Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1666results about "Stretching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

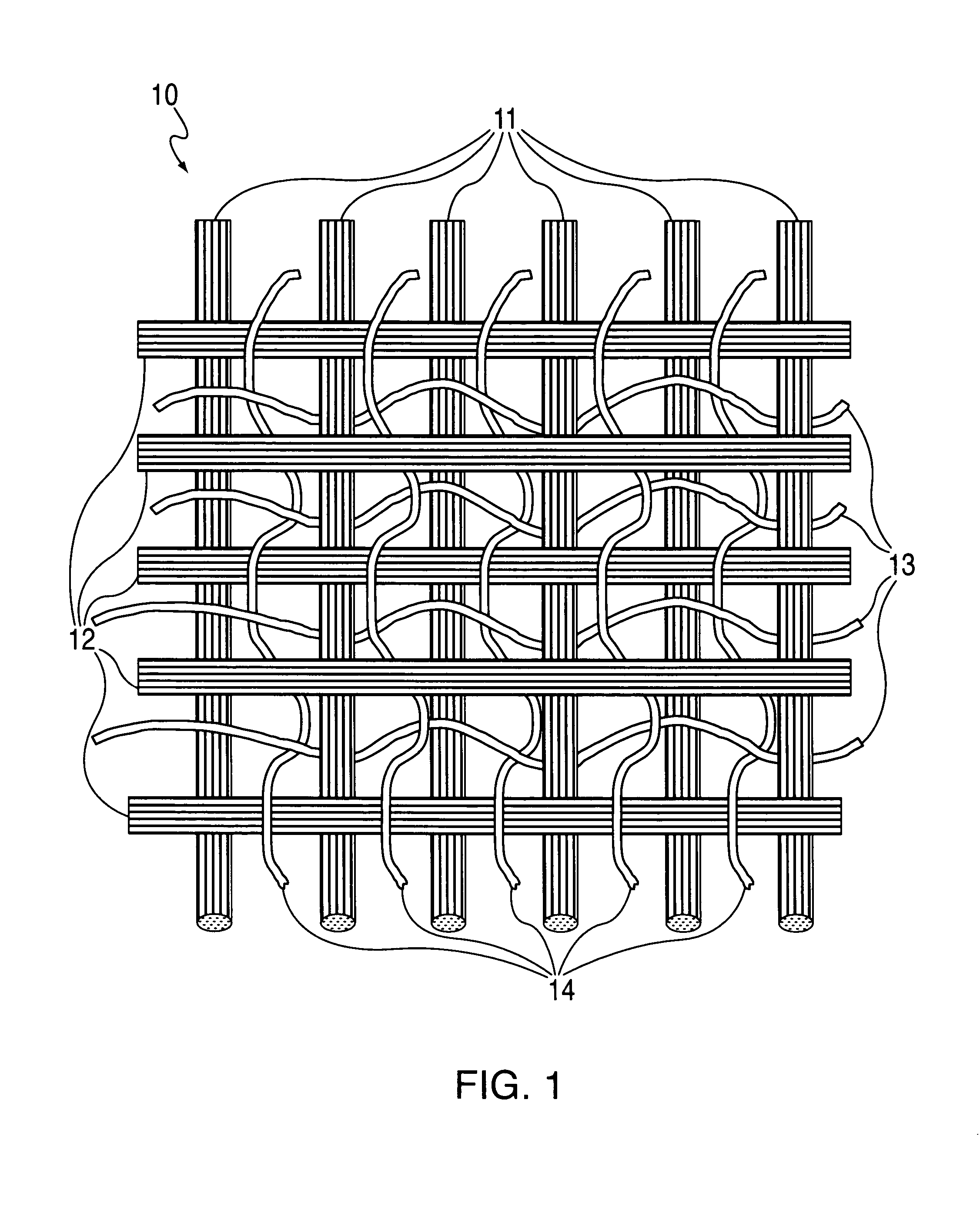

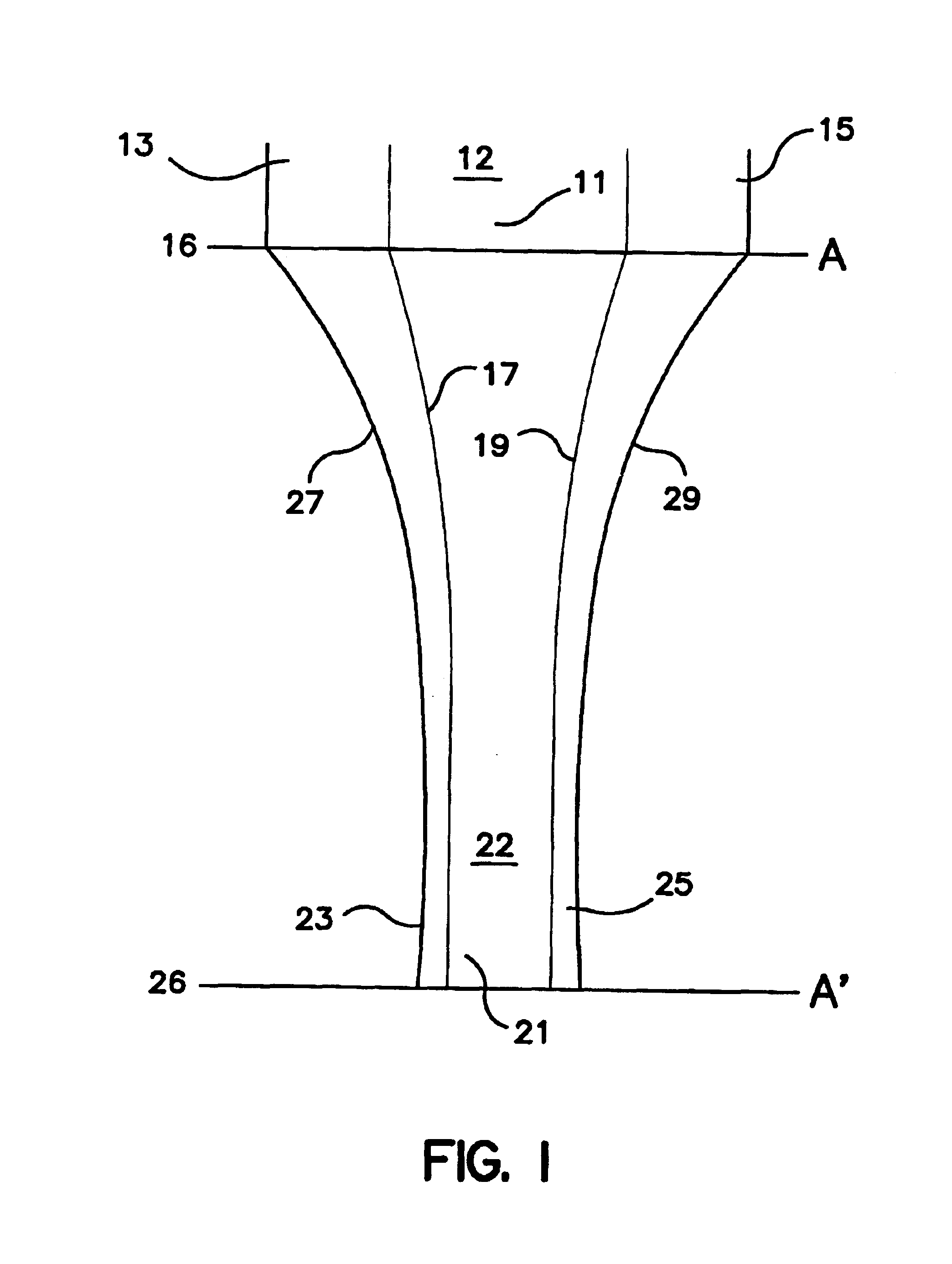

Bi-directional and multi-axial fabrics and fabric composites

InactiveUS6841492B2Increase resistanceImprove effectivenessOrnamental textile articlesProtective fabricsYarnEngineering

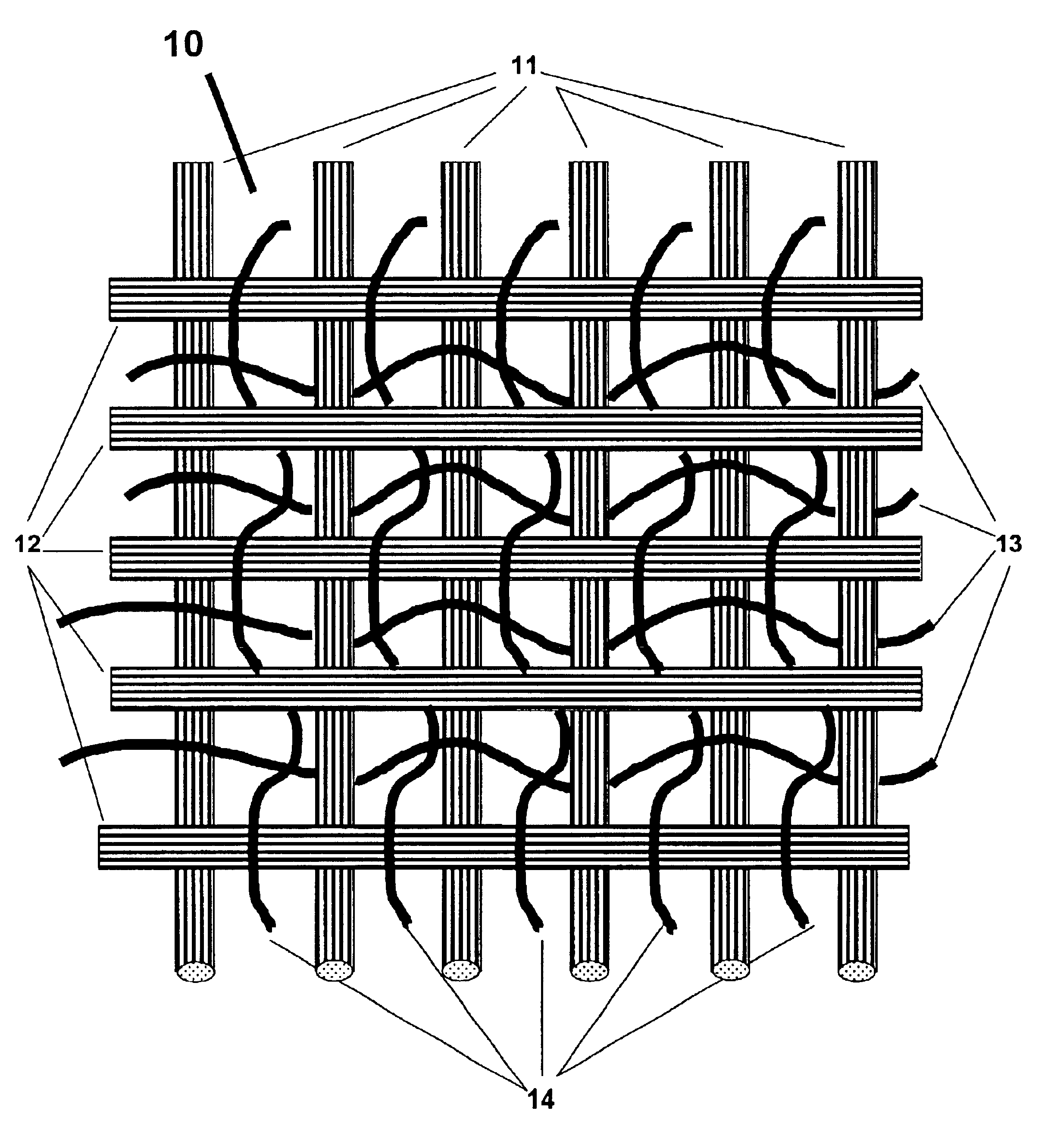

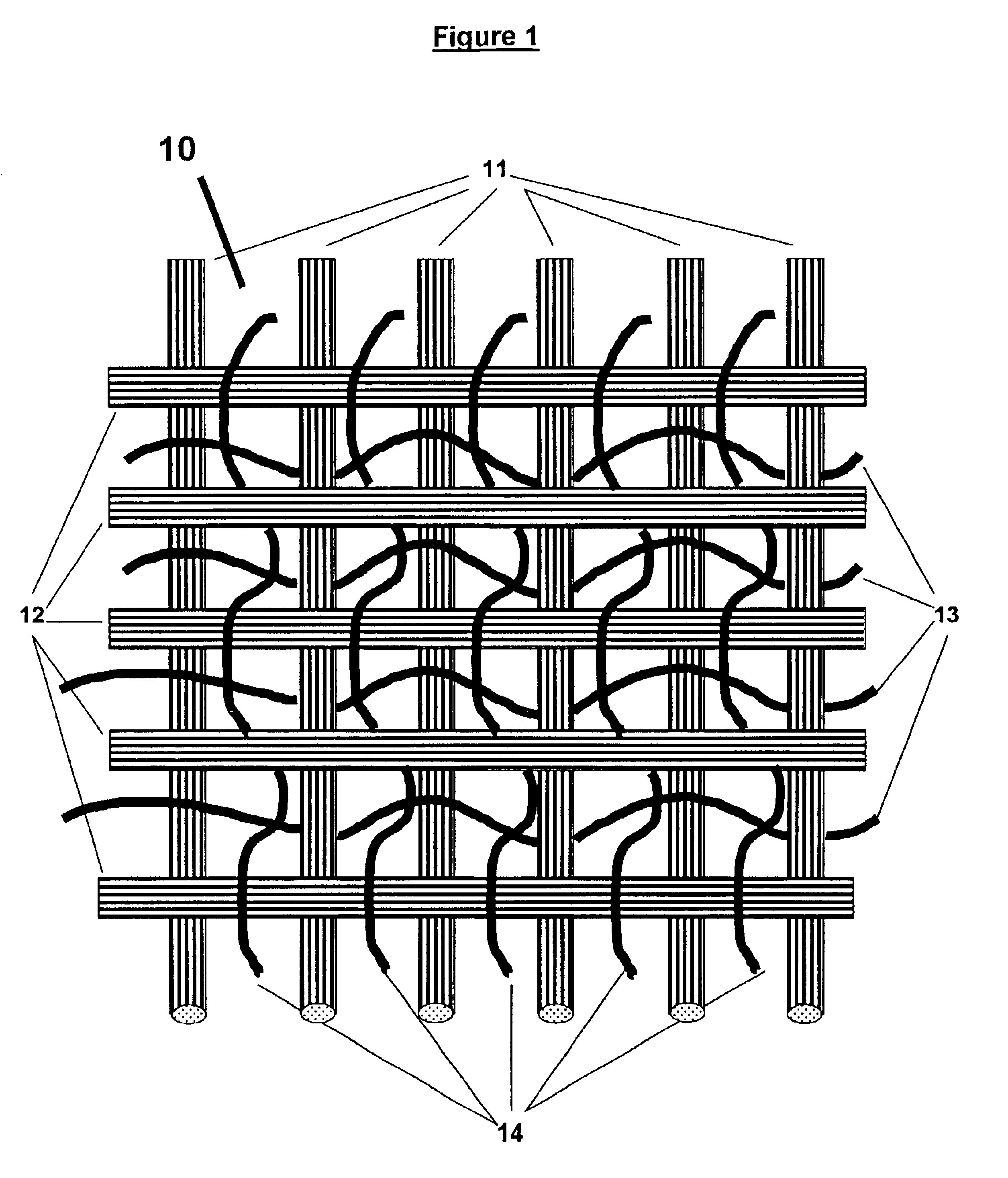

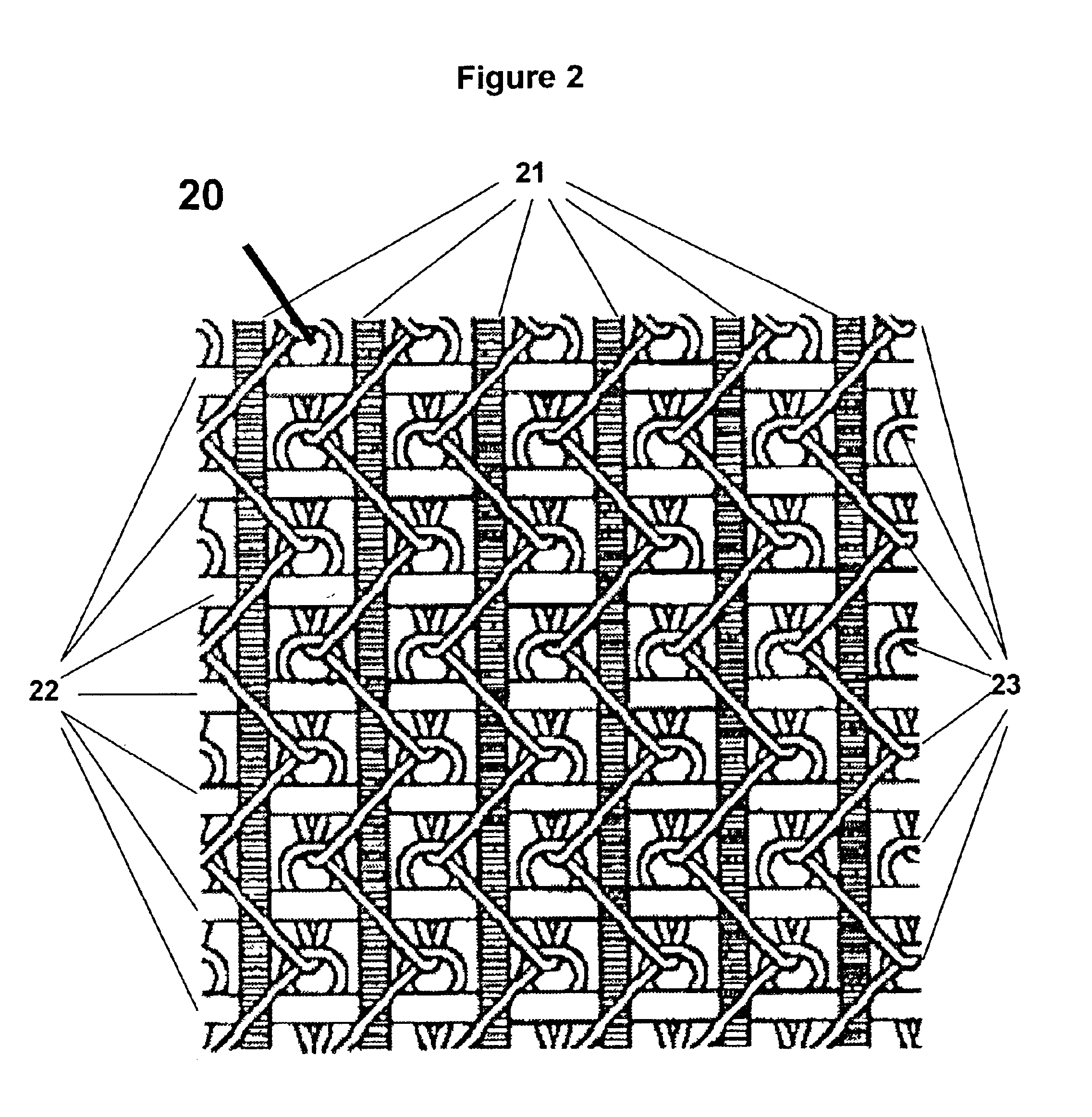

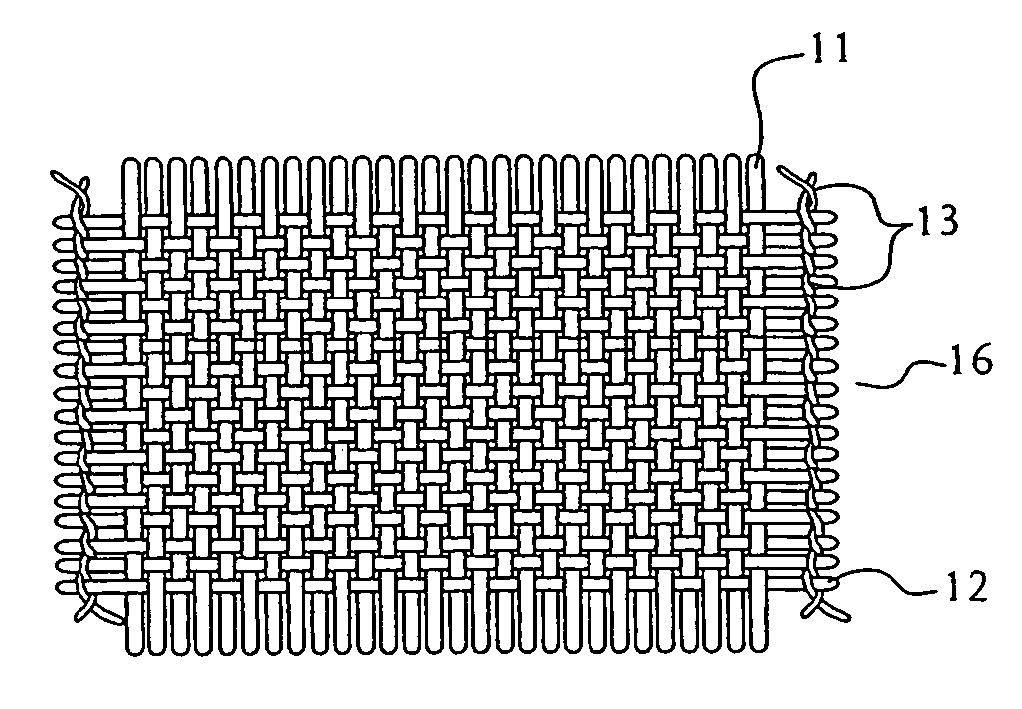

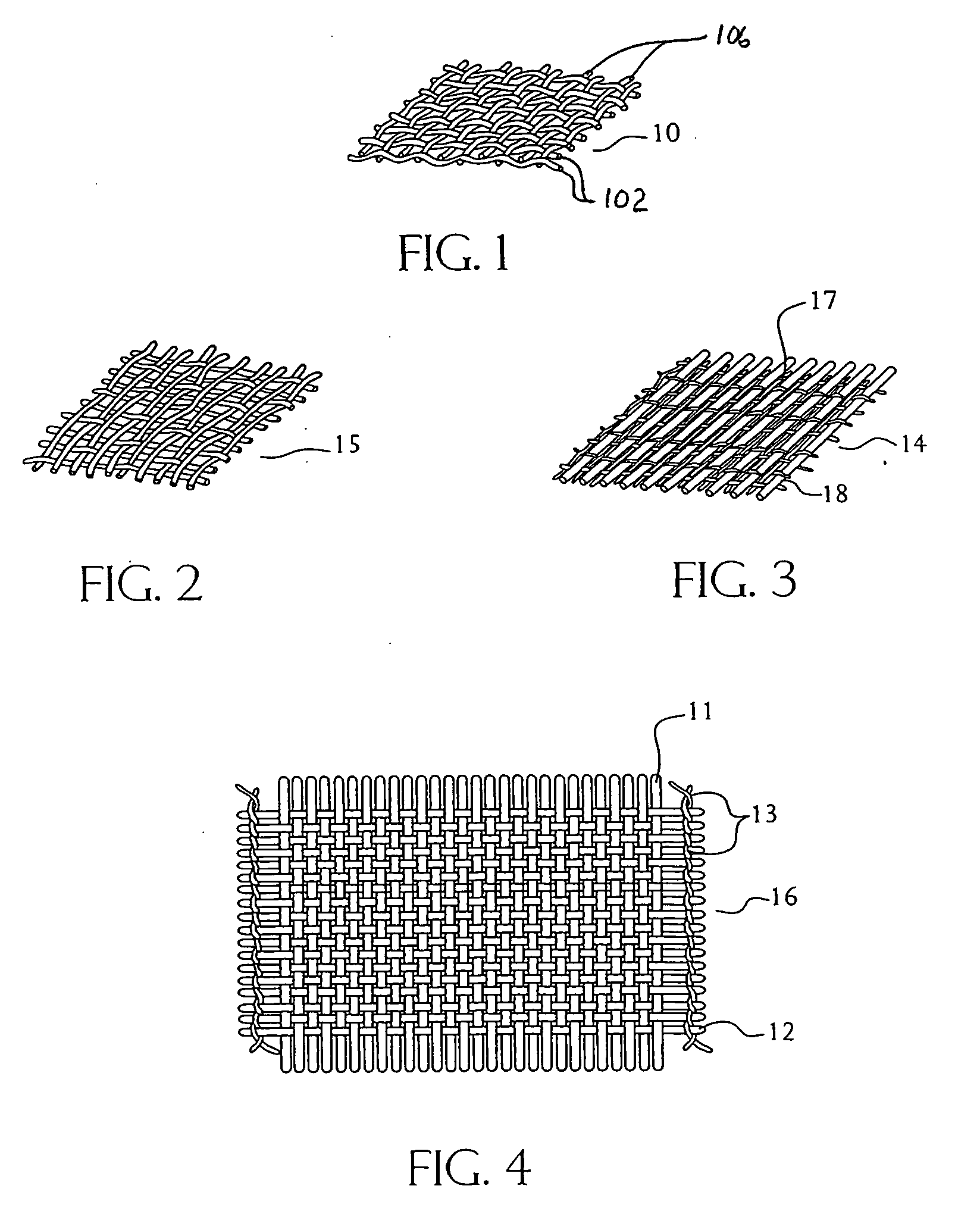

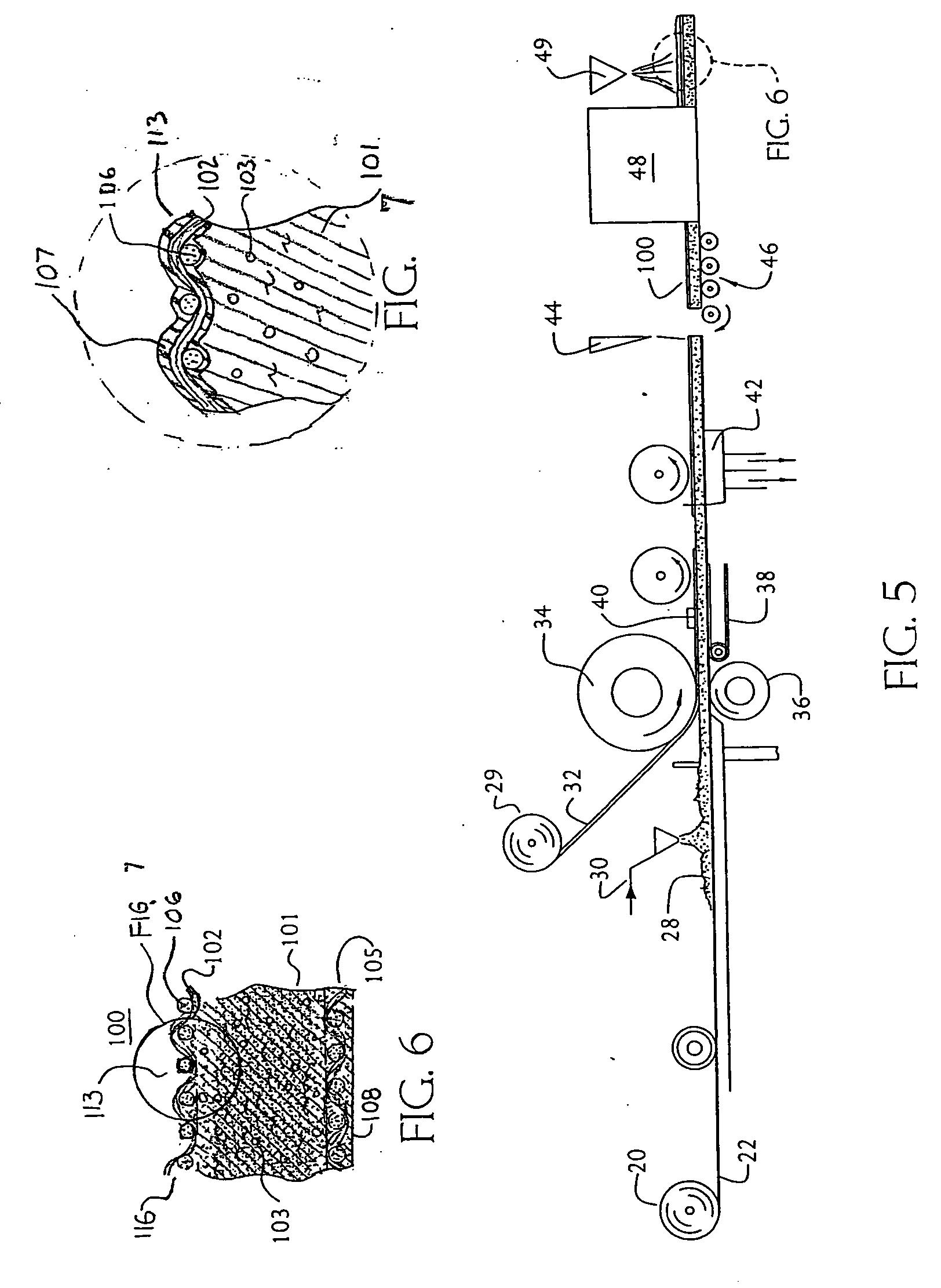

Bi-directional and multi-axial fabrics, fabric composites, ballistically resistant assemblies thereof, and the methods by which they are made. The fabrics are comprised of sets of strong, substantially parallel, unidirectional yarns lying in parallel planes, one above the other, with the direction of the yarns in a given plane rotated at an angle to the direction of the yarns in adjacent planes; and one or more sets of yarns having lower strength and higher elongation interleaved with the strong yarns. The fabrics of the invention provide superior ballistic effectiveness compared to ordinary woven and knitted fabrics but retain the ease of manufacture on conventional looms and knitting machines.

