Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Accelerate breakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

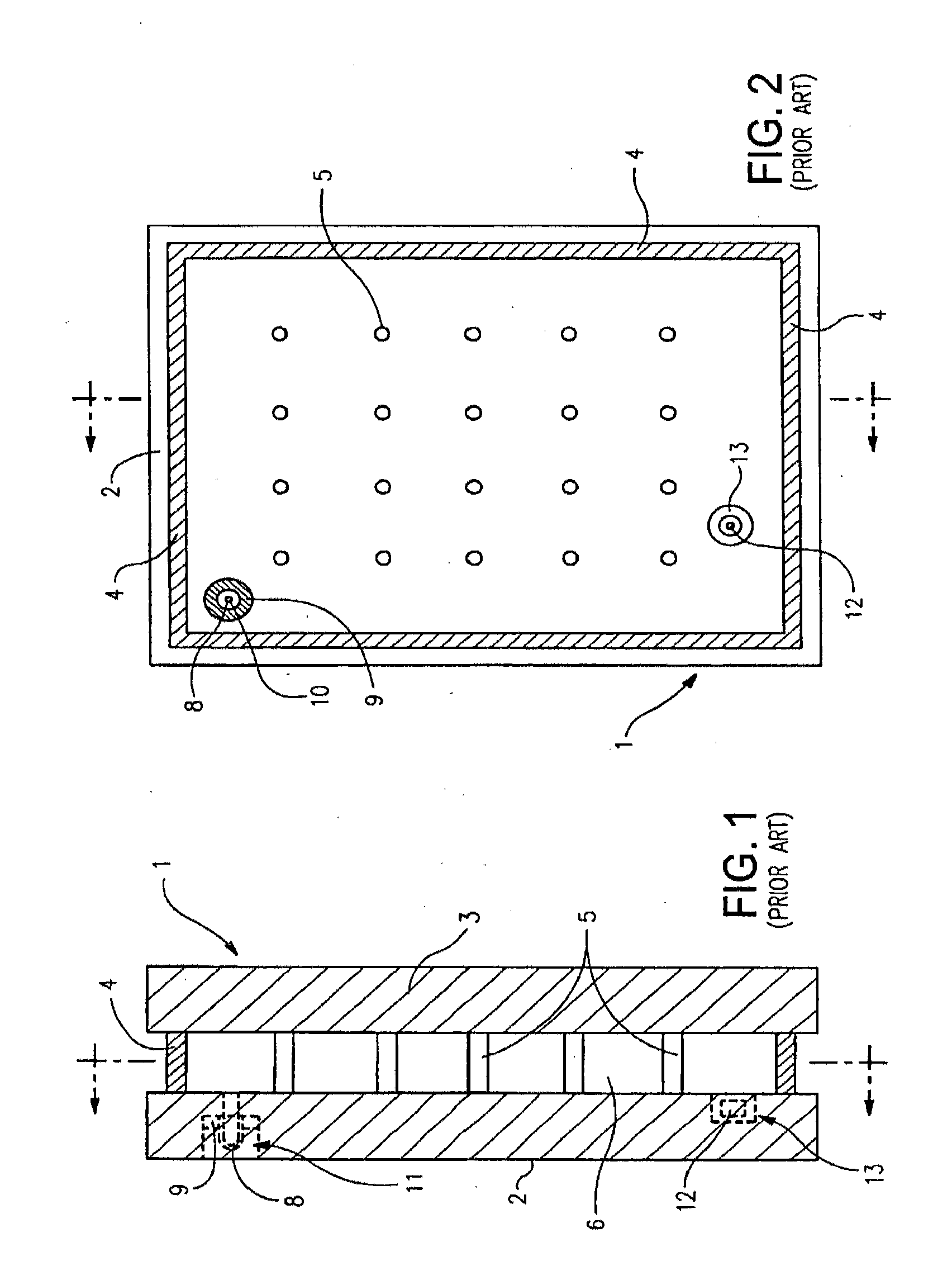

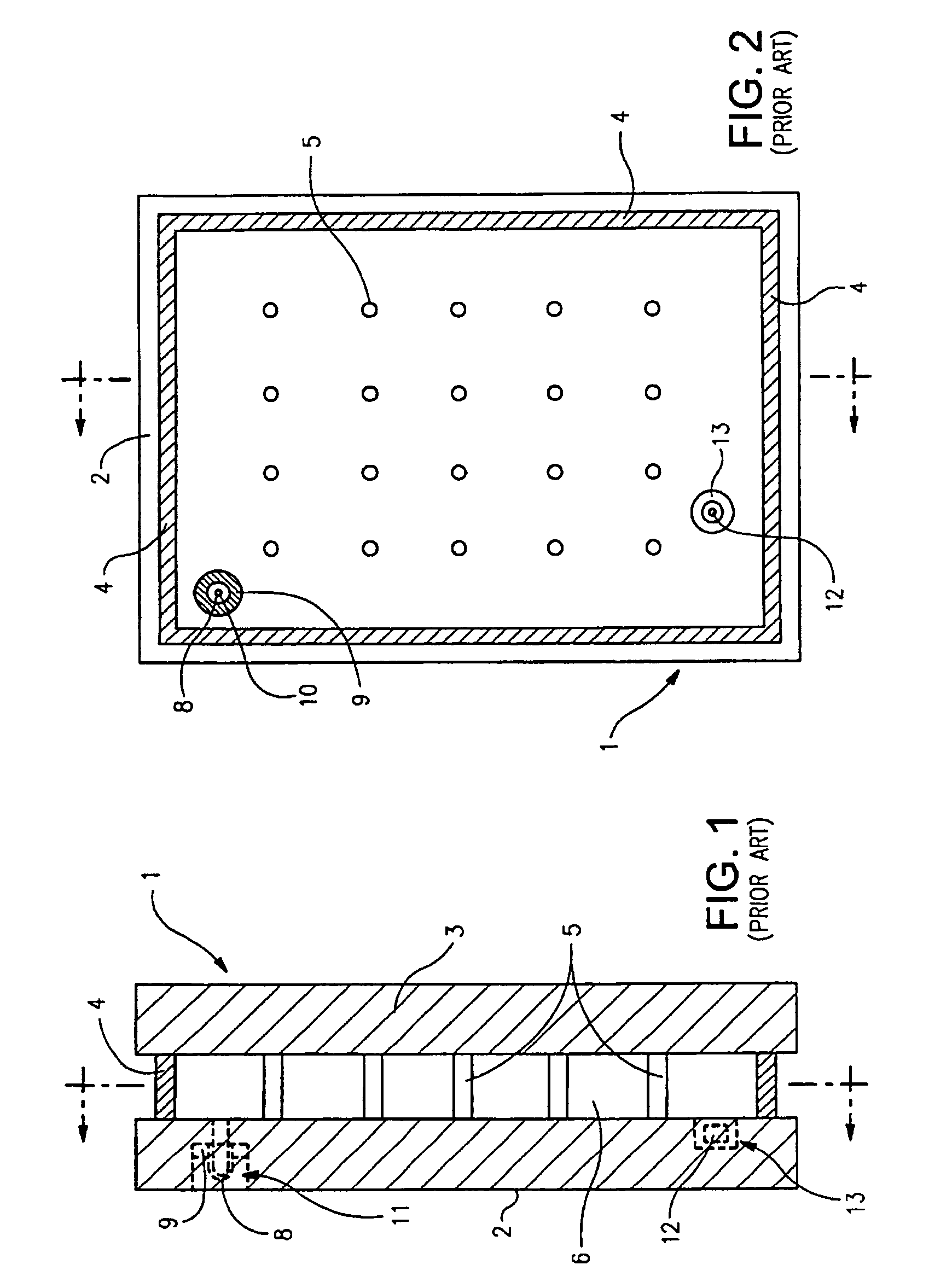

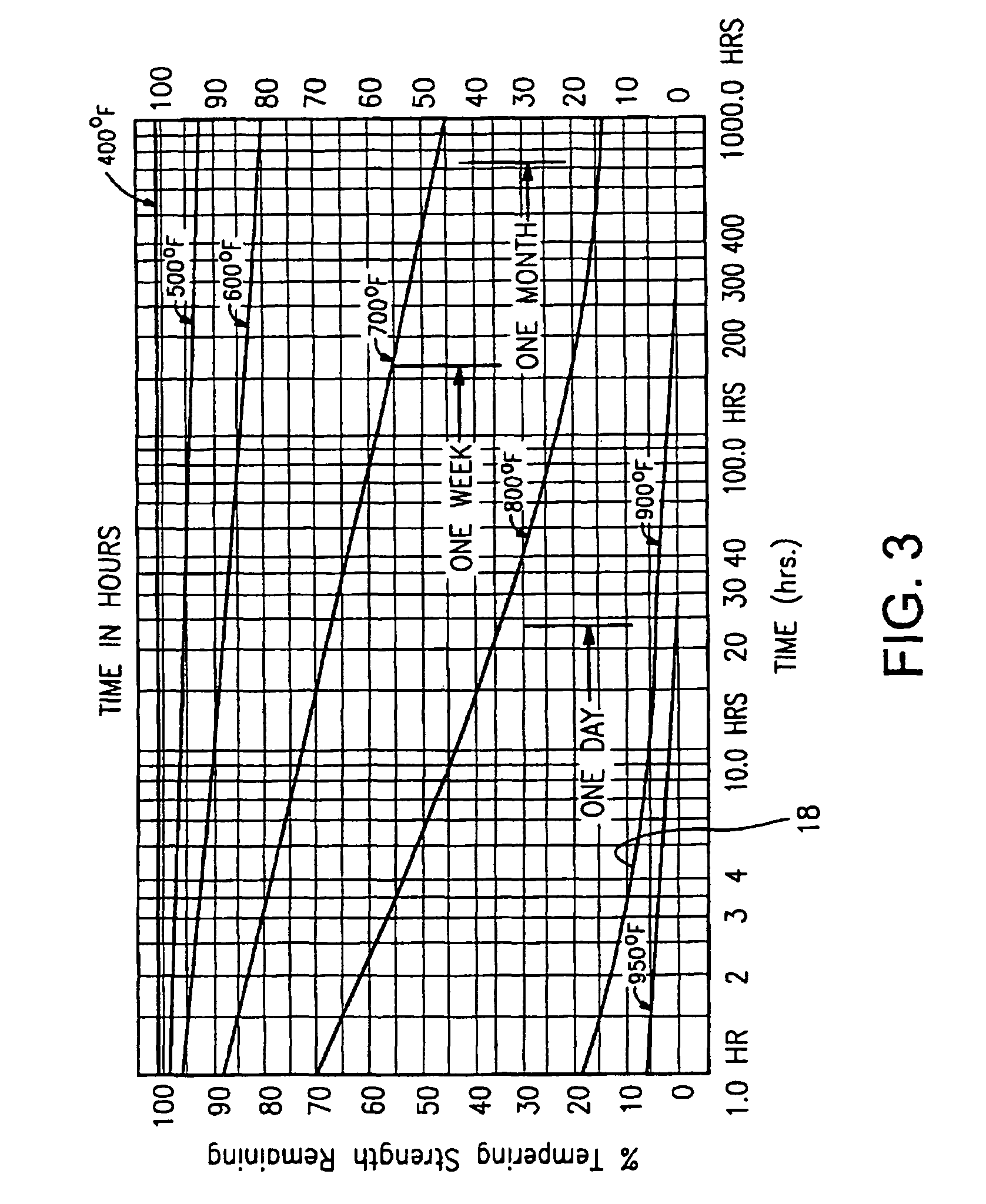

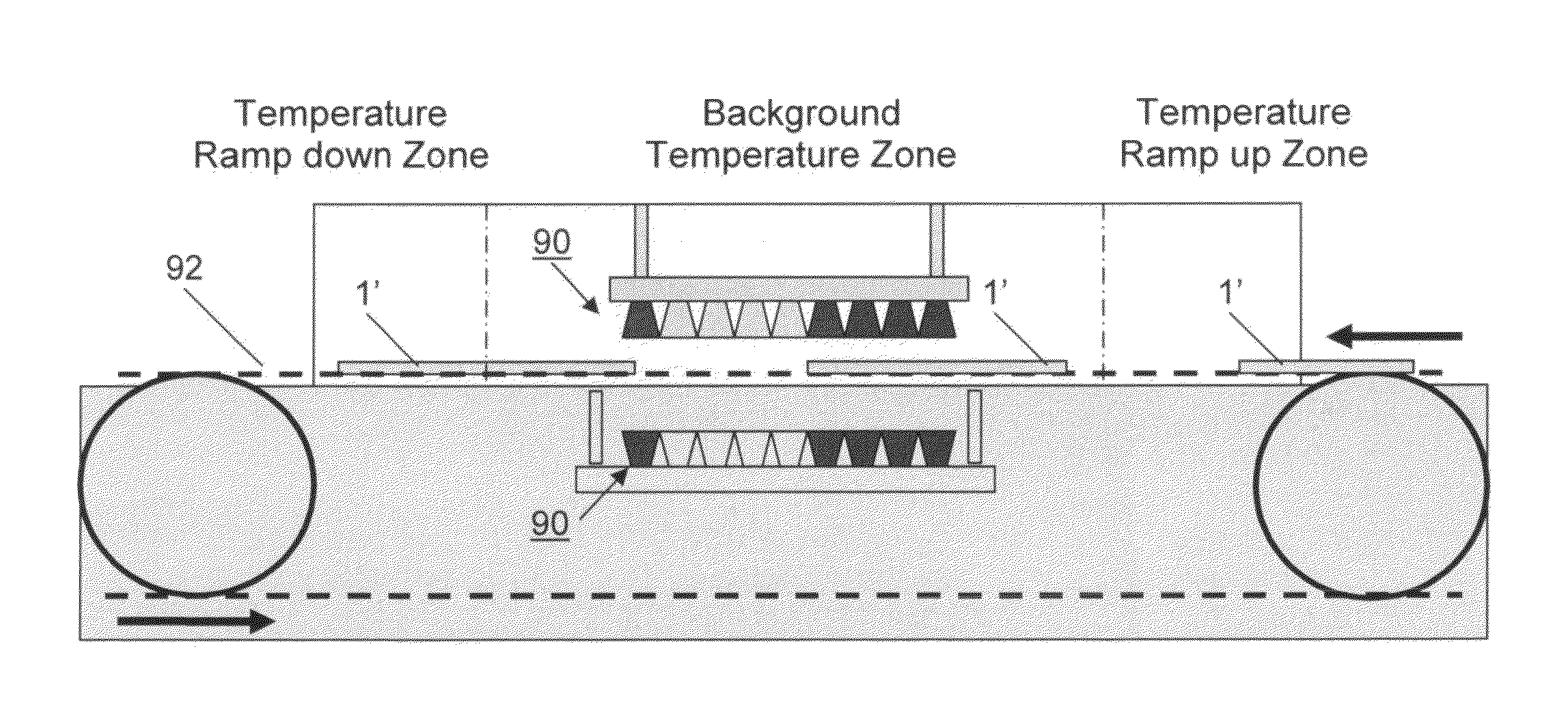

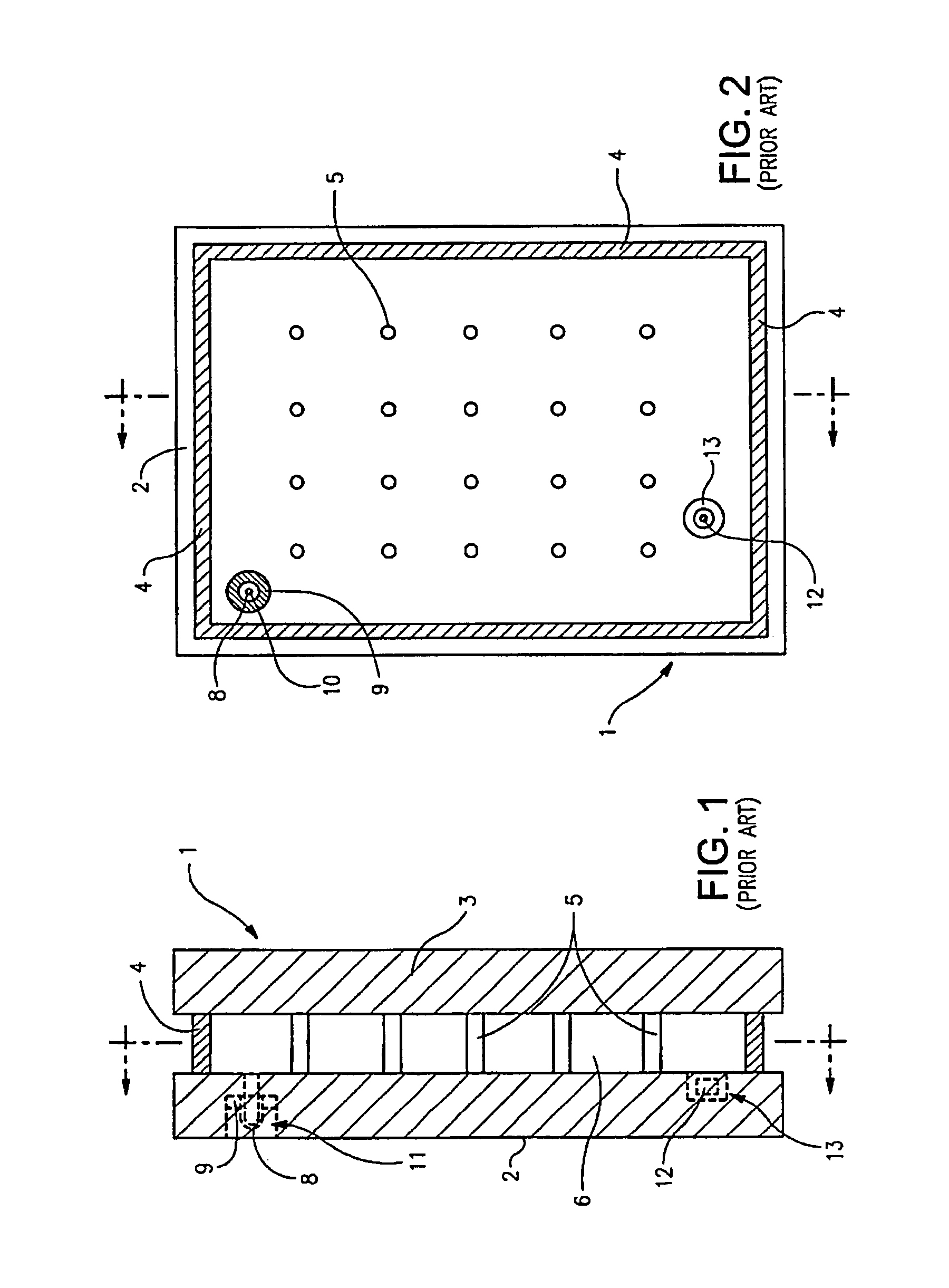

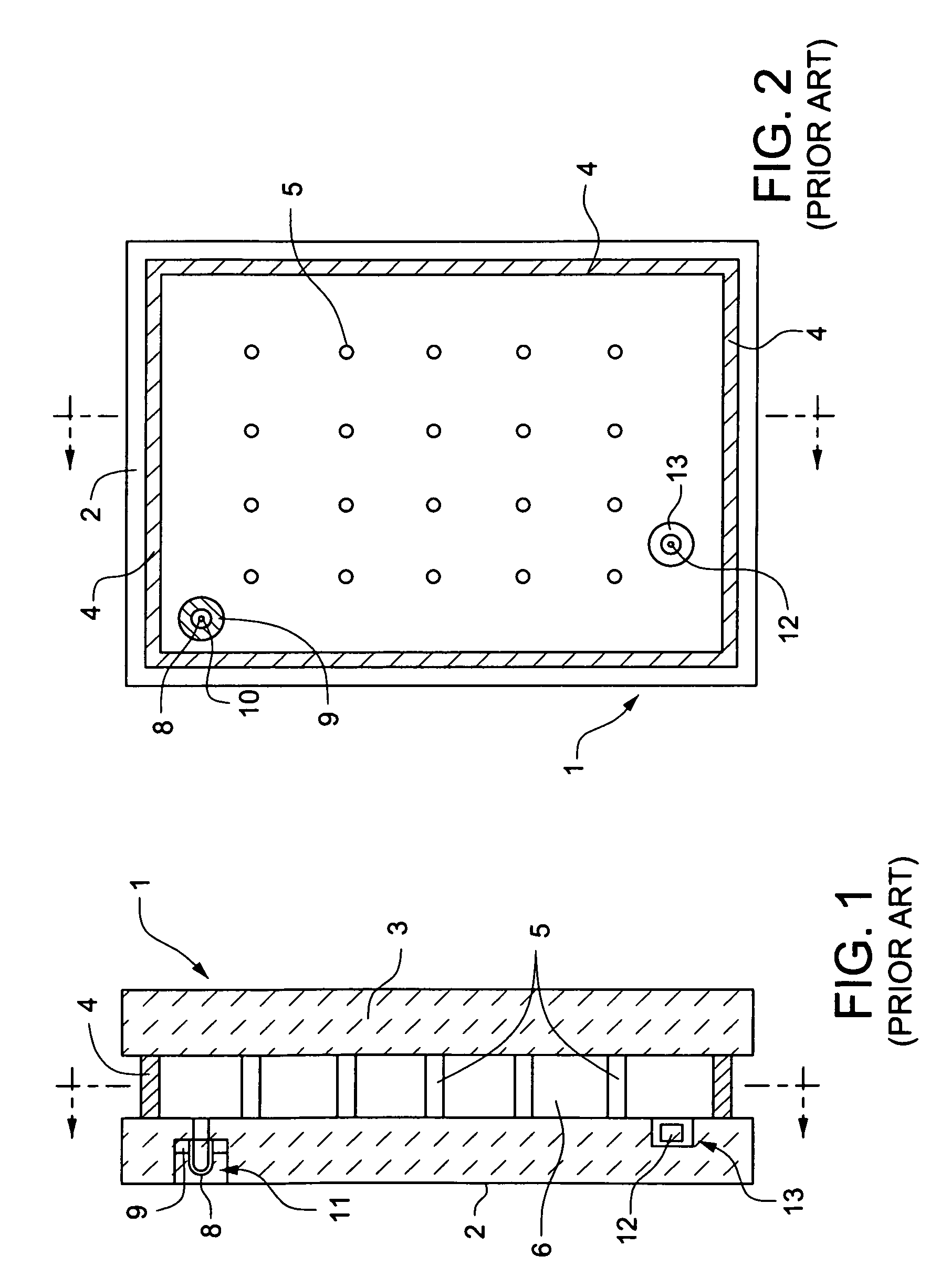

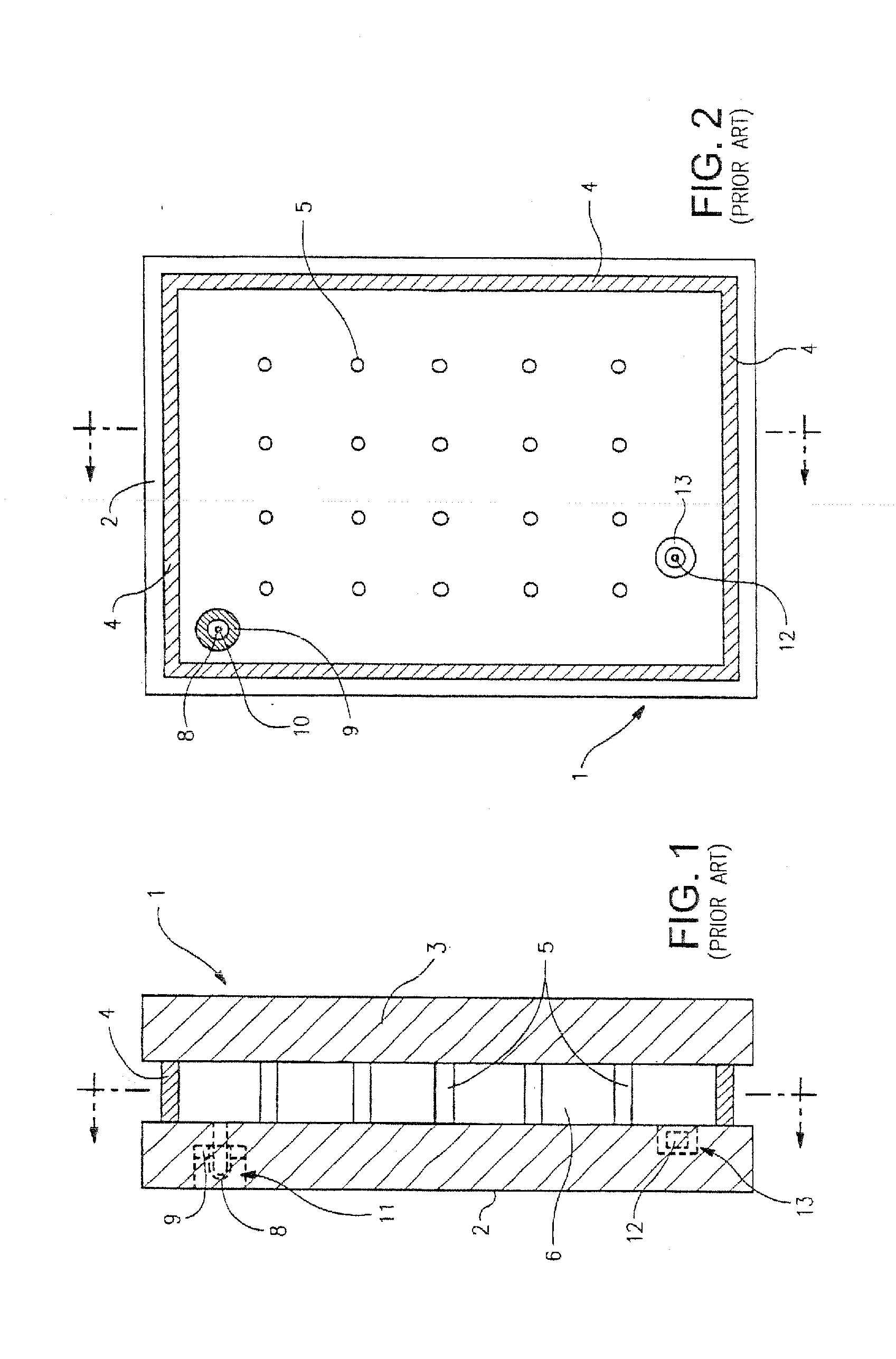

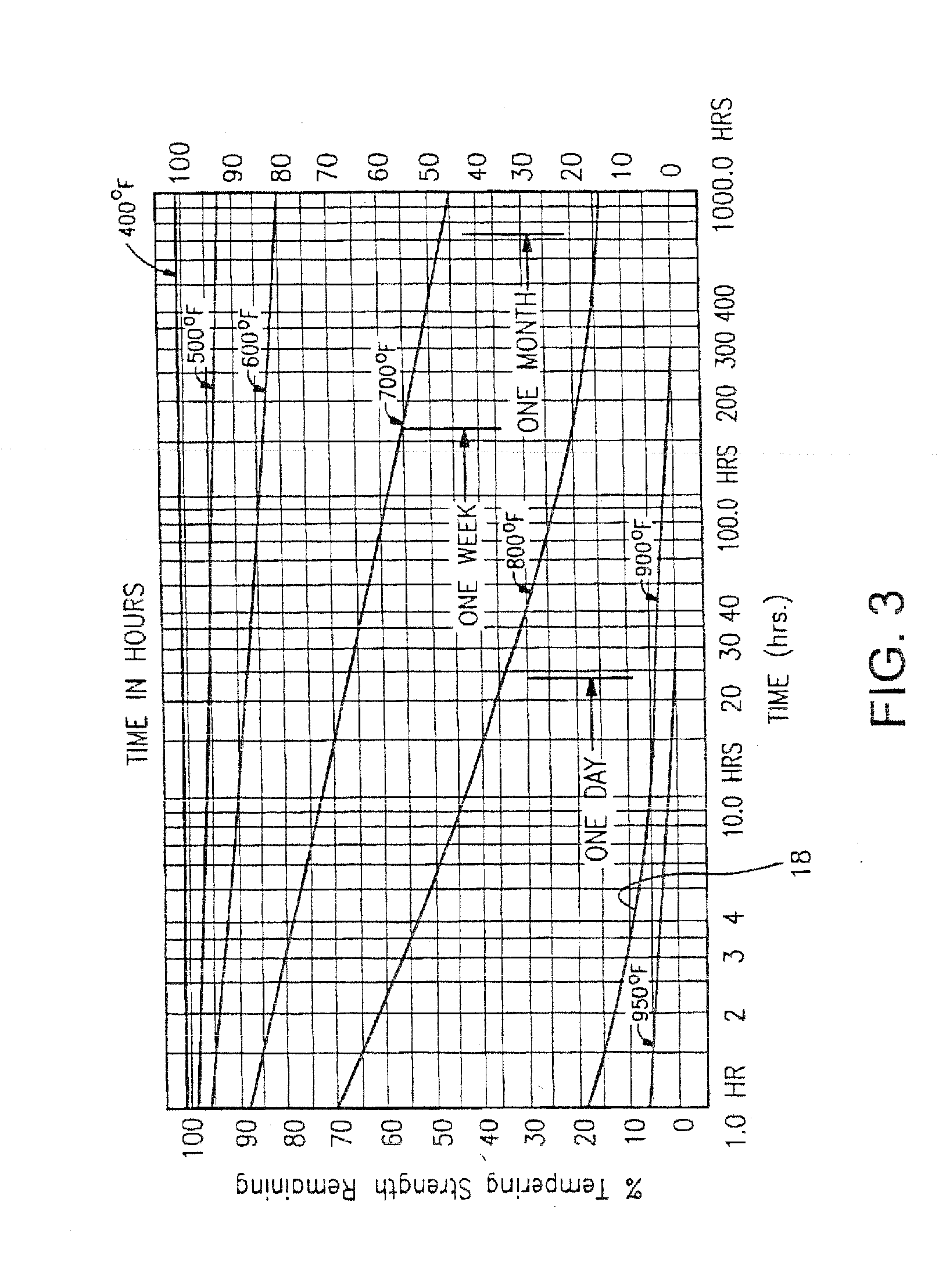

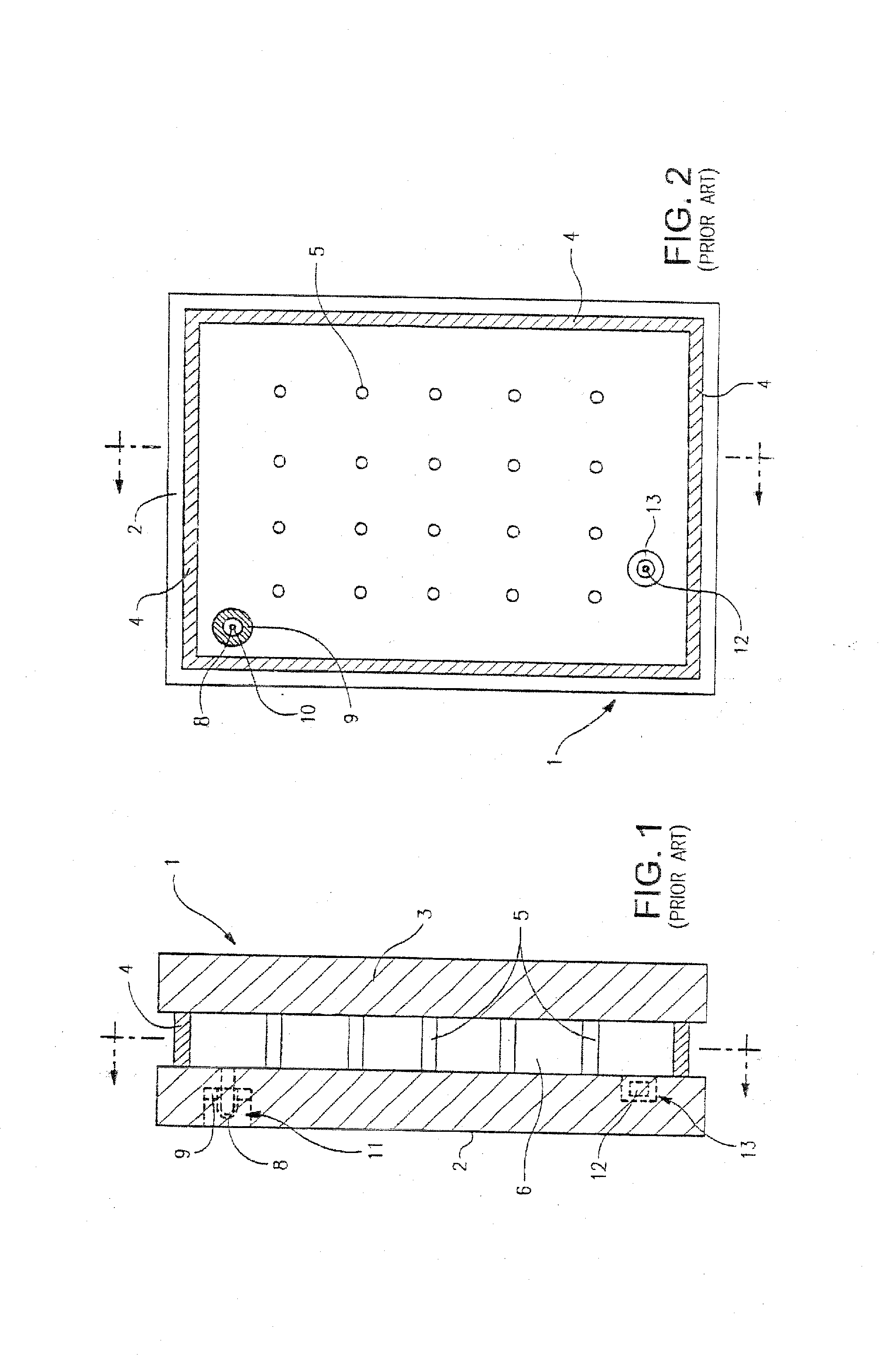

Localized heating via an infrared heat source array of edge seals for a vacuum insulating glass unit, and/or unitized oven with infrared heat source array for accomplishing the same

