Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1631results about How to "Reduce acidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gastro-electric stimulation for reducing the acidity of gastric secretions or reducing the amounts thereof

InactiveUS7620454B2Lower costLow amountInternal electrodesPharmaceutical delivery mechanismSecretion productGastric secretions

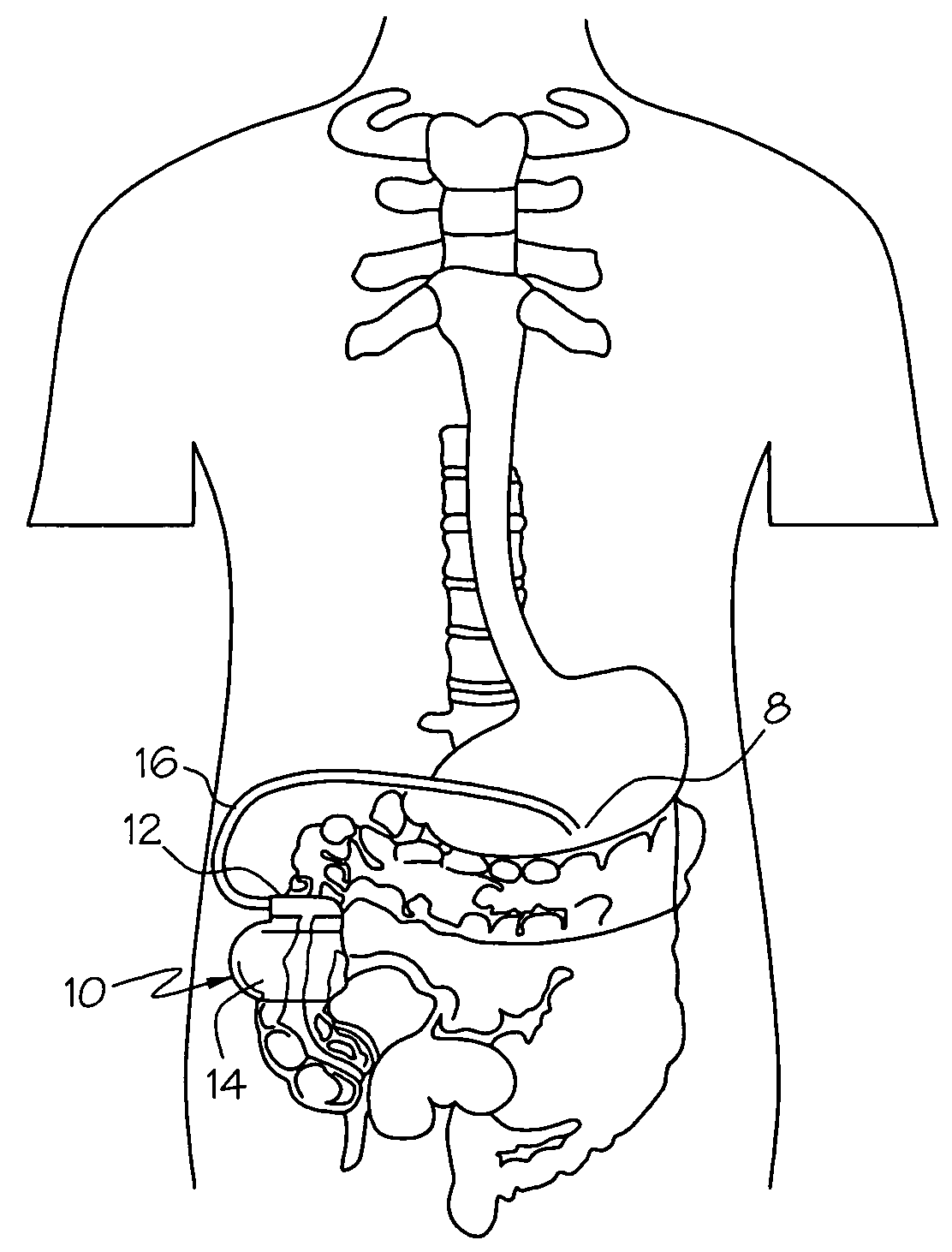

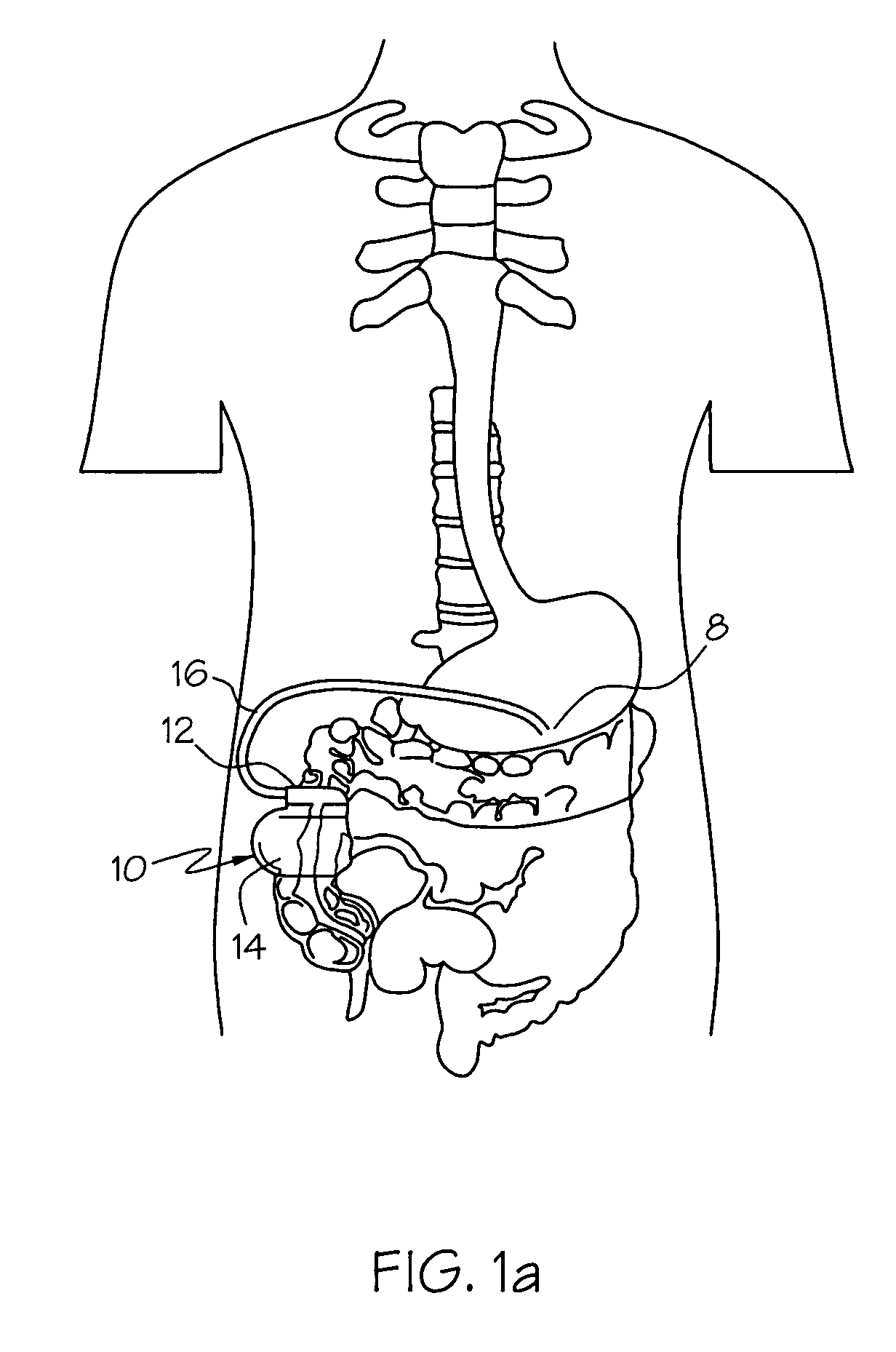

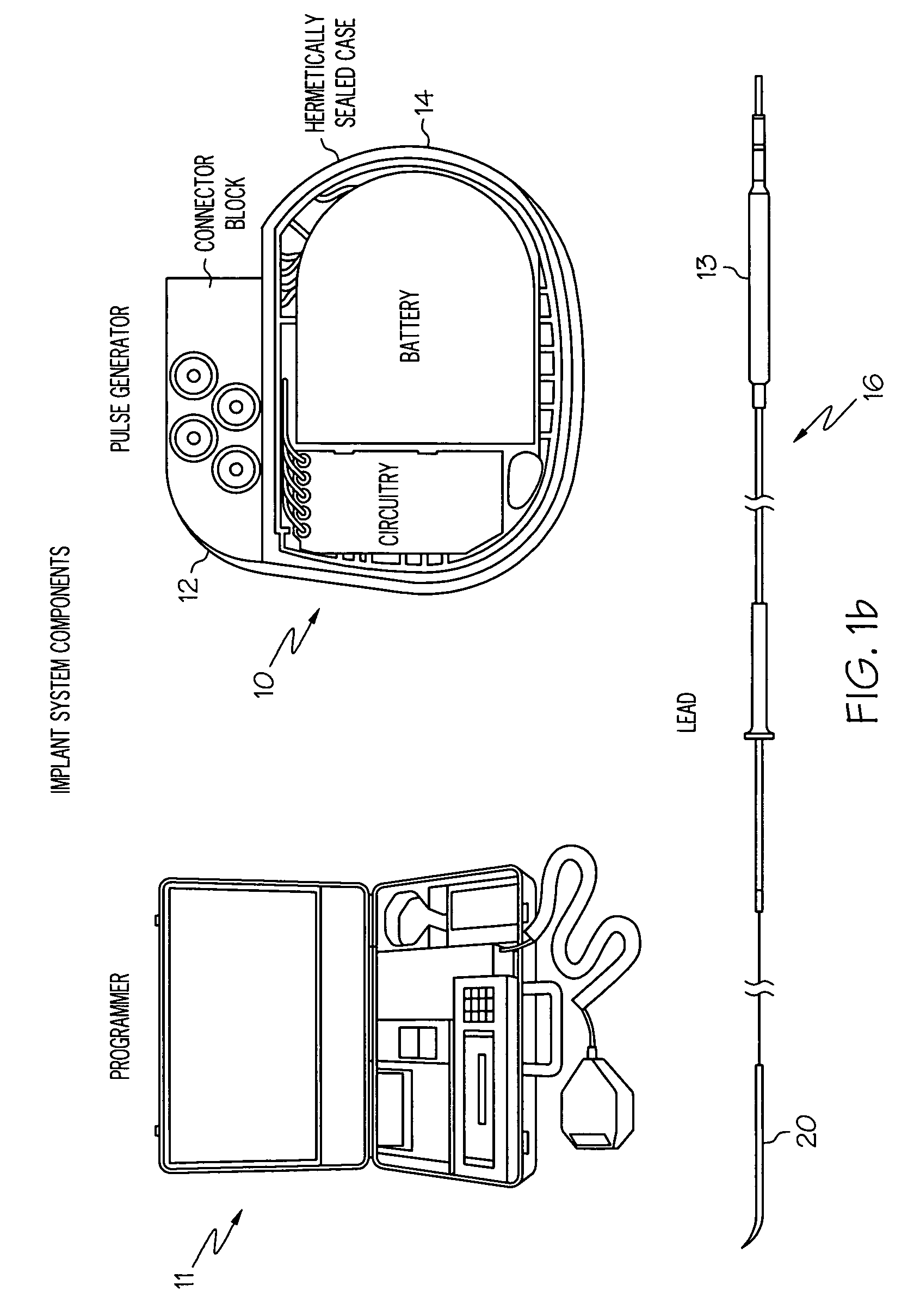

A gastro-electric stimulation system includes an INS for producing an electrical stimulation signal, at least one medical electrical lead, and at least two electrical contacts. The medical electrical lead has a proximal end and a distal end, the proximal end being connected to the INS, the distal end being adapted for placement in or near a patient's stomach or appropriate nerve or nerve portion. The electrodes are disposed near the distal end of the medical electrical lead, and are electrically connected through the medical electrical lead to the INS to receive the electrical stimulation signal and convey such signal to the selected electrode implant position. The electrical stimulation signal is provided in an amount and manner adapted to increase the pH of the gastric acid in the patient's stomach and / or to decrease the amount of gastric acid produced thereby.

Owner:MEDTRONIC INC

Amorphous silica-alumina, a carrier combination and a hydrocracking catalyst containing the same, and processes for the preparation thereof

InactiveUS6399530B1Increase surface areaLarge hole volumeMolecular sieve catalystsHydrocarbon oil crackingSilicon dioxideHigh activity

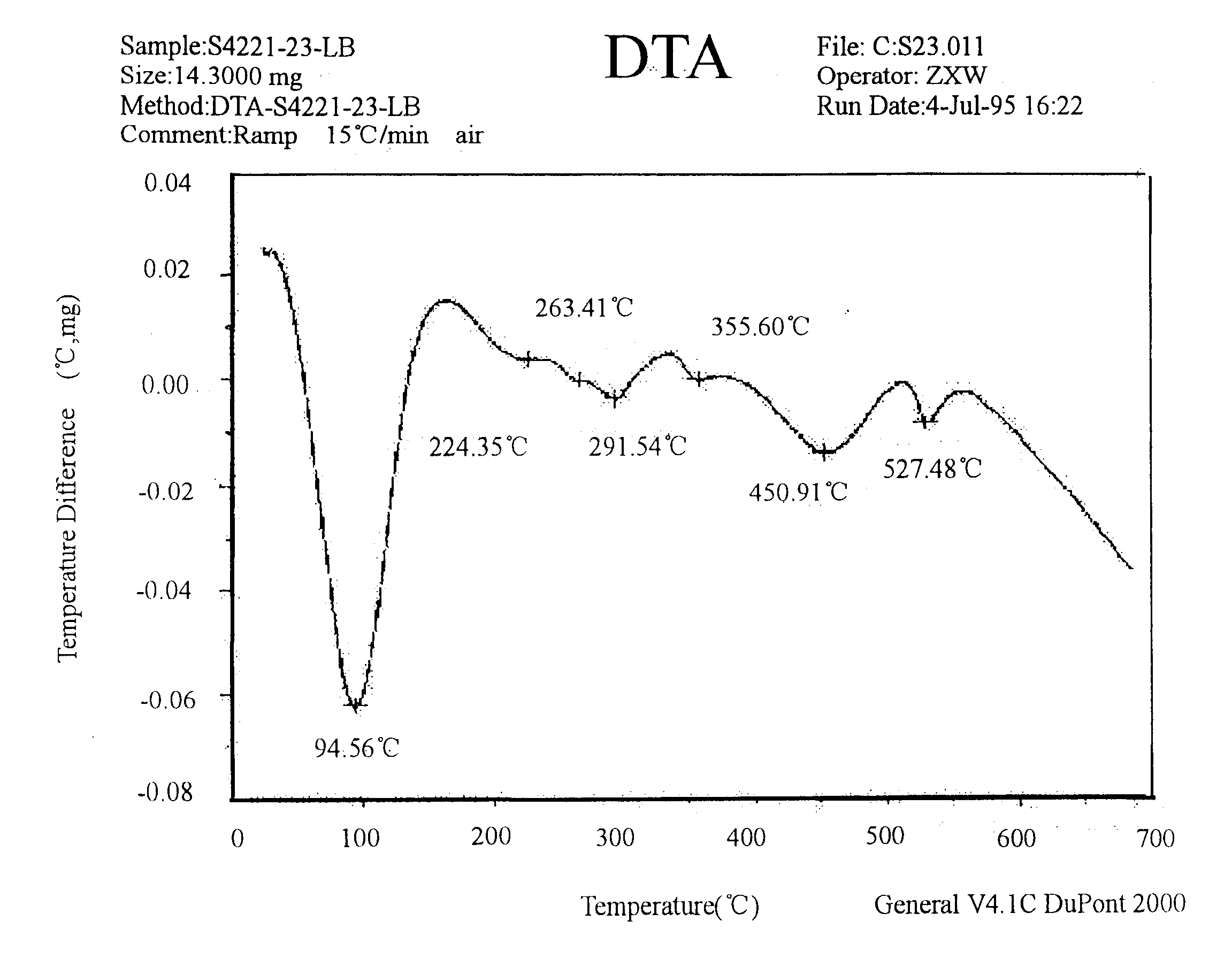

An acidic amorphous silica-amumina has a large specific surface area and a large pore volume. A carrier complex and a hydrotreating catalyst containing acidic amorphous silica-alumina, in particular a hydrocracking catalyst containing acidic amorphous silica-alumina in combination with a modified zeolite-Y, treats petroleum hydrocarbon materials to produce middle distillates. The amorphous silica-alumina has a SiO2 content of 10-50 wt. %, a specific surface area of 300-600 m2 / g, a pore volume of 0.8-1.5 ml / g and an IR acidity of 0.25-0.60 mmol / g. The catalyst shows a relatively high activity and mid-distillate selectivity and can be particularly used in hydrocracking process for producing mid-distillates with a higher yield.

Owner:CHINA PETROCHEMICAL CORP +1

Y-zeolite containing anti-nitrogen hydrocracking catalyst

InactiveCN1508228AGuaranteed lytic activityHigh selectivityHydrocarbon oil crackingHigh activityRaw material

The invention relates to a Y-zeolite containing anti-nitrogen-type hydrocracking catalyst, selecting proper Y-zeolite to assort with special acidic unformed sial, to make the catalyst have higher activity and medium-oil selectivity, able to directly process high-nitrogen content raw material without prerefining segment, and able to meet cracking active requirement of full circulation. It is applied to maximumly producing the clean fuel.

