Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2508 results about "Copolyester" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copolyester forms when modifications are made to polyesters, which are combinations of diacids and diols. For example, by introducing other diacids, such as isophthalic acid (IPA), or other diols, such as cyclohexane dimethanol (CHDM) to the polyester polyethylene terephthalate (PET), the material becomes a copolyester due to its comonomer content.

Selectively absorbable/biodegradable, fibrous composite constructs and applications thereof

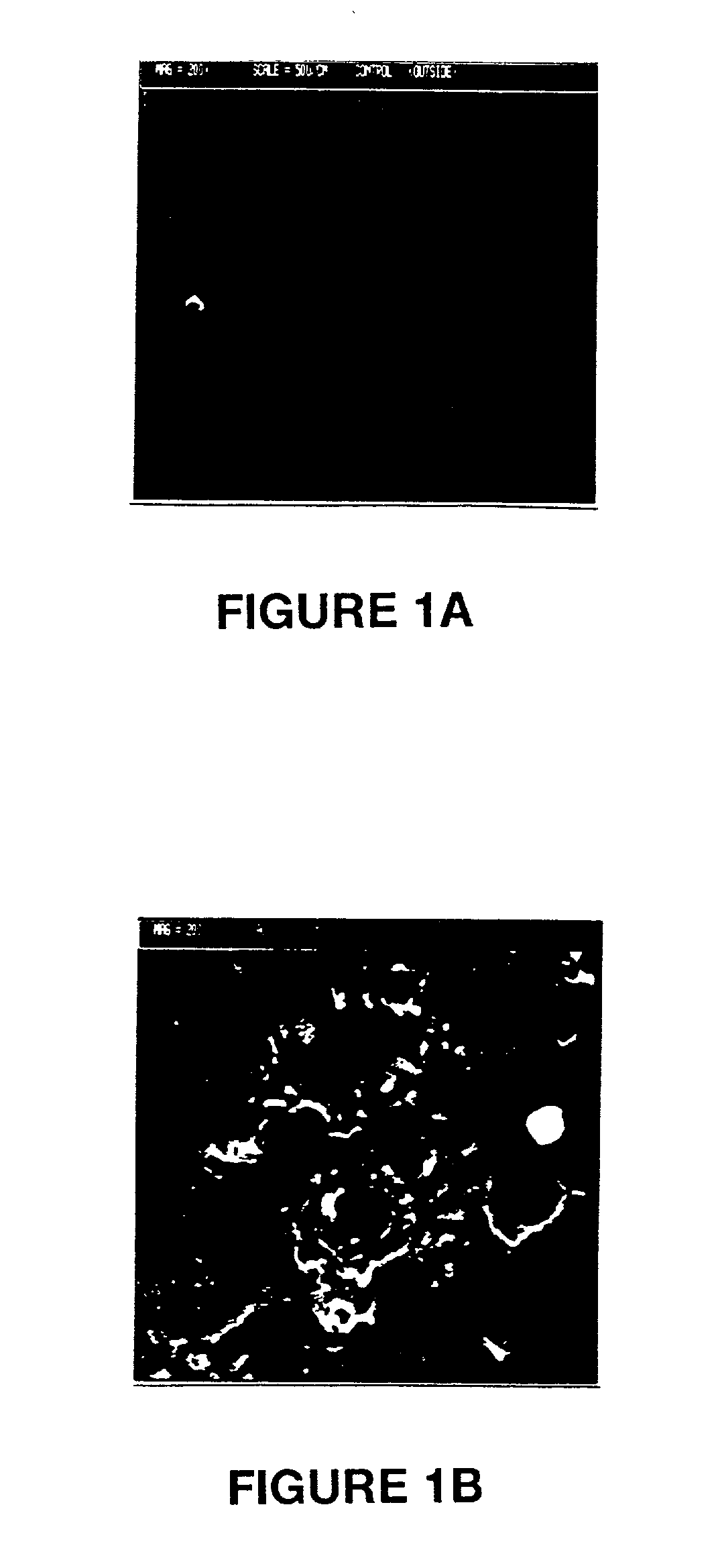

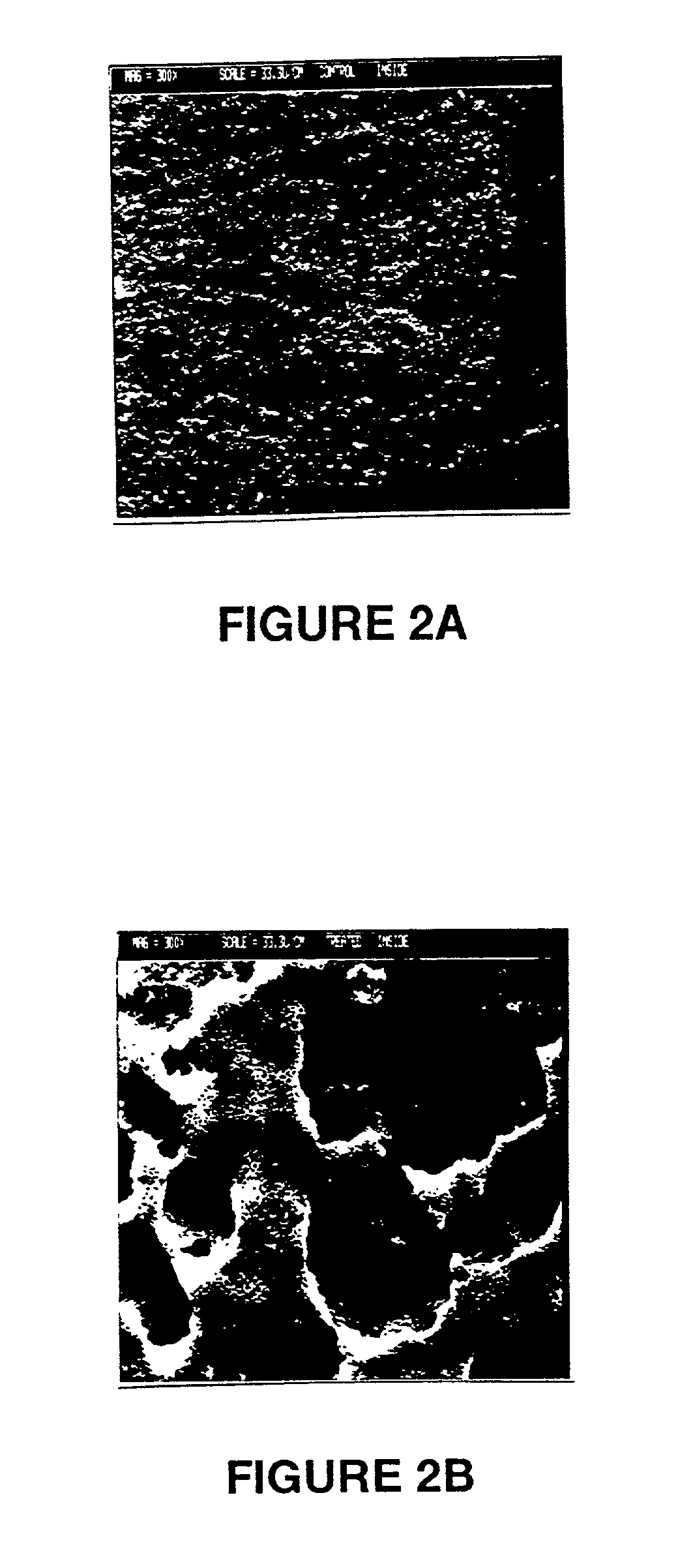

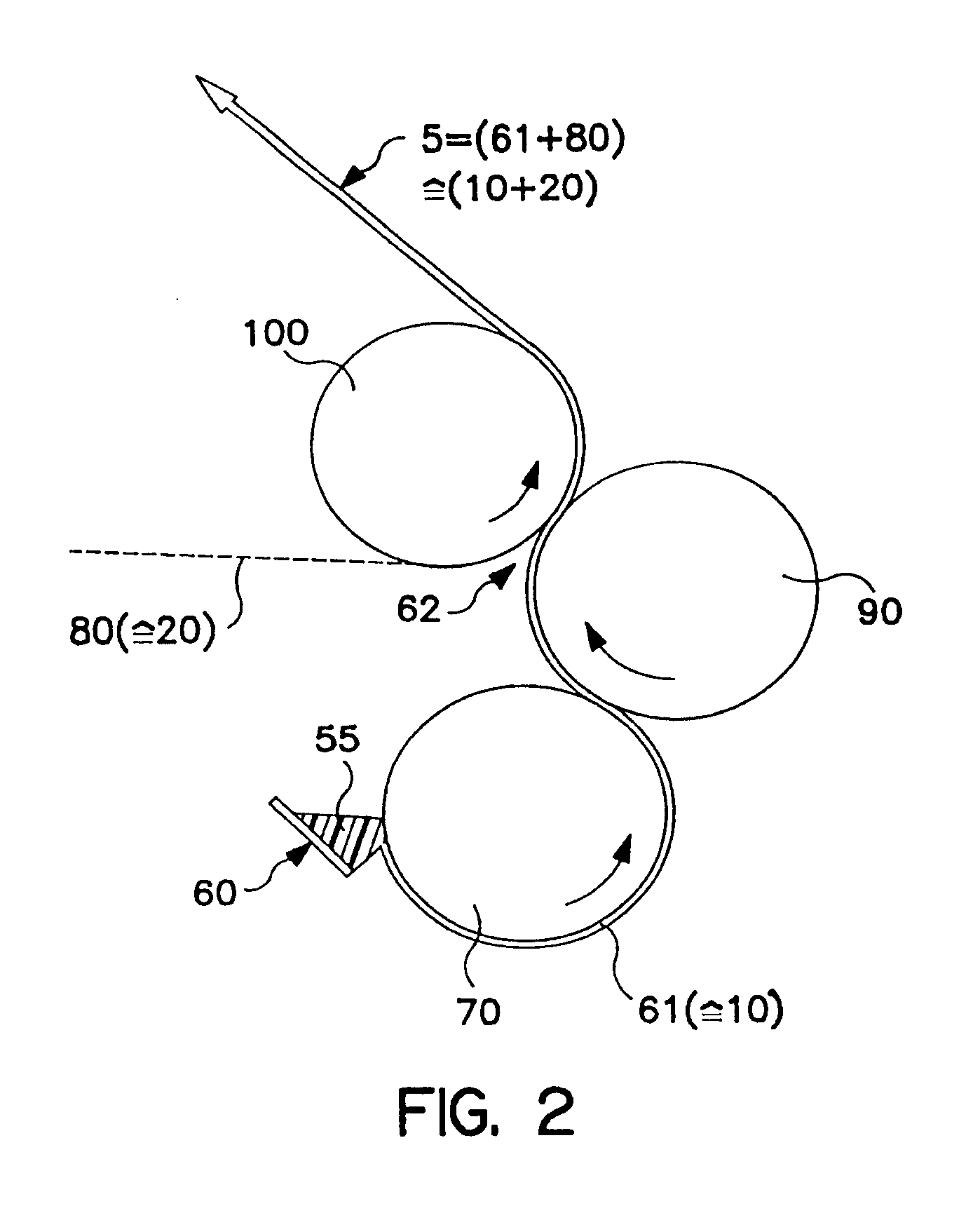

A family of selectively absorbable / biodegradable, fibrous composite constructs includes different combinations of biostable and absorbable / biodegradable yarns assembled as initially interdependent, load-bearing components, transitioning to exhibit independent functional properties during in vivo end-use. The family of constructs consists of two groups, one group is made of fiber-reinforced composites of high compliance, absorbable matrices of segmented polyaxial copolyesters reinforced with multifilament yarn constructs, which are combinations of ultrahigh molecular weight polyethylene fibers and at least one absorbable / biodegradable fiber selected from silk fibers and multifilament yarns made from linear segmented, l-lactide copolyesters and poly (3-hydroxyalkanoates, are useful in orthopedic, maxillofacial, urological, vascular, hernial repair and tissue engineering applications. The second group is made of coated and uncoated, warp-knitted mesh constructs for use in hernial, vascular, and urological tissue repair and tissue engineering.

Owner:POLY MED

Wound healing polymer compositions and methods for use thereof

The present invention provides bioactive polymer compositions that can be formulated to release a wound healing agent at a controlled rate by adjusting the various components of the composition. The composition can be used in an external wound dressing, as a polymer implant for delivery of the wound healing agent to an internal body site, or as a coating on the surface of an implantable surgical device to deliver wound healing agents that are covalently attached to a biocompatible, biodegradable polymer and / or embedded within a hydrogel. Methods of using the invention bioactive polymer compositions to promote natural healing of wounds, especially chronic wounds, are also provided. Examples of biodegradable copolymer polyesters useful in forming the blood-compatible, hydrophilic layer or coating include copolyester amides, copolyester urethanes, glycolide-lactide copolymers, glycolide-caprolactone copolymers, poly-3-hydroxy butyrate-valerate copolymers, and copolymers of the cyclic diester monomer, 3-(S)[(alkyloxycarbonyl)methyl]-1,4-dioxane-2,5-dione, with L-lactide. The glycolide-lactide copolymers include poly(glycolide-L-lactide) copolymers formed utilizing a monomer mole ratio of glycolic acid to L-lactic acid ranging from 5:95 to 95:5 and preferably a monomer mole ratio of glycolic acid to L-lactic acid ranging from 45:65 to 95:5. The glycolide-caprolactone copolymers include glycolide and ε-caprolactone block copolymer, e.g., Monocryl or Poliglecaprone.

