Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

783results about How to "High repeat positioning accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

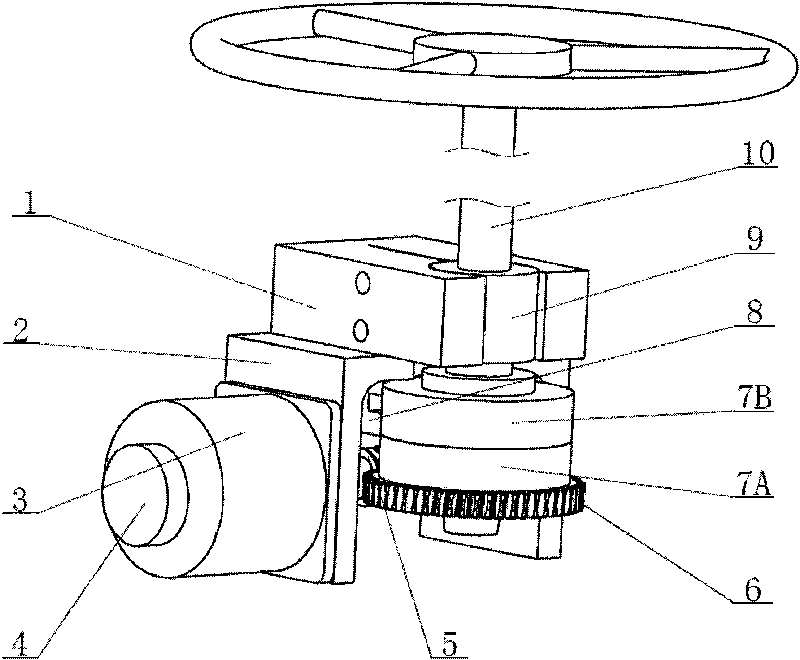

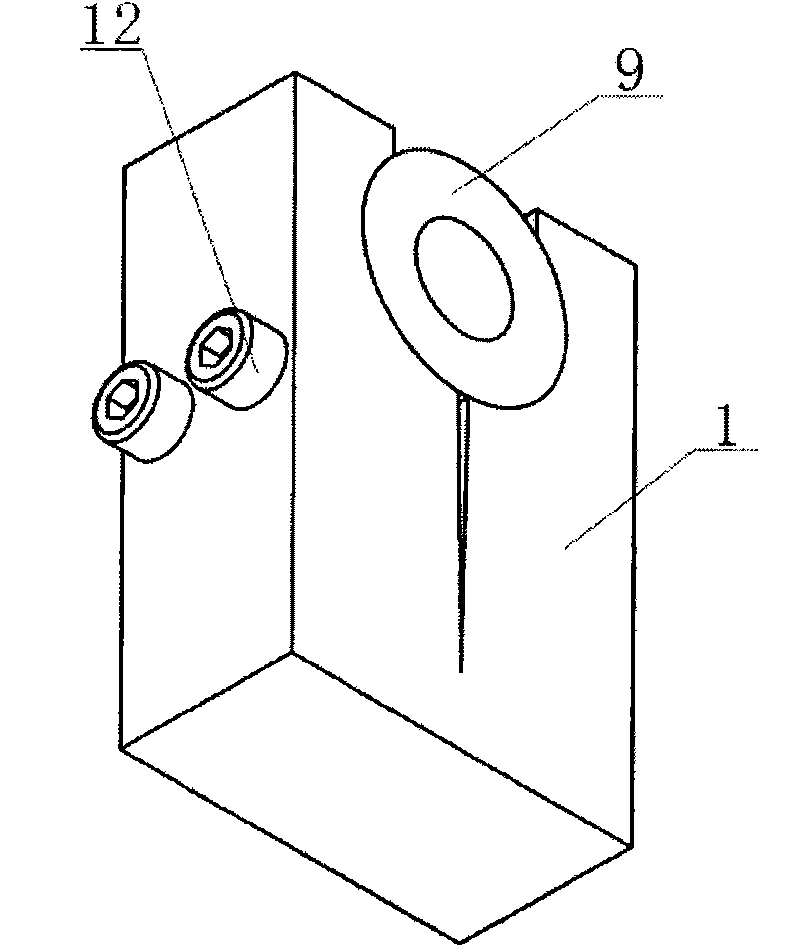

Steering gear of unmanned vehicle and control method thereof

ActiveCN101758855AGuaranteed compactnessGuaranteed validitySteering linkagesVehicle mounted steering controlsSteering wheelAutomatic steering

The invention discloses a steering gear of an unmanned vehicle and a control method thereof, wherein the steering gear is characterized by comprising a motor, a worm gear and a worm, an electromagnetic clutch and an encoder, wherein the motor is a steering drive mechanism; the worm gear and the worm are meshed with each other, and the worm is directly coupled with the output shaft of the motor; the electromagnetic clutch is fixedly coupled with the drive end of the electromagnetic clutch; and the encoder is fixedly coupled with a steering column of a steering wheel by the driven end of the electromagnetic clutch and is connected onto the output shaft of the rear end of the motor. The invention can realize the automatic steering control of the unmanned vehicle, can be freely switched between two modes of unmanned driving and manual driving the switching of which are not interfered with each other, and has compact structure, low cost, higher transmission efficiency, higher intelligent degree of vehicle automatic steering; and both the structure and the appearance of the original vehicle are not damaged, and the steering gear is easy to be assembled and dismantled and is applicable to other occasions with high automatic rotation requirements.

Owner:合肥中科自动控制系统有限公司

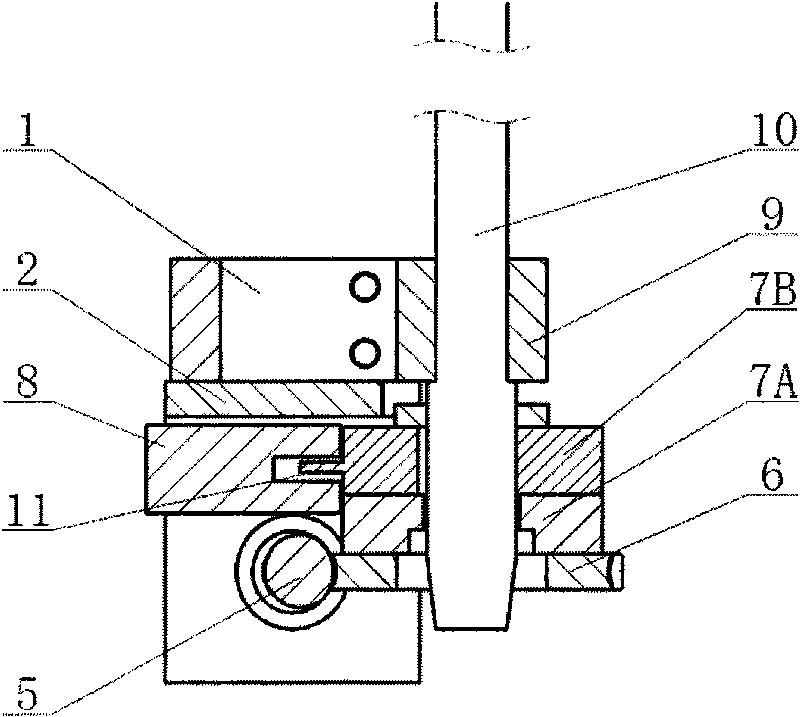

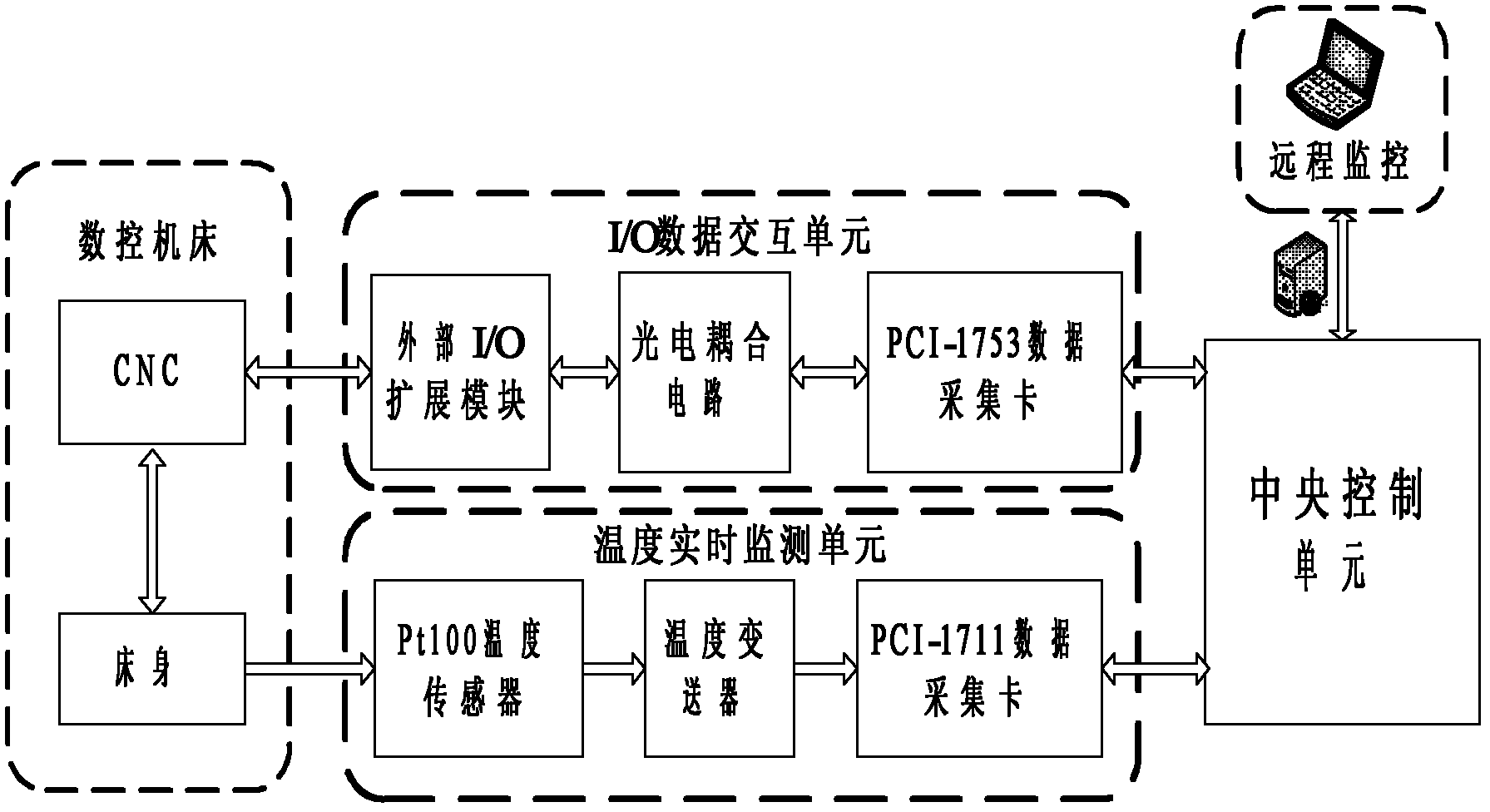

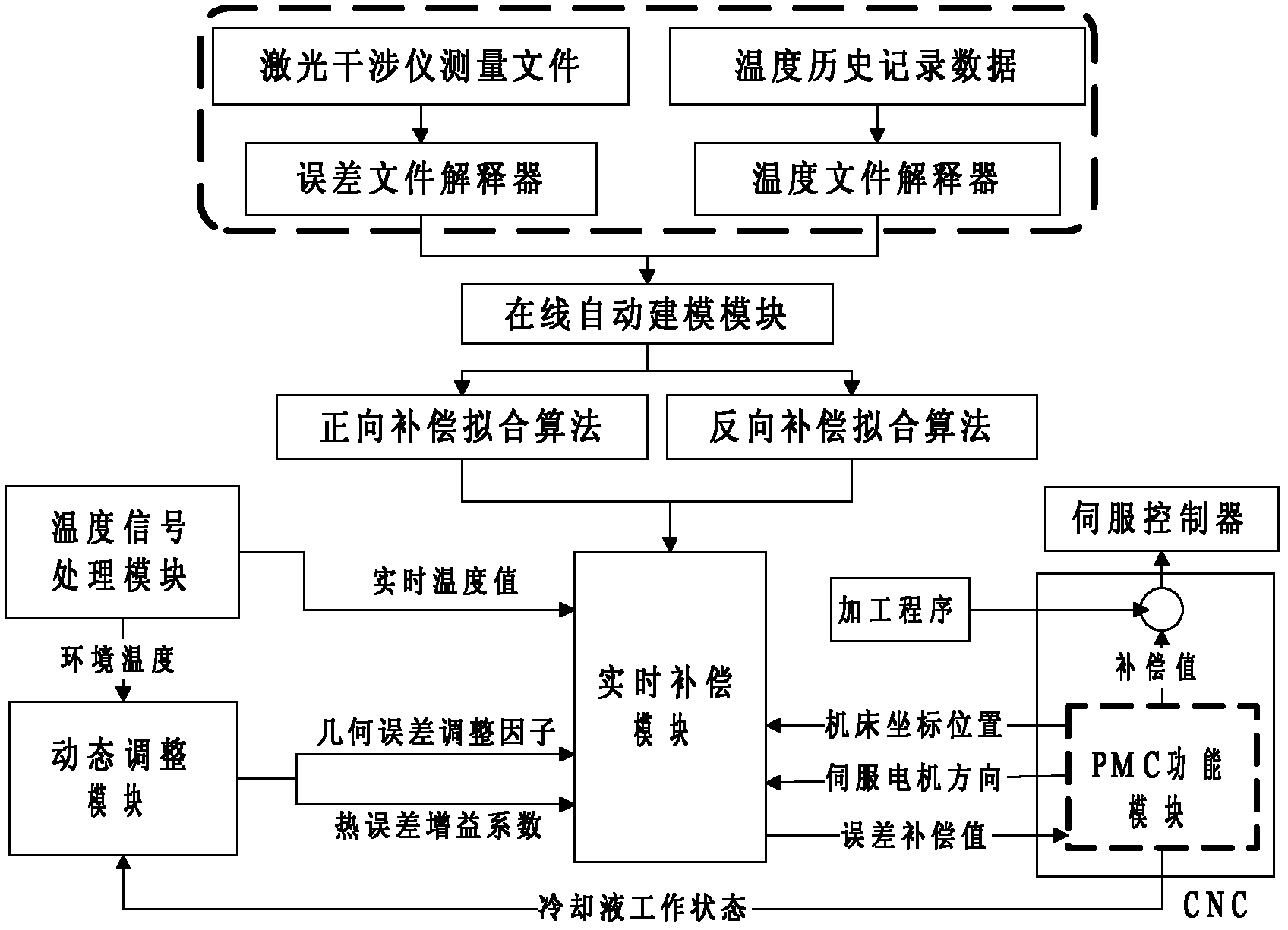

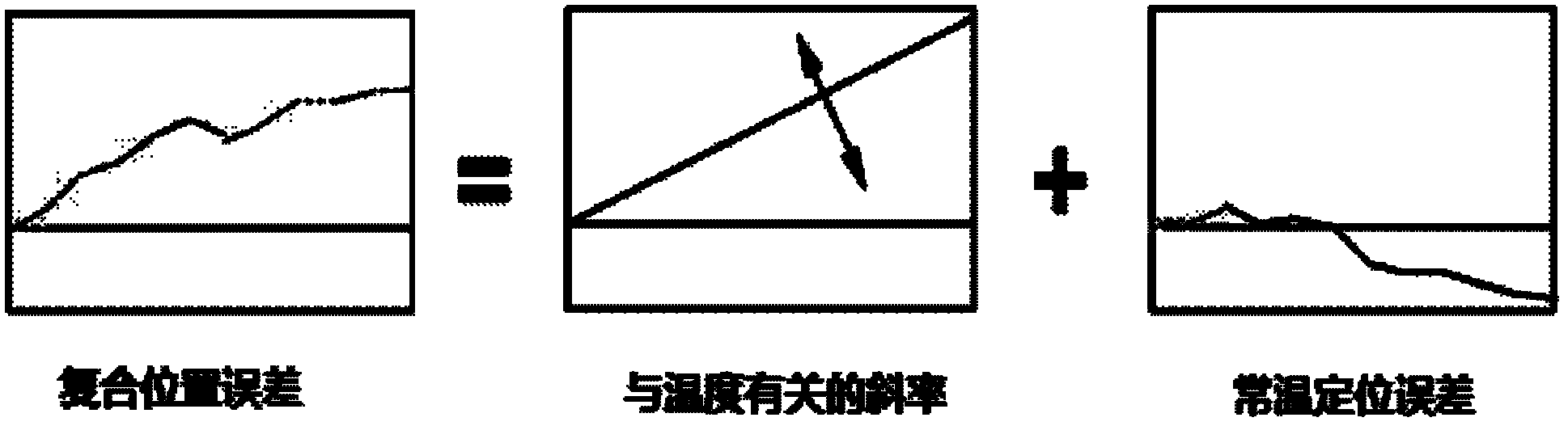

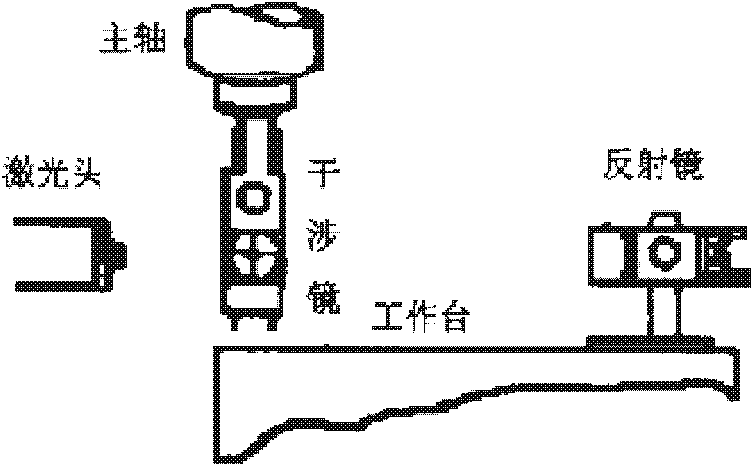

Intelligent compensation system for geometrical and heating position errors of numerical control machine

ActiveCN102629121AImprove robustnessHigh positioning accuracyProgramme controlComputer controlNumerical controlSimulation

The invention discloses an intelligent compensation system for geometrical and heating position errors of numerical control machine, which comprises a numerical control machine, a temperature real-time monitoring unit, an I / O data interaction unit and a center control unit, wherein the center control unit comprises a real-time compensation module, a temperature signal processing module, an online automatic modeling module, a dynamic regulation module, a machine performance analysis module and a remote monitor module. The system is capable of monitoring the temperature of external environment and the change of processing condition in real-time, and thereby updating the compensation model in real-time to further accomplish bidirectional compensation for the geometrical and heating position errors of the motion shaft of numerical control machine. The intelligent compensation system disclosed by the invention improves the location precision and repeating location precision in machine processing, and solves the problems of precision compensation in numerical control machine better.

Owner:SHANGHAI JIAO TONG UNIV

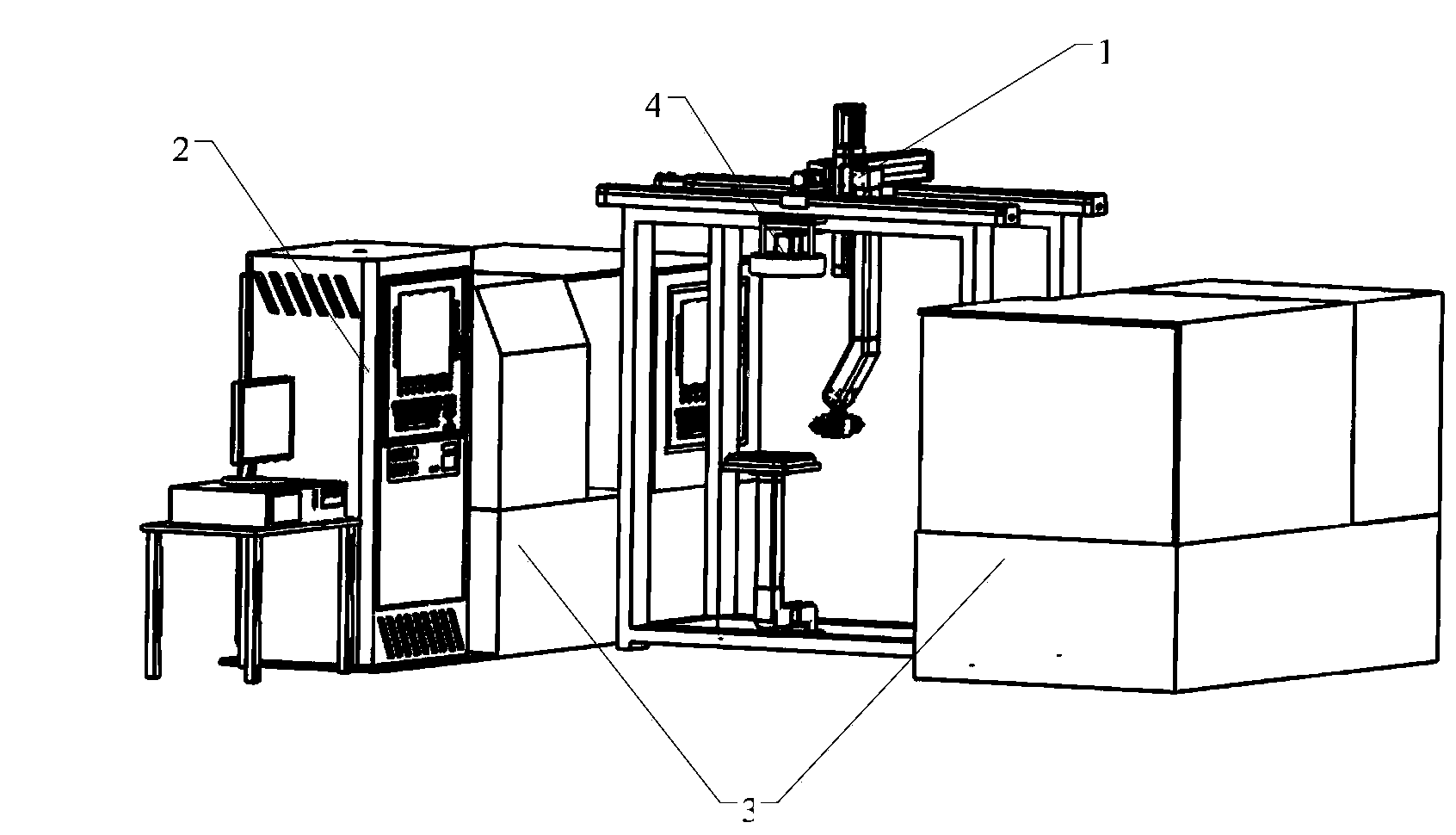

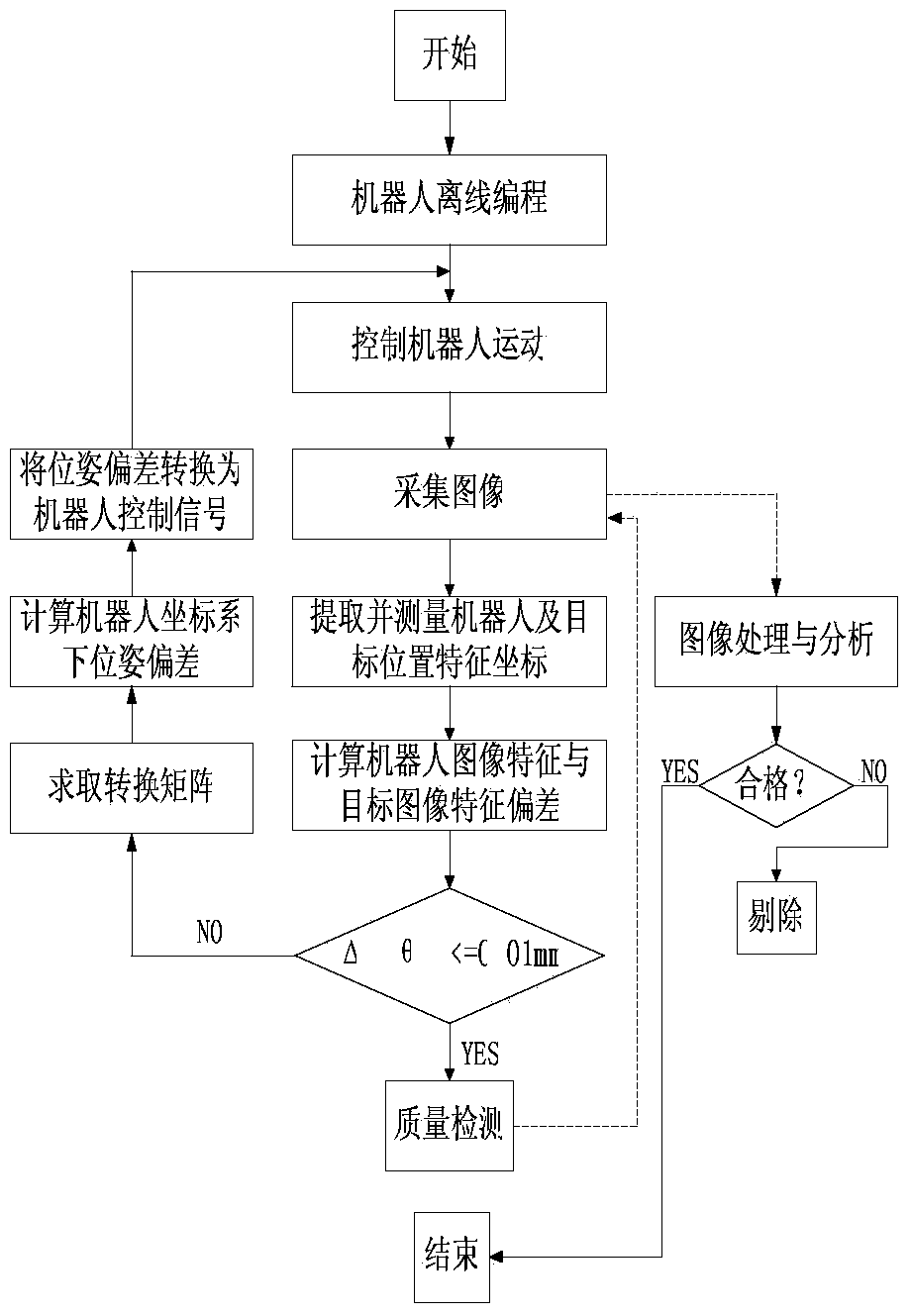

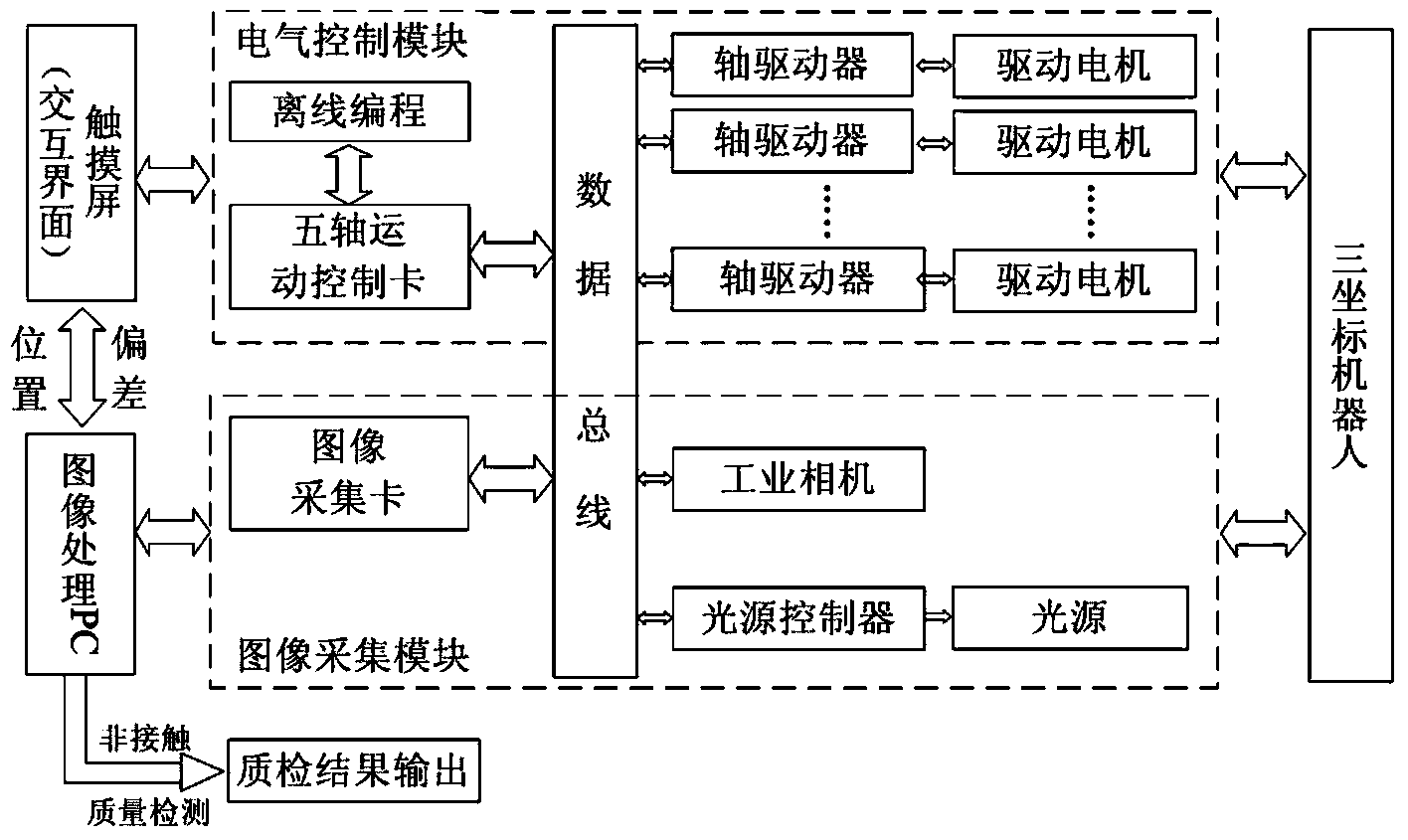

Robot system with visual servo and detection functions

ActiveCN103406905ARealize functionImprove motion control efficiencyProgramme-controlled manipulatorAutomatic controlControl signal

The invention discloses a robot system with visual servo and detection functions. The robot system comprises a robot, an image acquisition and image processing unit, a robot vision servo control unit and a communication network unit for connecting all the modules, wherein data and signal transmission among all the units is realized by the communication network unit; the robot vision servo control unit sends or receives a control signal of the robot by the communication network unit, rapidly understands the surrounding and constructs a vision feedback control model at the same time, so as to realize vision identification and movement control functions of the robot. The movement control of the robot adopts a method of combining offline programming with robot vision servo control to carry out automatic control on the robot and a tail end executer, so that the movement control efficiency of the robot and the repeated positioning precision and flexibility of the robot are improved; the robot system has higher intelligence. Robot control has a non-contact quality detection function based on robot vision; the robot system is simple in structure and convenient to operate.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