Owner:CHINA PETROLEUM & CHEM CORP +1

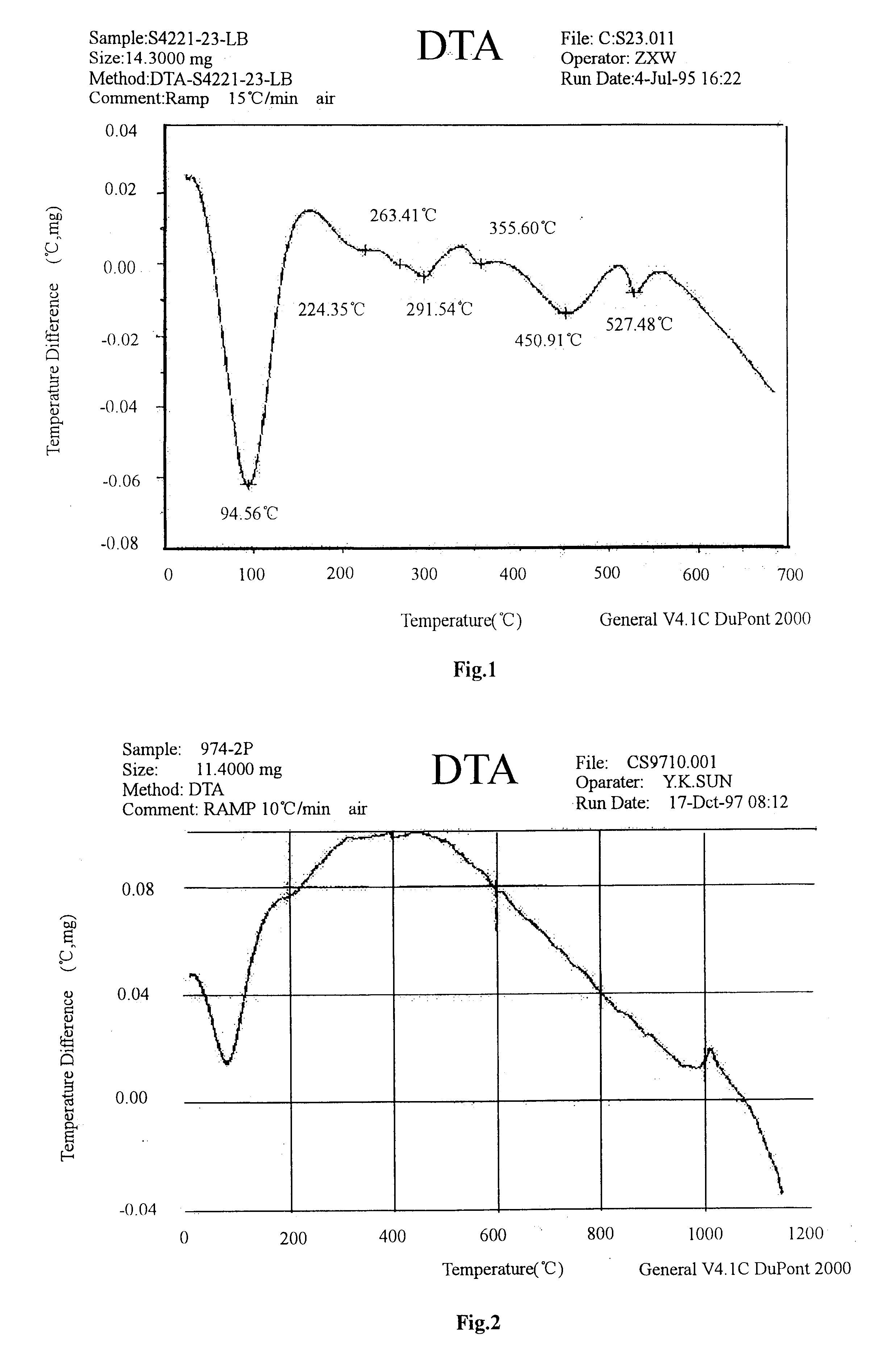

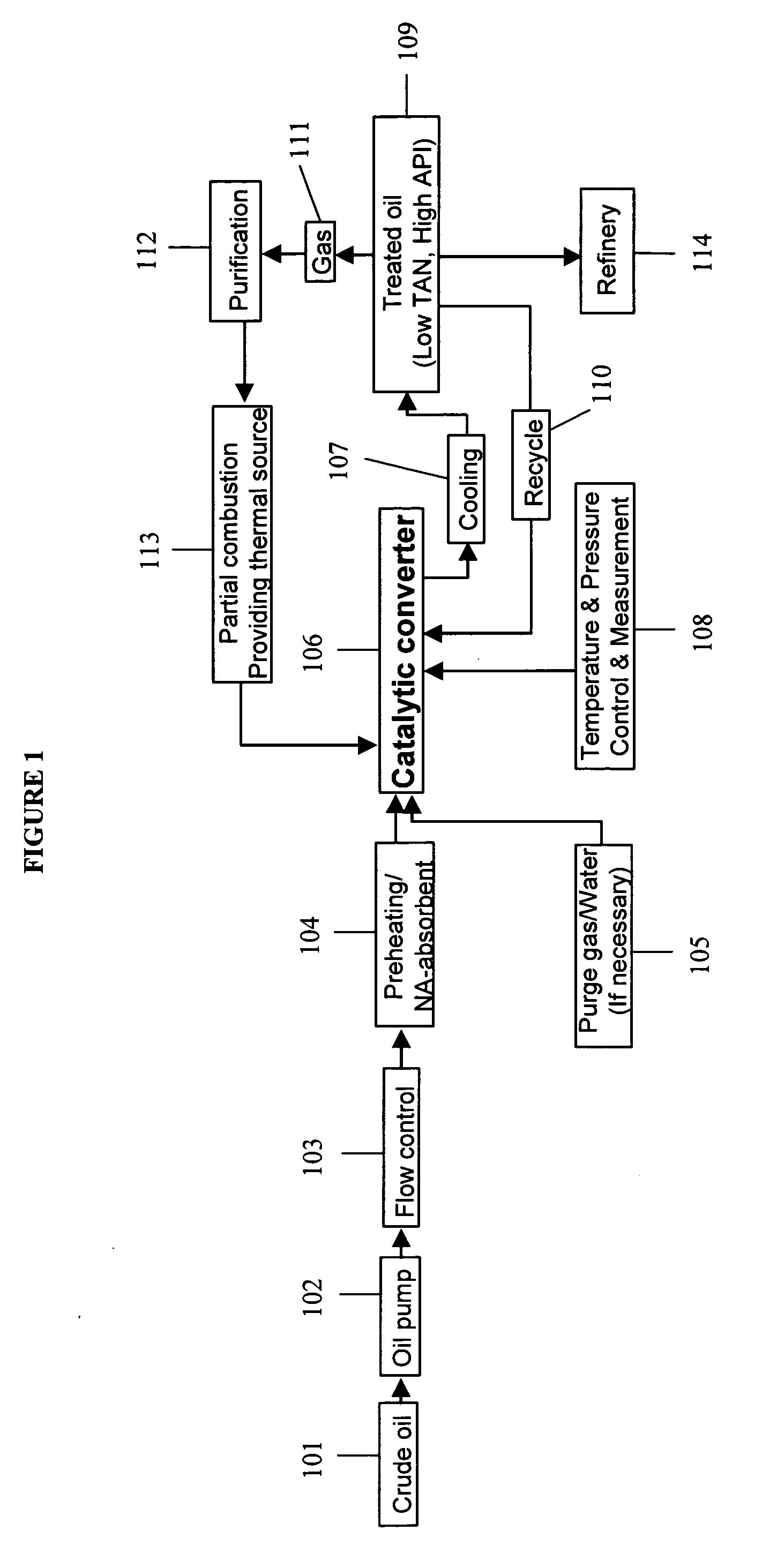

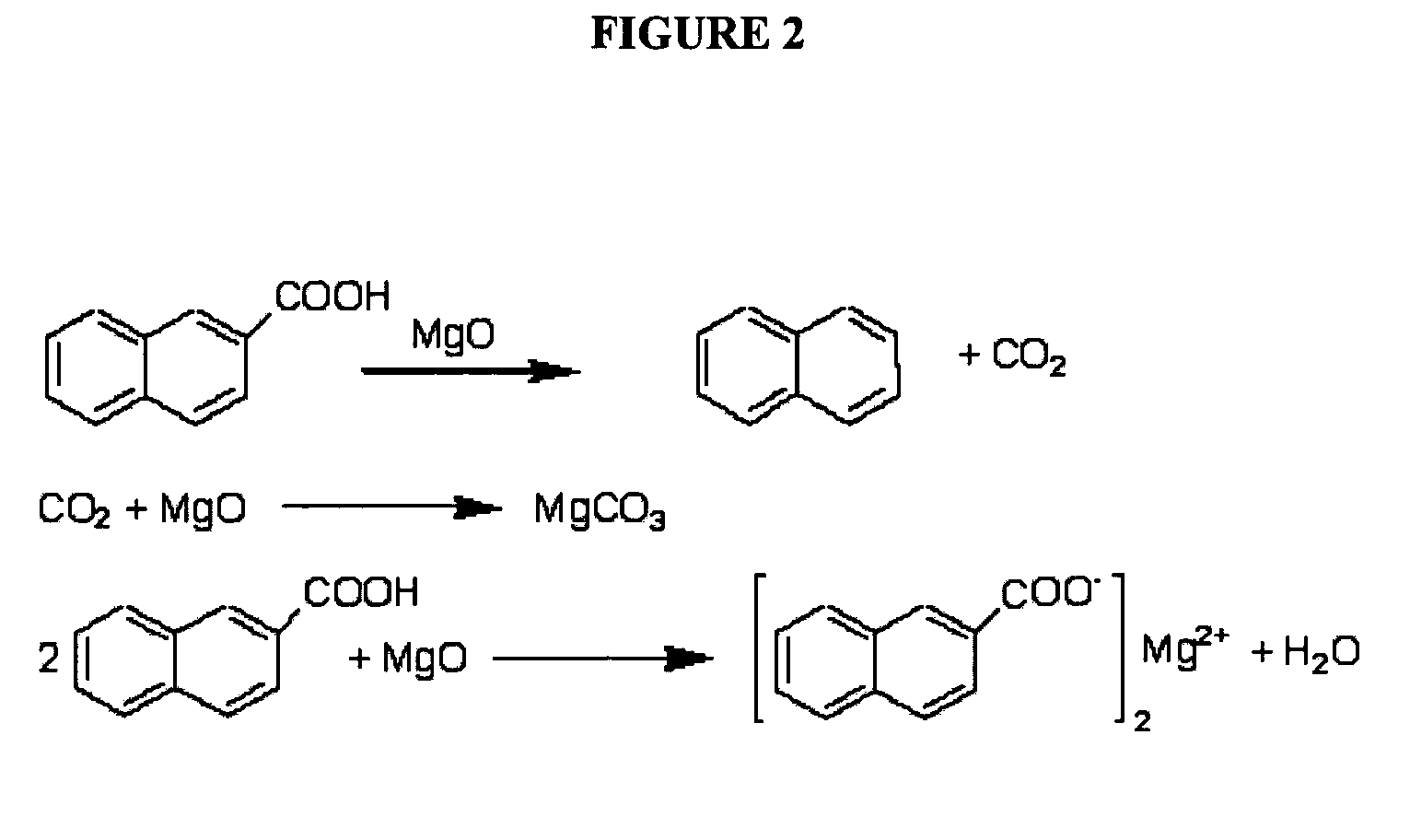

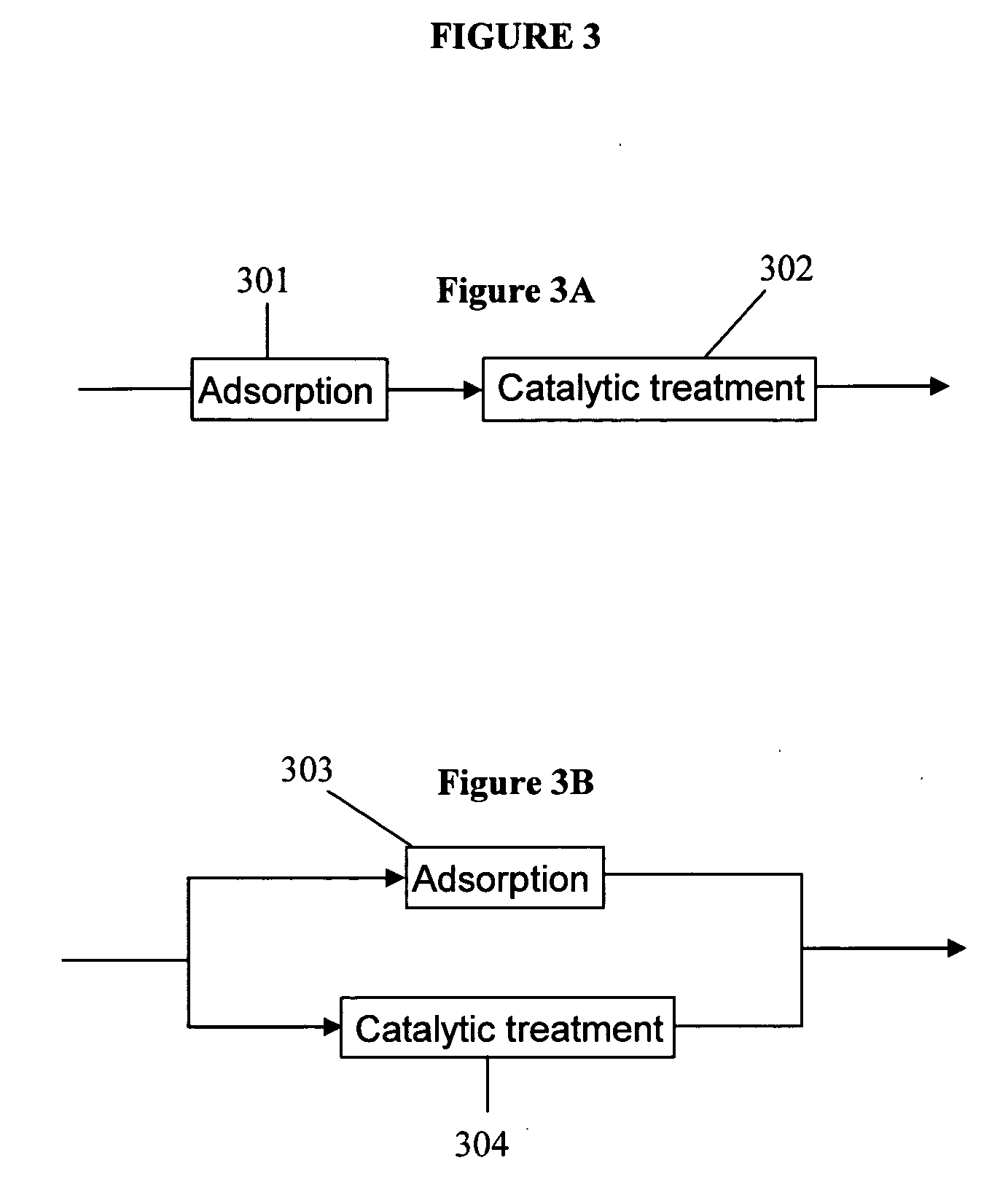

Process to upgrade oil using metal oxides

InactiveUS20060016723A1Reduce acidityReduce the numberRefining with metalsLiquid organic insulatorsHydrocotyle bowlesioidesCarboxylic acid

Described herein are compositions and methods for using metal oxides to upgrade oil. Metal oxides may be used as catalysts to reduce the TAN of the oil by converting carboxylic acids such as naphthenic acids into non-corrosive products. In some cases, the conversion occurs by a decarboxylation of the carboxylic acid to produce CO2. A second process promoted by metal oxides is hydrocarbon cracking. Cracking decreases the viscosity and increases the API, and produces lower molecular-weight hydrocarbons that are useful for many fuels and lubricants. Reductions in TAN and the increases in API improve the quality of increase the value of oil.

Owner:CALIFORNIA INST OF TECH

Insulated perfluoropolyether alkyl alcohols

InactiveUS20060287559A1Avoid eliminationReduce impactOrganic chemistryOrganic compound preparationIodidePerfluoropolyether

Perfluoropolyether alkyl alcohol comprising a perfluoropolyether segment and one or more alcohol segments wherein the alcohol segment has a general formula, —CH2(CqH2q)OH , wherein CqH2q represents a divalent linear or branched alkyl radical where q is an integer from 1 to about 10, such that the hydroxy group is insulated from fluorine atoms, are disclosed. Also disclosed herein are processes to produce these perfluoropolyether alkyl alcohols by reaction of perfluoropolyether primary or secondary bromides or iodides either an alkene or alkenol followed by further reaction to produce the alcohol.

Owner:TRINITY WESTERN UNIV +1

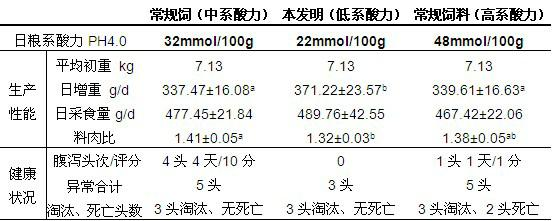

Suckling piglet feed with low acid-binding capacity and preparation method thereof

InactiveCN101999560AReduce acidityGuaranteed healthy growthFood processingAnimal feeding stuffBiotechnologyAnimal science

The invention discloses preparation of a suckling piglet feed with low acid-binding capacity and a production method thereof. The feed is prepared from corn, bean pulp, fermented bean pulp, whey powder, vitamin, microelements and the like which serve as raw materials by special processing modes such as puffing, crushing, low-temperature granulation and the like. Through the feed and the preparation method, the defects of the conventional suckling piglet feed with high acid-binding capacity are overcome, the condition of low digestibility of the suckling piglet is reduced, the palatability of the feed is improved, the health of the intestinal canal of the piglet is improved and the productivity of the suckling piglets is improved.

