Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2720 results about "Heat setting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat setting is a term used in the textile industry to describe a thermal process usually taking place in either a steam atmosphere or a dry heat environment. The effect of the process gives fibers, yarns or fabric dimensional stability and, very often, other desirable attributes like higher volume, wrinkle resistance or temperature resistance.

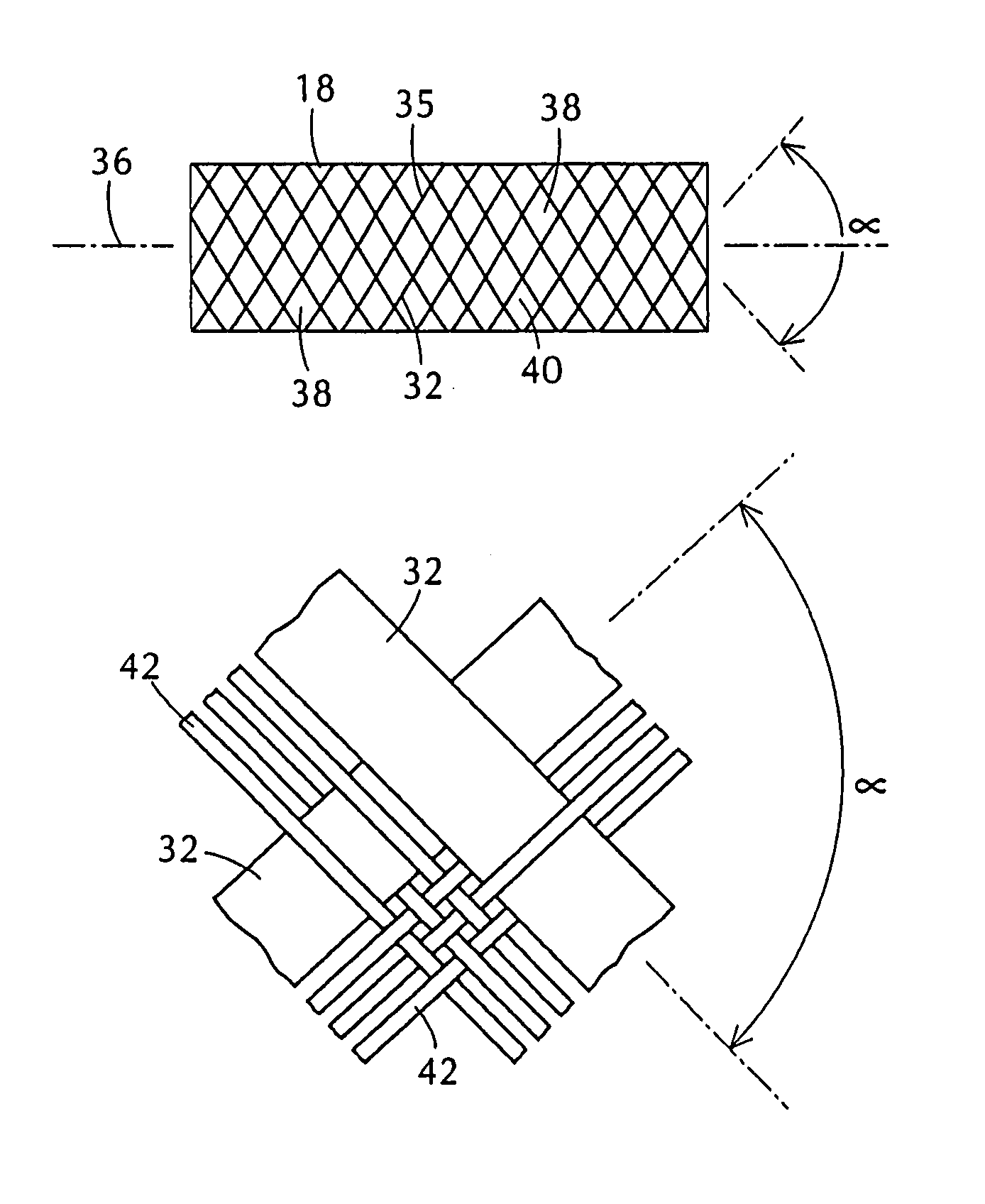

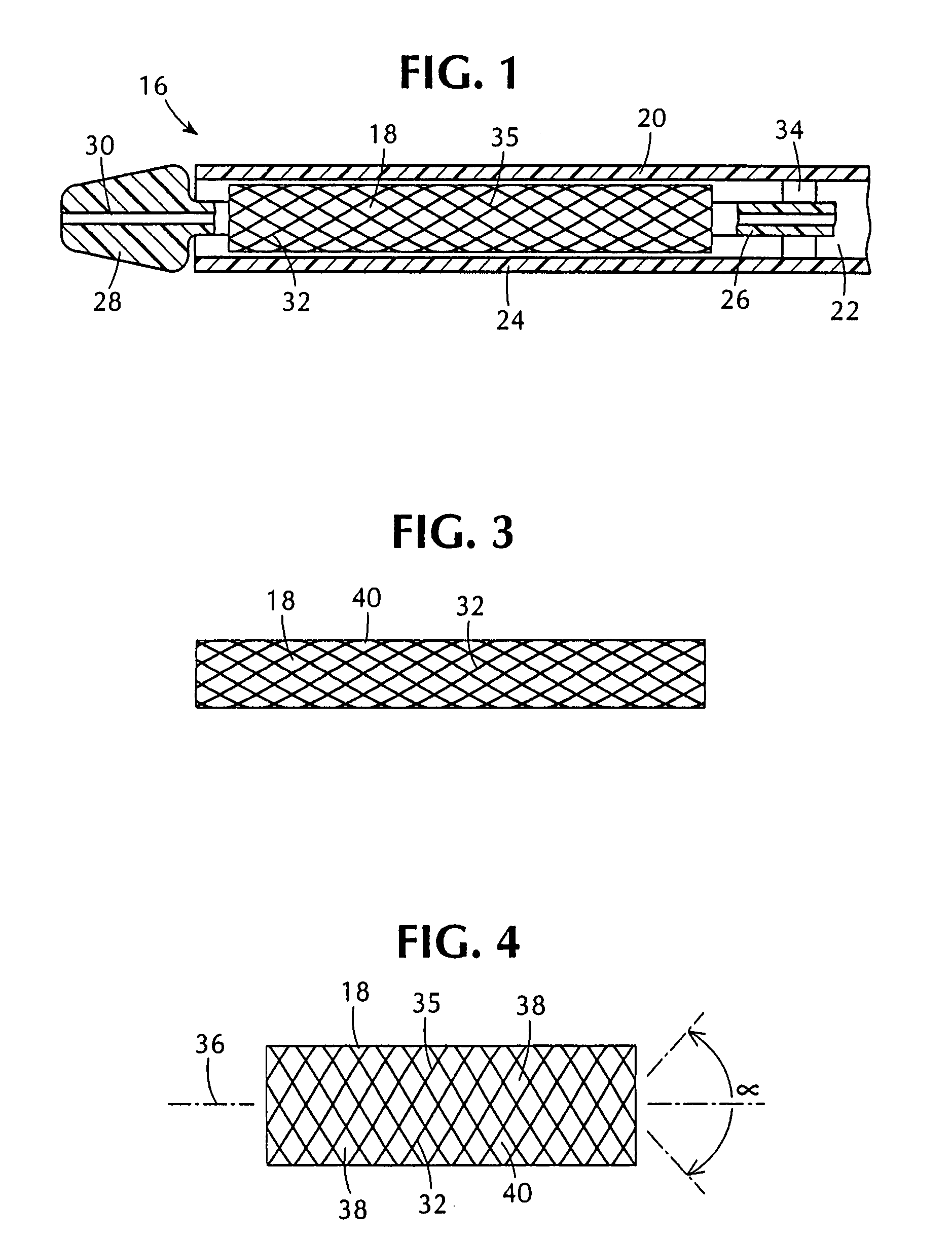

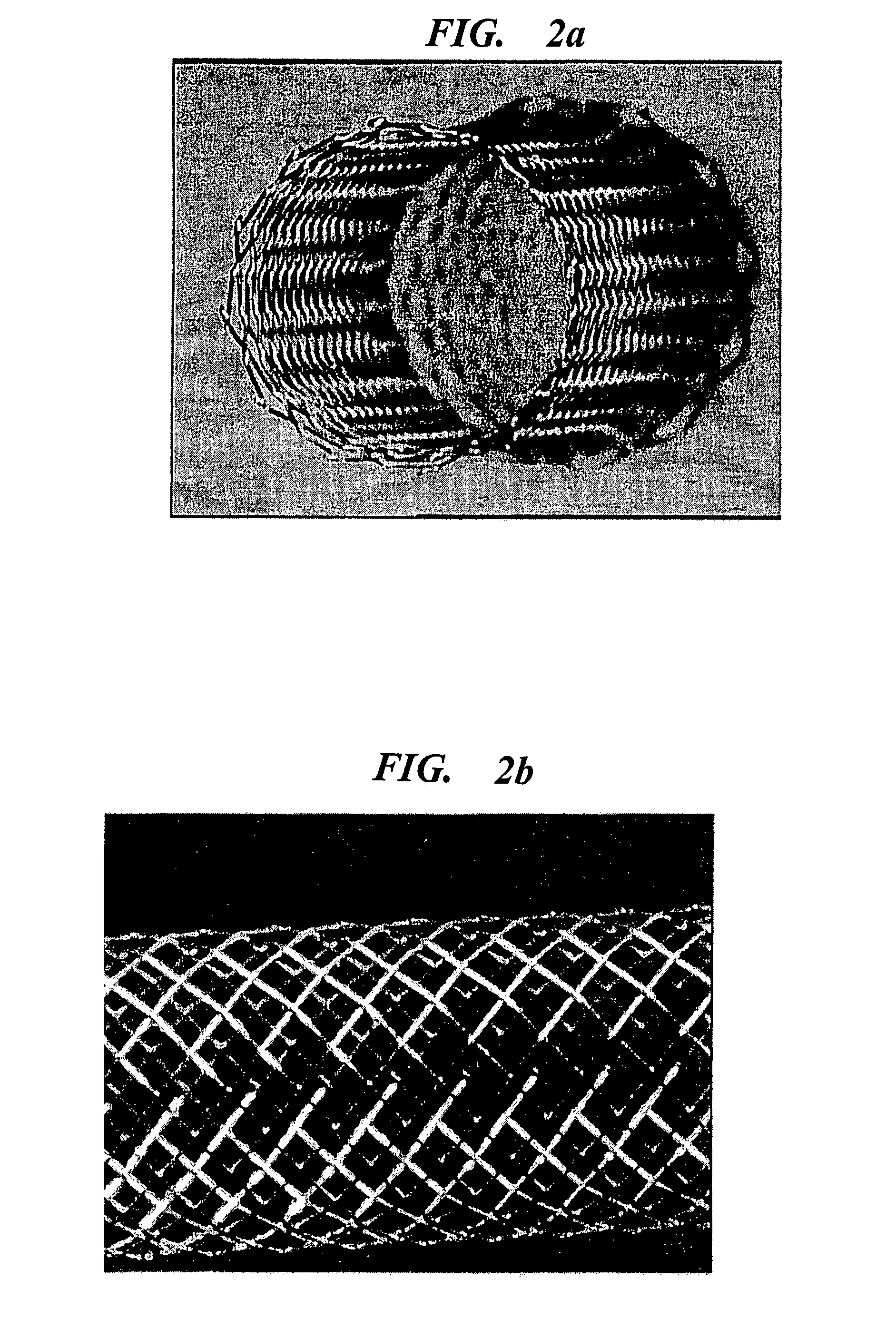

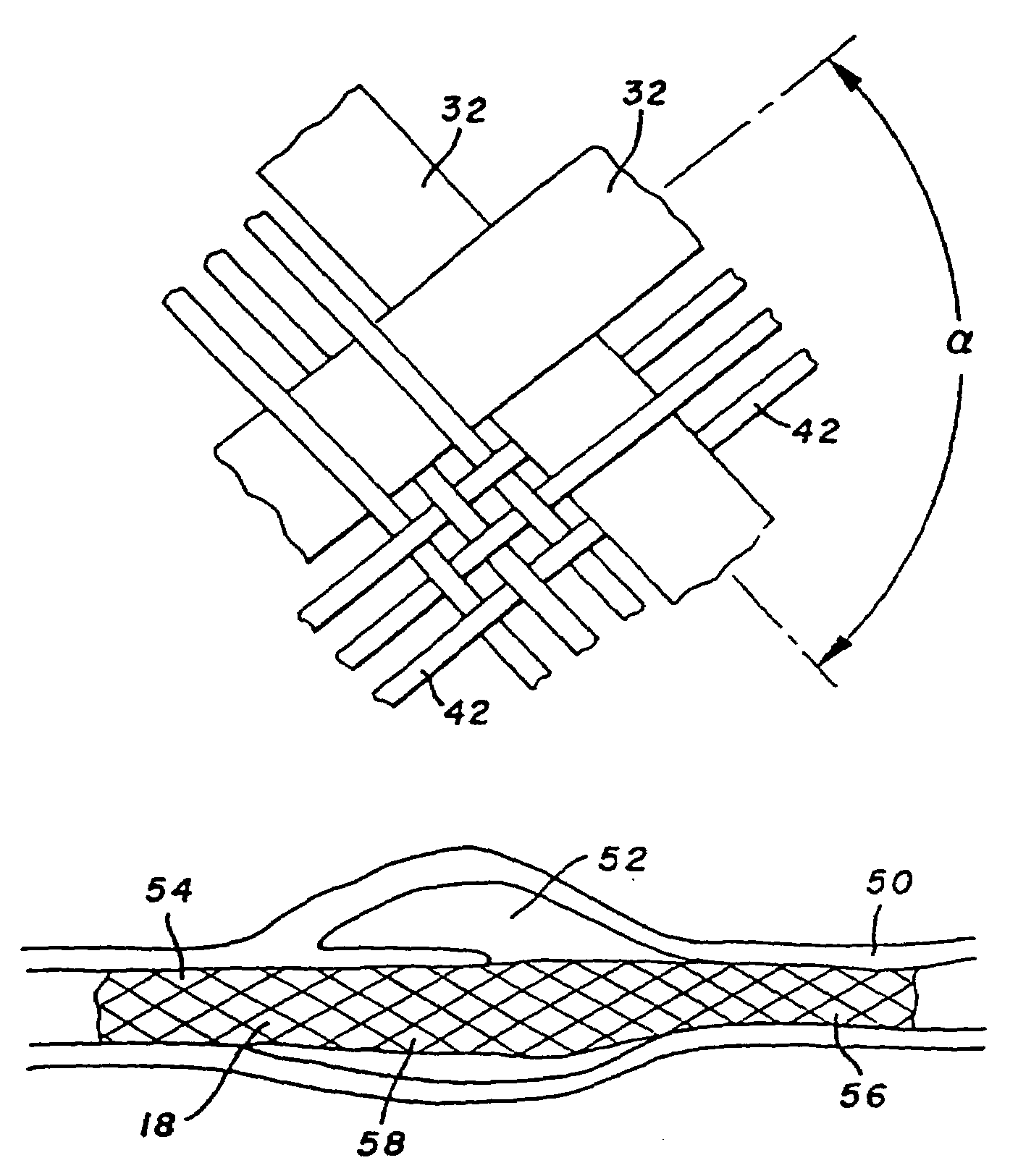

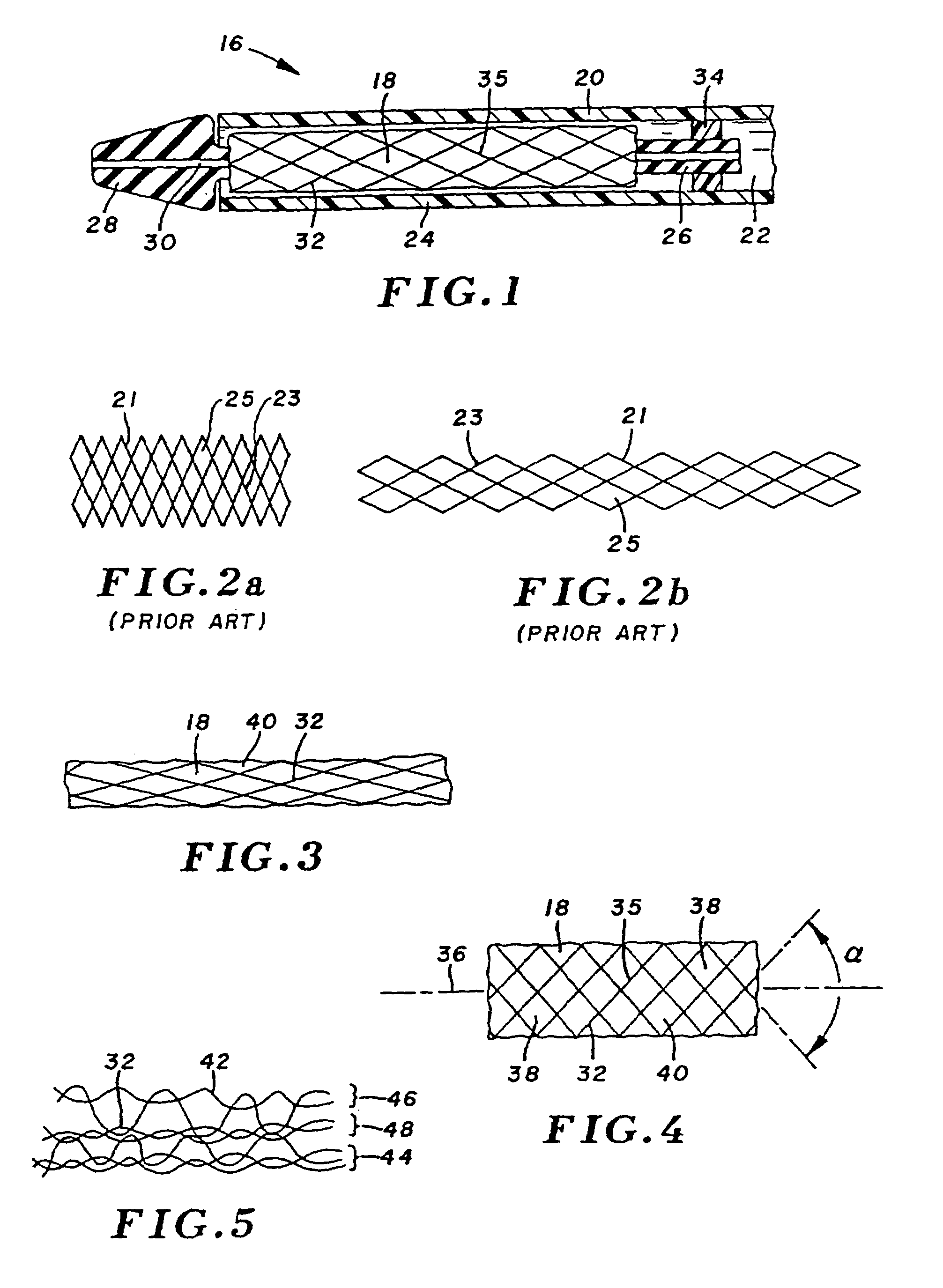

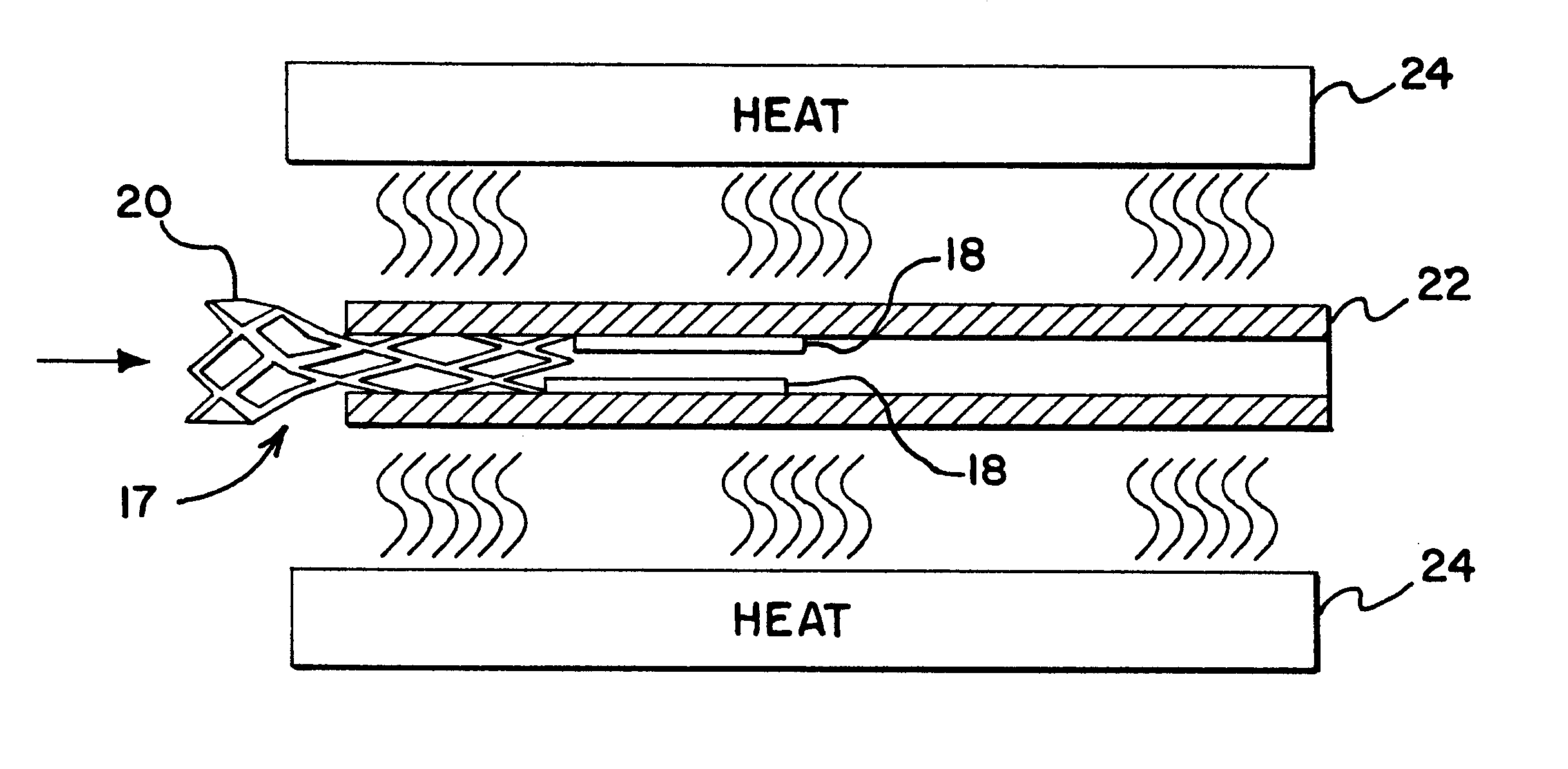

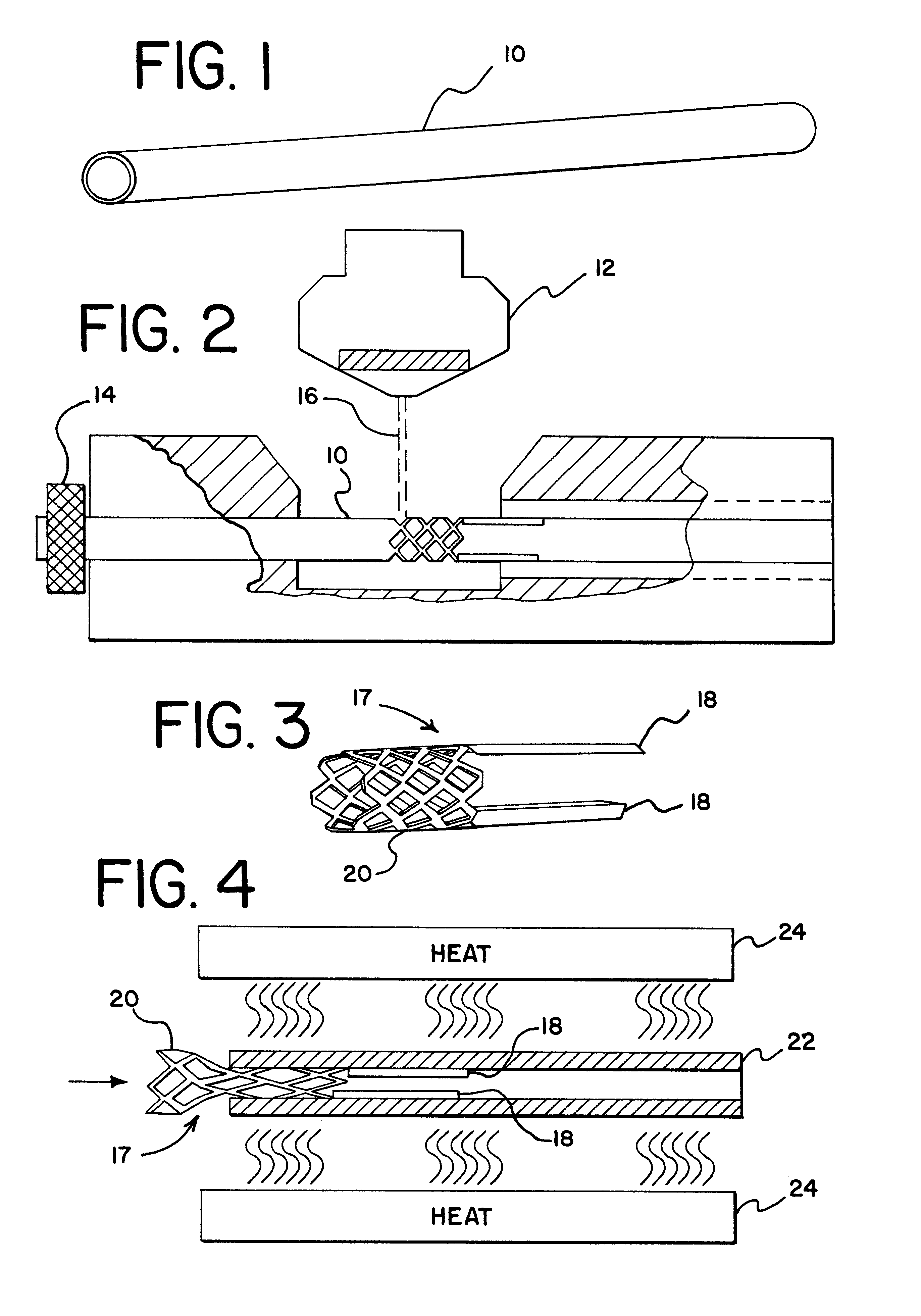

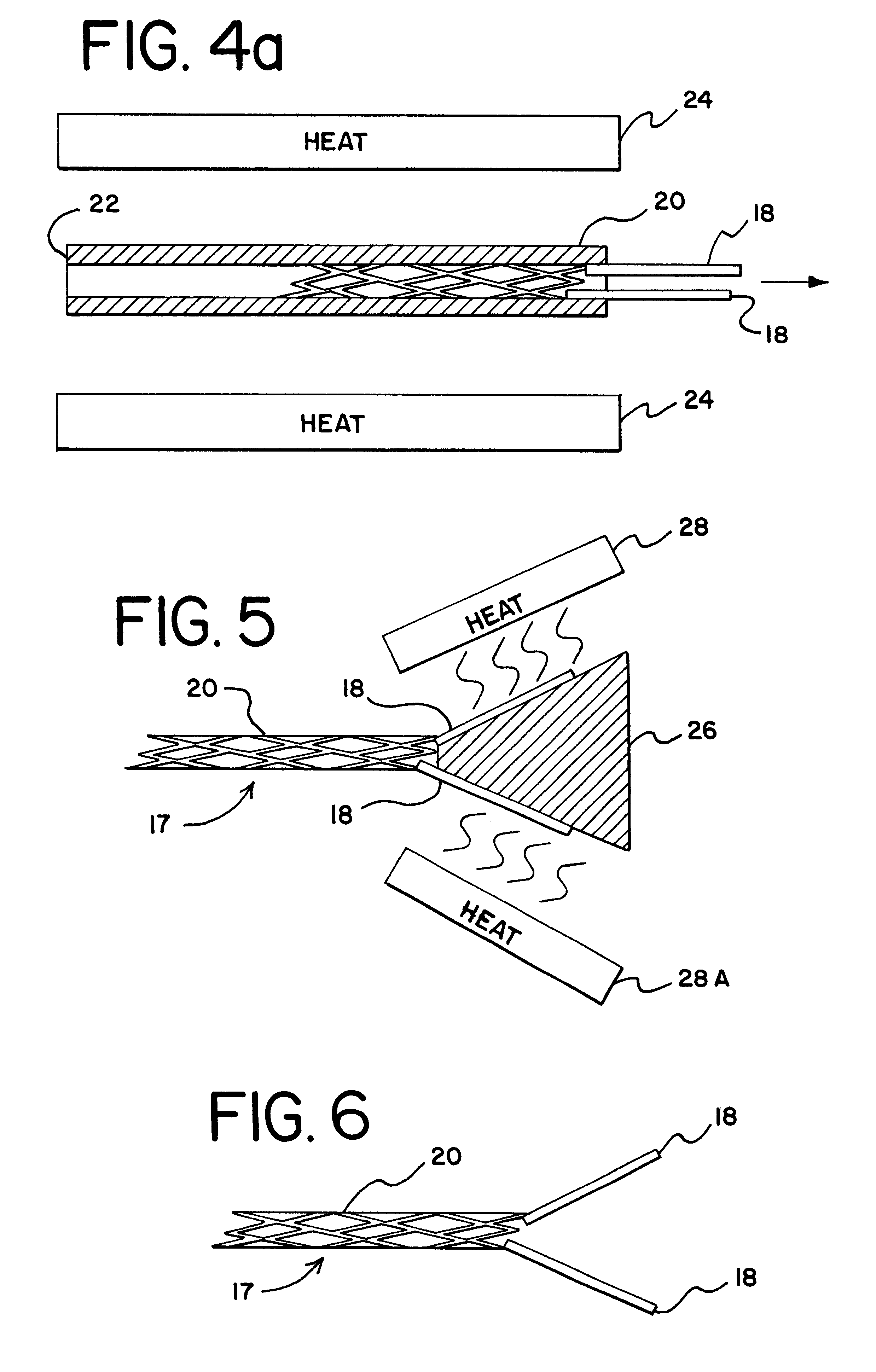

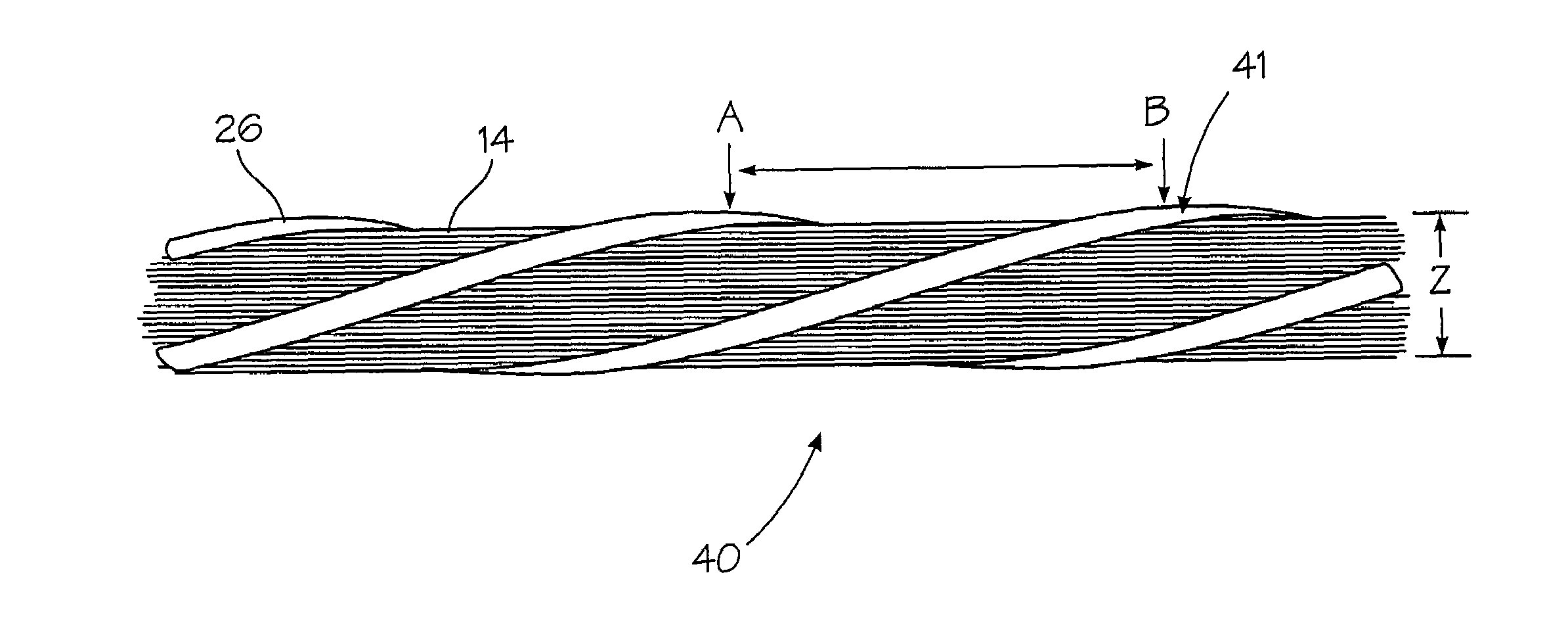

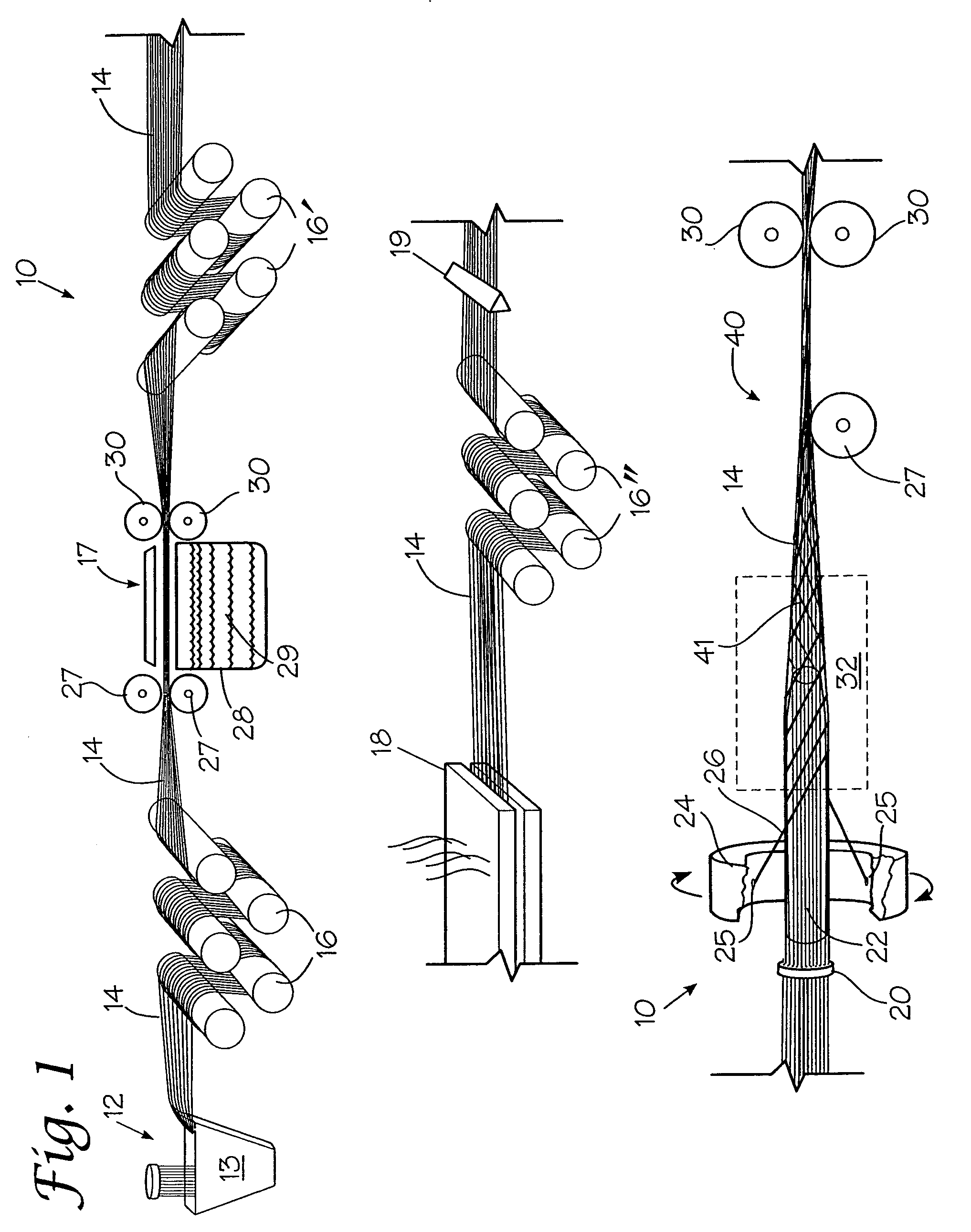

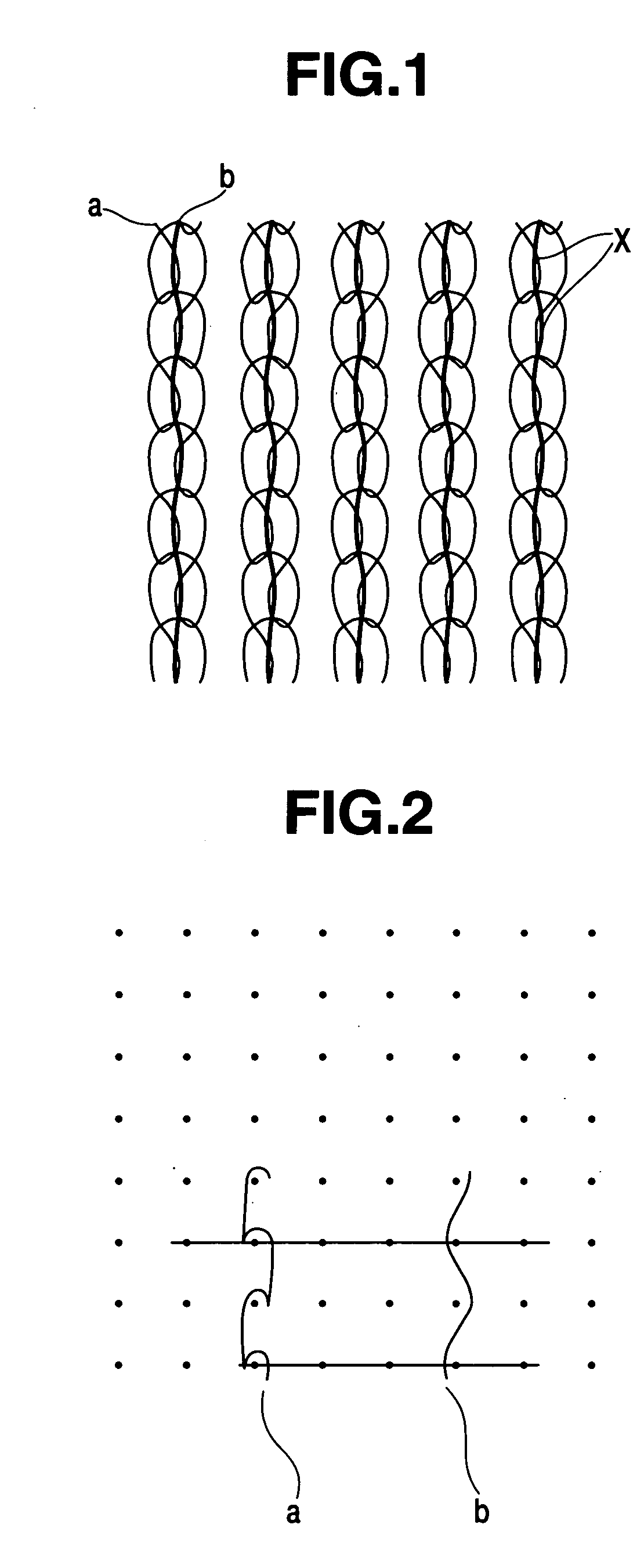

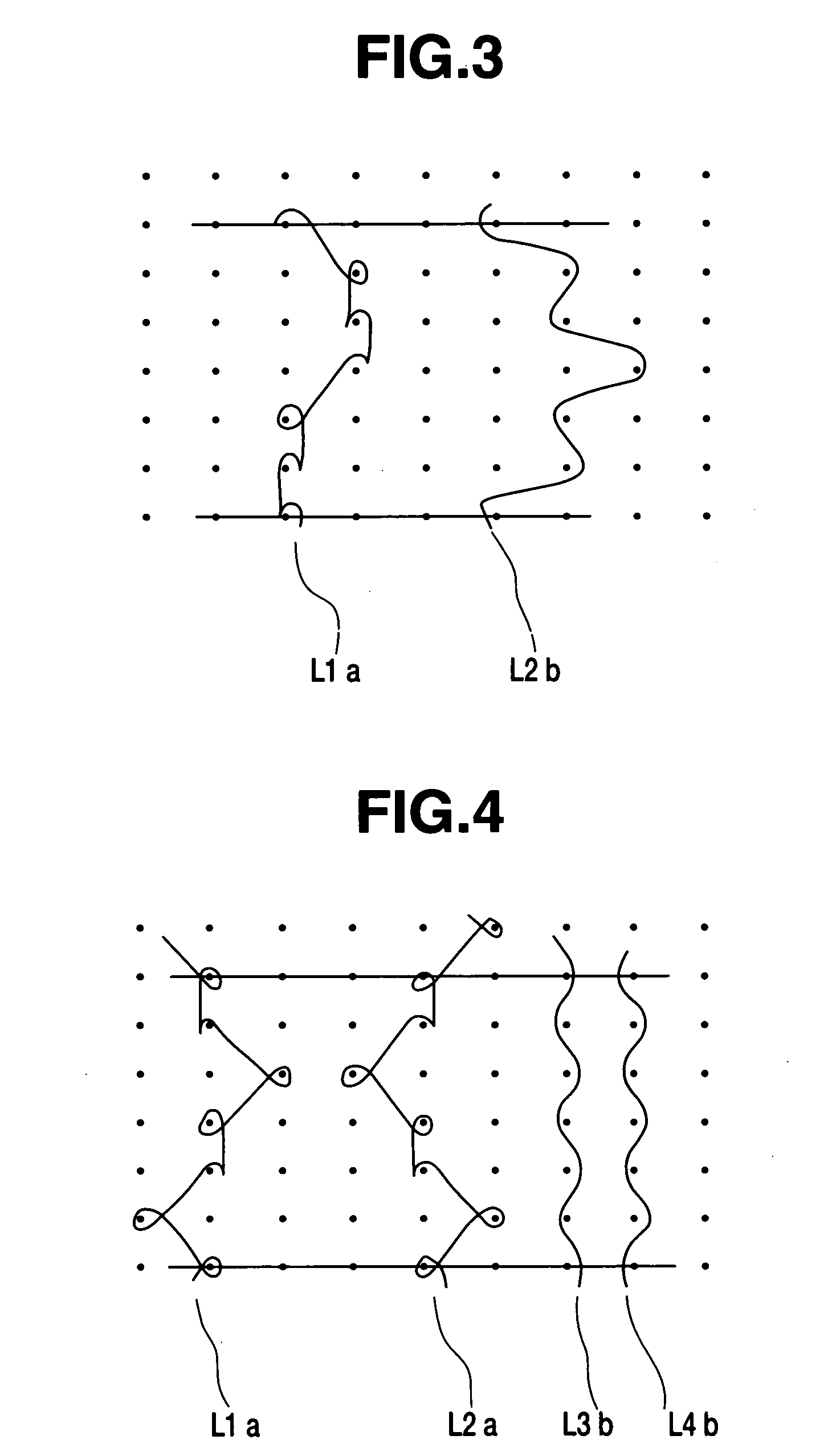

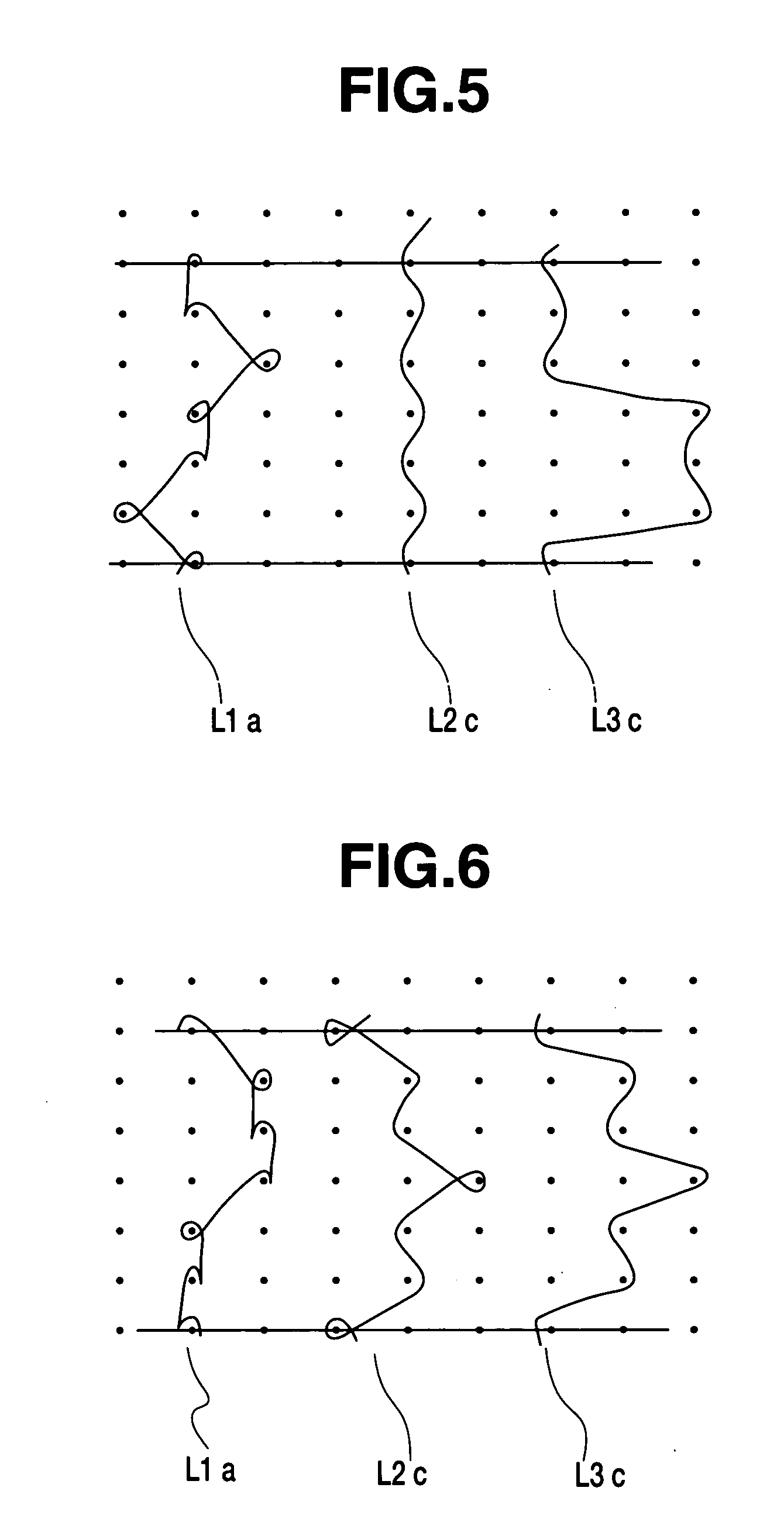

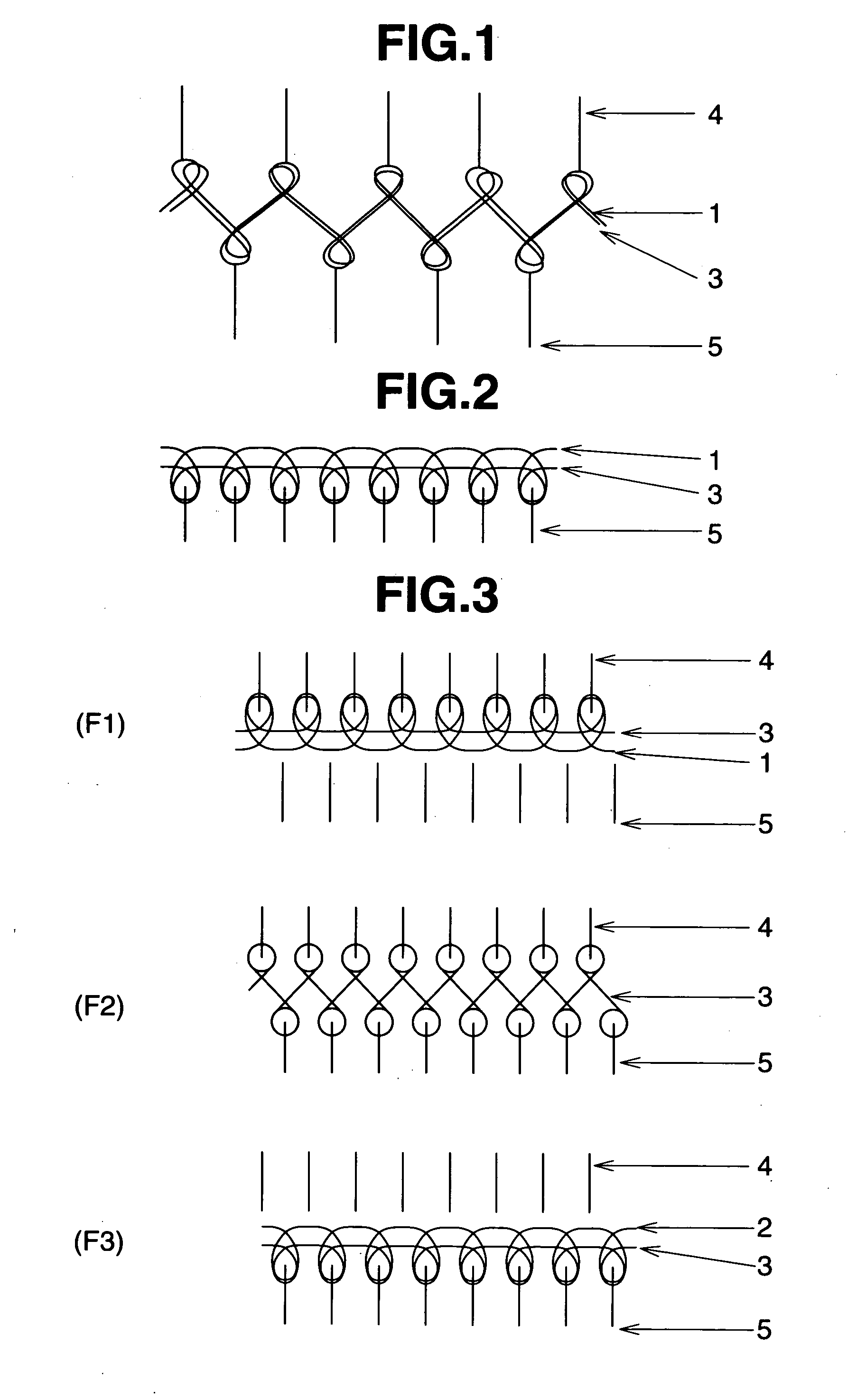

Braided composite prosthesis

A prosthesis for transluminal implantation consists of a flexible tubular interbraided structure of metal or polymeric monofilaments, and polymeric multifilament yarns. The prosthesis can be elastically deformed to reduce its diameter through axial elongation. The monofilaments and multifilament yarns are arranged in axially spaced apart helices, concentric on a common central axis of the prosthesis. The monofilaments are selectively shaped before their interbraiding with the multifilament yarns, either by an age-hardening or other heat-setting stage, or a cold-working stage that controllably plastically deforms the strands. The shaped structural strands cooperate to impart to the prosthesis its nominal shape and resilience. The textile strands cooperate to provide a sheeting that occupies interstices between adjacent structural strands, to reduce permeability and thereby enhance the utility of the prosthesis as a vascular graft. An alternative embodiment prosthesis includes elastically and plastically deformable structural strands, selectively plastically deformed by cold-working then interbraided to form the prosthesis.

