Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

731 results about "Dry basis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dry basis is an expression of the calculation in chemistry, chemical engineering and related subjects, in which the presence of water (and/or other solvents) is neglected for the purposes of the calculation. Water (and/or other solvents) is neglected because addition and removal of water (and/or other solvents) are common processing steps, and also happen naturally through evaporation and condensation; it is frequently useful to express compositions on a dry basis to remove these effects.

Carbonaceous Fuels and Processes for Making and Using Them

The present invention provides carbonaceous fuels and processes for making them. Moreover, the invention also relates to processes using the carbonaceous fuels in the production of cement products. One embodiment of the invention is a carbonaceous fuel comprising (a) unconverted fines of a carbonaceous feedstock, the carbonaceous feedstock having an ash content of greater than 1%, the fines having an average particle size less than about 45 μm; and (b) a char residue formed by catalytic gasification of the carbonaceous feedstock, the char residue having an ash content of greater than about 30%, wherein the ash includes at least one aluminum-containing compound or silicon-containing compound; and having a weight ratio of fines to char residue in the range of about 4:1 to about 1:4, and a total dry basis wt % of carbon of least about 40%. Another embodiment of the invention is a process of making a cement product comprising: (a) providing a carbonaceous fuel as described above; (b) passing the carbonaceous fuel into a cement-making zone; and (c) at least partially combusting the carbonaceous fuel to provide heat for a cement producing reaction within the cement-making zone.

Owner:SURE CHAMPION INVESTMENT LTD

Heavy oil hydrogenation catalyst and preparation method thereof

ActiveCN103769118AShorten drying timeAvoid pollutionCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsDry basisBULK ACTIVE INGREDIENT

The invention discloses a heavy oil hydrogenation catalyst and a preparation method thereof. The heavy oil hydrogenation catalyst comprises a carrier and an active ingredient; the carrier is aluminum oxide, and is prepared from pseudo-boehmite with dry basis content below 50% via moulding; the active ingredient are metals selected form family VIII, Co or Ni, and / or family VI B, Mo or W. The preparation method comprises following steps: preparation of pseudo-boehmite, preparation of the carrier, and loading of the active ingredient. The heavy oil hydrogenation catalyst is capable of maintaining high demetalization, desulphurization, and carbon residue removing activities, simplifying drying process of pseudo-boehmite preparation, avoiding dust pollution caused by moulding process, increasing production efficiency, reducing production energy consumption, and reducing catalyst cost further.

Owner:CHINA PETROLEUM & CHEM CORP +1

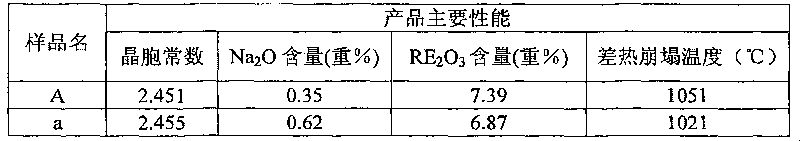

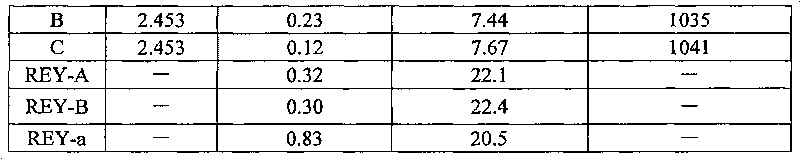

Alkali treatment modifying method of Y-shaped molecular sieve

ActiveCN101722022ALarge adsorption capacityImprove ion exchange efficiencyMolecular sieve catalystsMolecular sieveMass ratio

The invention provides an alkali treatment modifying method of a Y-shaped molecular sieve, which comprises the following steps of: beating and uniformly mixing the Y-shaped molecular sieve and a strong alkali aqueous solution according to the mass ratio of the molecular sieve, a strong alkali and distilled water as (0.1-2): (0.05-2): (4-15), and carrying out alkali treatment for 0.1-24 hours at the temperature of 0-120 DEG C; compared with a parent Y-shaped molecular sieve, the obtained molecular sieve has the advanced performance of higher N2 adsorptive capacity, larger water absorbing capacity and the like. On the basis of modified treatment, the invention also provides a preparation method of an NH4 molecular sieve and an ultrastable Y-shaped molecular sieve, which comprises ammonium exchange treatment and hydrothermal ultrastable treatment implemented for a modified NaY molecular sieve after alkali treatment, and the obtained NH4 molecular sieve has lower metallic ion residues; an obtained USY molecular sieve has more abundant secondary holes while keeping high degree of crystallinity, thereby improving the catalytic activity of the USY molecular sieve.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Preparation method of skeleton silicon-rich Y-shaped molecular sieve

ActiveCN101723399AImprove effective apertureIncreased secondary pore contentFaujasite aluminosilicate zeoliteMolecular sieveActive component

The invention discloses a preparation method of a skeleton silicon-rich Y-shaped molecular sieve, comprising the following steps of: firstly, carrying out desiliconizing pretreatment on a NaY molecular sieve with alkali lye and secondly carrying out ammonium exchange and dealumination and silicon reinsertion on the molecular sieve treated with alkali. The alkali treatment condition is to pulp and evenly mix the NaY molecular sieve and an alkali liquor in the mass ratio of NaY (dry basis): alkali: H2O being (0.1-2): (0.05-2): (4-15) and carry out alkali treatment at 0-120 DEG C for 0.1-24h. Compared with a product obtained by carrying out ammonium exchange and silicon-rich treatment on the NaY molecular sieve, the skeleton silicon-rich Y-shaped molecular sieve subject to the desiliconizing pretreatment has higher infrared acid quantity, B acid quantity and secondary pore content. A catalyst prepared from an active component which is the skeleton silicon-rich Y-shaped molecular sieve prepared by the method has stronger heavy oil transformation capability and higher light oil recovery rate when being used for a heavy oil cracking reaction.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

