Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

600 results about "1,3-Propanediol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

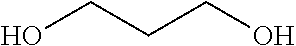

1,3-Propanediol is the organic compound with the formula CH₂(CH₂OH)₂. This three-carbon diol is a colorless viscous liquid that is miscible with water.

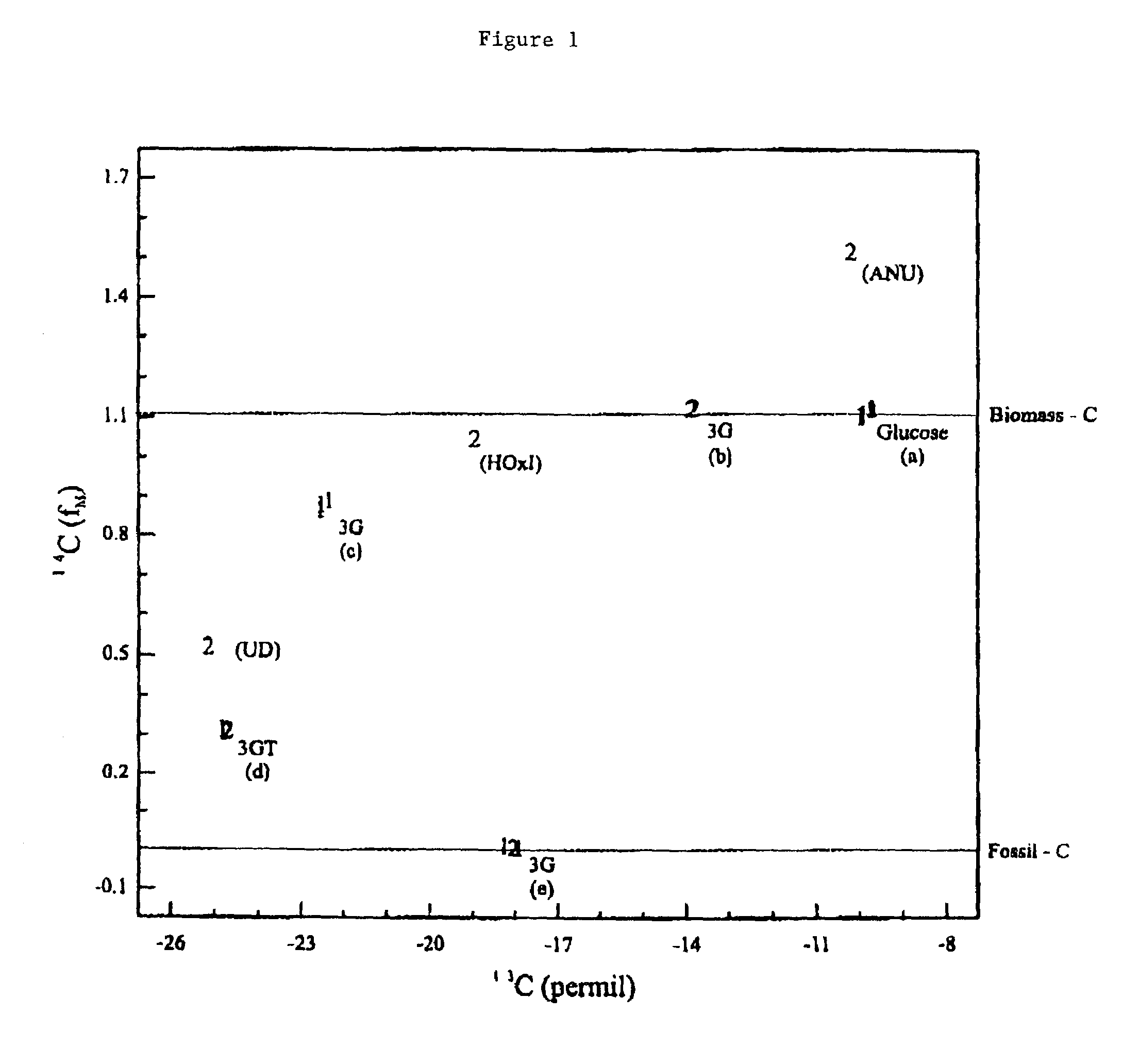

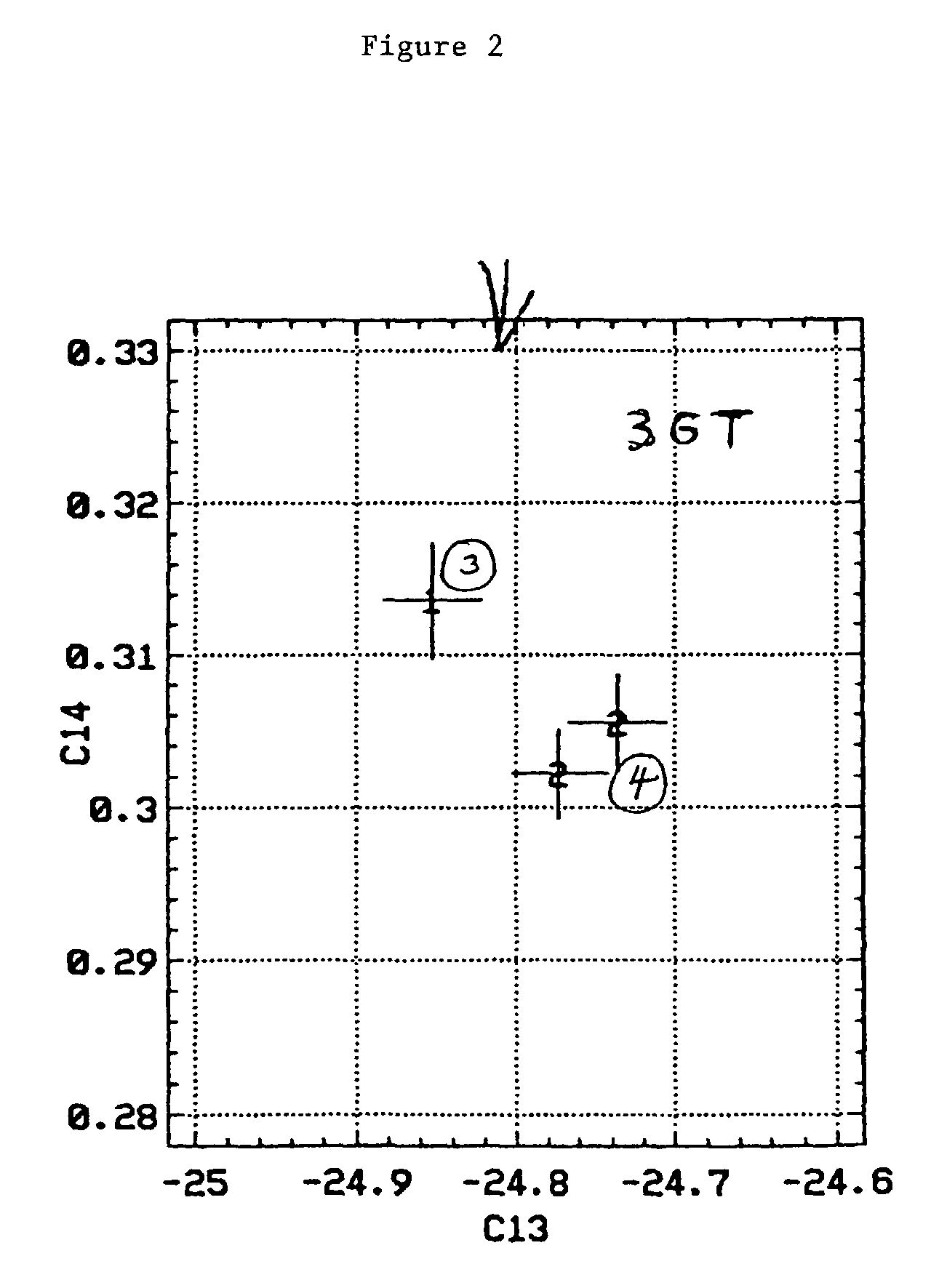

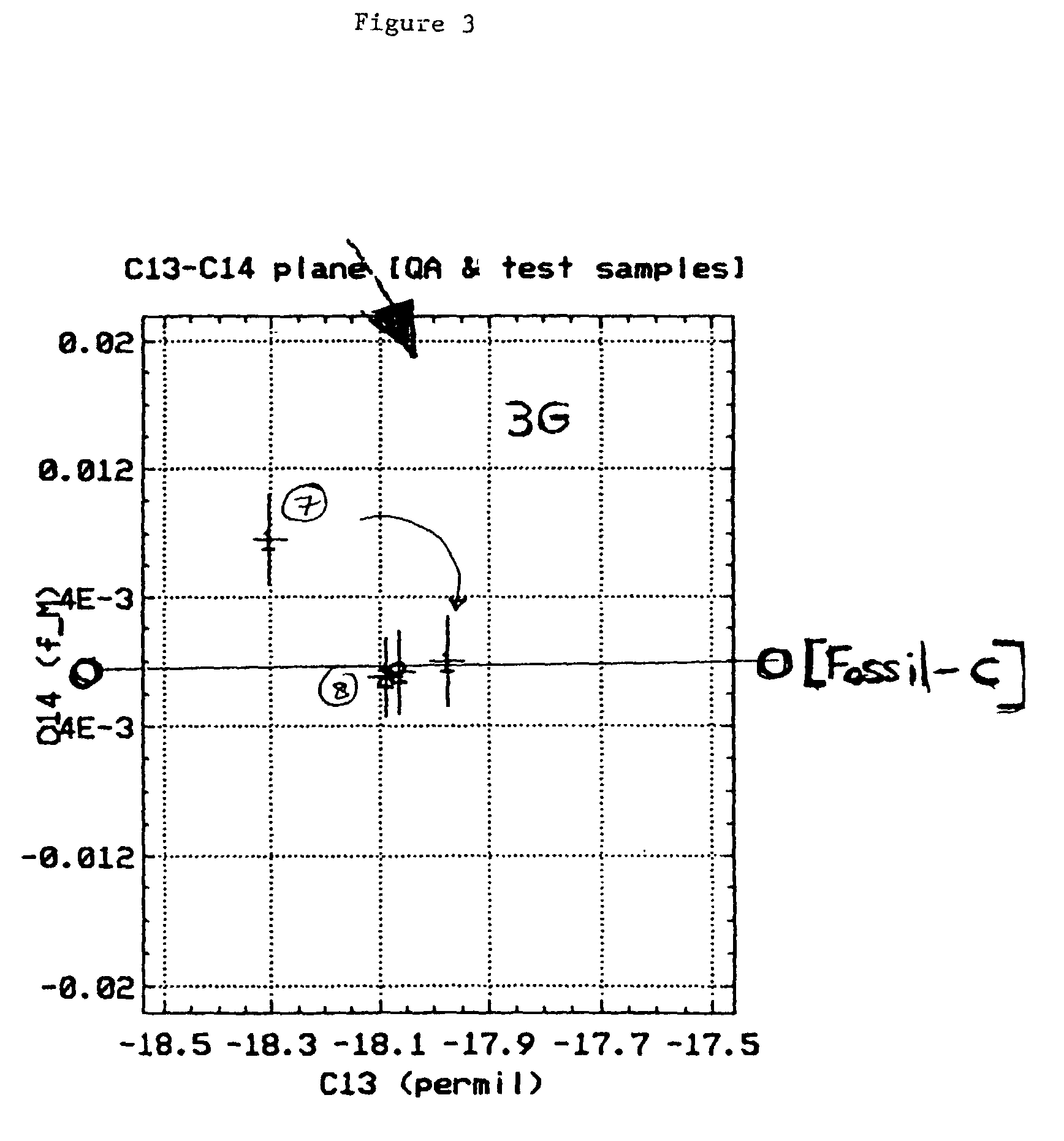

Bioconversion of a fermentable carbon source to 1,3-propanediol by a single microorganism

A new polypropylene terephthalate composition is provided. The polypropylene terephthalate is comprised of 1,3-propanediol and terephthalate. The 1,3-propanediol is produced by the bioconversion of a fermentatble carbon source, preferable glucose. The resulting polypropylene terephthalate is distinguished from petrochemically produced polymer on the basis of dual carbon-isotopic fingerprinting which indicates both the source and the age of the carbon.

Owner:EI DU PONT DE NEMOURS & CO +1

Continuous process for the preparation of polytrimethylene ether glycol

InactiveUS6720459B2Liquid-gas reaction as foam/aerosol/bubblesOrganic compound preparationGas phaseEther