Owner:LIFESHIELD SCI

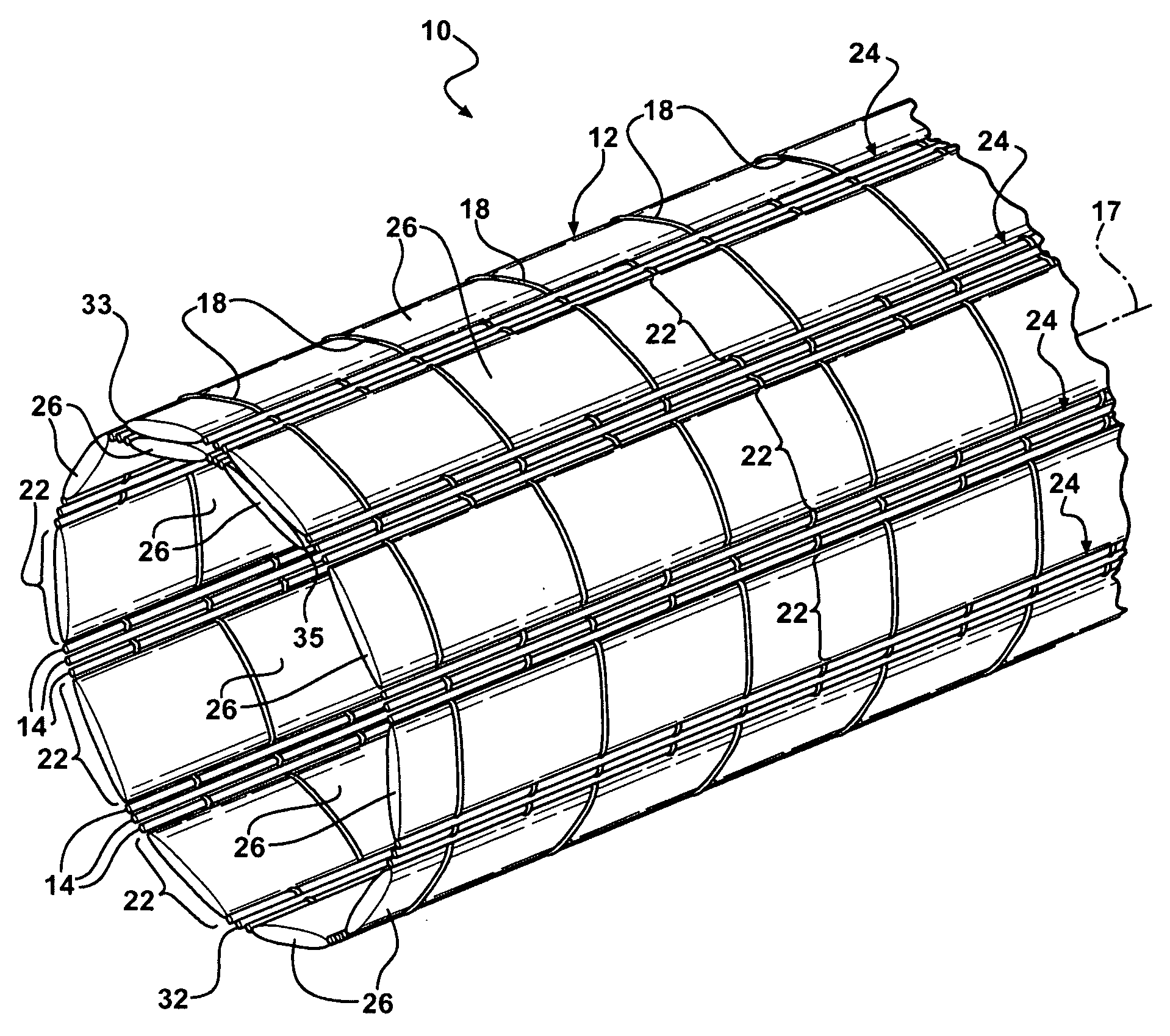

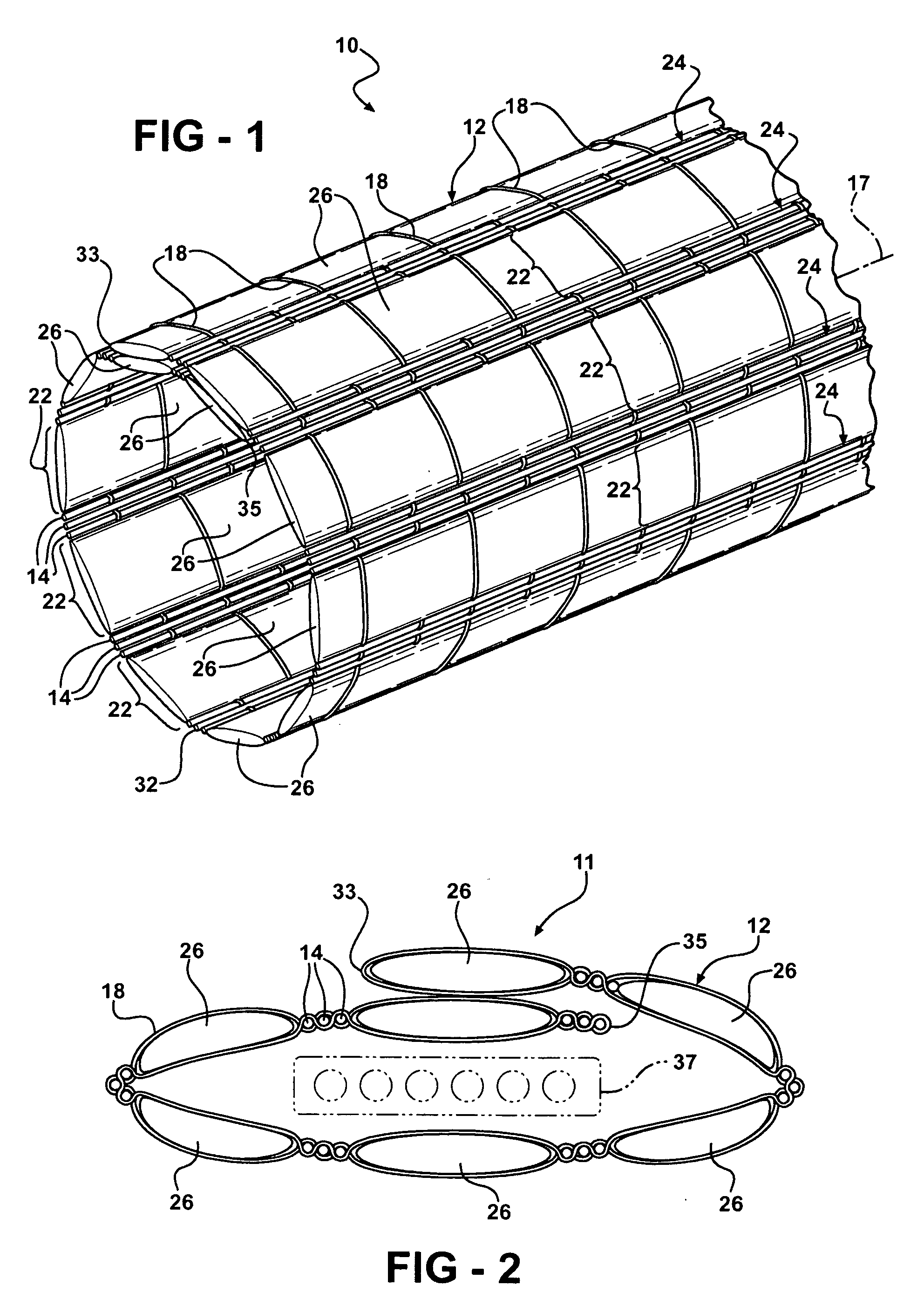

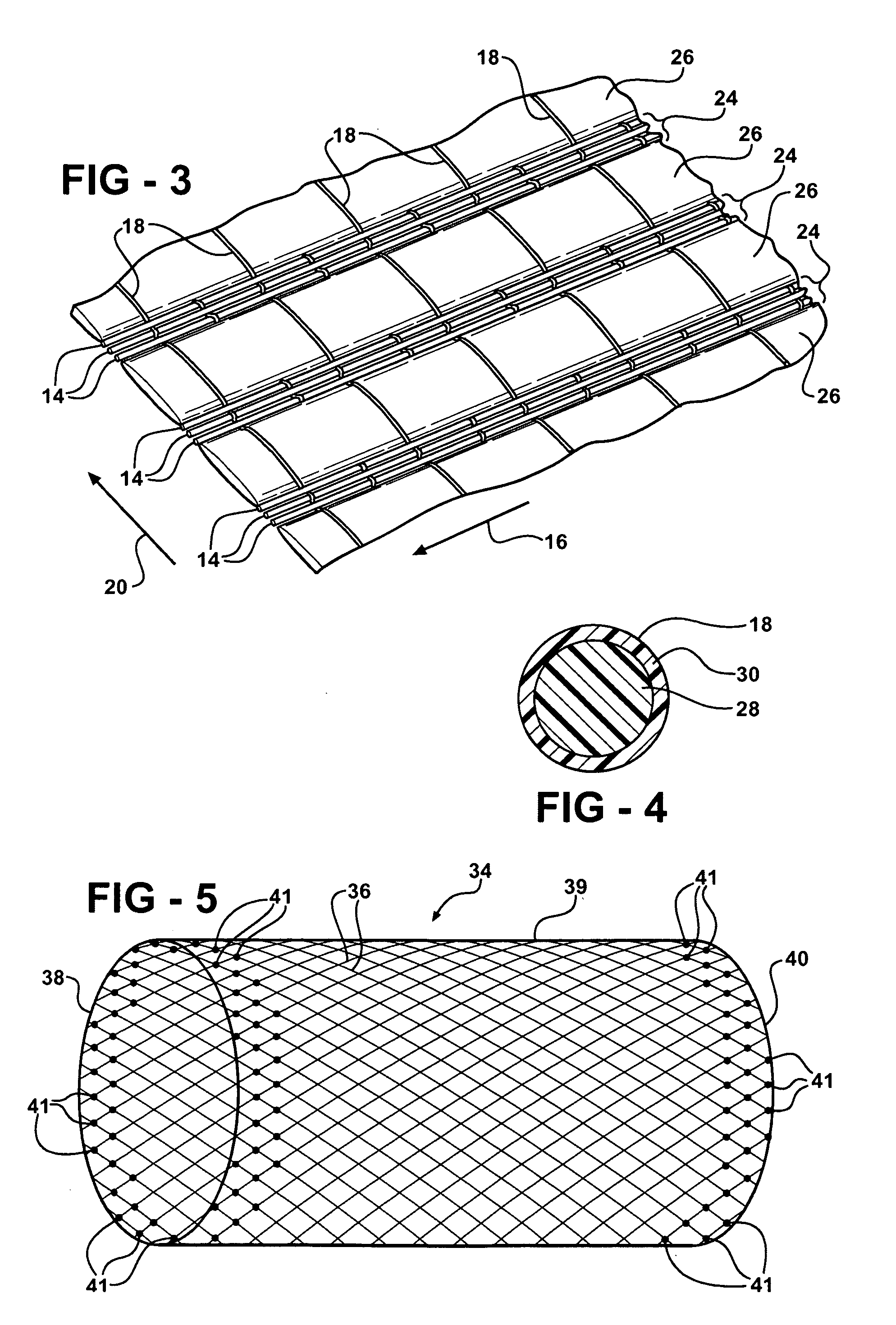

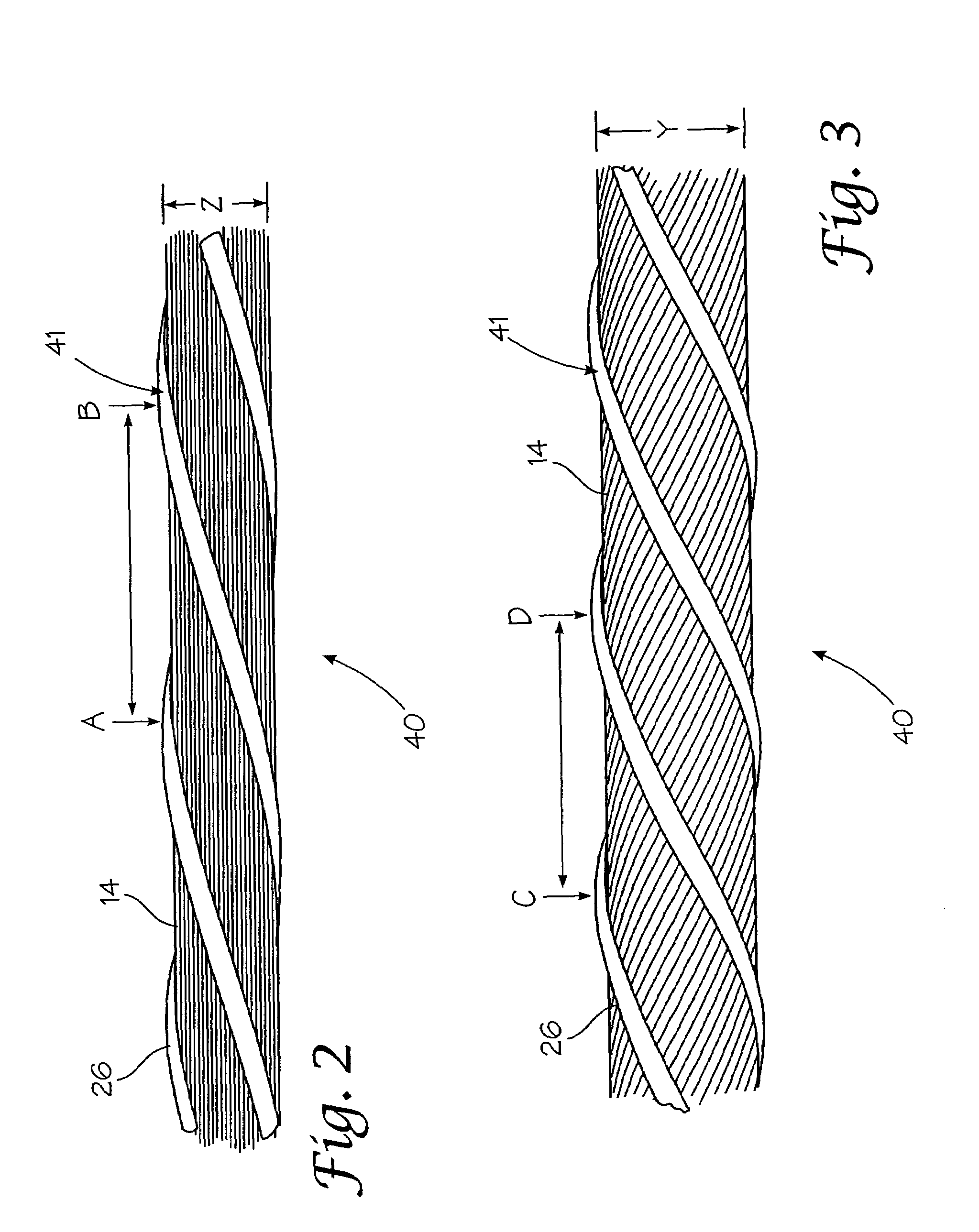

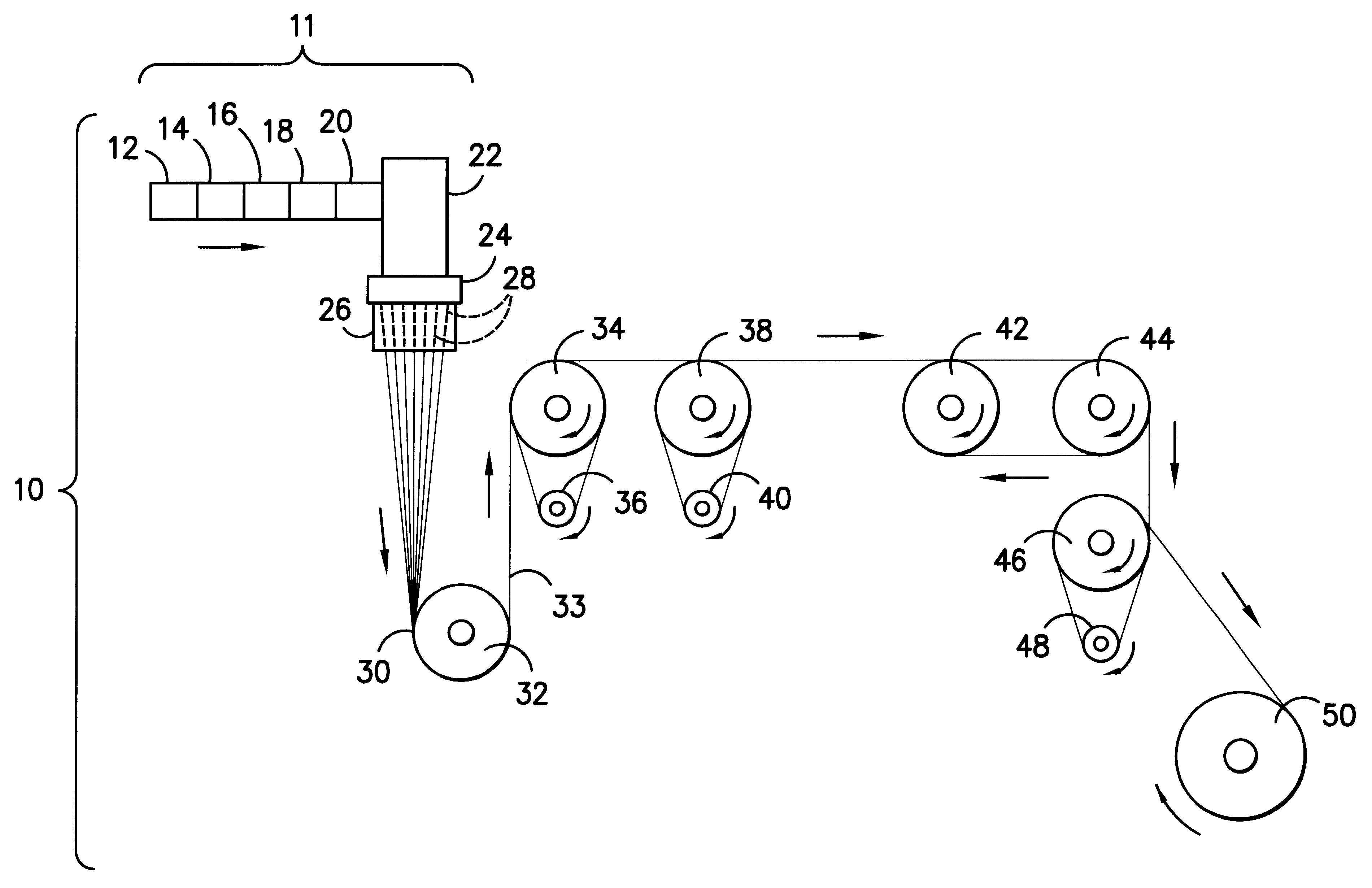

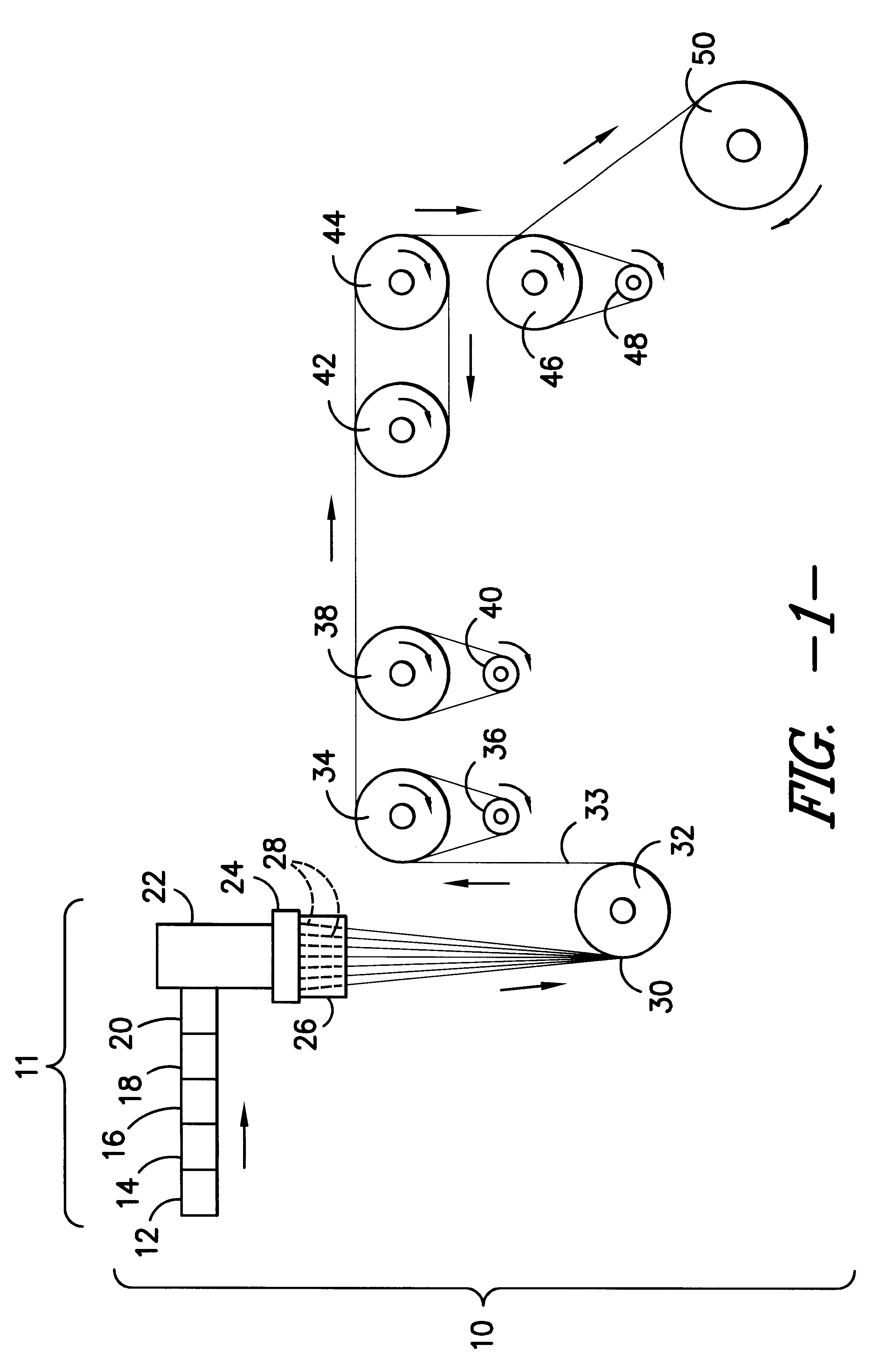

Three-dimensional braided covered stent

InactiveUS7052513B2Reduce manufacturing costSolve the lack of tensionStentsBlood vesselsYarnProsthesis

A prosthesis for transluminal implantation consists of a flexible tubular three-dimensionally braided structure of metal or polymeric monofilaments, and polymeric multifilament yarns. The prosthesis can be elastically deformed to reduce its diameter through axial elongation. The monofilaments and multifilament yarns are arranged in axially spaced apart helices, concentric on a common central axis of the prosthesis. The monofilaments are selectively shaped before their interbraiding with the multifilament yarns, either by an age-hardening or other heat-setting stage, or a cold-working stage that controllably plastically deforms the strands. The shaped structural strands cooperate to impart to the prosthesis its nominal shape and resilience. The textile strands cooperate to provide one or more layers of sheeting that reduce permeability and thereby enhance the utility of the prosthesis as a vascular graft. An alternative embodiment prosthesis includes elastically and plastically deformable structural strands, selectively plastically deformed by cold working, then three-dimensionally braided to form the prosthesis.

