Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

653results about "Straight-bar knitting machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

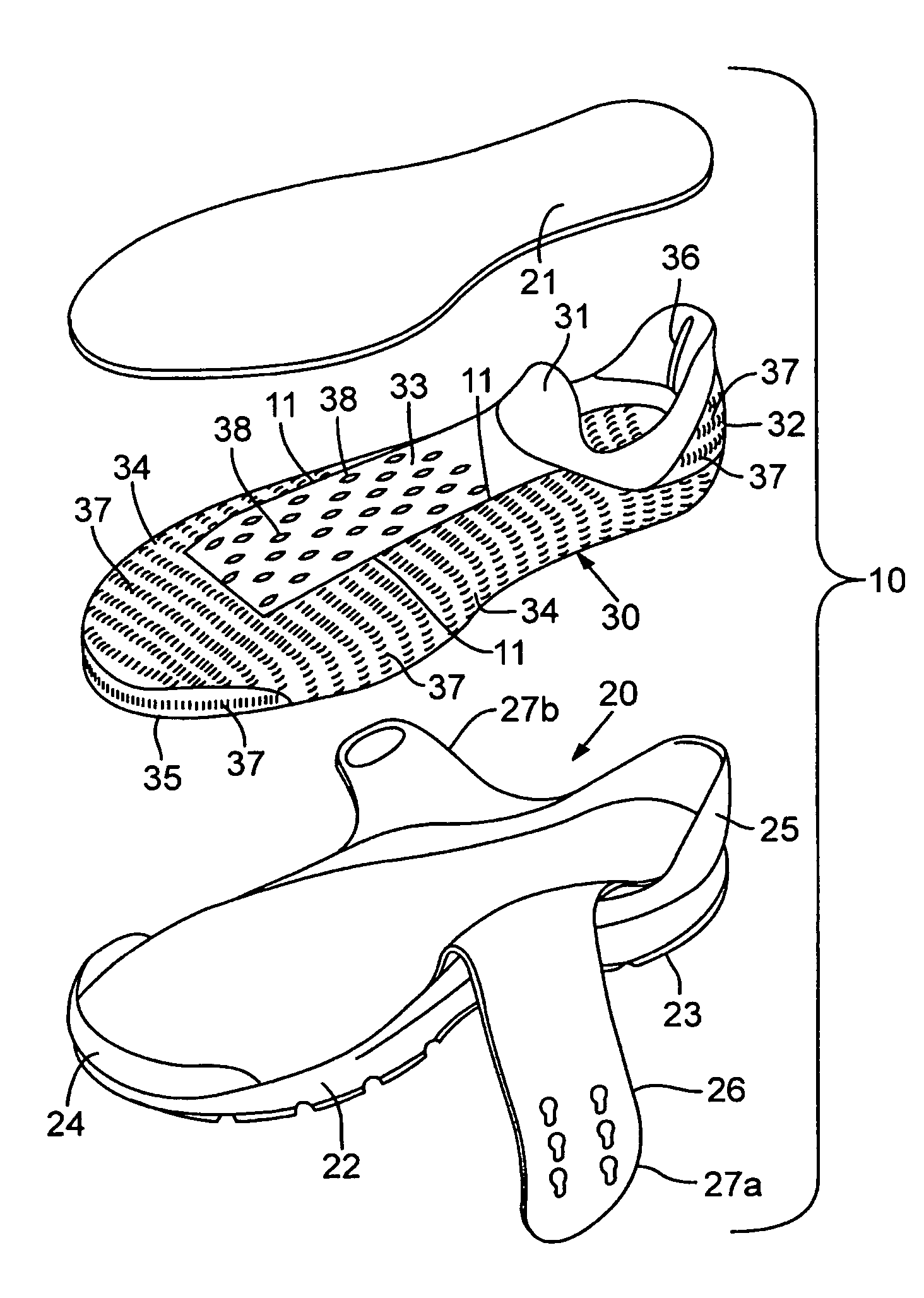

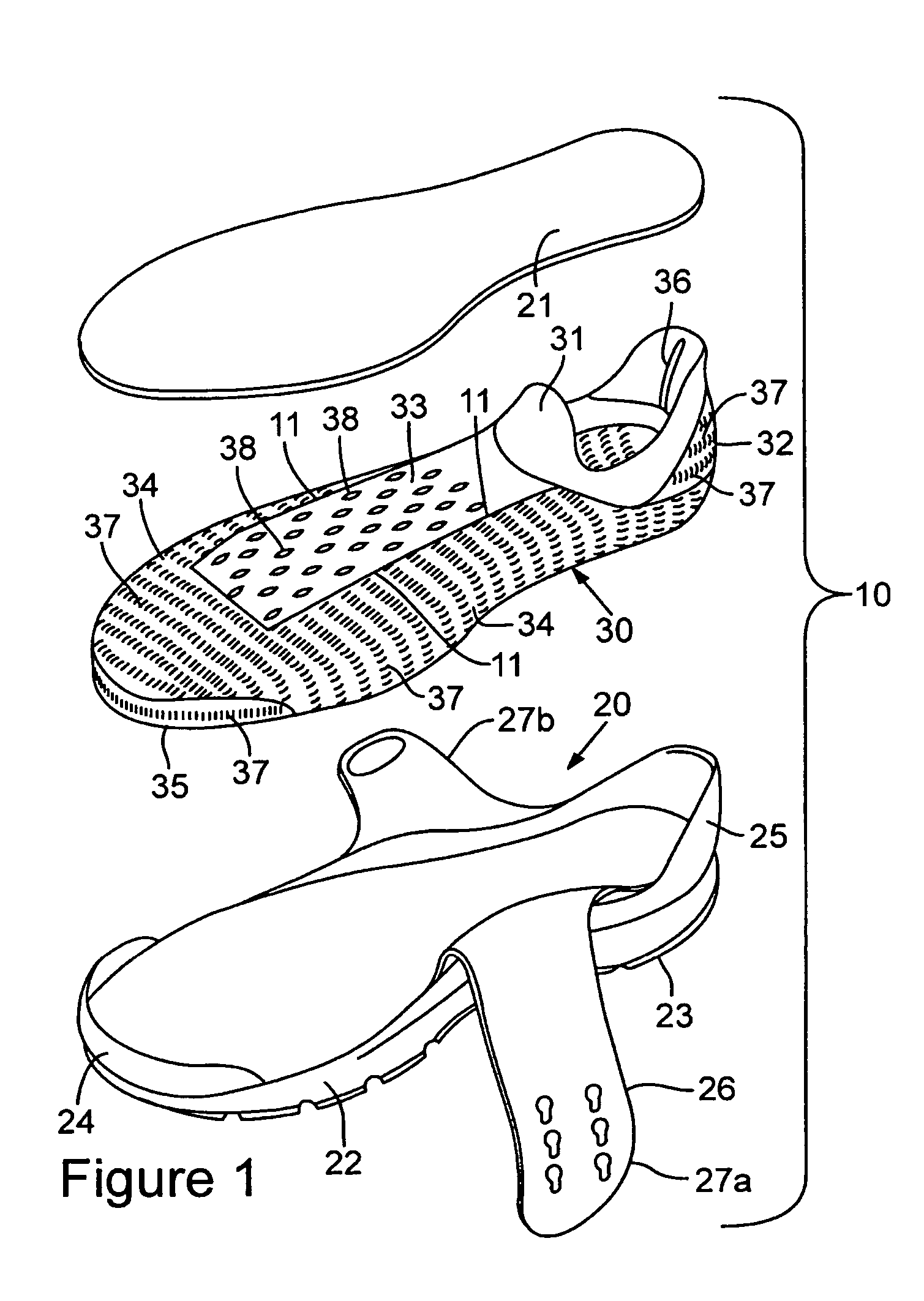

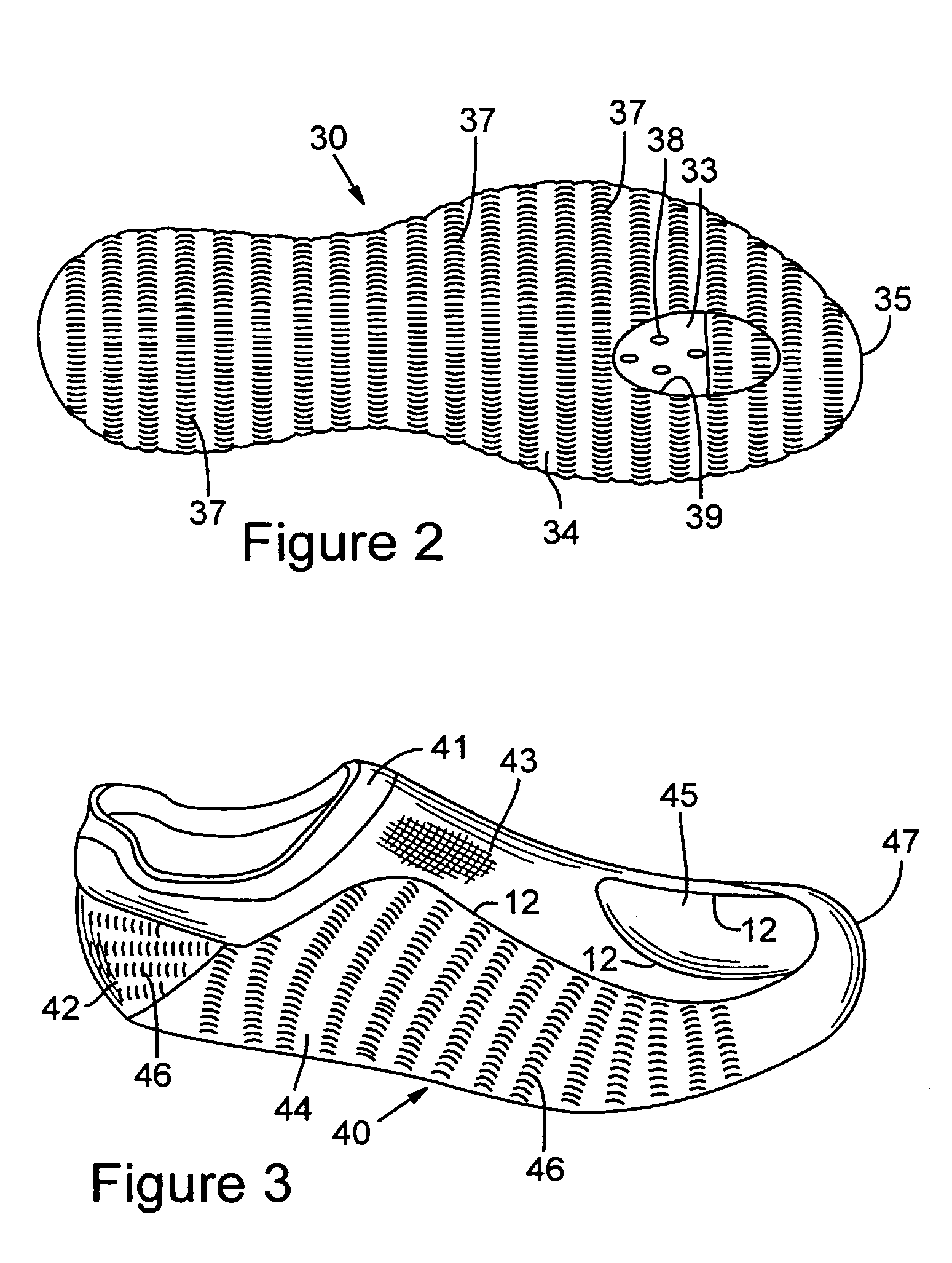

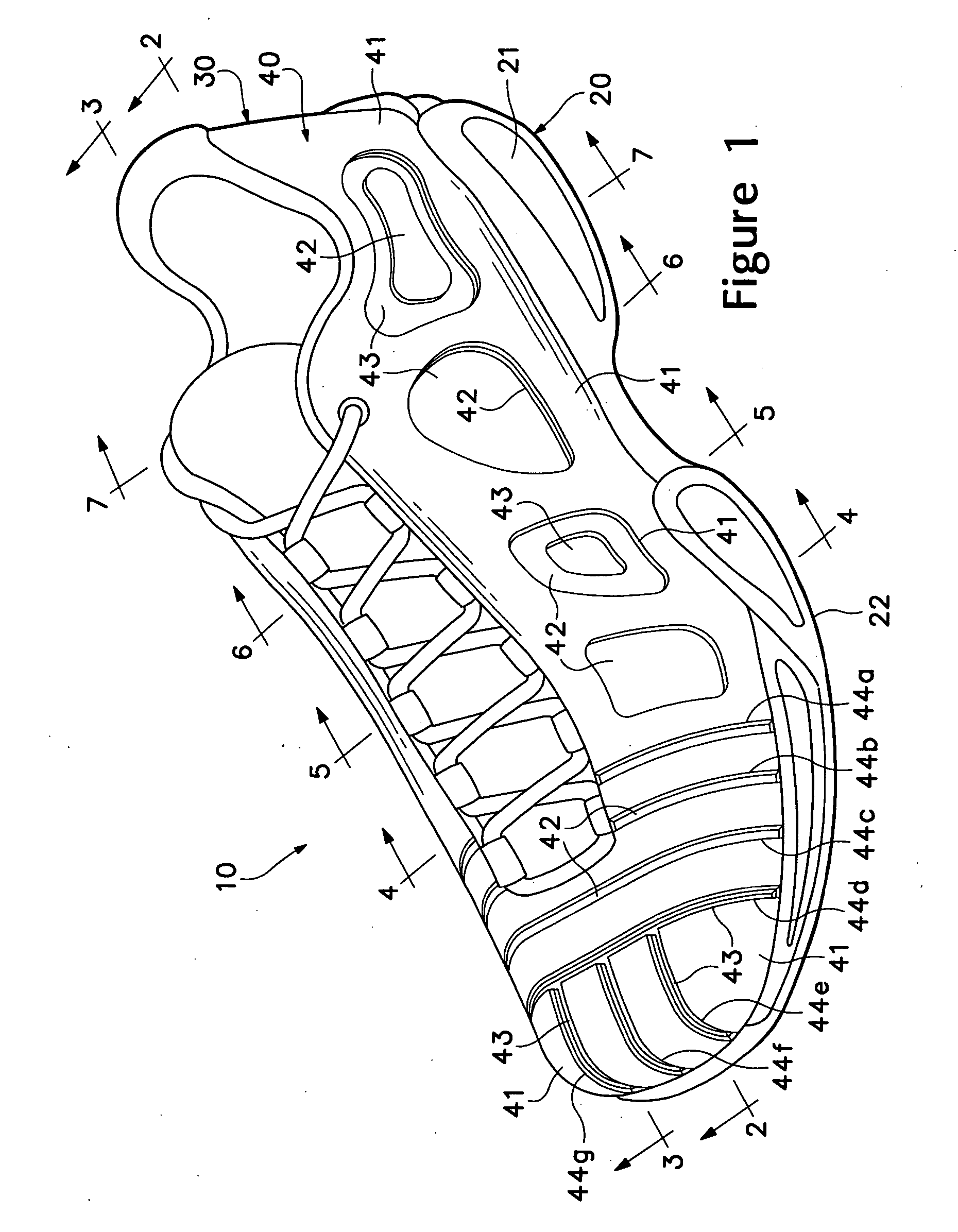

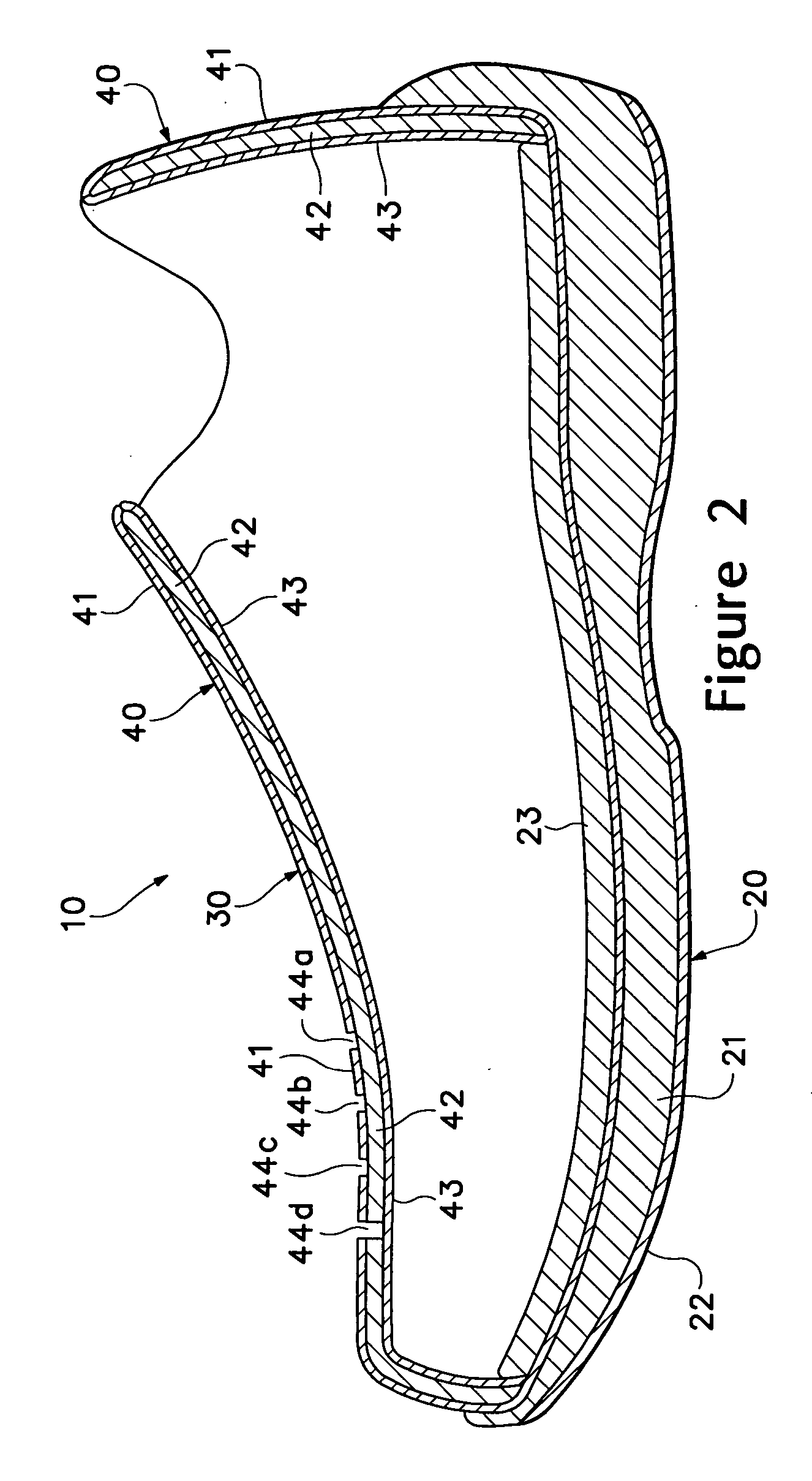

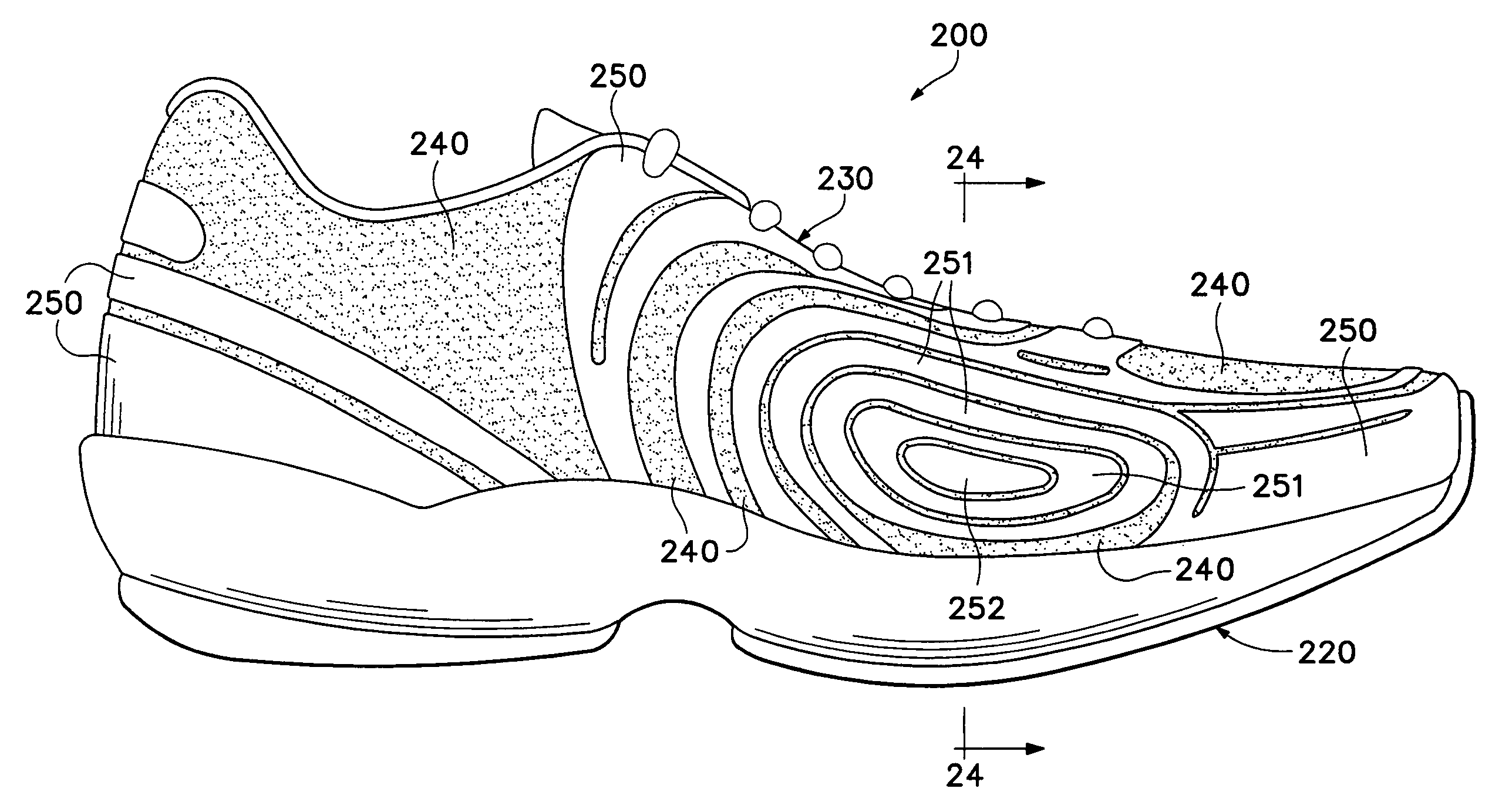

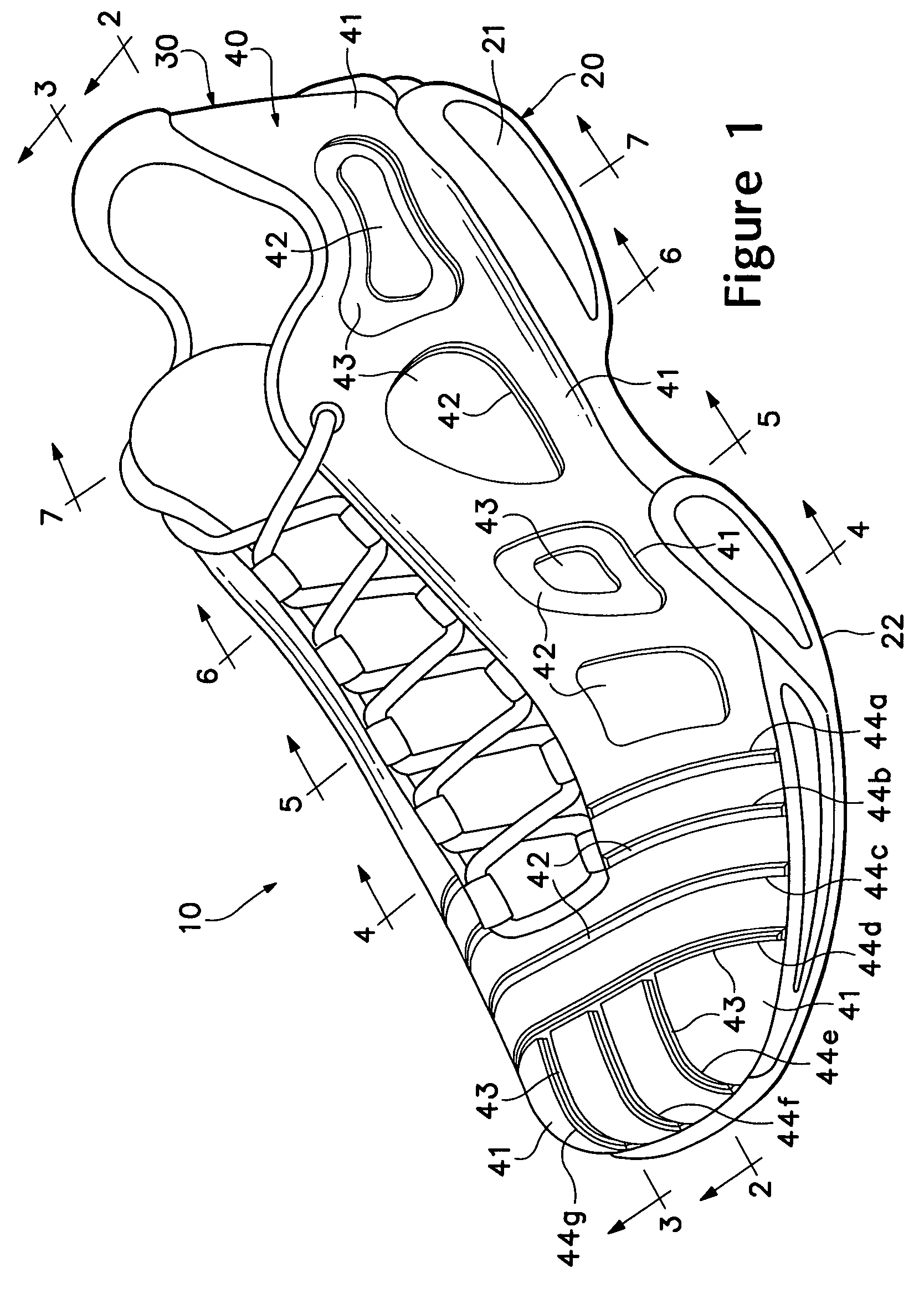

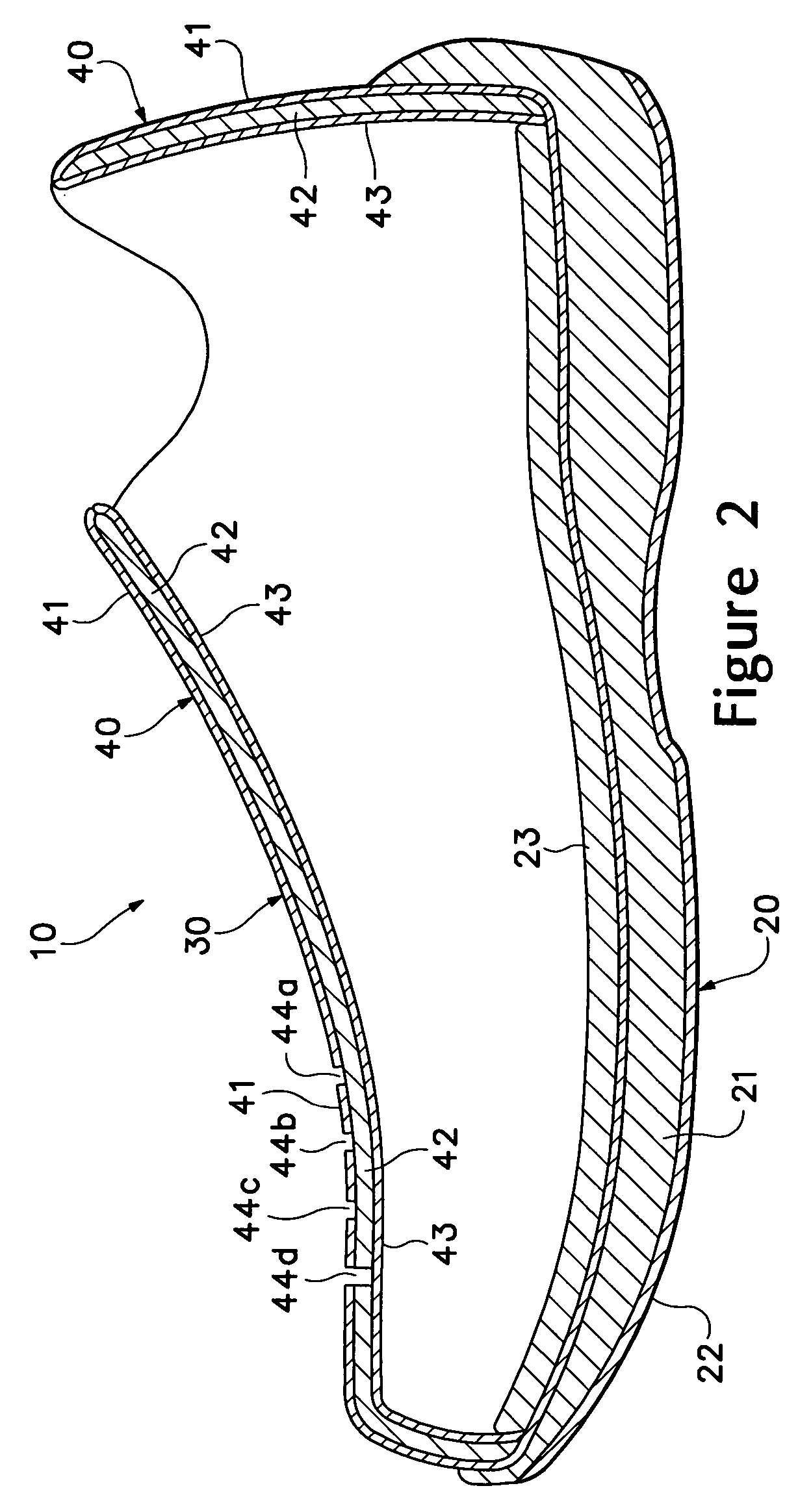

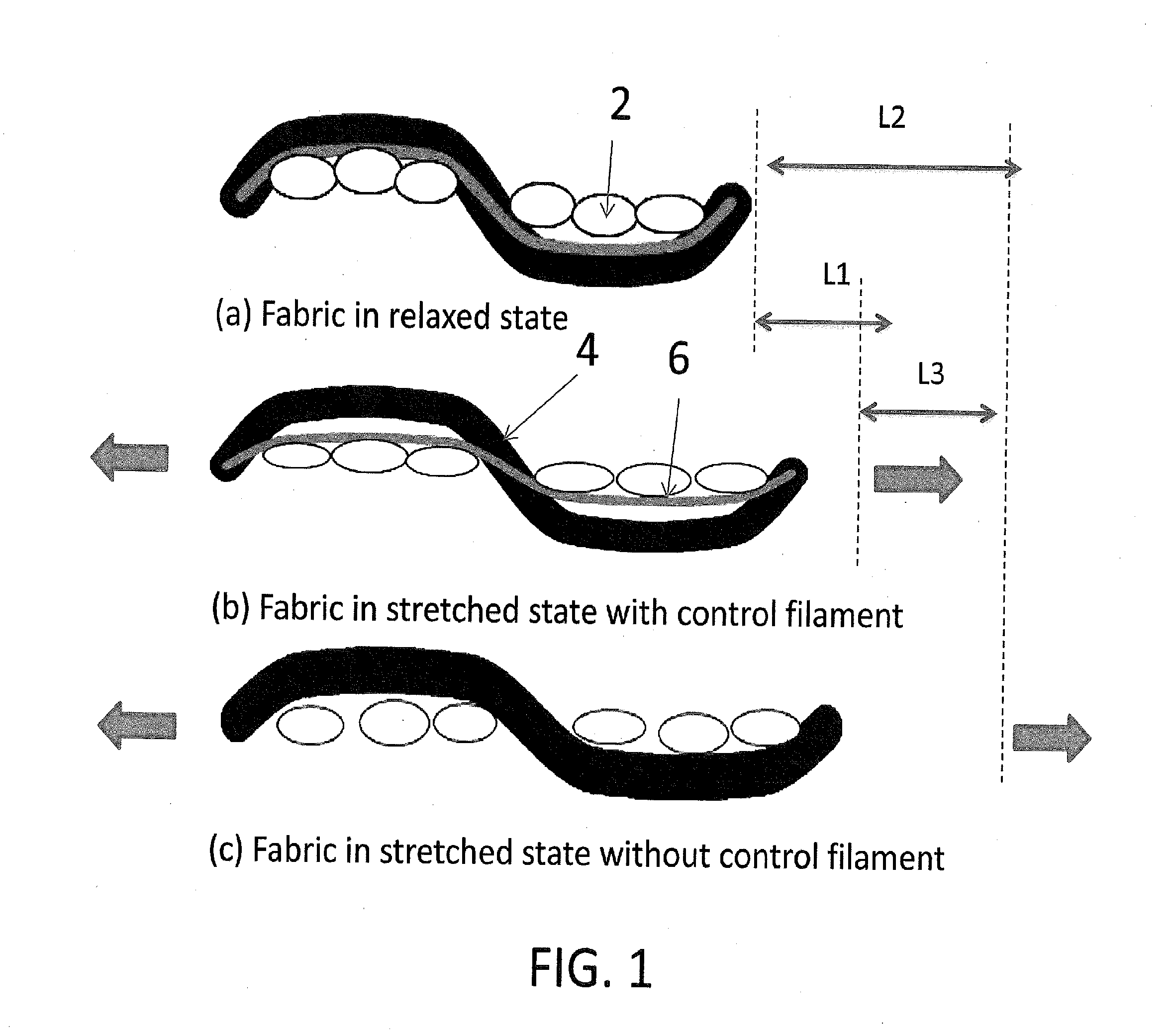

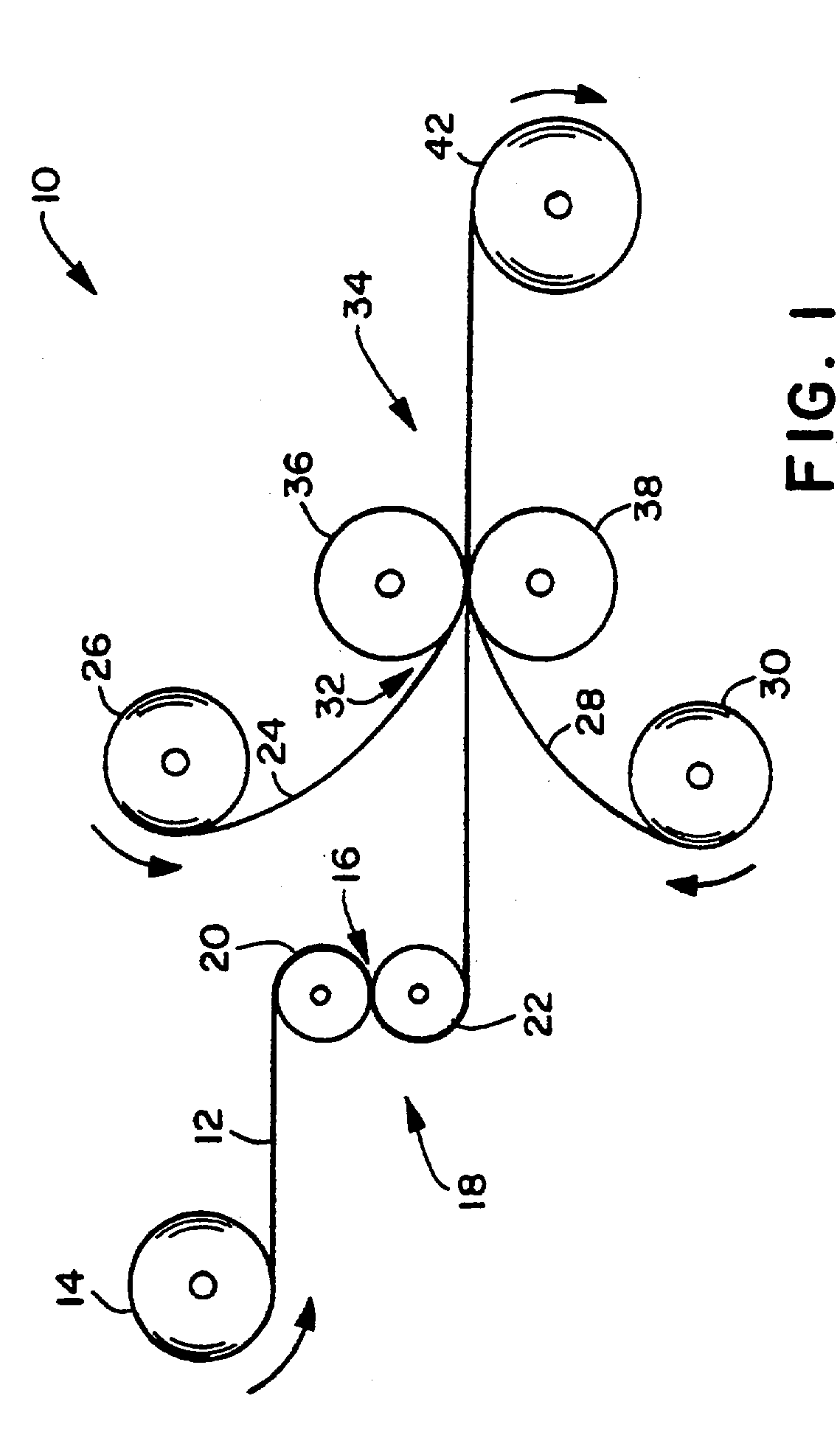

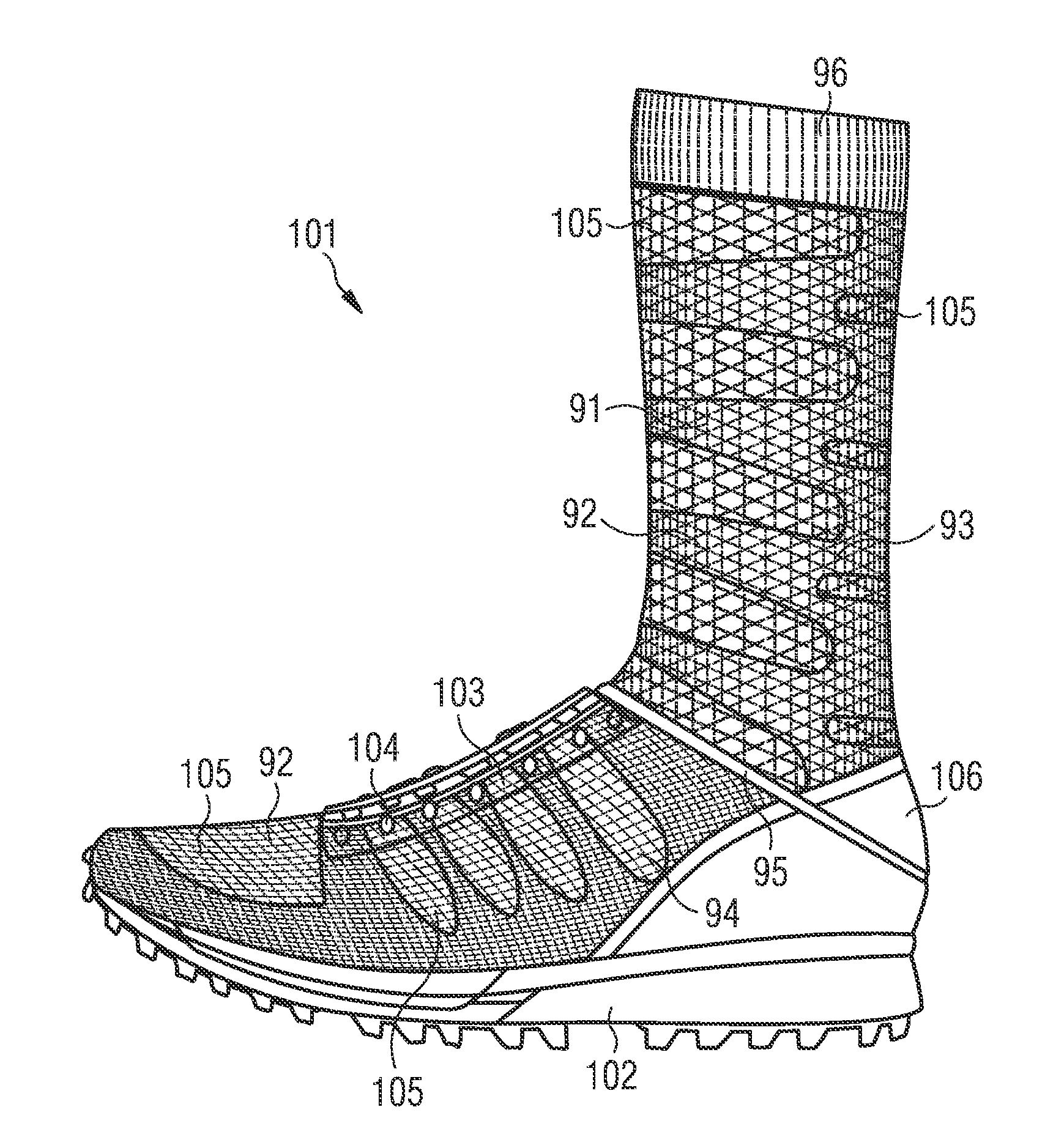

Footwear with knit upper and method of manufacturing the footwear

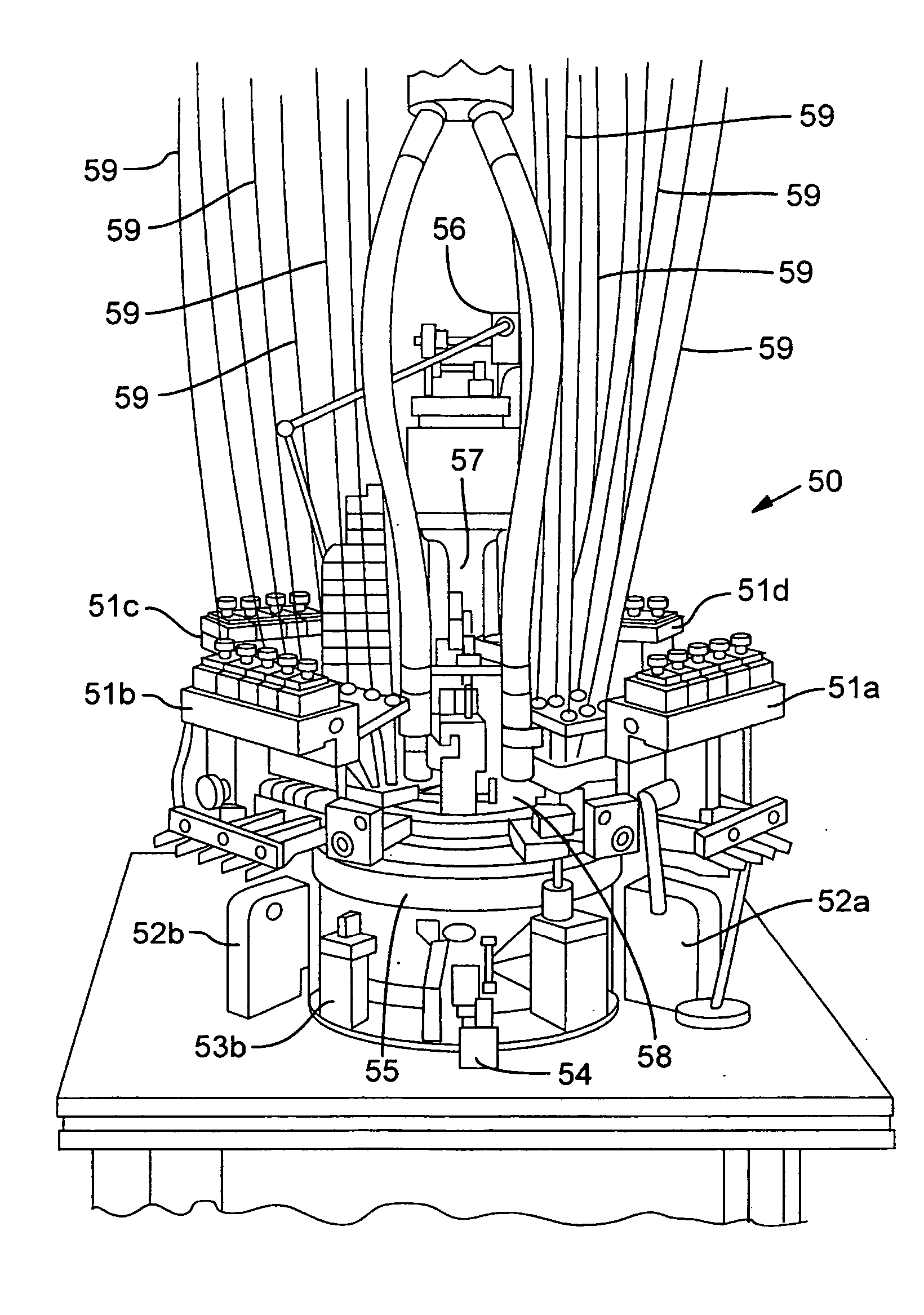

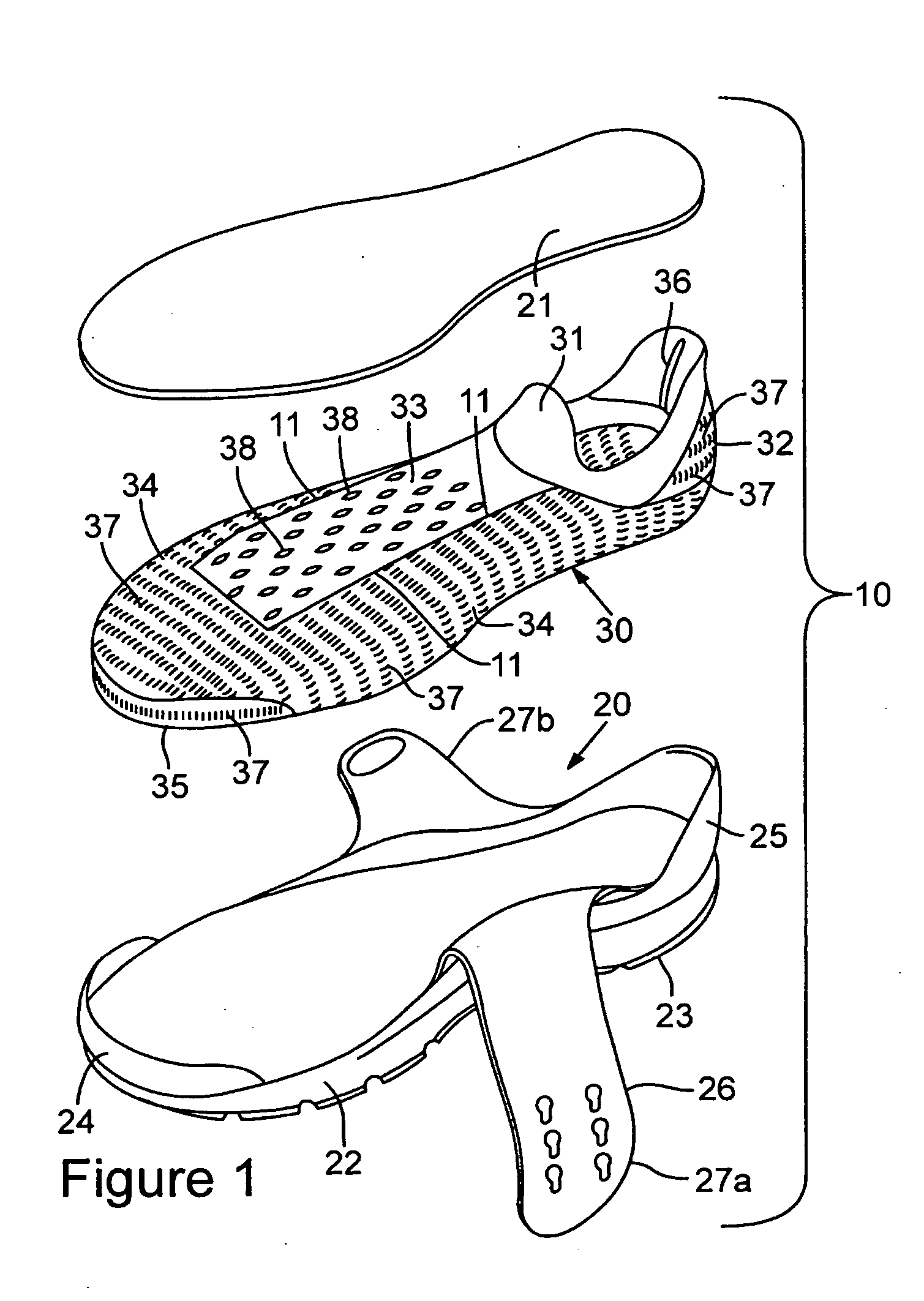

