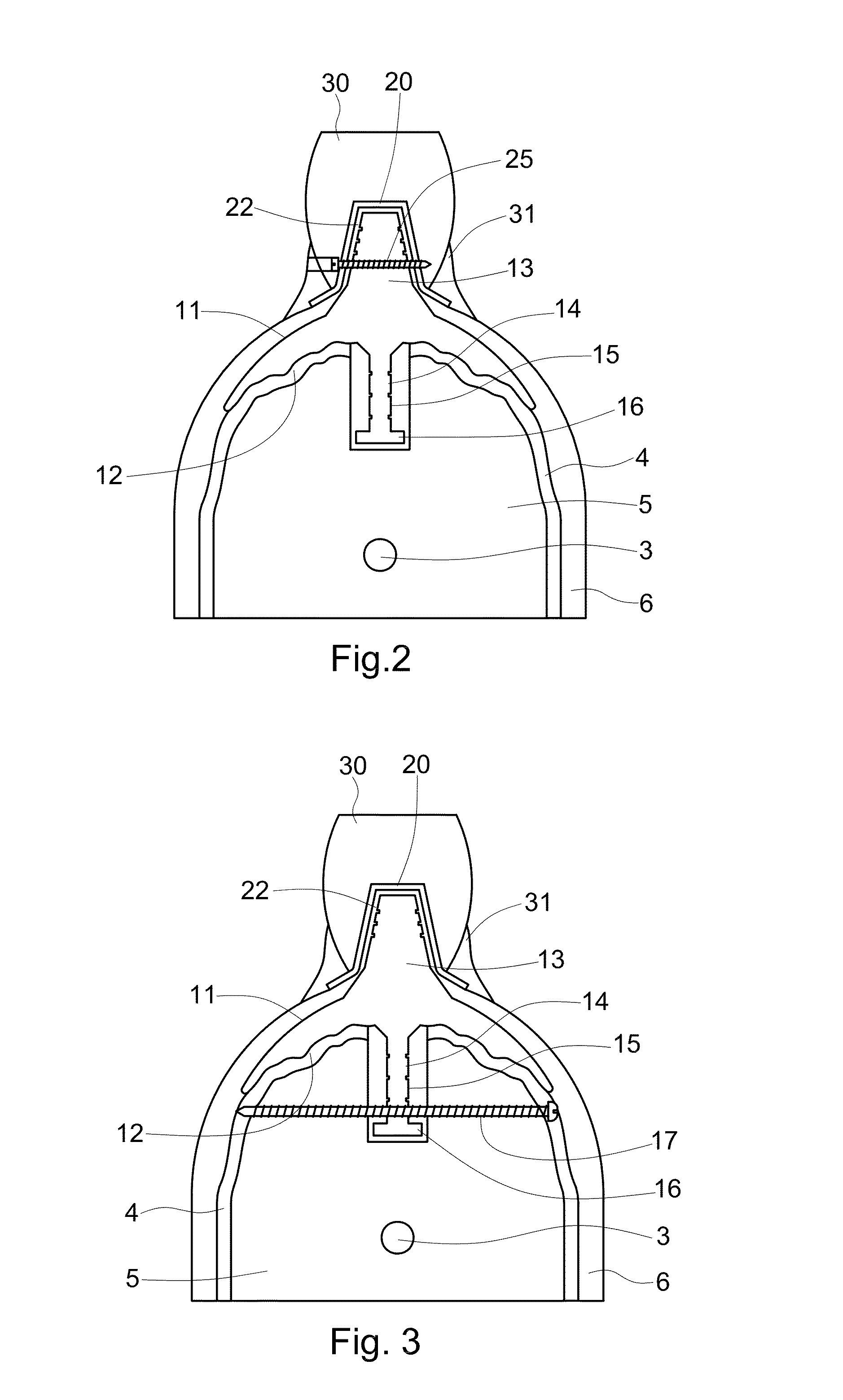

Artificial teethridge and fang

InactiveUS20130149668A1Uniform and stable forceCompact structureDental implantsArtificial teethProsthesisFang

A structure of the artificial teethridge, the fang and the prosthesis includes an artificial teethridge which has an arched top and an arched bottom, wherein the top and the bottom of the artificial teethridge are curved toward the same direction. The thickness of the artificial teethridge is relatively thicker at central part and gradually becomes thinner toward two lateral sides. A fang form integral on the top of the artificial teethridge. The artificial teethridge, the fang and prosthesis are an integral structure, whereby the artificial teethridge, the fang and the prosthesis form a mechanical conduction structure. The bottom surface of the artificial teethridge has a complementary structure which can be tightly matched and fixed on each point of the top surface of the alveolar bone without any gap, whereby the bottom of the artificial teethridge further includes a fastening fixture. A dental neck form integral between the artificial teethridge and prosthesis, the dental neck being formed in a waisted shape that is narrower at middle section and gradually becomes wider toward to two terminal sections.