Owner:HONEYWELL INT INC

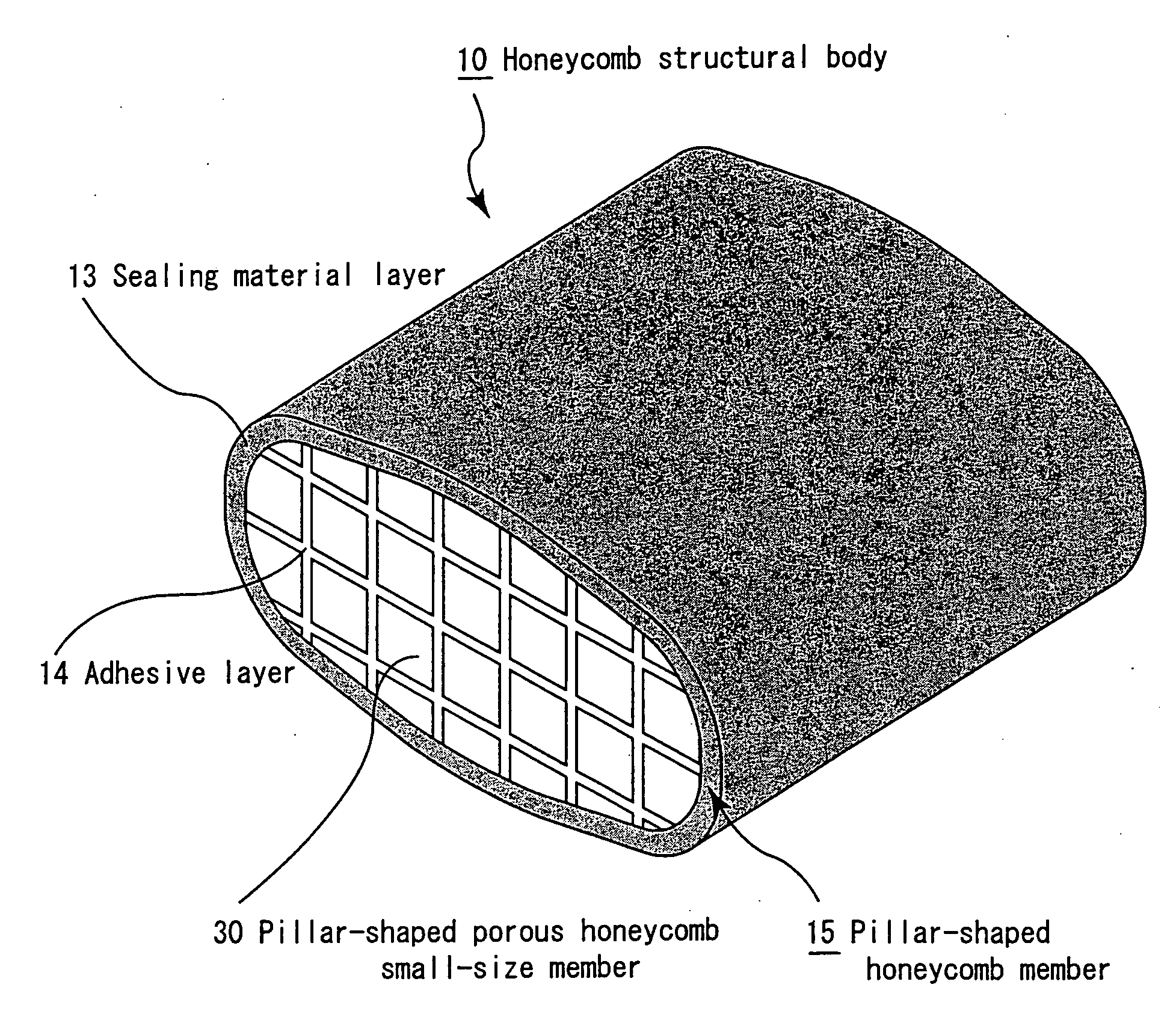

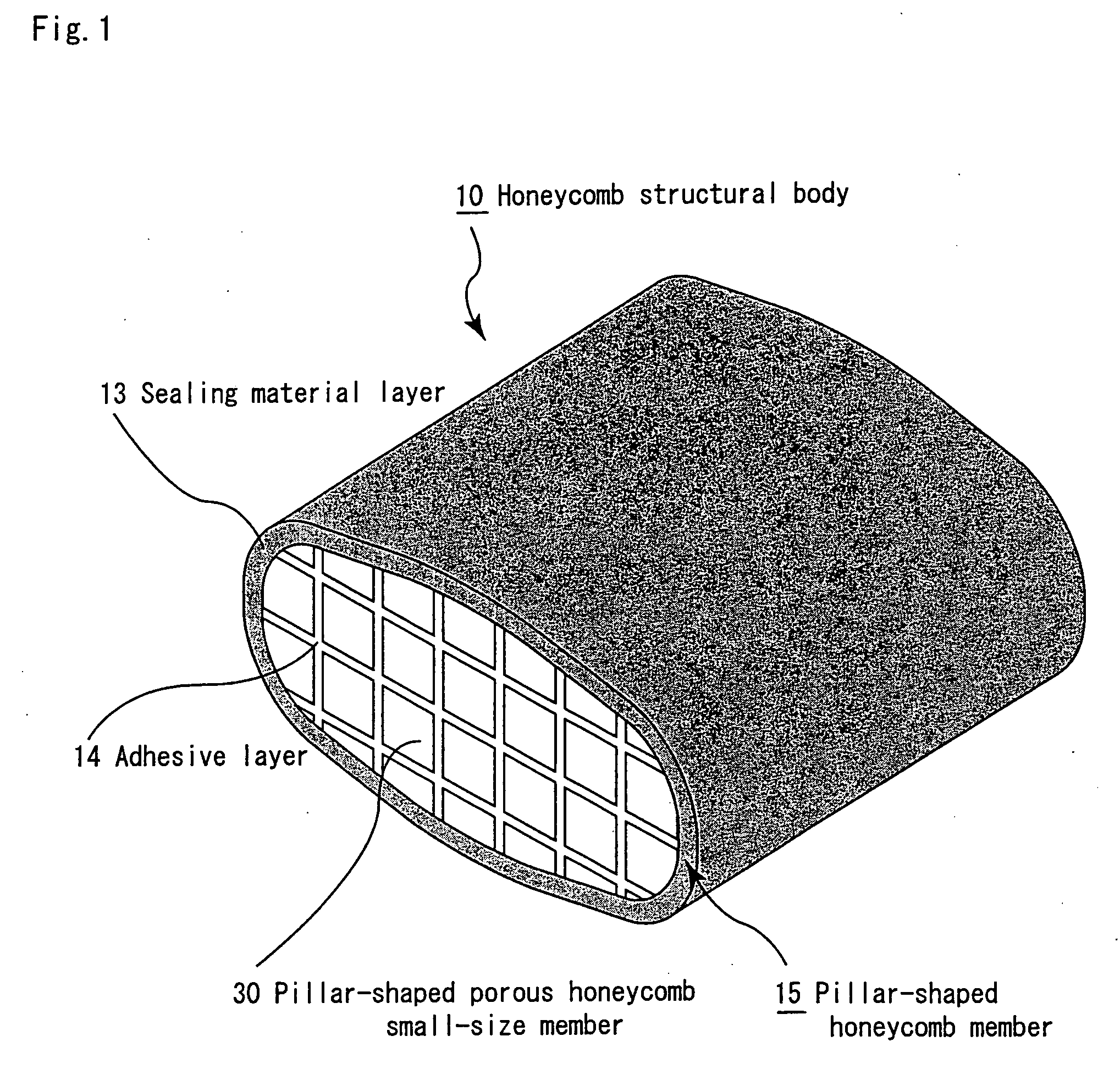

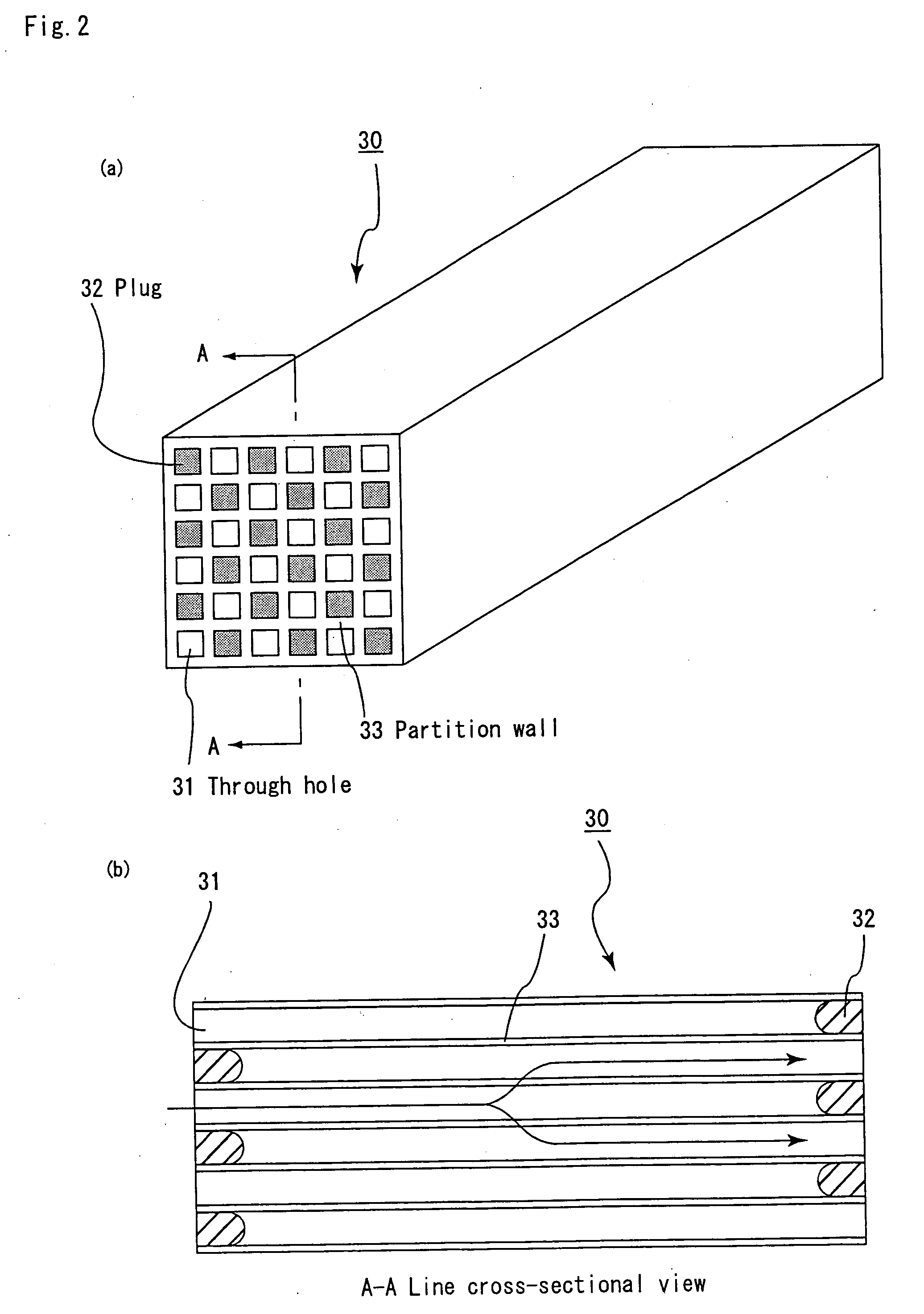

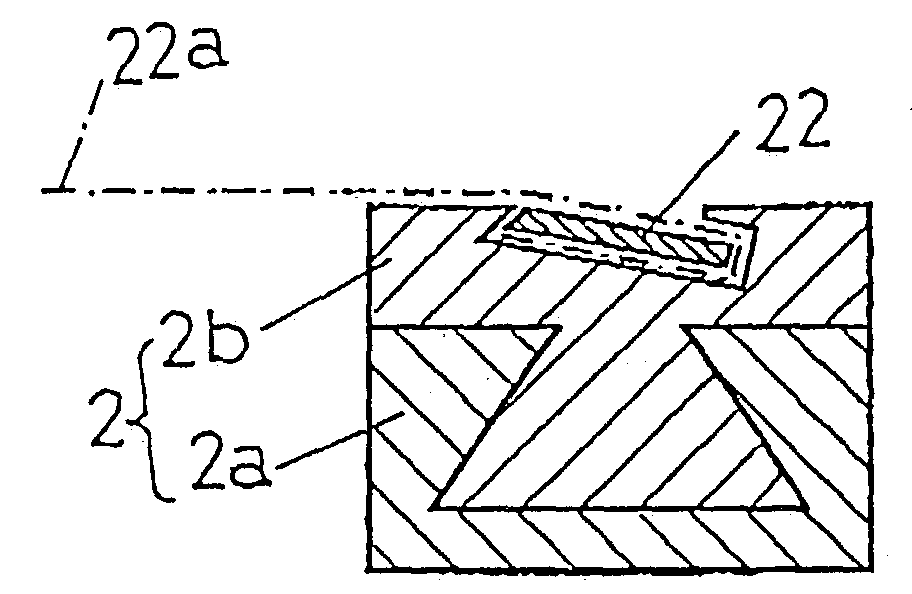

Manufacturing method of honeycomb structural body, and sealing material

ActiveUS20070126160A1Improve assembly effectAvoid separationExhaust apparatusConfectioneryHoneycomb structureRaw material

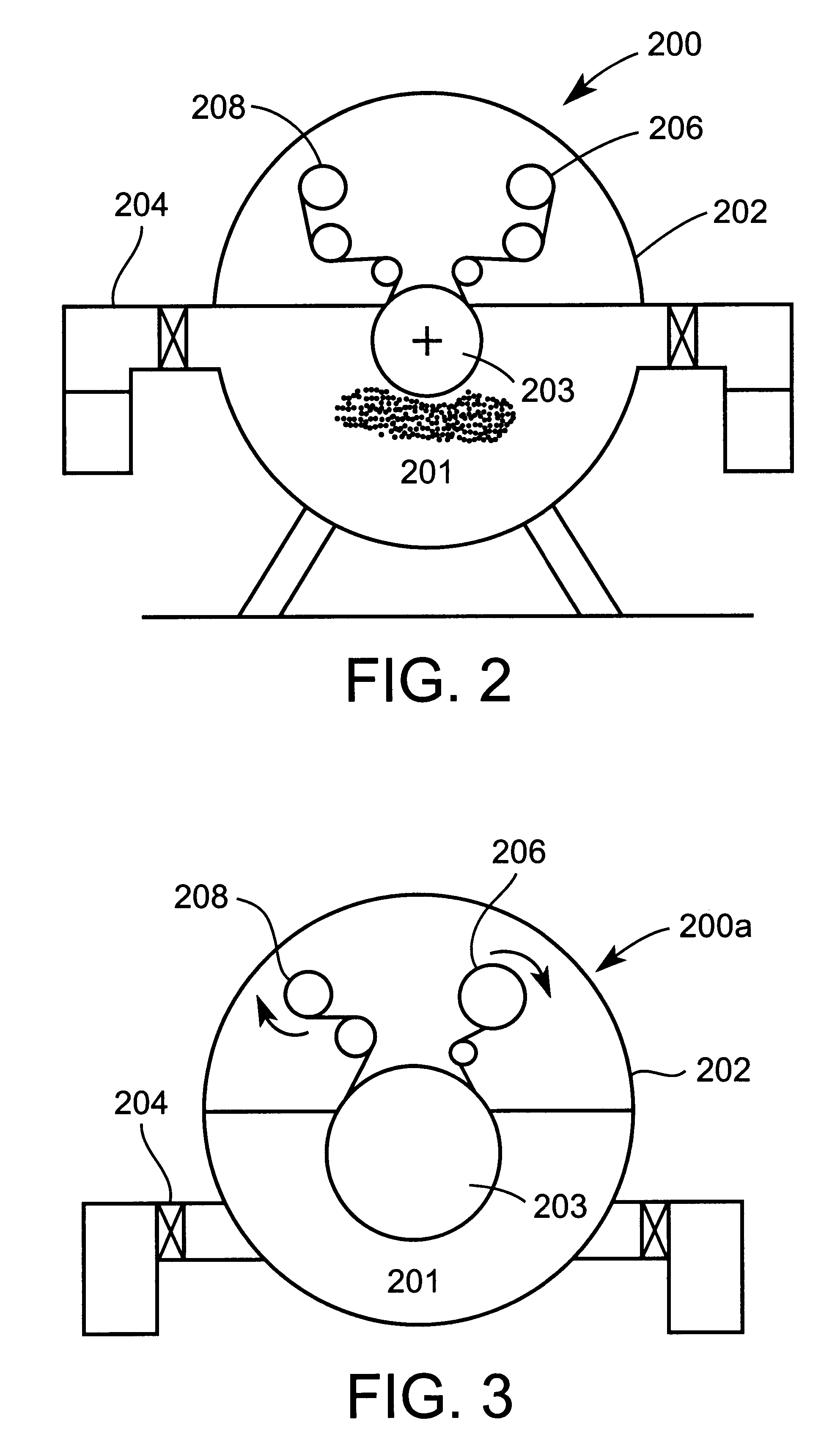

An object of the present invention is to provide a manufacturing method of a honeycomb structural body which makes the profile of a cross section perpendicular to the length direction thereof less likely to generate dispersion, and also makes the thickness of its sealing material layer thinner, and a sealing material that is suitably used in the manufacturing method of the honeycomb structural body. According to the present invention, the manufacturing method of a honeycomb structural body with a sealing material layer formed on the peripheral portion of a pillar-shaped porous honeycomb member includes a sealing material applying step of applying a paste-like sealing material, which is a raw material of the sealing material layer, onto a circumferential face of the pillar-shaped porous honeycomb member, and a scraping step of fitting a ring-shaped scraper, which can be brought into contact with the circumferential face of the pillar-shaped porous honeycomb member so as to slide thereon, to the pillar-shaped porous honeycomb member and moving said ring-shaped scraper in the length direction, thereby expanding the paste-like sealing material applied onto the circumferential face of the pillar-shaped porous honeycomb member so as to spread over the entire circumferential face of the pillar-shaped porous honeycomb member.

Owner:IBIDEN CO LTD

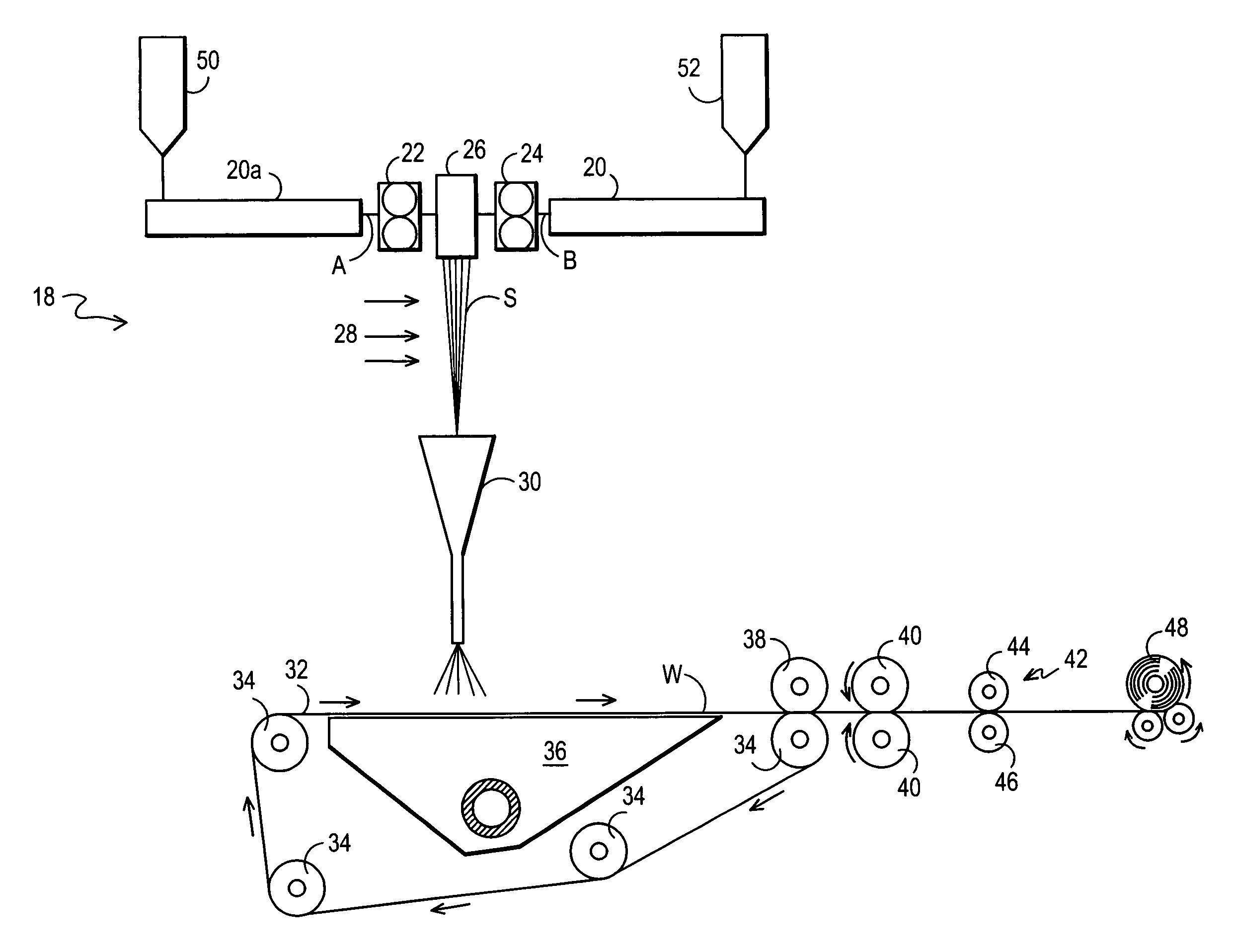

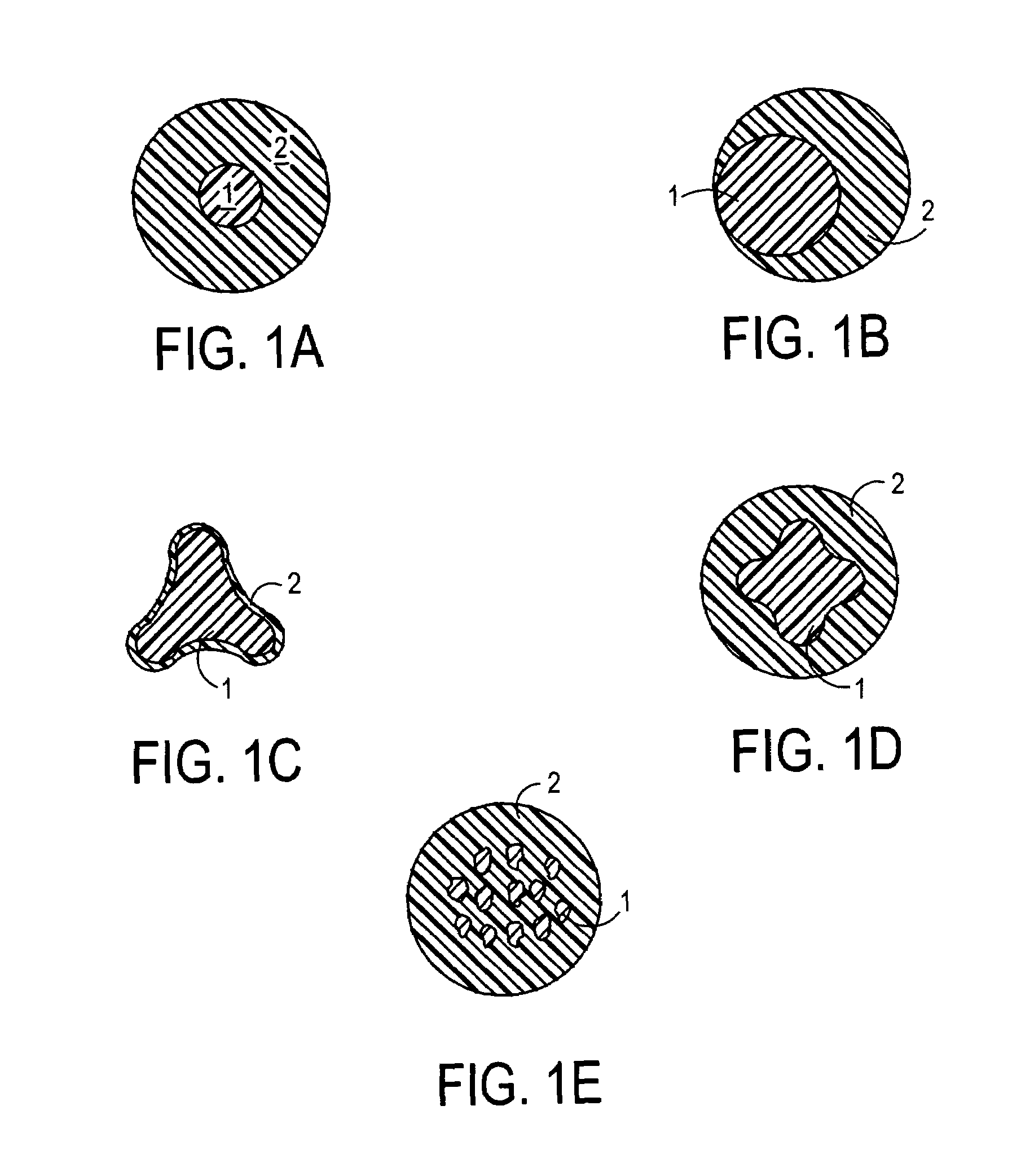

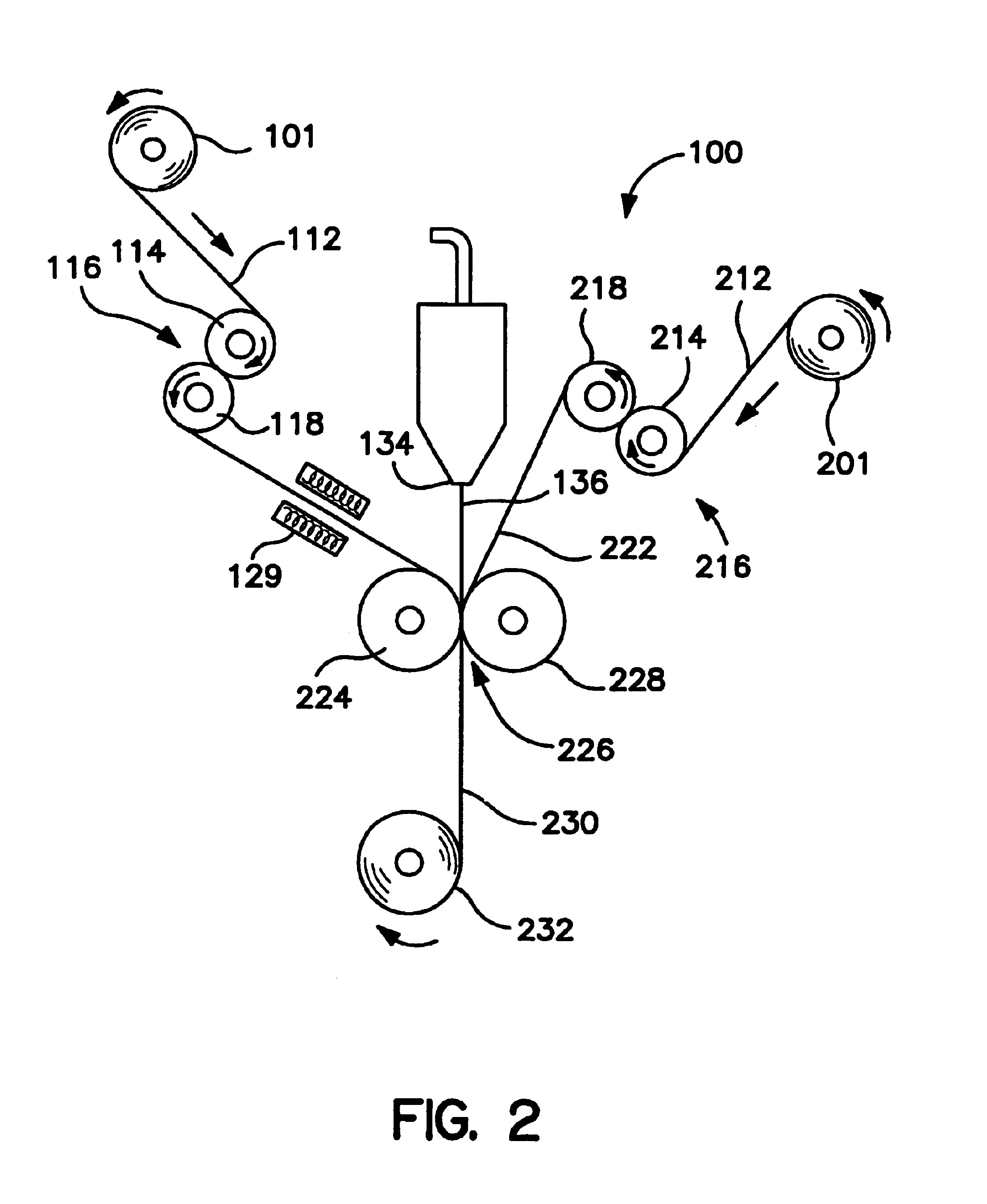

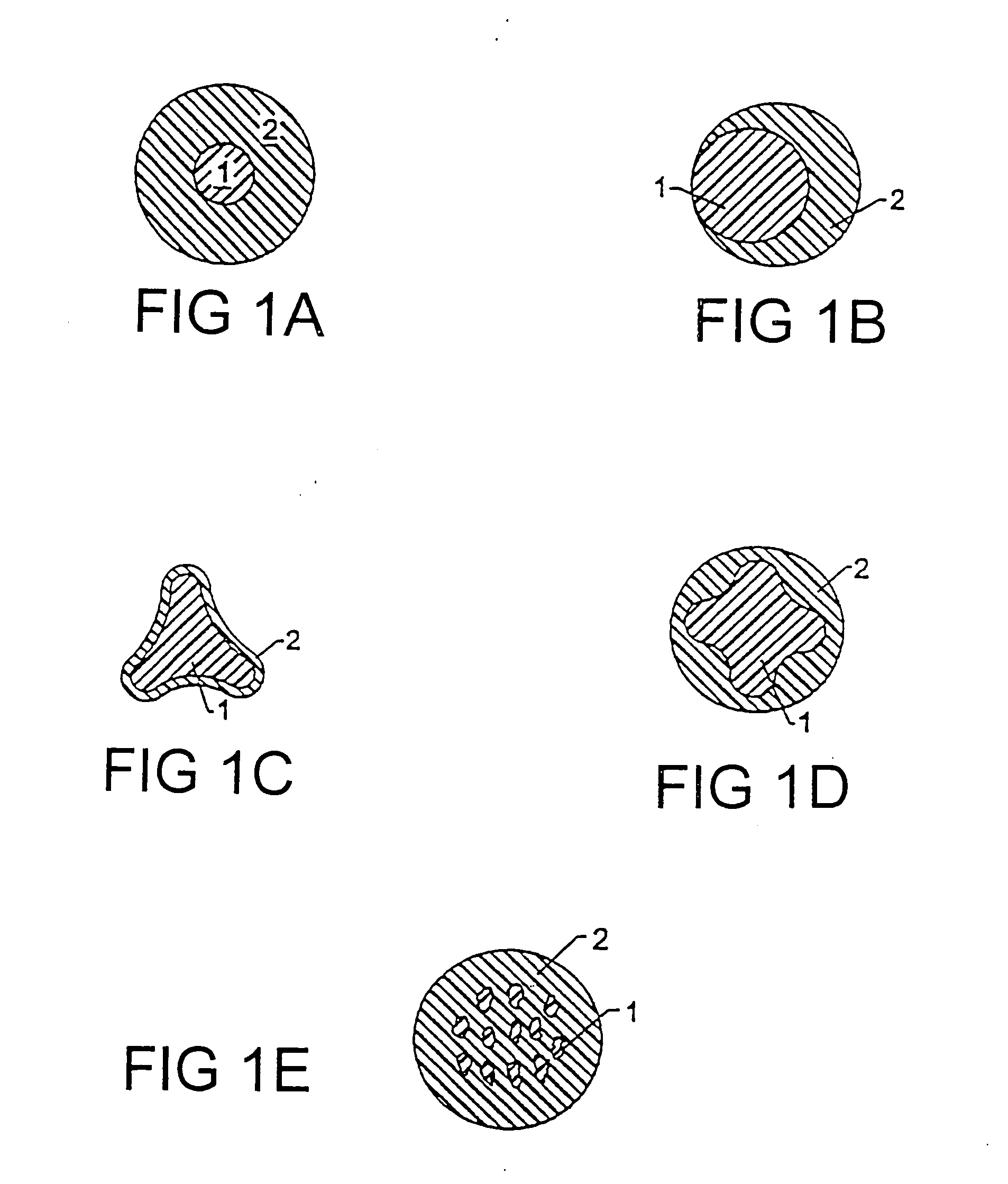

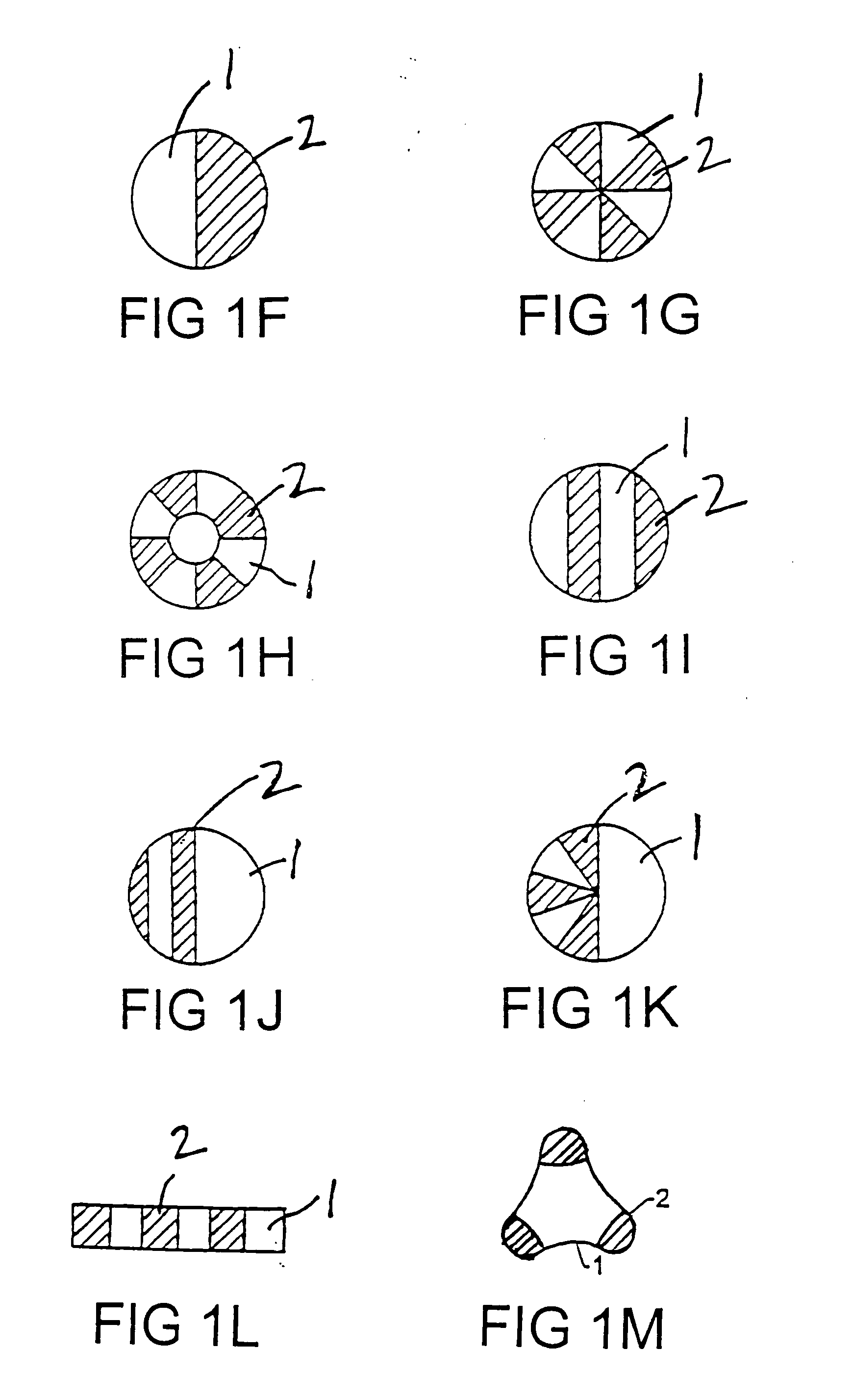

Elastomeric multicomponent fibers, nonwoven webs and nonwoven fabrics

A bonded web of multi-component strands that include a first polymeric component and a second polymeric component is capable of overcoming a number of problems associated with nonwoven webs including both stickiness and blocking. The first polymeric component and second polymeric component are arranged in substantially distinct zones extending longitudinally along at least a portion of a length of the strands which make up the web with the second component containing a zone constituting at least a portion of the peripheral surface of the strand. The first polymeric component also has an elasticity which is greater than that of the second polymer component. A process producing elastomeric spunbonded nonwoven fabrics which utilizes the activation by incremental stretching of the strands is also provided.

