Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2065results about How to "Smooth appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

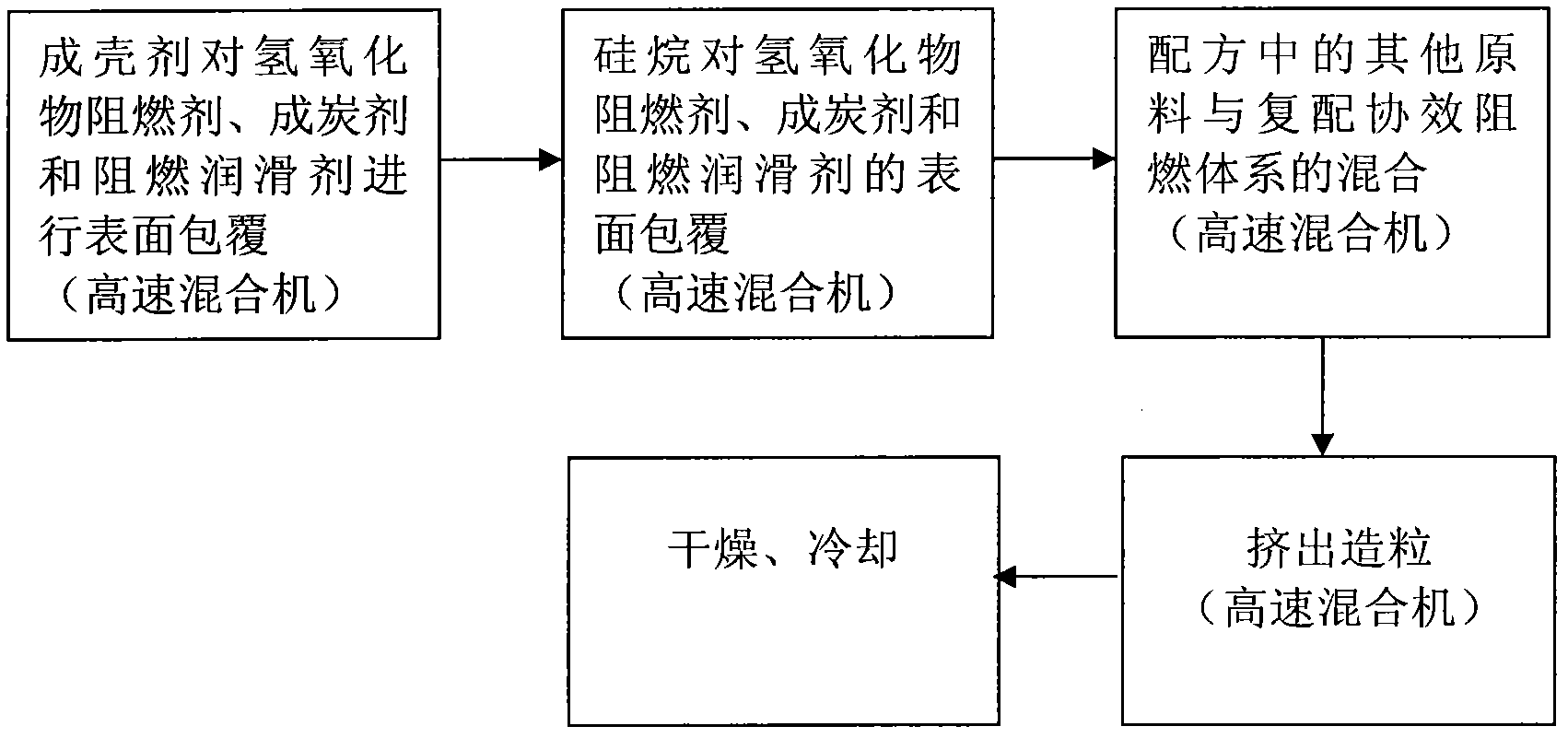

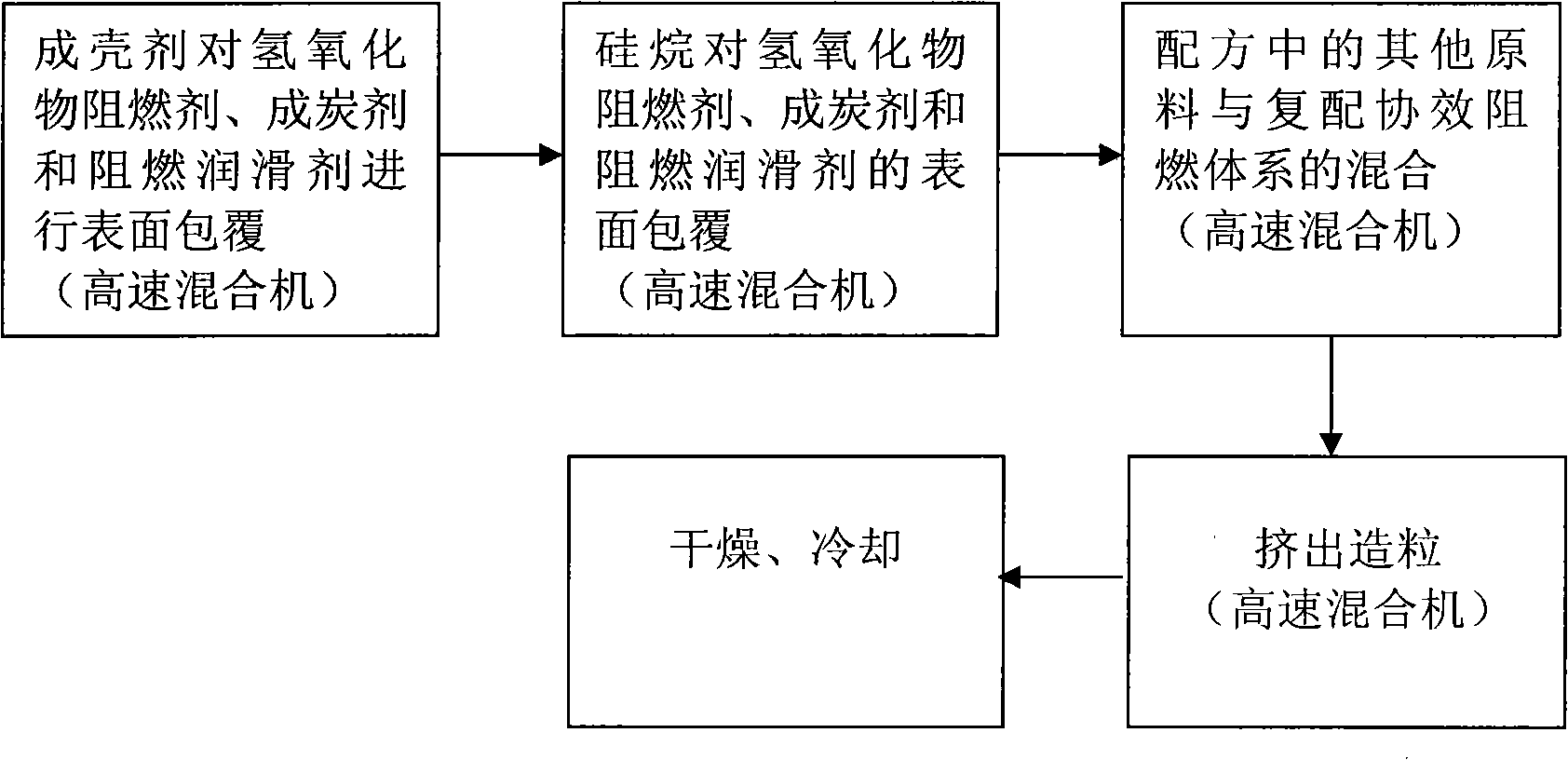

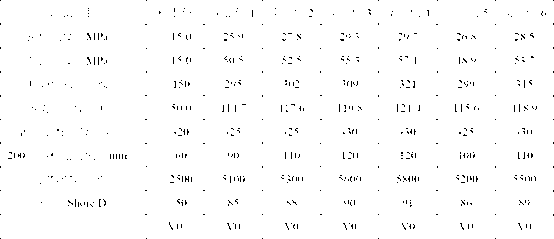

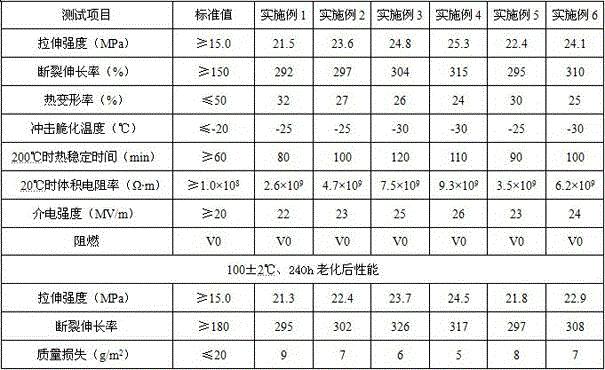

Irradiation crosslinking halogen-free high flame-retardant cable material and preparation method thereof

InactiveCN101914236AFast self-extinguishingImprove performancePlastic/resin/waxes insulatorsInorganic insulatorsPolyolefinPolymer science

The invention relates to an irradiation crosslinking halogen-free high flame-retardant cable material and a preparation method thereof. The cable materials comprise the following compositions: 45-90 parts of basic resin, 10-55 parts of functional polyolefine resin, 45-125 parts of carbonate hydroxide flame retardant, 30-50 parts of charing agent, 30-50 parts of flame-retardant lubricant, 0.3-3 parts of methyl silicone rubber shell forming agent, 0.5-2 parts of silane surface modifier, 2-5 parts of crosslinking sensitizing agent, 0.2-2 parts of antioxidant, 1-4 parts of lubricant and 0.1-1.0 parts of initiator. The preparation method of the cable material comprises the following steps of: stirring the carbonate hydroxide flame retardant, the charing agent and the flame-retardant lubricant at a high speed for 2 min; and then adding the shell forming agent and continuously stirring at a high speed until the temperature rises to above 100 DEG C, coating the surface of the mixture with the shell forming agent; adding silane coupling agent and stirring for 5-8 min, and carrying out secondary surface treatment; adding initiator-alcohol solution, and discharging after mixing; extruding and pelletizing; finally drying and cooling to obtain the finished cable material product. The flame retardant performance of the product is obviously enhanced, and the product has good shell forming performance in conbustion without droplets.