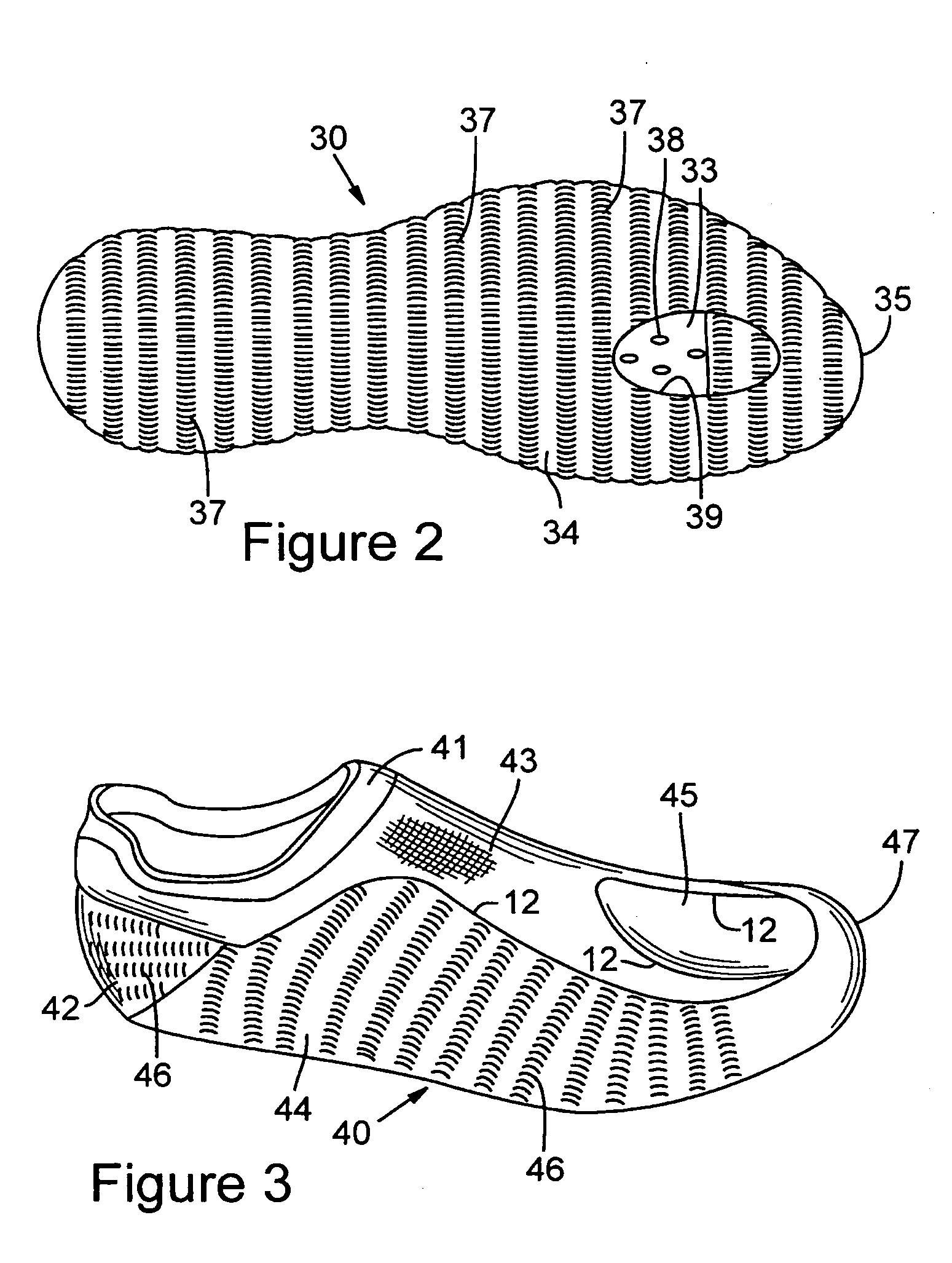

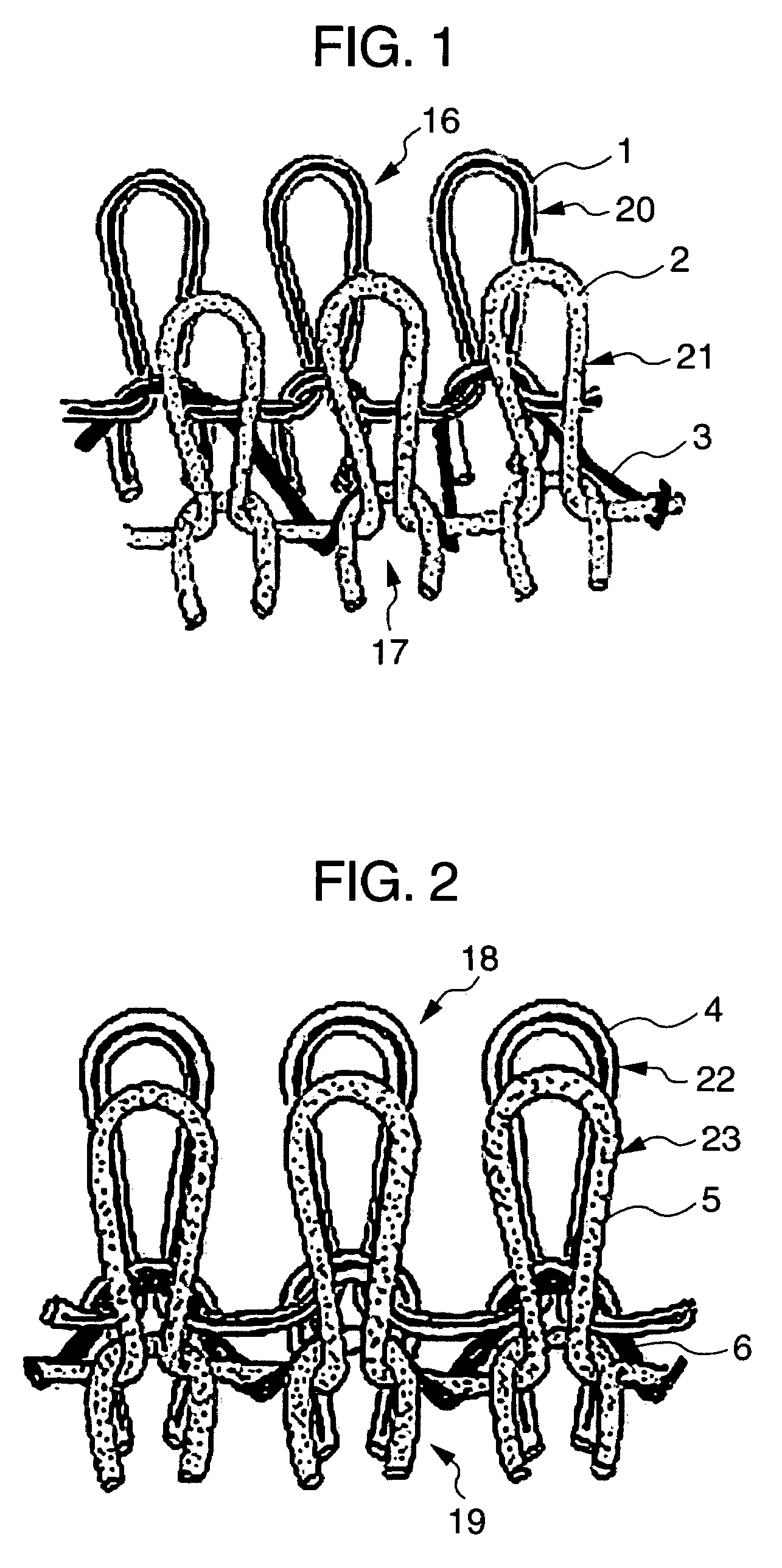

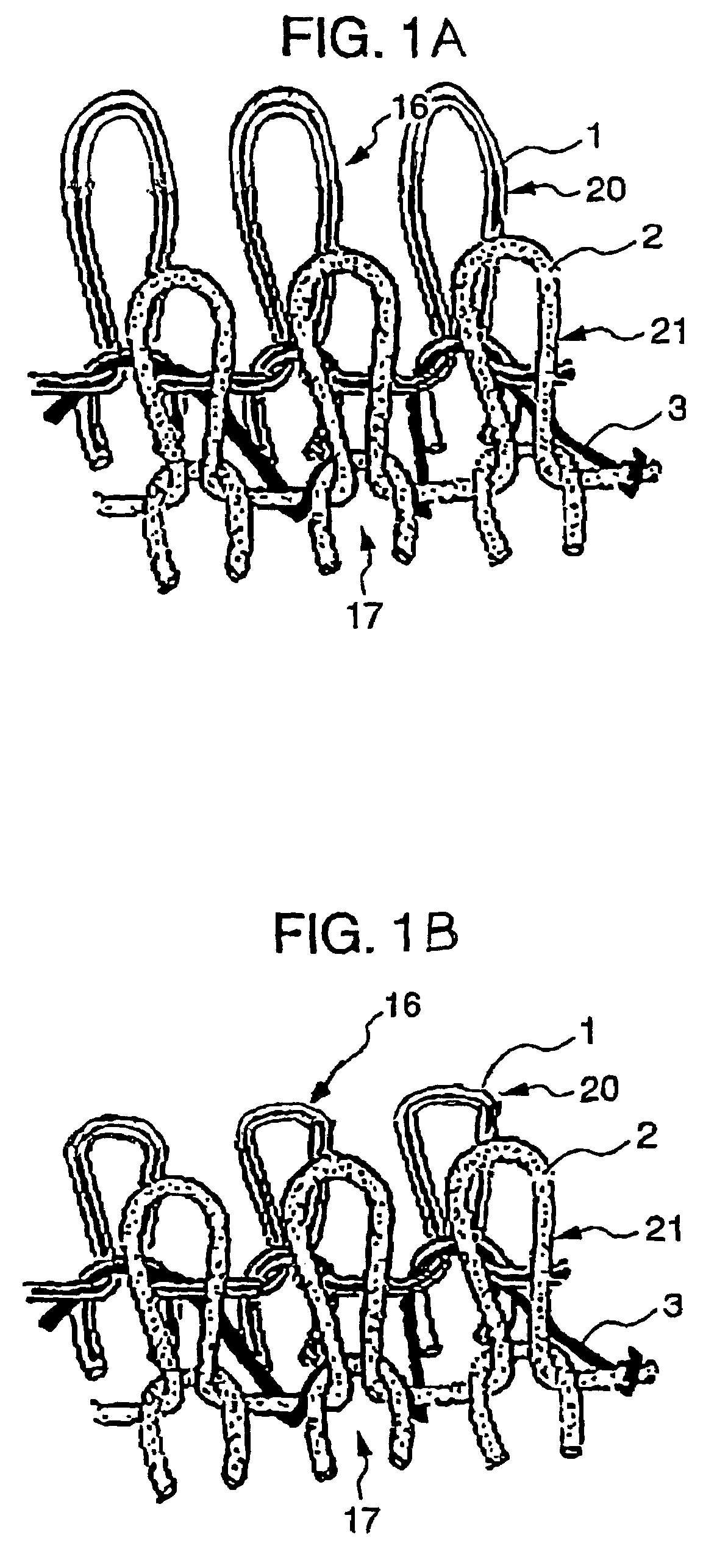

An article of footwear with a knit upper and a method of manufacturing the footwear are disclosed. The upper is formed through a knitting process to include a plurality of sections formed of different yarns and knits to provide the sections with different physical properties. In portions of the upper where sections formed of different yarns are in adjacent wales, a tuck stitch is utilized to join the sections. The method utilizes a circular knitting machine having multiple feeds that work together to knit the upper into a unitary, seamless structure. The multiple feeds, each of which provide multiple types of yarns, produce the sections to have varying physical properties.