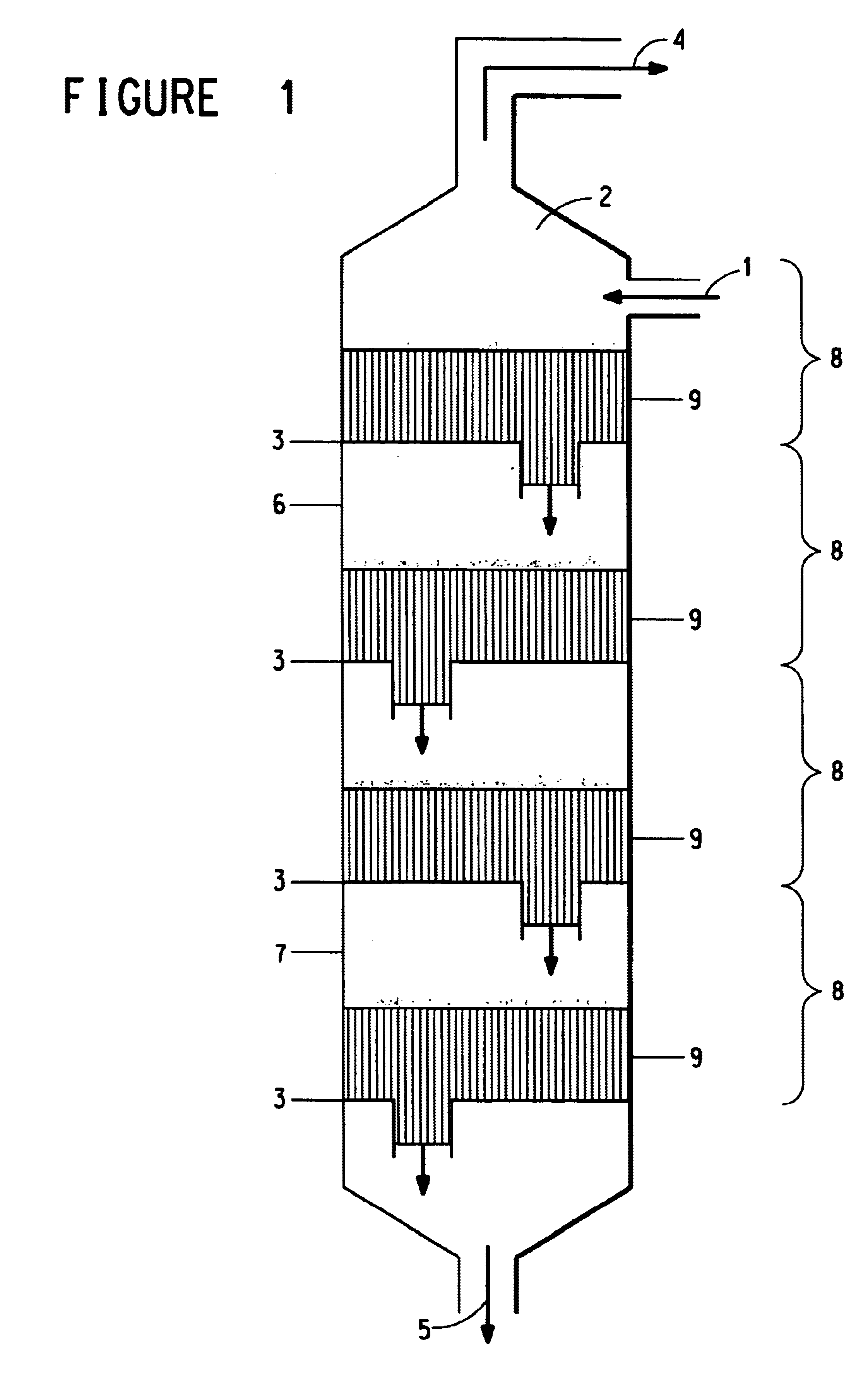

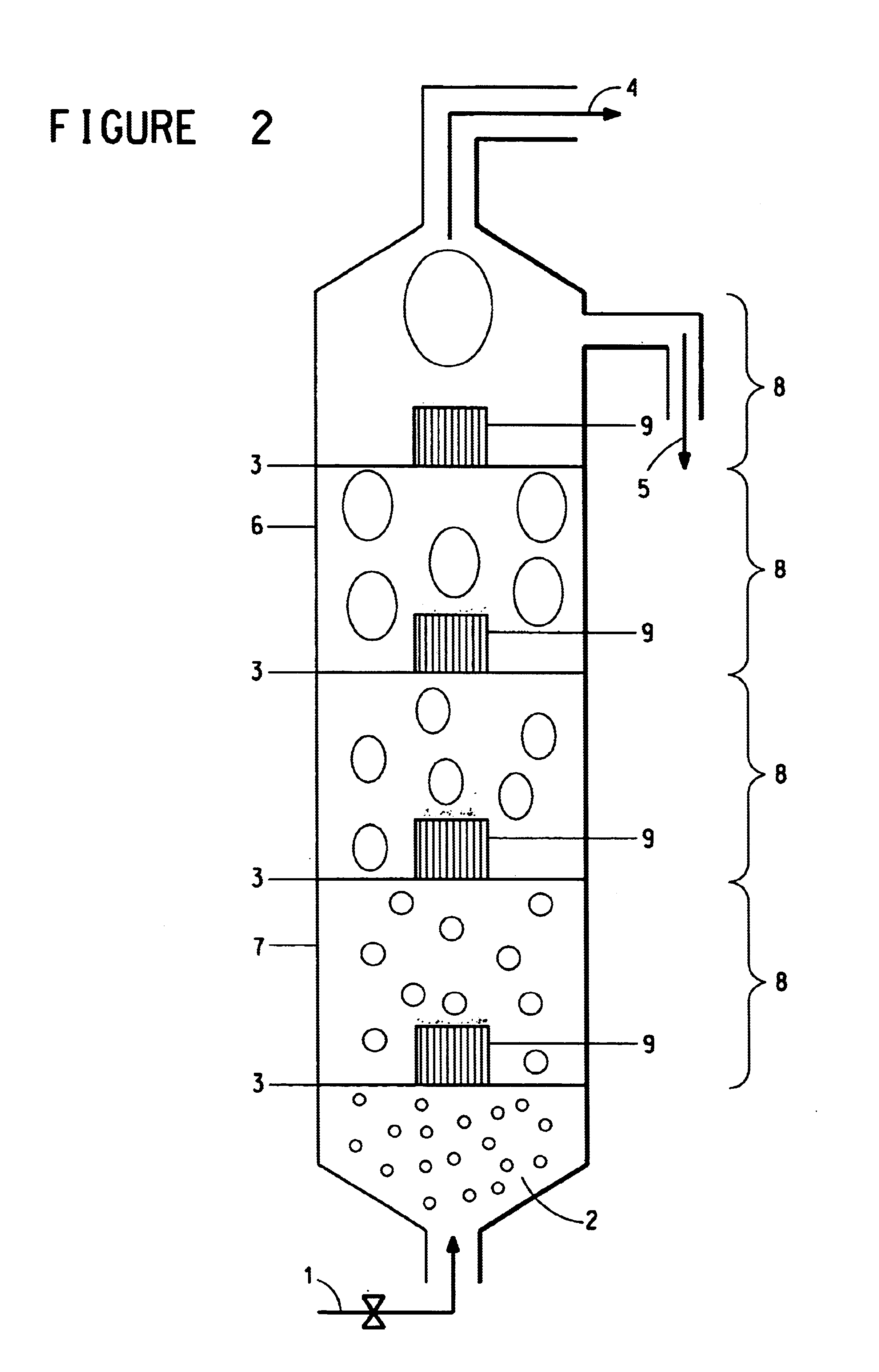

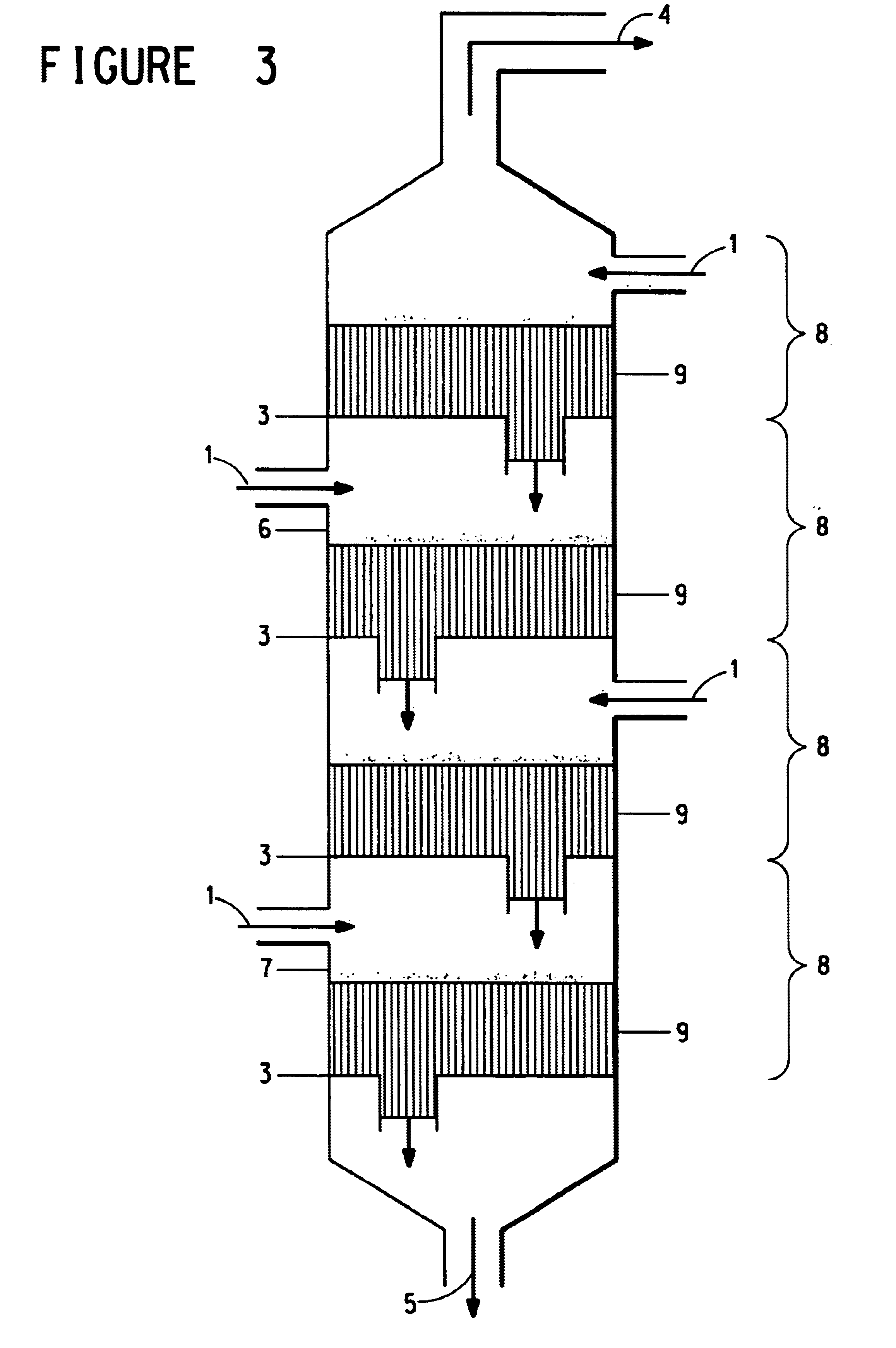

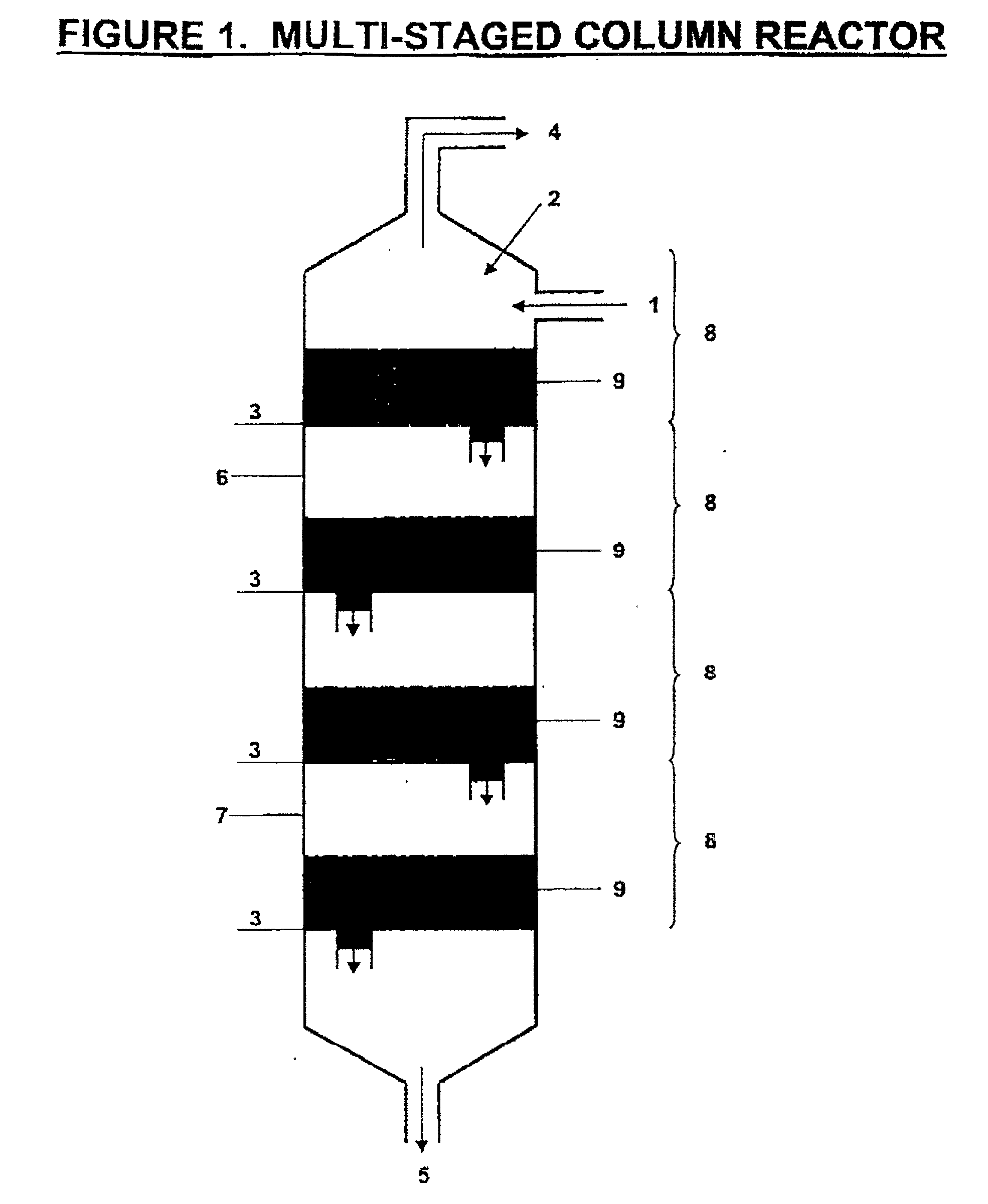

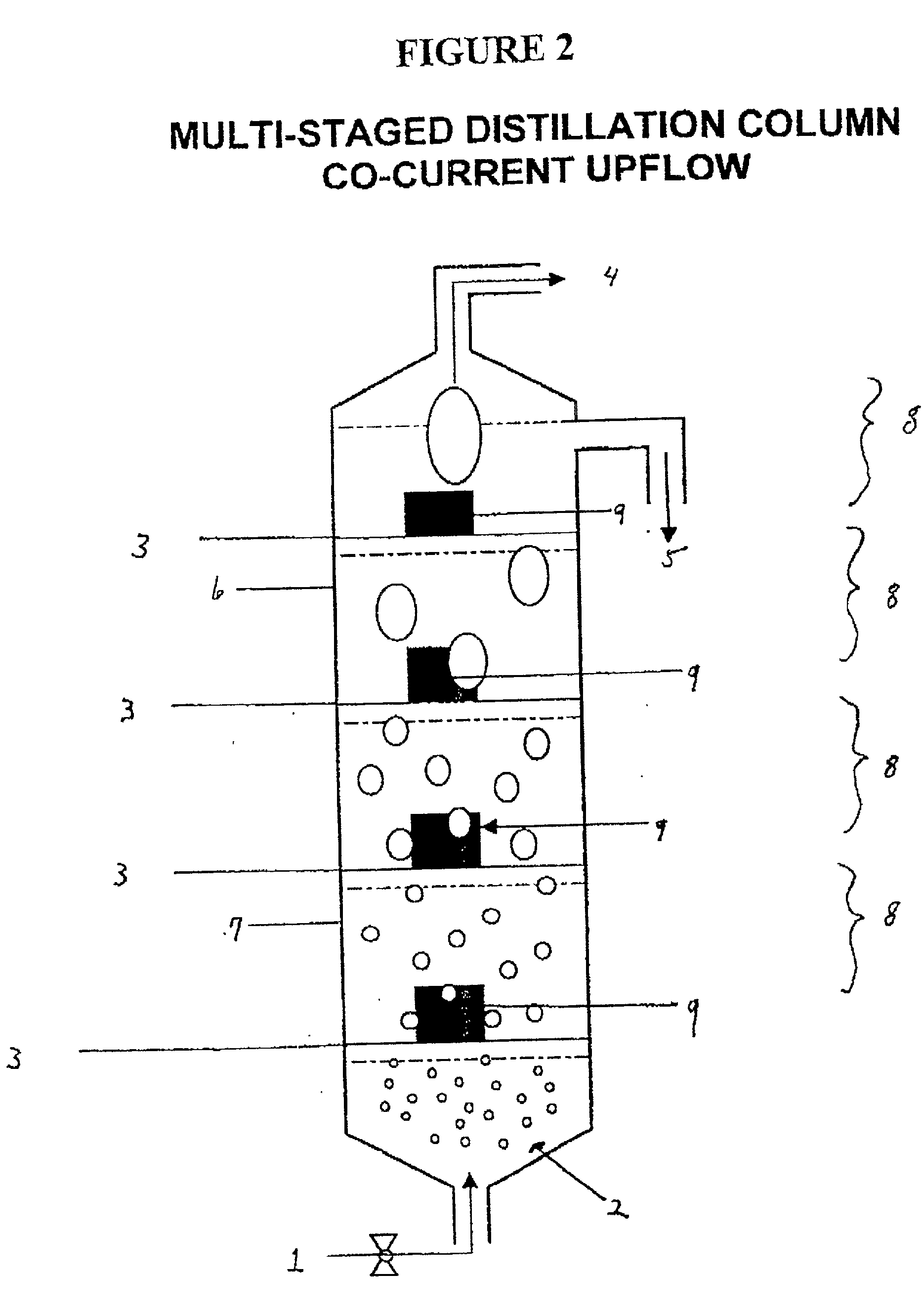

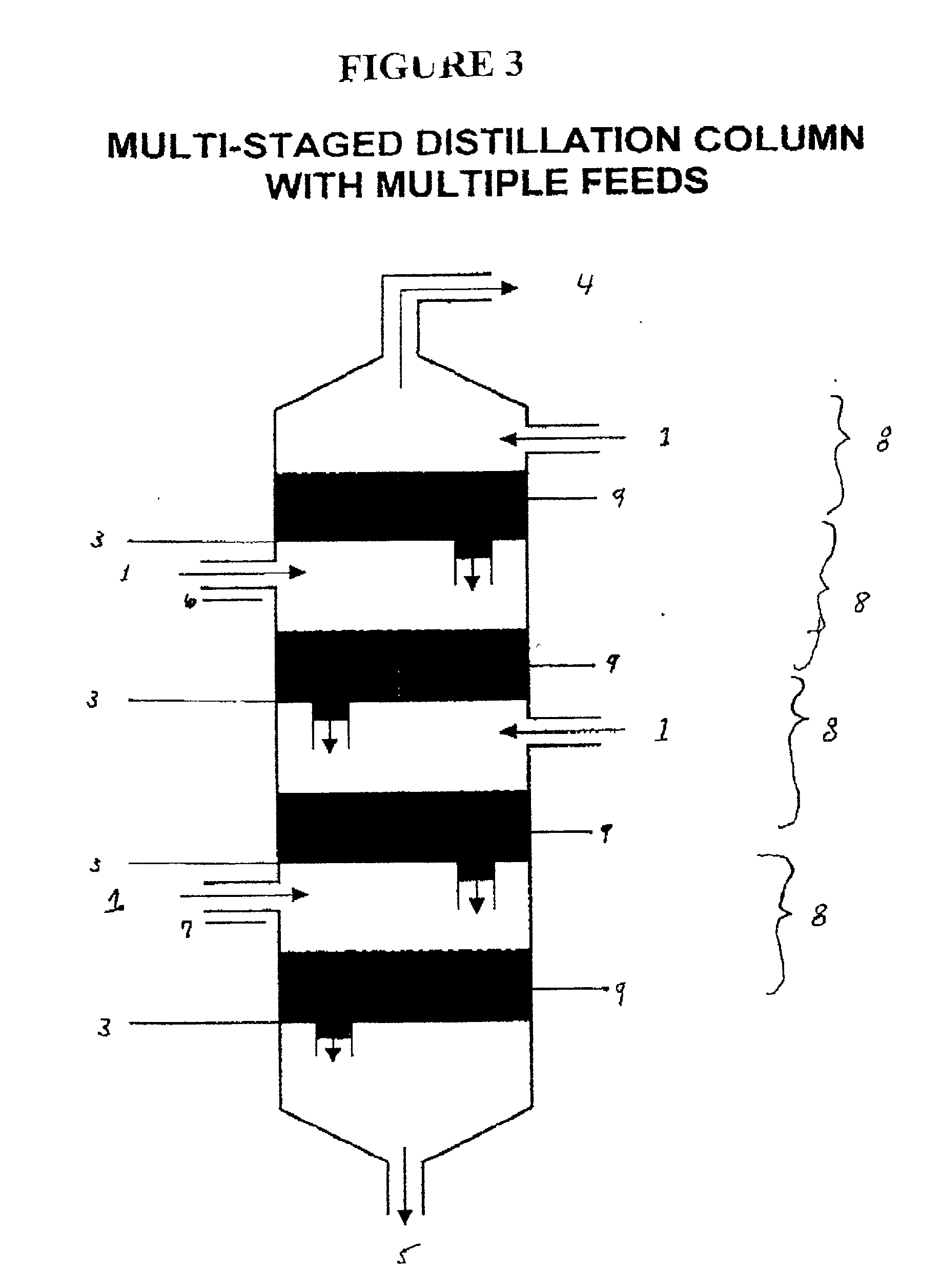

The invention is a continuous process for the preparation of polytrimethylene ether glycol from 1,3-propanediol reactant. In addition, the invention is directed to a continuous multi-stage process comprising reacting at least one reactant in a liquid phase in an up-flow column reactor, and forming a gas or vapor phase by-product wherein the gas or vapor phase by-product is continuously removed at the top and at least one intermediate stage.

Owner:DUPONT CA +1

Process for the purification of 1,3-propanediol

InactiveUS6235948B1Organic compound preparationOxygen compounds purification/separation1,3-PropanediolPropanediol

Disclosed is a process for the removal of impurities, especially color forming impurities, from 1,3-propanediol.

