Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2884results about How to "Low manufacturing cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Exercise equipment

InactiveUS6942605B1Low manufacturing costLow price of saleStraight-bar knitting machinesFootwearExercise equipmentPhysical medicine and rehabilitation

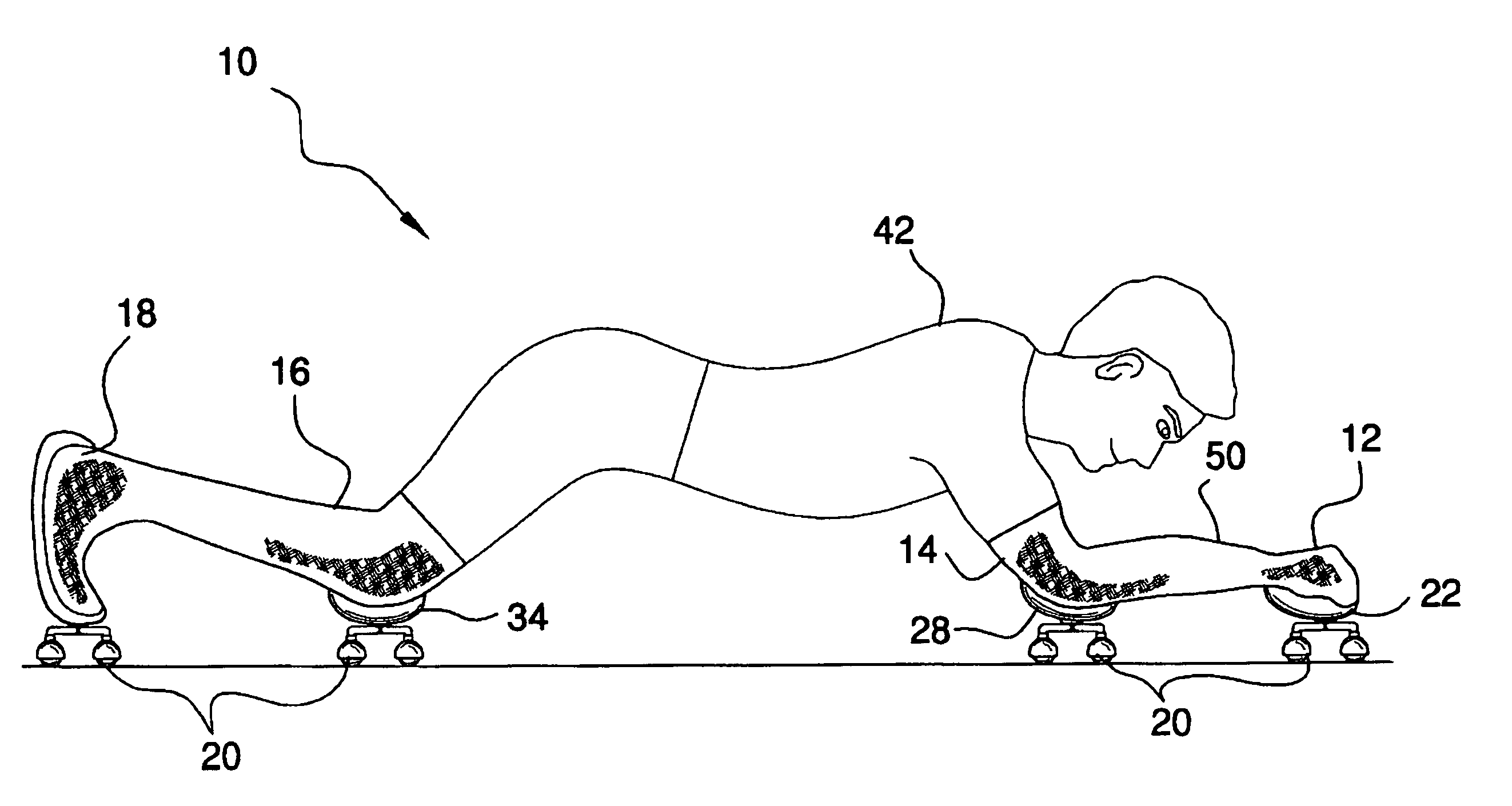

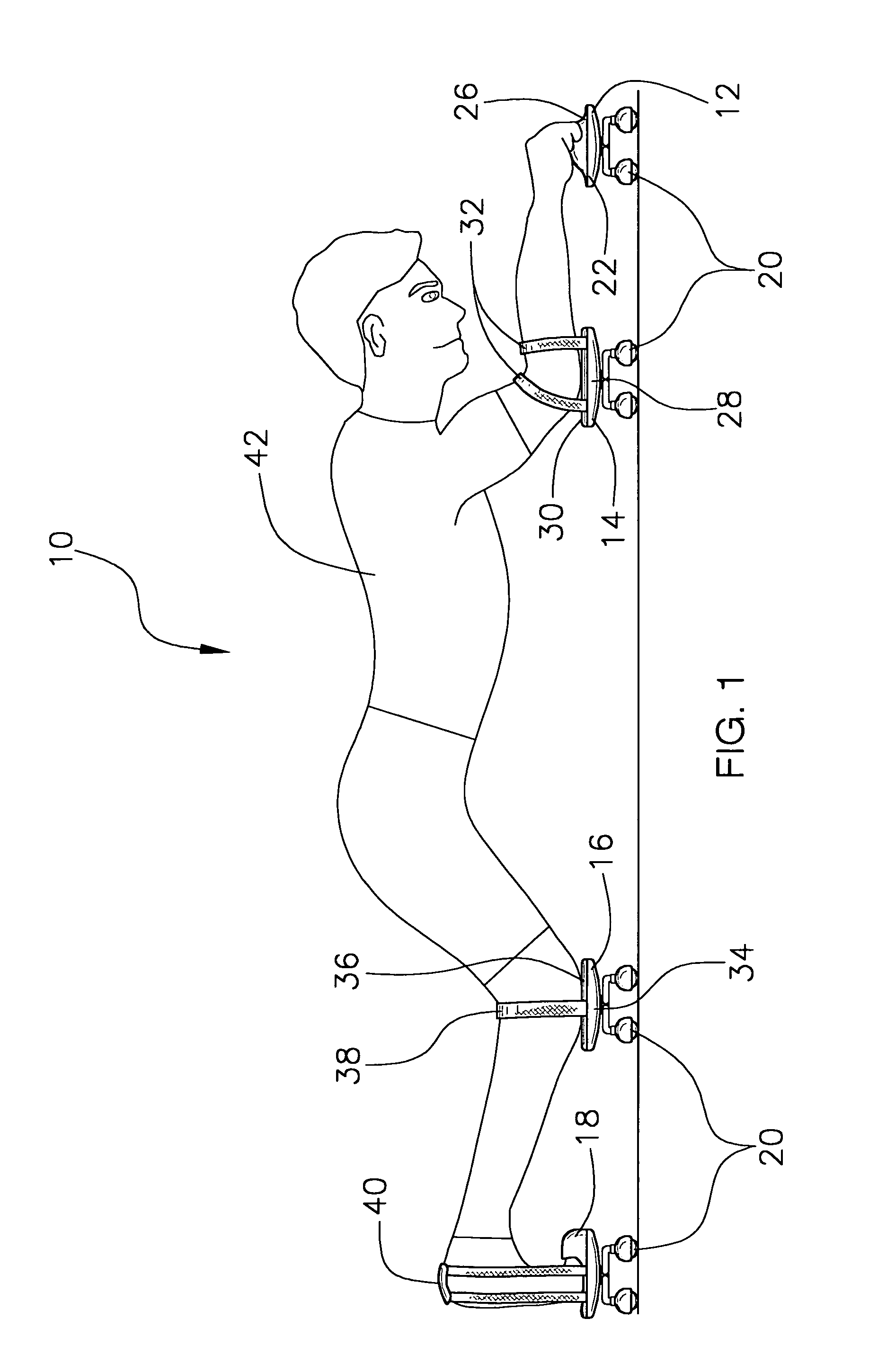

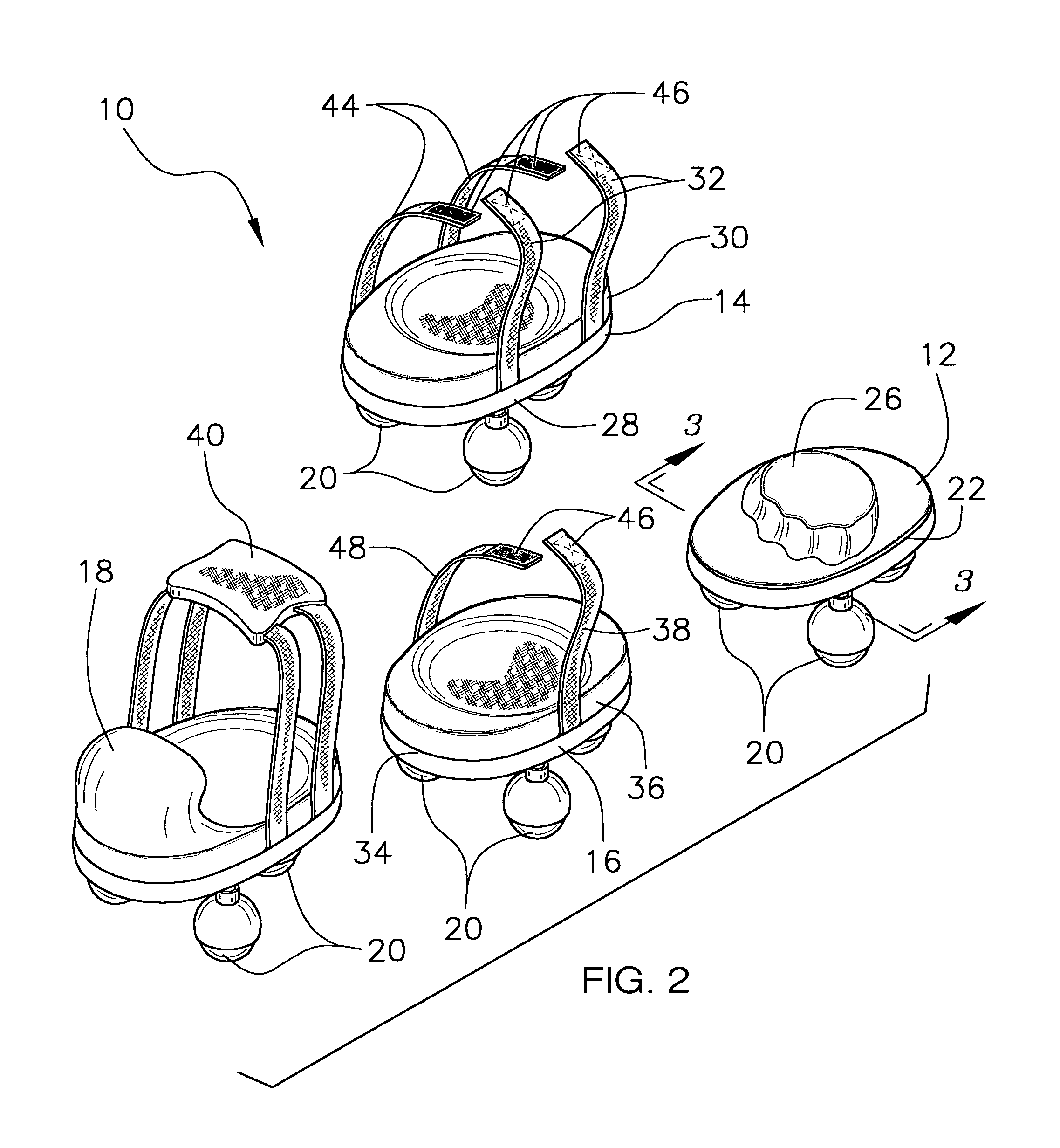

Exercise equipment toning and strengthening the muscles of the abdomen, back, shoulders, arms, and legs. A plurality of hand attachments, elbow attachments, knee attachments, and foot attachments are provided which allow the user to exercise their whole body. The bottom of the hand attachments, elbow attachments, knee attachments, and foot attachments have caster wheels attached so that they can roll on a variety of surfaces. The hand attachments and elbow attachments are combined to form gloves and the knee attachments and foot attachments are combined to form boots. Pads are provided on the top of the hand attachments, elbow attachments, and knee attachments to cushion the user.

Owner:SUKHOVITSKY FELIKS

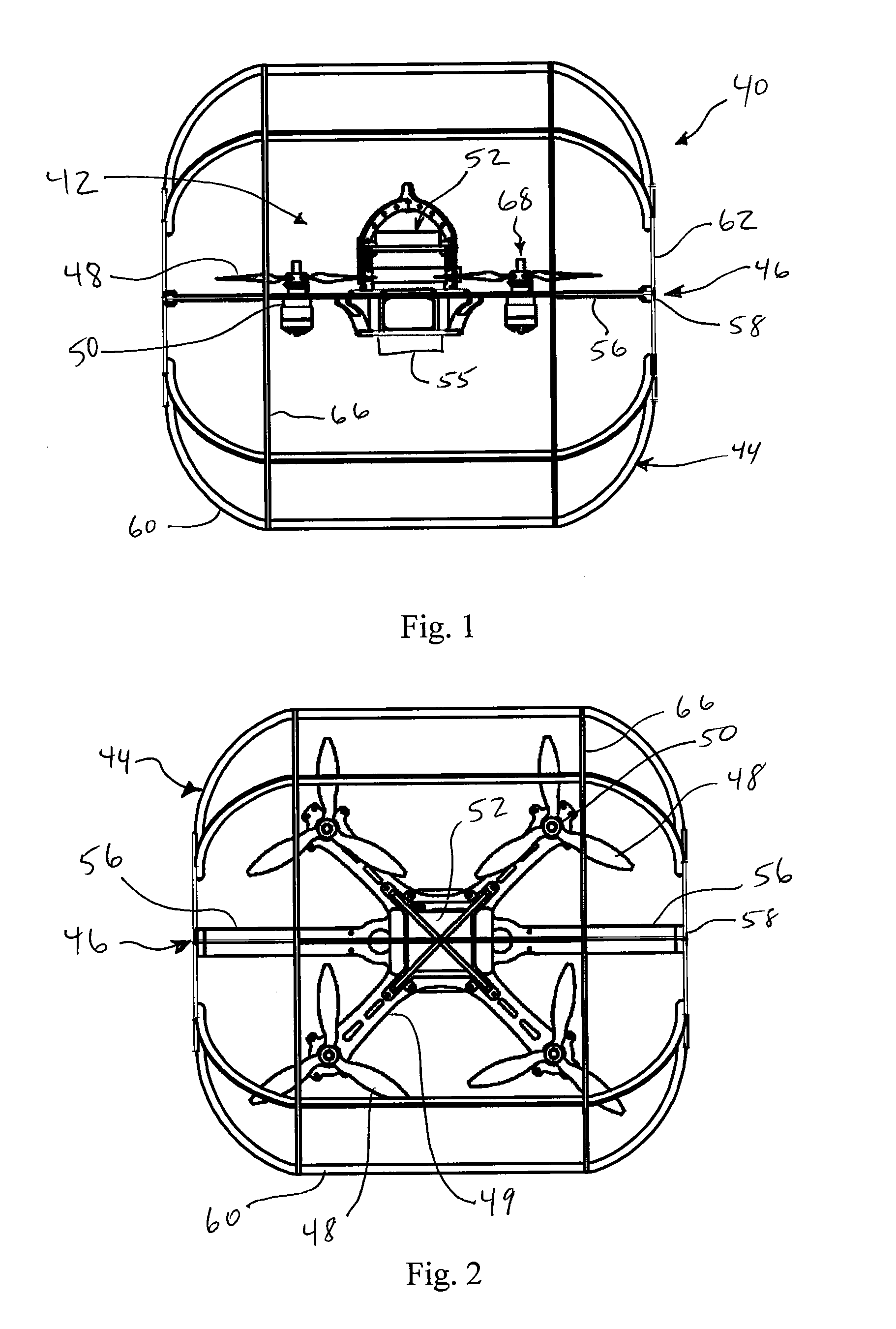

Hybrid aerial and terrestrial vehicle

ActiveUS20140131507A1Simple designLow manufacturing costConvertible aircraftsMicro-sized aircraftFlight vehicleTerrestrial locomotion

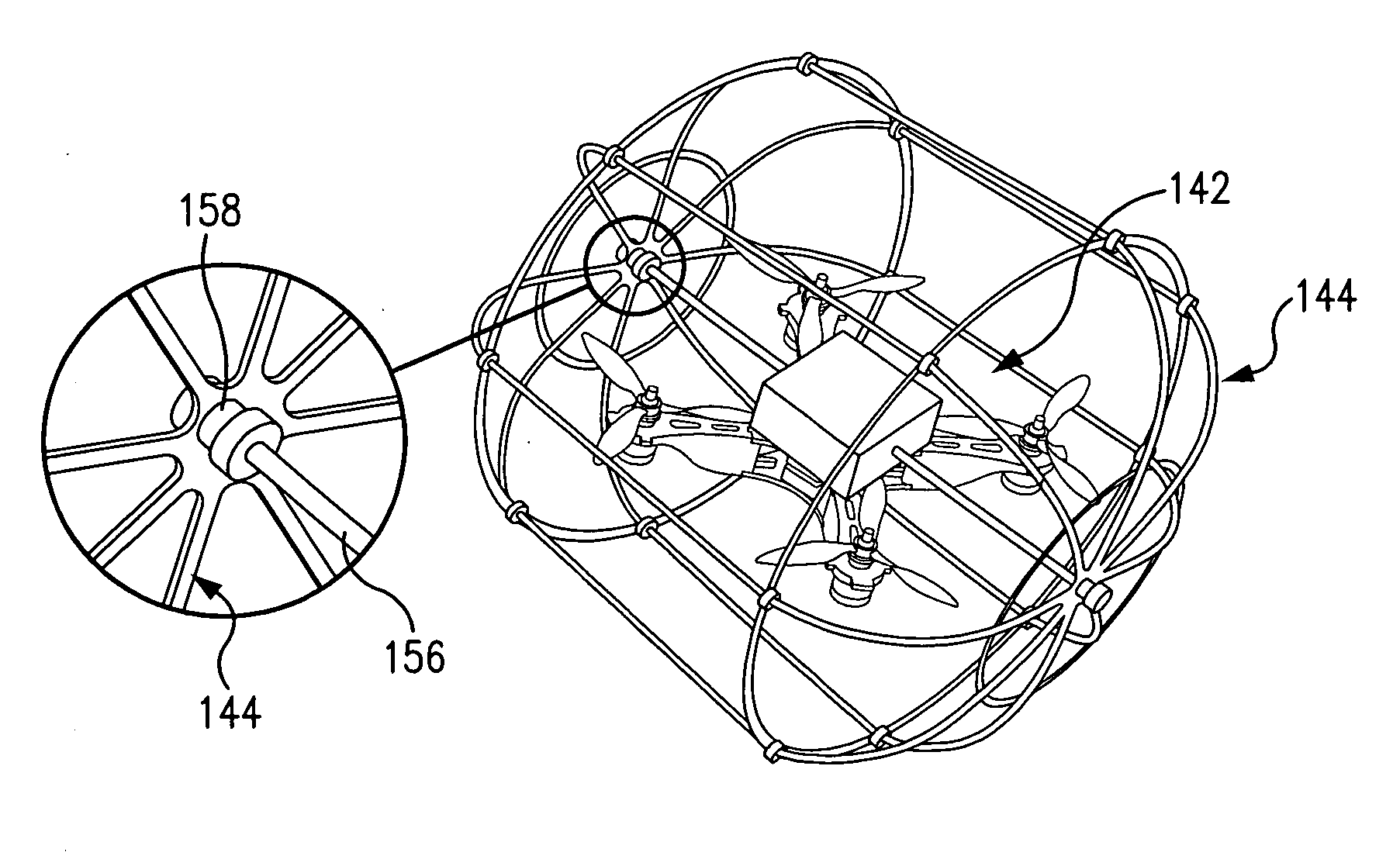

A vehicle capable of both aerial and terrestrial locomotion. The terrestrial and aerial vehicle includes a flying device and a rolling cage connected to the flying device by at least one revolute joint. The rolling cage at least partially surrounds the flying device and is free-rolling and not separately powered.

