Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

759 results about "Ferrous" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry, the adjective ferrous indicates a compound that contains iron in the +2 oxidation state, possibly as the divalent cation Fe²⁺. It is opposed to "ferric", which indicates presence of iron in a +3 oxidation state, such as the trivalent cation Fe³⁺. This usage has been largely replaced by the IUPAC nomenclature, which calls for the oxidation state being indicated by Roman numerals in parentheses, such as iron(II) oxide for ferrous oxide (FeO), iron(III) oxide for ferric oxide (Fe₂O₃), and iron(II,III) oxide for the oxide Fe3O4 that contains both forms of iron.

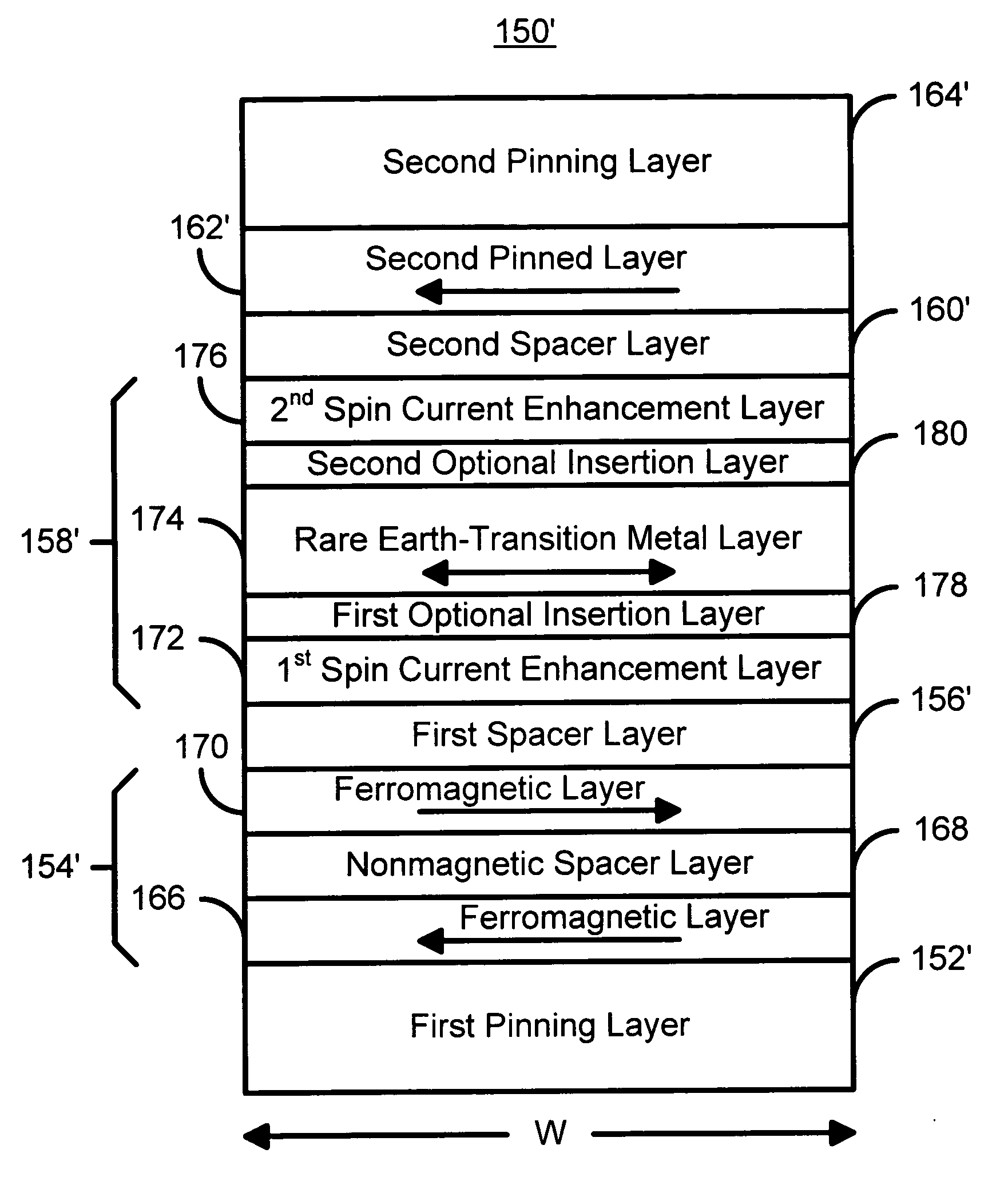

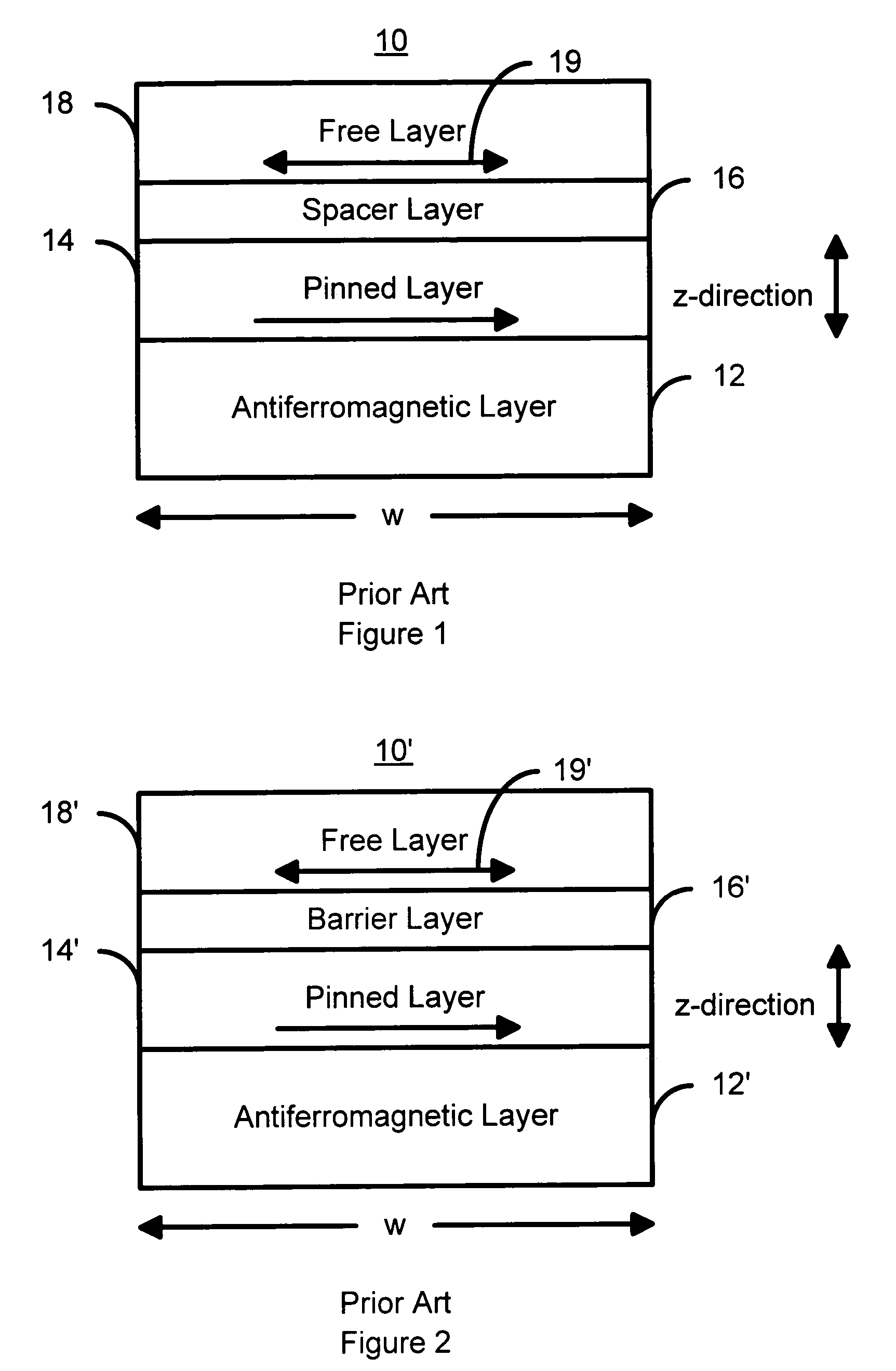

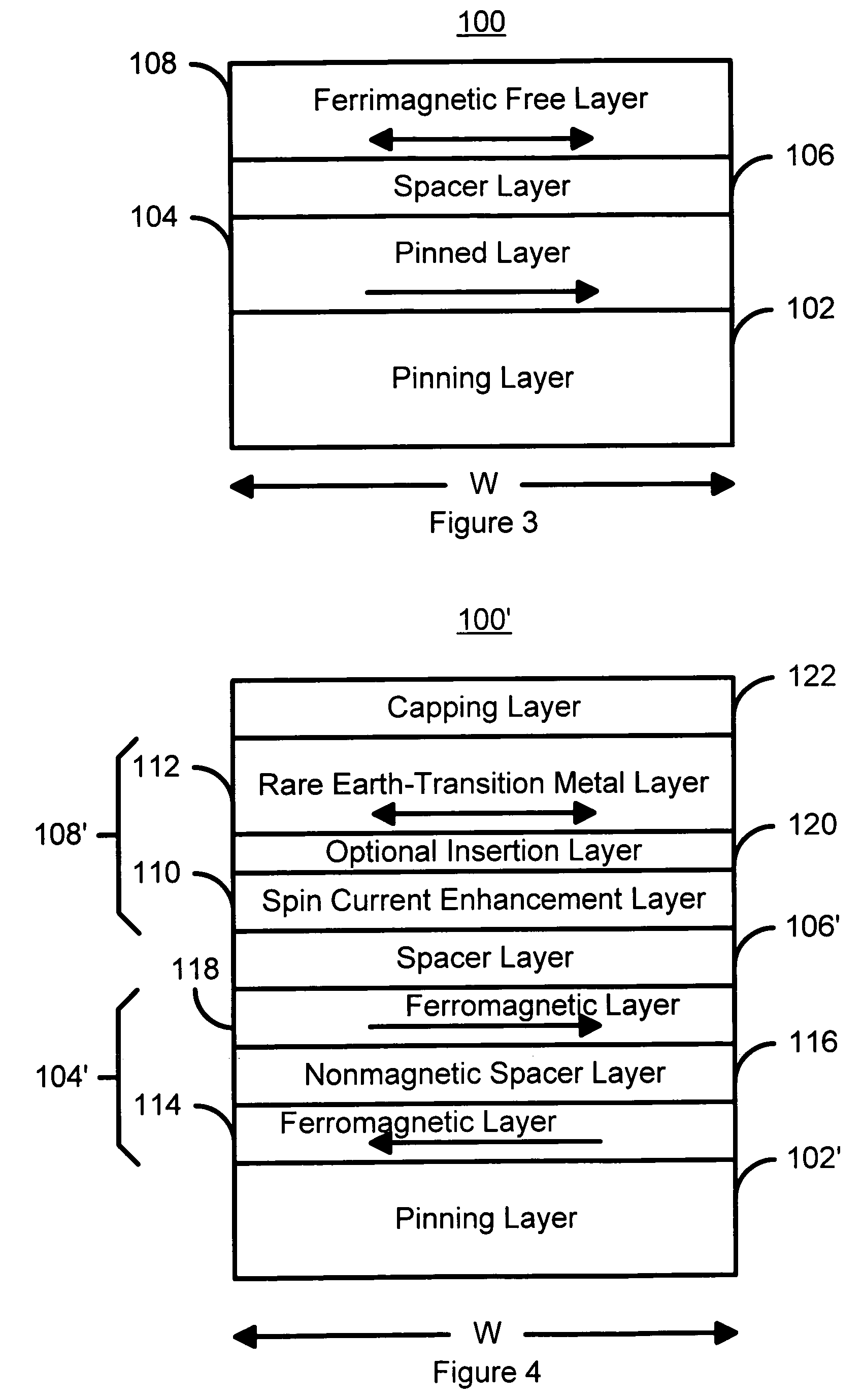

Spin-transfer switching magnetic elements using ferrimagnets and magnetic memories using the magnetic elements

Owner:SAMSUNG SEMICON

Preparation of iron-managanese compounded oxide/diatomite adsorbant, its using and regenerating method

ActiveCN101024160AImprove adsorption capacityGood arsenic removal effectOther chemical processesWater/sewage treatment by sorptionSorbentManganese oxide

The invention supplies a new type adsorbent--mixed oxide of iron and manganese / diatomite preparation, use and regeneration method, belongs to the treatment of technology. The method used the soluble ferrous permanganate and salt as raw materials, respectively prepared the solutions, after adequate lye into permanganate solution, mixed two salt solutions, by adding diatomite particles, full oscillation, standing aging, neutralize, washing and drying to get the manganese oxide / silicon algae absorbent. The adsorbent is larger than the surface area and good adsorption properties can be used to remove arsenic in water pollutants (especially tervalence arsenic), and the adsorption surface activity of the saturated absorption of pollutants can be directly passed to load manganese oxide compound to regeneration.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

High temperature glass fiber insulation

Owner:GLASS

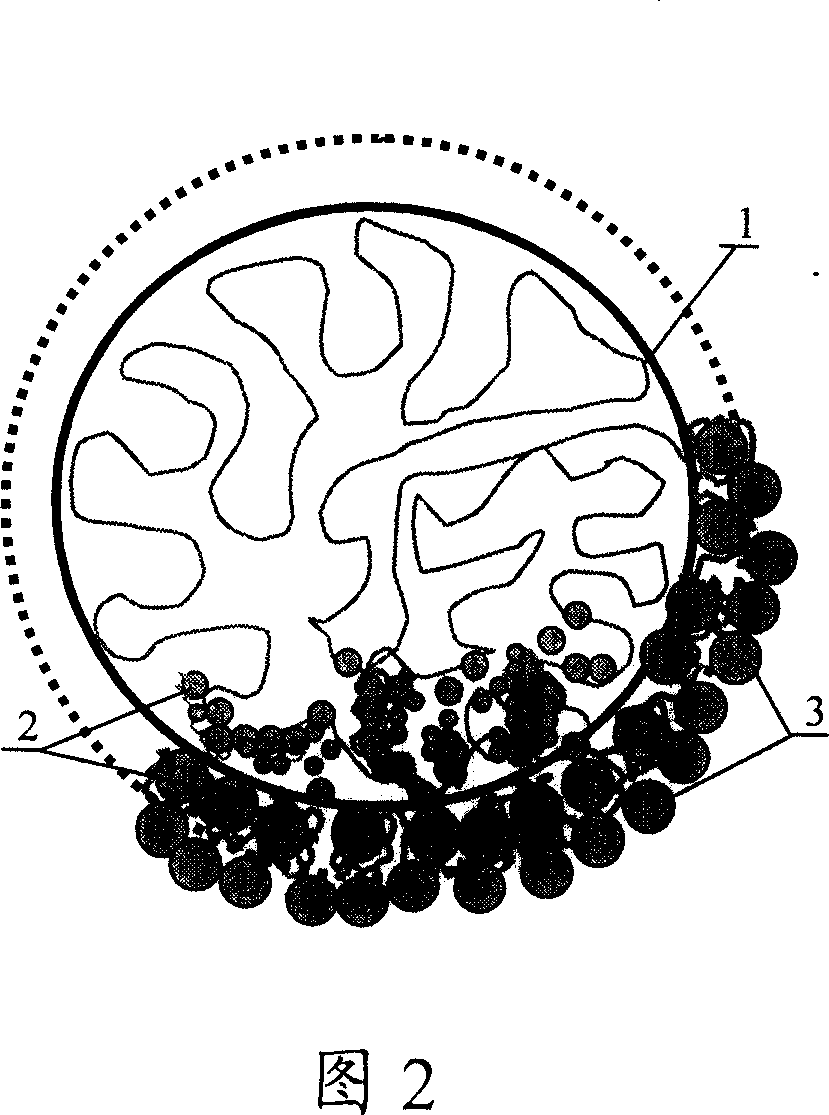

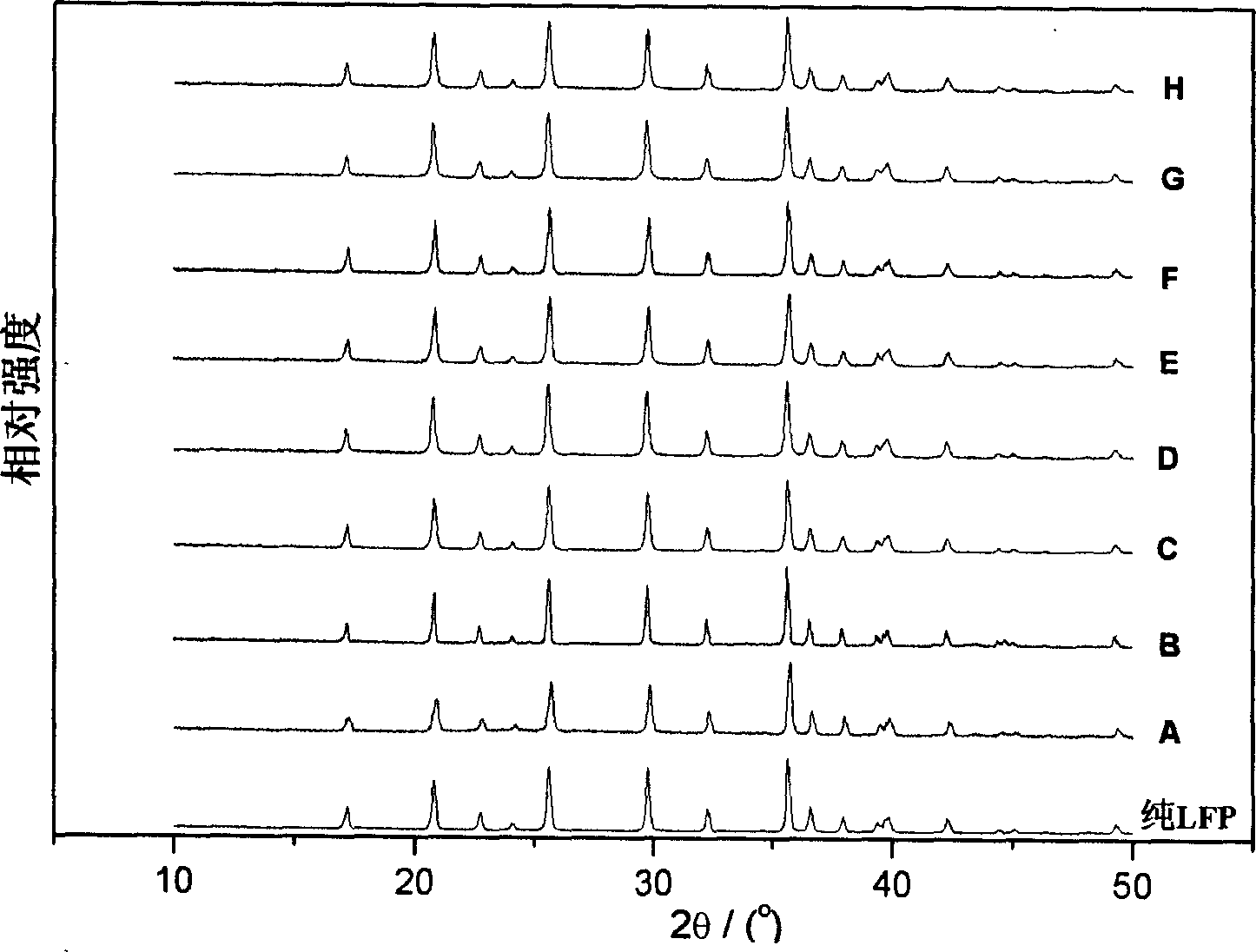

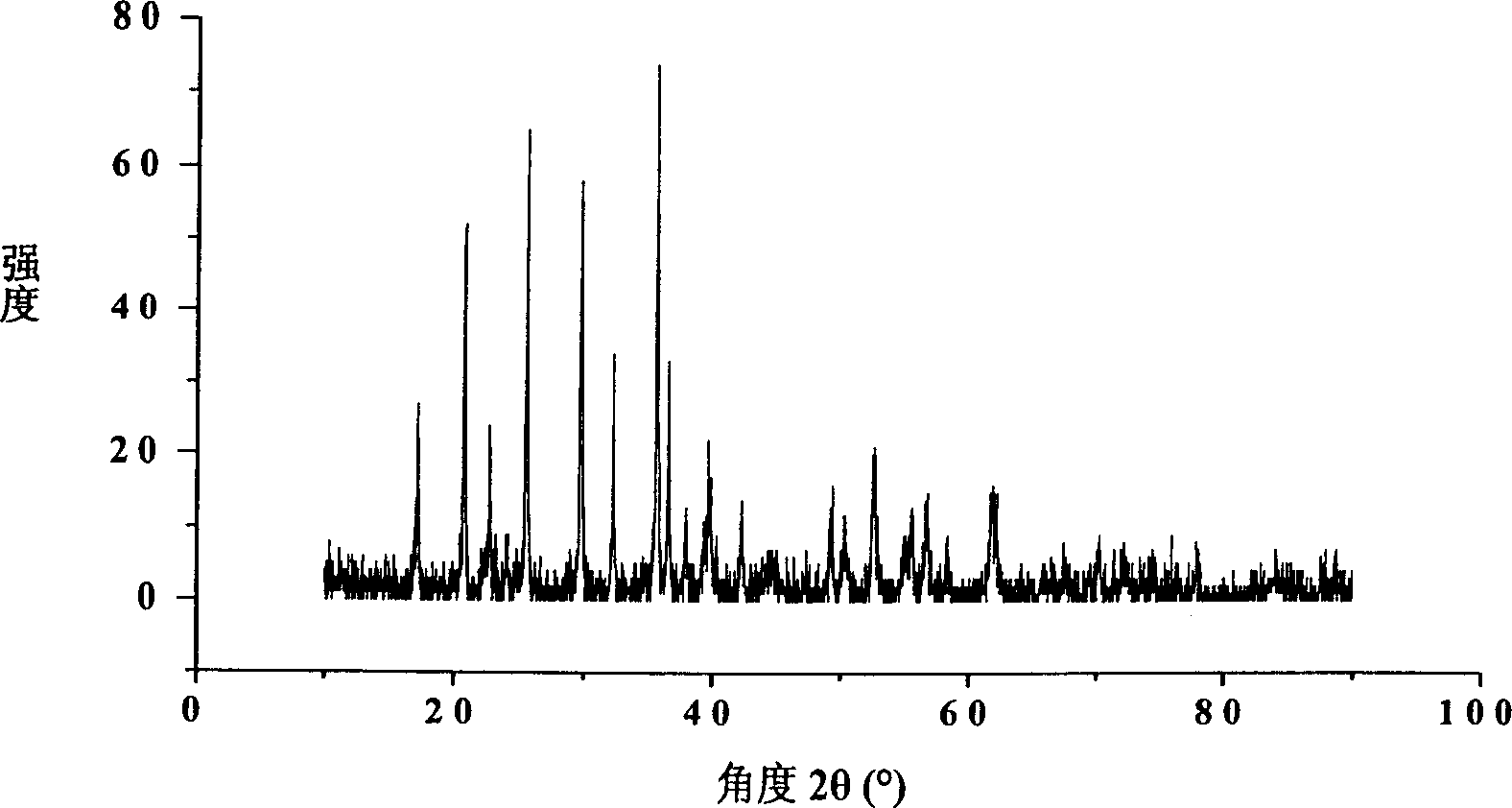

Prepn process of oxygen place doped lithium ferric phosphate powder

InactiveCN1772604AIncrease base capacityImprove cycle electrical performanceCell electrodesPhosphorus compoundsDopantLithium iron phosphate

The present invention belongs to the field of electrochemical power source material preparing technology, and is especially preparation process of oxygen place doped lithium ferric phosphate powder. The oxygen place doped lithium ferric phosphate as positive pole material in lithium ion cell has the molecular expression LiFeP(MxO4-x), and is prepared through mixing the dopant and the mother body material and sintering the mixture, or through solid phase reaction of the dopant and the mother body material. The preparation process has effective doping in the oxygen place of mother body material and the prepared material can raise the capacity and the circular discharge performance of the cell effectively and thus can find its wide application as positive pole material in secondary lithium ion cell and power cell.