Owner:MEDIVAS LLC

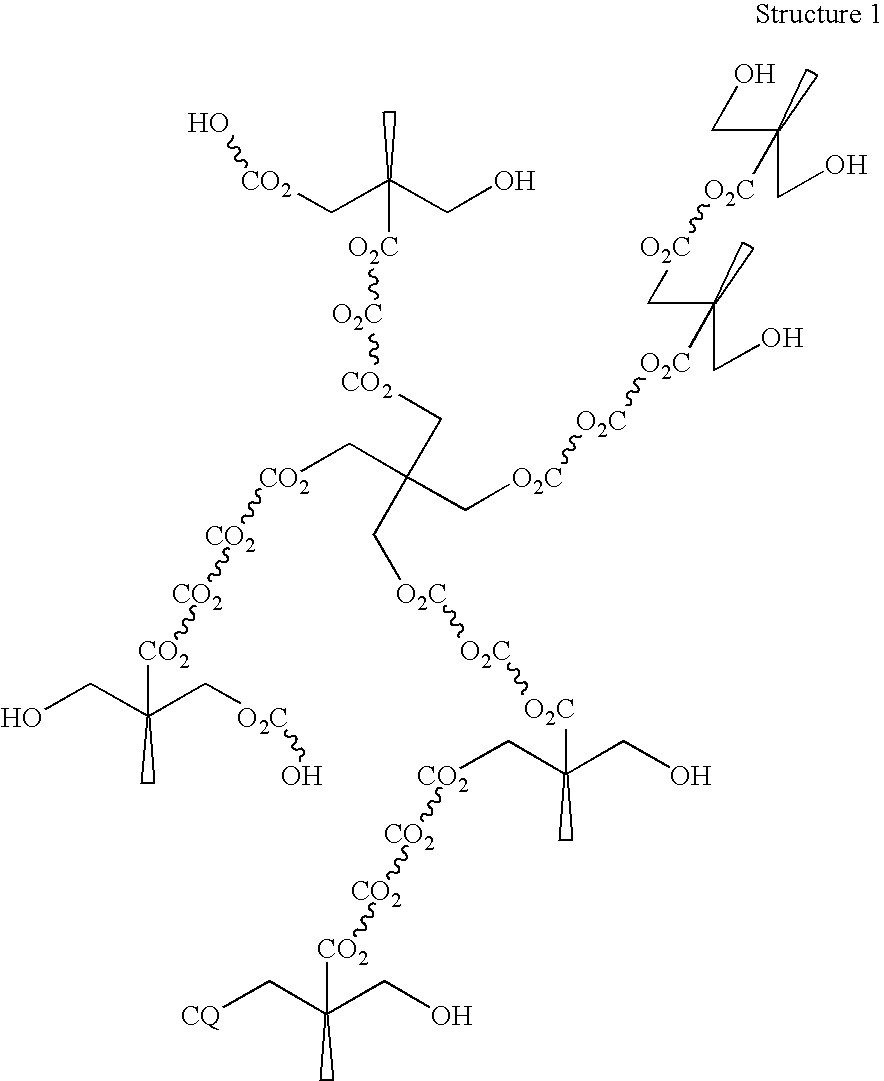

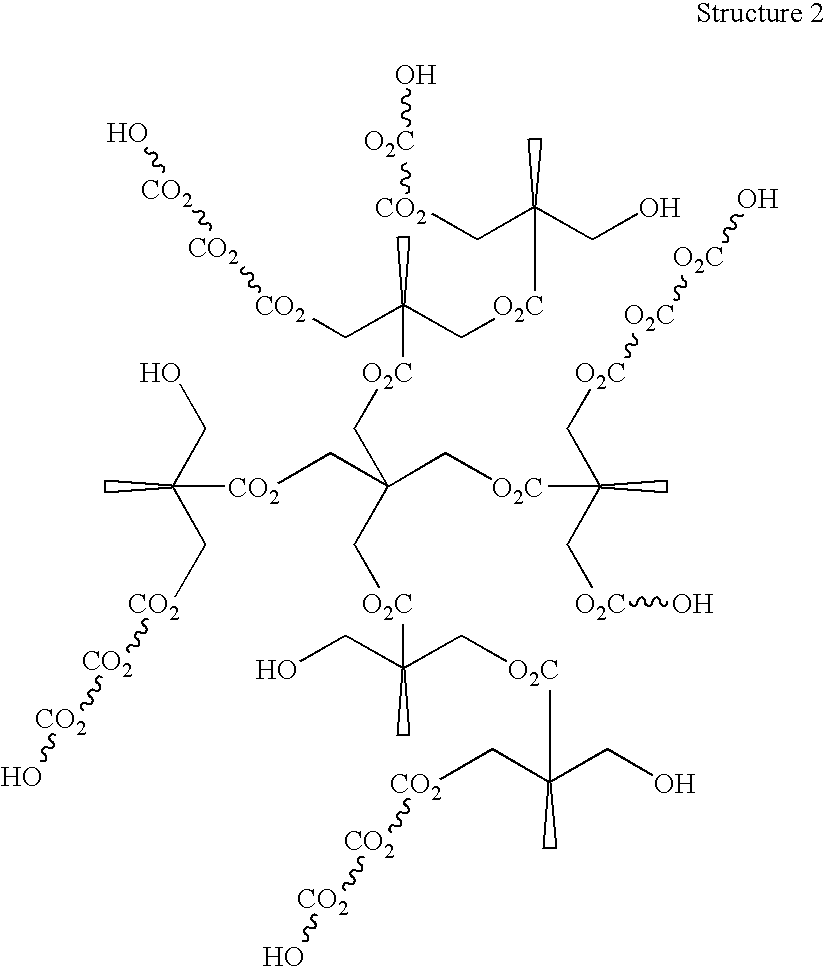

Lacquers containing highly branched copolyester polyol

Owner:AXALTA COATING SYST IP CO LLC

Oxygen scavenging plastic compositions

The present invention relates to a composition comprising a polyester, a copolyester ether and an oxidation catalyst, wherein the copolyester ether comprises a polyether segment comprising poly(tetramethylene-co-alkylene ether). The composition has oxygen scavenging properties and produces articles having low haze. Other embodiments of the present invention disclosed herein are articles made from the composition and methods to make such articles.

Owner:INVISTA NORTH AMERICA R L

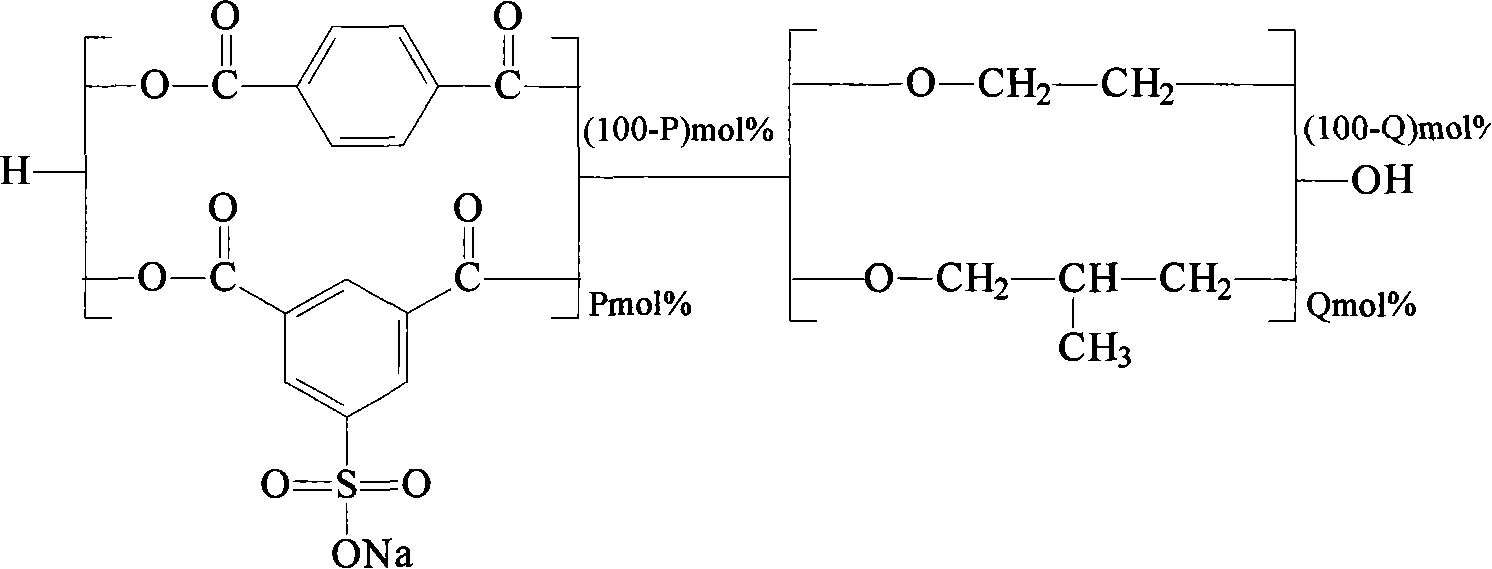

Sulfonated aliphatic-aromatic copolyesters and shaped articles produced therefrom

ActiveUS20050027098A1High crystallinityHigh heat distortion temperatureLayered productsCeramic shaping apparatusPolymer scienceCopolyester

Sulfonated aliphatic-aromatic copolyesters and articles made therefrom, and processes for producing the sulfonated aliphatic-aromatic copolyesters and articles are provided. Articles that can be made from the sulfonated aliphatic-aromatic copolyesters include films, coatings and laminates. Some of the compositions and articles are biocompostable. The films can further be used to form shaped articles such as sheets, food packaging such as sandwich wraps, thermoformed containers, and coatings for, for example, films and other substrates. The sulfonated aliphatic-aromatic copolyesters are derived from copolyesters produced from aliphatic-aromatic copolyesters formed from an aromatic dicarboxylic acid component, an aliphatic dicarboxylic acid component, a first glycol component consisting of 1,4-butanediol, a second glycol component, and optionally, a polyfunctional branching agent.

Owner:DUPONT POLYMERS INC

Modified copolyester slicer or fabric and method for making same

InactiveCN101063236ASoft lusterImprove shrinkageMonocomponent polyesters artificial filamentFiberAlcohol

The invention relates to a modified copolyester slice or fiber and a relative preparation, wherein the slice is copolymerized from terephthalic acid, ethandiol, isophthalate esters of sulfonic acid sodium (or potassium), and fatty group dibasic alcohol (or relative alkylate) with side chain. And the preparation comprises that (1), mixing the ethandiol and the fatty group dibasic alcohol (or relative alkylate) into a mixed alcohol, adding catalyzer and stabilizer to esterify the terephthalic acid under 220-260Deg. C, (2), adding 1-9%mol isophthalate esters of sulfonic acid sodium (or potassium) relative to the terephthalic acid for polycondensation at 250-300Deg. C, (3), drying, fusing, spinning, and drawing to obtain the modified copolyester filament. The inventive product can dye anion paint and disperse paint into deep color at normal pressure, with better feeling, high contraction, hidden micro coiled property, simple preparation, low cost and batch production support.

Owner:DONGHUA UNIV

Novel copolyester compositions with improved impact strength at low temperatures

This invention relates to a polyester composition comprising: (i) diacid residues comprising at least 80 mole percent, based on the total moles of diacid residues, of one or more residues of: terephthalic acid, naphthalenedicarboxylic acid, 1,4-cyclohexanedicarboxylic acid, or isophthalic acid; and (ii) diol residues comprising from about 25 to about 70 mole percent, based on the total moles of diol residues, of the residues of 1,4-cyclohexanedimethanol, and from about 75 to about 30 mole percent, based on the total moles of diol residues, of the residues of 1,3-propanediol. This invention has surprising improved impact strength at low temperatures.

Owner:EASTMAN CHEM CO

High molecular weight copolyesters from macrocyclic oligoesters and cyclic esters

InactiveUS6420048B1Synthetic resin layered productsThin material handlingTransesterificationCopolyester

High molecular weight copolyesters have been prepared from macrocyclic oligoesters and cyclic esters in the presence of a transesterification catalyst. The invention generally features a method of making a copolyester, a method of making a block copolymer of copolyester, and a copolyester prepared from macrocyclic oligoesters and cyclic esters.

Owner:CYCLICS CORP

Copolyesters and fibrous materials formed therefrom

InactiveUS20020132960A1Deep dyeabilityGood printabilityMonocomponent copolyesters artificial filamentArtificial filaments from cellulose derivativesCelluloseFiber

This invention relates to binary blends of cellulose esters and aliphatic-aromatic copolyesters, cellulose esters and aliphatic polyesters as well as ternary blends of cellulose esters and / or aliphatic polyesters and / or aliphatic-aromatic copolyesters and / or polymeric compounds as well as fibers, nonwovens, molded objects, and films prepared therefrom.

Owner:EASTMAN CHEM CO

Copolyester as well as preparation method and application thereof

InactiveCN102030893AImprove dyeing effectLow investment costMonocomponent copolyesters artificial filamentDisperse dyeSide chain

The invention discloses copolyester and a preparation method and application thereof. The copolyester comprises binary acid components and binary alcohol components, wherein in the binary acid components, the content of the terephthalic acid structural unit is more than 90mol%; and in the binary alcohol components, the content of the ethylene glycol structural unit is 70-99mol%, and the content of the aliphatic dihydric alcohol structural unit which contains side chains and less than 6 carbon atoms is 1-30mol%. The copolyester also comprises a polyethylene glycol structural unit. Because the aliphatic dihydric alcohol structural unit which contains side chains and less than 6 carbon atoms and the polyethylene glycol structural unit are added to the copolyester, the copolyester can be made into fiber with the known method, and the fiber can be made into fabric. The prepared finished product has good dyeing property on disperse dye at normal temperature and pressure, thus the high equipment investment and operation cost resulted from high-temperature and high-pressure dying can be reduced.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Polyester or copolyester/polyolefin laminate structures and methods of making the same

InactiveUS7037576B2Improve integrityHigh strengthCovering/liningsLayered product treatmentPolyolefinCopolyester

The invention relates to polyester / polyolefin laminate materials having improved properties. The invention also relates to copolyester / polyolefin laminate materials having improved properties. The laminates herein exhibit improved results in flammability studies. The invention further relates to methods of making laminate structures.