Owner:王进

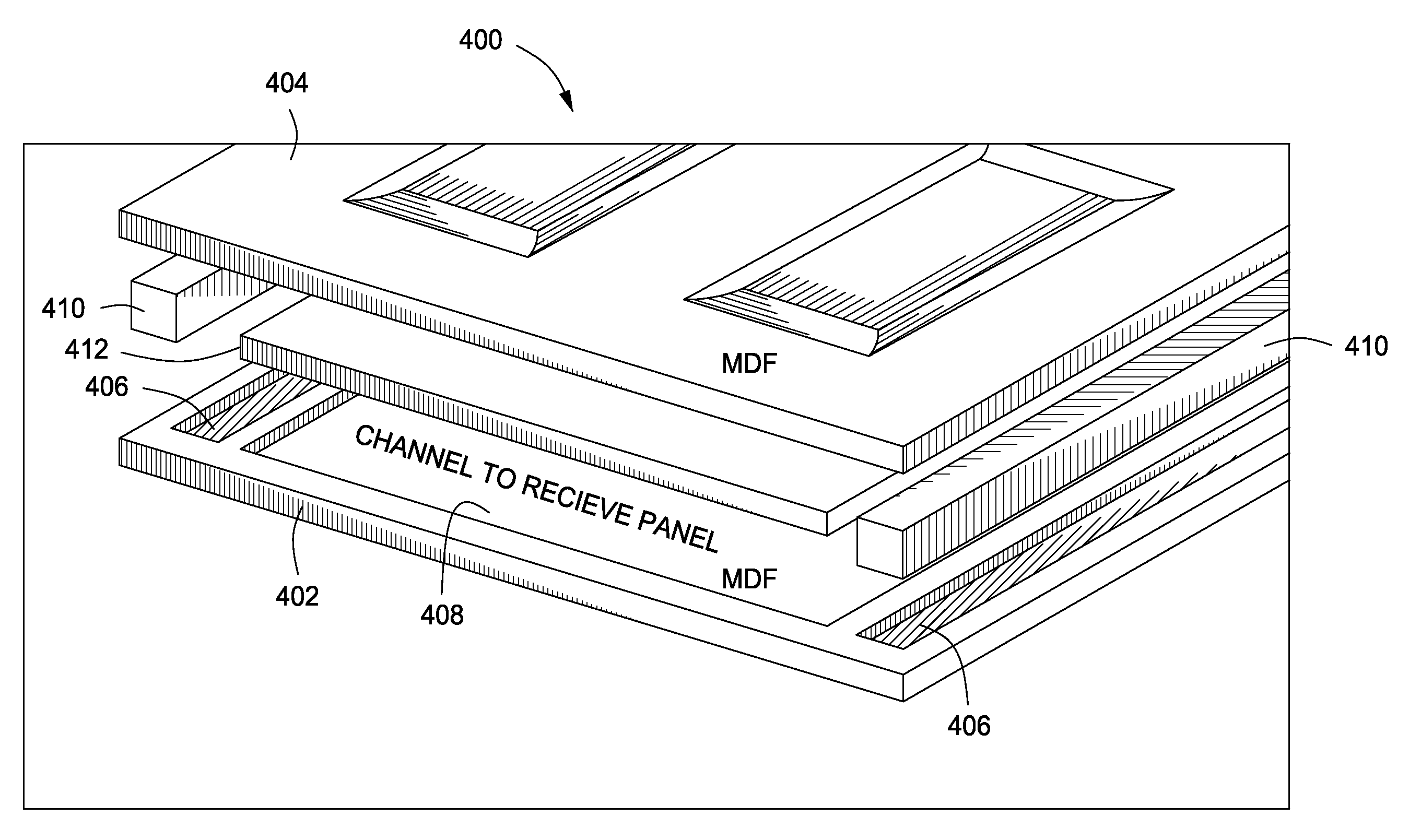

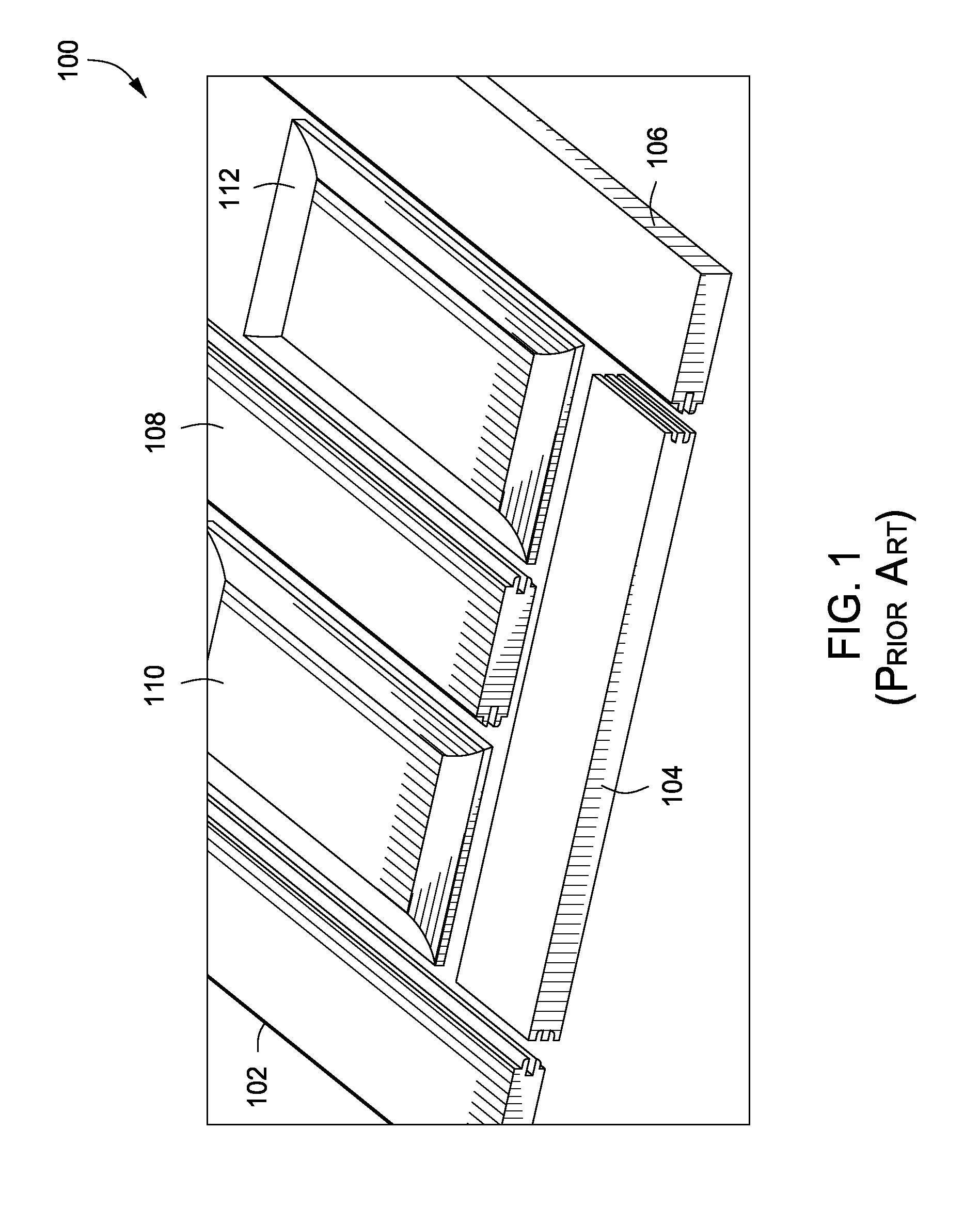

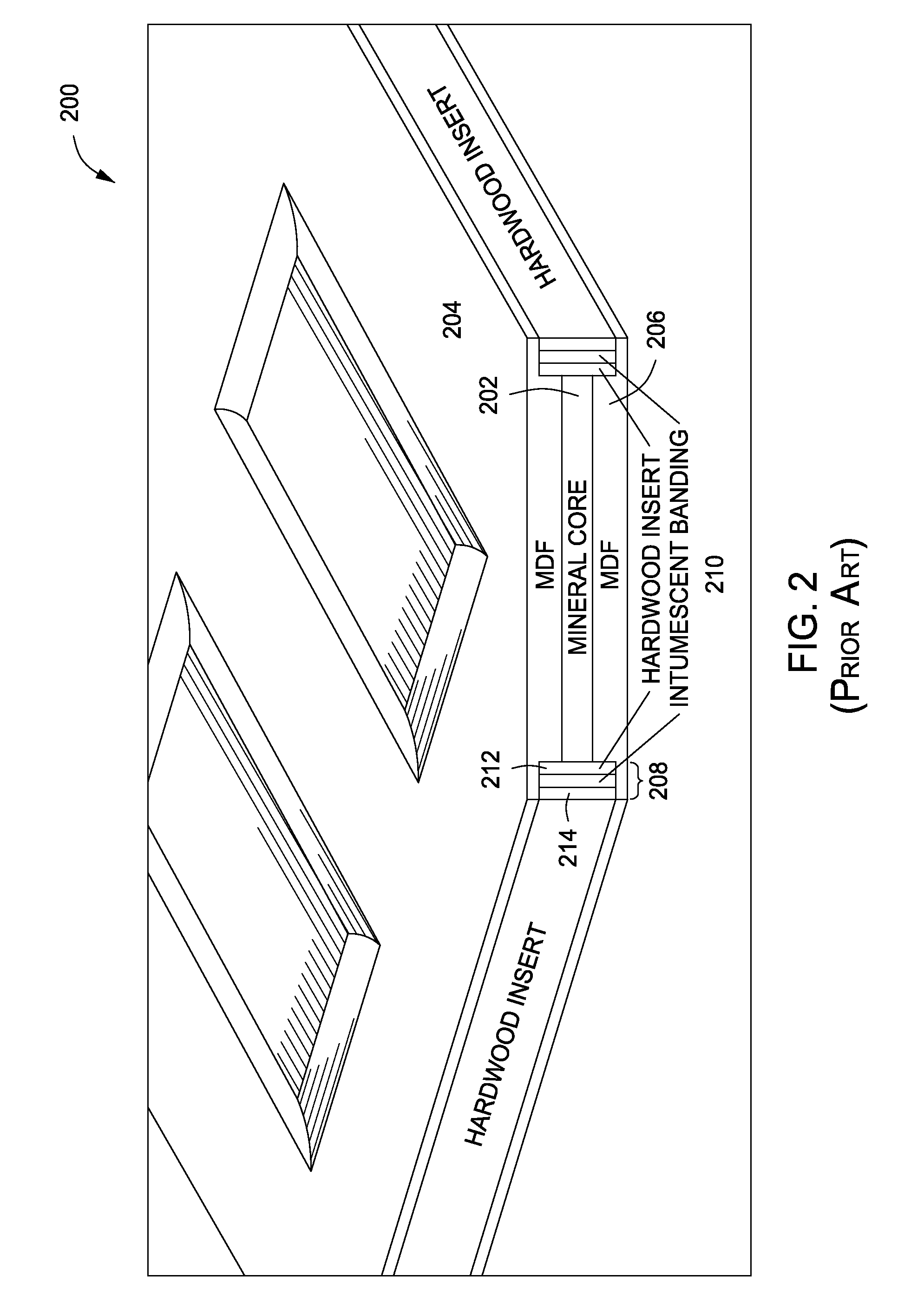

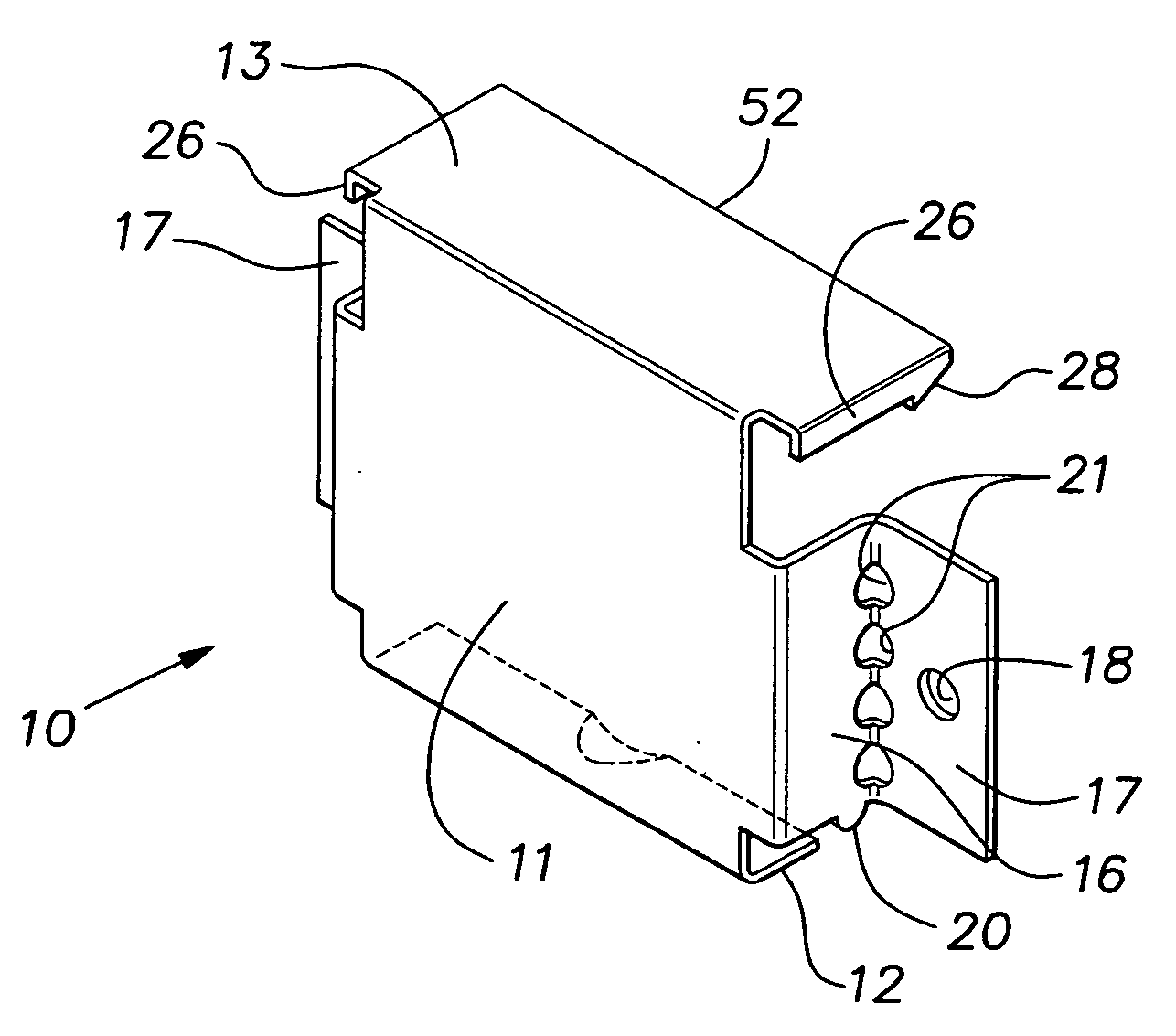

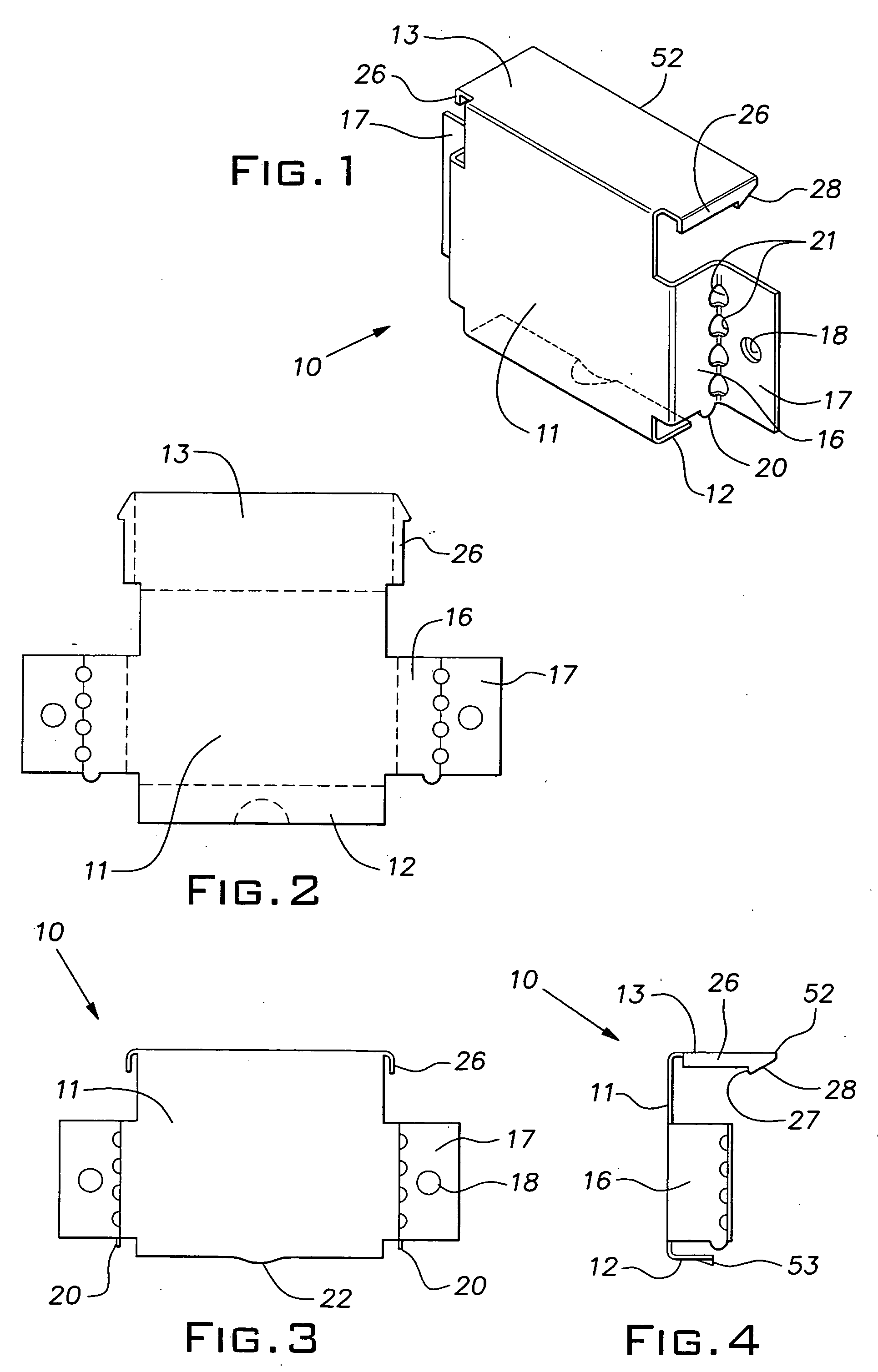

System, Method and Apparatus for Producing Fire Rated Doors

ActiveUS20070193220A1High strengthRaise the gradeFireproof doorsDoor leavesEngineeringUltimate tensile strength

The present invention provides a system, method and apparatus for producing fire rated doors having added strength, better finishing and low cost manufacturing flexibility. The fire rated doors are made from two panels “sandwiched” together. An optional interior layer (e.g., fire resistant material, lead sheeting, steel or Kevlar) can be added between the door panels for various purposes. Splines, stiles or sticks are inserted in longitudinal channels in the door panels to provide assistance in aligning the door panels and greater hardware holding strength. An intumescent banding material concealed by a banding material around the perimeter of the door seals the door within its frame during a fire. The door design and the automated manufacturing process provide greater design choice, reduced cost and faster fabrication.

Owner:POLYMER WOOD TECH

Production technology of barley seedling powder and product thereof

The invention relates to a production process of chewable tablets of barley shoot powder and a product thereof and belongs to the deep processing technology field of agricultural products. The production process is characterized in that the barley shoot powder is main base material, and the chewable tablets of the barley shoot powder with smooth appearance, green color and crispness and freshness is made after the processes of composite stabilizer, making soft material, granulation, drying, tabletting, sterilization and packing. The method has the advantages of simple process, higher industrialization degree, low production cost, realizing the full utilization of the barley shoot and promoting the added value of the barley shoot. The chewable tablets of the barley shoot powder produced by the invention which is leisure-base health care food can fully enhance physique and body immune, simultaneously has the function of catharsis, reducing blood lipid and preventing cerebral thrombosis and coronary heart disease.

Owner:NANJING AGRICULTURAL UNIVERSITY

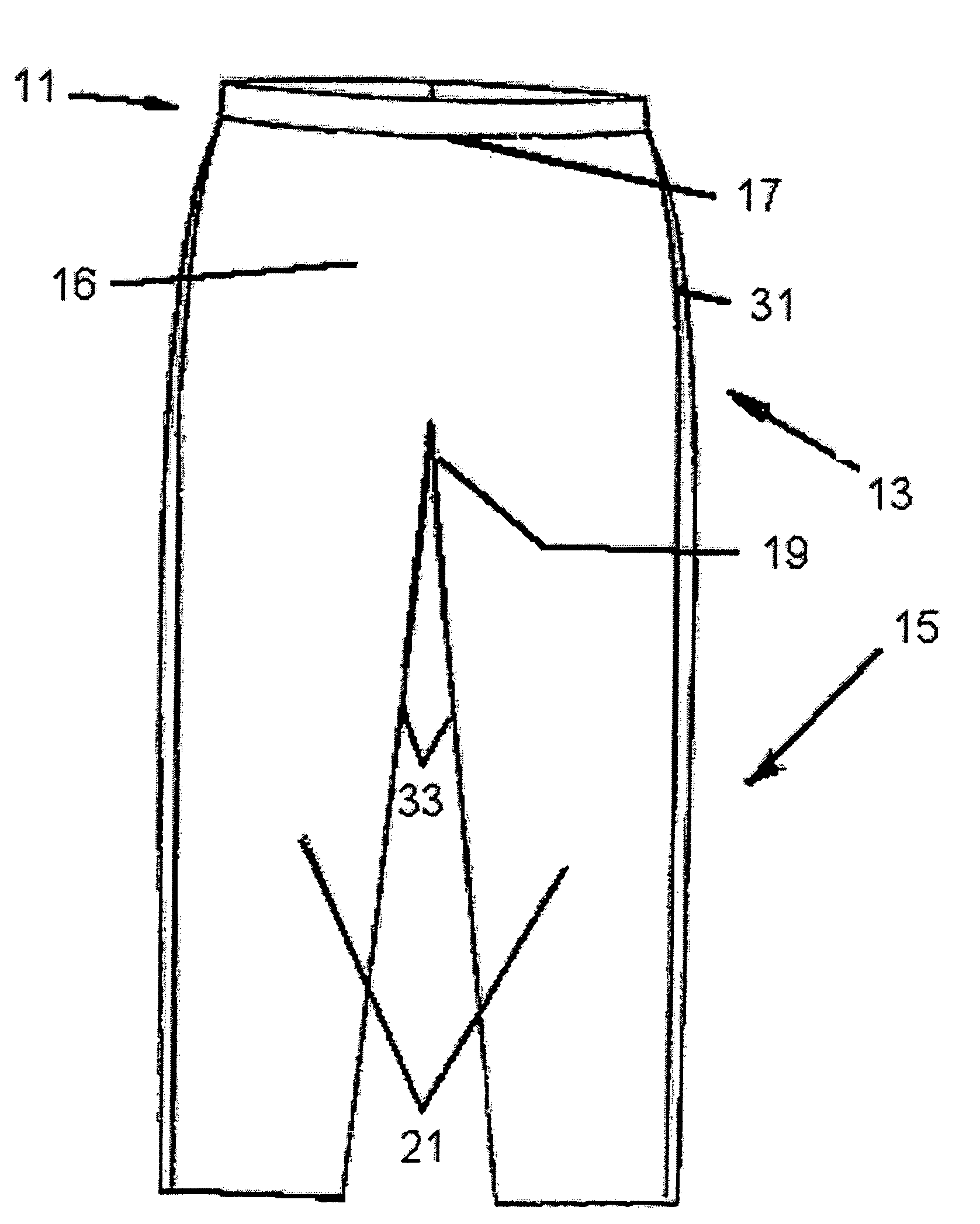

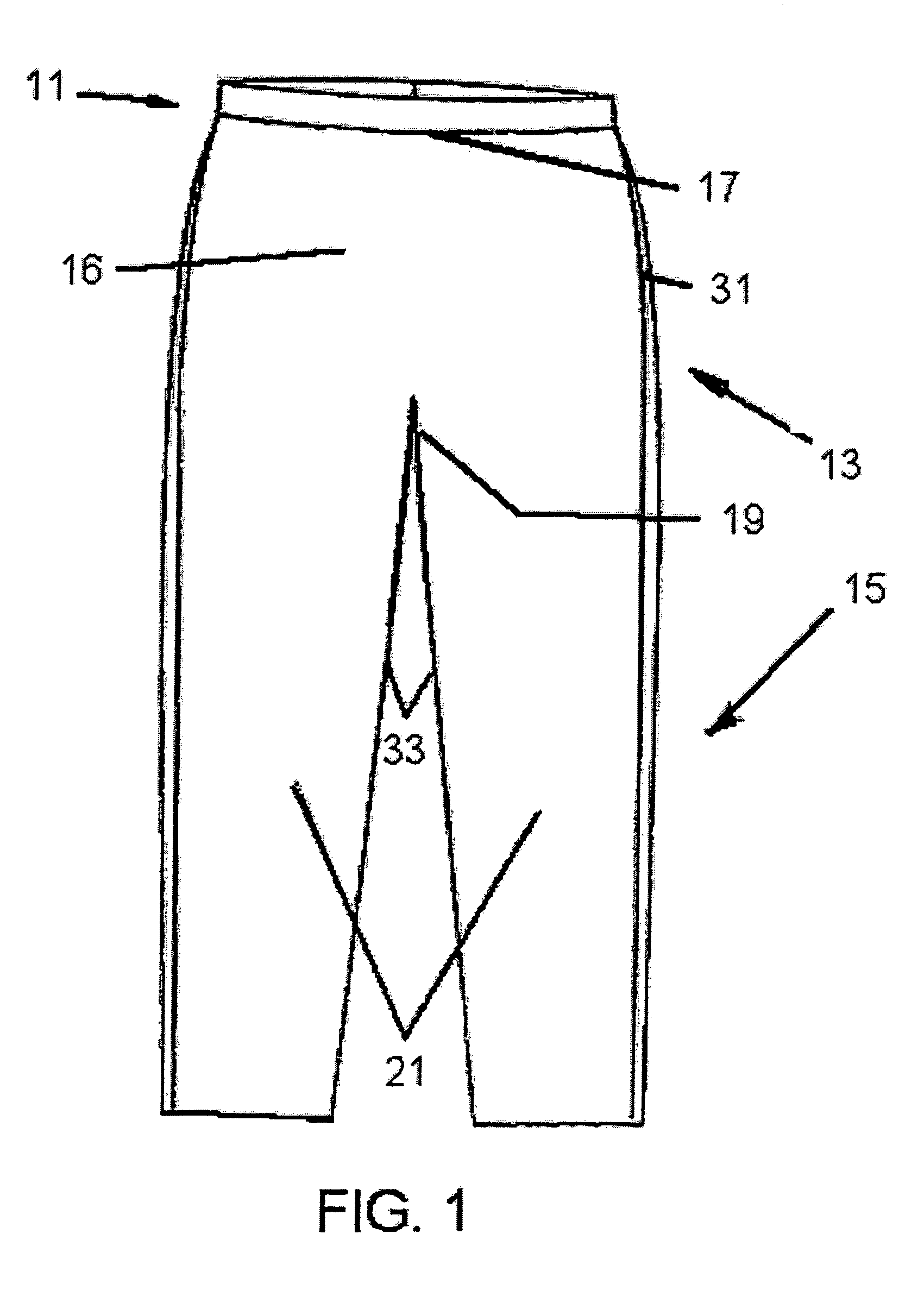

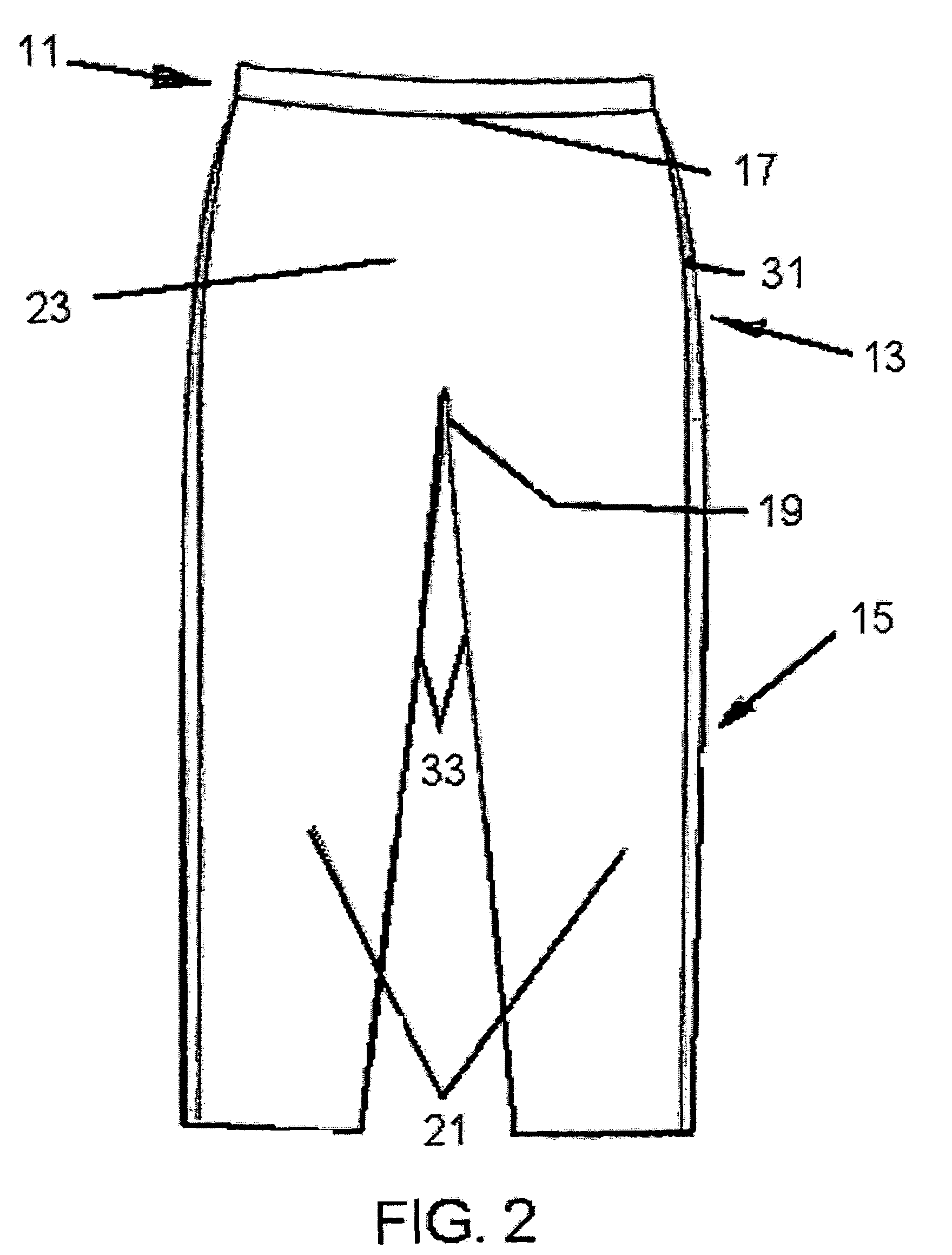

Garment with lifting feature

InactiveUS7341500B2Easy to shapeRaise hipsGarment special featuresTrousersEngineeringMechanical engineering

A garment with a seat area, a waist area and a crotch area, has a rear portion for defining the seat area and part of the waist and crotch areas, a front portion connected to the rear portion and defining part of the waist and crotch areas and an elastic panel assembly connected to the rear portion at least at the waist area and the crotch area. The panel assembly covers an inner surface of the rear portion over the seat area and comprises two sets of plural substantially vertical seams spaced symmetrically on opposite sides of a vertical center axis of the rear portion for defining at least two vertical elastic panels on each side of the center axis that are connected to the waist area, and an elastic lower panel such as a crotch panel or horizontal lower panel, connected to the crotch.