Owner:CHEN LIEH TANG +1

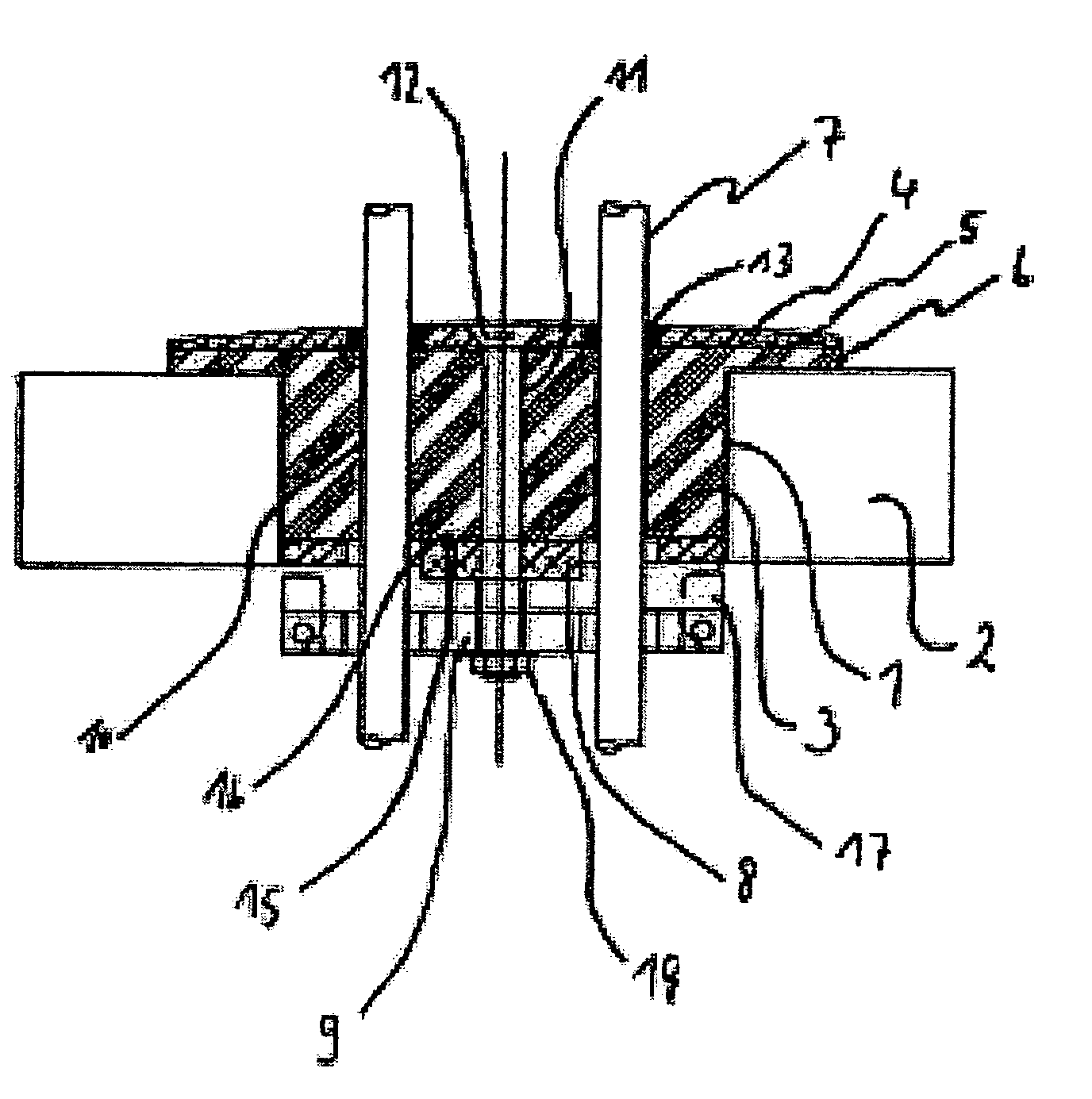

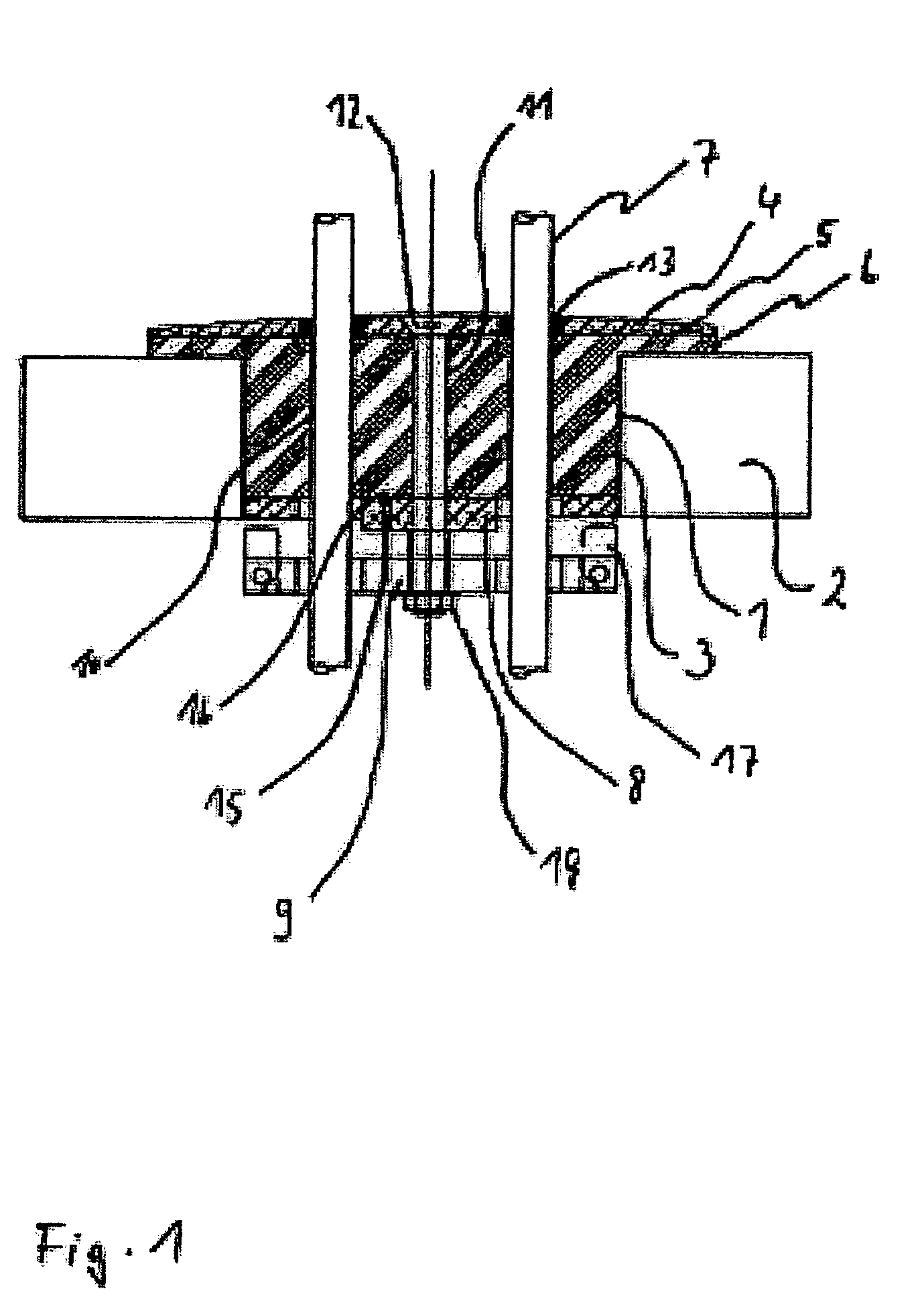

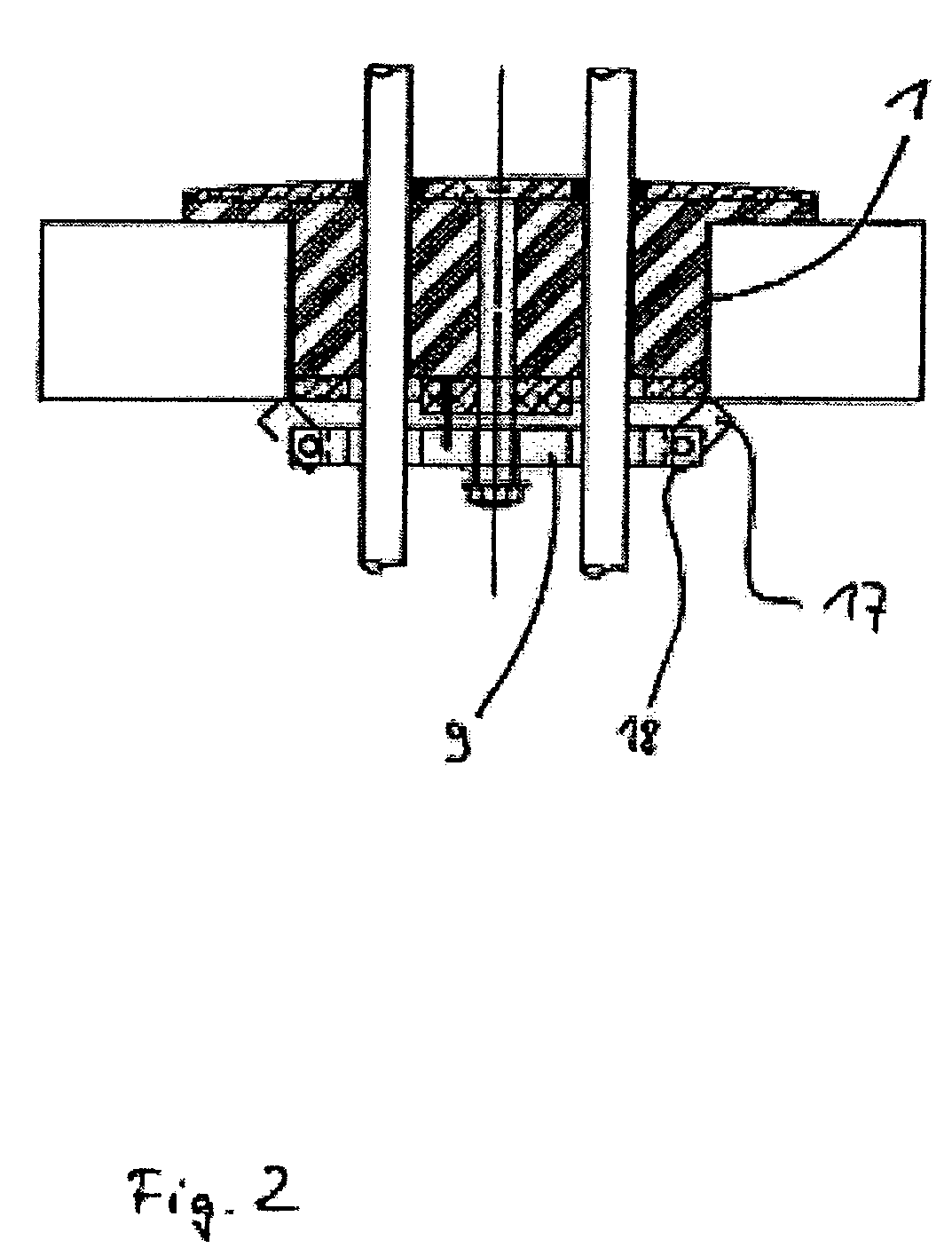

Fitting for a liquid-tight cable leadthrough

The invention relates to a fitting for a liquid-tight cable leadthrough in an opening (1) in a solid surface (2), which solid surface can be gripped from the back, wherein said fitting comprises an upper boundary plate (4) that covers the opening (1), an elastic moulded element (3) that flatly contacts and is connected to the upper boundary plate (4) and can be at least partially inserted into the opening (1), a lower boundary plate (8) that can be lead through the opening (1), wherein the lower boundary plate flatly contacts and is connected to the elastic moulded element (3) on the opposite side of the elastic moulded element (3) referred to the upper boundary plate (4), a locking plate (9) that can be moved relative to the lower boundary plate (8) and is providable with at least two pivoted