Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1235results about "Turning machine accessories" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

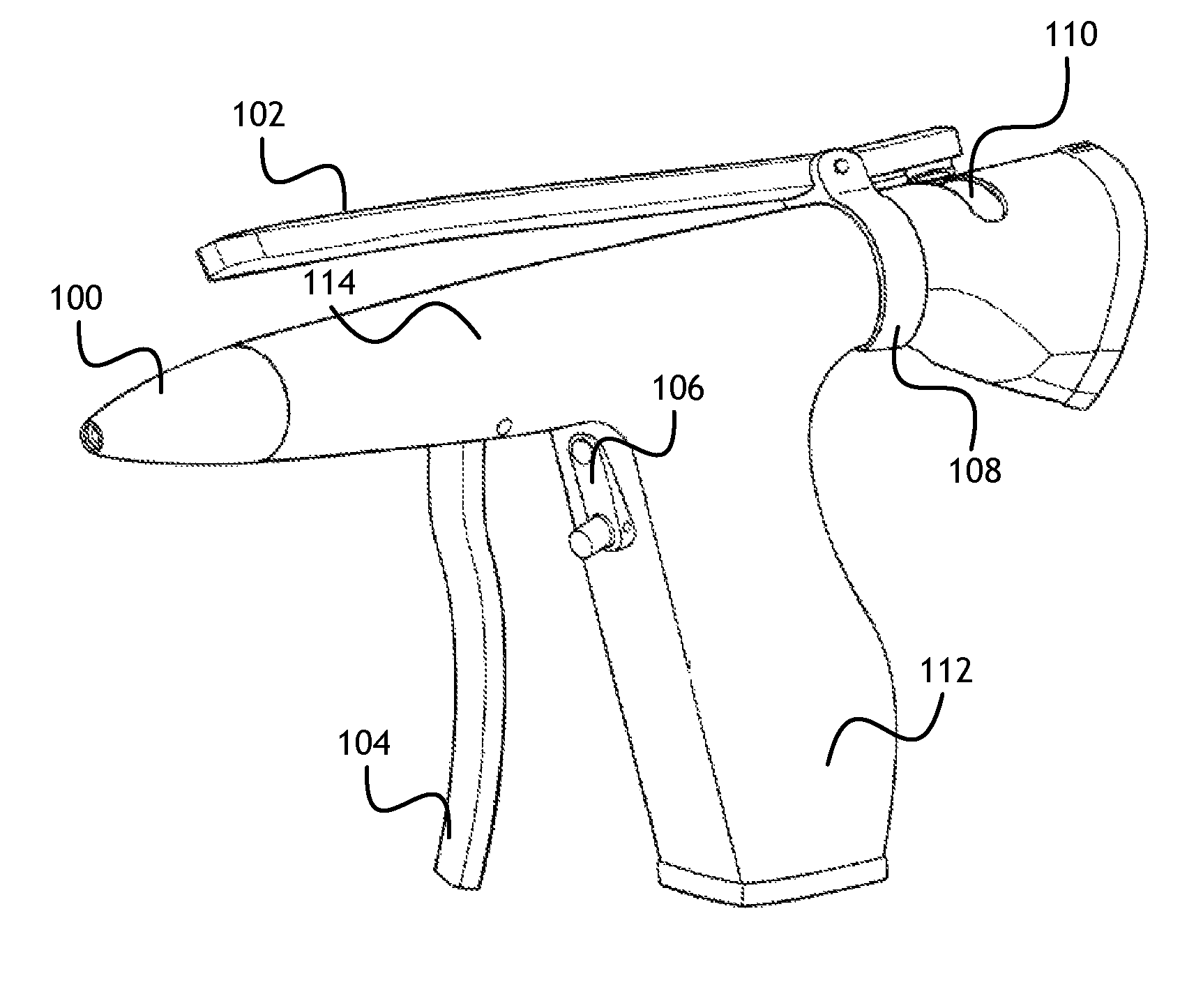

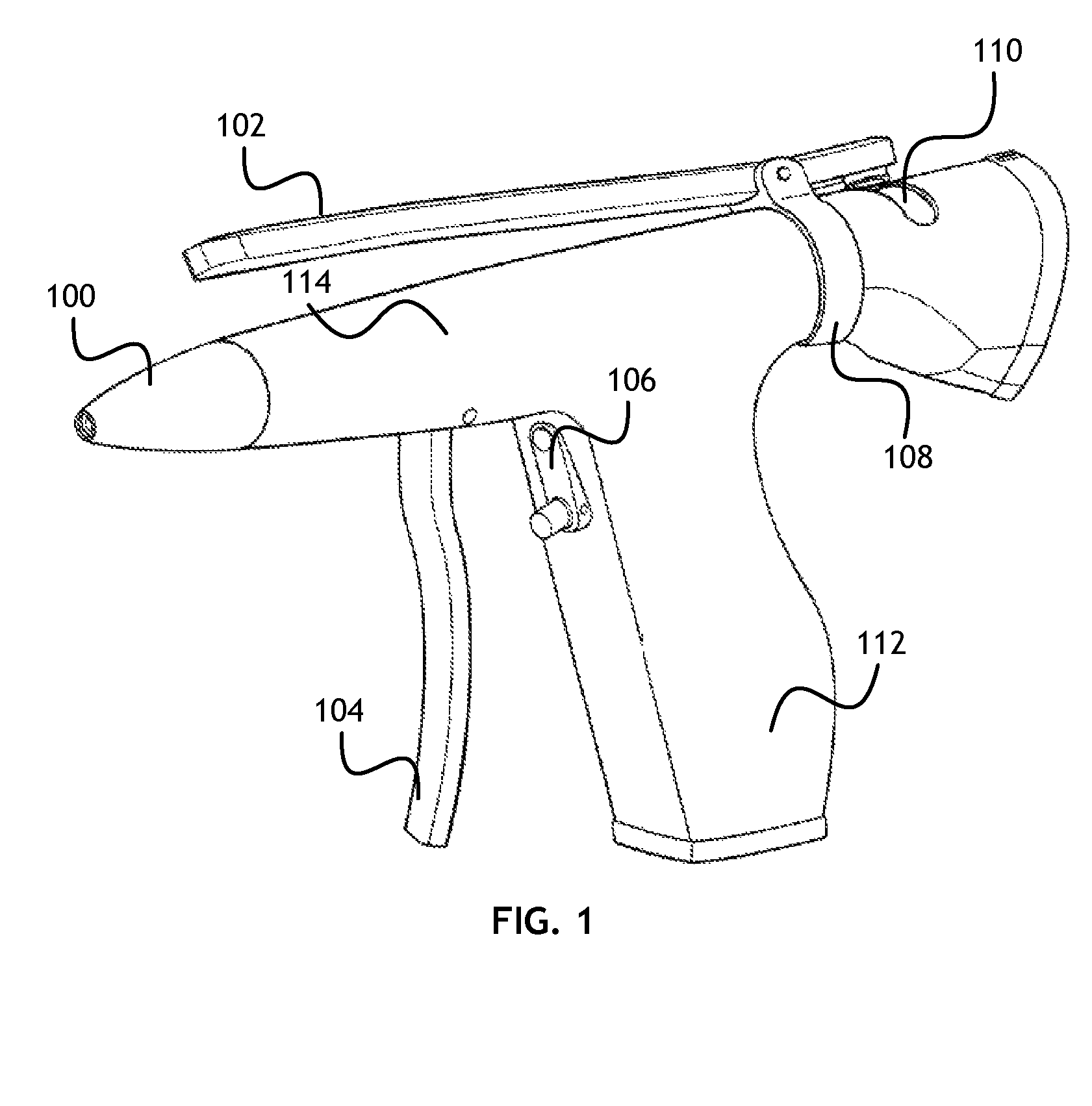

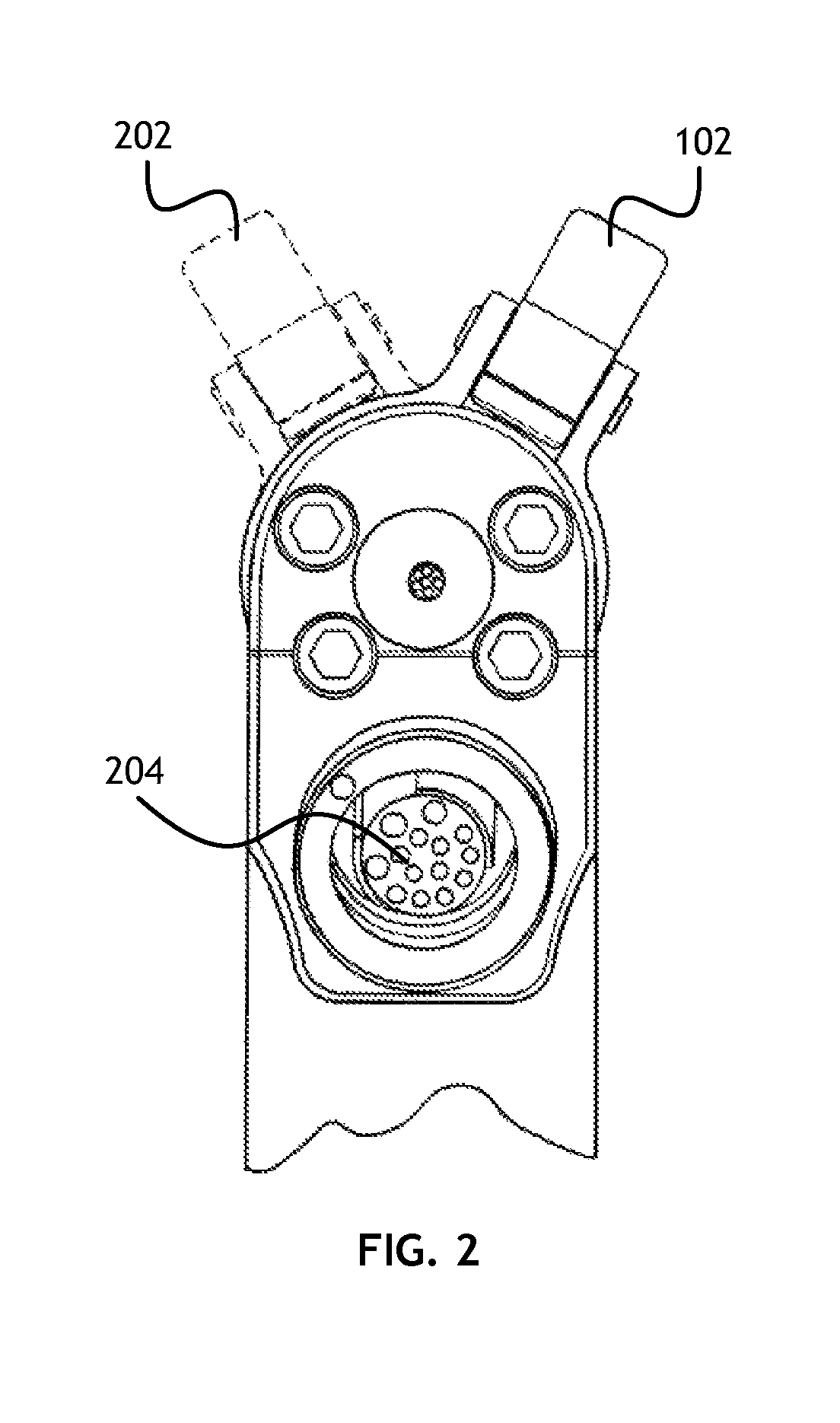

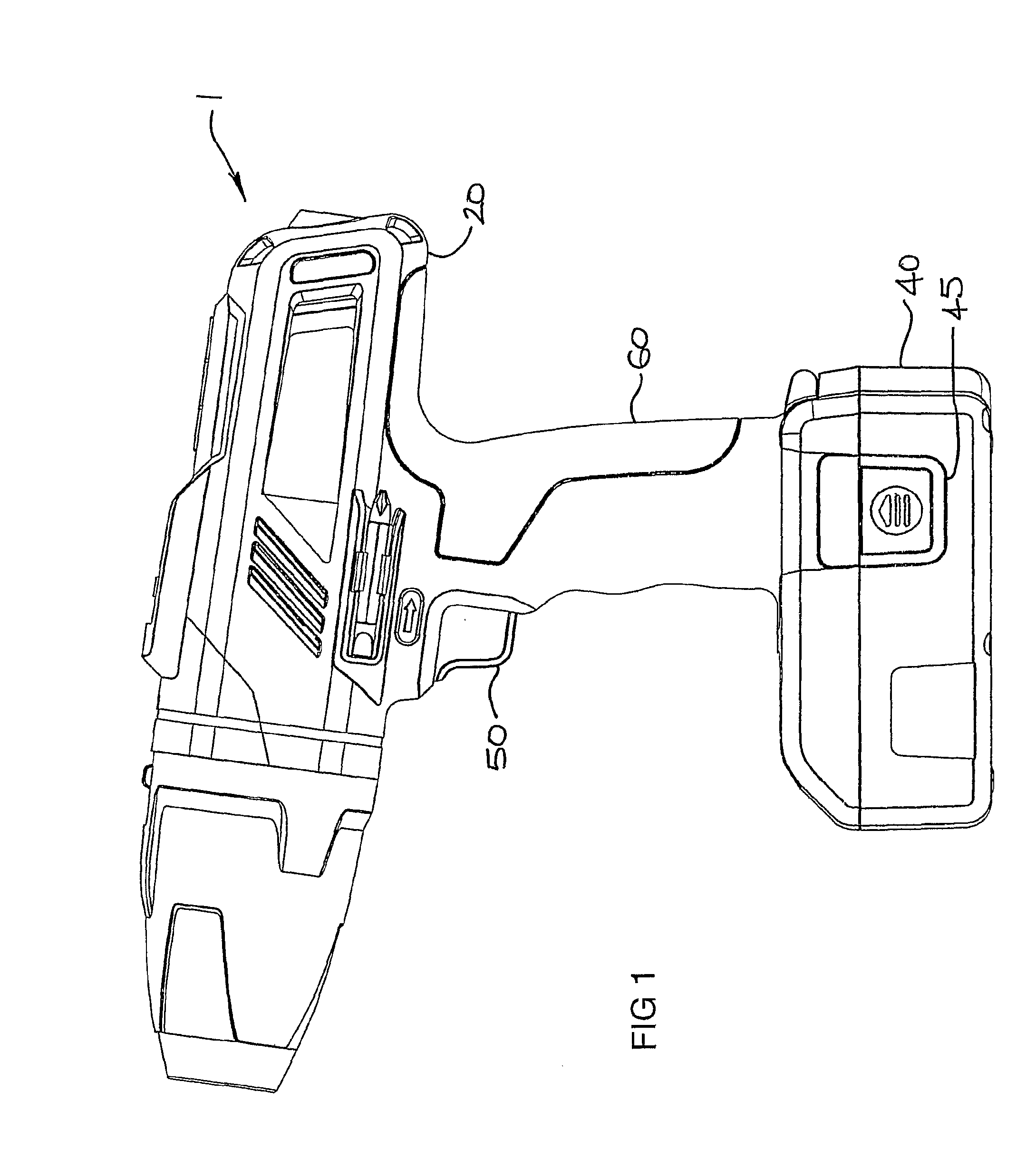

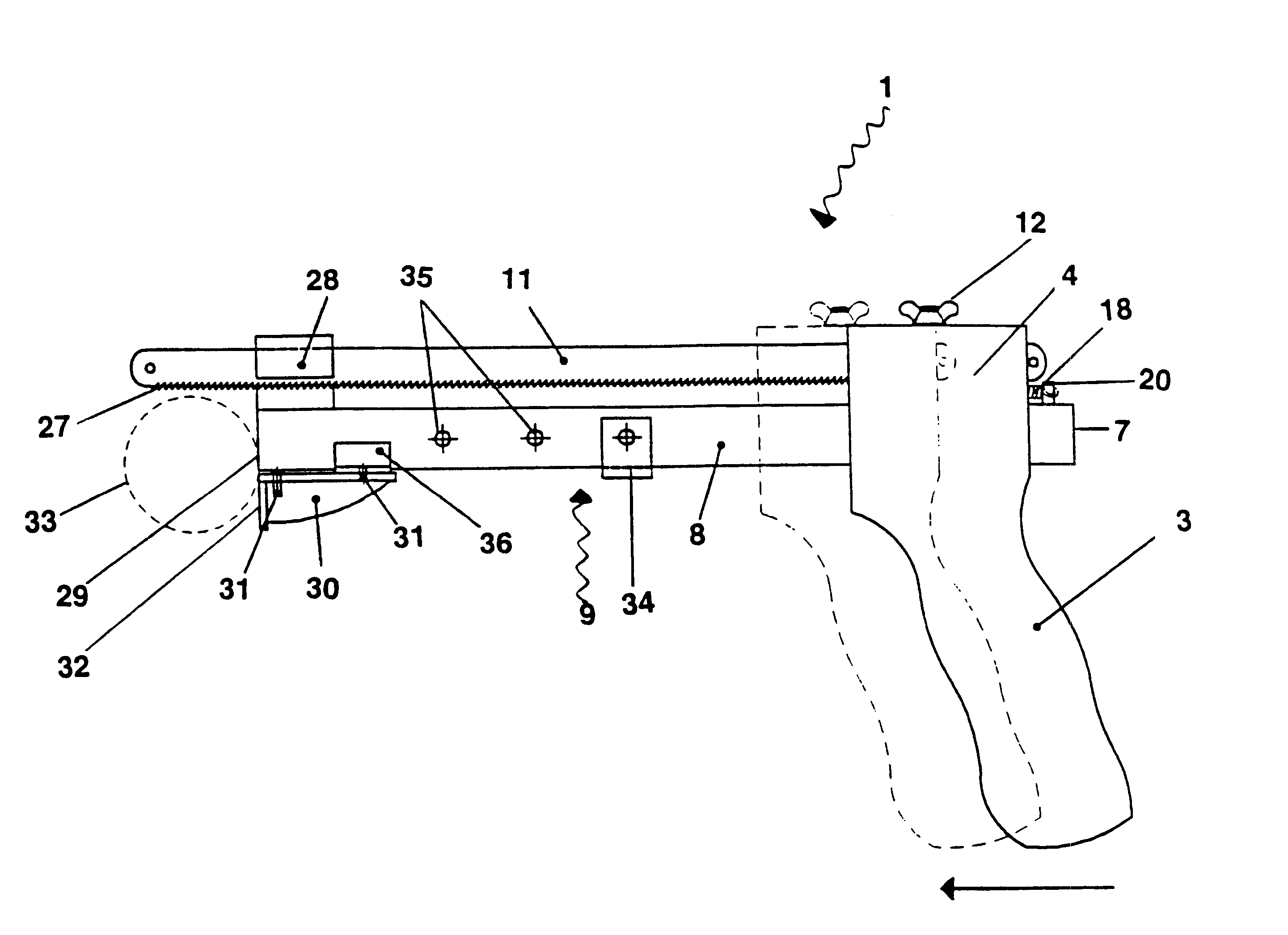

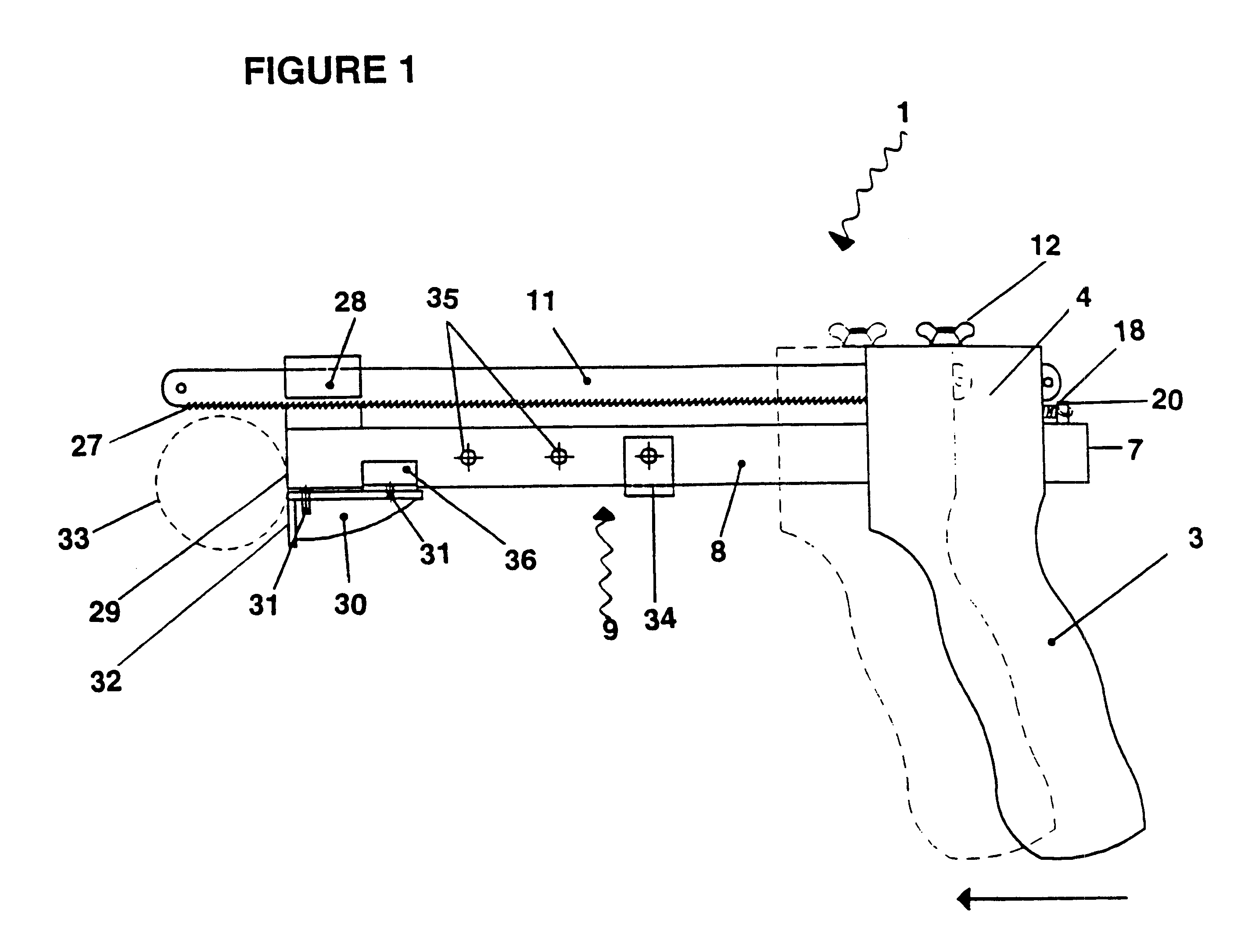

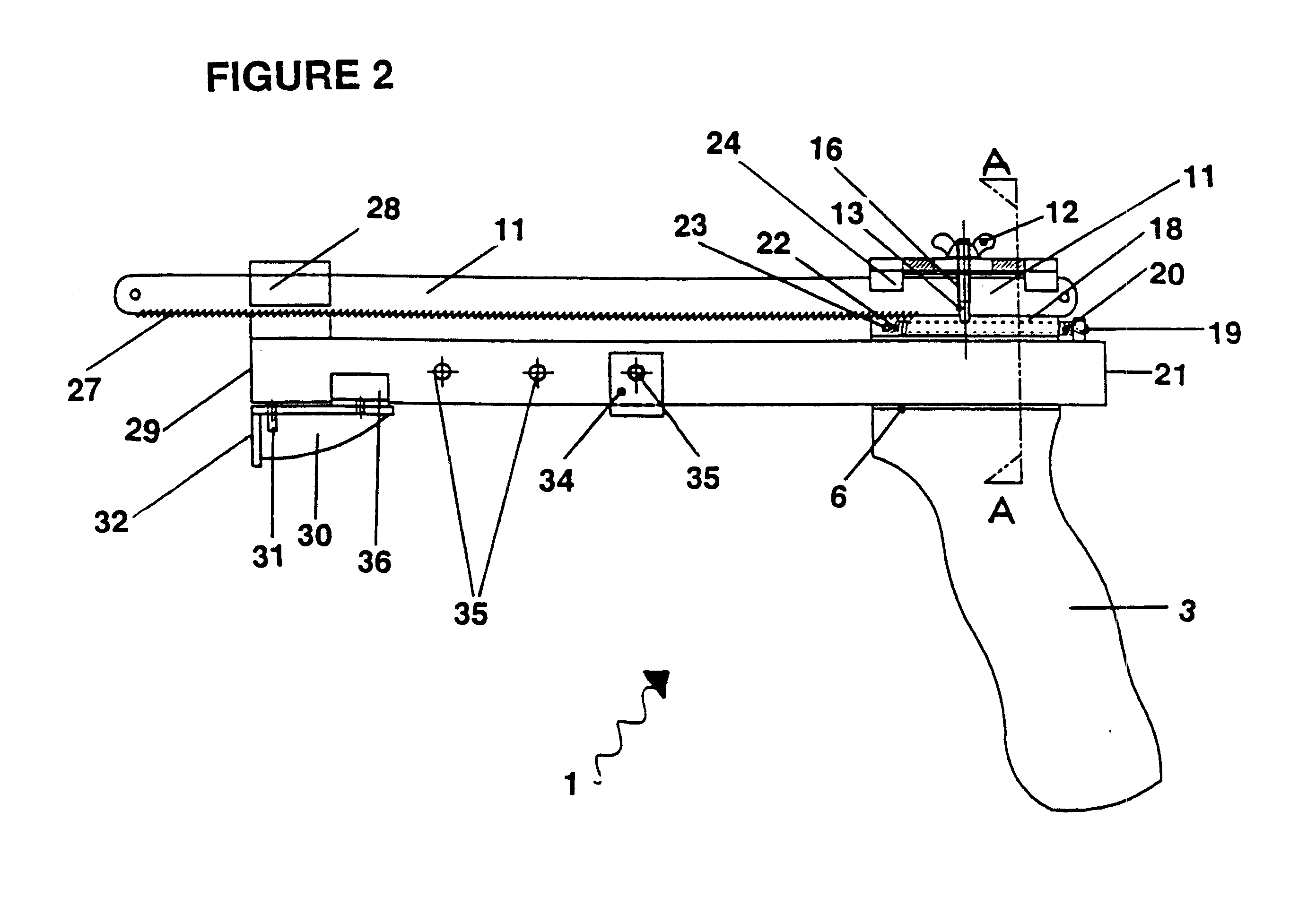

Method and device for ergonomically and ambidextrously operable surgical device

A handheld surgical device includes a multi-position throttle, rotatably attached to the body of the device, to allow for ambidextrous positioning of a motor speed control lever. The motor speed control lever may interact with a speed control sensor in the body of the device capable of detecting the actuation level of the motor speed control lever in any one of two or more positions.

