Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

498 results about "1,4-Butanediol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

1,4-Butanediol, colloquially known as BD, is the organic compound with the formula HOCH₂CH₂CH₂CH₂OH. It is a colorless viscous liquid. It is one of four stable isomers of butanediol.

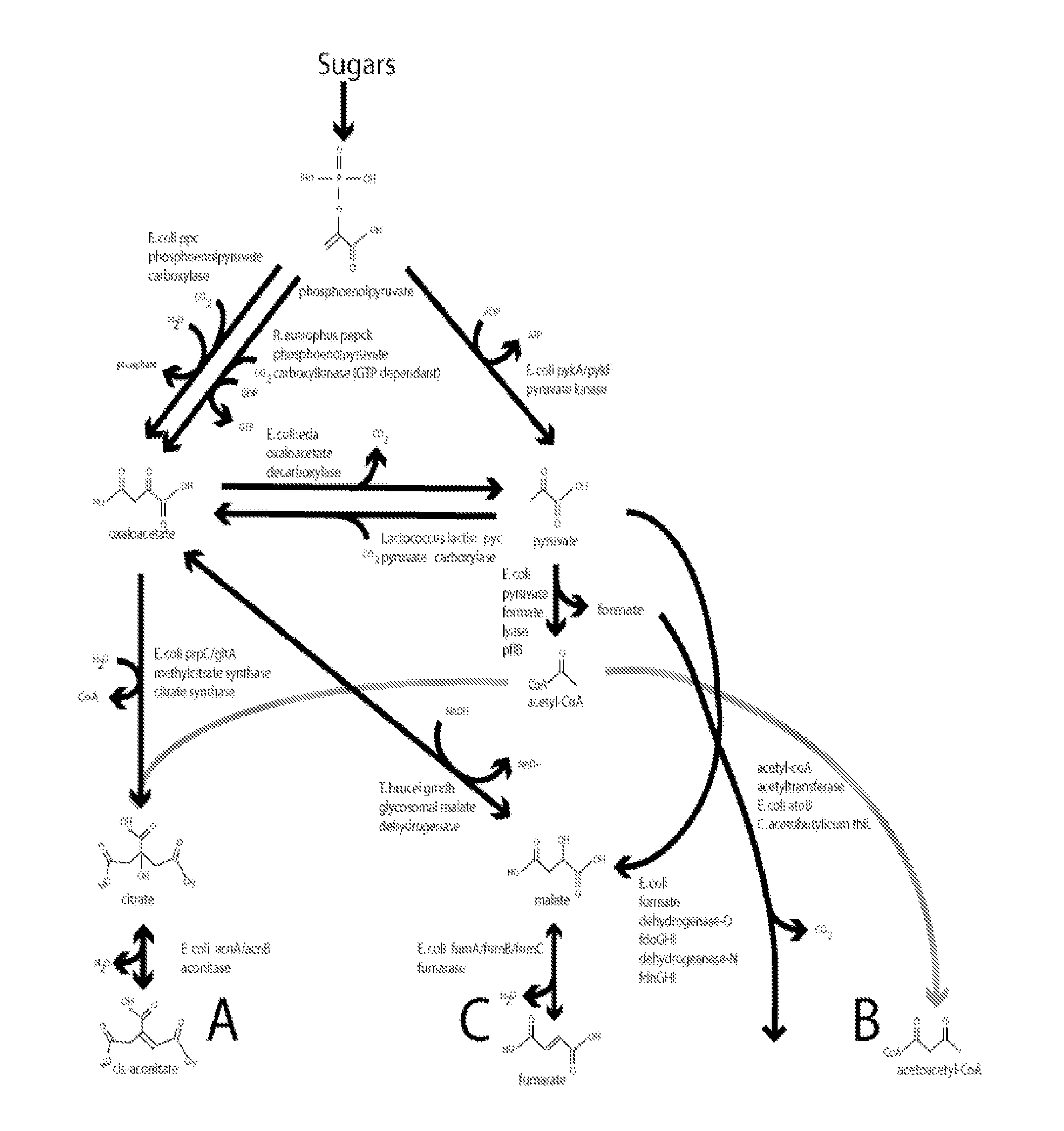

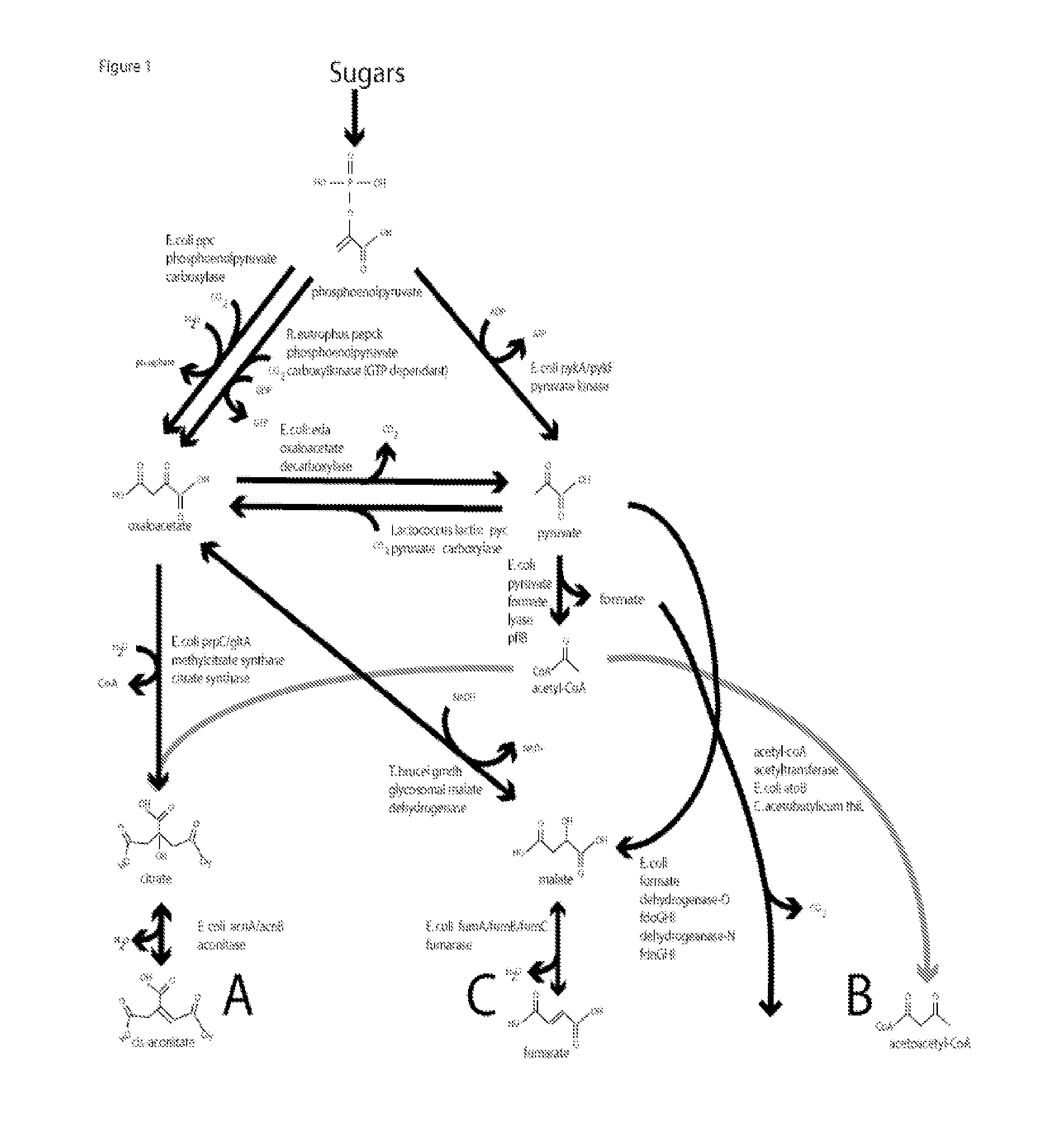

Methods and organisms for the growth-coupled production of 1,4-butanediol

The invention provides a non-naturally occurring microorganism comprising one or more gene disruptions, the one or more gene disruptions occurring in genes encoding an enzyme obligatory to coupling 1,4-butanediol production to growth of the microorganism when the gene disruption reduces an activity of the enzyme, whereby the one or more gene disruptions confers stable growth-coupled production of 1,4-butanediol onto the non-naturally occurring microorganism. The microorganism can further comprise a gene encoding an enzyme in a 1,4-butanediol (BDO) biosynthetic pathway. The invention additionally relates to methods of using microorganisms to produce BDO.

Owner:GENOMATICA INC

High surface area sol-gel route prepared hydrogenation catalysts

InactiveUS6686310B1Good dispersionImprove uniformityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsRheniumSilicon oxide

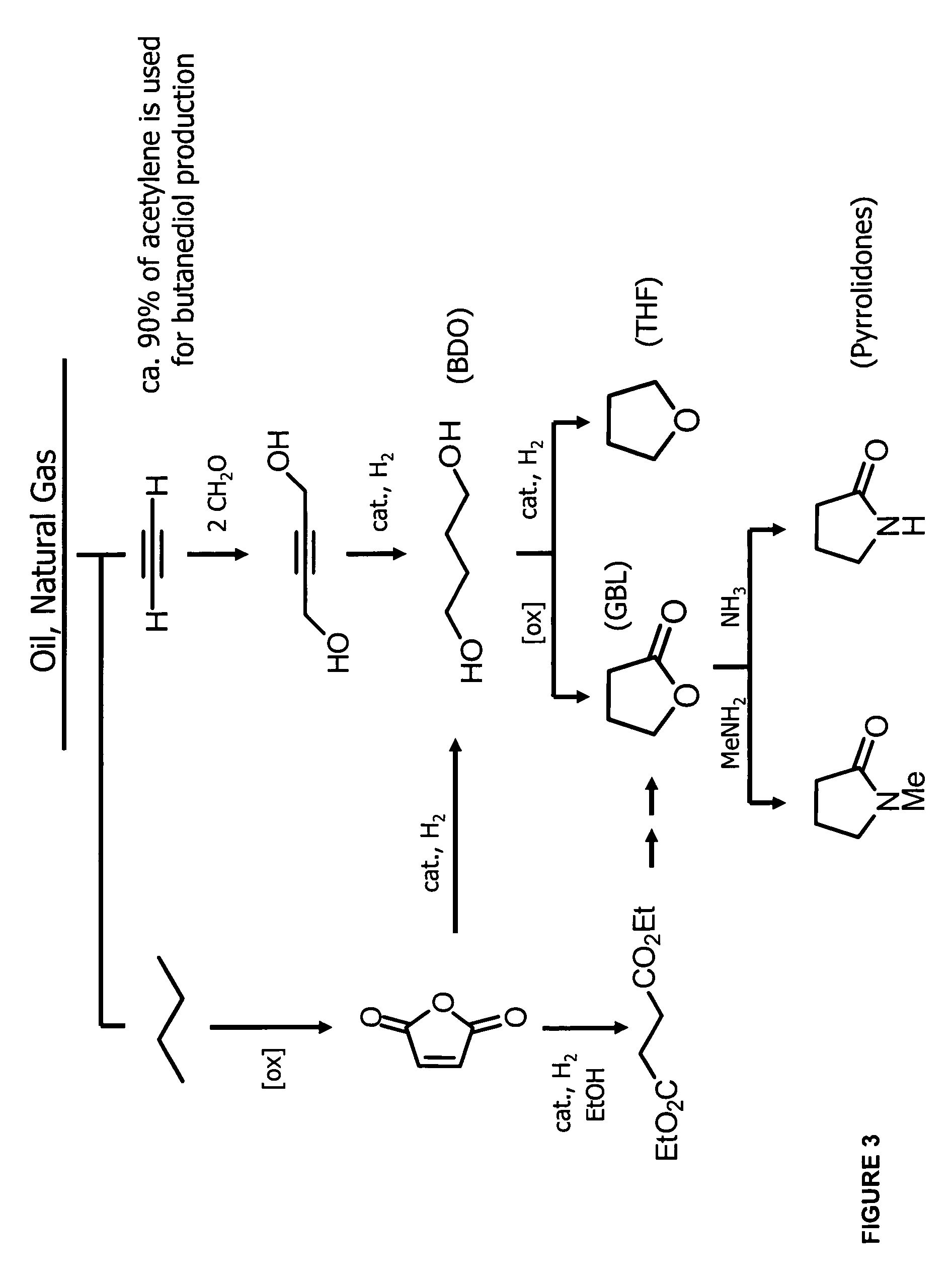

This invention concerns novel compositions, useful as hydrogenation catalyst, said compositions comprising metals and metal ions such as ruthenium (Ru) or palladium (Pd) dispersed in and distributed throughout a matrix comprising an inorganic or silicon oxide network. The catalyst may be prepared by the sol-gel method; a solution of at least one catalytic metal compound is added to a solution of at least one metal alkoxide selected from Al, Ti, Nb, Zr, Ta, Si and other inorganic alkoxides, and then gelling the mixture. Promotors such as rhenium (Re), molybdenum (Mo) and tin (Sn) may be added. The catalyst may be used in the reduction of metallic acid or gamma-butyrolactone to tetrahydrofuran (THF) and 1,4-butanediol (BDO).