locking elements (17), wherein said locking elements are supported between pairs of mounting limbs (20) by element of a bolt (22) and can be pivoted between a position in which the locking plate (9) can be lead through the opening (1) and a stopping position which they enables a gripping from the back of the solid surface (2), at least one clamping element for adjusting the spacing between the upper boundary plate (4) and the locking plate (9) against forces generated during a deformation of the elastic moulded element, and opening (10) that extends through the locking plate (9), the boundary plates (4, 8) and the elastic moulded element (3) and serves for accommodating a cable (7) to be lead through the solid surface (2).

Owner:AIRBUS OPERATIONS GMBH

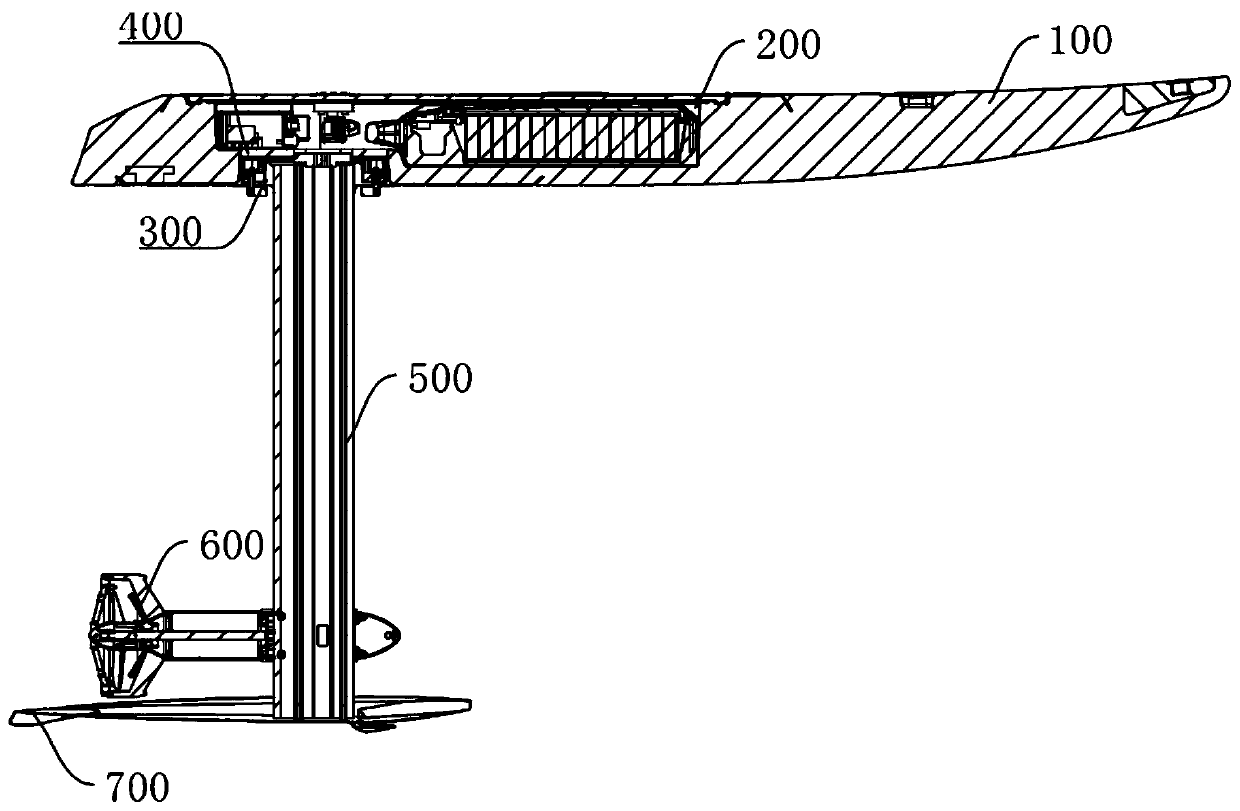

Electric surfboard and production process thereof

PendingCN110182331ASimplified molding stepsImprove molding efficiencyWaterborne vesselsSpecial purpose vesselsBiochemical engineeringPre embedding