Owner:TSINGHUA UNIV

Vacuum insulating glass unit including infrared meltable glass frit, and/or method of making the same

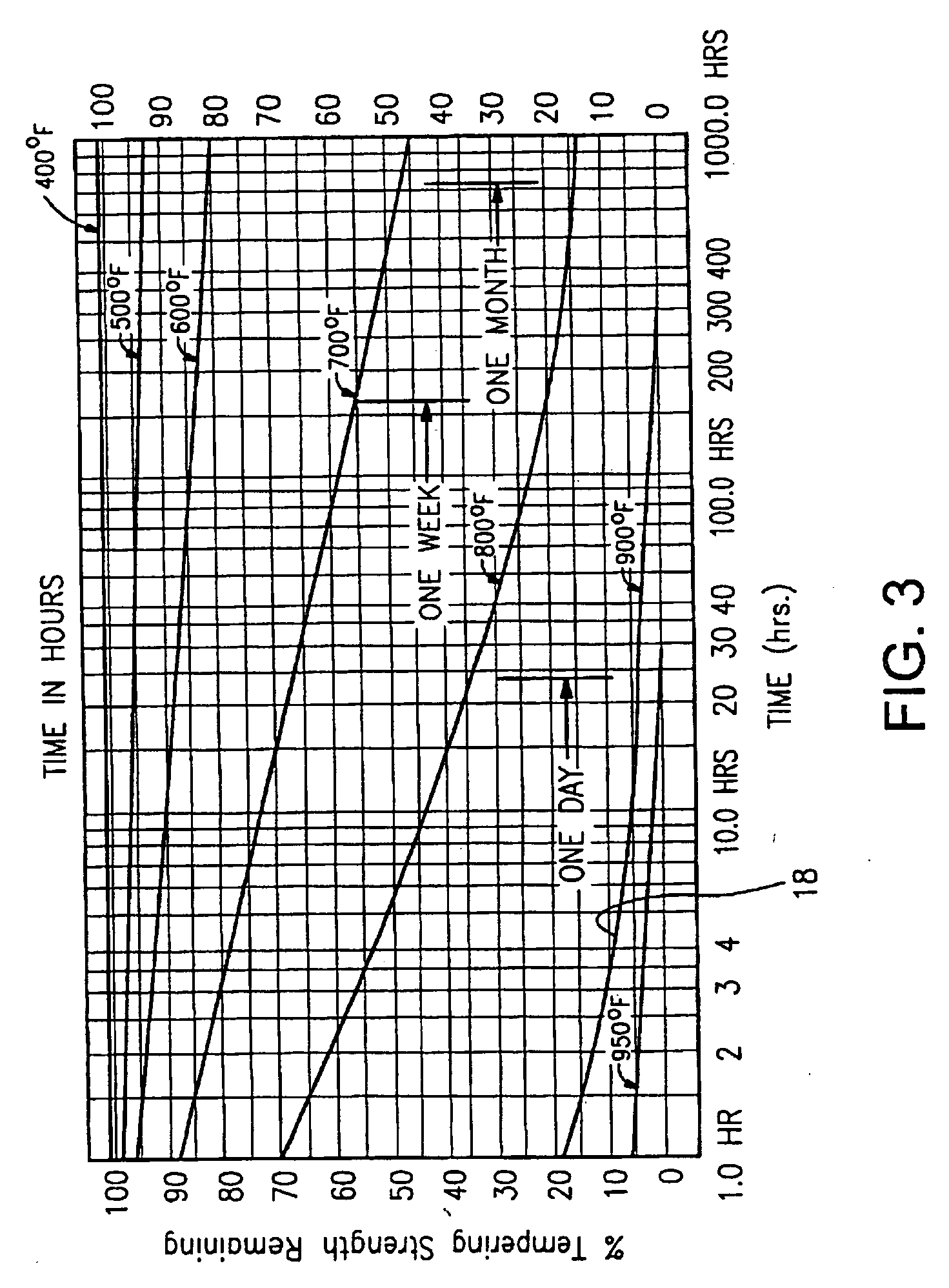

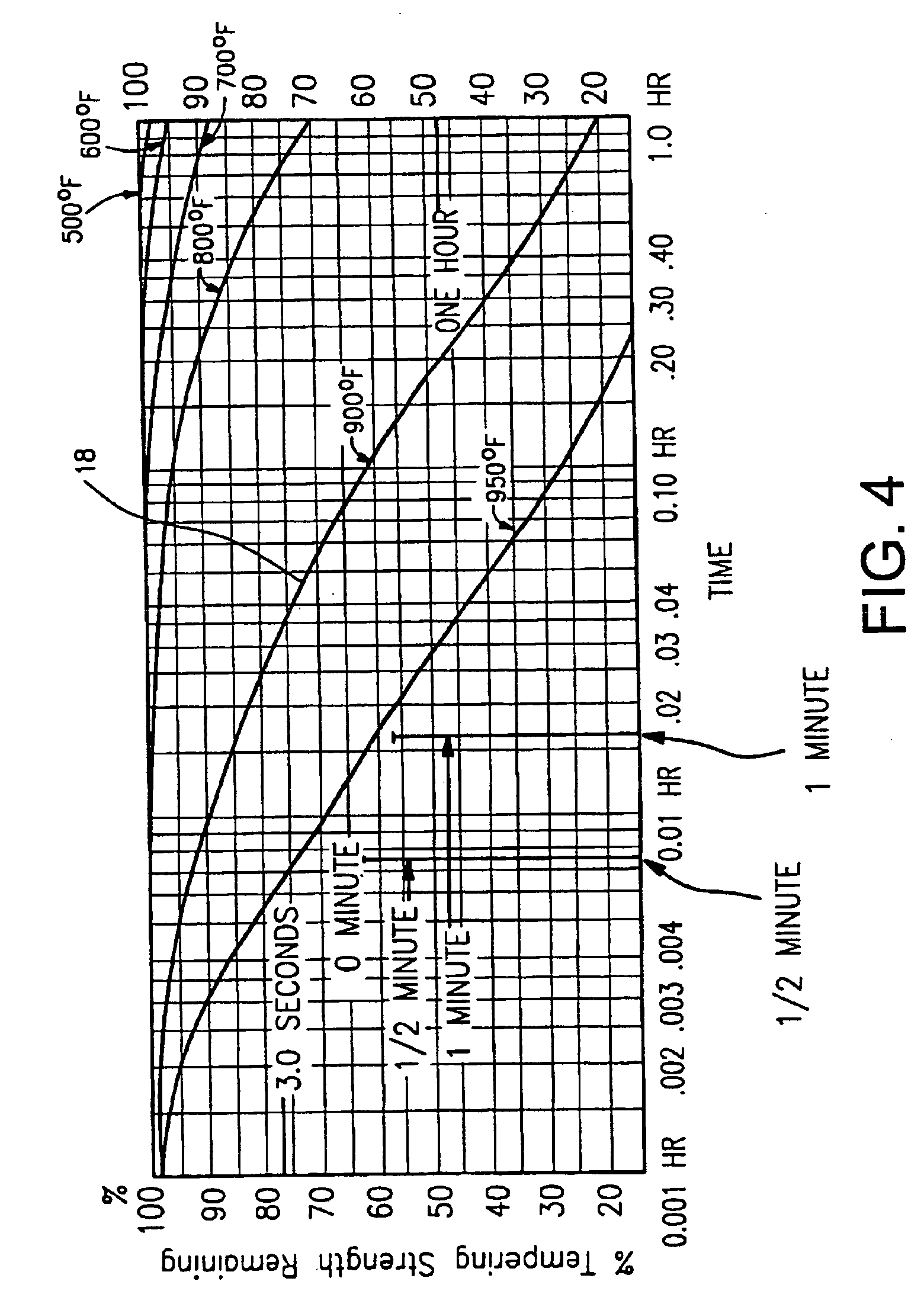

ActiveUS20100275654A1Reduce the temperatureAccelerate breakageDoors/windowsGlass furnace apparatusFritOxidation-Reduction Agent

Certain example embodiments of this invention relate to vacuum insulating glass (VIG) units including infrared meltable glass frits, and / or methods of making the same. More particularly, certain example embodiments relate to increasing the amount of ferrous oxide in glass frits (e.g., lead-free glass frits) used to form edge seals such that the glass frits absorb an increased amount of IR energy. The techniques of certain example embodiments make it possible to expose some or all of the VIG intermediate assembly to infrared source(s), since the glass frit will heat up faster than the substrates thereby reducing the likelihood of the first and / or second substrate melting and losing heat treatment strength. In certain example embodiments, the frit's glass redox (FeO / Fe2O3) preferably is at least about 0.02 higher than either (or the higher) of the substrates' glass redox (FeO / Fe2O3), more preferably at least about 0.04 higher, and most preferably at least about 0.06 higher.

Owner:GUARDIAN GLASS LLC

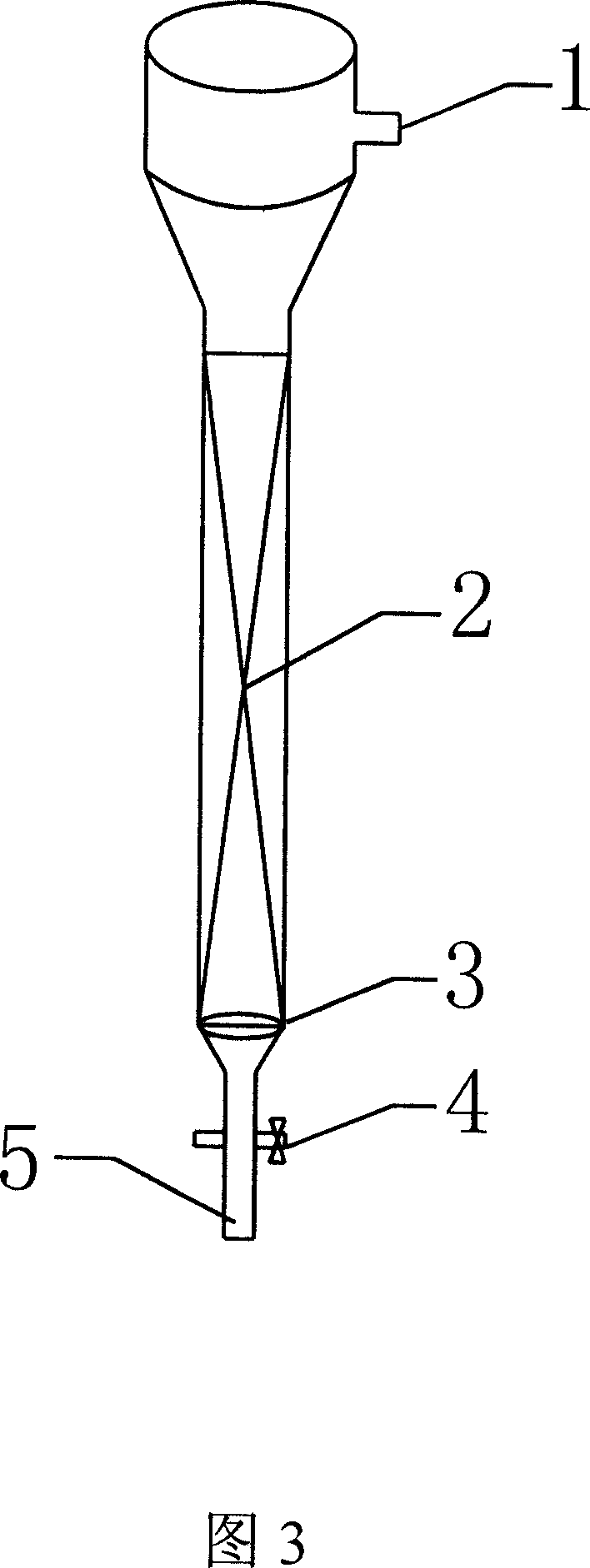

Method for preparing carbon coated lithium ferrous phosphate composite material including metal conductive agent

InactiveCN1649189AImprove electronic conductivityImprove protectionElectrode manufacturing processesPhosphatePhosphoric acid

This invention relates to a preparation method for LiFe PO4 / M / C compound positive material, the precursor of Li-Fe-PO4-M is synthesized with Li salt, Fe compound, phosphate, silver salt and organic acid as the raw materials by the sol-coagel method. Then the precursor mixed with pyrogenic-decomposed in inert atmosphere to get LiFePO4 / M / C compound positive material.

Owner:ZHEJIANG UNIV

Glass compositions

Improved glass fibers compositions, typically useful for fire resistant blankets or containers to provide high burn-through resistance at high temperatures of 2,400° F. and higher, and typically comprising silica, sodium oxide, potassium oxide, calcium oxide, magnesium oxide, ferrous+ferric oxide, and titanium oxide; the improved glass compositions may further include alumina, lithium oxide, and boron oxide.

Owner:GLASS

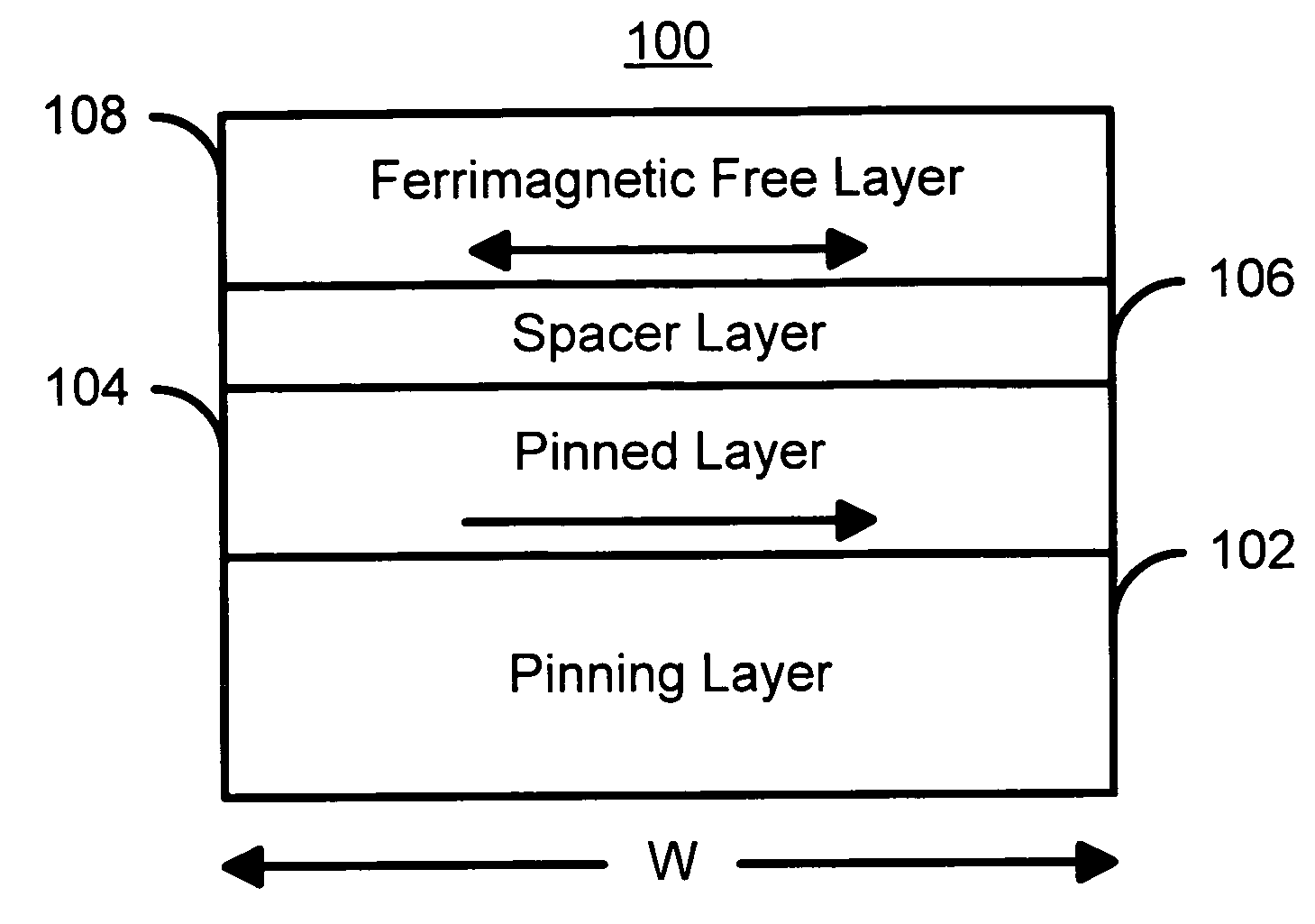

Spin-transfer switching magnetic elements using ferrimagnets and magnetic memories using the magnetic elements

A method and system for providing a magnetic element are disclosed. The method and system include providing a pinned layer, providing a spacer layer, and providing a free layer. The free layer is ferrimagnetic and includes at least one of a conductive ferrite, a garnet, a ferrimagnetic alloy excluding a rare earth, a heavy rare-earth-transition metal alloy, a half-metallic ferrimagnetic, and a bilayer. The bilayer includes a rare earth-transition metal alloy layer and a spin current enhancement layer. The magnetic element is configured to allow the free layer to be switched due to spin transfer when a write current is passed through the magnetic element.