Owner:EASTMAN CHEM CO

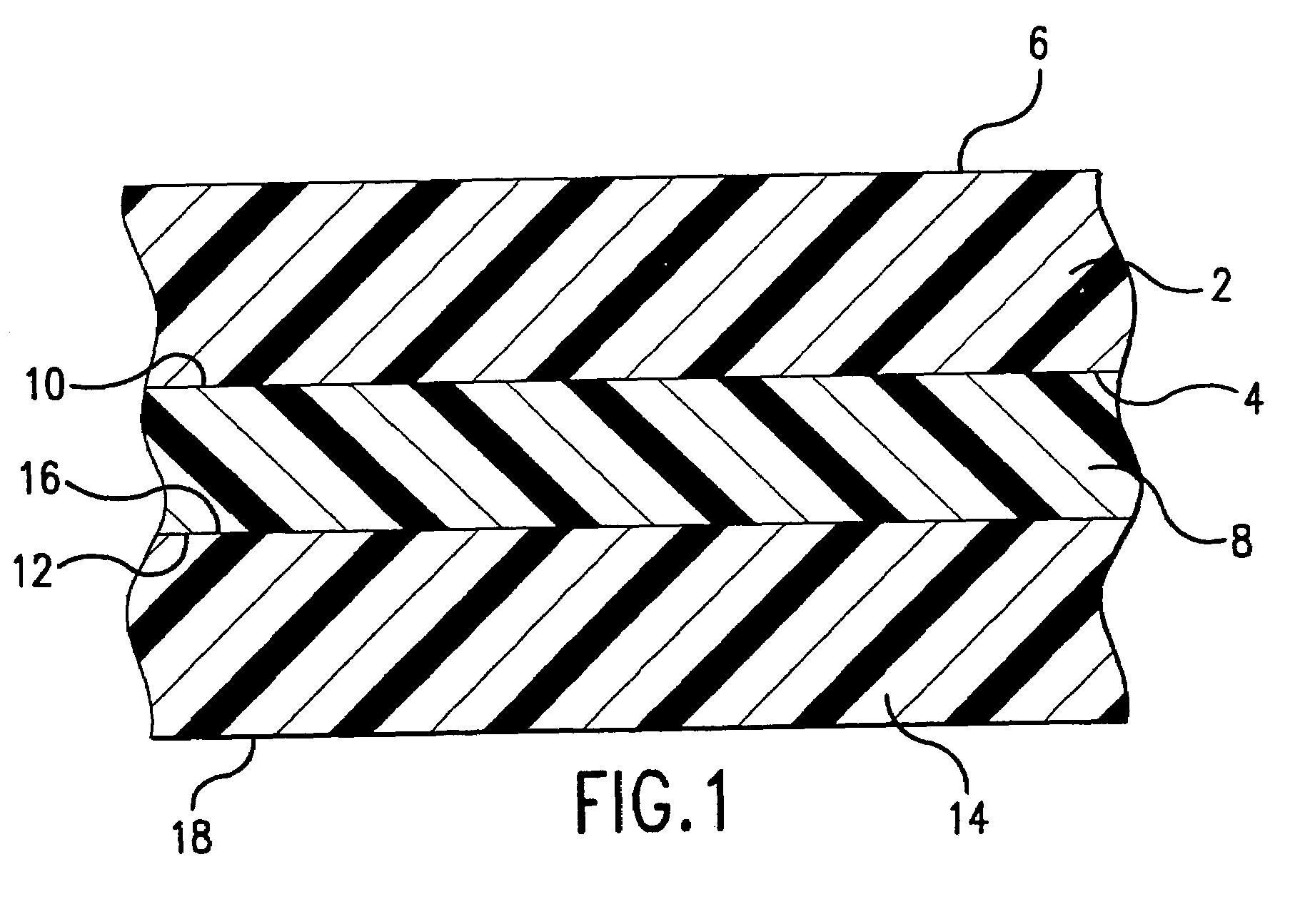

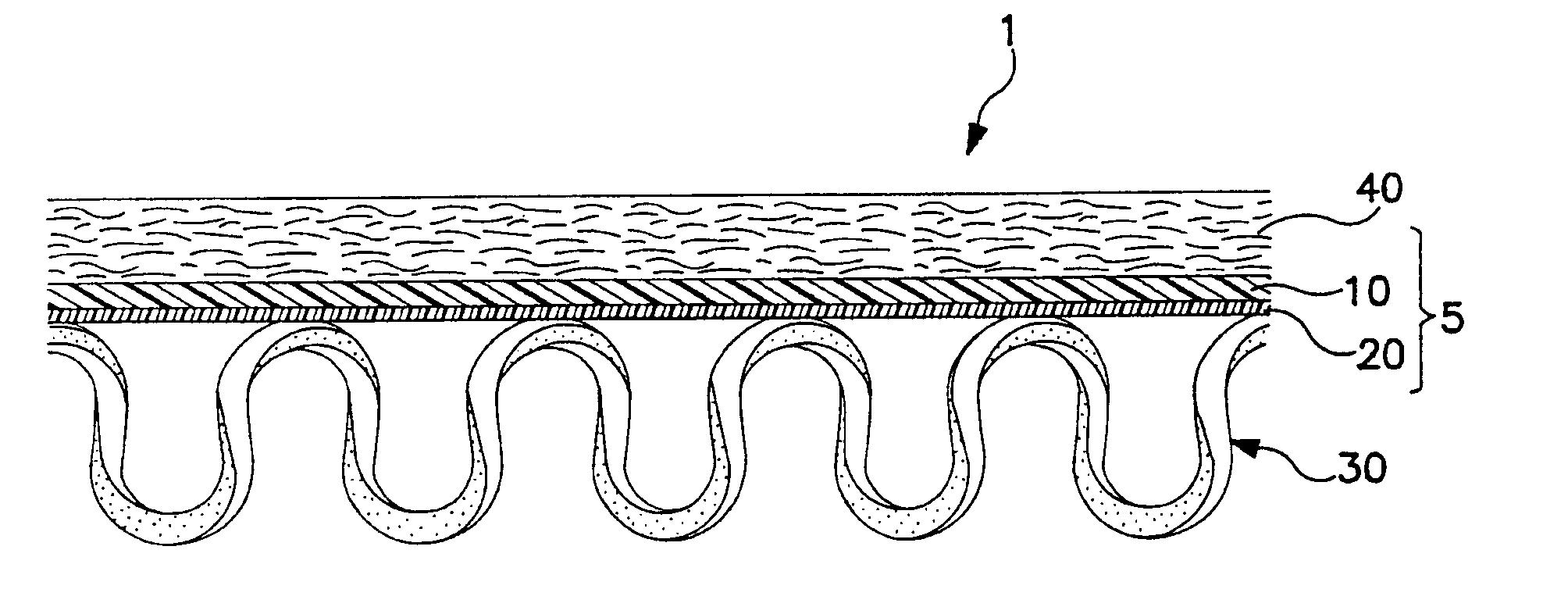

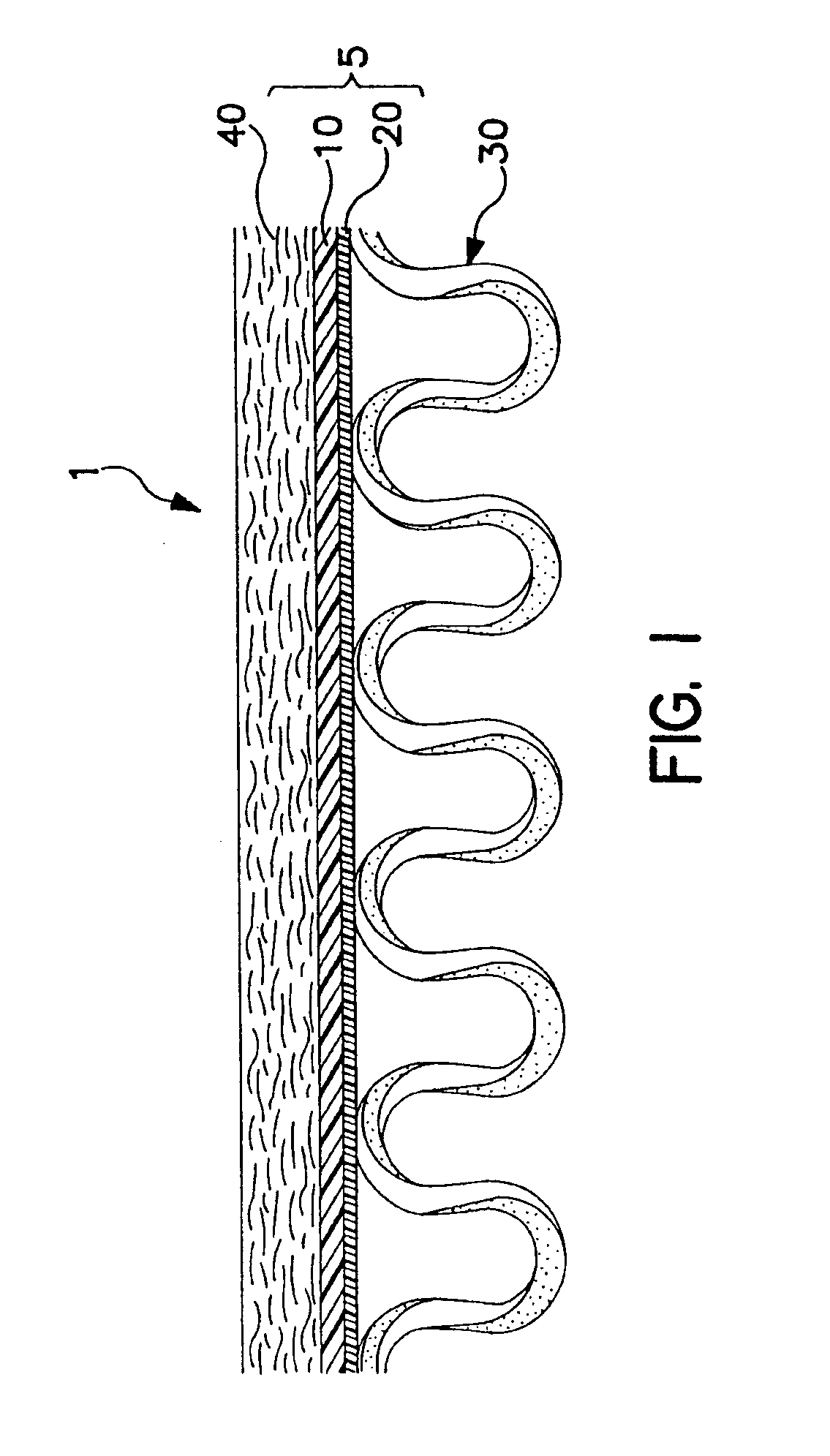

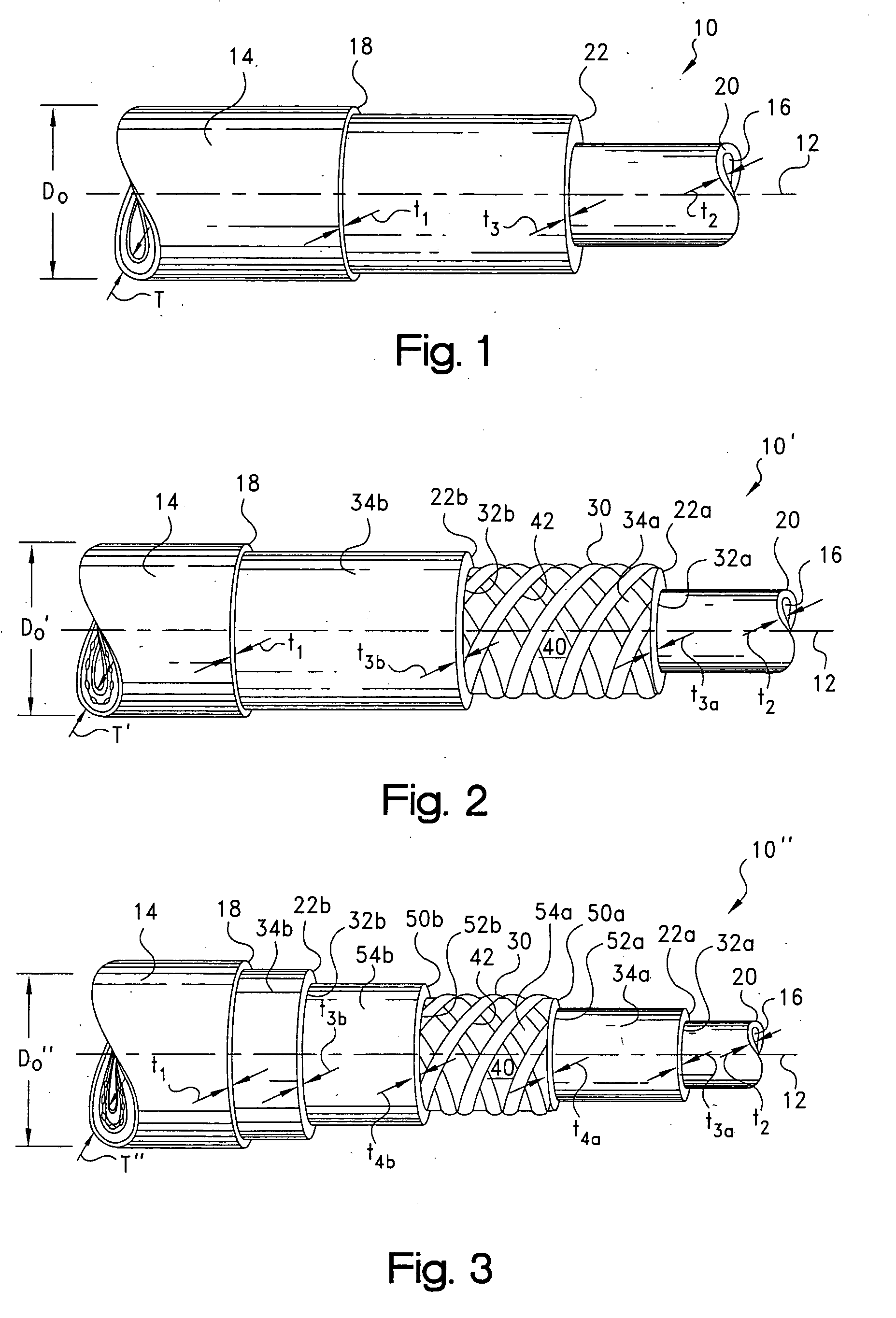

Seam joining a waterproof laminate with textile layer made of multi-component yarns

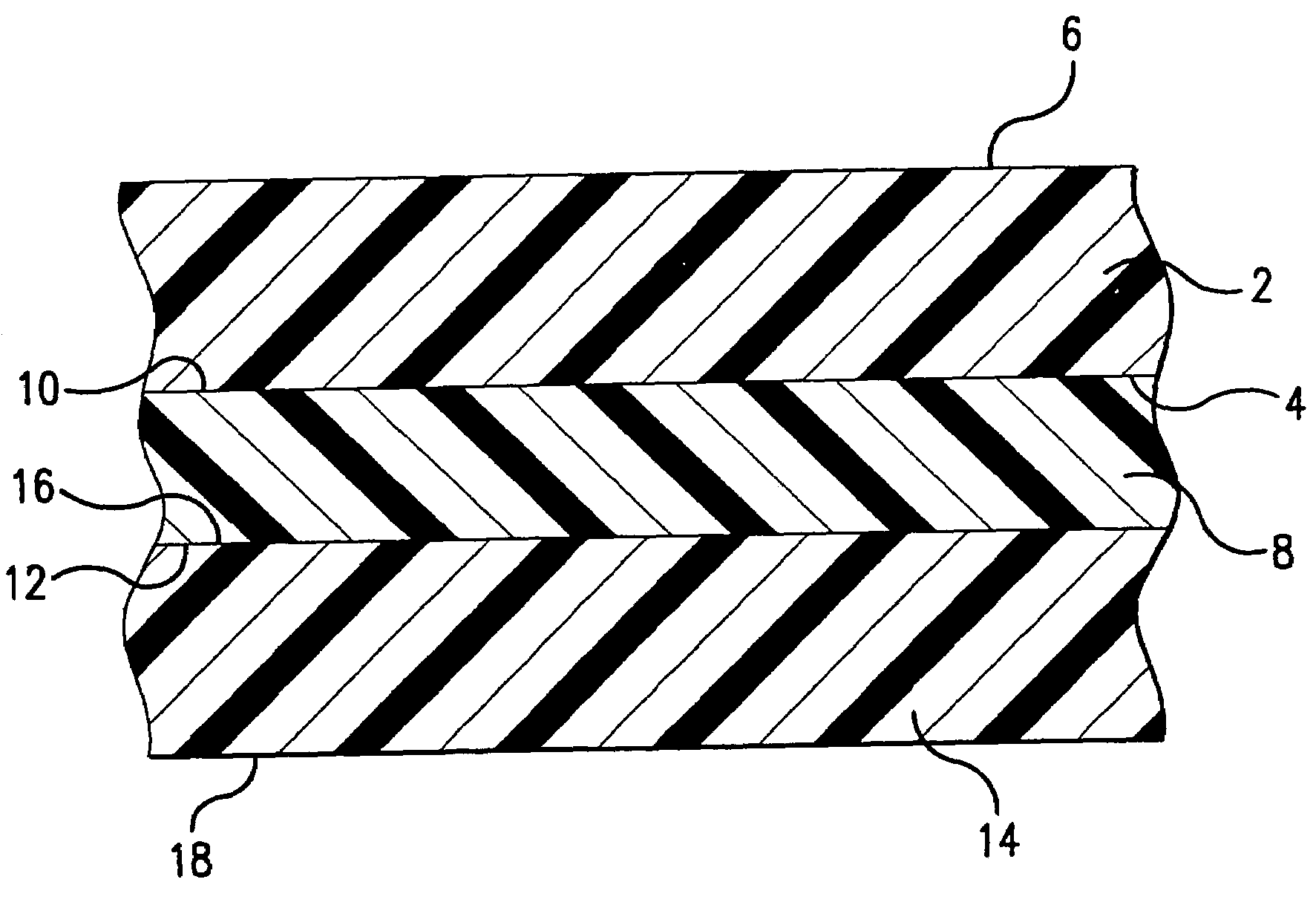

The invention discloses a textile laminate (1, 400, 450) with a first layer (5) comprising a waterproof and preferably breathable functional layer (10, 20) and a second layer (30) comprising at least a first component and a second component. The first component is stable to a first temperature and the second component melts at a lower second temperature. In one embodiment of the invention, the first component is polyester and the second component may be a thermoplastic such as copolyester, polyamide, copolyamide or polyethylene. The textile laminate (1) is particularly advantageous when two of such laminates (1, 400, 450) have to be joined or fused together. In this case a waterproof seam is created at the seam (500) between the two laminates (1, 400, 500).