The invention provides an electric surfboard and a production process thereof. The electric surfboard includes a surfboard body, a pre-embedded battery cabin, a pre-embedded connecting assembly and apre-embedded reinforcing assembly, the pre-embedded reinforcing assembly is at least partially clamped between the pre-embedded battery cabin and the pre-embedded connecting assembly, and the modulusof the pre-embedded reinforcing assembly is less than that of the pre-embedded battery cabin and the pre-embedded connecting assembly and greater than that of the surfboard body; and the surfboard body is formed by foam molding, wraps the pre-embedded battery cabin, the pre-embedded connecting assembly and the pre-embedded reinforcing assembly, and is an electric surfboard with high structural stability and long service life. The production process of the electric surfboard adopts the methods of pre-positioning and clamping the pre-embedded reinforcing assembly between the pre-embedded batterycabin and he pre-embedded connecting assembly for foam forming, the forming steps are simple, the forming efficiency is high, and the electric surfboard with high structural stability and long service life can be formed.

Owner:SHENZHEN WEIDU INTELLIGENT TECH CO LTD

Large-tonnage combination anchoring system and method for rocky slope

ActiveCN103397597AUniform force transmissionClear forceBridge structural detailsBridge erection/assemblyPre stressRock body

The invention discloses a large-tonnage combination anchoring system and method for a rocky slope and relates to the field of bridge construction. The large-tonnage combination anchoring system comprises at least one vertical distribution beam, a plurality of transverse distribution beams and a plurality of bundles of longitudinal prestress anchorage cables, wherein the vertical distribution beam is arranged along the rocky slope, the lower part of the vertical distribution beam is close to a rock surface, and the upper part of the vertical distribution beam is anchored with a backstay; the plurality of transverse distribution beams are fixed above the vertical distribution beam; one end of each bundle of longitudinal prestress anchorage cable extends into a rock body and is anchored, and the other end of the each bundle of the prestress anchorage cable is anchored to the transverse distribution beams via an anchorage; each bundle of the longitudinal prestress anchorage cable is vertical to the transverse distribution beam; the tail end of the longitudinal distribution beam is connected with a small distribution beam, and a cushion layer. According to the system and the method, under conditions of rocky slope and the like, large-tonnage anchoring force is provided for stay cables, dig engineering quantity is effectively decreased, and construction difficulty and construction risks are lowered.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

Connector for an articulated connection of a first and second pipeline

ActiveUS7677606B2Tolerance compensationAdjustable lengthSleeve/socket jointsEngine sealsEngineeringEngine power

A connector with an additional tolerance compensation capacity for articulately connecting a first and second pipeline of an engine-powered hot air supply system in an aircraft. One pipe end of the first pipeline is articulately connected by a tie rod with a pipe end of the second pipeline with the formation of a gap. The pipe ends each include a bearing ring incorporating an essentially centrically arranged receptacle for attaching the tie rod. The receptacle is connected with a bearing ring inner surface by at least two braces pointing radially outward. The opposing pipe ends are enveloped by a sealing unit for sealing the gap. A first end of the tie rod includes an adjusting unit in the form of a screw-on ball head for length adjustment while the second end includes a fixed ball head.

Owner:AIRBUS OPERATIONS GMBH

PE cable and cable clamp ball connecting performance test method

ActiveCN105258929AGreat anti-slip forceIncrease preloadMachine part testingMaterial strength using tensile/compressive forcesData acquisitionMechanical engineering

The invention relates to a PE cable and cable clamp ball connecting performance test method. The two ends of a PE cable anchorage device are each equipped with a tension tester. Test cable clamp balls and a brake cable clamp ball are installed in the central area of a PE cable. Parallel hydraulic jacks are arranged between the cable clamp balls. Pushing tool end plates are arranged between the hydraulic jacks and the cable clamp balls to transfer pushing force. The end of each test cable clamp ball is equipped with a displacement meter and a dial indicator which are connected with a dynamic data acquisition system to measure the displacement of the cable clamp balls relative to the PE cable. According to the invention, the most unfavorable slip plane during slipping of a cable clamp ball can be judged visually, the anti-slip friction resistance of a cable clamp ball under different cable forces and different surface contact conditions can be analyzed quickly, and the anti-slip friction coefficient can be calculated to guide cable clamp ball node design.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP +1

Doorsill longitudinal beam, electric automobile body frame and electric automobile

ActiveCN113602364AStable force transmissionUniform force transmissionElectric propulsion mountingSuperstructure subunitsBattery cellBattery pack

The invention relates to a doorsill longitudinal beam, an electric automobile body frame and an electric automobile. A first extrusion part in the doorsill longitudinal beam horizontally faces a floor cross beam, so that stable and uniform force transmission of side collision or column collision is ensured, the intrusion amount of a battery pack between two side edge beams is reduced, the battery pack does not bear the force transmission requirement of the side column collision at all, force transmission is completely borne by the vehicle body, so that the maximum arrangement space is provided for a battery core body; in addition, due to the fact that an installation gap is formed between the lower portion of a longitudinal beam inner plate and a side edge beam so as to install a pipeline connecting the front portion and the rear portion of the vehicle body, a middle channel can be omitted in the design process, and the riding experience of the whole vehicle is improved.

Owner:VOYAH AUTOMOBILE TECH CO LTD

Double beam floor structure

Owner:杨大刚

Guide pipe frame transition section

The invention discloses a guide pipe frame transition section. The section comprises a bottom plate, a main cylinder, an outer ring plate and a plurality of force transmission pieces; the first end ofthe main cylinder body is connected with the bottom plate, and the outer ring plate is arranged on the outer wall of the second end of the main cylinder body in a sleeved mode; the plurality of forcetransmission pieces are connected with the main cylinder body and the outer ring plate, and are arranged at intervals along the periphery of the main cylinder body, and the number and the position ofthe force transmission pieces are matched with guide pipe frame columns; the force transmission pieces comprise face plates and web plates, and the first ends of the face plates are connected with the outer ring plate; the second ends of the face plates cooperate with the top surfaces of the guide pipe frame columns; the web plates are fixedly connected between the face plates and the outer wallof the main cylinder body, and one ends of the web plates cooperate with the side faces of the guide tube frame columns. According to the guide pipe frame transition section, the arrangement height required by the force transmission pieces can be effectively reduced, the structural arrangement is more compact, the section is suitable for fans with different capacities and is not influenced by thesize of tower cylinders of the fans; the face plates and the web plates cooperate with the guide pipe frame column, the fan load is jointly transmitted to the guide pipe frame columns, the rigidity and the strength of the transition sections of the guide pipe frames are ensured, and the force transmission is uniform.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

Tunnel smooth blasting powder charging device and method

InactiveCN109612359AImprove blasting effectUniform force transmissionBlastingTunnelsSingle useInternal cavity

The invention discloses a tunnel smooth blasting powder charging device and method. Based on the smooth blasting peripheral hole non-coupling powder charging mode, a disposable buckle support device is adopted, so that a small-diameter cartridge is symmetrically fixed and supported to achieve the effect that the cartridge is arranged on the axial central line of a blasting shot hole in a filling manner; and the cartridge is precisely supported from the center, the smooth blasting effect is improved to the greatest extent. The tunnel smooth blasting powder charging device comprises a buckle elastic support component arranged at the two ends, in the axial direction, of the cartridge. The buckle elastic support component is provided with a clamping belt. Several fixing clamping teeth are arranged on the clamping belt. A fixed buckle and a movable buckle are arranged at the two ends of the clamping belt correspondingly. The fixed buckle and the movable buckle are each provided with an internal cavity, wherein the internal cavities allow the clamping belt to penetrate through. Springs are fixedly connected outside the fixed buckle and the movable buckle correspondingly.