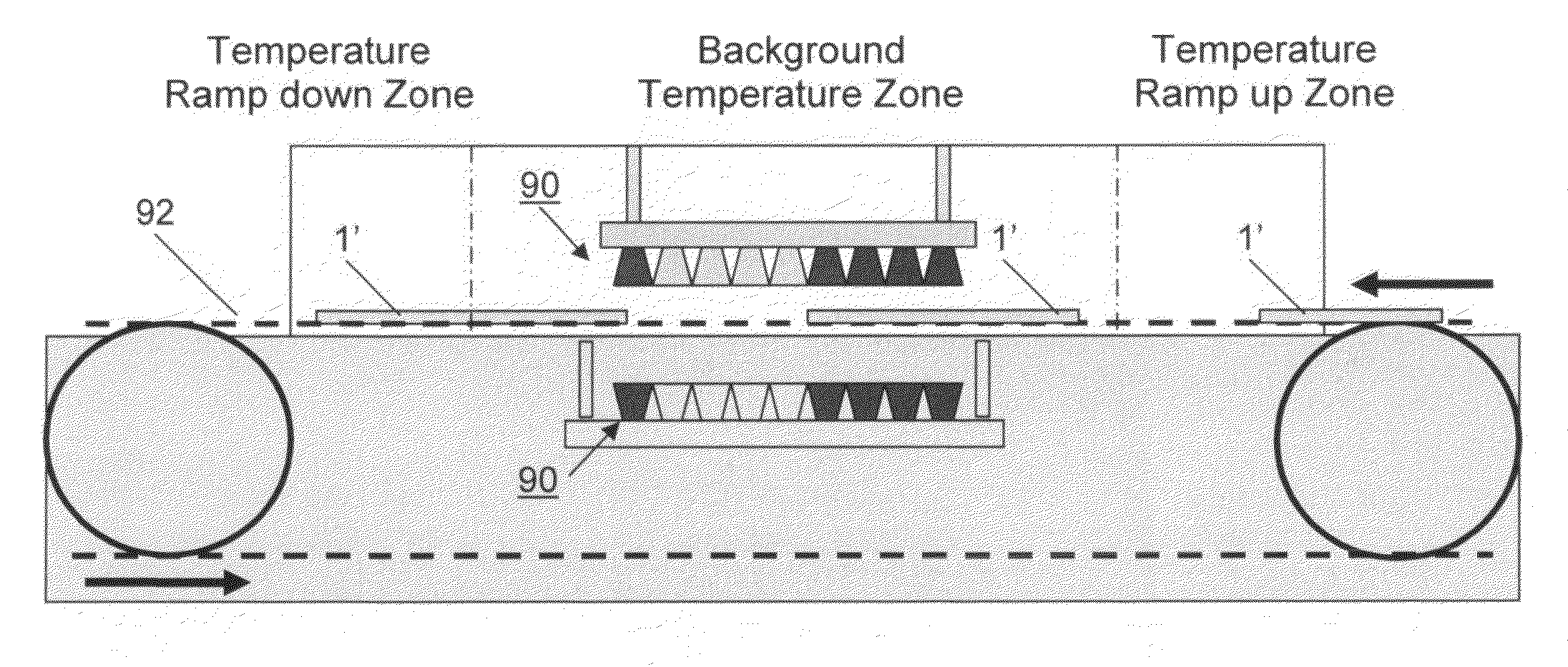

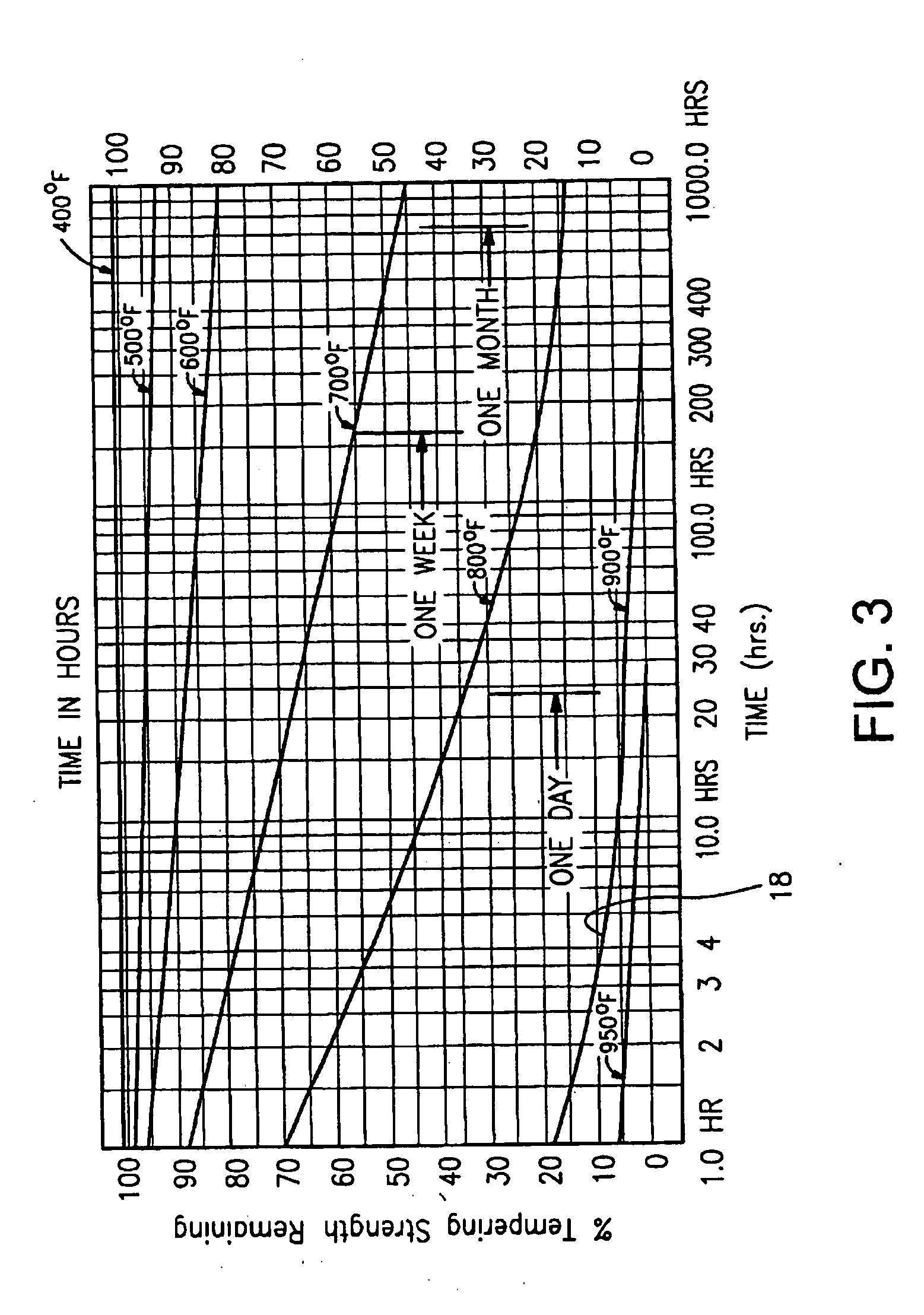

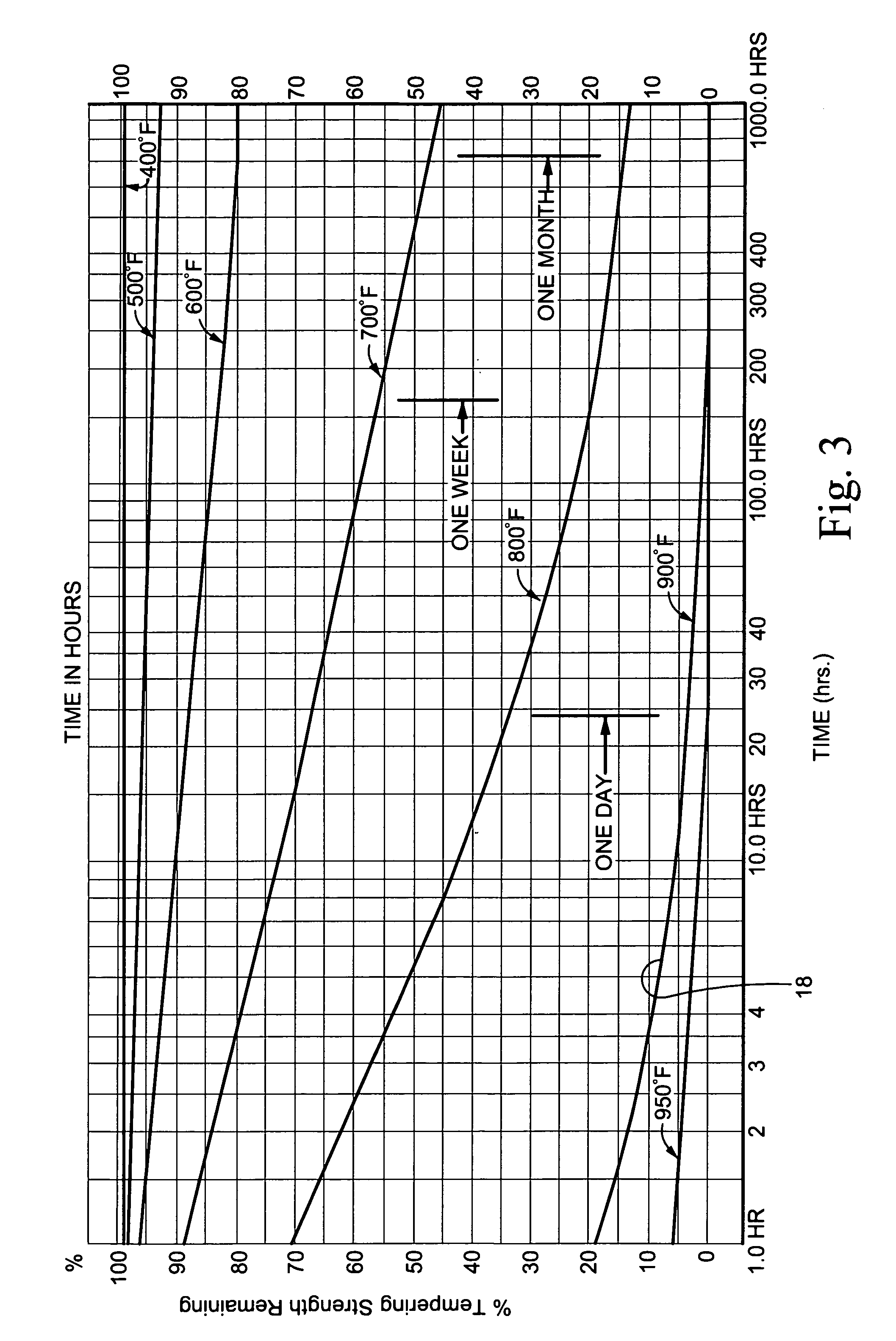

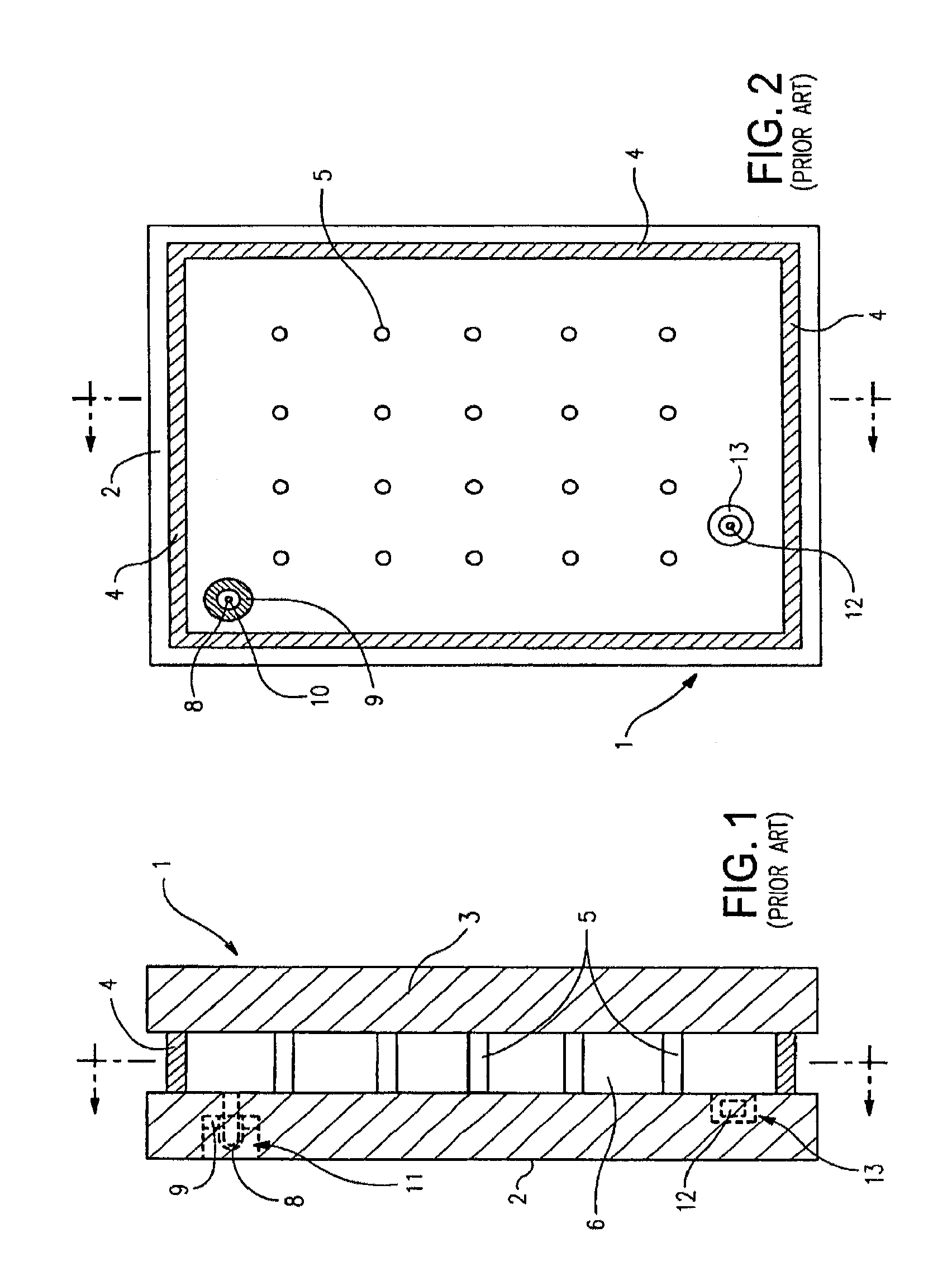

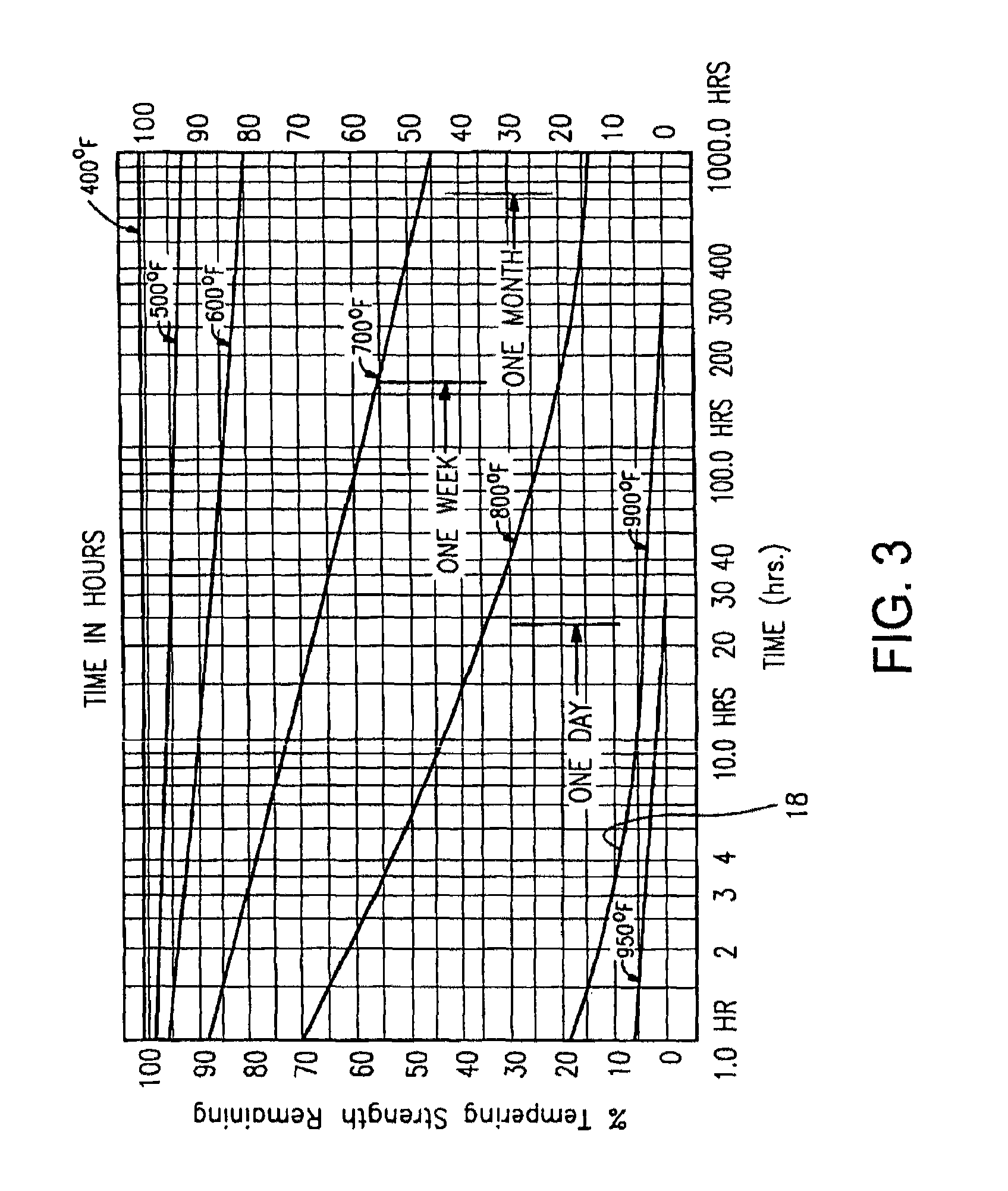

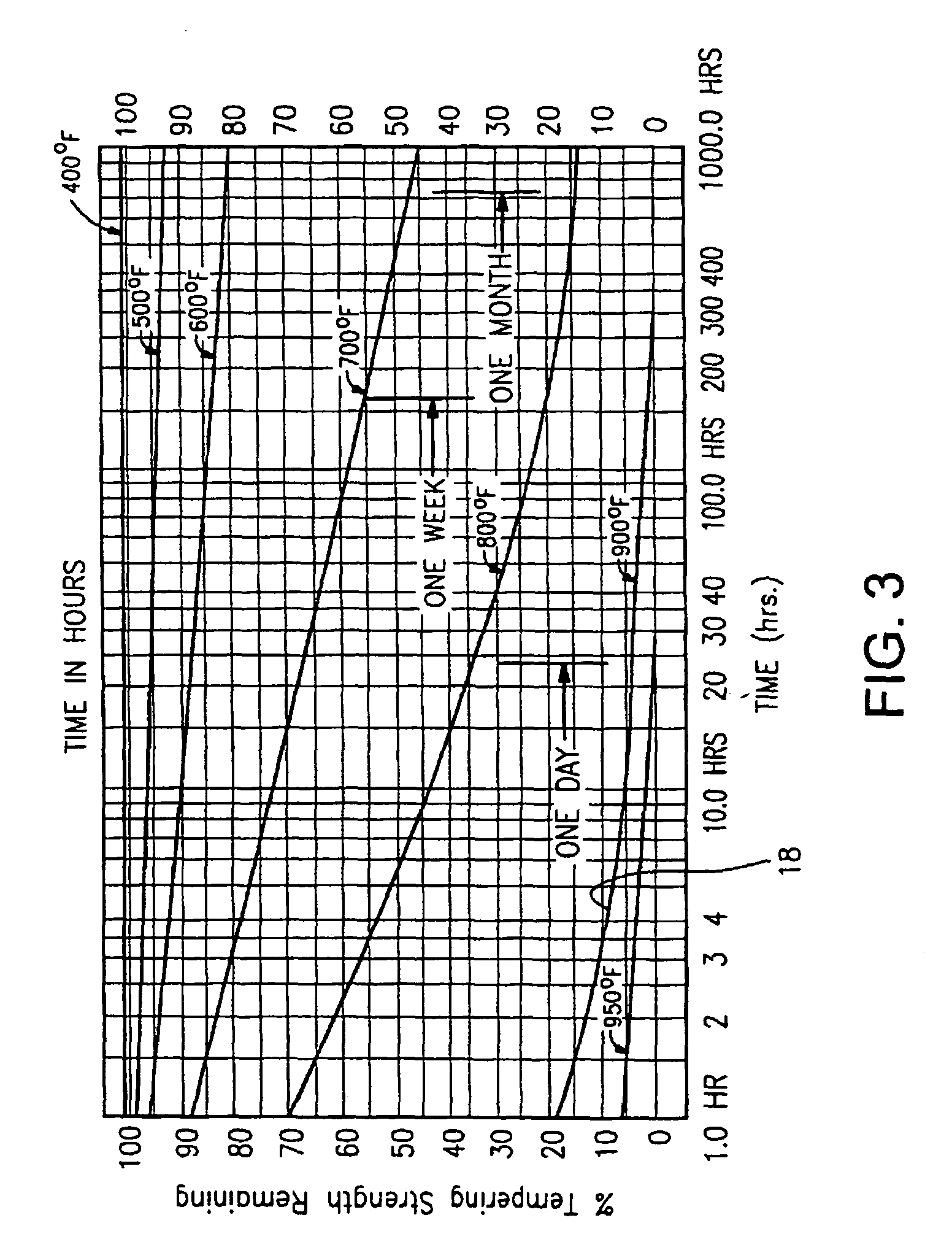

ActiveUS20090151855A1Lower temperatureIncrease likelihood of deformationClimate change adaptationLaminationEngineeringThermal source