Owner:ILLINOIS INSTITUTE OF TECHNOLOGY

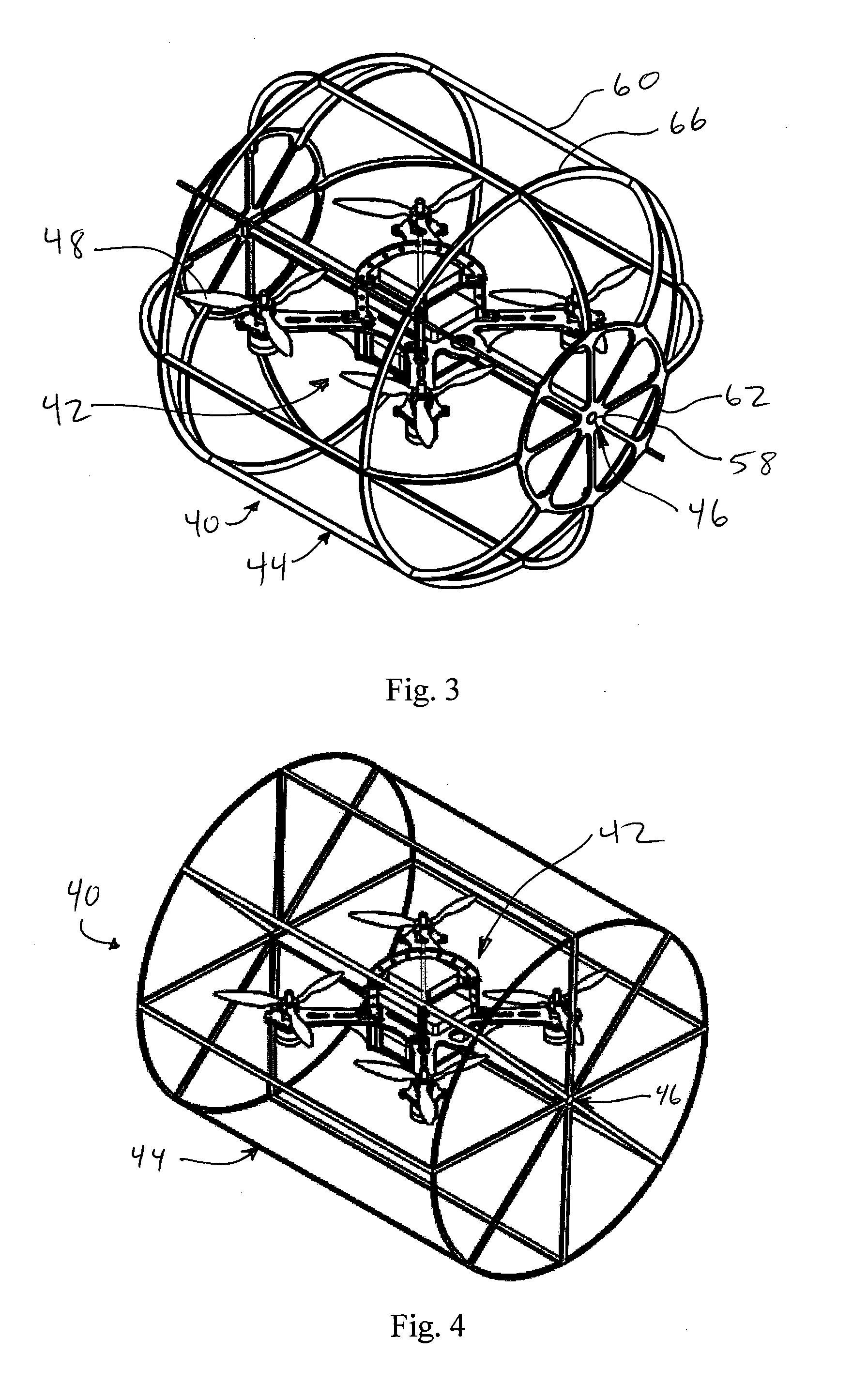

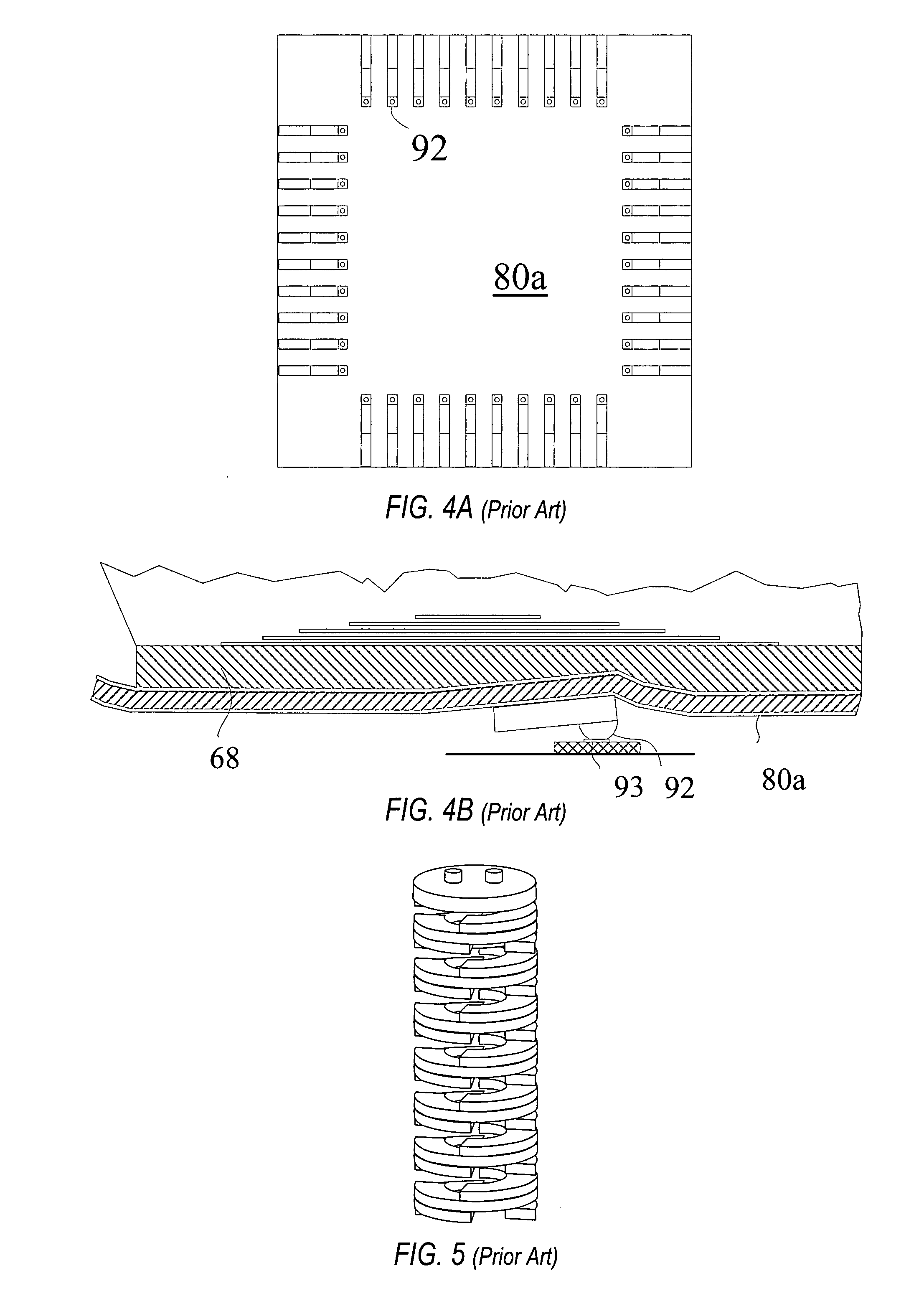

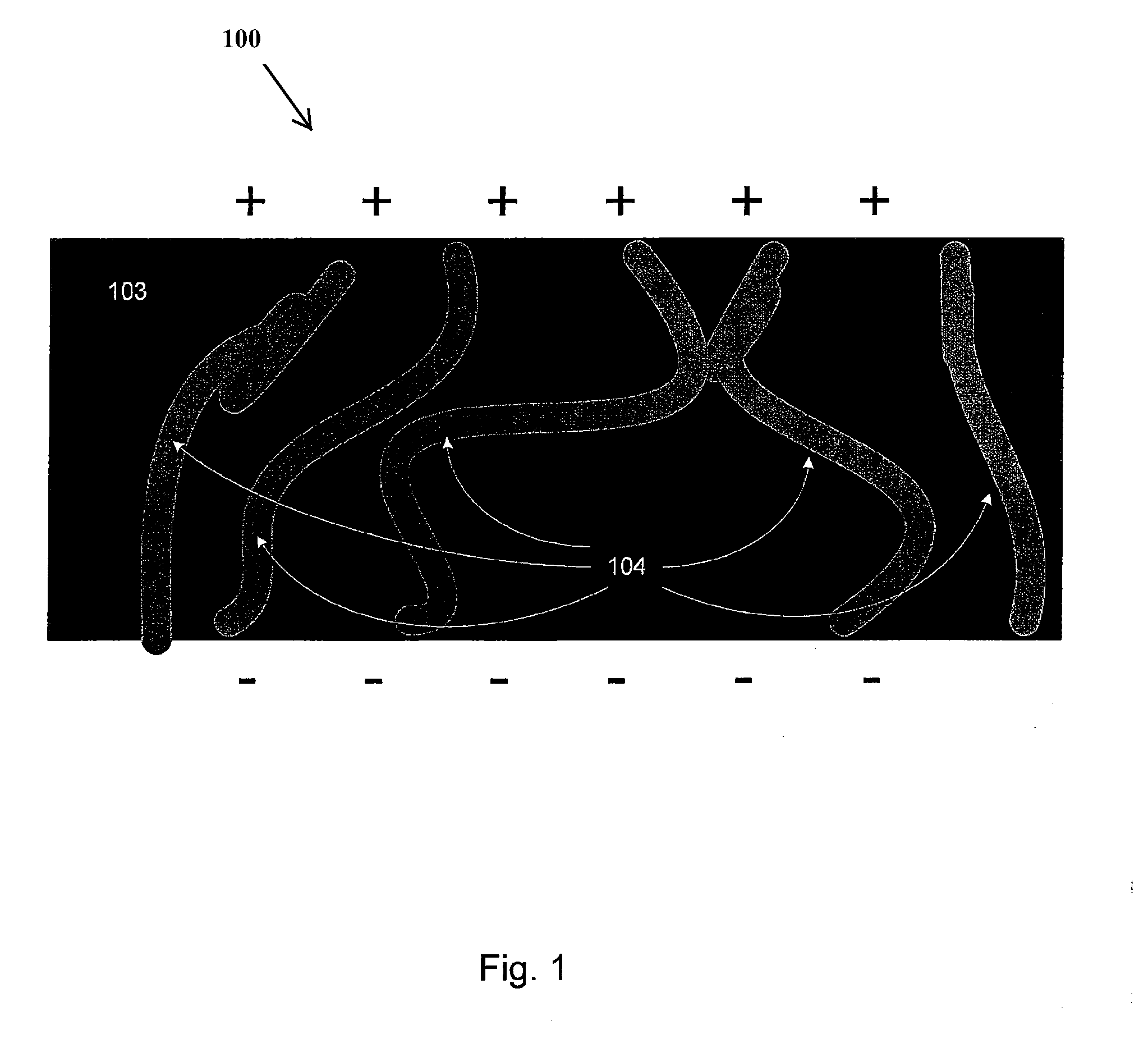

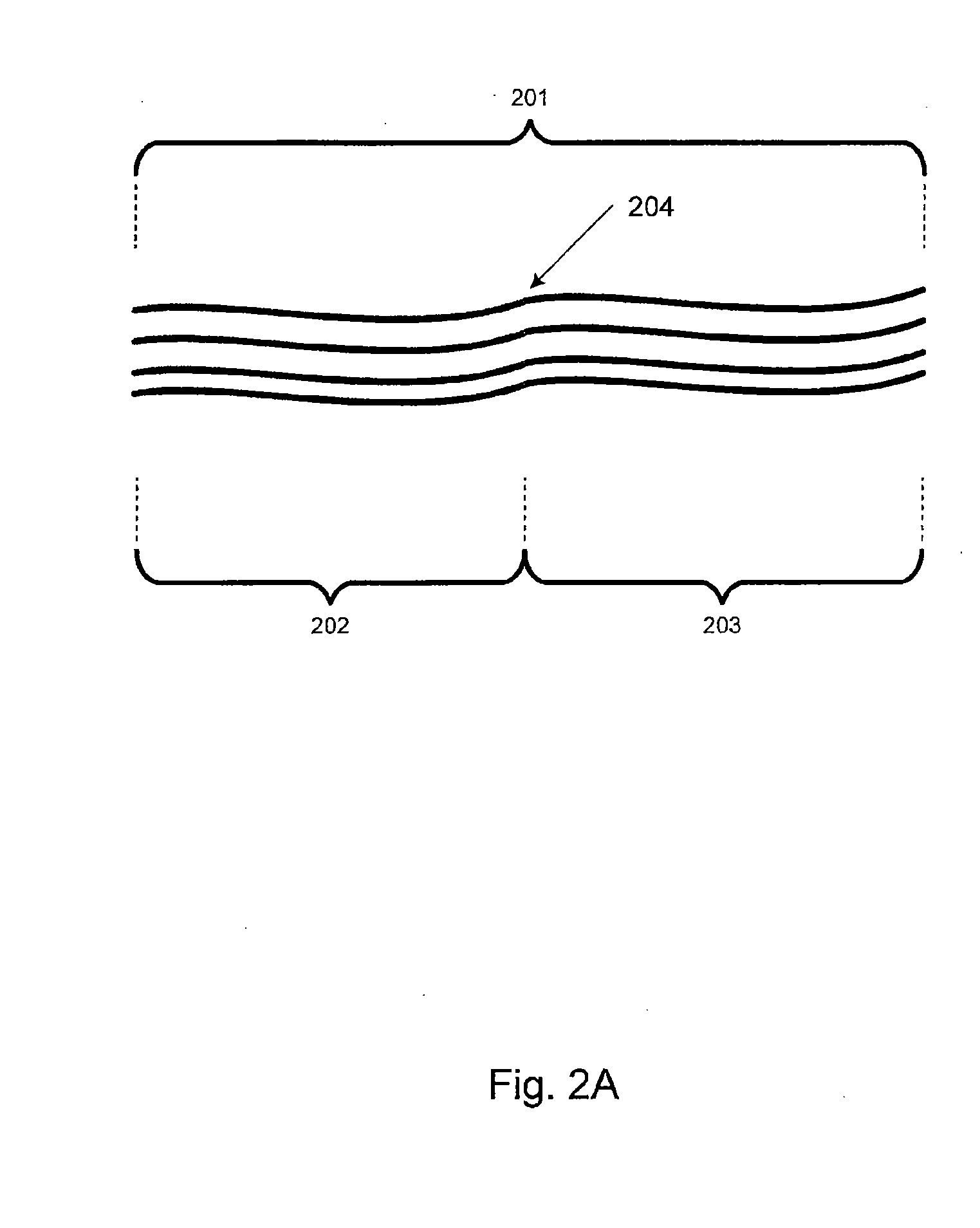

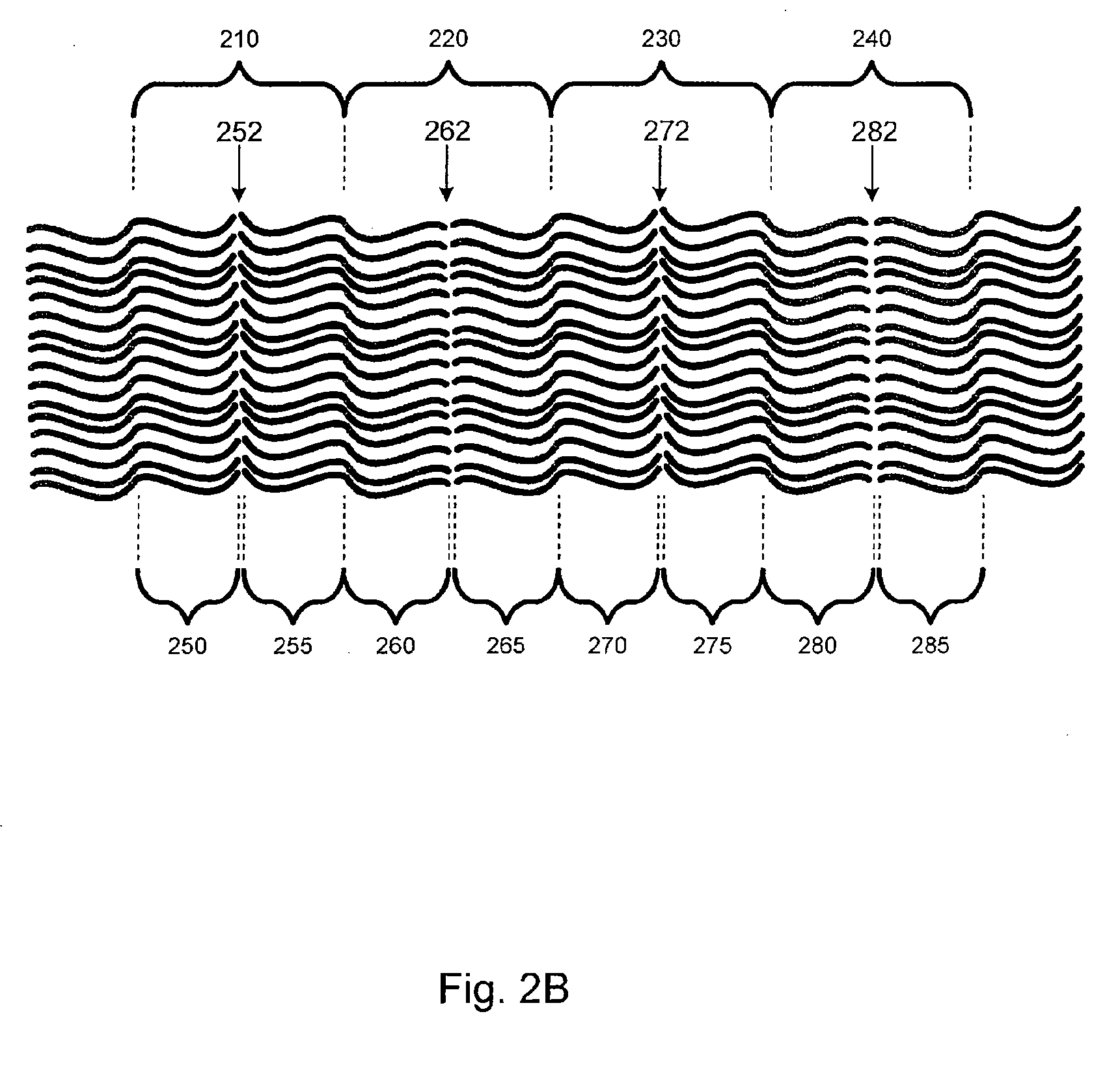

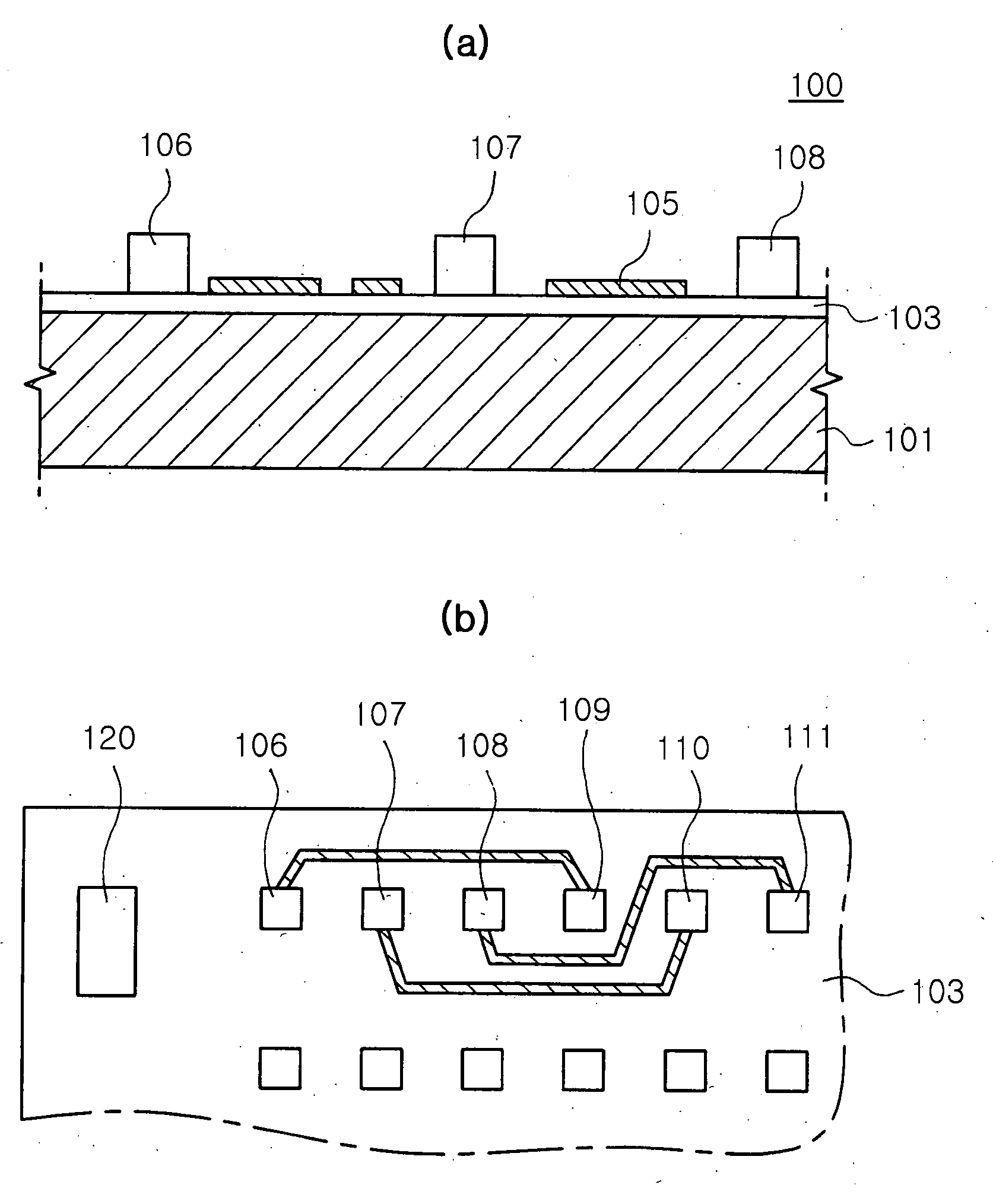

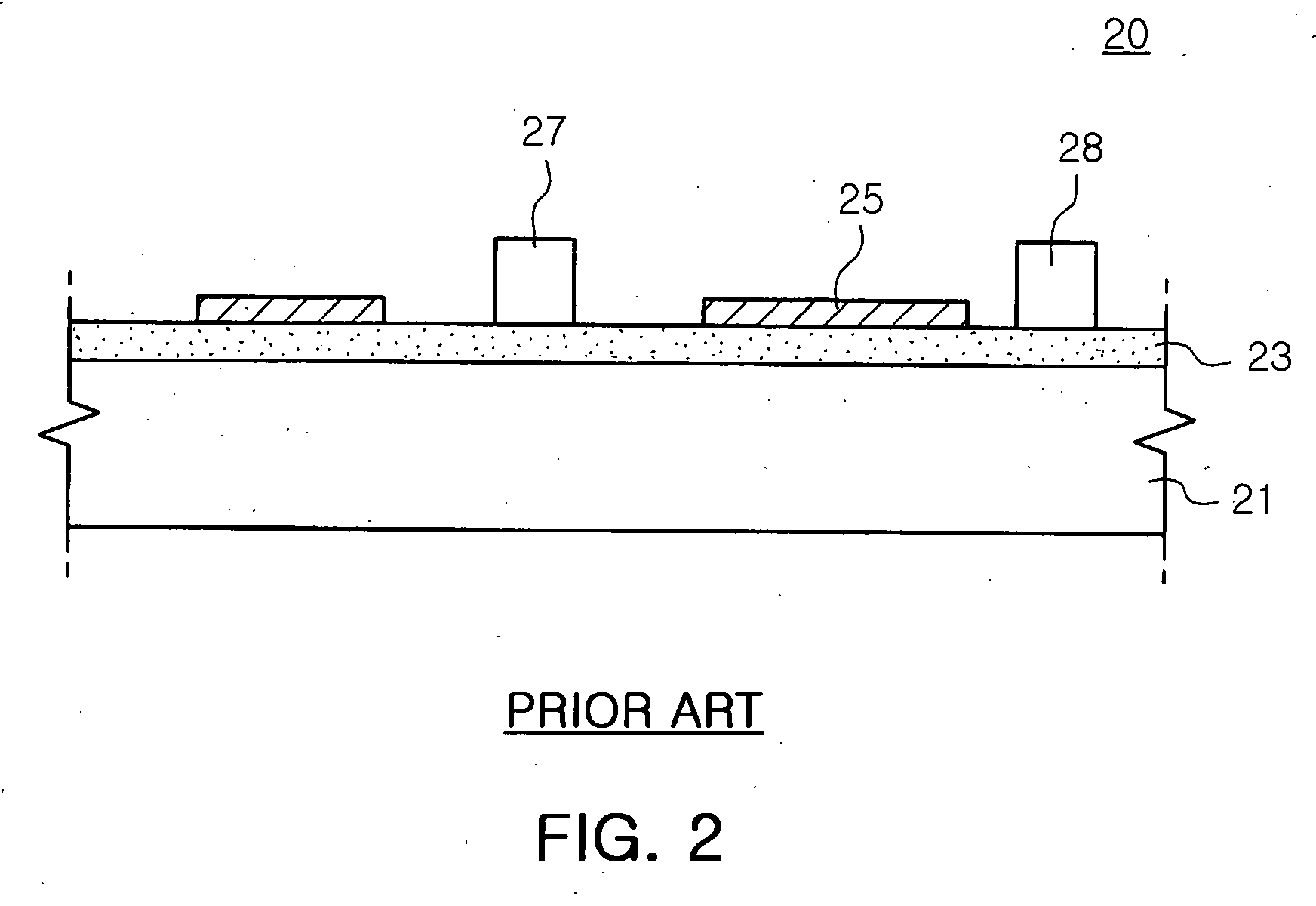

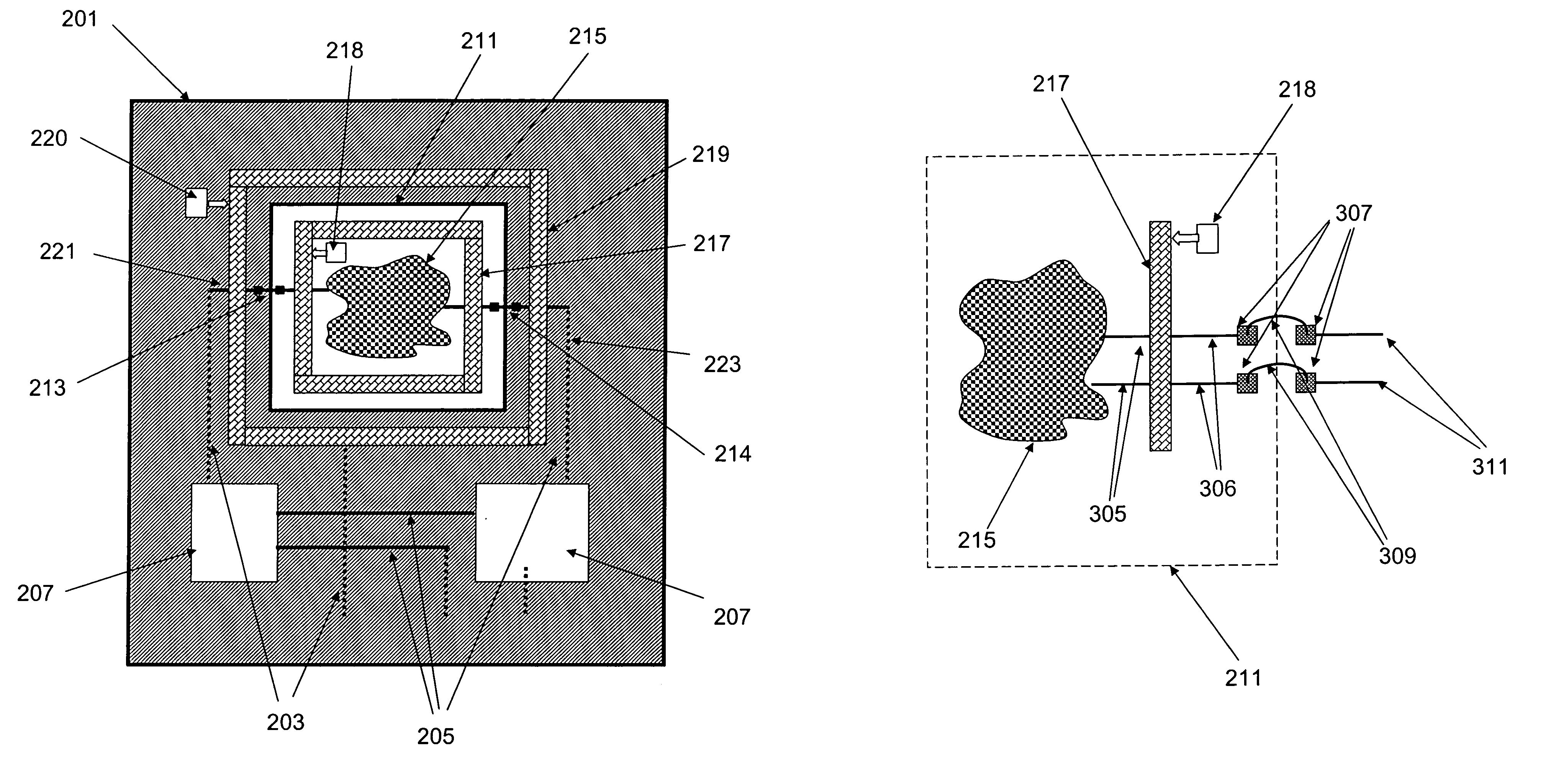

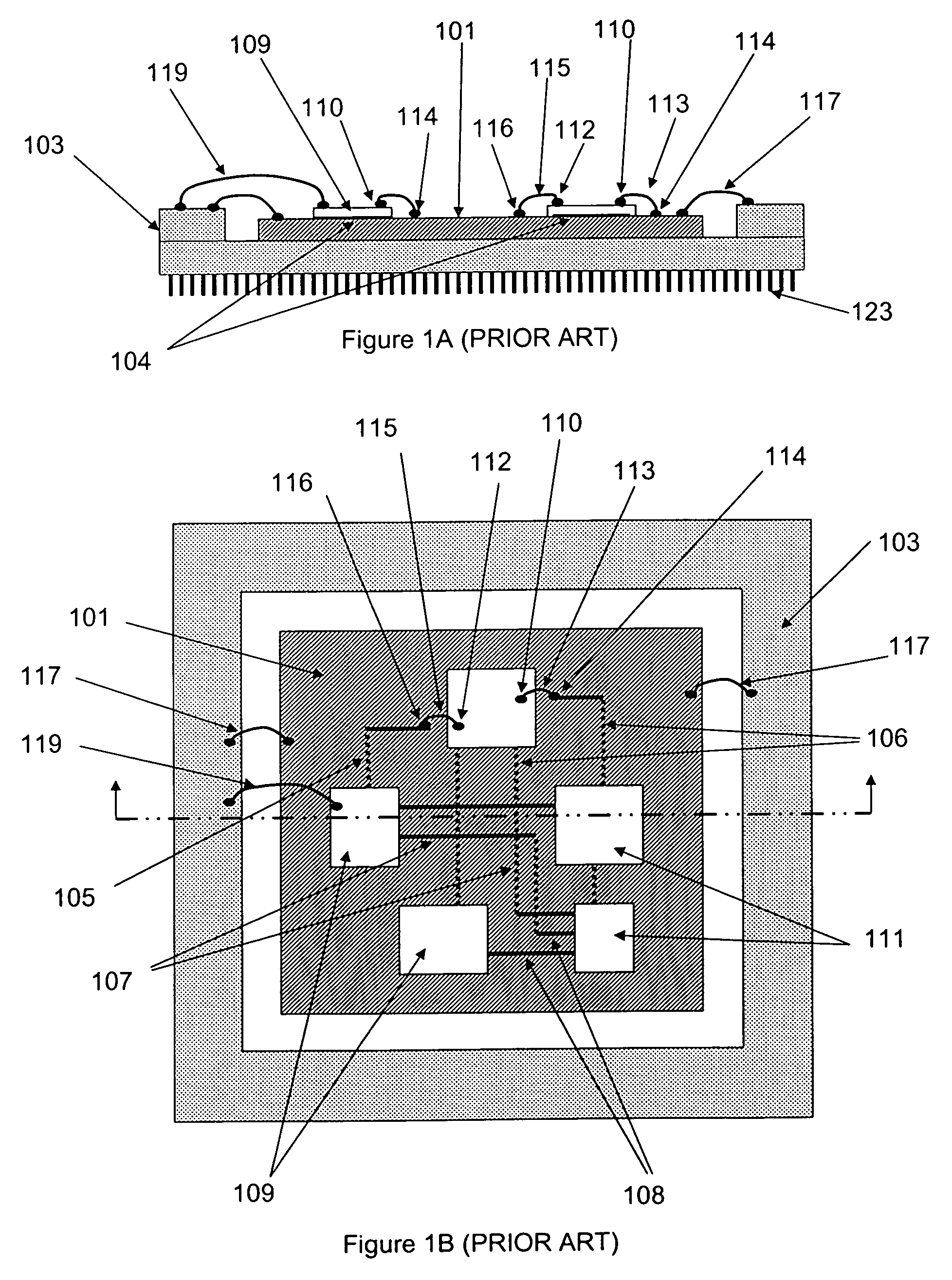

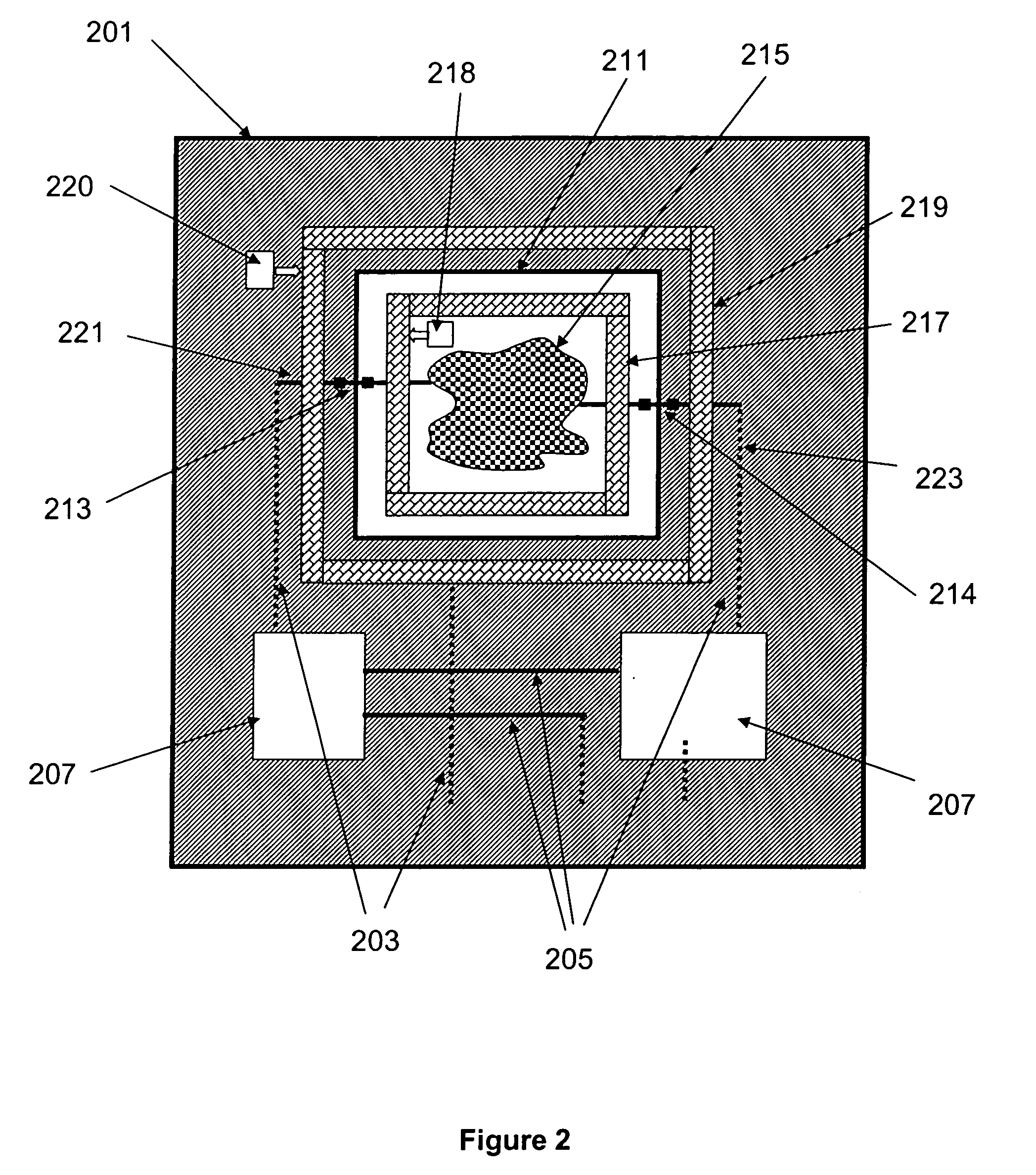

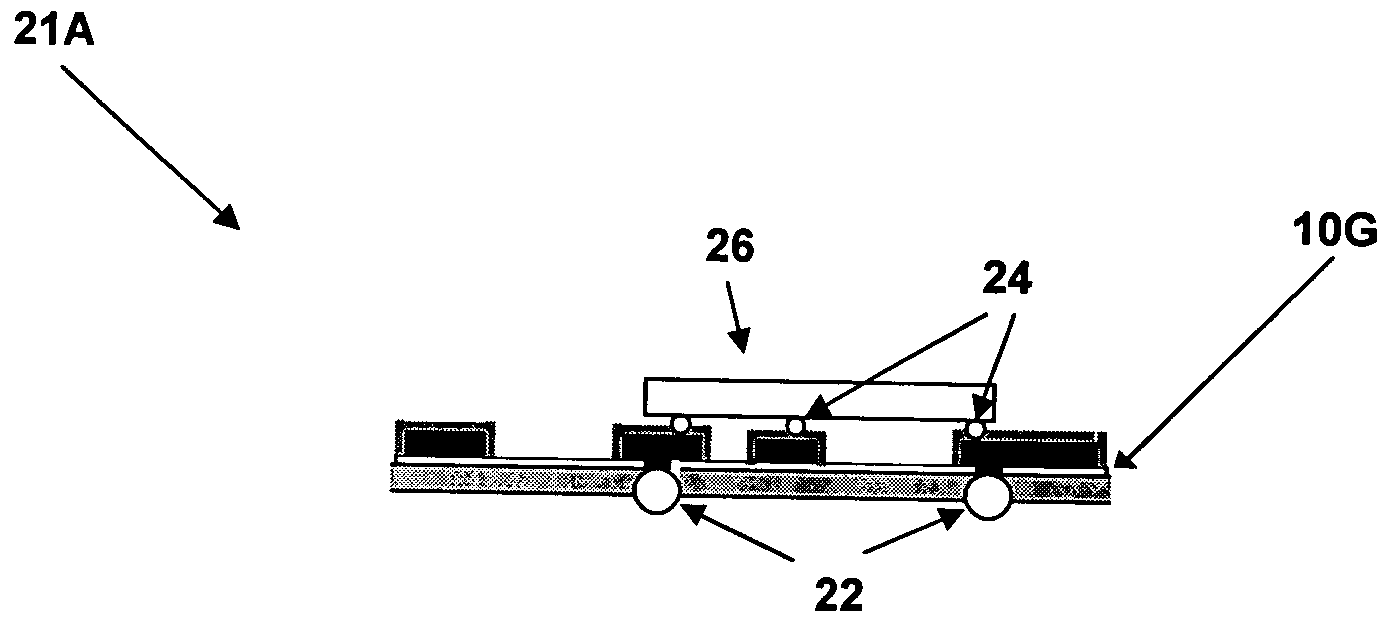

Compliance partitioning in testing of integrated circuits

InactiveUS20080061808A1Low manufacturing costGood impedance controlPrinted circuit assemblingElectrical measurement instrument detailsMembrane configurationEngineering

Probecard architectures partition the spring compliance required for IC testing between several different components. Such architectures can provide shorter springs, better impedance control, improved power / ground distribution and more direct paths to tester electronics. The probecards can also use thinner interconnector substrates to conform to the planarity of a DUT and may suspend such a substrate by wires attached to a perimeter edge of the substrate to permit the substrate to tilt. Tilting can also be facilitated by positioning tester-side springs away from the perimeter of the substrate. Low compliance MEMS probes for such architectures can be provided on replaceable coupons having attachment points away from electrical connections, and a method for fabricating probe springs can plate spring material on a membrane deformed by contact with a bumped substrate.

Owner:INNOCONNEX

Solid Electrolyte Material Manufacturable by Polymer Processing Methods

ActiveUS20090075176A1Enhanced securityLow manufacturing costSolid electrolytesAlkaline accumulatorsElastic modulusHigh energy

The present invention relates generally to electrolyte materials. According to an embodiment, the present invention provides for a solid polymer electrolyte material that is ionically conductive, mechanically robust, and can be formed into desirable shapes using conventional polymer processing methods. An exemplary polymer electrolyte material has an elastic modulus in excess of 1×106 Pa at 90 degrees C. and is characterized by an ionic conductivity of at least 1×10−5 Scm−1 at 90 degrees C. An exemplary material can be characterized by a two domain or three domain material system. An exemplary material can include material components made of diblock polymers or triblock polymers. Many uses are contemplated for the solid polymer electrolyte materials. For example, the present invention can be applied to improve Li-based batteries by means of enabling higher energy density, better thermal and environmental stability, lower rates of self-discharge, enhanced safety, lower manufacturing costs, and novel form factors.

Owner:RGT UNIV OF CALIFORNIA +1

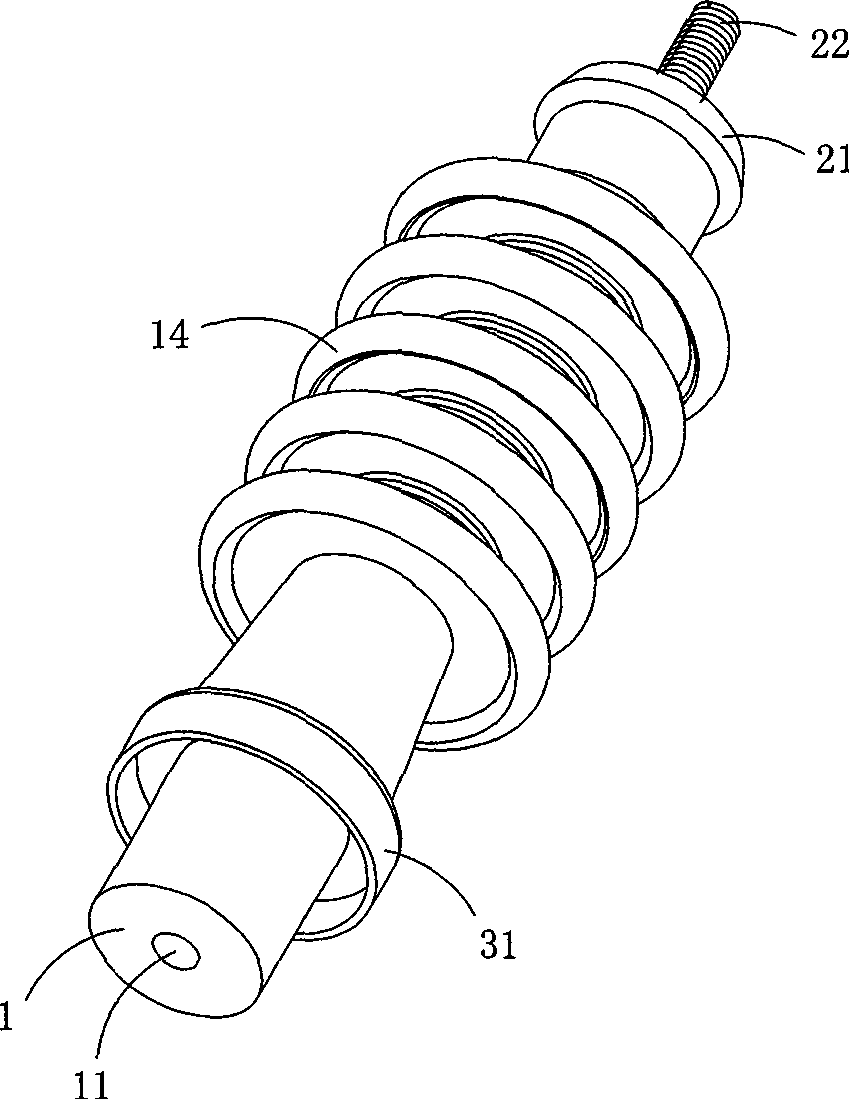

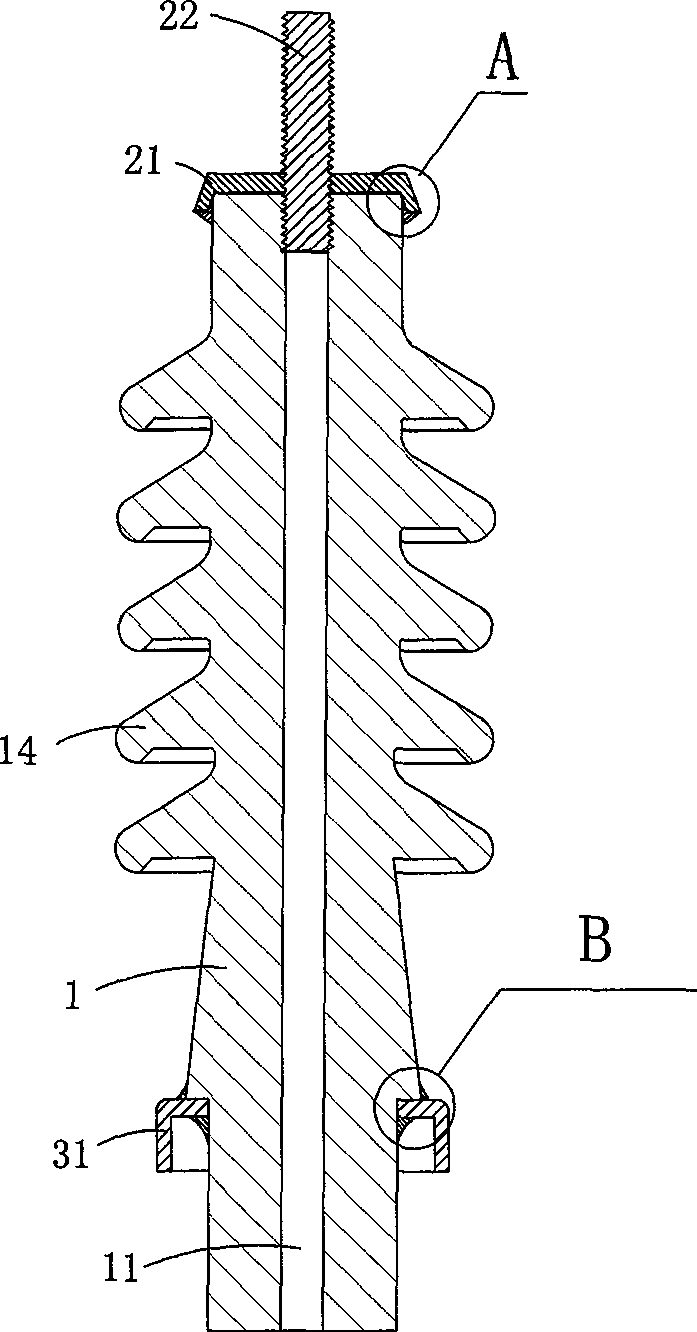

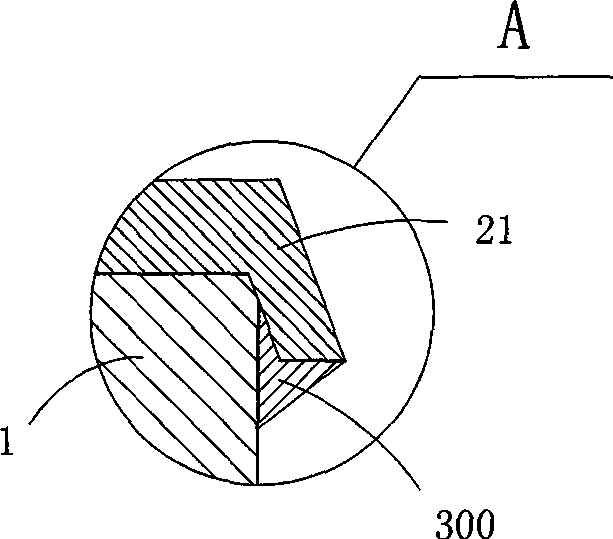

A ceramic insulator device for high voltage capacitor

InactiveCN101546636ALow manufacturing costReasonable structureSuspension/strain insulatorsHigh voltage capacitorsEngineering

The invention discloses a ceramic insulator device for high voltage capacitor comprising a ceramic insulator body, wiring assembly and mounting assembly; the insulator body is provided with an annular positioning boss at outer wall of bottom part; the mounting assembly comprises metal mounting base, upper seal ring, lower seal ring and two semi-circle metal baffle ring; the metal mounting base is basically tubular provided with a inward protruding baffle ring at lower part; the metal mounting base is sleeved onto outer wall of lower part of insulator body; the baffle ring is positioned at lower part of annular positioning boss; a lower seal ring is sleeved onto outer wall of insulator body and positioned between lower surface of annular positioning boss and baffle ring; upper seal ring is sleeved onto outer wall of lower part of the insulator body and positioned at upper surface of annular positioning boss; two metal baffle rings are provided at upper surface of upper seal ring and weldingly fixed with metal mounting base. The invention has merits of low cost, convenient processing and production.