Owner:MICROAIRE SURGICAL INSTR

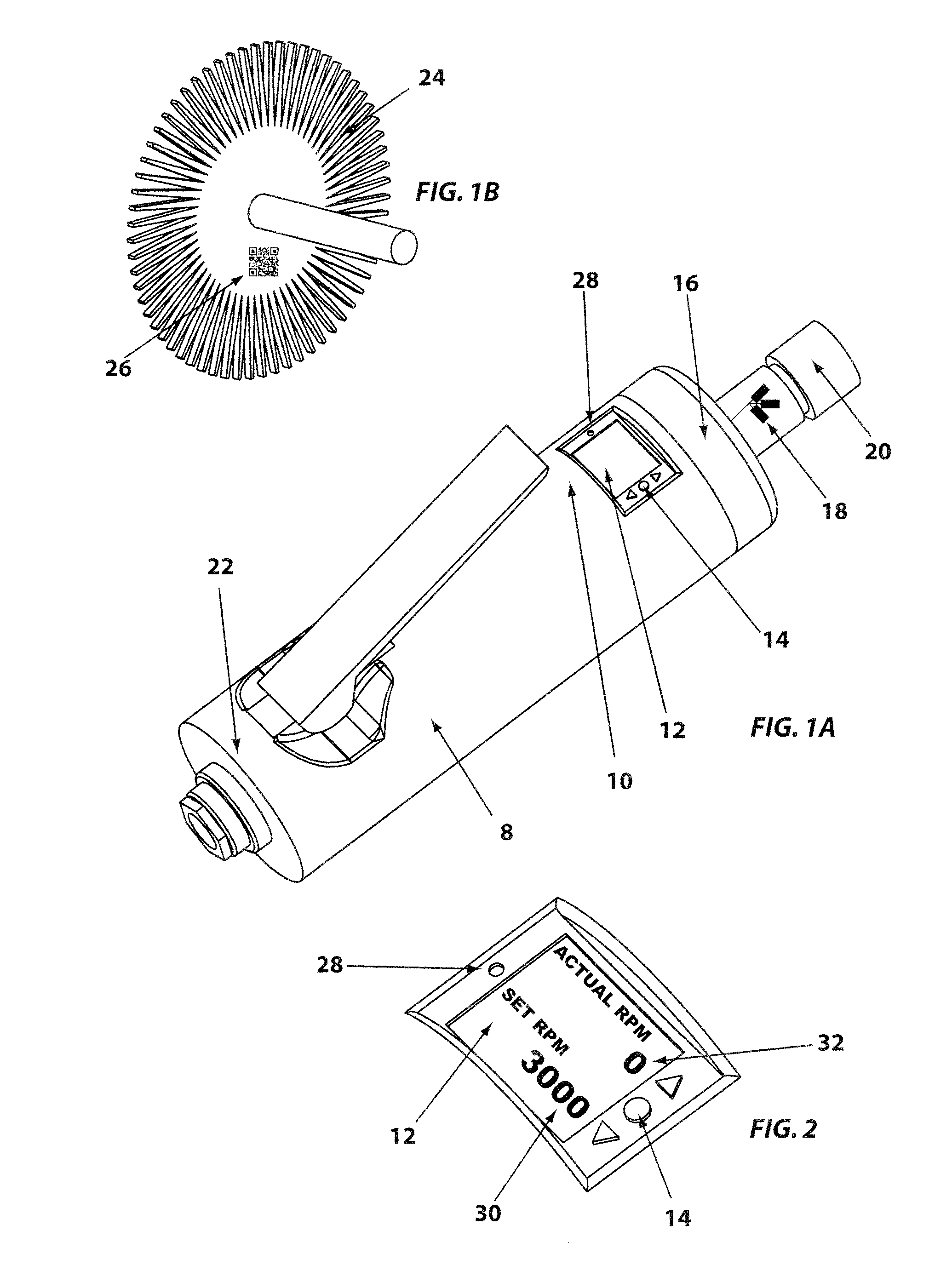

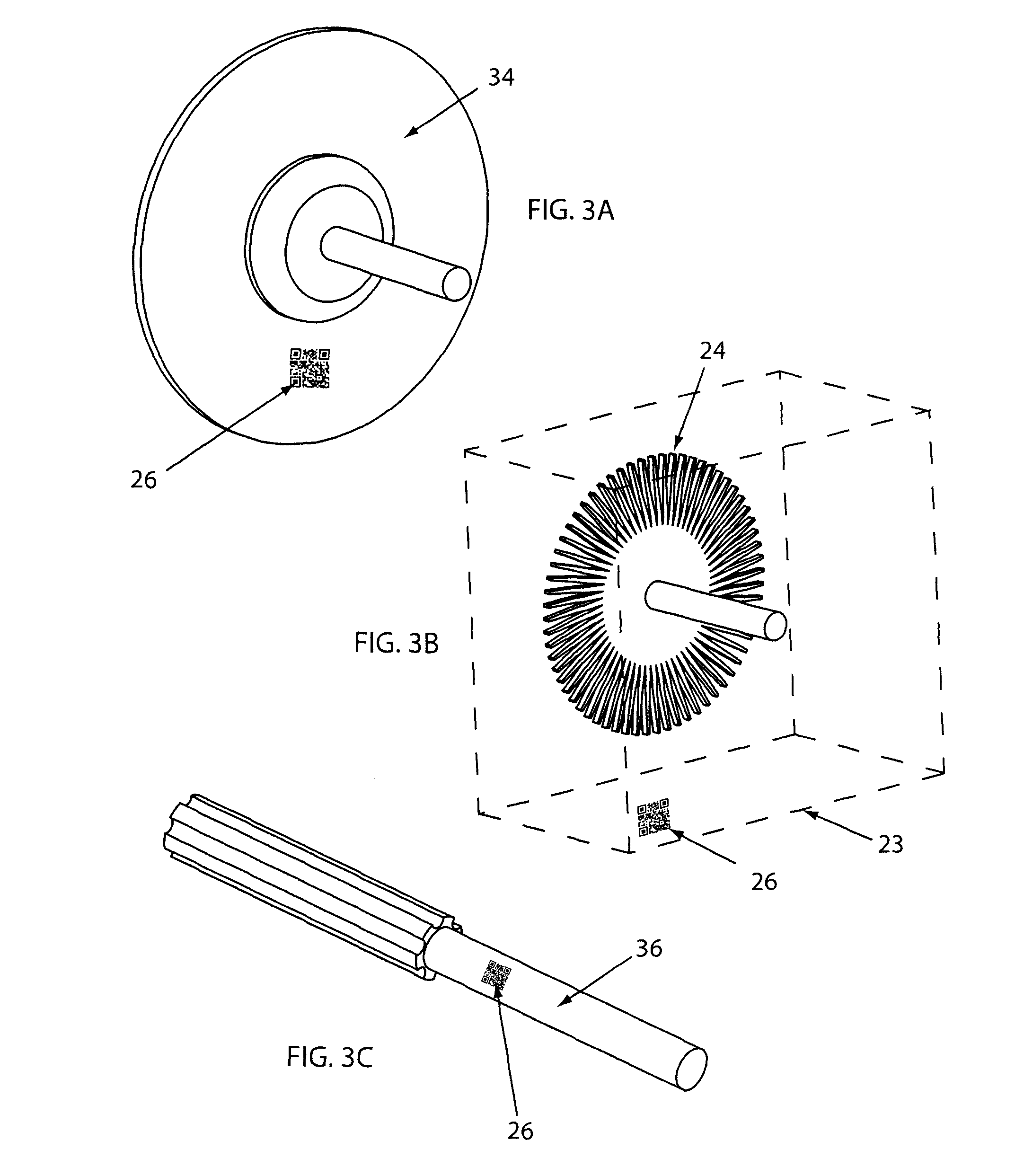

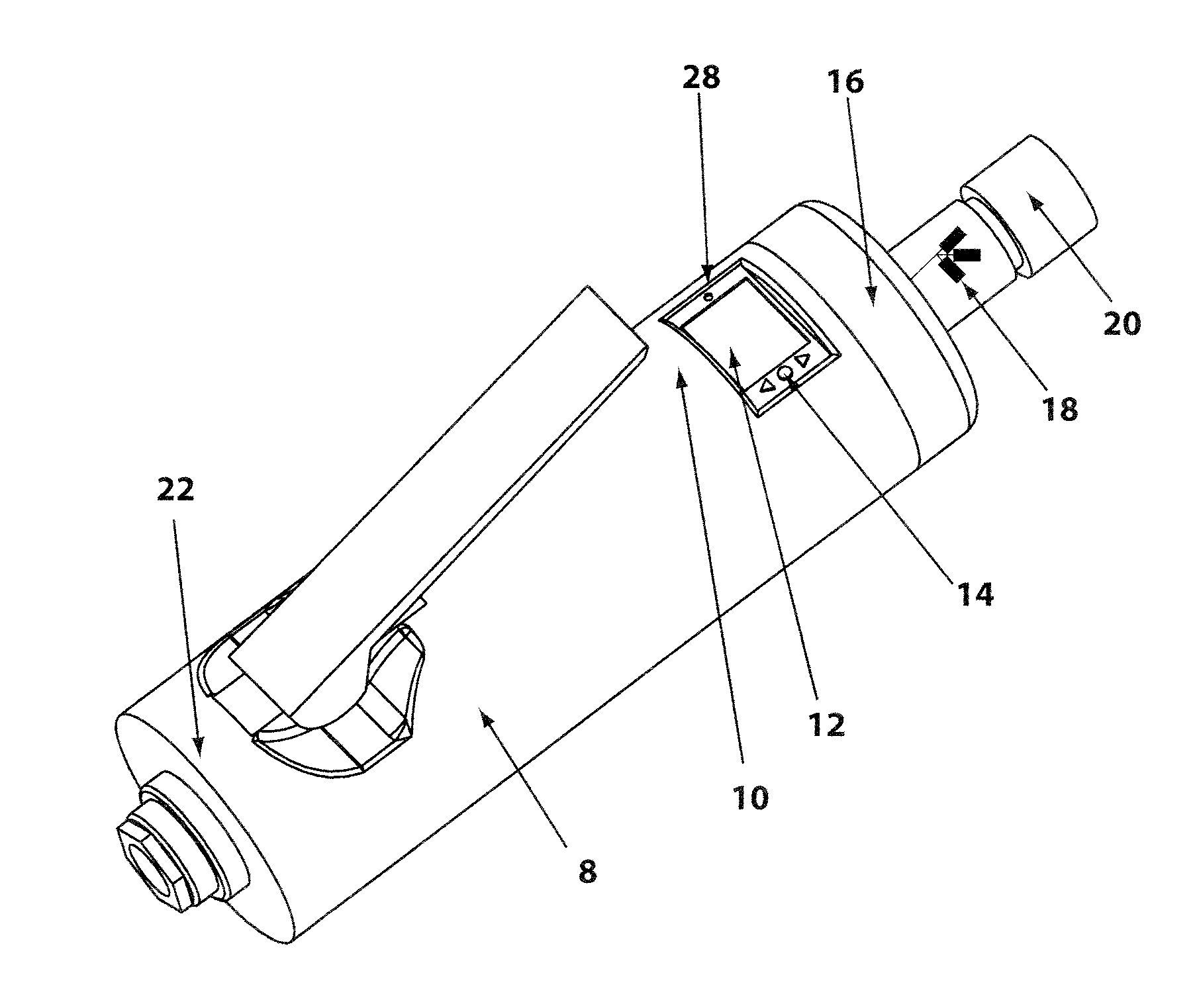

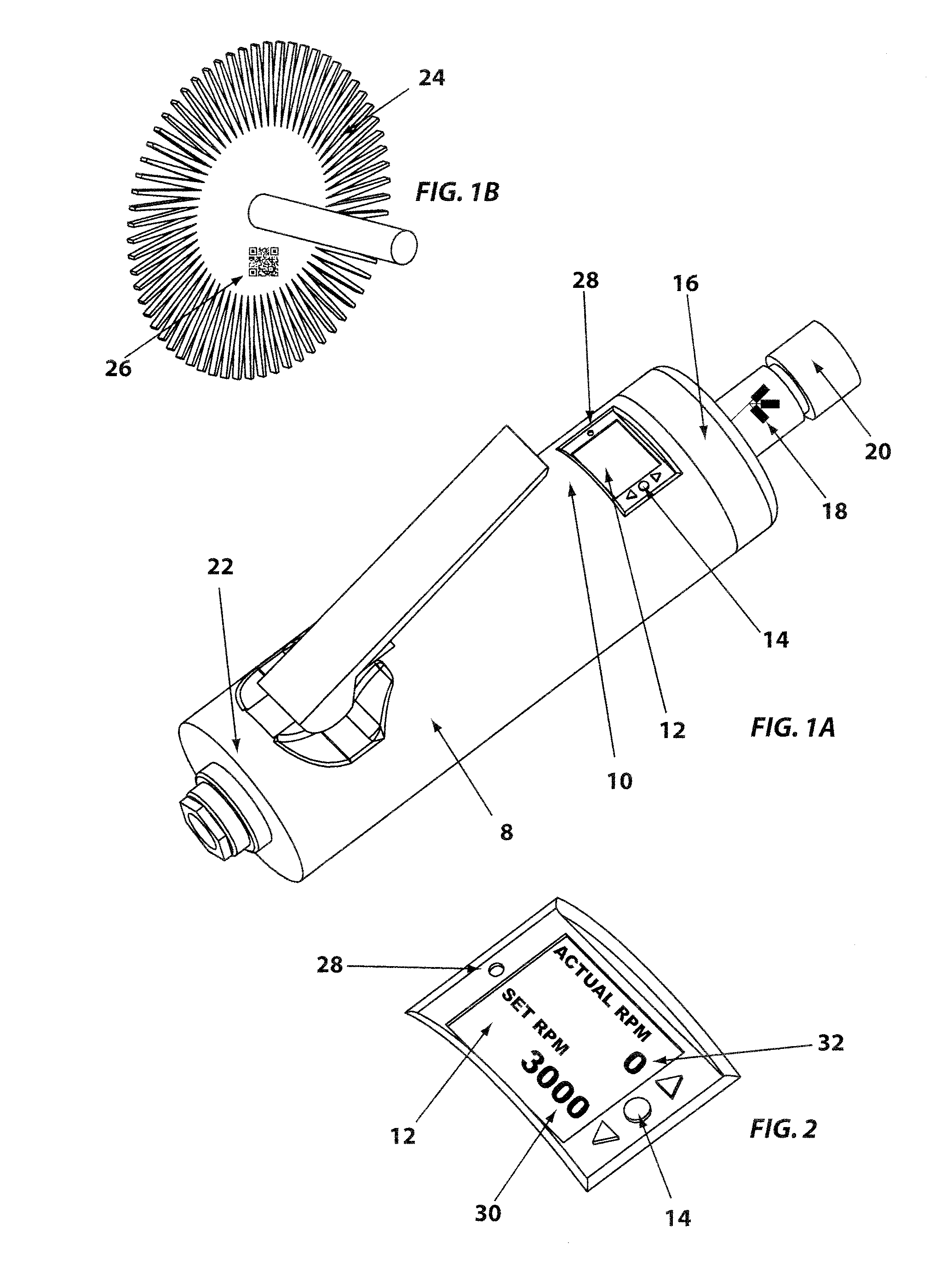

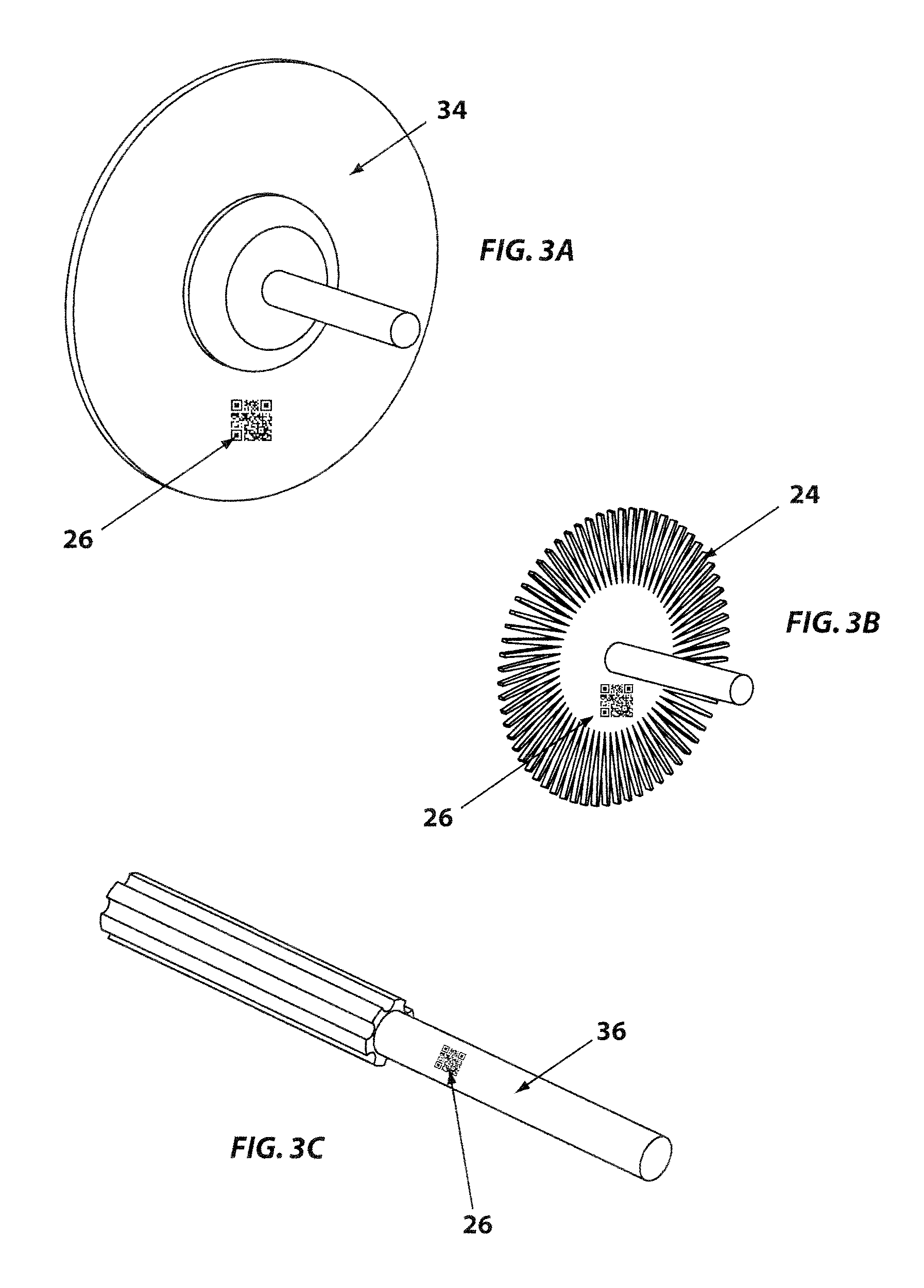

Controlled electro-pneumatic power tools and interactive consumable

Owner:FORGUES SYLVAIN +1

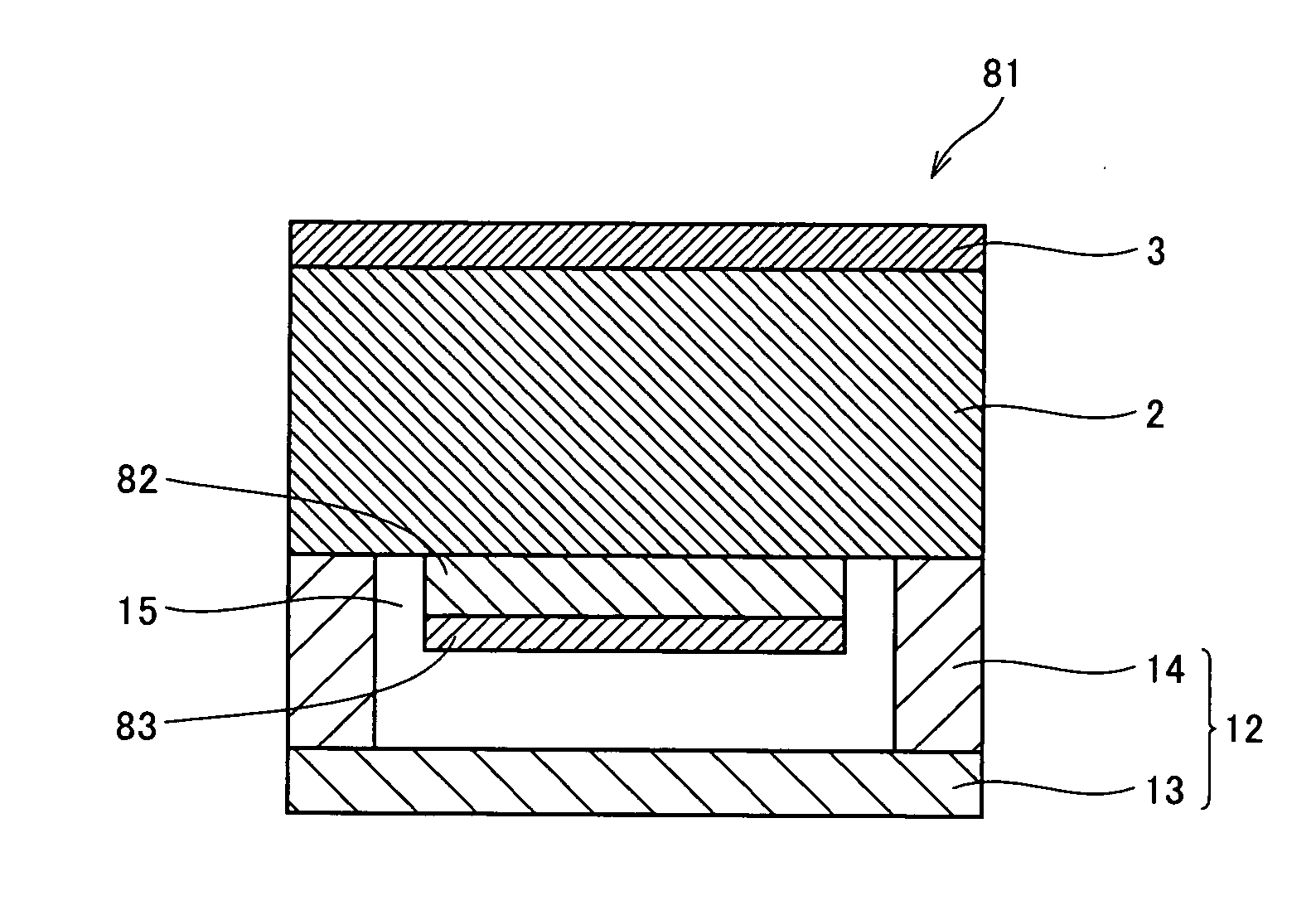

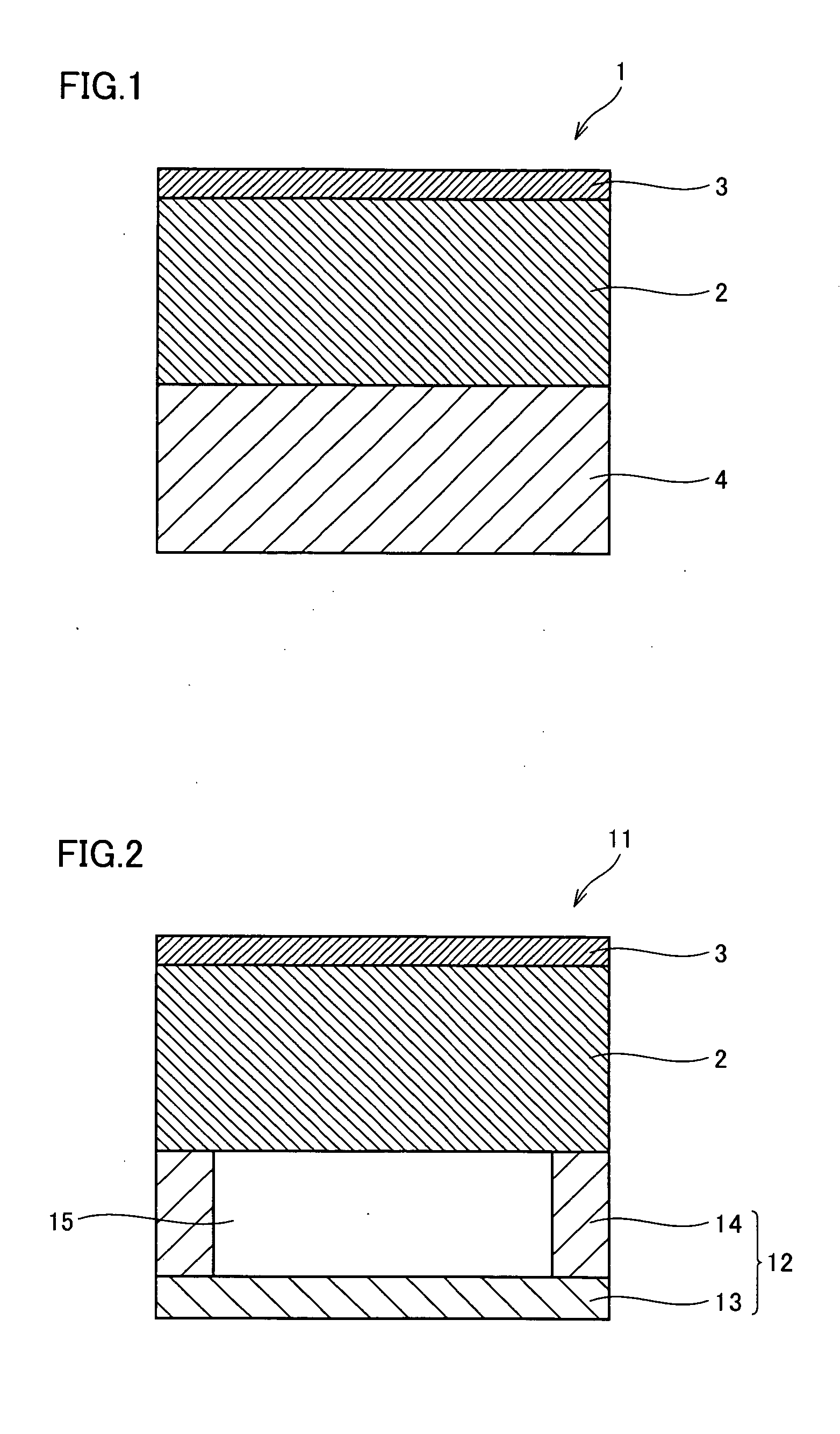

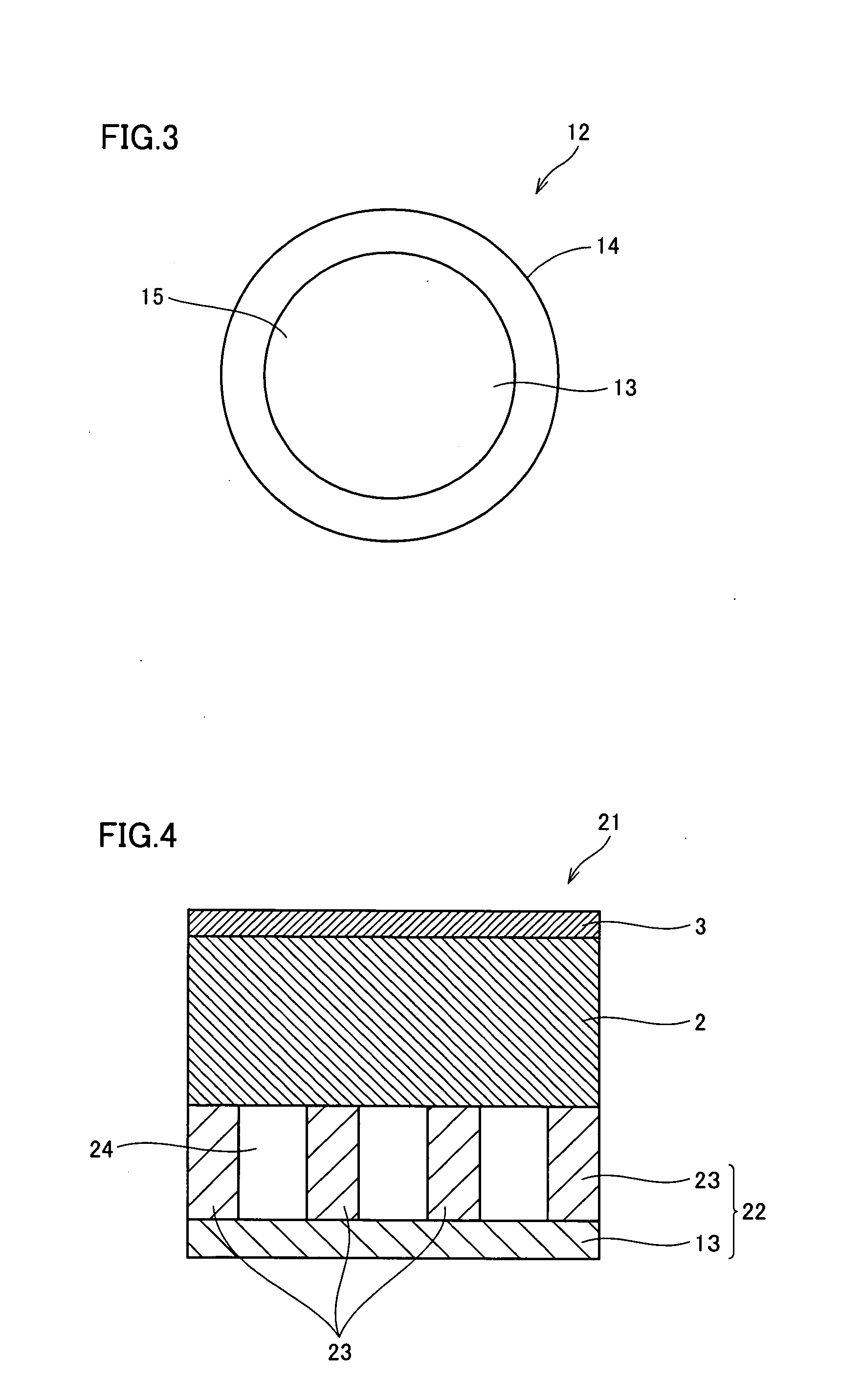

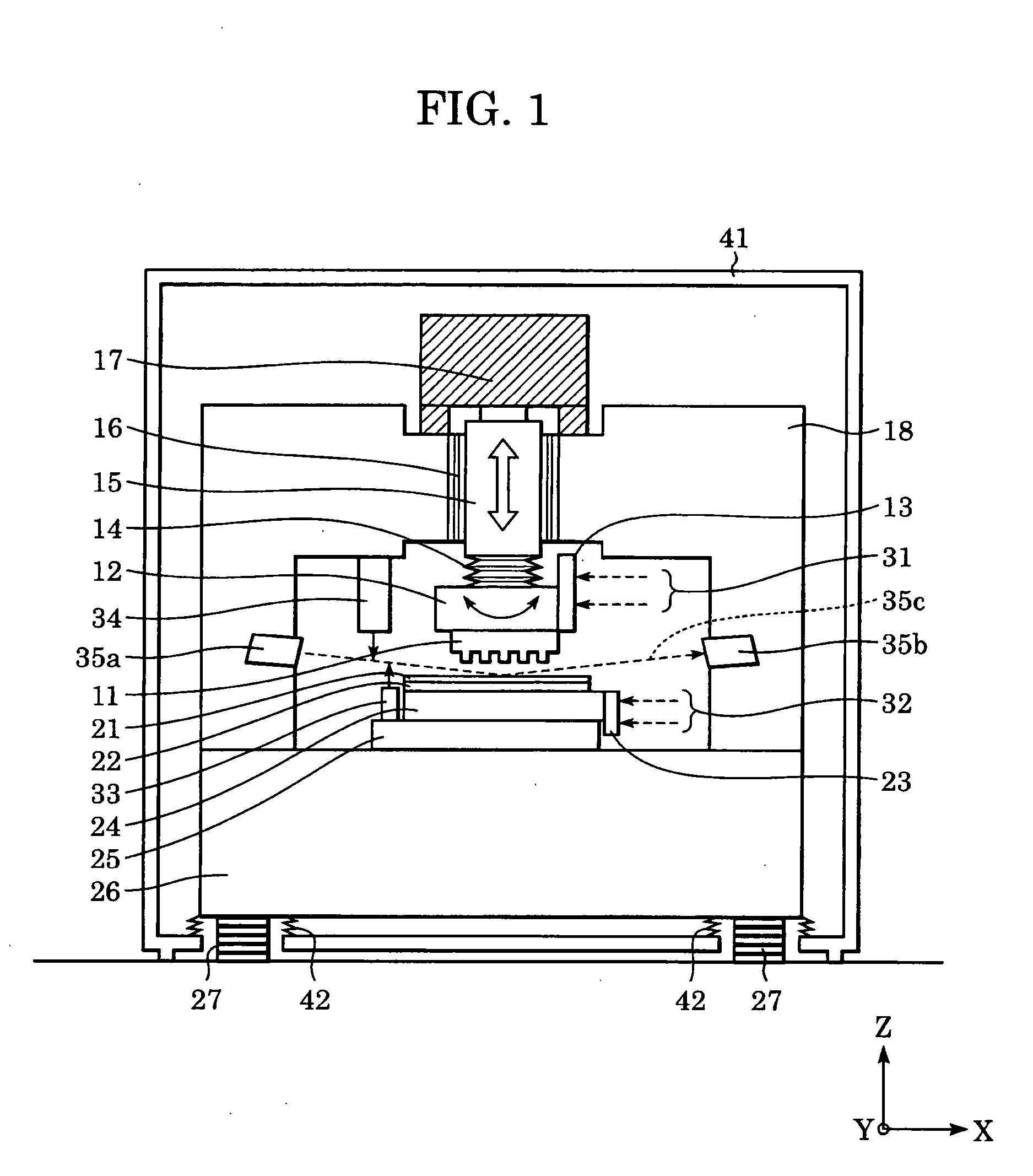

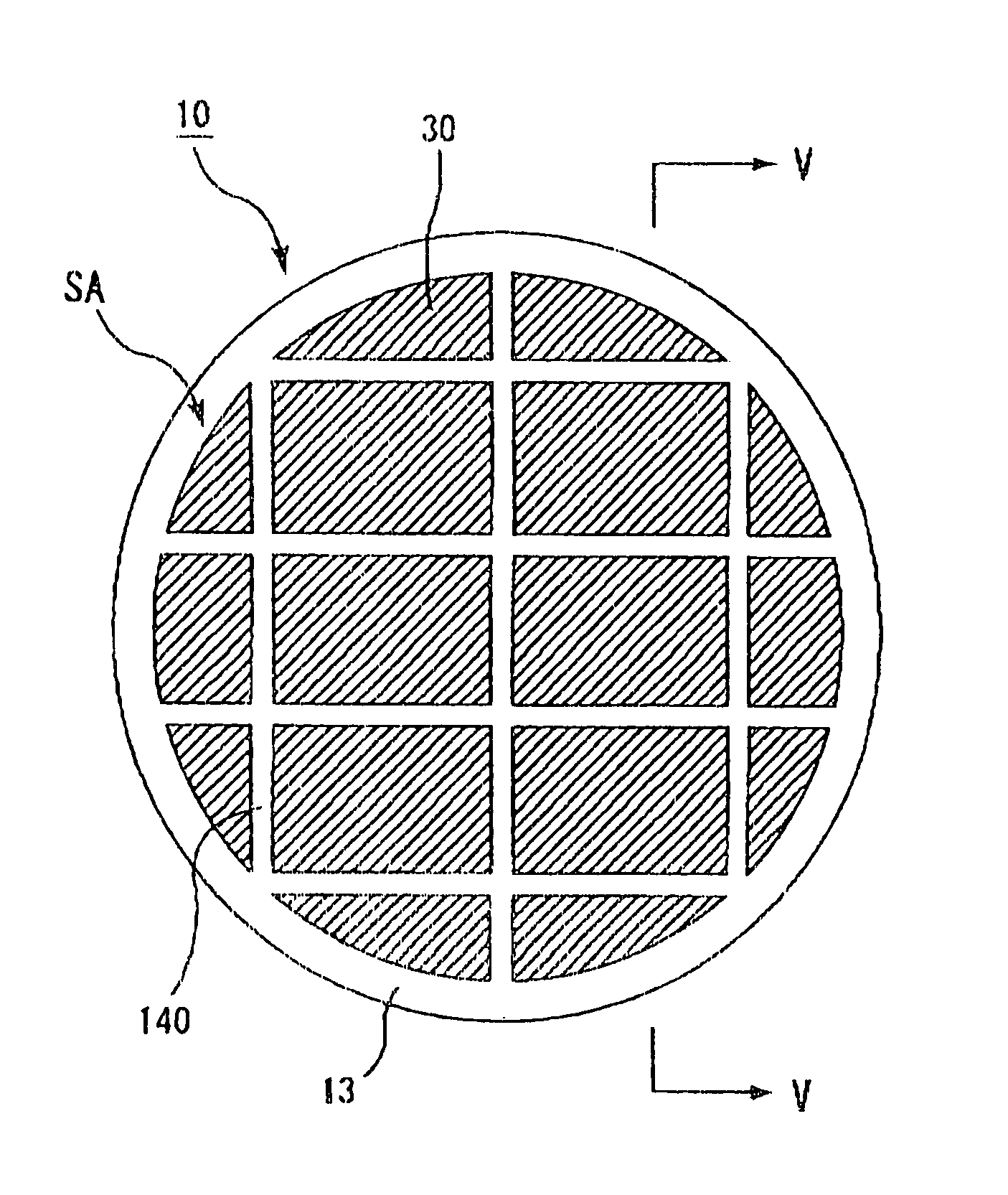

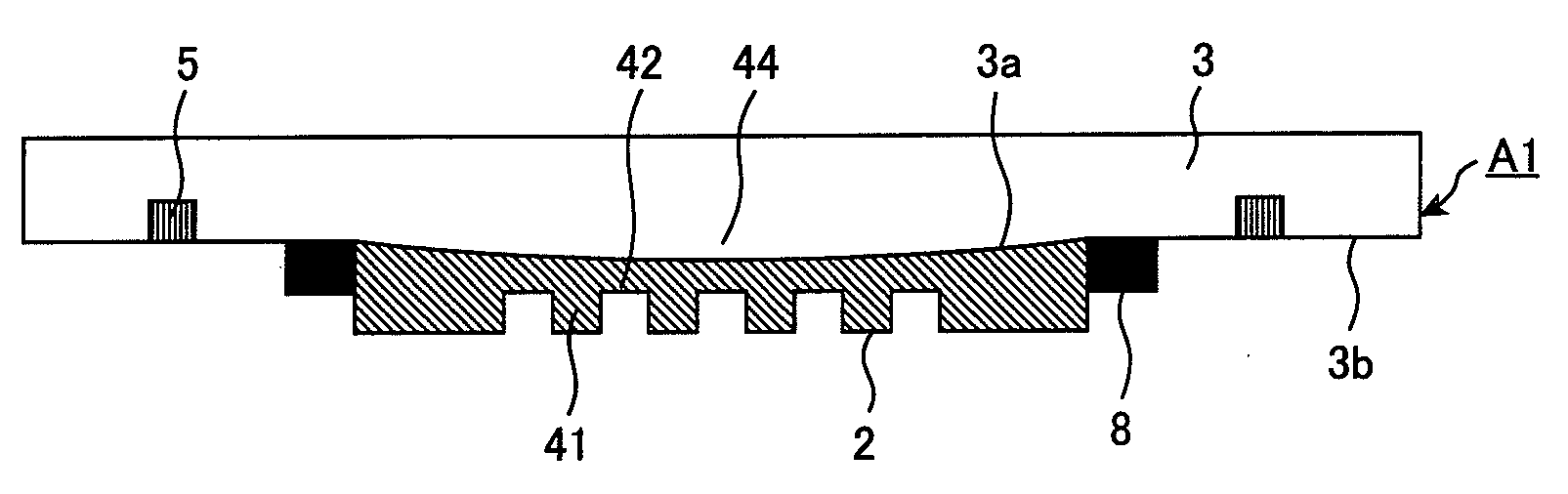

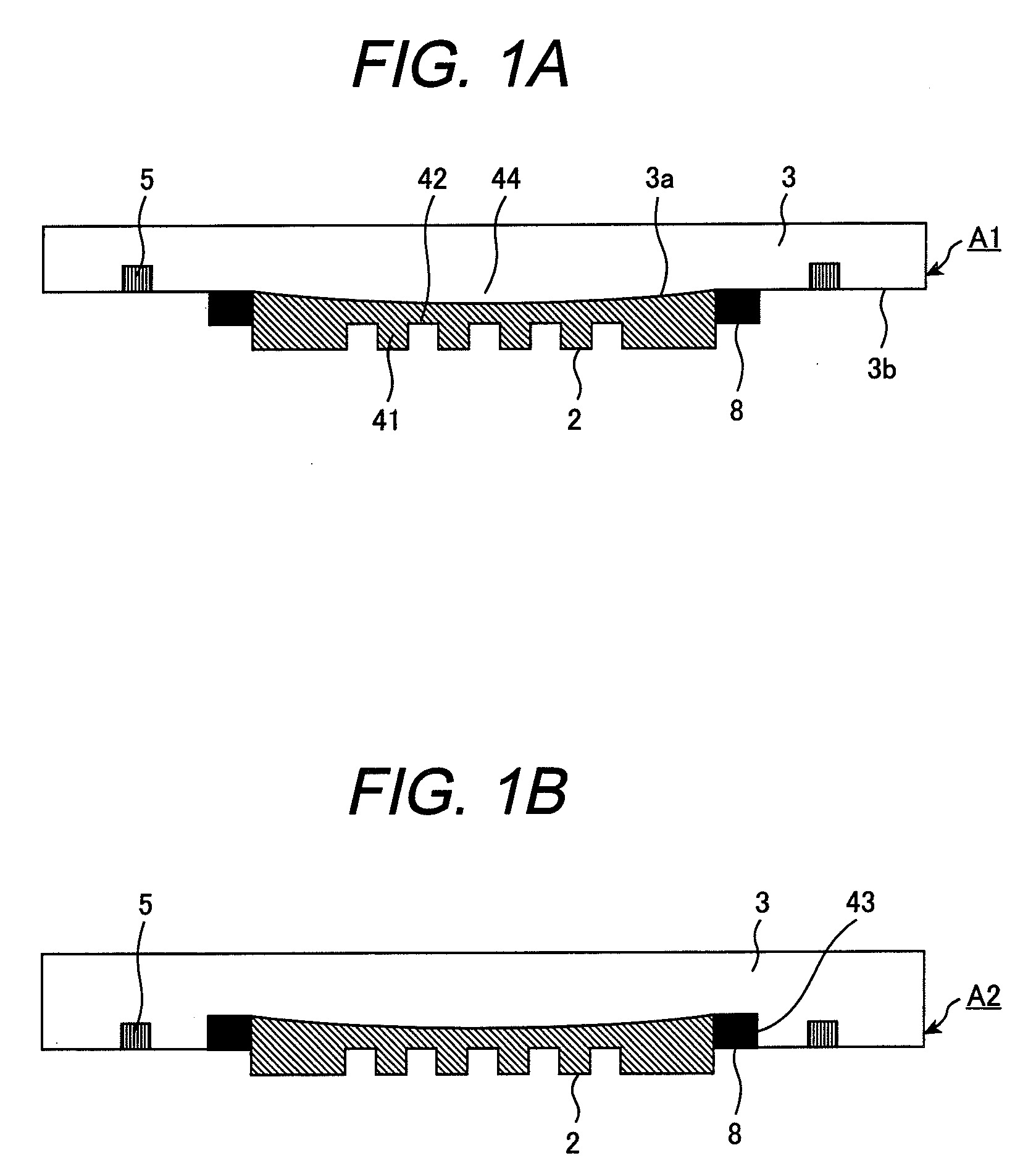

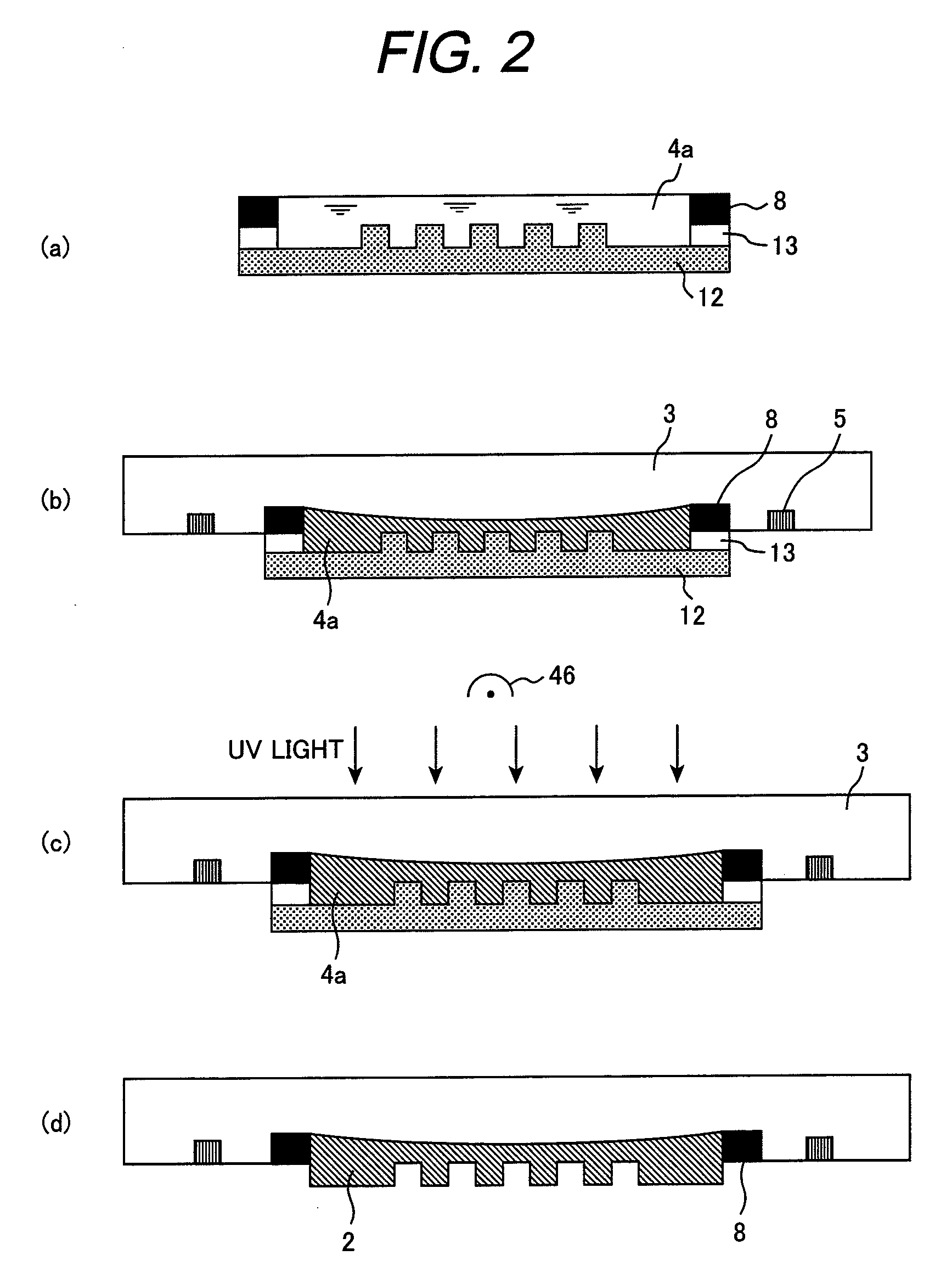

Wafer holder, heater unit used for wafer prober and having wafer holder, and wafer prober

InactiveUS20080211526A1Avoid contact failureAvoid temperature riseSleeve/socket jointsTurning machine accessoriesContact failureSemiconductor chip

By wafer holder including a chuck top for mounting a wafer and a supporter supporting the chuck top and having flatness of at most 0.1 mm, a heater unit for a wafer prober and the wafer prober using the wafer holder, a wafer holder and a wafer prober apparatus hardly deformable even under high load and capable of effectively preventing contact failure, and capable of preventing temperature increase in a driving system when a semiconductor wafer having semiconductor chips with minute circuitry that requires high accuracy is heated can be provided. In the wafer holder of the present invention, the flatness of the supporter is preferably at most 0.05 mm, and more preferably at most 0.01 mm.

Owner:SUMITOMO ELECTRIC IND LTD

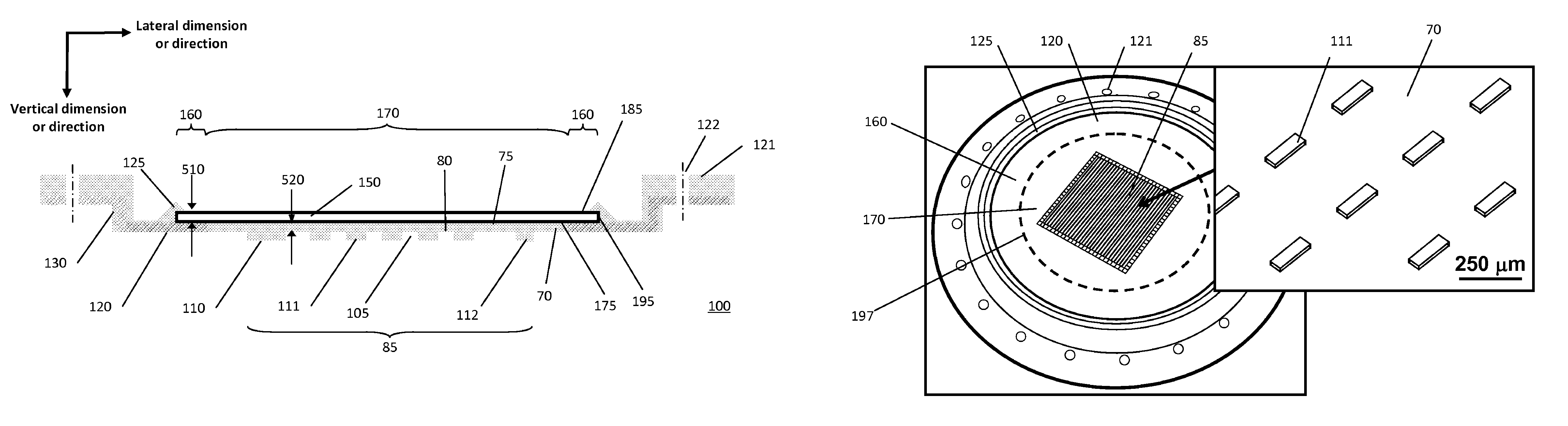

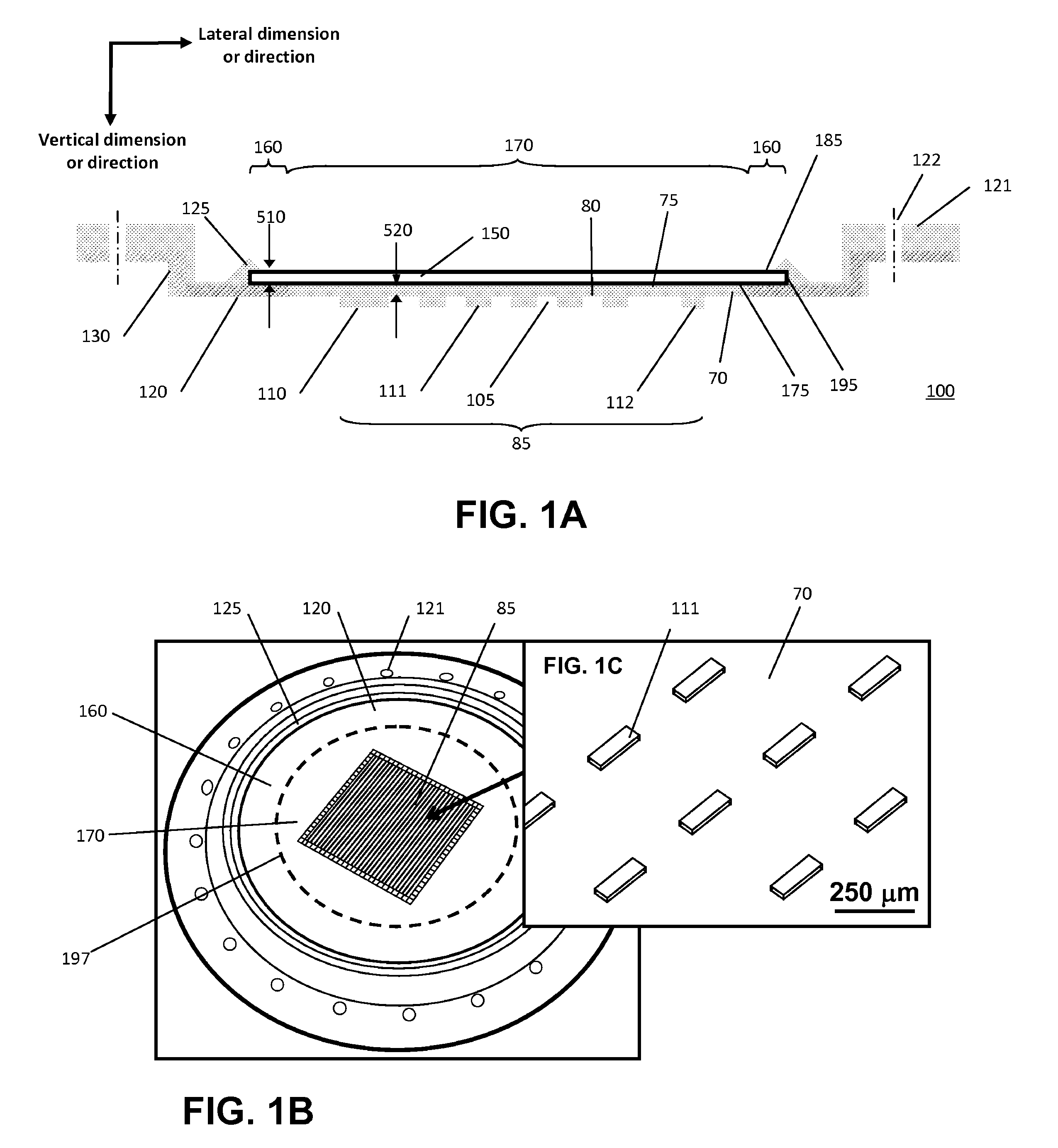

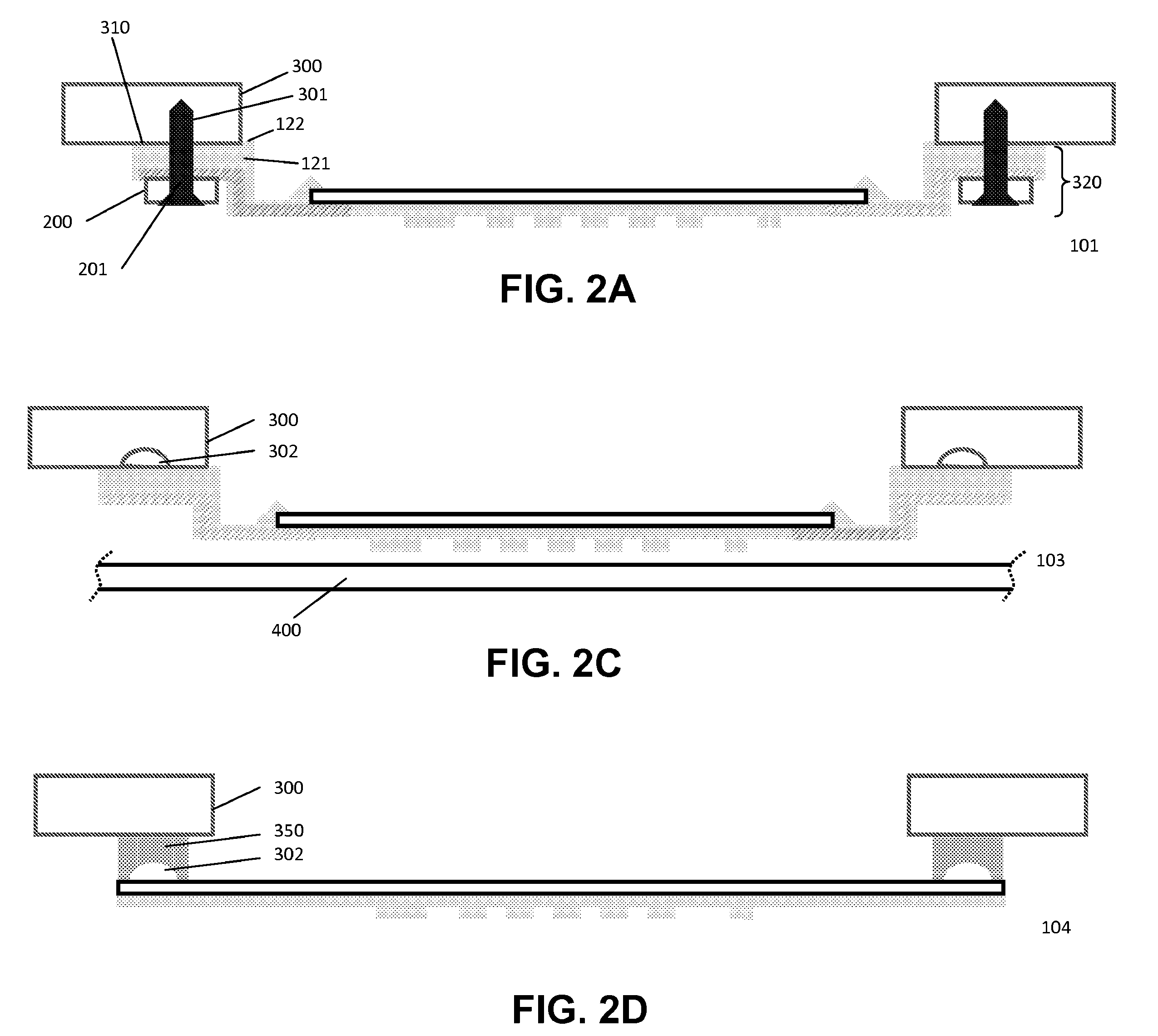

Reinforced composite stamp for dry transfer printing of semiconductor elements

ActiveUS7927976B2Easy to controlPrecise and repeatable vertical motionTurning machine accessoriesMouldsSemiconductor structureContact force

Provided are reinforced composite stamps, devices and methods of making the reinforced composite stamps disclosed herein. Reinforced composite stamps of certain aspects of the present invention have a composition and architecture optimized for use in printing systems for dry transfer printing of semiconductor structures, and impart excellent control over relative spatial placement accuracy of the semiconductor structures being transferred. In some embodiments, for example, reinforced composite stamps of the present invention allow for precise and repeatable vertical motion of the patterned surface of the printing apparatus with self-leveling of the stamp to the surface of a contacted substrate. Reinforced composite stamps of certain aspect of the present invention achieve a uniform distribution of contact forces between the printing apparatus patterned surface and the top surface of a substrate being contacted by the reinforced composite stamp of the printing apparatus.