Owner:BBA NONWOVENS SIMPSONVILLE

Method of producing low cost elastic web

InactiveUS20060063454A1Improve mechanical propertiesSynthetic resin layered productsAbsorbent padsEngineering

Owner:TREDEGAR FILM PROD CORP

Liquid crystalline polymer film, laminate sheet for optical element using same, and optical element using the laminate

InactiveUS6051289AImprove productivityContinuous productionLiquid crystal compositionsFilm/foil adhesivesProduction rateLiquid crystalline

To provide a film for optical element made of liquid crystal polymer whose productivity and economical efficiency are improved; a laminated sheet formed by bonding this film to a polarizing plate; and an optical element which can be optically inspected, and used under an environment of high temperature and high moisutre, and whose surface hardness is so high that the surface is not easily damaged. A long laminated sheet for optical element comprising a liquid crystal polymer layer, and a polarizing film layer; and a long laminated sheet for optical element comprising at least a liquid crystal polymer film layer oriented in the direction oblique to the MD direction at a given angle, and a polarizing film layer. An optical element having a laminated structure formed by laminating a layer of a cured acrylic resin having optical isotropy, an orientated liquid crystal polymer layer, a layer of pressure-sensitive adhesive, and a translucent base layer in that order, and a long laminated sheet for optical element having a laminated structure formed by laminating a layer of a cured acrylic resin having optical isotropy; an oriented liquid crystal polymer layer; a layer of pressure-sensitive adhesive; and a translucent base layer in that order, and a containing liquid crystal polymers orientated in the MD direction at an arbitrary angle.

Owner:NIPPON PETROCHEMICAL CO LTD

Display panels

InactiveUS7191555B2Improve transportation effectEasy to displayDoor/window protective devicesCurtain rodsEngineering

Owner:IFD LLC

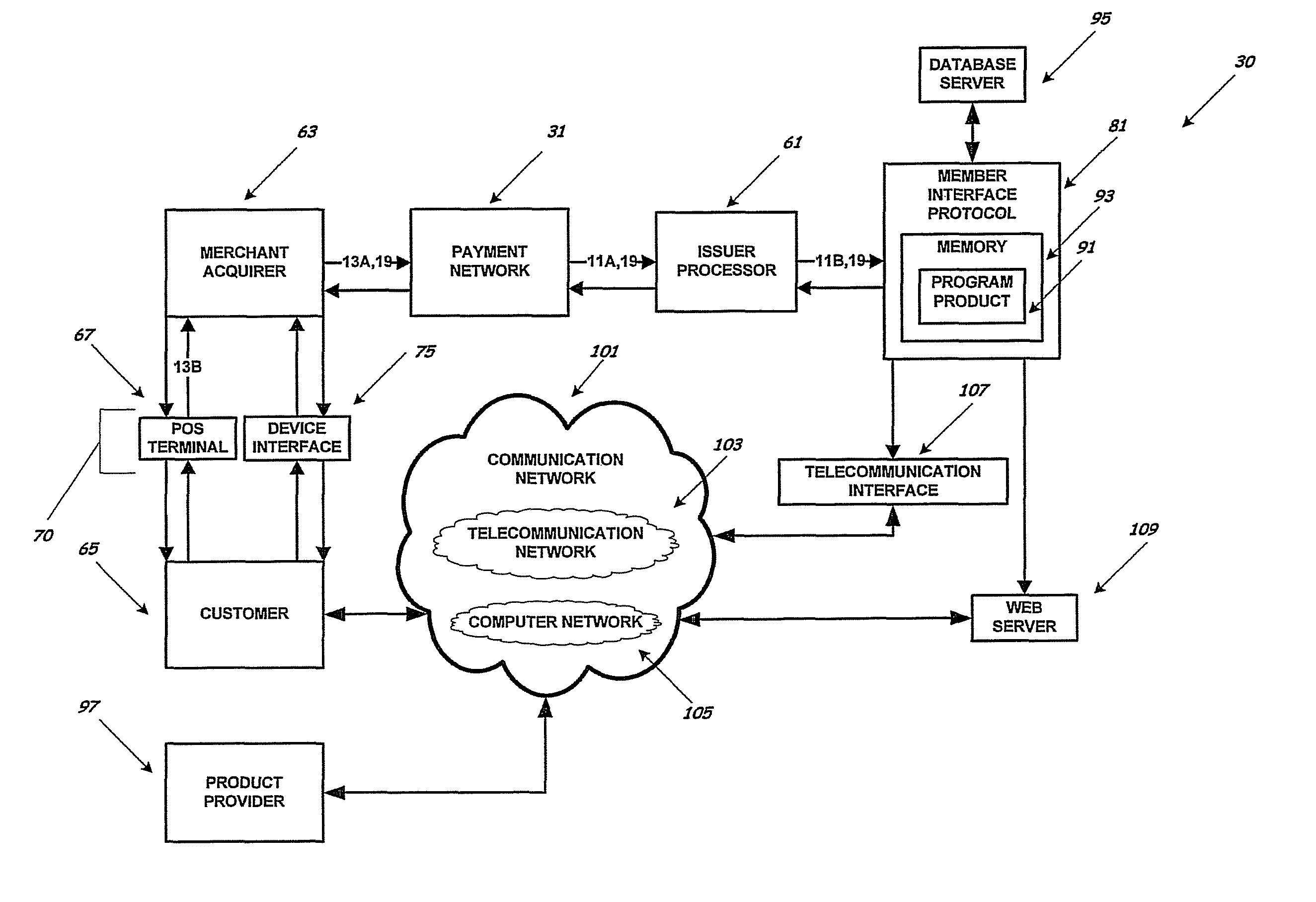

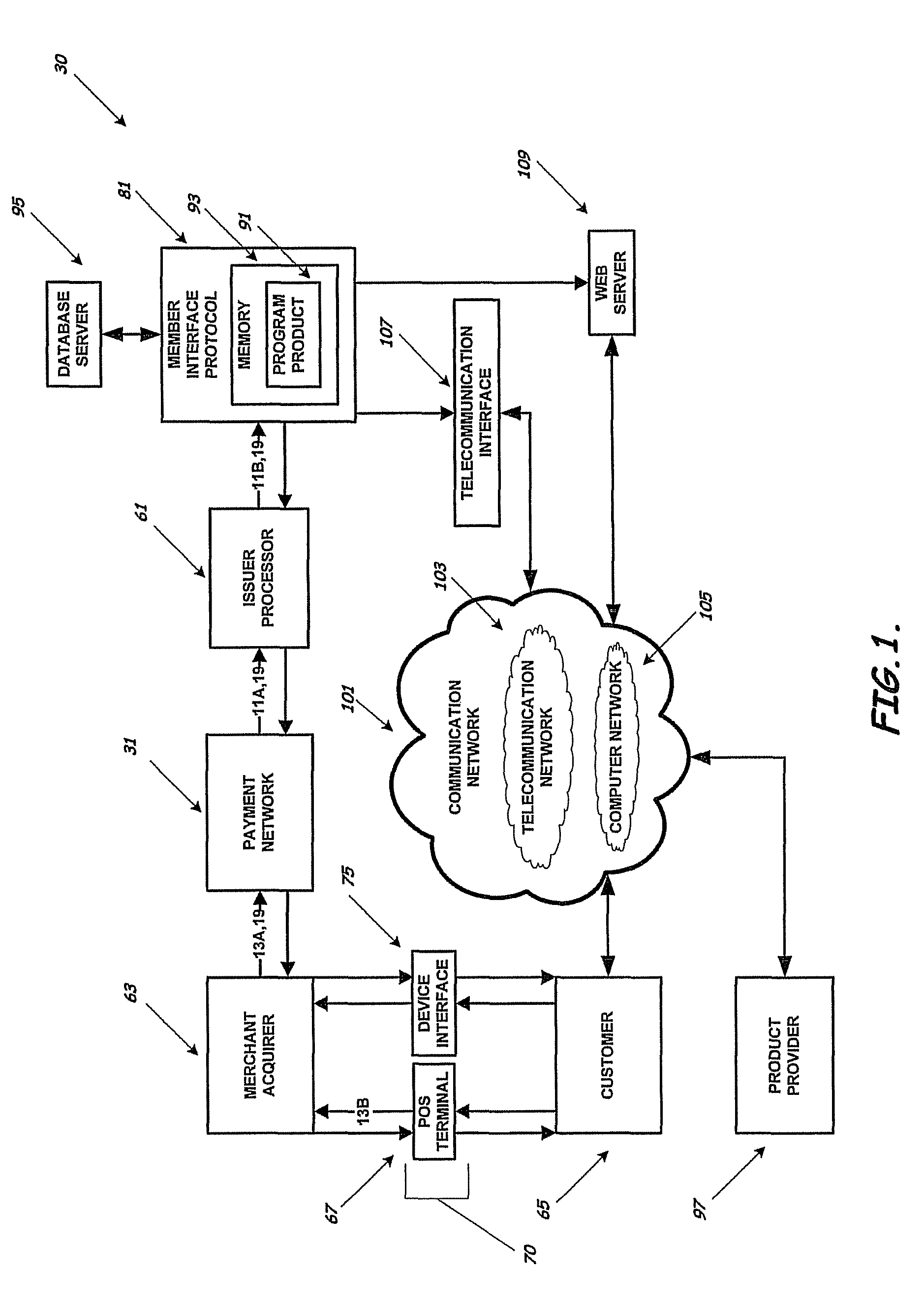

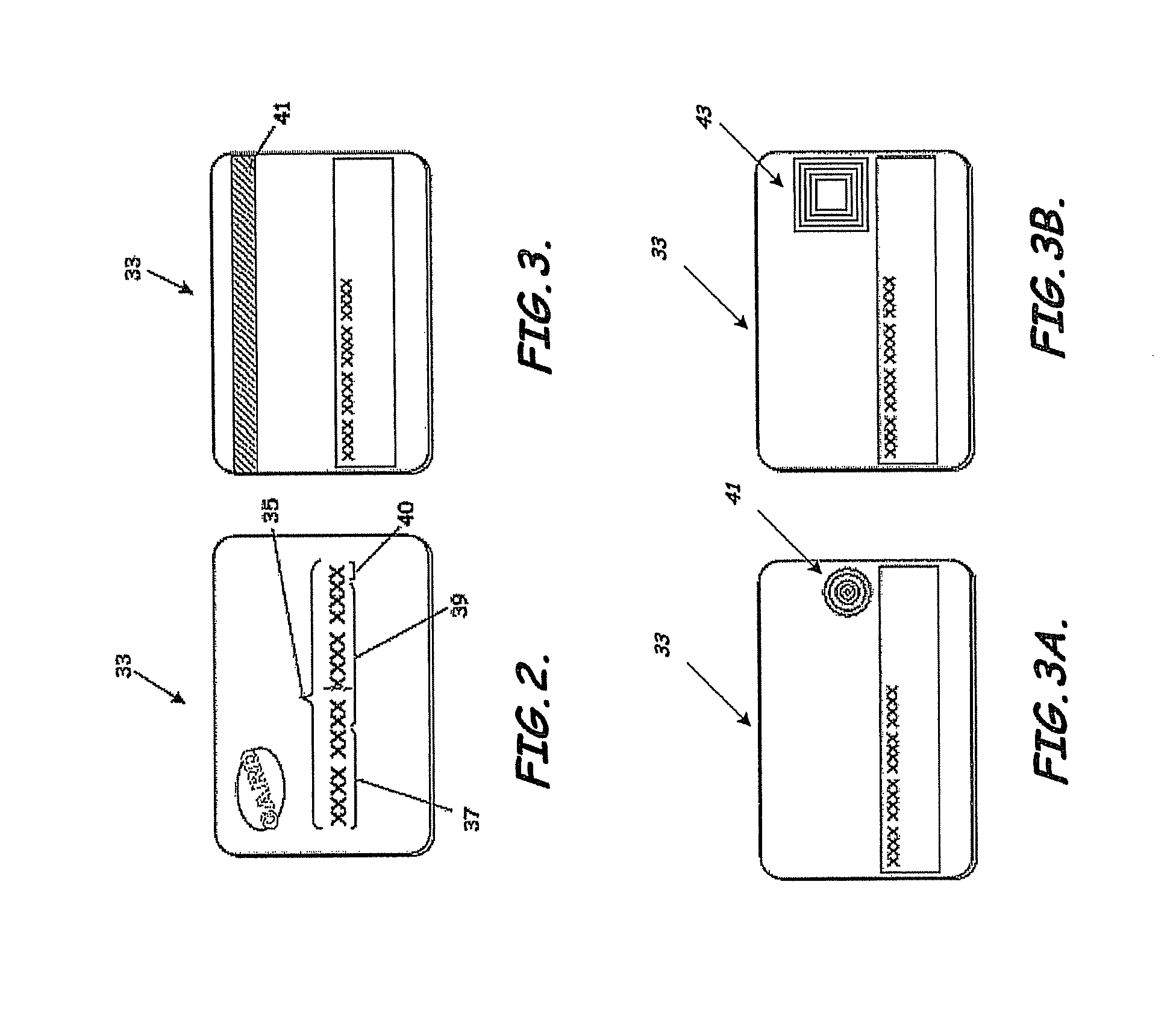

Machine, methods, and program product for electronic order entry

Systems, methods, and program product for facilitating electronic ordering of goods, services, or goods and services, or other products, through messaging over a financial services electronic payment network, are provided. A customer provides electronic order registration activation information for an electronic order transaction card. The customer is provided an electronic order card having a unique electronic payment network compatible electronic order card identifier including a non-financial transaction IIN and a customer number, and is provided a catalogue or list including product order codes each associated with a different product, to enable electronic ordering over the financial services electronic payment network. An electronic order card configured to interface with a conventional point-of-sale terminal can be used to facilitate the electronic ordering over the existing financial services electronic payment network when presented to the point-of-sale terminal with a product order code identifying a selected product.

Owner:PATHWARD NAT ASSOC

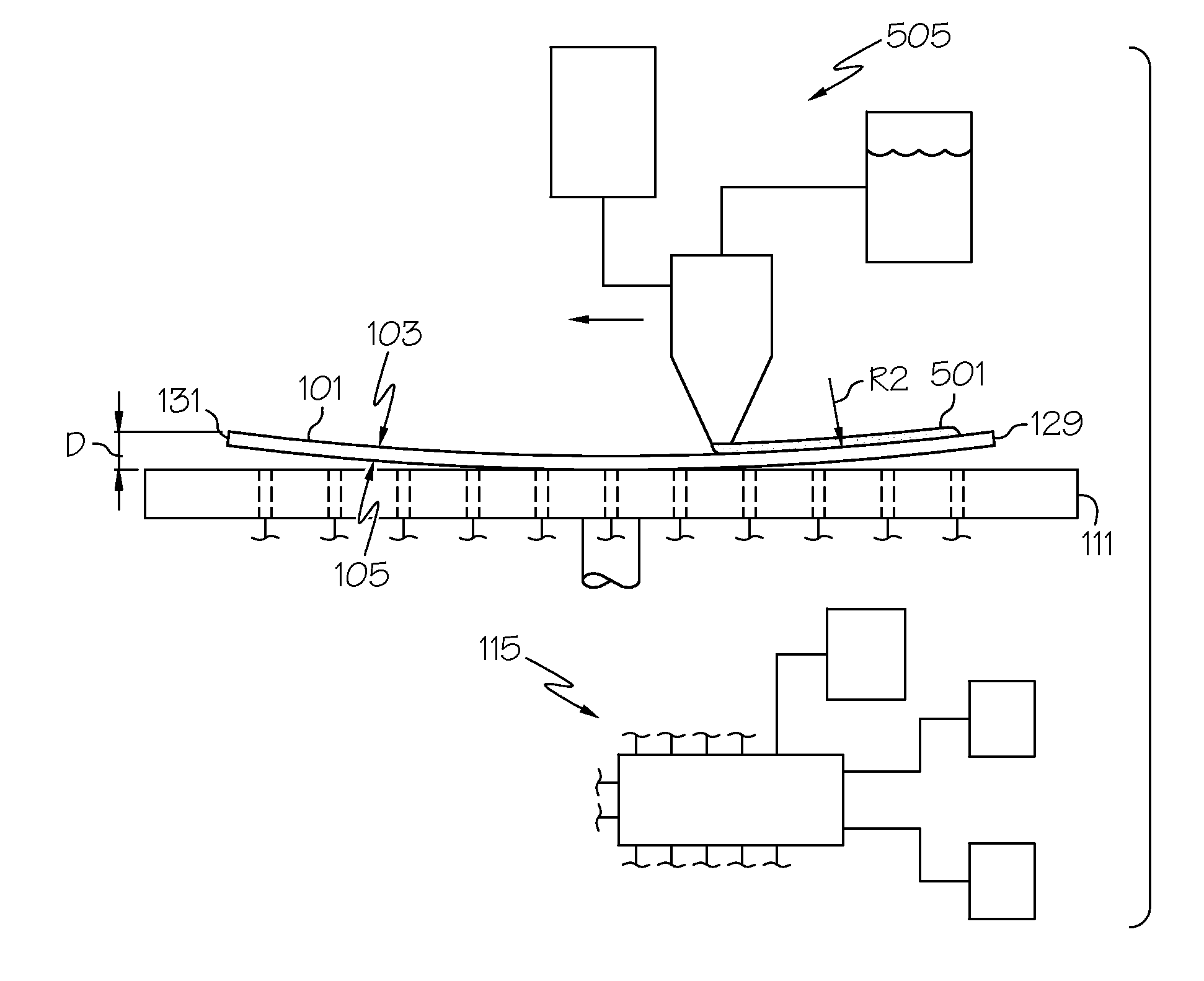

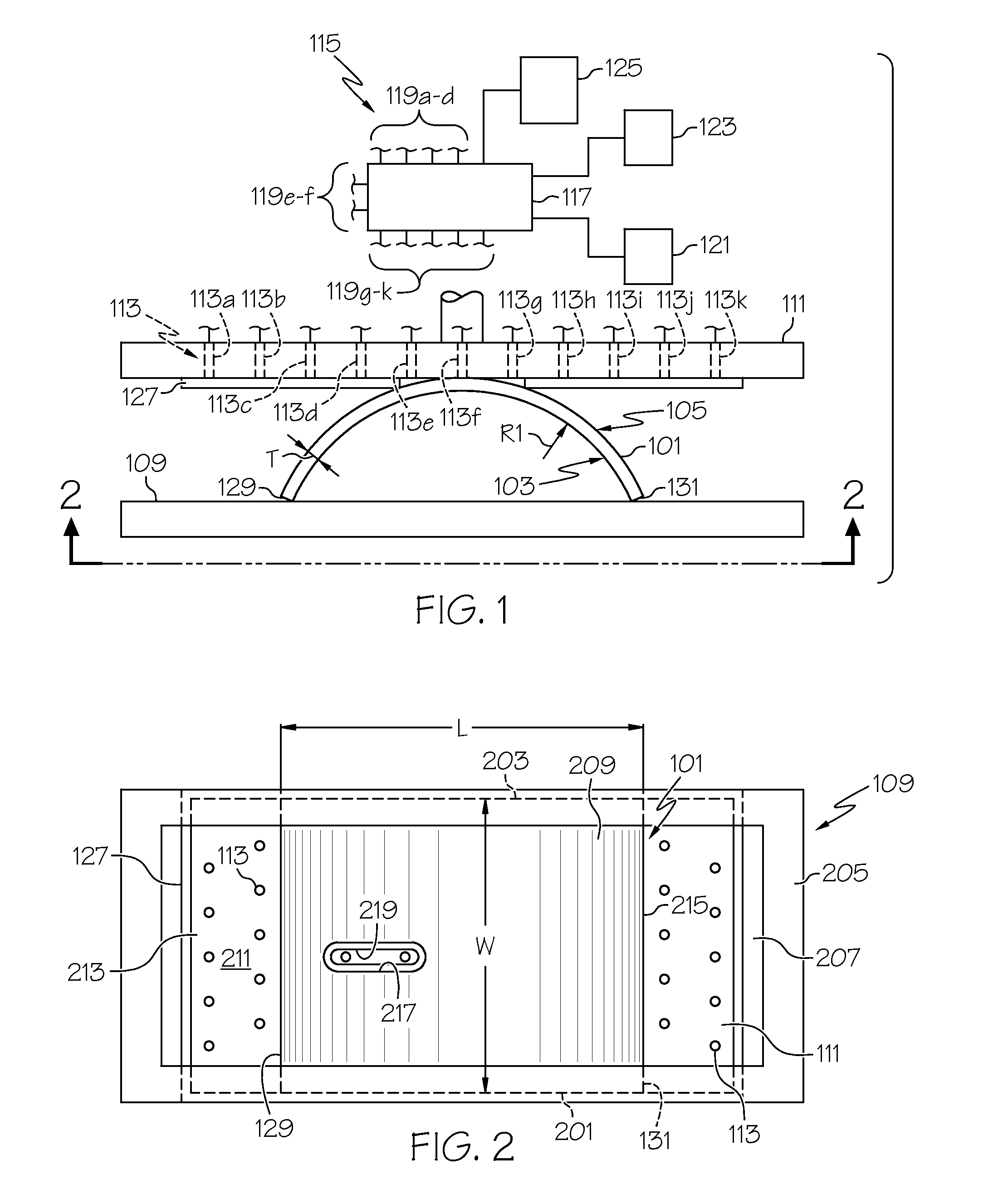

Methods of applying a layer of material to a non-planar glass sheet

Methods apply a layer of material to a glass sheet having a non-planar shape. The methods can each include the step of providing the glass sheet having an initial non-planar shape including a thickness defined between a first sheet surface and a second sheet surface. The method further includes the step of at least partially flattening the glass sheet into an application shape. The method further includes the step of applying the layer of material to the first sheet surface while the glass sheet is in the application shape. The method then includes the step of releasing the glass sheet to relax into a post non-planar shape.

Owner:CORNING INC

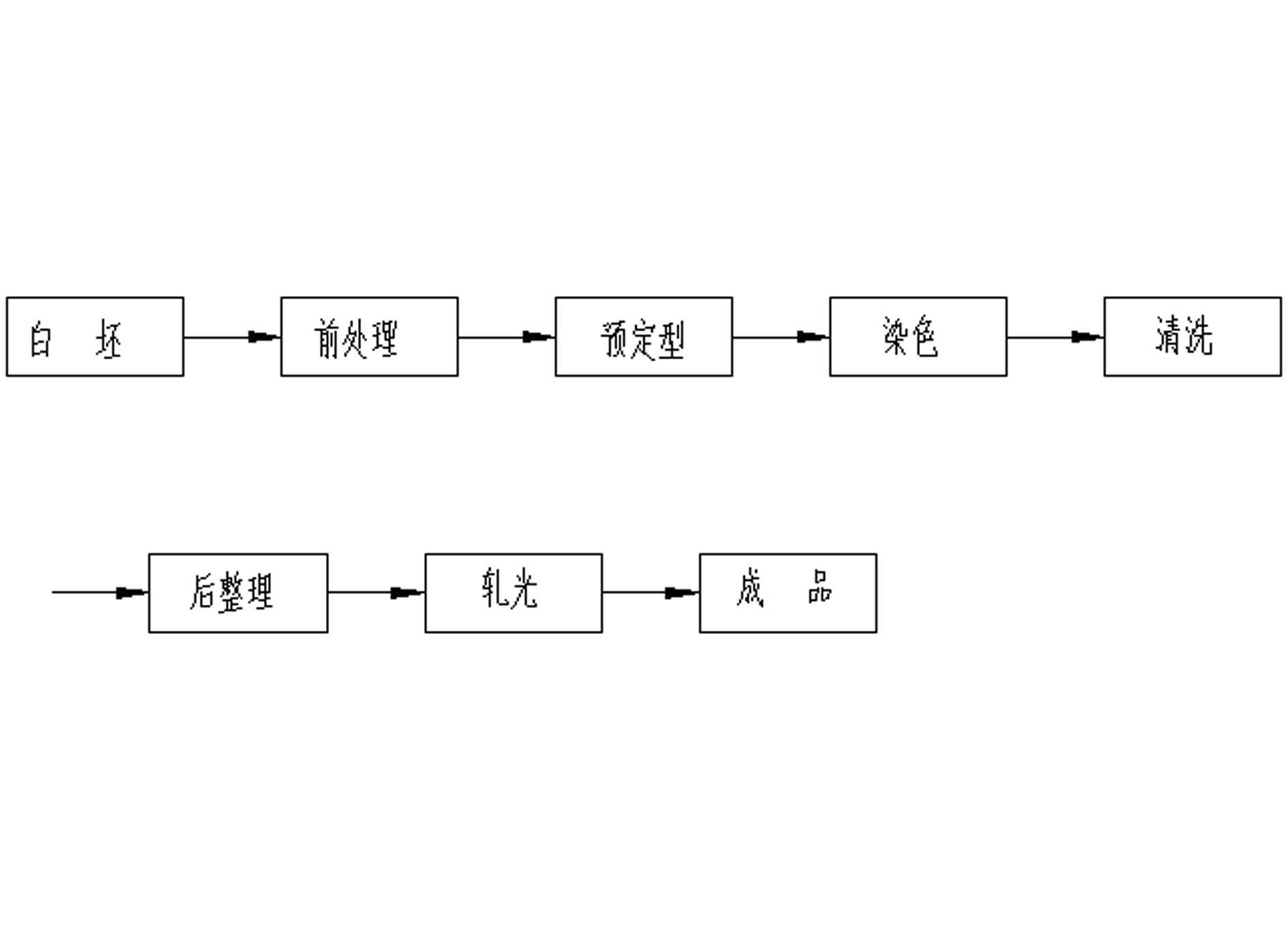

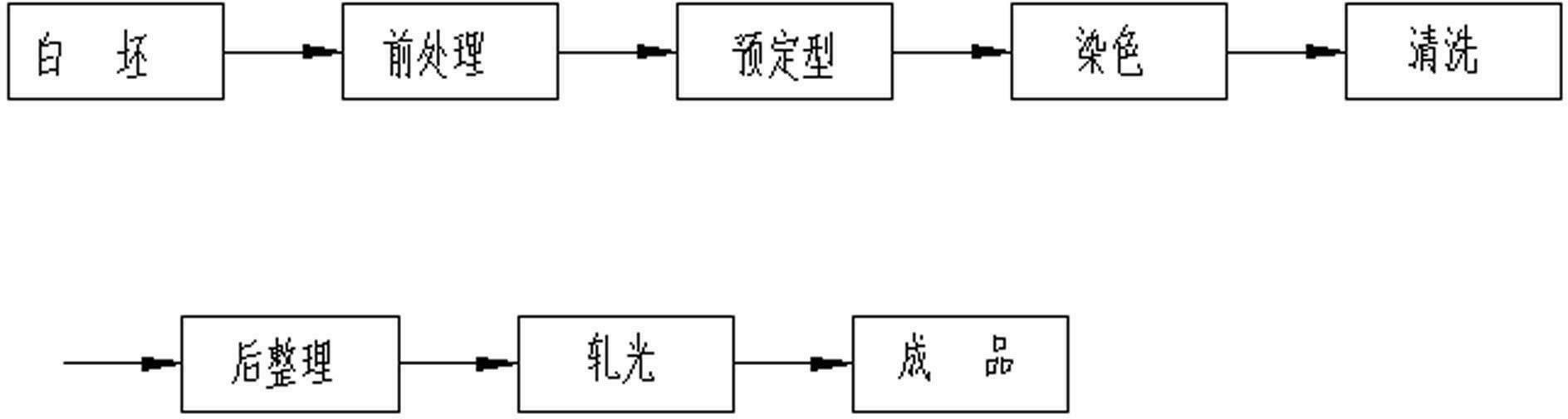

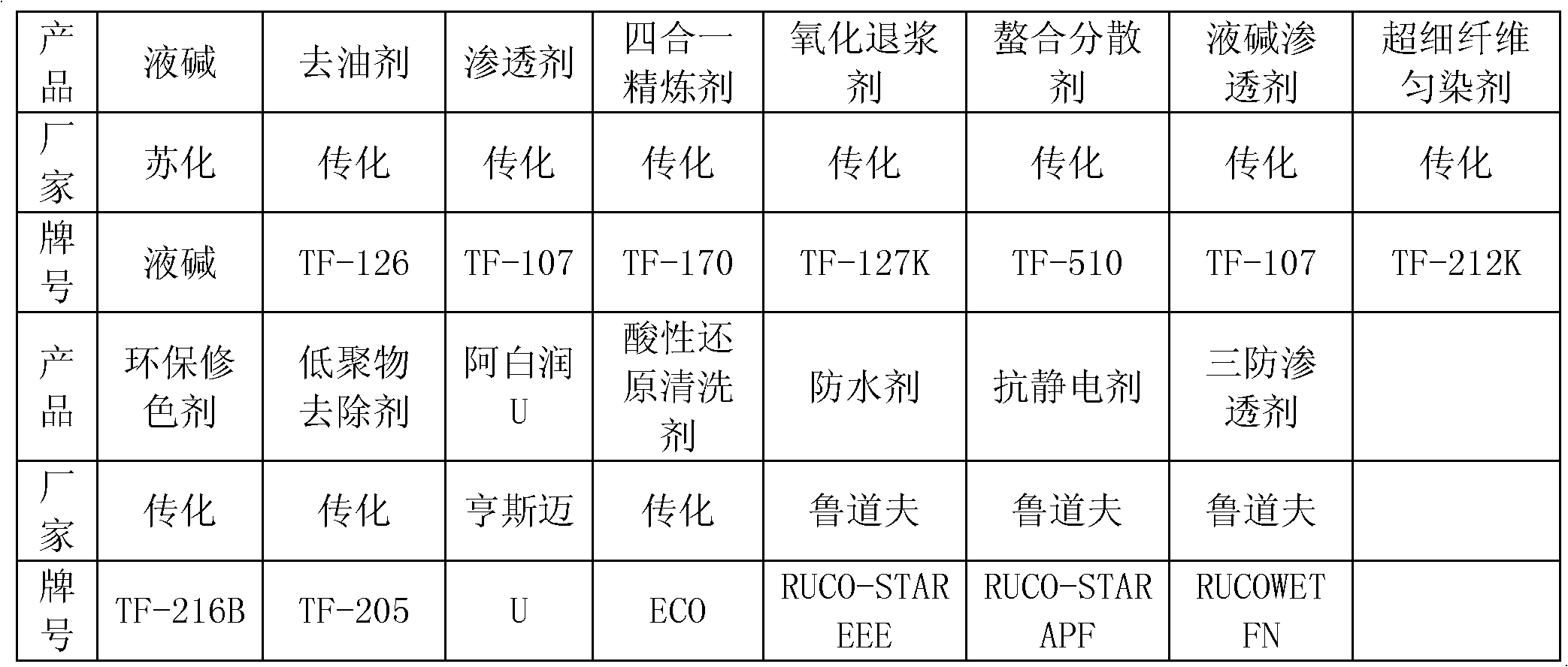

Novel dyeing and finishing processing technology of micro polyester fabric

ActiveCN102628211AReduce wrinklesReduce staining and chafingHeating/cooling textile fabricsDry-cleaning apparatus for textilesEnvironmental resistanceDisperse dye

The invention relates to a novel dyeing and finishing processing technology of a micro polyester fabric. The novel dyeing and finishing process disclosed by the invention is characterized by comprising the following steps of: (1) pretreatment, namely carrying out cold rolling and stacking processing comprising three stages, namely cold stacking, hot alkali treatment and high efficiency washing, on polyester gray fabric; (2) presetting, namely carrying out high temperature tentering and presetting on a pretreated fabric white body by utilizing a setting machine; (3) dyeing, namely dyeing the preset fabric white body by adopting superfine fiber leveling agent; and (4) cleaning, namely carrying out cleaning post-processing on the dyed fabric to remove disperse dyes which are not set after fibres are dyed. According to the novel dyeing and finishing processing technology disclosed by the invention, an environment-friendly and low-energy-consumption cold rolling and stacking pretreatment technology is used for carrying out pretreatment on the micro polyester fabric, on one hand, desizing effect is good and good dyeing and finishing processing conditions are provided for dyeing, and on the other hand, crease mark of the fabric can be effectively reduced; meanwhile, a formula of a dyeing process additive can be adjusted, albafluid U is added to reduce fabric dyeing scratch, and dyeing defects can be prevented from being caused.