Owner:HOTTNER MARTIN

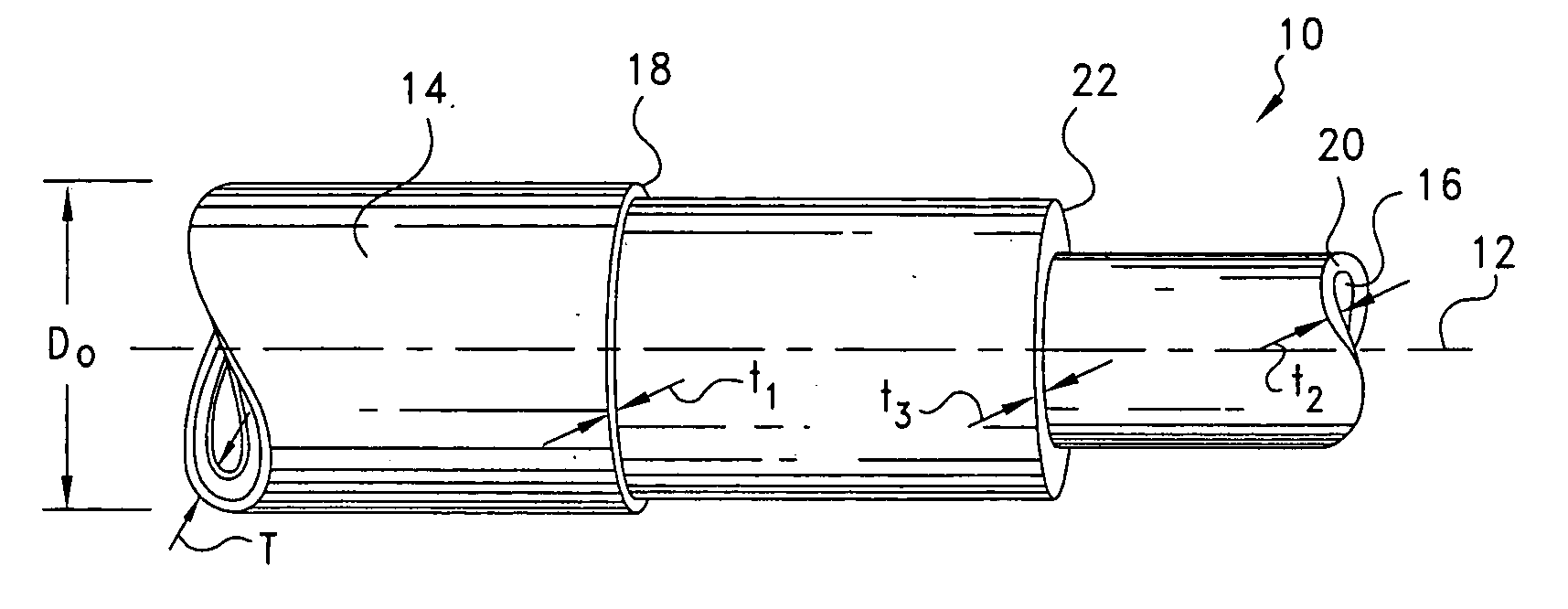

Tubular polymeric composites for tubing and hose constructions

InactiveUS20040134555A1Reduce manufacturing costIncrease awarenessSynthetic resin layered productsFlexible pipesPolyamideCopolyester

Multi-layer tubular polymeric composite for articles such as tubing and hoses. The composite may be formed of an innermost and an outermost layer, and at least one interlayer between the innermost and the outermost layer. The innermost and the outermost layer each may be bonded directly to one of the interlayers, and may be formed of a thermoplastic polymeric material which may be a polyamide. Each of the interlayers may be formed of a thermoplastic polymeric material which may be a polyester or copolyester, or a polyurethane.

Owner:PARKER HANNIFIN CORP

Aliphatic-aromatic polyetherester compositions, articles, films, coating and laminates and processes for producing same

Aliphatic-aromatic polyetherester compositions, articles made from the aliphatic-aromatic polyetherester compositions, and processes for producing the aliphatic-aromatic polyetherester compositions and articles are provided. Articles that can be made from the aliphatic-aromatic polyetherester compositions include films, coatings and laminates. Some of the compositions and articles are biocompostable. The films can further be used to form shaped articles such as sheets, food packaging such as sandwich wraps, thermoformed containers, and coatings for, for example, films and other substrates. The aliphatic-aromatic polyetheresters are based on copolyesters produced from a mixture of aromatic dicarboxylic acids, aliphatic dicarboxylic acids, poly(alkyene ether) glycols, and glycols.

Owner:DUPONT IND BIOSCIENCES USA LLC

Biodegradable Packaging Film

InactiveUS20090324917A1Conductive materialSynthetic resin layered productsWater vaporMechanical property

A biodegradable packaging film is provided. The film is formed from a blend that contains a thermoplastic starch and polylactic acid. Starch is a relatively inexpensive natural polymer that is also renewable and biodegradable. Polylactic acid is likewise an inexpensive synthetic polymer that is biodegradable and renewable, yet also capable of providing increased tensile strength to the film. Although providing a good combination of biodegradability / renewability and increased tensile strength, the polylactic acid is also relatively rigid and can result in films having a relatively high stiffness (e.g., high modulus of elasticity) and low ductility. While more ductile than polylactic acid, the thermoplastic starch is often difficult to melt process in film forming processes and very sensitive to moisture and water vapor, reducing its ability to be used as a stand alone packaging film. In an effort to counteract the effect of such polymers, an aliphatic-aromatic copolyester is also employed in the blend of the present invention. While such copolyesters are biodegradable, they also possess the melt properties and ductility that lend them well to the formation of films. Although the combination of these polymers may achieve a good balance between biodegradability / renewability, high tensile strength, and good ductility (e.g., high peak elongation), it is still often difficult to achieve a precise set of mechanical properties as desired for packaging films. In this regard, the blend also contains a filler. Due to its rigid nature, the amount of the filler may be readily adjusted to fine tune the blend to the desired degree of ductility (e.g., peak elongation) and stiffness (e.g., modulus of elasticity).

Owner:KIMBERLY-CLARK WORLDWIDE INC

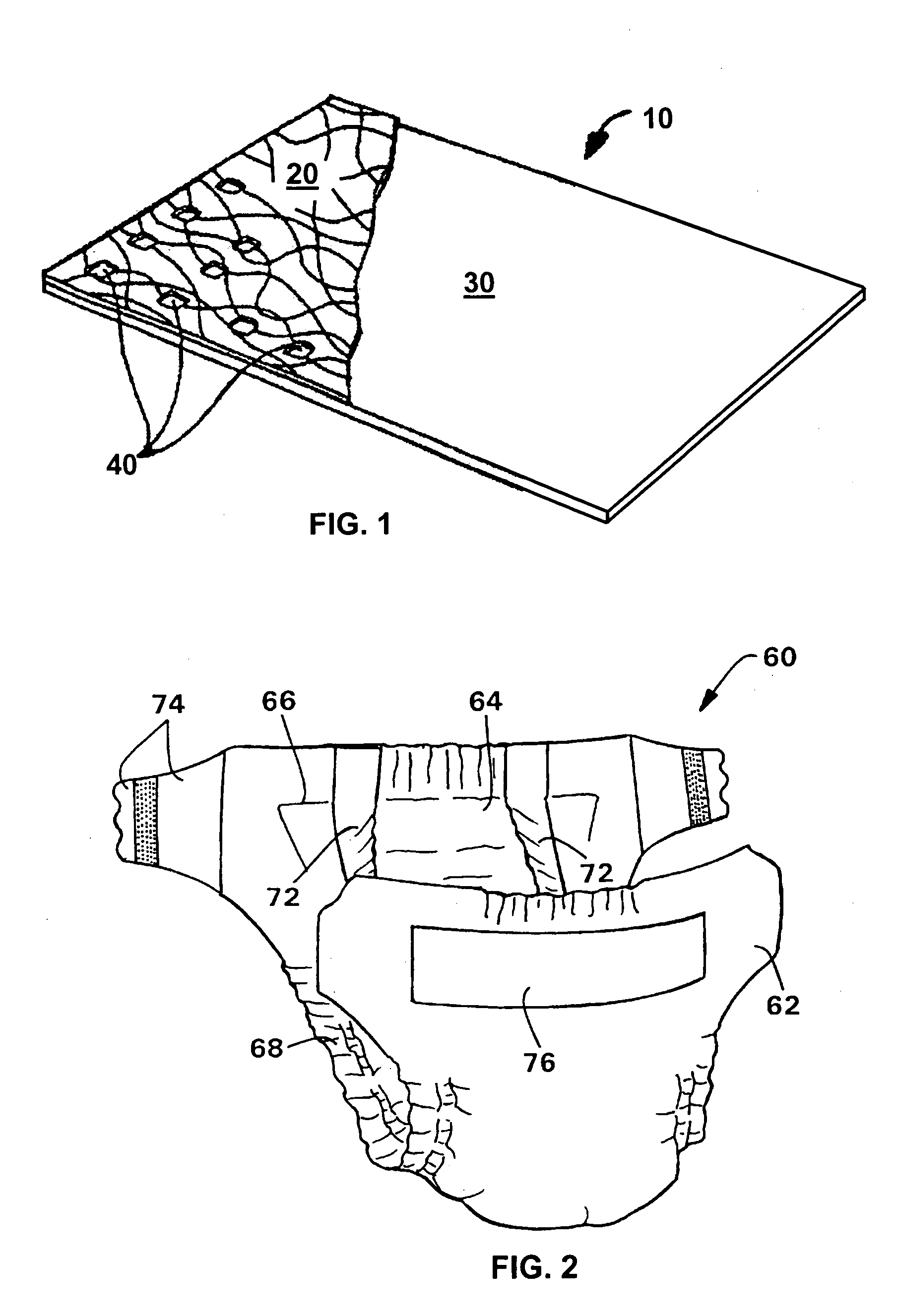

Biodegradable polymer compositions for a breathable film

The invention provides a biodegradable polymer composition for a breathable film which comprises a biodegradable polyester such as polylactic acid, a biodegradable copolyester such as an aliphatic / aromatic copolyester, and a filler such as calcium carbonate. These compounds are melt blended and film formed and the film is then stretched in a monoaxial or biaxial direction to enhance pore formation and hence also enhance the breathability of the film. The water vapor transmission rate (WVTR) of the film is typically greater than 3,000 grams per square meter per day so that the film is suitable for use in disposable articles such as wipes, diapers, training pants, absorbent underpants, adult incontinence garments, feminine hygiene products, medical garments, bandages and the like.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Copolyester resin composition and a process of preparation thereof

The present invention provides a copolyester resin composition which has good physical properties, biodegradability and processability and a process for preparing and / or producing the same. To improve the biodegradability and physical properties of the copolyester, the present invention applied multi-stage reaction step, and copolyester resin having number average molecular weight of from 30,000 to 70,000, weight average molecular weight of from 100,000 to 600,000, melting point of from 55° C. to 120° C., and melt index of from 0.1 to 30 g / 10 minute (190° C., 2,160 g) is obtained. The processability and physical properties of the copolyester resin of the present invention has been greatly enhanced by incorporating (i) an "aromatic-aliphatic prepolymers" having number average molecular weight of from 300 to 30,000 and the contiguous repeating unit of aromatic group in the dicarboxylic acid position of "aromatic-aliphatic prepolymers" is less than 5. Thus it can be processed by using the conventional processing equipment for polyethylene and polypropylene without any modification.

Owner:ANKOR BIOPLASTICS CO LTD

Sulfonated aliphatic-aromatic copolyesters and shaped articles produced therefrom

ActiveUS7220815B2High crystallinityHigh heat distortion temperatureLayered productsCeramic shaping apparatus1,4-ButanediolPolymer science

Sulfonated aliphatic-aromatic copolyesters and articles made therefrom, and processes for producing the sulfonated aliphatic-aromatic copolyesters and articles are provided. Articles that can be made from the sulfonated aliphatic-aromatic copolyesters include films, coatings and laminates. Some of the compositions and articles are biocompostable. The films can further be used to form shaped articles such as sheets, food packaging such as sandwich wraps, thermoformed containers, and coatings for, for example, films and other substrates. The sulfonated aliphatic-aromatic copolyesters are derived from copolyesters produced from aliphatic-aromatic copolyesters formed from an aromatic dicarboxylic acid component, an aliphatic dicarboxylic acid component, a first glycol component consisting of 1,4-butanediol, a second glycol component, and optionally, a polyfunctional branching agent.

