Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

826results about How to "Improve hydrogenation activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

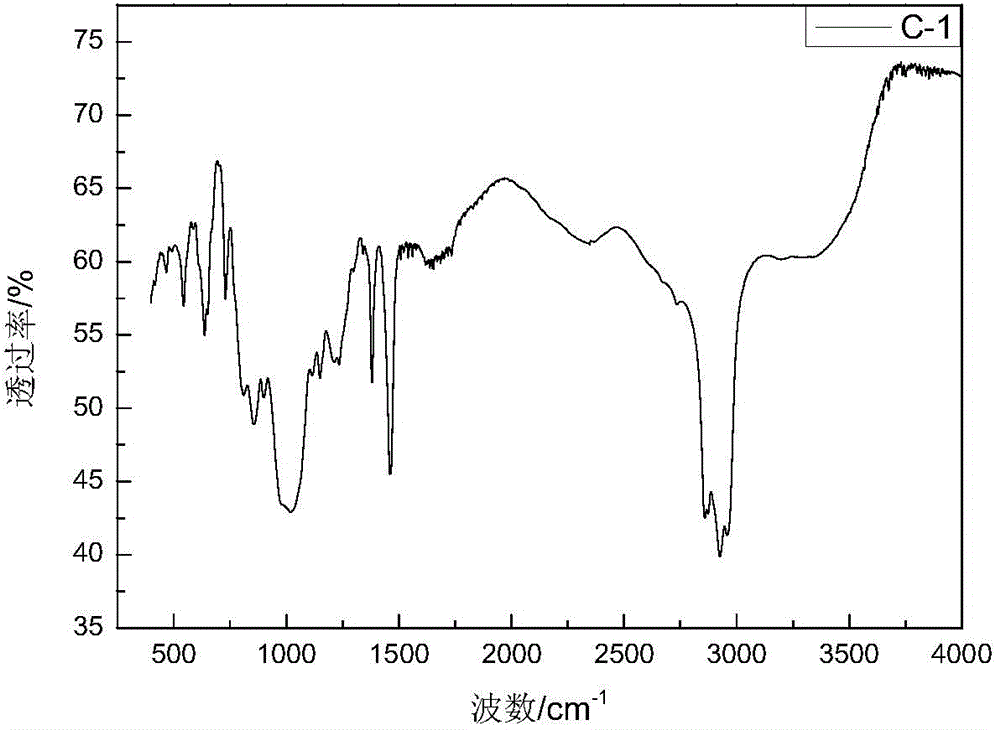

Palladium-silver bimetallic hydrogenation catalyst

ActiveCN102205243AGood choiceImprove hydrogenation activityHydrocarbon purification/separationHydrocarbonsHydrogenation processSolvation

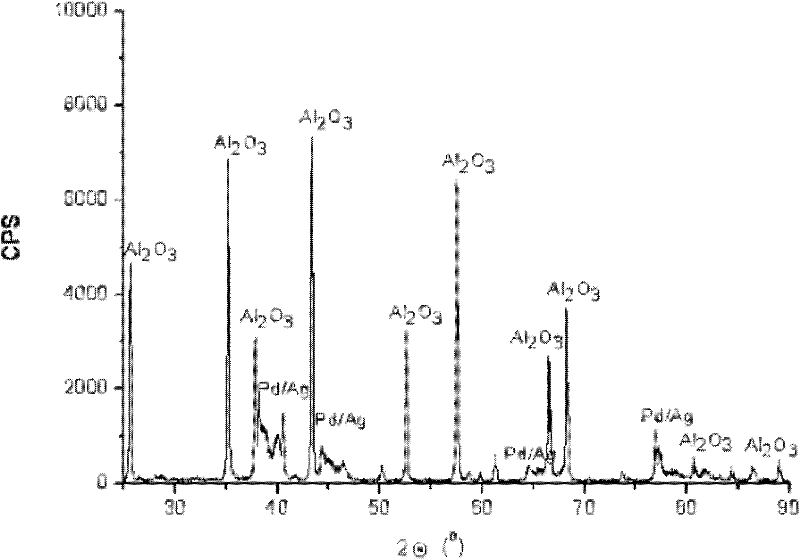

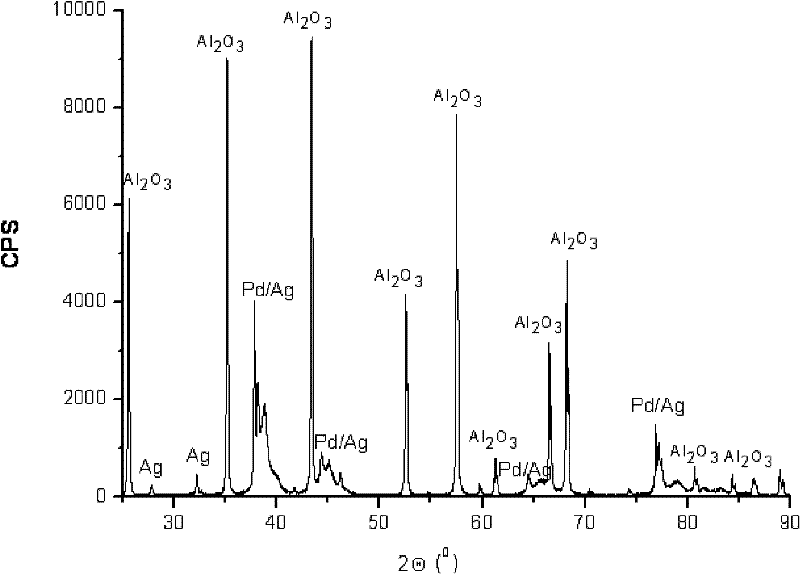

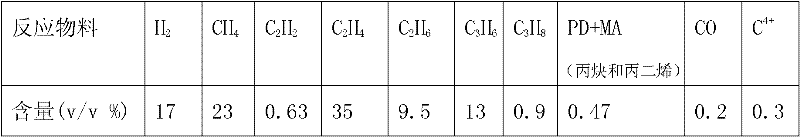

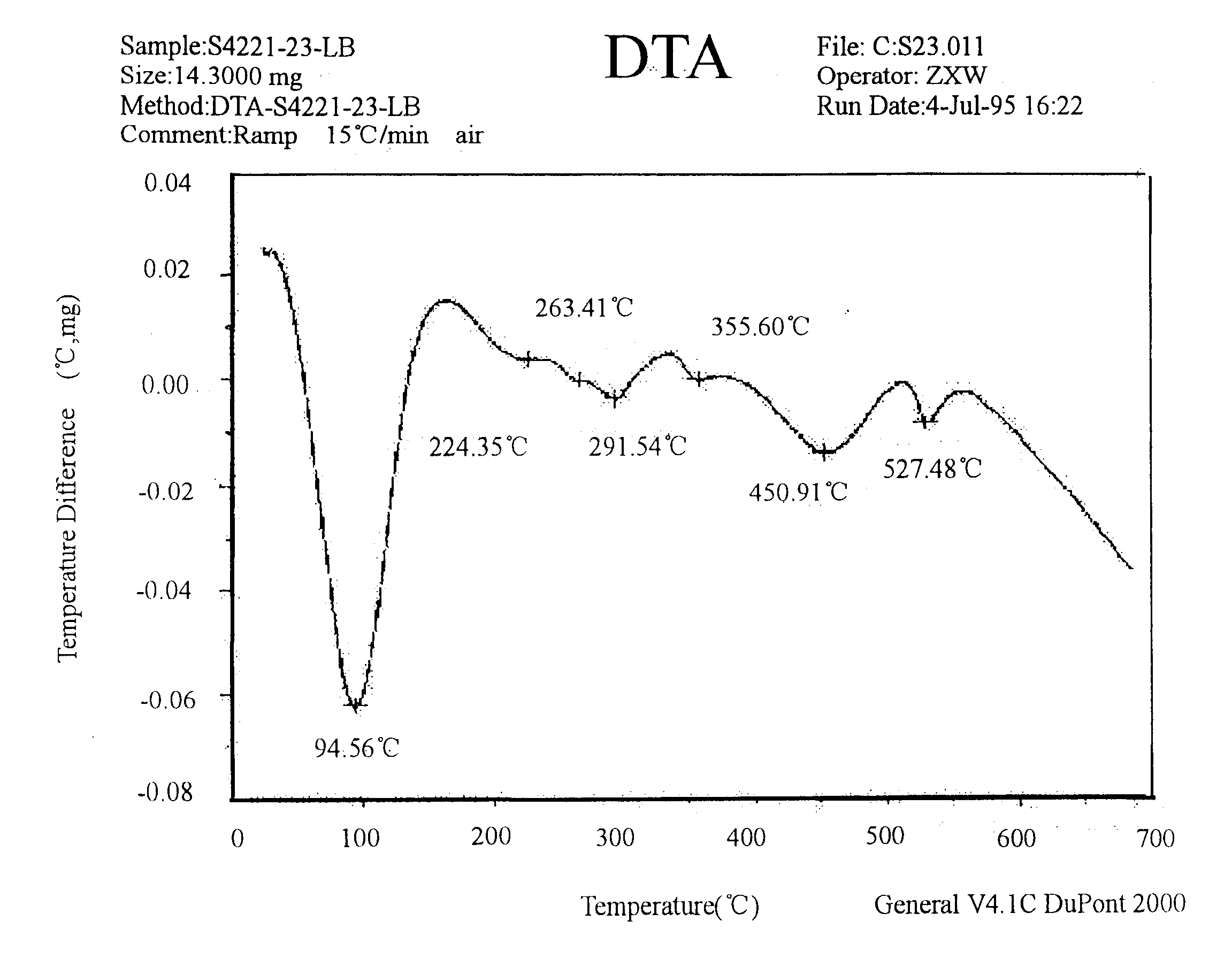

The invention relates to a palladium-silver bimetallic hydrogenation catalyst, a carrier of which mainly contains Al2O3 and which is characterized by comprising, based on 100% of the catalyst weight, 0.01-0.4% of Pd, 0.02-0.2% of Ag, and has a specific surface area of 1-100m<2> / g. The catalyst is obtained through three steps of: first, preparing a functionalized-high-molecular / Al2O3 precursor, then preparing a Pd-Ag-high-molecular / Al2O3 precursor, and lastly roasting the precursors at 380-550 DEG C for 2-6h. The preparation method overcomes the influences of dipping liquid surface tensionand solvation effect on palladium-silver disperseness, and the prepared catalyst has excellent selectivity. The catalyst of the invention can be applied to selective hydrogenation process of fractions such as C2 and C3, and has a good hydrogenation activity, excellent selectivity and good hydrogenation stability.

Owner:PETROCHINA CO LTD

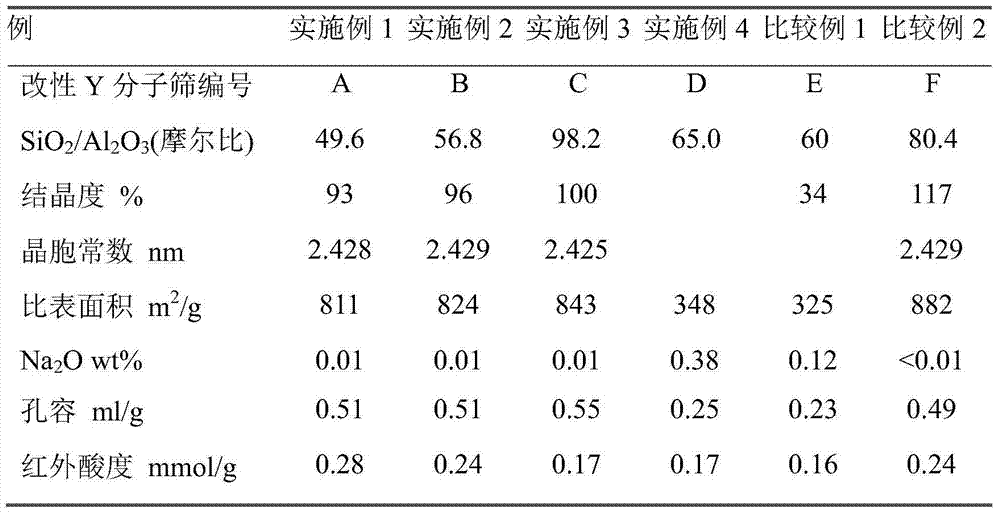

Amorphous silica-alumina, a carrier combination and a hydrocracking catalyst containing the same, and processes for the preparation thereof

InactiveUS6399530B1Increase surface areaLarge hole volumeMolecular sieve catalystsHydrocarbon oil crackingSilicon dioxideHigh activity

An acidic amorphous silica-amumina has a large specific surface area and a large pore volume. A carrier complex and a hydrotreating catalyst containing acidic amorphous silica-alumina, in particular a hydrocracking catalyst containing acidic amorphous silica-alumina in combination with a modified zeolite-Y, treats petroleum hydrocarbon materials to produce middle distillates. The amorphous silica-alumina has a SiO2 content of 10-50 wt. %, a specific surface area of 300-600 m2 / g, a pore volume of 0.8-1.5 ml / g and an IR acidity of 0.25-0.60 mmol / g. The catalyst shows a relatively high activity and mid-distillate selectivity and can be particularly used in hydrocracking process for producing mid-distillates with a higher yield.

