Method for comprehensively recycling valuable metals from spent lithium ion battery

A lithium-ion battery and valuable metal technology, which is applied in the smelting of valuable elements and the treatment of waste lithium-ion batteries, can solve the problems of not considering the side reaction between electrolyte and lithium and the volatilization environment, and simplify the pretreatment. , the effect of reducing the recovery rate and reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

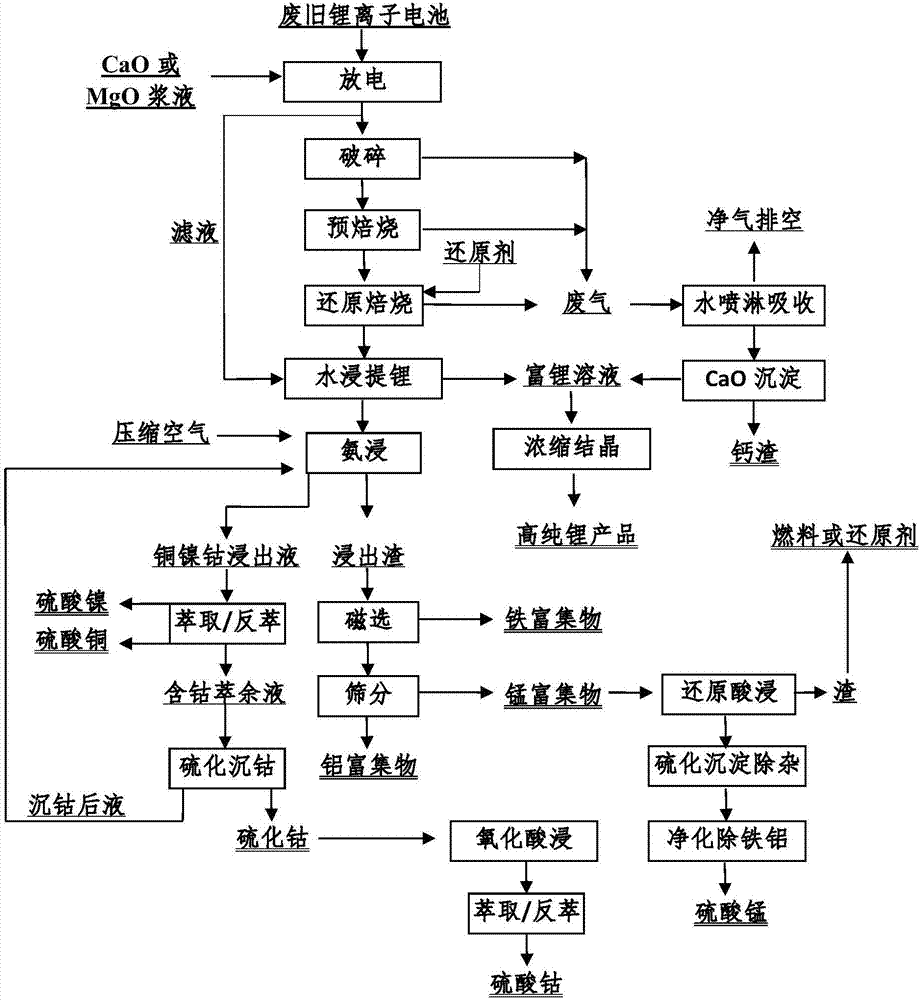

Image

Examples

Embodiment 1

[0027] Step (1): Punch out 1000g of lithium cobaltate, nickel-cobalt-manganese ternary, nickel-cobalt-aluminum ternary battery waste and soak in CaO slurry for 24 hours, then remove the battery for crushing, and set a suction hood above the crusher , Collect the volatilized electrolyte waste gas and absorb it with CaO slurry. After filtration, the filtrate is combined with the subsequent carbonated water infusion, and the filter residue is stored.

[0028] Step (2): Put the crushed battery material into a muffle furnace, and pre-calcine at 350° C. for 1 hour. After that, the material was mixed with 80 g of lignite (60% carbon content), and then reduced and roasted at 600° C. for 2 hours. The flue gas produced in the pre-roasting and reduction roasting processes is absorbed and treated with CaO slurry.

[0029] Step (3): Sieve the reduced and roasted material with a vibrating screen with a mesh size of 1mm, immerse the fine material smaller than 1mm in carbonation water at ro...

Embodiment 2

[0035] Step (1): Punch 1000g of lithium cobaltate, nickel-cobalt-manganese ternary, nickel-cobalt-aluminum ternary battery waste and soak in MgO slurry for 24 hours, then remove the battery for crushing, and set a suction hood above the crusher , Collect the volatilized electrolyte waste gas and absorb it with CaO slurry. After filtration, the filtrate is combined with the subsequent carbonated water infusion, and the filter residue is stored.

[0036] Step (2): Put the crushed battery material into a muffle furnace, and pre-calcine at 320° C. for 2 hours. After that, the material was passed through H at 450°C 2 Reduction roasting 1.5h, H 2 The flow rate is 1L / min, and the flue gas produced in the pre-roasting and reduction roasting processes is absorbed and treated with CaO slurry.

[0037] Step (3): Sieve the reduced roasted material with a vibrating sieve with a mesh size of 1 mm, and immerse the fine material smaller than 1 mm in water at room temperature, with a liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com