Owner:EI DU PONT DE NEMOURS & CO

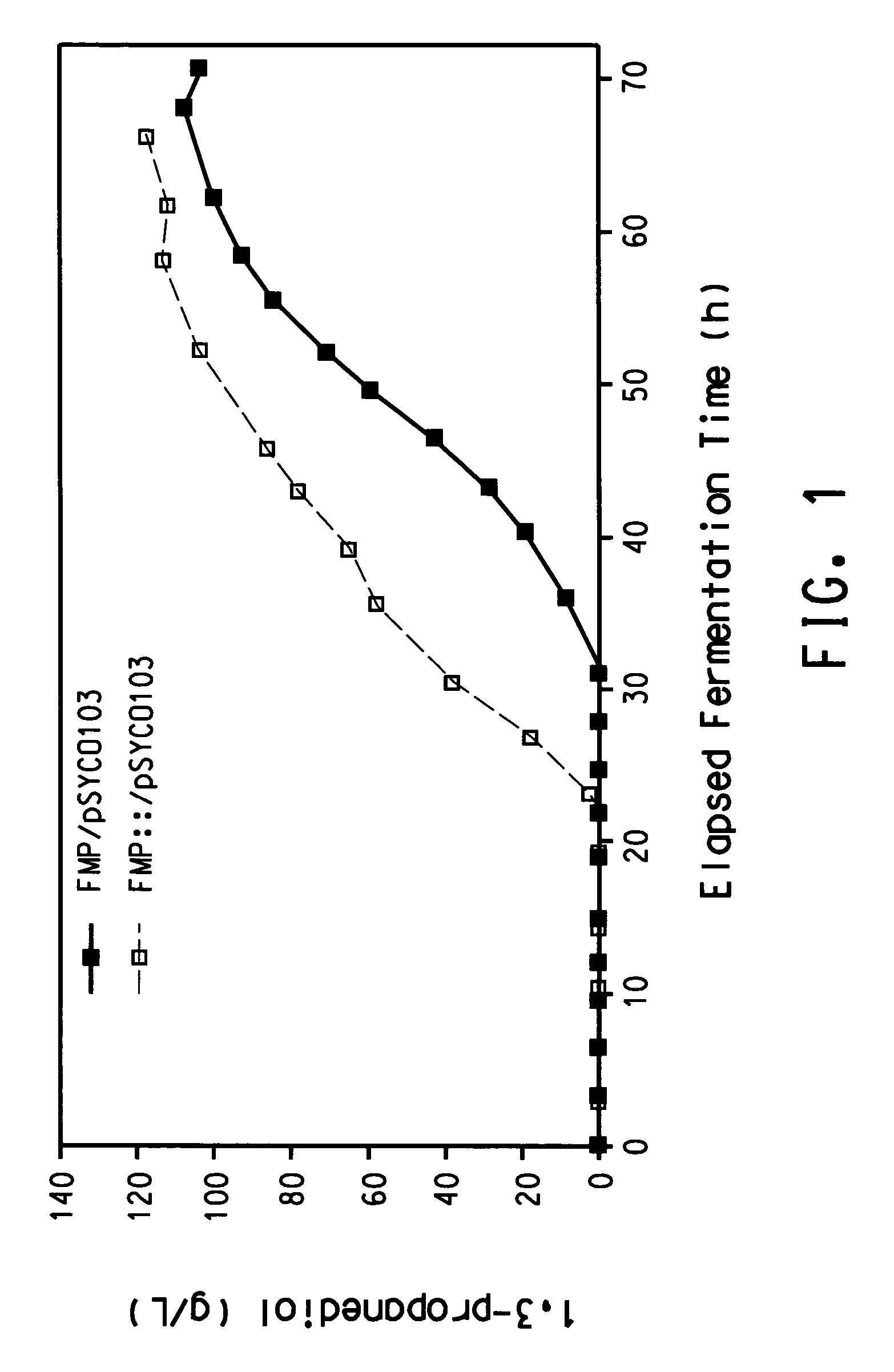

Process for the biological production of 1,3-propanediol with high yield

The present invention provides a microorganism useful for biologically producing 1,3-propanediol from a fermentable carbon source at higher yield than was previously known. The complexity of the cofactor requirements necessitates the use of a whole cell catalyst for an industrial process that utilizes this reaction sequence to produce 1,3-propanediol. The invention provides a microorganism with disruptions in specified genes and alterations in the expression levels of specified genes that is useful in a higher yielding process to produce 1,3-propanediol.

Owner:NUTRITION & BIOSCIENCES USA 4 INC +1

Production of polytrimethylene ether glycol and copolymers thereof

A process for the manufacture of polytrimethylene ether glycol comprising the steps of: (a) providing (1) 1,3-propanediol reactant selected from the group consisting of 1,3-propanediol and / or oligomers or prepolymers of 1,3-propanediol having a degree of polymerization of 2-9 and mixtures thereof, and (2) a polycondensation catalyst; and (b) polycondensing the 1,3-propanediol reactant to form a polytrimethylene ether glycol at less than one atmosphere pressure, and the product of the process. In addition, polytrimethylene ether glycol has a number average molecular weight greater than 1,500, an APHA color of less than 120, an unsaturation of less than 20 meq / kg, and a content of cyclic ether oligomers of less than 2%.

Owner:DUPONT IND BIOSCIENCES USA LLC

Continuous process for the preparation of polytrimethylene ether glycol

The invention is a continuous process for the preparation of polytrimethylene ether glycol from 1,3-propanediol reactant. In addition, the invention is directed to a continuous multi-stage process comprising reacting at least one reactant in a liquid phase in an up-flow column reactor, and forming a gas or vapor phase by-product wherein the gas or vapor phase by-product is continuously removed at the top and at least one intermediate stage.

Owner:DUPONT CA +1

Preparation of poly(trimethylene terephthalate)

In one embodiment, the invention is a process for the preparation of poly(trimethylene terephthalate) comprising (a) contacting terephthalic acid with 1,3-propanediol in the presence of an organic tin catalyst to form a bis(3-hydroxypropyl)terephthalate monomer; and (b) polymerizing said monomer in the presence of organic titanate polycondensation catalyst to obtain the poly(trimethylene terephthalate). In another embodiment, the invention is a process for the preparation of poly(trimethylene terephthalate) containing less than 1.6 mol % of DPG said process comprising contacting terephthalic acid with a 1.6 to 1 to 2:1 molar amount of 1,3-propanediol in the presence of 20 to 120 ppm (as tin), by weight of the poly(trimethylene terephthalate), of a organic tin catalyst, to form a bis(3-hydroxypropyl)terephthalate monomer and polymerizing said monomer to obtain the poly(trimethylene terephthalate). The invention is also directed to poly(trimethylene terephthalate) produced by the processes.

Owner:DUPONT IND BIOSCIENCES USA LLC

Purification of chemical 1,3-propanediol

InactiveUS7038092B2Organic compound preparationOxygen compounds purification/separationHydrogen1,3-Propanediol