Owner:X DISPLAY CO TECH LTD

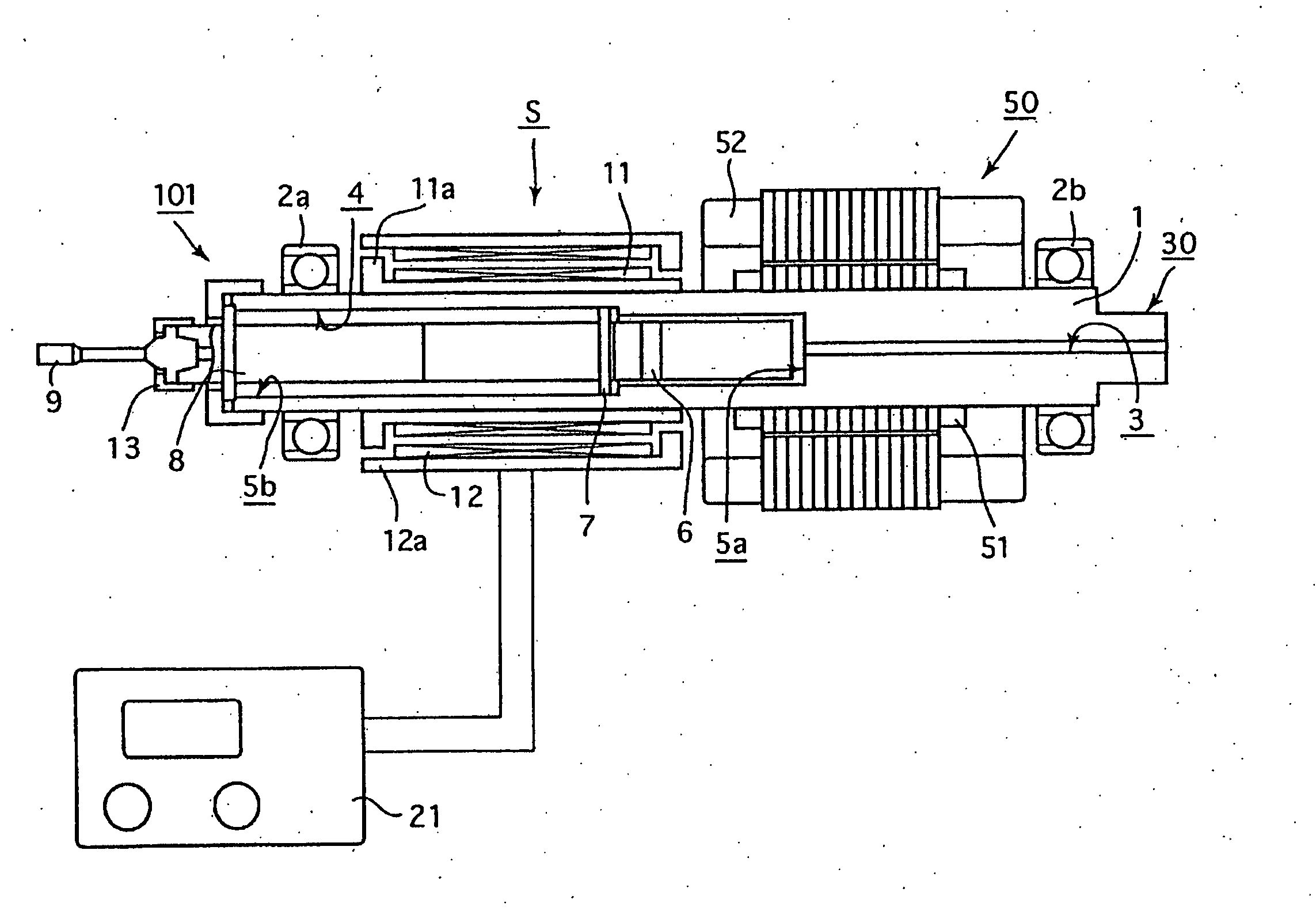

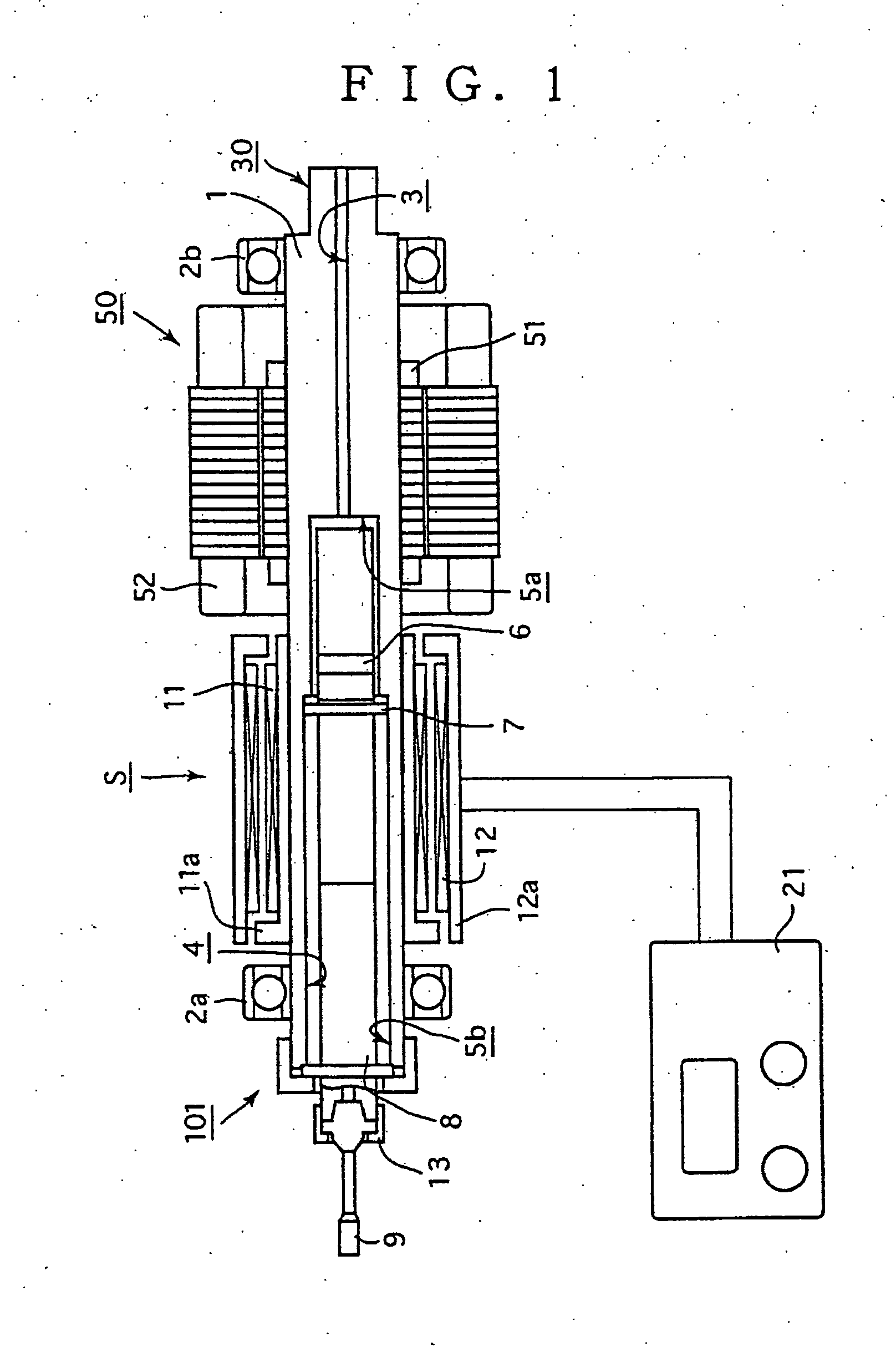

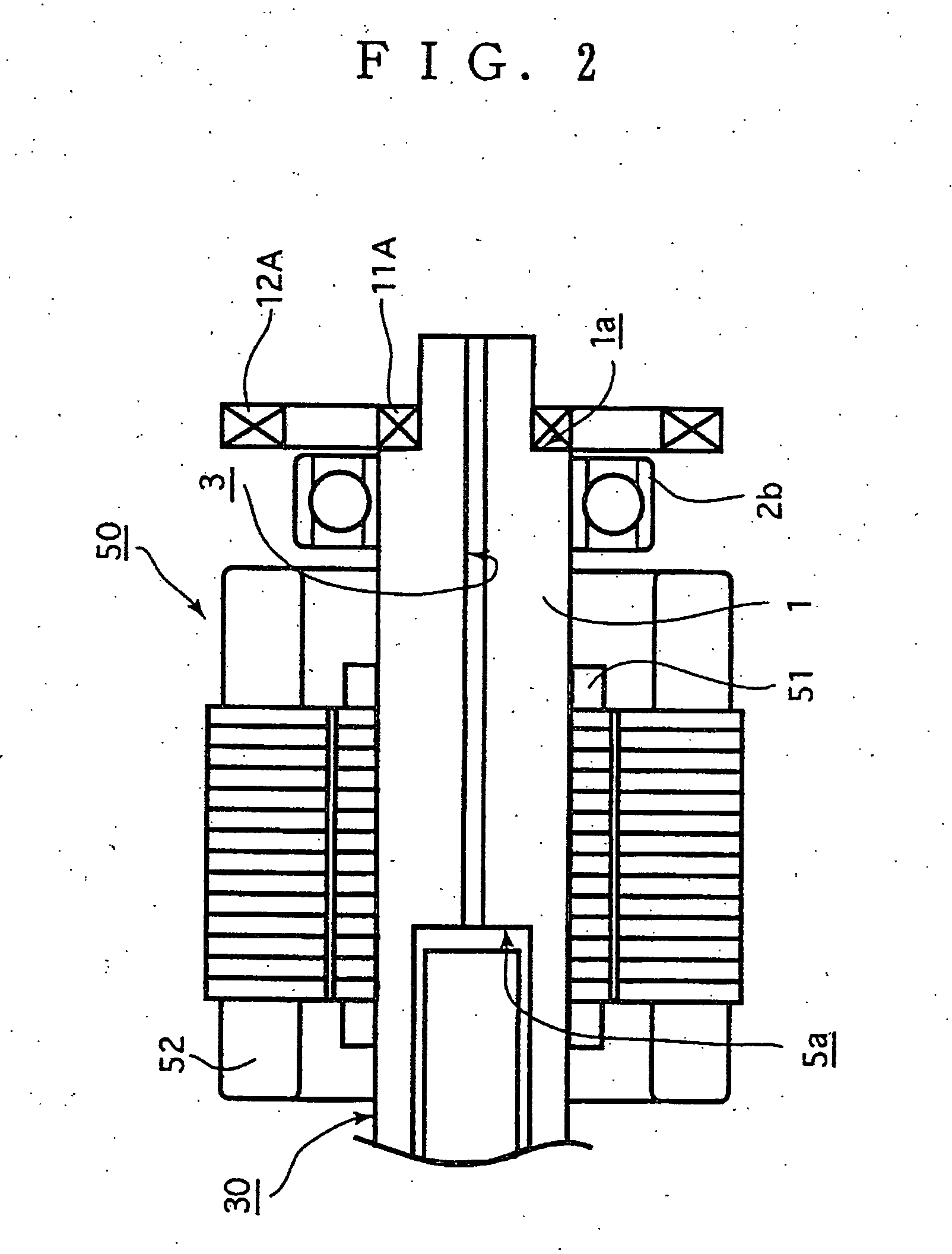

Ultrasonic spindle system

InactiveUS20100158307A1Stable supplyHigh speed rotationTurning machine accessoriesTransducer detailsEngineeringElectric signal

It is possible to stably supply an electric signal to an ultrasonic generation element without causing friction or damage on parts or without requiring periodical parts exchange. A reception coil (11) connected to a vibrator (6) is wound on the outer circumference of a housing (1) constituting a shaft (30) of a machining spindle (101). The reception coil (11) is surrounded coaxially by a transmission coil (12) at an appropriate interval. A predetermined electric signal outputted from an ultrasonic drive device (21) for driving the vibrator (6) is applied to the transmission coil (12). The predetermined electric signal may be applied to the vibrator (6) via the reception coil (11) by electromagnetic induction between the transmission coil (12) and the reception coil (11).

Owner:KUBOTA OSAMU +2

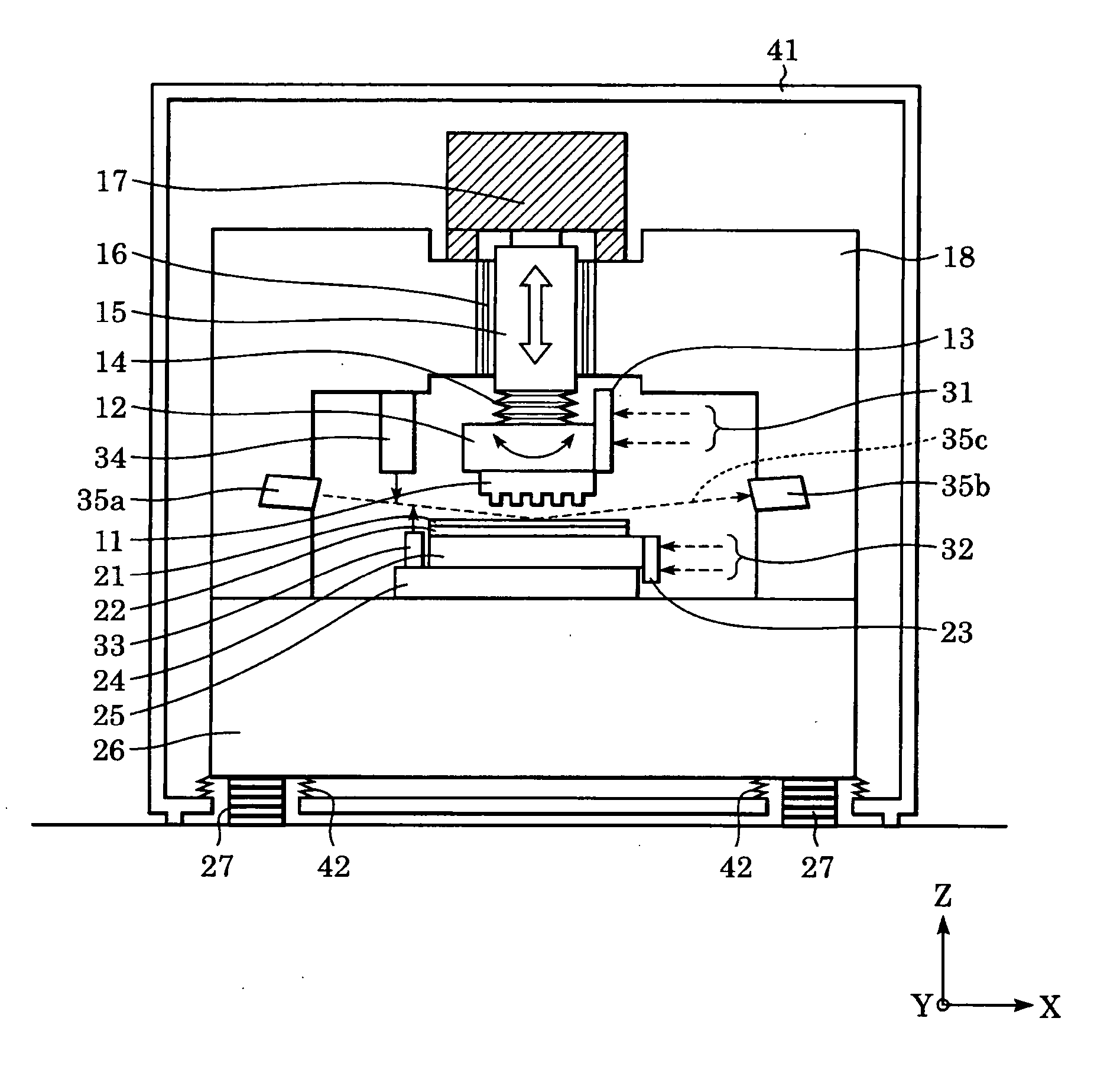

Pattern forming apparatus

InactiveUS20050064054A1High precision alignmentMechanical working/deformationTurning machine accessoriesMaterials scienceMachine press

Owner:CANON KK

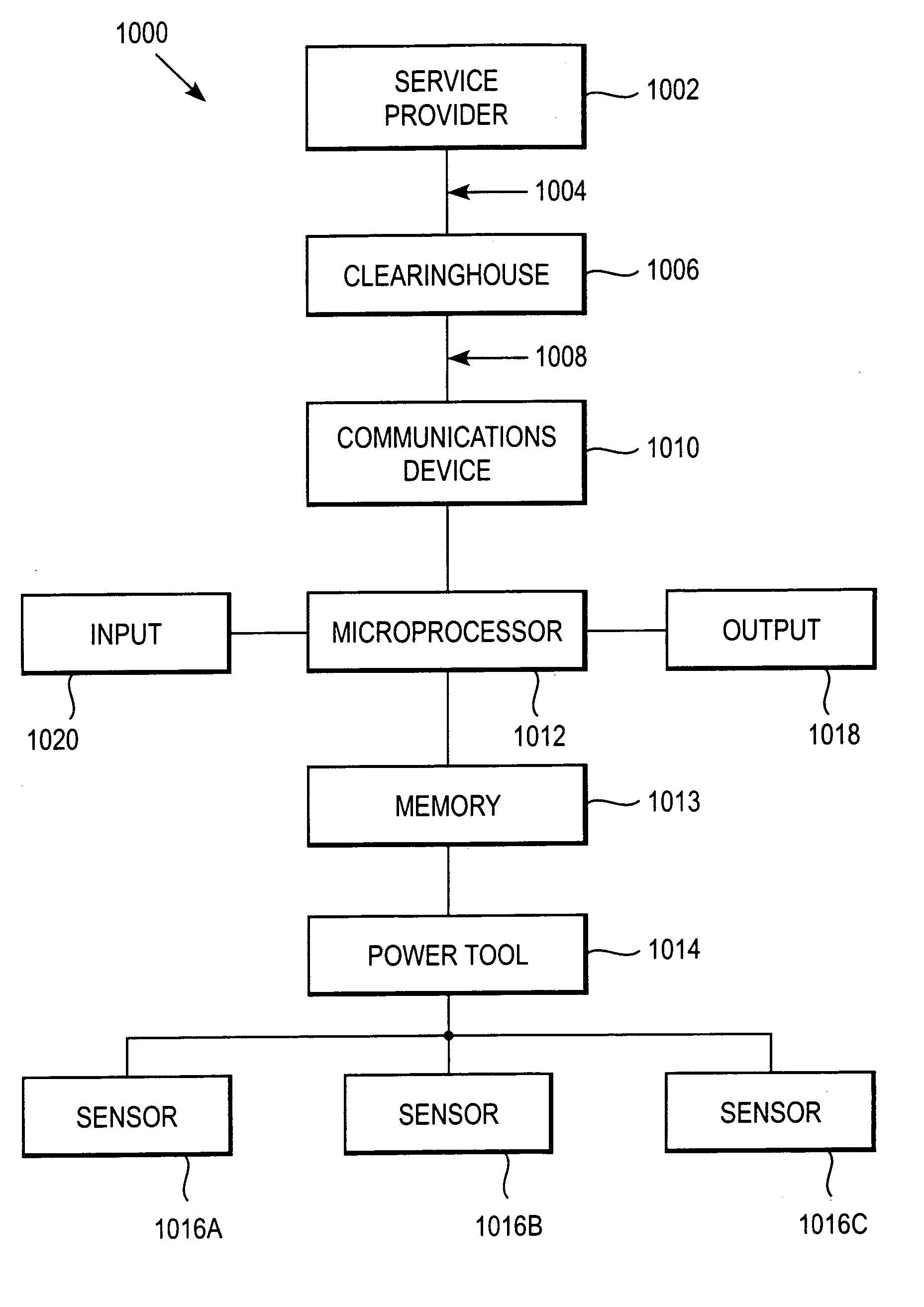

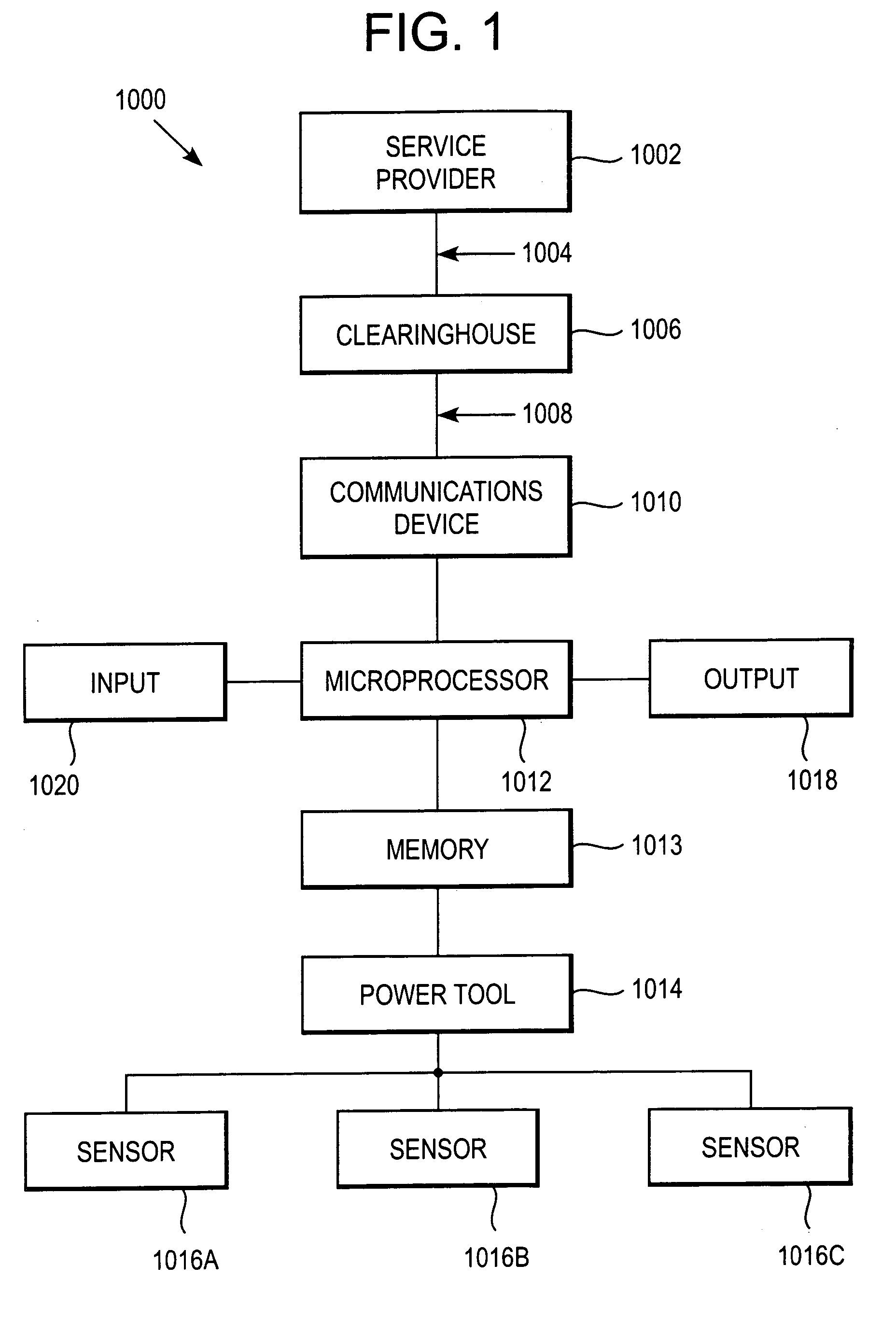

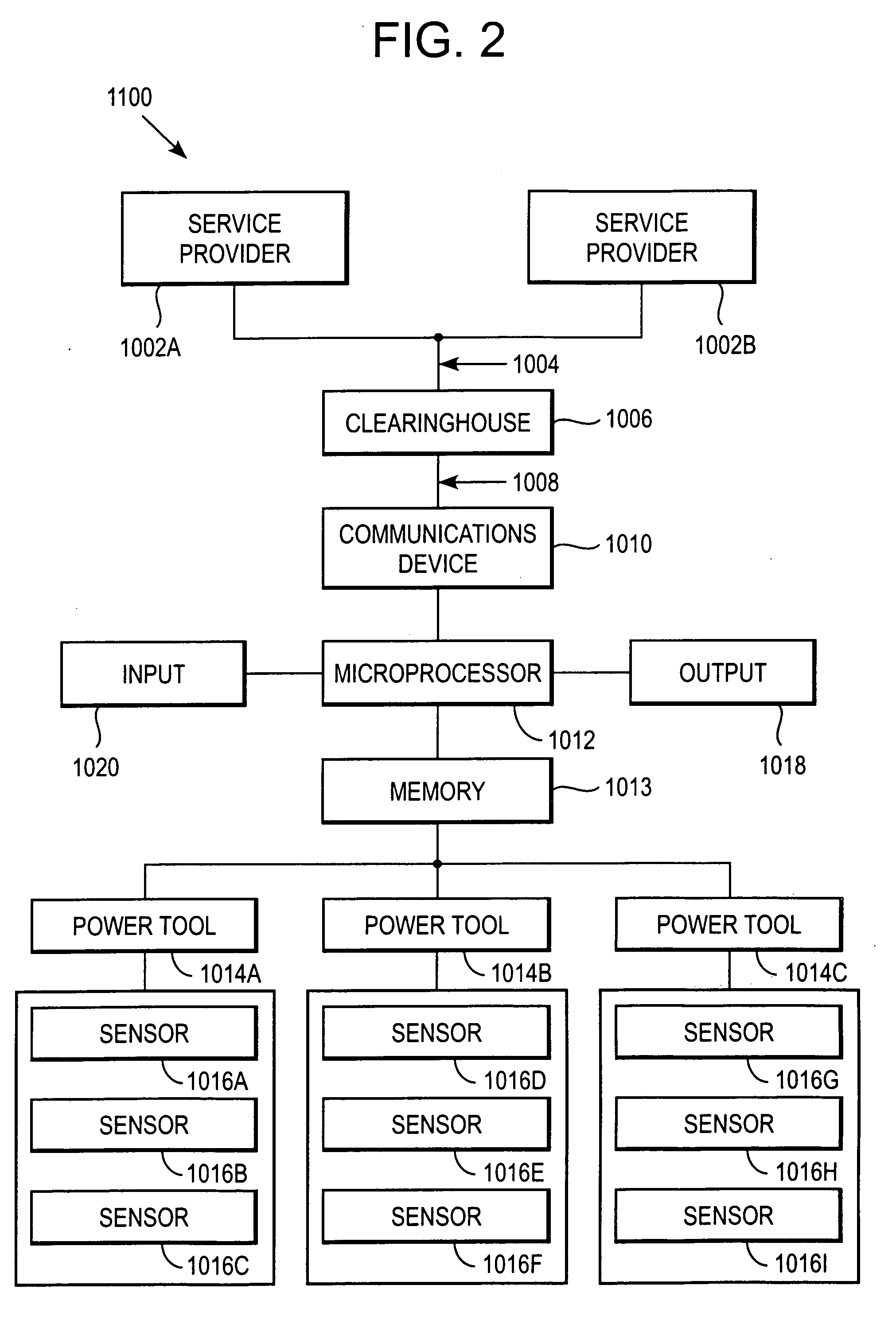

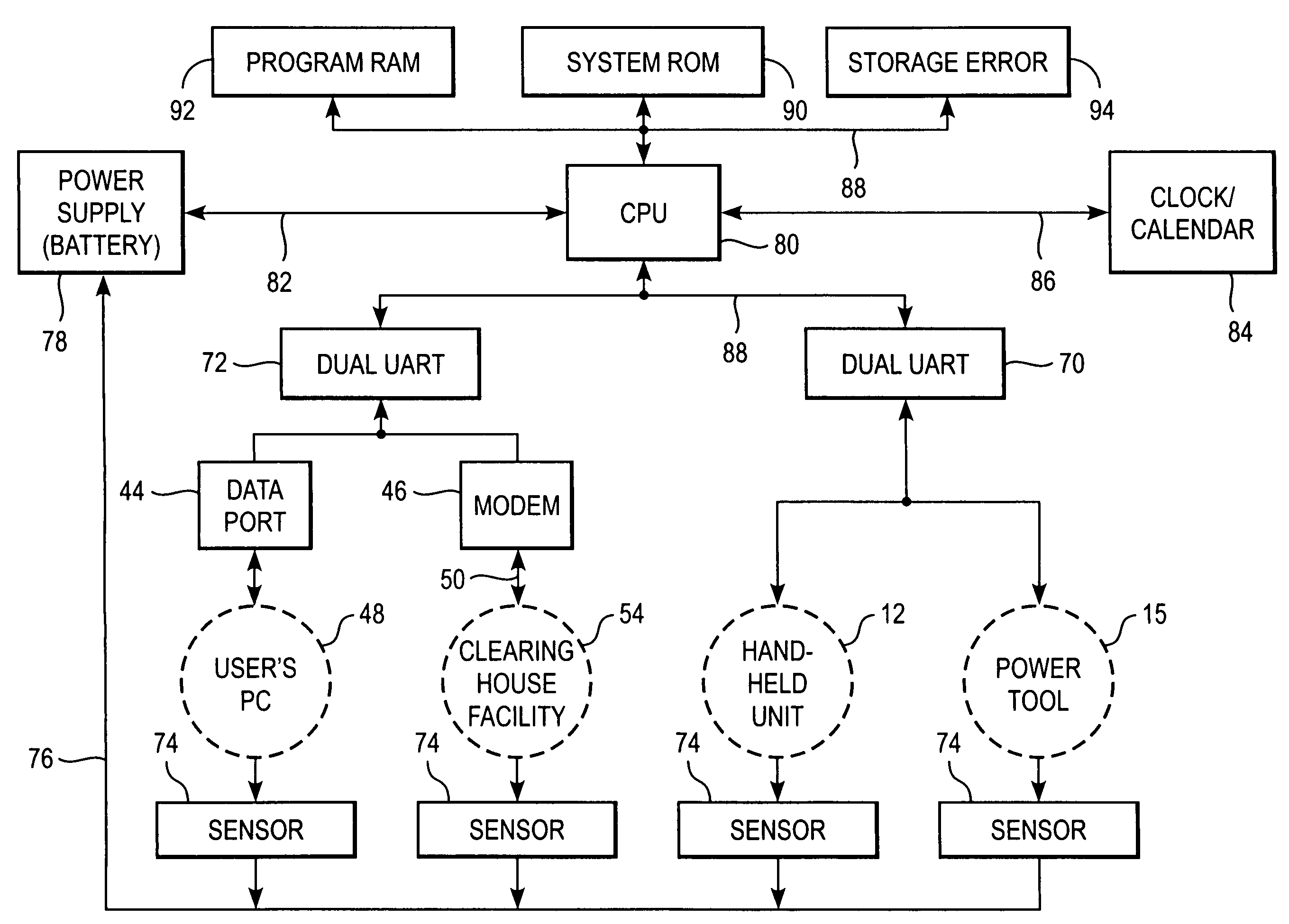

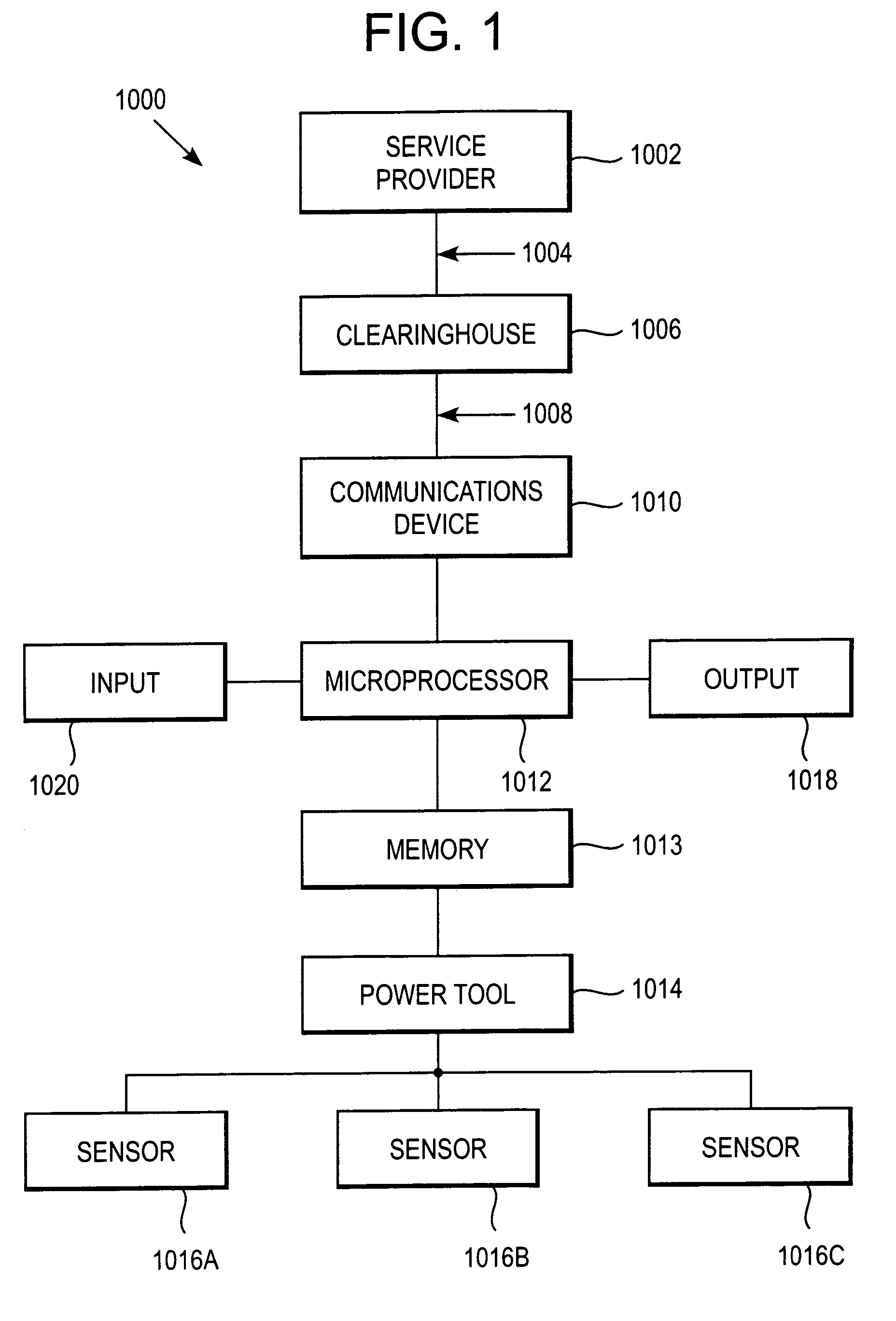

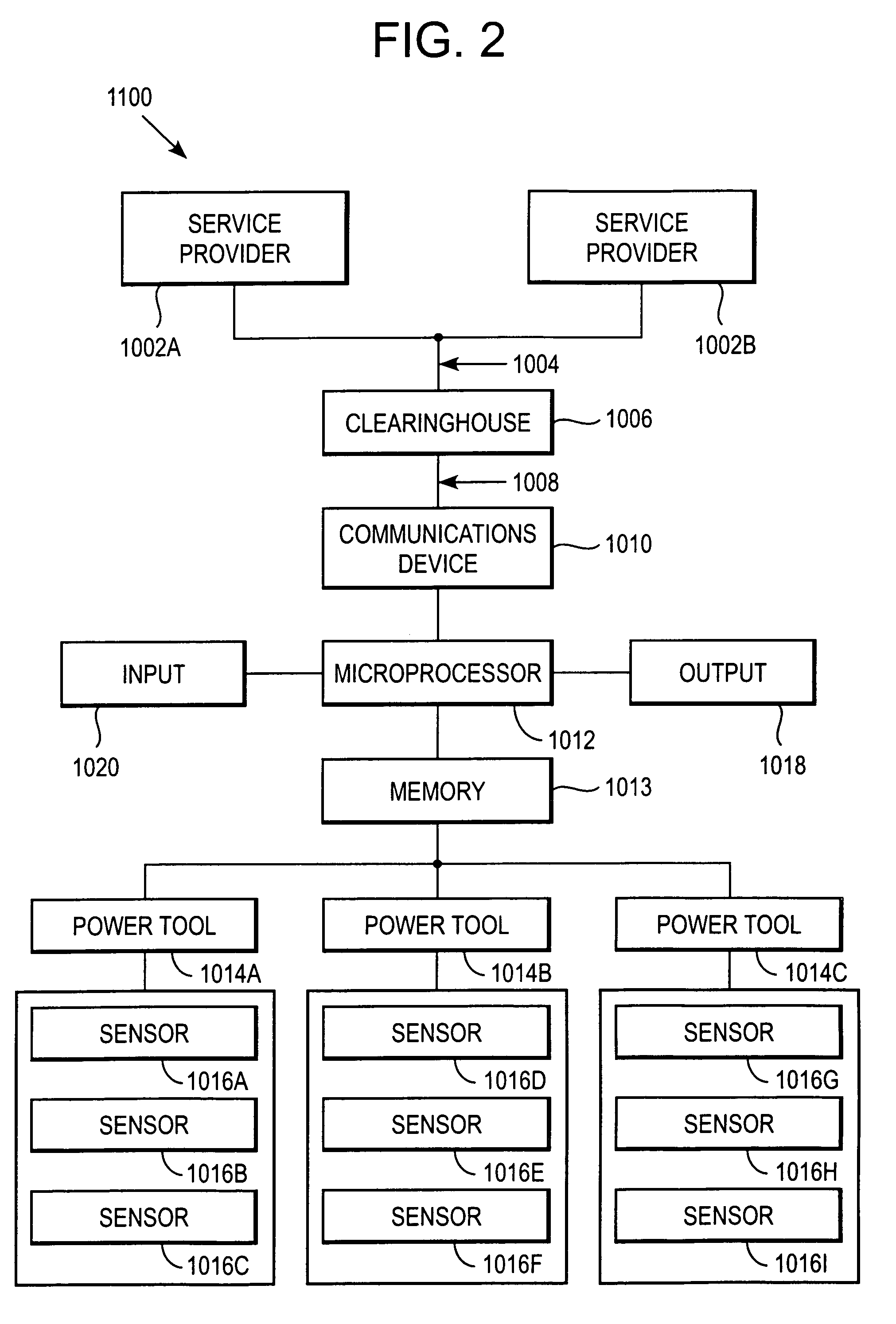

Modular microprocessor-based power tool system

InactiveUS20060155582A1Testing/calibration apparatusTurning machine accessoriesProgram instructionDisplay device

A power tool system and method of using the same is provided. The system can include a programmable microprocessor device including at least one input mechanism, and a memory having instructions and / or other information. The system can also include a display; at least one power tool having at least one sensor operable for monitoring a parameter associated with operation of the power tool. The system can further include a communications device connectable in signal communication with both the programmable microprocessor device and the at least one sensor and program instructions. The method can include the steps of (i) using stored program instructions to generate power tool related information on at least one display and (ii) collecting power tool related data using a programmable microprocessor.

Owner:HEALTH HERO NETWORK

Modular microprocessor-based power tool system

InactiveUS7613590B2Turning machine accessoriesTesting/calibration apparatusProgram instructionDisplay device

A power tool system and method of using the same is provided. The system can include a programmable microprocessor device including at least one input mechanism, and a memory having instructions and / or other information. The system can also include a display; at least one power tool having at least one sensor operable for monitoring a parameter associated with operation of the power tool. The system can further include a communications device connectable in signal communication with both the programmable microprocessor device and the at least one sensor and program instructions. The method can include the steps of (i) using stored program instructions to generate power tool related information on at least one display and (ii) collecting power tool related data using a programmable microprocessor.

Owner:HEALTH HERO NETWORK

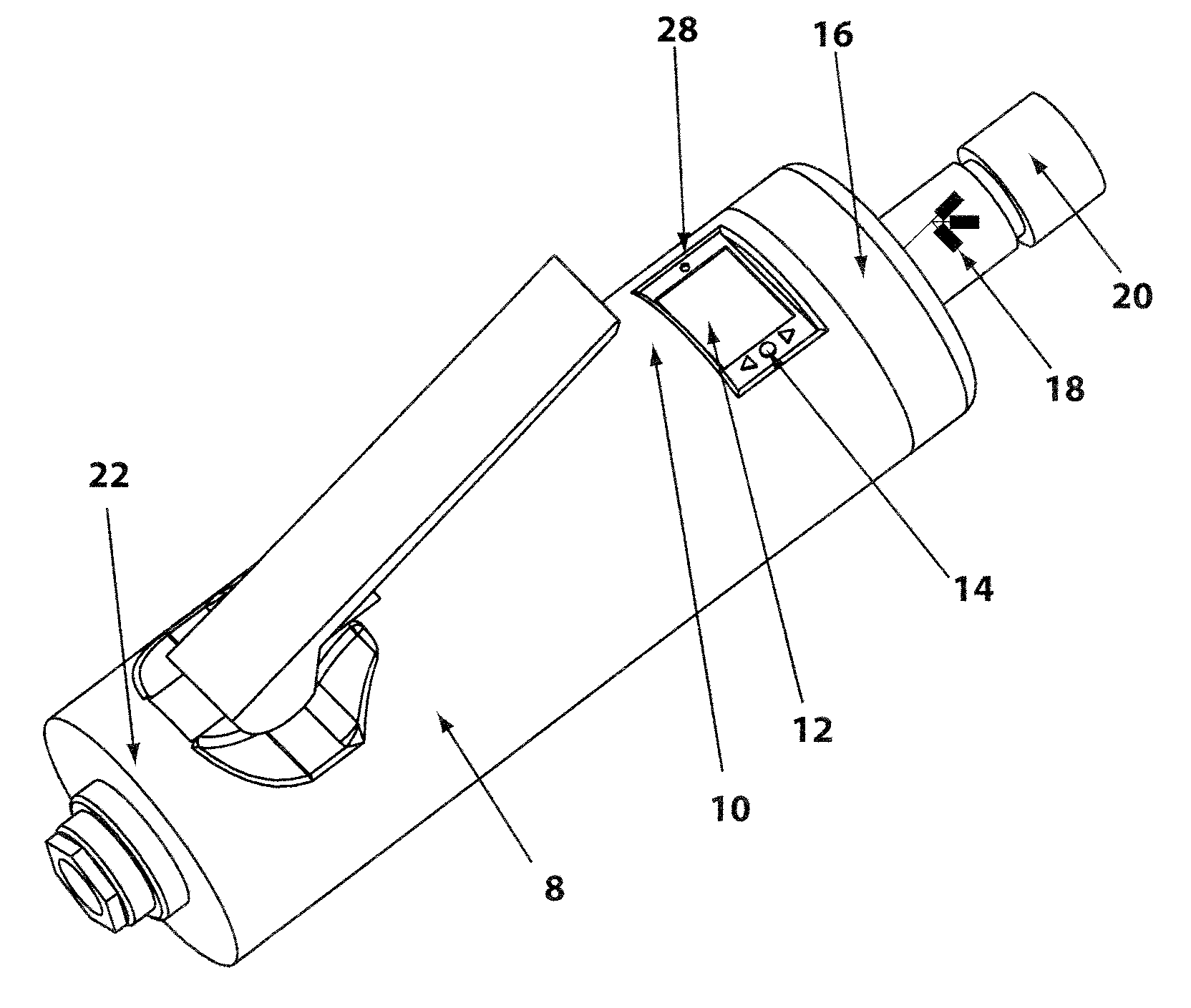

Controlled electro-pneumatic power tools and interactive consumable

ActiveUS20120007748A1Electric signal transmission systemsTelemetry/telecontrol selection arrangementsMicrocontrollerElectrical battery

A controlled electro-pneumatic power tool includes an electro-mechanical adjustable valve, a pneumatic motor and a rotational speed sensor connected to a microcontroller for the selection, monitoring and adjustement of the rotational speed in real time. The electro-pneumatic power tool may include input buttons, data ports to save data and a communication port to read / write data from an interactive consumable. The electo-pneumatic power tool may also include a battery and a generator as well as a variable speed transmission with flexible shaft and lightweight handpiece. Using the communication port, important data for the consumable, such as optimum rotation speed, optimum applied pressure and average usage time, can be transmitted to the controlled electro-pneumatic power tool. The controlled electro-pneumatic power tool can read and utilise the transmitted data to select, adjust and maintain the optimum process parameters for the consumable without any input from the operator person. Furthermore, the communicated data can be used to warn the operator person that the tool used is inadequate for the selected consumable, to caution the operator person if he is using the consumable inadequately and to advise him when the consumable should be replaced for safe operation. This will increase the safety of the operator person, improve the quality of the work performed with pneumatic power tools and limit potential damages to the parts being treated.