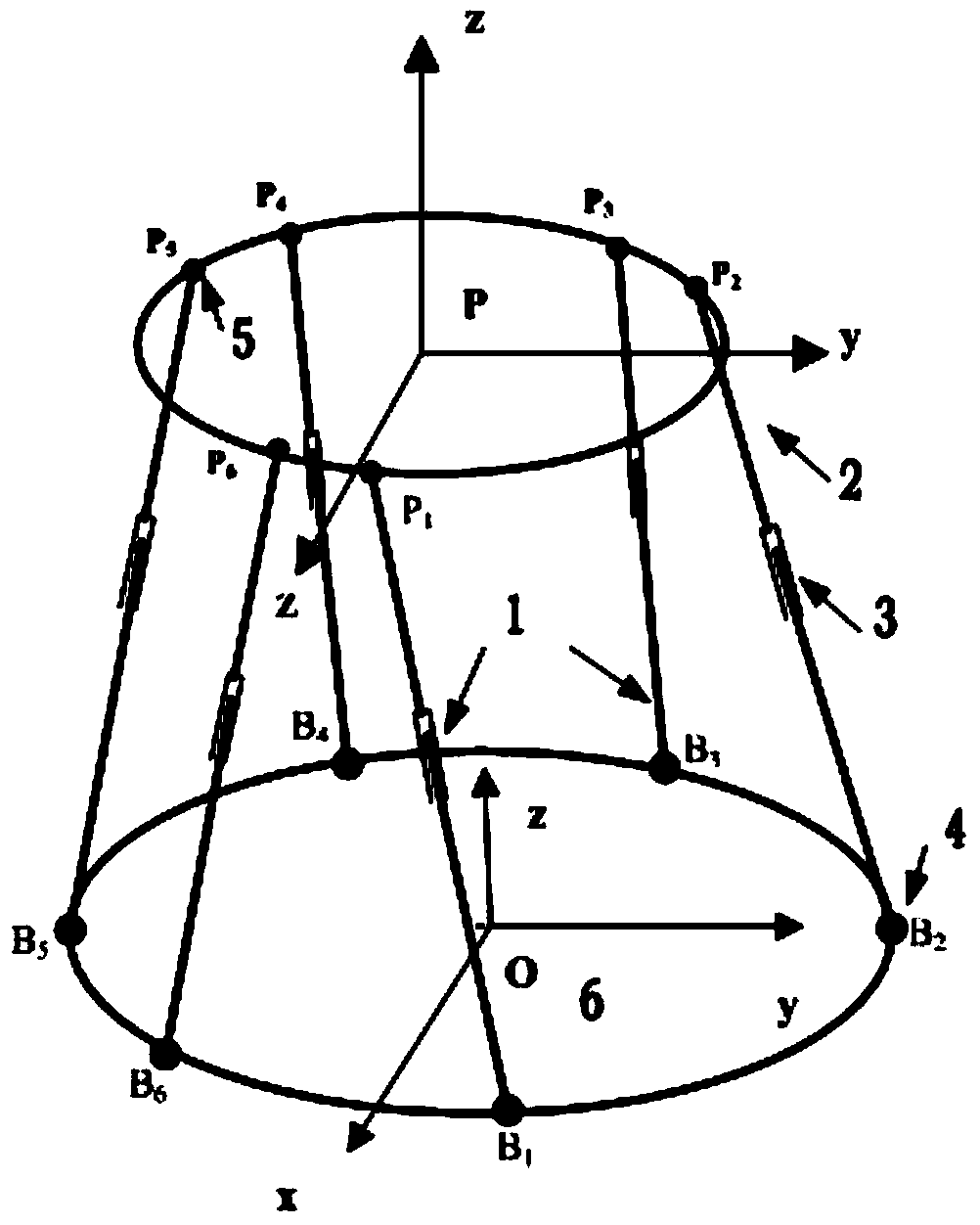

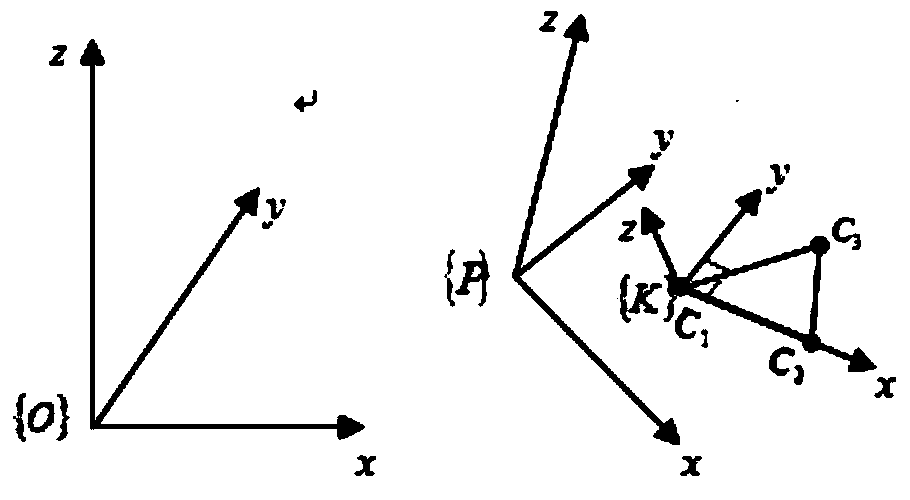

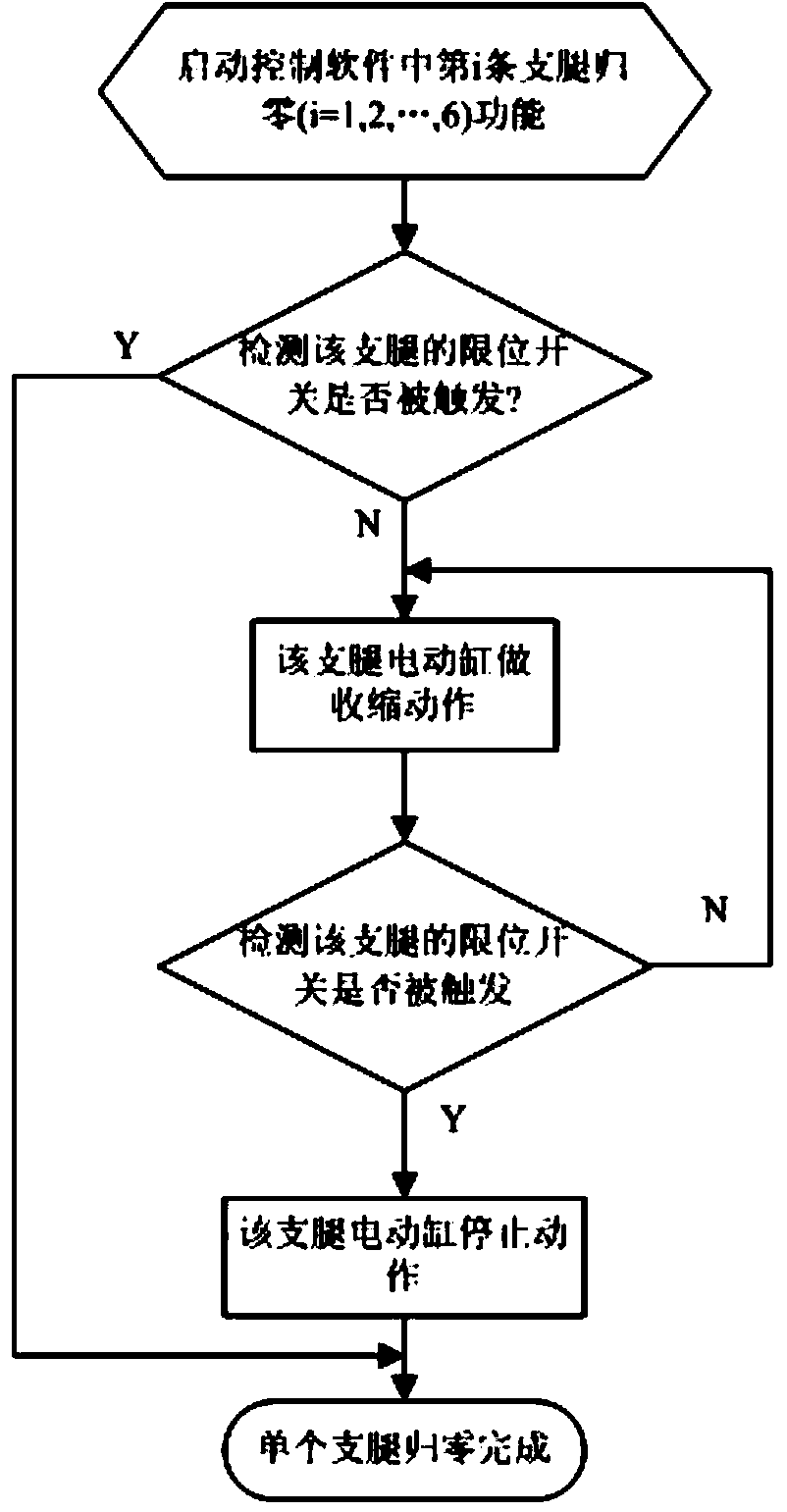

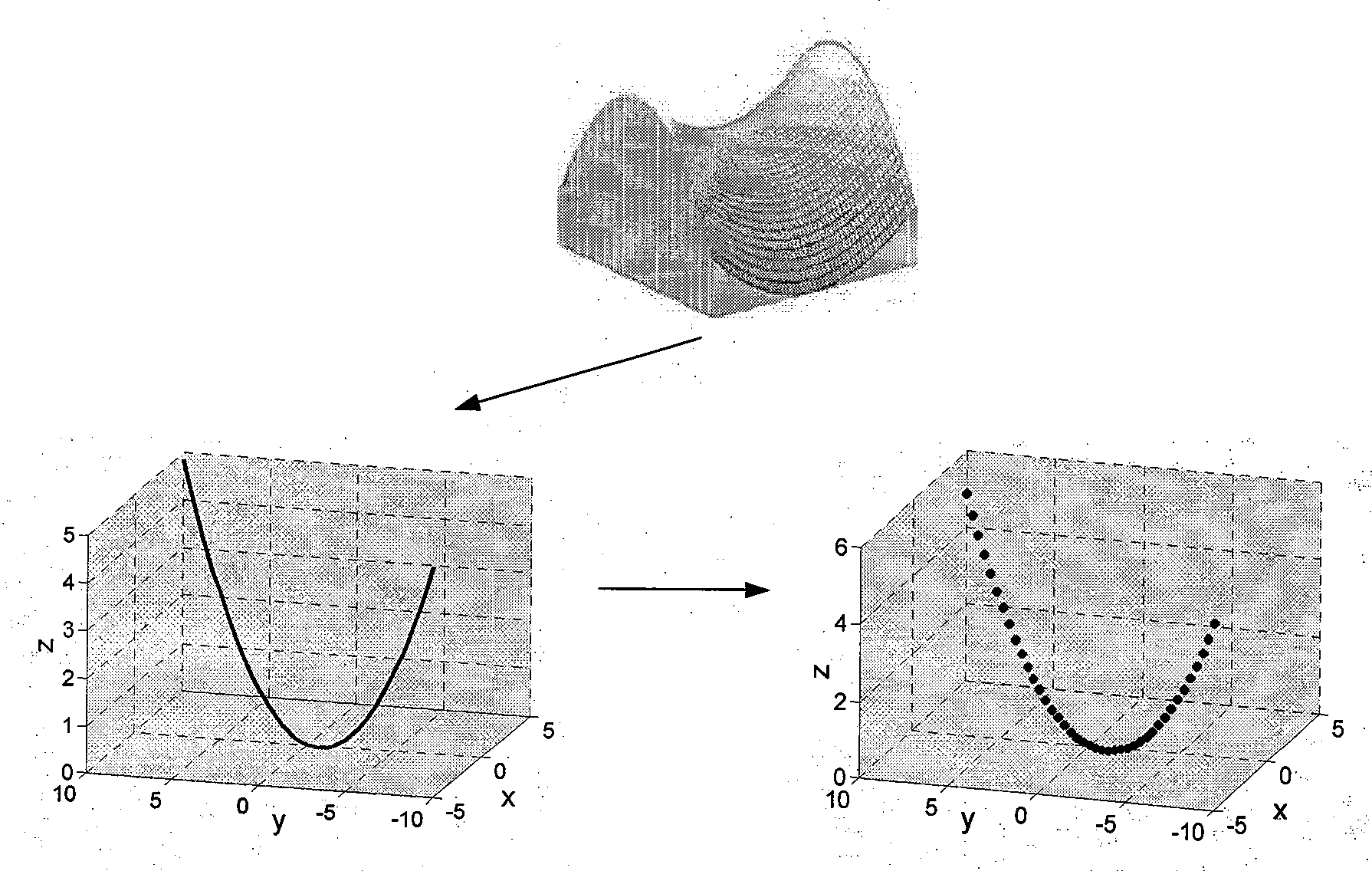

Standard pose calibration method for six-degree-of-freedom parallel robot used for Stewart platform structure

ActiveCN104390612AHigh repeat positioning accuracyStrong reliabilityNavigational calculation instrumentsCoordinate vectorSimulation

The invention discloses a standard pose calibration method for a six-degree-of-freedom parallel robot used for a Stewart platform structure. The method comprises the following steps: establishing a base coordinate system {O} and a motion platform coordinate system {P}; under the condition of six-degree-of-freedom parallel robot open chain organization, calibrating position coordinate vectors of Hooke hinge centers and spherical hinge centers of the parallel robot in the{O} and the {P} respectively; selecting three mark points on a motion platform and measuring local coordinates of the mark points in the motion platform coordinate system; installing an optocoupler limit switch at the push rod extending end of an electric cylinder of each supporting leg, and assembling the parallel robot to form a closed chain organization; controlling each supporting leg of the six-degree-of-freedom parallel robot to shorten slowly at a constant speed until each optocoupler limit switch is triggered and stimulates the six legs to stop moving successively, and thus the standard pose of the motion platform is generated; measuring the three mark points on the motion platform, ad calculating the standard pose of the parallel robot; and calculating the initial length of the supporting leg corresponding to the standard pose according to the standard pose. With the method, repeated positioning accuracy is high and reliability is high.

Owner:XIDIAN UNIV

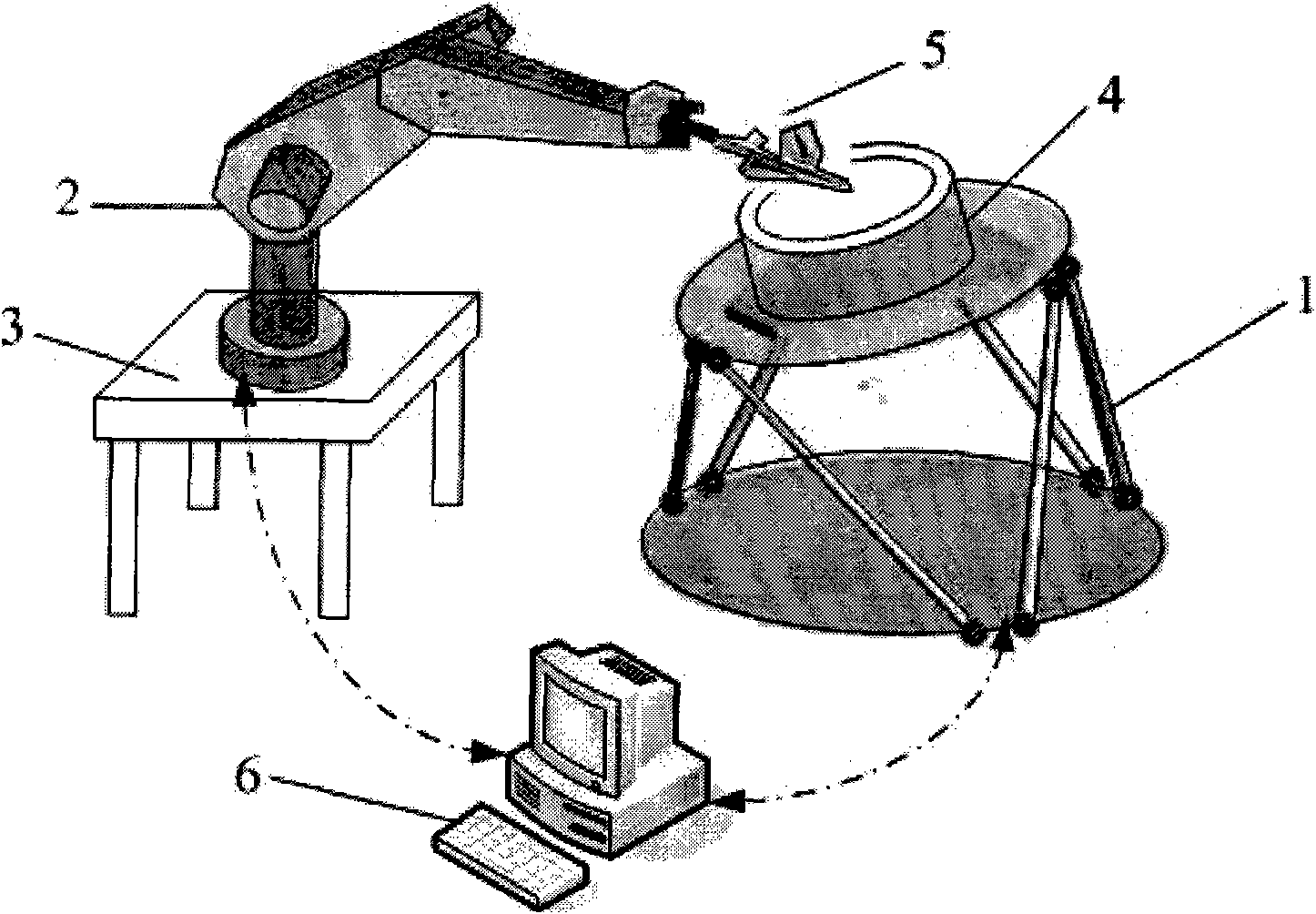

Series-parallel robot combined processing system and control method thereof

InactiveCN101811301AImprove adaptabilityIncrease flexibilityProgramme-controlled manipulatorControl systemEngineering

The invention discloses a series-parallel robot combined processing system and a control method thereof. The system comprises a series robot, a parallel robot, a controller, a platform, workpieces to be processed and a terminal executer. The controller controls the series robot and the parallel robot by adopting a layering control system, the upper controller is used for distributing tasks and controlling movement, and the lower series-parallel robot is used for driving hardware and executing the tasks. The invention combines the system hardware with software, thereby enhancing the automation degree, production efficiency, bearing capability and repetitive positioning accuracy of processing, strengthening the flexibility and adaptability of the system, realizing real-time control on line, and having a certain intelligent performance.

Owner:BEIHANG UNIV

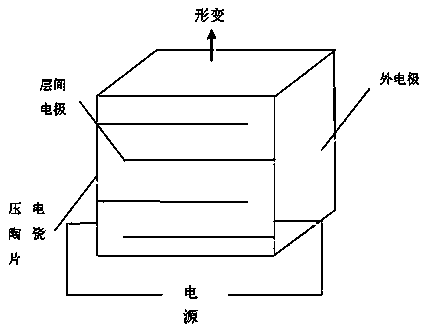

Adaptive learning control method of piezoelectric ceramics driver

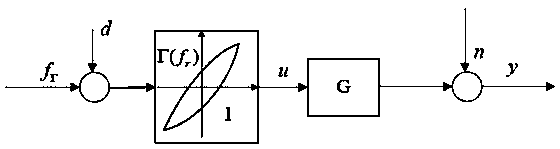

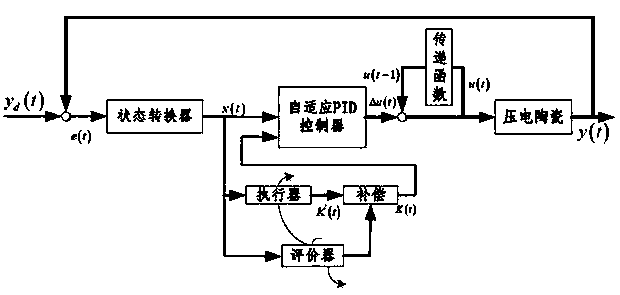

InactiveCN103853046ASolving Hysteretic Nonlinear ProblemsHigh repeat positioning accuracyAdaptive controlHysteresisActuator

The invention relates to an adaptive learning control method of a piezoelectric ceramics driver. The adaptive learning control method of the piezoelectric ceramics driver comprises the following steps of (1), building a dynamic hysteretic model of the piezoelectric ceramics driver and designing a control method with the artificial neural network and a PID combined, (2), adopting a reinforcement learning algorithm to achieve adaptive setting of PID parameters on line, (3), adopting a three-layer radial basis function network to approach a strategic function of an actuator in the reinforcement learning algorithm and a value function of an evaluator in the reinforcement learning algorithm; (4), inputting a system error, an error first-order difference and an error second-order difference through a first layer of the radial basis function network, (5), achieving mapping of the system state to the three PID parameters through the actuator in the reinforcement learning algorithm, and (6), judging the output of the actuator and generating an error signal through the evaluator in the reinforcement learning algorithm, and updating system parameters through the signal. The adaptive learning control method of the piezoelectric ceramics driver solves the hysteresis nonlinear problem of the piezoelectric ceramics driver, improves the repeated locating accuracy of a piezoelectric ceramics drive platform, and eliminates influence on a system from hysteresis nonlinearity of piezoelectric ceramics.

Owner:GUANGDONG UNIV OF TECH

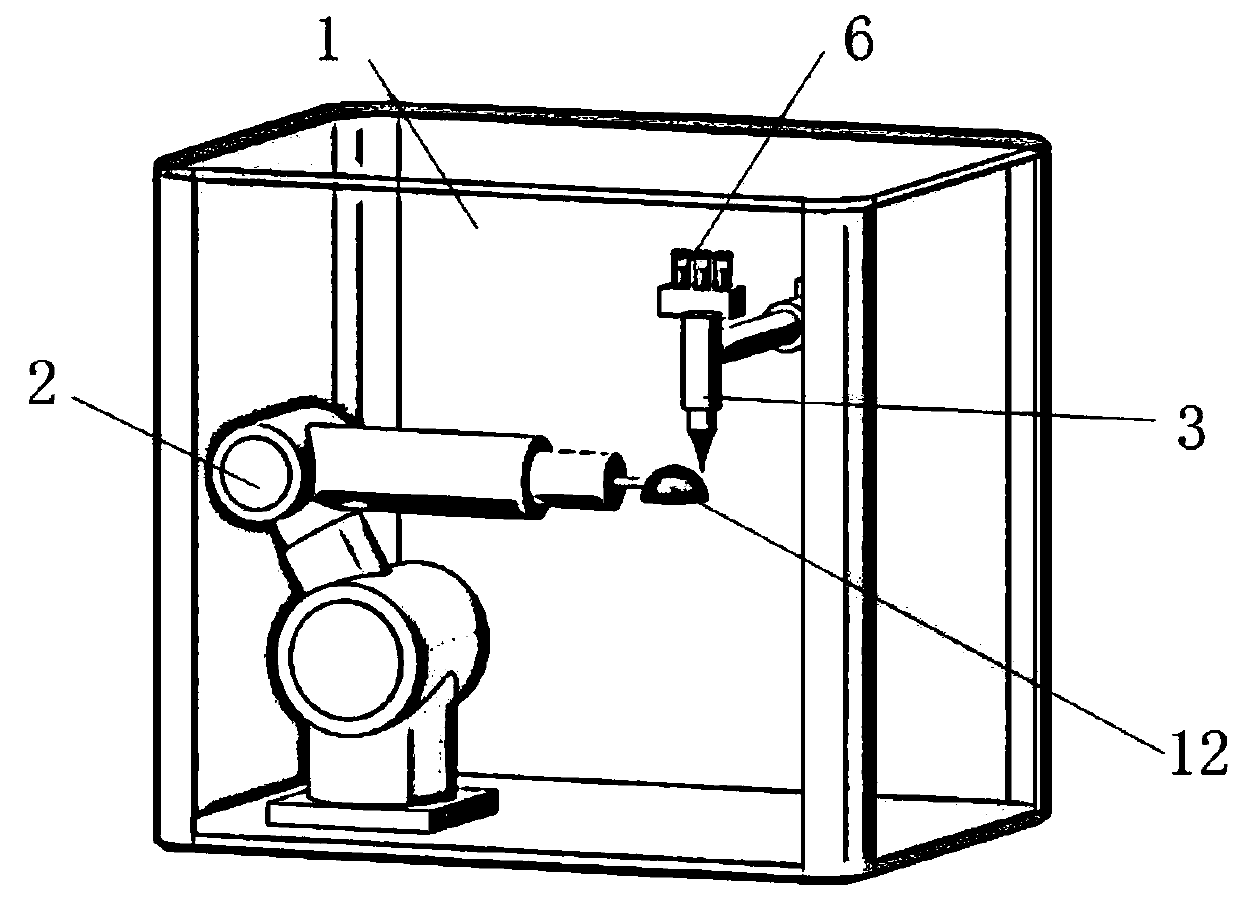

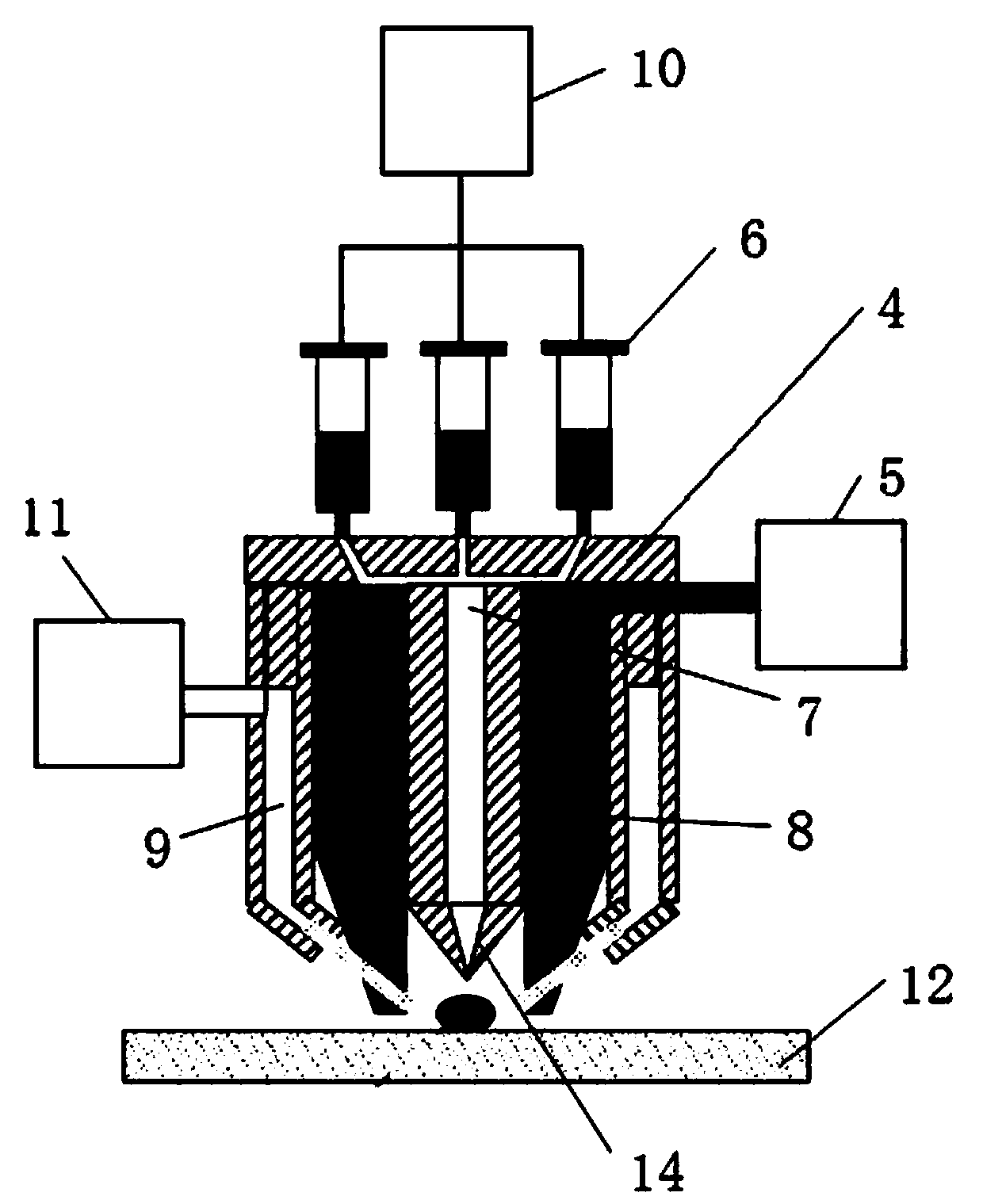

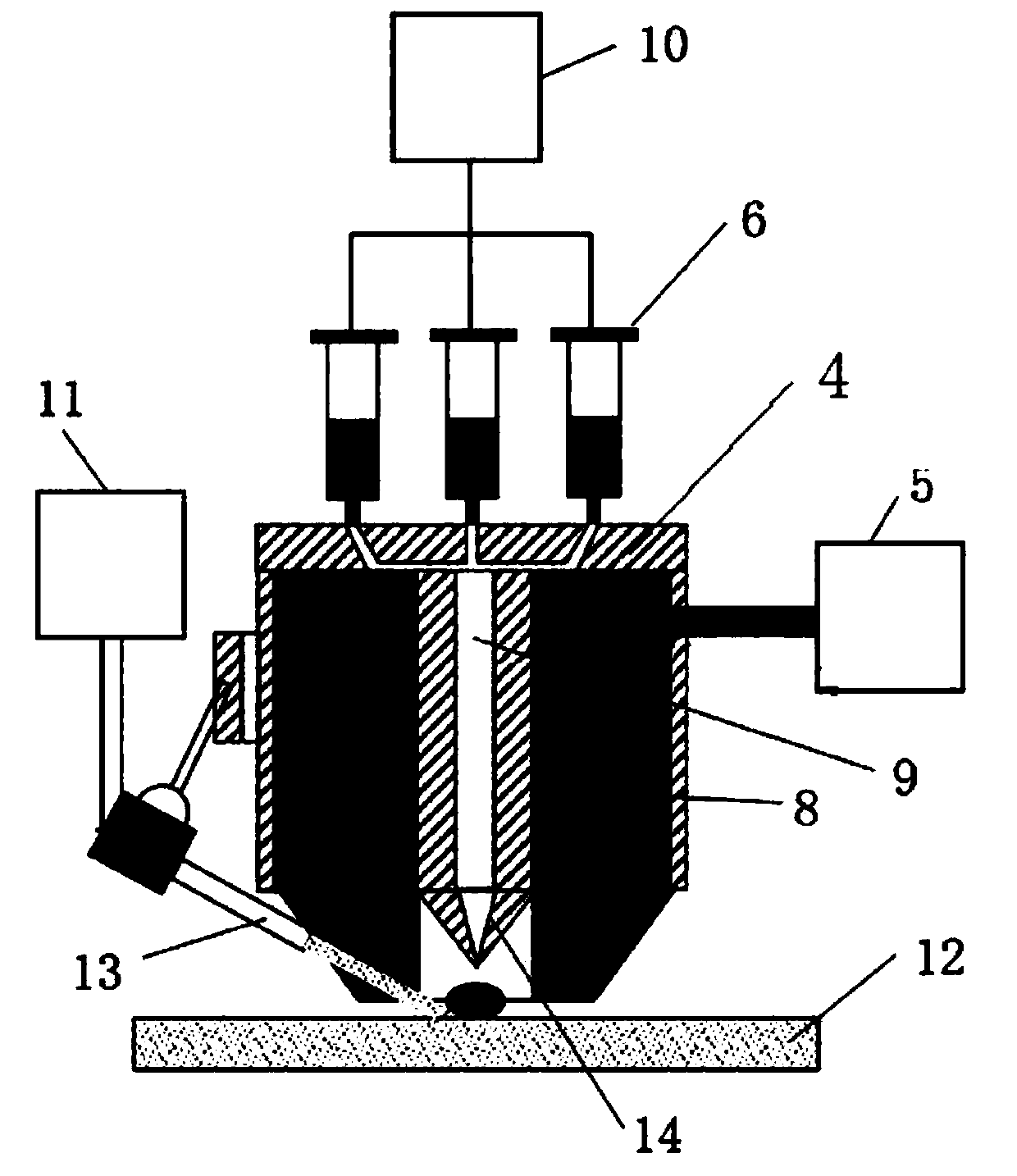

Multi-material laser direct writing conformal system and method

InactiveCN104260360ALarge adjustment rangeHigh repeat positioning accuracyMulti materialControl system

The invention discloses a multi-material laser direct writing conformal system and a method. The system comprises a vacuum seal case, a multi-joint mechanical arm, a multi-material laser direct writing head and a control system for controlling the constituent parts, wherein the mechanical arm and the laser direct writing head are arranged in the vacuum seal case; the laser direct writing head comprises a direct writing head body, a laser and at least two groups of material cylinders; a material channel and a laser focusing channel communicated with the laser and the material cylinders respectively are arranged on the direct writing head body; and the at least two groups of material cylinders are arranged on the direct writing head body in parallel. A particular process is as follows: the mechanical arm drives a workpiece to move along a set path; a material controller selects the corresponding material cylinders; a discharge head delivers and allows materials to be attached to the surface of the workpiece; and at the same time, laser light emitted from the laser focusing channel carries out solidifying or sintering forming on the attached materials. According to the invention, a control process is simple, the forming precision is high, continuous production is achieved, and production efficiency is improved.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