Owner:TONGWEI

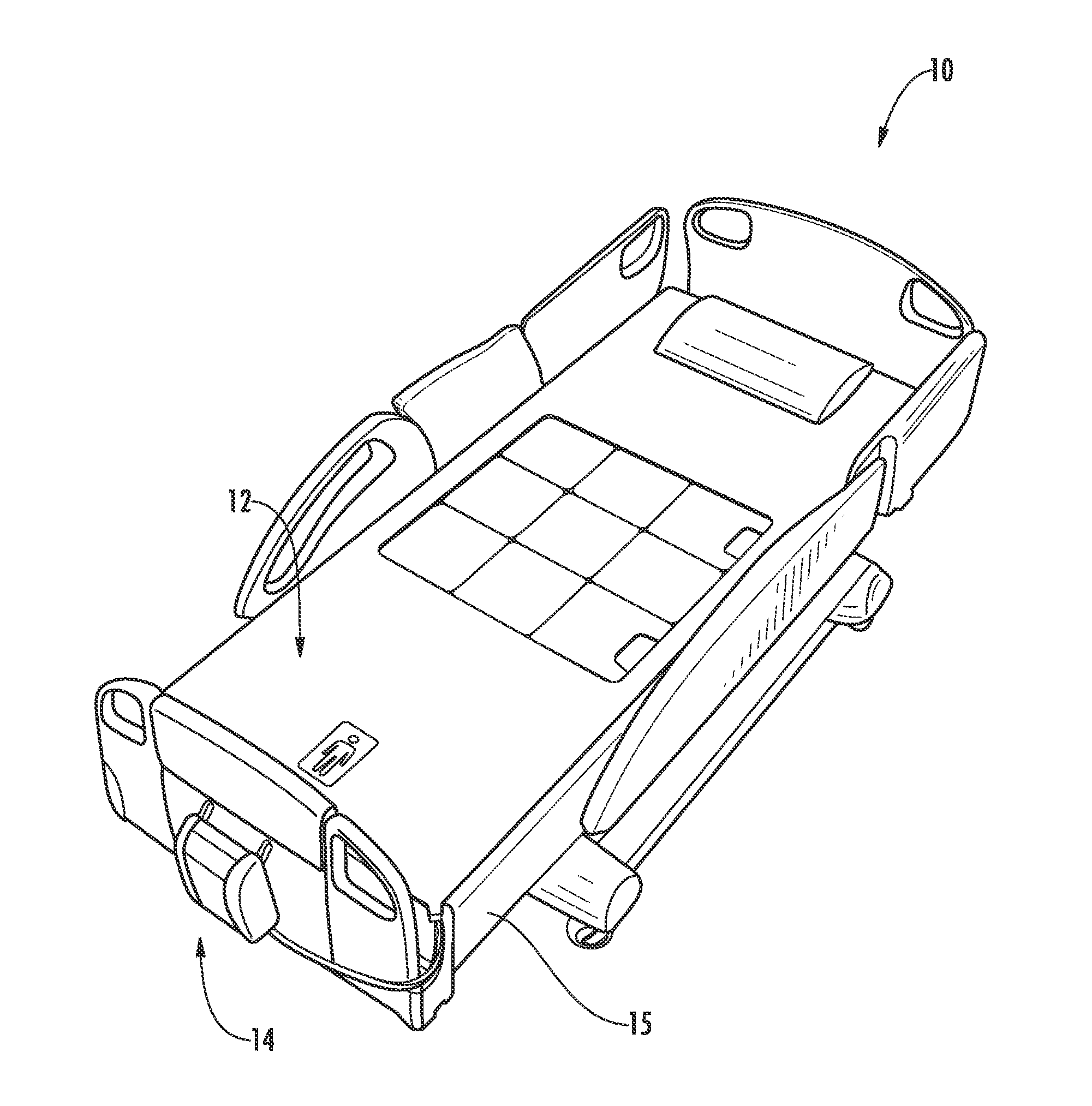

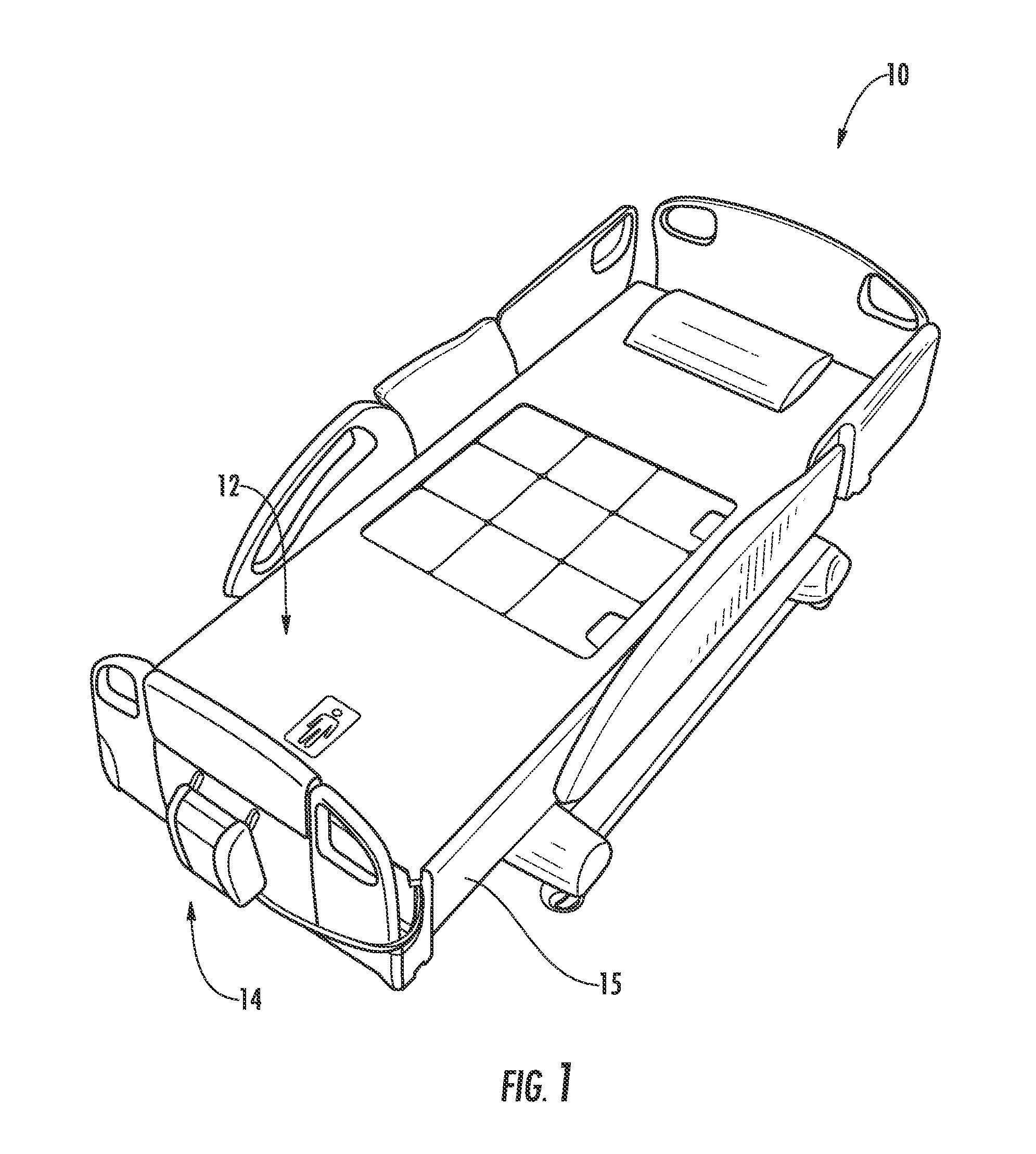

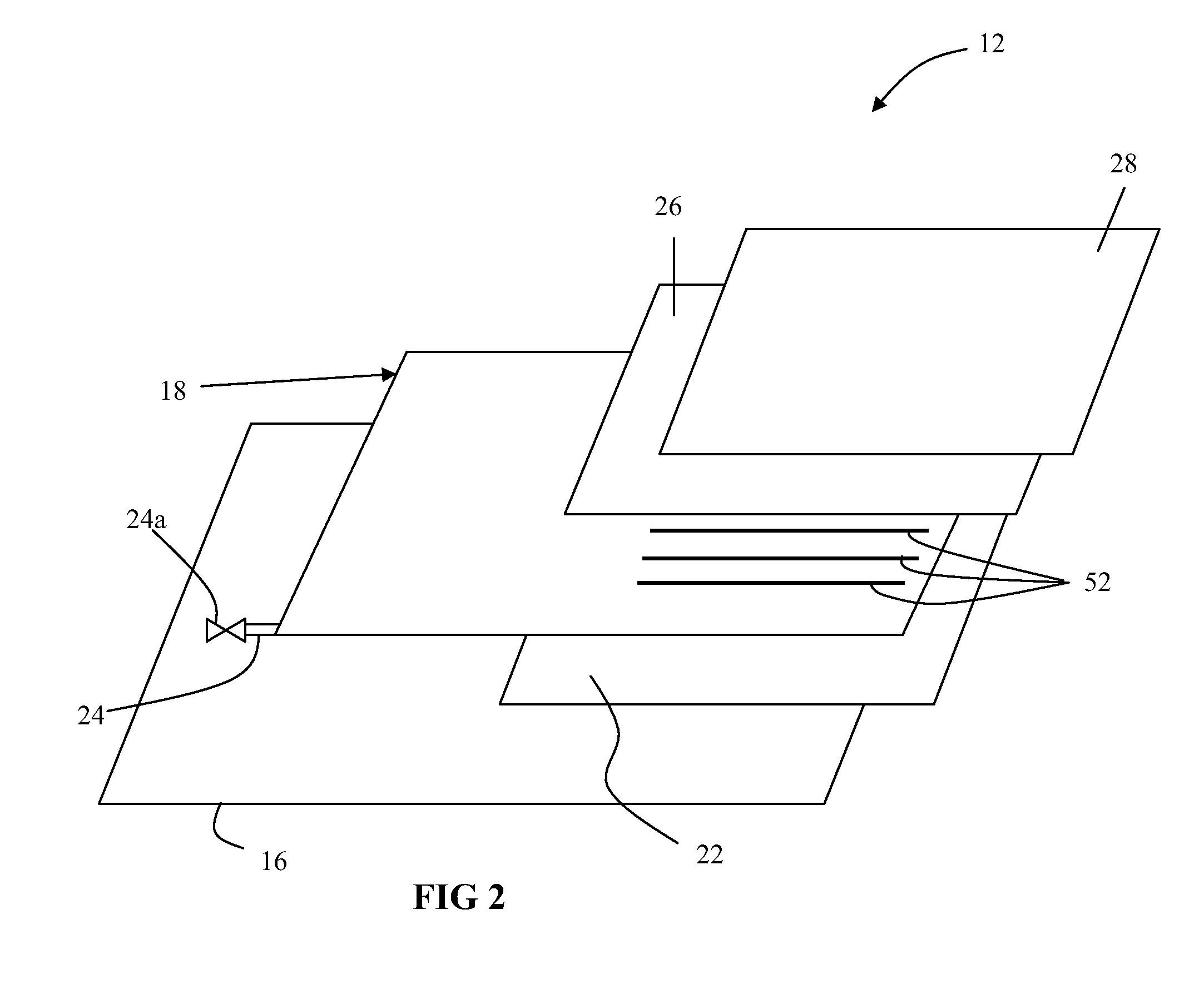

Microclimate management system

InactiveUS20110092890A1Easy to controlReduce sensitivityDiagnosticsMedical devicesEngineeringManagement system

A microclimate management sheet, for placing against a person's body, includes a flexible generally fluid impermeable first layer, a flexible generally fluid impermeable second layer with a gas permeable region for facing a patient's body. The first layer is joined with the second layer in a manner to form a chamber between the first layer and the second layer. An inlet operative to be in fluid communication with a supply of gas and in fluid communication with the chamber is provided for delivering a gas to the chamber, with the gas permeable region for directing the gas the patient's body.

Owner:STRYKER CORP

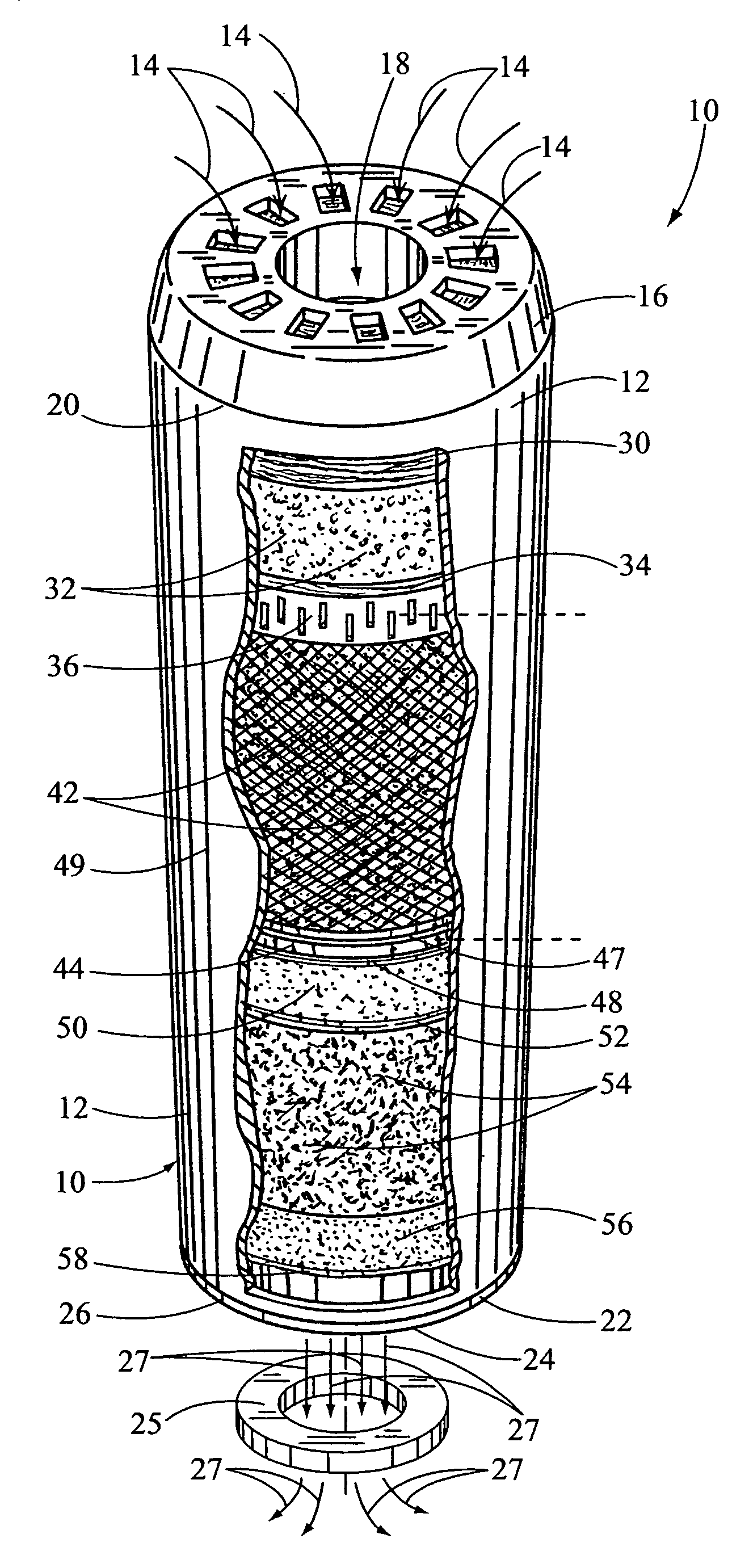

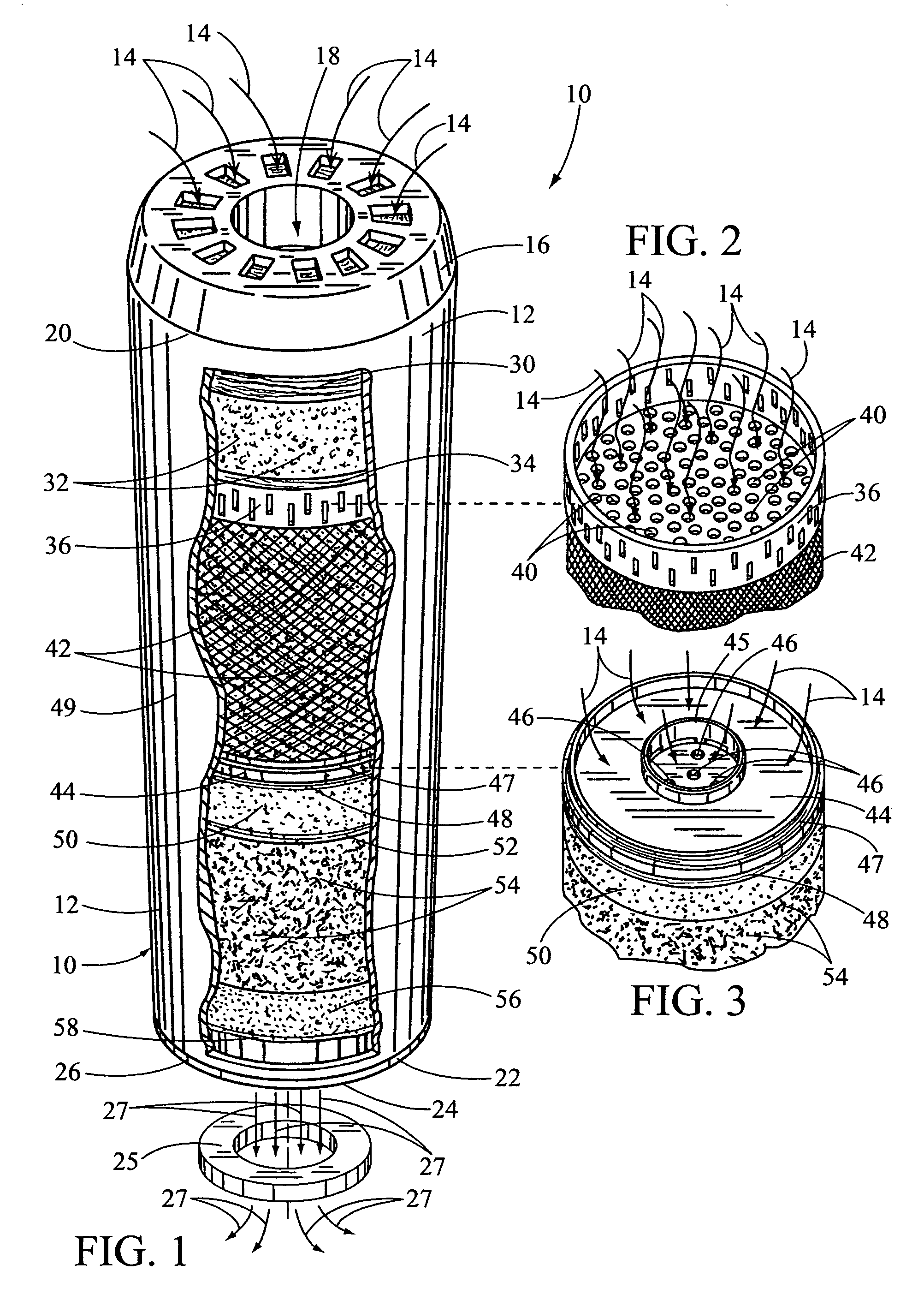

Drinking water filter used with tap water and other water sources

InactiveUS7156994B1Save spaceEliminate needTreatment involving filtrationWater/sewage treatment by ion-exchangeWater sourceFiltration

A drinking water filter for filtering major water contaminates from tap water and other drinking water sources. The water filter a cylindrical cartridge for receiving a plurality of sponge filters used as dividers between different layers of filtration material and along a length of the cartridge. The sponge filters are designed to remove large and small sediments in the water from 1 to 100 microns in size and greater when the water is introduced through the cartridge. The layers of filtration material includes a layer of granulated zinc and copper alloy, a fine mesh carbon block, a layer of granulated ion exchange resin, a layer of granulated activated carbon and layer of granulated activated calcite. The carbon block and the granulated carbon material is used for removing chlorine, odor, color, cysts, protozoa and organic contaminants such as pesticides, herbicides, arsenic, mercury, and trihalomnethanes. The zinc and copper alloy is used for removing chlorine and heavy metals in the water and reducing bacteria in the water. The calcite is used to raise the pH in the filtered water when the pH is below neutral.

Owner:ARCHER VIRGIL L

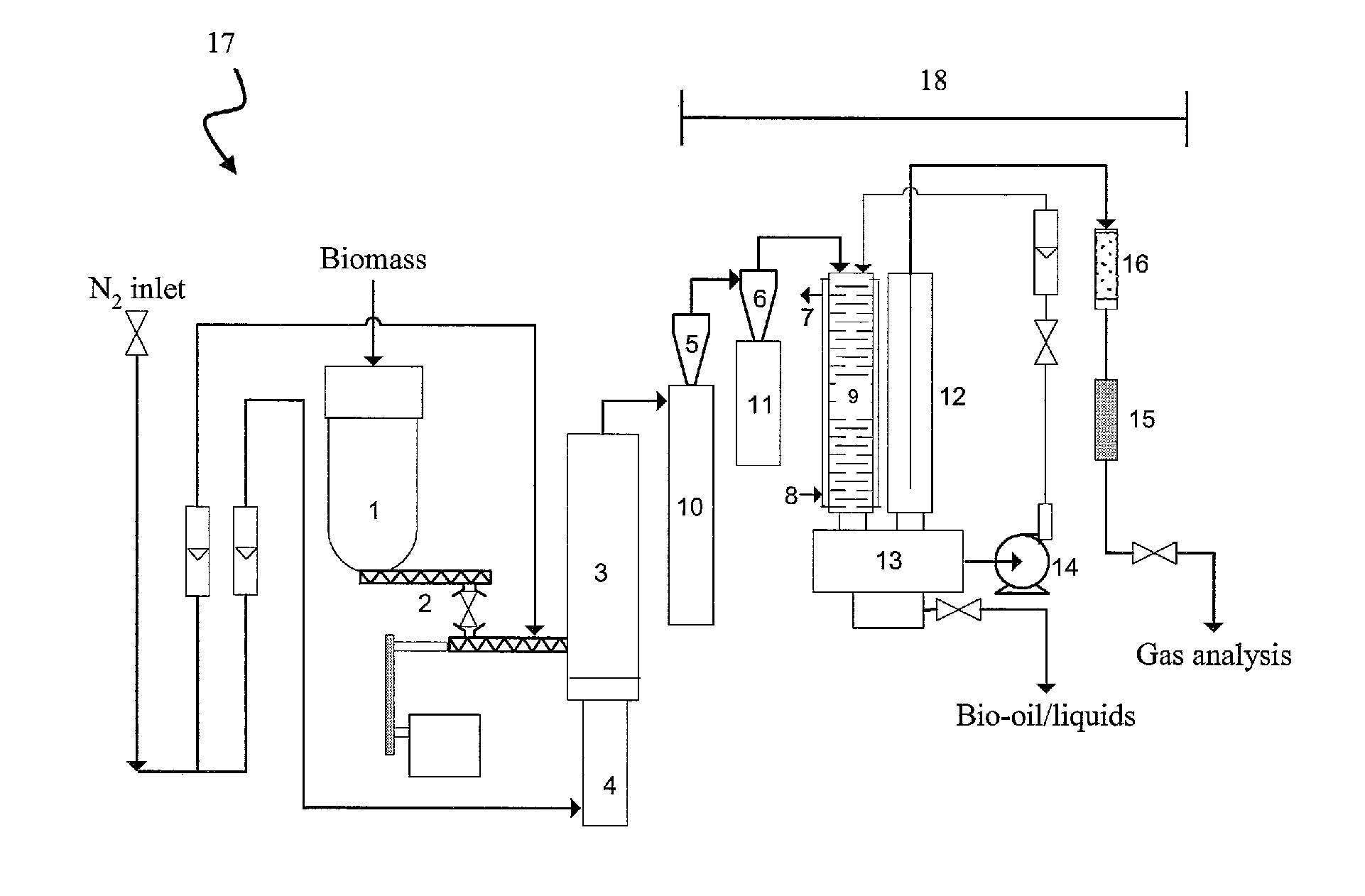

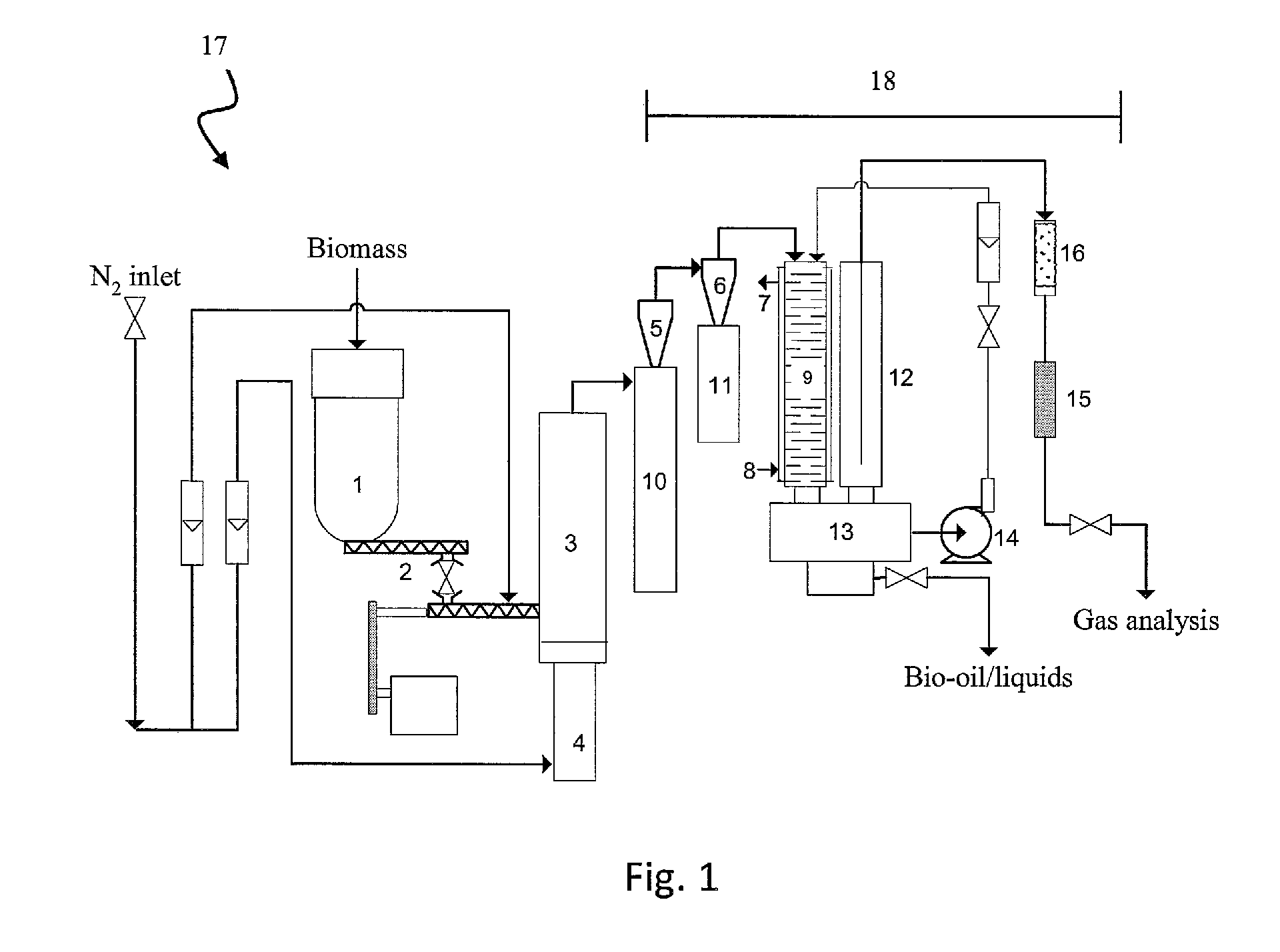

Biomass pyrolysis

InactiveUS7998315B2Reduce probabilityReduce in quantityCombustible gas coke oven heatingDirect heating destructive distillationChemistryPyrolysis

