Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

783 results about "Electronic waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electronic waste or e-waste describes discarded electrical or electronic devices. Used electronics which are destined for refurbishment, reuse, resale, salvage recycling through material recovery, or disposal are also considered e-waste. Informal processing of e-waste in developing countries can lead to adverse human health effects and environmental pollution.

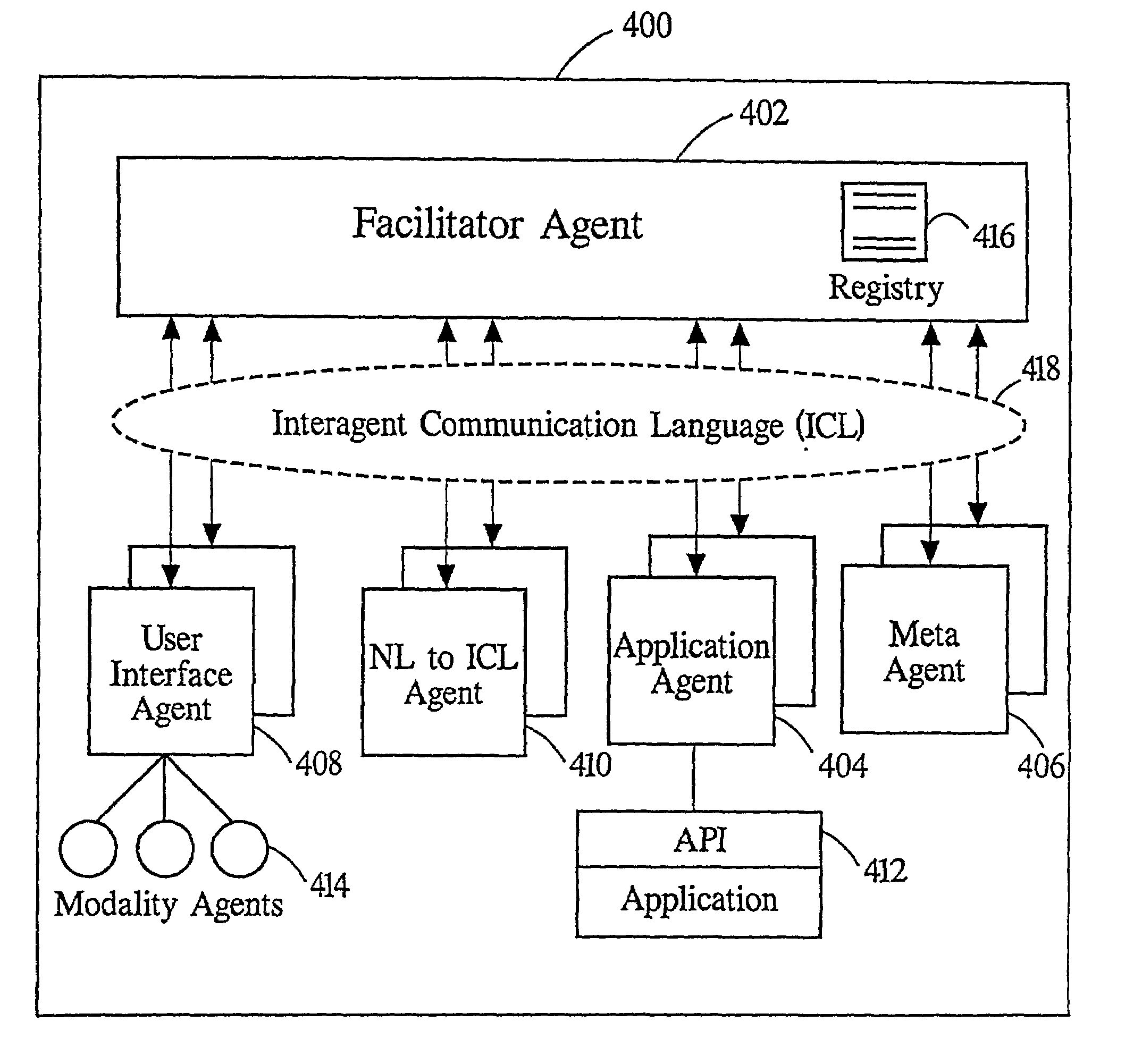

Using a community of distributed electronic agents to support a highly mobile, ambient computing environment

InactiveUS7036128B1Minimize dependenciesIncreased leverageDigital data information retrievalInterprogram communicationJet aeroplaneApplication software

A highly mobile, ambient computing environment is disclosed for serving a knowledge worker away from the their desk. The present invention allows a knowledge worker to get increased leverage from personal, networked, and interactive computing devices while in their car, airplane seat, or in a conference room with others. An Open Agent Architecture is used to incorporate elements such as GPS agents, speech recognition, and opportunistic connectivity among meeting participants. Communication and cooperation between agents are brokered by one or more facilitators, which are responsible for matching requests, from users and agents, with descriptions of the capabilities of other agents. It is not generally required that a user or agent know the identities, locations, or number of other agents involved in satisfying a request, and relatively minimal effort is involved in incorporating new agents and “wrapping” legacy applications. Extreme flexibility is achieved through an architecture organized around the declaration of capabilities by service-providing agents, the construction of arbitrarily complex goals by users and service-requesting agents, and the role of facilitators in delegating and coordinating the satisfaction of these goals, subject to advice and constraints that may accompany them.

Owner:IPA TECH INC

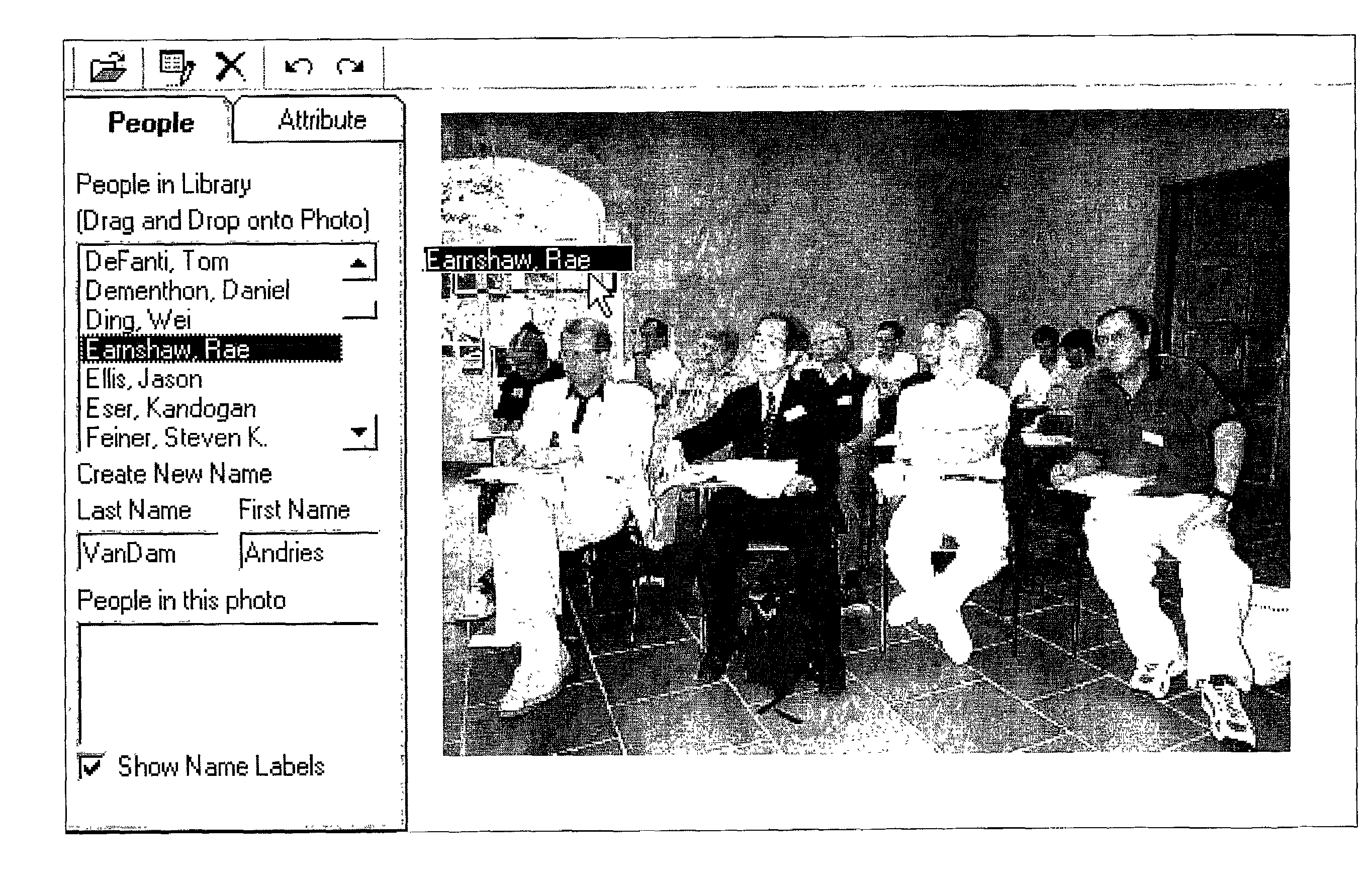

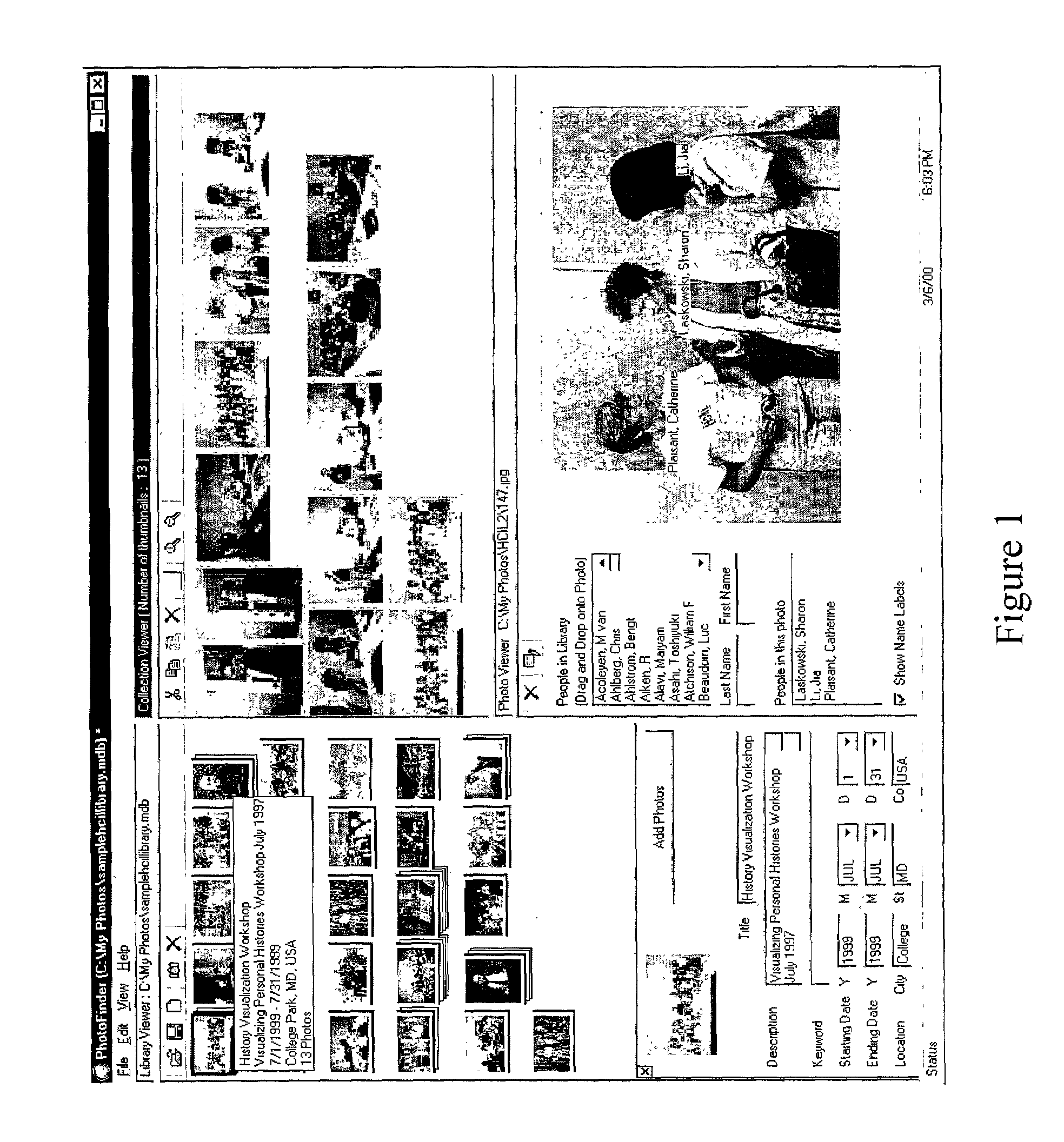

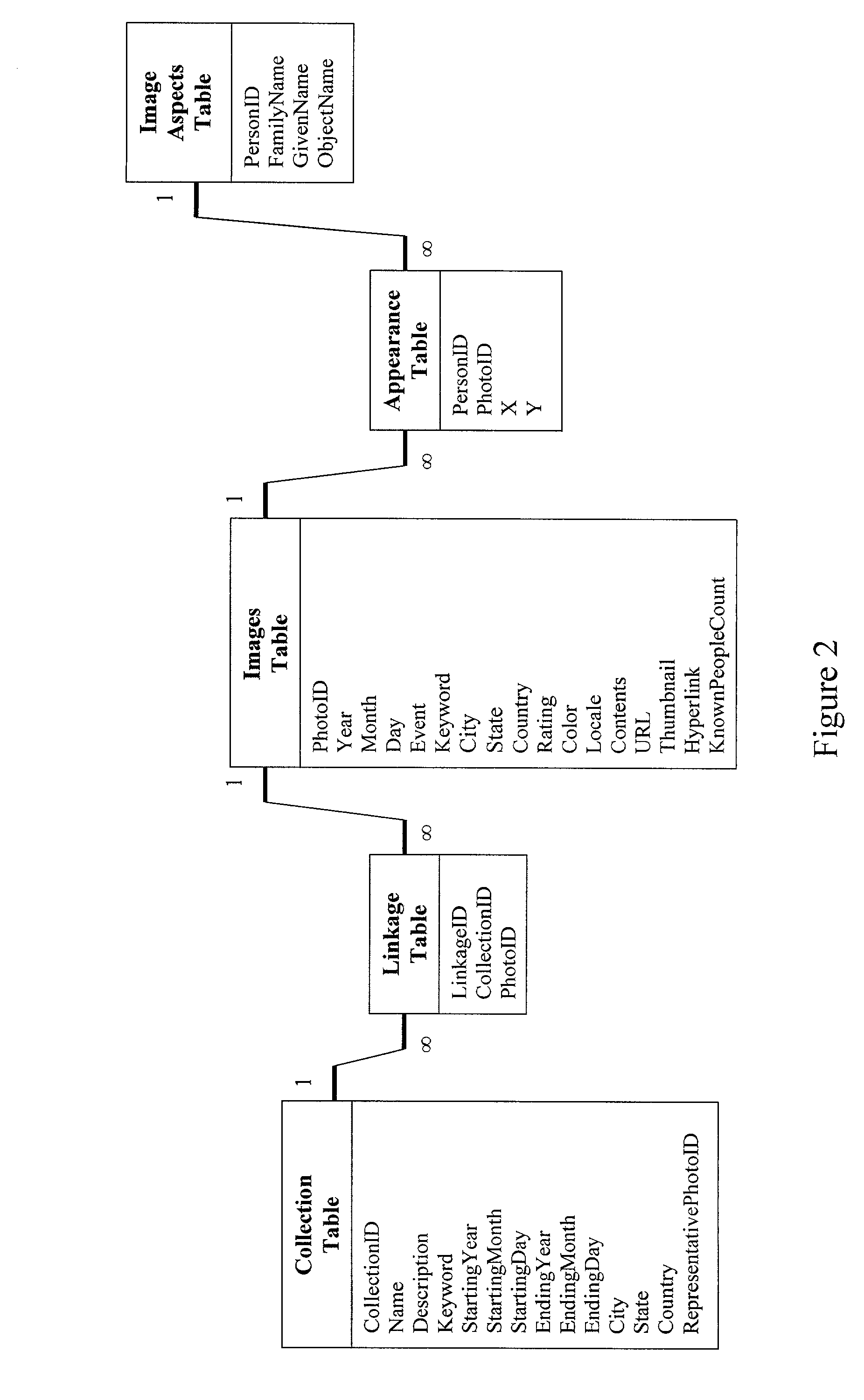

Methods for the electronic annotation, retrieval, and use of electronic images

InactiveUS7010751B2Flexible and easy to learnReduce error rateData processing applicationsDigital data processing detailsDrag and dropComputer graphics (images)

The present invention provides software for electronically annotating electronic images, such as drawings, photographs, video, etc., through the drag-and-drop of annotations from a pre-defined, but extendable, list. The annotations are placed at a user-selected X, Y location on the image, and stored in a searchable database. Thus, they can be searched in order to retrieve, organize, group, or display desired electronic images or collections of such images. The annotations may be text, images, sounds, etc. The invention provides a flexible, easy to learn, rapid, low error rate and satisfying interface for accomplishing such tasks.

Owner:MARYLAND COLLEGE PARK UNIV OF +1

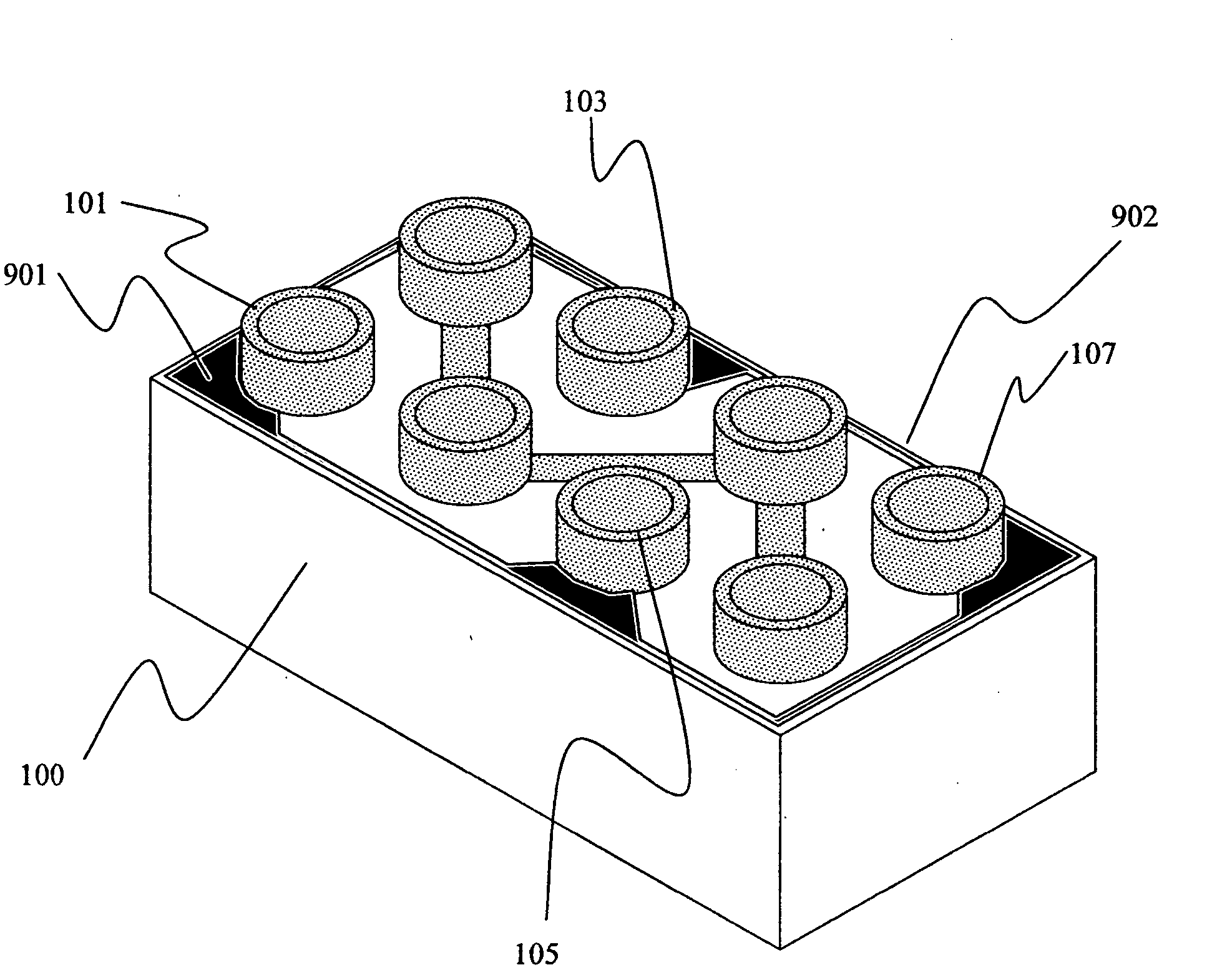

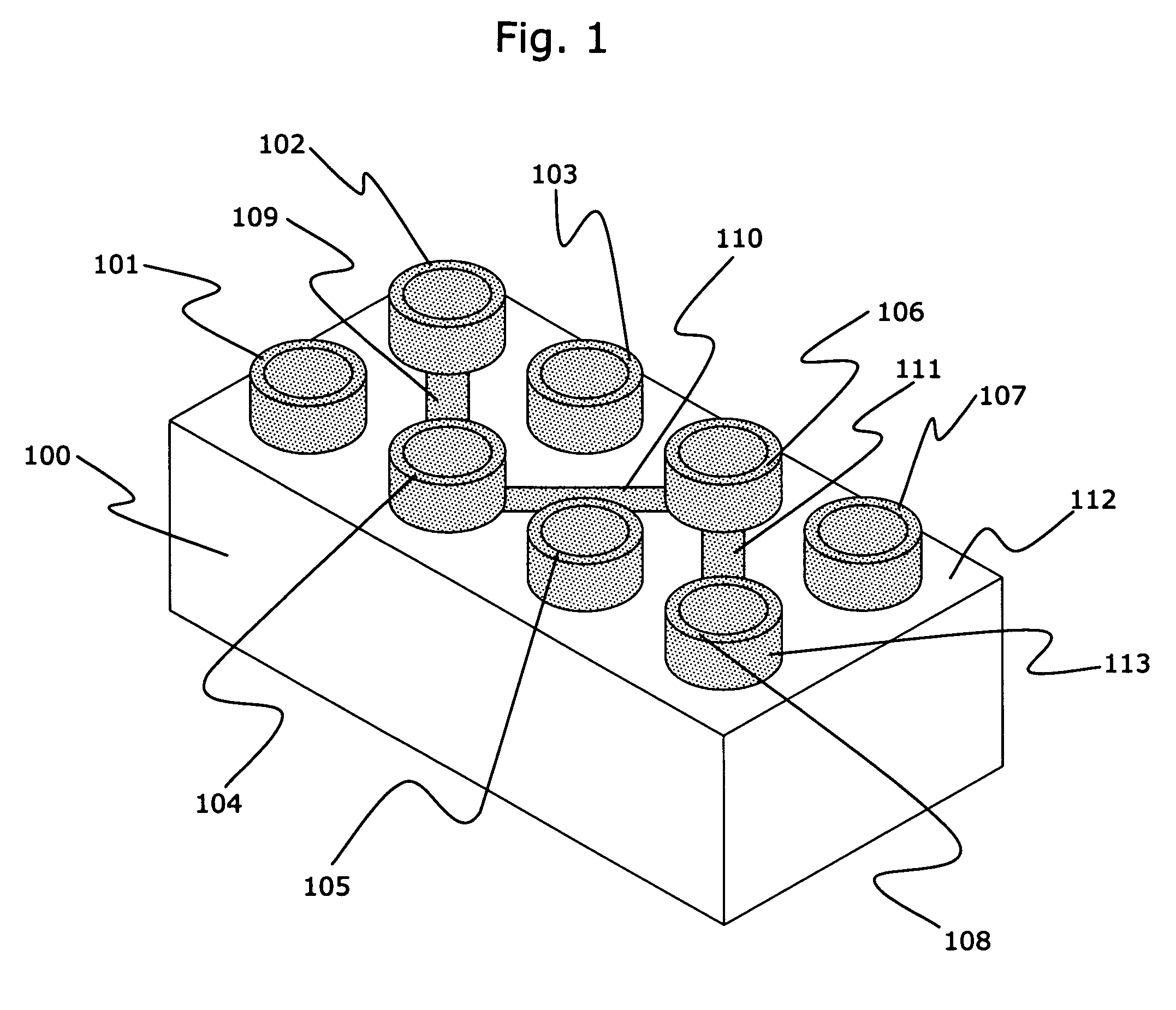

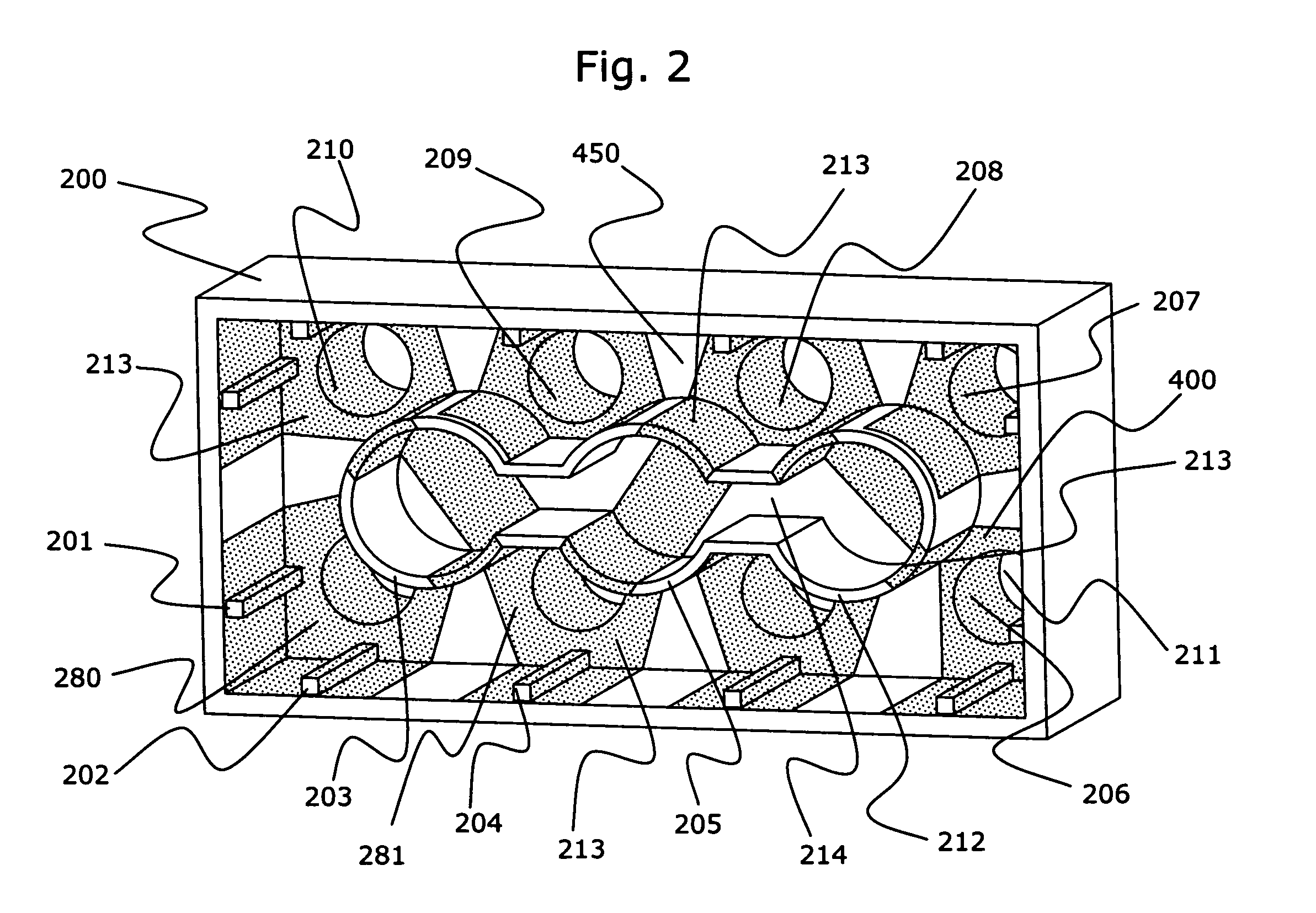

Stackable electonic blocks and a method for stacking the same

The present invention generally relates to a mechanical structure having electronic circuits that easily and quickly connect together. The mechanical structures may be building blocks which are stackable and reusable. The building blocks may be removably held together by, for example, gravity and / or friction. The building blocks have electronic circuits which may have numerous uses, including, but not limited to educational, industrial and entertainment uses. More specifically, a building block of the present invention may be insert on, and secured to, a second building block. The building blocks may be identical or may have different features which accomplish varying desired functions. For example, a building block of the present invention may have a light and / or sound feature. In addition, the circuitry of the building blocks of the present invention has unique electronic paths which prevent electronic shorts across a power source. More specifically, the electronic paths of the building blocks have diagonal spacing which may not be shorted as a result of the mechanical limitations in stacking the building blocks