Owner:FORGUES SYLVAIN +1

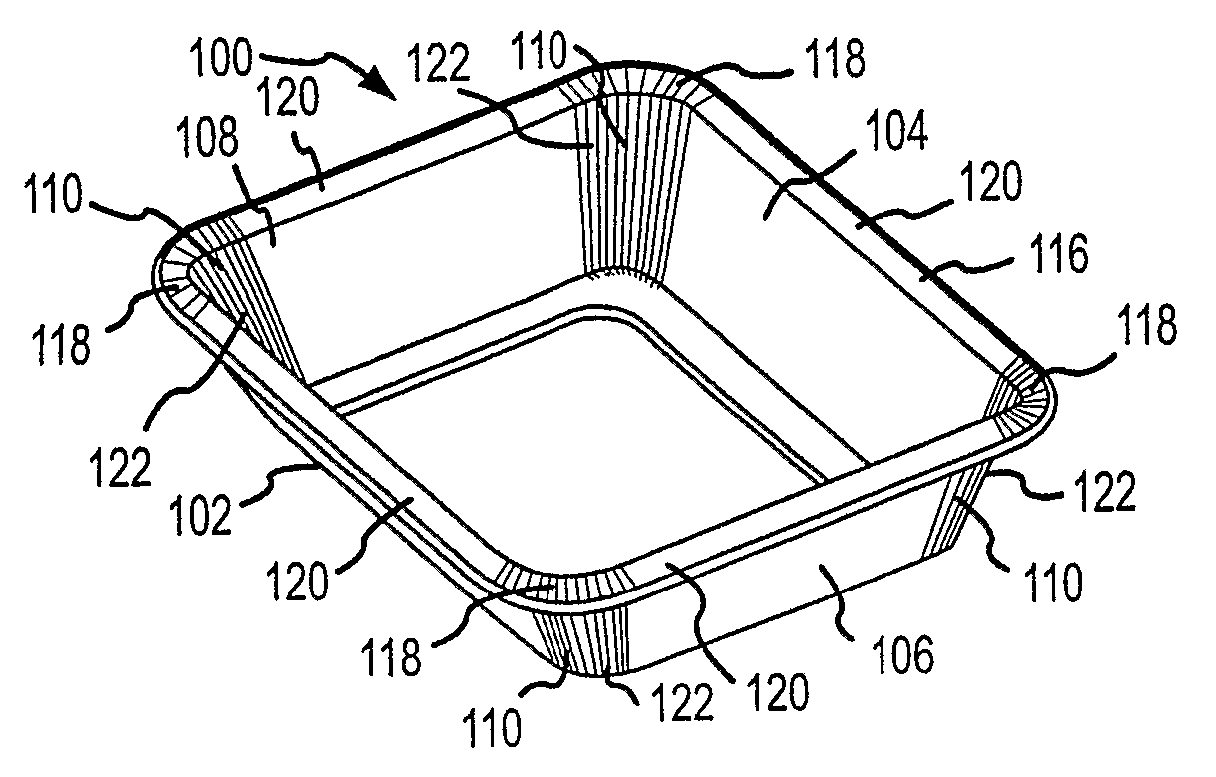

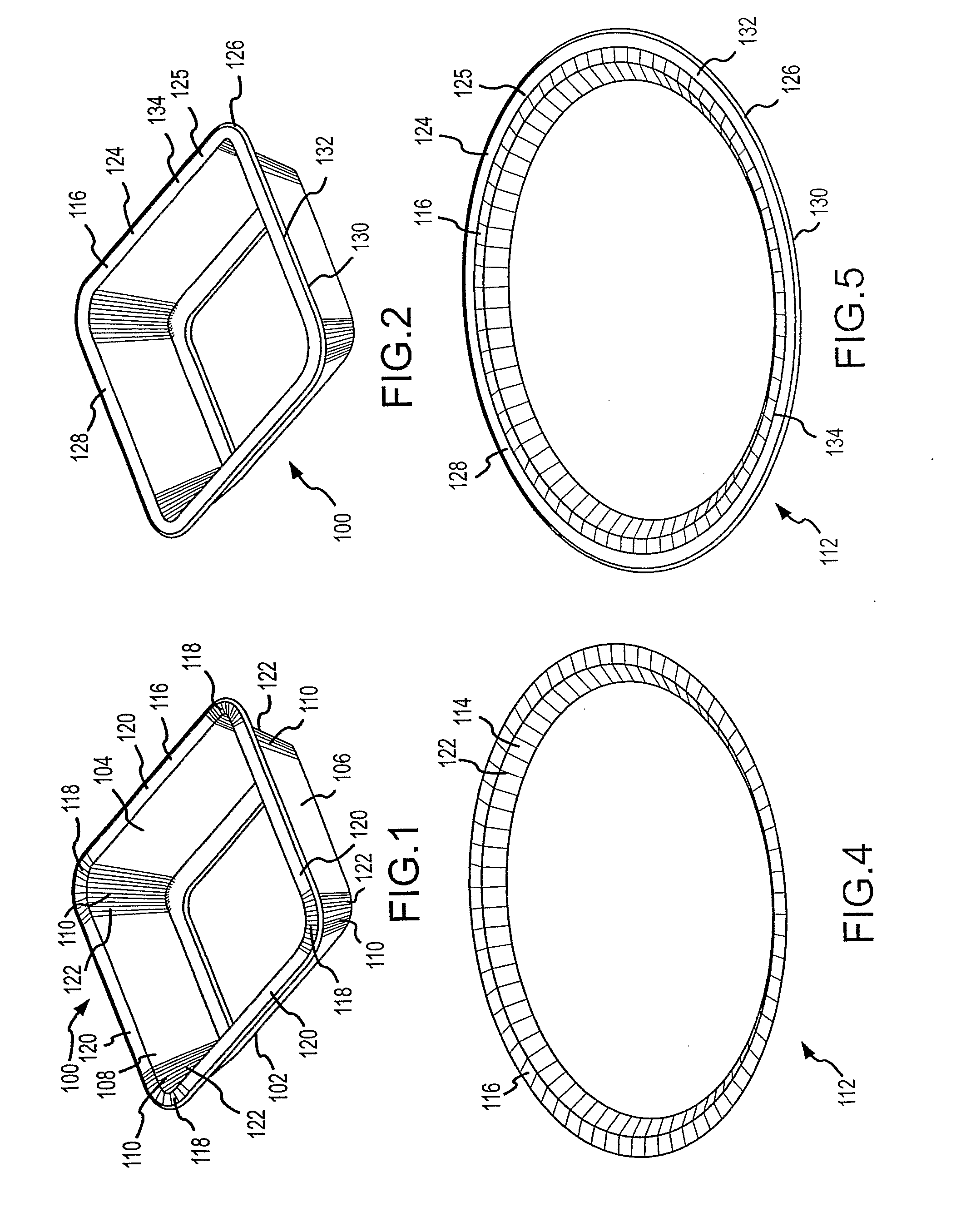

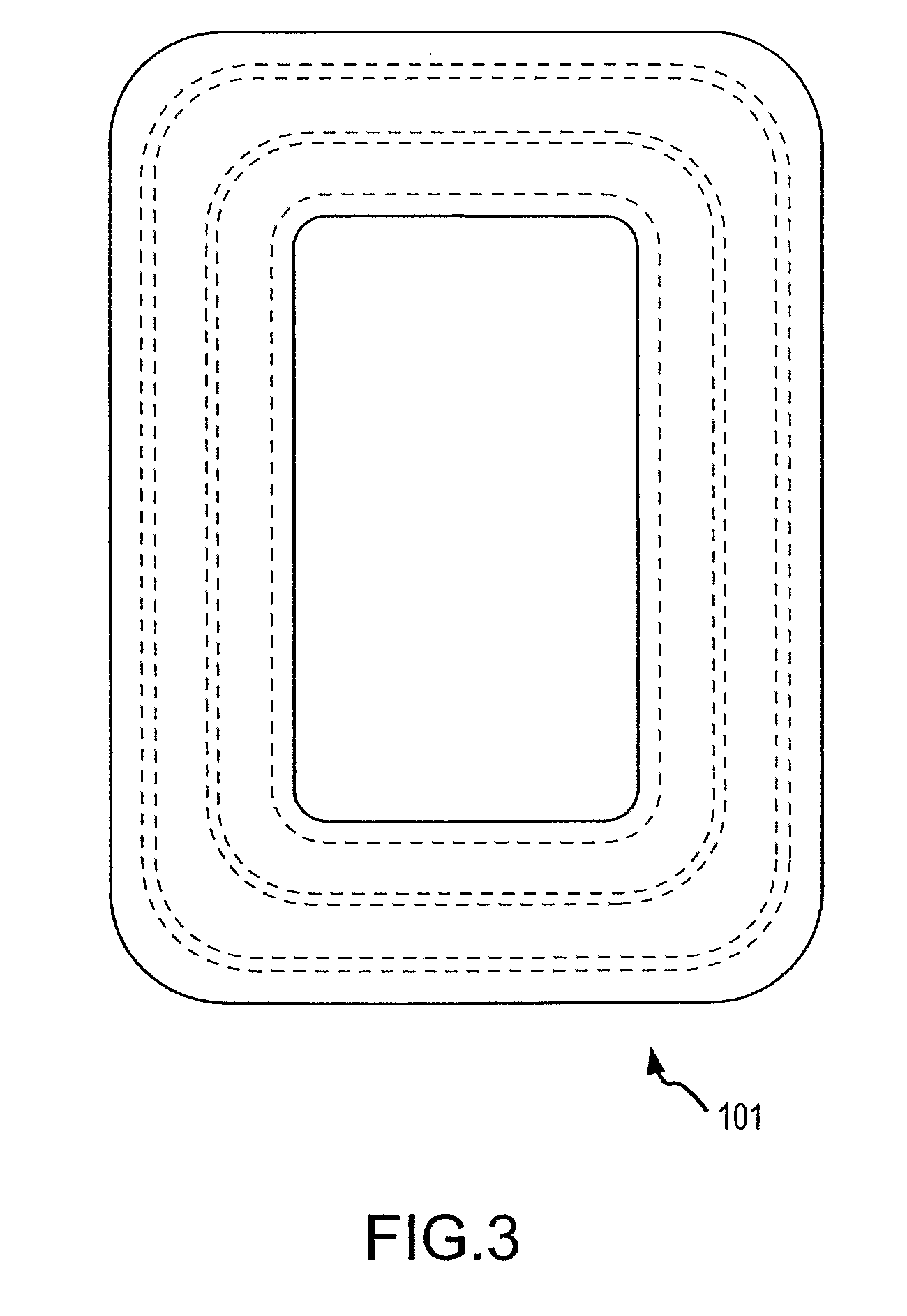

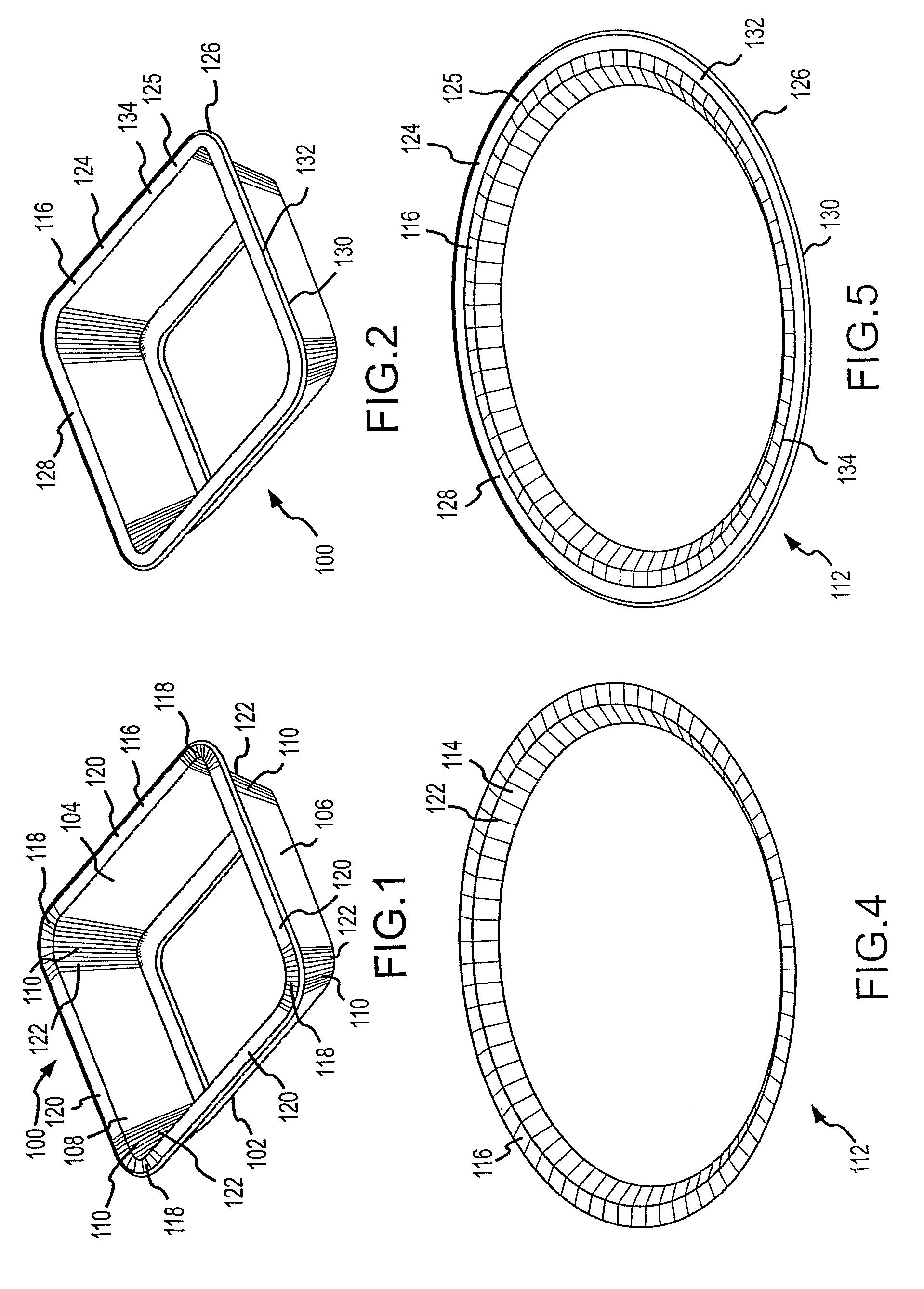

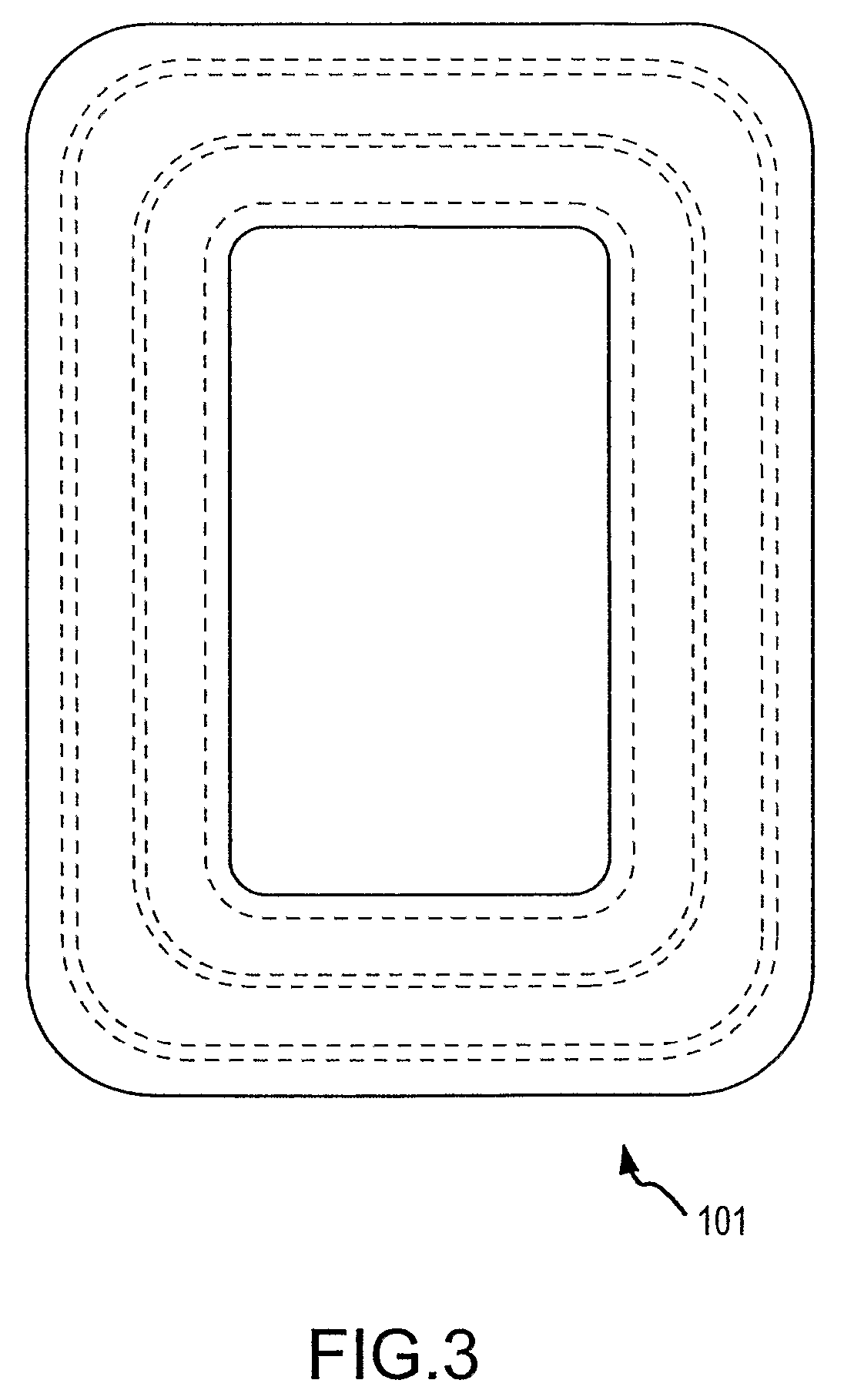

Container Having a Rim or other Feature Encapsulated by or Formed From Injection-Molded Material

ActiveUS20070267374A1Strengthen and stabilizeProvide supportClosure lidsTurning machine accessoriesHermetic sealEngineering

Owner:GRAPHIC PACKAGING INT

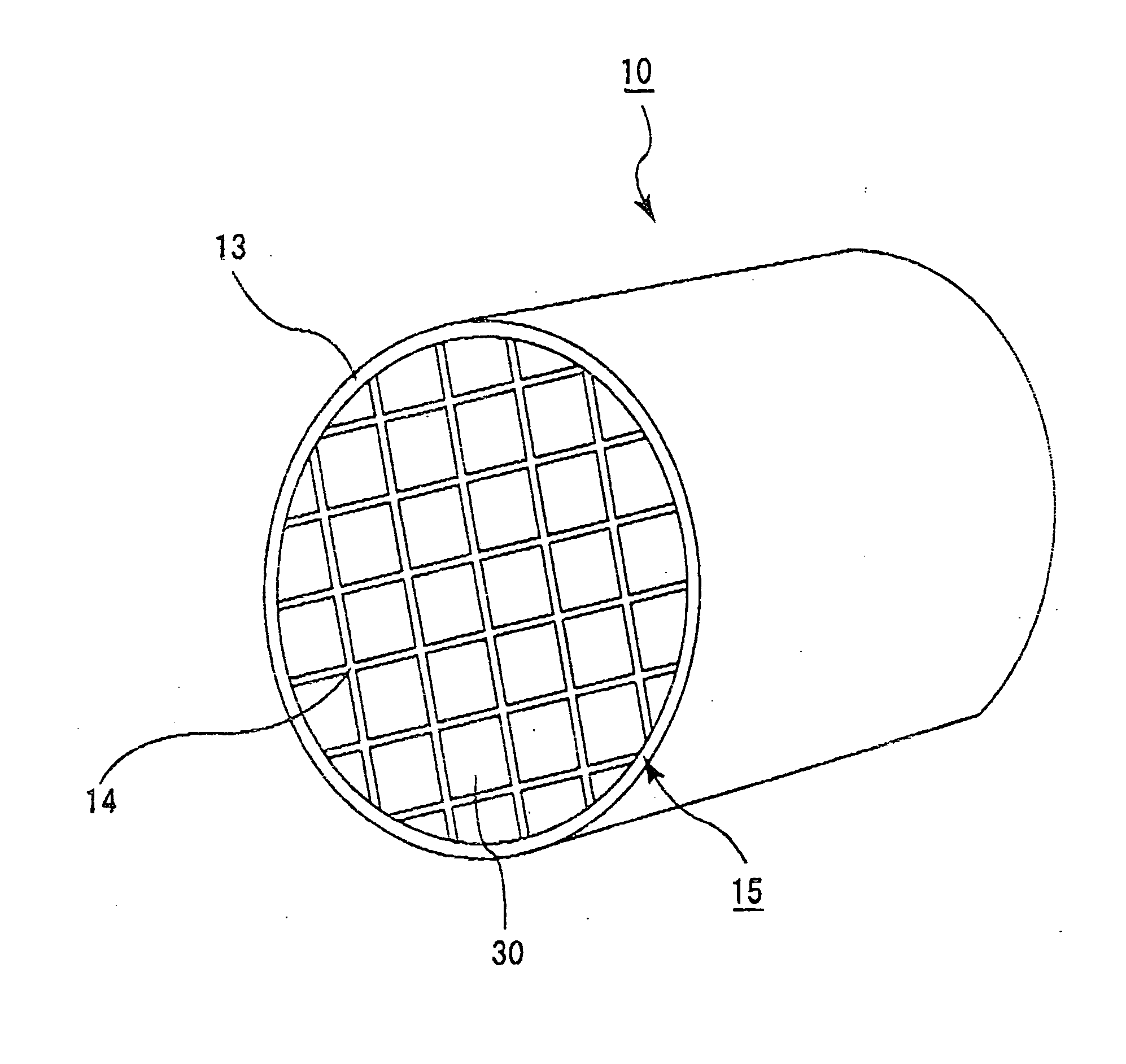

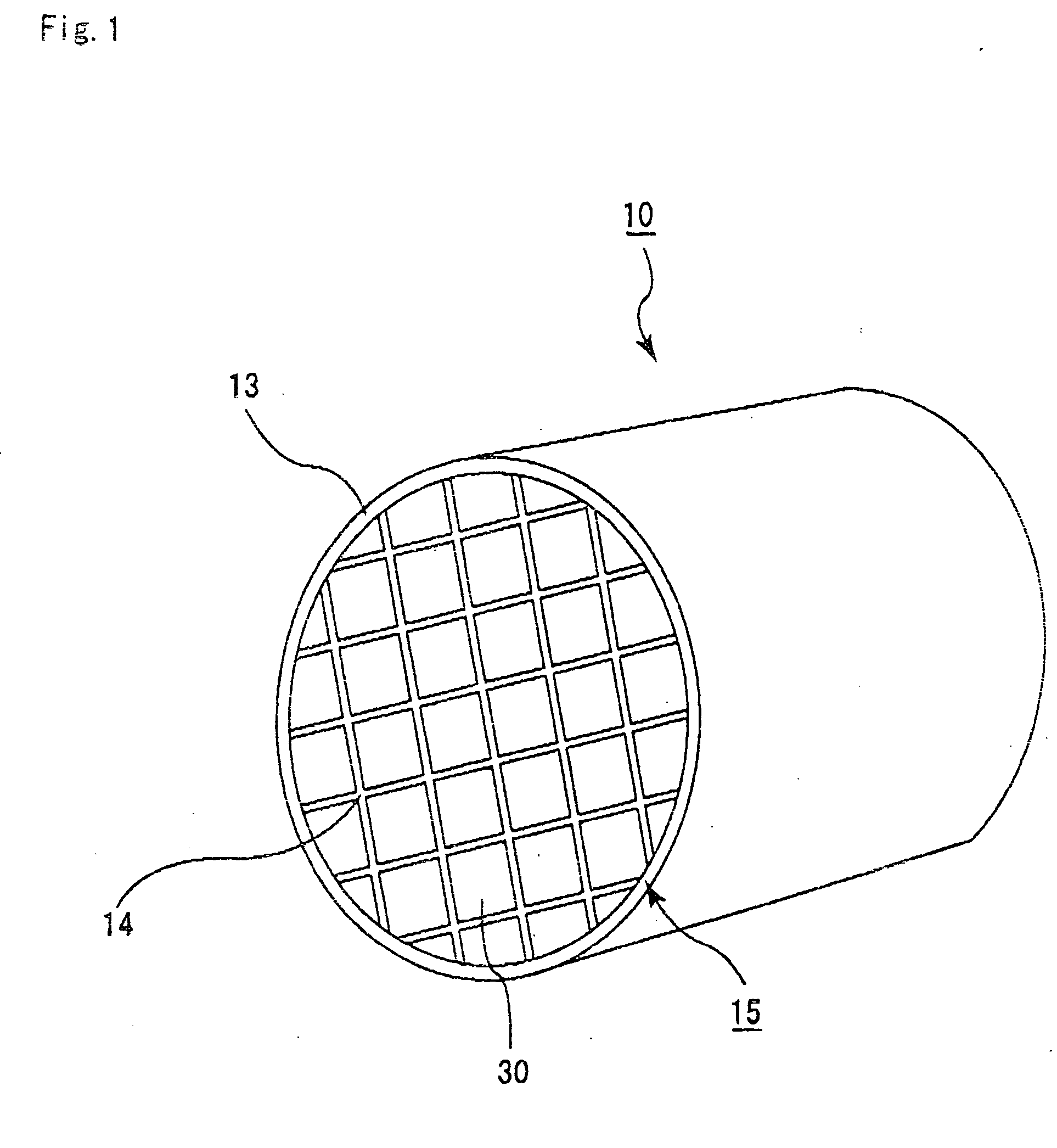

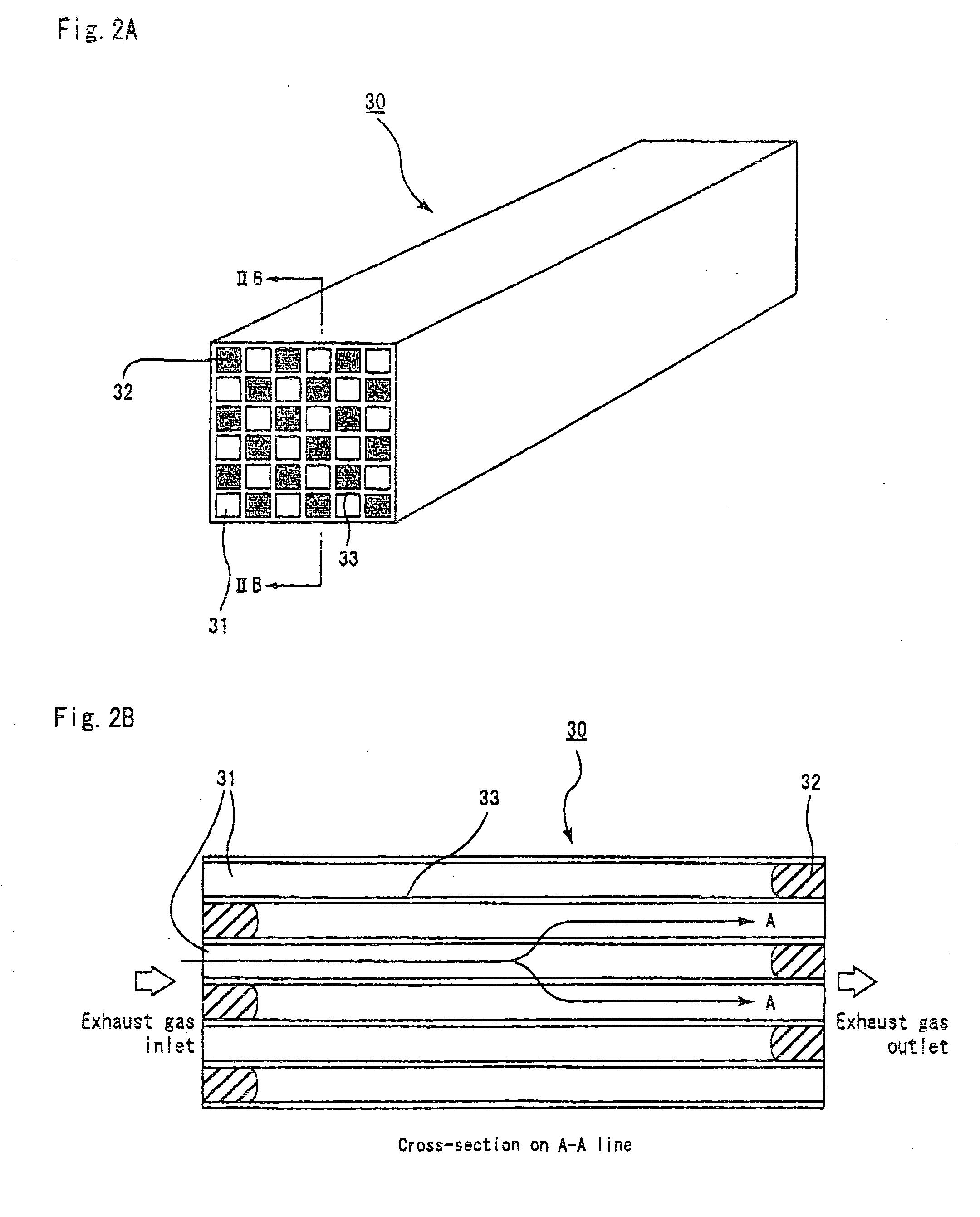

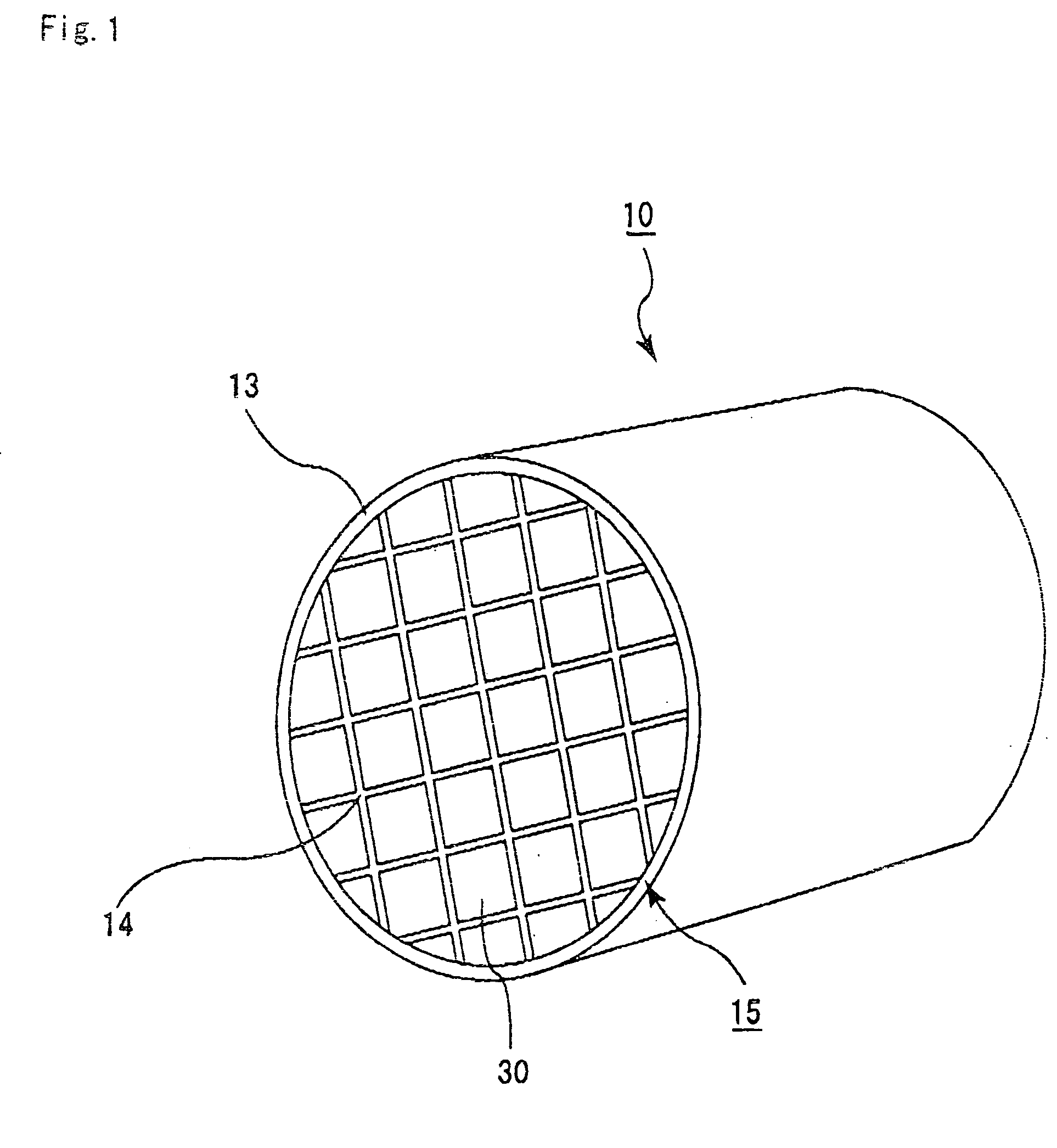

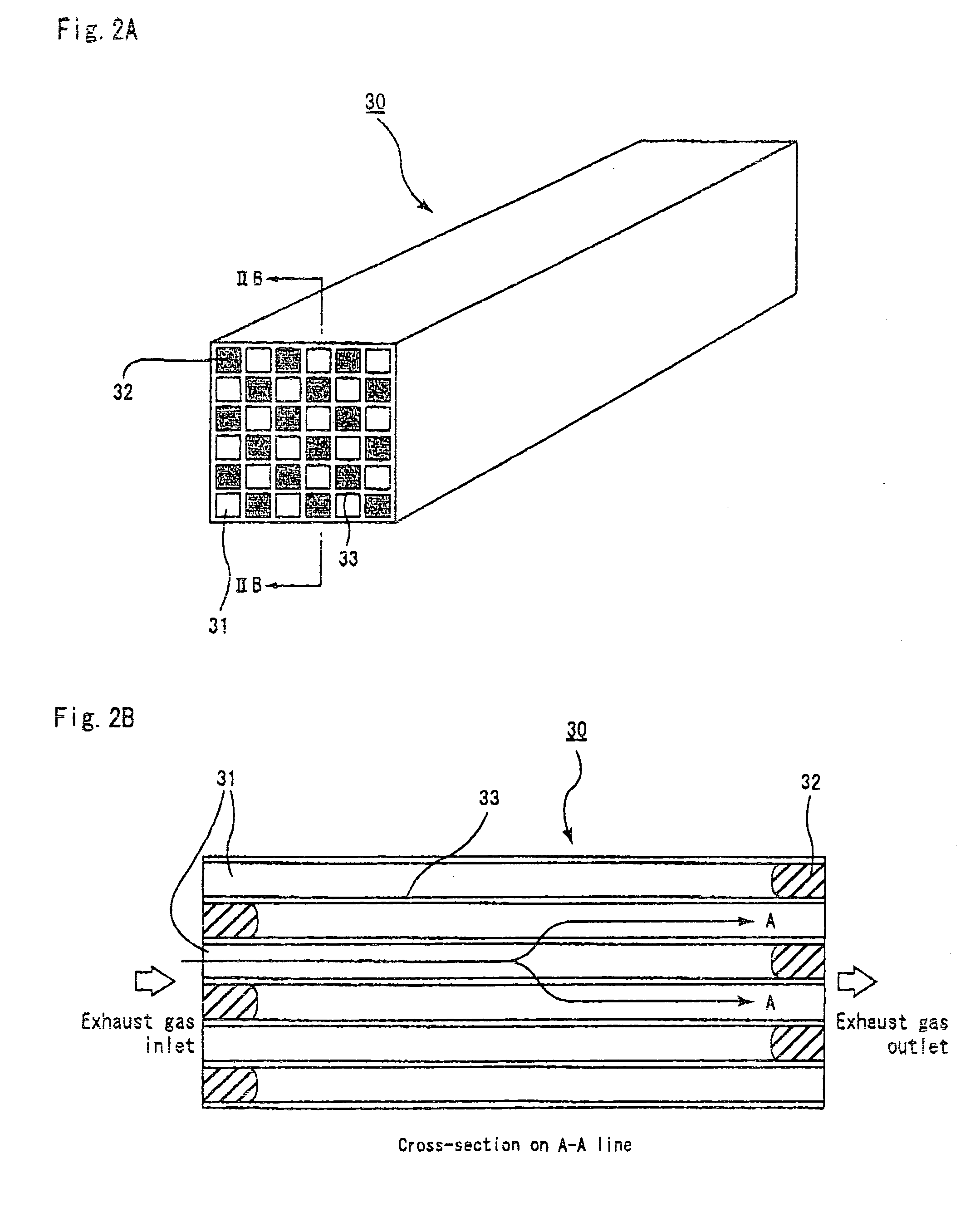

Ceramic structure, method of manufacturing ceramic structure, and device for manufacturing ceramic structure

ActiveUS20050178098A1Hardening the bonding materialCombination devicesAuxillary pretreatmentMetallurgyAdhesive

A ceramic structure includes a plurality of porous ceramic members each being warped, each of the plurality of porous ceramic members having a bonding portion and end portions at both ends of each of the plurality of porous ceramic members in a longitudinal direction of each of the plurality of porous ceramic members, and an adhesive provided only on the bonding portion between the plurality of porous ceramic members to connect the plurality of porous ceramic members except for the end portions of the plurality of ceramic members.

Owner:IBIDEN CO LTD

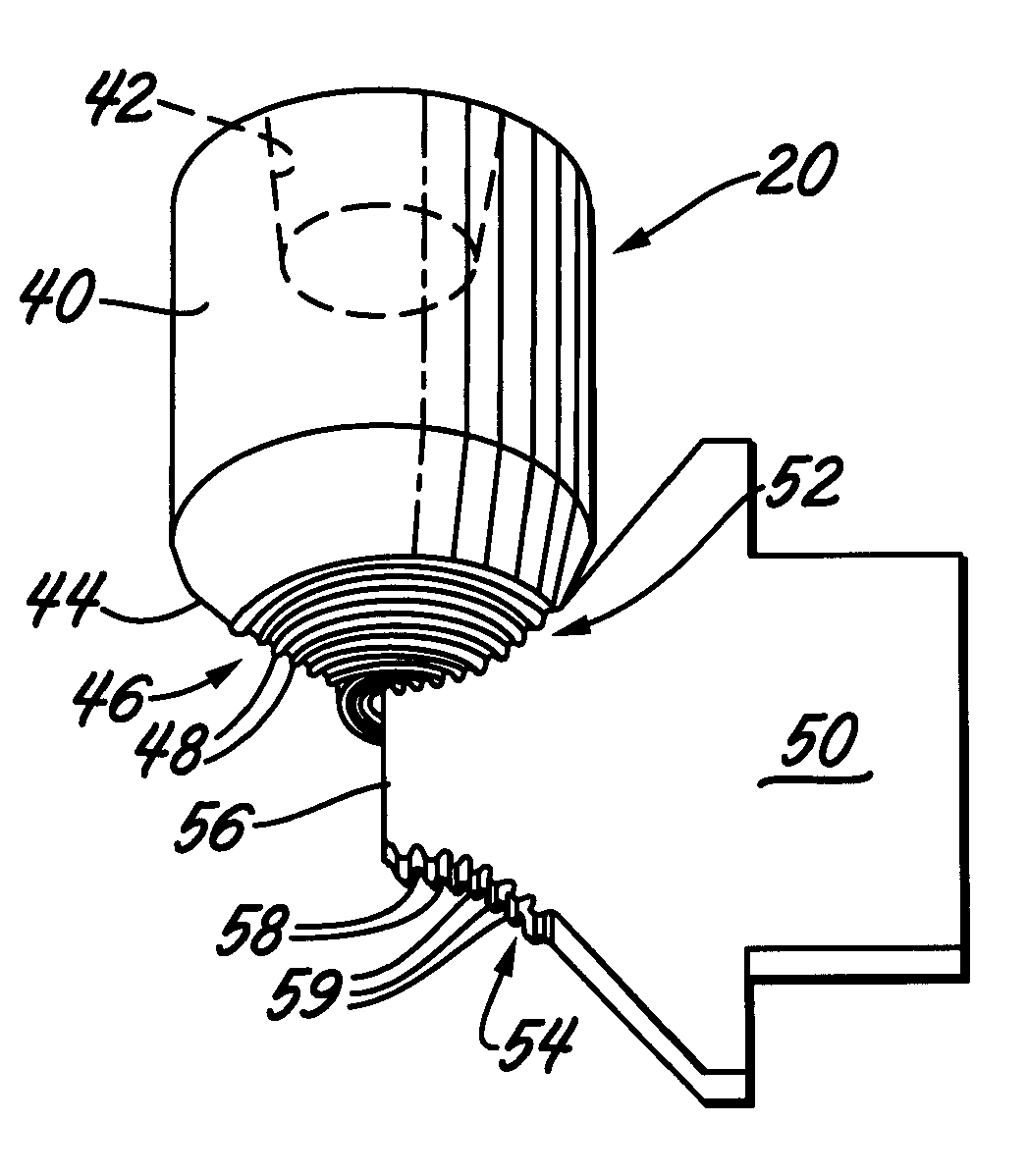

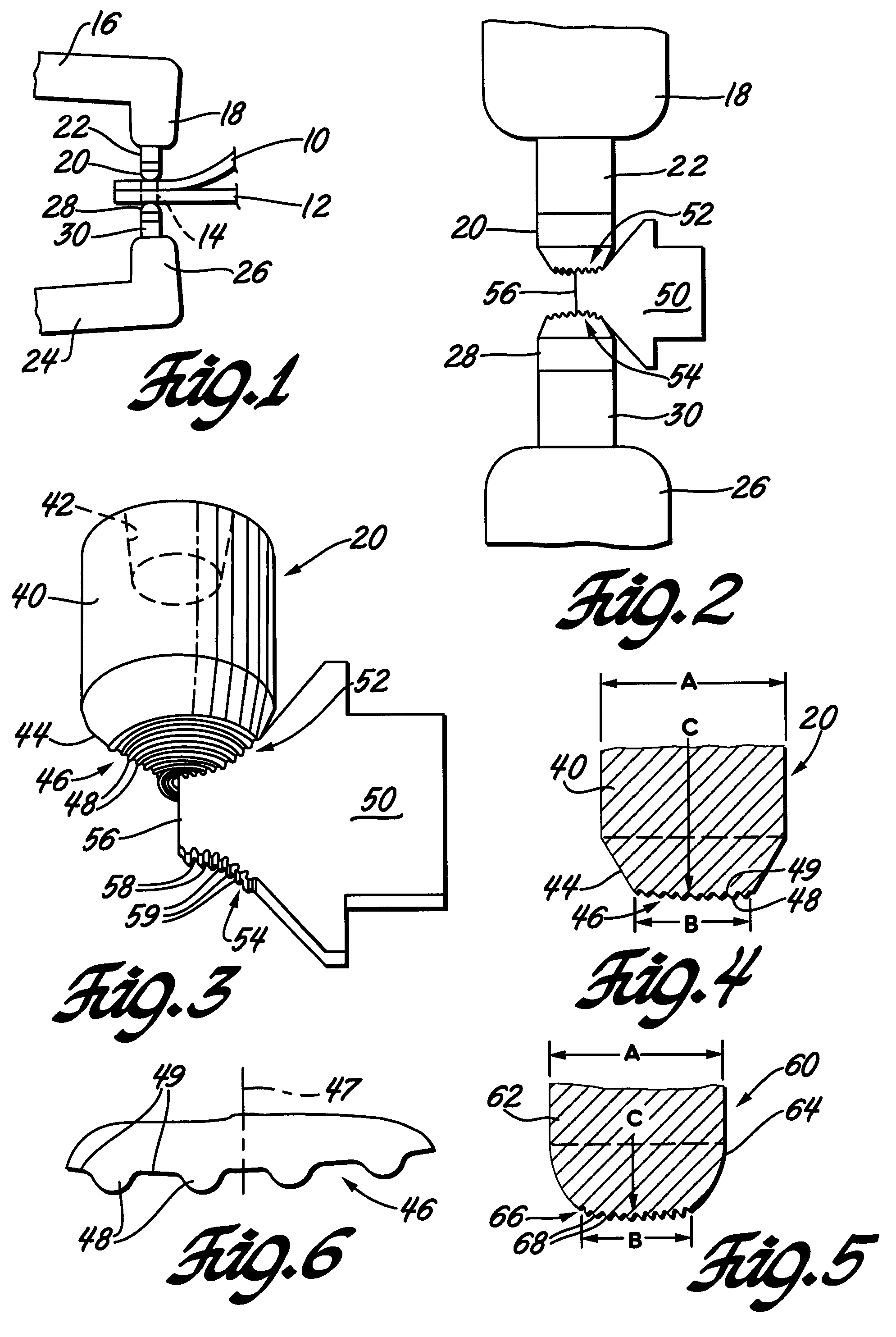

Welding electrode with contoured face

ActiveUS20080078749A1Well formedEasy alignmentTurning machine accessoriesOhmic-resistance electrodesElectrical resistance and conductanceEngineering

Welding electrodes with a welding face for contact with a metal surface for electrical resistance welding are provided with concentric contoured rings formed into the face. The rings may, for example, be ridges upstanding in the face or grooves depressed into the face. The contoured rings may be radially spaced with relatively flat (depending on the curvature of the face) intervening rings. When the electrode is pressed into contact with the surface of the workpiece for delivery of a welding current, the features of the concentric rings penetrate surface oxides or other conductivity barriers. When ongoing welding operations have eroded the contoured rings they may be rapidly reformed in the weld face in a surface re-dressing operation.