Owner:VICTORIAS SECRET STORES BRAND MANAGEMENT

Base for synthetic leather and synthetic leathers made by using the same

ActiveUS7932192B2Good lookingMaintain good propertiesFibre treatmentSynthetic resin layered productsFiber bundleVolumetric Mass Density

A substrate for artificial leathers, comprising a nonwoven fabric body made of microfine fiber bundles and an elastic polymer impregnated therein. The substrate for artificial leathers simultaneously satisfies the following requirements 1 to 4: (1) each of the microfine fiber bundles contains 6 to 150 bundled microfine long fibers in average; (2) a cross-sectional area of the microfine long fibers constituting the microfine fiber bundles is 27 μm2 or less, and 80% or more of the microfine long fibers has a cross-sectional area of from 0.9 to 25 μm2; (3) an average cross-sectional area of the microfine fiber bundles is from 15 to 150 μm2; and (4) on a cross section parallel to a thickness direction of the nonwoven fabric body, cross sections of the microfine fiber bundles exist in a density of from 1000 to 3000 / mm2 in average. The raised artificial leathers and grain-finished artificial leathers made from the substrate for artificial leathers are excellent in the properties which are hitherto difficult to be combined.

Owner:KURARAY CO LTD

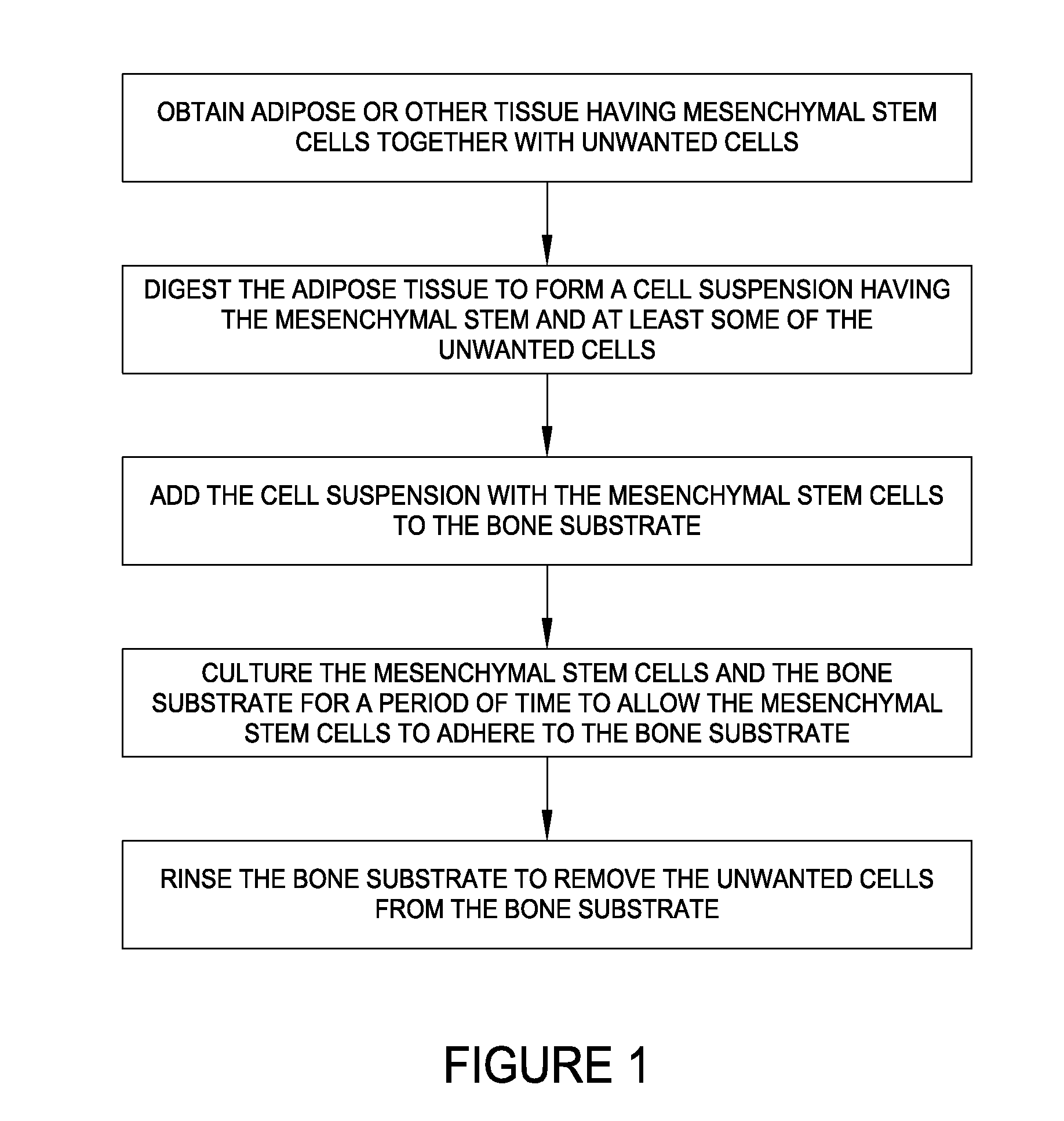

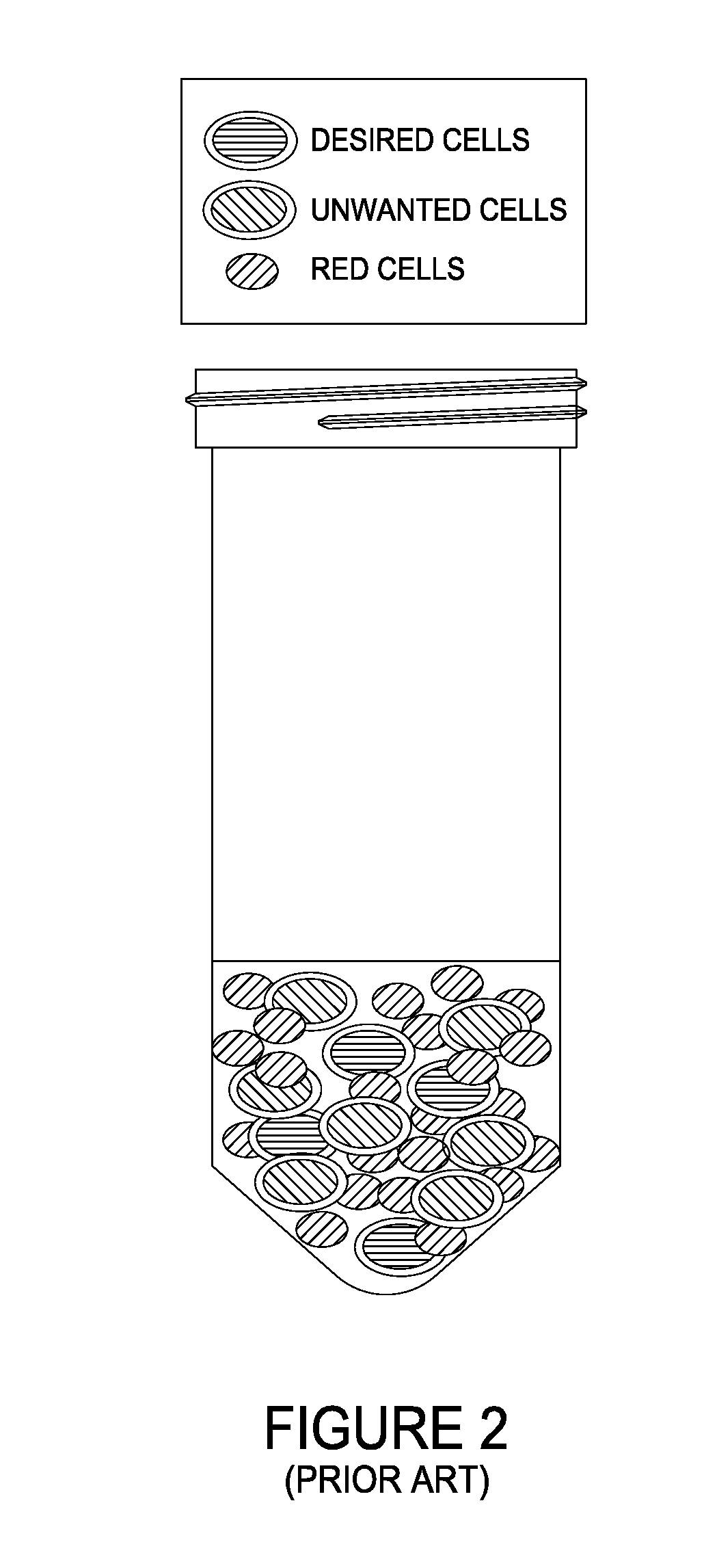

Allografts combined with tissue derived stem cells for bone healing

ActiveUS20100124776A1Smooth appearanceCell dissociation methodsMammal material medical ingredientsWound healingMuscle tissue

There is disclosed a method of combining mesenchymal stem cells (MSCs) with a bone substrate. In an embodiment, the method includes obtaining tissue having MSCs together with unwanted cells. The tissue is digested to form a cell suspension having MSCs and unwanted cells. The cell suspension is added to the substrate. The substrate is cultured to allow the MSCs to adhere. The substrate is rinsed to remove unwanted cells. In various embodiments, the tissue is adipose issue, muscle tissue, or bone marrow tissue. In an embodiment, there is disclosed an allograft product including a combination of MSCs with a bone substrate in which the combination is manufactured by culturing MSCs disposed on the substrate for a period of time to allow the MSCs to adhere to the substrate, and then rinsing the substrate to remove unwanted cells from the substrate. Other embodiments are also disclosed.

Owner:ALLOSOURCE

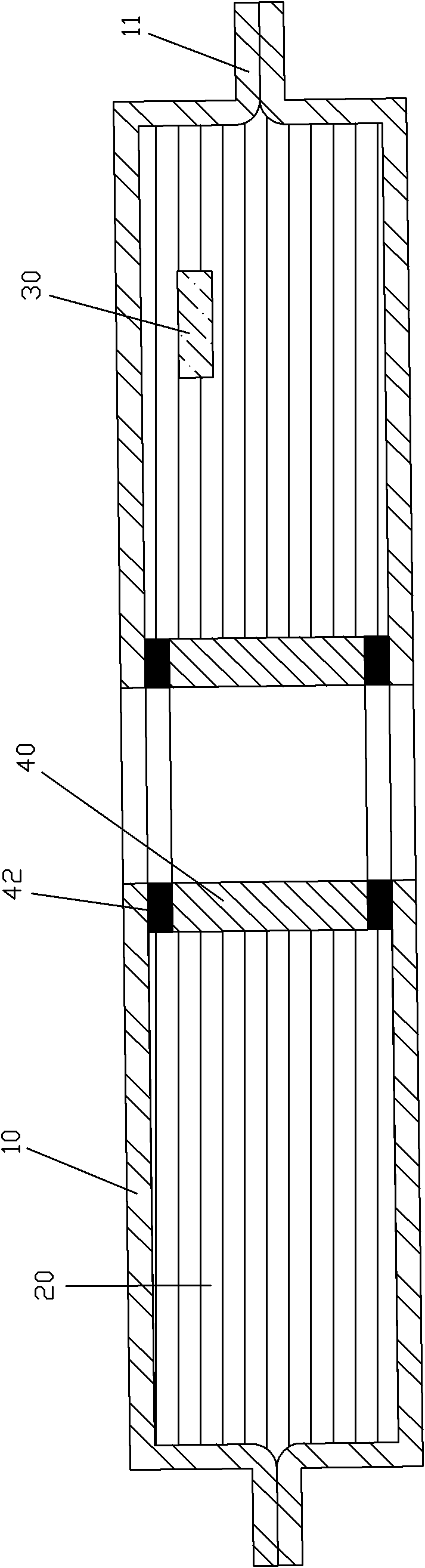

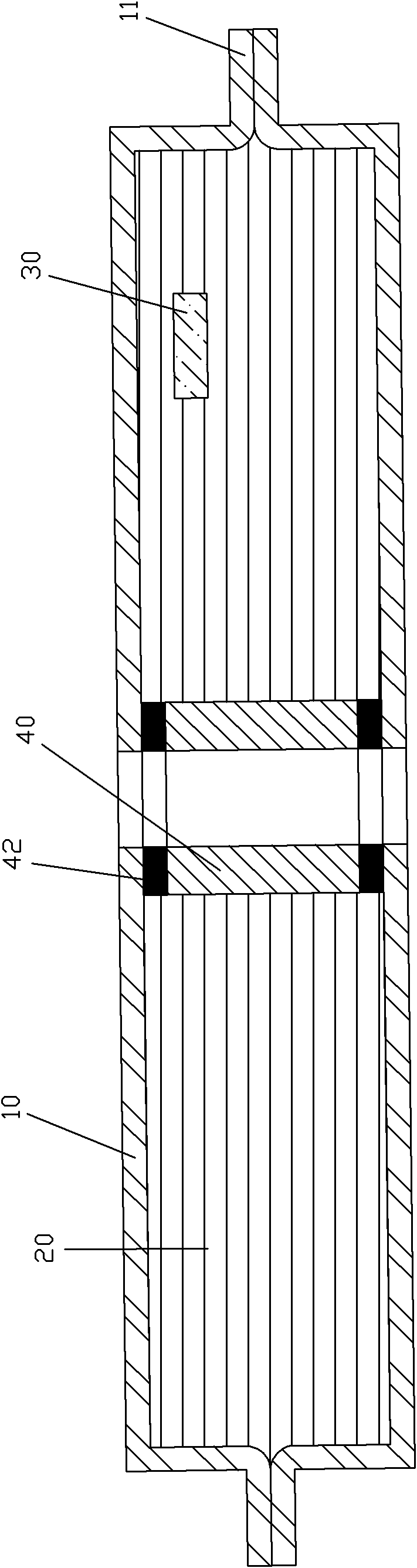

Vacuum insulation panel and manufacturing method thereof

ActiveCN102102796ASmooth appearanceEliminate wrinklesThermal insulationClimate change adaptationGetterEngineering

The invention relates to a vacuum insulation panel and a manufacturing method thereof. The vacuum insulation panel comprises a high-barrier packaging bag and a heat insulation core, wherein the heat insulation core is arranged in a vacuum sealed bag made of a high-barrier packaging material; a getter is arranged in the heat insulation core; a hole is reserved on a panel surface of the vacuum insulation panel; a hole-reserving structural piece is arranged in the hole and is a tubular section having high-barrier performance; and the hole-reserving structural piece and the high-barrier packaging bag are welded or bonded together to form a vacuum sealed chamber. Compared with the prior art, the vacuum insulation panel is smooth in appearance after hole reserving, so that a wrinkle is eliminated, the air-permeating quantity of the wrinkle of the high-barrier packaging bag is reduced and the service life of the vacuum insulation panel is prolonged; the mechanical strength of the hole after the hole reserving is relatively high; and the vacuum insulation panel can be connected with other materials by a riveting piece at the hole, so that the vacuum insulation panel is more convenient to use and the application range of the vacuum insulation panel is expanded.

Owner:FUJIAN SUPERTECH ADVANCED MATERIAL

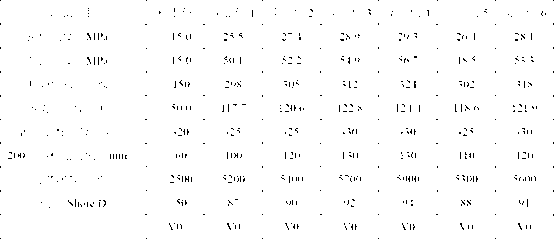

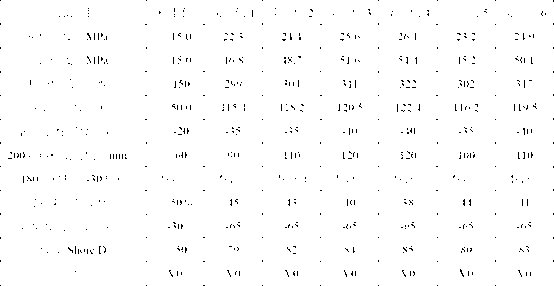

High-abrasion-resistant and environment-friendly polyvinyl chloride (PVC) modified materials and preparation method thereof

ActiveCN103059470AImprove wear resistanceImprove wet skid resistancePolymer sciencePolyvinyl chloride

The invention relates to the technical field of polyvinyl chloride composite materials, in particular to a high-abrasion-resistant and environment-friendly polyvinyl chloride (PVC) modified materials and a preparation method of the high-abrasion-resistant and environment-friendly PVC modified materials. The modified materials comprise following raw materials, by weight, 80-120 parts of PVC resin, 5-15 parts of stuffing bulking agents, 31-70 parts of plasticizer, 1-10 parts of abrasion resistant modifying agents, 1-10 parts of fire retardant, 1-10 parts of stabilizer, 10-20 parts of impact modifier and 0.2-2 parts of lubricating agents. The raw materials are weighed according to the weight and are blended, after the raw materials are stirred, the stirred raw materials are extruded to be granulated into particles through a double-screw extruder to produce the modified materials. The prepared modified materials are good in abrasion resistant property, environment-friendly, high in strength, good in flame retardant efficiency, strong in compression property and toughness, good in processing property, and good in comprehensive property. The preparation method of the high-abrasion-resistant and environment-friendly PVC modified materials is simple in craft, convenient to operate and control, stable in quality and high in production efficiency and can be produced in a large scale industrialization mode.

Owner:广东祺龙科技有限公司

High-temperature resistant flame-retardant environment-friendly PVC (polyvinyl chloride) modified material and preparation method thereof

Owner:广东祺龙科技有限公司

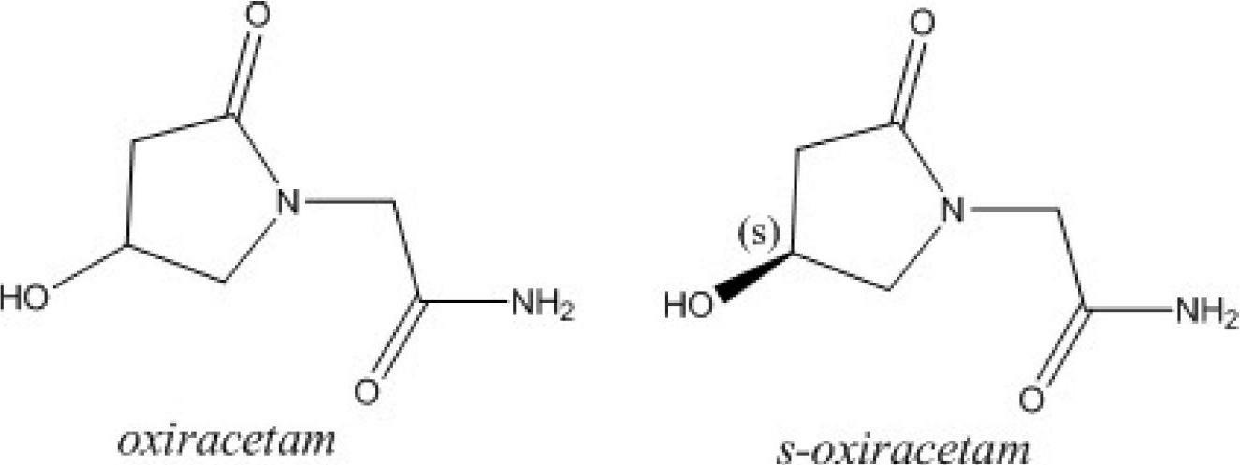

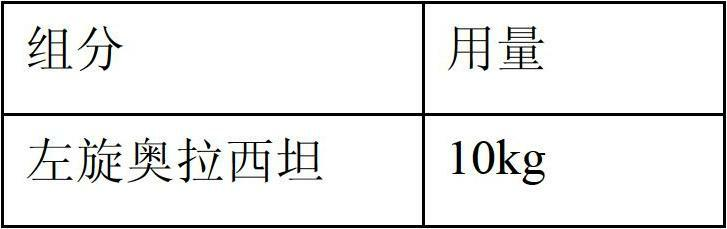

Freeze-dried powder injection of L-oxiracetam and process for preparing freeze-dried powder injection

ActiveCN102670527AFast sublimationShorten freeze-drying timePowder deliveryOrganic active ingredientsPolyethylene glycolEngineering

The invention relates to a freeze-dried powder injection of L-oxiracetam and a process for preparing the freeze-dried powder injection. The freeze-dried powder injection comprises, by weight, 1 part of the L-oxiracetam, 0.1 to 10 parts of an excipient, 0.01 to 1 part of an antisticking agent and 0.01 to 0.5 part of a pH regulator, wherein polyethylene glycol (PEG) series of products serve as the antisticking agent preferably. The freeze-dried powder injection which is prepared on the basis of a prescription according to the process has the advantages of being short in freeze-drying time, attractive in appearance, short in redissolving time and high in stability.