A process for pyrolyzing biomass is provided. The process comprises providing biomass to a pyrolysis reactor to produce a vapor product and condensing said vapor product to produce a condensed product, wherein a phase separation suppression agent is added during said process so as to promote the formation of a single phase condensed product.

Owner:ASTON UNIV

Enteric formulations of proanthocyanidin polymer antidiarrheal compositions

InactiveUS20050019389A1Reduce secretionReduce acidityAntibacterial agentsBiocideSecretory diarrheaPharmaceutical formulation

Pharmaceutical compositions containing a proanthocyanidin polymer composition which are useful for the treatment and prevention of secretory diarrhea are provided. The invention specifically relates to pharmaceutical formulations of a proanthocyanidin polymer composition which has been isolated from a Croton spp. or a Calophyllum spp. In particular, the invention relates to a formulation of a proanthocyanidin polymer composition which protects the composition from the effects of stomach acid after oral administration, particularly to those formulations which are enteric coated. The invention also relates to methods of producing a directly compressible proanthocyanidin polymer composition, as well as compositions containing the directly compressible proanthocyanidin polymer composition.

Owner:NAPO PHARMA INC

Volatile hydrocarbon adsorber unit

InactiveUS20040226440A1Improve adhesionEnhance integrityCombination devicesGas treatmentHydrogen compoundsMolecular sieve

A hydrocarbon adsorption unit for recovery of volatile hydrocarbons which emanate from several sources and which would otherwise be released into the atmosphere through the air cleaner of an automobile engine when the engine is shut-off. The unit is positioned in the air intake system such that all air flowing through the engine passes through the unit. The unit comprises a housing having an air inlet and an air outlet. The housing contains a substrate and a volatile hydrocarbon adsorber material coated on the surface of the substrate. The adsorber material may be silica gel, a molecular sieve and / or activated carbon. The material further contains a binder that will cause the material to adhere to the surface of the substrate.

Owner:BASF CATALYSTS LLC

Method for improving solid content of catalytic cracking catalyst slurry

ActiveCN101134906ASimple structureHigh solid contentCatalytic crackingCatalyst activation/preparationMolecular sieveColloid

The present invention is method of raising solid content in catalytic cracking catalyst slurry. The method includes mixing clay, molecular sieve slurry, aluminum-containing binder, pseudo boehmite and inorganic acid to form catalyst slurry and the subsequent spray drying. It features that the addition of inorganic acid before adding pseudo boehmite and the molecular sieve, and the addition of inorganic acid after adding kaolin and aluminum-containing binder or into the aluminum-containing binder. The present invention can raise the solid content in catalyst slurry to over 40 % to short the colloid forming time greatly, raise the catalyst producing efficiency and lower catalyst producing cost while ensuring the wear strength of catalyst. At the same time, the catalyst has great pore volume, high micro reaction activity and improved comprehensive reaction performance.

Owner:PETROCHINA CO LTD

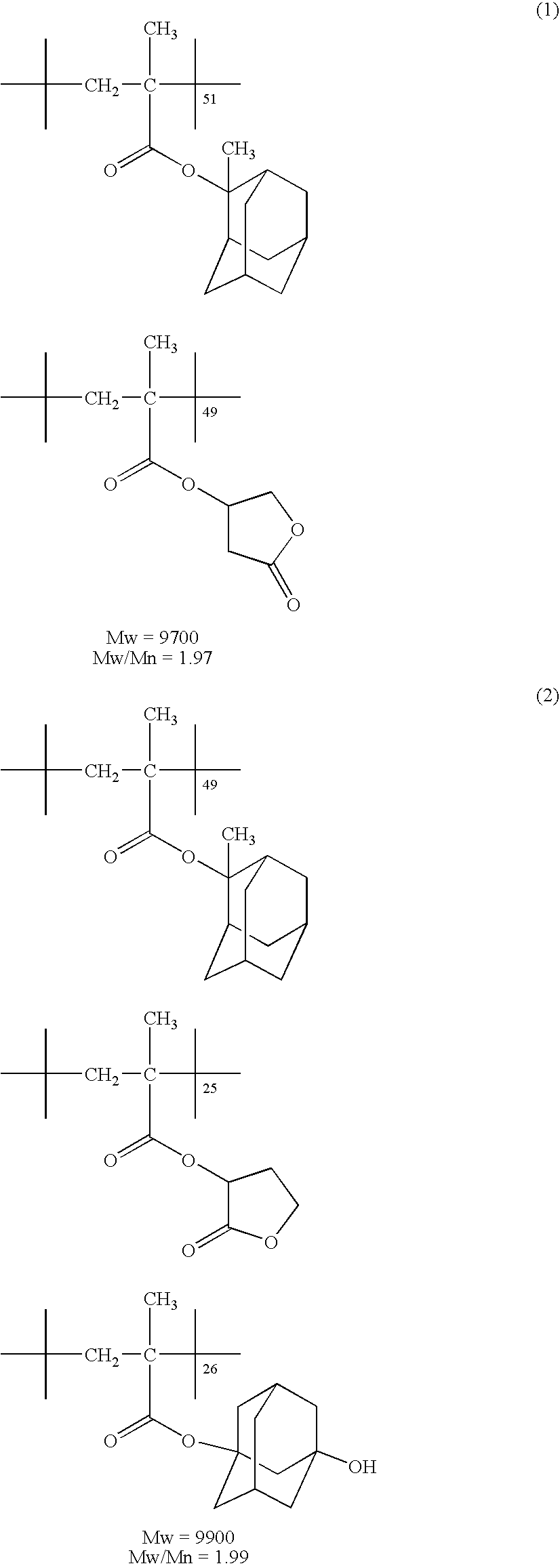

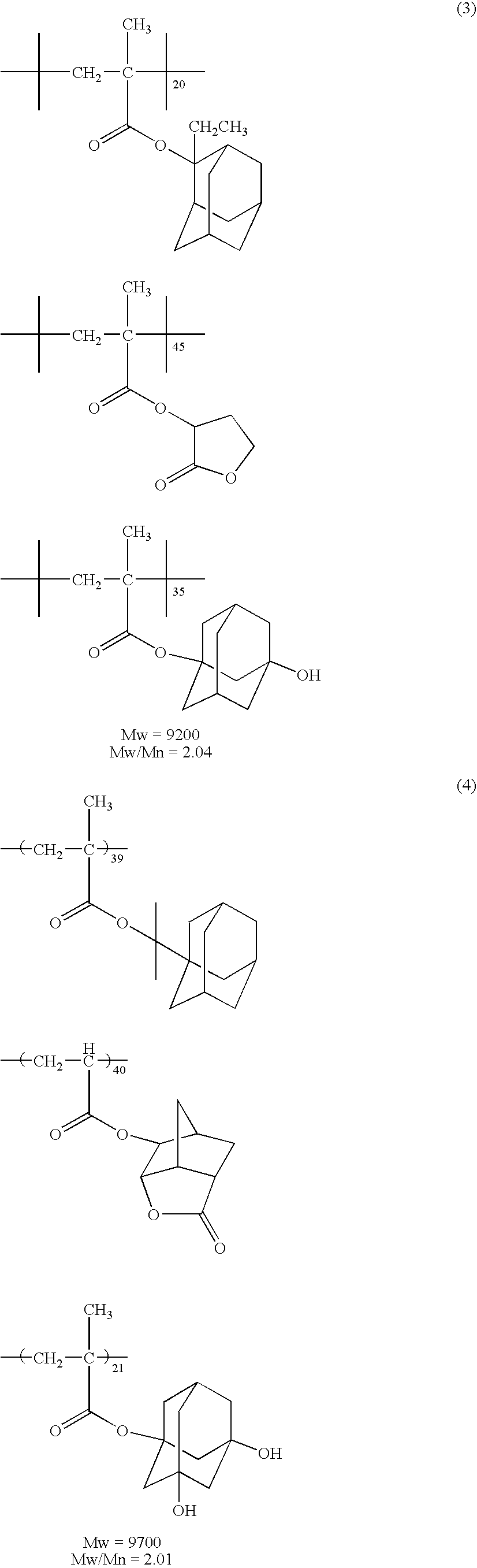

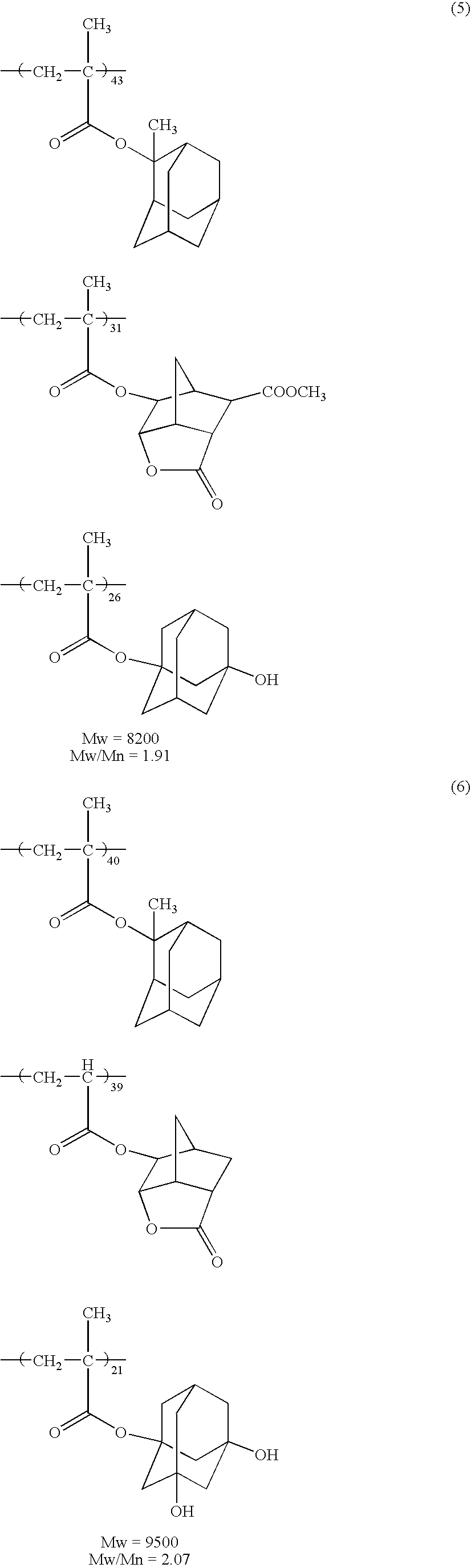

Pattern forming method

InactiveUS20050255414A1Reduce the amount requiredReduce pollutionSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusPhysical chemistryMaterials science

A pattern forming method includes (a) a step of forming a resist film on a substrate, (b) a pre-wet step of spreading a pre-wet solution on the resist film and after a fixed time, removing the pre-wet solution, and (c) a step of subjecting the resist film on the substrate to exposure through an immersion liquid.