Owner:ADVINS INC

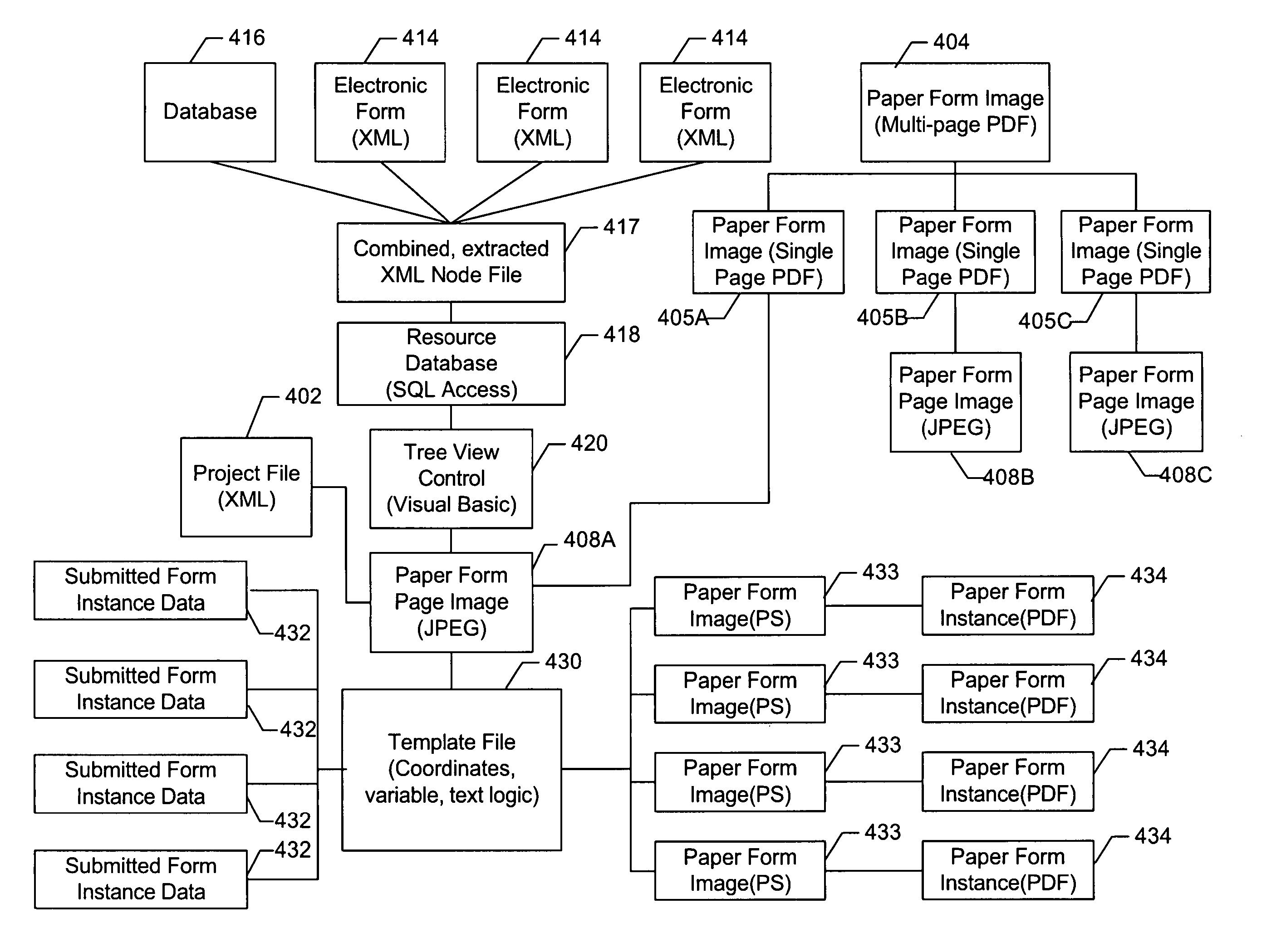

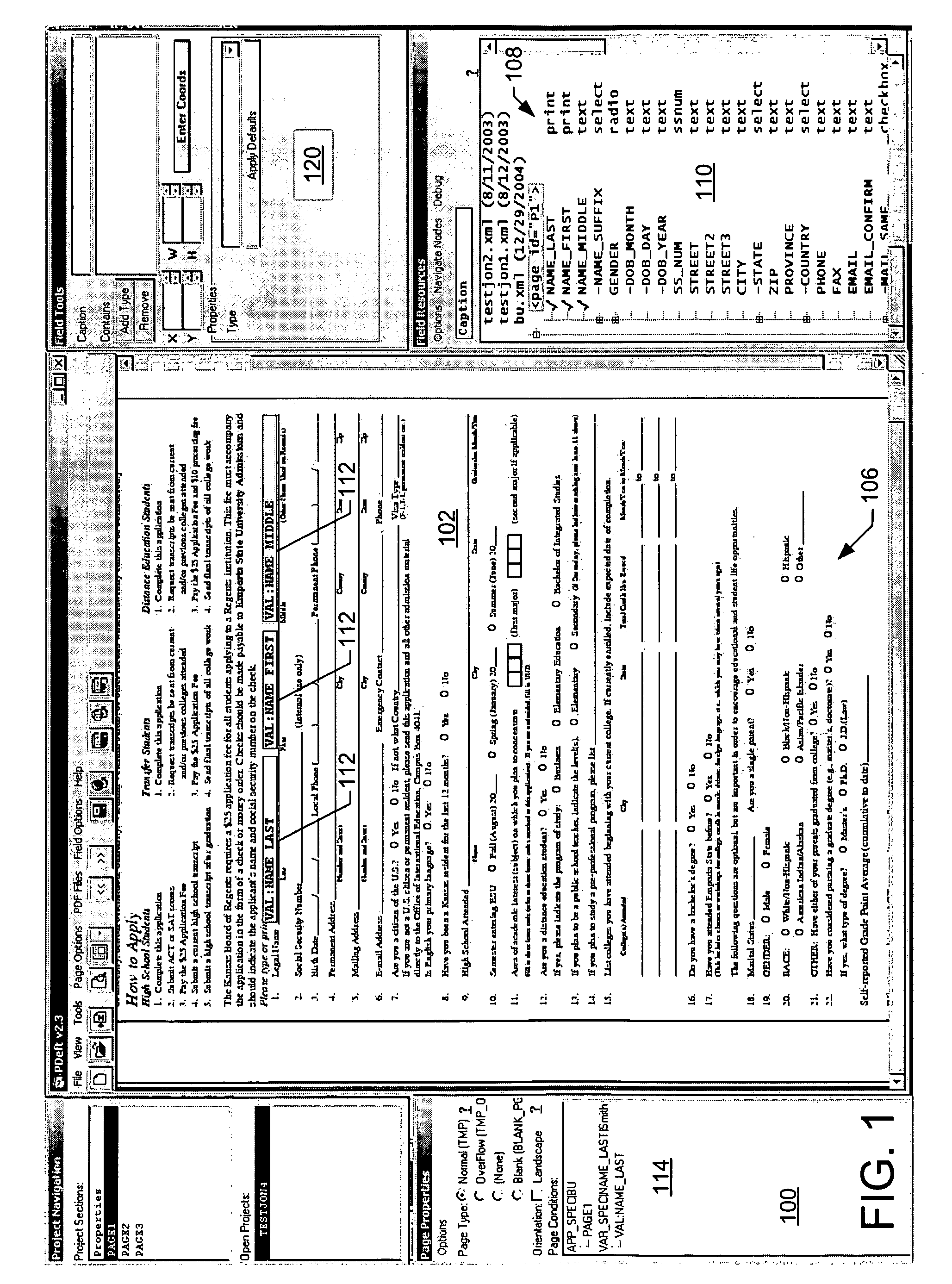

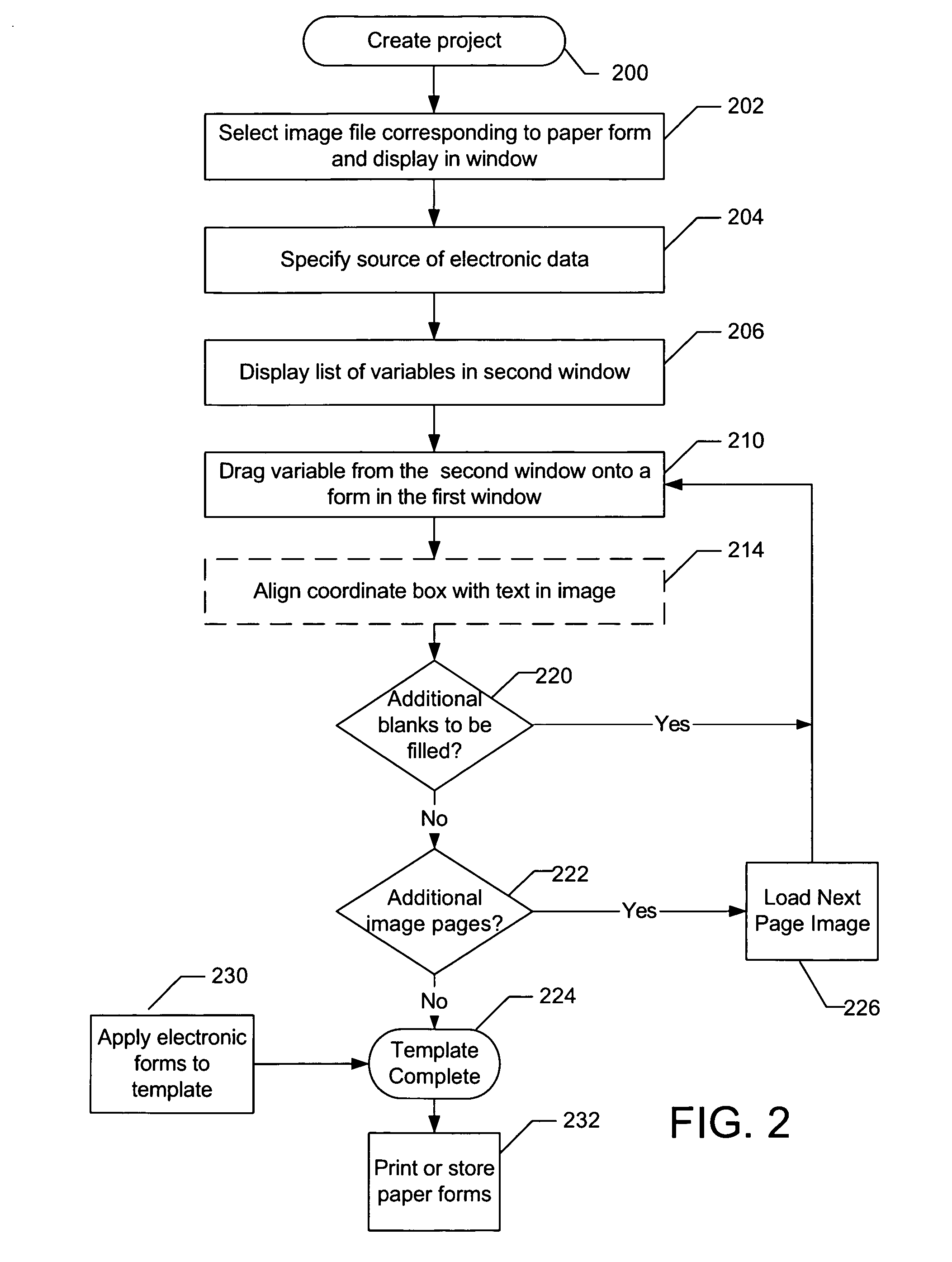

System for describing the overlaying of electronic data onto an electronic image

ActiveUS20050268217A1Natural language data processingSpecial data processing applicationsElectronic formEngineering

In an environment in which some forms are received in paper form and some in electronic form or an environment in which in which workers prefer using paper forms, the invention provides a method of producing a template for the purpose of producing paper forms from electronic forms, the paper forms produced from the electronic forms being similar in appearance to forms that were completed in hard copy. Variable information is extracted from one or more electronic forms that are to be mapped to the paper form. A template is created by placing the variables from the electronic form onto an image of the paper form. The template may include position coordinate information, variable name information, text, and logic. After the template is completed, the system uses the template to print paper forms from instances of electronic forms. In some cases, multiple electronic forms can be mapped to a single paper form, and a preferred system can create a template, even if questions presented in electronic forms vary, depending on answers of previous questions.

Owner:COLLEGENET

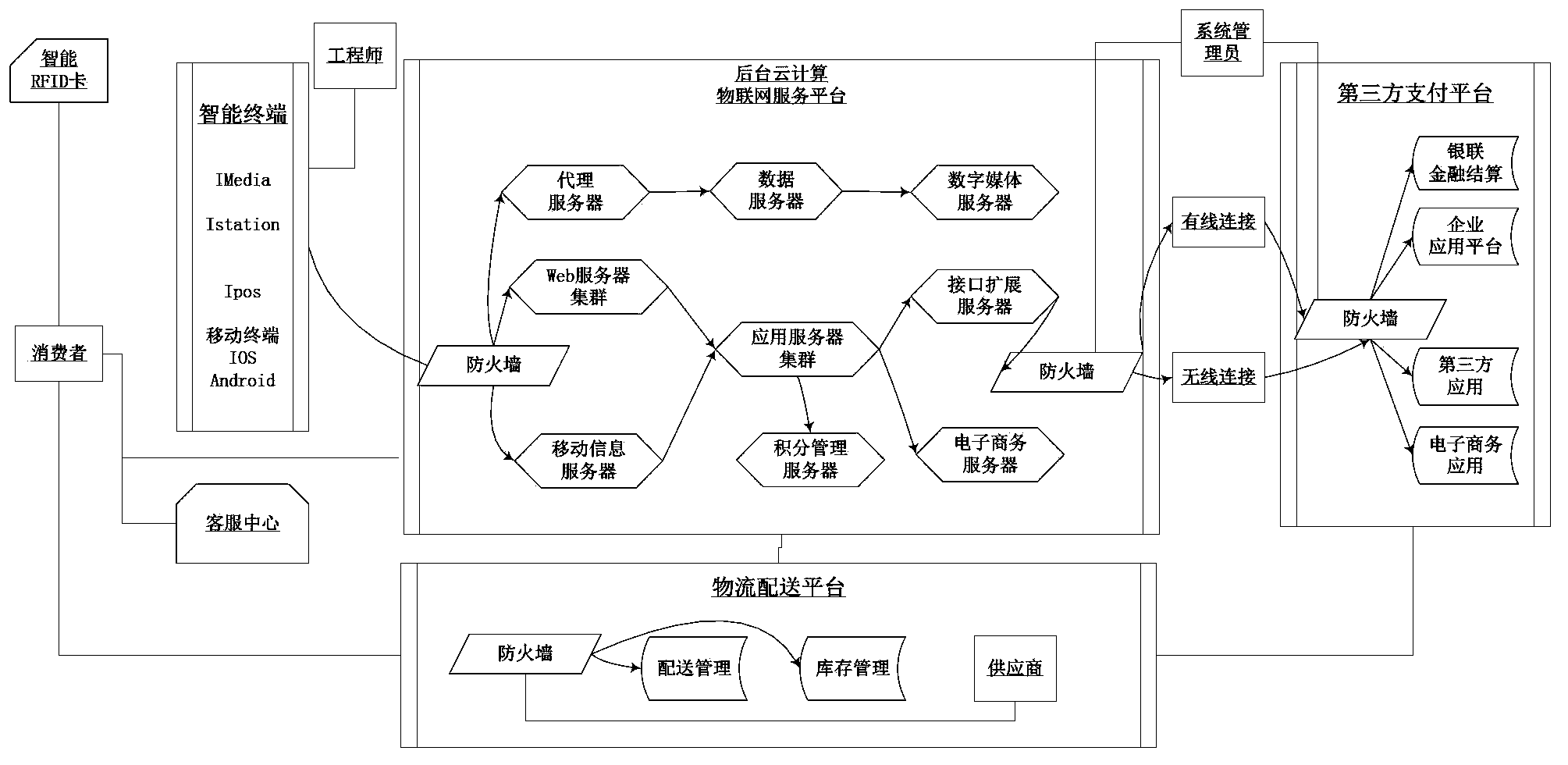

Service platform and method for classifying and intelligently recycling waste and old materials and garbage

InactiveCN103440607AEasy to recycleCommerceCoded identity card or credit card actuationLitterCommunity resident

The invention discloses a service platform and method for classifying and intelligently recycling waste and old materials and garbage. A new technology is adopted, the platform is a new media publicity platform for publicizing garbage classification at the same time, cartoons, video, games and other modes loved by community residents are adopted, the recycling process of the waste and old materials can be fast accepted by all kinds of crowds to the largest extent, the principle of environmental protection and renewable resources enjoys popular support among people, the technology of Internet of Things is adopted, electronic waste and old materials are convenient to recycle, RFID unique labels are attached to the electronic waste and old materials in the production and sale period of the electronic waste and old materials, the labels comprise product classification information, and according to the garbage classification, when the waste of this type is thrown, corresponding garbage recycling and classifying cans can be automatically opened, and other garbage recycling and classifying cans not related to this type cannot be opened.

Owner:HANGZHOU LANGDUN SCI & TECH CO LTD

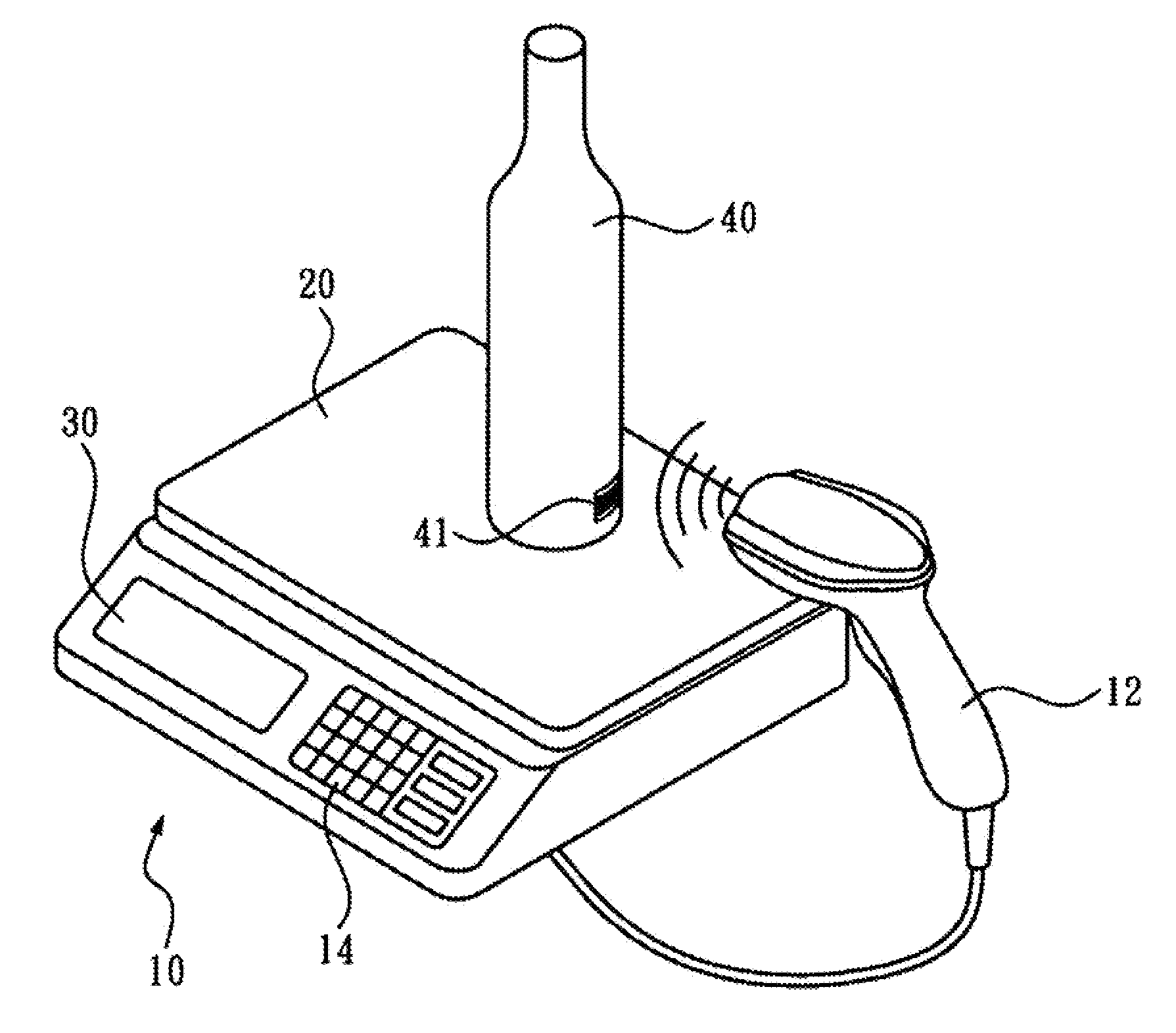

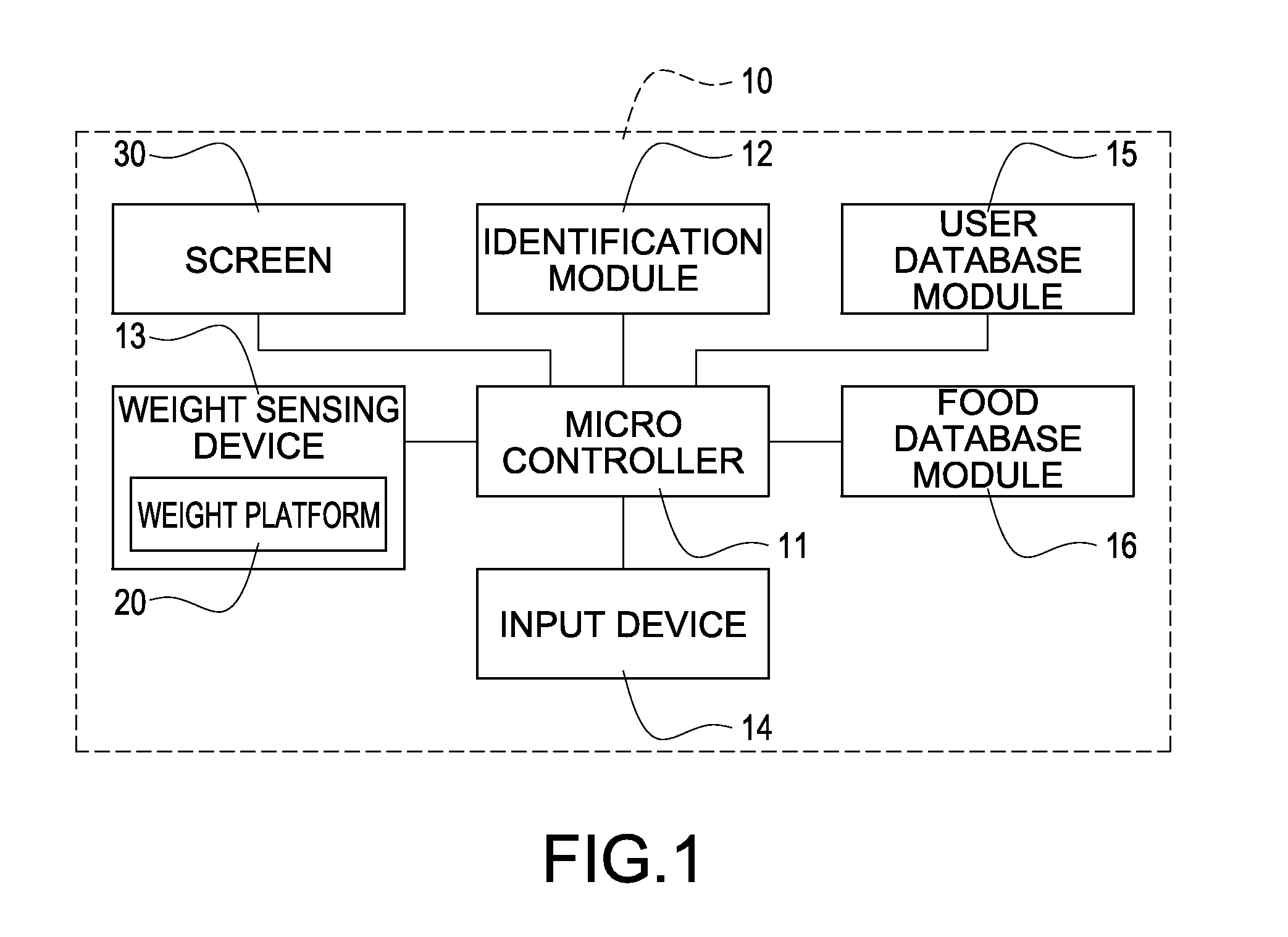

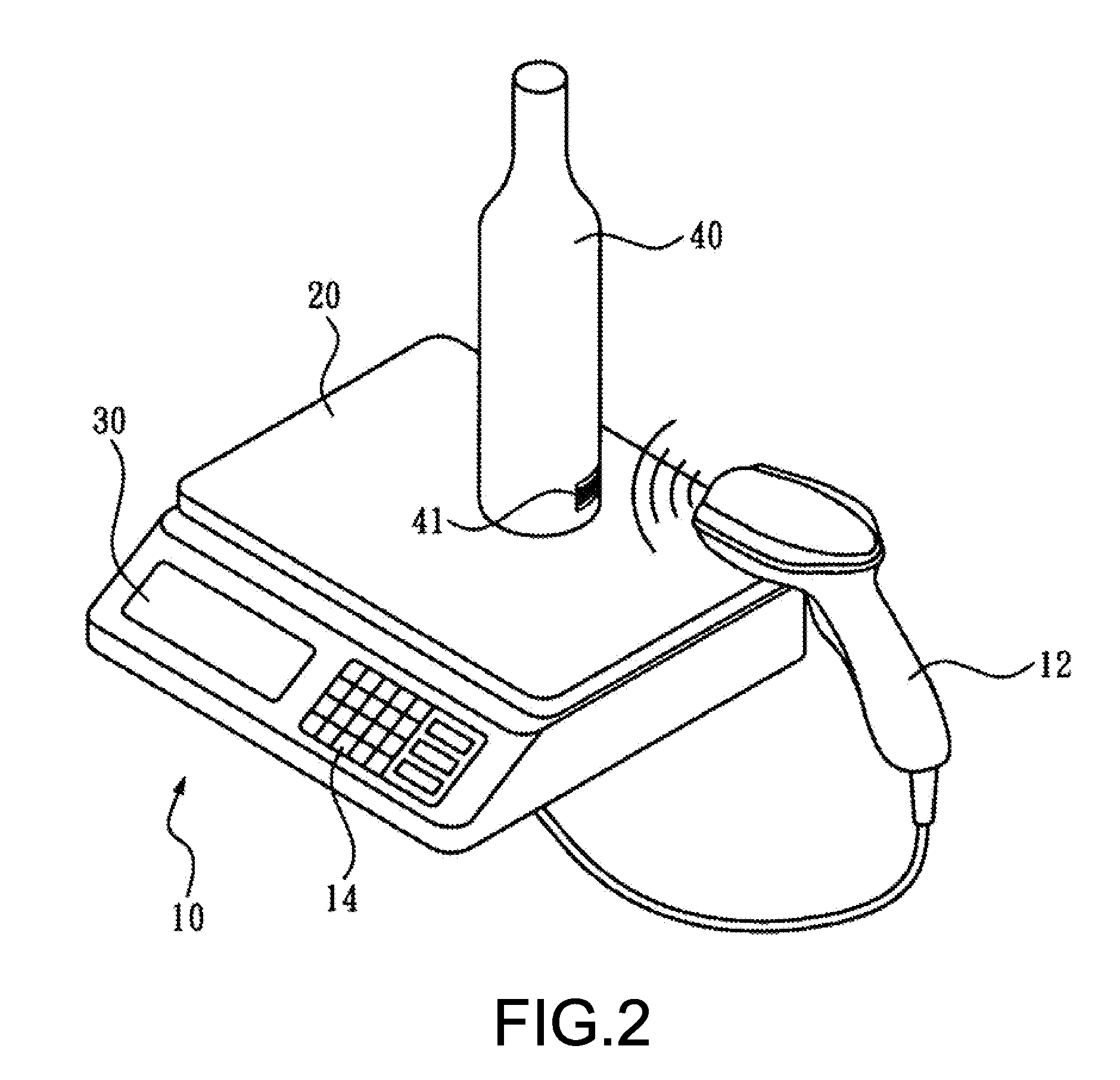

Electronic scale for recording health administration data

InactiveUS20120055718A1Easy retrievalReduce search timeNutrition controlWeighing indication devicesEmbedded applicationsElectronic waste

An electronic scale for recording health administration data comprises: a micro controller, a food database module, a weight sensing device, an identification module, the food database module, and the user database module. The micro controller has at least an embedded application for processing data input, output, analysis, and calculation. The food database module is provided for storing detailed food data item. The weight sensing device comprises a weight platform for receiving the food for weight measuring and sensing the food weight. The identification module is provided for identifying the data in an identification tag of the food for weight measuring. The data identified by the identification module is used to map to the corresponding food and the associated data in the food database module for performing analysis and calculation in the micro controller. The nutrition information such as nutrition components, calories of the food for measuring is displayed on a screen so as to provide recommendation intake quantity and warnings to user, and stores the recorded data of user diet in a user database module.