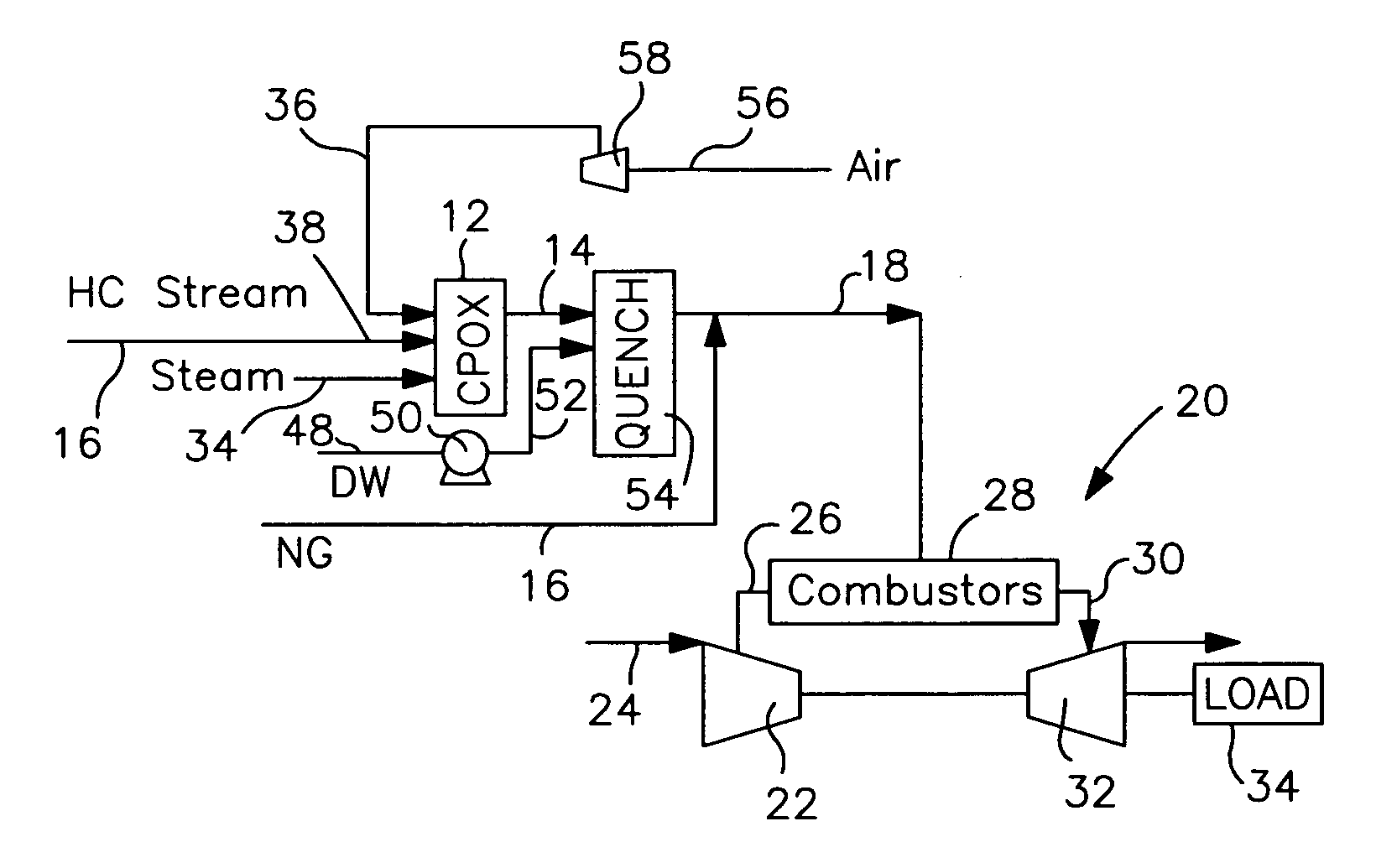

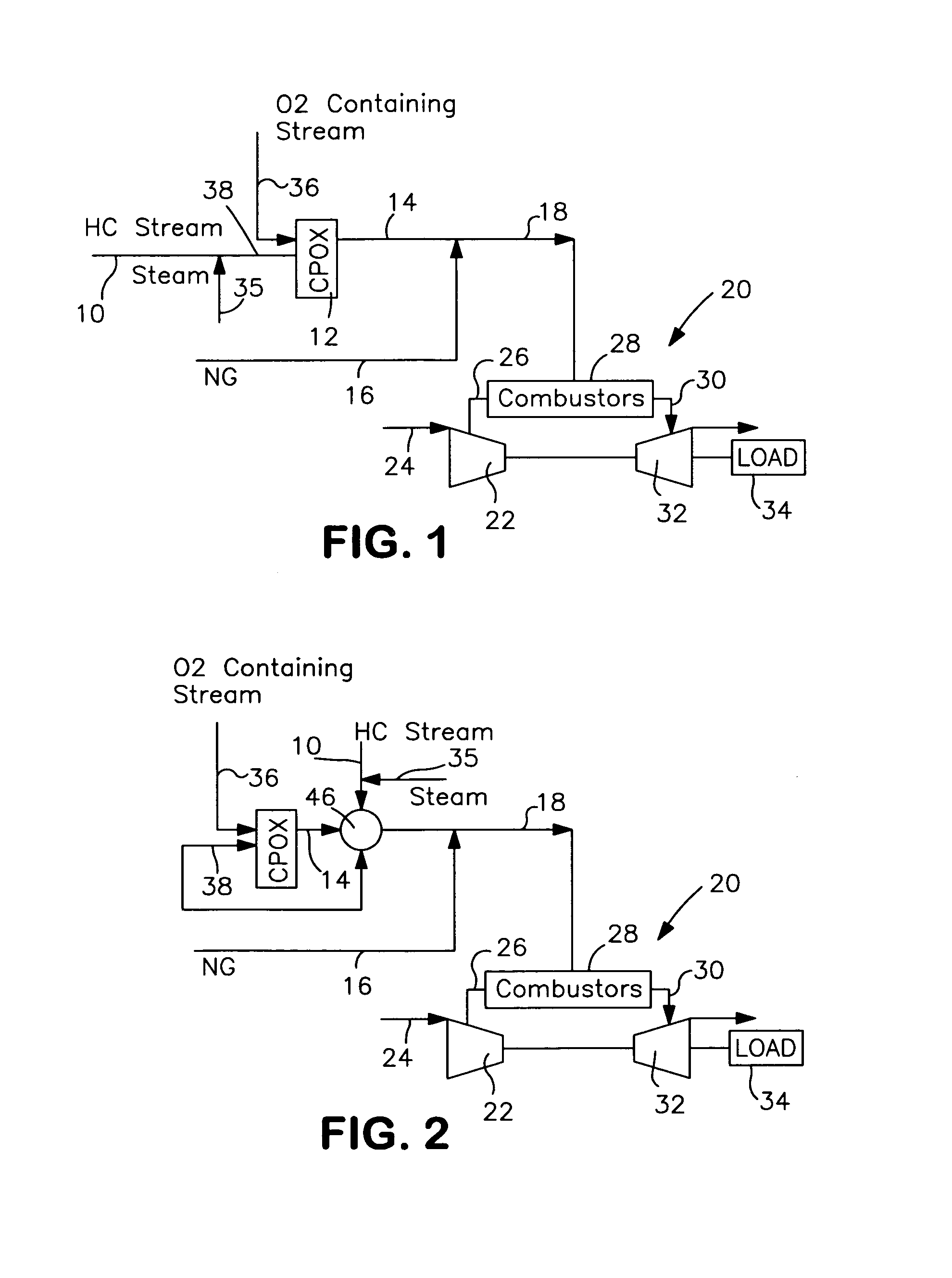

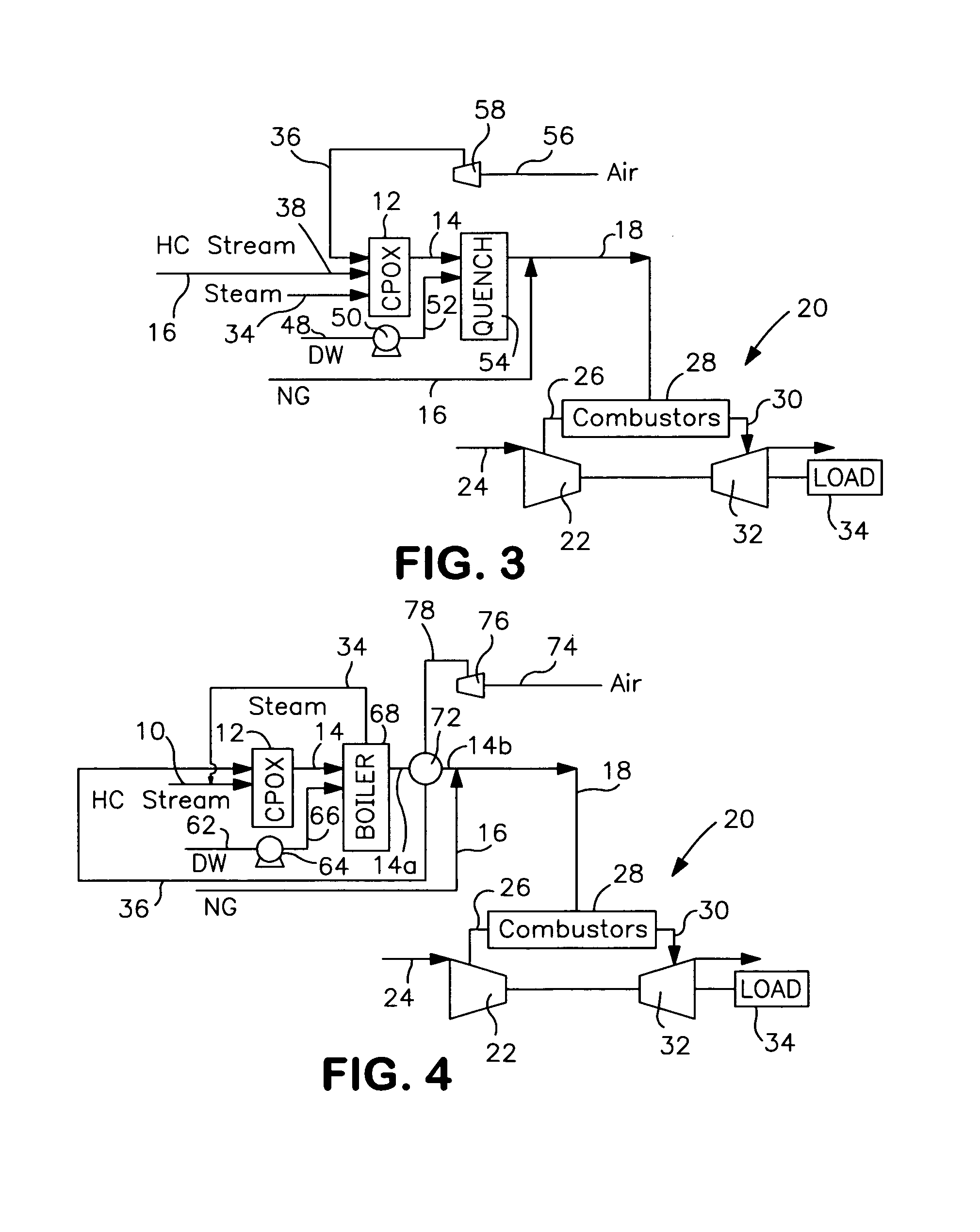

Gas turbine fuel preparation and introduction method

ActiveUS7395670B1Gaseous fuel feeder/distributionContinuous combustion chamberCombustorPartial oxidation

Method of preparing and introducing fuel into the combustors of a gas turbine in which a hydrocarbon containing feed, oxygen and steam are introduced into a catalytic partial oxidation reactor to produce a product stream. The hydrocarbon containing feed contains no less than about 15 percent by volume on a dry basis of hydrocarbons with at least two carbon atoms and / or at least about 3 percent by volume of olefins. The reactant mixture formed of the hydrocarbon containing feed, oxygen and steam has an oxygen to carbon ratio of between about 0.08 and about 0.25 and a water to carbon ratio of between about 0.05 to about 0.5. The hydrocarbon containing feed is introduced into the reactor alone or with a steam at a temperature no greater than 600° C. and the product stream is produced at a temperature of between about 600° C. and 860° C. and contains less than about 0.5 percent of olefins and less than 10 percent of hydrocarbons with two or more carbon atoms on a dry basis. After cooling the product stream the product stream is introduced into the combustors of the gas turbine to form part or all of the fuel required to support combustion.