Owner:OCEAN UNIV OF CHINA +1

Fabricated subway station and construction method thereof

ActiveCN112281918AGood sealing effectFirm fastening forceArtificial islandsProtective foundationConvex structureButt joint

The invention provides a fabricated subway station and a construction method thereof, and relates to the field of subway stations. The fabricated subway station comprises a plurality of components, wherein the plurality of components are annularly combined, the plurality of components include a bottom plate component, a bottom corner component, a side wall component, a middle plate component, a top corner component and a top plate component, concave-convex structures which are matched with one another are respectively arranged at the edges of the components, and the butt joint positions of every two adjacent components are filled with sealing structures; and embedded grooves which extend in a longitudinal direction are further formed in the edges of the components, the embedded grooves ofevery two adjacent components are oppositely formed, and connecting pieces which are used for forming opposite fastening force on every two adjacent components are installed in the embedded grooves. The opposite fastening force is formed on every two adjacent components through the connecting pieces, so that the sealing structures in the butt joint positions have good sealing effects; and a plurality of bolt structures are replaced by the complete connecting pieces, so that the bending moment is large, the force transmission is uniform, firm fastening force can be formed on every two adjacentcomponents, the high-performance waterproof requirement is met, the operation is simplified, and the construction efficiency is improved.

Owner:GUANGZHOU METRO DESIGN & RES INST

Hard rock tunnel boring machine

ActiveCN112554899ARapid expansionSmooth liftUnderground chambersTunnel liningTunnel boring machineRock tunnel

The invention provides a hard rock tunnel boring machine. The hard rock tunnel boring machine comprises a cutter head, a front shield, a main drive, a connecting bridge, a multifunctional assembling machine, a main propelling system and a tight supporting shield; the cutter head and the front shield are both connected with the main drive and used for driving the cutter head to work and protectingthe main drive; one end of the connecting bridge is connected with the front shield, and the other end of the connecting bridge is connected with the tight supporting shield; one end of the main propelling system is connected with the connecting bridge, and the other end of the main propelling system is connected with the tight supporting shield and used for providing thrust in the tunneling process; the connecting bridge is connected with the multifunctional assembling machine in a sliding manner; and the multifunctional assembling machine comprises a segment assembling machine body and a steel arch assembling machine body and is used for assembling segments, steel tiles and steel arches. The multifunctional assembling machine is installed on the connecting bridge and comprises the segment assembling machine body and the steel arch assembling machine body, and therefore different supporting modes can be selected according to different geologies when tunnel boring is conducted under the complex geological conditions.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Artificial teethridge and fang

InactiveUS20100035207A1Improve mechanical performanceTransmission of forceDental implantsEngineeringFang

A structure of the artificial teethridge and fang includes an artificial teethridge which has an arched top and an arched bottom, wherein the top and the bottom of the artificial teethridge are curved toward the same direction. The thickness of the artificial teethridge is relatively thicker at central part and gradually becomes thinner toward two lateral sides. A fang is installed on the top and the fang has a narrower fang top and a wider fang bottom, whereby the artificial teethridge and the fang form a mechanical conduction structure. The bottom surface of the artificial teethridge has a complementary structure which can be tightly matched and fixed on each point of the top surface of the alveolar bone without any gap, whereby the bottom of the artificial teethridge further includes a fastening fixture.

Owner:5 7 CORP LTD

Water-abrasive cutting system

ActiveUS10525569B2Accurate detectionUniform force transmissionAbrasive machine appurtenancesAbrasive blasting machinesEngineeringPhysics

A water-abrasive cutting system includes a cutting head (2) which includes a fixing device (16, 18, 20) for fixing the cutting head (2) on the wall to be cut as well as a nozzle head (10) disposed on the cutting head (2). At least one cutting nozzle (12), for an application of a cutting jet (14), is disposed in the cutting head (2). A cutting monitoring device (26) includes at least one hydrophone (30) and at least one further sensor. The cutting monitoring device (26) is configured to detect a complete penetration and / or cutting-through of the wall on the basis of the sensor signals of the hydrophone (30) and the at least one further sensor.

