Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9410results about "Moulds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

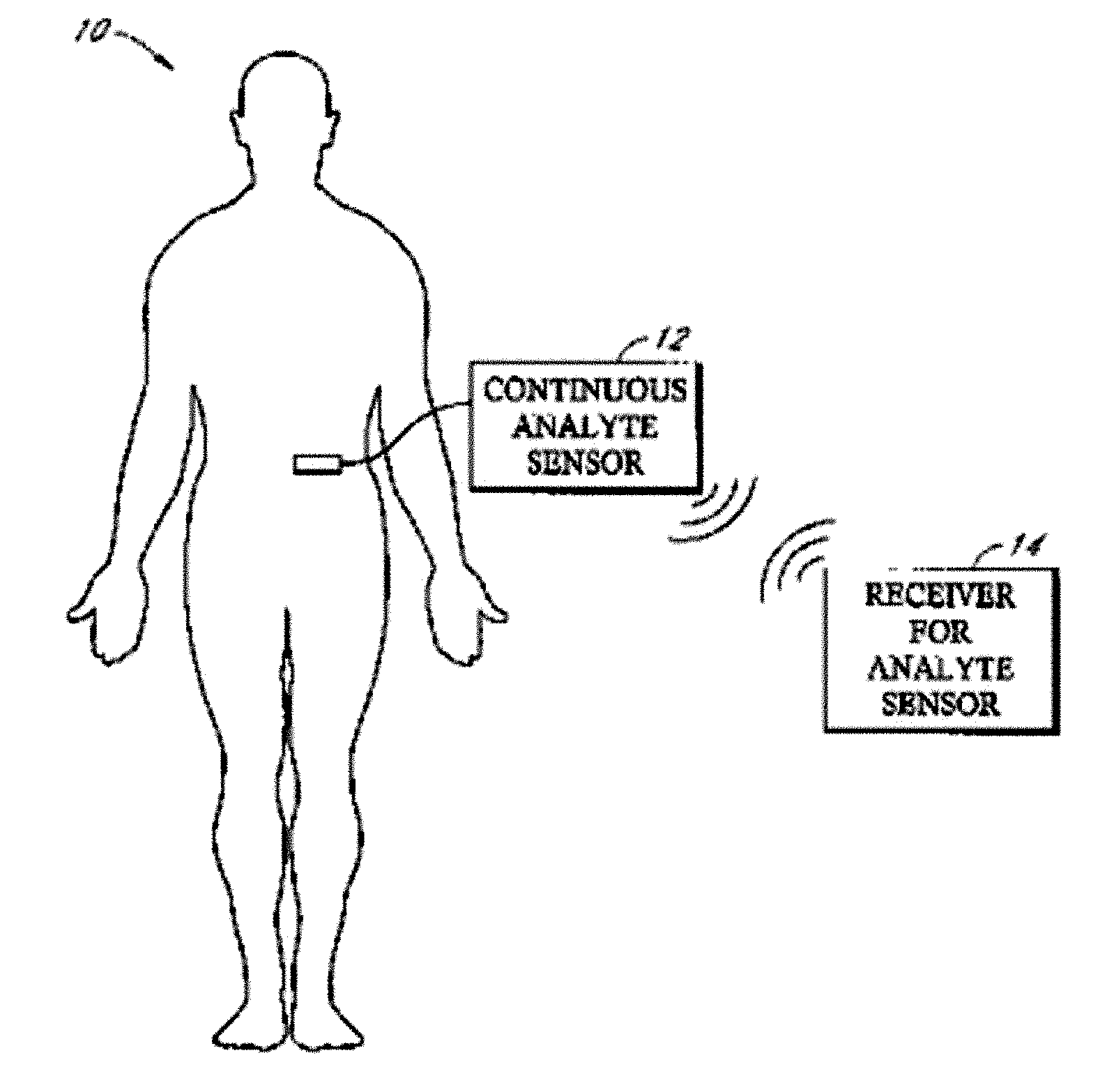

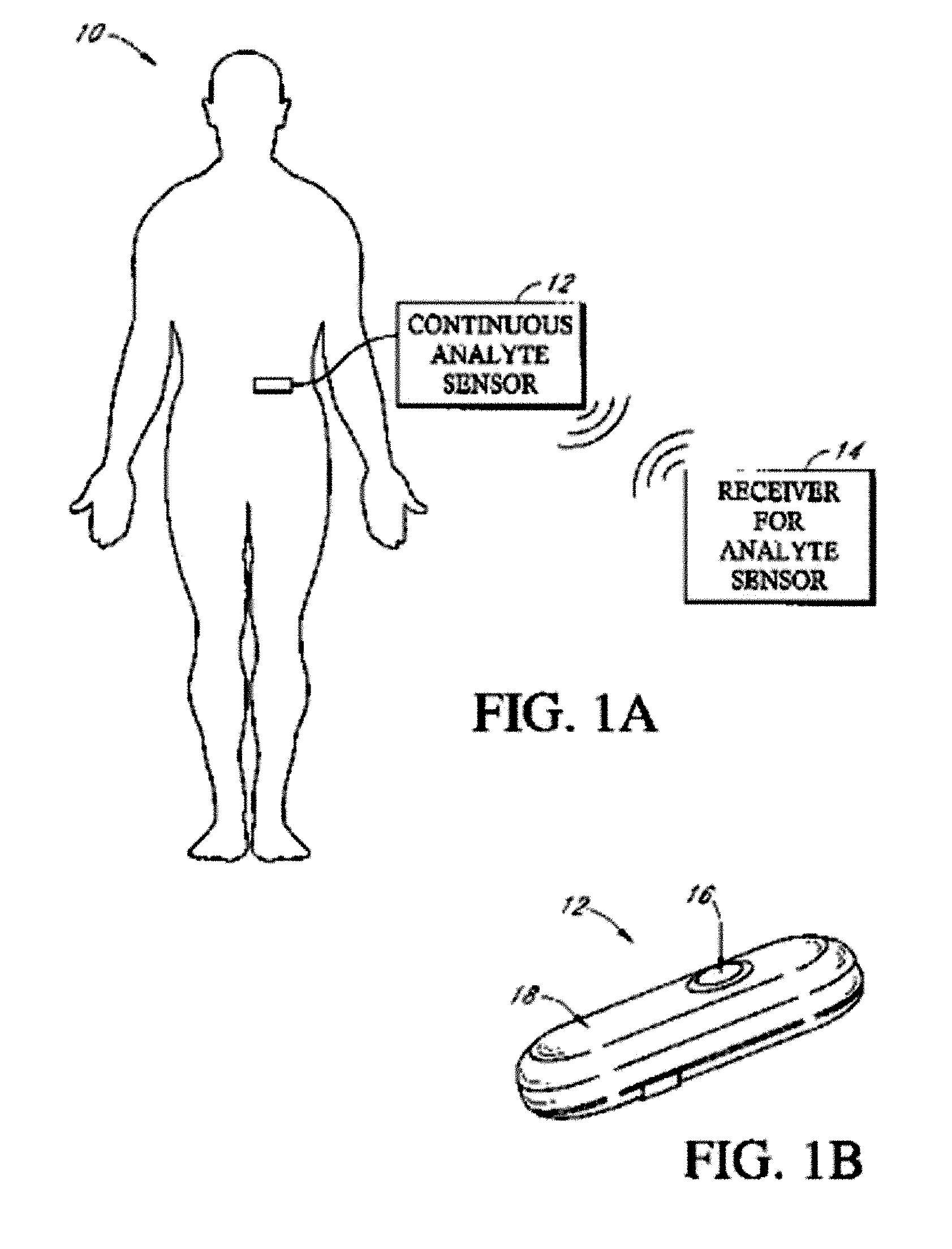

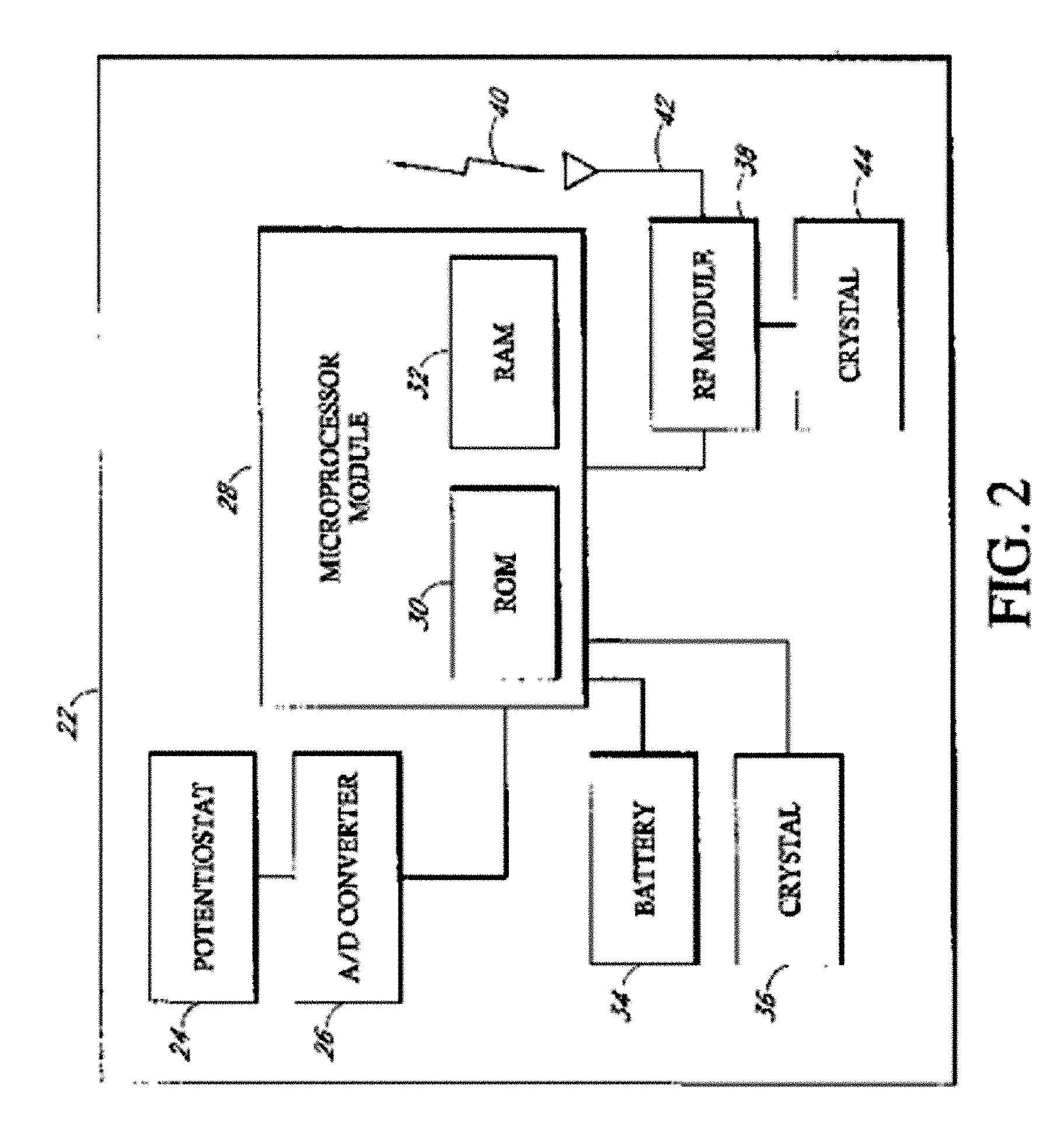

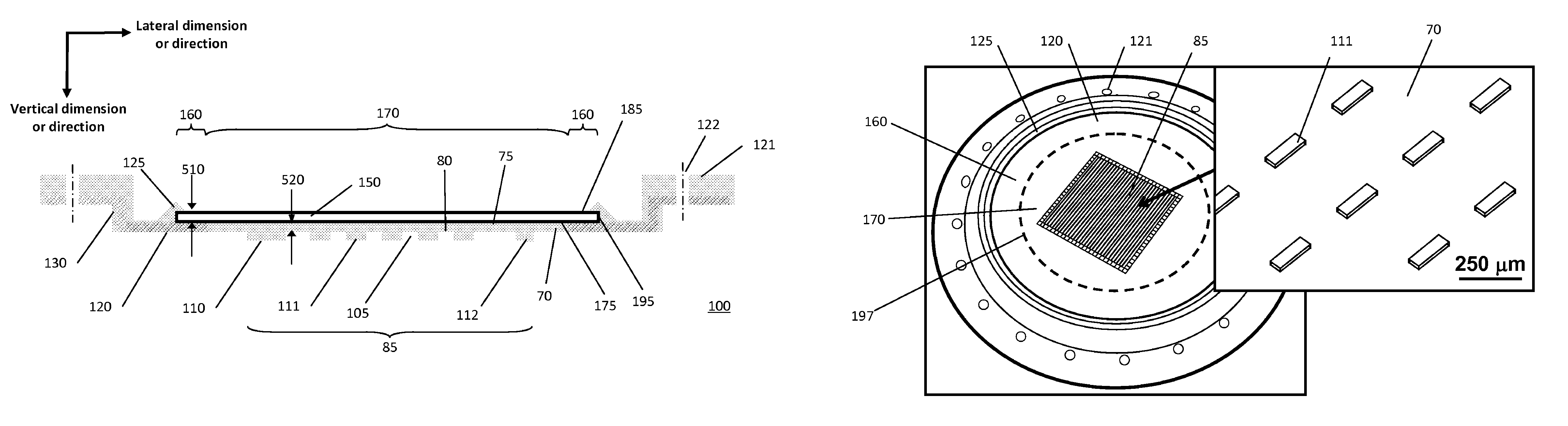

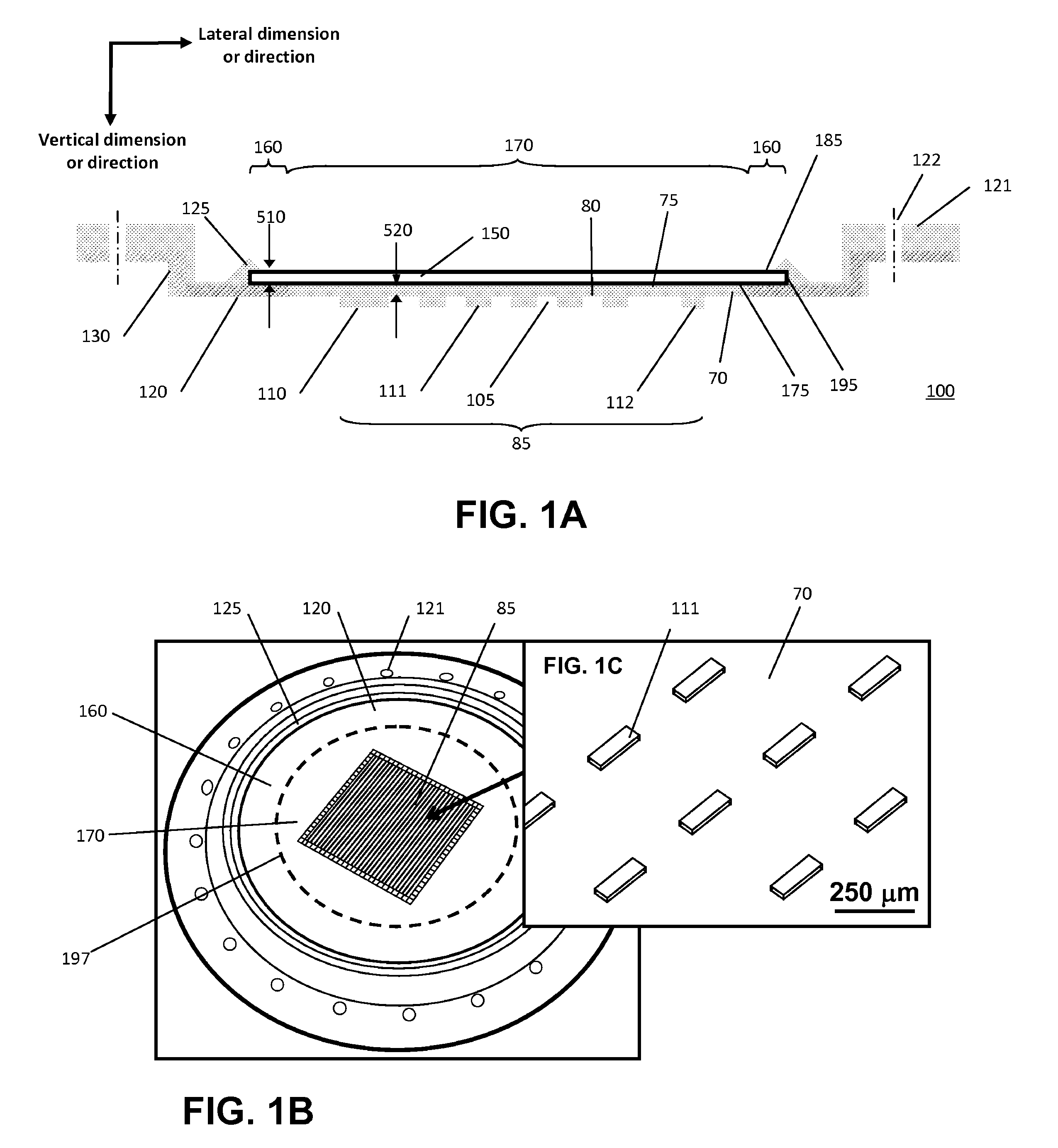

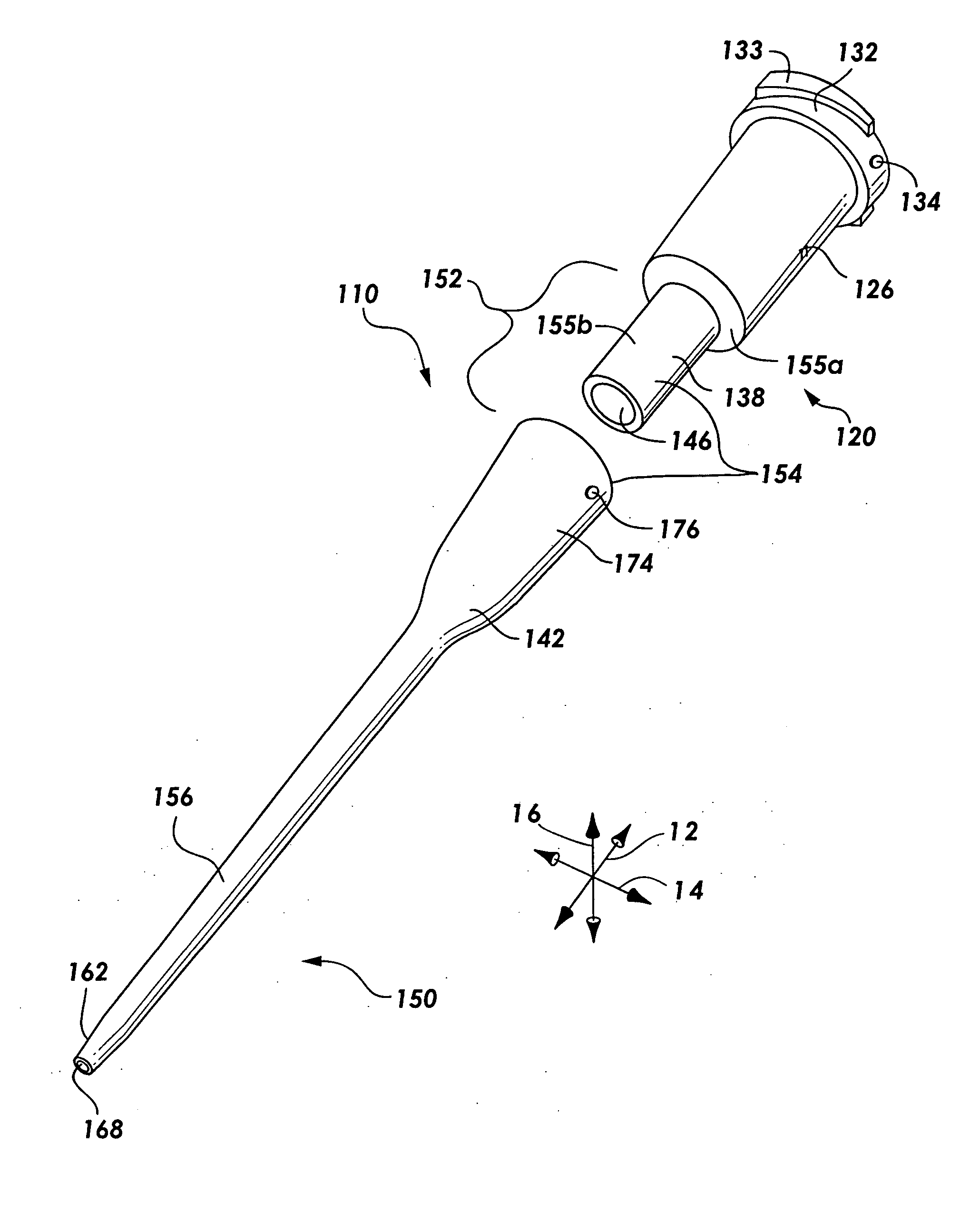

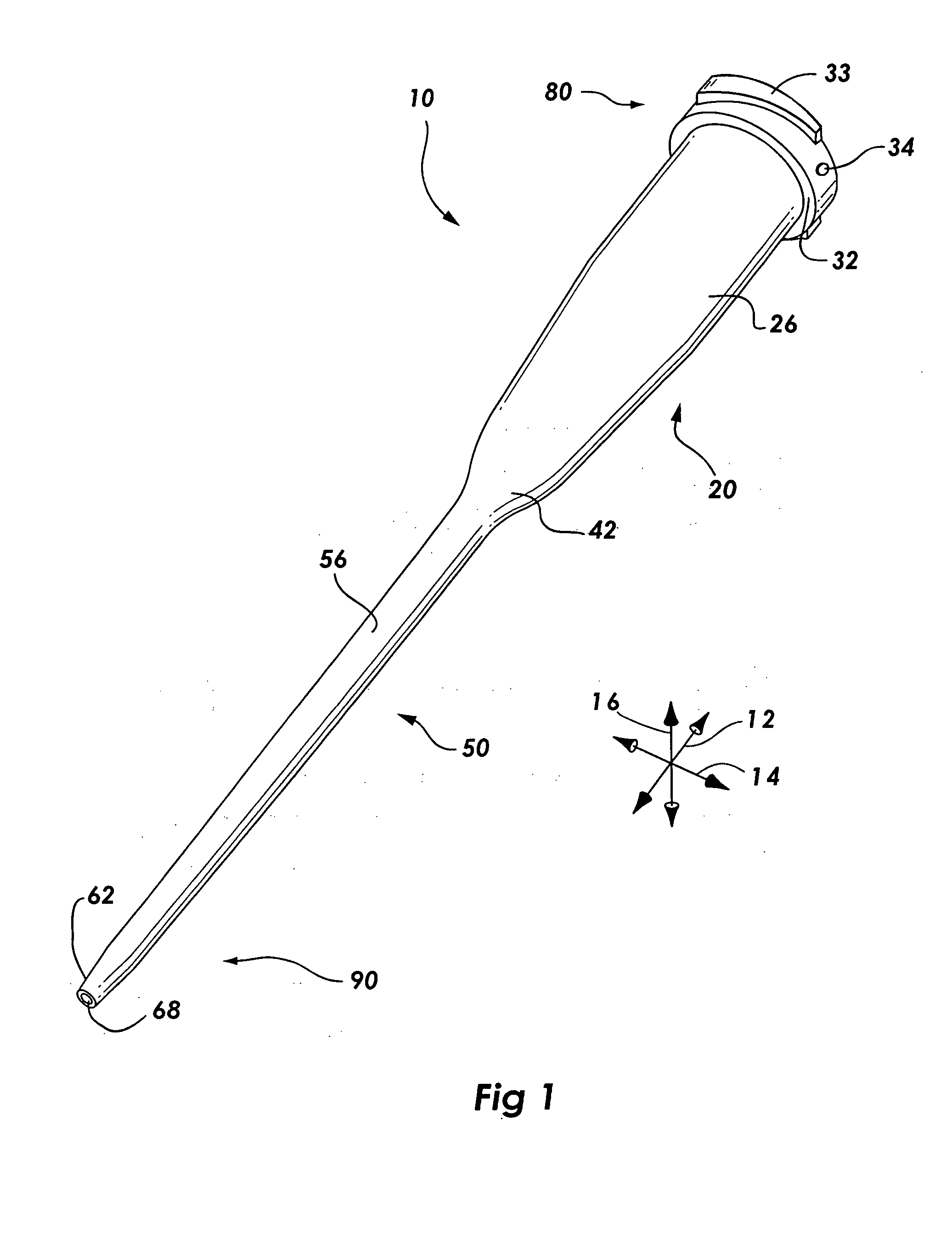

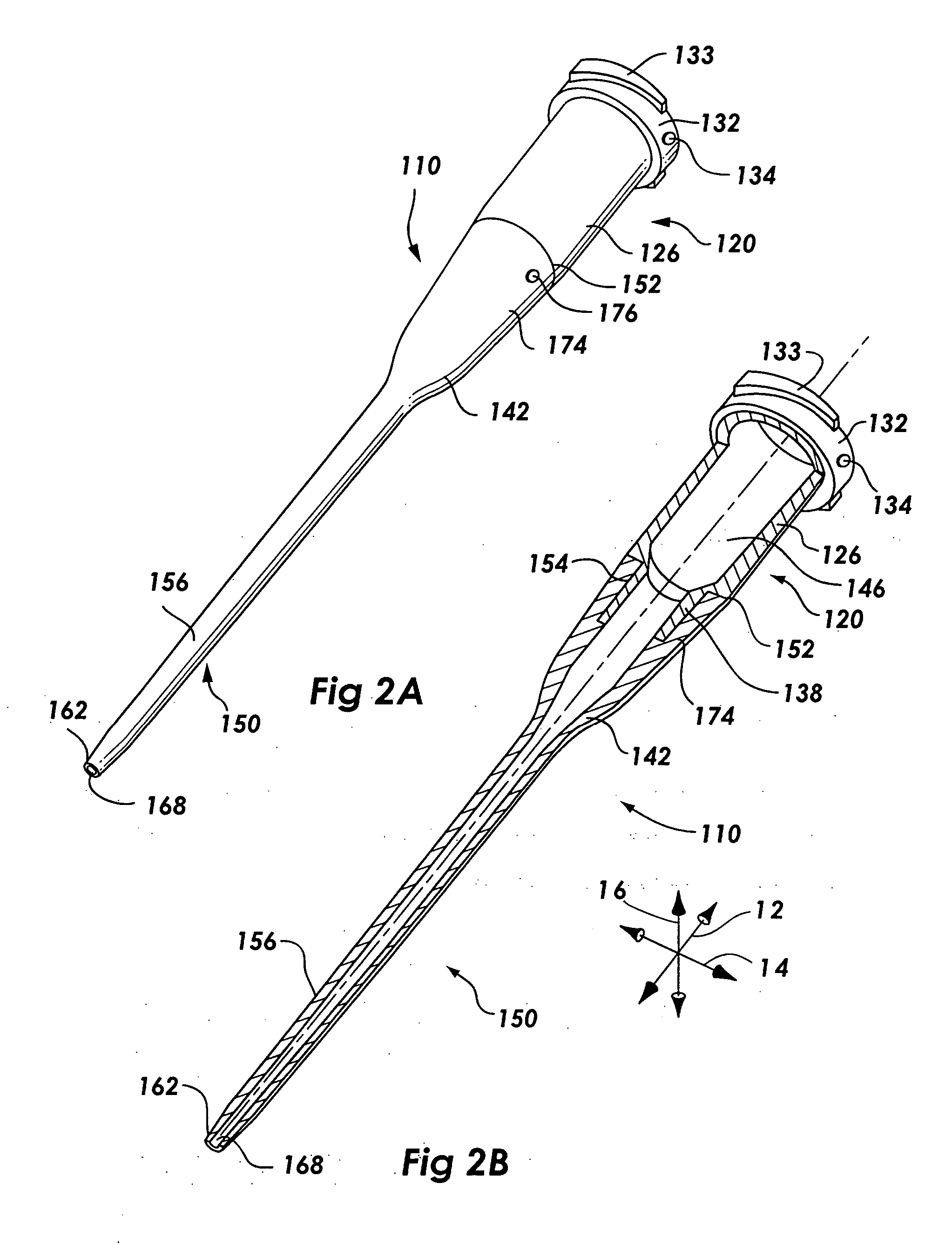

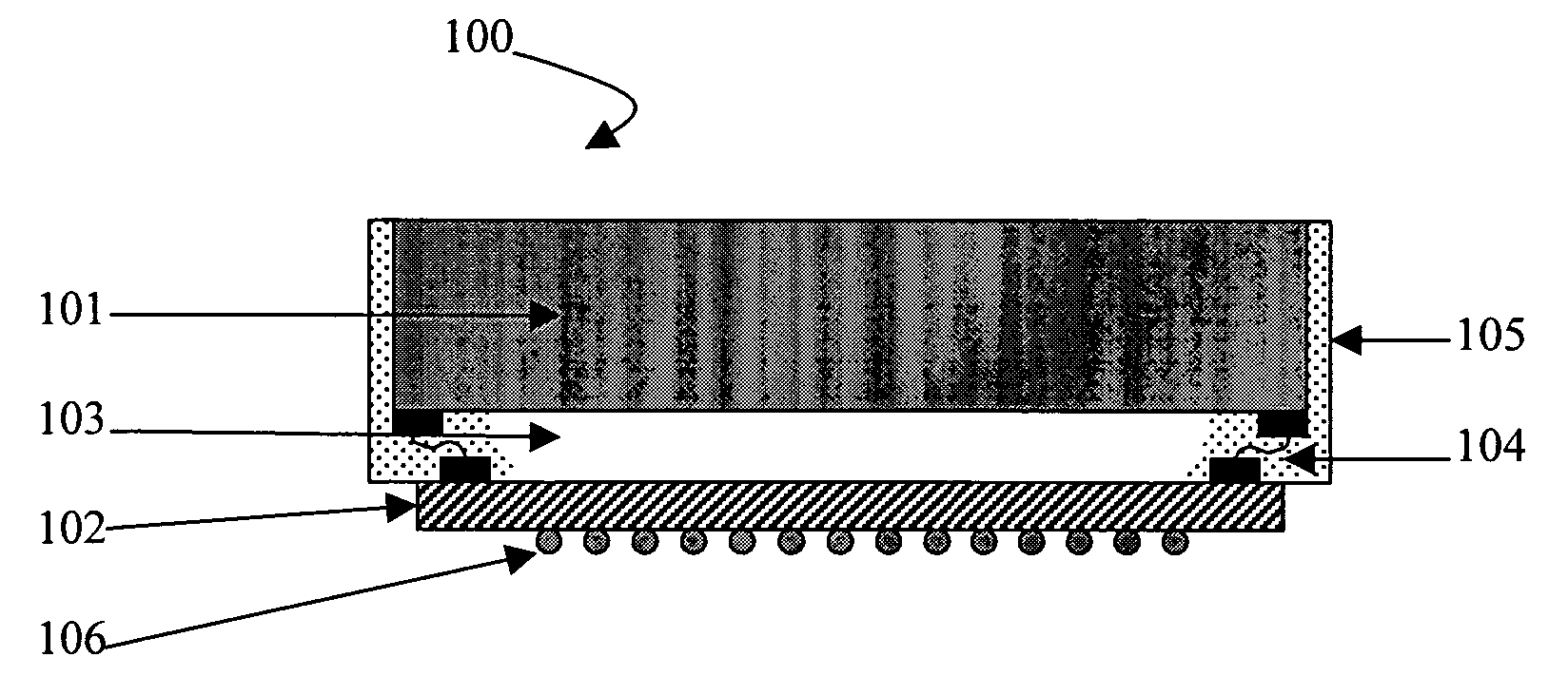

Implantable analyte sensor

ActiveUS20050242479A1Improved patient convenienceConvenient careImmobilised enzymesBioreactor/fermenter combinationsAnalyteMiniaturization

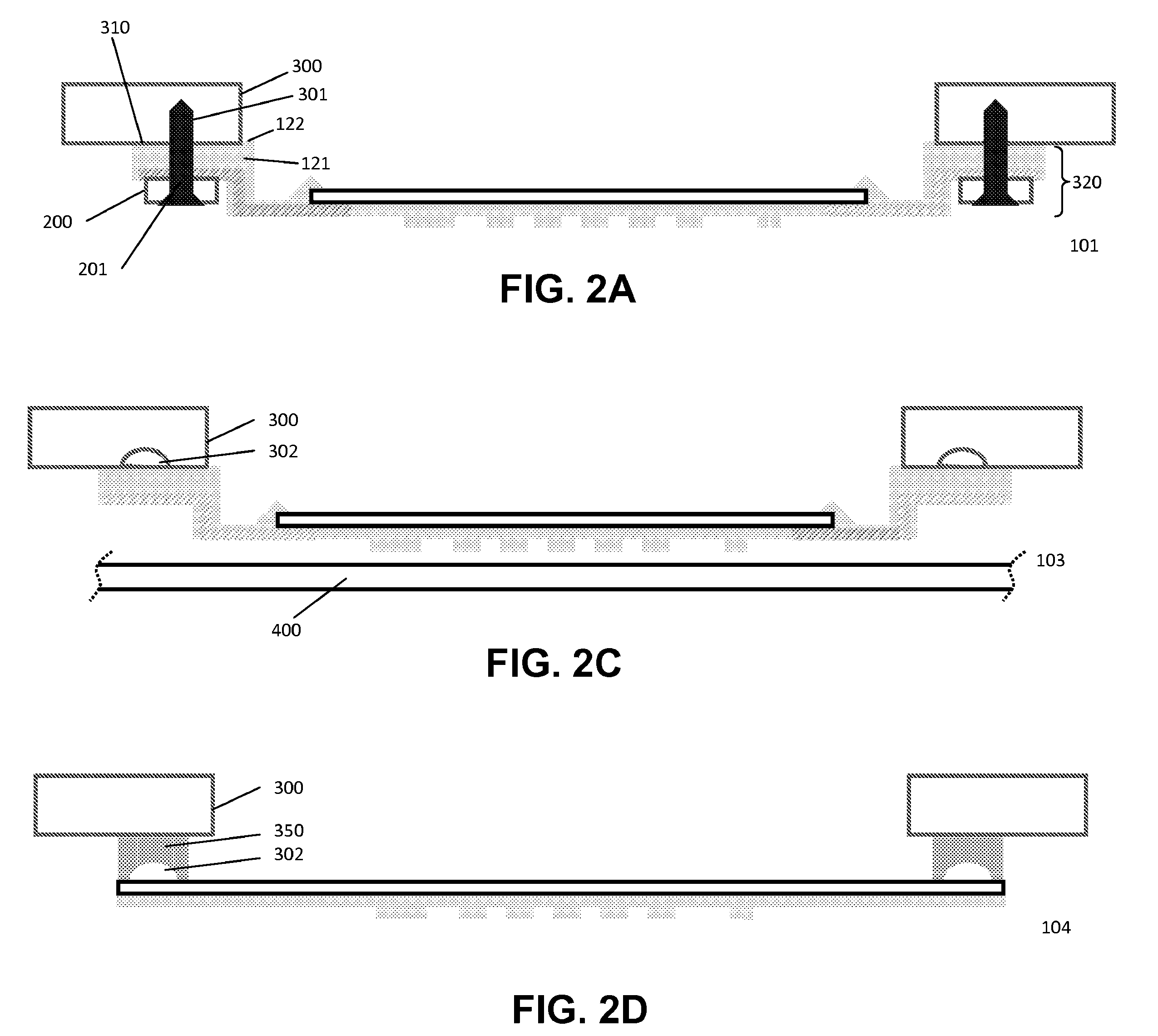

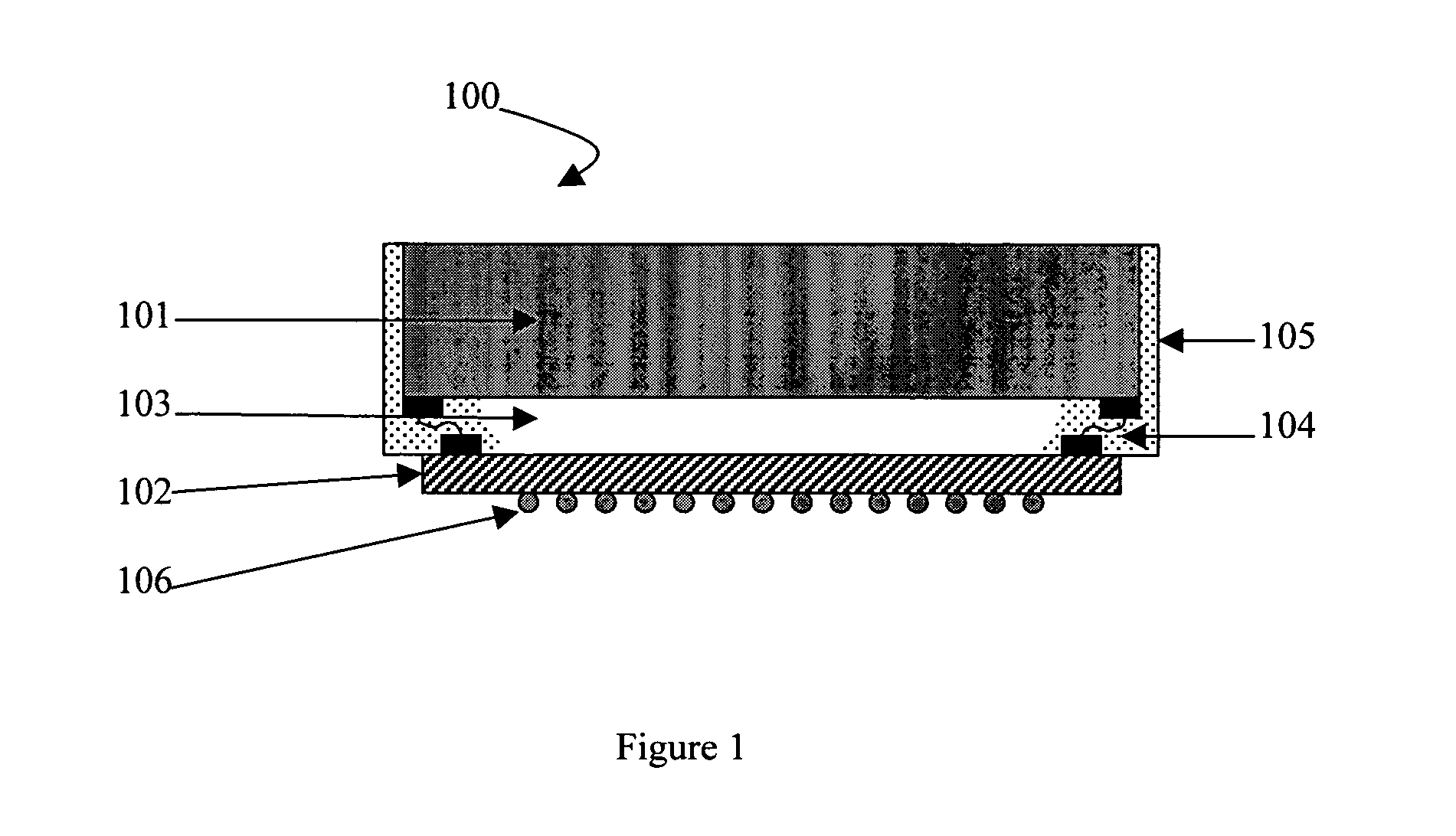

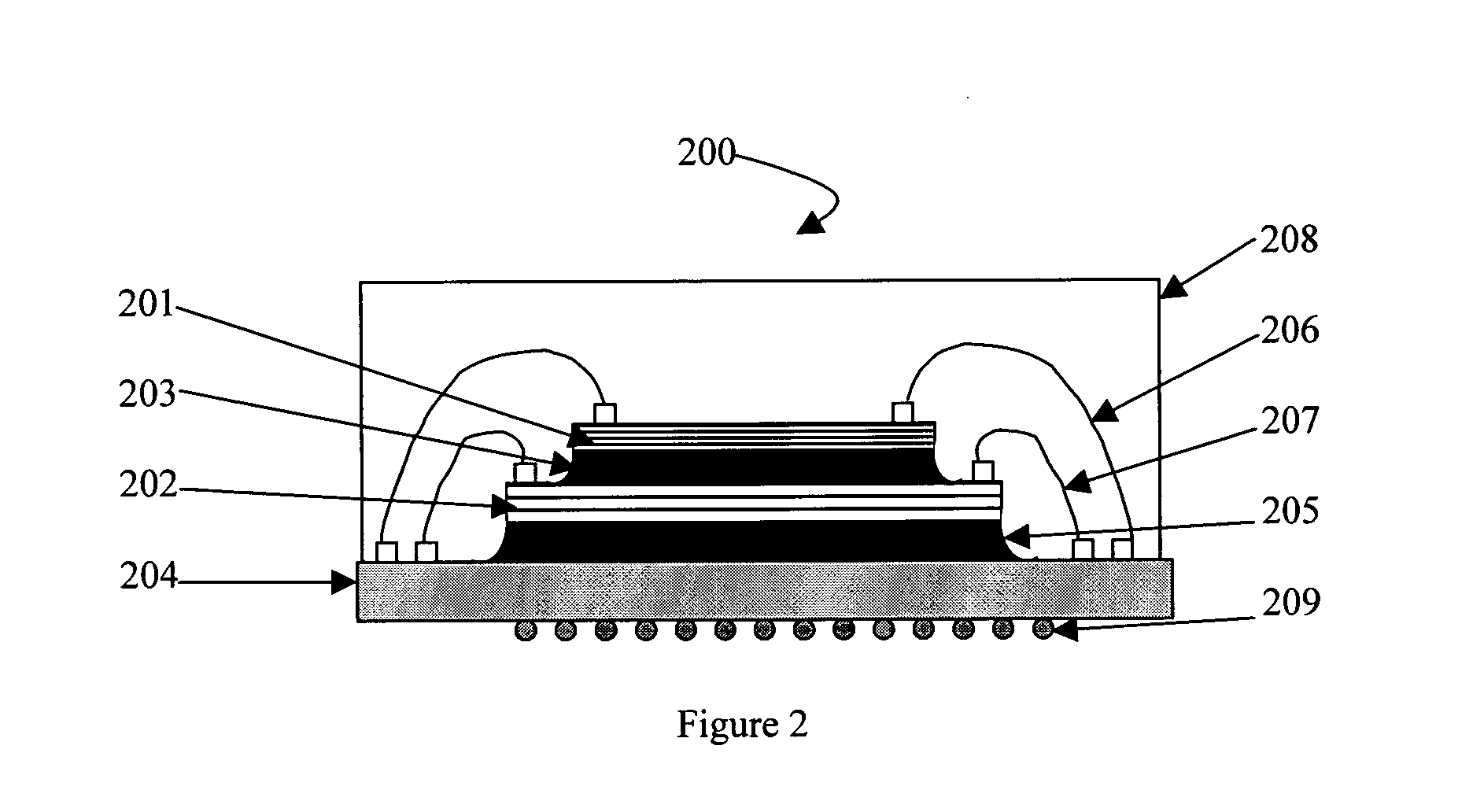

Abstract of the DisclosureAn implantable analyte sensor including a sensing region for measuring the analyte and a non-sensing region for immobilizing the sensor body in the host. The sensor is implanted in a precisely dimensioned pocket to stabilize the analyte sensor in vivo and enable measurement of the concentration of the analyte in the host before and after formation of a foreign body capsule around the sensor. The sensor further provides a transmitter for RF transmission through the sensor body, electronic circuitry, and a power source optimized for long-term use in the miniaturized sensor body.