Owner:王海龙

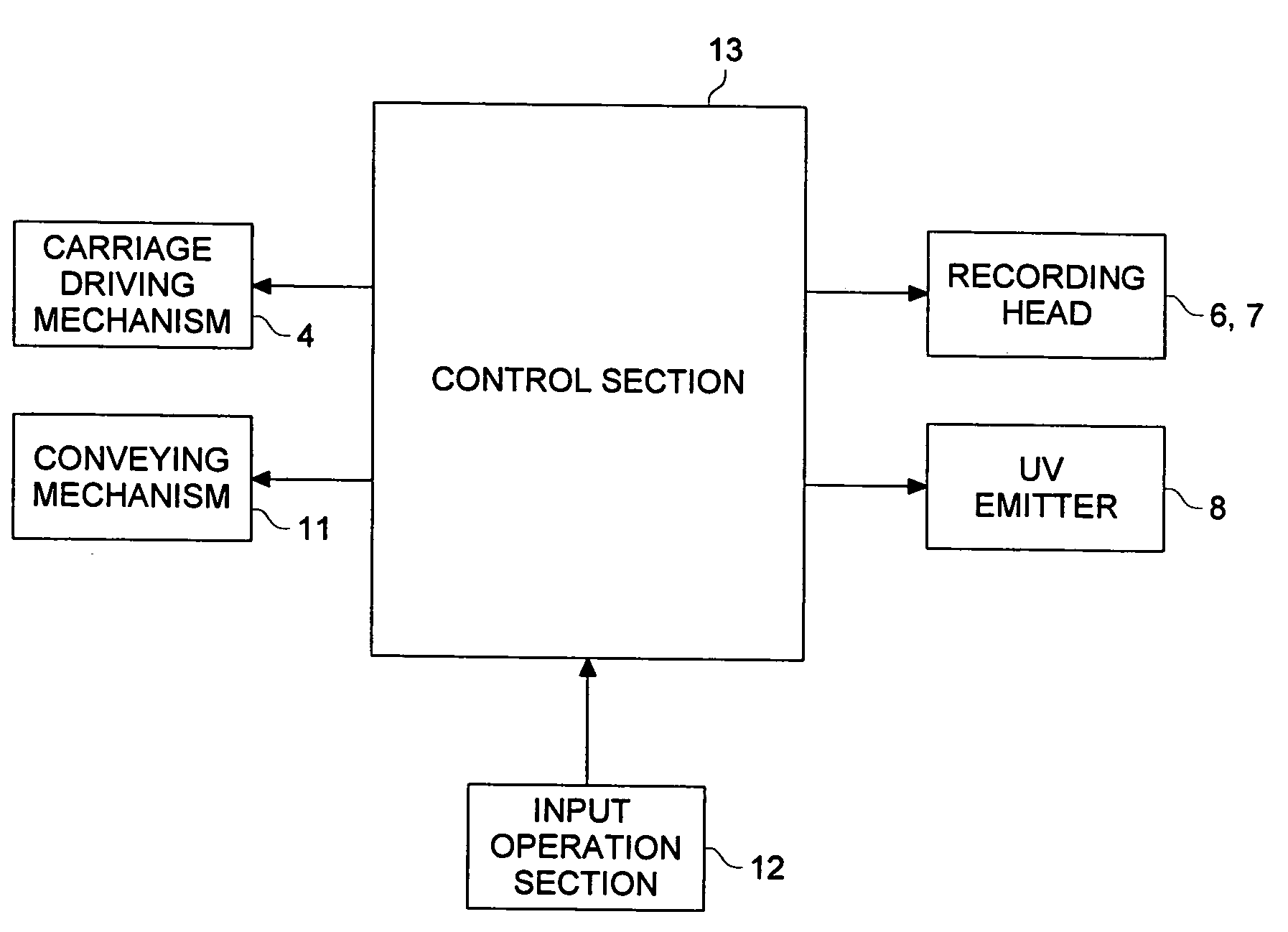

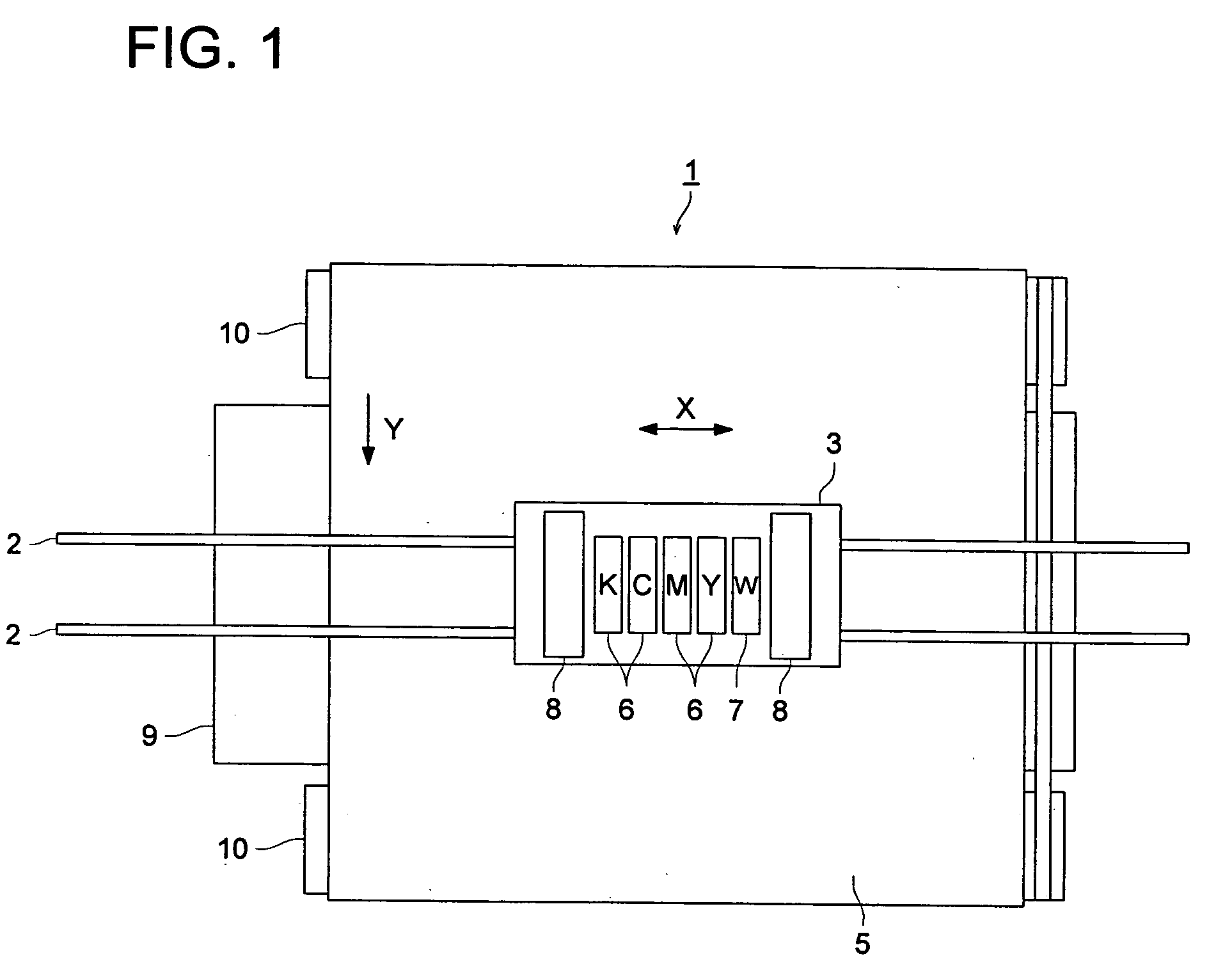

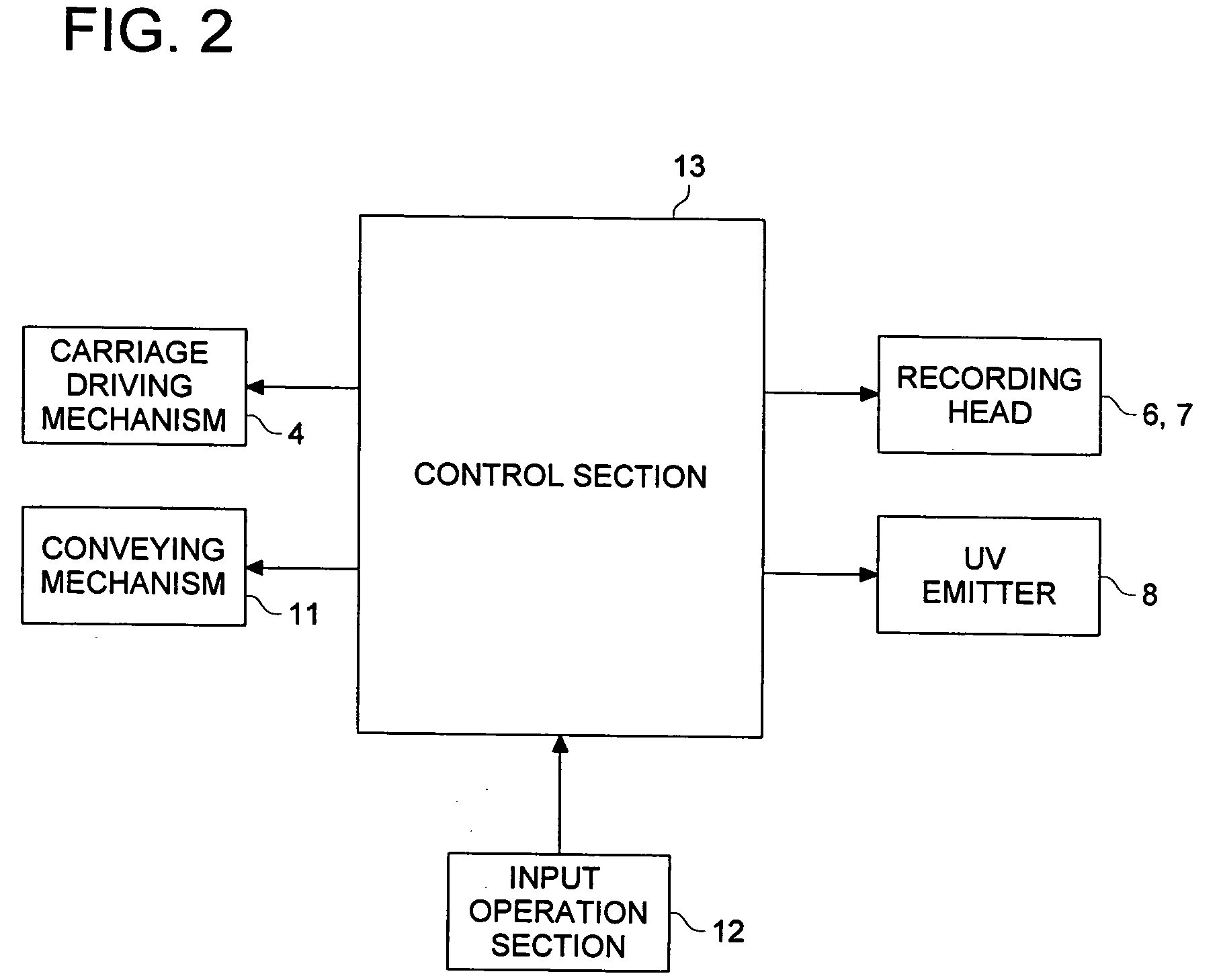

Inkjet recording apparatus

InactiveUS20050237352A1Low manufacturing costFine image qualityTypewritersOther printing apparatusSpray nozzleImage recording

An inkjet recording apparatus includes an image recording head for jetting image recording ink onto a recording medium conveyed in a sub scanning direction, while the recording head reciprocally moving in the main scanning direction, the image recording head having an image recording nozzle array including a plurality of nozzles; an auxiliary recording head for jetting auxiliary recording ink for enhancing image recording, the auxiliary recording head having an auxiliary recording nozzle array including a plurality of nozzles, the auxiliary recording nozzle array being disposed along the sub scanning direction in parallel to the image recording nozzle array; and a control section for controlling the image recording nozzle array and the auxiliary recording nozzle array so as to change respective ink jetting areas by selecting nozzles, for respectively jetting ink, from the image recording nozzle array and the auxiliary recording nozzle array, according to a recording mode.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

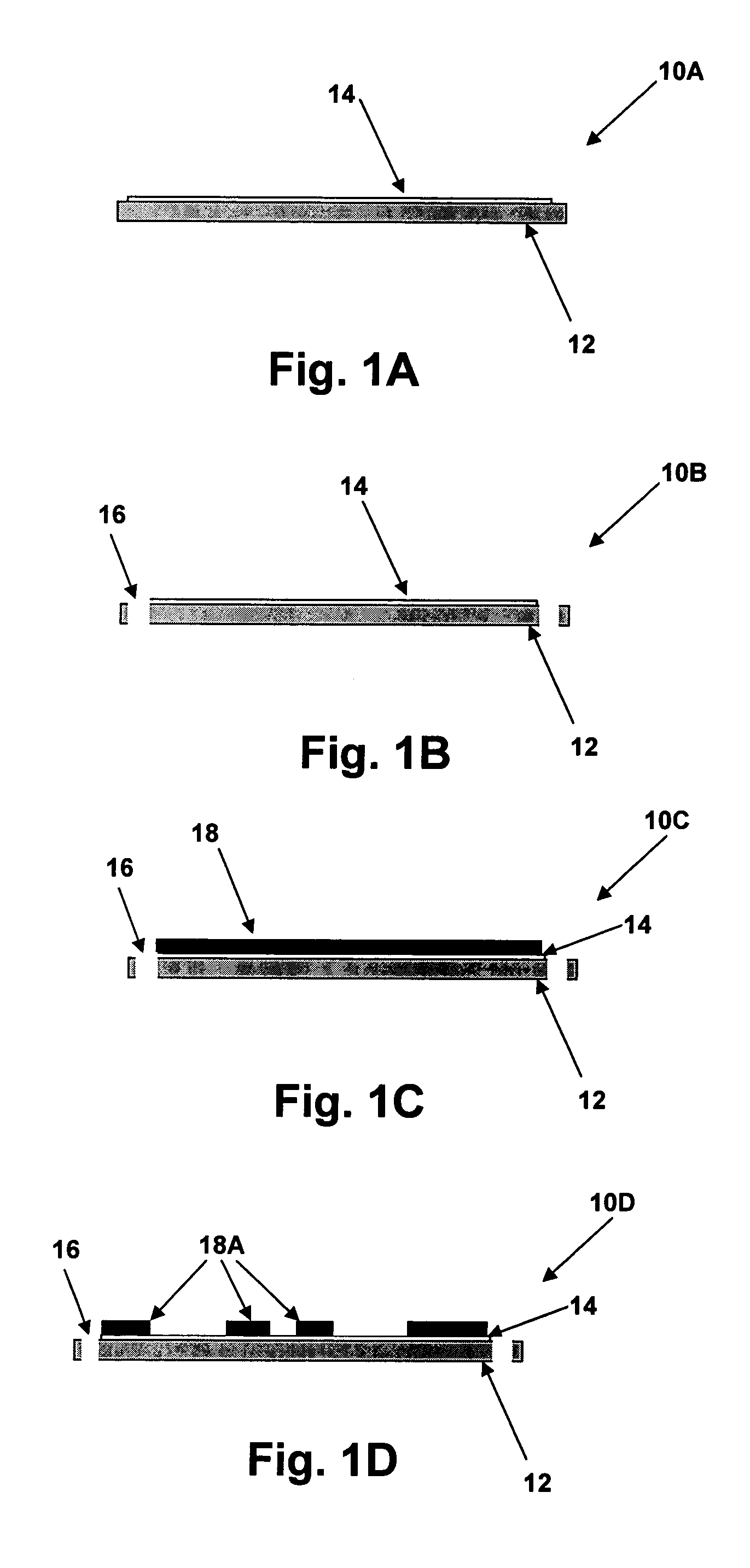

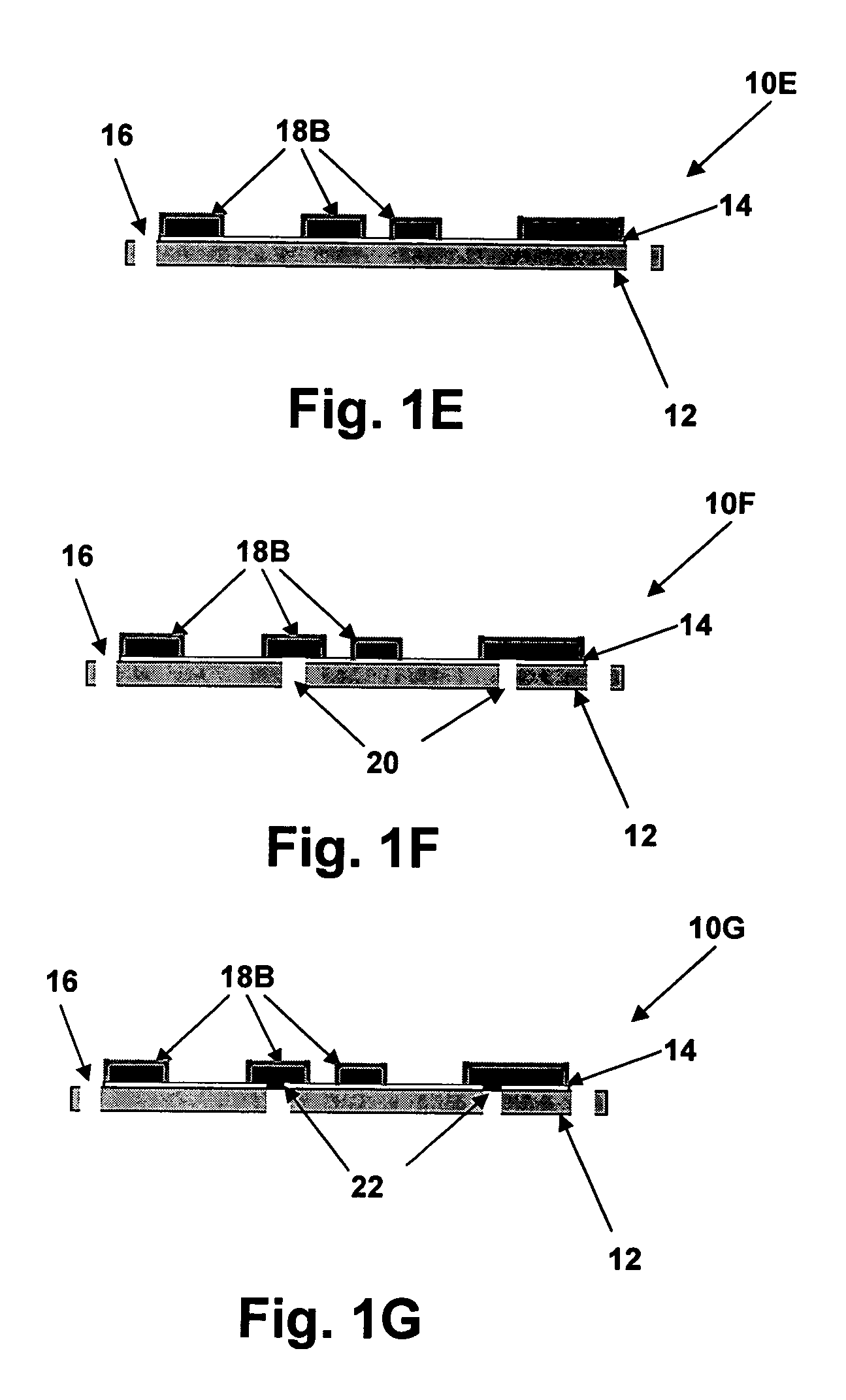

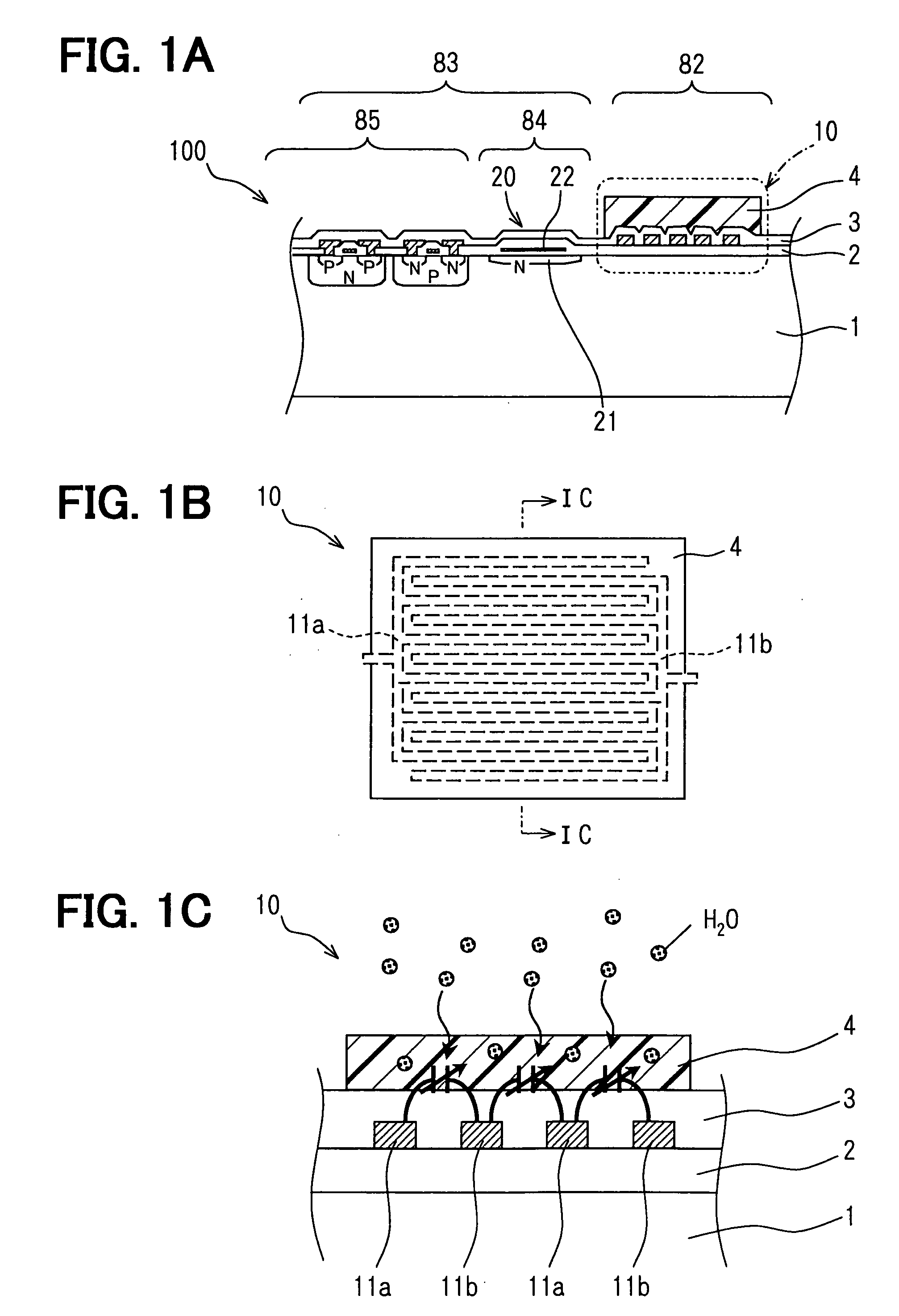

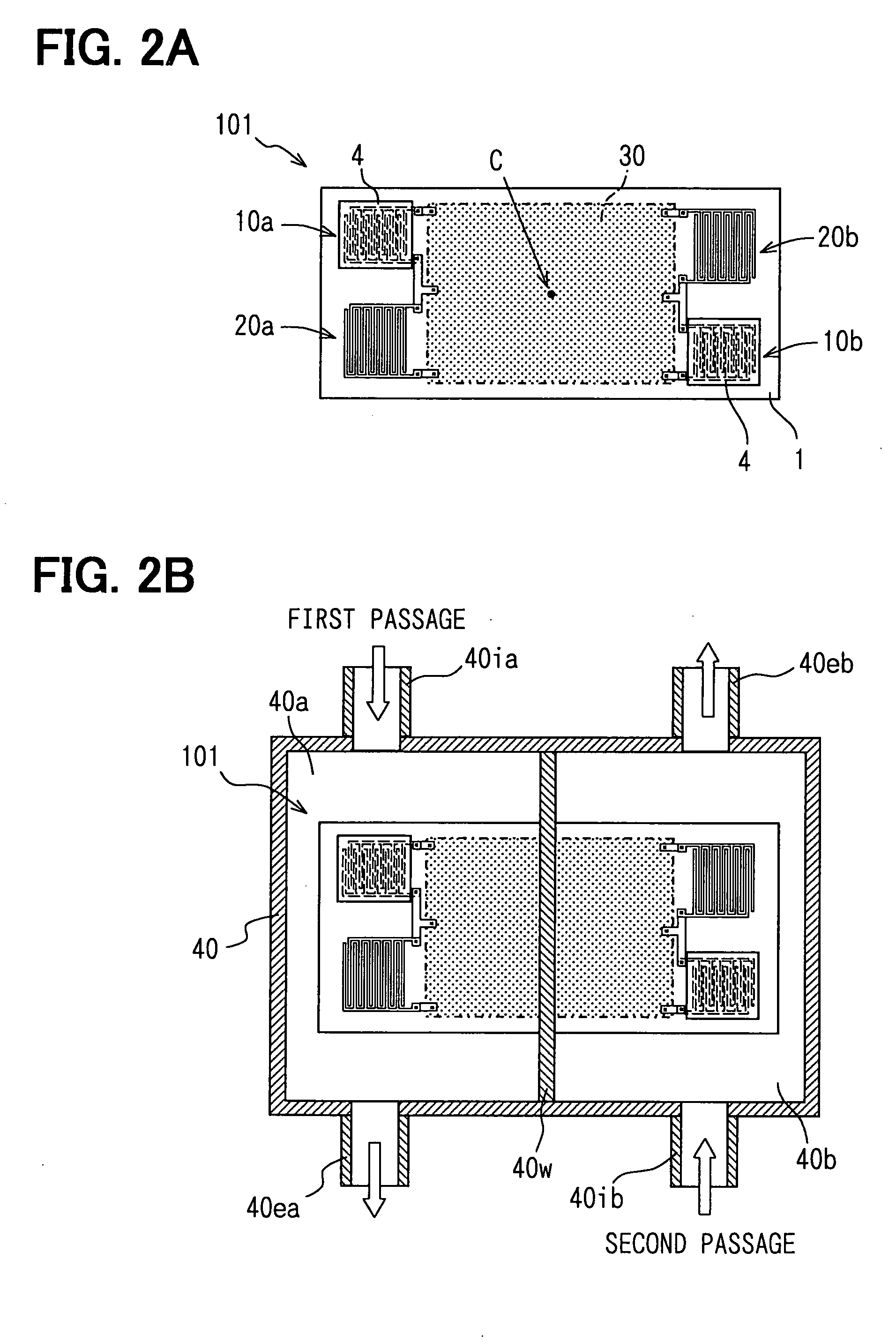

Anodized metal substrate module

ActiveUS20070217221A1Excellent heat radiation propertyLow manufacturing costElectric discharge tubesLighting heating/cooling arrangementsRadiation propertiesMetal substrate

Owner:SAMSUNG ELECTRONICS CO LTD

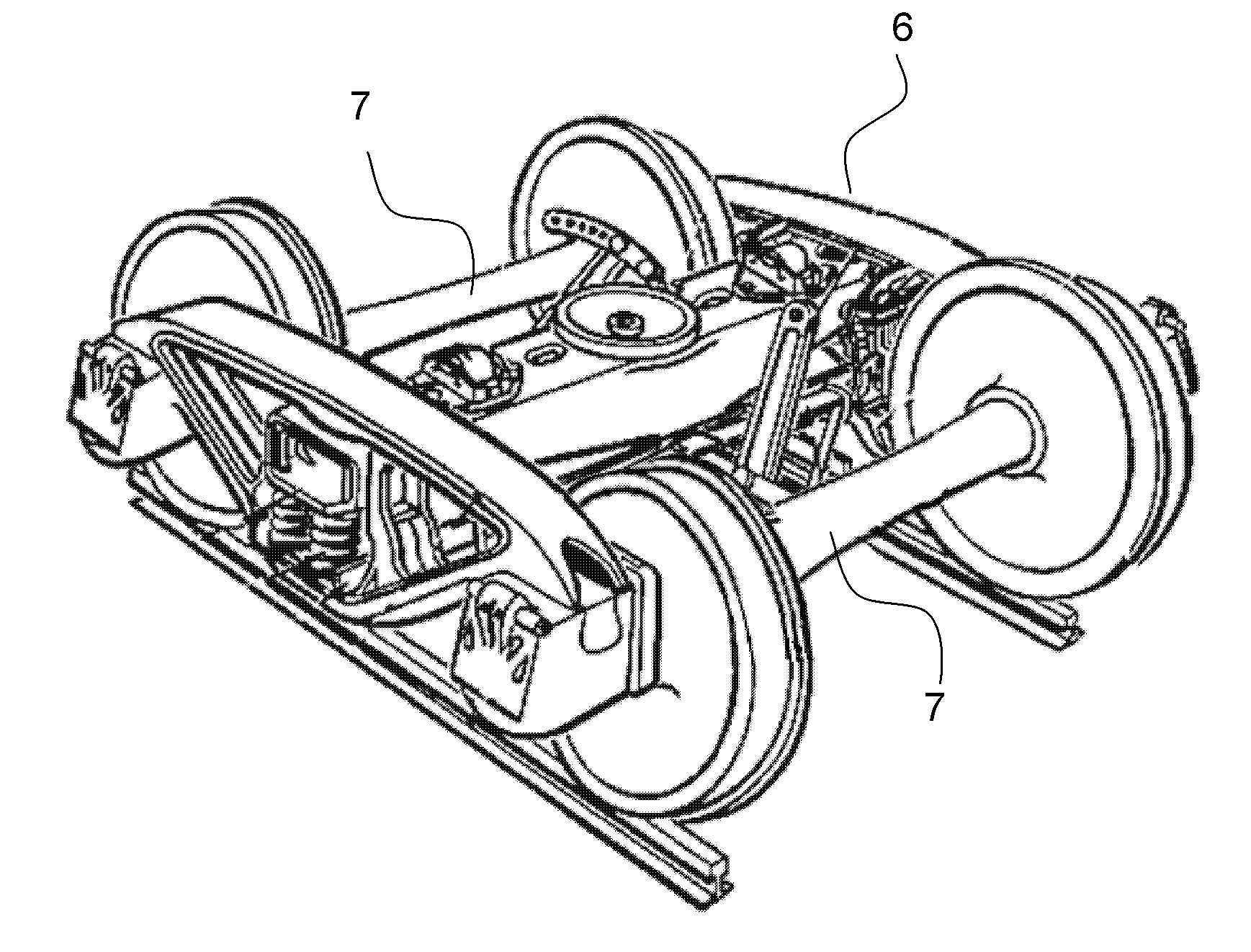

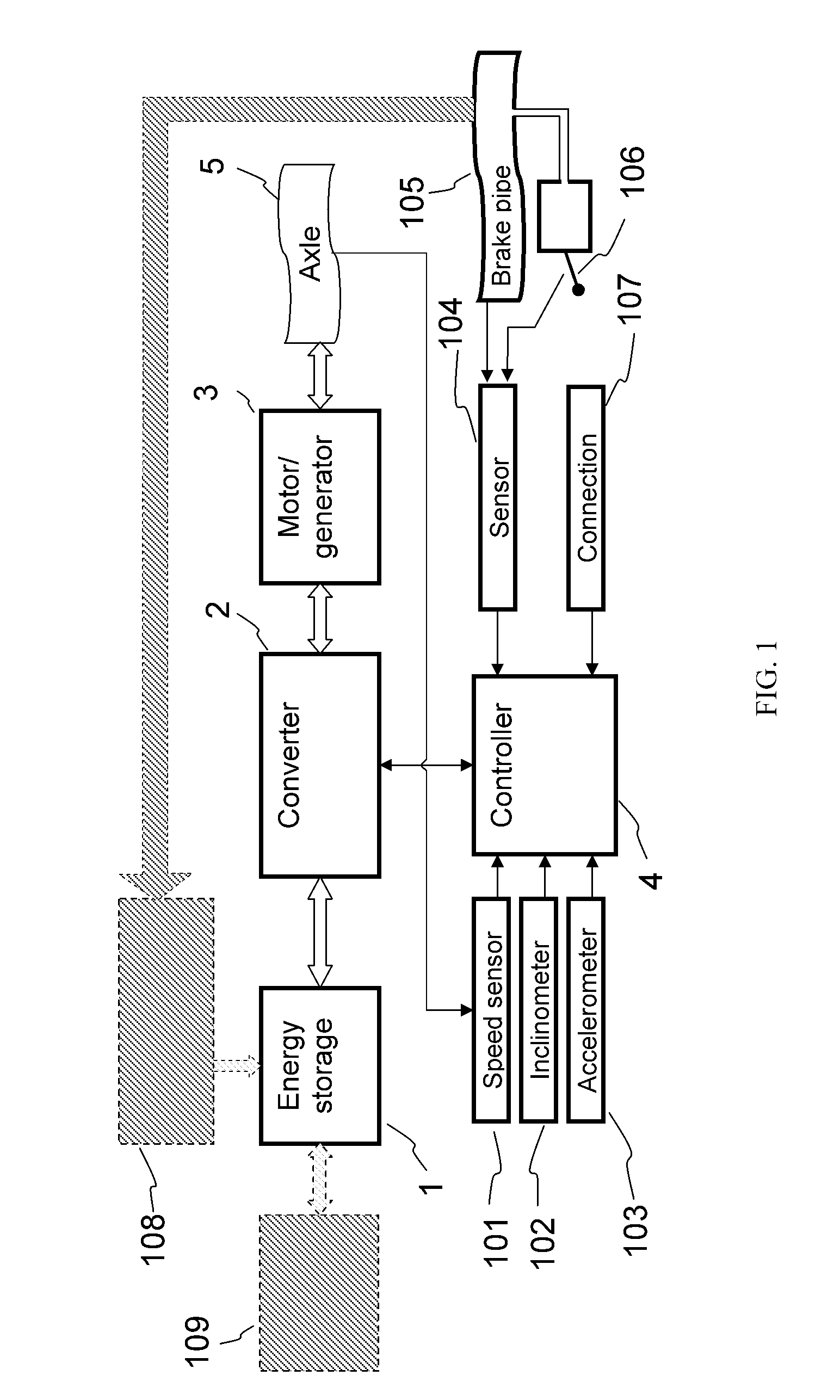

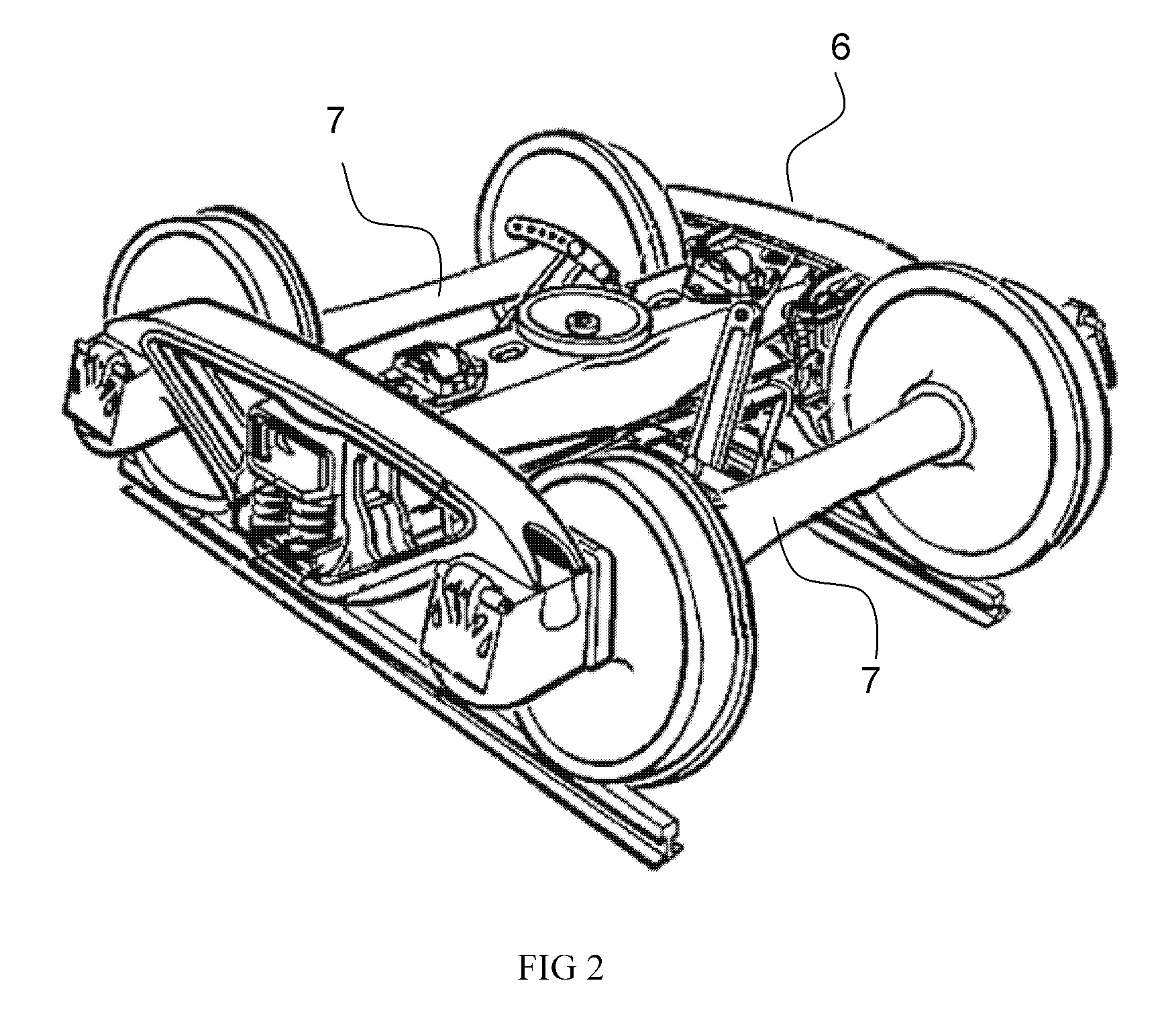

Quasi self-contained energy storage and power supply system

InactiveUS20100282122A1Reduce wearLow manufacturing costHybrid vehiclesAuxillary drivesAutomotive engineeringTractive effort

Quasi-autonomous system of energy storage and electrical motorization that can be installed on carrying axles or bogies of railway cars or road trailers to provide a tractive effort or electrical braking without an external power supply and assemblies, convoys and trains. The recharging energy of the energy storage system is principally obtained from regenerative braking and generated by the inertia of the convoy or by the traction of the convoy motor coach; the stored energy is returned as tractive effort when necessary. The system has a controller independent of all external control.