Owner:CHEN JIUNN RONG

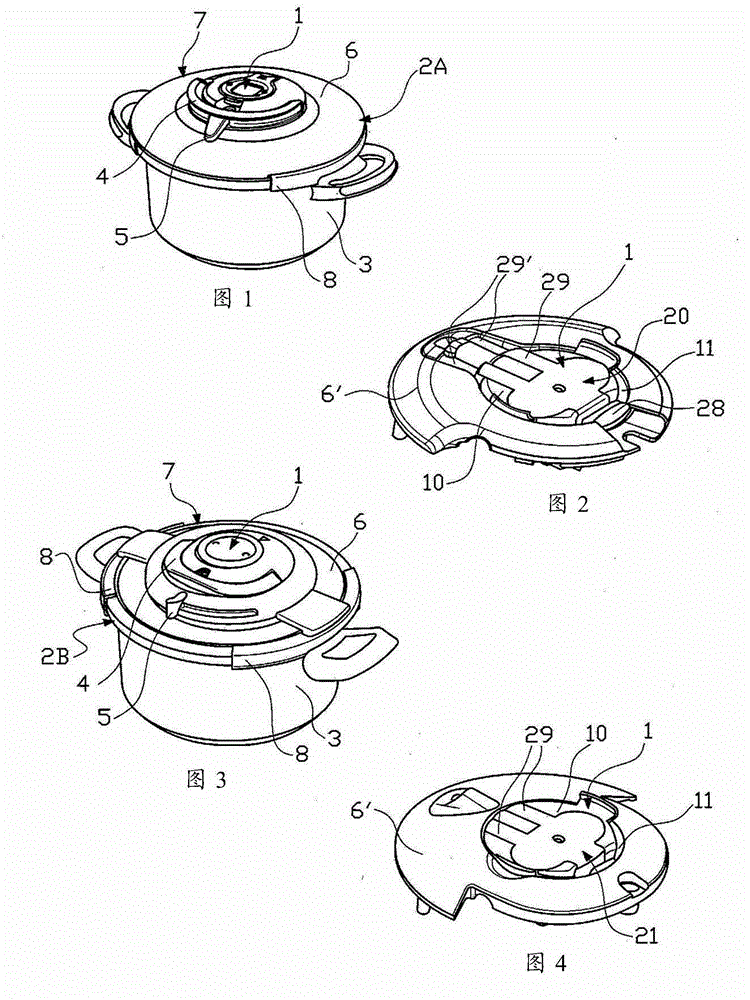

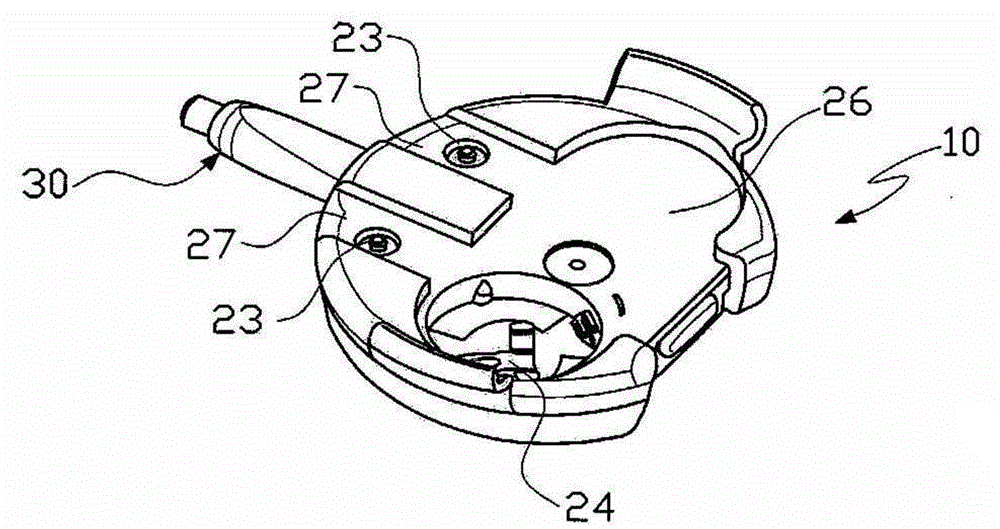

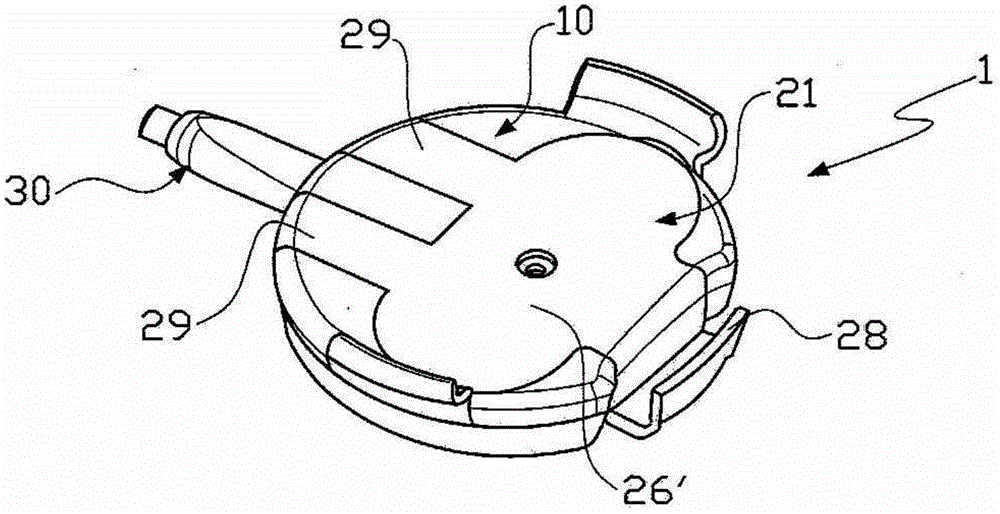

Electronic assembly with information on the operation of household appliances

The invention relates to an electronic assembly (1) with information on the operation of household appliances, for providing the user with information on the operation of at least two different models of household appliances and thereby forming at least one first pattern (2A) and at least a second pattern (2B), said assembly comprising: - a universal connection base(10) to be mounted either on said at least one first pattern (2A) or said at least one second model (2B), said base comprising: at least a first sensor for giving information of operation of said first model (2A) and at least a second sensor for giving operation information of said second model (2B), an electronic assembly for processing signals which may come from the first sensor and the second sensor, - at least two adapter modules. - Household Appliances.

Owner:SEB SA

Vehicle traffic accident automatic detection method

InactiveCN101105892ARealize automatic analysis and judgmentAutomate analysisDetection of traffic movementClosed circuit television systemsOperational costsBlack spot

The invention discloses a method for checking traffic accidents automatically through road site video, and includes the following steps: 1) install electronic eyes at black spots; 2) transmit video images shot by electronic eyes to a monitor server; 3) the monitor server makes continuous analysis of the video images. If the moving subjects in the video images stop suddenly and keep still for a while, the subjects are assumed to encounter traffic accidents. The invention will automatically trigger the server to give alarm to the alarm center, and record the process and site of the traffic accidents automatically. The technical proposal of the invention can realize automatic analysis of traffic accidents through electronic eyes, discovering and processing traffic accidents as early as possible to lower the loss of people involved and the stability of the society with low construction and operation costs.

Owner:SHENZHEN TEMOBI SCI &TECH

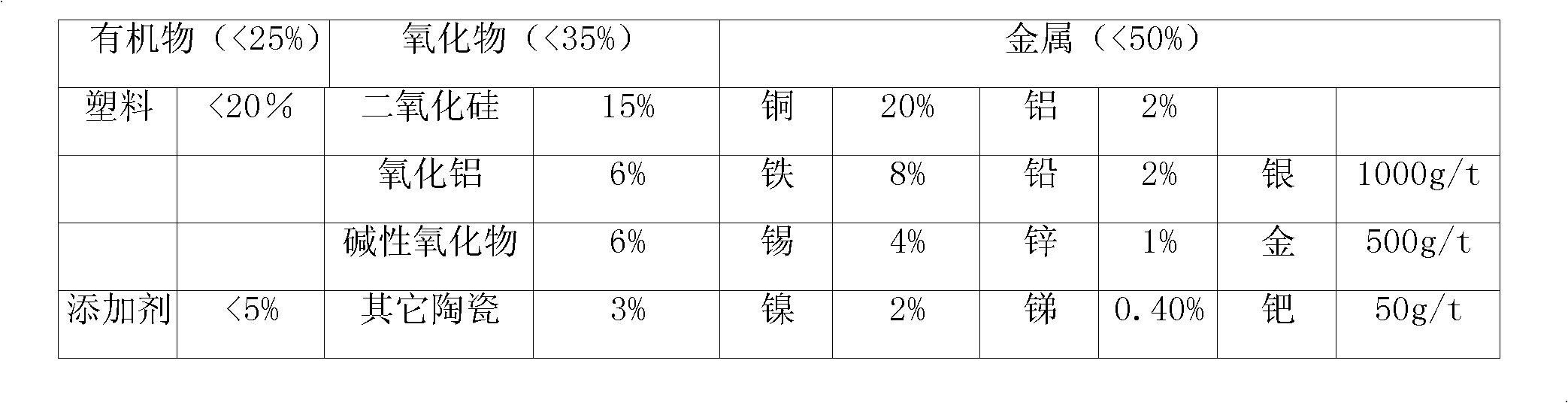

Regenerating method and process for recycling rare precious metals from electronic wastes

ActiveCN103397186AAdvanced technologyLow costProcess efficiency improvementMagnetic separationTelevision setHigh voltage

The invention discloses a regenerating method and process for recycling rare precious metals from electronic and electric wastes, and particularly discloses a process for recycling non-ferrous and rare precious metals such as copper, tin, gold, silver, platinum, palladium, rhodium and the like from electronic wastes. The regenerating method comprises the following steps of: smashing circuit boards and elements dismounted from waste electronic and electric appliances such as waste computers, waste mobile phones, waste televisions and the like to 40-200 meshes; dissolving a binder by using an organic solvent; then, separating metals and nonmetals by using a high voltage electrostatic method; next, leaching the precious metals by using sulfuric acid and aqua regia; extracting silver, gold, platinum, palladium and rhodium step by step by using a liquid membrane; and finally, carrying out purification treatment to obtain nonferrous metals such as copper and tin and the rare precious metals such as gold, silver, platinum, palladium, rhodium and the like, so that the waste secondary resource is regenerated and recycled. The regenerating method has the advantages of simplicity and convenience in process, high comprehensive metal recycle ratio, few three wastes, easiness for treatment and low cost, is a favorable technical approach for efficient utilization of mineral resources of cities, and not only has an environment-friendly benefit, but also has favorable economic and social benefits.

Owner:HUNAN TONGLI ELECTRONICS WASTE RECOVERING DISSEMBLING & UTILIZATION

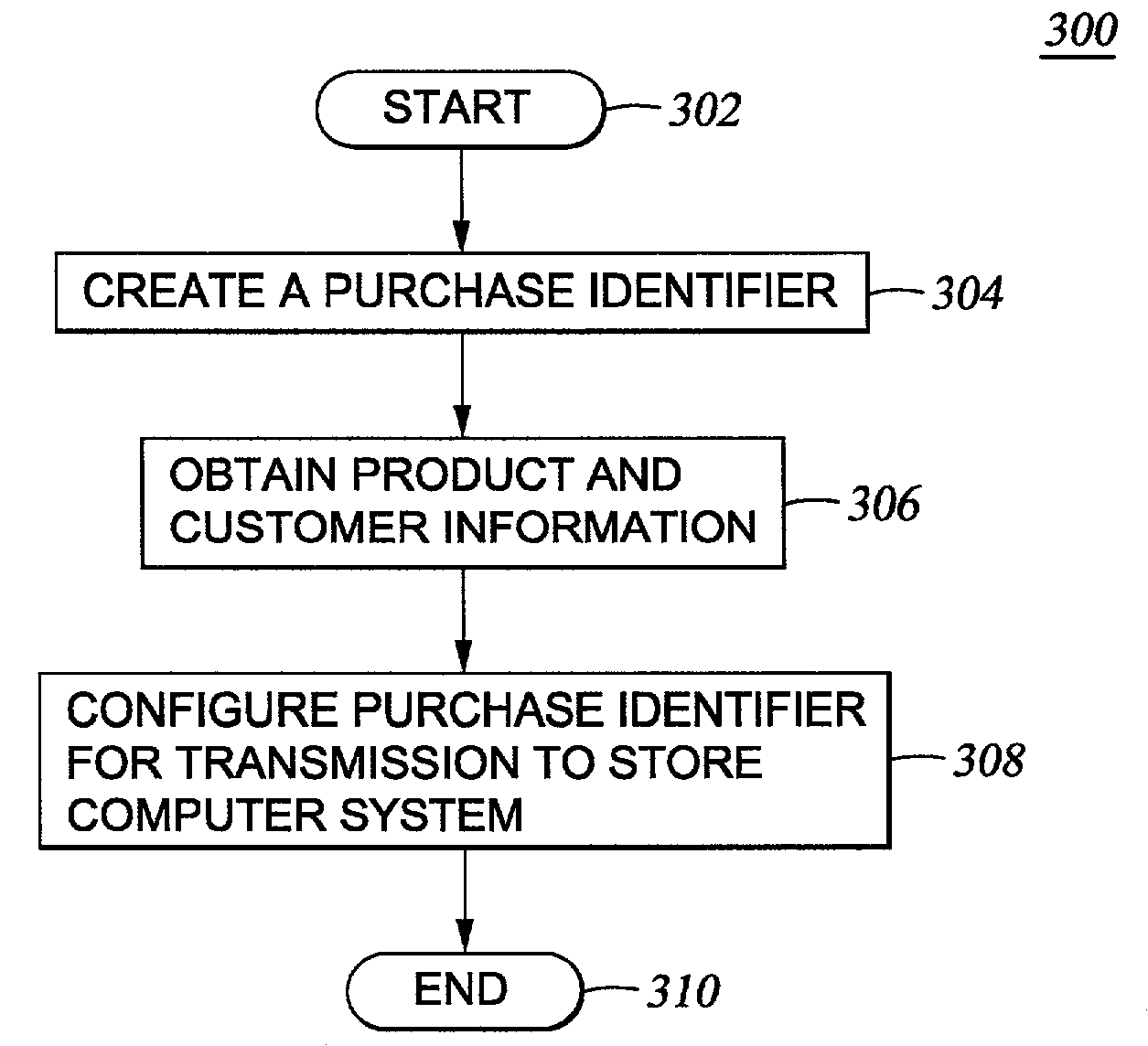

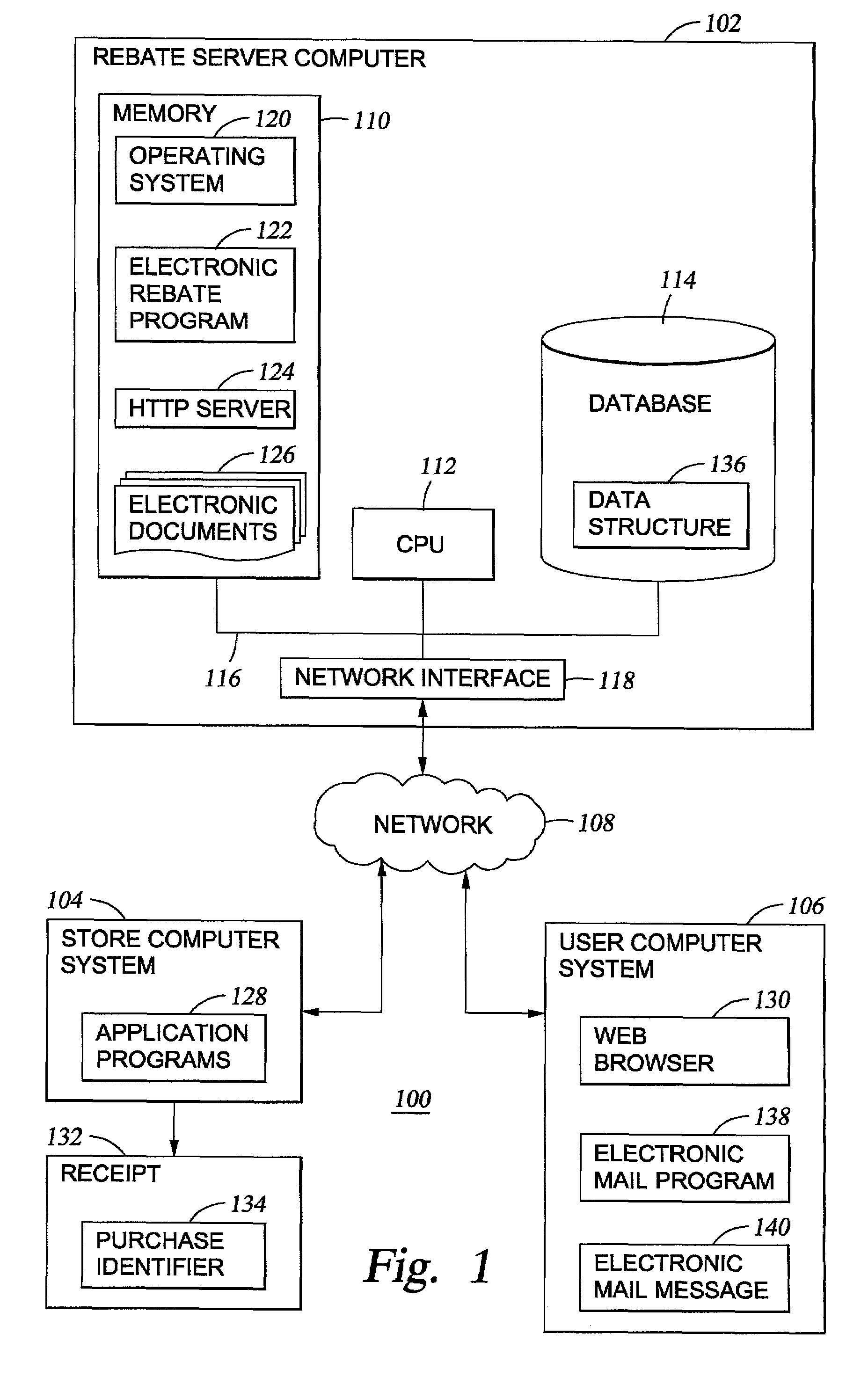

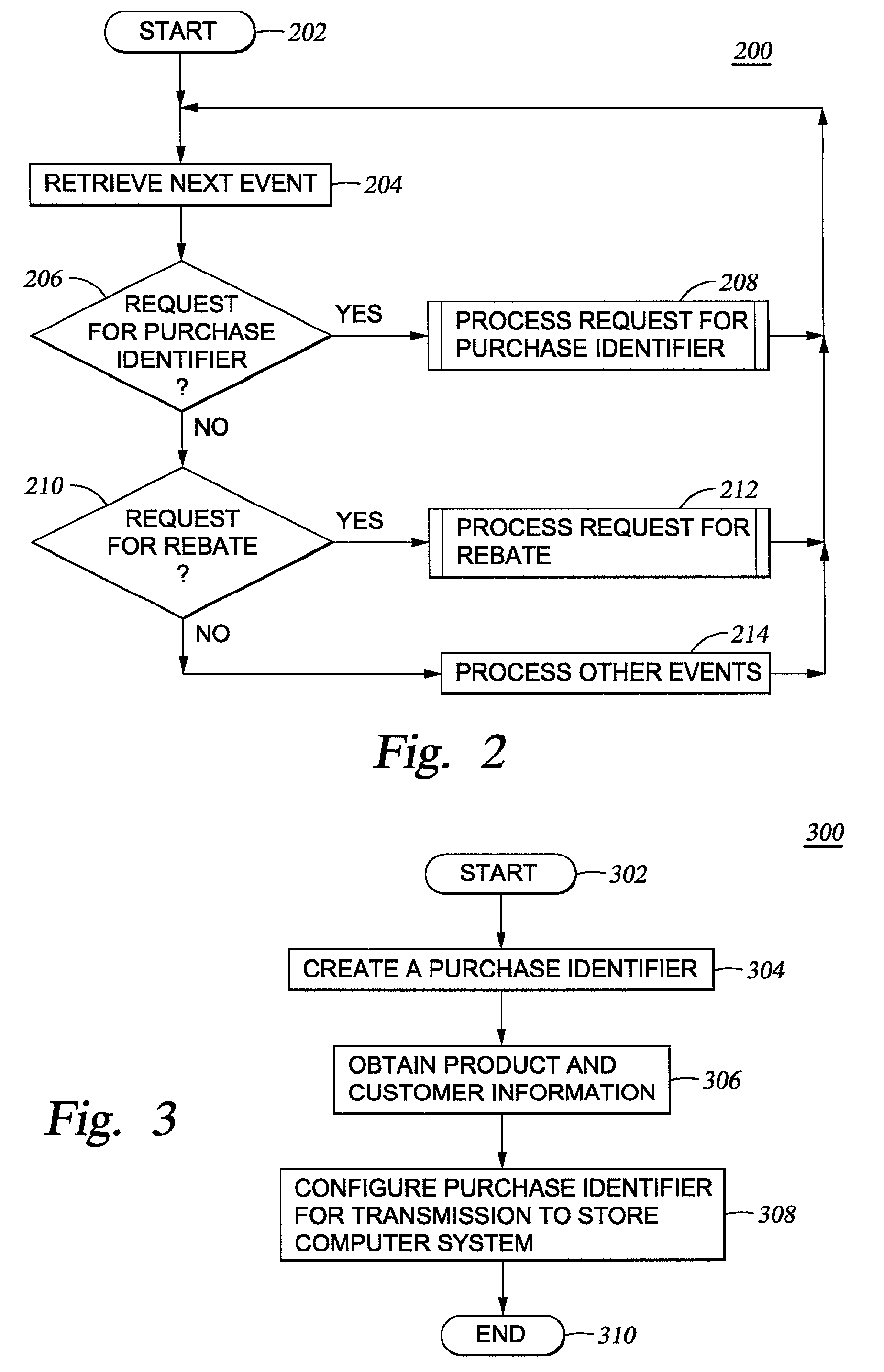

Method for processing electronic rebates

A method for processing electronic rebates is disclosed. In one embodiment, a purchase identifier is linked to a purchase of a product. The purchase identifier is listed on a receipt upon the purchase of the product or contained in an electronic mail message sent to an electronic mail address accessible using a user computer system. Information is then received via a network from a user of the user computer system to complete a rebate claim for the purchased product. The received information is verified to determine whether the purchase identifier was provided. The rebate claim is granted if the received information is verified as correct.