Owner:DEXCOM

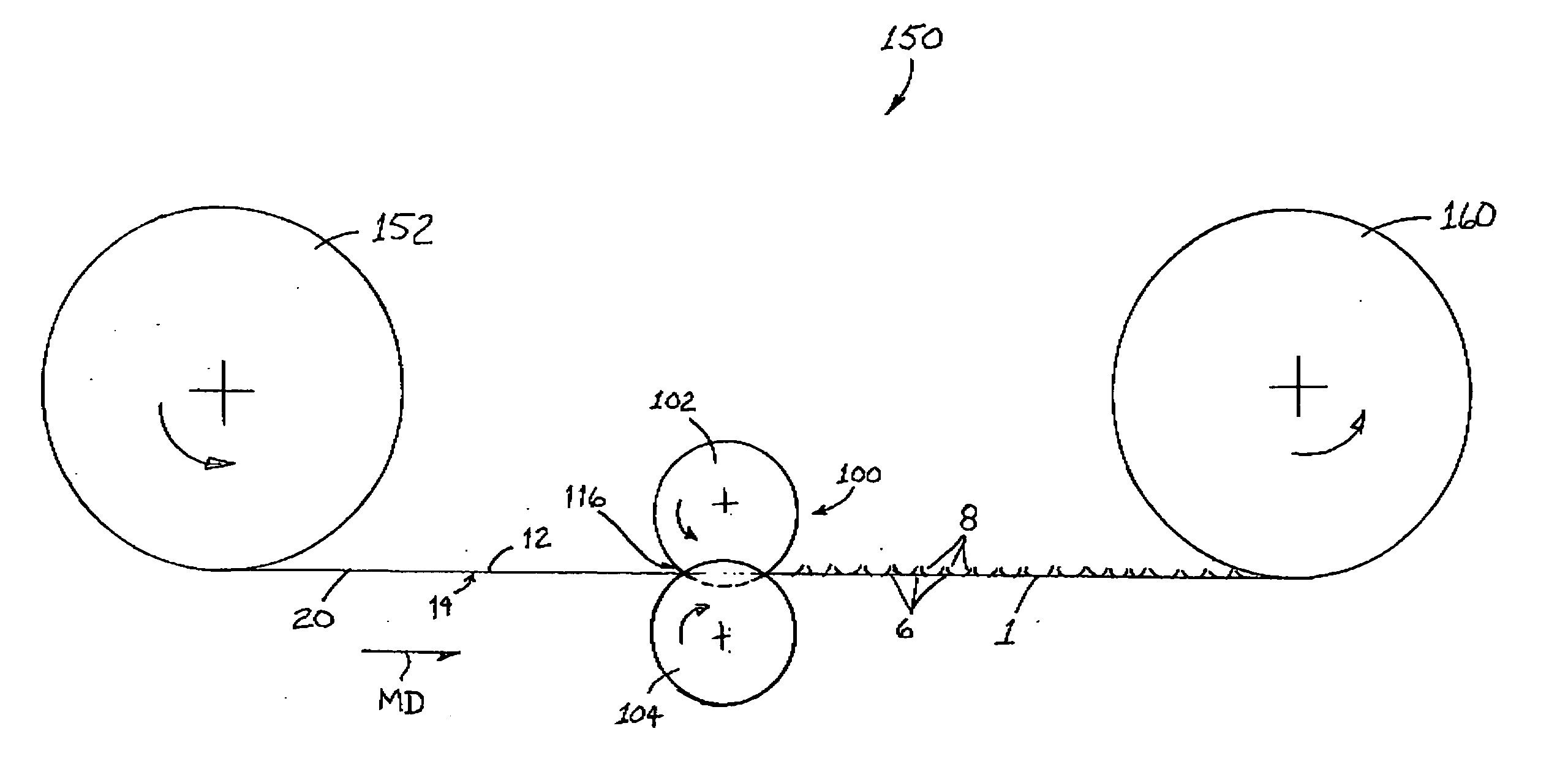

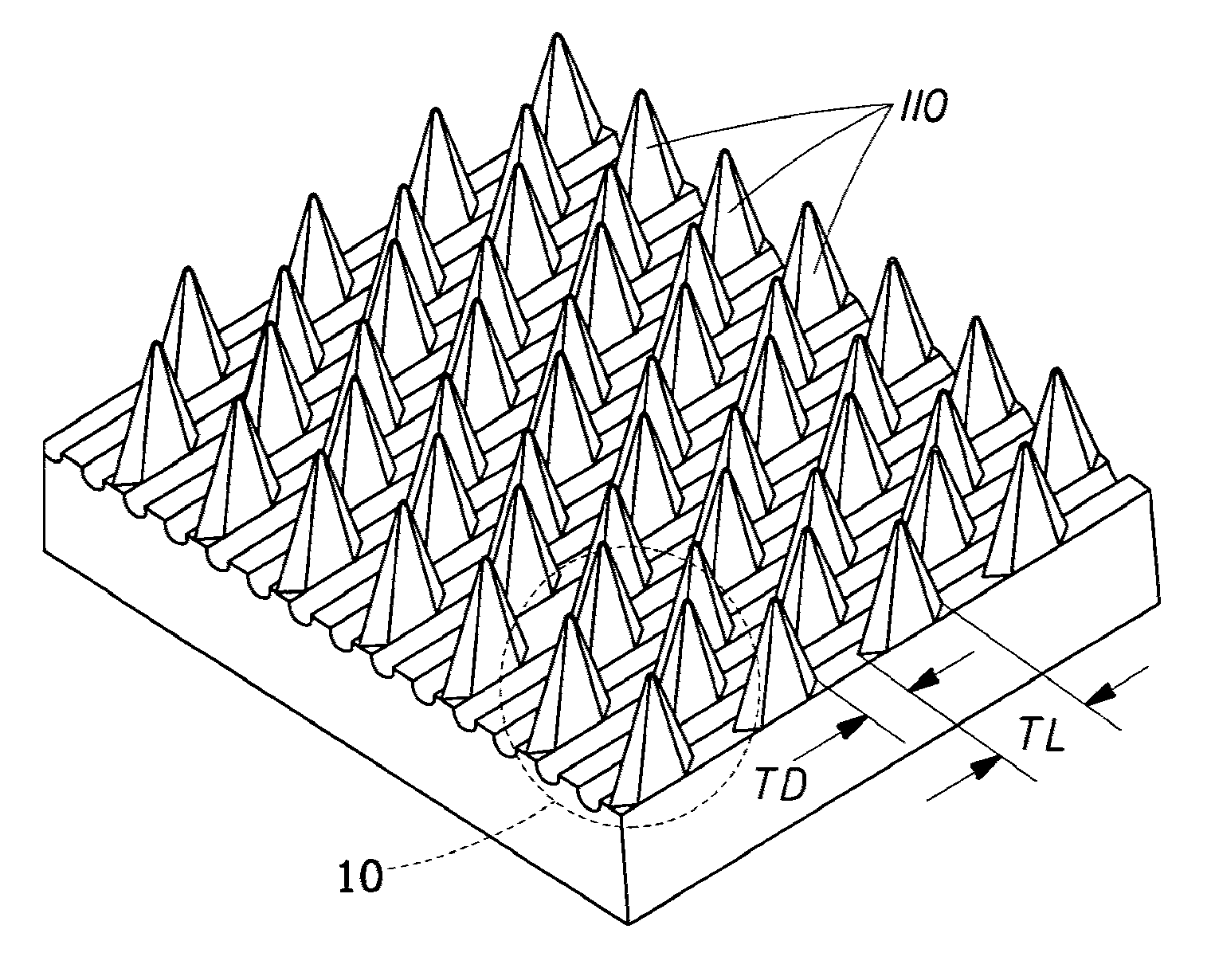

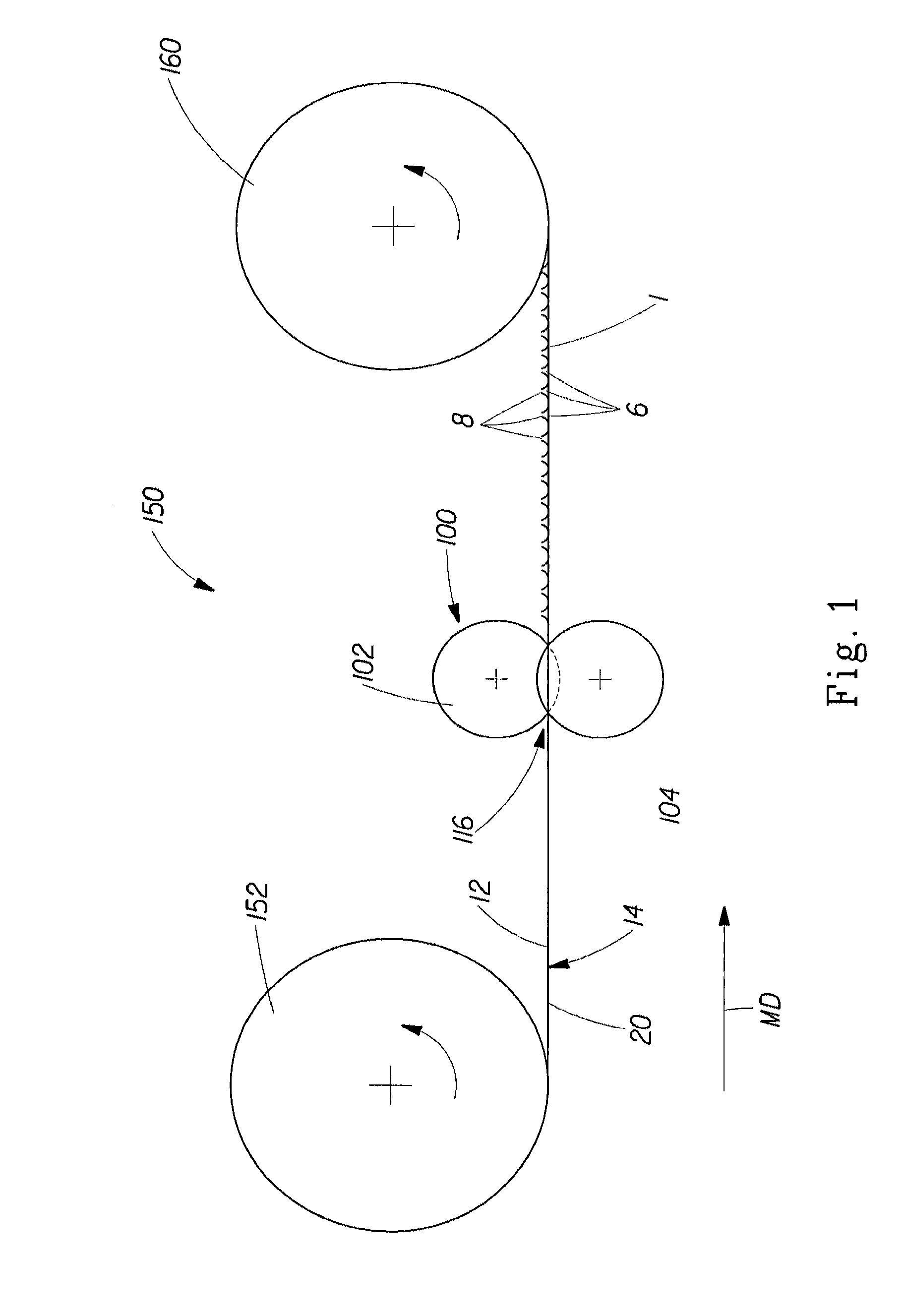

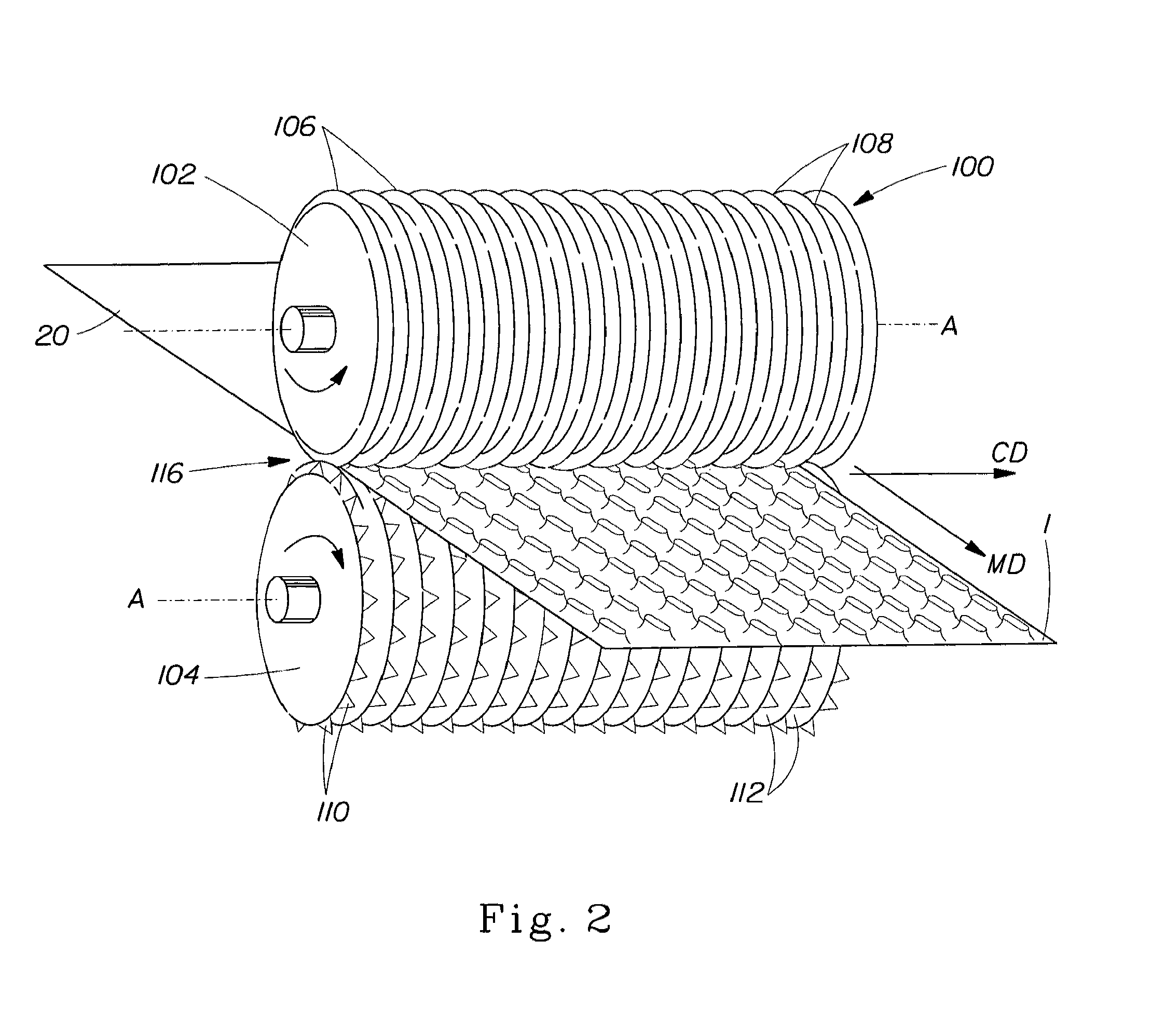

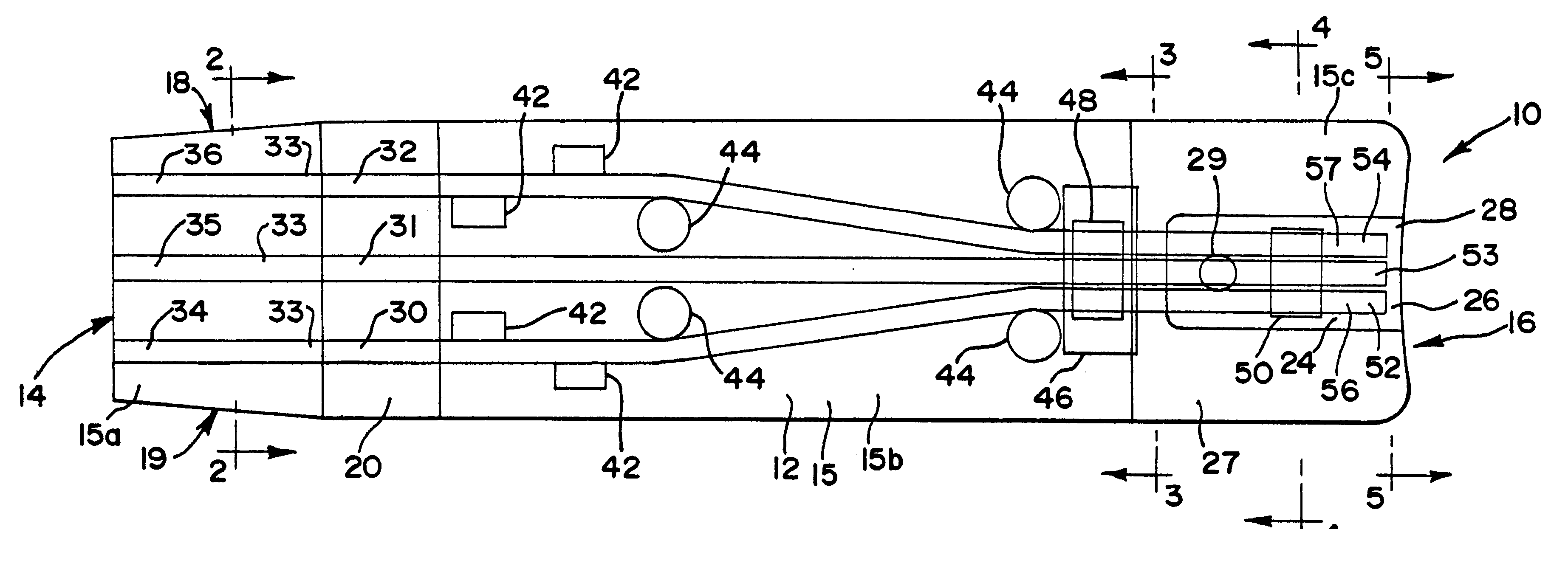

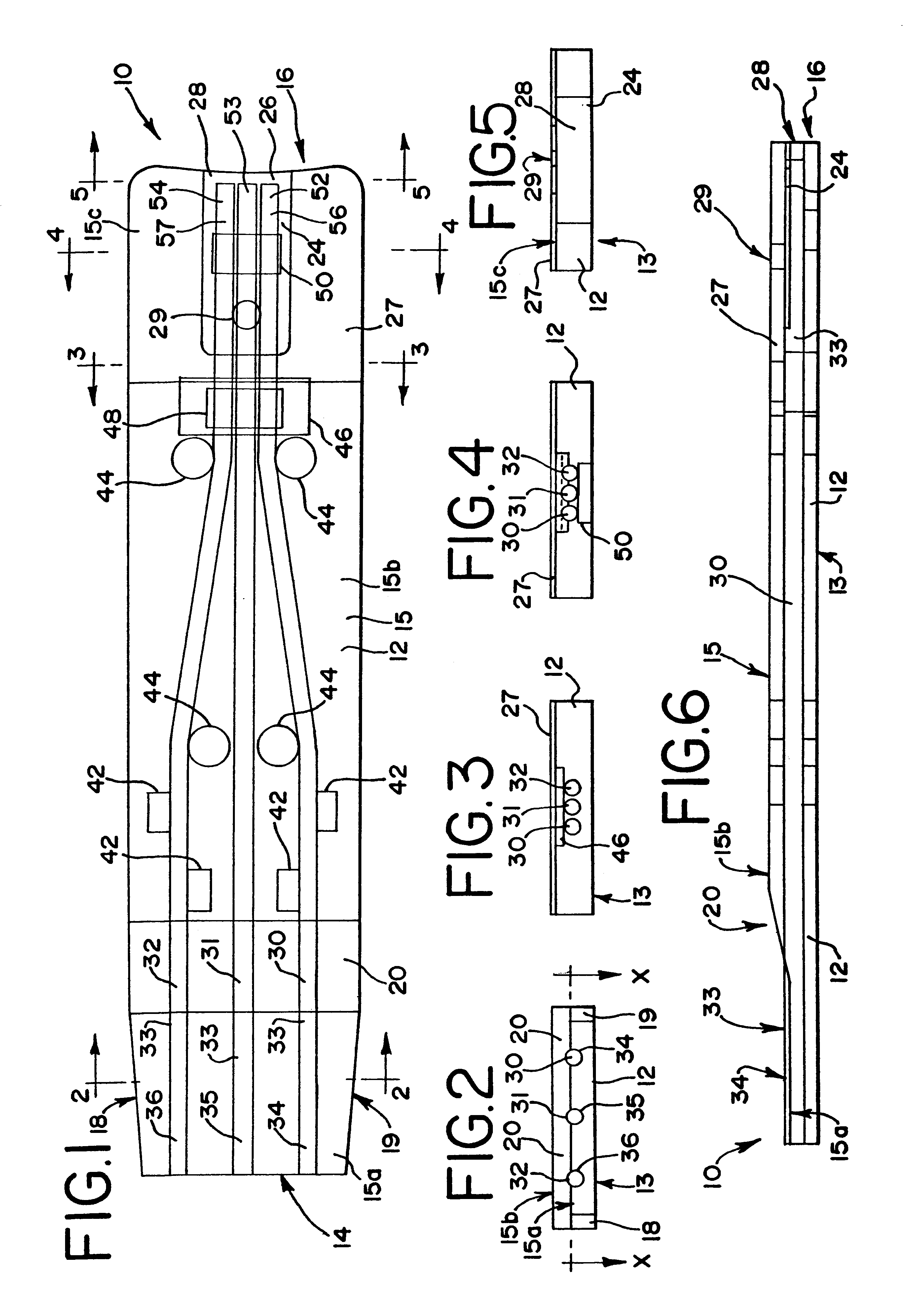

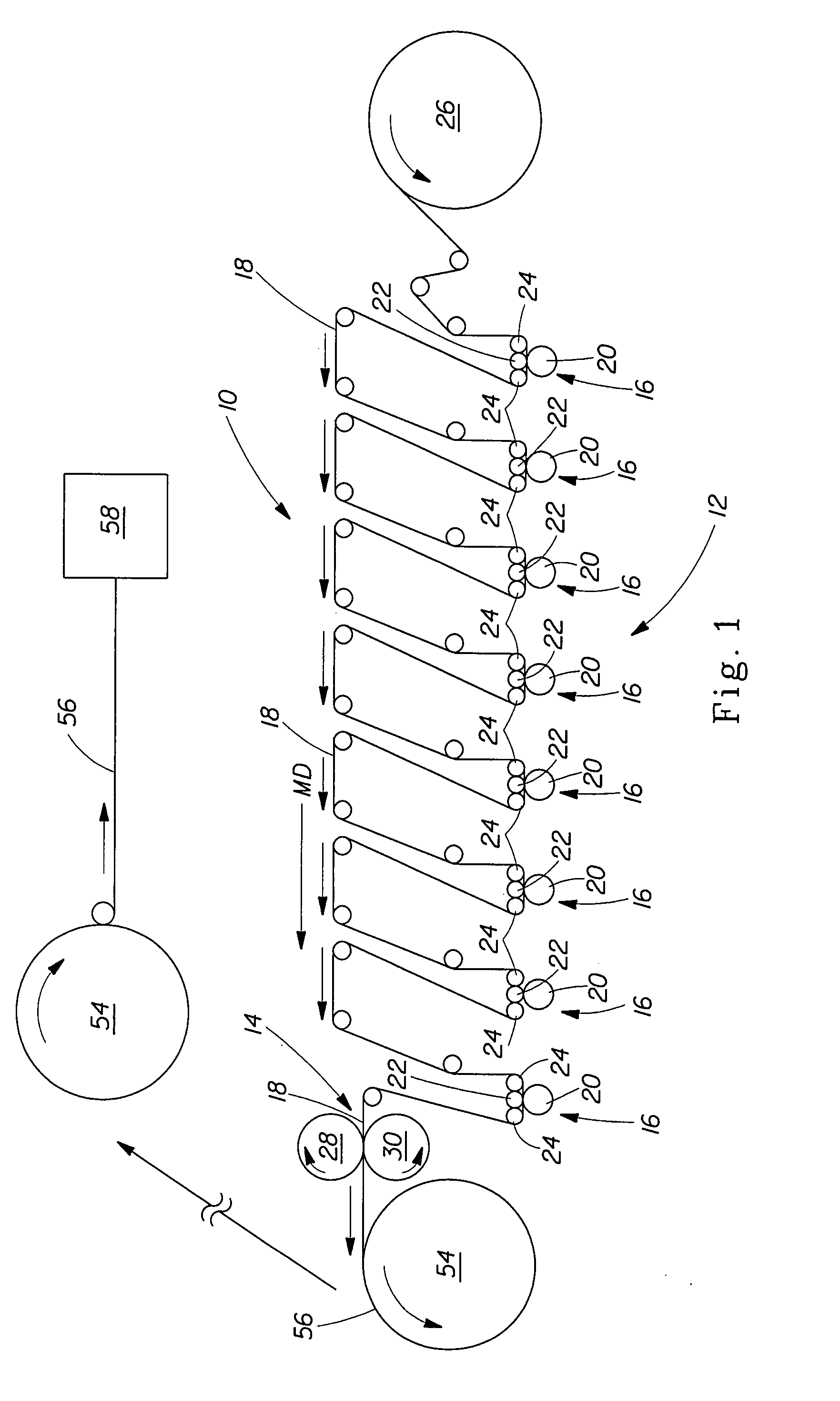

Method and apparatus for making an apertured web

Owner:THE PROCTER & GAMBLE COMPANY

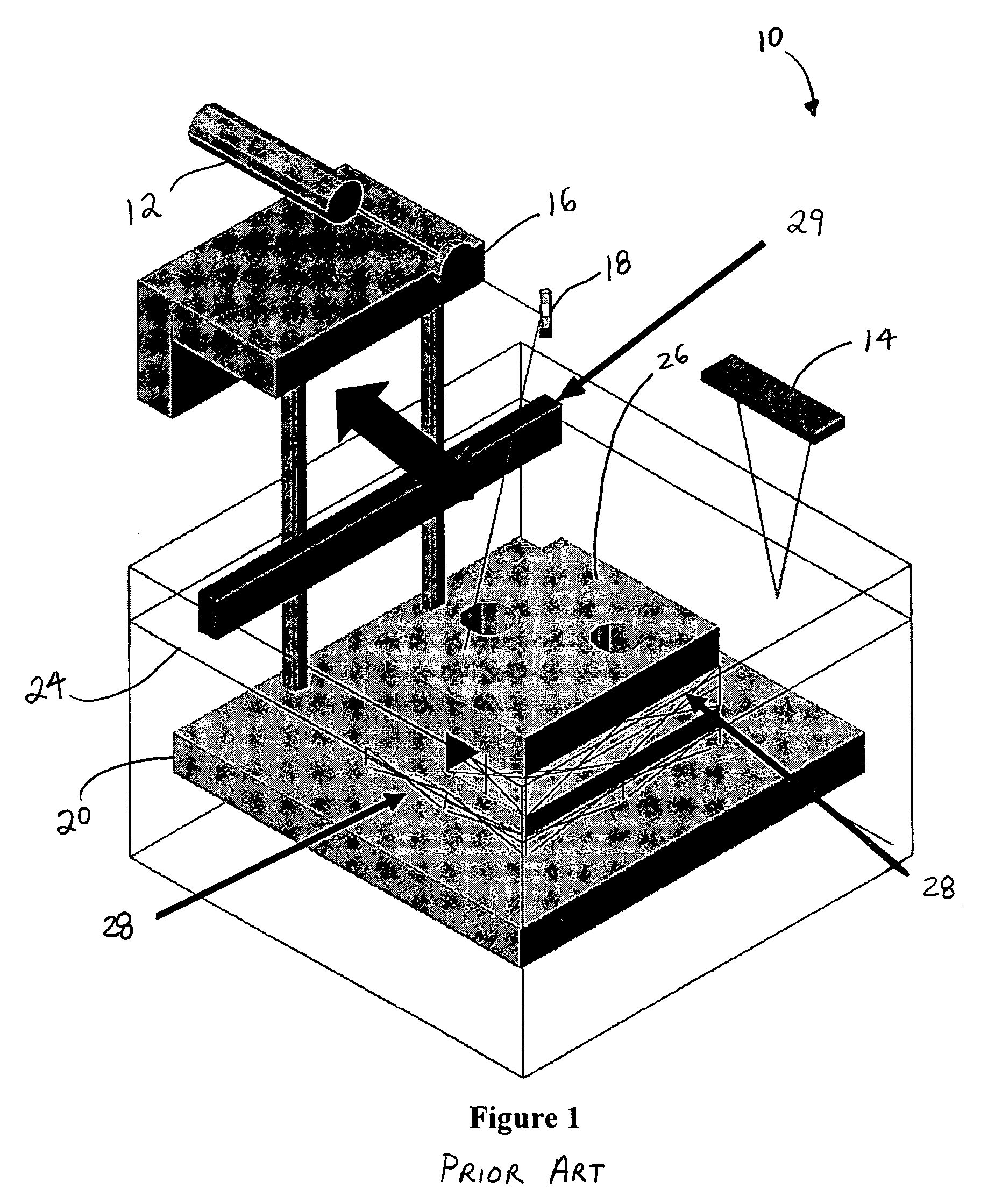

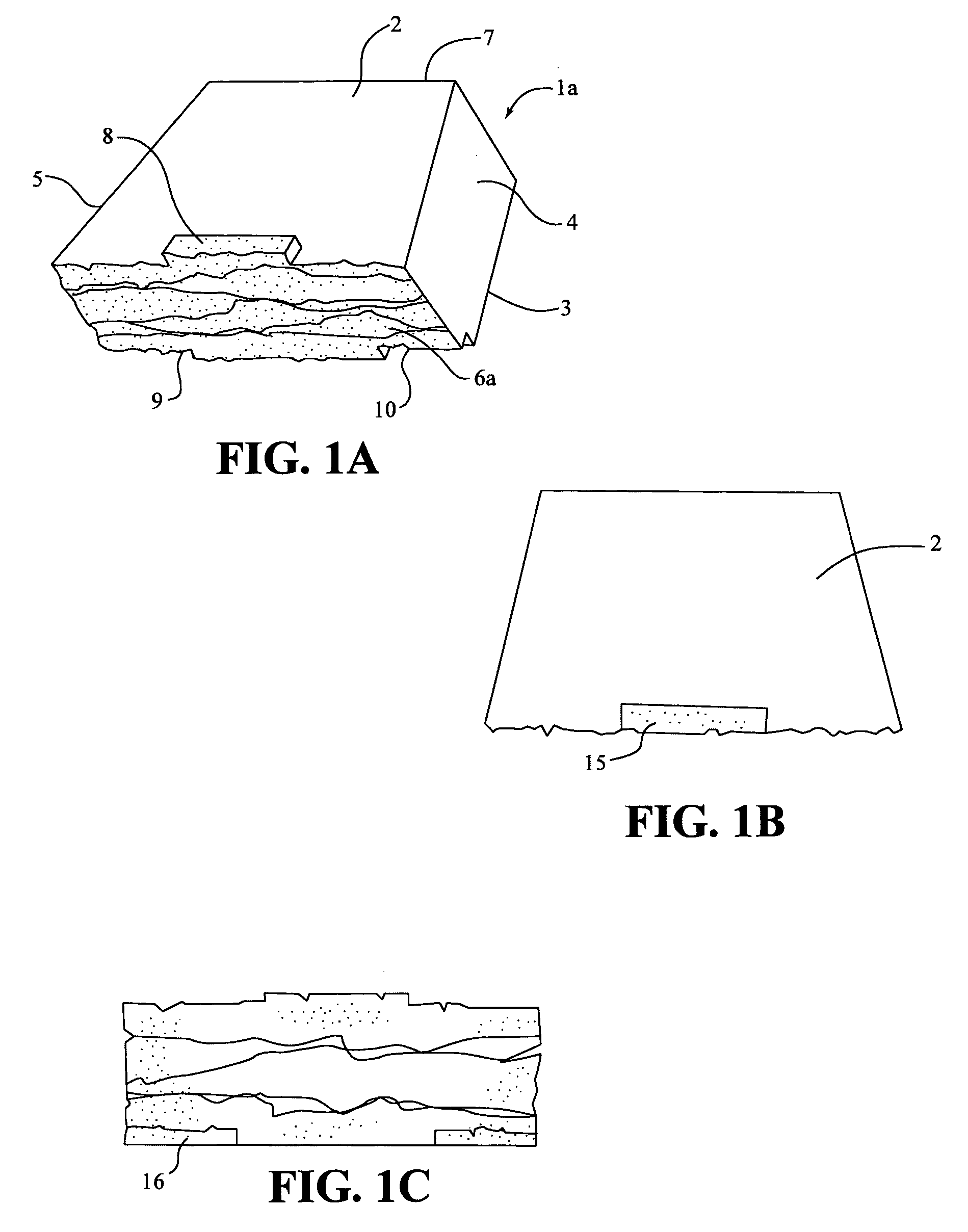

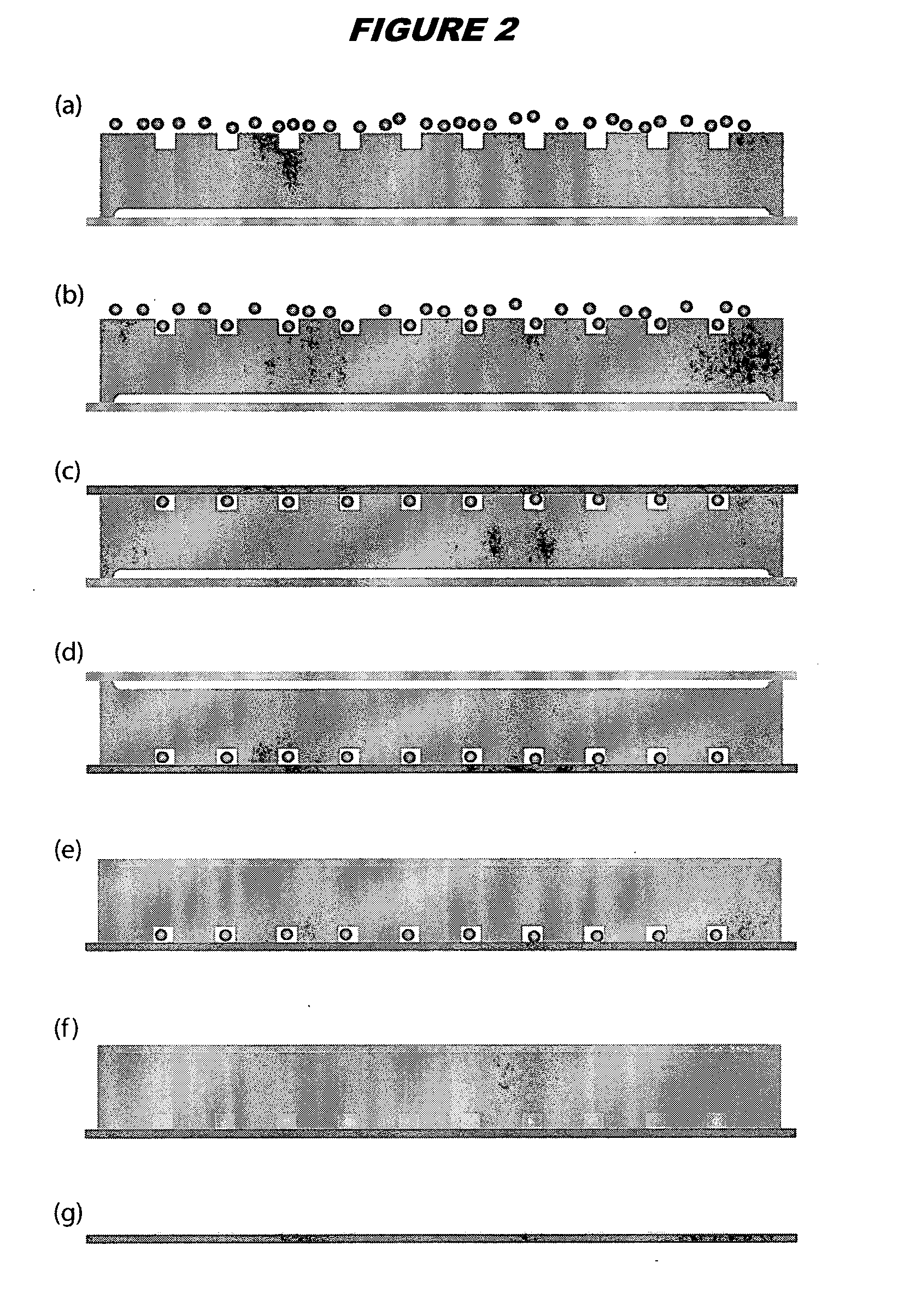

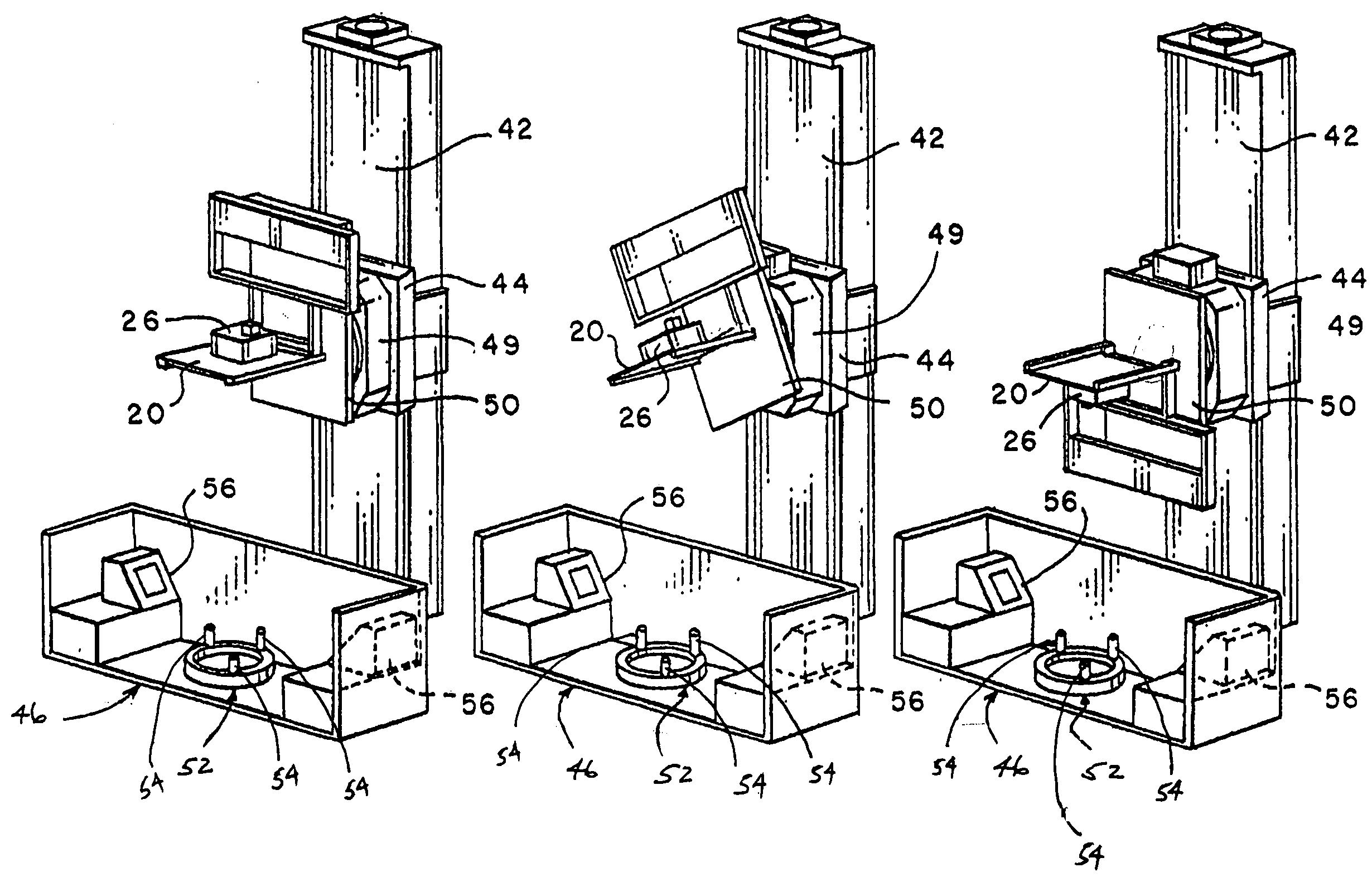

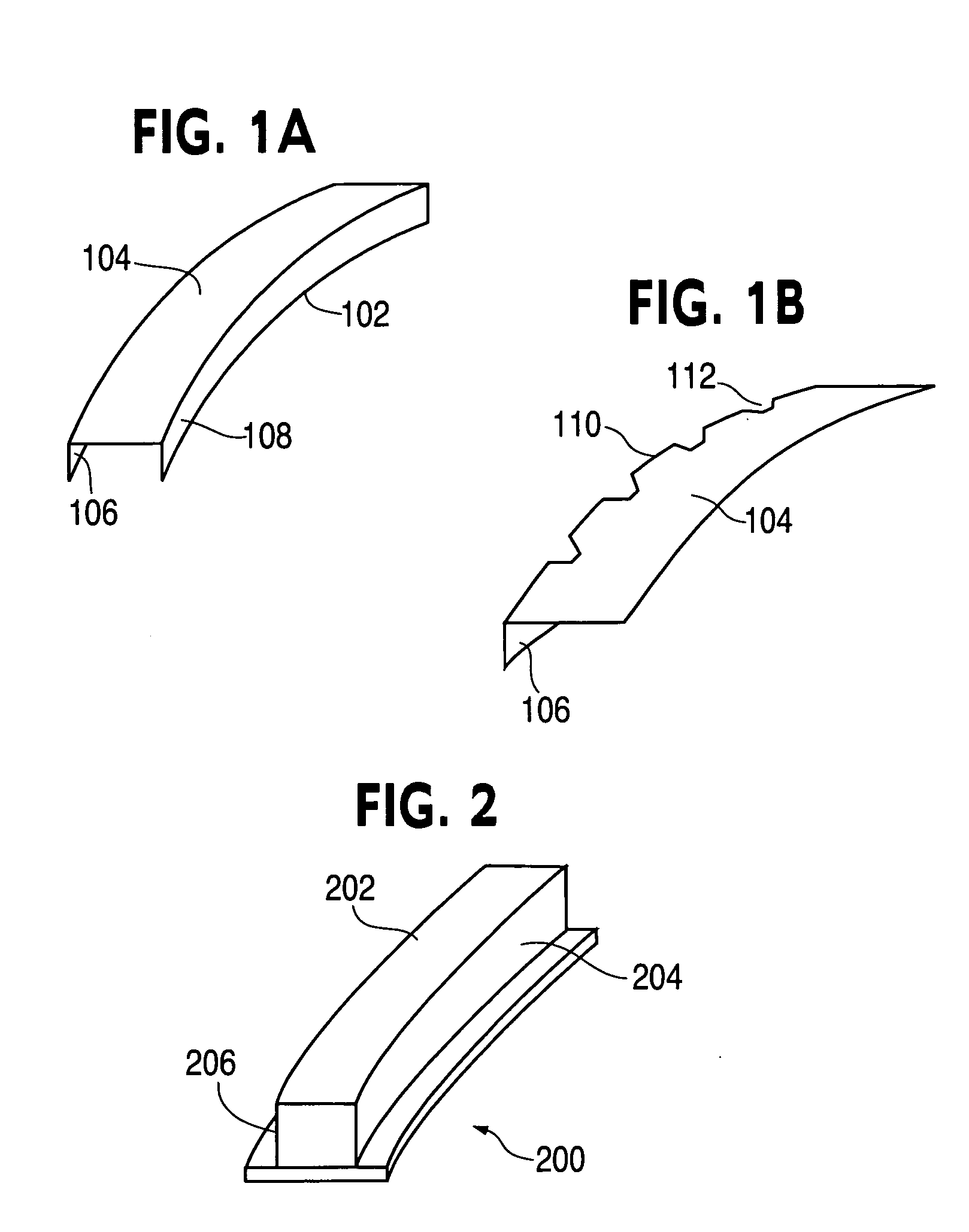

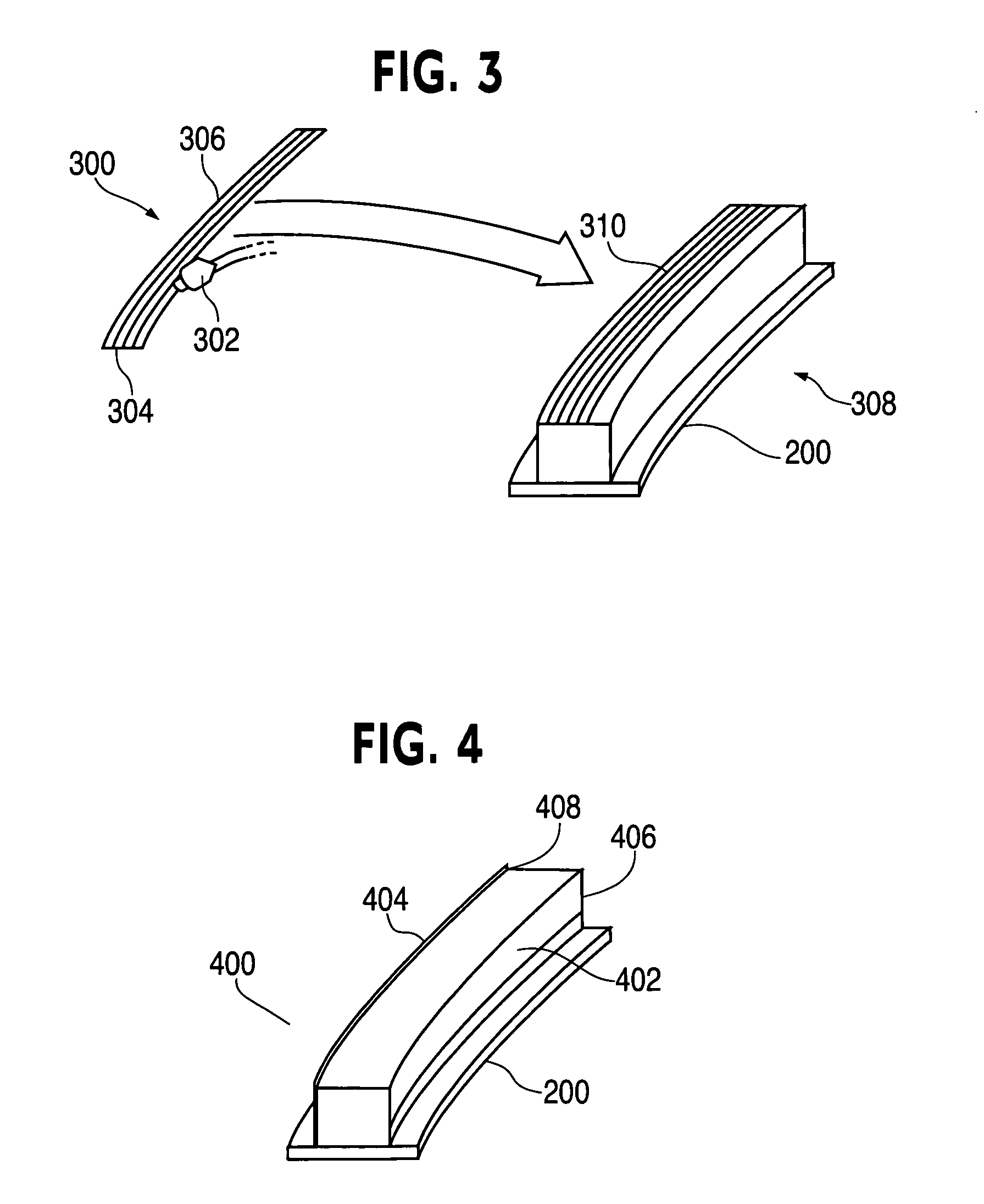

Reinforced composite stamp for dry transfer printing of semiconductor elements

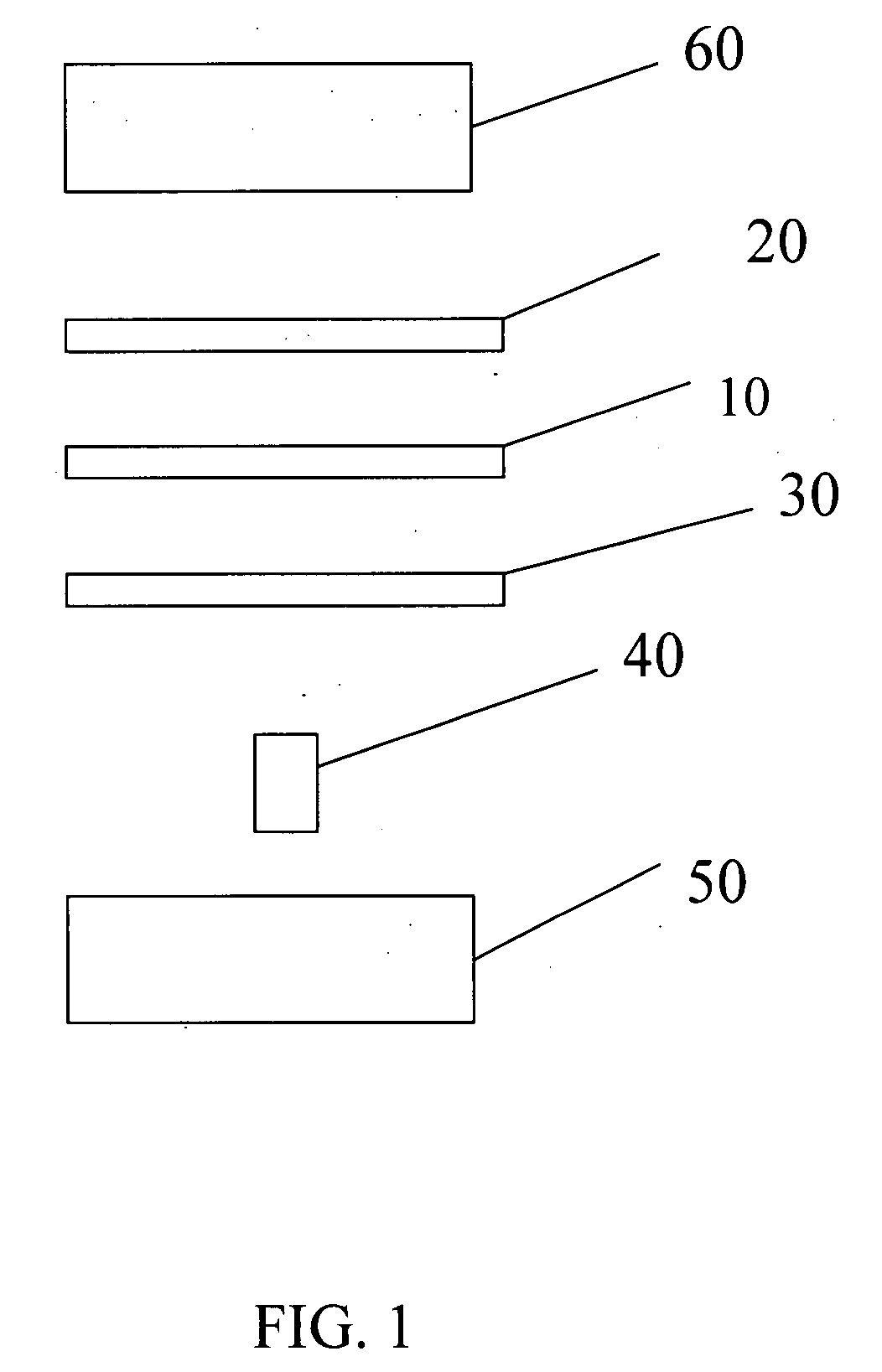

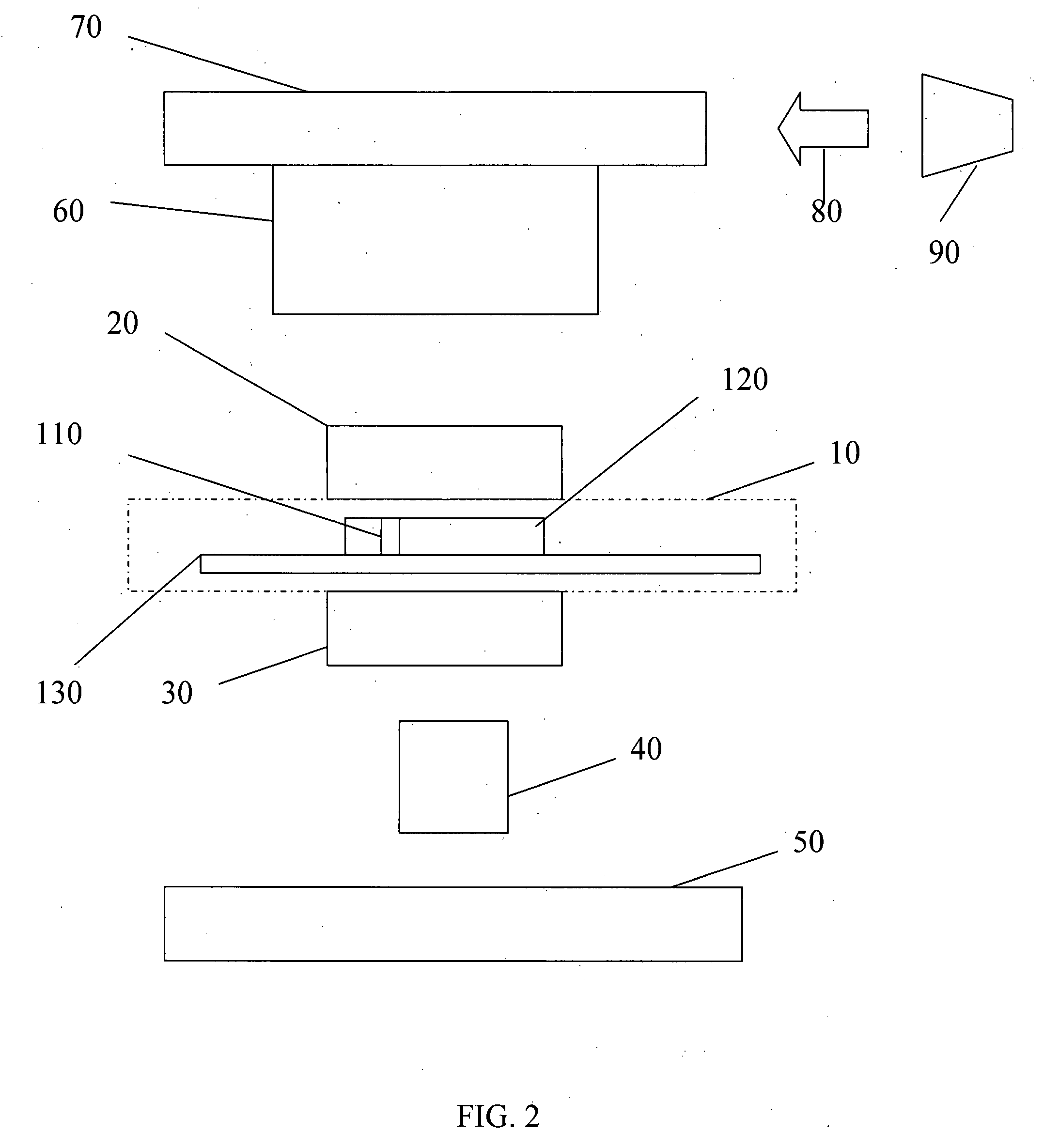

ActiveUS7927976B2Easy to controlPrecise and repeatable vertical motionTurning machine accessoriesMouldsSemiconductor structureContact force

Provided are reinforced composite stamps, devices and methods of making the reinforced composite stamps disclosed herein. Reinforced composite stamps of certain aspects of the present invention have a composition and architecture optimized for use in printing systems for dry transfer printing of semiconductor structures, and impart excellent control over relative spatial placement accuracy of the semiconductor structures being transferred. In some embodiments, for example, reinforced composite stamps of the present invention allow for precise