Owner:GM GLOBAL TECH OPERATIONS LLC

Ceramic structure, method of manufacturing ceramic structure, and device for manufacturing ceramic structure

A ceramic structure includes a plurality of porous ceramic members each being warped, each of the plurality of porous ceramic members having a bonding portion and end portions at both ends of each of the plurality of porous ceramic members in a longitudinal direction of each of the plurality of porous ceramic members, and an adhesive provided only on the bonding portion between the plurality of porous ceramic members to connect the plurality of porous ceramic members except for the end portions of the plurality of ceramic members.

Owner:IBIDEN CO LTD

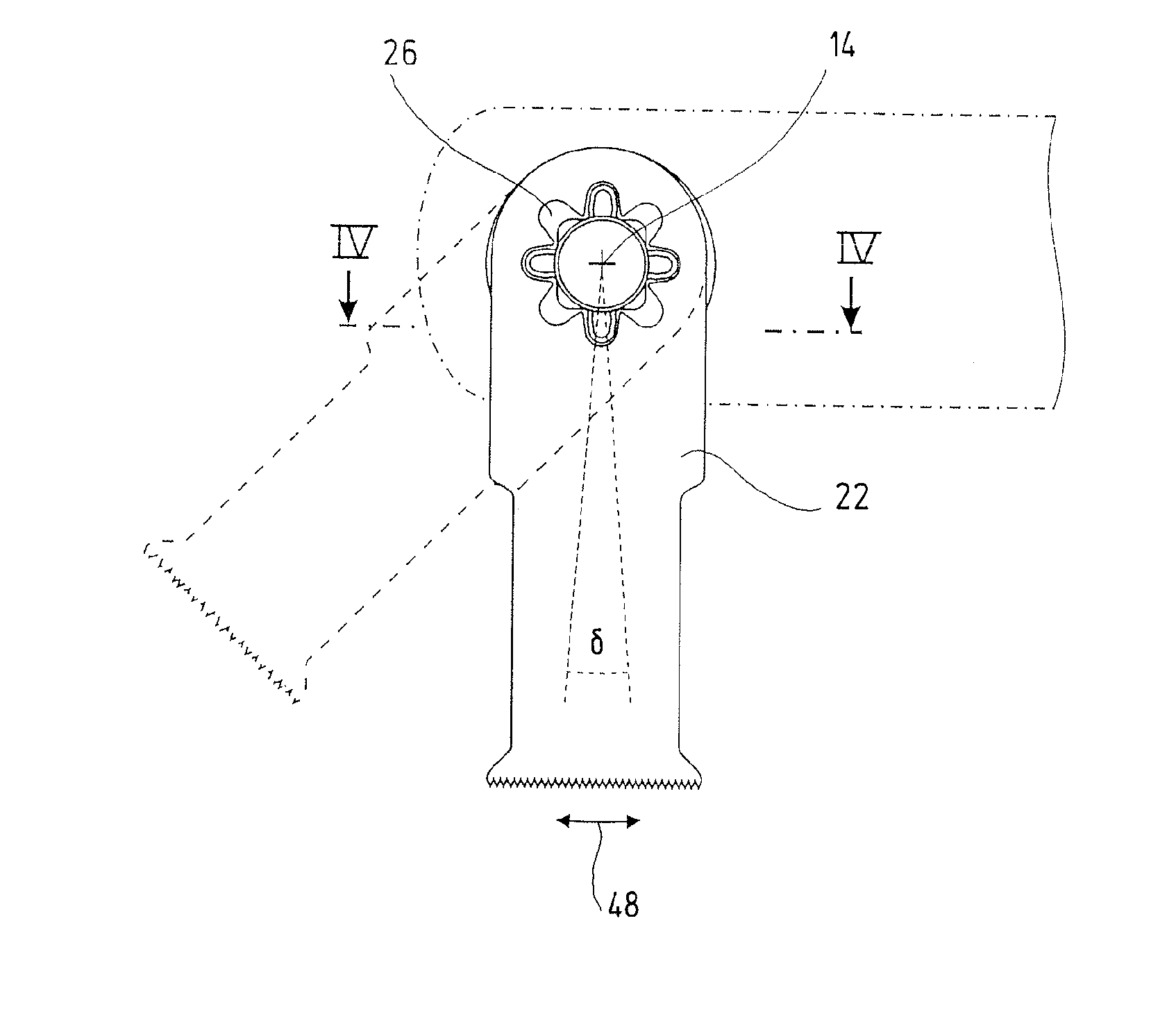

Oscillatory Drive

ActiveUS20070295156A1Reduce disadvantagesImprove transmittanceGrinding wheel securing apparatusTurning machine accessoriesPre stressPre stressing

The invention relates to an oscillatory drive having an output shaft that can be driven to perform a rotationally oscillating movement about its longitudinal axis and that comprises a free end, a holding fixture at the free end of the output shaft comprising a contact surface for attachment of a tool, a mounting section on the holding fixture, raised relative to the contact surface, that projects to the outside in the direction of the longitudinal axis and that is designed for form-locking connection with a mounting opening of a tool placed in contact with the contact surface, and having a securement for fixing the tool with its mounting opening on the holding fixture, the securement permitting the tool to yield in axial direction under the action of a torque, against a pre-stress, and the mounting section permitting the tool to rotate by a certain angle of rotation when the tool gives way axially.

Owner:C & E FEIN

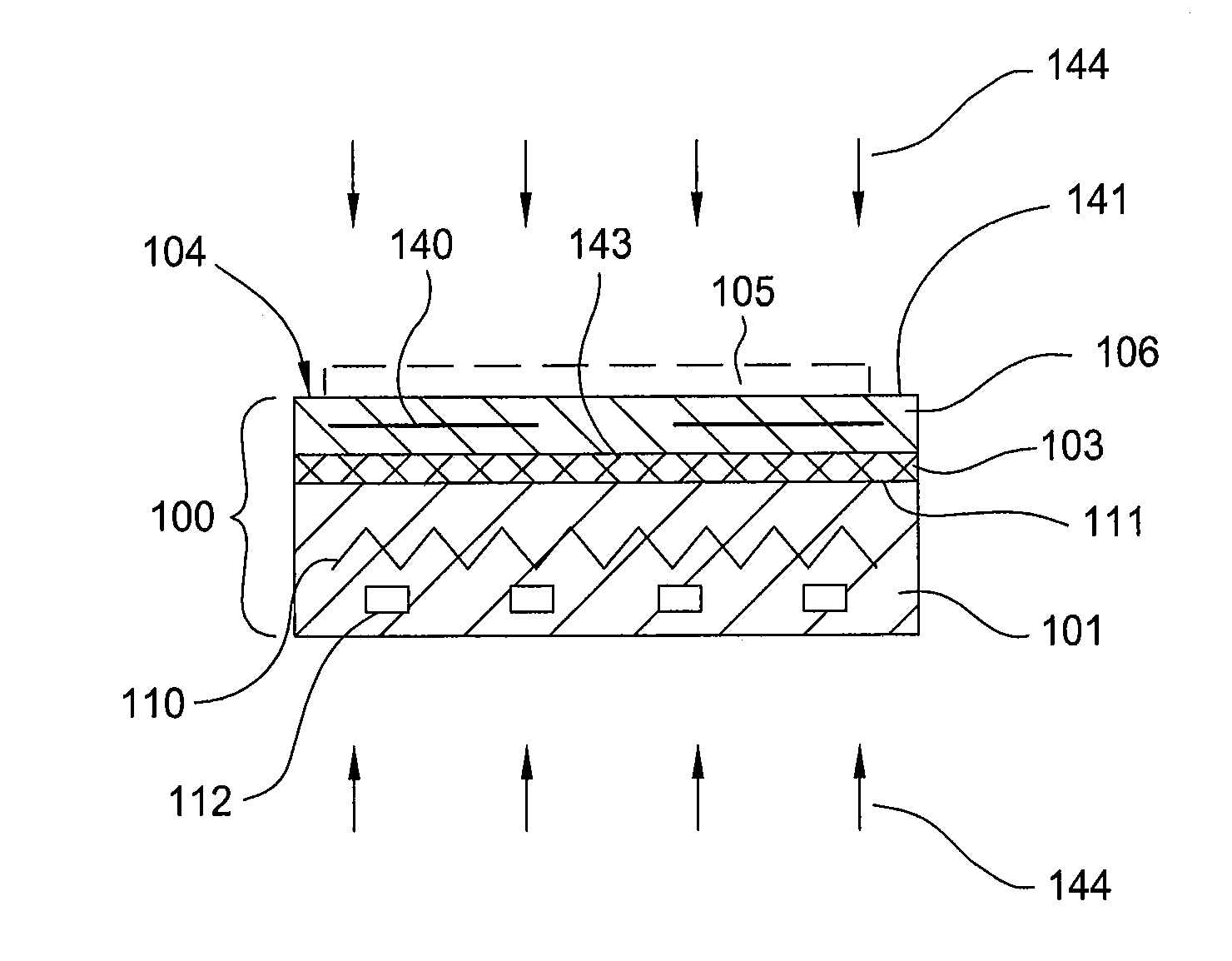

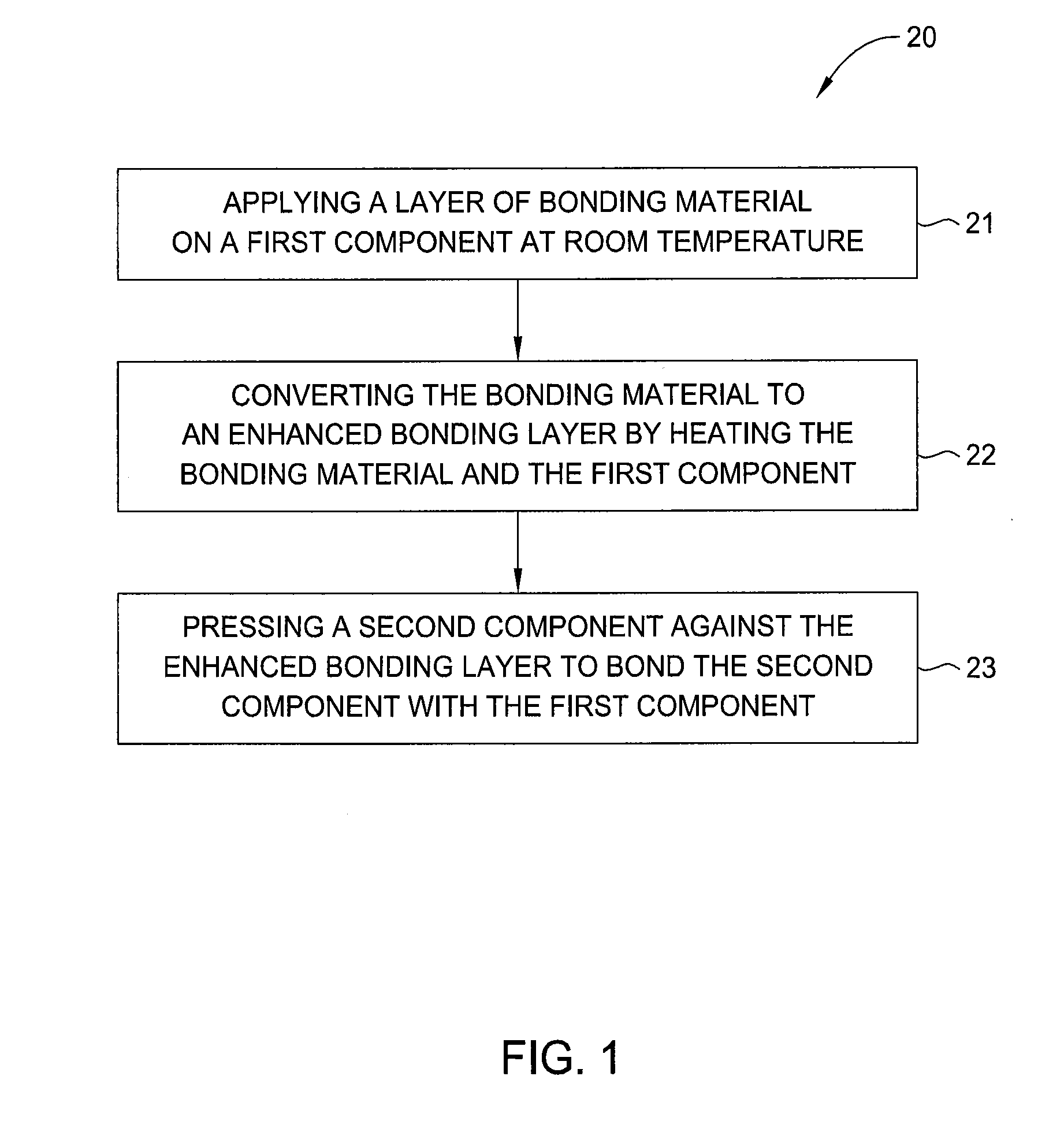

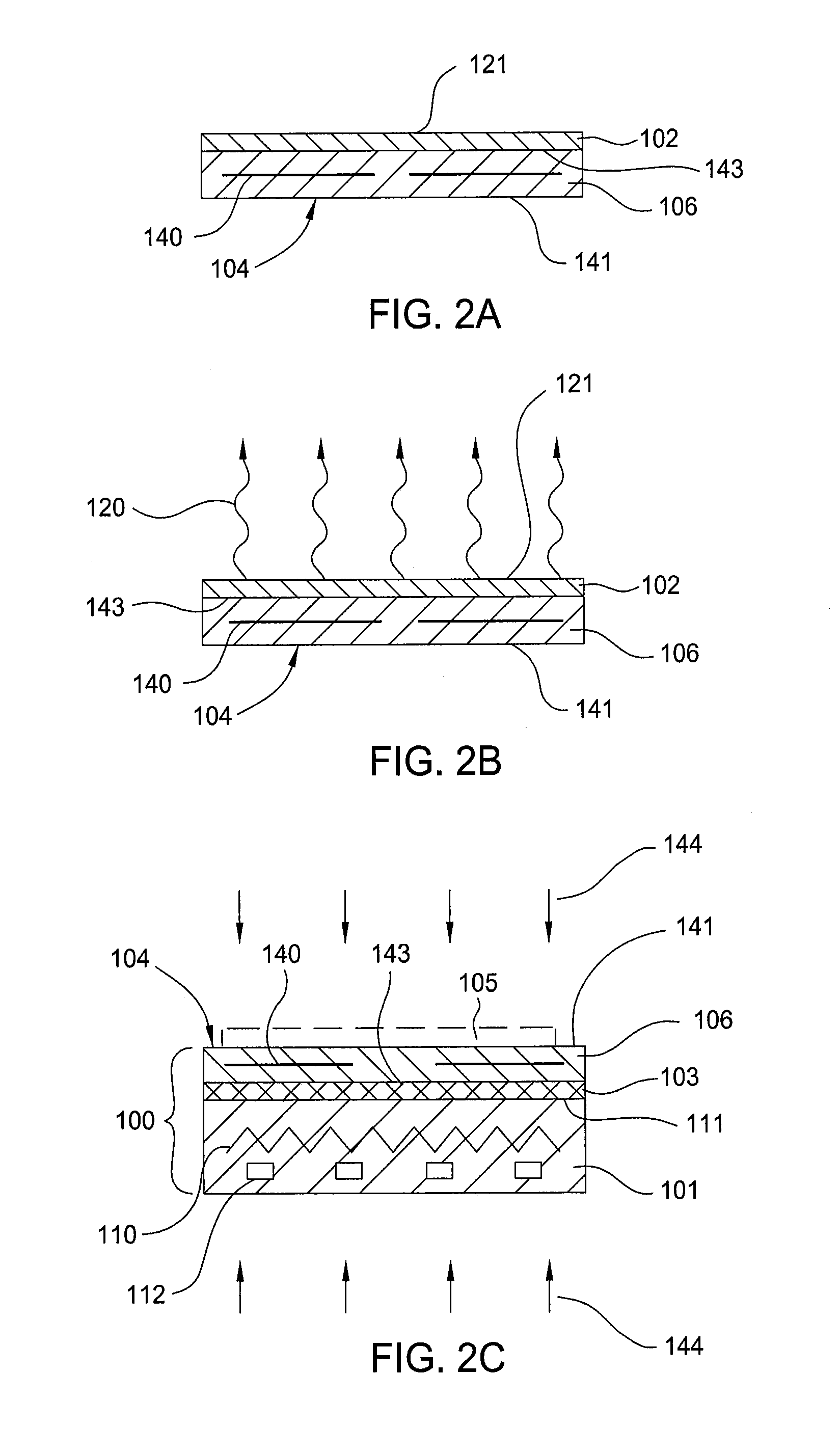

Electrostatic chuck and showerhead with enhanced thermal properties and methods of making thereof

ActiveUS20120104703A1Improve thermal stabilityImprove thermal performanceBurnersTurning machine accessoriesMaterials scienceComposite structure

Embodiments of the present invention generally provide chamber components with enhanced thermal properties and methods of enhancing thermal properties of chamber components including bonding materials. One embodiment of the present invention provides a method for fabricating a composite structure. The method includes applying a bonding material to a first component, and converting the bonding material applied to the first component to an enhanced bonding layer by heating the bonding material to outgas volatile species from the bonding material. The outgassed volatile species accumulates to at least 0.05% in mass of the bonding material. The method further includes contacting a second component and the enhanced bonding layer to join the first and second components.

Owner:APPLIED MATERIALS INC

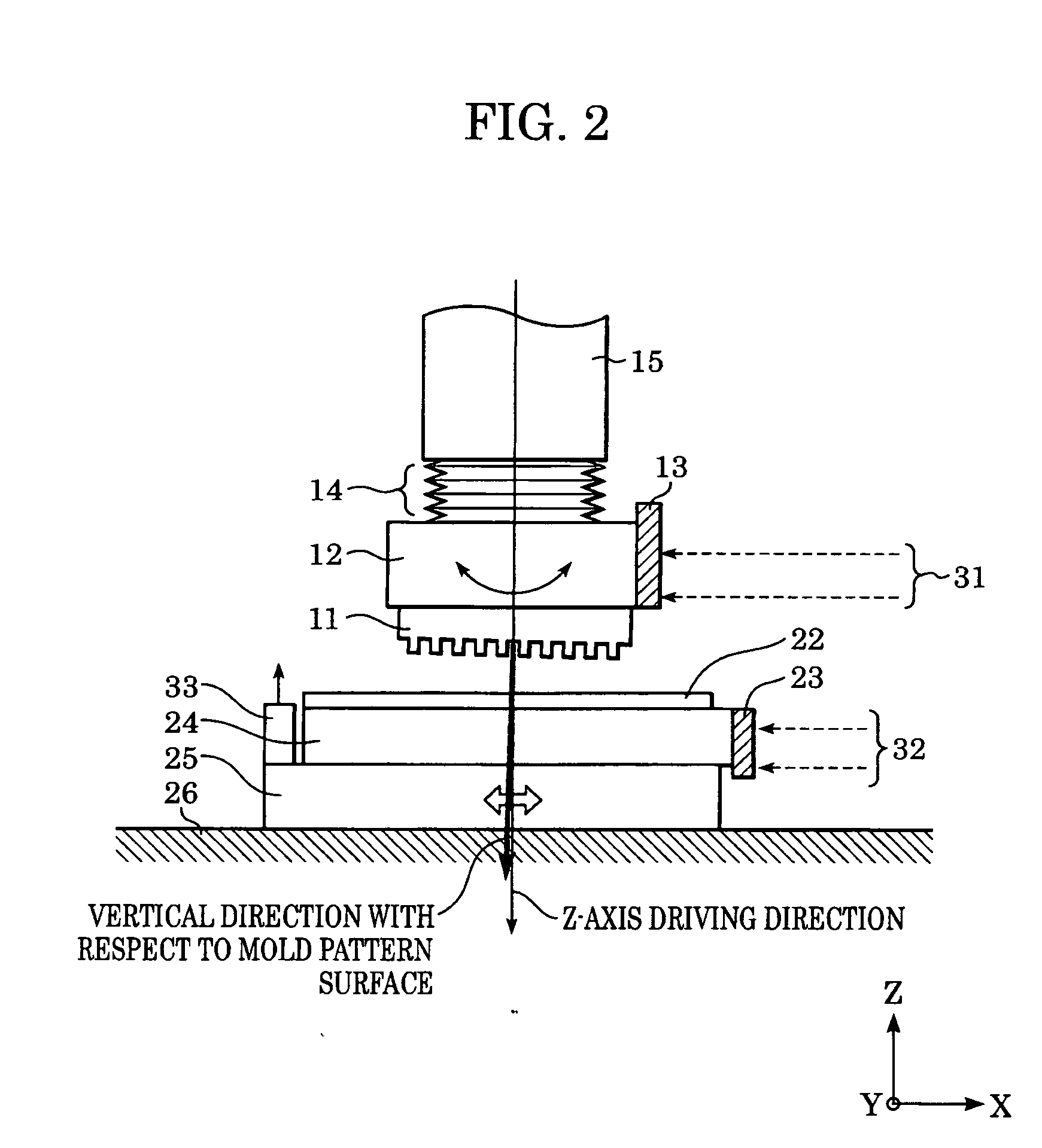

Method and apparatus for imprinting microstructure and stamper therefor

InactiveUS20090243126A1High precisionPrecise alignmentTurning machine accessoriesNanoinformaticsMicrometerOptoelectronics

A method of imprinting a microstructure comprising: contacting a stamper comprising a pattern layer with the microstructure of the order of from micrometers to nanometers in one face of the pattern layer and a substrate supporting the pattern layer with an imprinting member having a deformable layer to which the microstructure is imprinted, wherein the pattern layer is supported on a round surface having a prescribed radius of curvature of the substrate, the center of the round surface protruding towards the rear face of the pattern layer; causing the deformable layer on the imprinting member; and separating the stamper from the cured deformable layer.

Owner:HITACHI LTD

Fly-cutting system and method, and related tooling and articles

Methods of fly-cutting a workpiece are disclosed, and in methods in which the position of a fly-cutting head or its associated cutting element is known as a function of time. Also disclosed are methods of forming features, such as grooves or groove segments, in a workpiece such as a cylindrical roll. The features may be provided according to one or more disclosed patterns. Articles made using tools machined in the manner described are also provided, such as polymeric film or sheeting that exhibit certain beneficial properties.

Owner:3M INNOVATIVE PROPERTIES CO

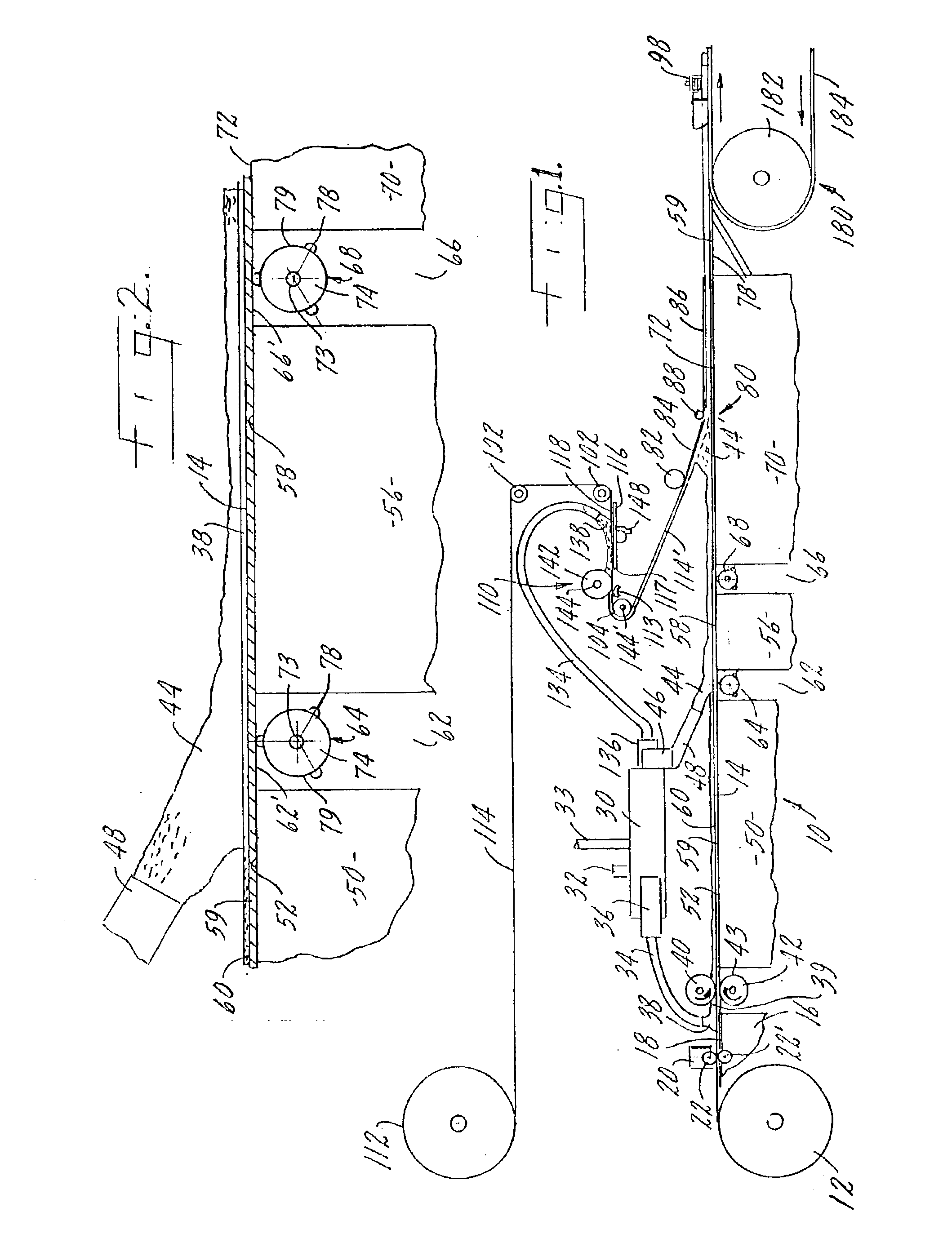

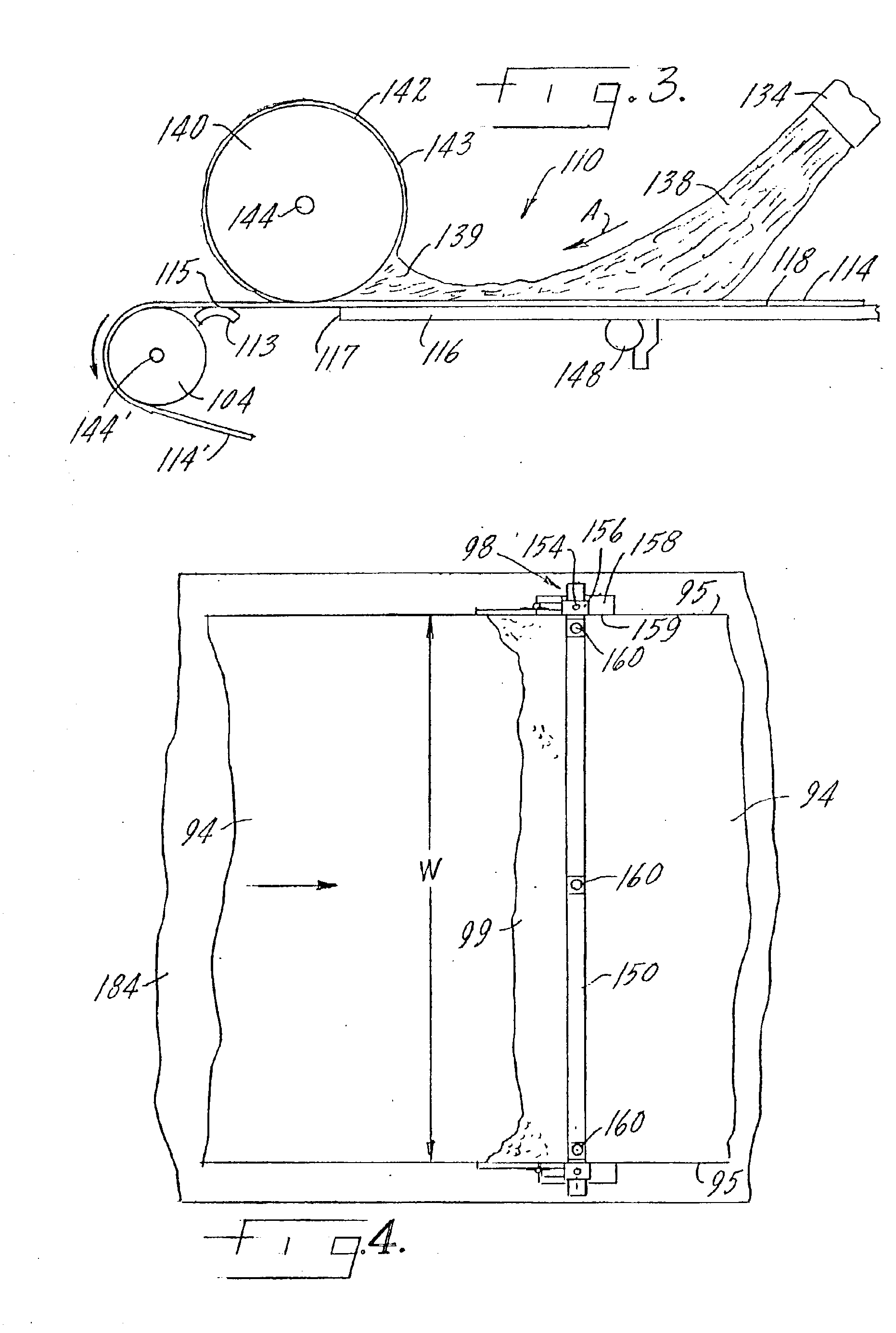

Gypsum board forming device

A gypsum board forming device having a gypsum forming station including two laterally disposed edger shoes, and at least one laterally disposed edger bar clamping element on the edger bar. In one embodiment a laterally extending forming plate extends over the top surface of the formed gypsum board, the forming plate including a plurality of micropore conduits through which pressurized water is supplied to provide a film of smoothing water over the top surface of the gypsum board. In another embodiment the edger shoes have a flapper mechanism for retaining unset slurry skimmed off the surface of the gypsum board by the edger bar.