Owner:PRAXAIR TECH INC

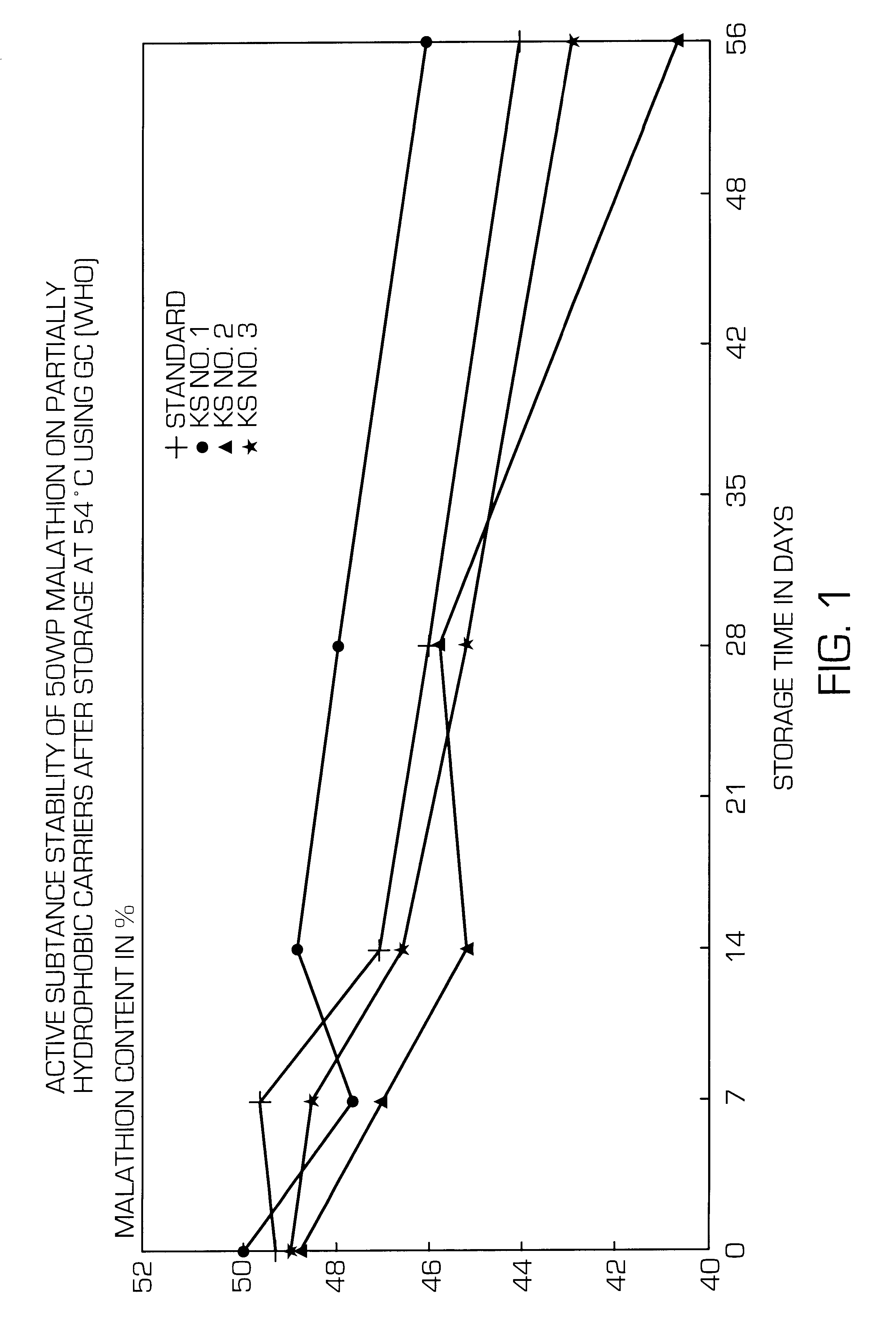

Partially hydrophobic precipitated silicas

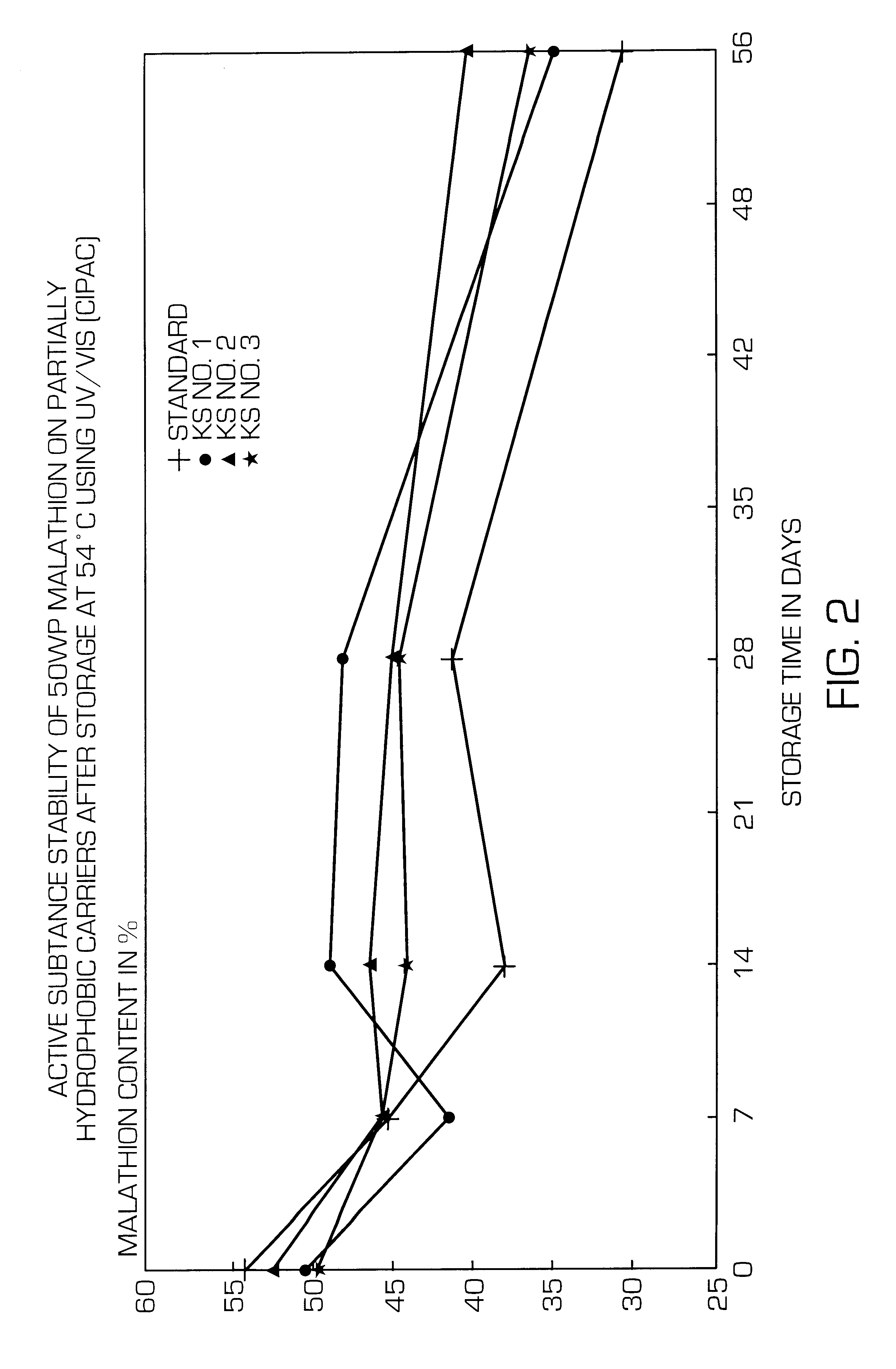

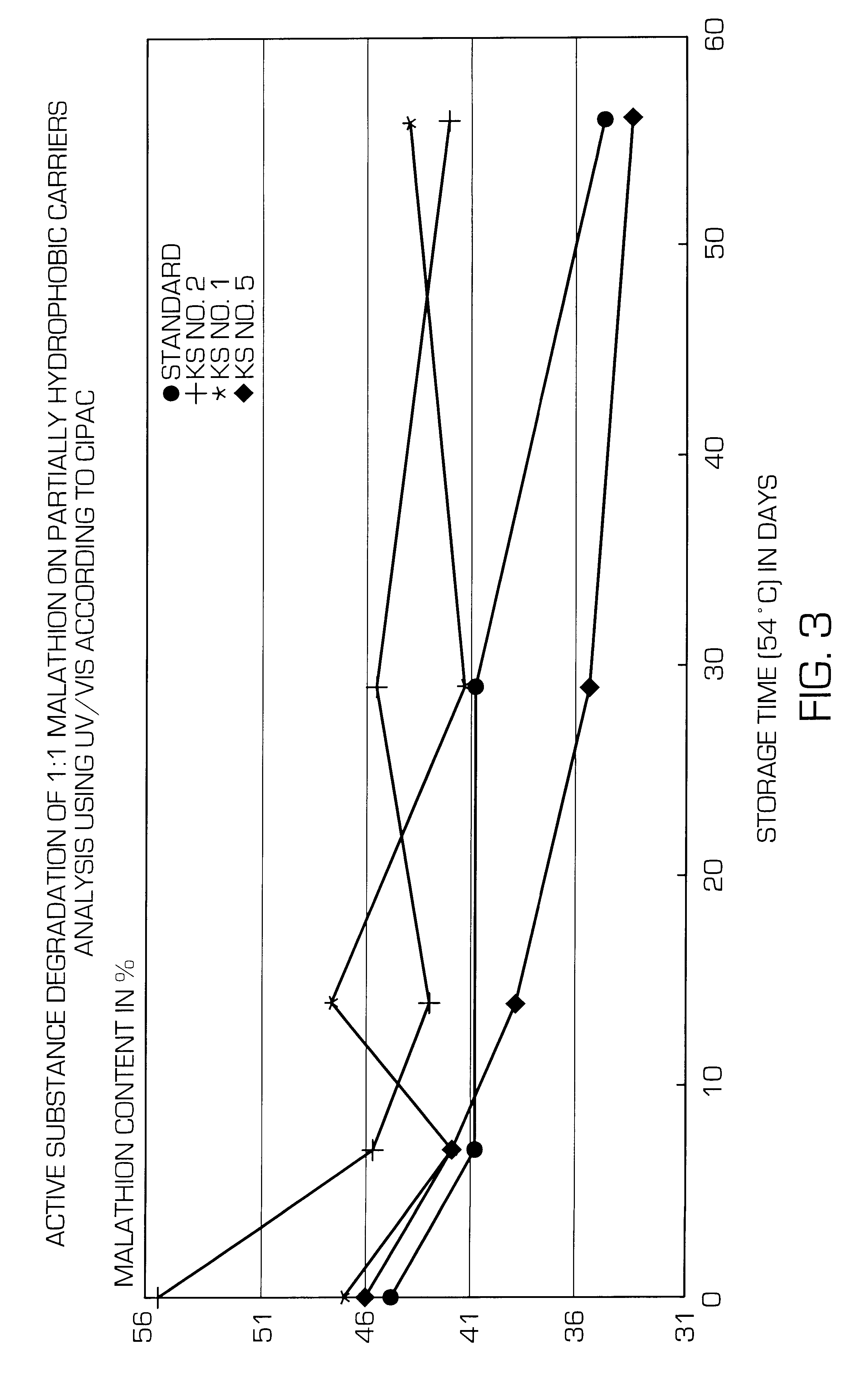

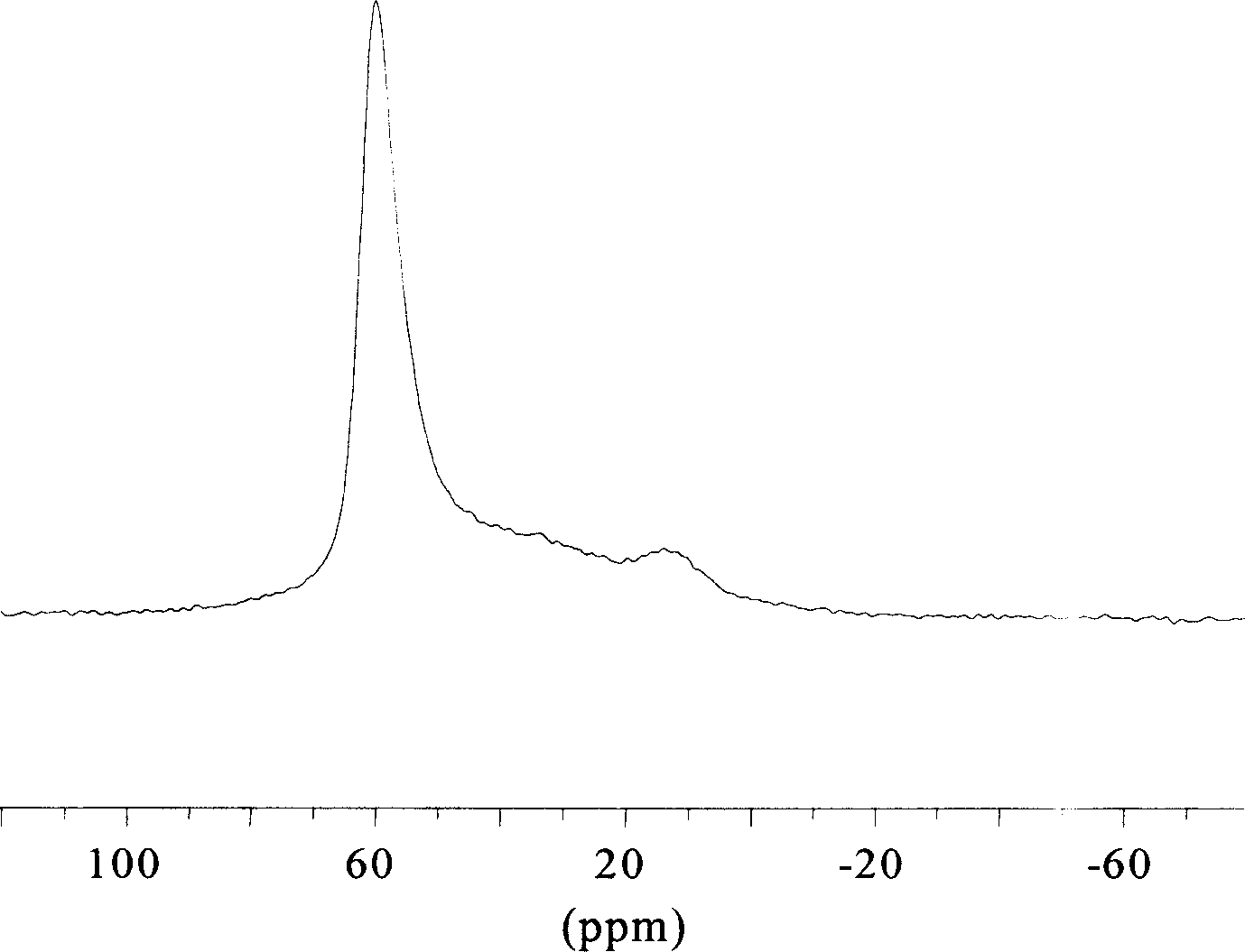

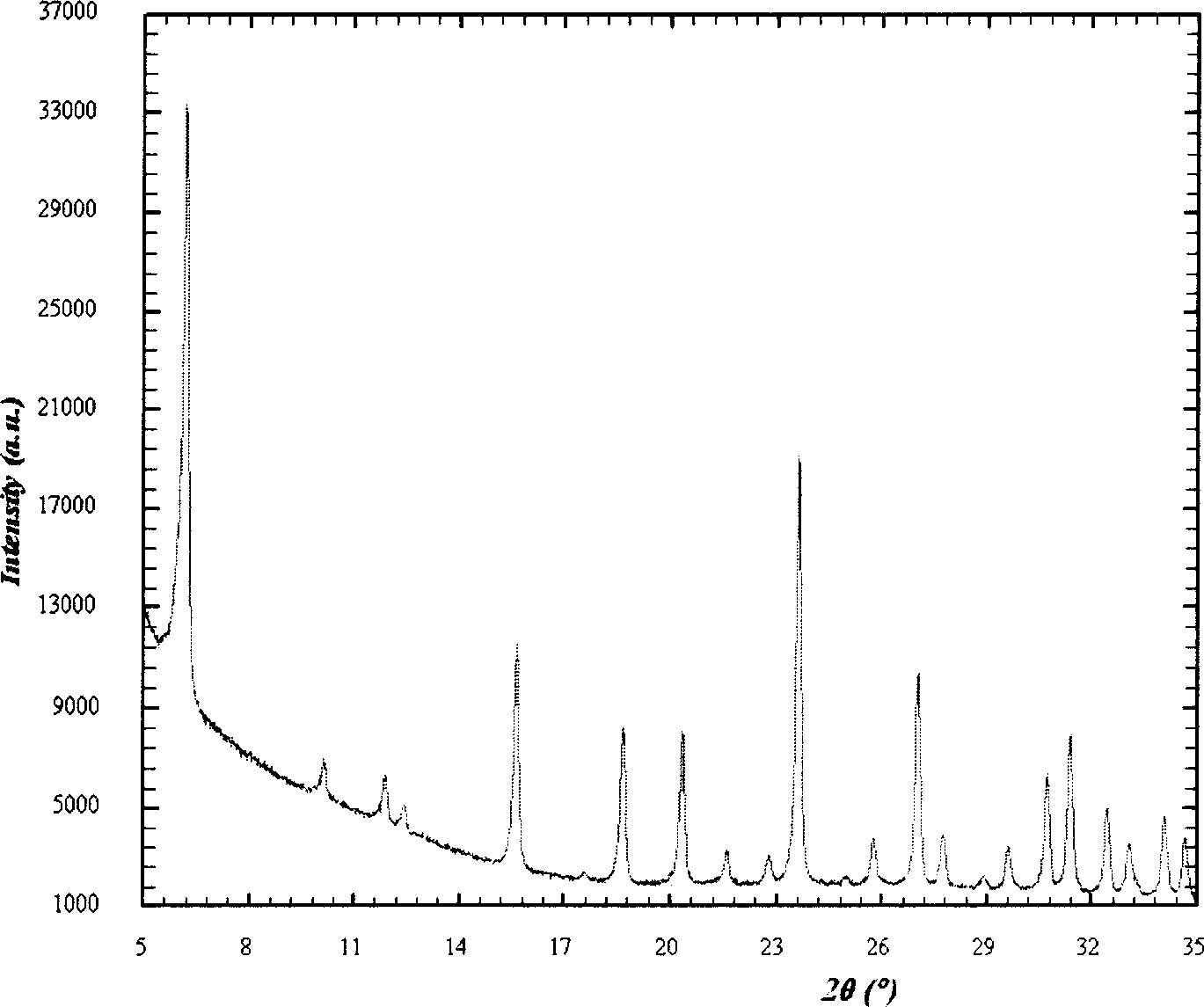

A partially hydrophobic precipitated silica having a methanol wettability of 10 to 49%, in particular with a DBP uptake on a dry basis of greater than 250 g / 100 g and a mean particle size of 1 to 12 mum and / or a carbon content of 0.3 to 1.85% and / or a loss on drying of 2.6 to 10.0% and / or a pH value of 5.5 to 10.0, is prepared by mixing the amount of water-repellent agent with the precipitated silica suspension at very short residence time and low pH value, filtering off the solid substance, washing free of salt, drying, post-treating thermally and milling. The partially hydrophobic precipitated silica can be used in active substance formulations and active substance formulations of hydrolysis-sensitive substance and in defoaming agents.