and repeatable vertical motion of the patterned surface of the printing apparatus with self-leveling of the stamp to the surface of a contacted substrate. Reinforced composite stamps of certain aspect of the present invention achieve a uniform distribution of contact forces between the printing apparatus patterned surface and the top surface of a substrate being contacted by the reinforced composite stamp of the printing apparatus.

Owner:X DISPLAY CO TECH LTD

Stent and process for producing the same

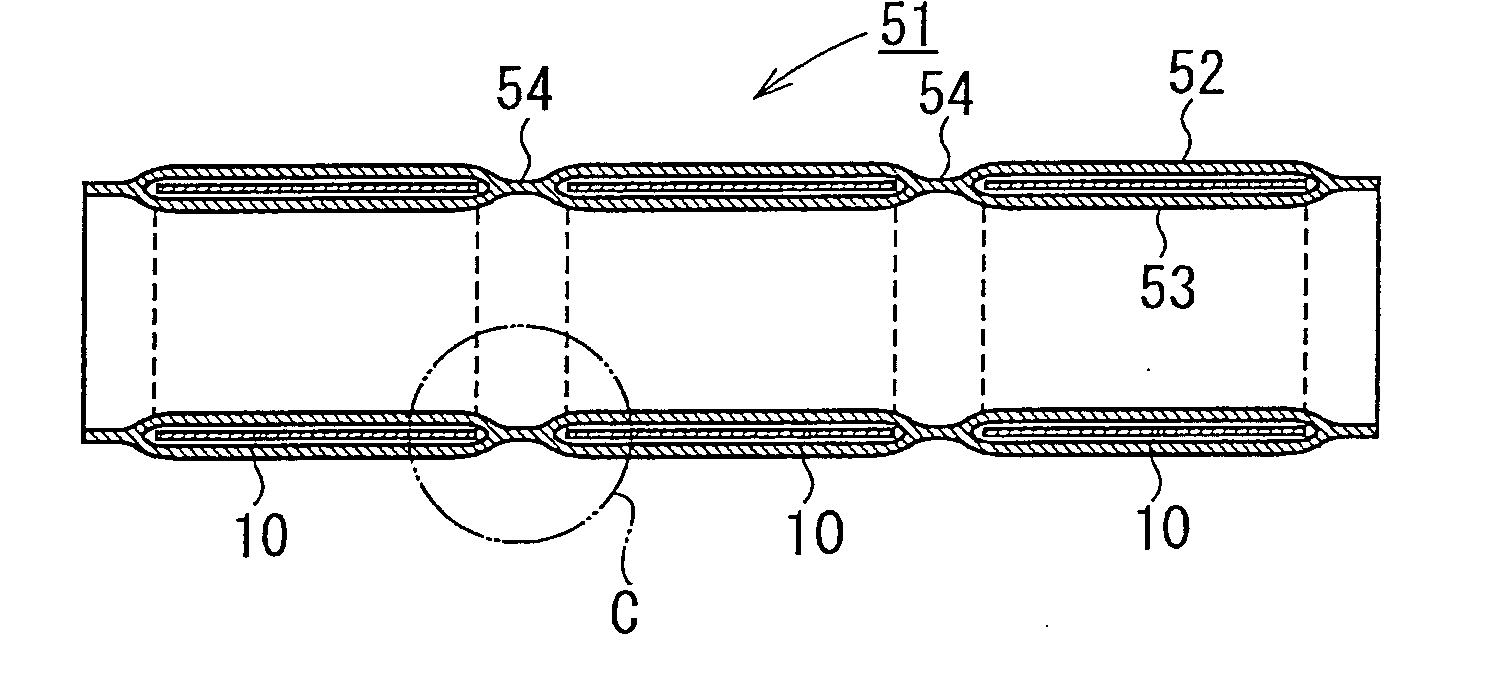

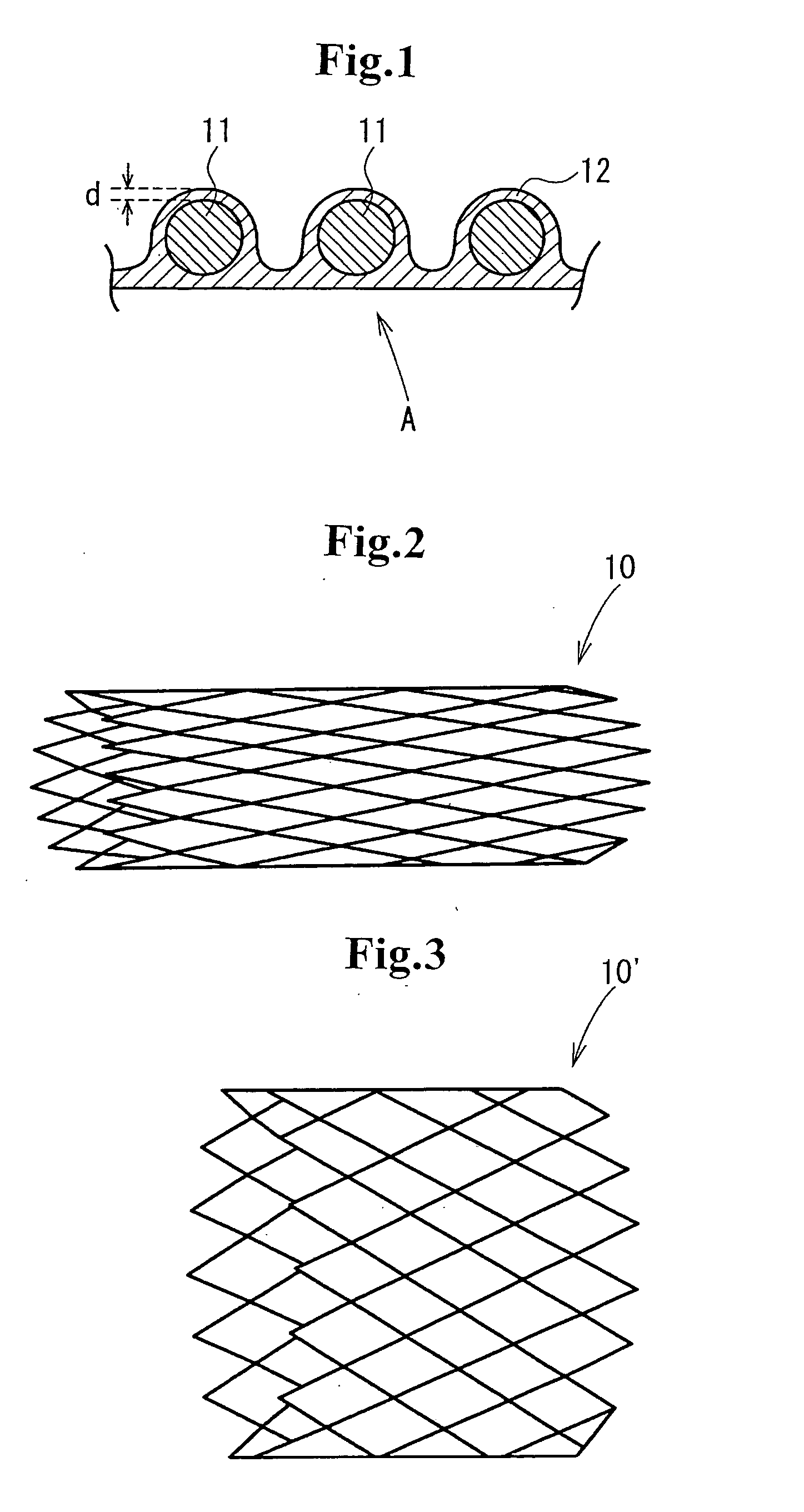

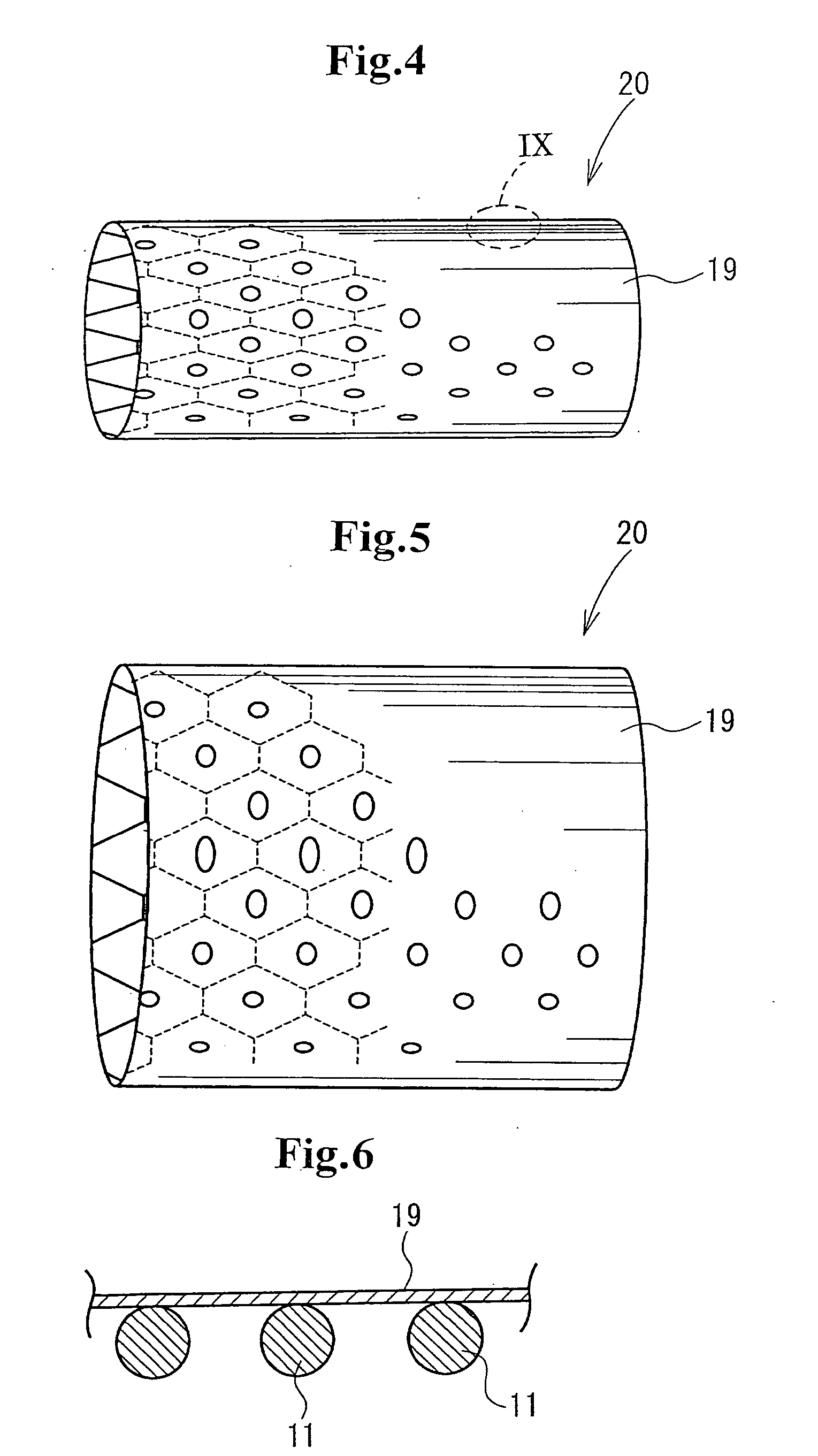

A stent comprising a tubular stent matrix of which diameter is extendable and a flexible polymer layer covering the stent matrix. The polymer layer is closely attached to and covers the entire surface of the stent matrix. Since the flexible polymer layer closely covers the entire surface of the stent matrix not only the outer periphery of the stent matrix, the stent has no problem of causing allergic to metal, stimulus of tissues due to metal, and rust development. Since the inner periphery of the stent is a flat and smooth surface covered by the polymer layer without convexes and concaves, the formation of thrombus can be inhibited well. There is no problem of drift between the polymer layer and the stent matrix, thereby maintaining the positional relationship between the stent matrix and the polymer layer before and after the expansion of the stent.