Owner:TOSHIBA GLOBAL COMMERCE SOLUTIONS HLDG

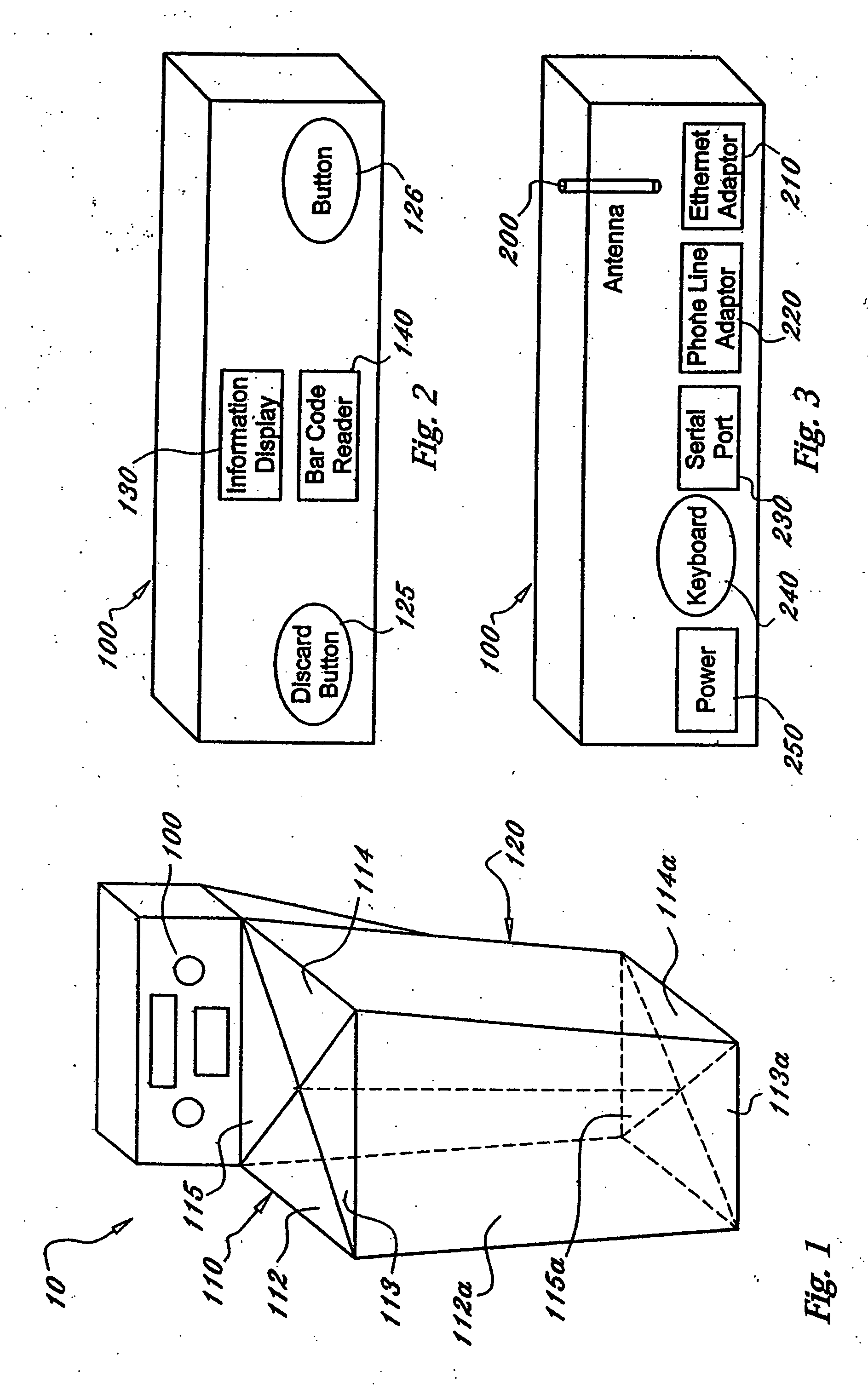

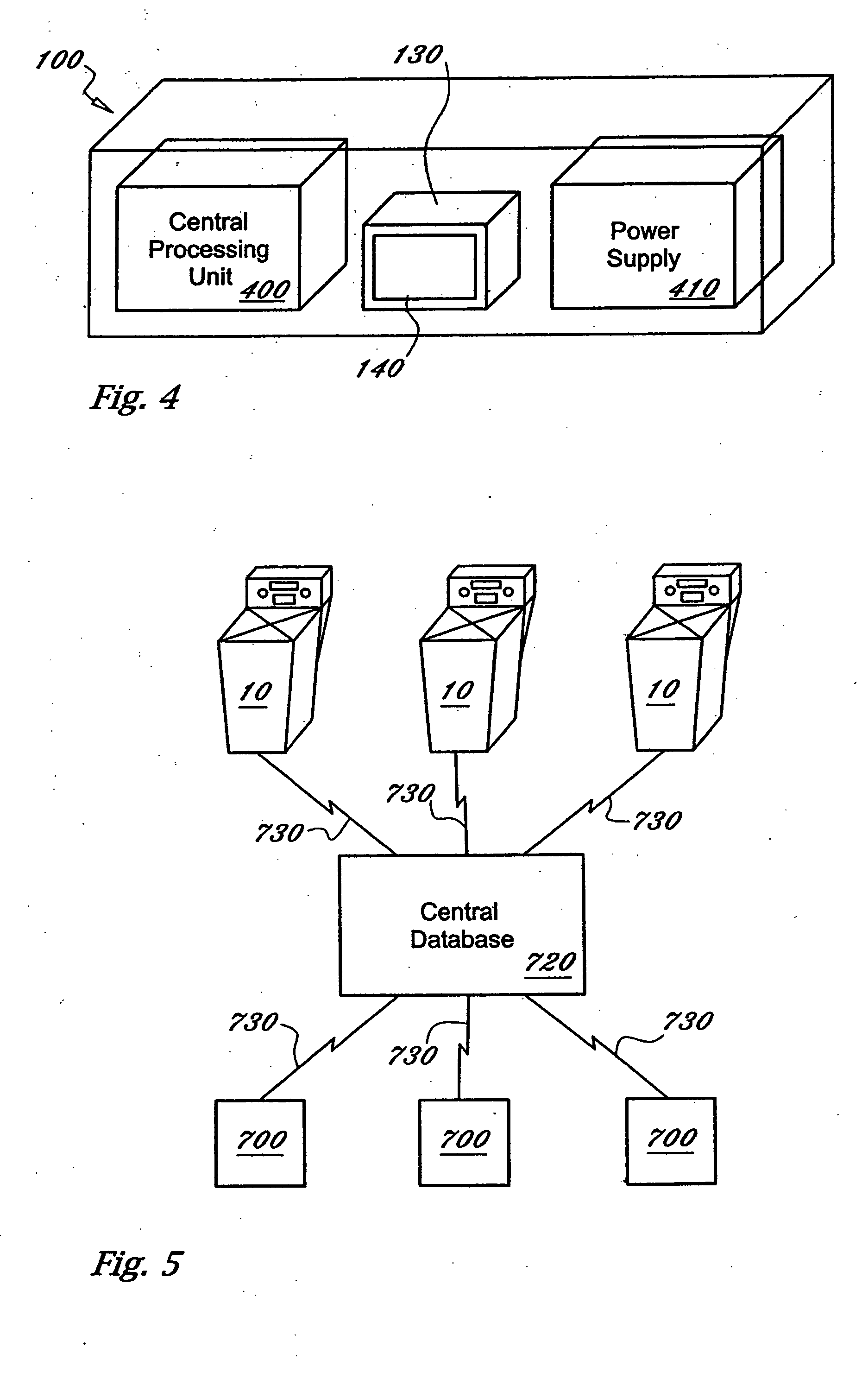

Method and system for disposing of discarded items

An electronic trash disposal unit comprises a control unit which scans and identifies disposed items to store them in an appropriate recycling bin. The unit is connectable to a communication network which updates a central database with the contents of each unit. The unit initiates a reorder instruction to suppliers.

Owner:FRESHUB

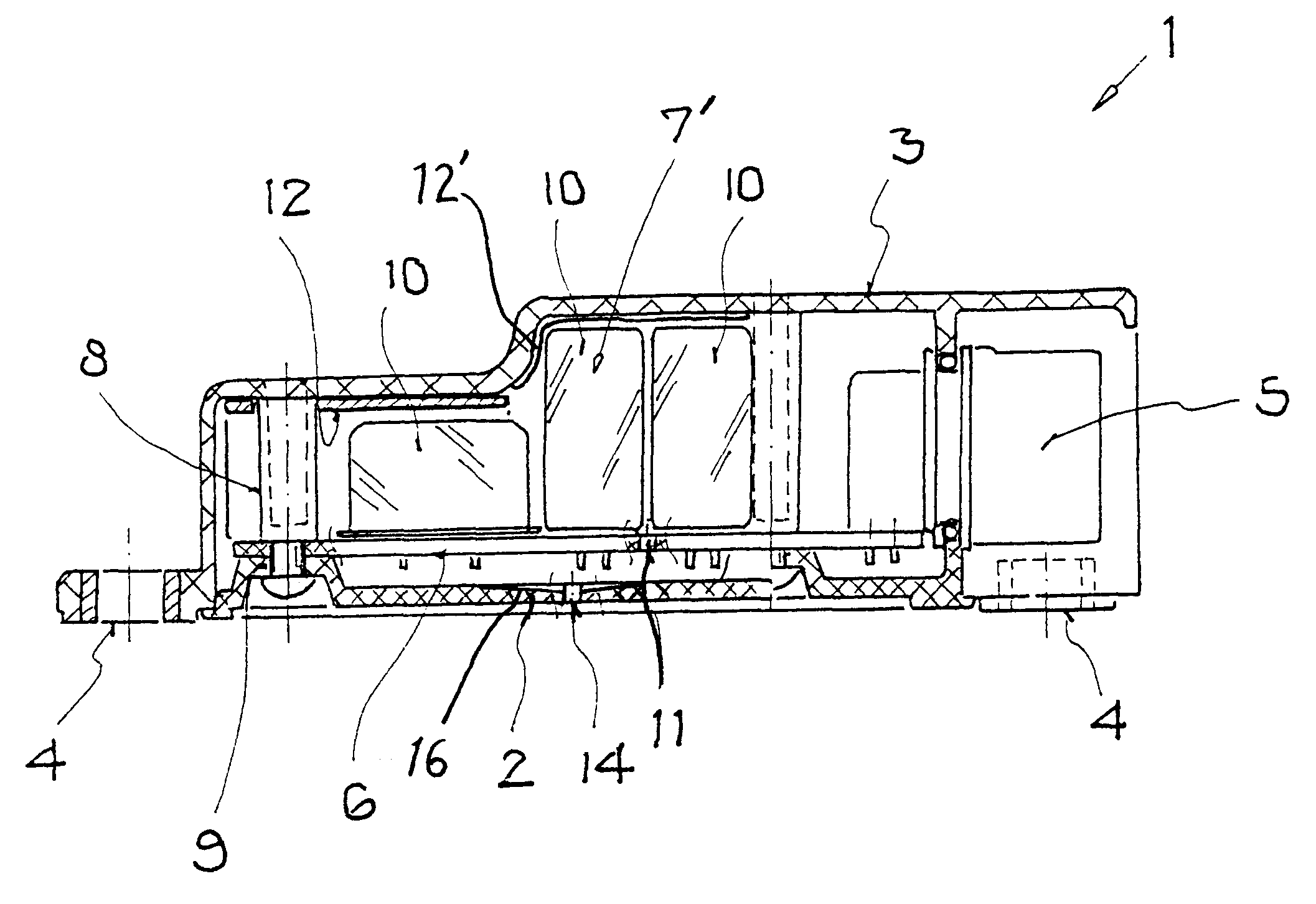

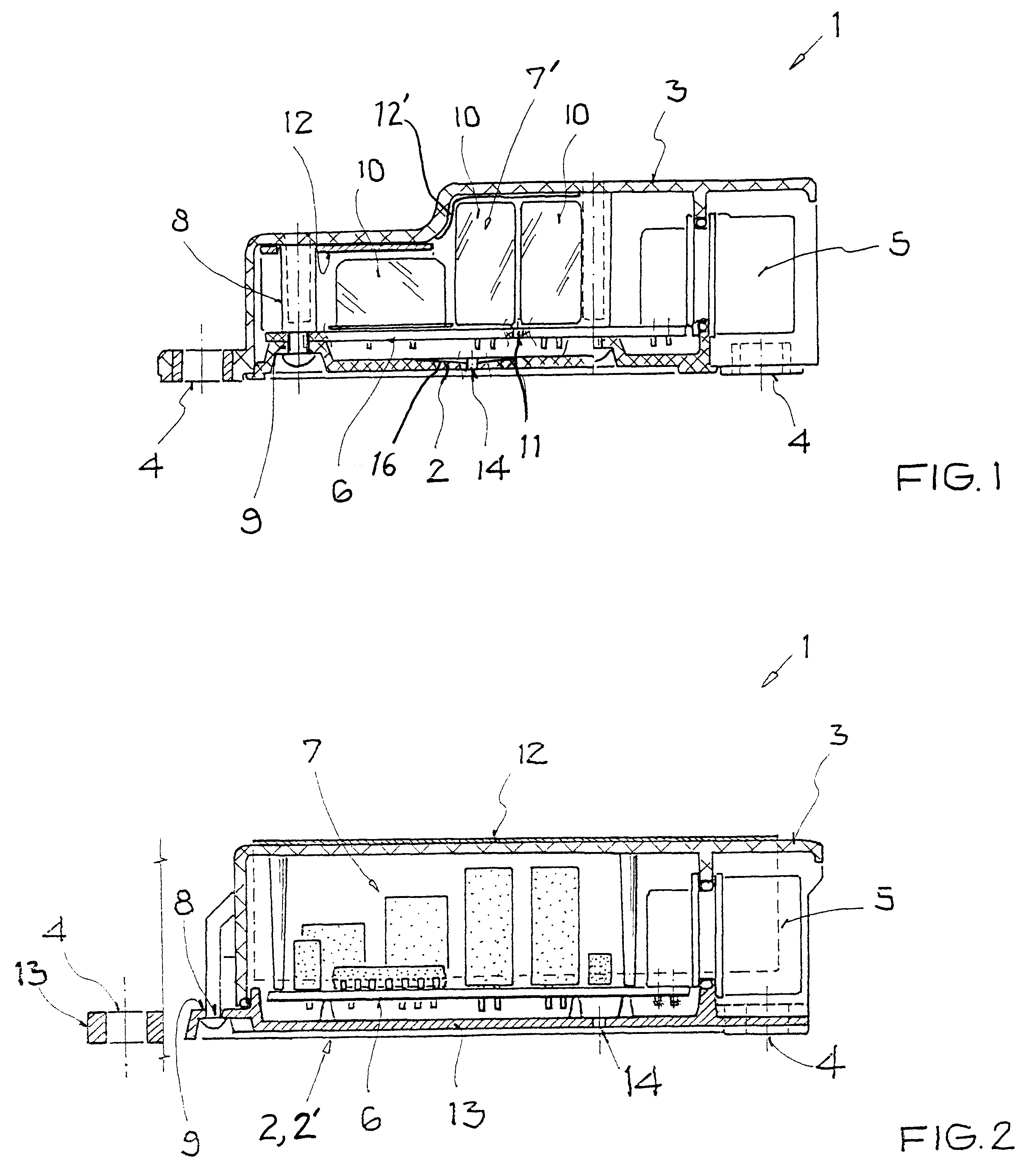

Plastic housing with condensation protection for electric and electronic assemblies

InactiveUS6445568B1Inhibit currentAvoid dangerSubstation/switching arrangement detailsDigital data processing detailsElectronic wasteElectronic component

A housing for an assembly of electronic components mounted on a circuit board is predominantly made of plastic, and includes a plastic housing cover and a housing floor. Metal surfaces are provided in the housing to preferentially condense moisture from the air in the housing upon cooling, to avoid condensation on the circuit board or the electronic components. The metal surfaces may be a metal casing around an electronic component, a metallized layer deposited on an inner surface of the housing, a metal insert in the housing, a metal housing floor, or an additional metal floor plate adjacent to a plastic housing floor. A hydrophobic film enforces condensate droplet formation, and channels and drain holes drain the condensate droplets out of the housing. An encapsulating film is unnecessary on the electronic components, because condensation on these components is avoided.

Owner:DAIMLER AG

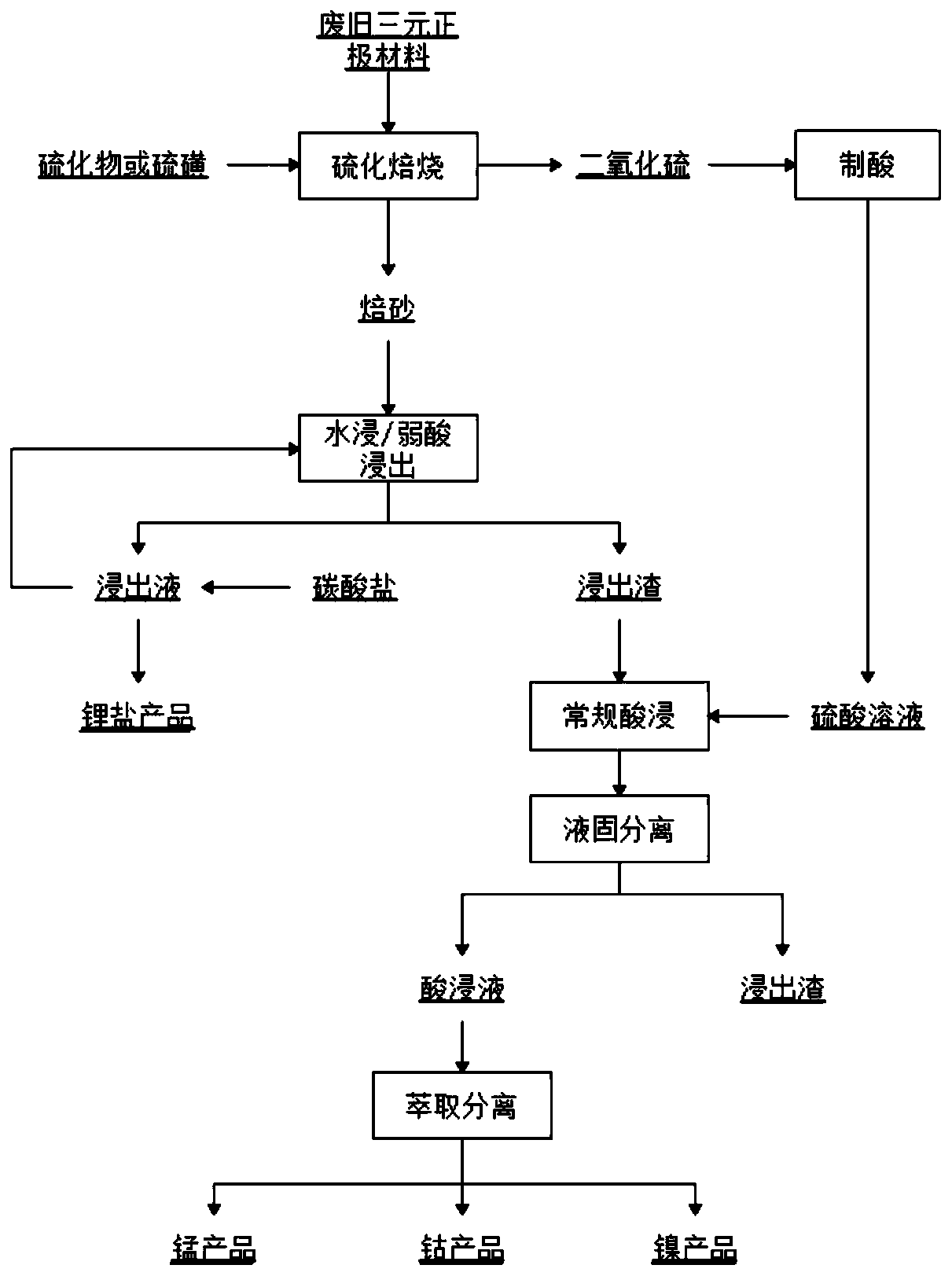

Method for recovering valuable metal from waste lithium ion battery material

ActiveCN109935922AAchieve separationReduce consumptionWaste accumulators reclaimingProcess efficiency improvementNickel saltManganese

The invention discloses a method for recovering valuable metal from a waste lithium ion battery material, and belongs to the technical field of comprehensive recycling and resource recycling of electronic wastes. The method comprises steps of mixing the cathode material of the waste lithium ion battery with low-valence sulfate such as sulfur or sulfide; subjecting the mixture to a sulfuration calcination treatment at a temperature of 300 to 900 degrees centigrade; immersing a calcined product in water to obtain a lithium salt aqueous solution which can be further used for preparing a lithium carbonate product; subjecting to water leaching residues to oxidation acid leaching or direct acid leaching to extract valuable elements such as nickel, cobalt and manganese; and purifying and extracting the leaching solution to obtain the corresponding cobalt salt and nickel salt products. The method of the invention has a simple process and a short process flow. The sulfur dioxide gas generated by calcining the sulfide can be used for preparing sulfuric acid used for subsequent nickel-cobalt leaching, thereby achieving zero pollution discharge and finally achieving a purpose of comprehensively recovering the valuable metal in the lithium ion battery cathode material at high efficiency and low cost.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

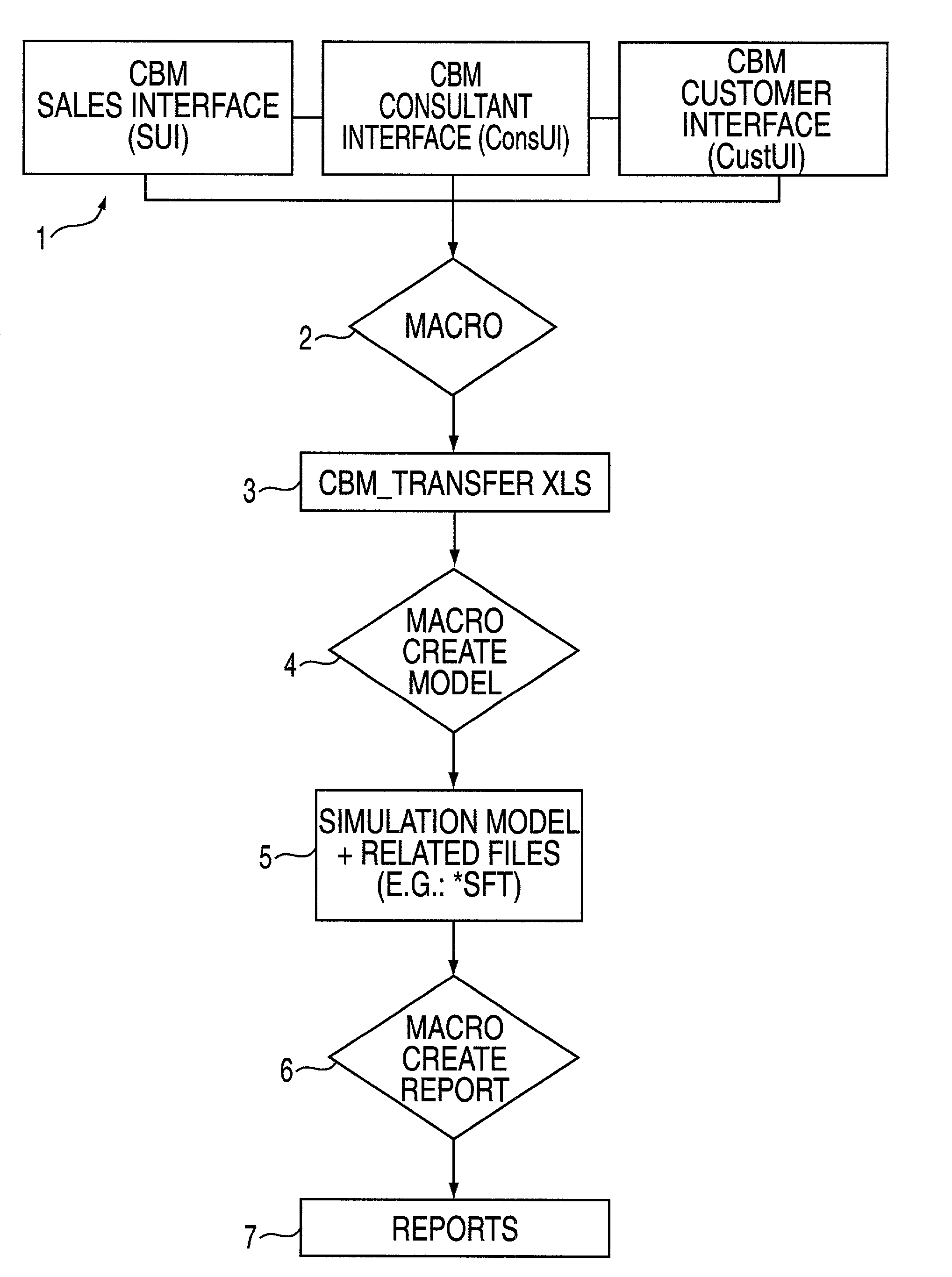

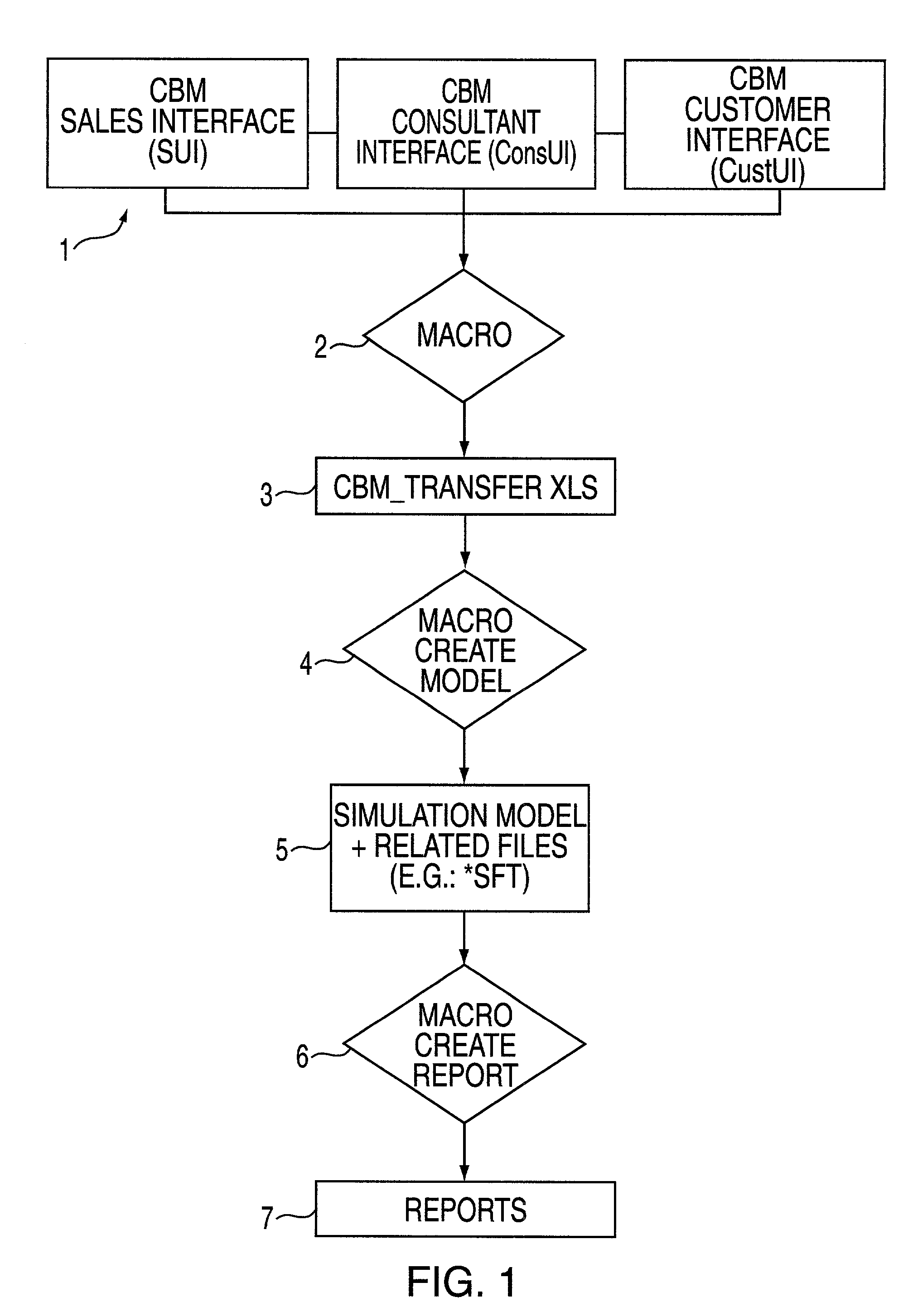

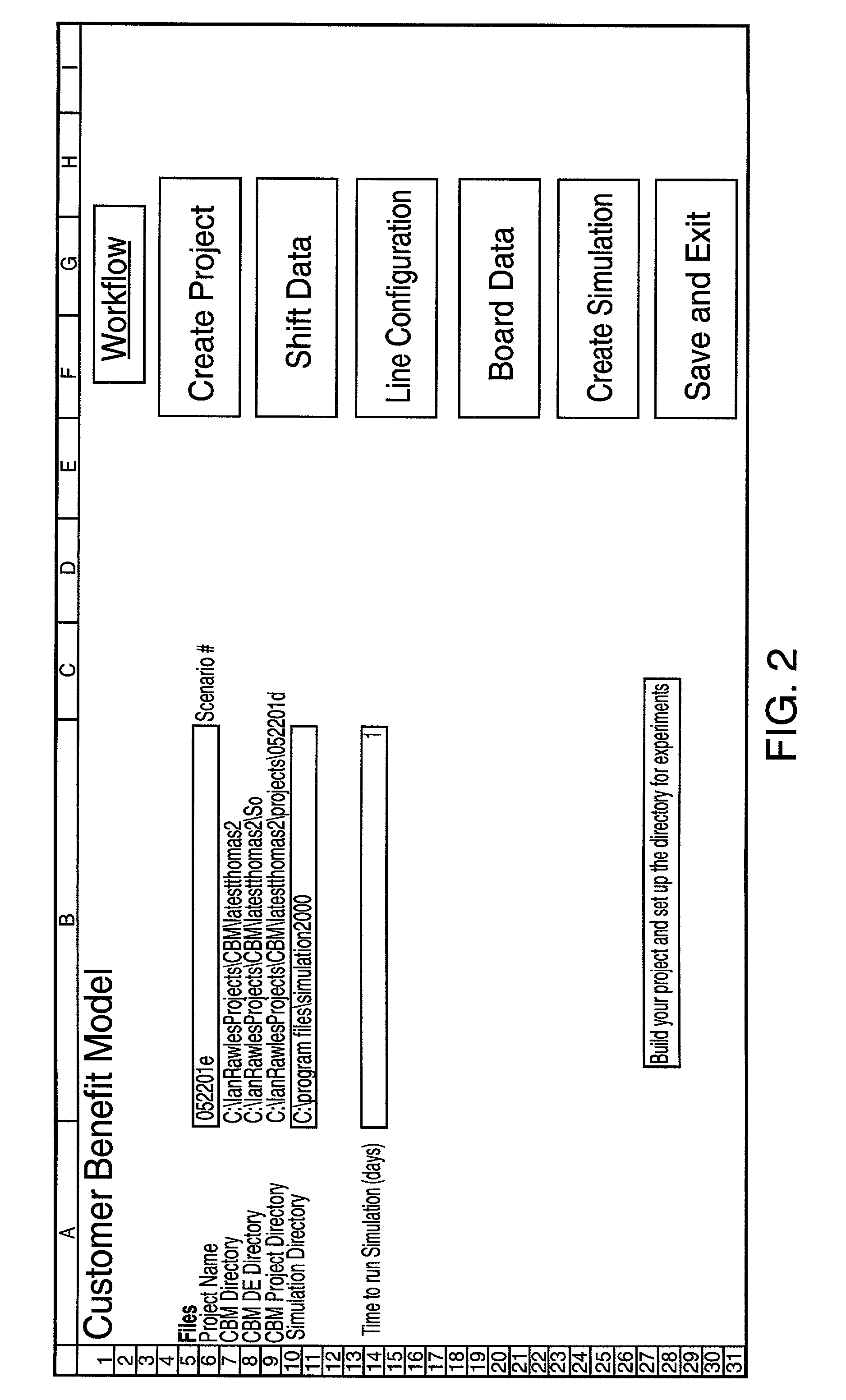

Electronics assembly systems customer benefit modeling tools and methods

InactiveUS6983232B2Accurate representationAccurate modelingComputation using non-contact making devicesAnalogue computers for electric apparatusUser inputData filling

Methods and tools for quickly and accurately performing complex customer benefit modeling for an electronic components assembly system are disclosed. In one embodiment, predefined user interfaces allow a consultant, customers, salespersons, or line designers to input a line configuration by selecting from a list predefined objects that represent specific line components. In addition, the user inputs other line configuration data specific to the line being configured. The information contained in the user interface is extracted for use a discrete event simulator. Templates for simulation objects may be created in advance and populated with data from the input interface. A simulation is built and run. Simulation results may be exported to an output means, which may allow for custom generated reports. The reporting means may include a means for allowing customer specific information and data to be inputted.

