Method for pre-treating phosphorite by using acidic waste water in the production process of titanium pigment

A technology for acidic wastewater and production process, applied in phosphoric acid, phosphorus oxyacid and other directions, can solve the problems of no economic benefit, large energy consumption, reduced magnesium removal rate, etc., to reduce the cost of wastewater treatment, reduce sulfuric acid consumption, high economic sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

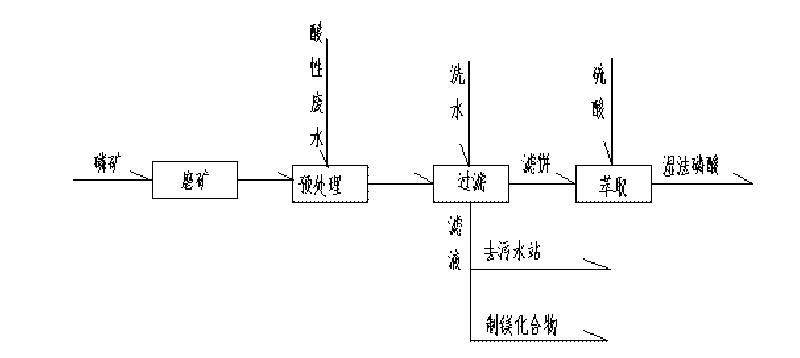

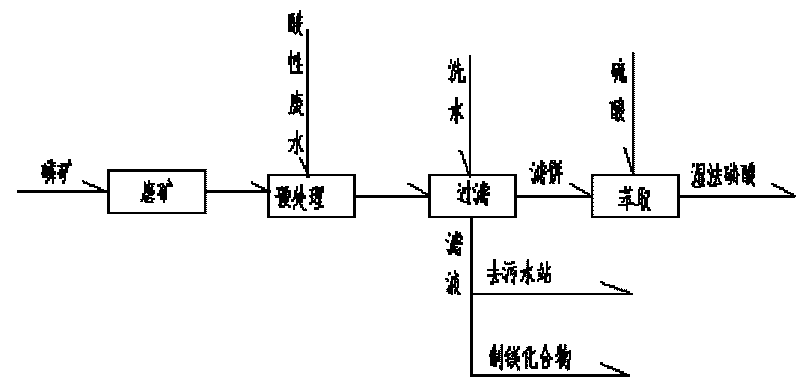

Image

Examples

Embodiment 1

[0028] 1000 kg of phosphate rock with a solid content of 75% (P 2 o 5 content of 26%, magnesium content of 2.4%, mineral powder 100 mesh sieve remaining 15%) ore pulp and acidic wastewater (sulfuric acid concentration of 3%, temperature of 45 ° C, titanium content of 0.15%, iron content of 0.26%) 3000 liters Input 10 cubic meters of pretreatment reaction tank through the pipeline, make the phosphate rock and acid wastewater react under stirring, the stirring speed is 100rpm, the initial pH value of the reaction mixture is controlled to be 2, the initial reaction temperature is 40°C, and after 2 hours of reaction The final pH was 2.8 and the temperature was 37°C. The reaction slurry out of the reaction tank is separated from solid and liquid by pressure filtration, and the P in the filter cake base 2 o 5 The content is 27.1%, the magnesium content is 0.65%, the titanium content is 0.09%, and the iron content is 0.07%. The sulfuric acid content in the filtrate is 0.4%, the m...

Embodiment 2

[0031] The ore pulp and the acid waste water in the embodiment 1 are input into the continuous reaction tank of 10 cubic meters through the pipeline with 10 liters / minute and 30 liters / minute feeding rate respectively, keep the liquid level in the reaction tank stable with the output of 40 liters / minute , the stirring speed is 100rpm, the pH value of the feed port of the reaction tank is stable in the range of 2-2.2, the temperature is at 41°C, the pH value of the discharge port of the reaction tank is stable in the range of 2.7-3.0, and the temperature is maintained at 36-37°C. Filter cake base P after discharge pressure filtration 2 o 5 The content is 27.5%, the magnesium content is 0.58%, the titanium content is 0.09%, and the iron content is 0.08%. The acid content in the filtrate was 0.39%, the magnesium content was 0.43%, the titanium content was 0.14%, the iron content was 0.23%, and the phosphorus content was 75ppm.

[0032] In this embodiment, the magnesium removal ...

Embodiment 3

[0034] The water content of the filter cake after press filtration in Example 1 is 20%, and after washing with 150 liters of circulating water, the filter cake base P 2 o 5 The content is 27.2%, the magnesium content is 0.42%, the titanium content is 0.08%, and the iron content is 0.03%. The magnesium content in the washing liquid is 0.21%, the titanium content is 0.1%, the iron content is 0.22%, and the phosphorus content is 12ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com