Owner:JAPAN STENT TECH CO LTD +1

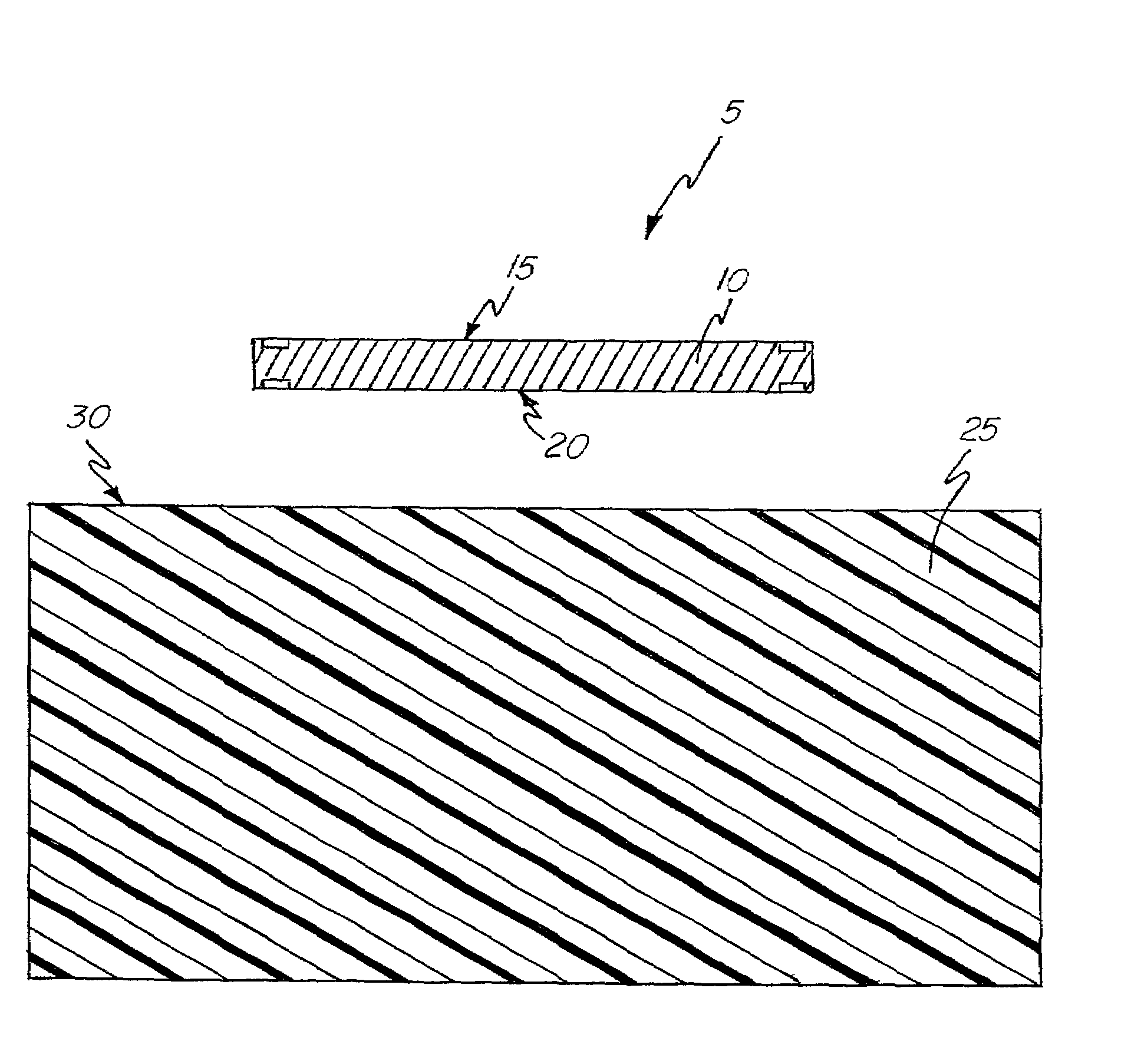

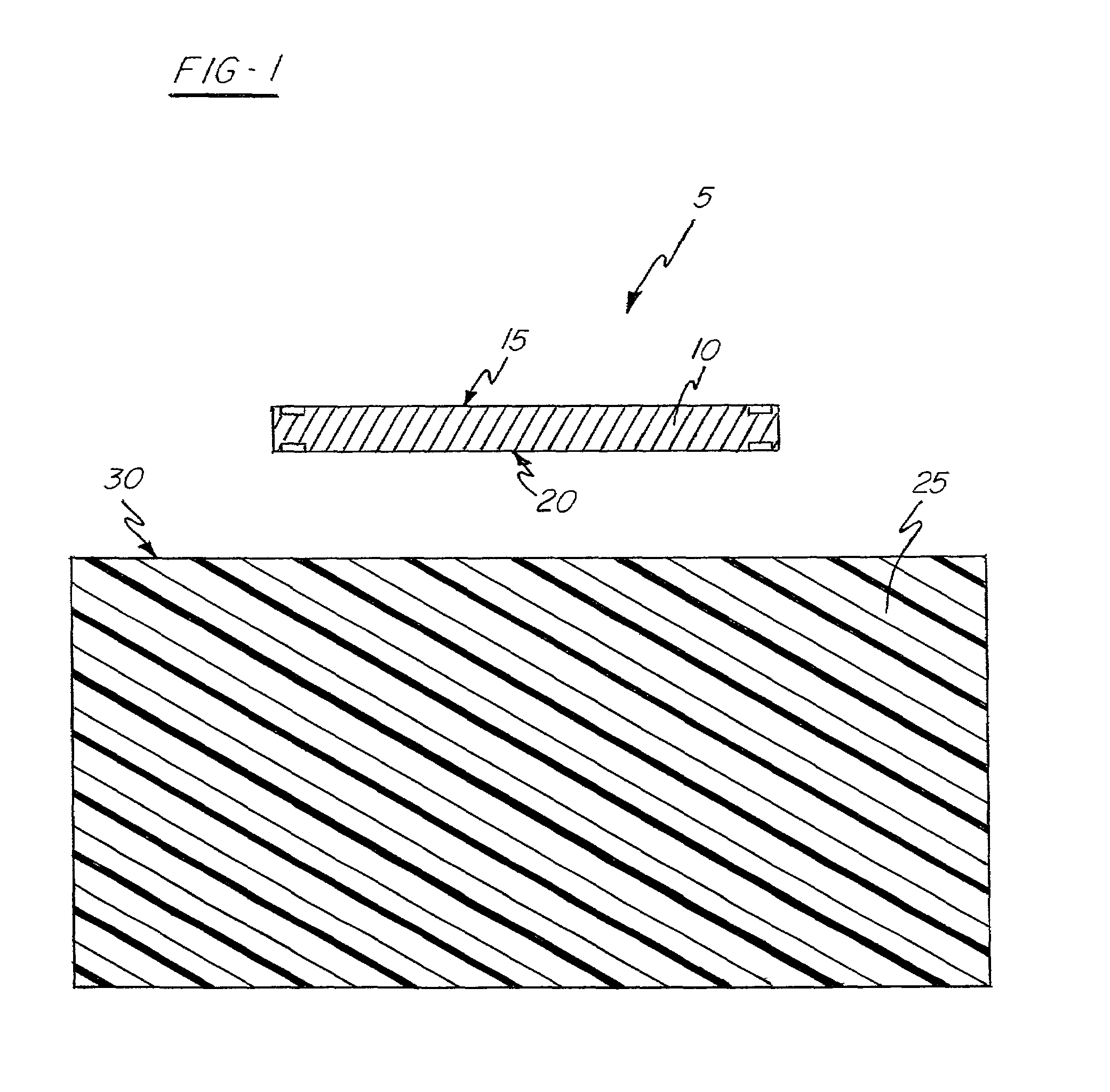

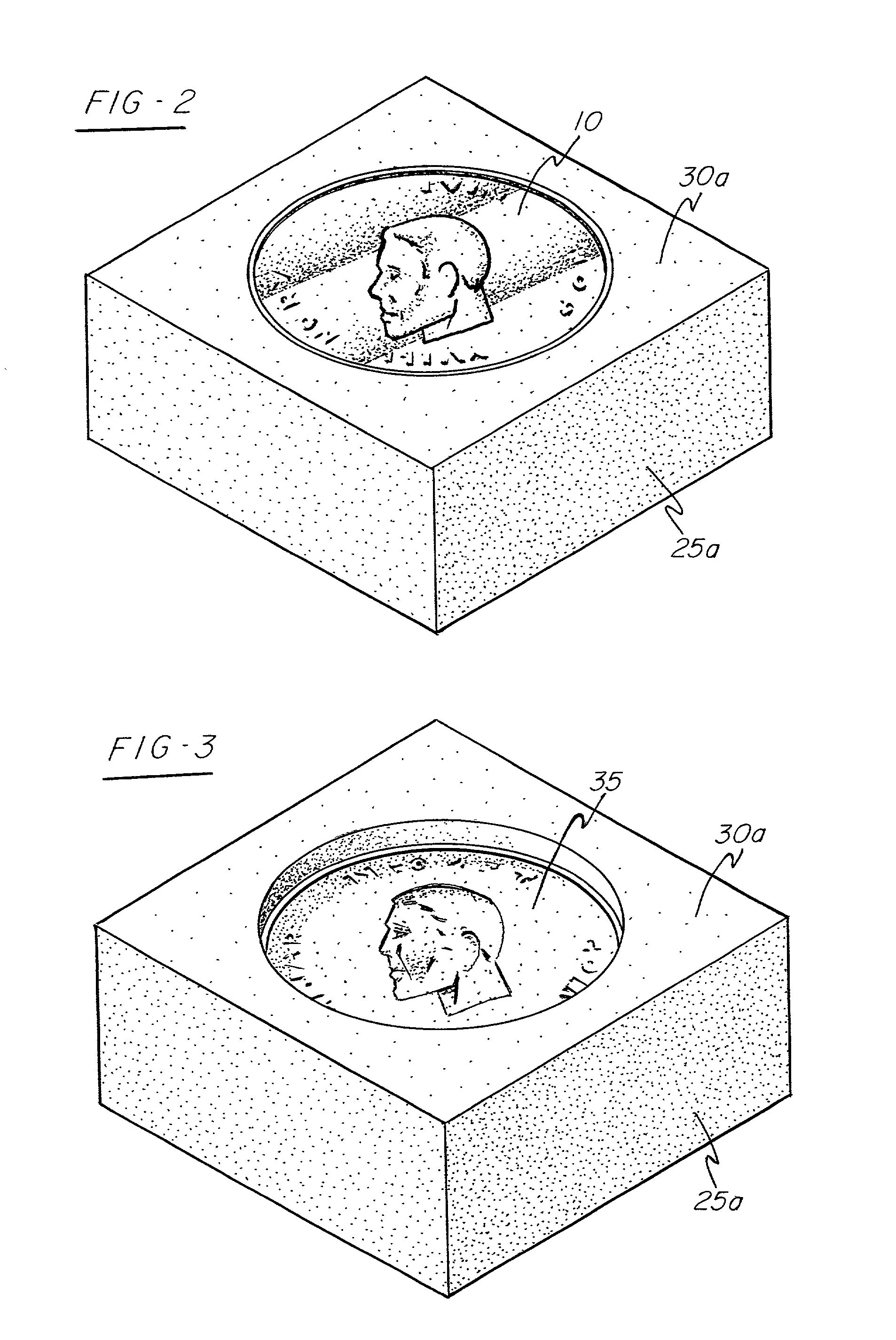

Structural and optical applications for shape memory polymers (SMP)

InactiveUS6986855B1Easy to processReduce handling costsDischarging arrangementMouldsVisual inspectionUltraviolet

The methods of manufacturing molds from shape memory materials and molds made thereby, in accordance with the present invention, provide numerous advantages for molding castable composite parts. The initial mold cost is low enough to accommodate economical production of as few as a single part incorporating high surface definition and intricate three dimensional detail. The preferred methods and molds made thereby are transparent, thereby, curing of the corresponding part by ultra-violet and infra-red light is made possible, as well as, visual inspection during injection and curing of the given resin. Removal of the cured part from within the mold is simplified.

Owner:SPINTECH LLC

Implantable analyte sensor

ActiveUS8277713B2Improve convenienceMinimize movementImmobilised enzymesBioreactor/fermenter combinationsAnalyteMiniaturization

An implantable analyte sensor including a sensing region for measuring the analyte and a non-sensing region for immobilizing the sensor body in the host. The sensor is implanted in a precisely dimensioned pocket to stabilize the analyte sensor in vivo and enable measurement of the concentration of the analyte in the host before and after formation of a foreign body capsule around the sensor. The sensor further provides a transmitter for RF transmission through the sensor body, electronic circuitry, and a power source optimized for long-term use in the miniaturized sensor body.

Owner:DEXCOM INC

Catheter assemblies and injection molding processes and equipment for making the same

InactiveUS20050033237A1Increased complexityExtension of timeMouldsInfusion syringesMulti materialCatheter hub

Various single-part catheter assemblies, multi-part integrated catheter assemblies, and methods and apparatus for making the same are disclosed. The single-part catheter assemblies include a catheter hub integrally formed with a catheter tube for insertion into the bloodstream of a patient. The multi-part integrated catheter assemblies include a catheter hub integrally formed to a catheter tube for insertion into the bloodstream of a patient. The catheter assemblies of the invention may be injection molded in a single step or in multiple steps by injecting flows of molten plastic into a cavity of molds provided herein such that the flows converge into an even distribution about the circumference of the sleeve. The mold may have a core pin designed to fit into the cavity. Through the use of the even distribution of flows, the core pin may be seated within the cavity in an untensioned manner. The catheter assemblies of the invention may be produced of a single material or of multiple materials.

Owner:BECTON DICKINSON & CO

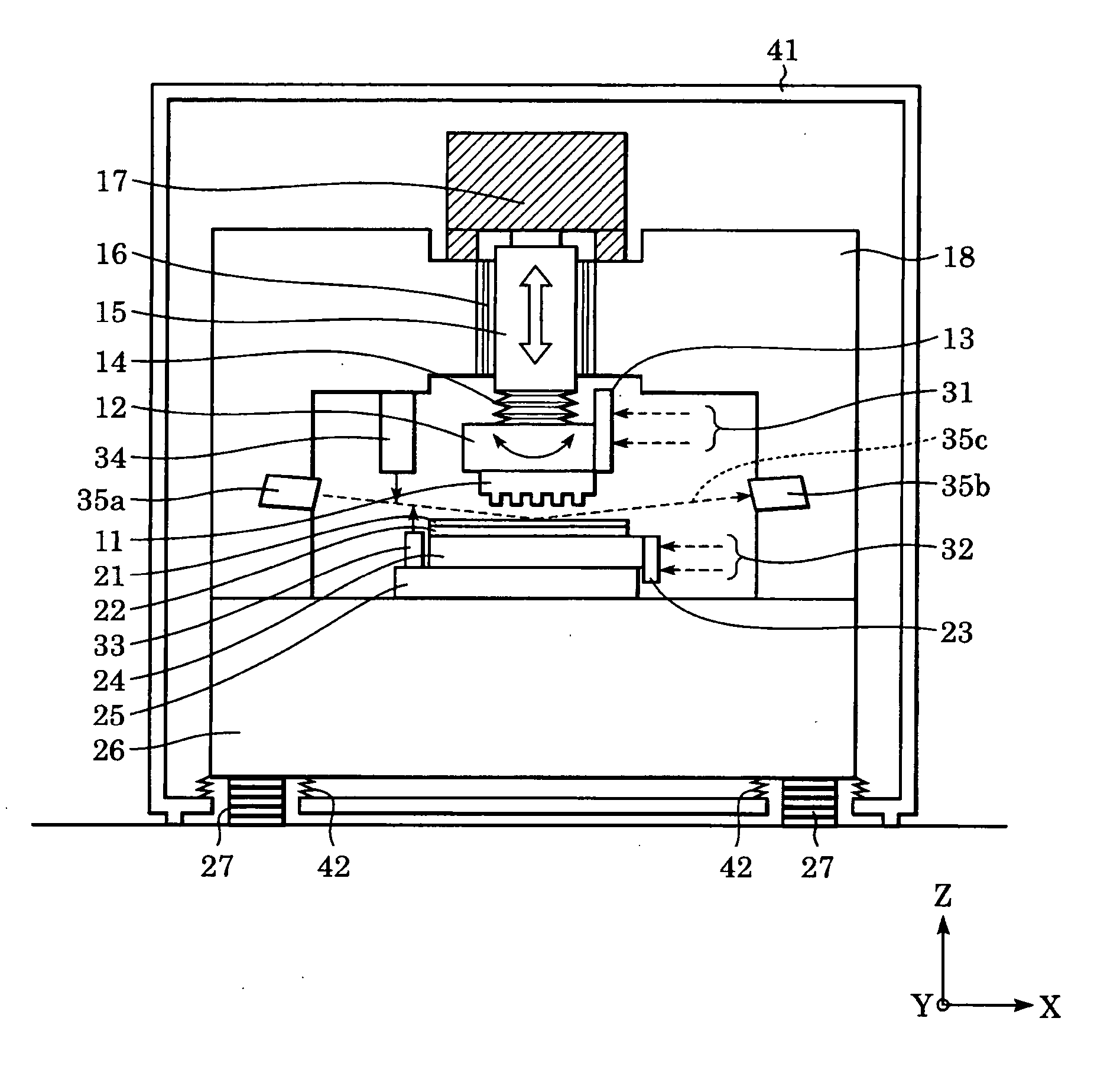

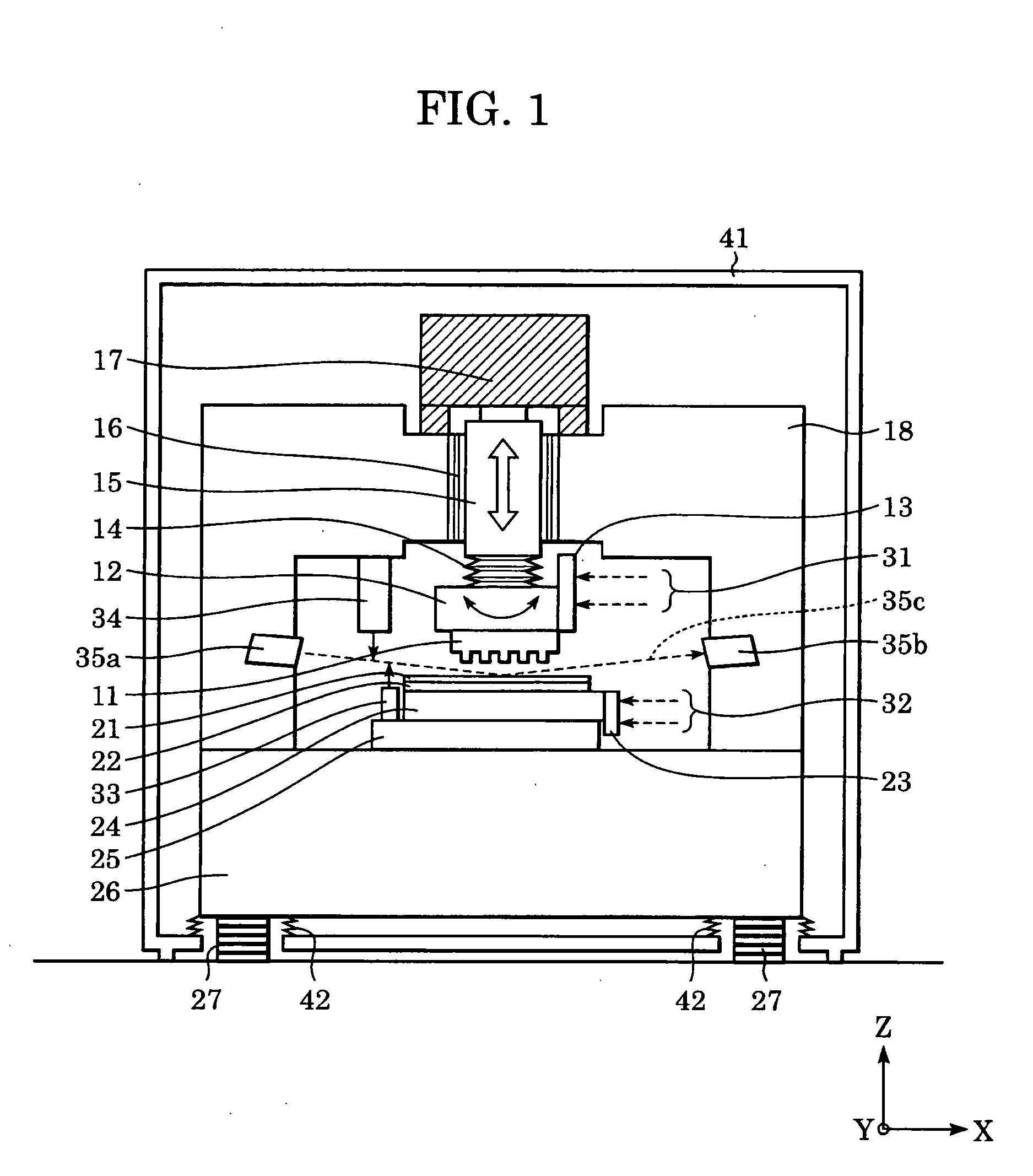

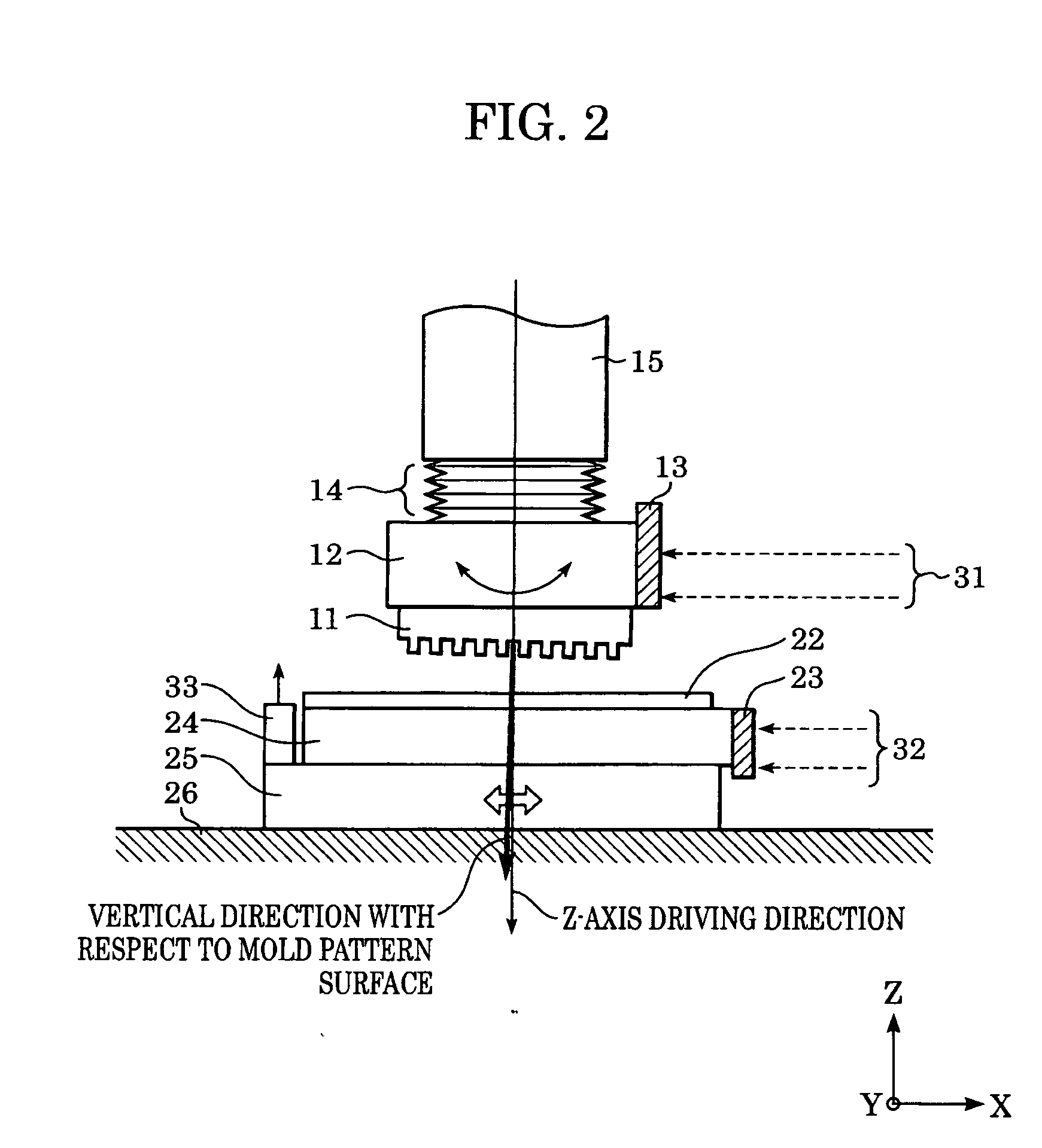

Pattern forming apparatus

InactiveUS20050064054A1High precision alignmentMechanical working/deformationTurning machine accessoriesMaterials scienceMachine press

Owner:CANON KK

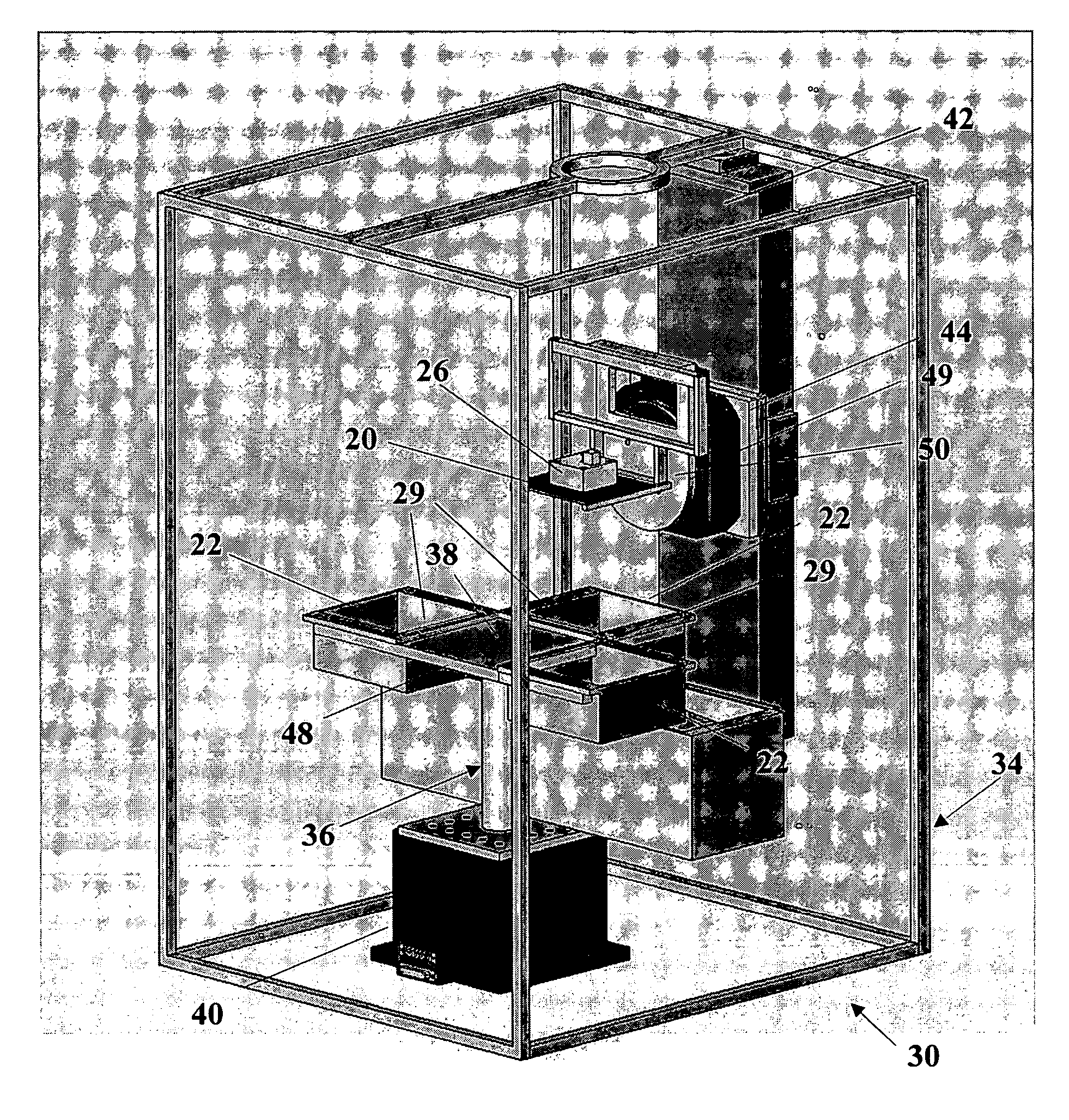

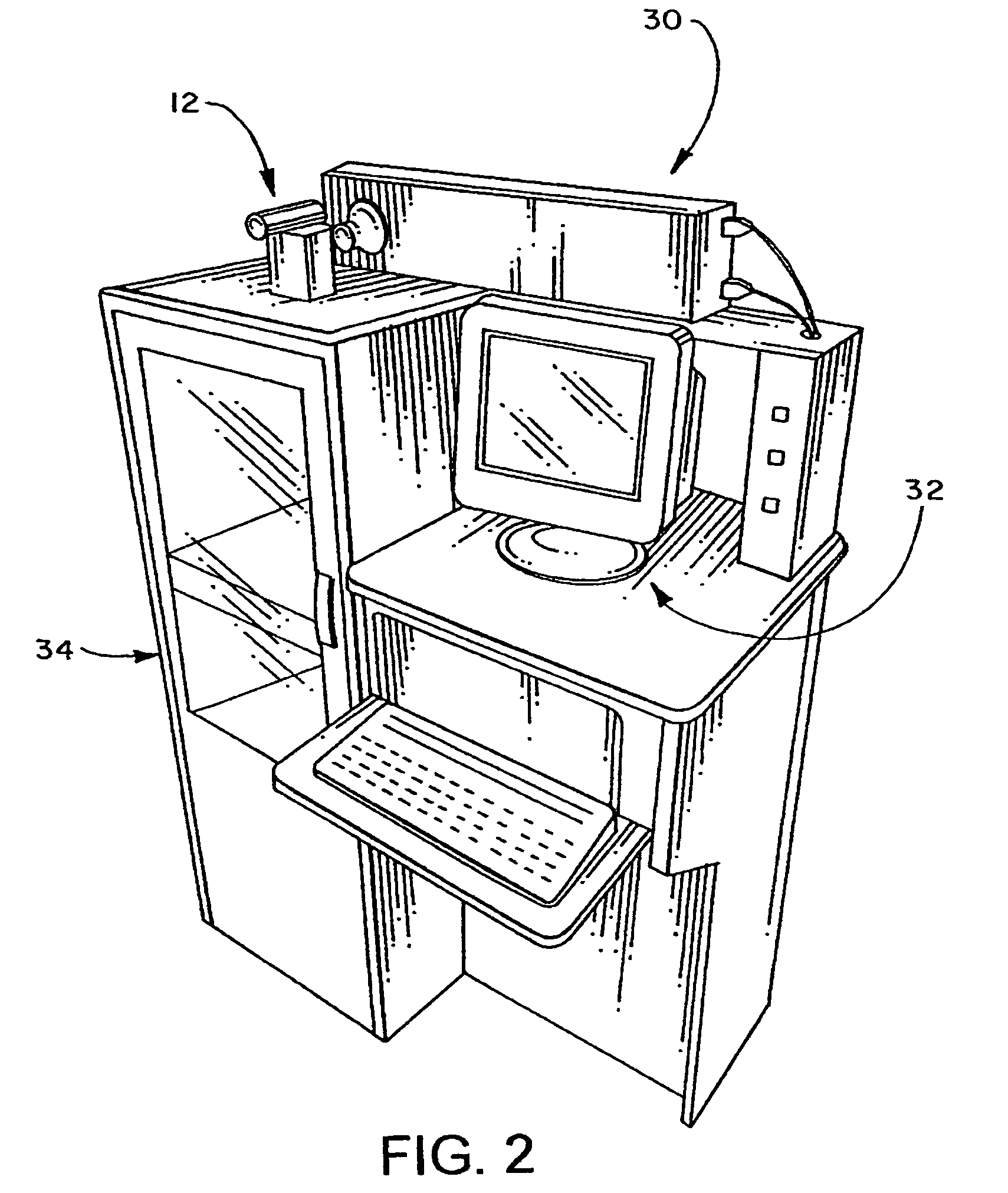

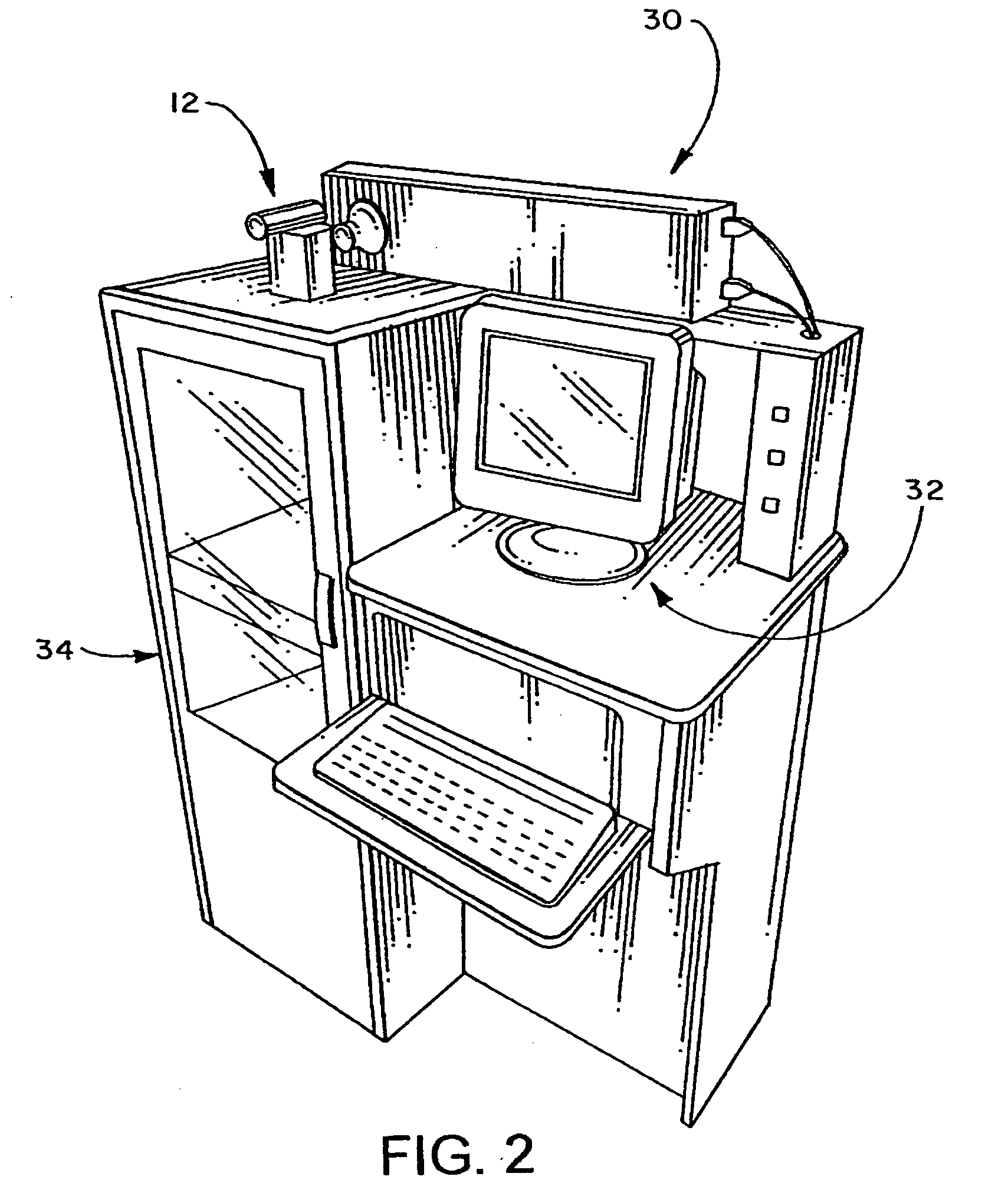

Multi-material stereolithography

Methods and systems of stereolithography for building cost-efficient and time-saving multi-material, multi-functional and multi-colored prototypes, models and devices configured for intermediate washing and curing / drying is disclosed including: laser(s), liquid and / or platform level sensing system(s), controllable optical system(s), moveable platform(s), elevator platform(s), recoating system(s) and at least one polymer retaining receptacle. Multiple polymer retaining receptacles may be arranged in a moveable apparatus, wherein each receptacle is adapted to actively / passively maintain a uniform, desired level of polymer by including a recoating device and a material fill / remove system. The platform is movably accessible to the polymer retaining receptacle(s), elevator mechanism(s) and washing and curing / drying area(s) which may be housed in a shielded enclosure(s). The elevator mechanism is configured to vertically traverse and rotate the platform, thus providing angled building, washing and curing / drying capabilities. A horizontal traversing mechanism may be included to facilitate manufacturing between components of SL cabinet(s) and / or alternative manufacturing technologies.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