Owner:SIEMENS ELECTRONICS ASSEMBLY SYST LLC +1

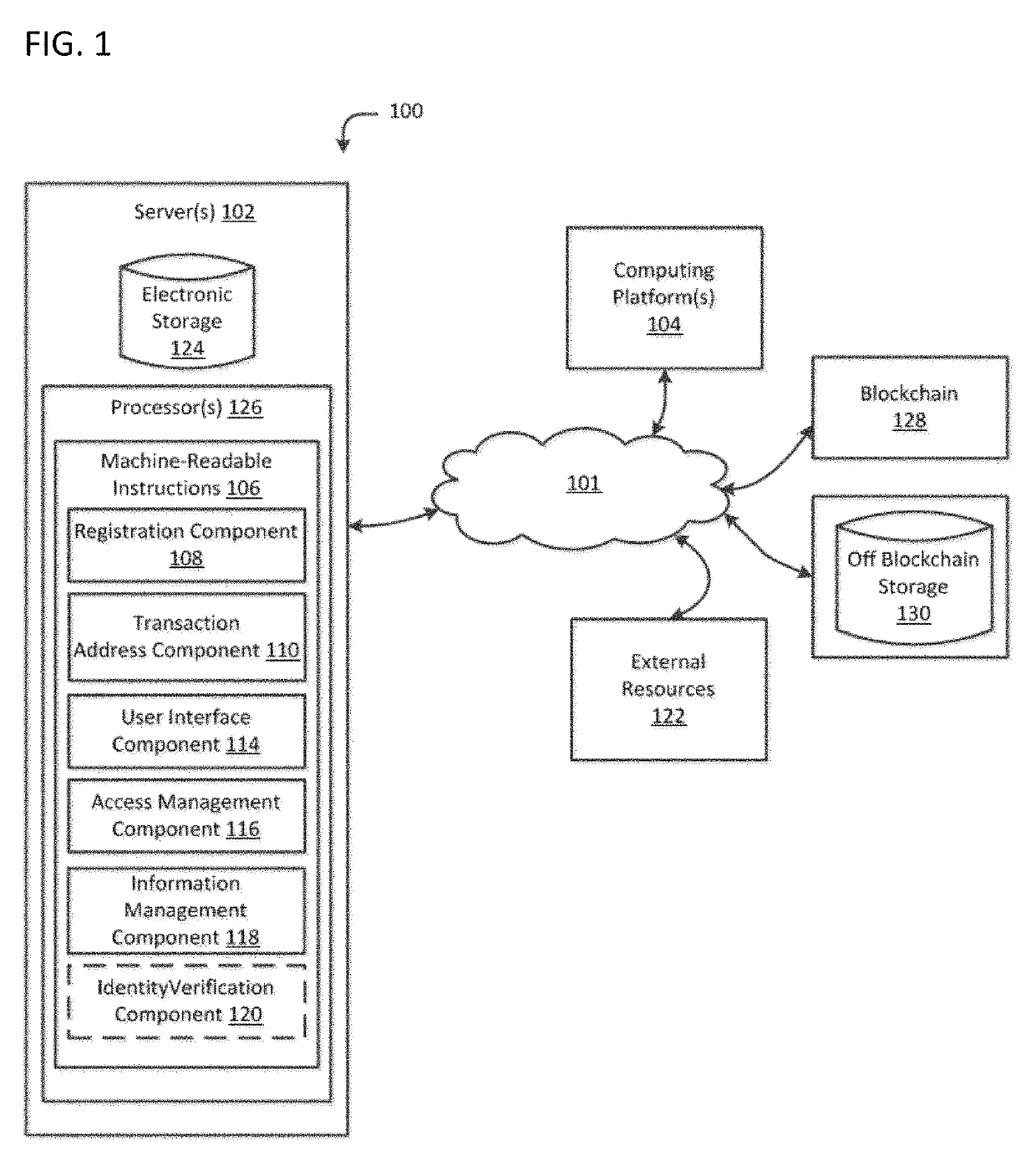

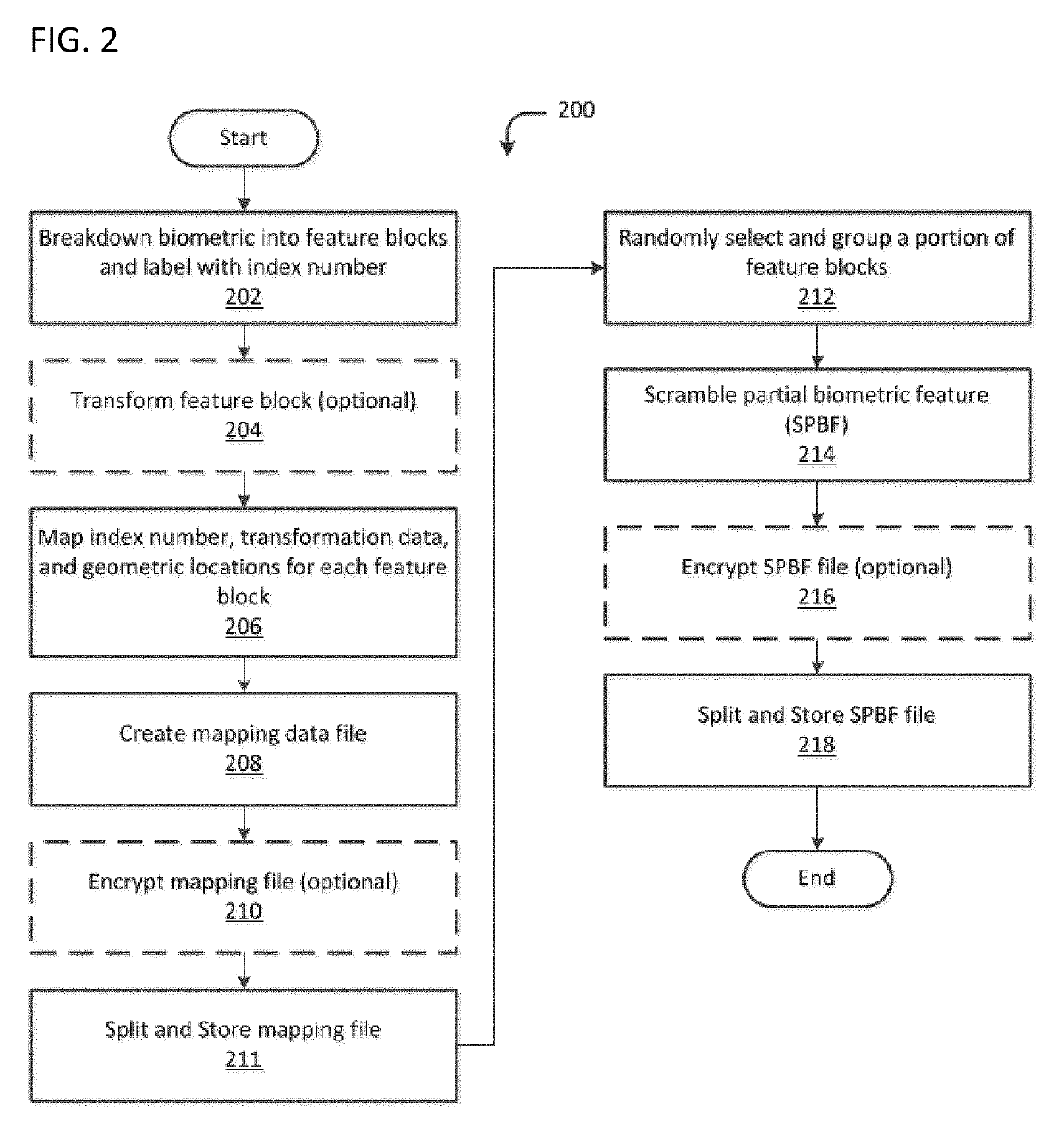

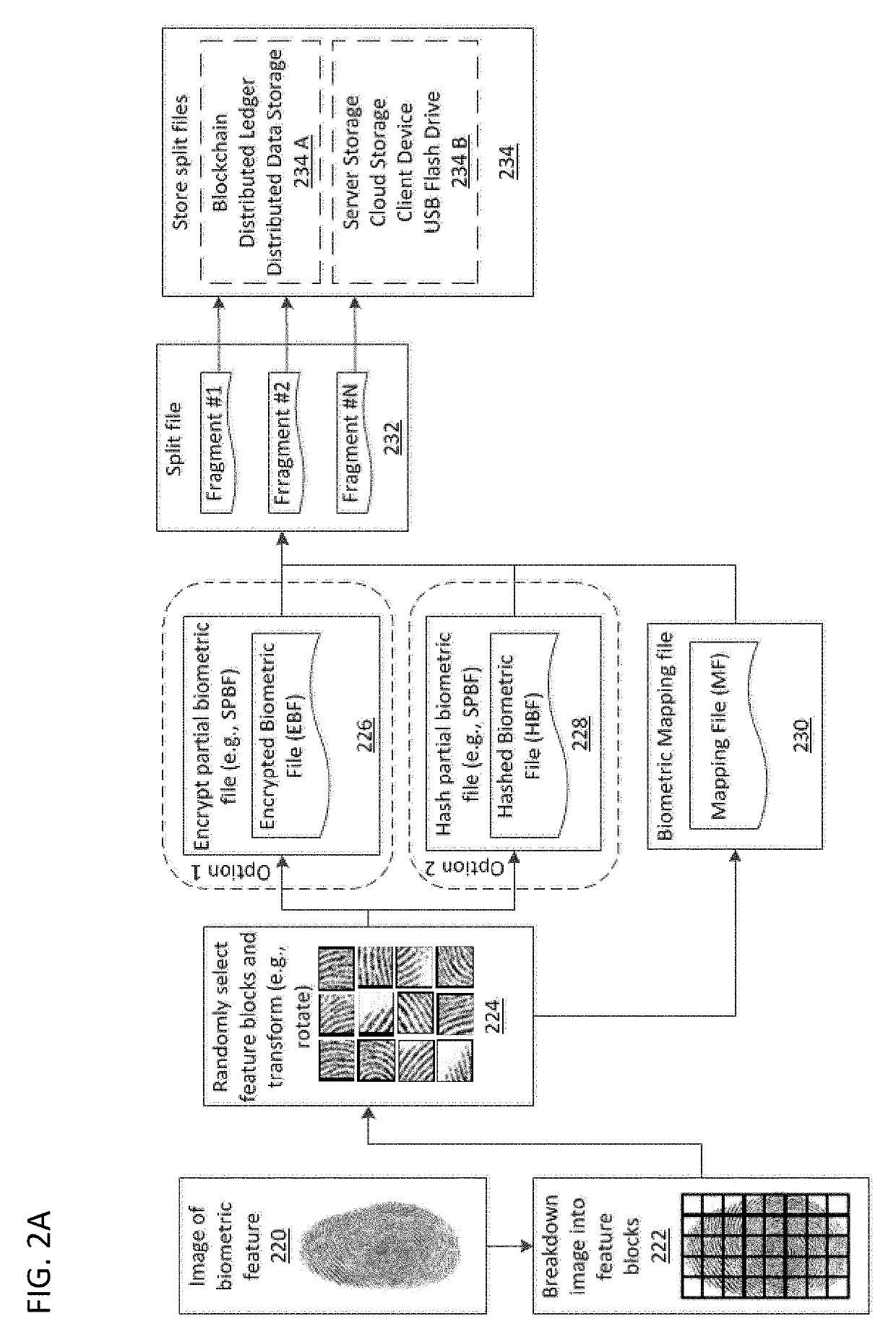

System and method for secure storage of electronic material

InactiveUS20190311148A1Encryption apparatus with shift registers/memoriesDigital data protectionUser deviceElectronic waste

A secure storage system and method for storing electronic material, e.g., digital files, is disclosed. In the system and method, a digital file is broken down into file fragments and one or more fragments are stored on a distributed ledger or distributed ledgers, and the remaining (one or more) fragments are stored off the distributed ledger, e.g., on a secure server or servers, and / or on a user device or devices. The files that are stored may be biometric or partial biometric files. The files may be encrypted or hashed. The file fragments are preferably unintelligible except when decrypted and fully assembled. For example, theft or copying or hacking of one file fragment will not be effective to steal or copy intelligible, useful information. In some embodiments, the benefits of storage on a distributed ledger or distributed ledgers are combined with the benefits of storage on a secure server or servers (and / or on a user's device or devices) or both.

Owner:BLACK GOLD COIN INC

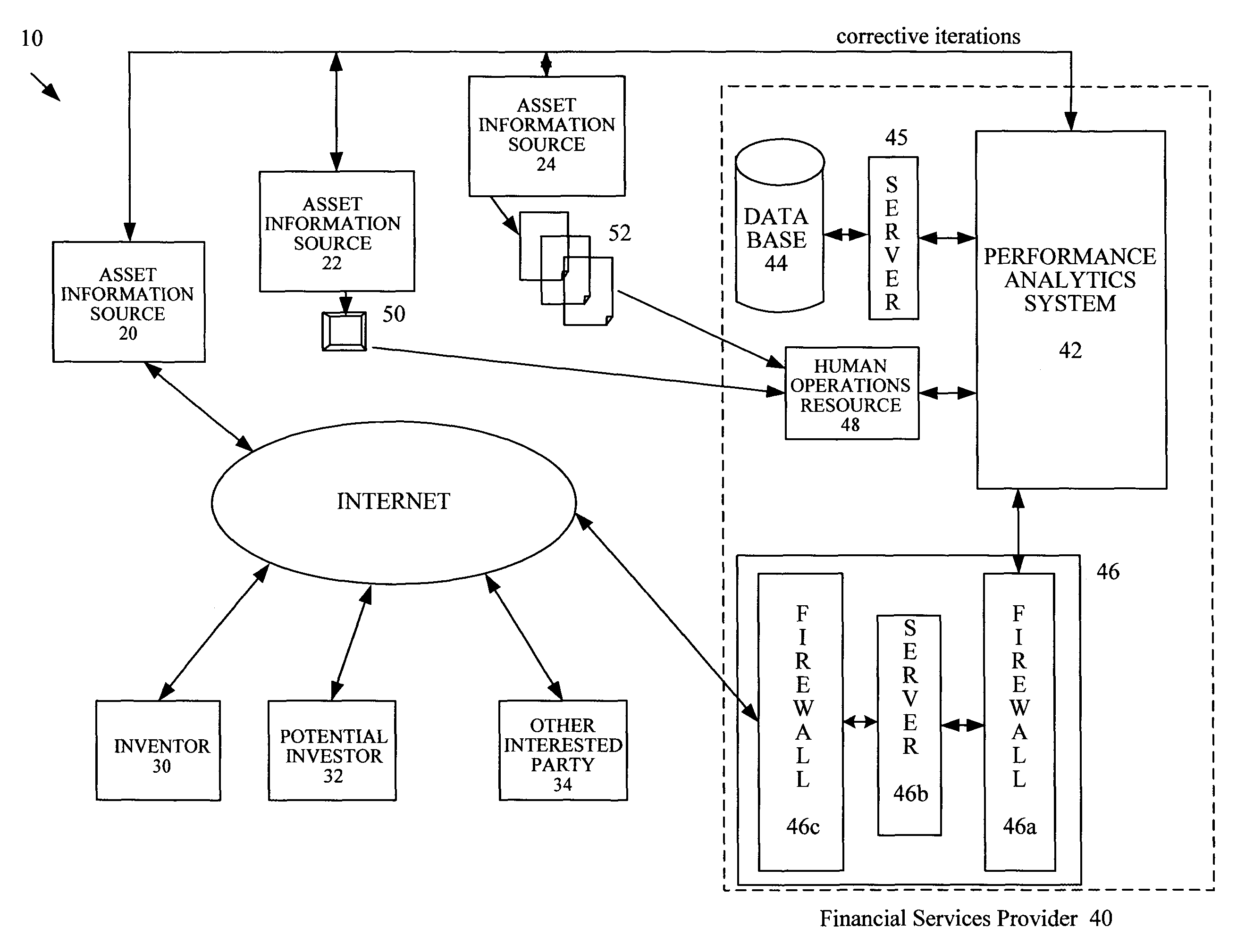

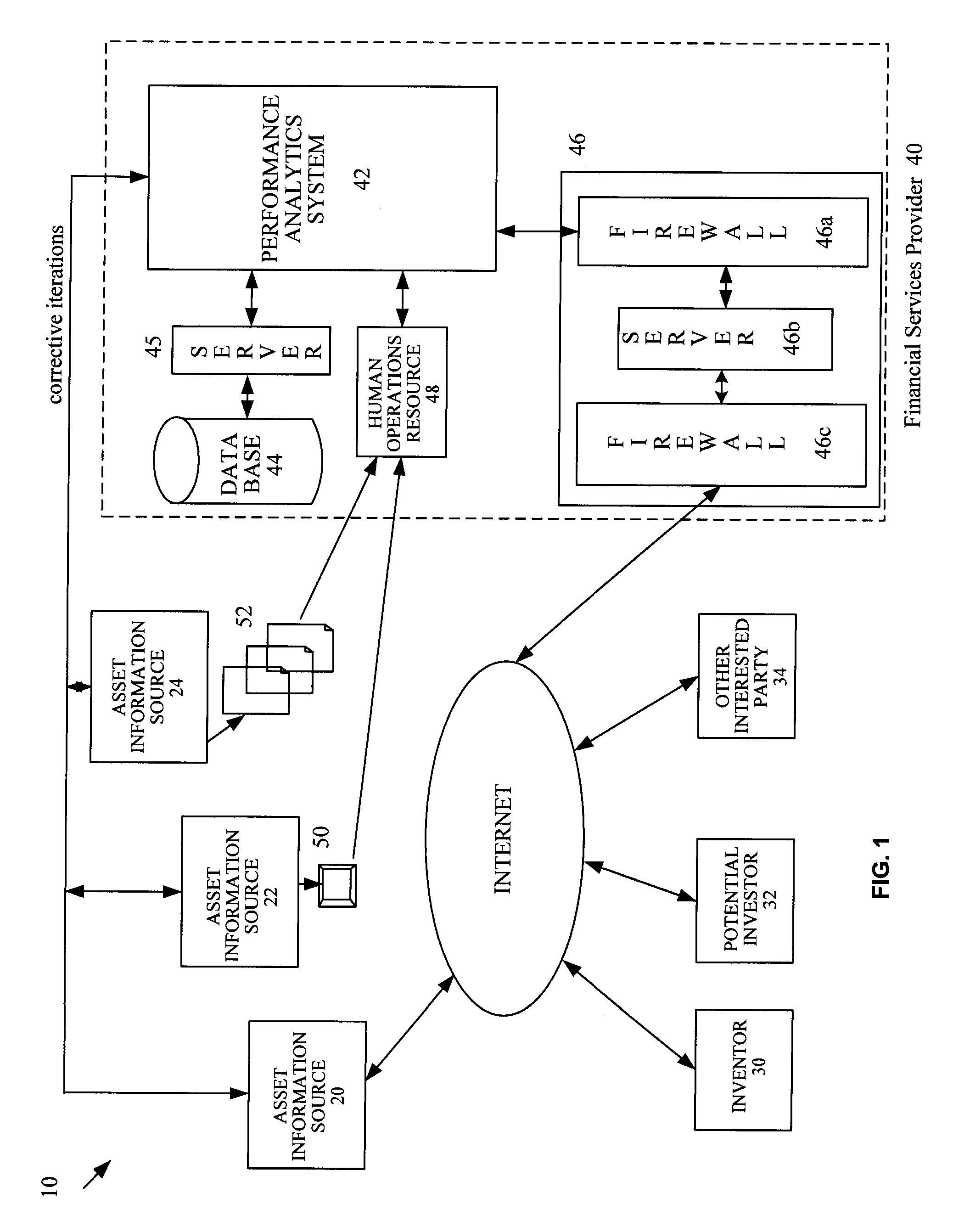

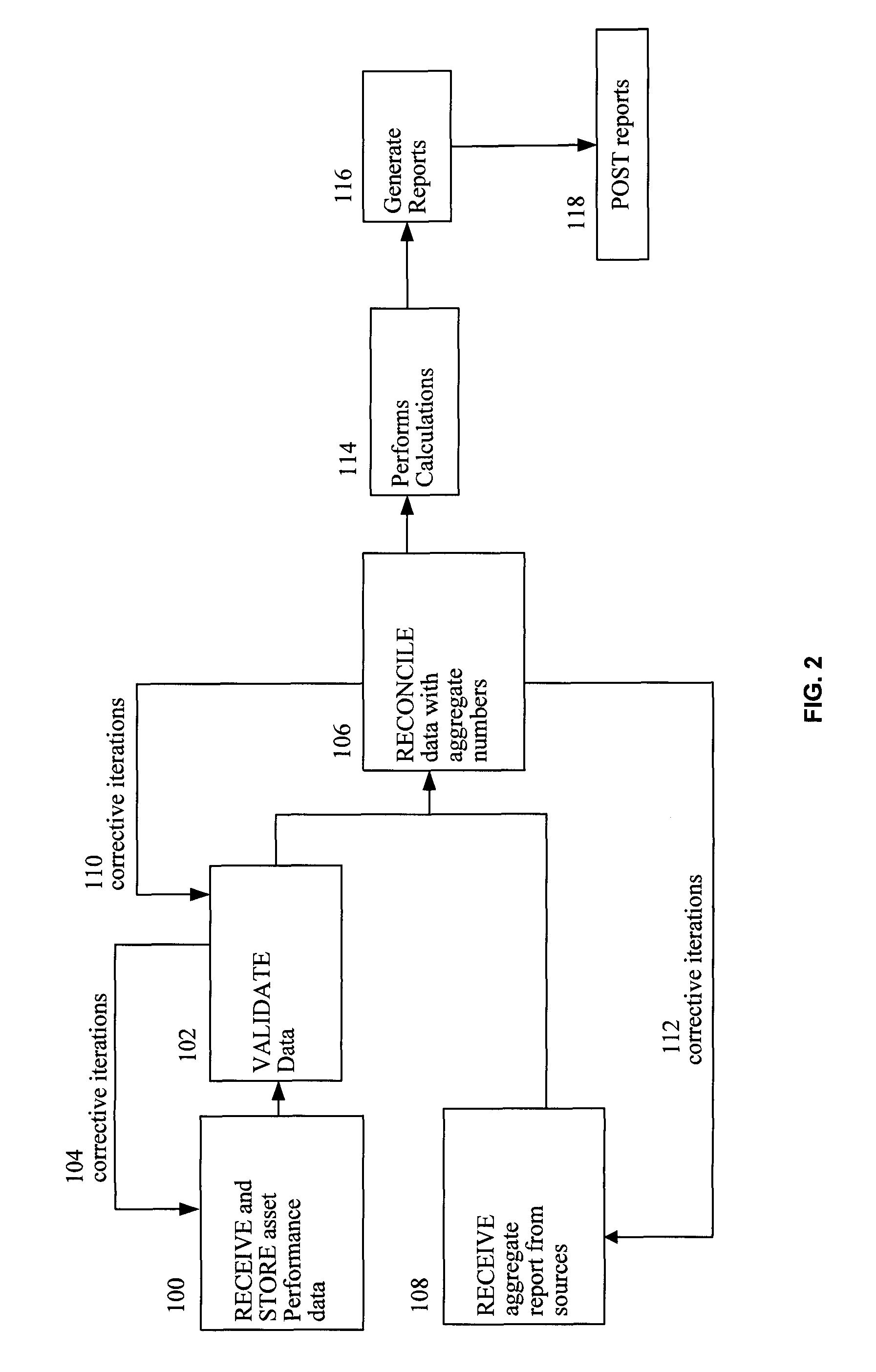

Structured finance performance analytics system

InactiveUS7966234B1Overcome disadvantagesFinanceSpecial data processing applicationsElectronic wasteData mining

A method for providing users with financial reports over a computer network, comprising the steps of: storing respective financial performance data for each of a plurality of securities, each security underlying one of a plurality of structured securities transactions sold by issuers to investors; maintaining an electronic site on the computer network to which the users may connect; receiving search criteria over the computer network from at least one of the users for identifying at least a subset of the financial performance data; retrieving the subset of financial performance data identified by the search criteria, at least some of the subset of financial performance data being arranged in a time series; and providing at least one electronic screen to the at least one user over the computer network, the at least one screen including the subset of financial performance data.