Owner:EI DU PONT DE NEMOURS & CO

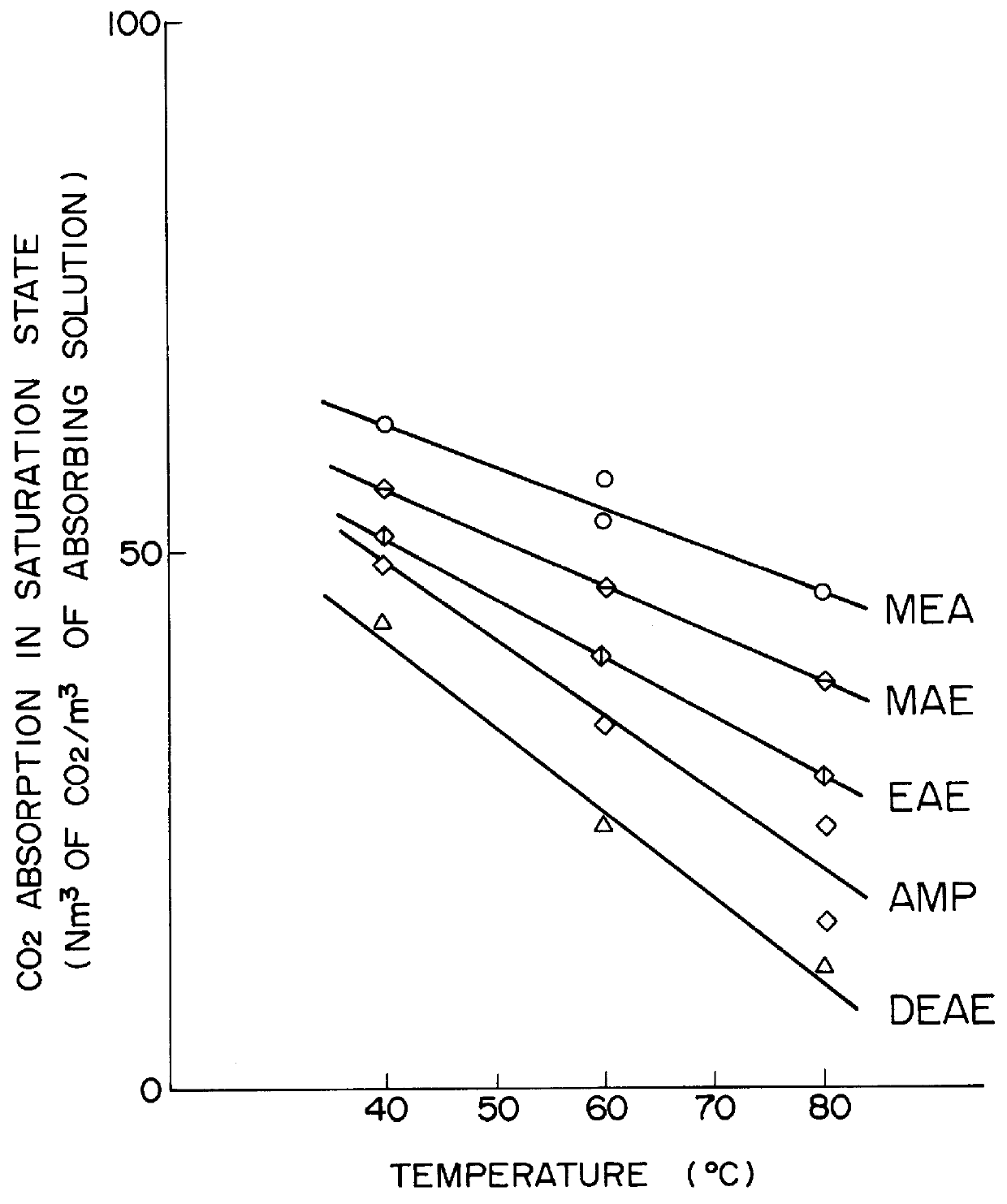

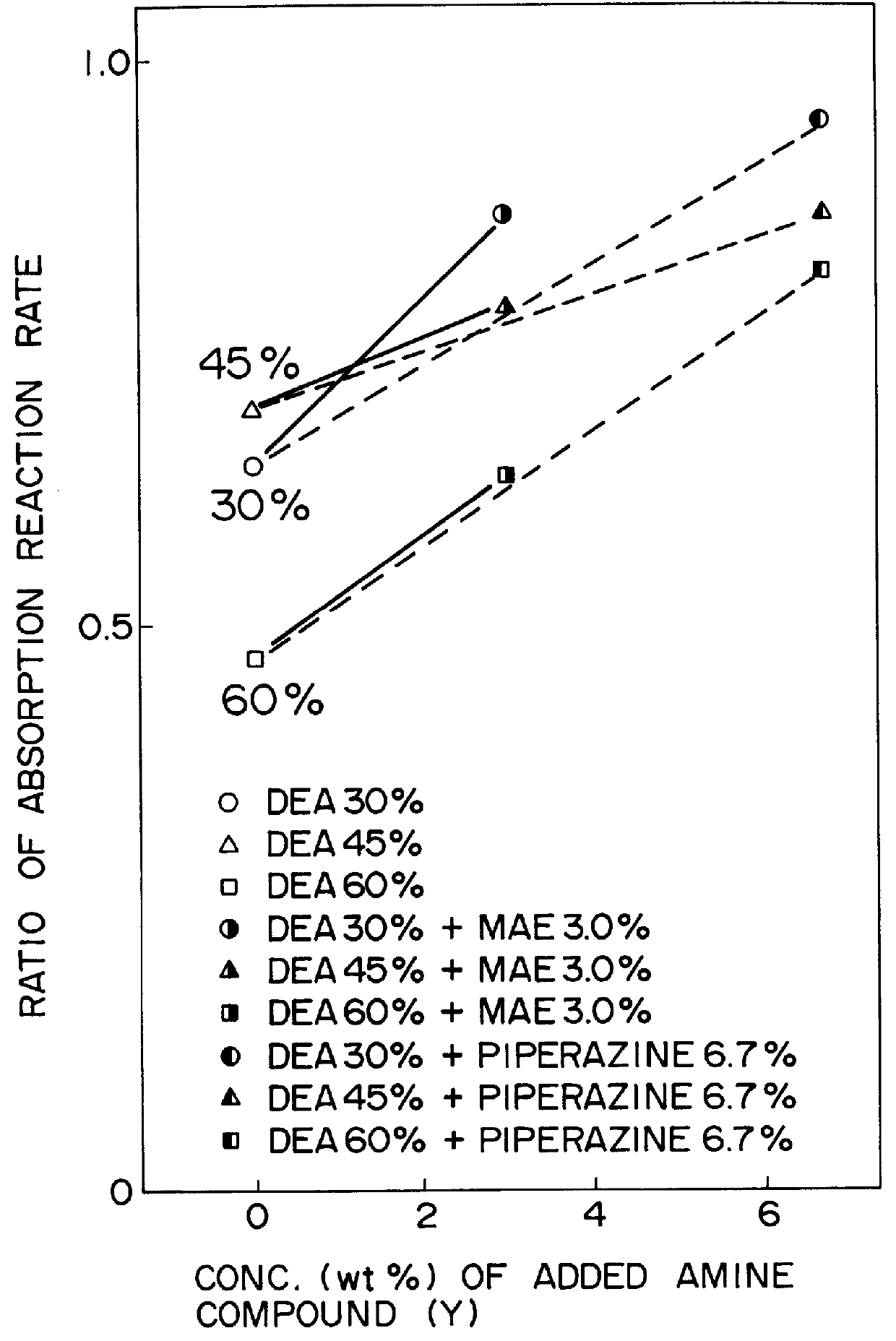

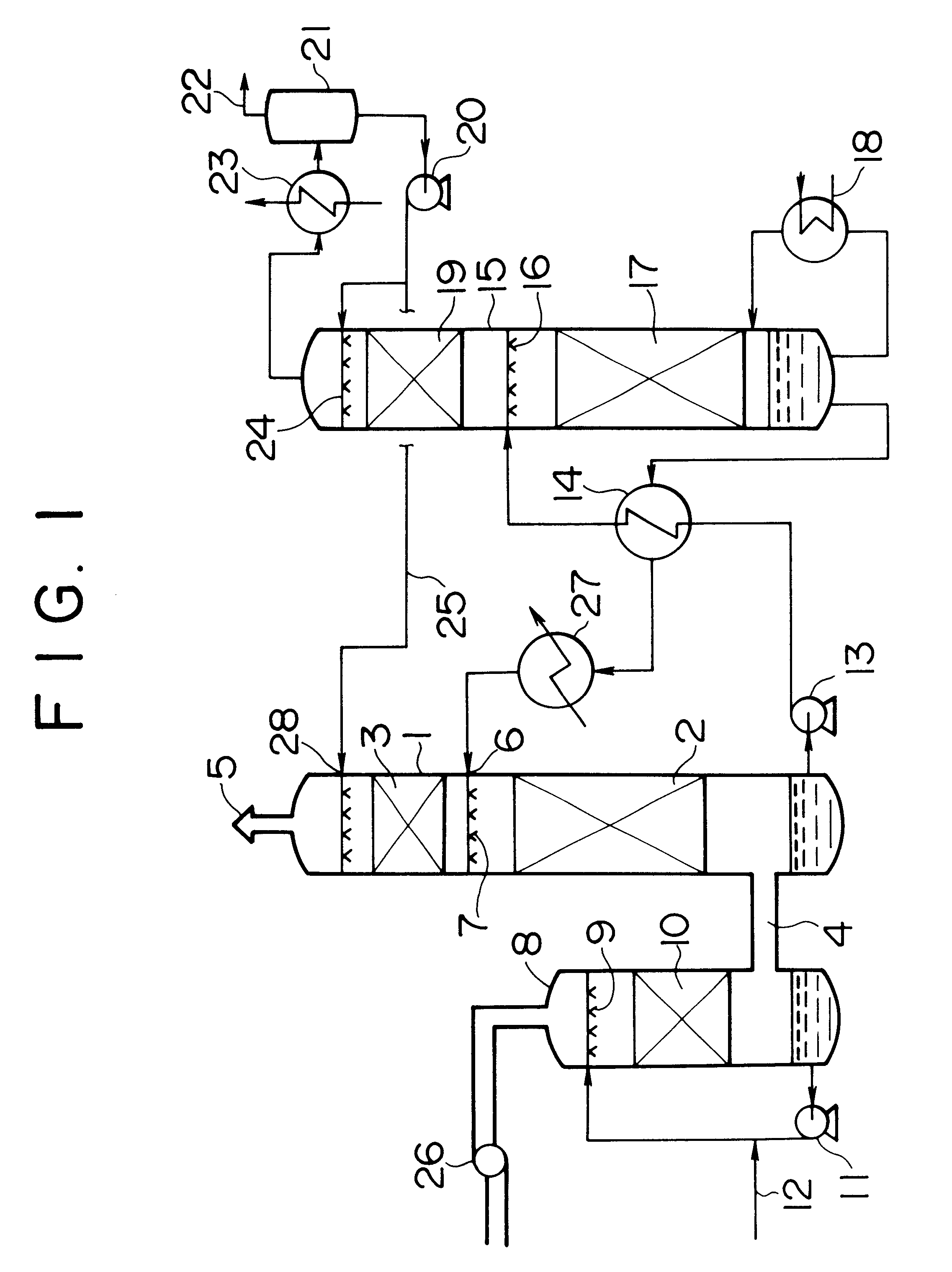

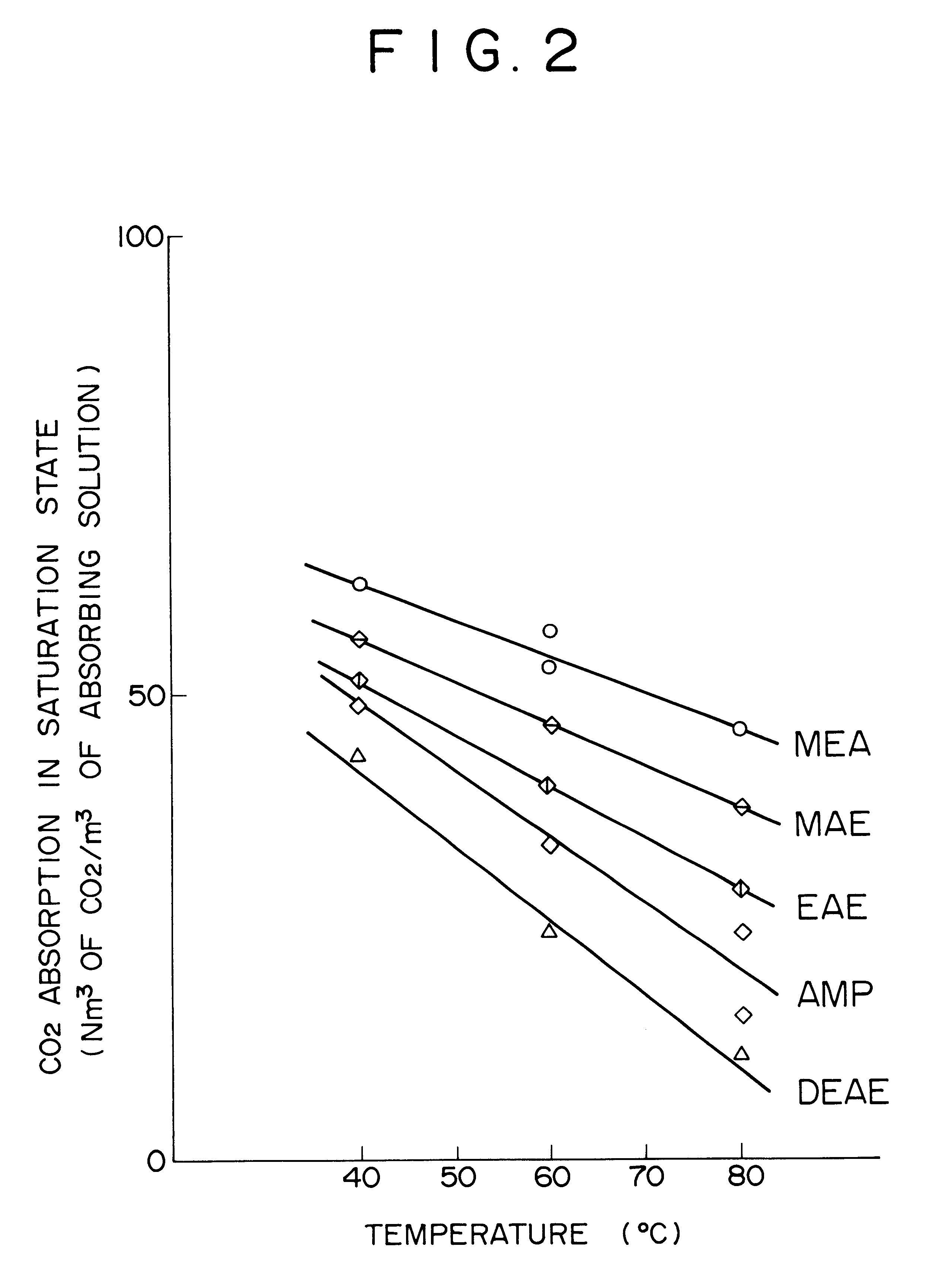

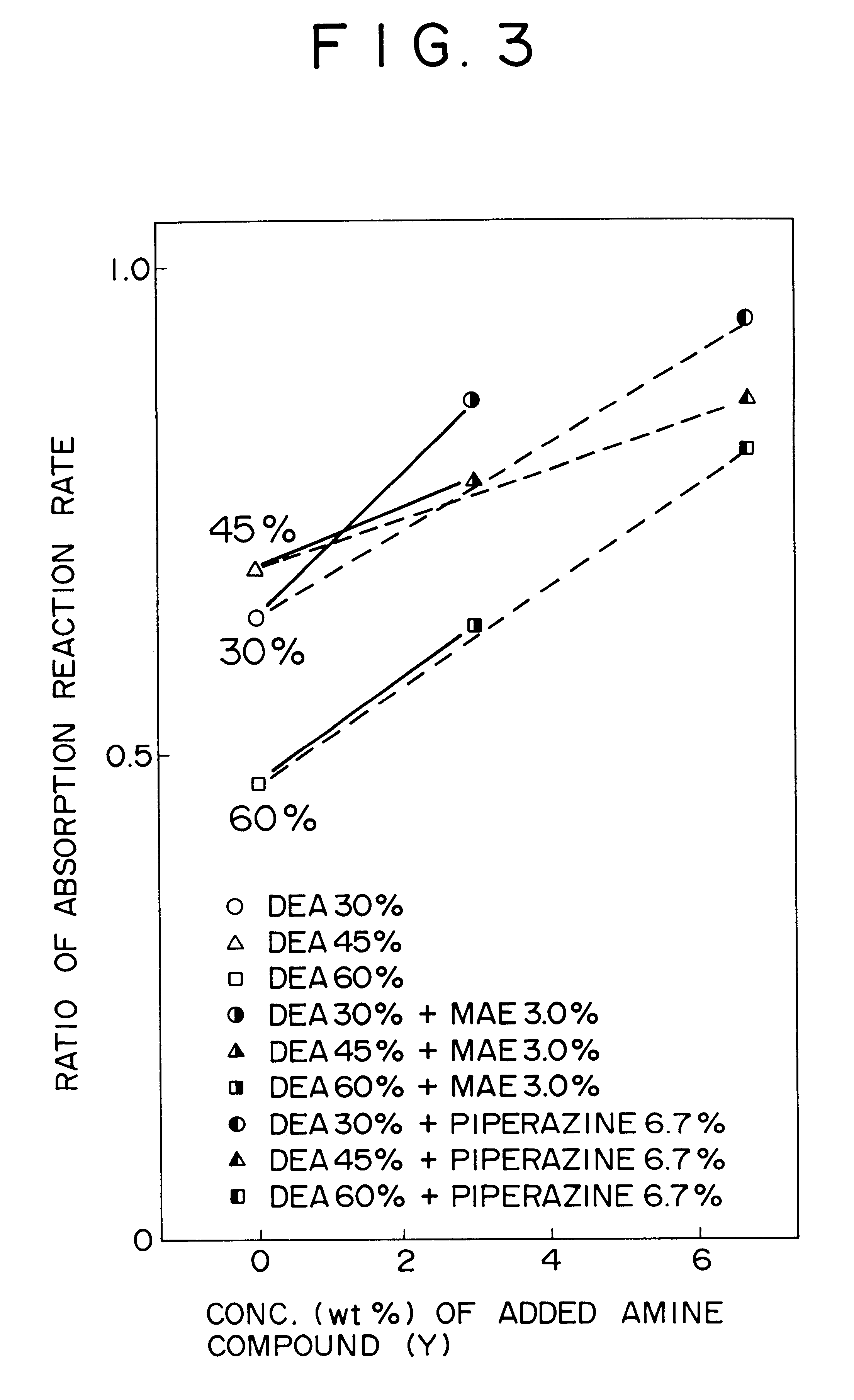

Method for removing carbon dioxide from combustion exhaust gas

InactiveUS6036931AHigh absorption rateImprove absorption rateDispersed particle separationHydrogen sulfides2-methylaminoethanolMorpholine

There are disclosed a method for removing CO2 from a combustion exhaust gas which comprises the step of bringing the combustion exhaust gas under atmospheric pressure into contact with an aqueous solution of a hindered amine selected from the group consisting of 2-amino-2-methyl-1-propanol, 2-methylaminoethanol, 2-ethylaminoethanol and 2-piperidineethanol; and another method for removing carbon dioxide from a combustion exhaust gas which comprises the step of bringing the combustion exhaust gas under atmospheric pressure into contact with a mixed aqueous solution of 100 parts by weight of an amine compound (X) selected from the group consisting of 2-amino-2-methyl-1,3-propanediol, 2-amino-2-methyl-1-propanol, 2-amino-2-ethyl-1,3-propanediol, t-butyldiethanolamine and 2-amino-2-hydroxymethyl-1,3-propanediol; and 1-25 parts by weight of an amine compound (Y) selected from the group consisting of piperazine, piperidine, morpholine, glycine, 2-methylaminoethanol, 2-piperidineethanol and 2-ethylaminoethanol.

Owner:THE KANSAI ELECTRIC POWER CO +1

Novel copolyester compositions with improved impact strength at low temperatures

This invention relates to a polyester composition comprising: (i) diacid residues comprising at least 80 mole percent, based on the total moles of diacid residues, of one or more residues of: terephthalic acid, naphthalenedicarboxylic acid, 1,4-cyclohexanedicarboxylic acid, or isophthalic acid; and (ii) diol residues comprising from about 25 to about 70 mole percent, based on the total moles of diol residues, of the residues of 1,4-cyclohexanedimethanol, and from about 75 to about 30 mole percent, based on the total moles of diol residues, of the residues of 1,3-propanediol. This invention has surprising improved impact strength at low temperatures.

Owner:EASTMAN CHEM CO

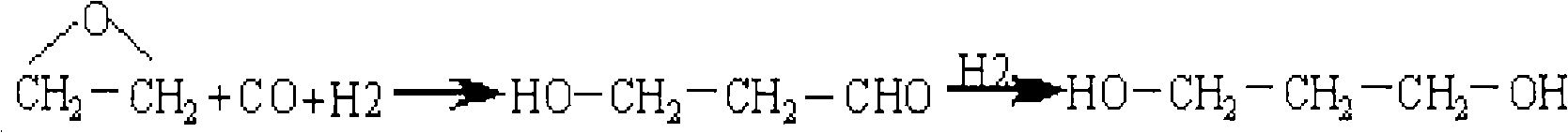

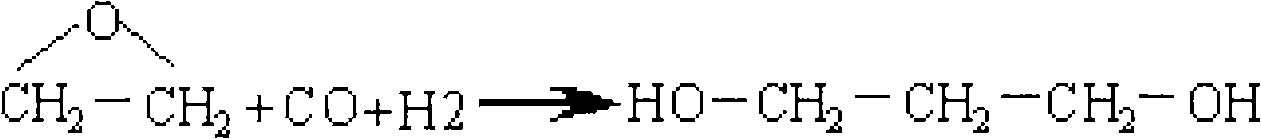

Catalytic hydrogenation of 3-hydroxypropanal to 1,3-propanediol

InactiveUS6342646B1Improves performance and lifetimeImprove hydrogenation activityOrganic compound preparationOxygen compounds preparation by reductionAsymmetric hydrogenation1,3-Propanediol

The present invention provides an improved process for the hydrogenation of 3-hydroxypropanal to 1,3-propanediol which comprises purifying an aqueous solution of 3-hydroxypropanal by contacting said aqueous solution with a purifying agent prior to hydrogenation.

Owner:EI DU PONT DE NEMOURS & CO

Preparation of poly(trimethylene terephthalate) with low level of di(1,3-propylene glycol)

A process of preparing poly(trimethylene terephthalate) containing less than 2.0 mole % of DPG comprising:(a) providing a molar amount of 1,3-propanediol:C1 to C4 dialkyl ester of terephthalic acid of 1.2:1 to 1.9:1,(b) reacting the 1,3-propanediol with the C1 to C4 dialkyl ester of terephthalic, acid to form bis(3-hydroxypropyl)terephthalate monomer in the presence of 10-100 ppm (as titanium metal) of an organic titanate catalyst, by weight of the poly(trimethylene terephthalate), and(c) polymerizing the bis(3-hydroxypropyl)terephthalate monomer to obtain the poly(trimethylene terephthalate); andpoly(trimethylene terephthalate) produced by the process.

Owner:DUPONT IND BIOSCIENCES USA LLC

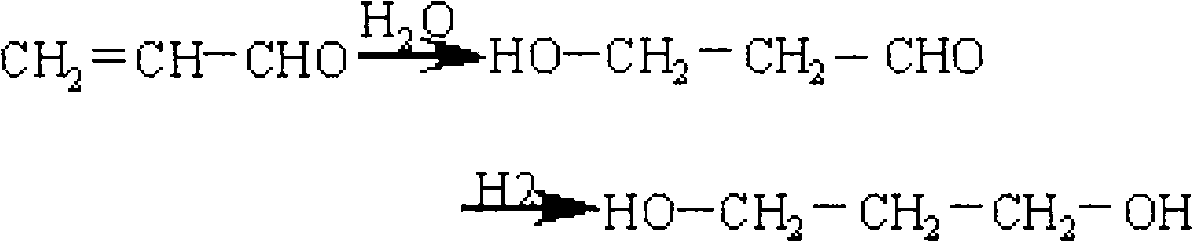

Method for simultaneously producing 1,3-propylene glycol and 1,2-propylene glycol

The invention relates to a chemical material production method, in particular to a method for simultaneously producing 1,3-propylene glycol and 1,2-propylene glycol. Alkyl carboxylic acid vinyl ester carries out hydroformylation with carbon monoxide and hydrogen under the action of olefin hydroformylation catalyst, so that 3-alkylacyloxy propaldehyde and 2- alkylacyloxy propaldehyde are produced, the 3-alkylacyloxy propaldehyde and the 2- alkylacyloxy propaldehyde react with hydrogen under the action of aldehyde hydrogenation catalyst, so that 3-alkylacyloxy propyl alcohol and 2-alkylacyloxy propyl alcohol are produced, and the 3-alkylacyloxy propyl alcohol and the 2-alkylacyloxy propyl alcohol are hydrolyzed under the action of esterolytic catalyst, so that the 1,3-propylene glycol and the 1,2-propylene glycol are produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for removing carbon dioxide from combustion exhaust gas

InactiveUS6500397B1Improve absorption rateHigh absorption rateHydrogen sulfidesDispersed particle separation2-methylaminoethanolMorpholine

There are disclosed a method for removing CO2 from a combustion exhaust gas which comprises the step of bringing the combustion exhaust gas under atmospheric pressure into contact with an aqueous solution of a hindered amine selected from the group consisting of 2-amino-2-methyl-1-propanol, 2-methylaminoethanol, 2-ethylamino-ethanol and 2-piperidineethanol; and another method for removing carbon dioxide from a combustion exhaust gas which comprises the step of bringing the combustion exhaust gas under atmospheric pressure into contact with a mixed aqueous solution of 100 parts by weight of an amine compound (X) selected from the group consisting of 2-amino-2-methyl-1, 3-propanediol, 2-amino-2-methyl-1-propanol, 2-amino-2-ethyl-1, 3-propanediol, t-butyldiethanolamine and 2-amino-2-hydroxymethyl-1,3-propanediol; and 1-25 parts by weight of an amine compound (Y) selected from the group consisting of piperazine, piperidine, morpholine, glycine, 2-methylamino-ethanol, 2-piperidineethanol and 2-ethylaminoethanol.