Owner:DUPONT POLYMERS INC

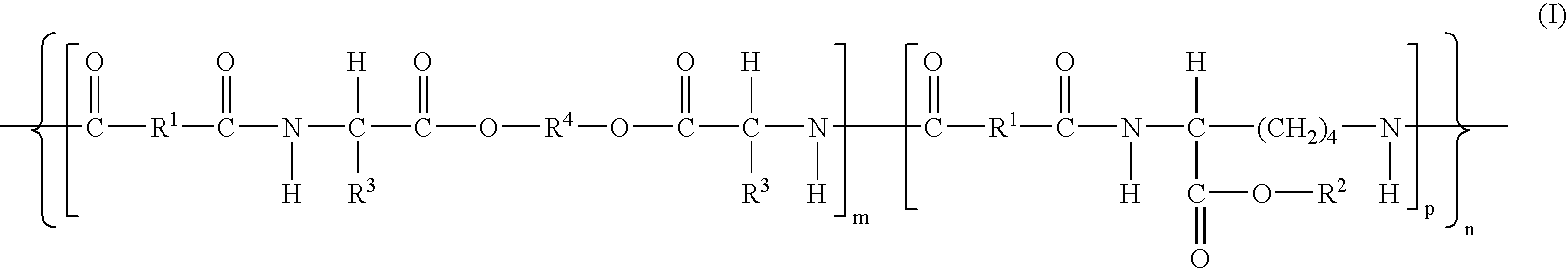

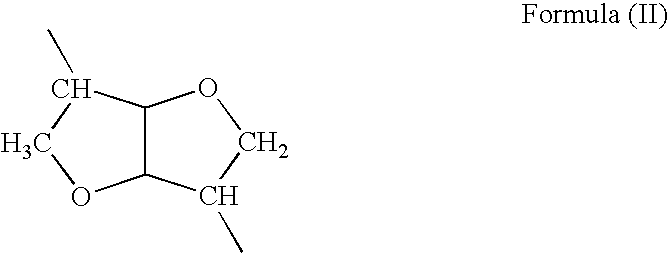

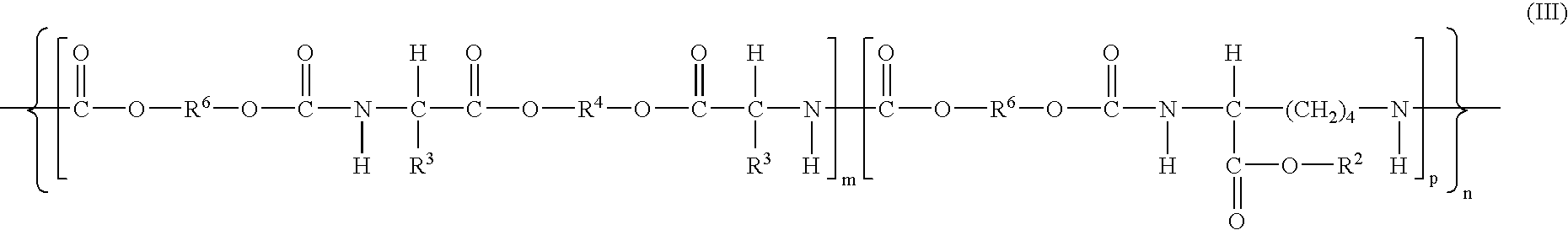

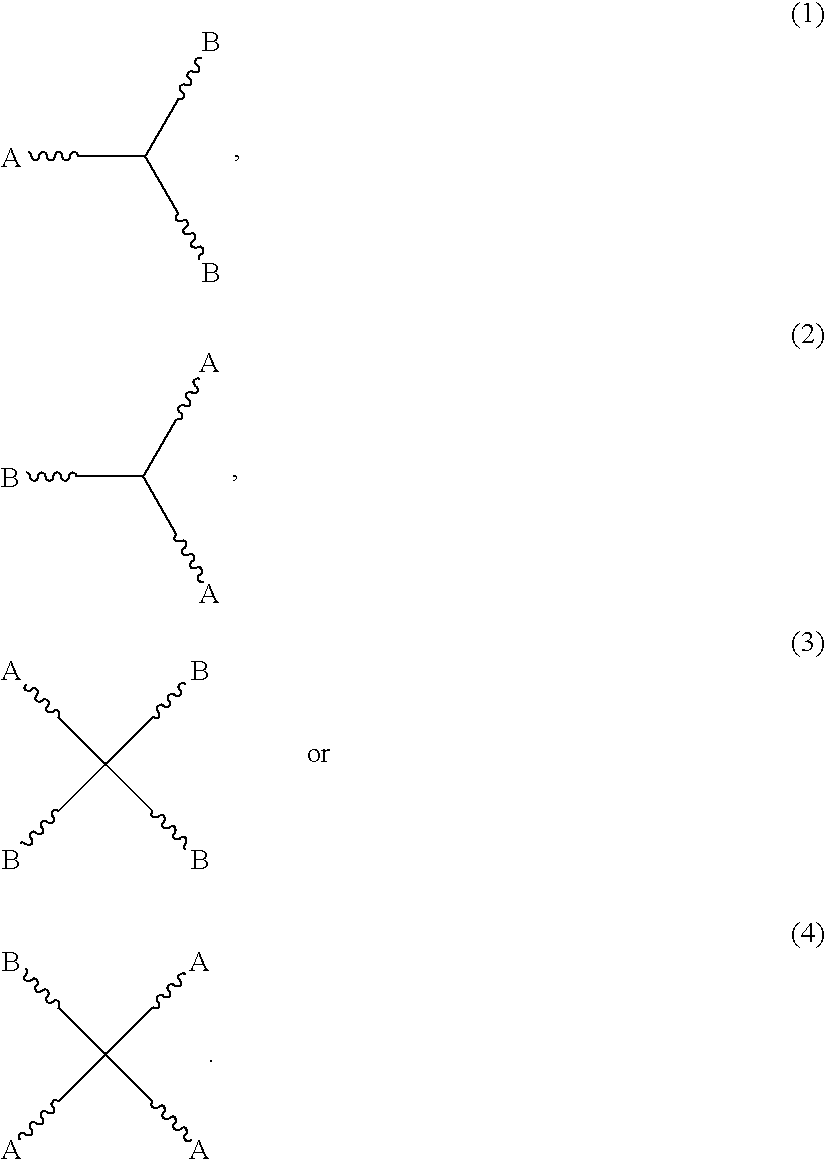

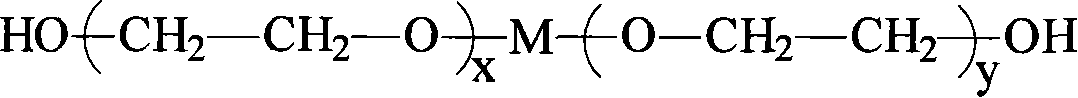

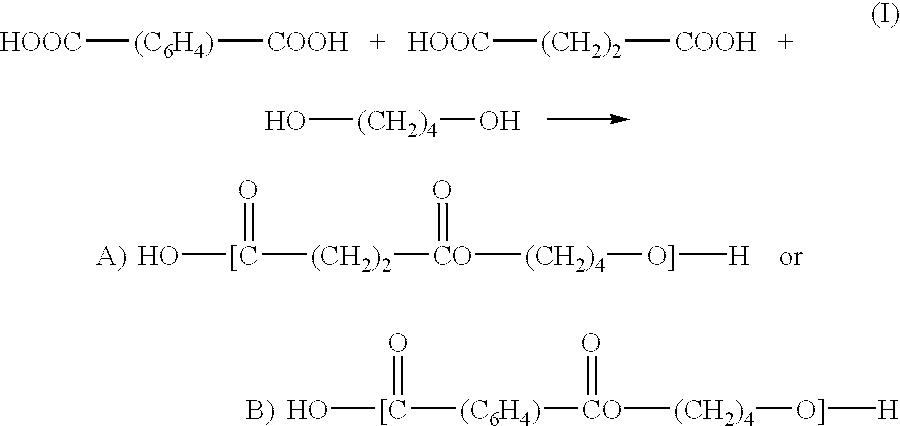

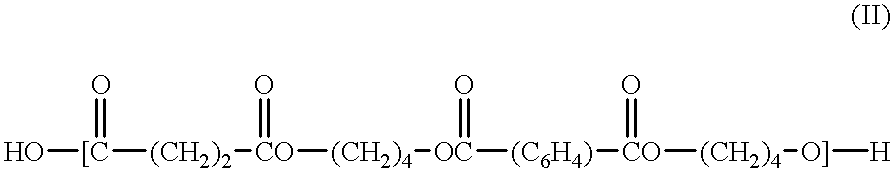

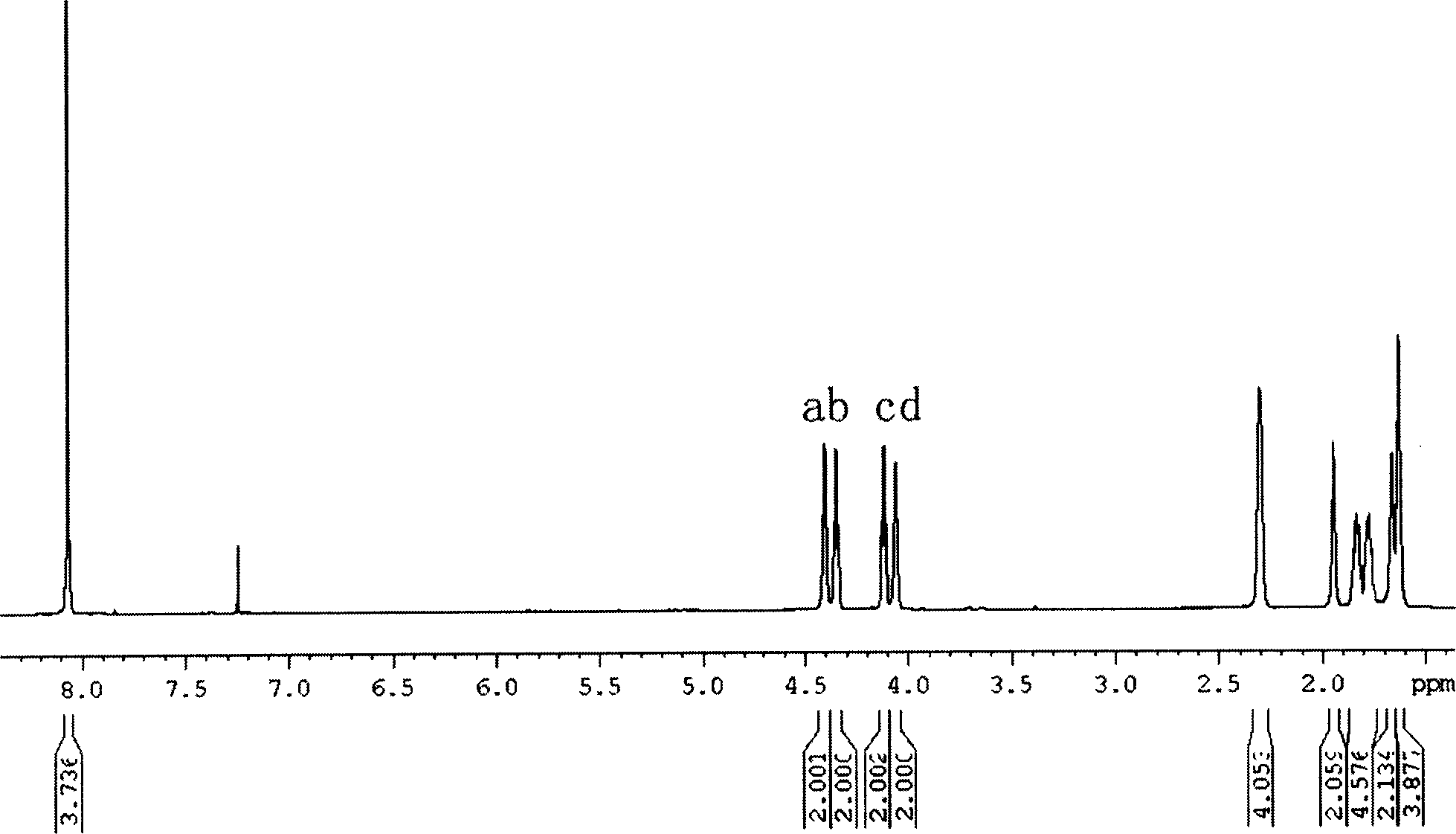

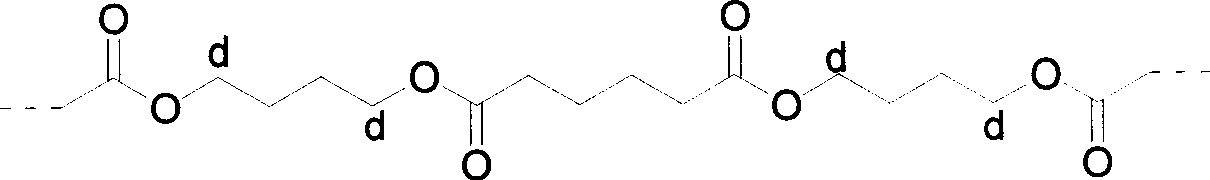

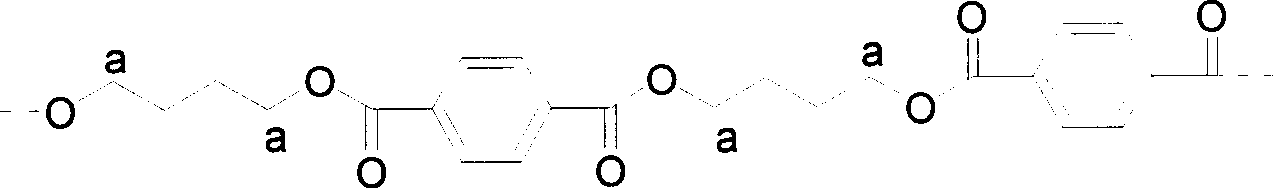

Biodegradable linear random copolyester and its preparation method and uses

ActiveCN1807485AGood colorSimple operation processMonocomponent polyesters artificial filamentPolyester coatingsCopolyesterStructural unit

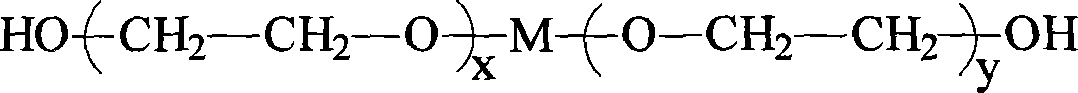

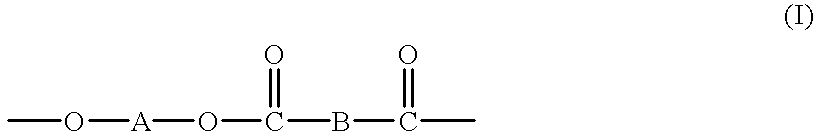

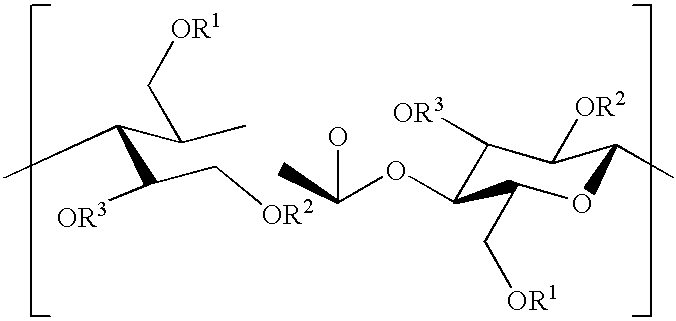

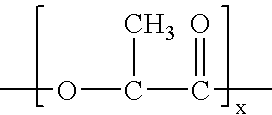

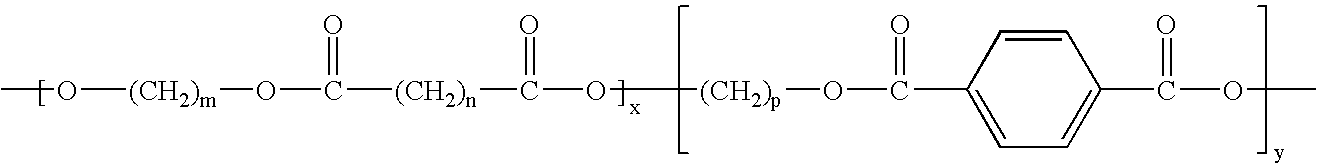

The invention discloses a biodegradable linear random copolyester, its preparation method and uses, wherein the copolyester has a structural unit of (1), wherein m is an integer of 2-10, n is an integer of 0-8, p is an integer of 2-10, m, n, p are identical or different, x is an integer of 1-10, y is an integer of 1-10, the average molecular weight Mw of the copolyester is 100,000-600,000g / mol, its molecular weight distribution is 1.2-3, which is measured through GPC method. The copolyester can be widely applied into section bar, film, fabric and coating.