Owner:SERISE TECH

Hybrid semiconductor circuit with programmable intraconnectivity

InactiveUS6991947B1Improve yieldLow manufacturing costSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsProgrammable logic deviceProgrammable circuits

Field programmable circuits and redundant logic are added to the substrate of a hybrid circuit with functionality to bypass and / or repair unusable dies in order to enhance yield and lower costs of manufacture. In a preferred embodiment, a collar of programmable logic is inserted between the functional component on the hybrid die and its I / O terminals. The programmable logic collar can be programmed after hybrid assembly and test in order to correct assembly errors or die failures through one or more of the following actions: switch between redundant functional units and I / Os on the hybrid die; switch between redundant IC dies on the substrate, invert signal polarity; correct crosstalk errors; perform test and fault isolation.

Owner:GHEEWALA TUSHAR

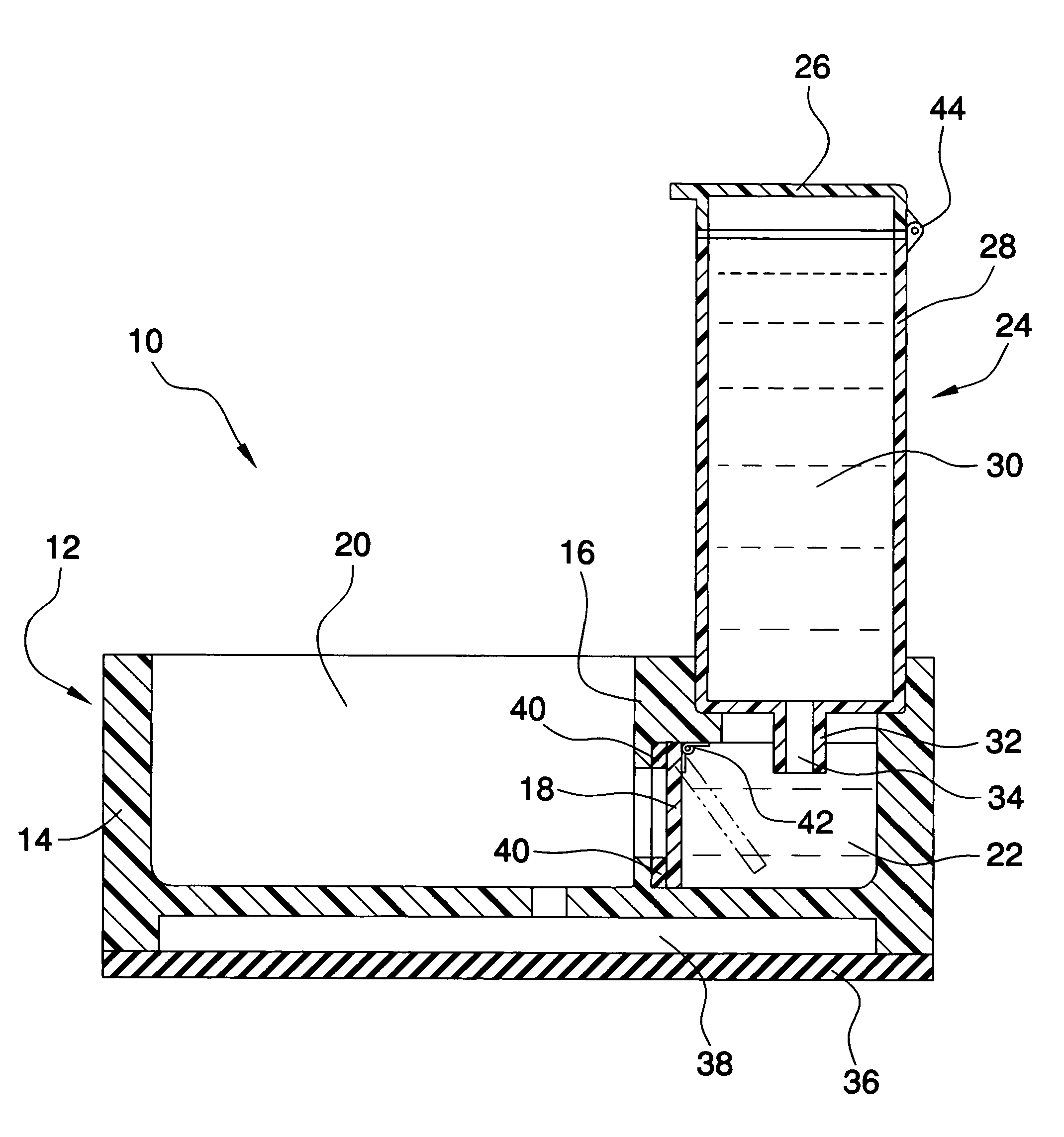

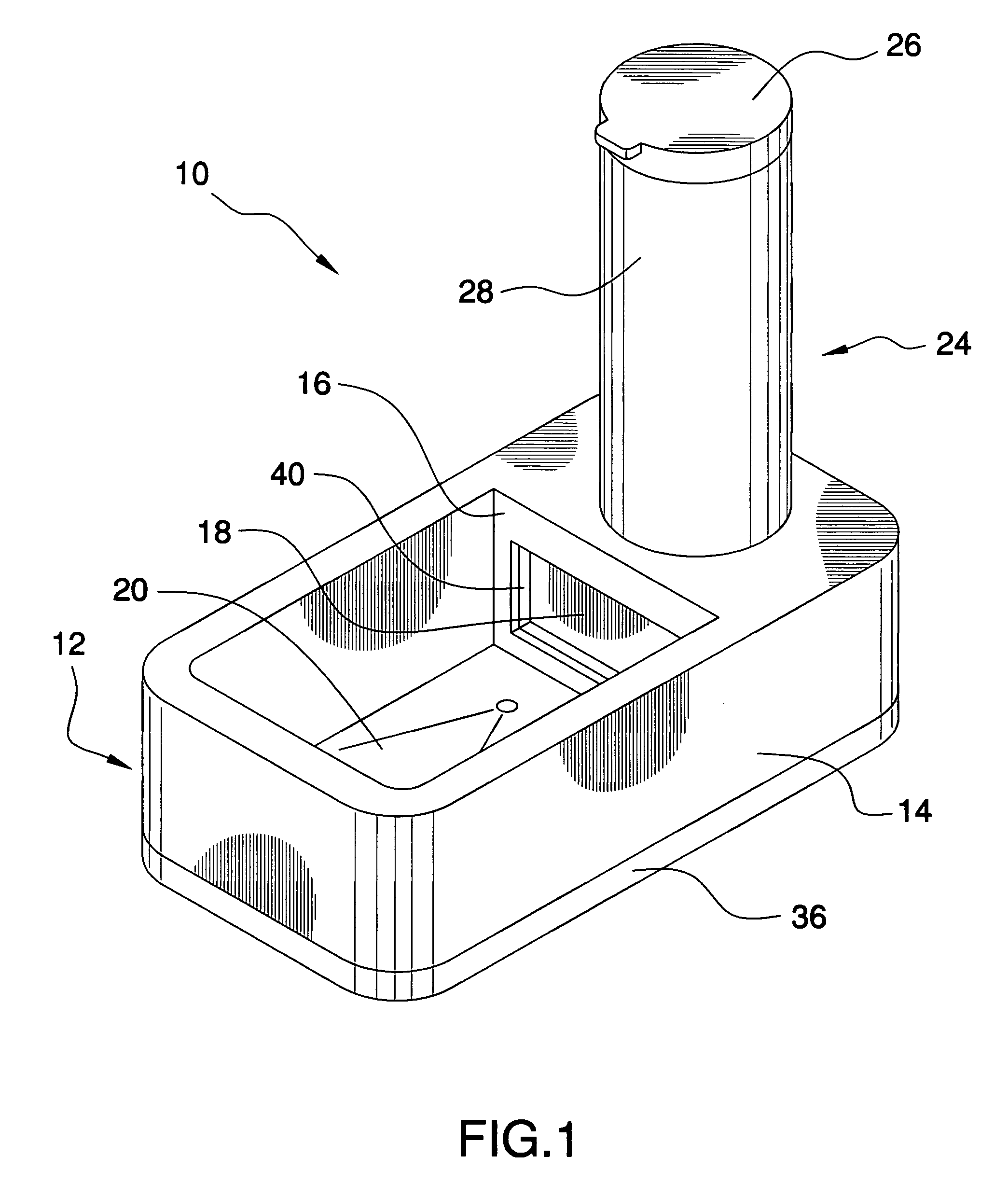

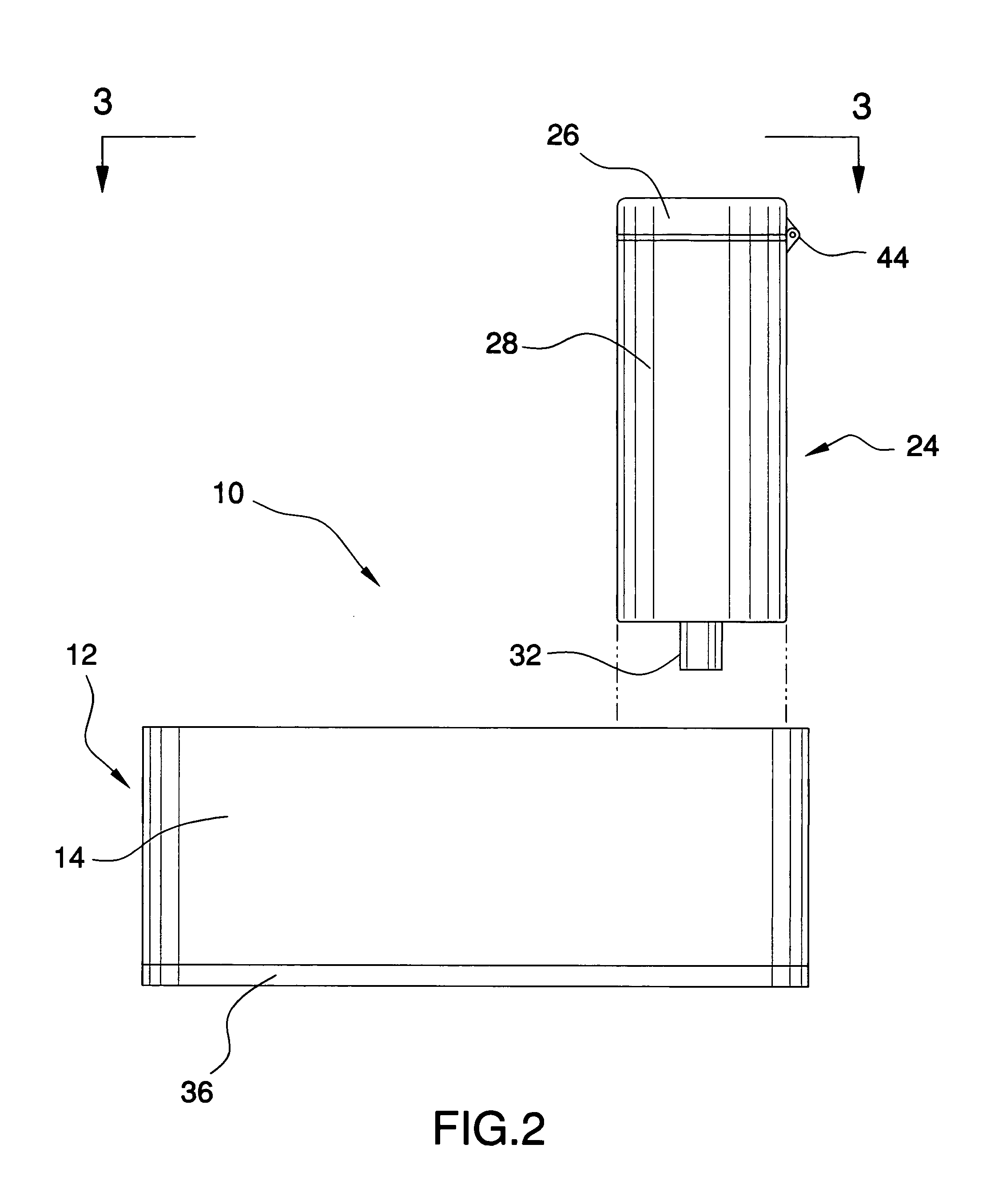

Water dispensing device, kit and method

InactiveUS6971331B1Easily and efficiently manufacture and marketLow manufacturing costClosuresAnimal watering devicesEngineering

Owner:ROHRER MICHAEL W

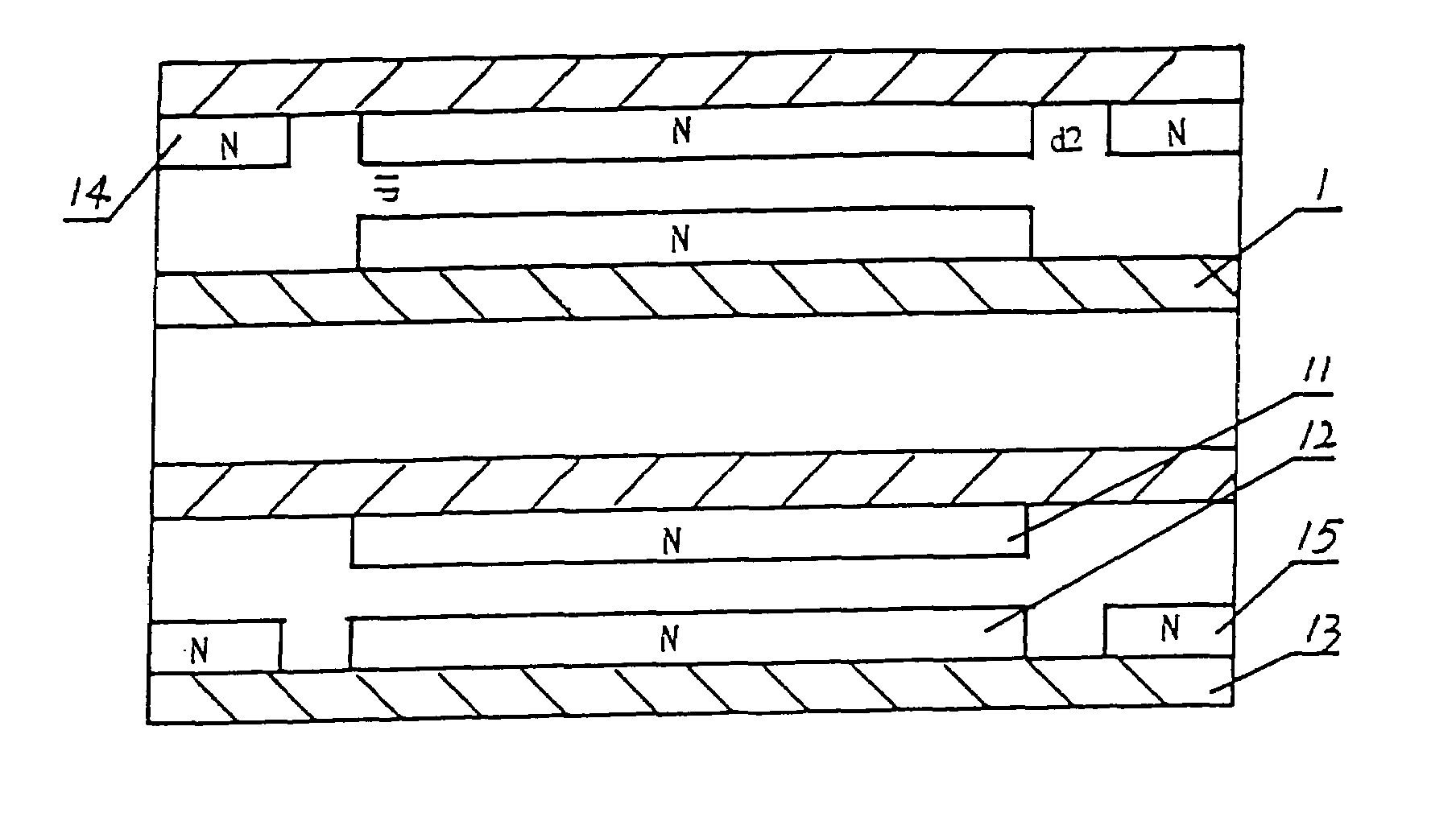

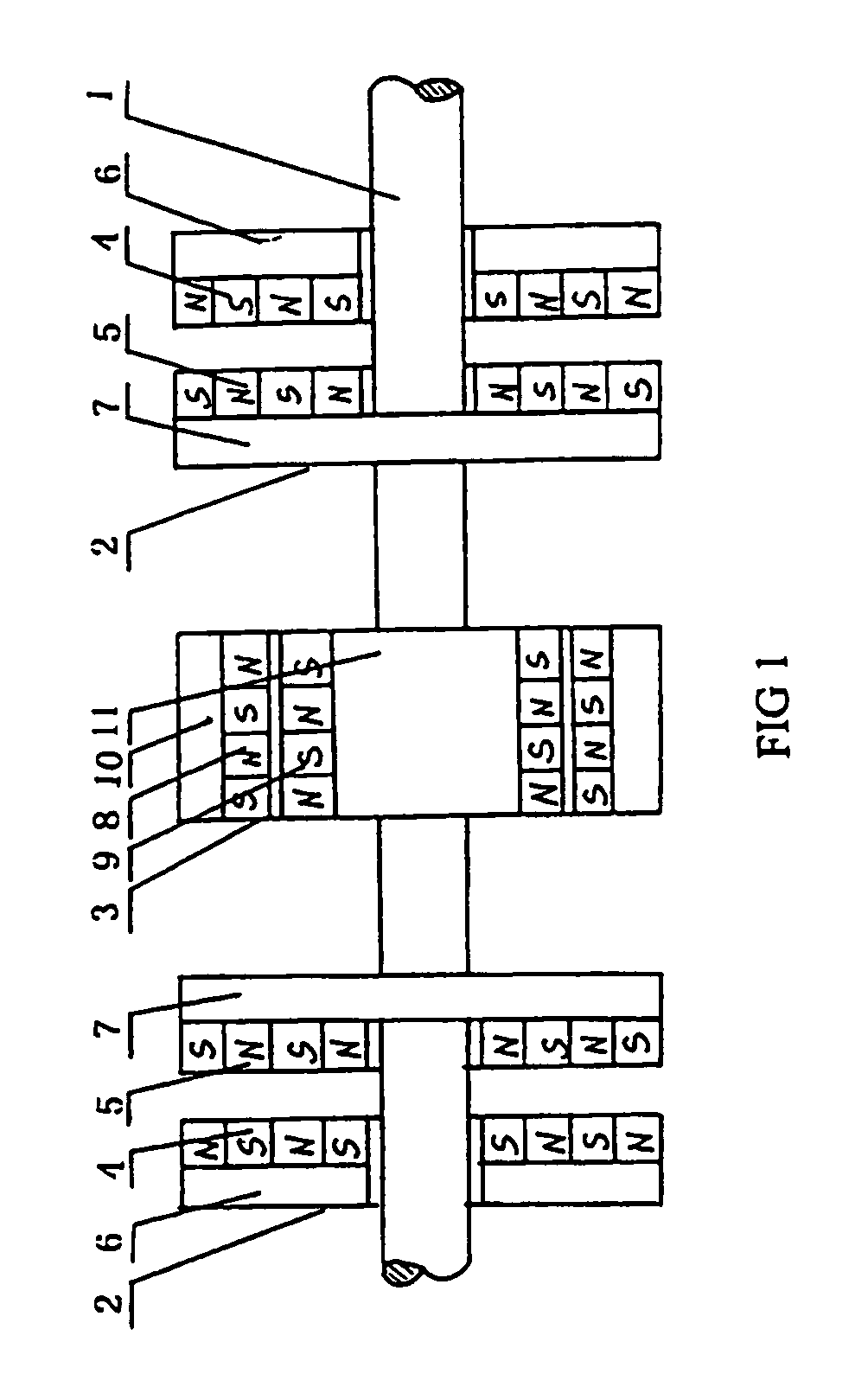

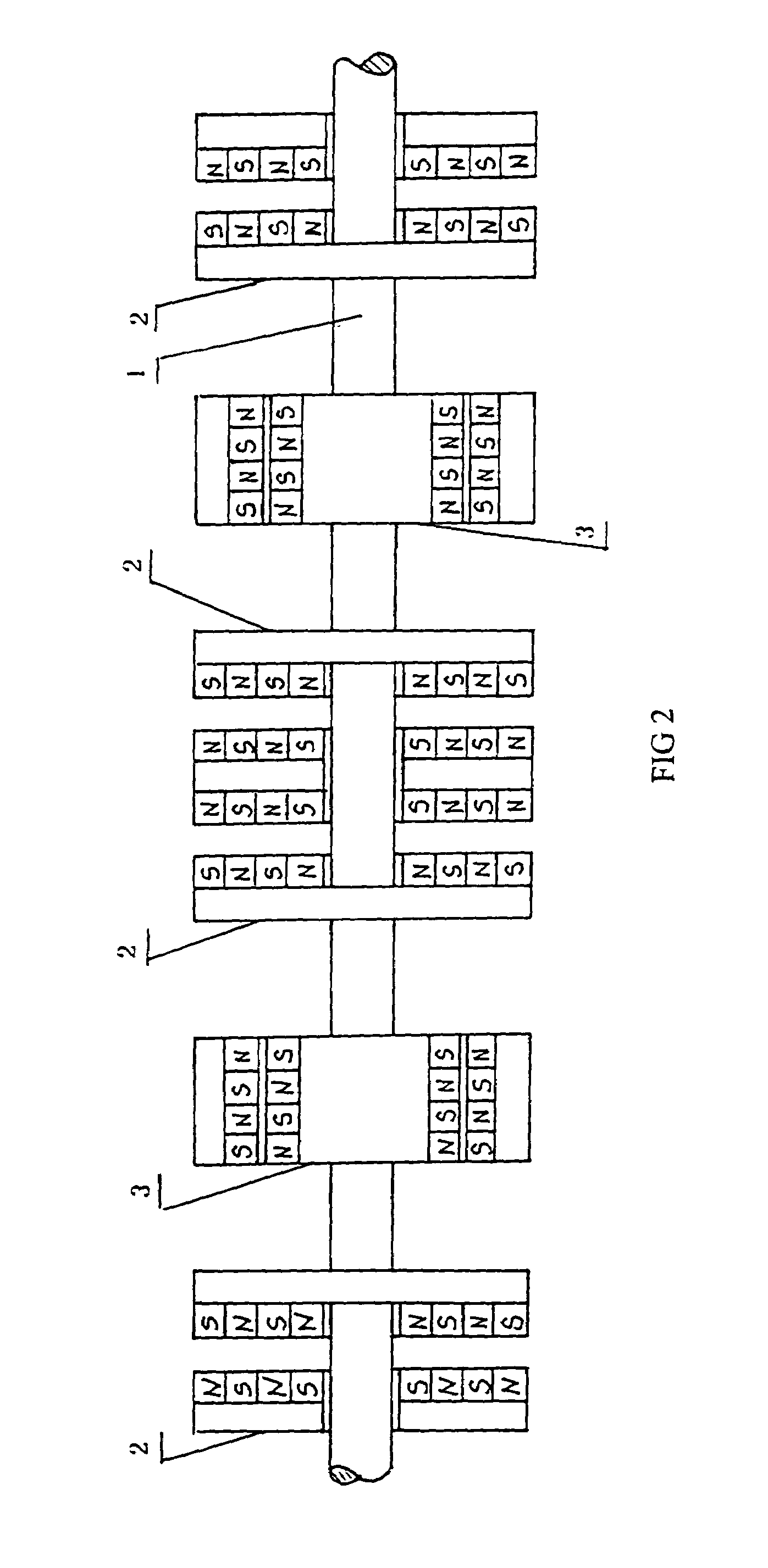

Magnetic suspension bearing

InactiveUS7262531B2Simple structureLow manufacturing costEmergency protective circuit arrangementsMagnetic bearingsEngineeringMagnetic polarity

The present invention relates to a magnetic suspension bearing supported by magnetic force, which comprises one or more magnets fixed on a shaft directly or indirectly which can rotate with said shaft, and matching magnets provided in a certain space, wherein the magnetic polarity and magnitude of magnetic force of the matching magnets match with the magnetic polarity and magnitude of magnetic force of said one or more magnets to achieve the full suspension rotation of said shaft, and said magnets and / or matching magnets are permanent magnets. The present invention is of simple design and large power, with many other advantages such as great rigidity and great load-bearing capability and widely use in various fields.

Owner:LI GUOKUN +2

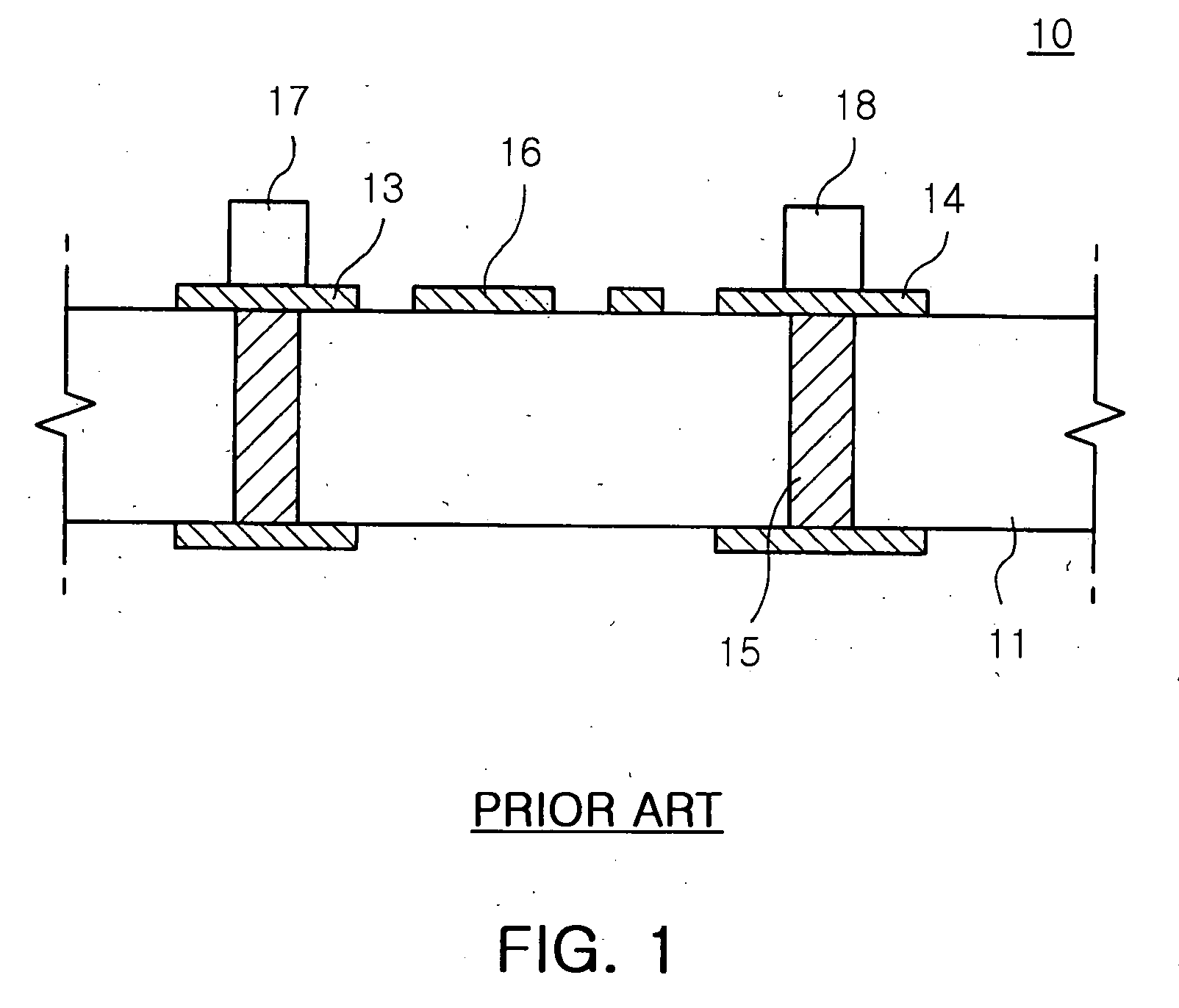

Integrated circuit substrate having laser-exposed terminals

InactiveUS7028400B1Improve interconnect densityLow manufacturing costPrinted circuit assemblingLine/current collector detailsIntegrated circuitElectroplating

An integrated circuit substrate having laser-exposed terminals provides a high-density and low cost mounting and interconnect structure for integrated circuits. The laser-exposed terminals can further provide a selective plating feature by using a dielectric layer of the substrate to prevent plating terminal conductors and subsequently exposing the terminals via laser ablation. A metal layer may be coated on one or both sides with a dielectric material, conductive material embedded within the dielectric to form conductive interconnects and then coating over the conductive material with a conformal protective coating. The protectant is then laser-ablated to expose the terminals. A dielectric film having a metal layer laminated on one side may be etched and plated. Terminals are then laser-exposed from the back side of the metal layer exposing unplated terminals.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

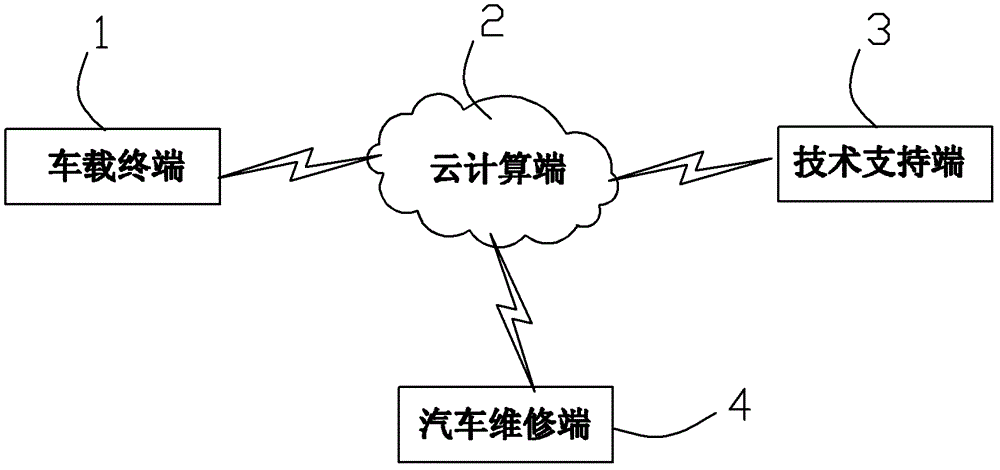

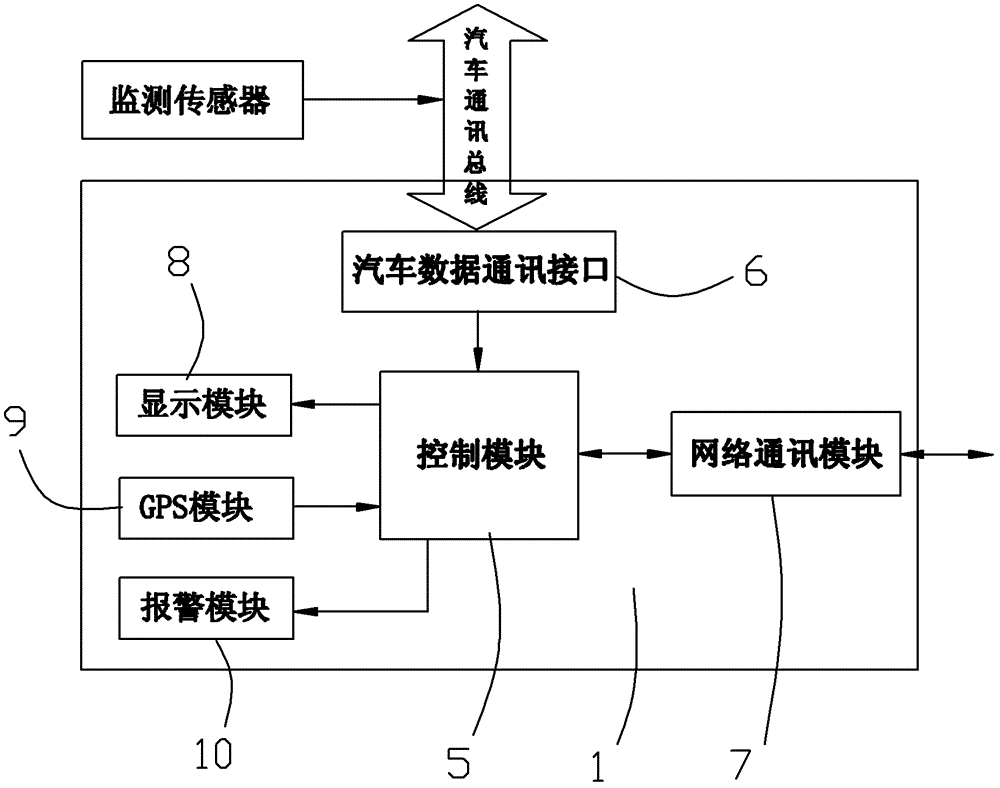

Automobile failure detection system based on cloud calculation

ActiveCN102752360ALow manufacturing costReduce security risksTelephonic communicationTransmissionCloud computingCommunication interface

The invention relates to an automobile failure detection system based on cloud calculation. The automobile failure detection system solves the problems that a general automobile does not have a function of automobile failure detection or is not specific in failure detection, and users cannot maintain the automobile timely, so that safety hazard is added, simultaneously the failure can be serious, and maintenance cost is added. The automobile failure detection system comprises a vehicle-mounted terminal and a cloud calculation side, wherein the vehicle-mounted terminal comprises an automobile data communication interface module, a control module, a network communication module and a display module, and the vehicle-mounted terminal is connected with the cloud calculation side through a network. The automobile failure detection system based on cloud calculation has the advantages that the sensor technology, the wireless network technology and the cloud calculation technology are integrated, the automobile only needs to be installed a simple vehicle-mounted terminal, specific failure diagnosis is completed by the cloud calculation side, and the automobile failure diagnosis function can be achieved with no need of installing a failure diagnosis instrument, so that users can timely maintain the automobile, maintenance cost and safety hazard of the automobile are reduced, simultaneously the structure of the automobile is simplified, and purchasing cost is reduced.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