Owner:FUJIFILM CORP +1

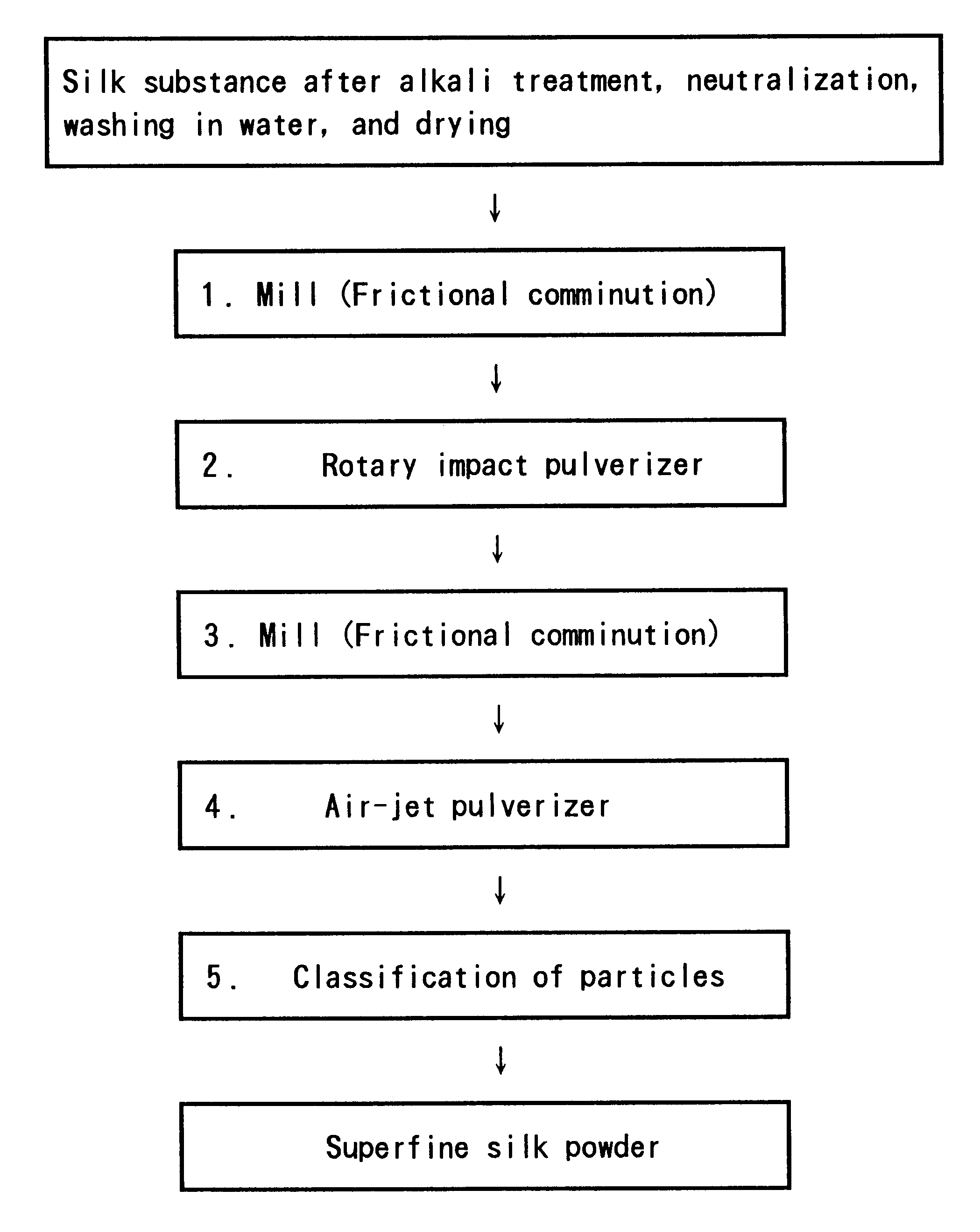

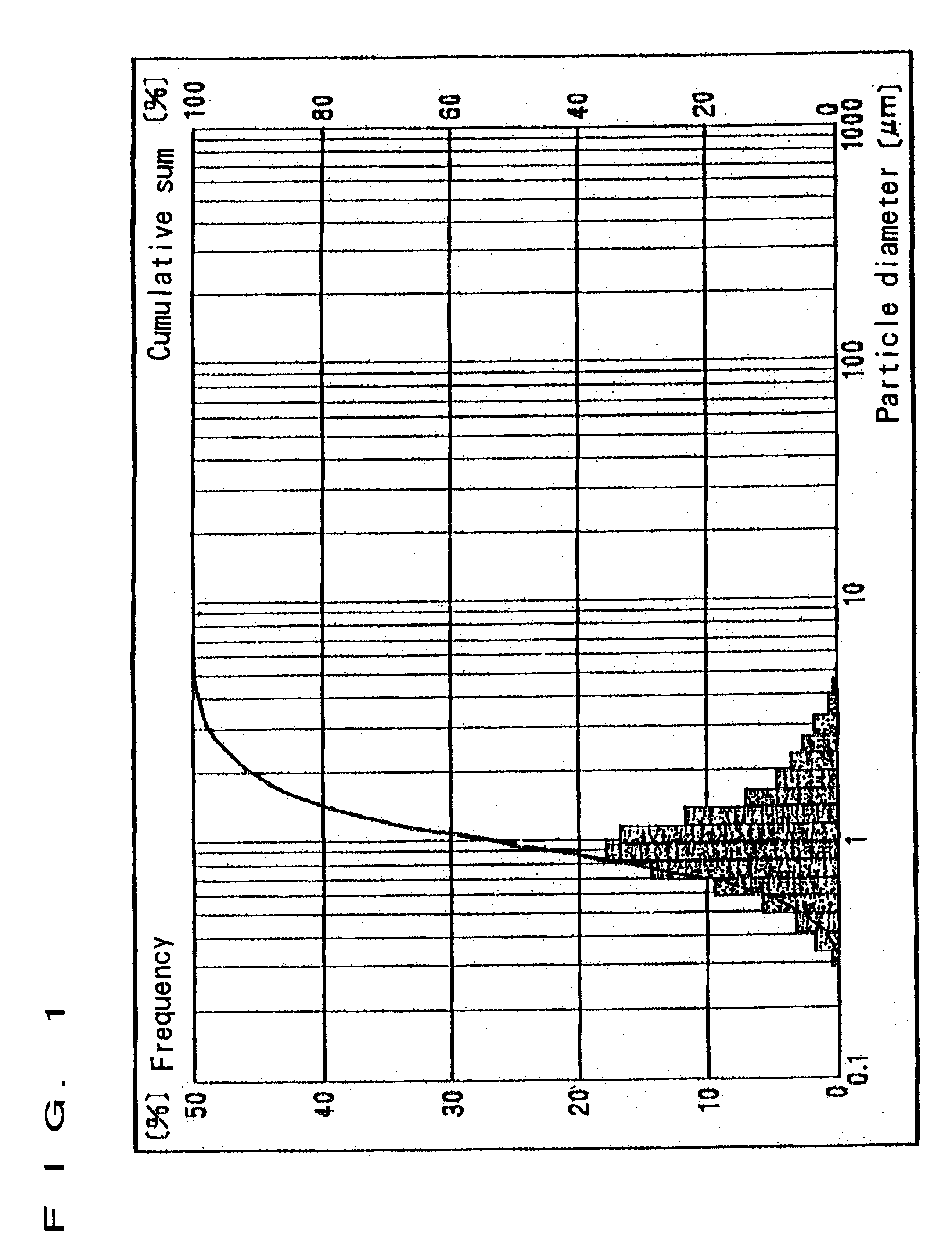

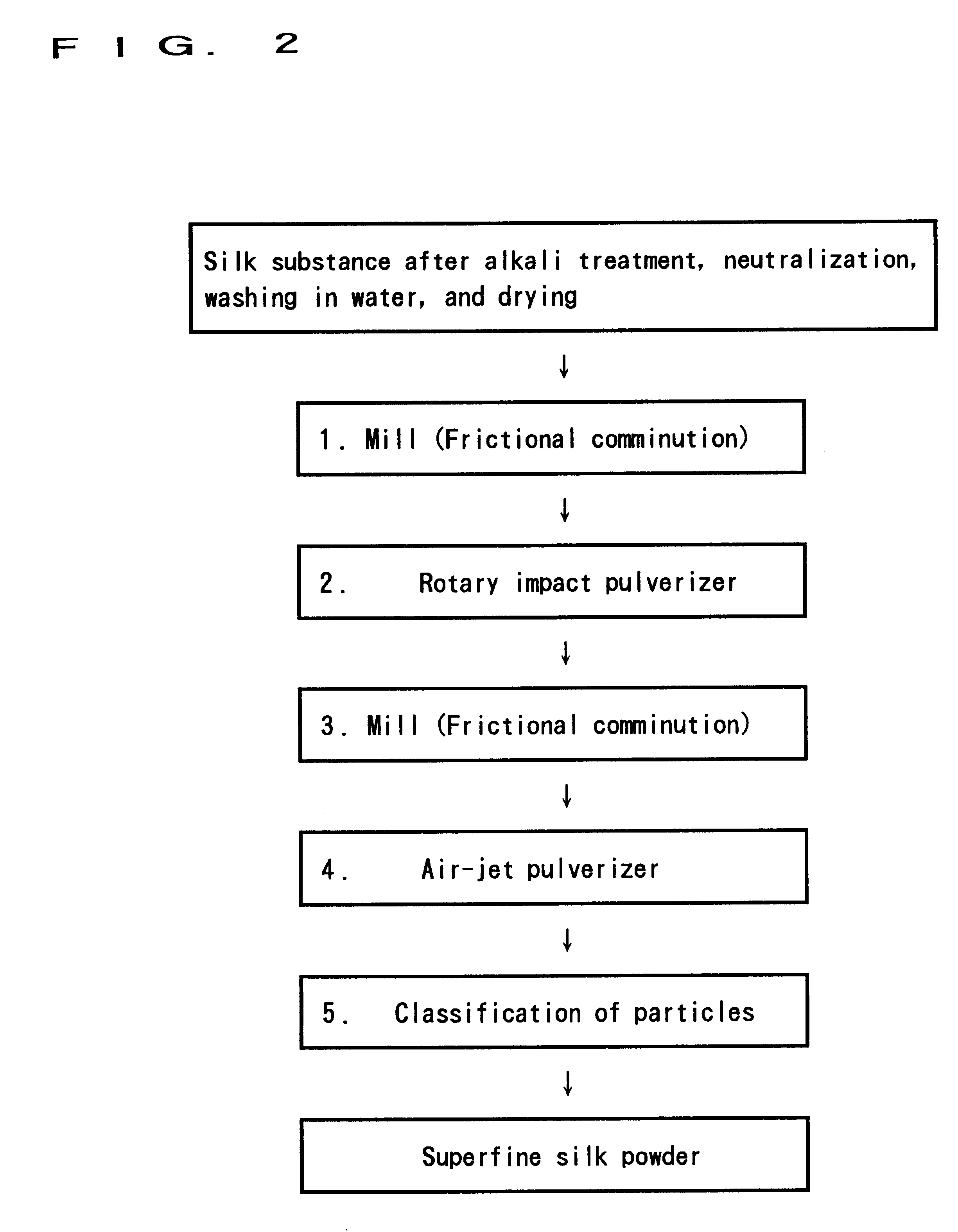

Method for manufacturing crystalline superfine silk powder

The main theme of the invention is to provide a method for manufacturing industrially, by mechanically comminuting silk yarn, crystalline silk fibroin powder below 3 mum in an average particle diameter, which can be used for various applications. A silk substance such as cocoon filament, silk yarn, or raw silk is brought into an alkali aqueous solution under a pressure of 1 through 5 atmospheric pressure at temperatures from 100° C. through 150° C. to reduce the tensile strength of the silk substance to around 0.02 g / d or less. Thereafter, the resultant silk substance is subjected to dealkalization and drying. Subsequently, the resultant dried silk substance is comminuted into powder below 3 mum in an average particle diameter. Thus, the crystalline silk fibroin powder below 3 mum in an average particle diameter is manufactured.

Owner:JAPAN AS REPRESENTED BY DIRECTOR GENERAL OF NAT INST OF SERICULTURAL & ENTOMOLIGICAL SCI MINIST OF AGRI FORESTRY & FISHERIES +1

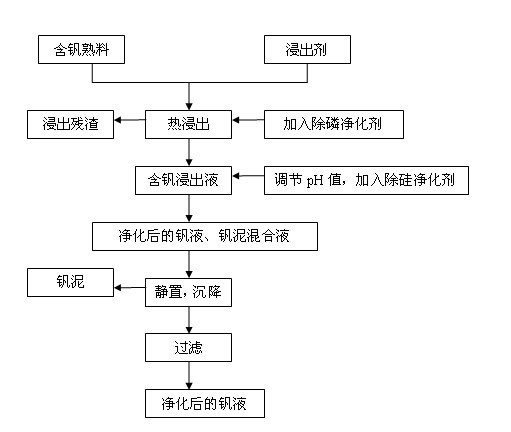

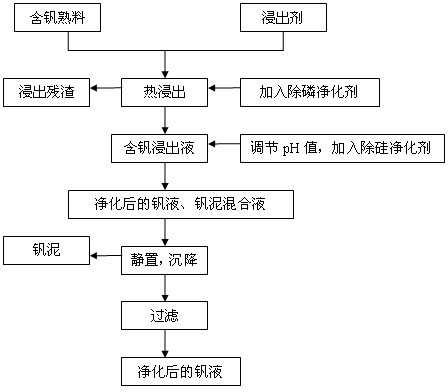

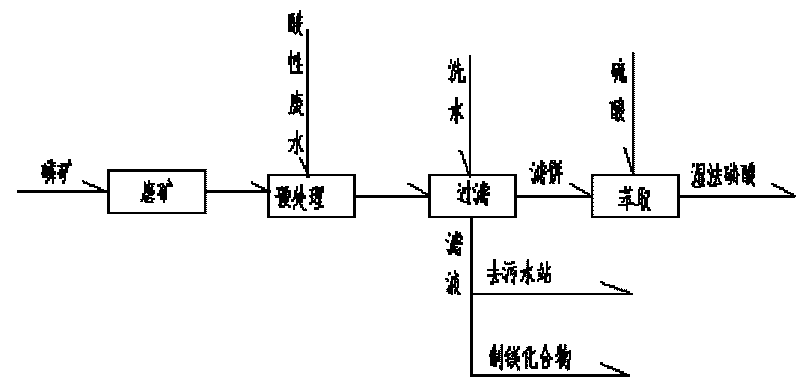

Method for purifying vanadium leaching solution

The invention discloses a method for purifying vanadium leaching solution and belongs to the technical field of purification of vanadium leaching solution after vanadium extraction from vanadium slag. The invention adopts a technical scheme that the method comprises: 1, setting the temperature of the leaching solution of a vanadium-containing clinker to be between 60 and 100 DEG C, and adding phosphorus-removing purifying agent; 2, regulating the pH value of vanadium leaching solution by using an acid and adding a silicon-removing purifying agent; and 3, after the reaction is finished, cooling, standing, and filtering to obtain vanadium solution with low silicon and phosphorus content. The method has the advantages that: the operation is simple, the requirements on the acidity and impurity content of original vanadium solution are low, the pH value after purification is 5 to 8, the reaction time and standing time of the vanadium solution are short, and the industrial and continuous production is made easier; and the whole purification system adopts sulfate, so the introduction of chlorine ions is avoided, environment pollution is avoided, equipment requirements are low, corrosion to a pipe in a subsequent process is relieved, and the treatment of acid waste water is promoted.

