Small-sized five-shaft linkage numerically controlled machine

A five-axis linkage, CNC milling machine technology, applied in milling machine equipment, milling machine equipment details, large fixed members, etc., can solve the problems of difficulty in processing small parts with three-dimensional curved structure, waste of energy and space, and bulky machine tools. Simple, high machining accuracy, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

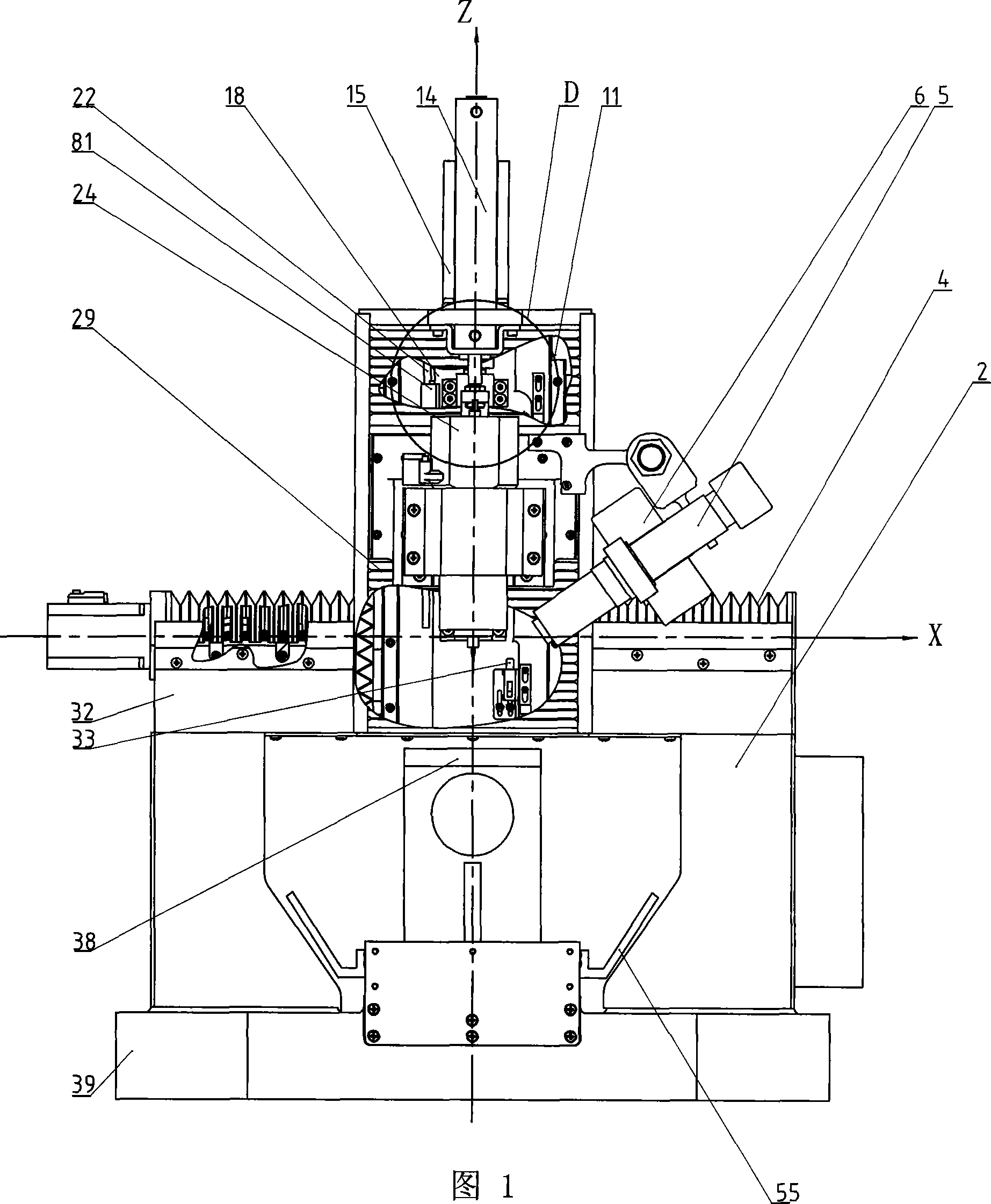

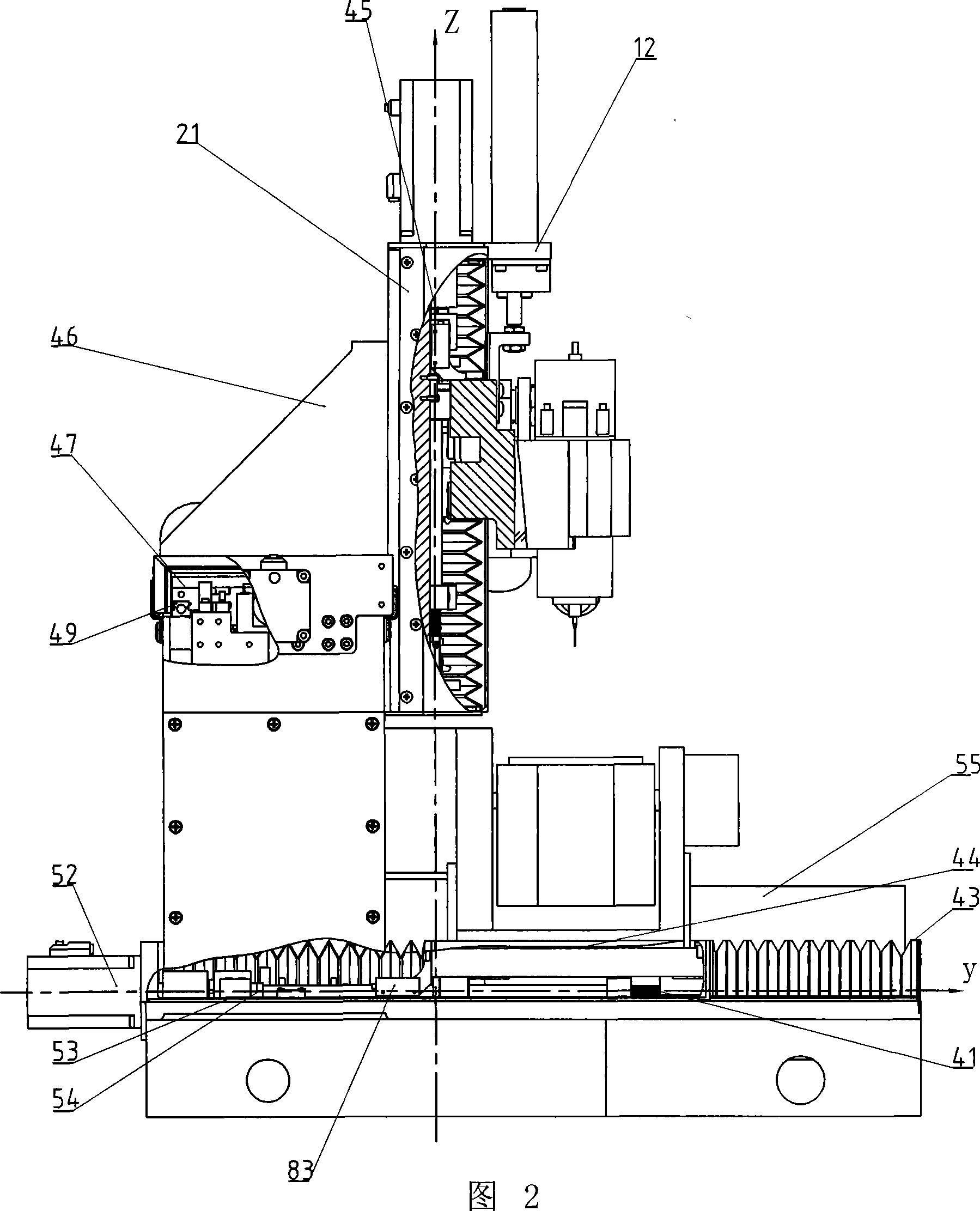

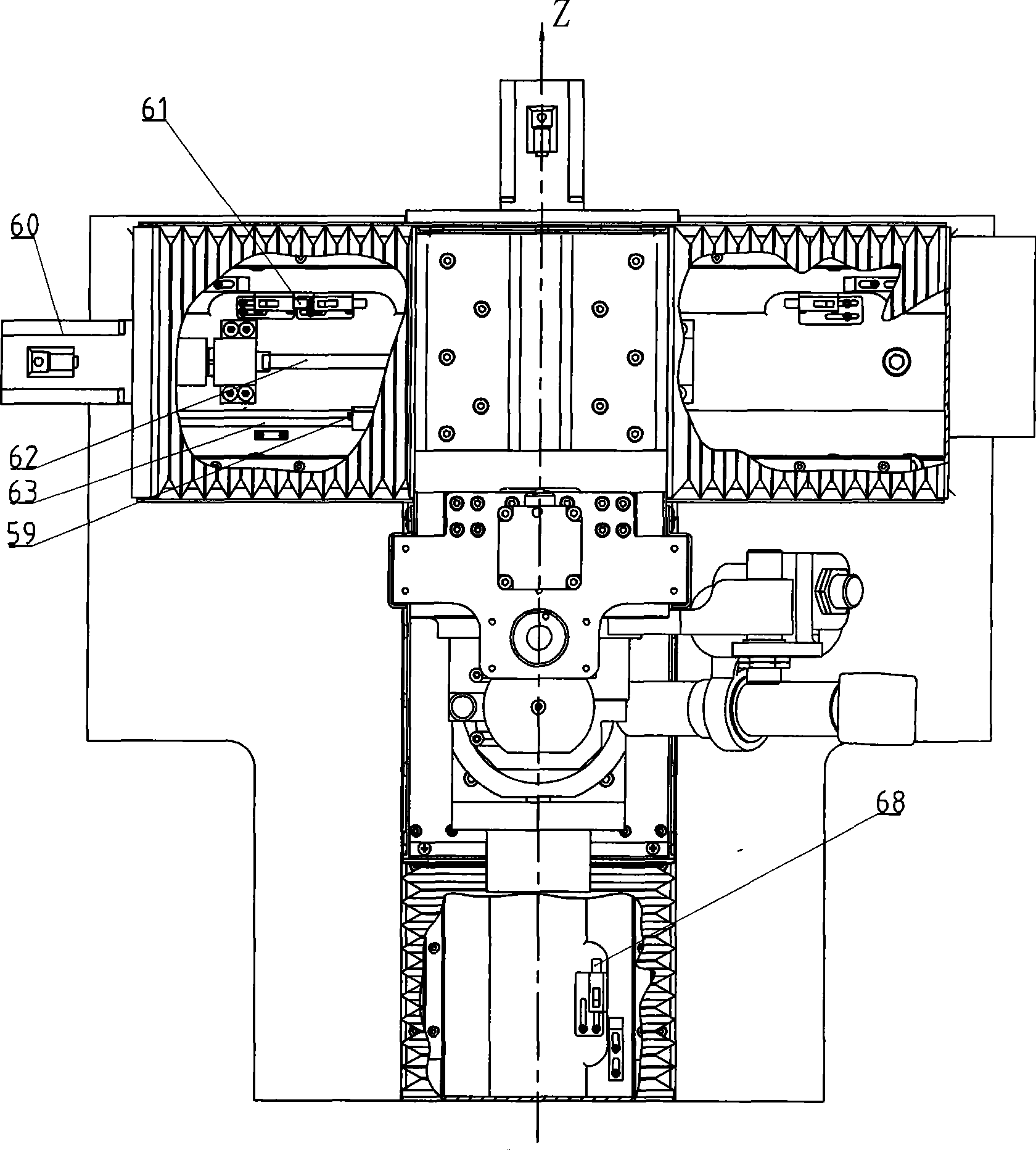

[0008] Specific implementation mode one: in conjunction with Fig. 1~ Figure 5 Describe this embodiment, the milling machine of this embodiment includes gantry frame bed, base 39, electric spindle 24, X-axis servo drive assembly, Y-axis servo drive assembly, Z-axis servo drive assembly, work turntable assembly, Cylinder