Owner:南京博德生物制药有限公司

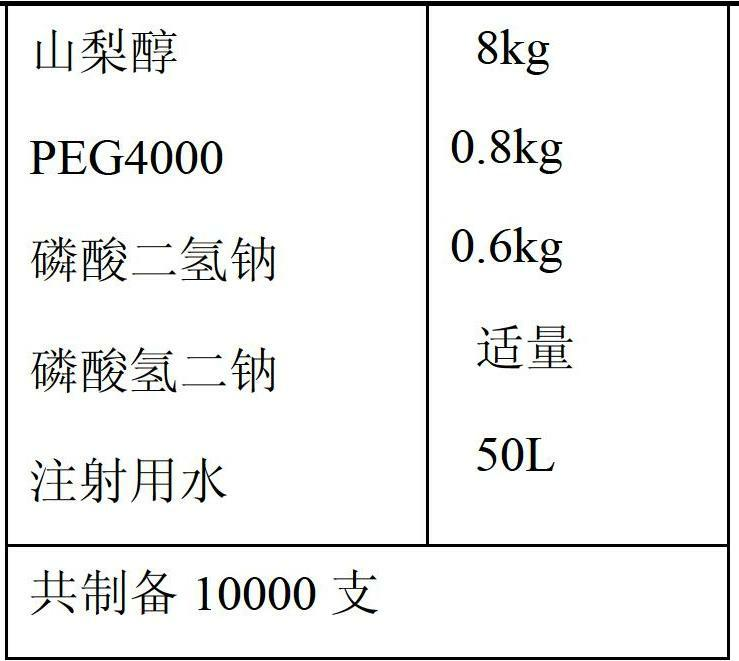

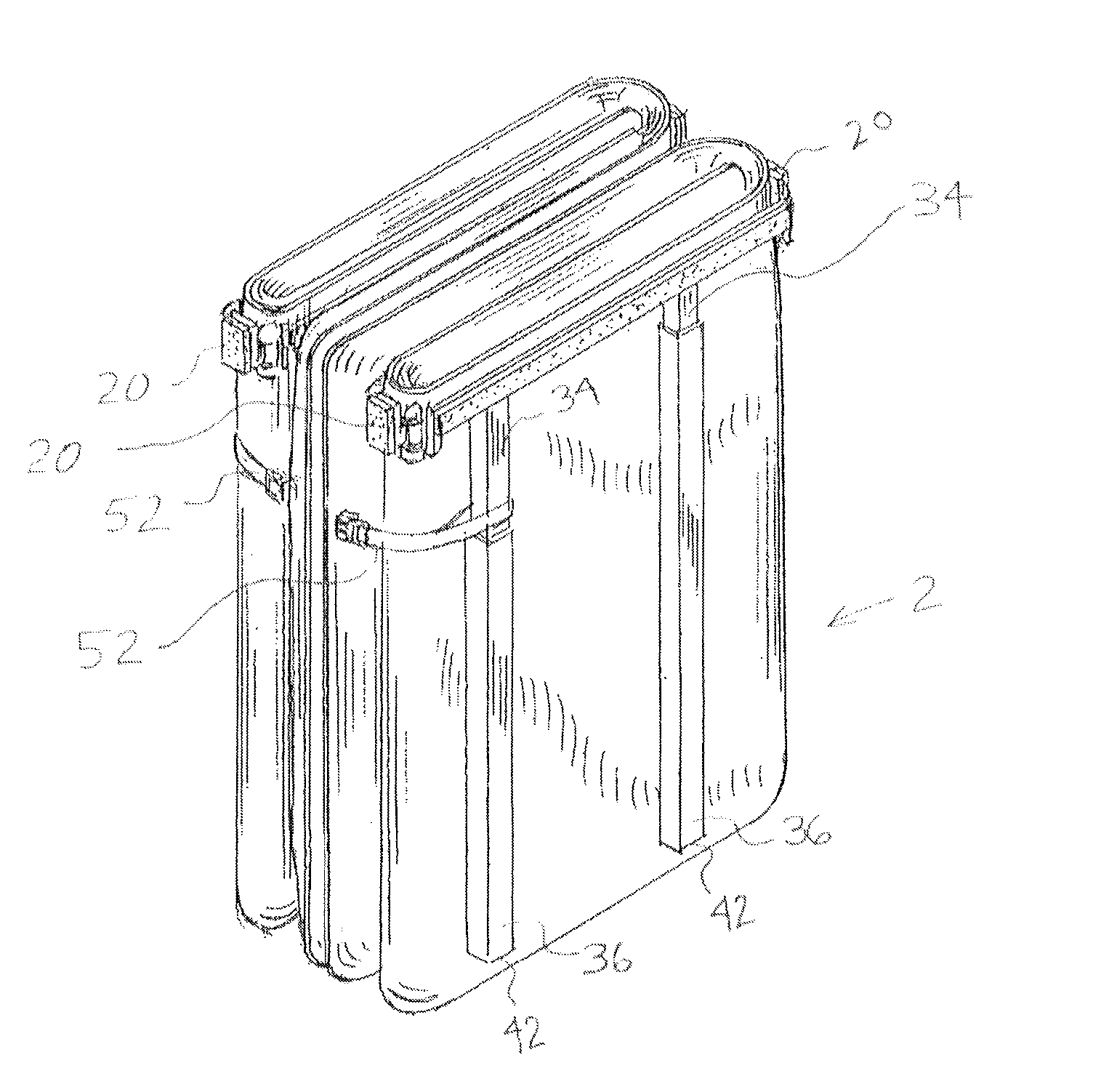

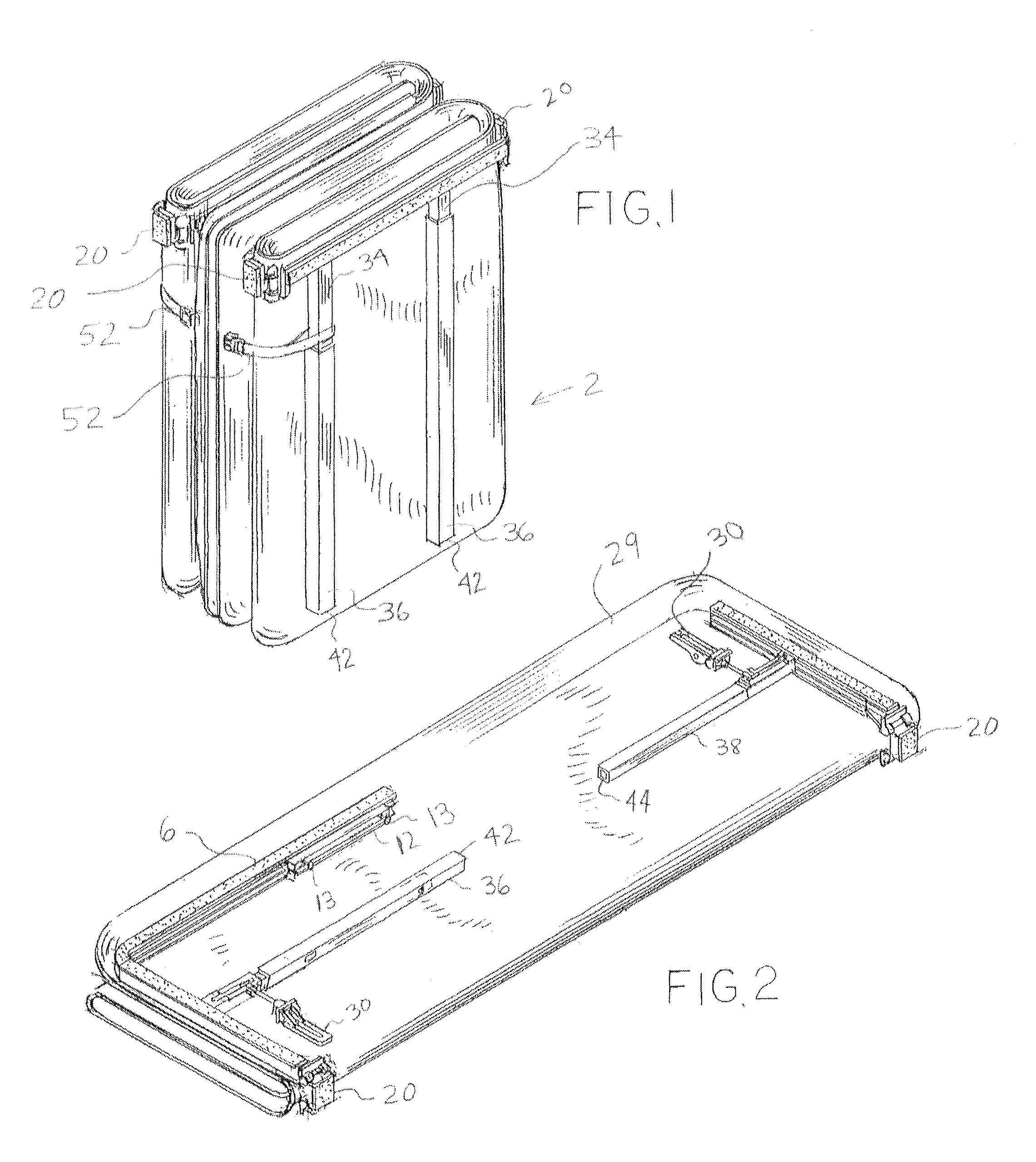

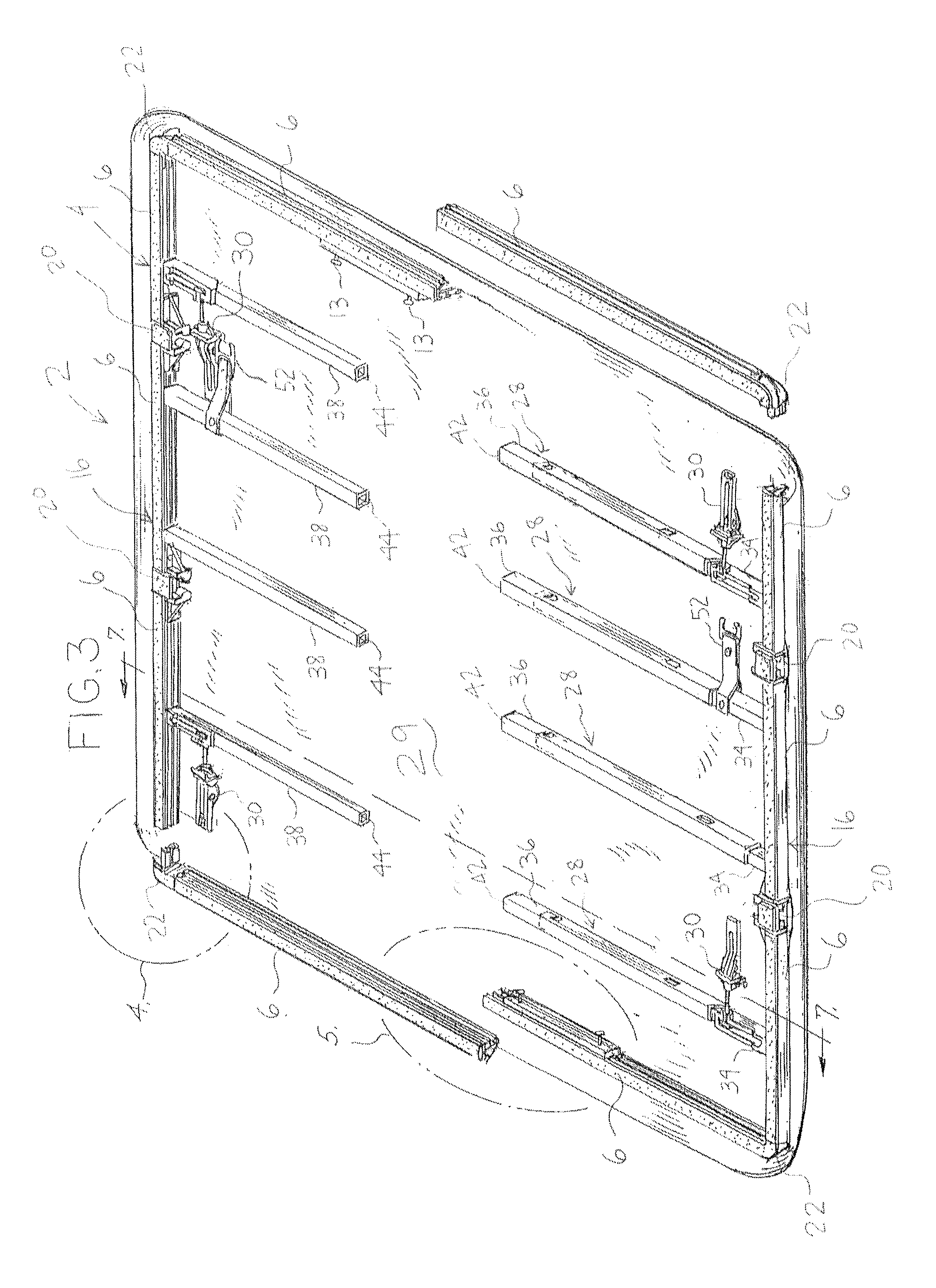

Foldable tonneau cover

ActiveUS7384090B1Prevent saggingSmooth appearanceRemovable external protective coveringsLoad coveringEngineeringTruck

A flexible tonneau cover for trucks that is easily folded for storage or shipping. The tonneau cover has a collapsible peripheral frame, with supporting bows spanning the width of the frame. The bows include separable parts for storage or shipping and can be assembled and expanded to spread the frame.