Owner:NIKE INC

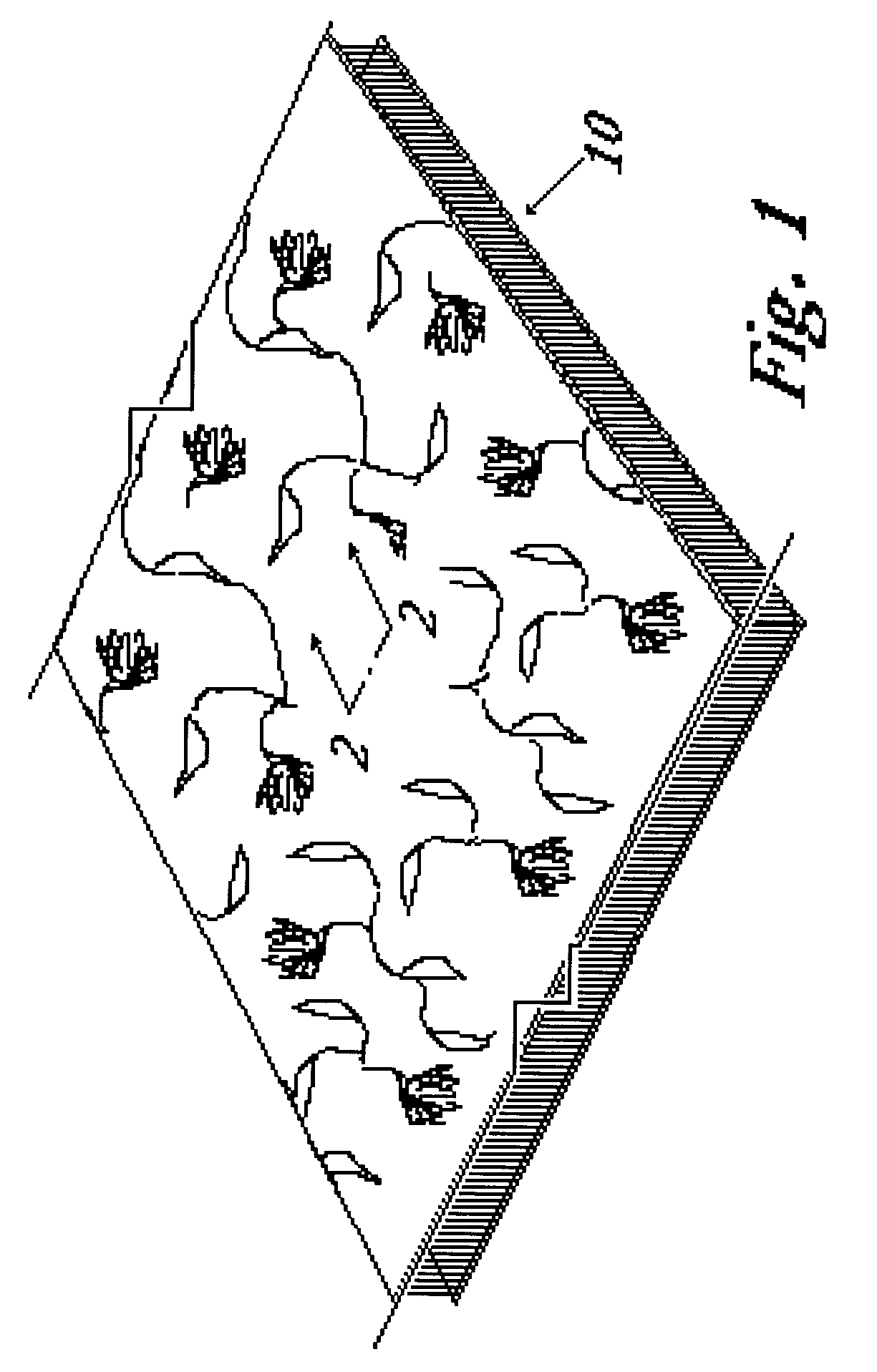

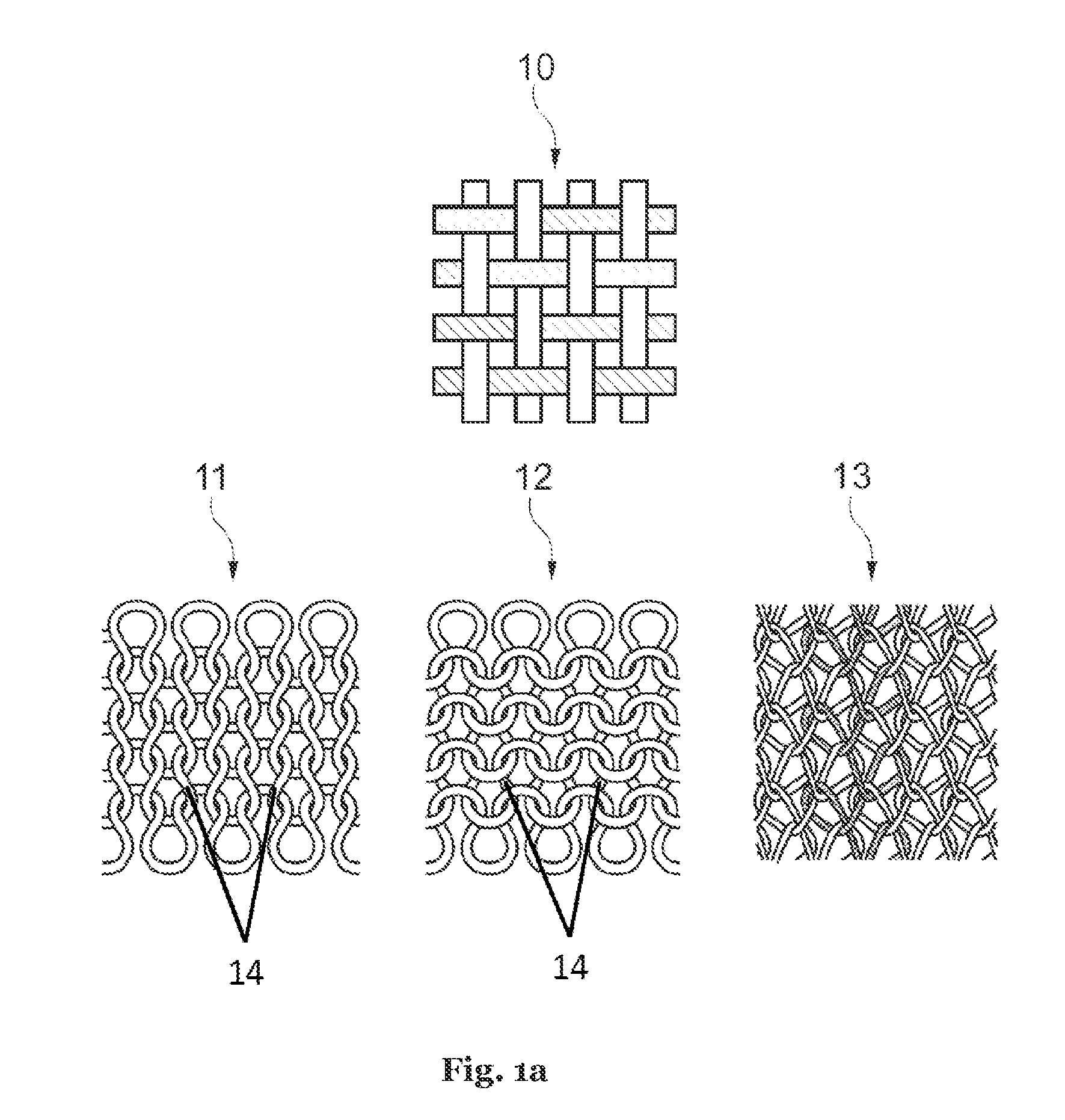

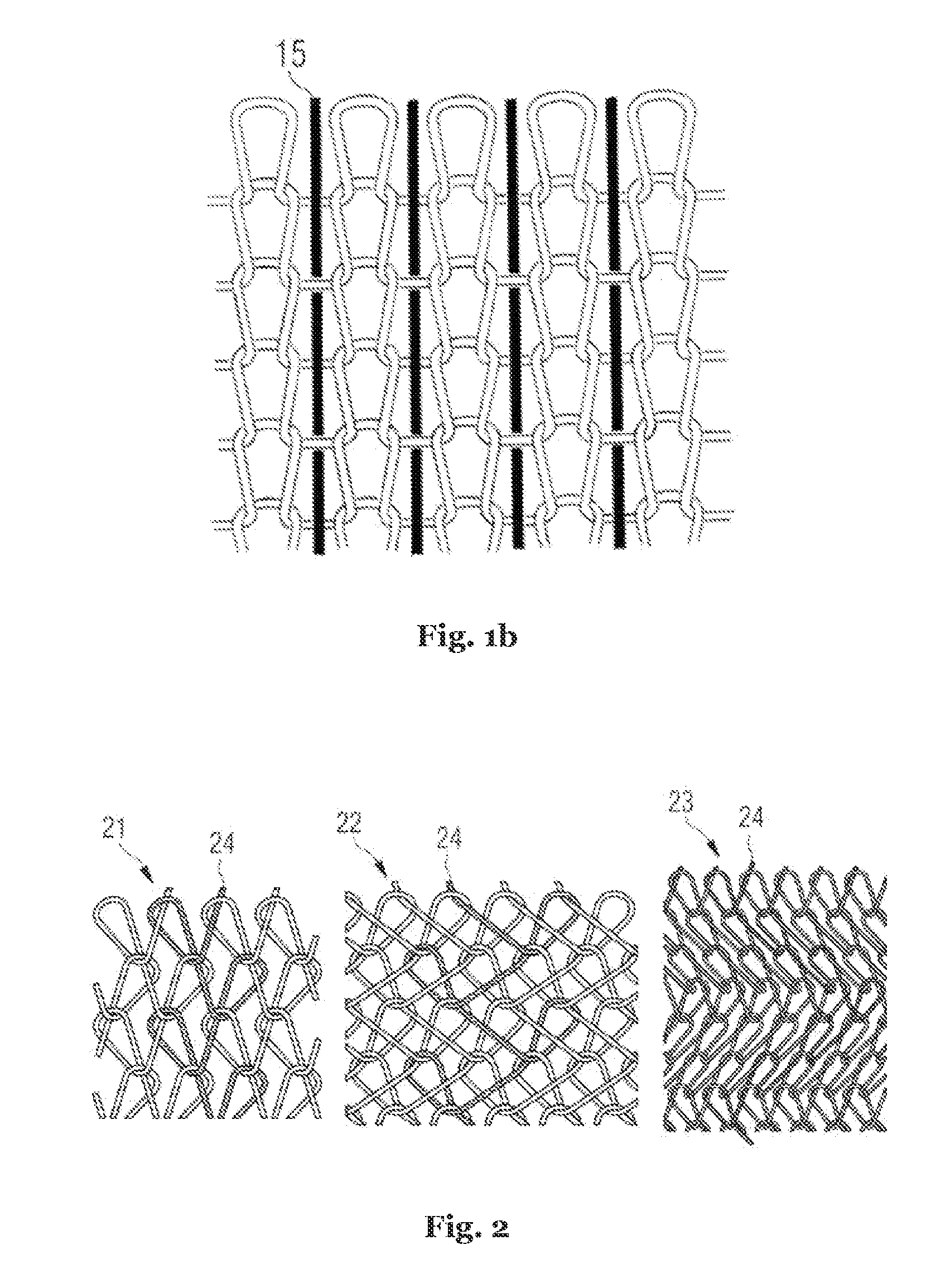

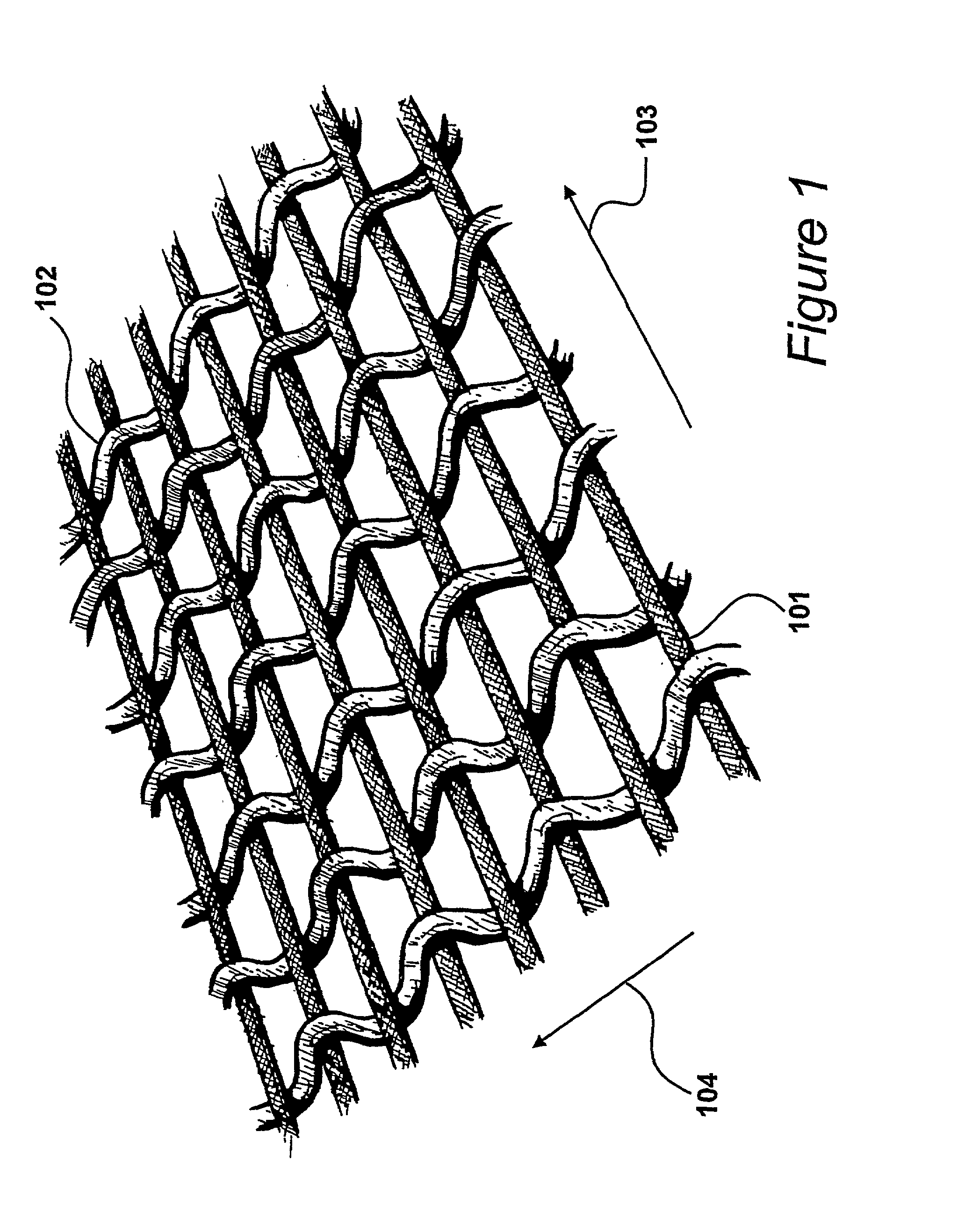

Bi-directional and multi-axial fabrics and fabric composites

InactiveUS6841492B2Increase resistanceImprove effectivenessOrnamental textile articlesProtective fabricsYarnEngineering

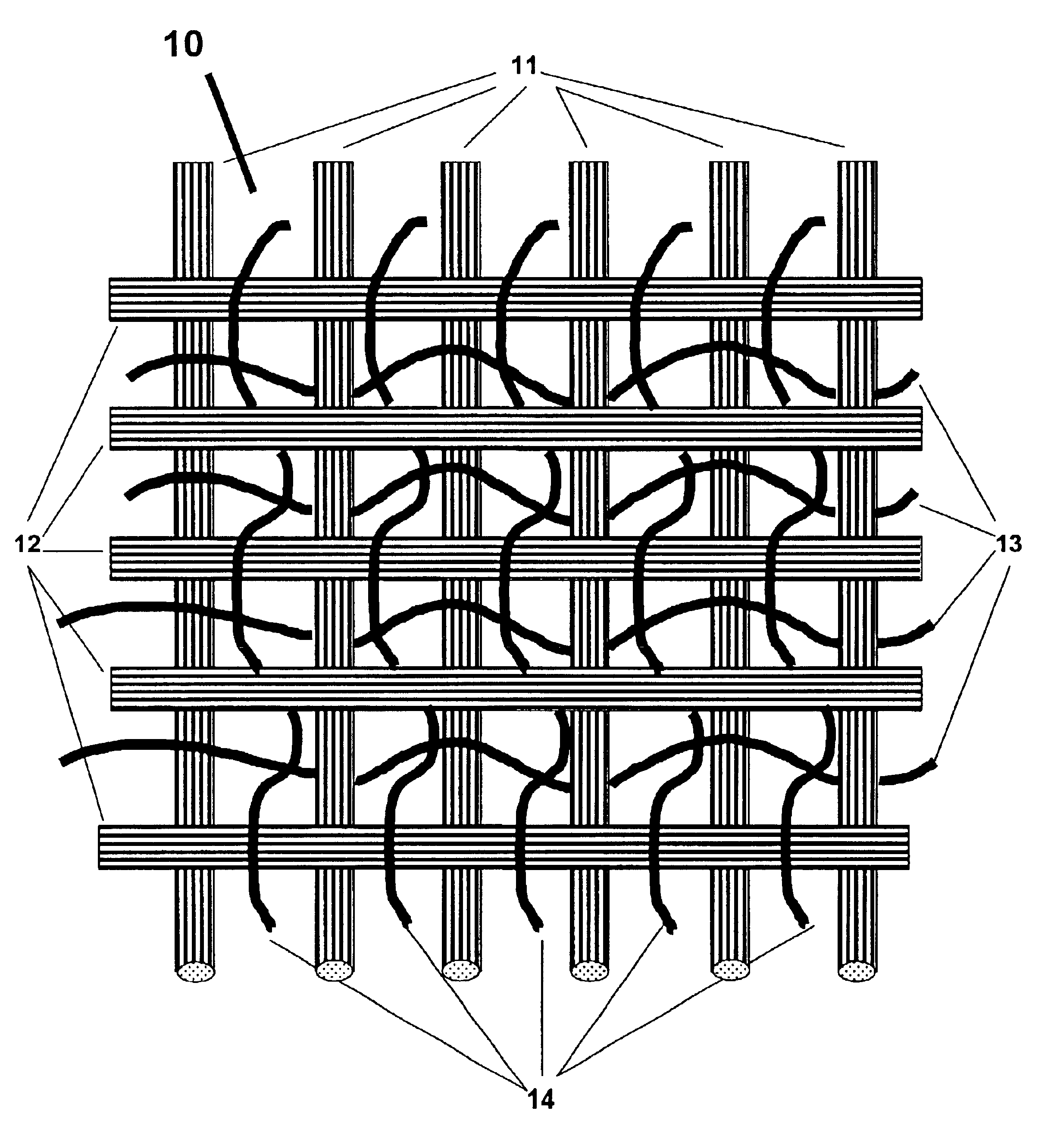

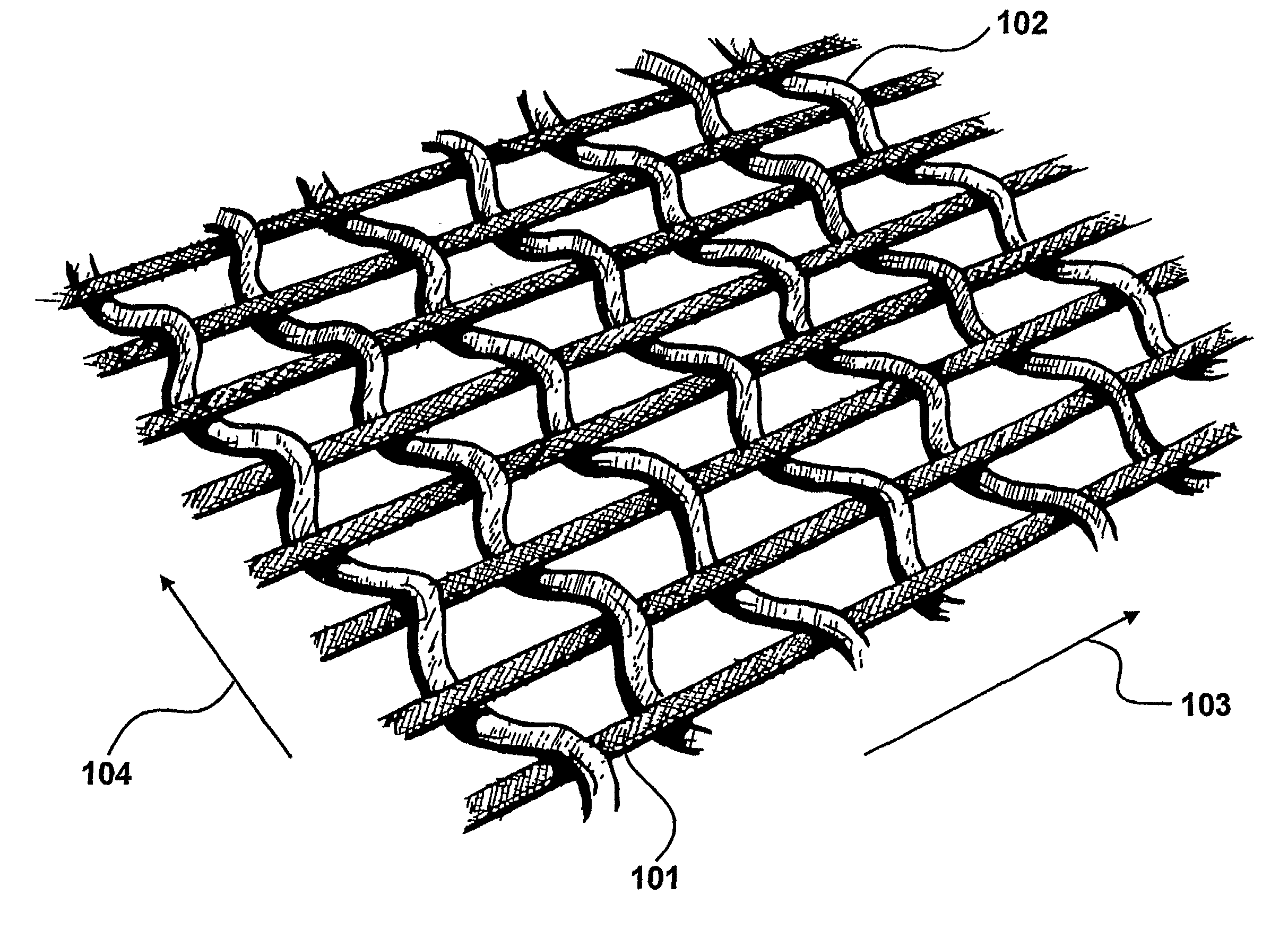

Bi-directional and multi-axial fabrics, fabric composites, ballistically resistant assemblies thereof, and the methods by which they are made. The fabrics are comprised of sets of strong, substantially parallel, unidirectional yarns lying in parallel planes, one above the other, with the direction of the yarns in a given plane rotated at an angle to the direction of the yarns in adjacent planes; and one or more sets of yarns having lower strength and higher elongation interleaved with the strong yarns. The fabrics of the invention provide superior ballistic effectiveness compared to ordinary woven and knitted fabrics but retain the ease of manufacture on conventional looms and knitting machines.

Owner:HONEYWELL INT INC

Flame resistant fabrics and garments made from same

InactiveUS20080057807A1Inexpensive and comfortable to wearerCotton-low durability-isWarp knittingAnimal housingPolymer scienceNatural fiber

Unique blends of fibers that incorporate synthetic cellulosic fibers to render fabrics made with such blends more durable than fabrics made with natural cellulosic fibers such as cotton. While more durable than cotton, the synthetic cellulosic fibers used in the blends are still inexpensive and comfortable to the wearer. Thus, the benefits of cotton (affordability and comfort) are still attained while a drawback of cotton—low durability—is avoided. In one embodiment, the fiber blend includes FR modacrylic fibers and synthetic cellulosic fibers, preferably, but not necessarily non-FR lyocell fibers such as TENCEL™ and TENCEL A100™. Other fibers may be added to the blend, including, but not limited to, additional types of inherently FR fibers, anti-static fibers, anti-microbial fibers, stretch fibers, and / or high tenacity fibers. The fiber blends disclosed herein may be used to form various types of FR fabrics. Desired colors may be imparted in a variety of ways and with a variety of dyes to the fabrics disclosed herein. Fabrics having the fibers blends disclosed herein can be used to construct the entirety of, or various portions of, a variety of protective garments for protecting the wearer against electrical arc flash and flames, including, but not limited to, coveralls, jumpsuits, shirts, jackets, vests, and trousers.

Owner:SOUTHERN MILLS

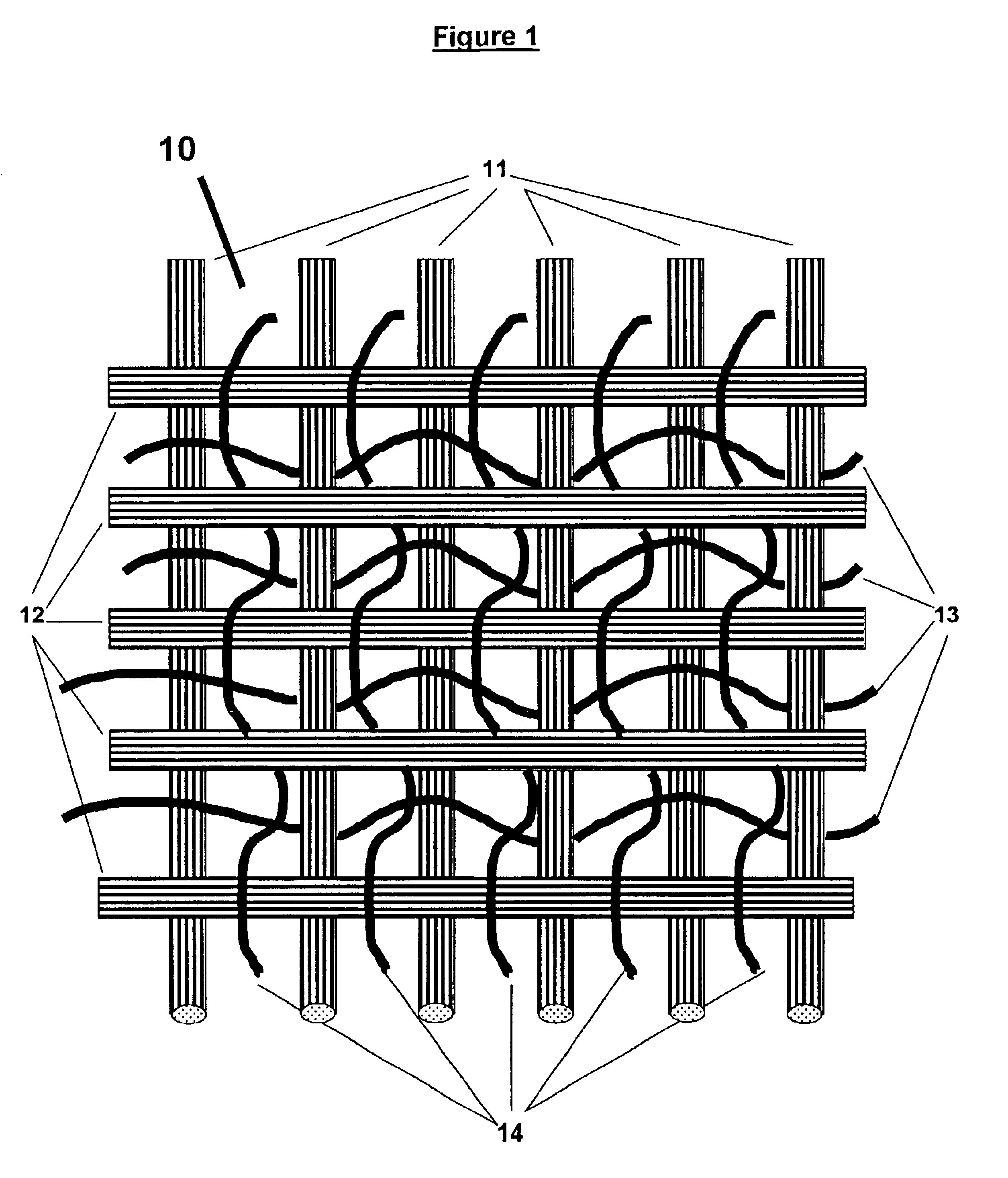

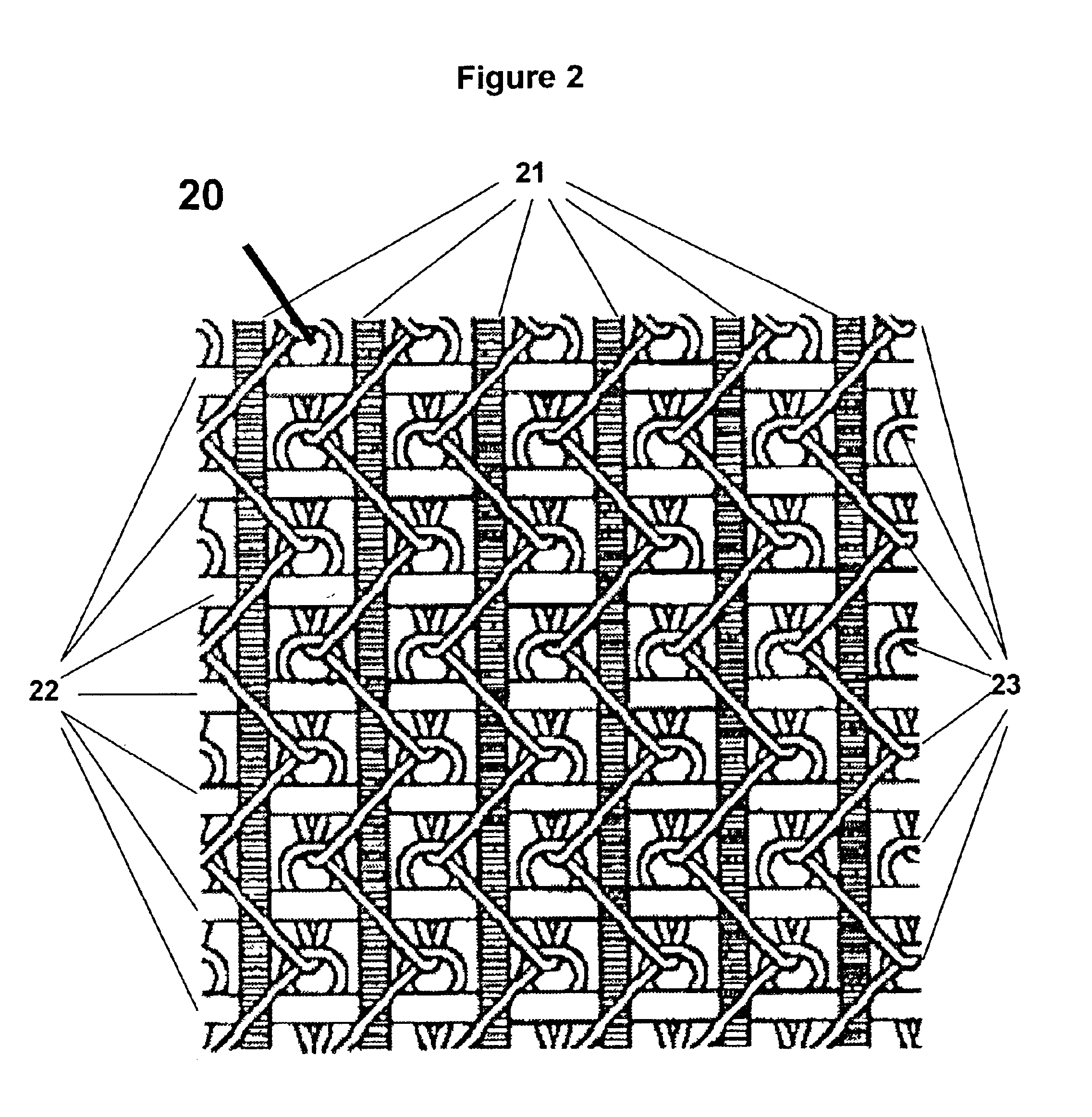

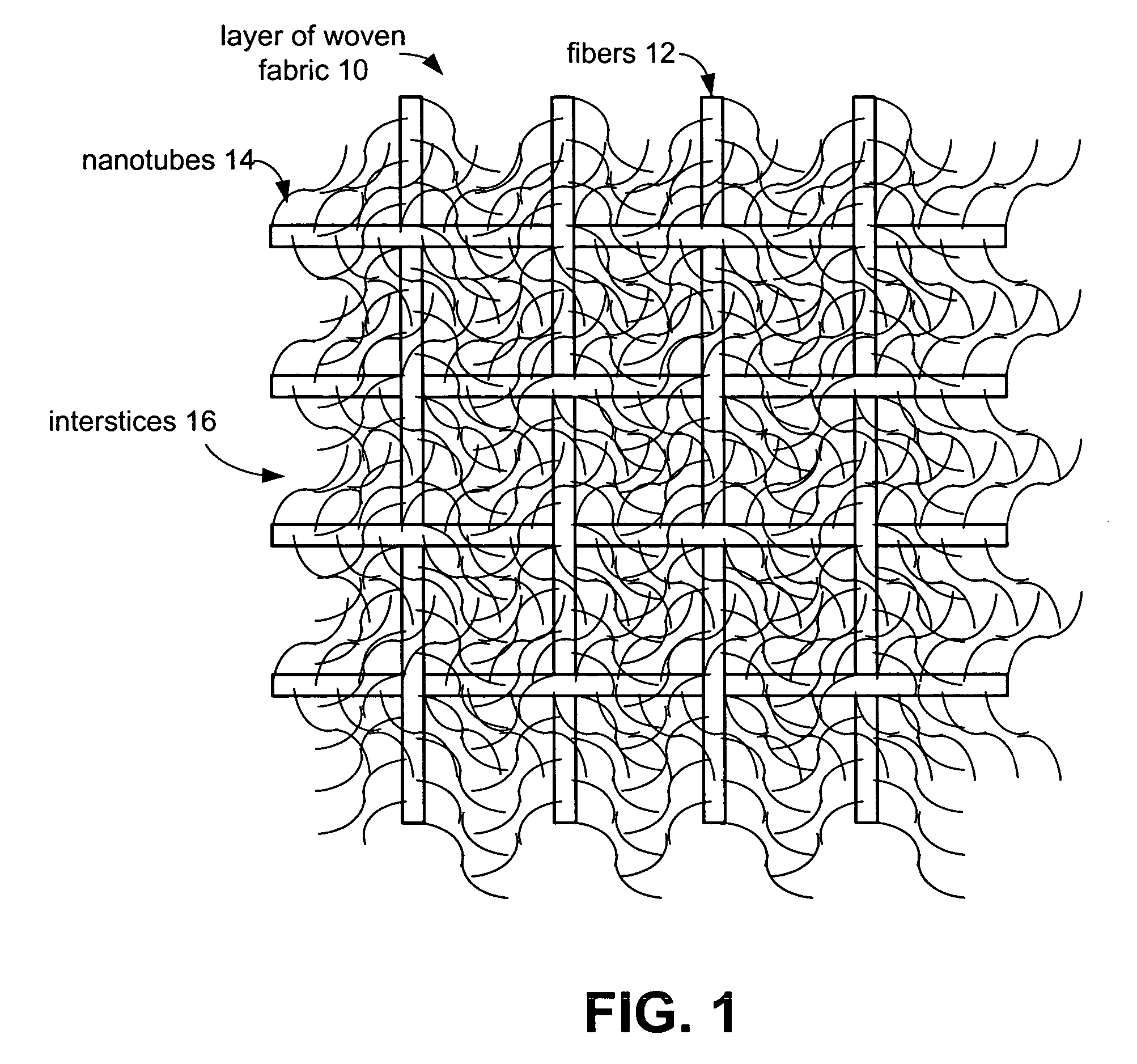

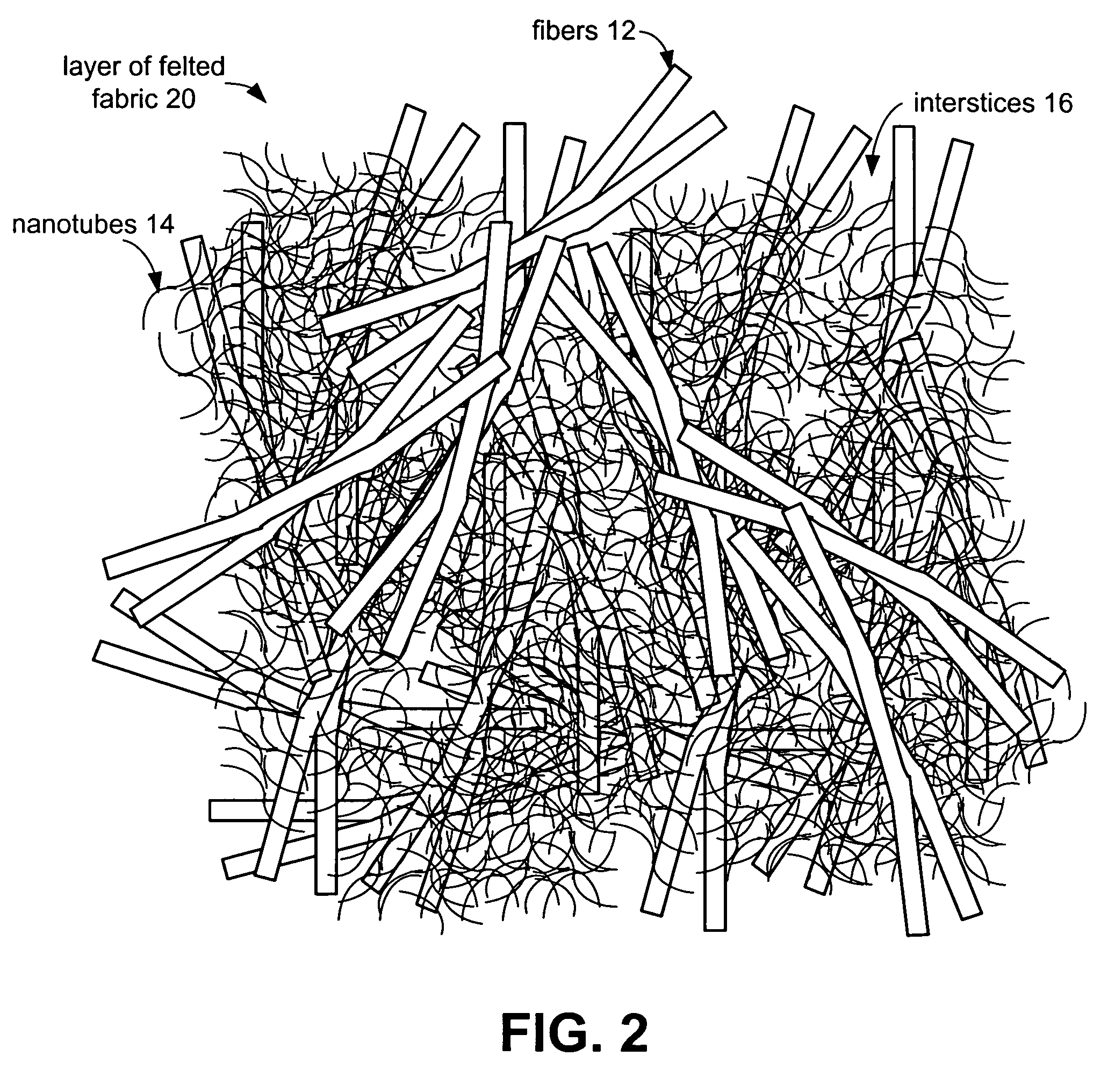

Ballistic fabrics with improved antiballistic properties

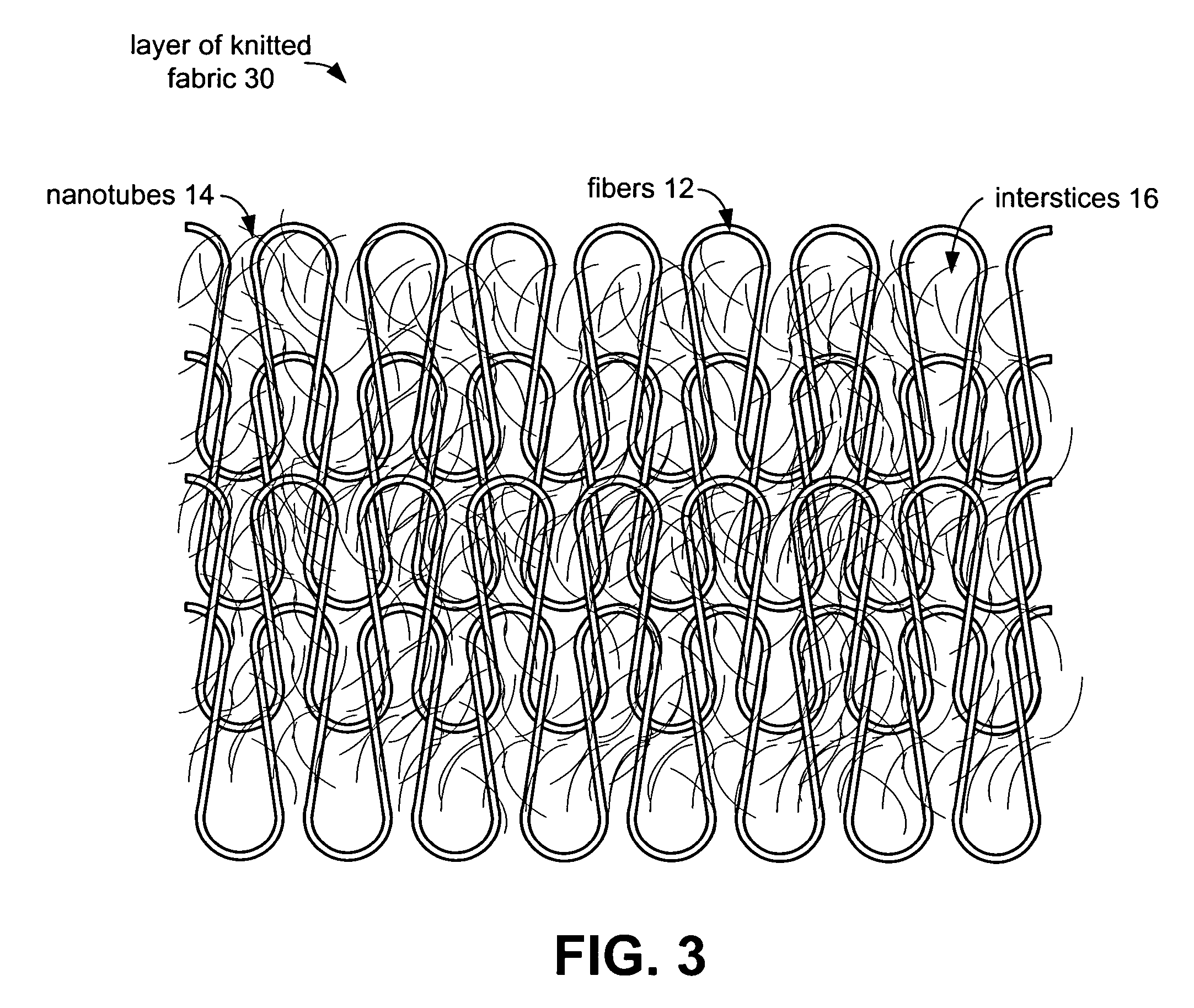

ActiveUS20060062944A1Good physical propertiesImprove propertiesMaterial nanotechnologyWarp knittingFiberYarn

The present invention provides fabrics that have unique mechanical, chemical, electrical, and thermal properties. The fabrics comprise layers of woven, knit or felted fibers, yarns or tow. Interstitially synthesized nanotubes, such as single-walled or multi-walled carbon nanotubes, enhance the fabric's antiballistic properties. These nanotubes may also insulate, semi-conduct or super-conduct electrical charges, or provide enhanced thermal properties of these fabrics which can be layered to form unique garments or structures.