Owner:CHINA PETROCHEMICAL CORP +1

Acetylene hydrocarbon selective hydrogenation method

ActiveCN101434508AGood hydrogenation effectImprove hydrogenation activityHydrocarbon by hydrogenationHydrocarbon purification/separationButadiene DioxideUnsaturated hydrocarbon

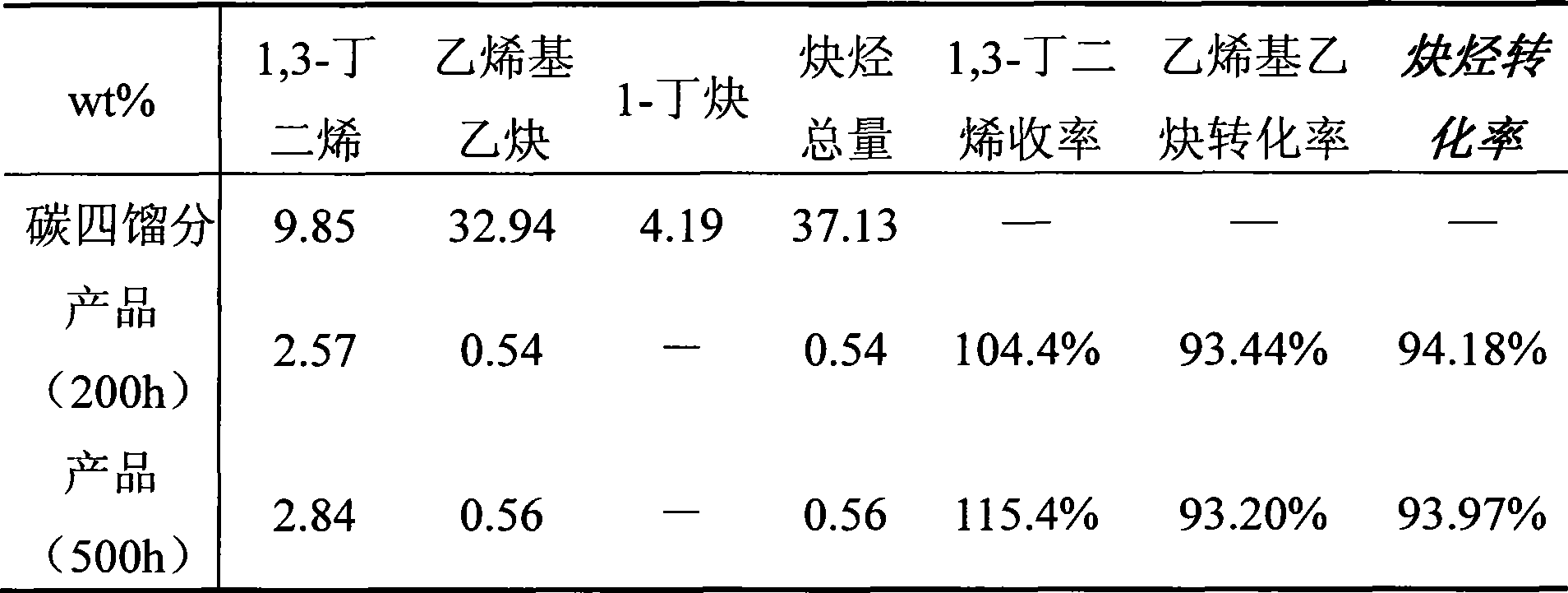

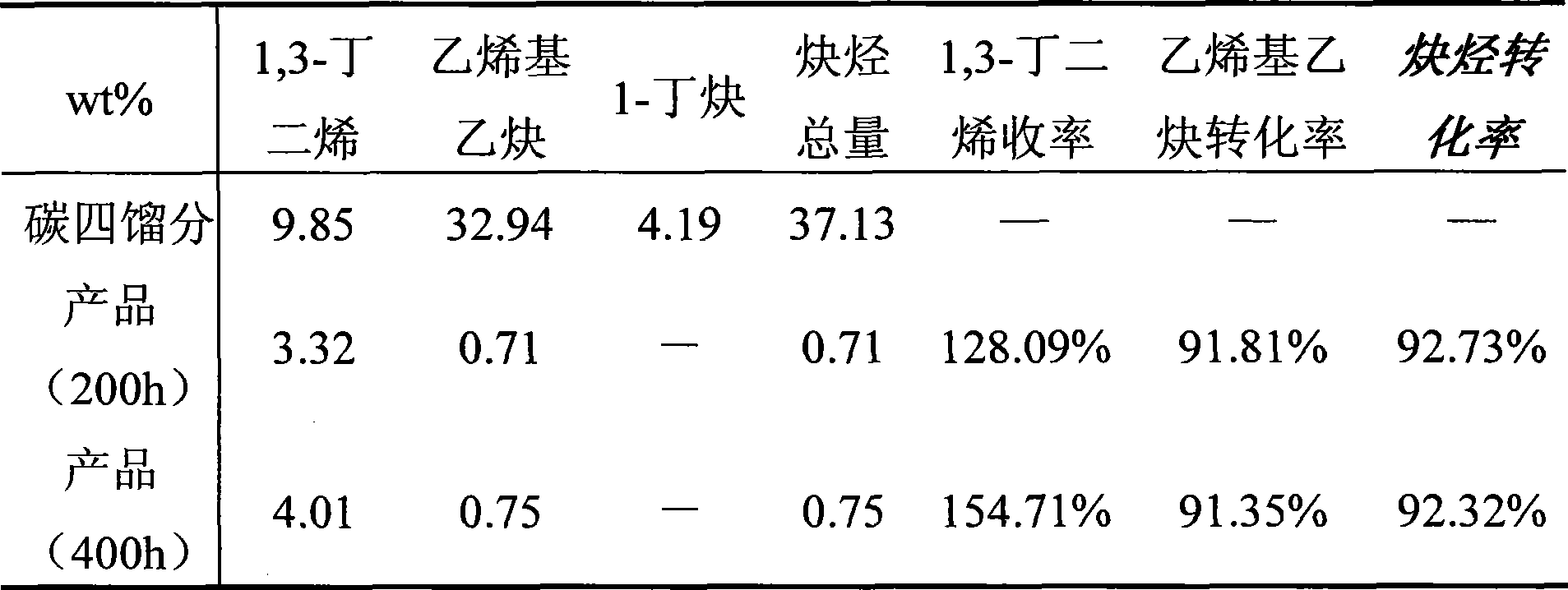

The invention relates to a selective hydrogenation method of high unsaturated hydrocarbons in C4 fractions, which is characterized in that salvage stores which are rich in acetylene hydrocarbon and prepared by extracting butadiene are used as the material, and a fixed bed reactor is adopted to obtain 1, 3-budiene by selective hydrogenation under the existence of a catalyst. The adopted process conditions are as follows: the reaction temperature is between 30 DEG C and 90 DEG C, the reaction pressure is between 1.0 MPa and 4.0 MPa and the liquid space velocity is 7 to 20h<-1>. The catalyst is preferably a palladium system catalyst with alumina as a carrier, the specific surface is 50 to 150m<2> / g and the specific pore volume is 0.25 to 1.0ml / g. The method has remarkable good effects on reducing waste of resources and improving economic benefits by effectively utilizing the salvage stores rich in acetylene hydrocarbon and prepared by extracting butadiene.

Owner:PETROCHINA CO LTD

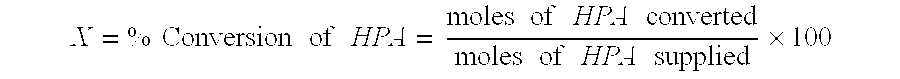

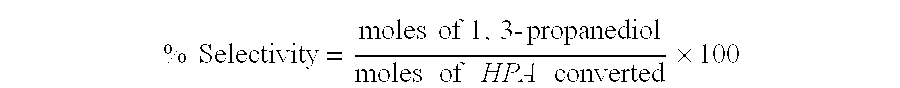

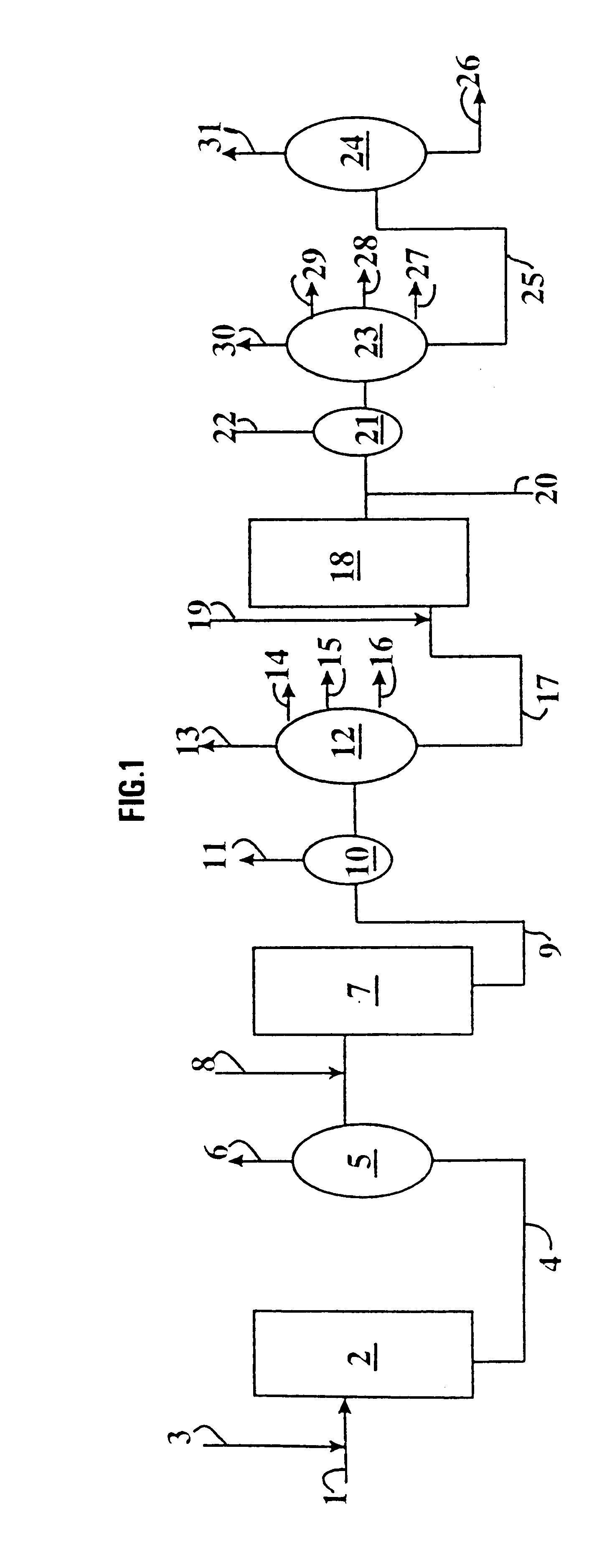

Catalytic hydrogenation of 3-hydroxypropanal to 1,3-propanediol

InactiveUS6342646B1Improves performance and lifetimeImprove hydrogenation activityOrganic compound preparationOxygen compounds preparation by reductionAsymmetric hydrogenation1,3-Propanediol

The present invention provides an improved process for the hydrogenation of 3-hydroxypropanal to 1,3-propanediol which comprises purifying an aqueous solution of 3-hydroxypropanal by contacting said aqueous solution with a purifying agent prior to hydrogenation.

Owner:EI DU PONT DE NEMOURS & CO

Nickel system hydrogenation catalyst, preparation method and application

ActiveCN101037613AImprove hydrogenation activityImprove stabilityHydrocarbon by hydrogenationRefining to eliminate hetero atomsResistAdjuvant

The invention realtes to a nickel based hydrogenation catalyst, preparation and application thereof. Using alumina or and monox silica as carrier, the catalyst prepared by means of coprecipitation, main containing active component Ni, is characterized in catalyst composed by active component Ni, La, adjuvant X1 and carrier X2O. Calculated by weight of component, the catalyst including: NiO 40-70%, La2O3 2-5%, X2O 20-50%, wherein X1 is selected from one or more of Cu, Mg, Zr, X2 is selected from Al or and Si; surface area to volume ratio thereof is 80-200 m<2> / g, pore volume ratio is 0.4-0.8 ml / g. The catalyst is suit for mono olefin hydrogenation, especially for hydrogenation of pyrolysis C9 distillation, which has higher hydrogenation activity, definited sulfur poison resist and carboid resist to fit for higher require of high colloid raw material hydrogenation which of catalyst has high hydrogenation activity and good stability.

Owner:PETROCHINA CO LTD

Unsupported catalyst and preparation method thereof

ActiveCN101255356ALarge specific surface areaImprove hydrogenation activityRefining to eliminate hetero atomsUreaCatalytic hydrogenation

Disclosed are a unsupported catalyst for deeply hydrofinishing of intermediate distillate and method for making the same, particularly a catalyst particle with nanometer pore and relatively high specific surface area obtained by urea melt reaction. The most outstanding technical feature of the invention is that by adopting synthesis technique of urea melt reaction, metal is free of loss, prepared metal composite has nanometer pore and relatively high specific surface area, and could provide abundant catalytic hydrogenation activity bits, and the inventive catalyst has much higher catalytic hydrogenation activity comparing with conventional supported catalyst because of this. Meanwhile, the invention is simple in process, easy to operate, fast in reaction, suitable for industrial production.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Hydrogenation catalyst, its process and use

ActiveCN1644656AIncrease surface areaLarge hole volumeRefining by selective hydrogenationAluminium hydroxideNickel compounds

A hydrogenation catalyst and its preparation and use are disclosed. The said catalyst consists of NiO 10-30wt.% and Al2O3 70-90wt.%, obtained by: drying quasi-hydrated aluminum oxide powder, passing steam to ream, roasting to have macroporous aluminum oxide carrier, dipping it in a solvent containing nickel compound, filtering, drying, roasting to form the final product. It is suitable for fractional oil containing dialkene and styrene and their derivatives to directly prepare solvent with high aromatic hydrocarbon and gasoline with high octane level by hydrogenation.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