Owner:EVONIK DEGUSSA GMBH

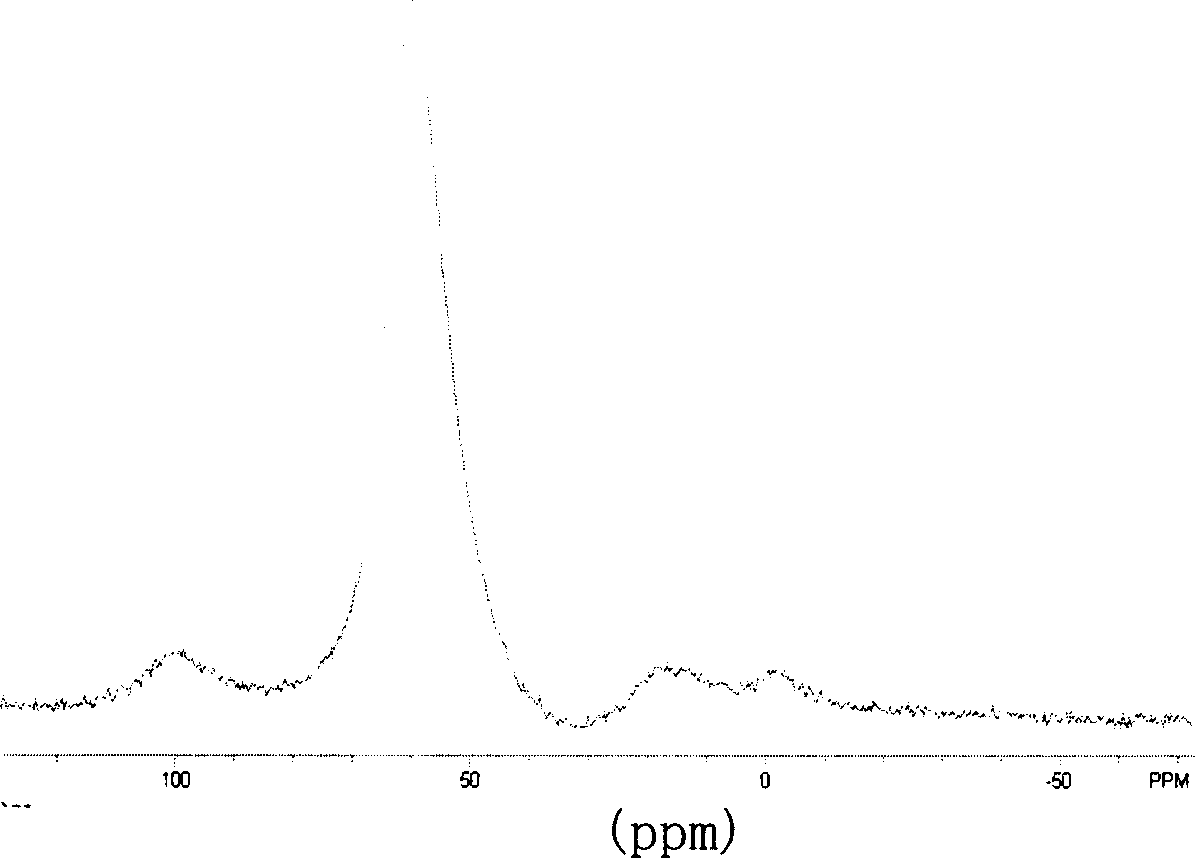

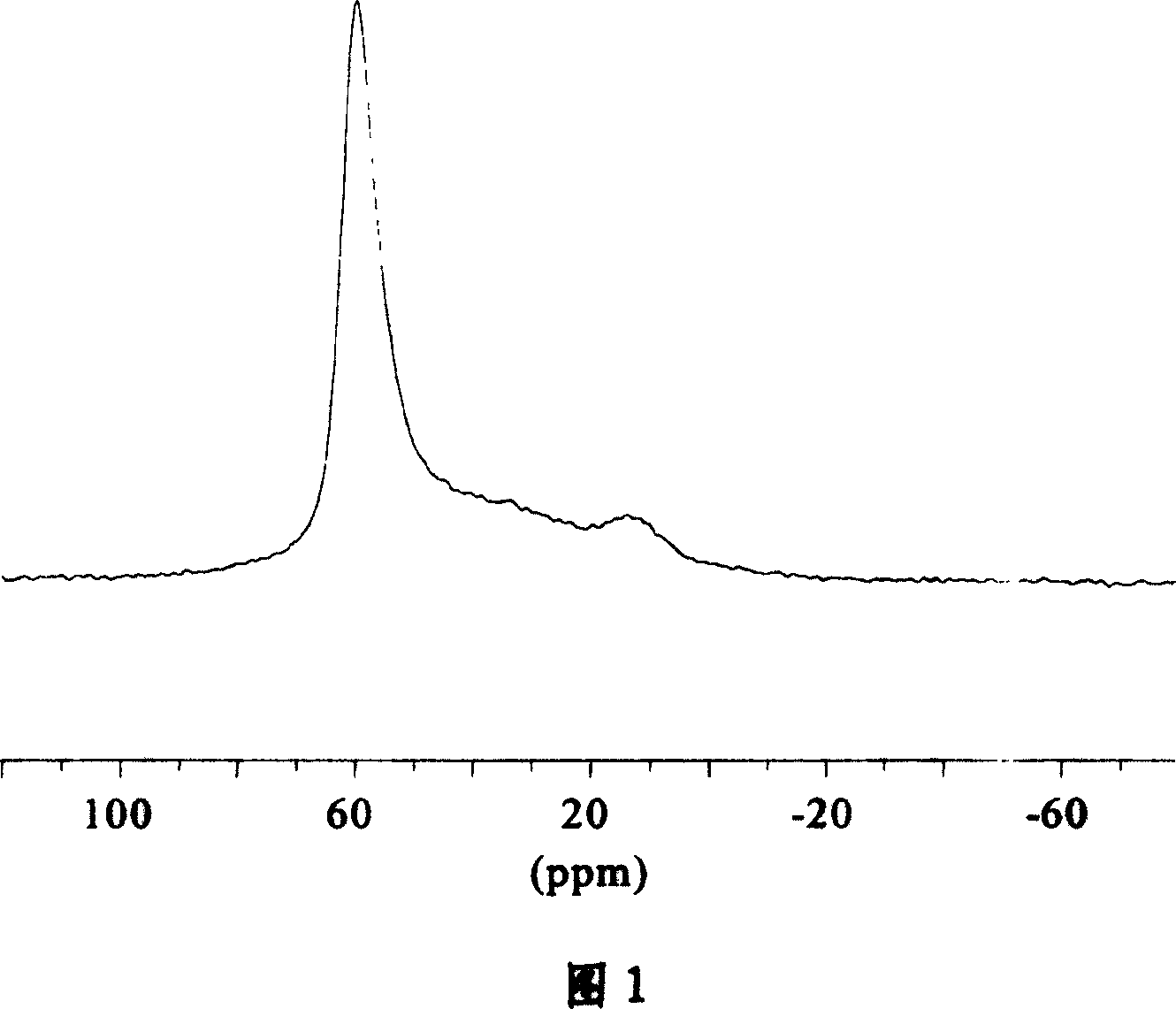

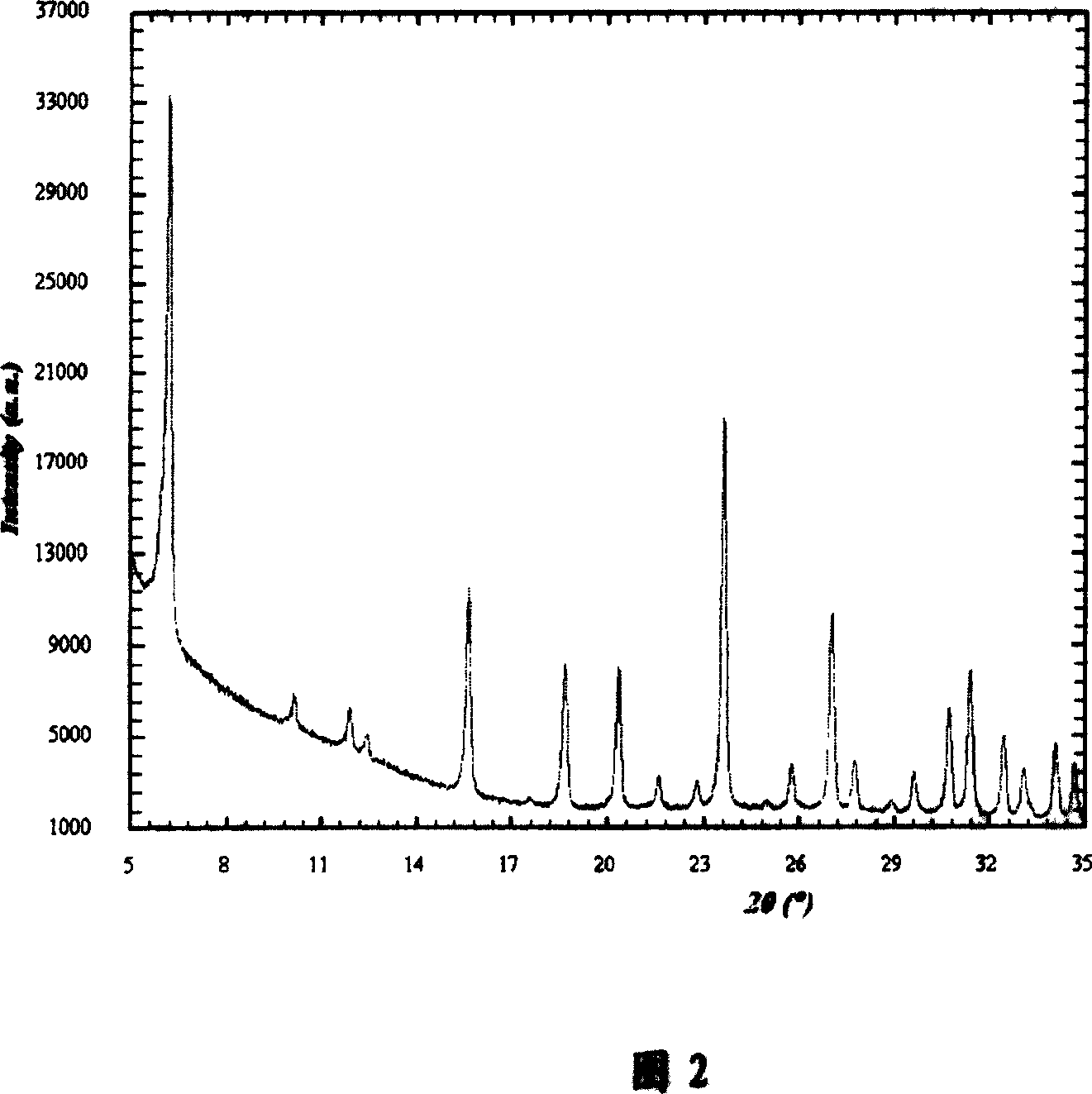

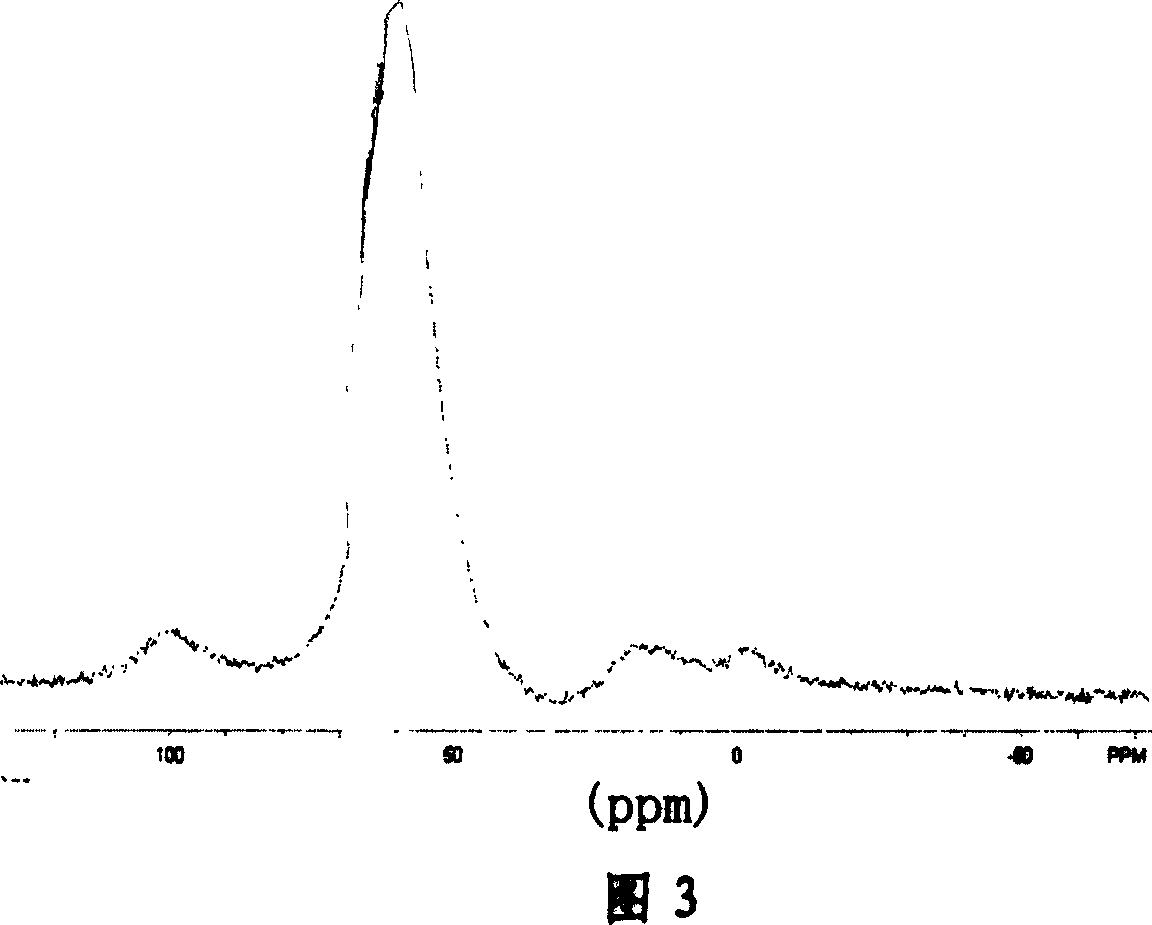

Rare earth Y molecular screen and process for preparing the same

This invention discloses a rare earth Y molecular sieve and preparation; wherein, the rare earth content is 12~22 w.t% considering the quantity of rare earth oxide in molecular sieve, all rare earth ion is in molecular sieve small cage; there is no peak at 0ppm in 27Al M AS NMR spectrogram. The step to obtain molecular sieve comprises: exchanging NaY molecular sieve liquid with ammonium salt or not, taking ion exchange with rare earth chloride by weight ratio of NaY dry basis:RECl3=1:0.17~0.35 at temperature 5~100Deg; pH=2.5~7.5, water: NaY=3~50; adjusting pH value to 8~11 with alkaline solution; mixing, filtering, cleaning, drying; baking for more than 0.1h with 0~100% vapor at temperature 200~950Deg; then, dealing with the molecular sieve according to weight ratio molecular sieve dry basis: ammonium salt :water=1:0~1:2~50 at temperature 60~100Deg; finally, cleaning, filtering, drying and obtaining the product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Rare earth Y molecular screen and process for preparing the same

Owner:CHINA PETROLEUM & CHEM CORP +1

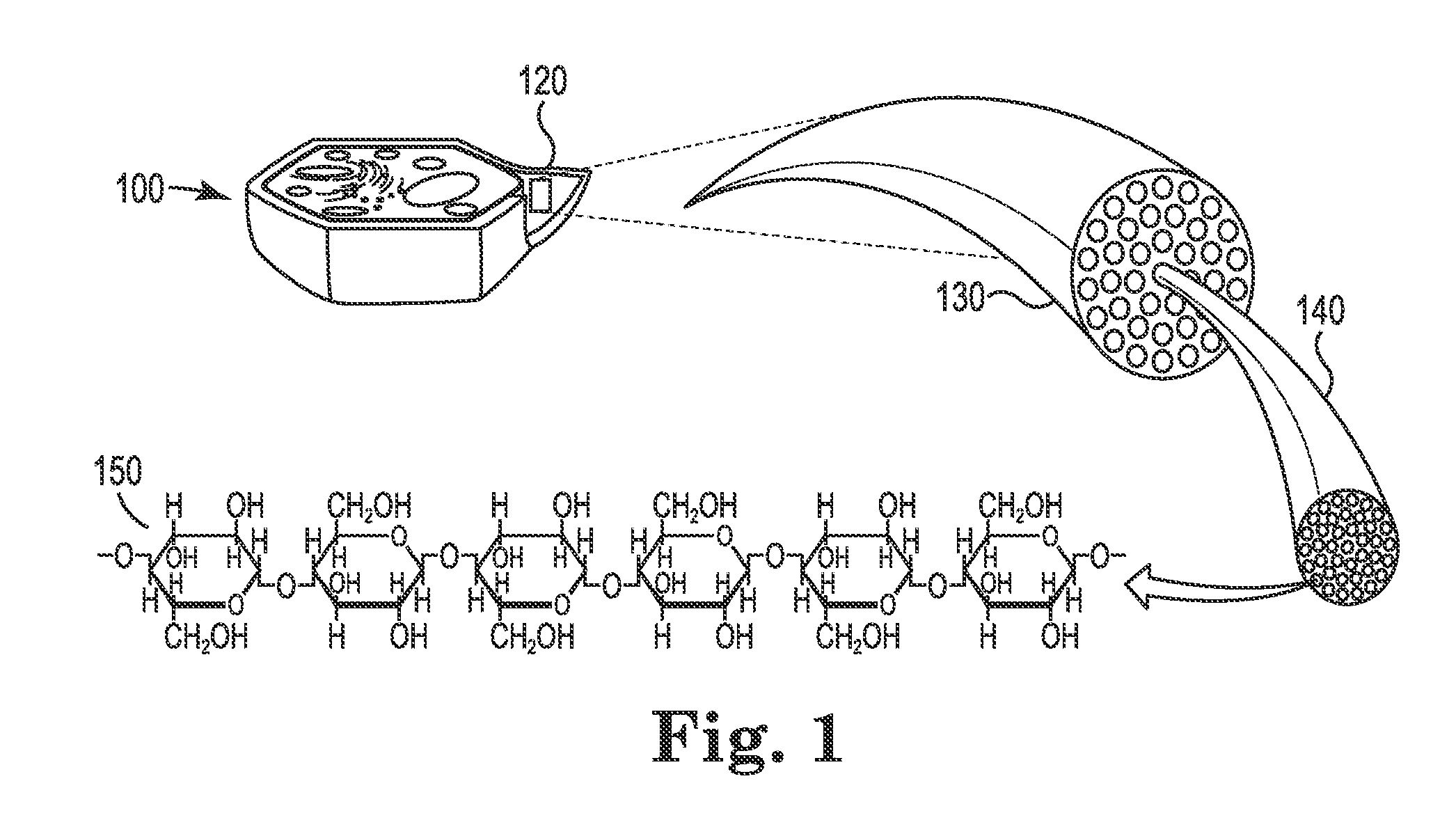

Antibacterial heal-promoting gel material used for preparing medical wound dressing and preparation method thereof

ActiveCN101791425AGood biocompatibilityEffective absorptionAbsorbent padsBandagesCross-linkOrganic acid

The invention relates to an antibacterial heal-promoting gel material used for preparing medical wound dressing and a preparation method thereof. The antibacterial heal-promoting gel material used for preparing the medical wound dressing is characterized in that the antibacterial heal-promoting gel material comprises natural gel agents, chitosan, bioactive materials, soluble silver salt and organic acids, water is added into the ingredients, the water content accounts for 5 to 20 times of the weight sum of the natural gel agents and the chitosan, and then, the antibacterial heal-promoting gelmaterial of any forms can be obtained through cross-linked curing and aftertreatment. The antibacterial heal-promoting gel material is metered according to dry basis, and is prepared form the following ingredients in percentage by weight:57 to 90.9 percent of natural gel agents, 5 to 25 percent of bioactive materials, 2 to 8 percent of chitosan, 0.1 to 2 of soluble silver salt and 2 to 8 percent of organic acids. The antibacterial heal-promoting gel material has good biocompatibility, good antibiotic property, strong tissue regeneration promoting capacity and various forms, and can be easily and conveniently prepared into the medical wound dressing.