Owner:ADVANTAGE TRUCK ACCESSORIES

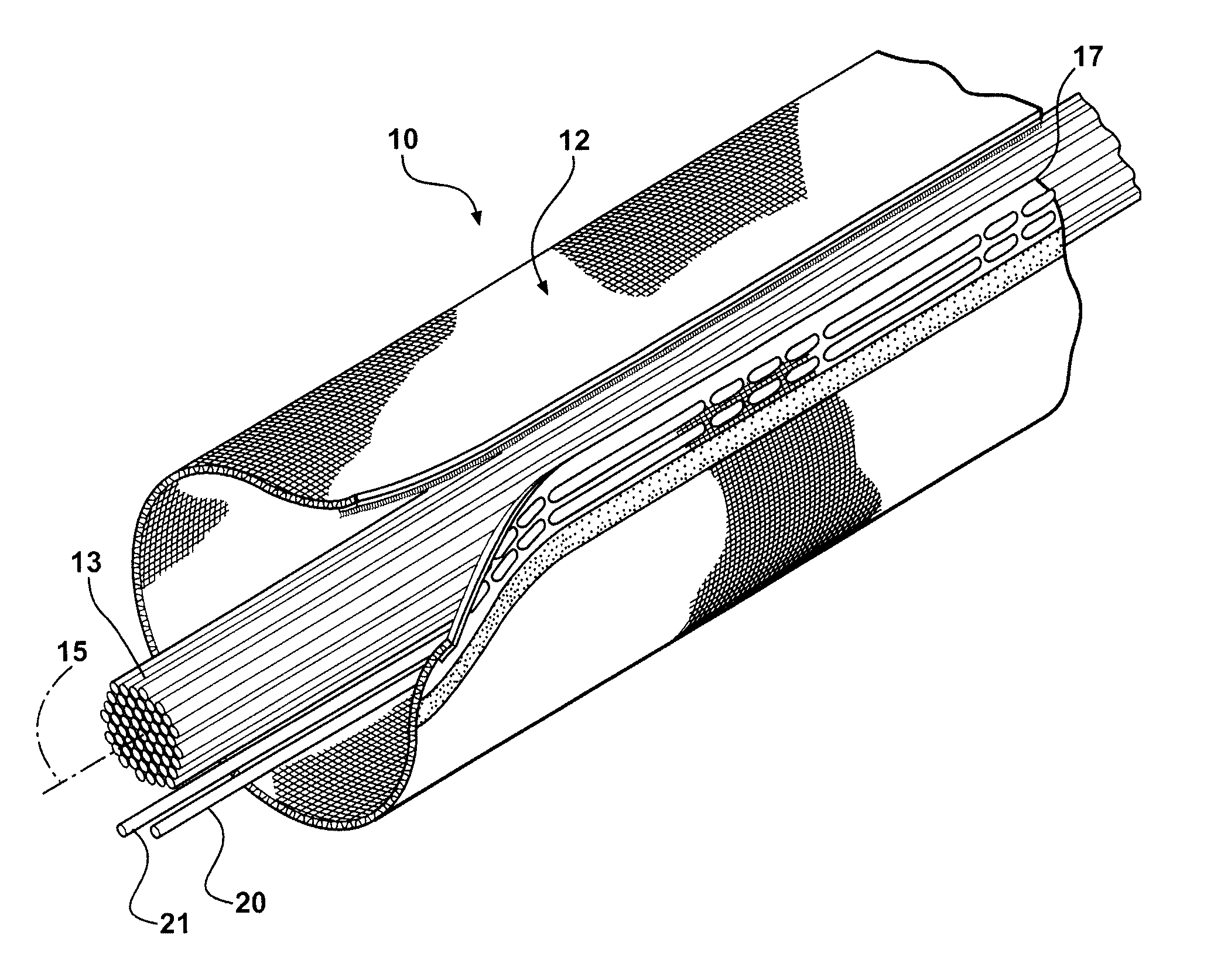

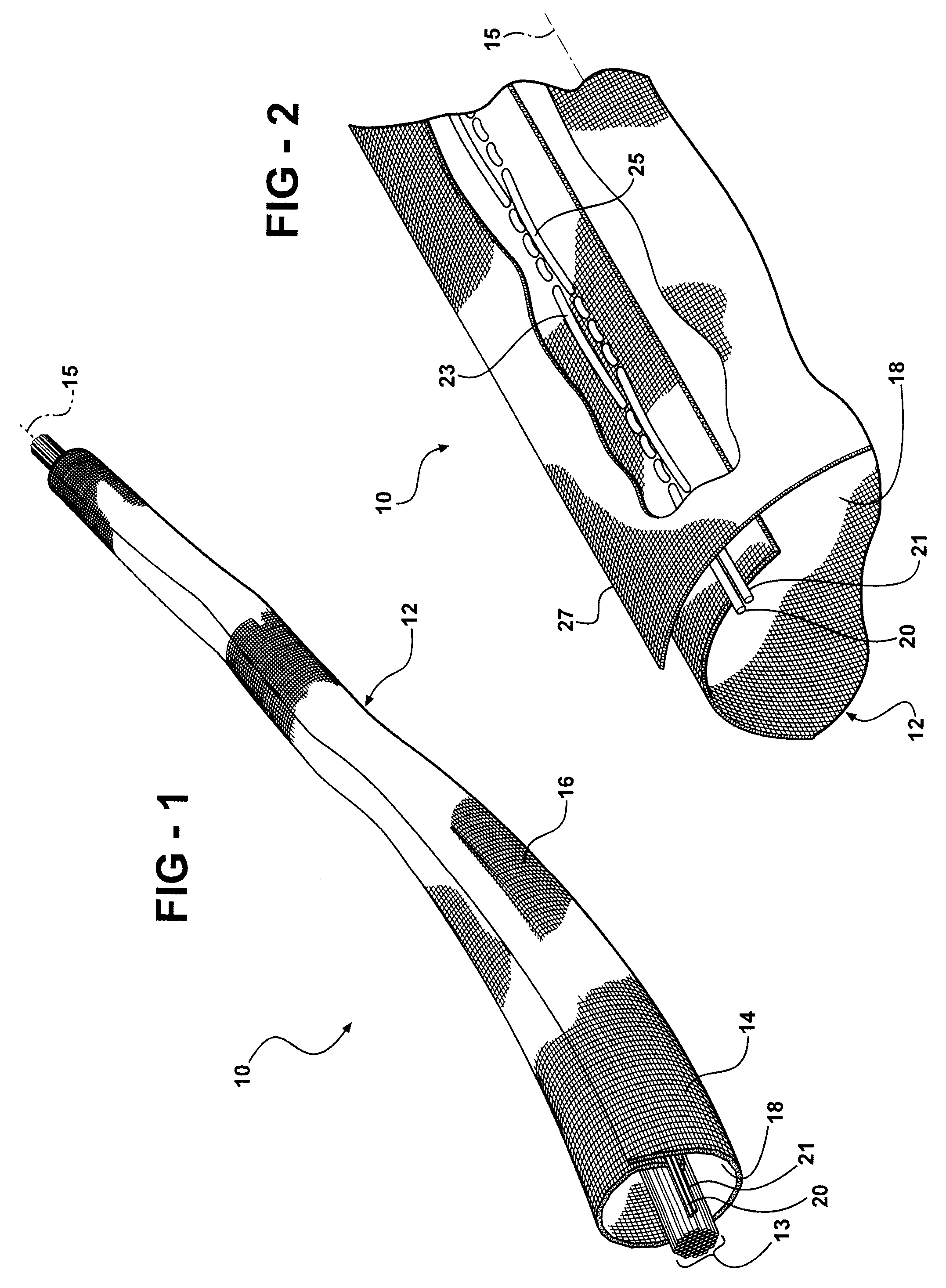

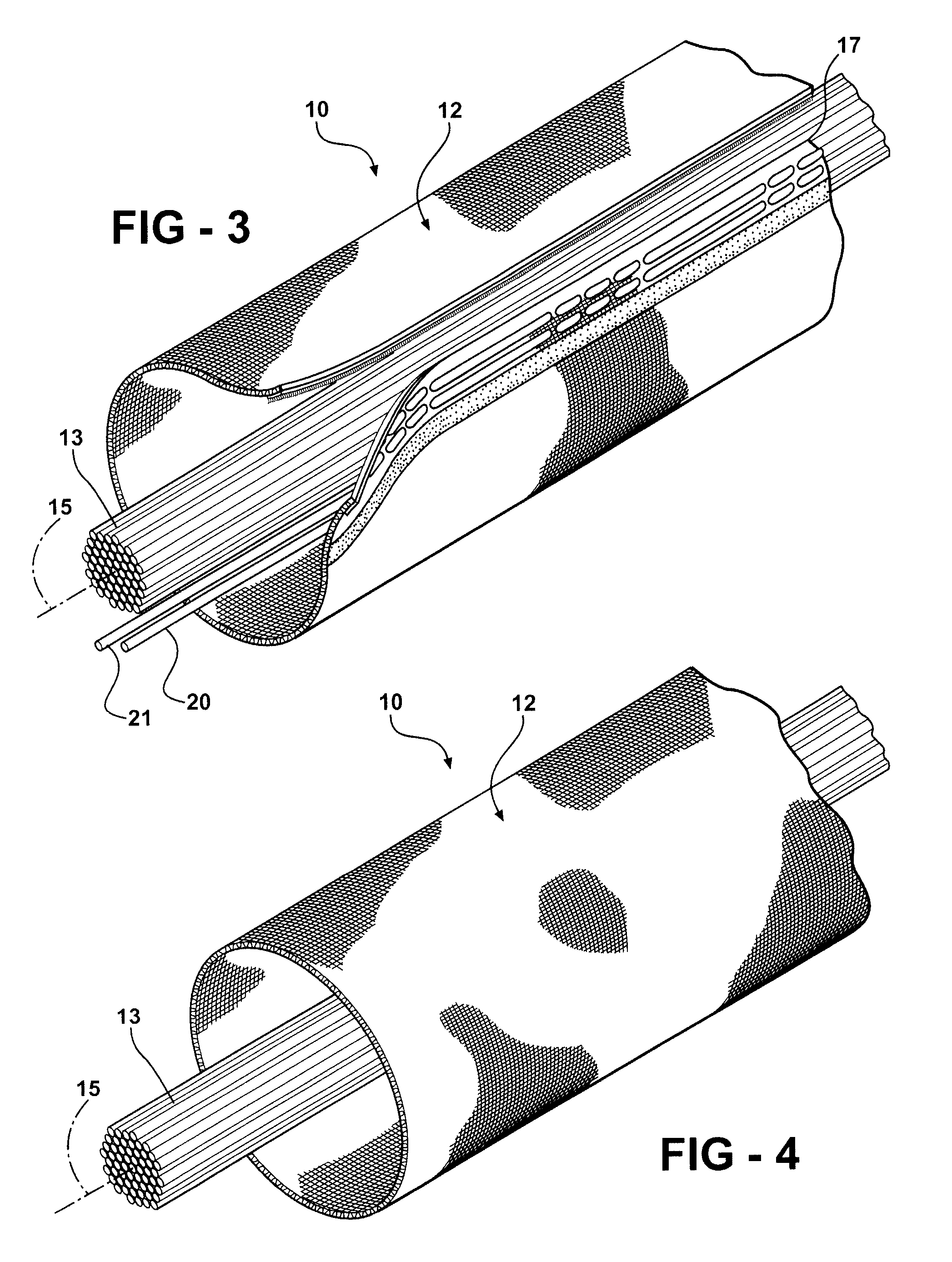

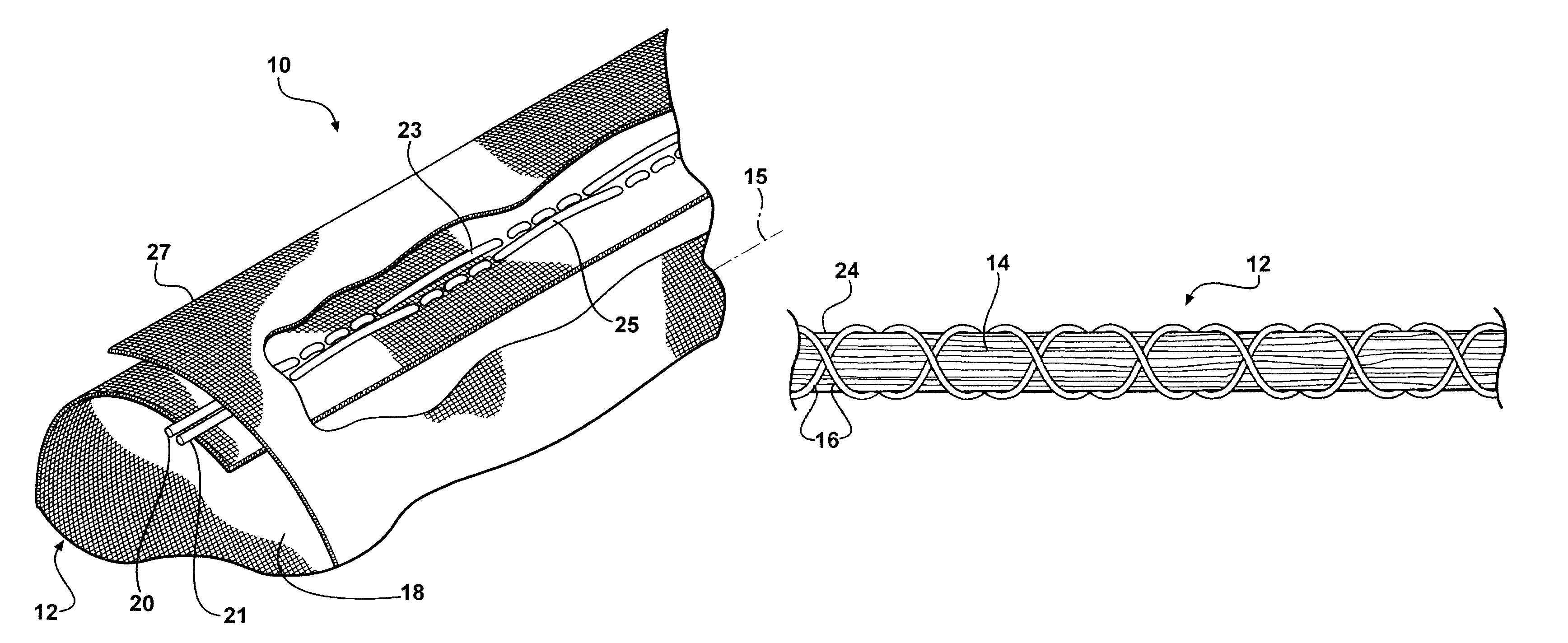

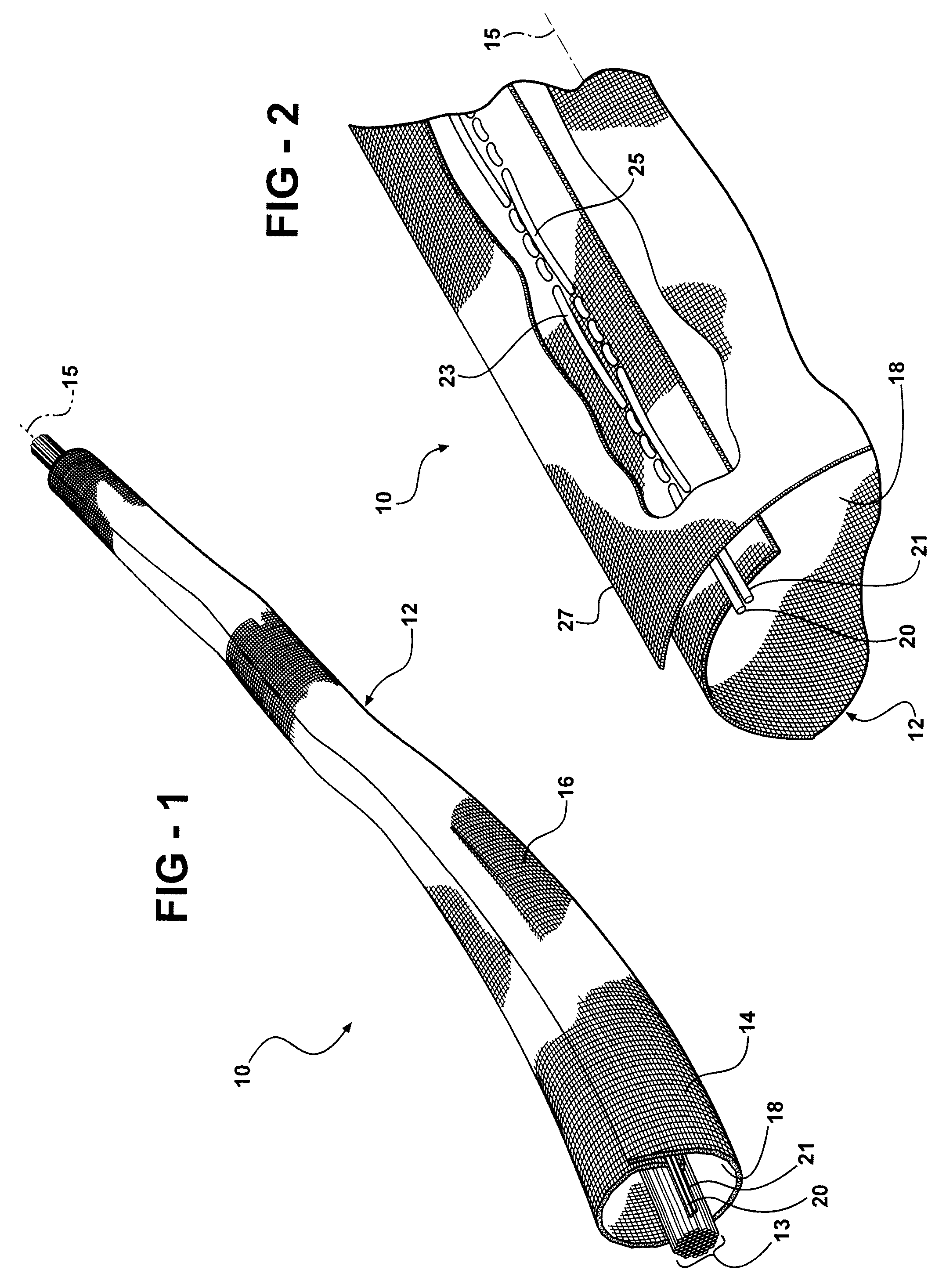

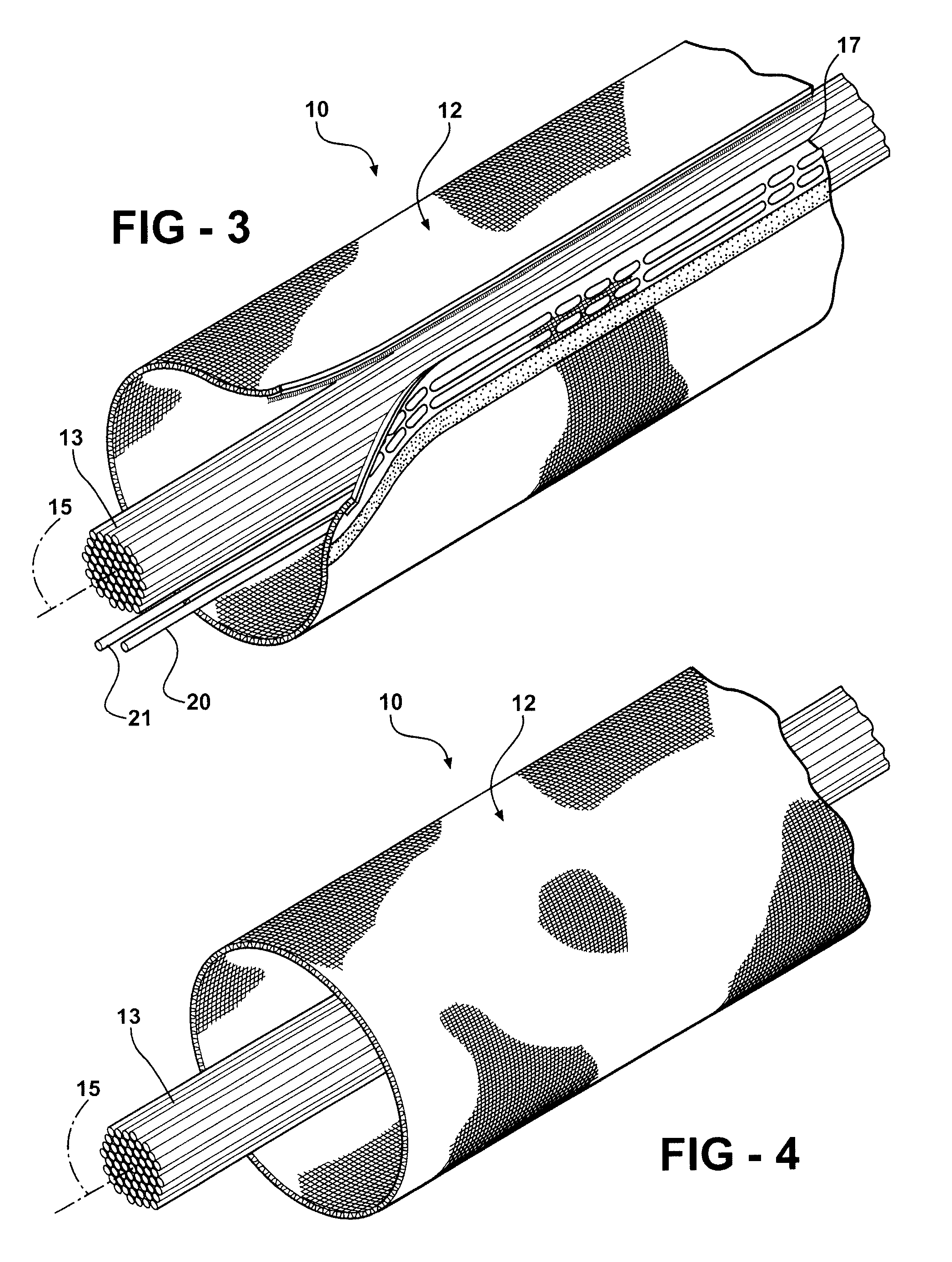

Protective sleeve fabricated with hybrid yarn having wire filaments and methods of construction

ActiveUS20070275199A1Provide protectionImprove conductivityLayered productsPedestrian/occupant safety arrangementYarnArchitectural engineering

A fabric sleeve and hybrid yarn filament used in construction of the sleeve for protecting elongate members against at least one of EMI, RFI or ESD, and methods of construction of the sleeve and hybrid yarn filament. The sleeve includes at least one interlaced hybrid yarn filament having a non-conductive filament and at least one conductive wire filament overlying an outer surface of the non-conductive filament. The hybrid yarn filament is arranged in electrical communication with itself or other hybrid yarn filaments to provide uniform shielding against EMI, RFI, and / or ESD.

Owner:FEDERAL MOGUL WORLD WIDE LLC

Hydrotalcite-rare earth-calcium zinc stablizer for PVC and its preparation method

InactiveCN101007878AImprove long-term thermal stabilityGood initial colorabilityChemical synthesisHydrotalcite

The invention discloses a PVC hydrotalcite- rare earth- calcium zinc stabilizing agent and the method for preparing the same, which in detail erlates to plastic composite stabilizing agent and the preaparing method, belonging to chemical field. The main component for stabilizing comprises column- supported hydrotalcite, unsaturated rare earth, and epoxy aliphatic acid calcium zinc, and it is prepared through chemical synthesis, reformed treatment and optimization compound. The product is characterized by outstanding thermal stabilizing effect, good first stage coloring property, sound plasticizing property, good transparenty, weatherability, improved quality, high effeciciency, no toxicity, no pollution, low cost. It can replace expensive organotin thermal stabilizing agent and is widely used in PVC product preparation, such as water- supply pipes, section bar, transparent granulate, film, medical apparatus, toy, fridge stamp and box sheet material.

Owner:扬州科宇化工有限公司

High-chloride-capacity liquid-phase dechlorinating agent as well as preparation method and application thereof

InactiveCN104437342ASmooth appearanceAvoid crackingOther chemical processesHydrocarbon oils refiningHas active ingredientAlkaline earth metal

The invention provides a high-chloride-capacity liquid-phase dechlorinating agent as well as a preparation method and an application thereof. The high-chlorine-capacity liquid-phase dechlorinating agent is suitable for removing inorganic chlorine from an oil product and is particularly suitable for removing hydrogen chloride from reformate. A carrier of the dechlorinating agent is a carbon molecular sieve, active ingredients of the dechlorinating agent comprise an alkali metal and an alkali earth metal oxide, and an auxiliary agent component is copper oxide, ferric oxide or zinc oxide. The preparation method of the solid dechlorinating agent provided by the invention comprises the following steps: dipping soluble copper salt, calcium salt, magnesium salt, barium salt and the like to a cylindrical carbon molecular sieve, drying, and performing stabilizing treatment to obtain the dechlorinating agent. The dechlorinating agent provided by the invention has the advantages of being relatively high in chloride capacity, low-price and easily available in raw material, having active ingredients uniformly distributed on the carrier, good in thermal stability, strong in water resistance, high in mechanical strength and the like, and the dechlorinating agent has desulfurization and denitrification effects at the same time.

