Large-tonnage combination anchoring system and method for rocky slope

A large-tonnage, anchoring technology, which is applied in arch bridges, buildings, bridge construction, etc., can solve problems such as high construction risk, difficult foundation pit excavation, and difficult anchorage layout, so as to achieve clear force, convenient installation and disassembly, and The effect of clear force transmission path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

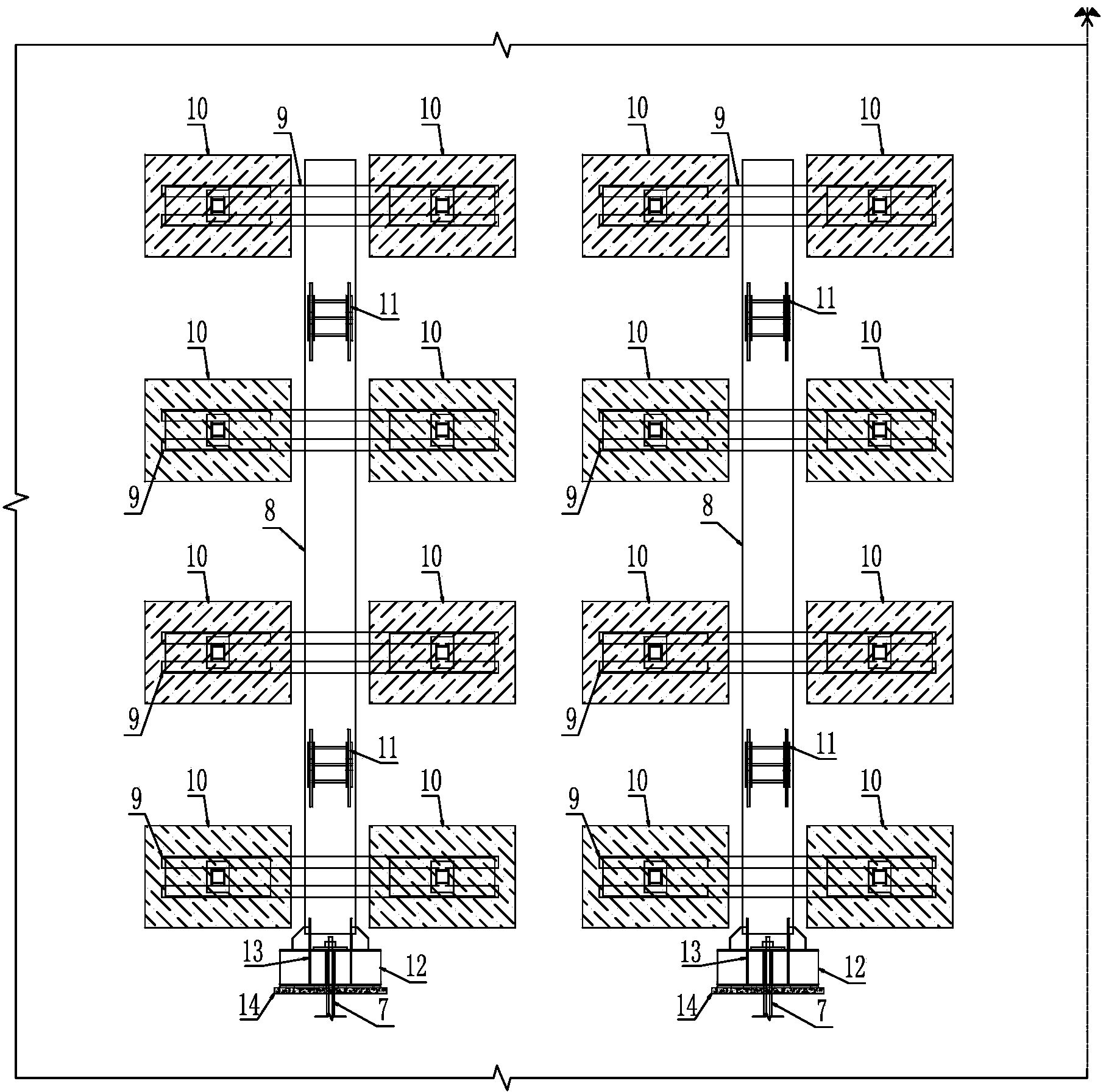

[0026] Such as figure 1 As shown, the present invention is applicable to a large-tonnage combined anchoring system for steep rock slopes, and is connected to one end of the back cable 1 to provide the anchoring position and anchoring reaction force for the back cable 1 . The other end of the back rope 1 is a tension end, which can be arranged on the main structure 2, or on the temporary structure 3 at the top of the main structure 2. In this embodiment, the tension end of the back rope 1 is arranged on On the main structure 2. The tension end of the buckle cable 4 corresponding to the back cable 1 is also arranged on the main structure 2 or on the temporary structure 3 , and the anchoring end of the buckle cable 4 is arranged on the arch rib structure 5 . The vertical component force generated by the arch rib structure 5 is balanced by tensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com