Owner:HEBEI IRON AND STEEL

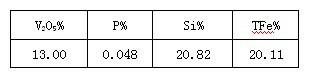

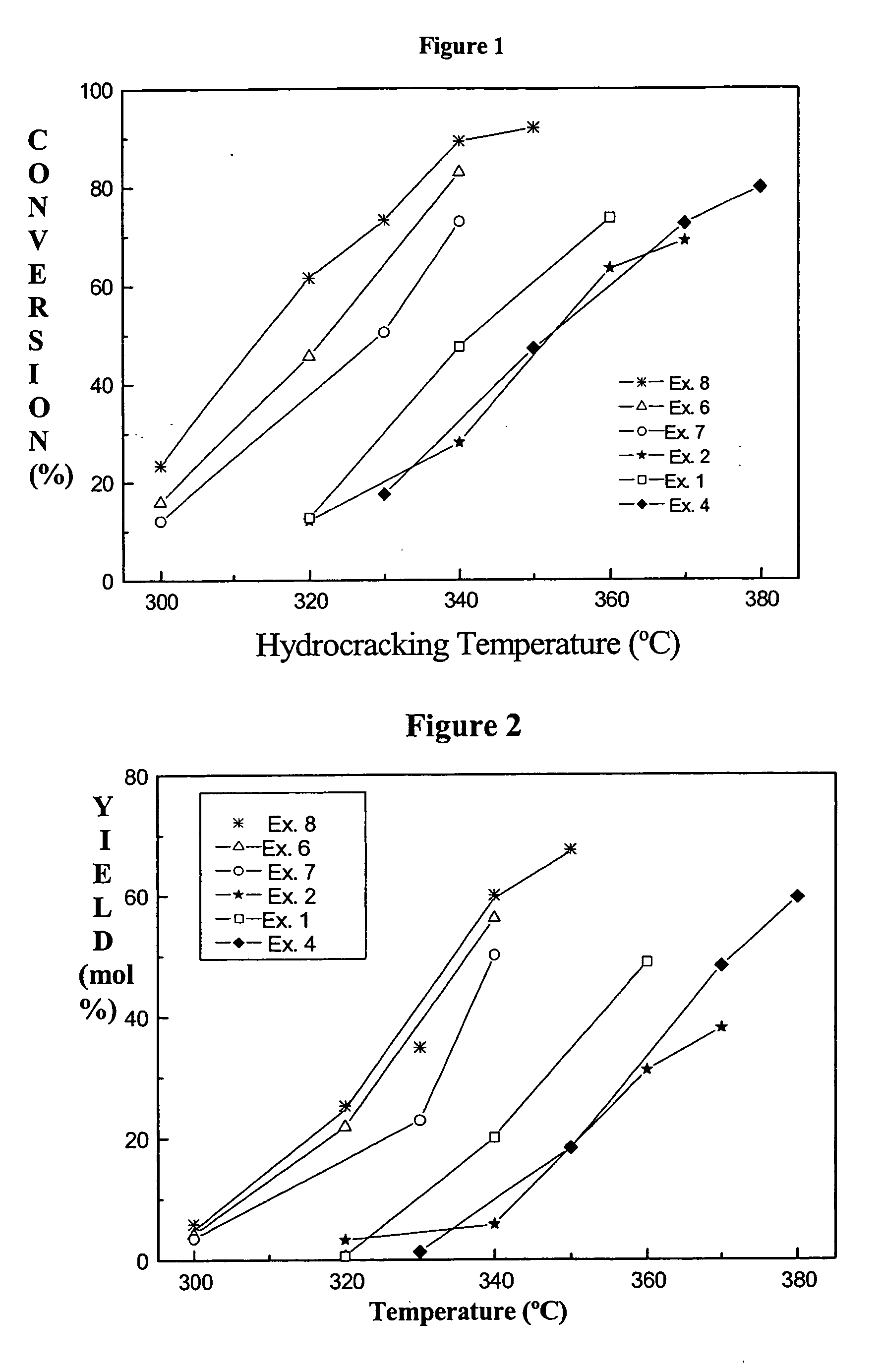

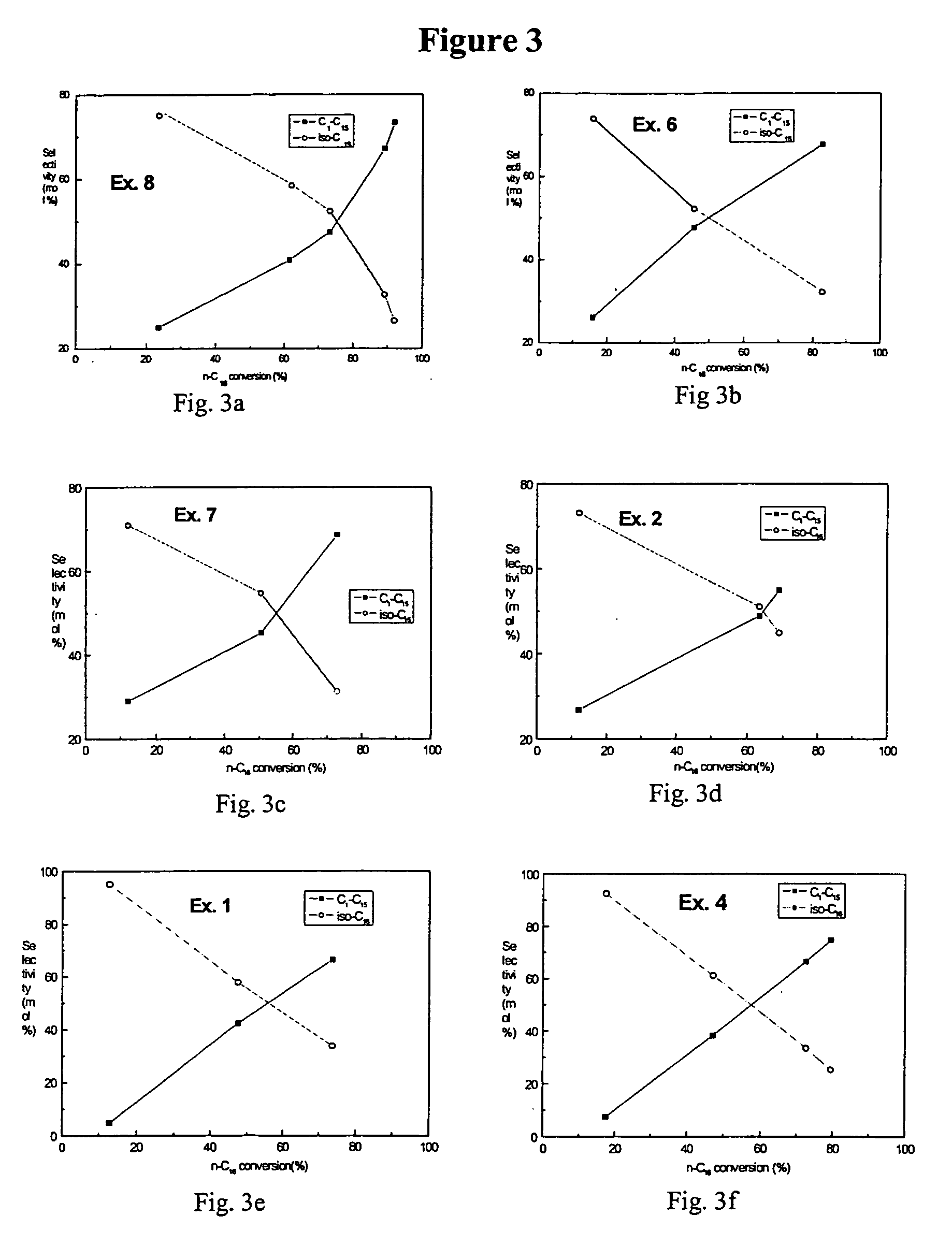

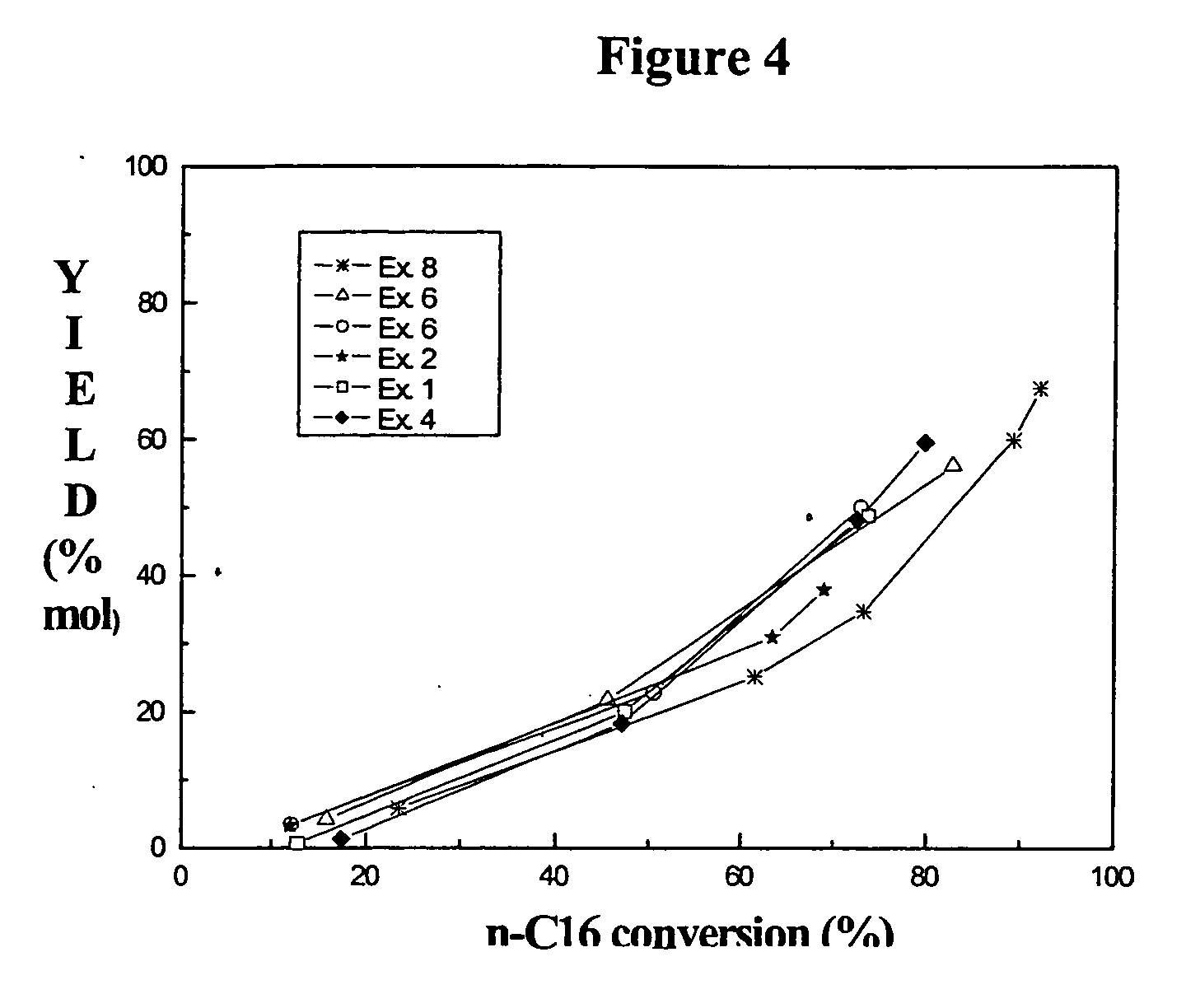

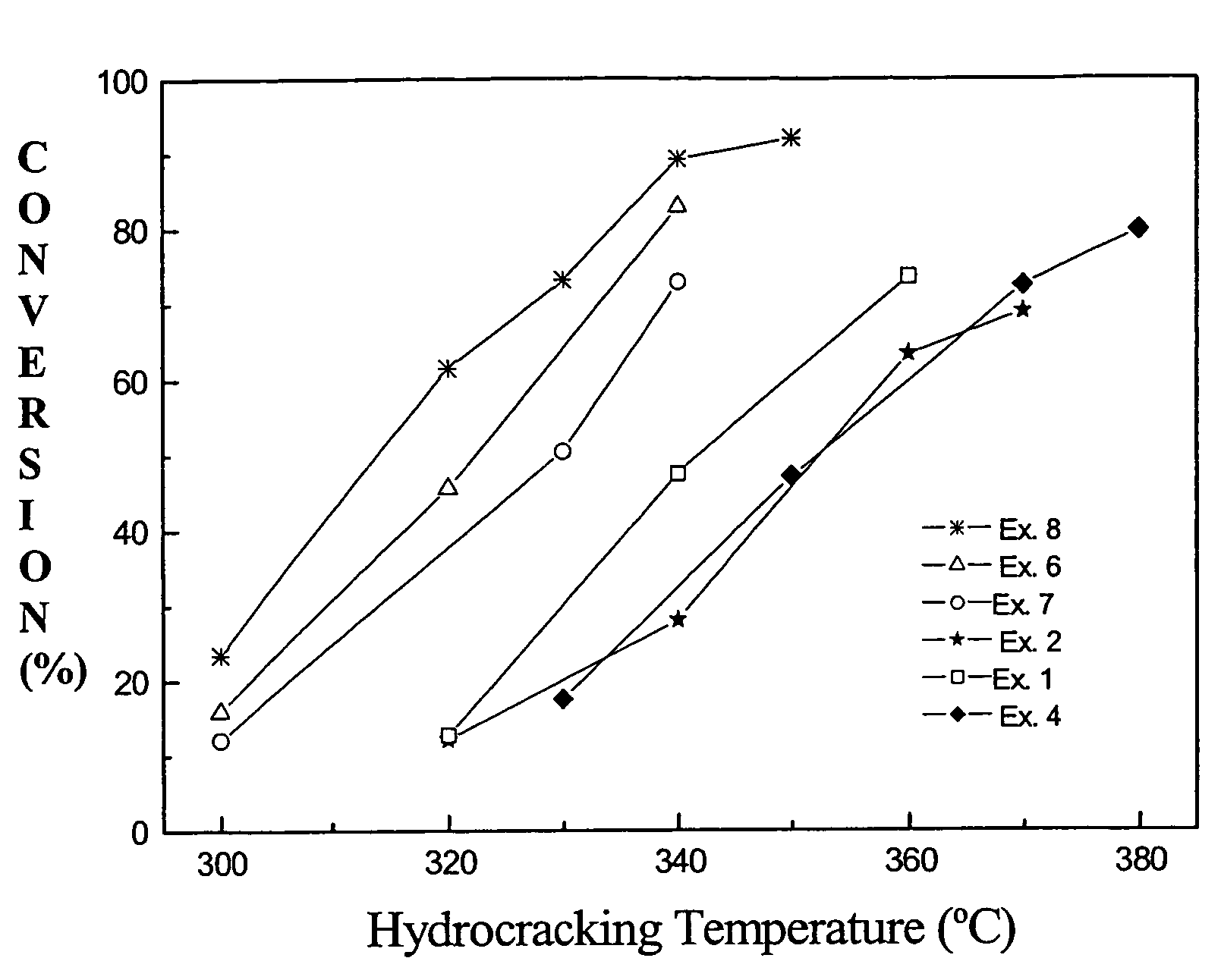

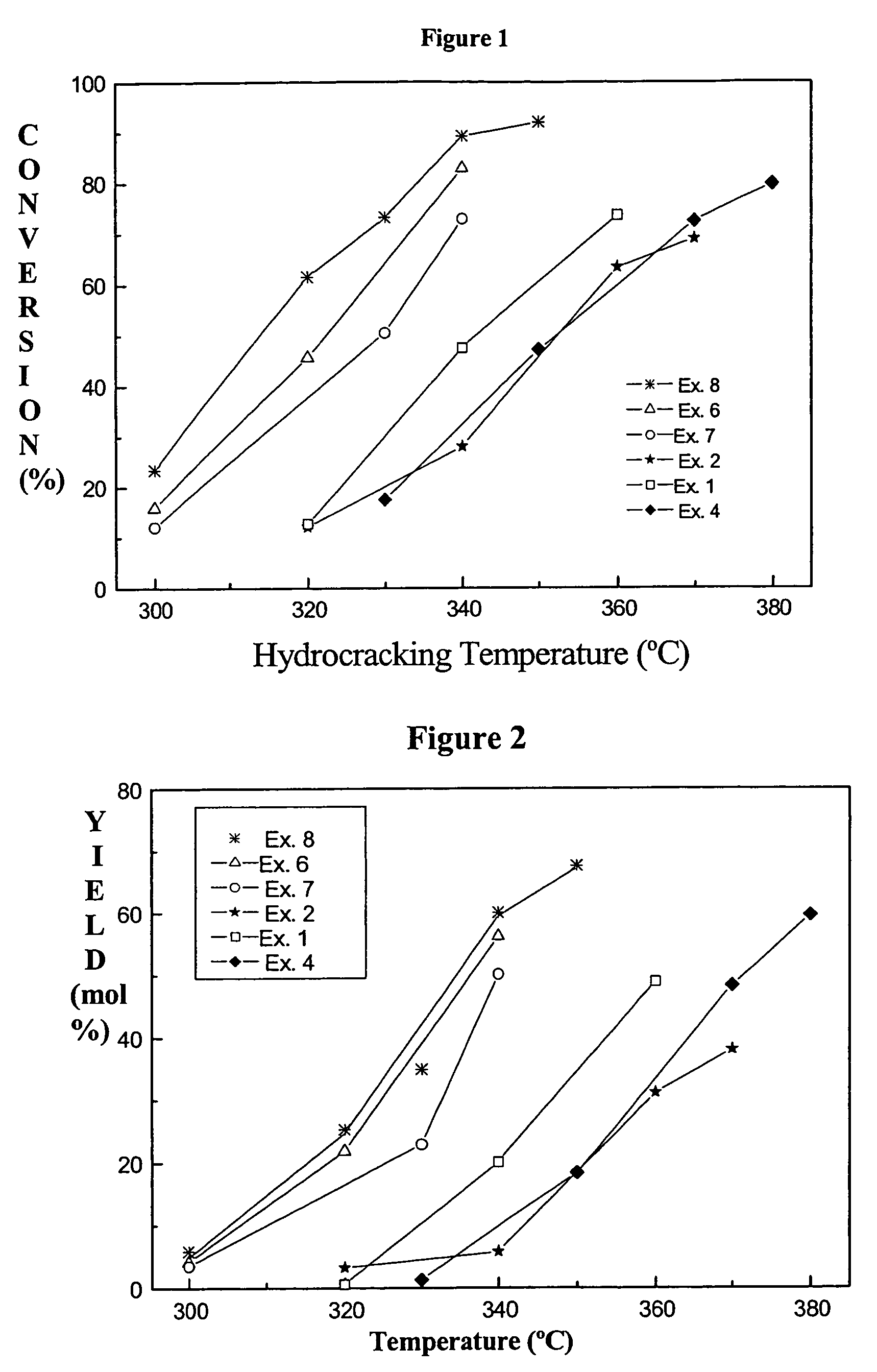

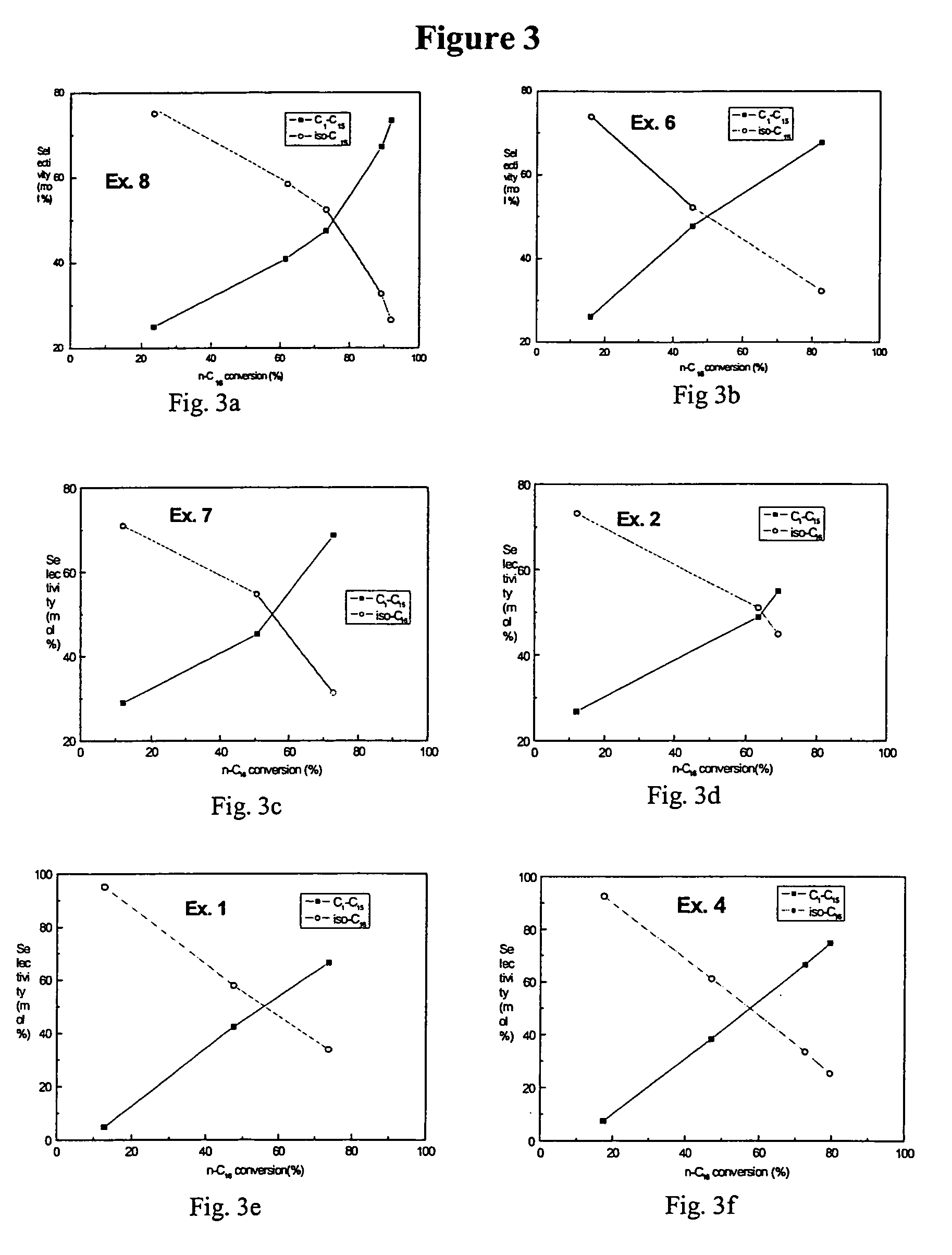

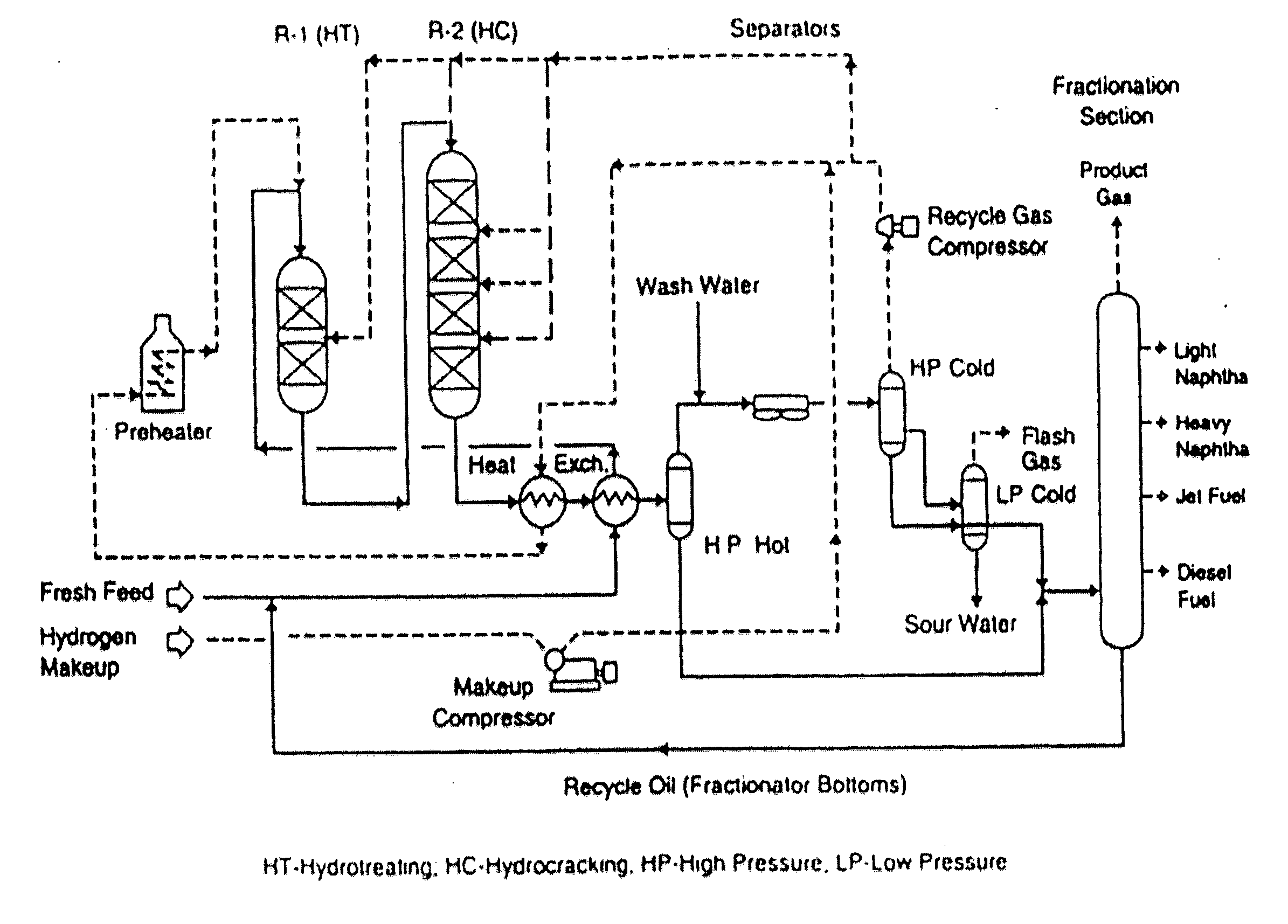

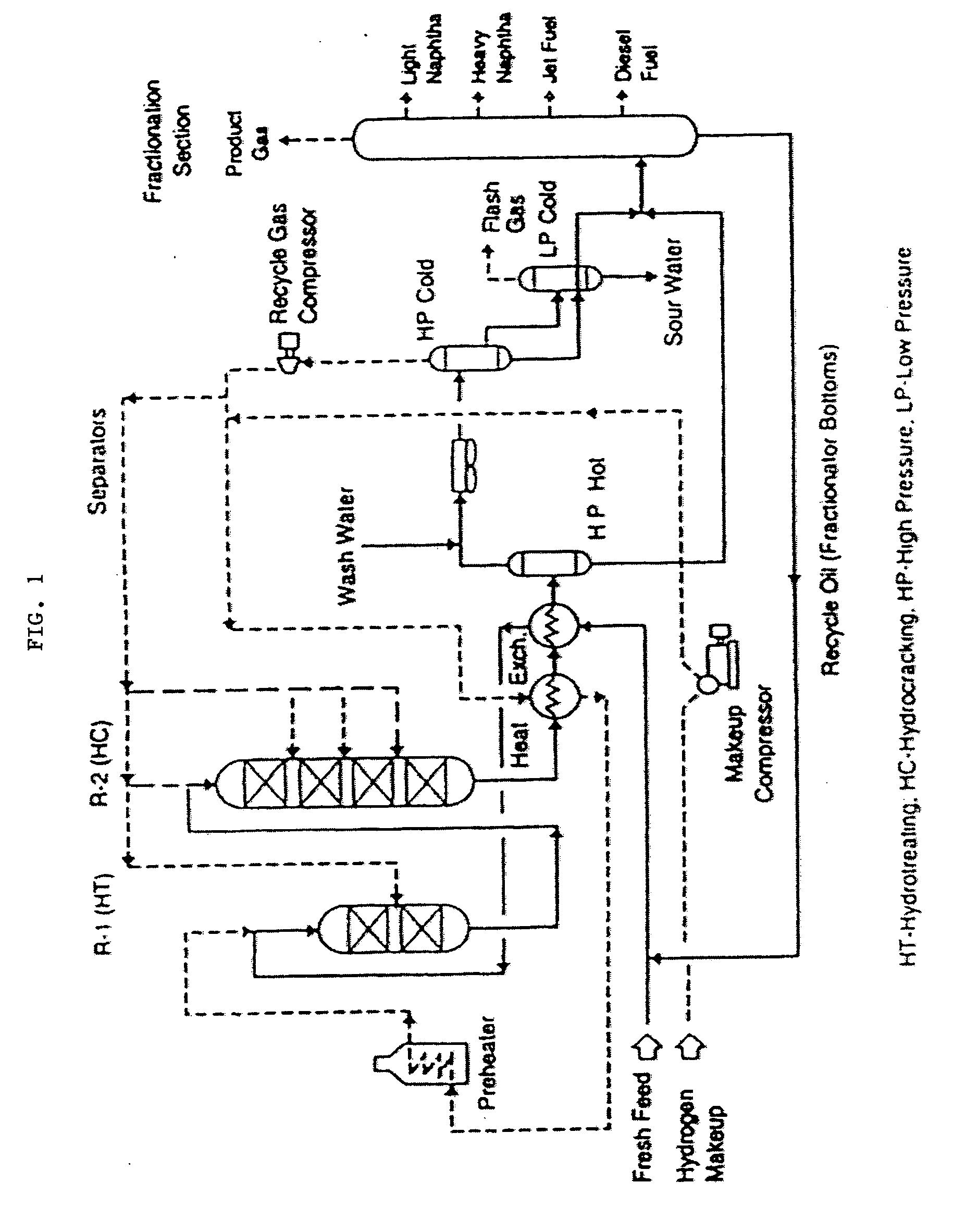

Combination of amorphous materials for hydrocracking catalysts

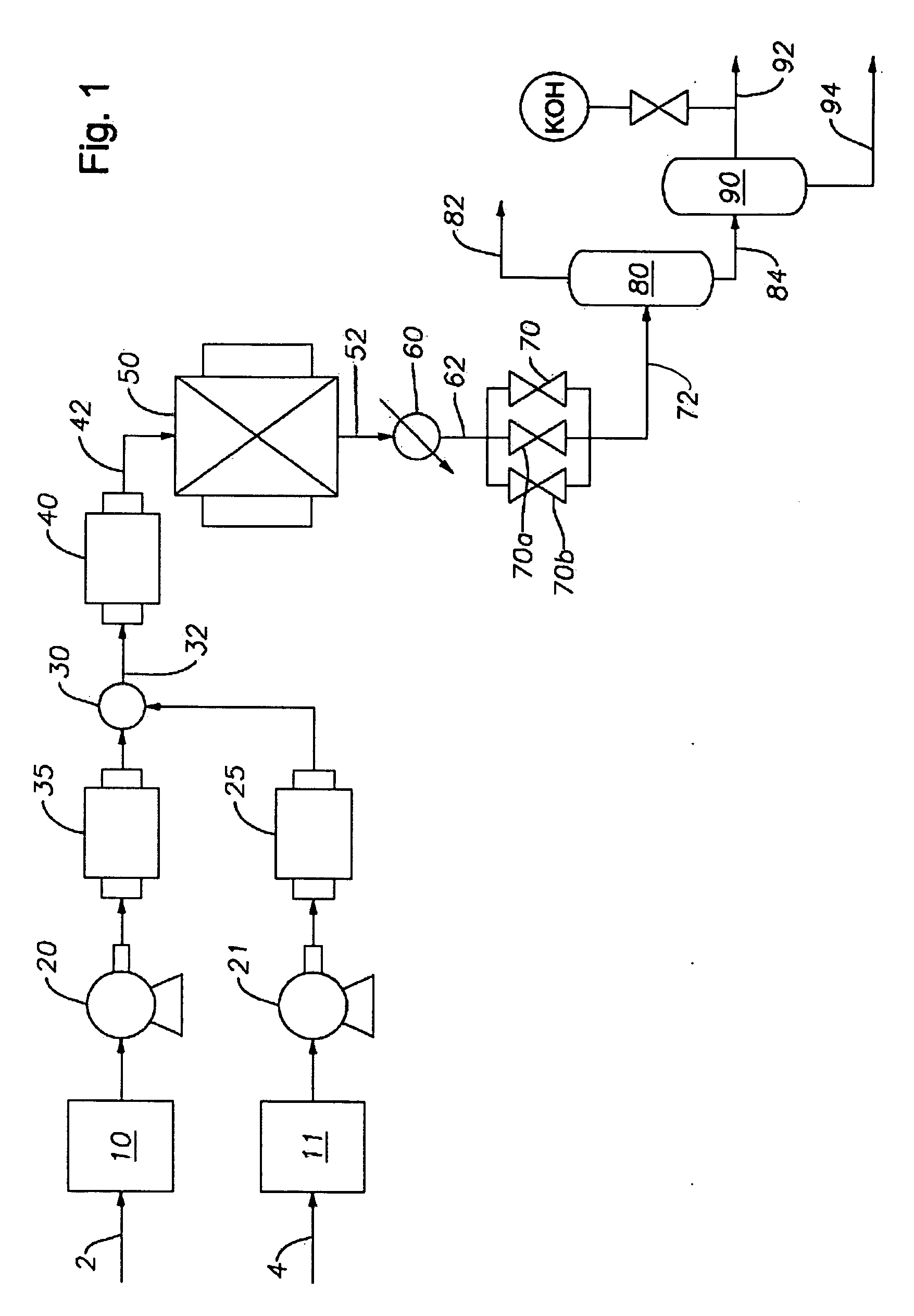

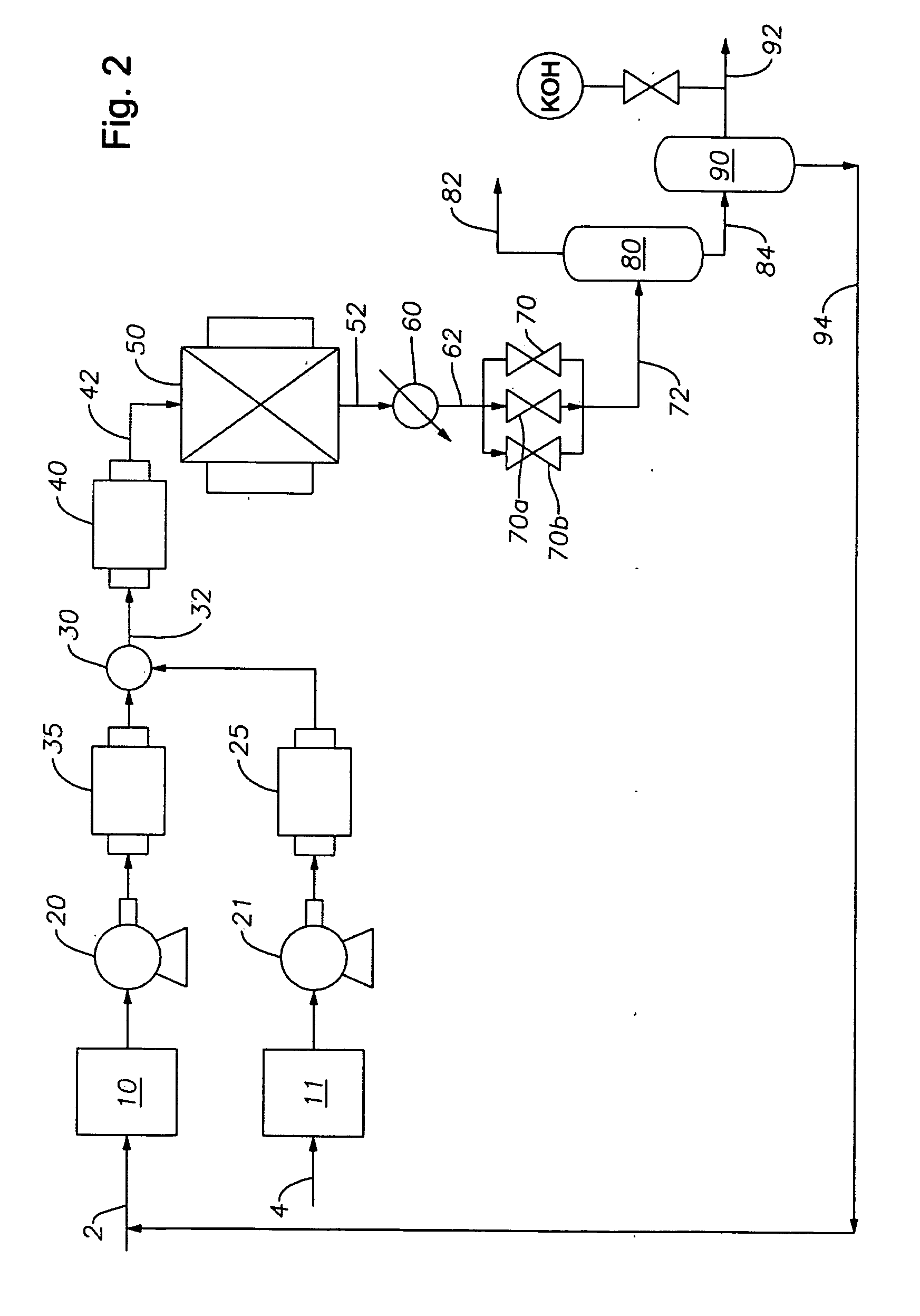

ActiveUS20060011512A1Reduce acidityIncrease acidityOther chemical processesCatalyst activation/preparationHydrocarbonCatalyst support

An amorphous support, methods for making the same and methods of using, particularly in hydrocracking. A method of making may comprise mixing a first amorphous material and a second amorphous material of different acidities to form a mixture, and treating by either separately treating the first and second amorphous materials before mixing or treating the mixture, so as to form an amorphous catalyst support. Treating preferably includes calcining. The acidity of the amorphous support may be modified by the different acidities of the precursor amorphous materials, their proportions in the mixture, and / or the order of the mixing and treating steps. A method of use may comprise reacting a hydrocarbon fraction with hydrogen over a hydrocracking catalyst comprising the amorphous catalyst support to form a hydrocracked product. Further embodiments include the first and second amorphous materials comprising silica-alumina, and / or differing in Brönsted acidity, Lewis acidity, or acidity index.

Owner:PHILLIPS 66 CO

Combination of amorphous materials for hydrocracking catalysts

ActiveUS7323100B2Effective control over acidityReduce acidityOther chemical processesCatalyst activation/preparationHydrogenCatalyst support

An amorphous support, methods for making the same and methods of using, particularly in hydrocracking. A method of making may comprise mixing a first amorphous material and a second amorphous material of different acidities to form a mixture, and treating by either separately treating the first and second amorphous materials before mixing or treating the mixture, so as to form an amorphous