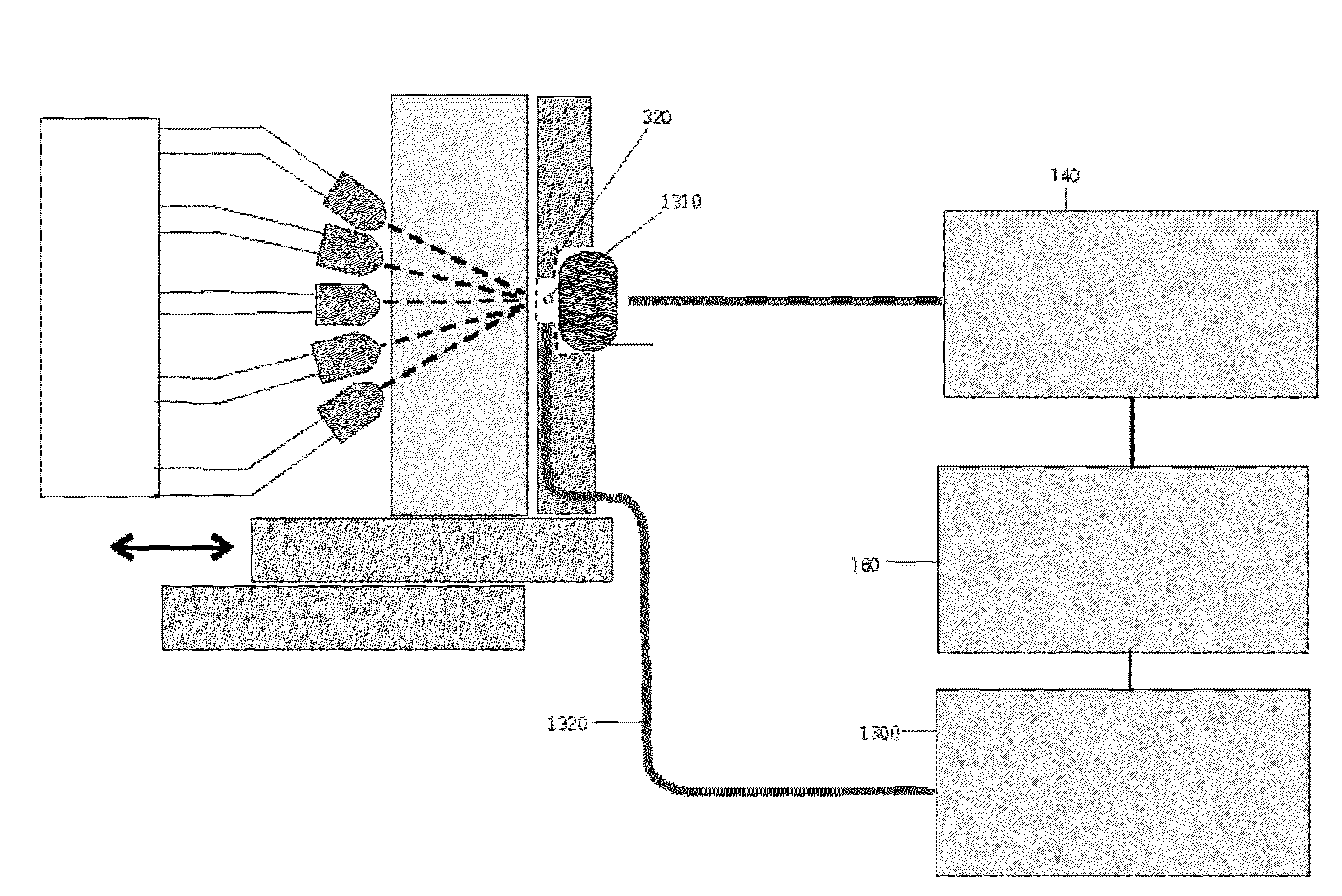

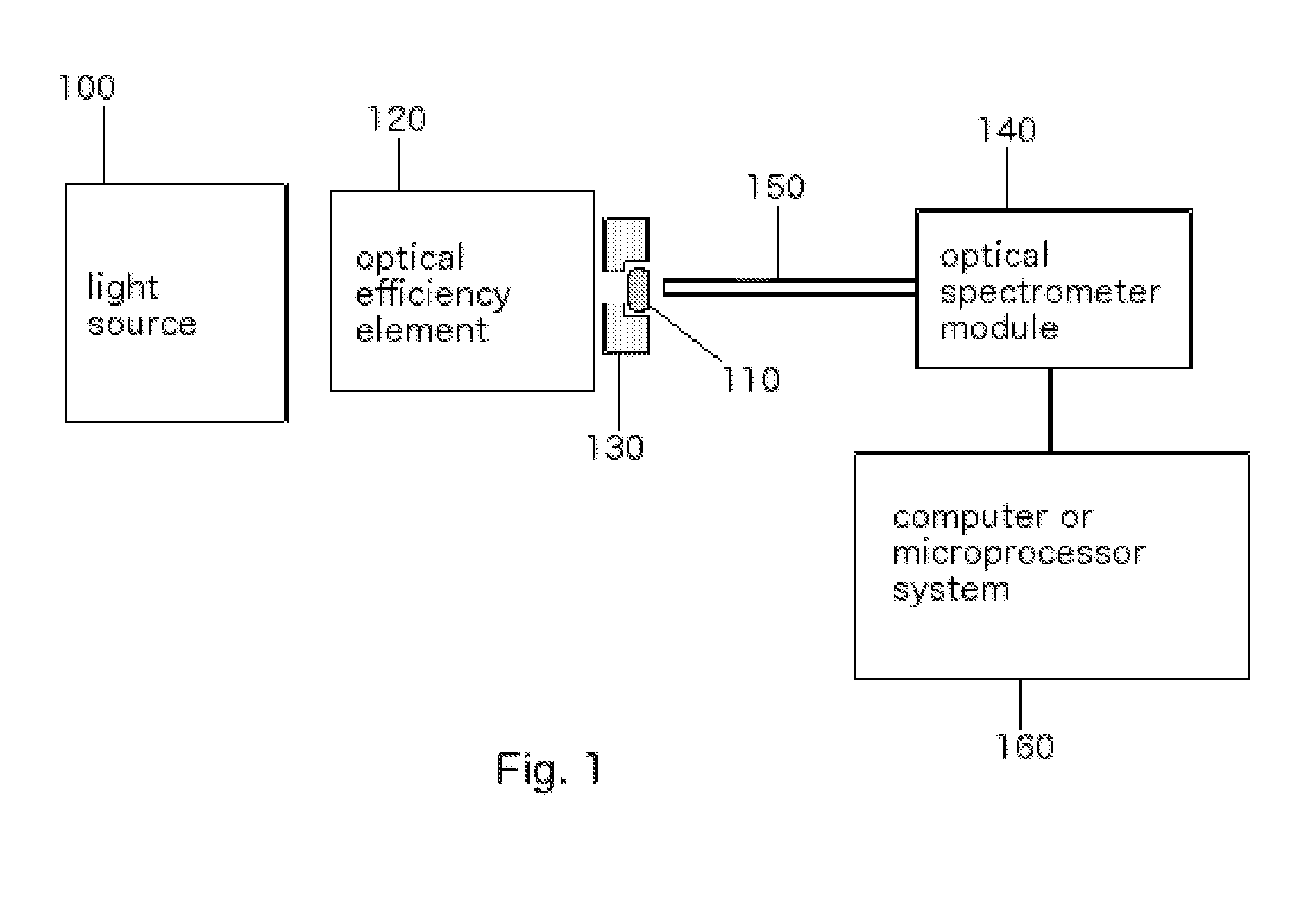

Optical analyzer for identification of materials using transmission spectroscopy

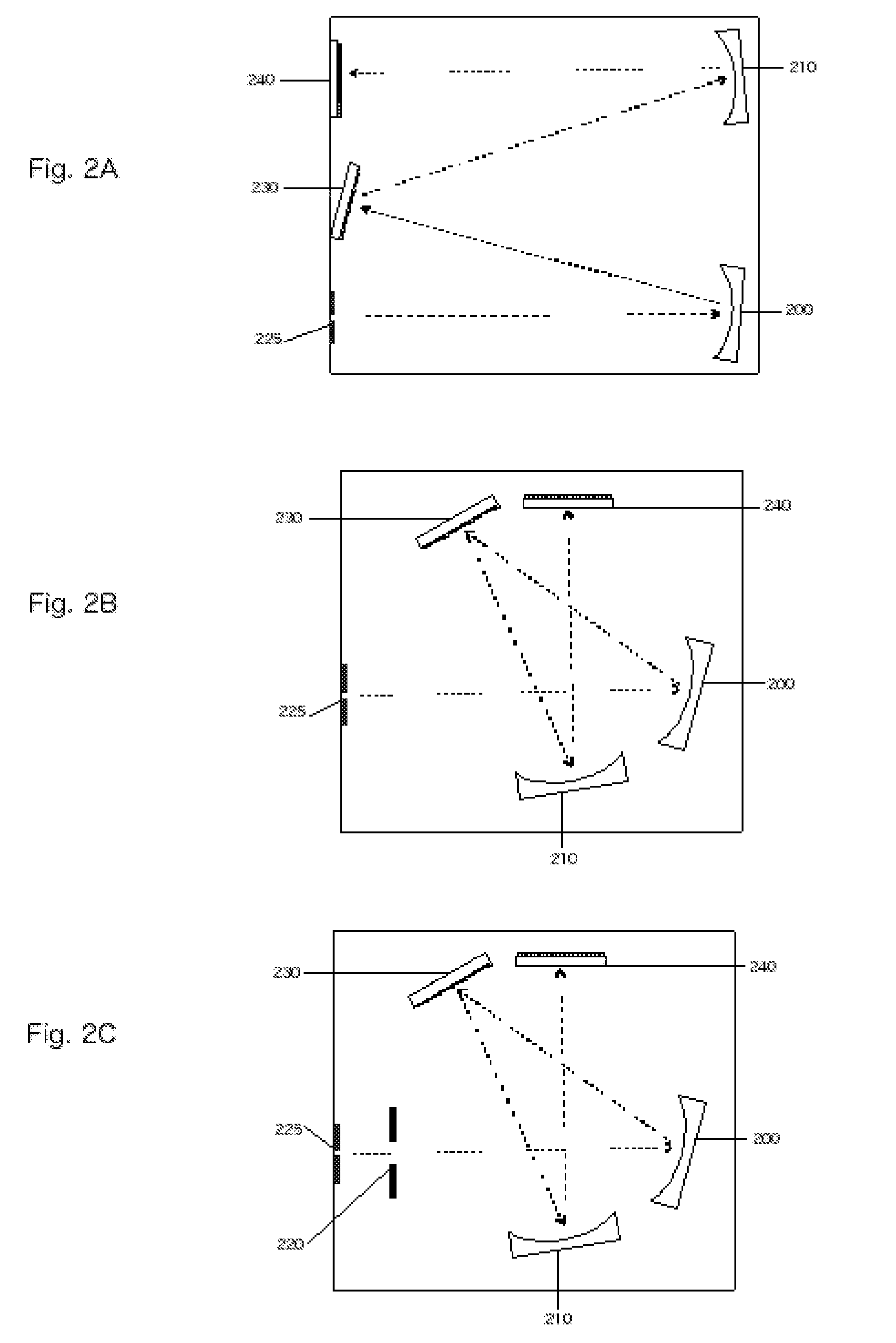

ActiveUS20130265568A1Low manufacturing costSmall sizeRadiation pyrometryAbsorption/flicker/reflection spectroscopyMultivariate calibrationWavelength range

A device and method for identifying solid and liquid materials use near-infrared transmission spectroscopy combined with multivariate calibration methods for analysis of the spectral data. Near-infrared transmission spectroscopy is employed within either the 700-1100 nm or the 900-1700 nm wavelength range to identify solid or liquid materials and determine whether they match specific known materials. Uses include identifying solid (including powdered) and liquid materials with a fast measurement cycle time of about 2 to 15 seconds and with a method that requires no sample preparation, as well as quantitative analysis to determine the concentration of one or more chemical components in a solid or liquid sample that consists of a mixture of components. A primary application of such analysis includes detection of counterfeit drug tablets, capsules and liquid medications.

Owner:INNOVATIVE SCI TOOLS

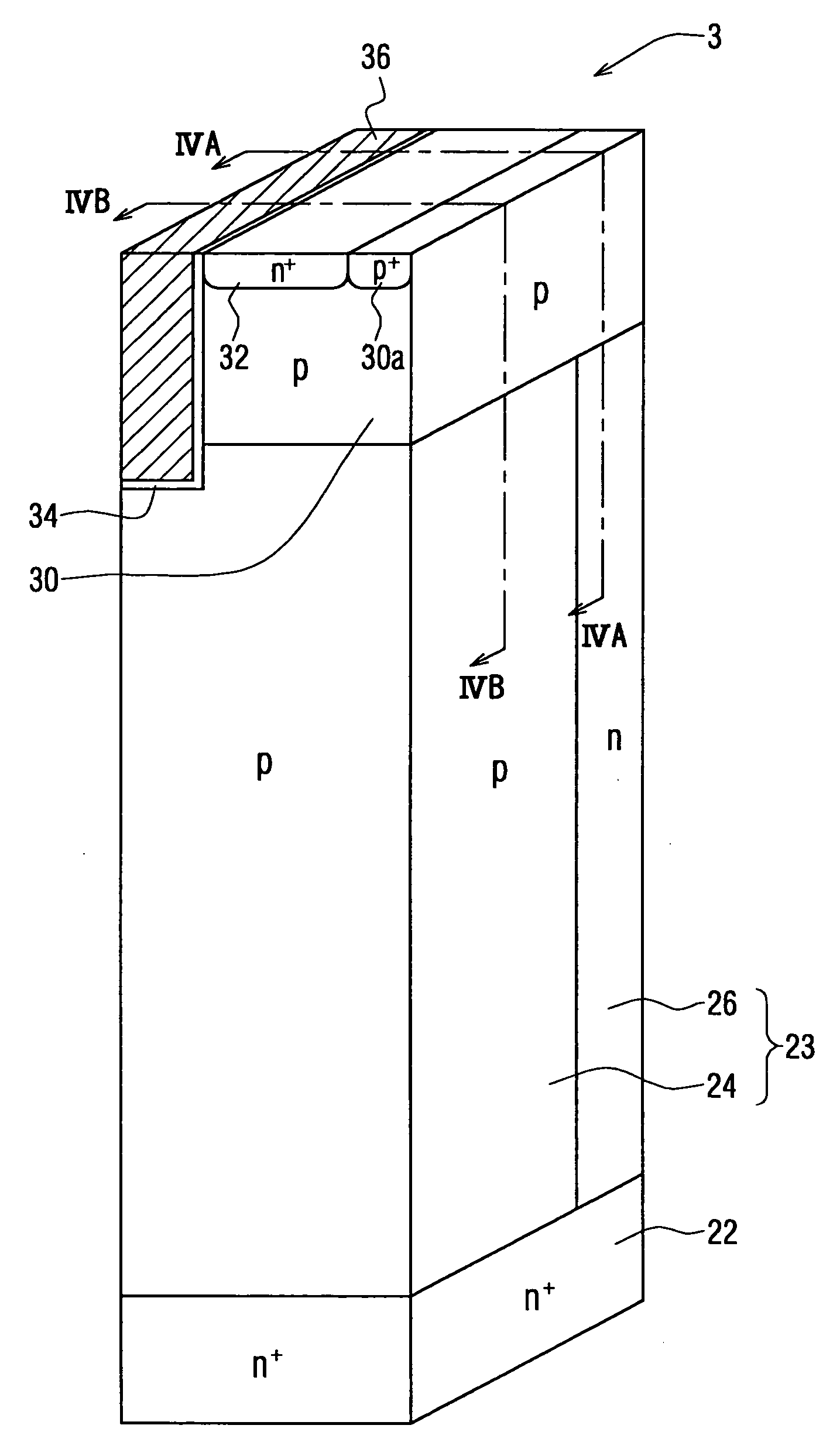

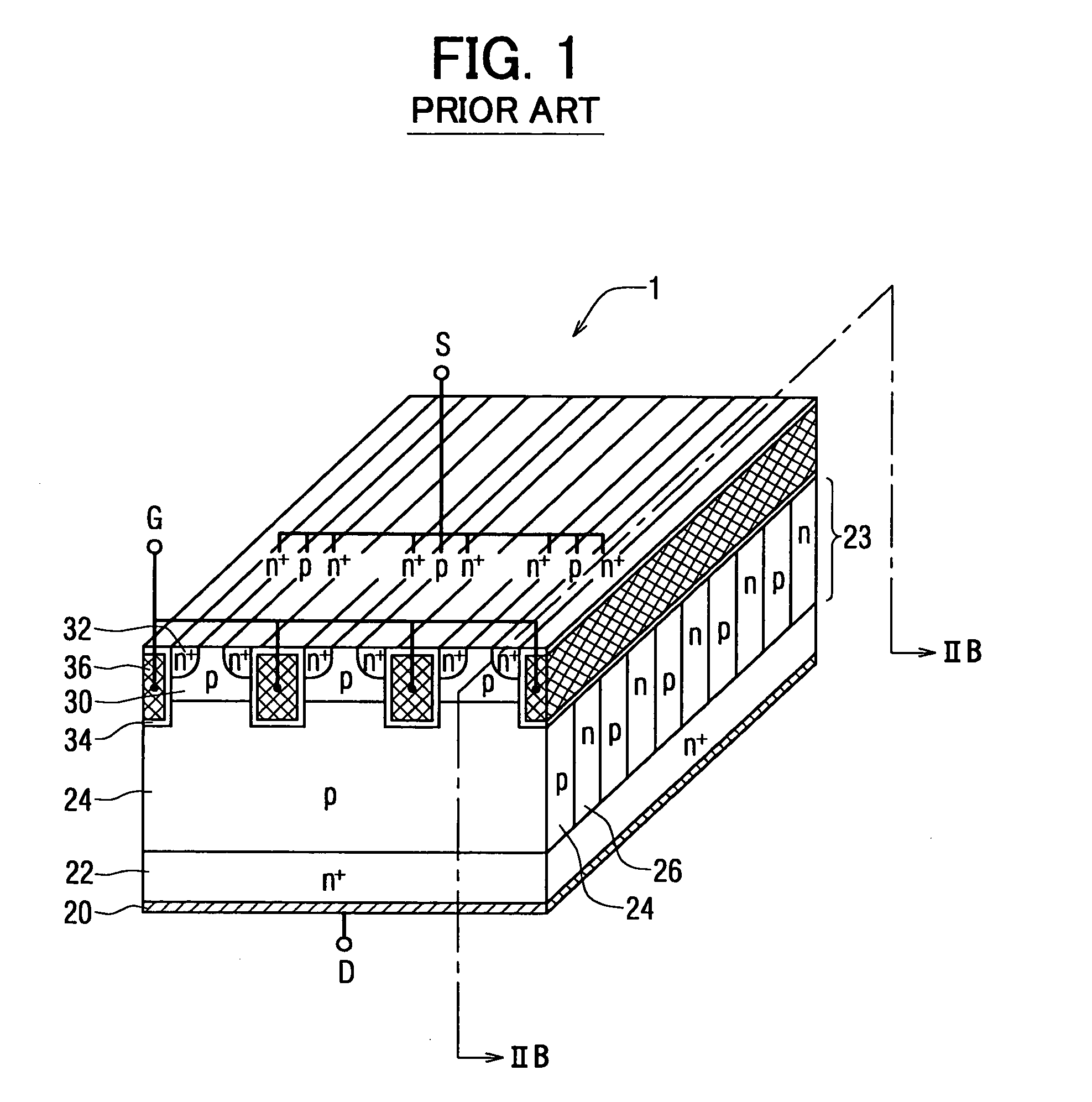

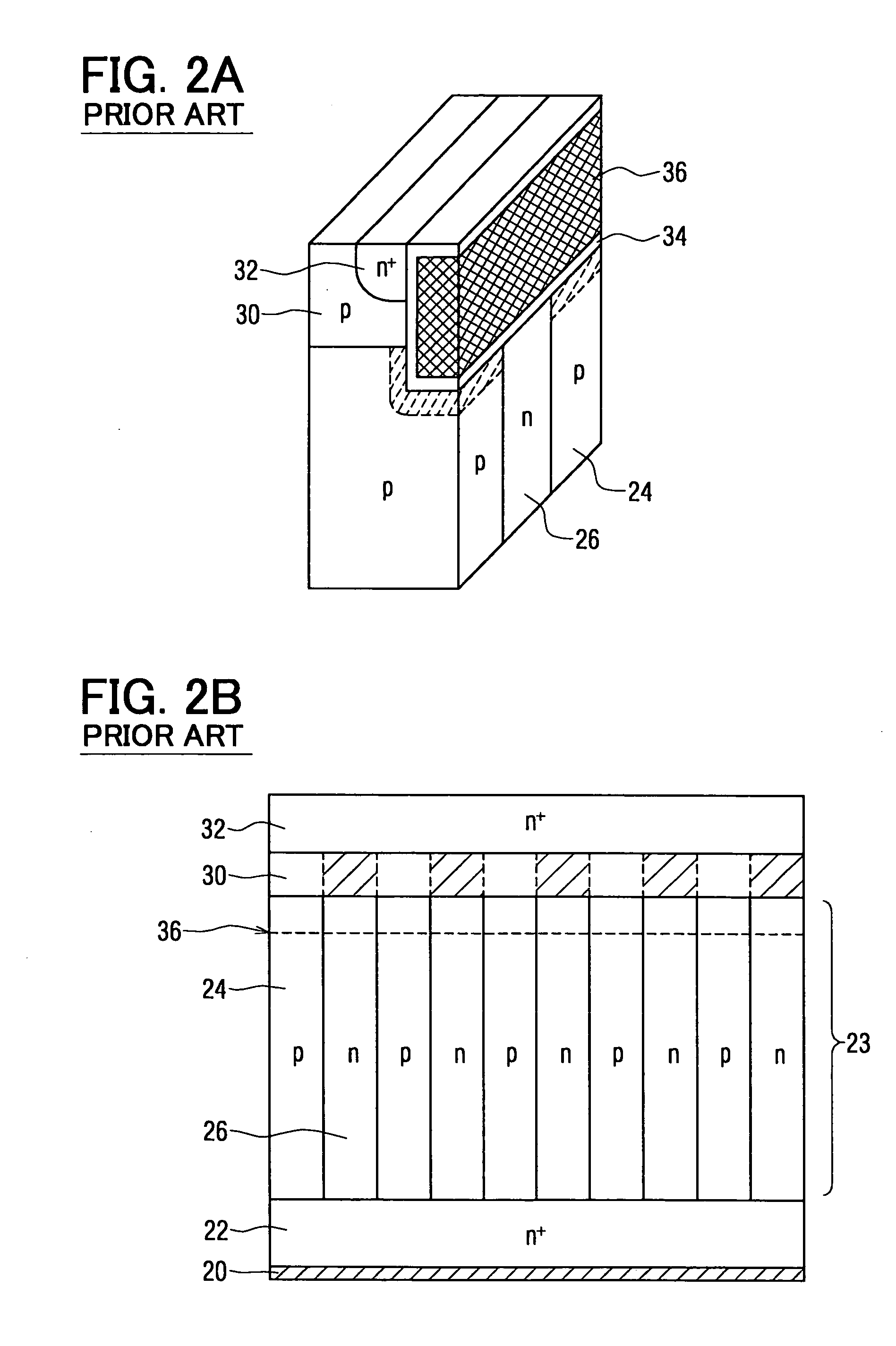

Semiconductor device having super junction construction and method for manufacturing the same

InactiveUS20050006717A1Low manufacturing costStable withstand voltageSemiconductor/solid-state device manufacturingSemiconductor devicesPhysicsBody region

A semiconductor device includes a body region, a drift region having a first part and a second part, and a trench gate electrode. The body region is disposed on the drift region. The first and second parts extend in an extending direction so that the second part is adjacent to the first part. The trench gate electrode penetrates the body region and reaches the drift region so that the trench gate electrode faces the body region and the drift region through an insulation layer. The trench gate electrode extends in a direction crossing with the extending direction of the first and second parts. The first part includes a portion near the trench gate electrode, which has an impurity concentration equal to or lower than that of the body region.

Owner:DENSO CORP

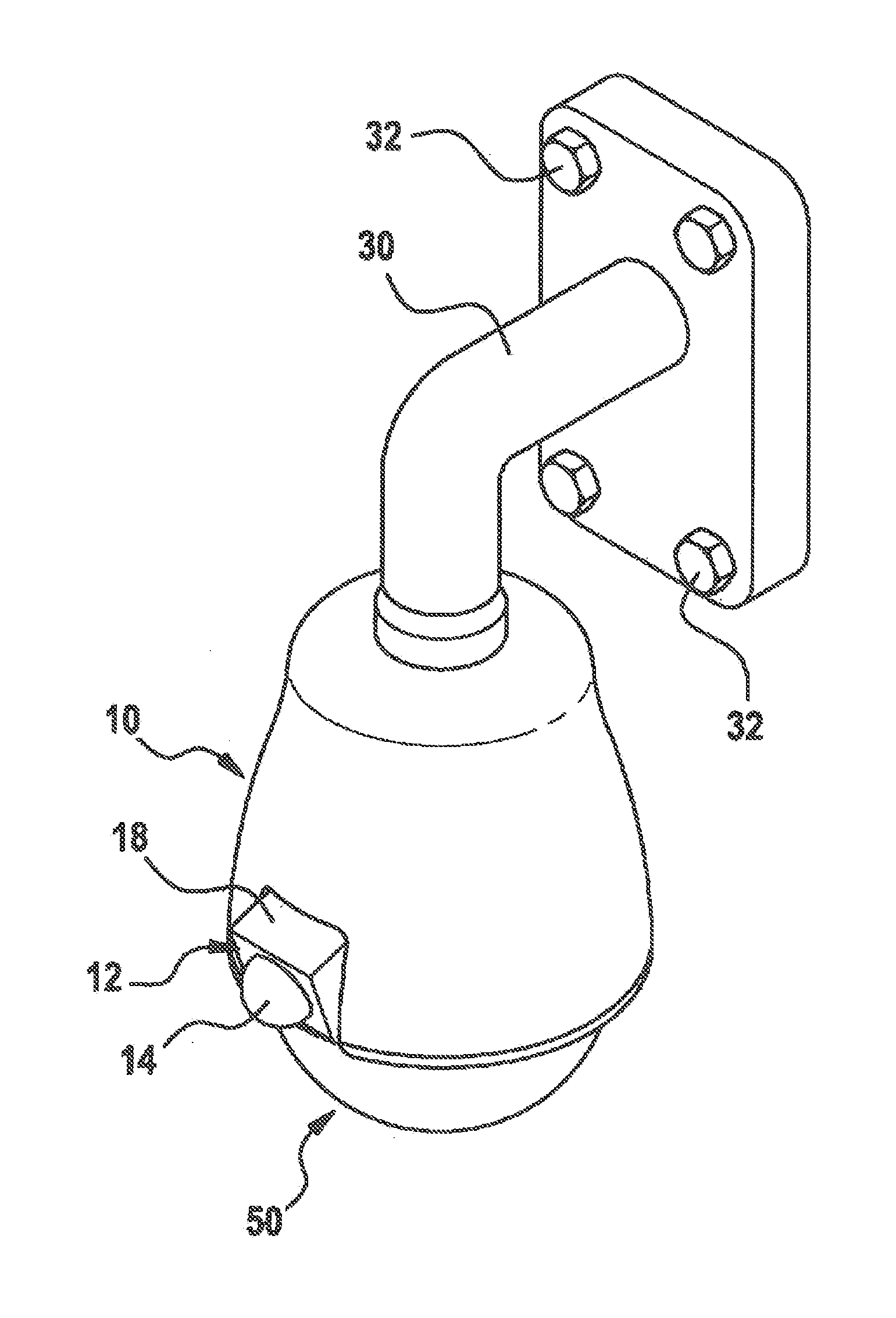

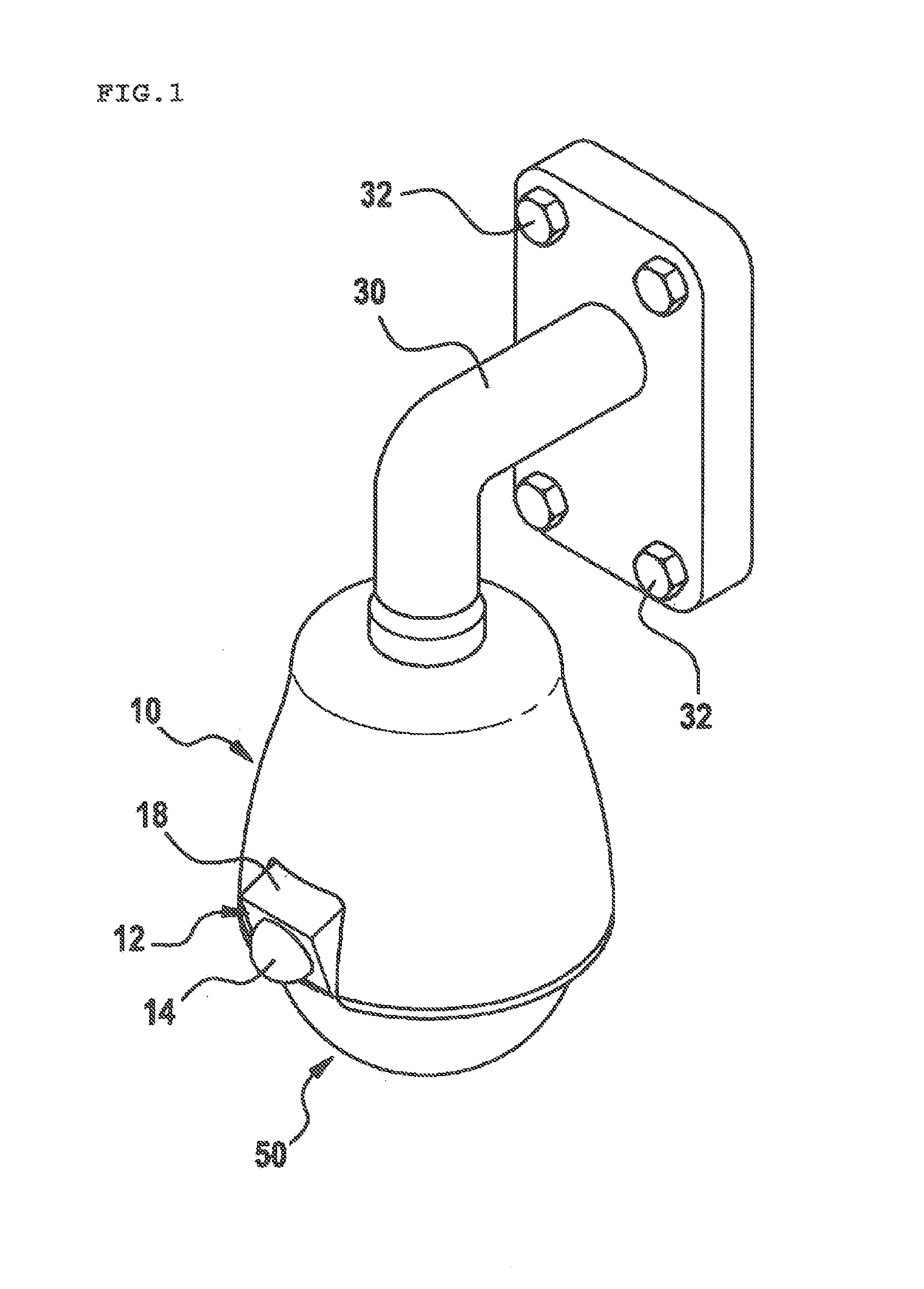

Tracking and monitoring camera device and remote monitoring system using same

InactiveUS20120257064A1Maximum rangeLow manufacturing costTelevision system detailsClosed circuit television systemsCamera lensWide-angle lens

A camera apparatus including a wide area monitoring camera and an intensive monitoring camera as one body. The camera apparatus includes a main frame, a first camera unit and a second camera unit. The main frame has a lens installation surface where a normal line is directed to the lower outside. The first camera unit is installed in the main frame, has a wide angle lens disposed on the lens installation surface so as to direct an optical axis to lower outside and a first image sensor for converting light entering through the wide angle lens into an electrical signal, and photographs images of neighboring areas including an area directly below the camera apparatus. The second camera unit has a second image sensor and is installed so as to rotate horizontally and vertically with respect to the main frame.

Owner:YOUNG KOOK ELECTRONICS

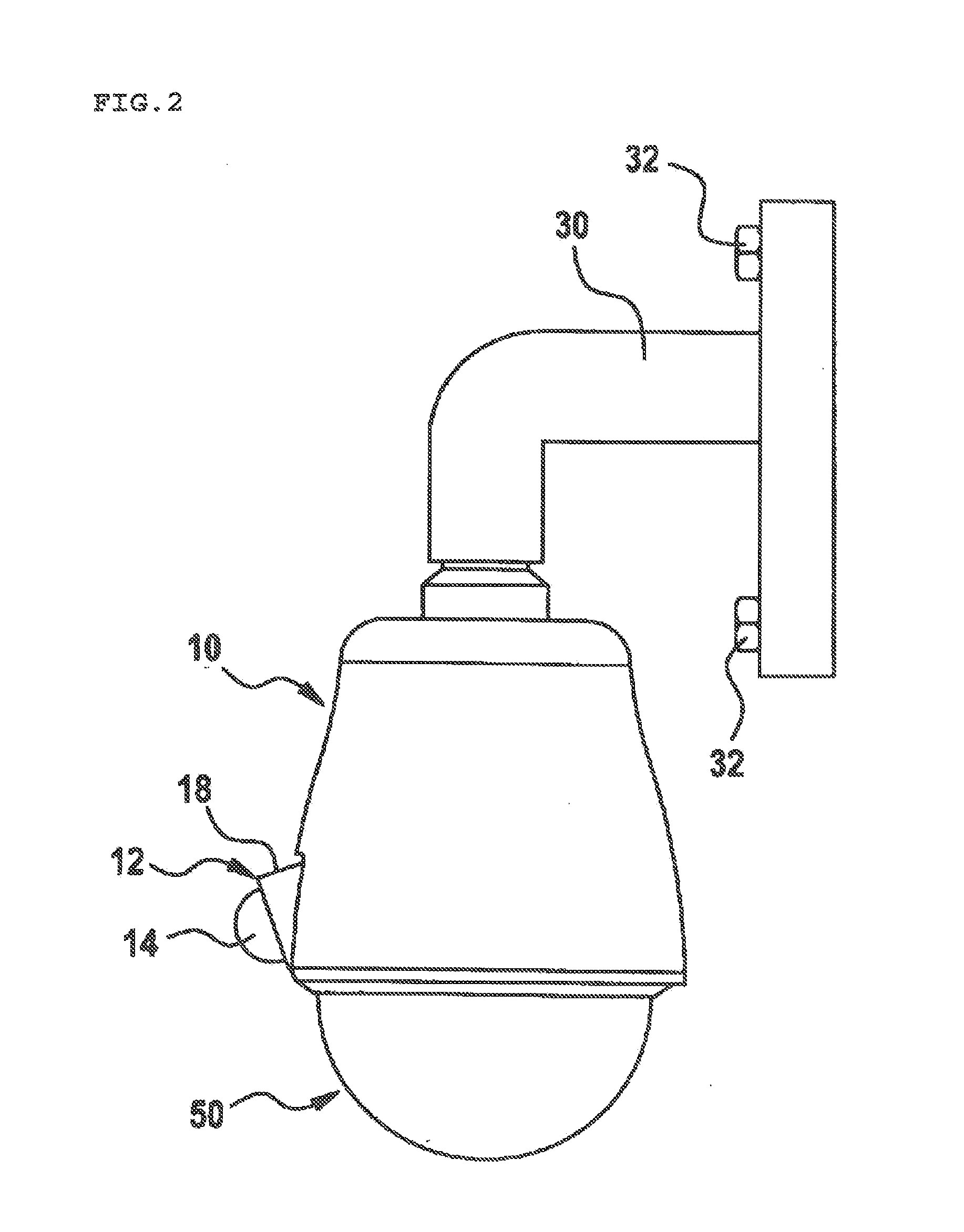

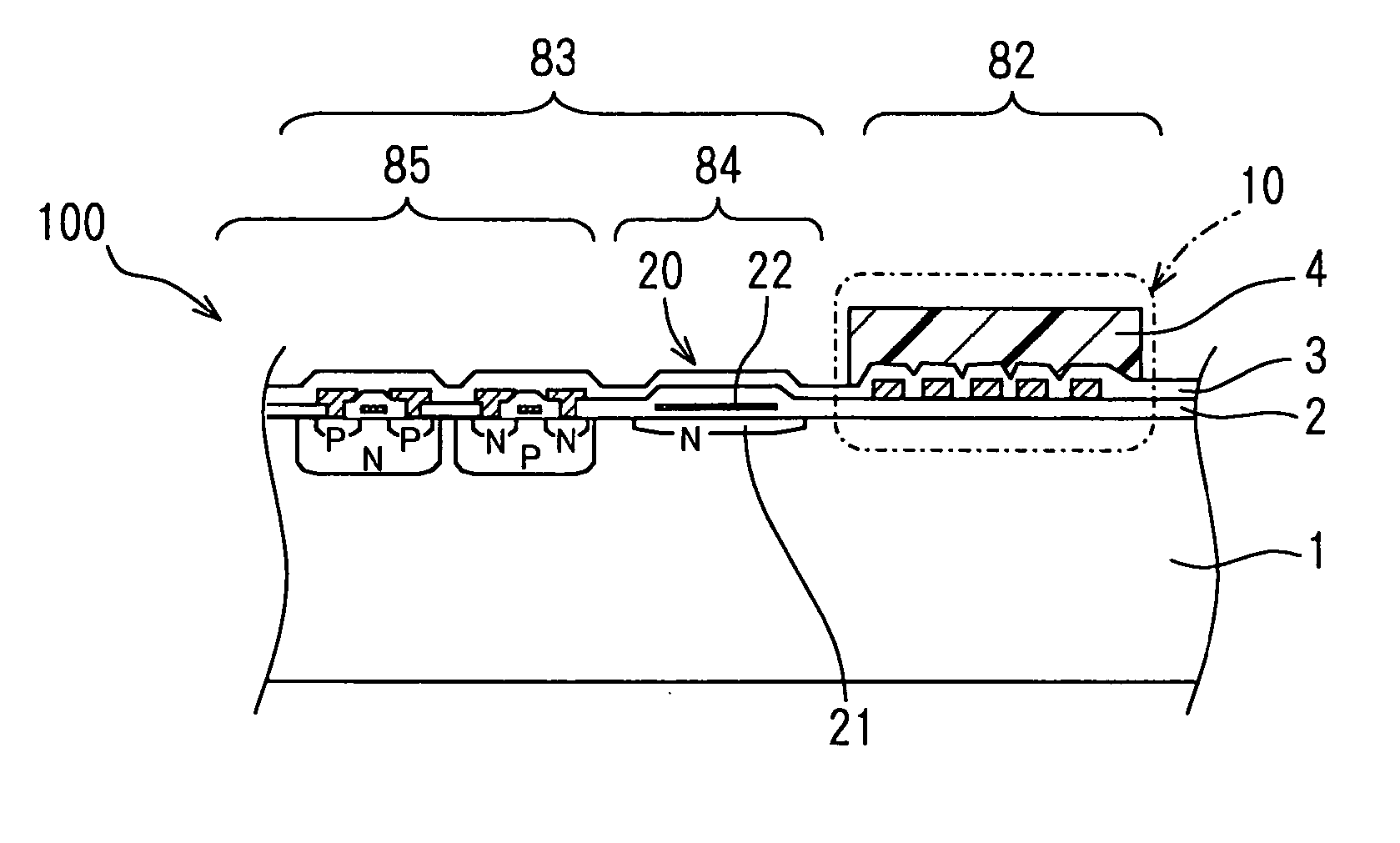

Capacitive type humidity sensor

InactiveUS20050188764A1Small sizeLow manufacturing costSamplingUsing mechanical meansCapacitanceEngineering

A capacitive type humidity sensor includes: a semiconductor substrate; a plurality of humidity devices having a capacitance variable in accordance with a humidity; a standard capacitance device having a standard capacitance, a capacitance change of which in accordance with the humidity is smaller than that of the capacitance of each humidity device; and a CV converter circuit for converting a capacitance difference between the capacitance of each humidity device and the standard capacitance of the standard capacitance device to a signal voltage. The humidity devices, the standard capacitance device and the CV converter circuit are disposed on one side of the substrate.