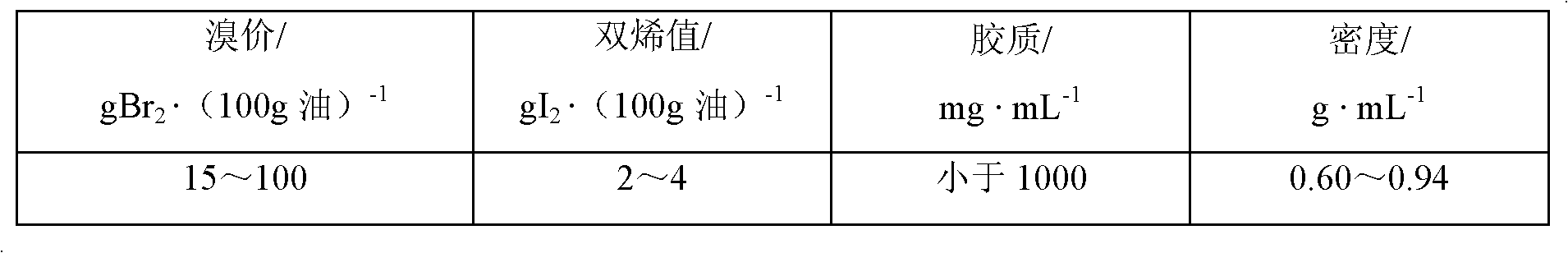

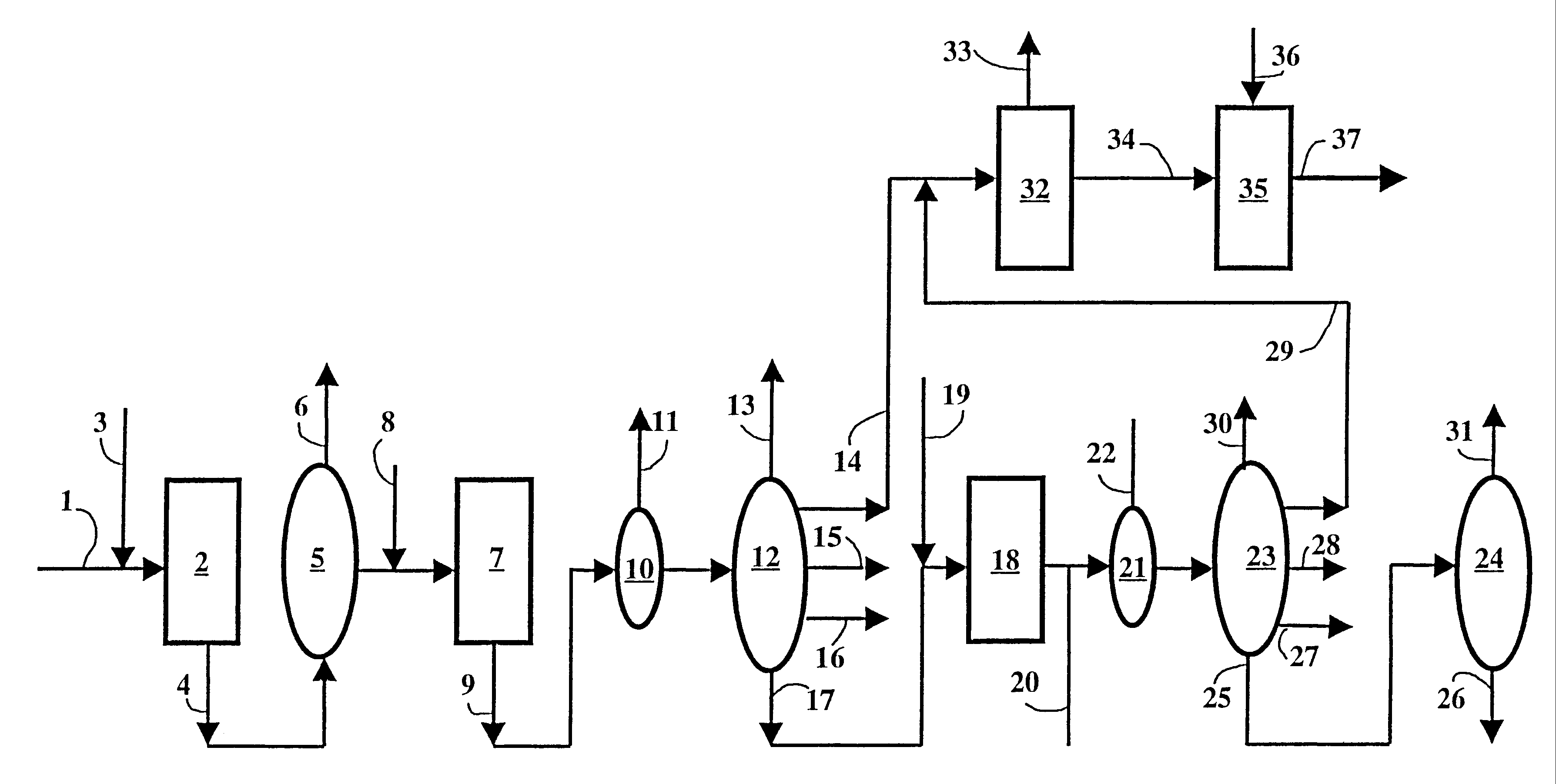

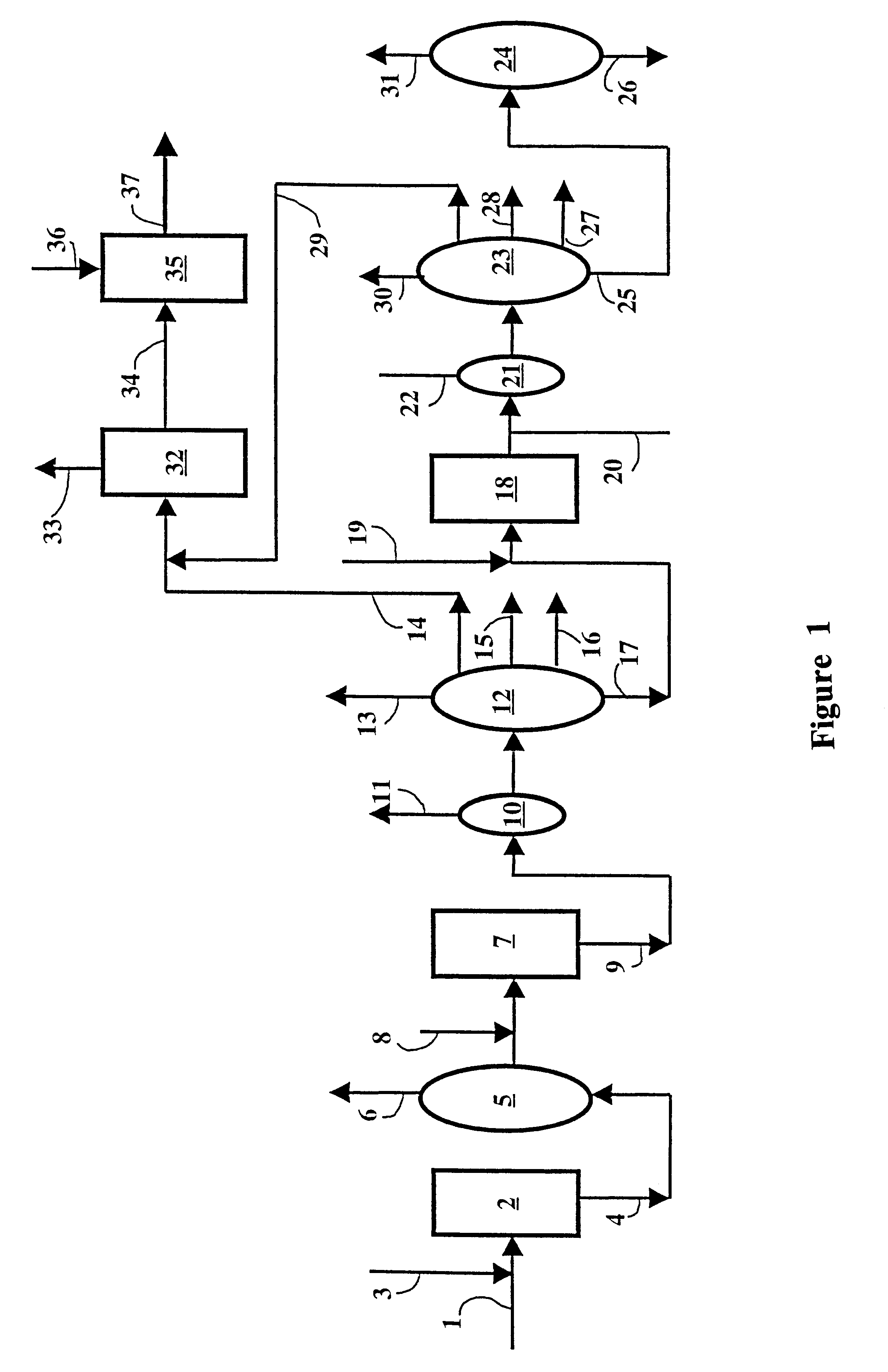

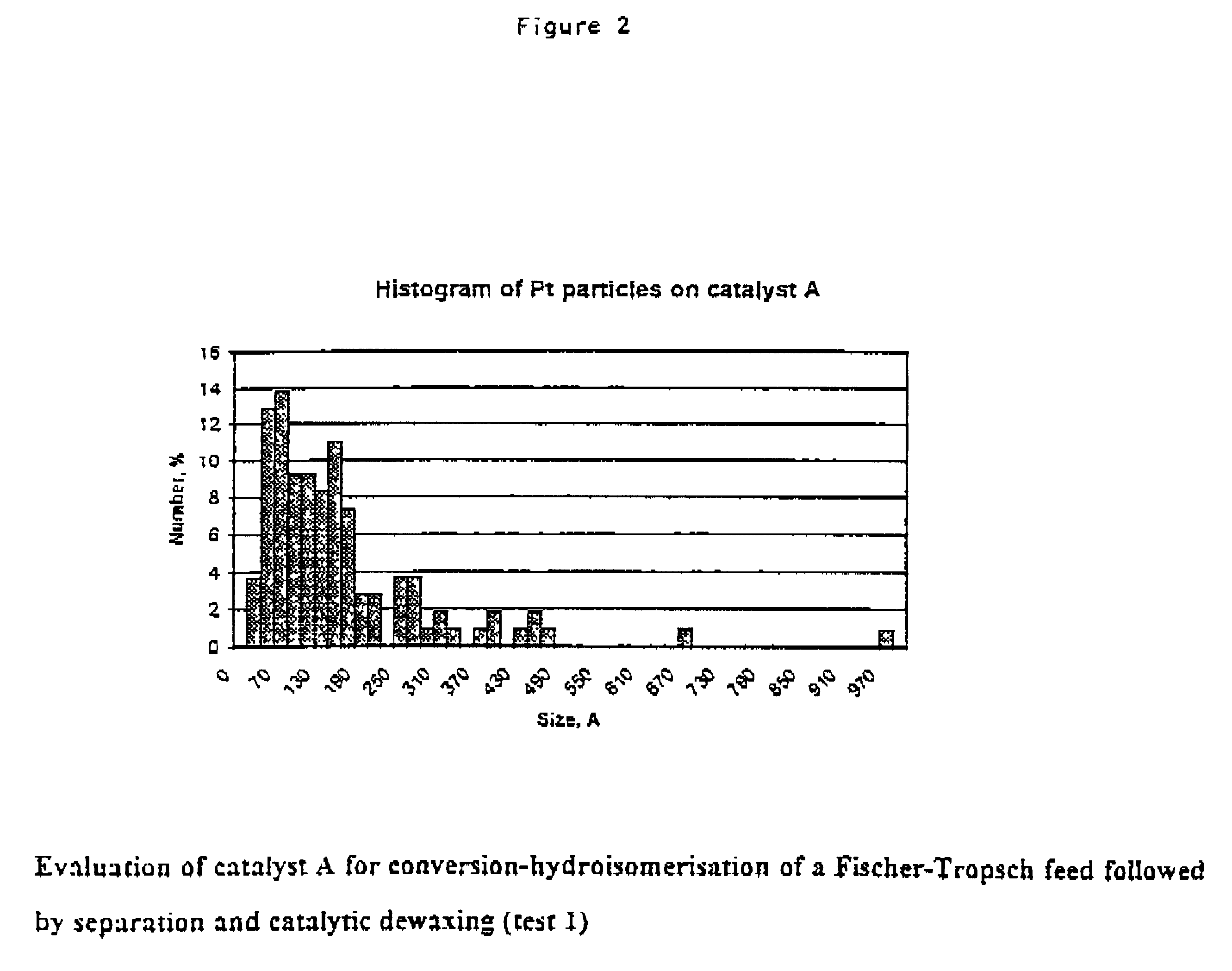

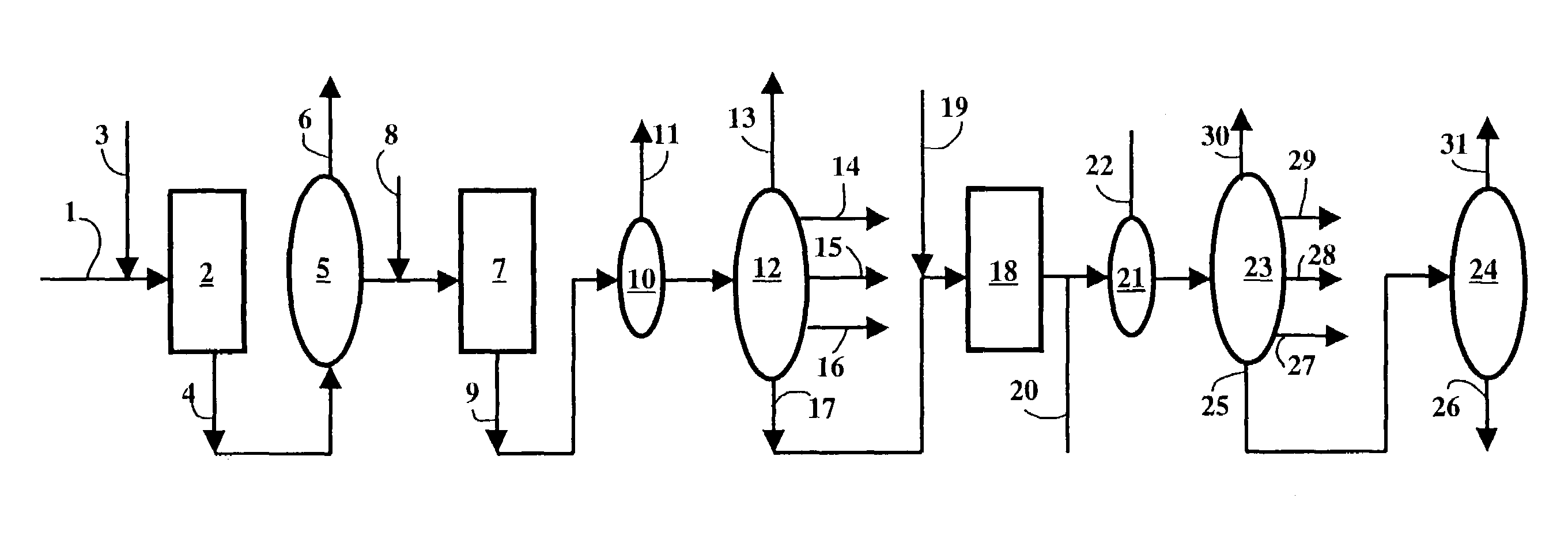

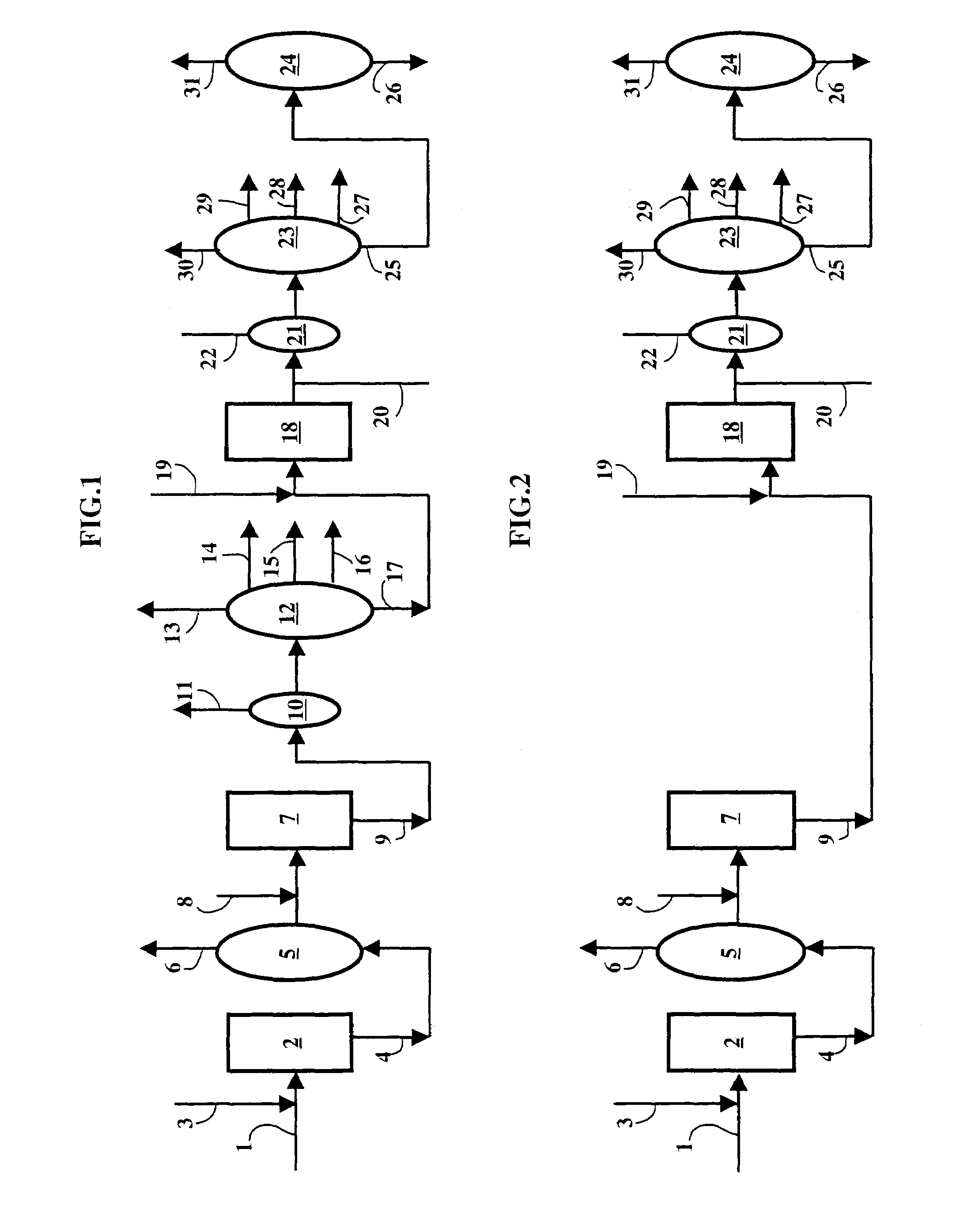

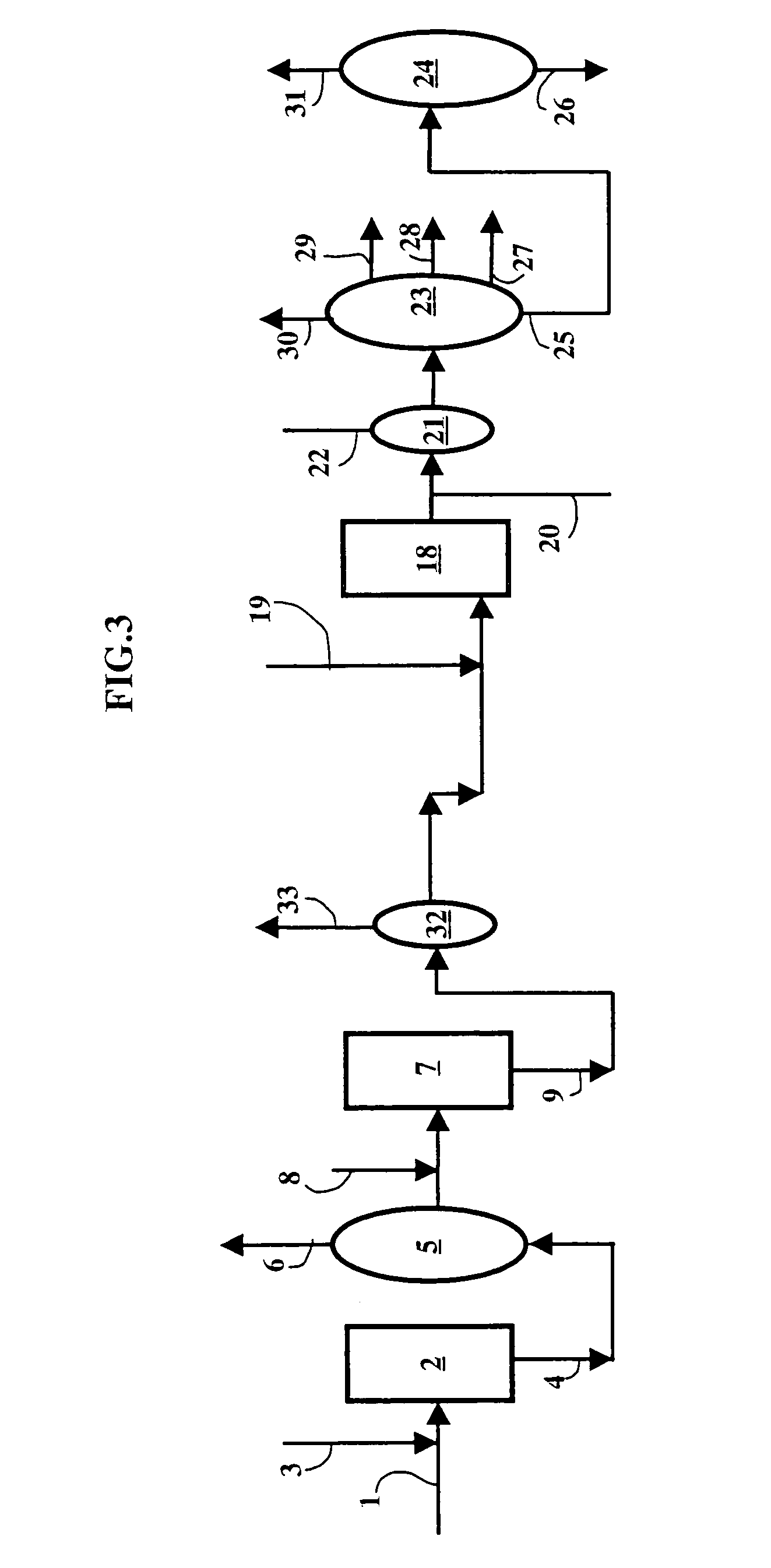

Flexible process for producing base stock and distillates by conversion-hydroisomerisation using a catalyst with low dispersion followed by catalytic dewaxing

InactiveUS6602402B1Facility of preparationImprove hydrogenation activityMolecular sieve catalystsRefining to change hydrocarbon structural skeletonPtru catalystEngineering

An improved process for producing very high quality base stock and for simultaneous production of high quality middle distallates, comprising successive hydroisomerisation and catalystic dewaxing steps wherein hydroisomerisation is carried out in the presence of a catalyst containing at least one noble metal deposited on an amorphous acidic support, the dispersion of the metal being less than 20%. The support is preferably an amorphous silica-alumina. Catalytic dewaxing is carried out in the presence of a catalyst containing at least one hydrodehydrogenating element (group VIII) and at least one molecular sieve (preferably zeolite). The sieve is preferable selected from NU-10, EU-1, EU-13, zeolite and ferrierite.