Owner:LOCKHEED MARTIN CORP

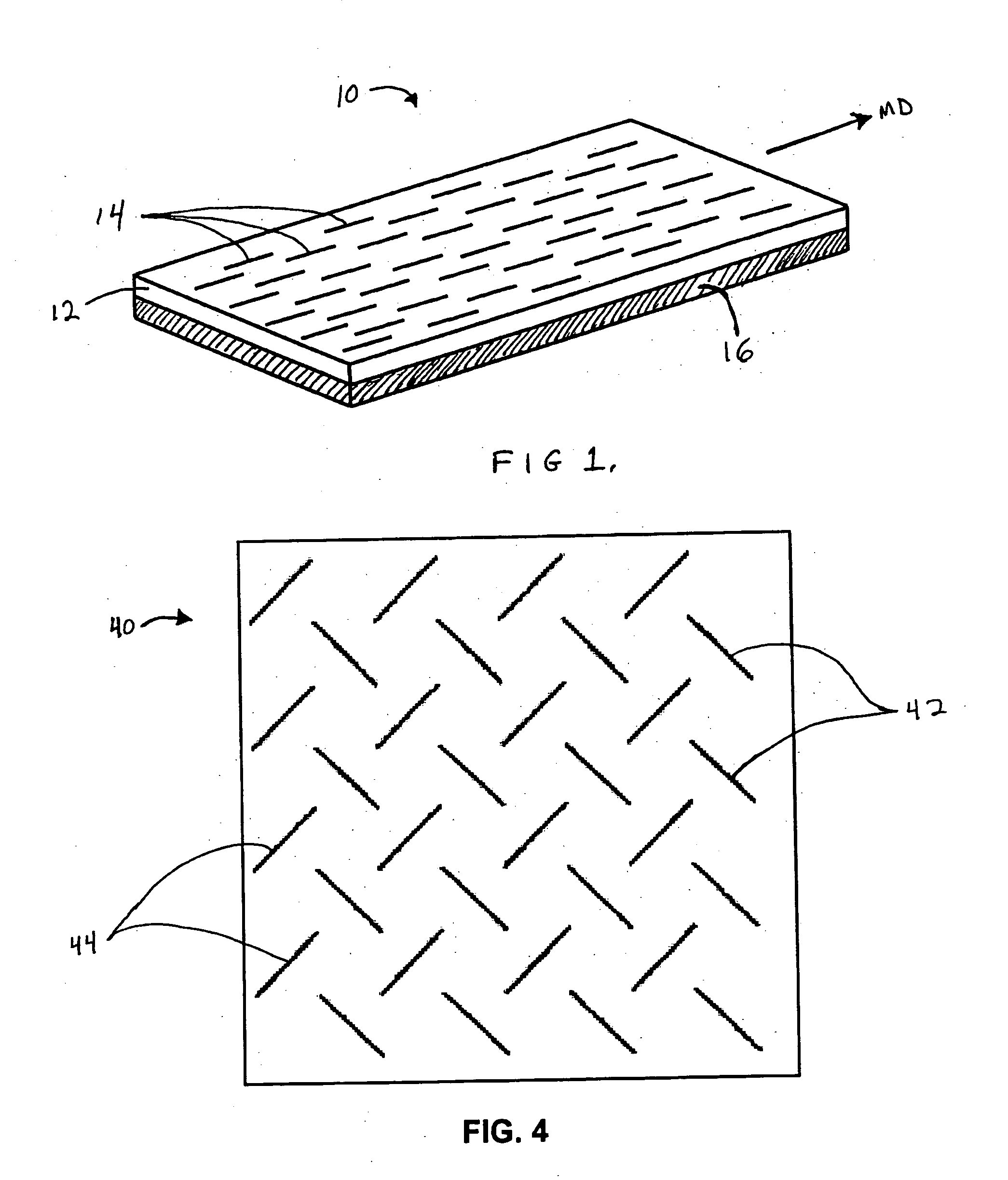

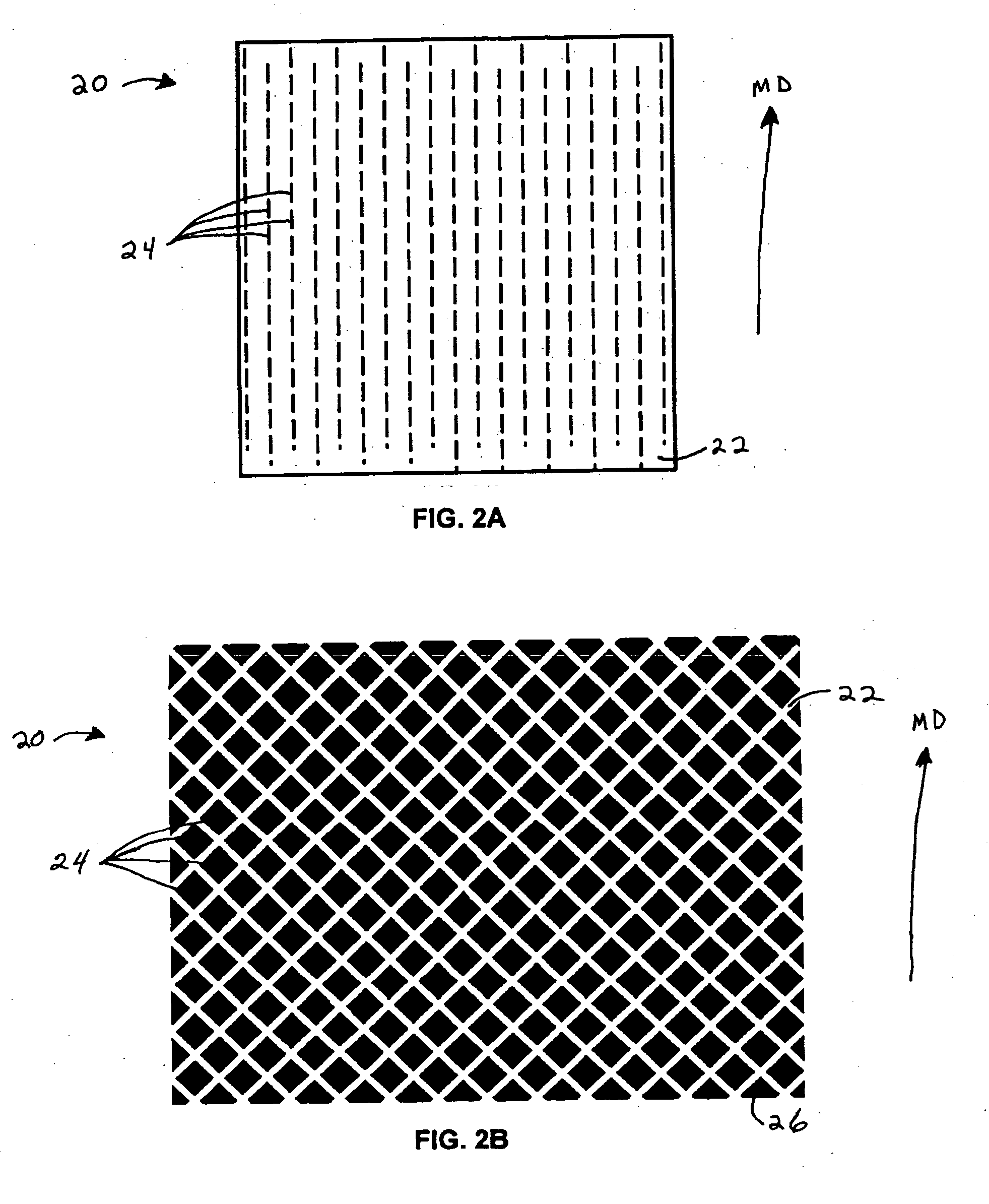

Color change laminate material

Disclosed herein are color change laminate materials suitable for a variety of uses. The color change laminate materials include at least two layers of extensible materials having visually distinct coloration, and indicate a stretched or extended state by exposing the previously covered coloration of a lower layer. The color change laminate materials may also indicate the amount of stretching or extension is applied to the laminate. When the laminate includes elastic materials capable of stretch and recovery, the color change laminate materials may further be reversible color change laminate materials that can display color change upon extension and then recover the extension and return to the original coloration. Such color change laminate materials and reversible color change laminate materials are highly useful for use in garments or other textile type applications, in or on personal care products, protective wear products, health care and medical care products, bandages and the like.

Owner:KIMBERLY-CLARK WORLDWIDE INC

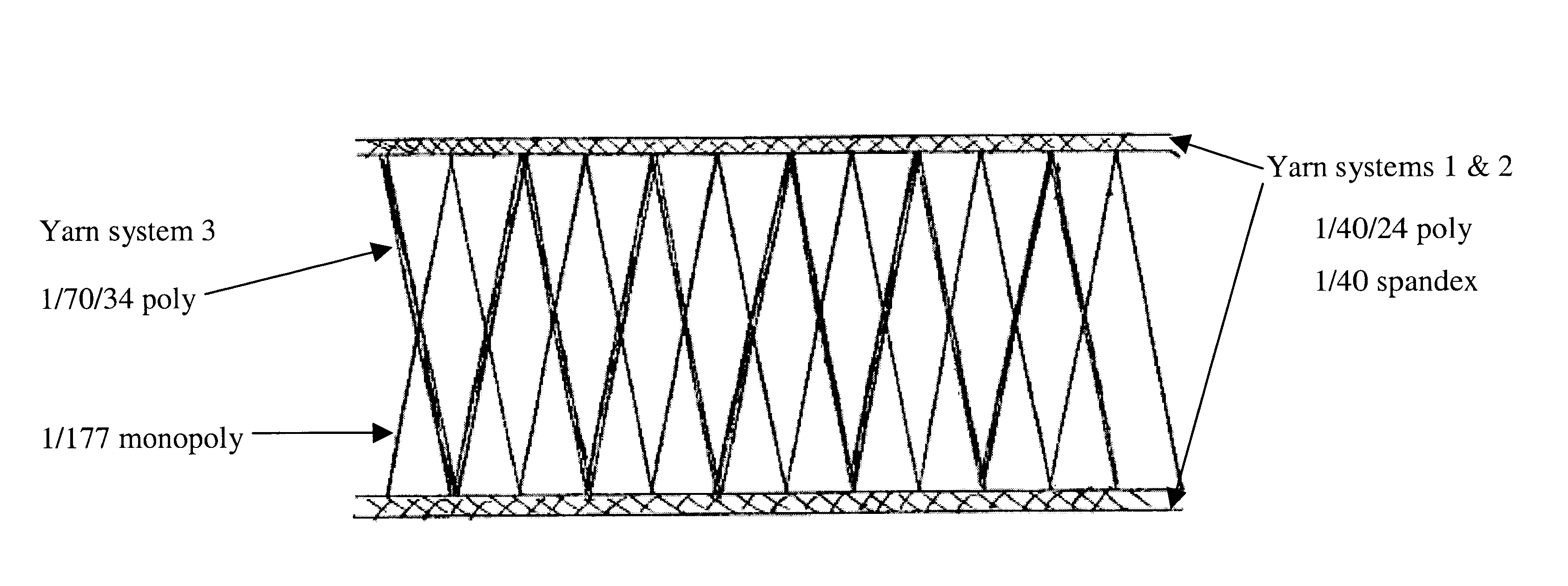

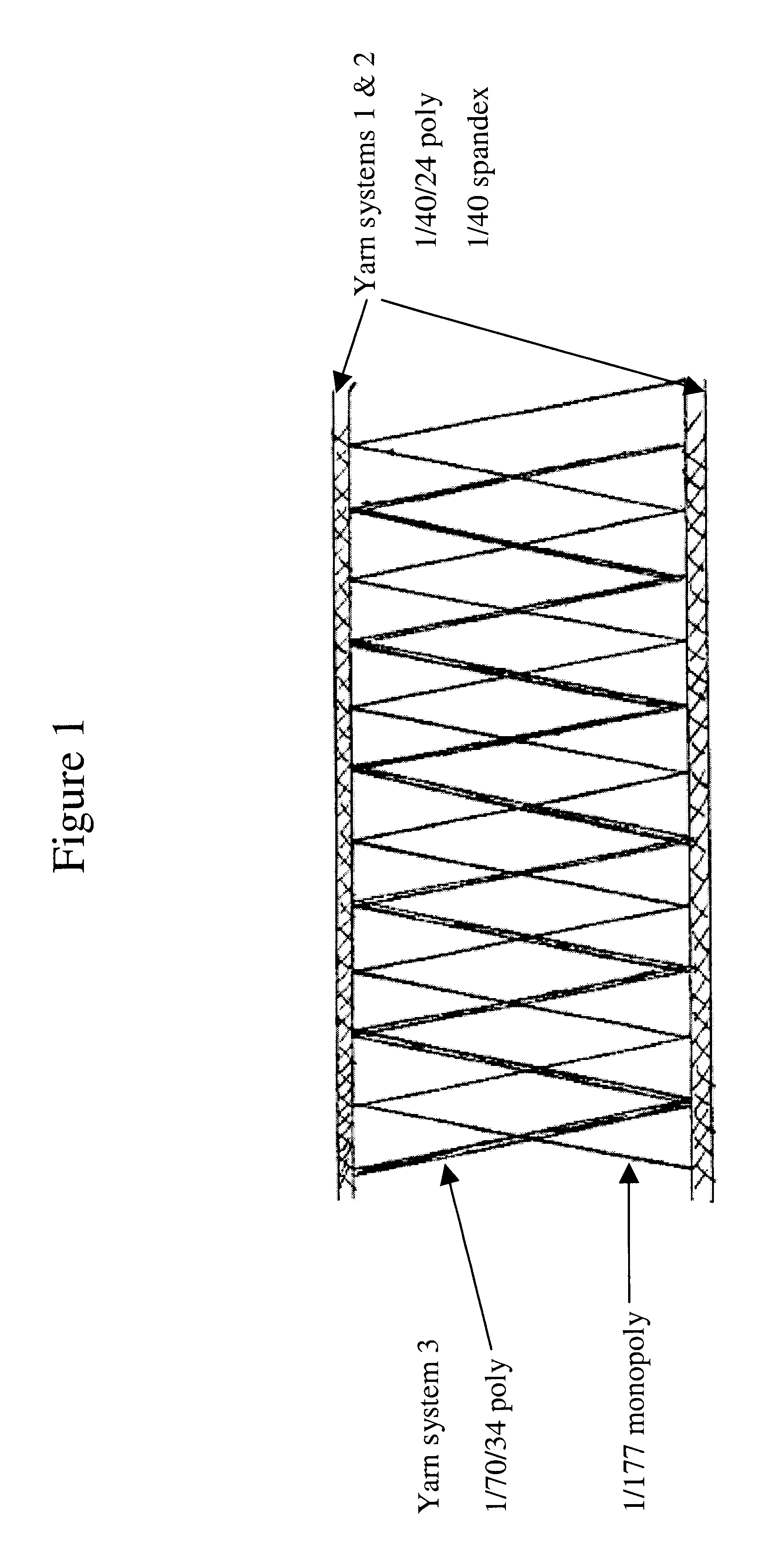

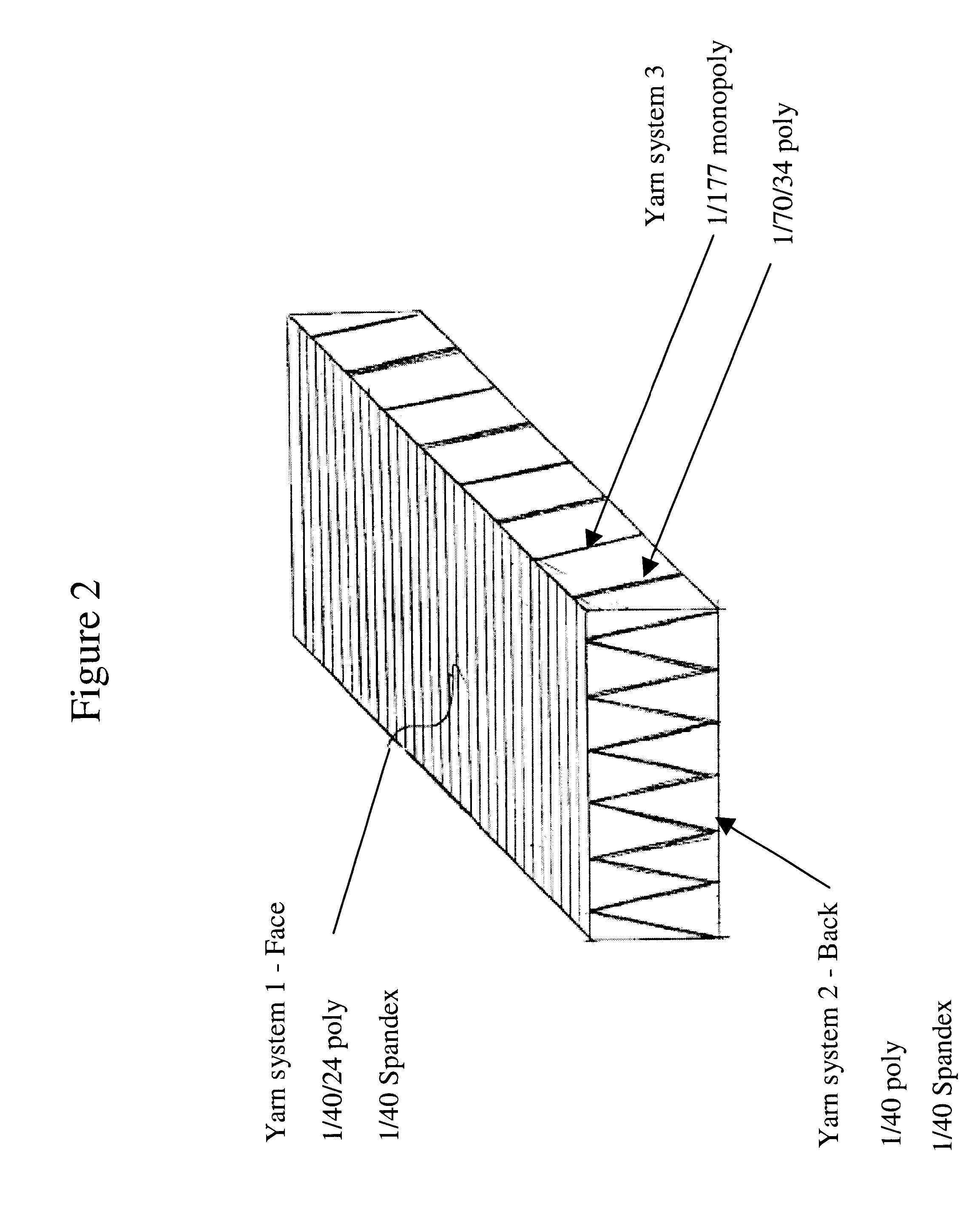

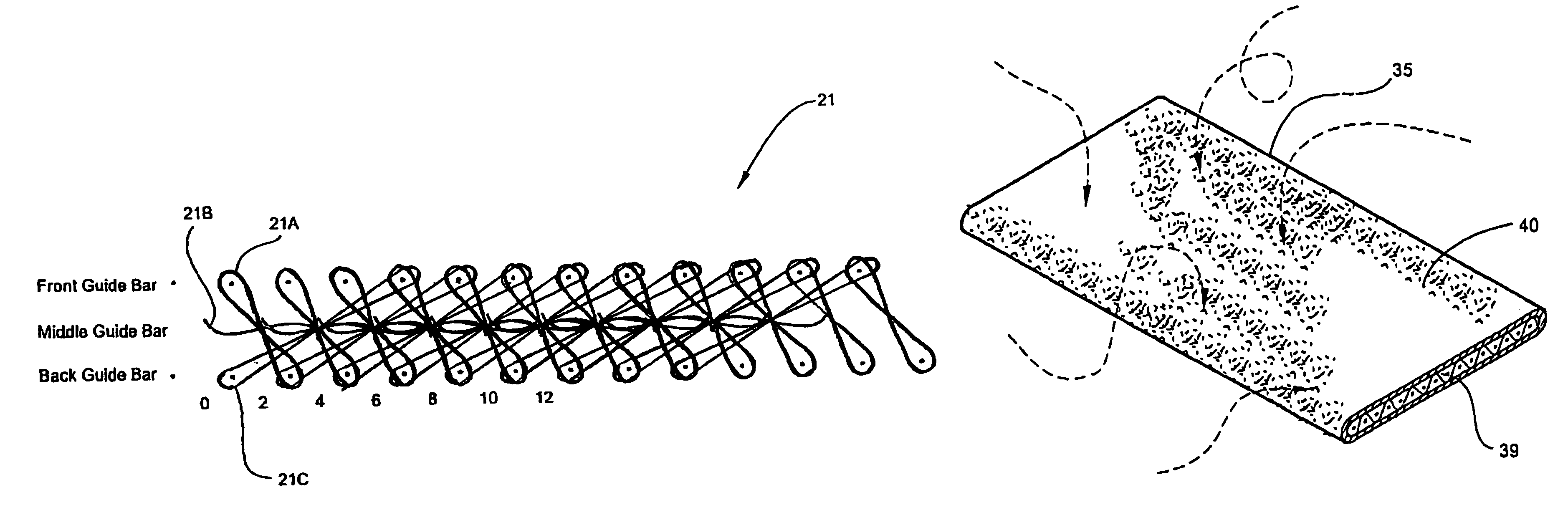

Knitted stretch spacer material and method of making

A knitted spacer material including the use of a stretch yarn component for stretch, compression resistance, decreased weight, and improved drape and / or conformability.

Owner:SYTZ RONALD M

Footwear with knit upper and method of manufacturing the footwear

An article of footwear with a knit upper and a method of manufacturing the footwear are disclosed. The upper is formed through a knitting process to include a plurality of sections formed of different yarns and knits to provide the sections with different physical properties. In portions of the upper where sections formed of different yarns are in adjacent wales, a tuck stitch is utilized to join the sections. The method utilizes a circular knitting machine having multiple feeds that work together to knit the upper into a unitary, seamless structure. The multiple feeds, each of which provide multiple types of yarns, produce the sections to have varying physical properties.

Owner:NIKE INC

Decorative faced multi-layer weft knit spacer fabric, method, and articles made therefrom

A breathable, stretchable, and heat-moldable multi-layer weft knit spacer fabric having a substantially decorative first layer and a spaced less decorative second layer. Also, a method of integrally knitting the multi-layer knitted fabric on a circular weft knit machine is also described. Articles of the manufacture comprising the fabric are also described.

Owner:MCMURRAY BRIAN

Abrasion-resistant sleeve for wiring and the like

The present invention is directed to an abrasion-resistant tubular sleeve formed from a crocheted fabric cloth which is heat set into a resilient tubular sleeve. The fabric cloth is formed with a first monofilament weft and a second textured multifilament weft. A set of warps including a plurality of textured multifilament yarns forming a chain stitch lap is crocheted into the fabric cloth. Optionally, a textured multifilament yarn may be utilized as a placed or a lay-in warp in the fabric to provide further continuity on the face of the fabric cloth.