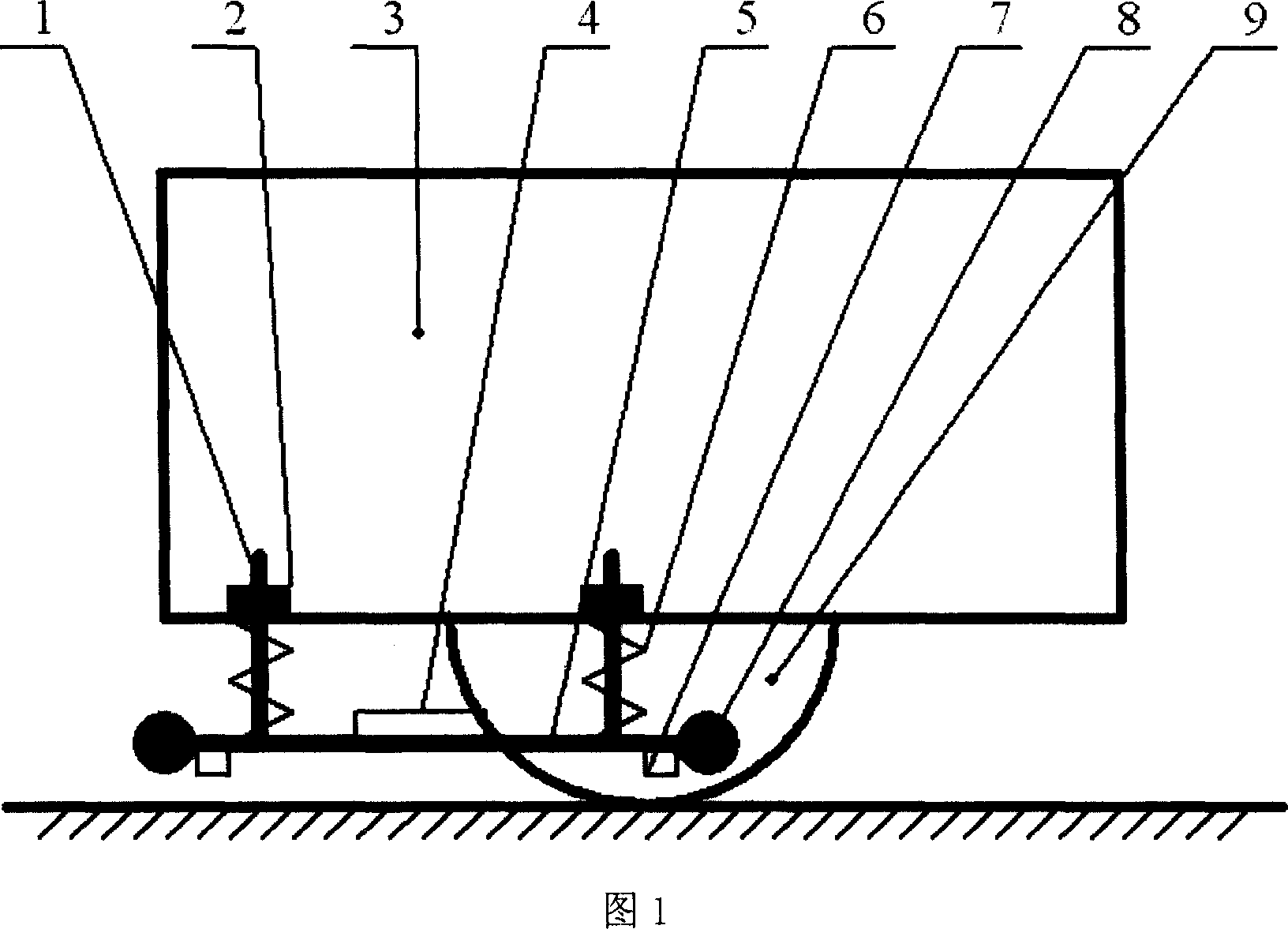

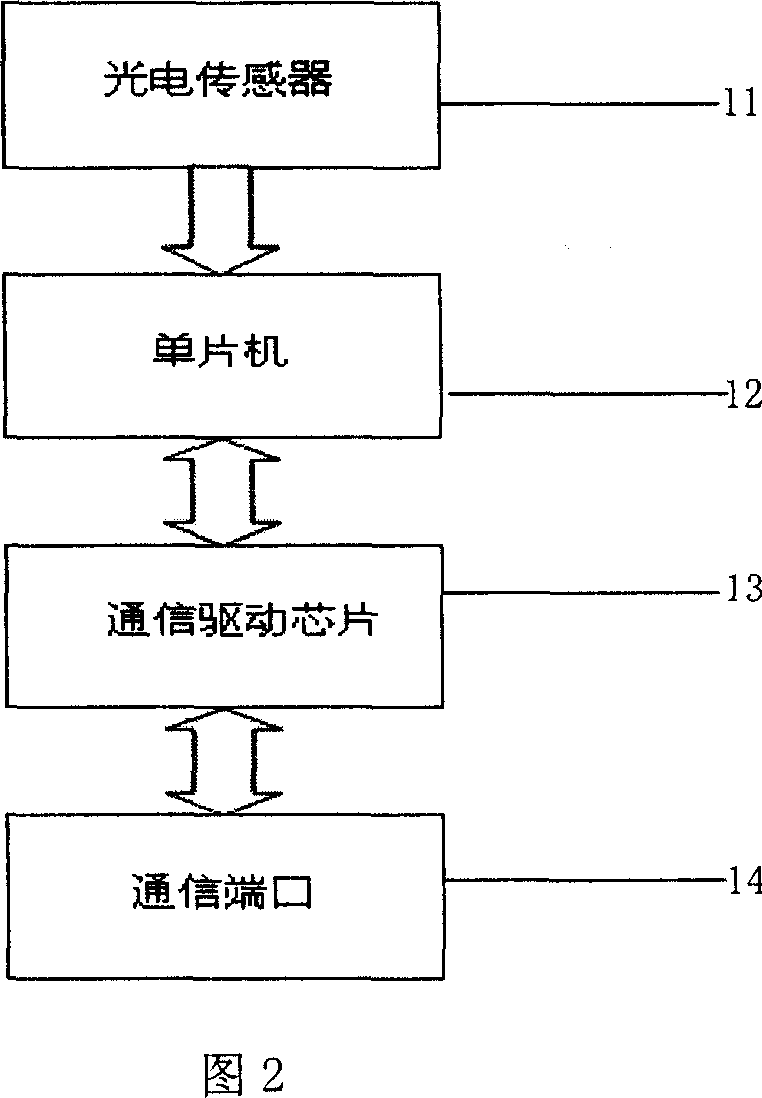

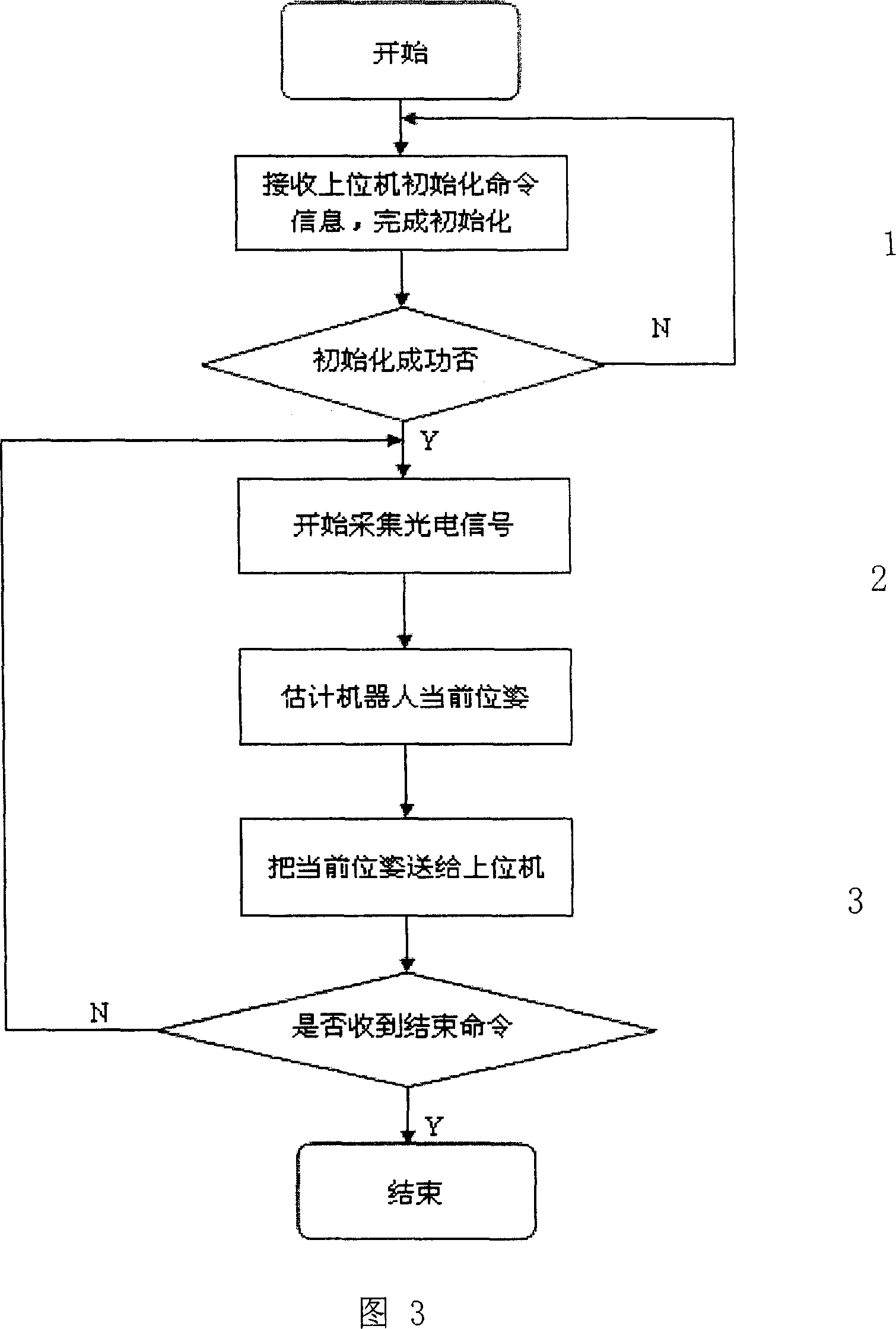

Pose sensing system and method for mobile robot

InactiveCN101049697ASimple circuitLow costElectric programme controlManipulatorModularityCommunication interface

A position-posture sensing system of movable robot is composed of a photoelectric sensor for detecting the change of position and posture and converting the change to digital signals, an elastic pressing unit for ensuring the proper distance between said photoelectric sensor and ground, and a controlling-processing circuit consisting of a single-chip microprocessor, a communication interface chip, and the firmed programs. Its method is also disclosed.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

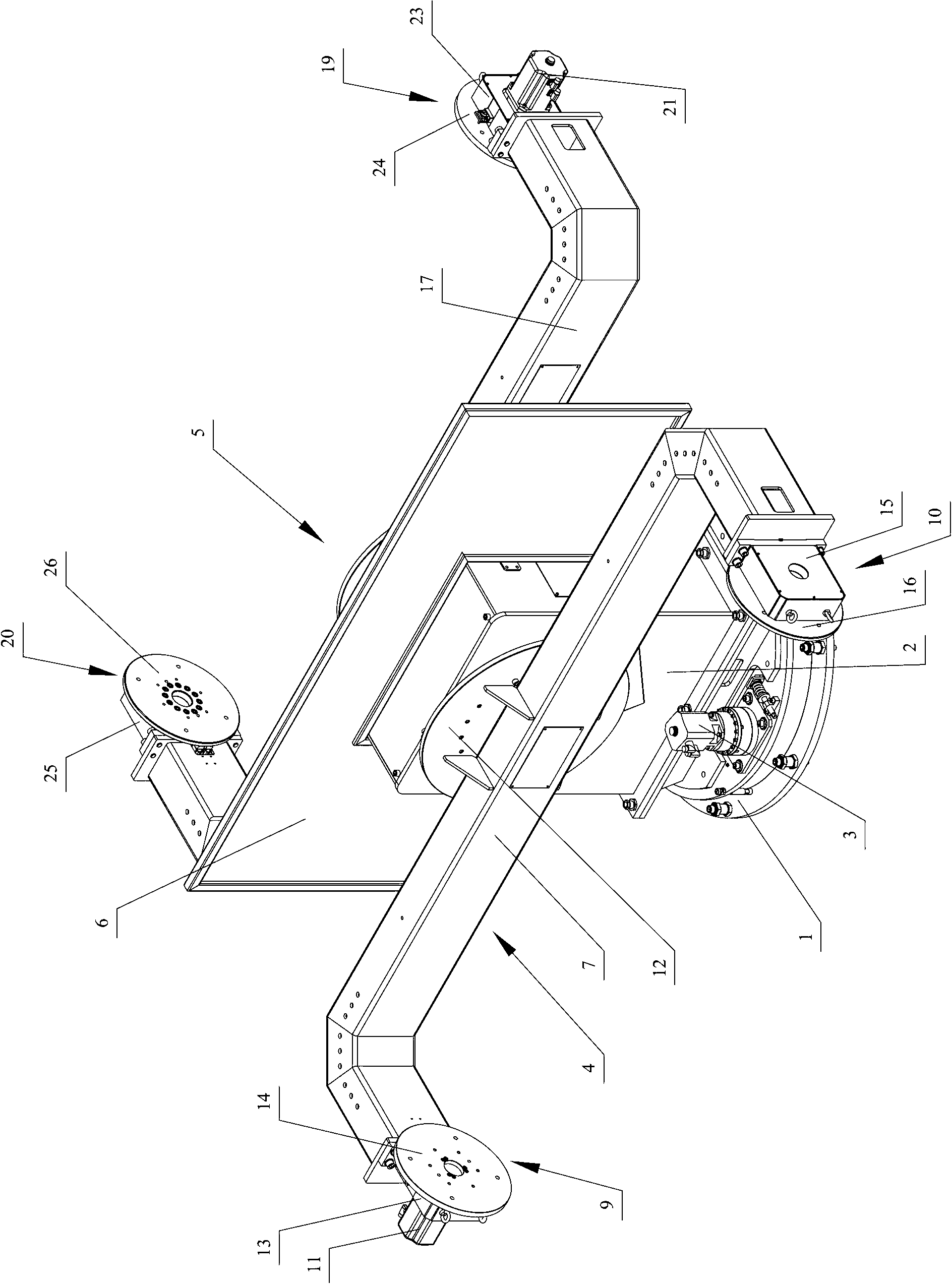

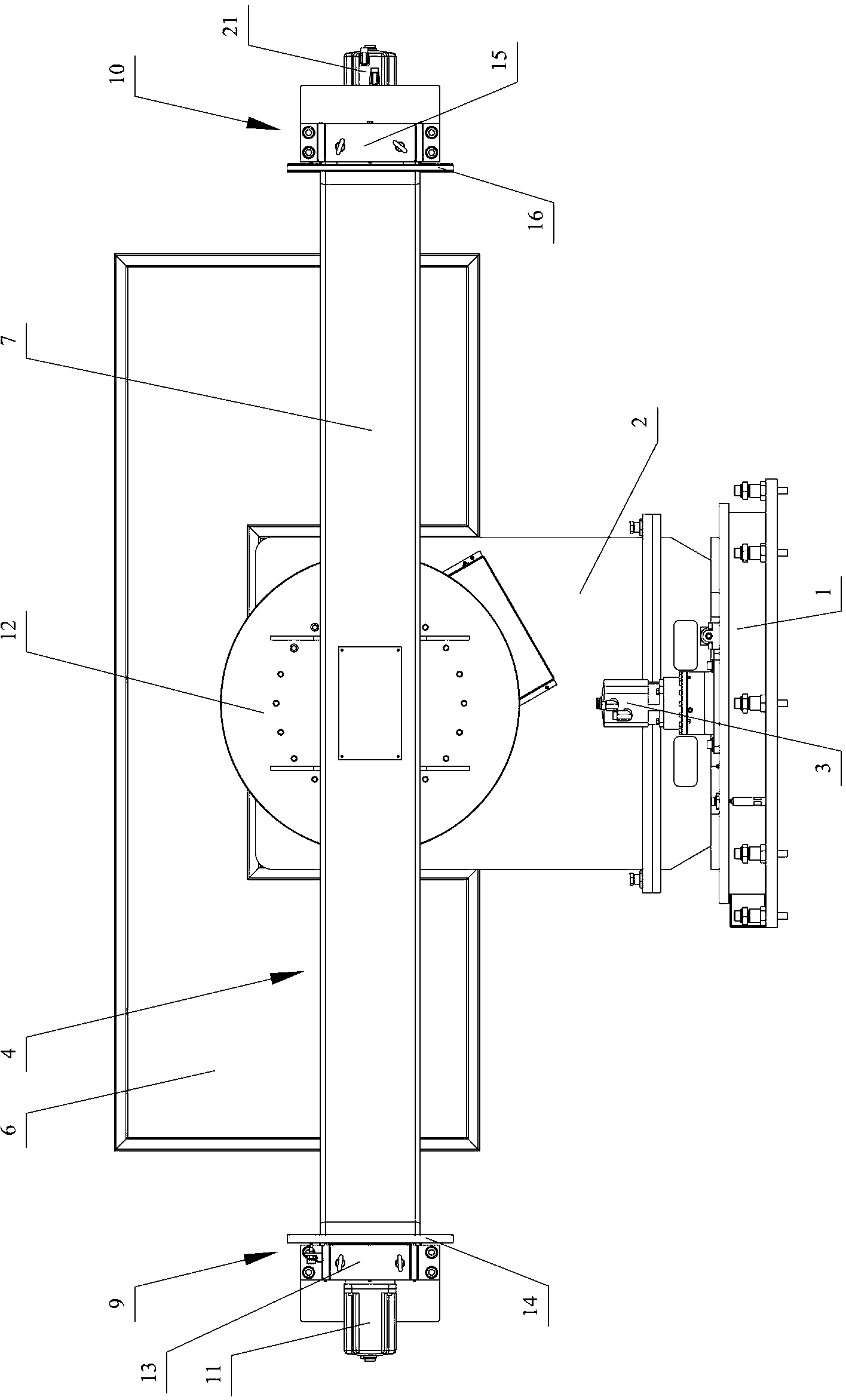

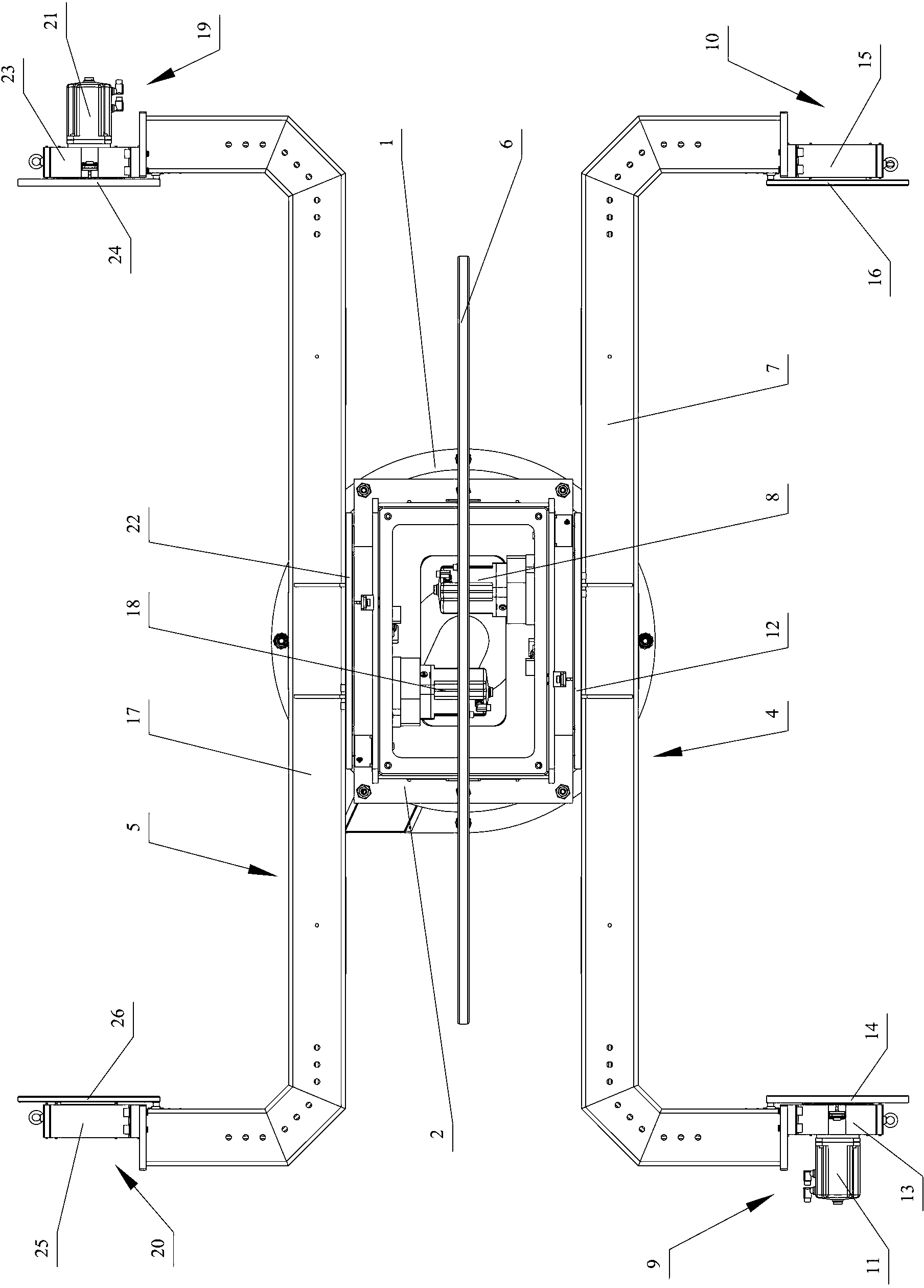

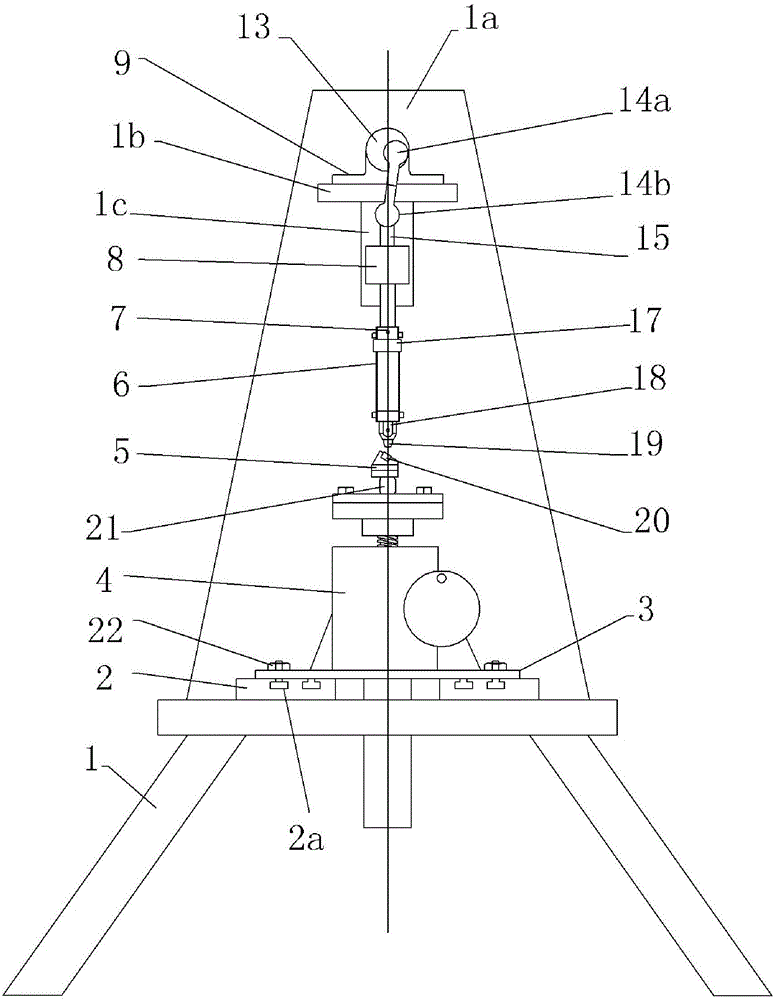

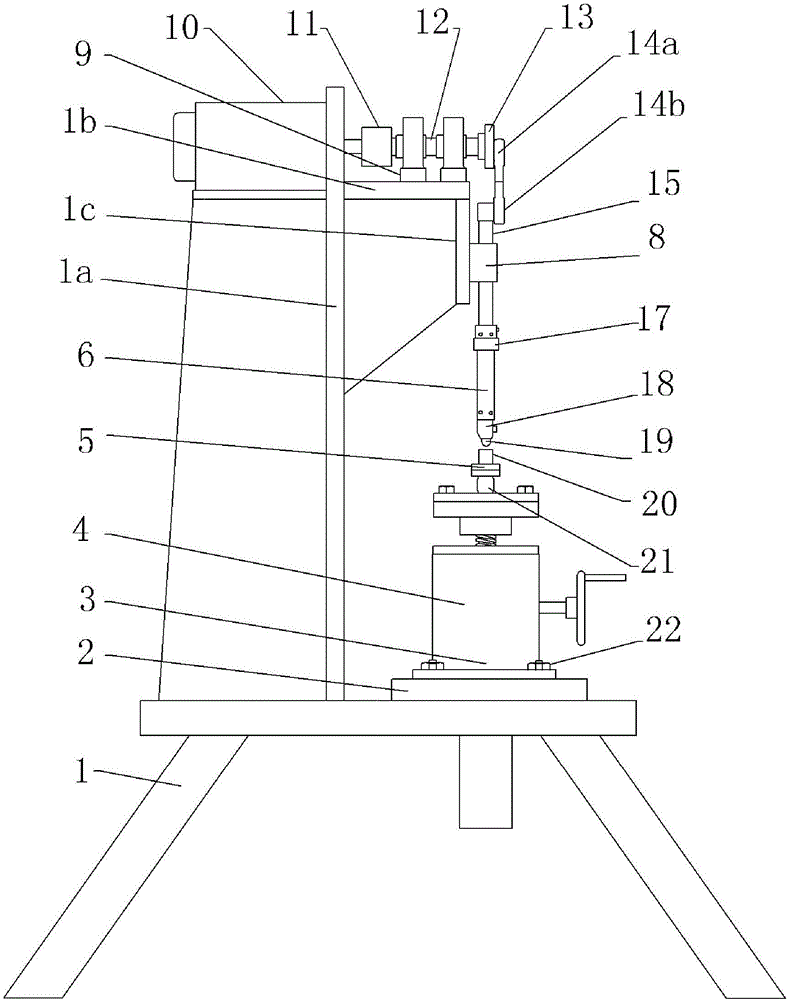

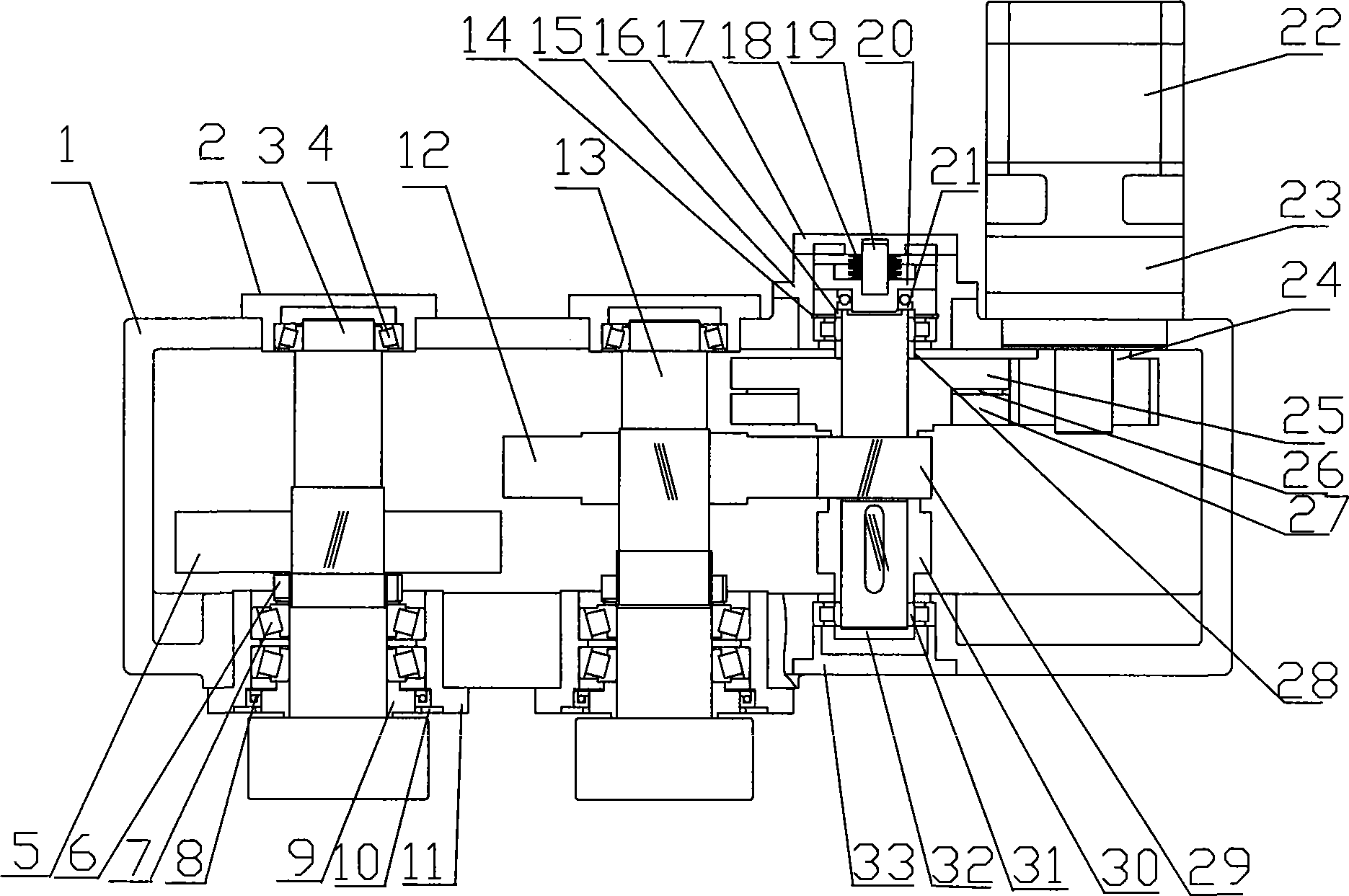

Precision five-axis double-station position changing machine

ActiveCN102699612AReduce production timeIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesRocker armEngineering

The invention relates to a precision five-axis double-station position changing machine. The machine comprises a rotating base, an upright post box arranged on the rotating base in a horizontal rotating mode, a first servo motor for driving the upright post box to rotate, and a first clamping device and a second clamping device which are respectively arranged on the two sides of the upright post box, wherein the first clamping device comprises a first rocker arm, a second servo motor for connecting the upright post box and the first rocker arm and driving the first rocker arm to vertically rotate, a first headstock and a first tailstock which are arranged on the first rocker arm, and a third servo motor for driving the first headstock to rotate; and the second clamping device comprises a second rocker arm, a fourth servo motor for connecting the upright post box and the second rocker arm and driving the second rocker arm to vertically rotate, a second headstock and a second tailstock which are arranged on the second rocker arm, and a fifth servo motor for driving the second headstock to rotate. Double position-changeable stations are arranged, so that a welding robot can continuously work, time consumption during production is reduced, production efficiency is improved, and rotating accuracy and repositioning accuracy are high.

Owner:XUZHOU HUAHENG ROBOT SYST

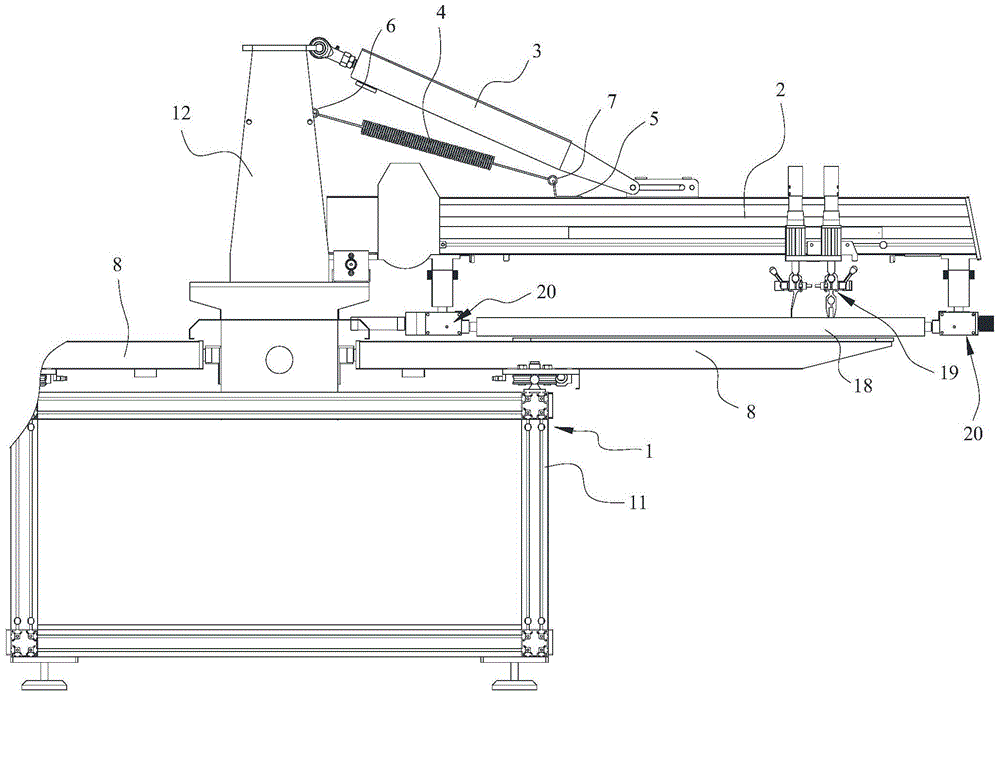

Novel decorating machine

The invention discloses a novel decorating machine. The novel decorating machine comprises a table rack, a printing arm, a cylinder, an extension spring, an elastic table plate, a screen frame, a scraper, and a screen frame fixing device, wherein the table rack comprises a rack leg and a fixed arm fixed on the rack leg, the fixed arm is linear, the rack leg wounds the periphery of the fixed arm, one end of the printing arm is hinged to the lower portion of the fixed arm, a piston rod of the cylinder extends out of one end of a cylinder body of the cylinder to be hinged to the upper end of the fixed arm, the other end of the cylinder body of the cylinder is hinged to the middle of the printing arm and is in sliding match with the printing arm in the direction of the length of the printing arm, one end of the extension spring is connected with the middle of the fixed arm, the other end of the extension spring is connected with the printing arm through a sliding plate, the sliding plate is in sliding match with the printing arm, and the bottom of the elastic table plate is in sliding match with the rack leg. The novel decorating machine is capable of buffering the action performed by the cylinder to lift or press the printing arm, greatly reducing vibration by the aid of an elastic force produced by the elastic table plate, and improving register accuracy.