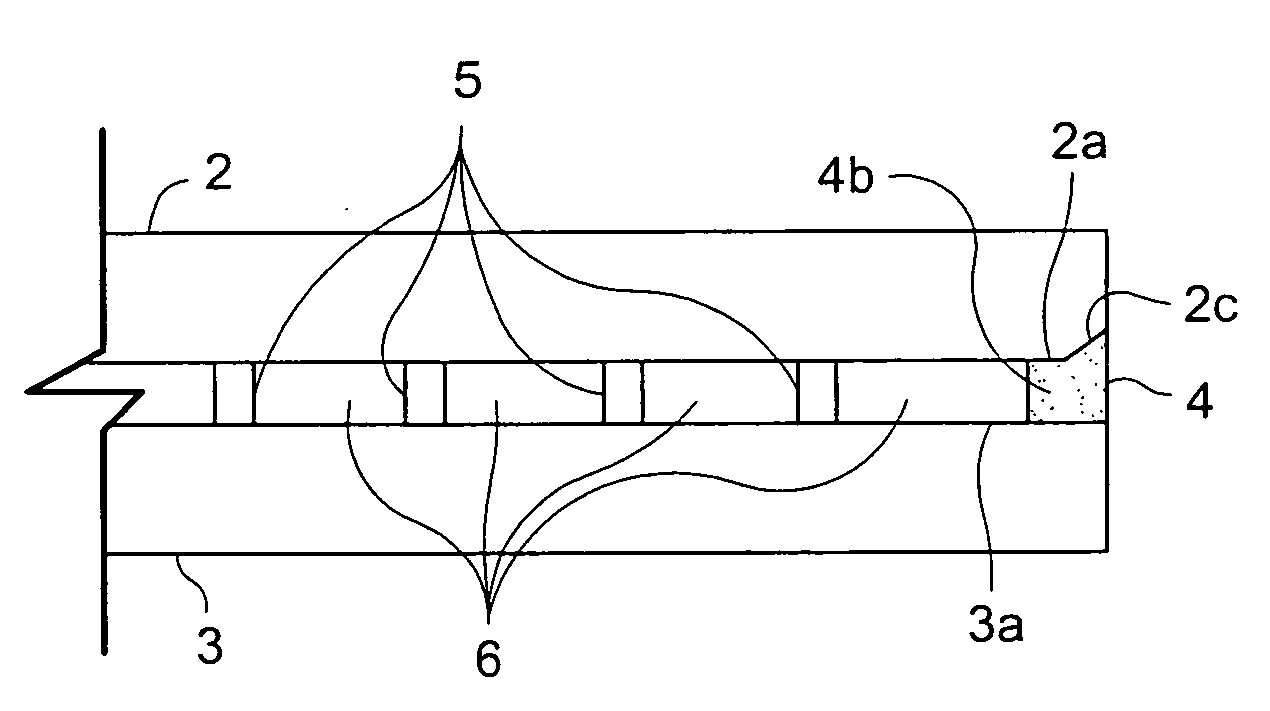

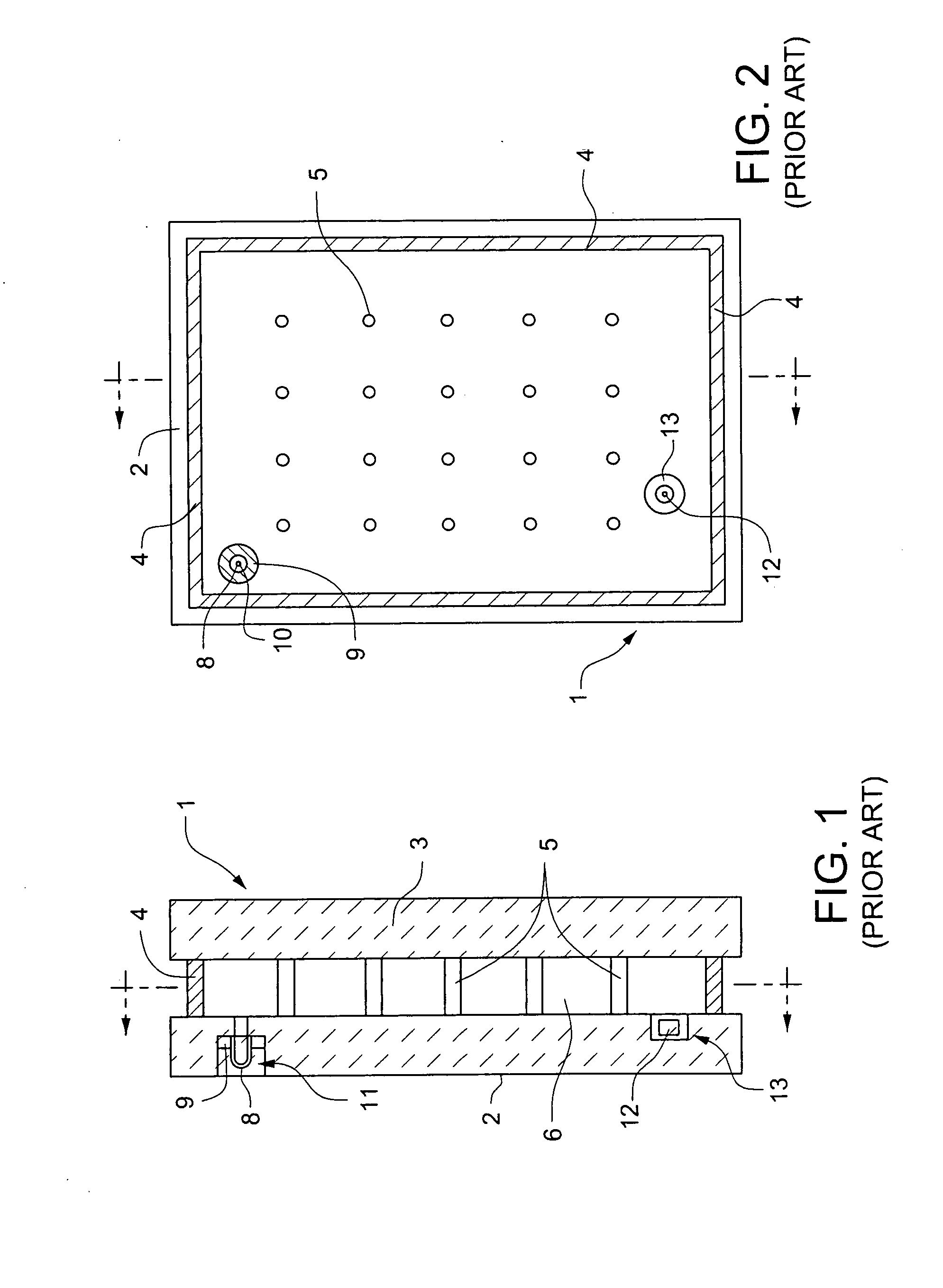

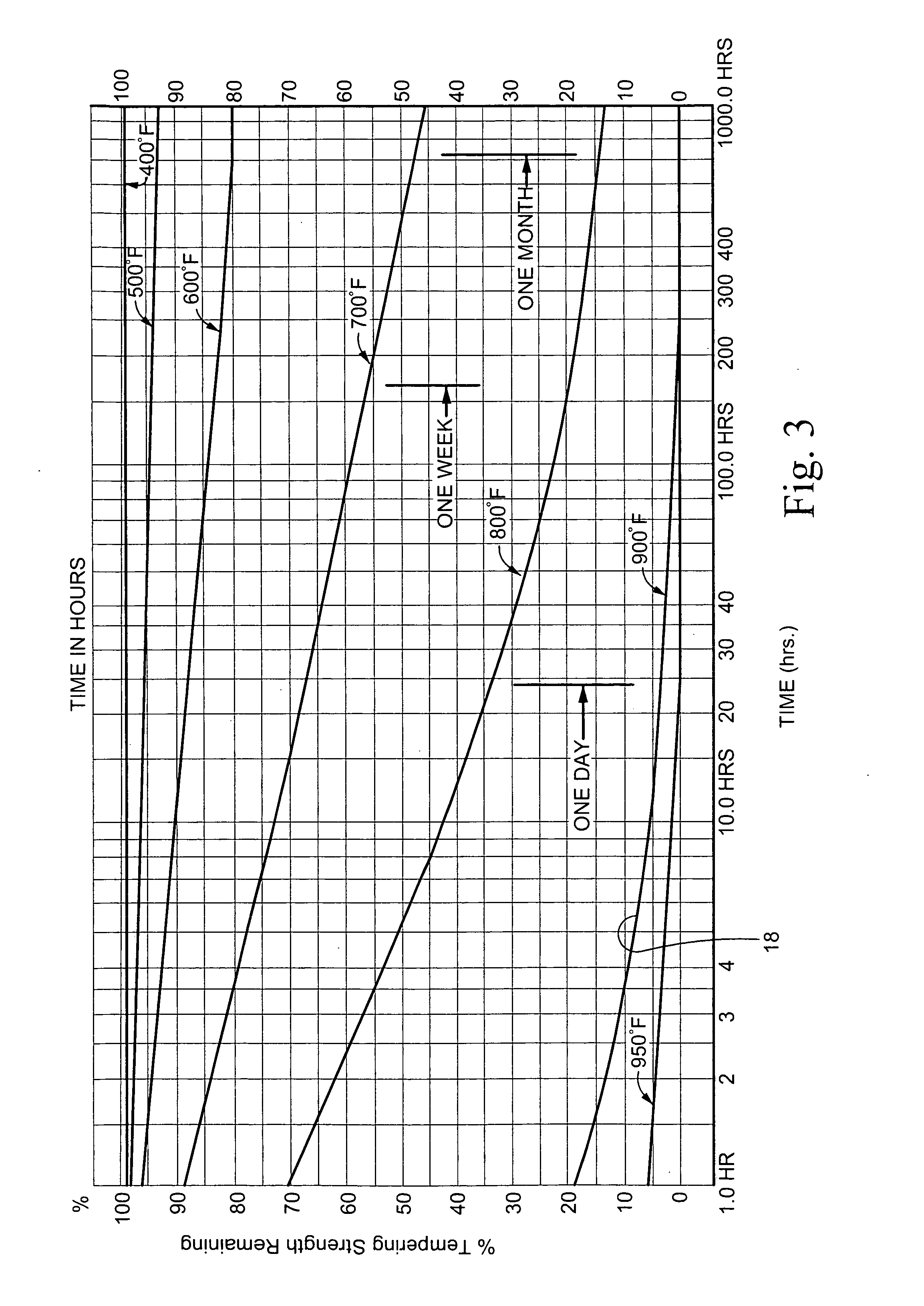

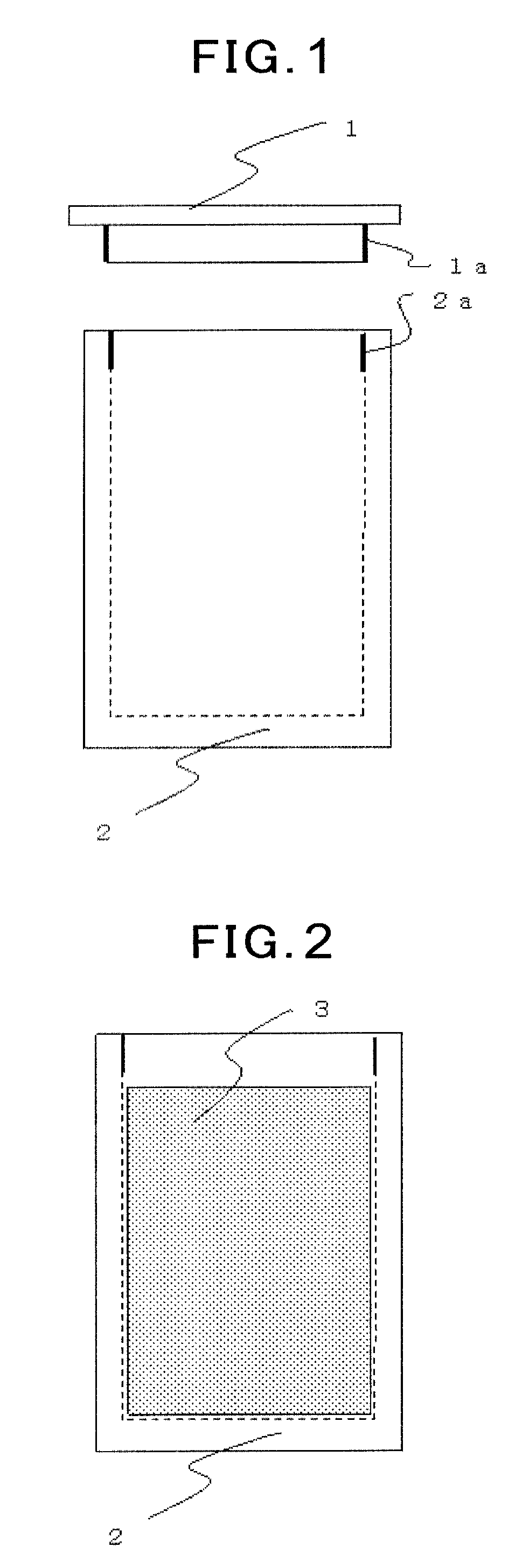

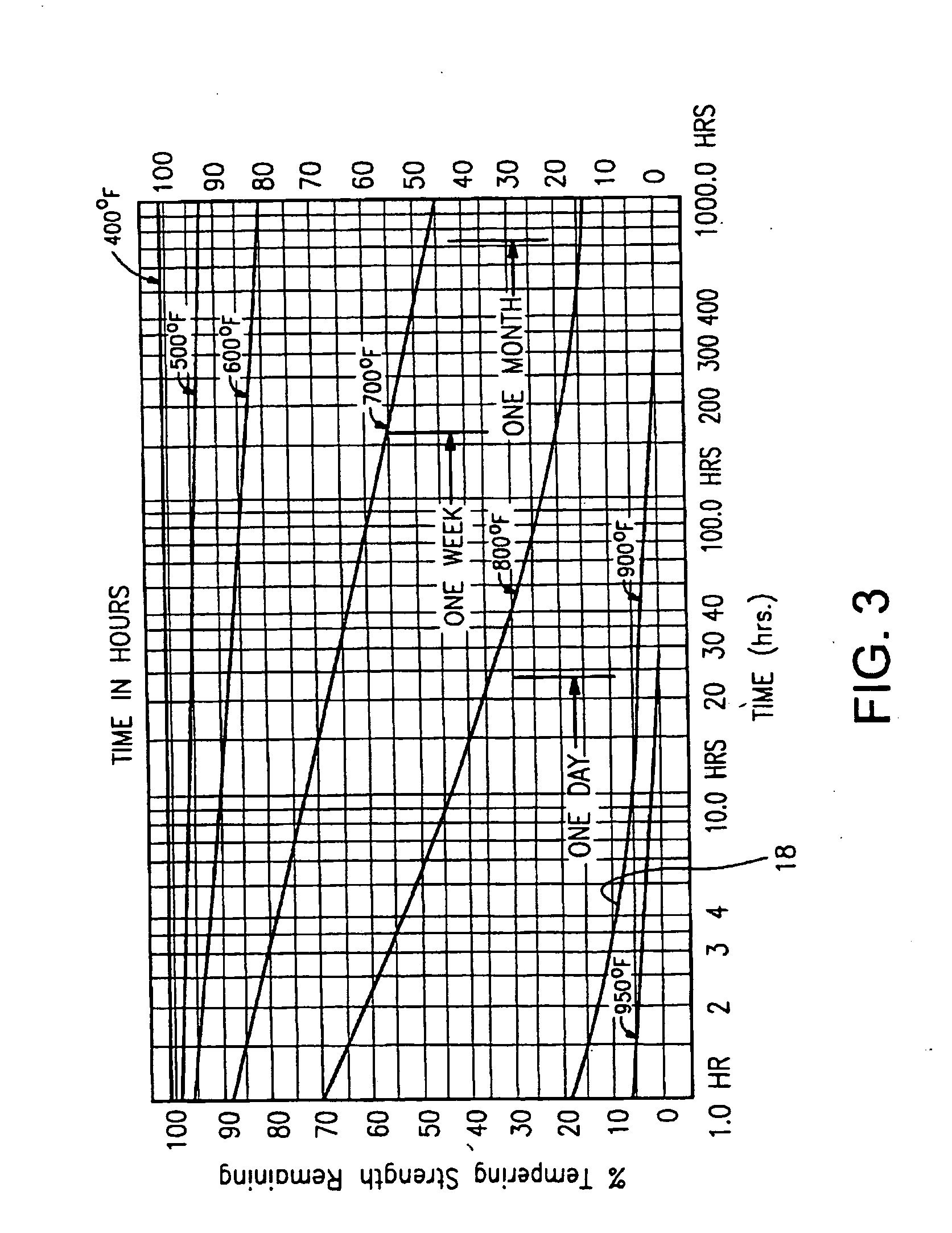

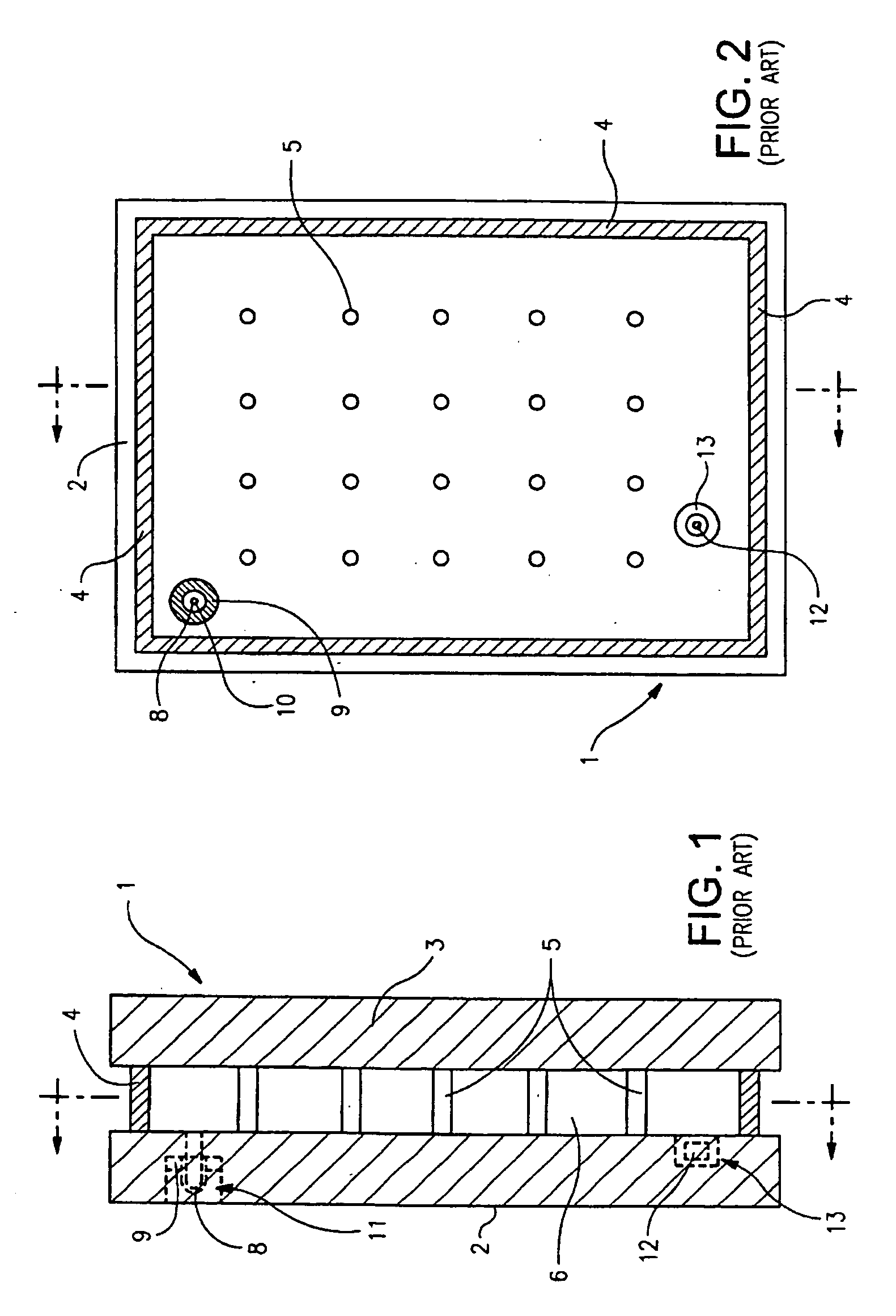

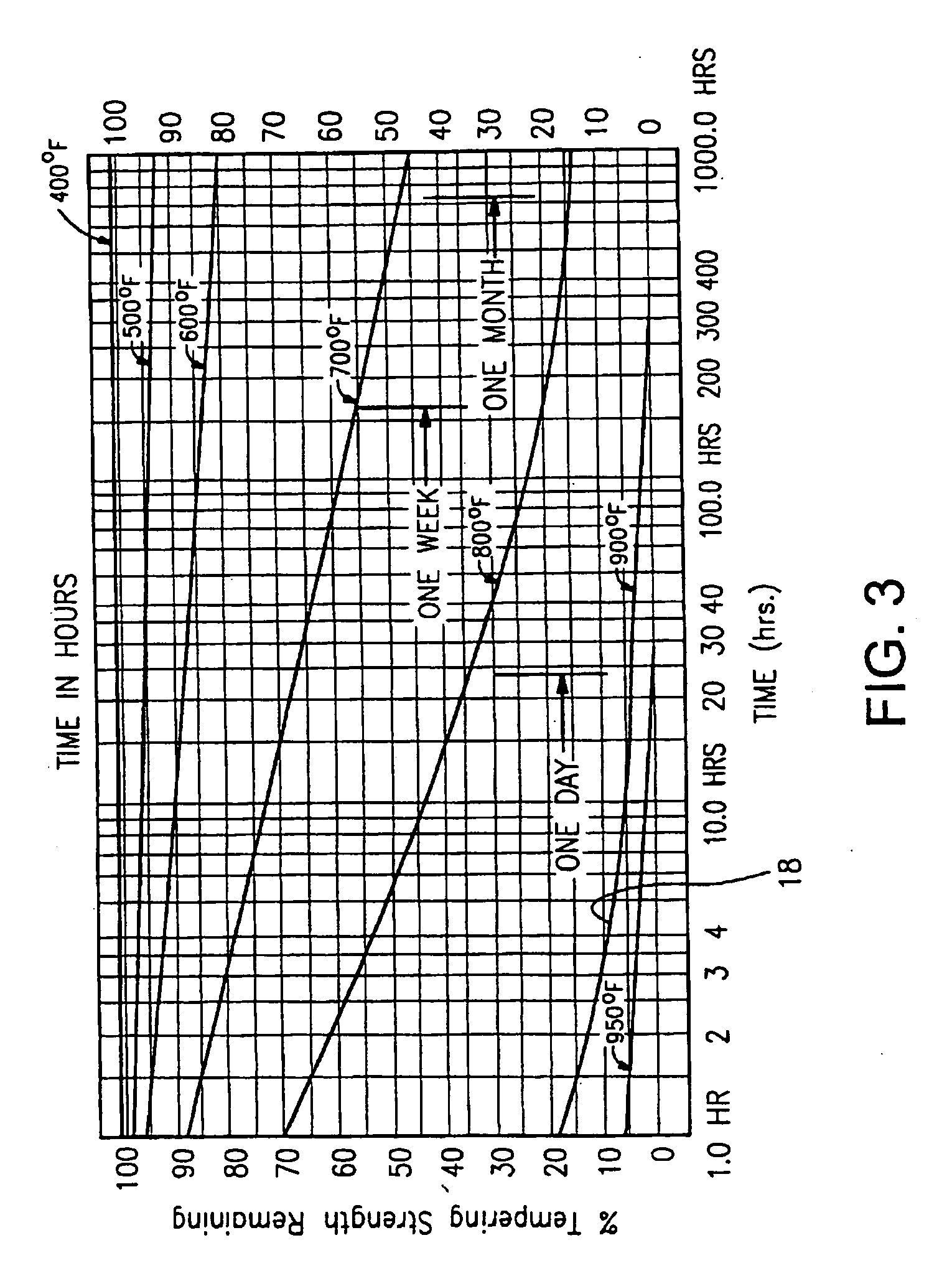

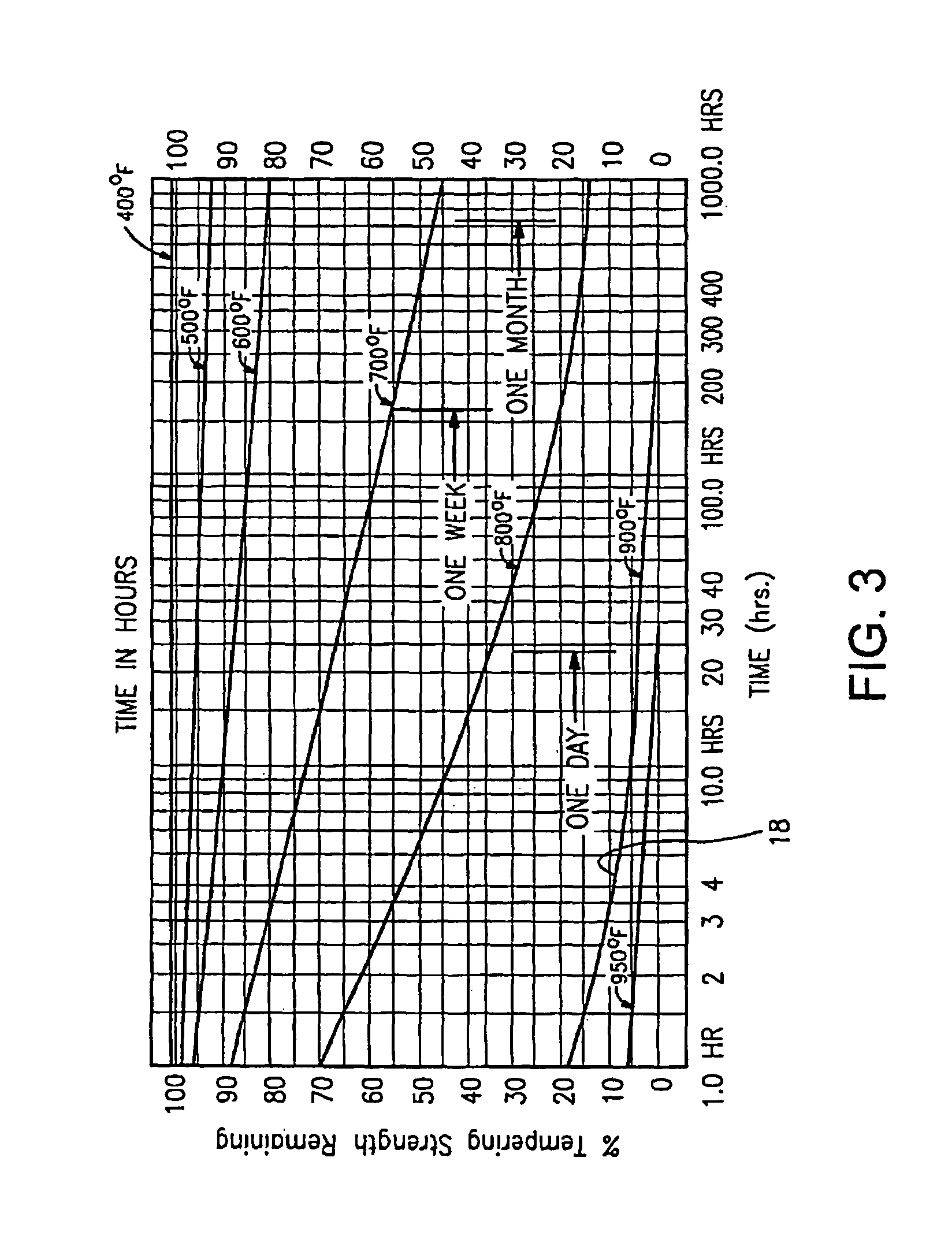

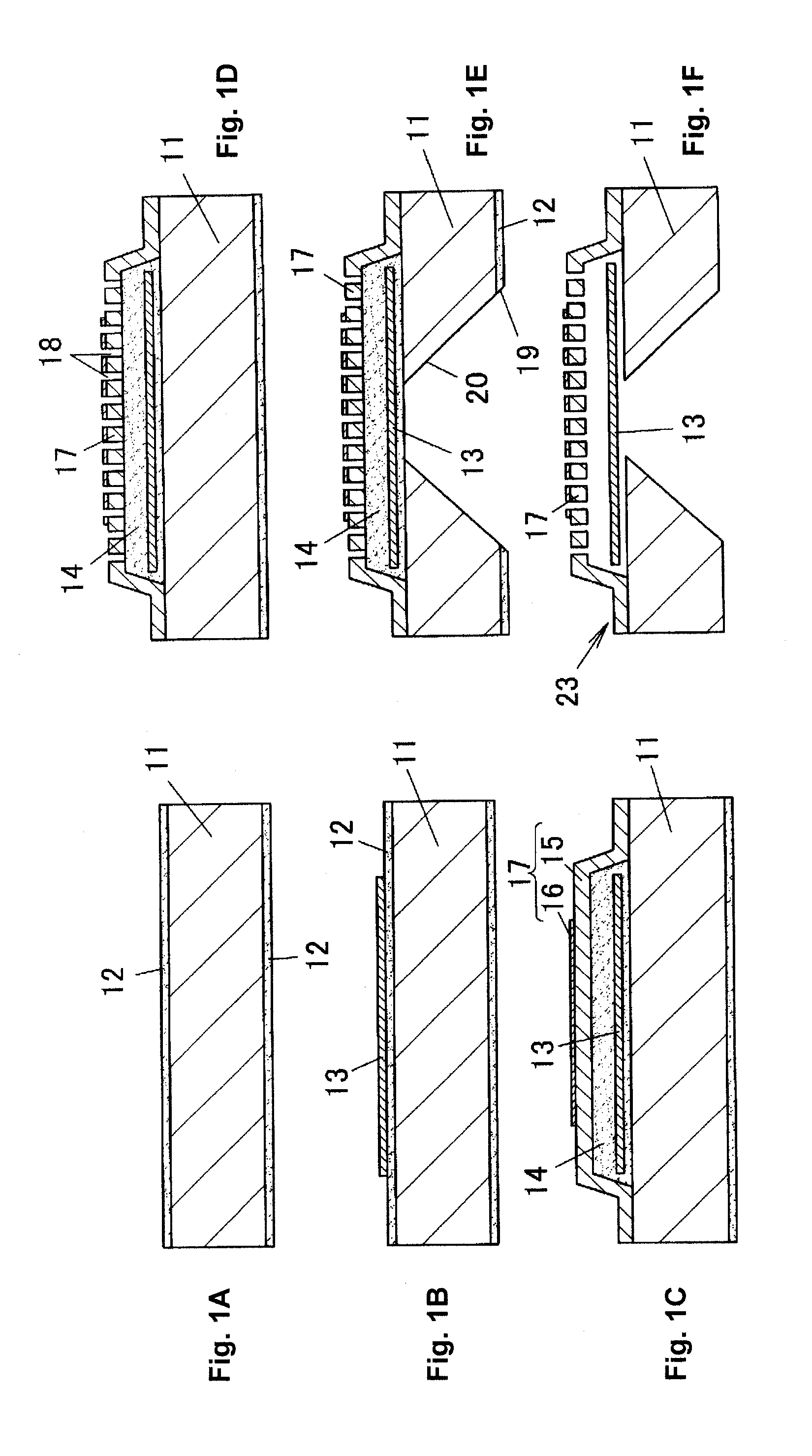

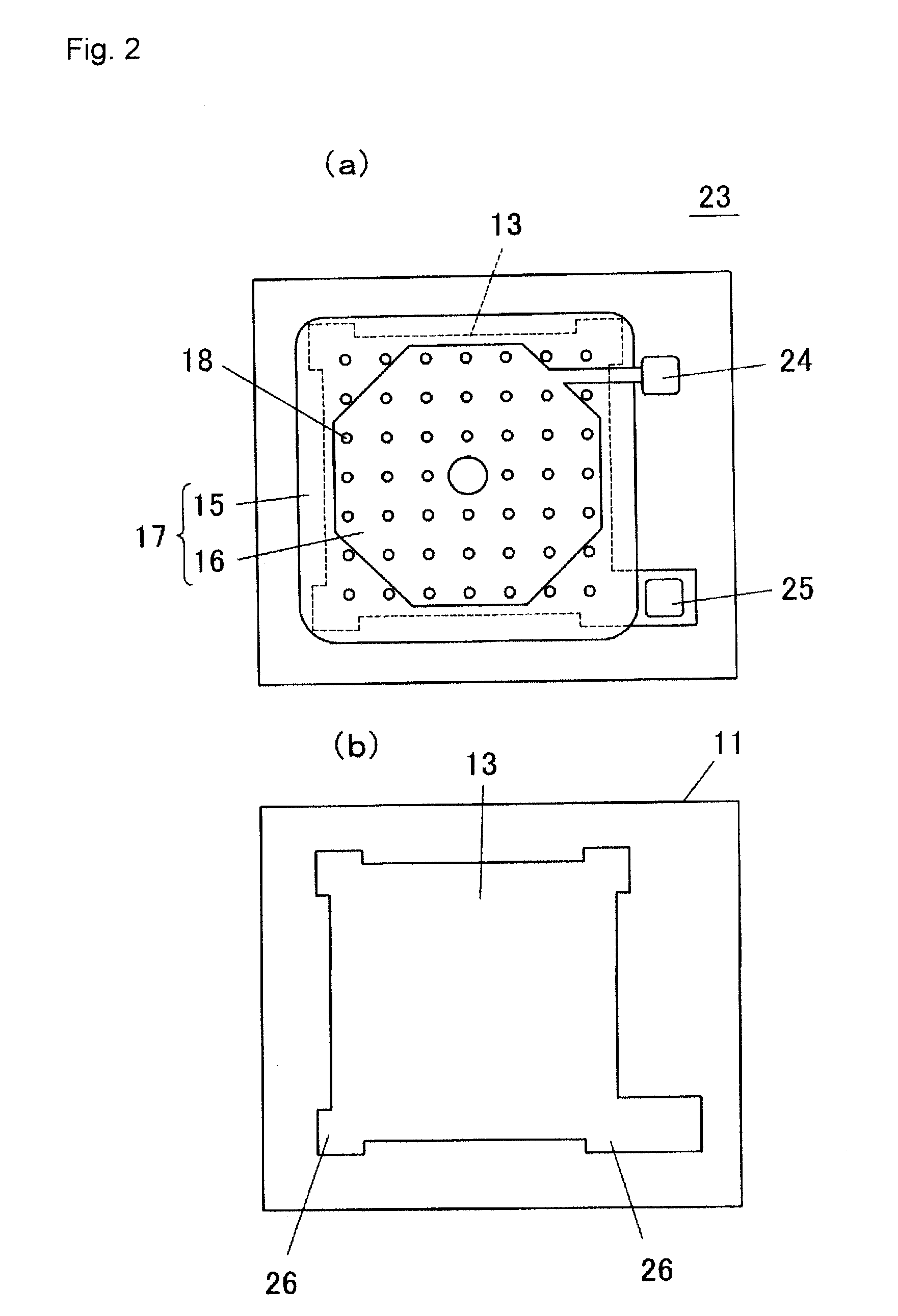

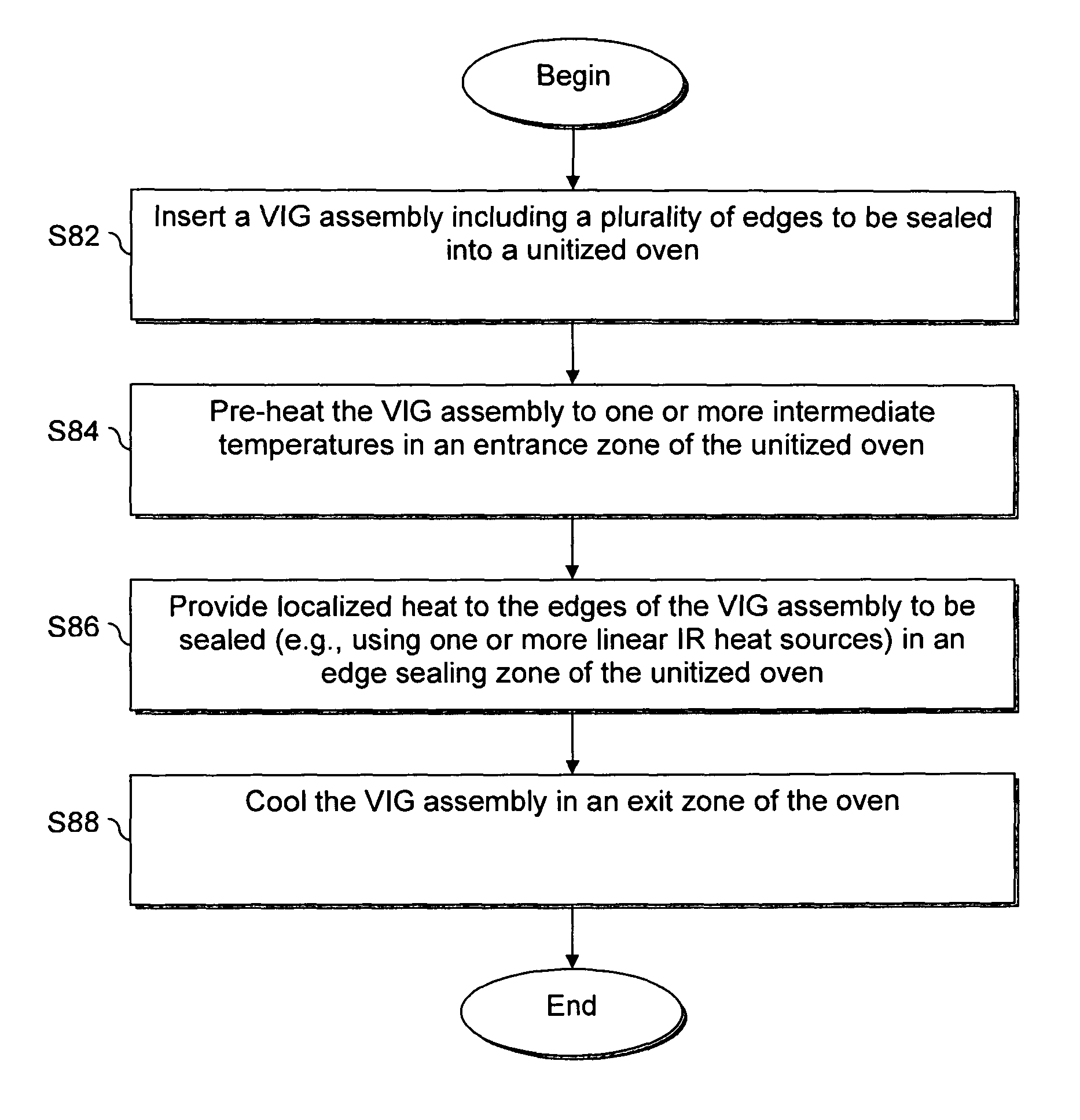

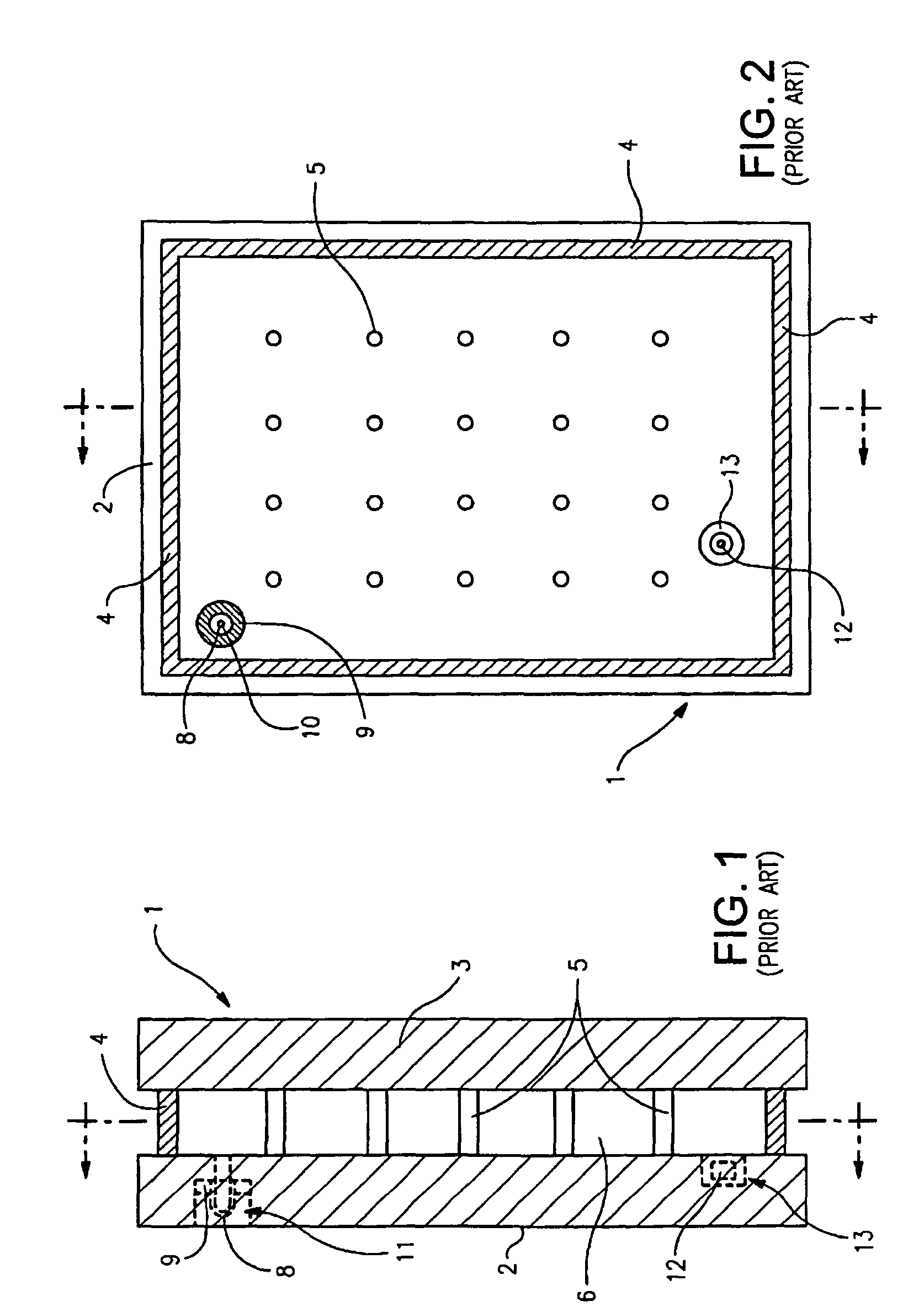

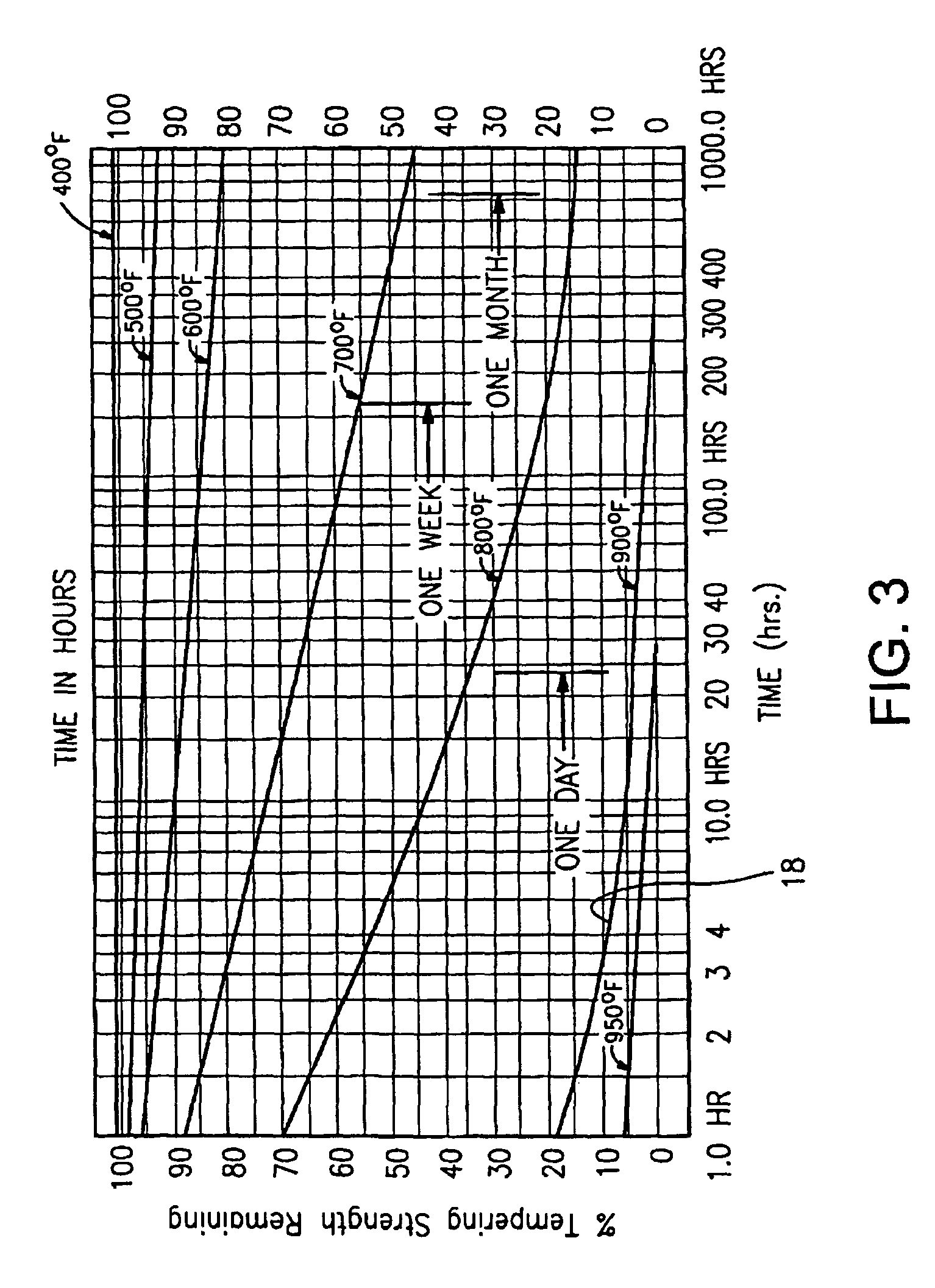

Certain example embodiments of this invention relate to edge sealing techniques for vacuum insulating glass (VIG) units. More particularly, certain example embodiments relate to techniques for providing localized heating to edge seals of units, and / or unitized ovens for accomplishing the same. In certain example embodiments, a unit is pre-heated to one or more intermediate temperatures, localized heating via at least one substantially two-dimensional array of heat sources is provided proximate to the peripheral edges of the unit so as to melt frits placed thereon, and cooled. In certain non-limiting implementations, the pre-heating and / or cooling may be provided in one or more steps. An oven for accomplishing the same may include multiple zones for performing the above-noted steps, each zone optionally including one or more chambers. Accordingly, in certain example embodiments, a temperature gradient proximate to the edges of the unit is created, thereby reducing the chances of breakage and / or at least some de-tempering of the substrates.