Owner:DENSO CORP

Use of simple amino acids to form porous particles

InactiveUS7252840B1Low manufacturing costHigh doPowder deliveryIn-vivo radioactive preparationsAmino acidPorous particle

Particles having a tap density of less than 0.4 g / cm3 include a hydrophobic amino acid or salt thereof and a therapeutic, prophylactic or diagnostic agent or any combination thereof. Preferred particles include a phospholipid, have a median geometric diameter between about 5 and about 30 microns and an aerodynamic diameter between about 1 and about 5 microns. The particles can be formed by spray-drying and are useful for delivery to the pulmonary system.

Owner:CIVITAS THERAPEUTICS

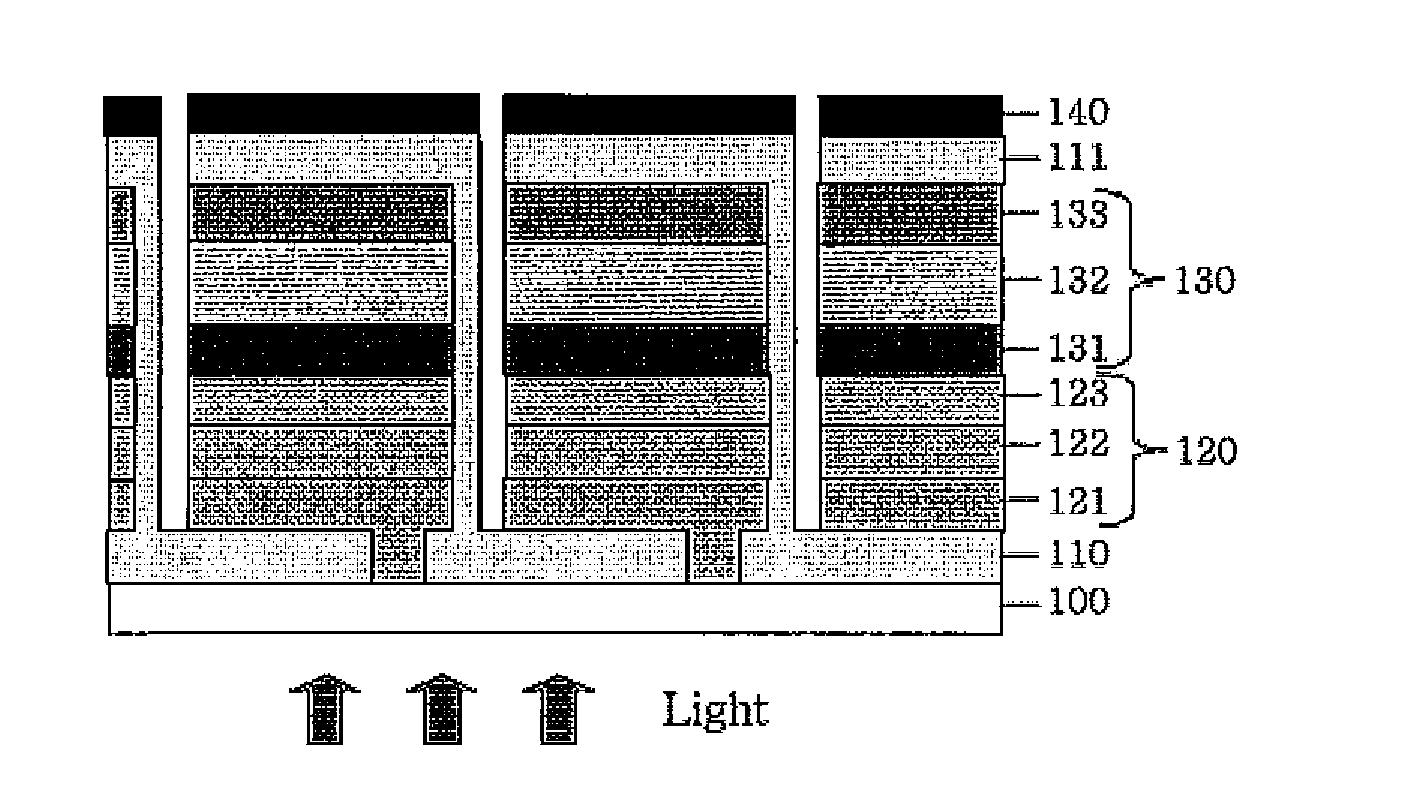

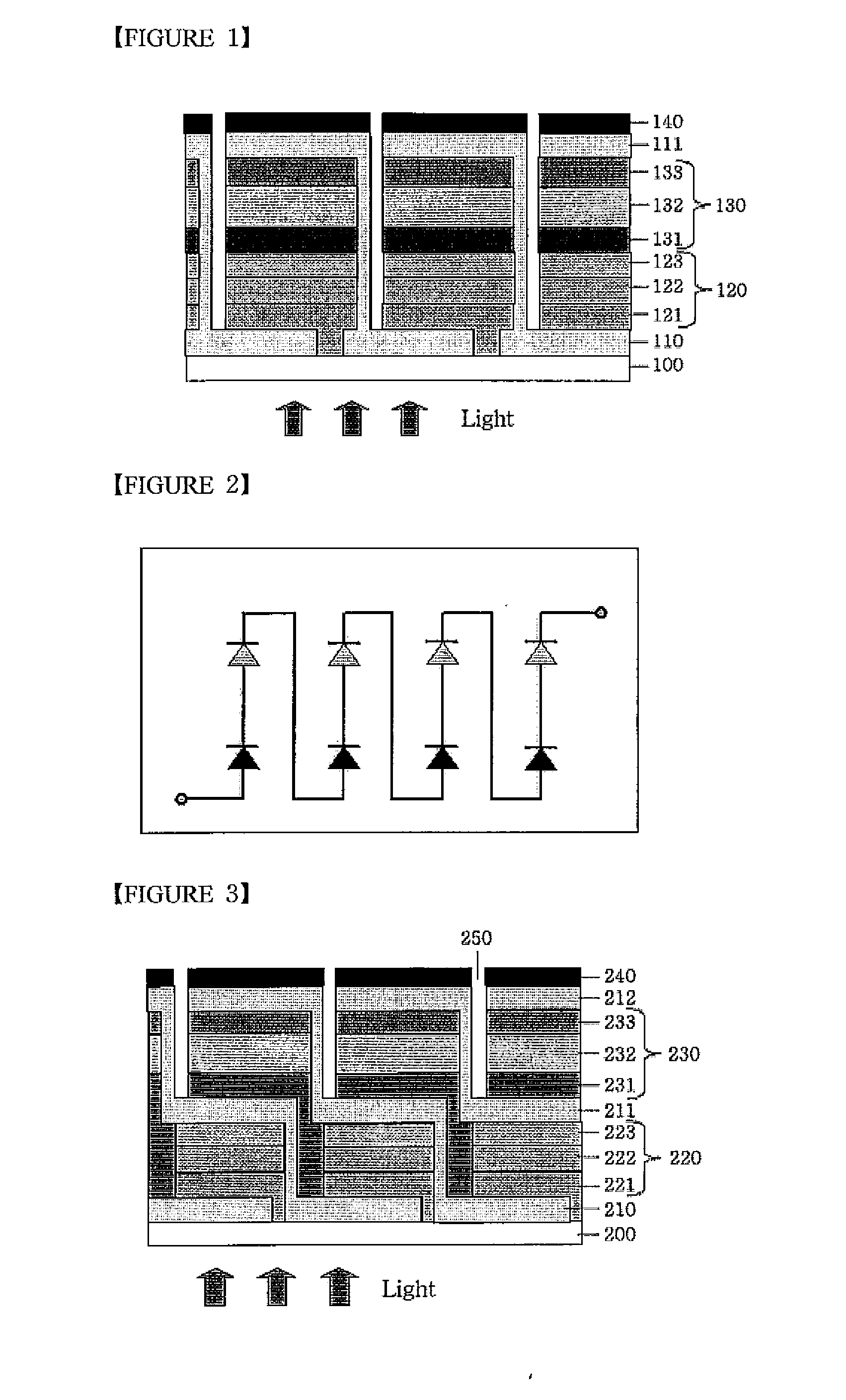

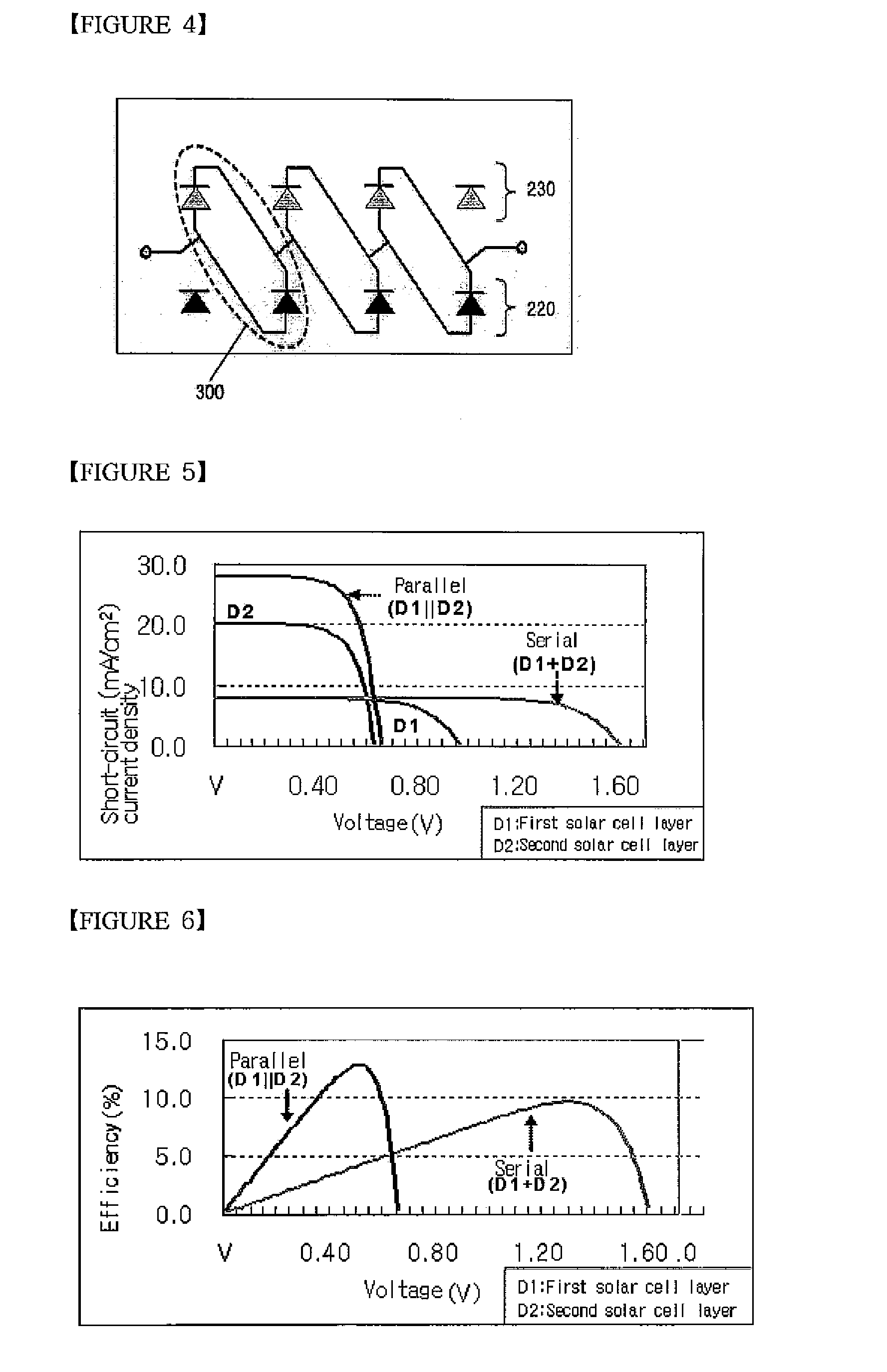

Thin-film solar cell and fabrication method thereof

InactiveUS20090242018A1High efficiencyLow manufacturing costSemiconductor/solid-state device manufacturingPhotovoltaic energy generationPhysicsMultijunction photovoltaic cell

The present invention relates to a thin-film solar cell and a fabrication method thereof, the solar cell having a structure that a glass substrate, a transparent conductive oxide, a multi-junction solar cell layer and an electrode layer are stacked, wherein a first solar cell layer and a second solar cell layer, which are in a multi-junction, are electrically connected with each other in parallel, and one or more unit cells connected in parallel are grouped to be electrically connected with each other in series. According to the present invention, a thin-film solar cell having a unit cell in a structure that two solar cell layers having different characteristics are connected with each other in parallel, and having a structure that several unit cells are connected with each other in series, can achieve higher output and efficiency than a thin-film solar cell having a structure that several solar cell layers are connected in series.

Owner:LG ELECTRONICS INC

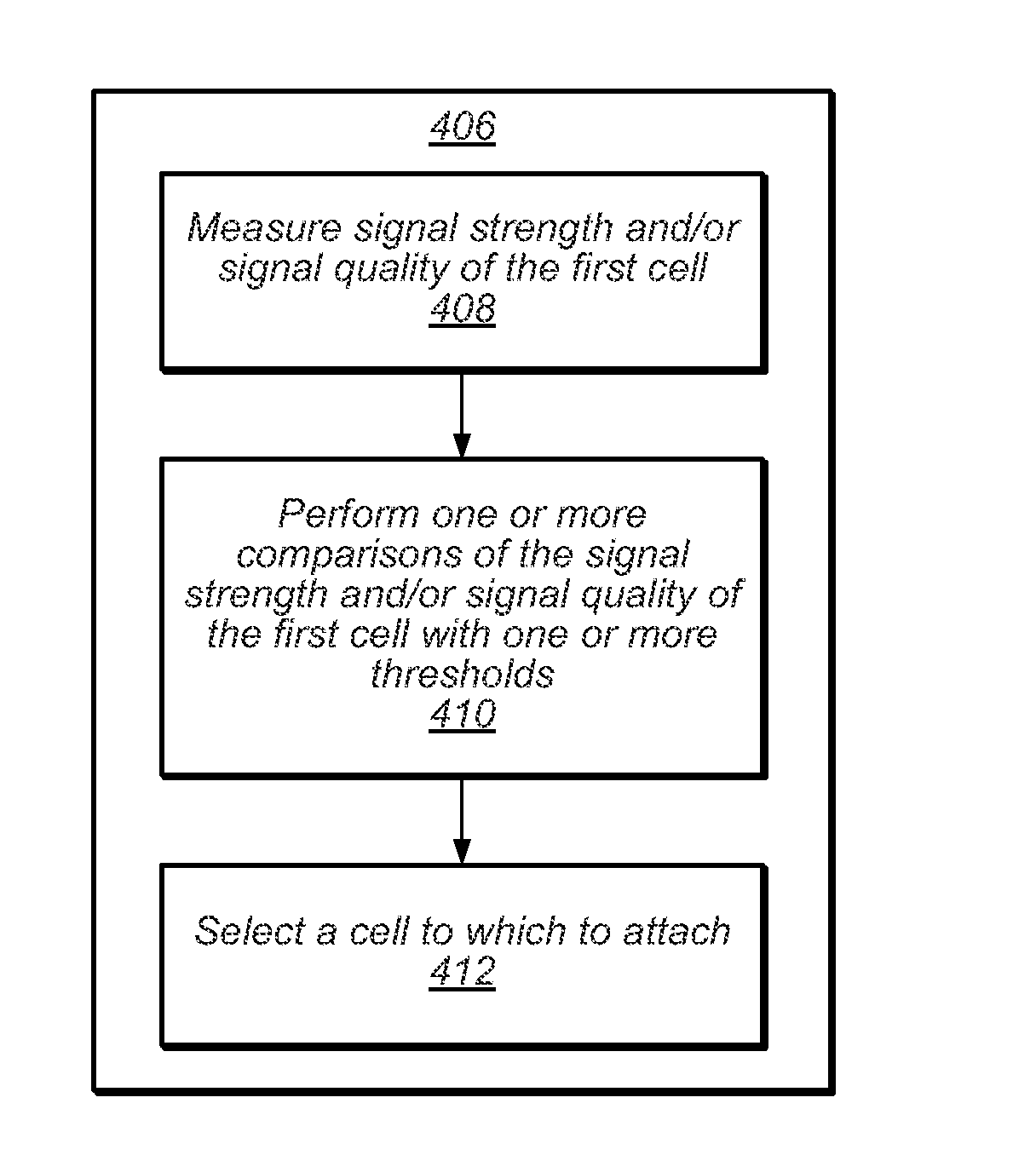

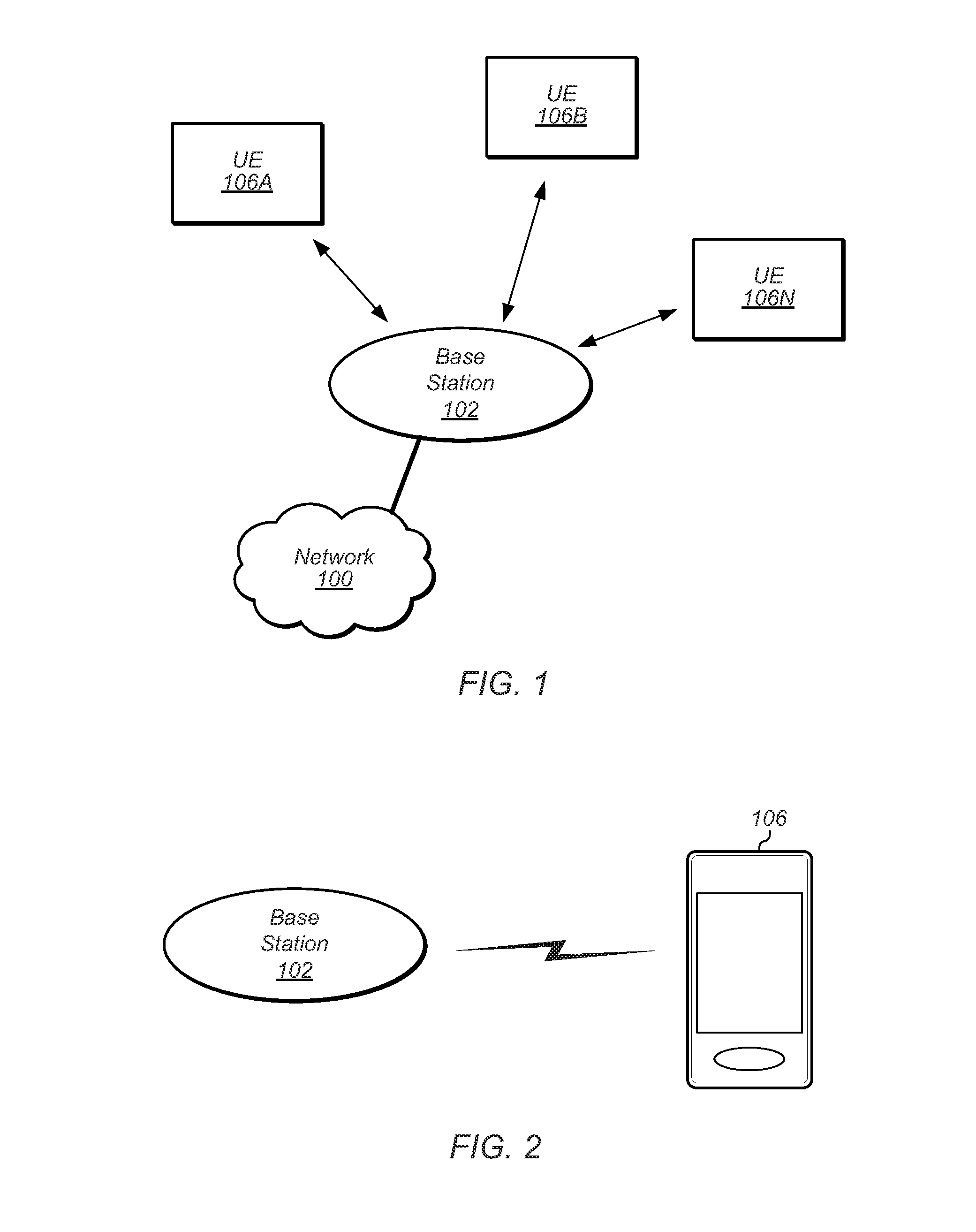

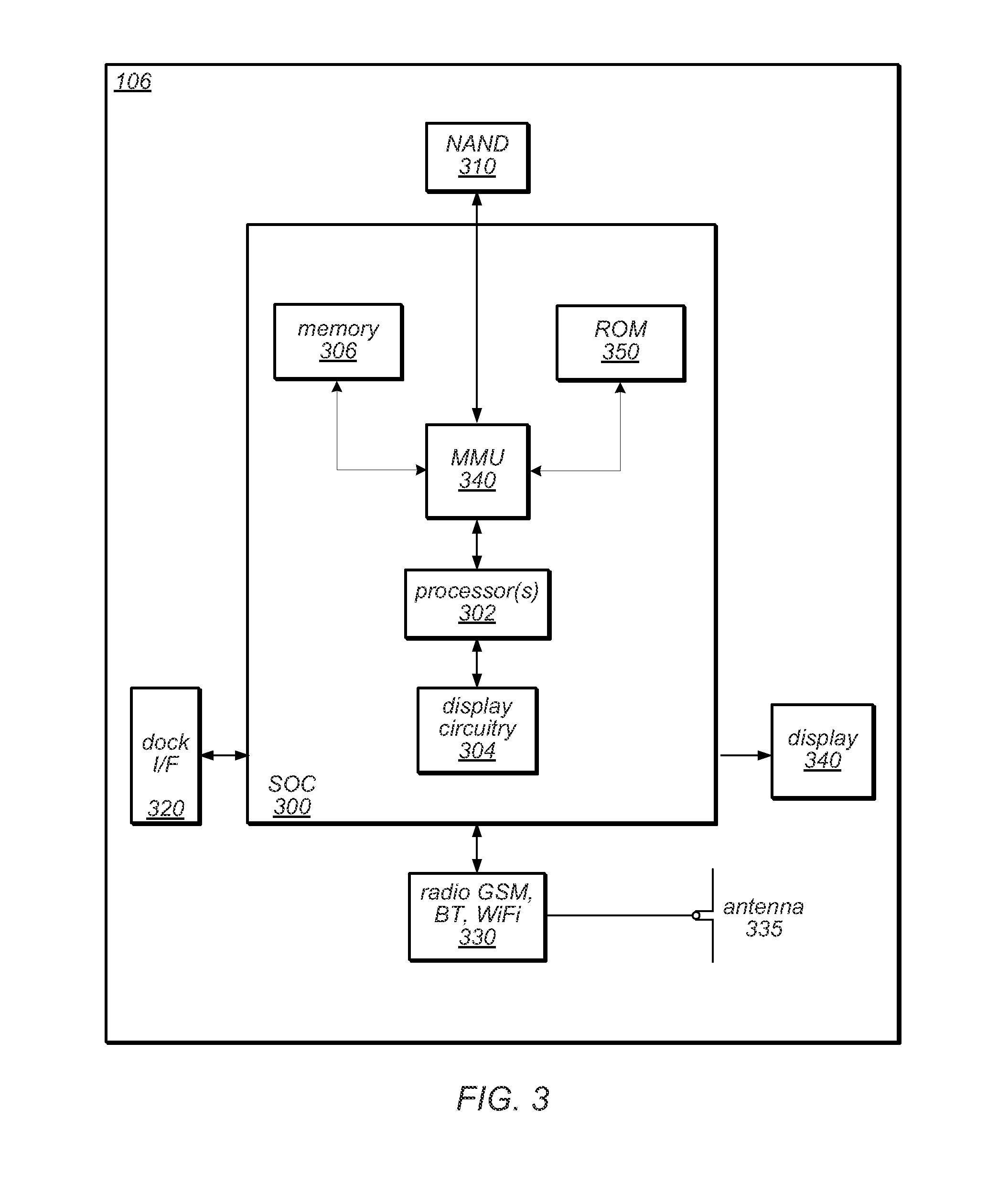

Cell Re-Selection in a Device Configured to Operate According to Multiple Cellular Communication Protocols

ActiveUS20130344872A1Low manufacturing costEfficient in operationPower managementAssess restrictionReal-time computingSignal quality

Cell re-selection in a device configured to operate according to multiple cellular communication protocols. The device may operate according to a first cellular communication protocol at a first time, which may include attaching to a first cell. The device may operate according to a second cellular communication protocol at a second time. Operations according to the first cellular communication protocol may be suspended while operating according to the second cellular communication protocol. The device may attempt to resume operating according to the first cellular communication protocol at a third time. This may include measuring one or more of signal strength or signal quality of the first cell. The wireless device may select a cell to which to attach at the third time based at least in part on the measured signal strength and signal quality of the first cell.

Owner:APPLE INC

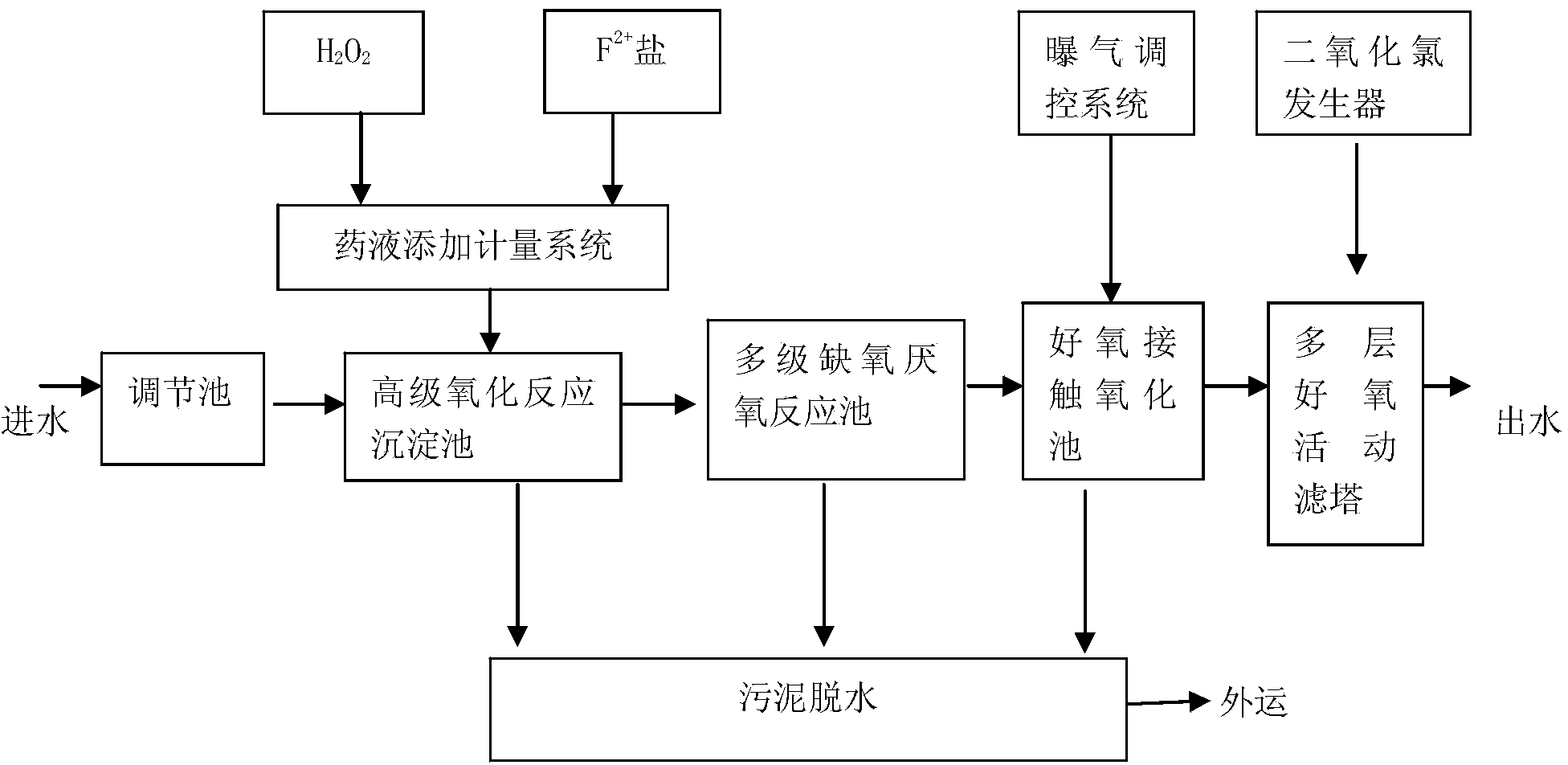

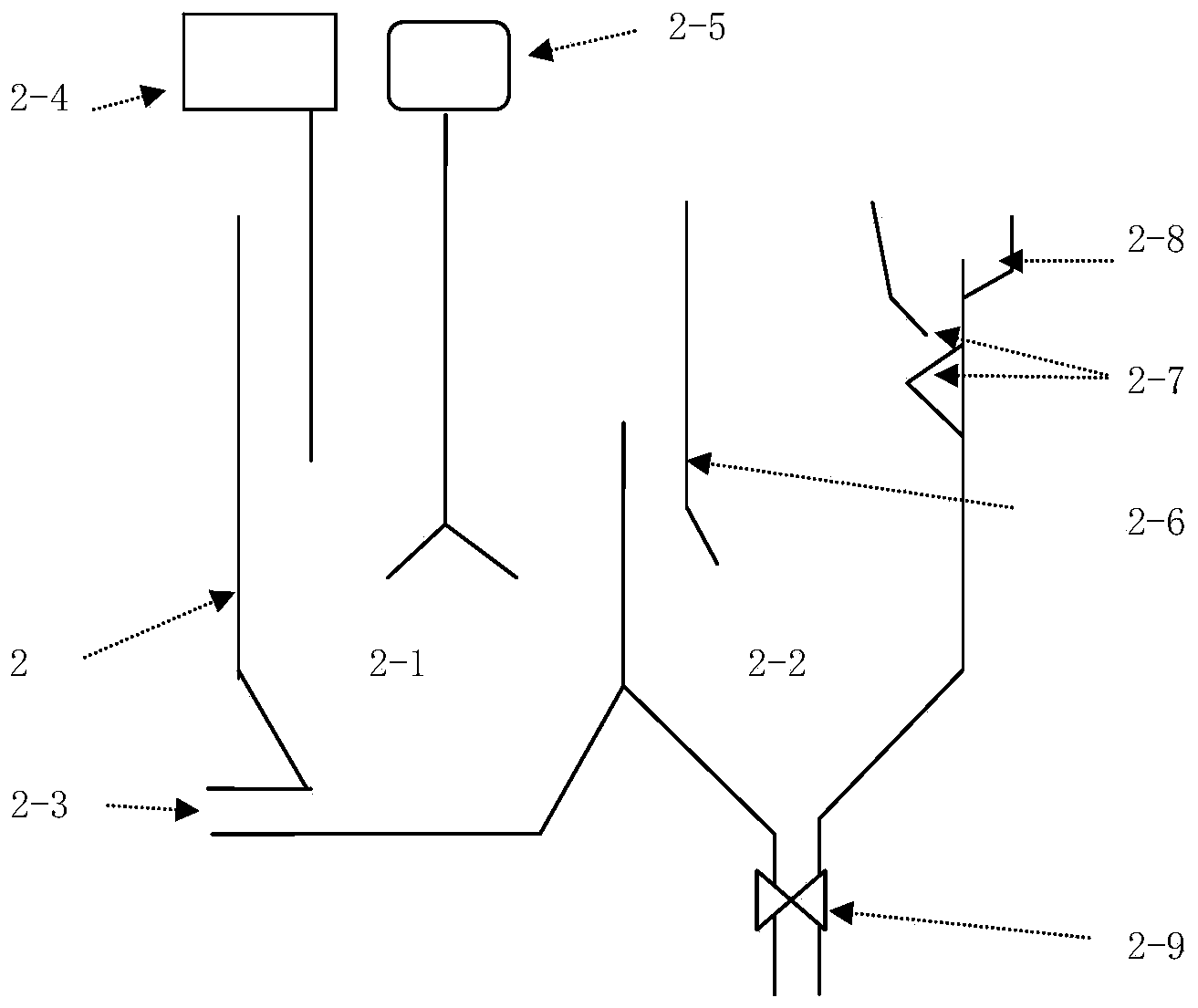

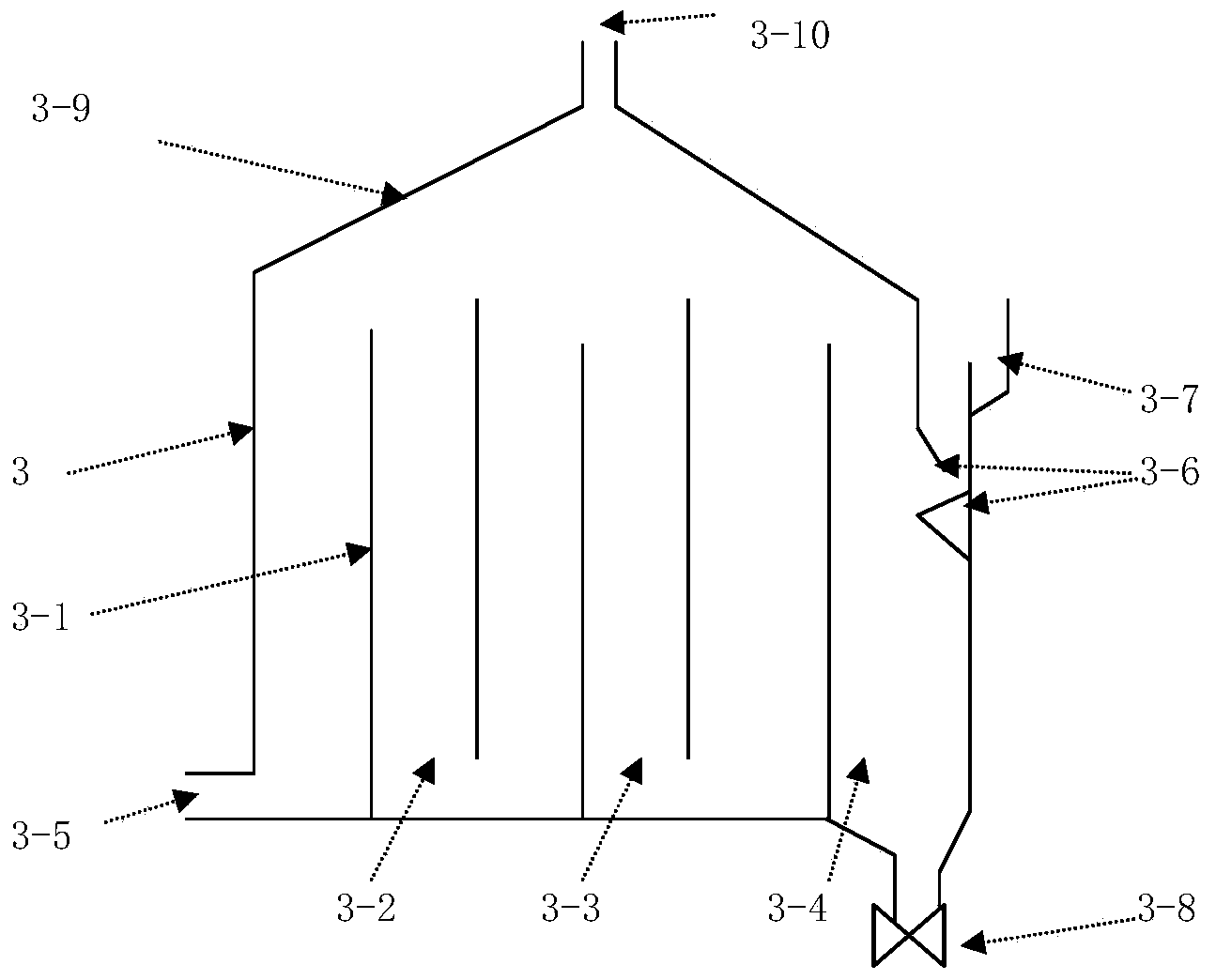

Garlic wastewater treatment method and device

ActiveCN103755102ASimple structureLow manufacturing costMultistage water/sewage treatmentChemistryFilter material

The invention relates to a garlic wastewater treatment method and a device. The garlic wastewater treatment device comprises a wastewater regulating tank, an advanced oxidation reaction sedimentation tank, a multistage hypoxic and anaerobic reaction tank, an aerobiotic contact oxidation tank and a multilayer aerobiotic activity filtration tower, wherein the advanced oxidation reaction sedimentation tank comprises a mixing region and a sedimentation region; the multistage hypoxic and anaerobic reaction tank comprises a facultative section, a hypoxic section and an anaerobic section; an aeration controlling system is arranged at the middle lower part in the aerobiotic contact oxidation tank and comprises an aeration disc, an air blower and a dissolved oxygen measurement controlling device; and the multistage hypoxic and anaerobic reaction tank adopts multistage arrangement, particle sizes of a filter material are gradually decreased from top to bottom, an air inlet, a water collection groove and a water outlet pipe are arranged at the bottom of the filtration tower, and disinfection equipment is installed at the upper part of the water collection groove and is connected with a chloride dioxide generator. The garlic wastewater treatment device has a simple structure, is lower in manufacturing cost, is suitable for sewage treatment of larger volume and has very good treating effect to garlic wastewater.