Owner:HENAN SUPER ASIA MEDICAL EQUIP

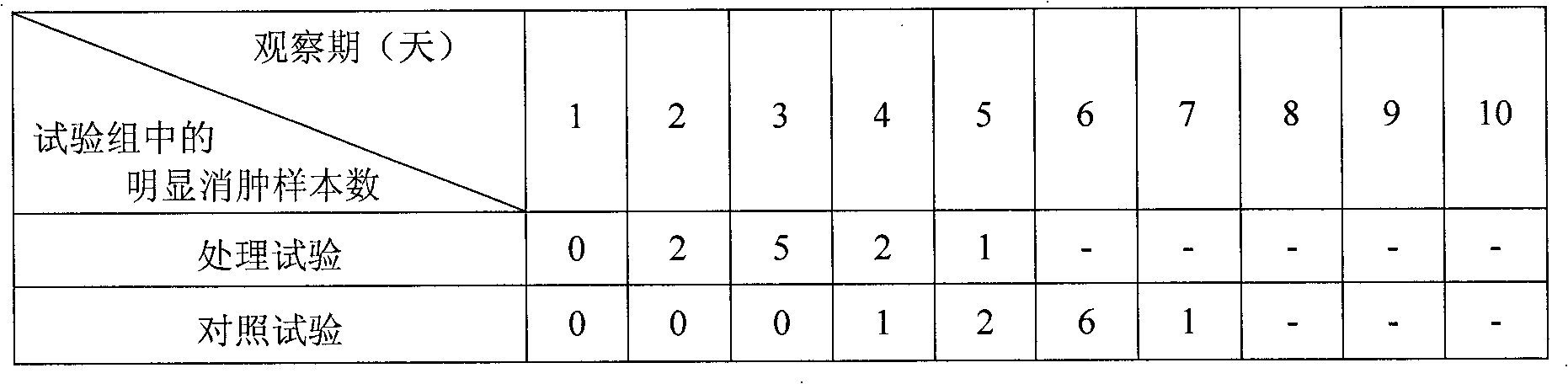

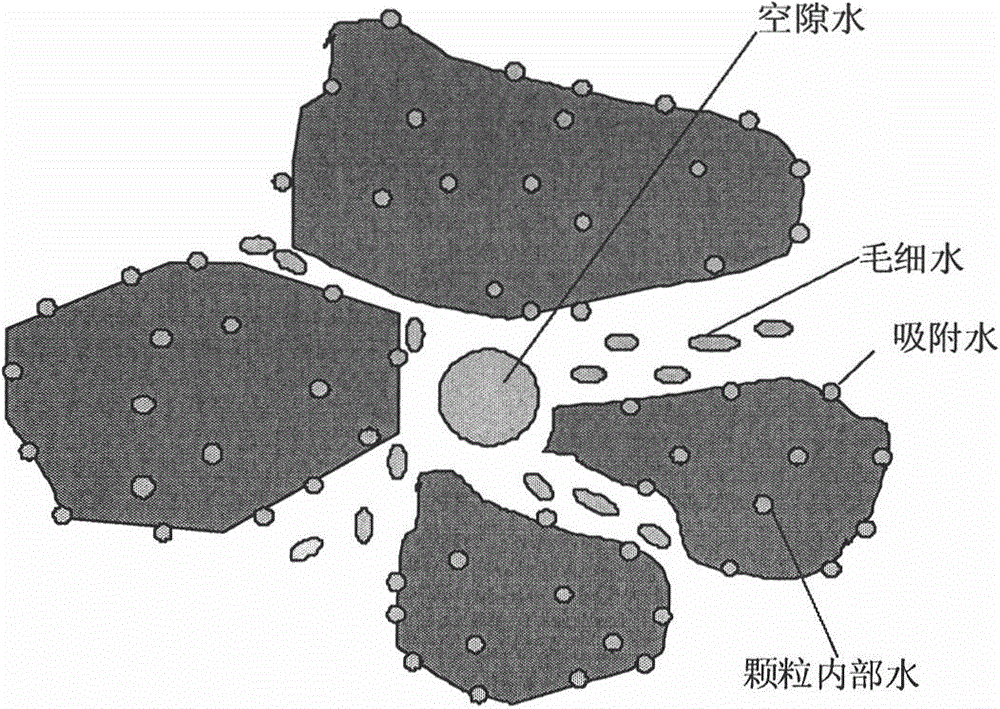

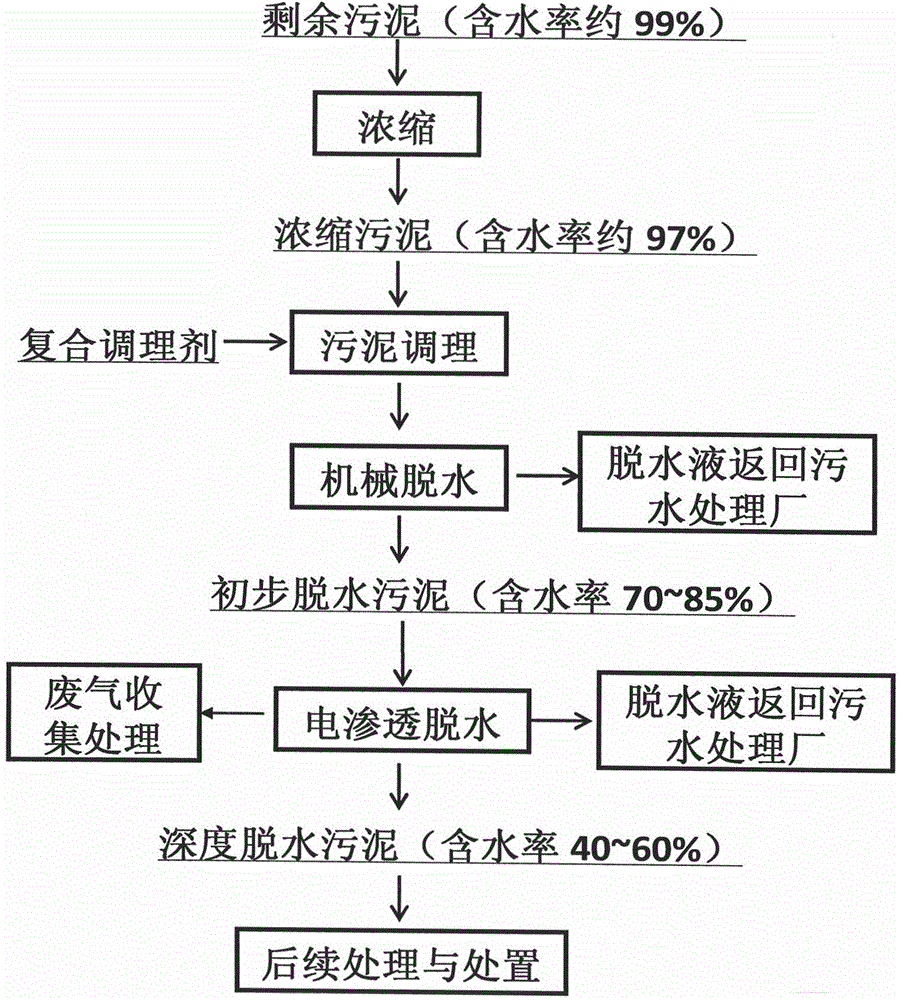

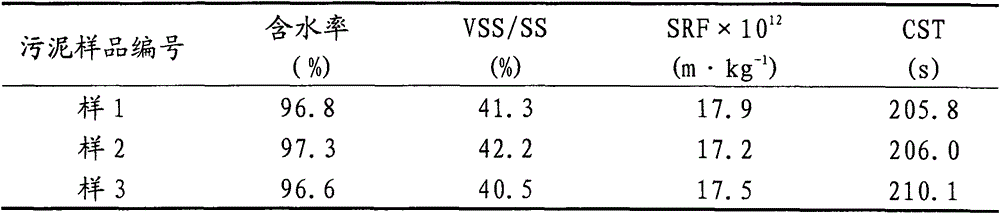

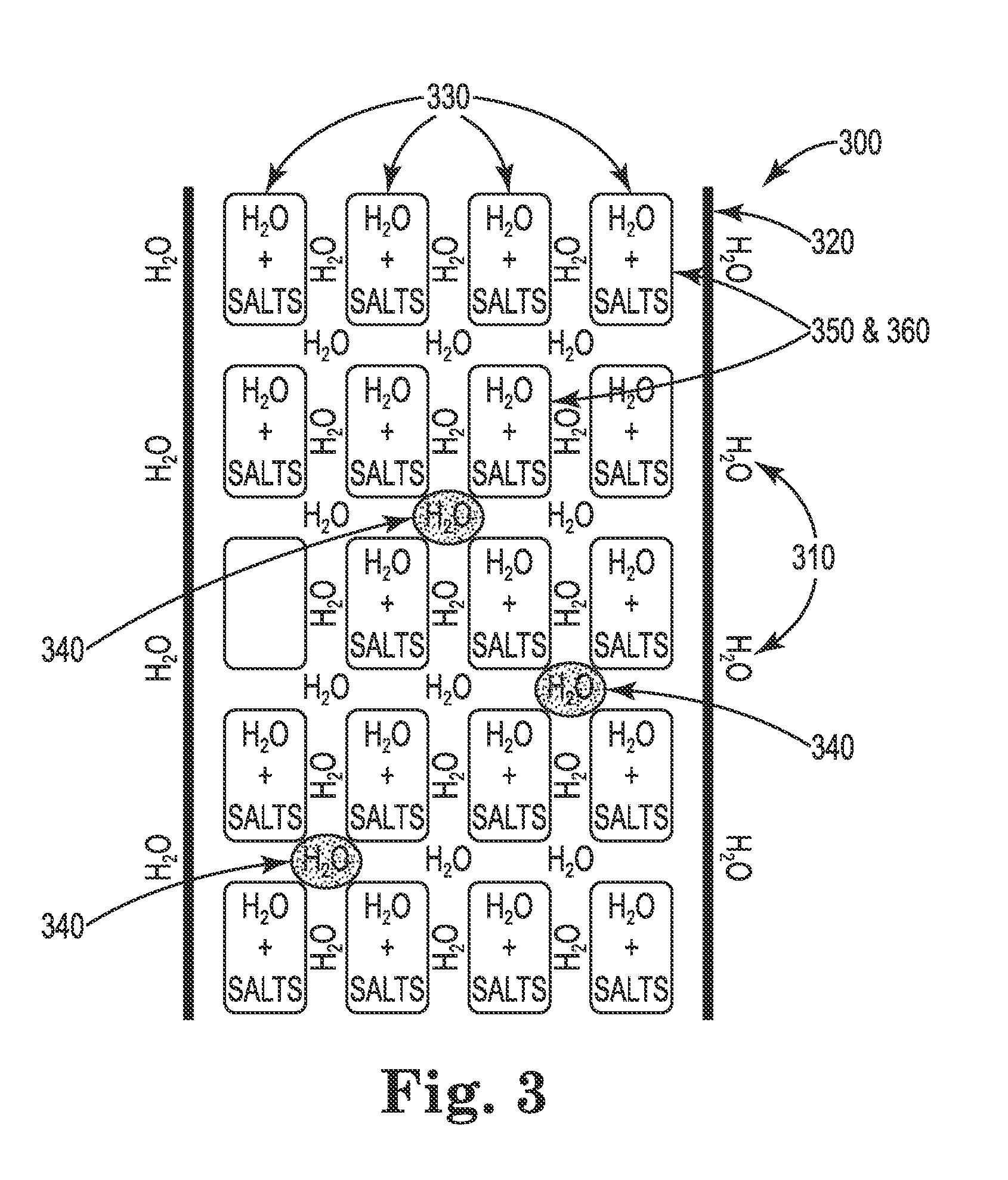

Municipal sludge two-stage deep dehydration method combining chemical regulation strengthening preliminary mechanical dehydration and electroosmosis

ActiveCN104098250AImprove the efficiency of primary mechanical dehydrationImprove dehydration efficiencySludge treatment by de-watering/drying/thickeningSludge cakeBound water

The invention relates to a municipal sludge deep dehydration composite conditioner and a dehydration method, the composite conditioner accounting for 3-30% by dry basis weight of sludge is added for conditioning modification of domestic sewage treatment plant concentrated sludge with the moisture content of about 97% to improve sludge preliminary mechanical dehydration and subsequent electroosmosis dehydration ability; the moisture content of the preliminarily dehydrated conditioned modified sludge is reduced to 70-85%; the preliminarily dehydrated sludge directly enters into electroosmosis dehydration equipment for deep dehydration, the moisture content of the sludge is reduced to 40 to 60%, landfill disposal, thermal conversion, use as building materials and other treatment, dispose and resource utilization can be directly carried out. The method can realize the continuous operation of sludge dehydration, is high in treatment efficiency, can effectively reduce the bound water content of the sludge, is good in dehydration effect, and low in moisture content of deeply dehydrated sludge cake, and is suitable for a newly-constructed sewage treatment plant and design requirements of reconstruction, expansion and contingency plans of sludge dehydration treatment of a sewage treatment plant in the prior art.