Owner:SHENGHONG GRP CO LTD

Fabric reinforcement and cementitious boards faced with same

ActiveUS20060013950A1Improve coating uniformityConvenient coatingPretreated surfacesWood working apparatusCement boardEngineering

Fabric and reinforcements are provided by this invention which, in a first embodiment, include a plurality of warp yarns having a first twist (turns / inch) and a plurality of weft yarns having a second twist which is greater than the first twist. A coating is applied over a substantial portion of the warp and weft yarns after they are assembled or laid together, so as to produce a weight distribution ratio of less than about 2.0:1, based upon the weight of the resinous coating of the weft yarns over the weight of the resinous coating on the warp yarns. This can be achieved, in substantial part, due to the difference in the twist ratios of the warp and weft yarns, which difference permits a more uniform coating to be applied. Further embodiments of this invention include a cementitious board and methods of making a coated fabric and cementitious board.

Owner:SAINT GOBAIN ADFORS CANADA LTD

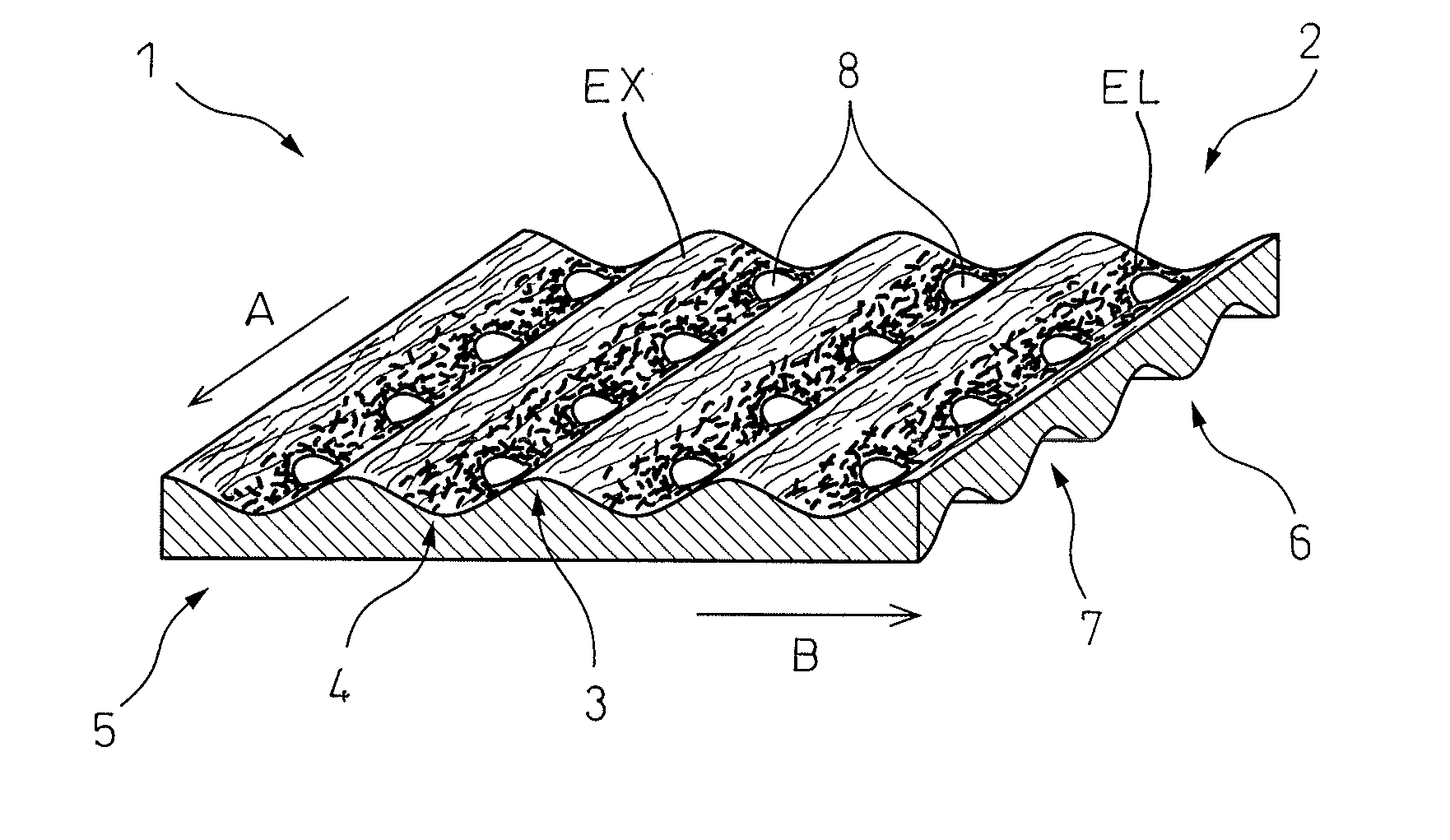

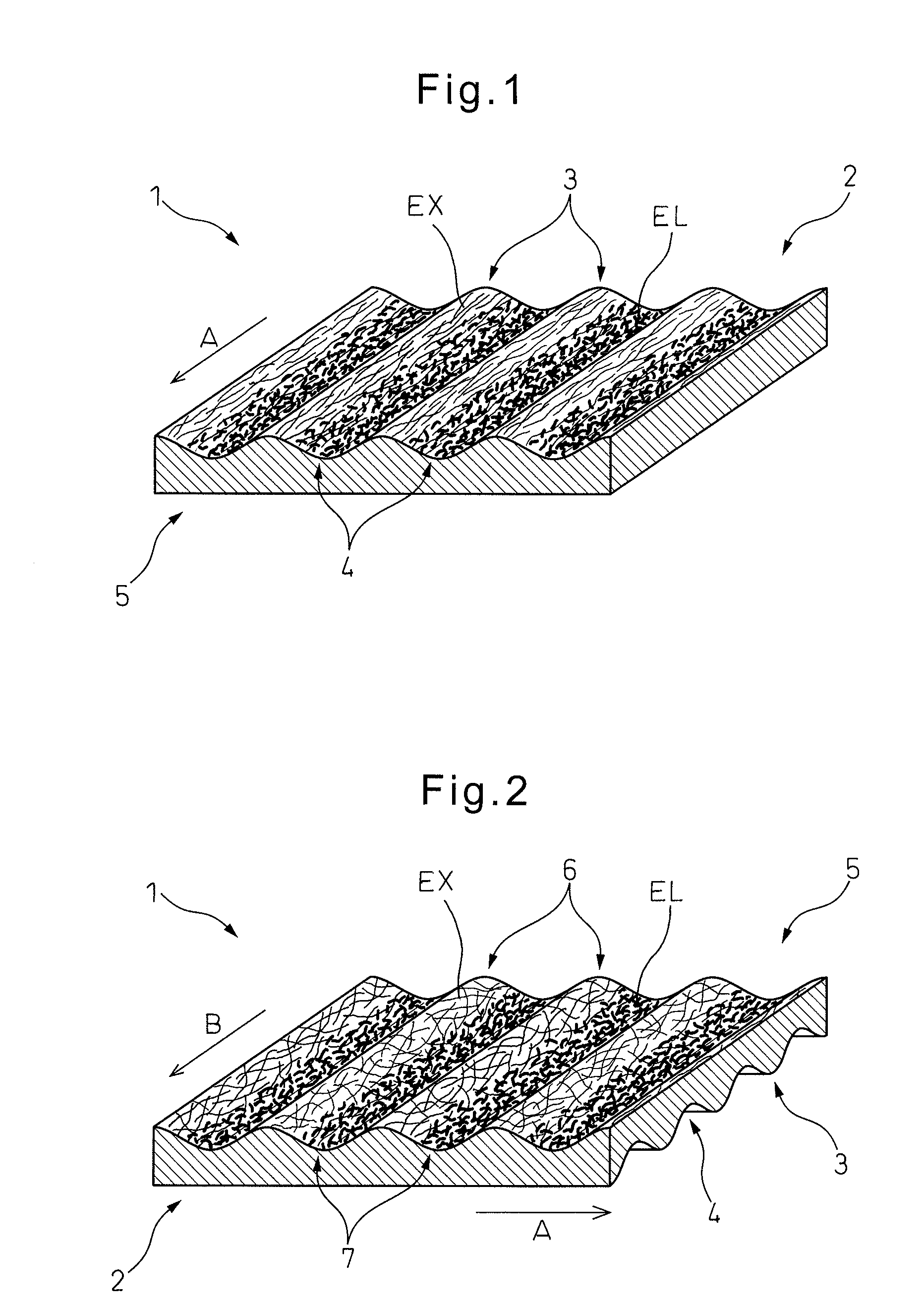

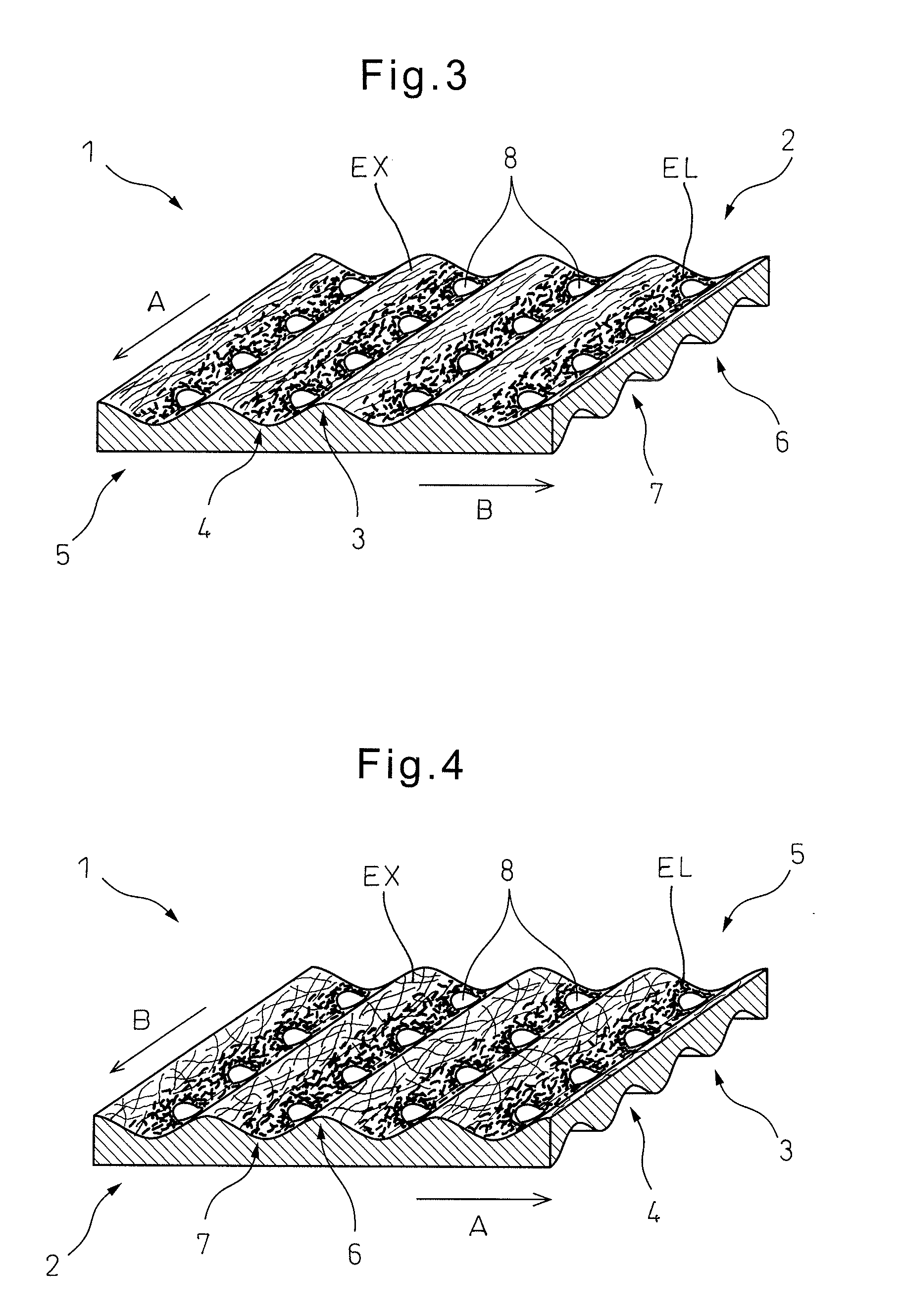

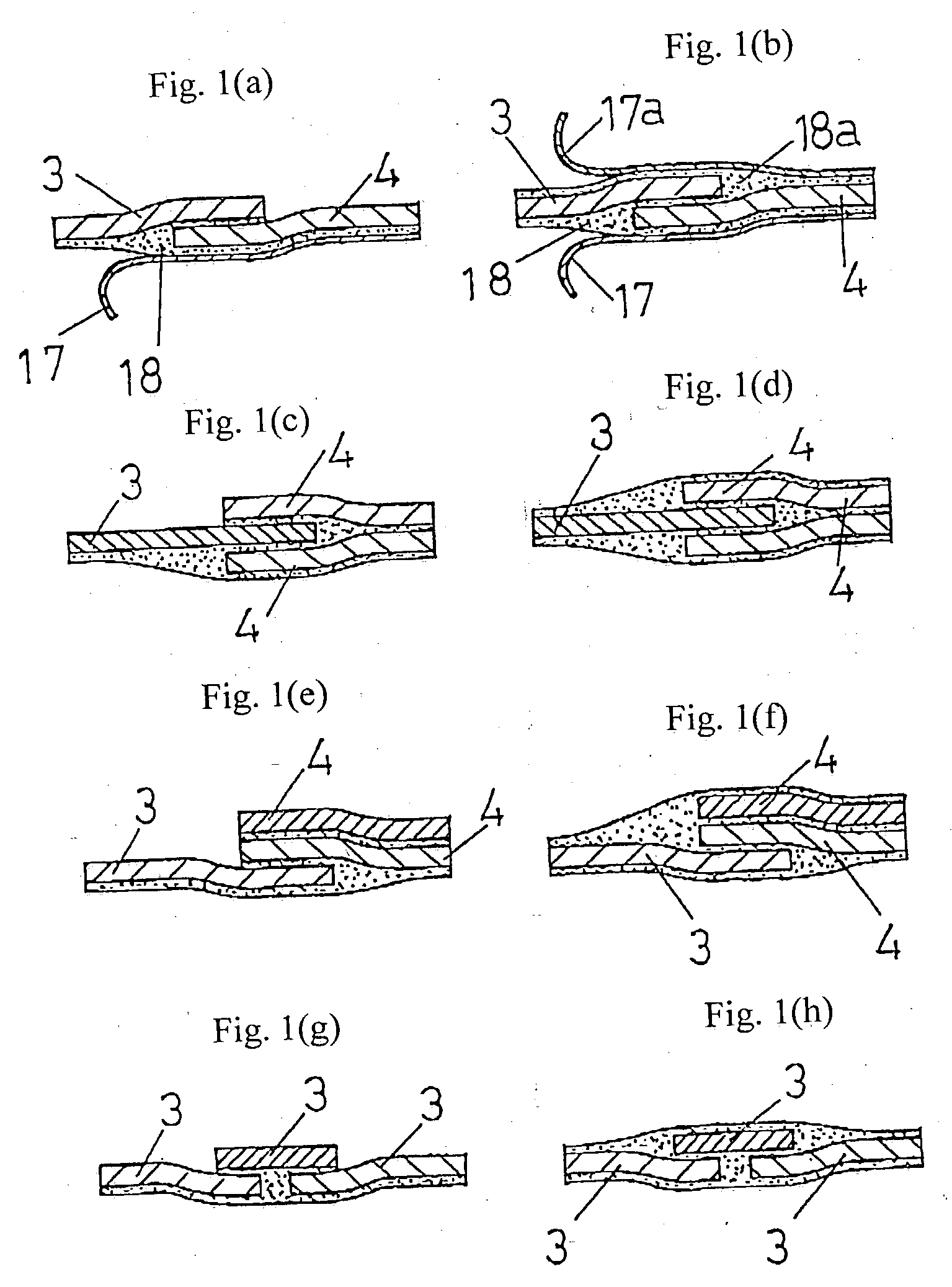

Nonwoven fabric having projections and recesses, comprising extensible fiber and elastic fiber, and method of producing nonwoven fabric

InactiveUS20130034686A1Good skin feelIncrease elasticityPattern makingLayered productsNonwoven fabricElastic fiber

It is an object of the invention to provide a nonwoven fabric having projections and recesses, comprising extensible fiber and elastic fiber, which has excellent feel on the skin and elasticity, and excellent air permeability in the planar directions and the thickness direction, as well as a method of producing the nonwoven fabric.A nonwoven fabric having projections and recesses, comprising extensible fiber and elastic fiber, wherein the first surface of the nonwoven fabric has a plurality of projections and a plurality of recesses, and the proportion of extensible fiber in the projections is higher than the proportion of extensible fiber in the recesses.

Owner:UNI CHARM CORP

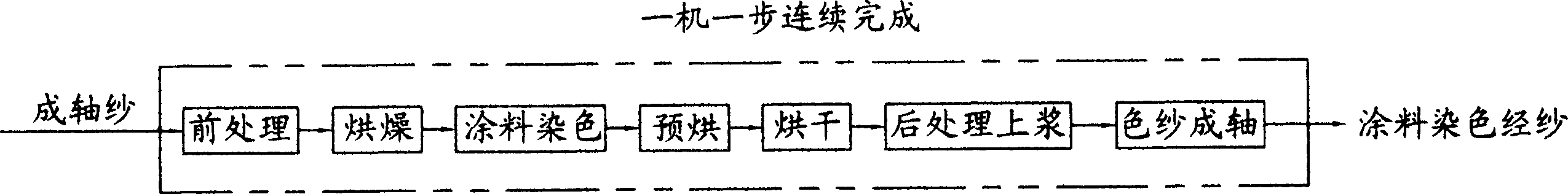

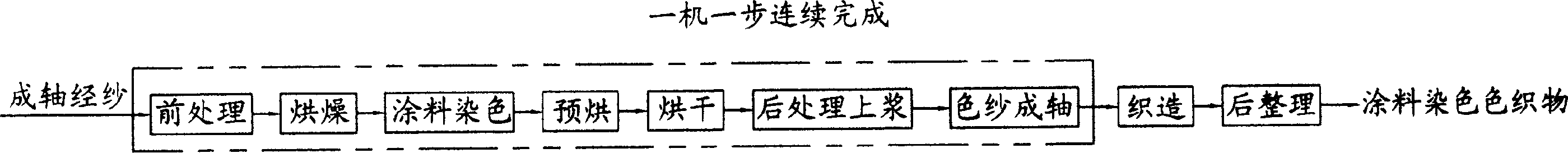

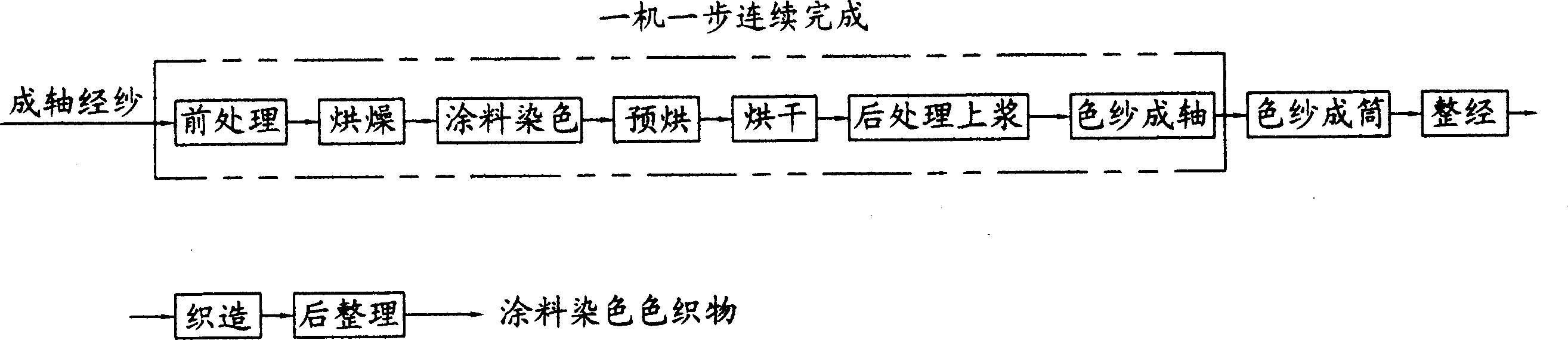

Pigment dyed colored cloth production method

InactiveCN1884659AQuality improvementGood processing depthSucessive textile treatmentsSingeingSewageEnergy consumption

The invention discloses a manufacturing method of paint dyeing weaver with oxford textile, chambray and denim, which comprises the following steps: predisposing warp; drying; dyeing; predrying; drying; after-treating; shafting warp; weaving; dressing; finishing one step by one machine continually. The invention satisfies large batch and scale manufacturing request, which is fit for producing original paint dyeing and other pain dyeing weaver product.

Owner:常州市森容纺织品有限公司

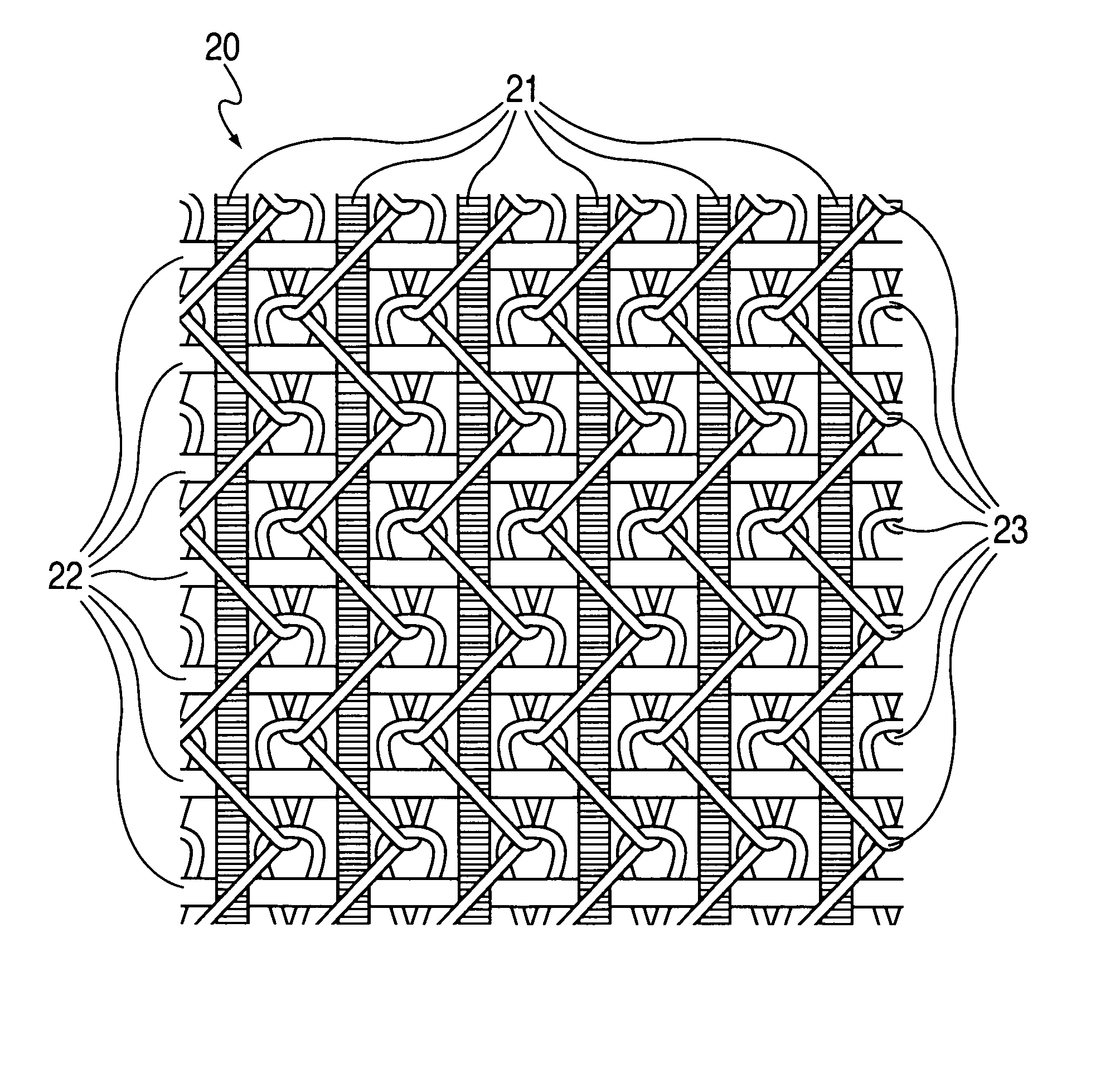

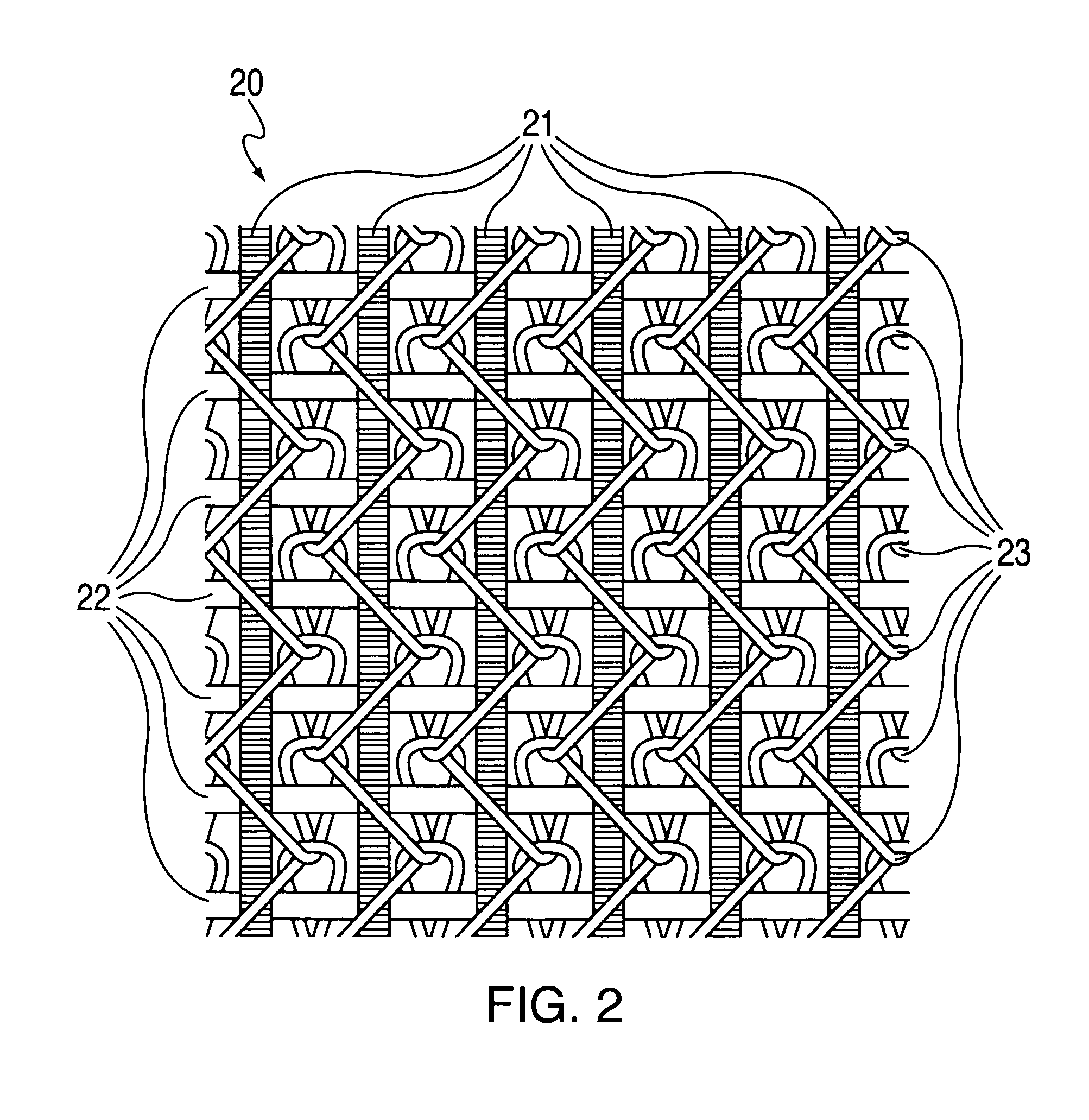

Bi-directional fabric and fabric composites

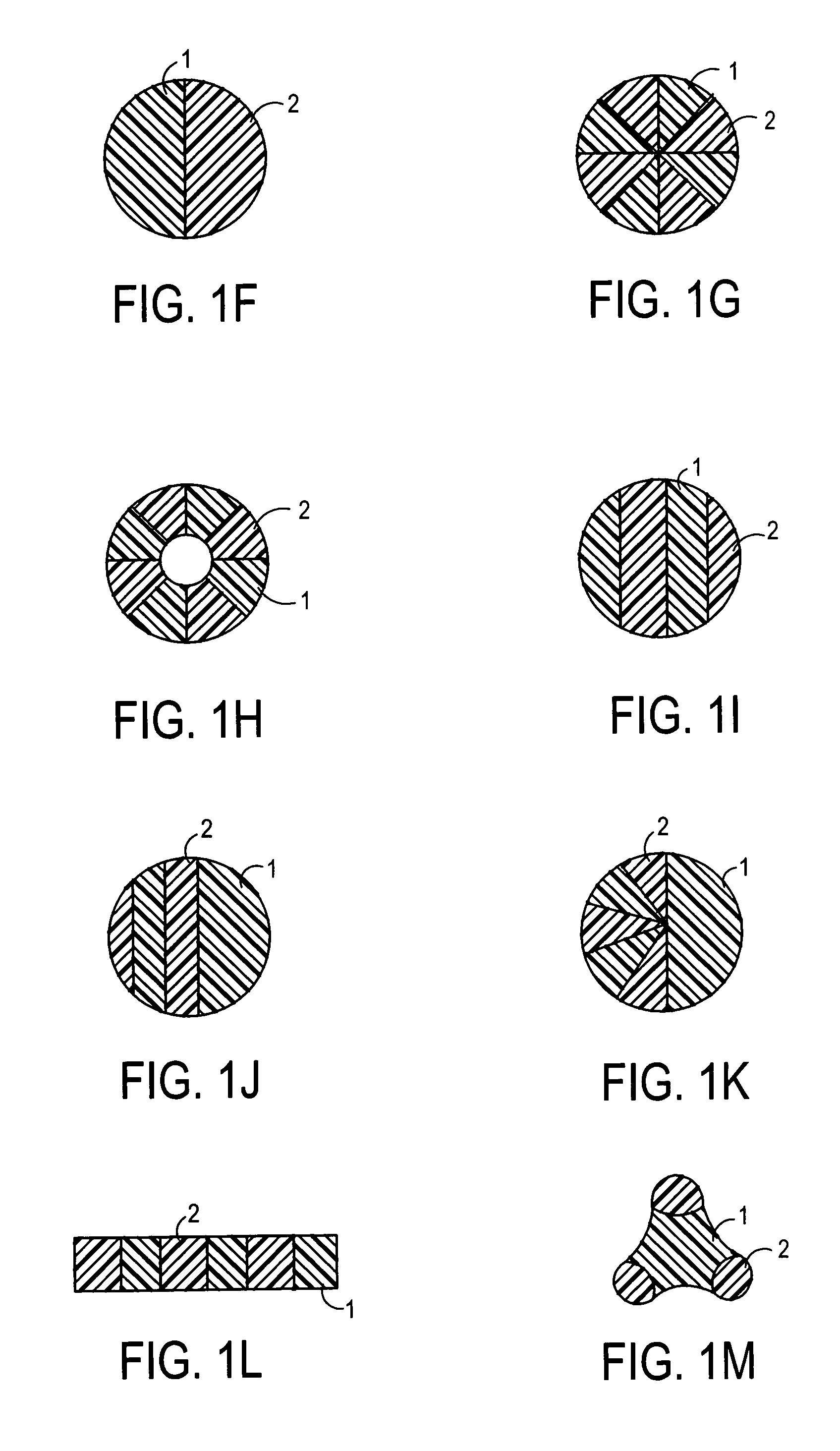

InactiveUS20050081571A1Increase resistanceSuperior ballistic effectivenessOrnamental textile articlesProtective fabricsYarnEngineering