Owner:SOFANOU INC

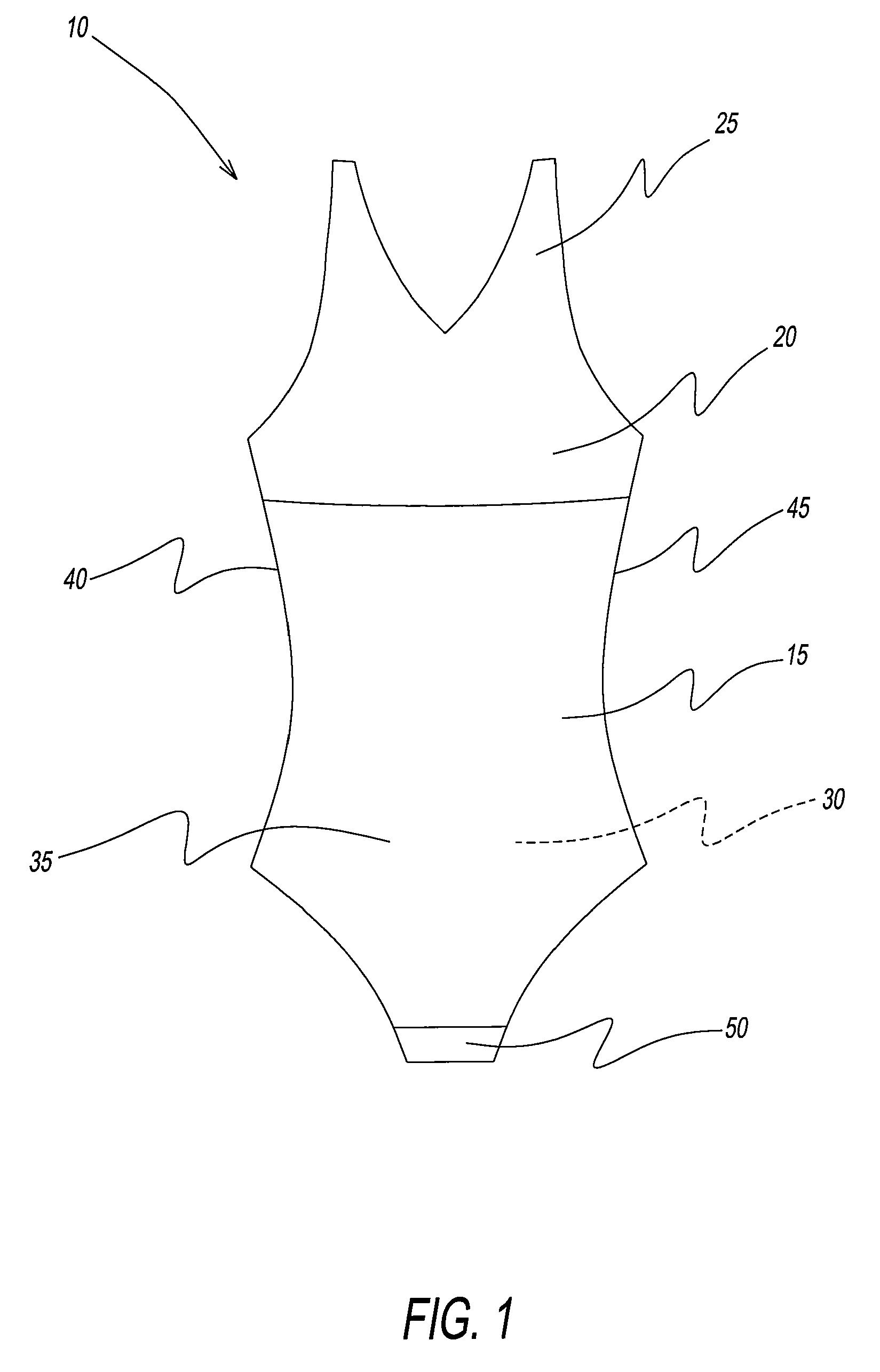

Article of apparel incorporating a stratified material

Owner:NIKE INC

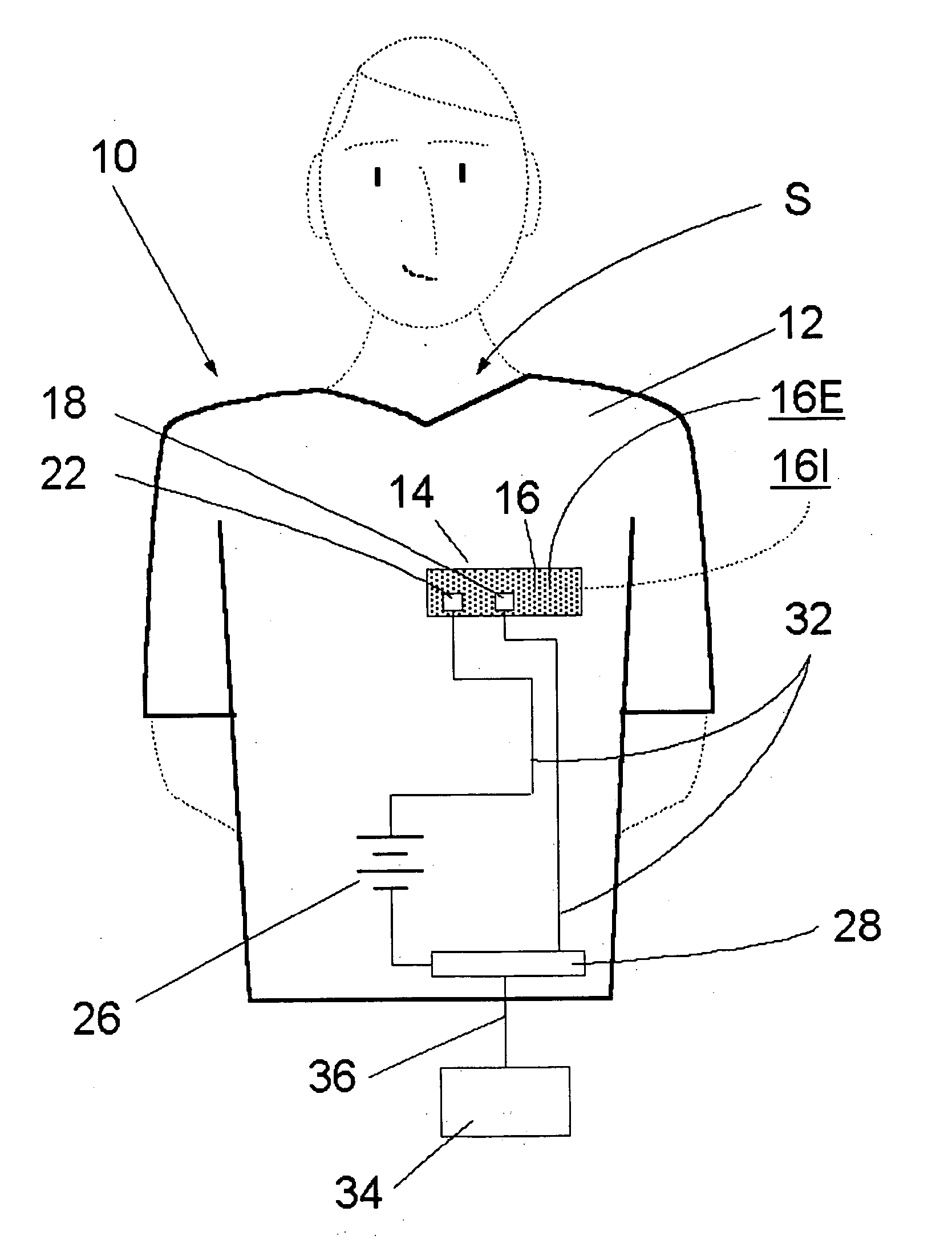

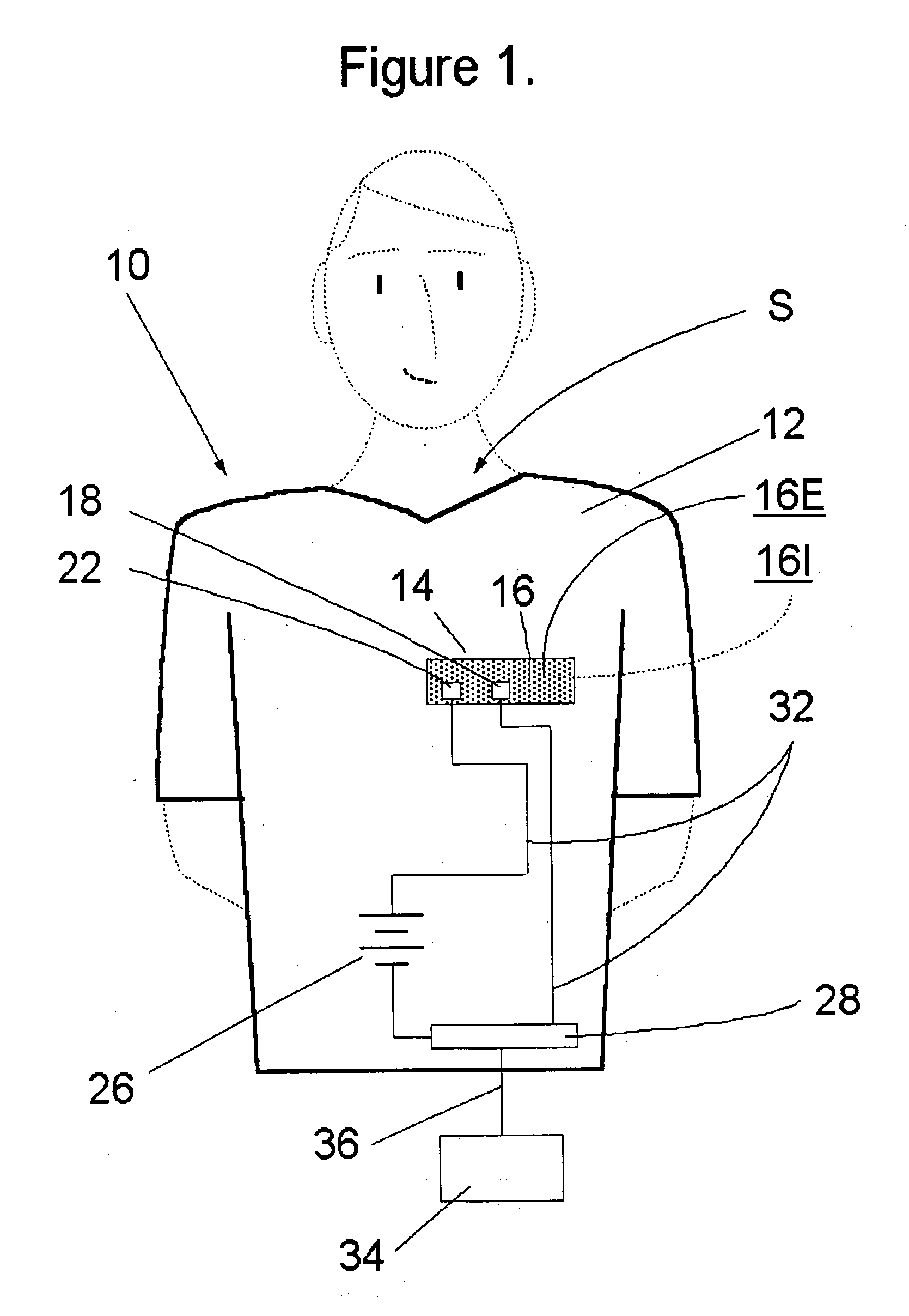

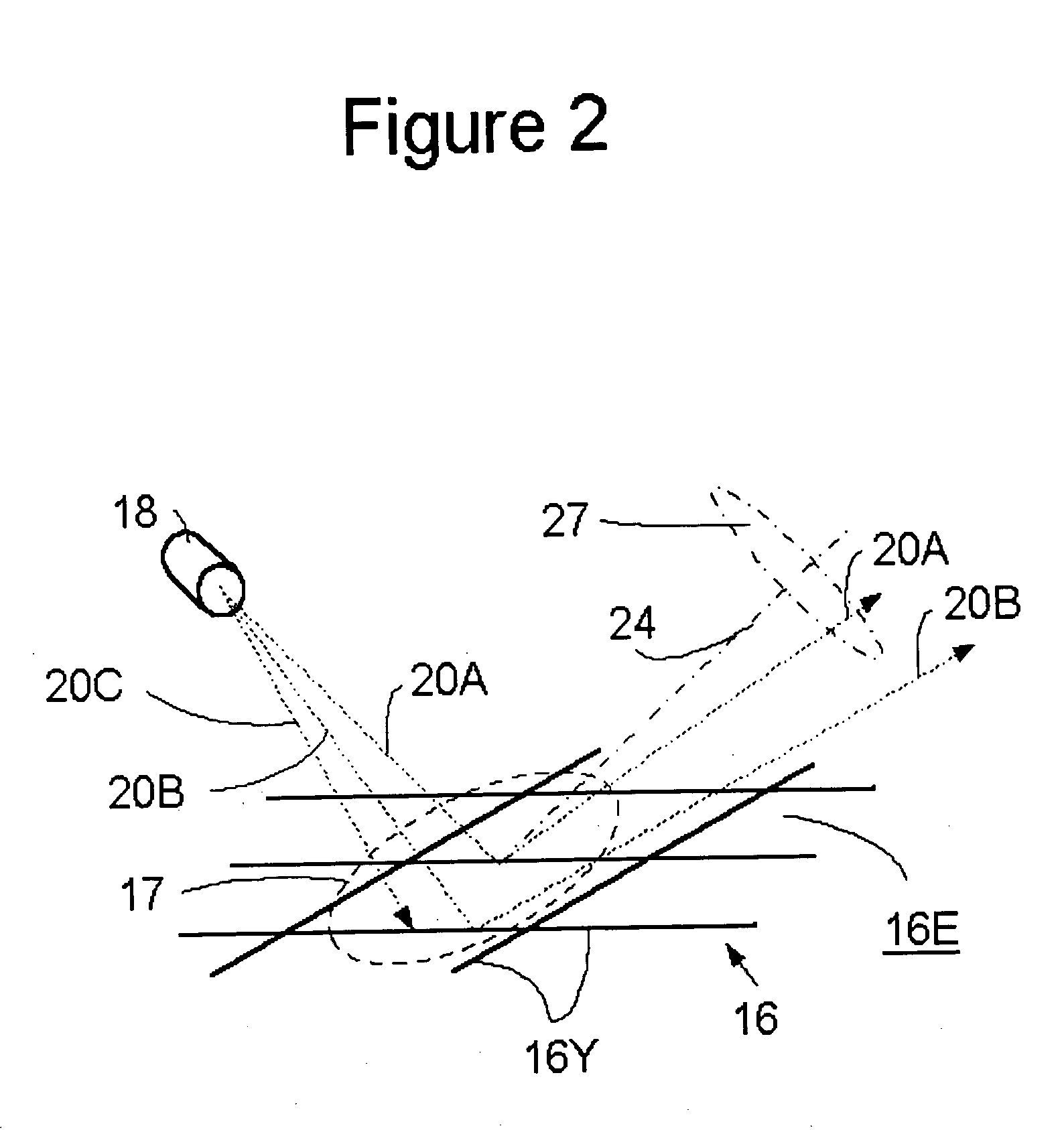

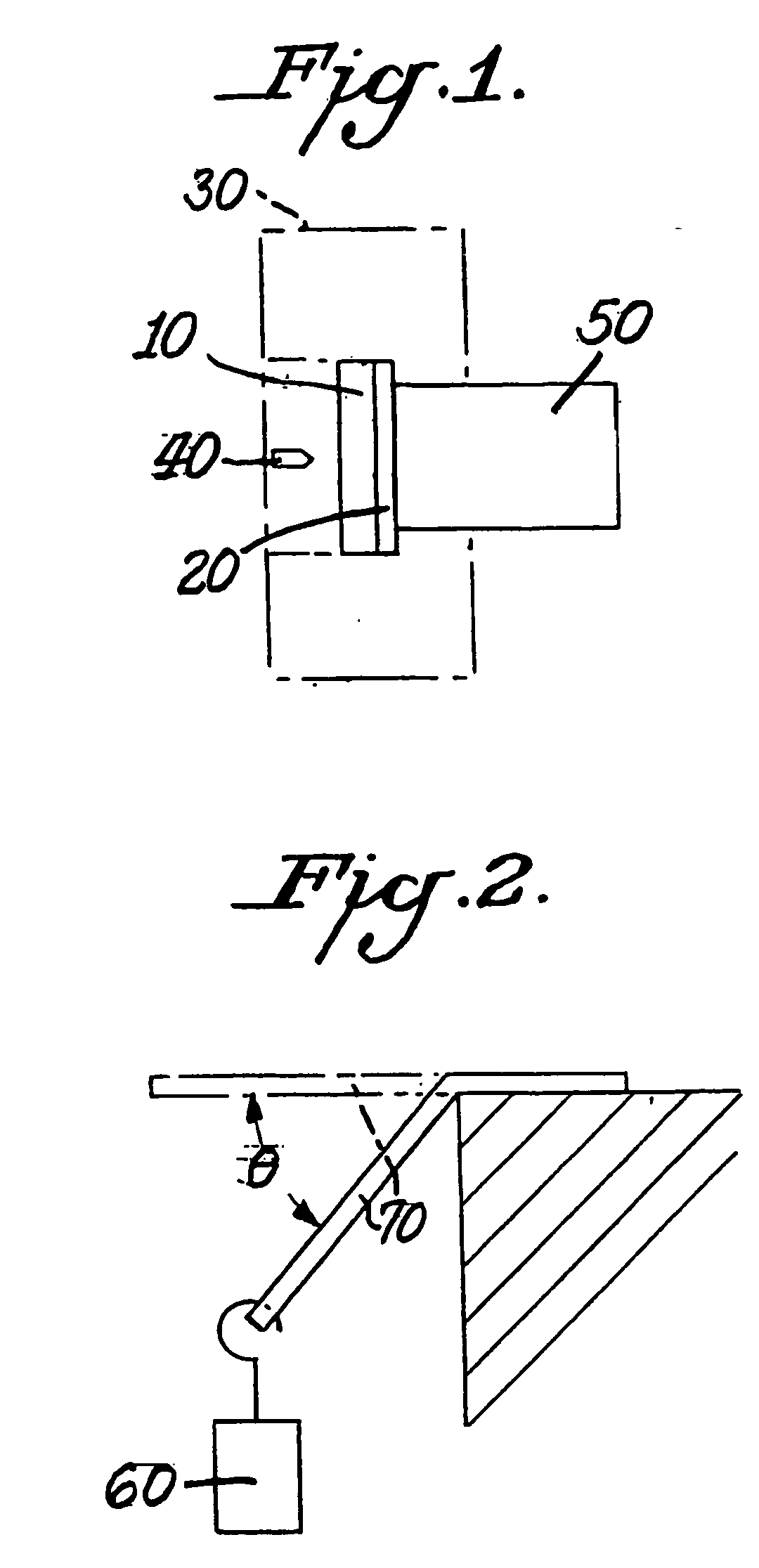

Extended optical range reflective system for monitoring motion of a member

A garment and system includes a monitoring fabric that exhibits a light reflection property and substantially no light transmission property when the fabric is illuminated with light having wavelength(s) in the range of 400 to 2200 nanometers. The amount of useful light reflected by the fabric into an aperture of acceptance defined with respect to an axis extending from the fabric relative to the amount of light lost to the aperture of acceptance detectably changes when the fabric stretches in response to motion, as the motion induced by physiological activity (e.g., heart rate). The system includes at least one radiation source and at least one radiation detector, with the detector disposed in the aperture of acceptance. The source and detector may be attached to the fabric in relative positions such that the reception of incident radiation by the detector is directly affected by a change in the amount of useful light reflected by the fabric into the aperture of acceptance as the fabric stretches in response to motion.

Owner:ADIDAS

Article of apparel incorporating a stratified material

Owner:NIKE INC

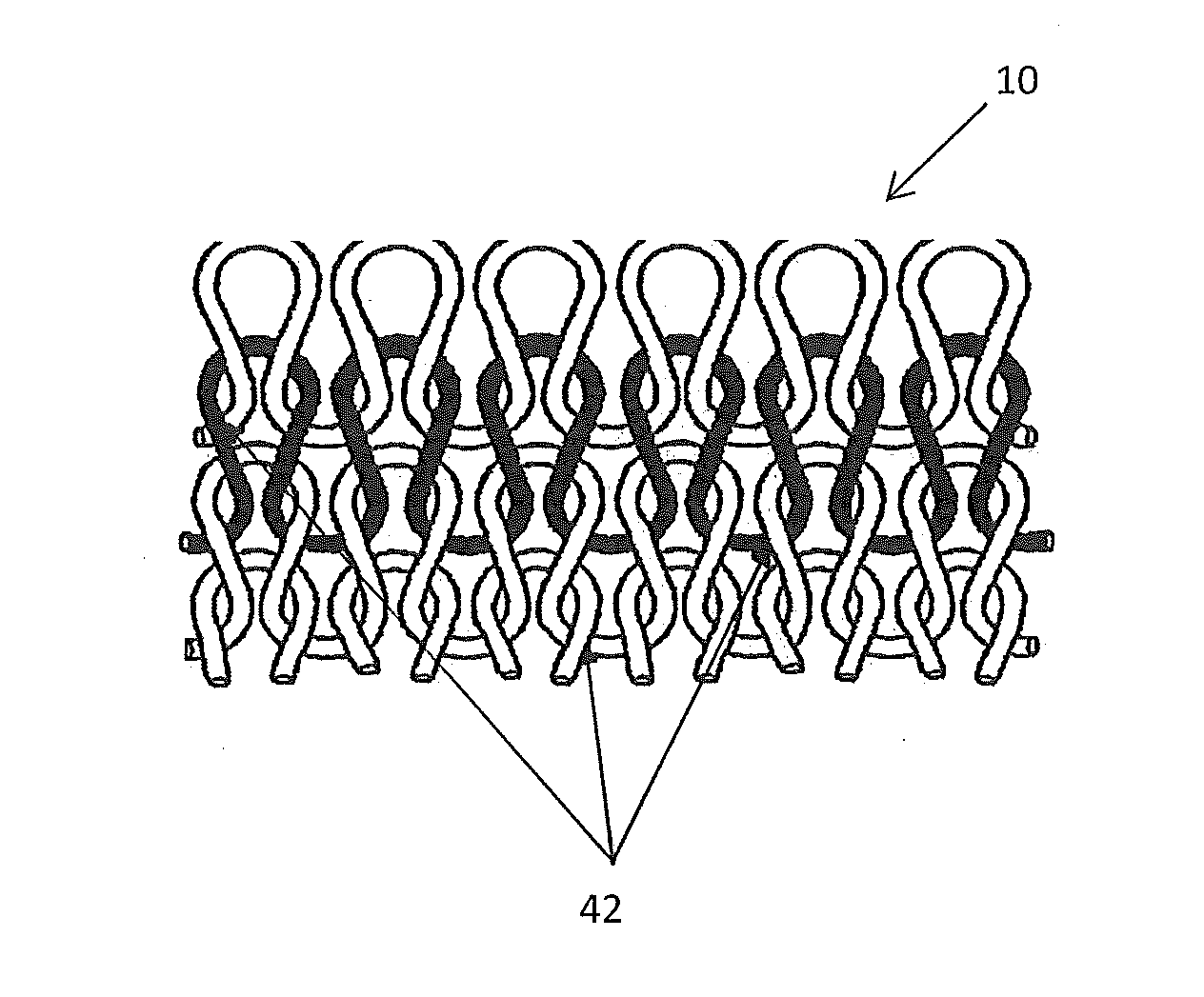

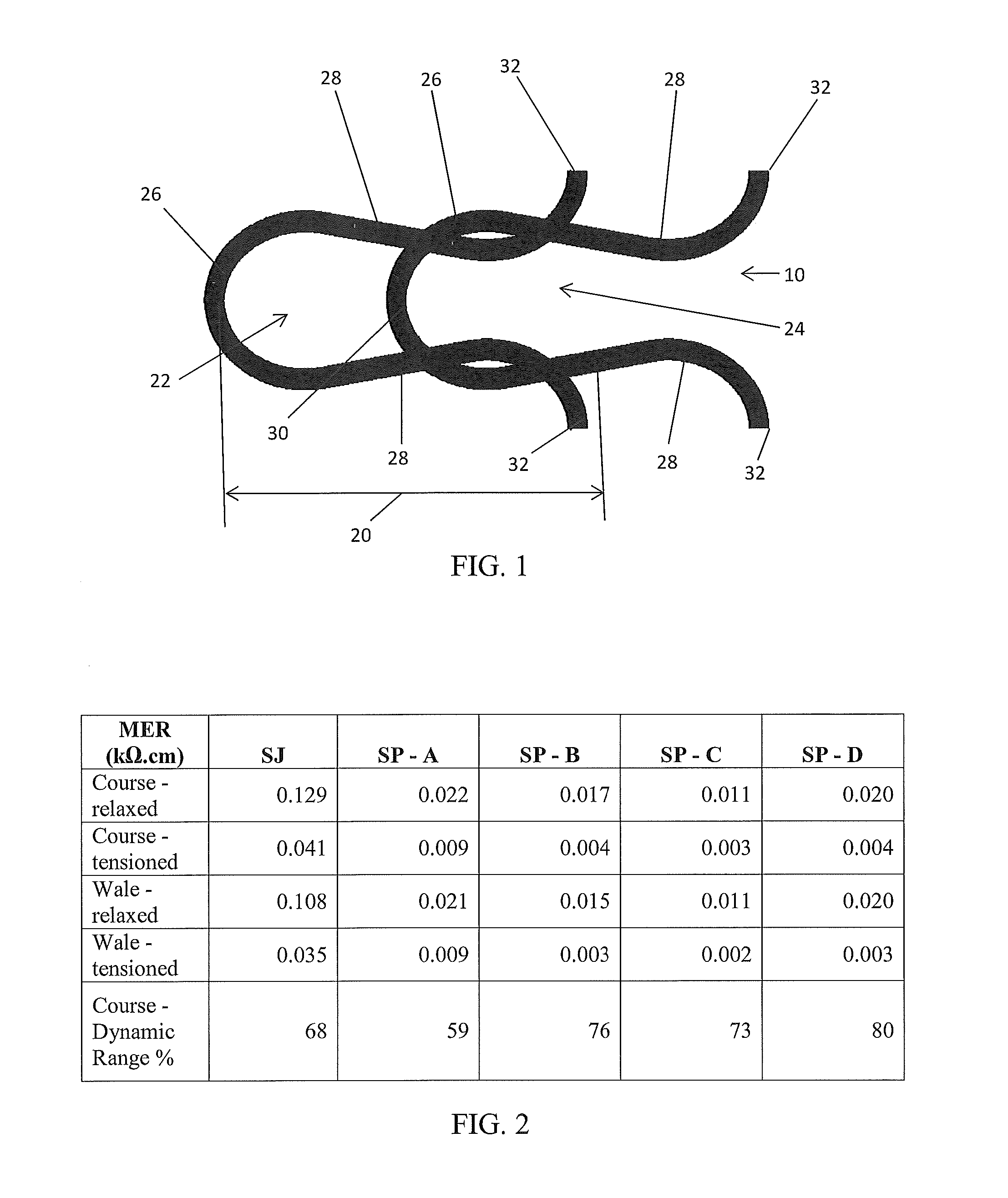

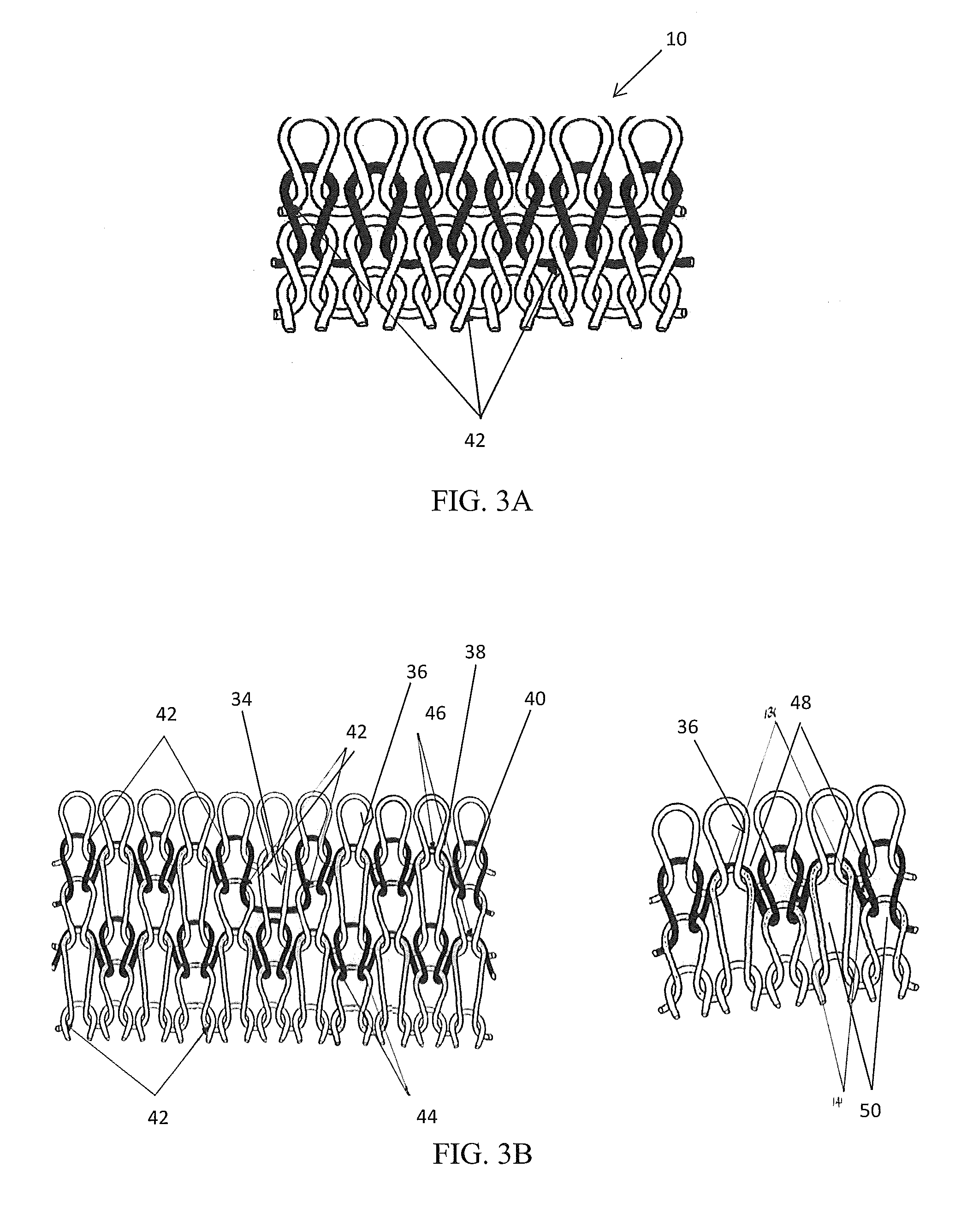

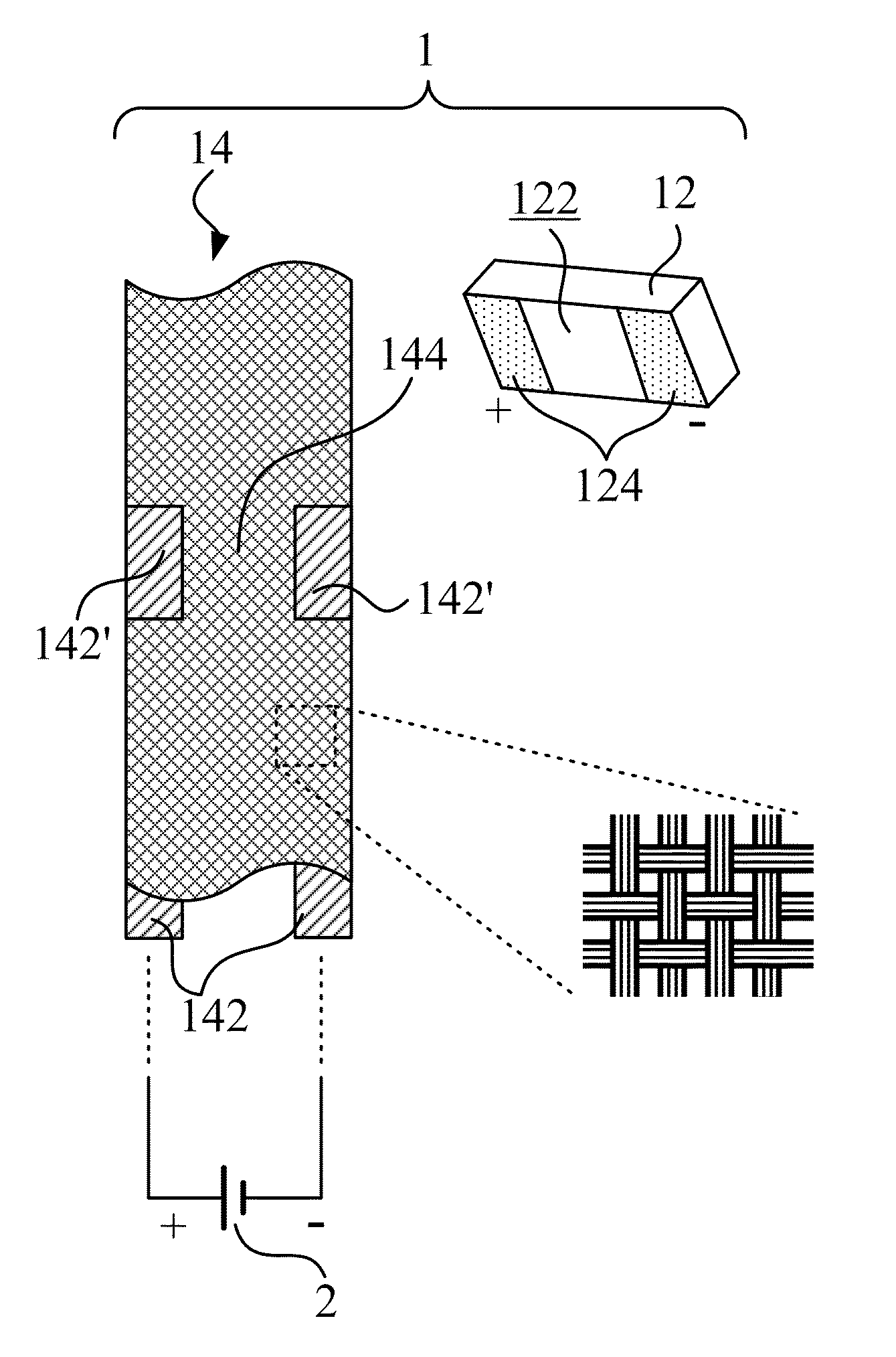

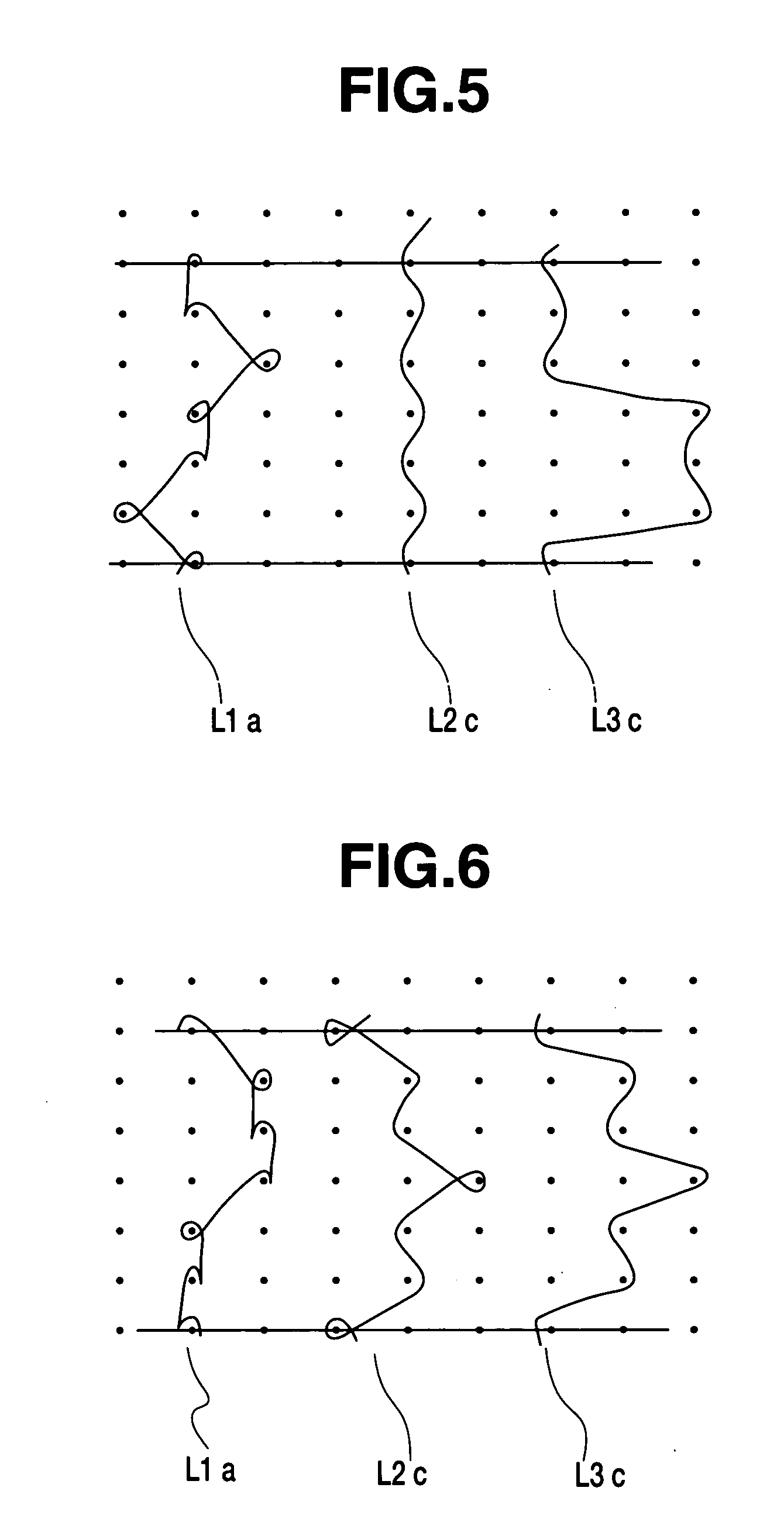

Method for making electrically conductive textiles and textile sensor

ActiveUS20160186366A1Automatically calibratingIncrease contact resistanceCrochetingOrnamental textile articlesYarnElectrical resistance and conductance

A method for making a textile sensor and a textile sensor can include selecting a combination of variables from the group consisting of yarn variables, stitch variables, and textile variables; and knitting an electrically conductive yarn in the textile sensor in accordance with the selected combination of variables, wherein the combination of variables is selected so as to provide a controlled amount of contact resistance in the textile sensor. The method and textile can further include a capacitive textile-sensor having at least two integrally knit capacitor plate elements and having a configuration adapted for a sensing activity. Resistance in the textile sensor can automatically calibrate to a stable baseline level after the textile sensor is applied to a body.

Owner:FOOTFALLS & HEARTBEATS (UK) LTD

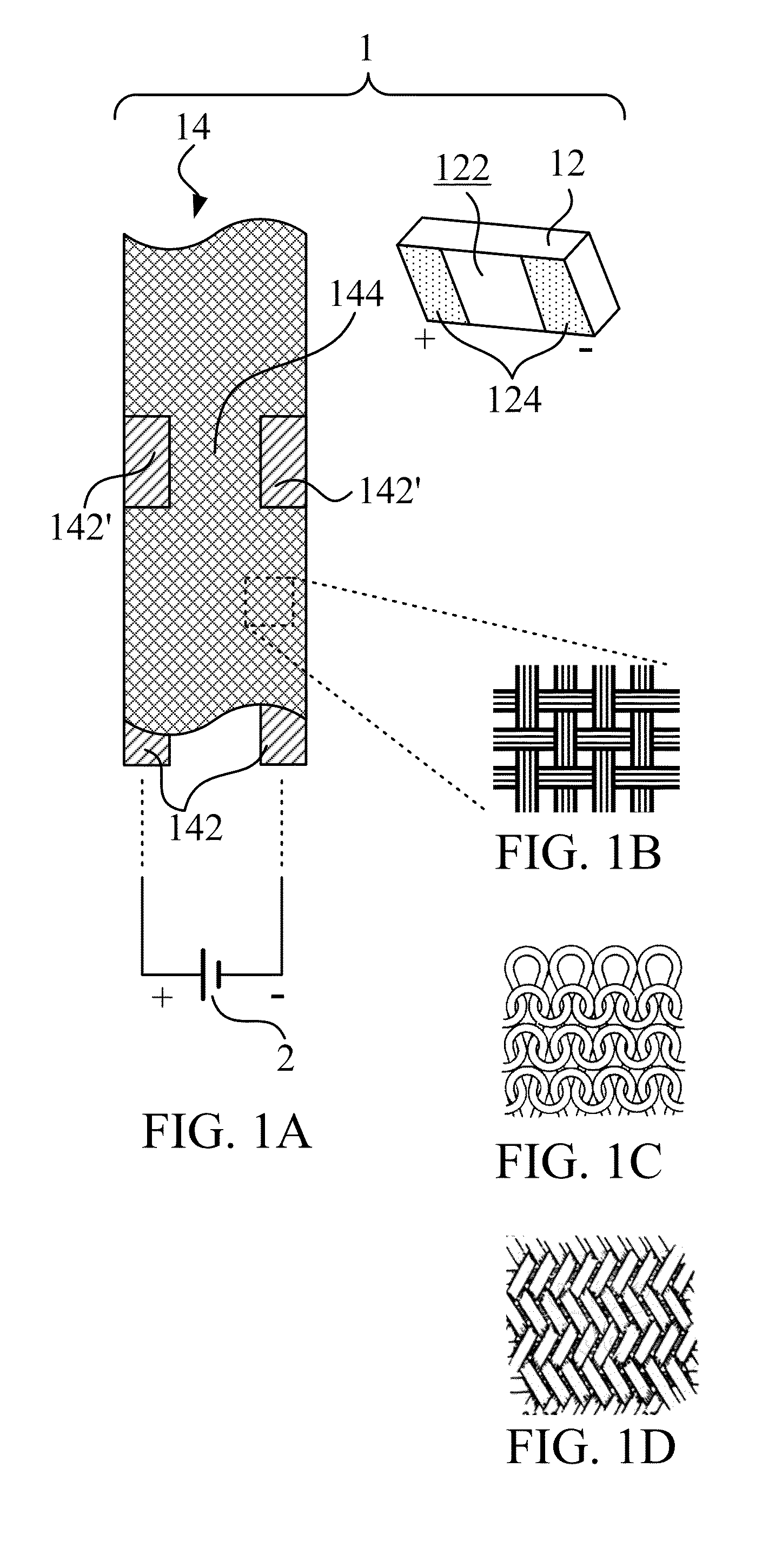

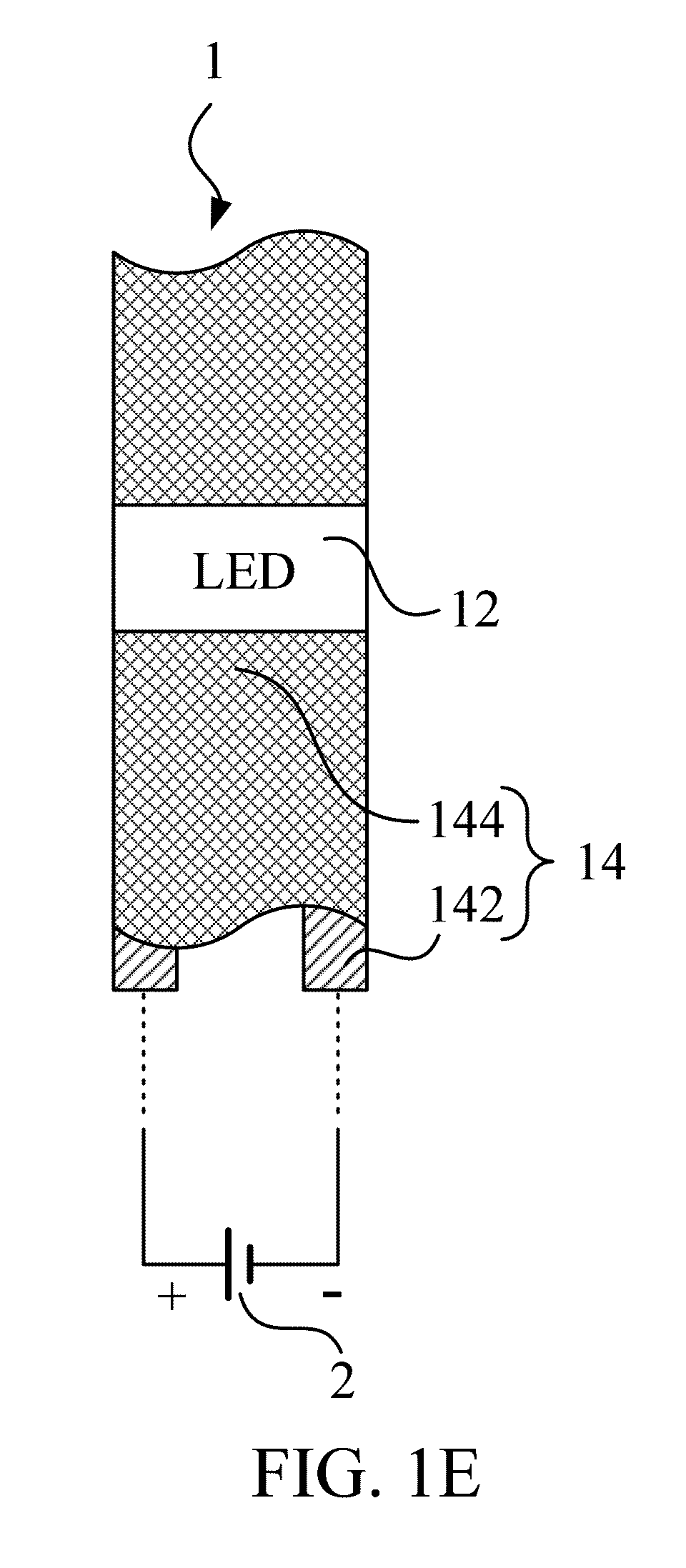

Illuminating textile article

The invention discloses an illuminating textile article including a diode-based lighting device and a textile body. The diode-based lighting device has M contact points where M is an integer equal to or larger than 2. The textile body is constituted by N conductive yarns and at least one non-conductive yarn where N is an integer equal to or larger than 2, and provides M′ conductive exposed portions of the conductive yarns which are separated by the at least one non-conductive yarn from one another. Each of the M contact points corresponds to one of the M′ conductive exposed portions and is fixed to the corresponding conductive exposed portion. The conductive yarns provide terminals for electric connection of a power supply.