Owner:LIFESHIELD SCI

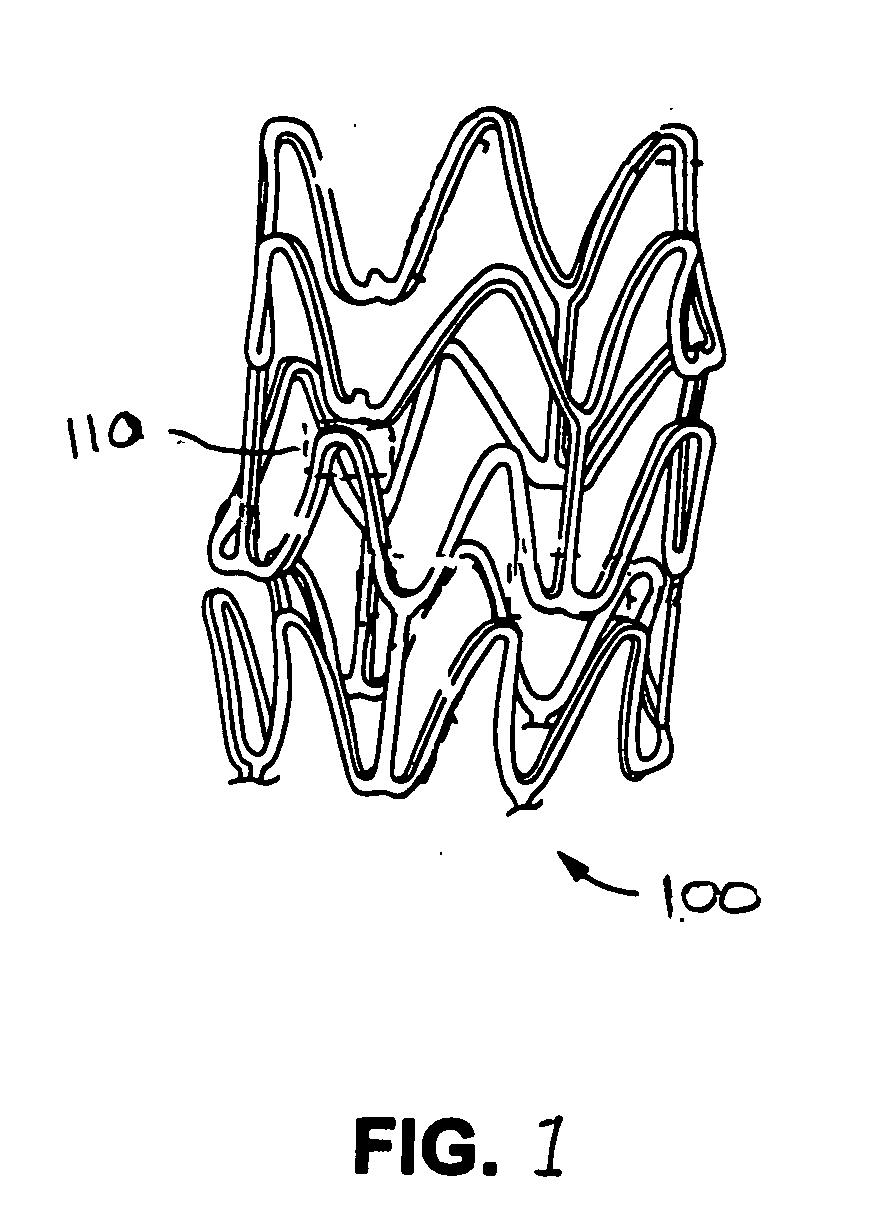

Method of fabricating an implantable medical device to reduce chance of late inflammatory response

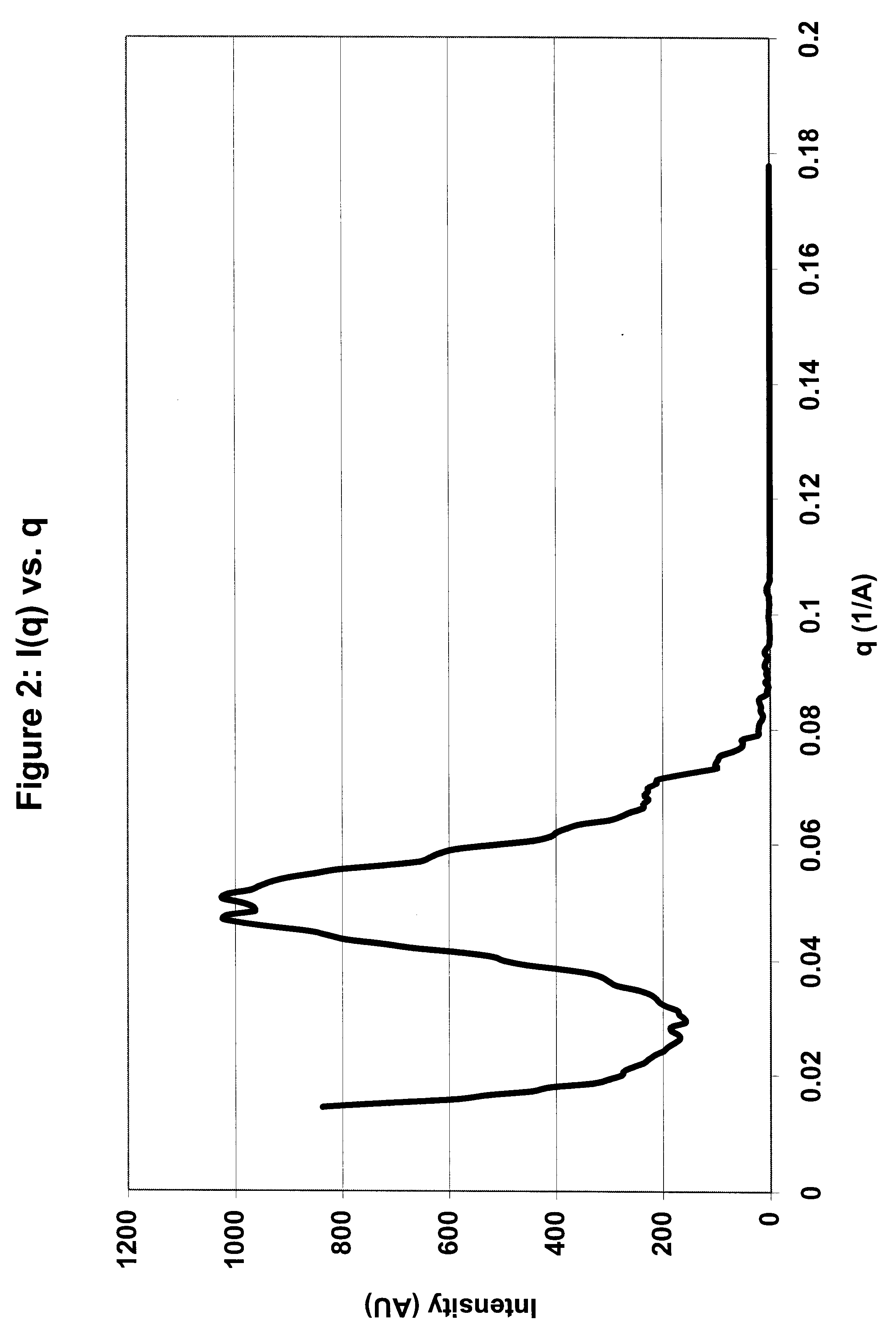

The invention provides a method for fabricating an implantable medical device to increase biocompatibility of the device, the method comprising: heat setting a polymer construct, wherein the polymer construct is at a temperature range of from about Tg to about 0.6(Tm−Tg)+Tg such that the set polymer construct comprises a crystalline structure having crystals at a size less than about 2 microns; and fabricating an implantable medical device from the heat set polymer construct.

Owner:ABBOTT CARDIOVASCULAR

Method of manufacturing small profile medical devices

Owner:CODMAN & SHURTLEFF INC +1

Thermoplastic monofilament fibers exhibiting low-shrink, high tenacity, and extremely high modulus levels

InactiveUS6759124B2High tensile strengthLow shrinkageSynthetic resin layered productsFilament/thread formingThermoplasticYarn

Unique thermoplastic monofilament fibers and yarns that exhibit heretofore unattained physical properties are provided. Such fibers are basically manufactured through the extrusion of thermoplastic resins that include a certain class of nucleating agent therein, and are able to be drawn at high ratios with such nucleating agents present that the tenacity and modulus strength are much higher than any other previously produced thermoplastic fibers, particularly those that also simultaneously exhibit extremely low shrinkage rates. Thus, such fibers require the presence of certain compounds that quickly and effectively provide rigidity to the target thermoplastic (for example, polypropylene), particularly after heat-setting. Generally, these compounds include any structure that nucleates polymer crystals within the target thermoplastic after exposure to sufficient heat to melt the initial pelletized polymer and allowing such an oriented polymer to cool. The compounds must nucleate polymer crystals at a higher temperature than the target thermoplastic without the nucleating agent during cooling. In such a manner, the "rigidifying" nucleator compounds provide nucleation sites for thermoplastic crystal growth. The preferred "rigidifying" compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as [2.2.1]heptane-bicyclodicarboxylic acid, otherwise known as HPN-68, sodium benzoate, certain sodium and lithium phosphate salts [such as sodium 2,2'-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11]. Specific methods of manufacture of such inventive thermoplastic fibers, as well as fabric articles made therefrom, are also encompassed within this invention.

Owner:MILLIKEN & CO

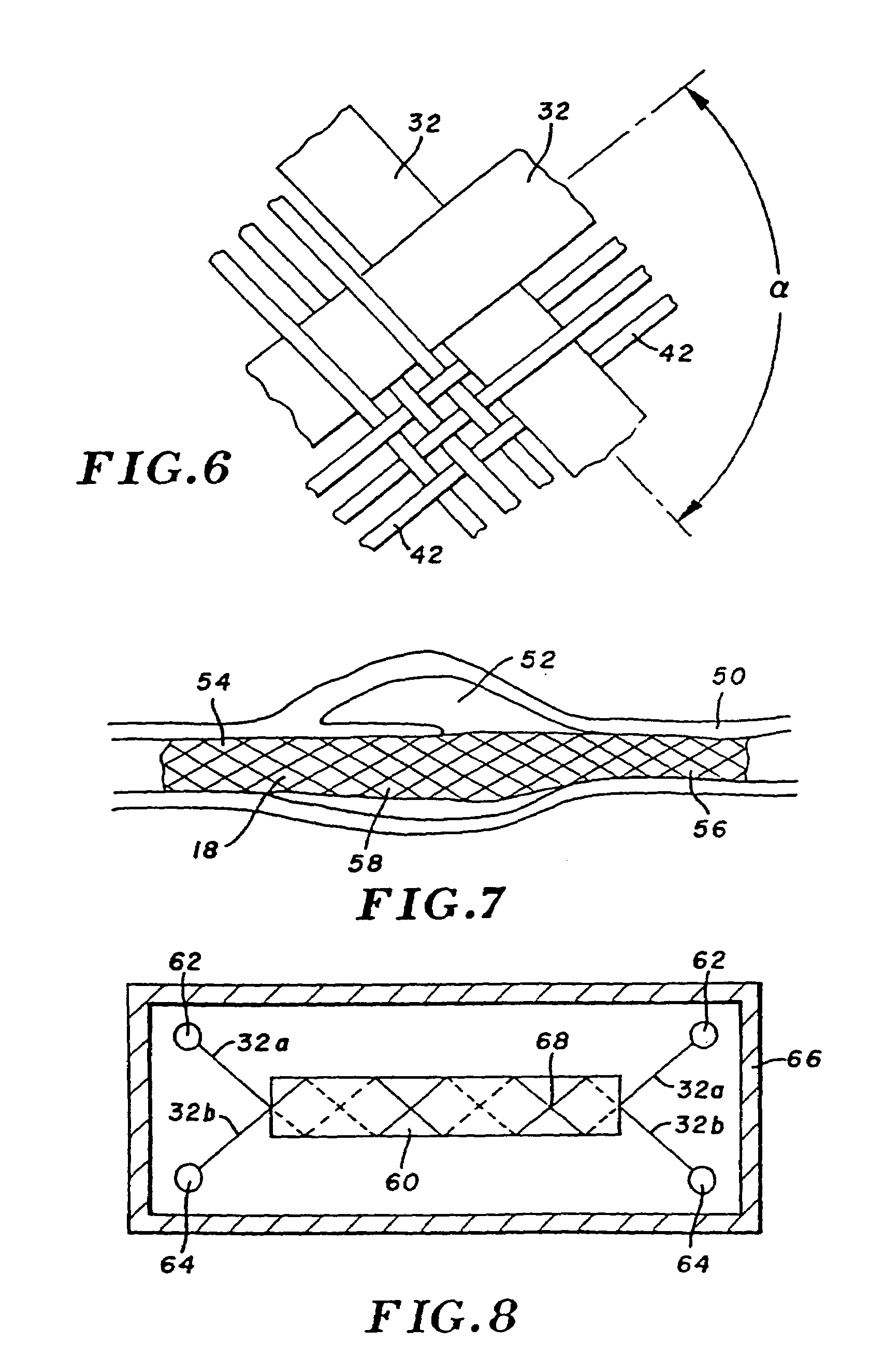

Implant, a mandrel, and a method of forming an implant

ActiveUS20080228216A1Effective embolizationEasy to packStentsFilament handlingThree dimensional shapeHeat setting

This invention is directed to an implant having a coil for embolizing a vascular site, such as aneurysm. The coil has a specific three-dimensional shape that is achieved by winding the coil around a mandrel in a specific pattern and then heat setting the coil and the mandrel, another aspect of the invention. The three-dimensional shape resembles unclosed mobius loops. Also provided are methods of making the coil and methods of embolizing vascular site.

Owner:TYCO HEALTHCARE GRP LP

Fabric for end fray resistance and protective sleeves formed therewith and methods of construction

ActiveUS20070166495A1Prevent the sleeve from frayingElectrical apparatusPedestrian/occupant safety arrangementHot meltEngineering

An elongated protective textile sleeve for protecting elongate members and methods of constructing a fabric substrate therefore. The fabric substrate has a plurality of filamentary members either woven, knitted or braided with one another. At least some of the filamentary members of the substrate extend to cut edges and are fabricated of a multi-component material that includes a core of a first polymeric material and an outer sheath of a second polymeric material. The outer sheath is heat-fusible and the inner core is heat-settable. The outer sheaths of the filamentary members are heat fused at least in the regions near the cut edges to keep the cut edges from fraying or the filamentary members from pulling out of the substrate. The core is heat set to form the desired shape of the protective sleeve.

Owner:FEDERAL MOGUL WORLD WIDE LLC

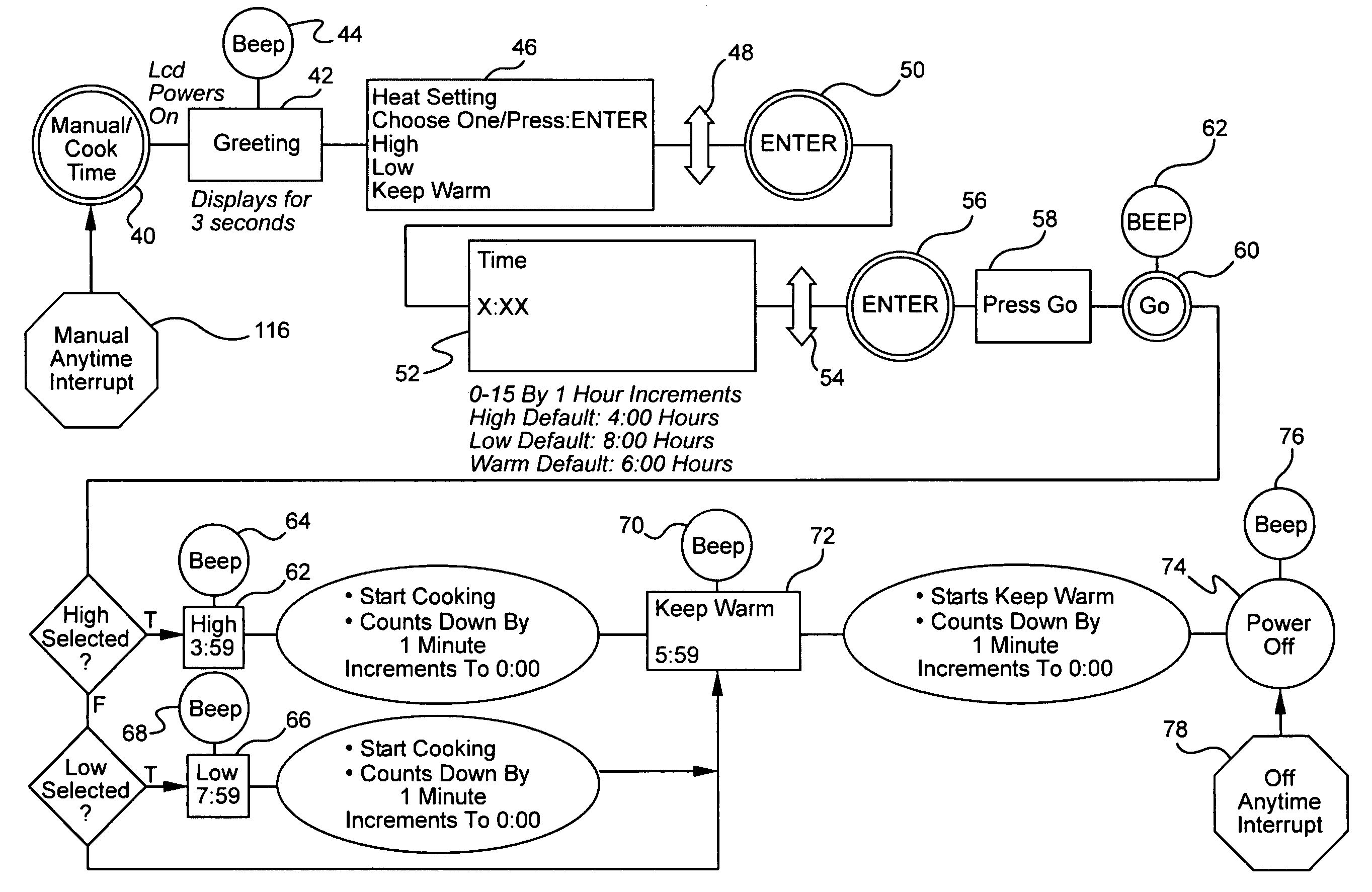

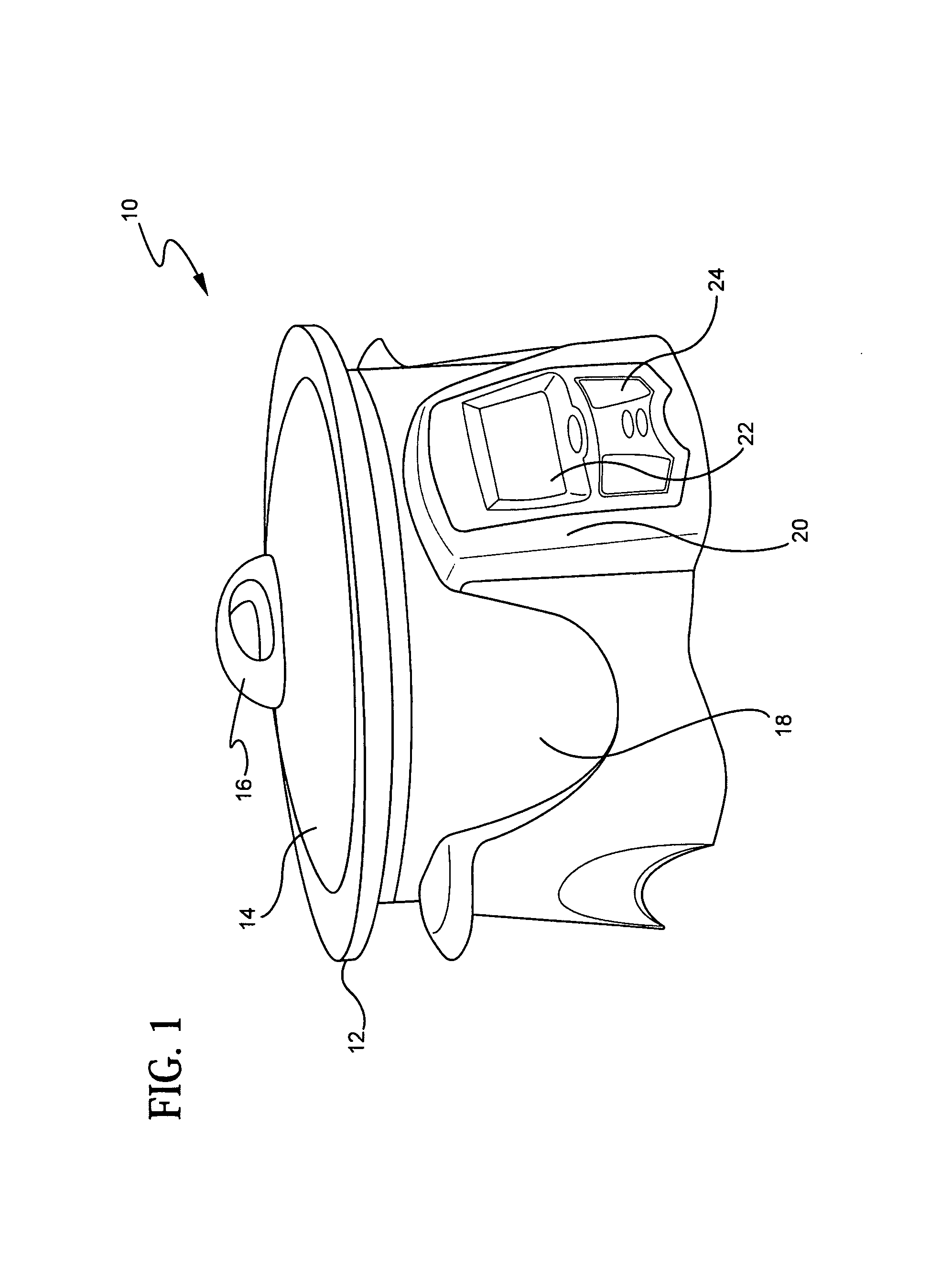

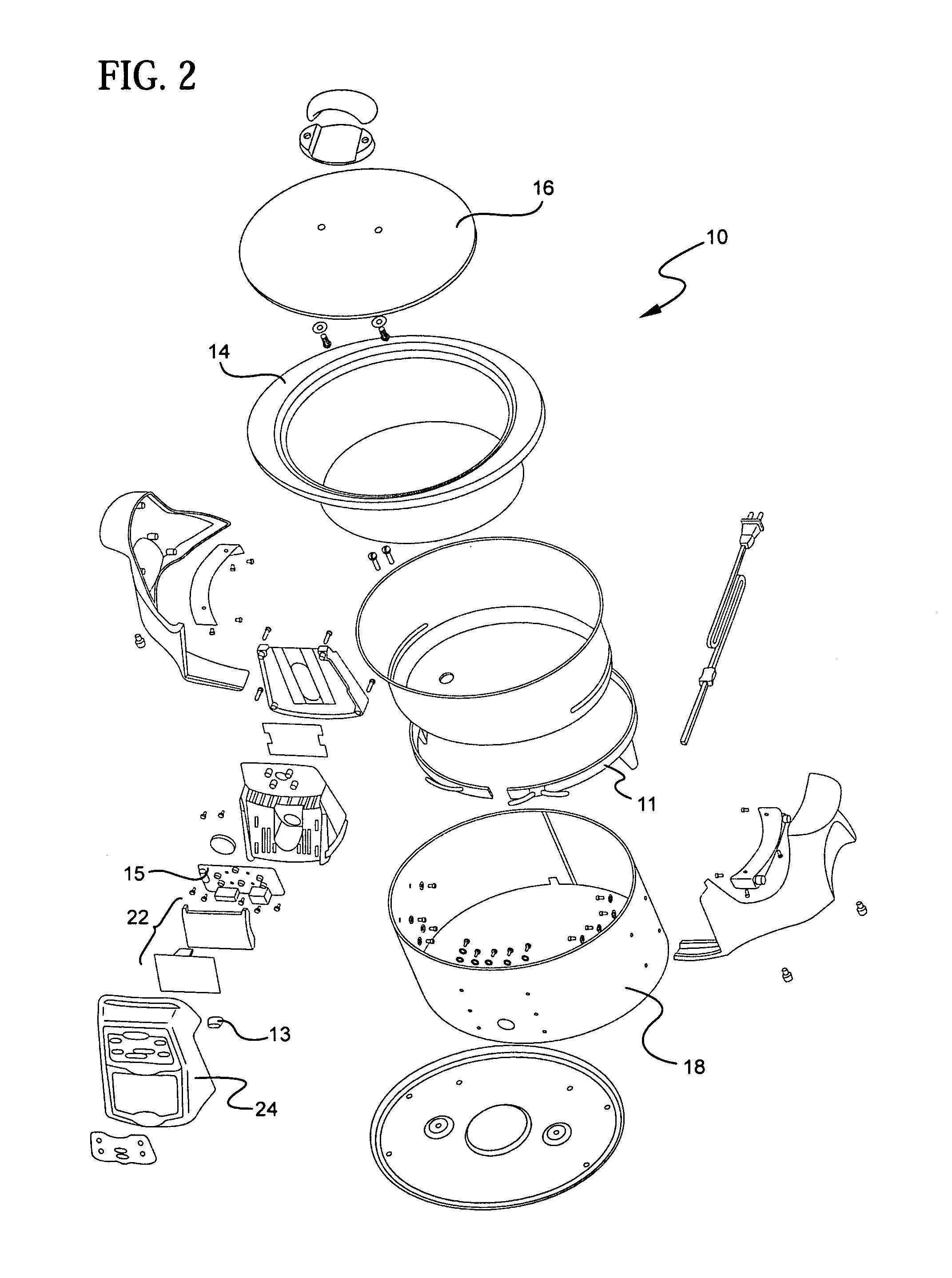

Cooking apparatus with electronic recipe display

InactiveUS7109445B2Simple taskEliminate needBoiling over preventionElectric heatingDisplay deviceProcess engineering

A cooking apparatus includes a cooking chamber and user interface, which includes a controller, display, and memory for storing recipes. The display is coupled to the controller and displays recipes. A method includes selectively displaying recipes and selecting a manual or recipe mode. In the manual mode, a heat setting and cooking time is selected. The selected cooking time is decremented in predetermined increments and the heating element is energized in accordance with the selected heat setting, after which the heating element is energized according to a keep warm setting for a predetermined time, following which it is de-energized. In the recipe mode, a main menu is displayed, from which the user selects a recipe category. A sub menu is displayed, from which the user selects a recipe identifier associated with the selected recipe category. A list of ingredients for the selected recipe identifier is then displayed.