Owner:CHINA PETROLEUM & CHEM CORP +1

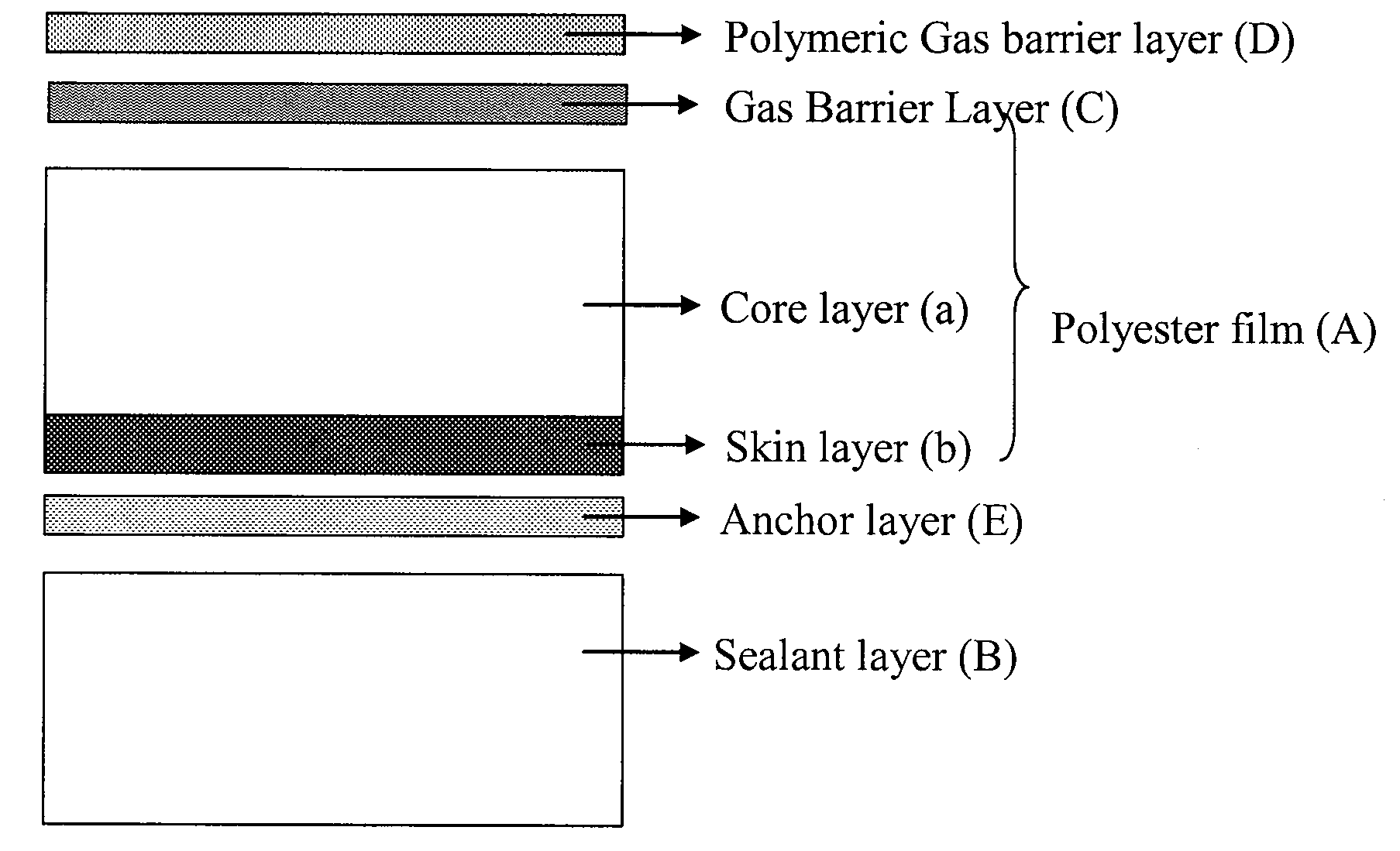

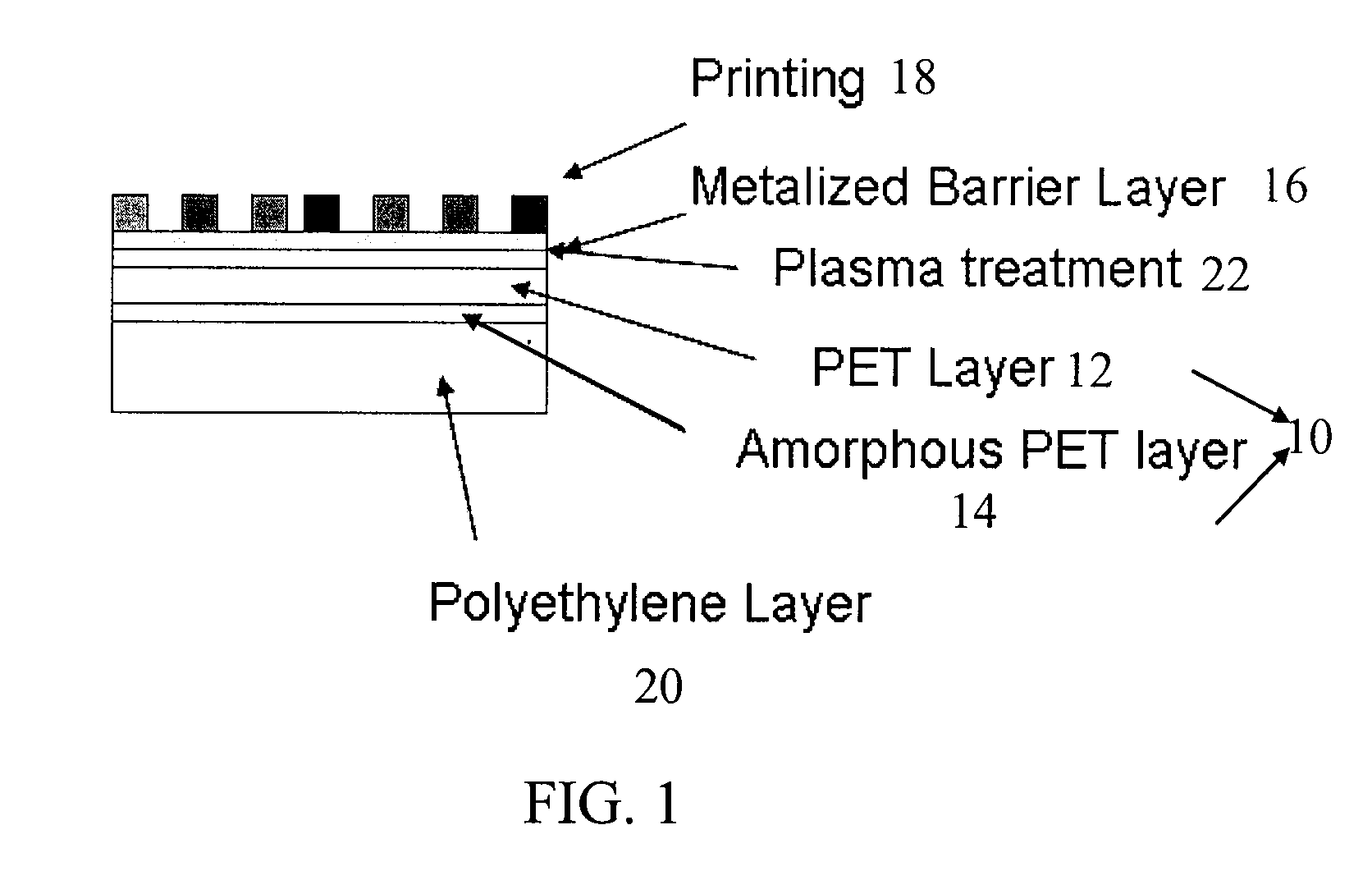

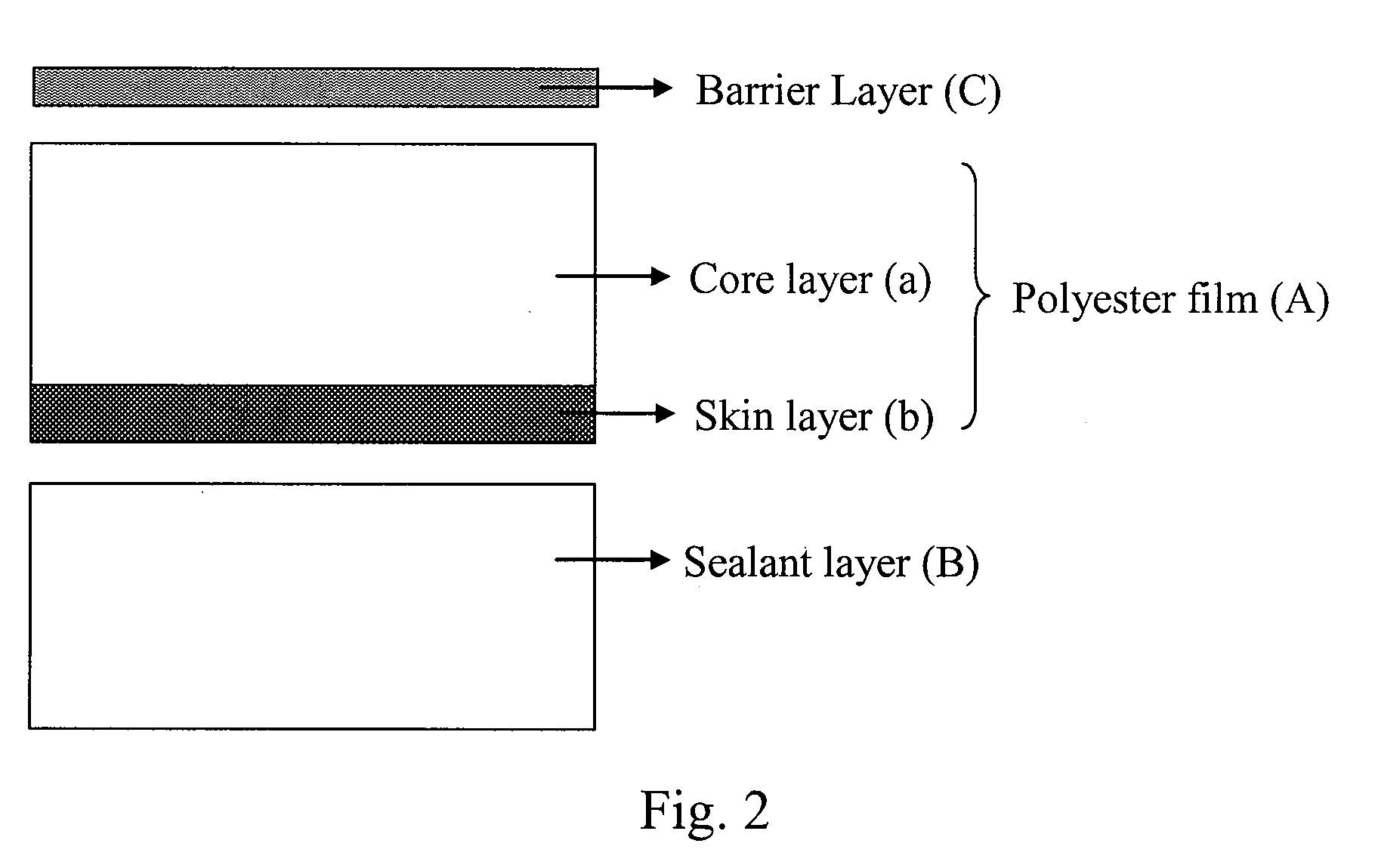

Lighter than air balloon made from a biaxially oriented polyester film

ActiveUS20090022919A1Low densityEnvelopes/bags making machineryVacuum evaporation coatingCopolyesterLighter than air

A long life balloon formed from a lamination. The lamination includes a polyester film with a total thickness of 4 μm to 12 μm. The polyester film includes a biaxially oriented polyester core layer and at least one amorphous copolyester skin layer. The lamination also includes a sealant layer and a gas barrier layer on an opposite side of the polyester film from the sealant layer. The oxygen transmission rate of the balloon is less than 0.1 cc / 100 sqin / day, a bonding strength of the gas barrier layer to the surface of the polyester film is more than 300 g / in at dry conditions, a sealing strength of the balloon is more than 3.5 kg / in, and a floating time of the balloon is more than 20 days.

Owner:TORAY PLASTICS AMERICA +1

Solvent-containing coating compositions

ActiveUS7198849B2Coating suitableGood chemical resistanceFlexible coversLiquid surface applicatorsEndcappingCopolyester

A solvent-containing coating composition contains at least one hydroxyl-containing saturated copolyester, a phenol-formaldehyde resin, a benzoguanamine-formaldehyde resin and / or a blocked polyisocyanate, a catalyst and at least one solvent, and can further contain aids and additives.

Owner:EVONIK OPERATIONS GMBH

Security card and method for making same

InactiveUS6110864AImprove adhesionSure easyLiquid crystal compositionsPattern printingCopolyesterEngineering

A security card comprising a backing, a cover film, and a security image, the security image being located between the backing and the cover film, the backing and the cover film being laminated together without an intermediate adhesive layer, wherein the backing comprises an amorphous copolyester or polyvinyl chloride, and the cover film comprises the other of polyvinyl chloride or an amorphous copolyester. Also, a method for making such security cards.

Owner:3M INNOVATIVE PROPERTIES CO

Method of preparing modified polyester bottle resins

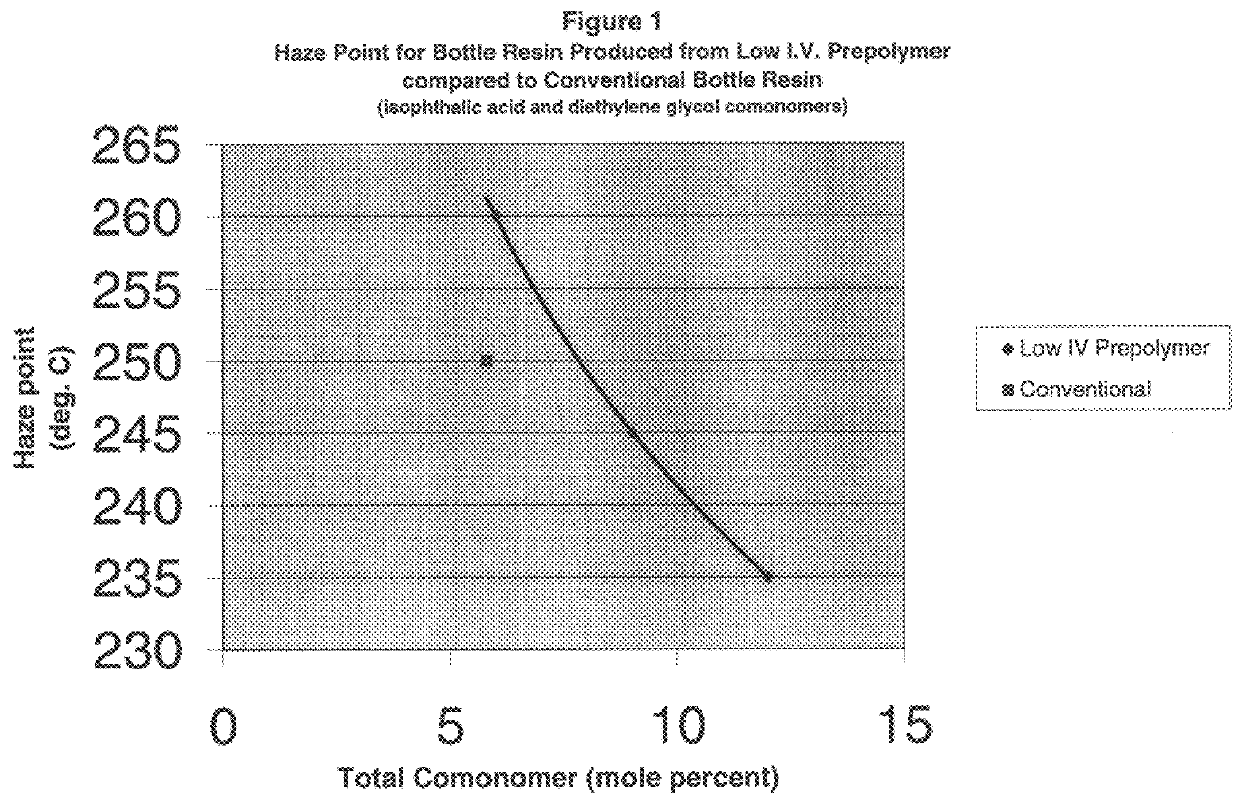

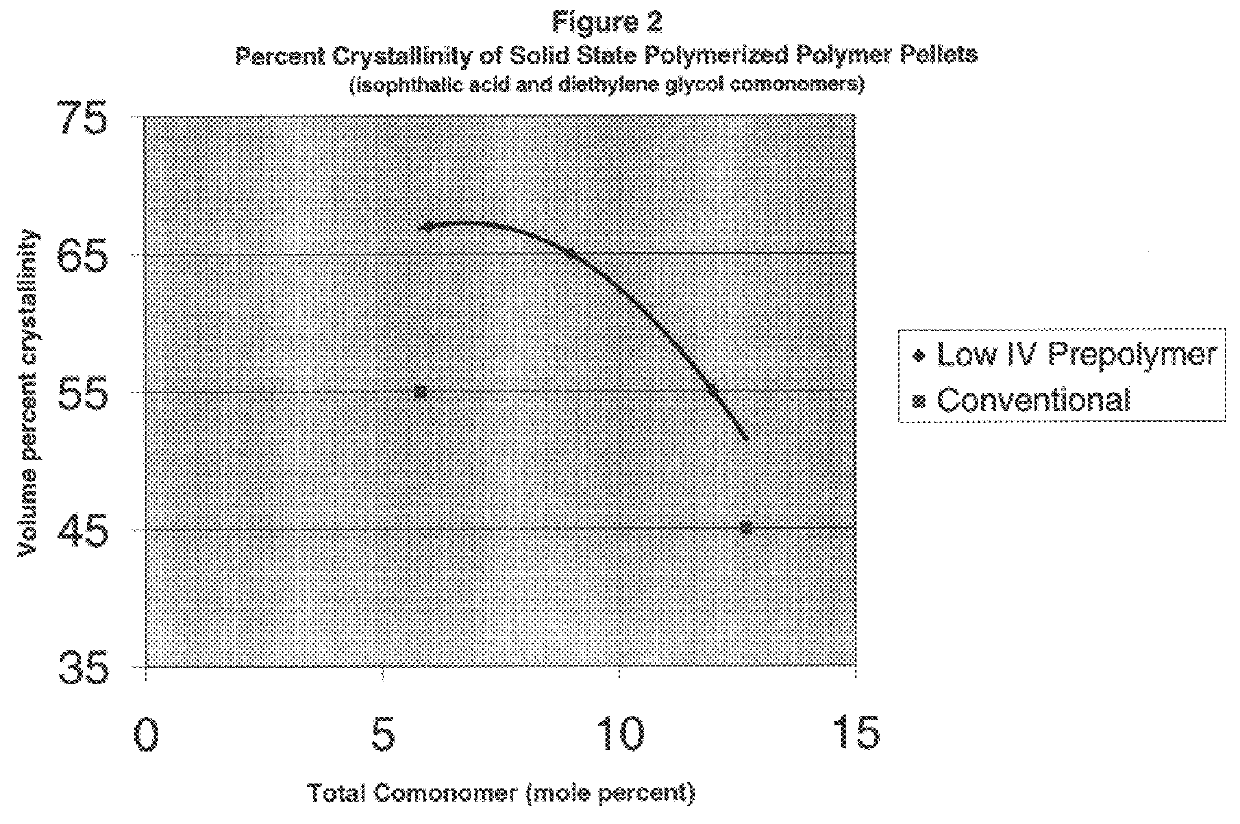

InactiveUS6284866B1Low haze pointLess heatBottlesSynthetic resin layered productsDimethyl terephthalatePolyethylene terephthalate

The present invention is a method of preparing a high molecular weight copolyester bottle resin that has excellent melt processing characteristics. The method includes the steps of reacting a diacid or diester component and a diol component to form modified polyethylene terephthalate, wherein diol component is present in excess of stoichiometric proportions. Together, the diacid or diester component and the diol component must include at least 7 percent comonomer. The remainder of the diacid component is terephthalic acid or dimethyl terephthalate and the remainder of the diol component is ethylene glycol. The modified polyethylene terephthalate is copolymerized in the melt phase to an intrinsic viscosity of between about 0.25 dl / g and 0.40 dl / g to thereby form a copolyester prepolymer. Thereafter the copolyester prepolymer is polymerized in the solid phase to form a high molecular weight bottle resin that has an intrinsic viscosity of at least about 0.70 dl / g, and a solid phase density of less than 1.413 g / cc.