Owner:邳州市博睿投资管理有限公司

Building material produced from construction garbage and preparation thereof

InactiveCN101348343ALow manufacturing costImprove the ecological environmentSolid waste managementBuilding materialQuality standard

The invention discloses a method for manufacturing building materials with construction debris. The technical problem resolved by the invention is to simplify material formula and lower cost. The building material of the invention comprises the following components in weight portion: 85 to 97 portions of construction debris and 3 to 15 portions of quicklime, wherein the construction debris comprises bricks, stones and concrete, and the effective content of CaO of quicklime is more than or equal to 80 percent. The preparation method of the invention comprises the following steps of: initial separation, crushing, raw material mixing, shaping and high pressure steam curing. Compared with prior art, the method of the invention has the advantages of utilizing construction debris as main materials, realizing the cyclic utilization of waste, reducing the manufacturing cost of products and improving the ecological environment, along with safety and reliability; moreover, the building materials of the invention meet the quality standards of building materials.

Owner:SHENZHEN ZHONGXINHUAN SCI

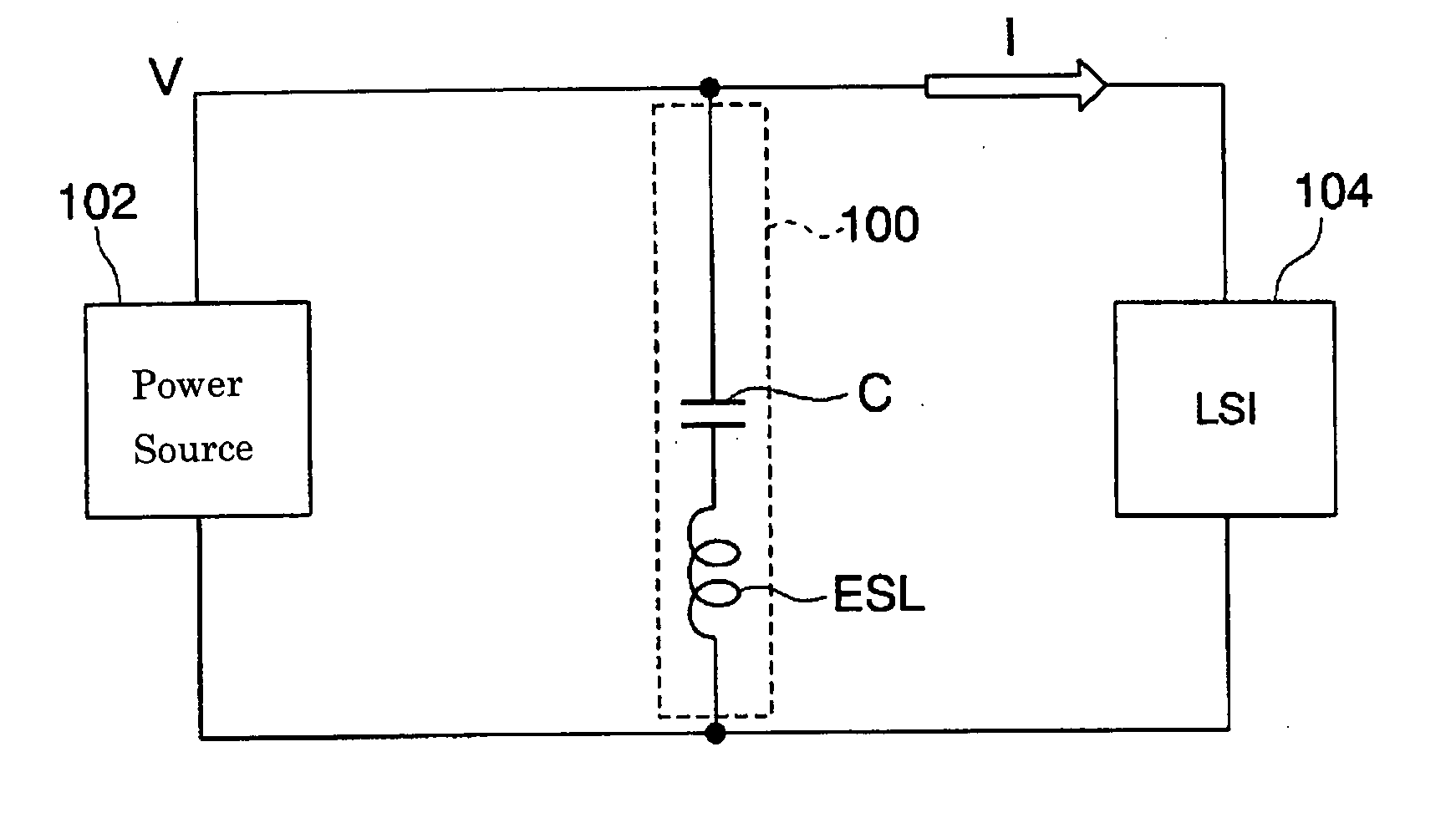

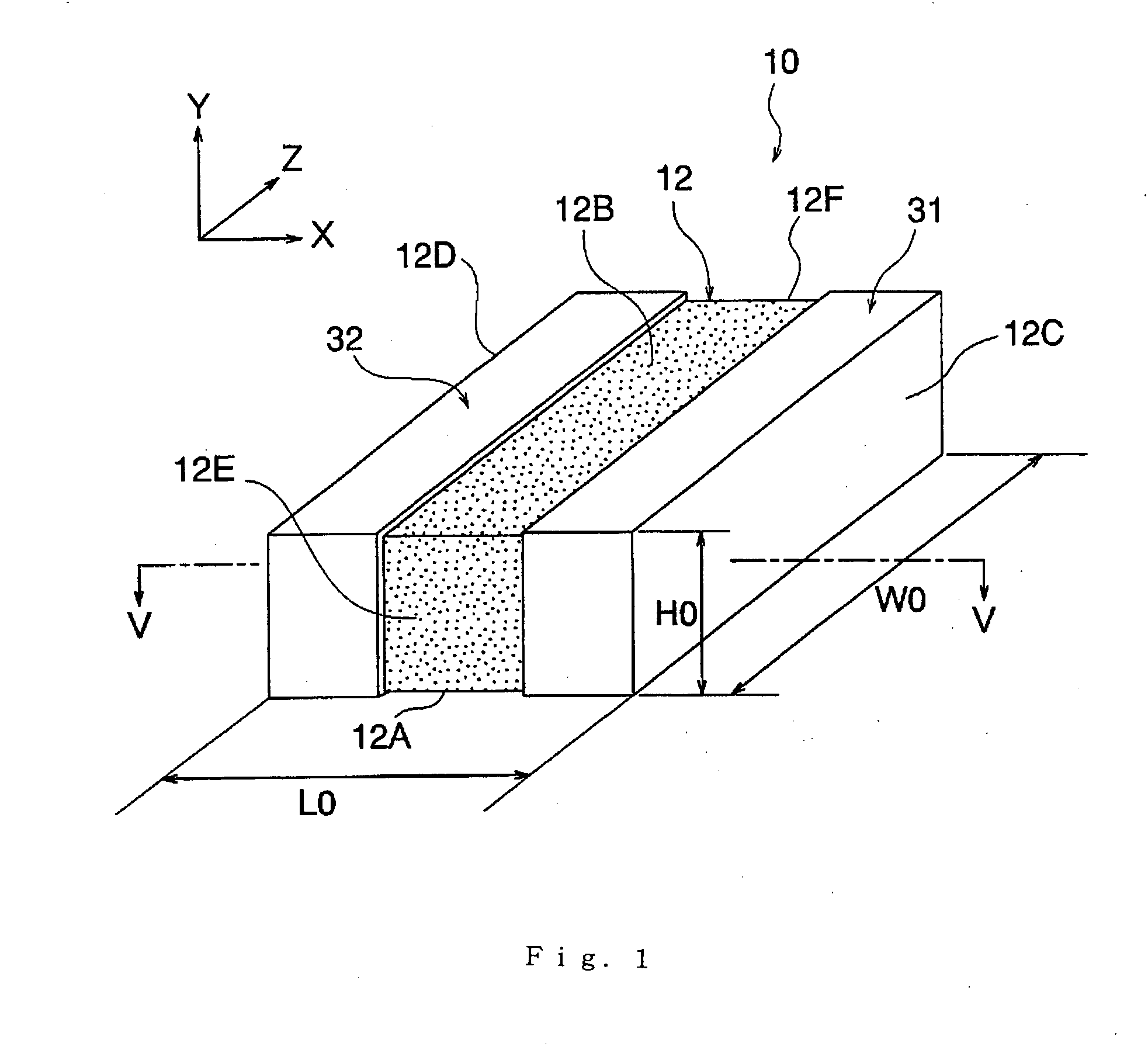

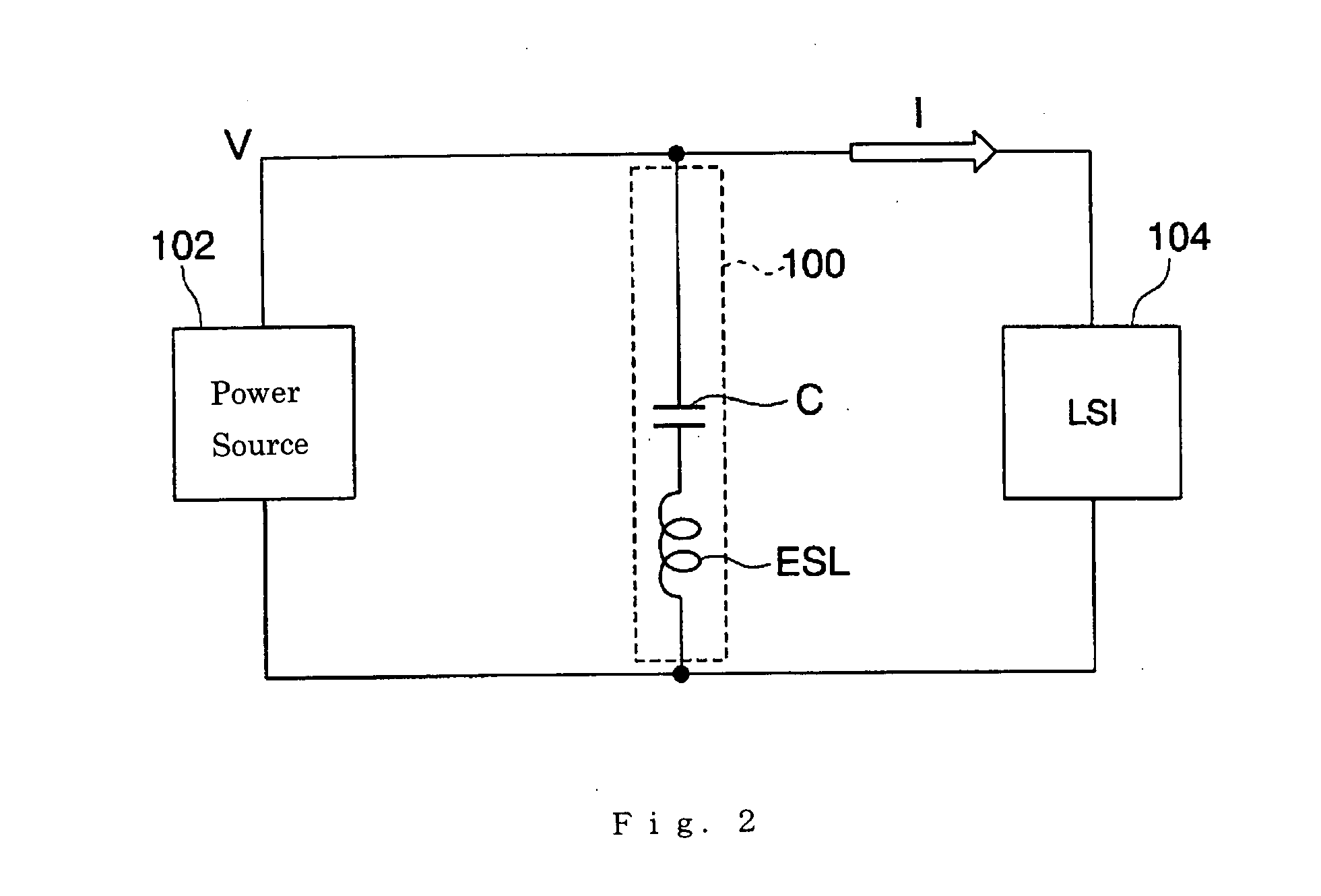

Multilayer capacitor

ActiveUS20080144253A1Reduce ESLLow manufacturing costFixed capacitor electrodesFixed capacitor dielectricElectrical conductorDielectric layer

A multilayer capacitor 10 comprising a dielectric body 12 having an approximately rectangular parallelepiped shape formed by alternately stacking a plurality of dielectric layer 12a, a first conductor layer 21, a second conductor layer 22, a first terminal electrode 31 and a second terminal electrode 32 formed on a first side face 12A of side faces 12 of the dielectric body in parallel to a stacking direction Z. The first conductor layer 21 comprises a first lead portion 21L connected to the first terminal electrode 31, the second conductor layer 22 comprises a second lead portion 22L connected to the second terminal electrode 32. Between a length “a” of the first lead portion 21L and the second lead portion 22L in vertical direction to the stacking direction Z, a length “b” of conductor layers positioned at both ends of the dielectric body 12 in the stacking direction, a space length “c” of the first side face 12A and the first conductor layer 21, a total number of the conductor layers 22, 22, (a+c) / (b×n)≦0.035 is consisted.

Owner:TDK CORPARATION

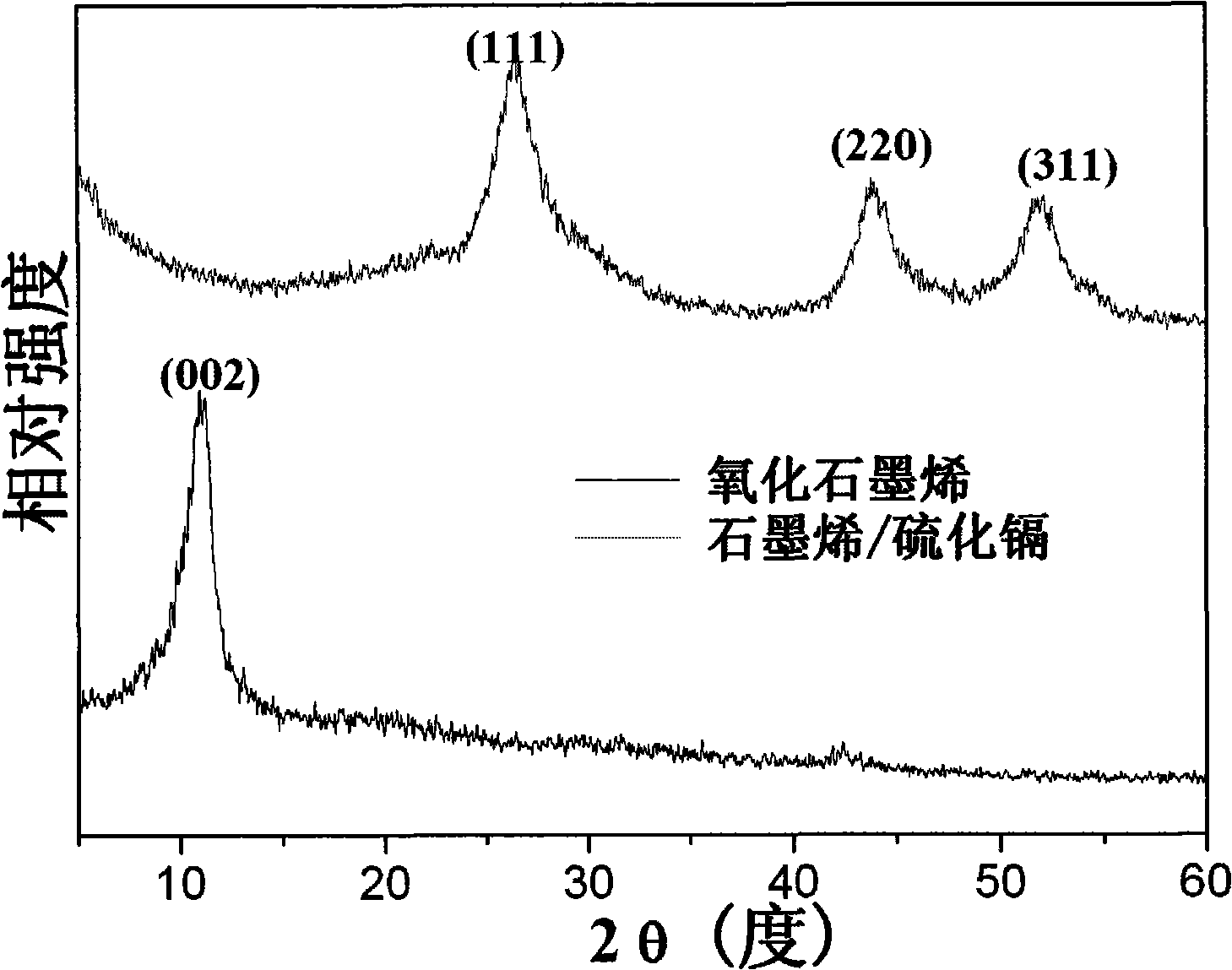

Method for directly preparing graphene/cadmium sulfide quantum dot nano composite material with one step by adopting graphite oxide as material

InactiveCN101559919ALow manufacturing costImprove energy conversion efficiencyNanostructure manufactureCvd grapheneHigh energy

The invention relates to a method for directly preparing graphene / cadmium sulfide quantum dot nano composite material with one step by adopting the graphite oxide as material. The invention provides a simplified technique method, namely the independent preparation step of graphene is saved and skipped, the reduction of graphite oxide or graphene oxide and generation of composite material are finished simultaneously or in one step; and the cadmium sulfide quantum dot has grown on the graphene while the graphite oxide or graphene oxide is reduced to graphene. Therefore, the method can greatly reduce the manufacturing cost of the composite material. The graphene / cadmium sulfide composite material prepared by the method can be used as novel photoelectric conversion material and has higher energy conversion rate.

Owner:SHANGHAI UNIV

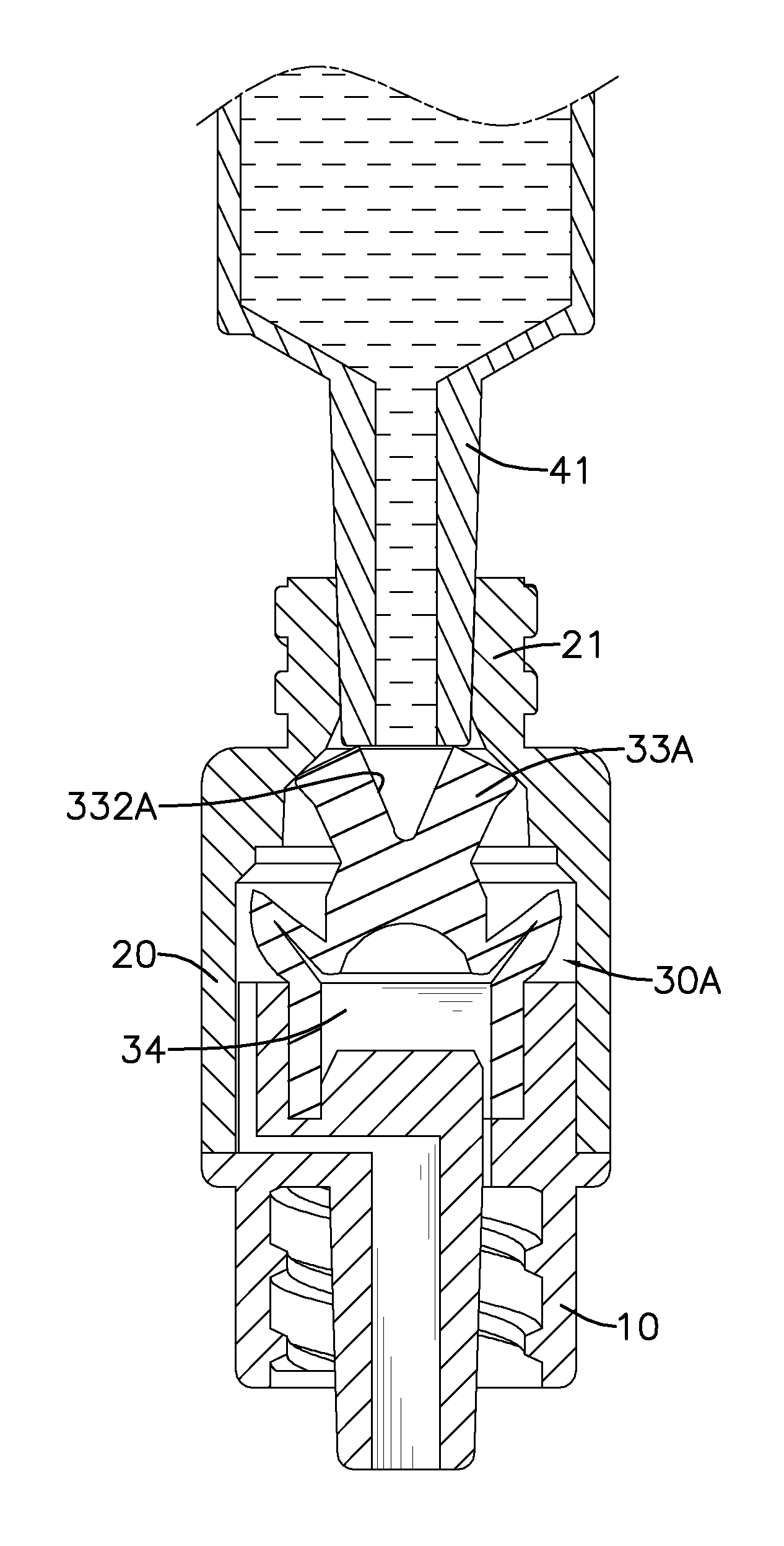

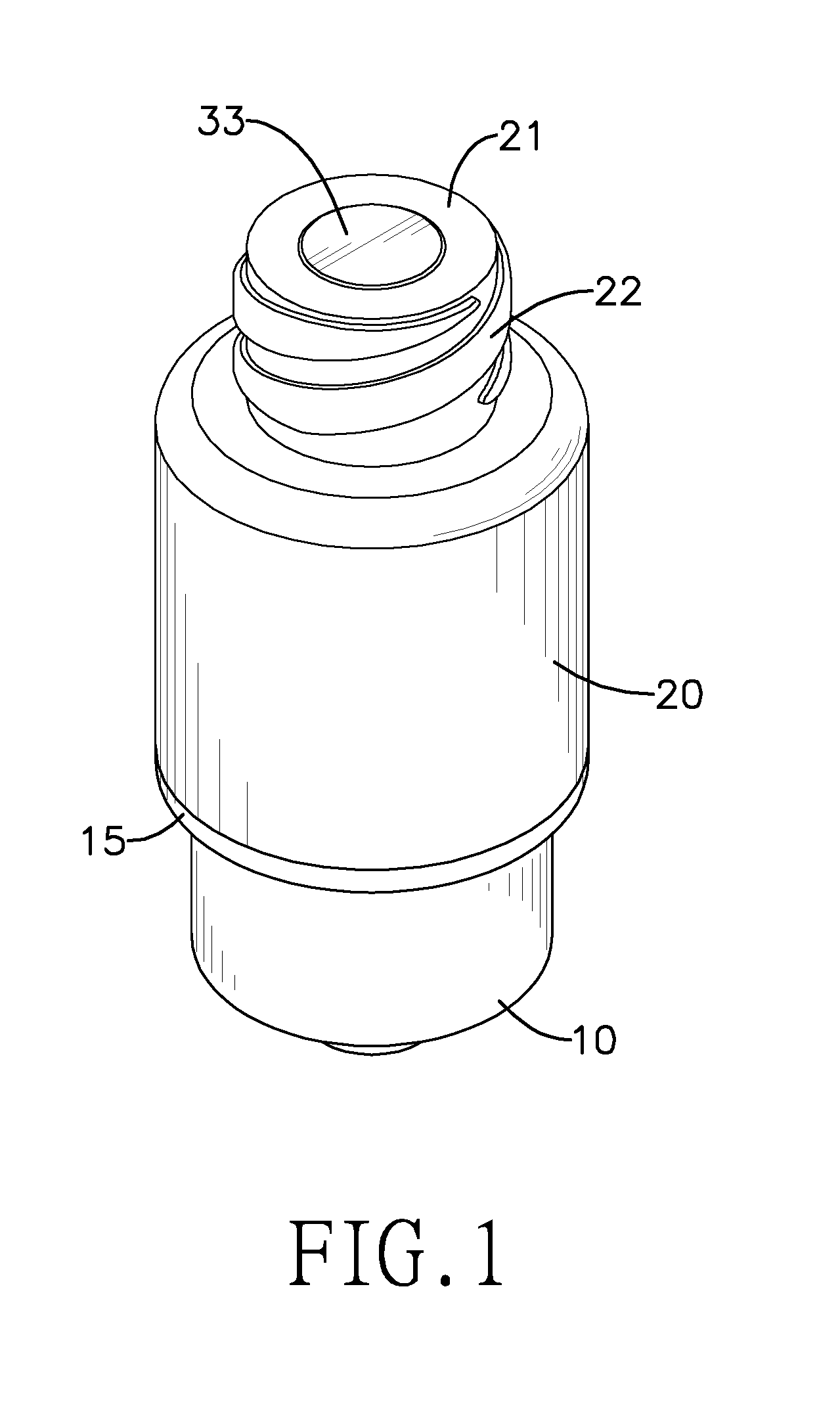

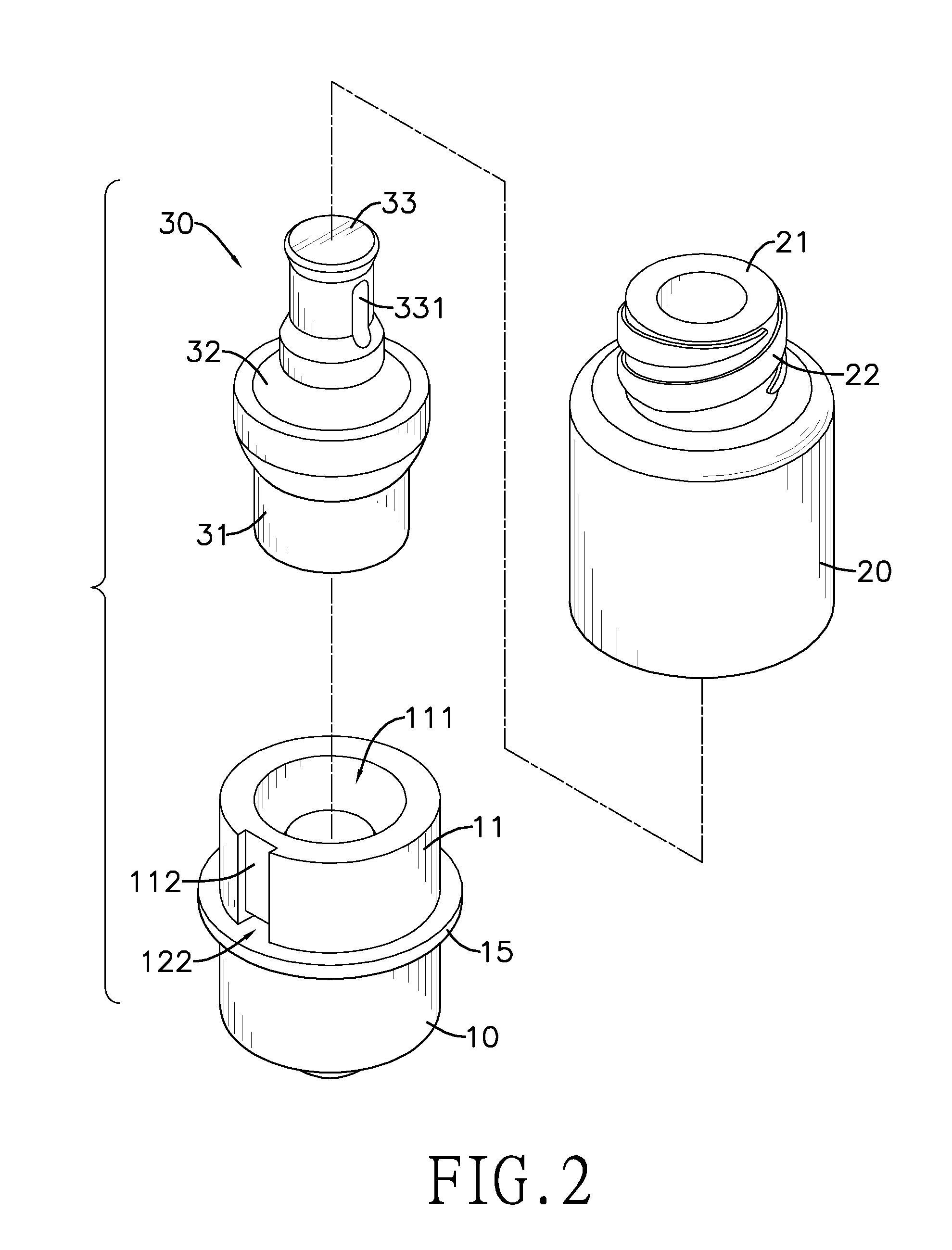

Syringe adapter with a ball-typed valve

ActiveUS20120059334A1Simplify assembly processLow manufacturing costInfusion syringesSurgerySyringeEngineering

A syringe adapter with a ball-typed valve has a base, a dosing tube mounted around the base and a resilient valve mounted in the base and the dosing tube. The base has a guiding groove and an inner liquid channel communicating with each other, as well as an exhaust channel. Liquid medicine injected into the syringe adapter flows through the guiding groove and causes the inner liquid channel to be injected into a patient's body. The liquid medicine remaining in the split is cleaned when cleaning fluid is injected to clean the syringe adapter. Air in the syringe adapter flows out through the exhaust channel and is not injected into the patient's body, so the patient is free from pain. Furthermore, elements and assembling processes of the syringe adapter are simplified and manufacturing cost of the syringe adapter is lowered.

Owner:SKILL PARTNER

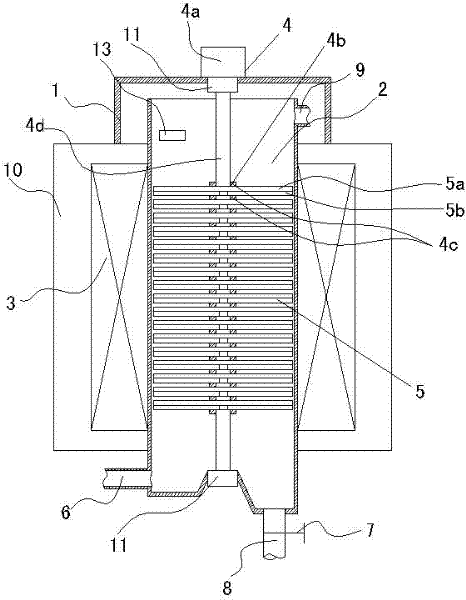

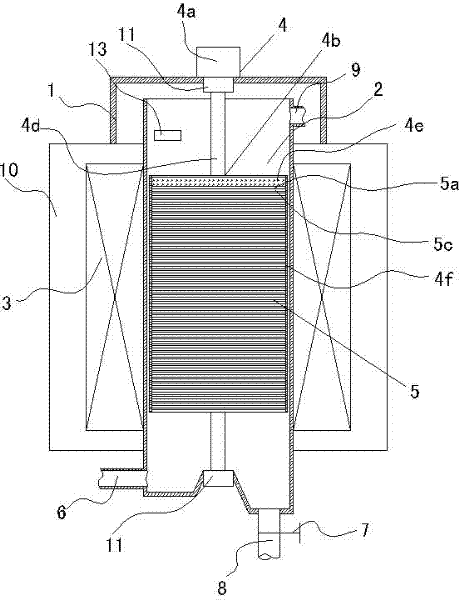

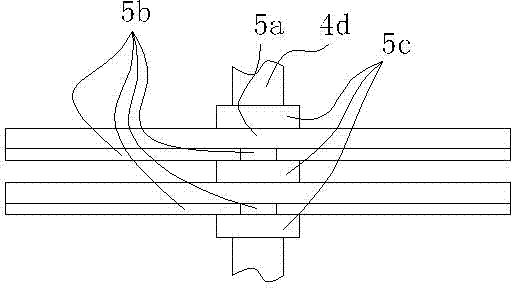

Electromagnetic iron-removing method and device

InactiveCN102343306ALow manufacturing costEnsure the effect of removing ferromagnetic substancesHigh gradient magnetic separatorsPower unitSoft magnet

The invention provides an electromagnetic iron-removing method and device. The device comprises a frame, a cylindrical fluid passage which is vertically arranged on the frame, electromagnetic coils and a soft magnetic medium member with a rotary power unit, wherein, the electromagnetic coils are wound on the external side face of the fluid passage; the soft magnetic medium member is arranged in the cylindrical fluid passage and comprises a plurality of layers of stacked mesh soft magnets or soft magnet steel wool balls which are alternately spaced; the rotary power unit is arranged on the frame; the entrance on the lower end of the cylindrical fluid passage is equipped with a fluid lead-in channel and a ferromagnetic substance discharge port with a valve; the upper end of the cylindrical fluid passage is equipped with a fluid discharge port; and the cylindrical fluid passage is made from a nonmagnetic material. Compared with the prior art, the electromagnetic iron-removing method and device have the advantages that by adopting a soft magnetic medium in an ideal physical form which can generate a high gradient magnetic field, the iron-removal effect for a ferromagnetic substance is ensured; and meanwhile a centrifugal cleaning mode is adopted, and the manufacturing cost is low.