Owner:EI DU PONT DE NEMOURS & CO

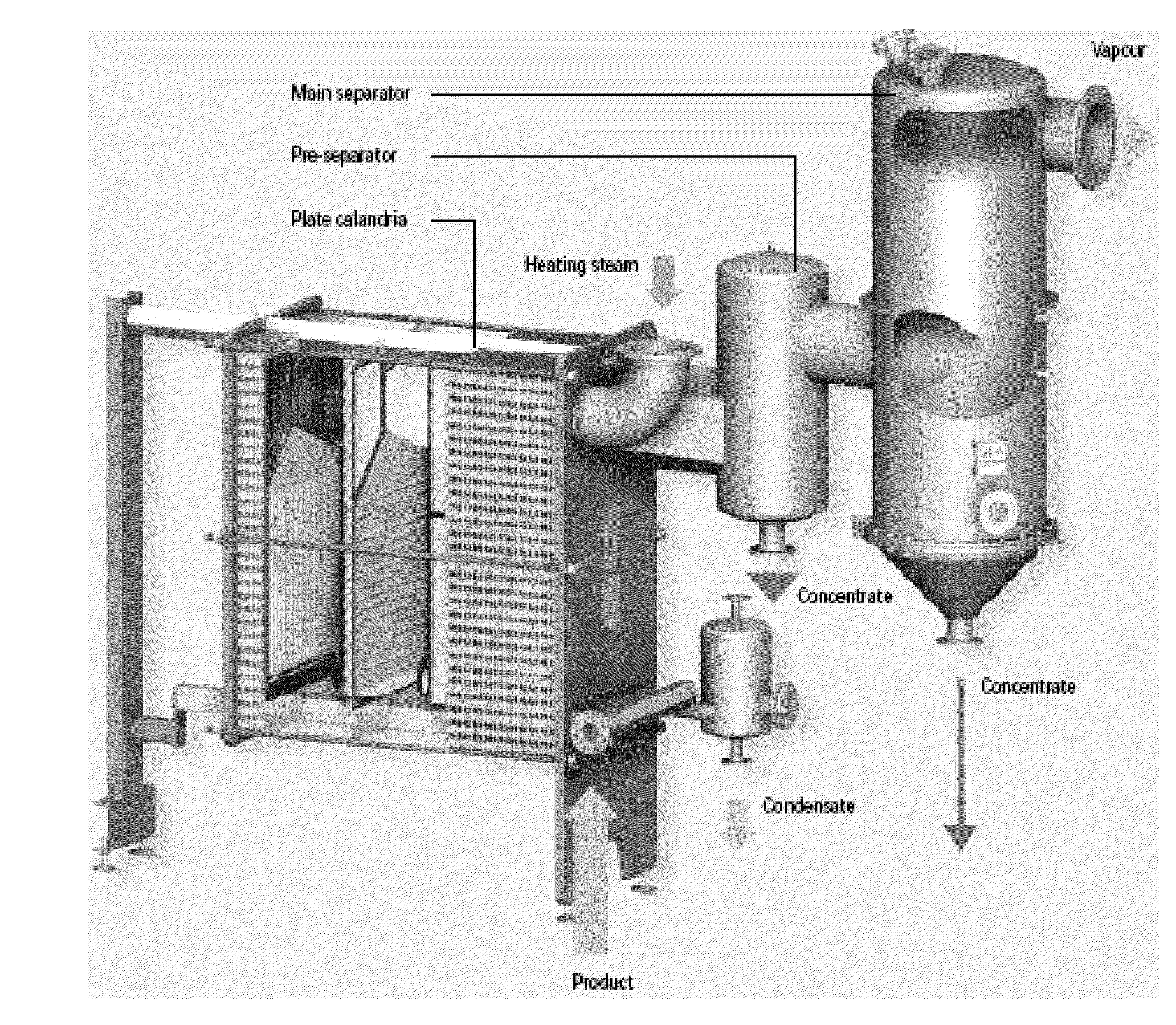

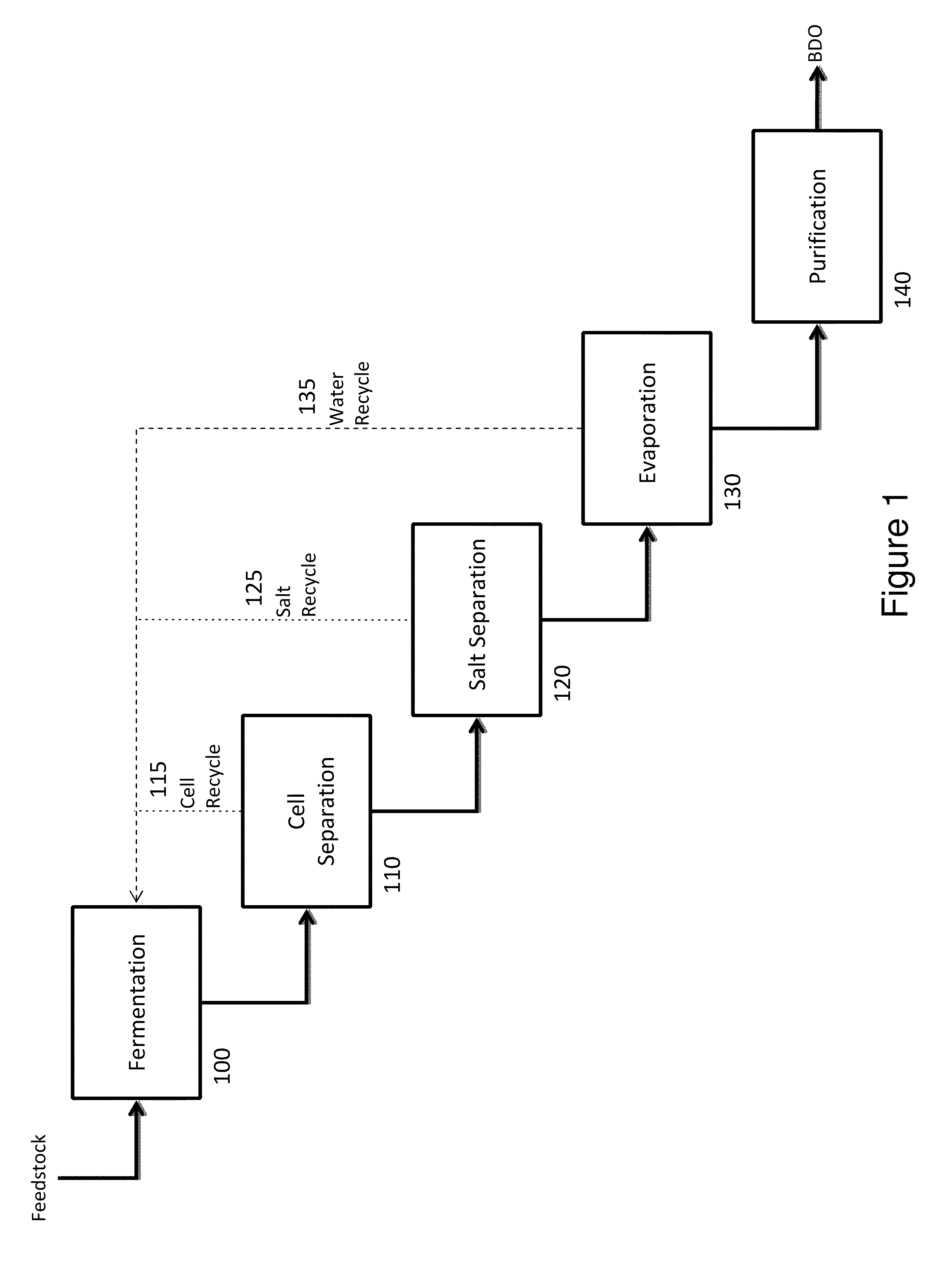

Process of separating components of a fermentation broth

ActiveUS20110003355A1Produce lotFermented solutions distillation/rectificationOrganic compound preparation1,4-ButanediolMicroorganism

A process of isolating 1,4-butanediol (1,4-BDO) from a fermentation broth includes separating a liquid fraction enriched in 1,4-BDO from a solid fraction comprising cells, removing water from said liquid fraction, removing salts from said liquid fraction, and purifying 1,4-BDO. A process for producing 1,4-BDO includes culturing a 1,4-BDO-producing microorganism in a fermentor for a sufficient period of time to produce 1,4-BDO. The 1,4-BDO-producing microorganism includes a microorganism having a 1,4-BDO pathway having one or more exogenous genes encoding a 1,4-BDO pathway enzyme and / or one or more gene disruptions. The process for producing 1,4-BDO further includes isolating 1,4-BDO.