Owner:GUARDIAN GLASS LLC

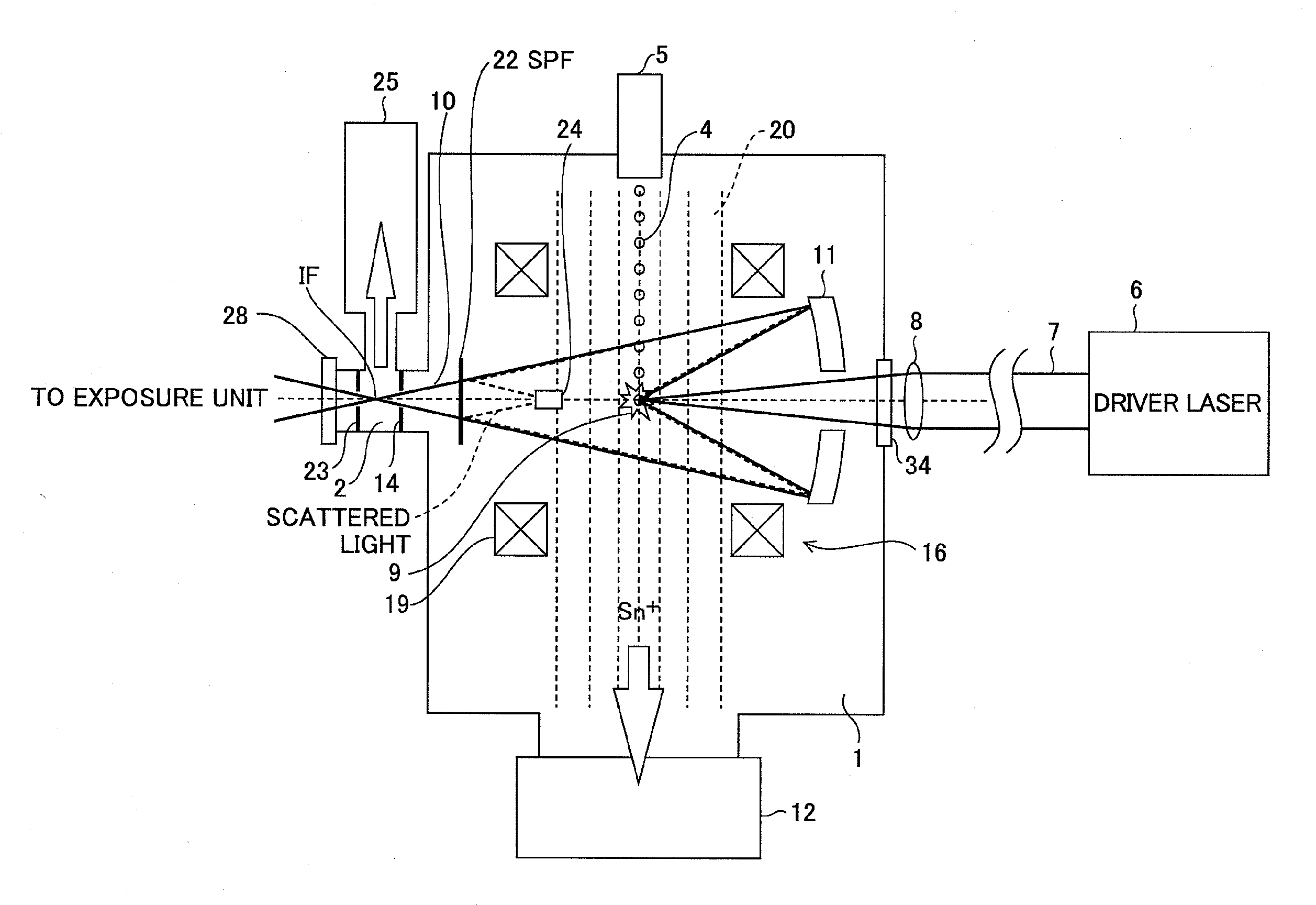

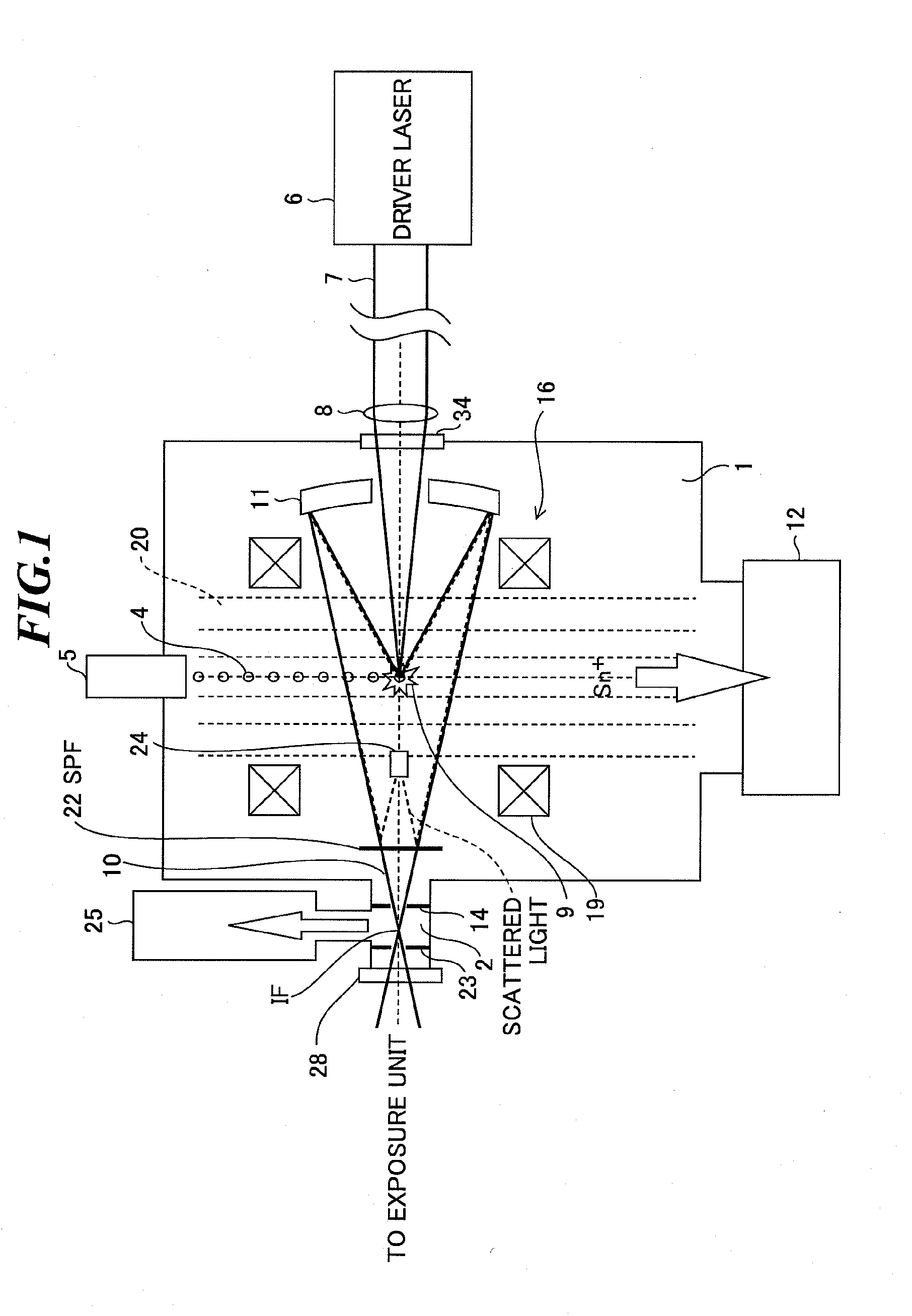

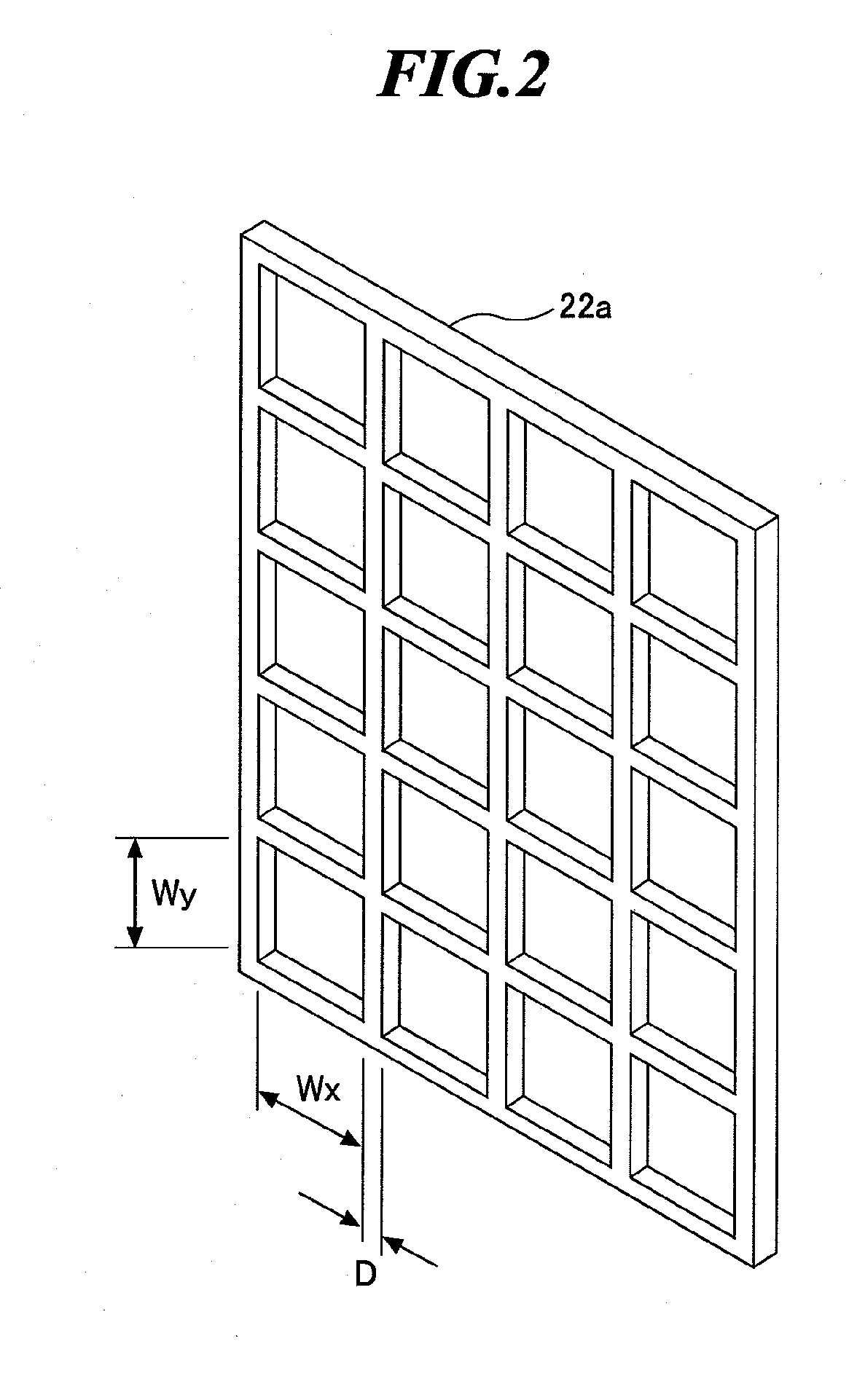

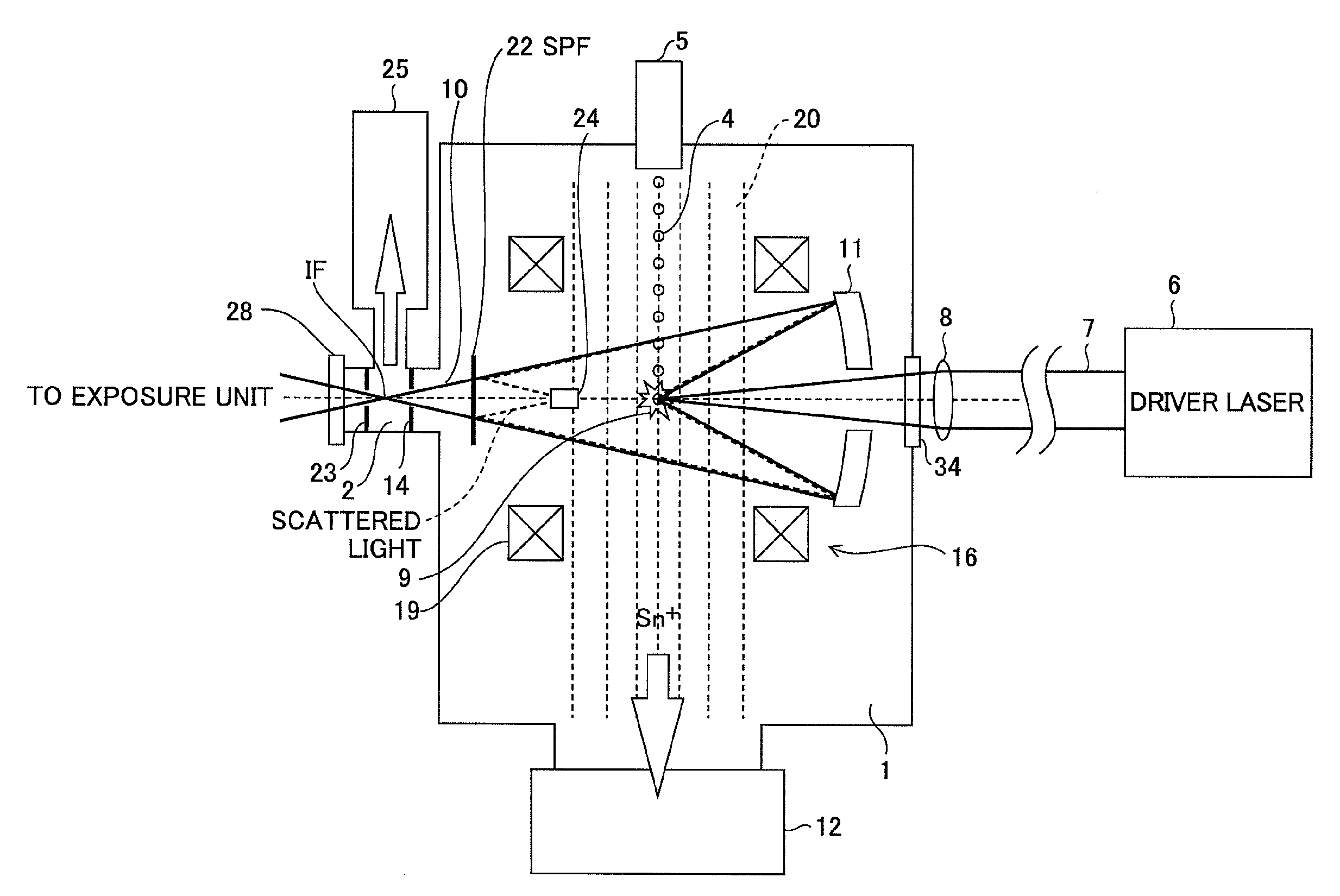

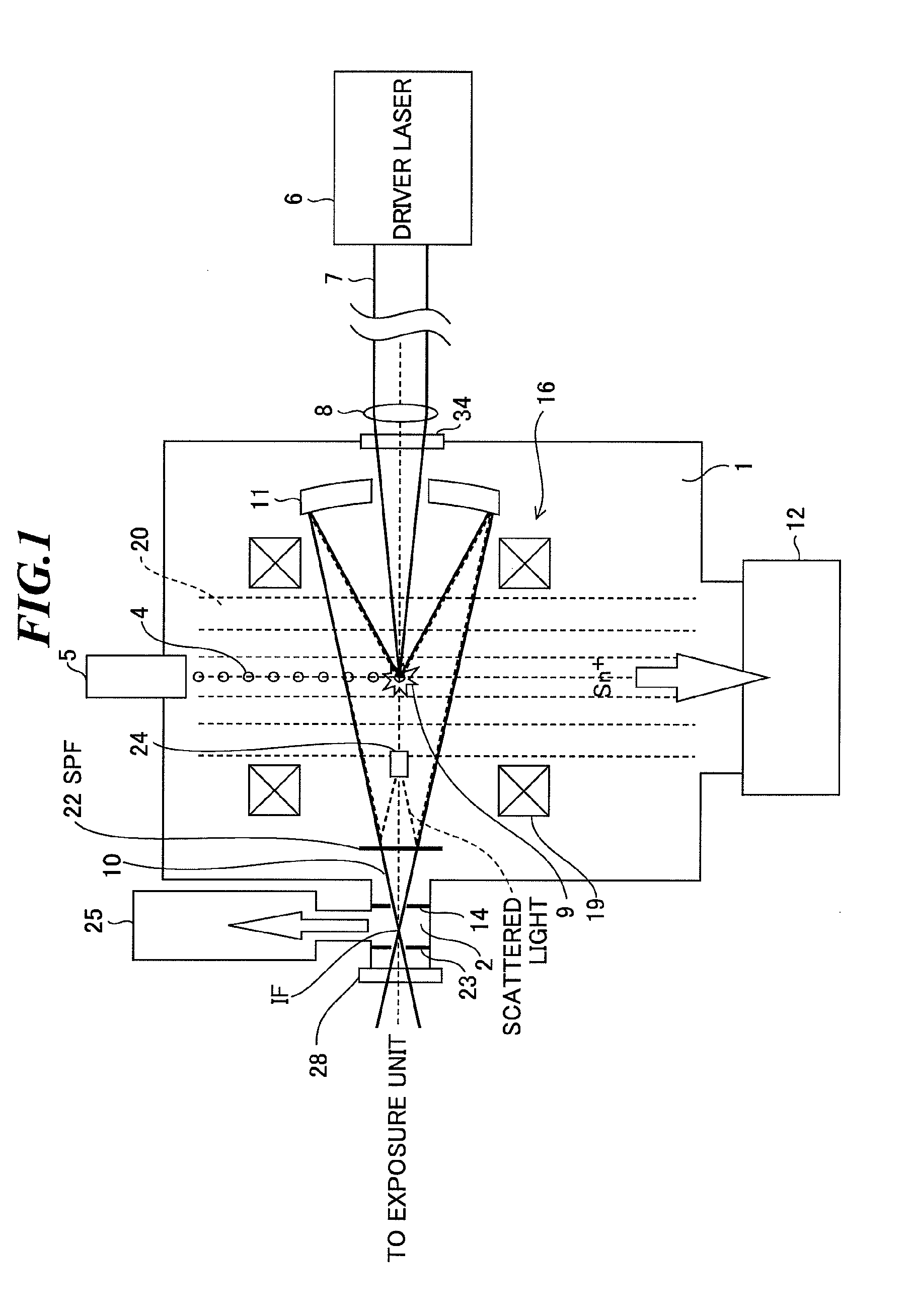

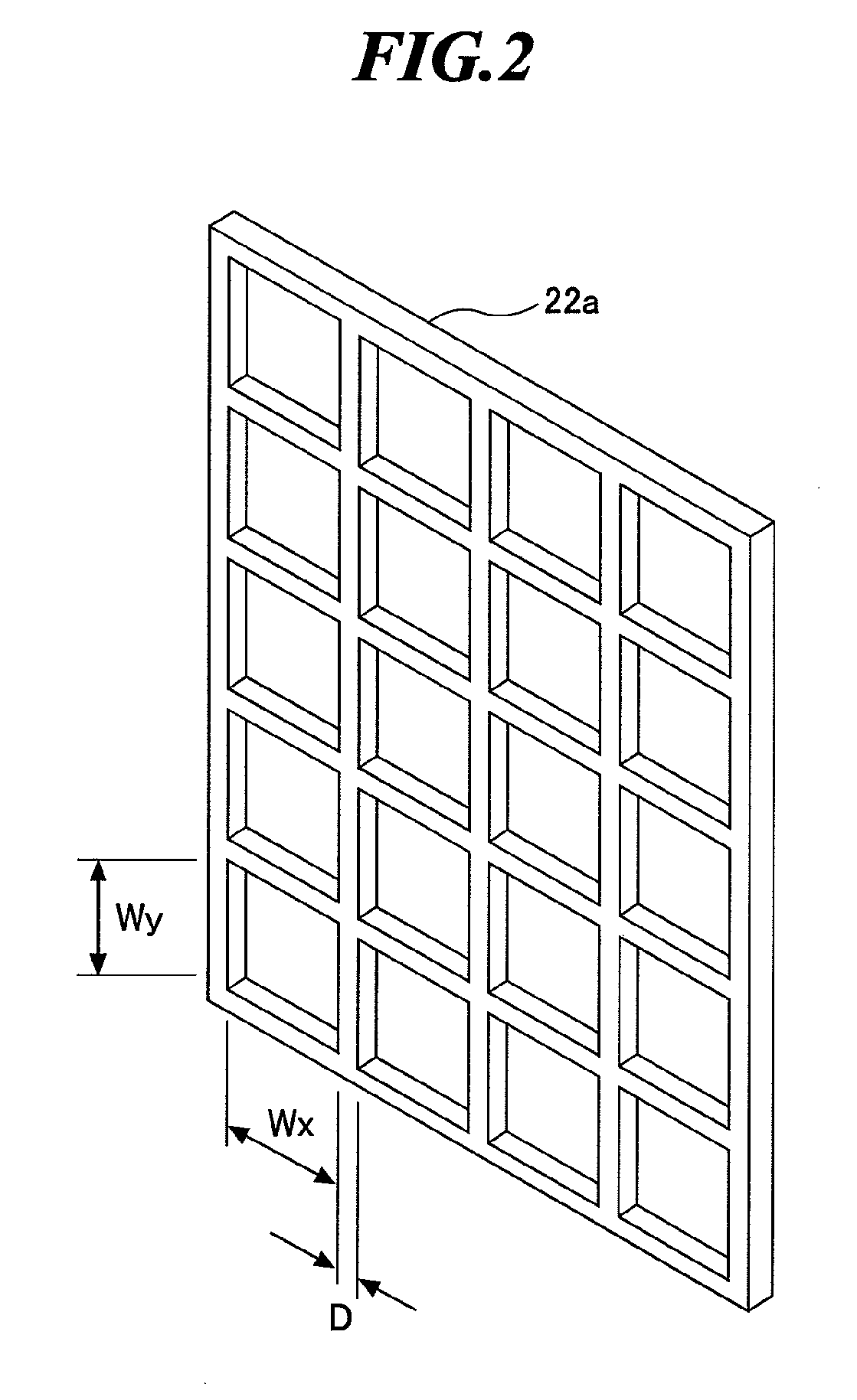

Extreme ultra violet light source apparatus

ActiveUS20090314967A1High spectral purityDifficult to absorbMirrorsOptical filtersLength waveExtreme ultraviolet

An extreme ultraviolet light source apparatus using a spectrum purity filter capable of obtaining EUV light with high spectrum purity. The apparatus includes a chamber; a target supply unit for supplying a target material; a driver laser using a laser gas containing a carbon dioxide gas as a laser medium, for applying a laser beam to the target material to generate plasma; a collector mirror for collecting and outputting the extreme ultraviolet light radiated from the plasma; and a spectrum purity filter provided in an optical path of the extreme ultraviolet light, for transmitting the extreme ultraviolet light and reflecting the laser beam, the spectrum purity filter including a mesh having electrical conductivity and formed with an arrangement of apertures having a pitch not larger than a half of a shortest wavelength of the laser beam applied by the driver laser.

Owner:GIGAPHOTON

Vacuum insulated glass (VIG) unit including nano-composite pillars, and/or methods of making the same

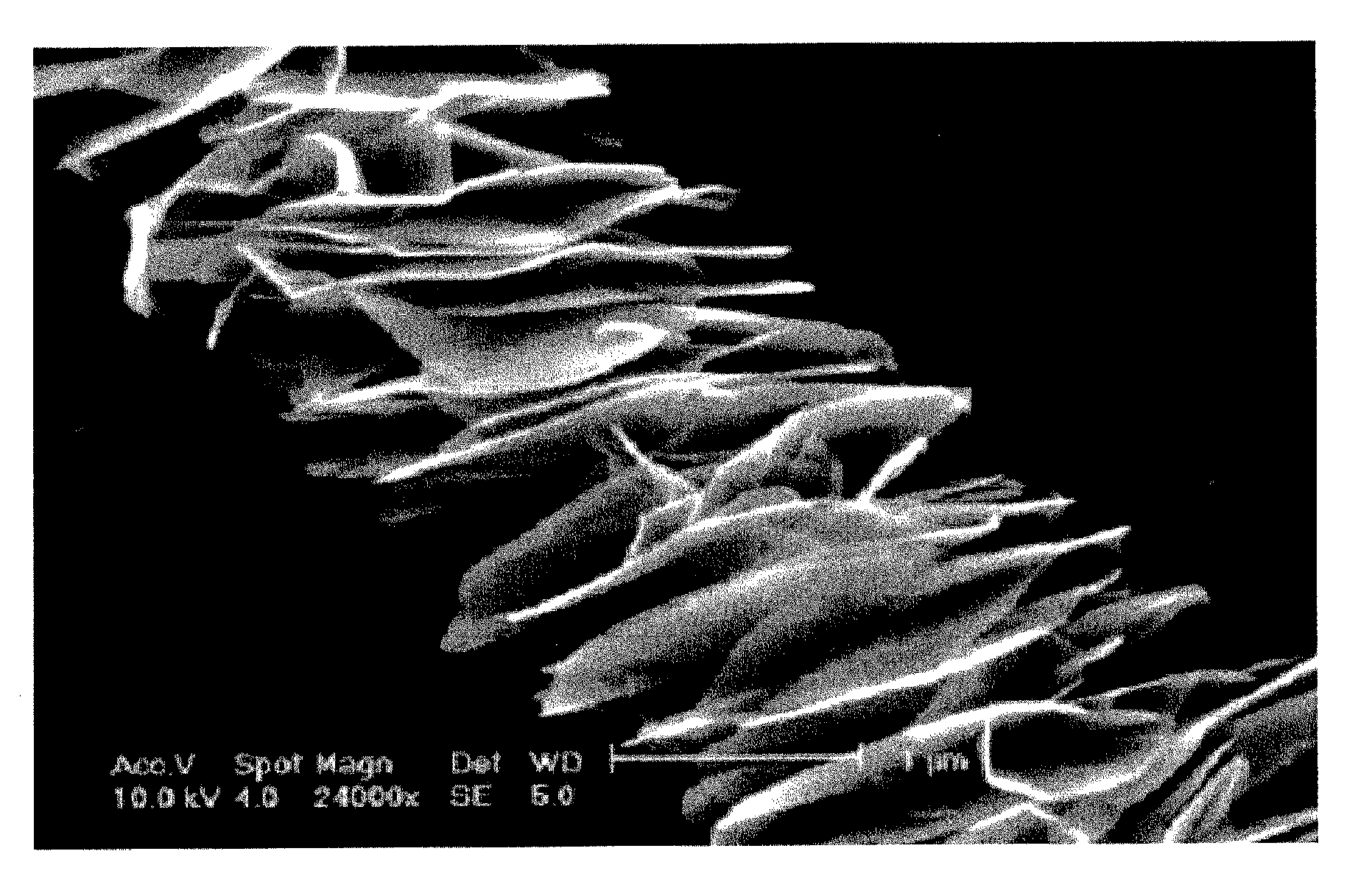

ActiveUS20120088045A1Accelerate breakageIncrease likelihoodClimate change adaptationLaminationHigh intensitySoft materials

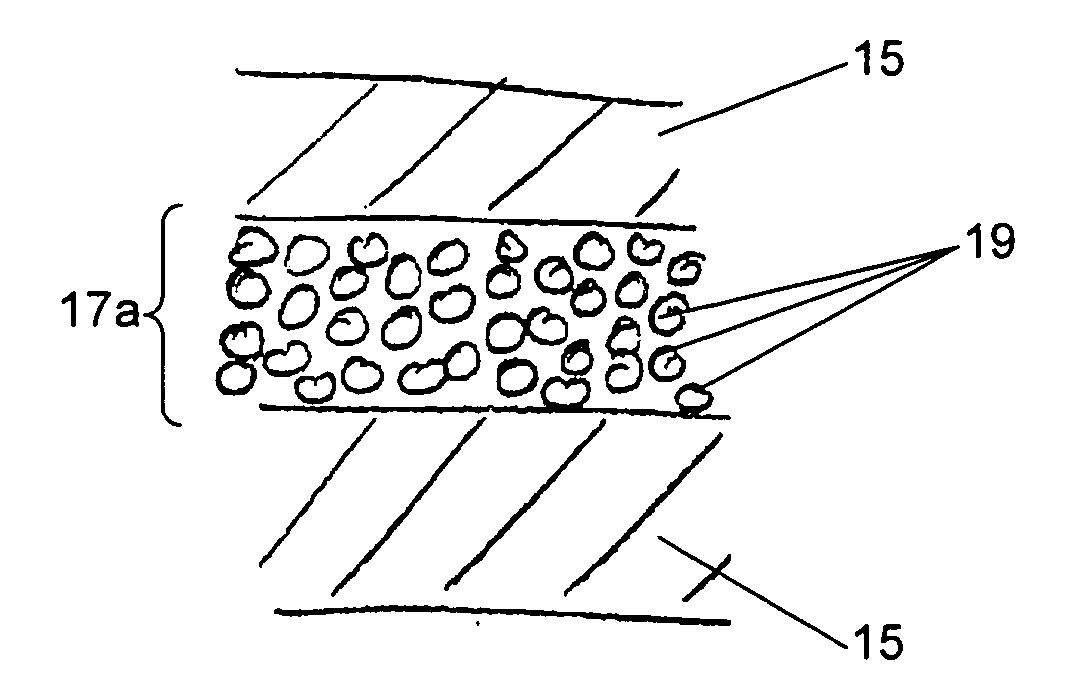

Certain example embodiments of this invention relate to composite pillar arrangements for VIG units that include both harder and softer materials. The softer materials are located on the outside or extremities of the central, harder pillar material. In certain example embodiments, a high aspect ratio mineral lamellae is separated by an organic “glue” or polymer. When provided around a high strength pillar, the combination of the pillar and such a nano-composite structure may advantageously result in superior strength compared to a monolithic system, e.g., where significant wind loads, thermal stresses, and / or the like are encountered.

Owner:GUARDIAN GLASS LLC

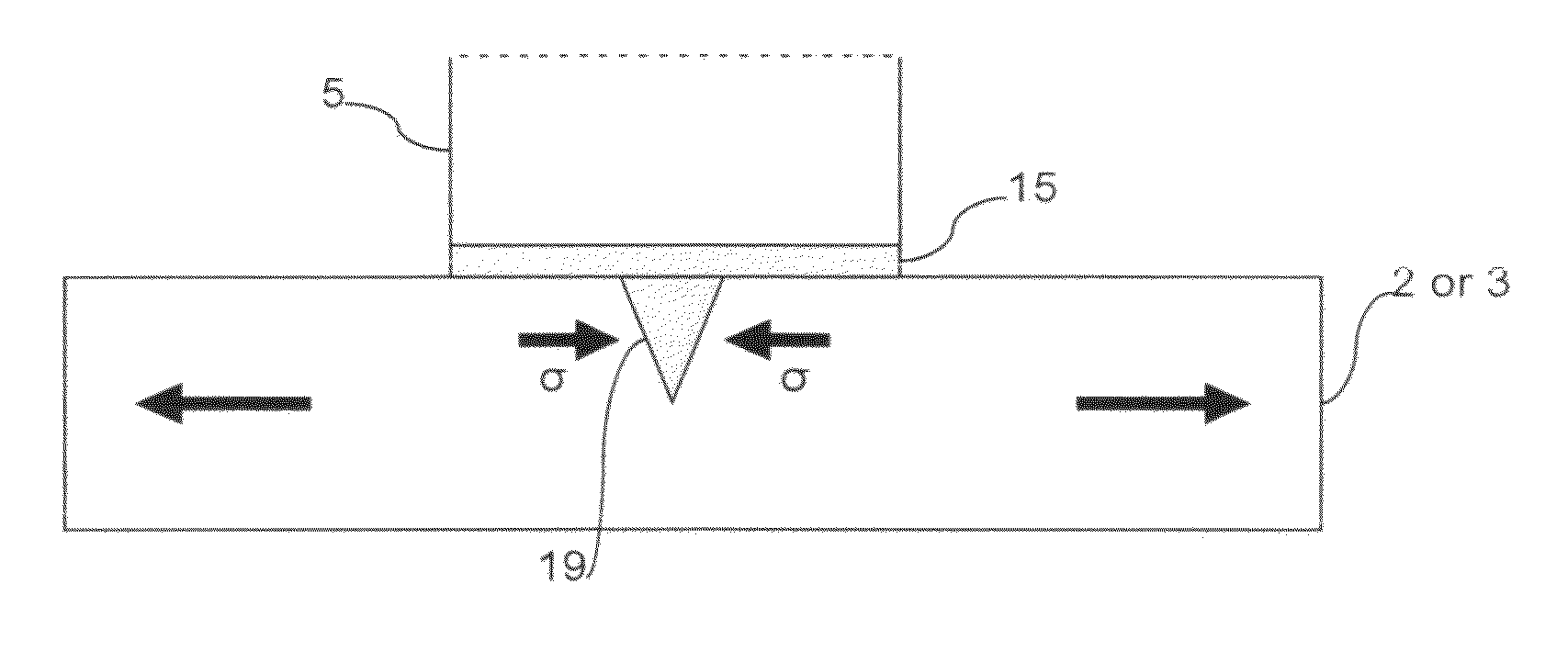

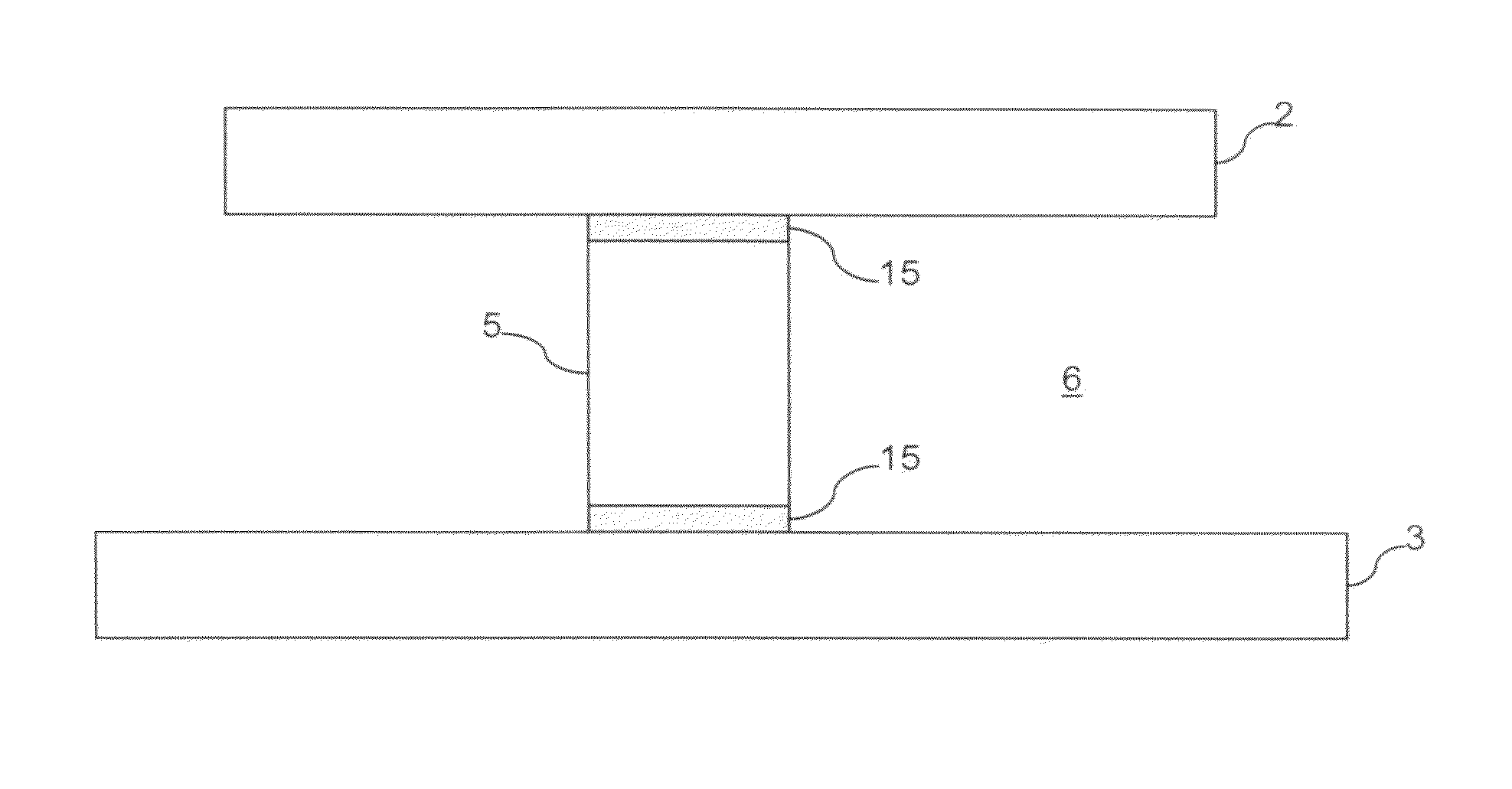

Edge profiles for vacuum insulated glass (VIG) units, and/or VIG unit including the same

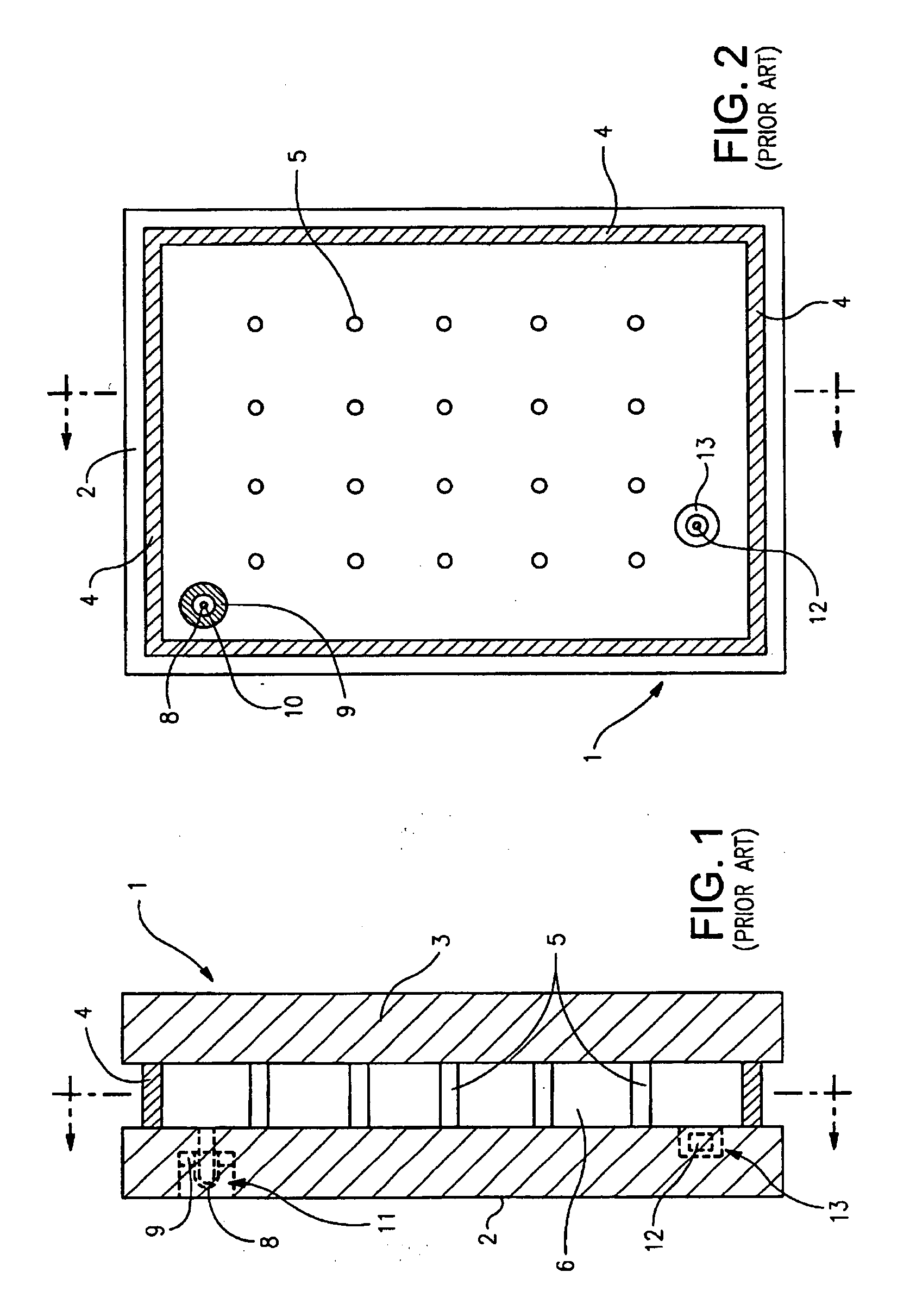

ActiveUS20100279038A1Accelerate breakageIncrease likelihoodCellulosic plastic layered productsGlass/slag layered productsEngineeringMechanical engineering

Certain example embodiments of this invention relate to vacuum insulated glass (VIG) units. The VIG unit may comprise first and second substrates with inner and outer substantially planar surfaces. For either or both of the first and second substrates, when considered along a side cross-section, a portion of the inner planar surface is removed proximate to an outer edge of the glass substrate so as to form a shoulder portion. An inner surface of the shoulder portion is angled (a negative number of degrees, zero degrees, or a positive number of degrees) relative to the inner and outer planar surfaces. The shoulder portion at its smallest height is at least about 50% of the glass substrate at its largest height. A side portion of the step proximate the edge also may be angled, e.g., so that it is or is not perpendicular to the planar surfaces.

Owner:GUARDIAN GLASS LLC

Carbon material and method for producing same

ActiveUS20120315482A1High crystallinityShorten the time periodFrom gel stateMaterial nanotechnologyPrillLithium-ion battery

There are provided a cluster of thin sheet graphite crystals or the like which is useful as an electrode material for lithium ion batteries, hybrid capacitors and the like, and a method for efficiently producing the same at high productivity. The method is one for producing a cluster of thin sheet graphite crystals composed of aggregates in such a state that thin sheet graphite crystals extend from the inside toward the outside, comprising charging a powdery and / or particulate material of an organic compound pre-baked to an extent of containing remaining hydrogen in a graphite vessel, and subjecting the powdery and / or particulate material together with the vessel to hot isostatic pressing treatment (HIP treatment) using a compressed gas atmosphere under the predetermined conditions.

Owner:INCUBATION ALLIANCE

Non-toxic water-based frit slurry paste, and assembly incorporating the same

ActiveUS20100330308A1Reduce temperatureSoftenCellulosic plastic layered productsLaminationSolventMaterials science

Certain example embodiments of this invention relate to a frit slurry paste for use in assemblies (e.g., a vacuum insulated glass unit or a plasma display panel), and methods of making the same. Frit powder, binder material, and a water-based solvent are mixed together to form an intermediate mixture. The frit powder is substantially lead free, and the water-based solvent is provided at a first temperature. Additional water-based solvent is added to the intermediate mixture to form a frit slurry paste. The additional water-based solvent is provided at a second temperature, with the second temperature being lower than the first temperature. The binder material is provided at a concentration of 0.001%-20% by weight with respect to the frit slurry paste or the frit slurry paste absent the frit powder. The frit slurry paste has a bulk viscosity of 2,000-200,000 cps.

Owner:GUARDIAN GLASS LLC

Frit or solder glass compound including beads, and assemblies incorporating the same

InactiveUS20100330309A1Less-expensiveLess-expensive to useClimate change adaptationLaminationFritSquare Shape

Certain example embodiments of this invention relate to frits or solder glass compounds that include beads, and / or assemblies such as, for example, vacuum insulated glass (VIG) units or plasma display panels (PDPs) including the same. In certain example embodiments, the beads may be hollow glass beads of any suitable shape (e.g., substantially spherical, substantially eye shaped, substantially oblong, substantially square shaped, etc.) with or without evacuated cavities. The inclusion of such beads in a frit material may improve the thermal properties of the bulk fired frit in certain example instances. Additionally, the inclusion of such beads in a frit material may take the place of other more expensive materials in the frit, thereby reducing the costs associated with the fabrication of the assemblies.