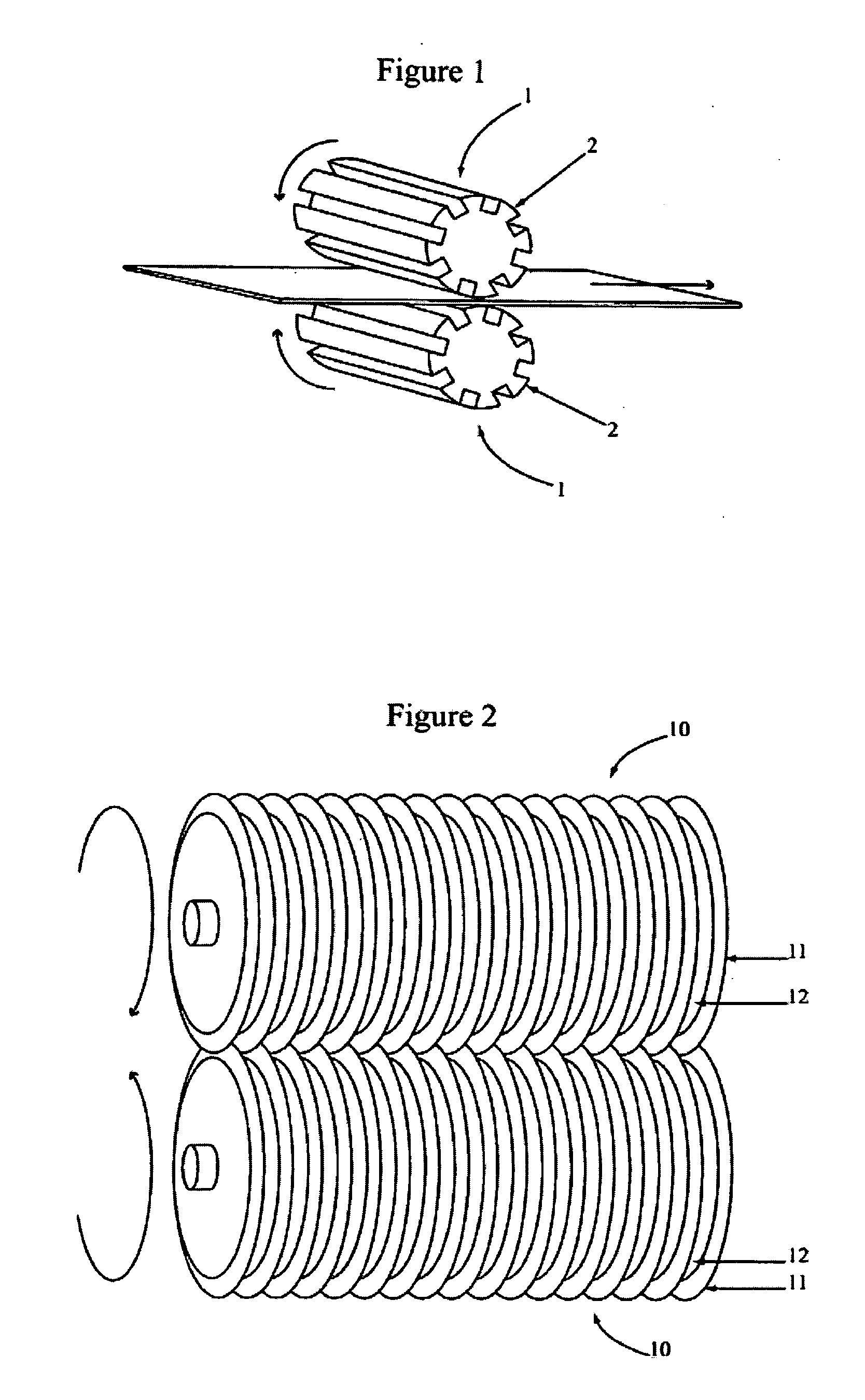

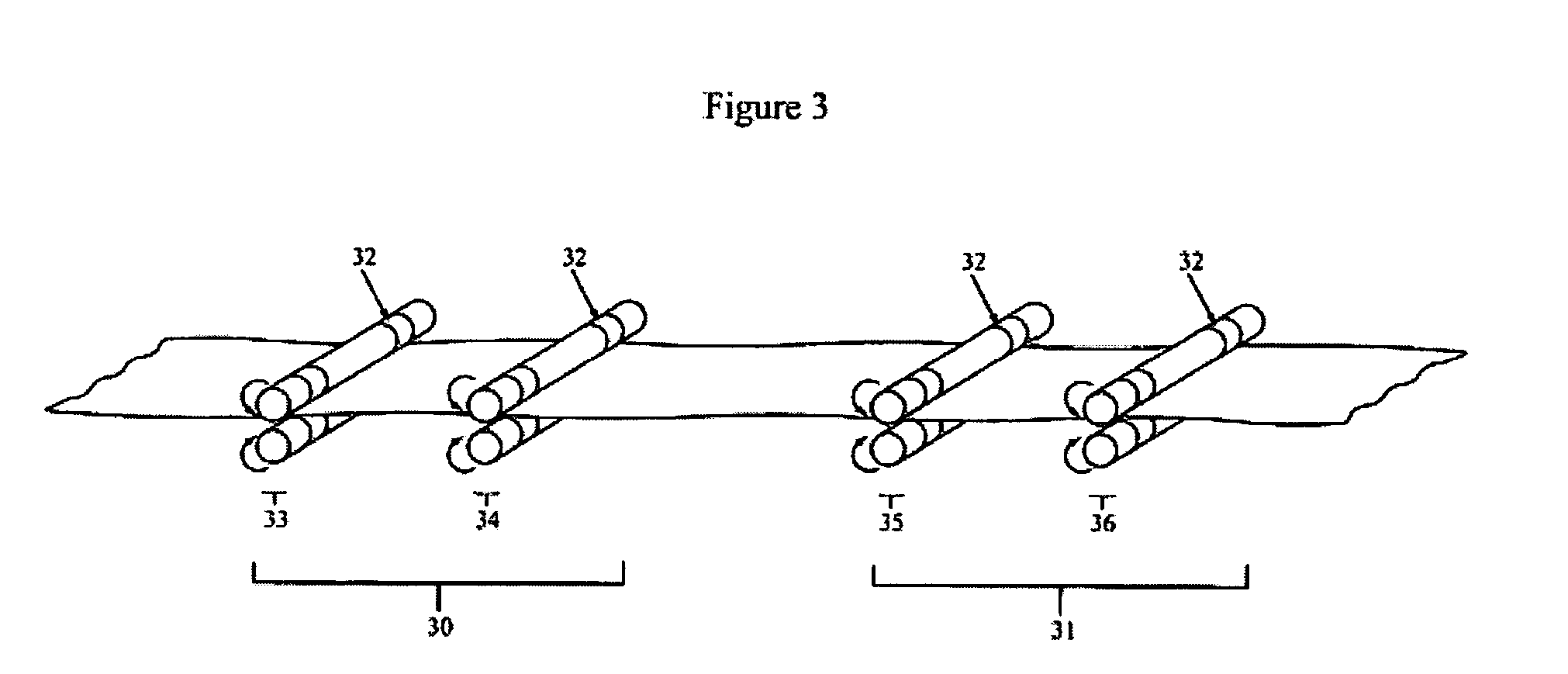

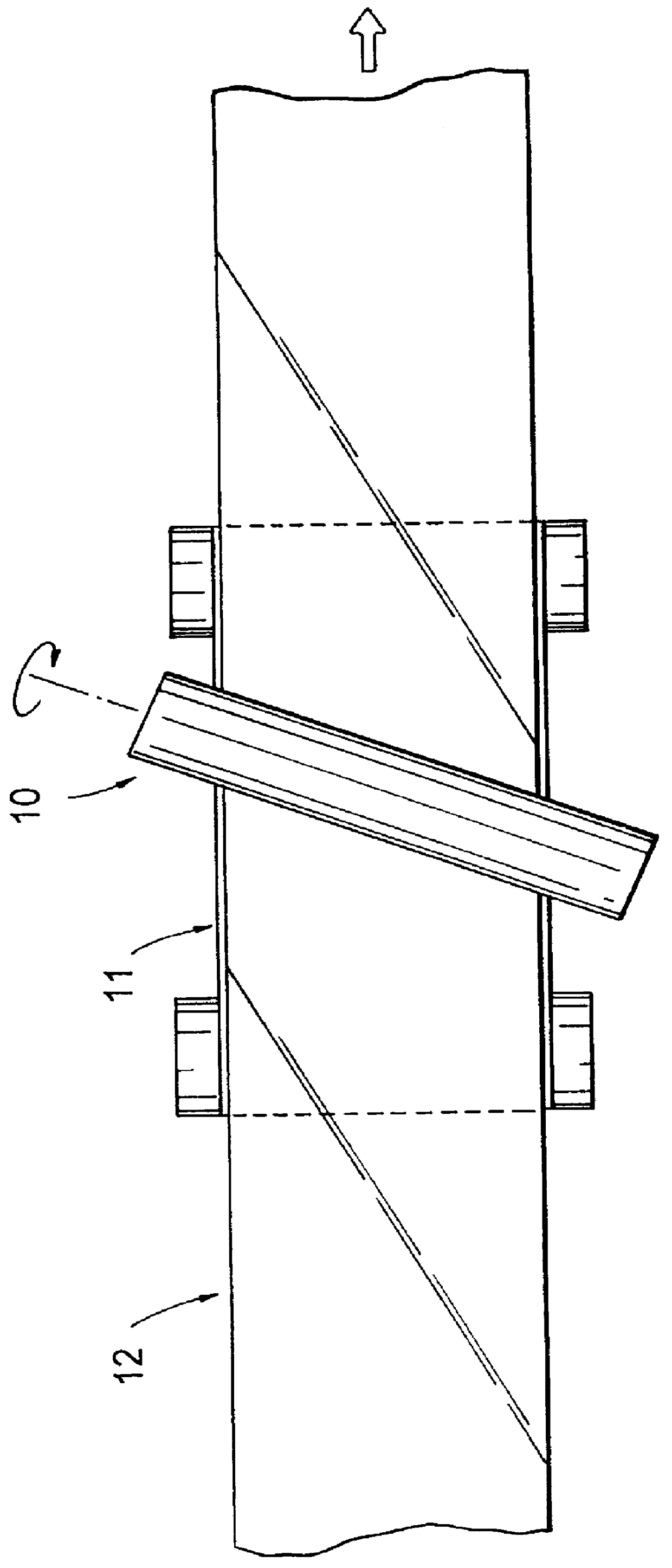

Bi-directional fabrics, fabric composites, ballistically resistant assemblies thereof, and the methods by which they are made. The bi-directional fabrics are comprised of a first set of strong, substantially parallel, unidirectional yarns lying in a first plane; a second set of strong, substantially parallel, unidirectional yarns lying in a second plane above the first plane and arranged transversely to the first set of yarns; and one or more sets of yarns having lower strength and higher elongation interleaved with the strong yarns. The bi-directional articles of the invention provide superior ballistic effectiveness compared to ordinary woven and knitted fabrics but retain the ease of manufacture on conventional looms and knitting machines.

Owner:HONEYWELL INT INC

Fastener loop material, its manufacture, and products incorporating the material

InactiveUS6869659B2Function increaseNetwork stabilitySynthetic resin layered productsPretreated surfacesFiberBiomedical engineering

Owner:VELCRO IND BV

High-elongation apertured nonwoven web and method for making

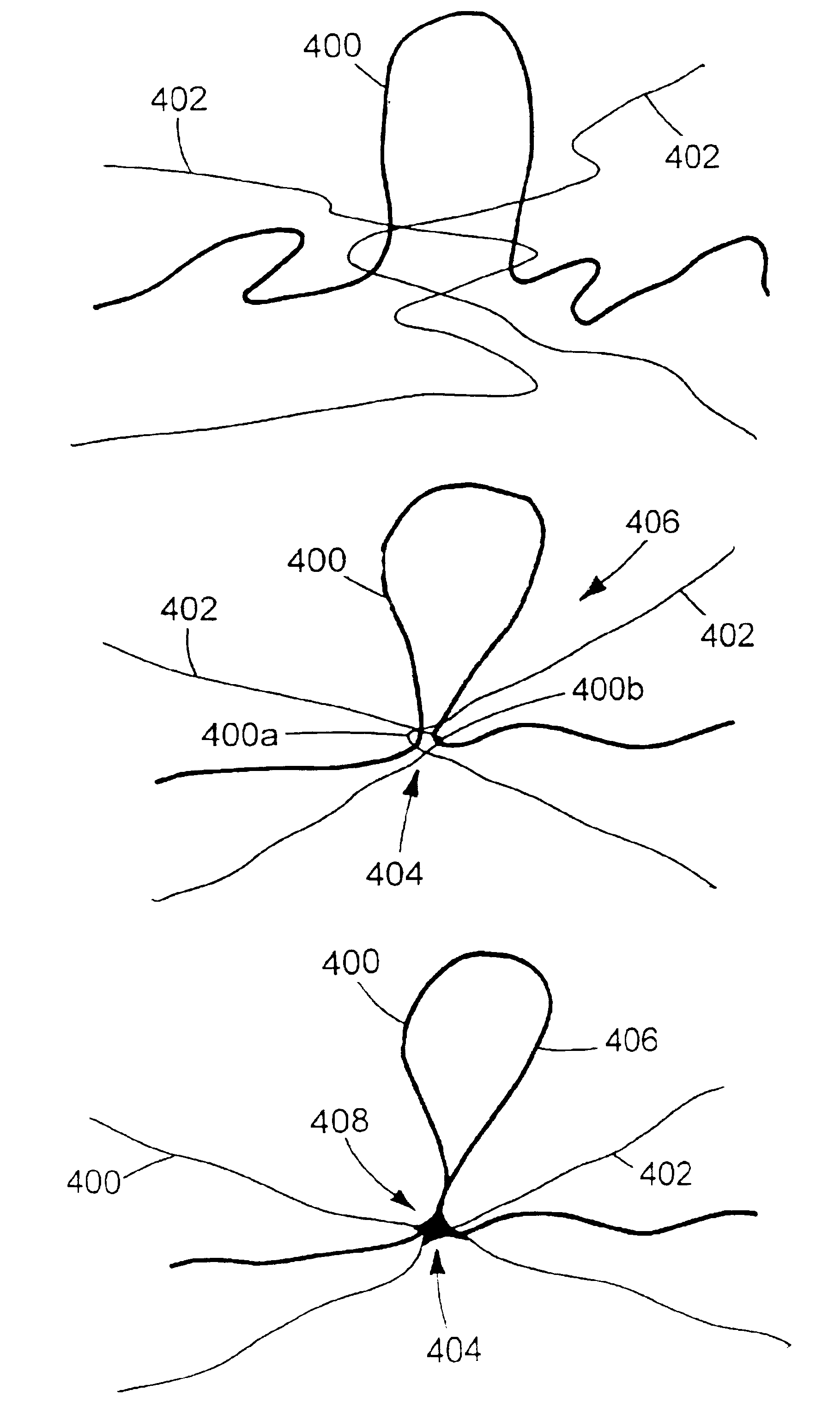

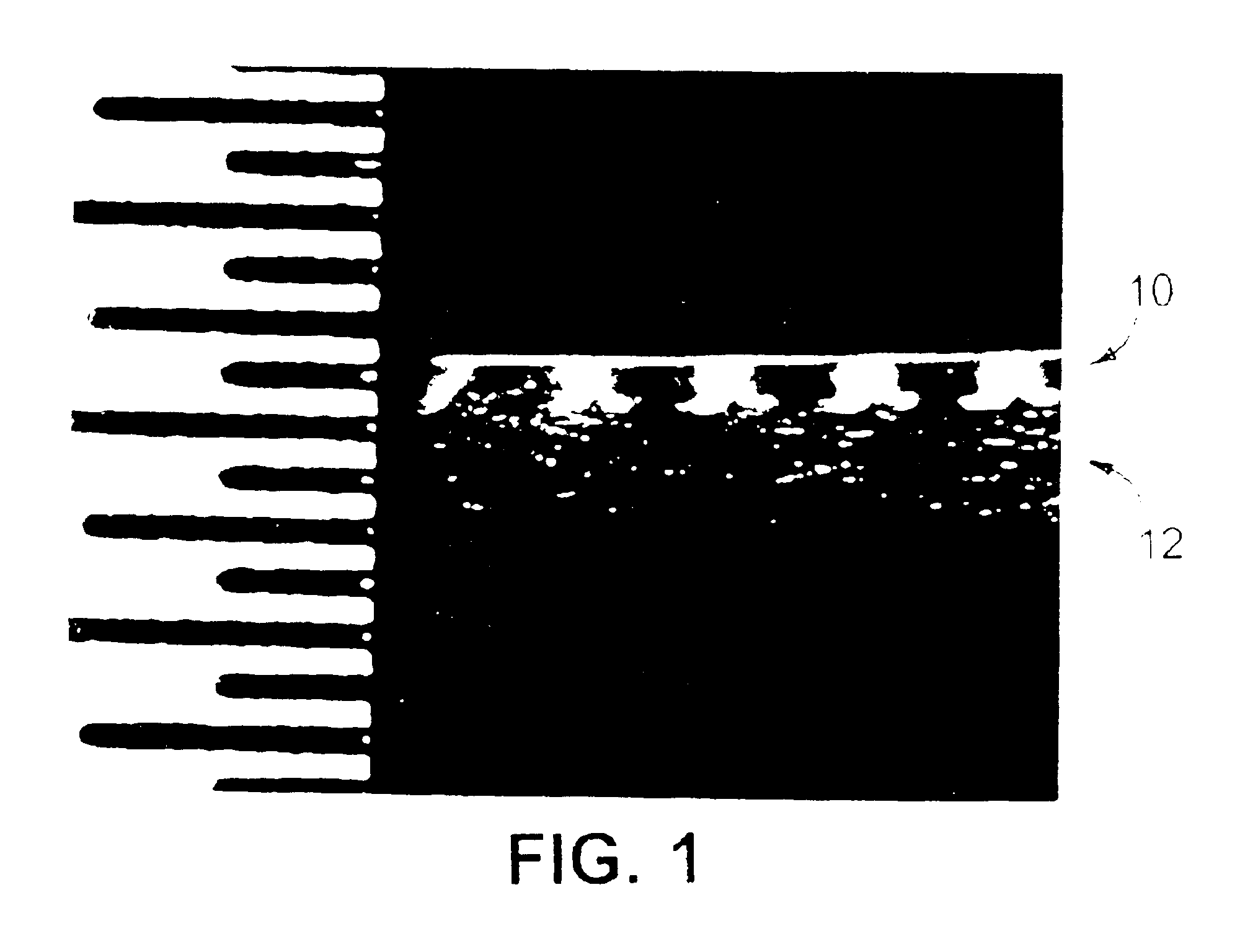

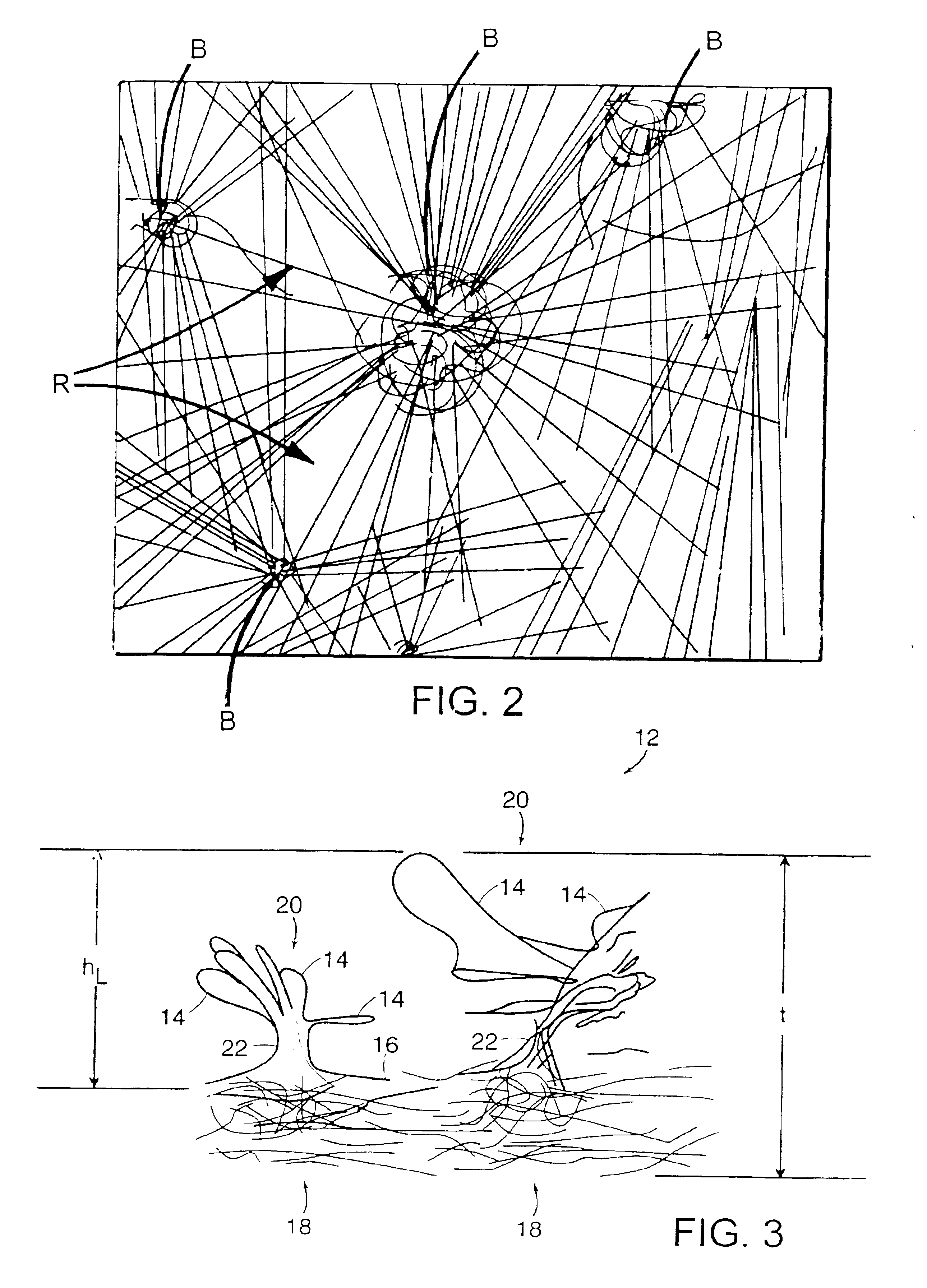

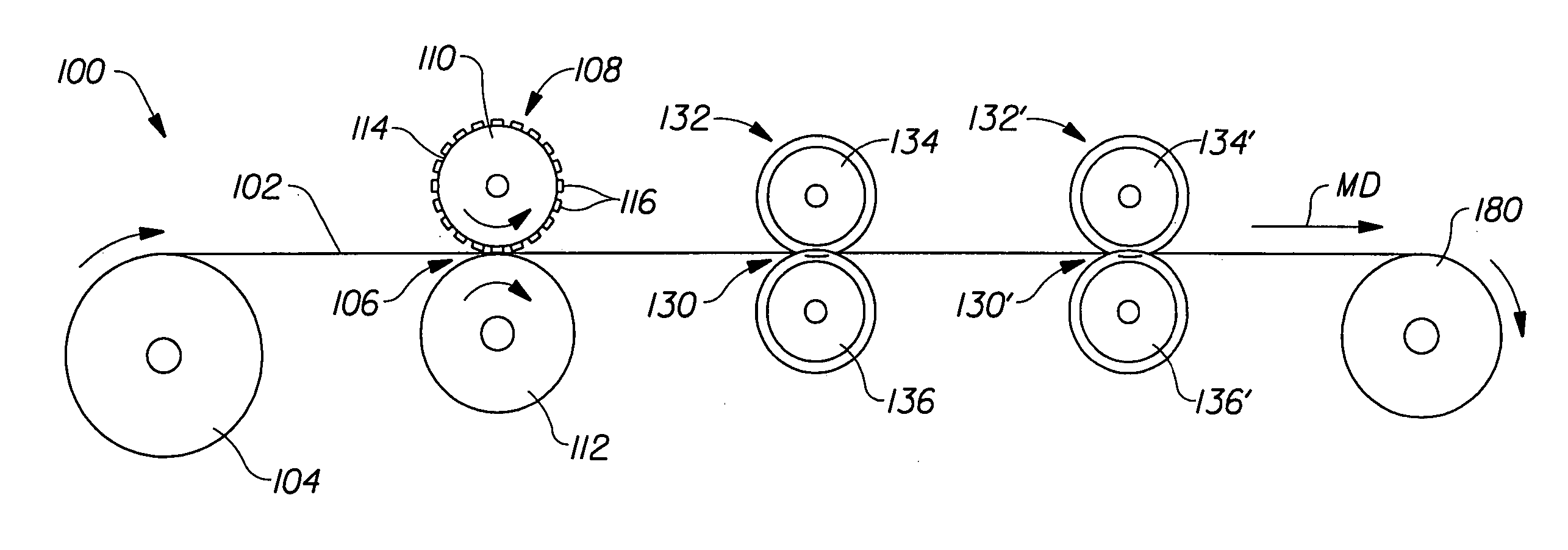

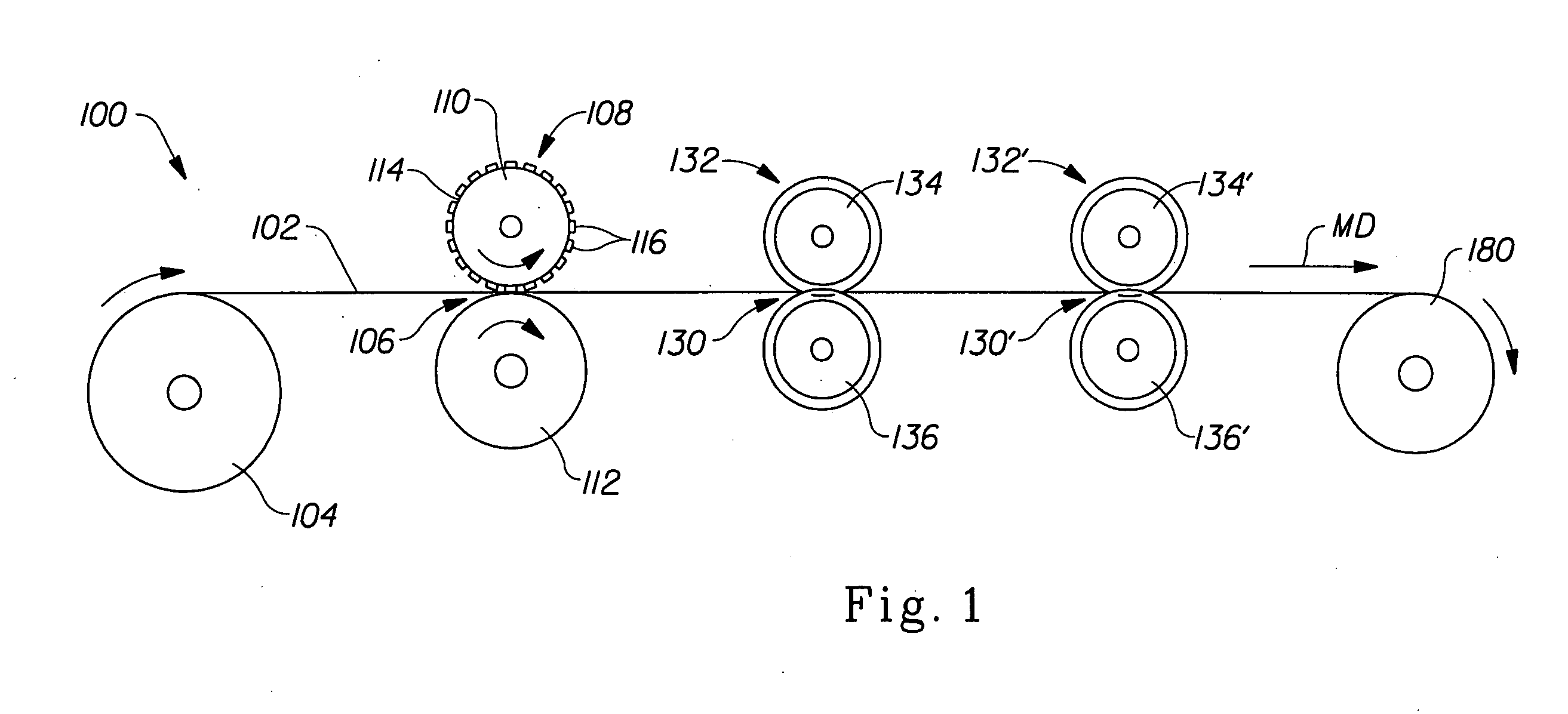

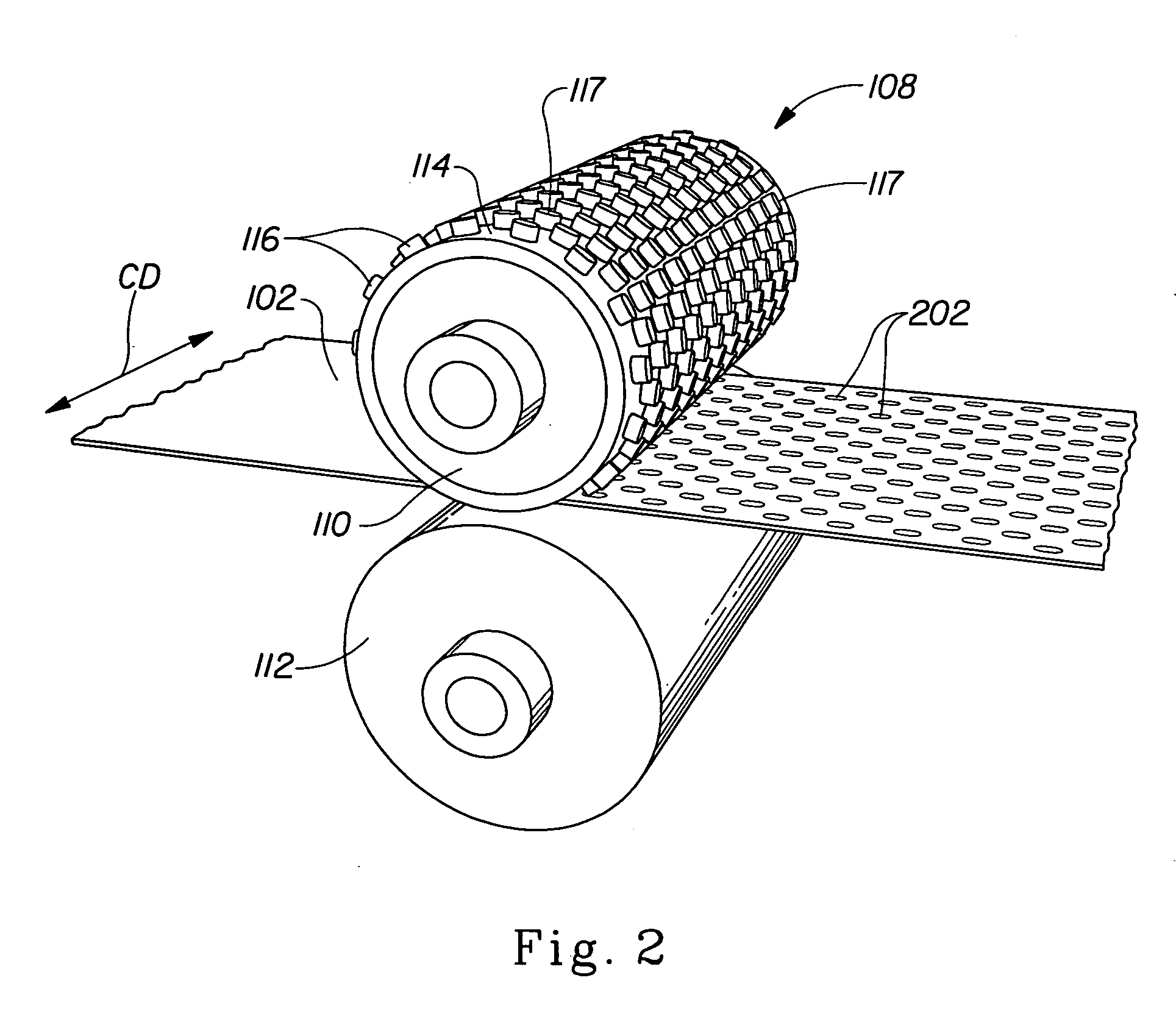

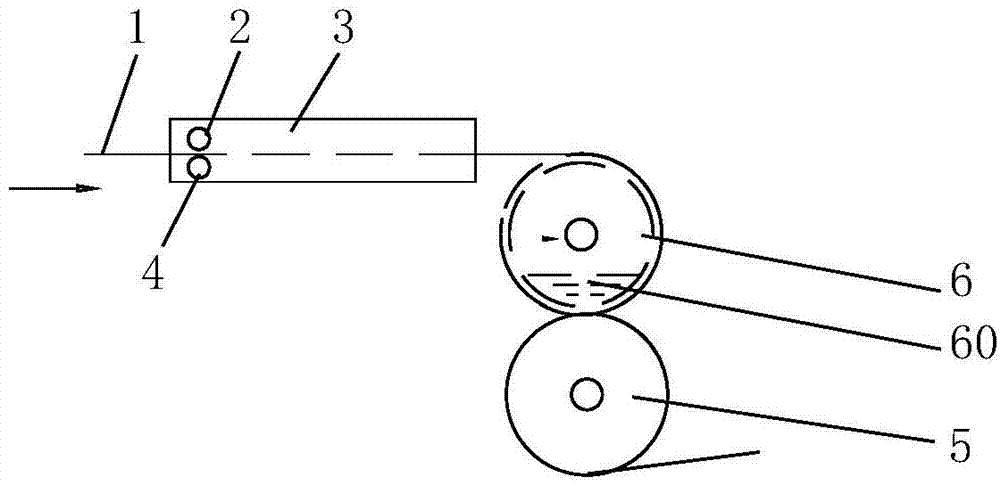

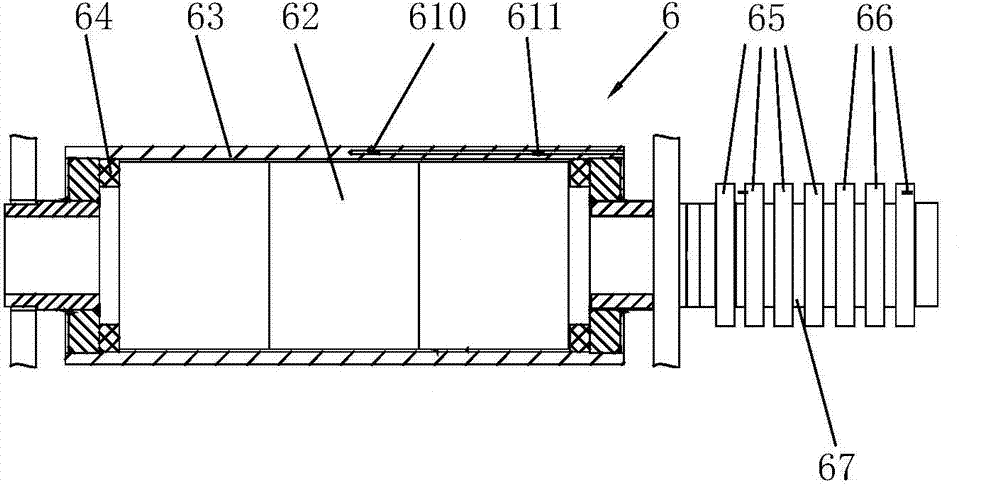

An extensible apertured nonwoven web, and a method for making such an apertured nonwoven web. In one embodiment the method comprises the steps of providing an apertured nonwoven web, incrementally stretching it in a direction substantially parallel to the cross machine direction, and applying tension in the machine direction such that the web width after applying tension is less than the web width after incremental stretching. In another embodiment the method comprises the steps of providing a nonwoven web; weakening the nonwoven web at a plurality of locations to create a plurality of weakened, melt-stabilized locations; applying a first tensioning force to the nonwoven web to cause the nonwoven web to rupture at the plurality of weakened, melt-stabilized locations creating a plurality of apertures in the nonwoven web coincident with the weakened, melt-stabilized locations, incrementally stretching the nonwoven web in a direction substantially parallel to the cross machine direction, and applying tension in the machine direction such that the web width after applying machine direction tension is less than the web width after incremental stretching. An apparatus for producing a web of the present invention by this method is also disclosed. The extensible apertured nonwoven web produced has a plurality of apertures each having a hole size greater than 2 mm2, and a hole aspect ratio less than 6, the nonwoven web having an open area greater than 15% and being capable of at least 70% extension in the cross machine direction at a loading of 10 g / cm.