Owner:THE KANSAI ELECTRIC POWER CO +1

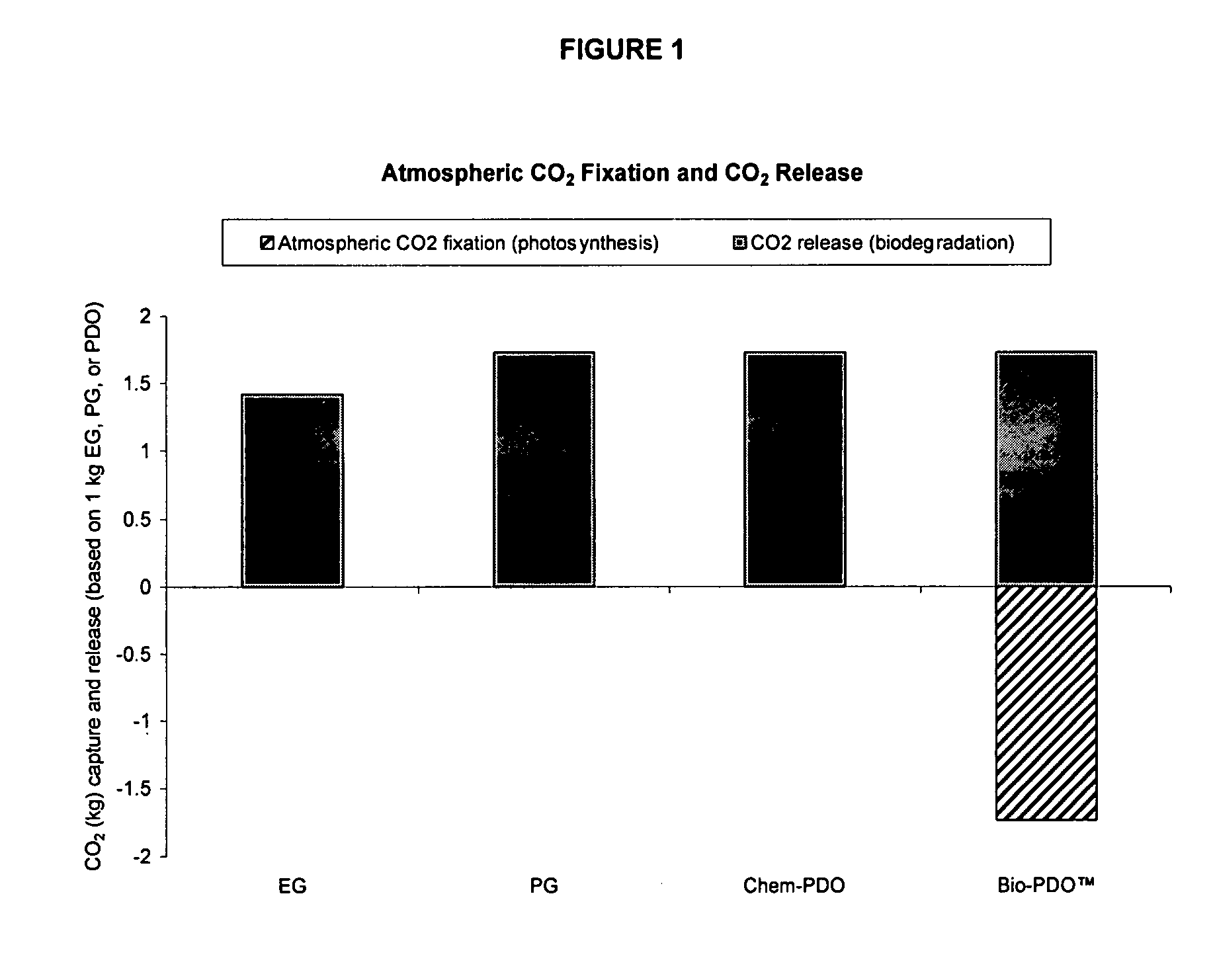

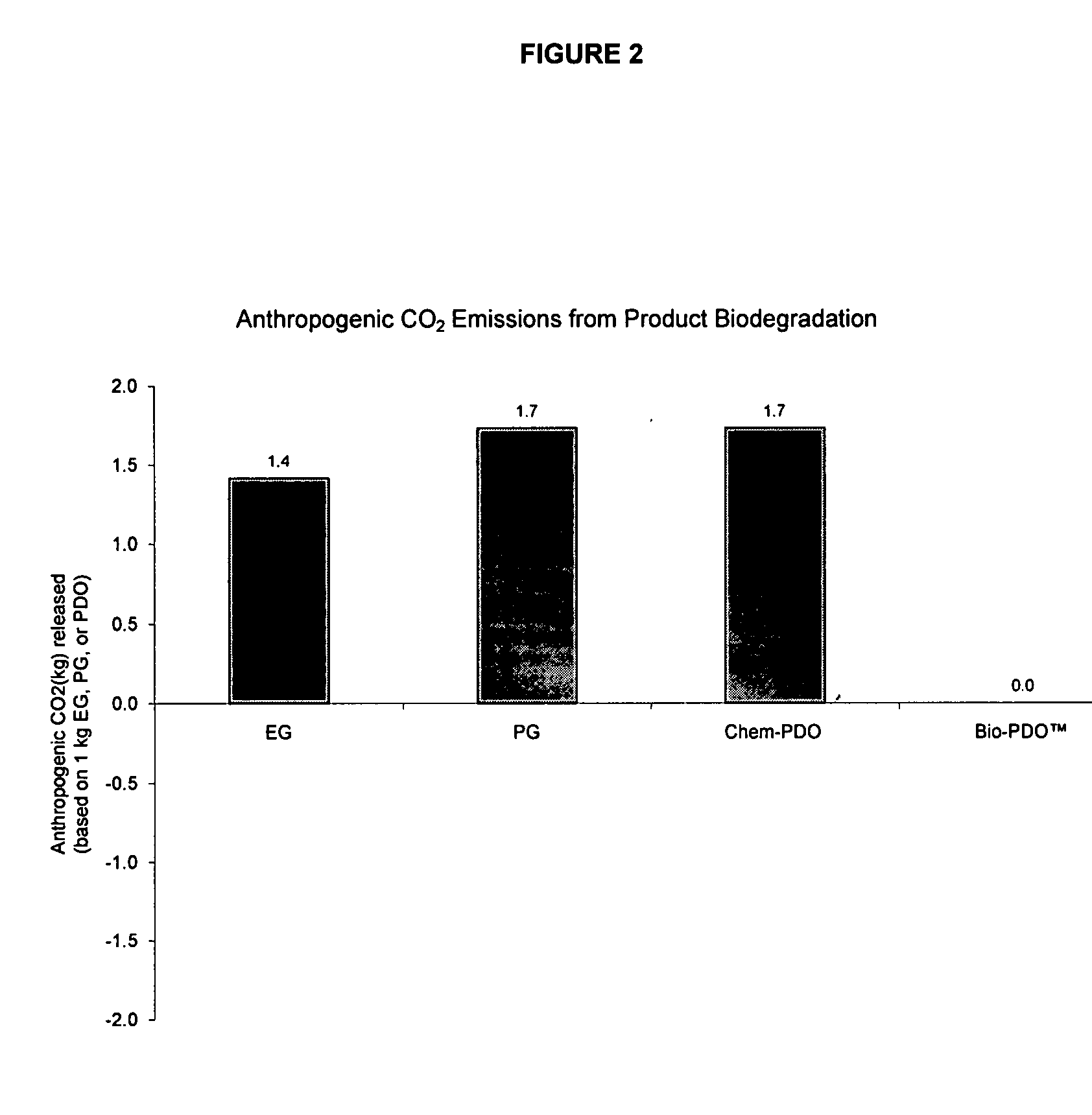

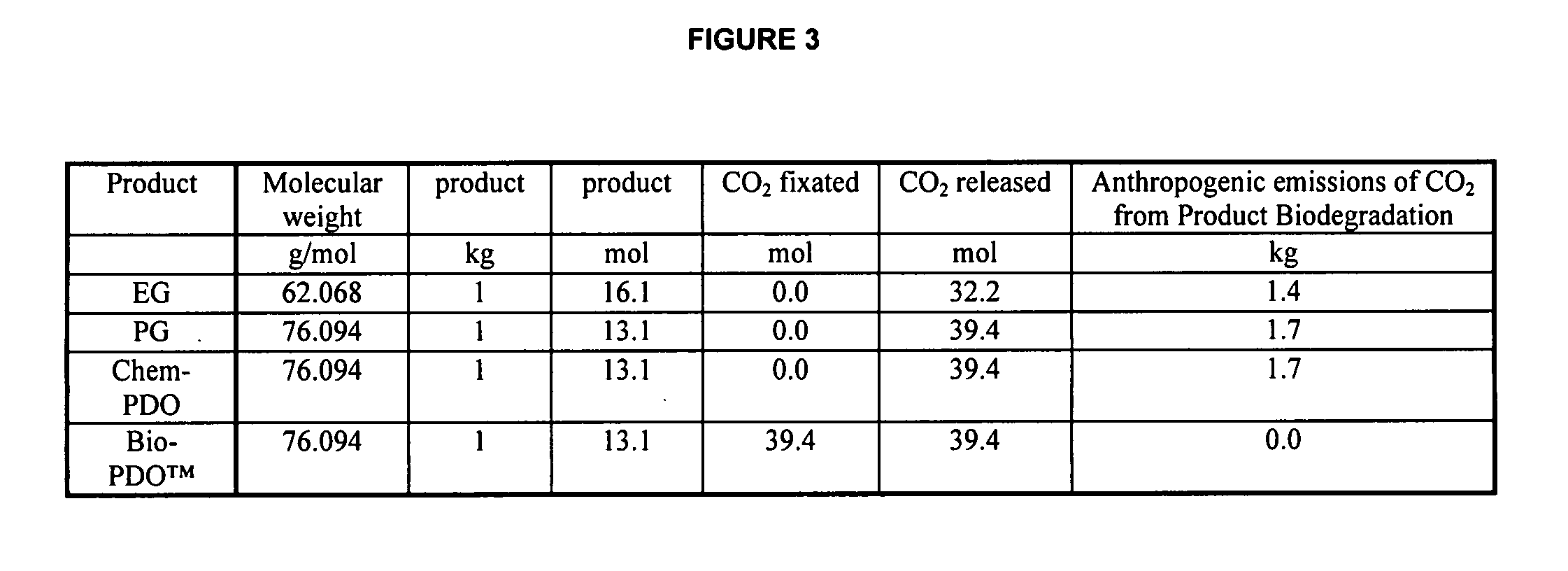

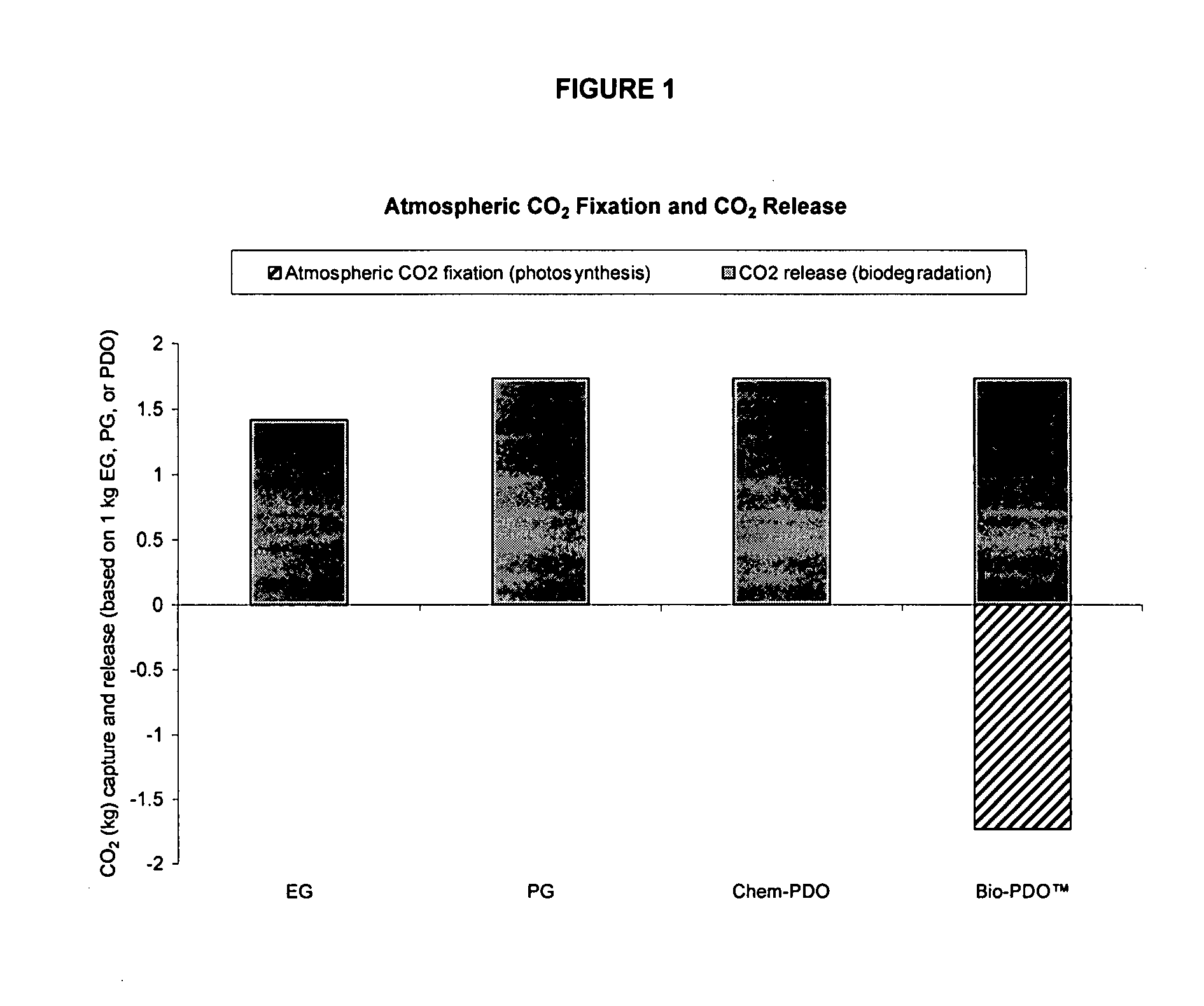

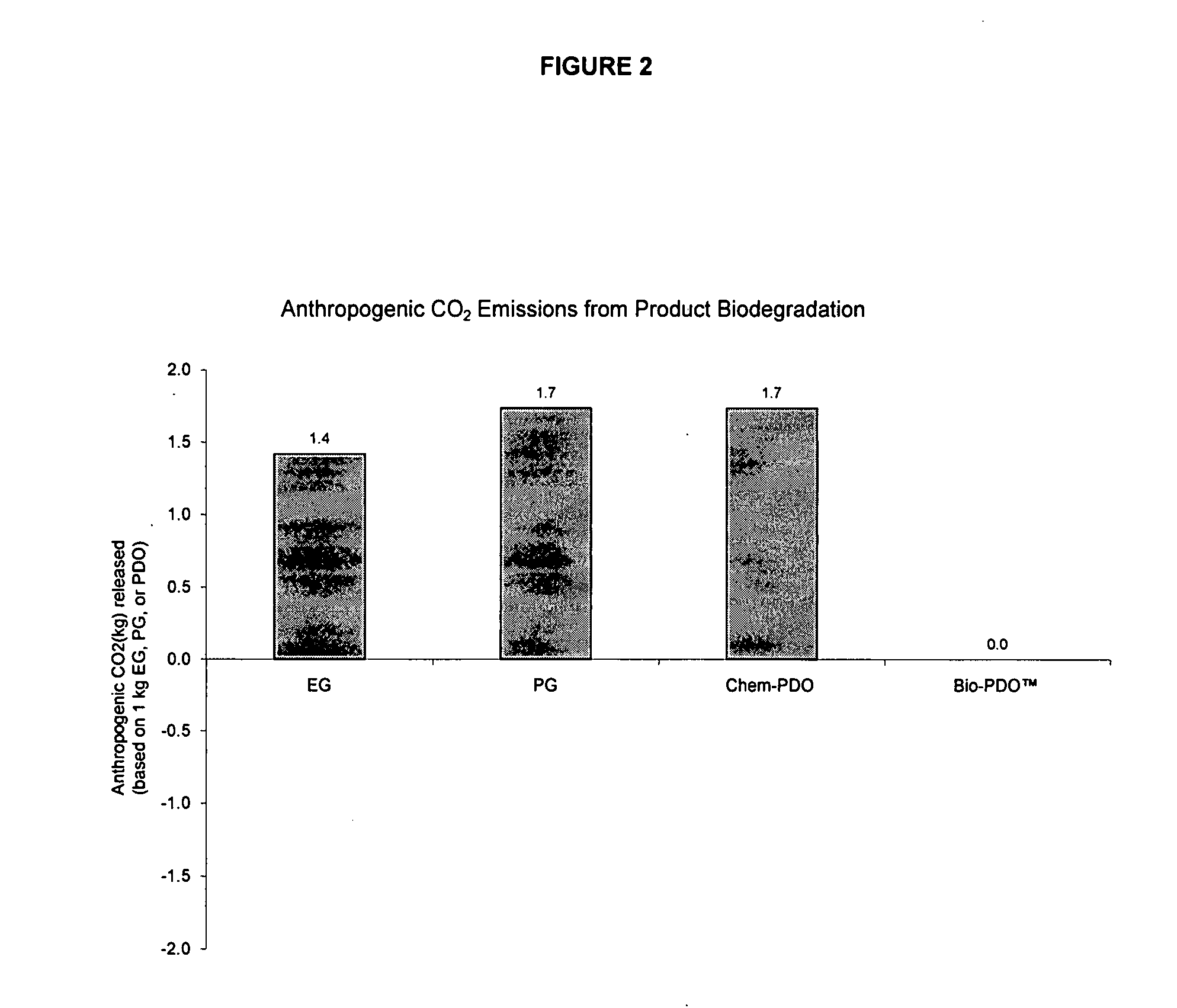

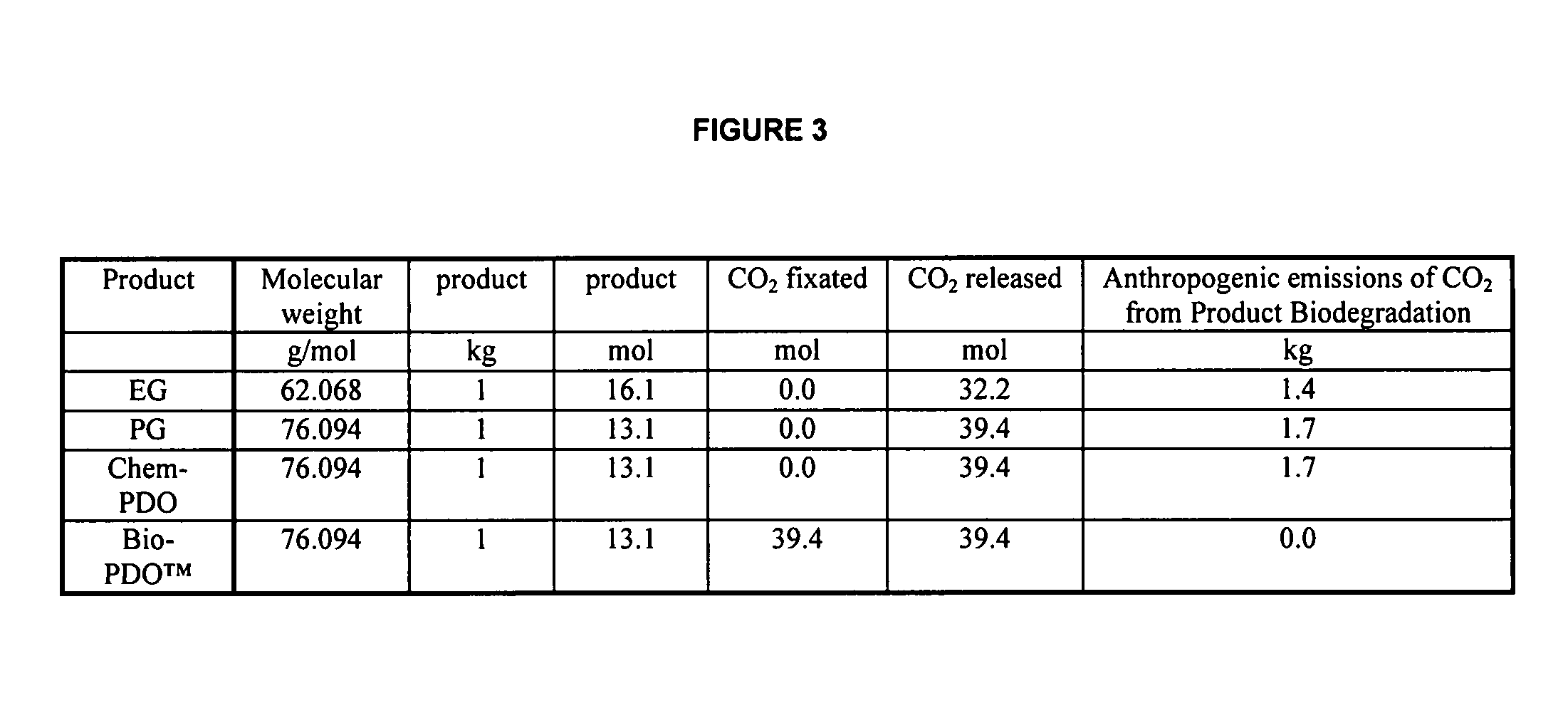

Natural deodorant compositions comprising renewably-based, biodegradable 1,3-propanediol

Disclosed herein are all natural or substantially natural deodorant and antiperspirant compositions comprising 1,3-propanediol wherein the 1,3-propanediol in said all natural or substantially natural deodorant or antiperspirant composition has a bio-based carbon content of about 1% to 100%. In addition, it is preferred that the 1,3-propanediol be biologically-derived, and wherein upon biodegradation, the biologically-derived 1,3-propanediol contributes no anthropogenic CO2 emissions to the atmosphere.