Owner:GUARDIAN GLASS LLC

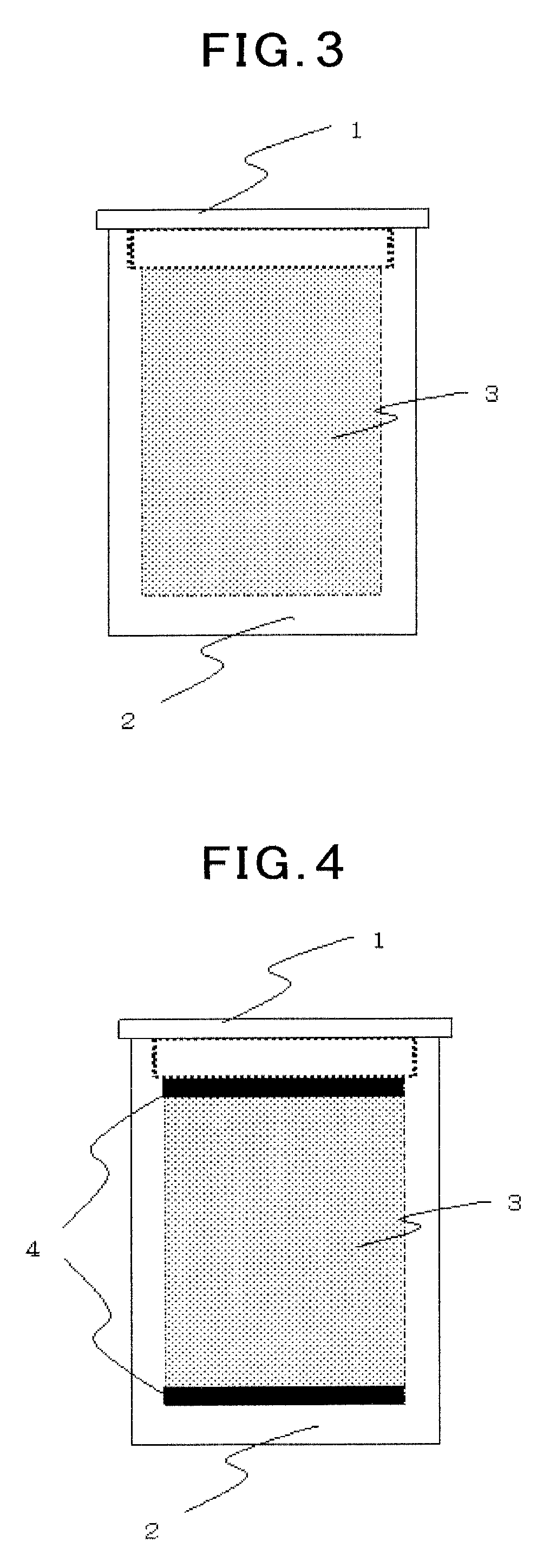

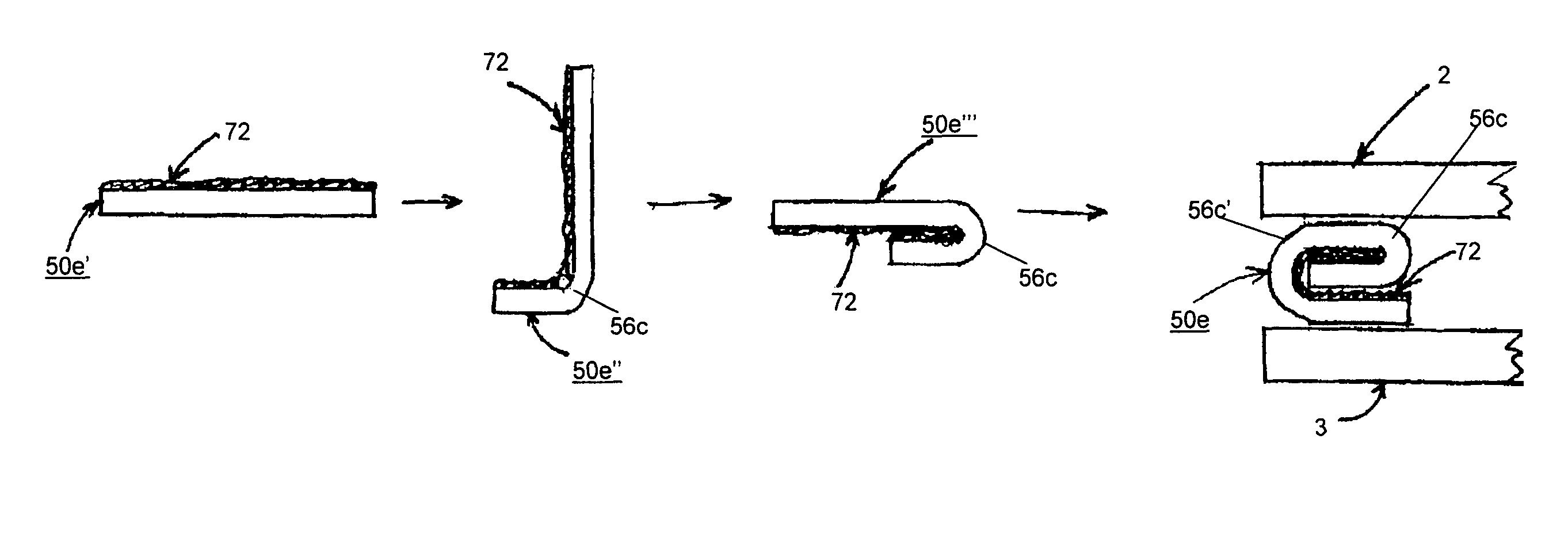

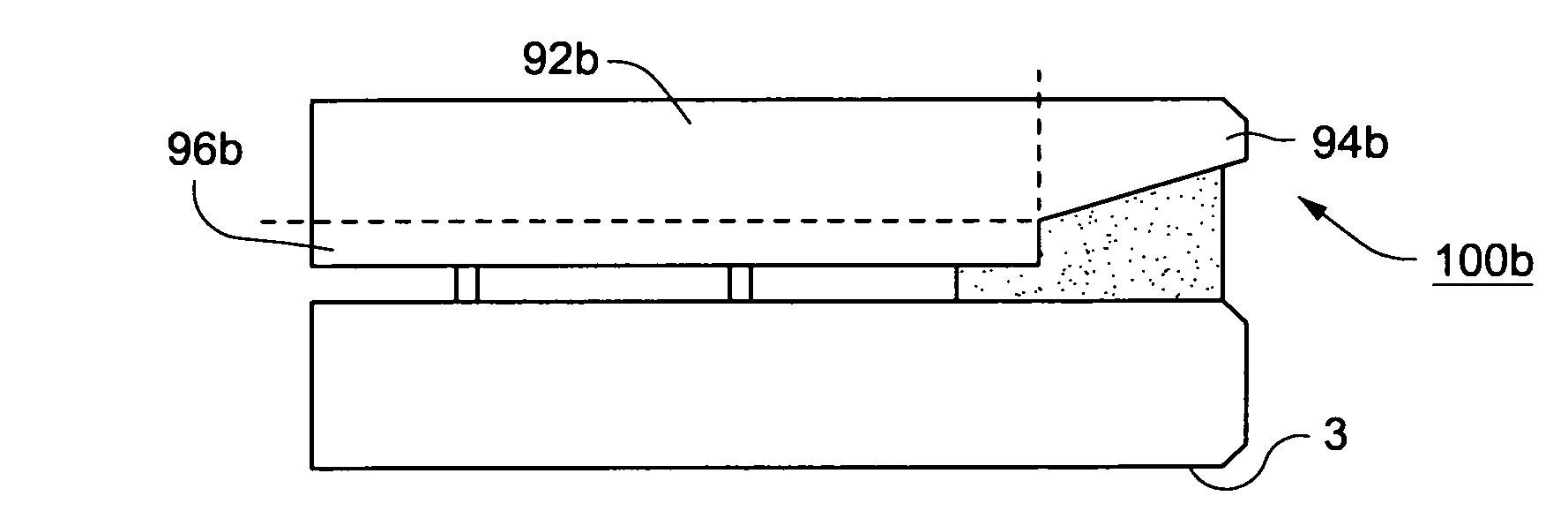

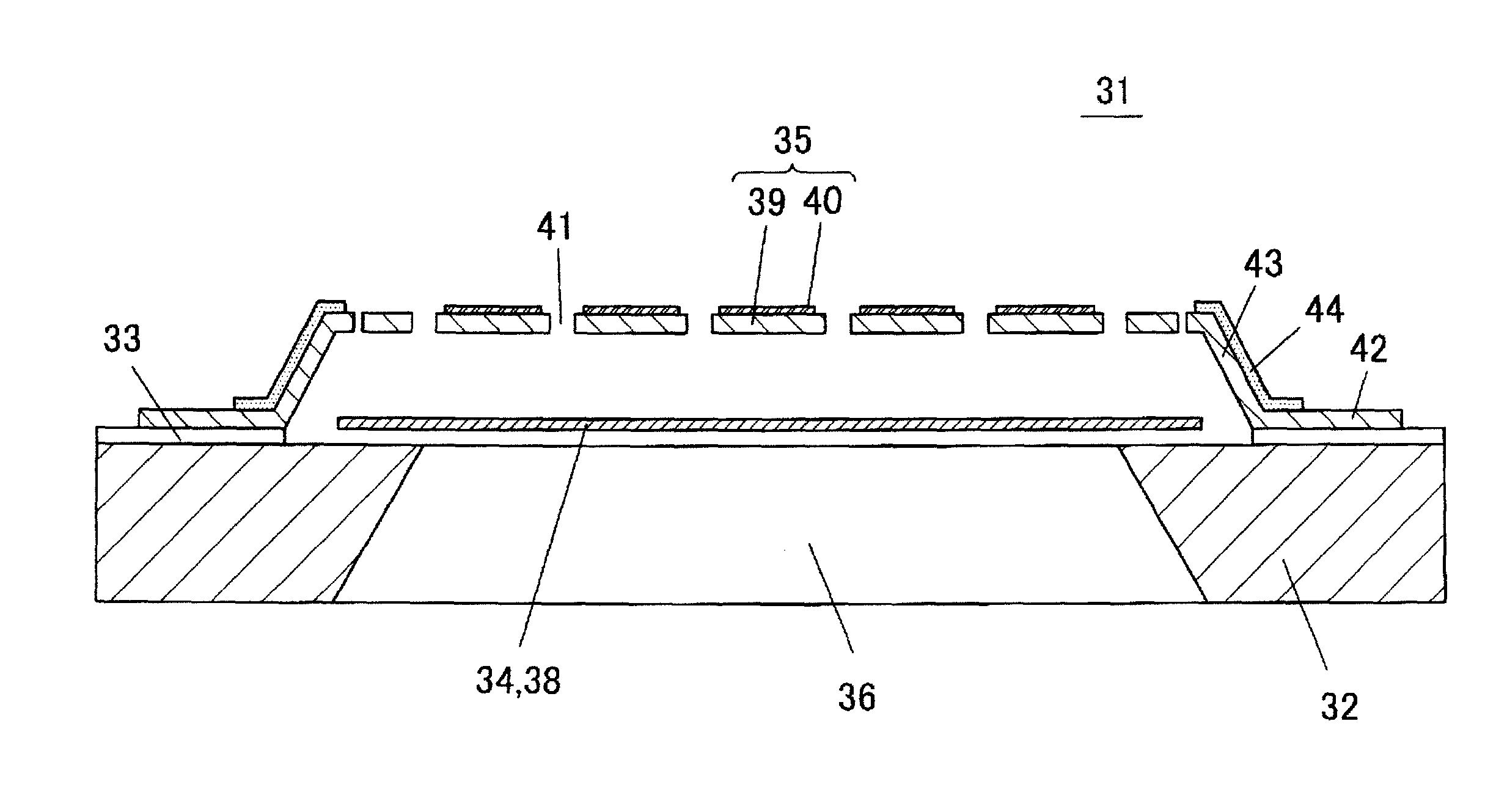

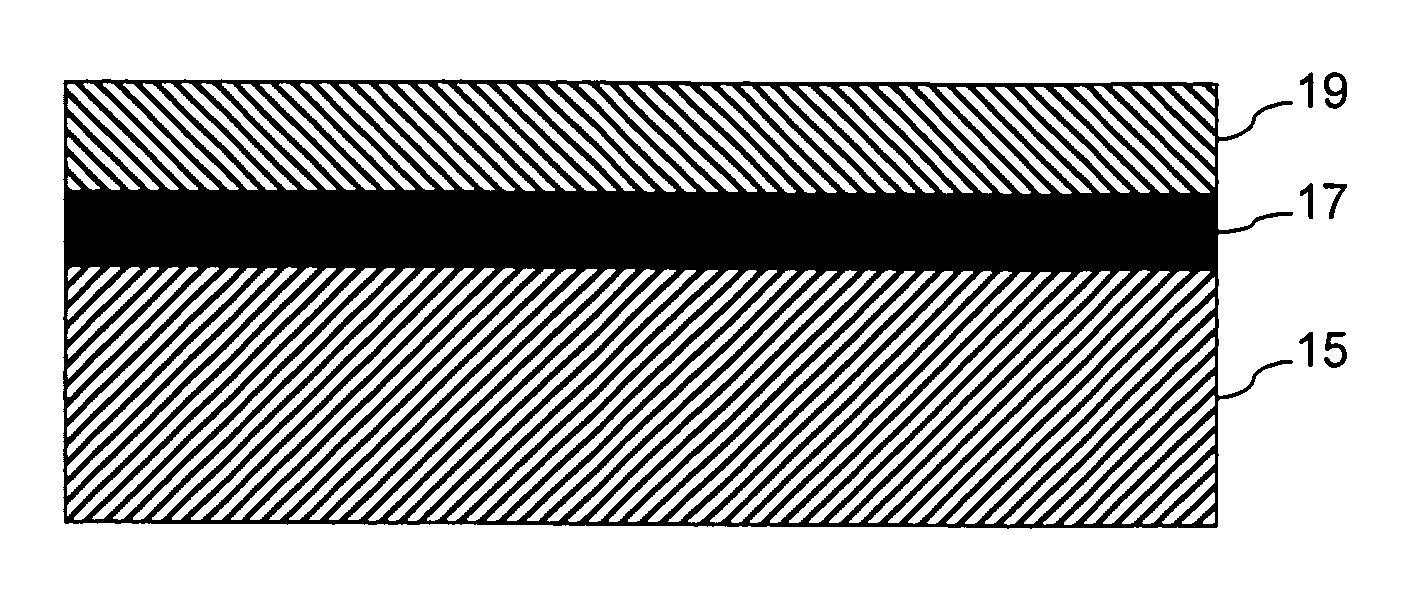

Metal-inclusive edge seal for vacuum insulating glass unit, and/or method of making the same

ActiveUS8512829B2Accelerate breakageIncrease likelihoodClimate change adaptationWindows/door improvementThermal expansionEngineering

Certain example embodiments of this invention relate to metal-inclusive edge seal designs for vacuum insulating glass (VIG) units, and / or methods of making the same. First and second substantially parallel spaced-apart glass substrates, including edge portions thereof, are provided. At least one metal-inclusive edge-sealing strip is located proximate to the edge portions of the first and second substrates, getter being applied to at least a portion of at least some of the edge-sealing strips, and the at least one edge-sealing strip being selected so as to have a coefficient of thermal expansion over a temperature range of interest within about 25% of a coefficient of thermal expansion of the first and second substrates, the temperature range of interest being from about −40° C. to about 50° C. The first and second substrates are sealed together proximate to the edge portions thereof with the at least one edge-sealing strip via an edge-sealing material provided to the at least one edge-sealing strip and / or the first and second glass substrates.

Owner:GUARDIAN GLASS LLC

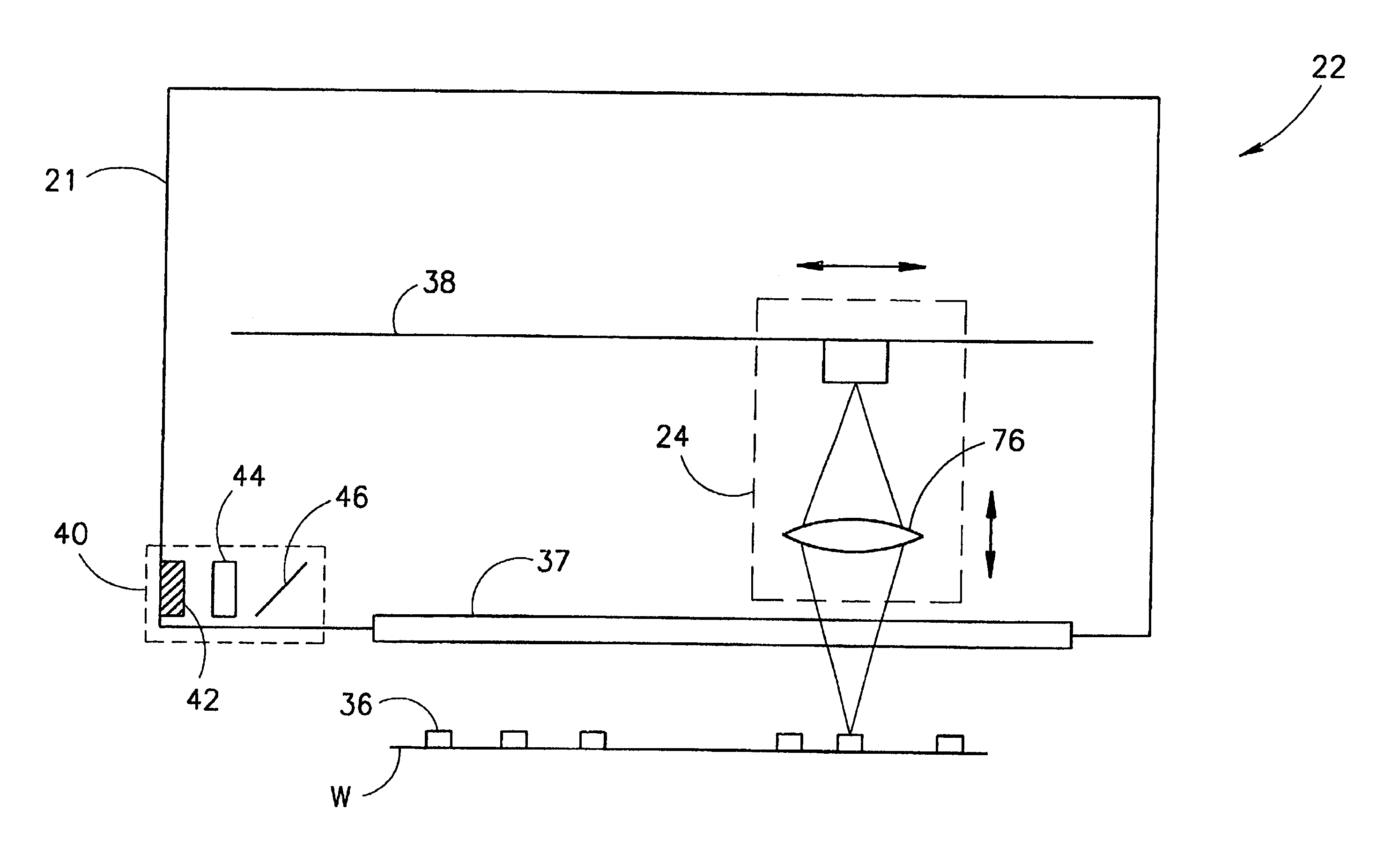

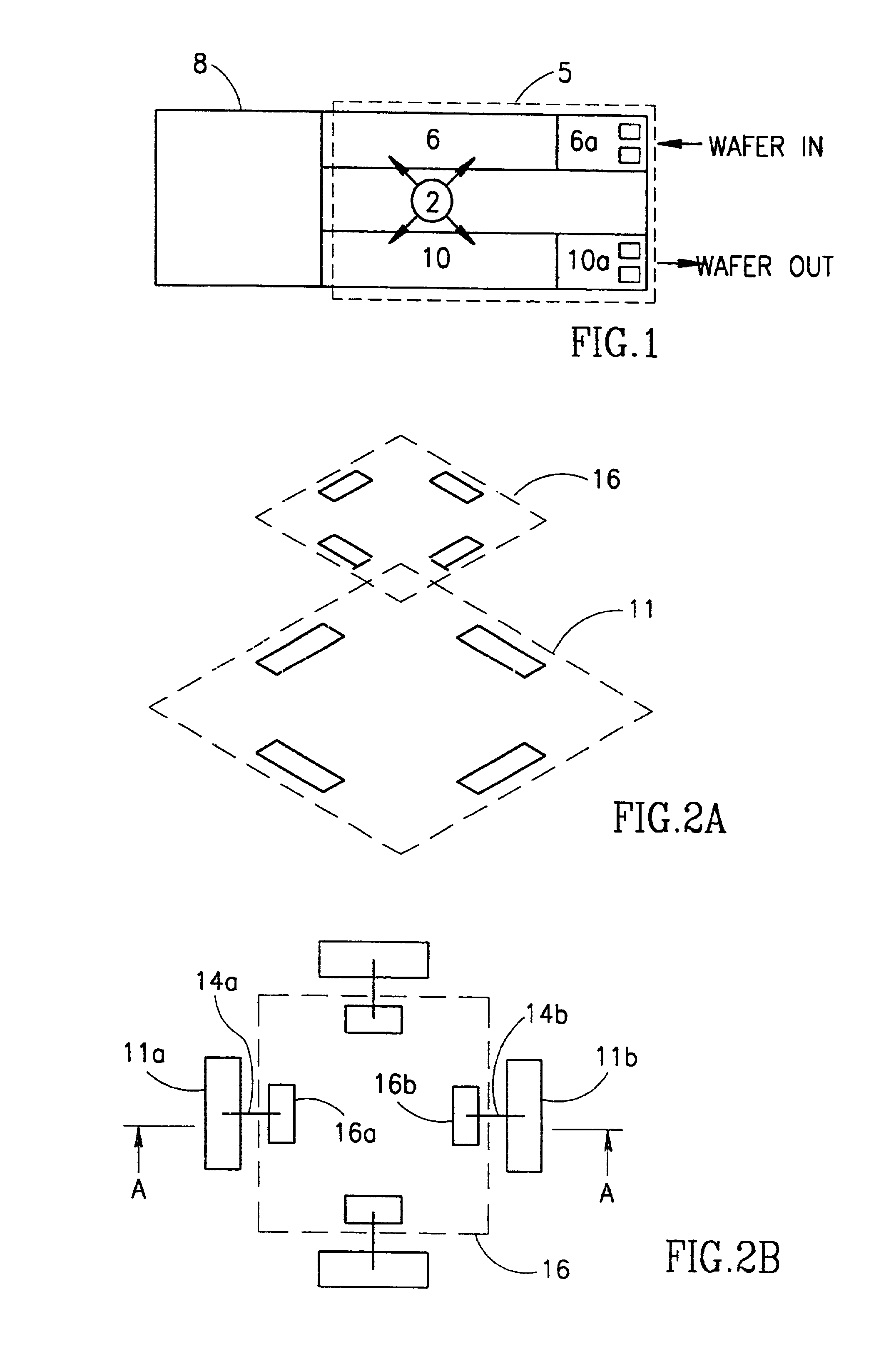

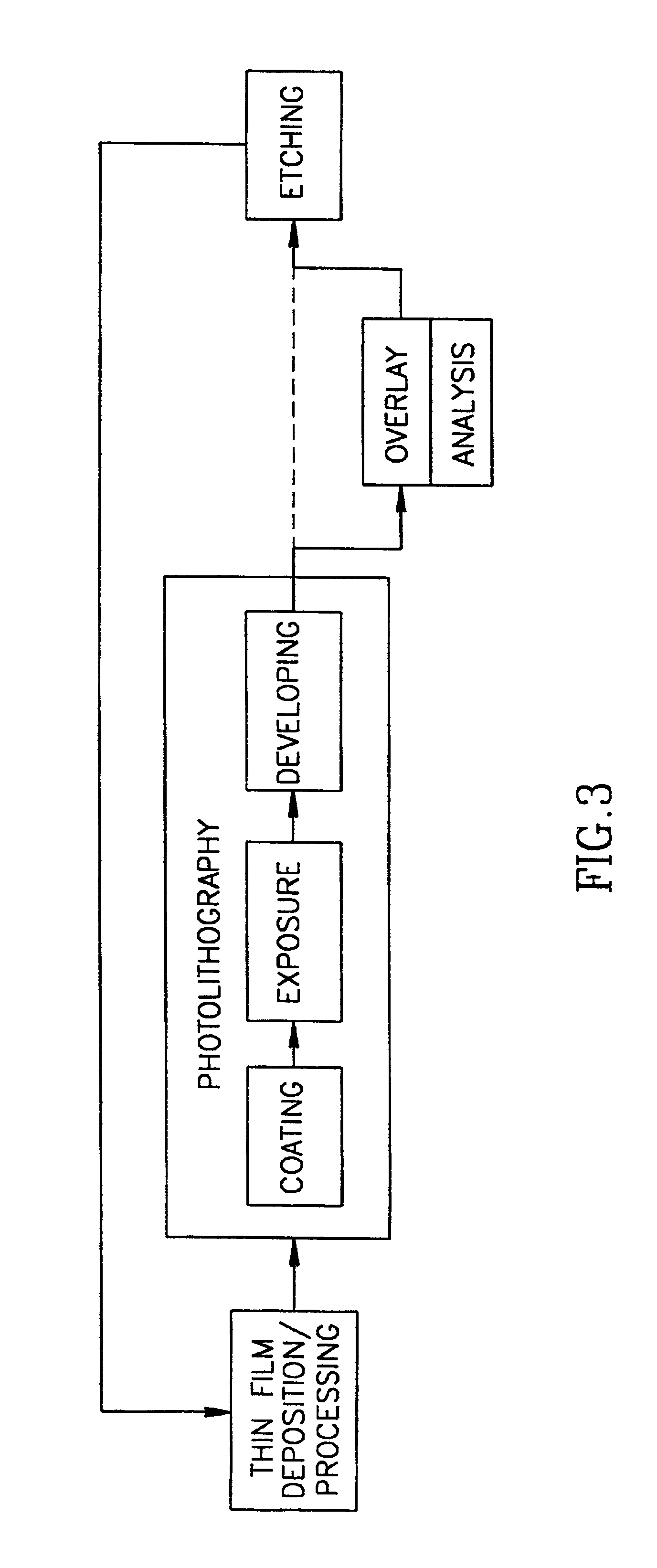

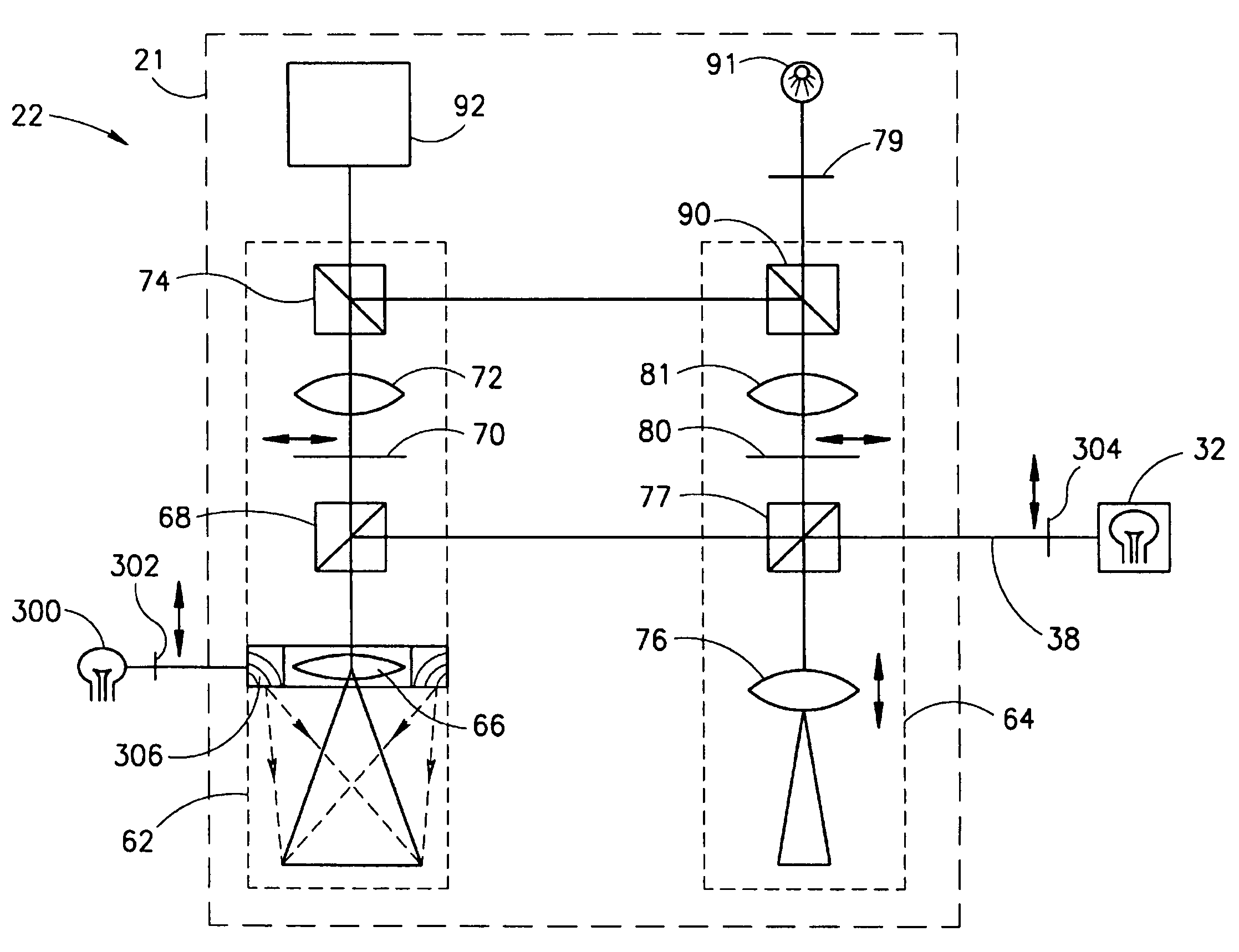

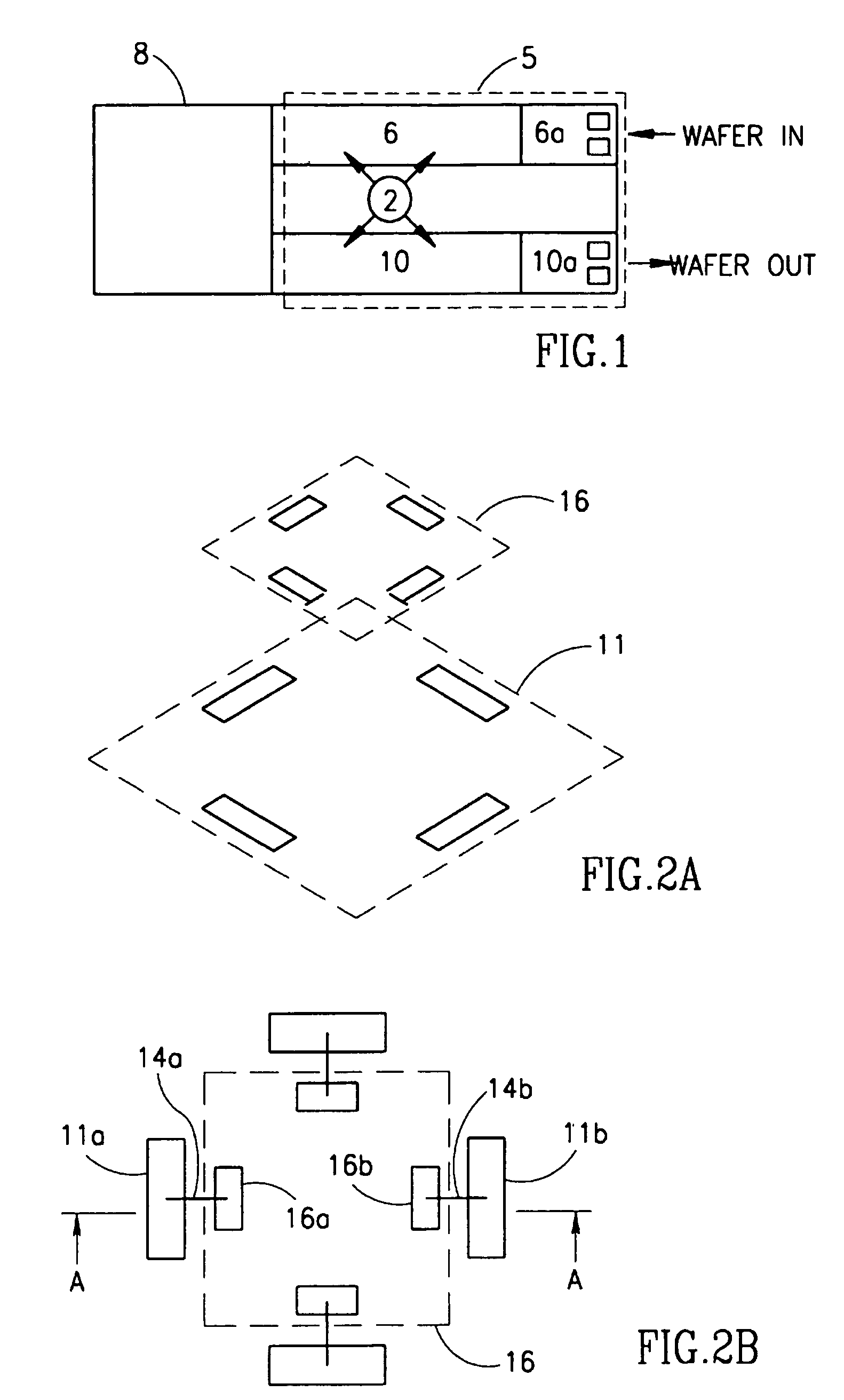

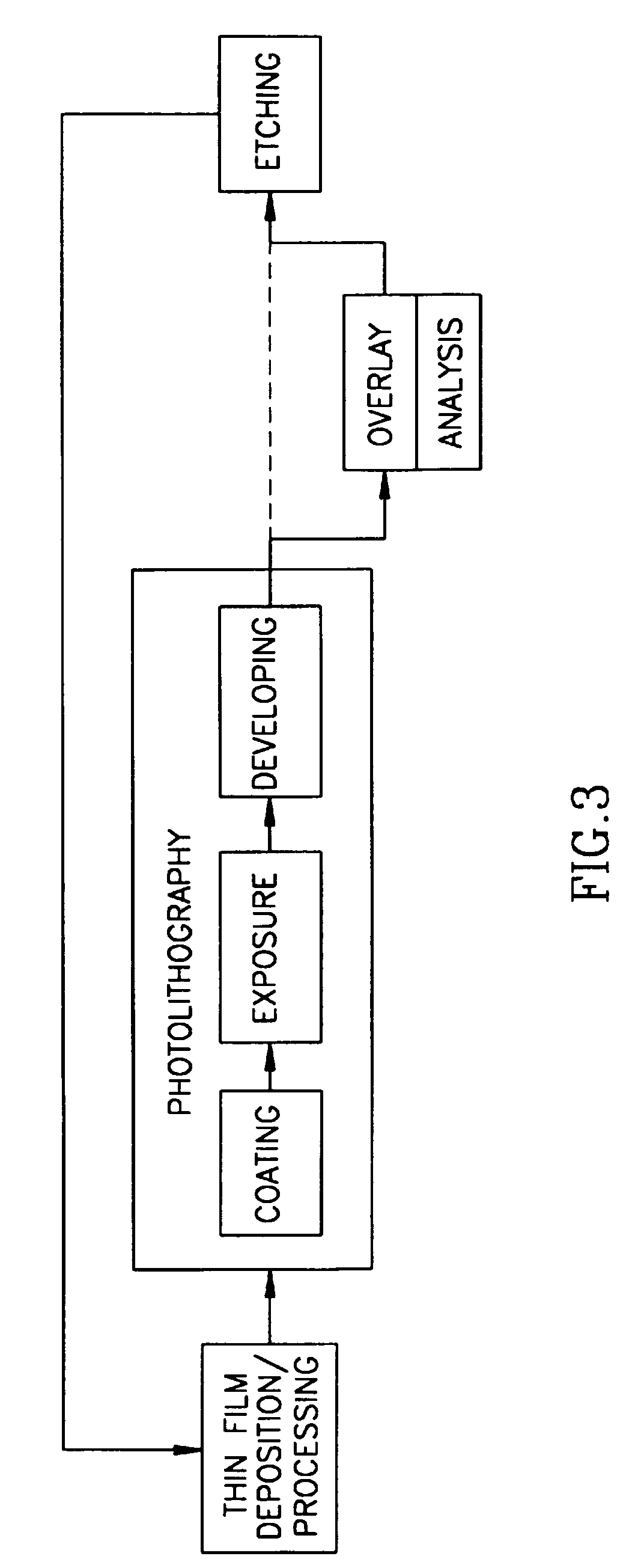

Monitoring apparatus and method particularly useful in photolithographically processing substrates

InactiveUS6842220B1Reduce the amount requiredExpensive utilization timeLiquid processingIndividual molecule manipulationProcess engineeringPhotolithography

A method for in process monitoring of the parameters of a substrate undergoing a processing within a photolithography tools arrangement which includes substrate loading and unloading stations, and substrate coating, exposure and developing stations. The method includes the step of supplying the substrate after being developed to a monitoring station and analyzing the monitoring data to estimate the photolithography process to be used for controlling thereof.