assembly, microscope assembly, Z-axis plate 21 and upper support frame 46; the gantry frame bed is fixed on the base 39, and the gantry frame bed is composed of a beam 32 and two columns 2, the two The two columns 2 are arranged oppositely, and the beam 32 is fixed on the two columns 2. The X-axis servo drive assembly consists of an X-axis AC servo motor 60, an X-axis ball screw 62, an X-axis linear guide 49, and an X-axis Guide rail bottom plate 47, X-axis micro switch 61, X-axis grating ruler 63 and X-axis grating ruler reading head 59, the Y-axis servo drive assembly is composed of Y-axis AC servo motor 52, Y-axis ball screw 54, Y-axis Axis linear guide rai...

specific Embodiment approach 2

[0009] Specific embodiment two: this embodiment is described in conjunction with Fig. 1 and Fig. 2, and the difference between this embodiment and specific embodiment one is: the milling machine of this embodiment also includes two chip baffles 55; A chip baffle 55 is respectively equipped with on the left and right sides of 44. This setting is beneficial to the removal of coolant and chips, and reduces the thermal deformation of the bed caused by the temperature change of the cutting fluid.

specific Embodiment approach 3

[0010] Specific embodiment three: This embodiment is described in conjunction with Fig. 1 and Fig. 2. The difference between this embodiment and specific embodiment one or two is: the milling machine of this embodiment also includes an X-axis dust cover 4; The dust cover 4 is arranged directly above the X-axis ball screw 62 , and the lower end of the X-axis dust cover 4 is connected to the beam 32 . Such arrangement can prevent dust and chips from falling on the X-axis ball screw 62 and ensure the normal rotation of the X-axis ball screw 62 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com