Owner:GENOMATICA INC

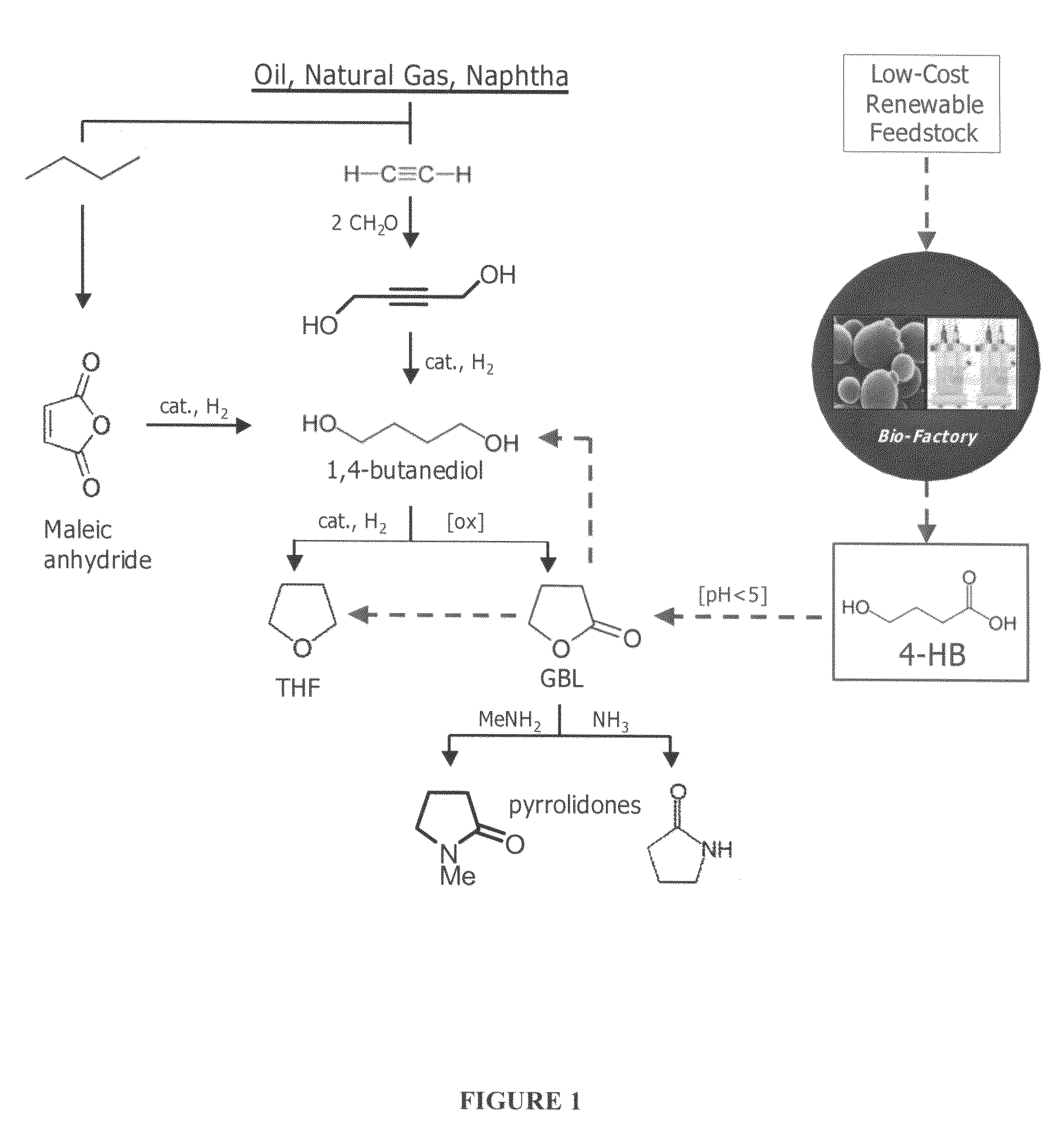

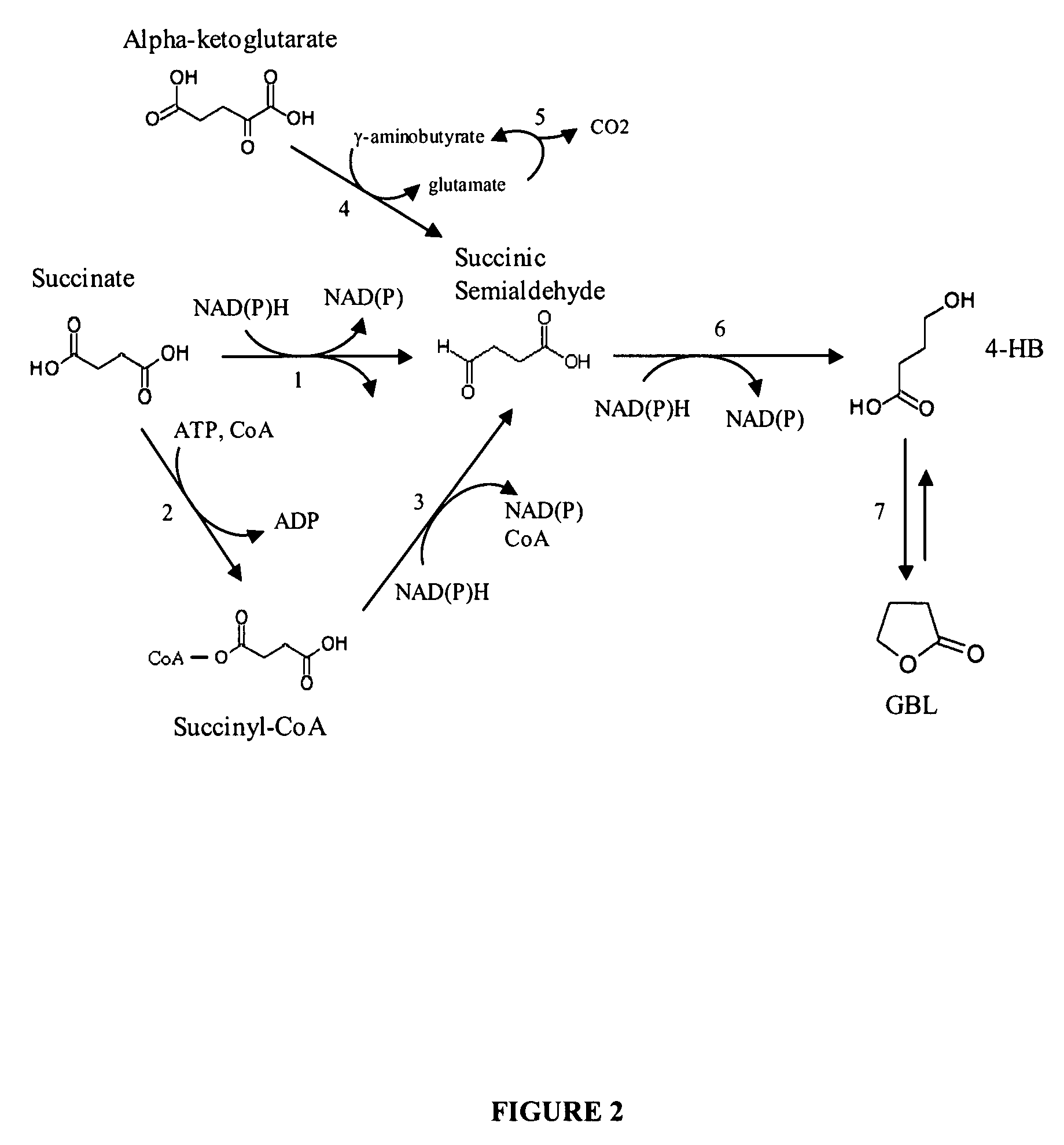

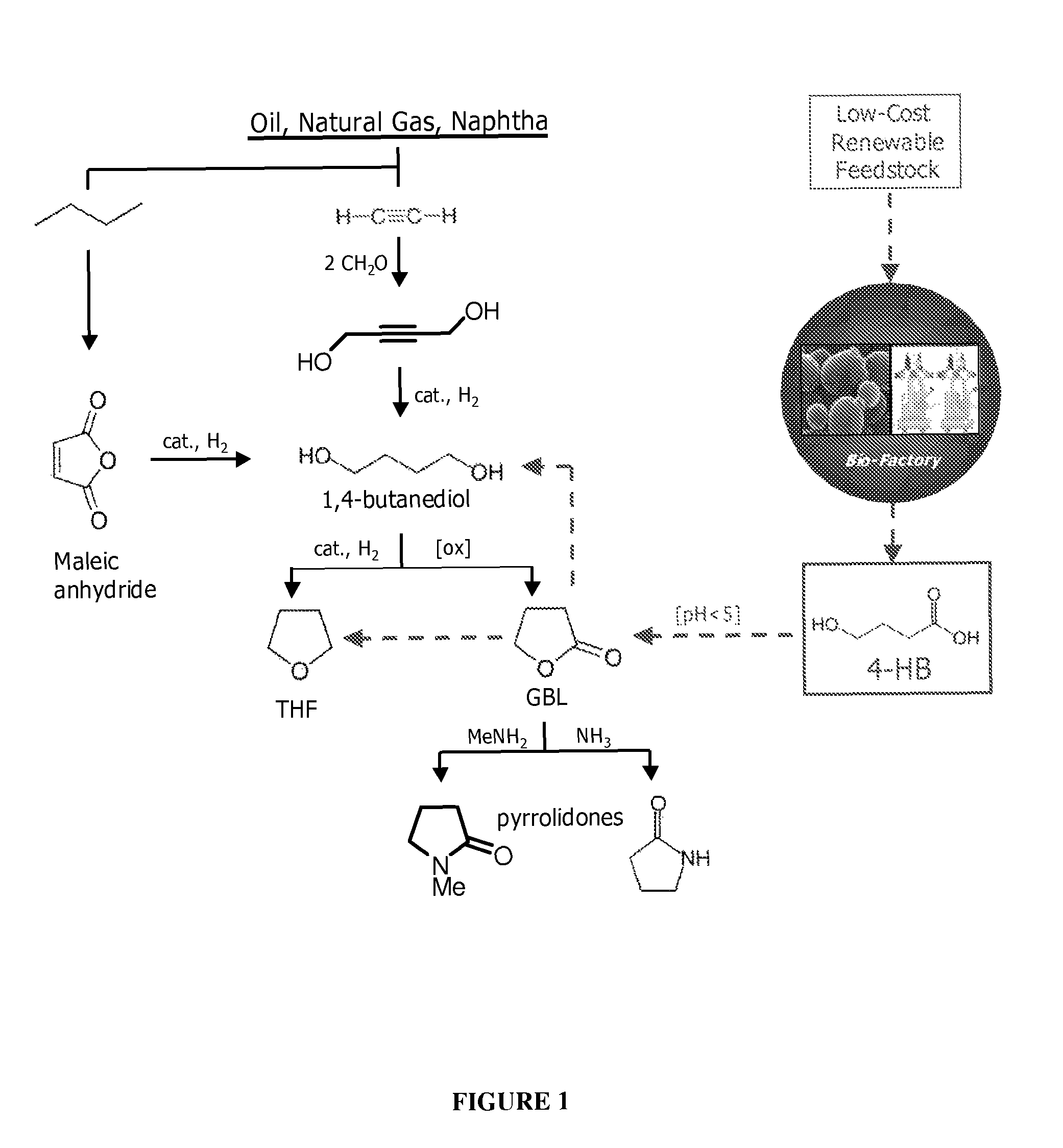

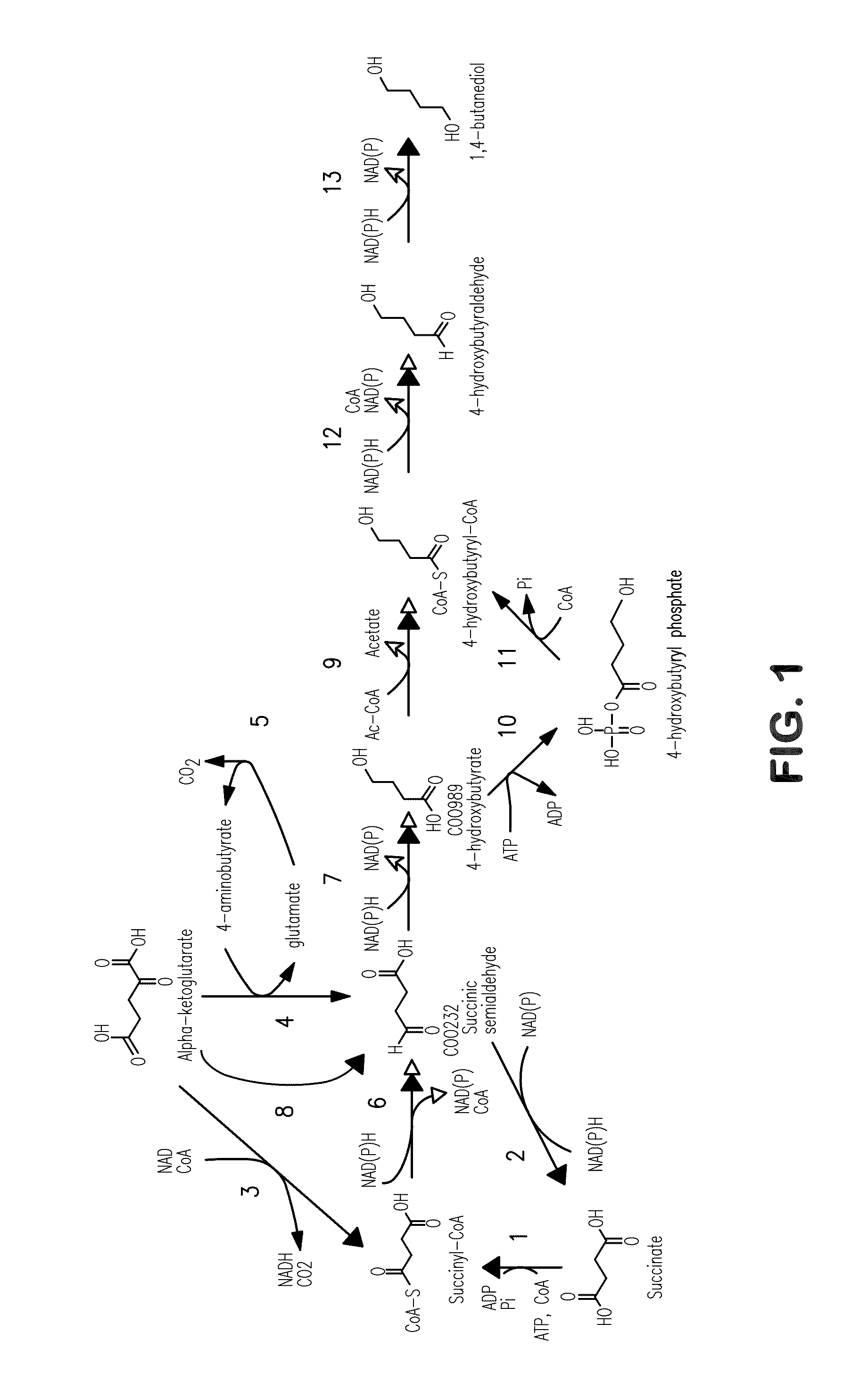

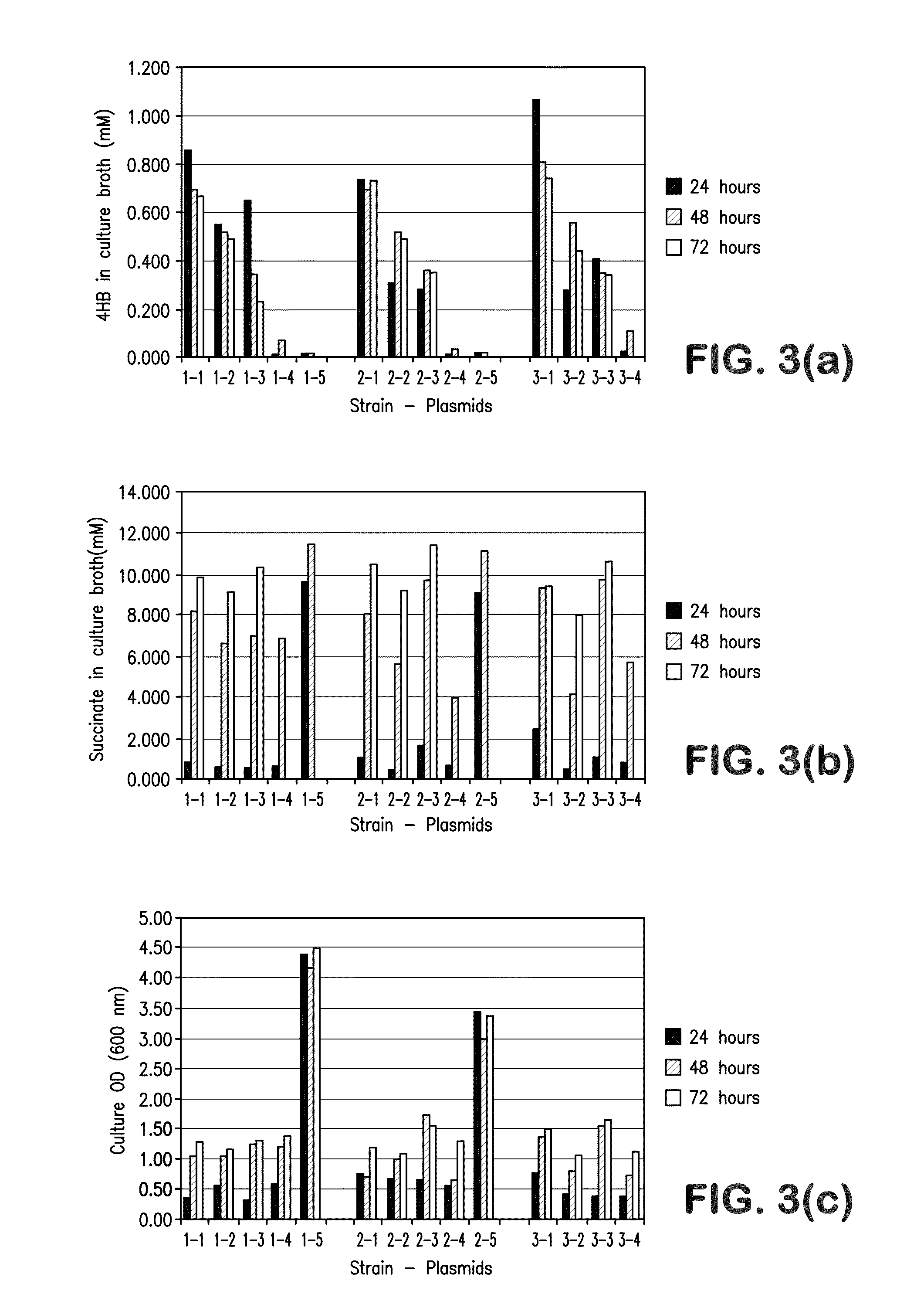

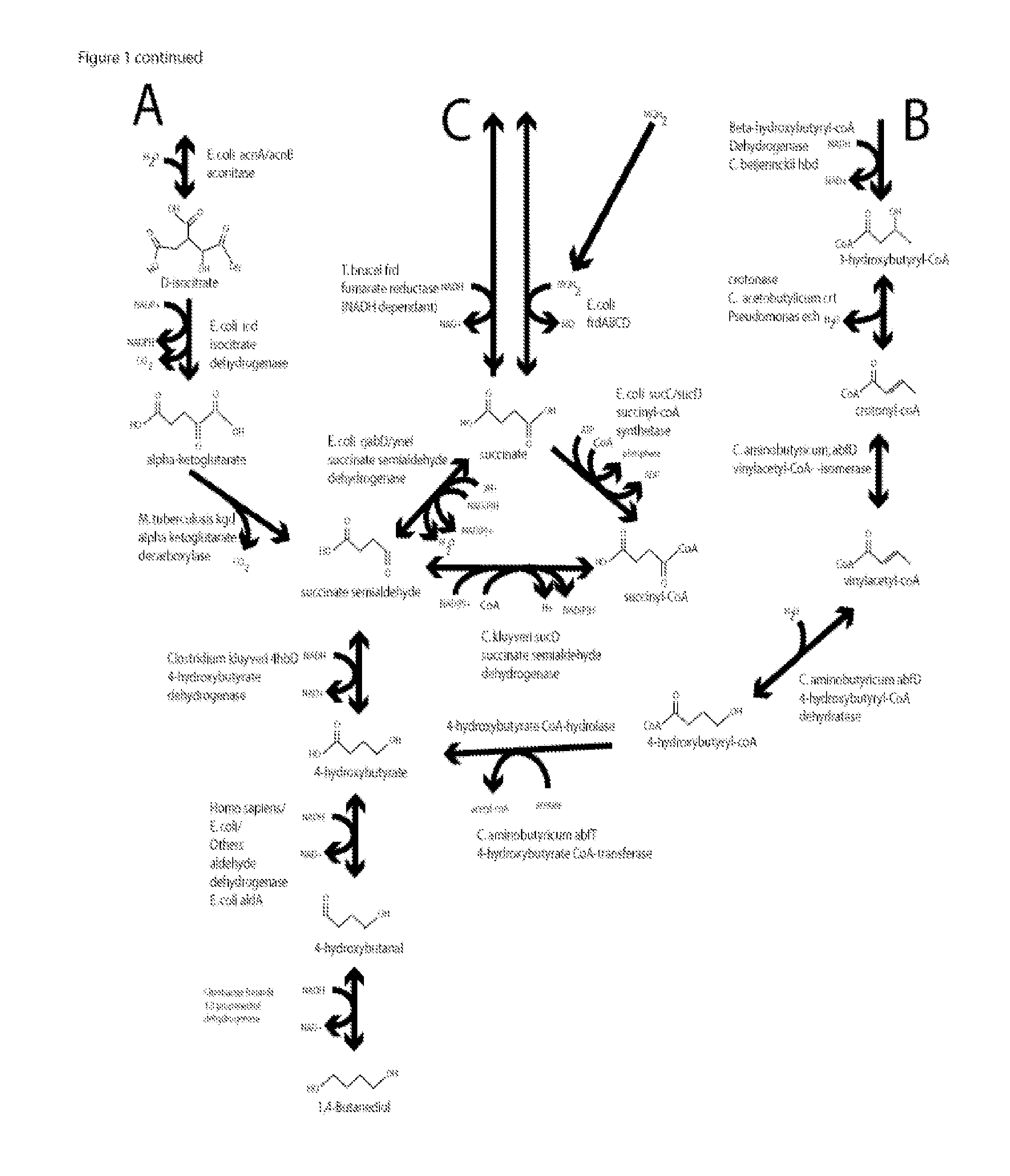

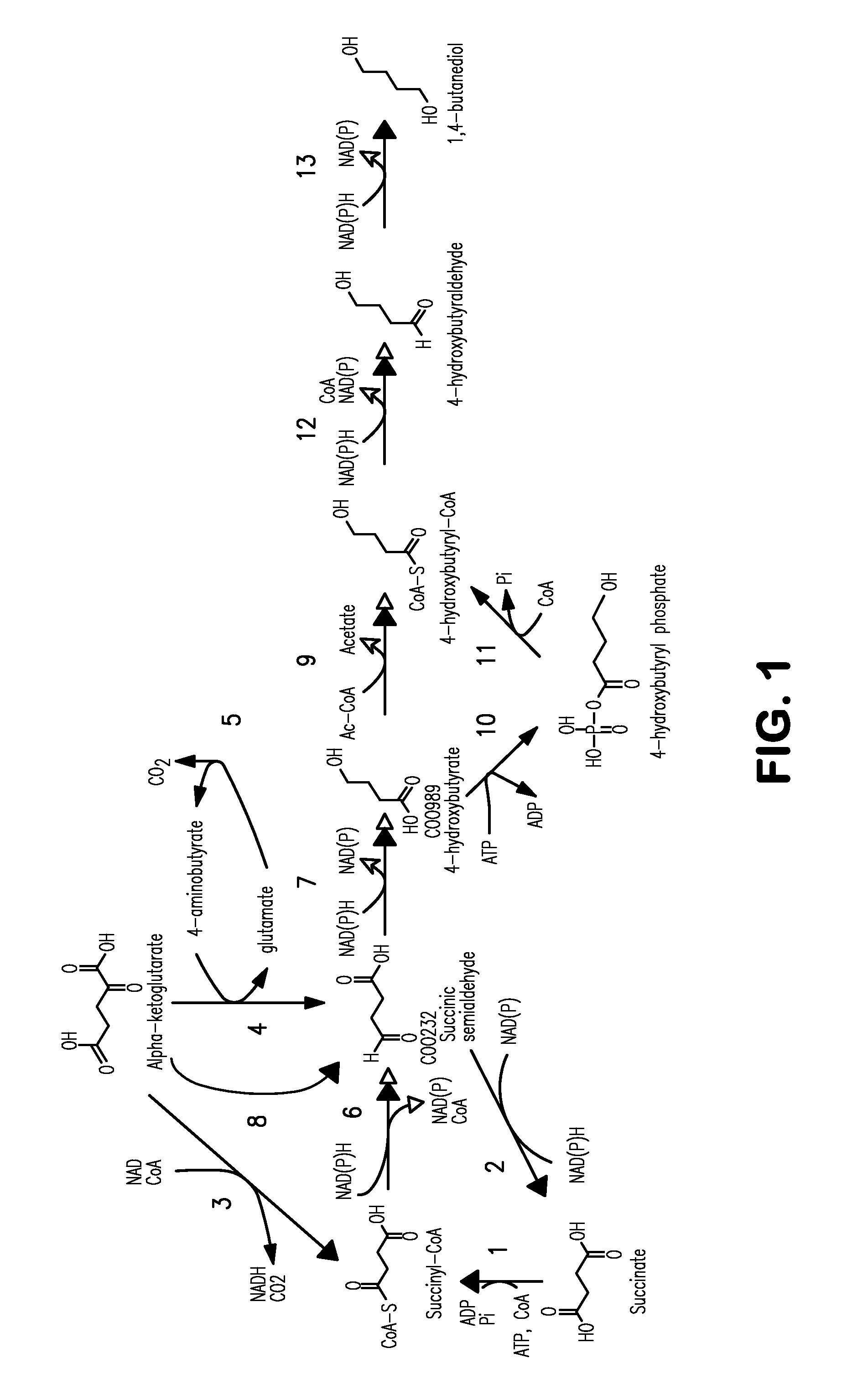

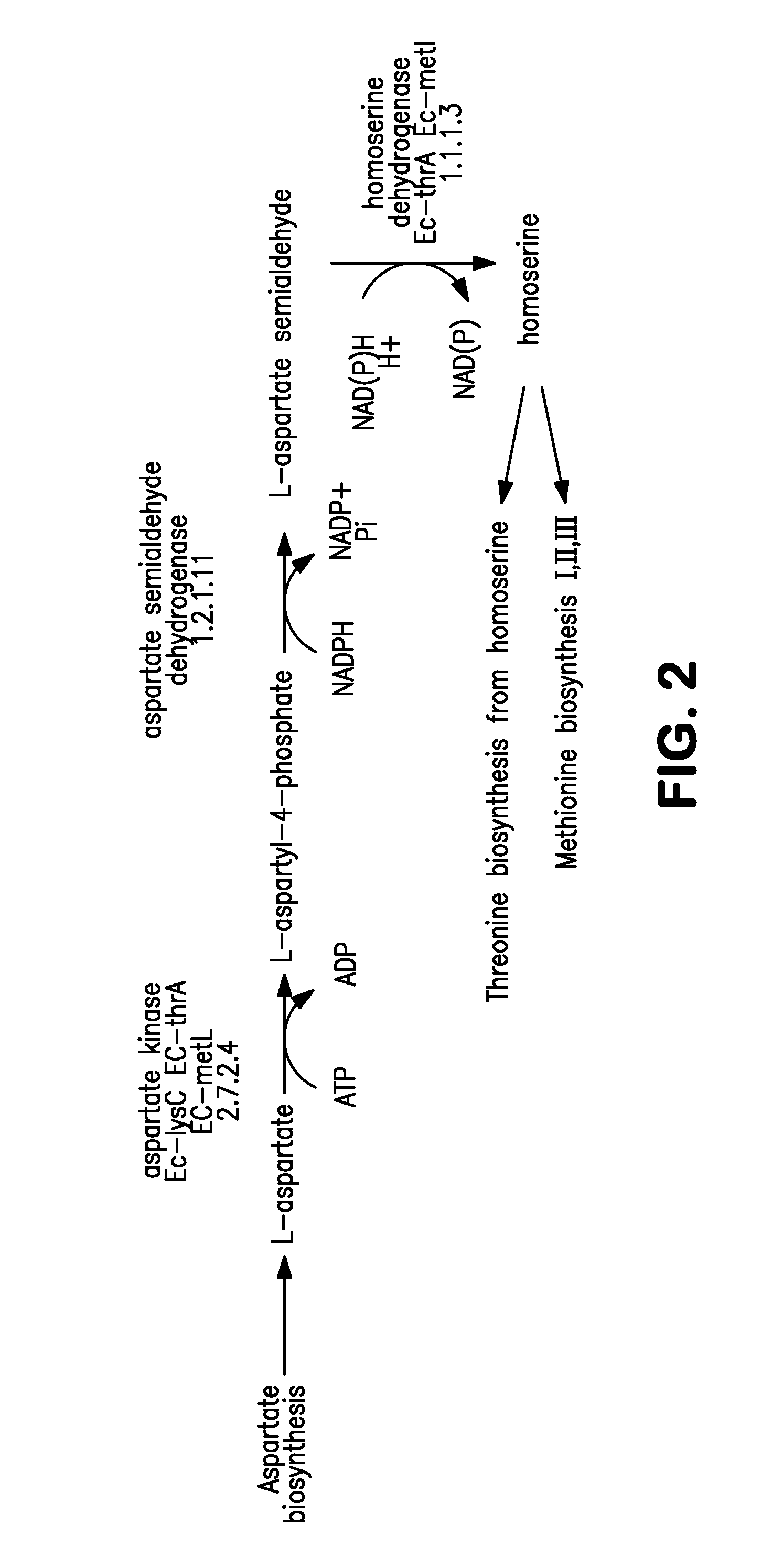

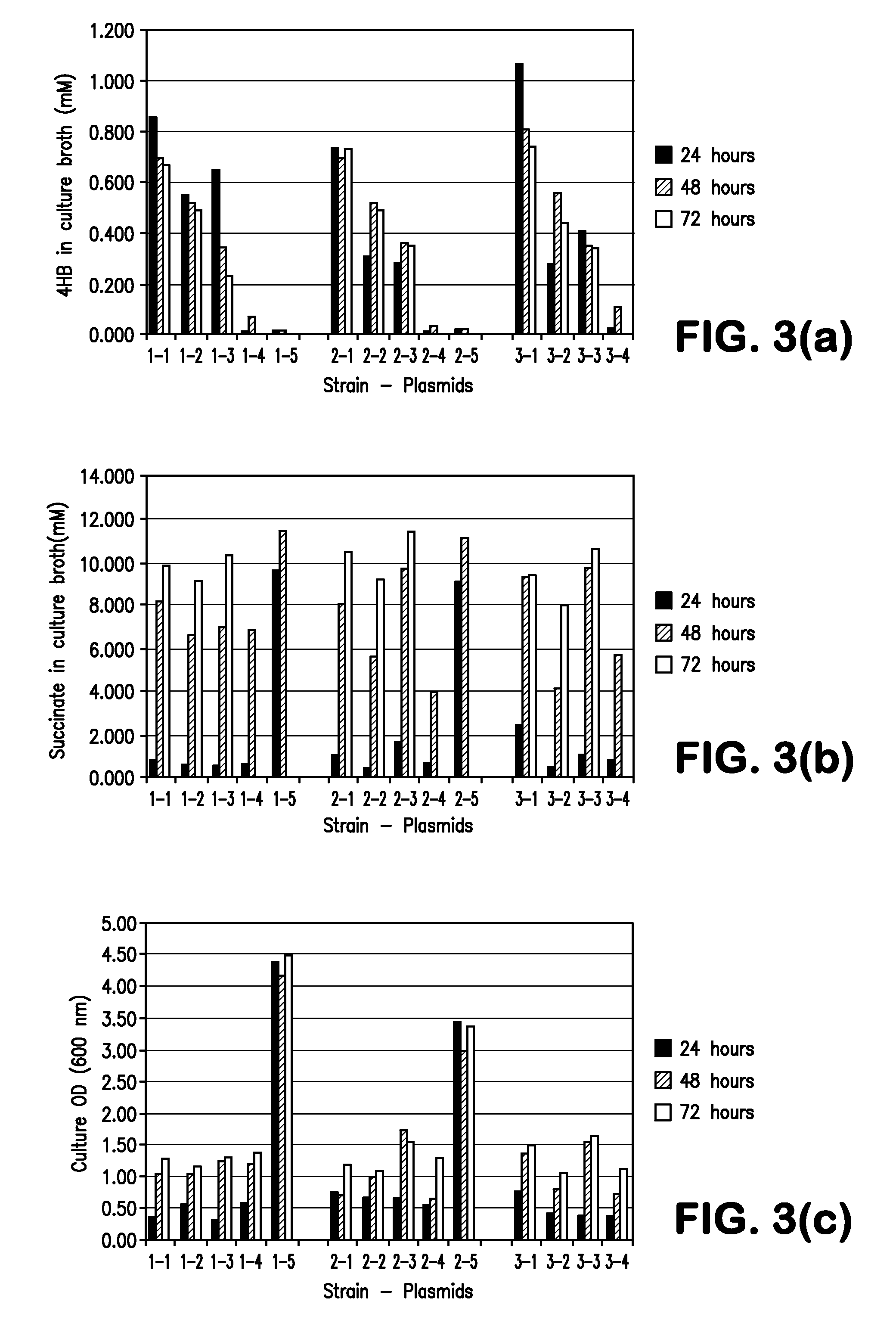

Compositions and methods for the biosynthesis of 1,4-butanediol and its precursors