Owner:NOVA MEASURING INSTR LTD

Localized heating via an infrared heat source array of edge seals for a vacuum insulating glass unit, and/or unitized oven with infrared heat source array for accomplishing the same

ActiveUS8506738B2Accelerate breakageIncrease likelihoodClimate change adaptationLaminationFritEngineering

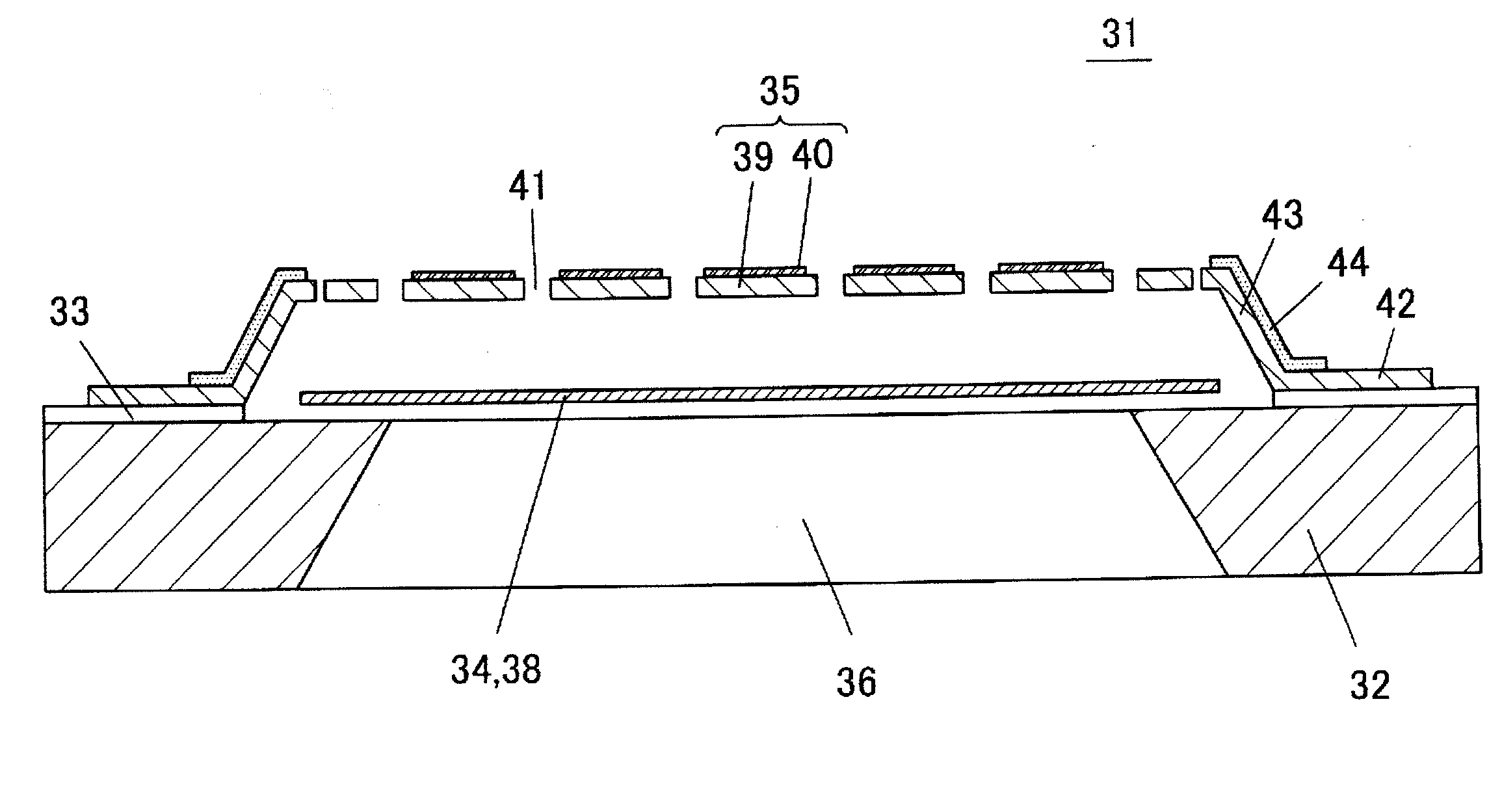

Certain example embodiments of this invention relate to edge sealing techniques for vacuum insulating glass (VIG) units. More particularly, certain example embodiments relate to techniques for providing localized heating to edge seals of units, and / or unitized ovens for accomplishing the same. In certain example embodiments, a unit is pre-heated to one or more intermediate temperatures, localized heating via at least one substantially two-dimensional array of heat sources is provided proximate to the peripheral edges of the unit so as to melt frits placed thereon, and cooled. In certain non-limiting implementations, the pre-heating and / or cooling may be provided in one or more steps. An oven for accomplishing the same may include multiple zones for performing the above-noted steps, each zone optionally including one or more chambers. Accordingly, in certain example embodiments, a temperature gradient proximate to the edges of the unit is created, thereby reducing the chances of breakage and / or at least some de-tempering of the substrates.

Owner:GUARDIAN GLASS LLC

Capacitive vibration sensor

ActiveUS20110140213A1Improve overall strengthIncreasing impact resistance and breakage resistanceSemiconductor electrostatic transducersElectrostatic transducer microphonesPhysicsOptoelectronics

A hollow part is formed in a silicon substrate through the front and the back. A vibration electrode plate is arranged on an upper surface of the silicon substrate to cover the opening on the upper surface. A fixed electrode plate covers the upper side of the vibration electrode plate while maintaining a microscopic gap with the vibration electrode plate, where the peripheral part is fixed to the upper surface of the silicon substrate. The fixed electrode plate has the portion facing the upper surface of the silicon substrate through a space supported by a side wall portion arranged on an inner edge of the portion fixed to the upper surface of the silicon substrate without interposing a space. The outer surface of the side wall portion of the fixed electrode plate is covered by a reinforcement film made of metal such as Au, Cr, and Pt.

Owner:MMI SEMICON CO LTD

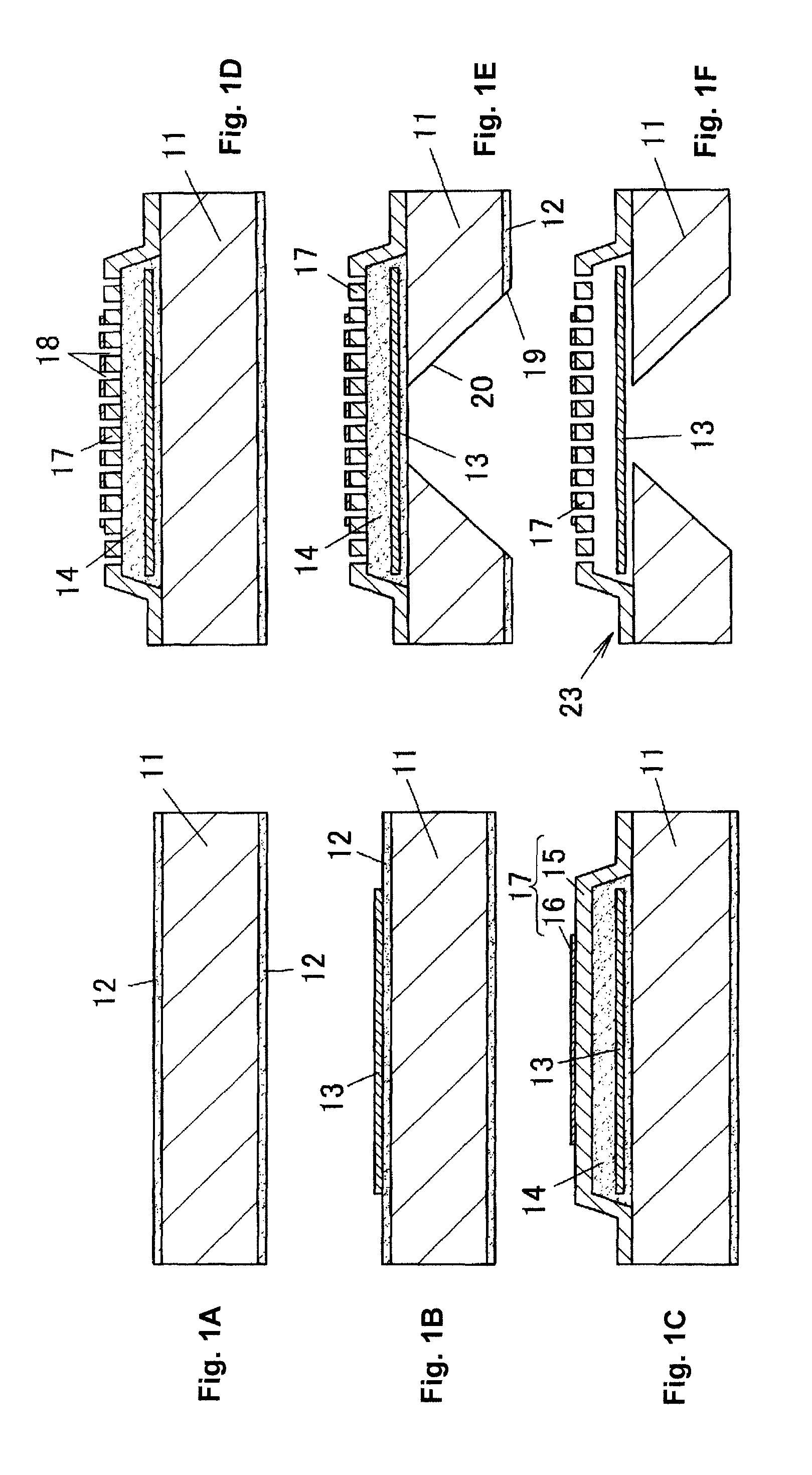

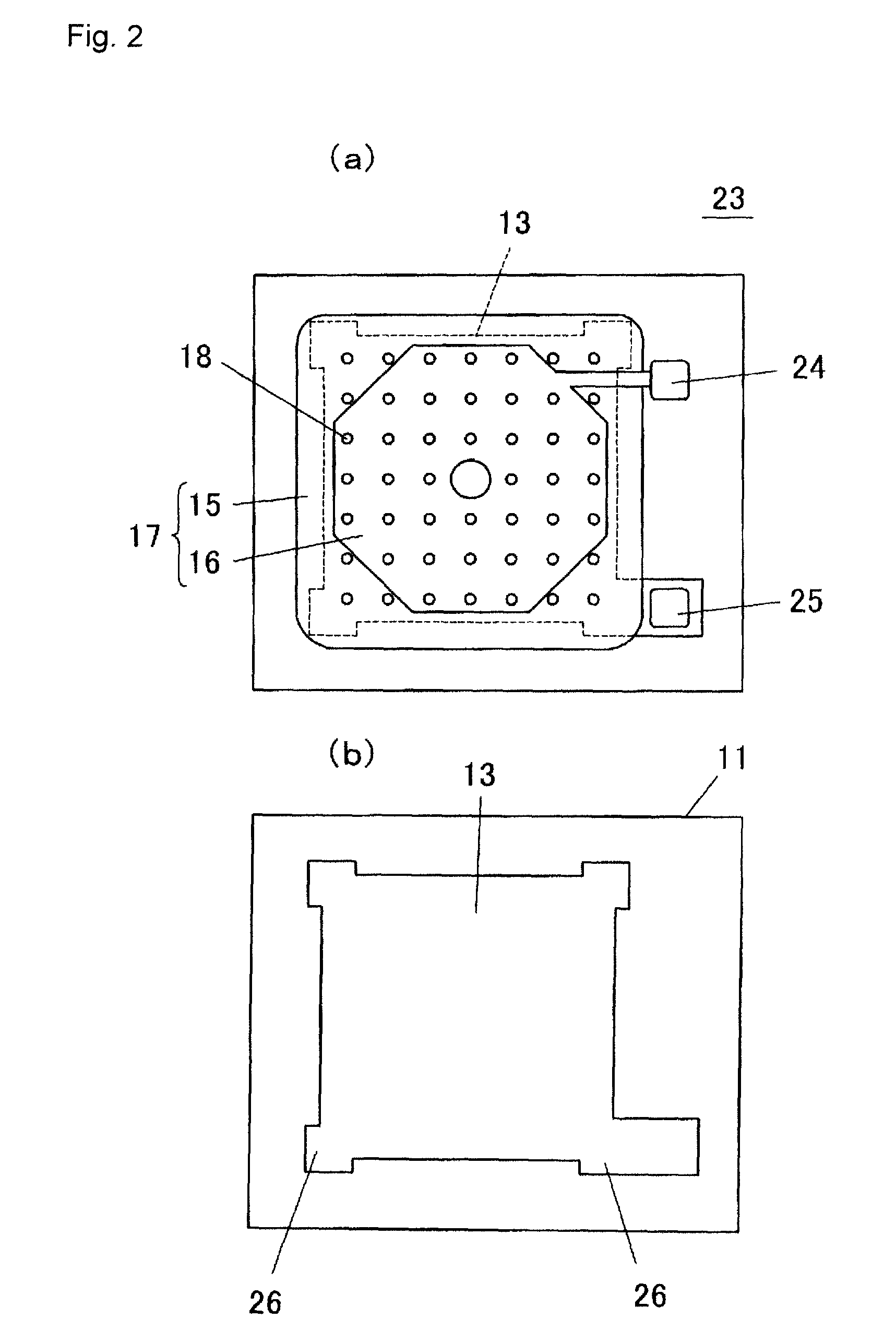

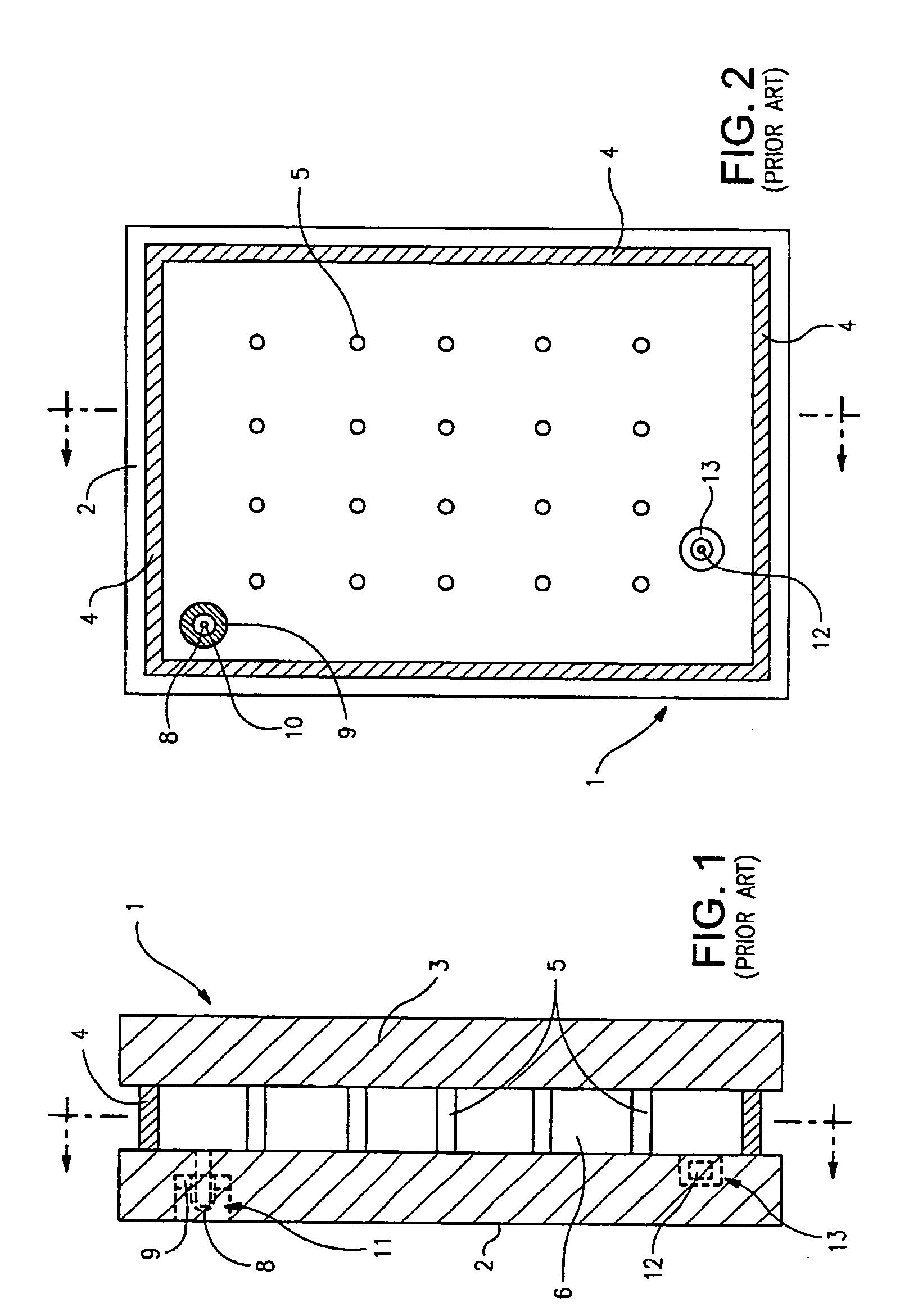

Localized heating of edge seals for a vacuum insulating glass unit, and/or unitized oven for accomplishing the same

ActiveUS8500933B2Accelerate breakageIncrease likelihoodClimate change adaptationLaminationFritEngineering

Certain example embodiments of this invention relate to edge sealing techniques for vacuum insulating glass (VIG) units. More particularly, certain example embodiments relate to techniques for providing localized heating to edge seals of units, and / or unitized ovens for accomplishing the same. In certain example embodiments, a unit is pre-heated to one or more intermediate temperatures, localized heating (e.g., from one or more substantially linear focused IR heat sources) is provided proximate to the peripheral edges of the unit so as to melt frits placed thereon, and cooled. In certain non-limiting implementations, the pre-heating and / or cooling may be provided in one or more steps. An oven for accomplishing the same may include multiple zones for performing the above-noted steps, each zone optionally including one or more chambers. Accordingly, in certain example embodiments, a temperature gradient proximate to the edges of the unit is created, thereby reducing the chances of breakage and / or at least some de-tempering of the substrates.

Owner:GUARDIAN GLASS LLC

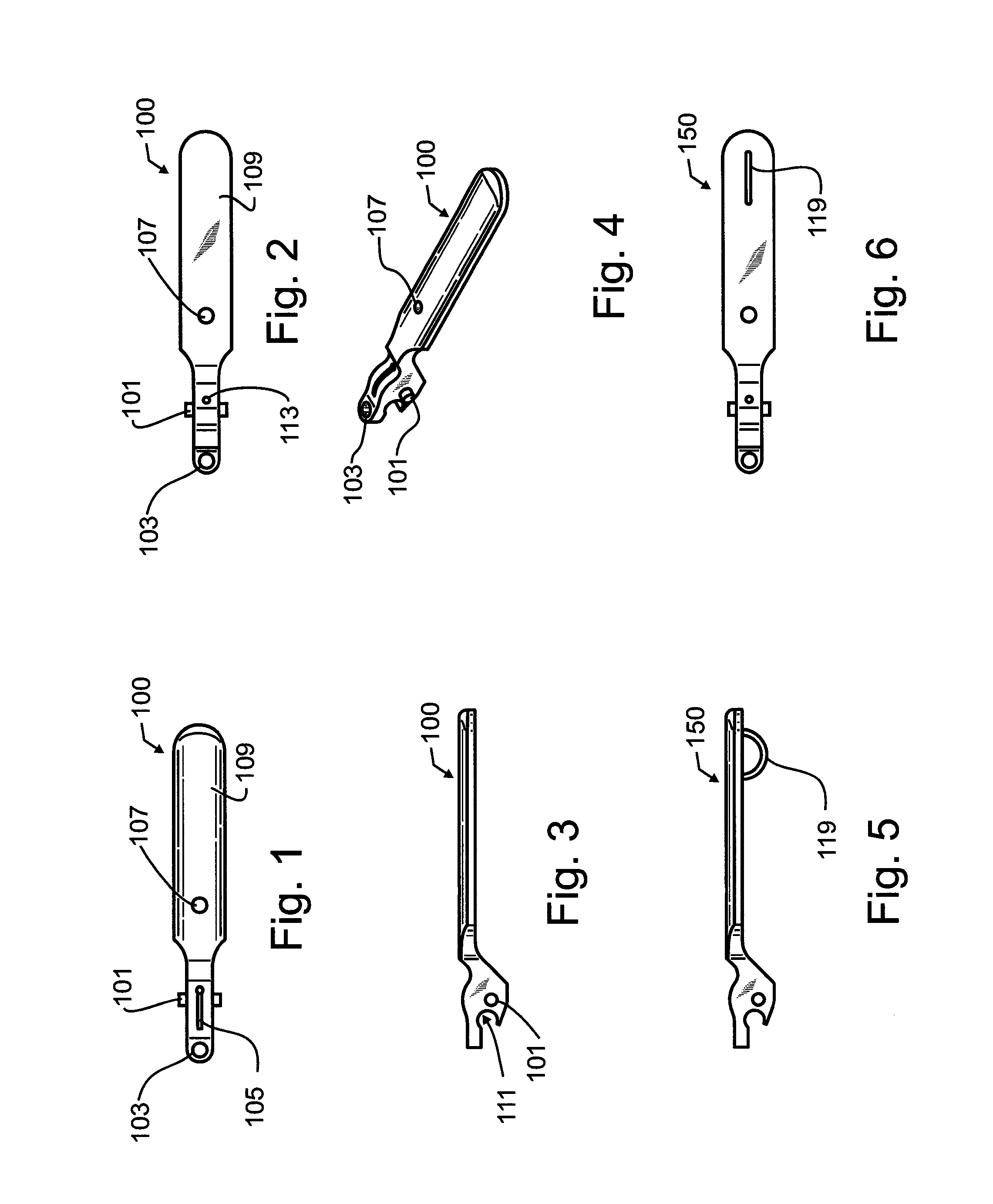

Musical instrument string bender

A guitar string bender bridge mount couples to a guitar bridge through an existing bridge string mount. The bridge mount has a side wall and a slot in and extending to an edge of the side wall. A mounting screw couples into a standard hole on a guitar bridge and is rotatable to adjust the tuning of at least one of the guitar strings. A saddle lever is supported by the bridge mount and is pivotal through a limited arc, limited by low and high stops. The saddle lever is selectively and manually removable from the bridge mount. A string attachment receives and retains a first end of a guitar string. A body wraps about the axis of rotation and is partially wrapped by the guitar string, and the pivoting varies an extent of wrap about the body, to thereby vary a tension upon the guitar string.

Owner:ROLLING KENNETH J

Edge profiles for vacuum insulated glass (VIG) units, and/or VIG unit including the same

ActiveUS8202587B2Accelerate breakageIncrease likelihoodCellulosic plastic layered productsWing framesInsulated glazingEngineering

Certain example embodiments of this invention relate to vacuum insulated glass (VIG) units. The VIG unit may comprise first and second substrates with inner and outer substantially planar surfaces. For either or both of the first and second substrates, when considered along a side cross-section, a portion of the inner planar surface is removed proximate to an outer edge of the glass substrate so as to form a shoulder portion. An inner surface of the shoulder portion is angled (a negative number of degrees, zero degrees, or a positive number of degrees) relative to the inner and outer planar surfaces. The shoulder portion at its smallest height is at least about 50% of the glass substrate at its largest height. A side portion of the step proximate the edge also may be angled, e.g., so that it is or is not perpendicular to the planar surfaces.

Owner:GUARDIAN GLASS LLC

Monitoring apparatus and method particularly useful in photolithographically processing substrates

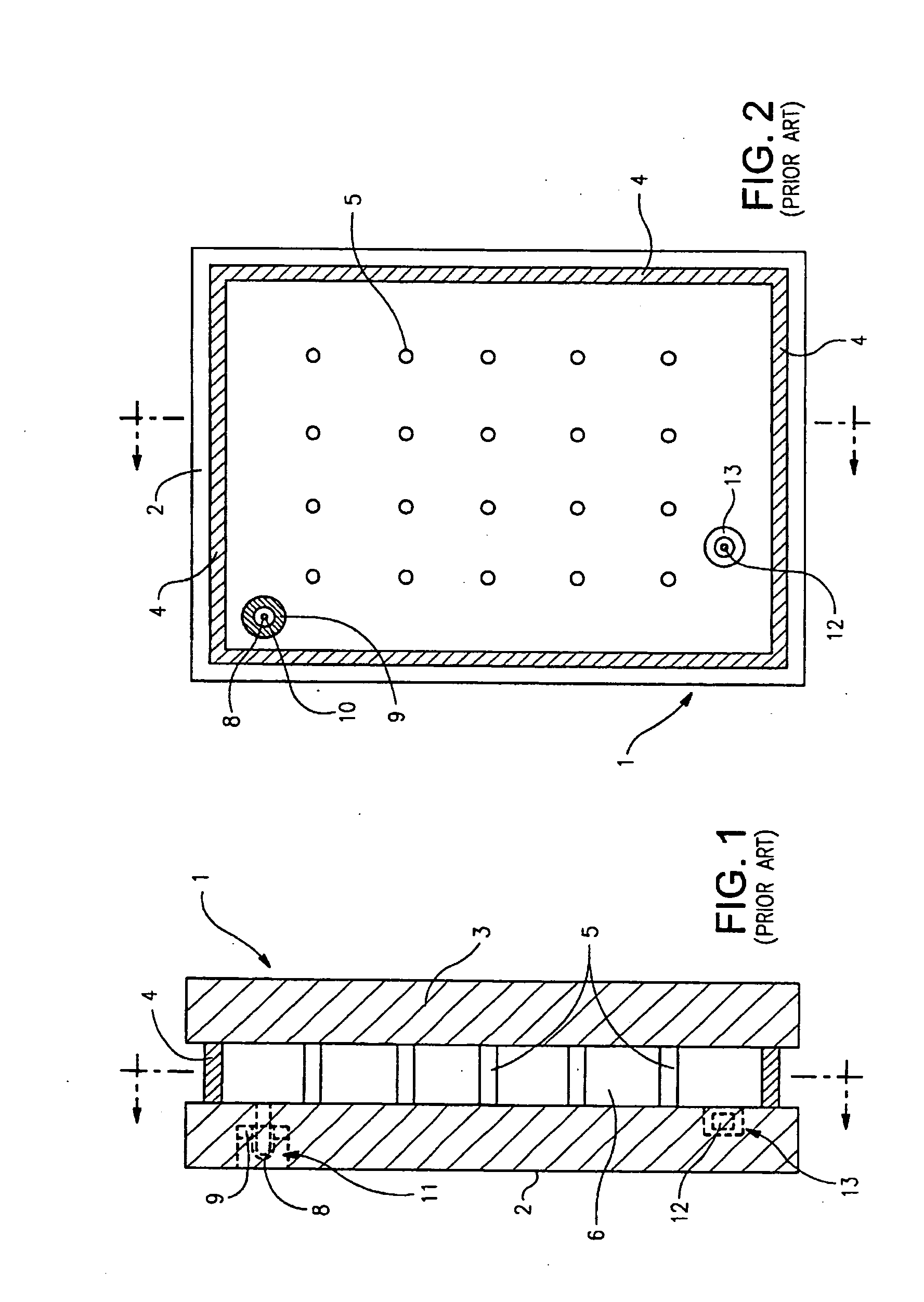

InactiveUS7030957B2Improve accuracyLow priceLiquid processingIndividual molecule manipulationResistLatent image

Apparatus for processing substrates according to a predetermined photolithography process includes a loading station in which the substrates are loaded, a coating station in which the substrates are coated with a photoresist material, an exposing station in which the photoresist coating is exposed to light through a mask having a predetermined pattern to produce a latent image of the mask on the photoresist coating, a developing station in which the latent image is developed, an unloading station in which the substrates are unloaded and a monitoring station for monitoring the substrates with respect to predetermined parameters of said photolithography process before reaching the unloading station.

Owner:NOVA MEASURING INSTR LTD

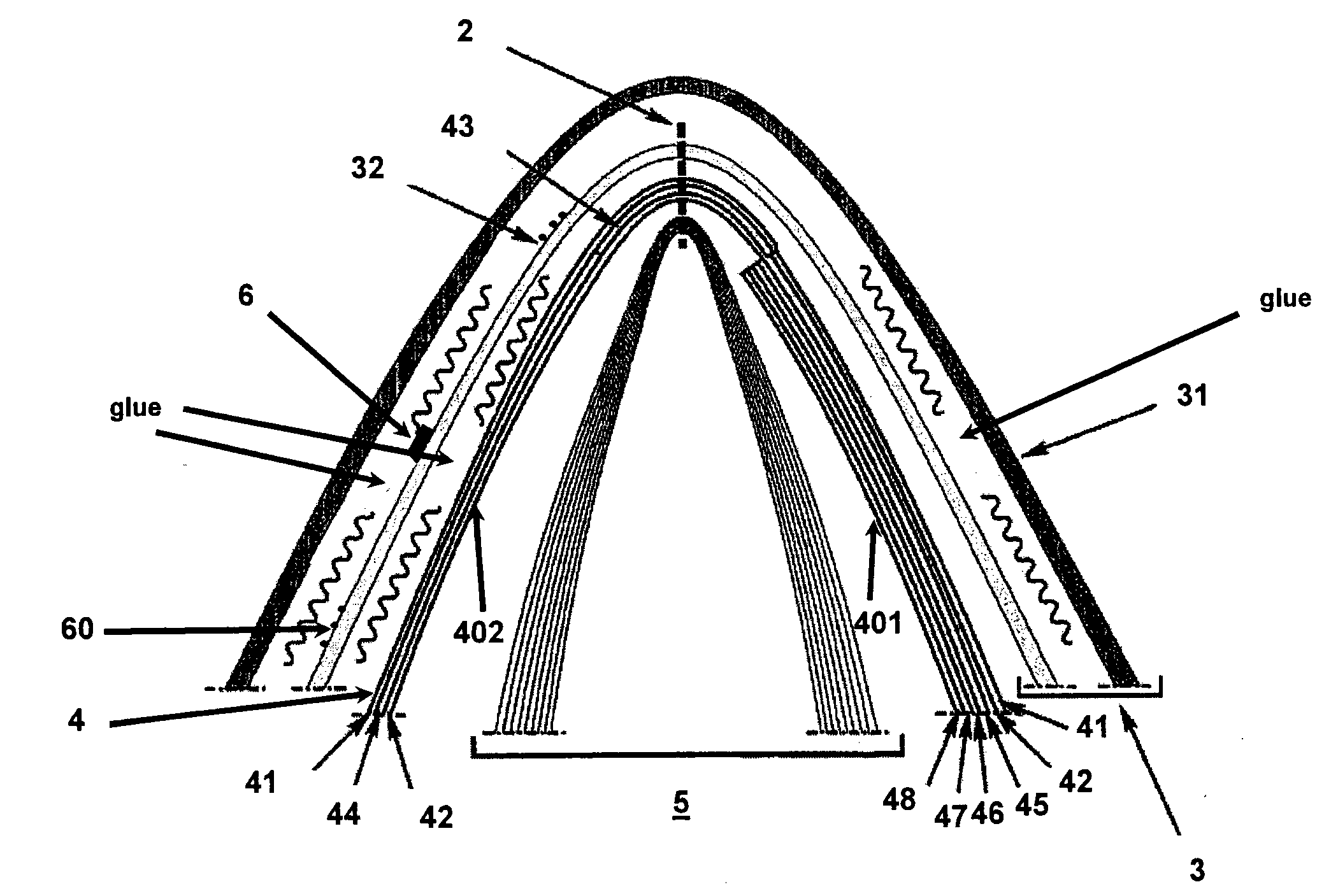

Vacuum insulated glass (VIG) unit including nano-composite pillars, and/or methods of making the same

ActiveUS8679598B2Accelerate breakageIncrease likelihoodClimate change adaptationLaminationInsulated glazingHigh intensity

Certain example embodiments of this invention relate to composite pillar arrangements for VIG units that include both harder and softer materials. The softer materials are located on the outside or extremities of the central, harder pillar material. In certain example embodiments, a high aspect ratio mineral lamellae is separated by an organic “glue” or polymer. When provided around a high strength pillar, the combination of the pillar and such a nano-composite structure may advantageously result in superior strength compared to a monolithic system, e.g., where significant wind loads, thermal stresses, and / or the like are encountered.

Owner:GUARDIAN GLASS LLC

Extreme ultra violet light source apparatus

ActiveUS8536551B2High spectral purityAccelerate breakageMirrorsOptical filtersExtreme ultravioletLaser beams

An extreme ultraviolet light source apparatus using a spectrum purity filter capable of obtaining EUV light with high spectrum purity. The apparatus includes a chamber; a target supply unit for supplying a target material; a driver laser using a laser gas containing a carbon dioxide gas as a laser medium, for applying a laser beam to the target material to generate plasma; a collector mirror for collecting and outputting the extreme ultraviolet light radiated from the plasma; and a spectrum purity filter provided in an optical path of the extreme ultraviolet light, for transmitting the extreme ultraviolet light and reflecting the laser beam, the spectrum purity filter including a mesh having electrical conductivity and formed with an arrangement of apertures having a pitch not larger than a half of a shortest wavelength of the laser beam applied by the driver laser.

Owner:GIGAPHOTON

Vacuum insulated glass (VIG) unit including nano-composite pillars, and/or methods of making the same

ActiveUS20130136875A1Accelerate breakageIncrease likelihoodClimate change adaptationWindows/door improvementInsulated glazingSoft materials

Certain example embodiments of this invention relate to composite pillar arrangements for VIG units that include both harder and softer materials. The softer materials are located on the outside or extremities of the central, harder pillar material. In certain example embodiments, a high aspect ratio mineral lamellae is separated by an organic “glue” or polymer. When provided around a high strength pillar, the combination of the pillar and such a nano-composite structure may advantageously result in superior strength compared to a monolithic system, e.g., where significant wind loads, thermal stresses, and / or the like are encountered.

Owner:GUARDIAN GLASS LLC

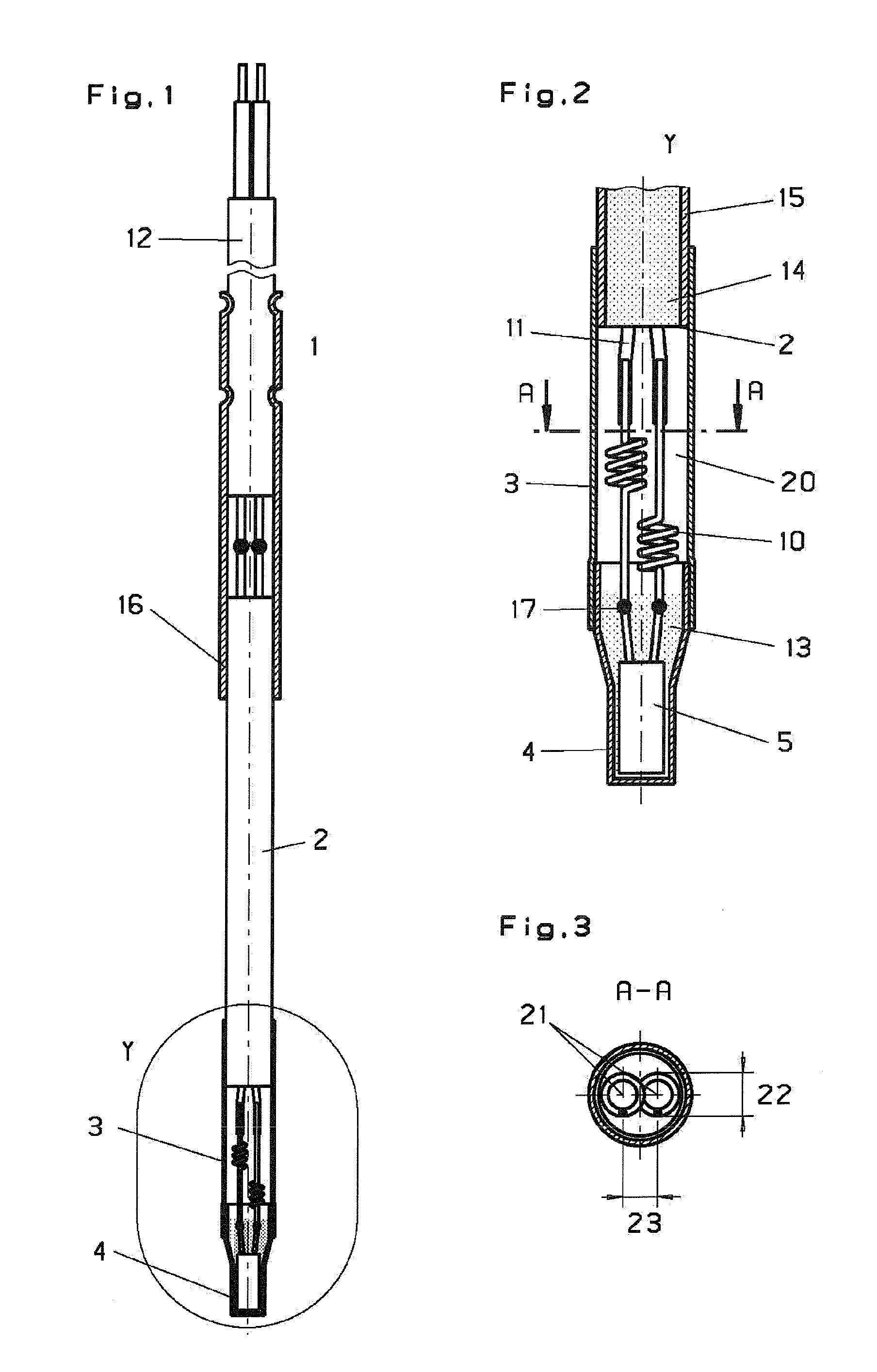

Turbocharger overheating protection device and method of its manufacture

InactiveUS20120110997A1Short response timeSimple designThermometer detailsTemperature measurement in motorsFilm resistanceElectrical resistance and conductance

A housing between mineral-insulated cable and connecting wire in a turbocharger overheating protection device may include the following characteristics:coiled regions of springs (10) arranged point-symmetrically to each other; orthe springs (10) are not placed on axes; orthe coil regions of the coil springs (10) for cushioning the film resistor are shorter than its substrate length and longer than its substrate width; orthe connecting wires of the film resistor are shorter than its substrate length and longer than its substrate width; orthe springs are arranged staggered in their longitudinal direction adjacent to each other; orcoil springs (10) are used, in which the coils are located only in one half of the spring (10) and the coils of one spring are arranged staggered in the longitudinal direction to the coils of the other spring (10).