Owner:SAMSUNG SEMICON

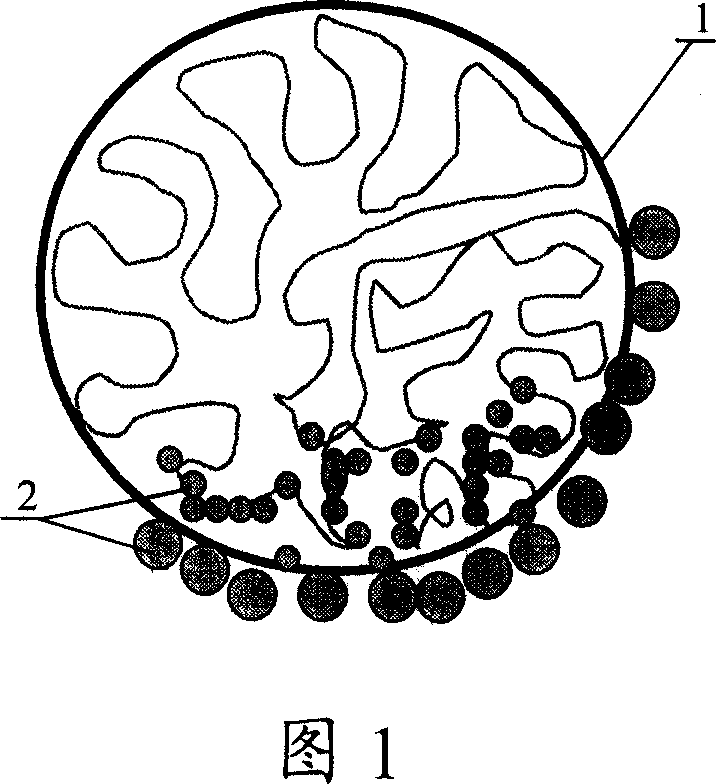

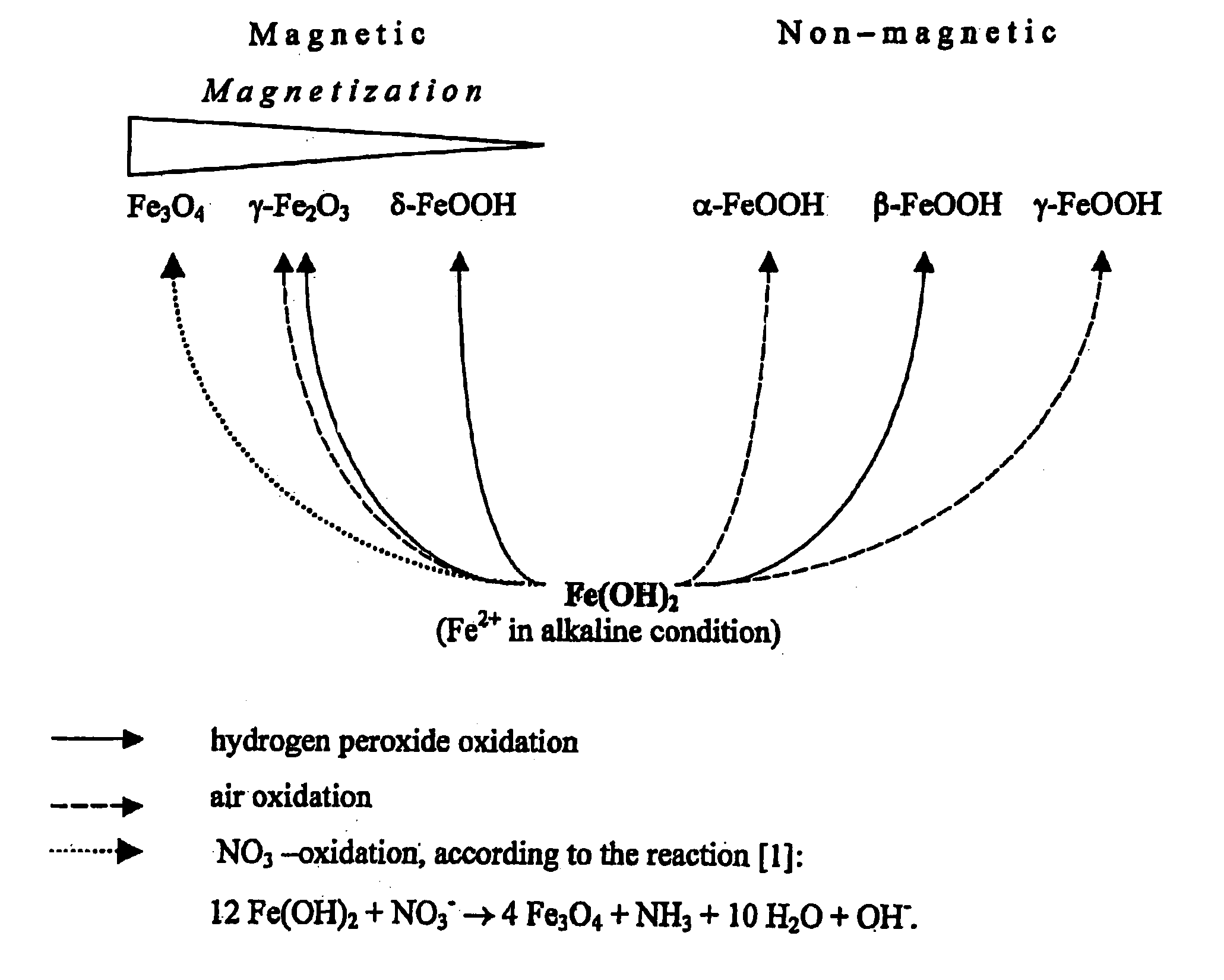

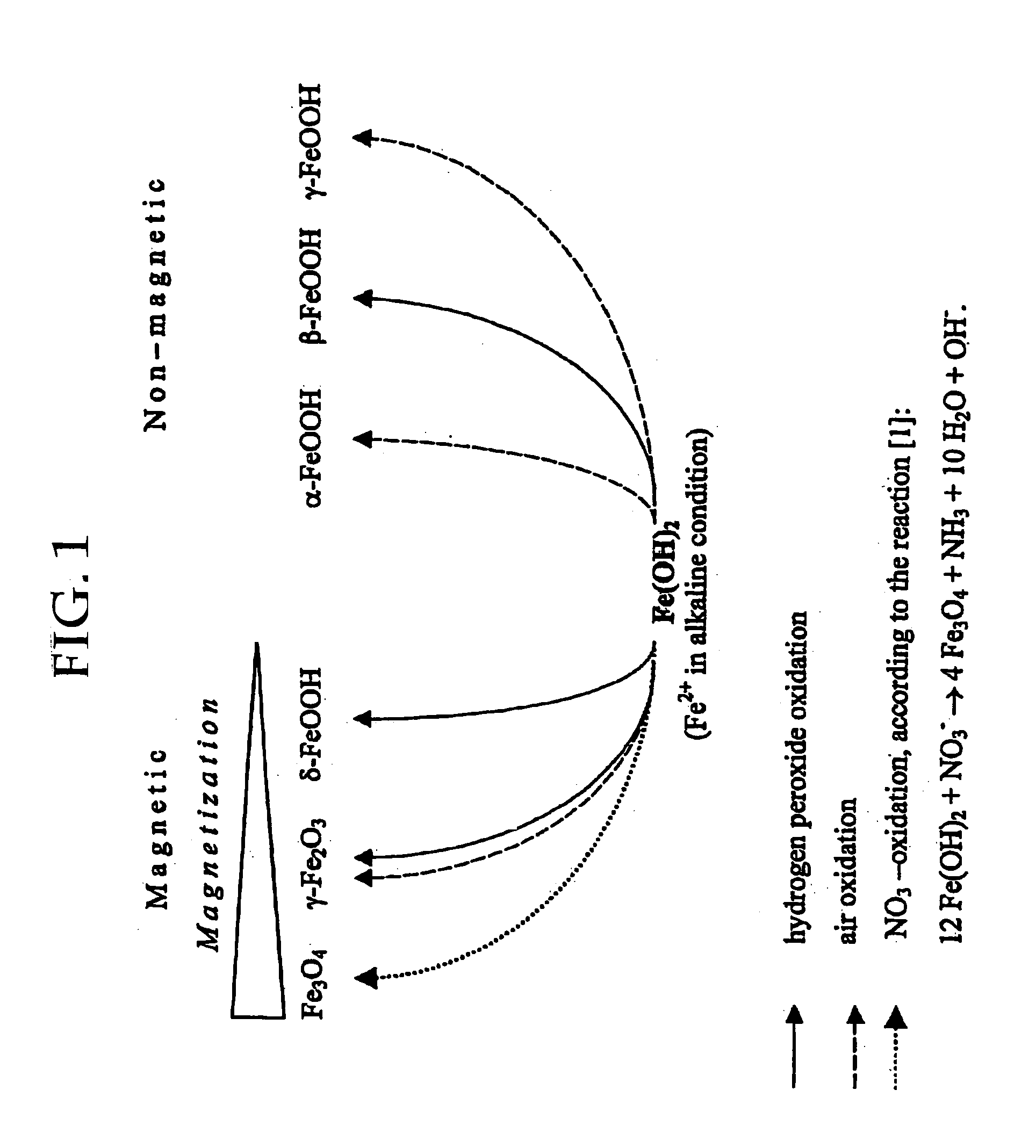

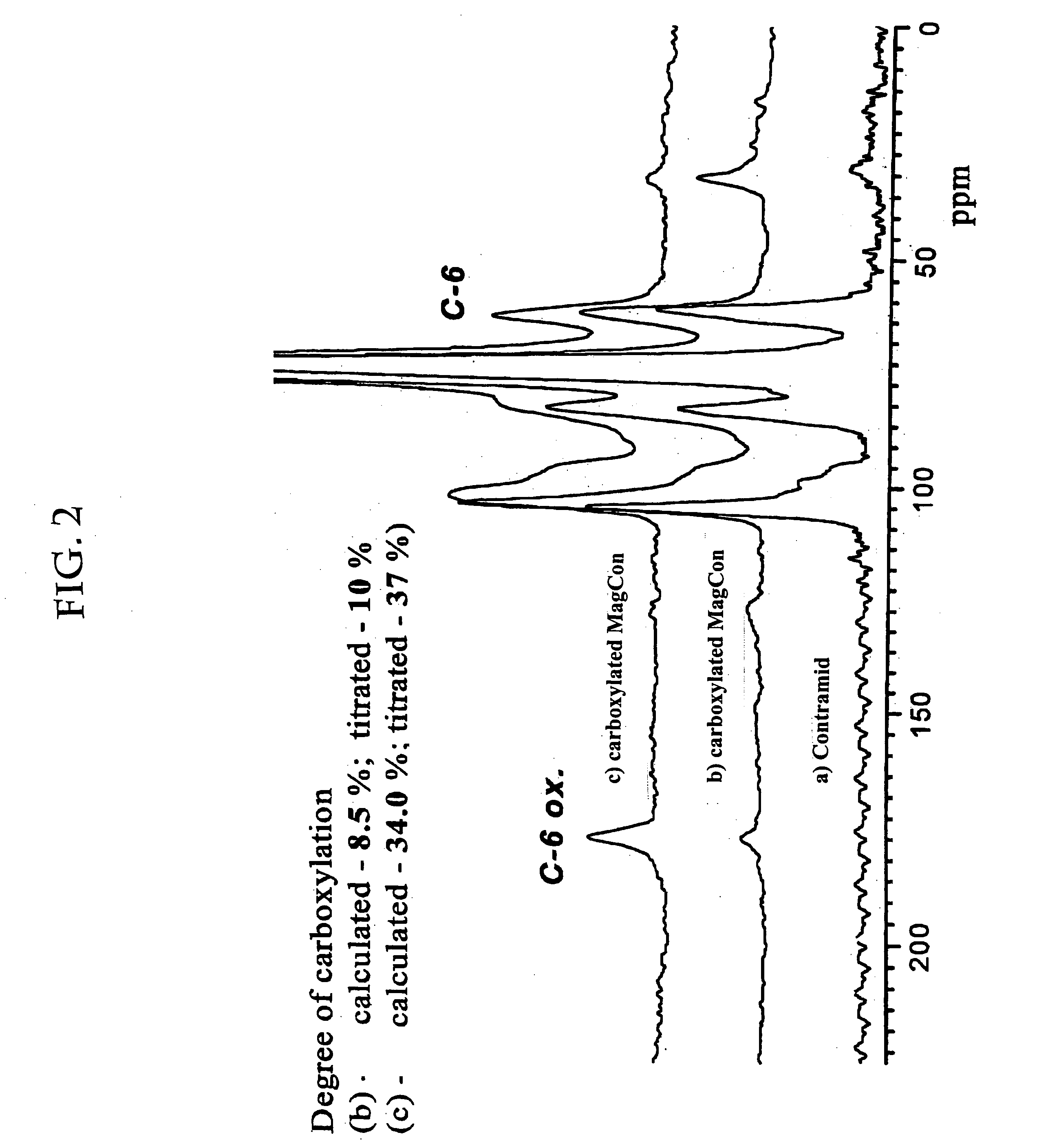

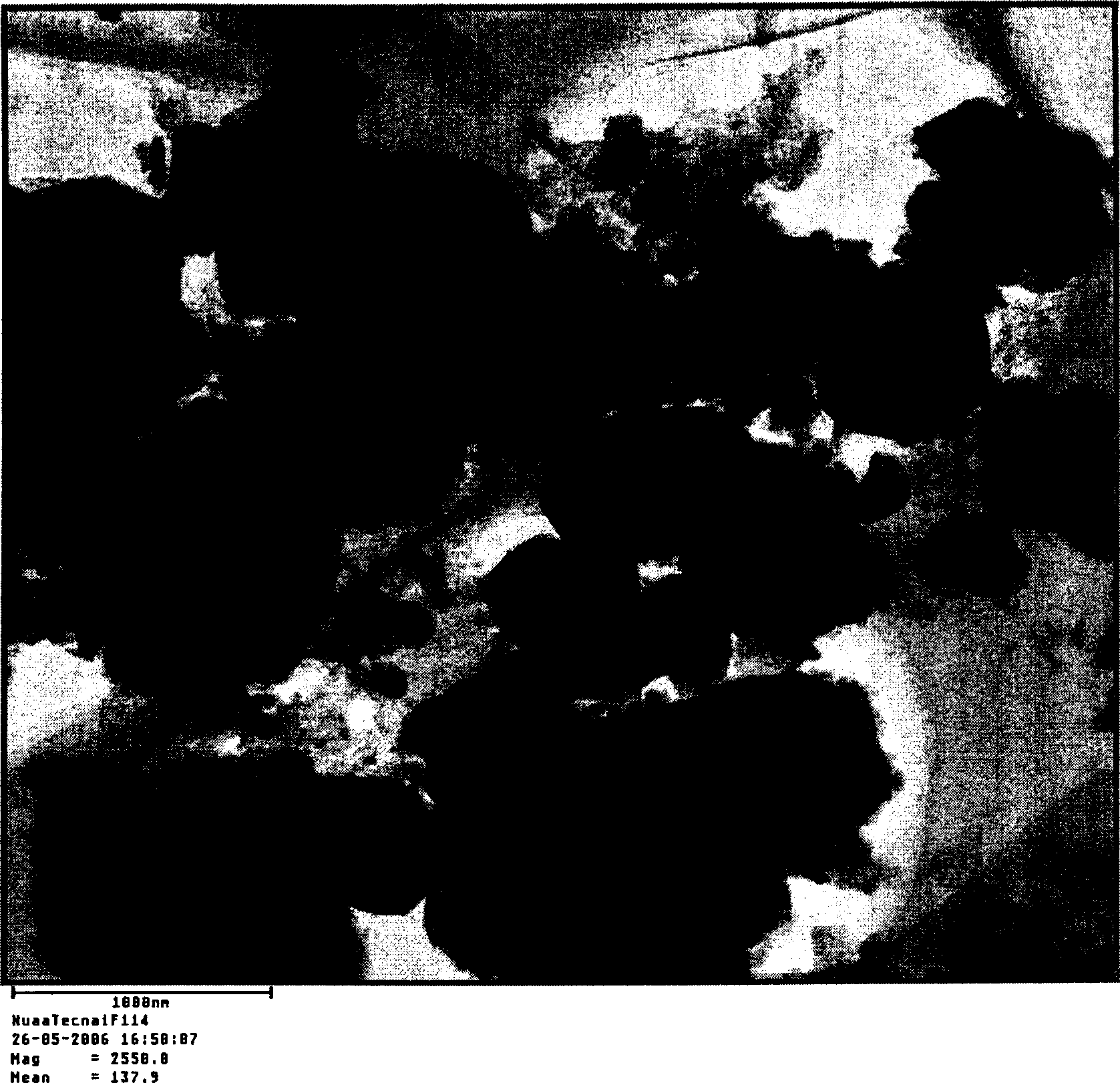

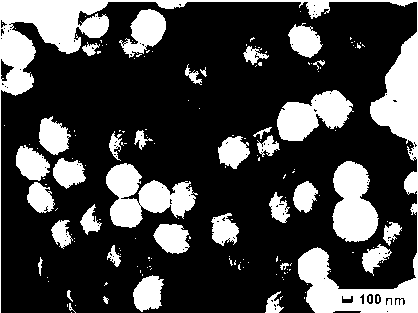

Formation of superparamagnetic particles

InactiveUS20050019755A1Efficient removalImprove conductivityNanomagnetismMicrobiological testing/measurementCross-linkNitrate

The present invention features a method for preparing superparamagnetic iron particles by the in situ formation of these particles in a cross-linked starch matrix or by the formation of a superparamagnetic chitosan material. The superparamagnetic materials are formed by mild oxidation of ferrous ion, either entrapped into a cross-linked starch matrix or as a chitosan-Fe(II) complex, with the mild oxidizing agent, nitrate, under alkaline conditions. The present invention further features superparamagnetic iron compositions prepared by the method of the invention. The compositions of the invention are useful for the separation, isolation, identification, or purification of biological materials.

Owner:MARCHESSAULT ROBERT H +5

Method for recovering gold, silver, tin and copper from industrial wastes

InactiveCN103305698AHigh recovery rateHigh enrichment rateProcess efficiency improvementSlagGoethite

The invention provides a method for recovering gold, silver, tin and copper from industrial wastes. The method comprises the following steps of: (a) adding the industrial wastes in hydrochloric acid solution, adding an oxidant, and performing oxidation acid-leaching treatment to obtain leaching slag, and solution containing tin ions and copper ions; (b) treating the leaching slag to obtain gold and silver; (c) adding iron in the solution containing tin ions and copper ions, and reacting to obtain copper, and a solution containing tin ions and ferrous ions; (d) adding lime in the solution containing tin ions and ferrous ions, and reacting to obtain tin, and solution containing ferrous ions; (e) heating the solution containing ferrous ions, charging air and adding lime, and reacting to obtain goethite and calcium chloride solution; (f) adding concentrated sulphuric acid in the calcium chloride solution to obtain calcium sulphate precipitate and hydrochloric acid solution. The various steps of the method disclosed by the invention are effectively coordinated; zero-discharge in production can be realized; precious metals are efficiently separated, and valent by-products of iron mine and gypsum are obtained; the method has good application prospect.

Owner:NANKANG HENGYUAN CYCLE TECH CO LTD

Microwave synthesis method for carbon coated iron phosphate of ion battery composite anode material

InactiveCN1911792AImprove conductivityReduce polarizationCell electrodesPhosphorus compoundsPhosphateSynthesis methods

The microwave synthesis process of carbon coated lithium iron phosphate as the composite positive electrode material for lithium ion cell includes the following steps: mixing material of lithium salt, organic ferrite, phosphate radical containing material and organic carbon source as coating material in the stoichiometric ratio of Li, Fe, P and C of 1 to 1 to 1 to 0.2-2 via ball milling with ethanol or acetone as dispersant for 3-6 hr; drying the mixture; tabletting; setting into alumina crucible together with active carbon and heating in microwave oven for 5-12 min. The lithium salt material may be inorganic Li2CO3 or LiOH, or organic lithium acetate, lithium lactate, lithium oxalate, lithium citrate or lithium formate; and the phosphate radical containing material may be (NH4)2HPO4 or (NH4)H2PO4.

