Grain type humic acid compound biological fertilizer and manufacturing method therefor

A compound fertilizer, humic acid technology, applied in the direction of organic fertilizer, fertilizer form, fertilizer mixture, etc., can solve the problems of plant leaf yellowing, death, mutual coordination and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

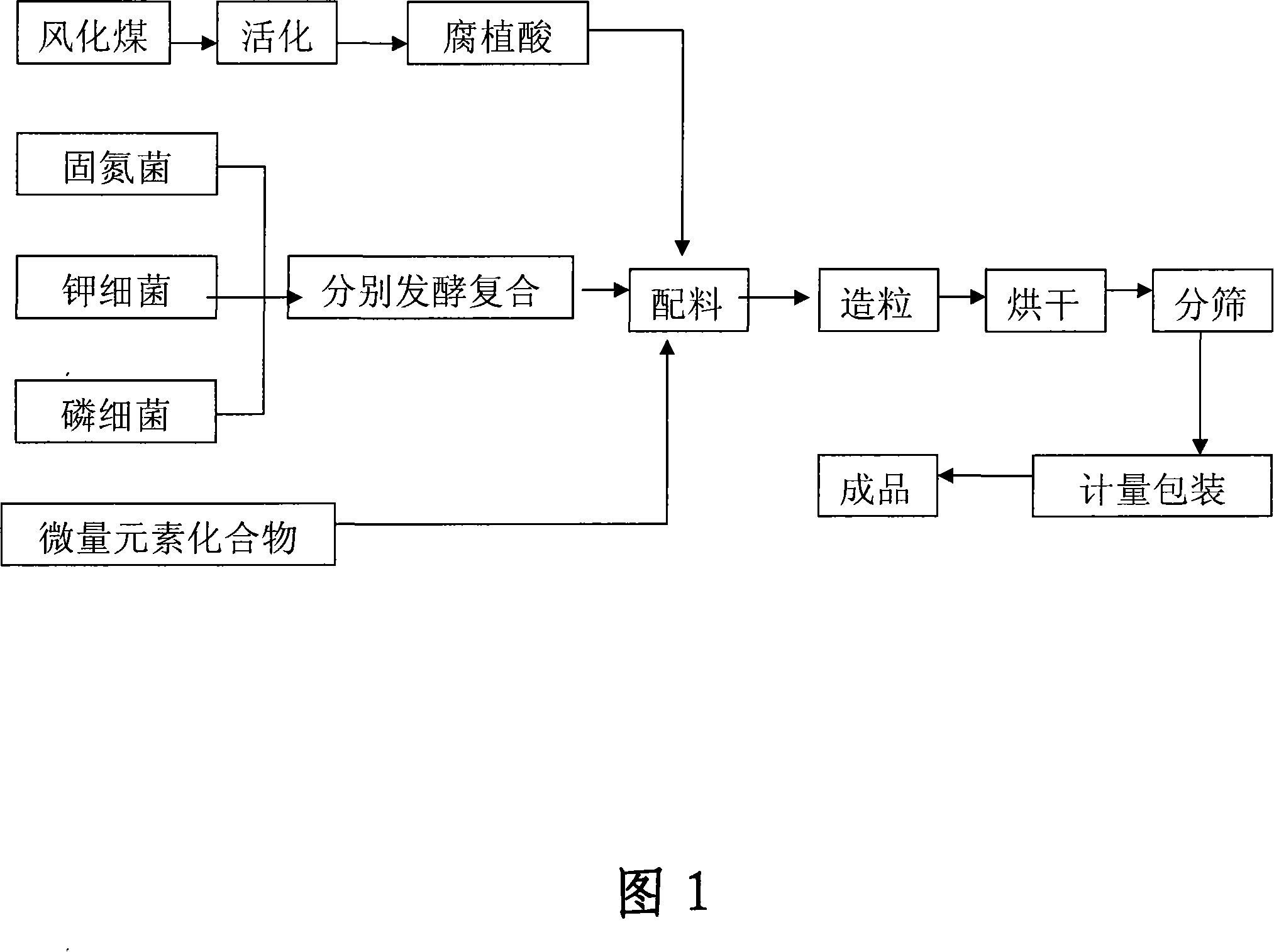

[0051] Embodiment one: the production of granular humic acid biological compound fertilizer

[0052] Granular humic acid bio-composite fertilizer The method for producing granular humic acid bio-composite fertilizer using the following microbial compound bacteria is as follows:

[0053] 1. Preparation of activated humic acid:

[0054] The weathered coal with a humic acid content of 50-75% (dry basis) (water content between 25-37%) is evenly sprayed with 15-30% NaOH solution per ton before stacking, and the natural drying reaction, 7 The effect is better for more than 15 days, and then crushed through 40 mesh, 60 mesh is better, and the weathered coal powder is sieved; dissolve the weathered coal with water (tap water can be used) with 60-100% weathered coal weight 12-20% NH by weight 4 HCO 3 and weathered coal weight 11-19% K 2 CO 3 or 15-26% Na 2 CO 3 The prepared solution and the weathered coal powder are stirred evenly in a mixer, and then the temperature is raised t...