Owner:DUPONT TATE &LYLE BIO PROD CO LLC

Utilization of fructose in microbial production strains

InactiveUS7524660B2Increase profitHigh activitySugar derivativesBacteriaSustained growthMicroorganism

Owner:EI DU PONT DE NEMOURS & CO

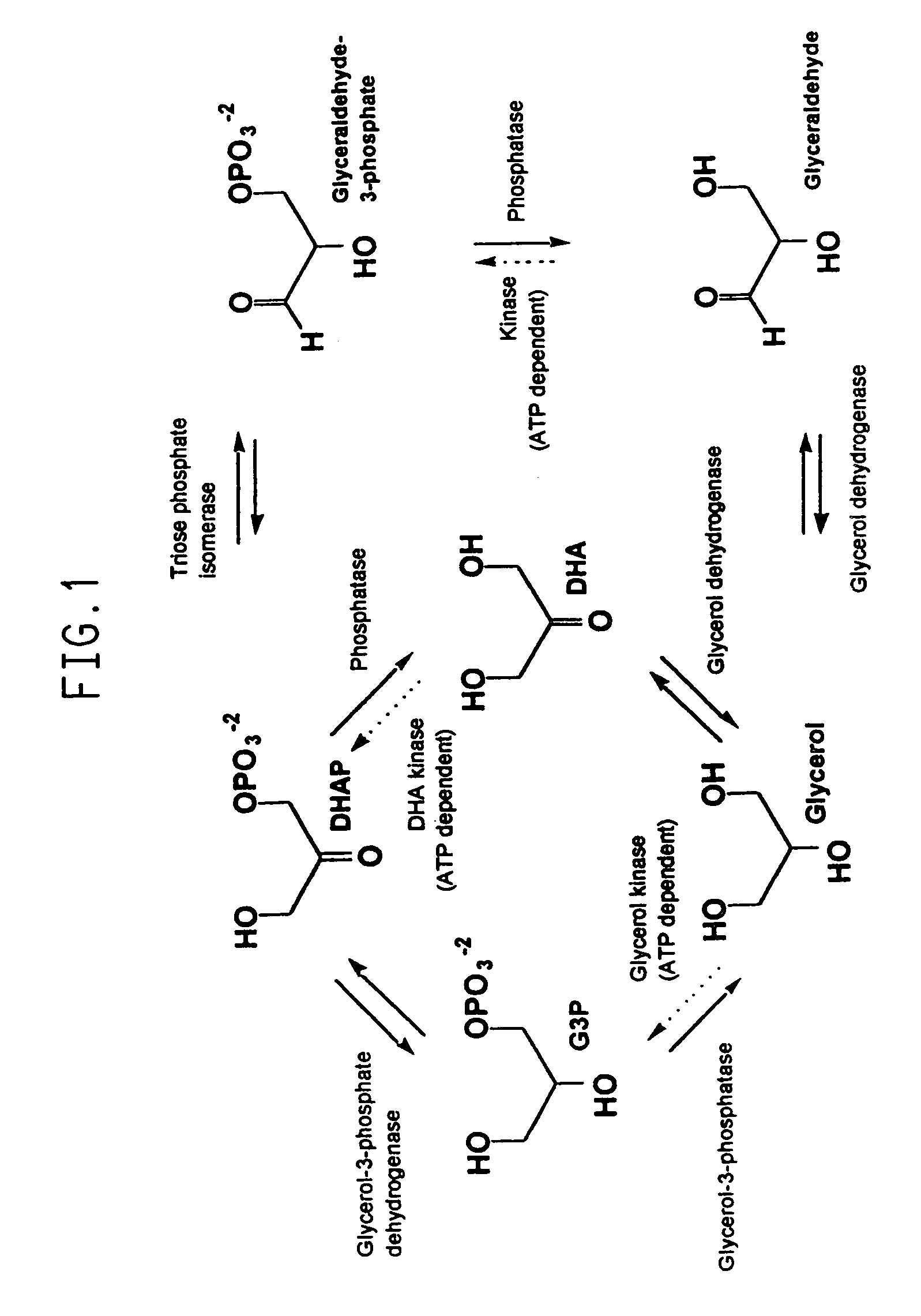

Transformed microorganisms and genes useful in the production of glycerol and 1,3-propanediol

Recombinant organisms are provided comprising genes encoding a glycerol-3-phosphate dehydrogenase and / or a glycerol-3-phosphatase activity useful for the production of glycerol from a variety of carbon substrates. The organisms further contain disruptions in the endogenous genes encoding proteins having glycerol kinase and glycerol dehydrogenase activities.

Owner:EI DU PONT DE NEMOURS & CO +1

Process for manufacture of polytrimethylene ether glycol

A process of manufacture of polytrimethylene ether glycol comprising:(a) polycondensing reactant comprising diol selected from the group consisting of 1,3-propanediol, 1,3-propanediol dimer and 1,3-propanediol trimer or mixtures thereof in the presence of acid polycondensation catalyst to form polytrimethylene ether glycol;(b) adding water to the polytrimethylene ether glycol and hydrolyzing the acid esters formed during the polycondensation to form a hydrolyzed mixture containing the polytrimethylene ether glycol and the hydrolyzed acid esters;(c) adding organic solvent that is miscible with water to the hydrolyzed mixture to form an aqueous-organic mixture comprising (i) organic phase containing polytrimethylene ether glycol and residual acid polycondensation catalyst from the polycondensing and (ii) water phase;(d) separating the water phase and the organic phase;(e) adding base to the separated organic phase to neutralize the residual acid polycondensation catalyst by forming salts of the residual acid polycondensation catalyst;(f) separating the organic phase into (i) liquid phase comprising the polytrimethylene ether glycol, the organic solvent and any residual water, and (ii) solid phase comprising the salts of the residual acid polycondensation catalyst and the base which is unreacted; and(g) removing the organic solvent and the residual water from the organic phase to obtain polytrimethylene ether glycol.

Owner:EI DU PONT DE NEMOURS & CO

Liquid composition for electronic cigarettes

InactiveUS20150351449A1Prevent undesired and possibly dangerous effectOrganic chemistryTobacco treatmentElectronic cigarette1,3-Propanediol

The liquid composition for electronic cigarettes includes water, a natural glycol, glycerol, natural flavorings and possibly nicotine. The natural glycol is composed of 1,3-propanediol, obtained through bioprocessing of corn sugars.

Owner:SINO BUSINESS

Use of a composition containing 1,3-propanediol as e-liquid

InactiveUS20160262443A1Improve bioavailabilityReinforce aromatic powerTobacco treatmentTobacco devicesElectronic cigarette1,3-Propanediol

A composition containing 1,3-propanediol for use as electronic cigarette liquid. A liquid composition for an electronic cigarette, including 1,3-propanediol, as well as at least one compound selected from nicotine, a nicotine substitute, and an aroma, and an electronic cigarette containing this composition.

Owner:LAB CERES

Polyester plasticizer and chlorine-containing resin compositions

ActiveUS20060025544A1Superior in plasticization efficiencyGood oil resistancePlastic/resin/waxes insulatorsLavatory sanitoryPolyesterAdipic acid

A polyester plasticizer which is obtained by reacting a diol component (a) consisting of 100 parts by mole of 2-methyl-1,3-propanediol, 10 to 1000 parts by mole of 3-methyl-1,5-pentanediol and 0 to 1000 parts by mole of other aliphatic diol with an organic dicarboxylic acid components (b) consisting of 100 parts by mole of adipic acid and 0 to 100 parts by mole of other organic dicarboxylic acid and a chain terminator (c) consisting of a monovalent aliphatic alcohol or a monovalent aliphatic organic acid and which has an average molecular weight of 500 to 5000. This plasticizer is excellent in plasticizing efficiency and can impart excellent oil resistance to synthetic resins such as chlorine-containing resins.

Owner:ADEKA CORP

Manufacture of polytrimethylene ether glycol

InactiveUS7157607B1Increase productionReduce fermentationOrganic compound preparationMixingOrganic solventEther

A process of manufacture of polytrimethylene ether glycol comprising:(a) polycondensing reactant comprising diol selected from the group consisting of 1,3-propanediol, 1,3-propanediol dimer and 1,3-propanediol trimer or mixtures thereof in the presence of acid polycondensation catalyst to form polytrimethylene ether glycol;(b) adding water to the polytrimethylene ether glycol to form an aqueous mixture;(c) heating the aqueous mixture to hydrolyze acid esters formed during the acid catalyzed polycondensation;(d) adding to the hydrolyzed aqueous mixture organic solvent that is miscible with polytrimethylene ether glycol to form (i) organic phase containing the polytrimethylene ether glycol and residual acid polycondensation catalyst from the polycondensing and (ii) aqueous phase;(e) separating the aqueous phase and the organic phase;(f) adding base to the separated organic phase to neutralize the residual acid polycondensation catalyst by forming salts of the residual acid polycondensation catalyst;(g) separating the organic phase into (i) liquid phase comprising the polytrimethylene ether glycol, the organic solvent and any residual water, and (ii) solid phase comprising the salts of the residual acid polycondensation catalyst and the base which is unreacted; and(h) removing the organic solvent and the residual water from the liquid phase to obtain polytrimethylene ether glycol.

Owner:EI DU PONT DE NEMOURS & CO

Water-soluble, liquid-containing pouch

InactiveUS7563757B2Aqueous liquid non-soap compositionsDetergent compounding agentsPolyvinyl alcohol1,3-Propanediol

The present invention relates to water-soluble pouch which contains a liquid detergent composition, wherein the pouch is a water-soluble film, the film material comprising a polyvinyl alcohol, and wherein the liquid detergent composition also comprises a plasticizer, wherein the plasticizer is selected from the group consisting of glycerol, ethylene glycol, diethylene glycol, triethylene glycol, 2-methyl-1,3-propane diol, sorbitol, methanol, diglycerol, 1,4-butane diol, urea and mixtures thereof, and wherein the liquid detergent composition further comprises a viscosity modifier, preferably a hydrogenated castor oil.

Owner:PROCTER & GAMBLE CO

Personal care and cosmetic compositions comprising renewably-based, biodegradable 1,3-propanediol

Disclosed herein are personal care and cosmetic compositions comprising 1,3-propanediol, wherein the 1,3-propanediol in said personal care or cosmetic composition has a bio-based carbon content of about 1% to 100%. In addition, it is preferred that the 1,3-propanediol be biologically-derived, and wherein upon biodegradation, the biologically-derived 1,3-propanediol contributes no anthropogenic CO2 emissions to the atmosphere.