Owner:NANJING UNIV

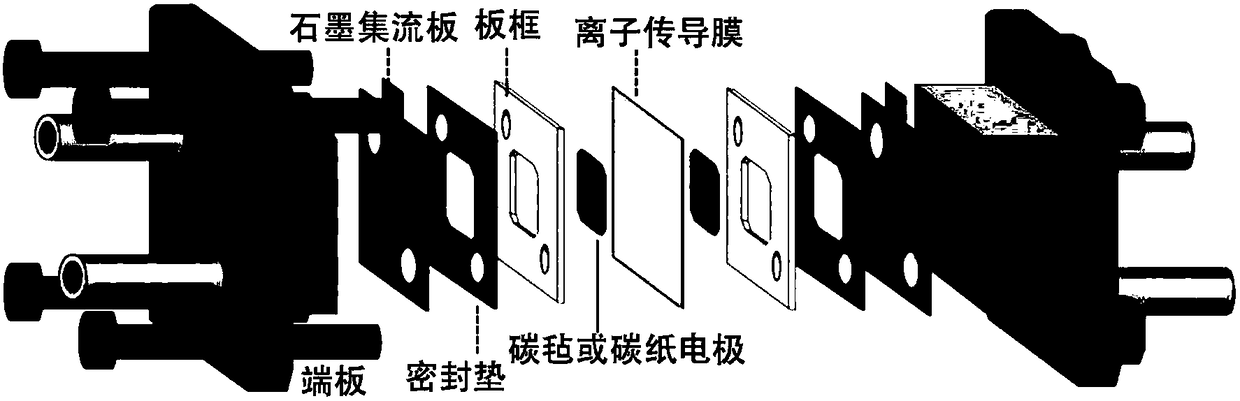

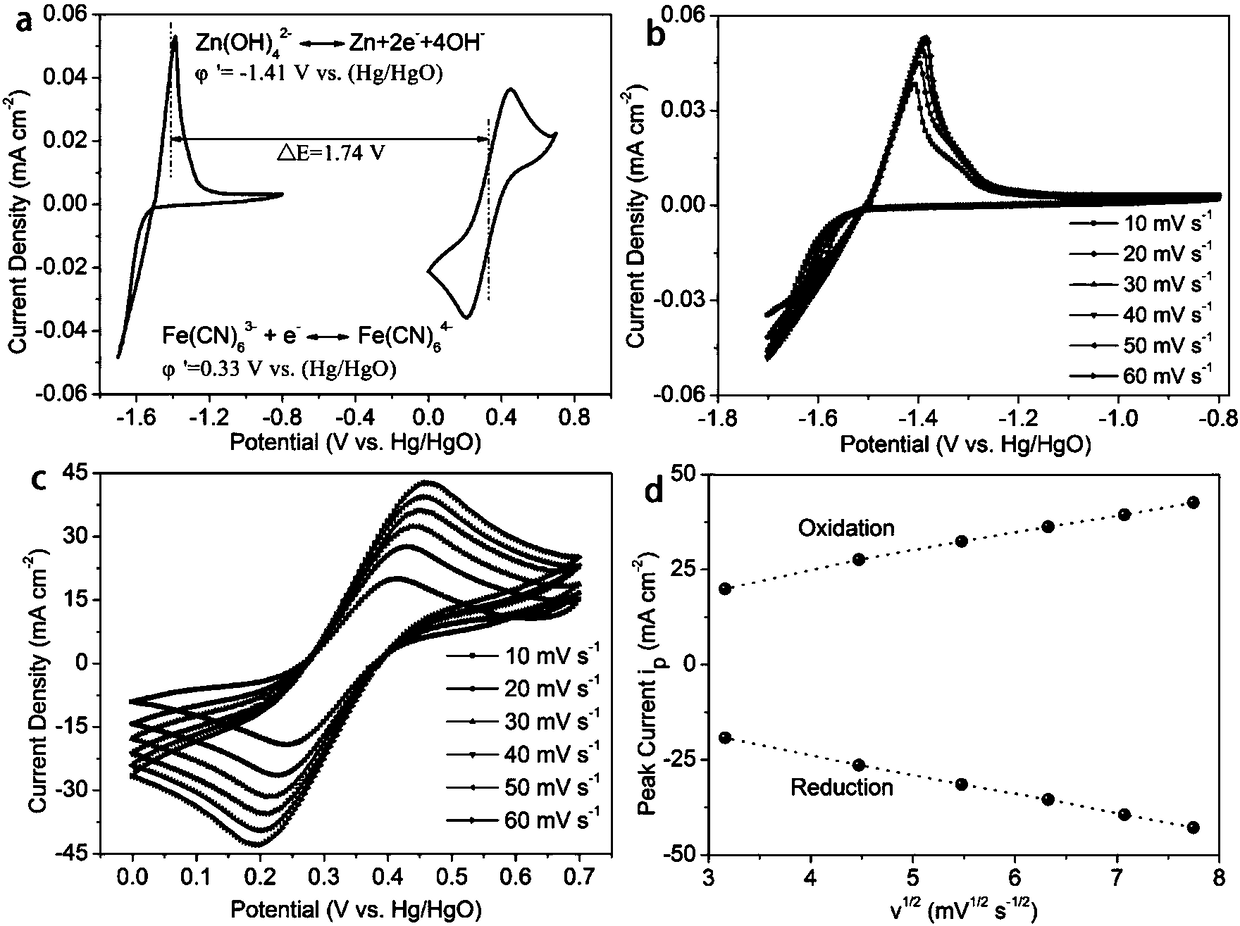

Alkaline zinc-iron flow battery

InactiveCN108461784ARich reservesLow costCell electrodesRegenerative fuel cellsHigh energyCarbon felt

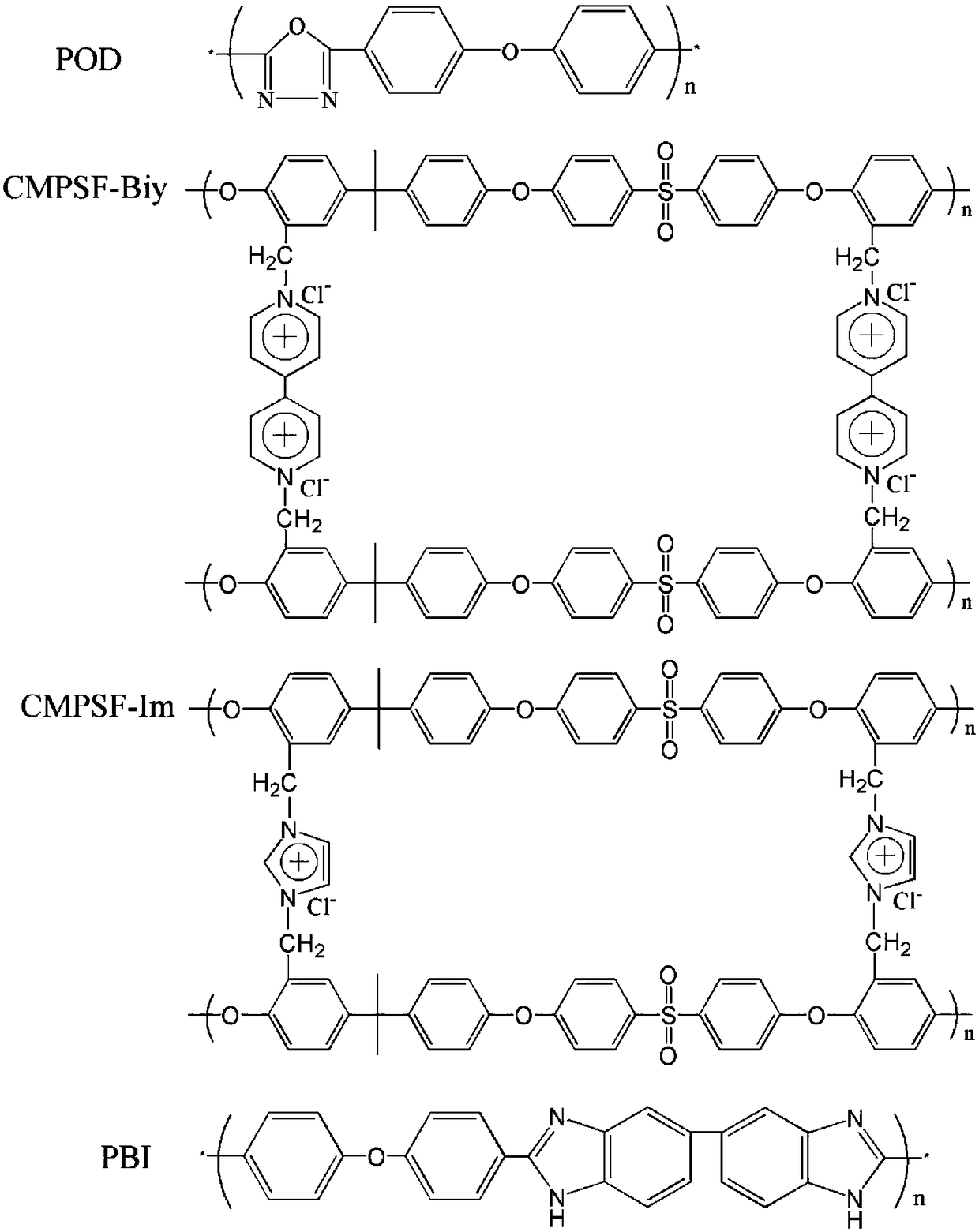

The invention relates to an alkaline zinc-iron flow battery, wherein an ion conduction membrane is prepared from an aromatic polymer containing nitrogen heterocycle, electrodes are carbon felt or carbon paper, a positive electrode electrolytic solution is the mixed aqueous solution of ferrocyanide and strong alkali, a negative electrode electrolytic solution is the mixed aqueous solution of a zincsalt or / and a zinc oxide and strong alkali, the concentrations of the strong alkalis in the positive electrode electrolytic solution and the negative electrode electrolytic solution are 0.001-10 mol / L, and the concentrations of the active substances in the positive electrode electrolytic solution and the negative electrode electrolytic solution are 0.001-3 mol / L. According to the present invention, a class of the alkaline zinc-iron flow batteries with characteristics of high energy density, high power density and long service life are provided, wherein the performance of the batteries is comparable to or superior to the current mature all-vanadium flow batteries, and the batteries have good application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

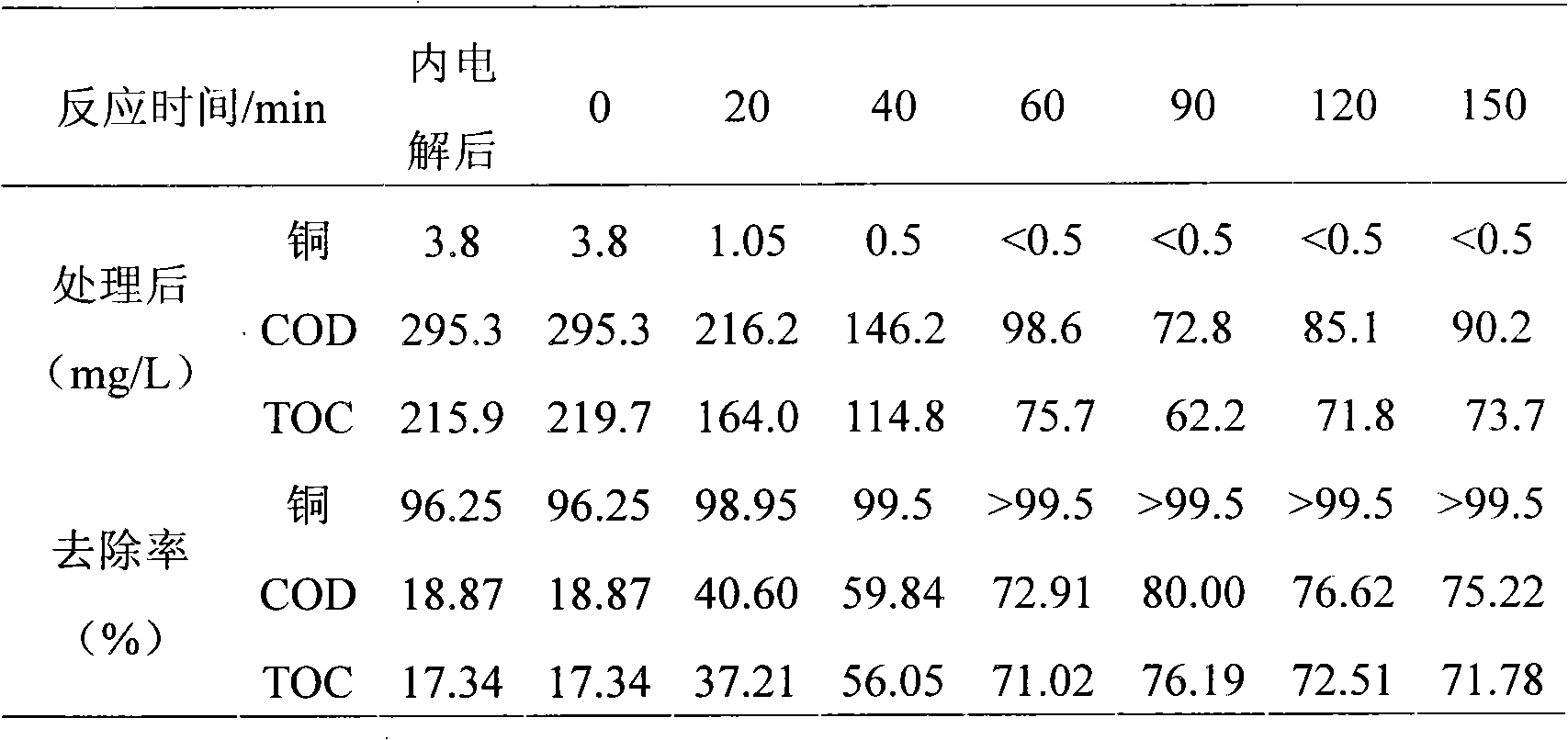

Method for processing heavy-metal complexed wastewater through Fenton reinforced iron-chip internal electrolysis process

InactiveCN102060355AReduce consumptionImprove biochemical propertiesWater/sewage treatmentElectrolysisWastewater

The invention discloses a method for processing heavy-metal complexed wastewater through a Fenton reinforced iron-chip internal electrolysis process. The method comprises the following steps of: filling an internal electrolysis filler into an iron-chip internal electrolysis reactor, then introducing the wastewater into the reactor after regulating the pH value of the wastewater to 1.5-3.5, adding a Na2SO4 solution, controlling dissolved oxygen to be not higher than 3.0mg / L, and controlling the flow speed of the introduced wastewater; then introducing the discharged water of the internal electrolysis reactor into a Fenton reactor, maintaining the ferrous concentration in the water to be 300-750mg / L, adding H2O2 according to the mass concentration ratio of H2O2 to Fe2+ of 2.0-7.0, and sufficiently reacting for 60-120 minutes under the condition of controlling the pH value to be 2.5-5.5; and regulating the pH value of the discharged water to 9.0-10.0, standing and settling, and separating mud from the water. According to the method disclosed by the invention, the operation is simple and convenient, the sewage biodegradability can be markedly improved, the difficulty and the organic load of subsequent processing are greatly reduced, and the cost is saved.