Owner:WELLMAN INC

Process of preparing PDT copolyester fiber

InactiveCN101046007ASpinning high speedHigh speed spinning equipmentMonocomponent copolyesters artificial filamentFiberAlcohol

The process of preparing PDT copolyester fiber includes the following steps: 1. saccharifying and catalytically hydrogenating corn starch to prepare sorbitol, catalytically hydrogenating to prepare multicomponent mixed alcohol, and fractionating in a fractionating tower at 182-212 deg.c to obtain corn-base ethylene glycol product of 89-99 % content and with ethylene glycol as main component and other diols; 2. detecting the contents of component diols in the ethylene glycol product and adding insufficient components for content fluctuation controlled within 10-30 %; and 3. adding nanometer titania in 0.05-1 wt% into the corn-base ethylene glycol product, and copolymerizing together with terephthalic acid at 280-288 deg.c for 5-7 hr to prepare PDT copolyester. The process is suitable for industrial production.

Owner:DONGHUA UNIV

Copolyester resin composition and a process of preparation thereof

InactiveUS6399716B2Improve biodegradabilityEasy to processPhosphorus organic compoundsCopolyesterPolyester resin

An aromatic group containing copolyester resin composition which has good biodegradability and physical properties, wherein; (i) 0.1 wt % to 30 wt % of an aliphatic prepolymers having number average molecular weight of from 300 to 30,000; (ii) one or a plurality of aromatic dicarboxylic acid (or an acid anhydride thereof which containing aromatic group in the molecule; (iii) one or a plurality of aliphatic (including cyclic type) dicarboxylic acid (or an acid anhydride thereof); and (iv) one or a plurality of aliphatic (including cyclic type) glycol, wherein the copolyester resin has number average molecular weight of from 30,000 to 90,000, weight average molecular weight of from 100,000 to 600,000, melting point of from 70° C. to 150° C., and melt index of from 0.1 to 50 g / 10min. (190° C., 2,160 g), and the process for preparing and / or producing the same. The composition and preparation method provides a high molecular weight copolyester resin which has good biodegradability and physical properties required for packaging film, trash bags and agricultural film.