Owner:THE PROCTER & GAMBLE COMPANY

High barrier metallized film with mirror-like appearance

InactiveUS6844077B2Improved gas propertyImproved moisture barrier propertyFilm/foil adhesivesSynthetic resin layered productsPolymer sciencePolyolefin

A metallized, multi-layer film is disclosed that comprises at least a polyolefin layer, a tie layer, and a metallized lactic acid polymer layer to yield a final film having improved moisture and gas barrier, optical, and mechanical properties.

Owner:EXXONMOBIL CORP (US)

Wrinkle removal equipment for synthetic leather machining

InactiveCN104264402AReasonable structureLow costHeating/cooling textile fabricsStretchingElectricityWrinkle skin

The invention discloses wrinkle removal equipment for synthetic leather machining. The wrinkle removal equipment for the synthetic leather machining comprises a coating machine; the wrinkle removal equipment is installed before the coating machine; the wrinkle removal equipment comprises heating rollers, impression rollers and a humidification box; the heating rollers compress the impression roller; a first steam inlet and a second steam inlet are formed inside the humidification box; cloth is conveyed to the coating machine through the heating rollers and the impression rollers after penetrating the humidification box; the first steam inlet and the second steam inlet are communicated with an ultrasonic wave water atomization generator; water mist output from the first steam inlet and the second steam inlet can wet two sides of the cloth; the heating rollers are provided with at least three electric heating bodies which are connected with an electric control controller, first temperature sensors and second temperature sensors; the heating rollers in the middle and at two ends allow setting of different temperature and are specifically used for removing wrinkle at two ends of the cloth. The wrinkle removal equipment for the synthetic leather machining has the advantages of being reasonable in structure, low in cost, saving electricity and water, saving sites and removing winkles on the cloth in a fixed form mode under high temperature, high humidity and high pressure.

Owner:福清市科技创新发展服务中心(福清市科技情报所)

Process for making anti-infrared multifunctional camouflaged color cloth

InactiveCN101397708AShort production processHue once goodFibre treatmentSingeingFiberTextile printer

The invention relates to a textile printing and dyeing technique, in particular to a manufacturing technique of an infrared ray resistant multi-functional camouflage fabric. The technique flow is as follows: original cloth seaming, singeing, old rolling, 180 pre-treatment, shaping, mercerizing, ground dyeing, pattern printing, baking, aging, stentering of post treatment, examination and acceptance; wherein, the ground dyeing flow is as follows: padding liquor, two groups of infrared rays and drying; a formula adopted in the ground dyeing flow comprises 2g / l to 10g / l of dispersion dyes, 5g / l to 15g / l of vat dyes and 0.01g / l to 1.0g / l of infrared ray resistant regulators; the formula of pattern printing is as follows: 2kg to 15.7kg of dispersion material, 2. kg / l to 10.5kg / l of vat material and 0.01kg to 2.5kg of infrared ray resistant regulators; post treatment has the function compatibility of multiple functions which are water proofing, oil repellence, ventilation, crease resistance and static resistance. The technique has the advantages of having short production procedure, color phase with good uniformity, stable infrared reflectivity, low cost, multiple functions, mainly using environment friendly dyes and being suitable for infrared ray resistant camouflage fabric products with different fibers and different specifications.

Owner:XIANYANG JIHUA NEW 30 DYEING & PRINTING

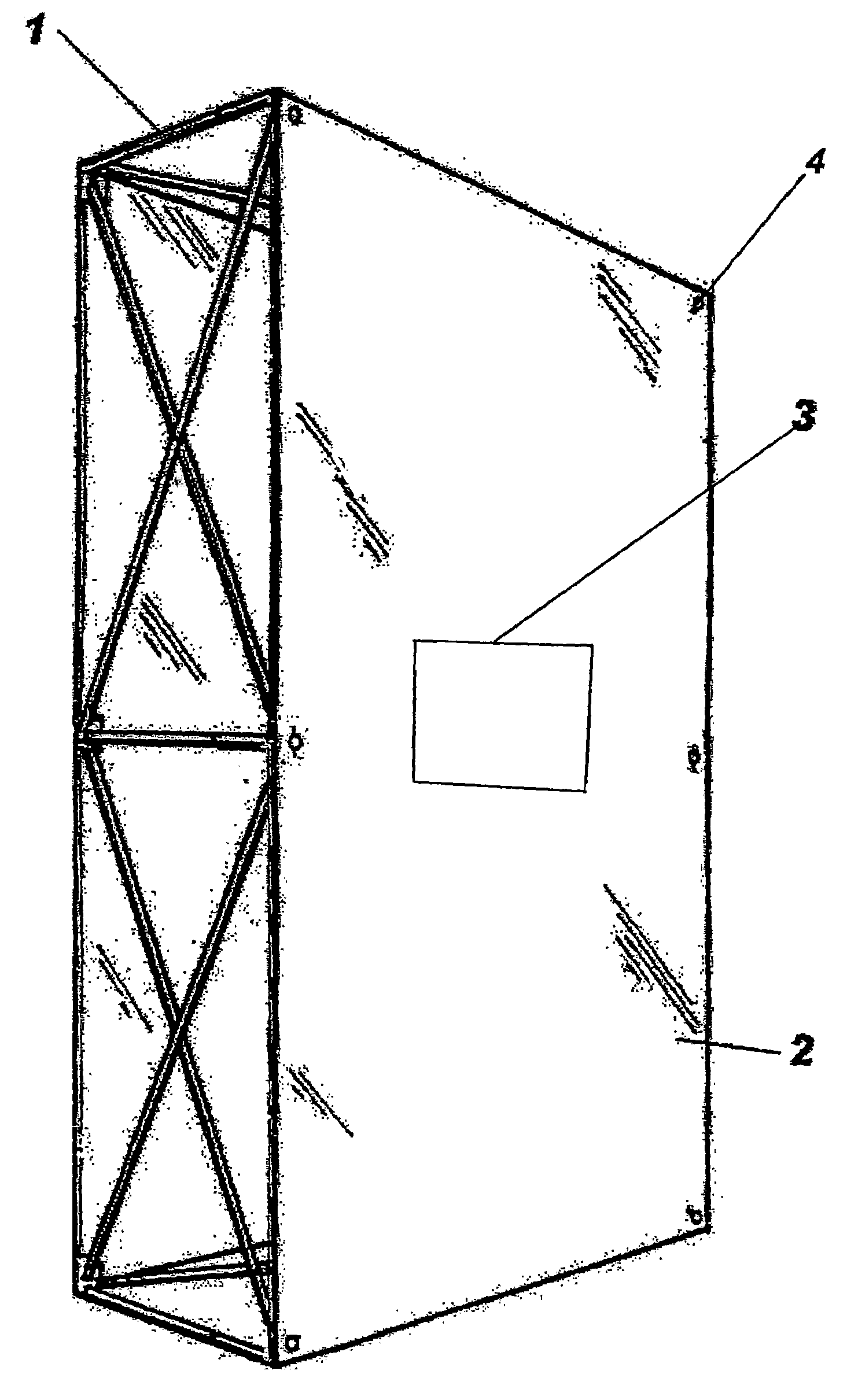

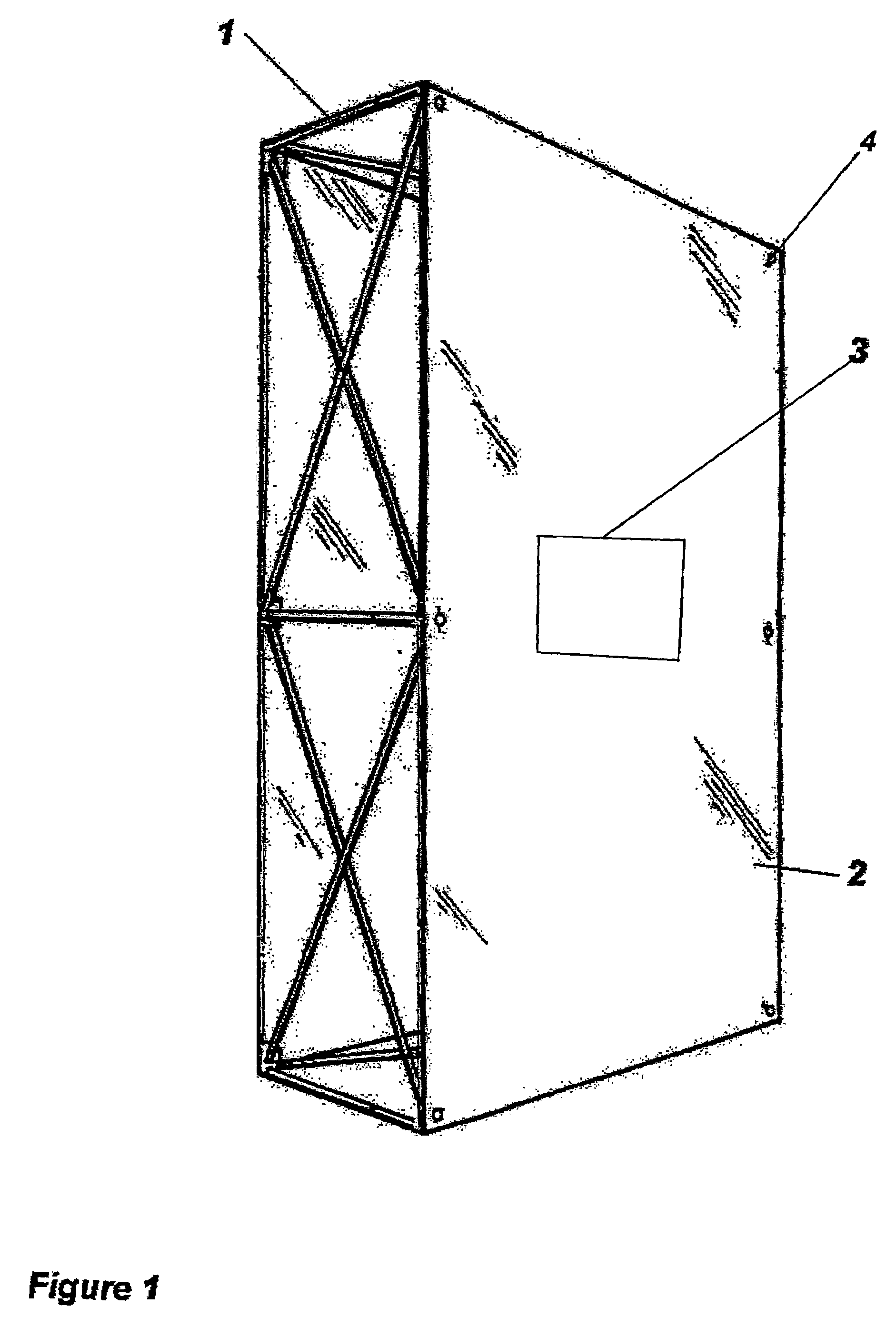

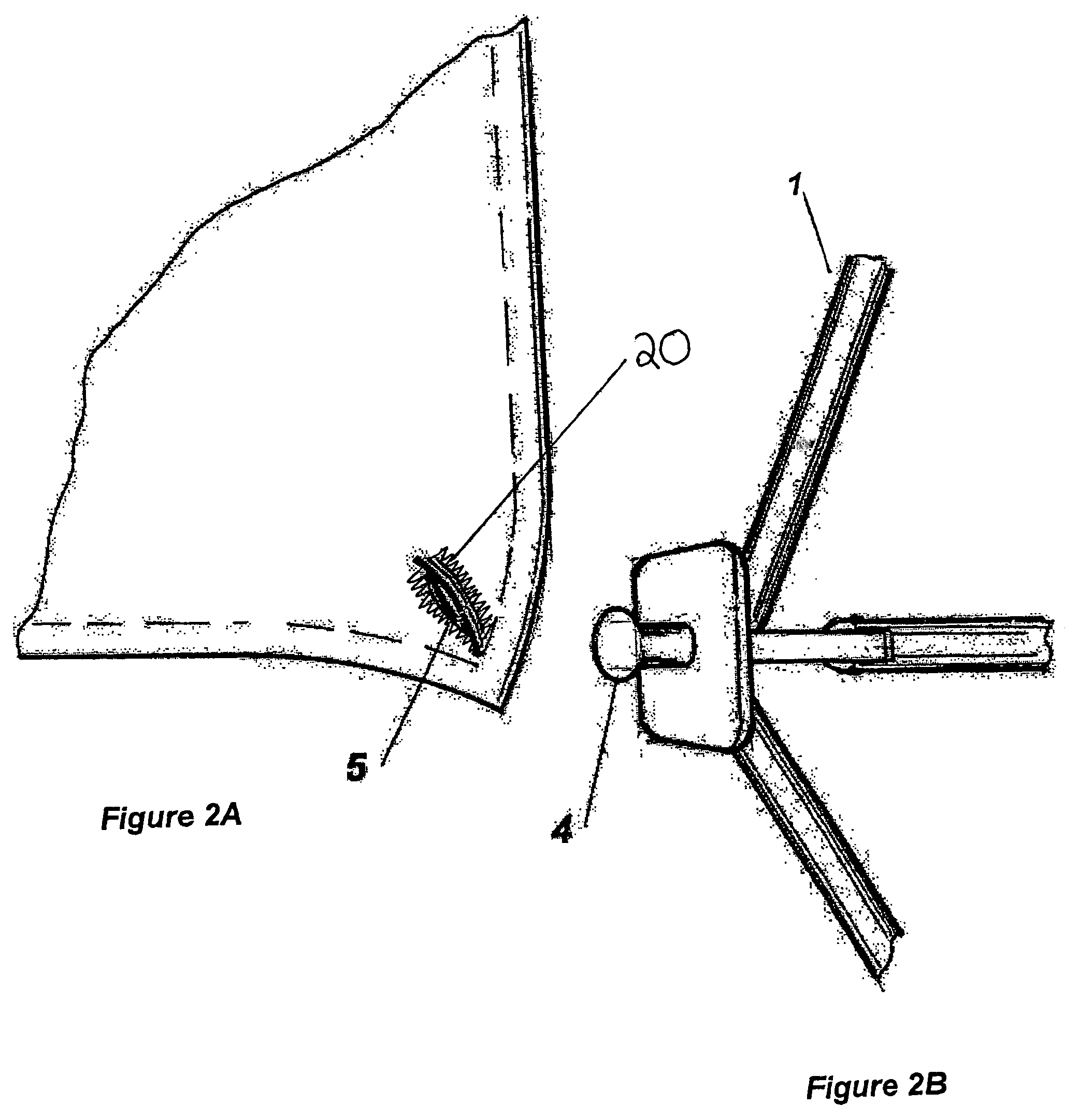

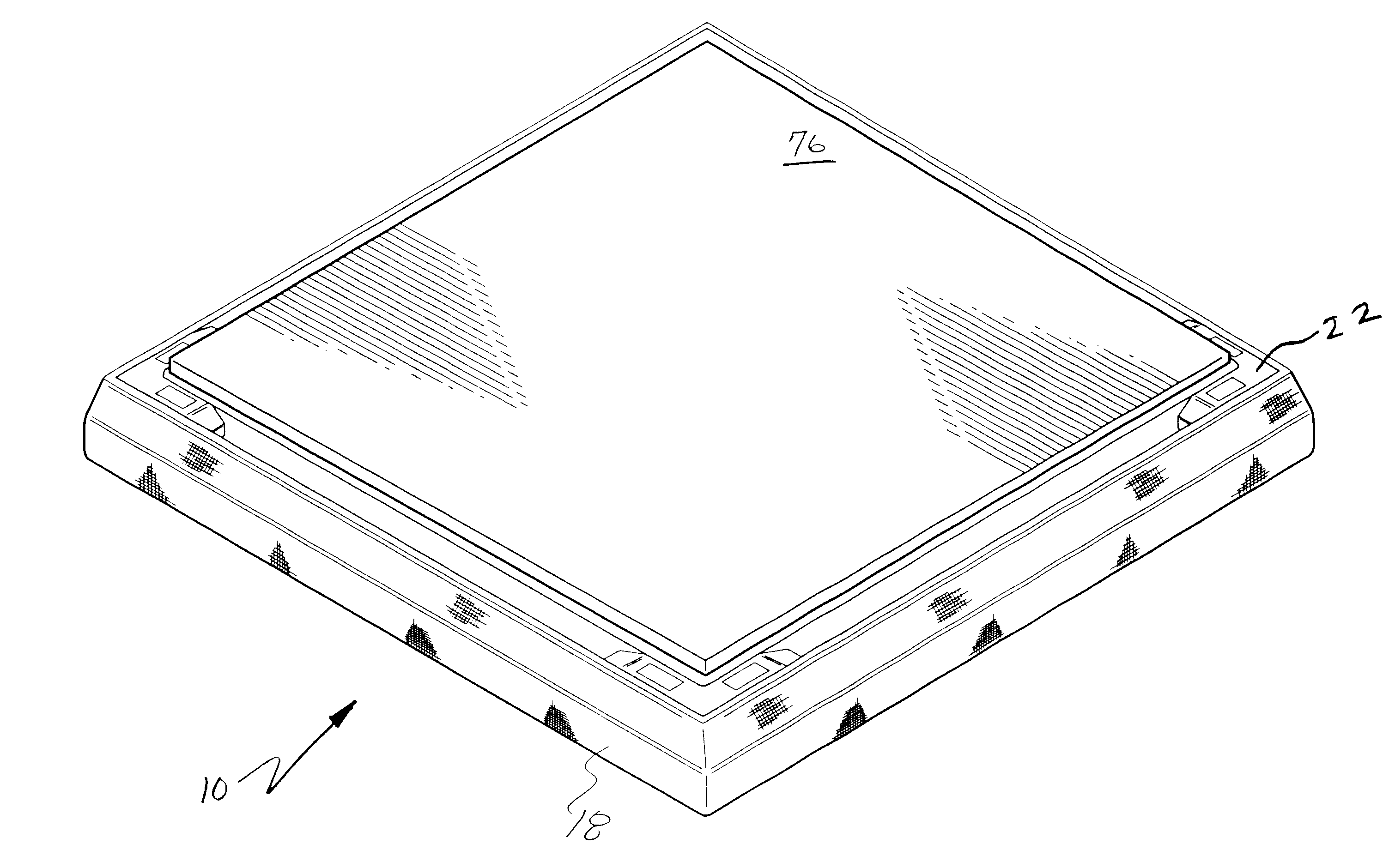

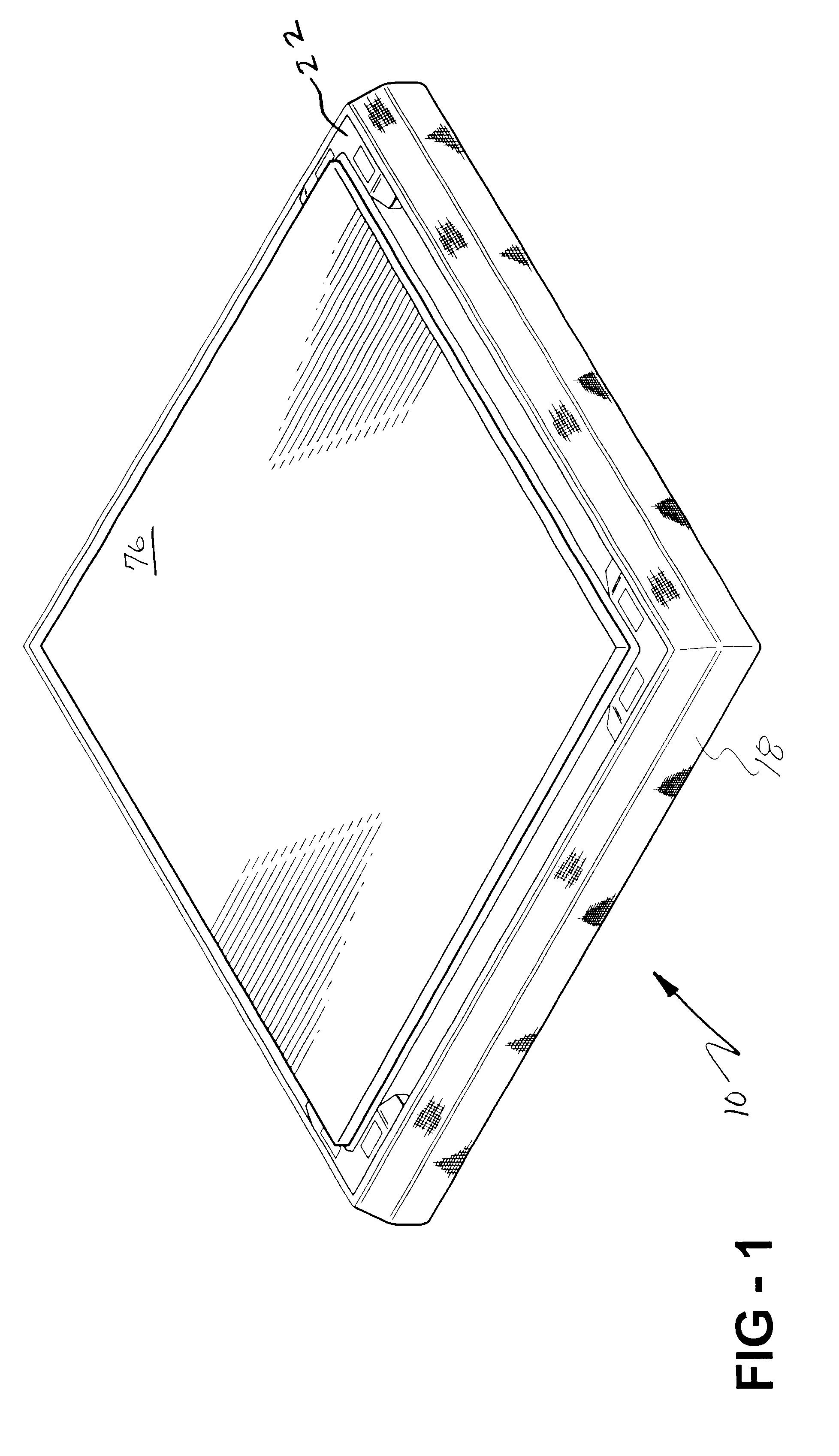

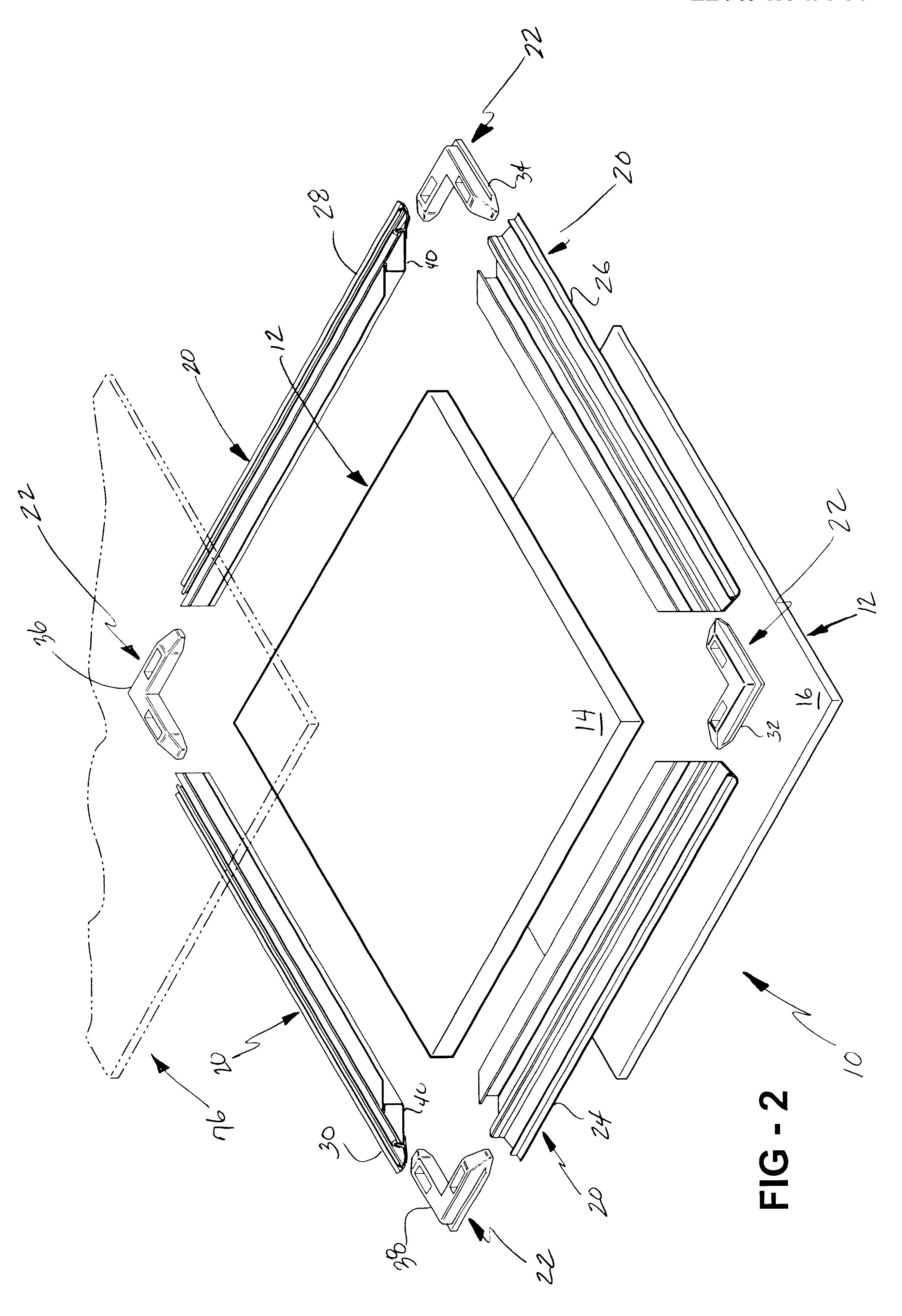

Method of assembling a frame assembly for a partition system

A method of assembling a frame assembly for a partition system is disclosed. The frame assembly includes a partition panel, a fabric covering the panel, and a frame component. The frame component automatically and evenly tensions the fabric about the panel. The frame component provided according to this method includes a support element, a lockable element, and an integral hinge defined between the support and lockable elements. The support element defines a cavity for receiving and supporting the panel. The lockable element extends from and is moveable relative to the support element. The panel is inserted into the cavity, and the fabric is mounted to the lockable element. Next, the lockable element is moved about the integral hinge such that the fabric mounted to the lockable element is automatically and evenly tensioned about the panel. A backing strip may be mounted to the frame component to protect the fabric from the integral hinge.