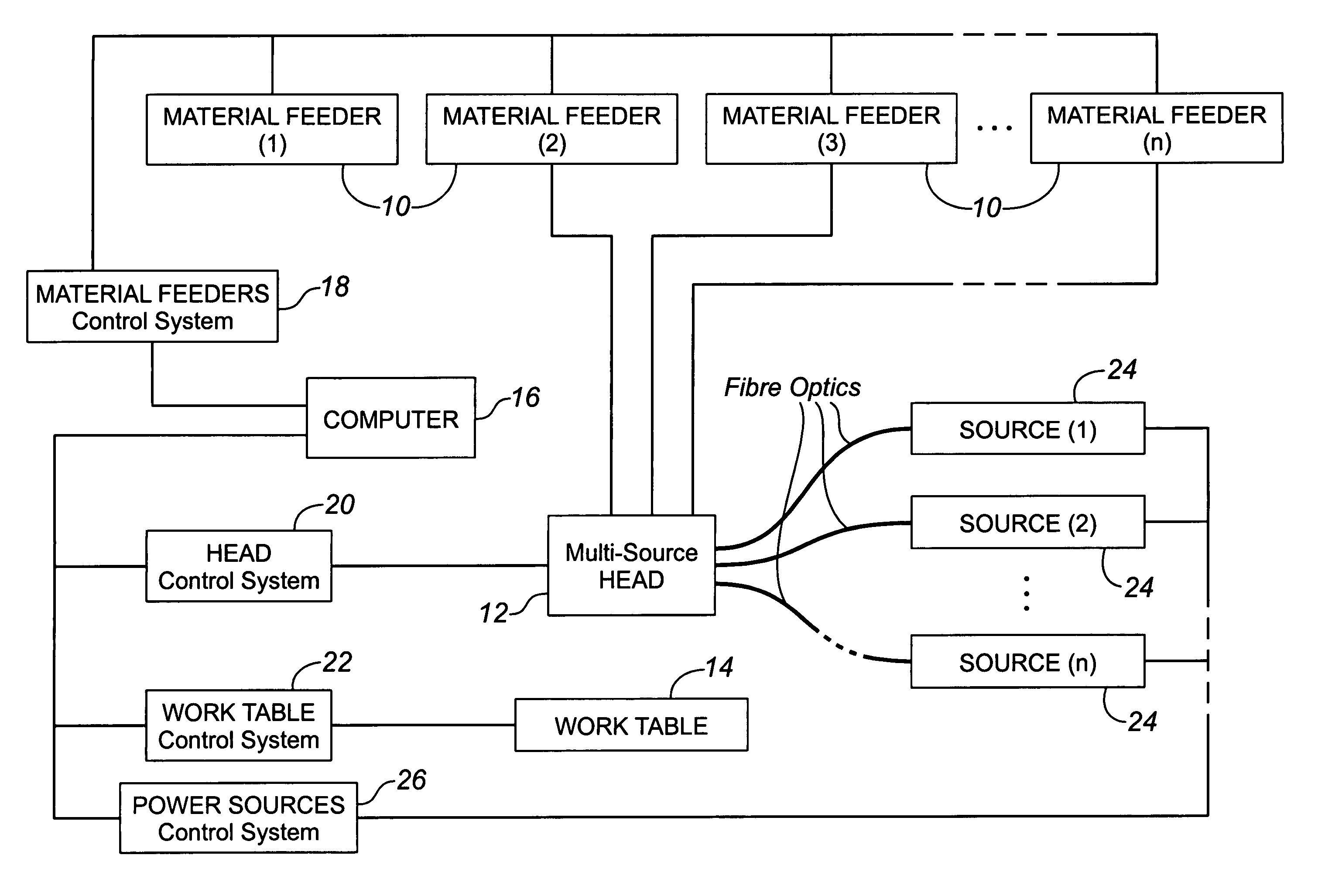

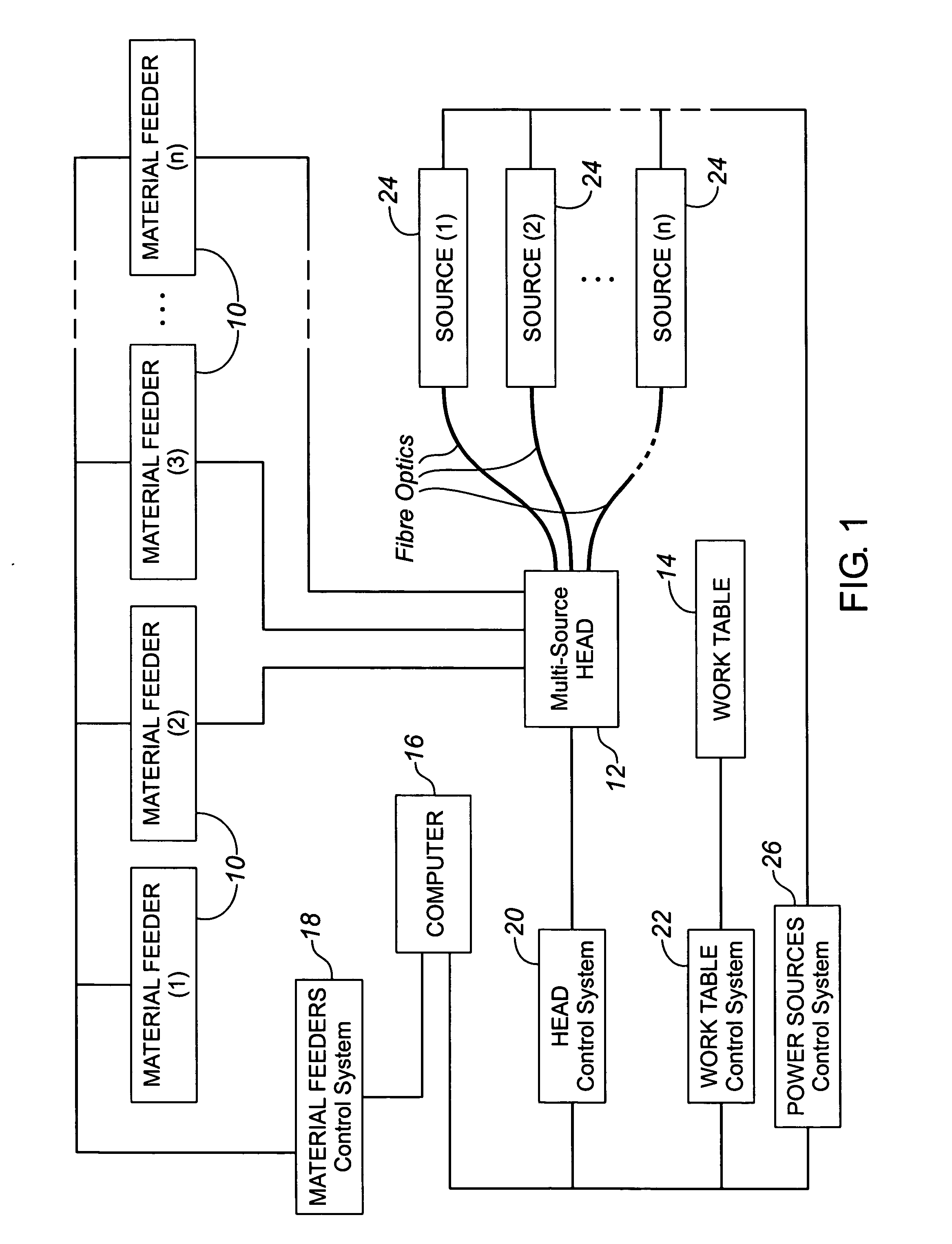

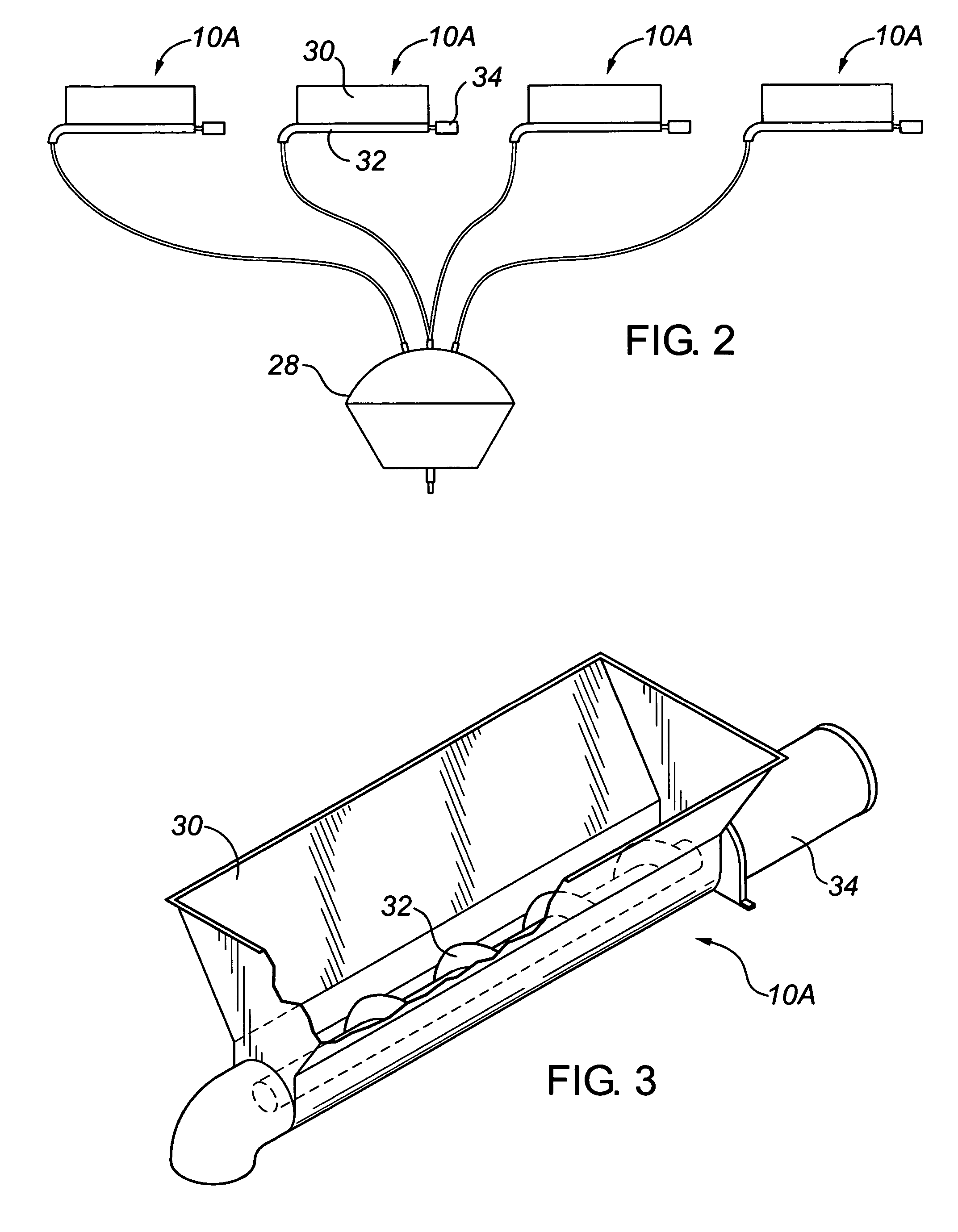

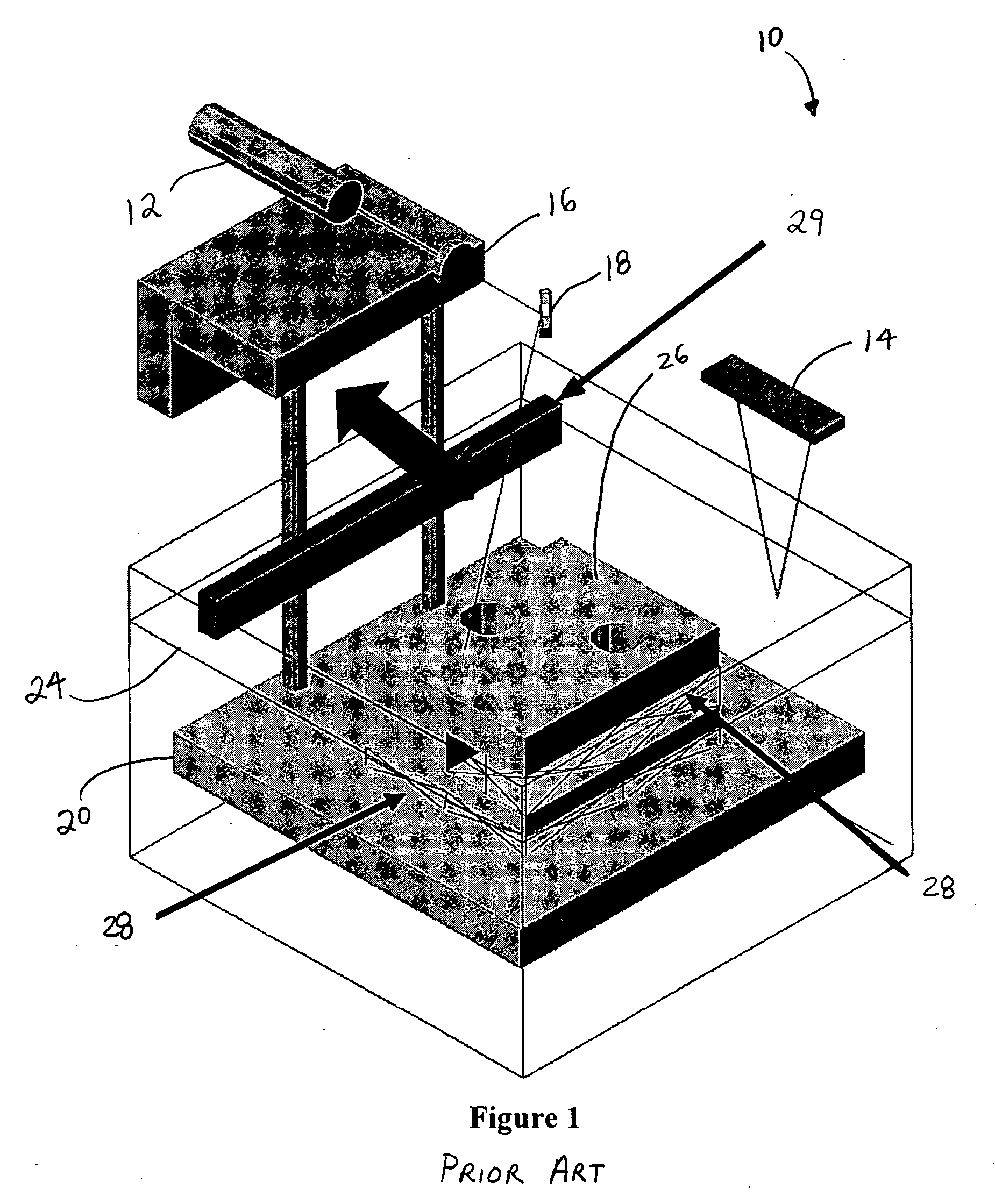

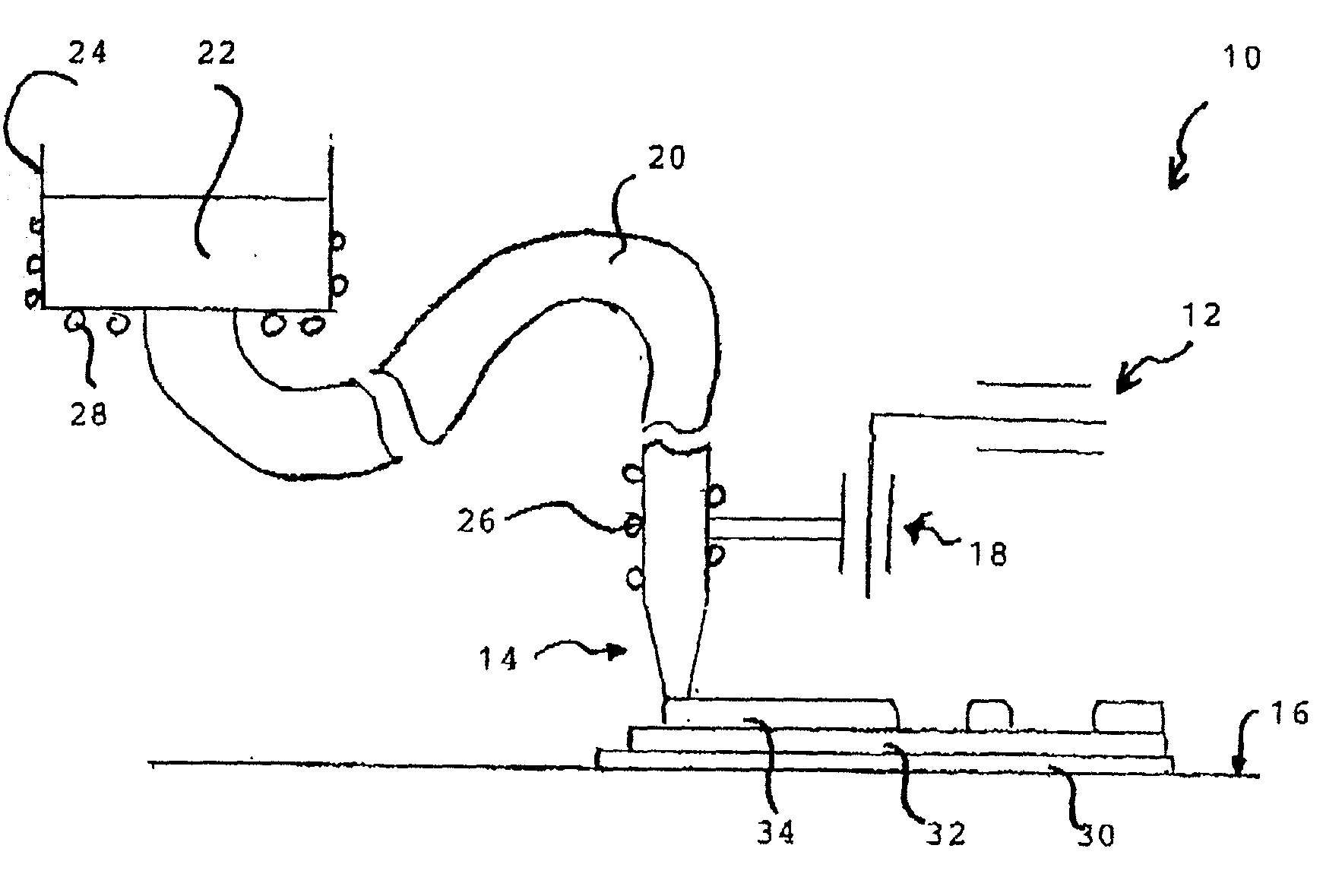

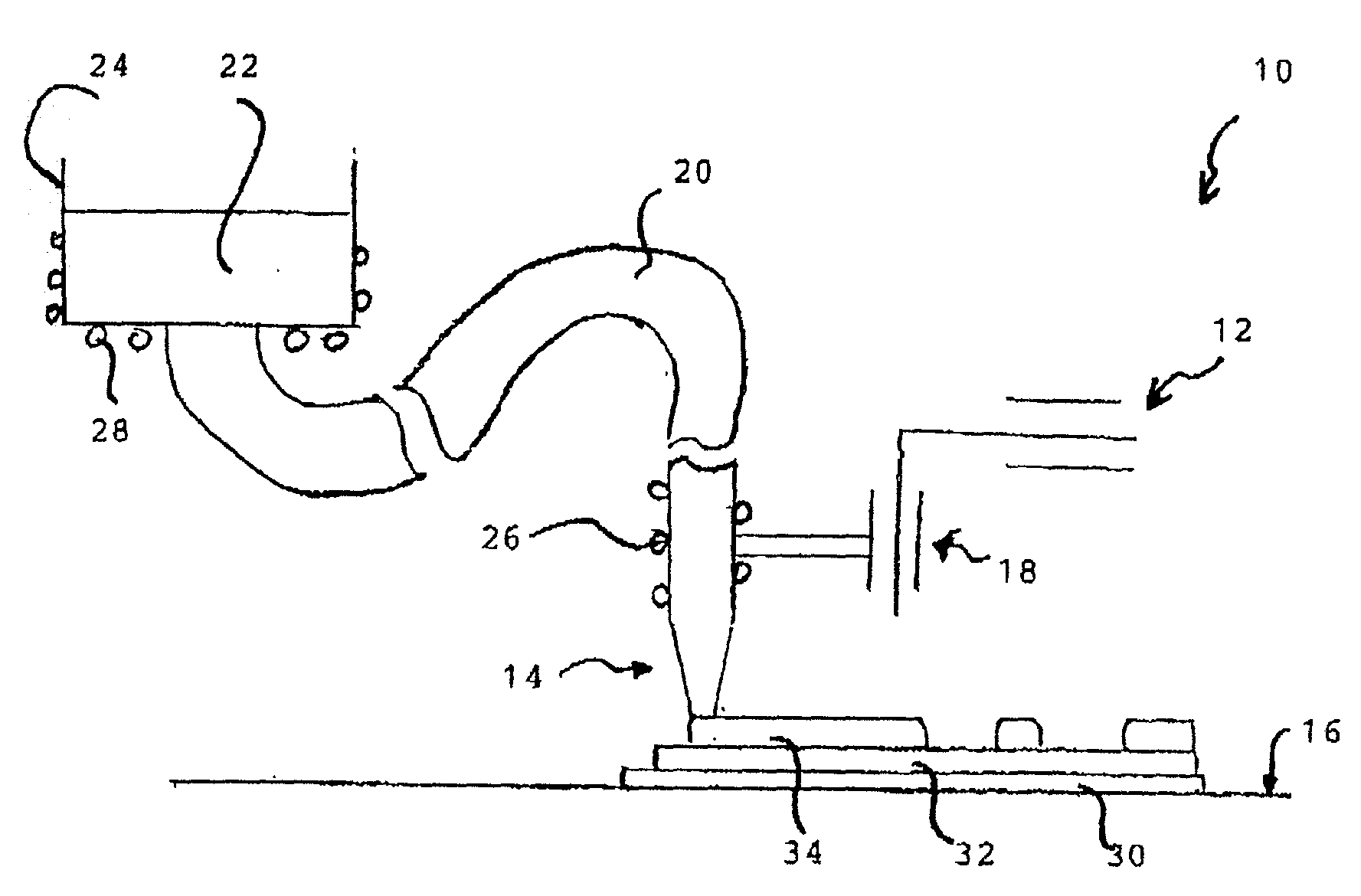

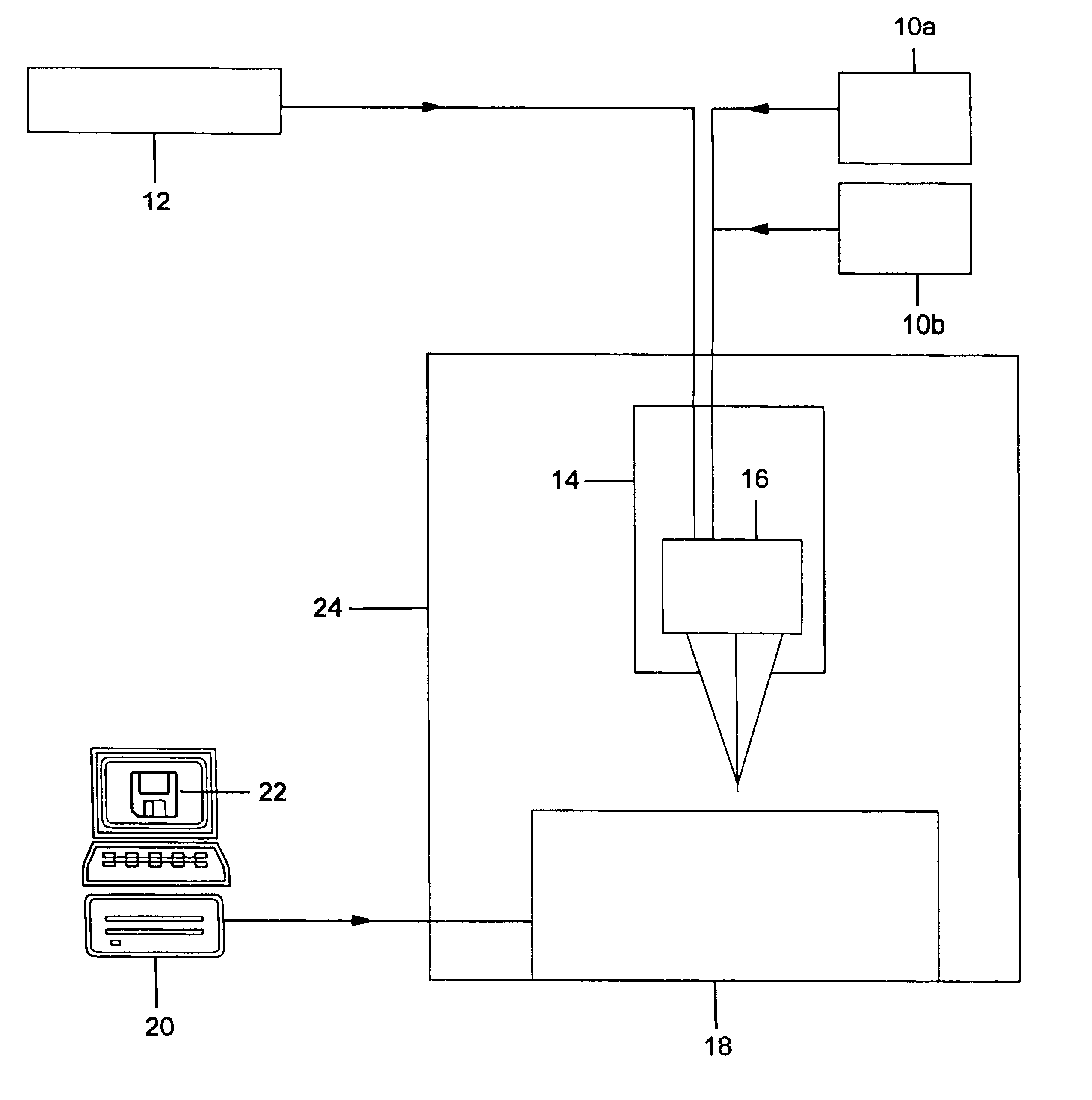

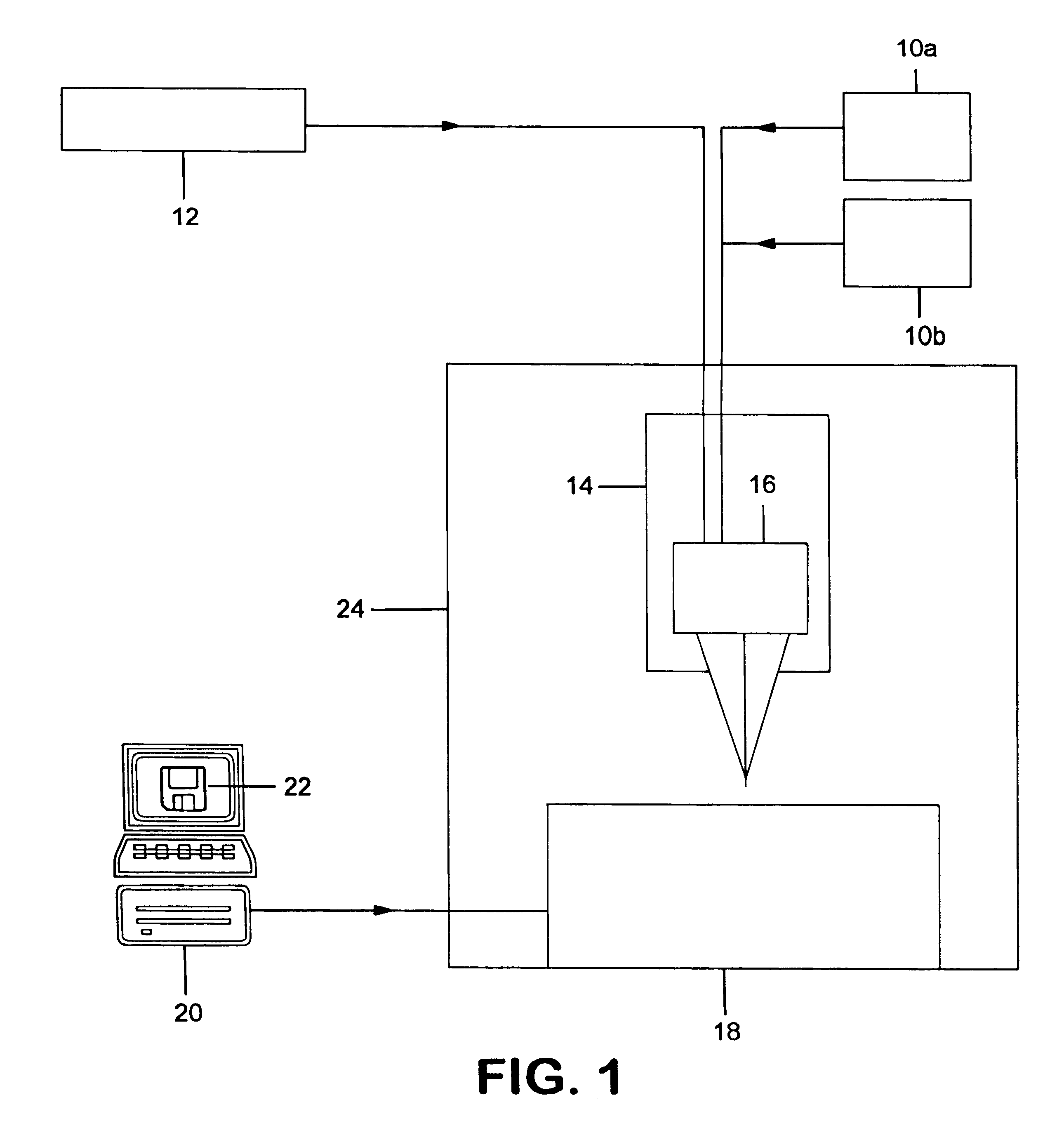

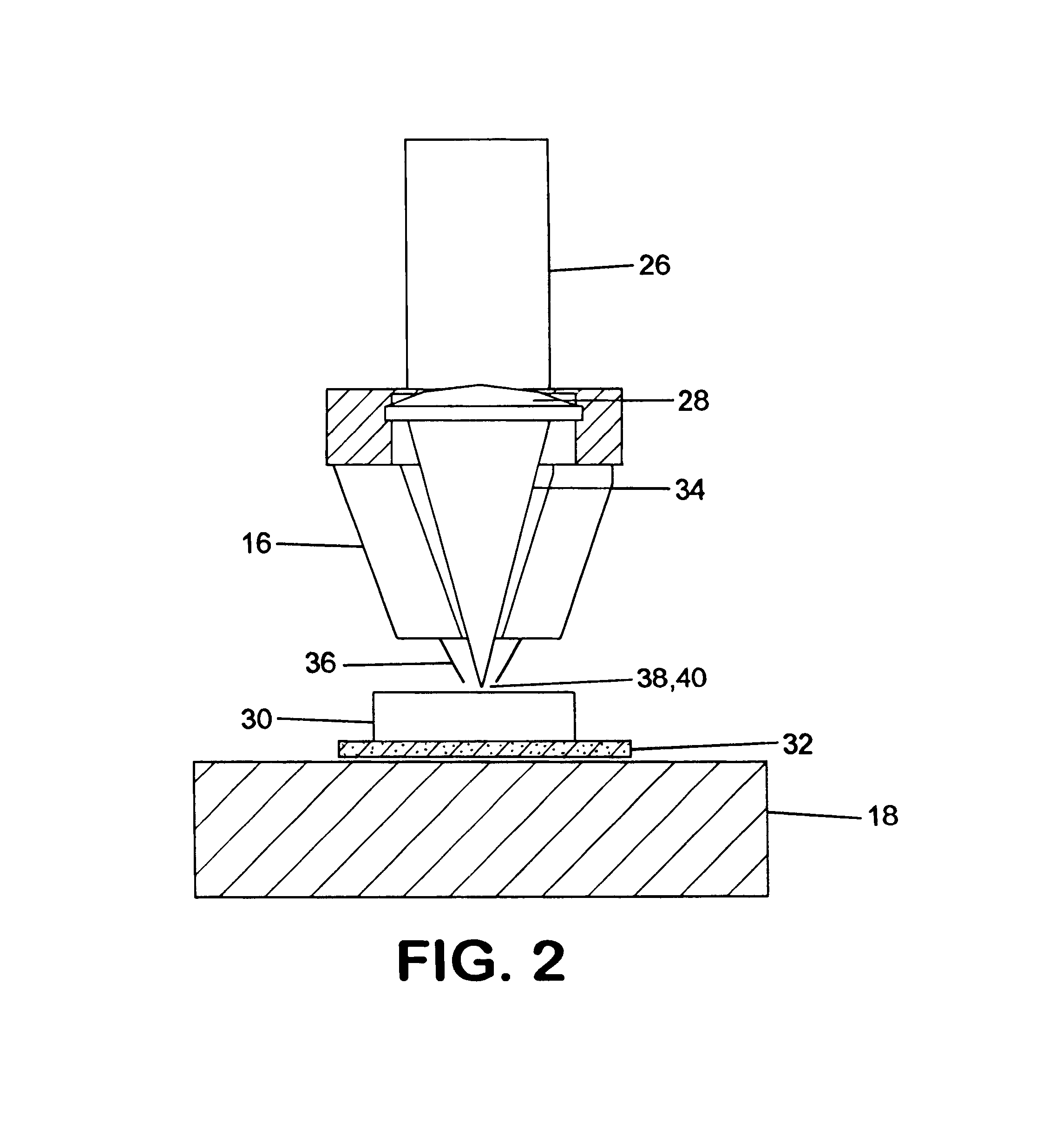

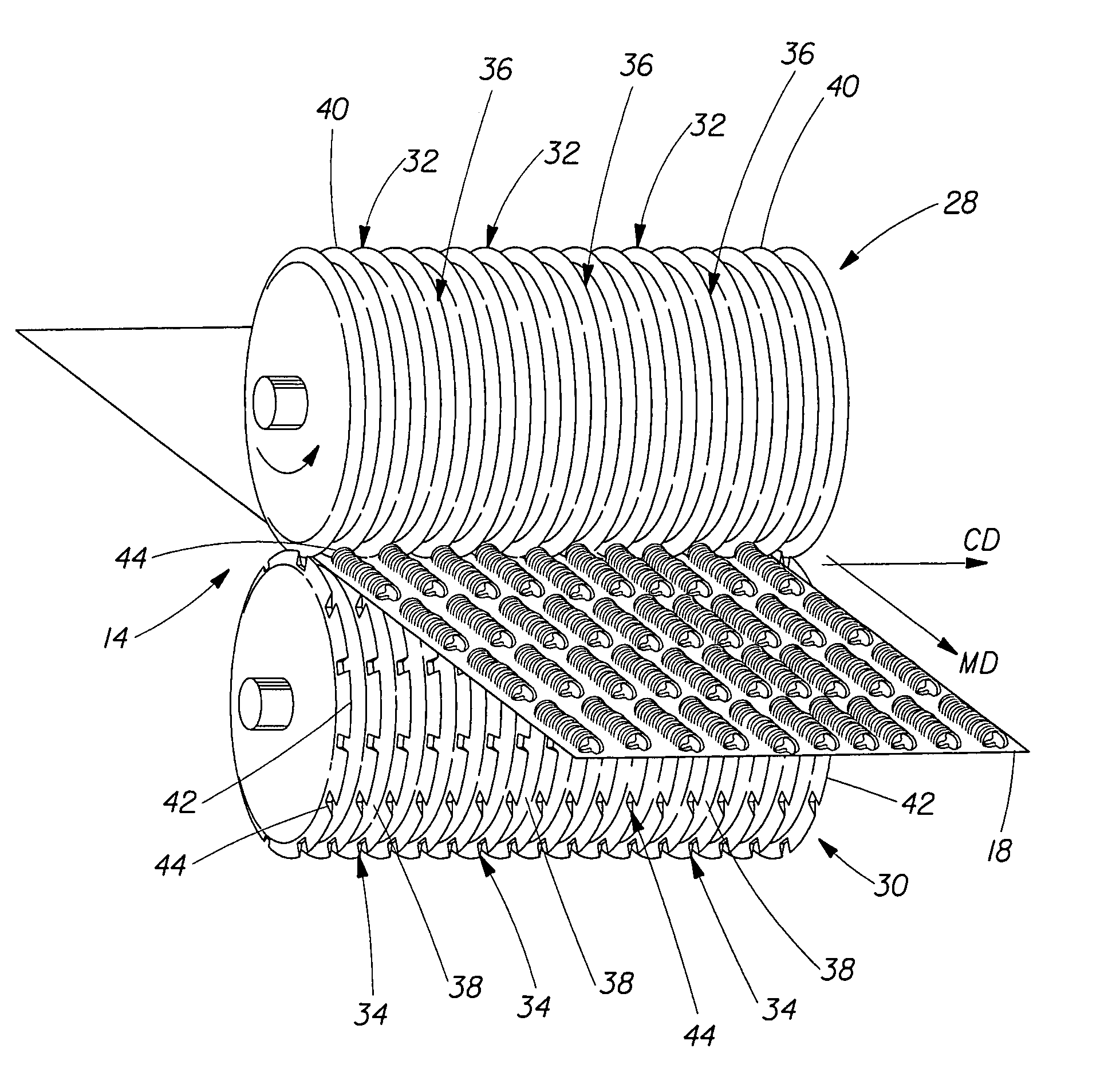

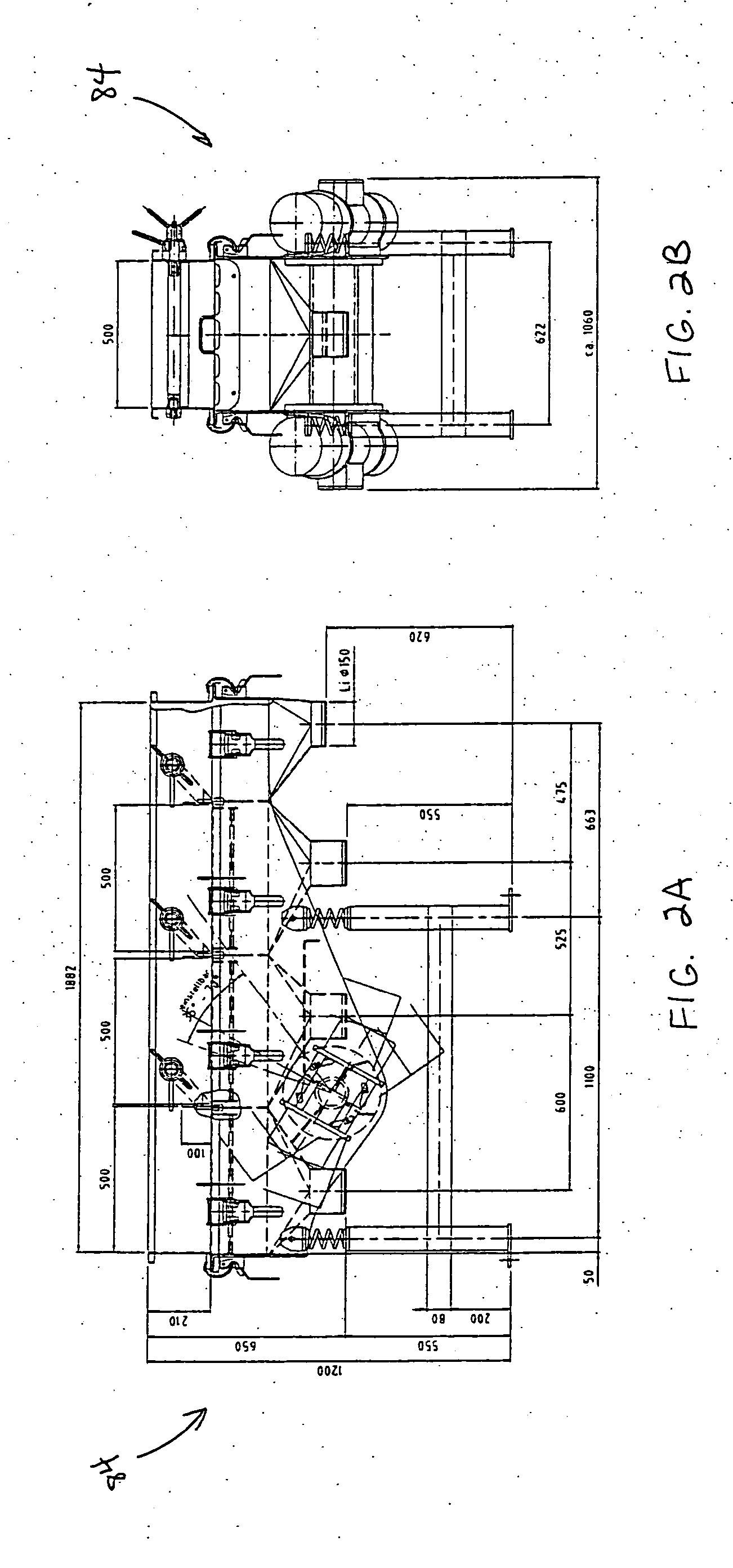

Multisource and multimaterial freeform fabrication

InactiveUS20050104257A1Liquid surface applicatorsMechanical working/deformationControl systemEngineering

An apparatus for forming freeform solid articles includes a head unit having a plurality of arc-shaped support arms. The support arms mount material feeders and power sources which are directed at a work table. The material feeders, power sources and movement of the head unit and work table are controlled by a computerized control system.

Owner:UNIV TECH INT

Retaining wall block with face connection

Single and multiple retaining wall blocks and block systems are disclosed. The blocks are provided with a face connection system which includes at least one front lip extending from a top surface of the block and a bottom channel formed into a front face and bottom surface of the block. The front lips have a length which is less than the width of the blocks.