Owner:JPMORGAN CHASE BANK NA

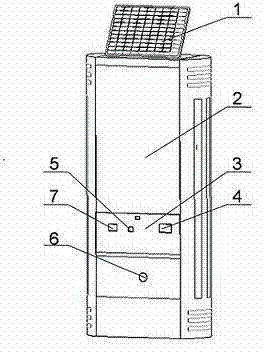

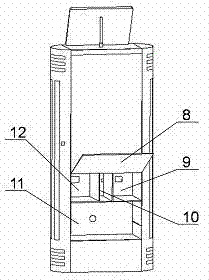

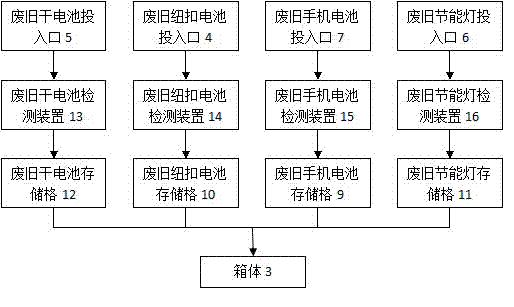

Waste and old electronic trash classified recycling bin capable of being used as advertising lamp box

InactiveCN103662541AAccurate classificationAccurate detectionWaste collection and transferRefuse receptaclesButton batteryEngineering

The invention discloses a waste and old electronic trash classified recycling bin capable of being used as an advertising lamp box. The waste and old electronic trash classified recycling bin capable of being used as the advertising lamp box comprises a bin body, an advertising lamp box and a solar panel, wherein the bin body is provided with a waste and old mobile phone battery slot, a dry battery slot, a button battery slot and an energy-saving lamp slot, wherein the slots are respectively provided with a detection device used for detecting whether trash is a waste and old battery or an energy-saving lamp; the solar panel supplies power to the operation of the advertising lamp box and the recycling bin. The waste and old electronic trash classified recycling bin capable of being used as the advertising lamp box can realize automatic detection, and the waste and old battery and the energy-saving lamp can be subjected to classification collection while the waste and old battery is prevented from being mixed with waste, thereby being favorable for collecting the waste and old battery and the energy-saving lamp. The recycling bin and the advertising lamp box are combined, so that the waste and old electronic trash classified recycling bin has the advantages of strong practicality and good publicity effect. Meanwhile, solar energy is used to supply power to the recycling bin, and therefore the waste and old electronic trash classified recycling bin has the advantages of saving energy, protecting the environment, and being convenient to install and use.

Owner:王冬栋

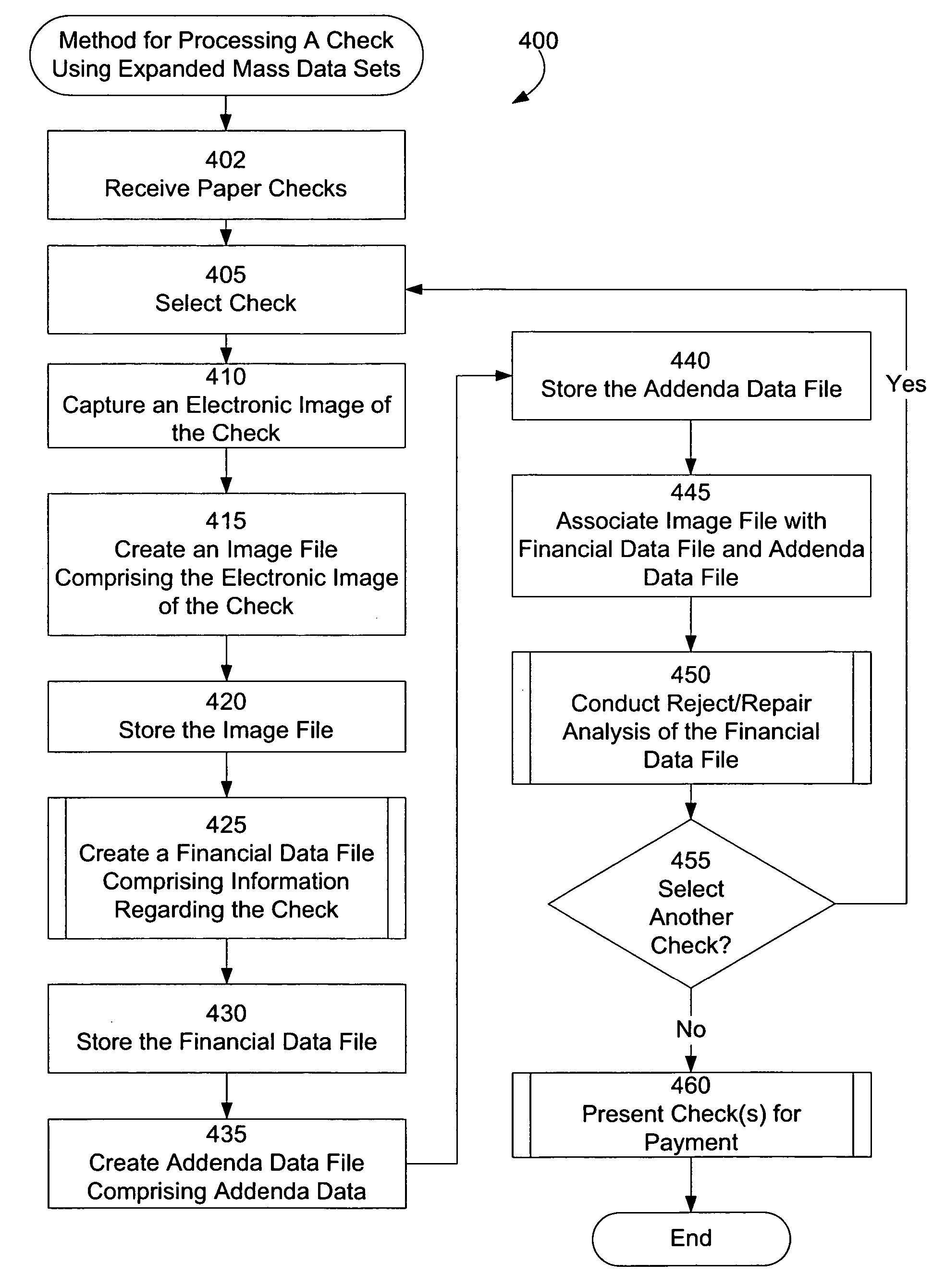

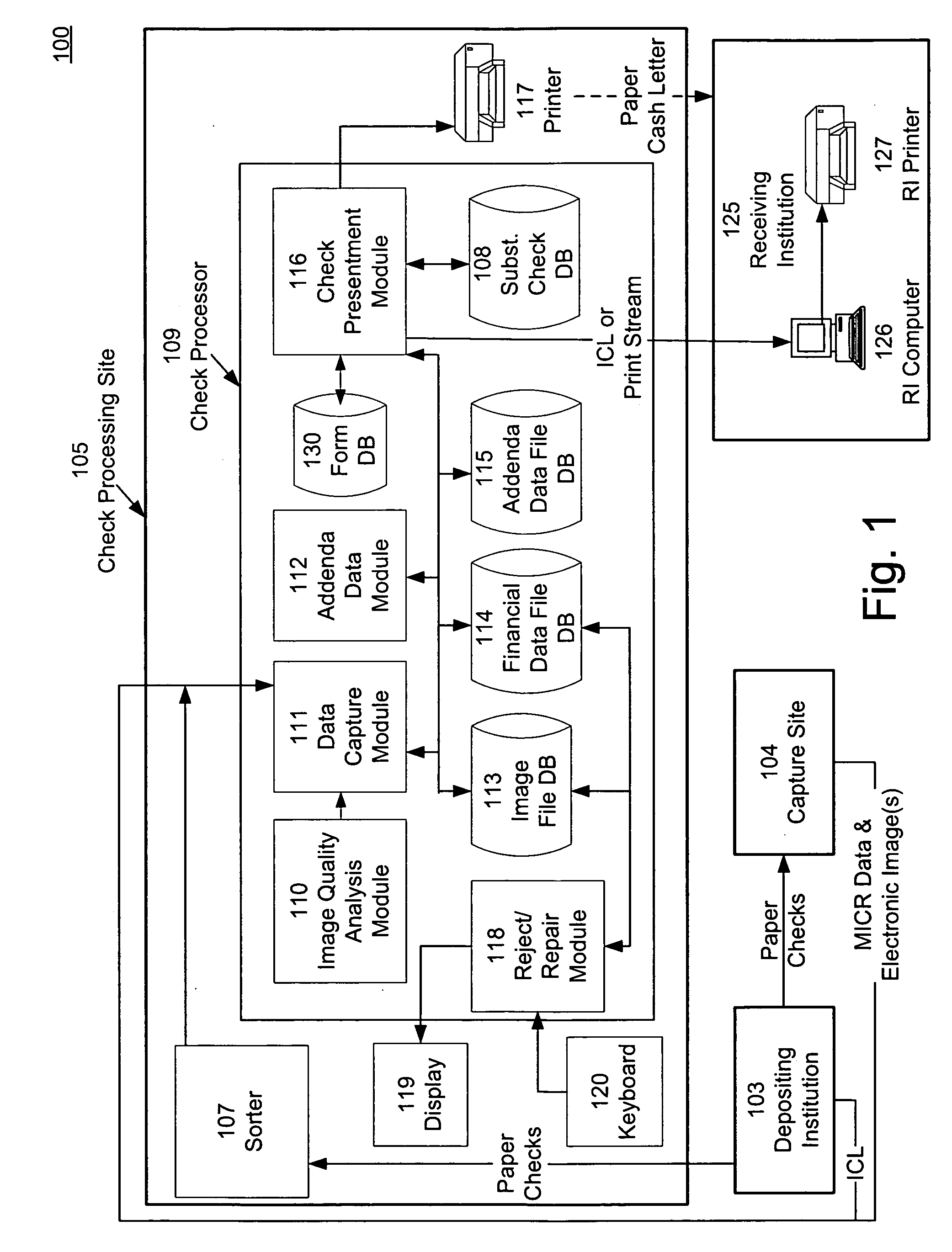

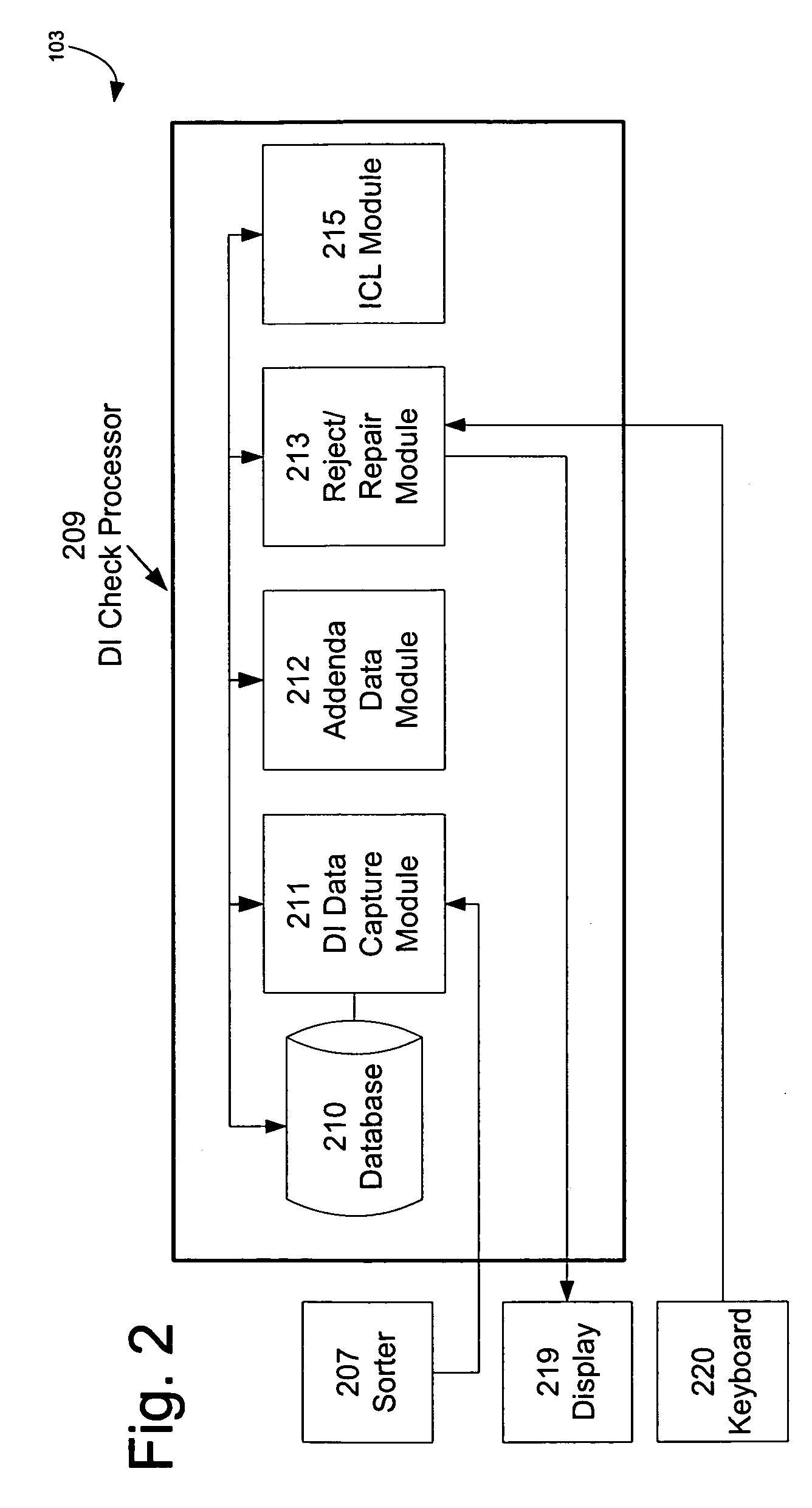

Expanded mass data sets for electronic check processing

ActiveUS20060237526A1Accurately and completely correct errorComplete banking machinesFinanceData setSubstitute check

Accommodating the data needed to process checks for payment under the Check Clearing for the 21st Century Act by using expanded fields of a financial data file. The financial data file can comprise the complete, original MICR data from an original or substitute paper check. The financial data file can comprise truncated data in conventional fields F1-F7 and untruncated data in expanded fields F10-F11. The financial data file further can comprise a result from an image quality analysis performed on an electronic image of the check. The untruncated MICR data and the electronic check image can be used to correct errors in the financial data file and to present the check for payment via a substitute check or an electronic image cash letter. The truncated MICR data can be used to electronically process the check via conventional means.

Owner:US FEDERAL RESERVE BANK OF CLEVELAND +2

Cleaning solution for substrates of electronic materials

InactiveUS7084097B2Easy to cleanAdsorption of particles can be preventedSurface-active detergent compositionsNon-surface-active detergent compositionsOrganic acidMetallic materials

The present invention relates to a cleaning solution capable of removing efficiently at the same time particles and metallic impurities from a substrate surface without corroding metallic materials.The cleaning solution for cleaning substrates of electronic materials comprises an organic acid compound and at least one selected from the group consisting of dispersants and surfactants.

Owner:KANTO CHEM CO INC

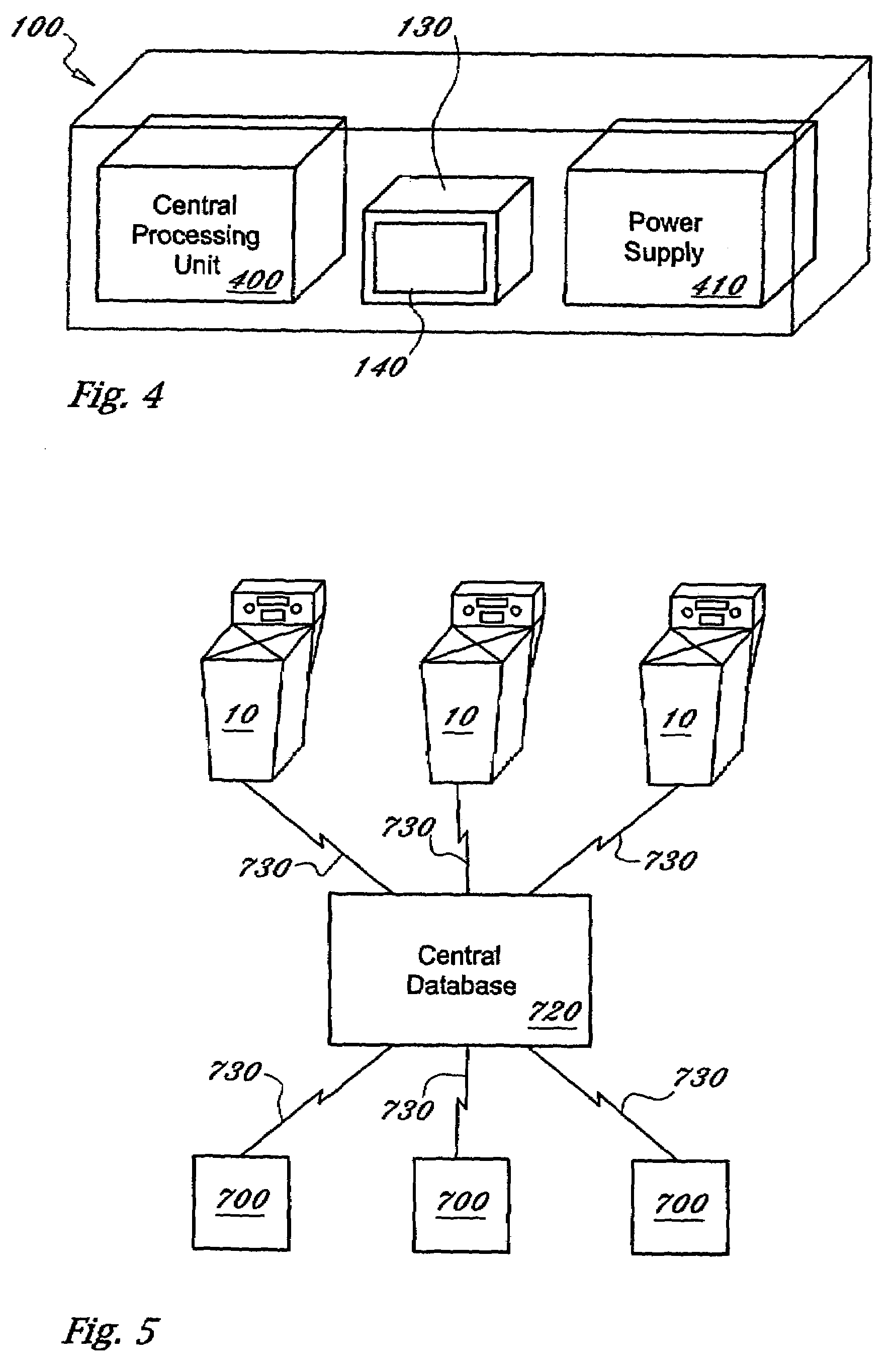

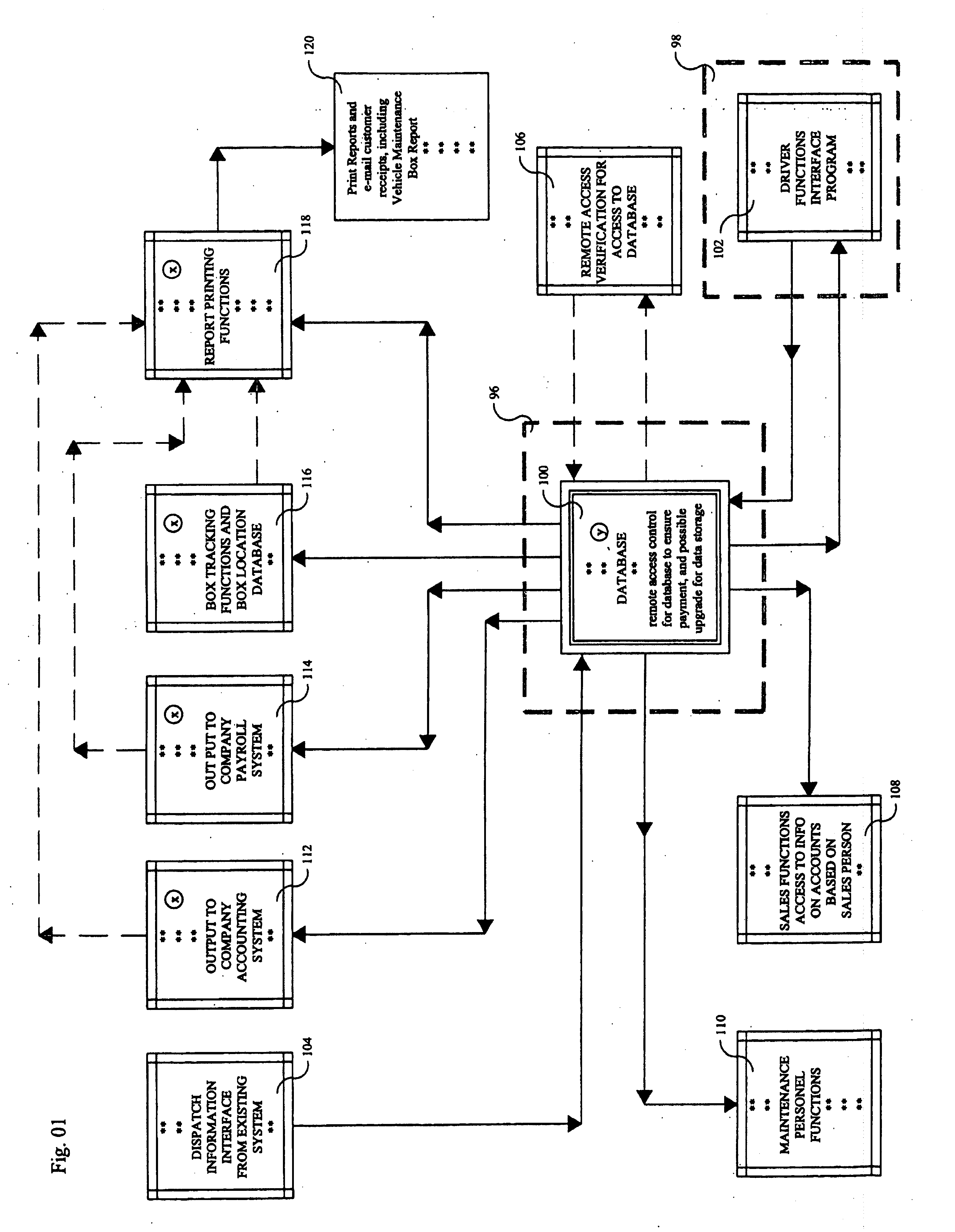

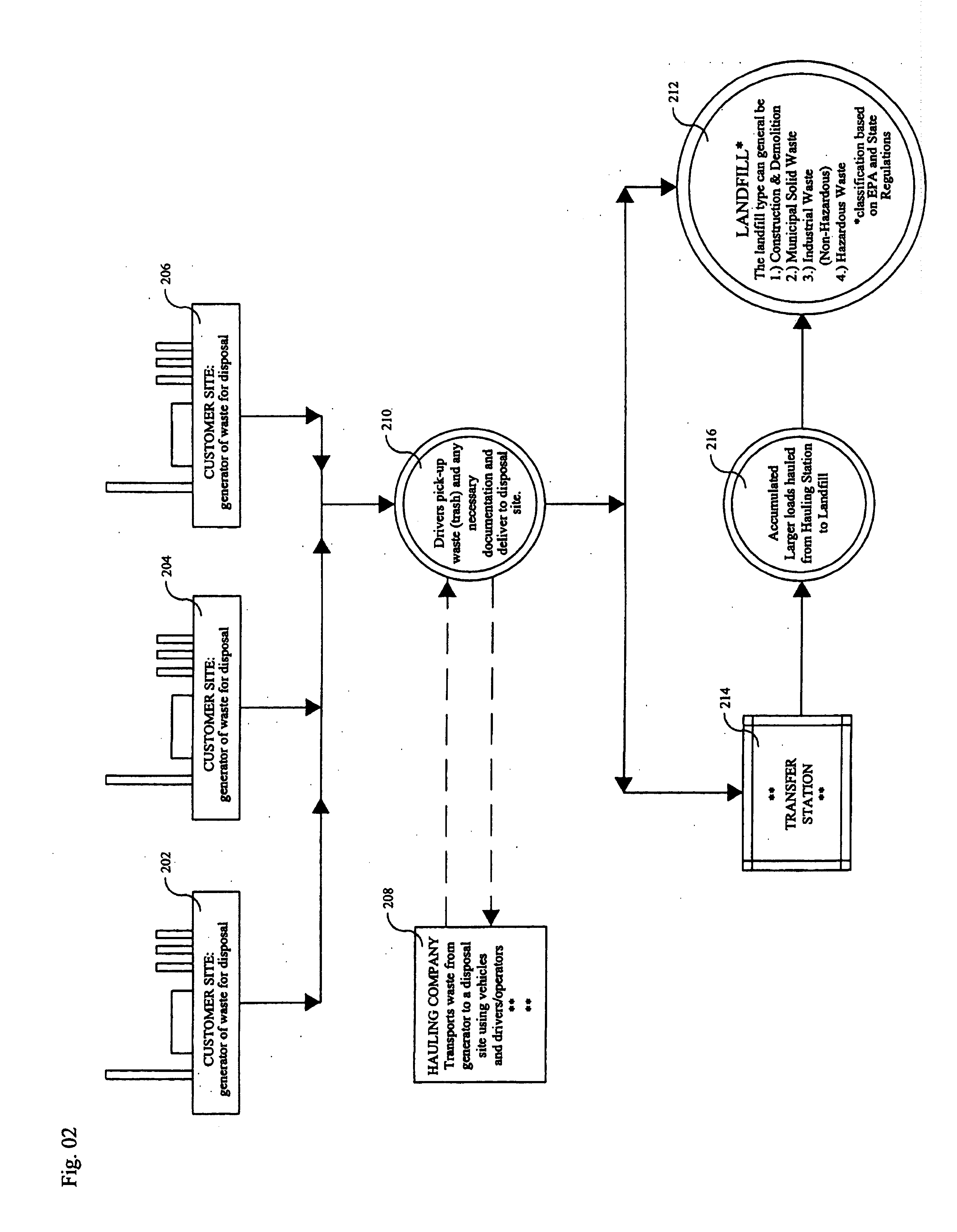

Electronic waste management system

InactiveUS20050261917A1Improve accuracyImprove completenessSustainable waste treatmentFinanceDriver/operatorInvoice

The present invention provides a system and method for electronically automating the solid waste hauling industry's existing paper system for tracking driver services. In at least one embodiment, the system directs the driver through his daily activities, allowing changes and corrections to customer service data along a route. This information is uploaded and converted to payroll data, customer service information, and invoicing for customers, among other aspects, periodically throughout the route or upon return to a home base after the route. The information that is collected on site and in real time into a unit available to the driver during the route can require specific and traceable entries that improve the accuracy and completeness of the data useful to the waste management system. The automation provides the information collected by a driver independently of additional clerks that heretofore have been used to input this information into a waste management system.