Owner:SUNBEAN PROD INC

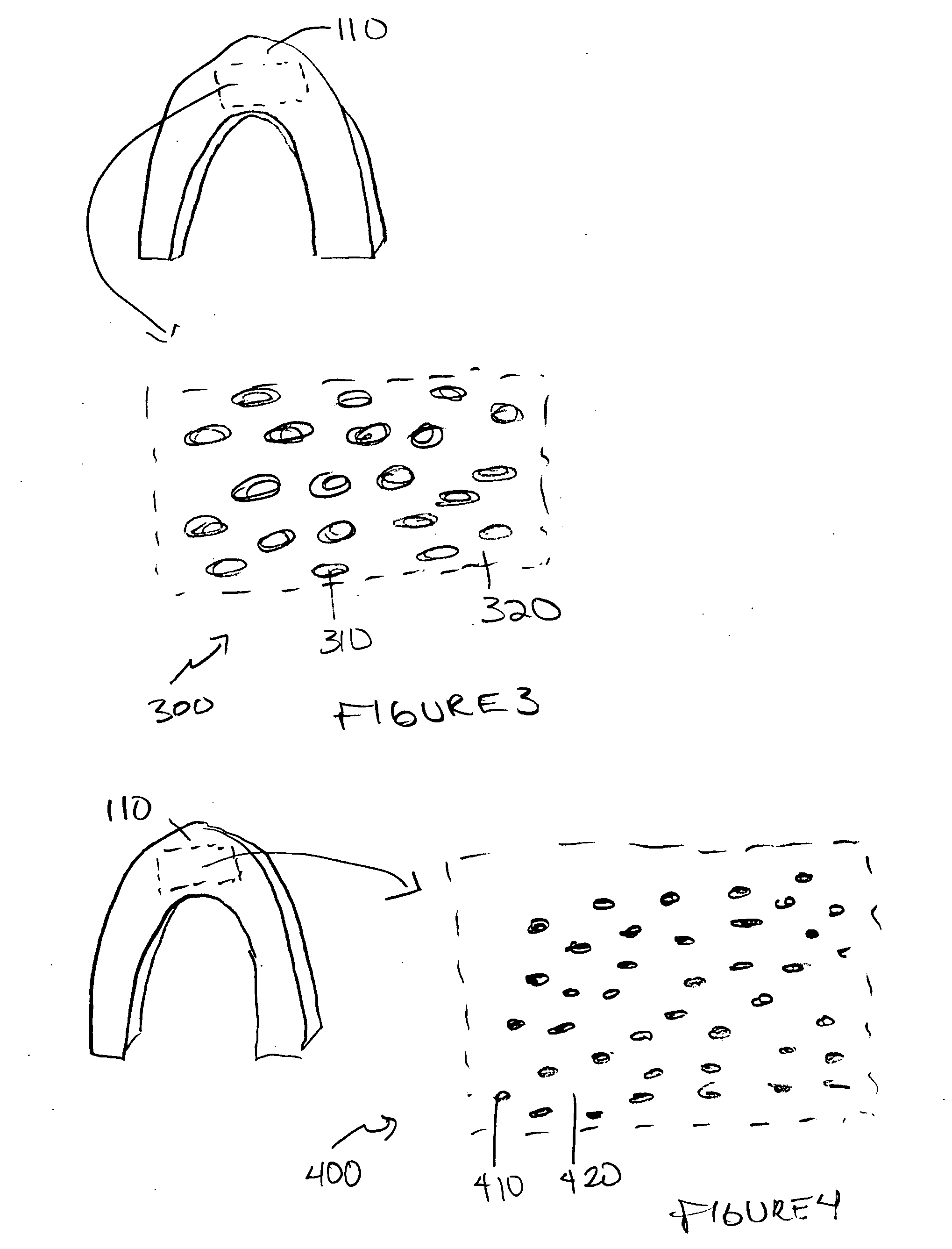

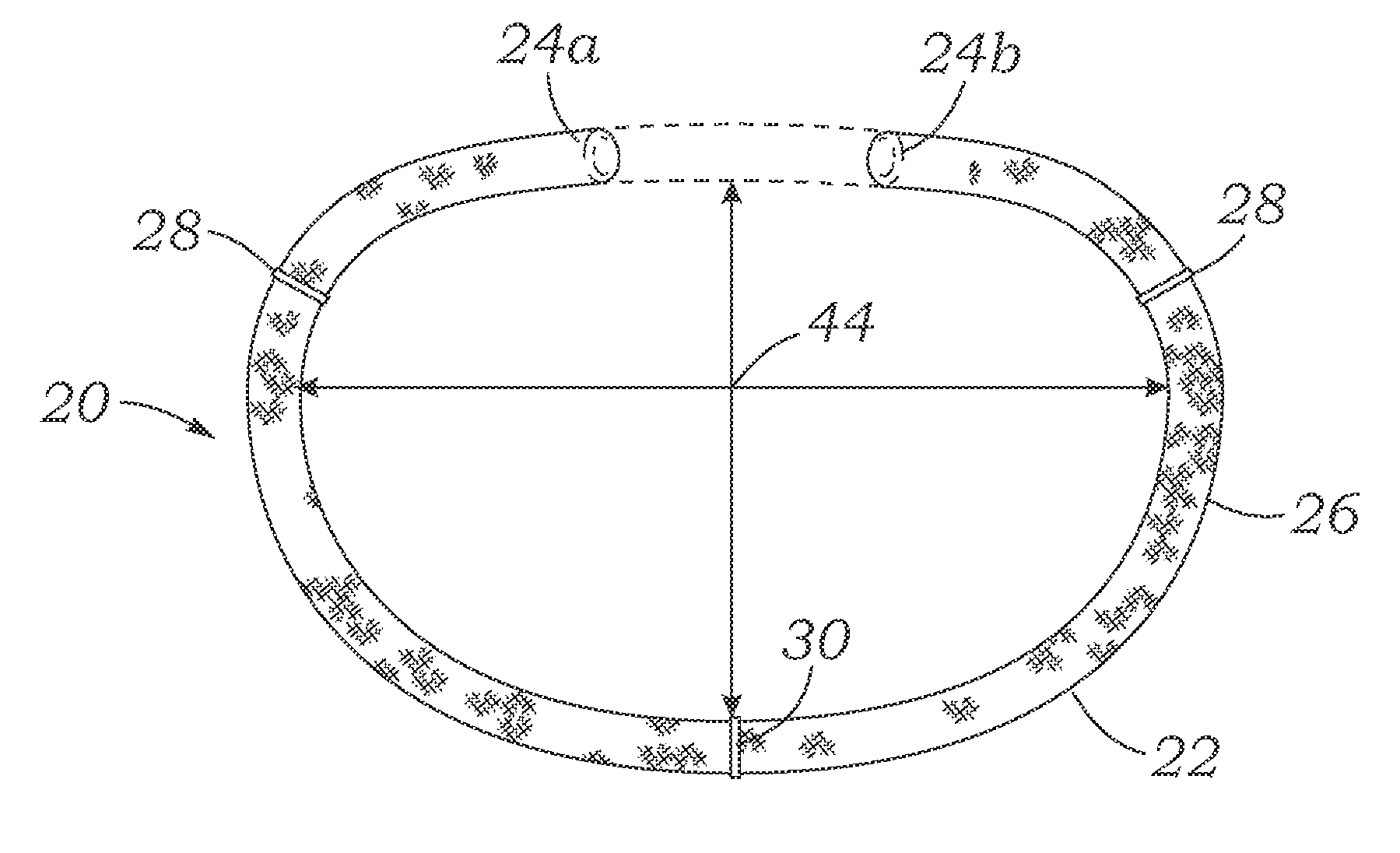

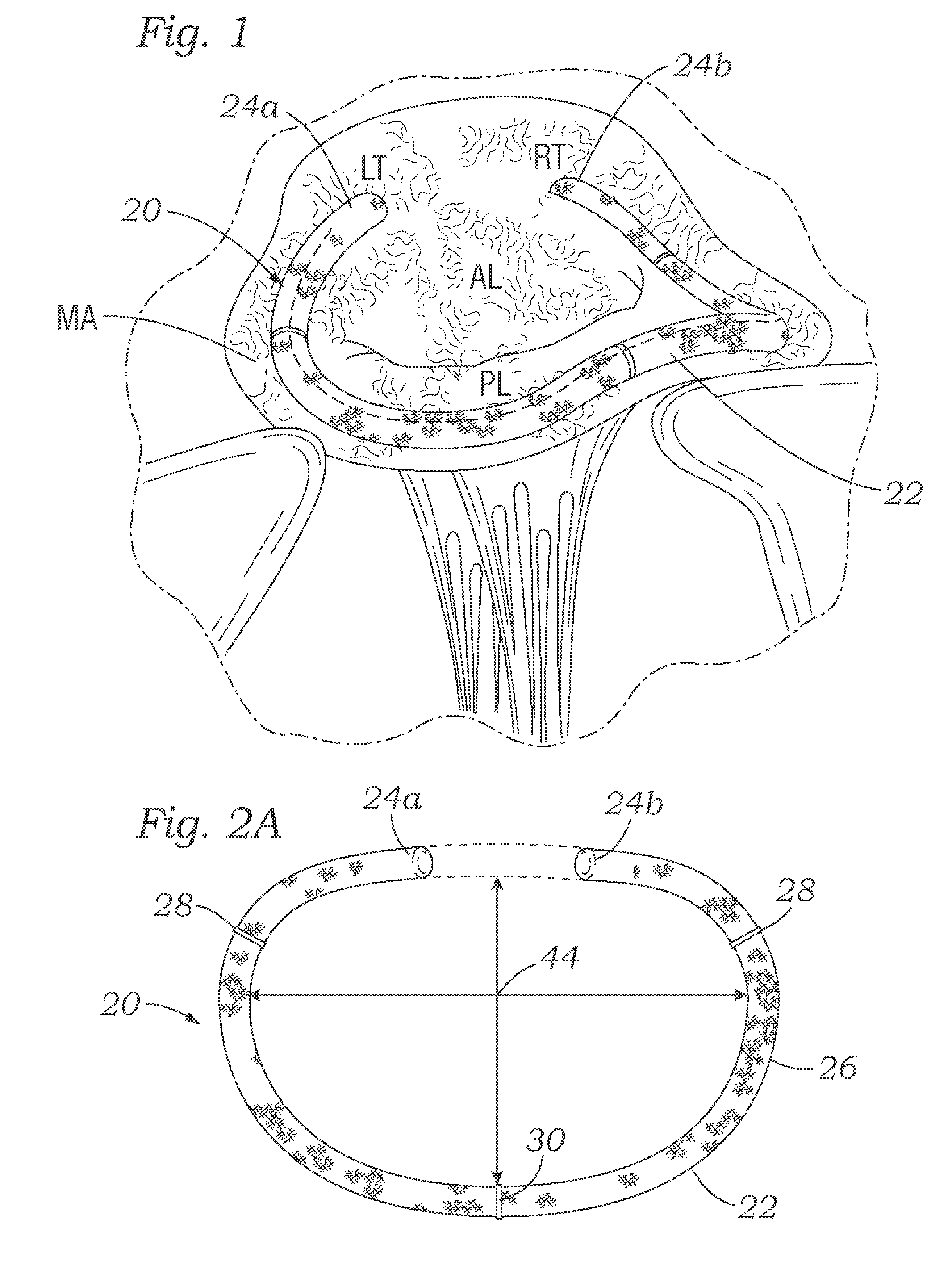

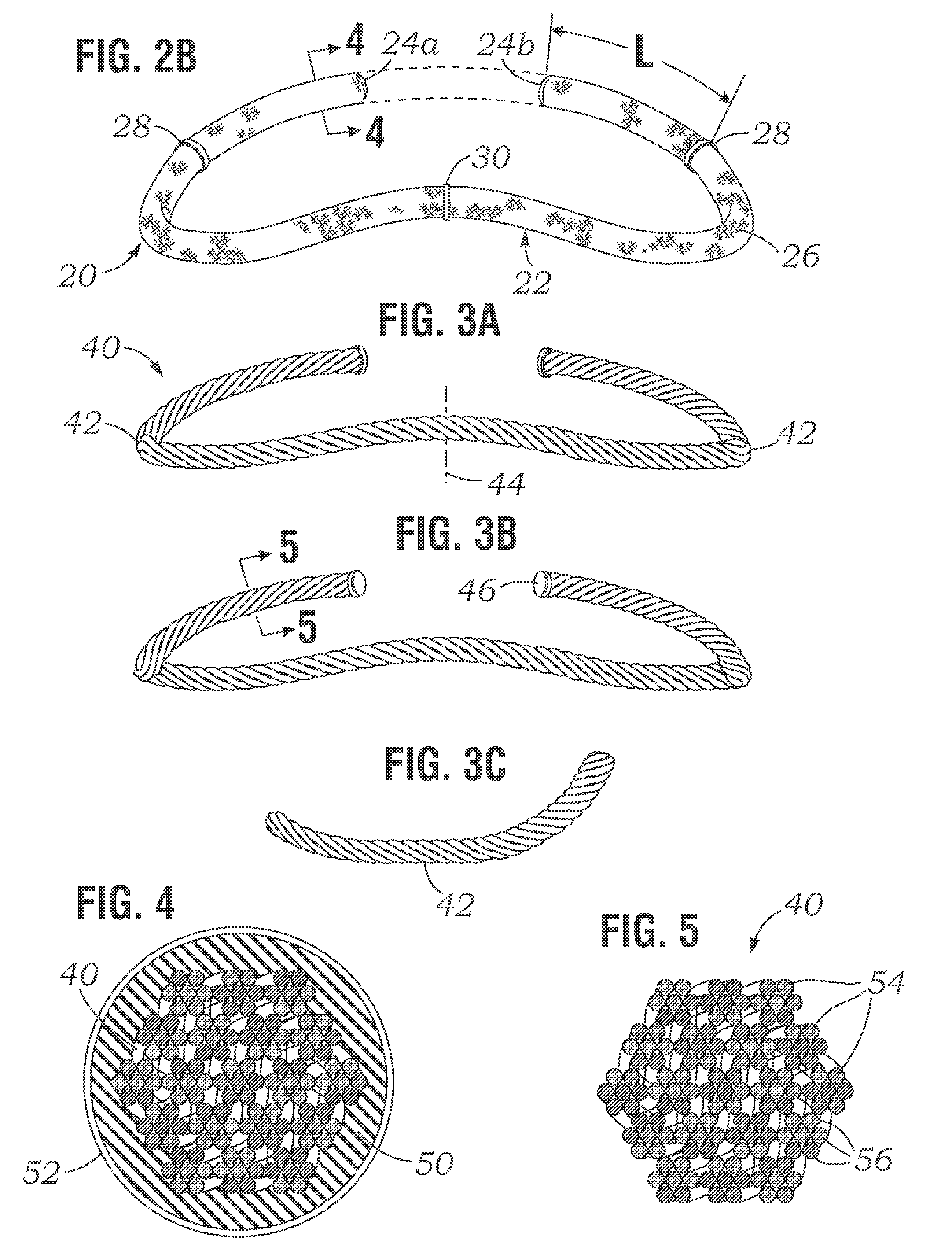

Multi-stranded heat set annuloplasty rings

ActiveUS20140277420A1Improve deployment flexibilitySufficient flexibilityBone implantAnnuloplasty ringsCardiac cycleEngineering

An annuloplasty repair segment for heart valve annulus repair. In one embodiment a multi-stranded cable replaces solid core wire for both the tricuspid and mitral valves. Cable allows for greater deployment flexibility for minimally-invasive surgical (MIS) implant, while still maintaining the required strength and similar tensile properties of solid-core wire. Stranded cable provides a MIS annuloplasty ring with sufficient flexibility in the x-y plane to allow a surgeon to squeeze the ring into a small incision, such as being able to pass through an 18Fr or smaller catheter, while maintaining structural rigidity under forces exerted on the implanted ring by the cardiac cycle. The particular shape of the annuloplasty ring is fixed using a heat setting process.

Owner:EDWARDS LIFESCIENCES CORP

Low-shrink polypropylene fibers

This invention relates to improvements in preventing heat- and moisture-shrink problems in specific polypropylene fibers. Such fibers require the presence of certain compounds that quickly and effectively provide rigidity to the target polypropylene fiber after heat-setting. Generally, these compounds include any structure that nucleates polymer crystals within the target polypropylene after exposure to sufficient heat to melt the initial pelletized polymer and upon allowing such a melt to cool. The compounds must nucleate polymer crystals at a higher temperature than the target polypropylene without the nucleating agent during cooling. In such a manner, the "rigidifying" nucleator compounds provide nucleation sites for polypropylene crystal growth. After drawing the nucleated composition into fiber form, the fiber is then exposed to sufficient heat to grow the crystalline network, thus holding the fiber in a desired position. The preferred "rigidifying" compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as sodium benzoate, certain sodium and lithium phosphate salts (such as sodium 2,2'-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11). Specific methods of manufacture of such fibers, as well as fabric articles made therefrom, are also encompassed within this invention.