Owner:TIANJIN POLYTECHNIC UNIV

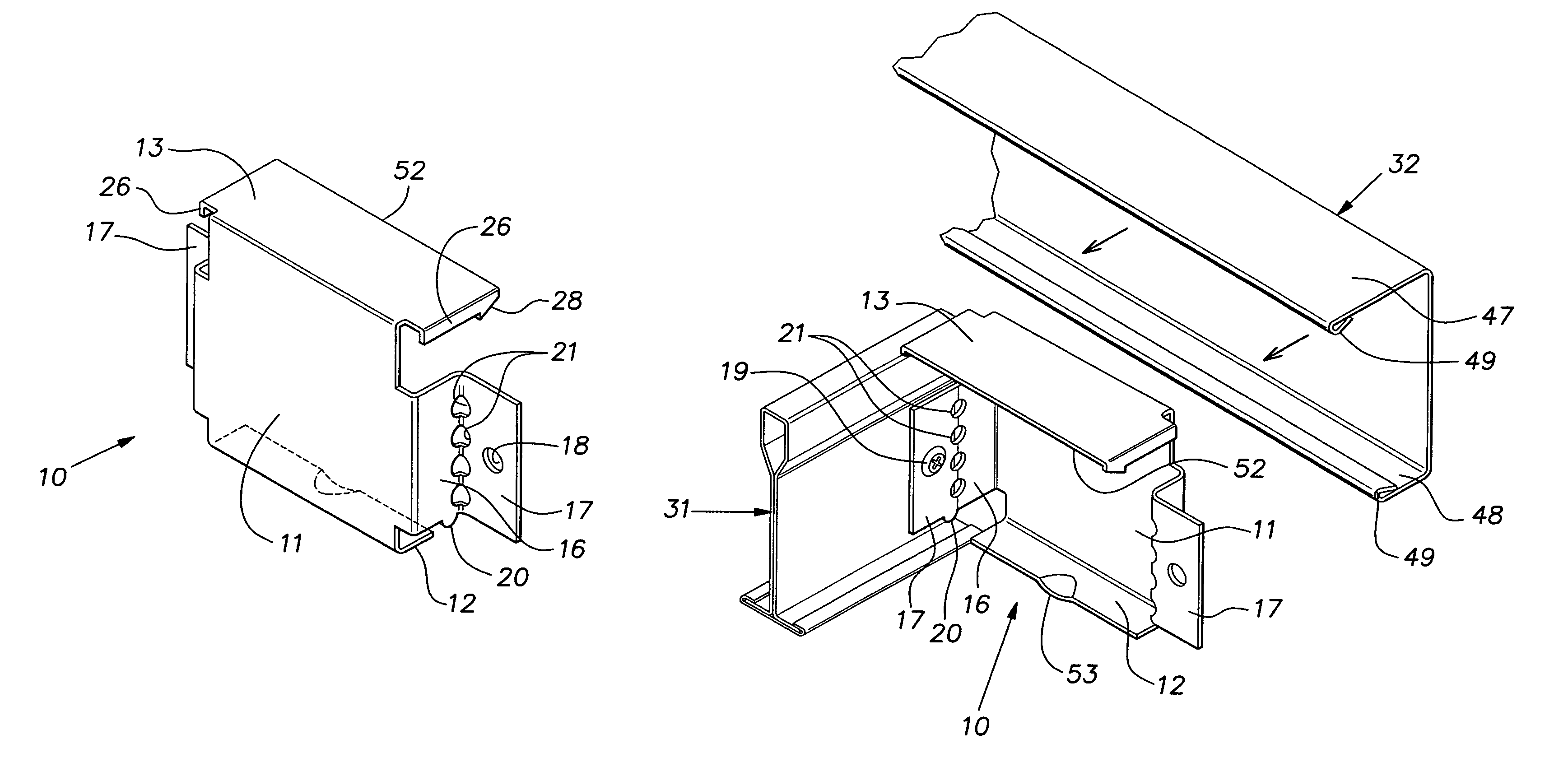

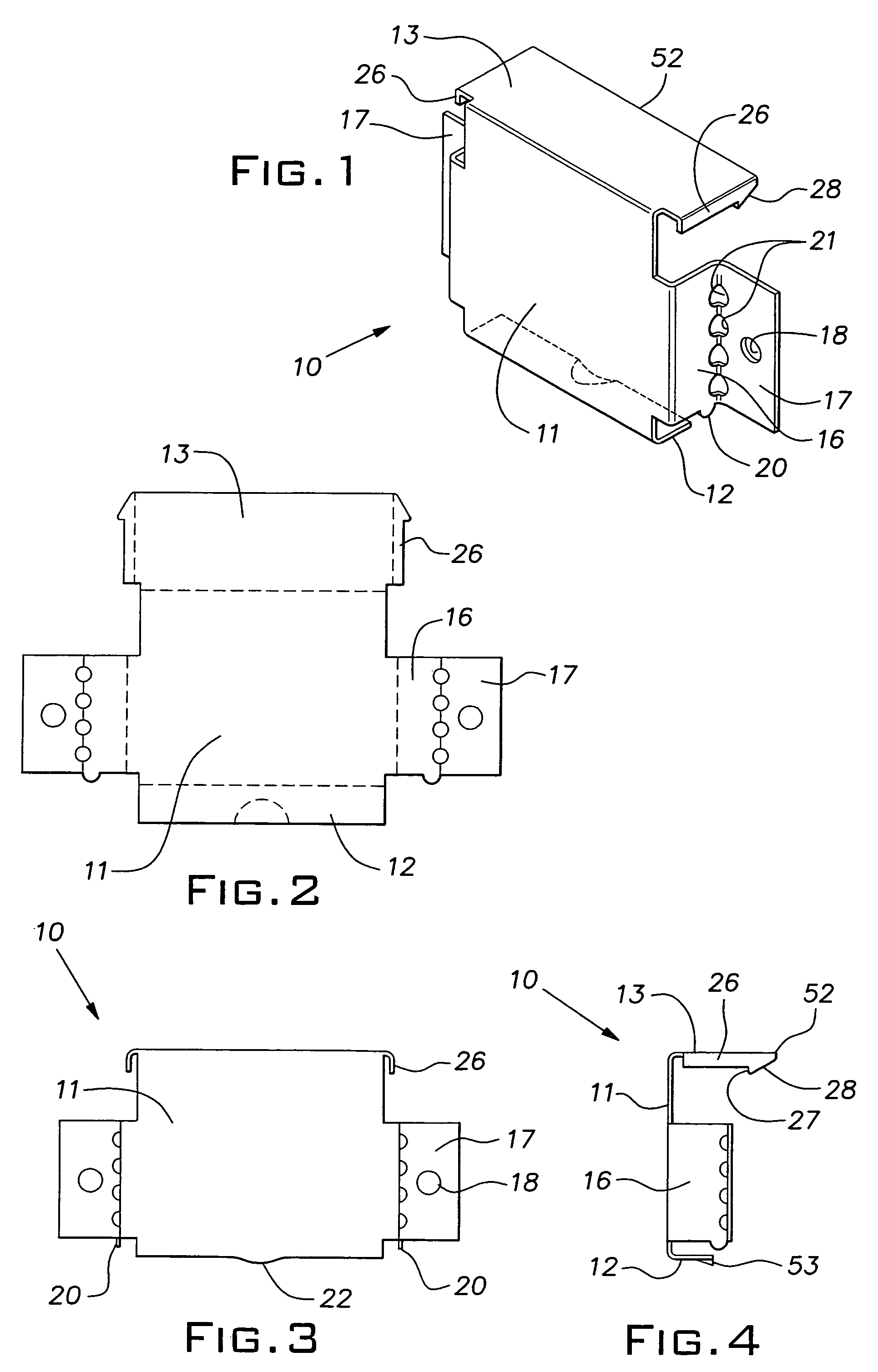

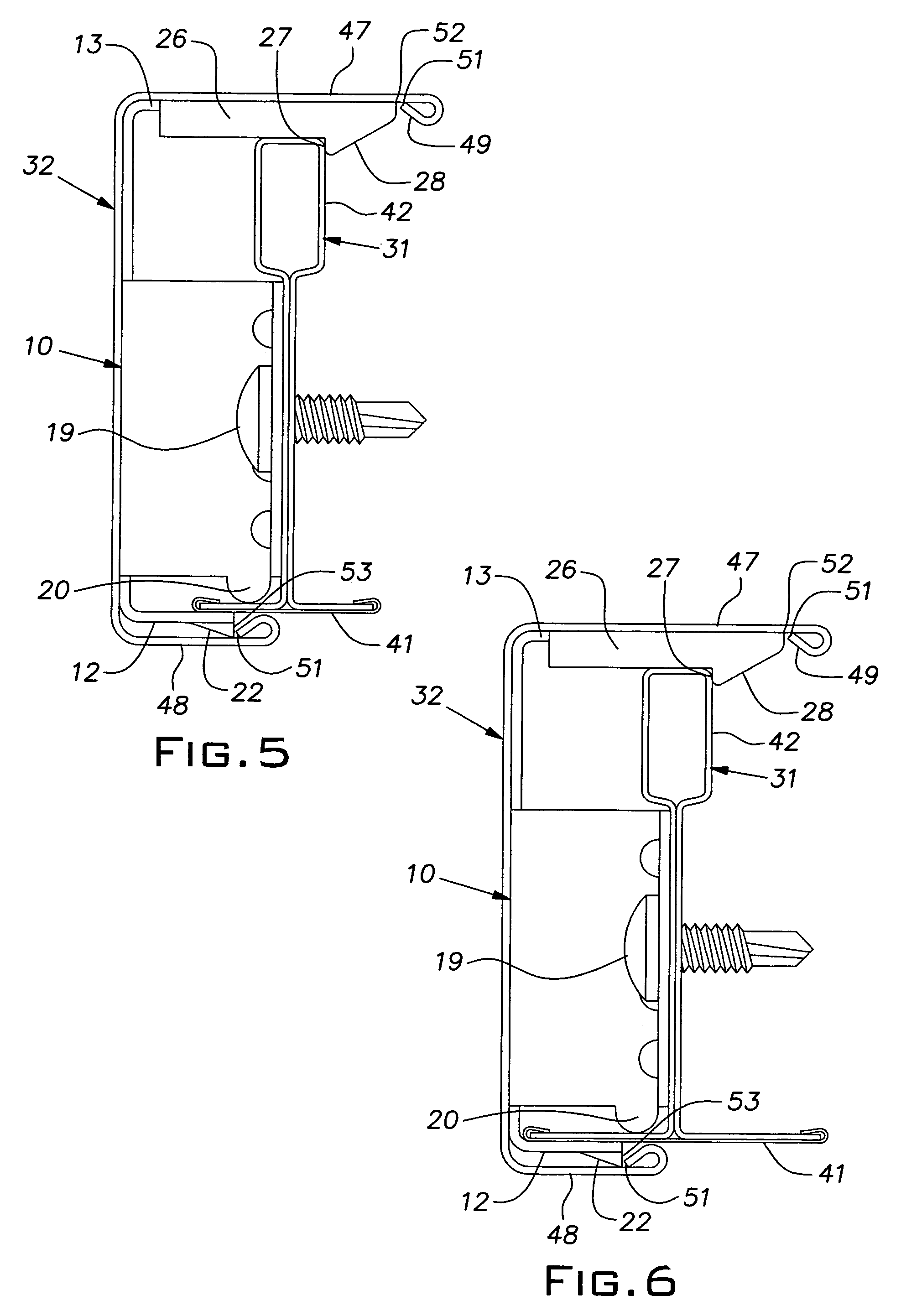

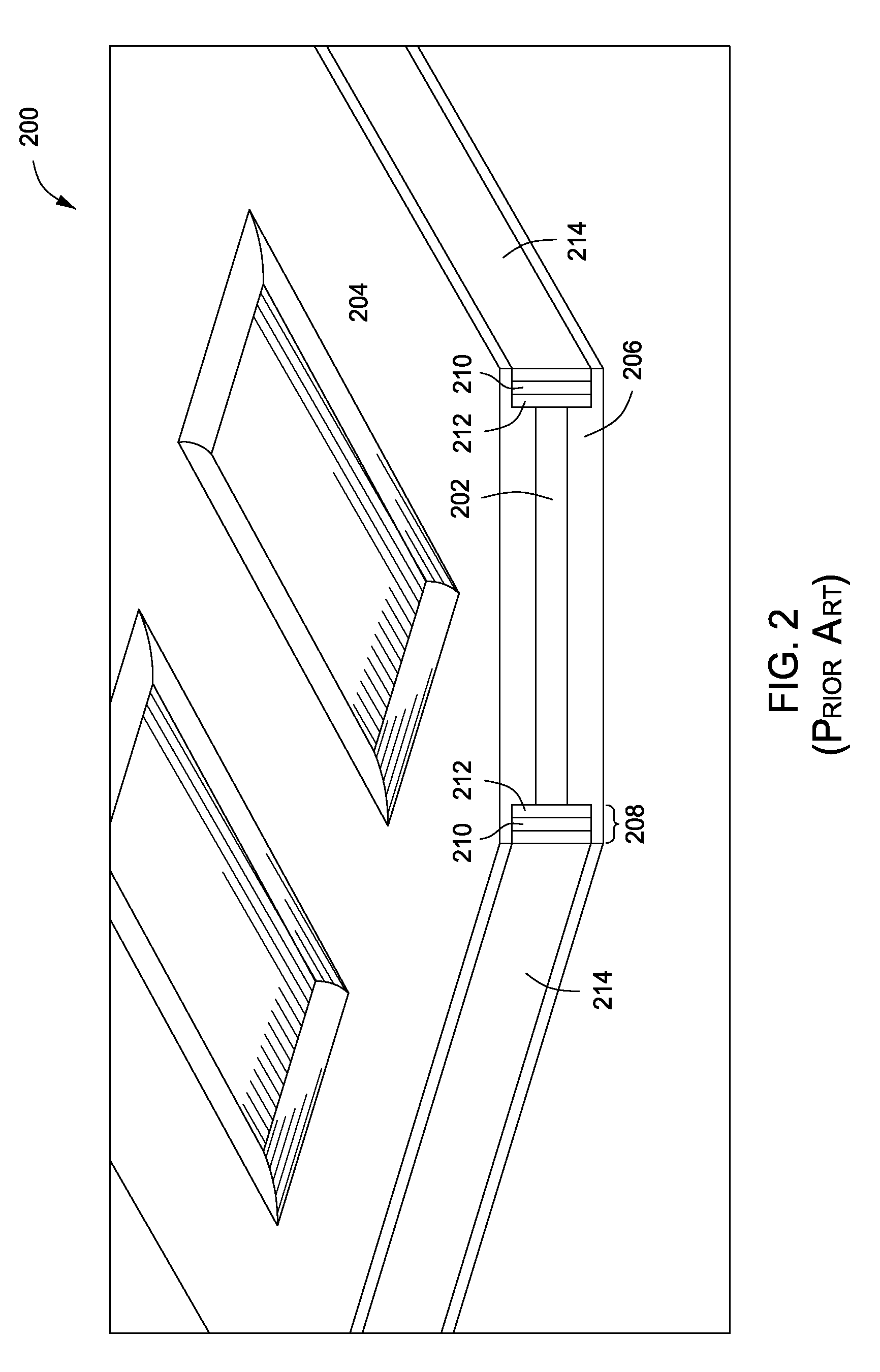

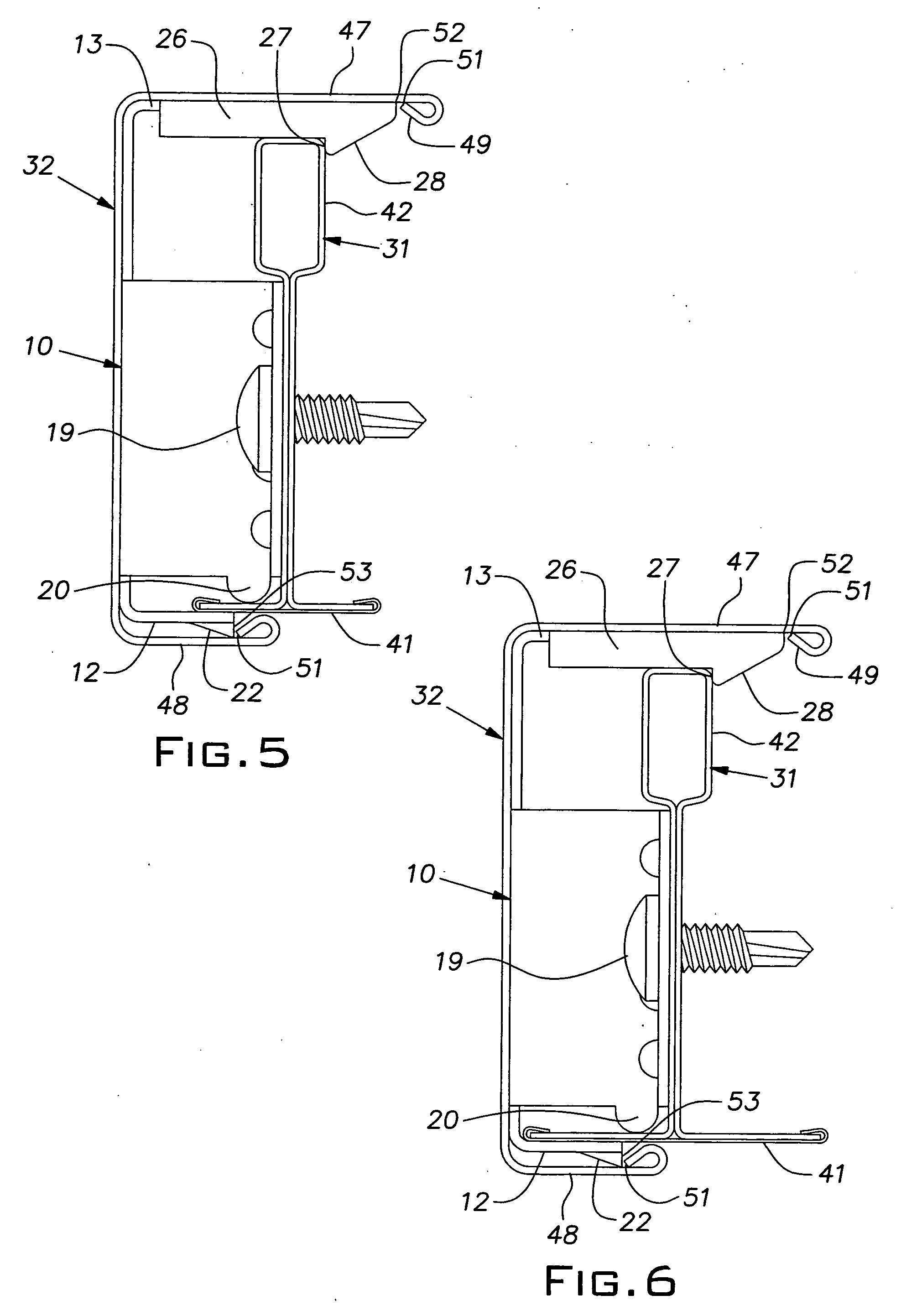

Trim system clip for island ceiling

An edge trim system for suspended island ceilings in which a one-piece clip couples standard grid tees to standard wall molding. The clip is arranged to snap onto the grid tees where the ceiling boundary is along a line of the grid and to be screw fastened onto a tee where the ceiling boundary is other than along the grid. The clip is arranged to snap into and retain the molding in place without fasteners.

Owner:USG INTERIORS INC

System, method and apparatus for producing fire rated doors

ActiveUS7832166B2High strengthRaise the gradeFireproof doorsDoor leavesEngineeringUltimate tensile strength

The present invention provides a system, method and apparatus for producing fire rated doors having added strength, better finishing and low cost manufacturing flexibility. The fire rated doors are made from two panels “sandwiched” together. An optional interior layer (e.g., fire resistant material, lead sheeting, steel or Kevlar) can be added between the door panels for various purposes. Splines, stiles or sticks are inserted in longitudinal channels in the door panels to provide assistance in aligning the door panels and greater hardware holding strength. An intumescent banding material concealed by a banding material around the perimeter of the door seals the door within its frame during a fire. The door design and the automated manufacturing process provide greater design choice, reduced cost and faster fabrication.

Owner:POLYMER WOOD TECH

High heat resisting and high abrasion resistant polyvinyl chloride (PVC) modified material and preparation method thereof

ActiveCN103059465AImprove wear resistance and heat resistanceImprove surface gloss and surface smoothnessPelletizingPlasticizer

The invention relates to the technical field of polyvinyl chloride composite materials, in particular to high heat resisting and high abrasion resistant polyvinyl chloride (PVC) modified materials and a preparation method of the high heat resisting and high abrasion resistant PVC modified materials. The modified materials comprise the following raw materials, by weight, 80-120 parts of PVC resin, 25-60 parts of stuffing bulking agents, 21-60 parts of plasticizer, 1-10 parts of chlorinated polyvinyl chloride, 1-10 parts of fire retardant, 1-10 parts of stabilizer, 1-10 parts of impact modifier and 0.2-2 parts of lubricating agents. The raw materials are weighed according to parts by weight and are blended. After being blended, the raw materials are extruded out to be granulated through a double-screw extruder to produce the modified materials. The modified materials are good in heat resisting property and abrasion resistant property, environment-friendly, high in strength, good in flame retardant effect, strong in compressing property and toughness, good in processing property and good in comprehensive property. The preparation method is simple in craft, convenient to operate and control, stable in quality and high in production efficiency, and can be produced in a large scale industrialization mode.