Owner:SHENZHEN CNTOP DIGITAL EQUIP CO LTD

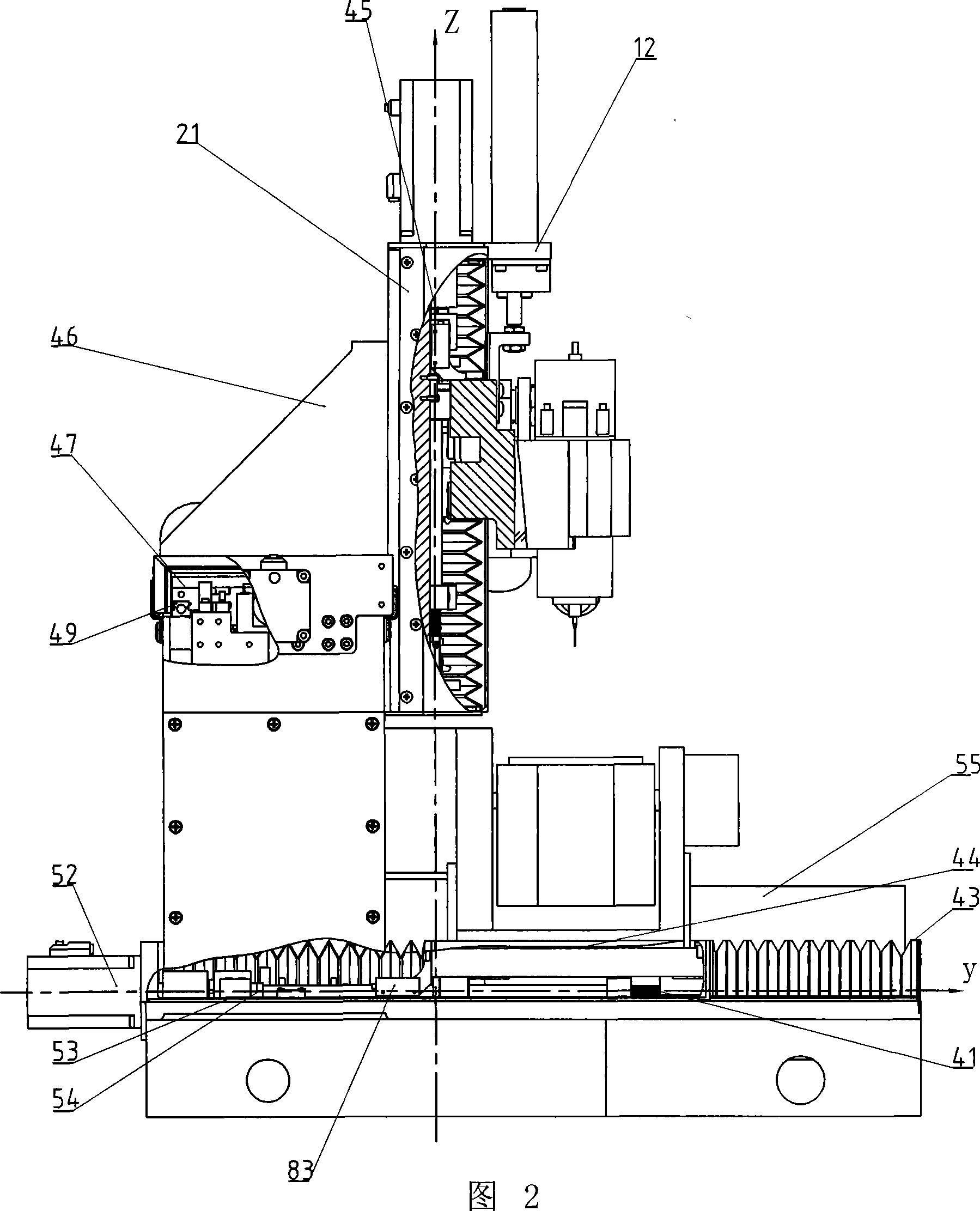

Small-sized five-shaft linkage numerically controlled machine

InactiveCN101439422AReduce volumeImprove machining accuracyLarge fixed membersMilling equipment detailsDrive motorMicroscope

The invention relates to a small five-axle-linkage numerical control milling machine, relating to a small numerical control milling machine. The invention aims at problems of conventional-size precise machine tool during cutting process of tiny parts, including large machine tool volume, high processing cost, low efficiency, uneconomical energy and space consumption and difficulties in the processing of complex tiny parts of three-dimensional camber structure. A portal frame-typed machine body is fixed on a base; and X-axis servo driving assembly is fixed on the portal frame-typed machine body; the upper end surface of the base is fixed with a Y-axis servo driving assembly; a Z-axis panel is connected with the X-axis servo driving assembly; a Z-axis servo driving assembly is fixed on the Z-axis panel; an electric principal shaft is fixed on the Z-axis servo driving assembly; a cylinder is connected with the Z-axis servo driving assembly; a microscope is connected with the Z-axis servo driving assembly; a working turntable provided with a motor therein is driven by a driving motor and forms a composite turntable rotating around the Z axis and the Y axis. The numerical control milling machine can realize five-axle linkage so as to satisfy processing requirements of three-dimensional camber structure and complex tiny parts.

Owner:HARBIN INST OF TECH

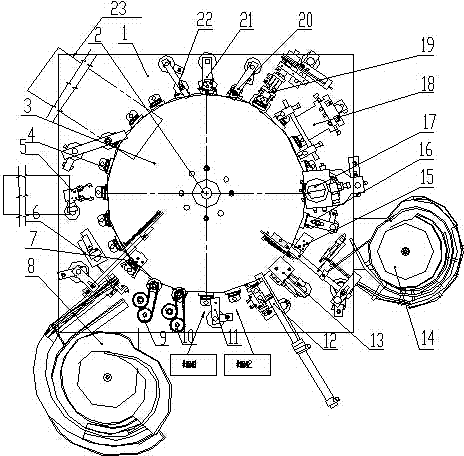

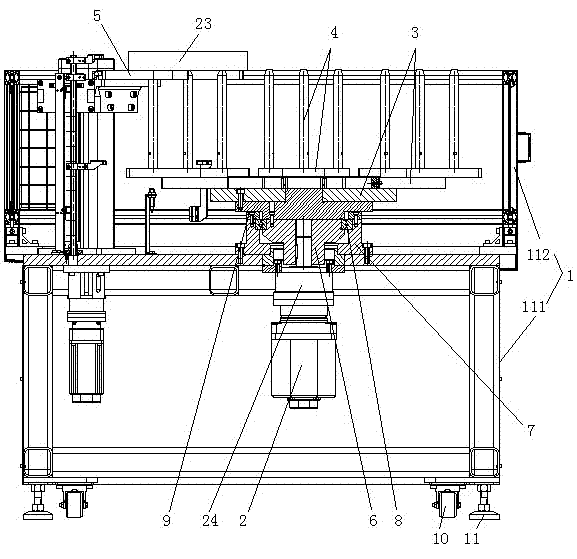

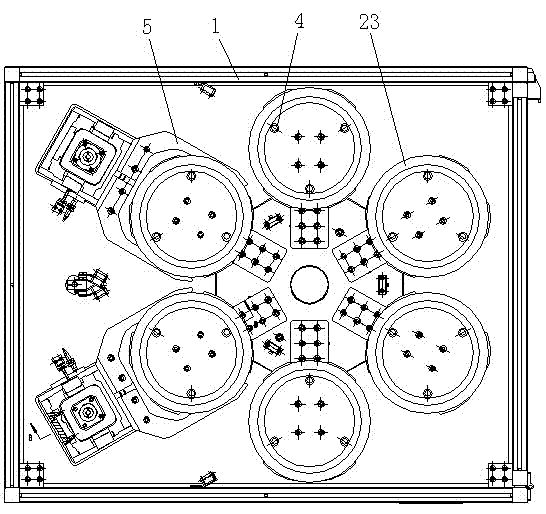

Full-automatic assembly machine of LED bulbs

InactiveCN104493478AImprove efficiencyHigh repeat positioning accuracySoldering apparatusAssembly machinesManipulatorSoldering

The invention relates to a full-automatic assembly machine of LED bulbs. The full-automatic assemble machine comprises a frame, a station index plate, a main transmission mechanism, a cam and link control mechanism, a pneumatic control mechanism, a lamp holder feeding mechanism, a lamp holder feeding manipulator, a lamp holder rivet feeding manipulator, a bulb shell feeding manipulator, a lamp holder cable sorting device, a lamp cap rotating device, a lamp cap riveting device, a lamp cap fixing device, a lamp cap preheating and soldering device, a lamp holder rotating device, a gluing device and a lamp holder press-down device. Lamp holder fixtures are evenly distributed on the station index plate. A station is provided with a detection system and a rejects remover. Conventional assembly of LED bulbs is manpowered and has the problems such as low efficiency, high cost and high output of inferior-quality products. In manual assembly, one worker can only assemble 300 LED bulbs per 8 hours; the full-automatic assemble machine allows 1200 LED bulbs to be automatically assembled each hour, with 9600 LED bulbs assembled per 8 hours each day, and the efficiency is increased by 32 times.

Owner:JIANGSU HAOMING PHOTOELECTRIC TECH

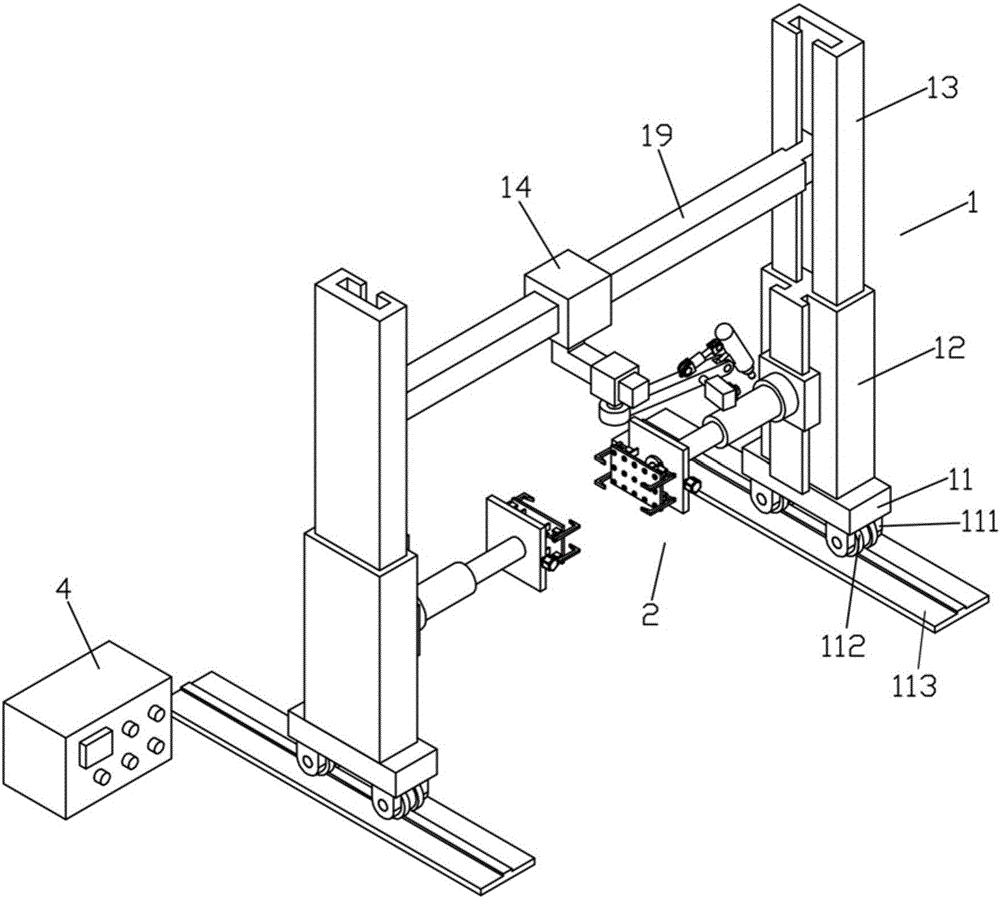

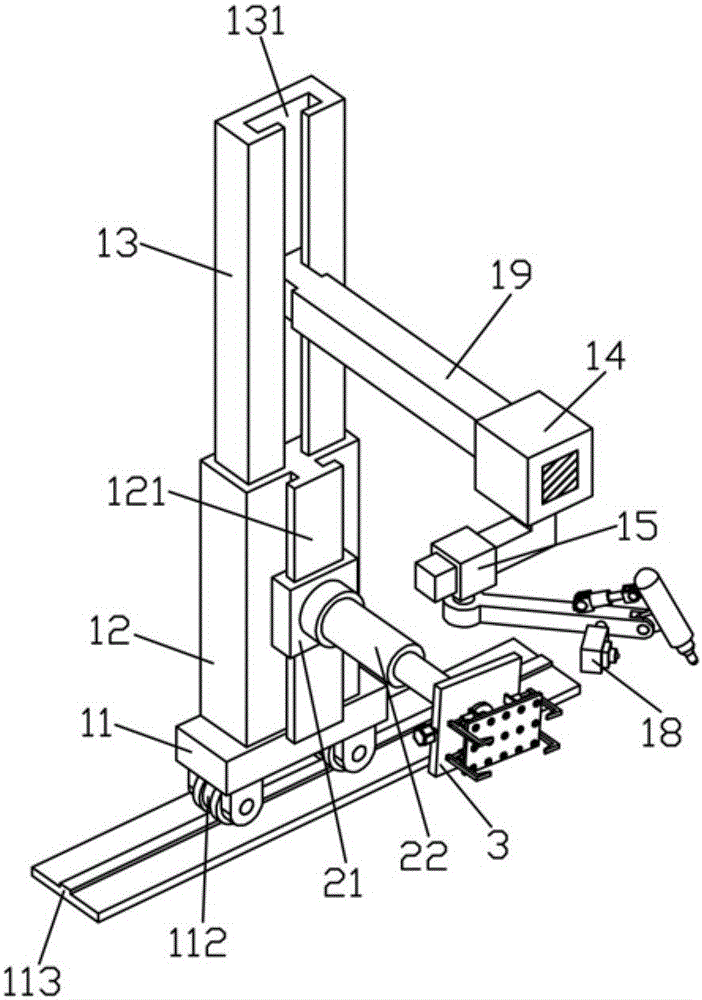

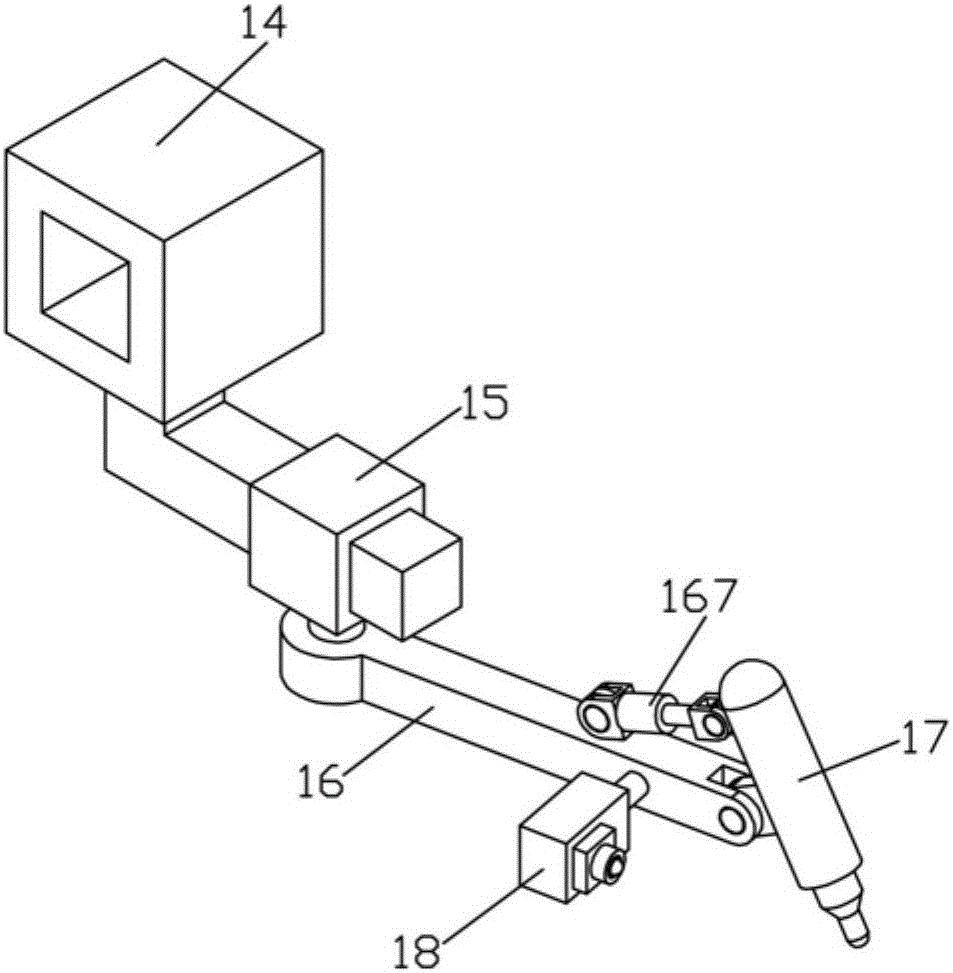

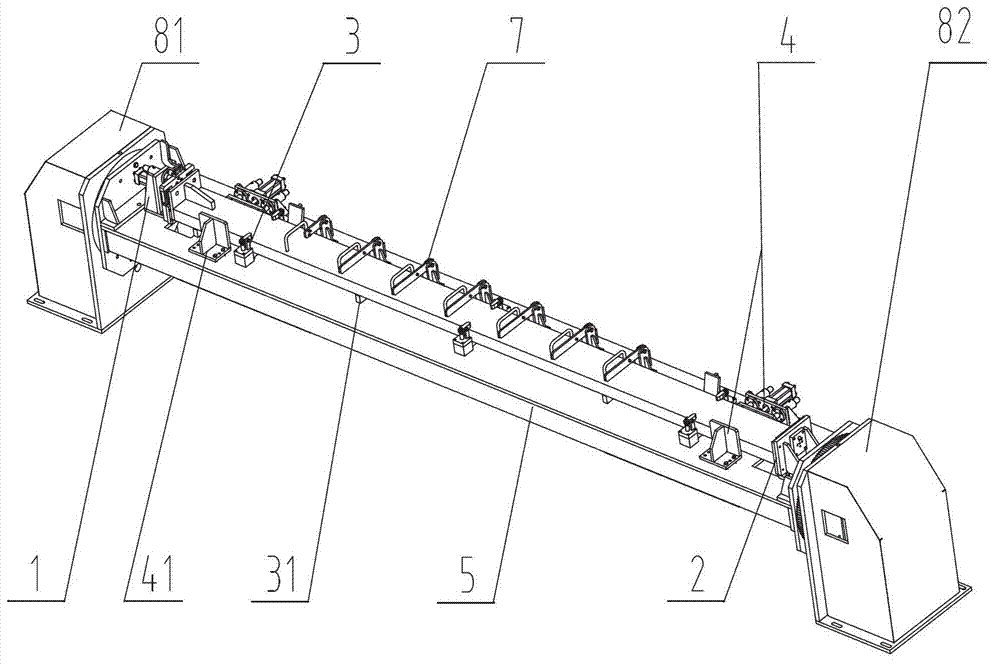

Complete equipment of welding robot and welding jig

InactiveCN105880894AGive full play to the role of flexibilityEasy to moveWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMulti degree of freedom

The invention discloses complete equipment of a welding robot and a welding jig. The complete equipment comprises a multi-degree-of-freedom welding manipulator assembly, a CCD camera, the welding jig and a control box, wherein the multi-degree-of-freedom welding manipulator assembly, the CCD camera and the welding jig are electrically connected with the control box; the control box is positioned beside the welding jig; the multi-degree-of-freedom welding manipulator assembly is positioned above the middle of the welding jig; the CCD camera is positioned on the multi-degree-of-freedom welding manipulator assembly; the control box comprises a host computer and a PLC; the PLC controls the actions of the multi-degree-of-freedom welding manipulator assembly and the welding jig at any time; in the welding process, a workpiece is fixed by the welding jig and is subjected to welding operation of the multi-degree-of-freedom welding manipulator assembly. The equipment simultaneously comprises the welding robot and the welding jig, the welding robot and the welding jig are excellent in mobility performance, the equipment is high in repeated positioning accuracy and convenient and rapid to load and unload, rapid welding of different products can be realized, and the flexibility effect of the welding robot is brought into well play.

Owner:唐山松众科技有限公司

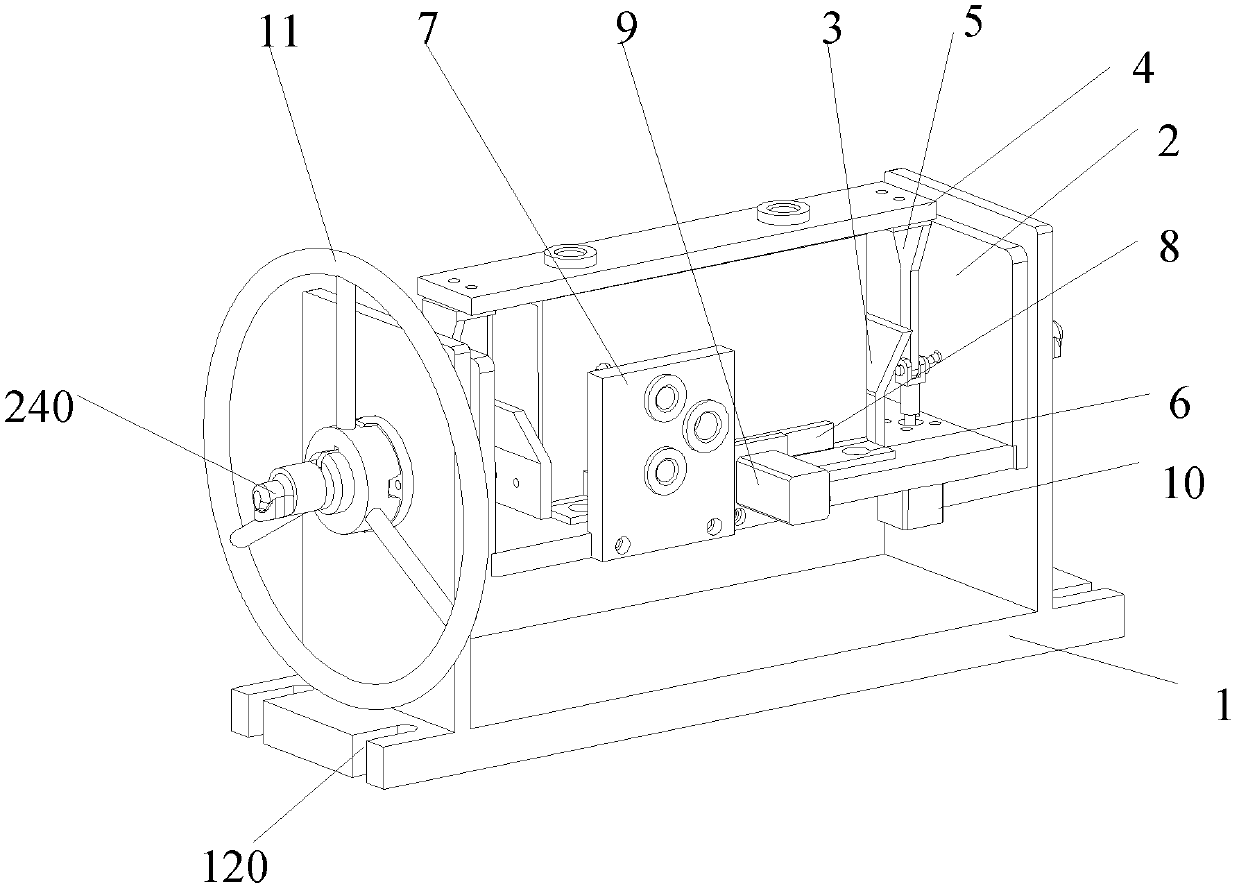

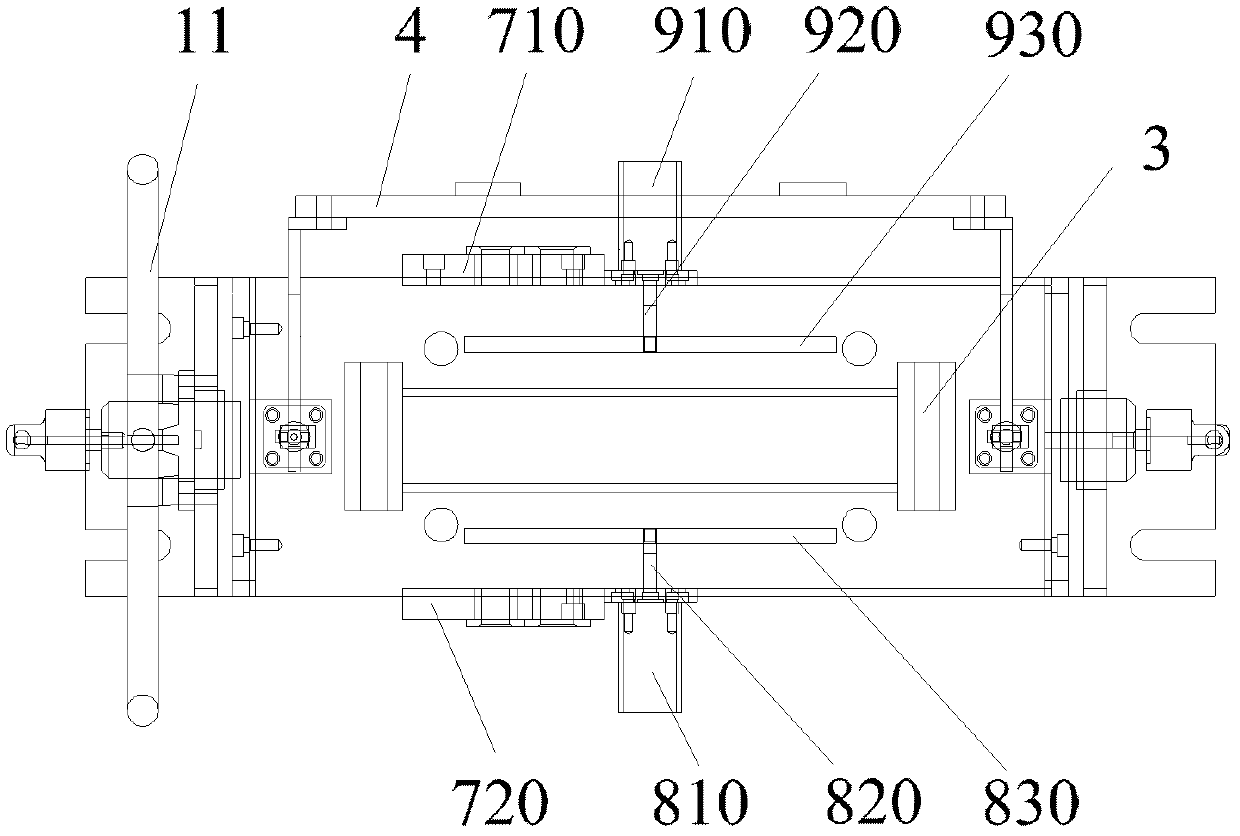

Impacting-sliding composite frictional wear testing device and method thereof

ActiveCN105891036ASimple structureReduce processing costsInvestigating abrasion/wear resistanceElectricityWear testing

The invention discloses an impacting-sliding composite frictional wear testing device and a method thereof. The method comprises the following steps that a spherical upper test piece is clamped on an upper clamp and a planar lower test piece is clamped by using a lower clamp; the lower clamp is controlled to move up and down by a precise screw lifting platform so that the upper test piece and the lower test piece come into contact; a servo motor drives the upper test piece to do up-down reciprocating motion at set frequency f, times N and displacement S by an eccentric disc, an upper knuckle bearing, a lower knuckle bearing, an impacting shaft, a spring leaf and an upper clamp, and carries out reciprocating impact on the lower test piece; in the impacting process, the spring leaf is deformed under the action of stress, so that impacting-sliding composite frictional wear between the upper test piece and the lower test piece is realized; and simultaneously, the force borne by the lower test piece is tested by a three-dimensional dynamic piezoelectric sensor connected with the lower clamp and is transmitted to a data acquisition control system, and a friction coefficient-cycle time curve is obtained by analysis. The impacting-sliding composite frictional wear testing device and the method disclosed by the invention have the advantages that the material can conveniently generate rigidity-adjustable impacting-sliding composite frictional wear, the automation degree is high and the repeatability of experimental data is good.

Owner:SOUTHWEST JIAOTONG UNIV

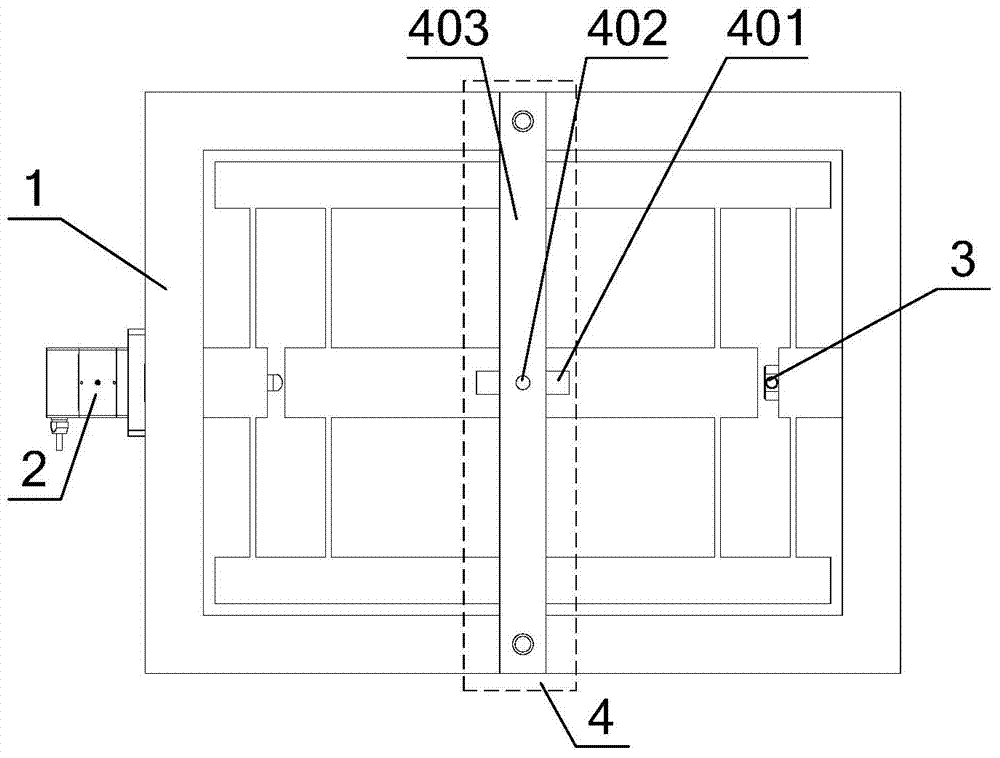

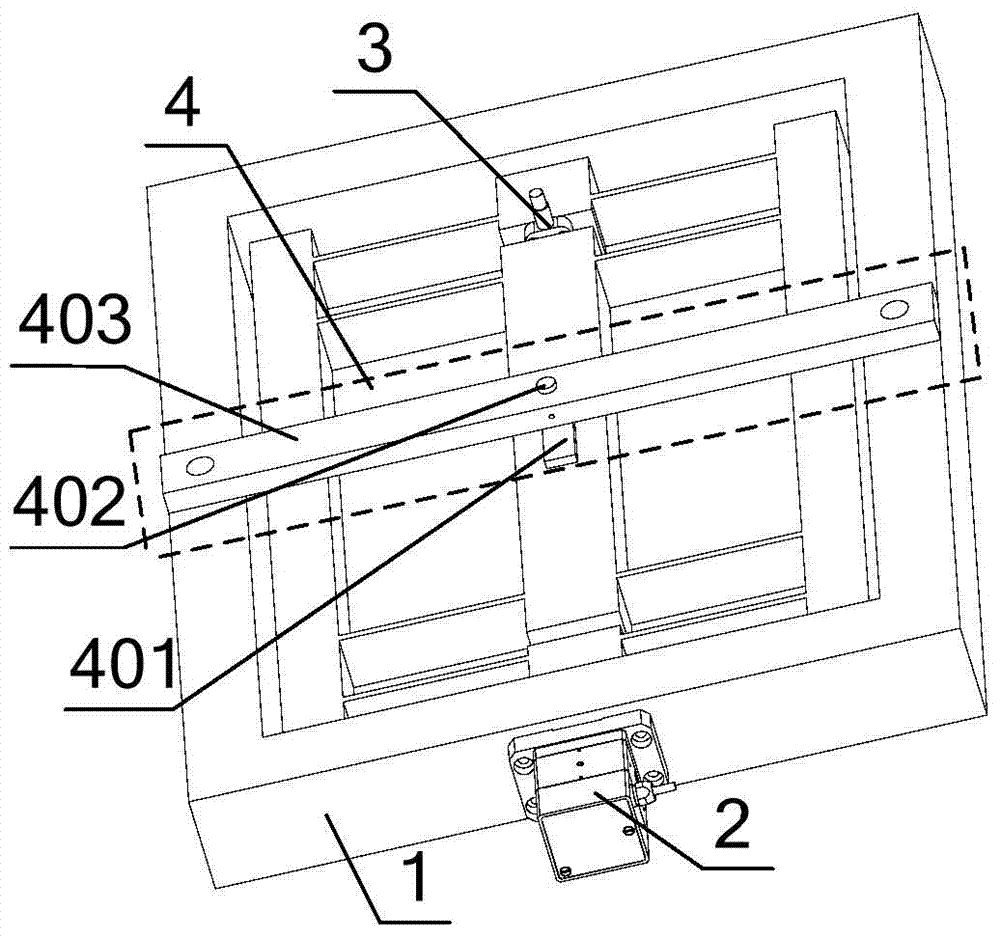

Accurate positioning storage bin

ActiveCN103028998AIncrease loading capacitySmall footprintMetal working apparatusMotor driveSmall footprint

The invention discloses an accurate positioning storage bin. The accurate positioning storage bin comprises a storage bin frame, workpiece lifting mechanisms and a workpiece horizontal rotary conveying mechanism; the workpiece horizontal rotary conveying mechanism comprises a first motor which is arranged on the storage bin frame, a rotary disc which is connected with a first motor rotor and workpiece loading mechanisms which are arranged along the peripheral direction of the rotary disc at equal intervals; and two sets of workpiece lifting mechanisms are arranged and are distributed opposite to the two sets of workpiece loading mechanisms, and each workpiece lifting mechanism comprises a clamping jaw for conveying workpieces on the workpiece loading mechanisms and a drive device for driving the clamping jaw to lift and descend. According to the accurate positioning storage bin, the first motor drives the rotary disc so as to drive the workpiece loading mechanisms to rotate horizontally, so that the transmission error existing in conventional storage bin chain wheel and chain transmission is eliminated, the repeat positioning precision along the horizontal direction is high, and a manipulator of processing equipment can accurately take and store materials; and moreover, a plurality of workpiece loading mechanisms can be arranged on the same rotary disc, the loading capacity of the storage bin is large and the storage bin occupies a small area.

