Method for producing felt polyester staple fiber by recycling polyester bottle slice

A polyester staple fiber and linoleum based fabric technology, which is applied in fiber processing, single-component polyester rayon, melt spinning, etc., can solve the problems of recycled polyester bottle flakes with many impurities and inability to produce high-end chemical fiber products. Achieve the effect of being beneficial to environmental protection, improving cost performance and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

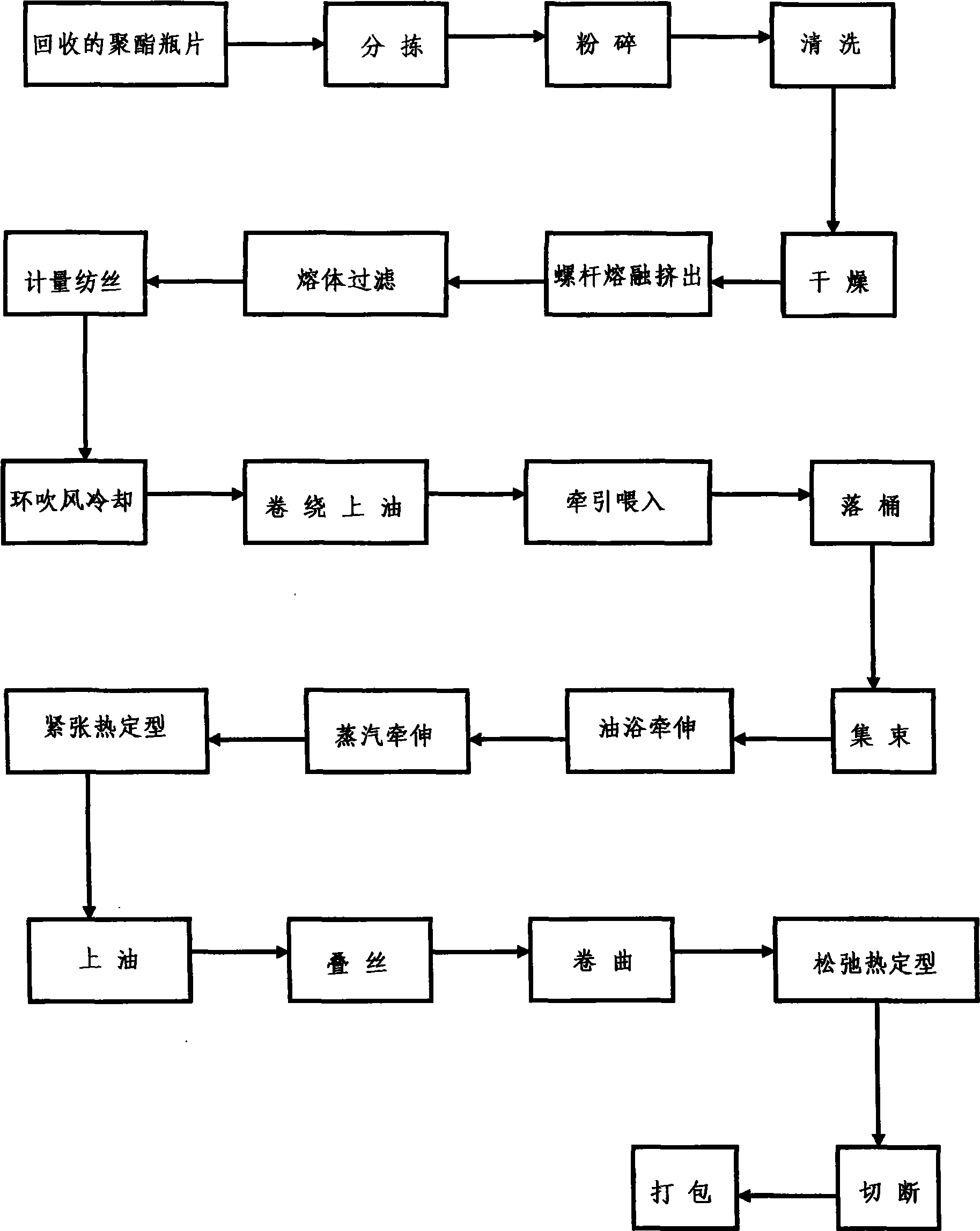

[0012] Referring to accompanying drawing 1, a kind of method of utilizing recycled polyester bottle flakes of the present invention to produce linoleum base cloth polyester staple fiber:

[0013] Firstly, the recycled waste PET bottle flakes are pretreated. Pretreatment includes a series of raw material preparations such as sorting, crushing, and cleaning the recovered polyester bottle flakes, and then undergoes high-temperature vacuum drying. The drying temperature is 130-160°C, the vacuum degree is 0.06-0.10Mpa, and the drying time is After 7 to 12 hours, the moisture content of the dried bottle flakes is ≤110PPm.

[0014] Then the high-temperature dried bottle flakes are melted through the screw extruder at high temperature, and a certain pressure is given at the same time. The ester melt enters the melt filter, the filter screen precision of the filter is 120-250 mesh, and the total filtering area of the filter is 4.5-12m 2 , The filter temperature is controlled at 260...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com