Owner:BPB LTD

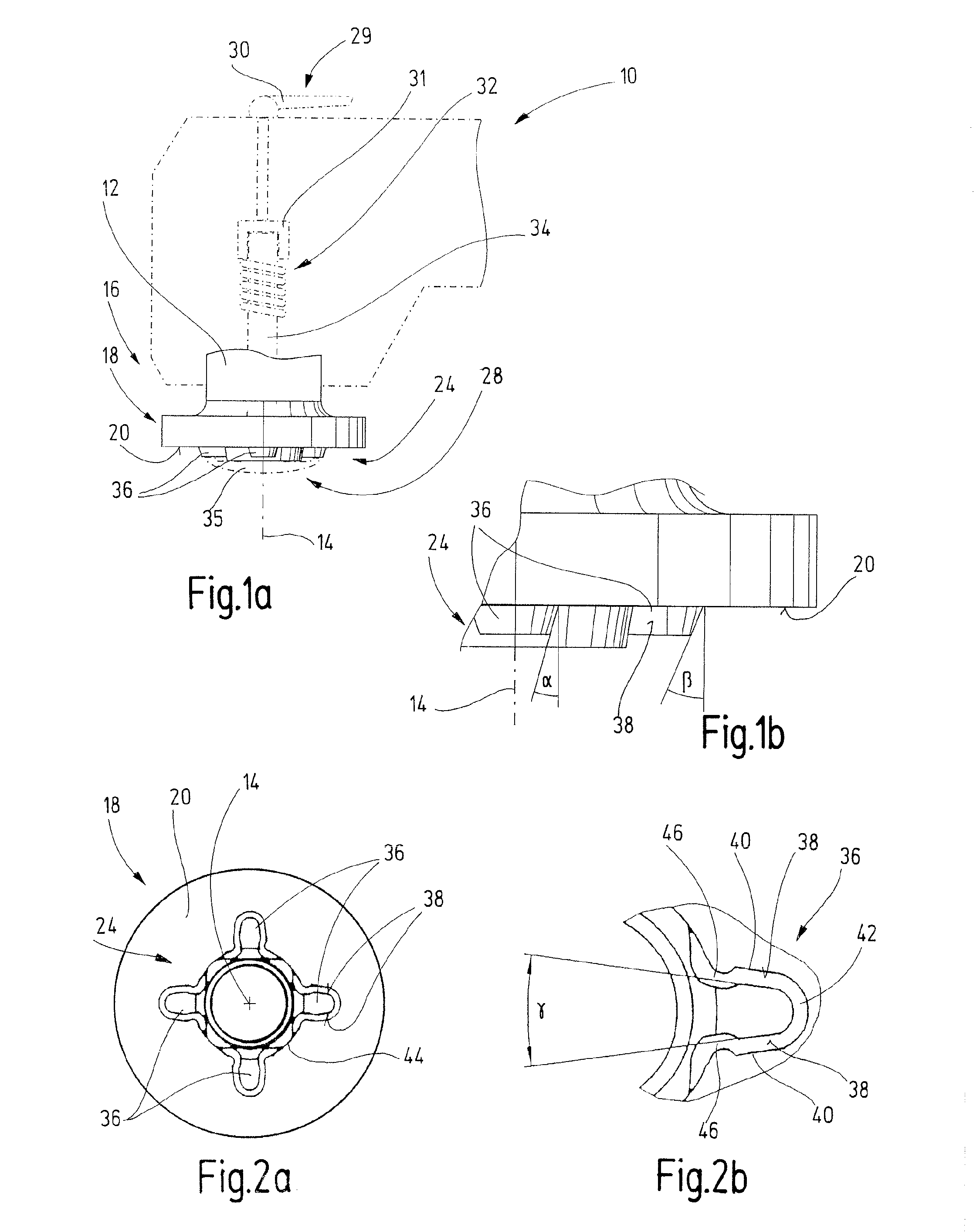

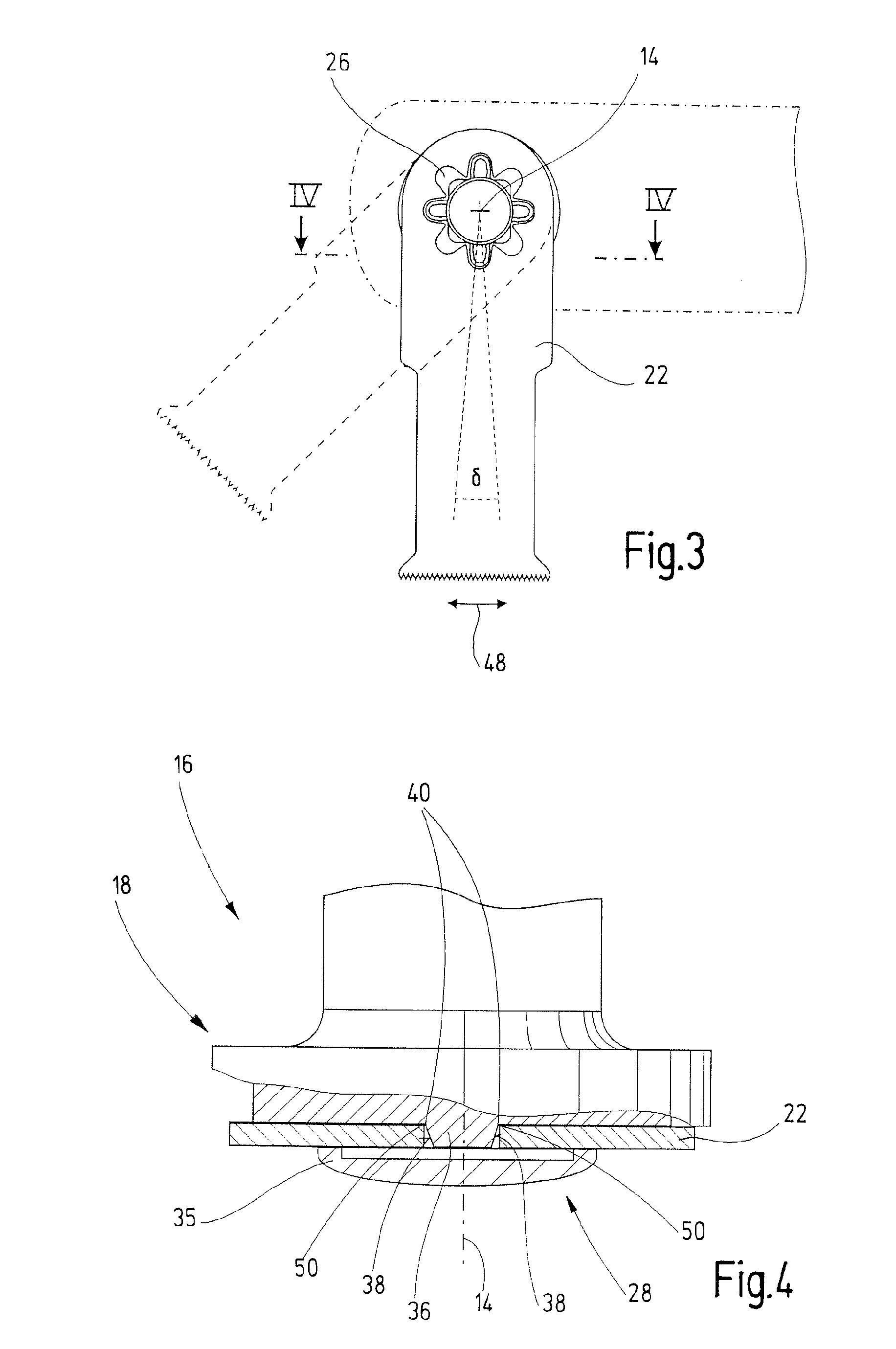

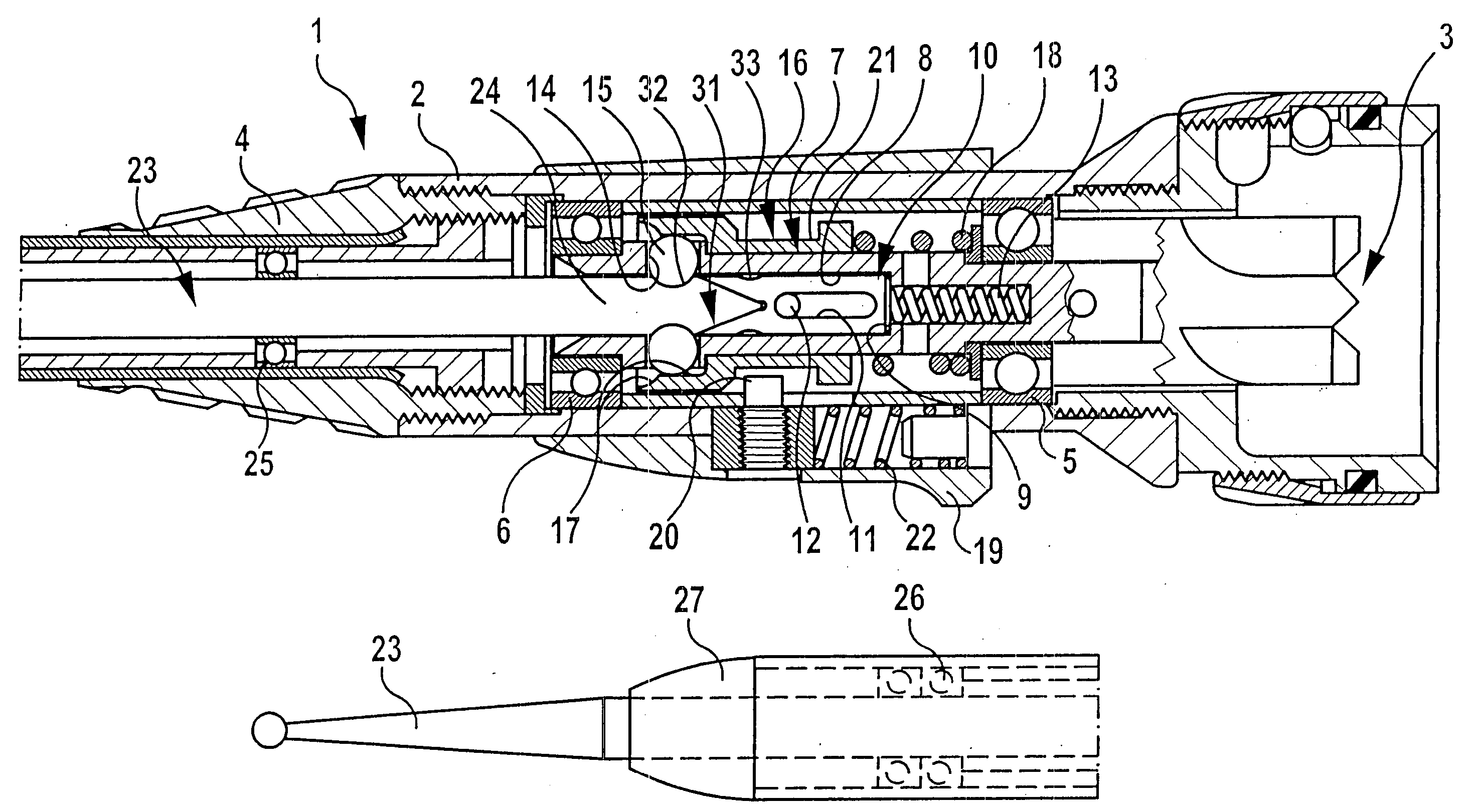

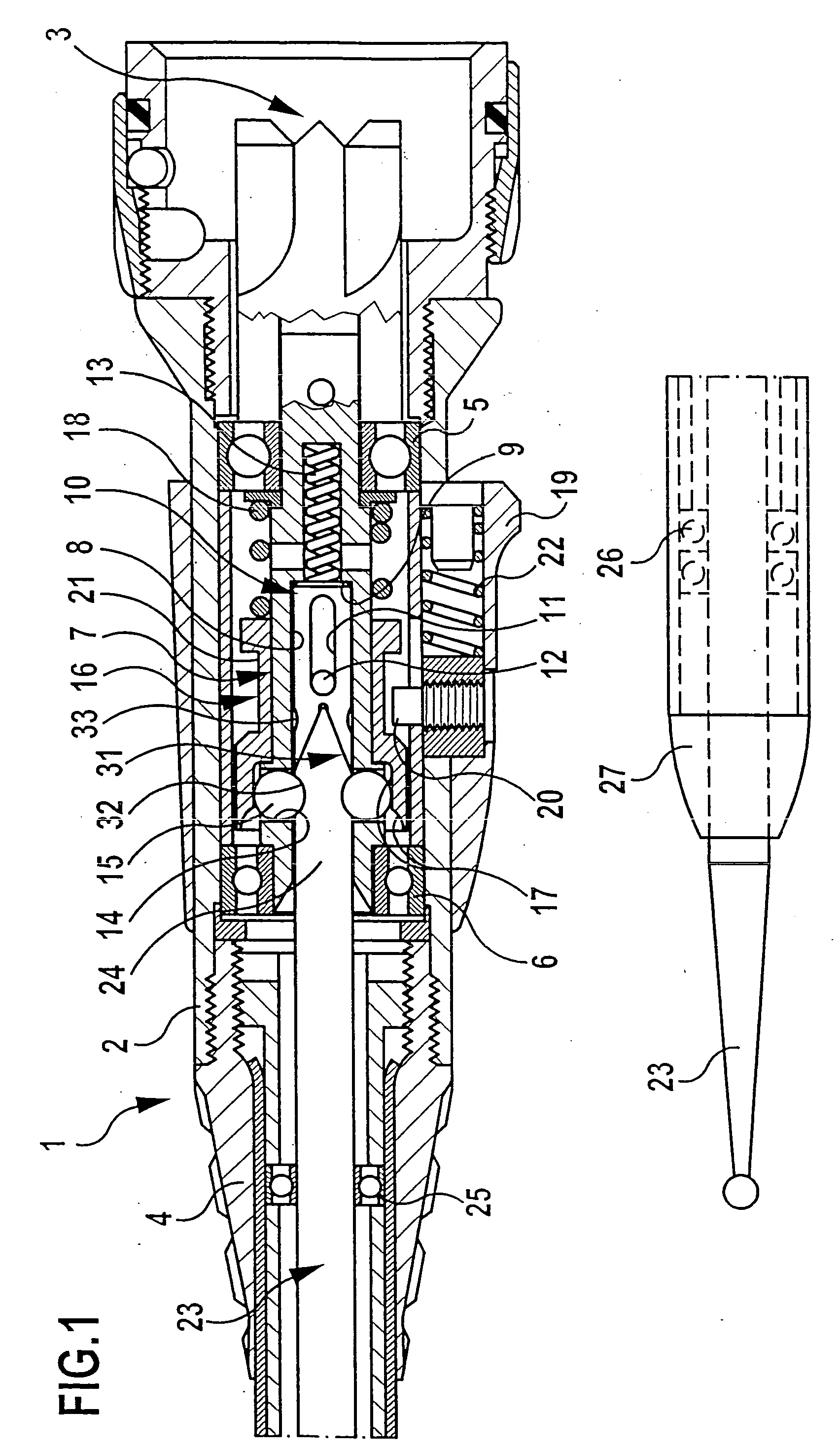

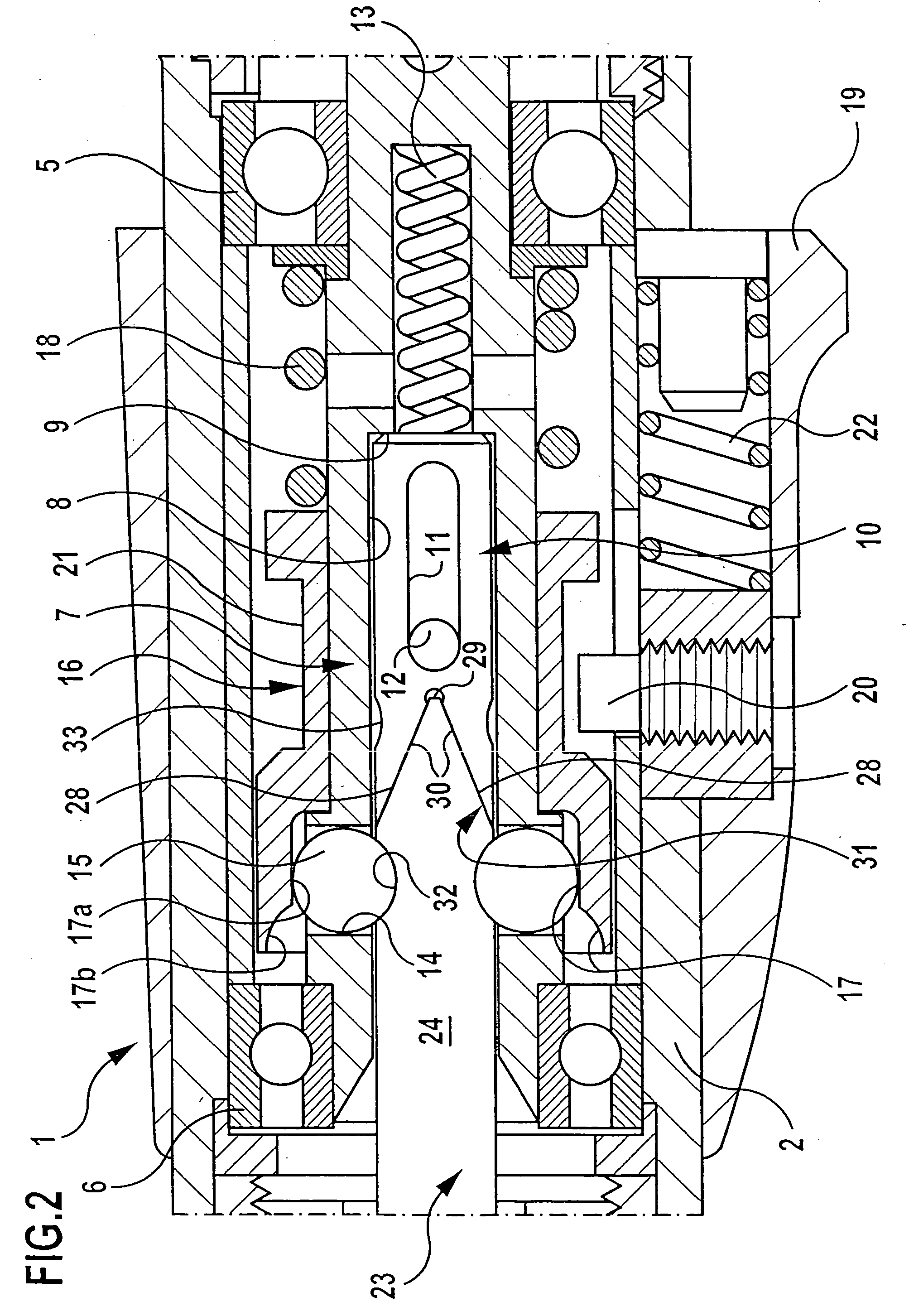

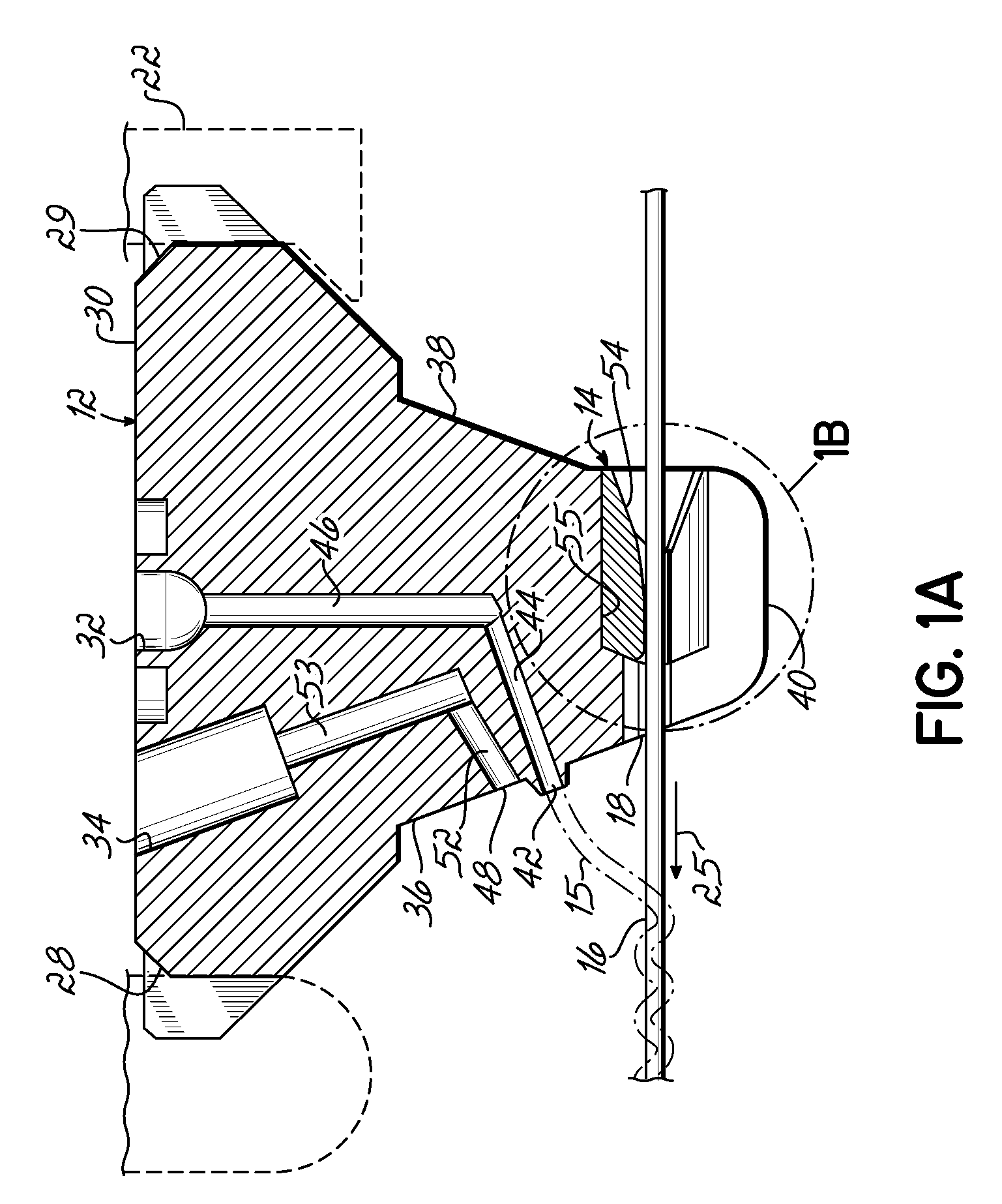

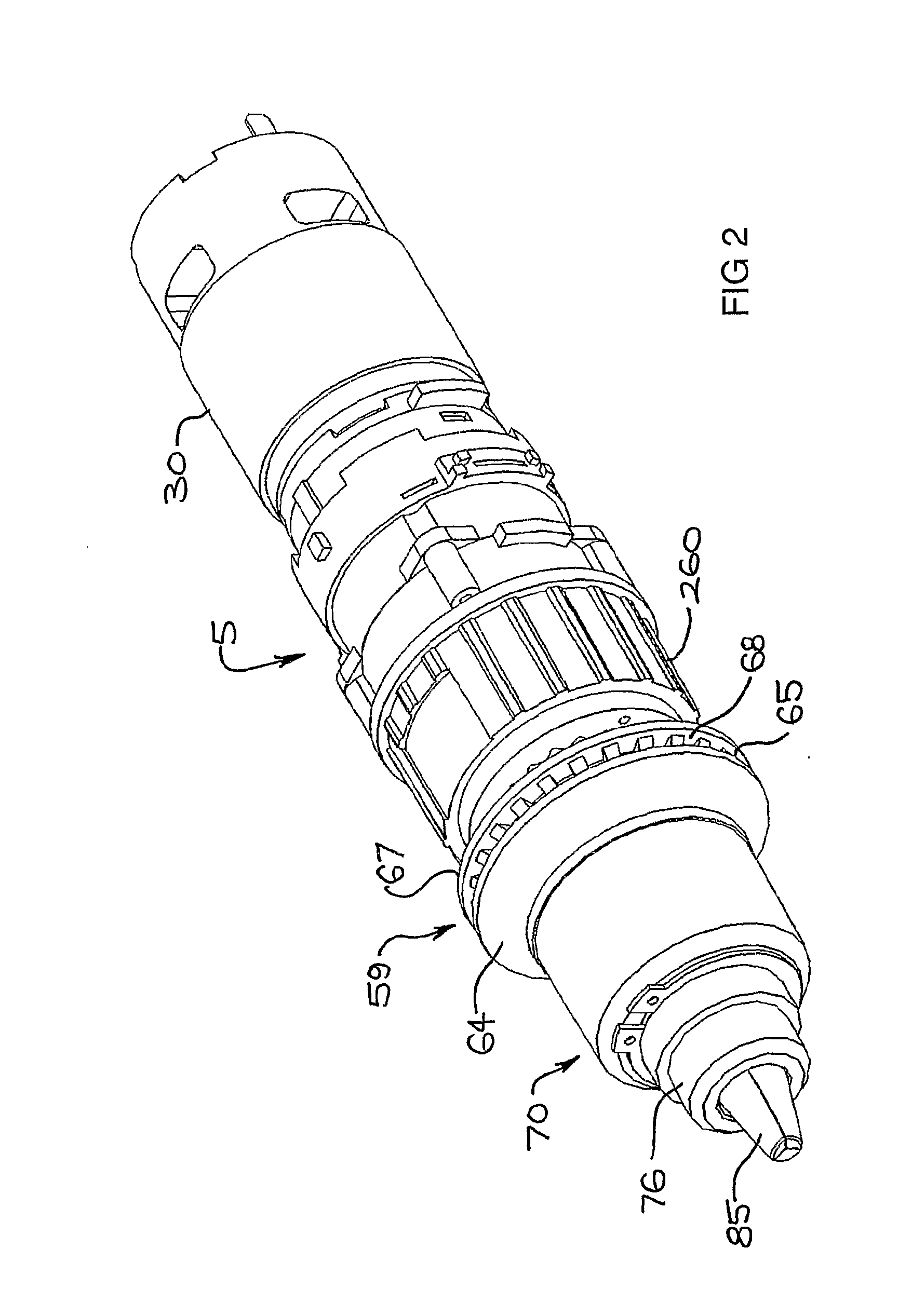

Coupling for a surgical rotary drive hand piece

In order to simplify the insertion of the tool in the case of a coupling for a surgical rotary drive hand piece including a tool which is mounted in the hand piece and driven thereby in rotary manner and incorporating a sleeve-shaped, rotary driven seating in the hand piece into which a shank of the tool is adapted to be inserted so as to form an interlocking rotary drive means, and including at least one locking body which is adapted to be inserted radially into the interior of the seating and which, in an inserted locking position, engages in a recess in the shank and thereby secures it from axial displacement, whereas, in a radially withdrawn position, it leaves the recess and thus enables an axial displacement of the shank in the seating, it is proposed that a driver having at least one contact surface on the side thereof facing the tool and which rotates with the sleeve and is axially displaceable with respect thereto be arranged in the sleeve-shaped seating for the purposes of forming an interlocking rotary drive means, in that the driver is displaceable by the effect of a spring into a pushed-out position in which the locking body or bodies rest thereon and are thus held in their release position, in that the driver is displaceable by means of the shank of the tool resting thereon against the effect of the spring into a pushed-in position in which the locking body or bodies enter the locking position and can secure the shank of the tool from axial displacement, and in that the shank of the tool in the pushed-in position thereof secured from axial displacement by the locking body or bodies pushes the driver against the effect of the spring into the seating in such a manner that its contact surfaces rest against the contact surfaces of the tool so as to form a rotary drive means.

Owner:AESCULAP AG

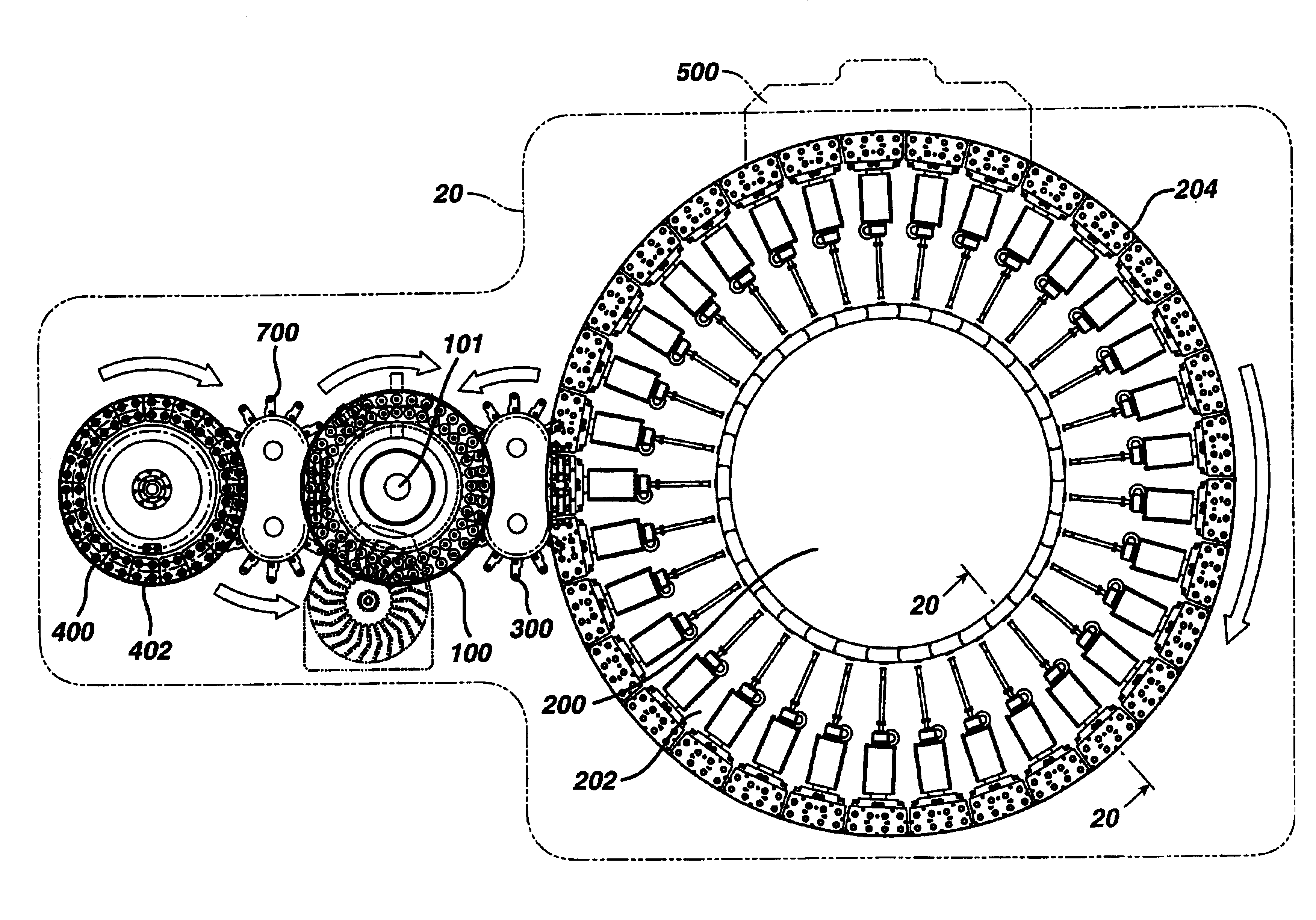

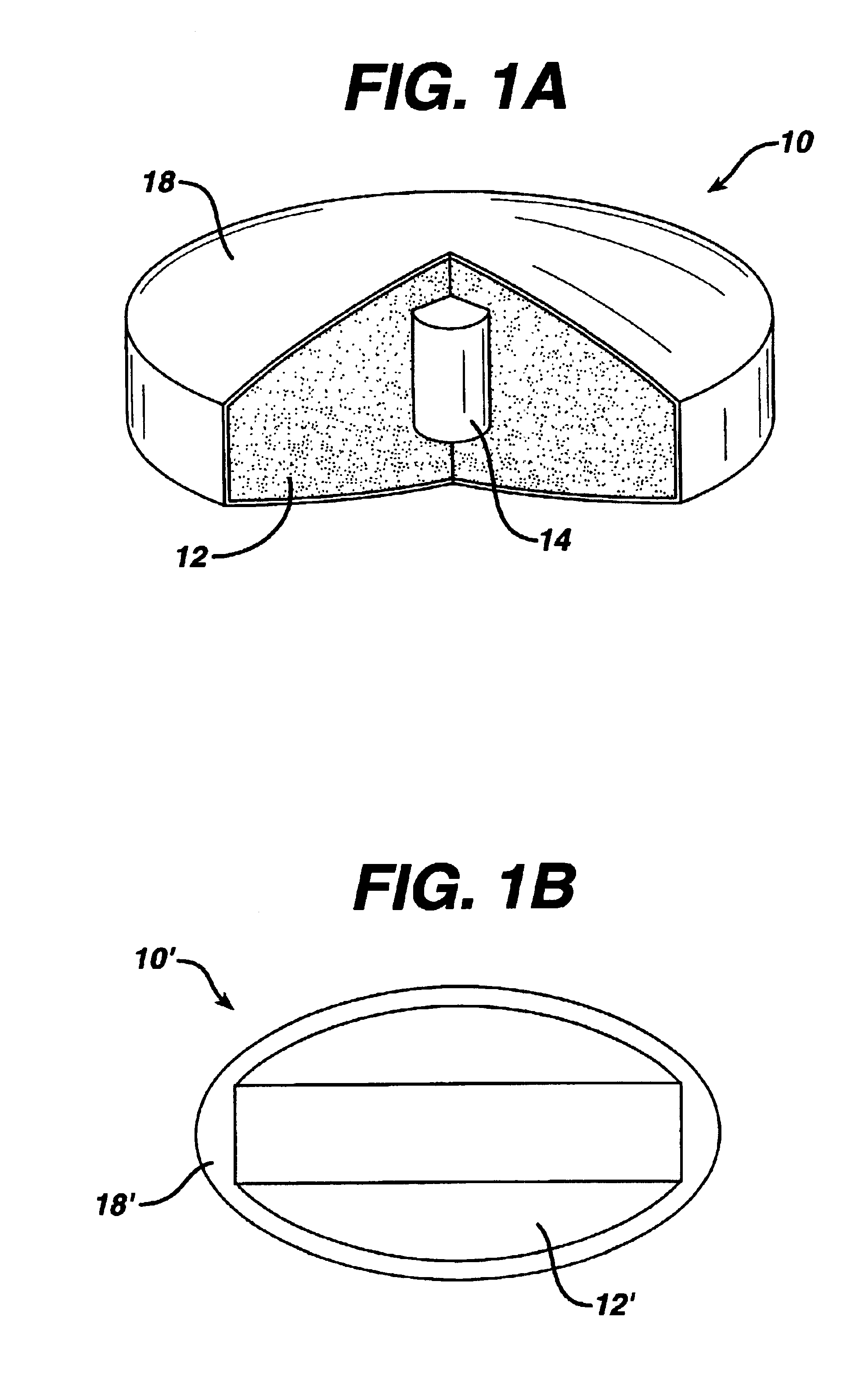

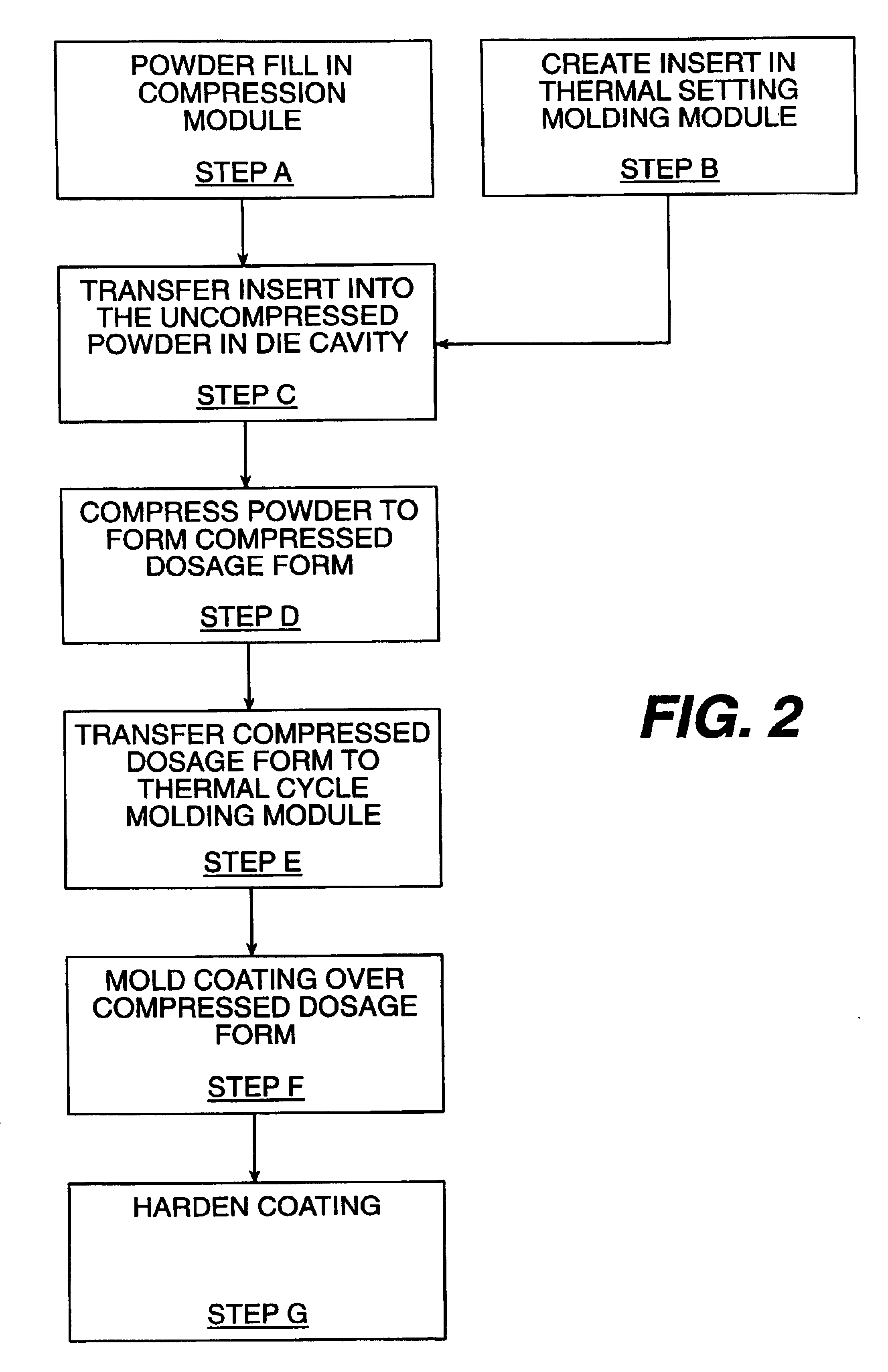

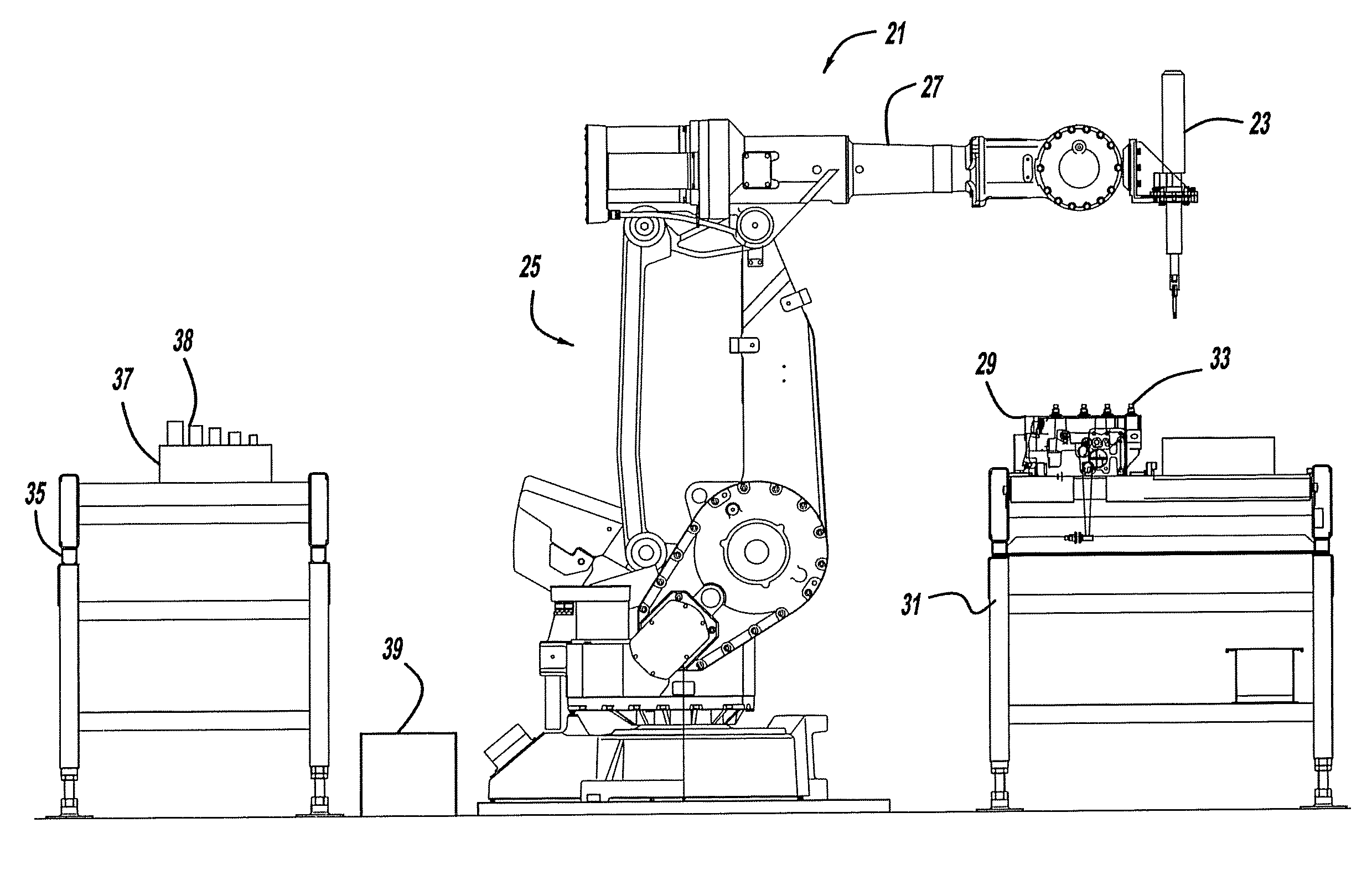

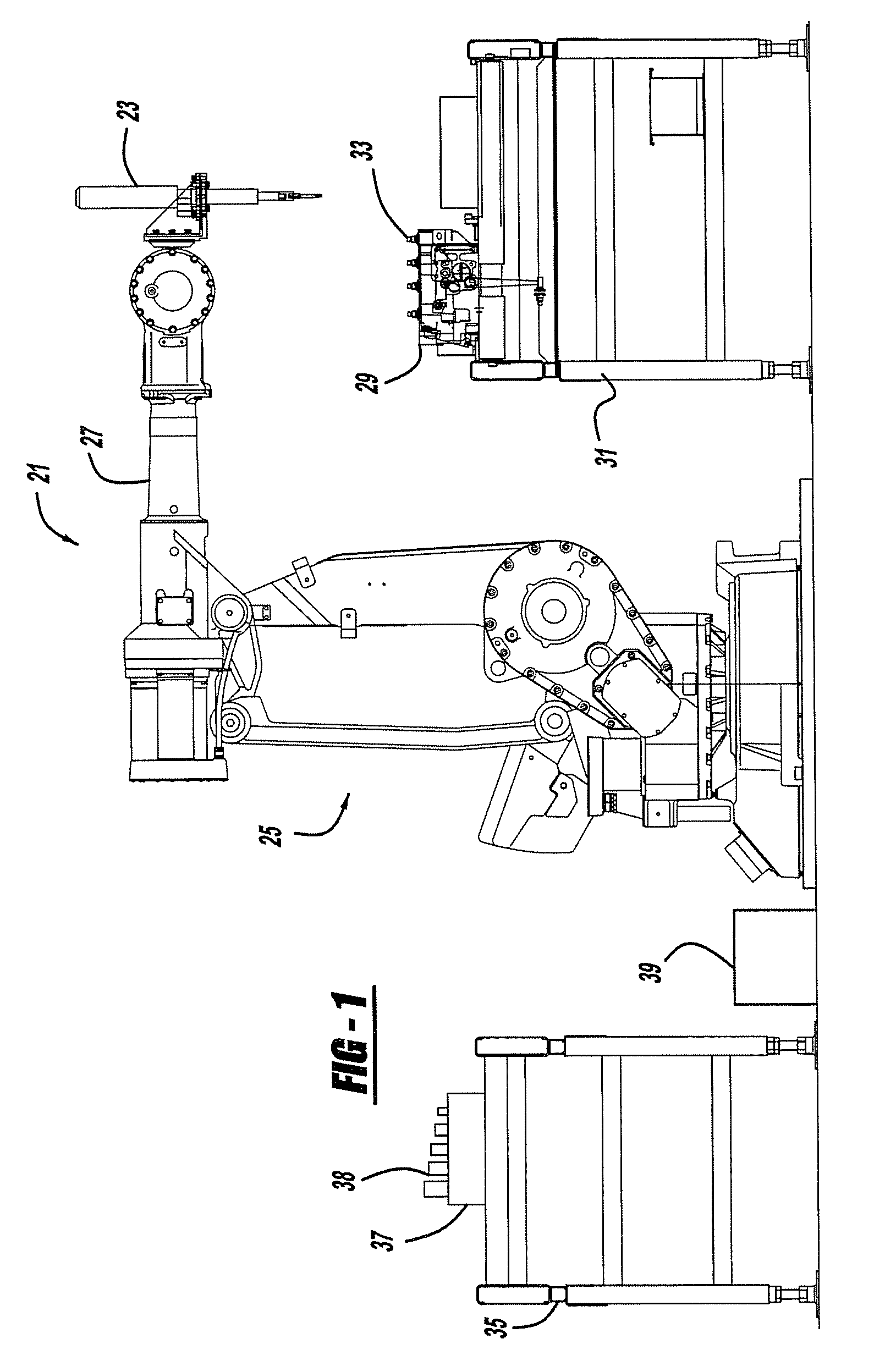

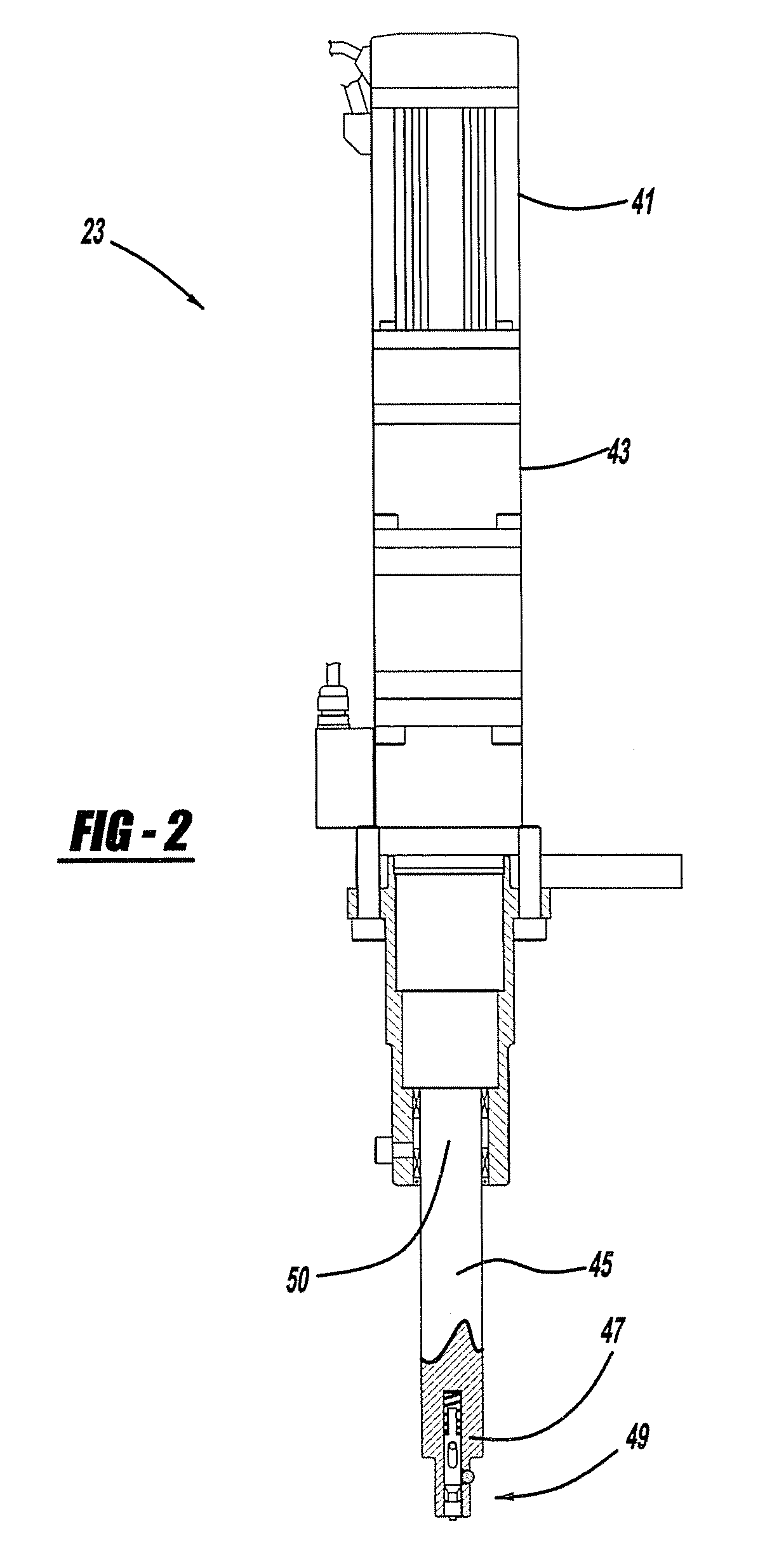

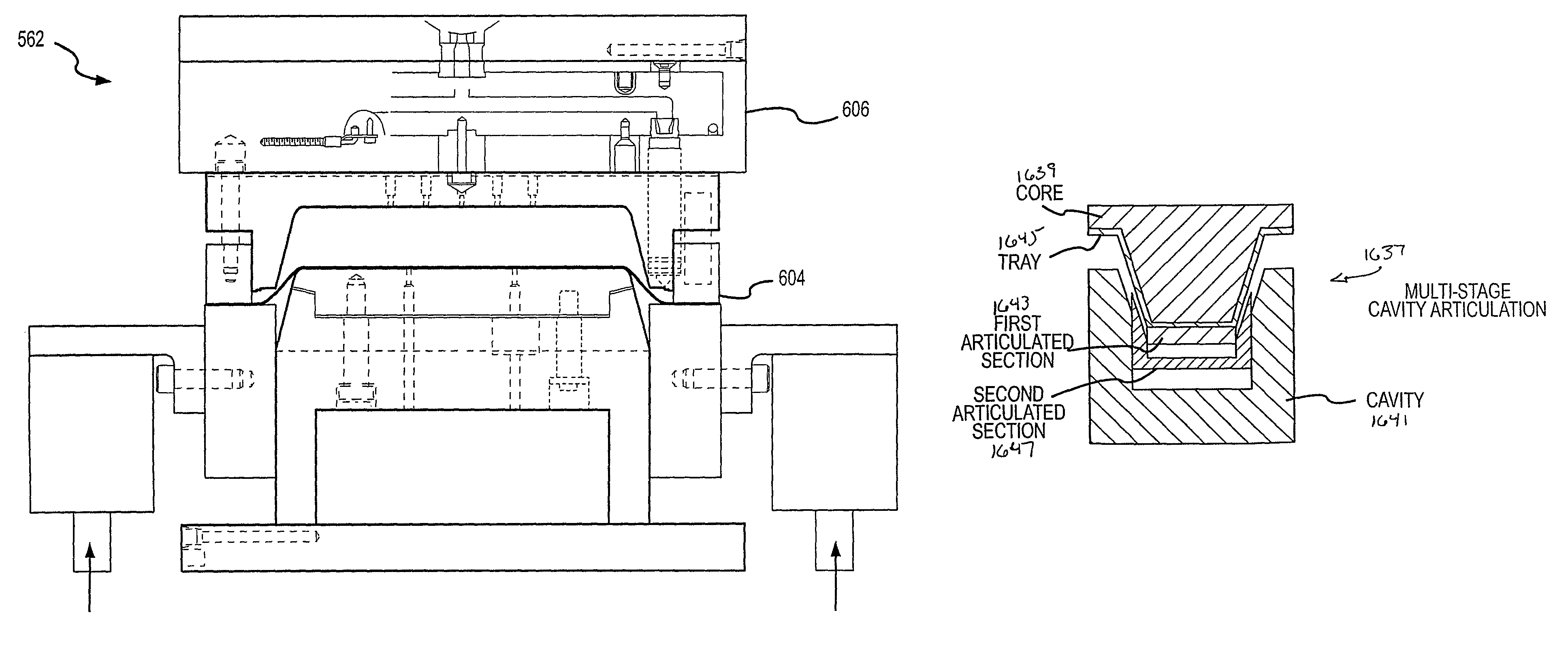

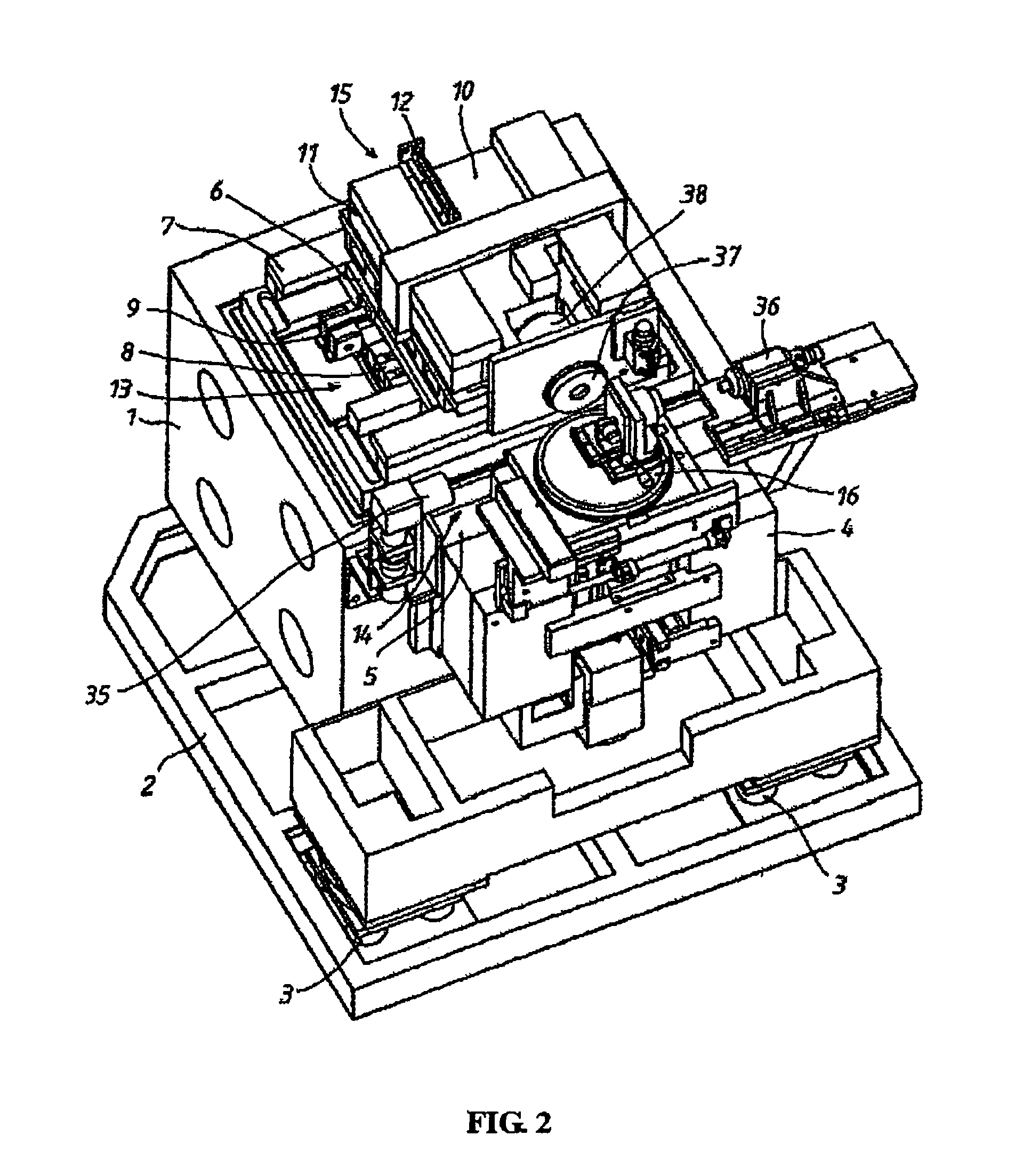

Apparatus for manufacturing dosage forms

InactiveUS6837696B2Organic active ingredientsTurning machine accessoriesComputer moduleBiomedical engineering

Systems, methods and apparatuses for manufacturing dosage forms, and to dosage forms made using such systems, methods and apparatuses are provided. Novel compression, thermal cycle molding, and thermal setting molding modules are disclosed. One or more of such modules may be linked, preferably via novel transfer device, into an overall system for making dosage forms.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

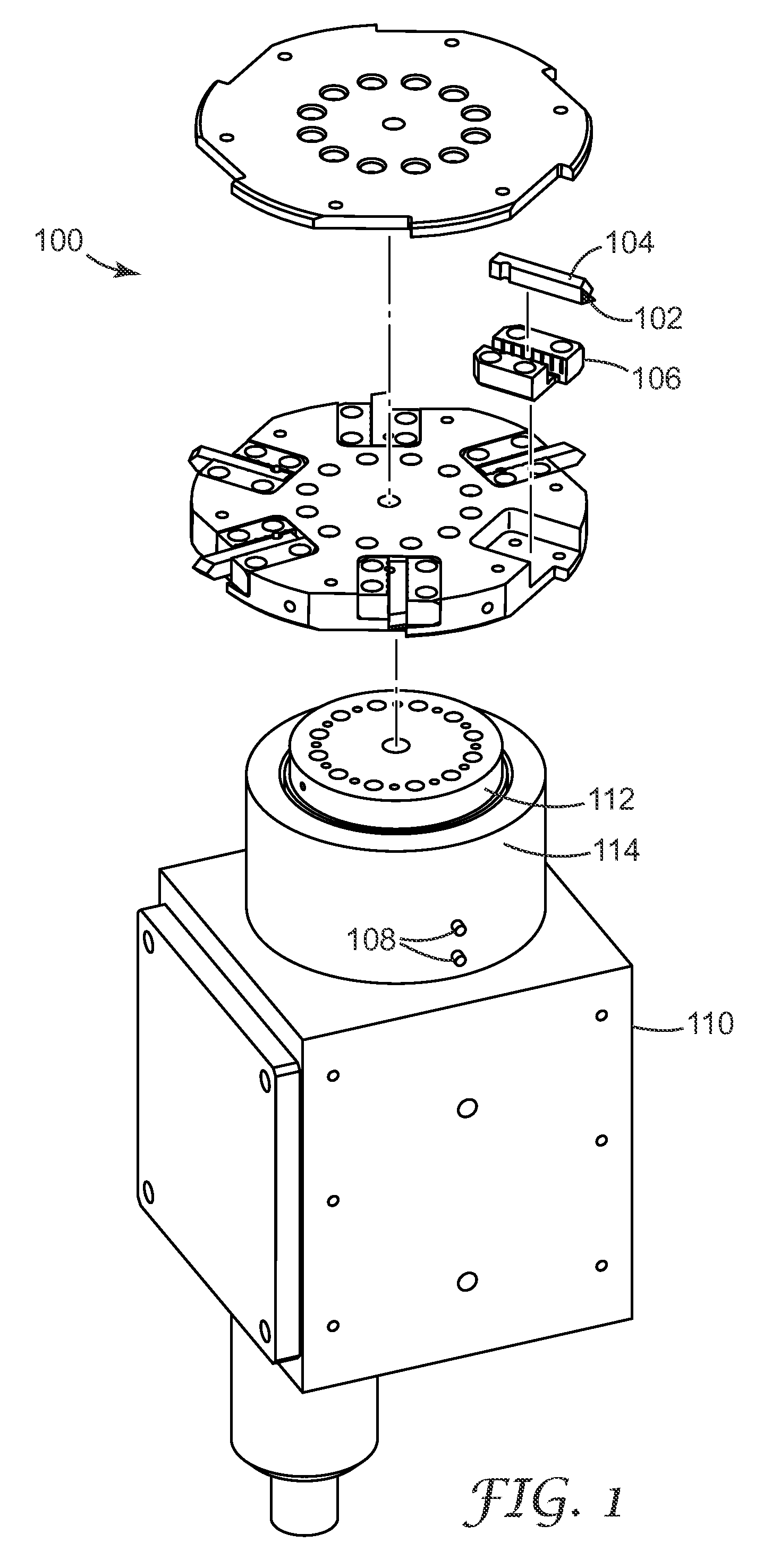

Quick change spindle

InactiveUS20090139375A1Quick changeImprove assembly cycle timeControl mechanismTurning machine accessoriesEngineeringFastener

An automated tool includes a quick change spindle assembly. In another aspect of the present invention, the quick change spindle includes an attachment assembly for interchangeable fastener drivers. A further aspect of the present invention employs release member to actuate a drive member in the spindle assembly causing a retainer to uncouple a fastener driver with the spindle.