Owner:HSU FU BIAU

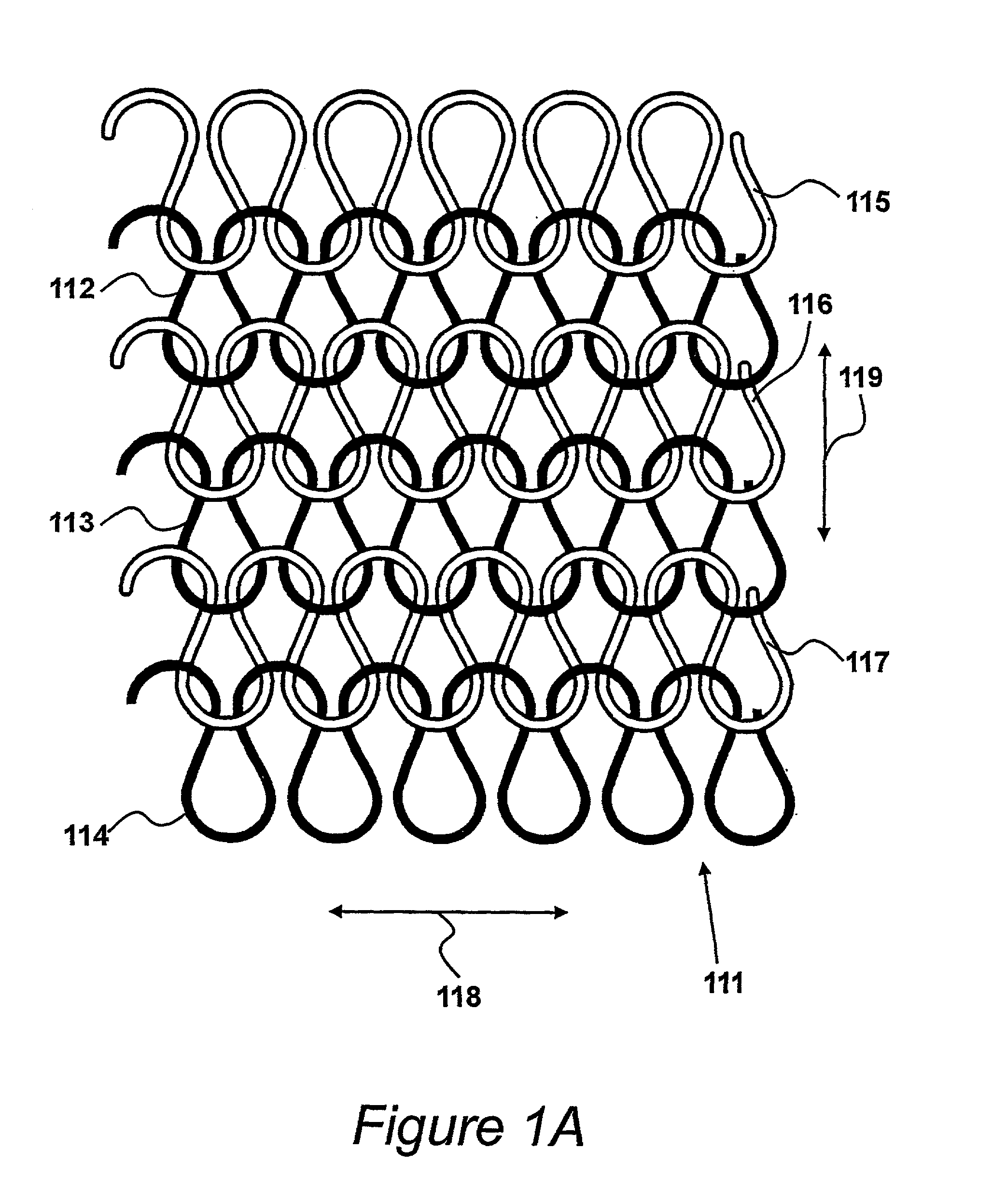

Bi-ply fabric construction and apparel formed therefrom

A knitted fabric comprising two confronting webs, each web being formed by a series of continuous lengths of yarn extending generally parallel to one another and having loops arranged in walewise and coursewise rows. One web overlies the other and, the two webs being united at intervals by a tuck stitch of yarn of one web engaging the other web. The tuck stitches are spaced apart walewise by a plurality of courses to create channels between the stitches. The channels extend walewise of the webs. At least one yarn is inserted under tension between the two fronting webs and held in parallel relation to the parallel lengths of yarn. When relaxed, the yarn inserted under tension causes the confronting webs to be spaced apart within each of the channels.

Owner:HBI BRANDED APPAREL ENTERPRISES

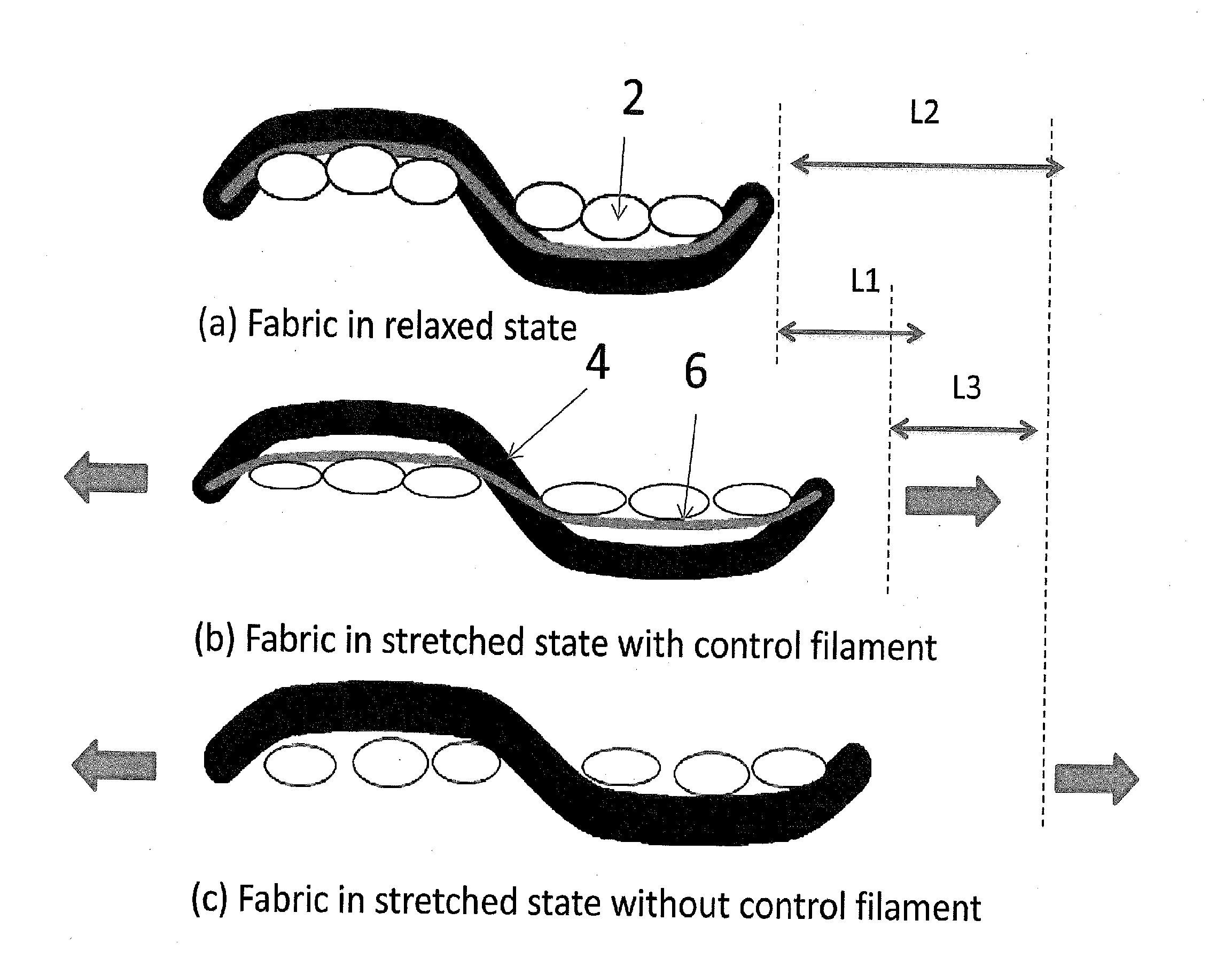

Stretch wovens with a control yarn system

ActiveUS20150133017A1Better recovery powerImprove the level ofShrinkingPattern makingEngineeringElastic fiber

An article including a woven fabric comprising warp yarns and weft yarns, wherein at least one of either the warp yarns or the weft yarns includes: (a) a corespun elastic base yarn having a denier and including staple fiber and an elastic fiber core; and (b) a separate control yarn selected from the group consisting of a single filament yarn, a multiple filament yarn, a composite yarn, and combinations thereof; having a denier greater than zero to about 0.8 times the denier of the corespun elastic base yarn; wherein the woven fabric includes (1) a ratio of corespun base yarn ends to control yarn ends of up to about 6:1; or (2) a ratio of corespun base yarn picks to control yarn picks of up to about 6:1; or (3) both a ratio of corespun base yarn ends to control yarn ends of up to about 6:1; and a ratio of corespun base yarn picks to control yarn picks of up to about 6:1.

Owner:THE LYCRA CO LLC

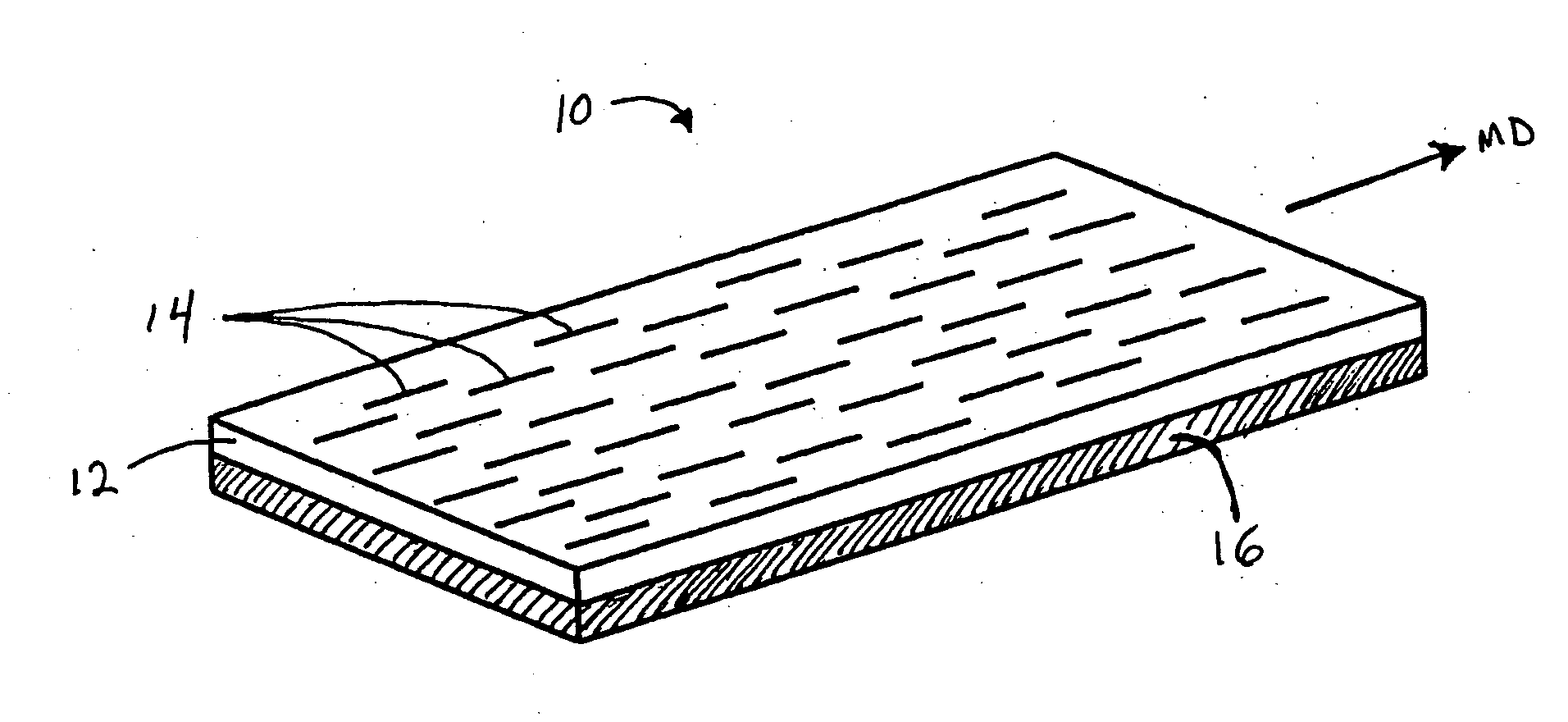

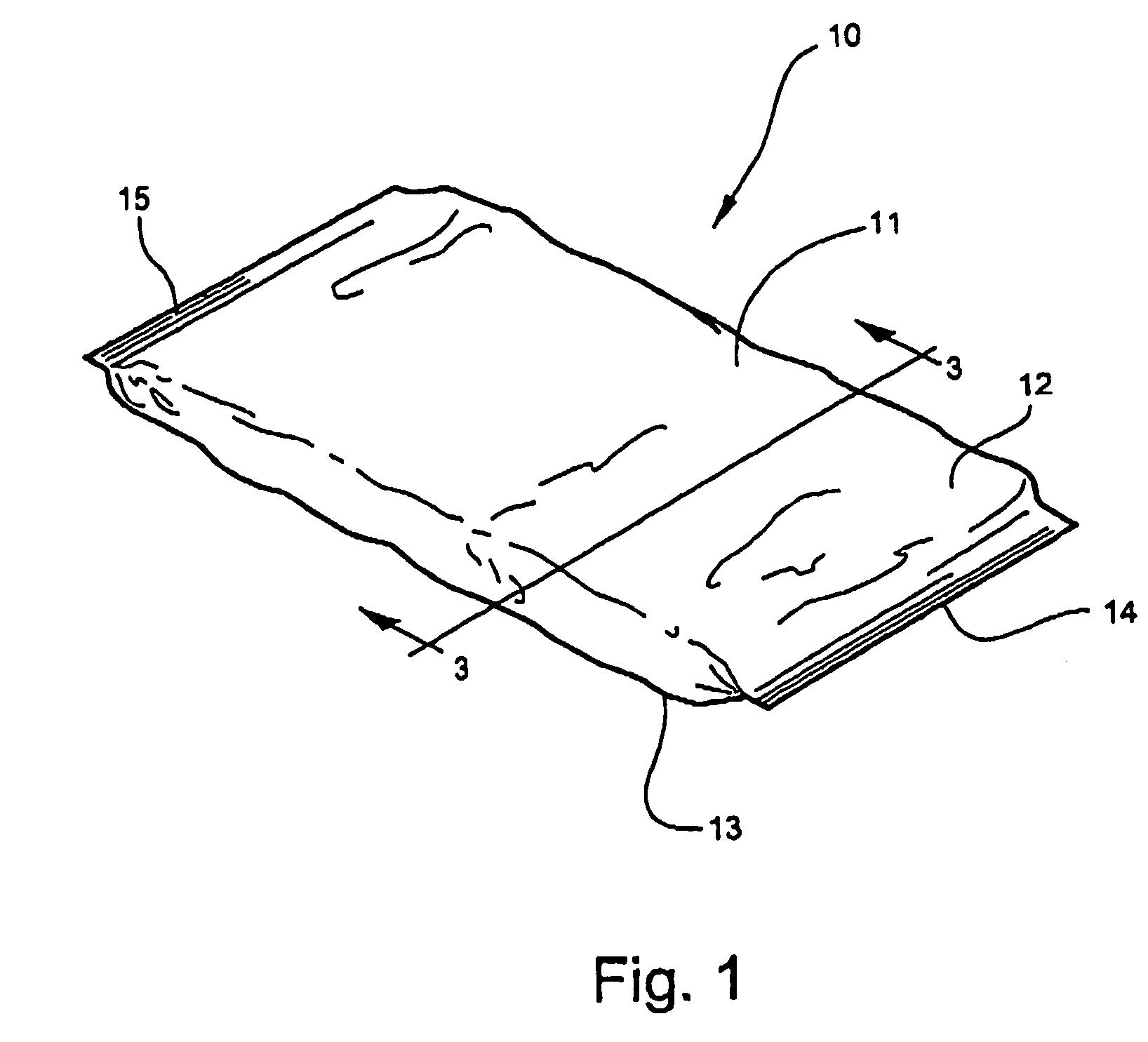

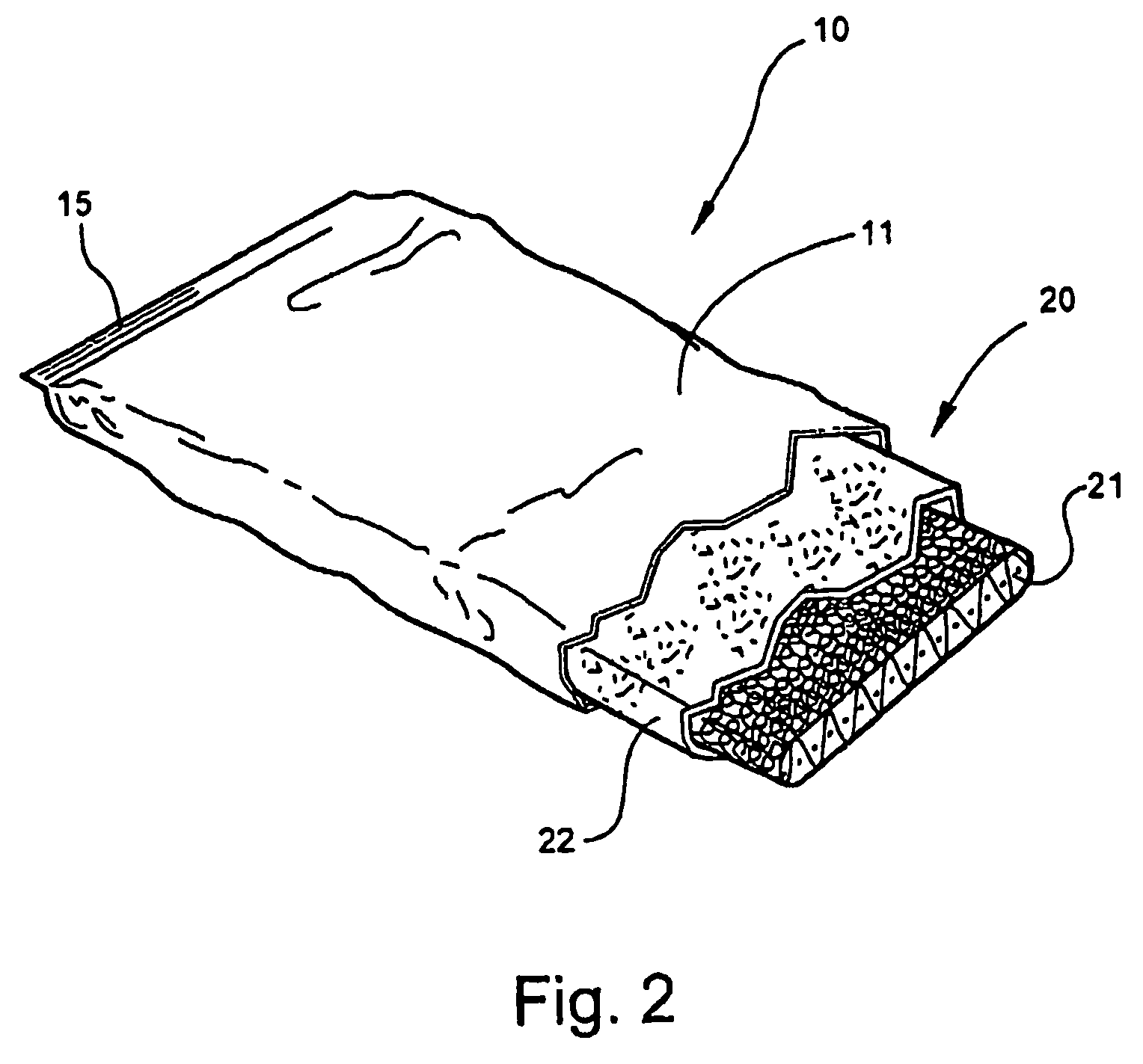

Composite elastic material

The present invention is directed to an elastic composite material having an elastic layer having a first side and a second side; at least one gatherable layer bonded to at least one of the first side and second side of the elastic layer; and a fibrous material entangled and intertwined with both the elastic layer and the gatherable layer. The resulting elastic composite provides a stretchable material which can conform to surfaces and has desirable properties of the fibrous material entangle and intertwined with both the elastic layer and the gatherable layer and does not suffer from the loss of the fibrous material from the stretchable substrate. The composite is usable in as bandages, durable wipes, durable mops and personal care products, such as diapers and feminine napkins. Also disclosed is a method for making the composite.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Elastic knitting fabric having multilayer structure

InactiveUS7240522B2Improve tensile propertiesImproved shape stabilityOrnamental textile articlesStraight-bar knitting machinesFiberElastic fiber bundle

An elastic knitted fabric having a multilayer structure, made by binding separate front and back two-layer ground knitted fabrics together, wherein the above described two-layer ground knitted fabrics are bound together with only a bare string(s) of polyurethane based elastic fibers of 17 to 3000 decitexes.

Owner:ASAHI KASEI FIBERS CORPORATION

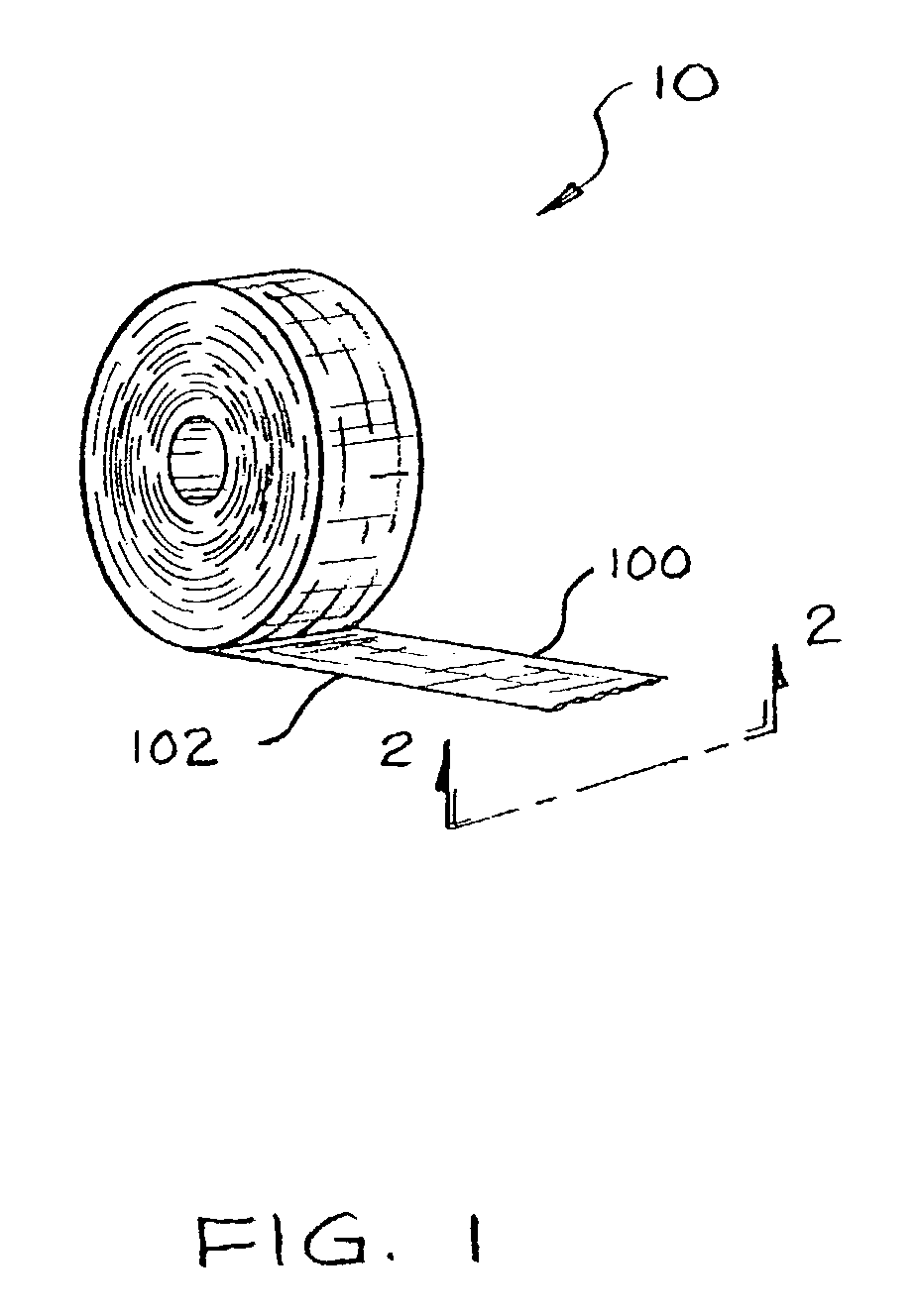

Knitted substrate for use in medical bandaging product, bandaging product and method of forming the same

ActiveUS7854712B2High strengthOrnamental textile articlesPlaster of paris bandagesYarnReactive system

A medical bandaging product having a predetermined length suitable for a given medical use, including an enclosure formed of a moisture-impervious material sealable to prevent entry of moisture and a medical bandage material positioned in the enclosure and sealed therein against entry of moisture until use. The medical bandage material includes a substrate formed from a single integrated knitted fabric layer having a plurality of interconnected knitted fabric yarns forming a three-dimensional structure. A reactive system is impregnated into or coated onto the substrate. The system remains stable when maintained in substantially moisture-free conditions and hardens upon exposure to sufficient moisture to cooperate with the three-dimensional structure to form a rigid, self supporting structure. A soft, flexible protective wrapping encloses the substrate along its length for providing a cushioning barrier interposed between the substrate and a patient when the medical bandage material is in use.

Owner:BSN MEDICAL INC

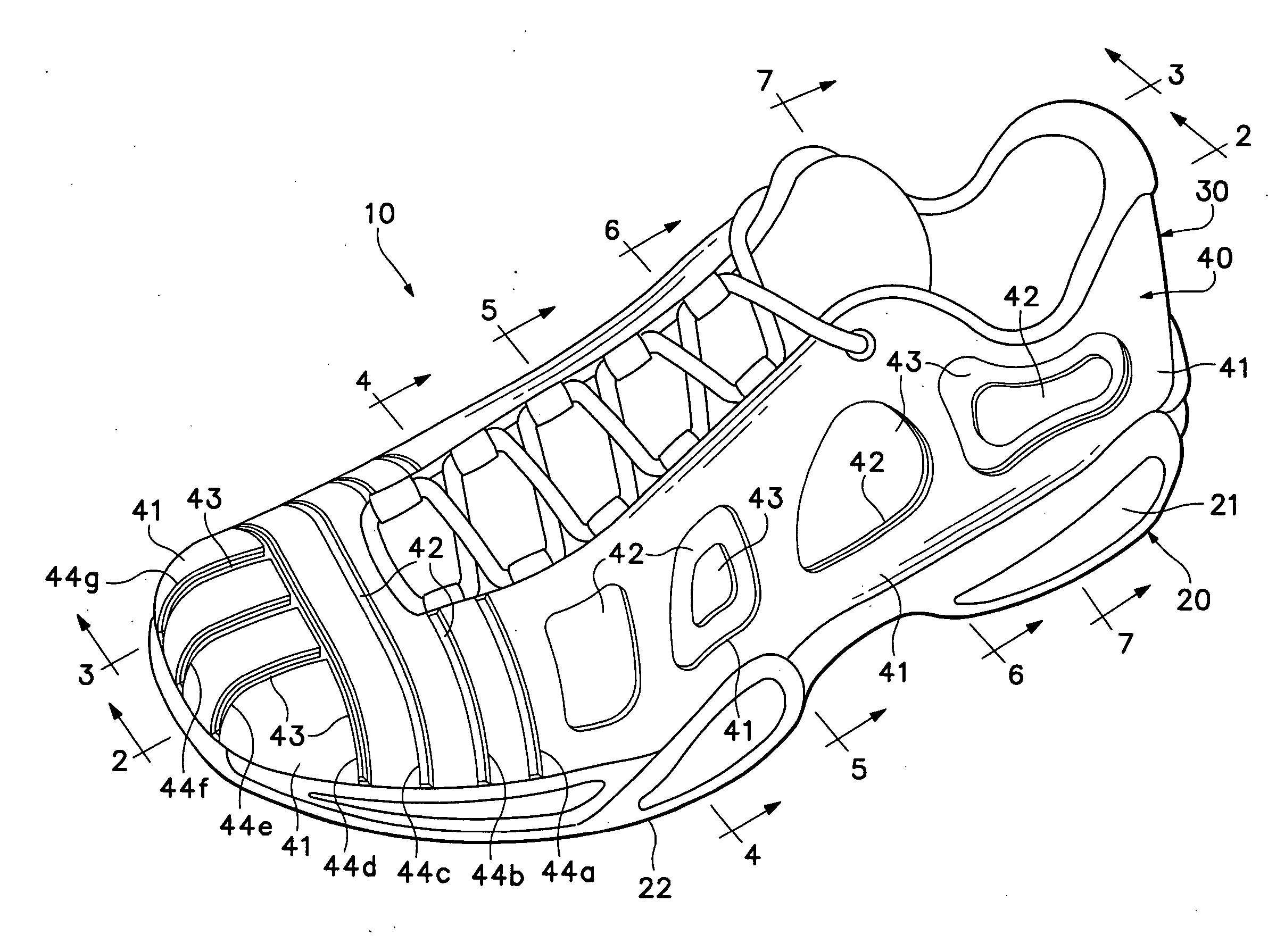

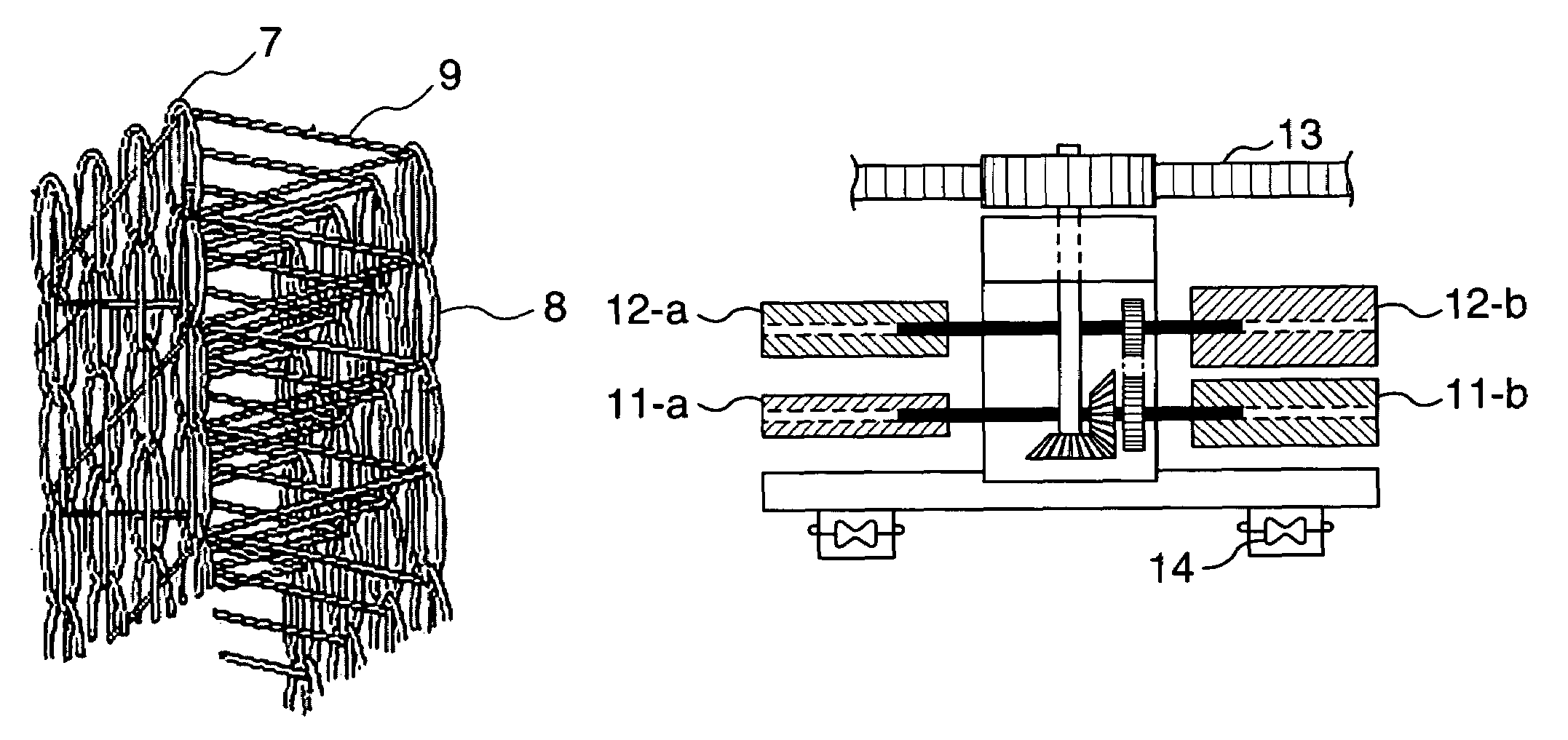

Flat weft-knitted upper for sports shoes

Owner:ADIDAS

Advanced body armor utilizing shear thickening fluids

InactiveUS20060234577A1High strengthNot impede fabric flexibilityWarp knittingCircular knitting machinesPuncture resistanceBody armor

An armor composite material has been invented which contains a fabric which has been impregnated with shear thickening fluid. This invention offers a ballistic resistant material that is more flexible and less bulky than comparable, conventional ballistic fabric. The material in the alternative can be puncture resistant. The invented material offers superior ballistic performance and / or puncture resistance compared to conventional ballistic fabric-based materials of equal thickness. The invented material can be applied to applications requiring armor that is compact and / or flexible, such as body armor, protective clothing and flexible protective devices and shields, and stab resistant clothing and devices.