Embodiment 2

[0064] Embodiment two: the preparation of active humic acid raw material

[0065] Humic acid content is 50-75% (dry basis) weathered coal pulverized through 60 mesh effect is better, weathered coal powder is sieved; with weathered coal weight 60-100% water (using tap water can be used) to dissolve the weathered coal weight 12-20% ammonium bicarbonate and weathered coal weight 11-19% potassium chloride or 15-26% potassium nitrate to make a solution and weathered coal powder in a mixer and stir evenly, then heat up to 35 ° C under stirring -75°C insulation reaction for 5-10 hours is better), then dry below 100°C (in a desiccator) (storage and application effect are best when the water content is lower than 24%), and obtain potassium ammonium humate. Active weathered coal.

[0066] The particle size of the weathered coal is above 60 mesh, and the content of humic acid is 50%; the activator is NaOH, KOH, NaOH 2 CO 3 、K 2 CO 3 , NH 4 HCO 3 and / or NH 4 The catalytic oxidant ...

Embodiment 3

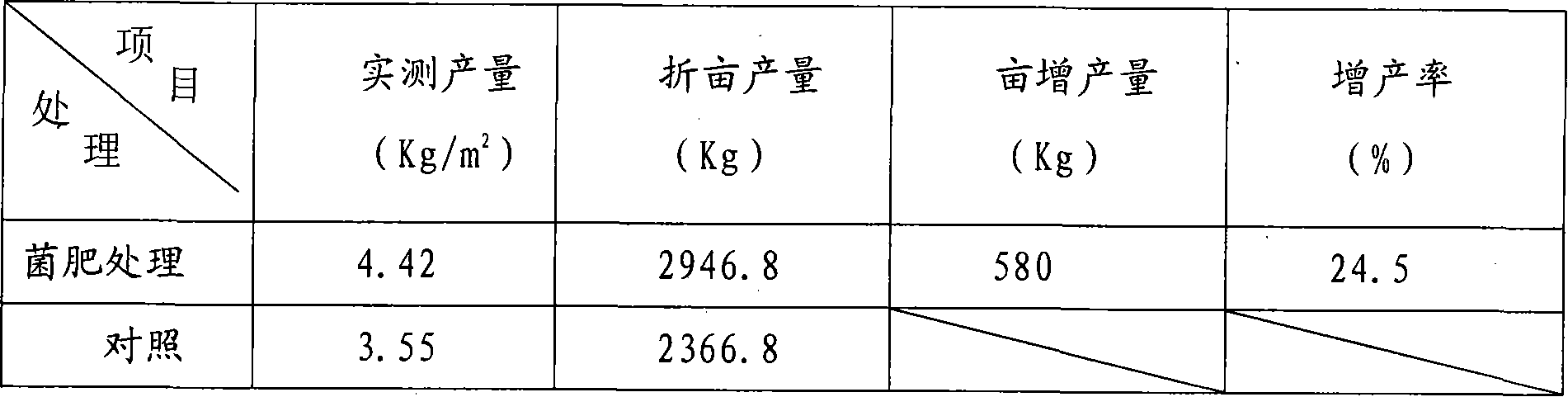

[0067] Embodiment 3: Granular humic acid biological compound fertilizer prevents and treats cotton fusarium wilt

[0068] By applying granular humic acid biological compound fertilizer, it can effectively prevent and control plant diseases and insect pests, treat yellow leaf disease caused by iron deficiency, promote the transportation of fertilizer in plants, and make the absorption of fertilizer more fully. According to Wang Shuqi of the Henan Institute of Chemistry, Shandong Agricultural College experimented with a new type of granular humic acid biological compound fertilizer for root irrigation, seed dressing, and spraying. It has no significant effect on the control of cotton yellow and yellow disease, and 500ml / mu (2000 times) is used for root irrigation. The control effect reaches 60-90%, the control effect reaches 43-75% with 25-150g / mu FA seed dressing, and the control effect reaches 23-27% with 1500 times application, and the root irrigation is the best.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com