Owner:CINETIC AUTOMATION

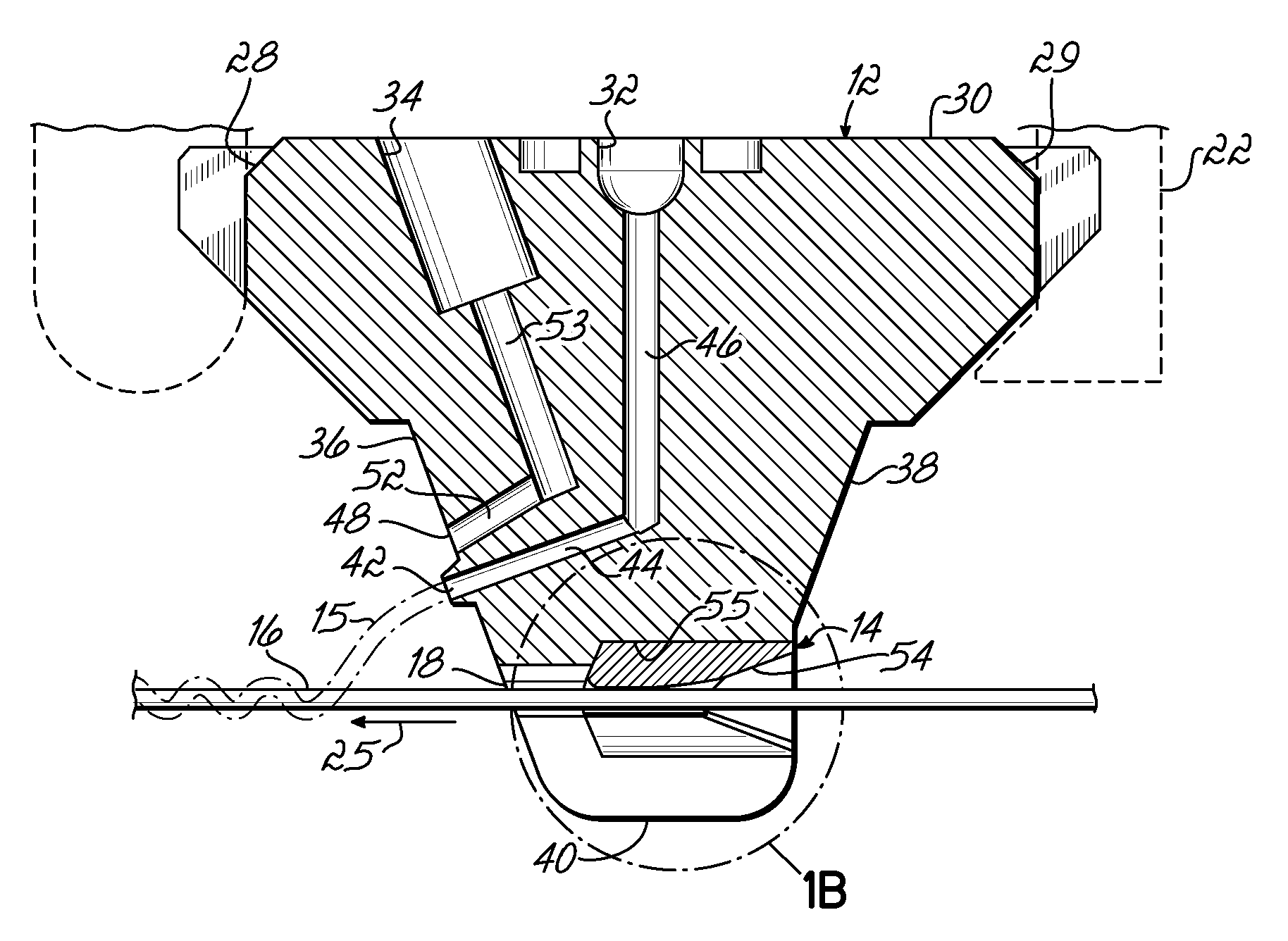

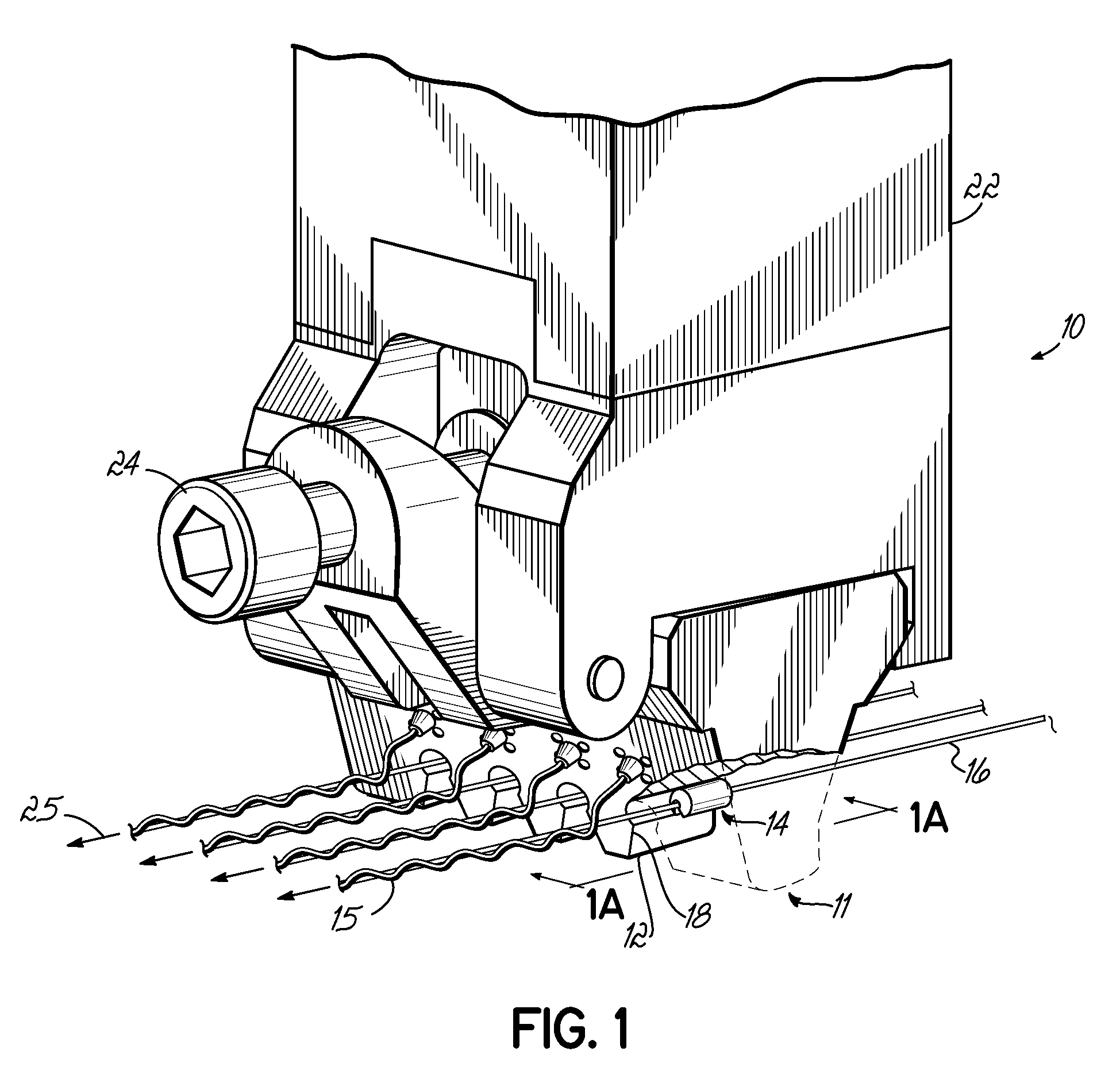

Protective member and nozzle assembly configured to resist wear

InactiveUS20100024987A1Avoid contactSolve the lack of wear resistanceTurning machine accessoriesFilament handlingWear resistanceNozzle

A protective member (14) and a nozzle assembly (11) incorporating the protective member (14) are provided. The protective member (14) is for use with a nozzle (12) having a strand guide passageway (18) for receiving a strand (16) of material. Protective member (14) comprises a body (60) configured to be received in the strand guide passageway (18) of the nozzle (12). The body (60) of the protective member (14) has a passageway (63) for the strand (16) and is disposed between the strand guide passageway (18) and the moving strand (16). The body (60) of the protective member (14) is composed, at least in part, of a material having a wear resistance sufficient to resist wear caused by the strand (16) being guided thereby. Alternatively, a portion of the body (60) may be coated with a material having a wear resistance sufficient to resist wear caused by the strand (16).

Owner:NORDSON CORP

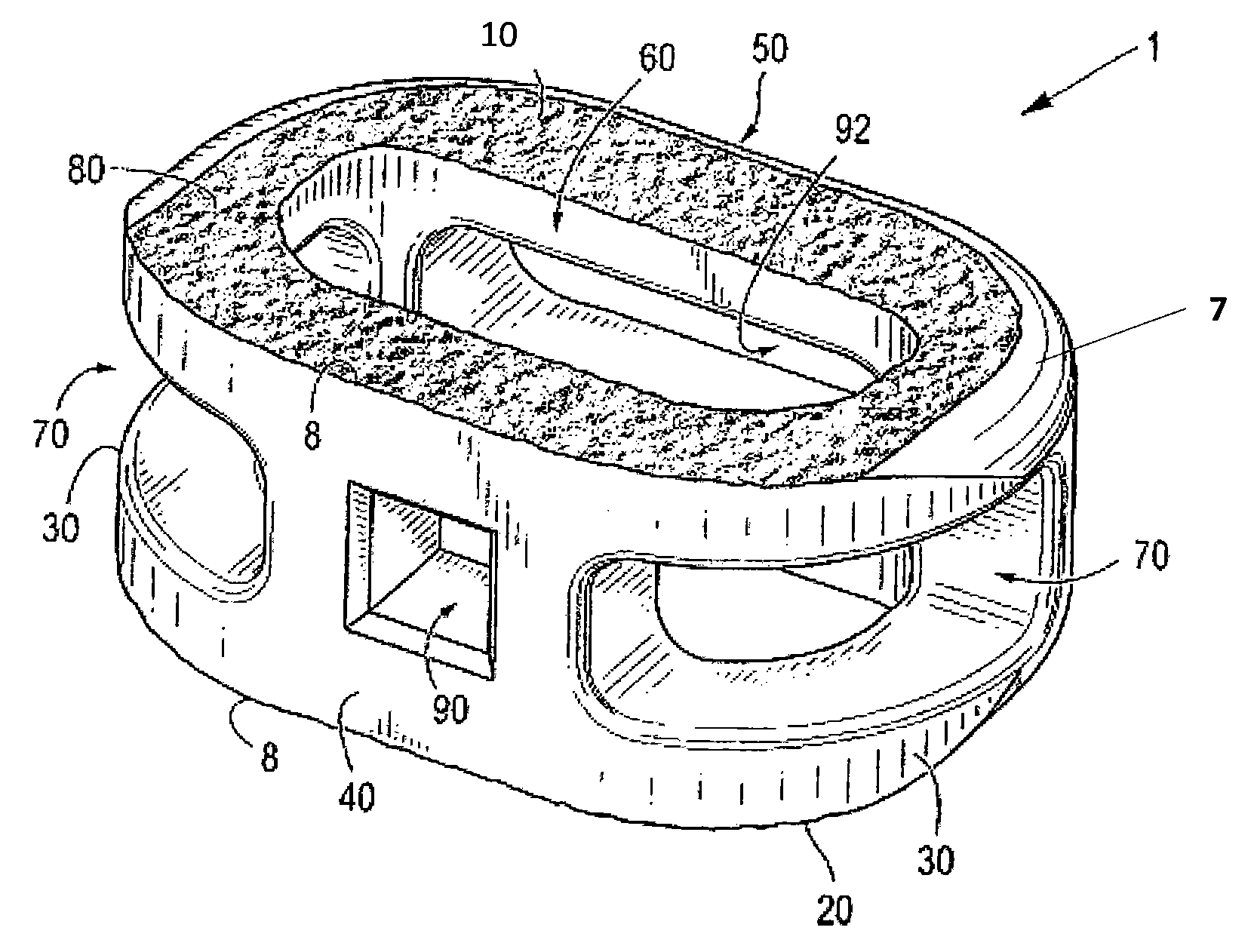

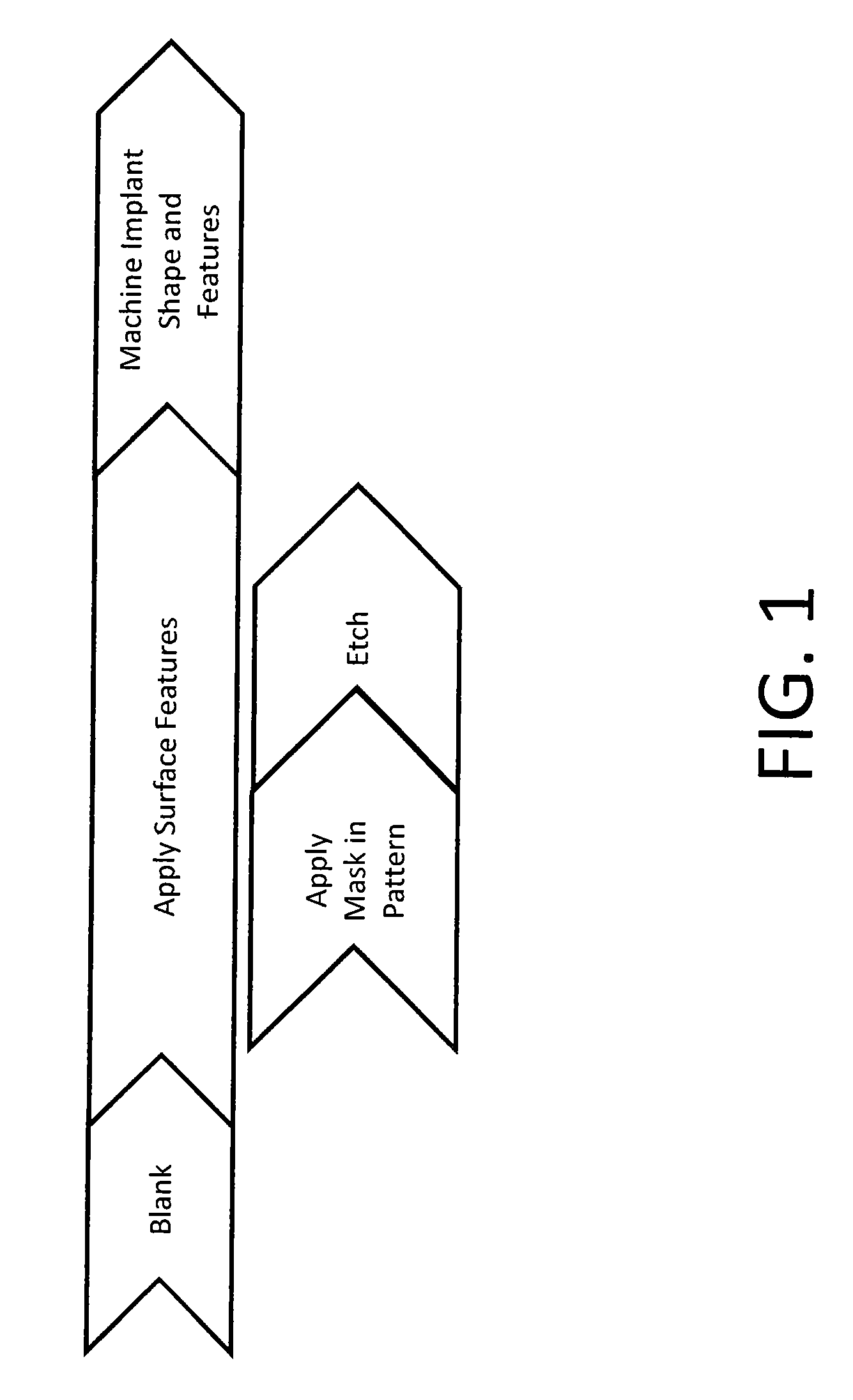

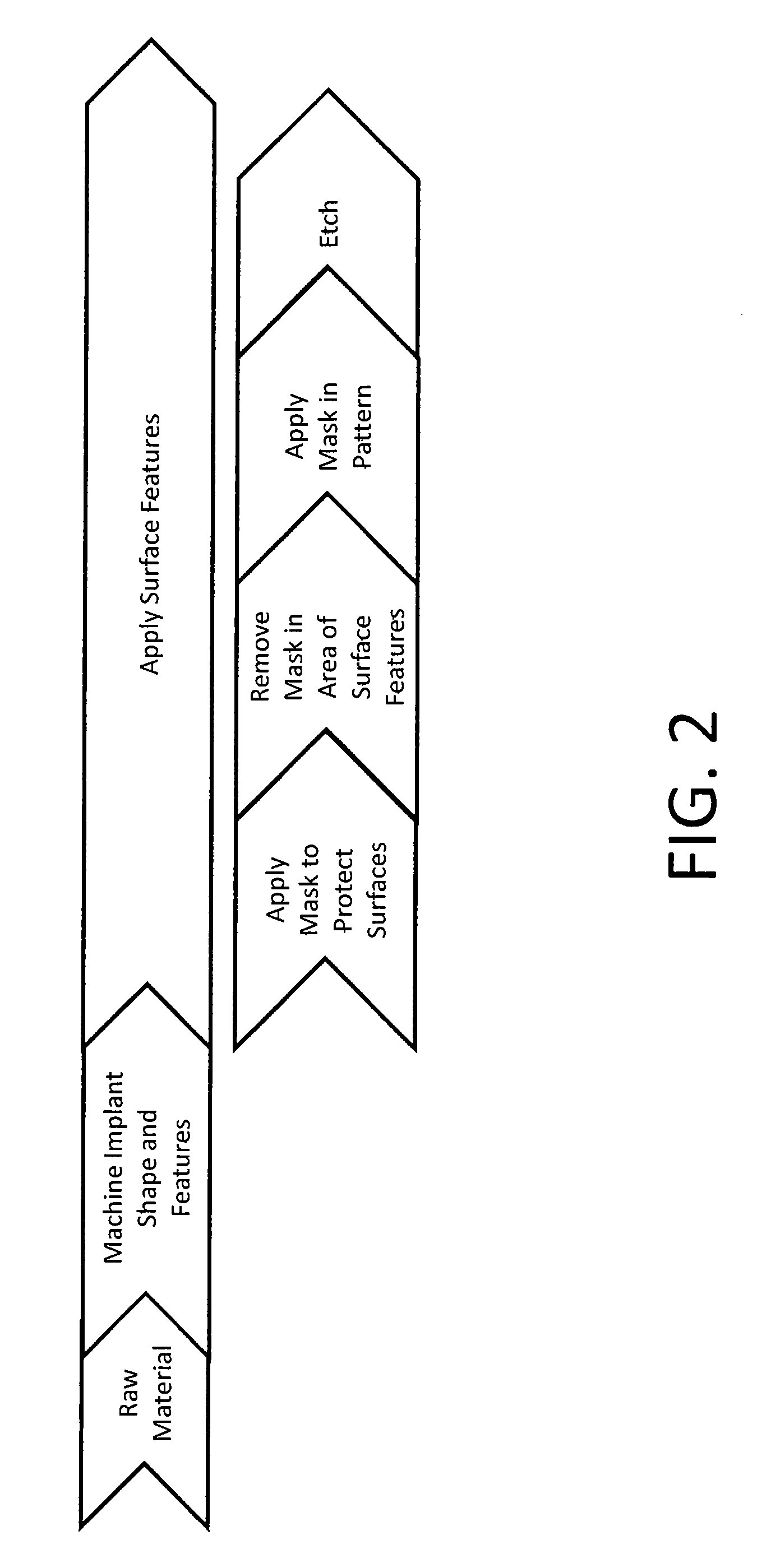

Methods for manufacturing implants having integration surfaces

InactiveUS20120312779A1Quality improvementImprove reliabilityTurning machine accessoriesDecorative surface effectsSpinal implantRough surface

A method of producing an interbody spinal implant. The method includes the steps of obtaining a blank having a top surface, bottom surface, opposing lateral sides, and opposing anterior and posterior portions, and applying a subtractive process (e.g., masked acid etching) to the top surface, the bottom surface, or both surfaces of the blank to form a roughened surface topography. Subsequently, the blank is machined to form the interbody spinal implant, which includes a body having a top surface, a bottom surface, opposing lateral sides, opposing anterior and posterior portions, a substantially hollow center, and a single vertical aperture where the top surface, the bottom surface, or both surfaces of the interbody spinal implant have the roughened surface topography produced by the subtractive process. This simplified method produces more accurate and repeatable implants with fewer process steps and defects, reducing process time and costs.

Owner:TITAN SPINE

Container having a rim or other feature encapsulated by or formed from injection-molded material

ActiveUS7862318B2Strengthen and stabilize traySimplify carryingClosure lidsTurning machine accessoriesEngineeringFlange

Owner:GRAPHIC PACKAGING INT

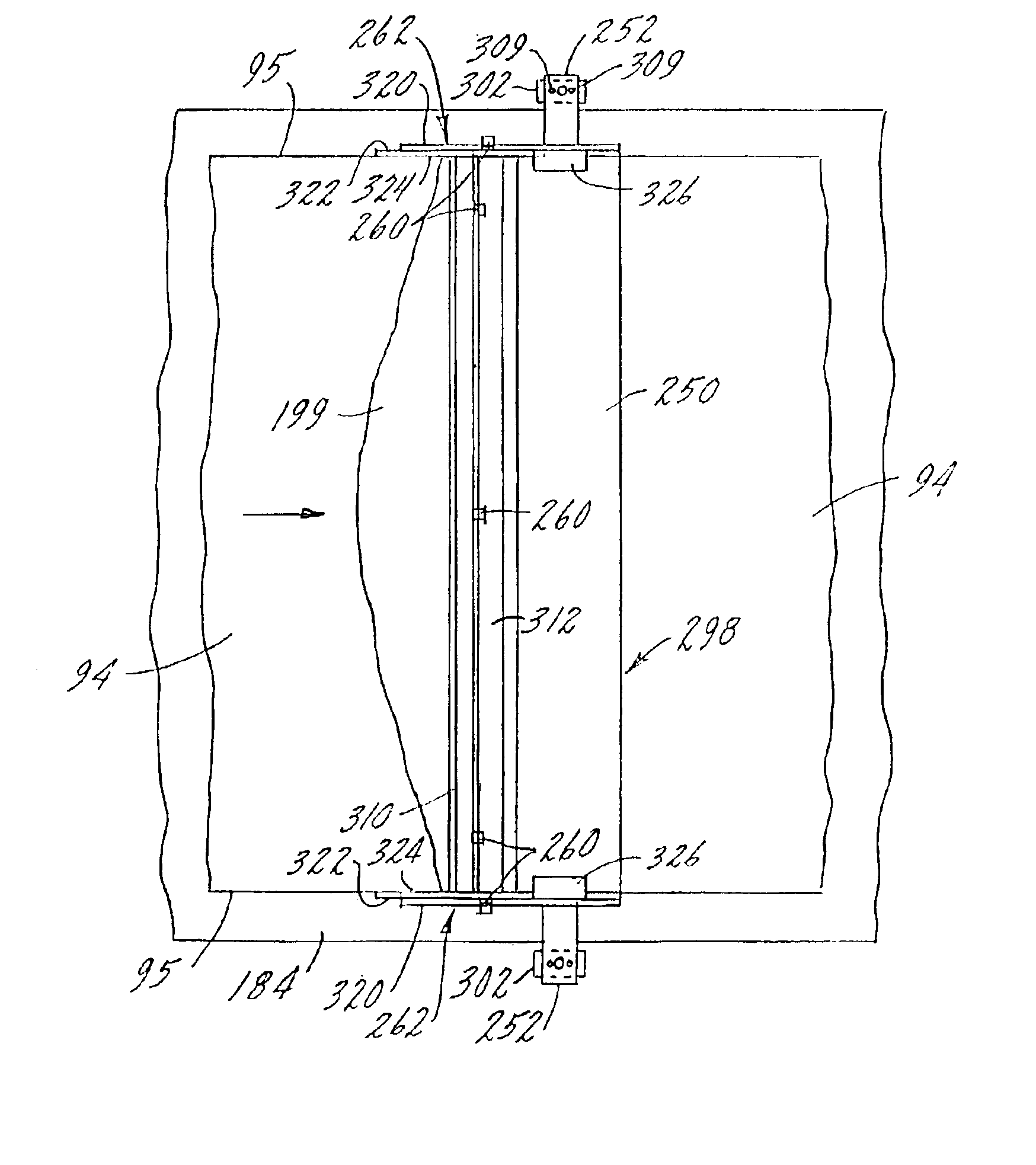

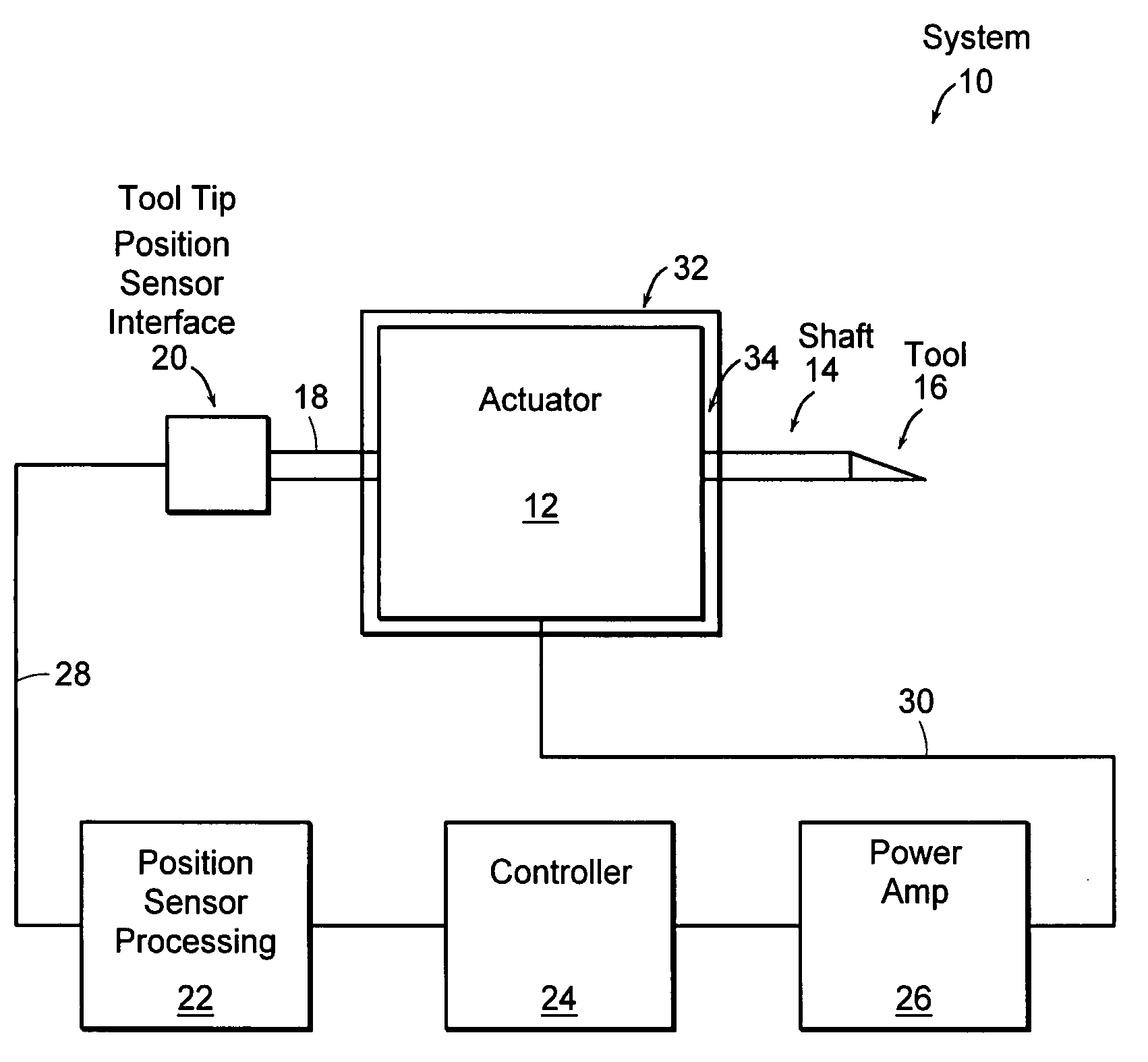

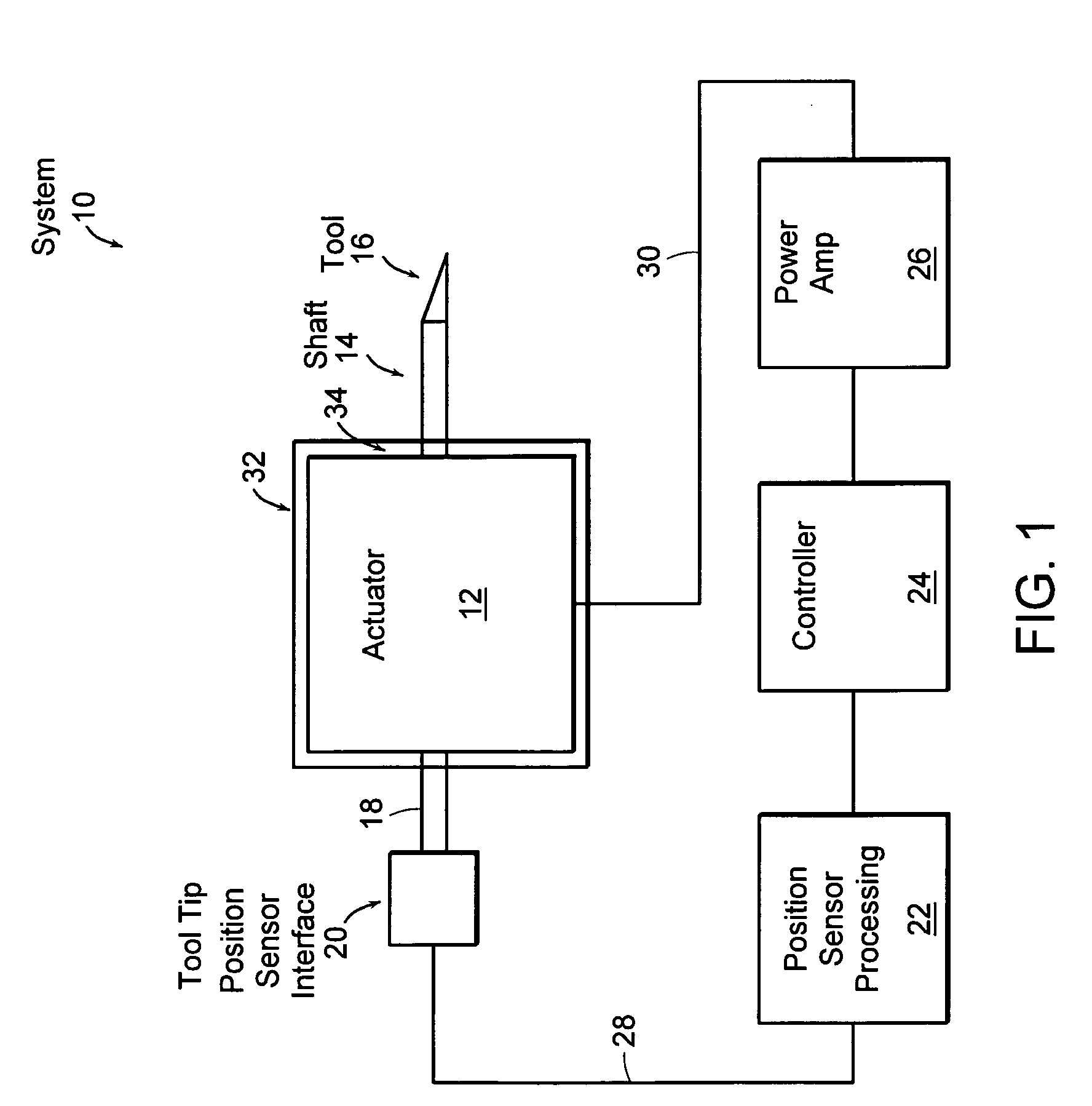

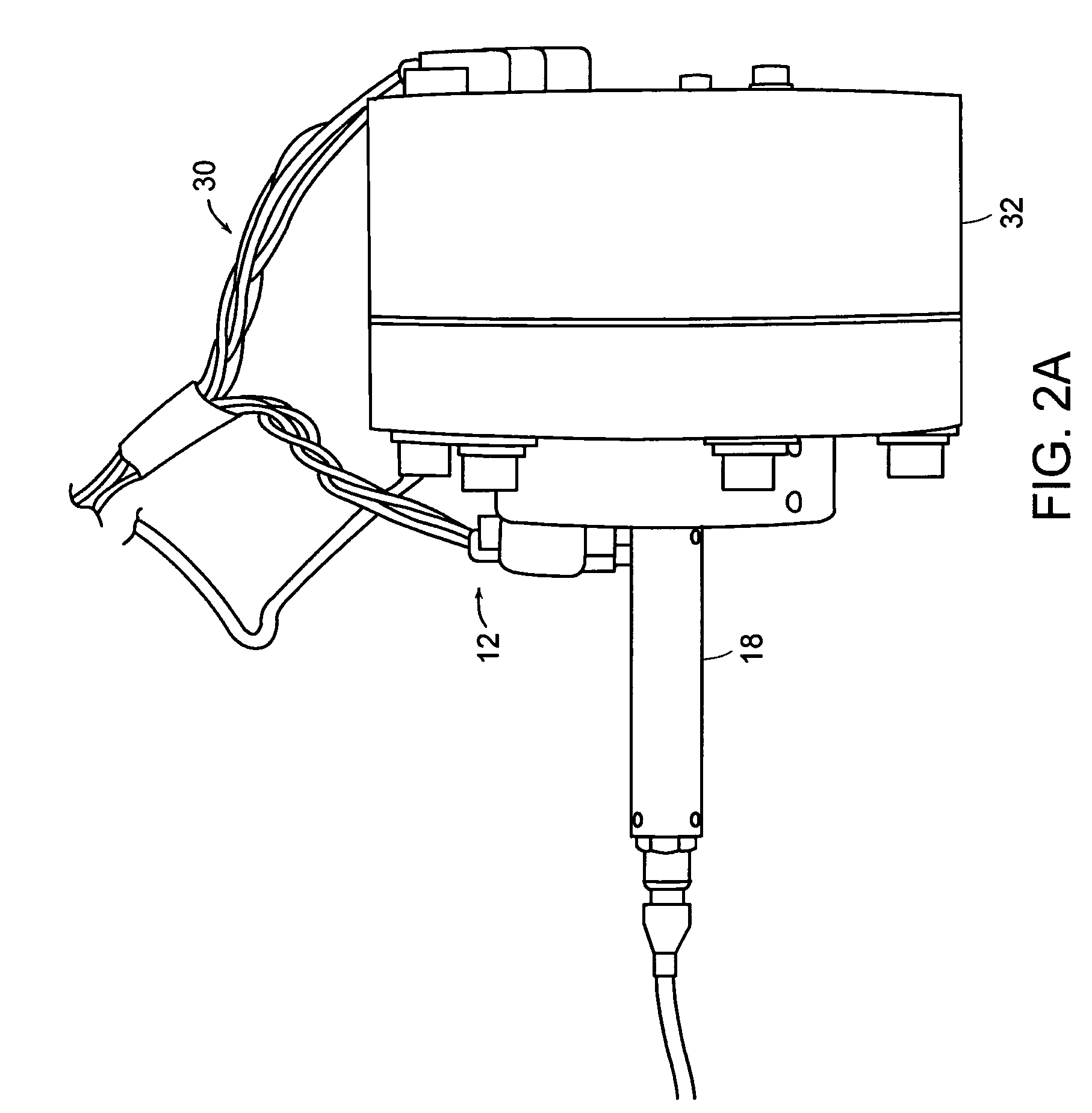

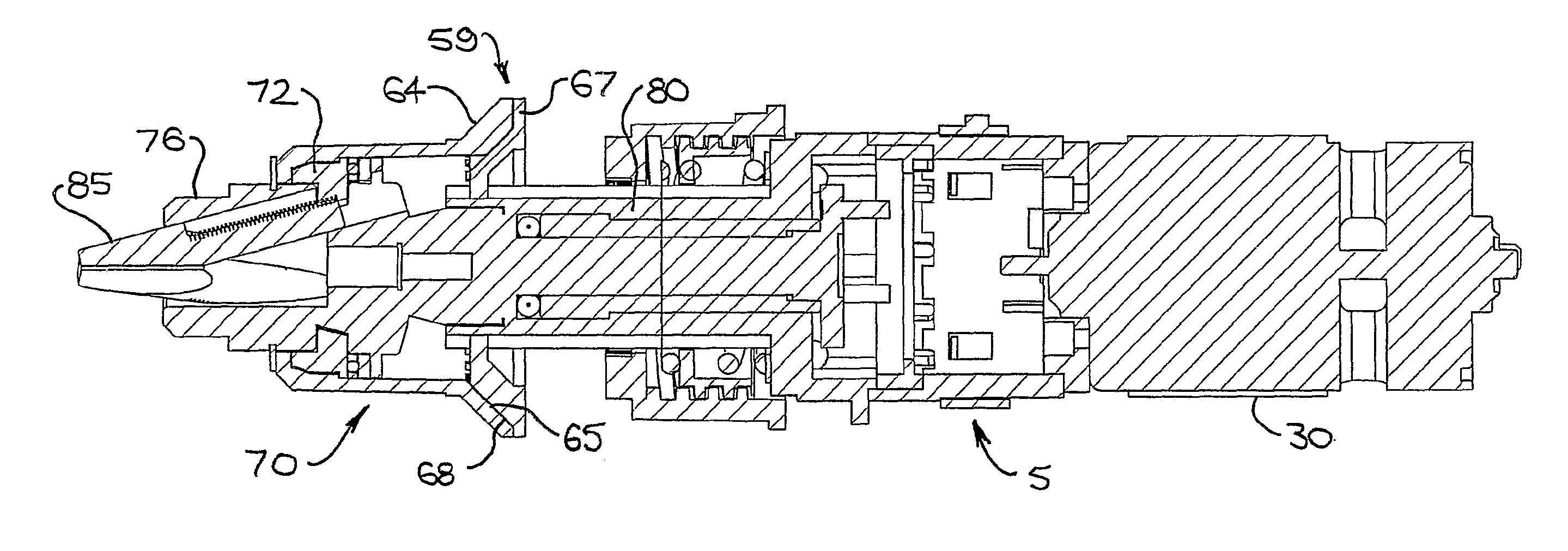

Variable reluctance fast positioning system and methods

InactiveUS20050223858A1Easy to operateElectromagnets without armaturesTurning machine accessoriesClosed loopLoop bandwidth

The preferred embodiments of the present invention are directed to high bandwidth positioning systems such as fast tool servos (FTS). The applications of this invention include, for example, diamond turning of mold with structured surface for mass production of films for brightness enhancement and controlled reflectivity, diamond turning of molds for contact lens and micro-optical positioning devices. Preferred embodiments of the fast tool servo can have a closed-loop bandwidth of approximately 20±5 kHz, with acceleration of up to approximately 1000 G or more. The resolution or position error is approximately 1 nm root mean square (RMS). In a preferred embodiment, the full stroke of 50 μm can be achieved up tol kHz operation.