Owner:INST FR DU PETROLE

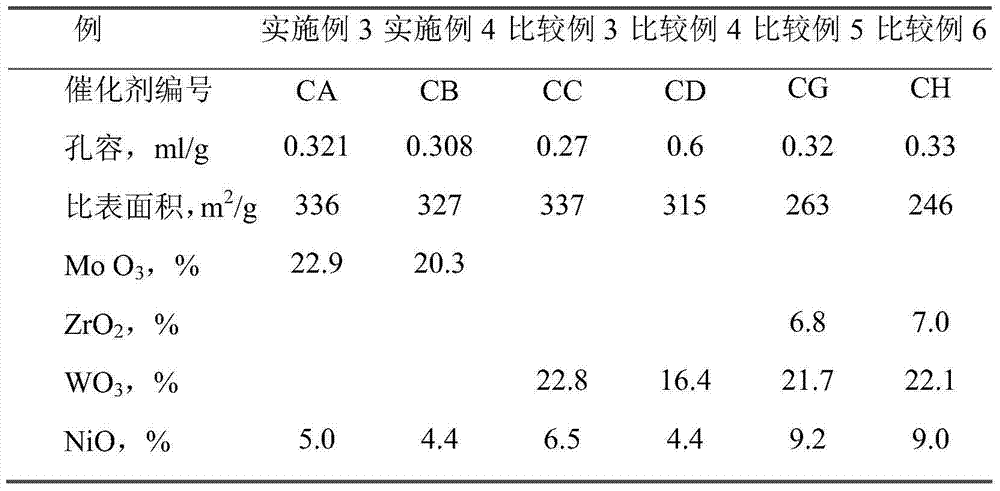

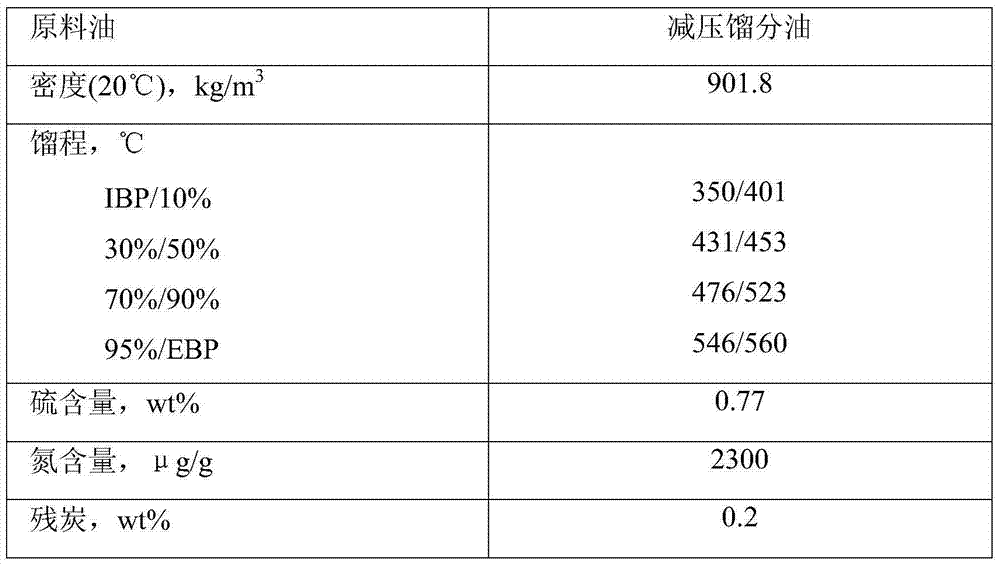

Hydrocracking catalyst and preparation method thereof

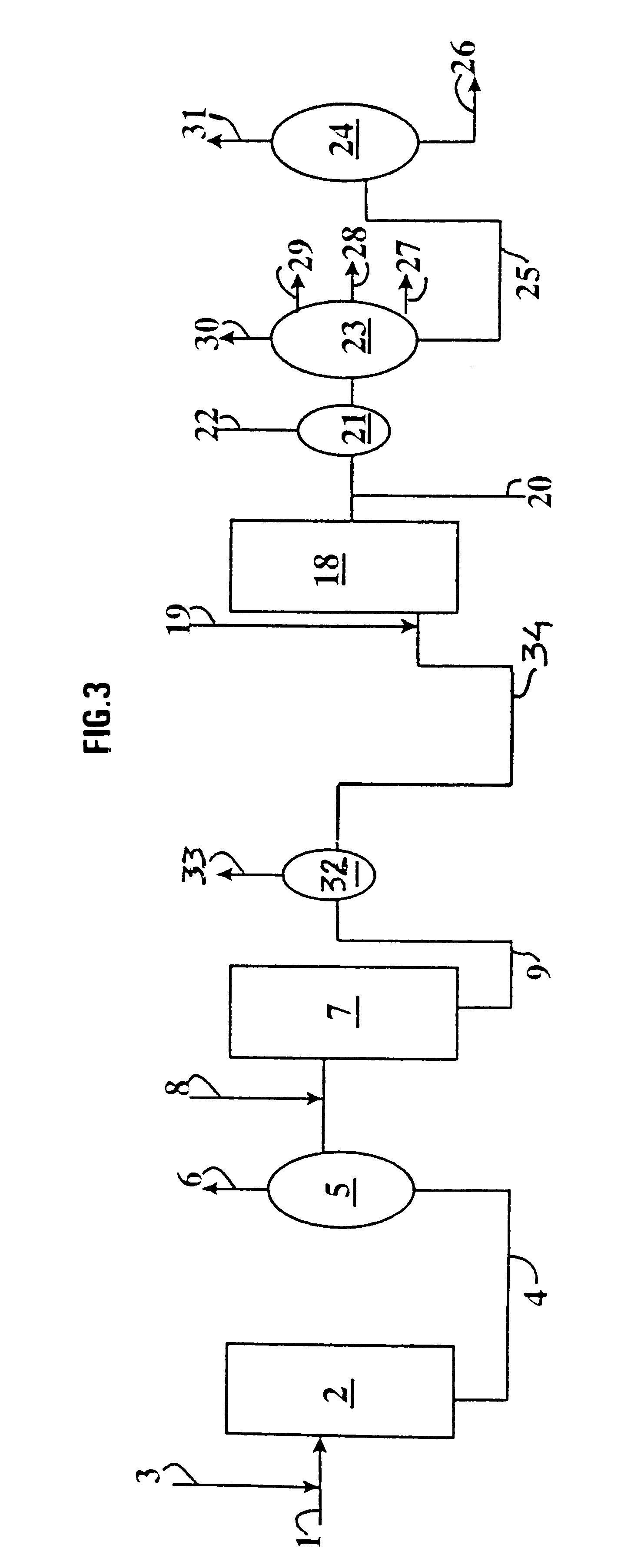

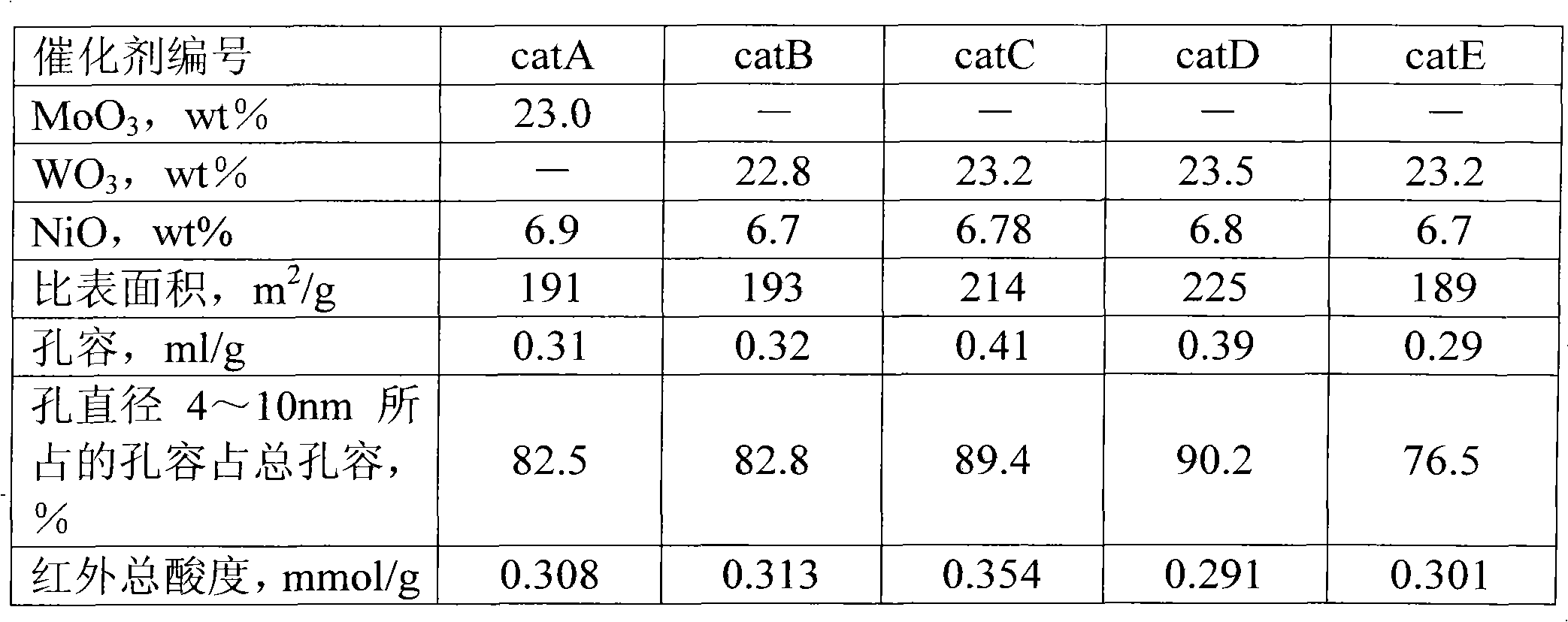

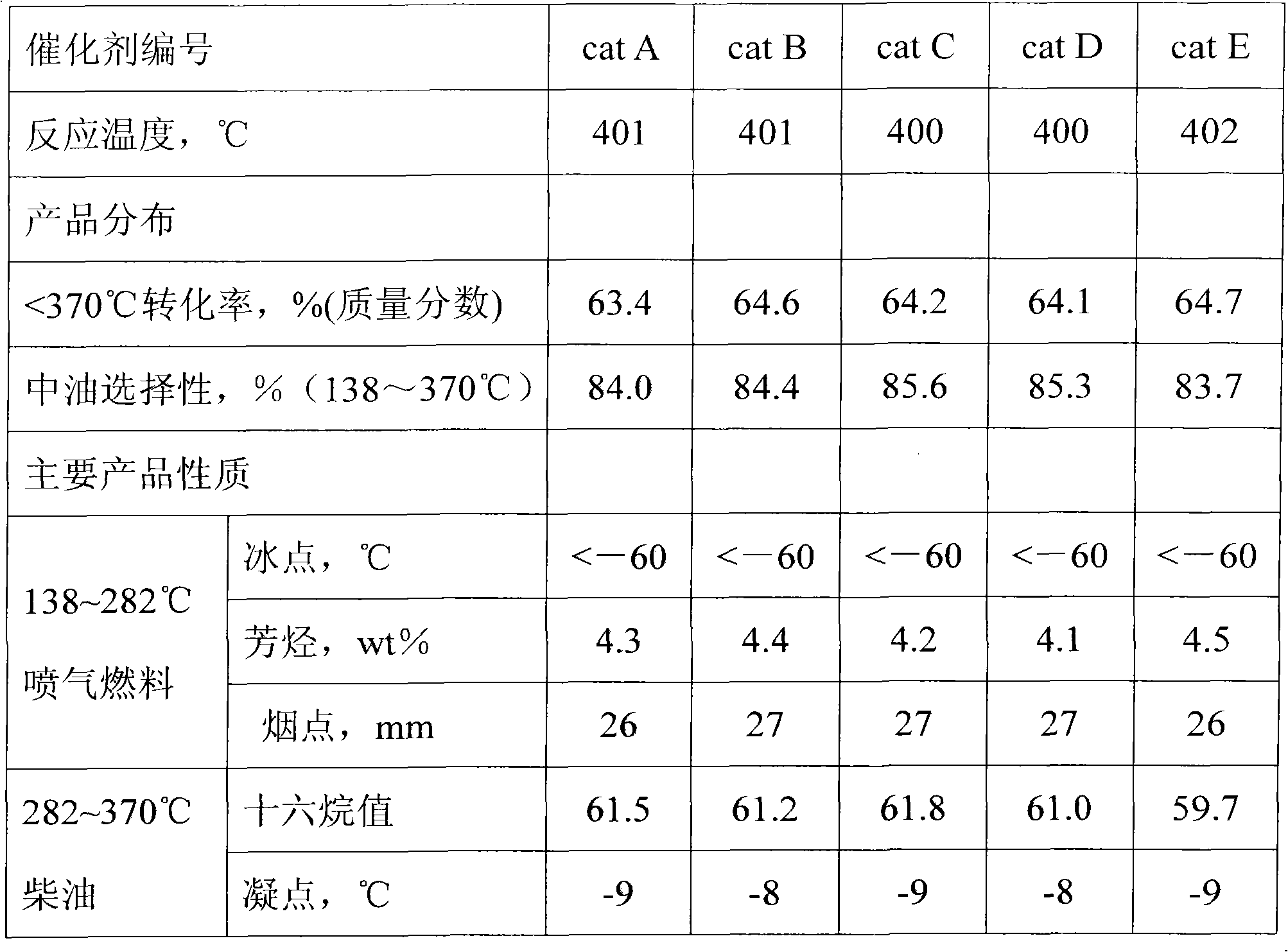

ActiveCN102039151AImprove hydrogenation activityHigh selectivityMolecular sieve catalystsCatalyst activation/preparationPore distributionSingle stage

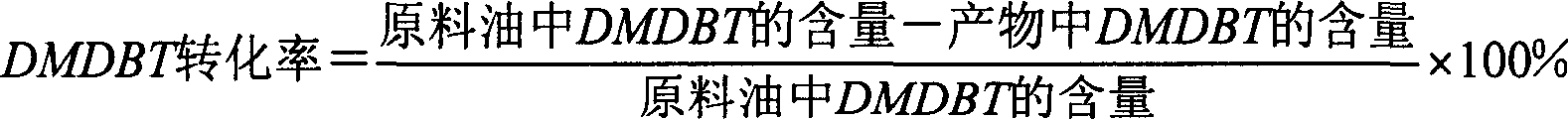

The invention discloses a hydrocracking catalyst and a preparation method thereof. The catalyst is prepared by a carbonization method and is amorphous silica aluminum subject to hydro-thermal treatment. The amorphous silica aluminum prepared by the method has the characteristics of large specific surface, large pore volume, centralized pore distribution and appropriate acidity; an enough channel is provided for reactants, the reactants and products are convenient to enter / exit, the active ingredients of the carrier are greatly increased, and the distribution uniformity of the acid centre in the pore channel is improved; and moreover, as a larger space and a specific surface are provided for loading metal, the hydrogenated metal has higher dispersibility, the metal utilization rate is improved, and the catalyst provided by the invention has appropriate cracking activity as well as high hydrogenation activity and medium oil selectivity. The catalyst provided by the invention is particularly suitable for finishing the single-stage hydrocracking process once.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation catalyst with silicon oxide-alumina as carrier and its preparation

ActiveCN1840618AHigh activityImprove hydrogenation activityRefining to eliminate hetero atomsSilicon oxideHydrocarbon

Owner:CHINA PETROLEUM & CHEM CORP +1

A recapitalization generating oil hydrogenation catalysts and its preparing method

ActiveCN101157031ANo need to regenerateReduce lossesHydrocarbon oils refiningMetal/metal-oxides/metal-hydroxide catalystsOrganic acidActive component

The invention discloses reformate hydrogenation catalyst and the production method thereof. The invention is characterized in that the catalyst consists of a main active component, auxiliary agent, and carriers, the structural formula is Pd-Ma (Mb) / carriers; the main active component is a double noble metal component Pd, and the content is 0.01 to 0.5 wt percent; Ma is one of Au, Ag, Pt, Rh, and Ir, and the content is 0.01 to 0.5 wt percent; Mb is one of Sn, Pb, Sb, and Bi, and the content is 0.2 to 1.0 wt percent; the rest are carriers; inorganic acid or organic acid is taken as competitive adsorption auxiliary agent to achieve that the active component presents the distribution of an eggshell-shaped shallow layer, the active metal and the auxiliary agent are loaded by a distribution impregnation method or a co-impregnation method, and then the hydrogenation catalyst is produced through drying and roasting.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Selective hydrodesulfurization catalyst and preparation method thereof

ActiveCN102335612AReduce acid strengthEnhance the interaction strengthMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsAlkaline earth metalHydrodesulfurization

The invention relates to a selective hydrodesulfurization catalyst contains cobalt and molybdenum as active components. The selective hydrodesulfurization catalyst is characterized in that silicon oxide and aluminum oxide are used as carriers of the catalyst; based on the total weight of 100%, the catalyst comprises 2-6wt% of cobalt oxide, 9-15 wt% of molybdenum oxide, 2-8wt% of alkaline earth metal oxide, 2-6wt% of phosphorus oxide, 3-5wt% of alkali metal oxide, 2-6wt% of silicon oxide and 54-80 wt% of aluminum oxide; and the catalyst has the specific surface area of 200-300m<2> / g and the pore volume of 0.5-0.7mL / g. The catalyst has high hydrogenation activity and selectivity, good stability, low research octane number loss and high liquid yield. The catalyst is suitable for selective hydrodesulfrization of low-quality gasoline and is particularly suitable for selective hydrodesulfrization of low-quality FCC (Family Car China) gasoline.

Owner:PETROCHINA CO LTD

Inferior diesel hydrogenation catalyst

InactiveCN1778873AHigh yieldWeak ring opening cracking performanceRefining to eliminate hetero atomsLanthanumChemistry

A hydrotreating catalyst of inferior diesel consists of alumina 20.0í½80.0wt% and molecular sieve 3.0í½60.0w%. The catalyst is prepared by loading at least one Fe, Co and Ni metal of ó° family and MO and W metal of ó÷B family as metal active component and adding one or above oxide or fluorinated compound of titanium, magnesium, zirconium, lanthanum, iron, phosphorus, silicon and boron as active auxiliaries. It can decrease content of sulfur and arenes and increase cetyl value in products. It can be used for cryogenic hydrogenation desulfurization, denitridation and hydrogenation dearomatization.

Owner:PETROCHINA CO LTD +1

Composite molecular sieve-containing medium oil type hydrocracking catalyst, preparation method and application thereof

ActiveCN103551186BHigh crystallinityIncrease surface areaMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

The invention relates to a composite molecular sieve-containing medium oil type hydrocracking catalyst, which comprises an active component and a binder, wherein the active component adopts amorphous SiO2-Al2O3 as a carrier, adopts a composite molecular sieve as an acid component, and adopts a group VIB metal and a group VIII metal as hydrogenation activity components, and the composite molecular sieve comprises a Y molecular sieve and a ZSM-23 molecular sieve. According to the present invention, the deep dealuminzation modified Y molecular sieve has characteristics of high crystallinity, large surface area, high silica-alumina ratio, low cell constant, rich secondary pore, low acid center density, high moderate-intensity acid center ratio, and the like; the modified ZSM-23 molecular sieve has characteristics of smooth pore channel, less acid center and outstanding isomerism performance, wherein a light naphtha component is isomerized so as to increase an octane number of naphtha; the composite molecular sieve compounded from the Y molecular sieve and the ZSM-23 molecular sieve is adopted as the acid cracking component so as to provide advantages of the Y molecular sieve and the ZSM-23 molecular sieve, and compounding is performed according to the ratio of the present invention, such that the best catalysis effect can be obtained, and the obtained catalyst is suitable for the medium oil type hydrocracking catalyst; and the catalyst prepared from the composite molecular sieve has characteristics of excellent medium oil selectivity, good activity and good stability.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Catalyst for hyrogenating deoxidating and olefine saturating of Feather synthesizing oil and its mfg. process and application

ActiveCN1597859AImprove hydrogenation activityRefining by selective hydrogenationPtru catalystCopper oxide

The invention is a hydro-deoxidation and alkene-saturation catalyst of Fischer-Tropsch oil product and its components in weight percent: nickel oxide 5.0-18.0%, cobalt oxide 0-11.0%, copper oxide 0-6.0%, iron oxide 0-12.0%, titanium oxide 0-12.0%, lanthanum oxide 0-8.0% and carrier 46.0-85.0%. Its preparing method includes in turn carrier preprocessing and after-processing of supported active component and catalyst. It has higher activity to hydro-deoxidation and alkene saturation of the oil product, especially applied to the hydrofining process of the iron-base paste Fischer-Tropsch oil product with higher content of oxygen-containing compound and alkene.