Owner:CHONGQING MACHINE TOOL GROUP

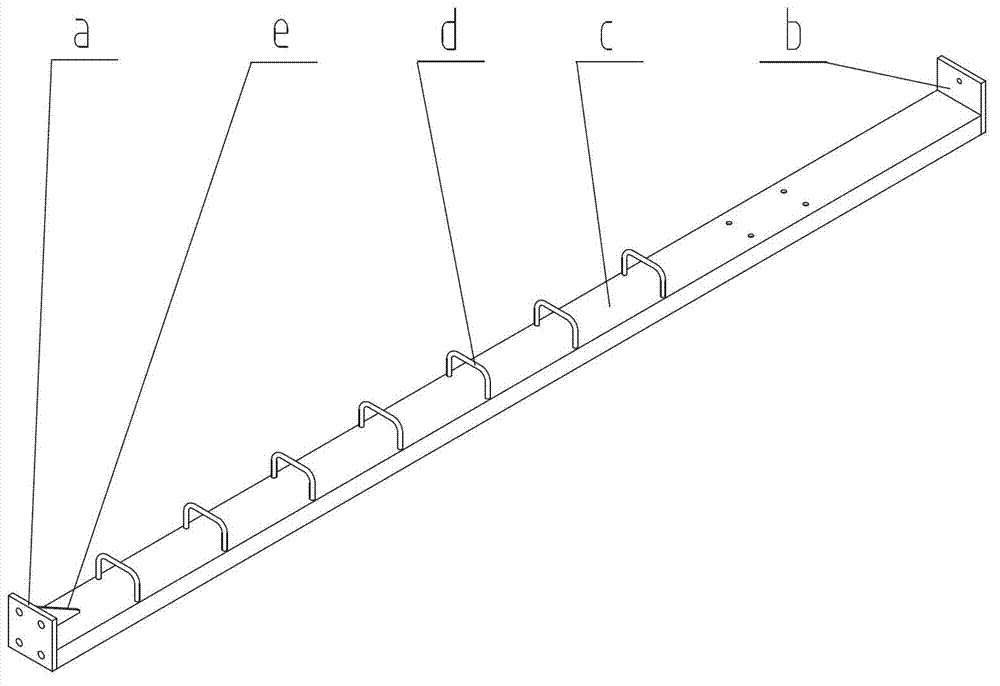

Standing column assembly welding tool

InactiveCN102825408AFast demouldingReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesEngineering

The invention provides a standing column assembly welding tool for welding a standing column of a mixing plant. The standing column assembly welding tool comprises a left and right limit mechanism, an up and down limit mechanism and side limit mechanisms. The left and right limit mechanism comprises a first end and a second end. A first connecting plate of the standing column is limited at the first end. A second connecting plate of the standing column is limited at the second end. The up and down limit mechanism is used for limiting fluctuation of a standing column body. The side limit mechanisms are disposed on sides of the standing column body and are used for limiting the forward and backward motions of the standing column body. By the aid of the limit mechanisms, all parts of the standing column can be limited. The standing column assembly welding tool has the advantages of high work efficiency, low labor intensity, high assembly precision.

Owner:SANY HEAVY IND CO LTD (CN)

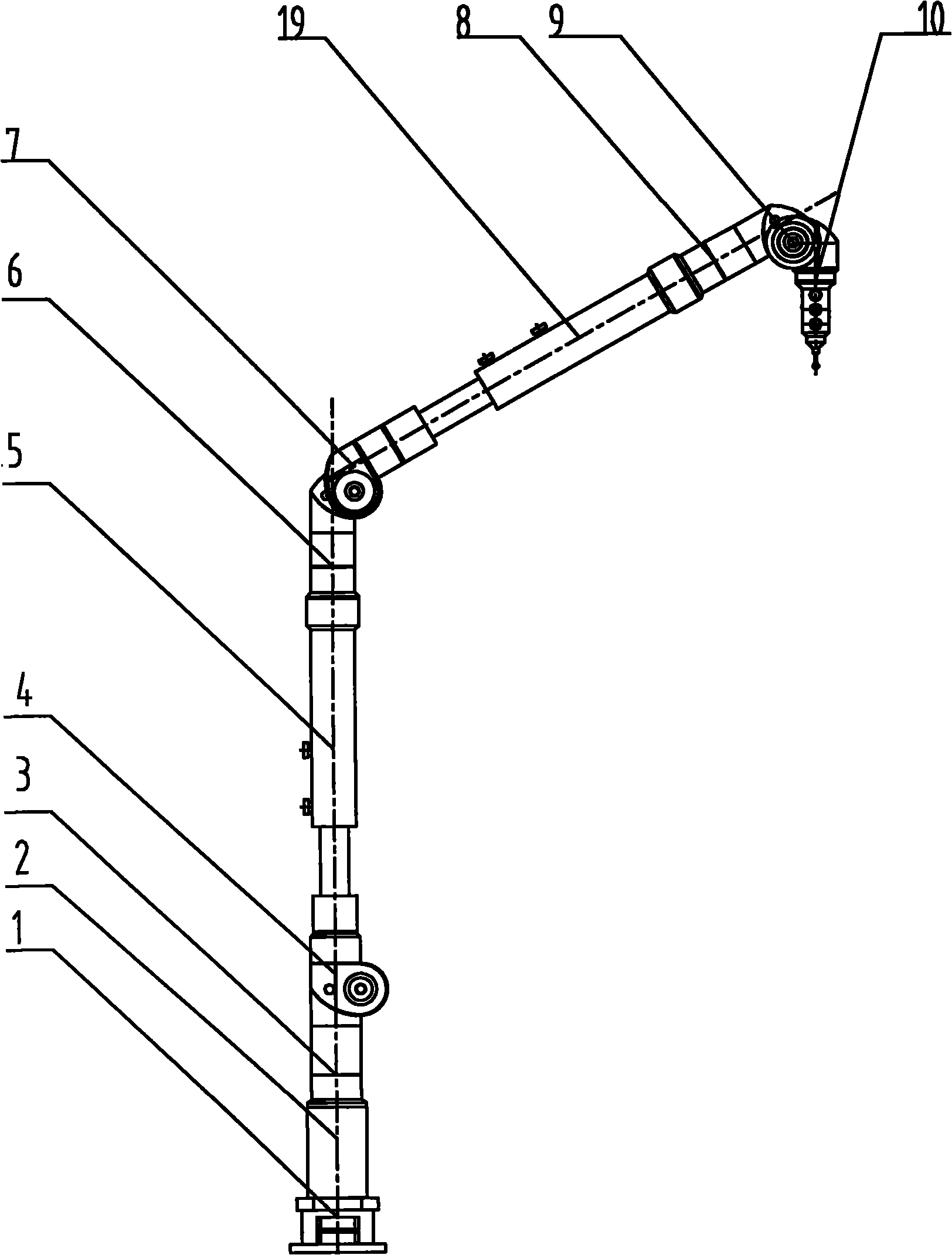

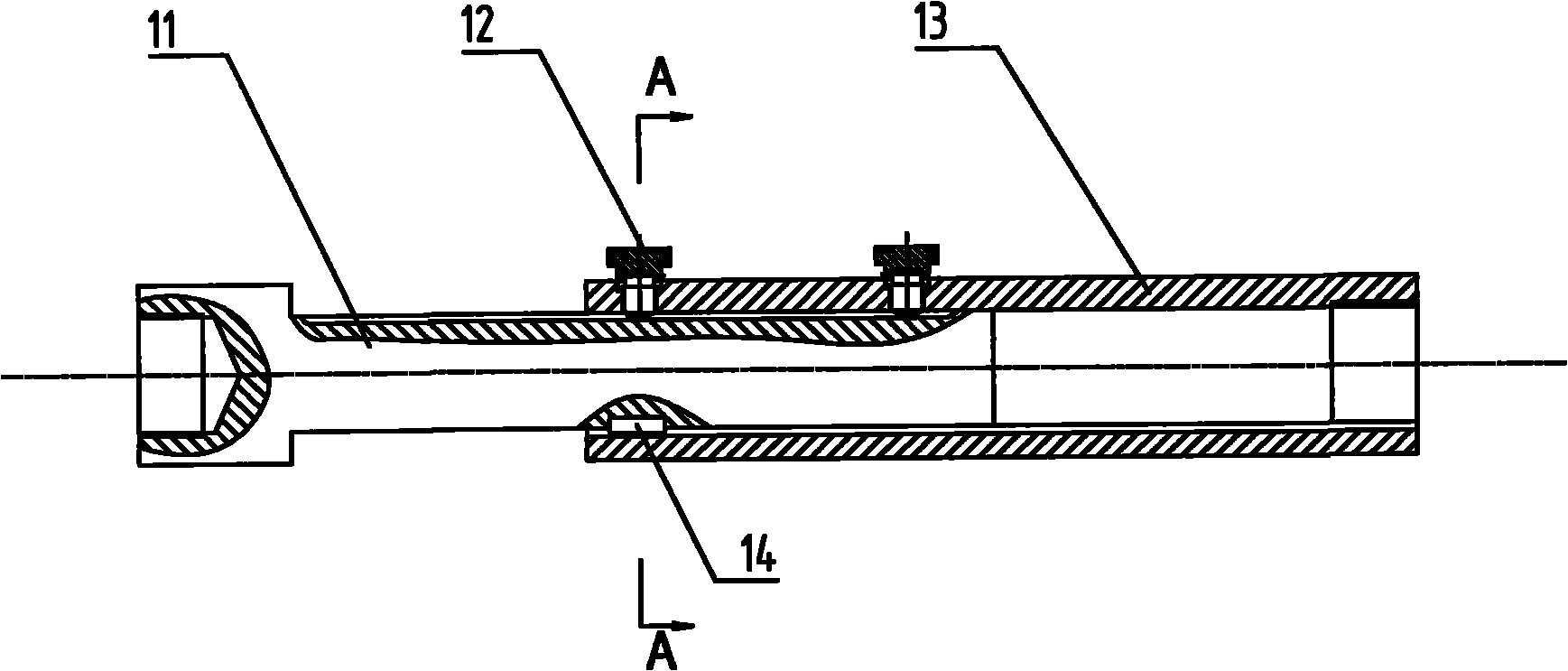

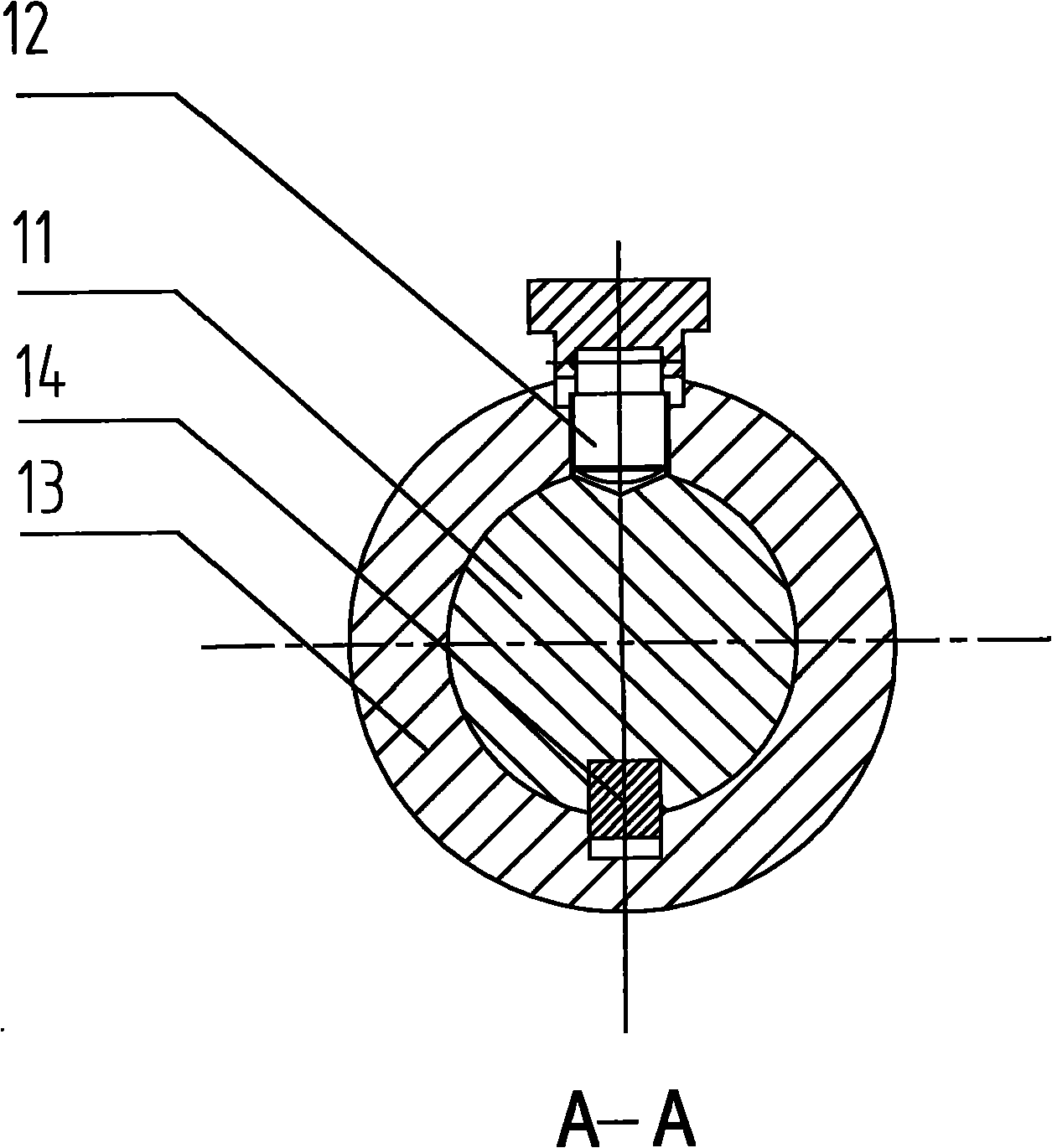

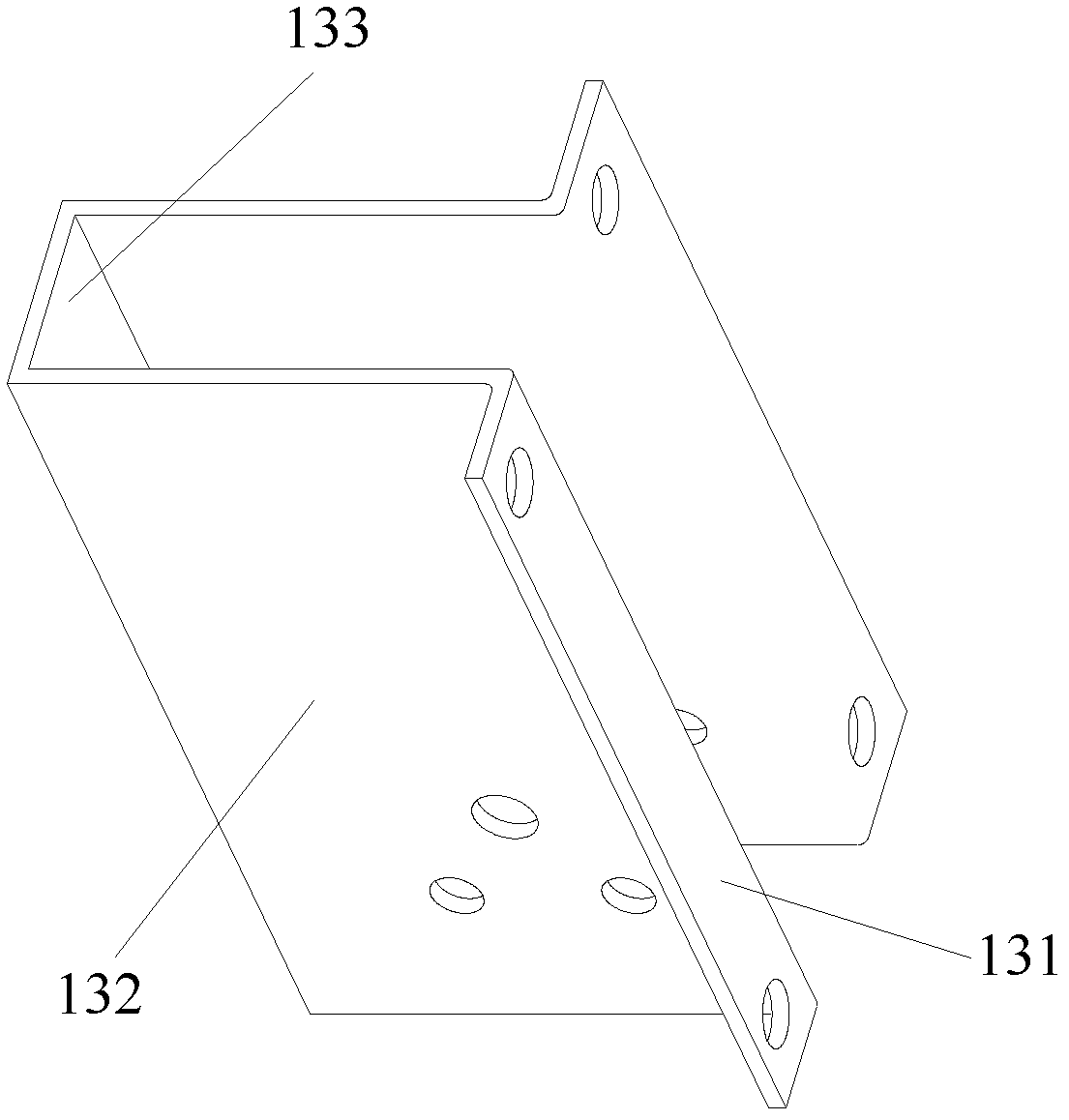

Variable rod length articulated arm type coordinate measuring machine

InactiveCN101871774AImprove work adaptabilityReduce the size of the measurement spaceMeasurement devicesObservational errorImage resolution

The invention discloses a variable rod length articulated arm type coordinate measuring machine which comprises a base, three rotary joints, three swing joints, a base measuring arm, two measuring arms and a measuring head, wherein the two measuring arms are telescopic measuring arms with the same structure, and each telescopic measuring arm comprises a core shaft, a fixing screw, a sleeve and a guide key; for each telescopic measuring arm, the core shaft is mounted in the sleeve, the two are in clearance fit, a section of guide slot is arranged on the inner wall of the sleeve, the guide key is arranged on the core shaft, the relative circumferential fixation of the core shaft and the sleeve can be realized through the guide key, two thread holes are arranged on the sleeve, the fixing screw is screwed in the sleeve through the thread holes, a section of V-shaped slot is arranged on the core shaft, and the fixing screw is screwed for leading an circular arc-shaped head of the fixing screw to tightly push the V-shaped slot of the core shaft, thereby realizing the relative fixation of the sleeve and the core shaft. The variable rod length articulated arm type coordinate measuring machine can reduce the size of measurement space by regulating the rod length of the measuring arms, reduce the measurement error, improve the measurement resolution, achieve the best measurement efficiency, and still have higher repeated positioning precision after the length change of the telescopic measuring arms.

Owner:ZHEJIANG UNIV

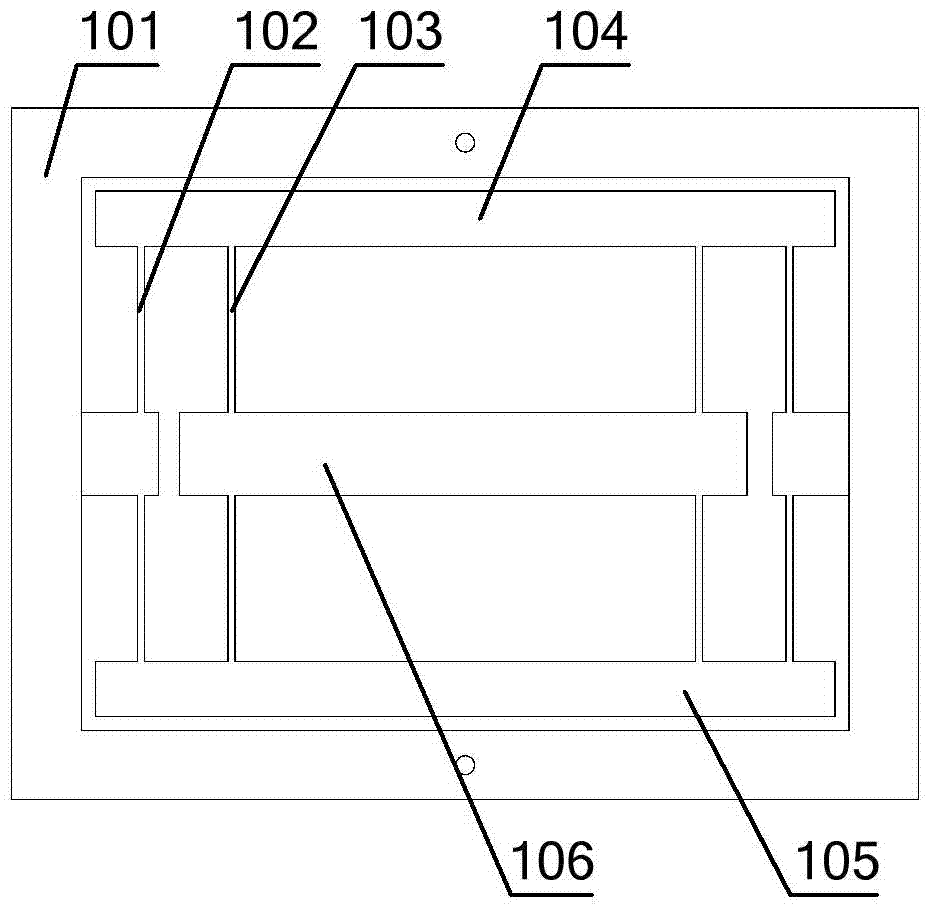

Workpiece drilling clamp

InactiveCN102430942ASimple structureEasy clampingPositioning apparatusDrill jigsBiochemical engineeringAutomation

The invention provides a workpiece drilling clamp, which comprises a base, a rotation support, a positioning mechanism, a clamping mechanism and two first drilling templates, wherein the base comprises a first base plate, a first side plate and a second side plate, and the first side plate and the second side plate are fixedly connected with the first base plate; the rotation support comprises a second base plate, a third side plate and a fourth side plate, and the third side plate and the fourth are fixedly connected with the second base plate; the rotation support is arrange inside the base, the first side plate is in rotating connection with the third side plate, and the second side plate is in rotating connection with the fourth side plate; the positioning mechanism is fixedly connected to the second base plate; the clamping mechanism comprises a first clamping mechanism and a second clamping mechanism, which are respectively arranged at both sides of the positioning mechanism; and the two first drilling templates are respectively arranged at both sides of the positioning mechanism and fixedly connected with the second base plate. The workpiece drilling clamp provided by the invention has the advantages of simple structure, convenience in assembling and clamping and high processing precision and automation degree, can greatly improve product assembly efficiency, and is suitable for volume-production.

Owner:SANY HEAVY IND CO LTD (CN)

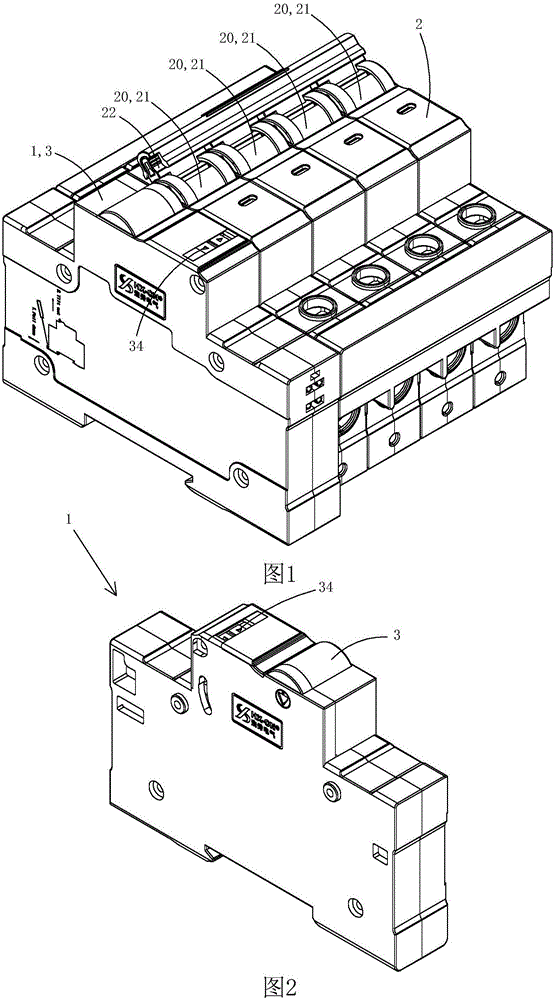

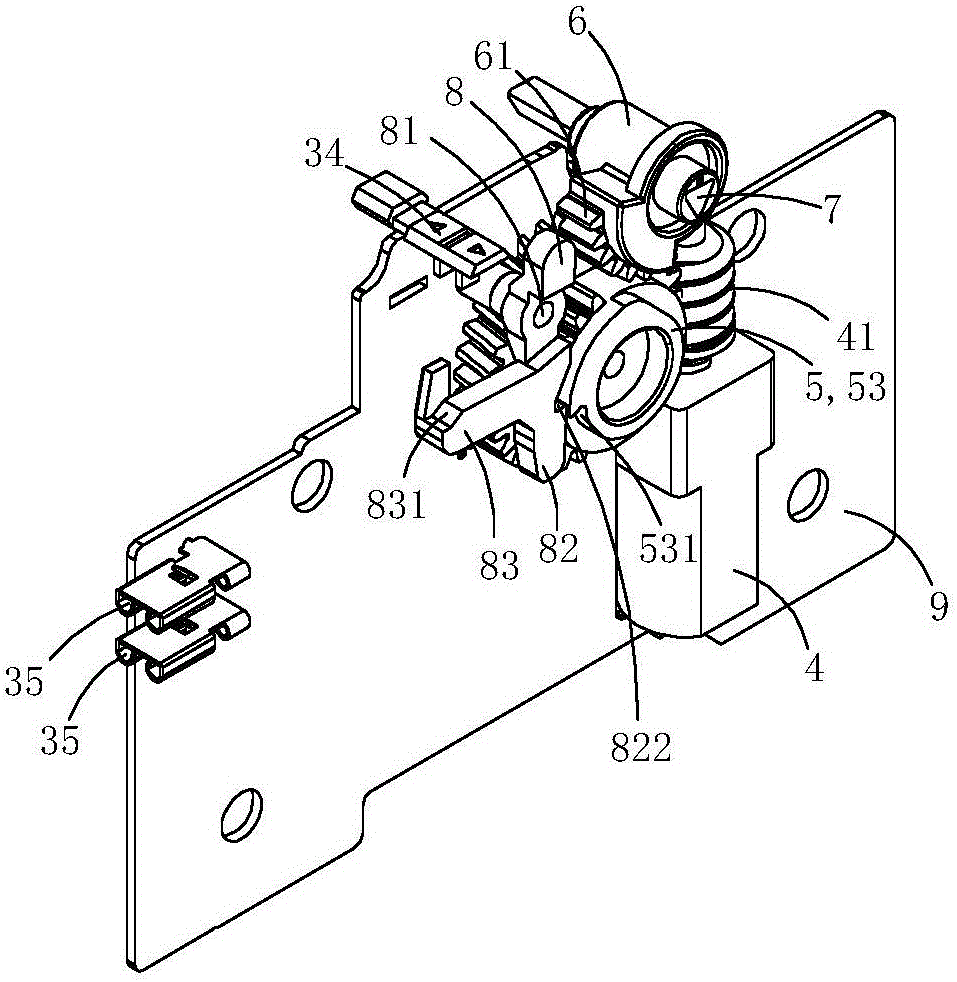

Automatic switching miniature circuit breaker

InactiveCN105719920AAvoid knocking and lockingAvoid damageProtective switch operating/release mechanismsGear wheelDrive motor

The invention discloses a small circuit breaker with automatic opening and closing, which comprises a circuit breaker body and an automatic opening and closing drive mechanism; the circuit breaker body includes one to four circuit breakers; each circuit breaker includes a plastic case, an opening and closing handle and an operating Mechanism; the rotation center of each opening and closing handle is provided with a spindle hole; the automatic opening and closing drive mechanism includes a housing, a driving motor with a driving turbine, a linkage turbine, a linkage gear, an output spindle and a tripping linkage; The linkage gear is a sector gear, and linkage teeth are set on one-sixth to one-third of the outer peripheral wall of the linkage gear; the driving motor drives the linkage turbine to rotate through the driving turbine, and the linkage turbine drives the tripping linkage through its cam linkage part. The part rotates reciprocally within the preset angle range, and the opening and linkage tripping lever is moved by the lever part of the tripping linkage part to perform a quick opening action; the linkage turbine drives the linkage gear and the output spindle to rotate synchronously through its driving teeth. The invention can realize electric opening and closing.