Owner:DUPONT TATE &LYLE BIO PROD CO LLC

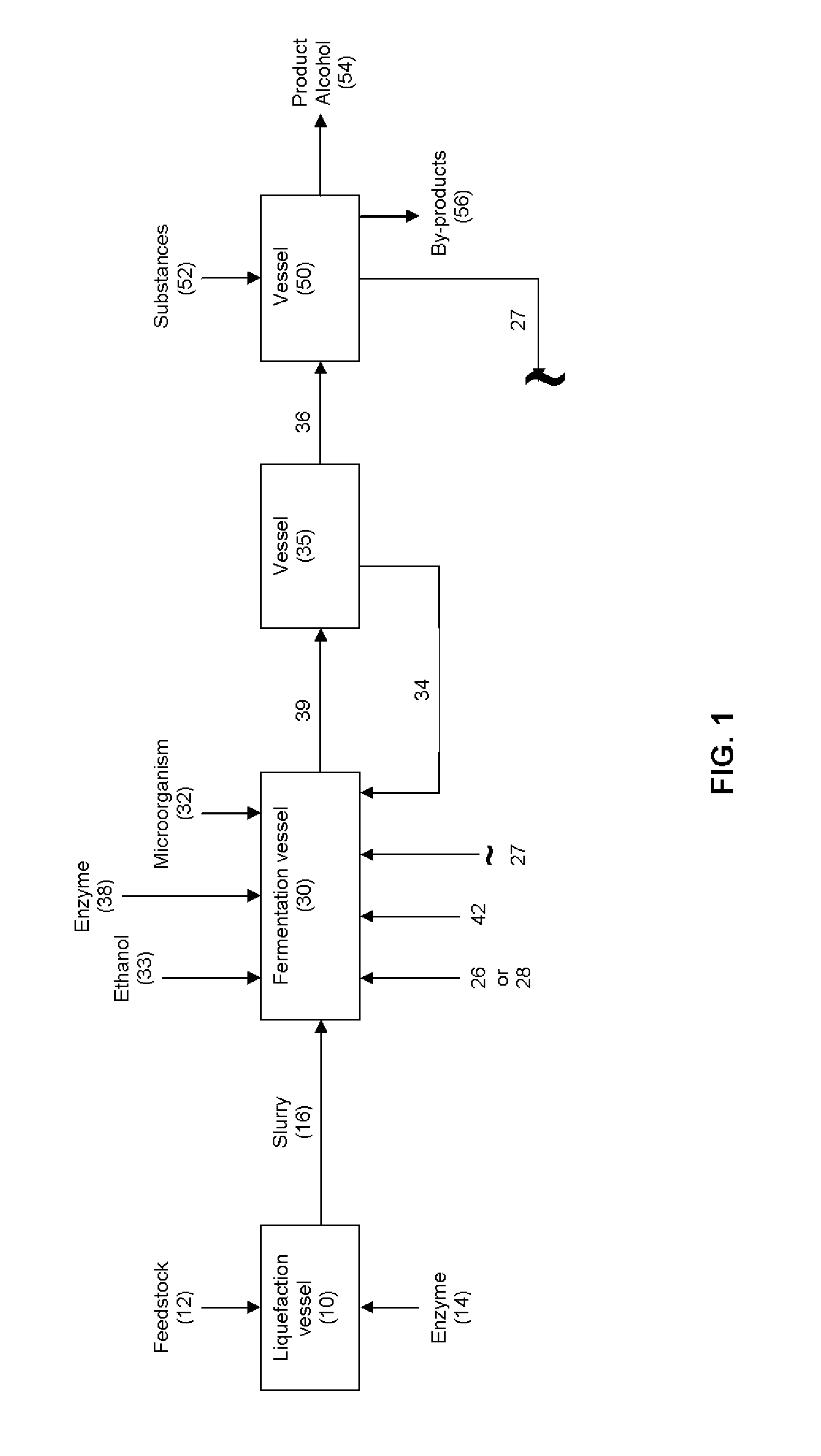

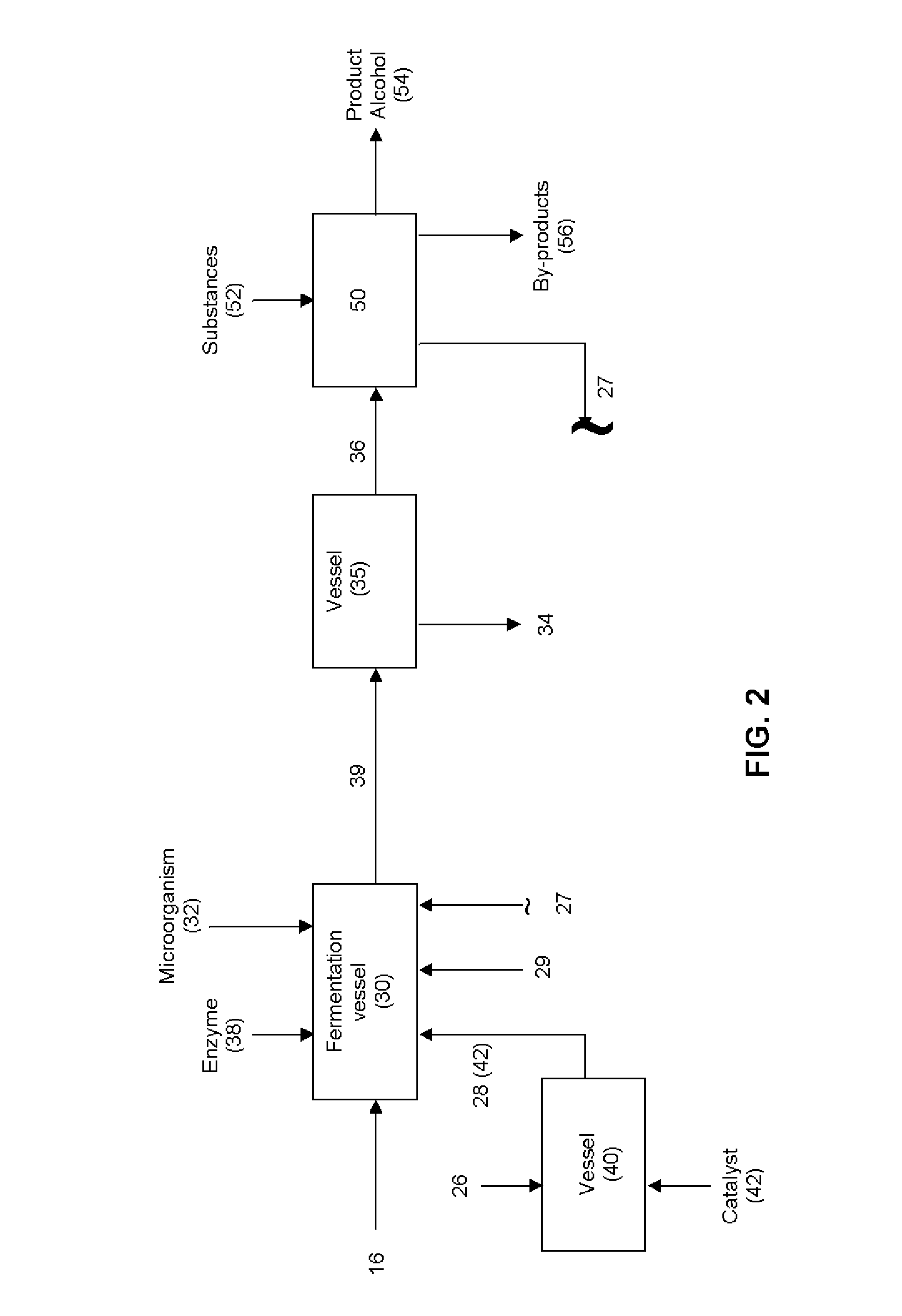

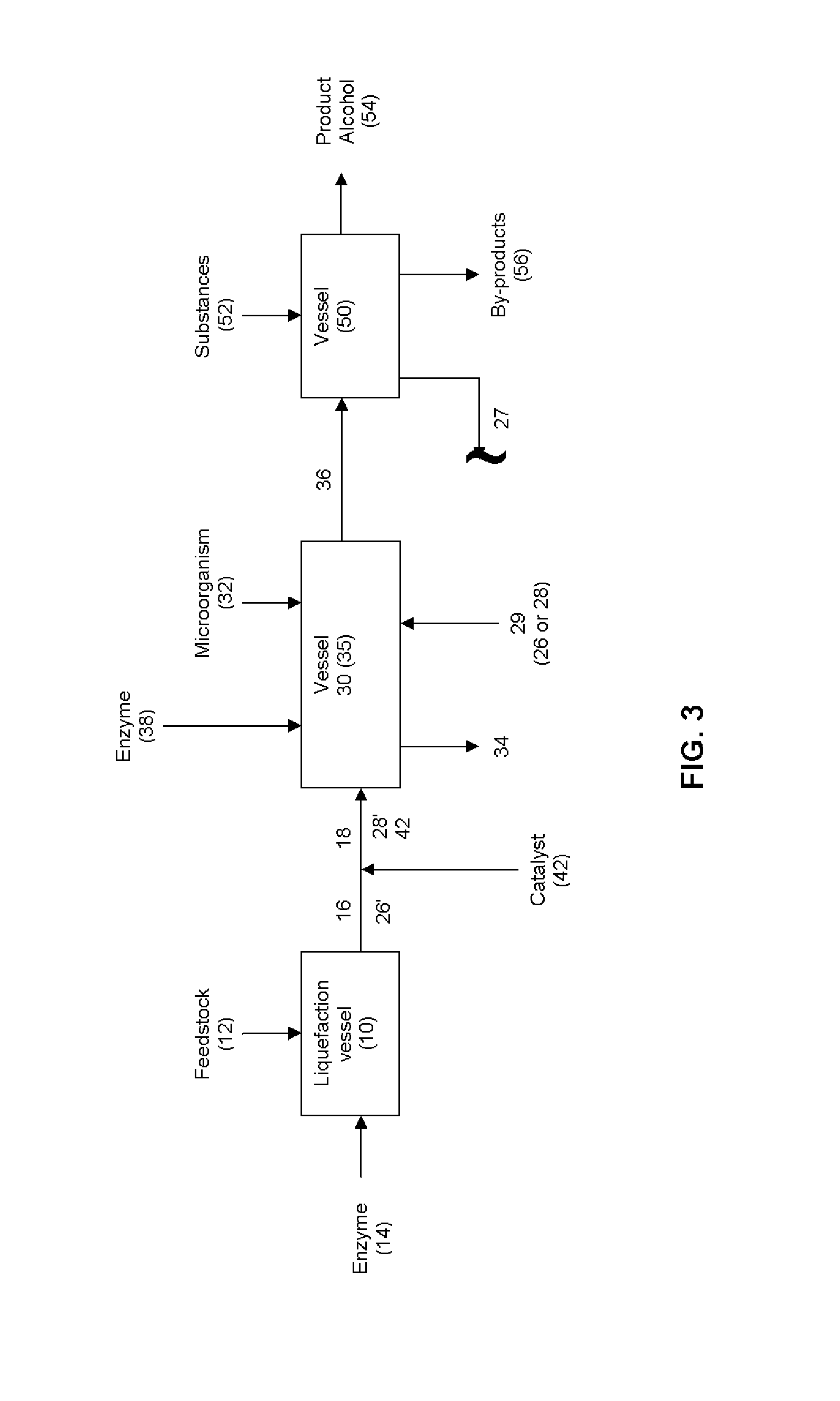

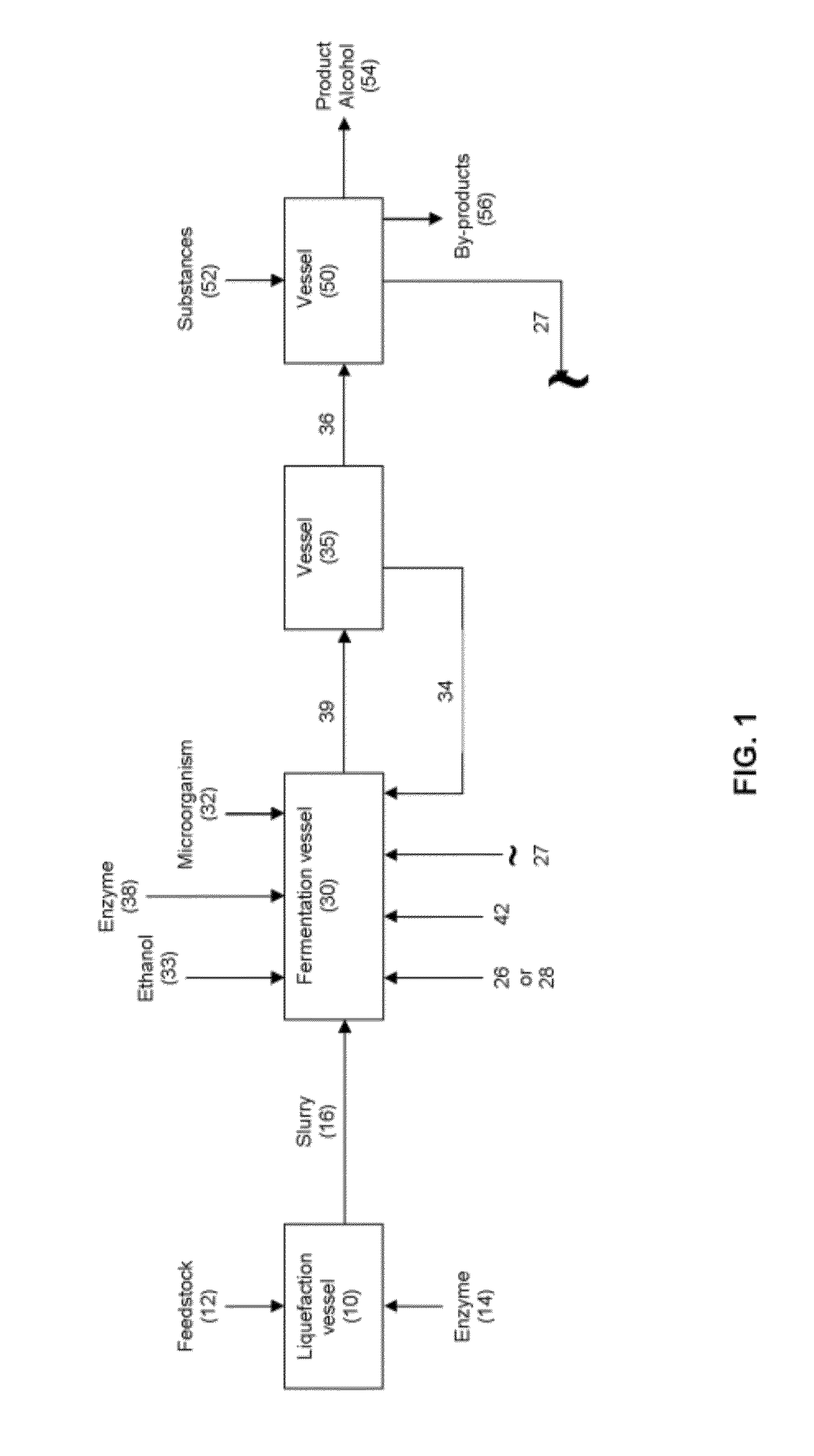

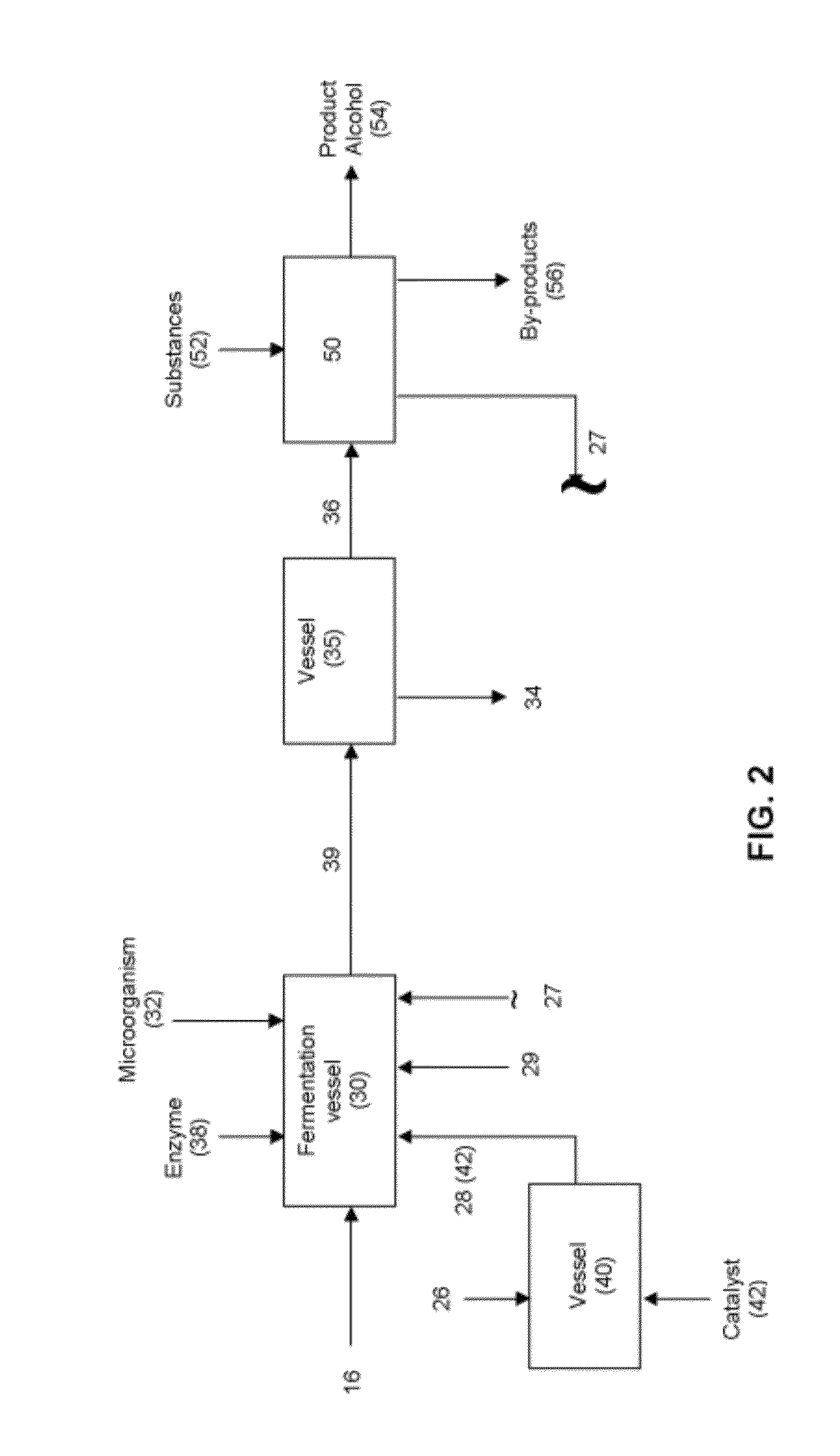

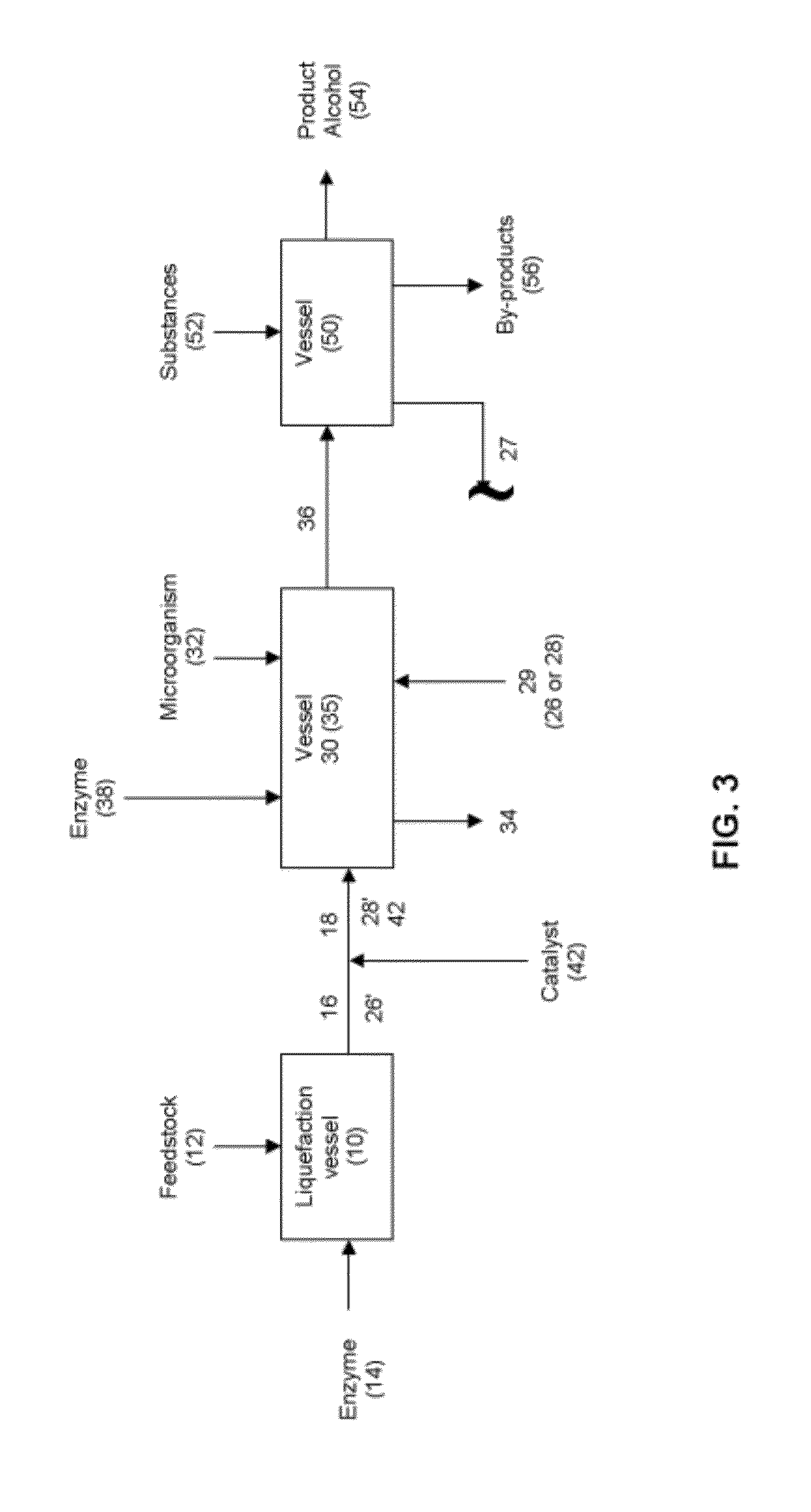

Enzymatic production of alcohol esters for recovery of diols produced by fermentation

InactiveUS20140178529A1Simplified recovery and purificationDecreasing rate of build-upHydrolasesFood processingAlcoholDiol

Diols produced in fermentation are processed in broth by esterification of the product diol with a carboxylic acid (e.g., fatty acid) and a catalyst (e.g., lipase) capable of esterifying the product diol, such as 1,3-propanediol, with the carboxylic acid to form the diol esters. The diol esters can be extracted from the broth, and the product diol recovered from the diol esters. The carboxylic acid can also serve as an extractant for removal of the diol esters from the fermentation medium.