Owner:MILLIKEN & CO

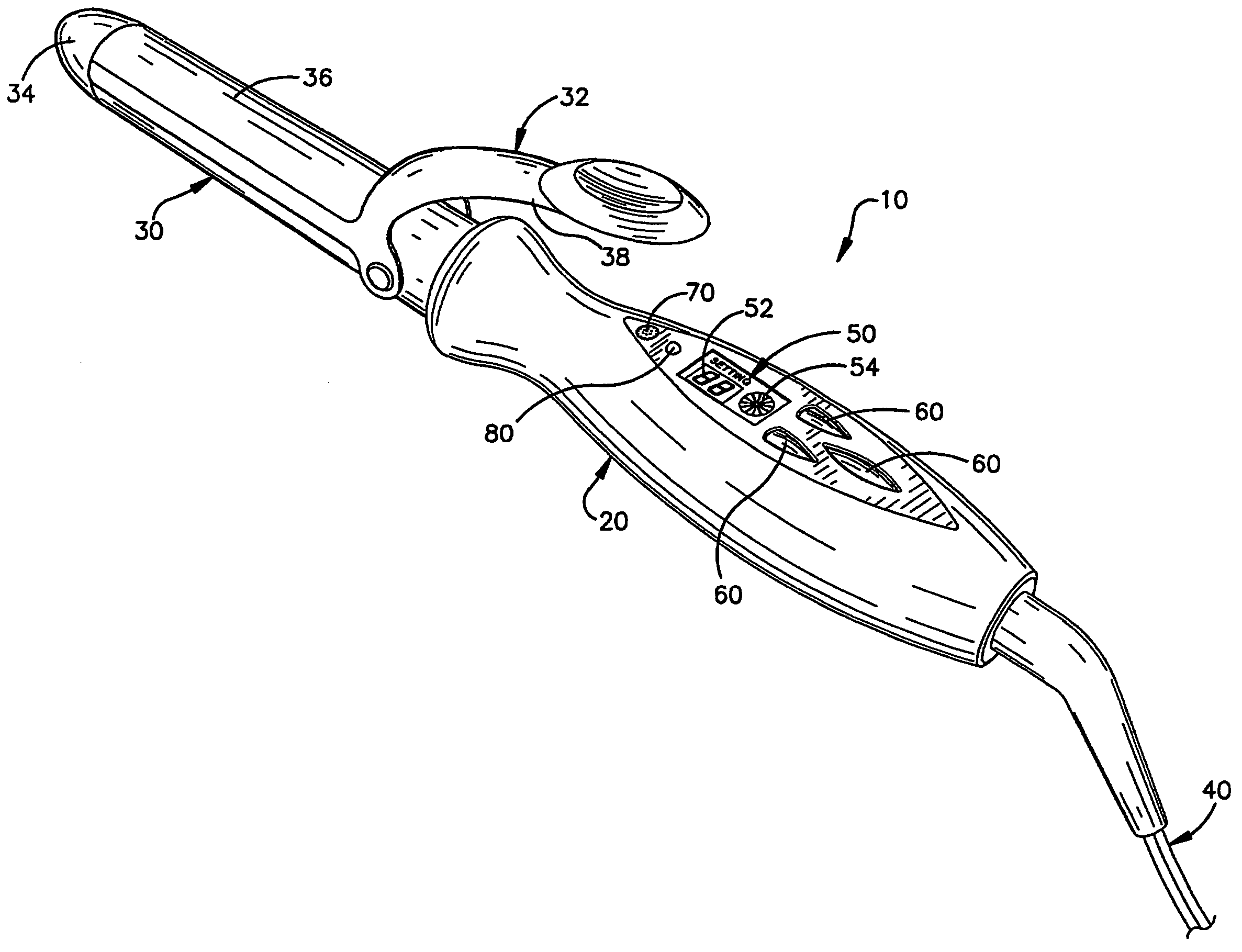

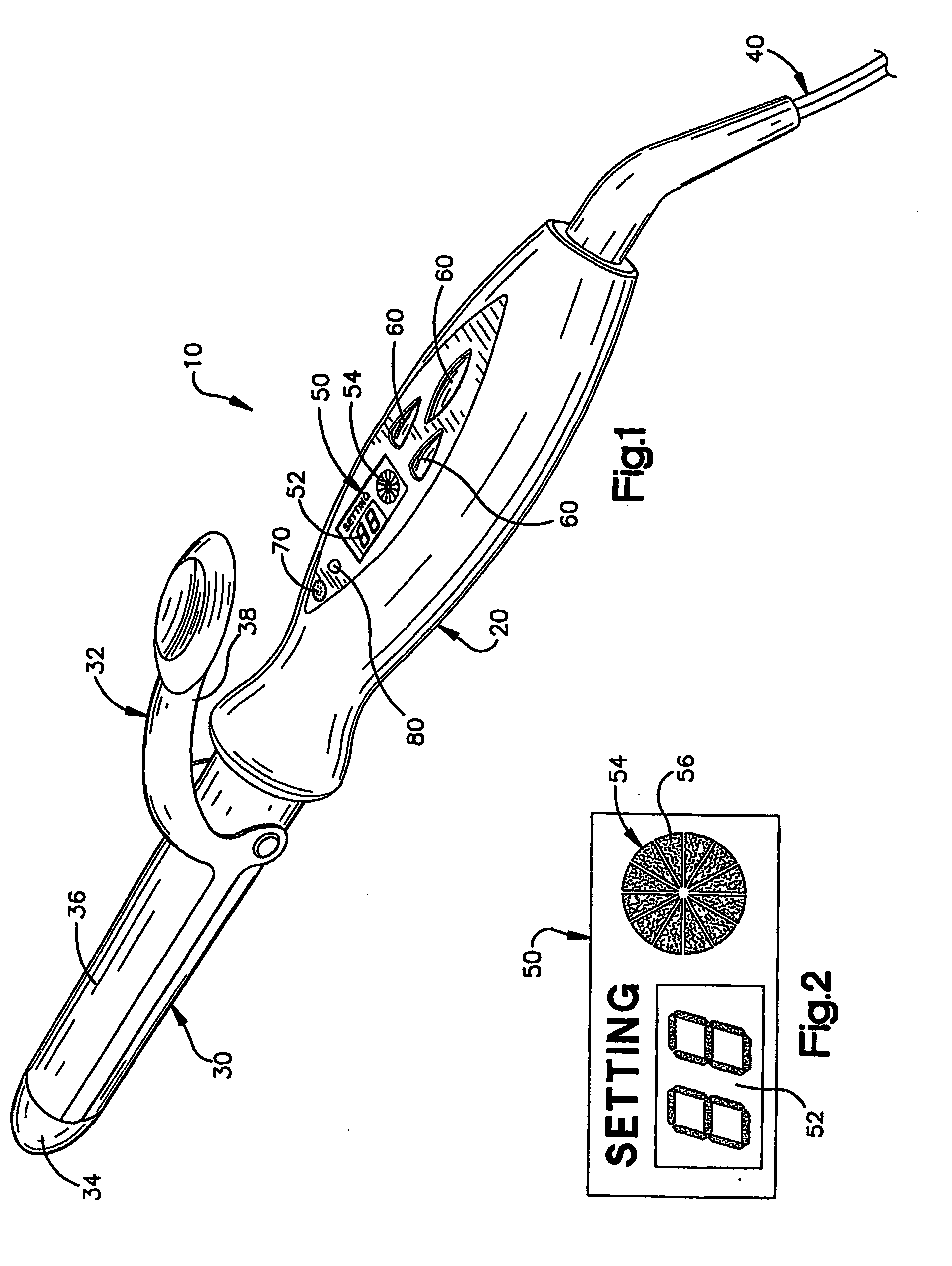

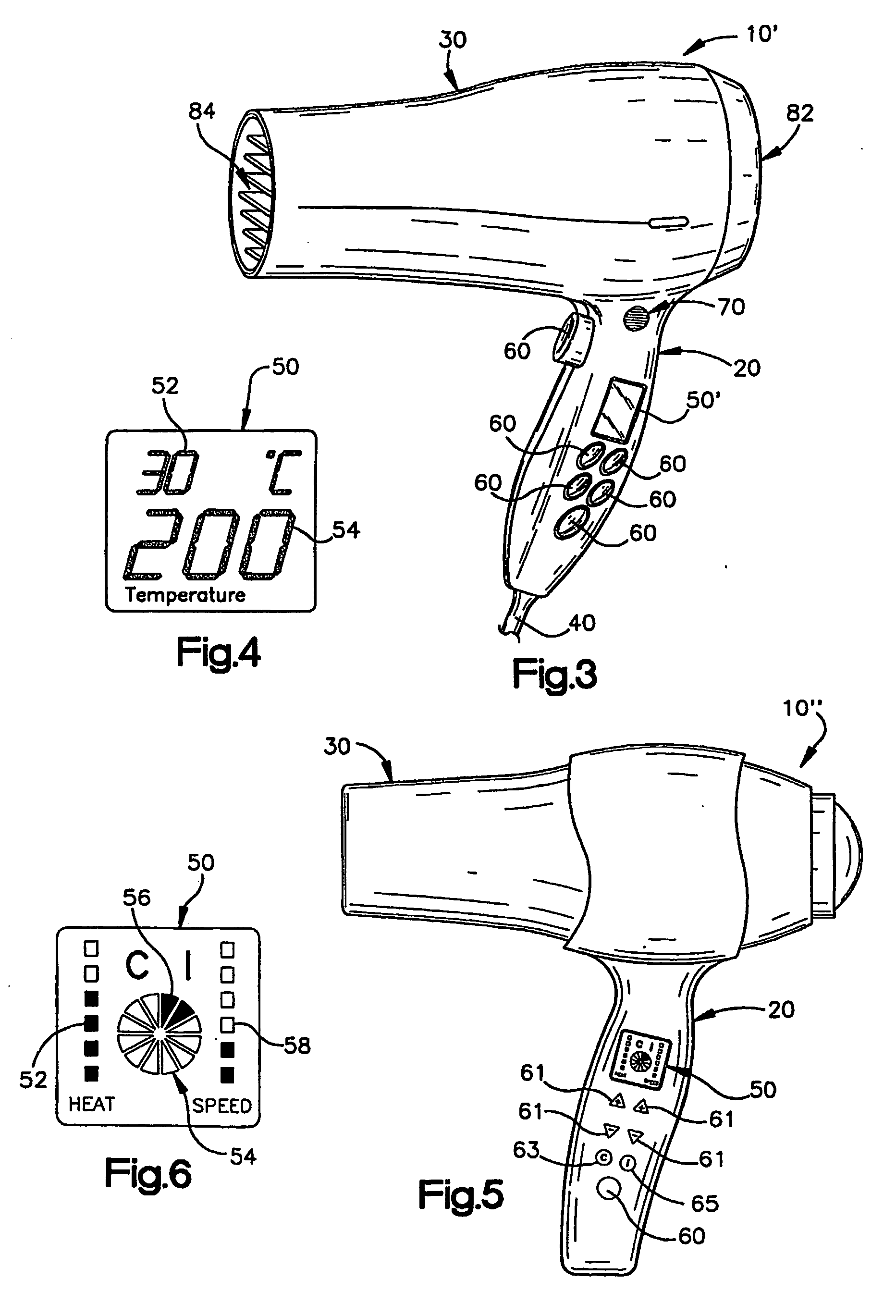

Visual user interface for hair styling apparatus

The present invention is a heated hair styling device comprising a handle (20), a body (30), an LCD visual interface (50), and an audible signal (70) to notify a user of particular states of operation of the hair styling device. The LCD (50) display provides information of at least one operating condition of the device, for example, the temperature of the device, the heat setting, the amount of time that the device has been “on”, etc.

Owner:RUBEN DAVID A

Method for preparing polyacrylonitrile carbon fiber protofilament by dry and wet methods

InactiveCN102146595AGive full play to the advantages of dry and wet methodsGive full play to the advantagesArtificial filament washing/dryingFilament/thread formingPolymer scienceCarbon fibers

The invention discloses a method for preparing polyacrylonitrile carbon fiber protofilament by dry and wet methods. The method comprises the steps of polymerization, demonomerization and defoaming, filtration, coagulation, washing and drafting, oiling densification, steam drafting, heat setting and drying. Three-level coagulating baths at the temperature of between 10 DEG C below zero and 70 DEG C and with dimethyl sulfoxide with concentration of 10 to 60 mass percent are adopted in the coagulation step, and the first coagulating bath contains aqueous ammonia accounting for 0.05 to 1 percent of the mass of the first coagulating bath; and a spinning head is subjected to 1.5 to 5 times positive drafting in the first coagulating bath, and the drafting is 0 in the second and third coagulatingbathes. According to the method for preparing the polyacrylonitrile carbon fiber protofilament, the spinning process is stable, the broken filament is little, the spinning speed is high, the spinningis stable, the prepared protofilament has few defects, the density is not less than 1.180g / cm<3>, and the tensile strength is not less than 7cN / dtex. The protofilament can be prepared into a high-performance carbon fiber with tensile strength of more than 4.9GPa and elastic modulus of between 260 and 280GPa by high-temperature carbonization.

Owner:KINGFA SCI & TECH CO LTD +1

Method for processing regenerated polyester staple fiber by using waste polyester textile

ActiveCN102899729AImprove qualityHigh strengthFilament forming substance formingMelt spinning methodsPolyesterPolymer science

The invention relates to a method for producing regenerated polyester staple fibers, in particular to a method for processing regenerated polyester staple fibers through a physical method by using waste polyester textiles. The method for processing regenerated polyester staple fibers by using waste polyester textiles comprises the following steps of: conducting color matching, proportioning and drying to friction materials produced by using the recovered waste polyester textiles; squeezing and fusing the dried friction materials to obtain fusant; primarily filtering the fusant, feeding the fusant into a high-vacuum tempering and viscosity-regulating reaction kettle; filtering the fusant, feeding the fusant into a spinning manifold and metering spinning; and after spun nascent fibers are bundled, conducting oiling through a dipping tank and a drawing tank, steam secondary drawing, overlapping, curling, relaxed heat setting, cutting and packing to obtain the regenerated polyester staple fibers. By adopting the method for processing regenerated polyester staple fiber by using waste polyester textiles, the technical problem of producing high-quality regenerated polyester staple fibers by using the recovered textiles is solved, the cost of raw materials for producing the regenerated polyester staple fibers is decreased and the problem of recovering the waste polyester textiles is solved.

Owner:余姚大发化纤有限公司

Expandable tubular fabric

Owner:EVELYN FLORENCE

Manufacturing technique of wash-resistant and flame-retardant blended fabric

ActiveCN102392356AImprove flame retardant performanceImprove wash resistanceHeating/cooling textile fabricsYarnGlass fiberPolyester

The invention provides a manufacturing technique of a wash-resistant and flame-retardant blended fabric. The technique comprises the following steps of: 1) preparing a cotton fiber flame-retardant coating adhesive; 2) coating the coating adhesive obtained in the step 1) on the cotton fiber and carrying out heat setting to the cotton fiber so as to obtain a flame-retardant cotton fiber; 3) preparing a glass fiber flame-retardant coating adhesive; 4) directly coating the coating adhesive obtained in the step 3) on the glass fiber and carrying heat setting on the coating adhesive so as to obtaina flame-retardant glass fiber; and 5) blending one of the flame-retardant cotton fiber obtained in the step 2) and a carbon fiber or the flame-retardant glass fiber obtained in the step 4) and one ofa flame-retardant polyester fiber or a flame-retardant nylon fiber so as to obtain the product of the invention. The manufacturing technique of the wash-resistant and flame-retardant blended fabric, provided by the invention, has the advantages of simple process, low cost, good product permeability, softness as well as good wash resistance and flame retardation. The manufacturing technique of thewash-resistant and flame-retardant blended fabric, provided by the invention, is mainly used for manufacturing products like smoke screens, fire-proof insulated curtains, bedspreads, flame-retardant furniture and the like.

Owner:应急管理部四川消防研究所

Methods of making low-shrink polypropylene fibers

InactiveUS6656404B2Monocomponent polypropylene artificial filamentWoven fabricsPhosphateLITHIUM PHOSPHATE

Improved polypropylene fibers exhibiting greatly reduced heat- and moisture-shrink problems and including certain compounds that quickly and effectively provide rigidity to the target polypropylene fiber after heat-setting are disclosed herein. In such a manner, the "rigidifying" compounds provide nucleation sites for polypropylene crystal growth. After drawing the nucleated composition into fiber form, the fiber is then exposed to sufficient heat to grow the crystalline network, thus holding the fiber in a desired position. The preferred "rigidifying" compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as sodium beuzoate, certain sodium and lithium phosphate salts (such as sodium 2,2'-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11).

Owner:MILLIKEN & CO

Blended woven or knitted fabrics containing polyerethane elastic fibers and process for the production thereof

A blended woven or knitted fabric which contains both highly fusible polyurethane elastic fibers exhibiting a retention of tenacity of 50% or above after the dry heat treatment at 150° C. for 45 s at 100% elongation and a melting point of 180° C. or below and at least one kind of non-elastic yarns and which is produced by fusing the polyurethane elasotomeric fibers to each other or the polyurethane elastic fibers to the non-elastic yarns at the crossover points by dry- or wet-heat setting; and a process for the production thereof.

Owner:NISSHINBO IND INC

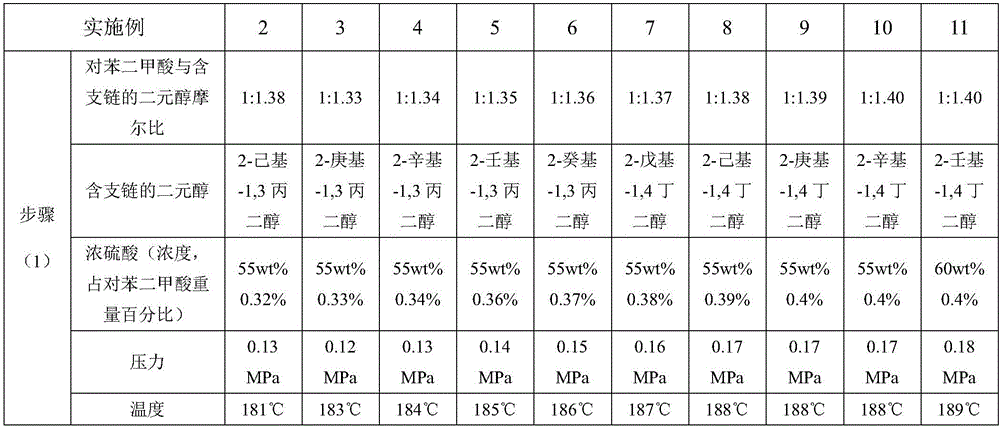

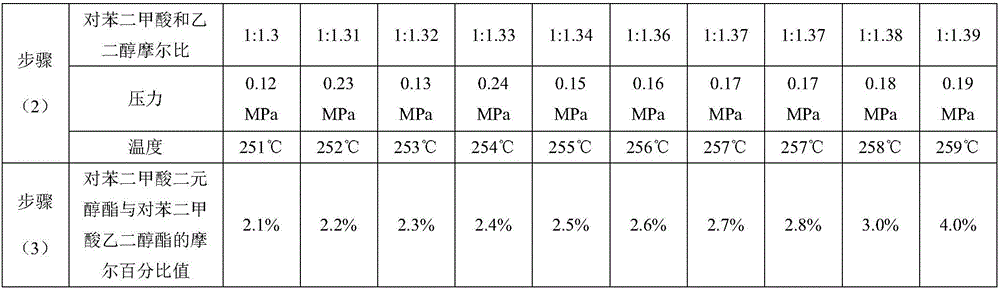

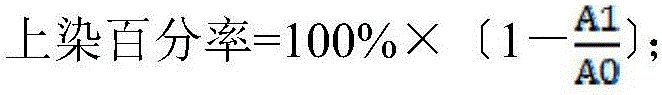

Polyester fibres and preparation method thereof

ActiveCN106367835AImprove dyeing effectEasy to processSpinnerette packsMonocomponent copolyesters artificial filamentSlurryLow vacuum

The invention relates to polyester fibres and a preparation method thereof. The raw material of the polyester fibres is modified polyester which consists of a terephthalic acid chain segment, an ethylene glycol chain segment and a branched chain-containing dihydric alcohol chain segment. The preparation method of the polyester fibres comprises the following steps: performing esterification reaction on terephthalic acid and branched chain-containing dihydric alcohol under the catalysis of concentrated sulphuric acid to obtain terephthalic acid dihydric alcohol ester; then, preparing the terephthalic acid and the ethylene glycol into slurry, and performing the esterification reaction on the slurry to obtain the terephthalic acid ethylene glycol ester; finally, stirring and mixing the terephthalic acid dihydric alcohol ester and the terephthalic acid ethylene glycol ester, and performing condensation polymerization in a low vacuum stage and a high vacuum stage under the action of a catalyst and a stabilizing agent to obtain modified polyester; metering, extruding, cooling, oiling, stretching, heat-setting and winding the polyester to prepare the polyester fibres. The increasing amplitude of the spatial gaps of the polyester fibres is much higher than that of branched chain-free polyester fibres at the same temperature, which is beneficial to the degree of micro particles, such as a dye, that enter the polyester; the dyeing rate is improved.

Owner:JIANGSU HENGLI CHEM FIBER

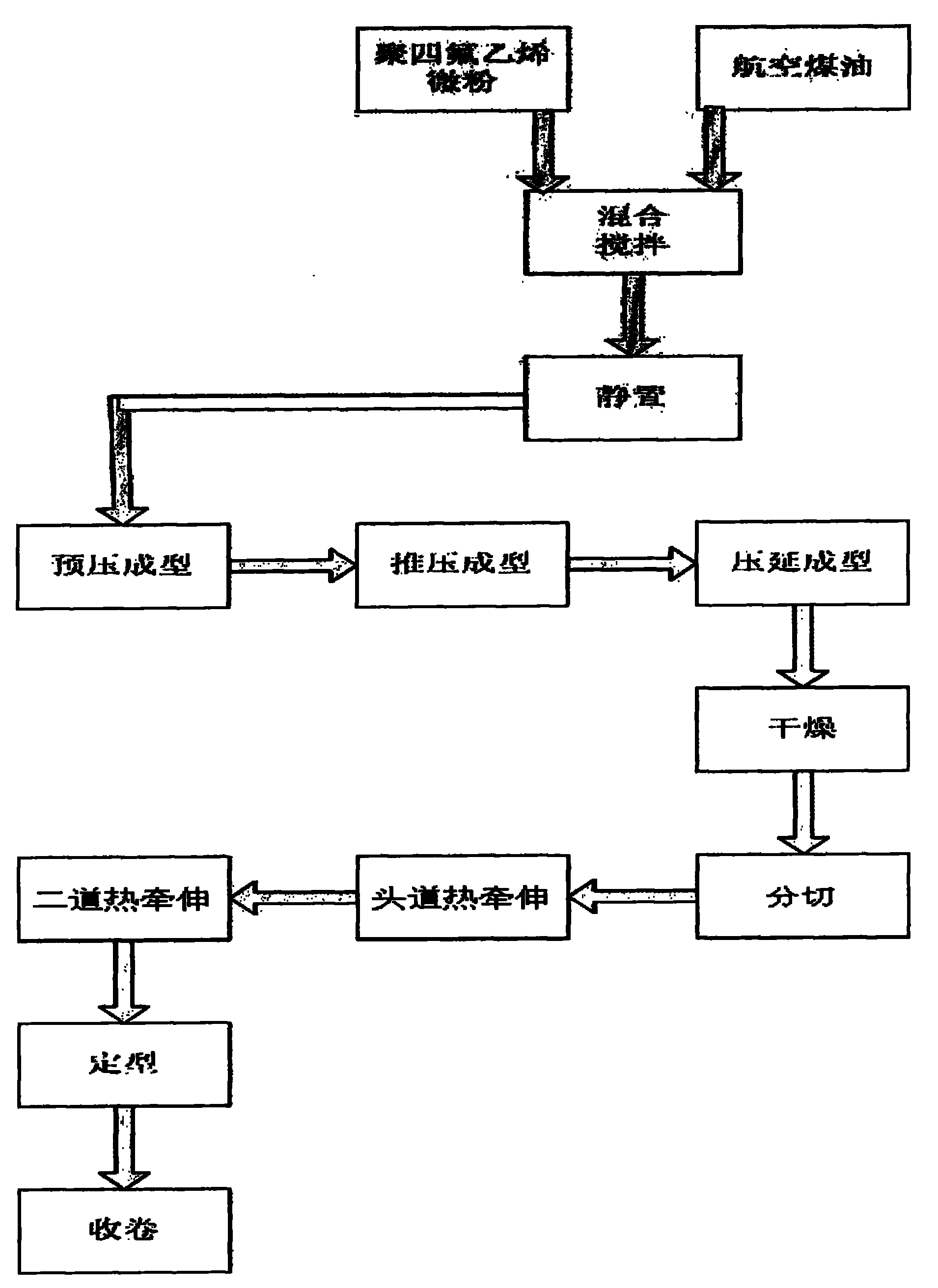

Manufacturing method of film split polytetrafluoroethylene fibers

ActiveCN102051703AWell mixedWeight optimizationFilament/thread formingMonocomponent halogenated hydrocarbon artificial filamentPre compressionHigh intensity

The invention aims to provide a manufacturing method of film split polytetrafluoroethylene fibers with high intensity, high uniformity and low production cost. A process comprises the following steps of: mixing polytetrafluoroethylene micro-powder and a lubricant; stirring; standing; performing pre-compression molding; performing press molding; performing calendaring molding; drying; cutting; performing primary hot stretching; performing secondary hot stretching; performing heat shaping; and winding so as to obtain high-intensity polytetrafluoroethylene fibers. In the manufacturing process, temperatures during drying, cutting, primary hot stretching, secondary hot stretching and heat shaping rise in turn.

Owner:ZHEJIANG HONGSHENG NEW MATERIAL TECH GRP CO LTD

Method for preparation of polytetrafluorethylene microporous film for the processing of high-temperature fume and flour dust

InactiveCN101081356ASimple processReduce manufacturing costSemi-permeable membranesDispersed particle separationPolymer scienceBurn treatment

The present invention discloses one kind of microporous teflon film for treating high temperature fume and dust and its preparation process. The preparation process includes mixing powdered teflon resin and powdered catalyst, adding liquid lubricant to the mixture, extruding, rolling, longitudinally stretching, transversely stretching, heat setting and other steps. The microporous teflon film for treating high temperature fume and dust has simple preparation process and low cost. It has pore size of 0.5-5 micron and dioxins eliminating rate at 200 deg.c as high as 95-98 %. It may be applied widely for high temperature tail gas treatment in refuse burning treatment plant, refuse burning power plant, coal burning power plant, cement mill, etc.