Owner:SOUTH CHINA UNIV OF TECH

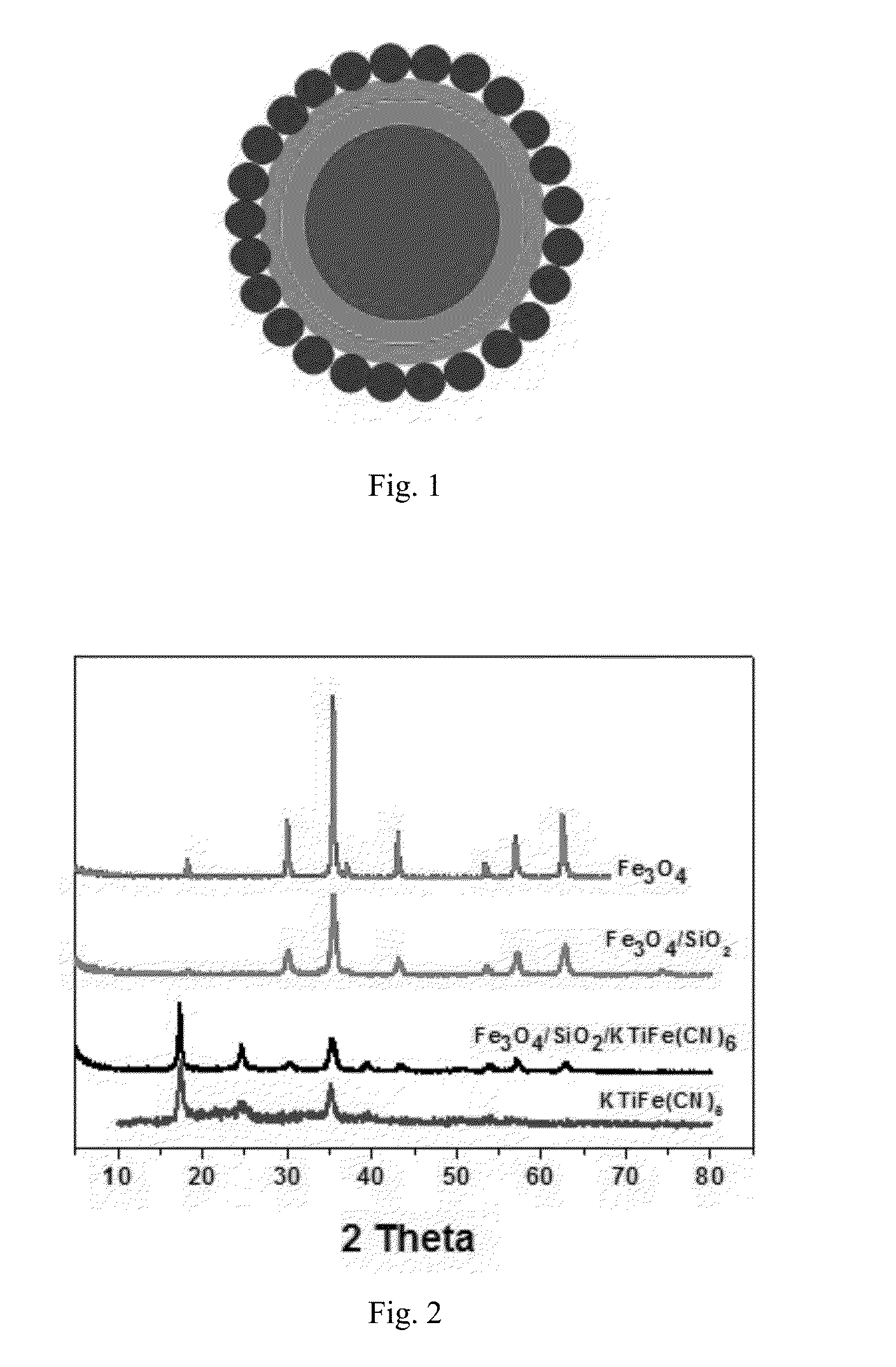

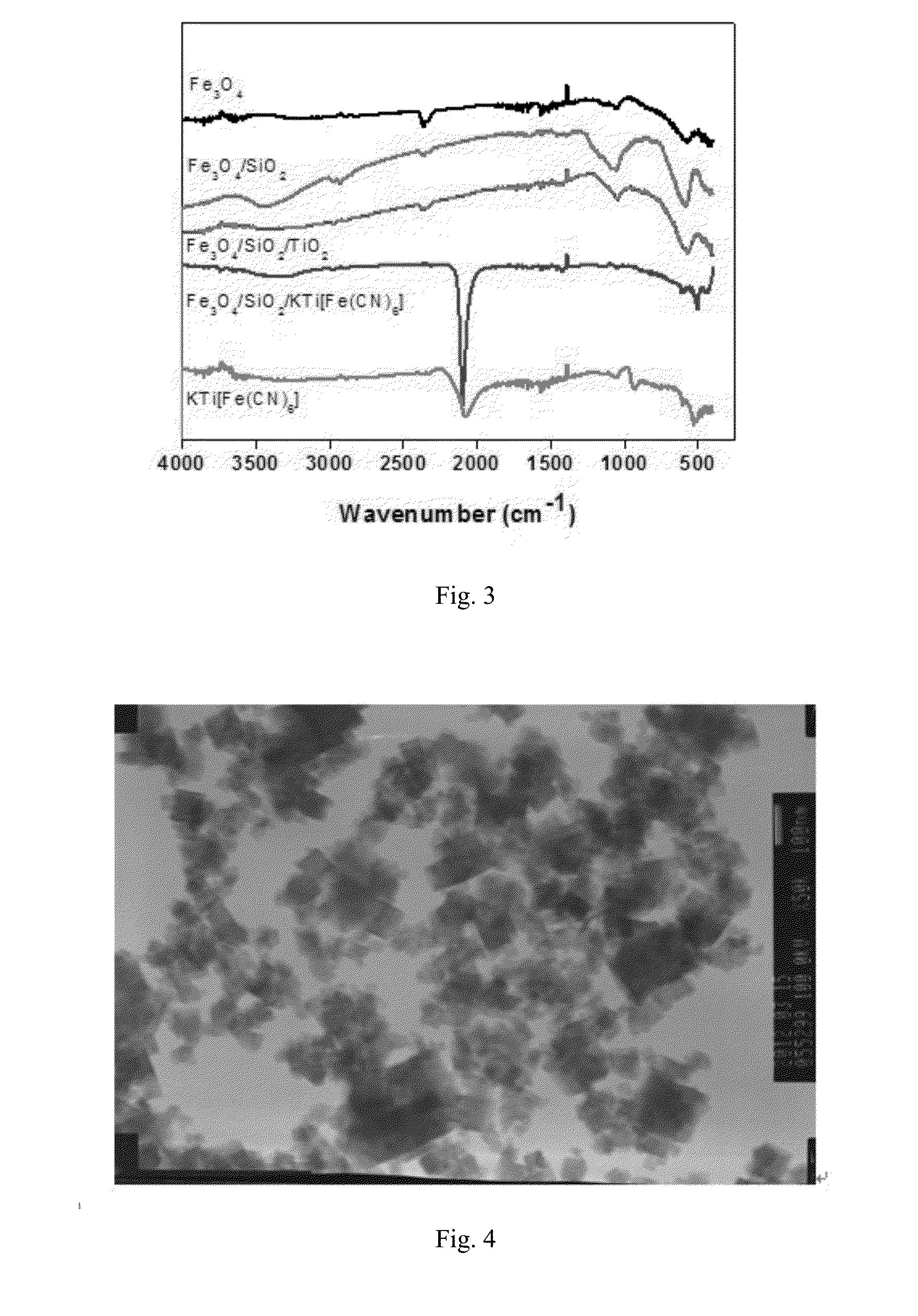

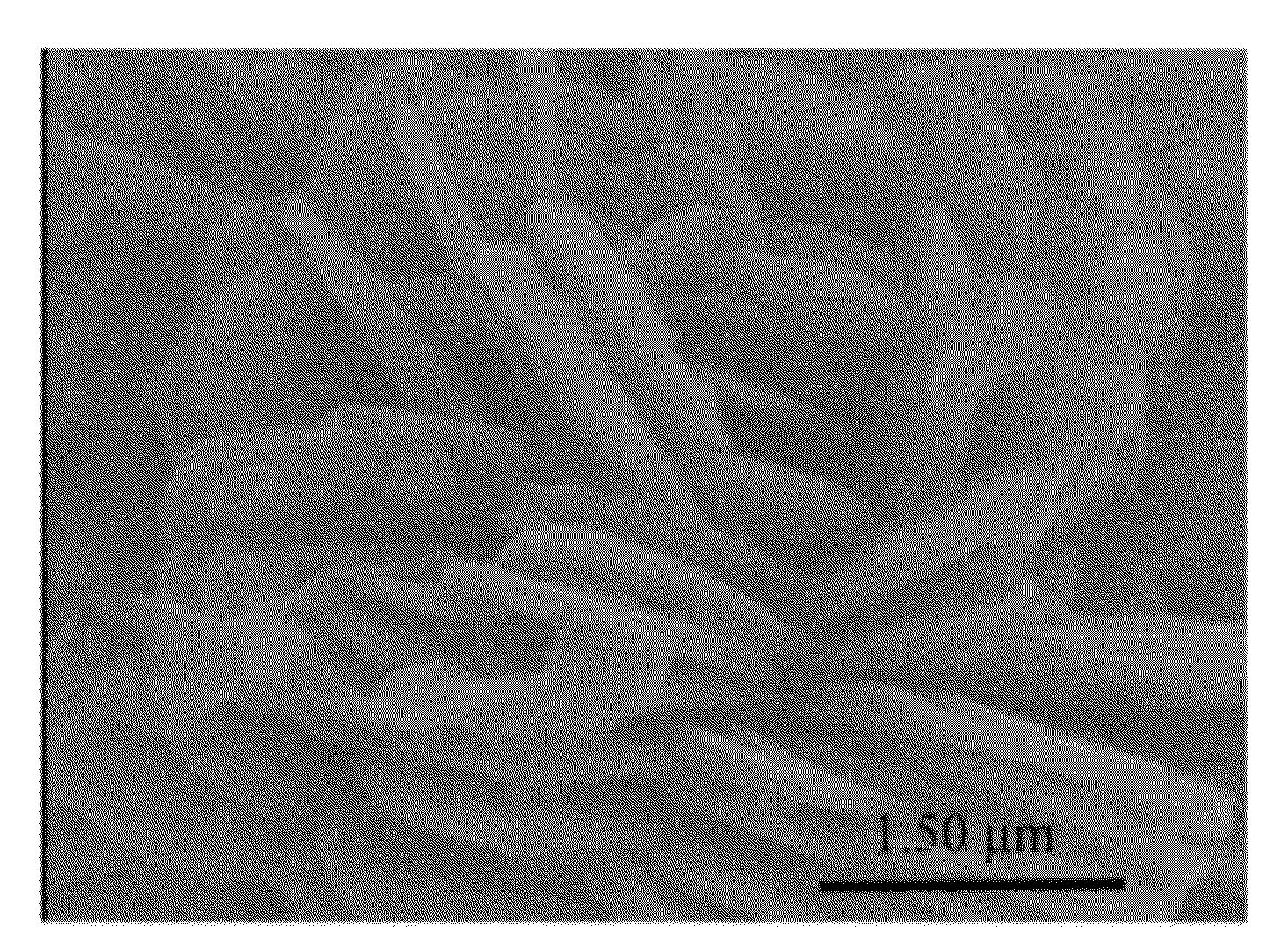

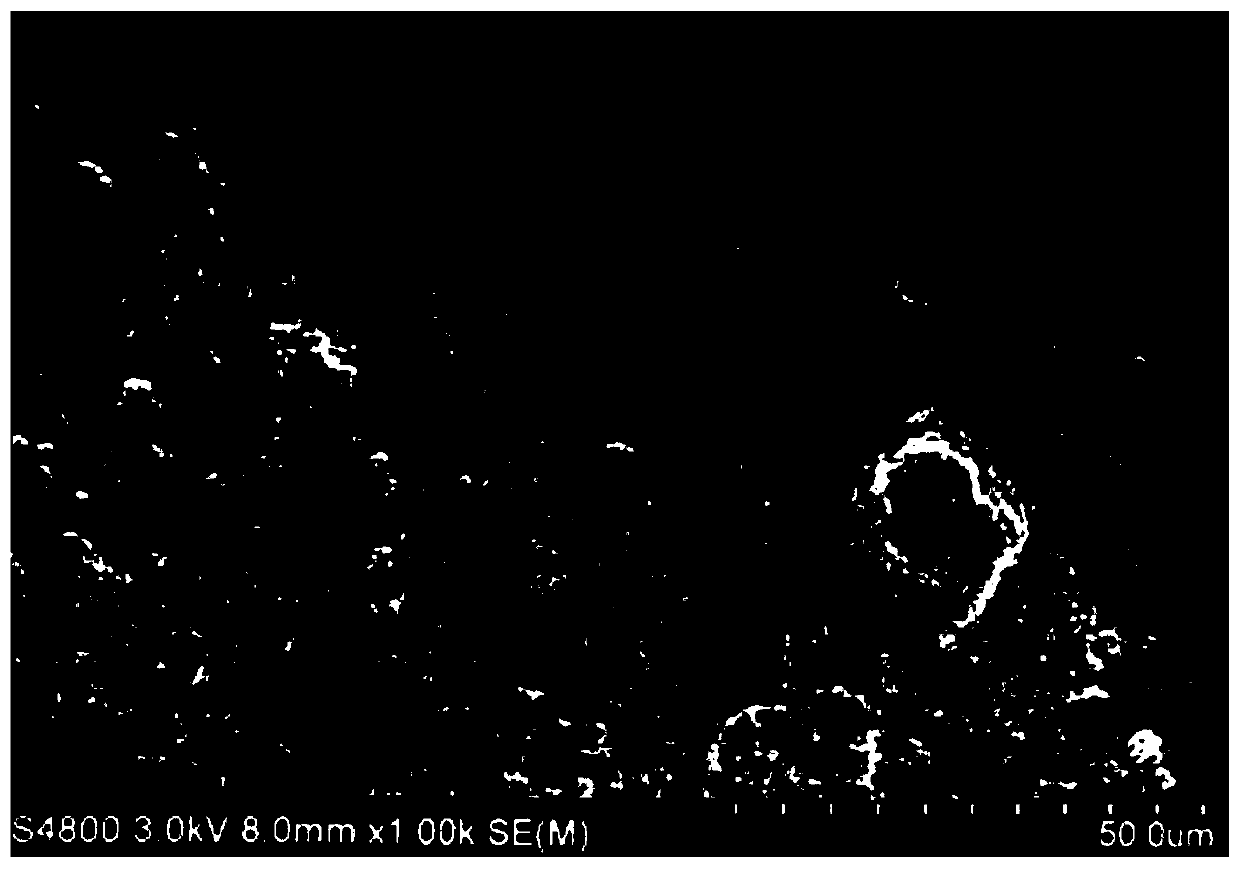

MAGNETIC CORE COATED INORGANIC ION ADSORBENT FOR REMOVING Cs IONS IN RADIOACTIVE WASTEWATER AND PREPARATION METHOD THEREOF

ActiveUS20150231598A1Good alkali resistanceInhibiting oxidation of the magnetic core materialOther chemical processesRadioactive contaminantsHydration reactionSorbent

The invention discloses a micron-grade magnetic core coated ferrocyanide adsorbent for removing Cs ions in radioactive wastewater and a preparation method thereof. The adsorbent takes magnetic Fe3O4 as a core, the surface is coated with a dense SiO2 single layer serving as a protective layer, and an active component is metal ion stabilized potassium ferrocyanide coated on the outer layer, wherein stabilized metal ions comprise Ti, Zn, Cu, Ni, Co, and Zr. The particle size of the adsorbent is 0.2-5 μm, the adsorbent in the outermost layer is conductive to improving the adsorption efficiency for Cs+ ions, and an external magnetic field is adopted for realizing solid-liquid phase separation. The preparation method comprises the following steps: coating a hydrated metal oxide of Ti, Zr or Co, Ni, Cu or Zn on the surface of Fe3O4SiO2 to form a composite magnetic material, wherein the hydrated oxide performs hydroxyl polymerization reaction with the surface of SiO2 to produce M—O—Si bonds to improve the bonding strength between M and the surface of SiO2; and finally reacting the composite magnetic material with a potassium ferrocyanide solution to form the required composite adsorbent, wherein the metal ions M achieve the effects of stabilizing the ferrocyanide and also achieve a bridge effect for bonding the ferrocyanide and the composite magnetic material together.

Owner:TSINGHUA UNIV

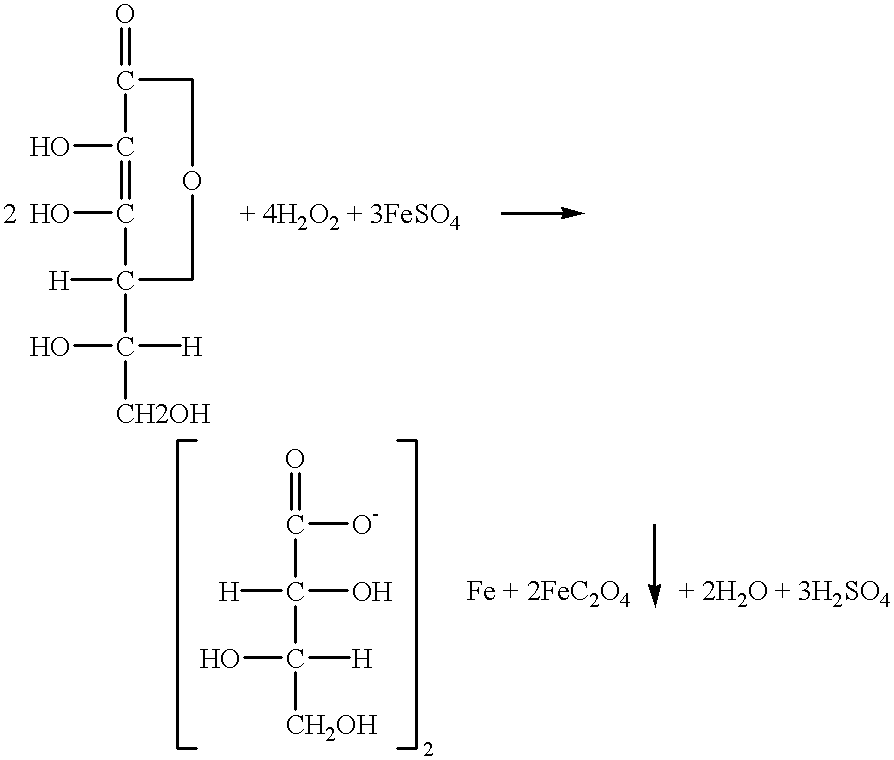

Deironing method for vanadium-bearing stone coal lixivium

ActiveCN105695738AReduce loss rateReduce the impact of vanadium enrichmentOrganic compound preparationCarboxylic acid salt preparationPregnant leach solutionIron powder

The invention relates to a deironing method for vanadium-bearing stone coal lixivium. According to the technical scheme, the deironing method comprises the steps that vanadium-bearing stone coal is firstly subjected to crushing, roasting and ore grinding to obtain vanadium-bearing stone coal roasted ore, the vanadium-bearing stone coal roasted ore and water are stirred to obtain vanadium-bearing stone coal ore pulp, then a leaching agent is added, heating and stirring are carried out, and solid-liquid separation is carried out to obtain the vanadium-bearing stone coal lixivium and leaching residues; reduced iron powder is added into the vanadium-bearing stone coal lixivium, and the adding amount of the reduced iron power is 2-4 times the stoichiometric number of the chemical reaction for reducing Fe3+ in the vanadium-bearing stone coal lixivium into Fe2+; heating and stirring are carried out, the pH value is adjusted to range from 1.5 to 5, heating and stirring are carried out, solid-liquid separation is carried out, and deironed lixivium and a filter cake are obtained; and the deironed lixivium is used for the vanadium enrichment technology, and a ferrous oxalate dehydrate byproduct is obtained after the filter cake is dried. Vanadium and iron in the vanadium-bearing stone coal lixivium can be effectively separated, the iron in the vanadium-bearing stone coal lixivium can be recycled, the vanadium loss rate in the deironing process is low, the iron content of the deironed lixivium is low, and the influence of the iron on the subsequent vanadium enrichment technology is reduced.