Owner:UNIVERSITY OF DELAWARE

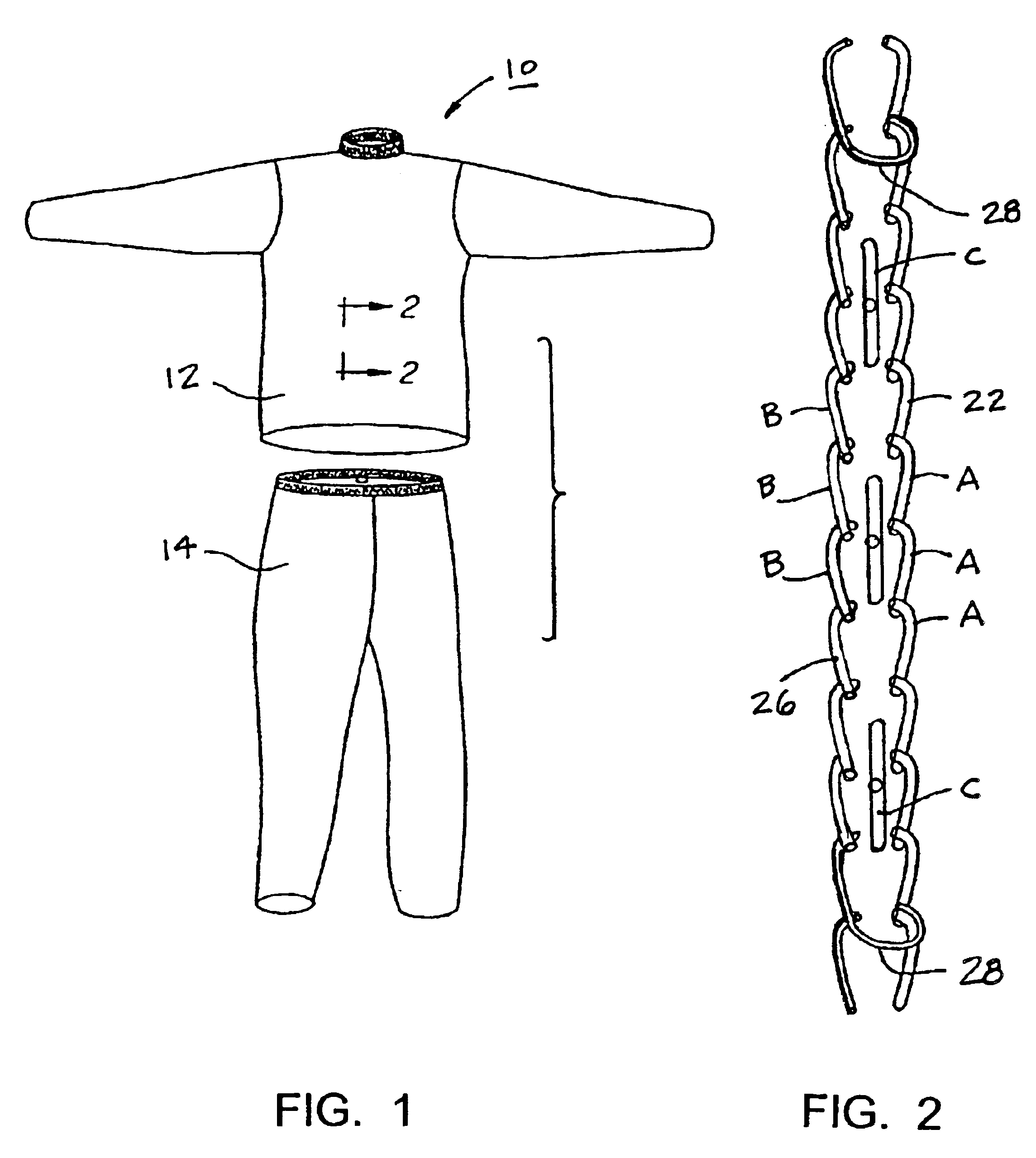

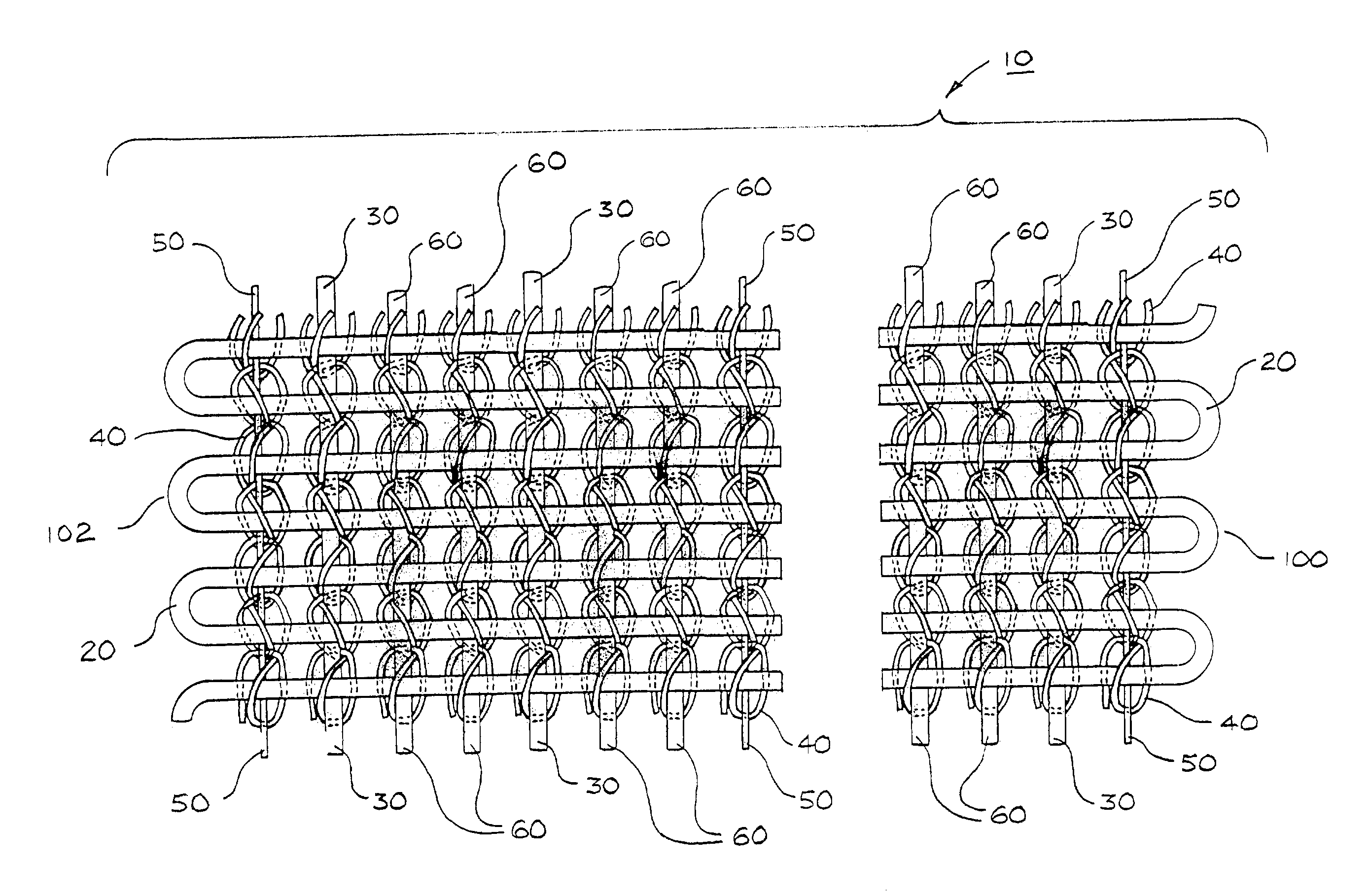

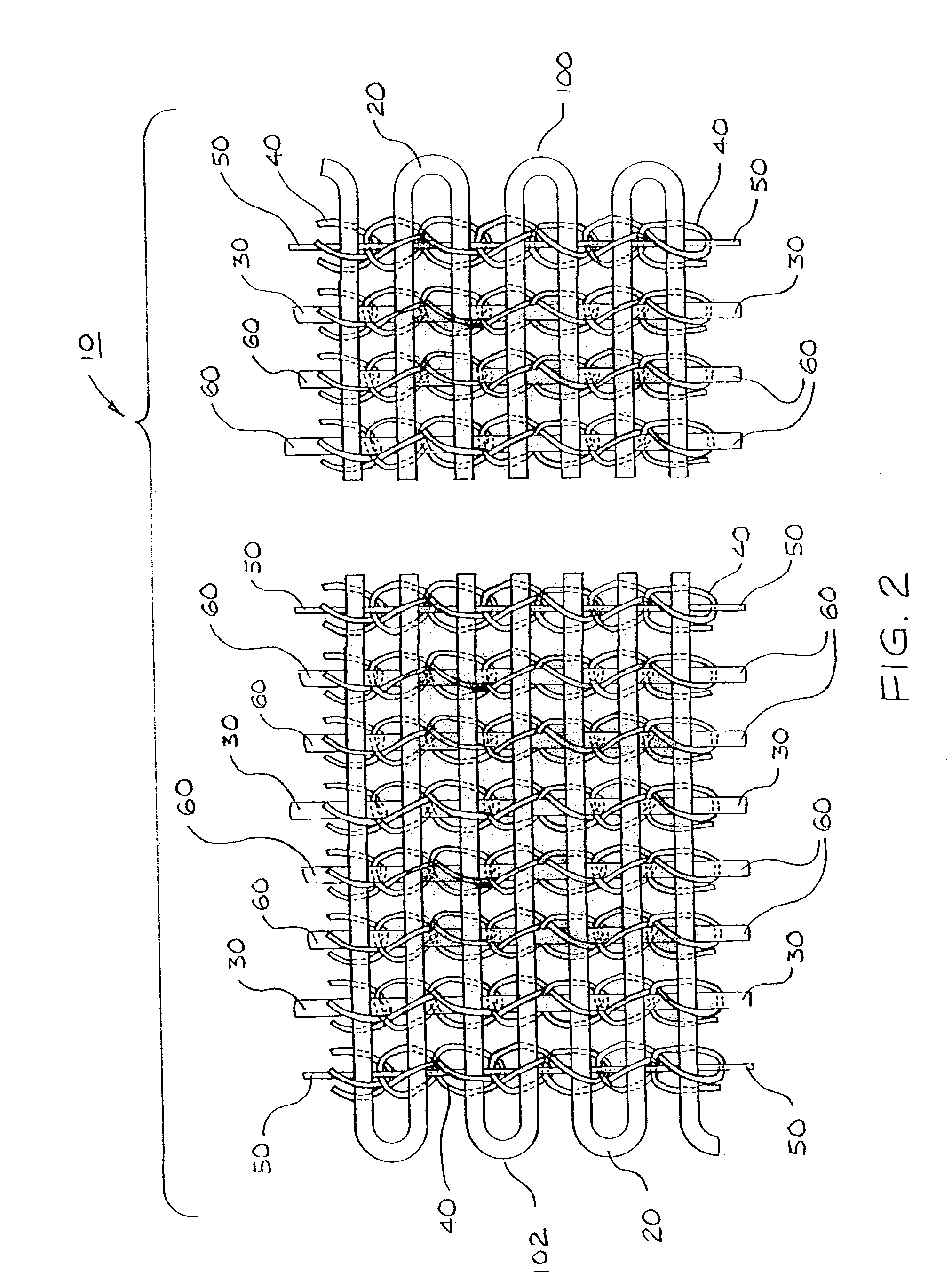

Wire-reinforced elastic webbing

InactiveUS6984596B2Limited elongationEvenly distributedOrnamental textile articlesWire networkYarnPolyester

A wire-reinforced webbing material is disclosed for use in furniture, bedding and the like. The webbing includes a flat knitted fabric comprised of substantially elastic yarns such as polyester. A plurality of reinforcement wires are integrally knitted into the fabric structure in a lengthwise direction. The wires may be thin-gauge titanium or titanium alloy wires. Elastomeric yarns or cards may also be integrally knitted into the fabric structure parallel to the reinforcement wires. The reinforcement wires and elastomeric cords combine with the knitted fabric to yield a webbing material having both a high tensile strength and a resilient responsiveness to applied external loads.

Owner:HICKORY SPRINGS MFG

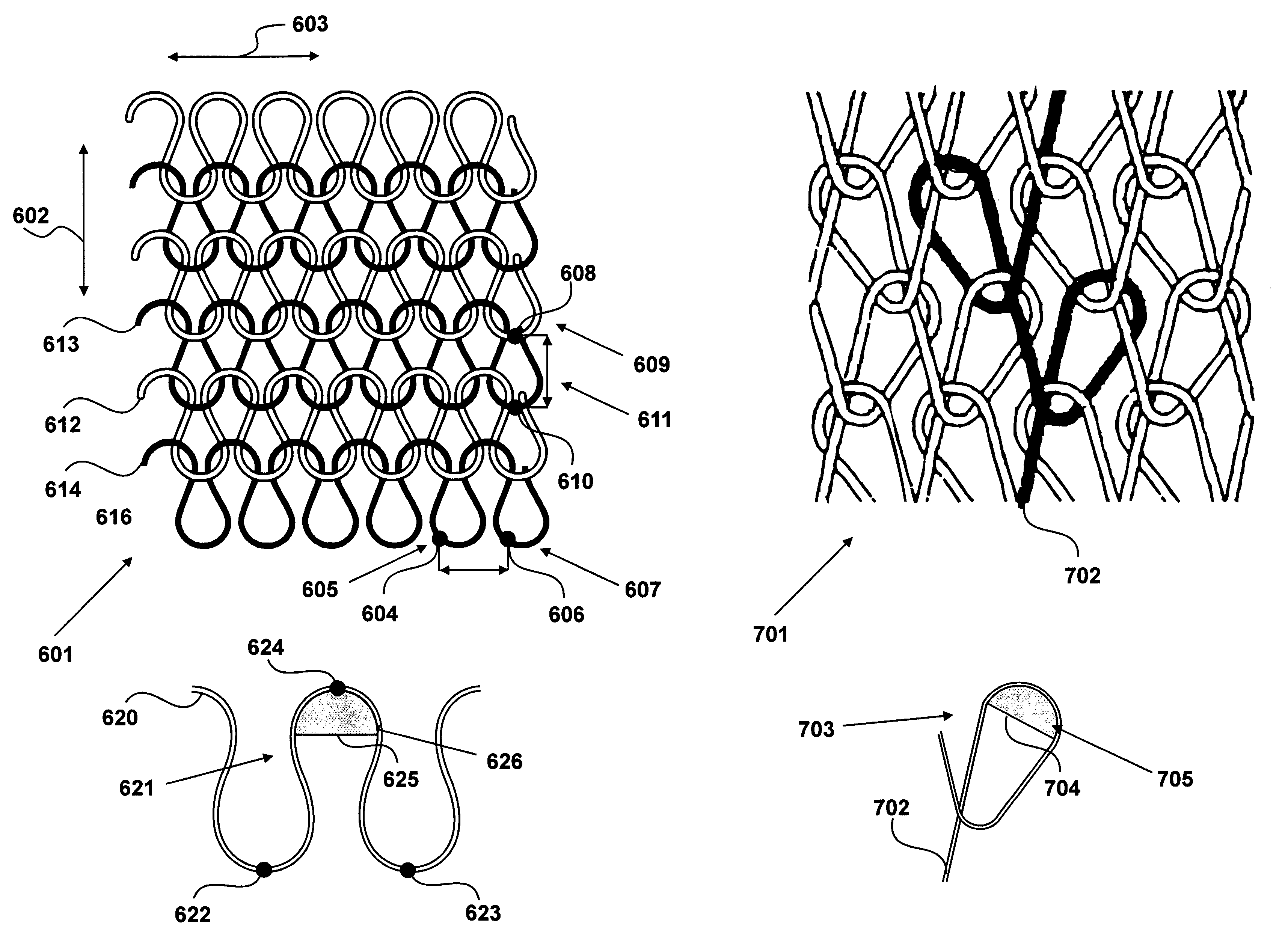

Knitted sensor

A sensor having a three layer construction comprising a first knitted conductive textile plane, a second conductive textile plane and an intermediate separating plane penetrable by the first knitted conductive textile plane to allow the first conductive textile plane and the second conductive textile plane to make electrical contact under a mechanical interaction. The intermediate separating plane defines structural endpoints from which the first knitted conductive textile plane deforms towards the second conductive textile plane under a mechanical interaction. The first knitted conductive textile plane has conductive yarn knitted to form a repeating pattern of stitches each comprising a stitch looping portion SLP having a looping portion footprint LPF. Within the sensor, there is at least one of a plurality of described dimensional relationships between stitches of the first knitted conductive textile plane and structural endpoints of the intermediate separating plane.

Owner:WEARABLE TECH LTD

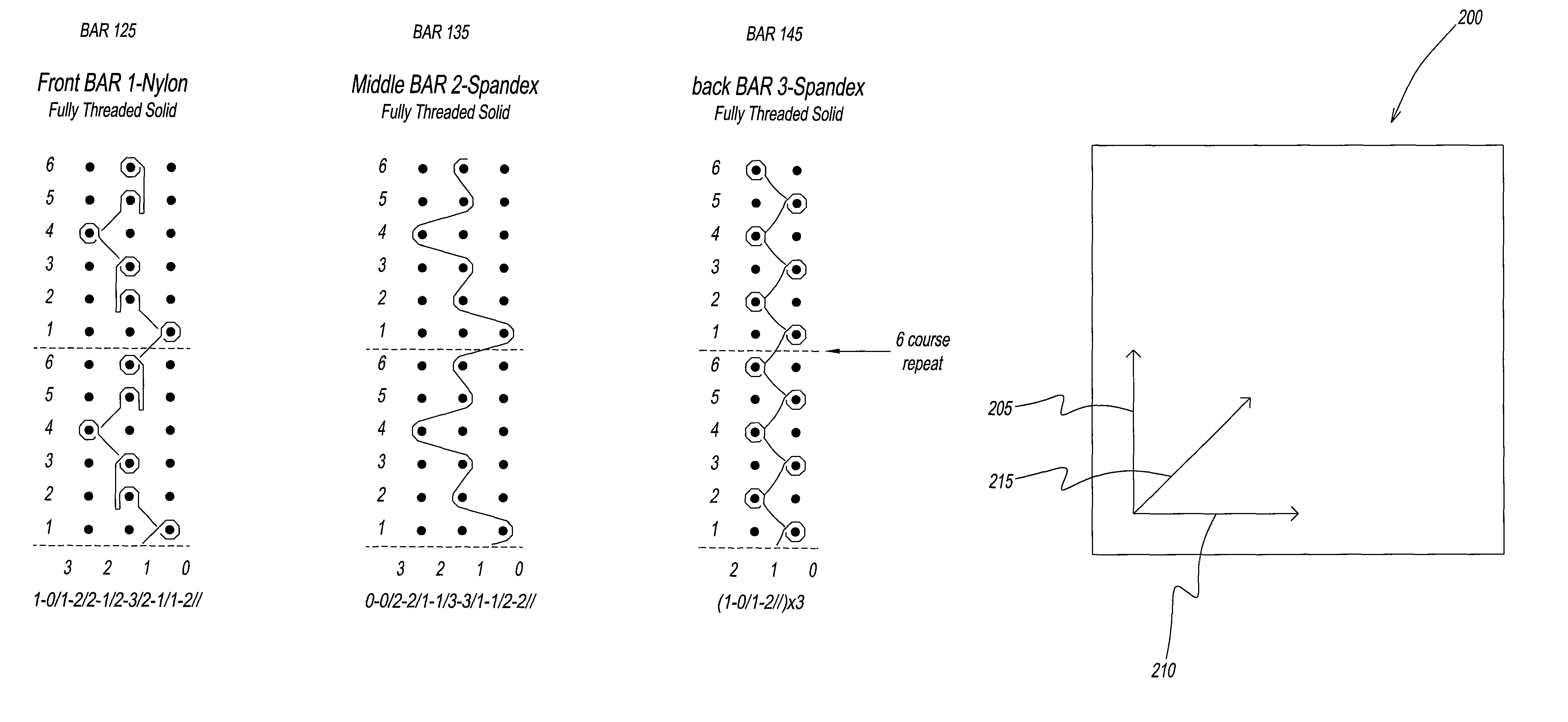

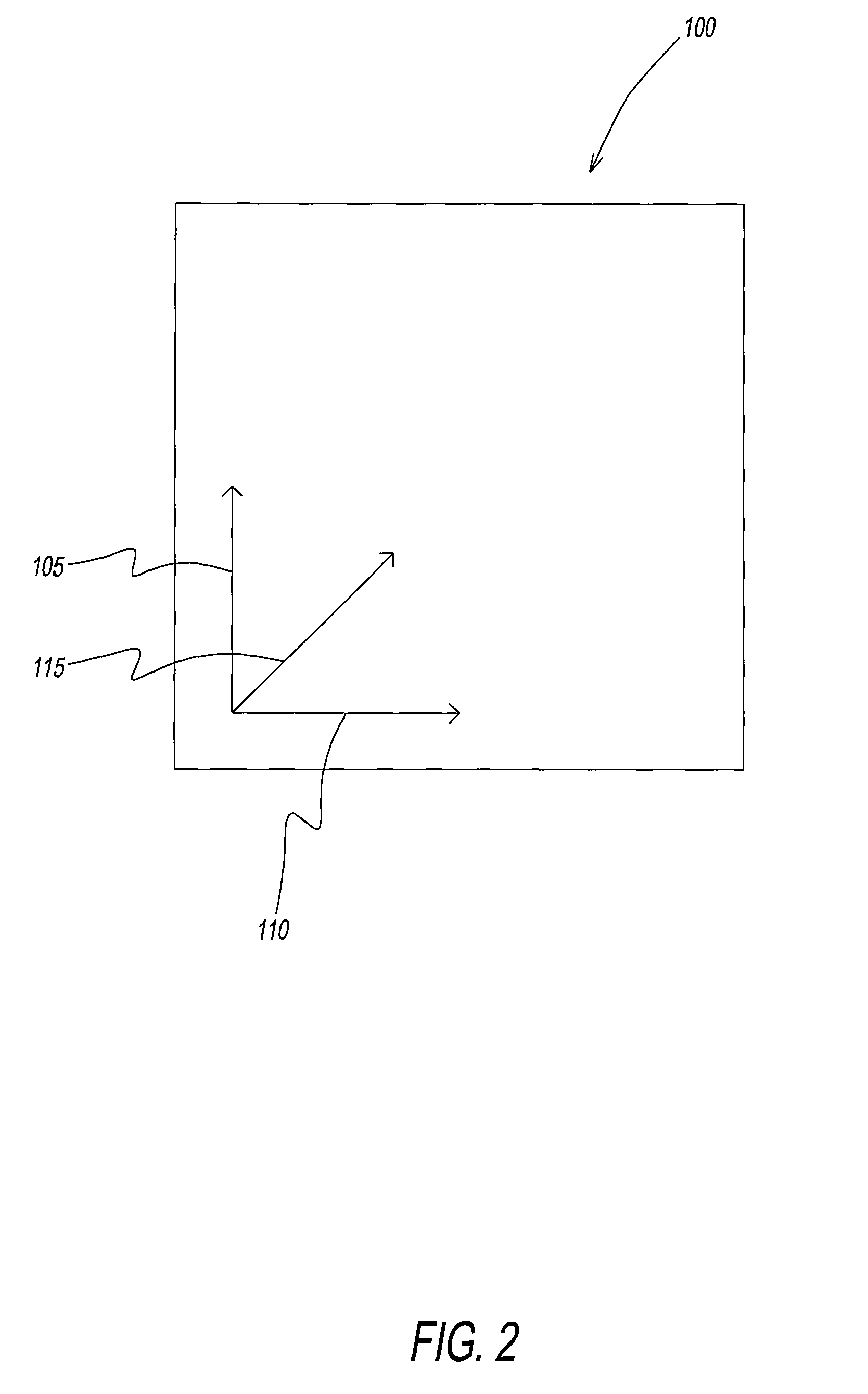

Fabric with equal modulus in multiple directions

ActiveUS8726700B2Balance balanceControl balanceStraight-bar knitting machinesWoven fabricsBi-isotropic materialEngineering

Owner:GLOBAL TRADEMARKS

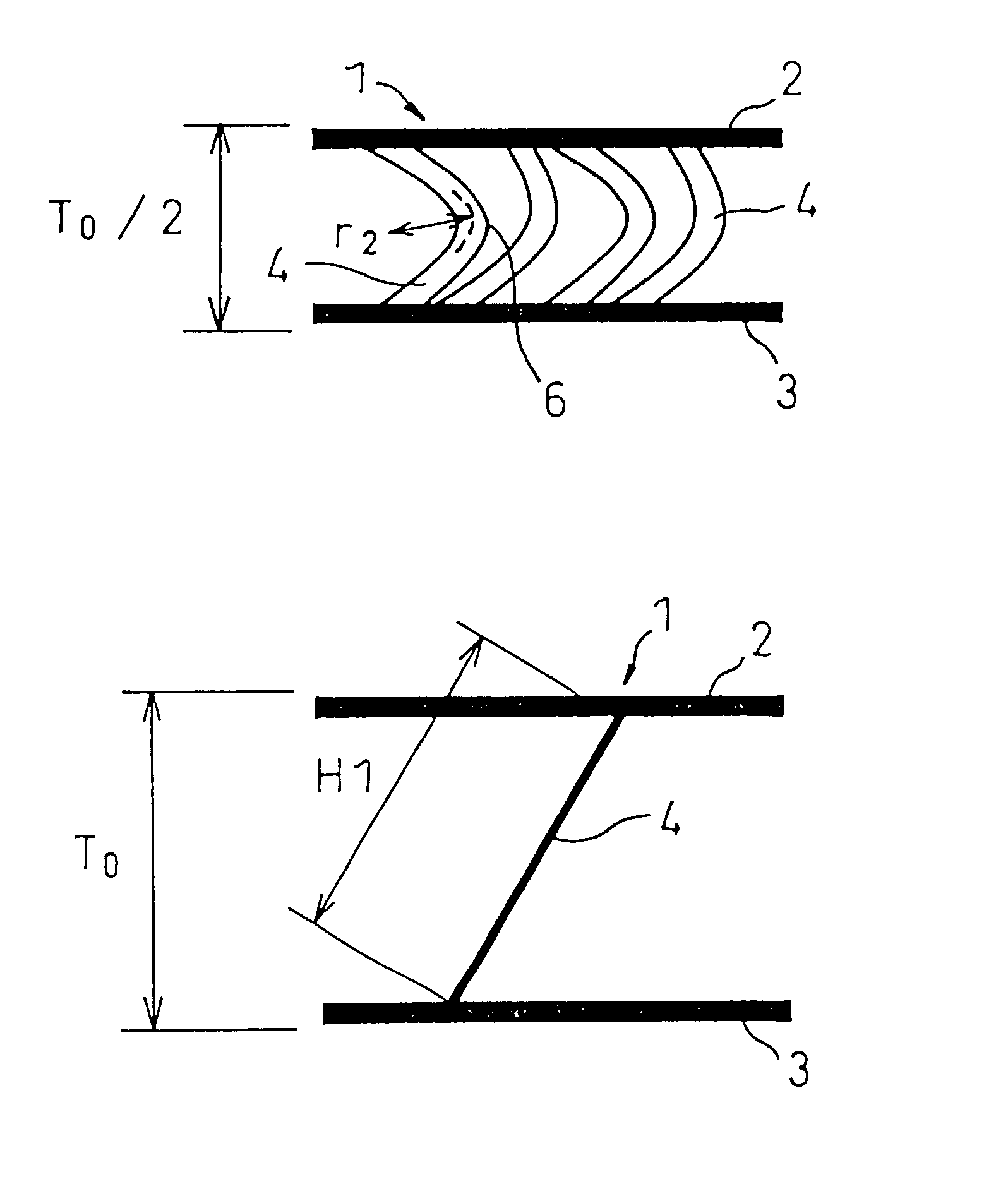

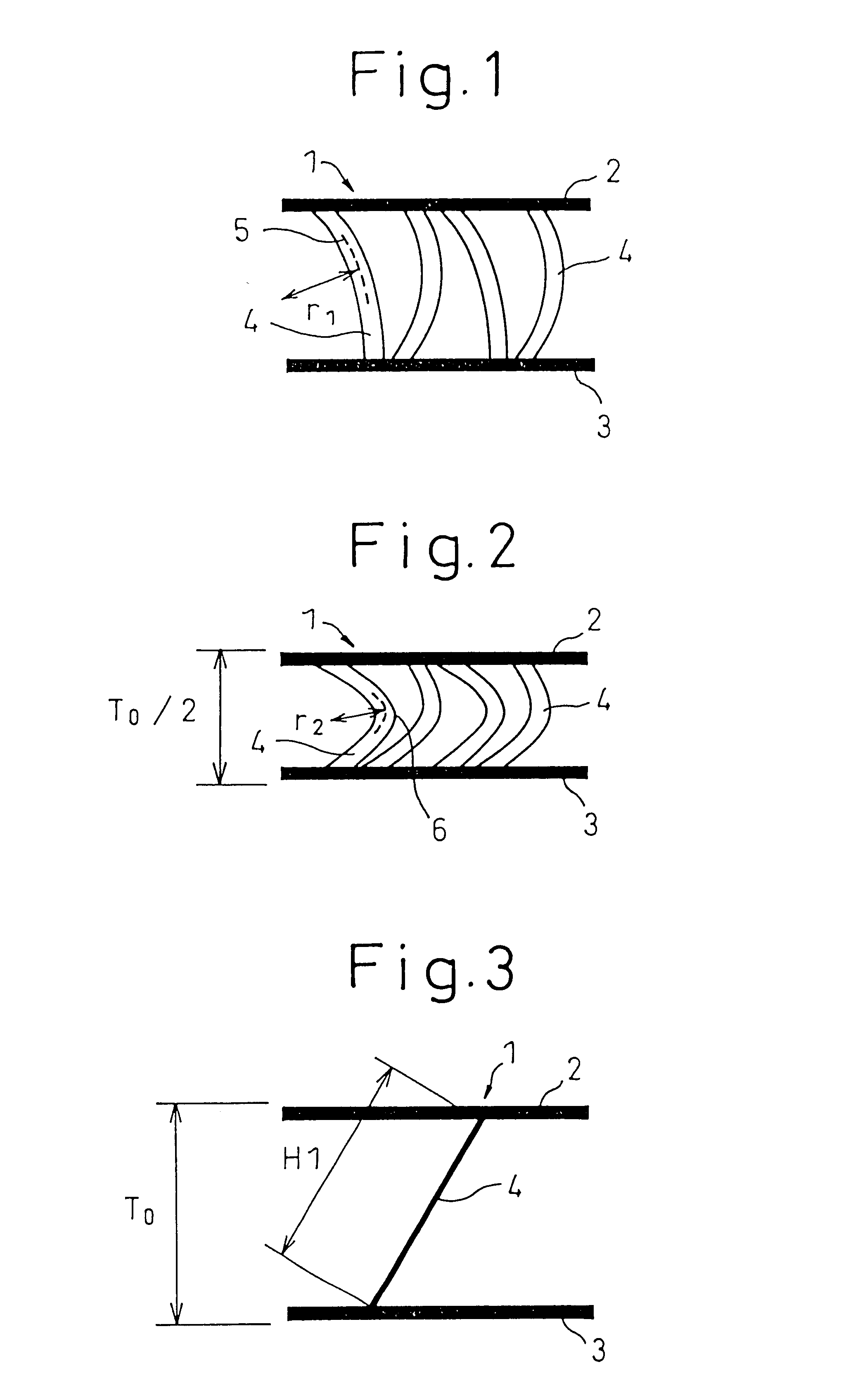

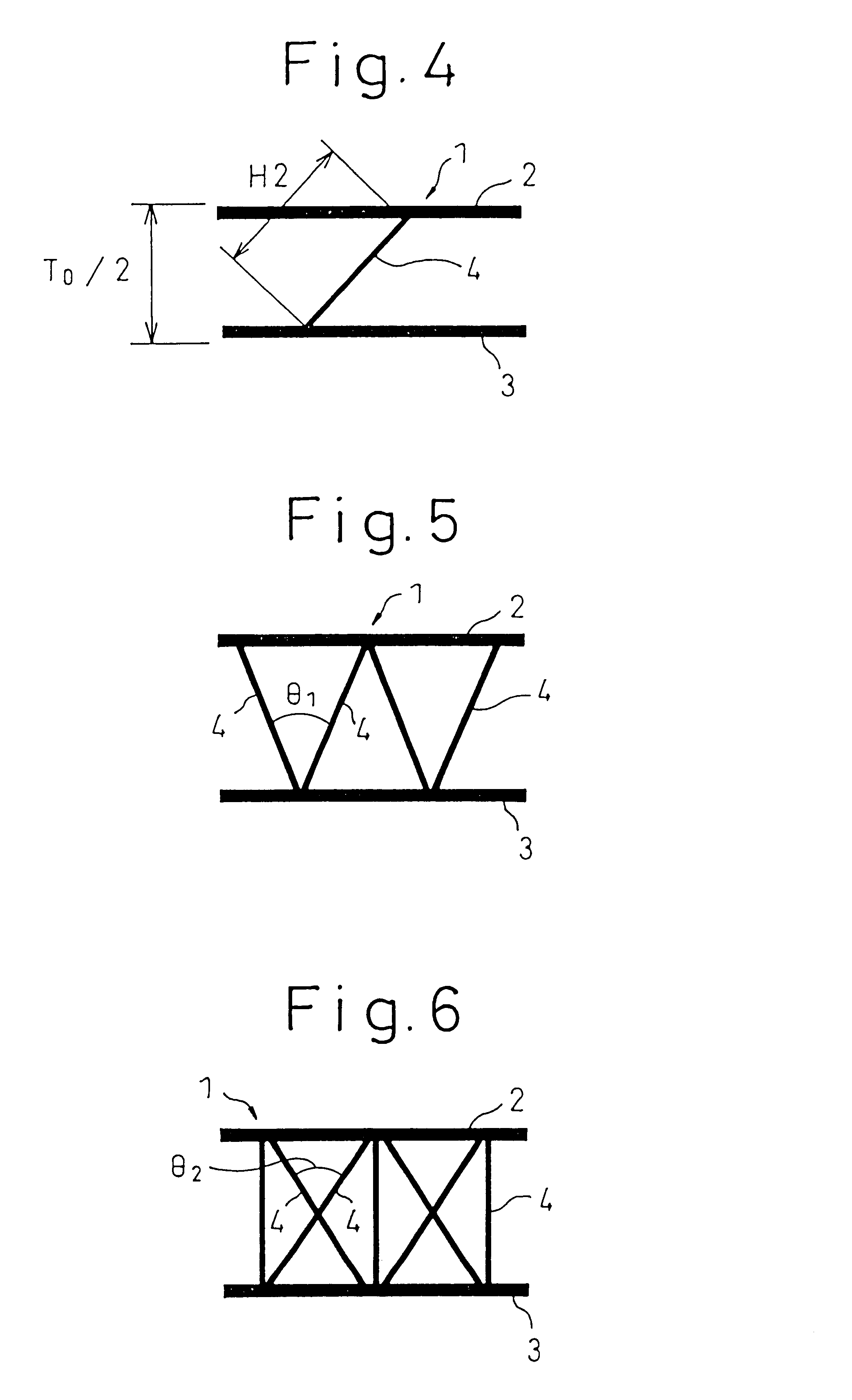

Three-dimensional fabric for seat

InactiveUS6644070B2Shape-retaining property is improvedMinimize hysteresis lossOrnamental textile articlesLayered productsYarnCivil engineering

A three-dimensional knit fabric having front and back knit layers and a monofilament yarn connecting the knit layers to each other, characterized in that the curvature of the monofilament yarn in the three-dimensional knit fabric is in a range from 0.01 to 1.6, and the bending elongation of the monofilament is 20% or less when the three-dimensional knit fabric is compressed to 50%. The three-dimensional knit fabric has a cushioning property in springiness which does not deteriorate even if the fabric is repeatedly used many times or for a long time, and thus this fabric is excellent in terms of durability of the cushioning property. In particular, the fabric is suitable for use as a hammock type seat and exhibits a cushioning property having a favorable springy feeling as well as a good fit feel.