Owner:ANT APPLIED NEW TECH

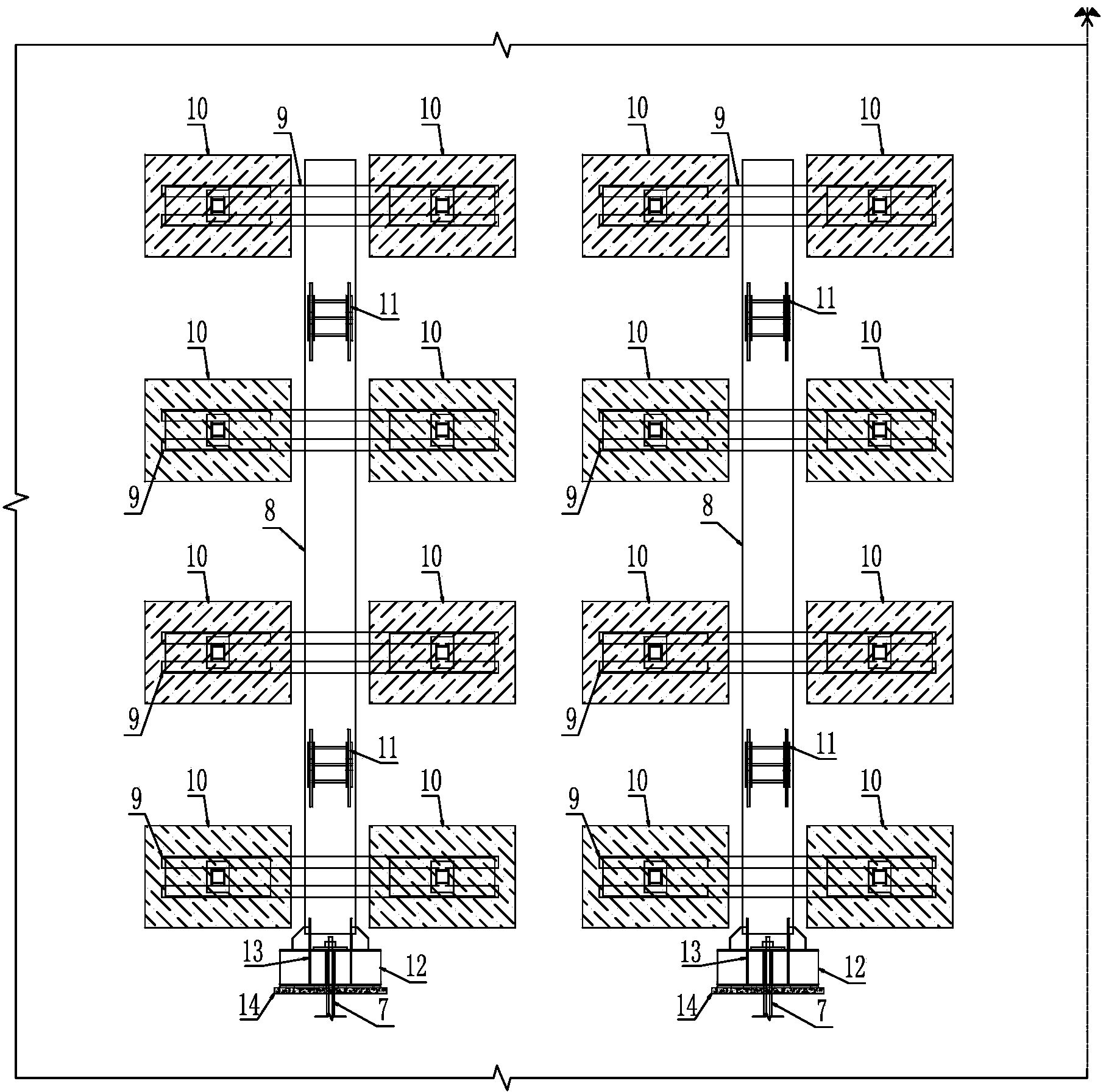

Compact unfolding and folding device for airborne radar large-array-plane antenna

The invention relates to a compact unfolding and folding device for an airborne radar large-array-plane antenna, and the device comprises a frame, a synchronizing shaft, a transmission rod and a driving device, wherein the driving device and the frame are arranged on a base, and the synchronizing shaft is arranged on the frame and can rotate relative to the frame; the transmission rod is in vertical transmission connection with the synchronizing shaft, the synchronizing shaft is connected with an antenna array plane, and the driving end of the driving device drives the transmission rod to movein the axial direction and drives the synchronizing shaft to rotate so as to unfold and fold the antenna array plane. The transmission rod is driven by the driving device to move in the axial direction, and then the synchronizing shaft is driven to rotate to achieve unfolding and folding of the antenna array plane, and enabling the antenna array plane to be attached to a belly of an airplane to the maximum extent. Moreover, the device is low in cost, is simple in motion, is high in reliability, is high in automation degree, and can meet the requirements of unfolding and folding work of the airborne large-array-plane antenna.