Owner:北京亿维德曼科技发展有限公司 +2

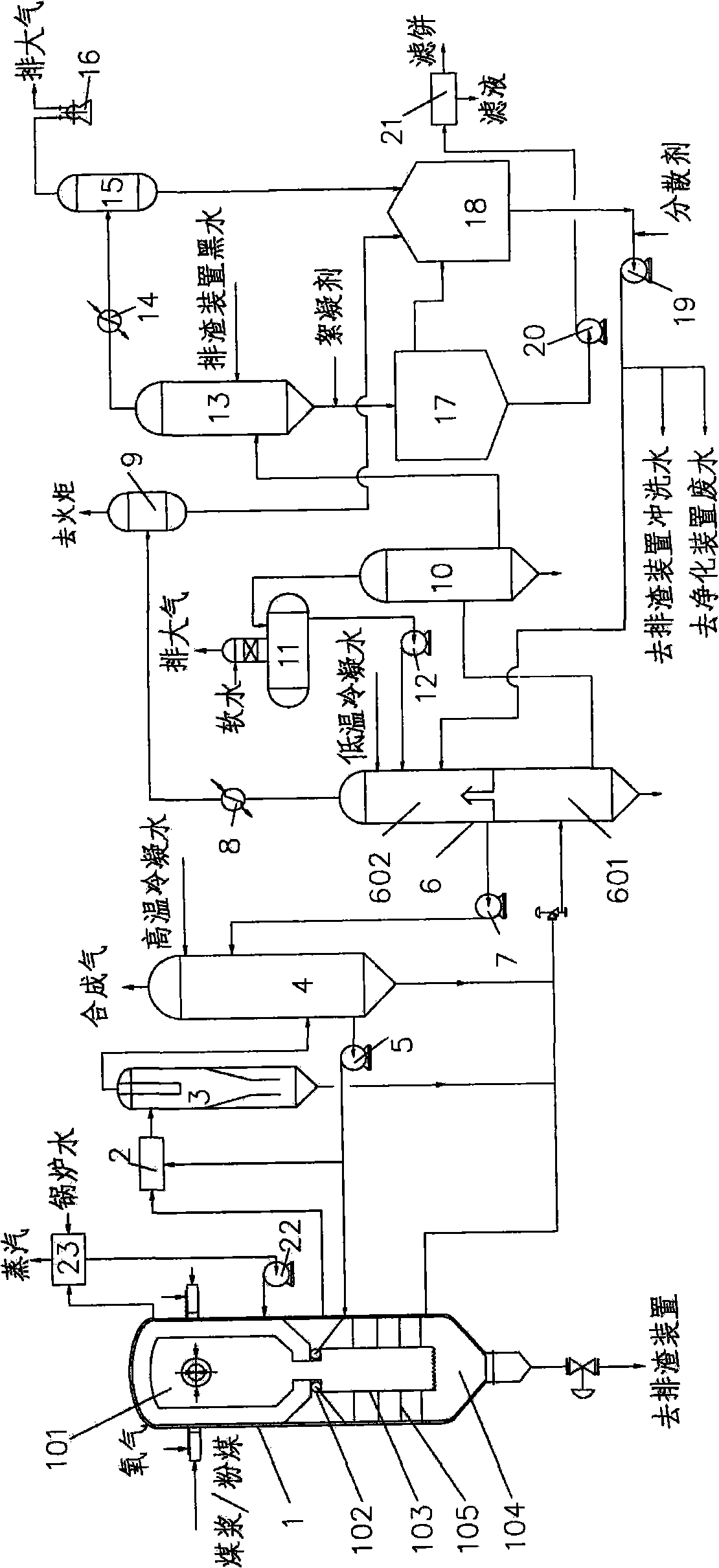

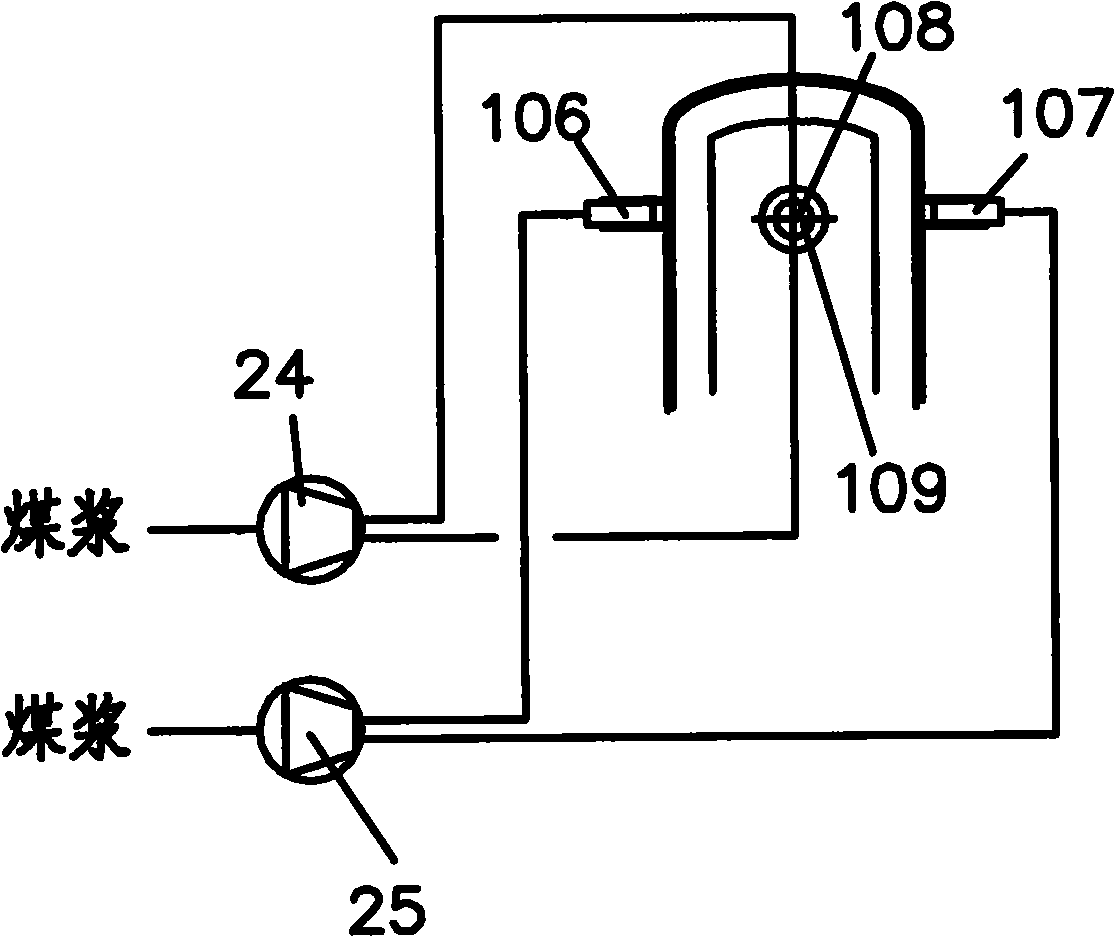

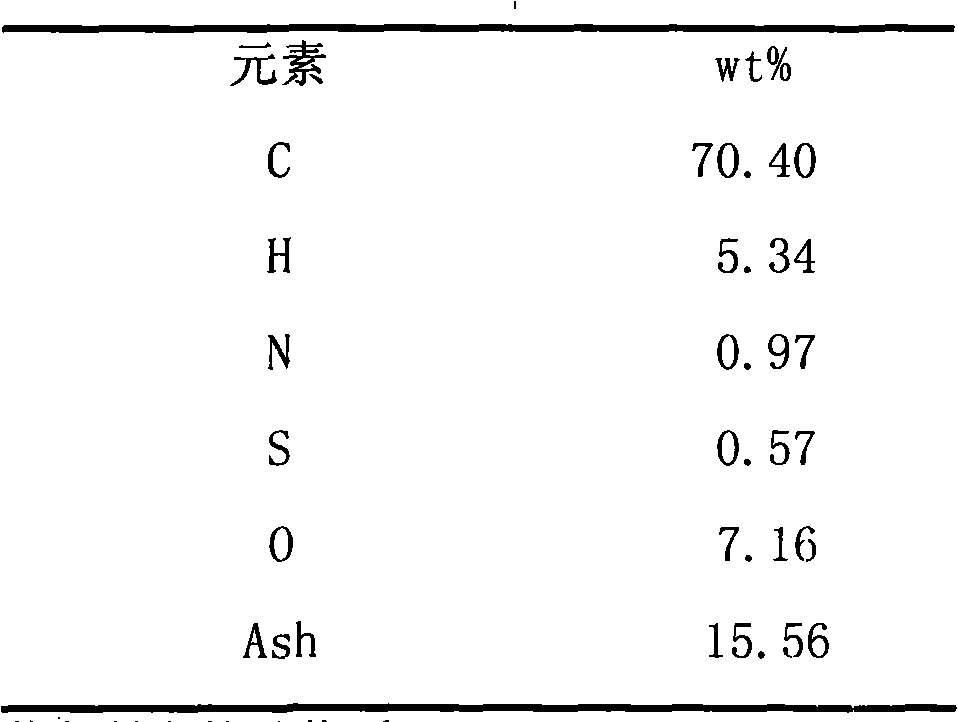

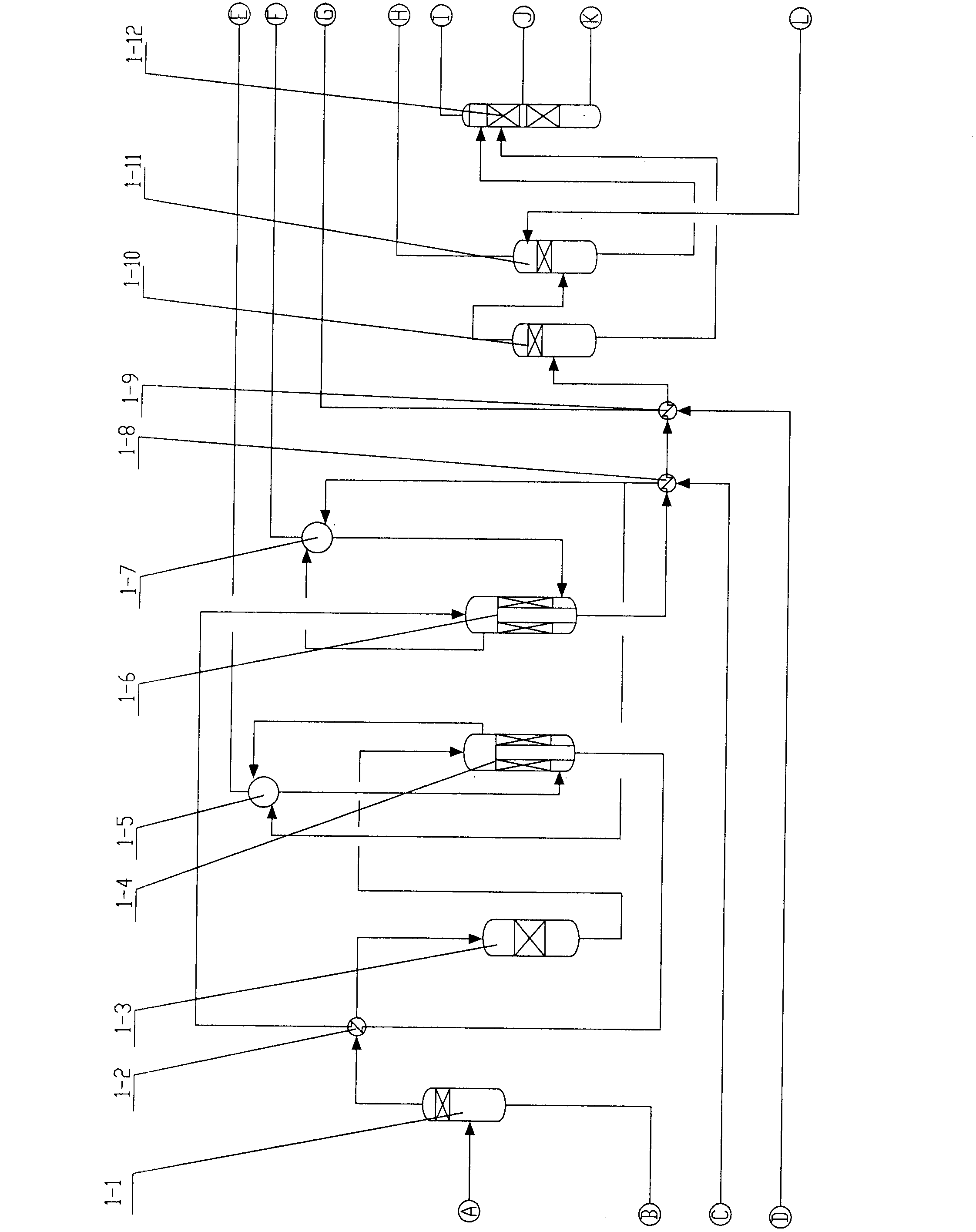

Gasification method of shock chilling type pulp or powder carbonaceous material

ActiveCN101298569AImprove water qualityReduce or eliminate emissionsChemical industryCombined combustion mitigationWater vaporWater quality

The invention discloses a gasification method of chilling slurry or powdery carbonic material. The method mainly consists of four technologies which are gasification in opposed multi-burner type, primary purification of synthetic gas, heat recovery and the treatment and recycling of black water, wherein, a gasification furnace is the core device of the method in the gasification process, which is provided with at least two pairs of opposed burners in uniform distribution and realizes the full gasification of the material under the operation pressure of 3-8 MPaG and the operation temperature of below 1200 DEG C-1700 DEG C. The invention has the following advantages: the carbon conversion rate in the gasification furnace is up to more than 90 percent, the effective gas content during slurry feeding is more than 84 percent and the effective content during powdery feeding is more than 90 percent; the ash content of the synthetic gas after primary purification is low, which can be lowered to below 1 mg / Nm<3>, thus having better water-gas ratio, i.e. the volume ratio of steam / synthetic gas (dry basis) is 1.3-1.5 / 1; the heat of the black water is totally recovered, the quality of ash water after purification is good and no fouling and clogging phenomena occur; the energy consumption, the oxygen consumption and the water consumption of the whole gasification process are relatively low, thus being capable of realizing long period stable operation with high efficiency.