Owner:ASAHI KASEI KK

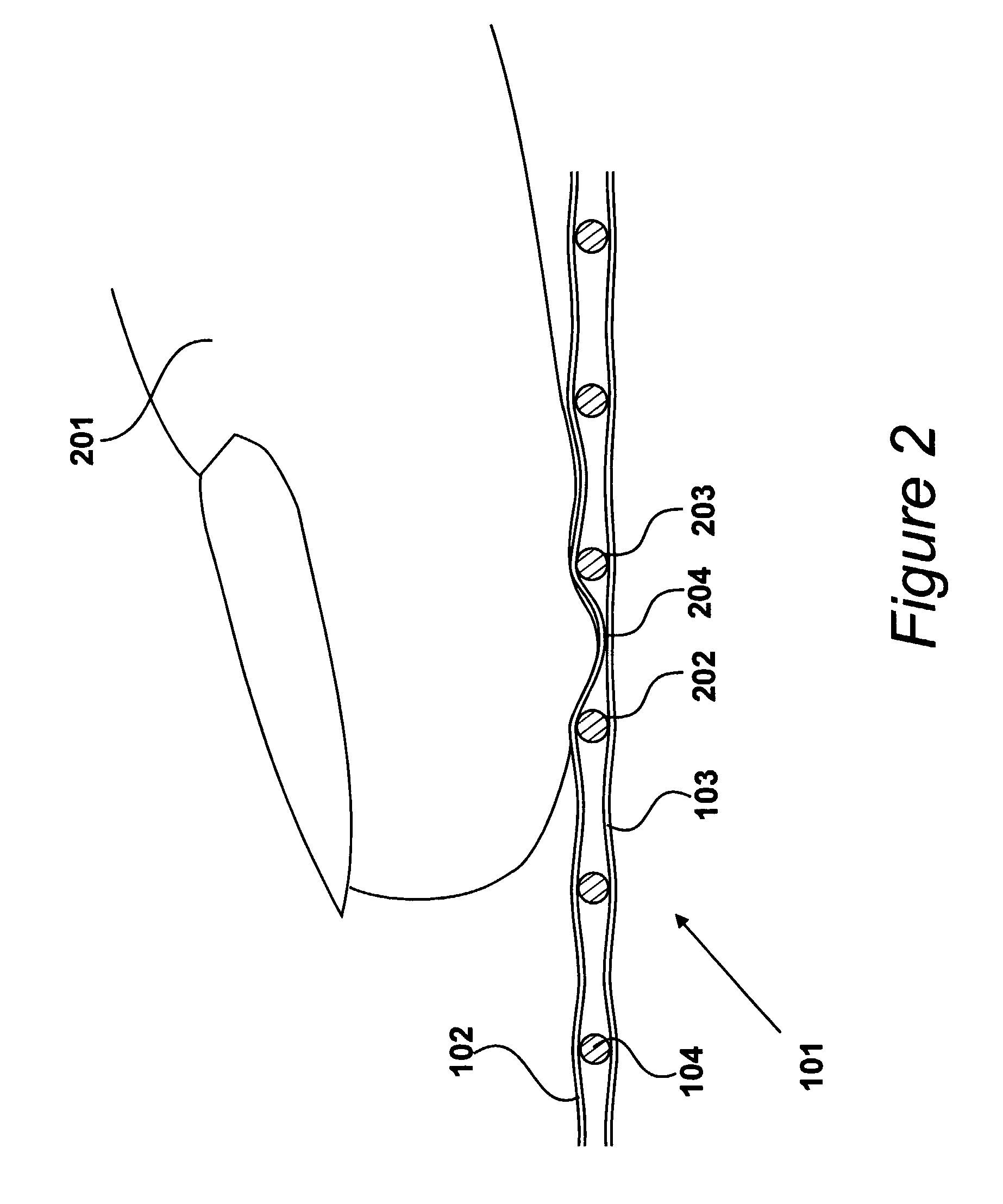

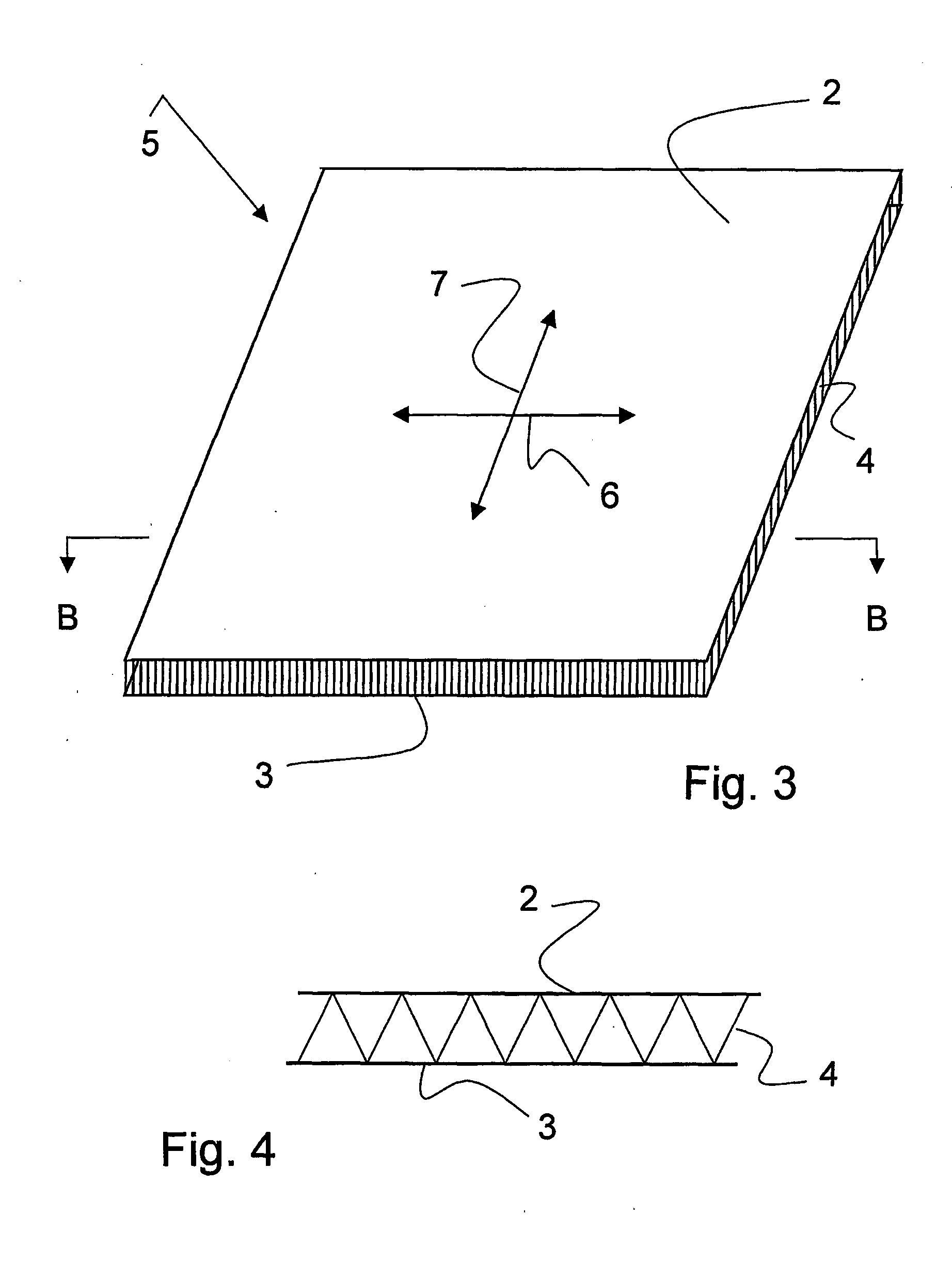

Tubular spacer fabric

InactiveUS20090126413A1Improve mechanical propertiesSubstantial isotropic propertyOrnamental textile articlesFeet bandagesPlastic surgeryBandage

The present invention relates to a weft-knitted tubular spacer fabric for use in orthopaedic products comprising a first outer layer, a second outer layer, and an intermediate spacer layer integrated with said first and second outer layers, said tube having a length. According to invention the spacer fabric is knitted in a tubular form with a circumference less than 1000 mm, said tubular spacer fabric not being cut open in its length direction, thereby conforming seamlessly to a body part or limb of a wearer. Hereby, a tubular spacer fabric is obtained which most expediently conforms seamlessly to a body part or limb of a wearer. This has the advantage that the seamless tubular spacer fabric may be used directly as a wrap, a bandage, a support or may be used as liner under casting.

Owner:TYTEX AS

Tubular spacer fabric

InactiveUS7937973B2Improve mechanical propertiesSubstantial isotropic propertyOrnamental textile articlesFeet bandagesPlastic surgeryBandage

The present invention relates to a weft-knitted tubular spacer fabric for use in orthopaedic products comprising a first outer layer, a second outer layer, and an intermediate spacer layer integrated with said first and second outer layers, said tube having a length. According to invention the spacer fabric is knitted in a tubular form with a circumference less than 1000 mm, said tubular spacer fabric not being cut open in its length direction, thereby conforming seamlessly to a body part or limb of a wearer. Hereby, a tubular spacer fabric is obtained which most expediently conforms seamlessly to a body part or limb of a wearer. This has the advantage that the seamless tubular spacer fabric may be used directly as a wrap, a bandage, a support or may be used as liner under casting.

Owner:TYTEX AS

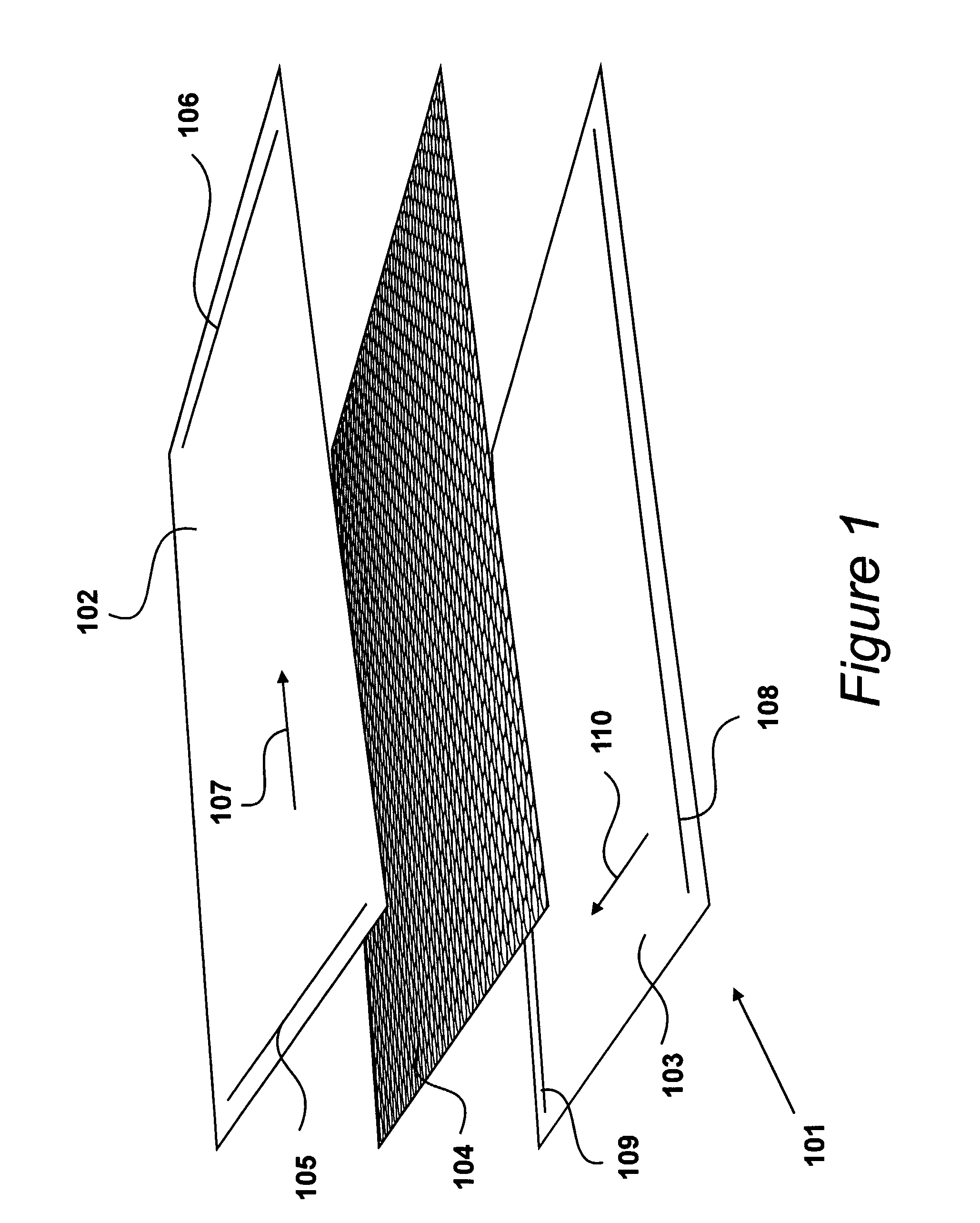

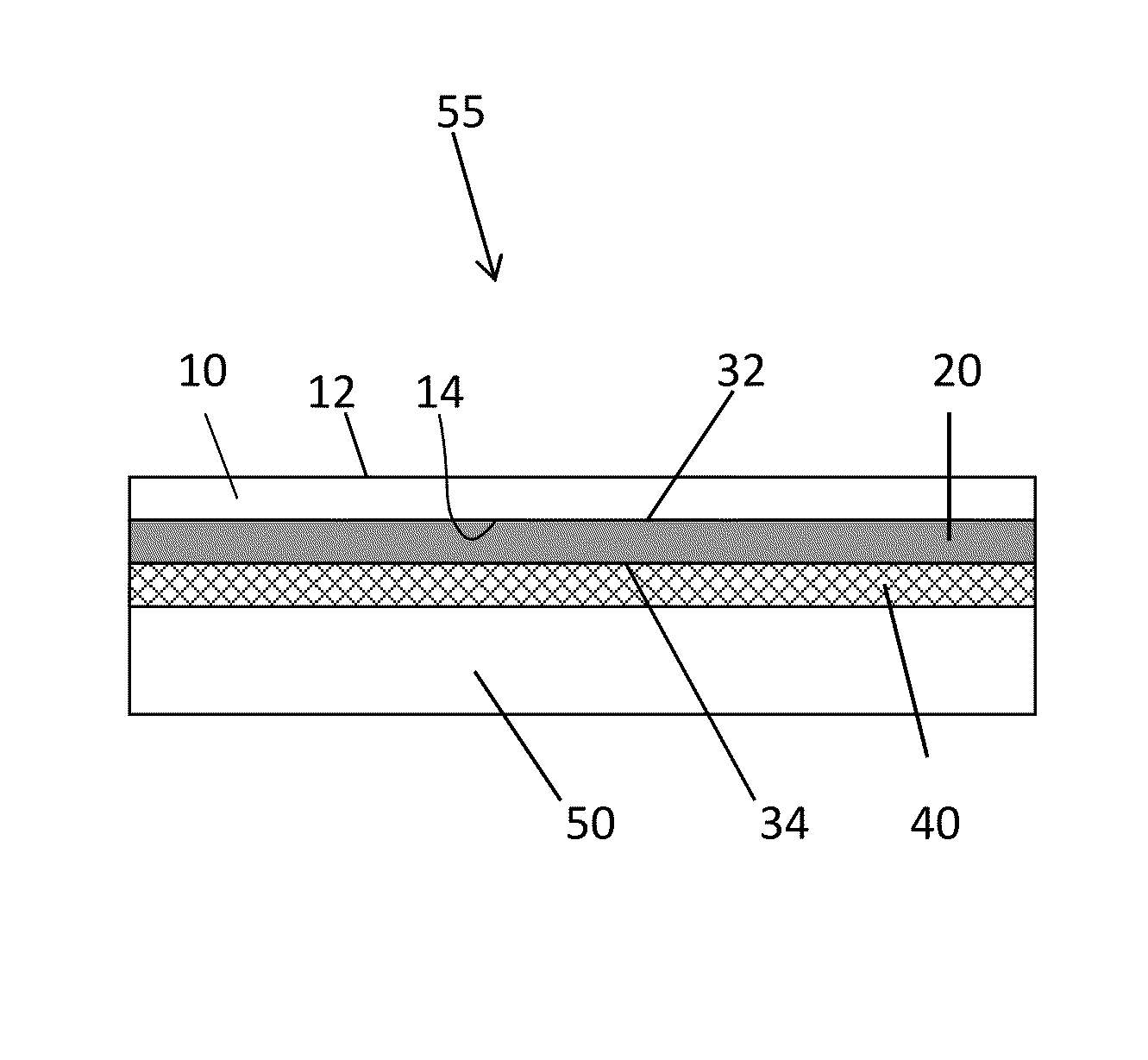

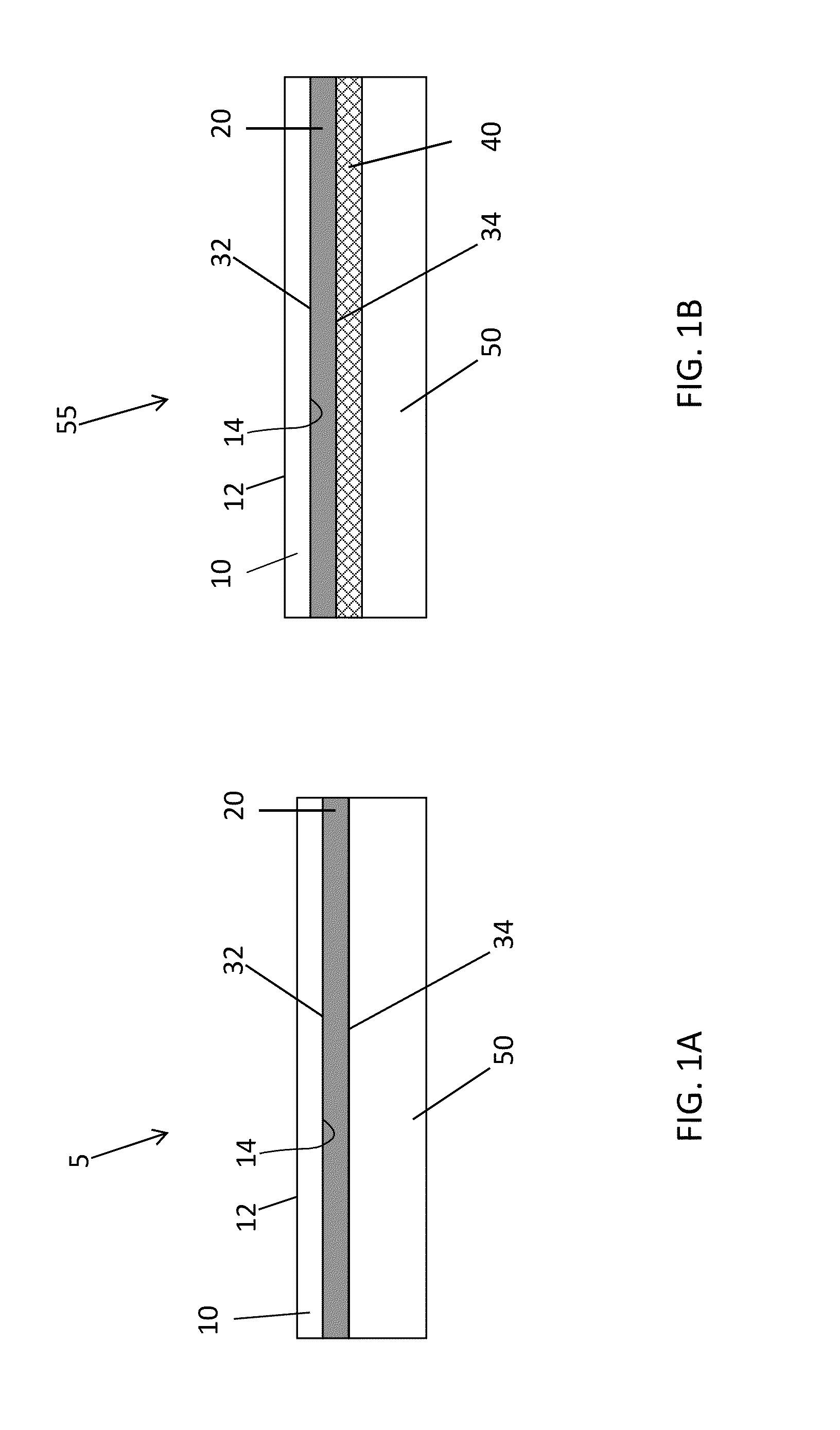

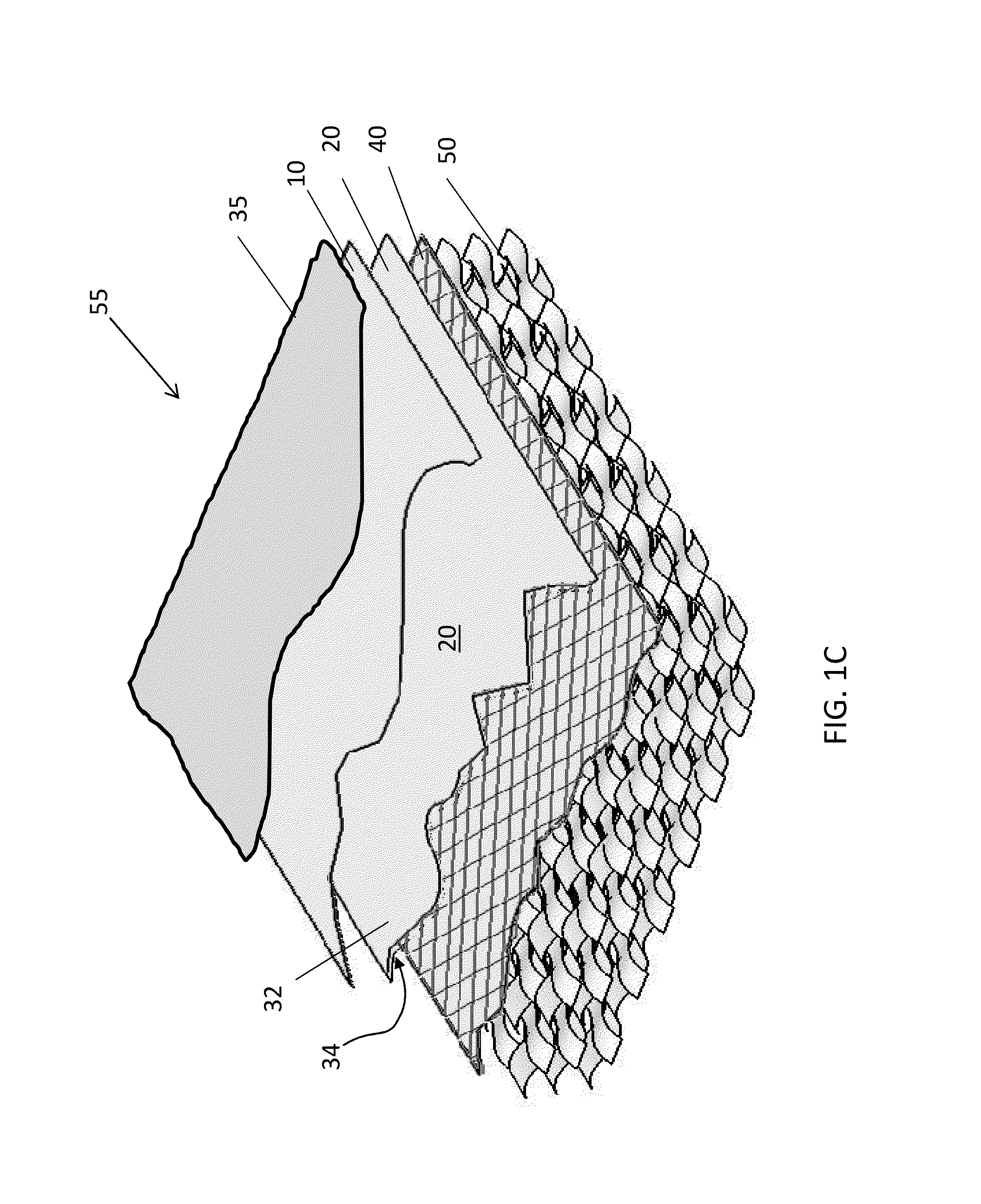

Nanoreinforced films and laminates for aerospace structures

ActiveUS20140011414A1Improved ultraviolet resistance and resistance to microcrackingMaterial nanotechnologyWarp knittingPolymer resinNanofiber

A composite laminate for use on an external part of an aerospace vehicle has improved ultraviolet resistance and resistance to microcracking from thermal cycling. The laminate comprises a nanoreinforcement film, a support veil, and a composite layer. The laminate also can have a lightning strike protection layer and an external paint and primer. The nanoreinforcement film can comprise carbon nanomaterial and a polymer resin, and the composite layer has one or more layers of a reinforcement and a polymer resin. The carbon nanomaterial can be carbon nanofibers, and the nanoreinforcement film can have an areal weight of less than about 100 g / m2. The carbon nanomaterial can also comprise carbon nanofibers and carbon nanotubes.

Owner:ROHR INC +1

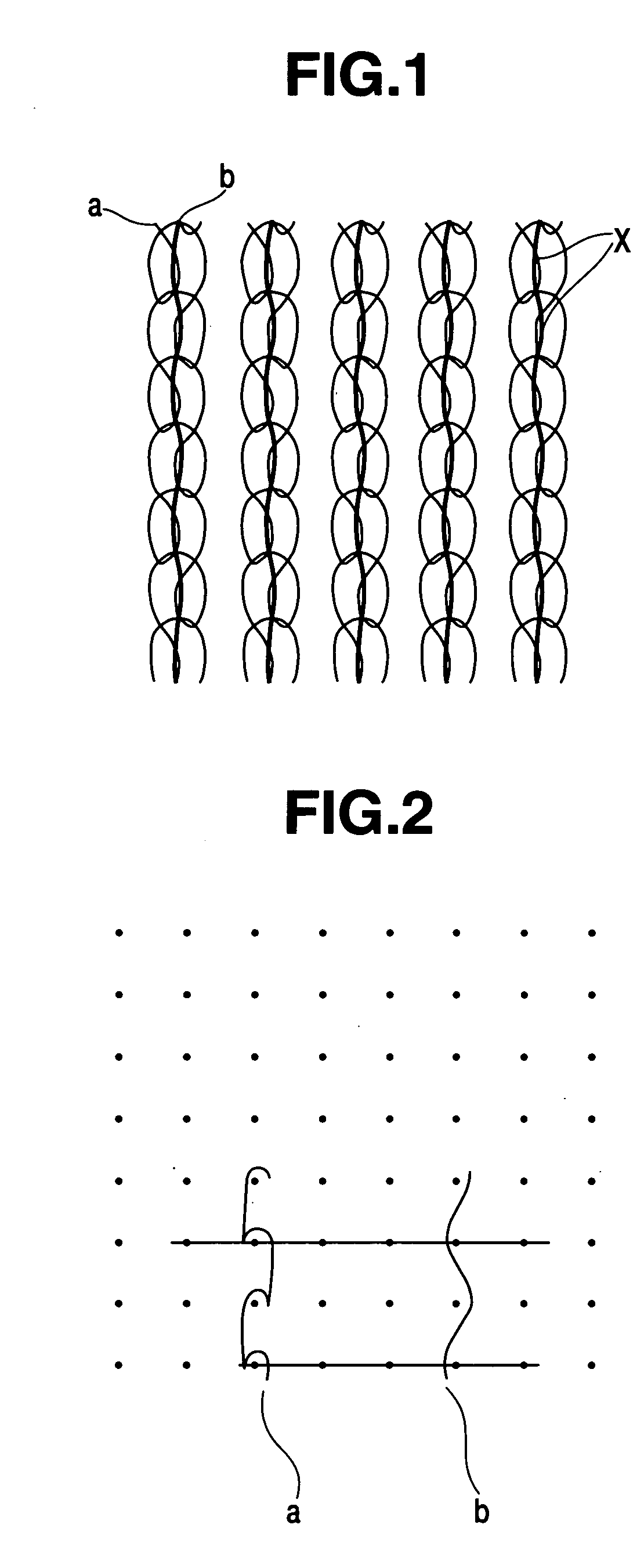

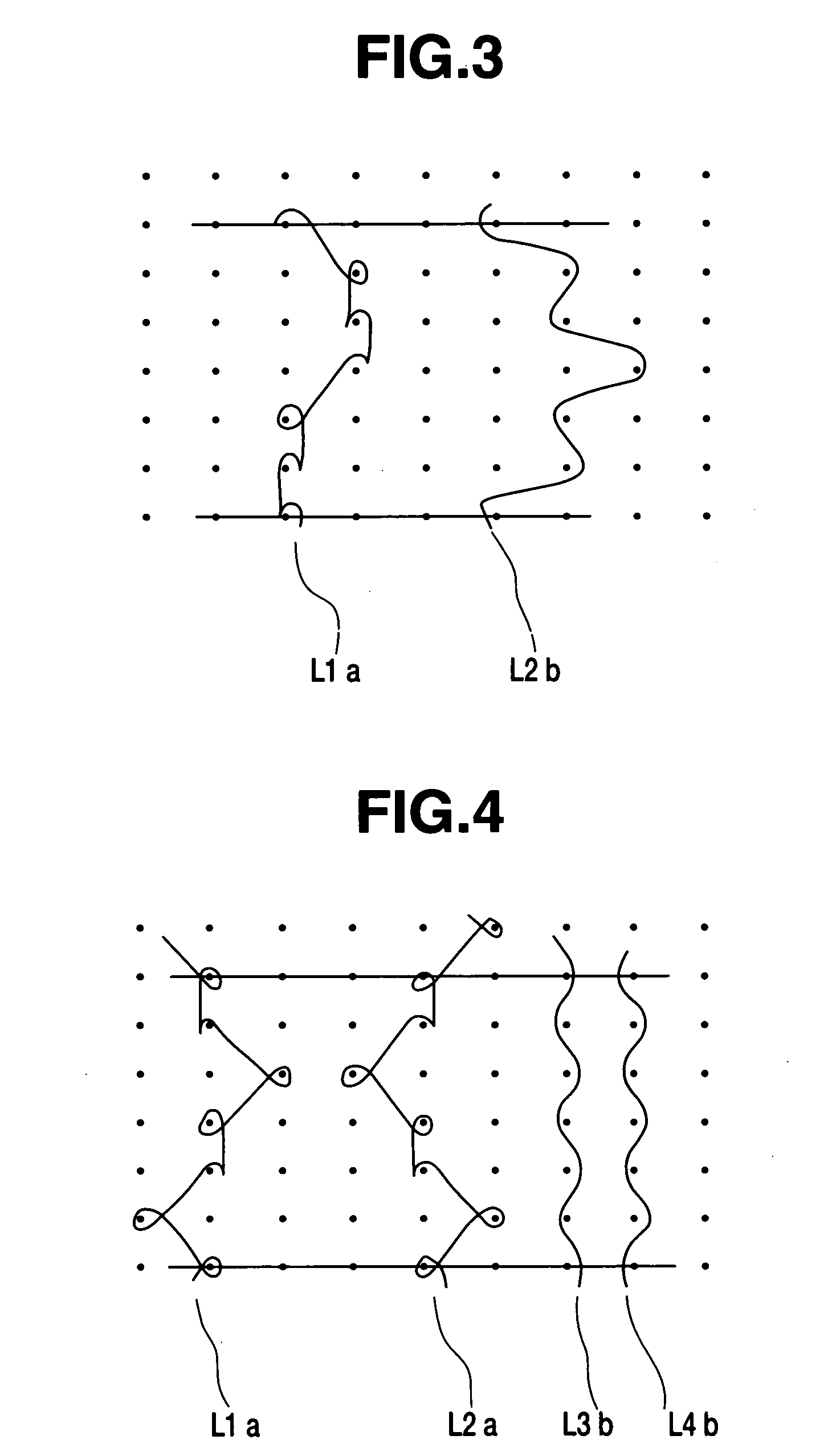

Detector constructed from electrically conducting fabric

InactiveUS7161084B2Ornamental textile articlesStraight-bar knitting machinesConductive yarnElectrically conductive

The present invention relates to a detector constructed from electrically conducting fabric and configured to present a varying electrical characteristic in response to a mechanical interaction. The detector comprises a first conducting layer (401) which is displaced from a second conducting layer (402) such that conduction between the layers results when the layers are mechanically forced together. In addition, the first of the layers has a plurality of lengths of conductive yarn and a plurality of lengths of non-conductive yarn machined therein, such that at least one length of conductive yarn is electrically isolated from another of the lengths of conductive yarn and the conducting yarns in the first of the layers are electrically grouped to define a plurality of identifiable rows. Each identifiable row has a respective electrical conductor; and define specific regions of the detector.

Owner:WEARABLE TECH LTD

Blended woven or knitted fabrics containing polyerethane elastic fibers and process for the production thereof

A blended woven or knitted fabric which contains both highly fusible polyurethane elastic fibers exhibiting a retention of tenacity of 50% or above after the dry heat treatment at 150° C. for 45 s at 100% elongation and a melting point of 180° C. or below and at least one kind of non-elastic yarns and which is produced by fusing the polyurethane elasotomeric fibers to each other or the polyurethane elastic fibers to the non-elastic yarns at the crossover points by dry- or wet-heat setting; and a process for the production thereof.

Owner:NISSHINBO IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com