Owner:WUHAN UNIV OF SCI & TECH

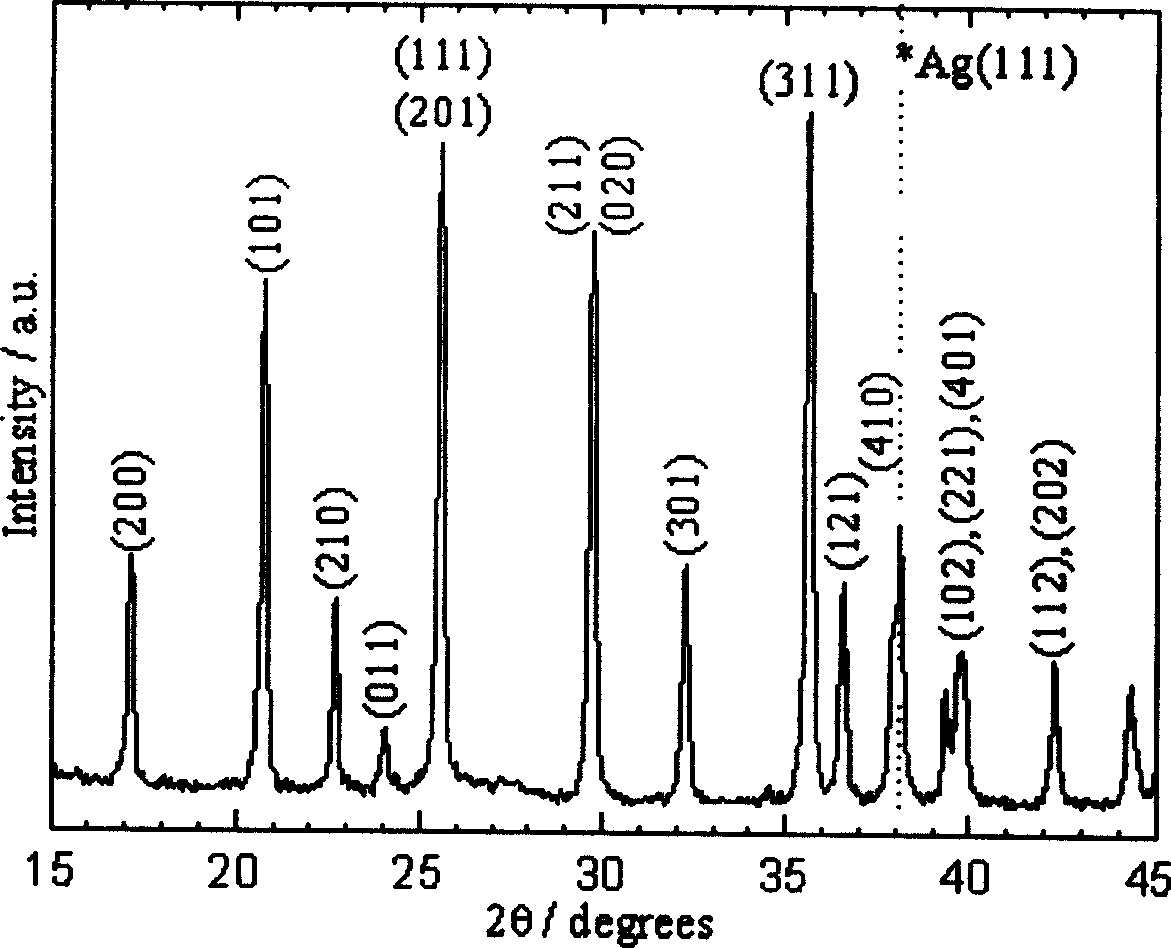

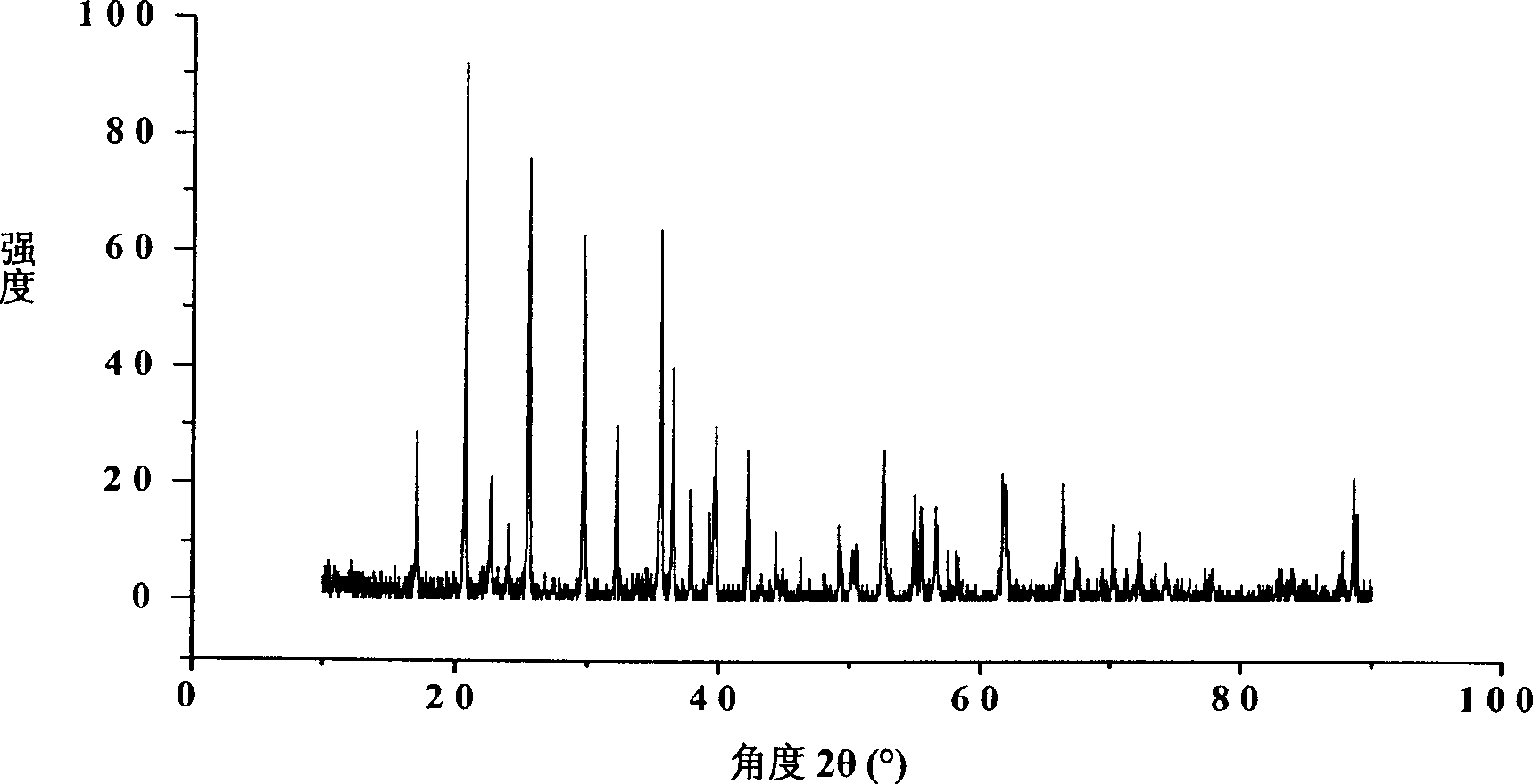

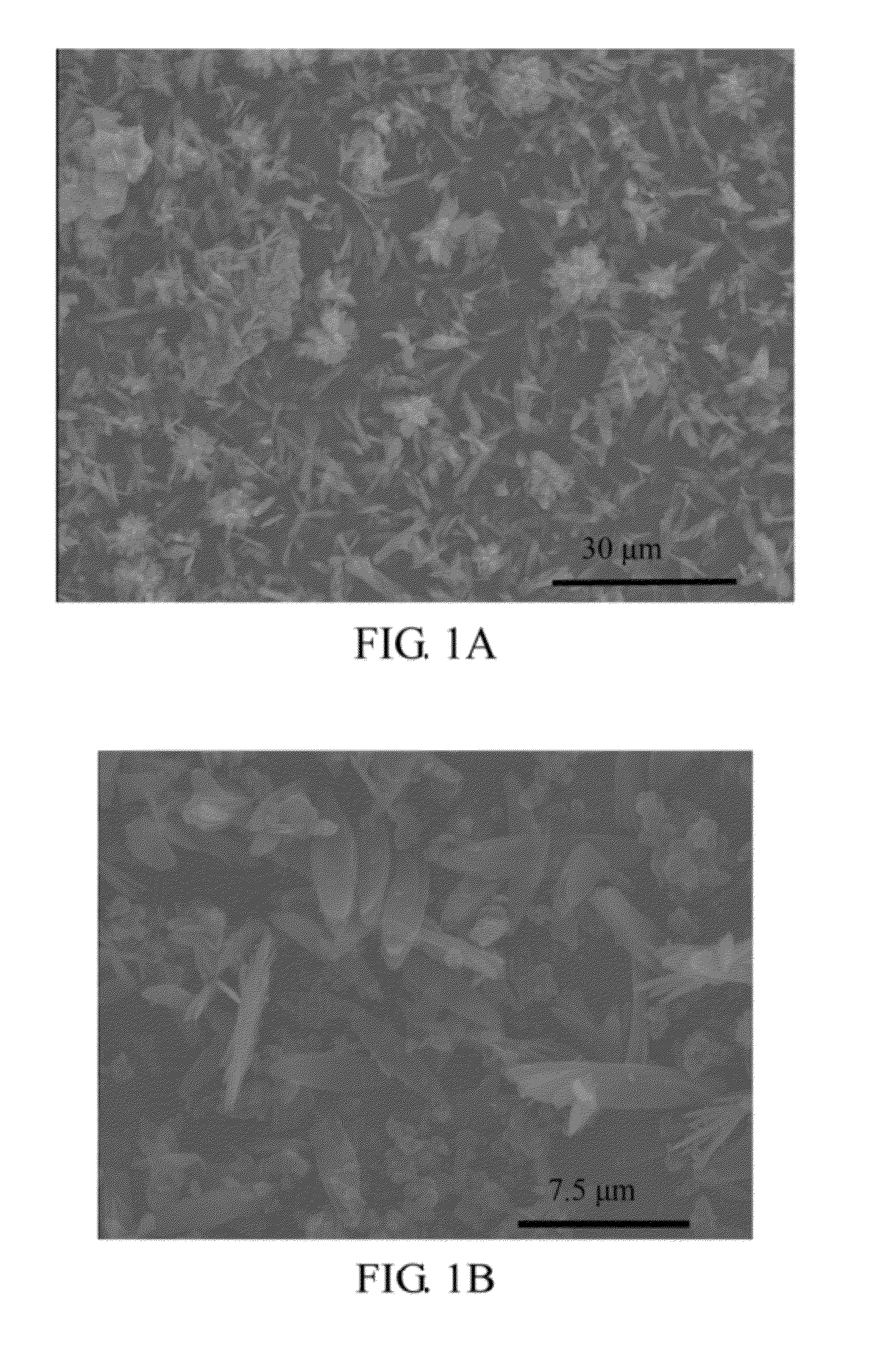

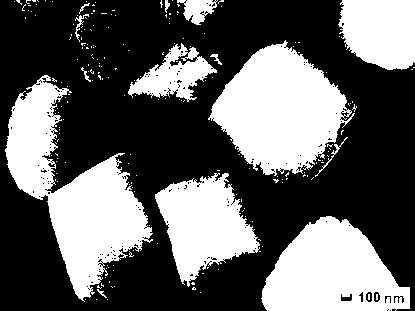

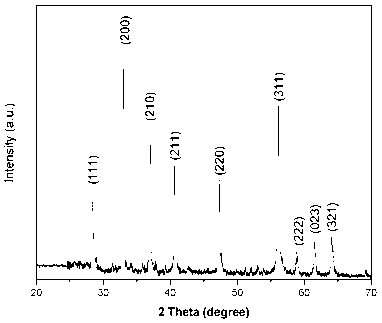

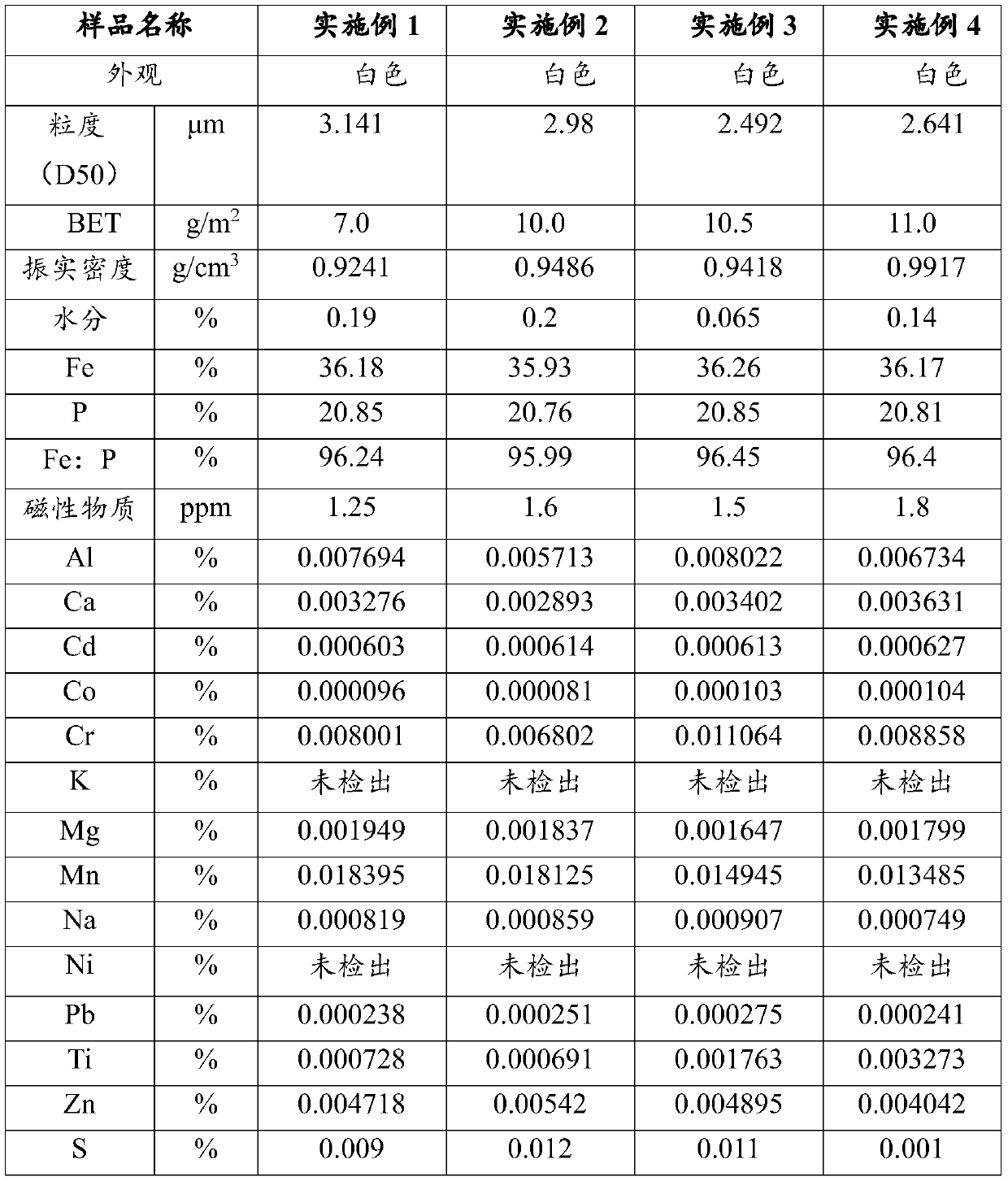

Ferrous phosphate (II) powders, lithium iron phosphate powders for li-ion battery, and methods for manufacturing the same

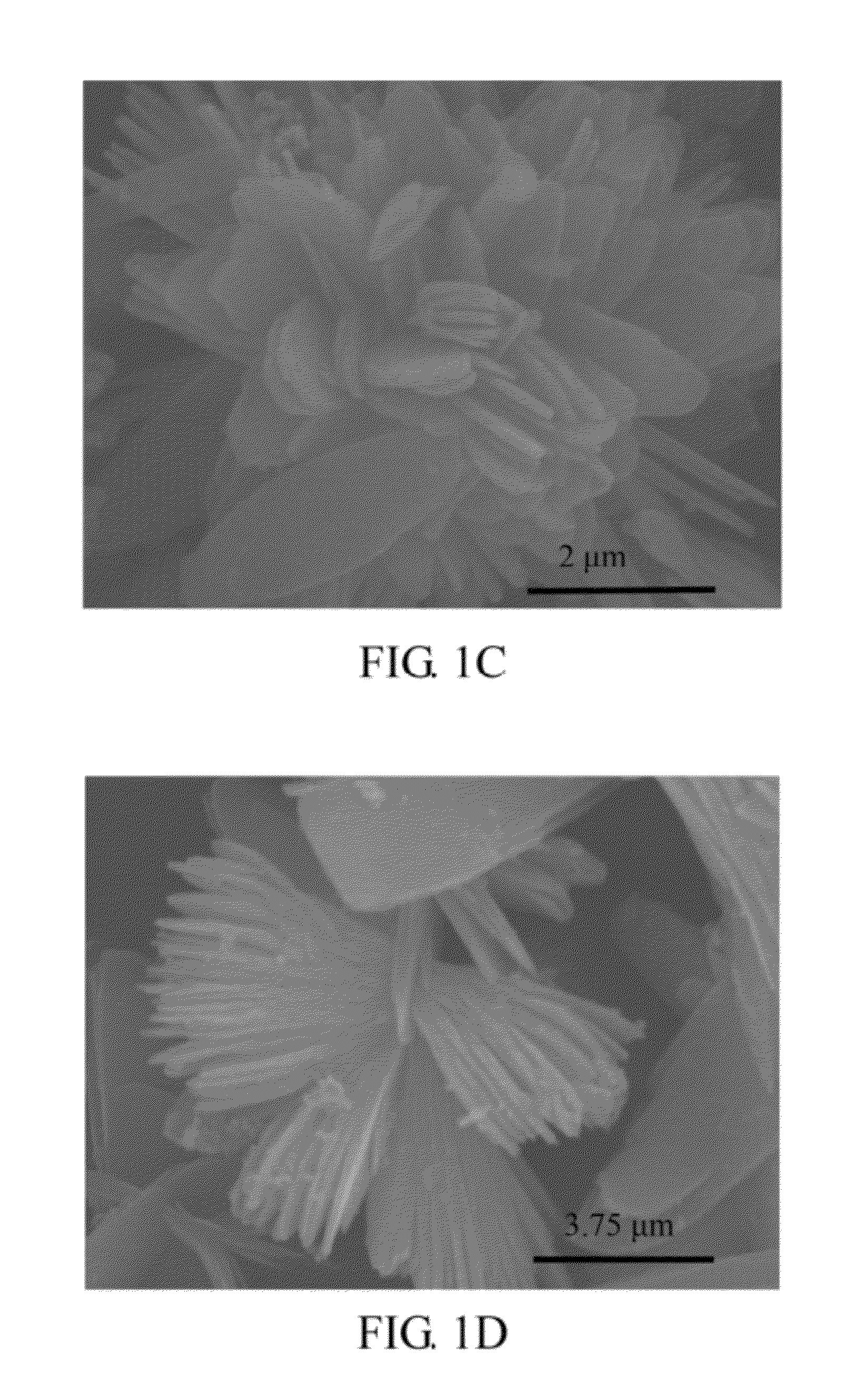

ActiveUS20120321958A1Uniform and small grain sizeUniform and small sizePhosphatesConductive materialLithium iron phosphatePhosphate

Ferrous phosphate (II) (Fe3(PO4)2) powders, lithium iron phosphate (LiFePO4) powders for a Li-ion battery and methods for manufacturing the same are provided. The ferrous phosphate (II) powders are represented by the following formula (I):Fe(3-x)Mx(PO4)2.yH2O (I)wherein, M, x, and y are defined in the specification, the ferrous phosphate (II) powders are composed of plural flake powders, and the length of each of the flake powders is 0.5-10 μm.

Owner:NATIONAL TSING HUA UNIVERSITY +1

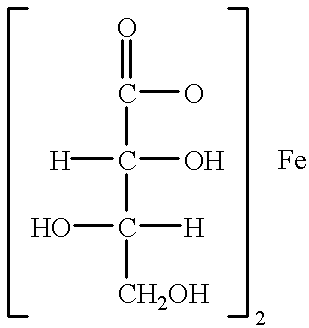

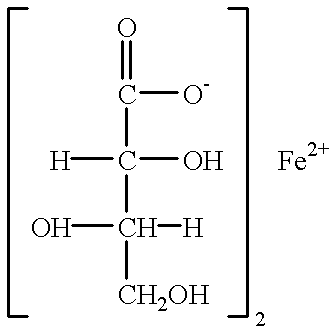

L-threonate ferrous, as well as pharmaceutical composition and use for improving and treating human anemia thereof

InactiveUS6313170B1High absorption rateImprove absorption rateHeavy metal active ingredientsBiocideBlood loss anemiaPhysiology

A compound of ferrous L-threonate with structure (I), its compostions and methods useful for iron supplementation for mammals, particularly for human body to improve and treat nutritional iron-deficiency anemia, blood loss anemia and hemolytic anemia.

Owner:JUNENG INDUSTRY CO LTD

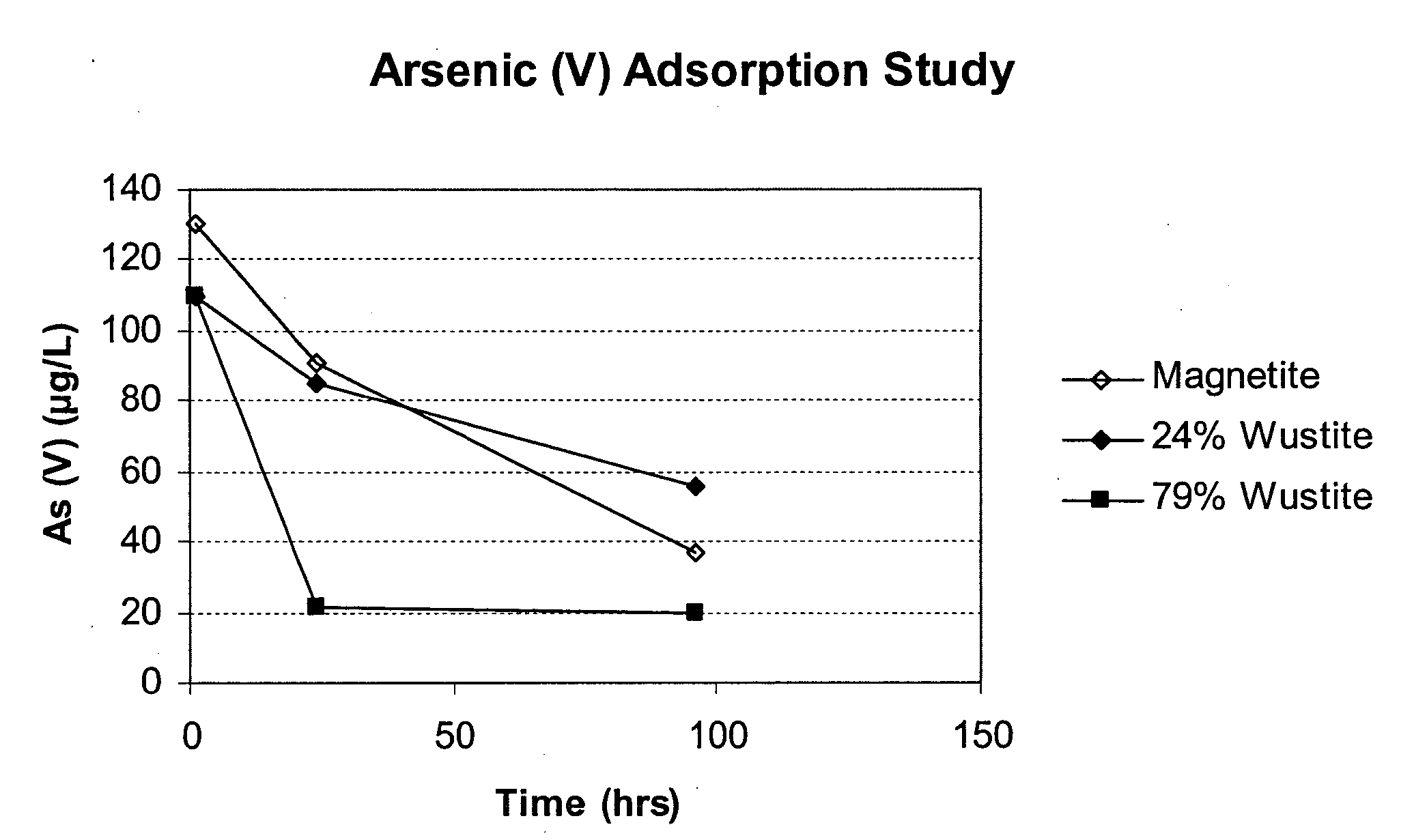

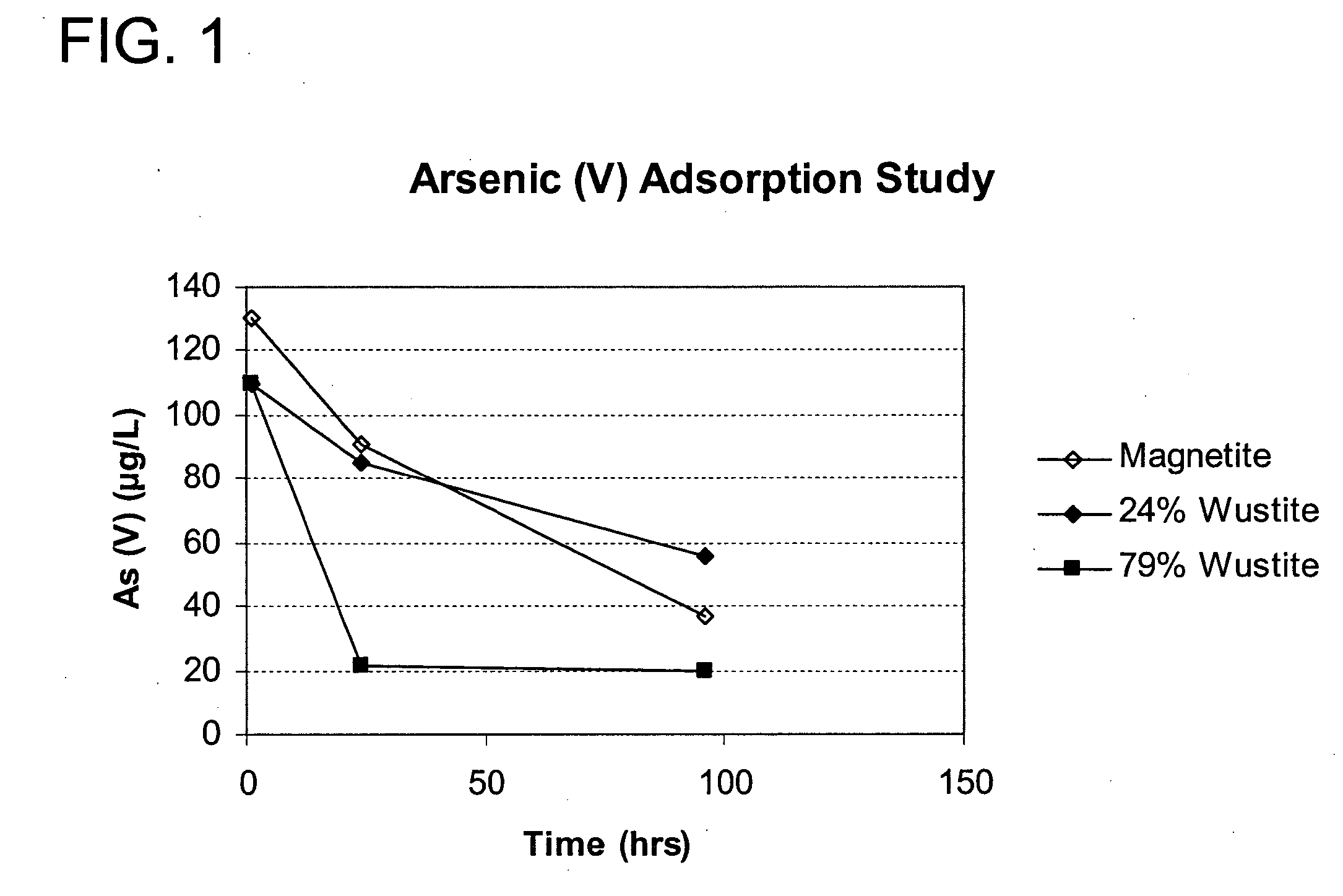

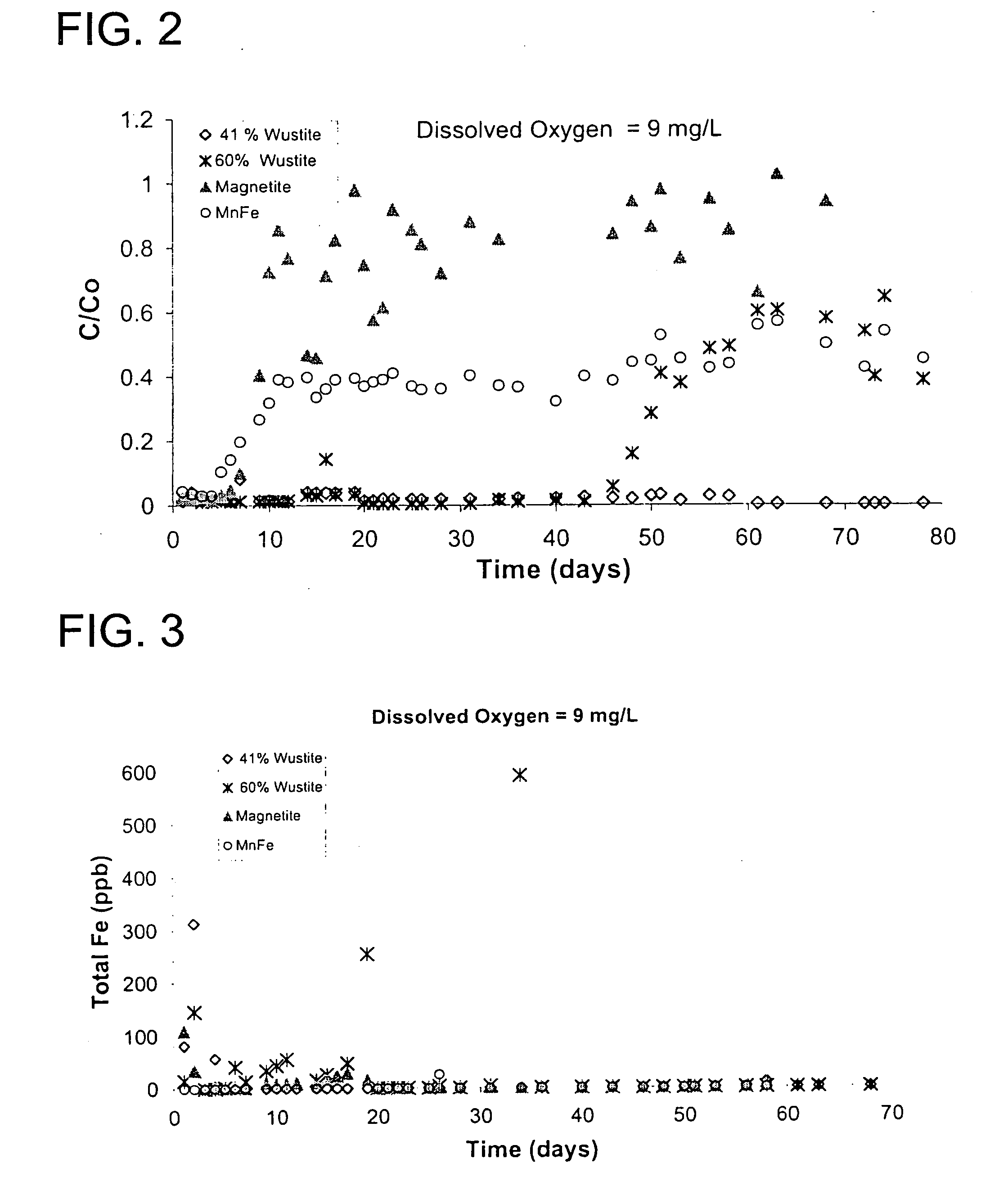

Reactive adsorbent for heavy elements

InactiveUS20060049091A1Improve the level ofReduce manufacturing costWater treatment parameter controlWater/sewage treatment by irradiationSorbentFerrous

An adsorbent is disclosed which uses an iron-containing metal oxide as an adsorbent for removing heavy elements from contaminated waters and method for the use of the same. The bed includes a non-stoichiometric ferrous oxide Fe1-xO, which is structurally in a Wustite crystal phase form having the rock salt, face-centered cubic lattice.