Owner:李泽 +1

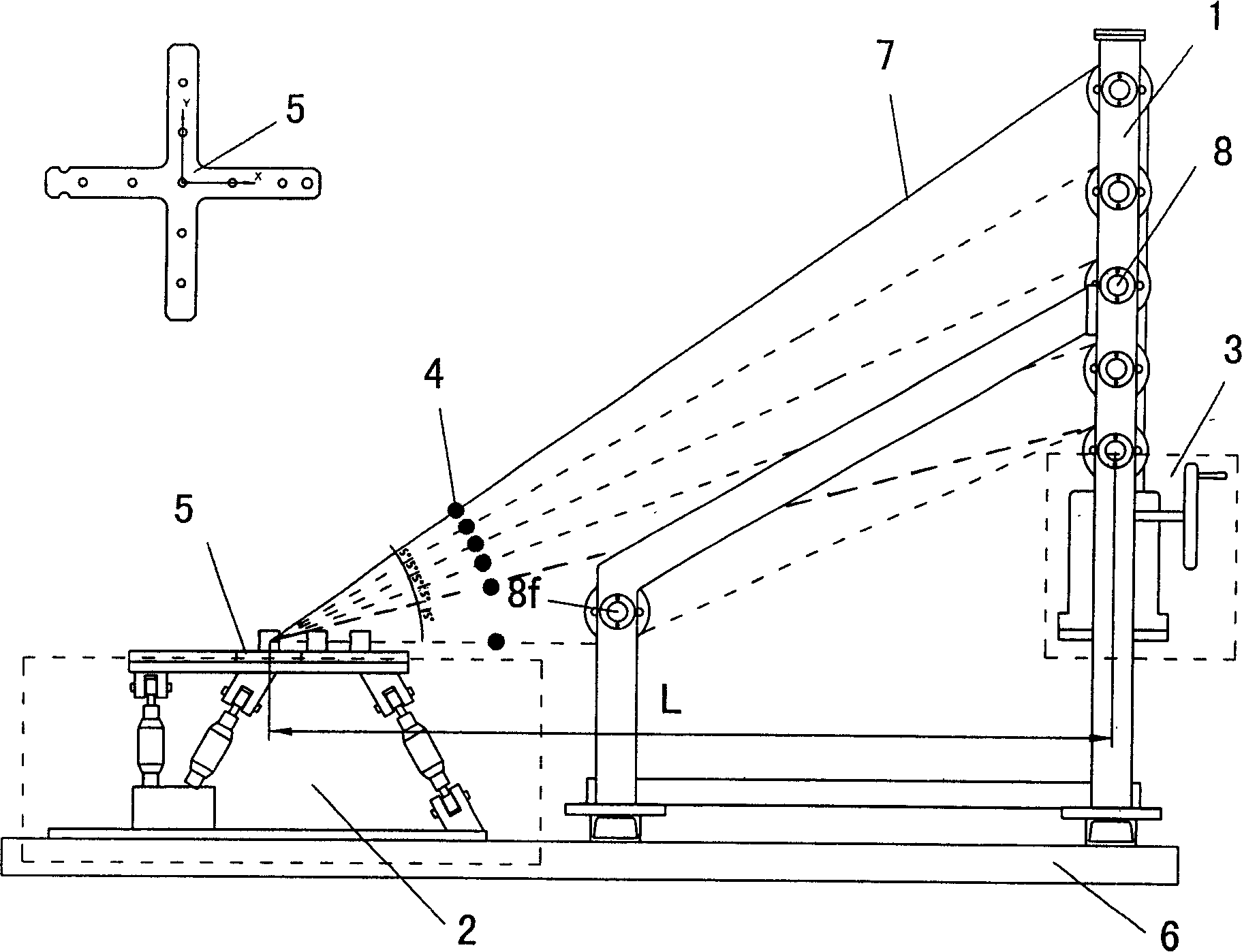

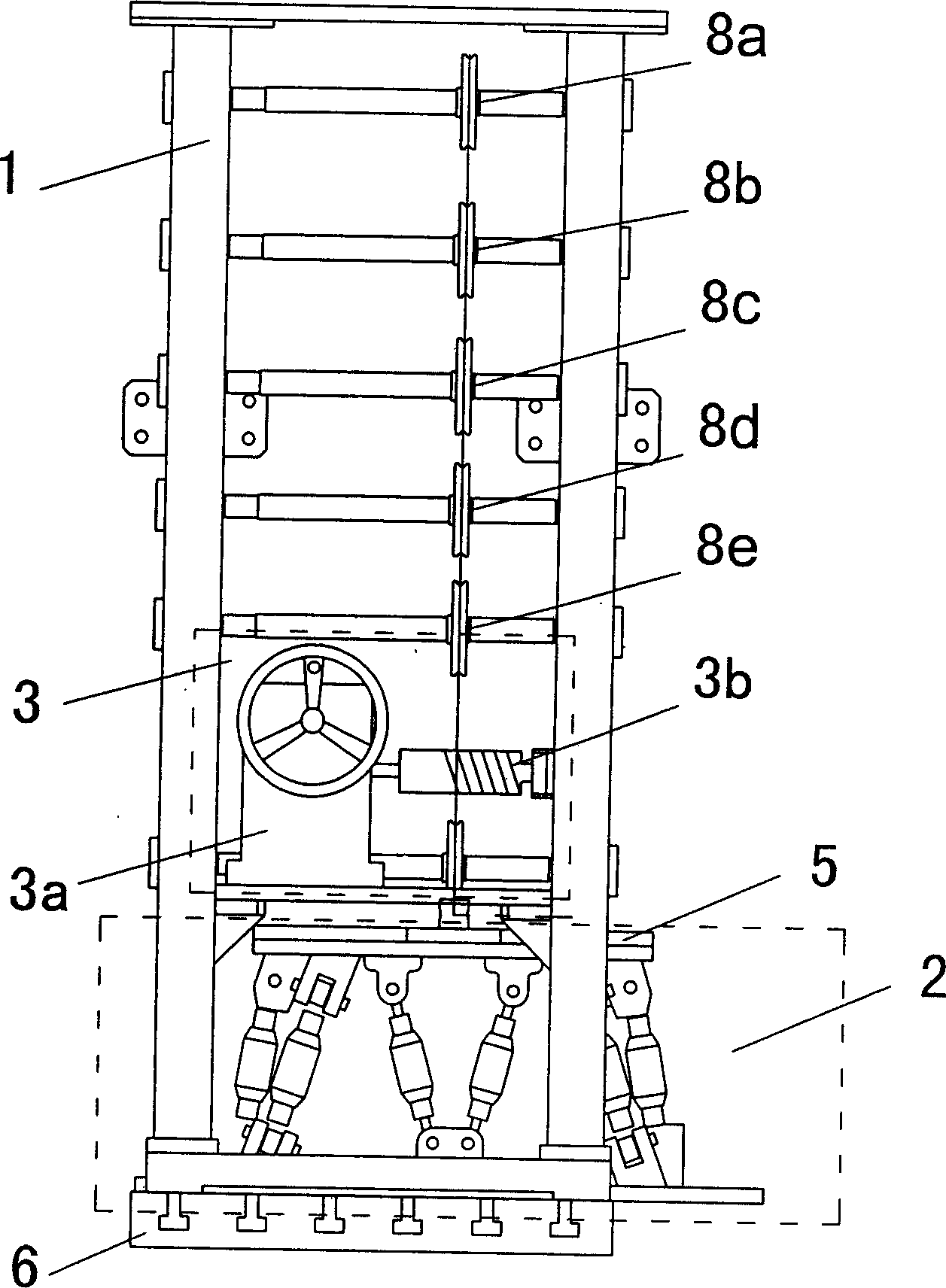

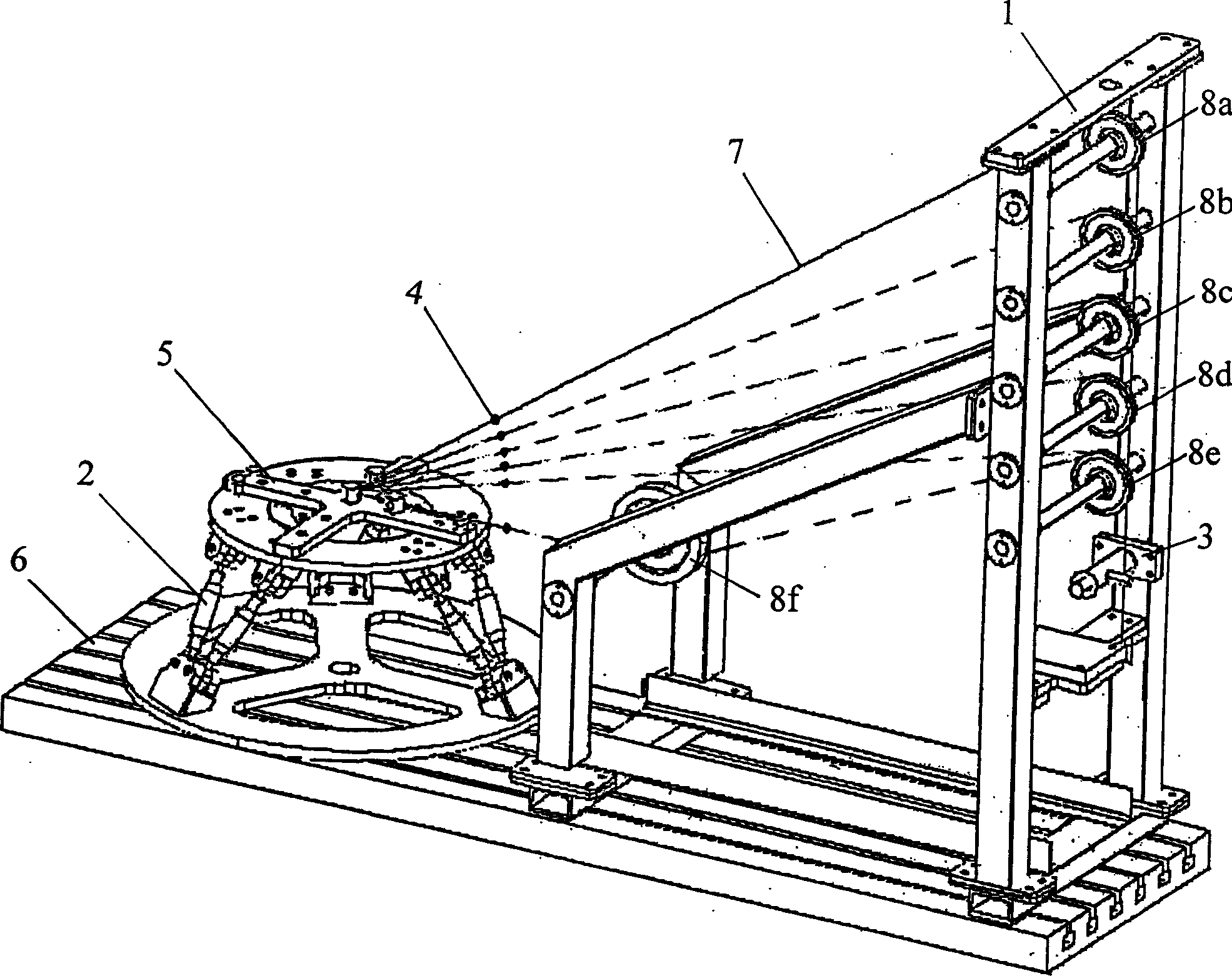

Device for calibrating parallel force transducer in six dimensions

InactiveCN1727861ASimple device structureLow manufacturing costForce/torque/work measurement apparatus calibration/testingEngineeringTransducer

A calibration device of parallel 6D force transducer consists of gantry support frame formed by long and short frames , load speed reducer , transducer of standard single direction force , load coordinate cross , fixing platform of calibration device , charge transmitting rope and pulley block . It features that speed reducer in large speed ratio is applied by calibration device for exerting charge and gantry structure is used as support frame.

Owner:ZHEJIANG UNIV

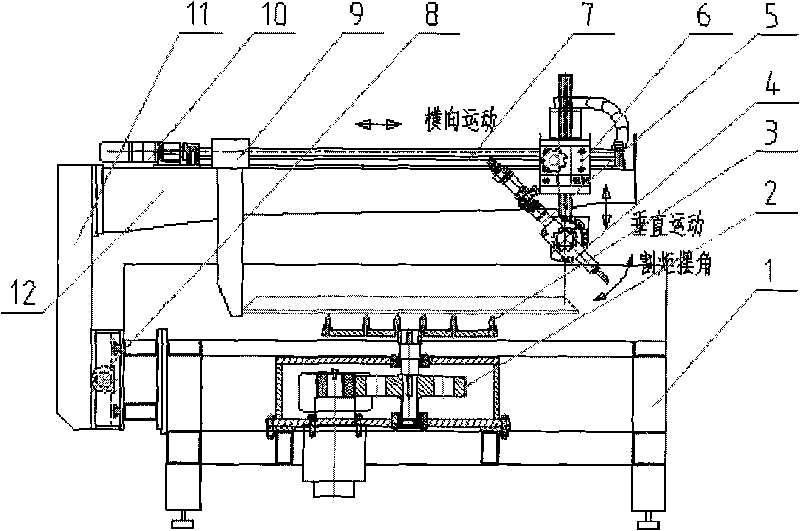

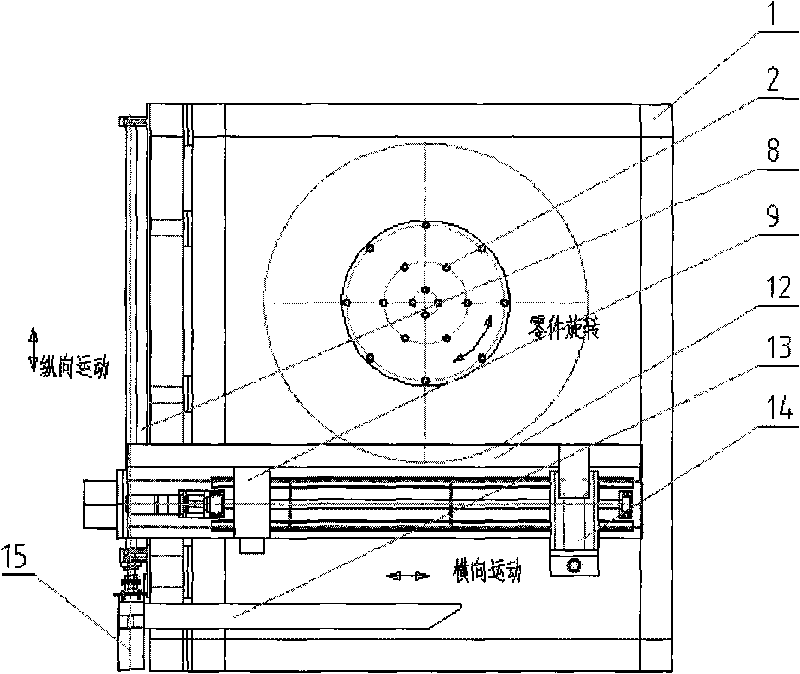

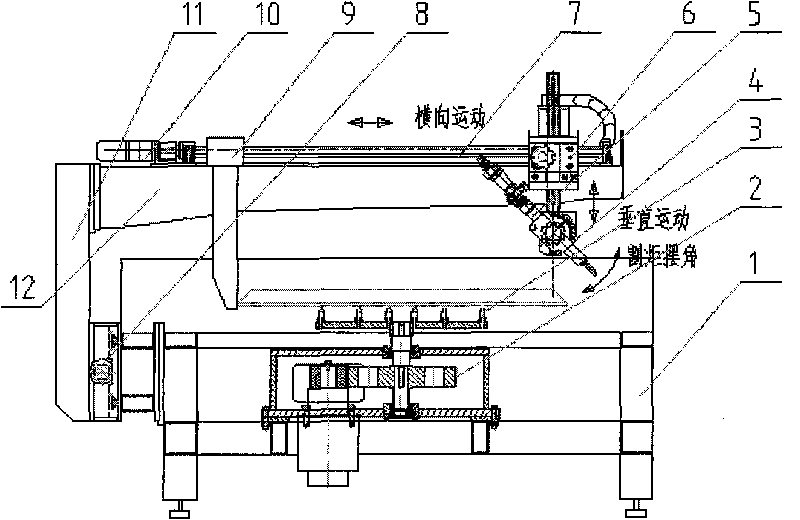

Machining method of workpiece welding groove-workpiece rotary type numerical control cutting machine

InactiveCN101716709ANovel structureLow manufacturing costWelding/cutting auxillary devicesAuxillary welding devicesGas pipelineEngineering

The patent of the invention relates to an innovative numerical control cutting machining method aiming at (sheet metal) workpiece welding grooves, which is a cutting application method combining blaze, plasma and flying optics laser and belongs to the field of industrial welding and cutting technology. The invention adopts a machining mode that workpiece actively rotates, the workpiece can be freely clamped, the invention is suitable for numerical control cutting machining of the welding groove with any curved profiles, the cutting quality, the production efficiency and the material utilization are obviously enhanced, and the device cost is low. The invention adopts the mode that the workpiece revolves around tools (cutting torch) to rotate, thoroughly solves the technology bottlenecks of complex structure (winding and restrictions of connecting cables, gas pipelines, and the like of the cutting torch caused by the rotation of the workpiece) of traditional numerical control cutting method, and the like. The technical implementation scheme is that a workpiece active (unlimited) rotary disk arranged on a substrate loads the workpiece; each axis (A, X, Y, W and Z) of the numerical control procedure control system moves the edge of the workpiece groove to a cutting zone, and cutting torch (Z) axis automatically falls downwards to a working height and completes initial cutting gesture according to groove angle and thickness of the programming workpiece; and the workpiece (W) placed on the unlimited rotary disk is continuously matched with the cutting torch to swing (A) to do transverse (X) and longitudinal associated movement after a numerical control cutting processing program is operated, and the cutting torch is placed in a normal section of a cut workpiece all along and completes processing molding of the welding groove of the workpiece. The invention can be widely applied and popularized in industrial welding and cutting field.

Owner:北京林克曼数控技术股份有限公司

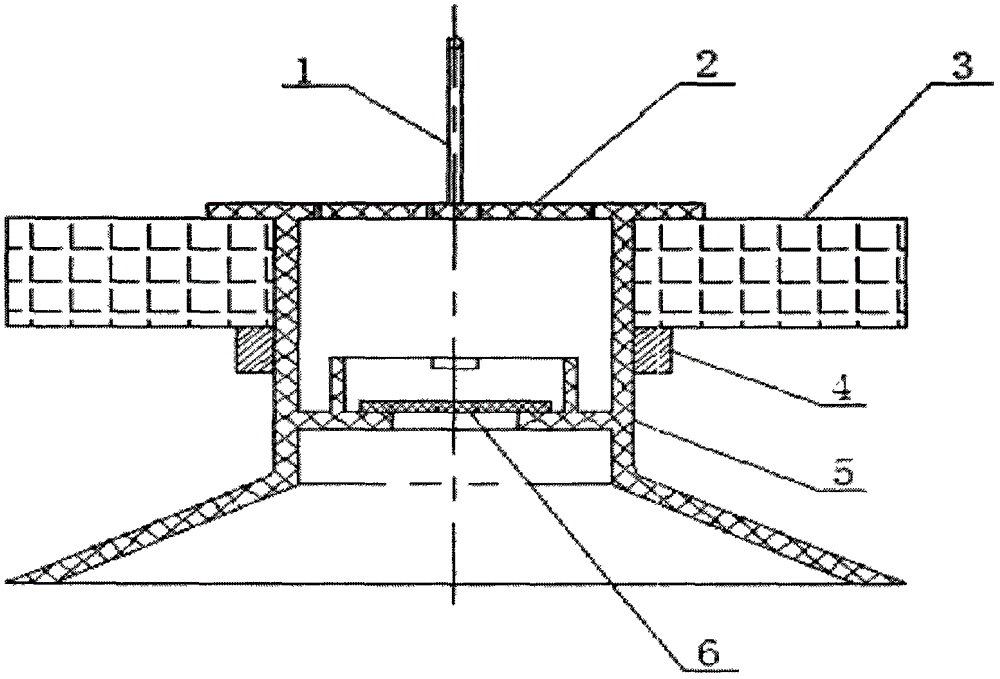

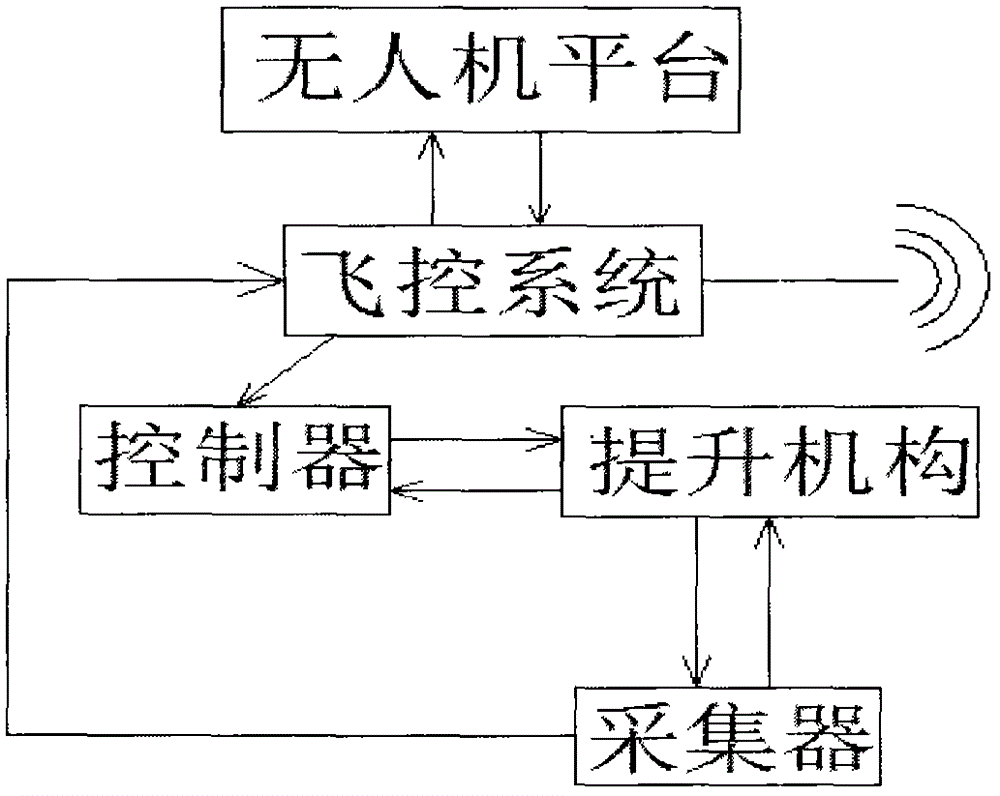

Unmanned aerial vehicle type automatic sampling system at fixed points of water surface

InactiveCN104458329ASimple structureLow manufacturing costWithdrawing sample devicesElectric machinerySelf locking

The invention relates to an unmanned aerial vehicle type automatic sampling system at fixed points of the water surface. The unmanned aerial vehicle type automatic sampling system comprises a water sampler, a lifting mechanism and a control circuit, wherein the water sampler comprises a barrel body and a periphery component, a large conical horn mouth is designed at the lower end of the barrel body, and an end cover exhaust device is arranged at the upper end of the barrel body; a buoyancy ring and a heavy ring are arranged at the outer side of the barrel body, the buoyancy ring is arranged at the lower end of an end cover, and the heavy ring is arranged at the lower end of the buoyancy ring; and a valve cover is arranged at the bottom of the inner side of the barrel body; the integrity is connected by a flying ring, the lifting mechanism is connected at the upper part of the flying ring, and is controlled by the control circuit. The lifting mechanism adopts a winding and distributing mechanism, the winding mechanism is composed of a power motor, a worm-gear speed reducer and a speed ratio guide wire wheel set, the speed ratio guide wire wheel set is connected with the flying ring by a connecting wire, the speed ratio guide wire wheel set is connected with the worm-gear speed reducer which is connected with the power motor; while the twisting force is increased, self locking can be achieved; and the system adopts the unmanned aerial vehicle system to realize sampling, the traditional manual sampling mode can be replaced completely, and rapid, intelligent and high-efficiency water sampling can be achieved.

Owner:QINGDAO OUSEN SYST TECH

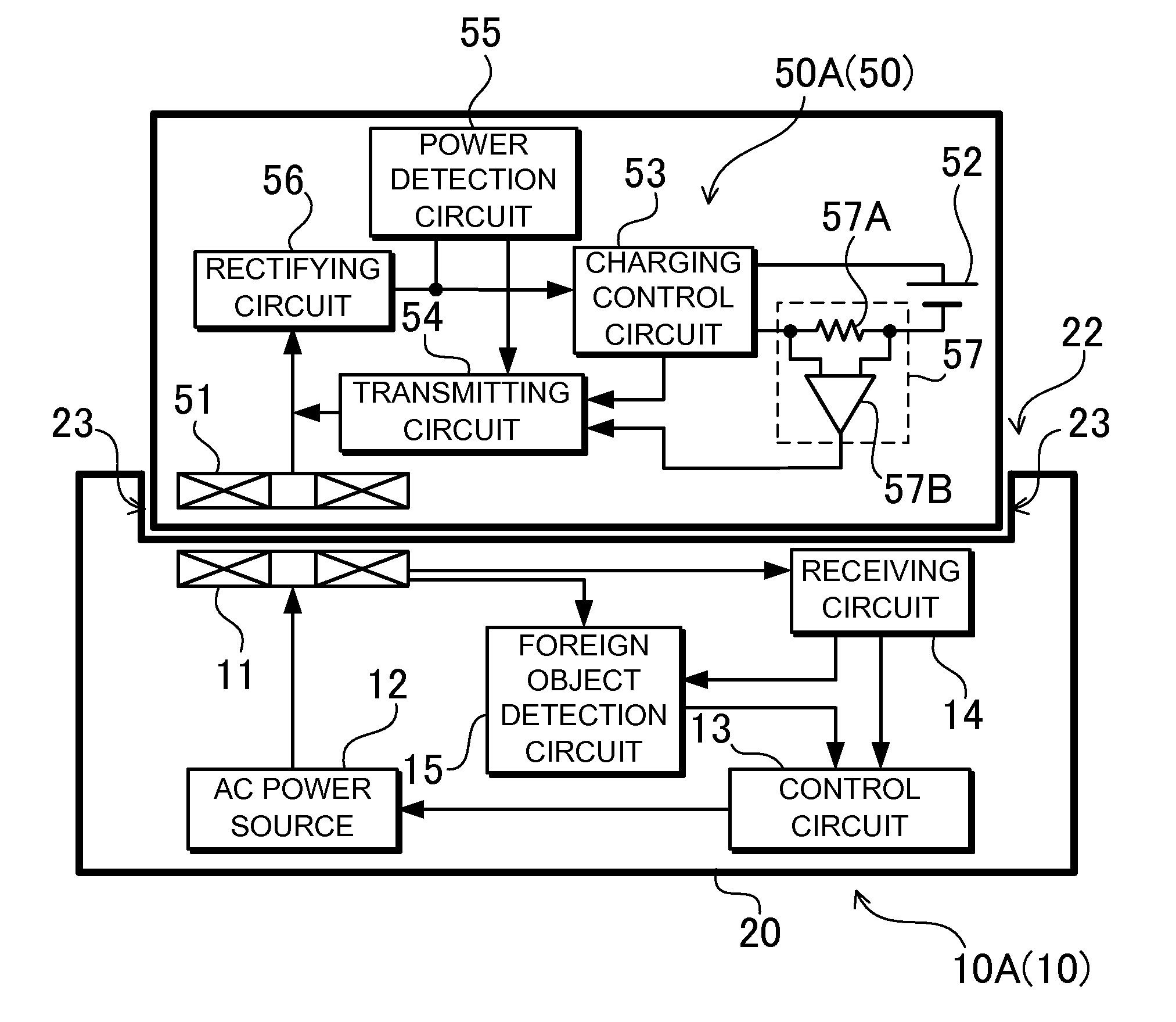

Contactless method of supplying power

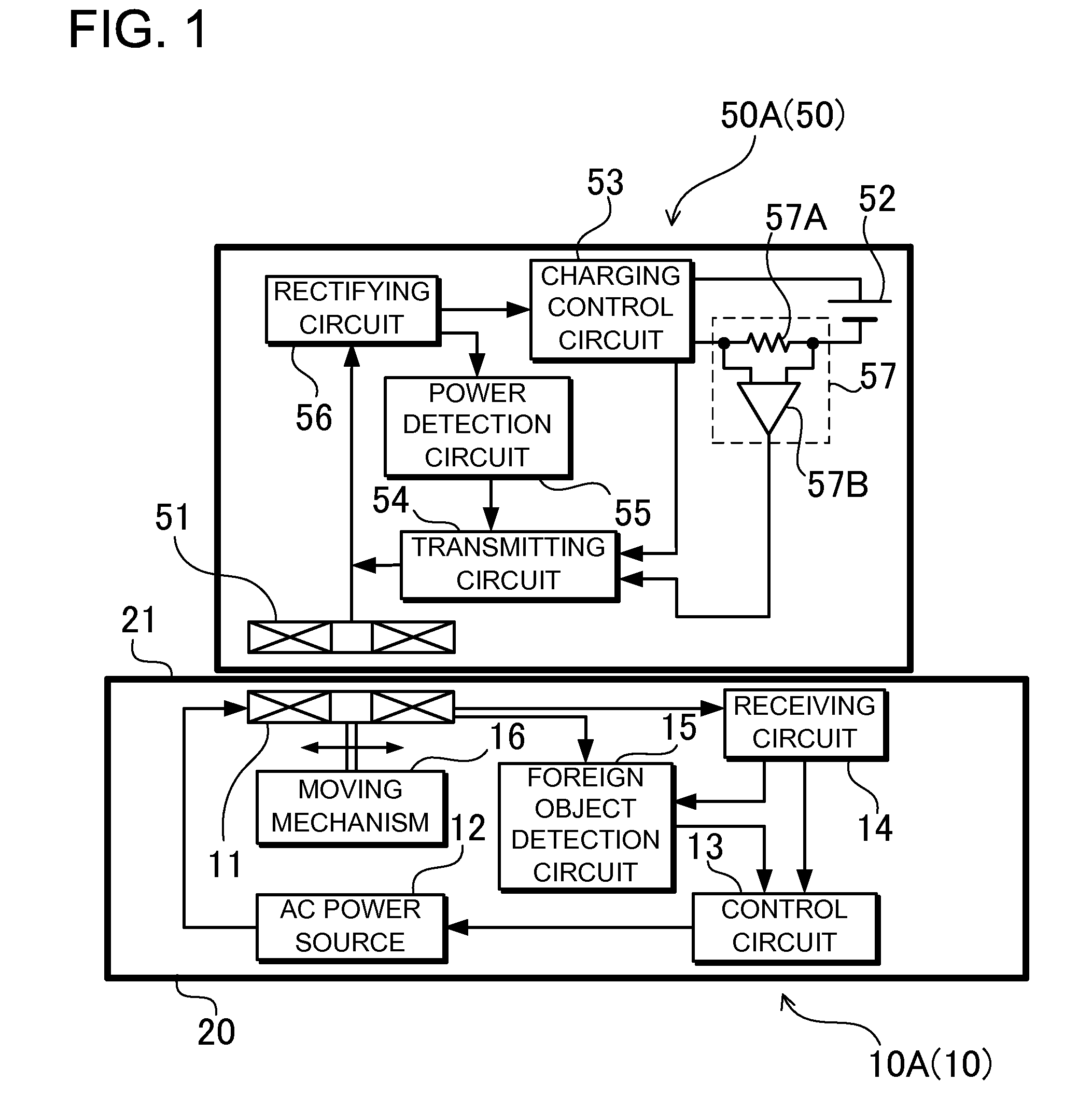

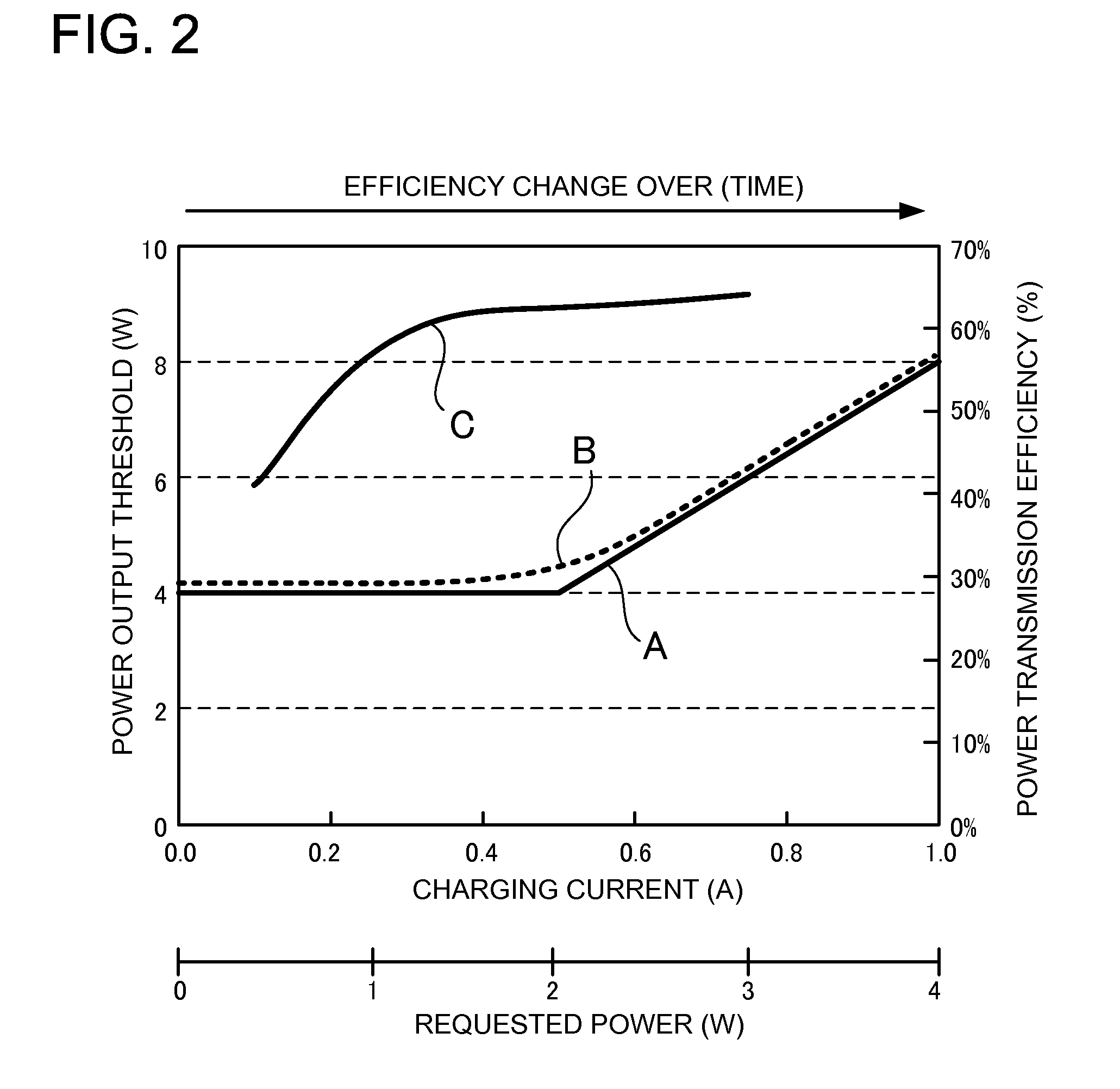

InactiveUS20130285618A1Simple circuit structureLow manufacturing costBatteries circuit arrangementsElectromagnetic wave systemForeign objectPower output

Power supply stand output to the portable device is adjusted according to the power adjustment signals. Maximum power supply stand output is limited to a power output threshold value. The portable device compares the power received from the power supply stand to the required power. When the received power is lower than the required power, the portable device sends a power adjustment signal to the power supply stand, which is an increase-power-request signal. When the received power is greater than the required power, the portable device sends a decrease-power-request signal to the power supply stand. The power supply stand adjusts output and limits it to the power output threshold value. When continuous output of increase-power-request signals from the portable device is detected over a preset time period, a foreign object is determined to be on the power supply stand.

Owner:DEPUY PROD INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com