Owner:QUANEX HOMESHIELD LLC

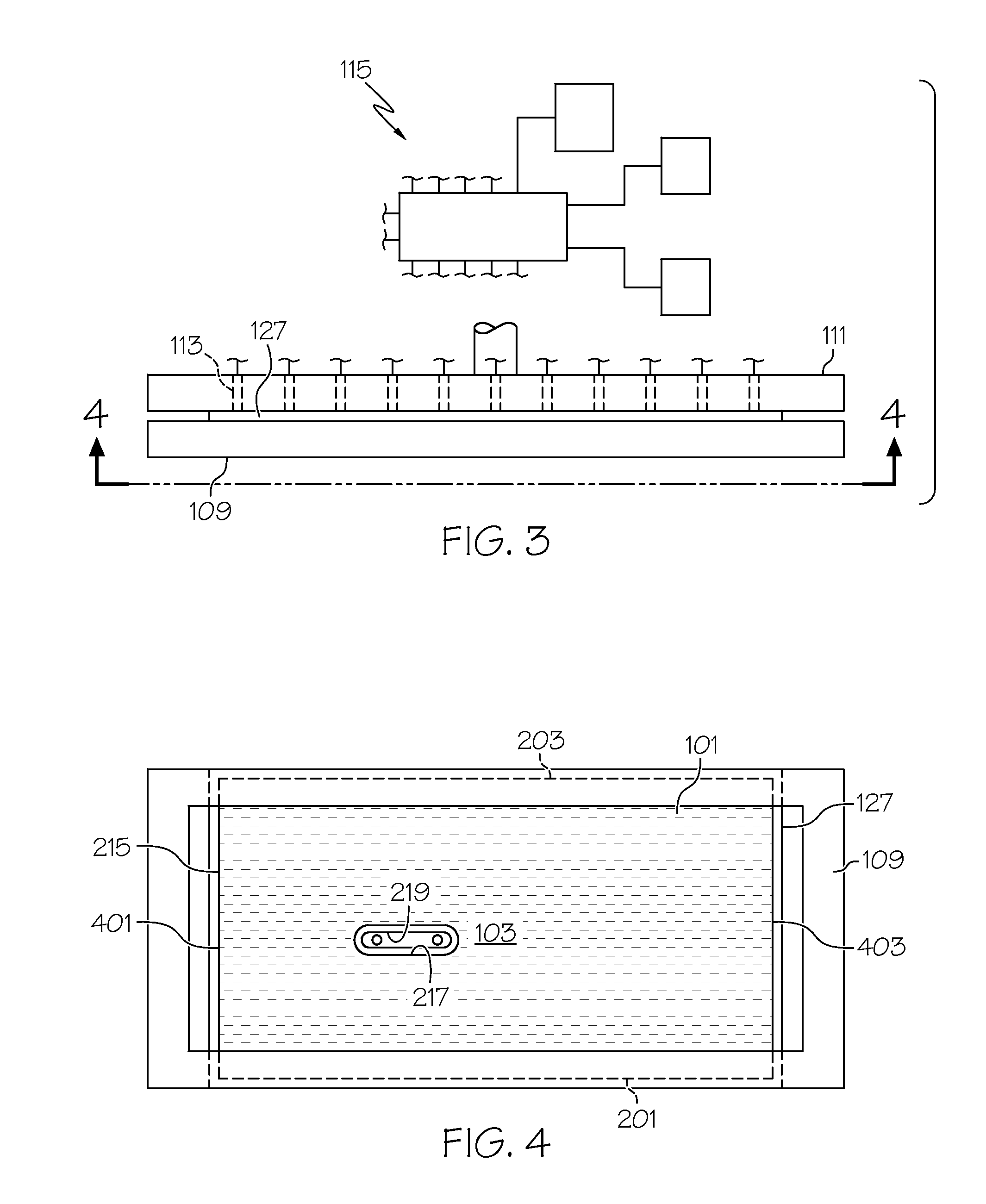

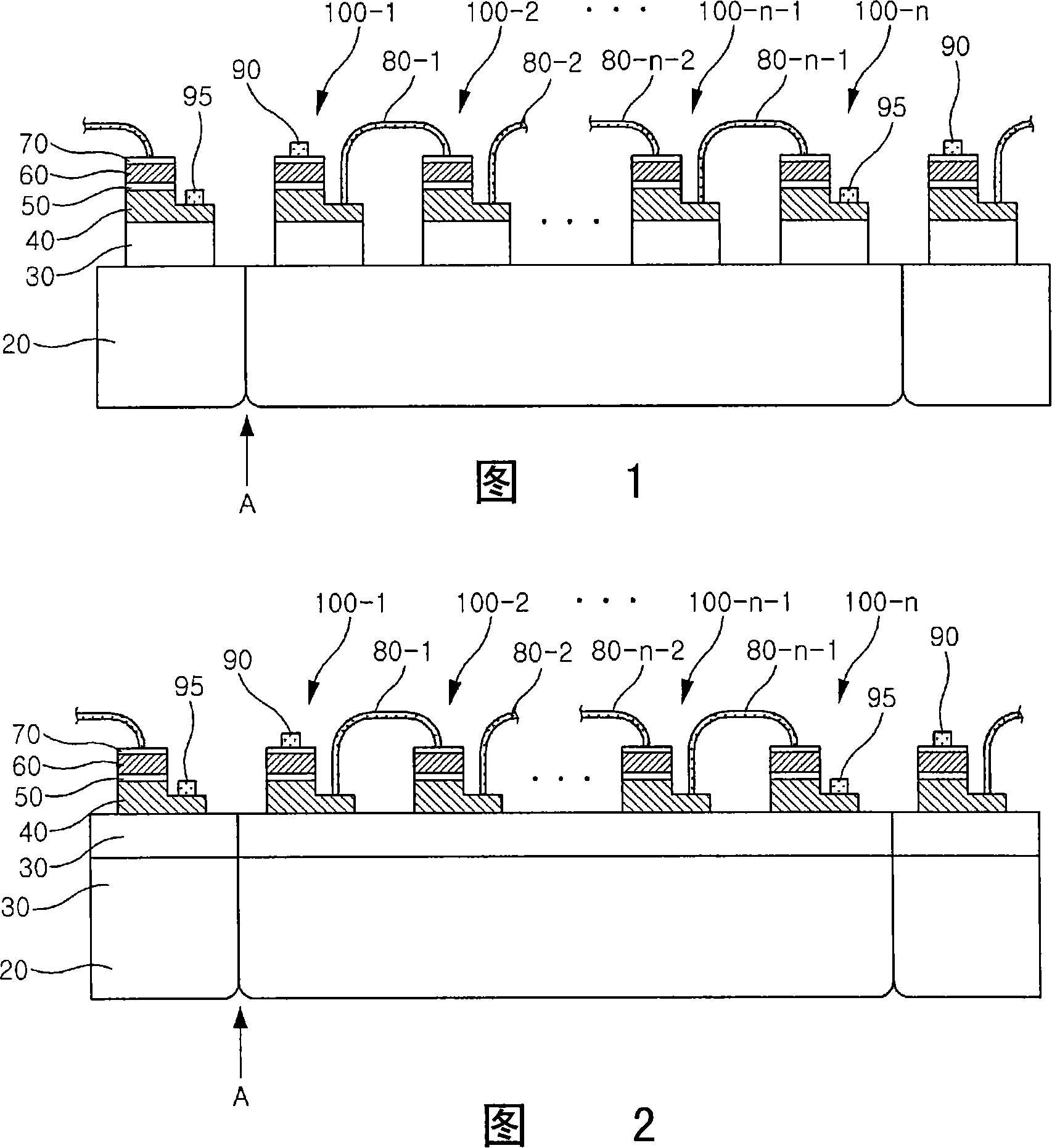

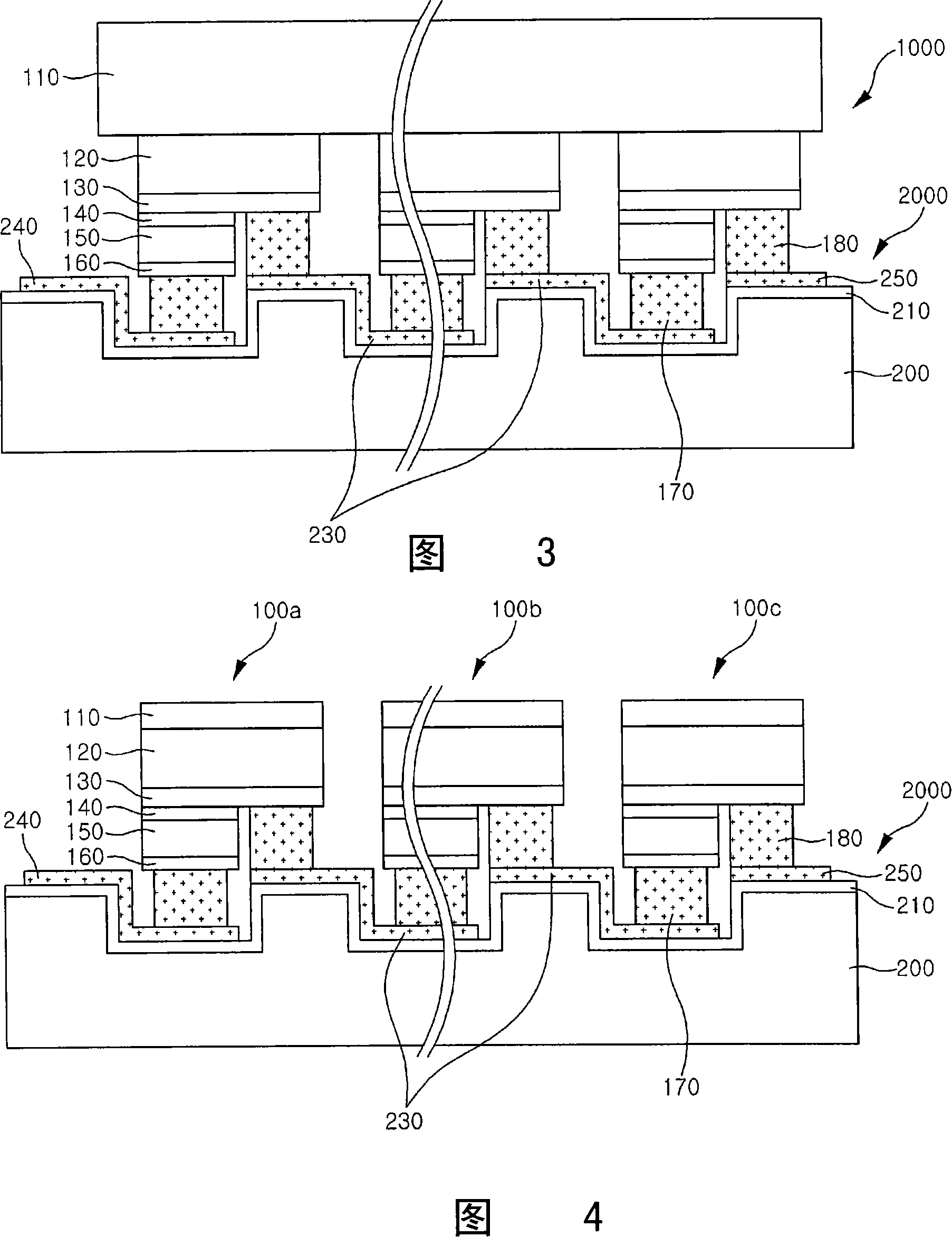

Led package having an array of light emitting cells coupled in series

ActiveCN101142692AStable structureImproved Photometric EfficiencySolid-state devicesStretchingEngineeringAC power

Disclosed is a light emitting diode (LED) package having an array of light emitting cells coupled in series. The LED package comprises a package body and an LED chip mounted on the package body. The LED chip has an array of light emitting cells coupled in series. Since the LED chip having the array of light emitting cells coupled in series is mounted on the LED package, it can be driven directly using an AC power source.

Owner:SEOUL SEMICONDUCTOR

Processing method of warp knitting plush fabrics with burning out printing terylens

InactiveCN101876121AImprove the three-dimensional effectIdeal embossing effectPattern makingHeating/cooling textile fabricsPolyesterEngineering

The invention relates to a processing method of warp knitting plush fabrics with burning out printing terylens. The processing method comprises the following steps of: materials selection: selecting DTY (Draw Textured Yarn) terylen low stretch yarns from 75 D to 150 D as felted yarn materials and selecting FDY (Fully Drawn Yarn) semi-dull polyester yarns from 50 D to 100 D as ground yarn materials, wherein the DTY terylen low stretch yarns account for 60-80% of the fabrics by weight percent, and the FDY semi-dull polyester yarns account for 20-40% of the fabrics by weight percent; weaving or slitting after weaving; thermally forming or pretreating after thermally forming; brushing and cropping the front surface or brushing and cropping the back surface, cropping the back surface and pilling; post-forming; burning out printing: carrying out burning out printing on grey fabrics subjected to the post-forming by using a burning out printing alkali slurry; steaming; post-treating; and forming a finished product. By the technical scheme, the fabrics can achieve the advantages of strong third dimension of patterns, ideal sculptured pattern effects and favorable shininess, residues does not generate in the weaving process, which is beneficial to protecting warp knitting machines.

Owner:CHANGSHU XINXIN WARP & KNITTING

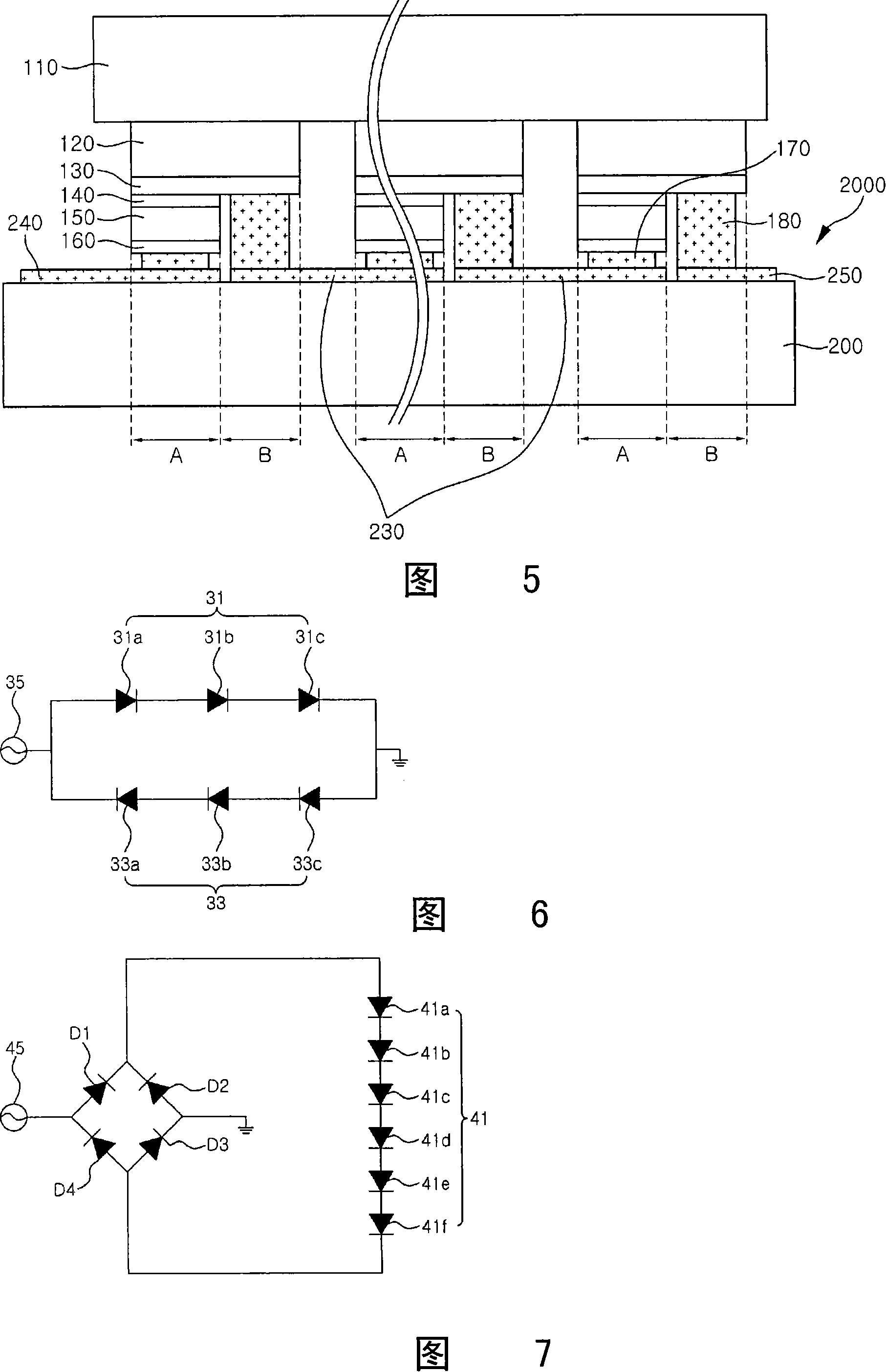

Packaging laminate with gas and aroma barrier properties

InactiveUS6338870B1Improved barrier and durability propertyWrappersMolten spray coatingThin oxidePaperboard

A packaging laminate (10) including a substrate film (15) coated with a carbon containing silicon oxide layer (16, 17) on both surfaces is disclosed herein. A method for producing the laminate (10), and blanks and packages fabricated from the laminate are also disclosed herein. The PECVD process of the present invention strains the substrate film (15) during deposition thereby creating a very thin oxide layer with superior durability, oxygen and aroma barrier properties. The carbon-containing silicon oxide coating (16, 17) has a stoichiometry of SiOxCy in which x is witin the range of 1.5-2.2 and y is within the range of 0.15-0.80. The substrate film (15) may include a core layer (12) of a material selected from the group consisting of paper, paperboard, a foamed core, polyethylene terephtalate, polyamide, polyethylene and polypropylene.

Owner:TETRA LAVAL HLDG & FINANCE SA

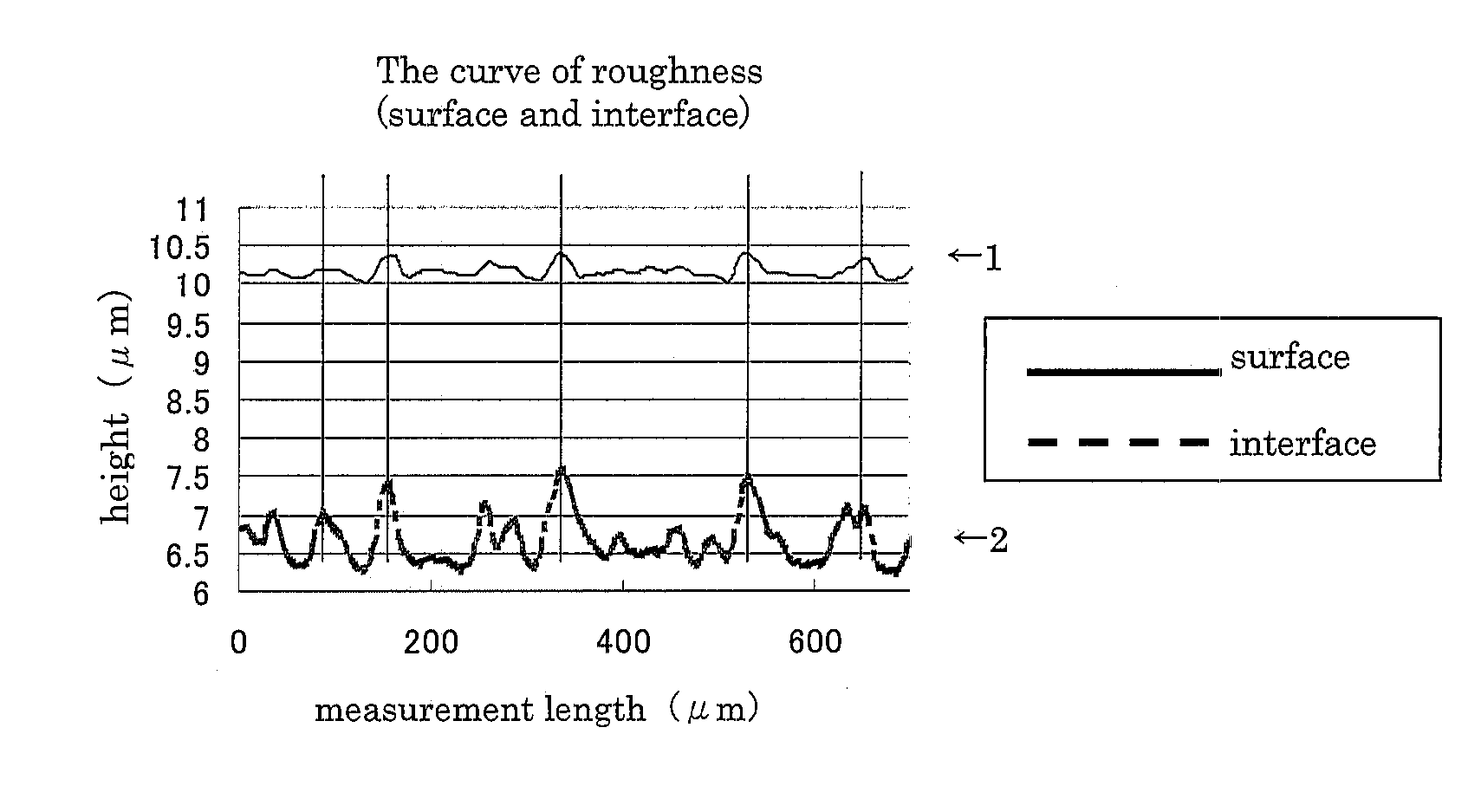

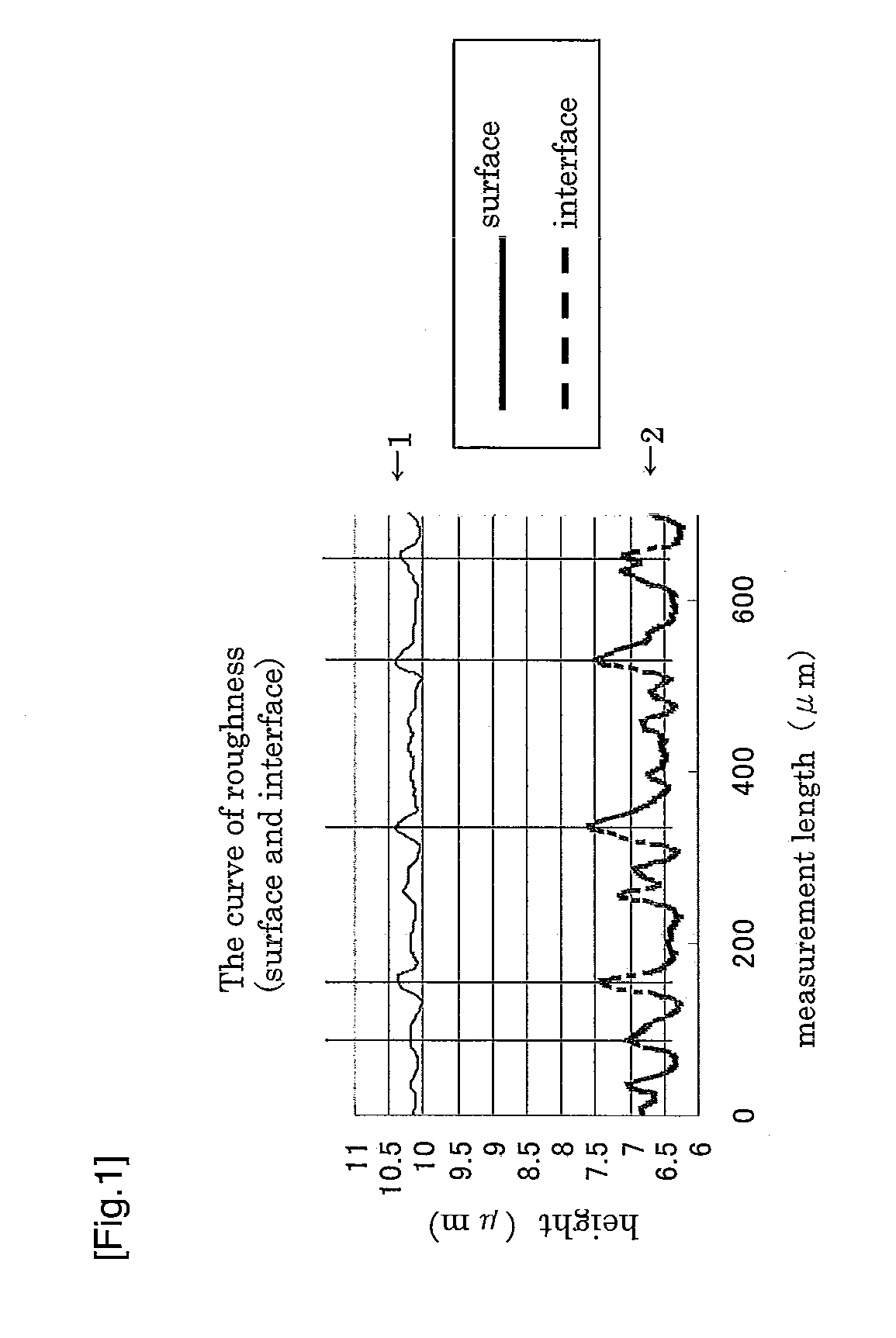

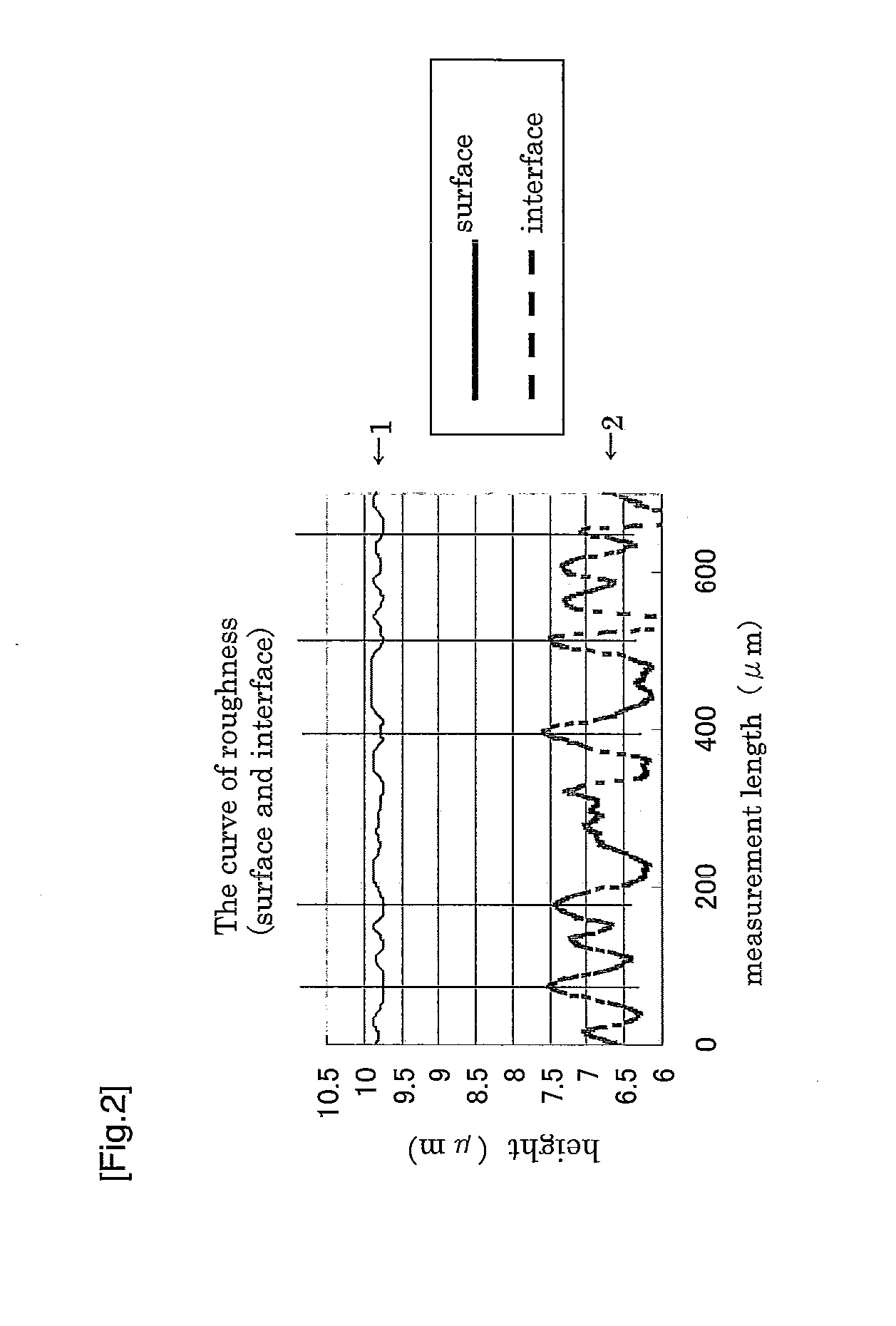

Hard-coated film, method for production thereof and antireflection film

ActiveUS20100028600A1Reduce distractionsImprove the level ofSynthetic resin layered productsPretreated surfacesPolyesterIrisation

There is provided a hard-coated film that includes a thermoplastic film and a hard coat layer placed thereon, has high surface hardness, is prevented from forming interference iris patterns, does not reduce image sharpness when used for antireflection films, and is prevented from causing screen glittering, external light reflection, or coloration irregularity of reflected light. The hard-coated film includes a polyester film and a hard coat layer placed on at least one side of the polyester film, wherein the hard coat layer has a surface with irregularities, an interface between the polyester film and the hard coat layer has irregularities, and the surface of the hard coat layer has 3D surface roughness parameters including an arithmetical mean deviation of surface Sa of from 15 nm to less than 150 nm and a kurtosis of surface height distribution Sku of from 1.5 to 5.

Owner:TORAY IND INC

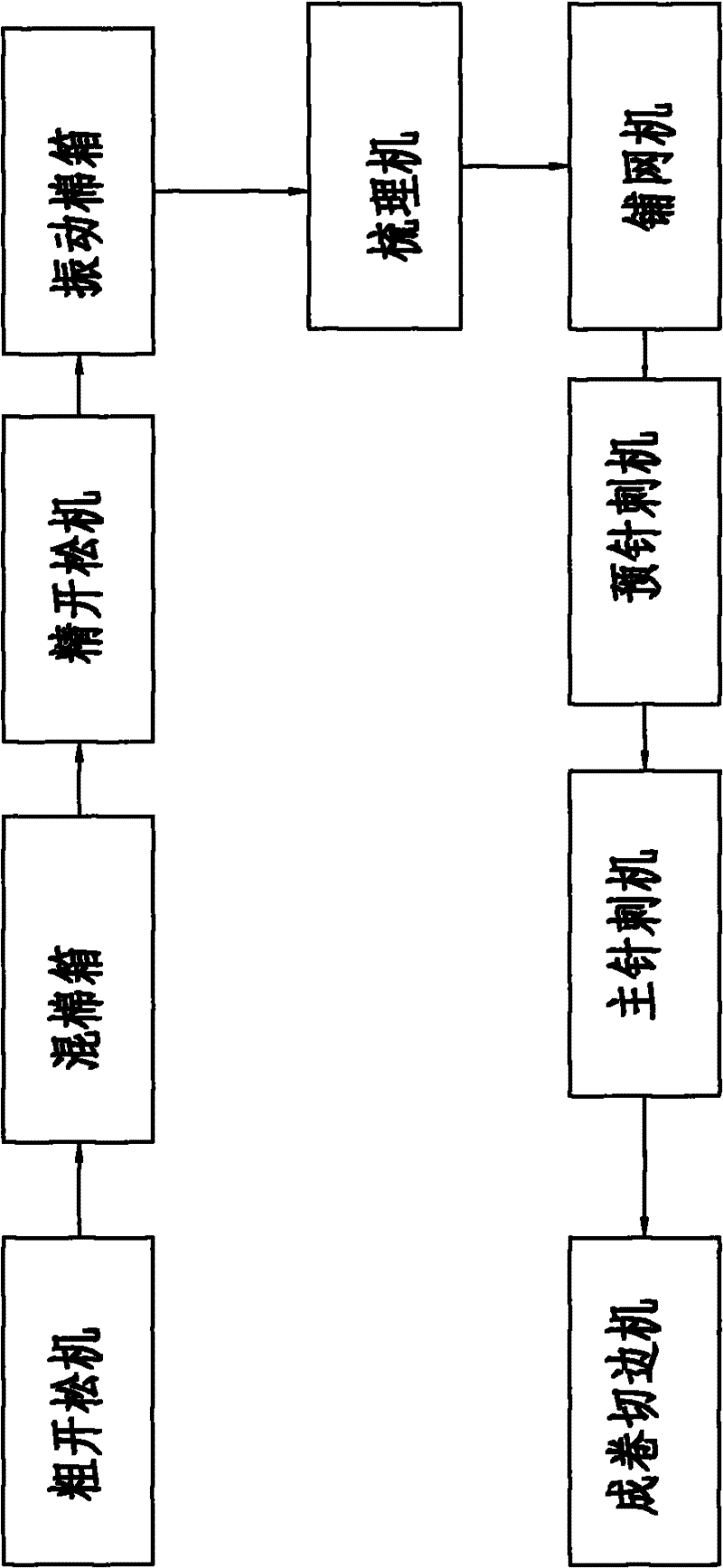

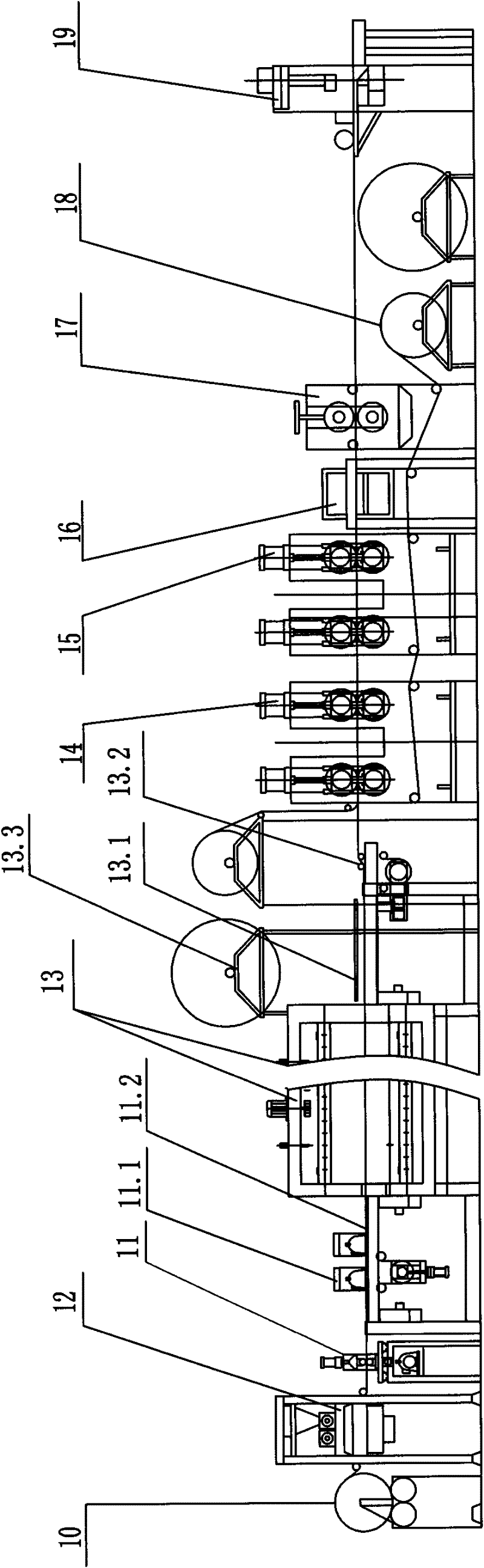

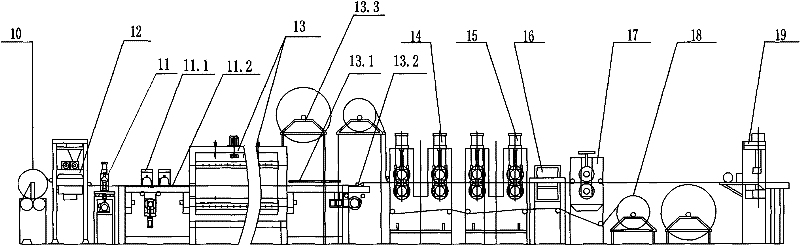

Method for preparing glass fiber and reinforced polypropylene fiber composite material

ActiveCN102303430AAchieving reinforcementHigh tensile strengthSynthetic resin layered productsLaminationGlass fiberPost-Procedure

The invention relates to a method for preparing a glass fiber and reinforced polypropylene fiber composite material. The method comprises a non-weaving process in pre-procedure and a thermal pressing and molding process in post-procedure; the non-weaving process in pre-procedure comprises the following steps of: weighing polypropylene fibers and glass fibers in proportion, loosening the fibers by a coarse opener, then conveying to a blending box by a cotton conveying blower, conveying to a fine opener, a vibrating cotton box and a big cotton bin, sufficiently mixing the fibers by means of a conveying curtain, an inclined curtain and a picker roller beater, outputting to a carding machine by a cotton pressing roller and an output curtain, lapping by a lapping machine, conveying the fiber mesh by a feeder to a pre-needling machine for pre-needling operation, and setting and needling into a felt material by using a main needling machine; and the thermal pressing and molding process in post-procedure comprises the following steps of aligning and unreeling, powdering, deviation correction, open-width feeding, heating of a drying room, thermal pressing and compounding, rolling and cooling, and air-cooling. The method for preparing the glass fiber and reinforced polypropylene fiber composite material has the advantages of stronger tensile strength and impact resistance performance, capability of satisfying the usage requirements in the high-load defending parts of automobiles and ships and the like, and wide application range.