Owner:DAFFENBERRY

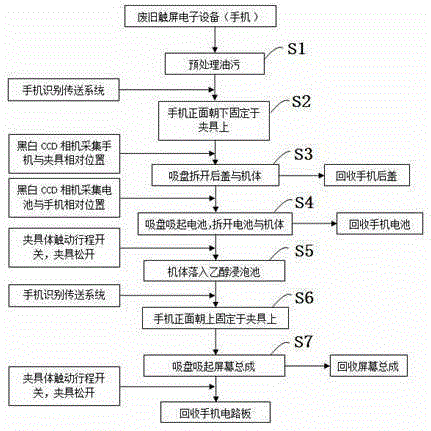

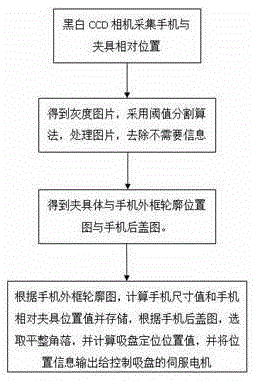

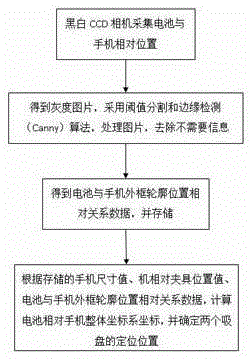

Automatic waste mobile phone detaching and recovering method and automatic work assembly line device thereof

ActiveCN105290081AReduce consumptionAvoid the disadvantages of lower recovery ratesSolid waste disposalElectronic waste recyclingRecovery methodResource recovery

The invention discloses an automatic waste mobile phone detaching and recovering method and an automatic work assembly line device thereof. In the form of an assembly line, the vacuum suction cup suction and pulling-out process is adopted. A mobile phone rear cover, a mobile phone battery, a mobile phone screen assembly and a mobile phone circuit board are separated step by step. When the mobile phone screen assembly and the circuit board are detached, the method of soaking a mobile phone in ethyl alcohol and heating the mobile phone through a clamp is adopted; the positions of the mobile phone and the battery relative to the clamp are sampled through a black and white CCD camera above a station and transmitted to a computer to be computed. The method is mainly applied to the field of electronic waste resource recovery treatment. Through the mechanical mode, waste mobile phones can be rapidly detached in batches, detaching efficiency is high, yield is guaranteed, operation is easy, and the environment is not damaged.

Owner:SHANGHAI UNIV

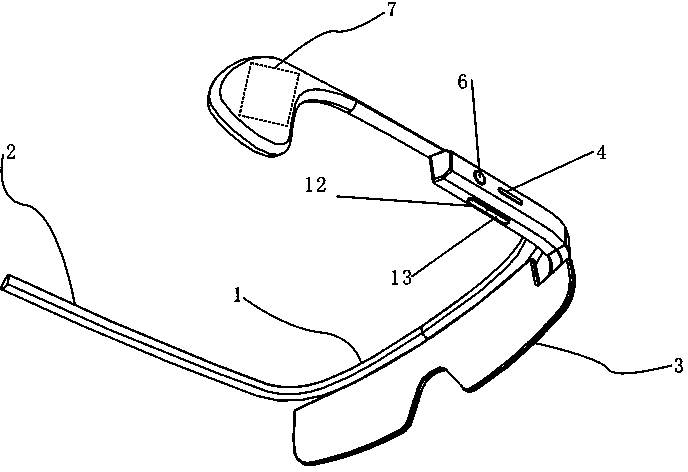

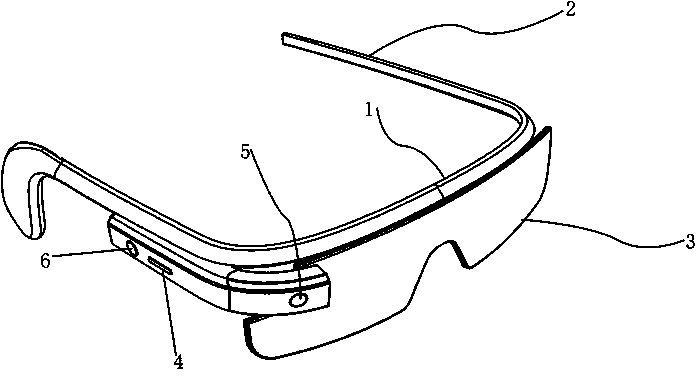

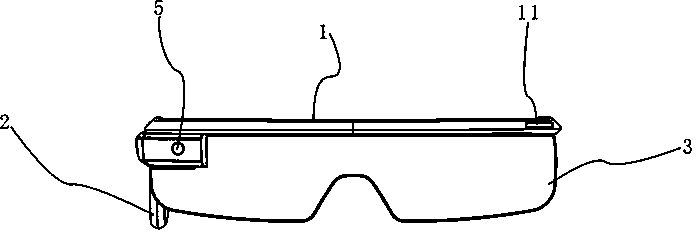

Intelligent cruise spectacles and control system thereof

InactiveCN104090383AReduce volumeEasy to wearTelevision system detailsNon-optical adjunctsImaging processingControl system

The invention discloses intelligent cruise spectacles and a control system thereof. The spectacles comprise a spectacles frame, spectacles legs and eyeglasses fixed on the spectacles frame, and the spectacles legs are hinged to the spectacles frame; and an integrated chip is arranged in each of the spectacles legs, the integrated chip is provided with an image processing module, a memory, a Bluetooth reception module, a voice processing module and a GPS positioning module, the voice processing module is connected with the GPS positioning module to form a GPS voice navigator, voices are processed by the voice processing module, the position of the cruise spectacles and a voice navigation destination are positioned by the GPS positioning module, and positioning information and voice information are stored in the memory. The addition of mobile shooting monitoring recording, shooting, voice call, voice navigation and GPS positioning functions of the disclosed spectacles relative to original spectacles makes the spectacles integrate the functions of many individual digital products, so energy saving, high efficiency and convenient carrying are reached, and environment pollution due to generated electronic wastes is avoided.

Owner:SHENZHEN HONGWEI ZHENGHE DIGITAL

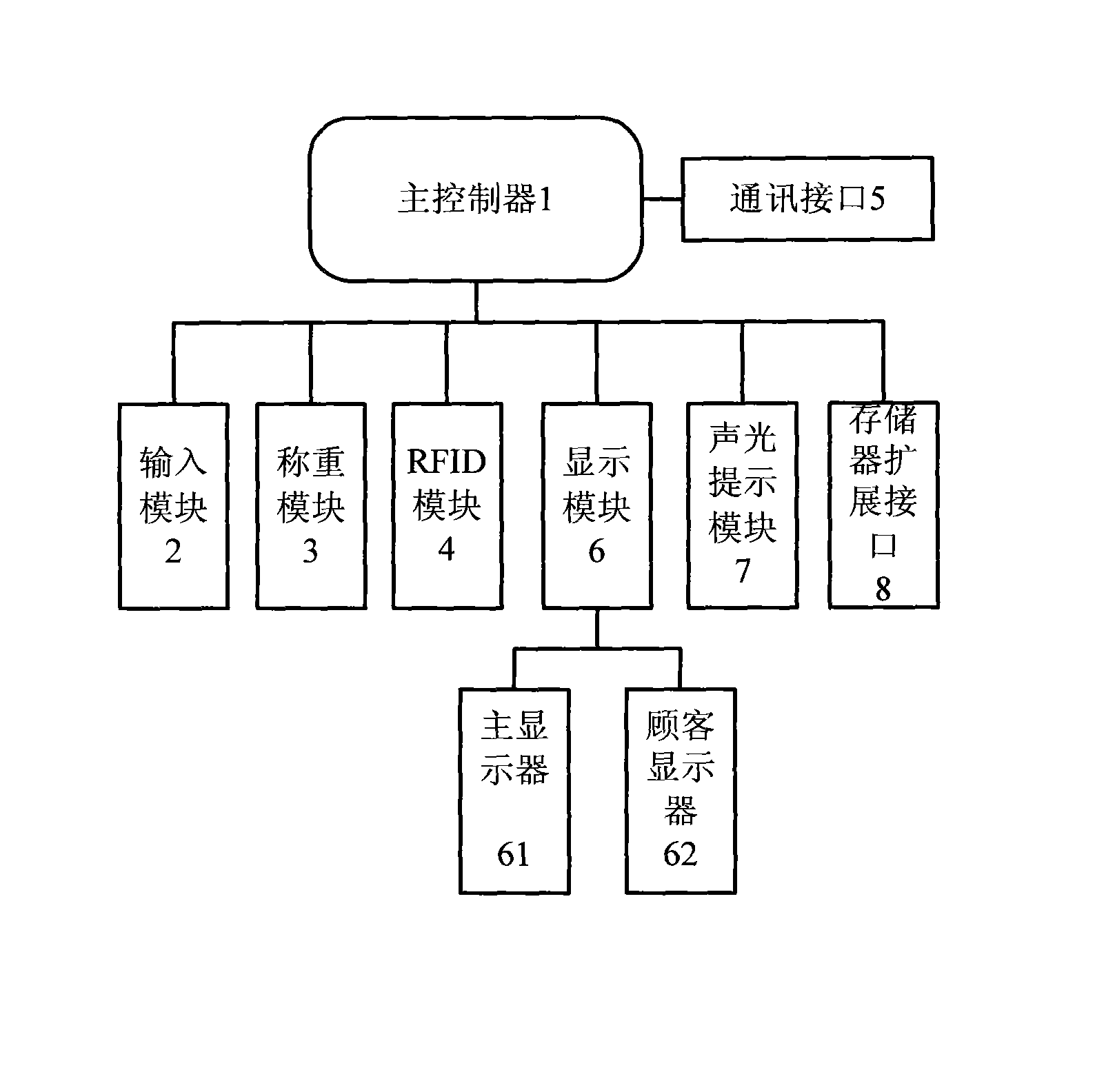

Electronic scale and working method thereof

InactiveCN101634585AEasy to operateOmit the procedure of printing and affixing barcode labelsCo-operative working arrangementsSensing record carriersData informationMaster controller

The invention discloses an electronic scale and a working method thereof. The electronic scale is used for weighing the articles with RFID tags through RFID (radio frequency identification devices) technology. The electronic scale comprises a main controller (1), an input module (2), a weighing module (3) and an RFID module (4). According to the situation that the RFID module (4) has read-only and read-write functions, the electronic scale can finish two charging modes of weighing in an online or an offline manner so that a settlement system can finish settlement quickly. The RFID electronic scale of the invention can simultaneously process a large amount of data information because the data transmitting rate of the RFID module (4) is quick; a settlement counter does not need to scan the tag of each article one by one; by using a non-contact mode, the reader-writer can quickly identify the article information in the RFID tag; so the speed of the follow-up settlement is greatly improved.

Owner:WEIHAI BEIYANG ELECTRIC GRP CO LTD BEIJING BRANCH

Method for extracting gold, silver, platinum and palladium from electronic waste

The invention relates to a method for extracting gold, silver, platinum and palladium from electronic waste and belongs to the field of resource utilization of the waste. The method comprises the following steps: gathering metals by using pretreatment, carrying out acid pickling and gathering precious metals, leaching the precious metals by using high-pressure chlorine gas, leaching gold, platinum and palladium for one step, extracting, separating and extracting gold, carrying out chemical precipitation, separating and extracting platinum and palladium, and extracting silver by using an ammoniation method. Through the method for extracting gold, silver, platinum and palladium from the electronic waste, the resource utilization of the electronic waste can be implemented; the extraction of gold, silver, platinum and palladium in the electronic waste can be implemented; the gold, silver, platinum and palladium are high in recovery rate, low in cost, short in process, few in environment hazards and low in yield of waste water and waste gas.

Owner:CHENGDU YUYA TECH

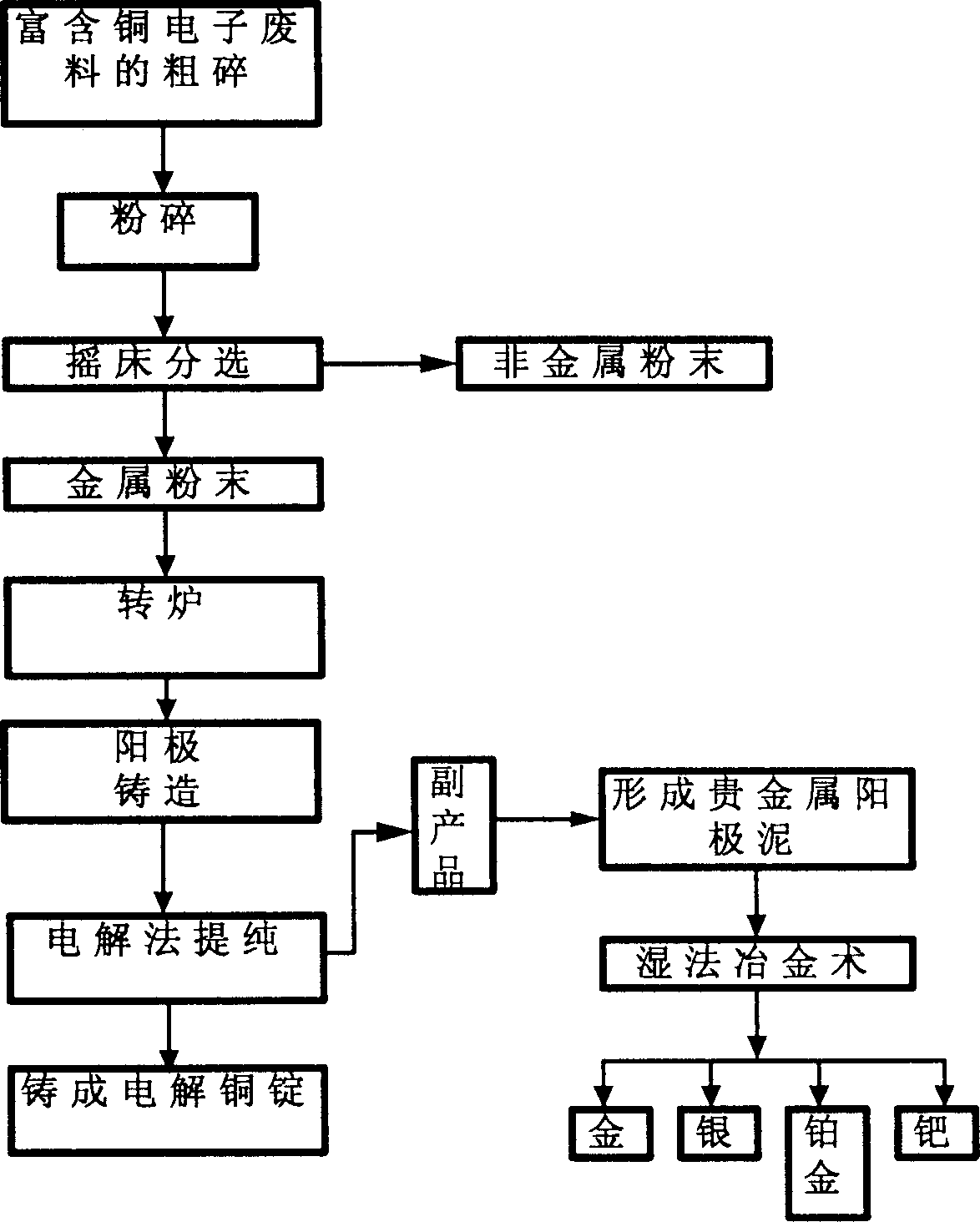

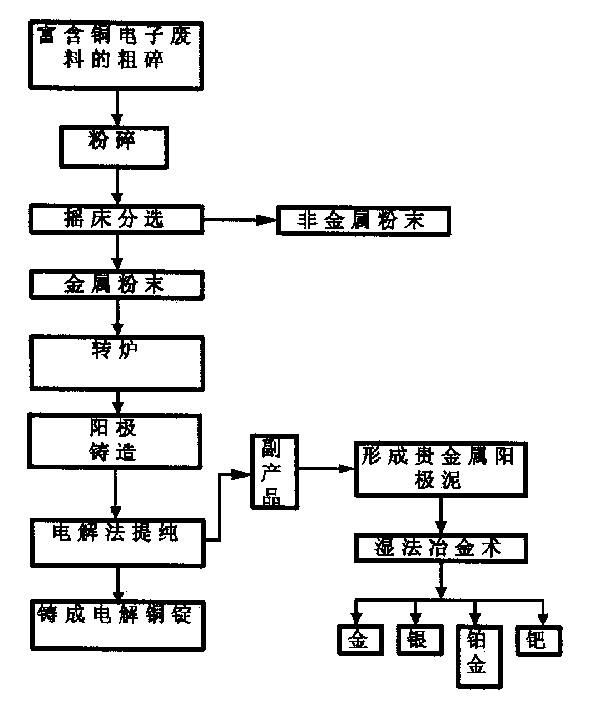

Process for recovering metal and non-metal materials from copper enriched electronic waste

InactiveCN1396281AEfficient emissionsEfficient separationSolid waste disposalMetallic materialsHydrometallurgy

A process for recovering metal and non-metal from waste electronic material richly containing copper includes such steps as spraying water on waste, crushing, pulverizing, gravitational separating in shaker with water, casting electrolytic anode with the separated metal powder, electrolyzing to extract pure co9pper, and wet metallurgy for extracting Au, Ag, Pt and Pd. Its advantages are low exhaustion of tail gas and dust, and high efficiency.

Owner:TSINGHUA UNIV

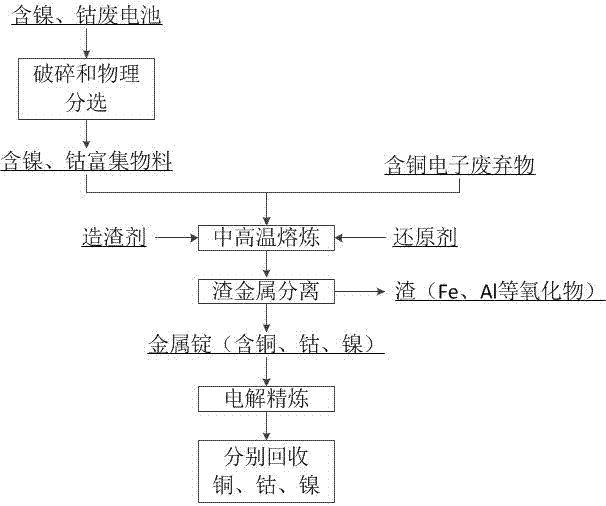

Synergetic metal recycling method for nickel and cobalt containing waste batteries and copper containing electronic waste

InactiveCN107012332AHigh purityAvoid efficiencyPhotography auxillary processesWaste accumulators reclaimingElectrolysisElectrical battery