Owner:EAST CHINA UNIV OF SCI & TECH

Production method for seaweed bio-composite organic liquid fertilizer

ActiveCN102731176AReduce manufacturing costAvoid high temperatureOrganic fertilisersWater useCompound organic

The present invention relates to a production method for a seaweed bio-composite organic liquid fertilizer. The method comprises the following steps: carrying out crushing grinding on fresh kelps; adding the crushed kelp slurry to a fermentation tank, and adding water; adjusting the pH value to 6.8-8.8, adding a composite enzyme and a microbial fermentation bacteria agent, uniformly stirring, and heating to a temperature of 25-60 DEG C, wherein the thermal insulation fermentation time is at least 85 hours; and filtering, and adding an acid production bacterial agent to obtain the seaweed bio-composite organic liquid fertilizer. According to the present invention, the water used in the method adopting the fresh kelps as the raw material to produce the product is saved by 90% compared with the method adopting the dried kelp raw material to produce the product; the energy is saved by 40% by adopting solar heating and thermal insulation fermentation production, the production cost can be reduced by 25%, and characteristics of energy saving, water saving, low carbon and environmental protection are provided; the seaweed bio-composite organic liquid fertilizer of the present invention has effects of combination of organic fertilizer, inorganic fertilizer, microbial fertilizer, and medium and trace element fertilizer, rapid acting, long lasting time, synergy, fertilizer retention, water retention, cold resistance, insect repelling, disease resistance, soil improving, and the like.

Owner:WEIHAI SHIDAI MARINE BIOTECH

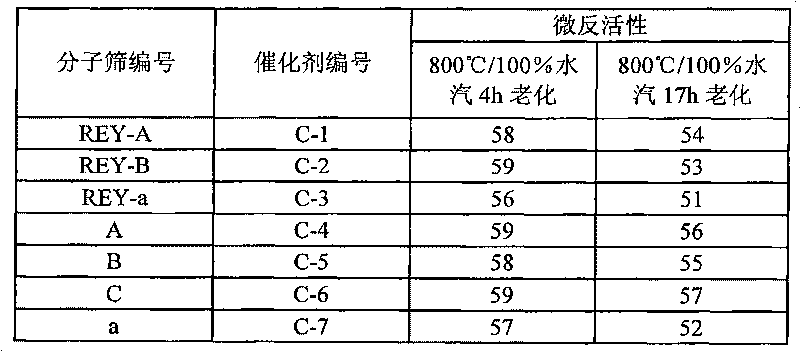

Compound type cracking catalyst and preparation method thereof

InactiveCN102133542AGood hydrothermal stabilityImprove pollutionCatalytic crackingMolecular sieve catalystsIn situ crystallizationMolecular sieve

The invention discloses a compound type cracking catalyst which contains the following materials according to dry basis mass: 20-70% of in-situ crystallization Y-shaped molecular sieve / matrix composite material, 0.3-12% of MFI structural molecular sieve, and 30-75% of clay and inorganic oxide bonding agent. The in-situ crystallization Y-shaped molecular sieve / matrix composite material is the matrix formed after the in-situ crystallization is conducted on kaolin, and is one or a mixture of REY, REHY, HY, REUSY and USY formed by modification of Nay combined by surface in-situ crystallization. The catalyst has excellent capability of resisting heavy metal pollution and heavy oil cracking, and good coking selection.

Owner:EAST CHINA UNIV OF SCI & TECH +1

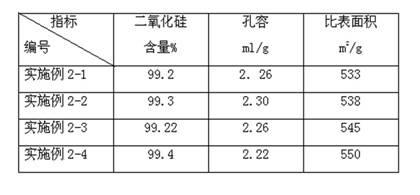

Silicon dioxide aerogel and preparation method thereof

The invention discloses silicon dioxide aerogel and a preparation method thereof. The silicon dioxide aerogel of a three-dimensional network structure is prepared by the step of subjecting alkaline silicate and inorganic acid to neutralization reaction, washing, rapidly dehydrating for drying, and crushing; the aerogel is internally filled with pores of about 20nm and has the silica content (dry basis) of more than 99.0%, the BET (Brunauer, Emmett and Teller) specific surface area of 300-800m<2> / g, the pore space volume of 1.6-3.0, the average granularity of 3-20 mum and the pore volume of 1.7-3.6ml / g. In the invention, the alkaline silicate is used as a silicon source and is subjected to neutralization reaction with the inorganic acid, the raw materials are readily available, cheap and innoxious, and the process flow is short and is easy for industrialization.

Owner:广州凌玮科技股份有限公司

Cracking auxiliary agent for raising density of propylene

This invention describes a pyrolysis assistant for increasing the propylene concentration, which, measured on dry basis, comprises 10-65 wt.% of modified ZSM-5 molecular sieve, 0-60 wt.% of clay, 15-60 wt.% of inorganic oxide binder, 0.5-15 wt.% of one or several metal additives selected from VIIIB group metals and 2-25 wt.% of phosphorus additive, wherein the said ZSM-5 molecular sieve is modified with phosphorus and a metal selected from ferrum, cobalt or nickel, whose anhydrous chemical formulation is (0-0.3)Na2Oíñ(0.5-5)Al2O3íñ(1.3-10)P2O5íñ(0.7-15)MxOyíñ(70-97)SiO2, wherein x represents the molecular number of M and y represents the number needed for the oxidation state of M. The said metal additive and phosphorus additive are both measured by their oxides. The process of this invention can increase the yield of the catalytic pyrolytic liquefied gas, the octane number of the catalytic pyrolytic gasoline, as well as the propylene concentration in the liquefied gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Microwave Produced Biochar from Beneficiated Organic-Carbon-Containing Feedstock

InactiveUS20150361369A1Reduces adverse corrosive wearReduces maintenance cleaningBiofuelsSolid fuelsMicrowaveRenewable biomass

A processed biochar composition made with an oxygen-starved microwave sub-system from a processed organic-carbon-containing feedstock made with a beneficiation sub-system is described. Renewable biomass feedstock passed through a beneficiation sub-system to reduce water content to below at least 20 wt % and water-soluble salt reduction of at least 60% from that of unprocessed organic-carbon-containing feedstock on a dry basis. The processed feedstock is introduced into a substantially microwave-transparent reaction chamber. A microwave source emits microwaves which are directed through the microwave-transparent wall of the reaction chamber to impinge on the feedstock within the reaction chamber. The microwave source may be rotated relative to the reaction chamber. The feedstock is subjected to microwaves until the desired reaction occurs to produce a solid processed biochar fuel.

Owner:BIOMASS ENERGY ENHANCEMENTS

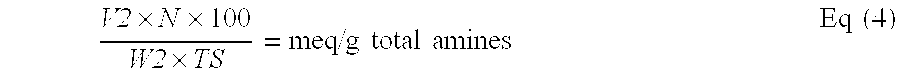

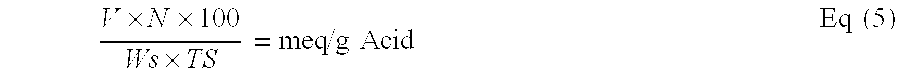

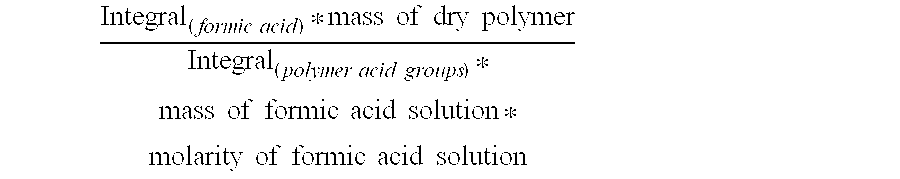

Reduced by product polyamine-epihalohydrin resins

Processes for rendering a polyamine-epihalohydrin resin storage stable, including processes that prepare a storage stable resin and / or processes that treat resins. A composition containing a polyamine-epihalohydrin resin which includes CPD-forming species can be treated with at least one agent under conditions to at least one of inhibit, reduce and remove the CPD-forming species to obtain a reduced CPD-forming resin so that a composition containing the reduced CPD-forming polyamine-epihalohydrin resin when stored for 2 weeks at 50° C., and a pH of about 2.5 to 3.5 contains less than about 250 ppm dry basis of CPD. The invention is also directed to a gelation storage stable reduced CPD-forming resin so that a composition containing the reduced CPD-forming polyamine-epihalohydrin resin, when stored at pH 1 for 24 hours at 50° C. and measured at 24 hours, produces less than about 1000 ppm dry basis of CPD. A paper product containing the storage stable polyaminopolyamide-epihalohydrin resin, when corrected for adding at about a 1 wt % addition level of the polyaminopolyamide-epihalohydrin resin, contains less than about 250 ppb of CPD. Moreover, a resin can be prepared starting from a prepolymer having a low acid number or low concentration of acid end groups. The invention is also directed to papers containing the resins.

Owner:SOLENIS TECH CAYMAN

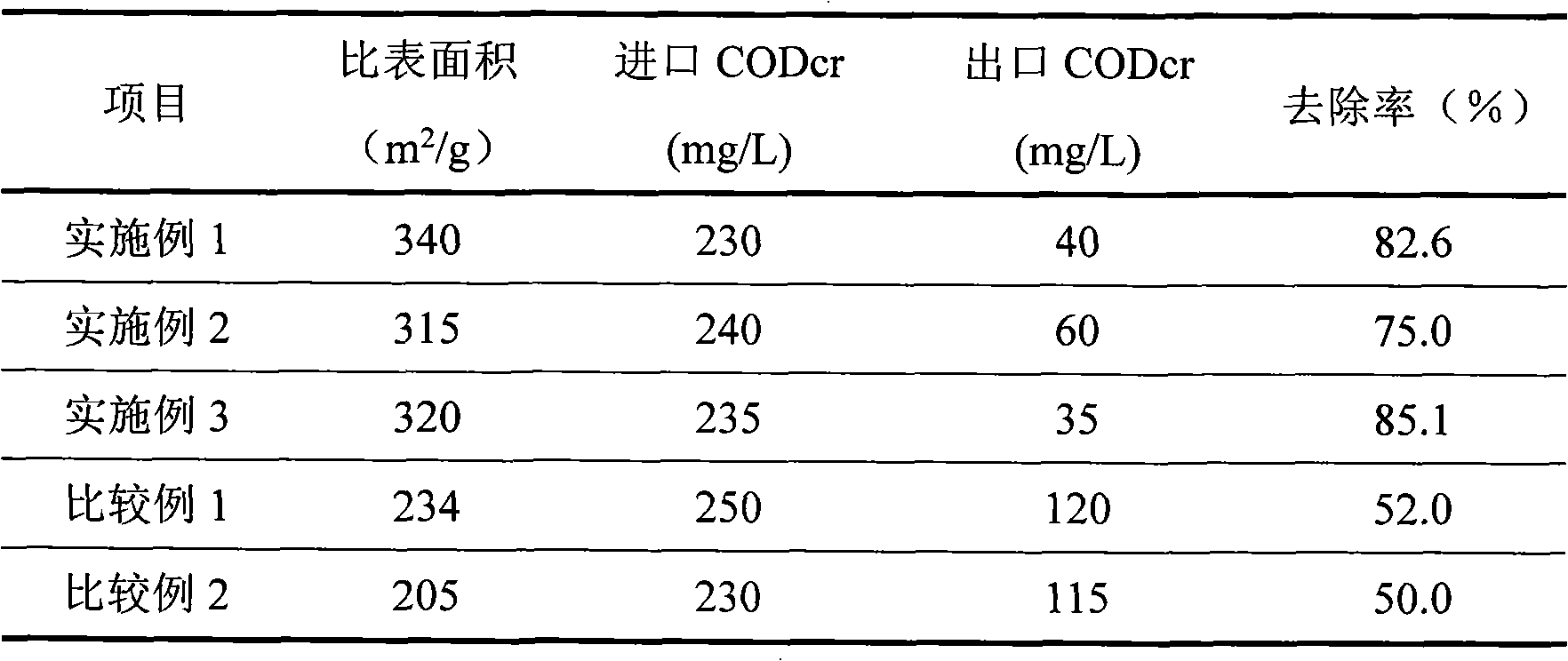

Preparation method of ozone catalytic oxidation catalyst used for treating oil refining waste water

ActiveCN101982237ASimple preparation stepsSuitable for industrial scale-upMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationParticulatesFerric hydroxide

The invention relates to a preparation method of ozone catalytic oxidation catalyst used for treating oil refining waste water. Amorphous aluminium oxide powder and ferric hydroxide powder are mixed by dry basis weight ratio of 100: 1-30, and rolling pelleting, maintaining, drying and roasting are carried out, thus obtaining the finished product catalyst. The method includes the following steps: (a) amorphous aluminium oxide and ferric hydroxide powder are mixed to be uniform; (b) the mixture is placed into a rotary pelleting machine, binder is sprayed, and rolling pelleting is carried out, the binder is sprayed in solution or colloid form in an atomizing way, and the amount of binder sprayed into the pelleting machine is 2-50% of total mass of amorphous aluminium oxide; and diameter of pelleting is controlled to be 1-8mm; (c) particle matter is maintained for 3-24 hours under the condition that temperature of water vapour is 100-110 DEG C; (d) catalyst is dried, drying temperature is 50-180 DEG C, drying time is 2-10 hours, and then roasting is carried out; and roasting temperature of catalyst is 400-600 DEG C, roasting time is 2-8 hours, and finished product catalyst is obtained.