Owner:HONGXIU ELECTRIC

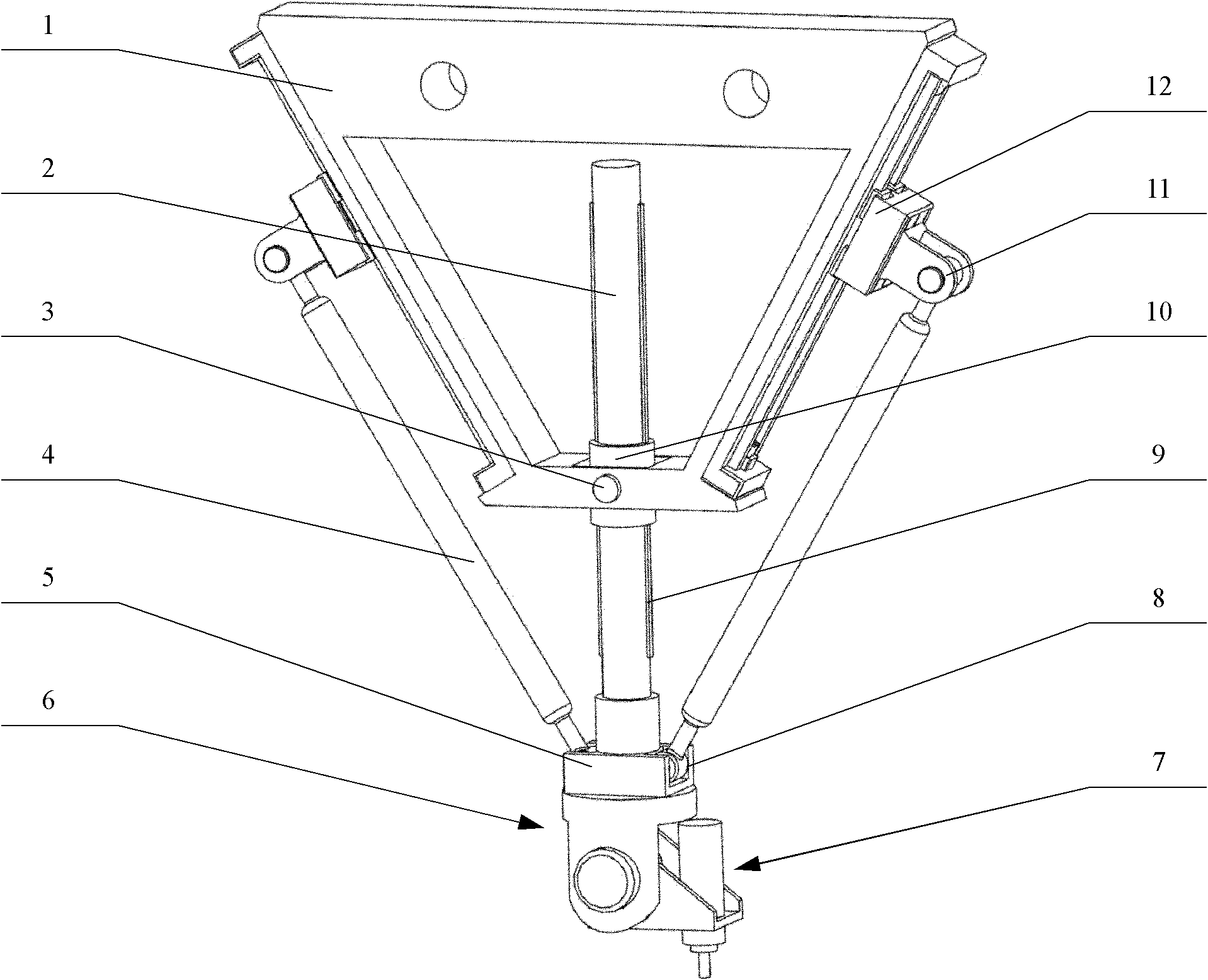

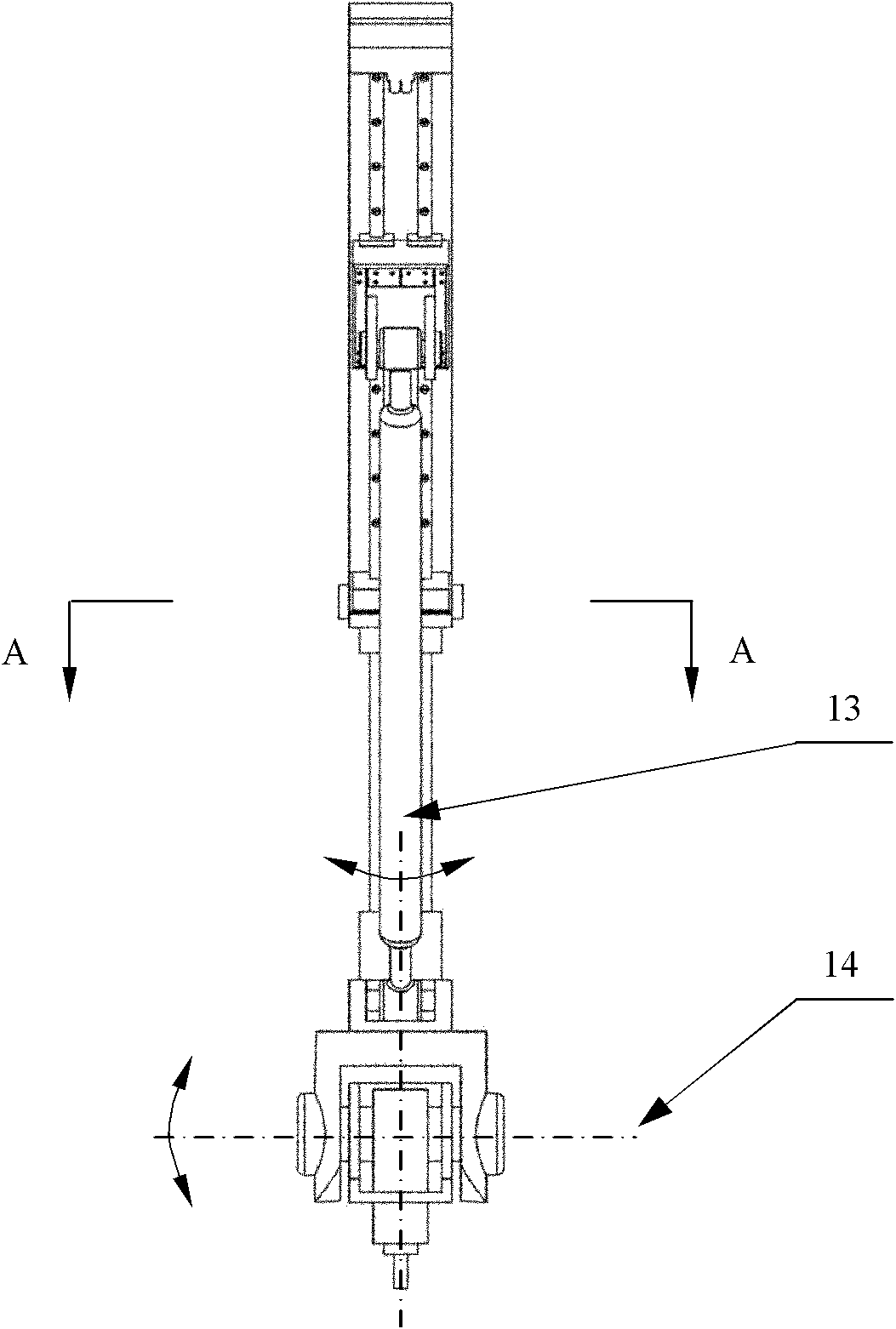

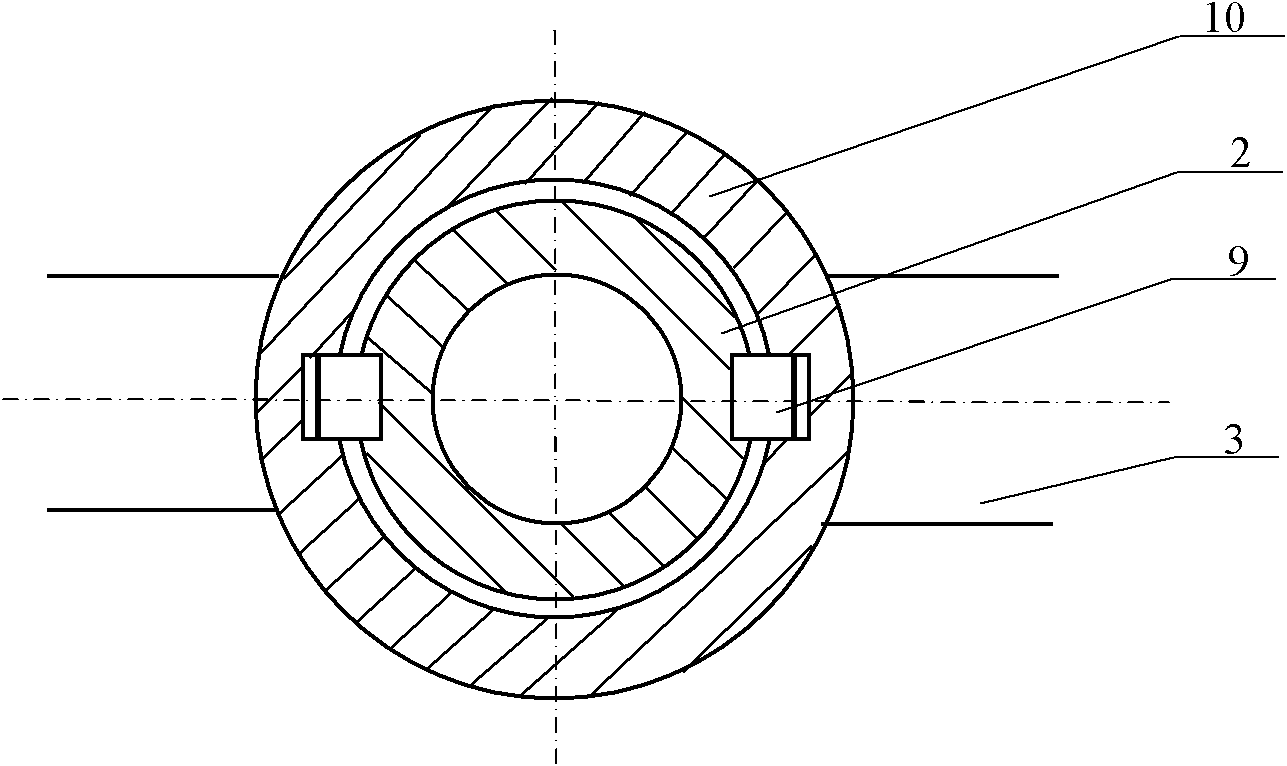

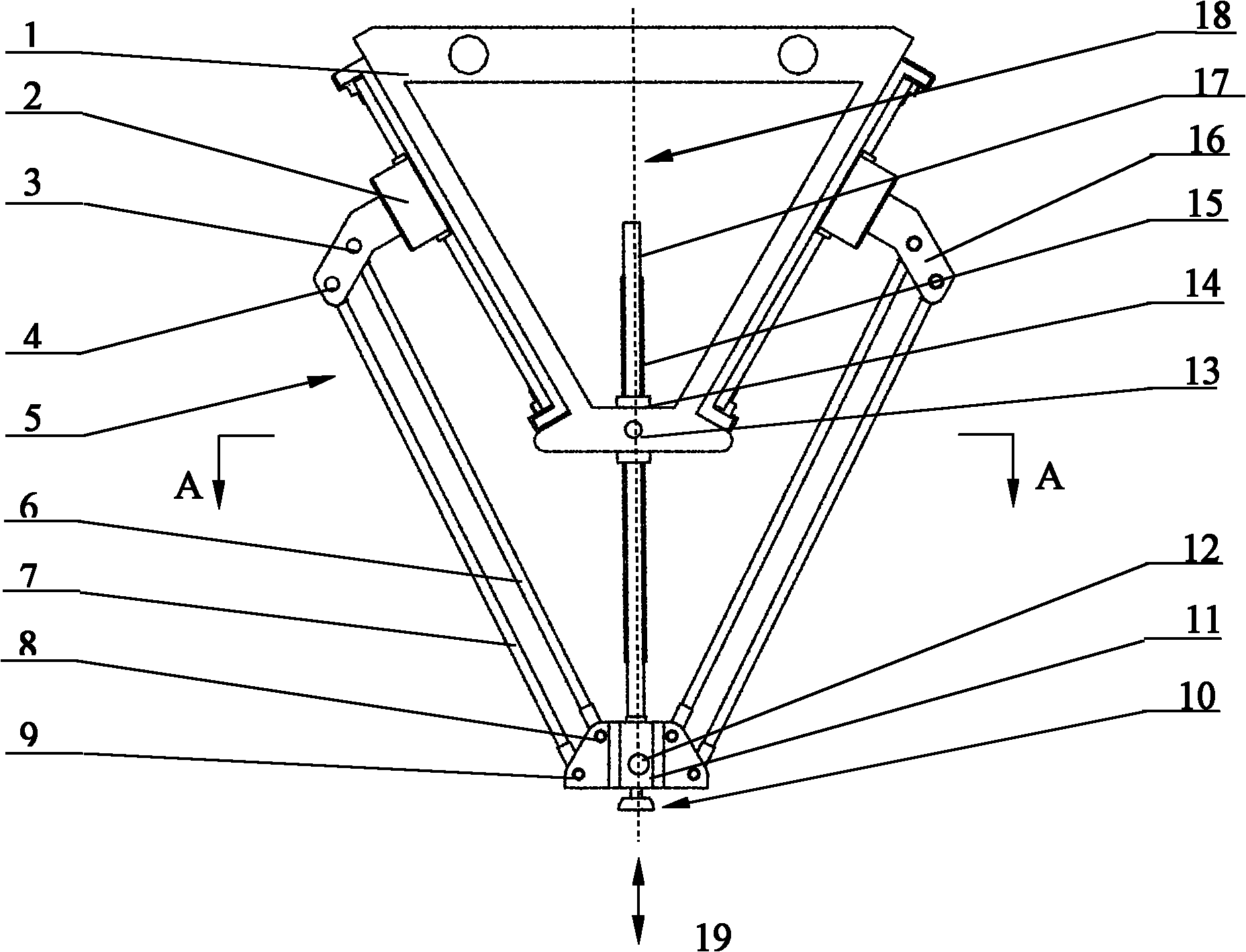

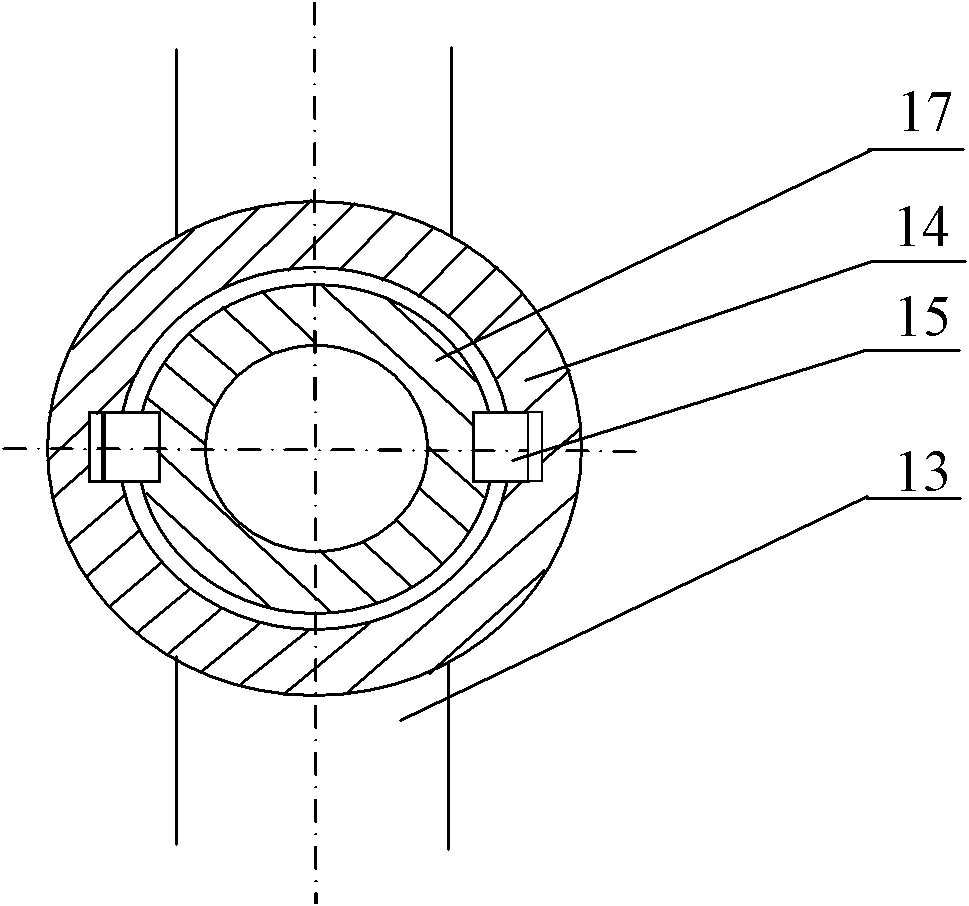

Linearly-driven four-degree of freedom hybrid mechanical arm

InactiveCN102069496AExpand the scope of workAccelerateProgramme-controlled manipulatorManipulatorHinge angle

The invention discloses a linearly-driven four-degree of freedom hybrid mechanical arm, which comprises a rack, wherein the two sides of the rack are symmetrically fixed with a linear motor guide rail of a linear motor respectively; a linear motor sliding block on the linear motor guide rail is connected with one end of a driving lever in a rotating way by a first hinge connected to the linear motor sliding block; the other ends of the two driving levers are symmetrically connected to the two ends of a movable platform in the rotating way by second hinges arranged on the movable platform respectively; a sleeve is connected to the middle part of the rack in the rotating way by a coaxial pin on the outer wall of the sleeve; a guide rod is sleeved in the sleeve; the bottom of the guide rod is fixedly connected with the movable platform; a swivel structure is arranged on the lower part of the movable platform; a support frame is connected to the swivel structure by a rotating shaft; and an end effector is connected to the support frame. The mechanical arm can effectively produce advantaged feeding directions or expand an operation range to realize the movement of high speed, high positioning accuracy and high repeated positioning accuracy.