Owner:HERAEUS NEXENSOS GMBH

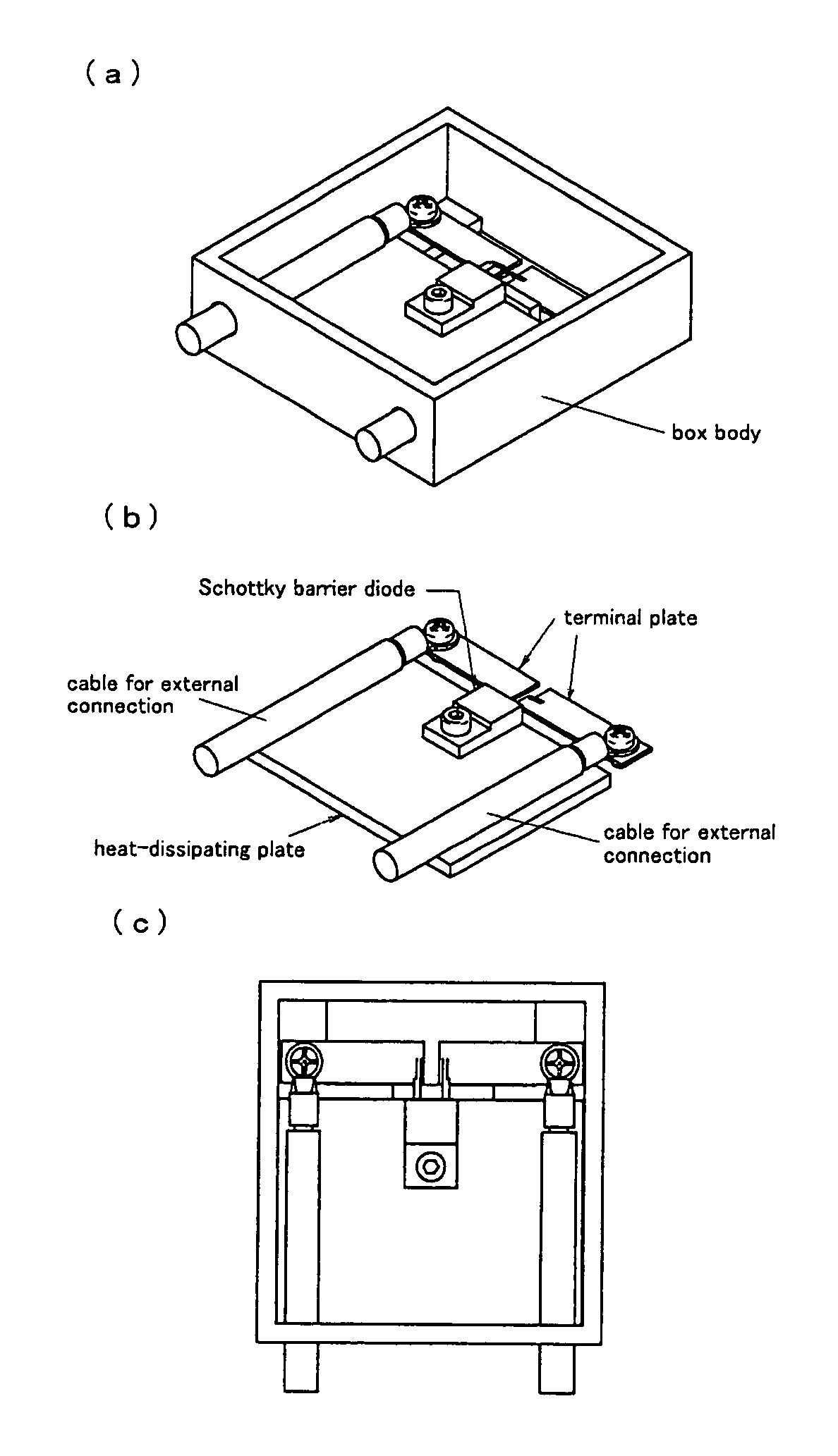

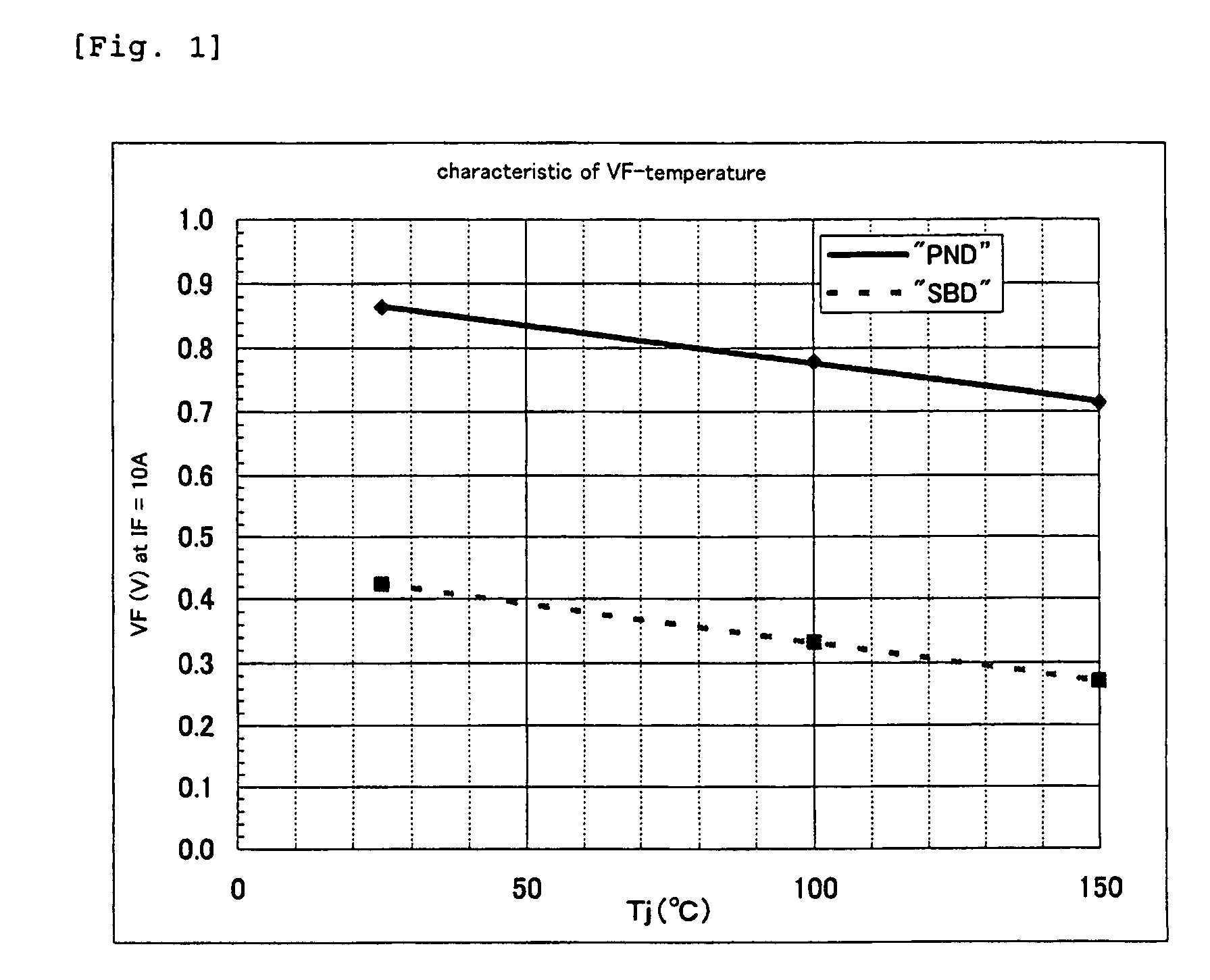

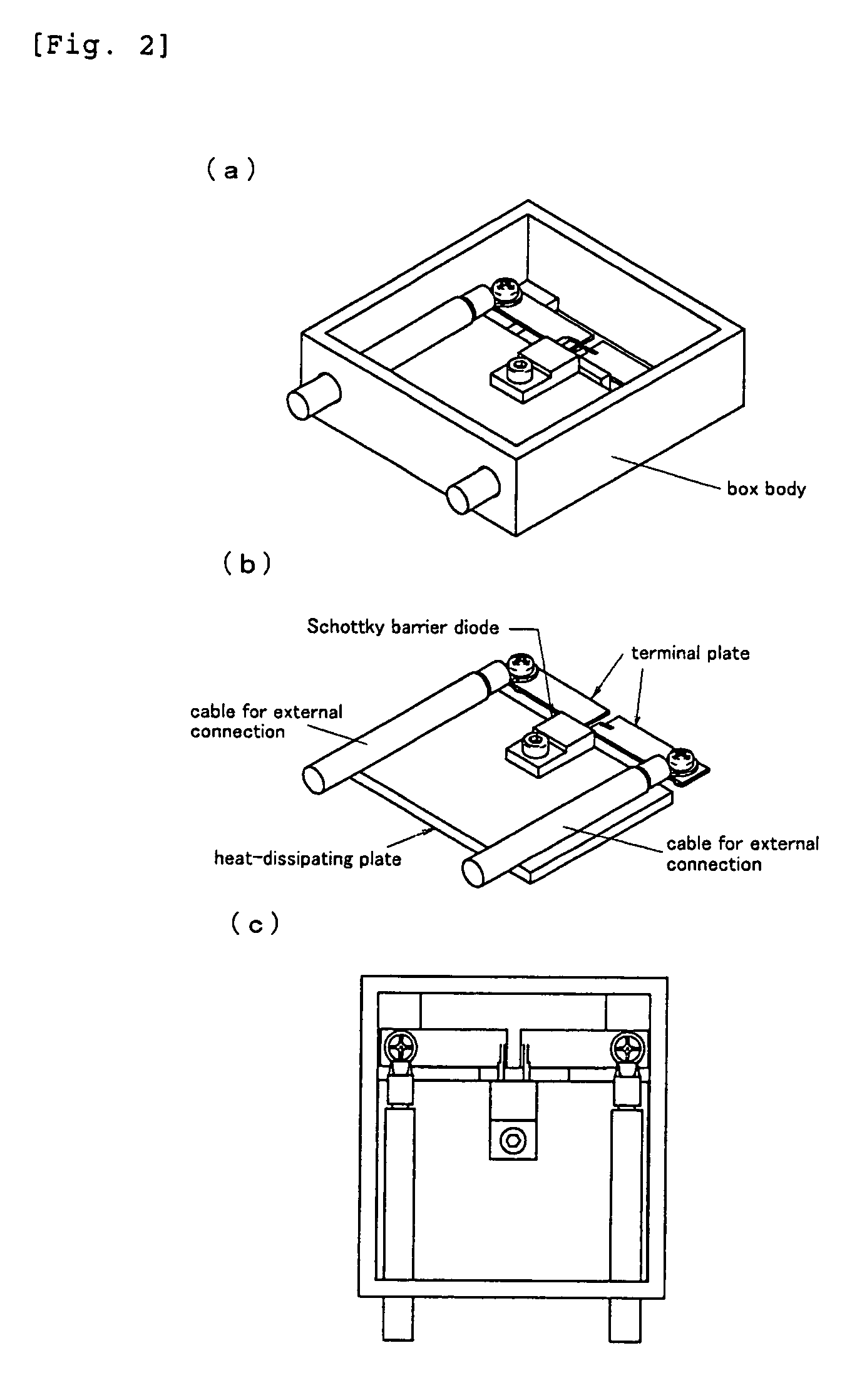

Terminal box for a solar cell panel

InactiveUS7928315B2Avoid feverAccelerate breakagePV power plantsCouplings bases/casesSchottky barrierSurface mounting

A means for effectively preventing the temperature rise of the diode when the bypass diode is operating in a terminal box for a crystalline silicon solar cell panel is provided. The present invention is characterized in that, in the terminal box for a crystalline silicon solar cell panel, Schottky barrier diode is used as a bypass diode. Preferably, the forward-direction voltage drop of the Schottky barrier diode is the specific value or below at the specific junction temperature. Preferably, as a Schottky barrier diode, a package diode which is surface-mounting type or non-insulation type is used.

Owner:ONAMBA CO LTD

Capacitive vibration sensor

ActiveUS8803257B2Improve the fixing strengthAccelerate breakageAcceleration measurement using interia forcesSemiconductor electrostatic transducersSiliconMetal

A hollow part is formed in a silicon substrate through the front and the back. A vibration electrode plate is arranged on an upper surface of the silicon substrate to cover the opening on the upper surface. A fixed electrode plate covers the upper side of the vibration electrode plate while maintaining a microscopic gap with the vibration electrode plate, where the peripheral part is fixed to the upper surface of the silicon substrate. The fixed electrode plate has the portion facing the upper surface of the silicon substrate through a space supported by a side wall portion arranged on an inner edge of the portion fixed to the upper surface of the silicon substrate without interposing a space. The outer surface of the side wall portion of the fixed electrode plate is covered by a reinforcement film made of metal such as Au, Cr, and Pt.

Owner:MMI SEMICON CO LTD

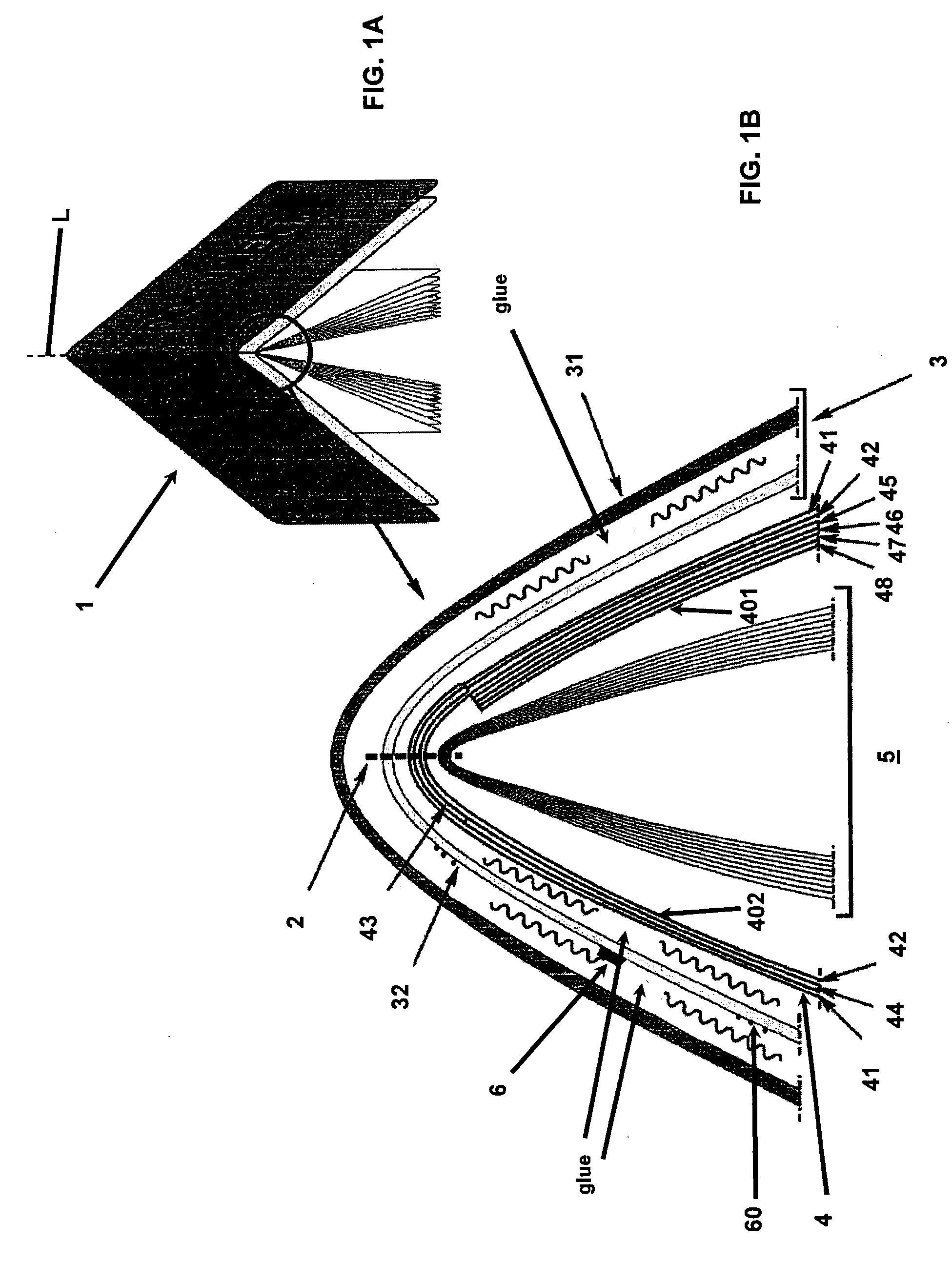

Electronic passport

ActiveUS20130233928A1Firmly connectedHigh safety standardsOther printing matterLamination ancillary operationsPlastic materialsEngineering

An electronic passport in the form of a booklet, bearing a plurality of sheets sewn there among at the respective longitudinal center lines is described. The electronic passport has a cover sheet and a data sheet. The cover sheet has a layer made of fabric, an electronic inlay and an internal flyleaf layer and embedding an electronic data storage means provided with an antenna for radio transmission. The data sheet is made by a first and a second layer of plastic material. The data sheet defines a data page bearing identification data of a subject and a connecting page made fixed with the cover sheet, and also comprises an intermediate layer of flexible material extending at the center line of sewing.

Owner:INST POLIGRAFICO E ZECCA DELLO STATO

Non-toxic water-based frit slurry paste, and assembly incorporating the same

ActiveUS8668798B2Accelerate breakageIncrease likelihoodCellulosic plastic layered productsLaminationWater basedFrit

Certain example embodiments of this invention relate to a frit slurry paste for use in assemblies (e.g., a vacuum insulated glass unit or a plasma display panel), and methods of making the same. Frit powder, binder material, and a water-based solvent are mixed together to form an intermediate mixture. The frit powder is substantially lead free, and the water-based solvent is provided at a first temperature. Additional water-based solvent is added to the intermediate mixture to form a frit slurry paste. The additional water-based solvent is provided at a second temperature, with the second temperature being lower than the first temperature. The binder material is provided at a concentration of 0.001%-20% by weight with respect to the frit slurry paste or the frit slurry paste absent the frit powder. The frit slurry paste has a bulk viscosity of 2,000-200,000 cps.

Owner:GUARDIAN GLASS LLC

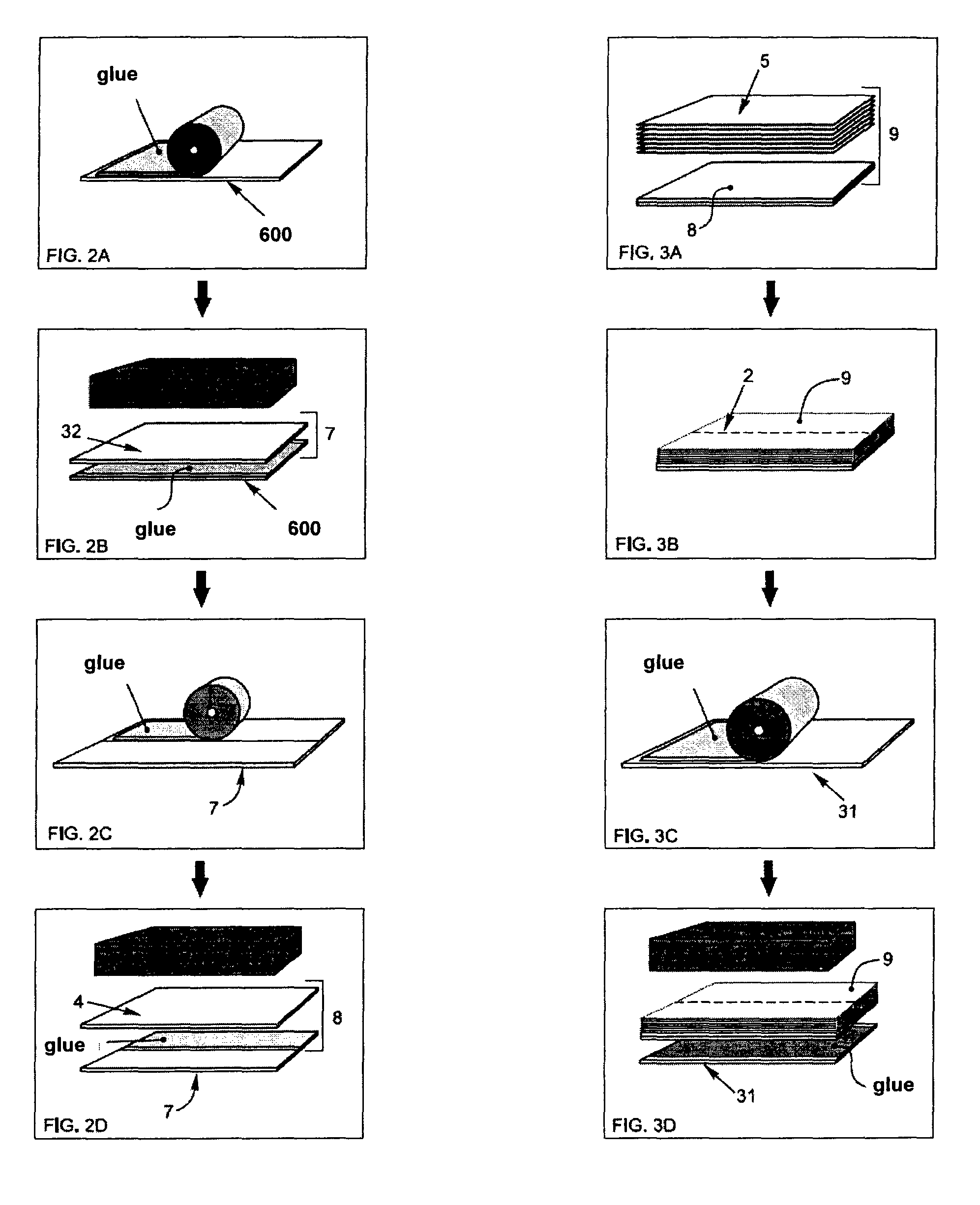

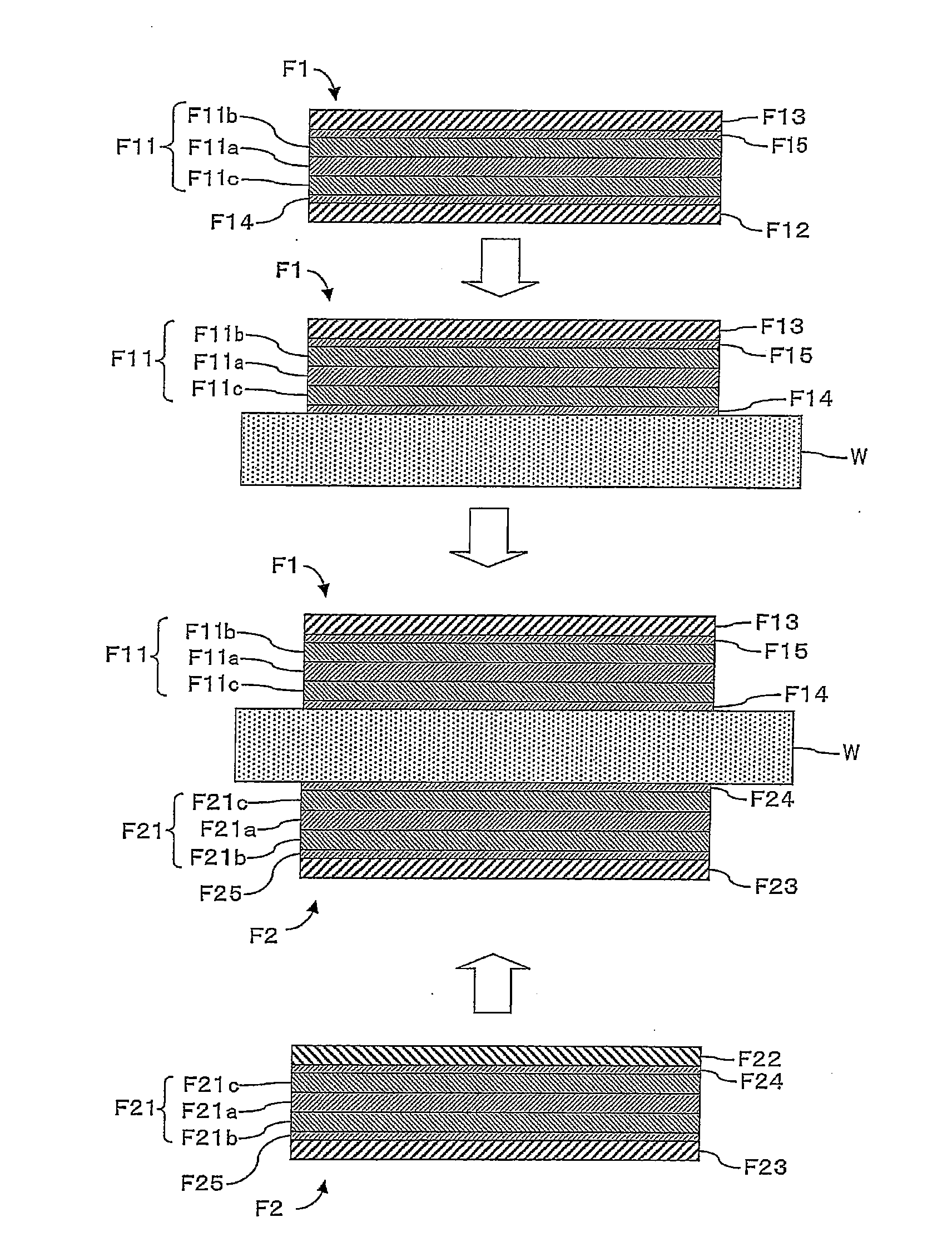

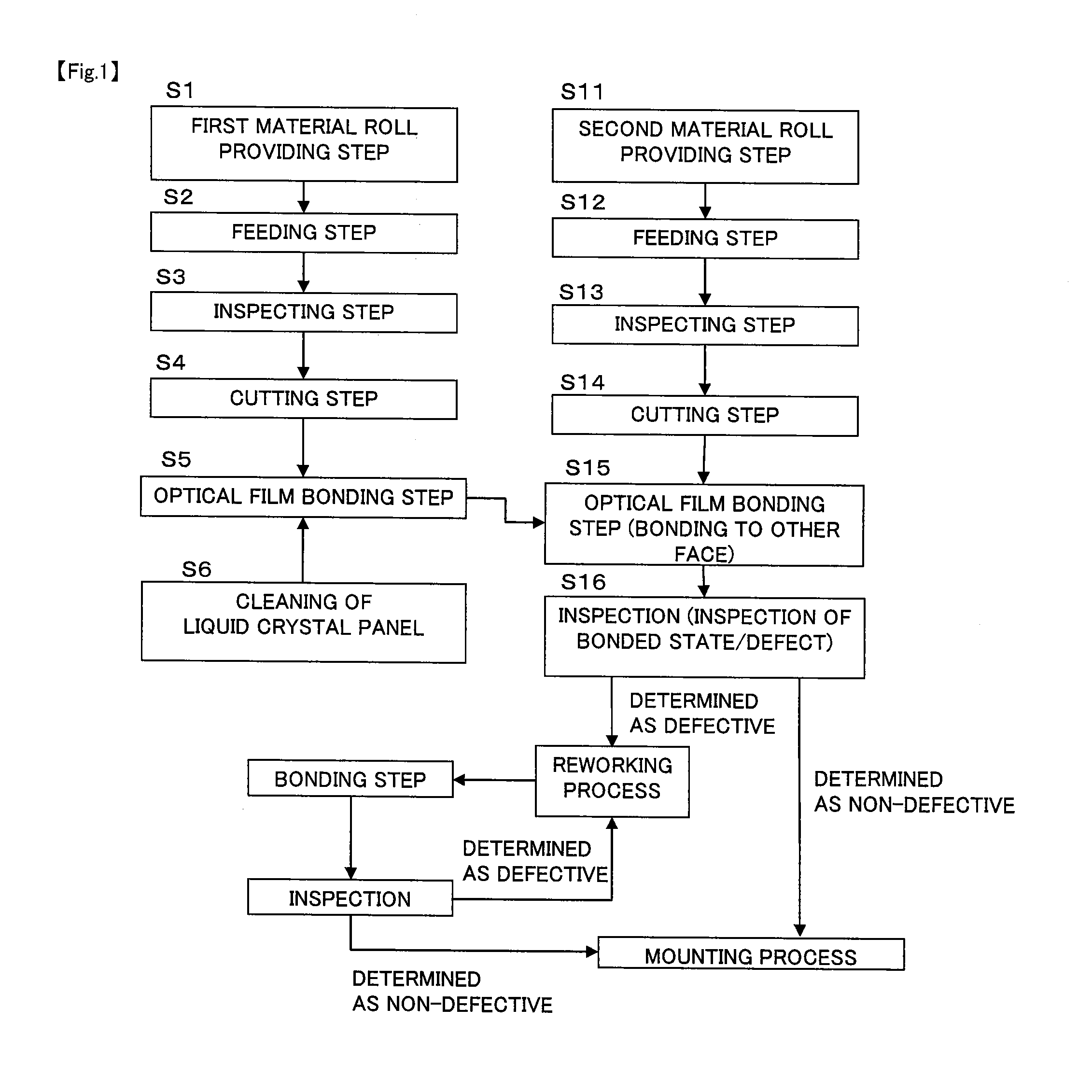

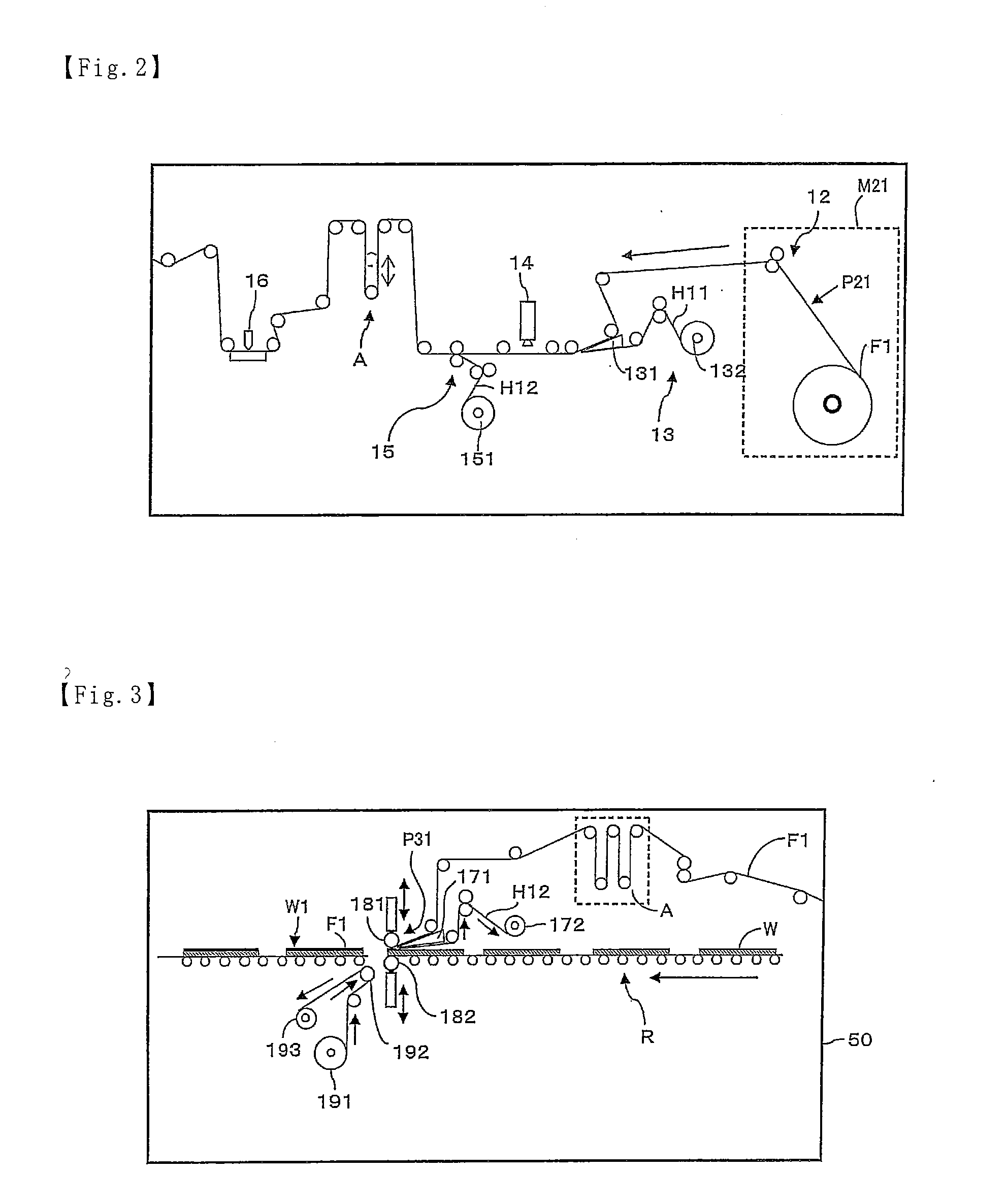

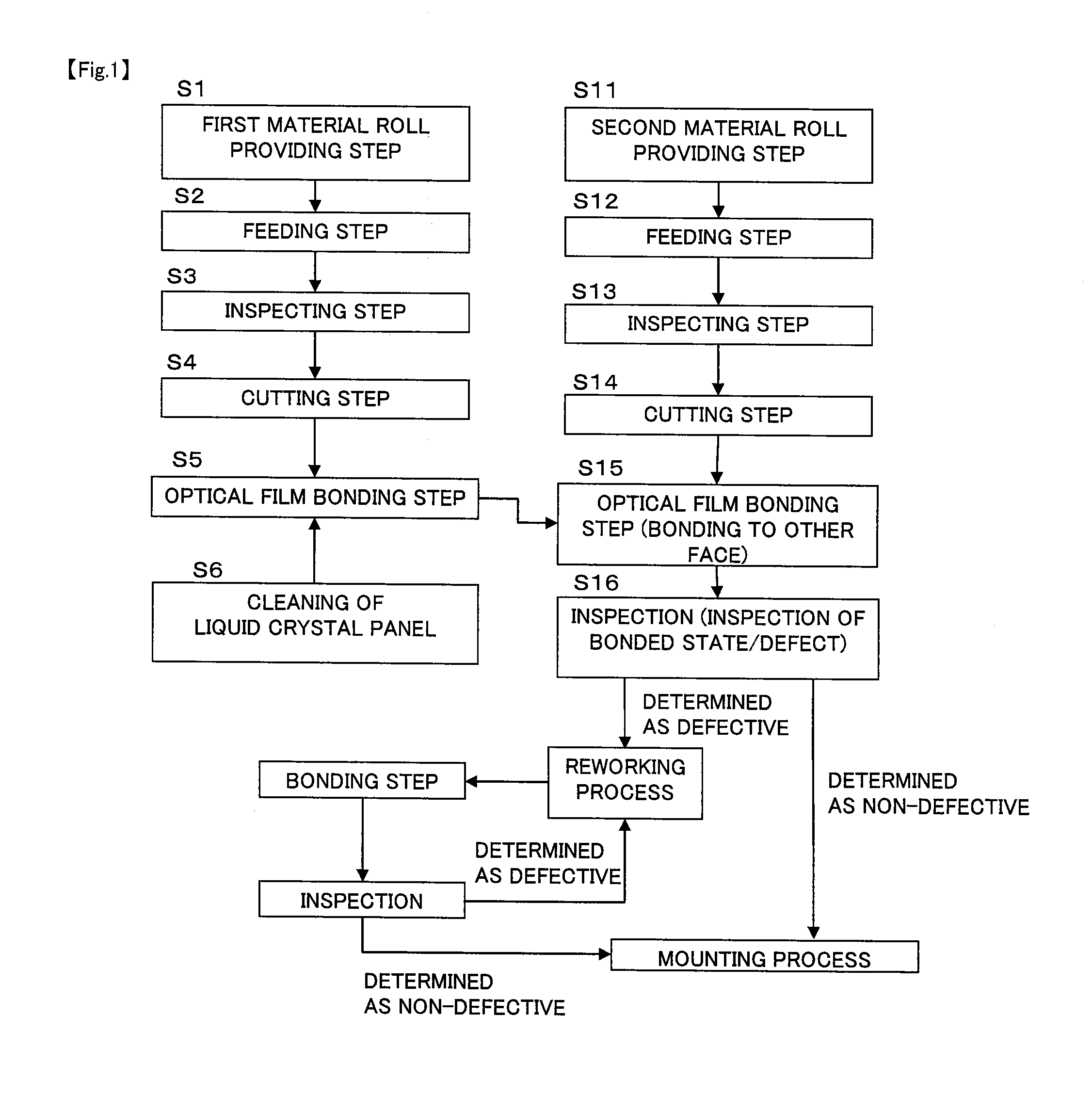

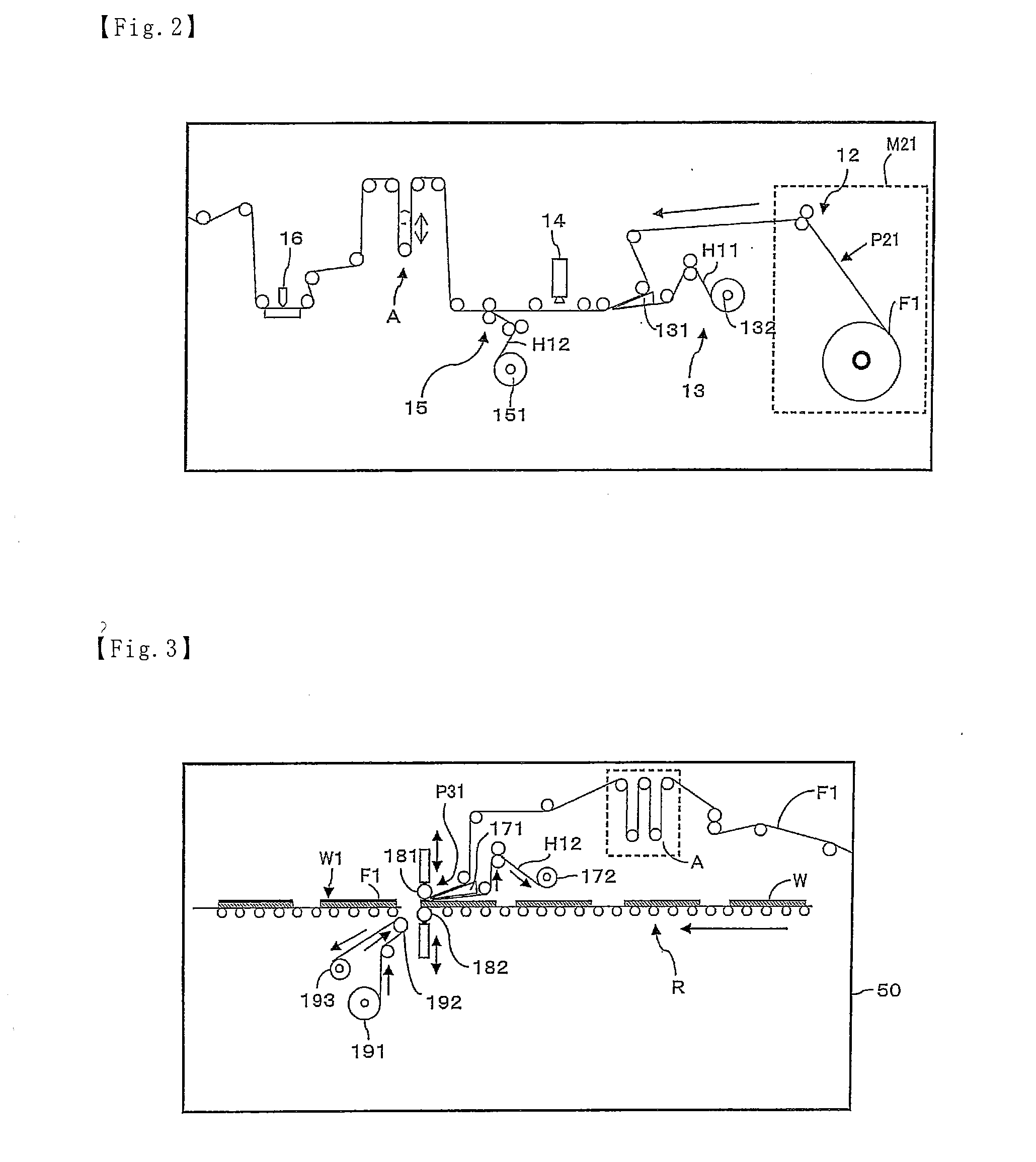

Method for manufacturing liquid crystal display element

ActiveUS20100236702A1Reliable cuttingReliable preventionLamination ancillary operationsLayered product treatmentLiquid-crystal displayBonding process