Owner:BUTAMAXTM ADVANCED BIOFUELS

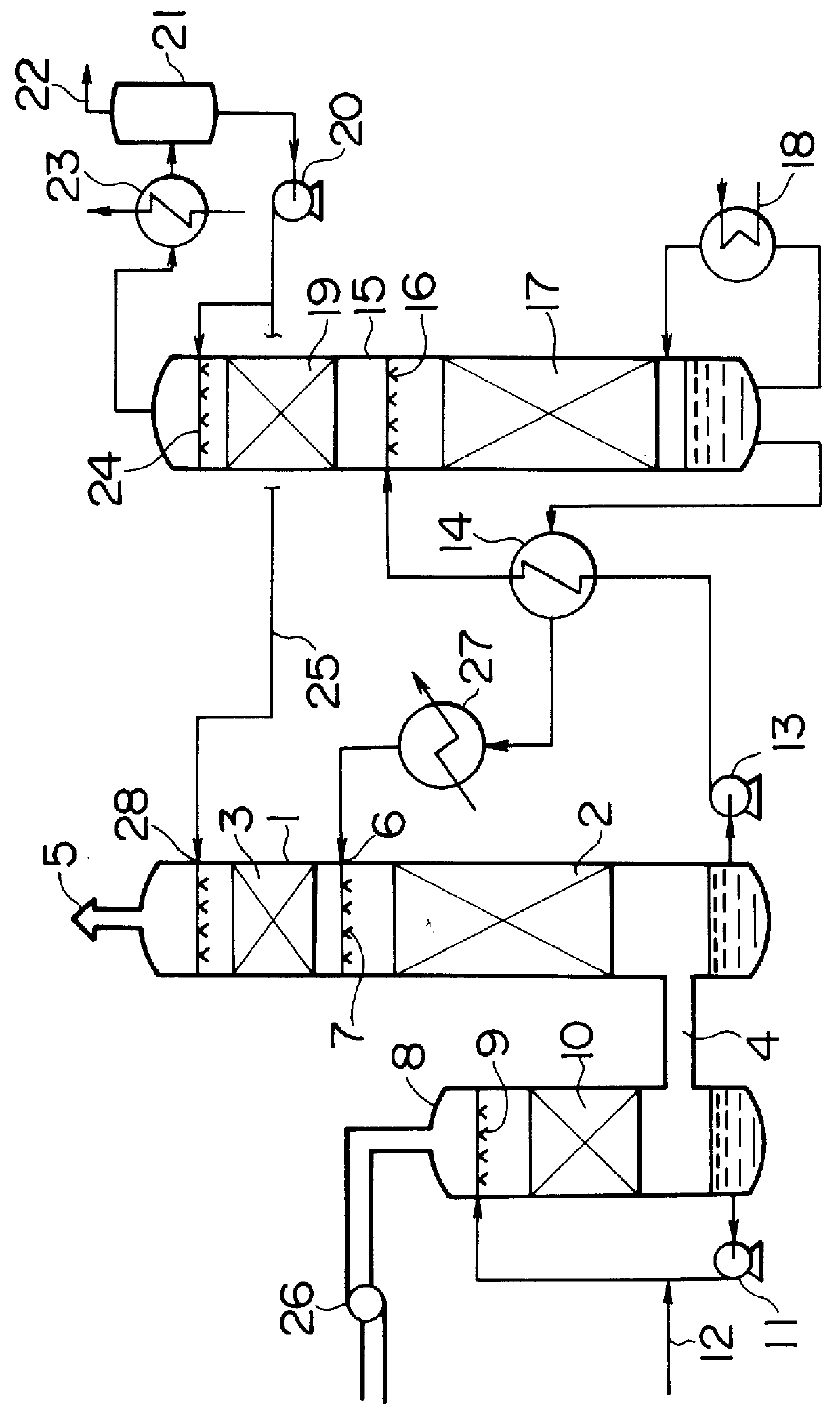

Esterification process

InactiveUS6887953B2Organic compound preparationCarboxylic acid esters preparationLiquid productOligomer

A process that can be used for direct esterification of a dicarboxylic acid such as terephthalic acid with a glycol such as 1,3-propanediol. The process comprises (1) contacting, at an elevated temperature, optionally in the presence of a preformed oligomer, the acid with the glycol to produce a product mixture comprising (i) a water-glycol vapor mixture, which or a portion of which exits the product mixture at the temperature to form a water-glycol vapor mixture and (ii) a liquid product mixture comprising an oligomer having a degree of polymerization of from about 1.9 to about 3.5 and comprising repeat units derived from the acid; (2) separating the glycol from the water-glycol mixture to produce a recovered glycol; and (3) returning the recovered glycol to the product mixture such that the liquid product mixture comprises an excess free glycol.

Owner:DUPONT IND BIOSCIENCES USA LLC

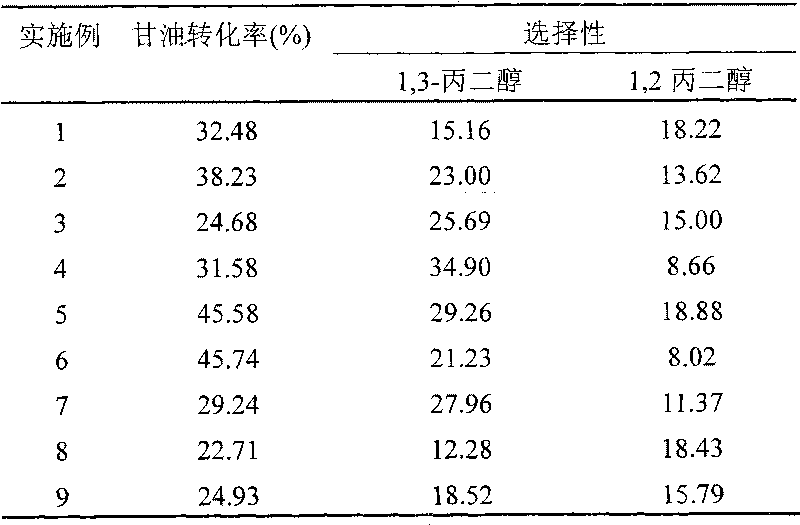

Method for preparing 1,3-propylene glycol by directly hydrogenizing glycerol

ActiveCN101723801AHigh selectivityImprove conversion ratePreparation by OH group eliminationMetal/metal-oxides/metal-hydroxide catalystsHydrogen pressureReaction temperature

The invention relates to a method for preparing 1,3-propylene glycol by directly hydrogenizing glycerol. A reaction system comprises glycerol, hydrogen, catalyzer and two or more of dissolvants. In the reaction system, the weight ratio of the dissolvants to the glycerol is 0.2-9.8:1, and the weight ratio of the catalyzer to the glycerol is 0.2-2:1; the reaction conditions are shown as follows: the reaction temperature is 80-300 DEC G, the hydrogen pressure is 0.1-18.0MPa, and the contact time of the glycerol and the catalyzer in the reaction process is 0.3-50h; the catalyzer contains a carrier and active components carried on the carrier, wherein the carrier is ZrO2, SiO2-Al2O3 or Al2O3, and the active components are one or more of Ru, Pt, Pd and Rh. The invention can obviously increase the selectivity of generating 1,3-propylene glycol by hydrogenizing glycerol or increase the percent conversion of glycerol and reduce the generation of the byproduct of 1,2-propylene.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Water-soluble, liquid-containing pouch

InactiveUS20060276364A1Aqueous liquid non-soap compositionsDetergent compounding agentsPolyvinyl alcohol1,3-Propanediol

The present invention relates to water-soluble pouch which contains a liquid detergent composition, wherein the pouch is a water-soluble film, the film material comprising a polyvinyl alcohol, and wherein the liquid detergent composition also comprises a plasticizer, wherein the plasticizer is selected from the group consisting of glycerol, ethylene glycol, diethylene glycol, triethylene glycol, 2-methyl-1,3-propane diol, sorbitol, methanol, diglycerol, 1,4-butane diol, urea and mixtures thereof, and wherein the liquid detergent composition further comprises a viscosity modifier, preferably a hydrogenated castor oil.

Owner:THE PROCTER & GAMBLE COMPANY

Enzymatic production of alcohol esters for recovery of diols produced by fermentation

ActiveUS20120322117A1Simplified recovery and purificationDecreasing rate of build-upHydrolasesFood processingAlcoholCarboxylic acid

Diols produced in fermentation are processed in broth by esterification of the product diol with a carboxylic acid (e.g., fatty acid) and a catalyst (e.g., lipase) capable of esterifying the product diol, such as 1,3-propanediol, with the carboxylic acid to form the diol esters. The diol esters can be extracted from the broth, and the product diol recovered from the diol esters. The carboxylic acid can also serve as an extractant for removal of the diol esters from the fermentation medium.

Owner:EI DU PONT DE NEMOURS & CO +1

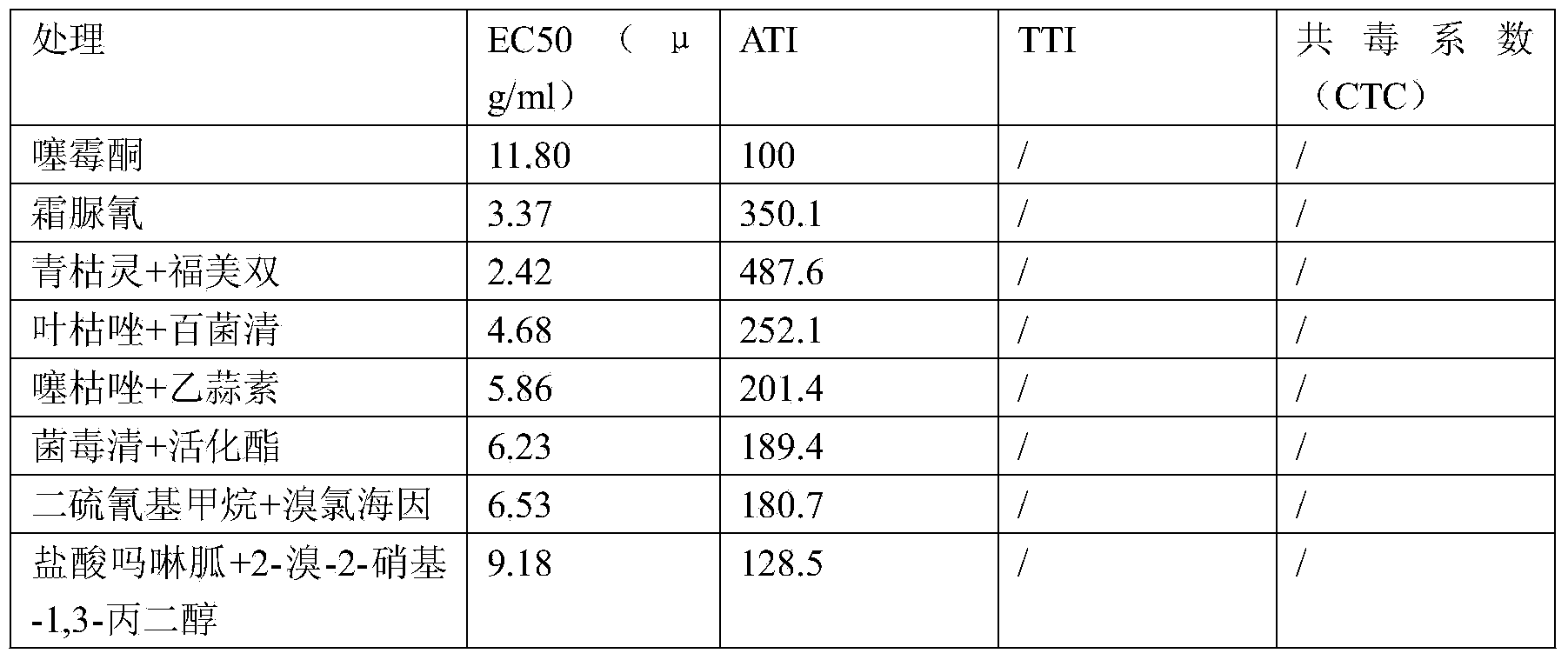

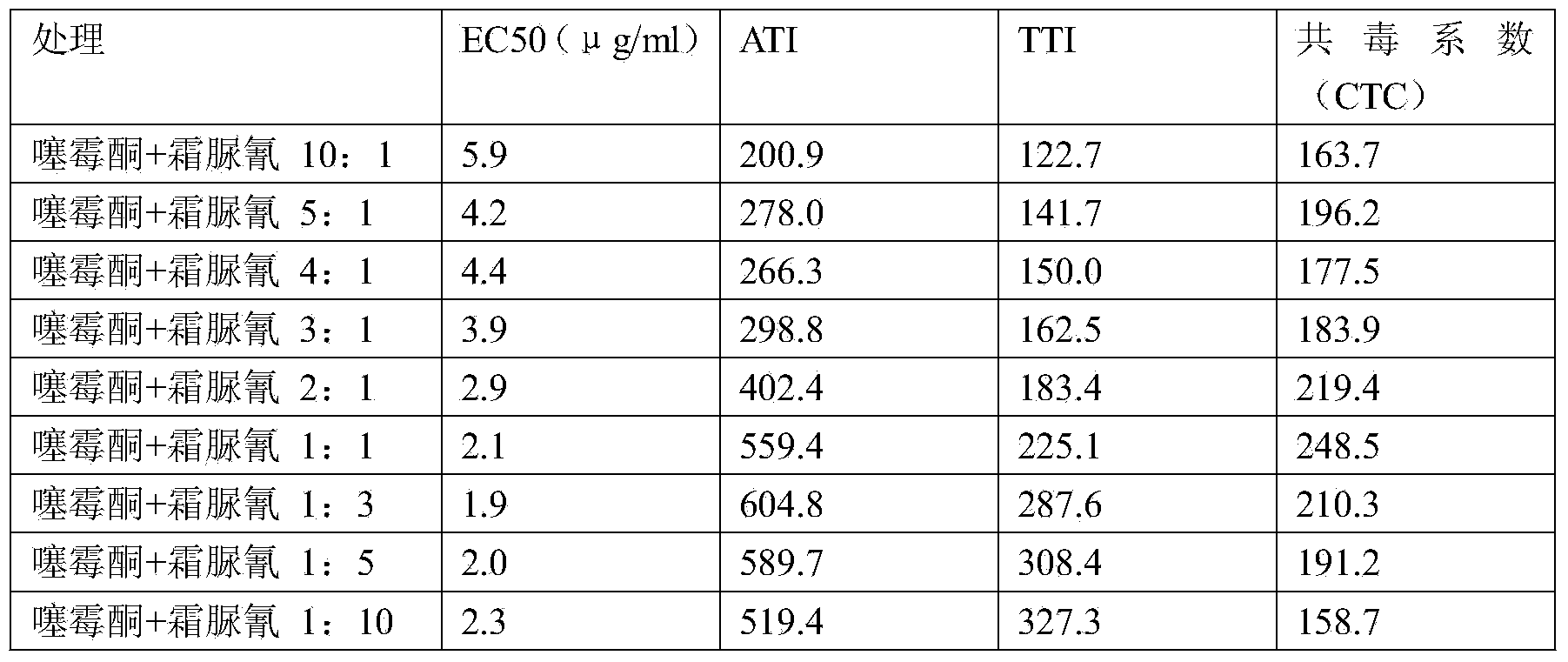

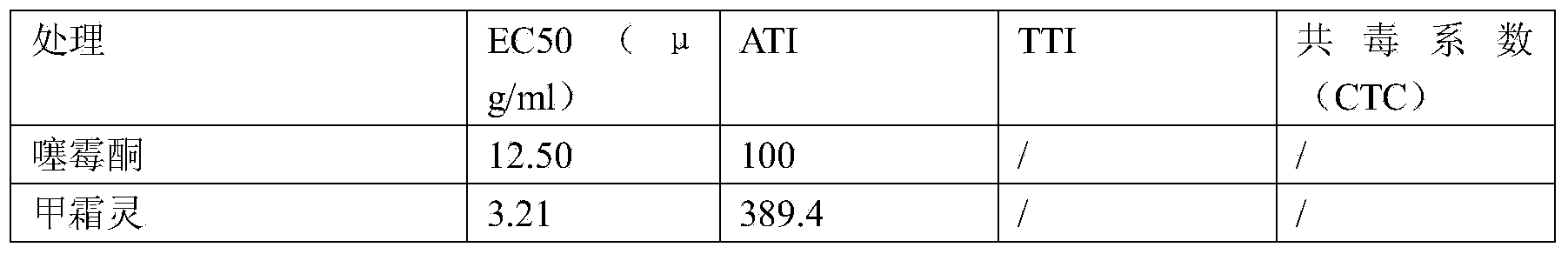

Composite for preventing and controlling agricultural bacterial disease

ActiveCN103704234AEasy to controlReduce the amount of applicationBiocideDisinfectantsBacterial disease1,3-Propanediol

The invention discloses a composite for preventing and controlling an agricultural bacterial disease, and belongs to the technical field of plant protection pesticides. The composite comprises an active component A and an active component B, wherein the active component A is benziothiazolinone; the active component B is one or two of cymoxanil, qingkuling, yekuzuo, bismerthiazol, ethylicin, thiram, dioctyl divinyltriamino glycine, active ester, metalaxyl, chlorothalonil, dithiocyano-methane, bromine chlorine hydantoin, 2-bromine-2-nitryl-1,3-propylene glycol and moroxydine hydrochloride; the weight ratio of the active component A to the active component B is 1:100 to 100:1. The composite disclosed by the invention obtains the synergetic effect through the mixing of the benziothiazolinone and other bacterial medications and is used for agricultural production.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com