Owner:SYNFUELS CHINA TECH CO LTD

Hydrofining catalyst and preparation method thereof

ActiveCN102861593ALarge hole volumeLarge specific surface areaMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsChemical industryRare-earth element

The invention discloses a hydrofining catalyst and a preparation method thereof, belonging to the field of catalysts used in the petroleum-chemical industry. The hydrofining catalyst disclosed herein comprises a carrier, an active component and an auxiliary agent, wherein the carrier is Ti-modified gamma-alumina, the active component comprises oxides of Mo, Co and Ni, and the auxiliary agent comprises oxides of rare earth. The catalyst is characterized in that: based on 100% of the total weight of the catalyst, Co (measured in CaO) in the active component accounts for 2.0-7.5% of the total weight of the catalyst, Mo (measured in MoO3) in the active component accounts for 4.0-18.0% of the total weight of the catalyst, Ni (measured in NiO) in the active component accounts for 0.2-5.0% of the total weight of the catalyst, the auxiliary agent accounts for 0.05-1.0% of the total weight of the catalyst, and the balance consists of the carrier. According to the invention, the catalyst prepared by the formula and the method disclosed in the invention can carry out hydrogenation on saturated monoolefine while the catalyst is used for carrying out hydrodesulfurization on oils, can be suitable for technical requirements of heavy oriention, changeable sulphur content, and high air speed of hydrogenation liquid for pyrolysis gasoline two-stage hydrogenated raw materials, and simultaneously, the catalyst has the advantages of low activation temperature and low loss of aromatics in the hydrogenation process.

Owner:CHINA PETROLEUM & CHEM CORP

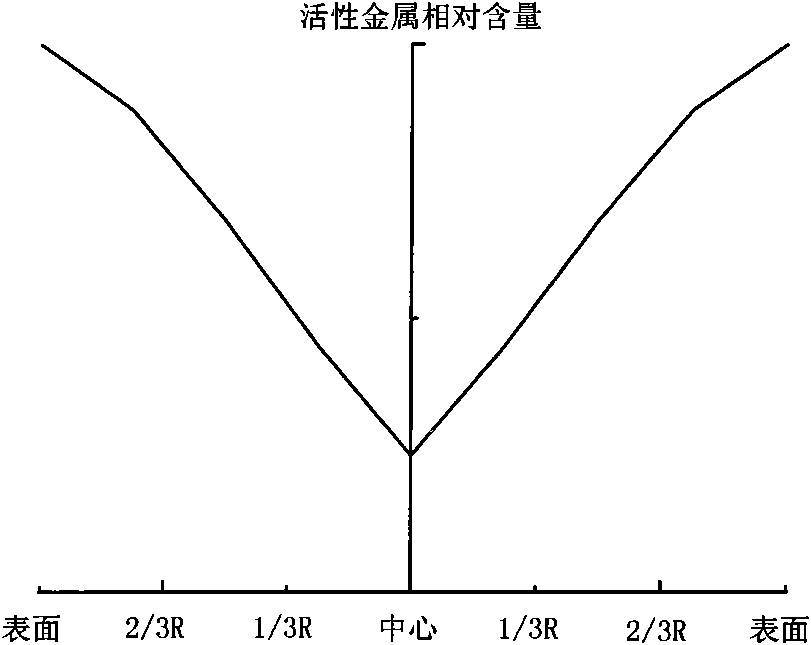

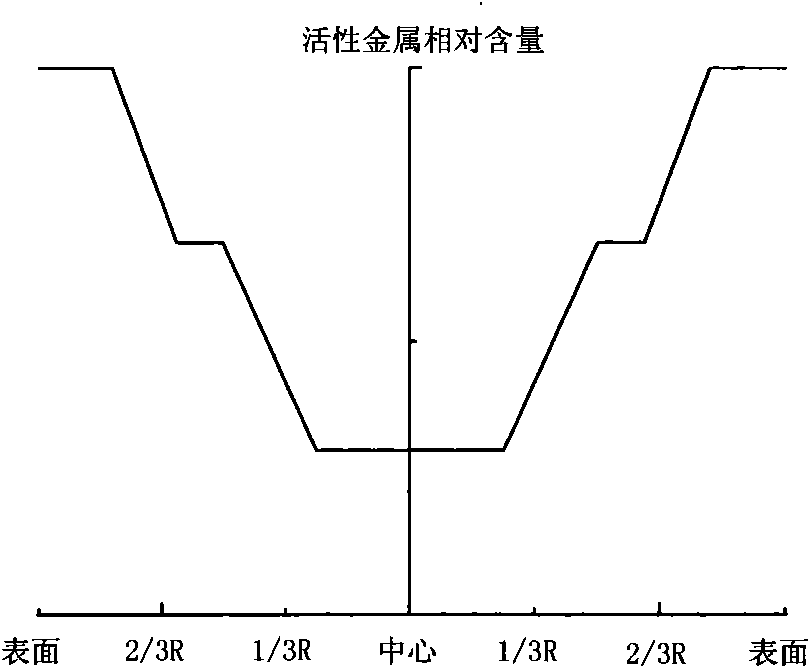

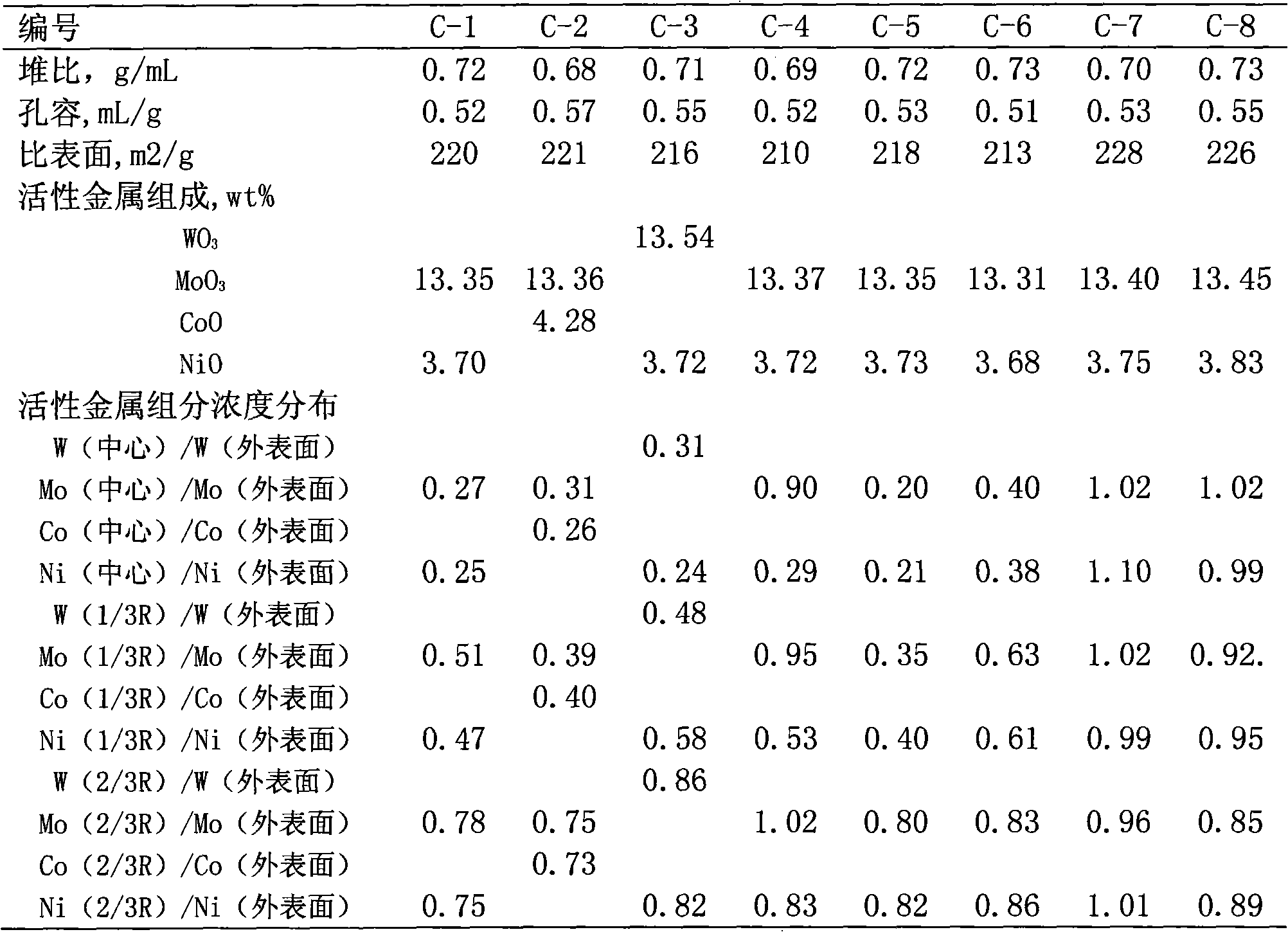

Hydrogenation catalyst with active metal component concentration in gradient increase and distribution and preparation method thereof

ActiveCN101927169AImprove desulfurizationPromote denitrificationCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsSal ammoniacHigh concentration

The invention relates to a hydrogenation catalyst with active metal component concentration in gradient increase and distribution and a preparation method thereof. The preparation method comprises the following steps of: mixing compounds of metal in VIB and / or VIII family with deionized water or ammonia to prepare a metal impregnating solution by using Al2O3 or Al2O3 containing SiO2, TiO2 and ZrO2 as a vector; preparing the hydrogenation catalyst by using a saturated impregnation method; gradually adding denser metal solution for saturated impregnation of the vector by preparing more dilute solutions of metal in VIB and / or VIII family or deionized water; or impregnating the vector first with the metal impregnating solution with low concentration and then with the metal impregnating solution with high concentration by preparing metal solutions of different concentrations; drying for 1 to 8 hours at 80 DEG C to 150 DEG C; and baking for 2 to 6 hours in an air of 300 DEG C to 650 DEG C. The catalyst has the advantages of high desulfurization, denitrification, residual carbon removing activity and stability, simple preparation and lower preparation cost and is suitable for the field of heavy oil hydrogenation.

Owner:PETROCHINA CO LTD

Process for producing gasoline with an improved octane number

InactiveUS6436278B1Excellent performanceFacility of preparationMolecular sieve catalystsCatalytic naphtha reformingChemistryAlkane

The invention concerns a process for producing gasoline with an improved octane number, optionally accompanied by oil and / or middle distillate production, by conversion-hydroisomerization of the paraffins in the feed using a catalyst containing at least one noble metal deposited on an amorphous acidic support. Isoparaffins are separated from the gasoline cut obtained, and normal paraffins and possibly monobranched paraffins contained in the resulting effluent are isomerized using a catalyst containing at least one hydrodehydrogenating metal and at least one acidic solid. The ensemble of the streams charged with isoparaffins with an improved octane number is sent to the gasoline pool. The residue undergoes catalytic dewaxing.

Owner:INST FR DU PETROLE

Glycol catalyst synthesized by hydrogenating oxalic ester and preparation method and application thereof

InactiveCN101524646AImprove hydrogenation activityLow investment costOrganic compound preparationHydroxy compound preparationHigh activityMetal

The invention discloses a glycol catalyst synthesized by hydrogenating oxalic ester and a preparation method and an application thereof. The catalyst has the chemical formula of CuO-AOx / Al2O3, wherein A is one or more than one metallic element of Zn, Mn, Mg and Cr, x is half of the valence number of A, the content of CuO accounts for 40 percent to 80 percent of the catalyst mass, the content of AOx accounts for 5 percent to 40 percent of the catalyst mass and the content of Al2O3 accounts for 5 percent to 30 percent of the catalyst mass. The catalyst has high activity and selectivity at low temperature and under low pressure, the energy and power consumption in production can be reduced greatly and the catalyst has good stability and long service life. The preparation method of the catalyst is simple and raw materials as industrial products are easily obtained and have low price.

Owner:DANYANG DANHUA COAL CHEM

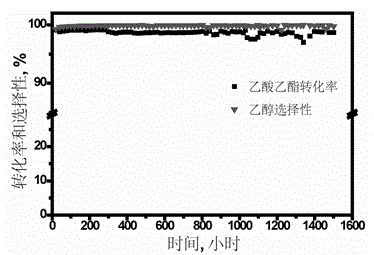

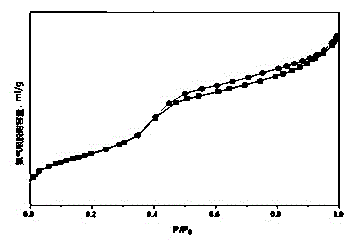

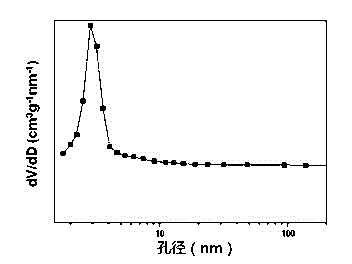

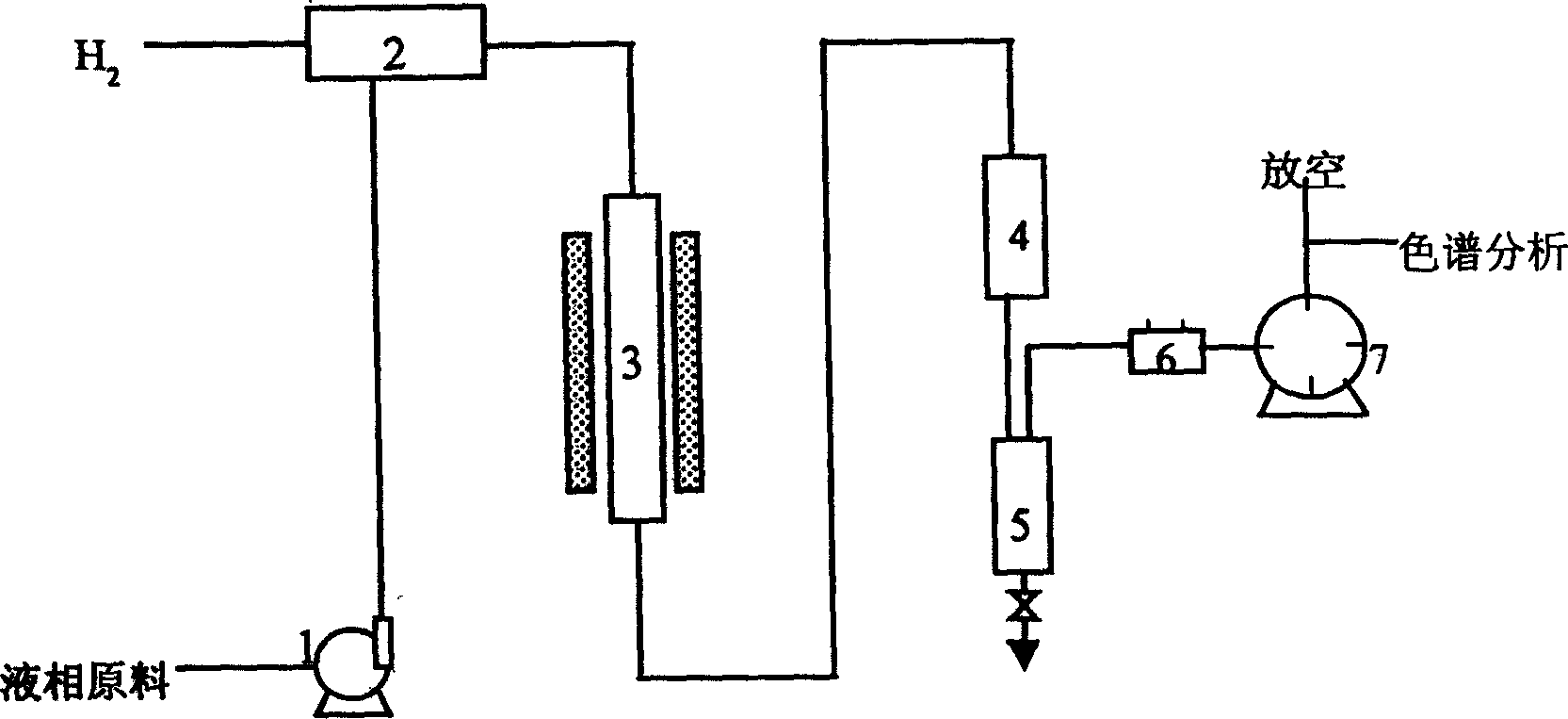

Method for preparing ethanol through acetic ester hydrogenation

ActiveCN102976892AImprove anti-sintering performanceHigh selectivityMolecular sieve catalystsOrganic compound preparationActive componentHydrogenation reaction