Owner:ZHEJIANG SCI-TECH UNIV

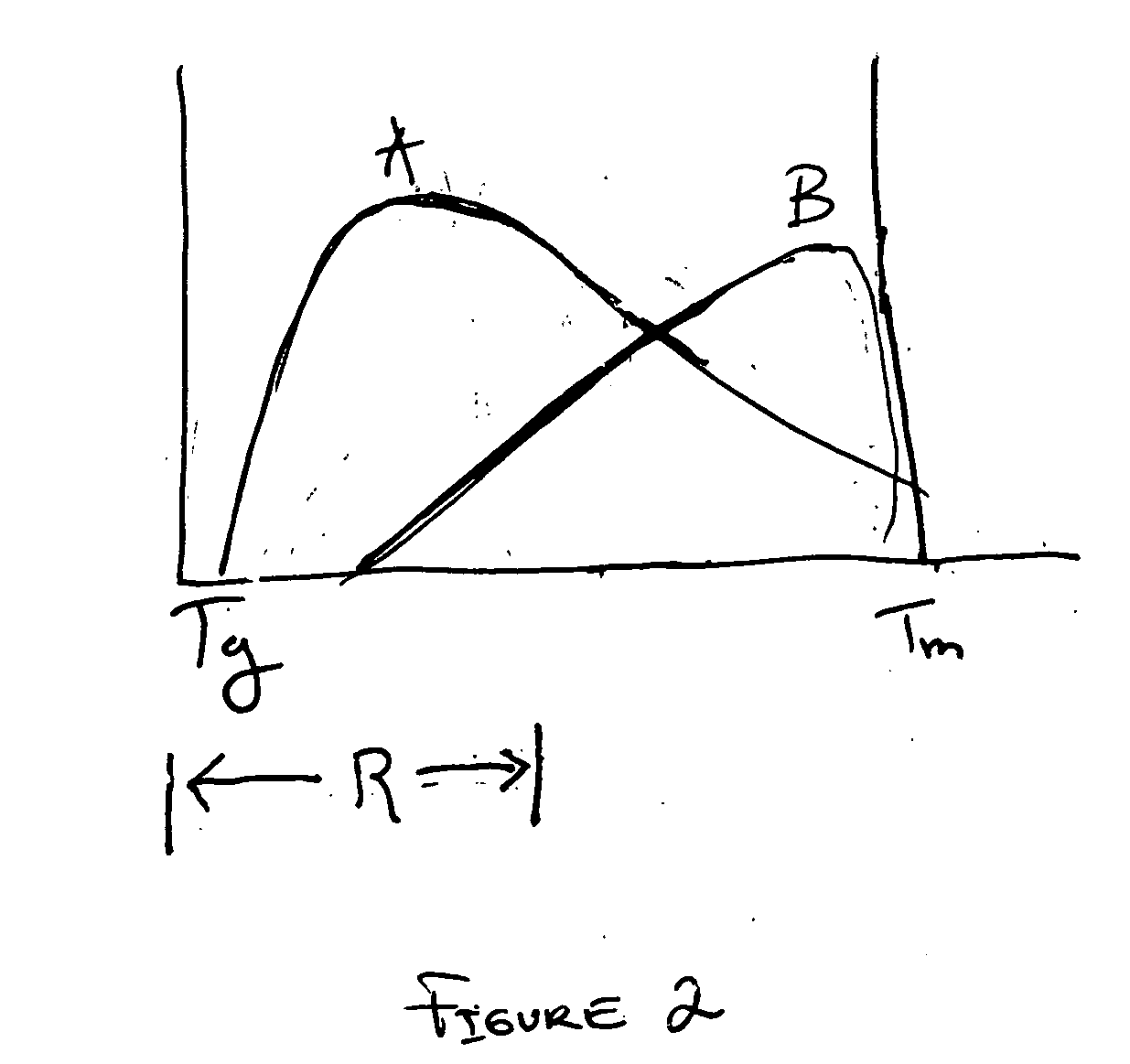

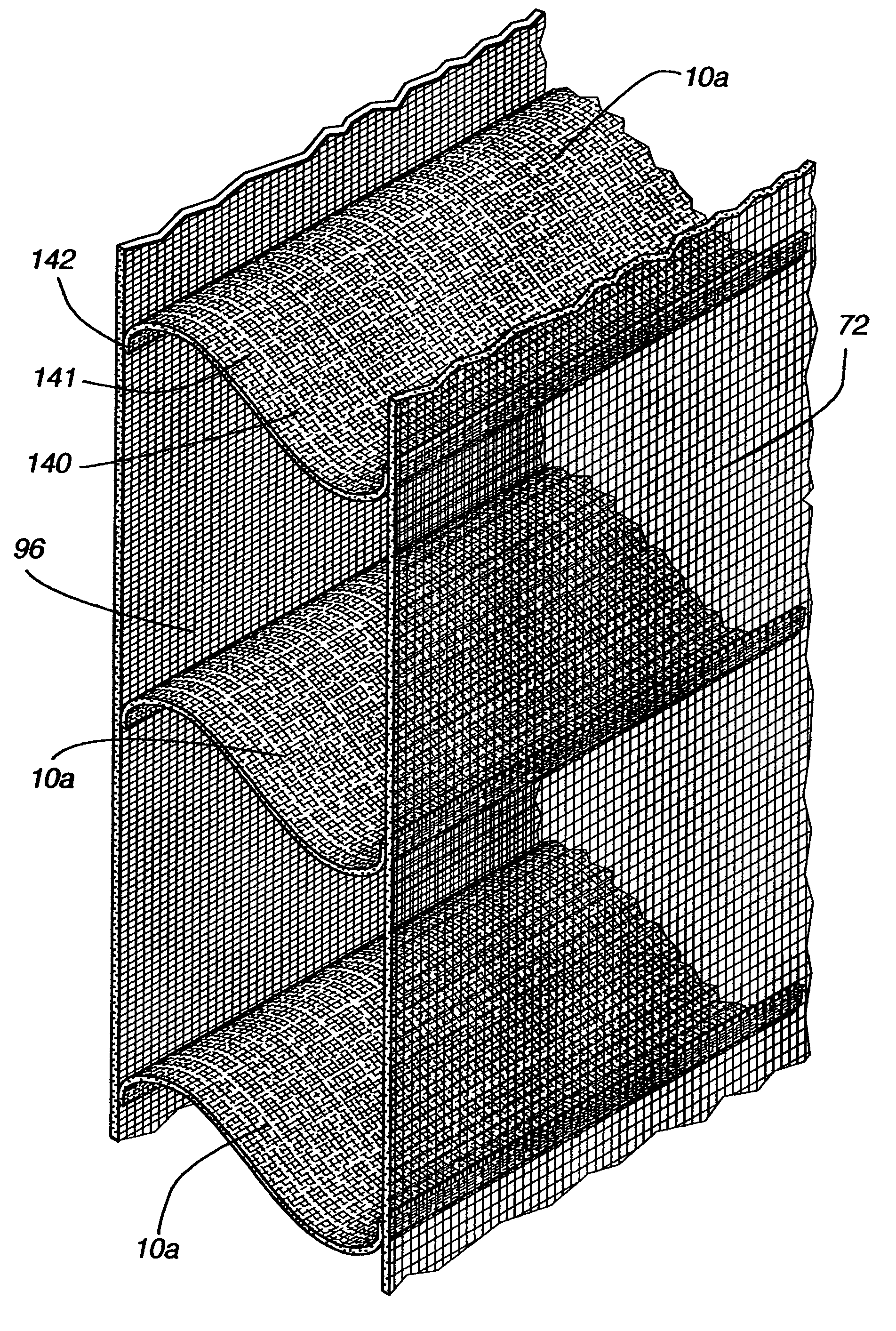

Fabric light control window covering

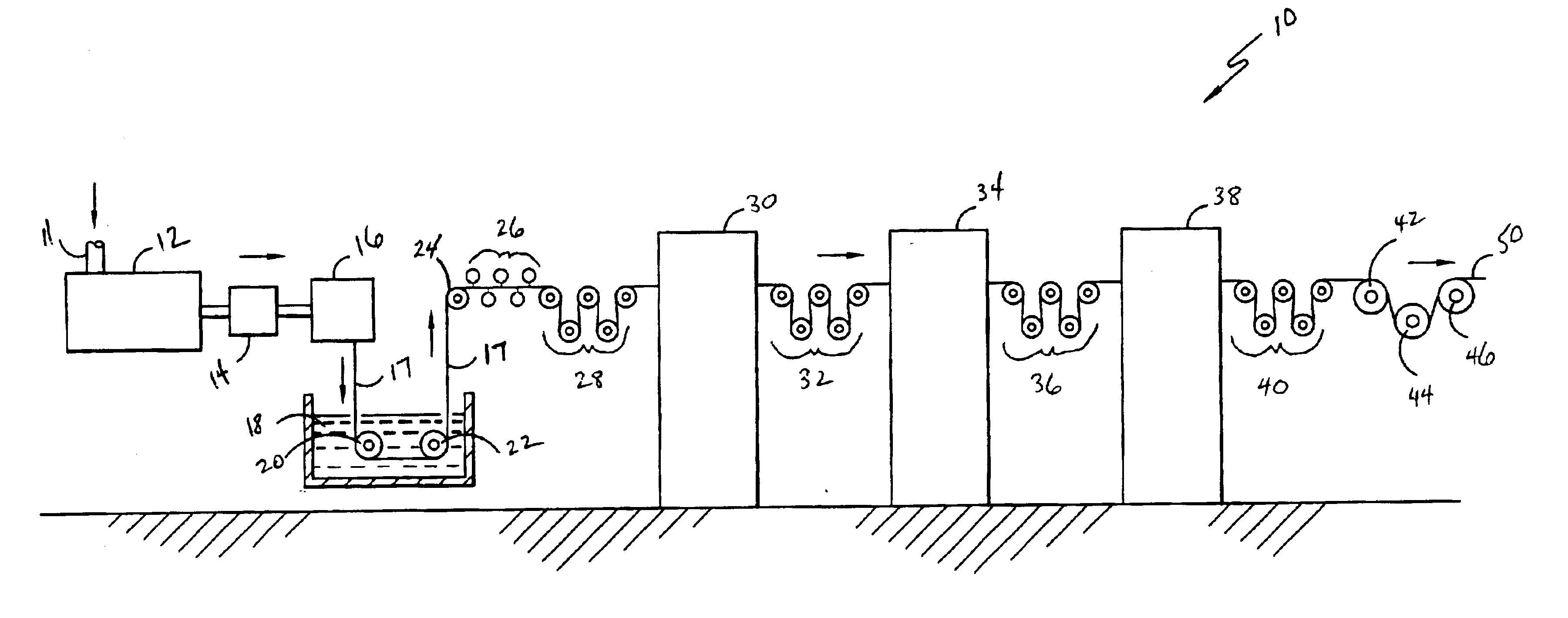

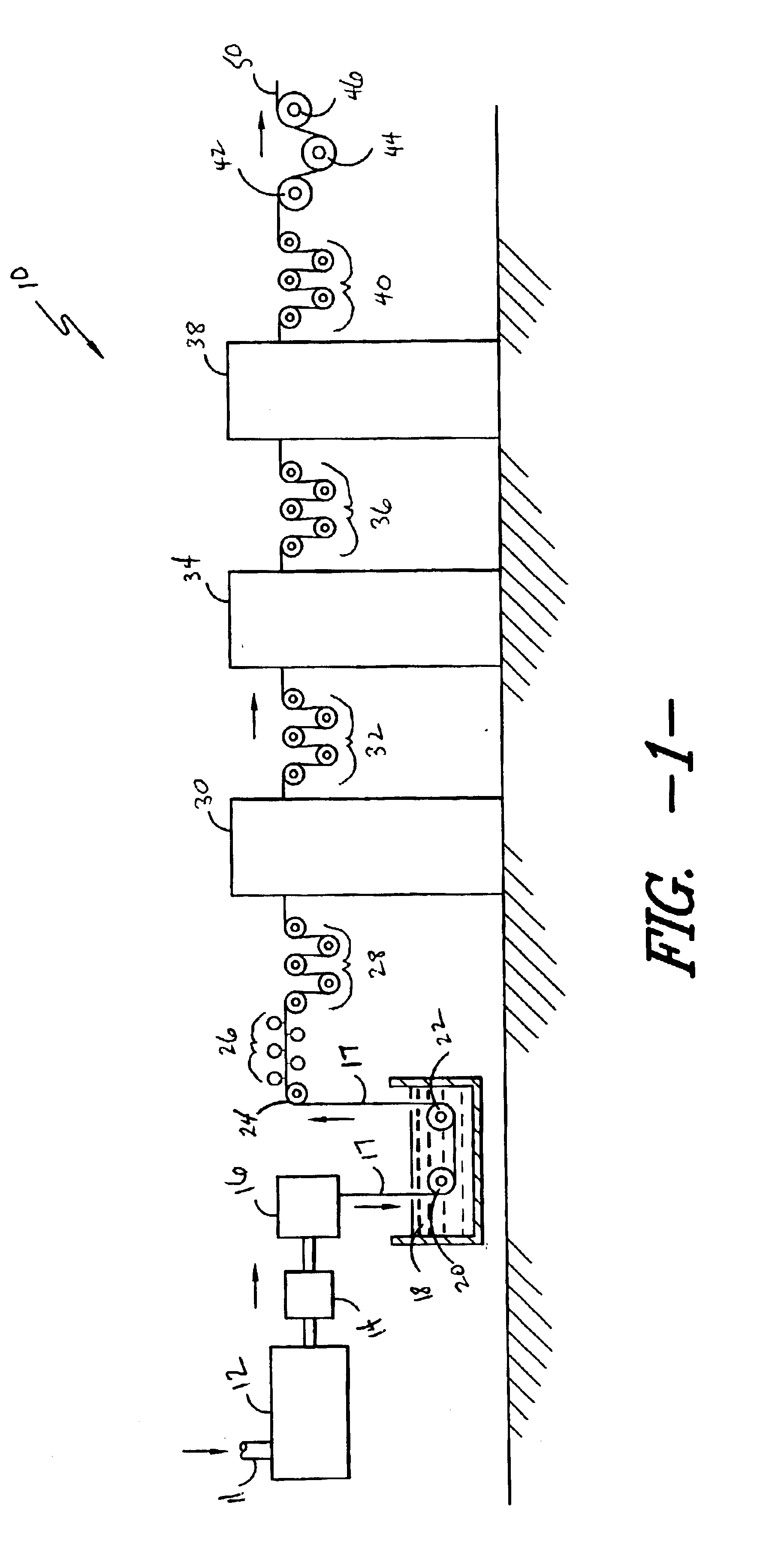

InactiveUS7059378B2Constant feed rateConstant and uniform pressureExtensible doors/windowsClosuresAdhesiveEngineering

A fabric light control window covering in which fabric vanes are adhesively bonded between two sheer fabric sheets such that relative movement between the sheer fabric sheets in a direction perpendicular to the longitudinal direction of the fabric vanes changes the angle of the fabric vanes and, thus, controls the amount of light admitted through the shade. The vanes are bonded to the sheer fabric sheets in a manner which tends to bias the sheer fabric sheets together to the nonlight admitting position. Also, disclosed are methods and apparatus for manufacturing the above window covering. The method features linear application of adhesive to the vane material which provides for a uniform appearance in the finished product. A heat setting process and apparatus is disclosed in which the bonded layers of sheer fabrics and vanes are fed between belts over hot and cool surfaces, under uniform tension and pressure. This provides for heat setting of the layers of the window covering to a uniform temperature-size relationship without inducing wrinkles or distortion into the fabric during heat setting.

Owner:HUNTER DOUGLAS INC

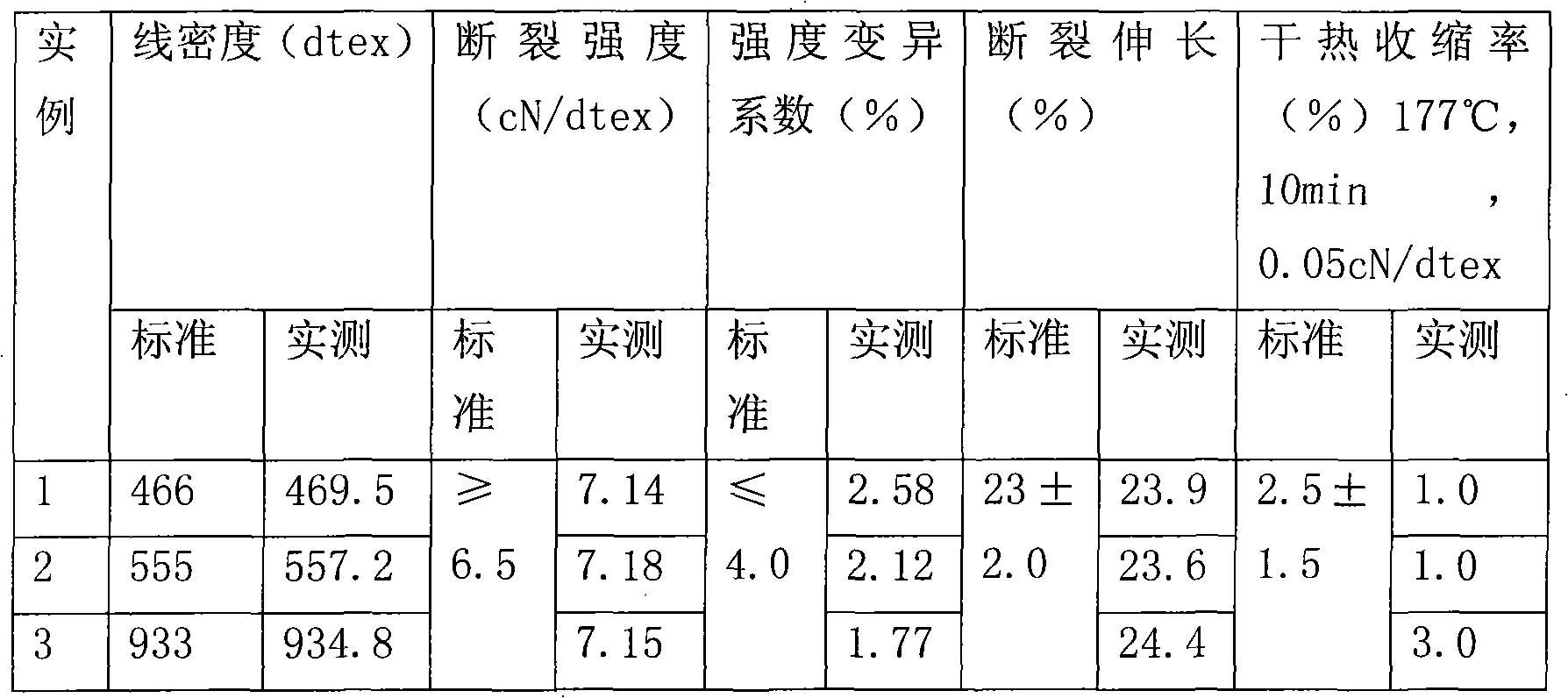

Method for producing felt polyester staple fiber by recycling polyester bottle slice

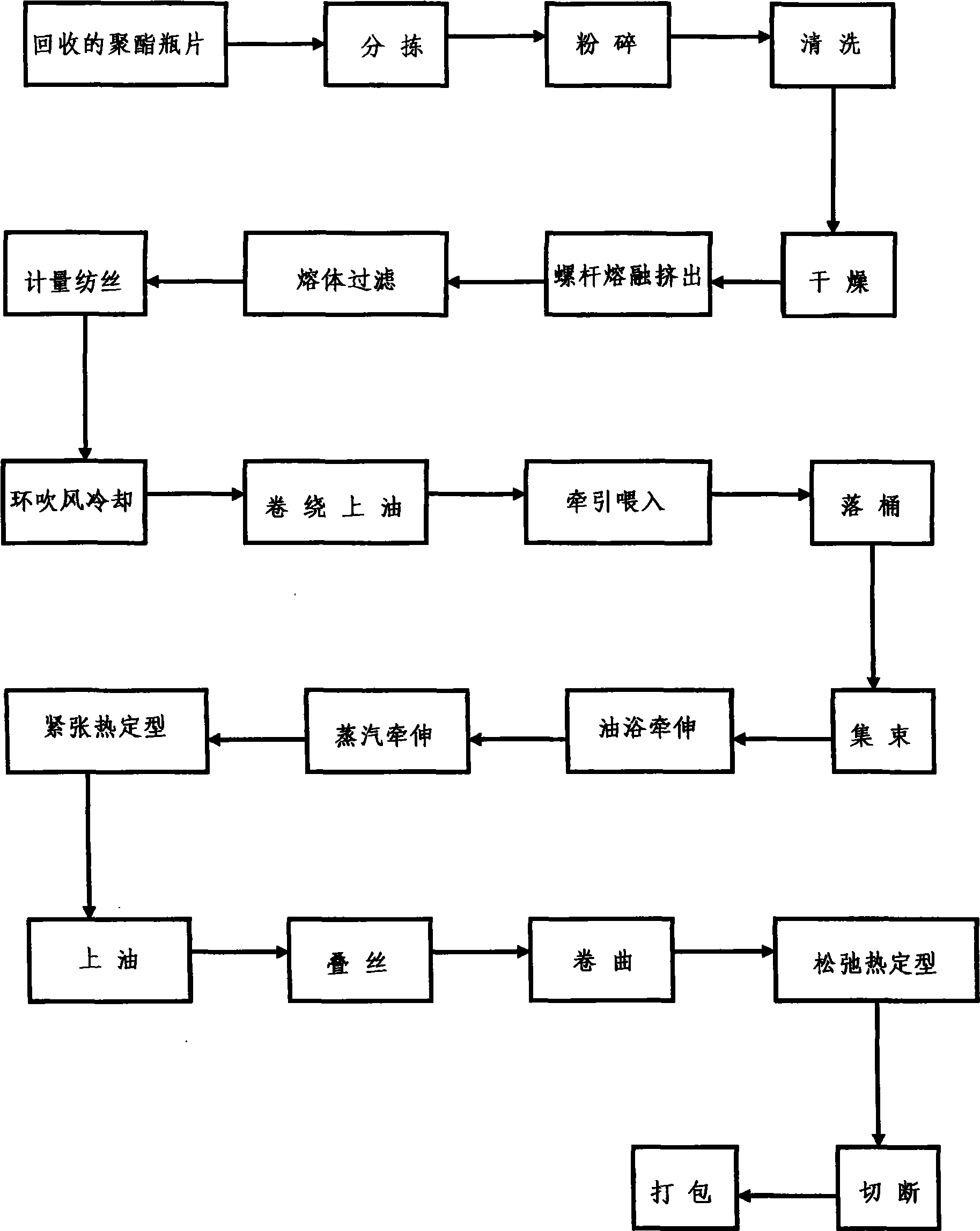

InactiveCN101487142APromote environmental protectionReduce manufacturing costFilament forming substance formingSevering to form staple fibresPolyesterBottle

The invention discloses a method for directly producing felt base cloth polyester short-fiber by recovered polyester bottle sheets, comprising the steps as follows: the recovered polyester bottle sheets are sorted, crushed, cleaned, dried, extruded in a melting state, filtrated, measured, spinned, cooled by circular wind, coiled and oiled, pulled, fed, dropped in a barrel, balanced, collected into bundles, primarily pulled by oil bath, secondarily pulled by steam, tensioned and thermally shaped, oiled, folded, curled, loosened and thermally shaped, cut off and finally packaged. Compared with the felt base cloth polyester short-fiber produced by taking the polyester new material as raw material, the felt base cloth polyester short-fiber produced by the method has almost the same performances and lower price, does not affect the production, processing and use of the next user product, still keeps all product performances of the next user product, lightens the harms of the wastes on the environment, and solves the environmental protection problem.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

Process for the production of brittle polymeric film

InactiveUS7718104B2Enhance the imageLow tensile strengthStampsCeramic shaping apparatusCarboxylic acidPolymer thin films