Owner:广东祺龙科技有限公司

Low temperature resistant environment-friendly polyvinyl chloride (PVC) modified material and preparing method thereof

ActiveCN103059468AGood flexibility and electrical insulation propertiesImprove low temperature resistancePelletizingPlasticizer

The invention relates to the technical field of polyvinyl chloride composite materials, in particular to a low temperature resistant environment-friendly polyvinyl chloride (PVC) modified material and a preparing method thereof. The modified material comprises by weight, 80-120 parts of PVC resin, 20-45 parts of filling agent, 41-80 parts of plasticizer, 1-10 parts of cold-resistant modifying agent, 1-10 parts of fire retardant, 1-10 parts of stabilizing agent, 5-15 parts of impact modifier and 0.2-2 parts of lubricating agent. Each raw material is weighed by weight and mixed, after being stirred; the raw material is squeezed out of prilling through a double-screw extruder and the modified material is available. The low temperature resistant performance of the modified material manufactured by the preparing method is fine; the minimum usage temperature can reach below 65 DEG C. The modified material is environment-friendly and has the advantages of high intensity, good flame retardant effects, strong compression performance and toughness, excellent processing performance and better comprehensive performance. The preparing method of the low temperature resistant environment-friendly polyvinyl chloride (PVC) modified material has the advantages of being simple in technology, convenient to control and operate, stable in quality, high in production efficiency. In addition, the preparation method of the low temperature resistant environment-friendly polyvinyl chloride (PVC) modified material can be used for a large scale industrial production.

Owner:广东祺龙科技有限公司

Lithium ion battery diaphragm and preparation method thereof

The invention relates to a lithium ion battery diaphragm. The lithium ion battery diaphragm comprises a polyolefin substrate and a composite coating, wherein the coating is connected with the polyolefin substrate through a binder, the coating is formed by stacking a plurality of inorganic particle layers, and each two adjacent inorganic particle layers of the coating are connected with each other through a binder; each inorganic particle layer consists of flaky inorganic particles, and the flaky inorganic particles are distributed in parallel or at a small angle in the coating. The invention also relates to a preparation method of the lithium ion battery diaphragm. The preparation method comprises the following steps: preparing flaky inorganic particles; screening first inorganic particles and second inorganic particles; preparing coating slurry; coating the polyolefin substrate with the coating slurry, and drying the polyolefin substrate with the coating to obtain a product. The lithium ion battery diaphragm is high in flatness, low in coarseness, low in water absorption rate, low inn coating expansion degree, capable of effectively reducing the natural crimpness of single-side coated diaphragm and capable of improving the assembling efficiency and rate of finished products of a laminated battery.

Owner:河南惠强新能源材料科技股份有限公司

Ceramic particle with adsorption, ion exchange and negative ion generating functions and preparation method thereof

InactiveCN101885605AMicropores are small and denseGood sintering strengthIon exchangeCeramic particle

The invention discloses a ceramic particle with adsorption, ion exchange and negative ion generating functions. The ceramic particle is prepared by the following raw materials by weight percentage content: 15-35% of natural adsorption material, 10-25% of ion exchange material, 20-45% of natural negative ion releasing material, 1-15% of rare earth material, 0.05-1.5% of radioactivity material, 5-25% of binding material and 2-12% of water. The invention also discloses a preparation method of the ceramic particle. The ceramic particle of the invention has strong adsorption property, good ion exchange property and high negative ion releasing quantity and has good washing, cleaning and purifying capabilities.

Owner:深圳市成为生物科技有限公司

Trim system for island ceiling

An edge trim system for suspended island ceilings in which a one-piece clip couples standard grid tees to standard wall molding. The clip is arranged to snap onto the grid tees where the ceiling boundary is along a line of the grid and to be screw fastened onto a tee where the ceiling boundary is other than along the grid. The clip is arranged to snap into and retain the molding in place without fasteners.

Owner:USG INTERIORS INC

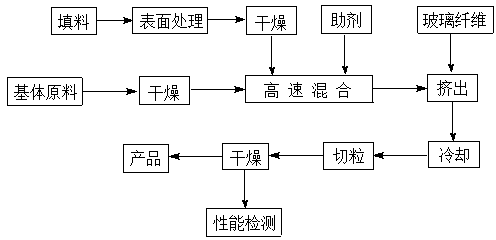

Multi-component compound modified nylon 6 composite material for carrier roller and preparation method thereof

The invention belongs to the field of high-molecular composite materials, and provides a high-performance multi-component compound modified nylon 6 composite material for a conventional carrier roller. The composite material consists of 100 parts of mixed nylon 6, 10-40 parts of alkali-free glass fiber, 5-30 parts of talcum powder, 0.01-1 part of nano silicon dioxide, 1-5 parts of solid lubricant, 0.01-3 parts of wear-resistant agent, 0.05-1 part of anti-aging agent, 0.2-1 part of dispersing agent and 0.01-0.5 part of silane coupling agent. After being uniformly mixed, the material system is extruded by a twin-screw extruder and granulated to obtain a high-performance composite material. By adopting the composite material provided by the invention, the prepared carrier roller has the characteristics of high strength, abrasion resistance, high-temperature resistance, light weight, low noise, long service life, appropriate price, convenience in maintenance and the like, and can be widely applied to the places such as mines except coal mines, wharfs, grain depots, cement plants, power plants, chemical plants, salt fields and the like.

Owner:HUNAN UNIV OF TECH

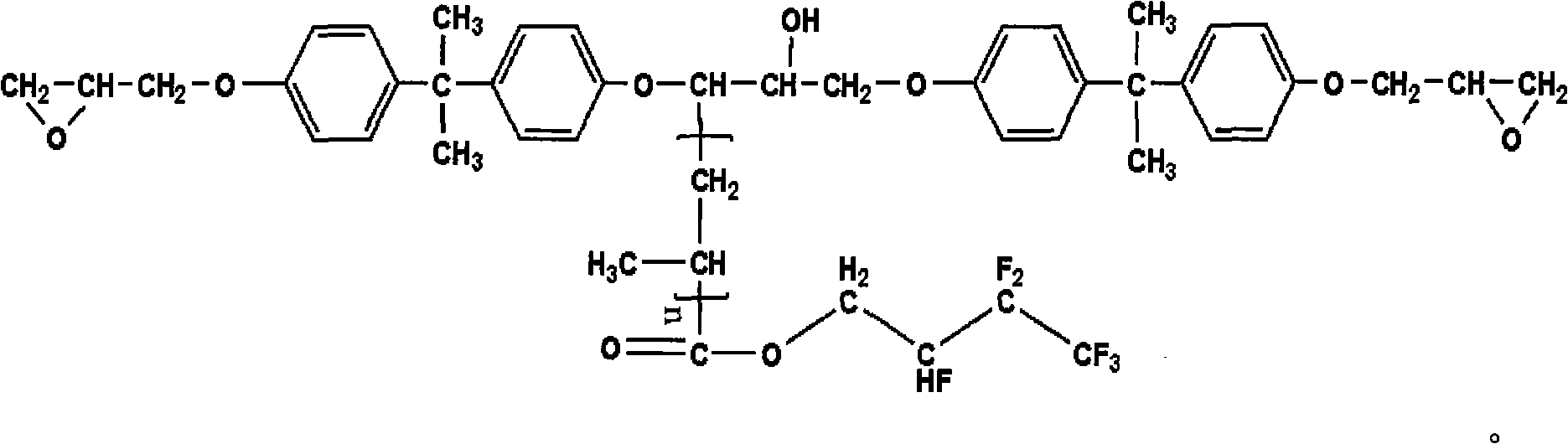

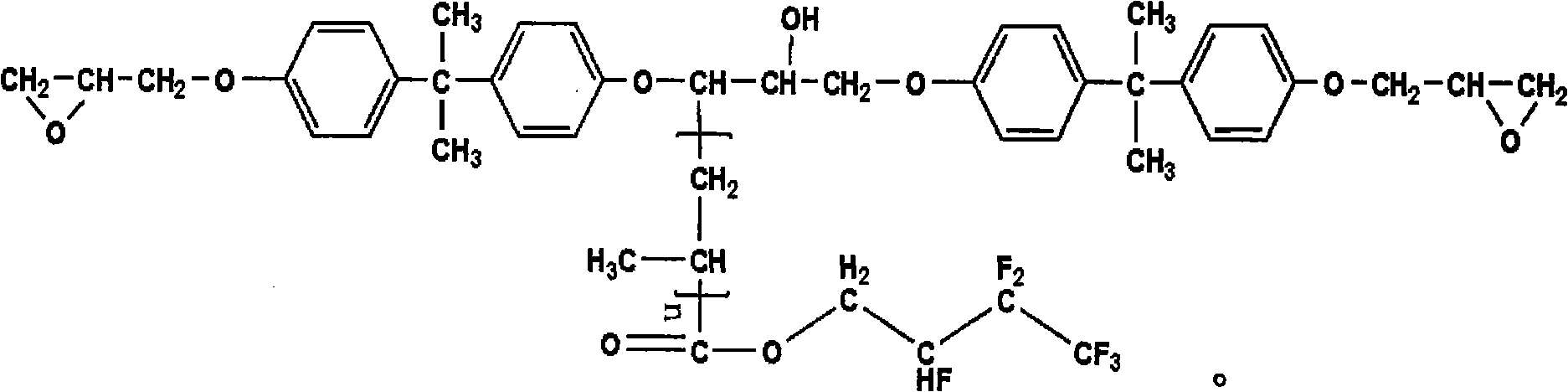

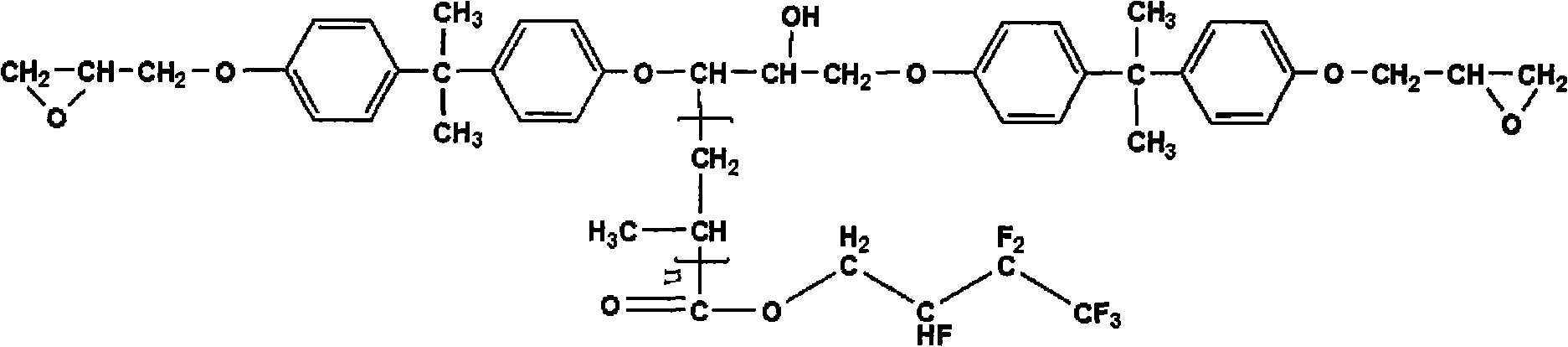

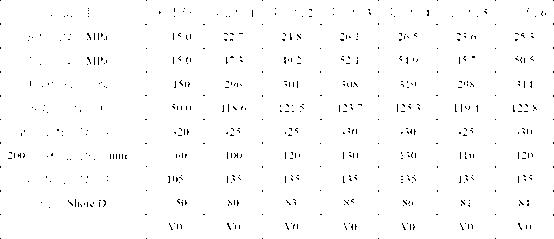

Fluorine-silicon modified epoxy resin power paint

InactiveCN101838495AImprove anti-pollution performanceBright appearancePowdery paintsEpoxyFumed silica

The invention discloses a fluorine-silicon modified epoxy resin power paint, which comprises the following raw materials in percentage by weight: 20-60% of fluorine modified methacrylic acid epoxy resin, 5-40% of organic silicon resin, 0.1-2% of nano fumed silica, 10-50% of heat-resistant filler, 1-15% of heat-resistant paint and 0.5-3% of leveling agent. Compared with the prior art, the heat resistant performance and the pollution resistant performance of the coating made of the fluorine-silicon modified epoxy resin power paint are both improved, the coating can be used in the environment at the temperature of 500 DEG C, and static contact angle to water at normal temperature can reach 100 degrees; and additionally, the fluorine-silicon modified epoxy resin power paint has the advantages of simple processing technology, low cost, and bright and smooth appearance of the coating, and can be thinly coated.

Owner:上海雄狮粉末科技股份有限公司

High temperature resistant environment-friendly polyvinyl chloride (PVC) modified material and preparing method thereof

The invention relates to the technical field of polyvinyl chloride composite materials, in particular to a high temperature resistant environment-friendly polyvinyl chloride (PVC) modified material and a preparing method thereof. The modified material comprises by weight, 80-120 parts of PVC resin, 30-70 parts of filling agent, 31-70 parts of plasticizer, 1-10 parts of hot-resistant modifying agent, 1-10 parts of fire retardant, 1-10 parts of stabilizing agent, 5-15 parts of impact modifier and 0.2-2 parts of lubricating agent. Each raw material is weighed by weight and mixed after being stirred; the raw material is squeezed out of prilling through a double-screw extruder and the modified material is available. The hot temperature resistant performance of the modified material manufactured by the preparing method is fine; the maximum usage temperature can reach up to 135 DEG C. The modified material is environment-friendly and has the advantages of high intensity, good flame retardant effects, strong compression performance and toughness, excellent processing performance and better comprehensive performance. The preparing method of the high temperature resistant environment-friendly polyvinyl chloride (PVC) modified material has the advantages of being simple in process, convenient to control and operate, stable in quality, and high in production efficiency. In addition, the preparation method of the high temperature resistant environment-friendly polyvinyl chloride (PVC) modified material can be used for a large-scale industrial production.

Owner:广东祺龙科技有限公司

Protective sleeve fabricated with hybrid yarn having wire filaments and methods of construction

ActiveUS7576286B2Provide protectionImprove conductivityLayered productsProtective fabricsYarnArchitectural engineering

A fabric sleeve and hybrid yarn filament used in construction of the sleeve for protecting elongate members against at least one of EMI, RFI or ESD, and methods of construction of the sleeve and hybrid yarn filament. The sleeve includes at least one interlaced hybrid yarn filament having a non-conductive filament and at least one conductive wire filament overlying an outer surface of the non-conductive filament. The hybrid yarn filament is arranged in electrical communication with itself or other hybrid yarn filaments to provide uniform shielding against EMI, RFI, and / or ESD.

Owner:FEDERAL MOGUL WORLD WIDE LLC

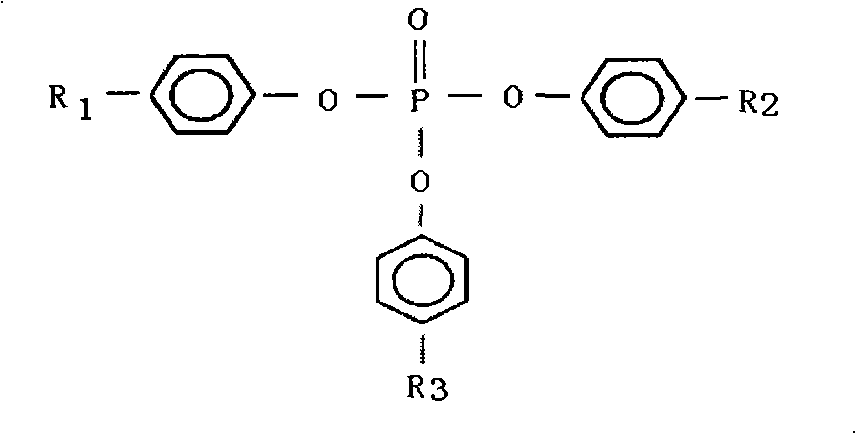

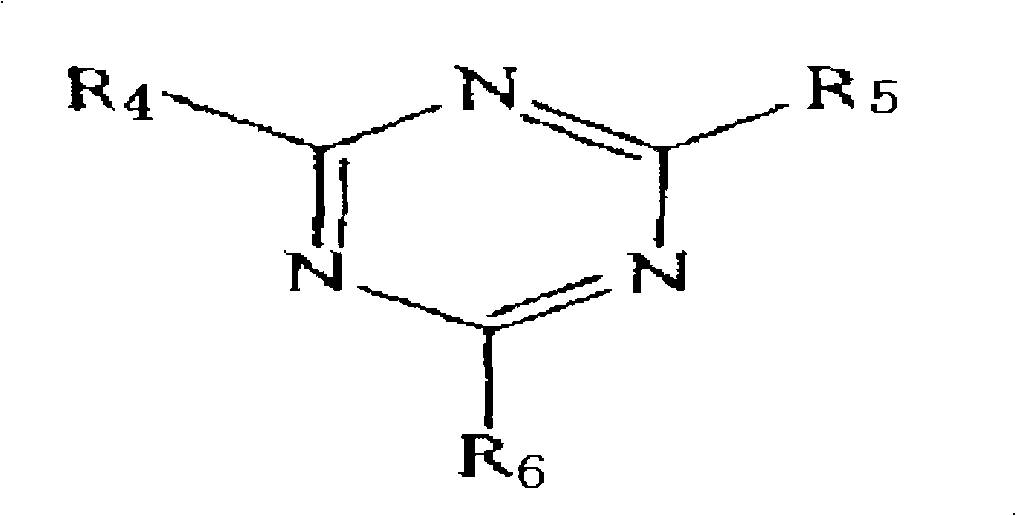

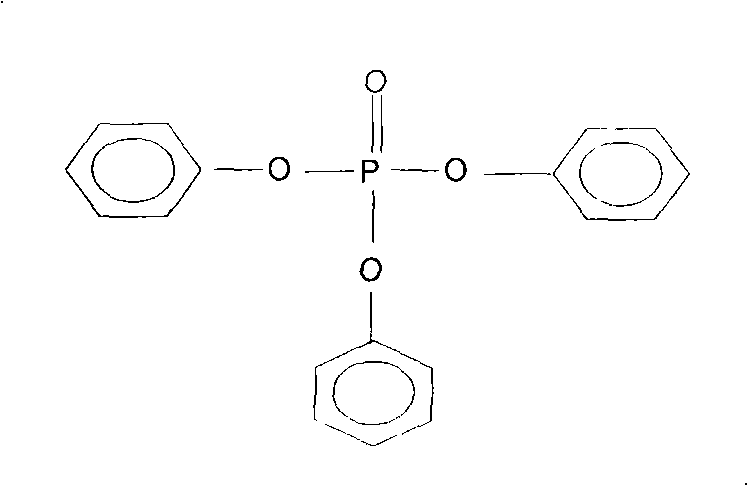

Flame-retardant anti-dropping resin composition

InactiveCN101348603AExcellent and durable flame retardantLittle impact on mechanical propertiesPolyesterFiber

The invention discloses a flame-retardant anti-dripping resin compound, consisting of 100 weight portions of thermoplastic resin, 0.01-5 weight portions of modified polytetrafluoroethylene anti-dripping agents and 20 to 40 weight portions of environment-friendly flame retardant containing phosphorus and / or nitrogen. The resin compound has strong anti-dripping effect and heat resisting performance, is level and smooth in exterior appearance, and can endow polyester fiber products with excellent enduring flame retardancy without using halogen (Cl and Br) flame retardant. The resin compound has the advantages of high oxygen index, droplet resistance, low heat release rate, no halogen, little toxicity, low smoke dust emission, little influence on the mechanical properties of base materials, etc.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

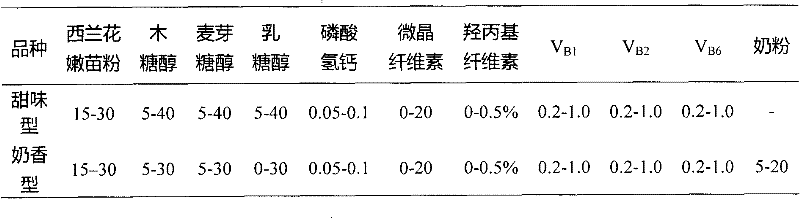

Process for preparing brassica vegetable seedling powder chewable tablets and brassica vegetable seedling powder chewable tablet product

InactiveCN102511753ASmooth appearanceEmerald green colorFood shapingFood preparationBrassica creticaBroccoli raab

The invention relates to a process for preparing brassica vegetable seedling powder chewable tablets and a brassica vegetable seedling powder chewable tablet product, belonging to the technical field of deep processing of agricultural products. The process is characterized by comprising the following steps of: with brassica vegetable seedling powder, such as broccoli and the like as a main basic stock, compounding, preparing a soft material, granulating, drying, tabletting, sterilizing and packing to prepare the brassica vegetable seedling powder chewable tablet with the advantages of clean appearance, green color and crispness. The process for preparing the brassica vegetable seedling powder chewable tablet, disclosed by the invention, is simple, has high industrial degree and can realize complete utilization on the brassica vegetable seedling, such as broccoli and the like, thereby increasing the additional value of the brassica vegetable seedling. The brassica vegetable seedling powder chewable tablets, including the broccoli and the like, prepared by the process disclosed by the invention have functions of resisting oxidation, slowing aging and resisting inflammation and cancer and the like of human bodies, and is a kind of casual healthcare food. According to the product of the process for preparing the brassica vegetable seedling powder chewable tablets, disclosed by the invention, the content of 4-methylsulfinylglucosinolate is up to 185.0-413.0mg / 100g, and the content of sulforaphane provided by each chewable tablet is equal to that provided by 30-75g of fresh brassica vegetable, such as broccoli and the like.