Owner:CONTECH TECH

Picowell capture devices for analysing single cells or other particles

InactiveUS20120156675A1Easy to adaptCompared rapidly and convenientlyBioreactor/fermenter combinationsBiological substance pretreatmentsIndividual analysisBiopolymer

Owner:OXFORD GENE TECH IP

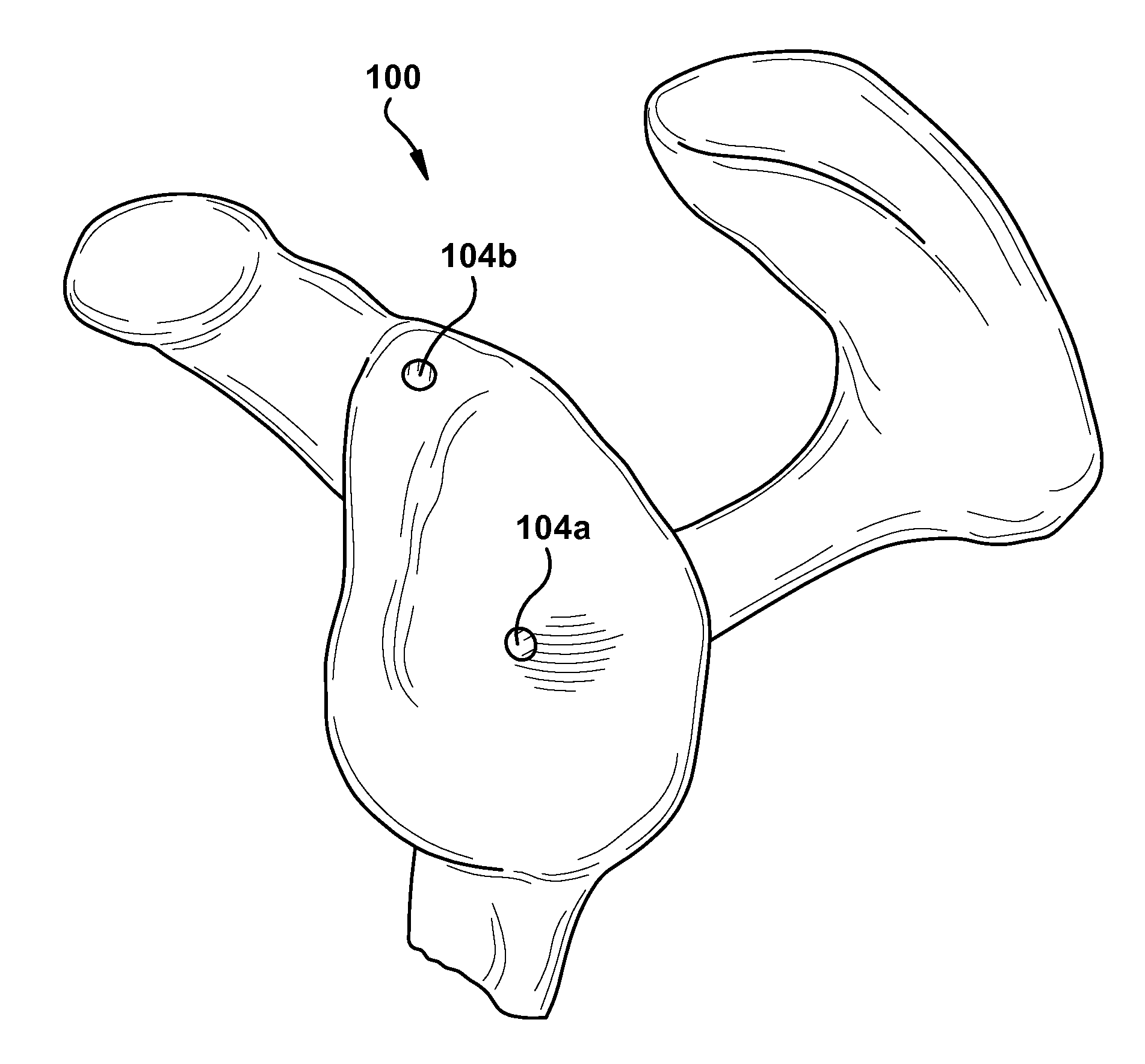

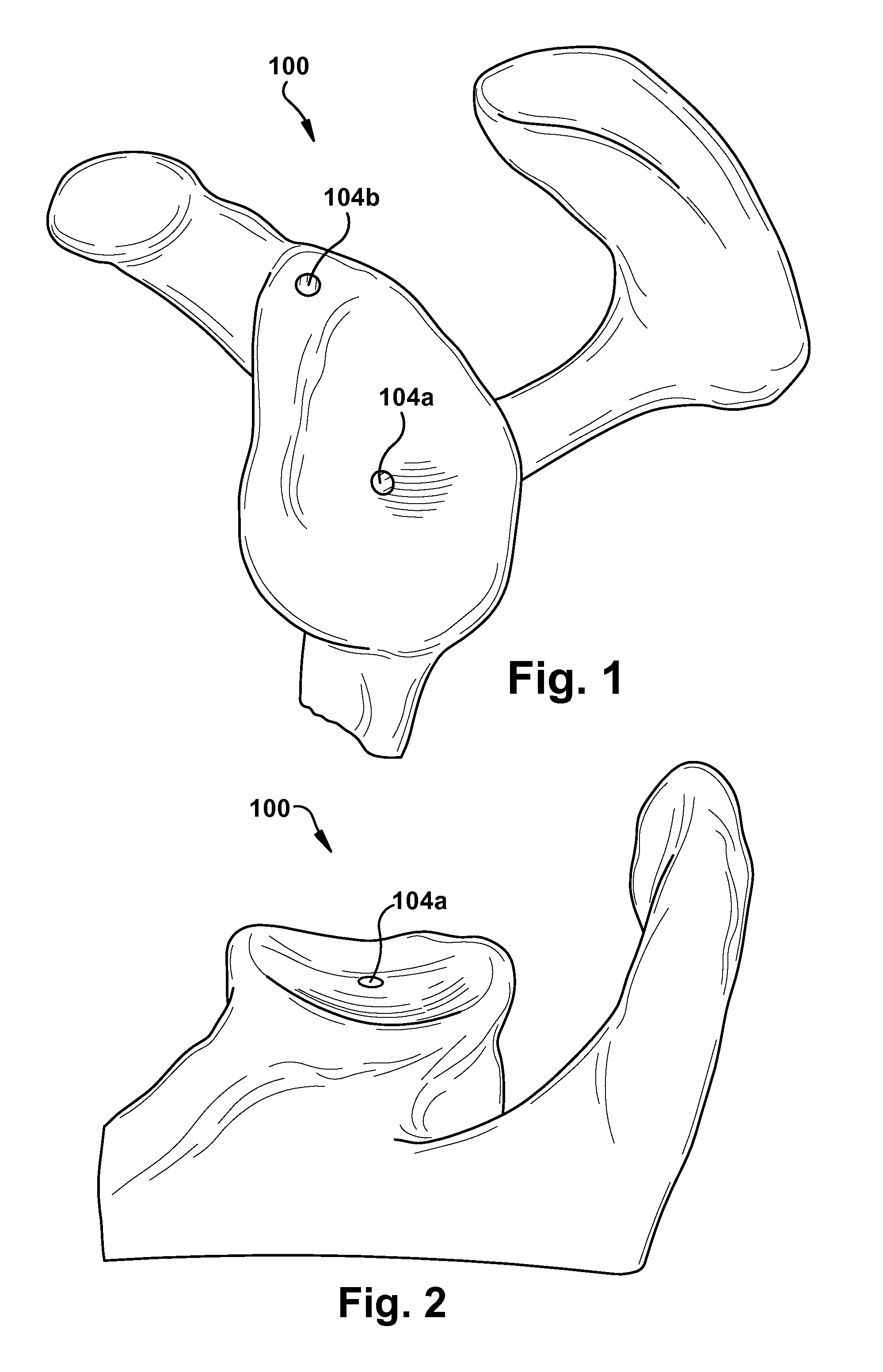

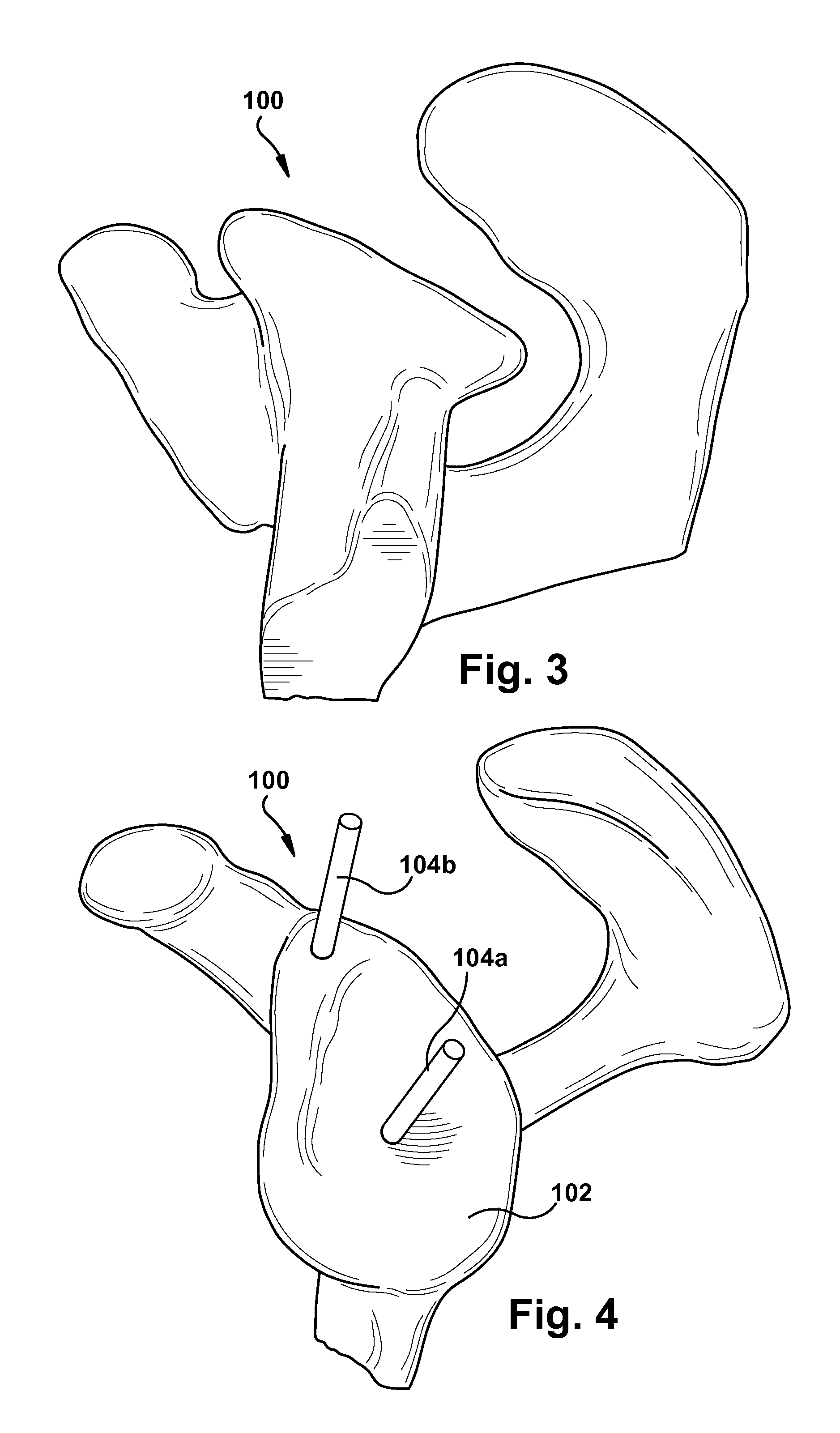

Method and system for producing at least one patient-specific surgical aid

InactiveUS20130119579A1Additive manufacturing apparatusDischarging arrangementTarget surfacePhysical model

A method for producing at least one patient-specific surgical aid includes providing a physical model of a native patient tissue. The physical model has at least one surface of interest. A constraining wall is placed in contact with at least a portion of the physical model. A moldable substance is placed into contact with at least a portion of the surface of interest. An impression of the surface of interest is maintained upon the moldable substance. The moldable substance is solidified into a patient-specific surgical aid. The patient-specific surgical aid is removed from the physical model. A system for producing at least one patient-specific surgical aid is also disclosed.

Owner:THE CLEVELAND CLINIC FOUND

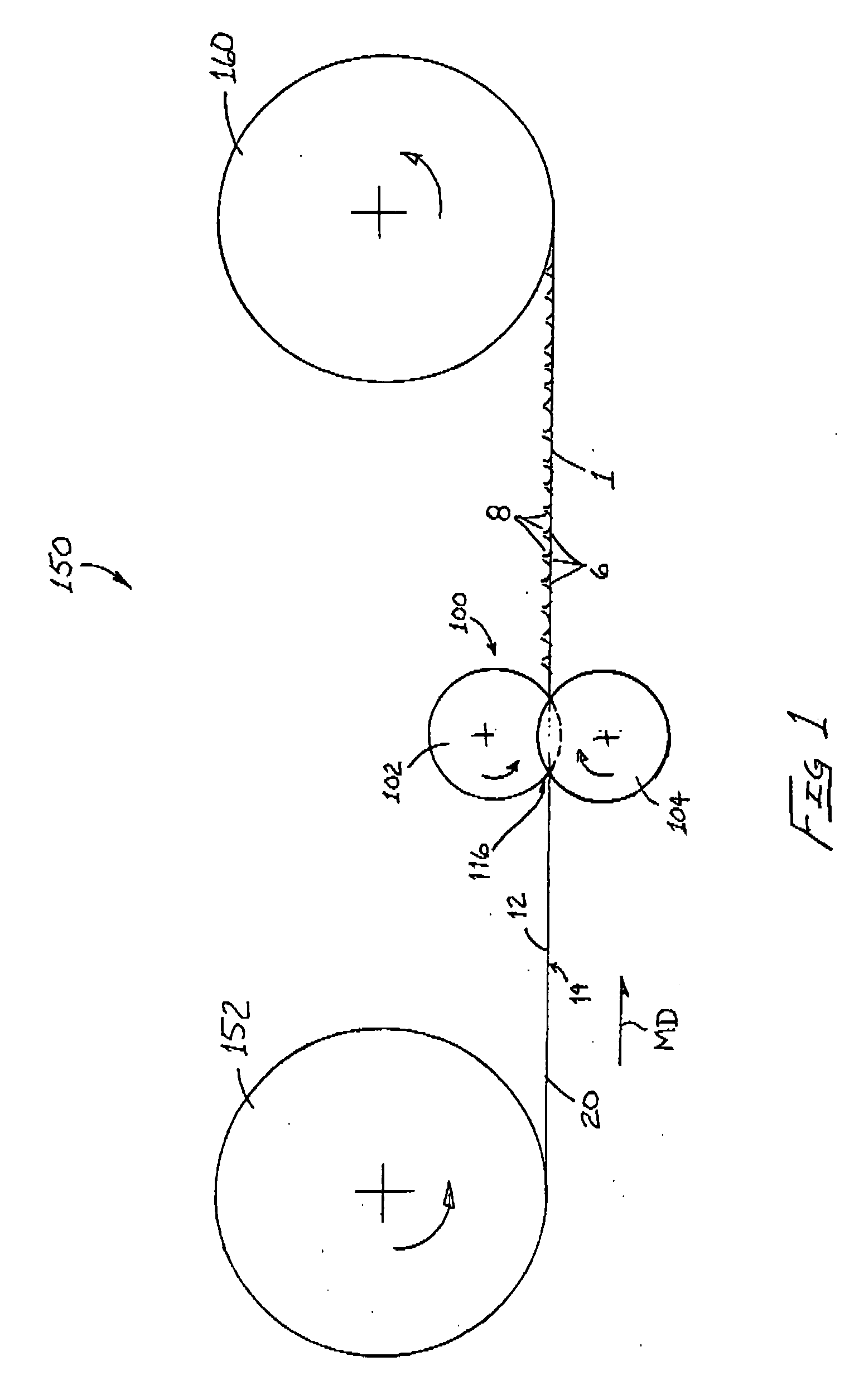

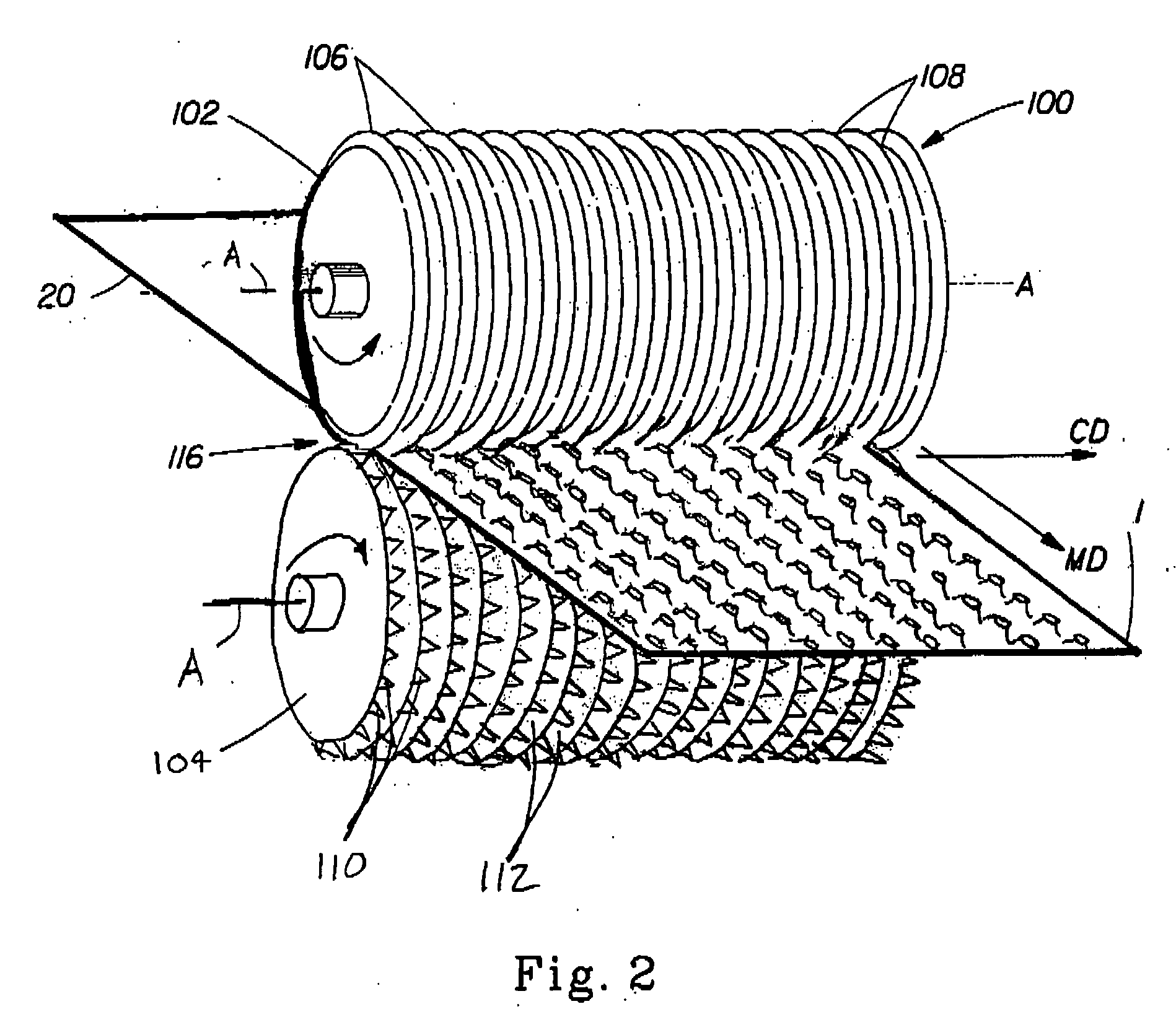

Method and apparatus for making an apertured web

Owner:PROCTER & GAMBLE CO

Multi-material stereolithography

ActiveUS20060022379A1Improves SL functionalityEliminate pollutionMouldsConfectioneryMulti materialManufacturing technology

Methods and systems of stereolithography for building cost-efficient and time-saving multi-material, multi-functional and multi-colored prototypes, models and devices configured for intermediate washing and curing / drying is disclosed including: laser(s), liquid and / or platform level sensing system(s), controllable optical system(s), moveable platform(s), elevator platform(s), recoating system(s) and at least one polymer retaining receptacle. Multiple polymer retaining receptacles may be arranged in a moveable apparatus, wherein each receptacle is adapted to actively / passively maintain a uniform, desired level of polymer by including a recoating device and a material fill / remove system. The platform is movably accessible to the polymer retaining receptacle(s), elevator mechanism(s) and washing and curing / drying area(s) which may be housed in a shielded enclosure(s). The elevator mechanism is configured to vertically traverse and rotate the platform, thus providing angled building, washing and curing / drying capabilities. A horizontal traversing mechanism may be included to facilitate manufacturing between components of SL cabinet(s) and / or alternative manufacturing technologies.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Desktop process for producing dental products by means of 3-dimensional plotting

InactiveUS20020167100A1High viscosityLess resourcesAdditive manufacturing apparatusImpression capsChemical reactionOligomer

A process for fabricating dental form pieces for dental restoration and replacement parts is provided and includes the step of applying a material, on a firm support or a fluid medium, by a three dimensional plotting technology in a layer by layer manner. The material has micro cords and / or micro drops which include at least one of a meltable, polymerizable, polycondensable, and polyaddable constituent element that is an unfilled monomer, a reinforced monomer, oligomer, polymer, or a ceramic element. The process also includes the step of hardening the applied material by cooling of the material, chemical reaction, polymerization with thermal handling, or polymerization by irradiation of the material with UV or visible light.

Owner:IVOCLAR VIVADENT AG

Method of making sensor

InactiveUS6849216B2Improve performanceRelieve pressureImmobilised enzymesBioreactor/fermenter combinationsElectron transfer mediatorReaction zone

A sensor is provided for the determination of various concentrations of one or more components within a fluid sample. The sensor includes an injection molded body, at least two electrodes, an enzyme, and if desired, an electron transfer mediator. The body includes a reaction zone for receiving a fluid sample. The electrodes are at least partially embedded within the plastic body and extend into the reaction zone. Also contained within the reaction zone is an enzyme capable of catalyzing a reaction involving a compound within the fluid sample. Additionally, the sensor incorporates fill detection which activates a meter, attached to the sensor, for measuring the electrochemical changes occurring in the reaction zone.

Owner:APPL BIOMEDICAL LLC

Method of manufacturing curved composite structural elements

A method of manufacturing curved composite structural elements can include fabricating a web ply in a flat curve over a removable substrate and laying up the ply on a curved web surface of a manufacturing tool. The method also can include laying up a diagonal ply with fibers oriented at + / −45° from the centerline of the web surface. The method further can include cutting a unidirectional composite tape into segments and laying up the tape segments to form a cross ply with a fiber orientation normal to the centerline of the web surface. One or both edges of the diagonal and cross plies may be folded over one or two sides of the manufacturing tool to form one or two flange surfaces. Additionally, a cap ply can be laid up on one or both flange surfaces using composite tape. The structural element layup can then be inspected and any excess composite material can be trimmed away.

Owner:THE BOEING CO

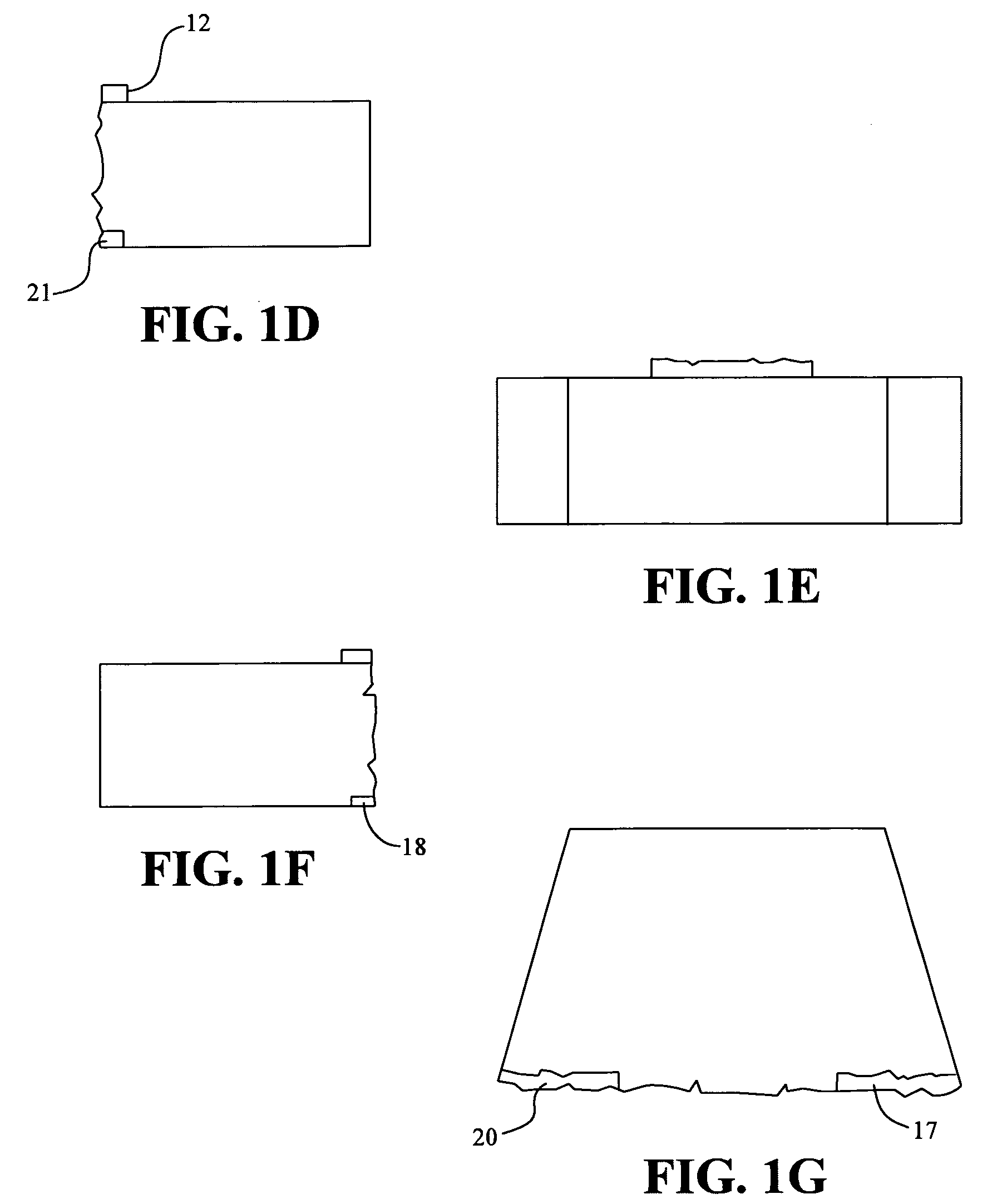

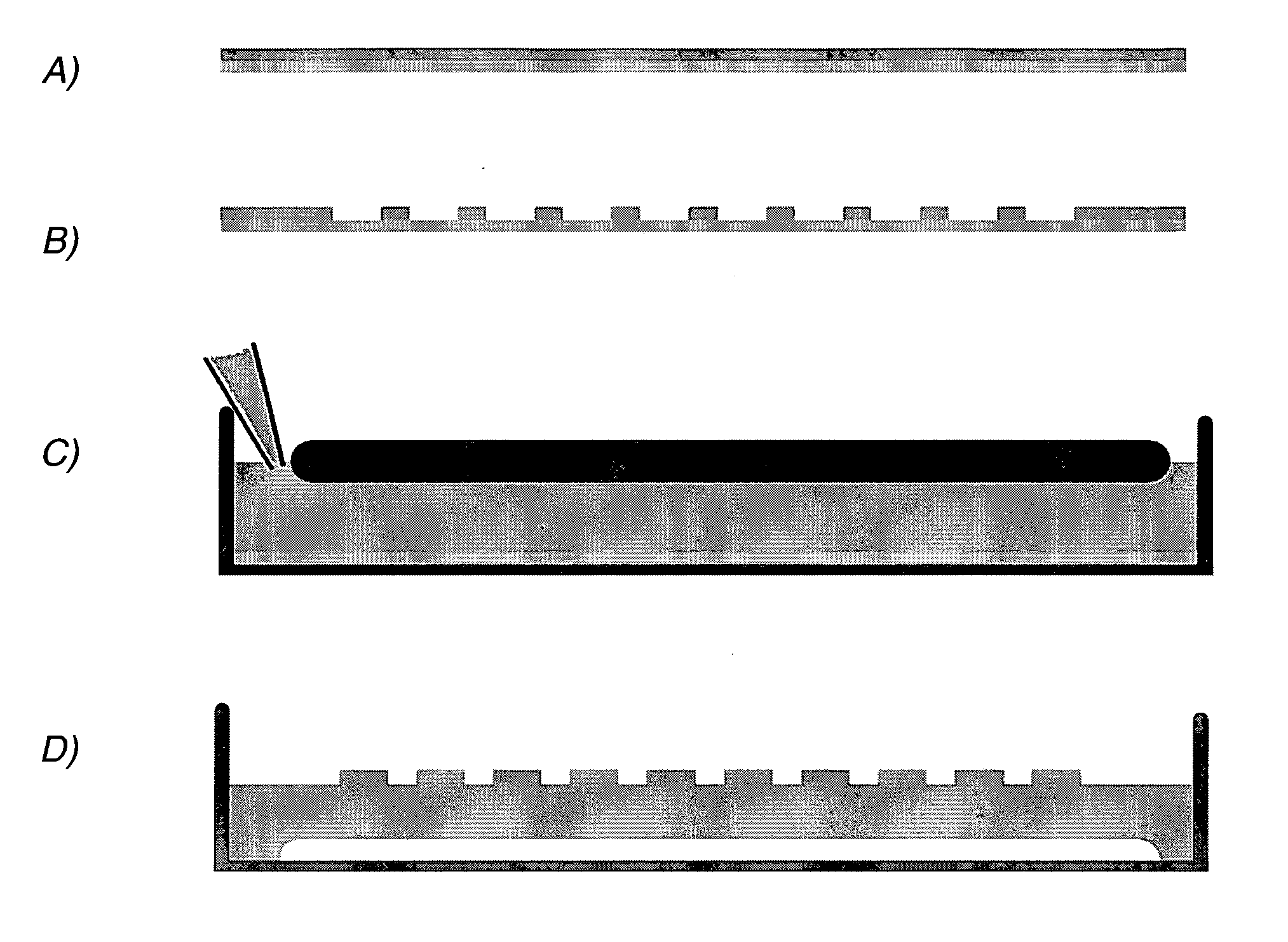

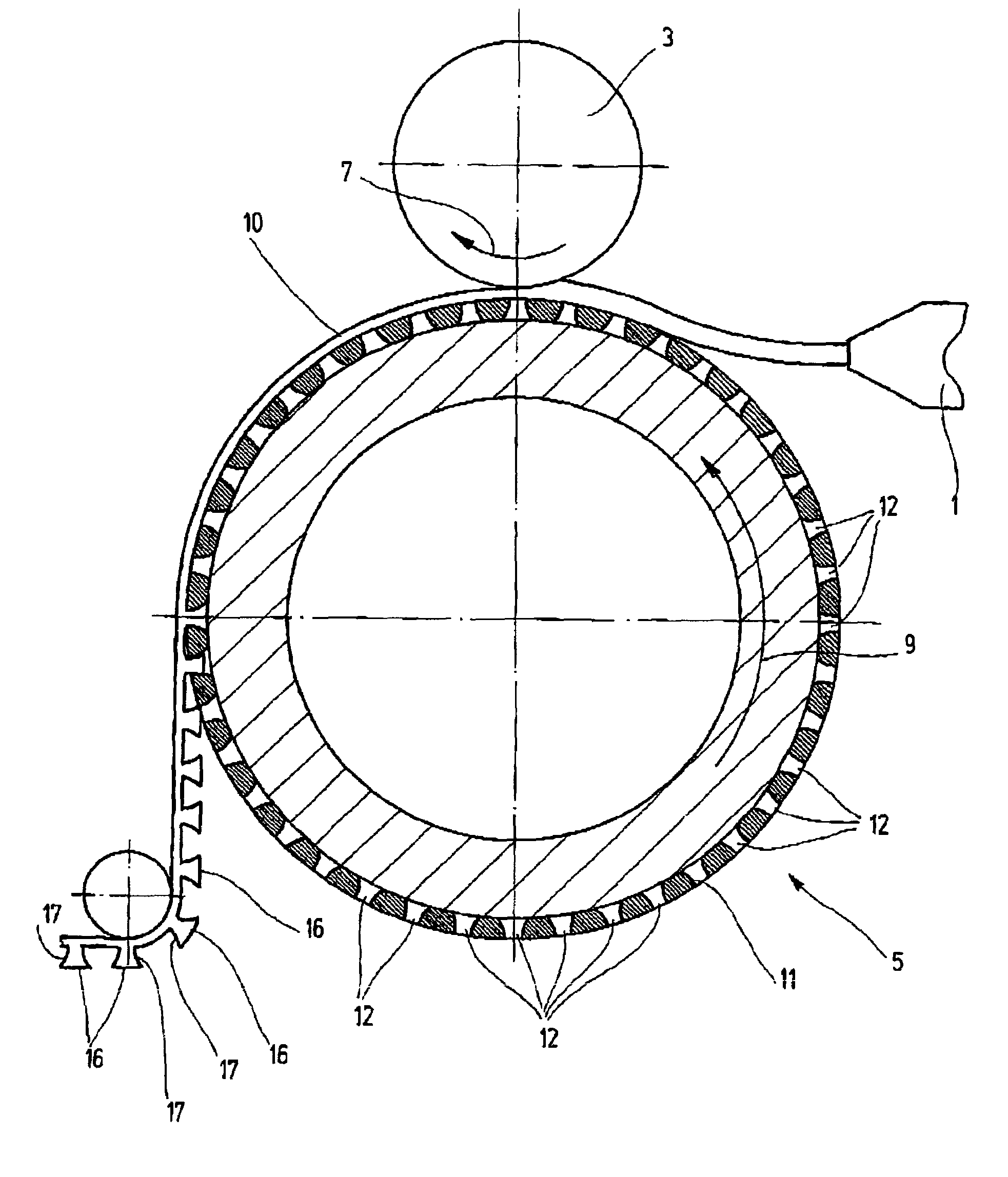

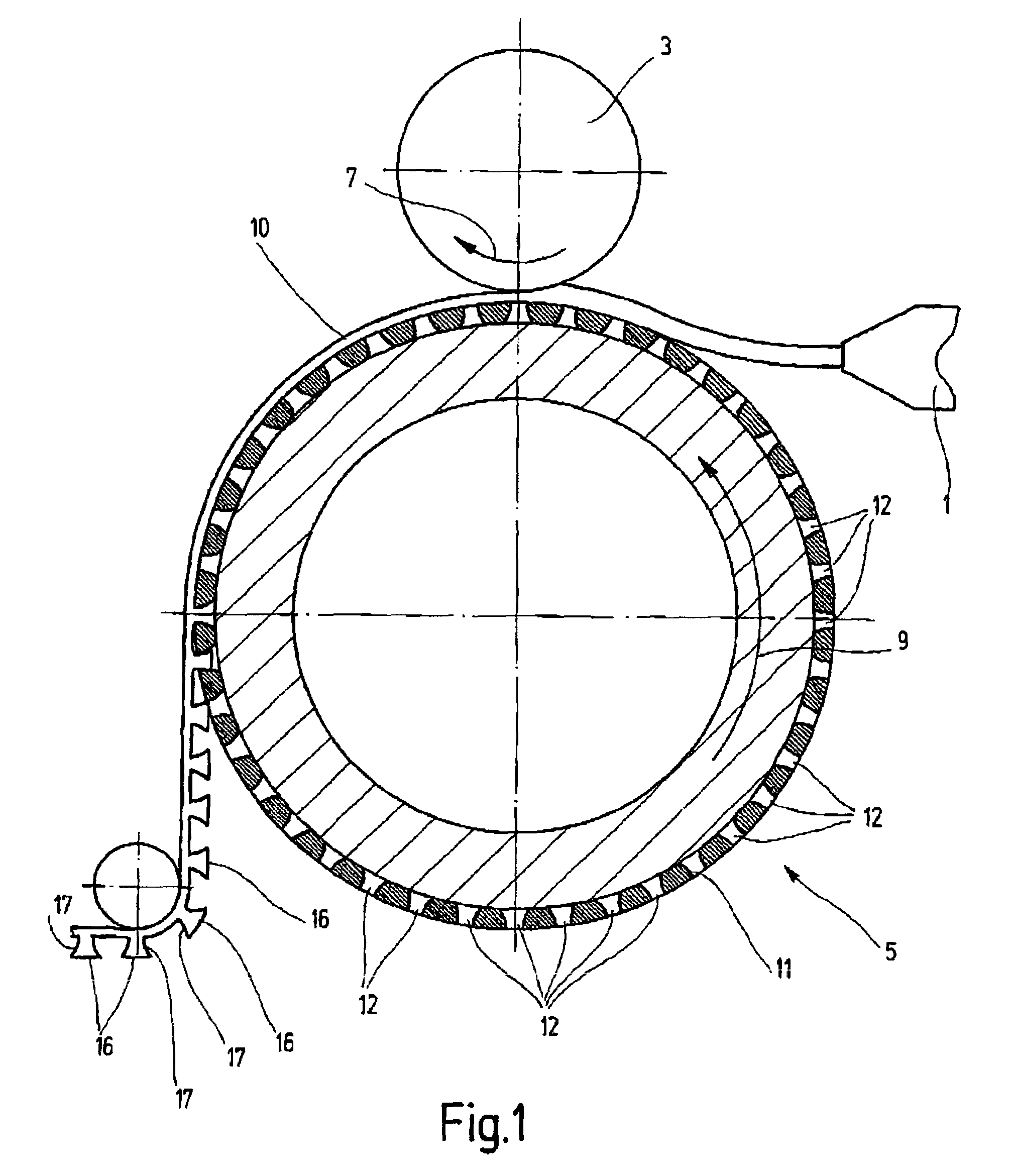

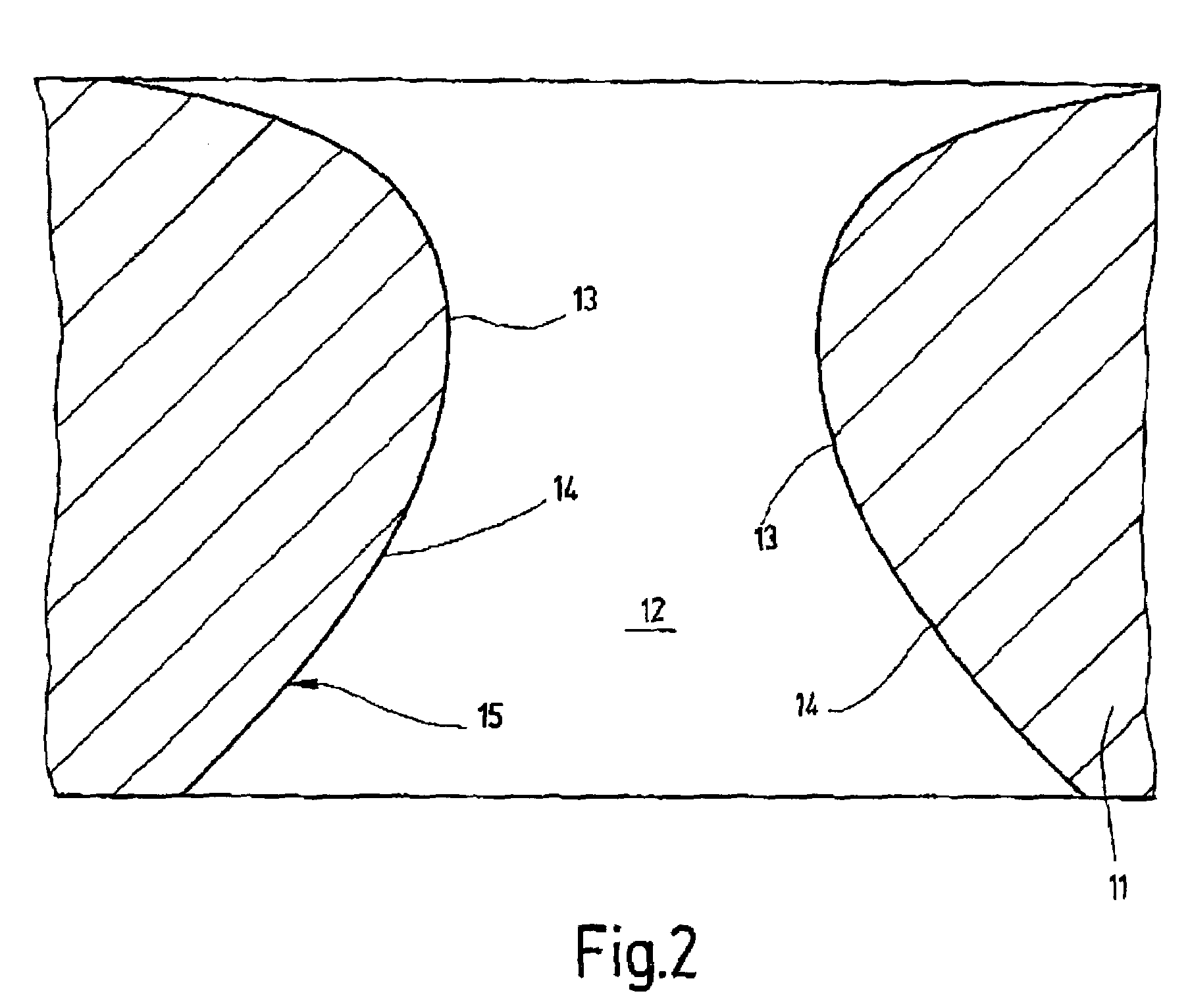

Method for producing an adhesive closing element

InactiveUS7198743B2Easy to demouldFavorable closing behaviorDischarging arrangementArtificial filament physical treatmentEngineeringHooking

A process for produces an adhesive closing element including a plurality of hook elements connected to a backing (10) forming a single piece with the hook elements and being disposed symmetrically thereon. The hook elements are provided in the form of a stem component (17) having a head piece (16). A deformable material is introduced into a forming zone in between a production master (3) and a forming tool (5). The opposite-lying defining walls, at least when seen in a longitudinal section of the respective forming cavity (12), are provided with a continuous convex trajectory. A continuous transition between the cross-sectional forms of the stem component (17) and the head piece (16) is provided for a hooking of the backing (10) resulting in seamless removal.