catalyst support. Treating preferably includes calcining. The acidity of the amorphous support may be modified by the different acidities of the precursor amorphous materials, their proportions in the mixture, and / or the order of the mixing and treating steps. A method of use may comprise reacting a hydrocarbon fraction with hydrogen over a hydrocracking catalyst comprising the amorphous catalyst support to form a hydrocracked product. Further embodiments include the first and second amorphous materials comprising silica-alumina, and / or differing in Brönsted acidity, Lewis acidity, or acidity index.

Owner:PHILLIPS 66 CO

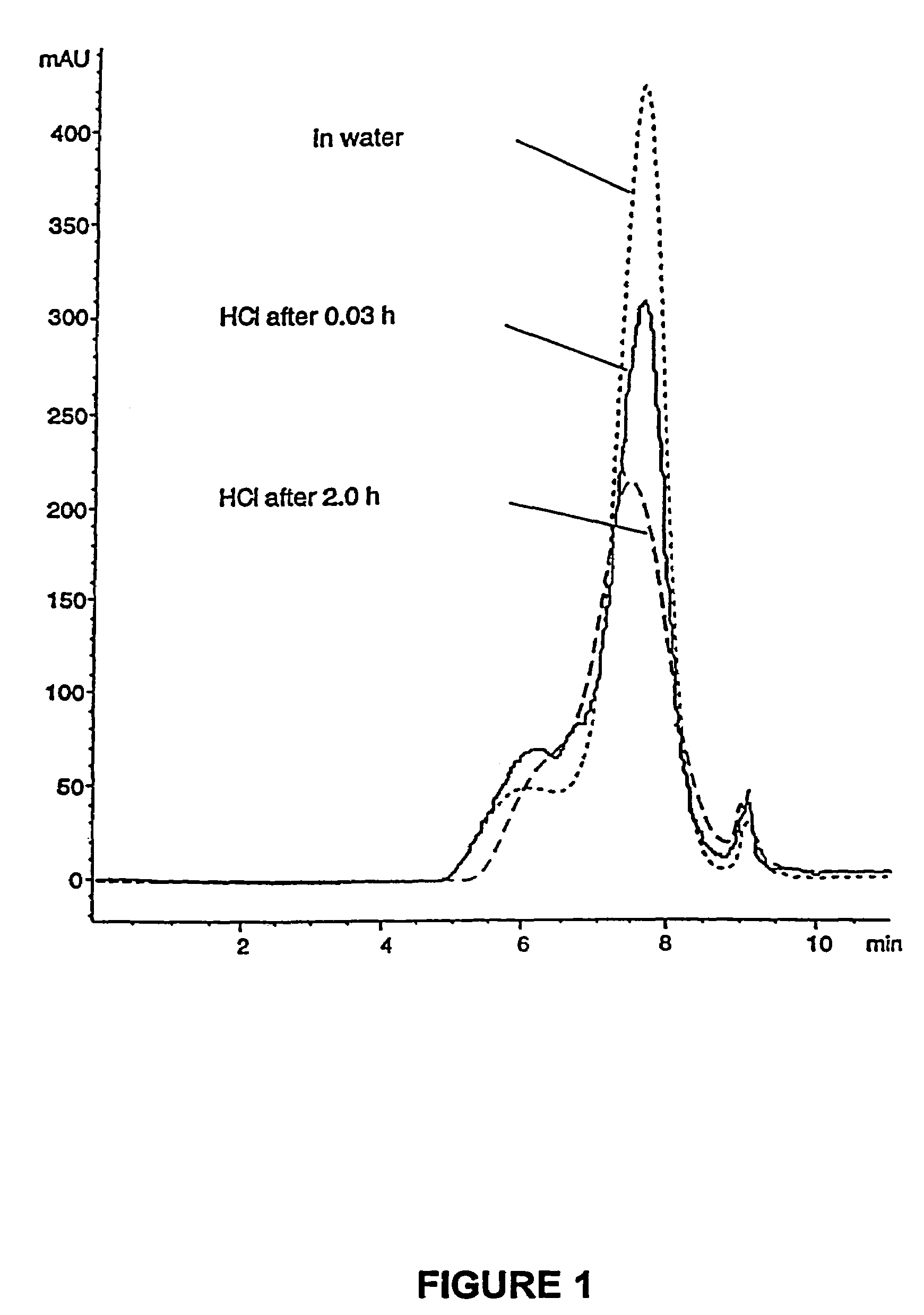

Oral immunotherapy of bacterial overgrowth

InactiveUS6096310AInhibiting and reducingReduce acidityBacterial antigen ingredientsSerum immunoglobulinsDiseaseBacteroides

The object of the present invention is the oral administration of animal immunoglobulins for the treatment of gastrointestinal disorders caused by bacterial and / or yeast overgrowth. Immunoglobulins derived from the blood, plasma or serum of animals, such as cow, goats, sheep and pigs, contain a broad spectrum of antibodies to bacteria and yeast that afflict the gastrointestinal tract of human patients.

Owner:BIER MILAN

Mesoporous composite of molecular sieves for hydrocracking of heavy crude oils and residues

ActiveUS20140124410A1High activityImprove stabilityMolecular sieve catalystsCatalyst activation/preparationMolecular sieveBoiling point

A hydrocracking catalyst having a support of a composite of mesoporous materials, molecular sieves and alumina, is used in the last bed of a multi-bed system for treating heavy crude oils and residues and is designed to increase the production of intermediate distillates having boiling points in a temperature range of 204° C. to 538° C., decrease the production of the heavy fraction (>538° C.), and increase the production of gasoline fraction (<204° C.). The feedstock to be processed in the last bed contains low amounts of metals and is lighter than the feedstock that is fed to the first catalytic bed.

Owner:INST MEXICANO DEL GASOLINEEO

Process to reduce acidity of crude oil

ActiveUS20090159504A1Reduce corrosionSimple methodThermal non-catalytic crackingRefining with metalsOrganic acidNaphthenic acid