A method for manufacturing a liquid crystal display element is provided which simultaneously achieves the object of cutting an optical film without causing degradation in appearance and the object of preventing the film from being broken in a continuous bonding process, and includes: providing a long sheet material including a laminate of an optical film containing a polarizer, a pressure-sensitive adhesive layer, and a carrier film temporarily bonded to the pressure-sensitive adhesive layer; cutting the long sheet material at predetermined intervals, while maintaining the continuity of the carrier film; peeling off the carrier film by a tensile force; and continuously bonding the resulting optical film pieces to liquid crystal panels, respectively, through the pressure-sensitive adhesive layer exposed by the peeling off, while feeding the resulting optical film pieces, wherein the cutting is performed to such a depth as to substantially reach the carrier film, and the carrier film is cut to a depth less than half of the thickness of the carrier film at least both end portions in the width direction of the carrier film.

Owner:NITTO DENKO CORP

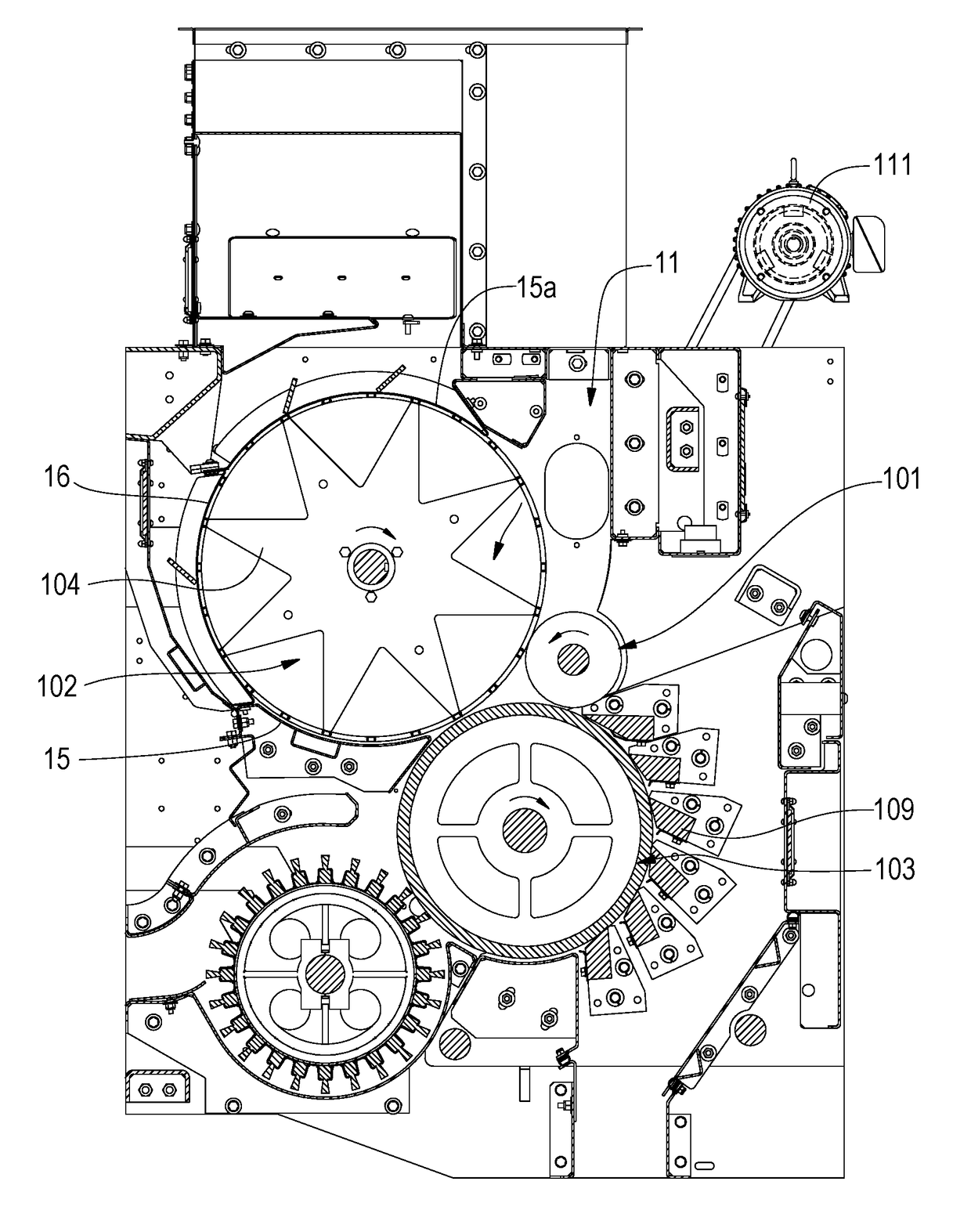

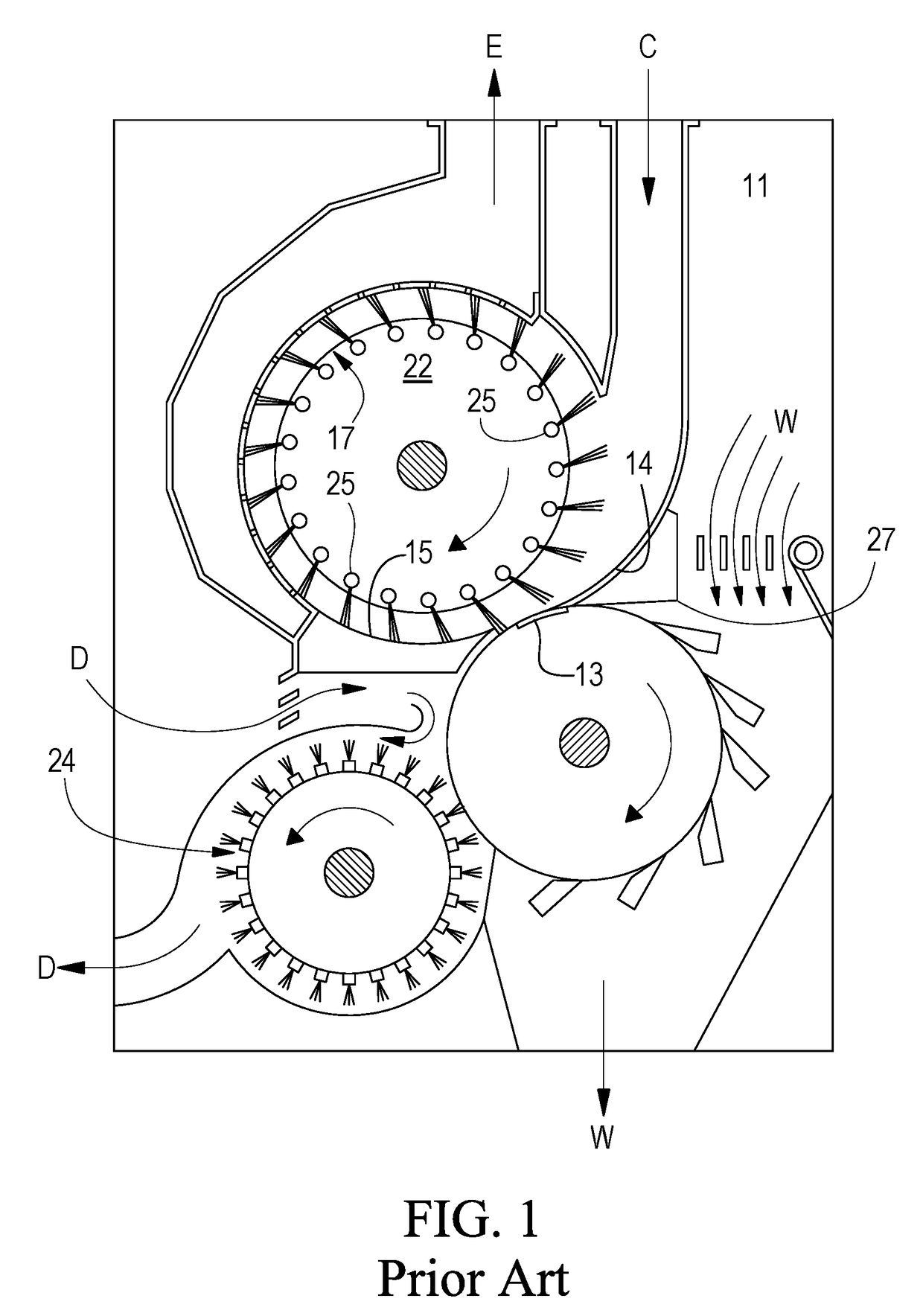

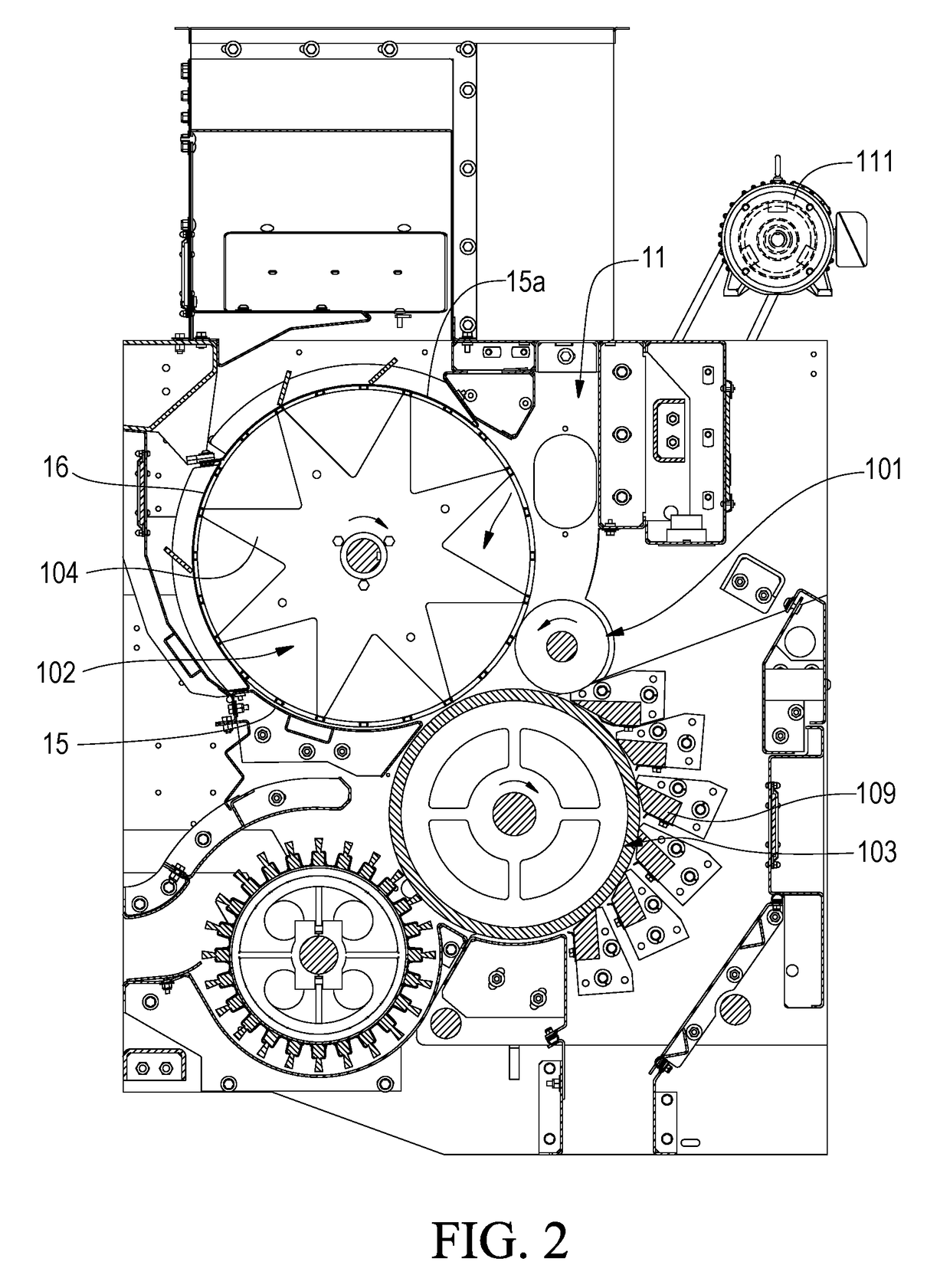

Lint cleaner

ActiveUS20170283991A1Smooth appearanceAccelerate breakageVegetable fibre separation from seedsFibre cleaning/opening by beater armsCombingEngineering

An apparatus for cleaning trash from cotton lint utilizes a combing cylinder having a plurality of teeth covering its surface and extending therefrom in a manner to release the cotton lint to a cleaning cylinder. The combing cylinder surface moves slower than the cleaning cylinder to comb the lint as it is delivered to the cleaning cylinder. Means are provided to vary the speed of the combing cylinder to match the lint processing parameters, including negating lint combing all together.

Owner:LUMMUS INDS

Method for manufacturing liquid crystal display element

ActiveUS20120160406A1Accelerate breakageLamination ancillary operationsLayered product treatmentLiquid-crystal displayPolarizer

A method for manufacturing a liquid crystal display element, includes: providing a long sheet material including a laminate of an optical film containing a polarizer, a pressure-sensitive adhesive layer, and a carrier film temporarily bonded to the pressure-sensitive adhesive layer; cutting the long sheet material at predetermined intervals, while maintaining the continuity of the carrier film; peeling off the carrier film by a tensile force; and continuously bonding the resulting optical film pieces to liquid crystal panels, respectively, through the pressure-sensitive adhesive layer exposed by the peeling off, while feeding the resulting optical film pieces, wherein the cutting is performed to such a depth as to substantially reach the carrier film, and the carrier film is cut to a depth less than half of the thickness of the carrier film at least both end portions in the width direction of the carrier film.

Owner:NITTO DENKO CORP

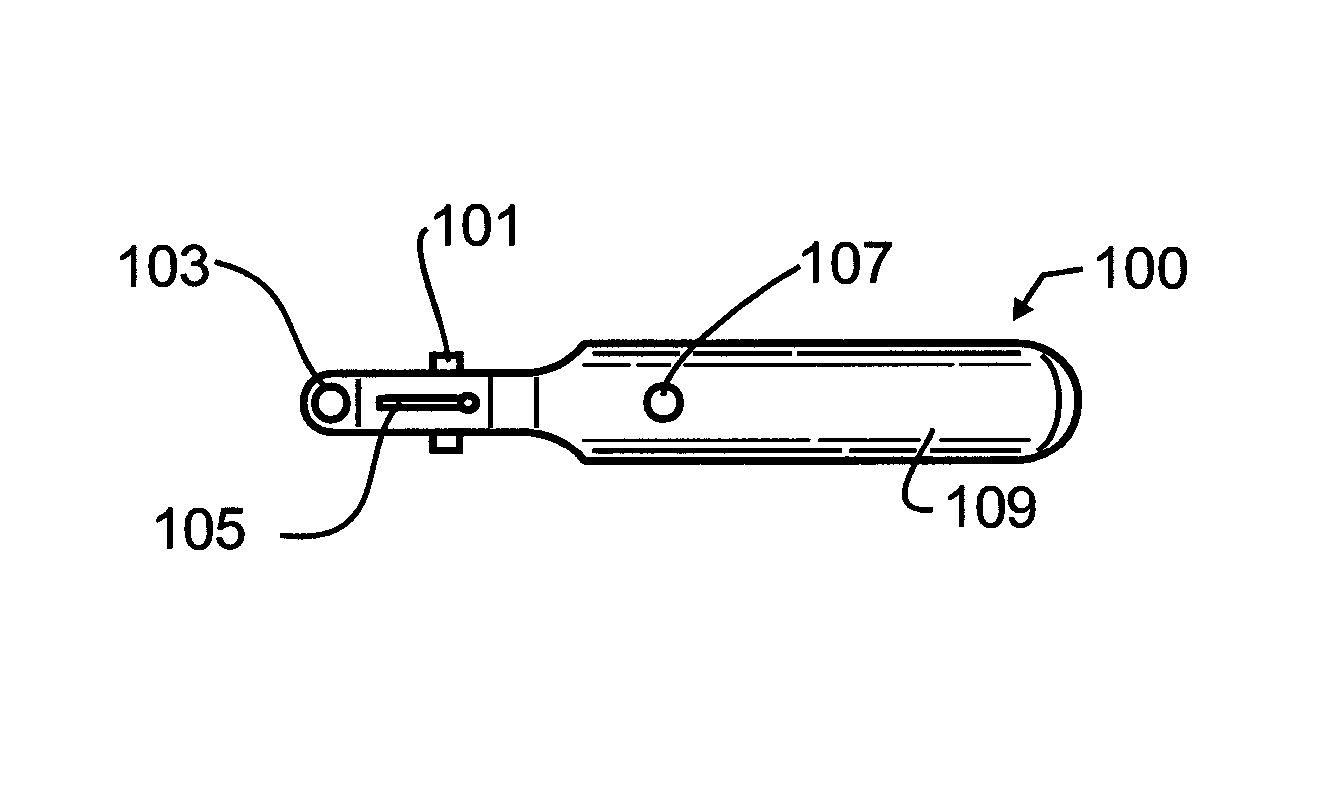

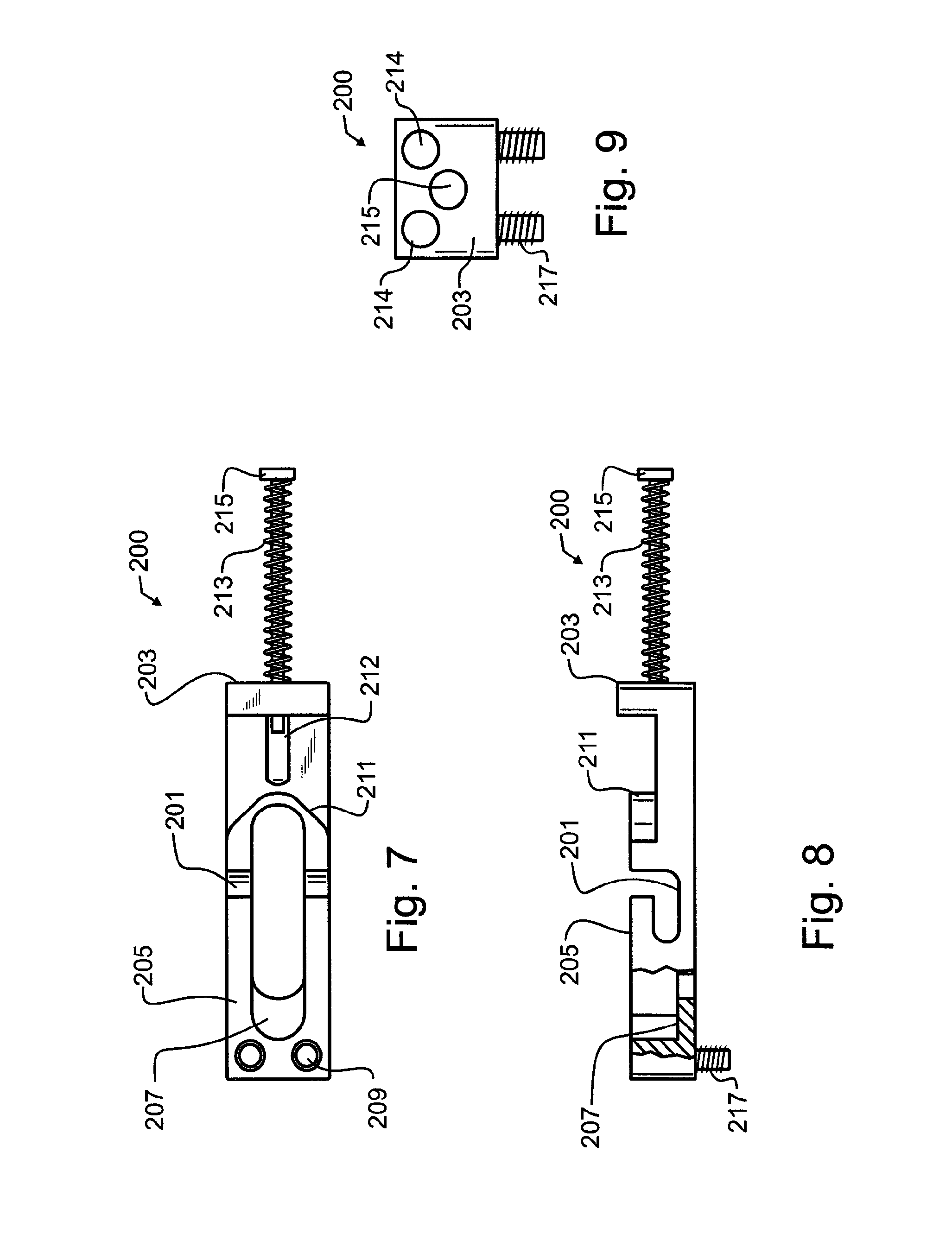

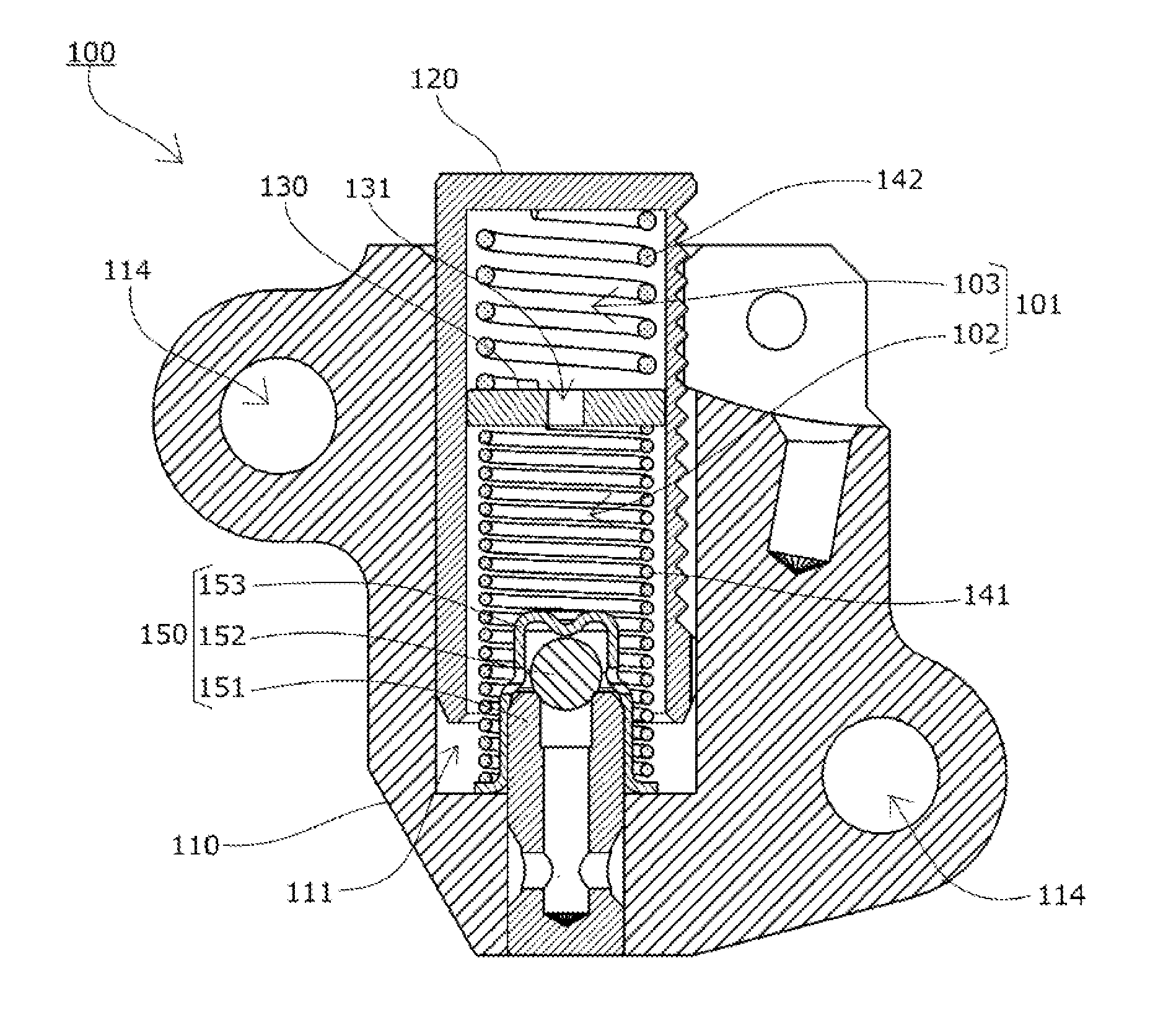

Chain tensioner

ActiveUS20160305512A1Small damping effectImprove vibrationGearingMachines/enginesEngineeringHigh pressure chamber

Provided is a chain tensioner that can always provide a suitable reaction force and damping force to various tension fluctuations of the chain, has a simple structure, is easy to produce, and also enables a reduction in the production cost. The chain tensioner 100 has a plunger 120 inserted in a plunger bore 111, and biasing means 140 for biasing the plunger in a protruding direction of the plunger. A plurality of biasing means 140 are accommodated so as to freely expand and contract inside a high pressure chamber 101 and arranged in series along the protruding direction of the plunger 120, with a separator plate 130 interposed therebetween. The separator plate 130 has one or more oil passages that adjust oil flow.

Owner:TSUBAKIMOTO CHAIN CO

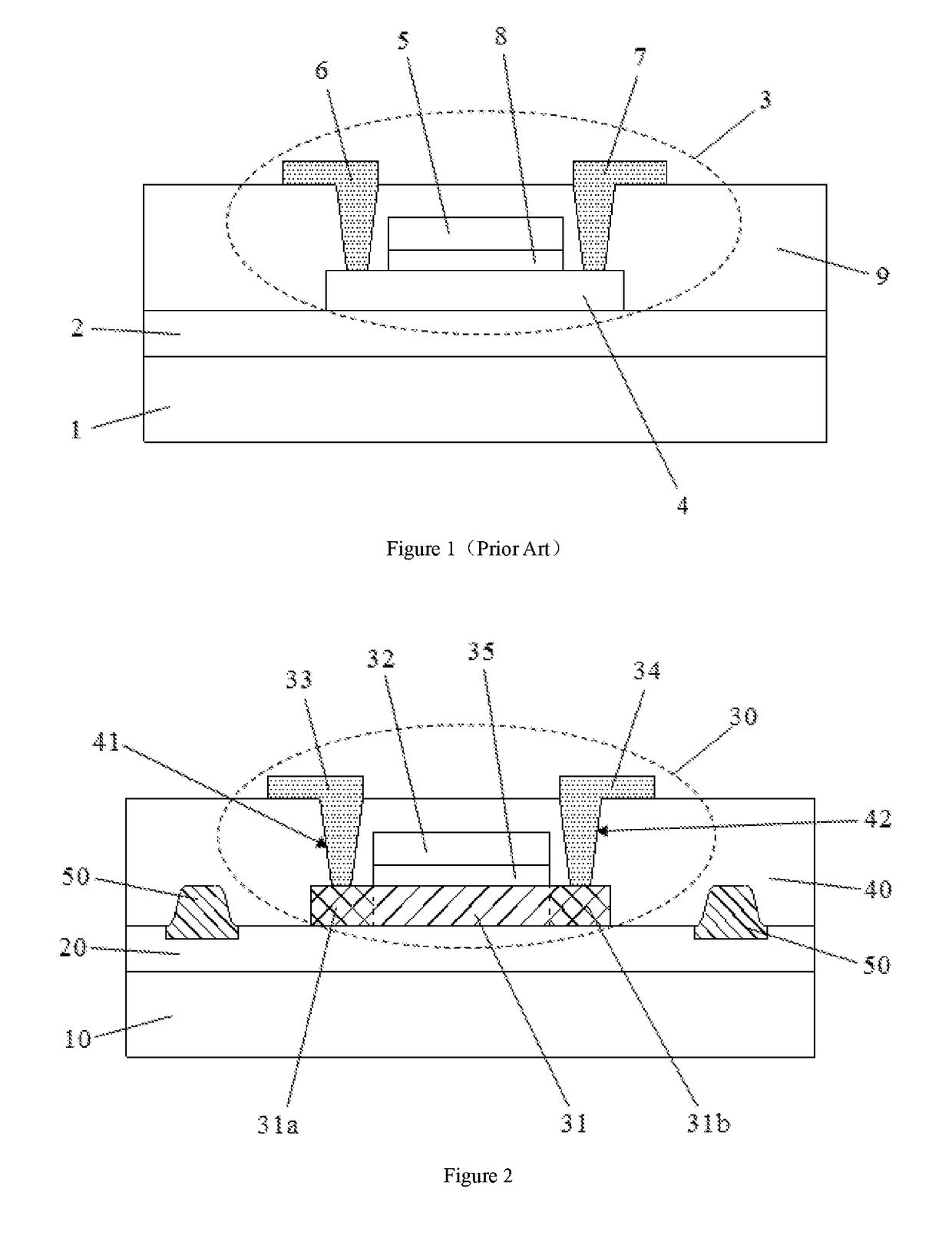

Flexible Array Substrate, the Preparation Method Thereof, and Flexible Display Device

InactiveUS20180219163A1Speed up the flowIncrease flexibilityFinal product manufactureSolid-state devicesFlexible displayDielectric layer

The present disclosure discloses a flexible array substrate, comprising a flexible substrate and a buffer layer on the flexible substrate. Multiple thin film transistors are provided on the buffer layer in array. An interlayer dielectric layer is provided on the thin film transistor. The interlayer dielectric layer covers the buffer layer. Wherein, an interconnecting structure is provided between the interlayer dielectric layer and the buffer layer. At least one interconnecting structure is respectively provided at both sides of each column of the thin film transistor. The interconnecting structure extends toward the direction parallel to the bending axis of the flexible array substrate. The present disclosure further discloses a preparation method of flexible array substrate and a flexible display device with the flexible array substrate. The present disclosure provides the interconnecting structure, which enhances the connecting performance of the interconnecting layer in the flexible array substrate.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Non-toxic water-based frit slurry paste, and assembly incorporating the same

ActiveUS20140154436A1Accelerate breakageIncrease likelihoodDoors/windowsCellulosic plastic layered productsWater basedFrit

Certain example embodiments of this invention relate to a frit slurry paste for use in assemblies (e.g., a vacuum insulated glass unit or a plasma display panel), and methods of making the same. Frit powder, binder material, and a water-based solvent are mixed together to form an intermediate mixture. The frit powder is substantially lead free, and the water-based solvent is provided at a first temperature. Additional water-based solvent is added to the intermediate mixture to form a frit slurry paste. The additional water-based solvent is provided at a second temperature, with the second temperature being lower than the first temperature. The binder material is provided at a concentration of 0.001%-20% by weight with respect to the frit slurry paste or the frit slurry paste absent the frit powder. The frit slurry paste has a bulk viscosity of 2,000-200,000 cps.

Owner:GUARDIAN GLASS LLC

Piezoelectric vibration device, method of manufacturing the same, and method of adjusting resonant frequency

InactiveUS20120038244A1Increase in roughnessRaise the resonant frequencyPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesYoung's modulusAcoustic wave

A method of manufacturing a piezoelectric vibration device having a surface acoustic wave element includes a step of forming a functional film adapted to increase a velocity of a wave on a surface of the surface acoustic wave element. Further, the Young's modulus of the functional film is higher than the Young's modulus of each of the excitation electrode and the piezoelectric body, and the density of the functional film is lower than the density of each of the excitation electrode and the piezoelectric body. Thus, it is possible to develop the frequency rise due to the elastic modulus rise while suppressing the influence of the frequency drop due to the mass attachment effect to thereby raise the resonant frequency of the surface acoustic wave element.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com