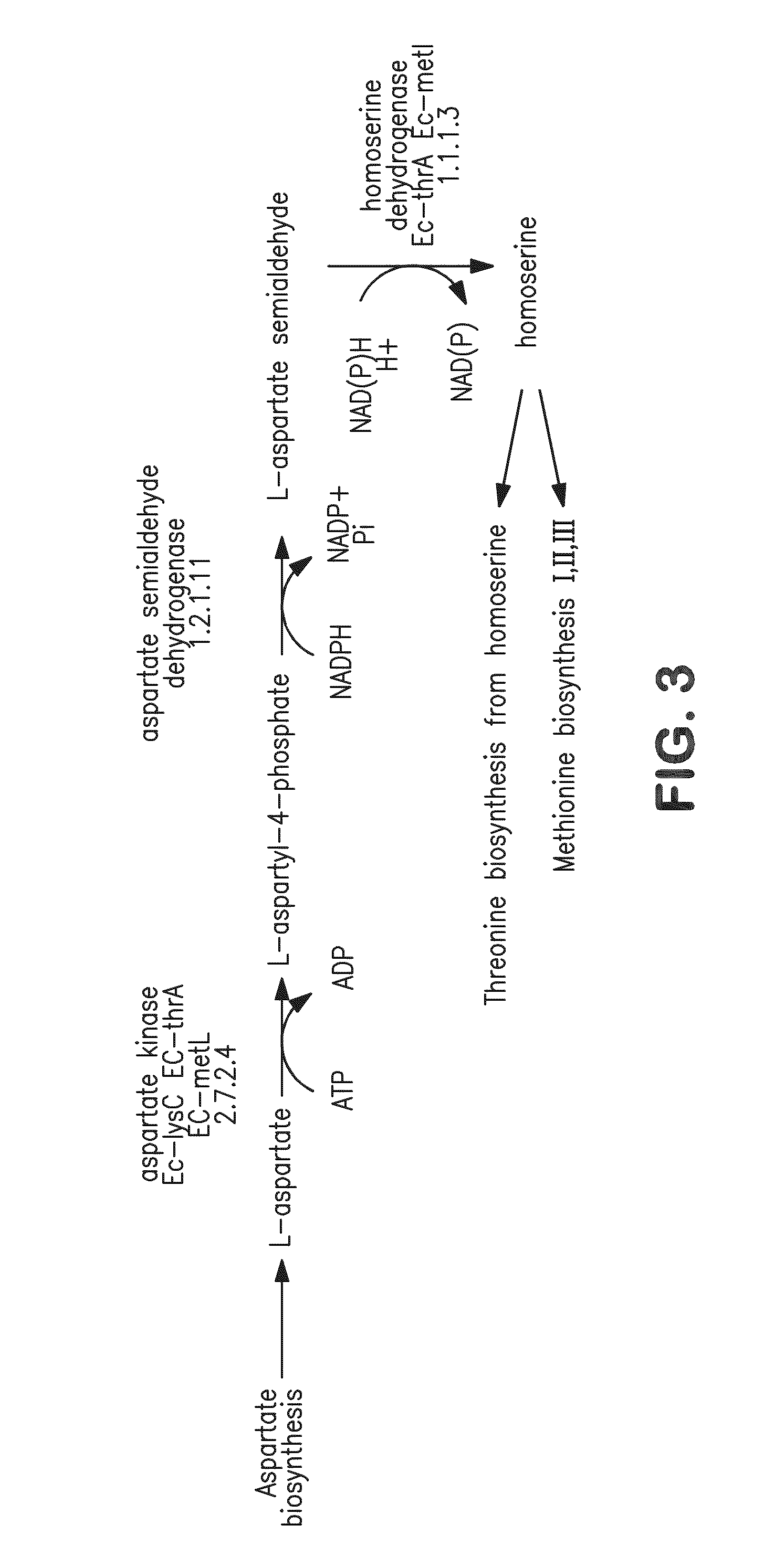

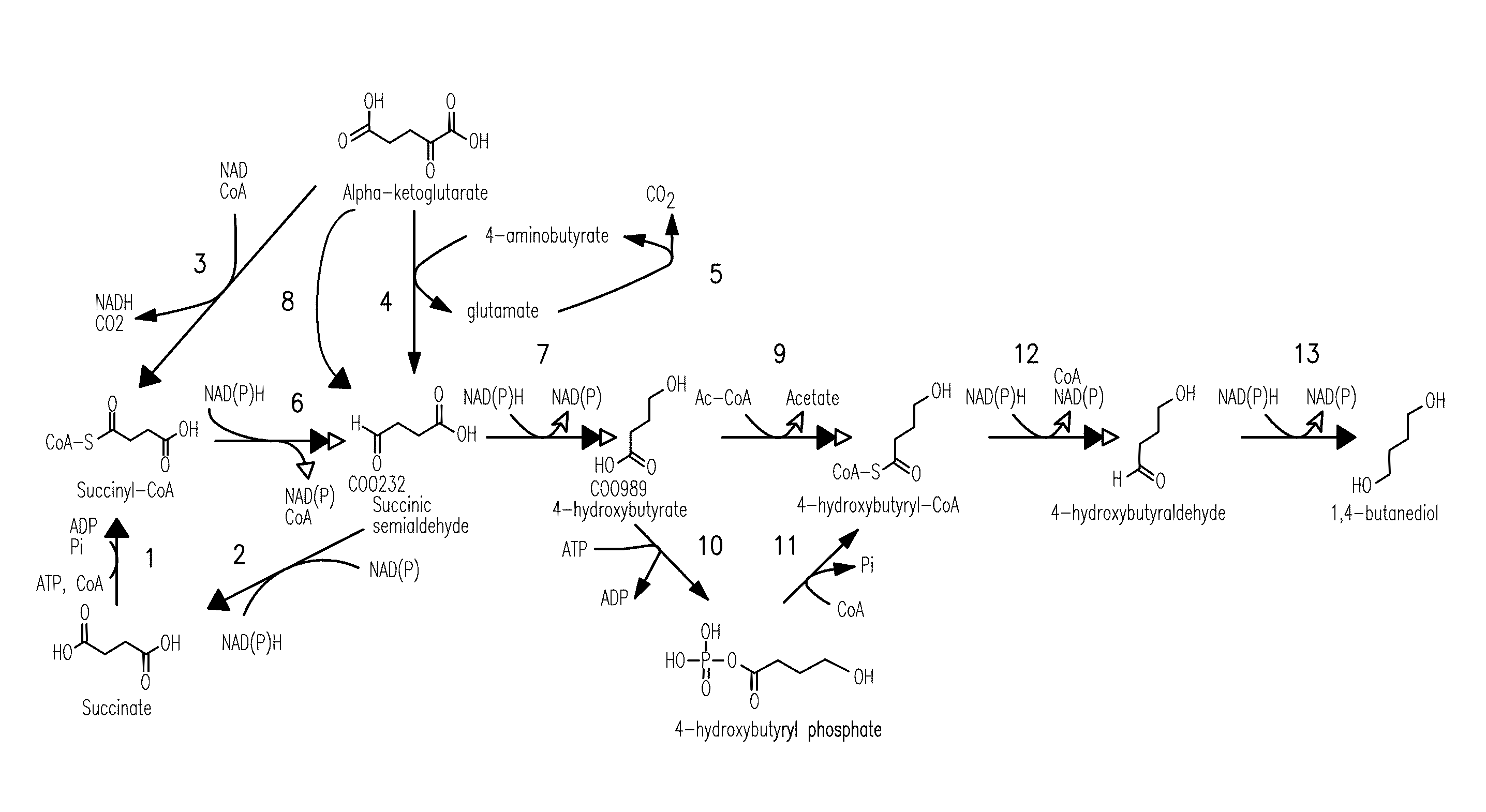

The invention provides a non-naturally occurring microbial organism having 4-hydroxybutanoic acid (4-HB) and 1,4-butanediol (1,4-BDO) biosynthetic pathways. The pathways include exogenous nucleic acids encoding a) an α-ketoglutarate decarboxylase; b) a 4-hydroxybutanoate dehydrogenase; c) a 4-hydroxybutyryl-CoA:acetyl-CoA transferase or a butyrate kinase and a phosphotransbutyrylase; d) an aldehyde dehydrogenase, and e) an alcohol dehydrogenase, wherein the exogenous nucleic acids are expressed in sufficient amounts to produce 1,4-butanediol (1,4-BDO). Also provide is a method for the production of 1,4-BDO. The method includes culturing the non-naturally occurring microbial organism having 4-HB and 1,4-BDO biosynthetic pathways substantially anaerobic conditions for a sufficient period of time to produce 1,4-BDO.

Owner:GENOMATICA INC

Microorganisms for the production of 1,4-butanediol and related methods

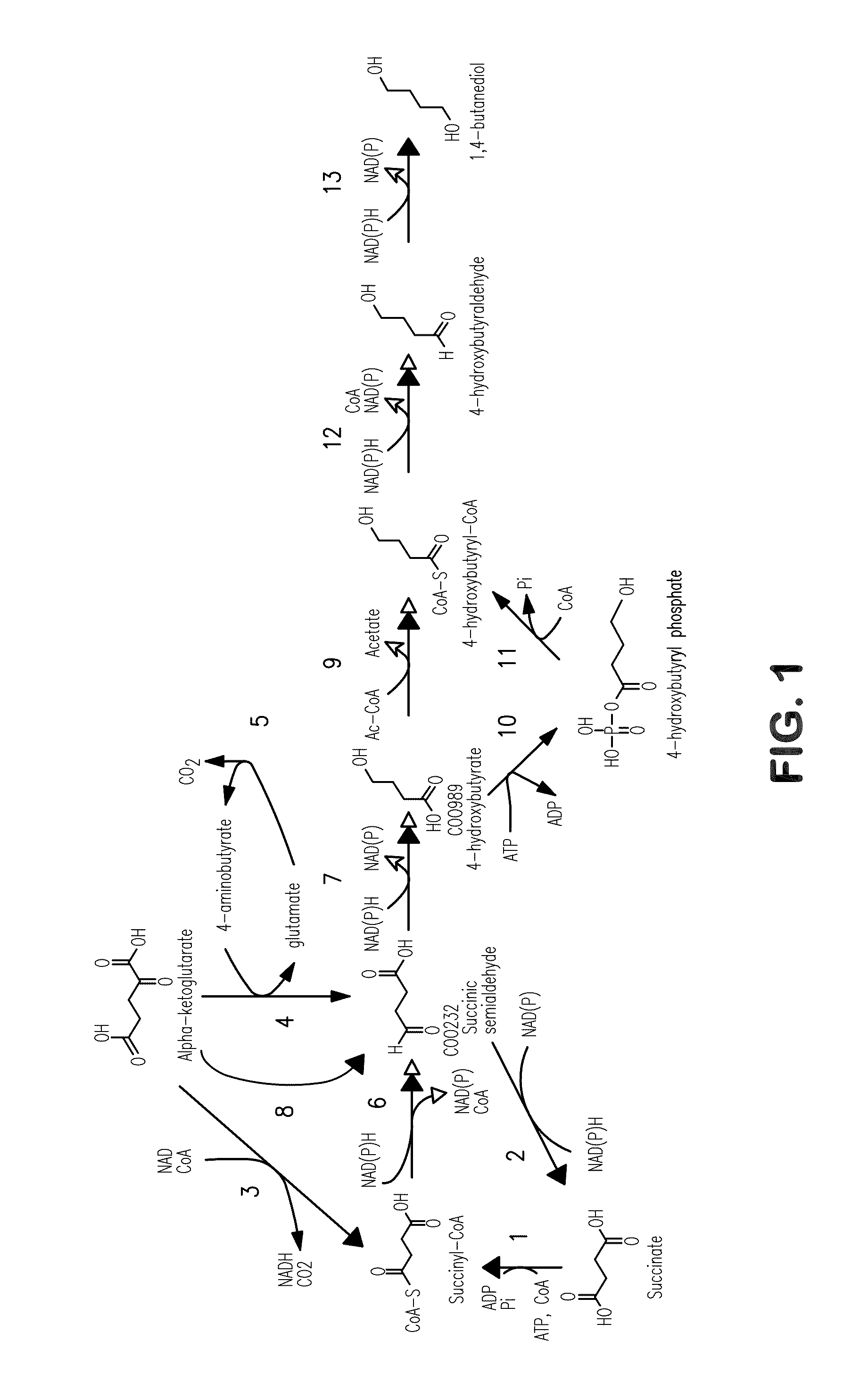

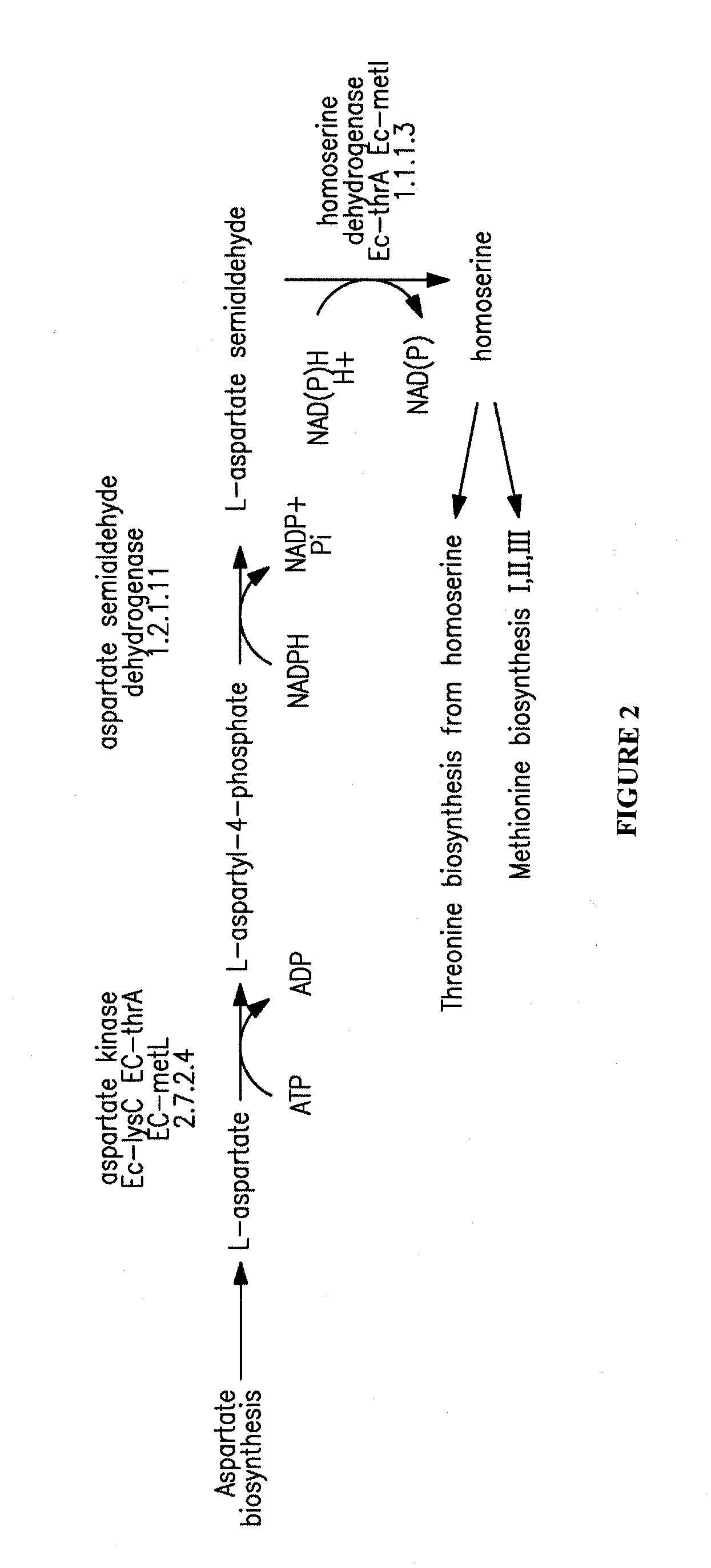

The invention provides non-naturally occurring microbial organisms comprising a 1,4-butanediol (BDO) pathway comprising at least one exogenous nucleic acid encoding a BDO pathway enzyme expressed in a sufficient amount to produce BDO and further optimized for expression of BDO. The invention additionally provides methods of using such microbial organisms to produce BDO.