Owner:ANKOR BIOPLASTICS CO LTD

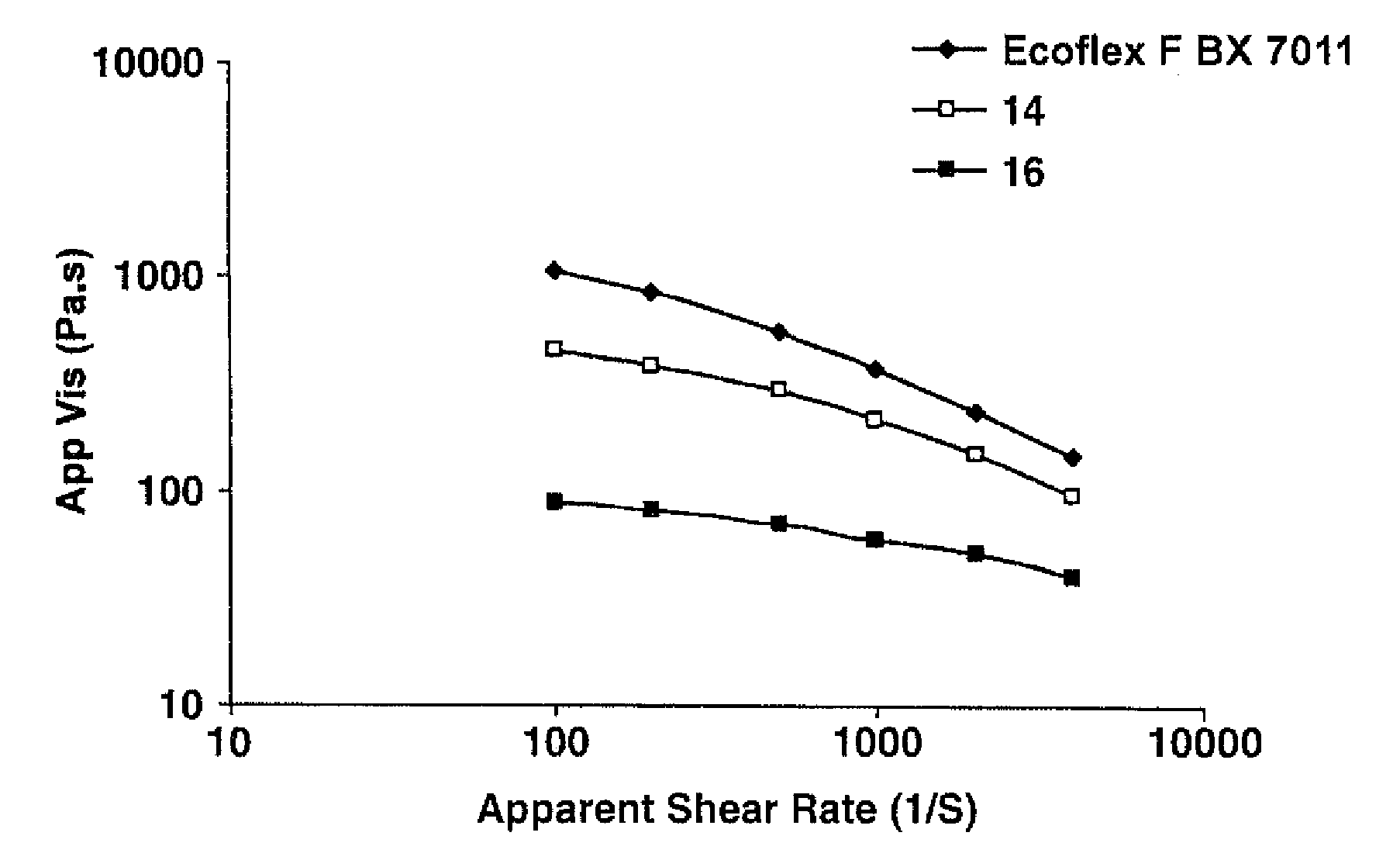

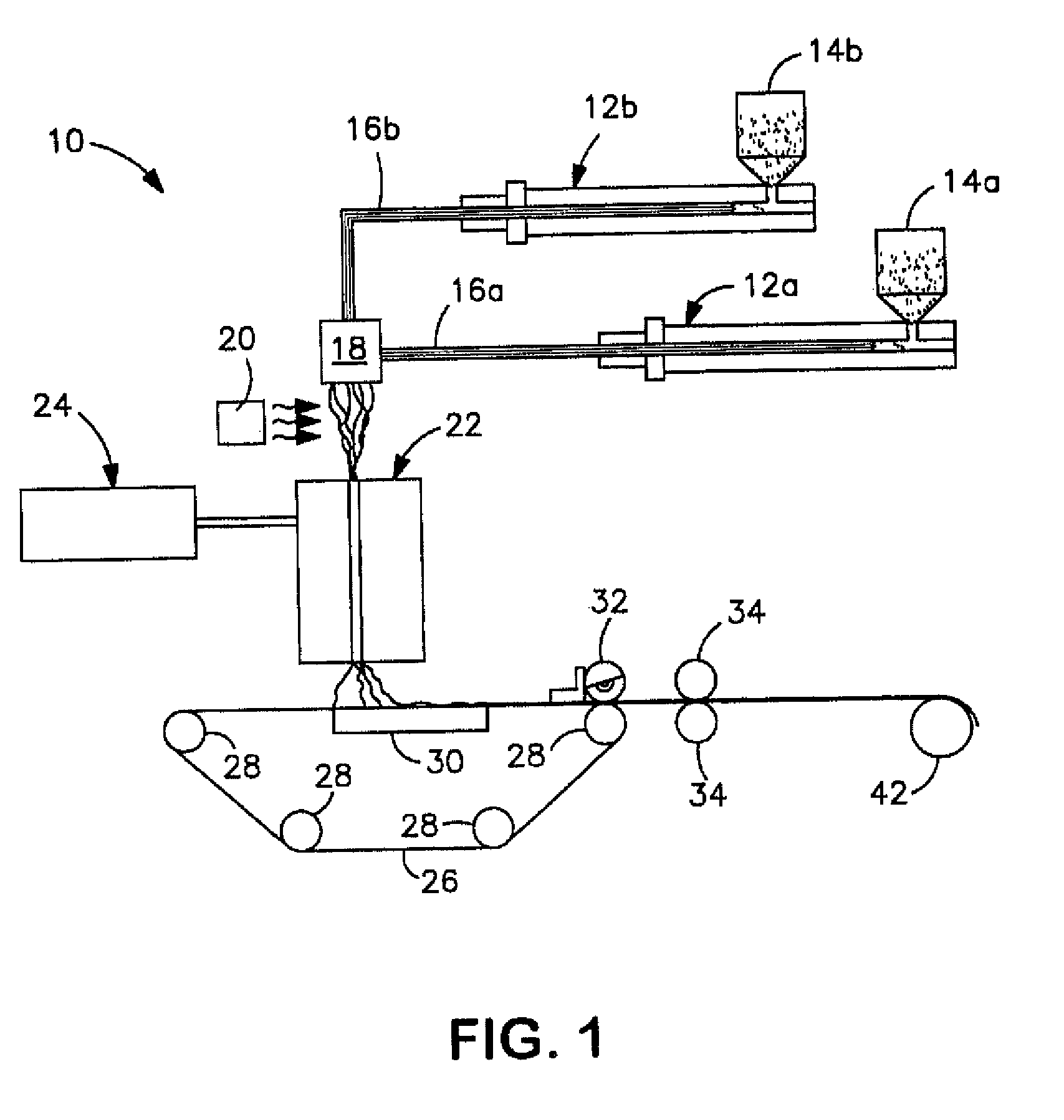

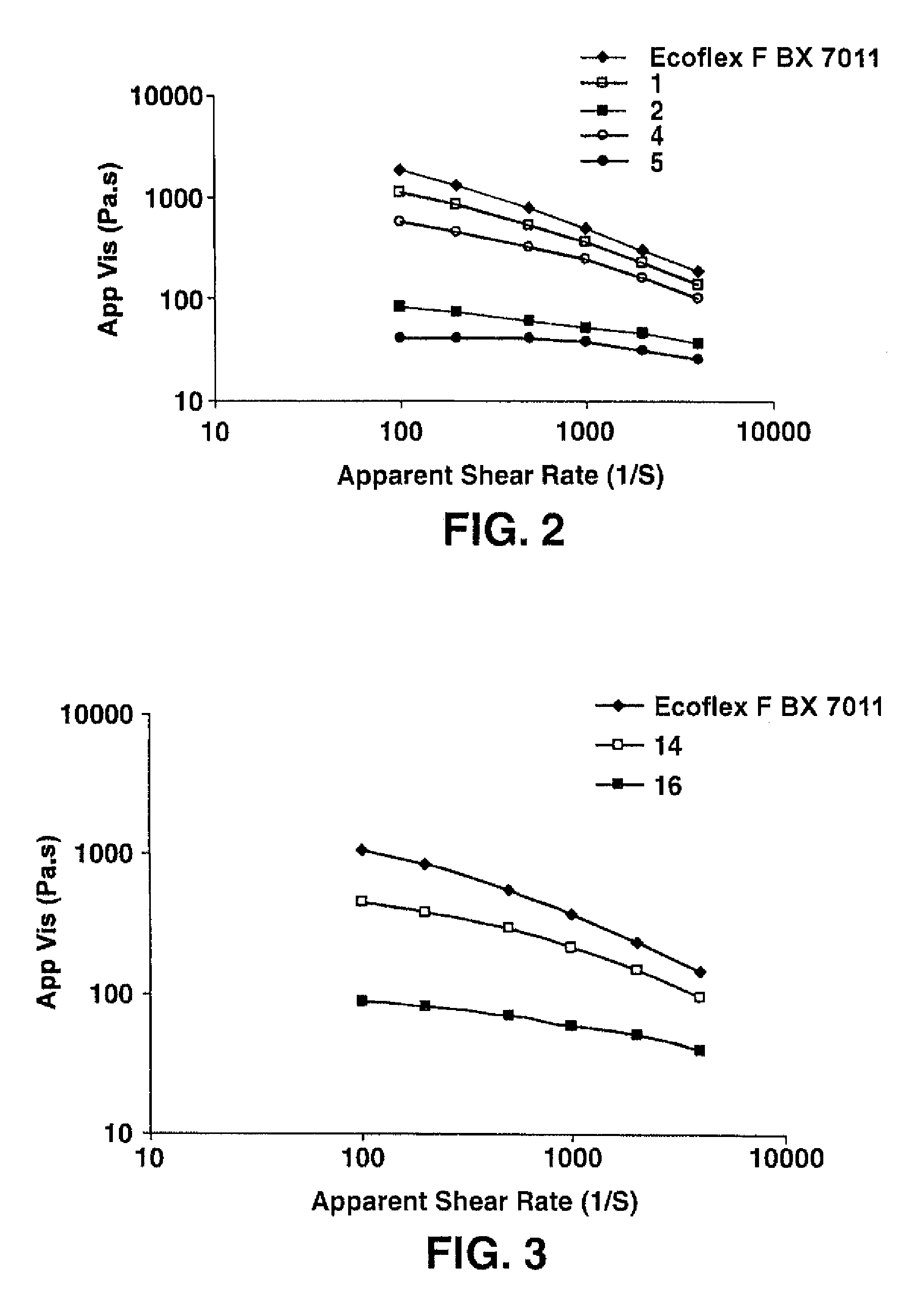

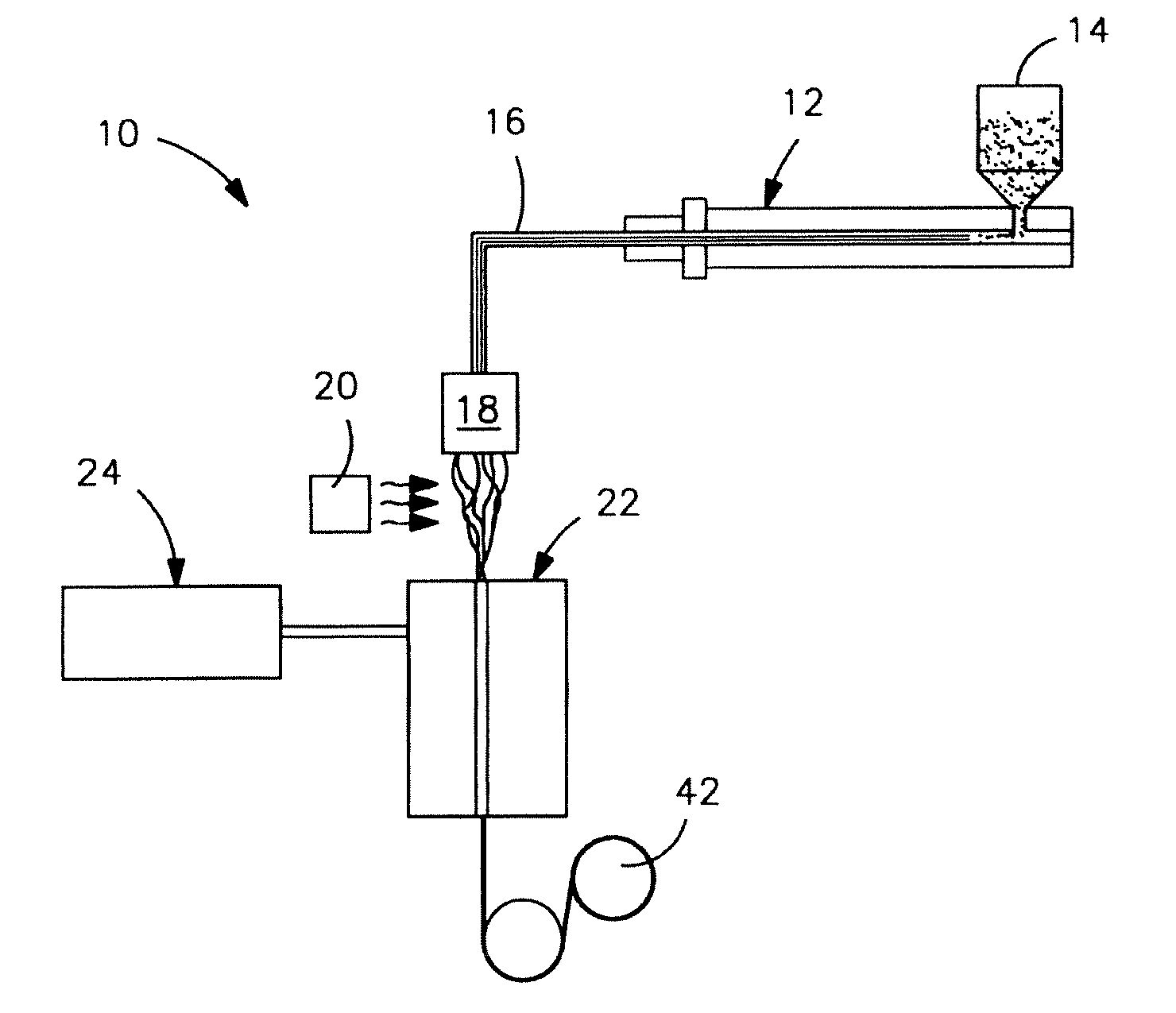

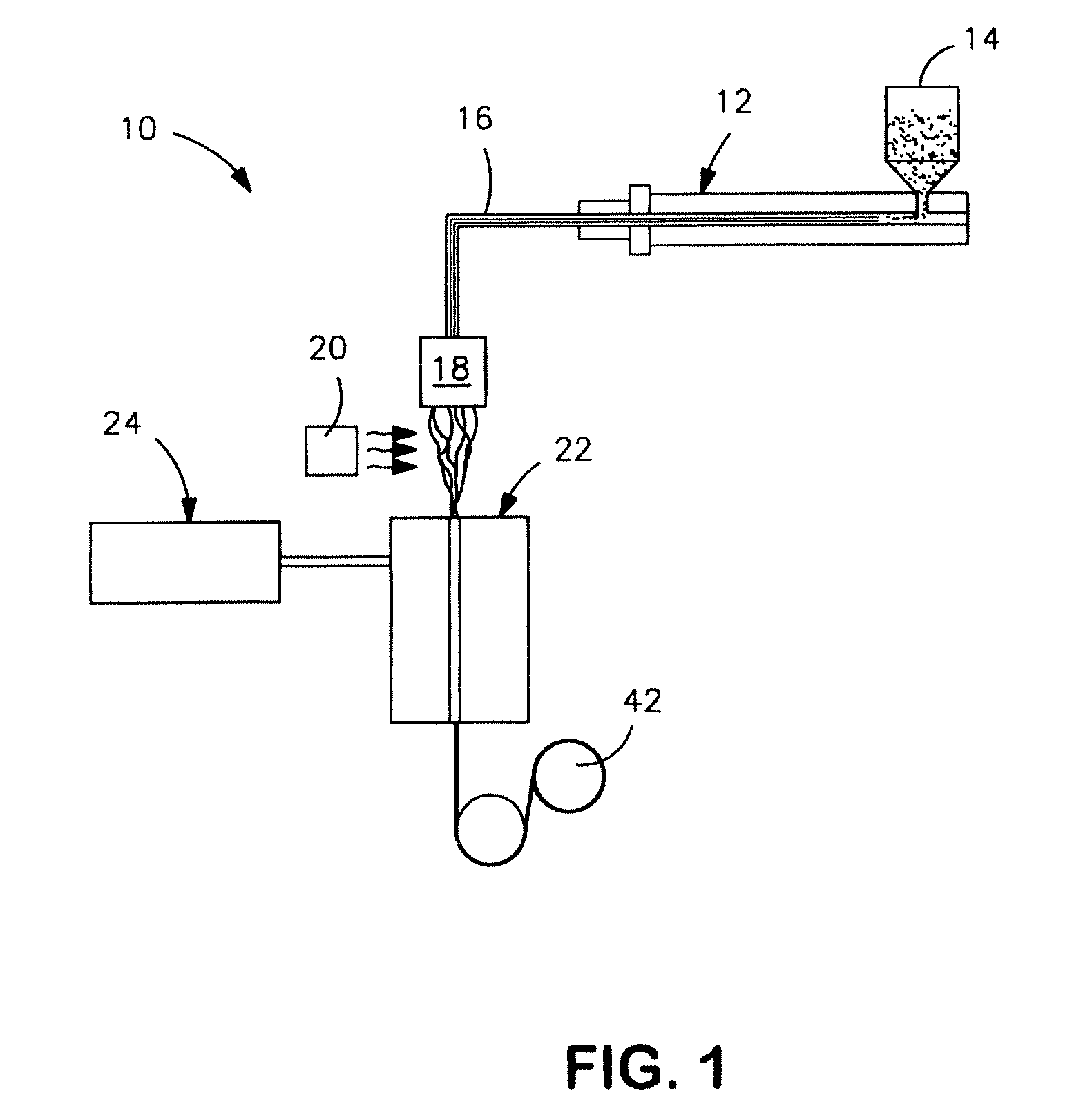

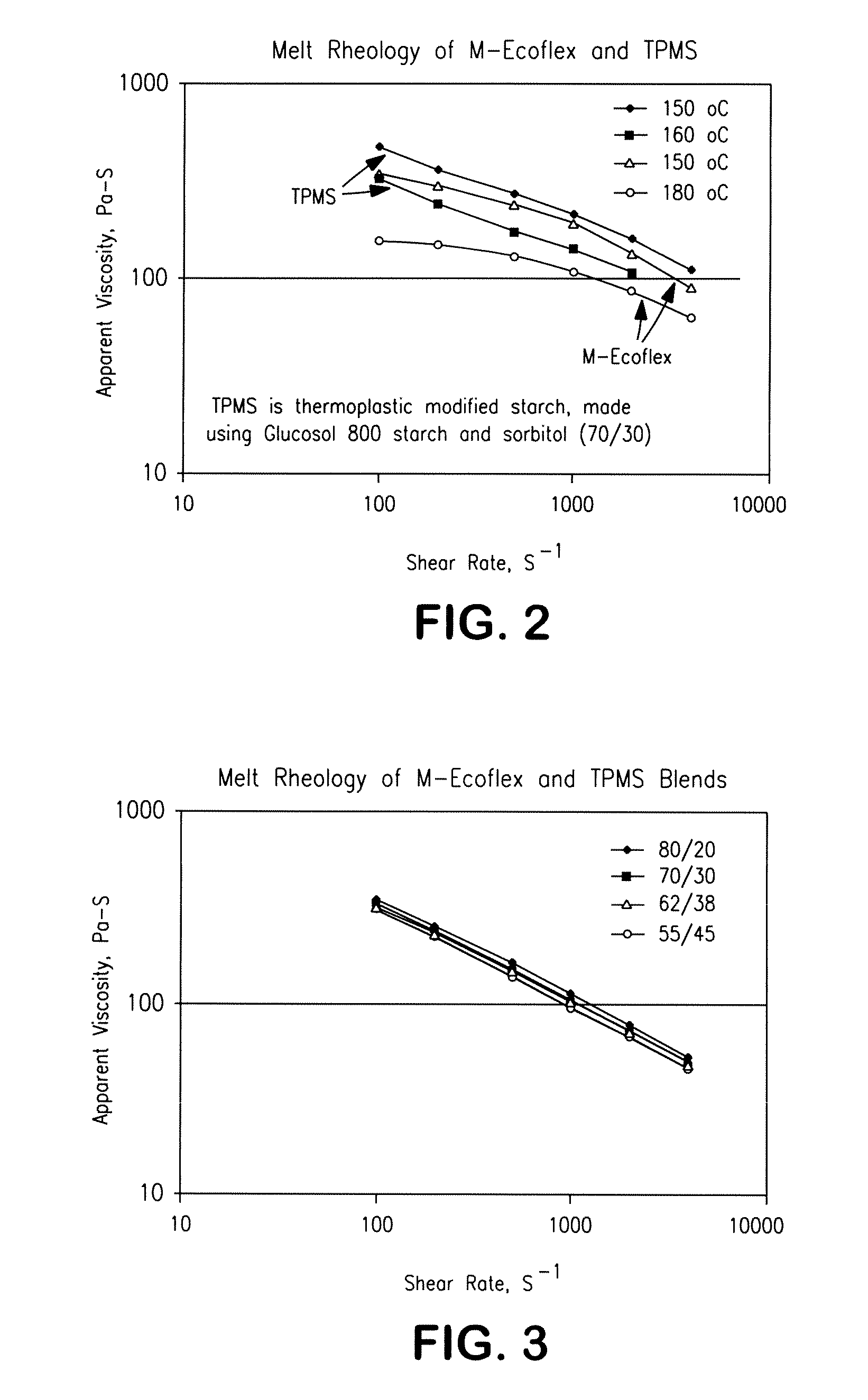

Multicomponent biodegradable filaments and nonwoven webs formed therefrom

A biodegradable, substantially continuous filament is provided. The filament contains a first component formed from at least one high melting polyester and a second component formed from at least one low melting polyester. The low melting point polyester is an aliphatic-aromatic copolyester formed by melt blending a polymer and an alcohol to initiate an alcoholysis reaction that results in a copolyester having one or more hydroxyalkyl or alkyl terminal groups. By selectively controlling the alcoholysis conditions (e.g., alcohol and copolymer concentrations, catalysts, temperature, etc.), a modified aliphatic-aromatic copolyester may be achieved that has a molecular weight lower than the starting aliphatic-aromatic polymer. Such lower molecular weight polymers also have the combination of a higher melt flow index and lower apparent viscosity, which is useful in the formation of substantially continuous filaments.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Sulfonated aromatic copolyesters containing hydroxyalkanoic acid groups and shaped articles produced therefrom

InactiveUS7358325B2Optimized balanceOptimized of dimensionalWrappers shrinkagePaper coatingPolymer scienceCopolyester

Owner:EI DU PONT DE NEMOURS & CO

Fibers Formed from a Blend of a Modified Aliphatic-Aromatic Copolyester and Thermoplastic Starch

ActiveUS20090305592A1Ceramic shaping apparatusMonocomponent copolyesters artificial filamentFiberAlcohol

A fiber formed from a thermoplastic composition that contains a thermoplastic starch and an aliphatic-aromatic copolyester is provided. The copolyester enhances the strength of the starch-containing fibers and also facilitates the ability of the starch to be melt processed. Due to its relatively low melting point, the aliphatic-aromatic copolyester may also be extruded with the thermoplastic starch at a temperature that is low enough to avoid substantial removal of the moisture found in the starch. Furthermore, the aliphatic-aromatic copolyester is also modified with an alcohol so that it contains one or more hydroxyalkyl or alkyl terminal groups. By selectively controlling the conditions of the alcoholysis reaction (e.g., alcohol and copolymer concentrations, temperature, etc.), the resulting modified aliphatic-aromatic copolyester may have a molecular weight that is relatively low. Such low molecular weight polymers have the combination of a higher melt flow index and lower apparent viscosity, which is useful in a wide variety of fiber forming applications, such as in the meltblowing of nonwoven webs.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Blends of aliphatic-aromatic copolyesters with ethylene-vinyl acetate copolymers

ActiveUS7241838B2Excellent fragmentation and breakdownImprove melt strengthPaper coatingSpecial tyresPolymer scienceCopolyester

Disclosed are blends of aliphatic-aromatic copolyesters with poly(ethylene-co-vinyl acetate) copolymers and shaped articles prepared therefrom. These blends have higher melt strength than the aliphatic-aromatic copolyester alone and exhibit increased melt strength and better processability. In addition, the blends and shaped articles show bio-disintegration and / or biodegradability in a composting environment.

Owner:EASTMAN CHEM CO

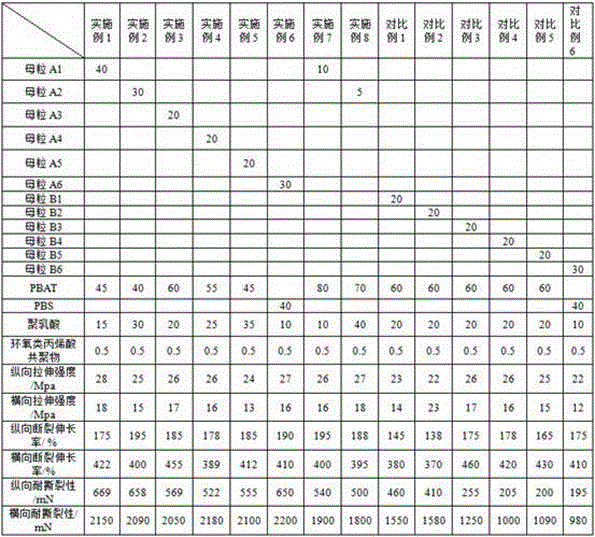

Full-biodegradable composite as well as preparation method and application of full-biodegradable composite

The invention discloses a full-biodegradable composite as well as a preparation method and application of the full-biodegradable composite. The full-biodegradable composite comprises the following components: 5-40 parts of inorganic filler full-biodegradable masterbatches, 40-80 parts of biodegradable copolyester, 10-40 parts of polylactic acid and 0.1-5 parts of a compatilizer, wherein the inorganic filler full-biodegradable masterbatches comprise the following components: 20-80 parts of the biodegradable copolyester, 20-80 parts of inorganic filler, 0.1-10 parts of a lubricating agent and 0.1-5 parts of the compatilizer; and the inorganic filler is one or a combination of modified kaolin, modified white carbon black and modified montmorillonite. According to the full-biodegradable composite, the modified montmorillonite, the modified kaolin or the modified white carbon black is added as an enhancer, and an epoxy acrylic copolymer is introduced as the compatilizer, so that the compatibility of inorganic filler and matrix resin is enhanced, and the uniform dispersion is achieved; and the masterbatches are added into the matrix resin, so that the problem of relatively low tearing strength of a blend film and a sheet can be effectively improved.

Owner:KINGFA SCI & TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com