Owner:NANJING AGRICULTURAL UNIVERSITY

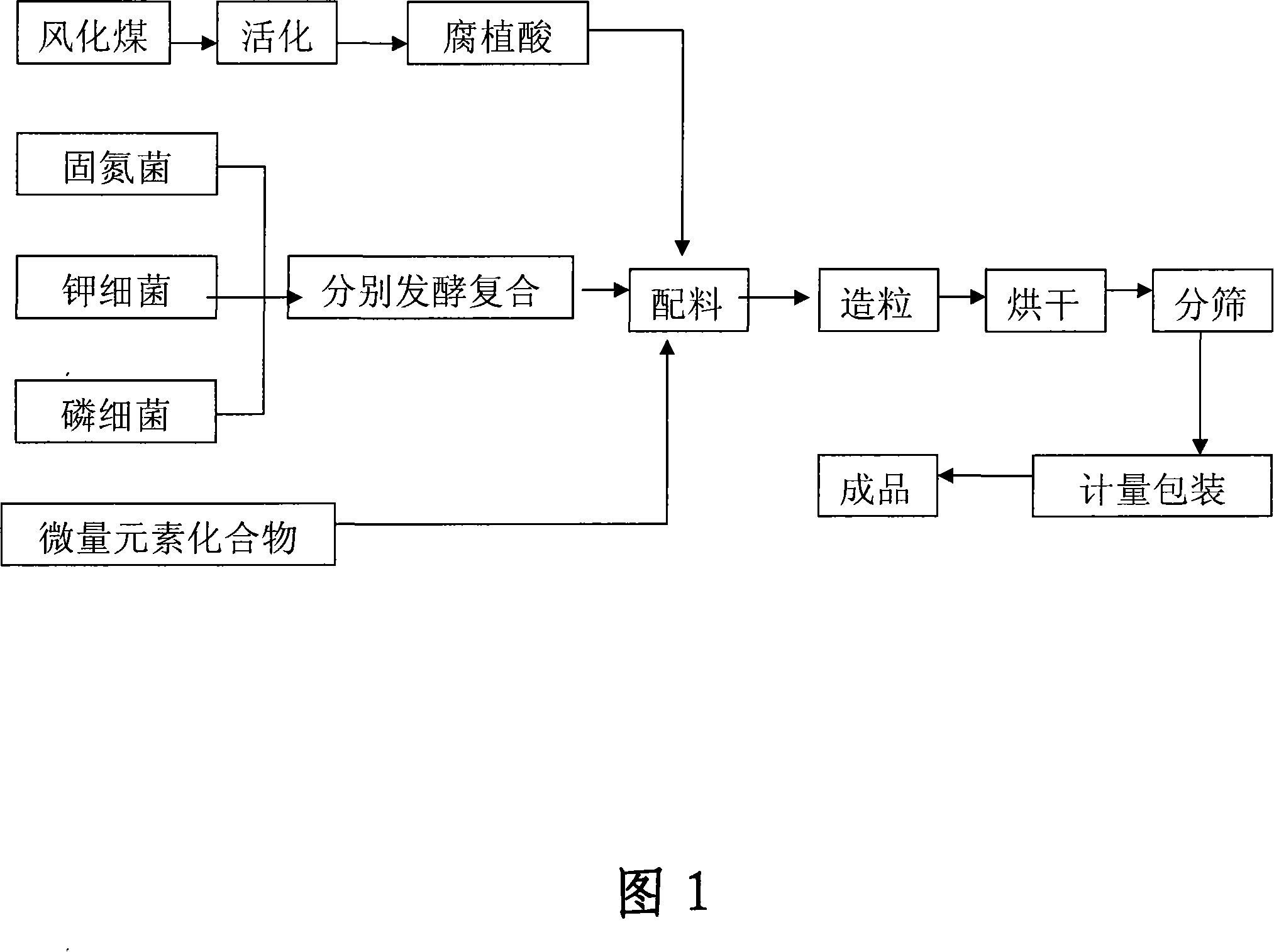

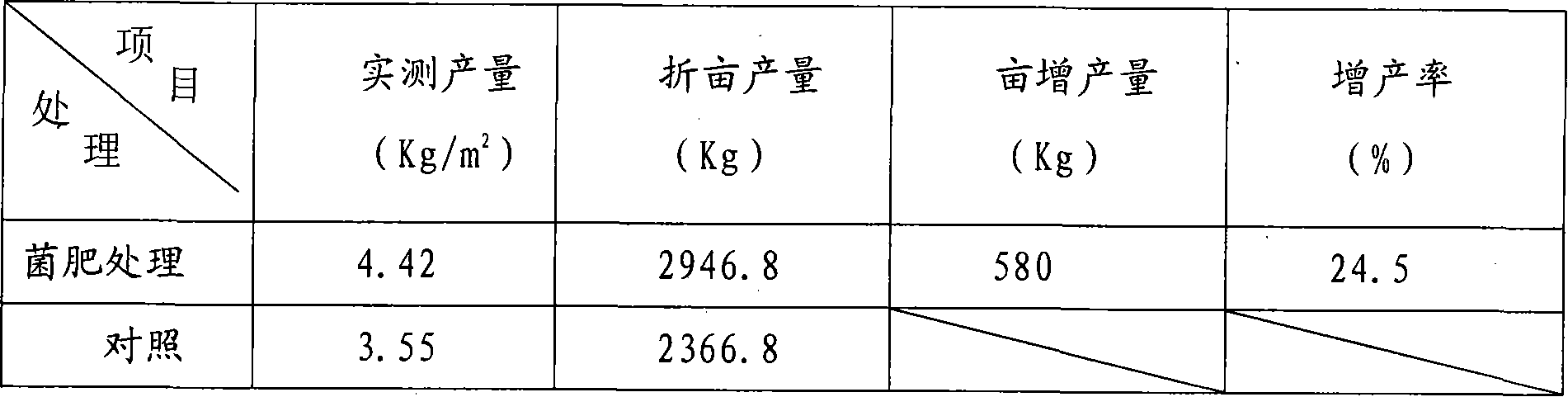

Grain type humic acid compound biological fertilizer and manufacturing method therefor

InactiveCN101130465AHigh activation rateImprove absorption efficiencyFertiliser formsOrganic fertilisersChemistryHumic acid

The invention discloses a particle-typed biological composite fertilizer and preparing method of humic acid, which is characterized by the following: adopting low-temperature graining and drying without breaking germ; dispensing solid particle typed fertilizer of humic acid, biological bacterial fertilizer and middle and trace element with weight rate at 2: (0. 1-0. 2): (0. 05-0. 1) through effective compatibility of microbe composite germ and humic acid and relative element; solving the coordinate action of each bacteria in the composite microbe fertilizer without mutual antagonism; making the bacteria display heat-proof property; blending the microbe and fitful quantity of azophoska fertilizer to act; fitting for increasing production and effectiveness in the agricultural domain.

Owner:新疆惠森生物技术有限公司

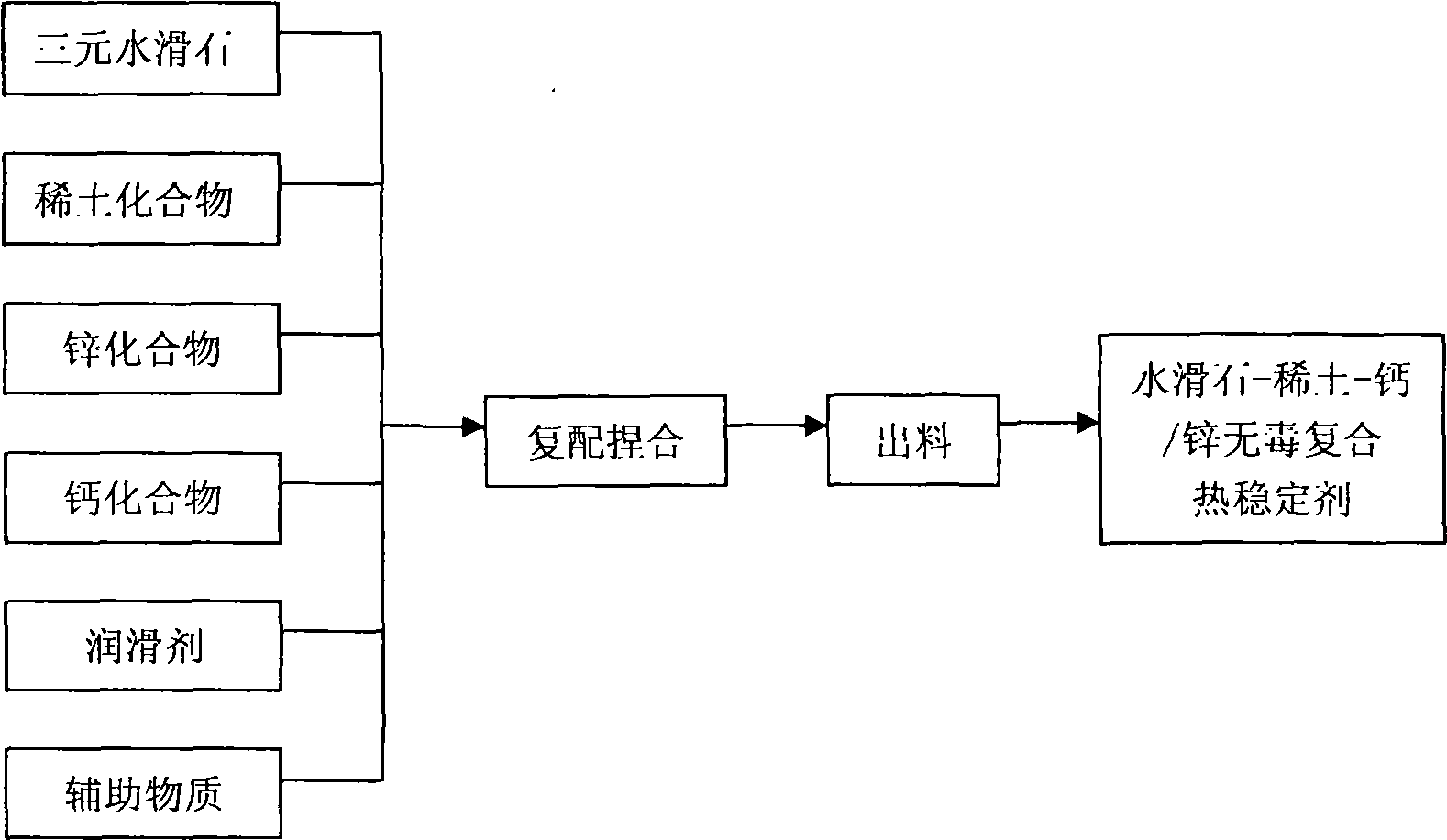

Ternary hydrotalcite-rare earth-calcium/zinc nontoxic composite heat stabilizer and preparation thereof

The invention relates to a preparation method of compound thermal stabilizer in plastic processing additive and pertains to the technical field of plastic processing additive. The invention discloses a ternary hydrotalcite-rare earth-Ca / Zn innoxious compound thermal stabilizer and a preparation method thereof. The invention comprises the materials of the stabilizer such as ternary hydrotalcite, organic rare earth compound, Ca compound and Zn compound, a synthetic preparation method thereof and an optimal compounding method of ternary hydrotalcite-rare earth-Ca / Zn innoxious compound thermal stabilizer. The ternary hydrotalcite-rare earth-Ca / Zn innoxious compound thermal stabilizer provided by the invention serves as a new generation high-efficiency innoxious stabilizer, can replace the traditional lead salt and expensive organic stannum thermal stabilizer and can be widely applied to the fields of PVC pipe material, section material, wire and cable, medical instrument and membrane, etc.

Owner:江西宏远化工有限公司

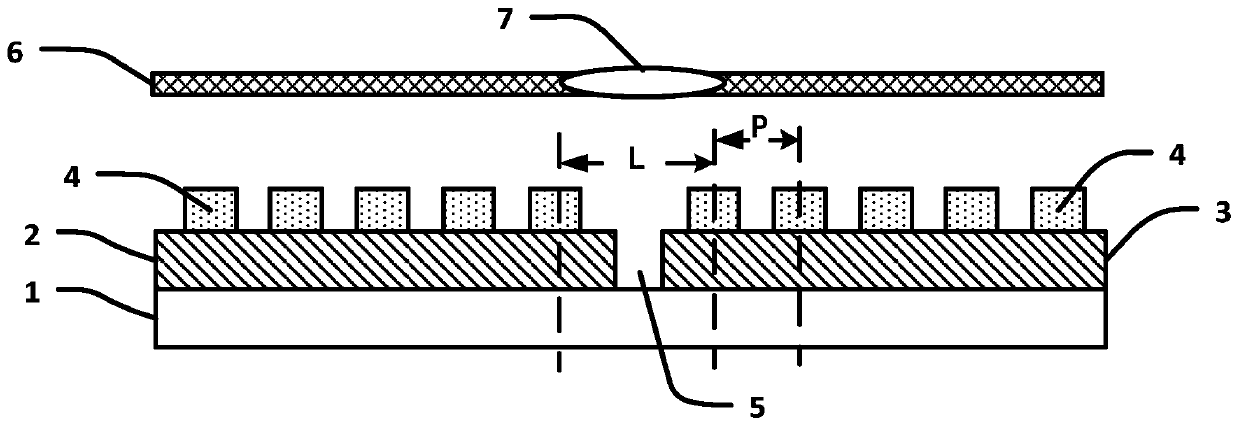

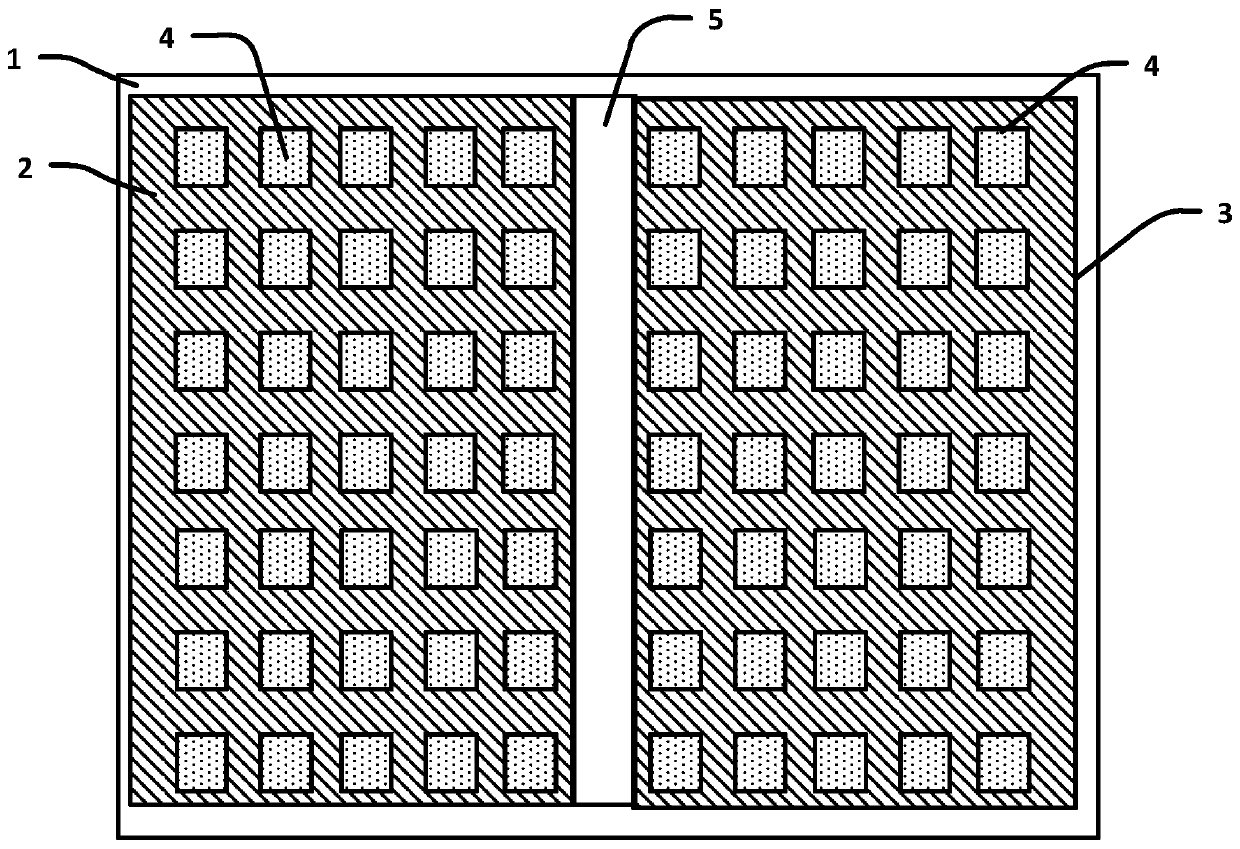

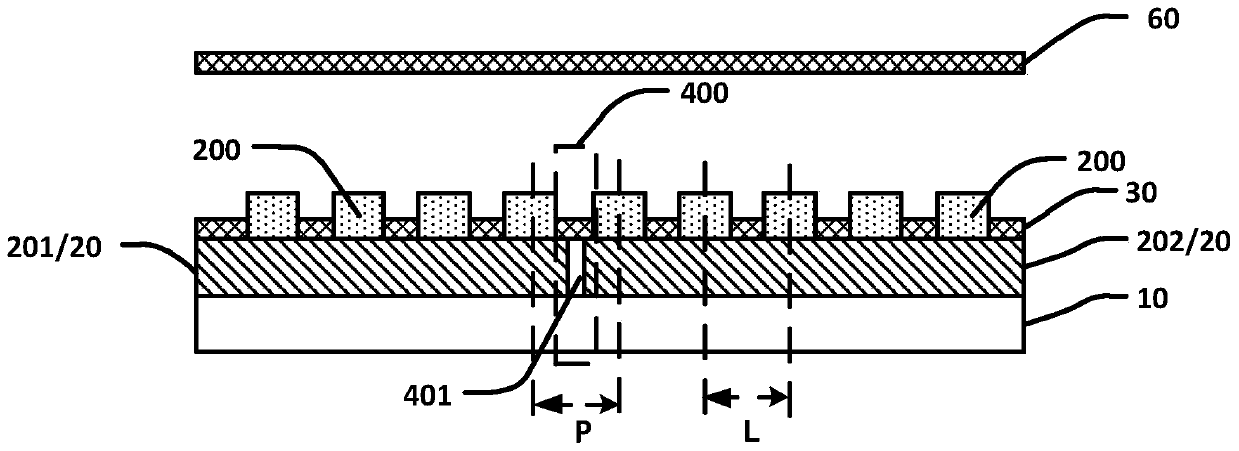

Backlight module and display panel

The invention provides a backlight module and a display panel. The backlight module comprises a back plate, lamp panels and a reflecting layer, wherein a plurality of lamp panels are arranged on an upper surface of the back plate in an array splicing manner, splicing areas are arranged between every two adjacent lamp panels, each splicing area is provided with a splicing seam, light supplementingmaterials are arranged in the splicing seams, and the reflecting layer is arranged on upper surfaces of the lamp panels and the splicing areas. The backlight module is advantaged in that the splicingseam is filled with the light supplementing materials and an emission sheet is arranged between a Mini-LED of a first column / row and a Mini-LED of a second column / row, the Mini-LED of the first column / row is closest to the Mini-LED of the second column / row, the Mini-LED is arranged in the splicing area so that light emitted by the Mini-LED is reflected to a reflector plate, the reflector plate reflects the light to the position of the splicing areas, the light-emitting hue of the splicing position is consistent with that of a normal area, brightness of the splicing areas is improved, chromaticaberration of the splicing areas is avoided, and the quality of light emitted by a backlight module is improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com