Owner:GENOMATICA INC

Microorganisms for the production of 1,4-butanediol and related methods

Owner:GENOMATICA INC

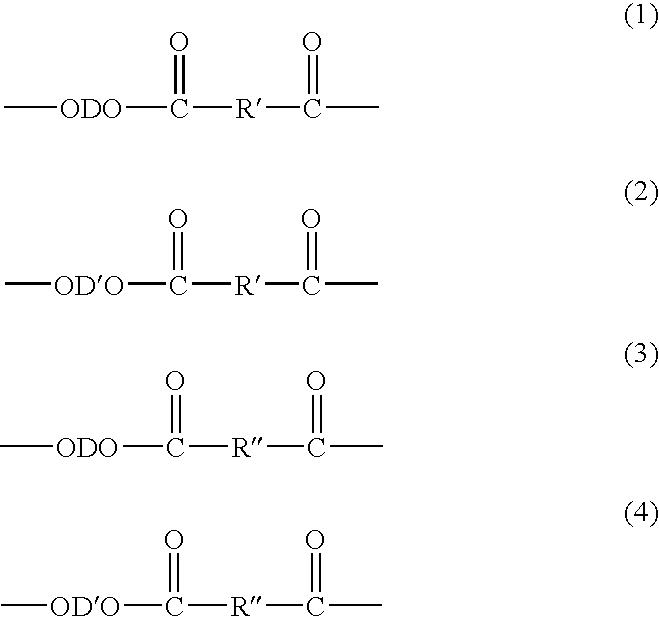

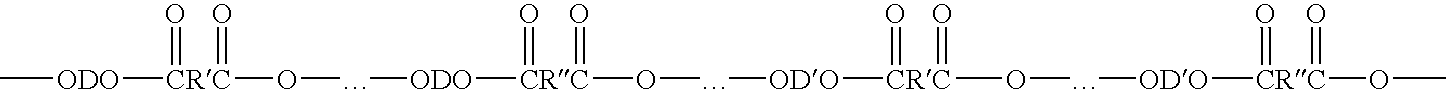

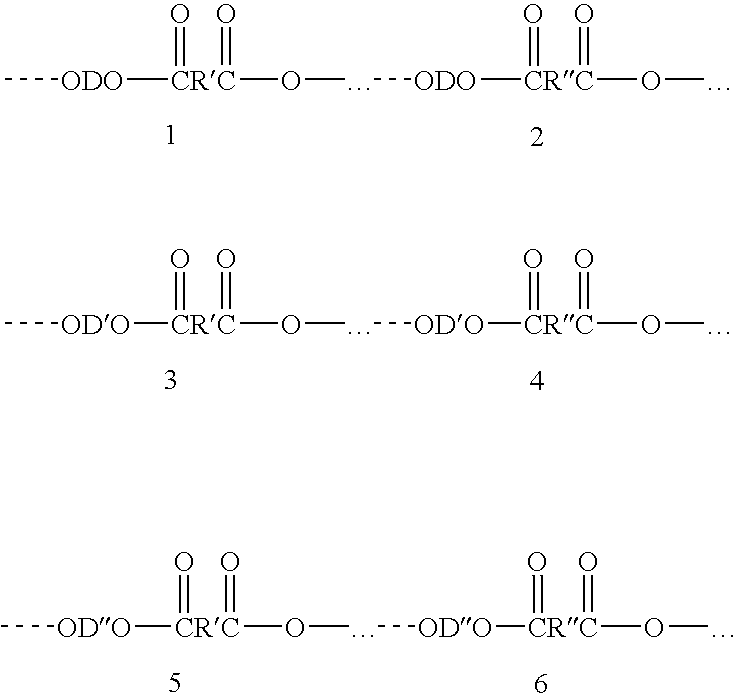

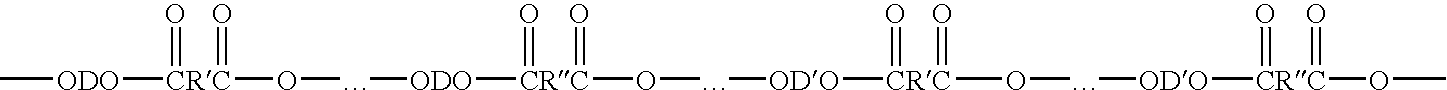

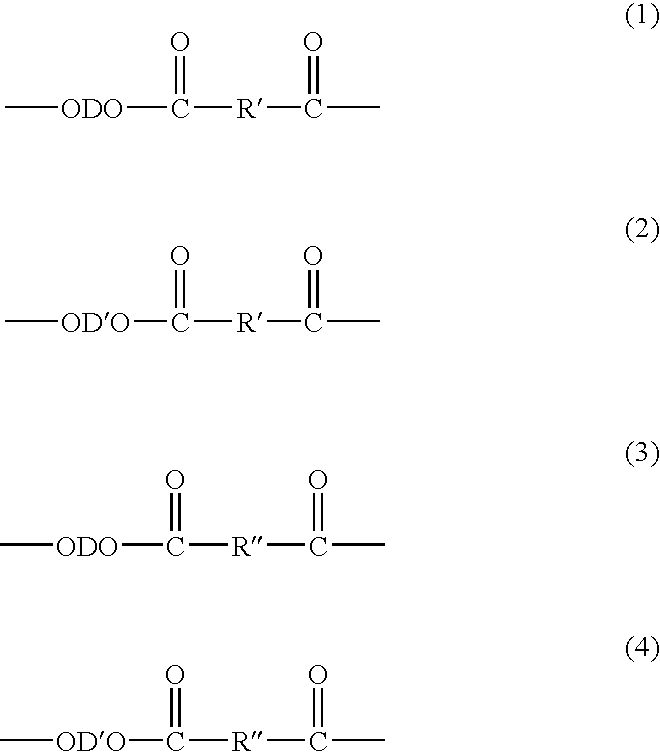

Sulfonated aliphatic-aromatic copolyesters and shaped articles produced therefrom

ActiveUS7220815B2High crystallinityHigh heat distortion temperatureLayered productsCeramic shaping apparatus1,4-ButanediolPolymer science

Sulfonated aliphatic-aromatic copolyesters and articles made therefrom, and processes for producing the sulfonated aliphatic-aromatic copolyesters and articles are provided. Articles that can be made from the sulfonated aliphatic-aromatic copolyesters include films, coatings and laminates. Some of the compositions and articles are biocompostable. The films can further be used to form shaped articles such as sheets, food packaging such as sandwich wraps, thermoformed containers, and coatings for, for example, films and other substrates. The sulfonated aliphatic-aromatic copolyesters are derived from copolyesters produced from aliphatic-aromatic copolyesters formed from an aromatic dicarboxylic acid component, an aliphatic dicarboxylic acid component, a first glycol component consisting of 1,4-butanediol, a second glycol component, and optionally, a polyfunctional branching agent.

Owner:DUPONT POLYMERS INC

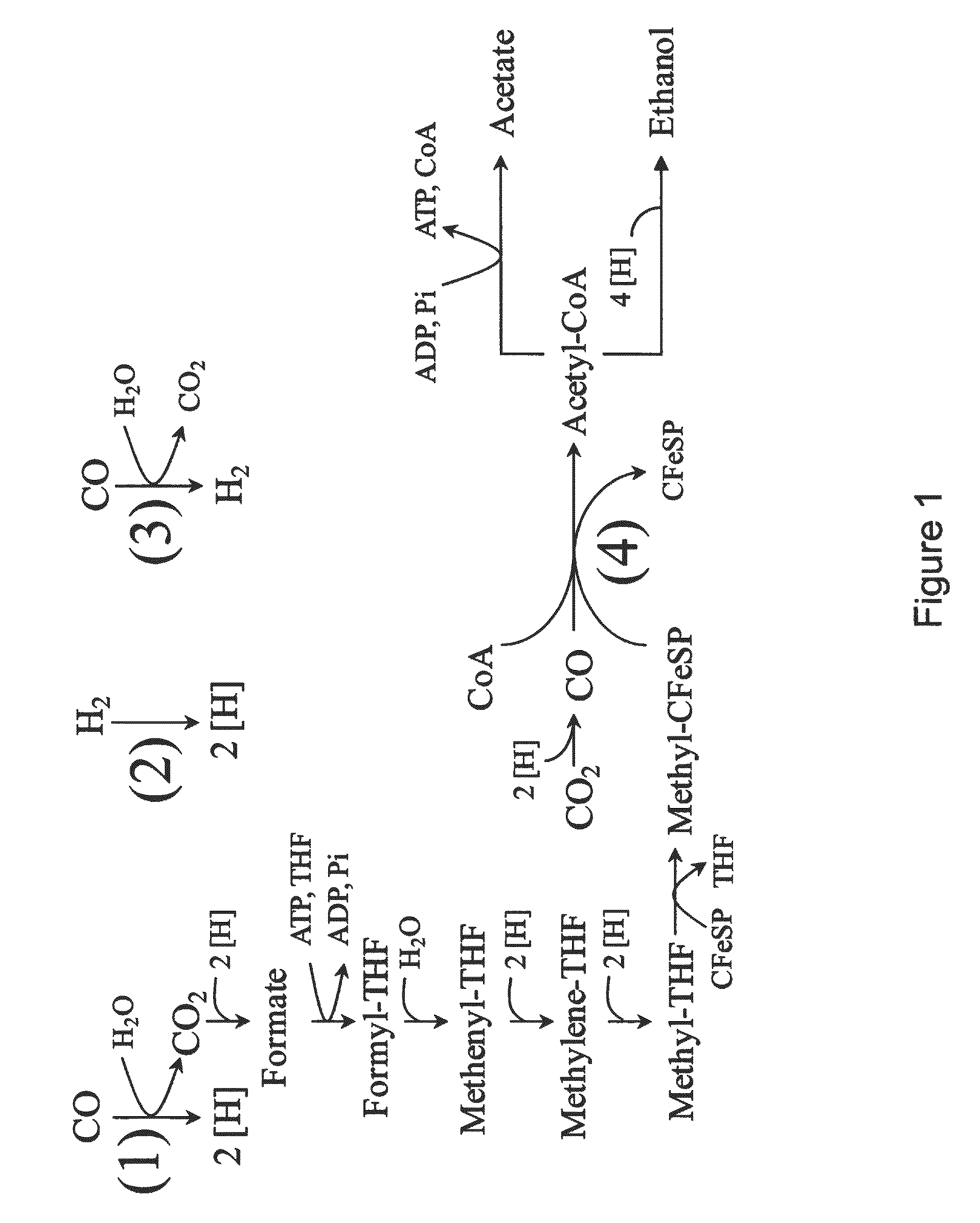

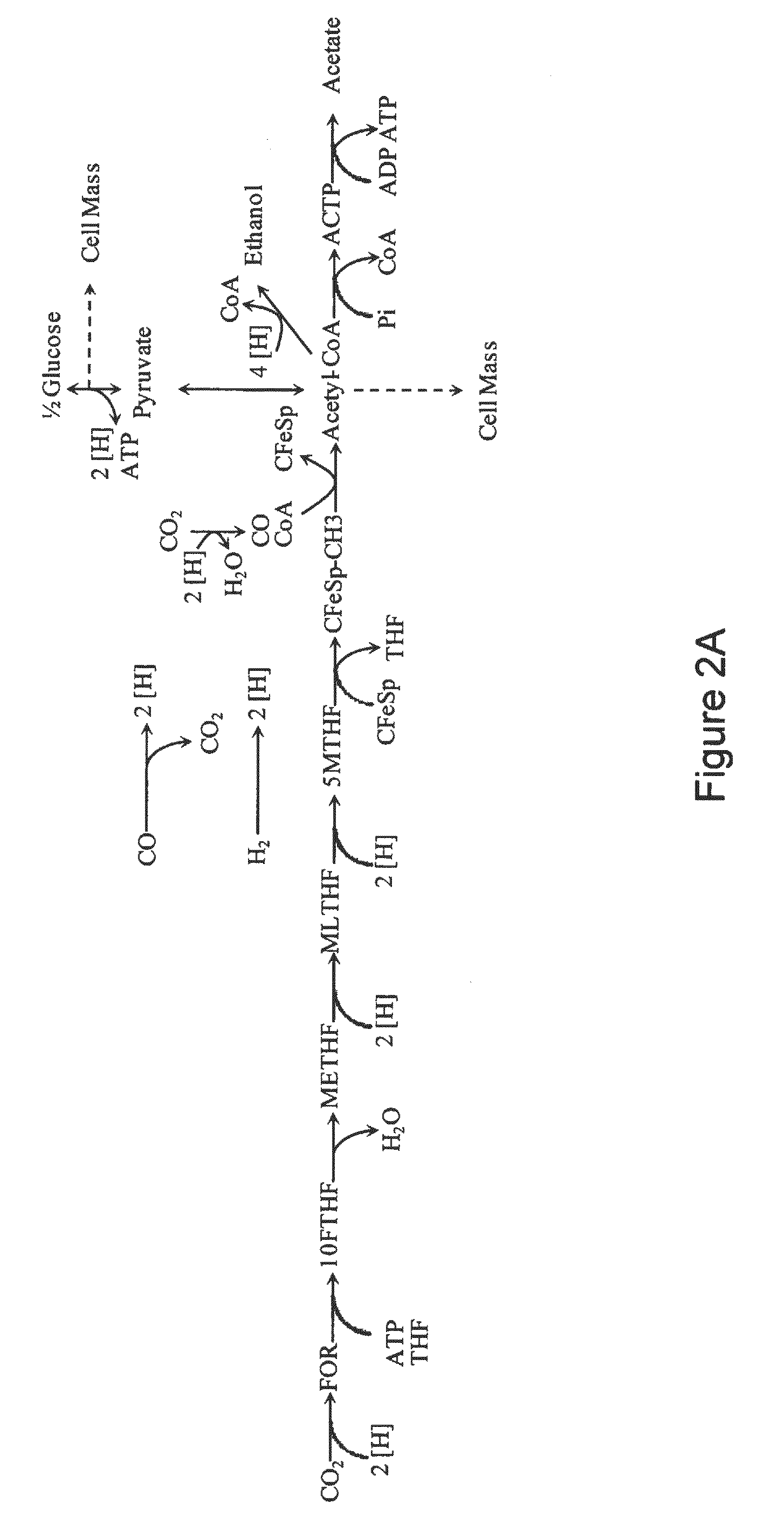

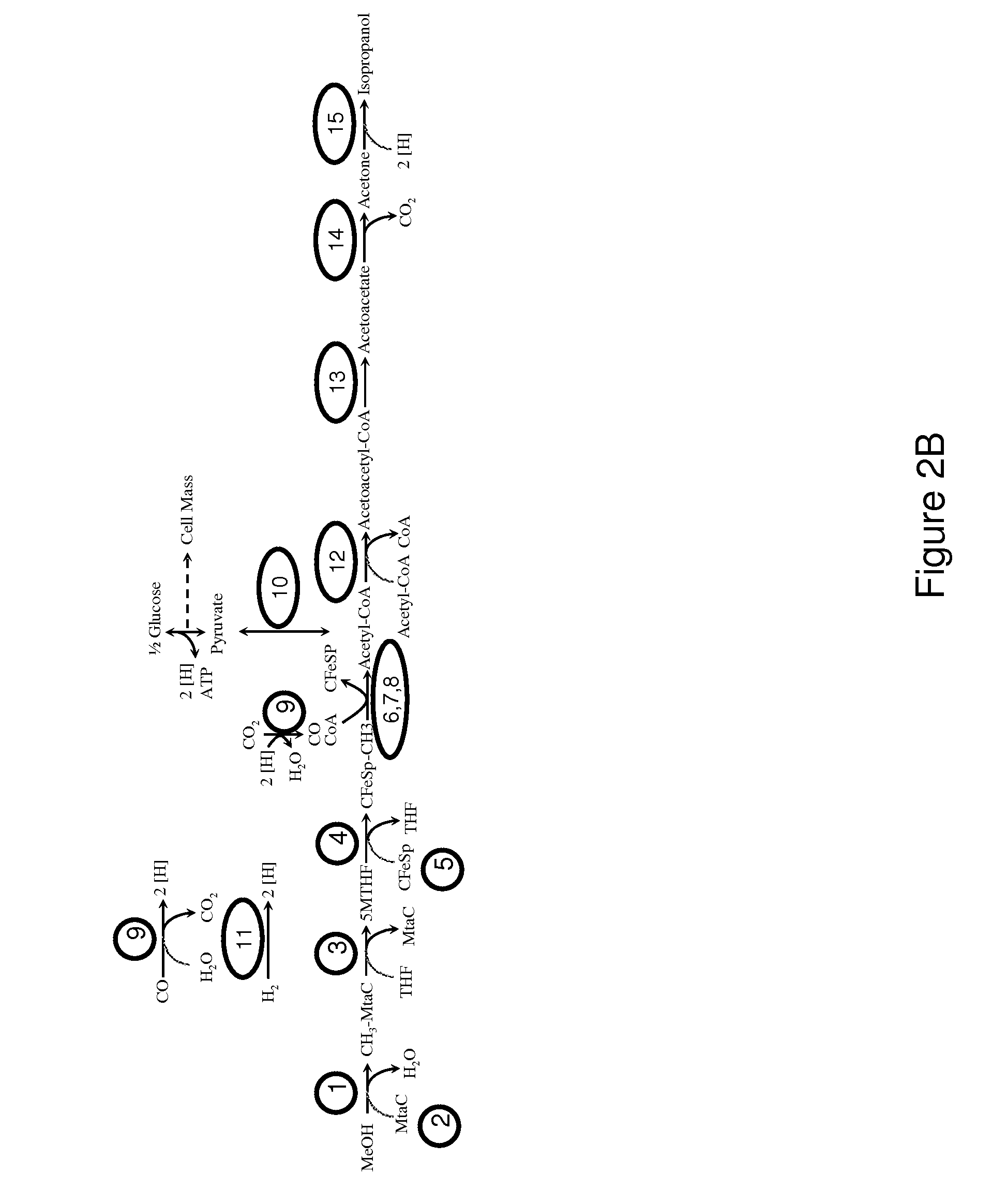

Microorganisms and methods for conversion of syngas and other carbon sources to useful products

A non-naturally occurring microbial organism having an isopropanol, 4-hydroxybutryate, or 1,4-butanediol pathway includes at least one exogenous nucleic acid encoding an isopropanol, 4-hydroxybutryate, or 1,4-butanediol pathway enzyme expressed in a sufficient amount to produce isopropanol, 4-hydroxybutryate, or 1,4-butanediol. The aforementioned organisms are cultured to produce isopropanol, 4-hydroxybutryate, or 1,4-butanediol.