Owner:GOTTLIEB BINDER

Manufacturable geometries for thermal management of complex three-dimensional shapes

Uniform cooling of complex surface shapes in injection mold tooling can be accomplished with cooling channels that conform to the shapes of the mold cavity or mold cone. By conventional methods this can be very difficult to accomplish. By applying methods of material deposition or material sintering, which include but are not limited to, laser metal deposition, where material is deposited on a layer by layer basis, certain cooling or heating passages could be integrated into the manufactured component that follow the contours and profiles of the mold's complex surfaces. These passages would act as internal heat sinks with a much higher surface area for heat transfer than traditional drilled and plugged straight passages. These geometries could also be incorporated into complex geometries such as, but not limited to, turbine blades where the cooling passages can follow the contour of the outer shape, provide a more uniform or controlled heat transfer from the component. Multiple loops of cooling or heating channels could be designed and manufactured into solid objects for small-scale heat exchanger technologies.

Owner:OPTOMEC DESIGN CO

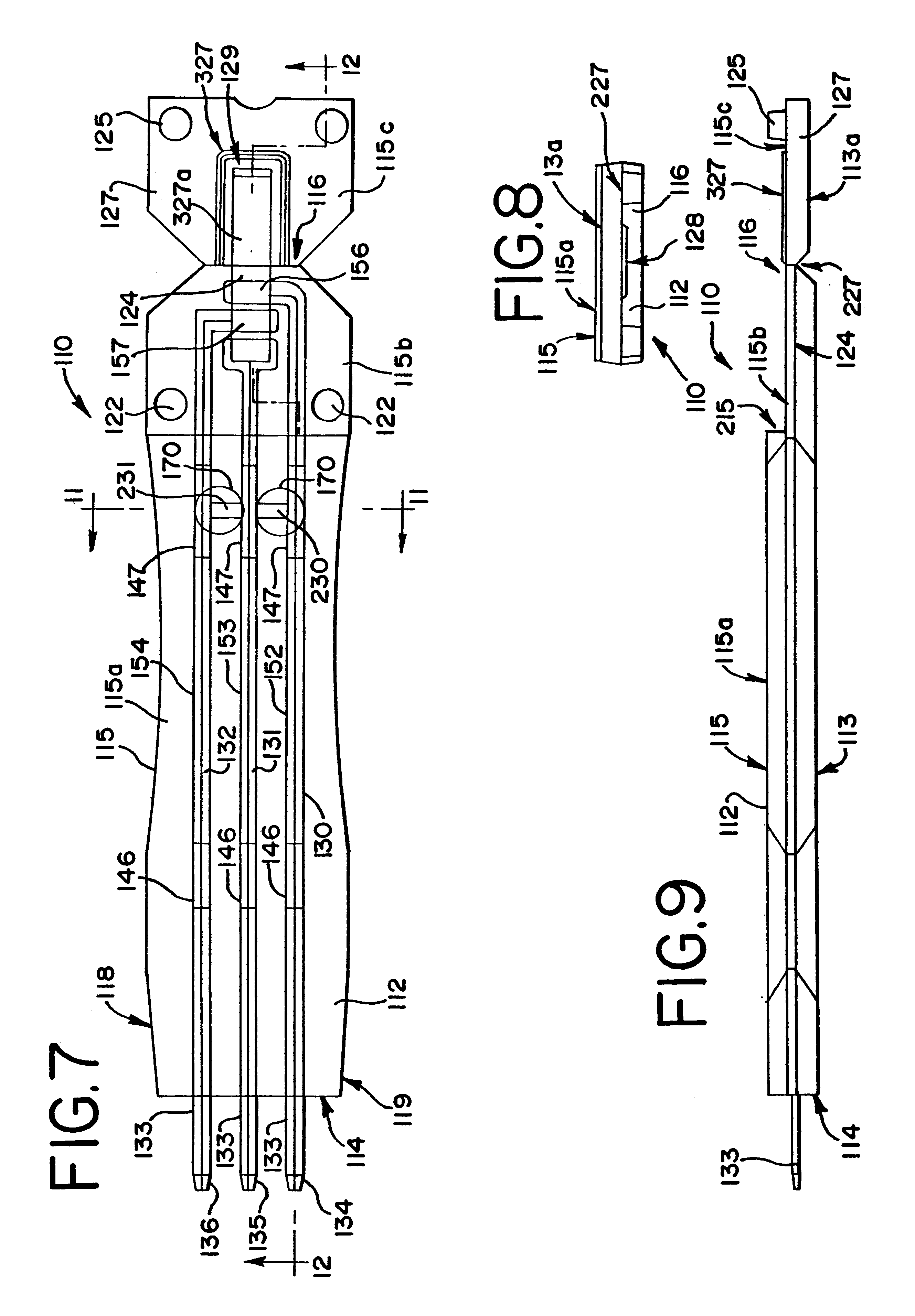

Apparatus and process for producing a web substrate having indicia disposed thereon and elastic-like behavior imparted thereto

Owner:THE PROCTER & GAMBLE COMPANY

Dental restorations formed by solid free-form fabrication methods

InactiveUS6994549B2Manufacture of restorationAdditive manufacturing apparatusImpression capsFree formThin layer

Solid free form fabrication techniques such as fused deposition modeling and three-dimensional printing are used to create a dental restoration. Three-dimensional printing comprises inkjet printing a binder into selected areas of sequentially deposited layers of powder. Each layer is created by spreading a thin layer of powder over the surface of a powder bed. Instructions for each layer may be derived directly from a CAD representation of the restoration. The area to be printed is obtained by computing the area of intersection between the desired plane and the CAD representation of the object. All the layers required for an aesthetically sound restoration can be deposited concurrently slice after slice and sintered / cured simultaneously. The amount of green body oversize is equivalent to the amount of shrinkage which occurs during sintering or curing. While the layers become hardened or at least partially hardened as each of the layers is laid down, once the desired final shaped configuration is achieved and the layering process is complete, in some applications it may be desirable that the form and its contents be heated or cured at a suitably selected temperature to further promote binding of the powder particles.

Owner:JENERICPENTRON

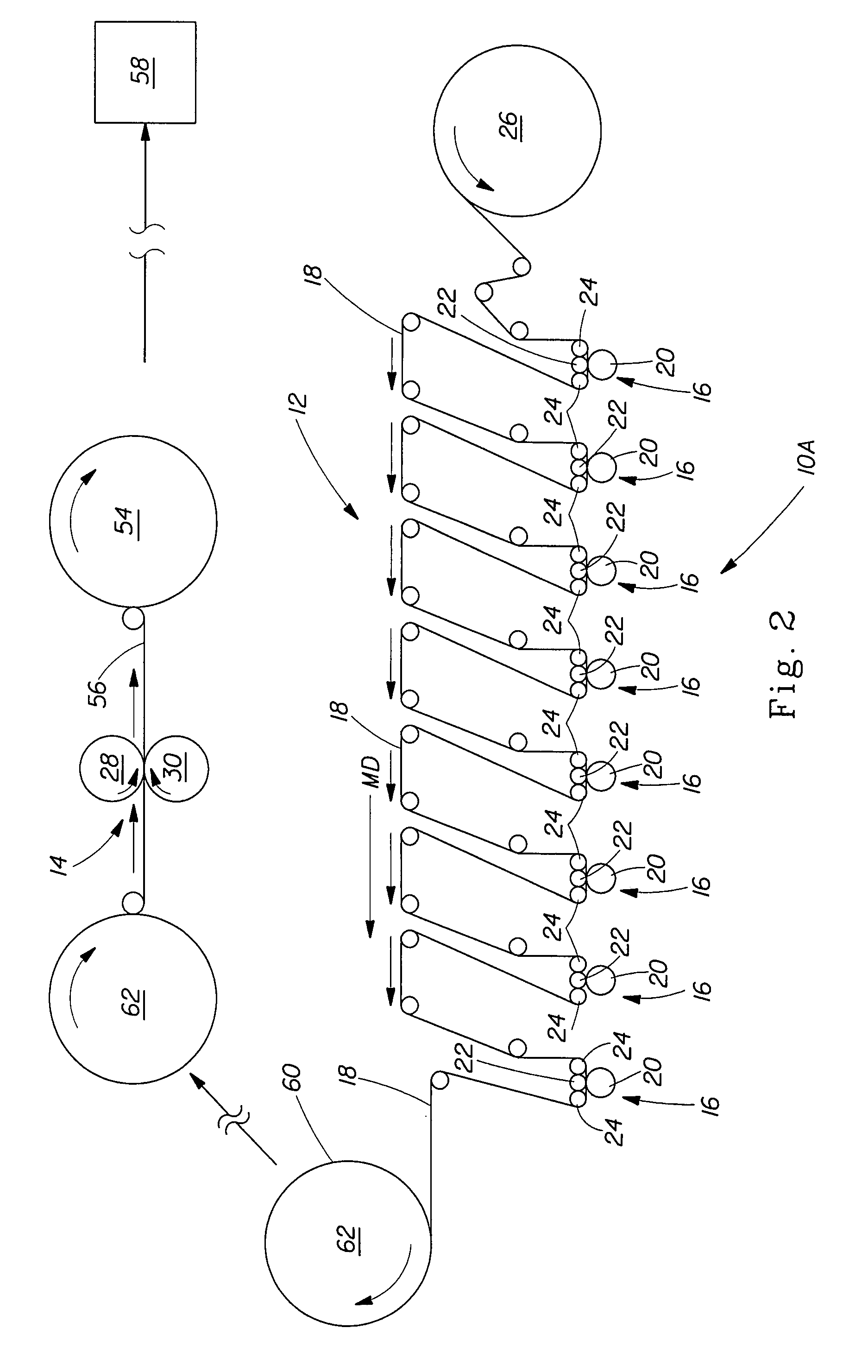

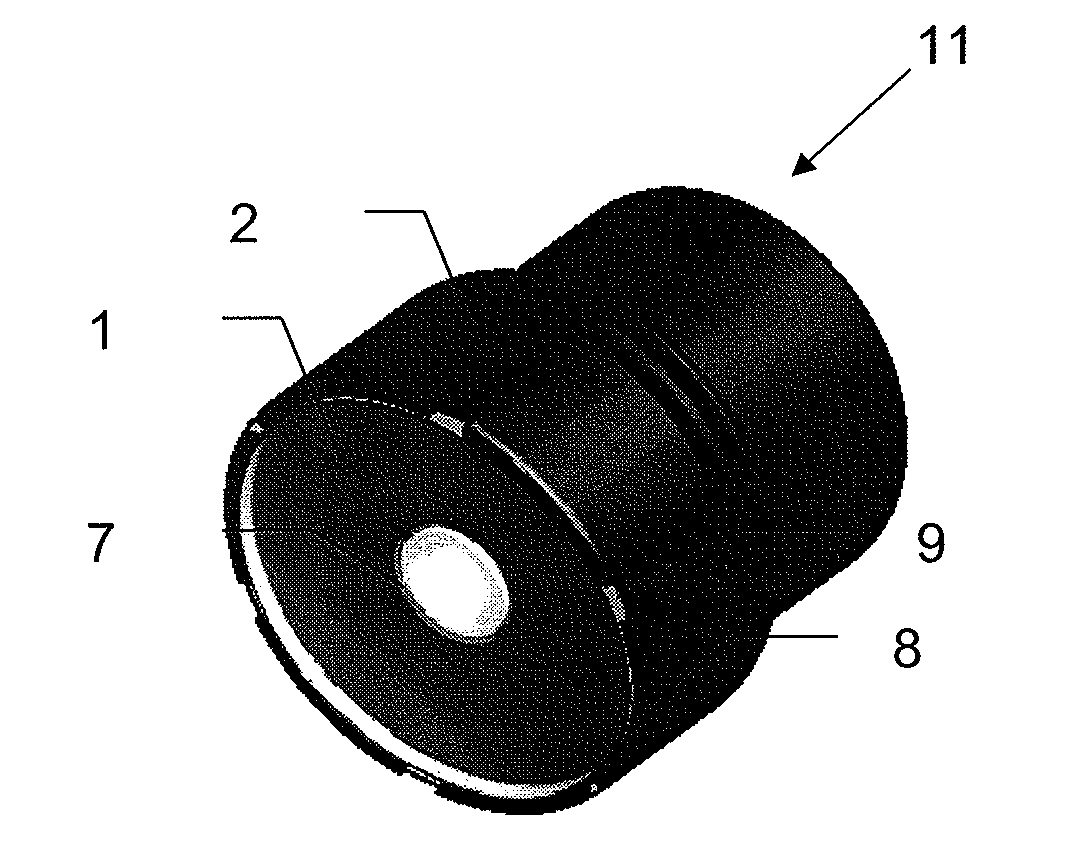

Method for manufacturing a membrane and object provided with such a membrane

InactiveUS20100109480A1Simple and efficientUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyUltrasonic sensorMembrane configuration

The present invention relates to a method for manufacturing a membrane or wall (3) of a material, which is capable of vapour / vacuum deposition, over an opening of an object (2). The method includes: placing the opening with a defined rim against a backing surface (4) coated with a layer (5) repellent to the depositable material; depositing of the depositable material on the object (2) and the backing surface (4) to form an element; separation of the element from the hacking surface (4) leaving a membrane (3) integral with the element. The invention also relates to such an object provided with a membrane (3), and particularly an ultrasonic transducer (11) provided with a front membrane (3).

Owner:ULTRAZONIX DNT

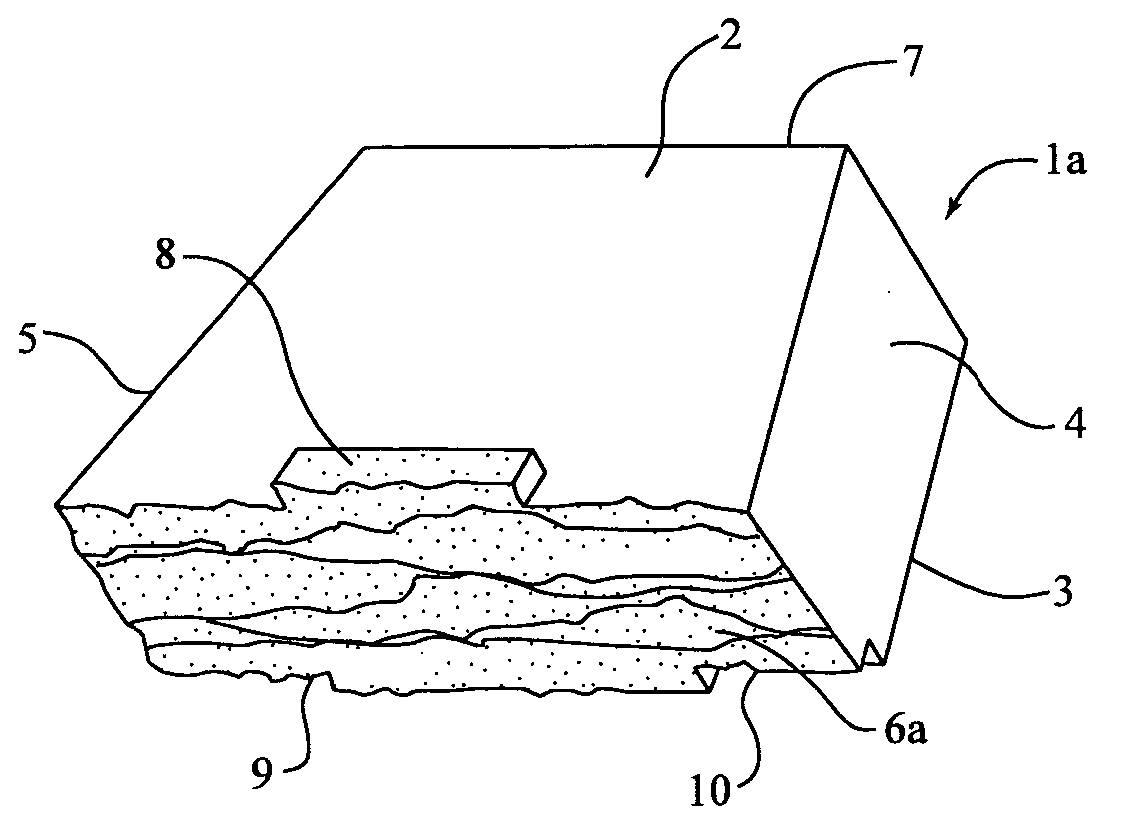

Multilayer containers and process for forming multilayer containers

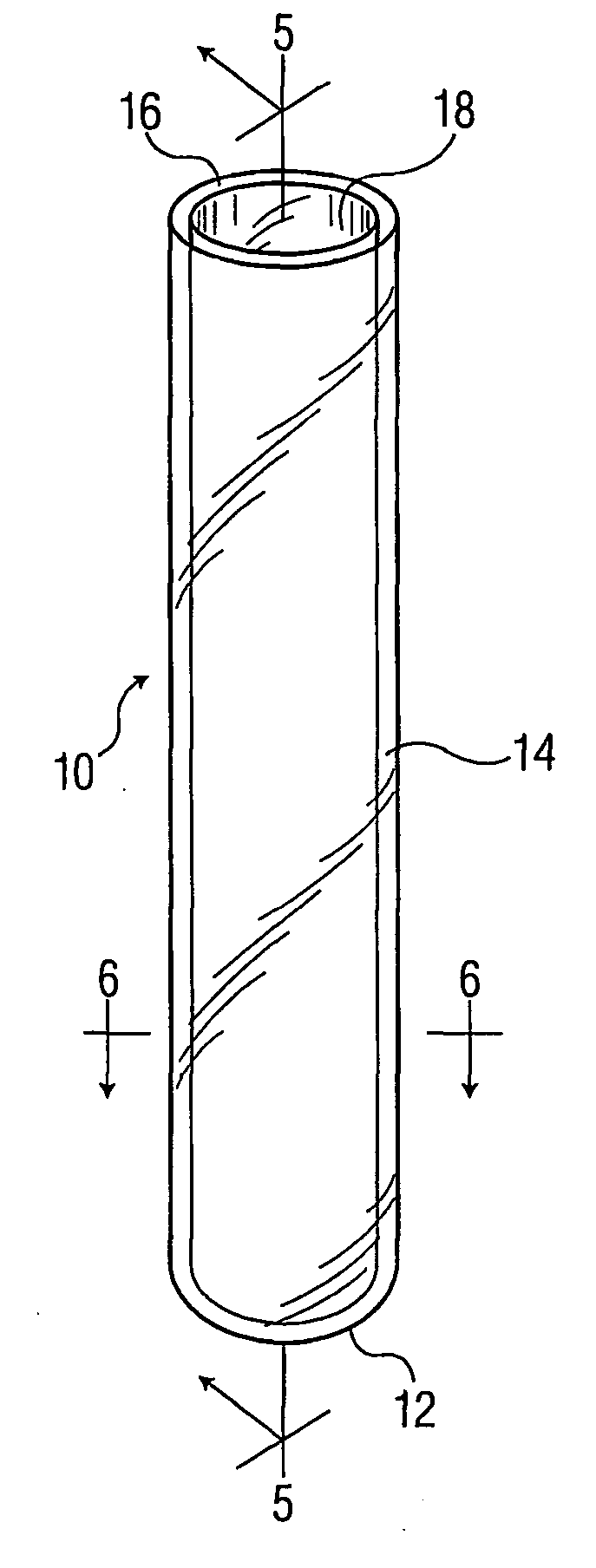

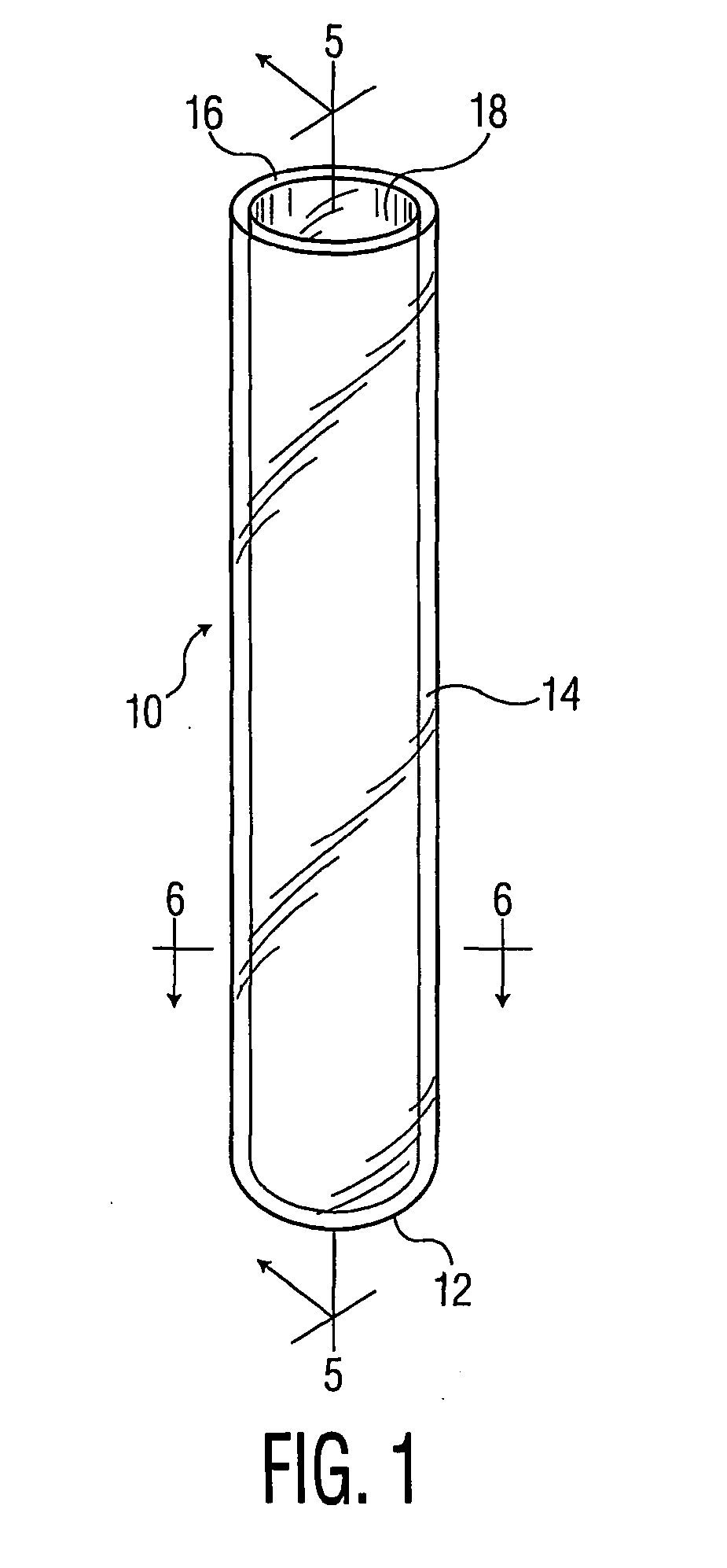

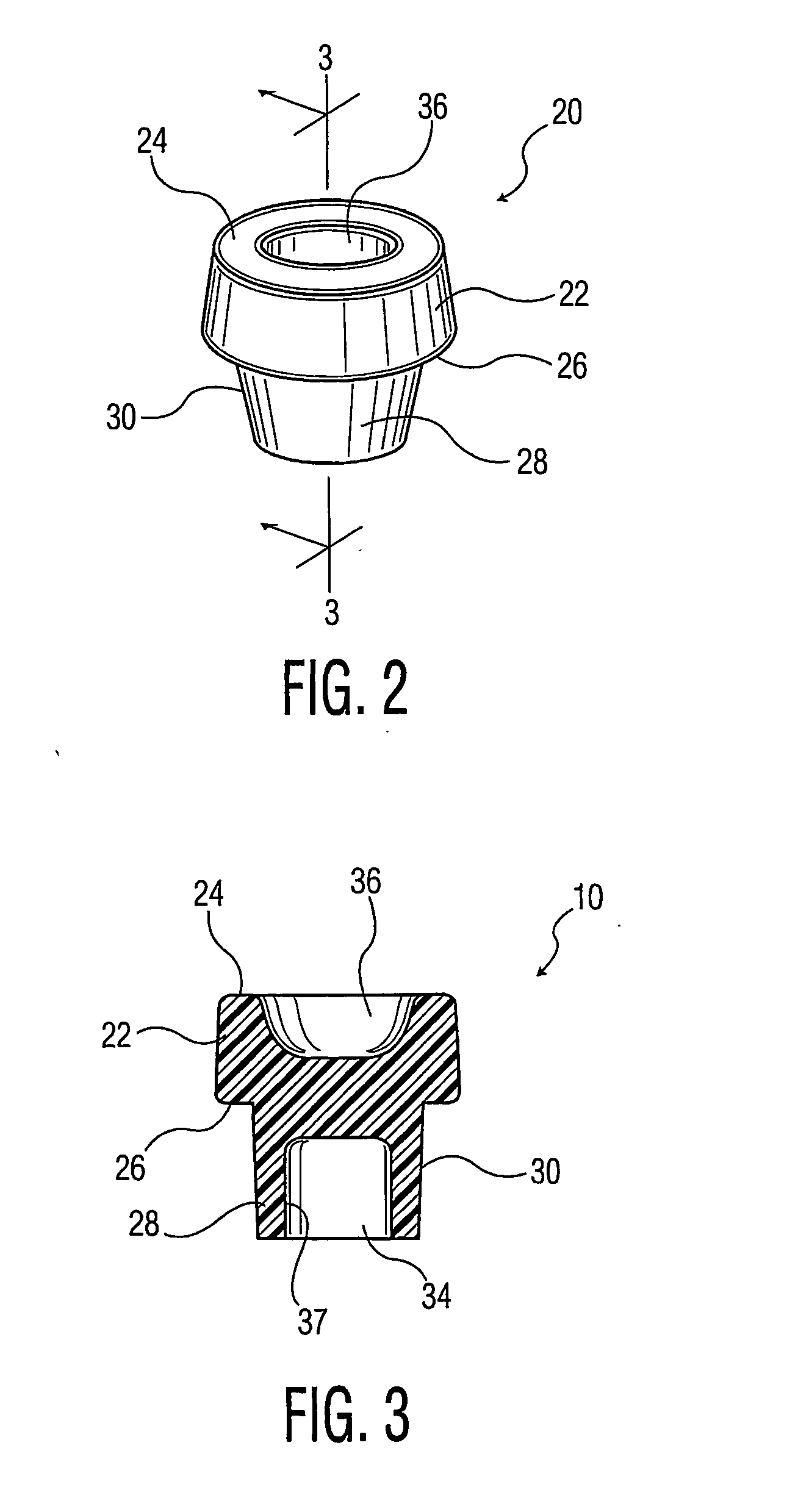

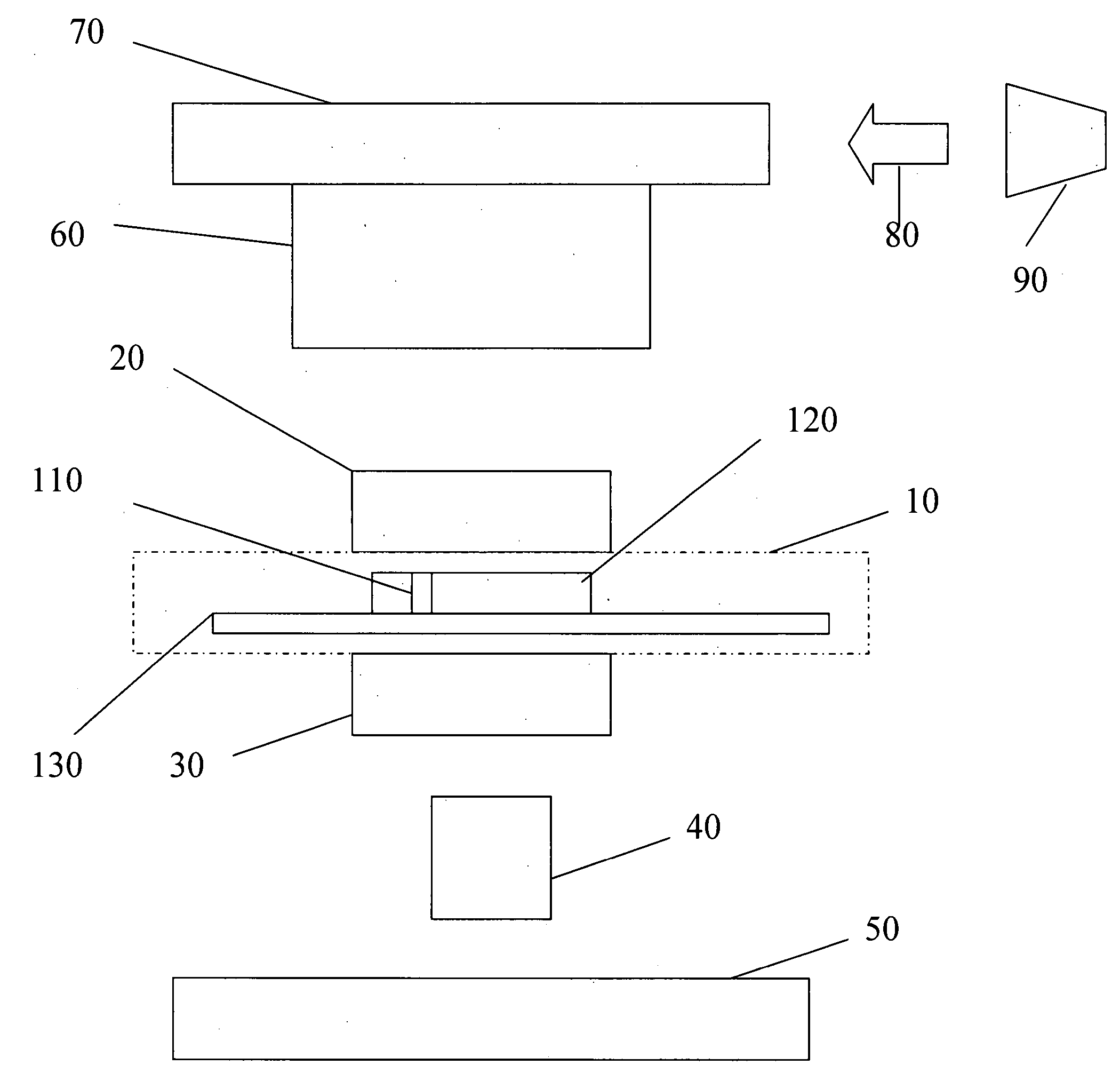

A co-injection process is provided for fabricating improved multi-layer containers, including but not limited to blood collection tubes, evacuated blood collection tubes, culture bottles, centrifuges tubes, and syringe barrels. The container includes a tube (10) having a bottom wall (12) and a side wall (14) with an open end (18). The container can be provided with a stopper having an upper portion (22) and a skirt with an outside portion (30), a well (34) and a cavity (36). The tube and stopper assembly can be used for medical purposes including containing a blood sample within an enclosed interior space (40).

Owner:BECTON DICKINSON & CO

Fluorescence detector, filter device and related methods

ActiveUS20080013092A1Small sizeIncrease costSemi-permeable membranesDischarging arrangementAntigenFluorescent light

Microfluidic assay detectors and microfluidic assay detection methods are disclosed. A microfluidic chip is coupled to a light emitting device, emission filters and excitation filters. Excited fluorescent light is detected by a camera and a lens. The correspondent reading allows parallel detection of features such as antigens and biomarkers. A microfluidic filter and related methods are also disclosed. The filter can be used with on-chip fluid filtration such as whole blood filtration for microfluidic blood analysis. The filter is able to filter the necessary volume of fluid and in particular blood in an acceptable time frame.

Owner:CALIFORNIA INST OF TECH

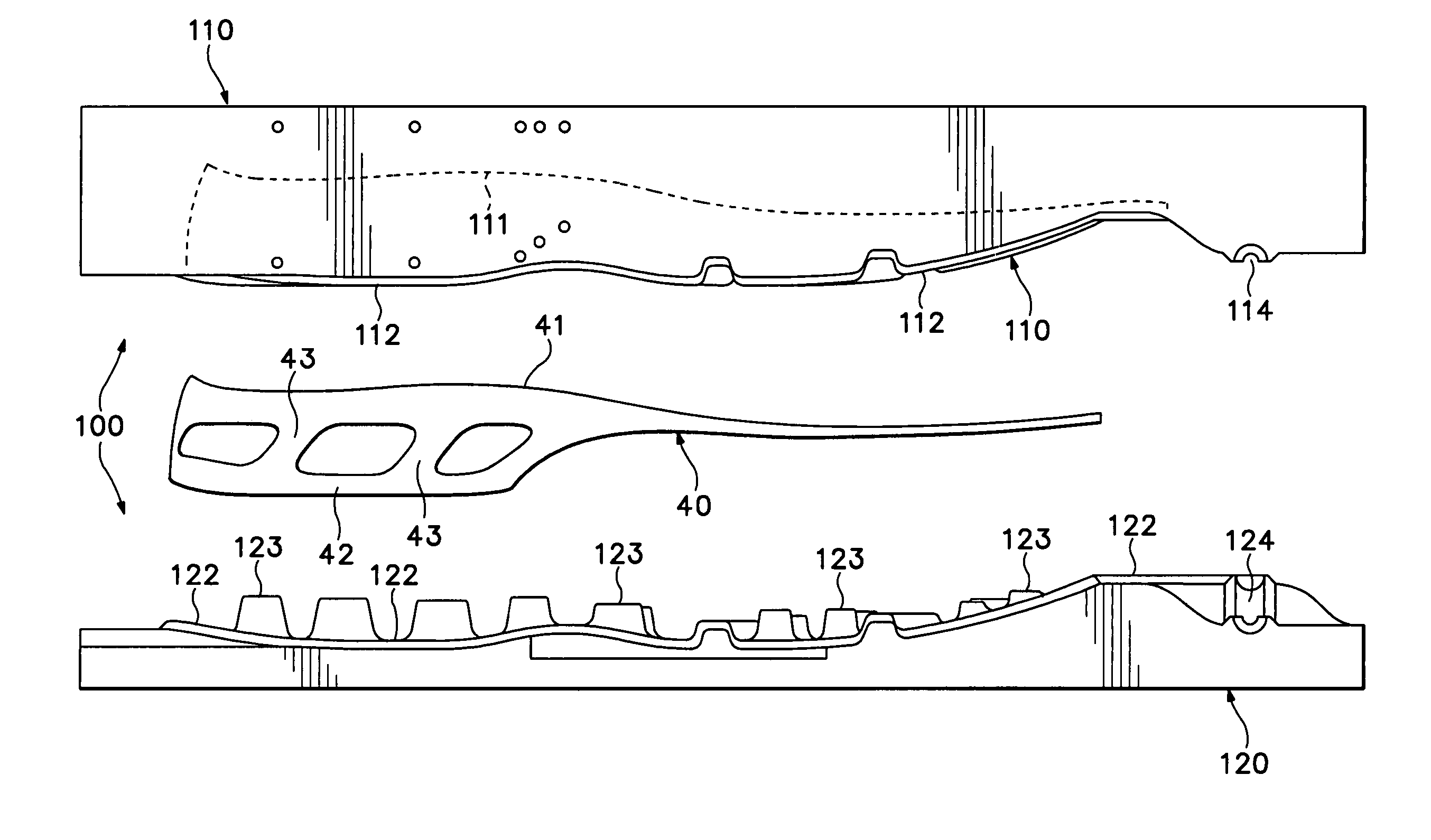

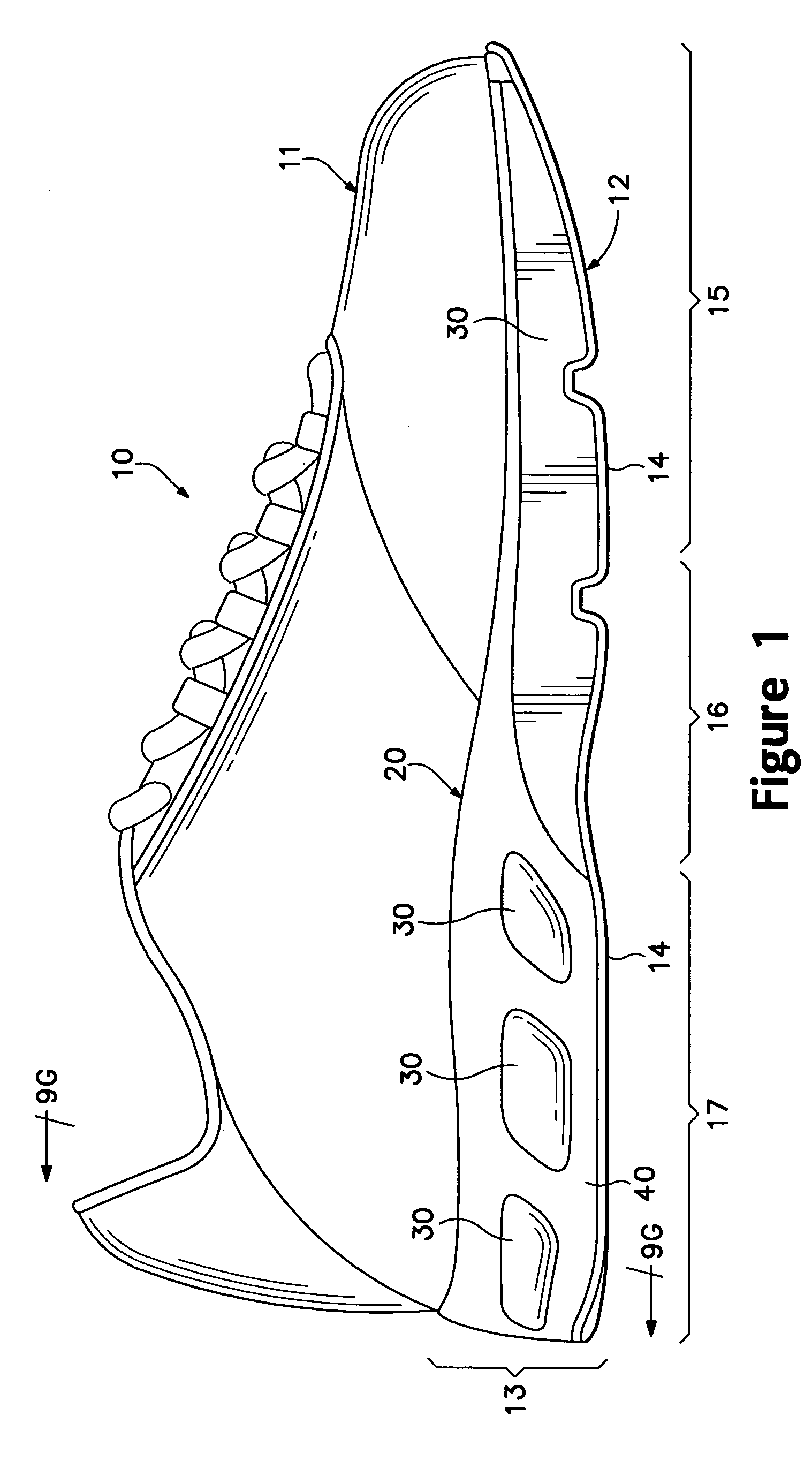

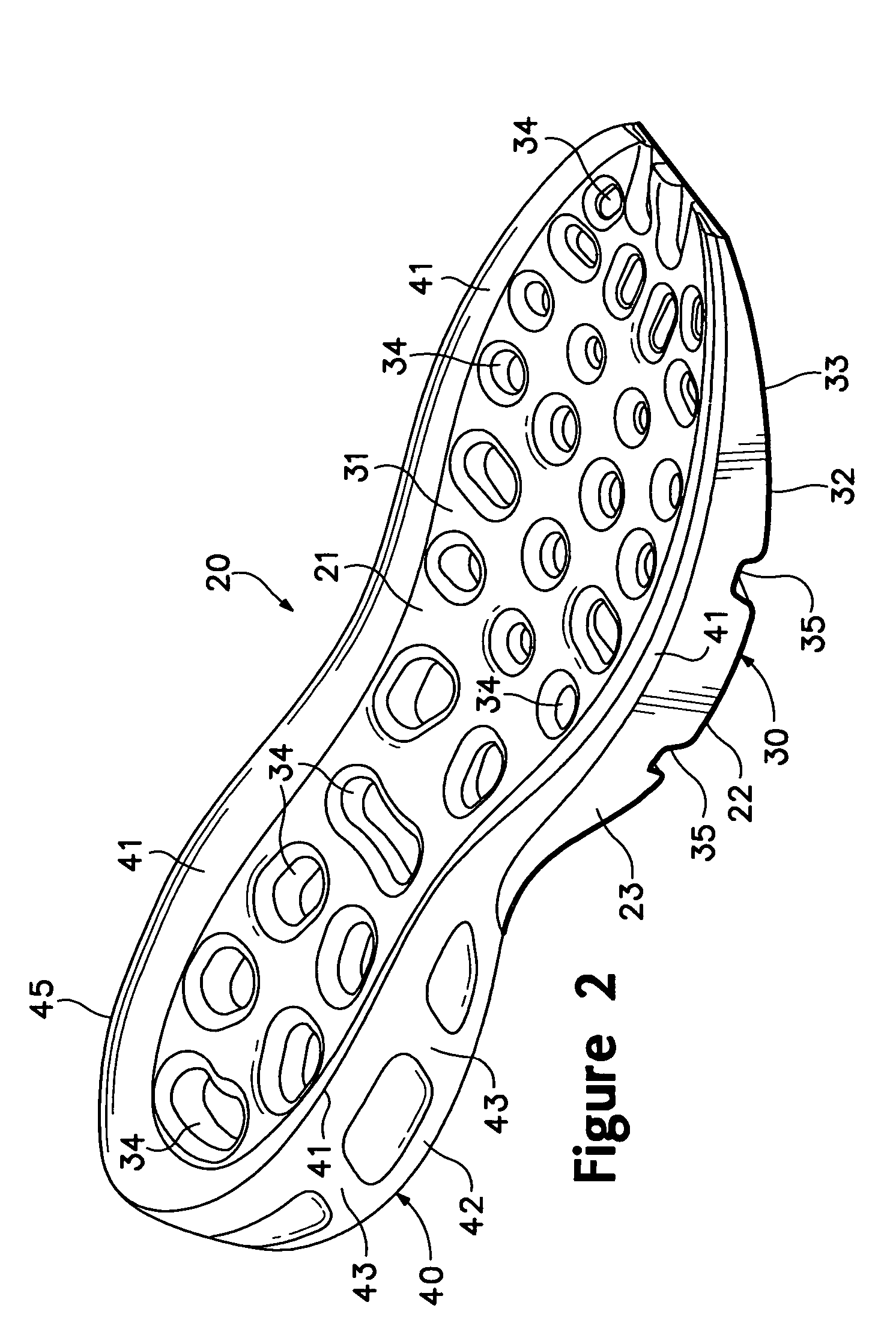

Method of making article of footwear having a fluid-filled bladder with a reinforcing structure