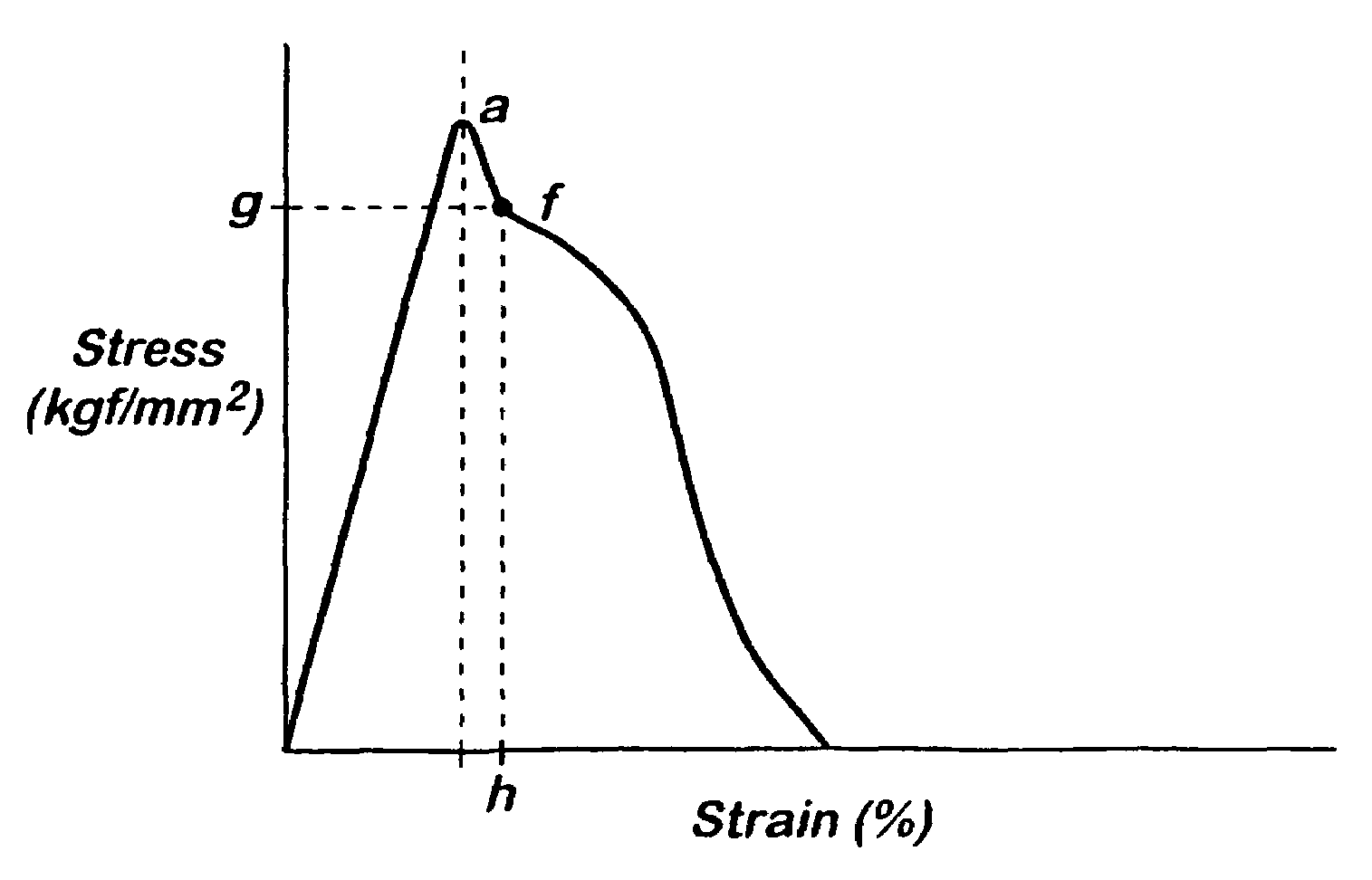

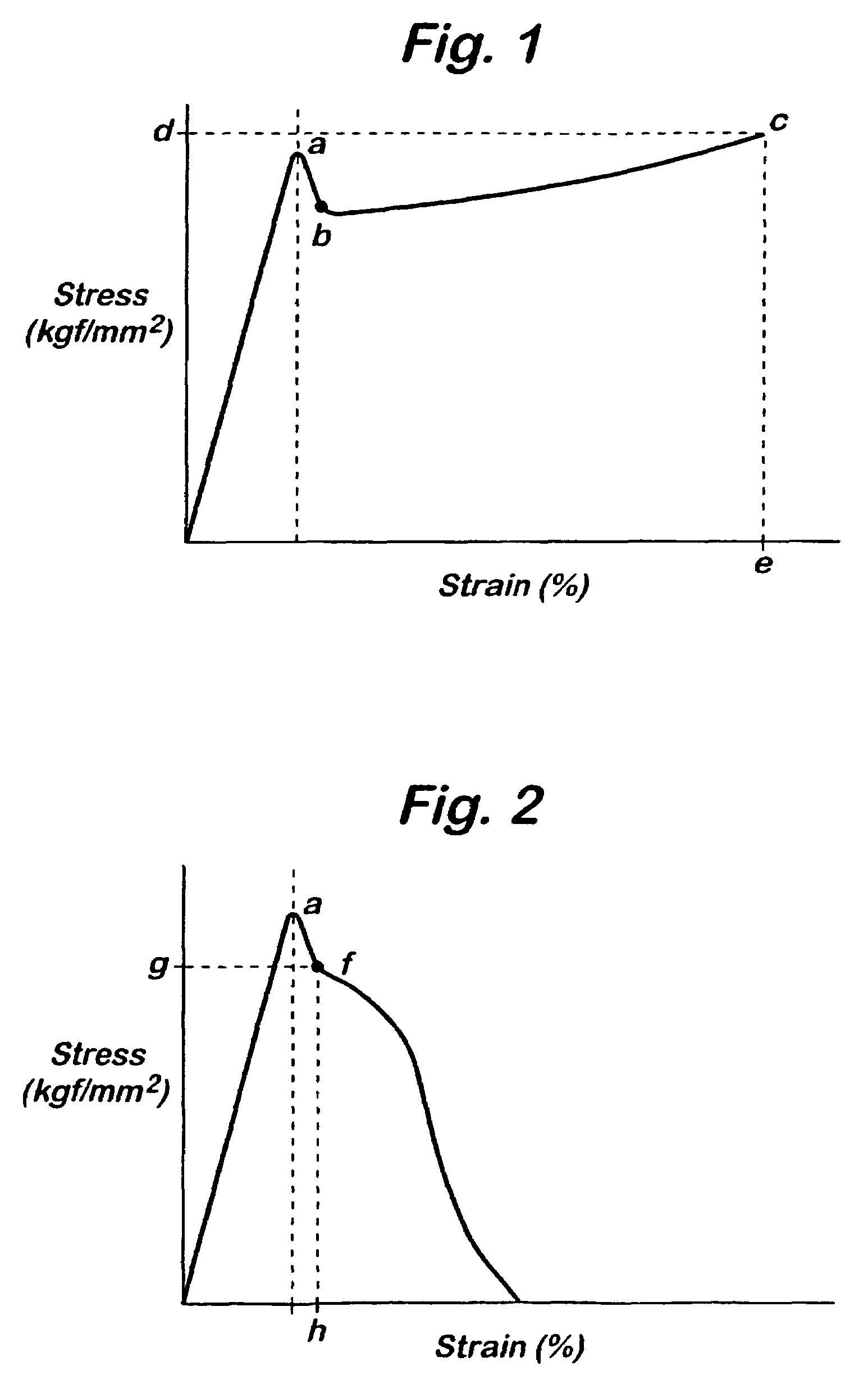

A process for the production of a polymeric film comprising a copolyester having an acid component and a diol component, said acid component comprising a dicarboxylic acid and a sulfomonomer containing a sulfonate group attached to the aromatic nucleus of an aromatic dicarboxylic acid, said process comprising the steps of: (i) melt-extruding a layer of said copolyester; (ii) stretching the extrudate in at least one direction; (iii) heat-setting the film by raising the temperature of the stretched film to a temperature T1 in a first heating zone such that (TM-T1) is in the range of from 5 to 30° C., and then raising the temperature of the film to a temperature T2 in a second heating zone such that (TM-T2 is in the range of from 0 to 10° C., wherein TM is the peak melting temperature of the polymeric film; wherein T2 is greater than T1; and wherein the times which a transverse section of the film spends in the first and second heating zones are defined by t1 and t2, respectively, such that the ratio of t1 to t2 is at least 2:1; and a polymeric film obtainable thereby having an ultimate tensile strength at destruction in the range of 2 to 15 kgf / mm2 in the machine direction and 2.5 to 17 kgf / mm2 in the transverse direction.

Owner:DUPONT TEIJIN FILMS US LTD

Process for producing polyester industrial fiber for processing safe air bag of automobile

ActiveCN101634052AHeat resistantAging resistantArtificial filament heat treatmentMelt spinning methodsPolyesterEngineering

The invention relates to a process for producing a polyester industrial long fiber for processing a safe air bag of an automobile, which sequentially comprises the following steps: A. processing a polyester slice with high viscosity: enabling the viscosity of the polyester slice to reach 1.0-1.1dl / g; B. melting and spinning: transmitting the polyester slice after solid phase polymerization to a spinning screw rod extruder, melting in a spinning screw rod, entering a spinning assembly by a metering pump and extruding from a fiber spray plate with a diameter of 190 mm to 220 mm to spin fusant, , then heating by a slow cooling heater, carrying out cooling for molding by a side-molding blowing device and then entering a spinning passage; C. stretching and winding: oiling the surface of a fiber and carrying out second-grade high-speed stretching with the total stretching multiple being 5.0 to 5.8, carrying out high-temperature loosing thermoforming at 230 DEG C-250 DEG C and carrying out winding for molding in the range of the winding process speed of 2,500-3,000 m / min to prepare a finished product. The fiber for the safe air bag, which is produced by the process, can completely replace a nylon 66 fiber, is used for spinning terylene safe air bag fabrics and greatly reduces the processing cost.

Owner:ZHEJIANG HAILIDE NEW MATERIAL

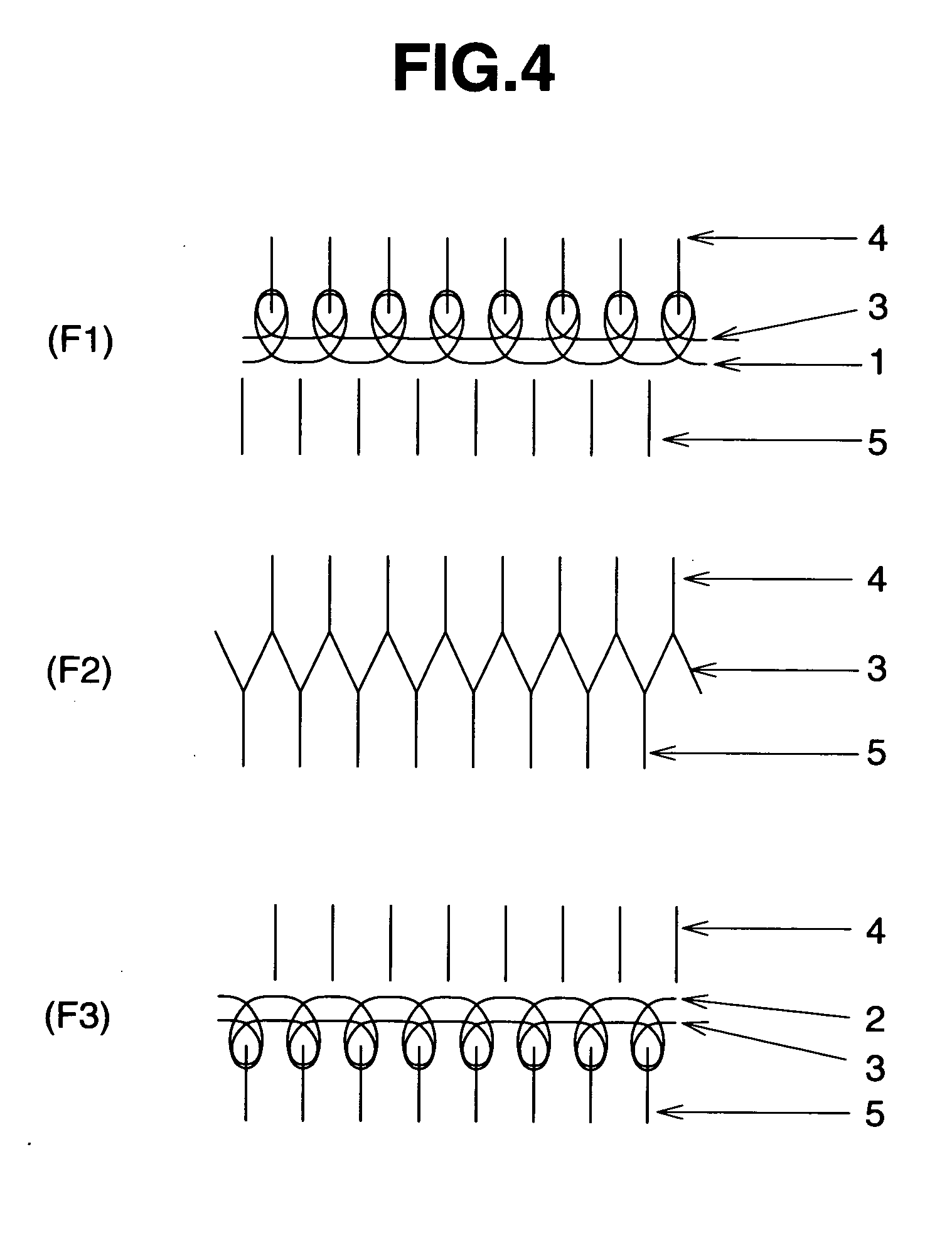

Weft Knitted Fabric Including Polyurethane Elastomer Fiber and Process for Producing the Same

ActiveUS20080032580A1Good extensibilityPromote recoveryOrnamental textile articlesWarp knittingYarnPolyurethane elastomer

A polyurethane elastomeric filament-containing weft knit fabric is obtained by plating a bare yarn of highly fusible, alkali-resistant polyurethane elastomeric filament having at least 50% retention of tenacity following dry heat treatment under 100% extension at 150° C. for 45 seconds, a melting point of 180° C. or below, and at least 60% retention of tenacity following treatment in a 2 g / L aqueous sodium hydroxide solution under 100% extension at 100° C. for 60 minutes at every loop of a weft knit fabric having a 1×1 rib. knit structure or a center yarn-containing reversible knit structure composed of at least one type of non-elastomeric yarn, then heat setting the plated structure so as to thermally fuse the highly fusible, alkali-resistant polyurethane elastomeric filaments to each other or to the non-elastomeric yarns at crossover points therebetween.

Owner:NISSHINBO TEXTILE INC +1

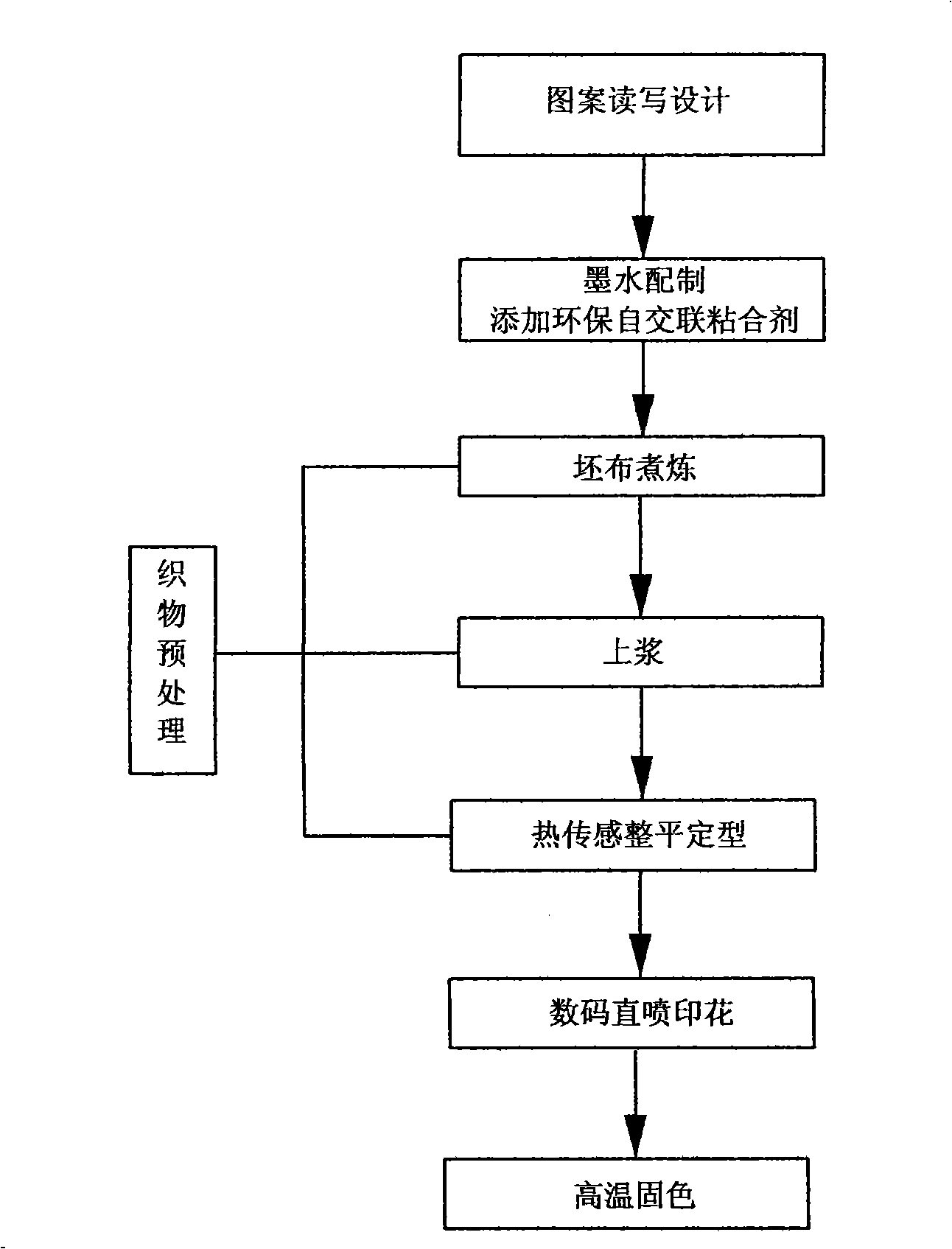

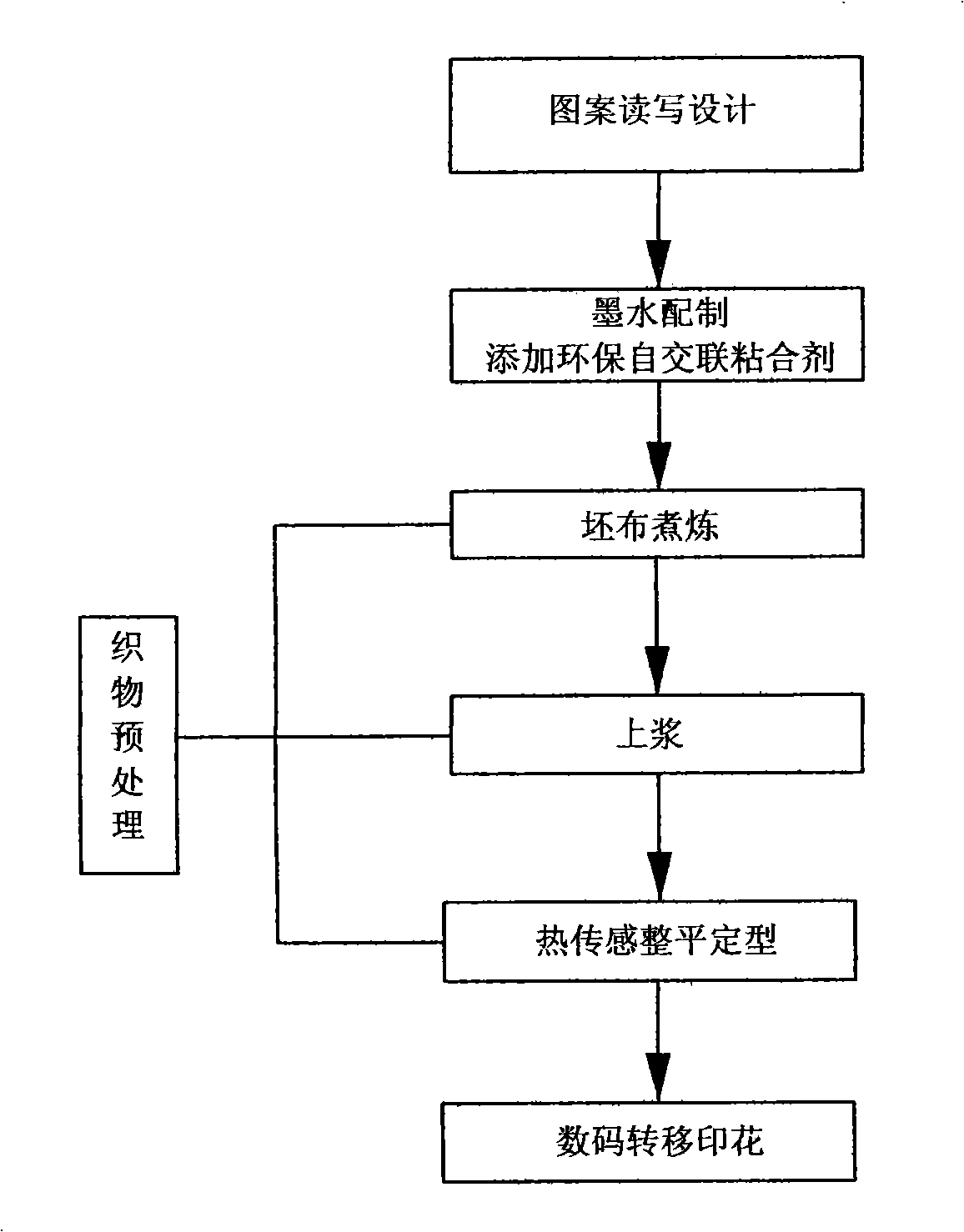

Real silk and real silk intimating digit printing process

The invention discloses a natural silk and artificial silk digital printing technique, which belongs to the printing technical field. The technique comprises the following steps: read-write design of patterns, preparation of ink, pretreatment of textile fabrics, digital jet printing and so on. By addition of an environment-friendly self-crosslinking adhesive into the ink and adoption of the special heat-setting technique, the upper part and the lower part of a blank after sizing are tightly pressed and heated by two electric blankets; and the pressure is between 2 and 3kgf / cm<2>, and the heating temperature is between 200 and 280 DEG C. Products prepared by adoption of the technique still can not be faded after water scrubbing for a plurality of times and even under more severe experimental environments and maintain the prior color and the prior brightness.

Owner:SHAOXING COUNTY YONGTONG SILK PRINTING

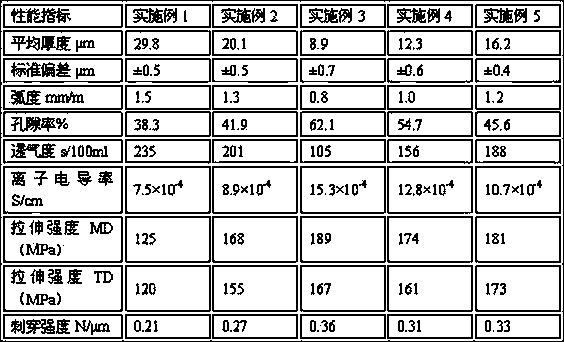

Polyolefin microporous film preparation method for lithium ion battery and microporous film

InactiveCN103522550AReduce unclampingReduce edge tearingCell component detailsFlat articlesPolymer sciencePolyolefin

The invention discloses a polyolefin microporous film preparation method for a lithium ion battery and a microporous film. A mode of twice bidirectional drawing is adopted, and the overall rate of the twice drawing is 16 to 100 times. The preparation method comprises the following steps of (a) extruding a casting piece; (b) performing primary bidirectional drawing at a bidirectional drawing rate which is controlled to be 4 to 10 times to obtain an oily thin film; (c) performing extraction to obtain a microporous film A; (d) performing secondary bidirectional drawing at a bidirectional drawing rate which is controlled to be 4 to 10 times to obtain a thinner microporous film B; (e) performing heat setting to obtain a polyolefin microporous film. The polyolefin microporous film microcosmically has a completely drawn fiber structure, is uniform in aperture and high in performance consistency, and has higher mechanical performance, higher air permeability and enhanced ionic conductivity; the yield can be greatly improved; the lithium ion battery adopting the microporous film has high assembling performance, and the performance and the stability of the battery are enhanced.

Owner:乐凯胶片股份有限公司

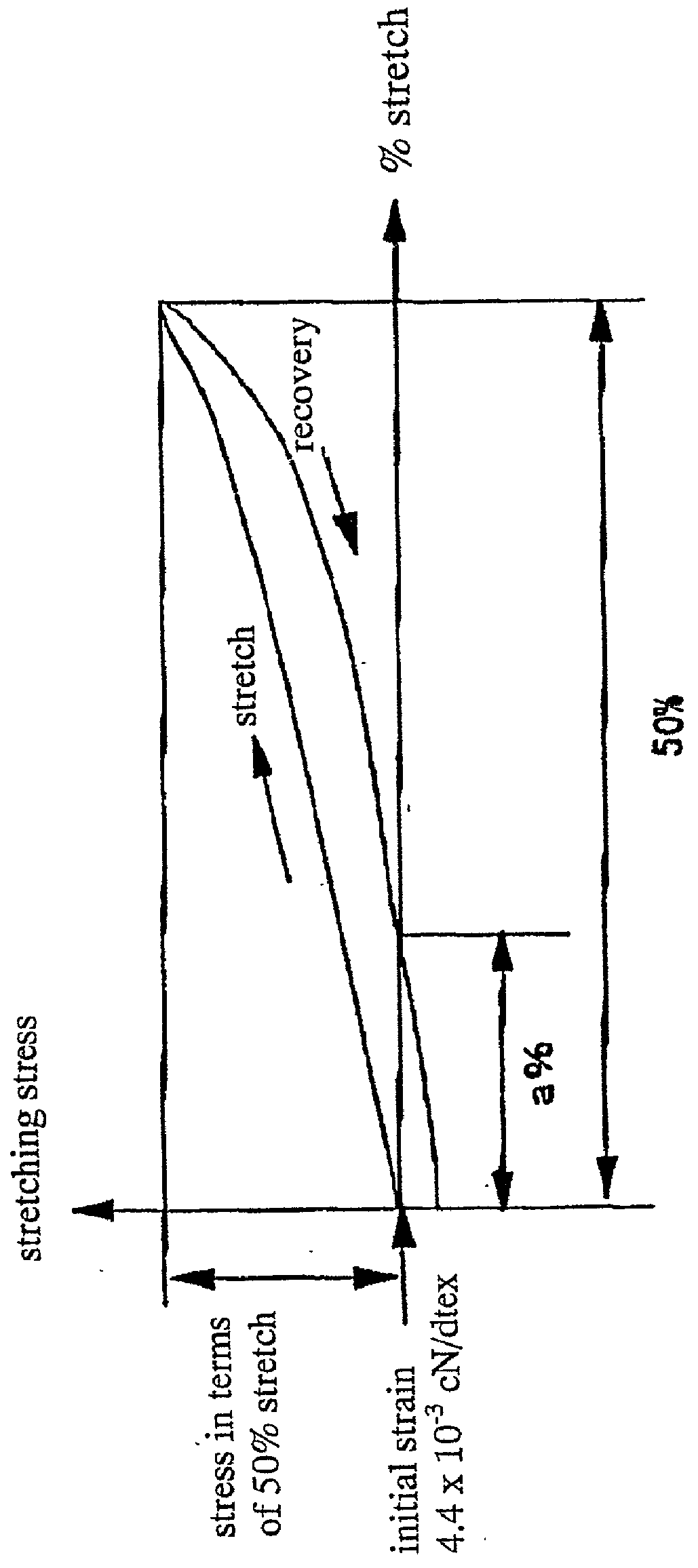

Soft stretch yarns and their method of production

InactiveUS20010055683A1Eliminate the problemImprove tensile propertiesHollow filament manufactureWoven fabricsPolyesterYarn

A soft stretch yarn substantially comprising polyester fibers has a stress, at 50% yarn stretch, of no more than 30x10-3 cN / dtex and, at the same time, a percentage recovery of at least 60%. Preferably, the Uster unevenness is no more than 2.0% and the crimp diameter is no more than 250 mum. This soft stretch yarn can be produced by spinning yarn of conjugate fibers comprising two types of polyester in which one component is PTT at a take-up velocity of at least 1200 m / min, drawing at a drawing temperature of 50 to 80° C. at a draw ratio such that the drawn yarn tensile elongation is 20 to 45%, and then heat setting.

Owner:TORAY IND INC

Polyamide composition with improved heat stability and whiteness

InactiveUS20080090945A1Improved in whiteness appearancePermanent whiteness improvementGroup 4/14 element organic compoundsDye addition to spinning solutionYarnPolyamide

A polyamide composition, which includes an optical brightener together with an anti-oxidant stabilizer, is disclosed. This composition is suitable for making yarns, such as sewing thread, and fabrics, garments, molded articles or other articles such as carpets from these yarns. Processes for incorporating optical brighteners into polyamide compositions, polymers and yarns to make fabrics and molded articles that exhibit superior whiteness after heat-setting are also disclosed.

Owner:INVISTA NORTH AMERICA R L

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com