Owner:SAUDI ARABIAN OIL CO

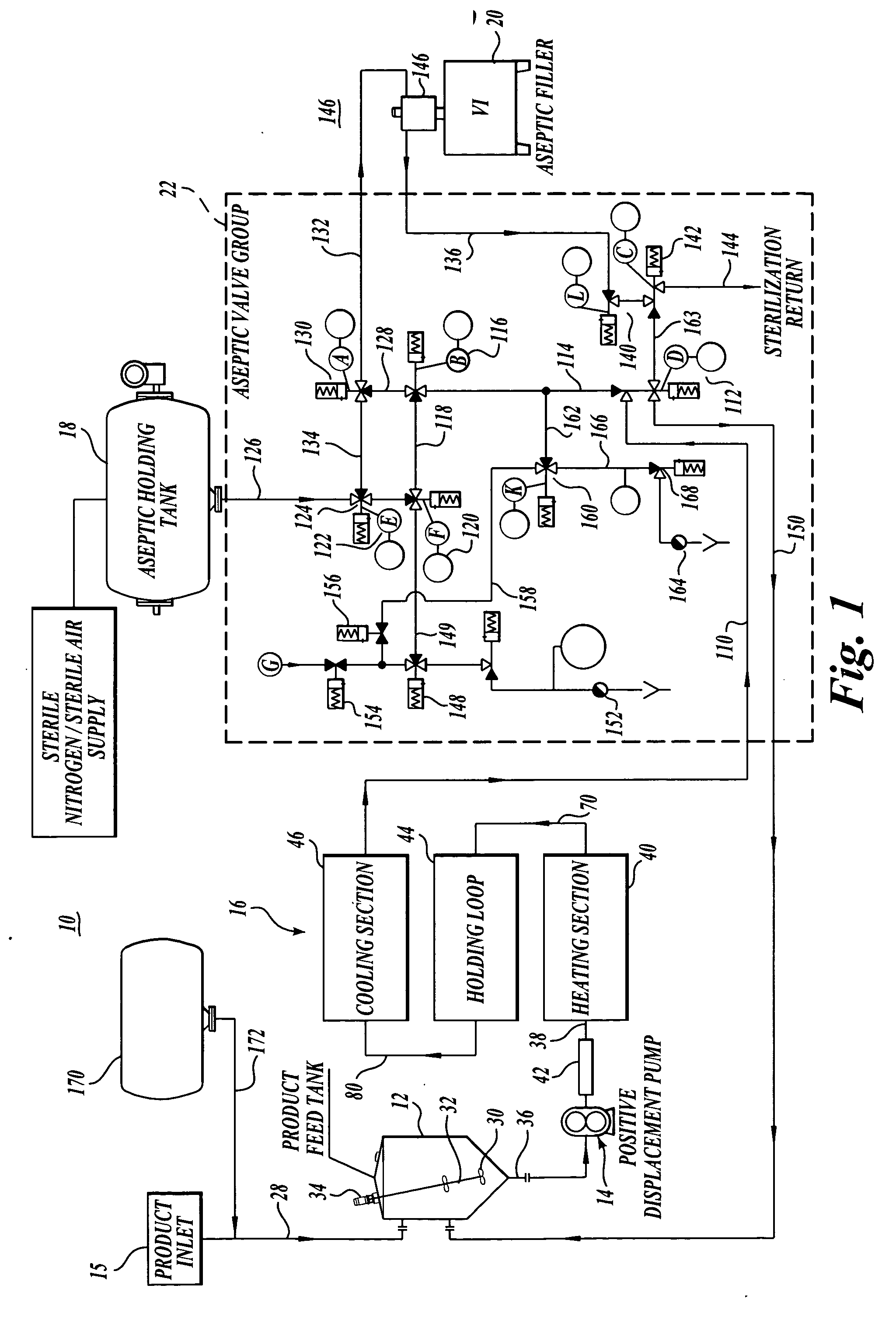

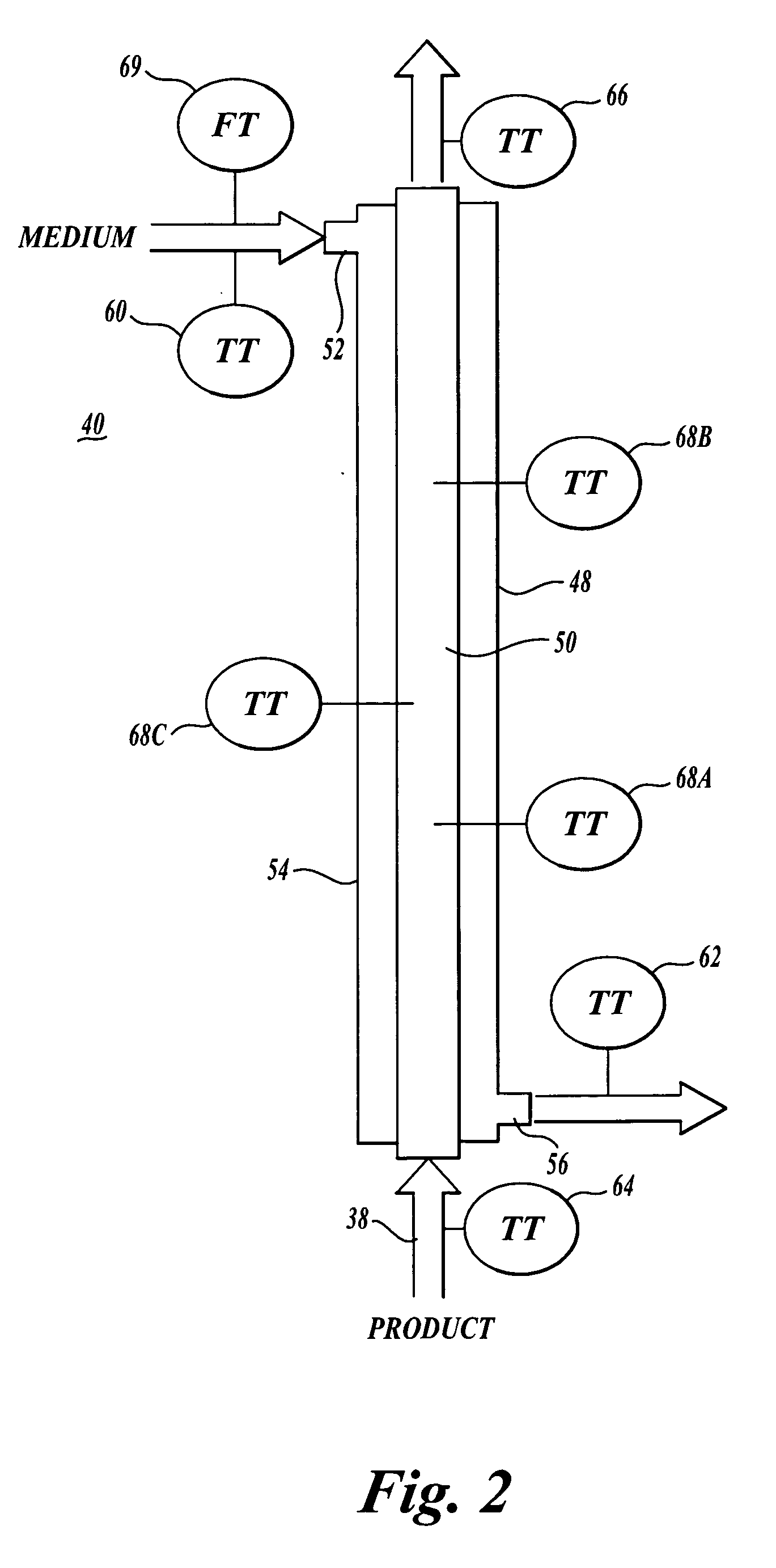

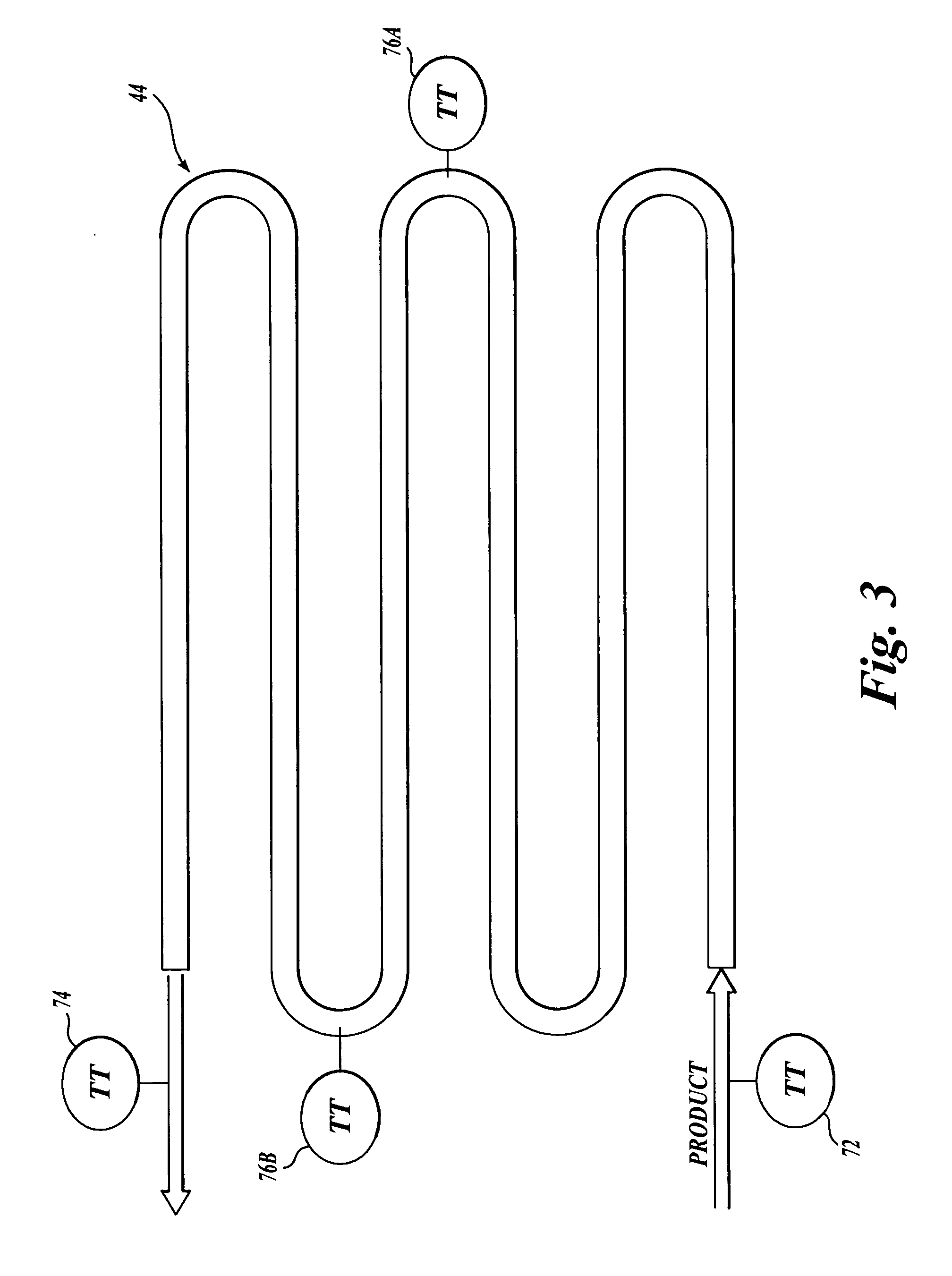

Aseptic processing system and method

A system (10) for aseptically sterilizing a heterogeneous food product (15) consisting of particulates in a liquid includes a heating section (40), a holding section (44), and a cooling section (46). From the cooling section, the food product is routed to an aseptic holding tank (18) and / or an apparatus (20) to fill aseptic containers. The temperature profile of the food product is monitored during processing, especially when passing through the heating section (40) and the holding section (44), thereby to make sure that the temperature meets scheduled temperatures pre-determined by mathematical modeling. If a significant deviation occurs between the actual temperature and the modeled temperature of the food product, the affected food product is not allowed to reach the aseptic holding tank or the aseptic filler apparatus, but instead is diverted to a holding tank located upstream of the heating section (40), or to another location.

Owner:JOHN BEAN TECH CORP

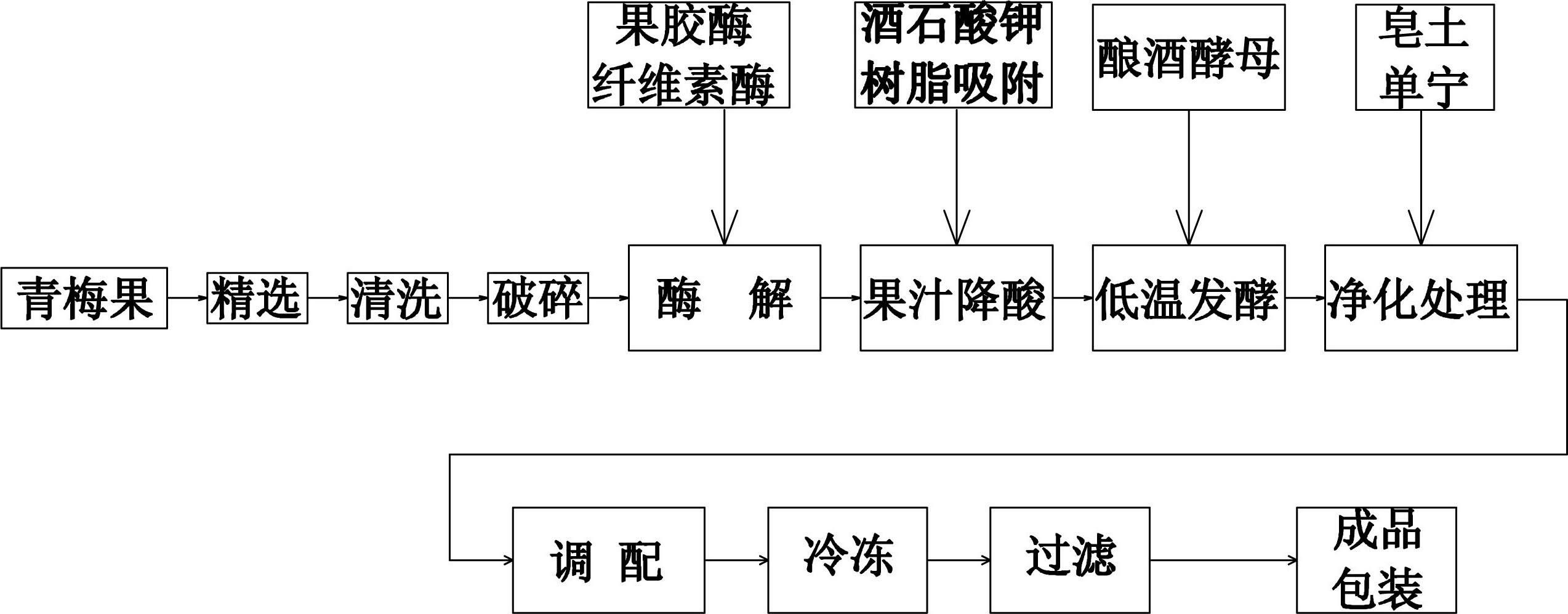

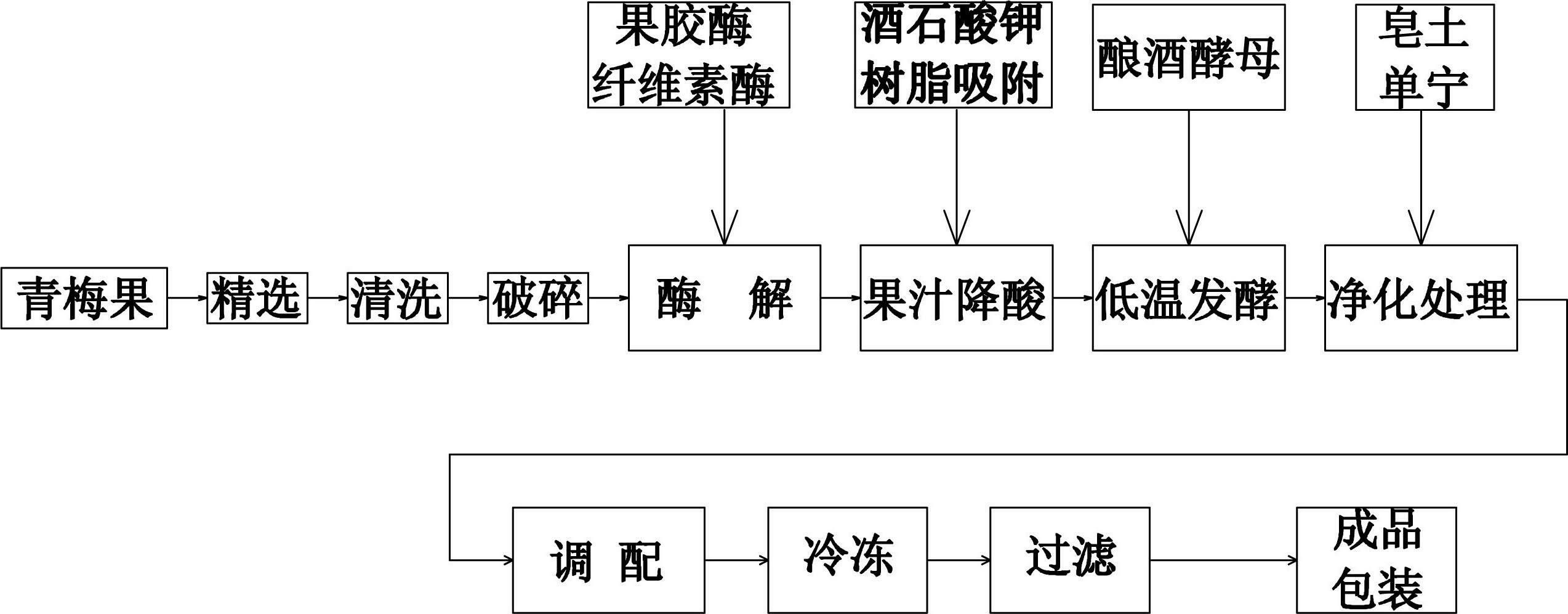

Production method and product of fermented green plum wine

InactiveCN102286320AReduce acidityPromote fermentationMicroorganism based processesAlcoholic beverage preparationFruit winePectinase

The invention discloses a production method of a fermented green plum fruit wine and a product thereof. The production method comprises the following steps: picking, cleaning and smashing on fresh green plum fruit utilized as a raw material, adding pectinase and cellulase to perform enzymolysis at 15-18 DEG C, then adding potassium tartrate to adjust and reduce the acidity at minus 6 DEG C to minus 8 DEG C, and using anion exchange resin to perform adsorption and reduce the acidity to 15g / L which is favorable for fermentation; placing clear juice in a fermentation tank, adding Saccharomyces cerevisiae to perform low-temperature fermentation; and adding bentonite and tannin in the fermented wine solution to perform compound purification, then performing low temperature freezing and clarification, blending, removing bacteria and filtering. The method has the advantages of good acidity-reducing effect and high composite enzymolysis juice yield; and by adopting the composite purification and freezing, the stability of the wine can be enhanced. The method is suitable for the production of the fermented green plum fruit wine.

Owner:YUNFU HUANAN LIQUOR

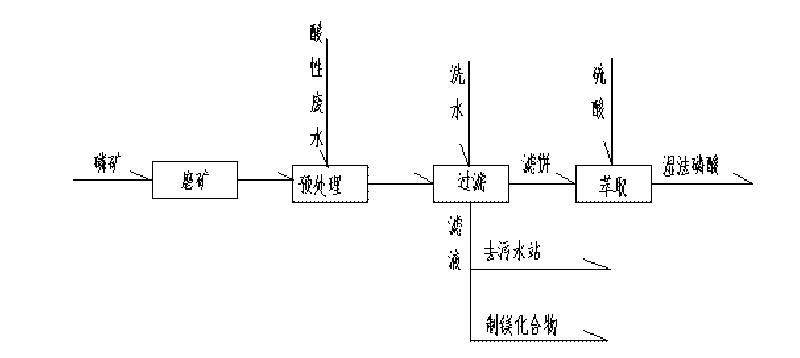

Method for pre-treating phosphorite by using acidic waste water in the production process of titanium pigment

ActiveCN101759166AReduce processing costsControl the strength of sulfuric acidPhosphoric acidPhosphoric acidSlurry

The invention discloses a method for pre-treating phosphorite of wet process phosphoric acid by using acidic waste water in the production process of titanium pigment, which comprises the following steps: (1), collecting the acidic waste water into an acidic waste water storage groove, controlling the acid degree to be 2 to 5 percent and the total iron concentration to be 0.3 to 0.5 percent; (2), adding the acidic waste water and the milled phosphorite in a solid-to-liquid ratio of 2-5:1 into a reaction groove for reaction; and (3), performing solid-liquid separation on the slurry which is obtained in the step (2) to obtain a solid phase, namely the required phosphorite. The content of magnesium in the phosphorite which is treated by the method is reduced by over 70 percent, the loss ratio of the phosphorus is controlled to be within 1 percent; when the phosphorite which is treated by the process is used for producing the phosphoric acid by a wet method, the consumption of the sulfuric acid for mine per ton is reduced by about 10 percent; and the acidic waste water pretreats phosphorite and then is delivered to a sewage station for treatment, the consumption of lime or other alkaline substance is reduced by 60 percent compared with the mode of directly delivering the waste water to the sewage station, so the economical efficiency of the process is high.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

Efficient methods for making tetrahalophthalate esters having excellent purity

InactiveUS6150552AReduce acidityImprove economyOrganic compound preparationCarboxylic acid esters separation/purificationAlcoholCatalytic metal

Provided are methods for the preparation and purification of alkyl tetrahalophthalate esters by the reaction of a tetrahalophthalic compound with an alkanol in the presence of a titanate catalyst. More particularly, improved methods are provided for making and recovering an ester with little contamination by catalytic metal components and color bodies, and with little acidity, in a high yield from the esterification reaction by pretreating the starting materials to reduce the acidity thereof, reacting the starting materials in the presence of a titanate catalyst, stripping excess alcohol, hydrolyzing the catalyst, and filtering out solids to yield a high purity tetrahalophthalate ester product.

Owner:PABU SERVICES

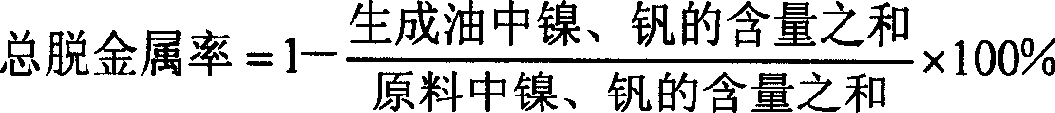

Hydrocracking catalysts for vacuum gas oil & de-metalized oil blend

InactiveUS20060157386A1Improve catalytic conversionSpeed up the conversion processCatalytic crackingMolecular sieve catalystsChemistryCarbon chain

This invention relates to a catalyst and a process for treating heavy hydrocarbons using the catalyst. The catalyst is useful for treating heavy hydrocarbons, de-metallize oil (DMO) and is particularly useful in VGO / DMO hydrocarbon blend. It is also useful for DAO. The catalyst acts to catalytically convert the VGO / DMO blend to shorter-chain valuable hydrocarbon products. The catalyst includes a catalytic support material, a catalytic metal impregnated upon the catalytic support material, and a promoter metal on the catalytic support material to enhance catalytic conversion. The combination of the catalytic support material with catalytic metal and promoter metal is operable to catalytically convert VGO / DMO into hydrocarbon products having shorter carbon chains.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS +1

Metallic ion modified polyphosphoric acid melamine salt and its preparation method

InactiveCN1733778AImprove thermal stabilityNo pollution in the processGroup 5/15 element organic compoundsMelamine phosphatePhosphate

The polyphosphoric cyanuric salt modified by metal ion comprises, oxygen 21~25wt%, carbon 15~18%, hydrogen 1~3%, phosphor 13~16%, nitrogen 37~42%, and metal ion 0.2~6%. The opposite preparation method comprises: dissolving or dispersing the metal hydroxides, oxide or carbonate into phosphoric acid solution with concentration as 80~90%; adding water, phosphoric acid solution with dihydric phosphate and melamine into kettle to react for two hours; heating the modified polyphosphoric cyanuric salt to 260~330Deg and taking polymerisation for 8~12h. The product has better thermallysis stability and flame retardant property to nylon. This method is simple, and has on-pollutant andhigh yield rate.

Owner:NORTHEAST FORESTRY UNIVERSITY

Enteric formulations of proanthocyanidin polymer antidiarrheal compositions

InactiveUS7323195B2Improve compression performanceReduce weightAntibacterial agentsBiocideSecretory diarrheaPharmaceutical formulation

Pharmaceutical compositions containing a proanthocyanidin polymer composition which are useful for the treatment and prevention of secretory diarrhea are provided. The invention specifically relates to pharmaceutical formulations of a proanthocyanidin polymer composition which has been isolated from a Croton spp. or a Calophyllum spp. In particular, the invention relates to a formulation of a proanthocyanidin polymer composition which protects the composition from the effects of stomach acid after oral administration, particularly to those formulations which are enteric coated. The invention also relates to methods of producing a directly compressible proanthocyanidin polymer composition, as well as compositions containing the directly compressible proanthocyanidin polymer composition.

Owner:NAPO PHARMA INC

Anthony pig feed

ActiveCN101703159AEffectively adjust the balanceReduce diarrheaAnimal feeding stuffAccessory food factorsMicrobial agentGut flora

The invention relates to anthony pig feed, which is prepared mainly by strictly controlling the quality of corns and adding a large amount of lactose, whey powder, fermented soybean meal, soya protein concentrate, plasma protein powder, fish meal, complex enzyme preparation, digestion acid, microbial agent and the like. The anthony pig feed obtained has a crude protein content of more than or equal to 18.6 percent, lysine content of more than or equal to 1.31 percent, digestible energy of more than or equal to 3,500Kcal / kg, an energy to protein ratio (Kcal / percent) of more than or equal to 188, a calcium content of more than or equal to 0.6 percent, a phosphorus content of more than or equal to 0.49 percent, a calcium to phosphorus ratio of more than or equal to 1.2:1 and a dietary electrolyte balance value (DEB) of more than or equal to 195 as well as high palatability, high digestibility and availability and low acid-binding capacity and can effectively regulate intestinal flora balance.

Owner:NINGXIA DABEINONG TECH IND

Process for preparing demetalizing and desulfurizing catalyst of heavy oil hydrogenation

InactiveCN1458236AReduce acidityImprove activity stabilityRefining to eliminate hetero atomsChemistryFuel oil

The present invention discloses a preparation process of heavy oil hydrogenating, demetallizing and desulfruizing catalyst. Aluminum containing material in two different forms, including roasted alumina and dry aluminum hydroxide glue powder, is used. Of the assistant alkali metal element and / or alkali earth metal element, part is mixed with dry aluminum hydroxide glue powder and part is loaded onto the carrier via soaking process, so as to result in the inhomogeneous distribution of the assistant on the carrier. The catalyst has high demetalizing activity and desulfurizing activity, and highactivity stability, especially high desulfurizing activity stability. The catalyst may be used in the hydrodemetalizing and hydrodesulfurizing treatment of heavy oil and residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com