Owner:NIKE INC

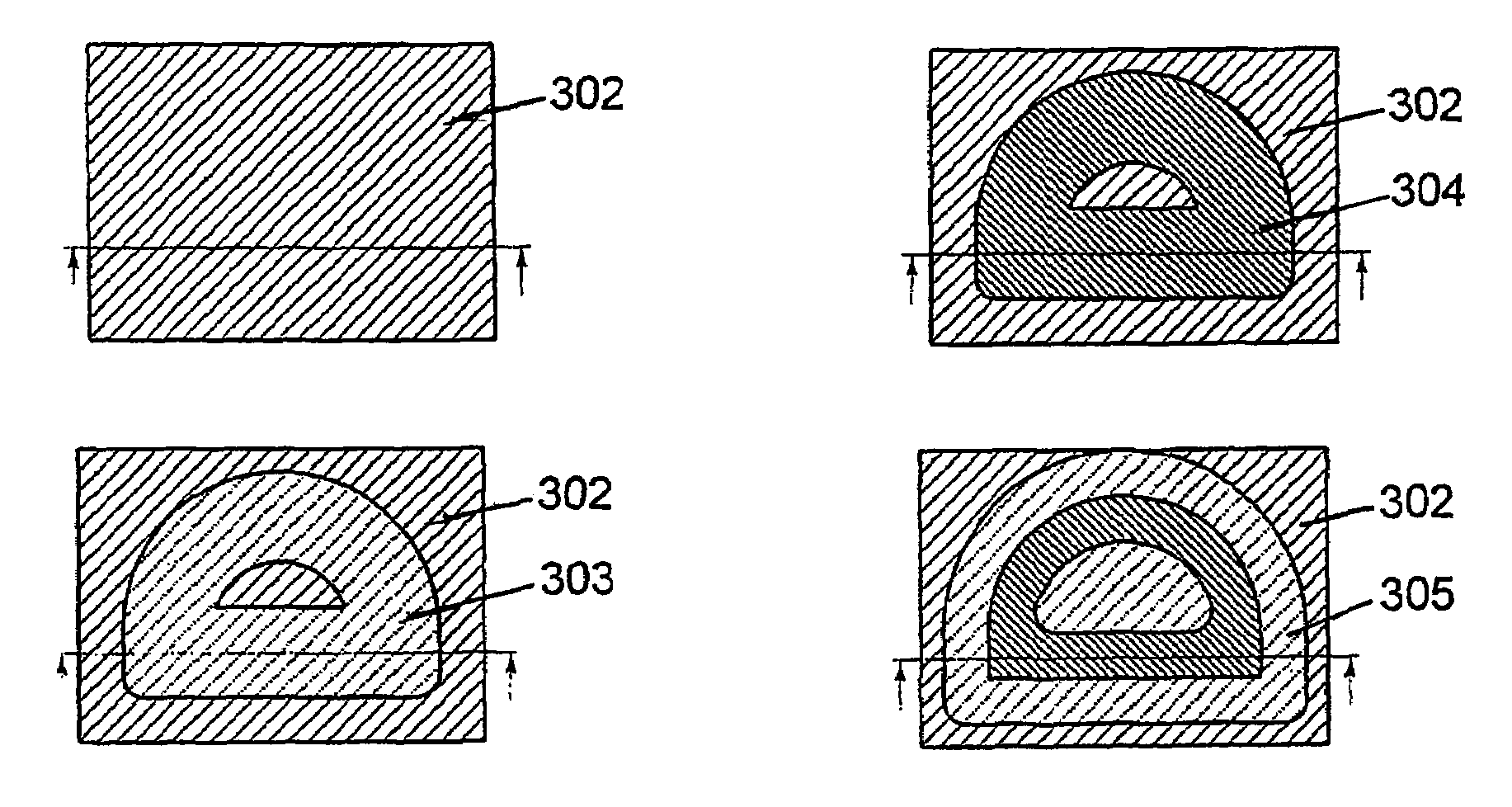

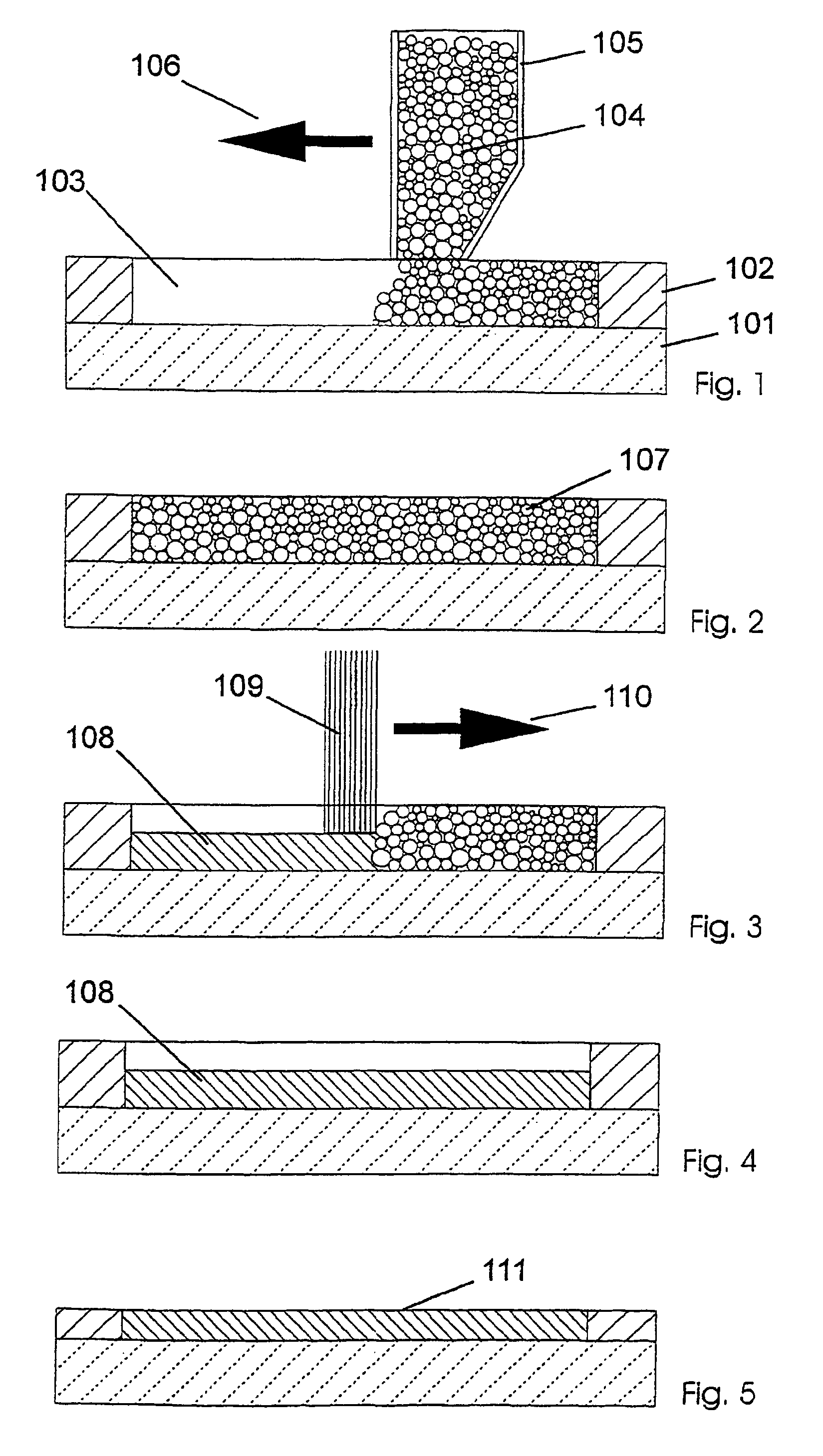

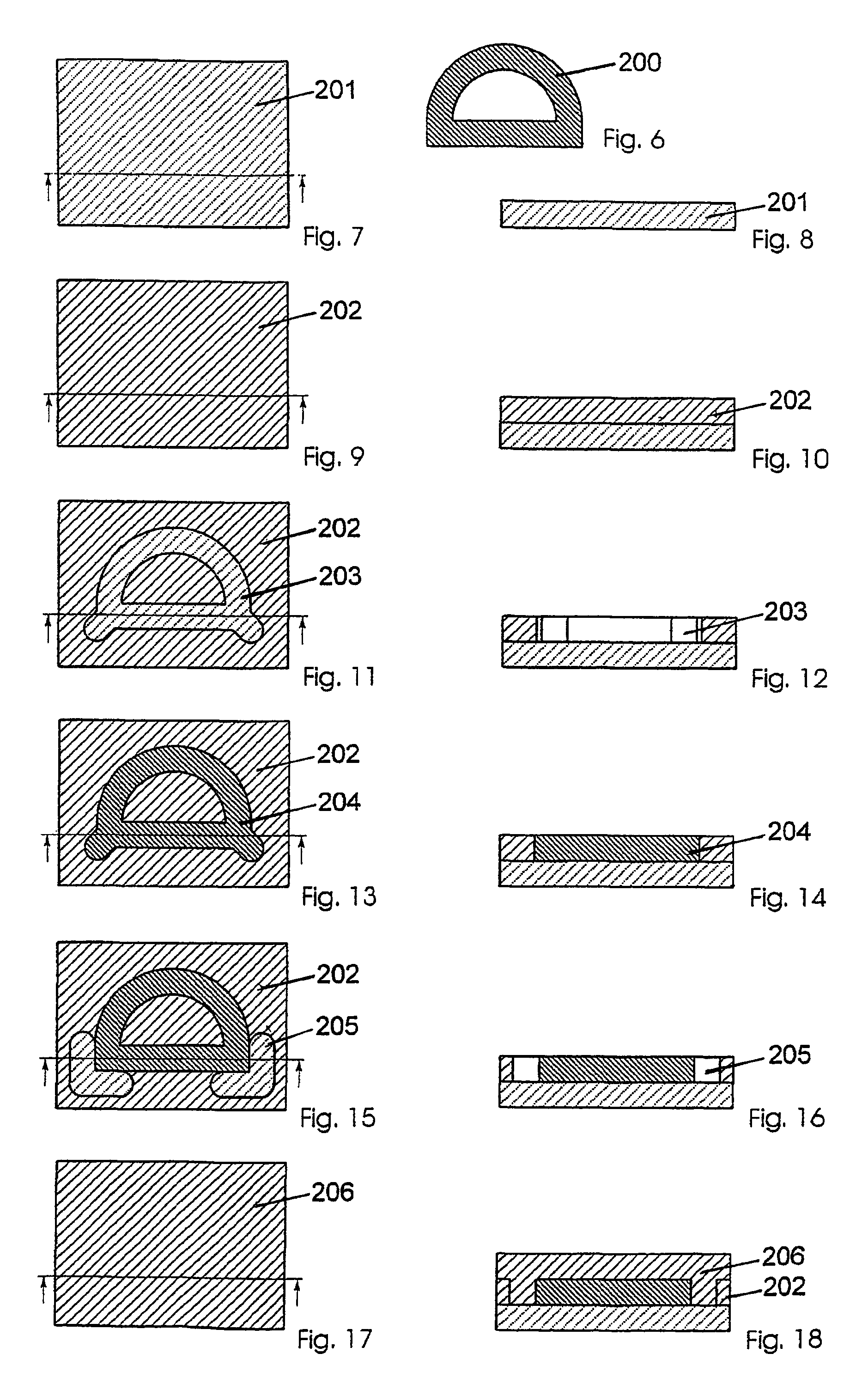

Method for producing a part and device for carrying out this method

InactiveUS7003864B2Faster machinabilityReduced tool wearMouldsWood working apparatusEngineeringRapid prototyping

The present invention relates to a method for producing a part (108, 200, 300), comprising the following steps:a) applying a first flat layer consisting of a support material (102, 202, 302), to a construction platform (101, 201, 301),b) introducing at least one recess (103, 203, 303) into the support material (102, 202, 302),c) filling the recess (103, 203, 303) with a construction material (104, 204, 304),d) applying a further layer of support material (102, 202, 302),e) repeating steps b) through d) until completion of the part (108, 200, 300), andf) removing the support material (102, 202, 302).This method is to provide a manufacturing method and a device that combine the advantages of the layerwise construction (rapid prototyping) with the advantages of machining (e.g. high-speed cutting) and particularly permit the production of sharp-edged contours.Furthermore, the present invention relates to a device for carrying out the method.

Owner:HERMLE MASCHENBAU

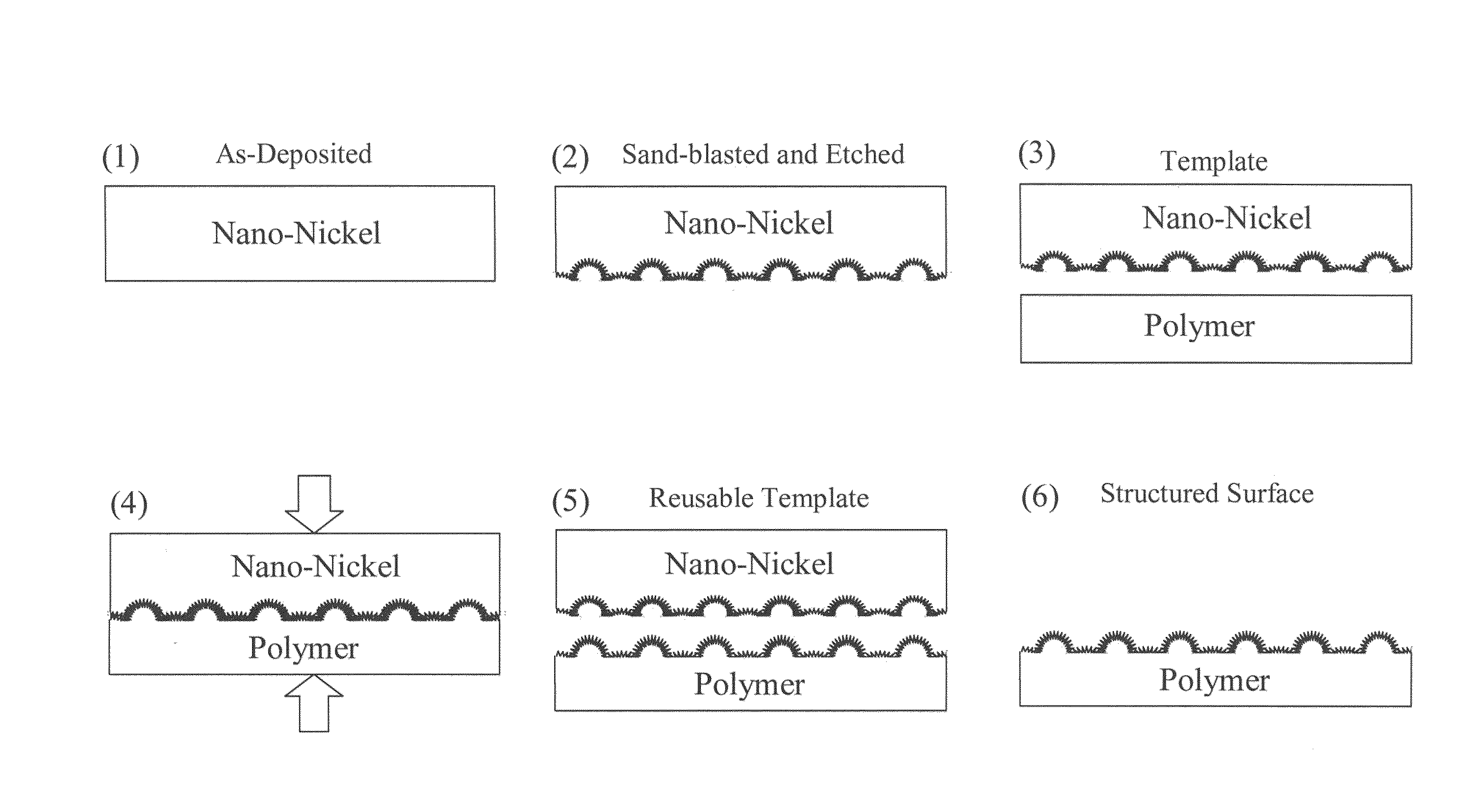

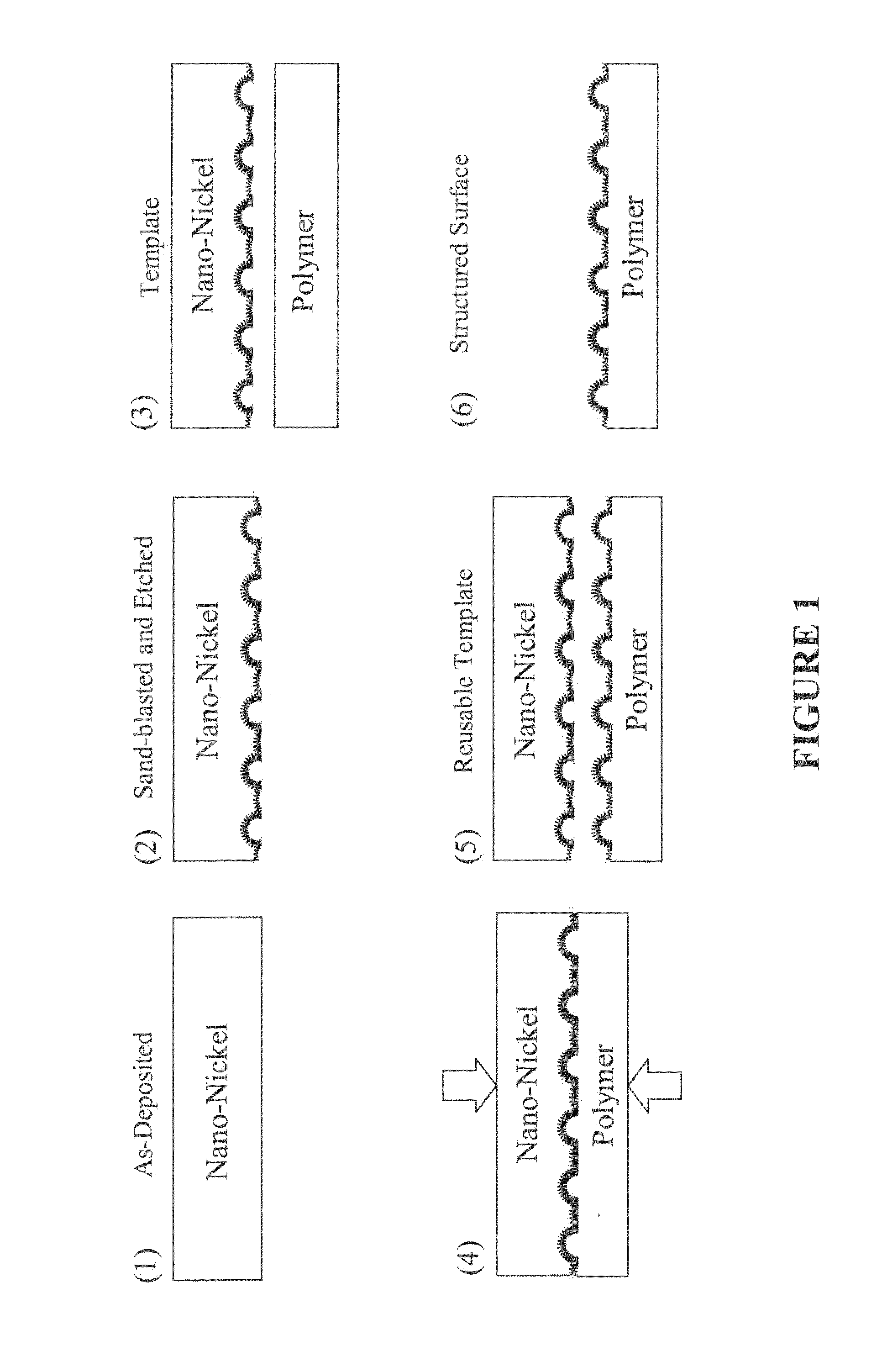

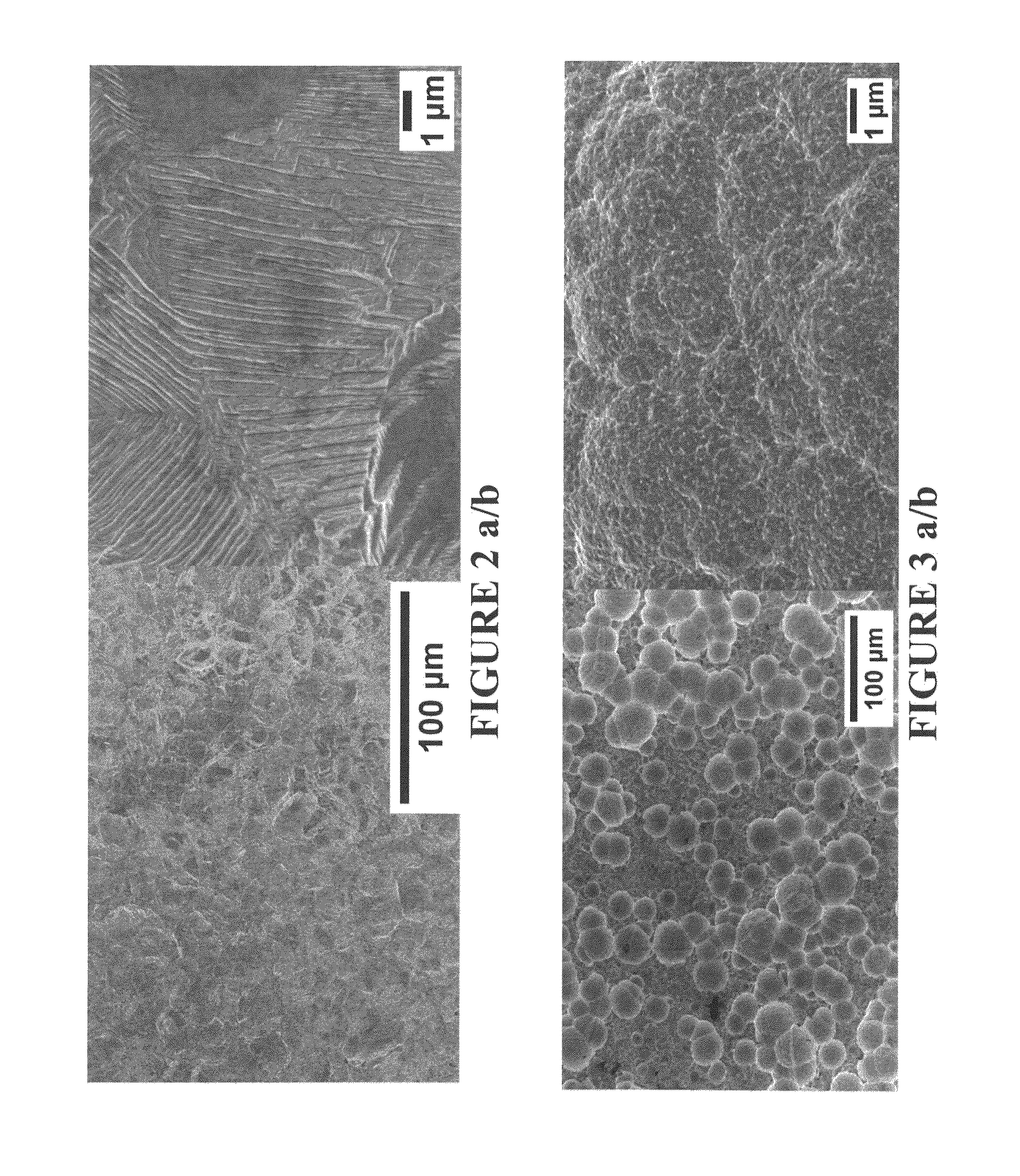

Articles with super-hydrophobic and/or self-cleaning surfaces and method of making same

ActiveUS20110287203A1Lower contact angleLarge scaleDischarging arrangementMouldsFine grainSelf-cleaning surfaces

Super-hydrophobic and self-cleaning articles produced by imprinting exposed surfaces with suitable fine-grained and / or amorphous metallic embossing dies to transfer a dual surface structure, including ultra-fine features less than or equal to 100 nm embedded in and overlaying a surface topography with macro-surface structures greater than or equal to 1 micron are disclosed.

Owner:INTEGRAN TECH

Silicones having improved chemical resistance and curable silicone compositions having improved migration resistance

InactiveUS20050038188A1Improve the immunityTrend downMouldsSemiconductor/solid-state device detailsHydrogenHydrogen atom

A composition is prepared by mixing components including: (I) a polyorganosiloxane having an average of at least two unsaturated organic groups per molecule, with the proviso that component (I) is free of fluorine atoms; optionally (II) an organohydrogenpolysiloxane having an average of at least two silicon-bonded hydrogen atoms per molecule, with the proviso that component (II) is free of fluorine atoms; (III) a hydrosilylation catalyst; (IV) a fluoroorganosilicone, with the provisos that (1) component (IV) has at least one functional group reactive with component (I), component (II), or both, (2) when component (II) is not present, then component (IV) has an average of at least two silicon-bonded hydrogen atoms per molecule, and (3) component (IV) is added to the composition in an amount sufficient to provide chemical resistance to a cured product of the composition; and (V) an adhesion promoter.

Owner:DOW CORNING CORP

Method and apparatus for making crystalline PET pellets

InactiveUS20050110182A1Reduce dwell timeIncrease speedMouldsDrying solid materials without heatSlurryCrystallinity

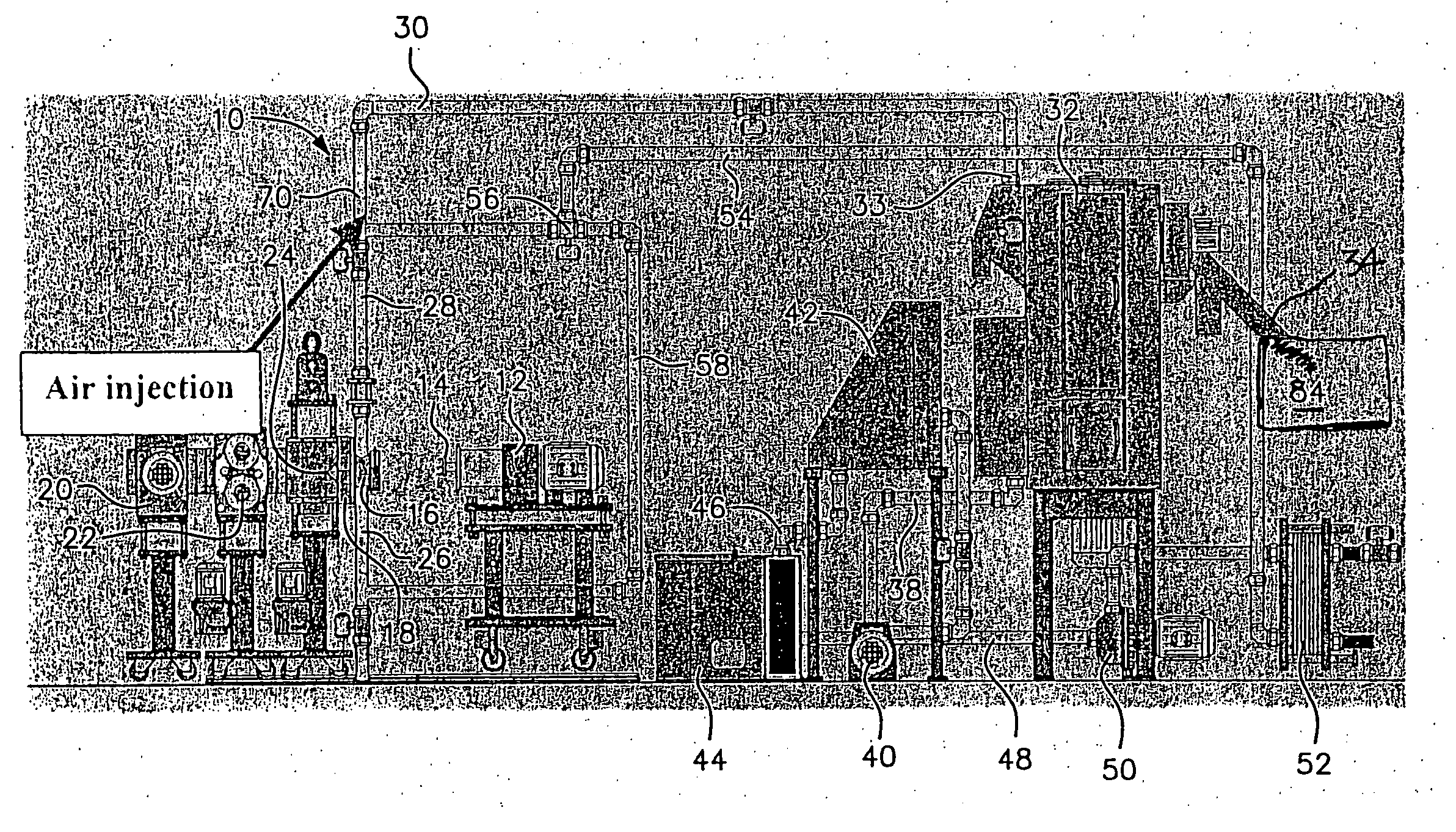

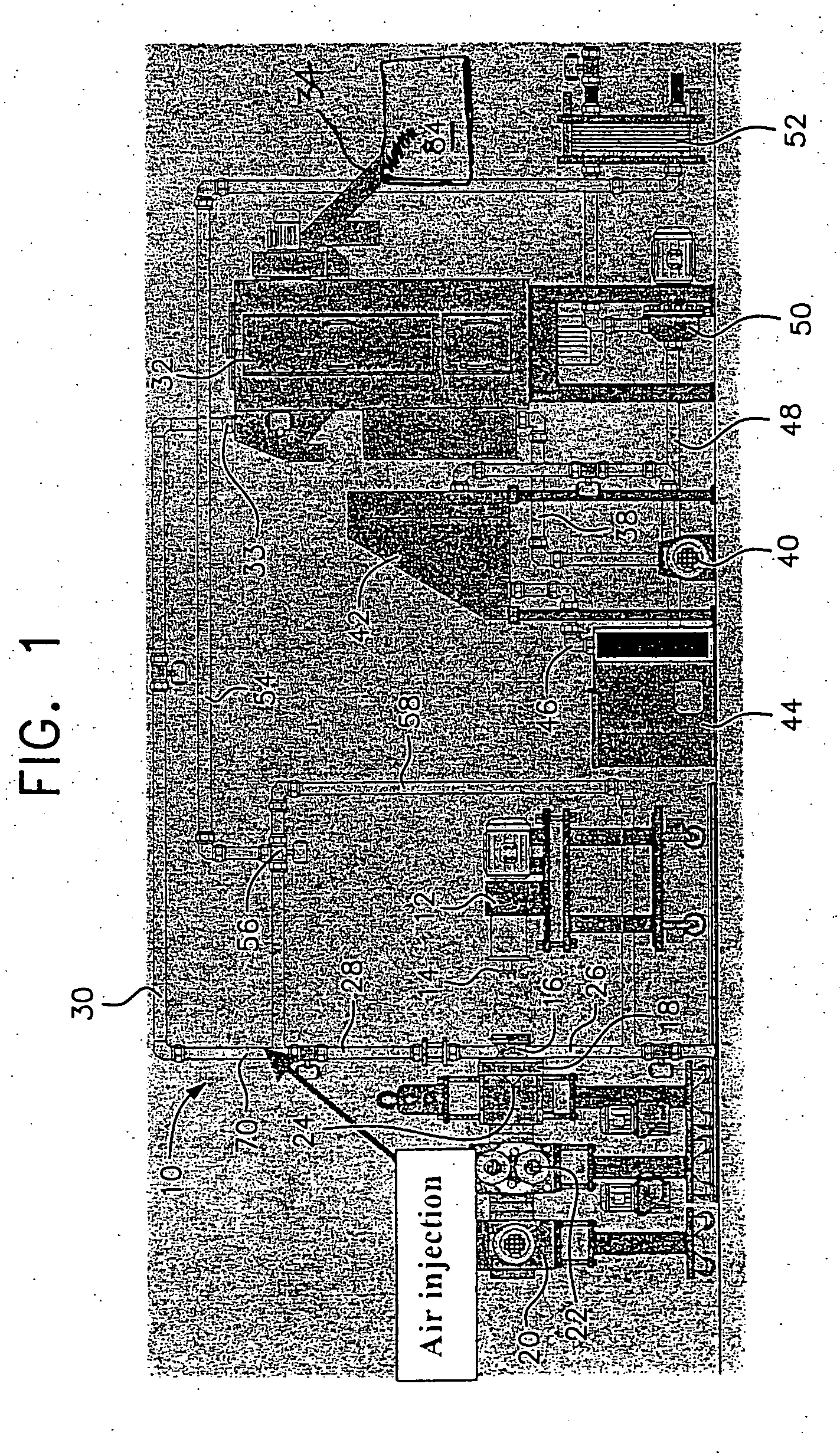

A method and apparatus for underwater pelletizing and subsequent drying of polyethylene terephthalate (PET) polymers and other high temperature crystallizing polymeric materials to crystallize the polymer pellets without subsequent heating. High velocity air or other inert gas is injected into the water and pellet slurry line to the dryer near the pelletizer exit. Air is injected into the slurry line at a velocity of from about 100 to about 175 m3 / hour, or more. Such high-speed air movement forms a vapor mist with the water and significantly increases the speed of the pellets into and out of the dryer such that the PET polymer pellets leave the dryer at a temperature sufficient to self-initiate crystallization within the pellets. A valve mechanism in the slurry line after the gas injection further regulates the pellet residence time and a vibrating conveyor after the dryer helps the pellets to achieve the desired level of crystallinity and to avoid agglomeration.

Owner:GALA INDUSTRIES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com