Owner:PELTECH +1

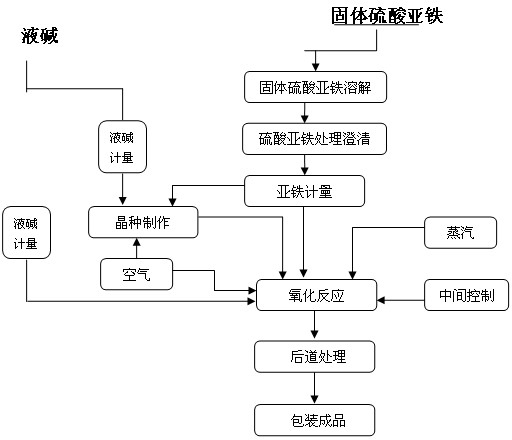

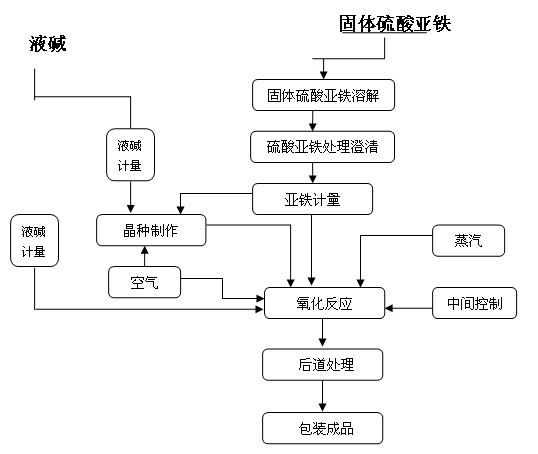

High-purity iron oxide black pigment and production method thereof

ActiveCN102139927AHeavy metal content controlHigh purityFerroso-ferric oxidesIron(II) oxideIron oxide black

The invention relates to a high-purity iron oxide black pigment and a production method thereof. The production method comprises the following steps of: with a crystal seed as a carrier in a liquid phase method production process, carrying out reaction on ferrous sulphate and sodium hydroxide in an oxidation barrel, immediately generating ferrous hydroxide sol under the alkali condition, introducing steam and warming for reaction, introducing air for oxidation after a specified temperature is reached, and reacting for a period of time to obtain the high-purity iron oxide black pigment. The granules of the product obtained by the method are small and uniform compared with a synthetic method, and the yield is high and the coloured light is good; meanwhile, the purity of the product is controlled, thus the operating requirement in the industry is met. The invention also aims at providing the high-purity iron oxide black pigment prepared by adopting the method.

Owner:SHENGHUA GROUP DEQING HUAYUAN PIGMENT

Strong UV and IR absorbing green glass

A green glass able to strongly absorb ultraviolet ray and infrared ray is characterized by that the colouring agent is used as part of raw materials for ordinary NaSiCa glass. Said colouring agent contains Fe2O3 (0.5-0.9 %), TiO2 (0.2-0.7%), and CeO2 (0.05-0.15%). Its advantages are low ultraviolet transmissivity (less than 17%), low infrared transmissivity (less than 28%) and high viual light transmissivity (more than 70%).

Owner:江苏华东耀皮玻璃有限公司

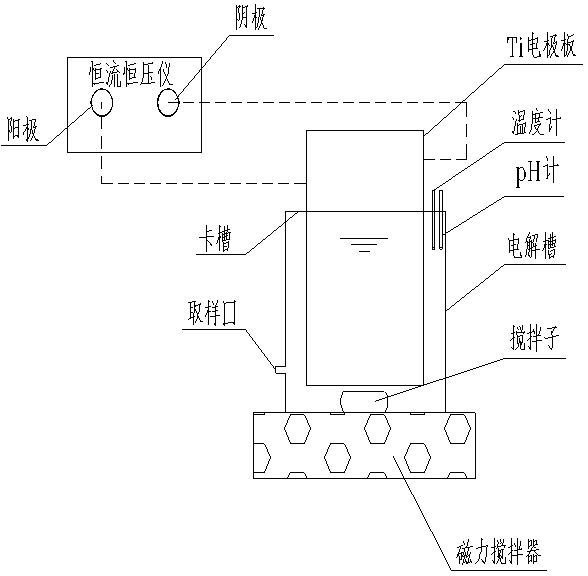

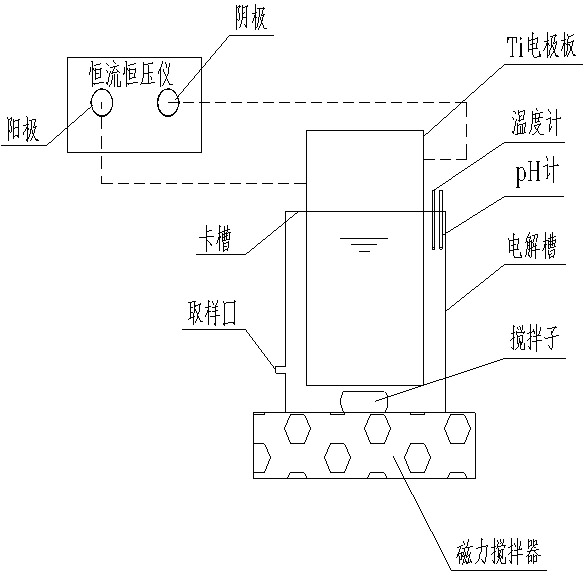

Method for removing harmful algae in water body by adopting electro-Fenton

InactiveCN101962216AStable in natureNo electrocoagulationWater/sewage treatment by oxidationFerric hydroxideElectrolysis

The invention belongs to the technical field of environmental protection and in particular relates to a method for removing harmful algae pollution in water body by adopting electro-Fenton. Hydrogen peroxide and ferrous ions in a reactor react to generate hydroxyl radicals, at the same time, the ferrous ions are regenerated from iron ions and iron hydroxide in the cathode region for electrolysis through reduction, thus continuously generating vast hydroxyl radicals, efficiently inactivating algae cells, simultaneously rapidly carrying out oxidation degradation on the microcystins and effectively avoiding secondary pollution. The body part of the reactor comprises a power source, electrodes, an electrolytic bath and a magnetic stirrer. After the algae liquid to be treated is introduced to the electrolytic bath, the magnetic stirrer at the bottom of the electrolytic bath is used for ensuring the algae liquid to be uniformly distributed in the whole reactor. Under the set process parameters, the method can realize rapid inactivation of the harmful algae and simultaneously realize efficient degradation of the microcystins.

Owner:FUDAN UNIV

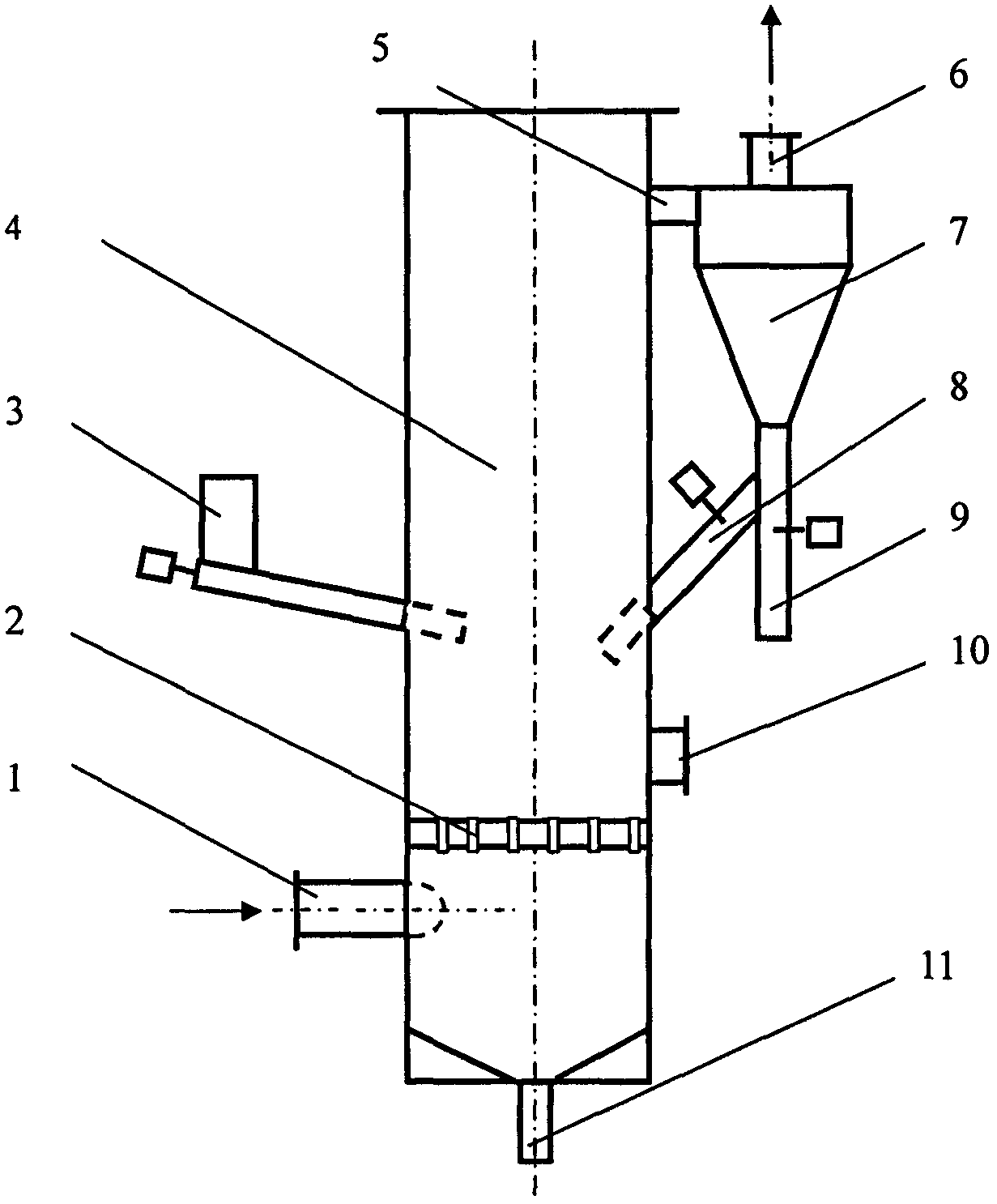

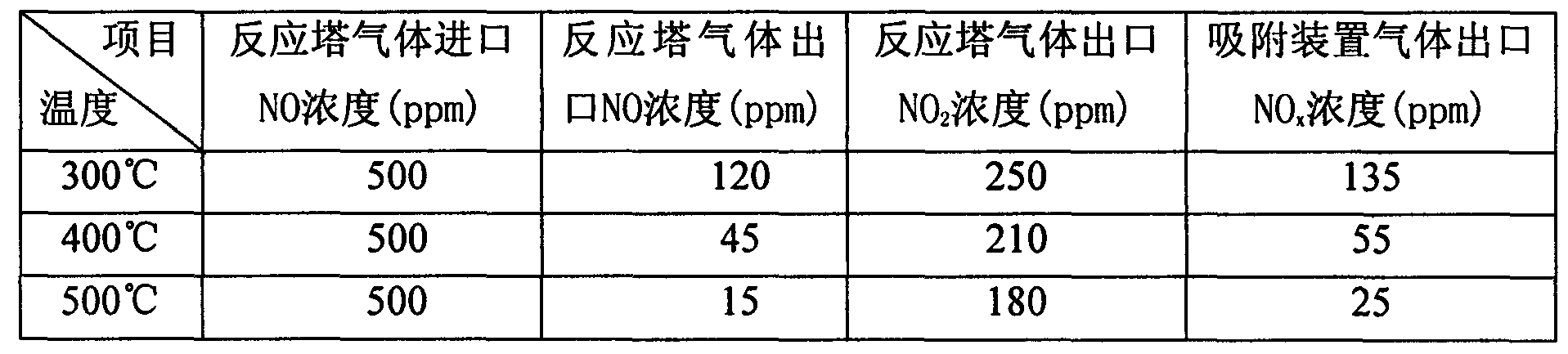

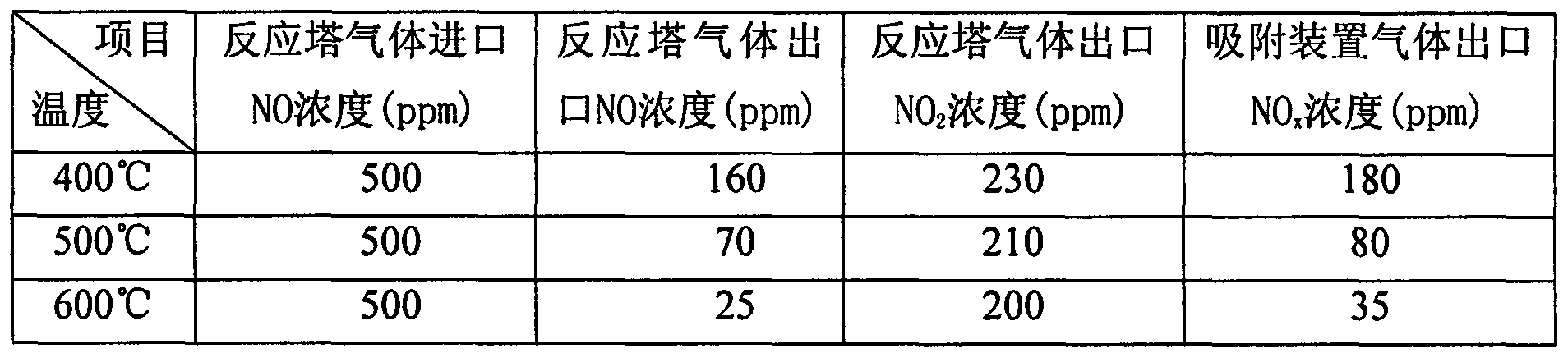

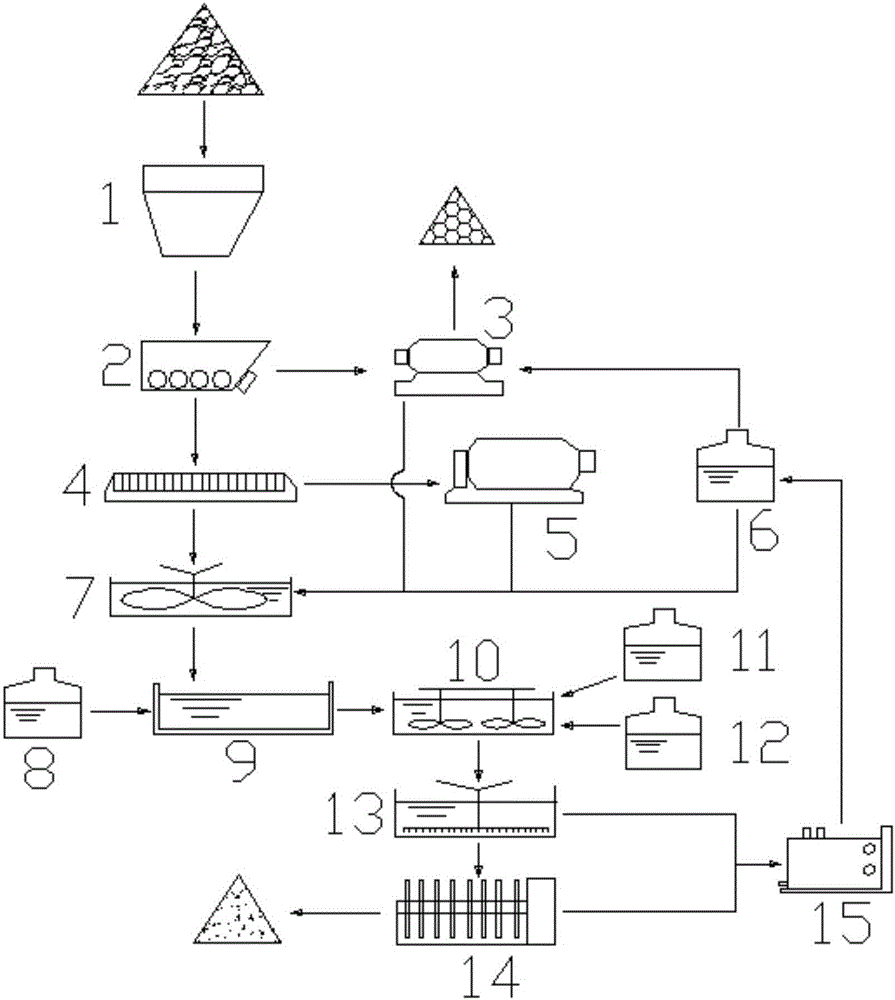

Method and device for simultaneous reduction and oxidation of nitrogen oxides from airflow

InactiveCN104353347ATo achieve the purpose of purificationImprove processing efficiencyDispersed particle separationAir quality improvementMetal chlorideNitrogen dioxide

The invention discloses a method and a device for simultaneous reduction and oxidation of nitrogen oxides from airflow. According to a treating process, the treated airflow is guided into a gas-solid reaction tower, solid ferrous chloride, ferric chloride, manganese chloride or magnesium chloride metal chloride particles are guided into the gas-solid reaction tower simultaneously, and the metal chloride is decomposed at the high temperature and reacts with nitric oxide in the airflow, so that part of nitric oxide contained in the airflow is reduced to nitrogen, the rest nitric oxide is oxidized into nitrogen dioxide, generated nitrogen dioxide reacts with an alkaline absorbent easily to be removed, and the purpose of gas purification is achieved. The invention further discloses the special device. The method and the device have the characteristics of low investment cost as well as operation and application cost, simplicity in operation, high treatment efficiency and high treatment capacity.

Owner:黄立维

Leaching method for remediating hexavalent chromium contaminated soil

InactiveCN106583436ASimple and fast operationImprove securityContaminated soil reclamationFiltration circuitsSlurryContamination

The invention discloses a leaching method for remediating hexavalent chromium contaminated soil. The method comprises the following steps: (1) slurrying the contaminated soil; (2) fully acidizing materials; (3) adding a reducing agent which is a mixture of calcium polysulfide and ferrite to reduce hexavalent chromium; (4) adding a neutralizing precipitant to precipitate trivalent chromium; and (5) separating solid and liquid, and preparing slurry through supernate. According to the method, a leaching agent and the leaching step are correspondingly simple and convenient to operate, high in safety, low in cost, high in hexavalent chromium recovering efficiency, and hard to cause secondary contamination; meanwhile, wastewater can be recycled, so that the requirement on water for leaching can be met, and as a result, the water resource can be greatly saved, and the secondary contamination caused by drained sewage can be avoided.

Owner:ELION SHOUJIAN ECOLOGICAL TECH CO LTD

Process for preparing battery-grade high-purity nano iron phosphate

ActiveCN107188149ALow costShort processMaterial nanotechnologyPhosphorus compoundsIron sulfateDistillation

The invention discloses a process for preparing battery-grade high-purity nano iron phosphate. The process comprises the steps that the pH is improved by using a titanium dioxide by-product, impurities are removed and a solution is purified by adding iron powder, then ferrous oxidization is performed to obtain ferric iron, the pH of iron sulfate is regulated, ferric ions in the iron sulfate are extracted by adopting di(2-ethylhexyl) phosphoric acid, a washed organic phase is obtained through 5-6 level counter-current extraction, 5-6 level counter-current acid solution washing and 2-3 level counter-current pure water washing, sulfonated kerosene is distilled out, the organic phase obtained after distillation is mixed with a catalyst, reaction is performed at the temperature of 300-320 DEG C for 3-4 hours, and the material obtained after reaction is washed by adding ethyl alcohol and is dried to obtain the high-purity nano iron phosphate. According to the process for preparing the high-purity nano iron phosphate, the high-purity nano iron phosphate can be prepared through the titanium dioxide by-product, the obtained iron phosphate is high in purity, small in particle size and large in specific surface area, the ferro-phosphorus ratio is 0.995-1.01, and the wastewater production amount is small.