The invention relates to a method for preparing ethanol through acetic ester hydrogenation. The method performs an acetic ester hydrogenation reaction to generate ethanol under the conditions of certain temperature, pressure, hydrogen / ester molar ratio and hydrogen circulation in a fixed-bed reactor filled with a copper-based catalyst, wherein in the copper-based catalyst, a mesoporous molecular sieve MCM-41 is used as a carrier, copper is used as an active component, and the oxide of at least one element of La and Ce is used as an auxiliary; and the MCM-41 accounts for 40-90% of the catalyst by weight, the active component copper accounts for 10-50% of the catalyst by weight, and the auxiliary accounts for 0.1-20% of the catalyst by weight. According to the method for preparing ethanol through acetic ester hydrogenation, provided by the invention, when the reaction temperature is 220 DEG C, the reaction pressure is 3MPa, the hydrogen / ester molar ratio is 30 and the mass airspeed of acetic ester is 2h<-1>, the conversion rate of acetic ester is 98.5%, and the ethanol selectivity is as high as 99.6%, thereby showing extremely high hydrogenation activity, selectivity and stability.

Owner:TIANJIN UNIV +1

Technology of hydrogenatioin to produce iso octanol using iso octaldehyde mixture and its catalyst

InactiveCN1478596AStrong abilityImprove hydrogenation activityCatalyst activation/preparationPreparation by oxygen reductionAldehydeNickel

A process and catalyst for preparing isooctanol by liquid-phase hydrogenation of the mixture of isooctanal and octylene alcohol is disclosed. Said catalyst is prepared from metallic Ni, alkali-earth metal oxide and / or alumina, and Si-contained compound as carrier through code position of Ni and carrier, kneading, and calcining at 300-800 deg.C. Its advantages are good porous structure, and high strength, hydrogenating activity, and output rate of isooctanol.

Owner:CHINA PETROLEUM & CHEM CORP

Hydrogenation catalyst steeping fluid composition and preparation method of hydrogenation catalyst

ActiveCN101462078AImprove hydrogenation activityHigh cracking activityCatalyst activation/preparationHydrocarbon oil crackingReaction temperatureFluid composition

The invention provides a hydrogenation catalyst soaking solution composition, which comprises a precursor of a hydrogenation active ingredient, a soaking additive and water, wherein the soaking additive has similar pKa value with that of the precursor of the hydrogenation active ingredient and comprises carbon-carbon double bond and / or carbon-carbon triple bond substances in molecular structure. The invention also provides a method for preparing a hydrogenation catalyst, which comprises: using the soaking solution to soak a catalyst carrier, and drying and roasting the catalyst carrier, wherein the soaking solution is the hydrogenation catalyst soaking solution composition. The hydrogenation catalyst prepared from the hydrogenation catalyst soaking solution composition has higher hydrogenation activity and higher cracking activity at the same reaction temperature compared with a hydrogenation catalyst prepared by the prior art.

Owner:CHINA PETROLEUM & CHEM CORP +1

Aluminium oxide carrier with composite holes structure and preparation method thereof

ActiveCN101121120AImprove hydrogenation activityExcellent high-resistant gelatinPhysical/chemical process catalystsRefining to eliminate hetero atomsPore distributionPore diameter

The invention relates to an alumina carrier with a composite pore structure and a preparation method thereof. The method mainly solves the technical problem that it is difficult to obtain macroporous alumina carriers with different pore distributions above 20 nanometers and the preparation method thereof in the prior art. In the present invention, the specific surface area of the alumina carrier is 40-160 m2 / g, the total pore volume is 0.3-1.2 ml / g, and the pore volume with a pore diameter of less than 30 nanometers accounts for 5-60% of the total pore volume. The pore volume of 30 to 60 nanometers accounts for 20 to 75% of the total pore volume, and the pore volume with a pore diameter > 60 nanometers accounts for 20 to 60% of the total pore volume as a composite carrier; the preparation method of the composite carrier adopts firstly alumina A Mixing with alumina B, molding, drying at 50-100°C for 1-24 hours, and then roasting at 800-1150°C for 1-10 hours to obtain a technical solution to the composite carrier solves this problem well, and can be used for pyrolysis gasoline In the industrial production of hydrogen catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrofining catalyst and preparation method thereof

InactiveCN101590417AImprove physical and chemical propertiesImprove adsorption capacityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsTitaniumBoron

The invention provides a hydrofining catalyst and a preparation method thereof. The catalyst comprises an aluminum oxide carrier which is modified by an assistant and VIII group and VIB group metal oxides which are loaded on the carrier, wherein, the assistant is at least one of boron, phosphorus, silicon and titanium compounds. The catalyst is prepared by an immersion method which is characterized in that an organic stabilizer is added into immersion fluid; the number of metal active centers of the catalyst is increased with the addition of the organic stabilizer; the physicochemical properties of the catalyst is improved by the way the aluminium oxide is modified by the assistant; therefore, the hydrofining catalyst prepared by the method in the invention has high desulfuration and denitrification activity, and is applicable to the hydrotreating process of various distillate oil, in particular to poor quality diesel oil.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD +1

Flexible method for producing oil bases and middle distillates with hydroisomerization-conversion followed by catalytic dewaxing

InactiveUS7267758B2Facility of preparationImprove hydrogenation activityTreatment with plural serial cracking stages onlyMolecular sieve catalystsMolecular sievePtru catalyst

For producing very high quality base stock and for simultaneously producing high quality middle distillates, successive hydroisomerisation and catalytic dewaxmg steps are employed wherein the hydroisomerisation is carried out in the presence of a catalyst containing at least one noble metal deposited on an amorphous acidic support, the dispersion of the metal being 20%-100%. The support is preferably an amorphous silica-alumina. Catalytic dewaxing is carried out in the presence of a catalyst containing at least one hydrodehydrogenating element (group VIII) and at least one molecular sieve selected from ZBM-30, EU-2 and EU-11.

Owner:INST FR DU PETROLE

Oil soluble molybdenum-based precursor of catalyst, preparation method and application thereof

InactiveCN103980320AGood oil solubilityReduce yieldPhysical/chemical process catalystsHydrocarbon oil crackingSlurry reactorDecomposition

The invention provides an oil soluble molybdenum-based precursor of a catalyst, a preparation method and application thereof, relating to the technical field of heavy oil hydrocracking catalysts and solving the problems of low catalytic hydrogenation activity and high cost of the existing catalysts. The preparation method for the precursor comprises the steps of (1) mixing a molybdenum source with water, reacting for 30-240 minutes at 70-90DEG C, and adding inorganic acid; (2) adding polycarbon alcohol into P2S5 in 5-15 minutes at 50-80DEG C, and reacting for 1-3 hours at 70-100DEG C; (3) adding the product of step (2) into the product of step (1), adding resin, and reacting for 4-8 hours at 70-110DEG C; (4) separating oil phase from the product of step (3) so as to obtain the target product. The precursor can form MoS2 active components through self sulfurization and in situ decomposition, is used in slurry reactor hydrocracking of poor heavy oil with high content of metal, carbon residue and sulfur, and can lower the yield of coke and keep a device to run for a long period.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

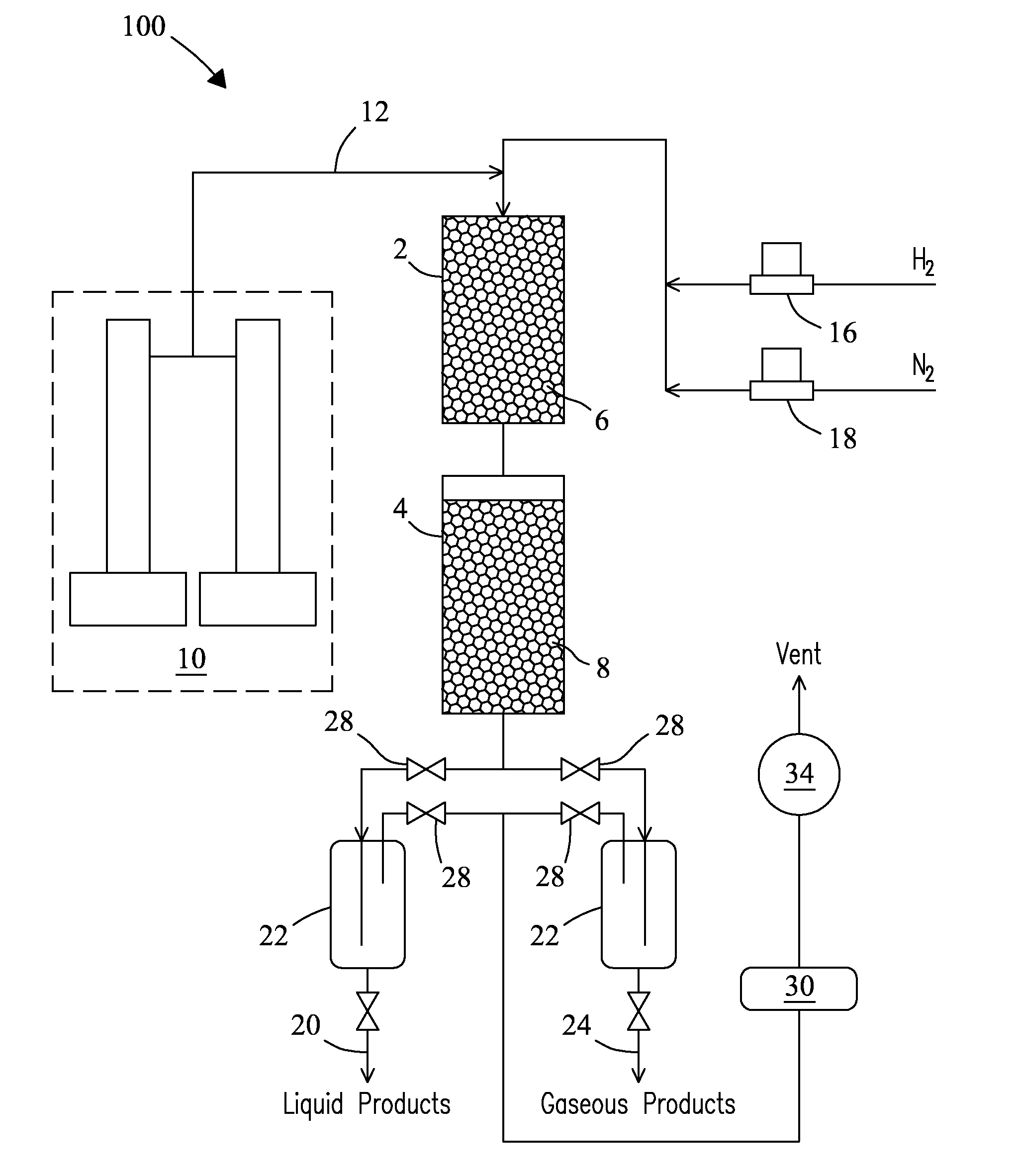

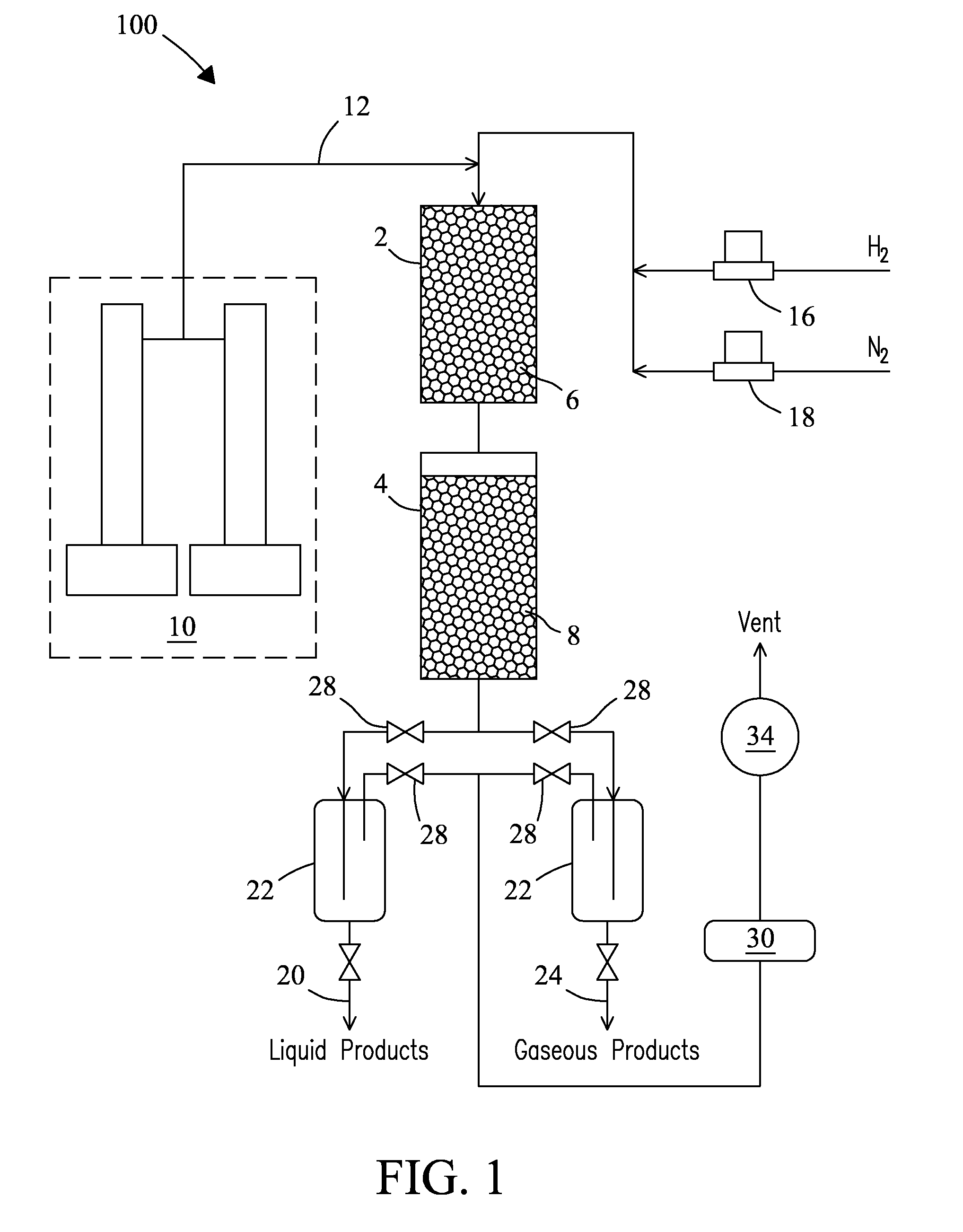

Bi-functional catalyst and processes for conversion of biomass to fuel-range hydrocarbons