Owner:NINGBO SUNLIGHT MOTOR PARTS

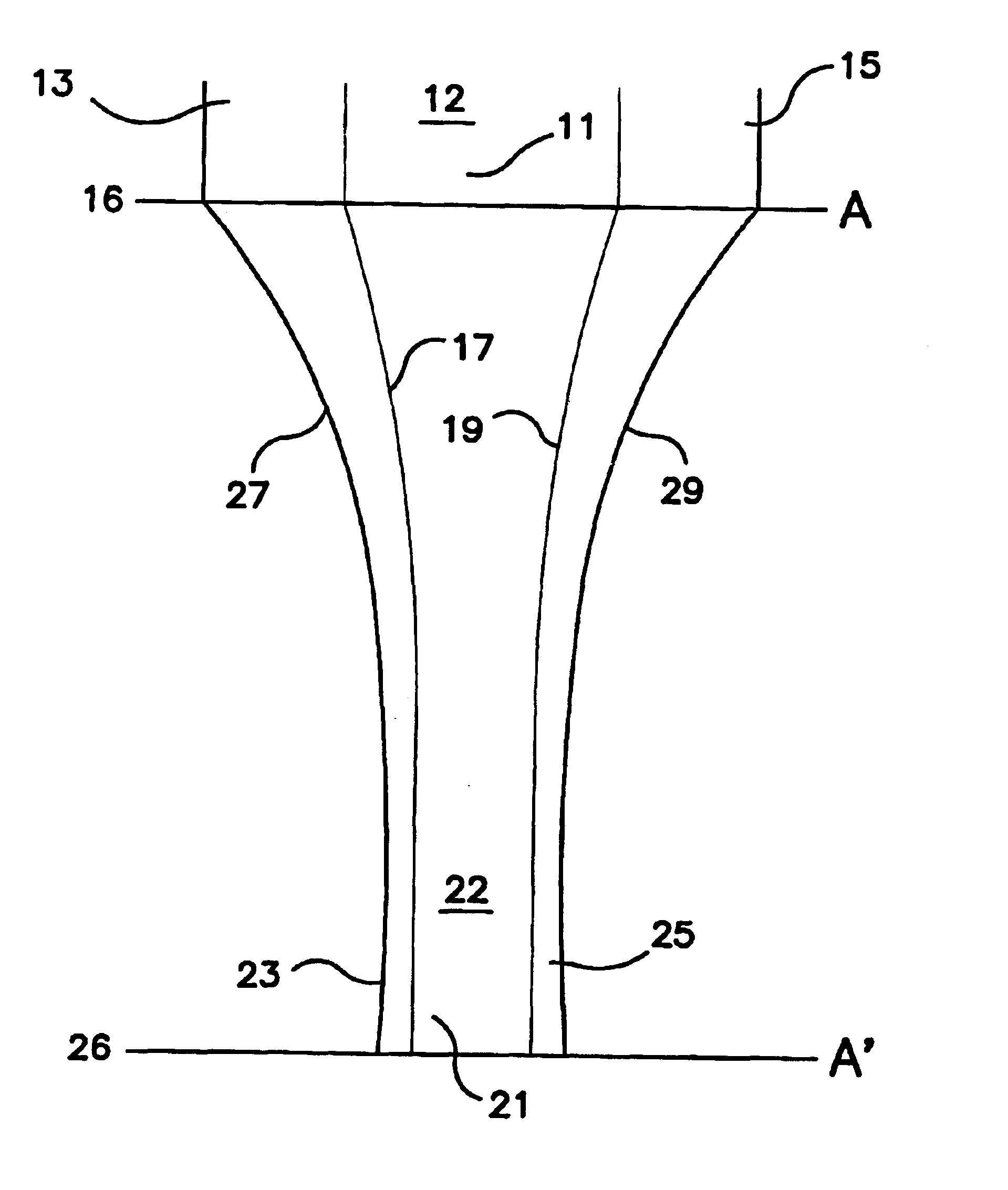

Nonwoven webs having improved necking uniformity

InactiveUS6900147B2Facilitates easier neckingEasy neckingSynthetic resin layered productsCellulosic plastic layered productsFiberEngineering

A neckable nonwoven web is provided with a central region and two edge regions, the central region being selectively easier to neck than the two edge regions. The nonwoven fibers in the central region have a polymer composition and / or physical properties which differ from the nonwoven fibers in the two edge regions. The selectively easier necking in the central region causes the central region to neck to about the same extent as the two edge regions, which otherwise would experience greater necking than the central region if the starting nonwoven web were completely uniform. Necked nonwoven webs and neck-bonded laminates made using the improved neckable nonwoven web, are also provided.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Screen printing screen, screen, screen frame, screen joining method, screen spreading method, painting canvas, advertisement sheet, and planer mirror

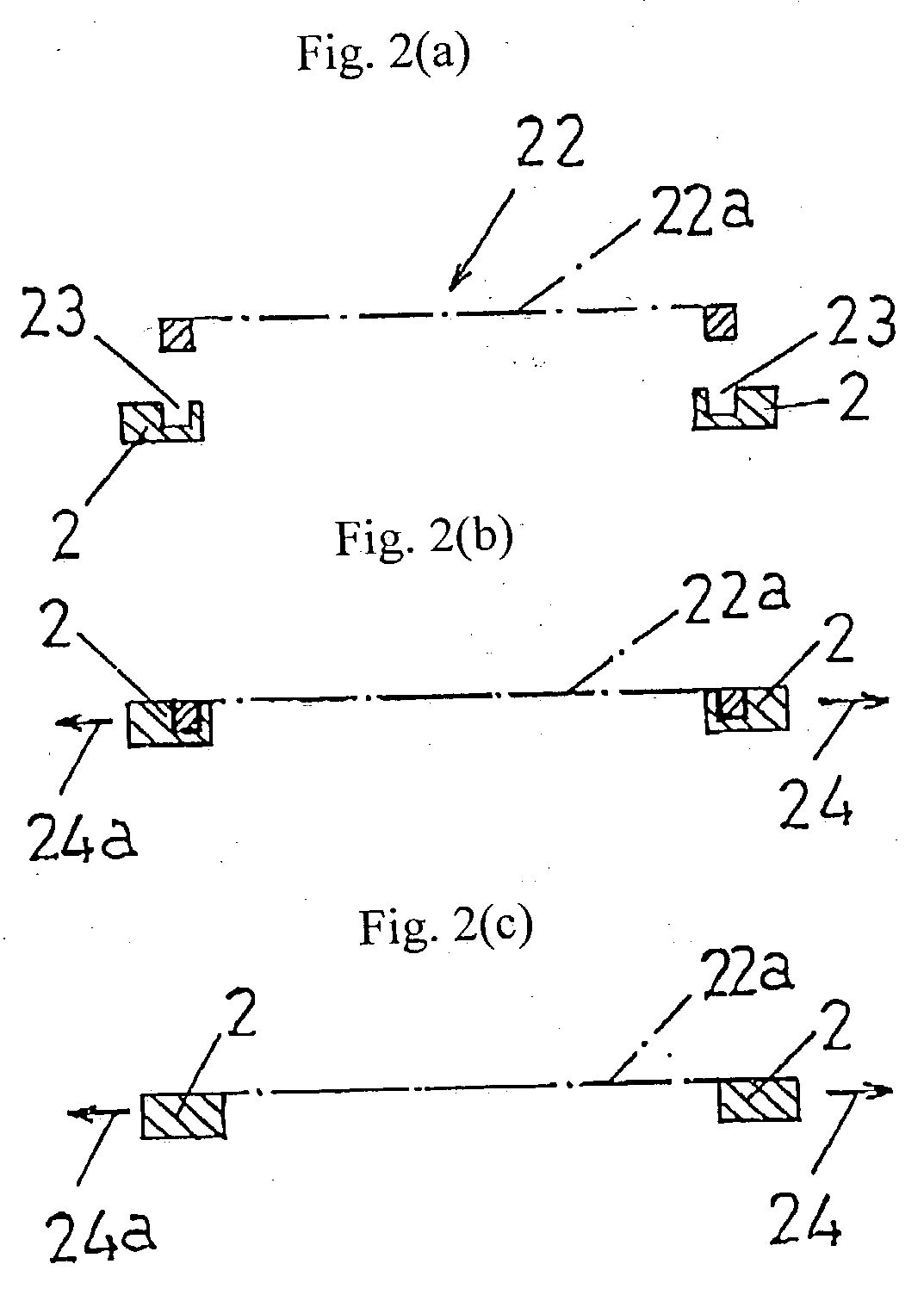

InactiveUS20050034614A1Easy to useControl tensionScreensLiquid surface applicatorsScreen printingTypes of mesh

The present invention relates to a screen for screen printing. More particularly, the structure of the screen can have different types of mesh or sheets joined together. The present invention also relates to a method of detachably spreading a screen to a screen frame.

Owner:KASUYA FURETABU

Woven monofilament and production method

InactiveCN101440542AWith ultra-thinSoft and breathableSingeingHeating/cooling textile fabricsYarnEngineering

The invention discloses a monofilament fabric and a method for producing the same, wherein warp yarn forming the fabric is a monofilament. The method comprises the following steps: a preparing process before weaving, weaving, dyeing and finishing processes, wherein the preparing process comprises warping, rebeaming, drafting and healding processes; and the dyeing and finishing process comprises gray cloth forming, refining, intermediate forming, decrement, dyeing, functional resin finishing, and finishing forming. The fabric has the characteristics of lightness, ultra-thinness, softness, air permeability and the like, and is applicable to various styles of fashionable clothes.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

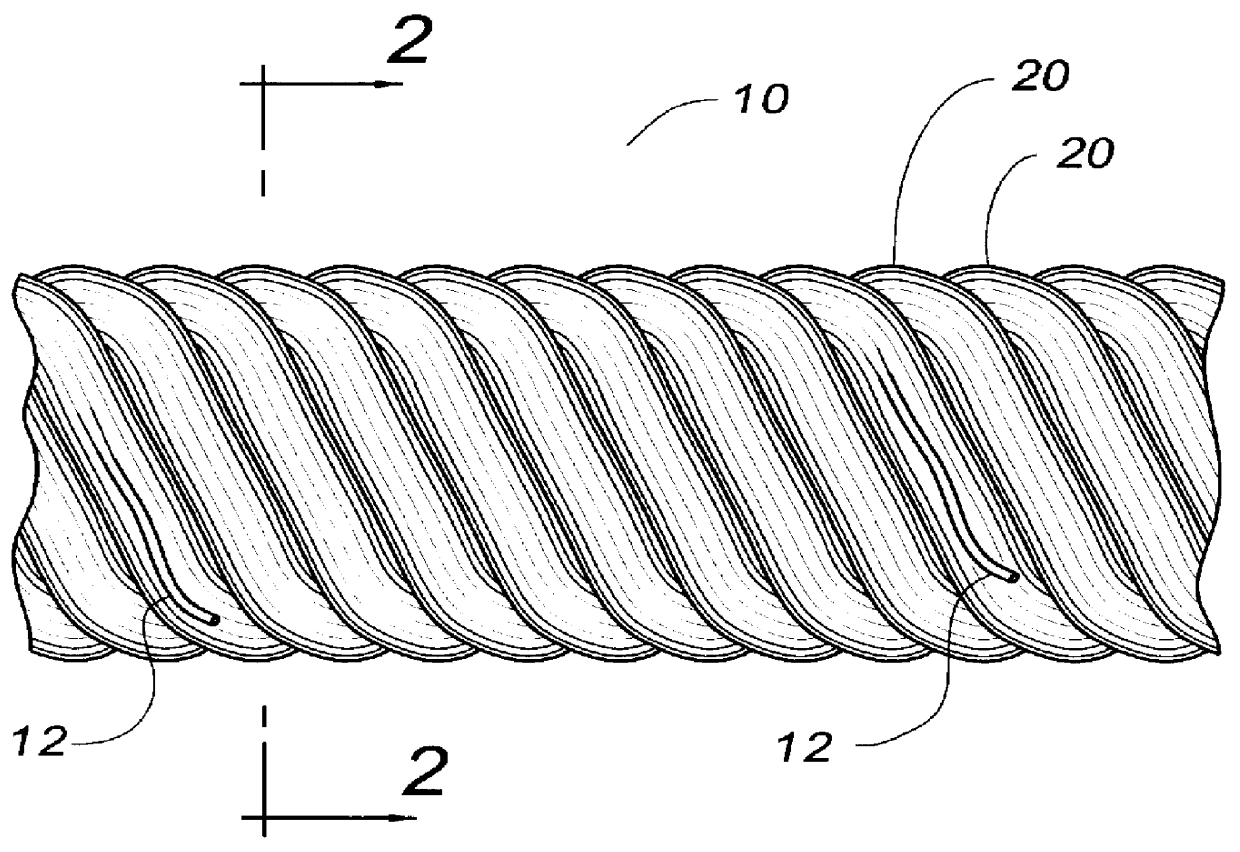

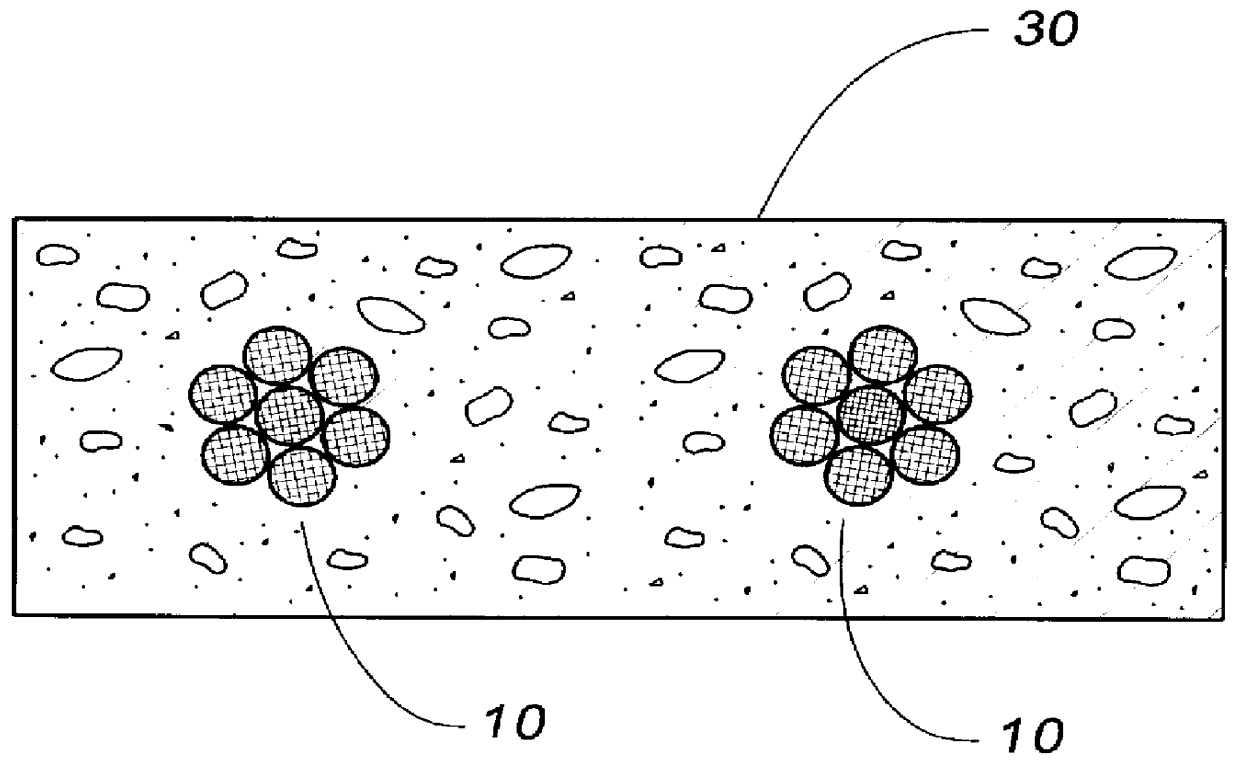

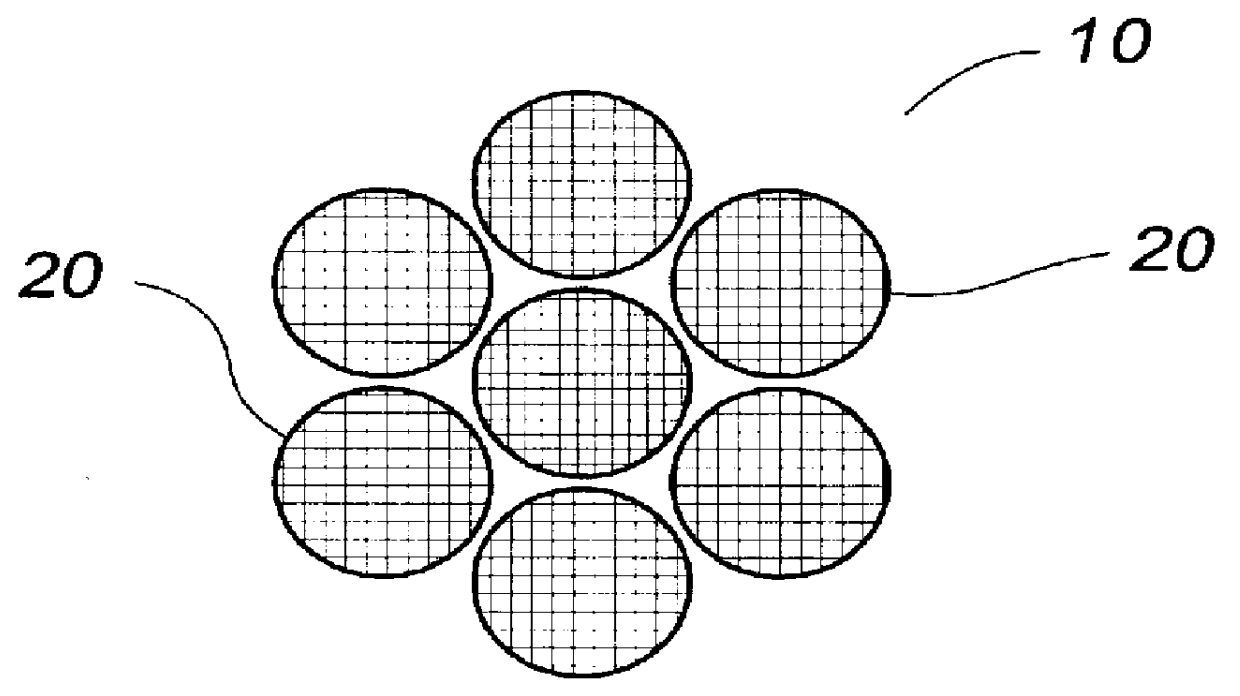

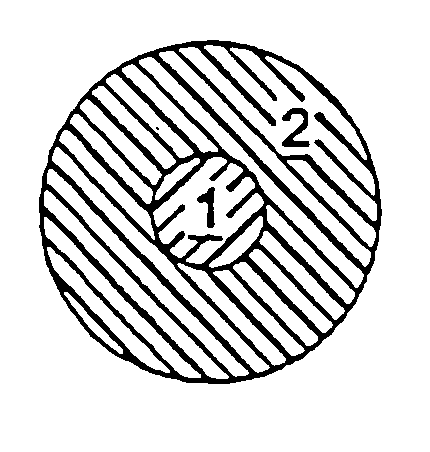

Composite reinforcing member

InactiveUS6048598AOvercome problemsLow costLayered productsVacuum evaporation coatingGlass fiberReinforced concrete

A corrosion resistant, light weight composite twisted rope rebar is disclosed for reinforcing concrete material, including providing a plurality of continuous glass fibers oriented substantially in the longitudinal axis and coated with a thermoset polyester resin and catalyst. In one aspect, the twisted rope rebar includes two or more bundles in a helical pitch of about two inches to six inches to form the twisted rope rebar.

Owner:BALABA CONCRETE SUPPLY

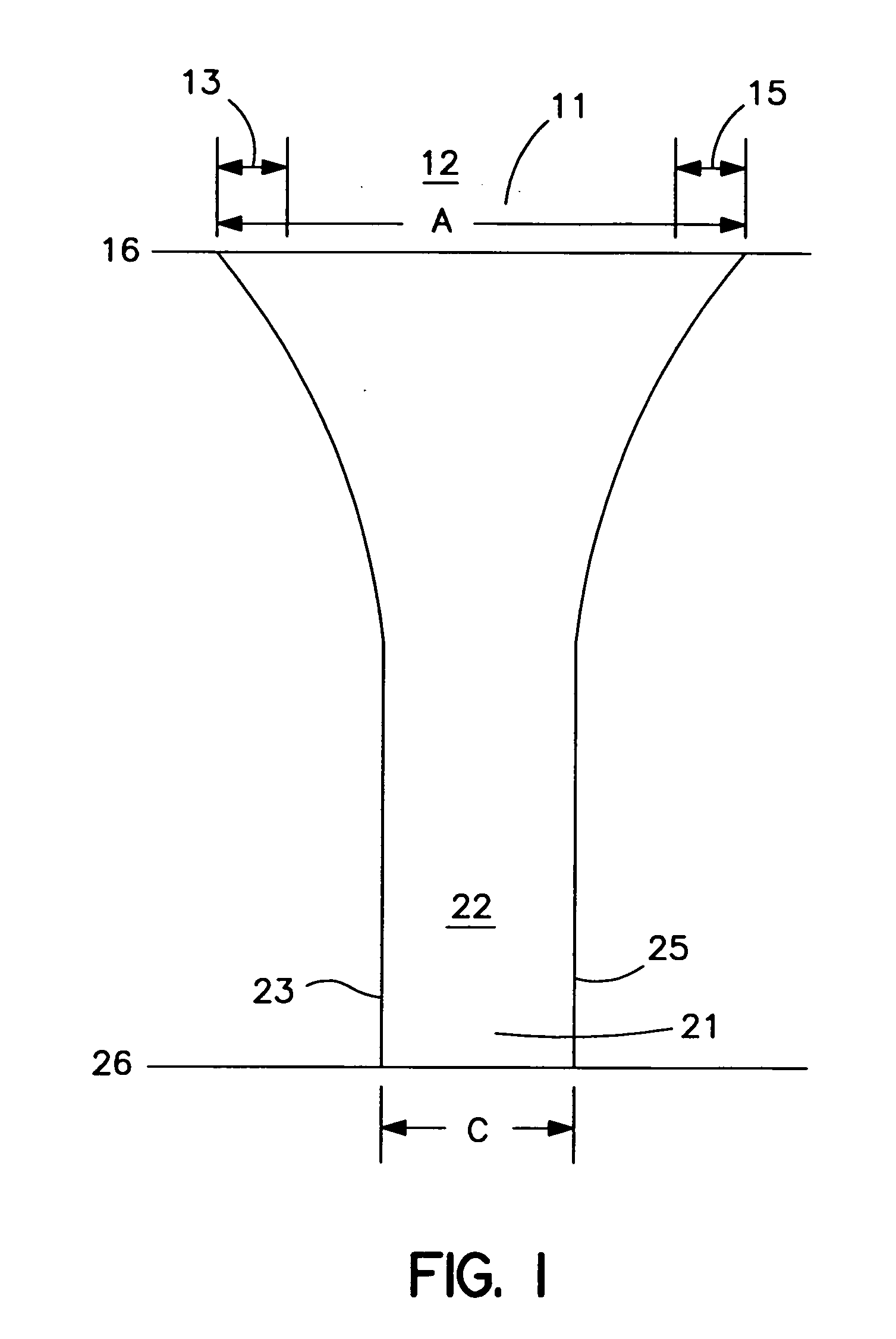

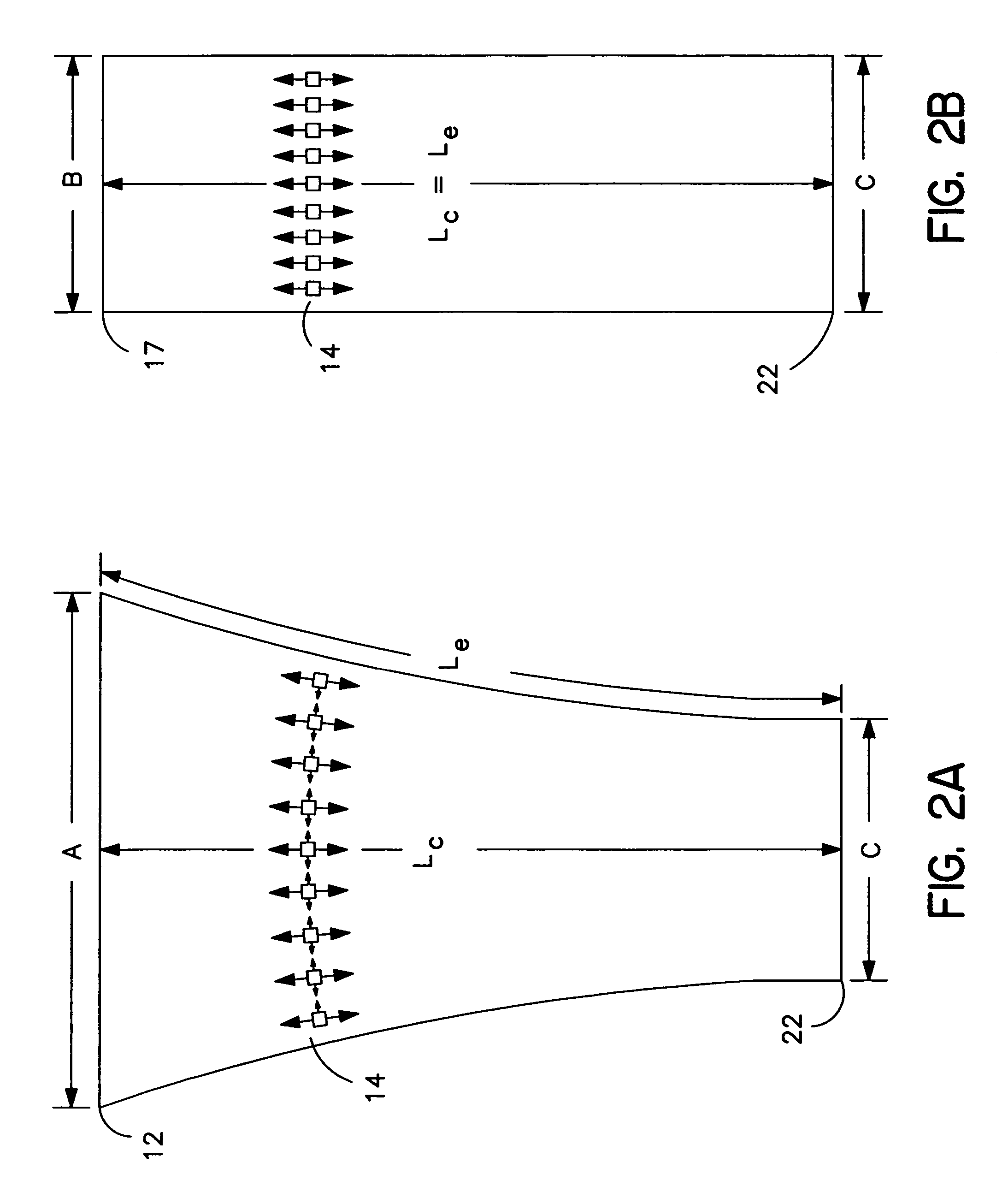

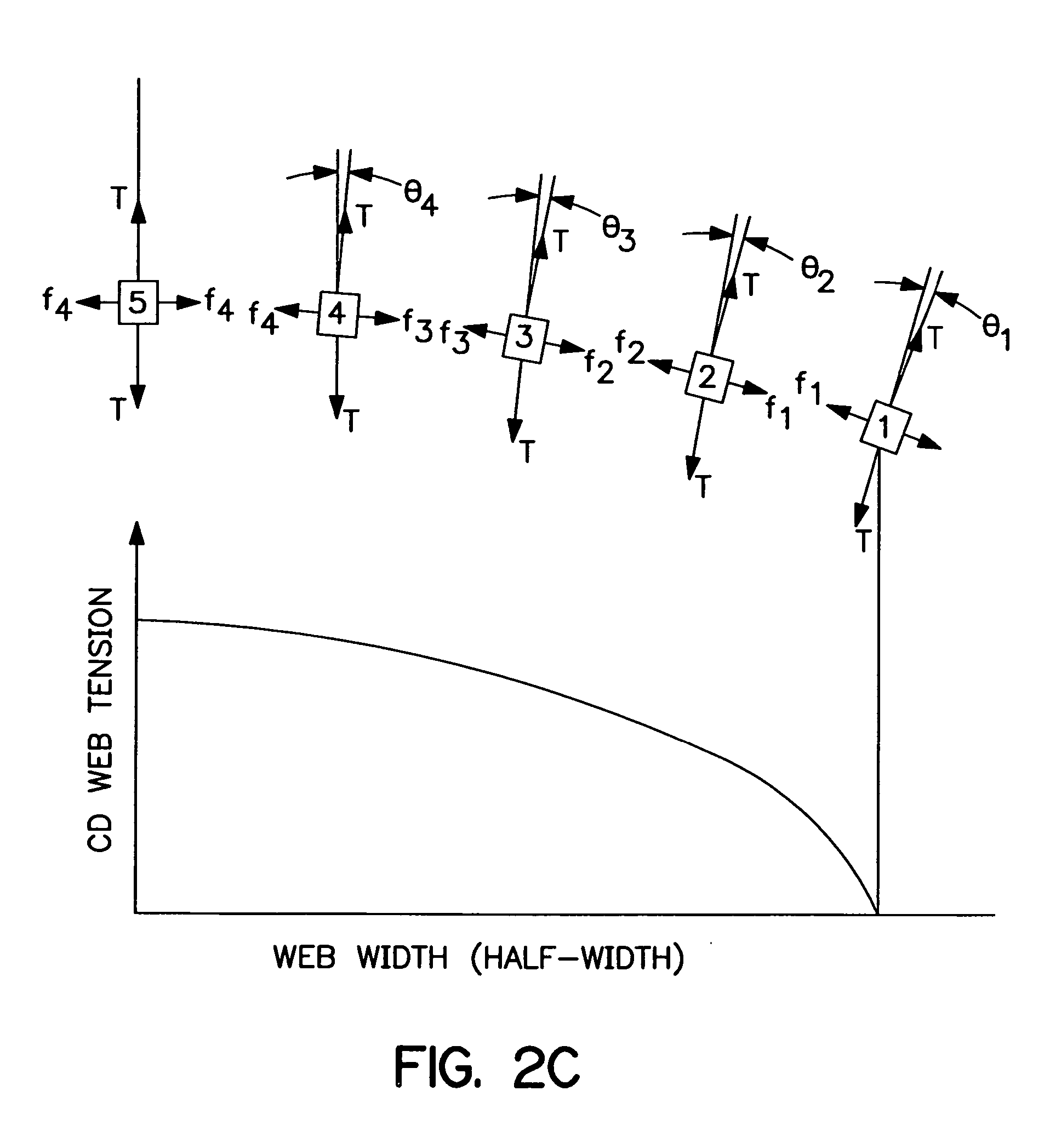

Process for making necked nonwoven webs having improved cross-directional uniformity

InactiveUS20070138698A1Improve lateral uniformityReduce widthMechanical working/deformationMouldsMechanical engineeringNeck stretching

Owner:KIMBERLY-CLARK WORLDWIDE INC

Elastomeric multicomponent fibers, nonwoven webs and nonwoven fabrics

A bonded web of multi-component strands that include a first polymeric component and a second polymeric component is capable of overcoming a number of problems associated with nonwoven webs including both stickiness and blocking. The first polymeric component and second polymeric component are arranged in substantially distinct zones extending longitudinally along at least a portion of a length of the strands which make up the web with the second component containing a zone constituting at least a portion of the peripheral surface of the strand. The first polymeric component also has an elasticity which is greater than that of the second polymer component. A process producing elastomeric spunbonded nonwoven fabrics which utilizes the activation by incremental stretching of the strands is also provided.

Owner:DOW GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com