Owner:MASSACHUSETTS INST OF TECH

Mechanical Assembly For A Power Tool

InactiveUS20100200257A1Shorten the lengthFacilitates power toolTurning machine accessoriesThread cutting machinesPower toolDriving mode

The invention relates to a mechanical assembly for a power tool, and a power tool incorporating the mechanical assembly. The mechanical assembly includes a first member having a first axis and a first engagement portion inclined relative to the first axis and a second member having a second axis and a second engagement portion inclined relative to the second axis. The first and second engagement portions engage each other by movement of the first and second members relative to each other in the direction of at least one of the axes. The power tool includes a power tool body and a rotatable driven member being operable for releasably gripping a working element, the driven member having a drive mode in which rotation of the driven member drives the working element relative to the power tool body and an adjustment mode in which rotation of the driven member causes the driven member to either grip the working element or release the working element or both. The power tool also includes means for adjusting the driven member between the modes which includes the mechanical assembly wherein the first and second engagement portions engage each other by movement of the first and second members relative to each other in the direction of at least one of the axes and wherein engagement between the first and second engagement portions adjusts the driven member to the adjustment mode and disengagement between the first and second engagement portions adjusts the driven member to the drive mode. The power tool may also include a first torque control means that is operable for controlling the amount of torque applied to the driven member by the power drive when in the drive mode and a second torque control means that is operable for controlling the amount of torque applied to the driven member by the power drive when in the adjustment mode. The power tool may further include a gearbox with one or more speeds and a switch with two or more positions that is operable for selecting the modes, the gear speeds and the first and second torque control means.

Owner:DEMAIN TECH

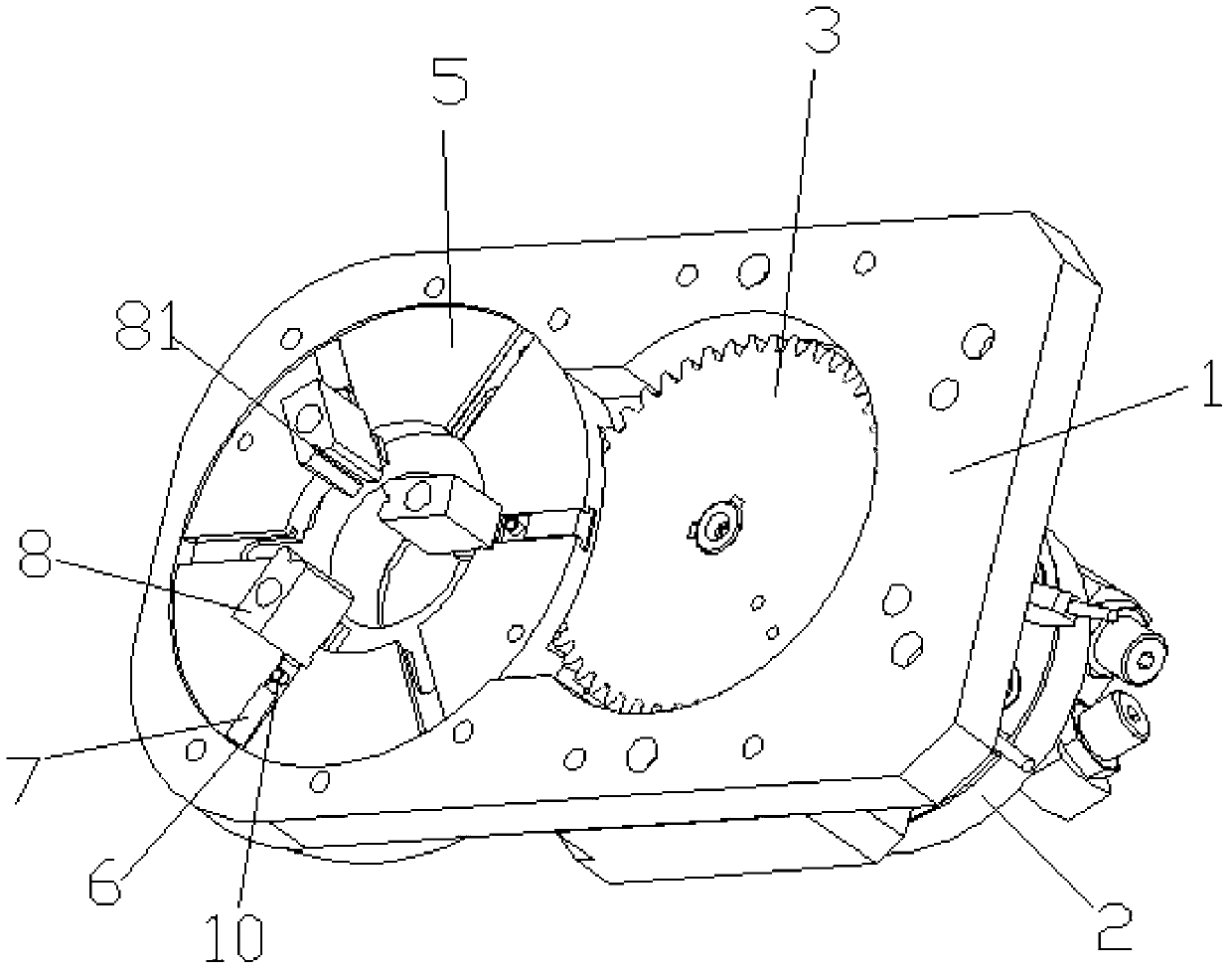

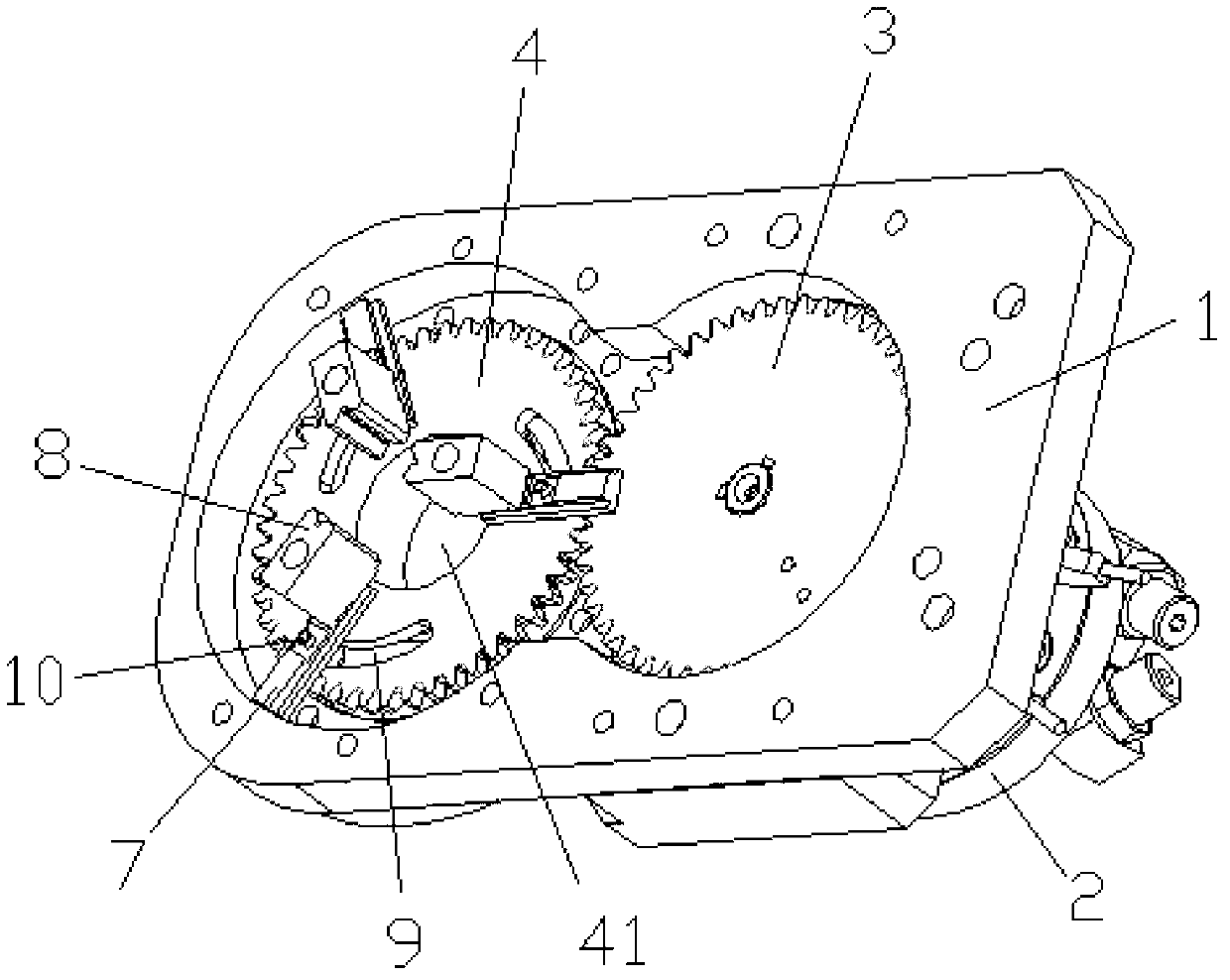

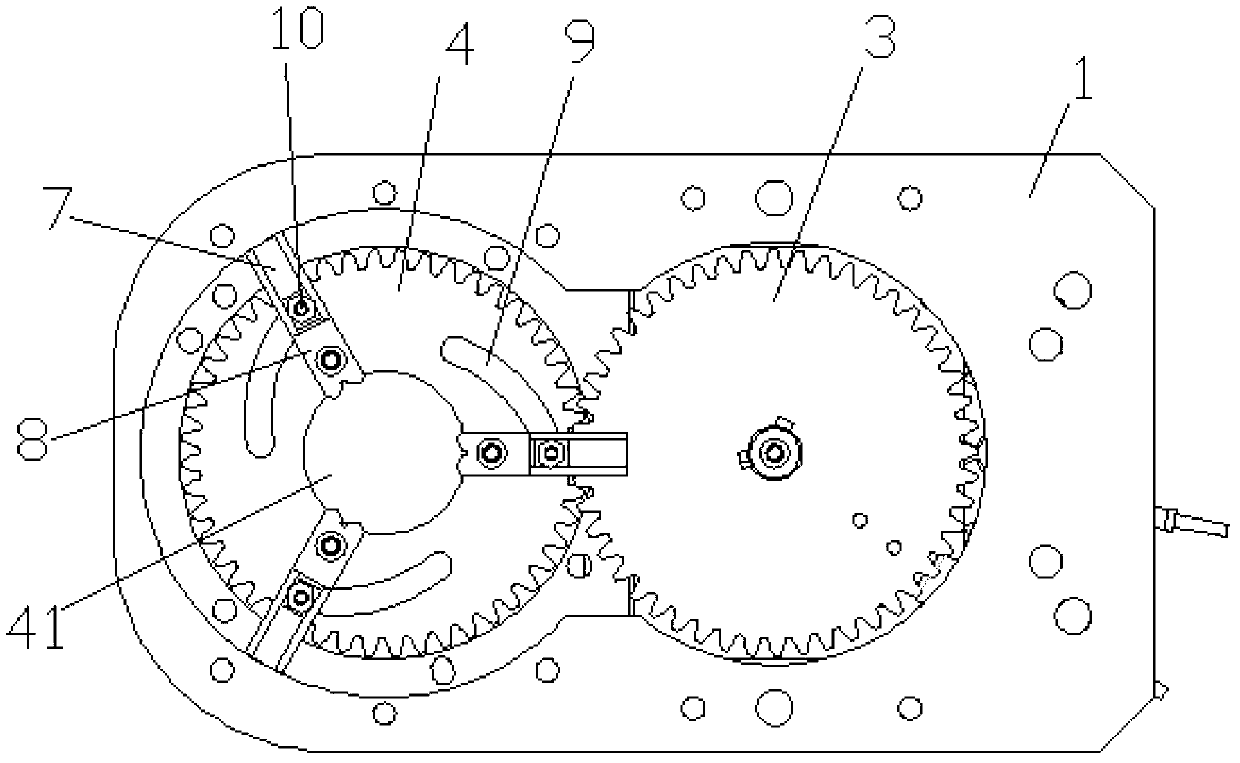

Three-jaw chuck locating mechanism

ActiveCN103121118AHigh repeat positioning accuracyImprove pass rateTurning machine accessoriesGear wheelEngineering

The invention discloses a three-jaw chuck locating mechanism. The three-jaw chuck locating mechanism comprises a base, a driving mechanism, a main drive gear and an auxiliary drive gear, wherein outsides of the main drive gear and the auxiliary drive gear are meshed mutually through teeth. The driving mechanism can drive the main drive gear to rotate around the axis of the main drive gear, an empty cavity used for placing to-be-located products is formed in the center of the auxiliary drive gear, three clamping jaws respectively pointing to the center of the auxiliary drive gear are arranged on the outer side face of the auxiliary drive gear at intervals, and the other ends of the three clamping jaws are respectively connected with a sliding block. The sliding blocks are respectively limited to slide in a sliding chute along the radius direction of the auxiliary drive gear, meanwhile, the three clamping jaws are respectively provided with a cam roller, and the other ends of the cam rollers are limited to slide in an arc-shaped sliding chute arranged in the outer side face of the auxiliary drive gear. According to the three-jaw chuck locating mechanism, the driving mechanism sequentially drives the main drive gear and the auxiliary drive gear to rotate, and therefore the three clamping jaws are driven to clamp and loose, and three-point locating is achieved. The three-jaw chuck locating mechanism is high in repeated locating accuracy, strong in clamping force, and good in generality for like products.

Owner:KUNSHAN BAIAO INTELLIGENT EQUIP CO LTD

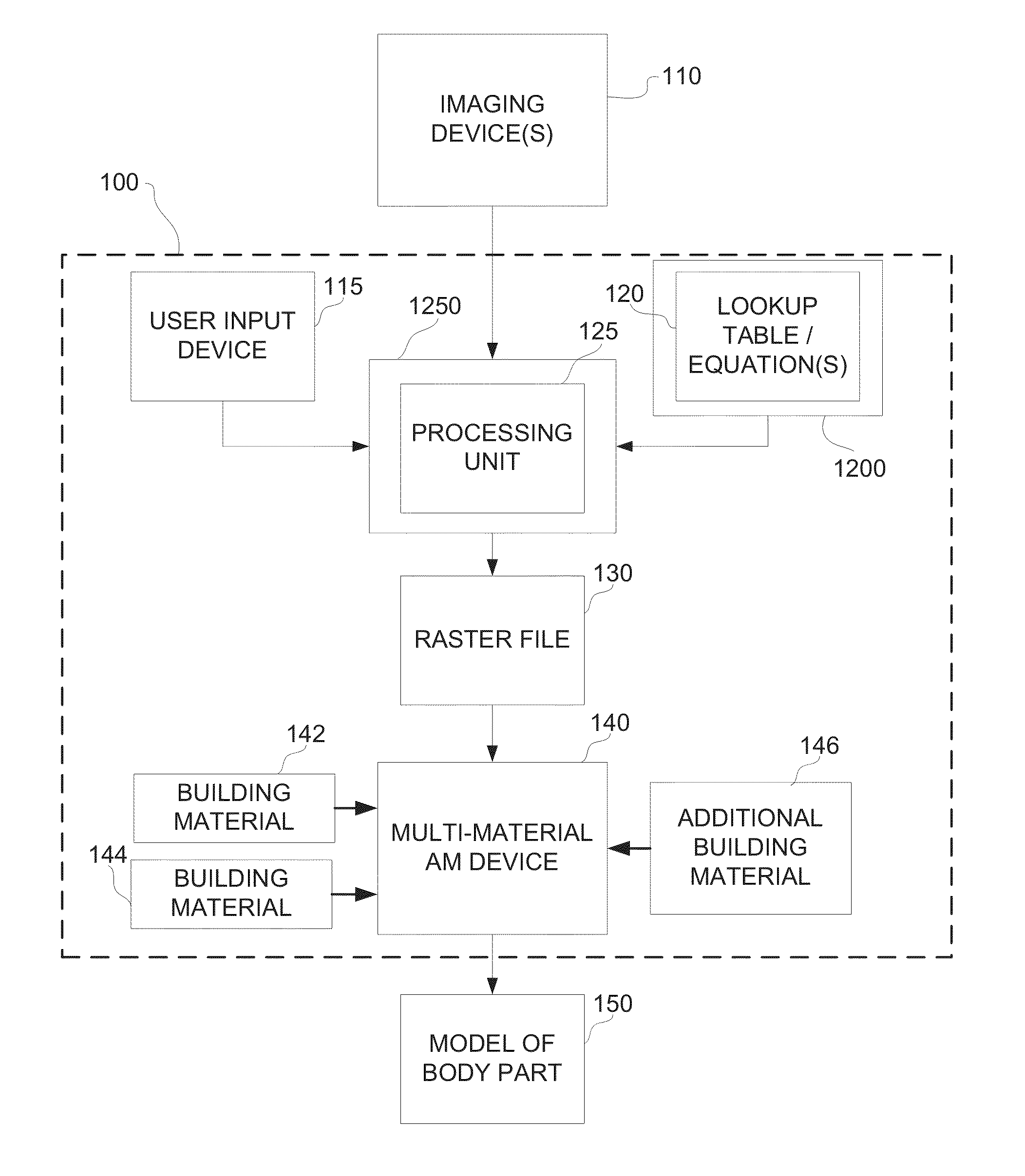

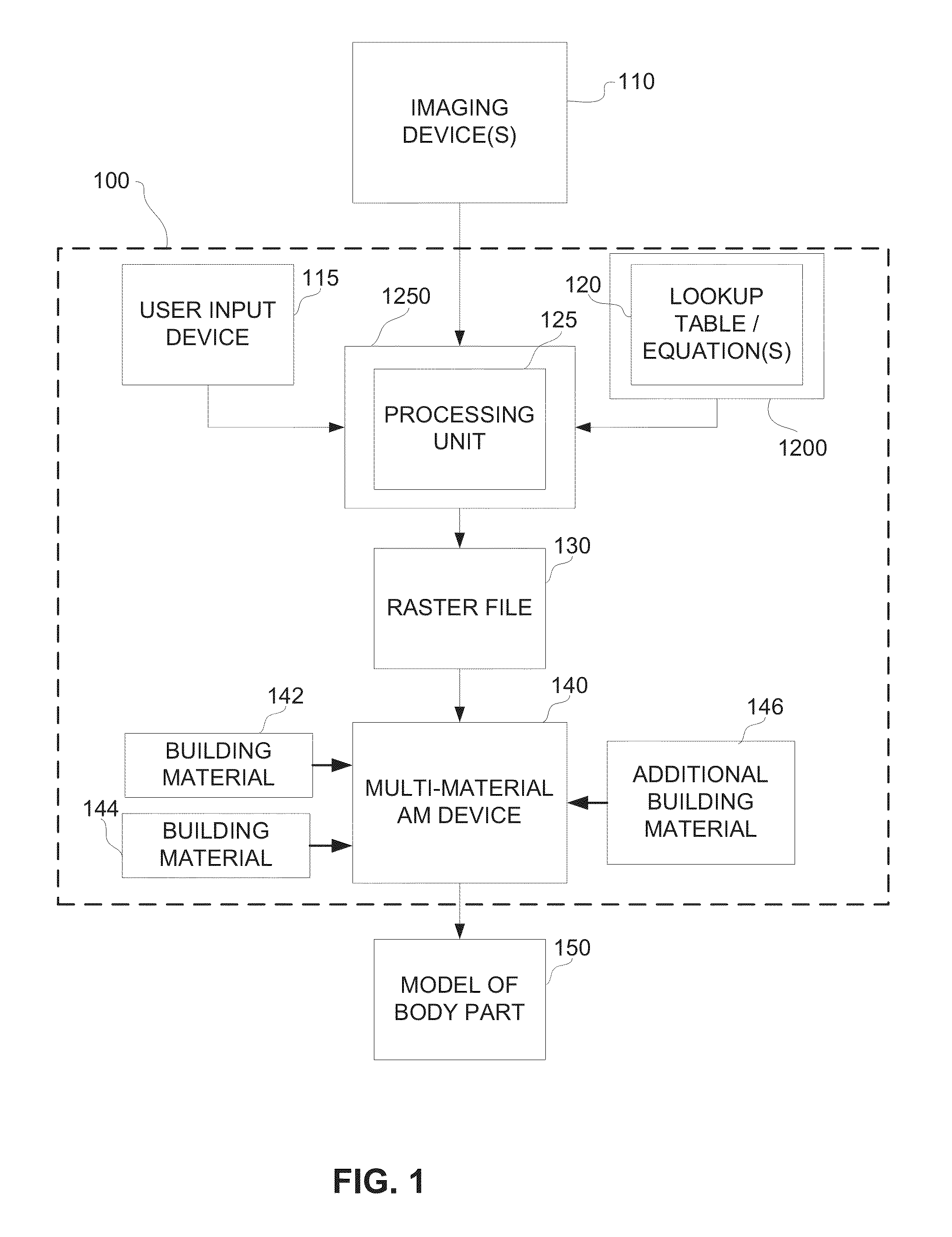

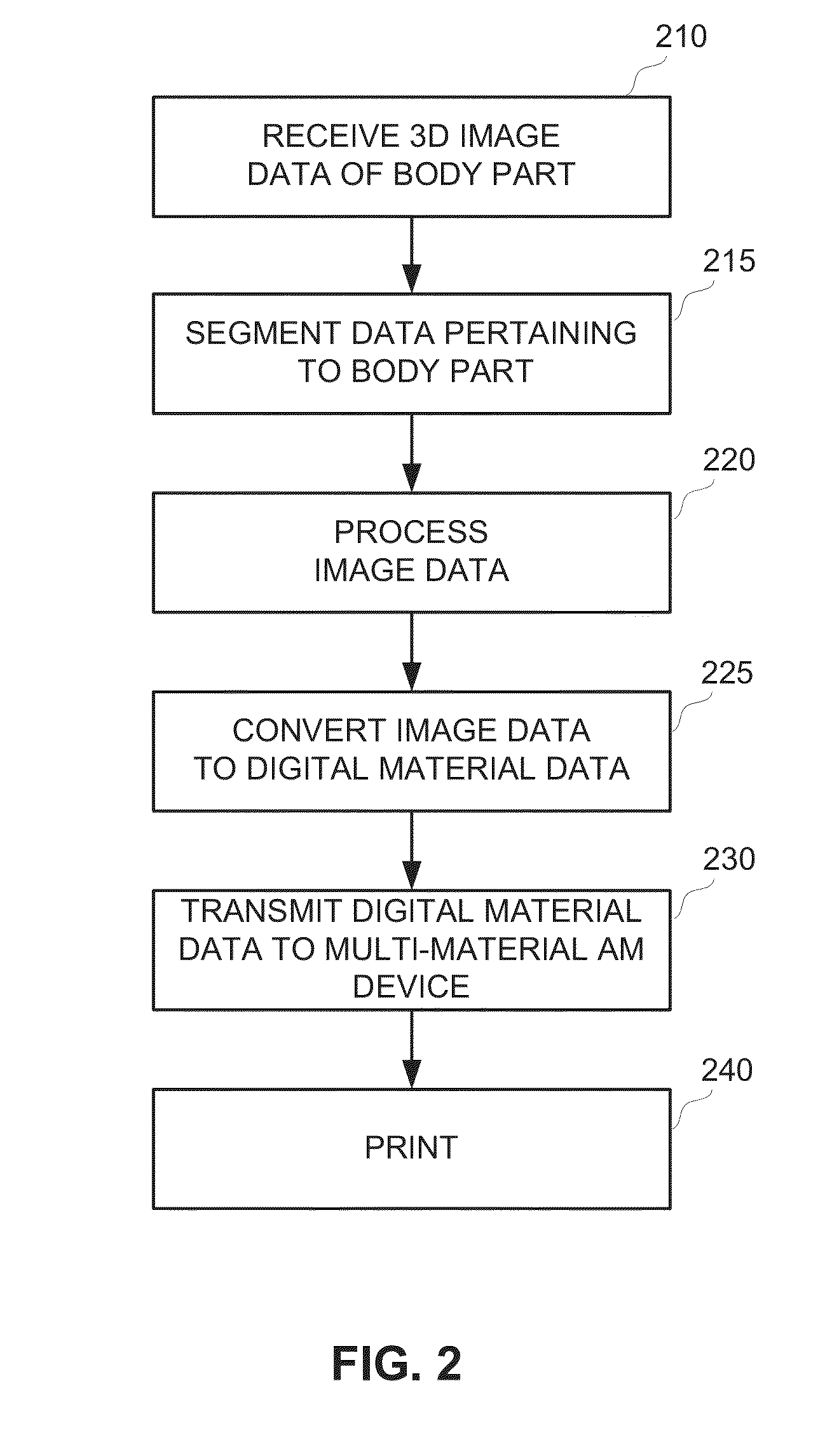

System and method for fabricating a body part model using multi-material additive manufacturing

ActiveUS20140312535A1Improve representationTurning machine accessoriesJoint implantsMulti materialVoxel

A method for physically reconstructing a body part using multi-material additive manufacturing includes receiving image data of the body part in the form of arrays of voxels, each array of voxels representing image data pertaining to cross-section of the body part, translating the image data in the arrays of voxels to printable bitmap images representing combinations of modeling materials for reconstructing the body part, and dispensing the combinations of modeling materials responsive to the bitmap images in a layerwise manner.

Owner:STRATASYS LTD

Tool

InactiveUS6578268B2Easy to disassembleEasy to slideTurning machine accessoriesPad sawsEngineeringHand tool

A hand tool includes a replaceable cutting portion having an elongate cutting surface, a body and a handle. The body receives displaceable protecting apparatus for shielding the cutting surface of the cutting portion when not in use. A forward distal end of the protecting apparatus contacts a portion of the surface of the object to be cut such that when pressure is applied against the object surface displacement of the protecting apparatus relative to the replaceable cutting portion is effected to expose only as much of the cutting surface as needed to effect the required cut. Alignment means maintain alignment of the replaceable cutting portion relative to the protecting apparatus throughout the cutting. When the cutting action is completed resilience means facilitates return of the protecting apparatus so the cutting surface is no longer exposed.

Owner:HAWKETTS GEOFFREY

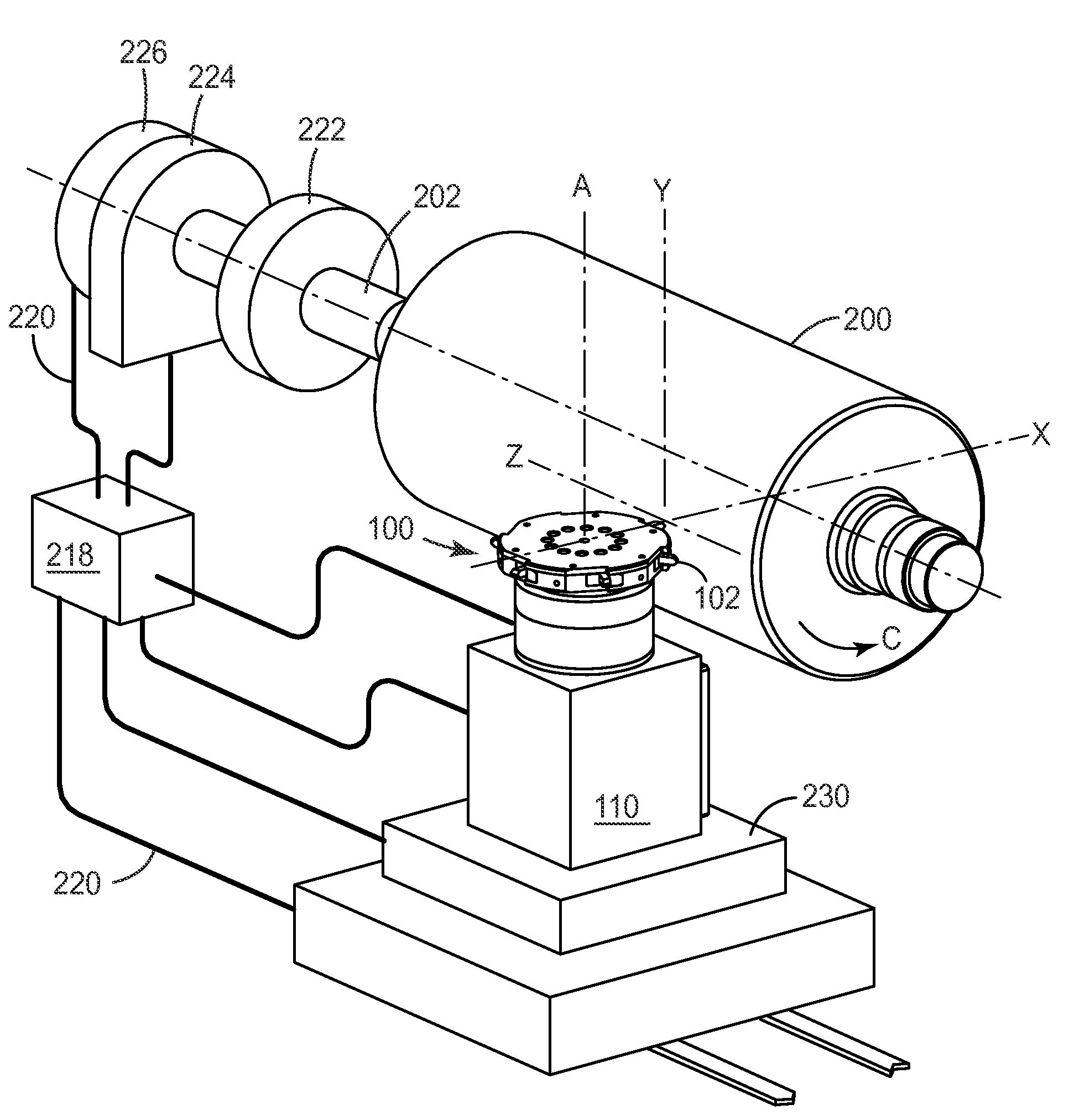

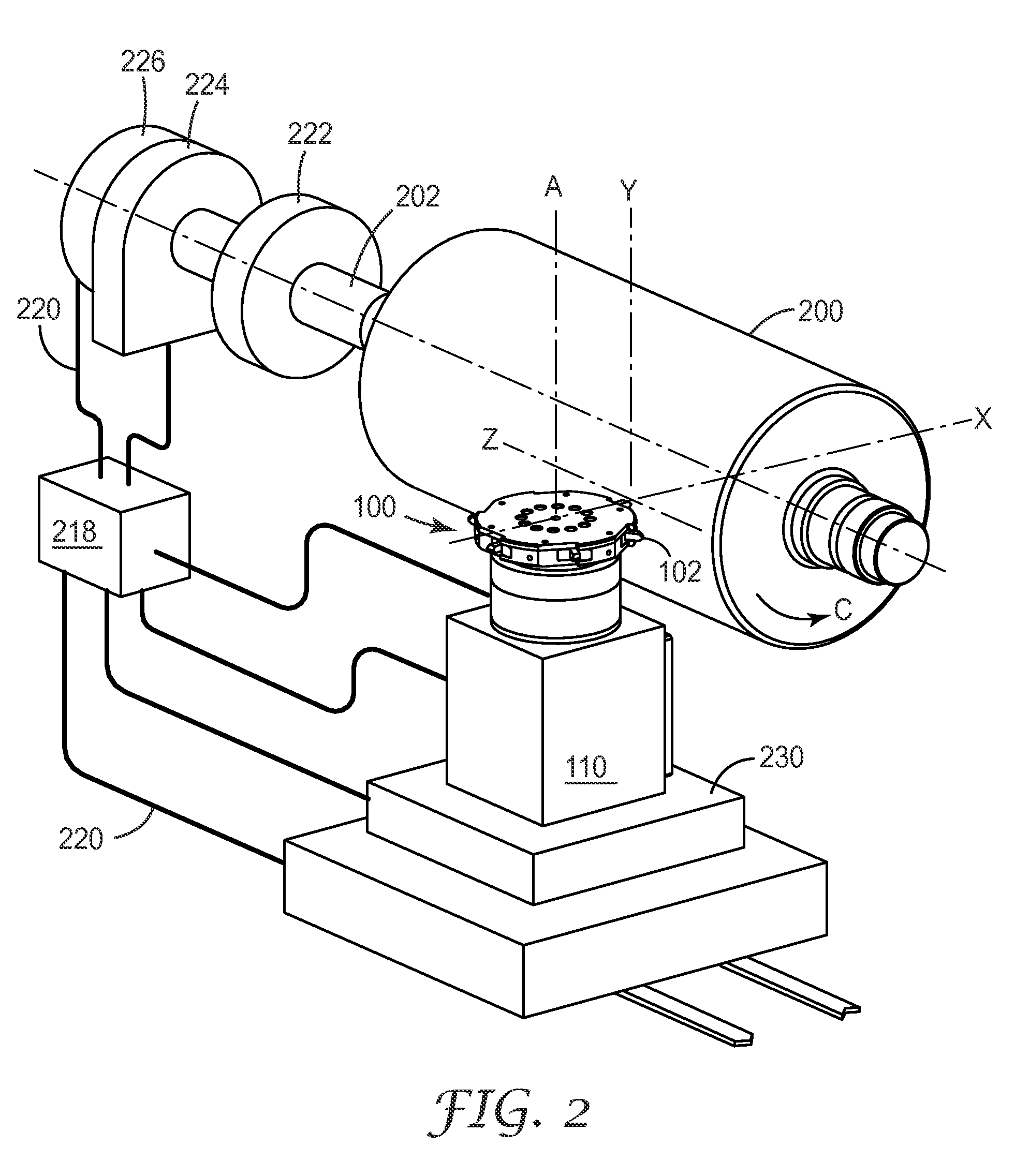

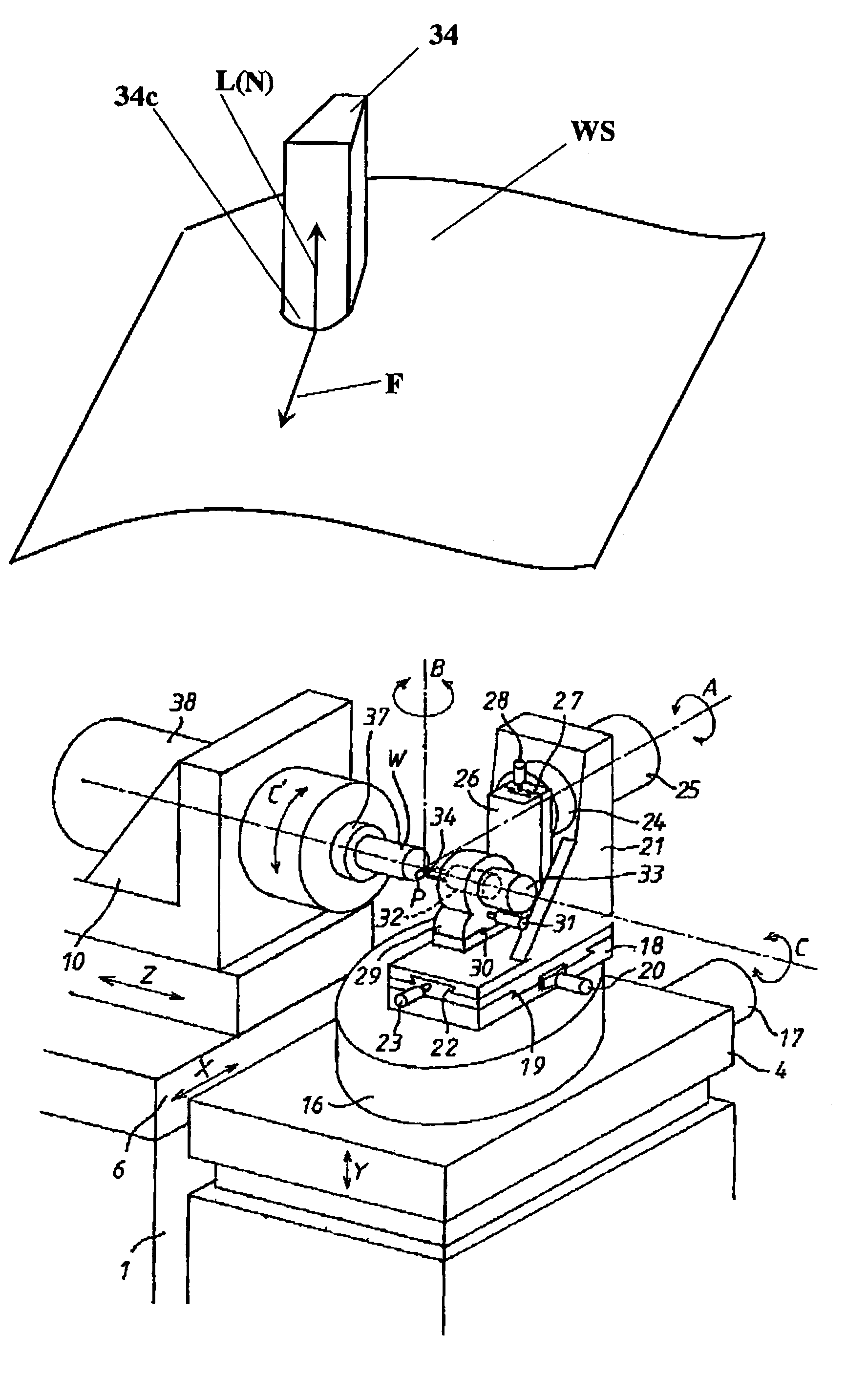

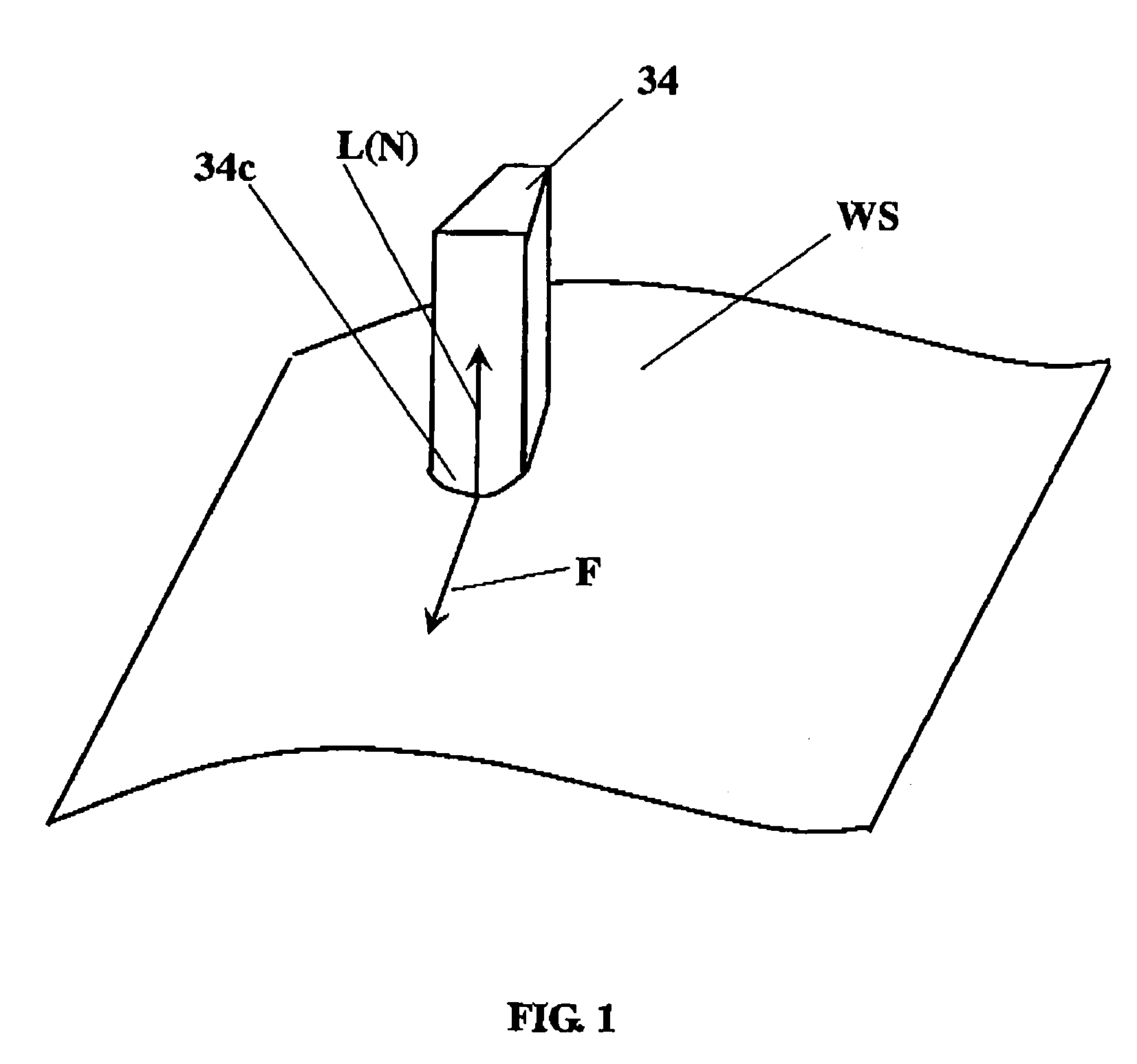

Hale-machining method and apparatus

InactiveUS7089836B2Easy to prepareHigh geometric accuracyLathesAutomatic/semiautomatic turning machinesRotary stageRotational axis

It is one object of a hale-machining method and apparatus thereof according to the present invention to achieve an easy preparation of an NC machining program and perform a high geometrical accuracy in the predetermined three-dimensional free curved surface.A haling tool 34 is set on a tool holder 32 in such a manner that a cutting point P of the haling tool 34 is substantially coincided with an intersection of a first rotating axis B, a second rotating axis A and a third rotating axis C. A rotary table 16 and a rotary base 24 are rotated in such a manner that a tool axis direction of said haling tool is substantially coincided with a normal direction of said machined surface. A tool holder 32 is rotated in such a manner that a front rake surface of the haling tool 34 is substantially directed in perpendicular to a feeding direction of said haling tool 34. A workpiece table holding a workpiece and the tool holder are relatively moved along a machined surface of said workpiece in three perpendicular axes including an axis parallel to said first rotating axis.

Owner:TOYODA MASCH WORKS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com