Owner:GENOMATICA INC

Conversion of contaminated polyethylene terephthalate to decontaminated polybutylene terephthalate

InactiveUS6518322B1Fast reaction timeCost is removed entirelyPolytetramethylene terephthalate1,4-Butanediol

Decontaminated crushed polyethylene terephthalate is converted to decontaminated PBT withtout requiring a catalyst by mixing with 1,4-butanediol under reduced pressure, transeterifying at 120-190° C., distilling off ethanediol and tetrahydrofuran under sub-atomspheric pressure. The method lowers costs, and decreases wasteful by-products and removes contaminants present in post-consumer PET, (e.g. paper, pigments, plastics, dyes, mineral sands, and clays) and chemical and water insoluble contaminants.

Owner:ALPHAPET LTD +1

Method of Making Polybutylene Terephthalate and Compositions and Articles Comprising the Same

A process for making modified polybutylene terephthalate random copolymers from a polyethylene terephthalate component includes reacting an oligomeric diol component selected from the group consisting of bis(hydroxybutyl)terephthalate, bis(hydroxybutyl)isophthalate, hydroxybutyl-hydroxyethyl terephthalate, and combinations thereof to a reactor; (i) a polyethylene terephthalate component selected from the group consisting of polyethylene terephthalate and polyethylene terephthalate copolymers with (ii) a diol component selected from the group consisting of 1,4-butanediol, ethylene glycol, propylene glycol, and combinations thereof, in the reactor under conditions sufficient to depolymerize the polyethylene terephthalate component into a first molten mixture; combining the first molten mixture is combined with 1,4-butanediol under conditions to form a second molten mixture; and placing the second molten mixture under conditions sufficient to produce the modified polybutylene terephthalate random copolymers. Also described are compositions and articles made from the process.

Owner:SHPP GLOBAL TECH BV

Process for making polybutylene terephthalate (PBT) from polyethylene terephthalate (PET)

The invention relates to a process for making modified polybutylene terephththalate random copolymers from a polyethylene terephthalate component. The invention relates to a three step process in which a diol component selected from the group consisting of ethylene glycol, propylene glycol, and combinations thereof reacts with a polyethylene terephthalate component under conditions sufficient to depolymerize the polyethylene terephthalate component into a first molten mixture; and where the first molten mixture is combined with 1,4-butanediol under conditions that create a second molten mixture that is subsequently placed under subatmospheric conditions that produce the modified polybutylene terephthalate random copolymers. The invention also relates to compositions made from the process.

Owner:SHPP GLOBAL TECH BV

Preparation method of thermoplastic polyurethane elastomer

InactiveCN103059554AImprove mechanical propertiesImprove heat resistancePolyethylene glycolHydrolysis

Owner:DONGGUAN JIXIN POLYMER SCI & TECH

Methods and Compositions for Treating Arg

InactiveUS20080293698A1BiocideHydroxy compound active ingredientsHydroxybutyric acidAcquired resistance

The invention provides dilute and concentrated, aqueous, pharmaceutical compositions comprising gamma-hydroxybutyric acid or pharmaceutically acceptable salts thereof; gamma-butyryl lactone; 1,4-butanediol; 4-hydroxyl pentanoic acid or pharmaceutically acceptable salts thereof; 4-hydroxyl pentanoic acid lactone, or combinations thereof, and a coloring agent and / or flavoring agent that is useful in preventing sexual assault or date rape. Methods of treating conditions responsive to the administration of gamma-hydroxyl butyric acid and / or its pharmaceutically acceptable salts; gamma-butyryl lactone; 1,4-butanediol; 4-hydroxyl pentanoic acid and / or its pharmaceutically acceptable salts; and 4-hydroxyl pentanoic acid lactone are also described. The invention provides methods for treating patients with acquired resistance to GABAnergic agents.

Owner:JOHNSON JOSEPH

Water-soluble, liquid-containing pouch

InactiveUS7563757B2Aqueous liquid non-soap compositionsDetergent compounding agentsPolyvinyl alcohol1,3-Propanediol

The present invention relates to water-soluble pouch which contains a liquid detergent composition, wherein the pouch is a water-soluble film, the film material comprising a polyvinyl alcohol, and wherein the liquid detergent composition also comprises a plasticizer, wherein the plasticizer is selected from the group consisting of glycerol, ethylene glycol, diethylene glycol, triethylene glycol, 2-methyl-1,3-propane diol, sorbitol, methanol, diglycerol, 1,4-butane diol, urea and mixtures thereof, and wherein the liquid detergent composition further comprises a viscosity modifier, preferably a hydrogenated castor oil.

Owner:PROCTER & GAMBLE CO

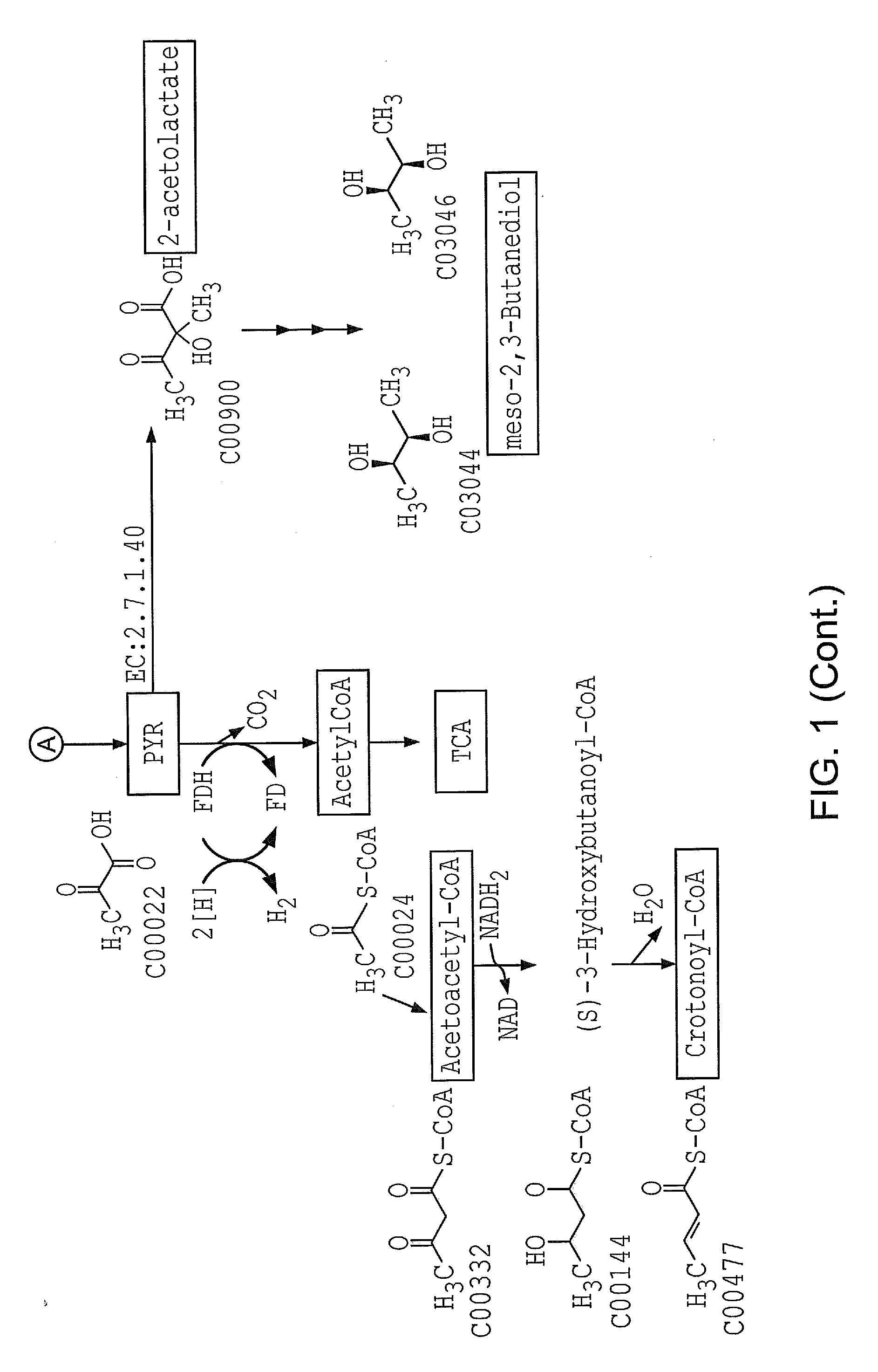

Methods, compositions and systems for biosynthetic bio-production of 1,4-butanediol

InactiveUS20110190513A1Improve toleranceYield andBioreactor/fermenter combinationsBiological substance pretreatments1,4-ButanediolMicroorganism

Three biosynthetic pathways are disclosed for microorganism bio-production of 1,4-Butanediol from various carbon sources. Exemplary methods are provided. The recombinant microorganisms comprising any of these 1,4-Butanediol biosynthesis pathways may also comprise genetic modifications directed to improved tolerance for 1,4-Butanediol.