Owner:TIANJIN UNIV

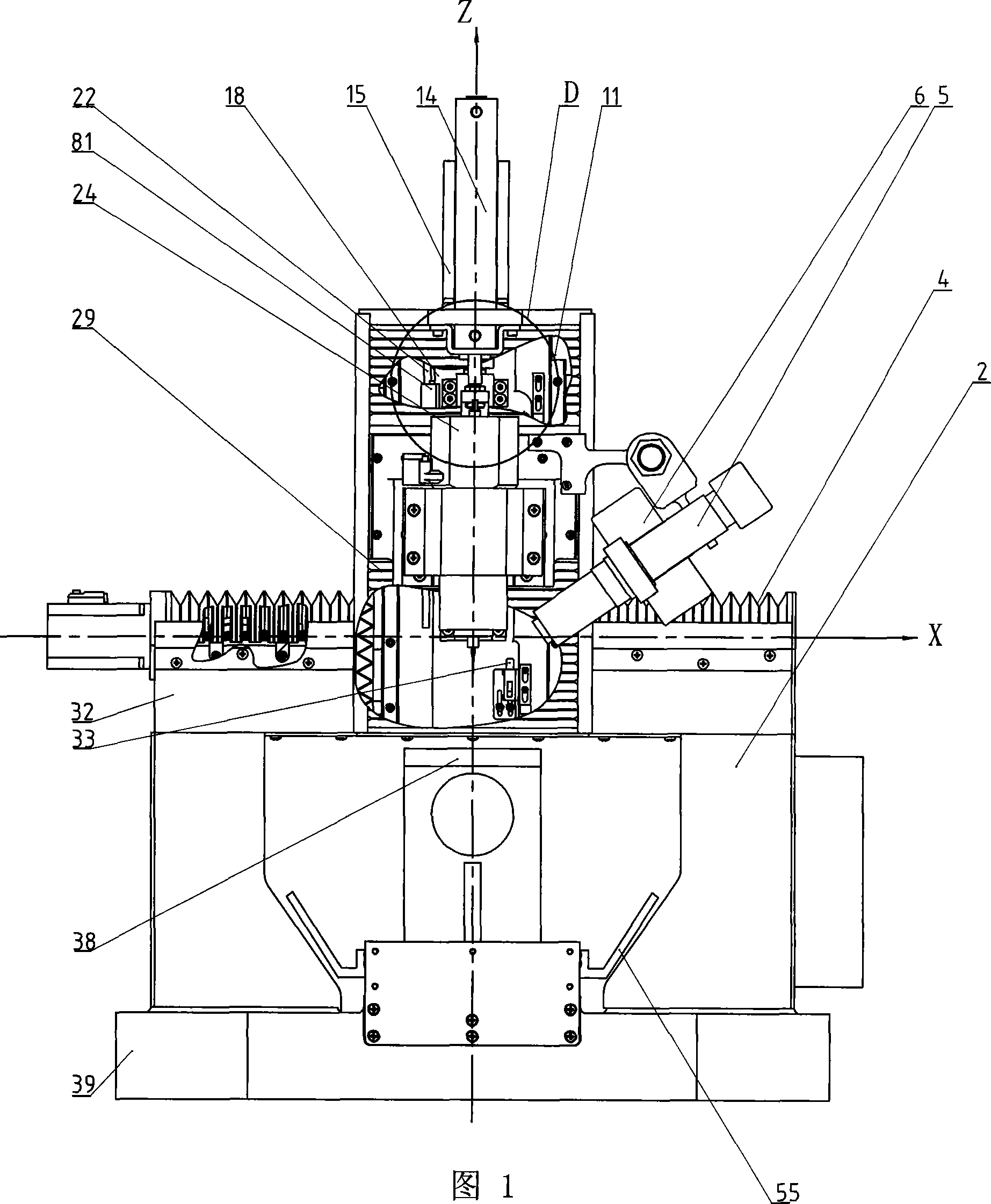

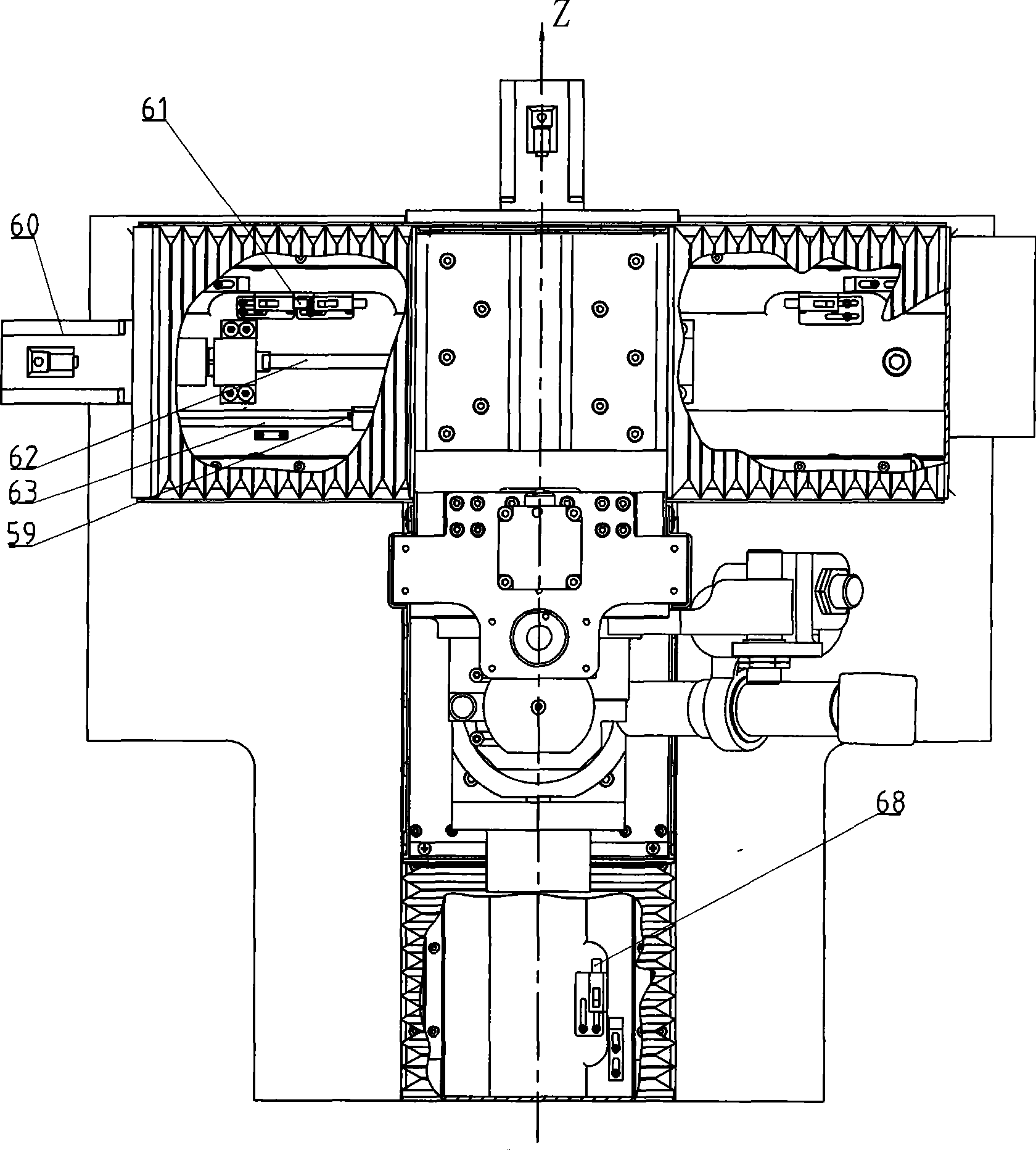

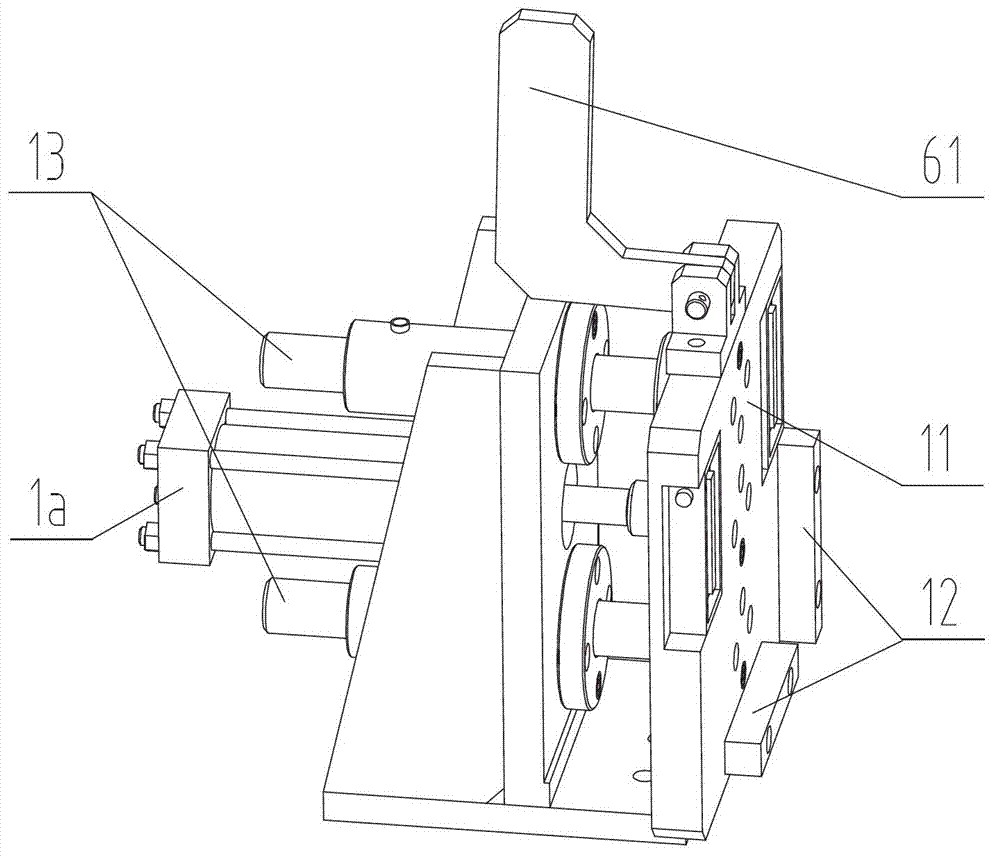

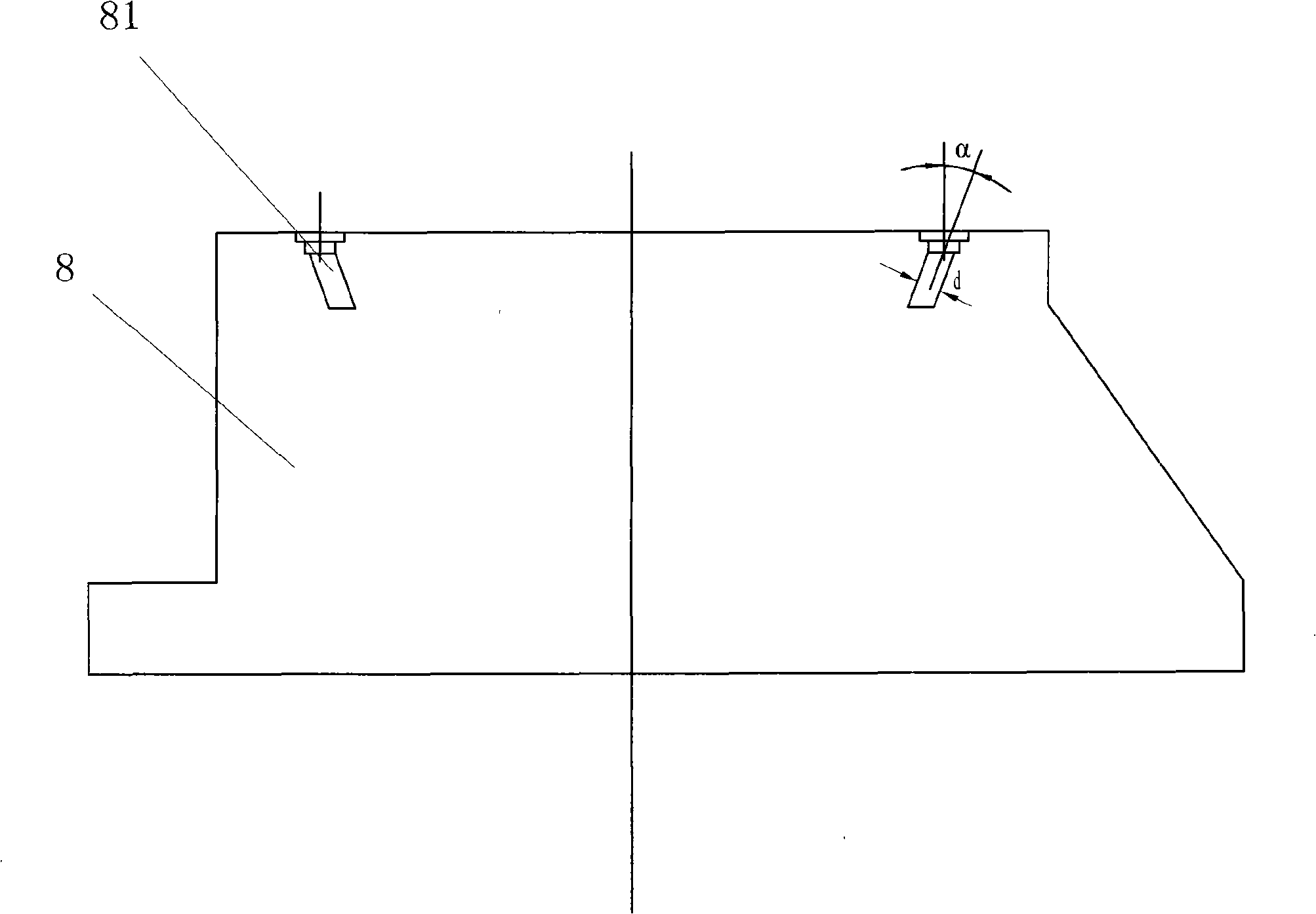

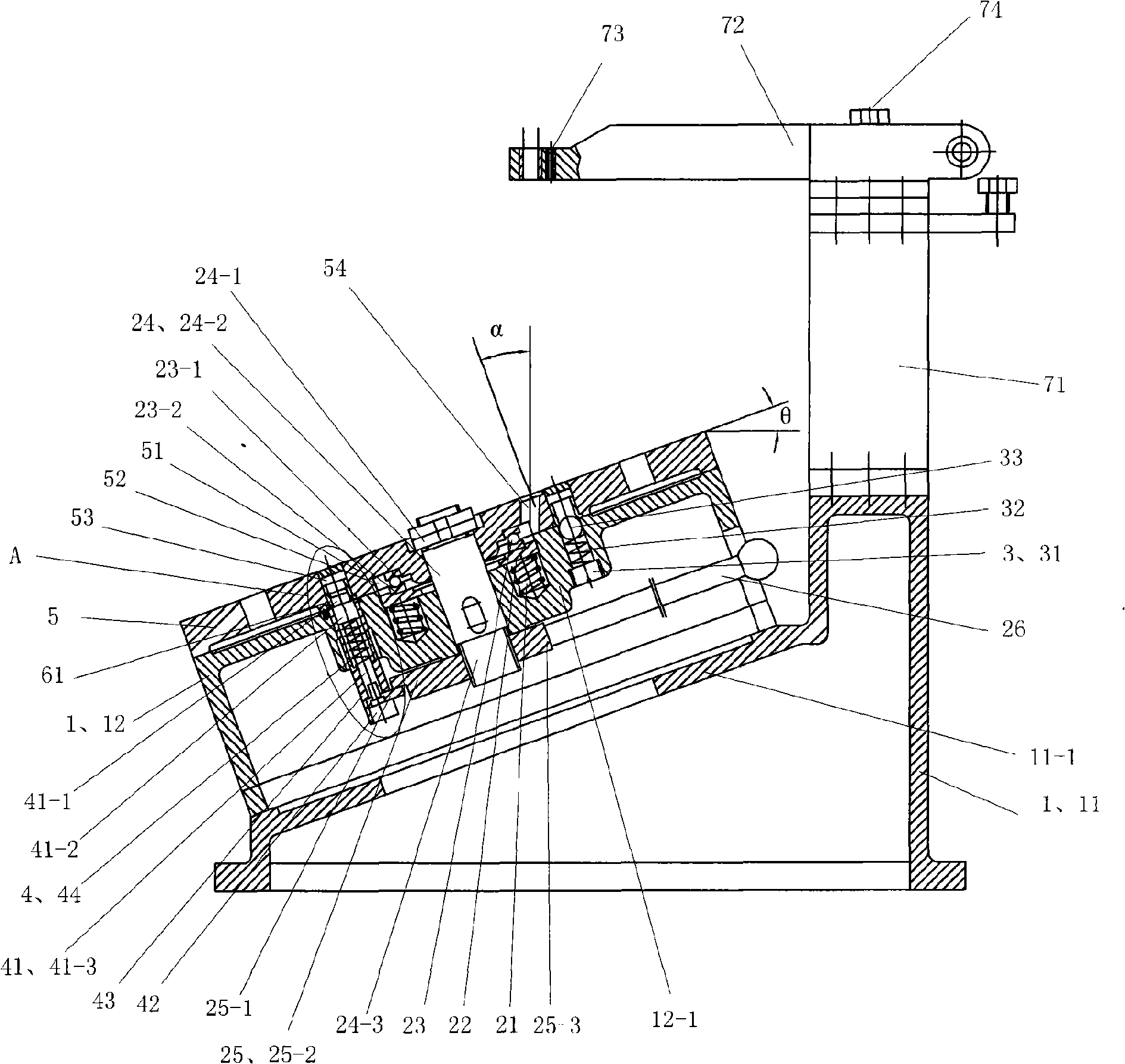

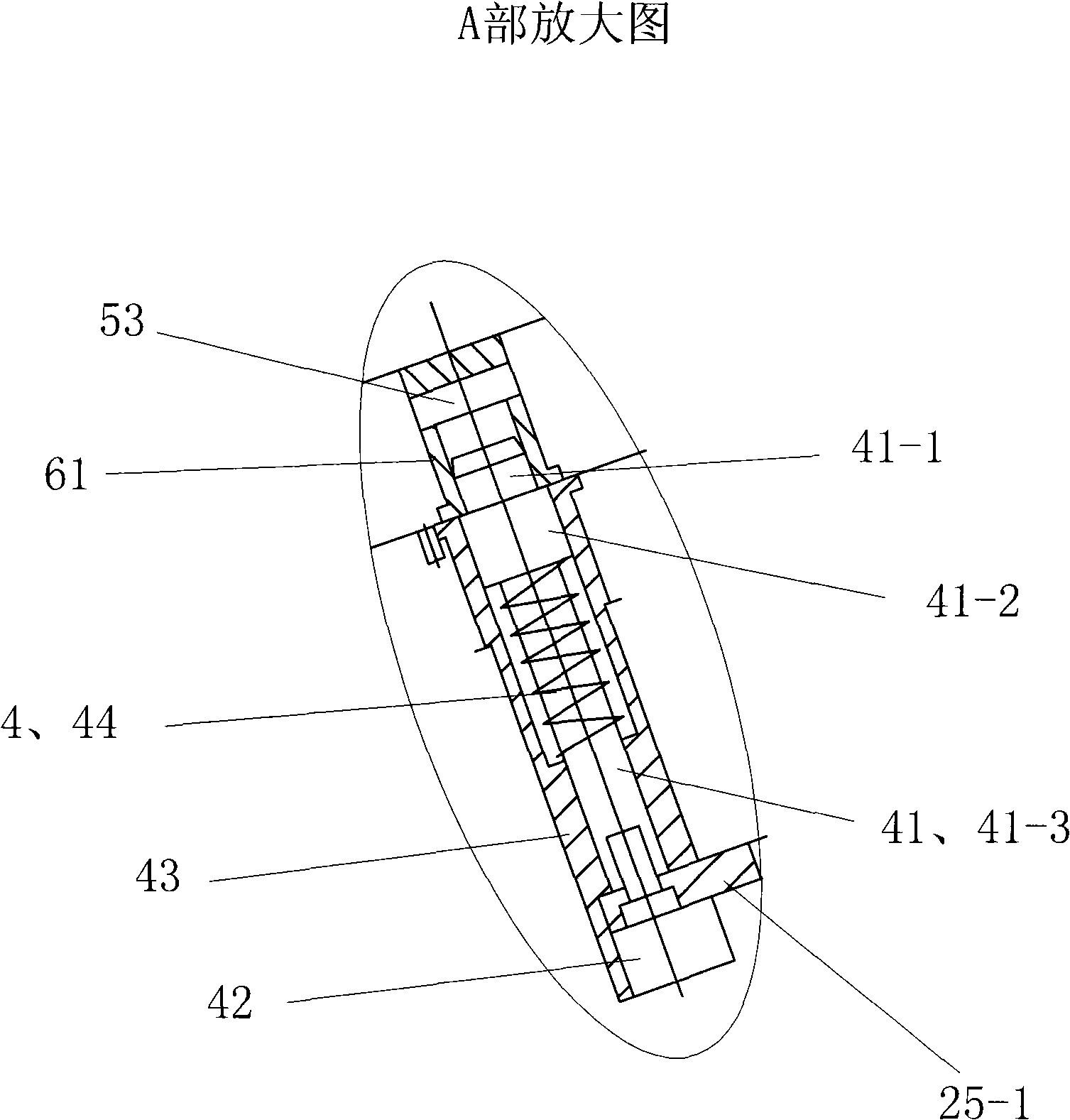

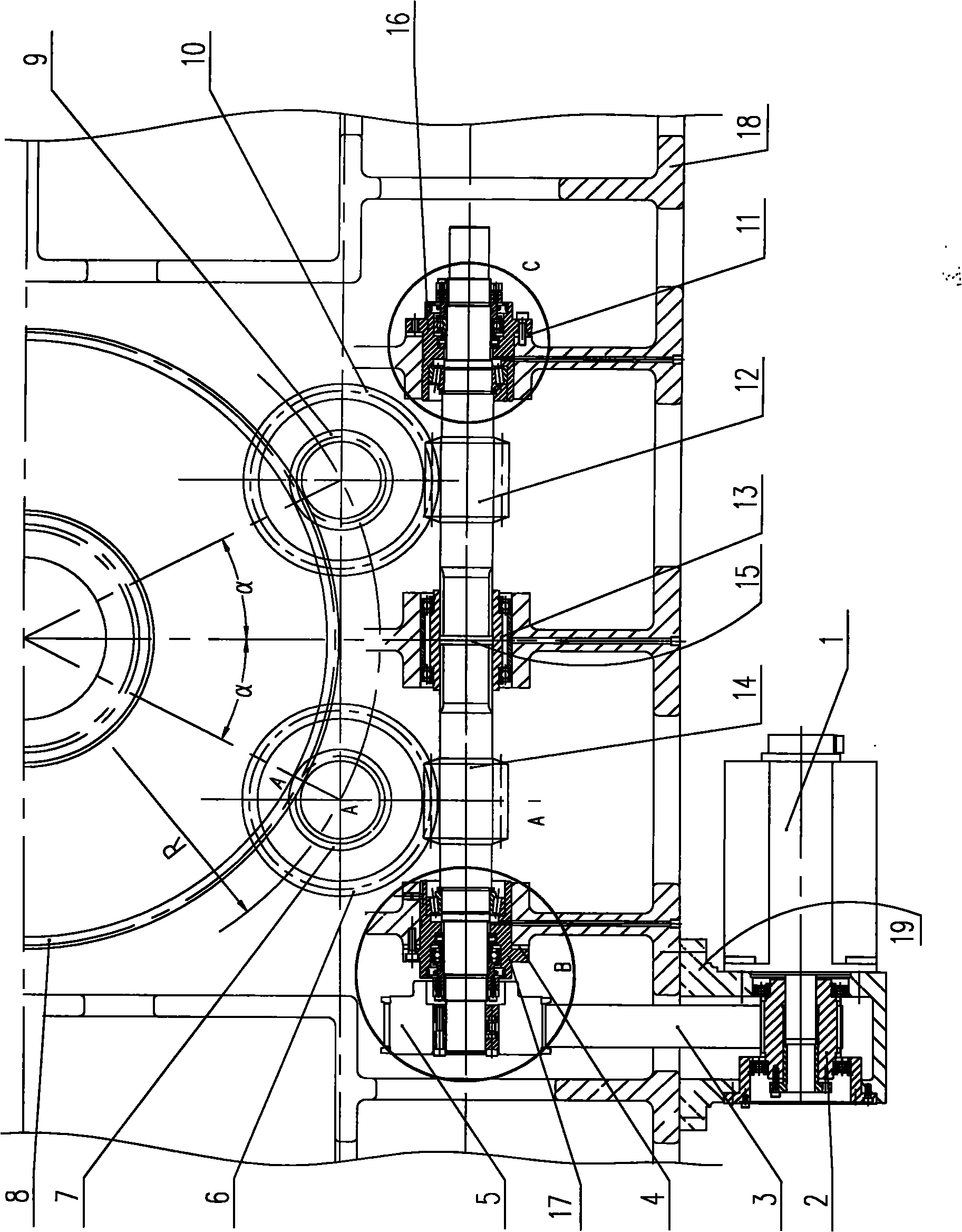

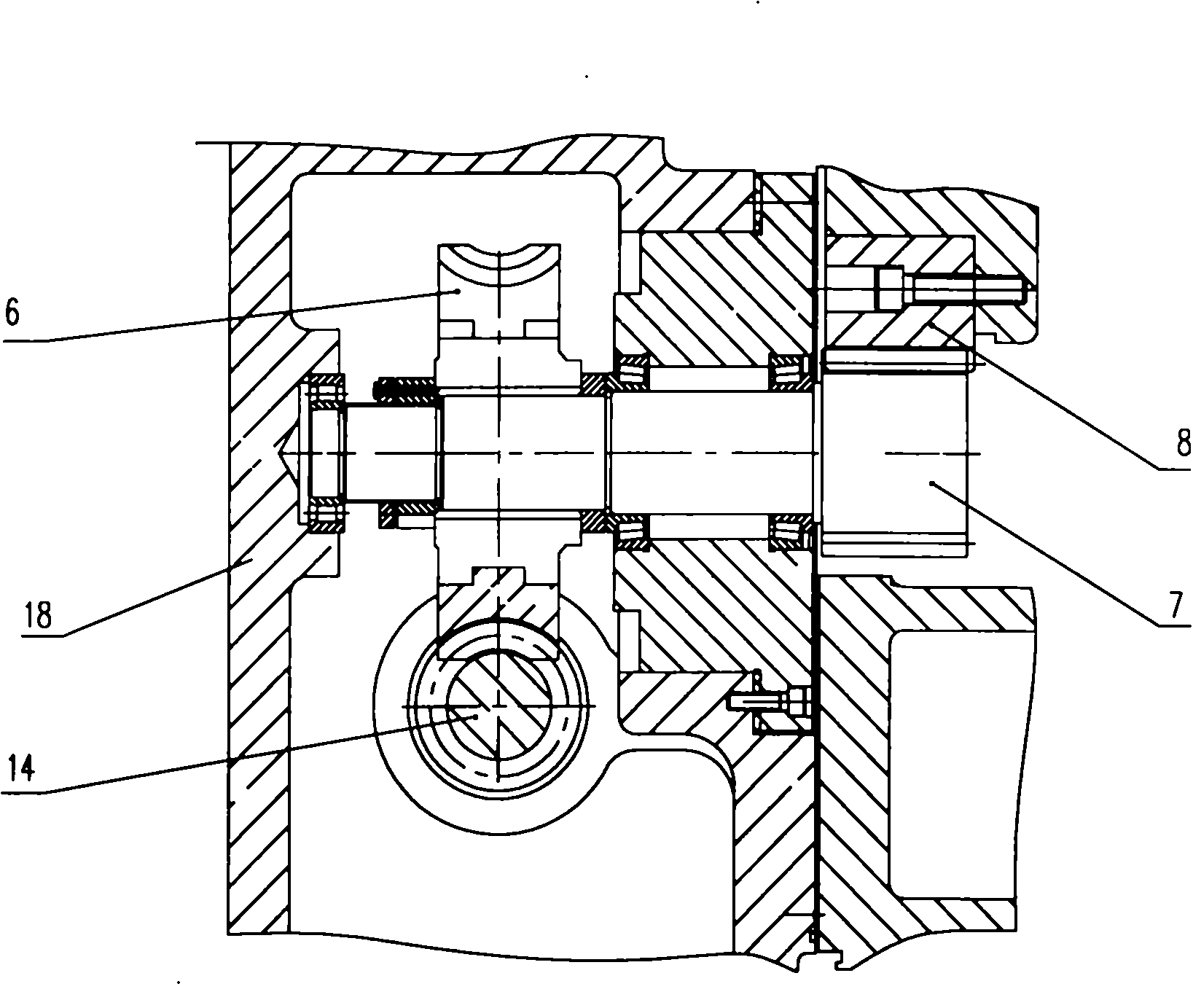

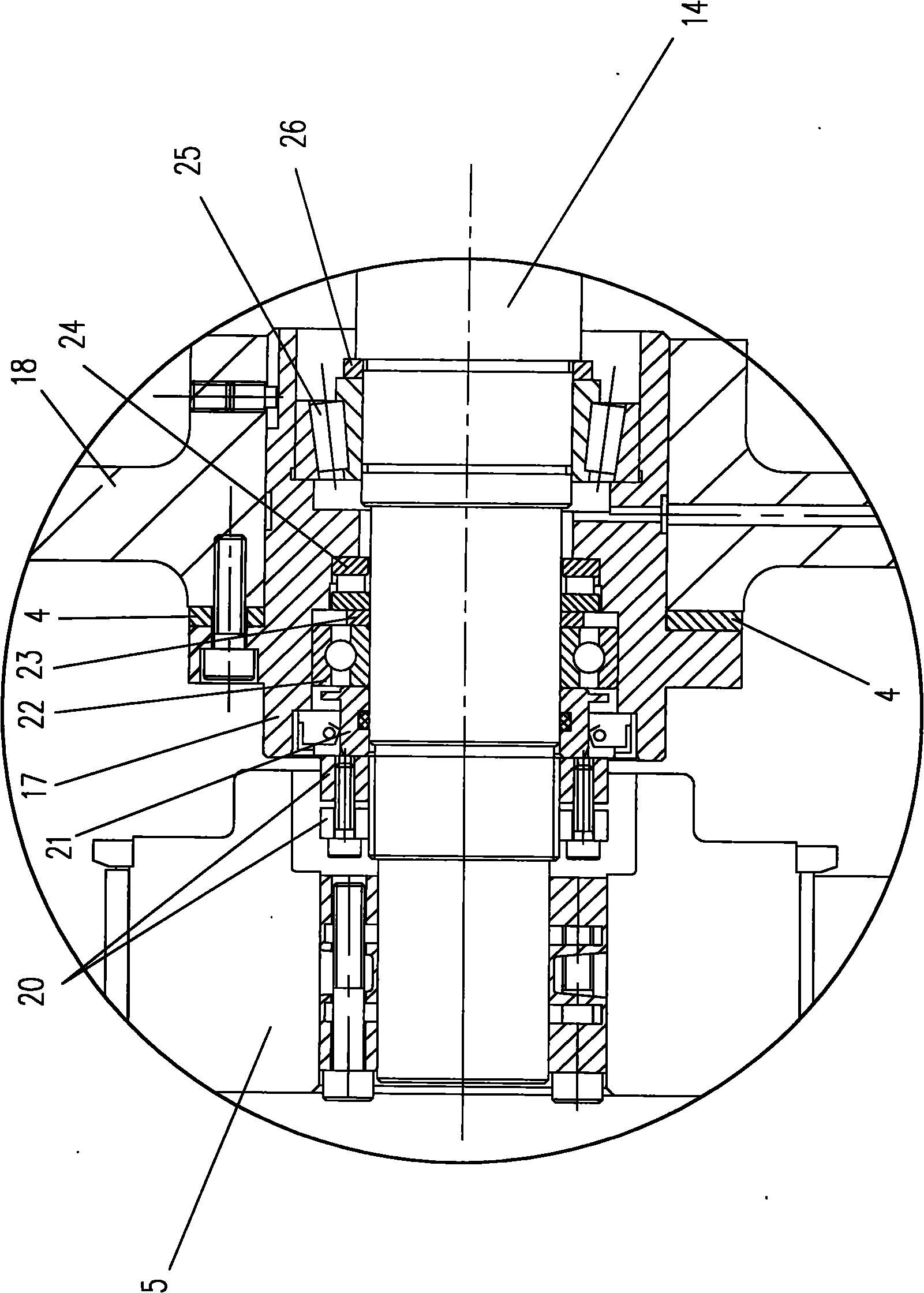

Diesel engine cylinder cover slant hole processing device

ActiveCN101306478AHigh repeat positioning accuracyEasy to assemble and disassemblePrecision positioning equipmentLarge fixed membersGyrationEngineering

The invention discloses an angular hole drilling device for a cylinder cover of a diesel engine. The device includes a working bench, a control component and a gyration index plate. The working bench includes a pedestal and a gyration support. A central hole, an annular spring support cavity, a knock hole and a location piece hole are formed on the central mounting part of the gyration support. The gyration index plate is provided with a connecting seat part, a bearing used annular seat cavity and an index locating hole. The gyration index plate is provided with a locating angular hole opening upwards; a first corner Alpha is formed between the axis of the locating angular hole and the central axis of the gyration index plate, a second corner Theta is formed between the horizontal plane and the upper end plane of the gyration index plate, and the value of the first corner Alpha is equal to that of the second corner Theta. The angular hole drilling device for the cylinder cover of the diesel engine can drill and form angular holes with higher working accuracy and quality.

Owner:CRRC QISHUYAN CO LTD

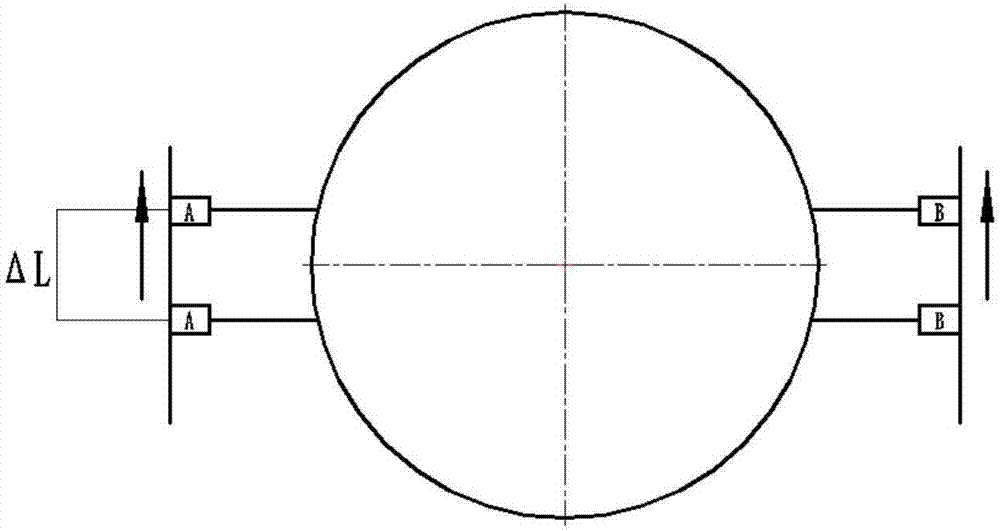

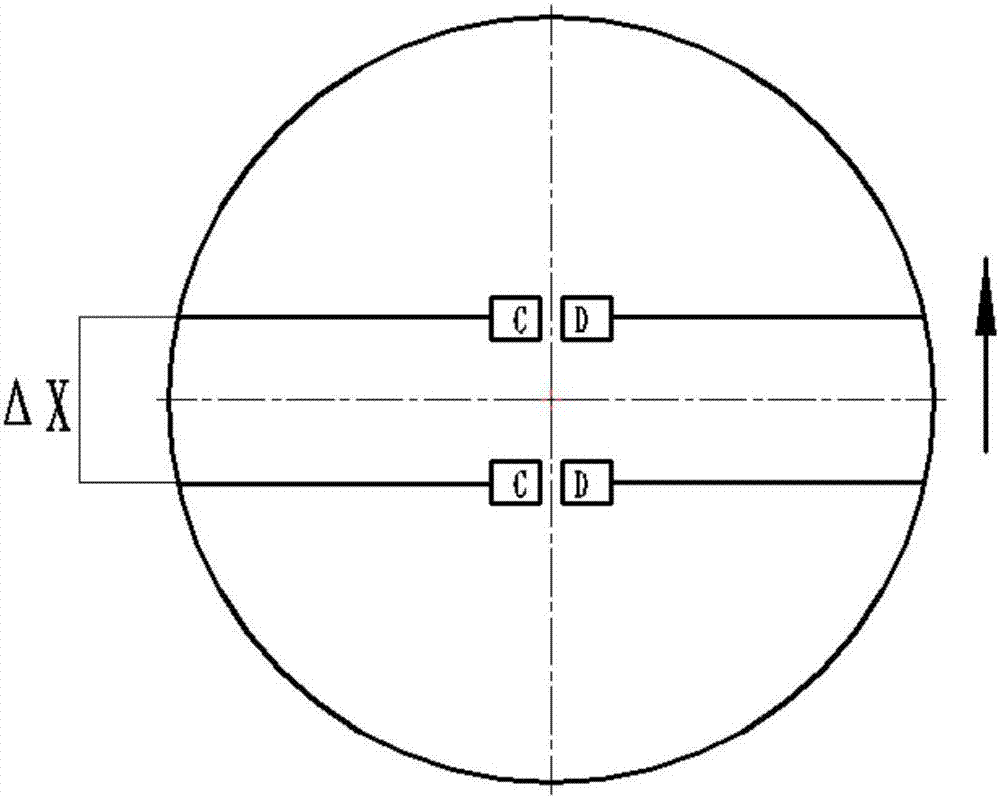

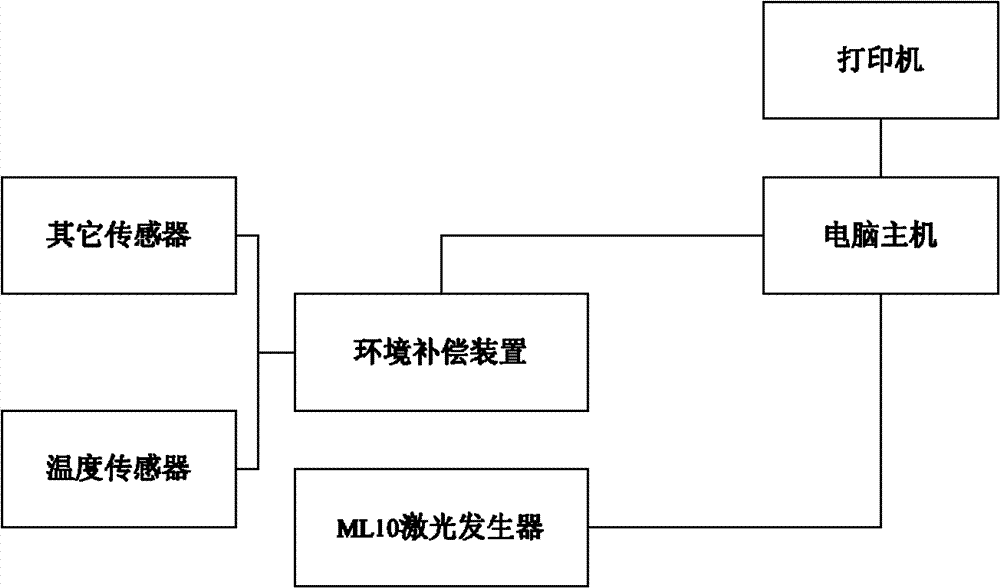

Detecting device and detecting method for measuring outer diameter and the inner diameter of wheel of motor train

InactiveCN107084673AMeasurement position does not occurPrecise control of measurement positionUsing optical meansEngineeringLaser

The invention discloses a detecting device and detecting method for measuring the outer diameter and the inner diameter of the wheel of a motor train. The device mainly comprises a wheel vertical detection platform, a horizontal detection platform, a fine reference support device, a coarse reference support device, a transportation platform, a rotary driving device. Four laser displacement sensors, including laser displacement sensors A and B installed on a crescent board tail end IV and laser displacement sensors C and D installed on the wheel vertical detection platform III, horizontally move a [delta]L and a [delta]X in the radial direction of the wheel of the motor train respectively. The scanning measured values in each length unit of the four laser displacement sensors are stored in an acquisition card. Then the maximum value of the measured data of each laser displacement sensor is selected to be compared with standard data to calculate the outer diameter and the inner diameter of the wheel. Then, the above operation is performed after a wheel rotary driving device is rotated by a certain angle. After measurement is performed three times, average values are acquired to be used as the measured values of the outer diameter and the inner diameter of the wheel.