Owner:SINO SCI PROCESS BEIJING SCI&TECH CO LTD

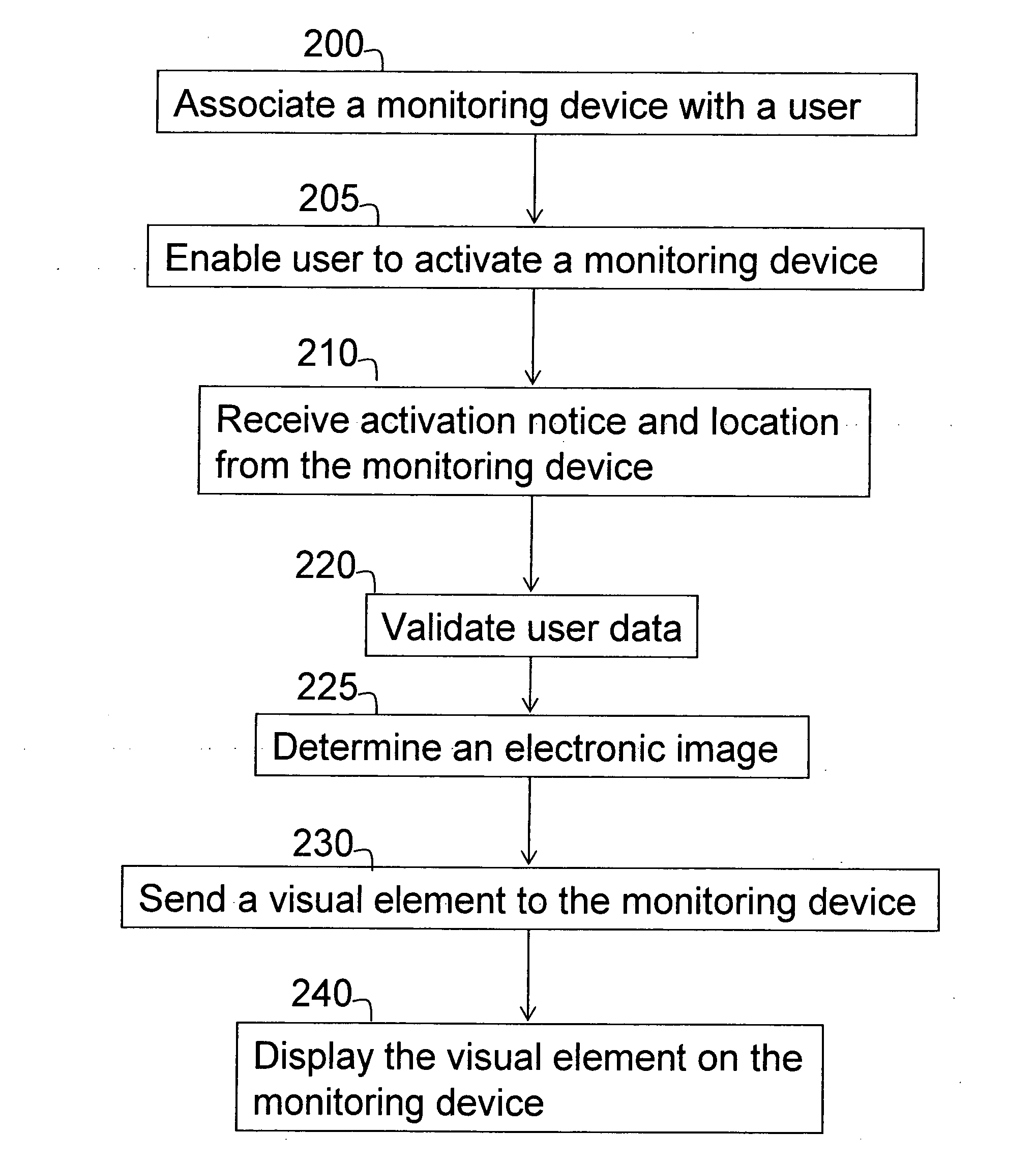

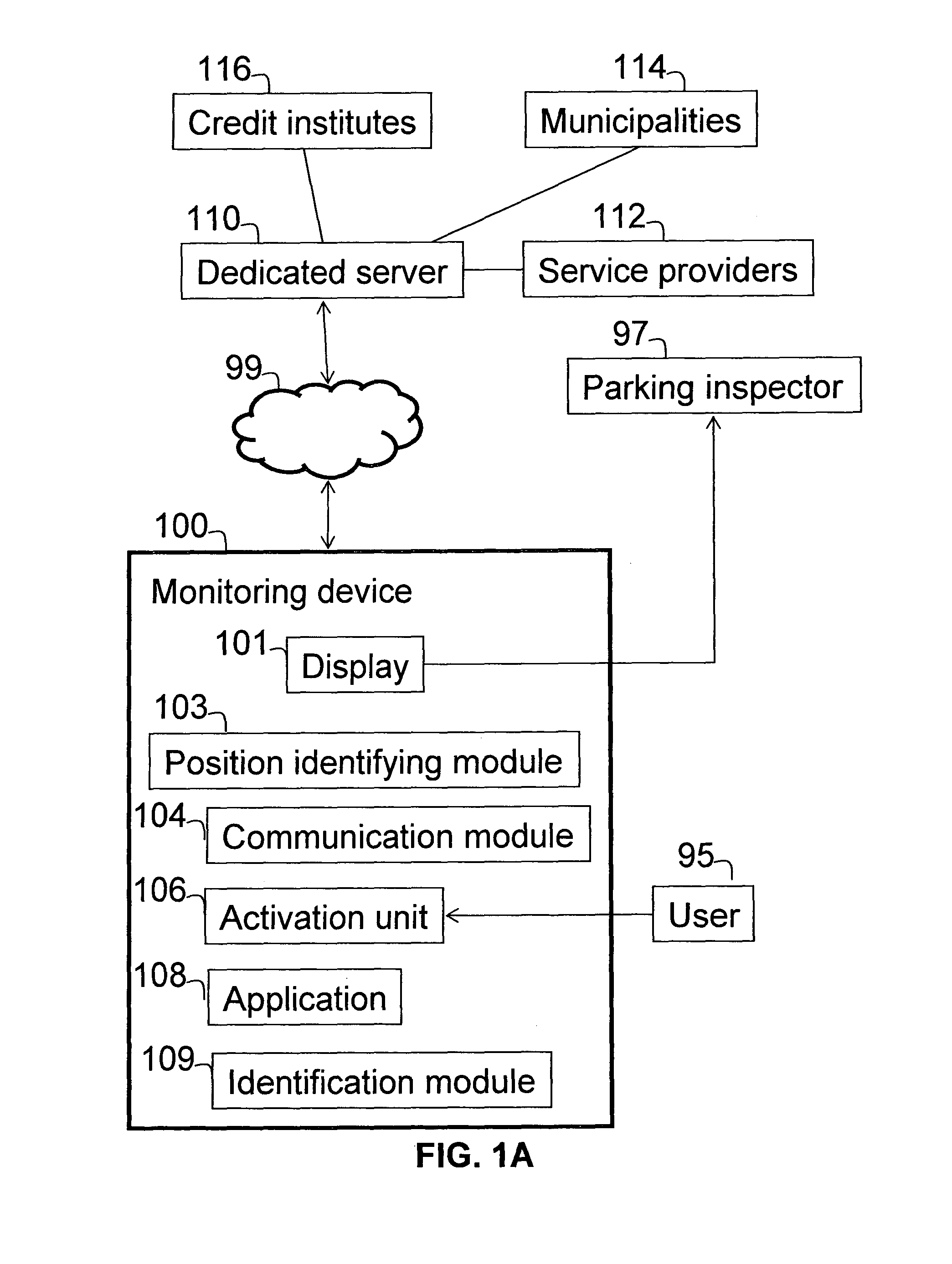

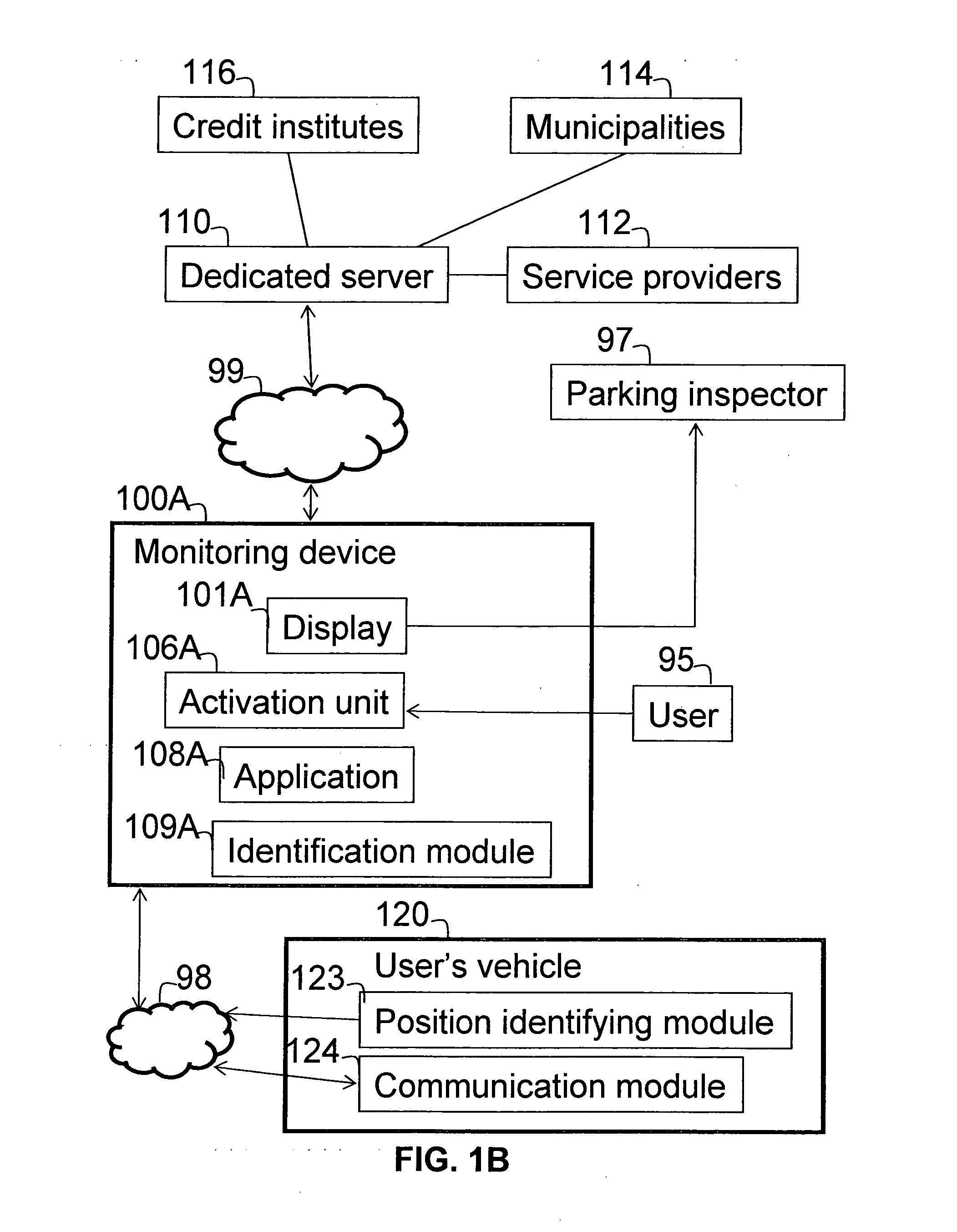

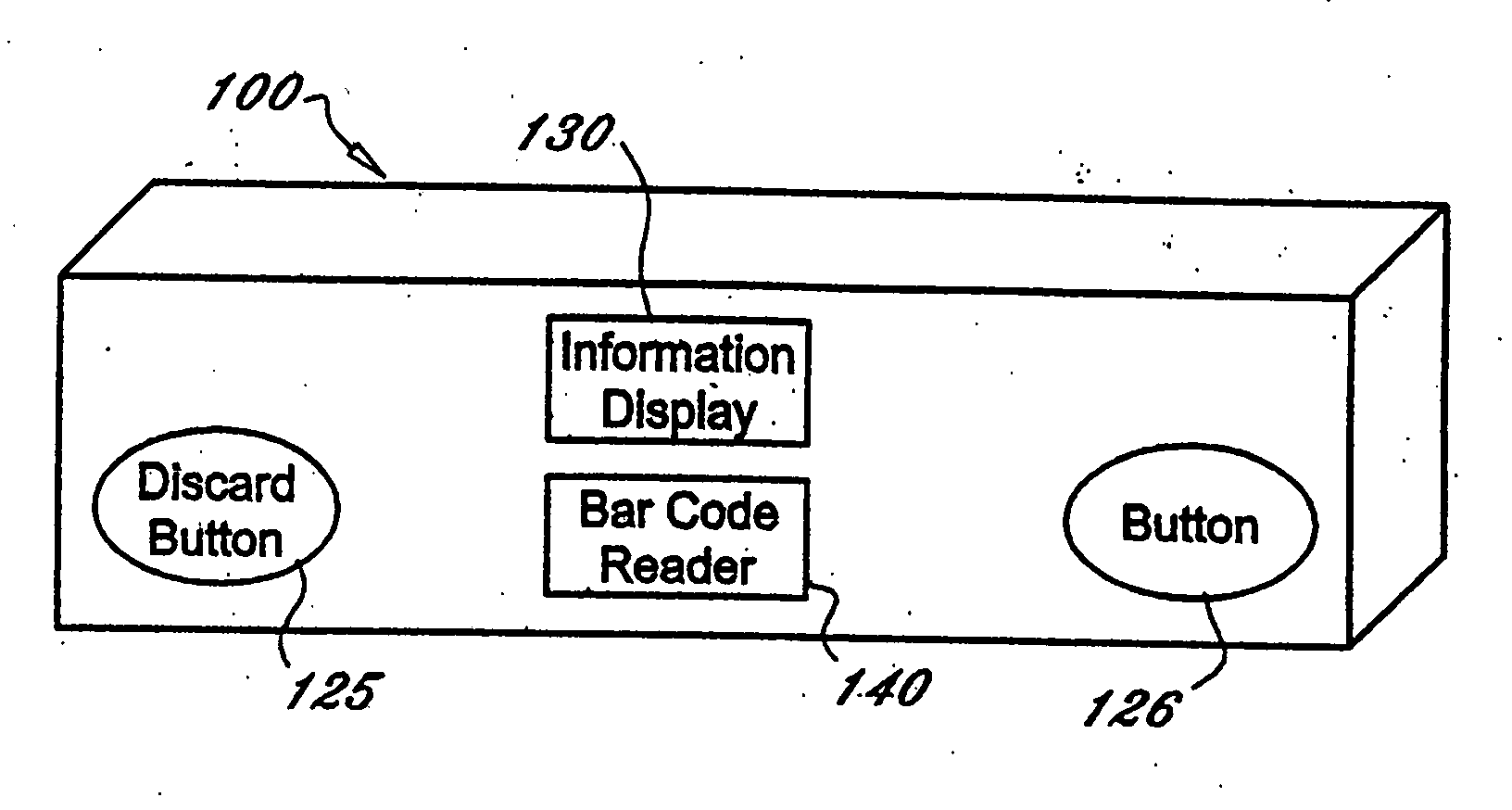

Managing Vehicle Usage

A system and method for managing vehicle usage. One system includes a monitoring device, a position identifying module, a communication module and a dedicated server. The monitoring device includes a display, an activation unit, an application and an identification module. The dedicated server is connected to the monitoring device via the communication module via a communication link The monitoring device and dedicated server are arranged to carry out the method that comprises the stages: (i) enabling a user to activate a monitoring device; (ii) receiving activation notice, user data and location from the monitoring device; (iii) validating user data; (iv) sending an electronic image to the monitoring device; and (v) displaying the electronic image on the monitoring device. The electronic image is sent upon validation of user data and in relation to the location received from the monitoring device, and authenticates vehicle usage conditions.

Owner:LESHEM YOAV

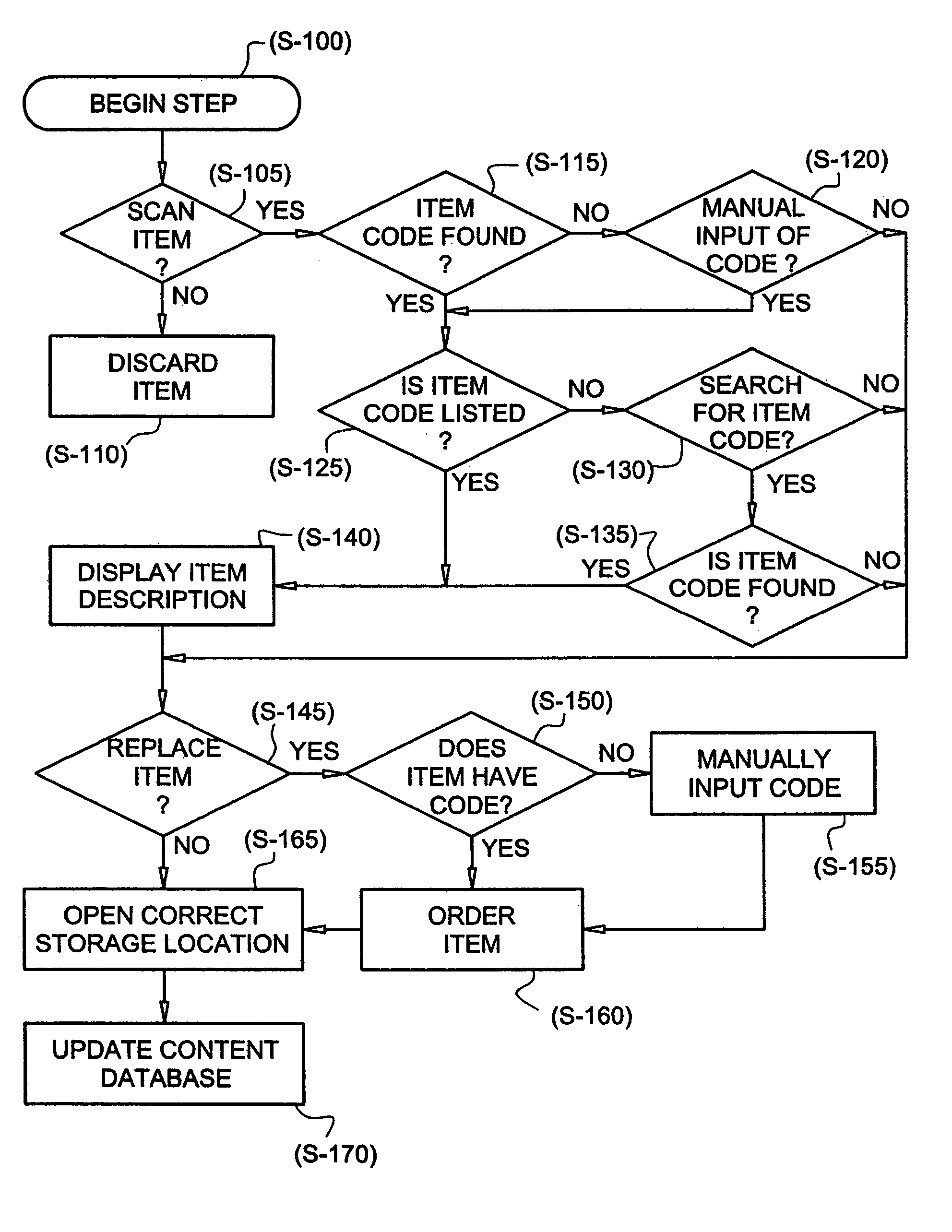

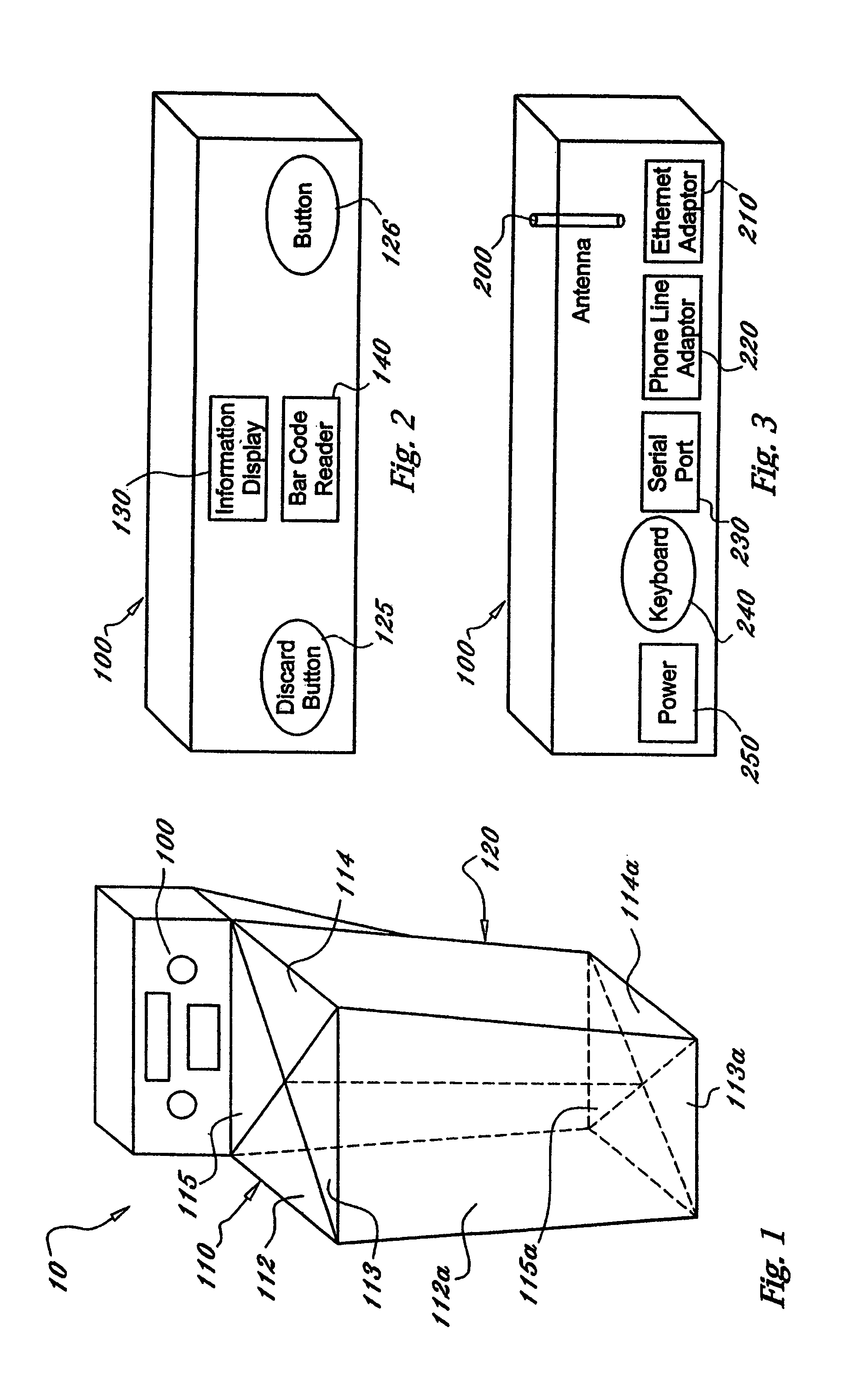

Method and system for disposing of discarded items

InactiveUS20060261165A1Waste collection and transferCharacter and pattern recognitionCentral databaseElectronic waste

An electronic trash disposal unit comprises a control unit which scans and identifies disposed items to store them in an appropriate recycling bin. The unit is connectable to a communication network which updates a central database with the contents of each unit. The unit initiates a reorder instruction to suppliers.

Owner:FRESHUB

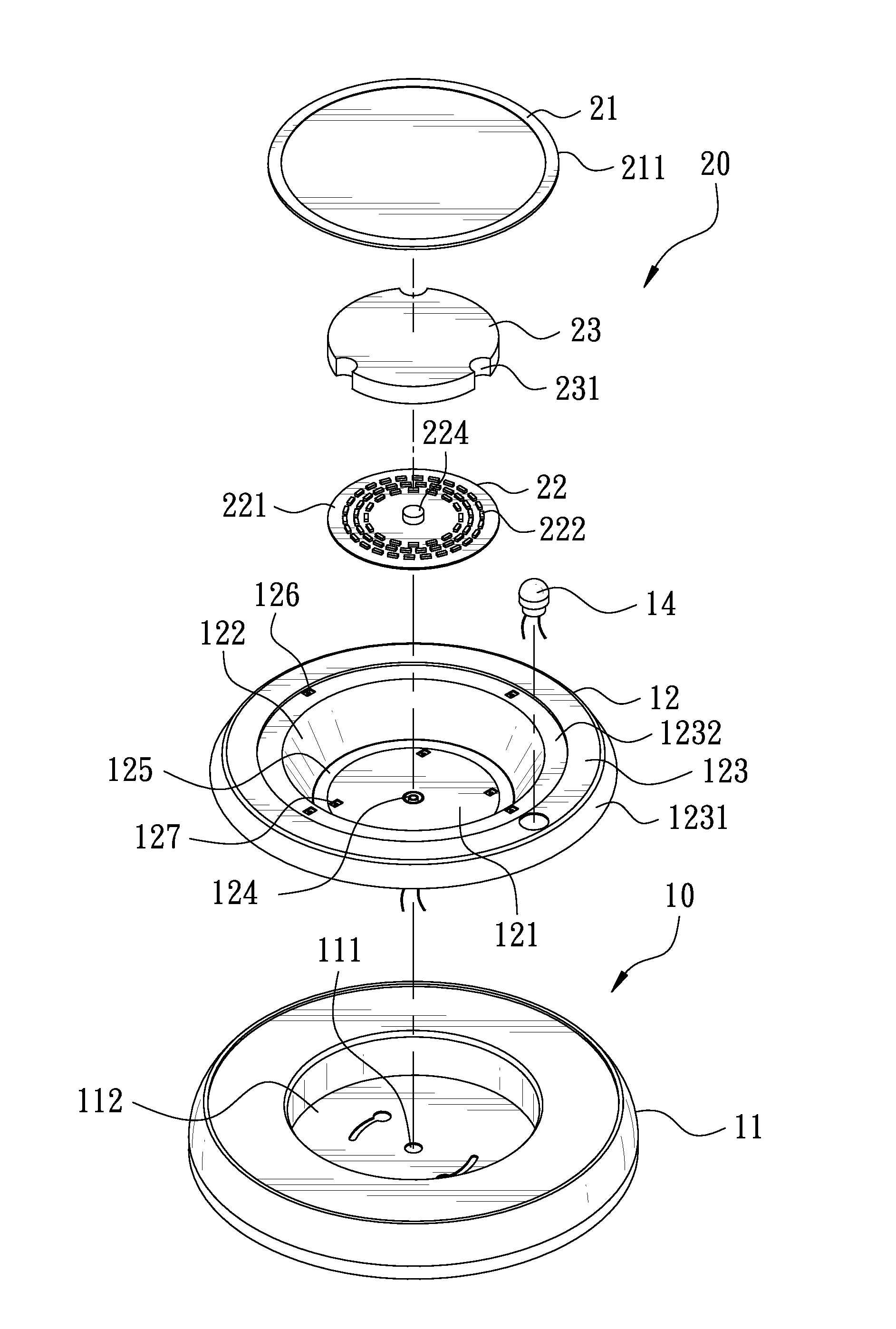

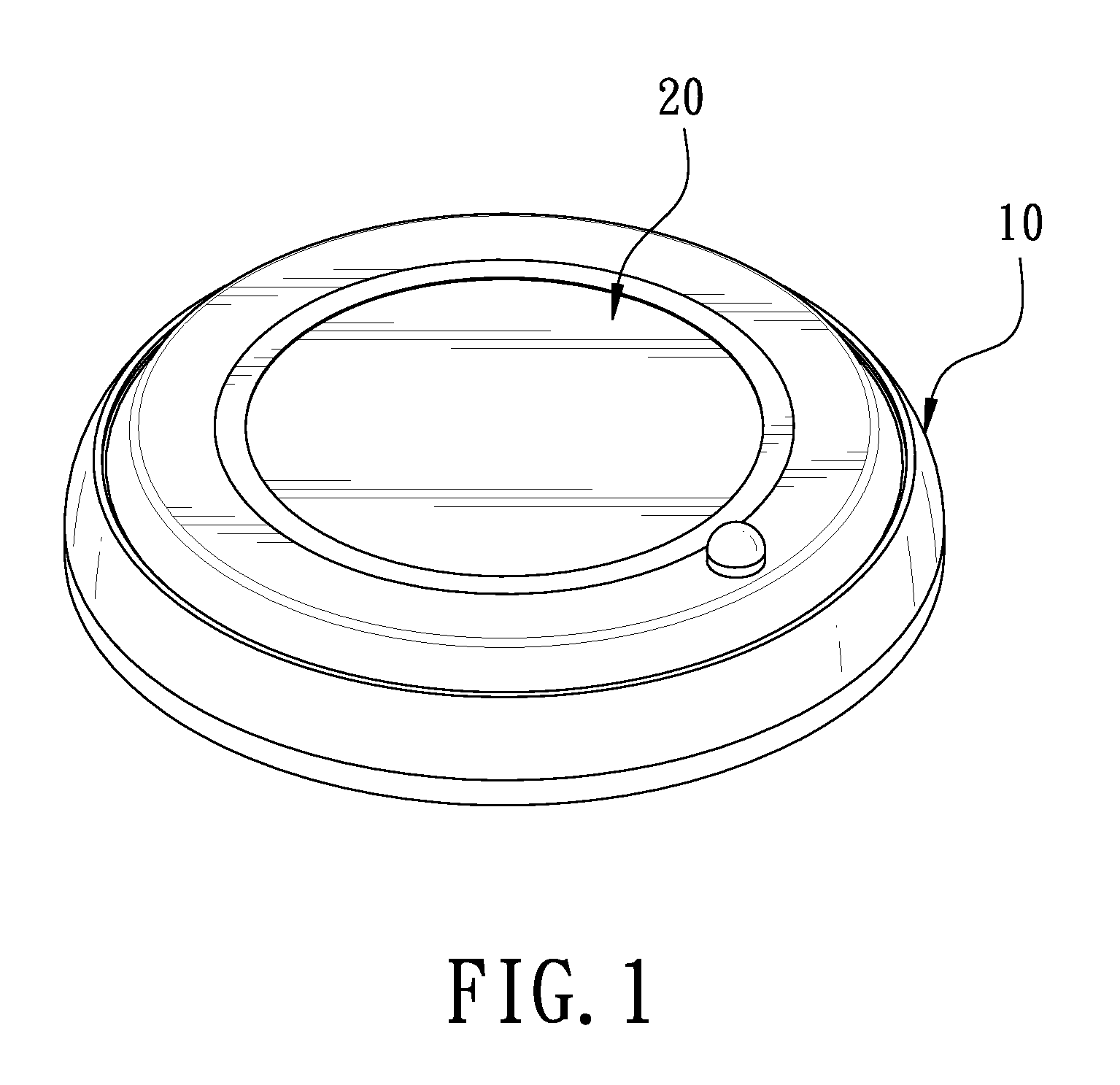

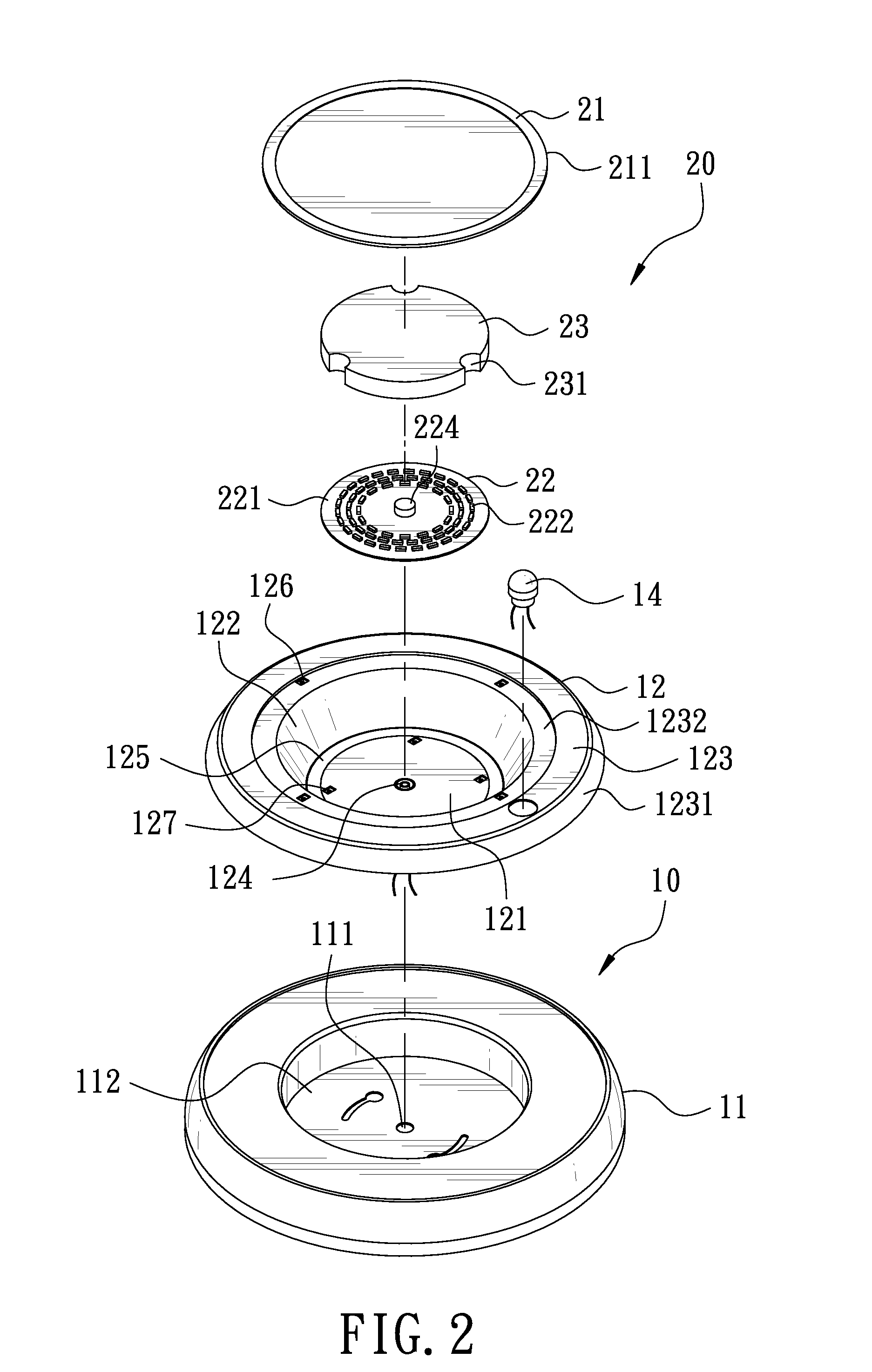

Magnetic detachable multi-functional LED lamp

InactiveUS8425082B2Convenient in assembling and disassembling and replacingPoint-like light sourceLighting support devicesEngineeringElectronic waste

A magnetic detachable multi-functional LED lamp includes a power source lamp seat and a luminous lamp unit. The power source lamp seat is provided with a plurality of magnetic units, while the luminous lamp unit is fixed with plural magnetic sucking members respectively corresponding with the magnetic units of the power source lamp seat. By so designing, the luminous lamp unit of the LED lamp can be attracted and fixed on the power source lamp seat by magnetic function of the magnetic units provided on the power source lamp seat, facilitating components of the LED lamp to be assembled, dissembled and replaced, attaining effects of energy saving and carbon reduction, lessening electronic waste and promoting green environmental protection.

Owner:CERAMATE TECH CO LTD

Method for extracting valuable metals from electronic waste

InactiveCN101575715AAdaptableMinor metal recoveryPhotography auxillary processesProcess efficiency improvementPregnant leach solutionSelective leaching

The invention discloses a method for extracting valuable metals from electronic waste. The method comprises the following concrete steps: smashing; oxidant ammoniac leaching; separating organic components; purifying leaching solution and electrodepositing to obtain the final products of organic granules, gold / silver / palladium powder and cathode copper, more concretely, the method comprises the following steps: carrying out the selective leaching on the smashed electronic waste by an oxidant ammoniac system; separating the organic granules on the basis of the characteristic that the organic components in the smashed electronic waste float on the surface layer of the leaching solution, for the density of the organic components is lower, whereas the valuable metals, such as Au, Ag, Pd, Cu, Ni, Cd, Zn and Pb, enter the solution; then, extracting the valuable metals of Au, Ag and Pd from the leaching solution by replacement; and finally obtaining the electrodeposit copper by the electro-deposition method, and extracting the metals of Ni, Pb, Zn and Cd from the electrolyte by the open-circuit method after the enrichment of the electrolyte. The invention has the outstanding advantages of high material adaptability, high metal recovery rate and low environmental pollution, and achieves the balance between the environmental benefit and the economic benefit.

Owner:CENT SOUTH UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com