Owner:OPX BIOTECH

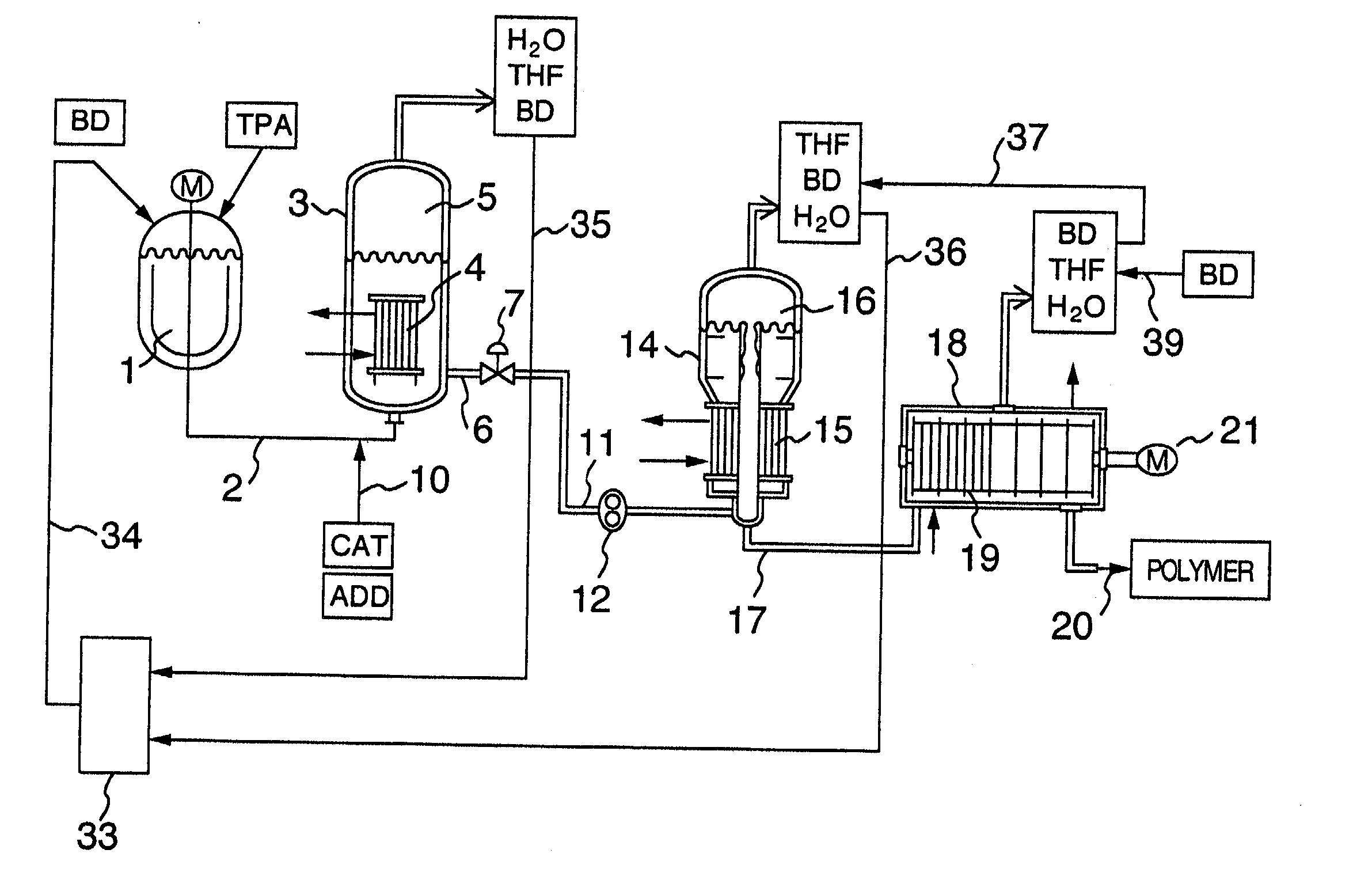

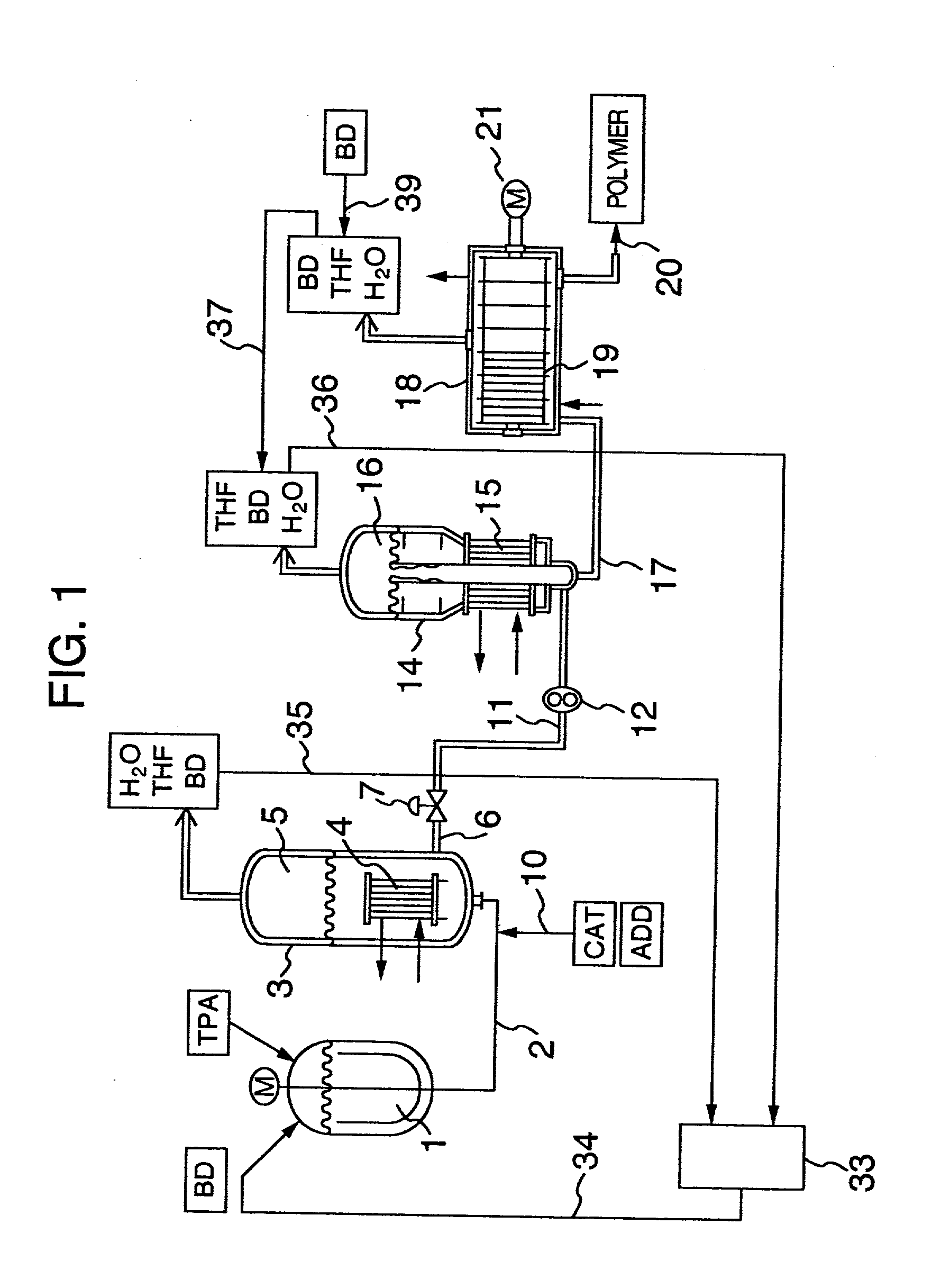

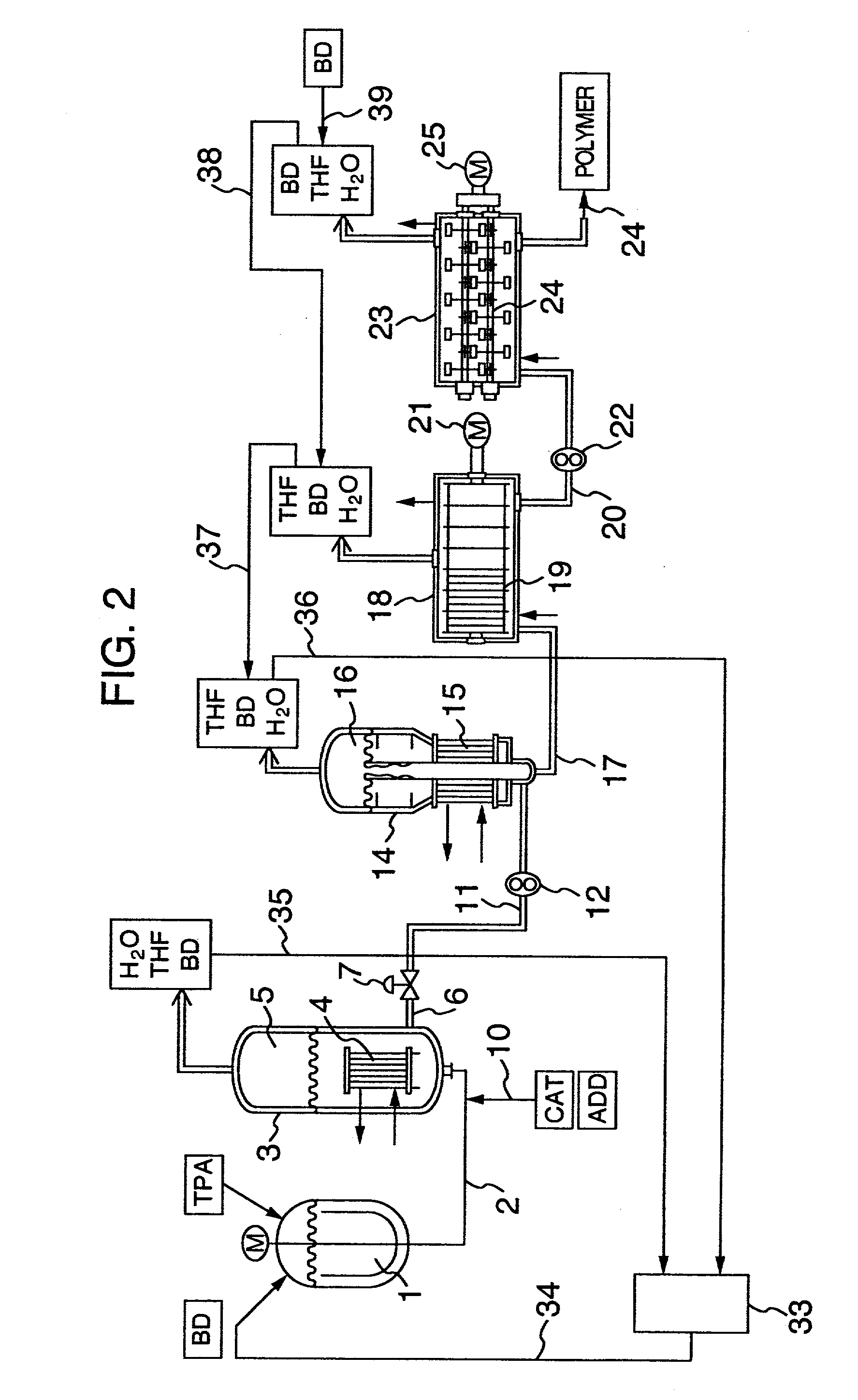

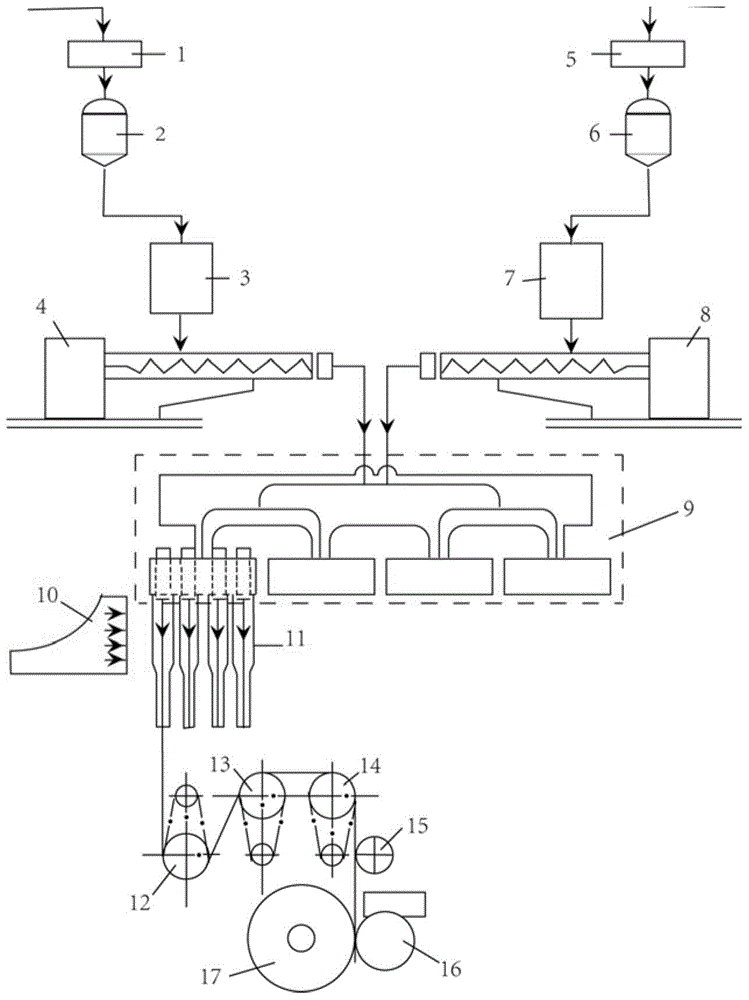

Process for continuously producing polybutylene terephthalate

InactiveUS20020128399A1Improve effectivelyGood molding effectChemical/physical/physico-chemical stationary reactorsLiquid-gas reaction processesPolytetramethylene terephthalatePolybutylene

Polybutylene terephthalate having good heat stability and excellent hydrolysis resistance is continuously produced in a series of a first reactor for reacting an aromatic dicarboxylic acid comprising terephthalic acid as a main ingredient or a derivative thereof with a glycol comprising 1,4-butanediol as a main ingredient, thereby producing an oligomer with an average degree of polymerization of 2.2 to 5, a second reactor for polycondensating the oligomer from the first reactor, thereby preparing a low polymerization product with an average degree of polymerization of 25 to 40, and a third reactor for further polycondensating the low polymerization product from the second reactor, thereby producing a high molecular weight polyester with an average degree of polymerization of 70 to 130, or followed by a fourth reactor for further polycondensing the polyester from the third reactor to an average degree of polymerization of 150 to 200, thereby producing a high molecular weight polyester. Another third reactor or a plurality of third reactors can be provided in parallel to the third reactor, thereby producing different kinds of polybutylene phthalate with different degrees of polymerization from that produced in the main line of the third and fourth reactors or adjusting operating conditions of each of a plurality of the third reactors to increase kinds, precise quality.

Owner:HITACHI LTD

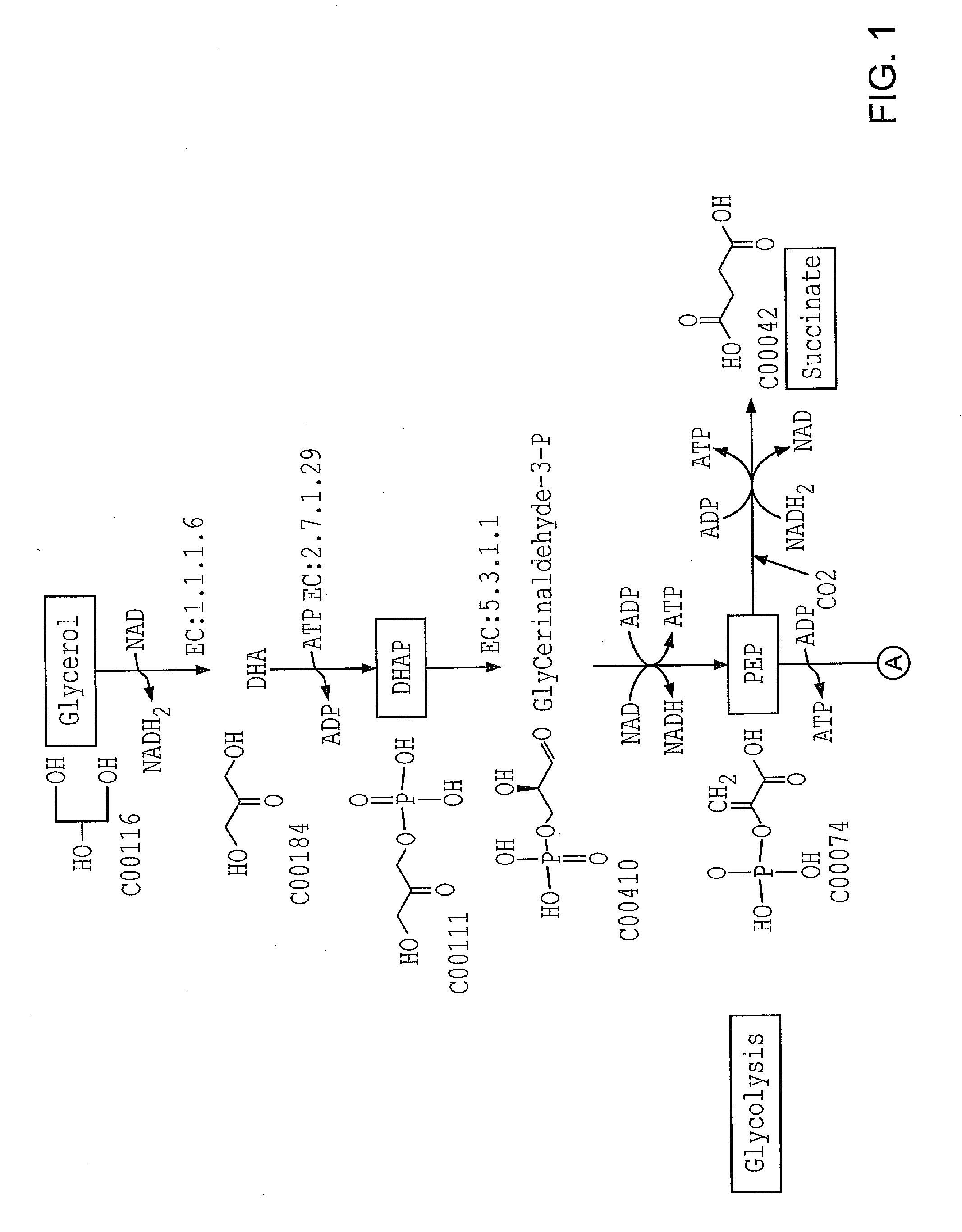

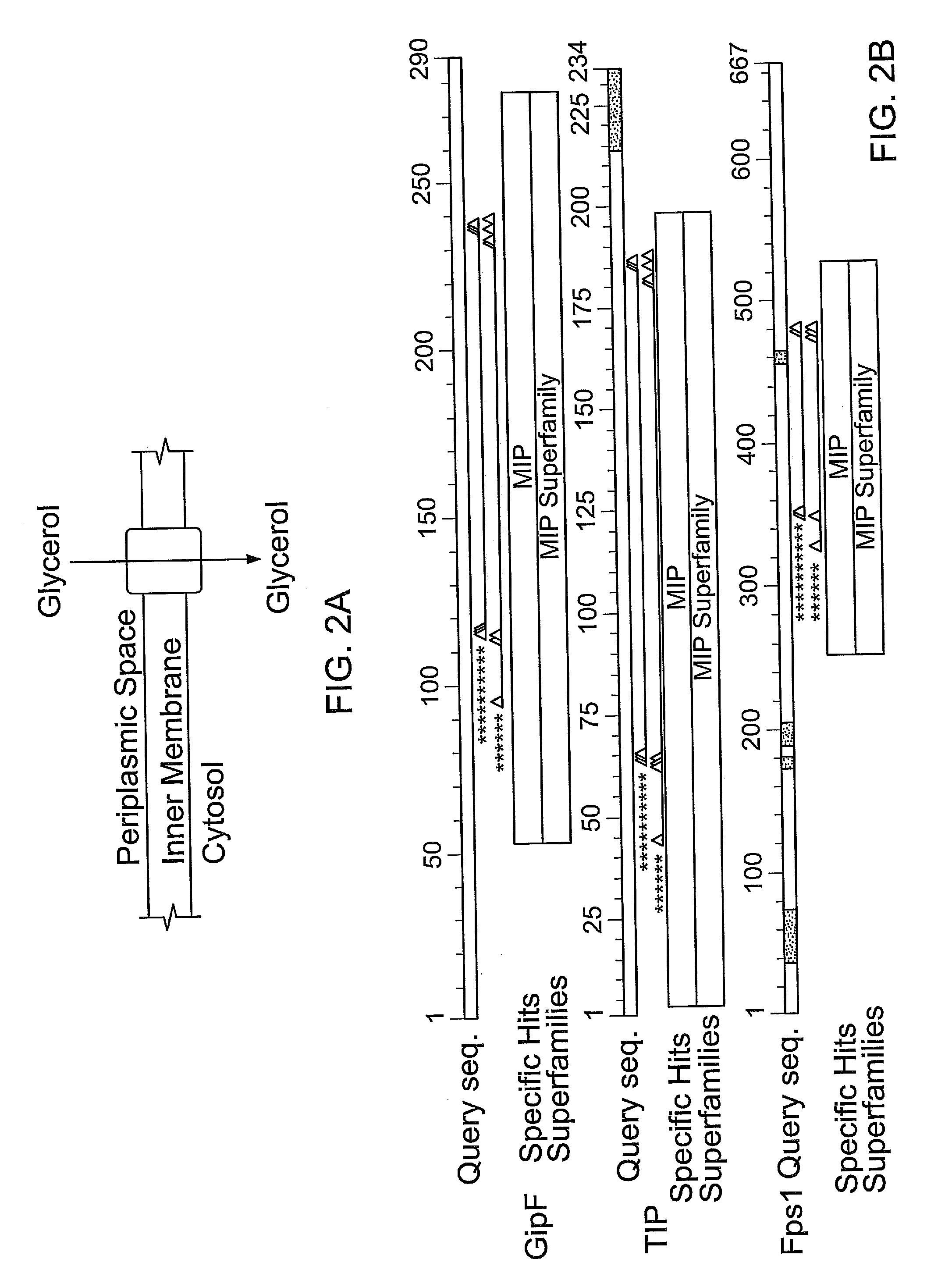

Methods of making nylon intermediates from glycerol

ActiveUS20130210090A1Reduce usageRate minimisedBacteriaHydrolases3-Hydroxypropionic acid2,3-Butanediol

Embodiments of the invention relate to the enzymatic conversion of bioderived feedstocks to commercially valuable chemicals. The enzymatic conversions of the embodiments of the invention offer the potential for lower cost routes to these value-added chemicals. Some of the chemicals that are useful include nylon intermediates such as caprolactam, adipic acid, 1,6-hexamethylene diamine; butanediols such as 1,4-butanediol, 1,3-butanediol, and 2,3-butanediol; butanols such as 1-butanol, and 2-butanol; succinic acid, butadiene, isoprene, and 3-hydroxypropanoic acid.

Owner:INV NYLON CHEM AMERICAS LLC

Water-soluble, liquid-containing pouch

InactiveUS20060276364A1Aqueous liquid non-soap compositionsDetergent compounding agentsPolyvinyl alcohol1,3-Propanediol

The present invention relates to water-soluble pouch which contains a liquid detergent composition, wherein the pouch is a water-soluble film, the film material comprising a polyvinyl alcohol, and wherein the liquid detergent composition also comprises a plasticizer, wherein the plasticizer is selected from the group consisting of glycerol, ethylene glycol, diethylene glycol, triethylene glycol, 2-methyl-1,3-propane diol, sorbitol, methanol, diglycerol, 1,4-butane diol, urea and mixtures thereof, and wherein the liquid detergent composition further comprises a viscosity modifier, preferably a hydrogenated castor oil.

Owner:THE PROCTER & GAMBLE COMPANY

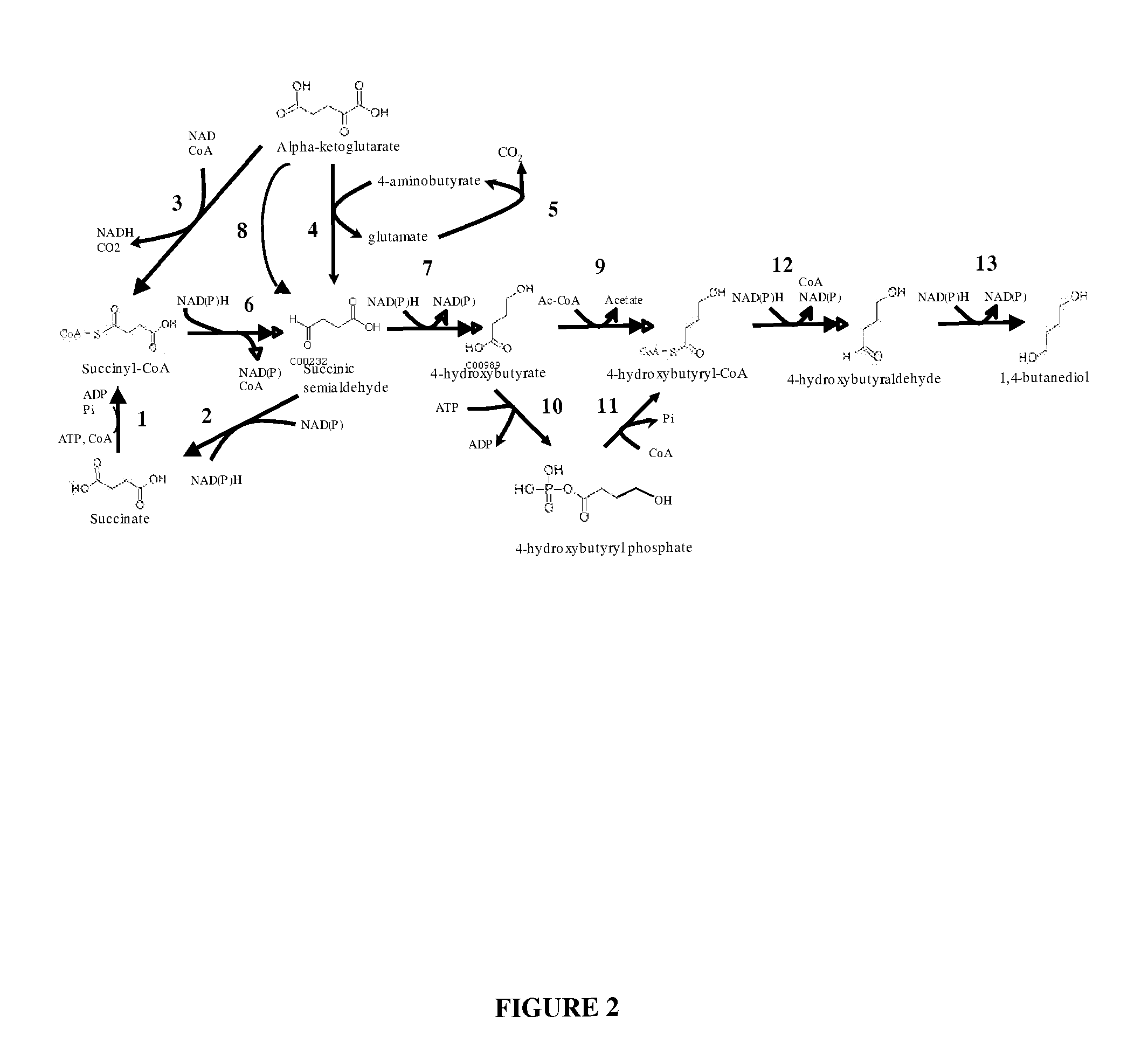

Microorganisms for the production of 1,4-butanediol, 4-hydroxybutanal, 4-hydroxybutyryl-coa, putrescine and related compounds, and methods related thereto

The invention provides non-naturally occurring microbial organisms comprising a 1,4-butanediol (BDO), 4-hydroxybutyryl-CoA, 4-hydroxybutanal or putrescine pathway comprising at least one exogenous nucleic acid encoding a BDO, 4-hydroxybutyryl-CoA, 4-hydroxybutanal or putrescine pathway enzyme expressed in a sufficient amount to produce BDO, 4-hydroxybutyryl-CoA, 4-hydroxybutanal or putrescine and further optimized for expression of BDO. The invention additionally provides methods of using such microbial organisms to produce BDO, 4-hydroxybutyryl-CoA, 4-hydroxybutanal or putrescine.