InactiveUS20150057475A1Improve hydrogenation activityMinimizing coke formationMolecular sieve catalystsCatalyst regeneration/reactivationCompound (substance)Bifunctional catalyst

Processes and bi-functional catalysts are disclosed for hydrotreating bio-oils derived from biomass to produce bio-oils containing fuel range hydrocarbons suitable as feedstocks for production of bio-based fuels.

Owner:BATTELLE MEMORIAL INST

Selective hydrogenation catalyst for alkadiene

ActiveCN1631526AImprove hydrogenation activityHydrocarbon by hydrogenationGaseous mixture working upAlkadieneHydrogen

This is about a kind of catalyst of adding hydrogen of choosing. The catalyst includes a kind of Oxidize the aluminum placer and Gu and / or Ni in ó°, Mu and / or Wu in ó÷ and alkali metal. Its feature is: the catalyst includes 0.5--8% by weight that is chosen Gu and / or Ni in ó°, 2--15% is chosen Mu and / or Wu in ó÷, >2--8% alkali metal. Compared to the current catalyst, the catalyst offend in the invention has much higher choosing ability and activity in adding hydrogen of gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

Liquid sol catalyst for hydrogenation of residual oil suspended bed

InactiveCN101011663AImprove hydrogenation activityHigh completeness of vulcanizationPhysical/chemical process catalystsHydrocarbon oil crackingDielectricOil processing

The invention discloses a catalyst of hydrogenated and cracked inferior heavy oil and residual oil suspending bed, which is characterized by the following: adopting 75-98m% water as dispersing dielectric; selecting 2-25m% transition sulfate metal (Fe, Co, Ni, Cr, Cu, Mn, Mo, W) as dispersing phase; controlling grain size between 0.1-100um; hydrogenating and cracking heavy oil into light oil.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

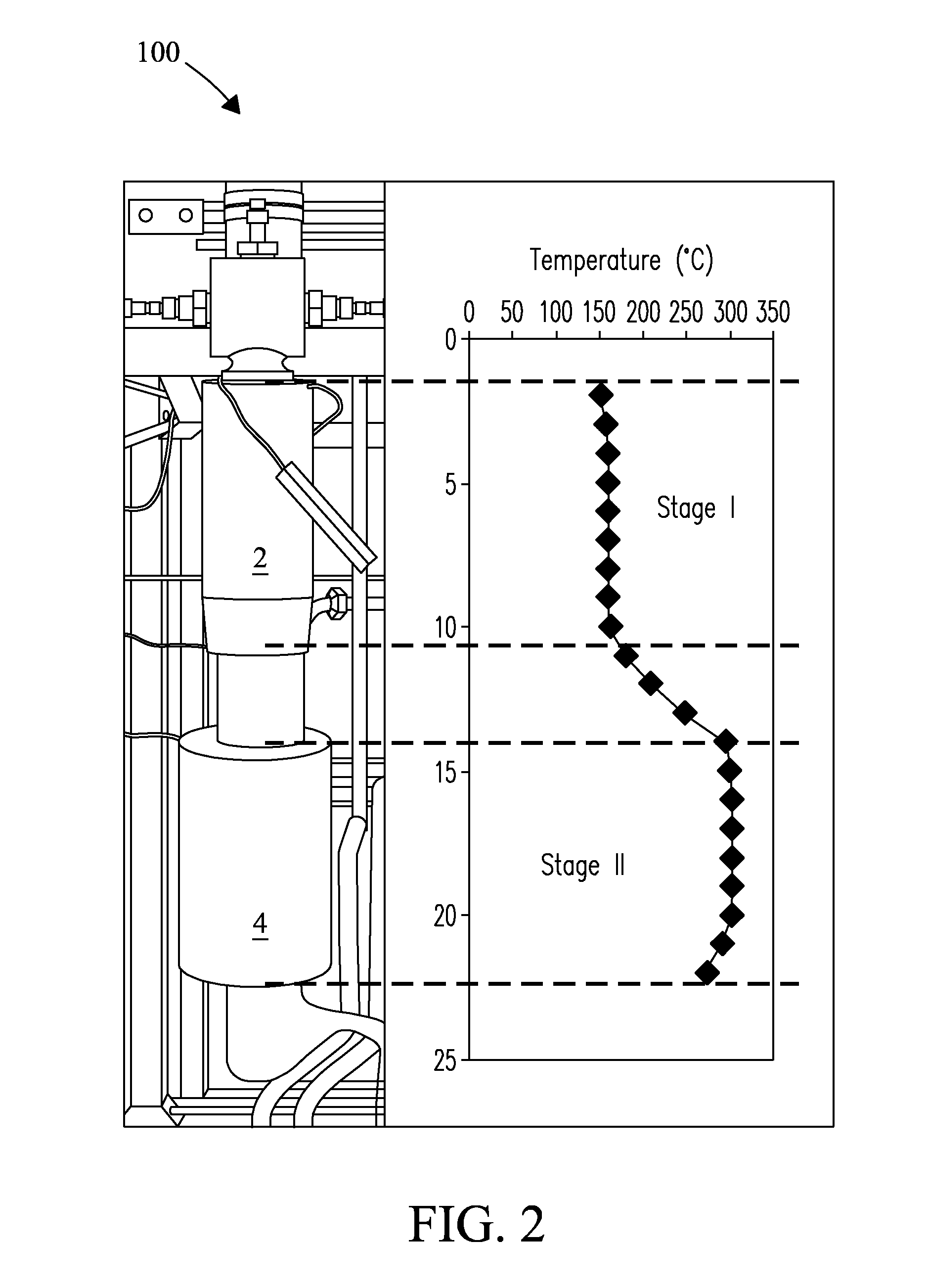

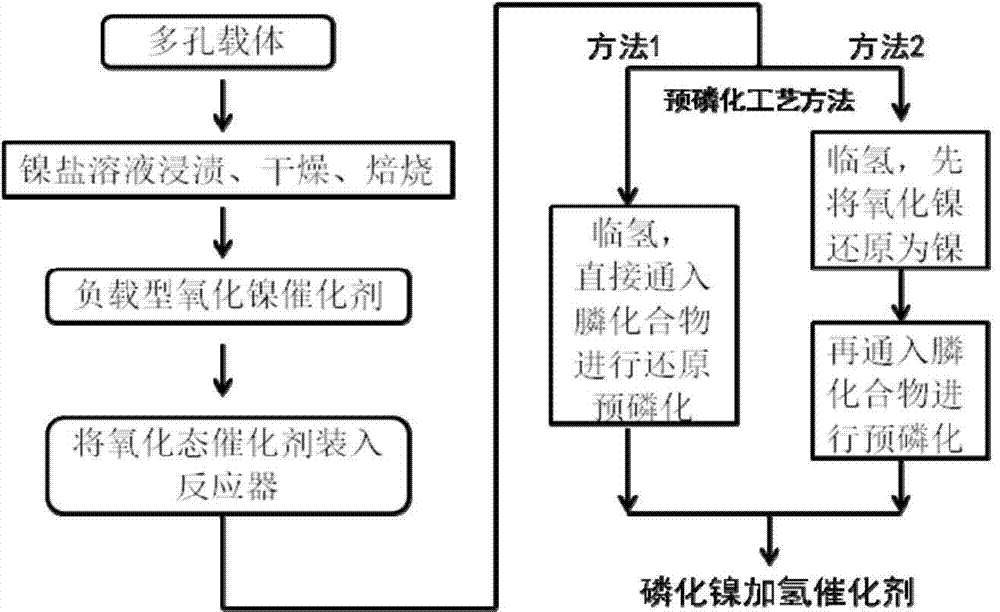

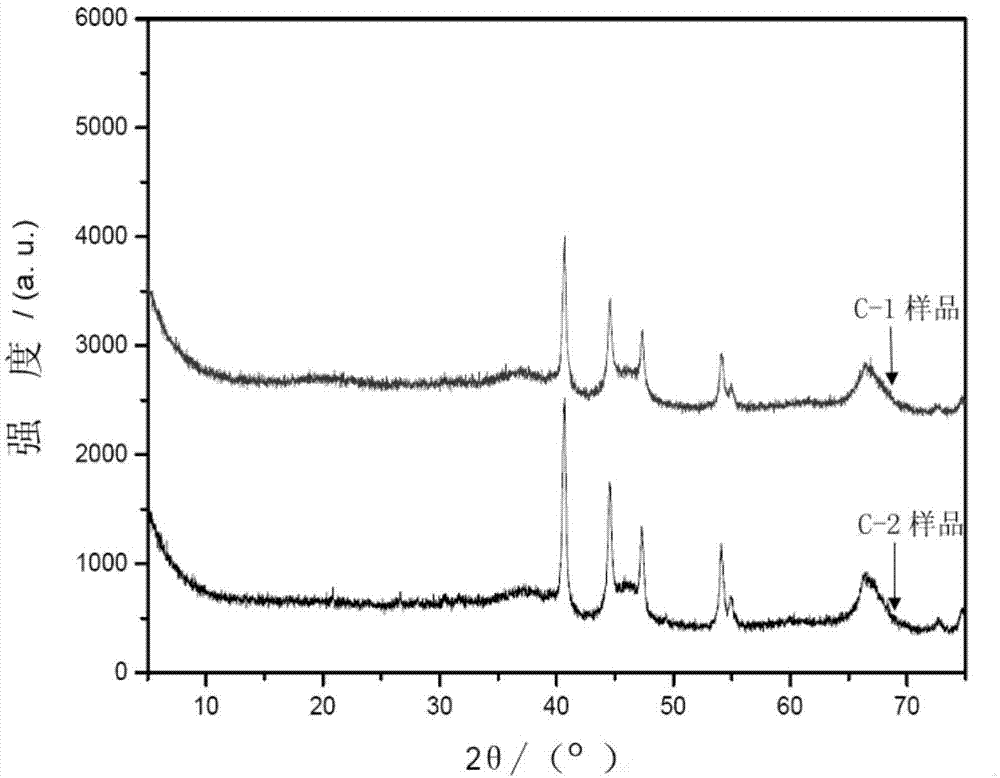

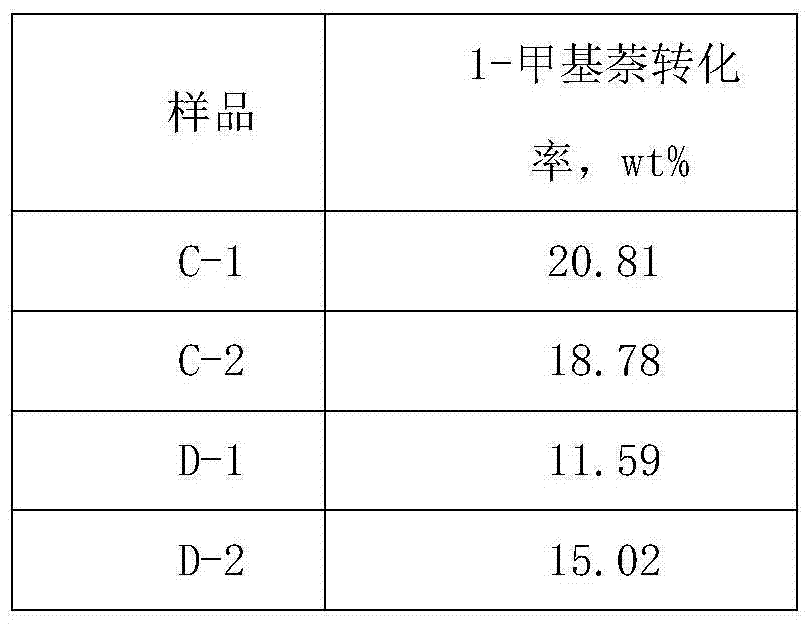

Load type nickel phosphide catalyst and pre-phosphating preparation method thereof

InactiveCN104841465AHigh purityGood dispersionPhysical/chemical process catalystsRefining to eliminate hetero atomsDispersityNickel salt

The invention discloses a load type nickel phosphide catalyst and a pre-phosphating preparation method thereof, belonging to the technical field of petrochemical engineering. The load type nickel phosphide catalyst is prepared by loading nickel salt on a carrier, then pre-phosphating a nickel oxide-loaded catalyst in a reactor, and enabling nickel oxide to be transformed into nickel phosphide in situ. The prepared catalyst is high in load capacity, better in dispersity, higher in purity and good in hydrogenation performance. Meanwhile, the method remarkably simplifies a preparation method of the nickel phosphide catalyst, simplifies preparation steps, reduces preparation cost and has a good application prospect.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com