Owner:BEIJING INST OF RADIO MEASUREMENT

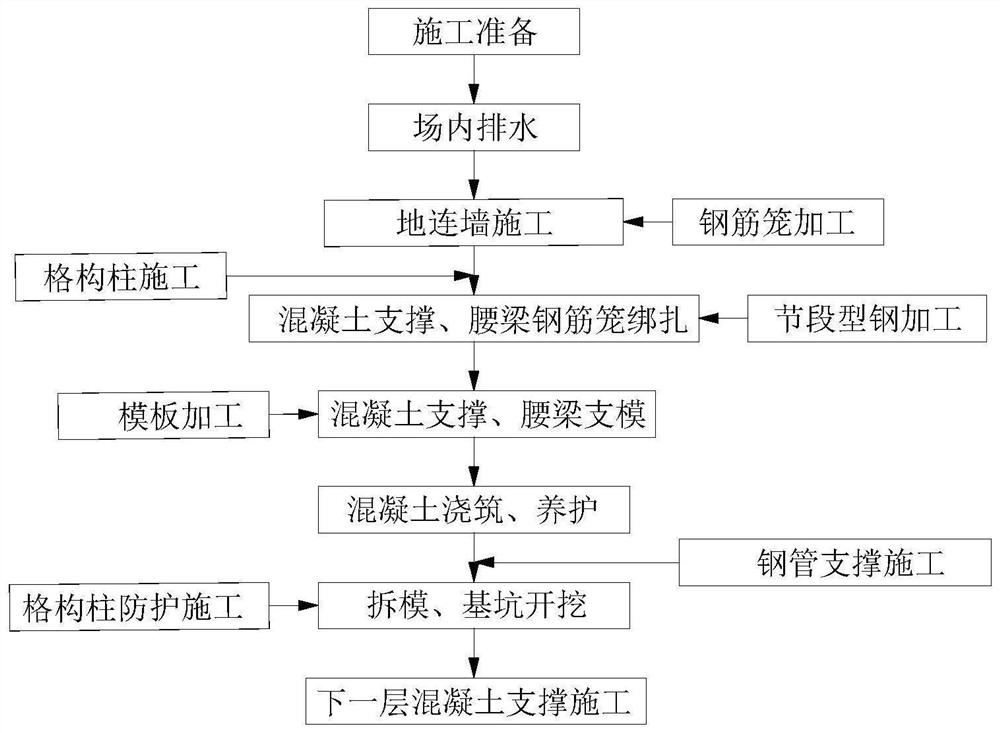

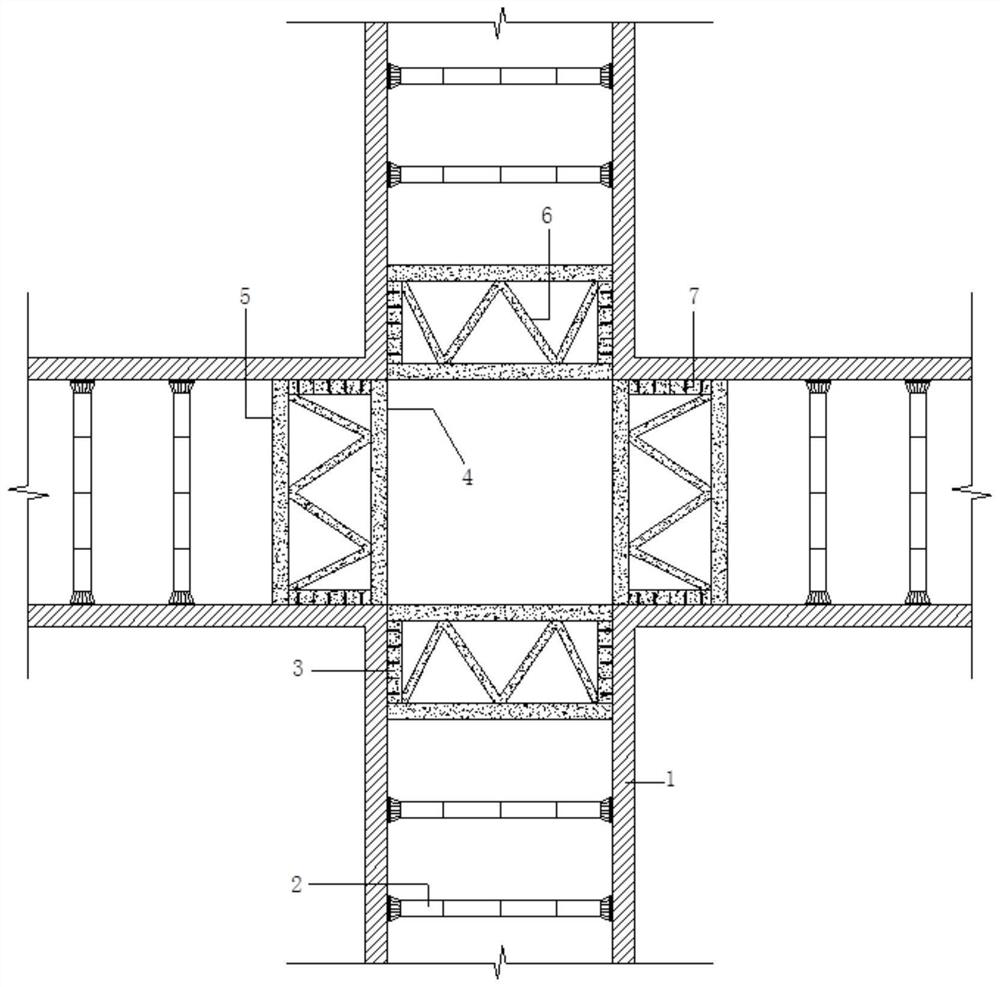

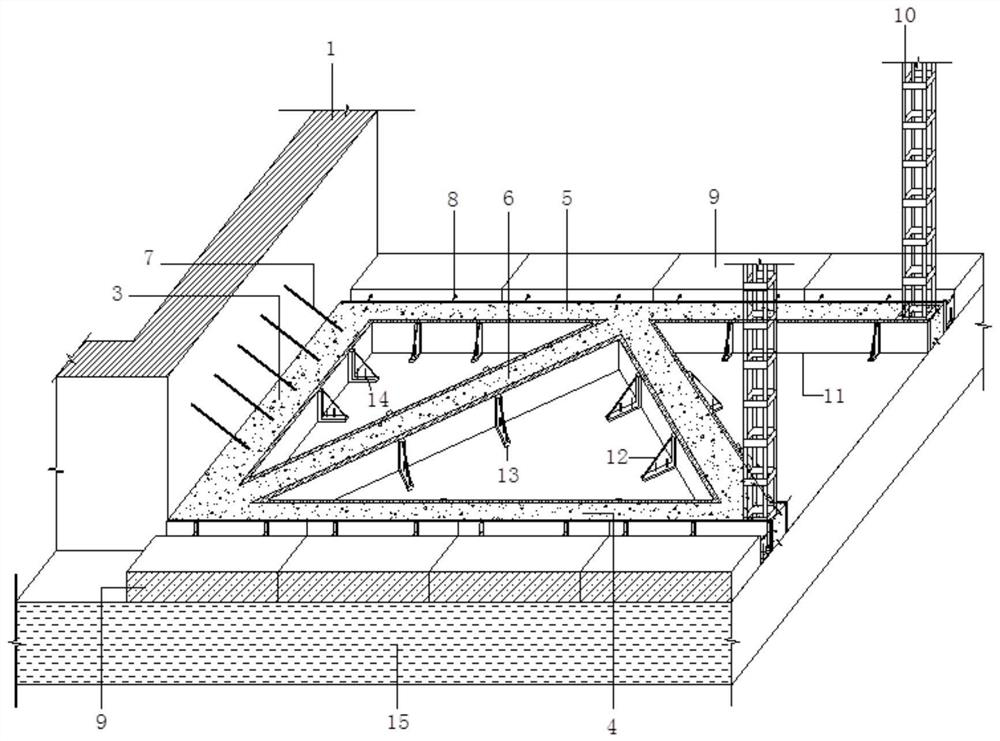

Subway transfer station deep foundation pit excavation support construction method

InactiveCN112813991AEnsure safetyEnsure stabilityExcavationsReinforced concreteArchitectural engineering

The invention discloses a subway transfer station deep foundation pit excavation support construction method. A diaphragm wall enclosure structure is adopted, concrete supports and steel pipe combined supports are arranged, the inner side concrete supports form annular reinforced concrete supports, concrete support formworks adopt prefabricated reverse pressing block reverse pressing easy-to-dismantle formwork systems and shaped formwork systems, built-in segmental steel of waist beams and the diaphragm wall enclosure structure are combined in an anchoring-hanging mode to form a whole, and latticed columns adopt flexible anti-collision construction protection devices. The construction method comprises the steps of (1) construction preparation, (2) drainage in a field, (3) diaphragm wall construction, (4) concrete support and waist beam reinforcement cage binding, (5) concrete support and waist beam formwork erection, (6) concrete pouring and maintenance, (7) formwork removal and foundation pit excavation, and (8) construction of the next layer of concrete supports. According to the subway transfer station deep foundation pit excavation support construction method, the overall safety and stability of a foundation pit are guaranteed, the construction speed is greatly increased, and obvious social benefits and economic benefits are achieved.