Owner:SICHUAN LOMON PHOSPHORUS CHEM

Preparation method of graphene oxide/iron disulfide composite nano particles

InactiveCN102910615AUniform particle sizeGood dispersionMaterial nanotechnologyCarbon compoundsHydration reactionPolyvinyl alcohol

The invention relates to nano FeS2 materials, and particularly relates to a preparation method of graphene oxide / iron disulfide composite nano particles. According to the preparation method of the graphene oxide / iron disulfide composite nano particles, ferrous chloride tetrahydrate (FeCl2.4H2O) and sulfur powder are used as raw materials, are dissolved in water together with surfactant polyvinyl alcohol (PVA) and polyvinylpyrrolidone (PVP), and then mixed with graphene oxide under a certain pH (potential of hydrogen) condition; the obtained mixed solution is arranged in a reaction kettle and sealed, is held for 12 hours to 24 hours in a constant-temperature box at 180 DEG C to 200 DEG C by using a hydrothermal method, is cooled to normal temperature, stood and separated, centrifugally washed and dried, finally the graphene oxide / iron disulfide composite nano particles can be obtained.

Owner:JIANGSU UNIV

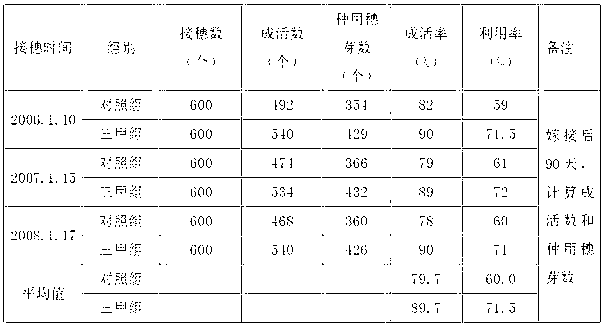

Nutrient solution for grafting of red kiwi and use method of nutrient solution

ActiveCN102795912AIncrease the effective waiting time for graftingReduce moisture evaporationFertilising methodsHorticultureSucrosePhosphate

The invention discloses a nutrient solution for grafting of red kiwi and a use method of the nutrient solution. The nutrient solution comprises an I type nutrient solution and an II type nutrient solution, wherein the I type nutrient solution contains the following constituents: 1,320mg ammonium nitrate, 1,150mg nitrate, 350mg calcium chloride, 240mg magnesium sulfate, 125mg potassium dihydrogen phosphate, 32.5mg sodium ethylene diamine tetracetate, 20.3mg ferrous sulfate, 4.3mg boric acid, 0.35mg potassium iodide, 15.7mg manganese sulfate, 0.02mg copper sulfate, and 7,200mg saccharum or agar that are dissolved in every 1L water, and the II type nutrient solution contains the following constituents: 0.35mg naphthylacetic acid and 0.35mg indolebutyric acid that are dissolved in every 1L water. The nutrient solution for the grafting of the red kiwi can prolong the effective to-be-grafted time of sprouting to be grafted, increase the survival ratio and utilization ratio of the grafting and facilitate the production and popularization of kiwi planting.

Owner:SICHUAN SANJIA AGRI SCI & TECH

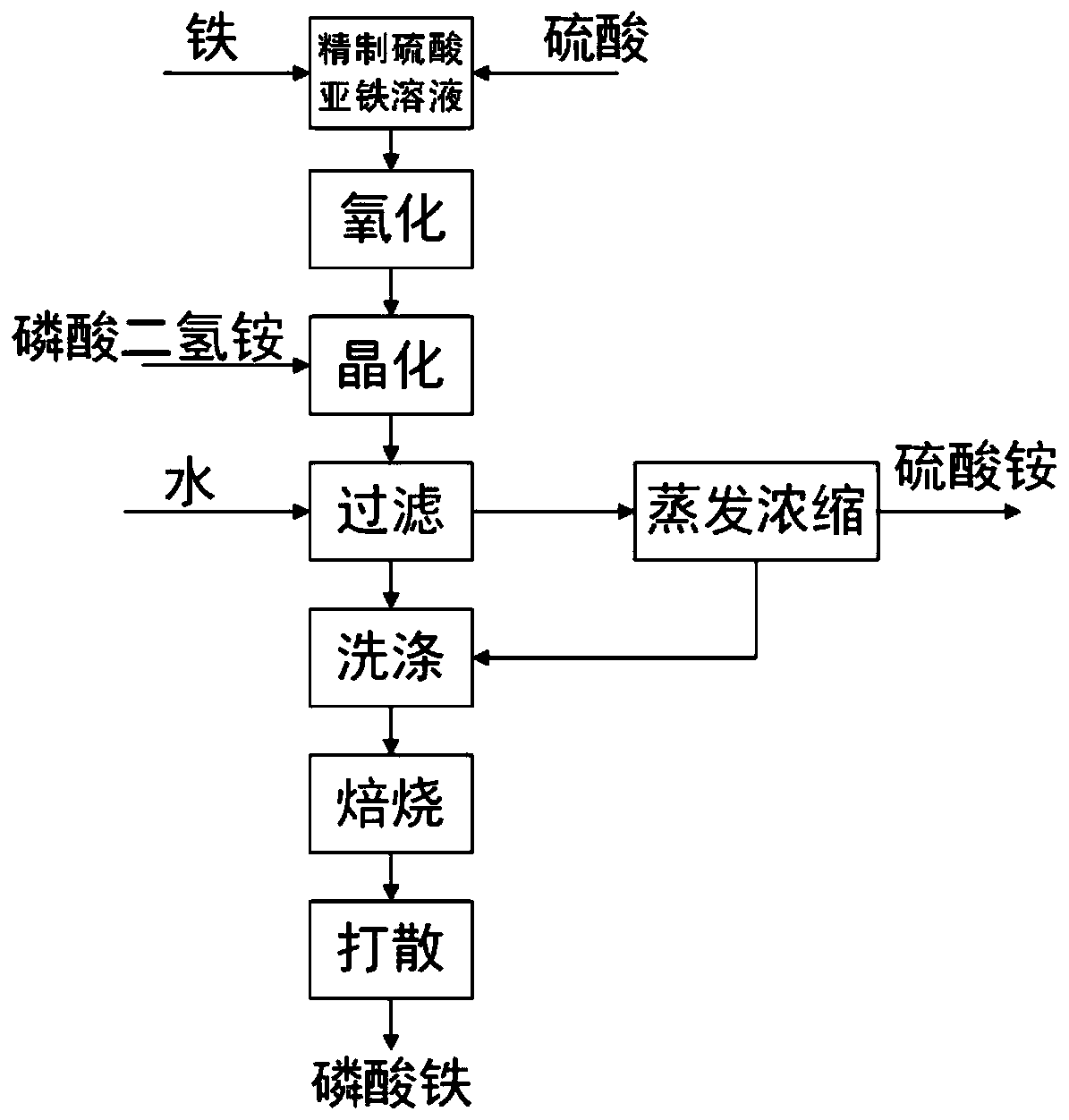

Preparation method of battery-grade anhydrous iron phosphate

ActiveCN110482514AEliminate microscopic component differencesImprove performancePhosphorus compoundsPhosphate ionPhosphoric acid

The invention belongs to the technical field of battery material preparation, and particularly discloses a preparation method of battery-grade anhydrous iron phosphate. The method includes preparing aferrous solution by adopting cold-rolled iron plate leftover materials and / or beneficiation reduced iron powder as an iron source, or preparing a ferrous solution by adopting by-product ferrous sulfate of sulfuric acid method titanium dioxide production; then removing impurities by using a flocculating agent; then oxidizing ferrous ions into ferric ions; mixing the ferric ions with a solution containing phosphate ions; adding a dispersing agent; carrying out crystallization reaction to obtain iron phosphate crystals; subjecting the iron phosphate crystals to drying and roasting to obtain thebattery-grade anhydrous iron phosphate. According to the preparation method, low-cost cold-rolled iron plate leftover materials, beneficiation reduced iron powder or byproduct ferrous sulfate in a sulfuric acid method titanium dioxide production process is used as an iron source for preparation; the flocculating agent is adopted for impurity removal, and then crystallization is performed to prepare the battery-grade anhydrous iron phosphate. The method has the advantages of low raw material cost, high product purity and high tap density, is of a spherical structure, and can be used as a precursor of lithium iron phosphate with high tap density.

Owner:安徽丰原锂电能源有限公司 +1

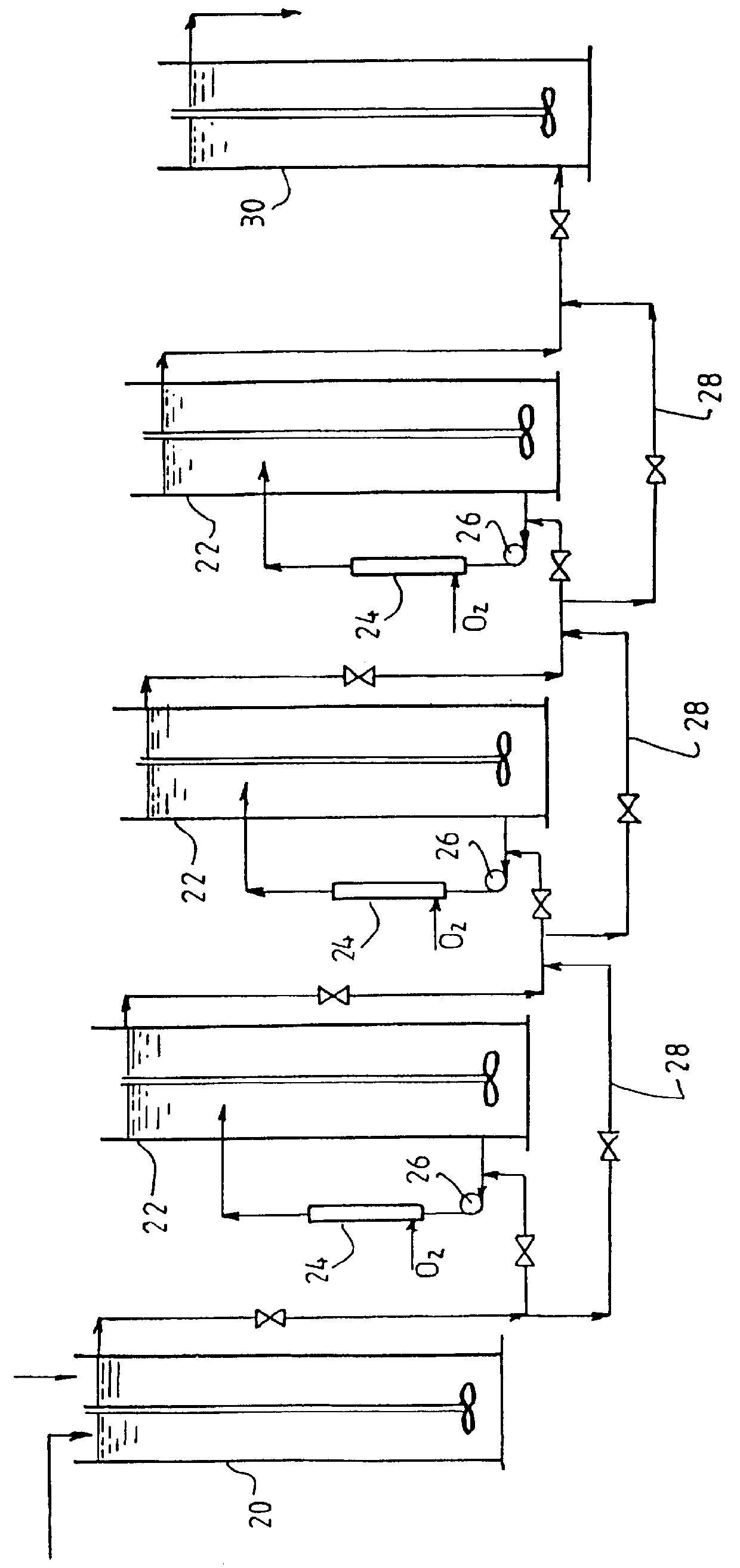

Leaching of mineral ores

A process for oxidation of ferrous ions in solution, and more particularly a process for improved base metal and / or uranium leaching from ores, concentrates or tailings using ferric ion as an oxidizing agent. A reaction vessel (10) holds a ferrous ion-containing solution, for example, a copper sulphide leach slurry or concentrate. An agitator (12) may be provided to promote leaching of the base metal into solution. Some of the ferrous ion-containing solution is drawn off from the reaction vessel (10) and pumped through an in-line mixer (14) via a feed pump (16). Oxygen is injected into the reactor (14) to facilitate oxidation of the ferrous sulphate to form ferric sulphate. The ferric ion-containing solution is then recirculated back to the reaction vessel (10) where the ferric ions are reused in the dissolution of copper sulphide into soluble copper sulphate. The two processes of ferrous oxidation and metal leaching can be conducted either simultaneously or sequentially to effect recovery of copper, other base metals or uranium from ores, concentrates or tailings.

Owner:ATOMAER

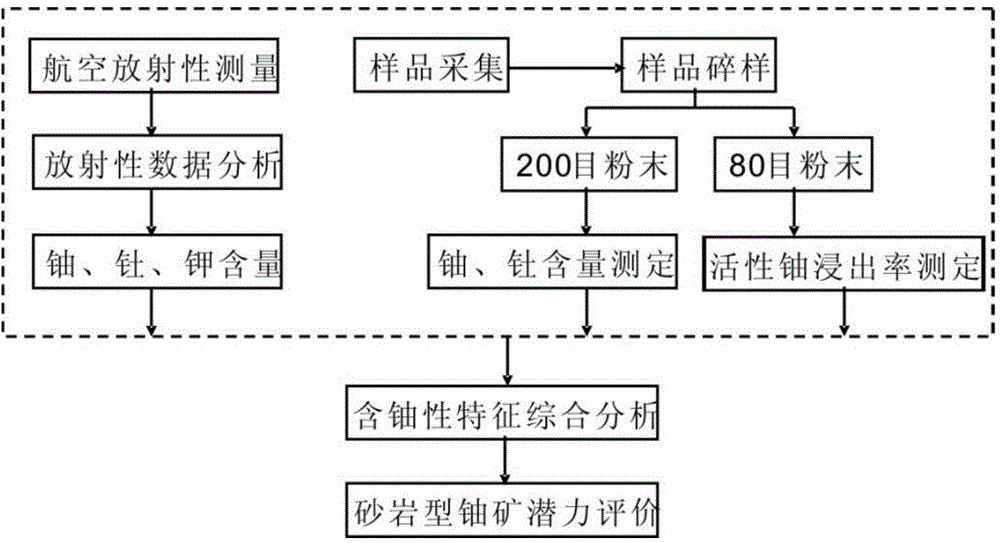

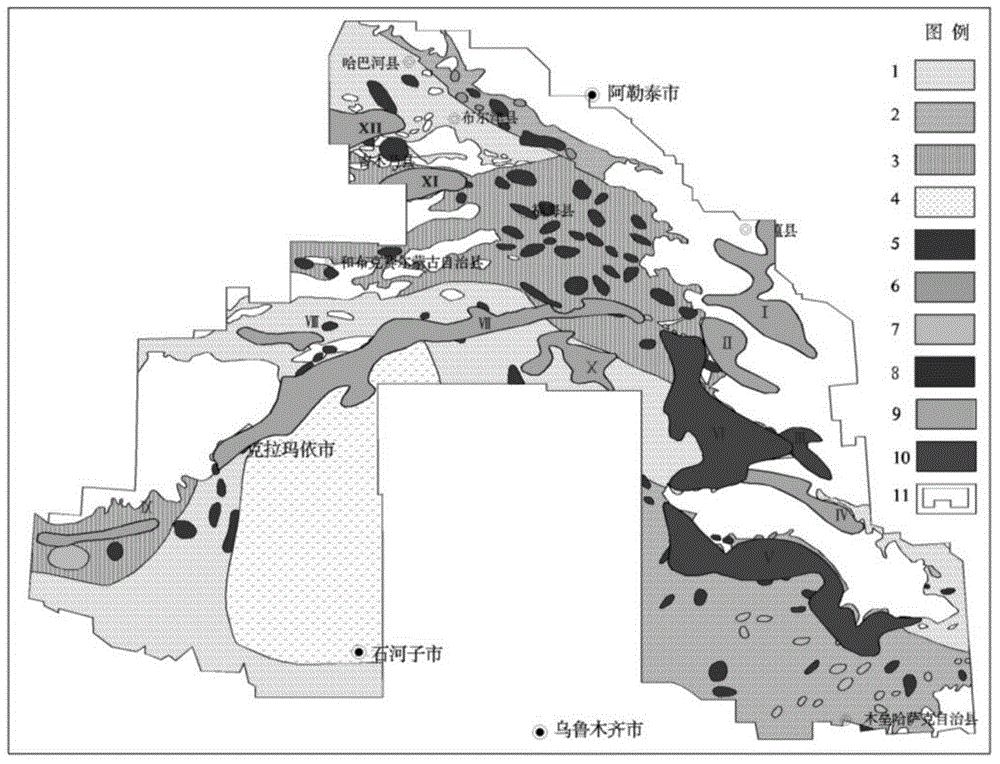

Sedimentary basin base uranium fertility and sandstone-type uranium deposit mineralization potentiality evaluation method

InactiveCN105807327AAnalytical testing requirements are clearEasy to operateNuclear radiation detectionGamma energySedimentary basin

The invention belongs to the technical field of uranium mines, and specifically discloses a sedimentary basin base uranium fertility and sandstone-type uranium deposit mineralization potentiality evaluation method. The method comprises the following steps: S1, comprehensively measuring aerial gamma energy spectra in a base provenance area; S2, collecting a medium acidic igneous rock sample in an aerial radioactivity measurement work area, and performing 80-mesh and 200-mesh pollution-free crushing on the sample; S3, measuring the quantity of ferrous oxide and major and minor components in the 200-mesh pollution-free powder; S4, measuring the share of active uranium in the 80-mesh pollution-free powder; S5, analyzing and arranging data about the content of uranium and thorium, the thorium-uranium ratio and the leaching rate of the active uranium; and S6, analyzing the base rock uranium fertility and evaluating the sandstone-type uranium deposit mineralization potentiality in combination with the data results of S1 and S4. The method is used for judging the uranium fertility of large sedimentary basin margin erosion source areas, and providing basis for large sedimentary basin sandstone-type uranium deposit mineralization potentiality evaluation.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

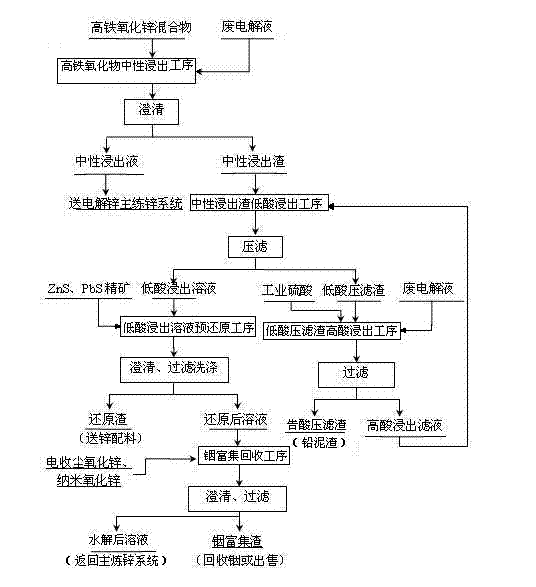

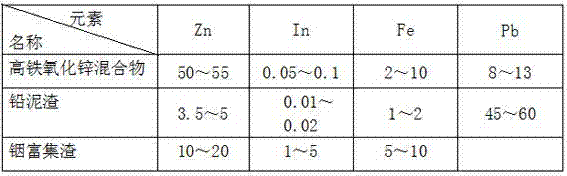

Method for recovering zinc, indium, iron, and lead from high-iron zinc oxide mixture smelted with zinc

ActiveCN103667720ASolve processing problemsReduce the amount addedProcess efficiency improvementPregnant leach solutionElectrolysis

The invention relates to the field of metal smelting, particularly to a method for recovering zinc, indium, iron, and lead from a high-iron zinc oxide mixture smelted with zinc. The method comprises the following processes: a high-iron zinc oxide mixture neutral leaching process, a neutral leaching residue low acid leaching process, a low acid pressure filter residue peracid leaching process, a low acid leaching liquid prereduction process, and a indium enrichment recycling process; valuable metals are comprehensively recovered from the high-iron zinc oxide mixture; a generated neutral leaching liquid is adopted by a main zinc smelting system to generate electrolytic zinc; a hydrolyzing filter liquor generated from the indium enrichment recycling process contains relatively rich ferrous ions; the hydrolyzing filter liquor is adopted by the main system for removing impurities and generating high-grade indium enrichment residues; therefore, the high-iron zinc oxide mixture is effectively recycled, the problem of high-iron zinc oxide mixture treatment is solved, capability of comprehensive utilization of metal resources is increased, so that resources are comprehensively recycled, and environment protection is facilitated; the method has relatively good economic benefits and social benefits.

Owner:HENAN YUGUANG ZINC IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com