Owner:CHANGCHUN INST OF TECH

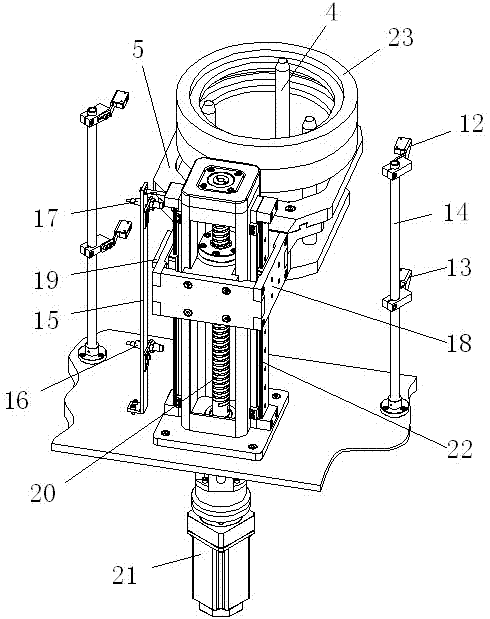

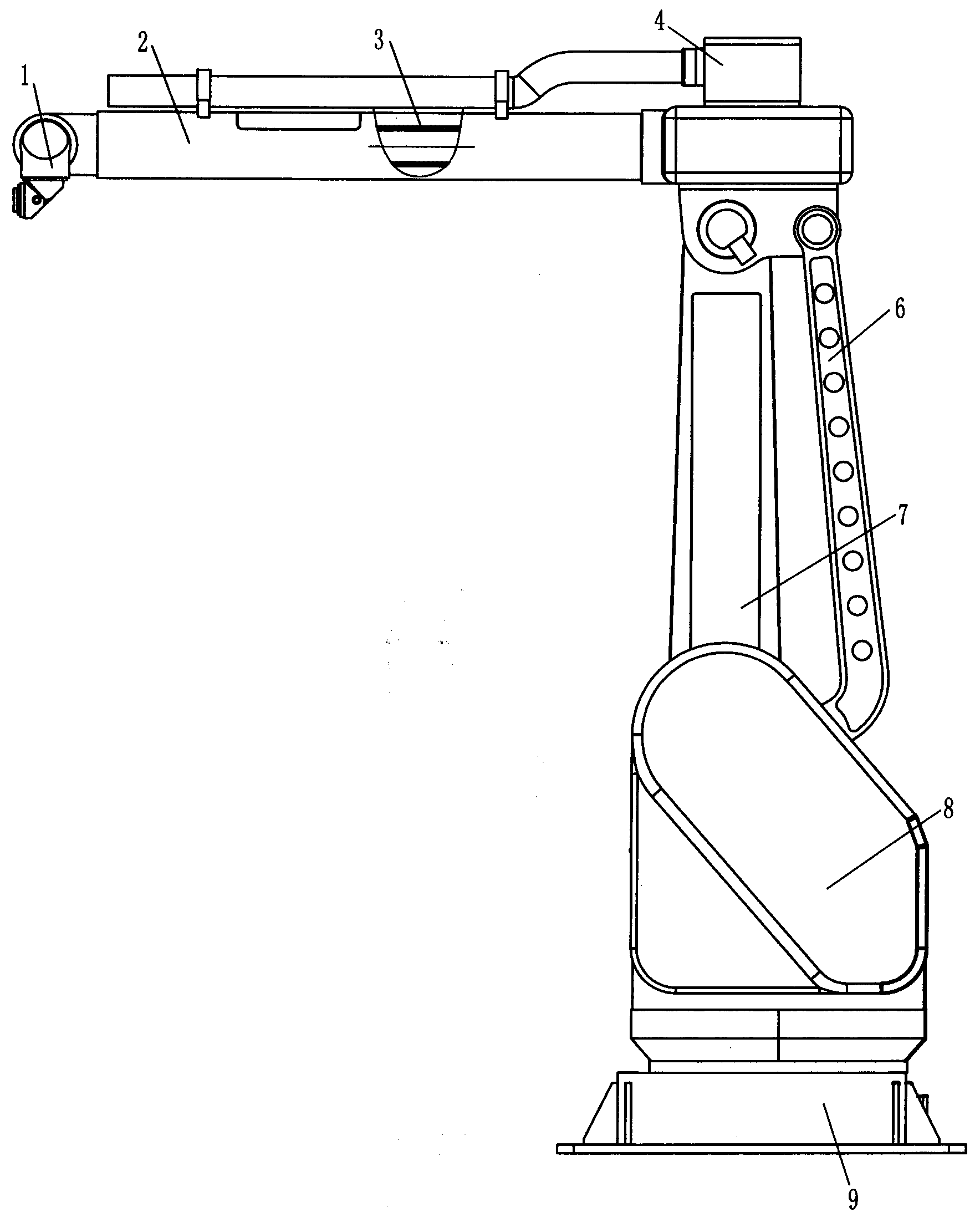

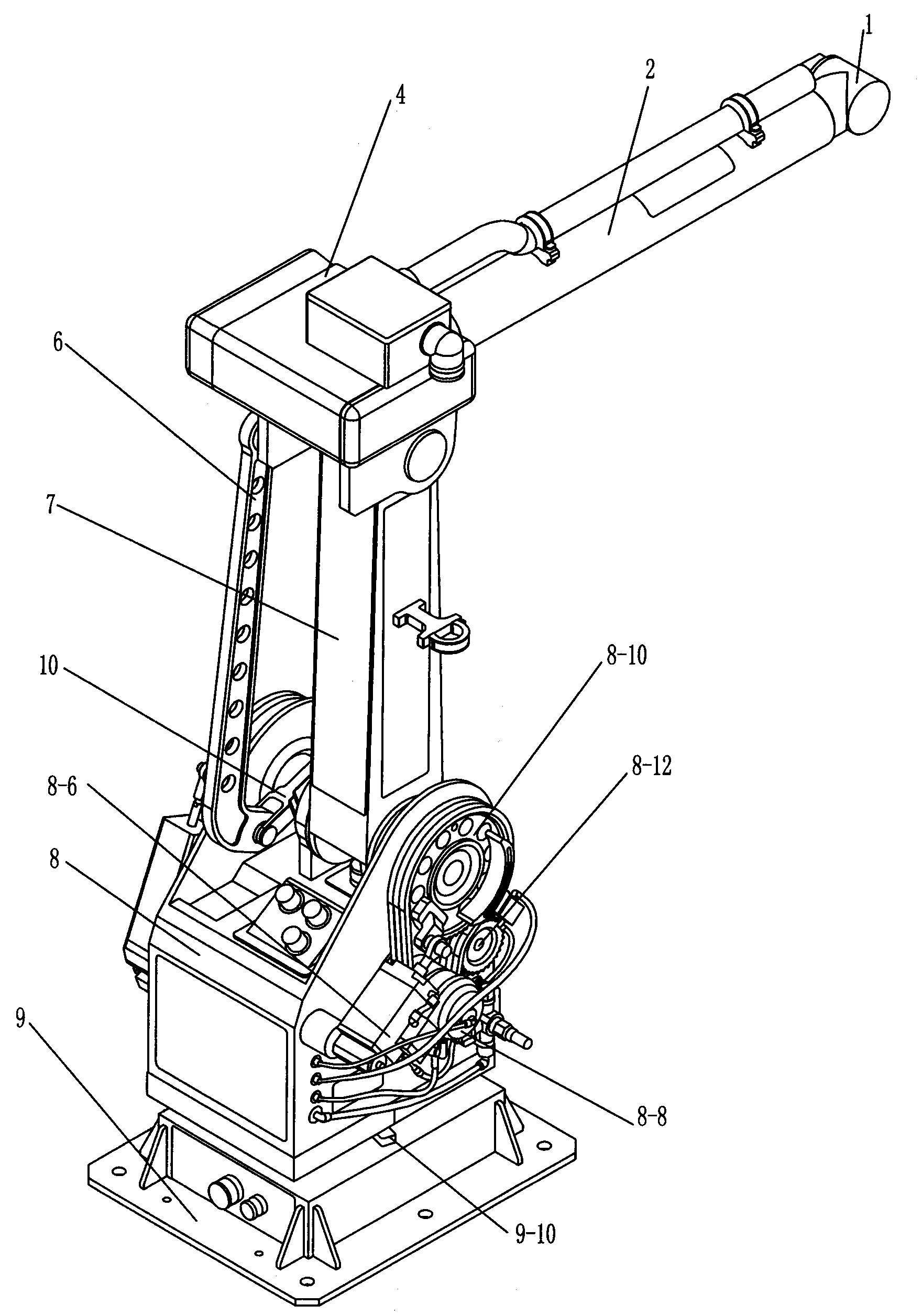

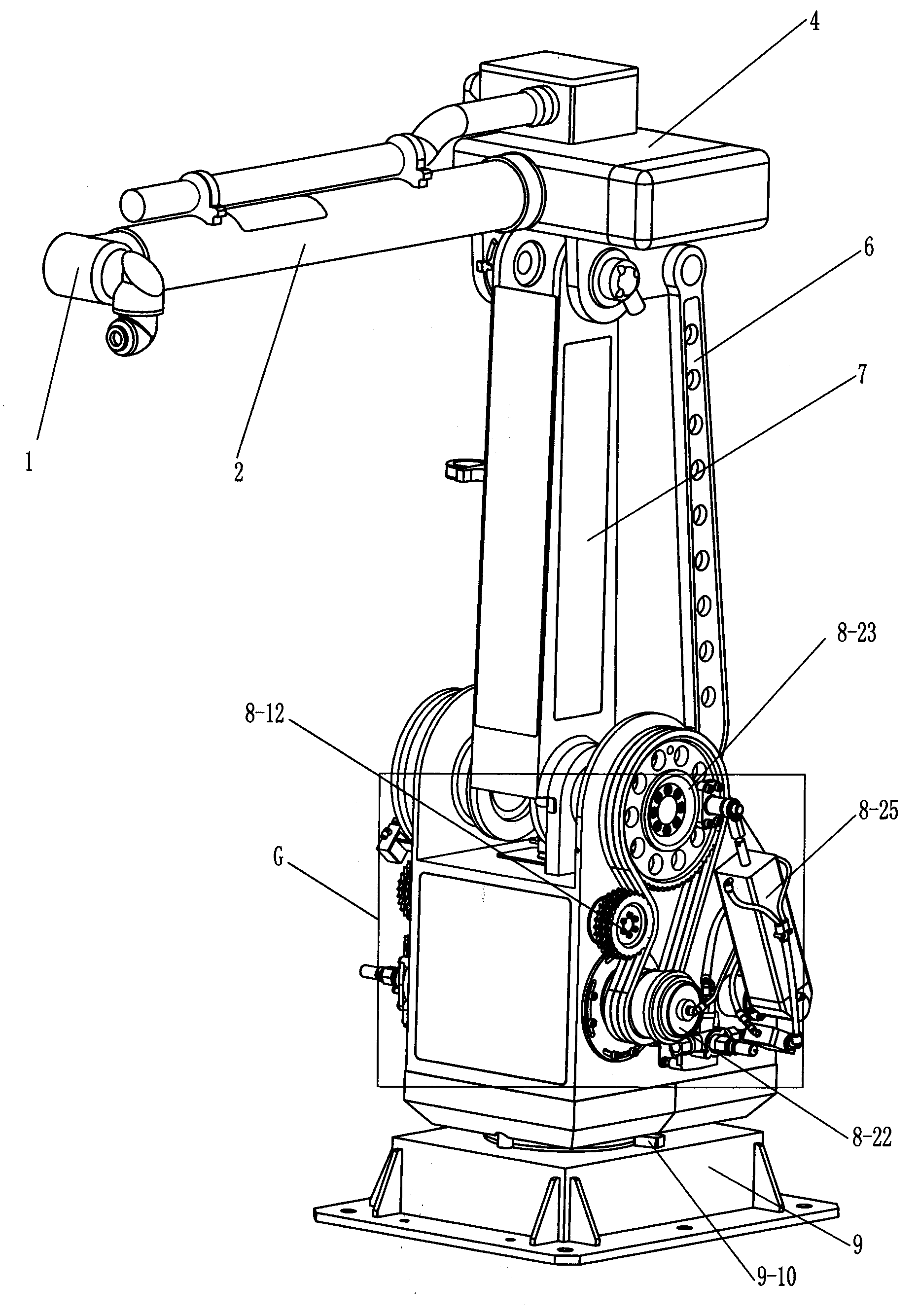

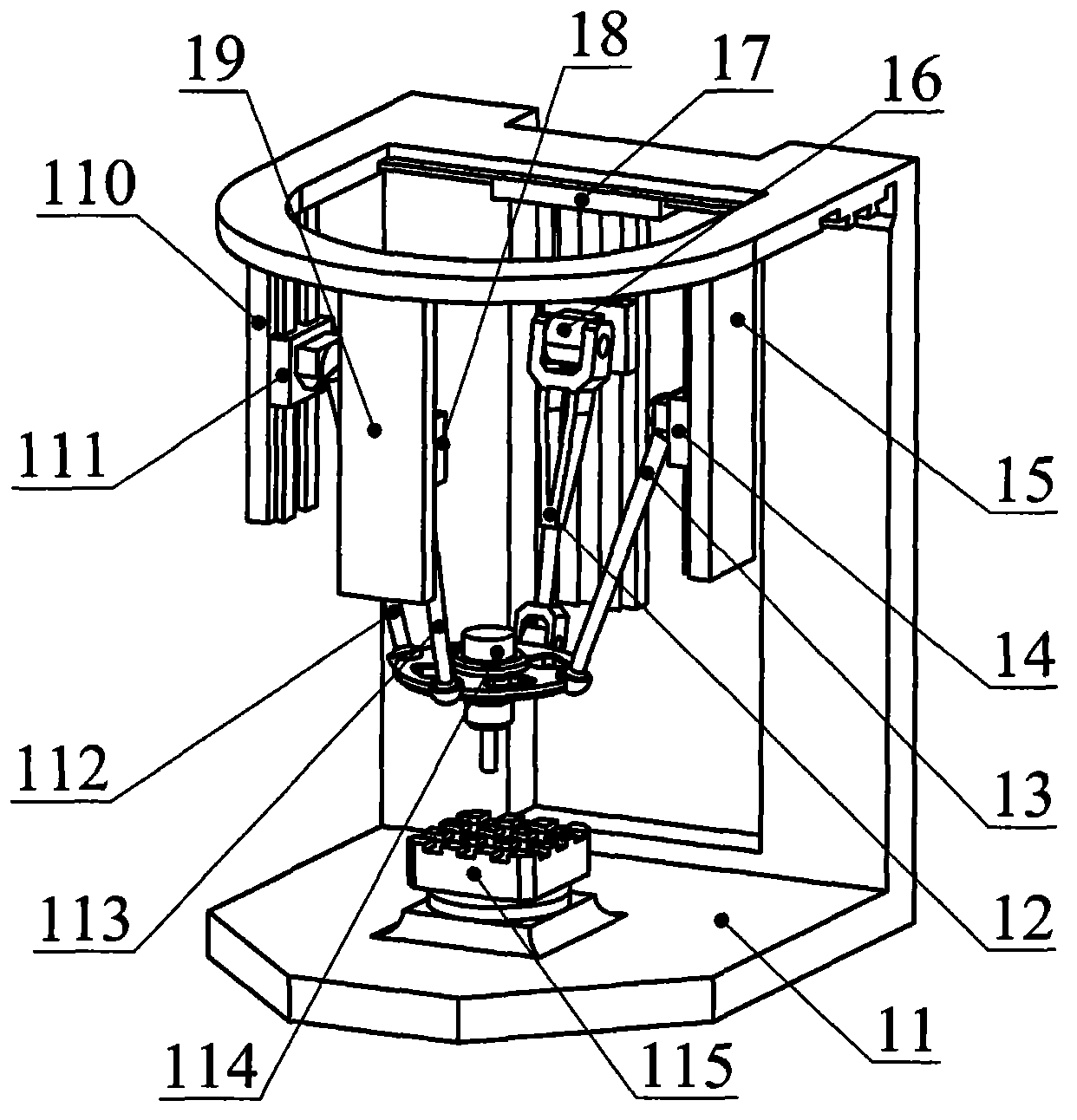

Professional glaze spraying six-axis robot

A professional glaze spraying six-axis robot belongs to the technical field of robot, and solves the problems of expensiveness, complicated operation and difficult maintenance of a foreign glaze spraying robot system in domestic application. The robot wrists are connected to a fourth, fifth and sixth axis motor through wrist transmission chains; the robot wrists, small arms and a fourth, fifth and sixth shaft seat assembly are orderly connected; the upper part of a big arm assembly is connected with the fourth, fifth and sixth shaft seat assembly through a bearing shaft seat one, and the part is connected with second and third axis large chain wheel assemblies; a second axis motor assembly drives the second large chain wheel assembly to rotate; a second axis cylinder assembly is fixed on a second and third axis box bodies and the second axis large chain wheel assembly; upper part of a third axis driving connecting rod through a bearing two is connected with the fourth, fifth and sixth shaft seats assemblies, and the lower part is connected with a third axis drive bracket through a bearing three; the third axis driving bracket is connected with the third large chain wheel assemblies; and the third axis motor assembly through a chain two drives the third large chain wheel assemblies to rotate. The invention is special for glaze spraying.

Owner:杭州钱江机器人有限公司

Swivel table driving device with double worm and gear backlash mechanisms

InactiveCN102029531AHigh precisionHigh repeat positioning accuracyPortable liftingLarge fixed membersGear transmissionWorm drive

The invention relates to a swivel table driving device with double worm and gear backlash mechanisms, which comprises a box body and a gear ring which is connected with the swivel table, wherein the box body is provided with two worm and gear transmission mechanisms; the transmission mechanisms are connected between a gear and a motor; a worm is connected with gearwheels coaxial with the worm; the gearwheels are meshed with the gear ring; the axial worm centerlines in both worm and gear transmission mechanisms are in the same straight line; gaps are reserved between adjacent ends of two gears; outer sides of the two ends are sleeved with middle sheaths which can axially move relatively to the gears; and a regulating pad for regulating the axial position of the worms is arranged between a bearing seat for supporting the gears and the box body. The swivel table driving device ensures that the gear ring eliminates a reversal transmission gap during forward-reverse conversion, and has smooth transition. The swivel table has high swivel positioning precision, high repeated positioning precision, low manufacturing cost and low operation cost.

Owner:DALIAN HUAGEN MACHINERY

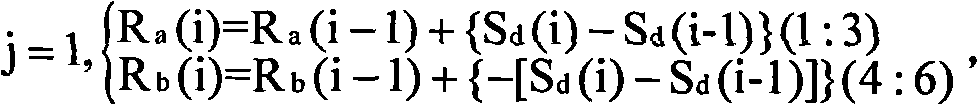

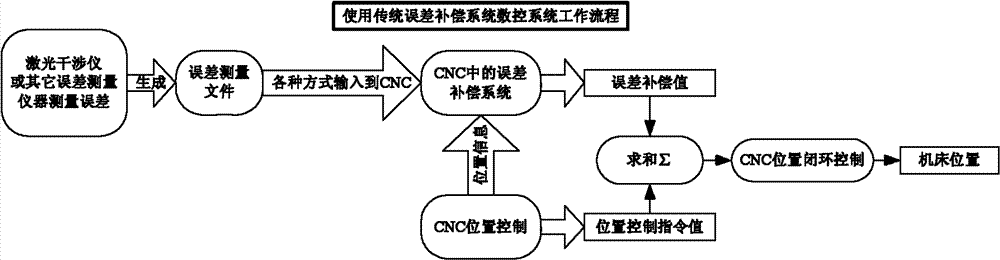

Compensation system with repeated error weighted stacking in numerical control system

ActiveCN102789199AImplement Compensation AdjustmentsHigh positioning accuracyProgramme controlComputer controlClosed loopMachine tool

A compensation system with repeated error weighted stacking in a numerical control system comprises an instrument for error measurement, a unit for adding error compensation files, an error file interpreter, an error compensation fitting algorithm arithmetic unit, a unit for calculating error compensation values and a servo position closed-loop controller for receiving error compensation value instructions. The unit for calculating error compensation values comprises a program code parser and an interpolator. According to the compensation system, the positioning accuracy and the repositioning accuracy of numerical control machine tools can be improved, accuracy debugging of tools is greatly facilitated for users, simultaneously, the weighting compensation operation for errors is provided, compensation adjustment of the whole measuring range is achieved, the weighting operation can be performed on a certain error compensation curve, therefore the users can improve the positioning accuracy of the numerical control machine tools continuously, and the installation debugging process of machine tools is greatly facilitated for the users.

Owner:KEDE NUMERICAL CONTROL CO LTD

Single-degree-of-freedom flexible fine adjustment mechanism-based micro-displacement sensor calibration device

InactiveCN103697818AHigh precisionHigh repeat positioning accuracyUsing optical meansElectricityGrating

The invention discloses a single-degree-of-freedom flexible fine adjustment mechanism-based micro-displacement sensor calibration device, belongs to the field of accurate fine adjustment and detection, and aims to solve the problems of poor repeated positioning accuracy and long-term stability of measurement in the prior art. The device comprises an adjustment frame, a piezoelectric driver and a calibration reference component, wherein the piezoelectric driver is fixedly arranged on the adjustment frame, and is used for driving a moving rod of the adjustment frame to move; the calibration reference component is fixedly arranged on the adjustment frame; the calibration reference component and a micro-displacement sensor to be calibrated are simultaneously used for measuring the output displacement of the moving rod. According to the calibration device, the moving rod capable of providing micro-displacement and a higher-accuracy sensor grating ruler used as a detection reference are provided, and the grating ruler and the micro-displacement sensor to be calibrated are simultaneously used for measuring the output displacement of the moving rod to realize the calibration of the micro-displacement sensor to be calibrated; the calibration device has the advantages of simple structure, high repeated positioning accuracy, high long-term stability and the like.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

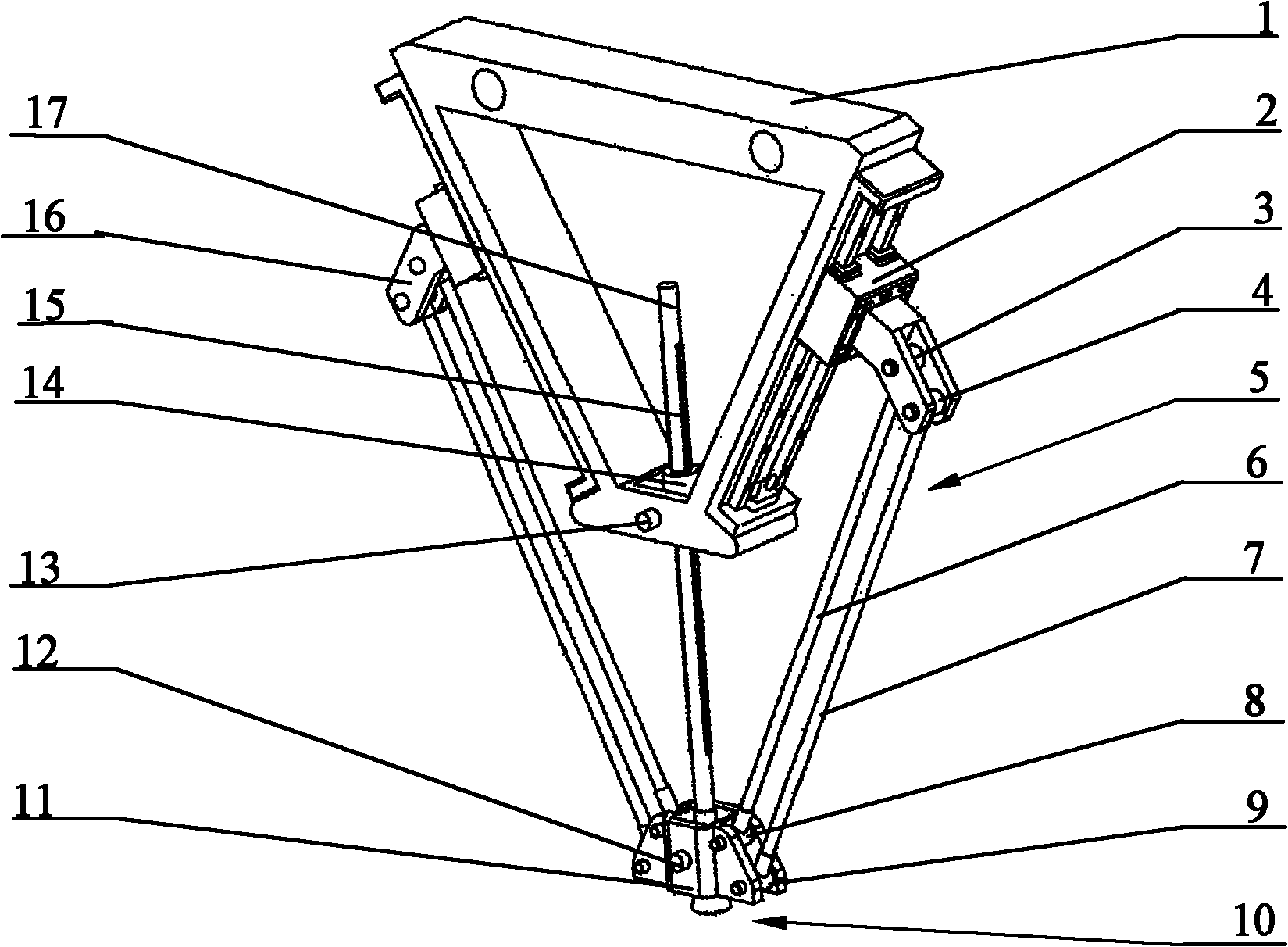

Linear-driven high-speed planar parallel mechanical arm

InactiveCN102152300ASmooth motionHigh speed accelerationProgramme-controlled manipulatorEngineeringLinear motor

The invention discloses a linear-driven high-speed planar parallel mechanical arm comprising an engine base and a moving platform, wherein two sides of the engine base are respectively provided with a moving chain connected with the moving platform; the moving chains are driven by linear motors arranged on the engine base; and the engine base is connected with a sleeve through two coaxial pins, the sleeve is internally provided with a guiding rod, the guiding rod is connected with the sleeve through a gliding pair, the lower part of the guiding rod is connected with the moving platform through a hinge, the guiding rod is located between two parallelogram mechanisms, and the axis of the guiding rod is coplanar with the two parallelogram mechanisms. The linear-driven high-speed planar parallel mechanical arm disclosed by the invention can realize two-dimensional movement of the moving platform at higher speed in different ranges, can simultaneously maintain the attitude of the moving platform unchanged, and has the advantages of higher bearing capacity and high positioning precision and repeated positioning precision.

Owner:TIANJIN UNIV

Gap eliminating transmission case

InactiveCN101382192ASimple structureGood backlashGearboxesMetal working apparatusNumerical controlDrive shaft

The invention provides an anti-backlash transmission box which is characterized in that: the middle part of a first output transmission shaft is connected with a first helical gear which is screwed to the right side; the middle part of a second output transmission shaft is connected with a second helical gear which is screwed to the left side; a gear transmission shaft is provided with a sixth helical gear and a fourth helical gear; a fifth helical gear is connected with the fourth helical gear; a motor and a planetary reducing gearbox are arranged on a box body 1; a motor output shaft is connected with a third helical gear; the third helical gear is engaged with the fourth helical gear and the fifth helical gear; the gear part of the helical gear transmission shaft is engaged with the second helical gear; a sixth helical gear is engaged with the first helical gear; the anti-backlash transmission box has simple structure and reasonably arranges the positions of the transmission gears, leads the internal structure of the anti-backlash transmission box to be compact, and saves the space; simultaneously, by reasonably adopting the anti-backlash mechanism, the anti-backlash transmission box has better reverse clearance, has good positioning precision and repeated positioning precision when being transmitted to the X-axis of the numerical control gantry milling processing center, and ensures the processing precision of the numerical control gantry milling processing center.

Owner:无锡桥联数控机床有限公司

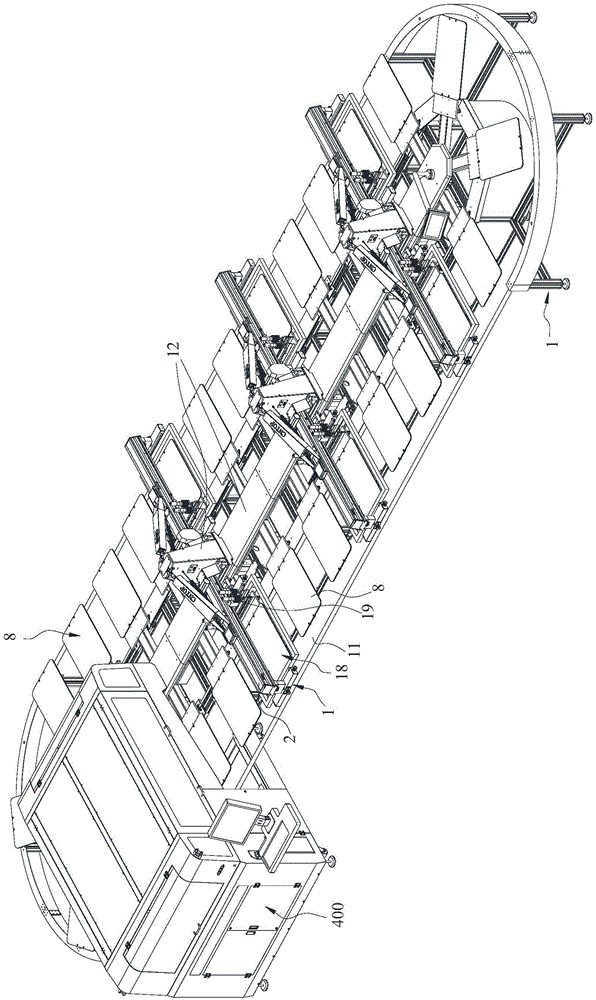

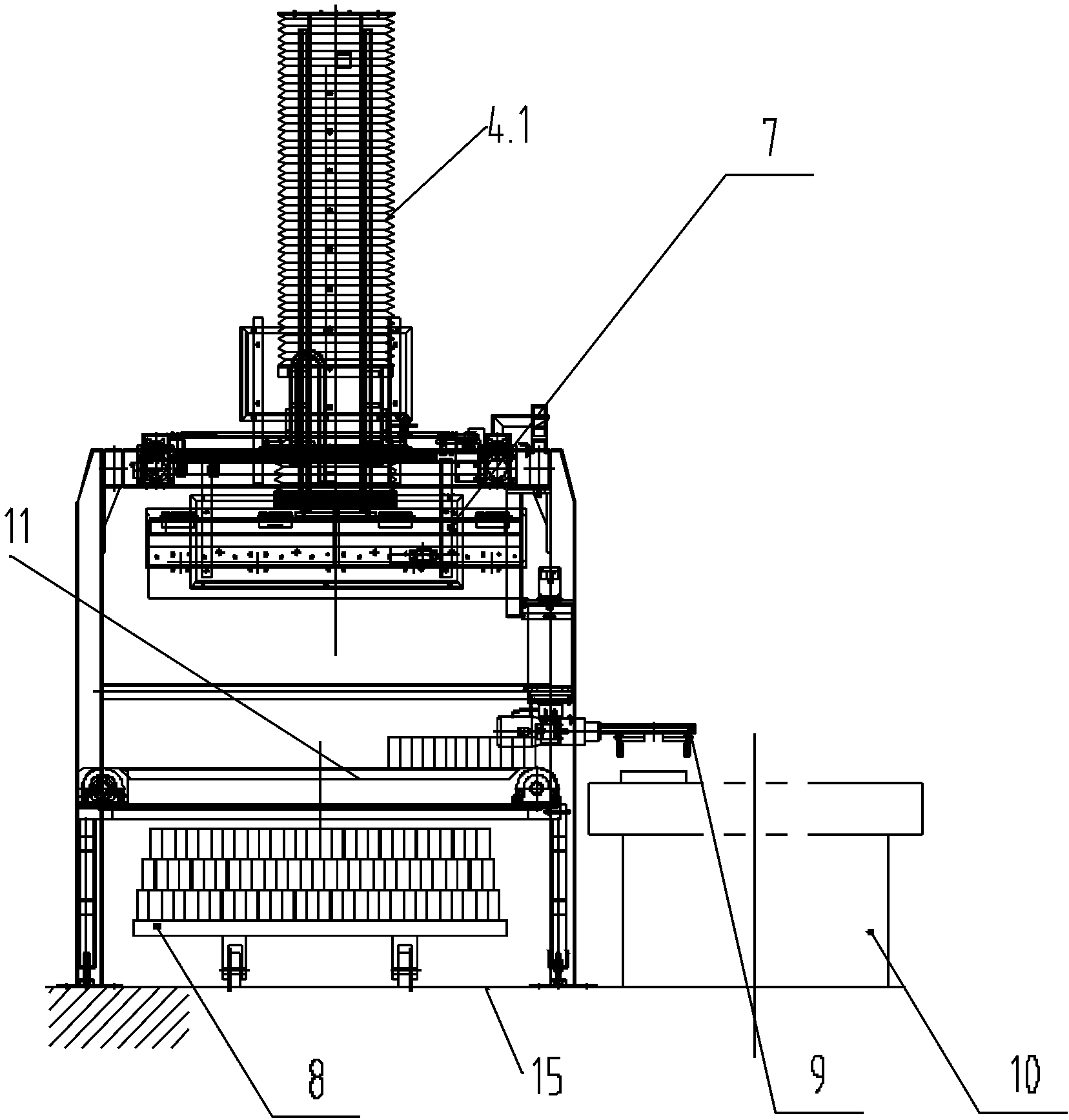

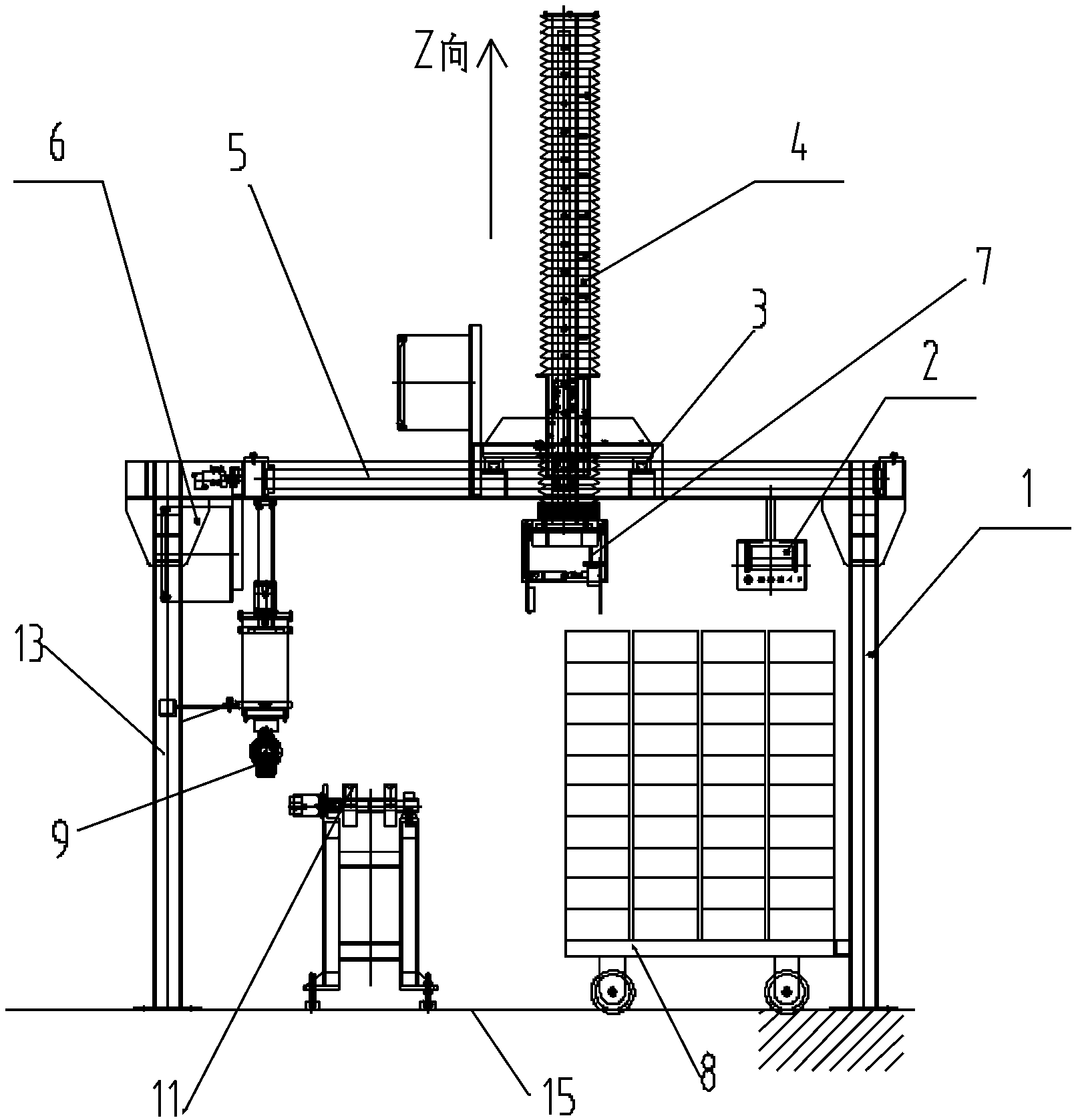

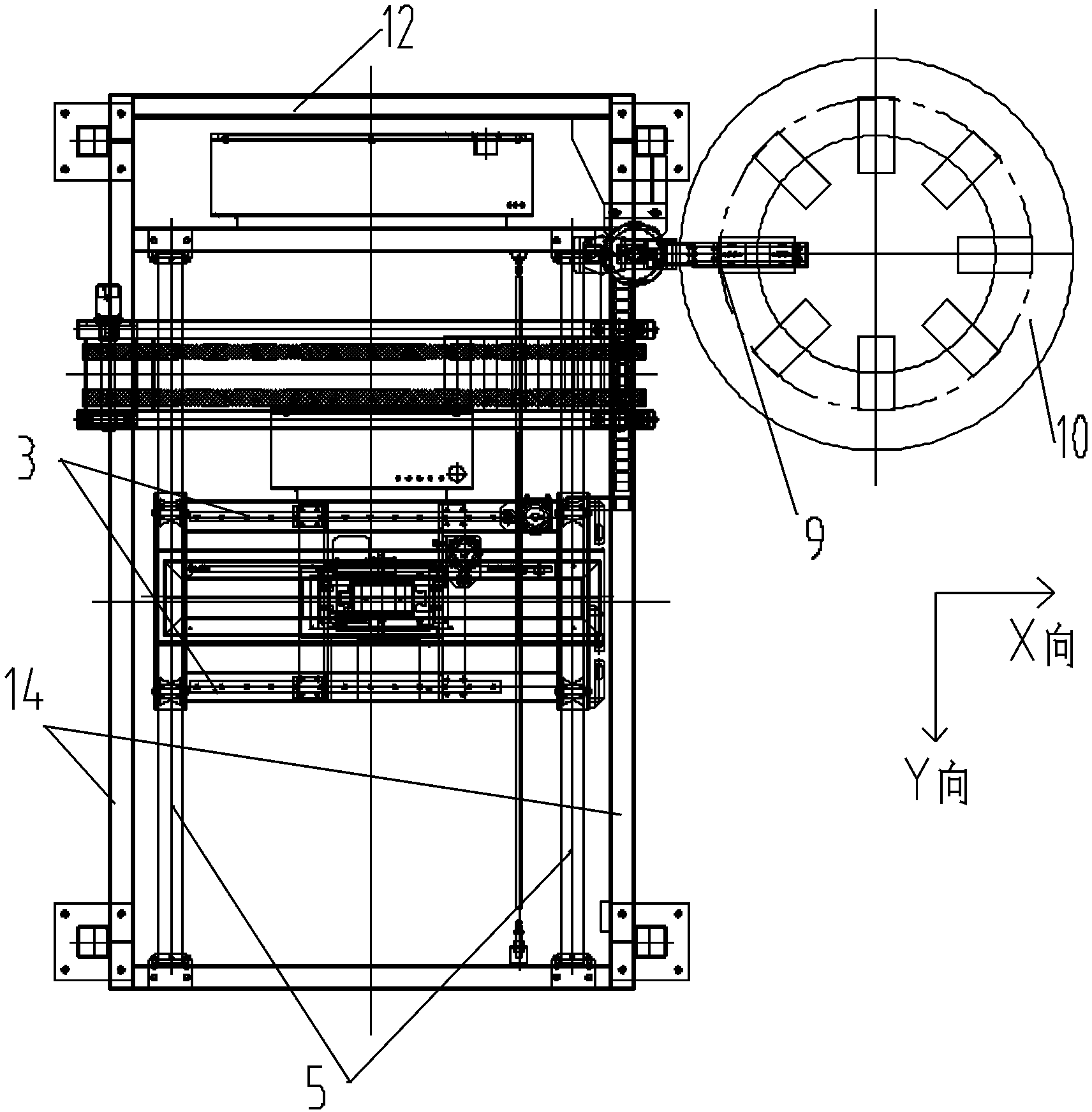

Air brick stacking manipulator system and control method

ActiveCN103832840AImprove beat matching problemsIncreased coherence of movementConveyorsStacking articlesBrickBarrel Shaped

The invention discloses an air brick stacking manipulator system and a control method. An air blank grabbing manipulator and an air brick stacking manipulator are integrated into a uniform connecting body through a portal frame foundation, after air bricks are grabbed by the air brick grabbing manipulator, the air bricks are transferred and carried subsequently by the air brick stacking manipulator, movement continuity is enhanced, working efficiency is substantially improved, the takt matching problem between two work procedures is solved, a lifting and swinging device of the whole small manipulator is integrated in a closed barrel-shaped structure, and the system is simple in structure, small in size, beautiful in appearance and convenient to mount in an inverted hanging mode; double-side supporting is formed by the large manipulator through an X-direction guide rail and a Y-direction guide rail on the two sides, and the problems that a traditional stacking manipulator is of a single stand column cantilever structure and is uneven in stress, and eccentric abrasion to the rails is caused are solved; both the two manipulators are installed in the inverted hanging mode, idle space in the portal frame space is utilized, the space utilization rate is high, and operation is not disturbed.

Owner:湖北成吉智能机械科技有限公司

Redundant driving five-axis linkage hybrid machine tool

ActiveCN103240614ACompact structureRelatively simple kinematicsLarge fixed membersKinematicsEngineering

The invention relates to a redundant driving five-axis linkage hybrid machine tool which comprises a tool body, a column extender fixed on the tool body, a movable platform for installing a spindle, a working table for installing a workpiece to be cut, a first branched chain, a second branched chain, a third branched chain and a fourth branched chain, wherein the first branched chain, the second branched chain, the third branched chain and the fourth branched chain are used for connecting the movable platform, the tool body and the column extender, and five-axis linkage control can be achieved. The redundant driving five-axis linkage hybrid machine tool has the advantages of being concise and compact in structure, relatively simple in kinematics, high in rigidity, good in repeated positioning accuracy, relatively large in working space and machine tool size ratio and the like.

Owner:JIANGSU GUOWEI ENG MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com