Owner:GENOMATICA INC

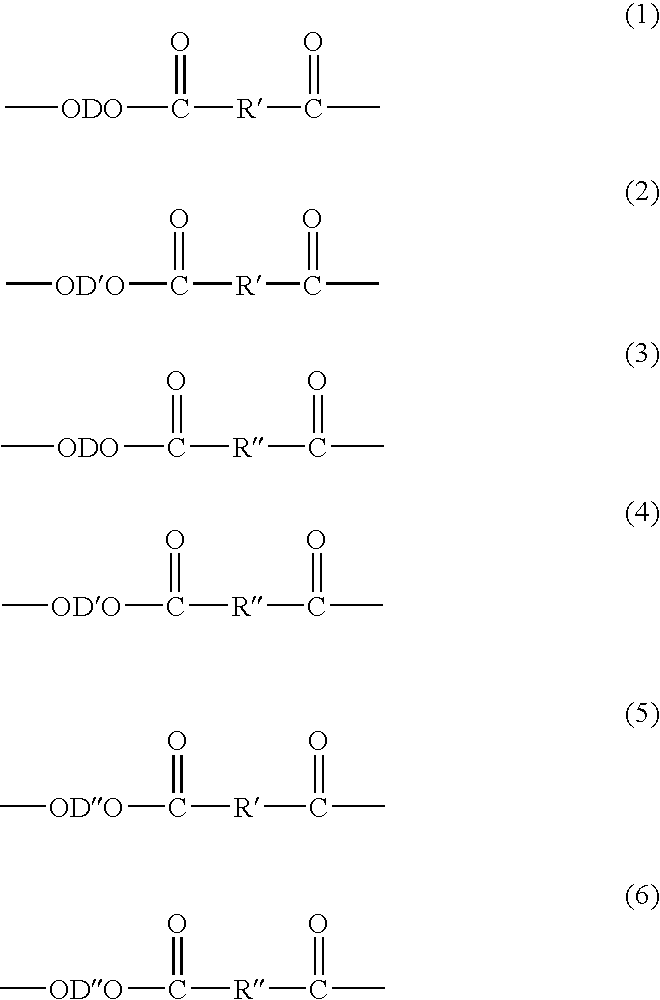

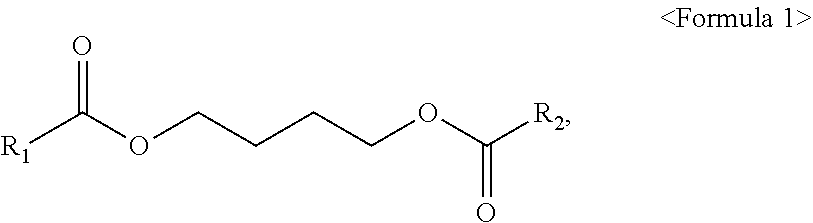

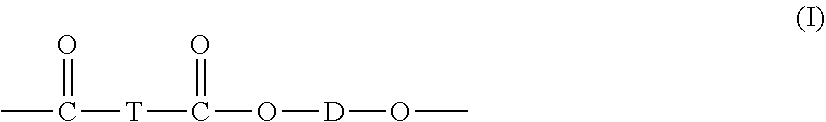

Plasticizer and polyvinyl chloride resin composition containing same

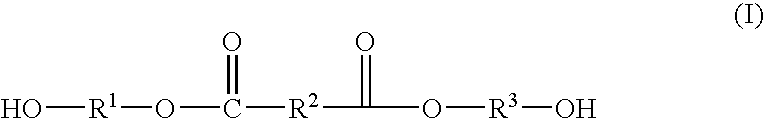

InactiveUS20110196081A1High plasticizing efficiencyHigh tensile strengthOrganic chemistryOther chemical processes1,4-ButanediolOrganic acid

The present invention provides an ester plasticizer, particularly, a plasticizer for a polyvinyl chloride (PVC) resin, and a plastic comprising the plasticizer. More concretely, the present invention provides a plasticizer prepared by the esterification reaction of 1,4-butanediol and organic acid.When a polyvinyl chloride resin composition is manufactured using the ester plasticizer of the present invention, there are advantages in that a product having excellent plasticizing efficiency can be obtained, and in that the physical properties such as tensile strength and the like of the product are improved.

Owner:SK INNOVATION CO LTD +1

Process for the manufacture of polybutylene terephthalate copolymers from polyethylene terephthalate, and compositions and articles thereof

ActiveUS20100168336A1Improved flow and mechanical propertyEfficient recyclingPlastic recyclingPolymer recoveryPolytetramethylene terephthalatePolymer science

A process comprises depolymerizing, with 1,4-butane diol, a first polymer comprising a polyethylene terephthalate component in the presence of at least one second polymer selected from the group consisting of polyvinyl chlorides, polyvinylidene chlorides, polyamides, polylactic acid, and combinations thereof to produce a molten mixture; and polymerizing the molten mixture under conditions sufficient to form a modified polybutylene terephthalate copolymer. The modified PBT comprises (a) at least one polyethylene terephthalate component residue, and (b) a member selected from the group consisting of (i) the at least one second polymer selected from the group consisting of polyvinyl chlorides, polyvinylidene chlorides, polyamides, polylactic acid, and combinations thereof; (ii) the at least one residue derived from the second polymer; and (iii) combinations thereof.

Owner:SHPP GLOBAL TECH BV

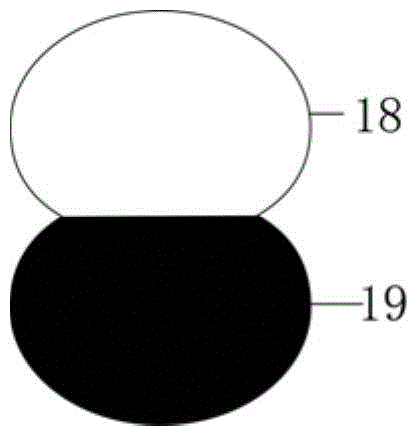

Polyester elastomer/PET composite elastic fiber and preparation method thereof

ActiveCN104831417AIncrease elasticityImprove performanceMelt spinning methodsConjugated synthetic polymer artificial filaments1,4-ButanediolElastomer

The invention discloses a polyester elastomer / PET composite elastic fiber and a preparation method thereof. The preparation method comprises the steps of firstly carrying out reduced-pressure direct esterification on terephthalic acid, 1,4-butanediol and double-ended hydroxyl polyether in a certain proportion in the presence of catalysts, carrying out melt polycondensation to obtain a polyester elastomer, and carrying out a spin-draw-winding one-step process on the prepared polyester elastomer and PET, so as to obtain the polyester elastomer / PET composite elastic fiber, wherein the breaking strength of the polyester elastomer / PET composite elastic fiber is 2.8cN / dtex-3.56cN / dtex, the elongation at break is 16.9%-30.4%, the curling degree is 60%-75%, the curling elasticity rate is 97%-99%, the capillary water absorption height is 9.7cm / 30min-14.1cm / 30min. Compared with normal composite elastic fibers, the polyester elastomer / PET composite elastic fiber has relatively excellent elasticity and relatively soft hand feeling, and the fabric capillary suction effect of the polyester elastomer / PET composite elastic fiber is even higher than those of cotton fabrics; the preparation method is short in production process, high in spinning speed and low in cost, and the prepared composite elastic fiber can be directly used in subsequent weaving without being processed into interlaced yarns.

Owner:SICHUAN UNIV +1

Microorganisms for the production of 1,4-butanediol, 4-hydroxybutanal, 4-hydroxybutyryl-coa, putrescine and related compounds, and methods related thereto

The invention provides non-naturally occurring microbial organisms comprising a 1,4-butanediol (BDO), 4-hydroxybutyryl-CoA, 4-hydroxybutanal or putrescine pathway comprising at least one exogenous nucleic acid encoding a BDO, 4-hydroxybutyryl-CoA, 4-hydroxybutanal or putrescine pathway enzyme expressed in a sufficient amount to produce BDO, 4-hydroxybutyryl-CoA, 4-hydroxybutanal or putrescine and further optimized for expression of BDO. The invention additionally provides methods of using such microbial organisms to produce BDO, 4-hydroxybutyryl-CoA, 4-hydroxybutanal or putrescine.

Owner:GENOMATICA INC

Flame resistant polyester compositions, method of manufacture, and articles thereof

A thermoplastic polyester composition comprising, based on the total weight of the composition, a chlorine- and bromine-free combination of: from 40 to 60 wt % of a modified poly(1,4-butylene terephthalate); from 25 to 35 wt % of a reinforcing filler; from 2 to 8 wt % of a flame retardant synergist selected from the group consisting of melamine polyphosphate, melamine cyanurate, melamine pyrophosphate, melamine phosphate, and combinations thereof; from 5 to 15 wt % of a phosphinate salt flame retardant; from more than 0 to less than 5 wt % of an impact modifier component comprising a poly(ether-ester) elastomer and a (meth)acrylate impact modifier; from more than 0 to 5 wt % poly(tetrafluoroethylene) encapsulated by a styrene-acrylonitrile copolymer; from more than 0 to 2 wt % of a stabilizer; wherein the thermoplastic polyester composition contains less than 5 wt % of a polyetherimide.

Owner:SHPP GLOBAL TECH BV

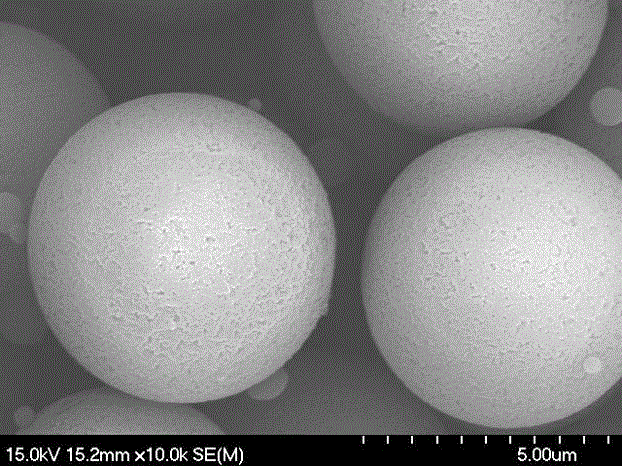

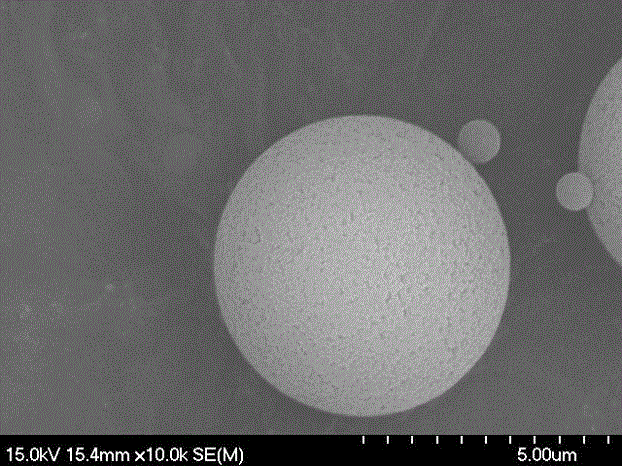

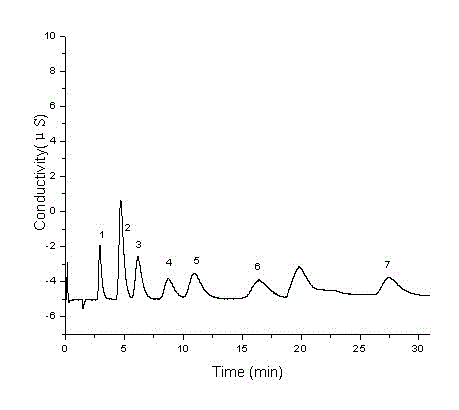

Preparation method of surface-grafting anion chromatography stationary phase

InactiveCN102941074ALow costNarrow particle size distributionOther chemical processesGlycidyl methacrylateMicrosphere

The invention relates to an anion chromatographic column a preparation method thereof, particularly relates to a preparation method of a surface-grafting anion chromatography stationary phase. The method disclosed herein is characterized by: preparing monodispersed linear polystyrene microspheres seeds by dispersion polymerization, activating the seeds, then synthesizing polystyrene-divinyl benzene-glycidyl methacrylate microballoons by one-step seed swelling method, and extracting to remove the pore forming agent; adopting multi-step grafting synthetic method, taking methylamine and 1,4-butanediol diglycidyl ether as raw materials, and introducing a large amount of positively charged quaternary ammonium groups as the anion exchange functional group to the surface of the prepared polystyrene-divinyl benzene-glycidyl methacrylate microballoons; and packing by homogenate method. According to the invention, the method disclosed herein has the advantages of low cost and simple process, the prepared filling material has uniform granularity and has no need to be screened, and the particle size distribution is narrow.

Owner:ZHEJIANG UNIV

Material capable of realizing ultraviolet-light crosslinking and application thereof to 3D printing material

ActiveCN103992628AHigh heat distortion temperatureLow mechanical strengthUltraviolet lightsSuccinic acid

A provided modified PBS material is characterized by comprising, in parts by weight, 90-99 parts of copolyester, 0.05-5 parts of an initiator, 1-5 parts of a crosslinking agent and 0-0.8 part of an anti-oxidant. The copolyester is a copolyester of succinic acid and / or anhydride thereof, and an unsaturated dicarboxylic acid and / or anhydride thereof, and 1,4-butanediol, and an optional other aliphatic dibasic acid and / or anhydride thereof and / or dihydric alcohol. The material is environment-friendly, has relatively high heat distortion temperature and mechanical strength, and has important industrial application value.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Non-aqueous secondary battery having enhanced discharge capacity retention

InactiveUS6866966B2High discharge capacity retentionLead-acid accumulatorsOrganic electrolyte cells1,4-ButanediolHalogen

A discharge capacity retention of a non-aqueous secondary battery is enhanced by incorporating into its non-aqueous electrolytic solution a small amount of a substituted diphenyldisulfide derivative in which each of the diphenyl groups has a substituent such as alkoxy, alkenyloxy, alkynyloxy, cycloalkyloxy, aryloxy, acyloxy, alkanesulfonyloxy, arylsulfonyloxy, alkoxycarbonyloxy, aryloxycarbonyloxy, halogen, CF3, CCl3, or CBr3. Preferably, a small amount of methyl 2-propylcarbonate, 2-propynyl methanesulfonate, 1,3-propanesultone, divinylsulfone, 1,4-butanediol dimethanesulfonate or cyclohexylbenzene is further incorporated.

Owner:UBE IND LTD

Water-based polyurethane composite emulsion and preparation method thereof

ActiveCN102838713ASpeed up evaporationLower glass transition temperatureGraft polymer adhesivesWater basedPolyester

The invention discloses a water-based polyurethane composite emulsion and a preparation method thereof. The preparation method is characterized by comprising the following steps: by using acetone or butanone and acrylic monomer as solvents, polymerizing diisocyanate (HDI), isophorone diisocyanate (IPDI), mixed polyester polyalcohol, dihydroxymethylpropionic acid, 1,4-butanediol, trimethylolpropane monoene propyl ether, 2-hydroxypropyl acrylate and 2-hydroxyethyl acrylate to obtain carboxylic polyurethane; neutralizing with tertiary amine, and removing the solvents to obtain a self-emulsified double-bond-containing water-based polyurethane anionic emulsion; and by using the emulsion as a seed, adding acrylate monomer and a right amount interpenetrating-network crosslinking agent monomer to carry out pre-emulsification, and carrying out seed emulsion polymerization to obtain the composite emulsion in an interpenetrating network structure. The invention has the advantages of energy saving, environmental protection, high early bonding force, safe and reliable technique and stable product quality.

Owner:广东多正树脂科技有限公司

Microorganisms for the production of 1,4-butanediol

ActiveUS20110159572A1Fermented solutions distillation/rectificationBacteria1,4-ButanediolBiotechnology

The invention provides non-naturally occurring microbial organisms comprising a 1,4-butanediol (BDO) pathway comprising at least one exogenous nucleic acid encoding a BDO pathway enzyme expressed in a sufficient amount to produce BDO. The invention additionally provides methods of using such microbial organisms to produce BDO.

Owner:GENOMATICA INC

Post plasma ashing wafer cleaning formulation

InactiveUS7534752B2Increase productionImprove adhesionDetergent mixture composition preparationSemiconductor/solid-state device manufacturingSulfolaneInorganic compound

A semiconductor wafer cleaning formulation for use in post plasma ashing semiconductor fabrication comprising at least one organic chelating agent and at least one polar solvent, wherein the chelating agent and polar solvent are in sufficient amounts to effectively remove inorganic compound residue from a semiconductor wafer. Preferably, the chelating agent is selected from the group consisting of 2,4-Pentanedione, Malonic acid, Oxalic acid, p-Toluenesulfonic acid, and Trifluoroacetic acid; and the polar solvent is selected from the group consisting of Water, Ethylene glycol, N-Methylpyrrolidone (NMP), Gamma butyrolactone (BLO), Cyclohexylpyrrolidone (CHP), Sulfolane, 1,4-Butanediol, and Butyl carbitol.

Owner:ENTEGRIS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com