Owner:ANHUI HIGHWAY BRIDGE ENG CO LTD

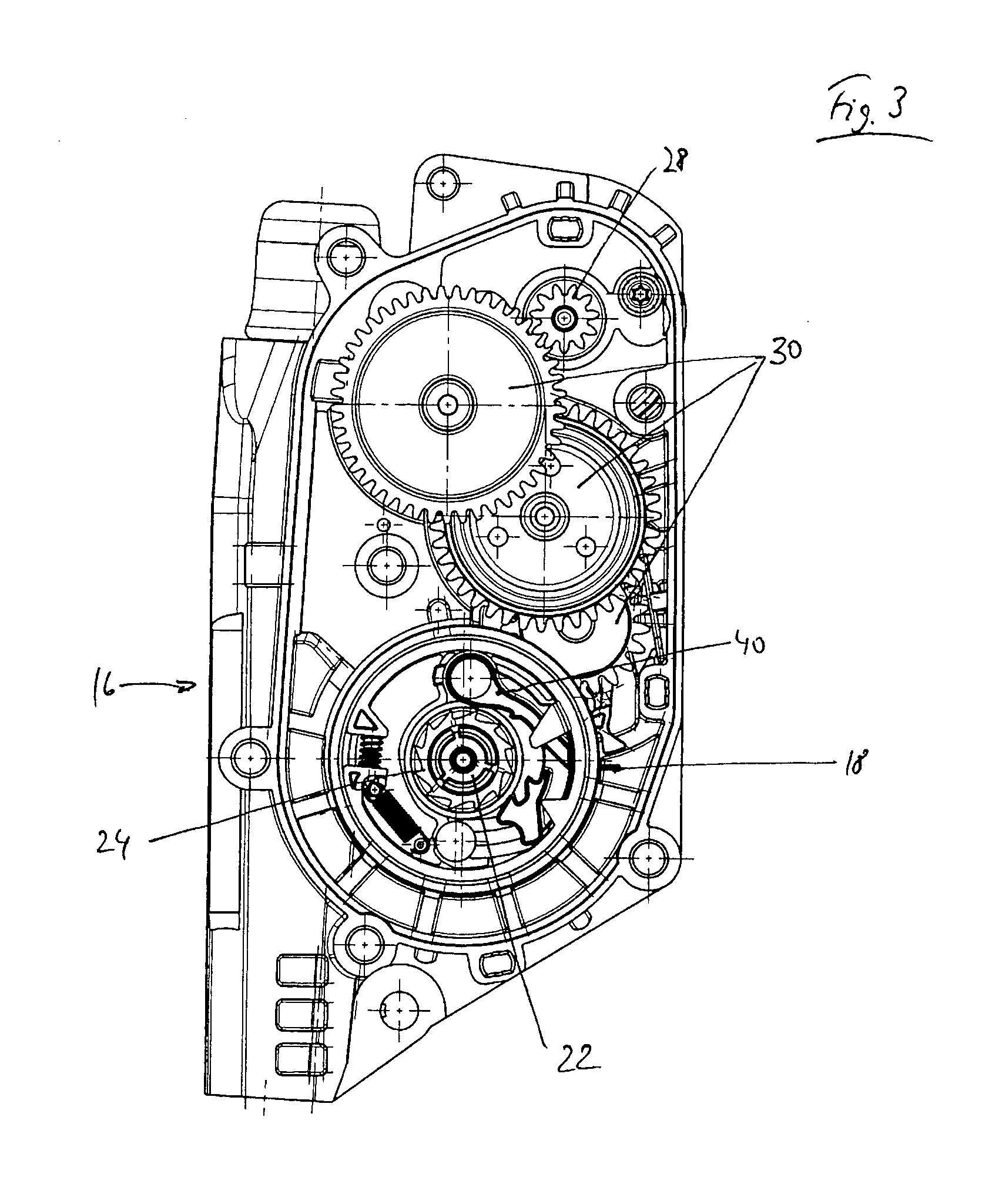

Coupling for a belt tensioner

ActiveUS20140318915A1Avoid disturbing noiseSimple structureBelt retractorsMechanical actuated clutchesEngineeringDriven element

A controllable clutch (18) for a belt tensioner (16) comprises a drive member (32), a driven element (24) and a clutch pawl (40) that is movably supported on the input side (30) between a home position and an engaged position and in the engaged position couples the drive member (32) to the driven element (24), wherein the clutch pawl (40) is tension-loaded in the engaged position.

Owner:TRW AUTOMOTIVE GMBH

Novel suspended monorail pier and track beam connecting structure

PendingCN109763419AReasonable and reliable forceUniform force transmission of the support structureRailway tracksBridge structural detailsCorbelMonorail

The invention discloses a novel suspended monorail pier and track beam connecting structure. The novel suspended monorail pier and track beam connecting structure comprises a hanging box arranged on apier and a corbel mounted on a track beam, wherein a support mounting base is arranged at the bottom of the hanging box; the corbel is mounted on the support mounting base through a support; the support comprises an upper support plate and a lower support plate; a sliding base is arranged between the upper support plate and the lower support plate; a longitudinal limiting device is further mounted on the support; a gap is formed between the longitudinal limiting device and the lower support plate; through the gap, the support can move longitudinally within the range of the gap; when the longitudinal displacement of the support exceeds the gap, the longitudinal limiting device can limit the support. The novel suspended monorail pier and track beam connecting structure solves the strict restriction of the specification on the displacement of the pier top of a suspended monorail pier, and can reduce the cross section of the pier body of the pier, so that the project cost is greatly saved.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Nut and bolt locking method and locking gasket thereof

The invention discloses a nut and bolt locking method and a locking gasket thereof. The nut and bolt locking method is characterized in that a rubber gasket (2) is arranged around a bolt external thread (7) between a nut (4) and a fastened part A (5); the nut (4) is tightened to extrude the rubber gasket (2) for deformation filling in gaps among the nut (4), the fastened part A (5), a bolt (1) andthe rubber gasket (2); through extrusion of rebound expansion force after extrusion of the rubber gasket (2), the friction force among the four is increased for elastic fixation as a whole, so that the nut (4) cannot generate the reversing looseness phenomenon; and the bolt (1), the fastened part A (5) and the nut (4) are locked to achieve the locking purpose. The locking gasket (2) is a soft O-shaped rubber gasket (2) with elasticity; and the section of the locking gasket (2) is one of the combinations of a T shape of two ellipses, circles, ellipses, rectangles, a circle+a rectangle, an ellipse+a rectangle, and a T shape of two rectangles.

Owner:杨富云

Building block die and method of carrying out pressing to form building block by utilizing same

The invention provides a building block die. The building block die is formed by horizontally arranging and combining at least one die unit. Each die unit comprises a supporting plate, a die box arranged on the supporting plate, a die core unit arranged in the die box and a pressure head which is inserted between the die box and the die core unit and is provided with a vertical hole structure. The building block die is used for forming an anti-seismic anti-cracking building block with a convex bolting part; the outer wall of the pressure head with the vertical hole structure is attached to the inner wall of the die box in a seamless manner; the pressure head with the vertical hole structure is a of a shape of a Chinese character 'ri' or 'tian'. The invention also provides a method for forming the building block by utilizing the building block die. The building block die is used for carrying out extrusion forming of the anti-seismic anti-cracking building block with the convex bolting part and the formed building block has excellent mechanical properties such as shear strength and the like.

Owner:段炼山

Building block mold and method for pressing and forming building block by using building block mold

Owner:段炼山

Mounting device and method for the counterforce-free mounting of pressure plate assembly on counterpressure plate, and method for counterforce-free dismounting

The present invention relates to a mounting device (11) for the counterforce-free mounting of a pressure plate assembly (1) on a counterpressure plate, said mounting plate having at least one release element (12) which can be displaced in an axial direction (A) relative to the pressure plate assembly and which is designed to exert an axial force on spring washer tongues (10) of the pressure plate assembly (1) in order to release the pressure plate assembly (1), which is normally engaged, and having at least one hook element (18) that is designed to engage behind a coupling lid (2) of the pressure plate assembly (1) in order to hold the mounting device (11) in place relative to the pressure plate assembly (1) at least in an axial direction when the release element (12) exerts axial force on the spring washer tongues (10) of the pressure plate assembly (1). The present invention also relates to a corresponding method for the counterforce-free mounting of the pressure plate assembly (1) and a corresponding method for the counterforce-free dismounting of the pressure plate assembly (1).

Owner:SCHAEFFLER TECH AG & CO KG

Precision injection molding machine clamping mechanism

InactiveCN103286928BImprove mechanical propertiesImprove efficiencyRolling resistanceInjection molding machine

Owner:上海云静企业发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com