Owner:CHINA NAT OFFSHORE OIL CORP +2

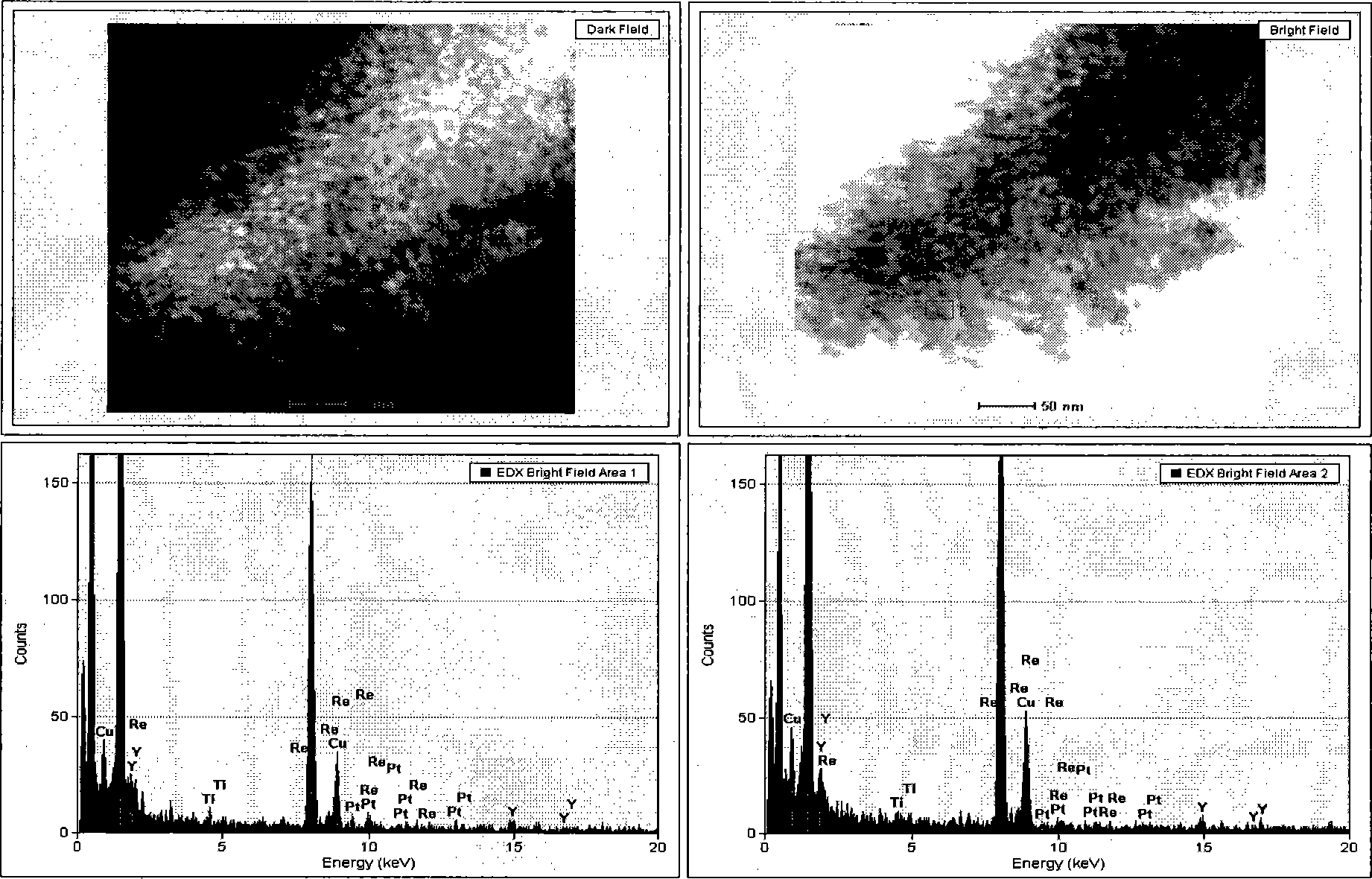

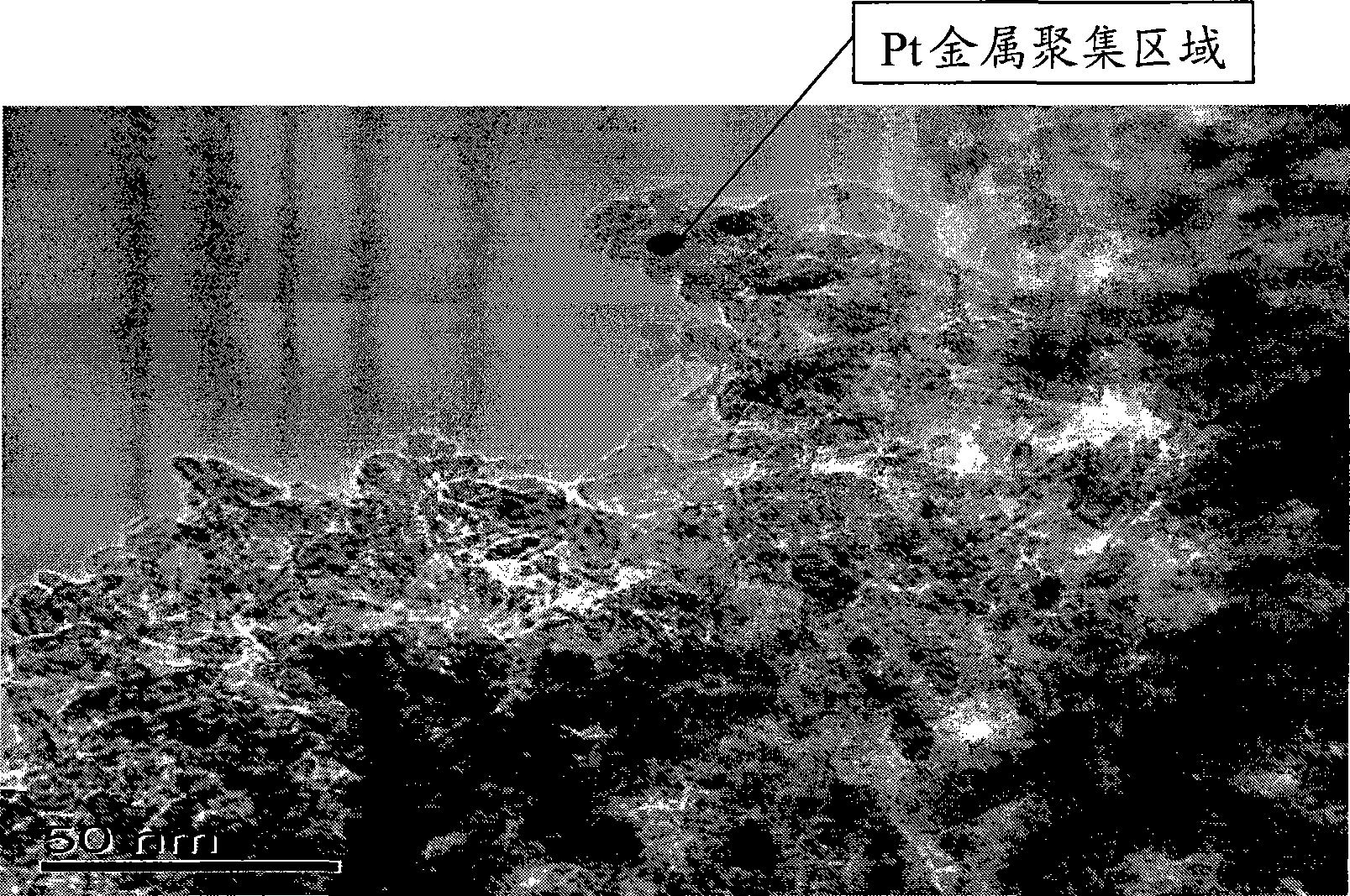

Method for preparing reforming catalyst

ActiveCN101468313AGood dispersionEvenly dispersedMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementHigh activity

The invention provides a method for preparing a reforming catalyst. The catalyst comprises the following active components calculated on the basis of the weight of a dry-basis alumina carrier: 0.01 to 2.0 percent of platinum group metals, 0.01 to 3.0 percent of VIIB group metals, 0.01 to 2.0 percent of third metal components and 0.1 to 5.0 percent of halogen. The third metal components are selected from rare earth elements or IIIA, IVA or VA group metals; the active components are introduced into the alumina carrier through fractional impregnation or co-impregnation, wherein impregnation liquid prepared from platinum group metals introduced into the carrier contains dispersant; the dispersant is selected from C1-C3 alcohol, organic acid, nitrogen-containing compounds or a mixture thereof; and the organic acid is formic acid, oxalic acid, tartaric acid, citric acid or acrylic acid. The reforming catalyst prepared by the method has the advantages of high activity stability and aromatic selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Water-coal-slurry additive and preparation method thereof

ActiveCN101550369AImprove hydrophilicityReduce viscosityLiquid carbonaceous fuelsAlkylphenolMethyl group

The invention provides a water-coal-slurry additive and a preparation method thereof. The additive is compounded by anionic surfactant naphthalene sulfonic acid formaldehyde condensation product sodium salt, lignosulphonate and non-ionic surfactant alkylphenol polyethenoxy ether (methyl) acrylic ester according to mass ratio of 8:1:1 to 1:8:1. The invention uses the naphthalene sulfonic acid formaldehyde condensation product sodium salt, lignosulphonate and alkylphenol polyethenoxy ether (methyl) acrylic ester in the preparation technology of water-coal-slurry, and the additive has wide adaptability to coal, in particular to coal with low degree of metamorphism. When ternary compound additive reaches 0.1-1wt percent of the weight (dry basis) of the coal, the water-coal-slurry with the content of coal dust being 62-70wt percent can be prepared. The slurry has good fluidity, lower apparent viscosity and favorable steady state stability. The ternary compound additive is simple in production process, excellent in performance and wide in the range of applicable coal.

Owner:ENN XINNENG BEIJING TECH

Fish protein powder and preparation method thereof

InactiveCN101595939AMeet the need for protein supplementationPromote digestionProtein composition from fishFood preparationWater solubleDigestion

The invention provides a fish protein powder which is water soluble with the color between light-yellow and pale-brown meal, wherein, the dry basis protein content of the fish protein powder is more than 80%; and a preparation method is provided for the fish protein powder. The method comprises the following steps: (1) preparing mincedfish seriflux; (2) preparing enzymatic hydrolyzate by the mincedfish seriflux; (3) preparing the fish protein powder by the enzymatic hydrolyzate. The fish protein powder prepared in the invention has the advantages of health, easy digestion, easy absorption, and the like; and can be widely used on protein-enhanced foods; the production process is simple, the production efficiency is high, and the raw materials have wide sources and can be obtained easily, thereby helping save cost.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing Y type molecular sieve containing rare earth

ActiveCN101722021AImprove patencyStrong ion exchange performanceMolecular sieve catalystsMolecular sieveActive component

The invention provides a method for preparing a Y type molecular sieve containing rare earth, which comprises the following steps of: firstly, carrying out alkali treatment and modification on the raw material Y type molecular sieve; and then carrying out ion exchange on the molecular sieve subjected to alkali treatment or further carrying out hydrothermal ultrastable treatment to obtain the rare-earth Y type molecular sieve or the rare-earth ultrastable Y type molecular sieve. The alkali treatment condition comprises the steps of pulping and uniformly mixing a Na Y type molecular sieve with an alkali solution according to the mass ratio of Na Y(dry basis): alkali:H2O=(0.1-2):(0.05-2):(4-15) and carrying out alkali treatment on the molecular sieve at 0-120 DEG C for 0.1-24 hours. A catalytic cracking reaction evaluating result displays that the rare-earth Y type molecular sieve and the rare-earth ultrastable Y type molecular sieve obtained by the modification of the method are catalysts prepared by active components and have high microreactivation when used for heavy oil cracking.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

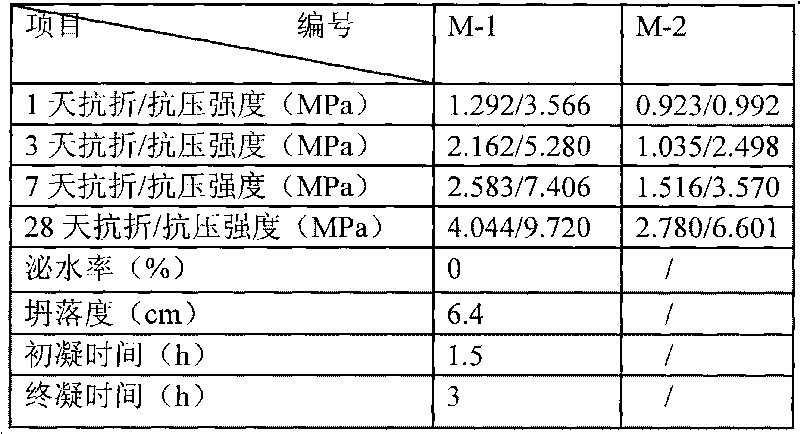

Method for producing pasty unclassified tailing filling materials containing red mud

ActiveCN101691291AHigh strengthImprove stabilitySolid waste managementCement productionFilling materialsSlag

The invention provides a method for producing pasty unclassified tailing filling materials containing red mud and belongs to the fields of environmental protection engineering and mineral engineering. The method is characterized by comprising the following steps: firstly, stoving the required materials comprising red mud, slag and desulfurized gypsum respectively; then, grinding red mud, slag, cement clinker and desulfurized gypsum with the corresponding dry-basis weight percentage being 24%-50%, 30%-56%, 1%-15%, and 1%-15% in a separate or mixed manner until the specific surface area thereof reaches 300-900m<2> / kg, to obtain a gel material; and evenly stirring by the weight ratio between the gel material and the unclassified tailings being 0.08-0.20 and the weight ratio between water and the gel material being 1.2-3.0, so as to obtain qualified pasty unclassified tailing filling materials. The invention can make good use of solid waste that is difficult to be comprehensively utilized, such as red mud, desulfurized gypsum and unclassified tailings and solve the problems of high cost and low early strength in cement-bonded filling mining.

Owner:SHANXI YUNQUAN GEOTECHNICAL ENG TECH CO LTD

Water heat-transfer shift process for by-product high-grade steam energy-saving deep conversion

ActiveCN102701149AGuaranteed service lifeEliminate "dew point corrosion"HydrogenChemical recyclingComing outThermal energy

The invention relates to a water heat-transfer shift process for by-product high-grade steam energy-saving deep conversion. According to the process, a primary water heat-transfer shift converter and a secondary shift converter are adopted, CO in feed gas reacts with H2O to generate H2 and CO2 under the catalysis of a Co-Mo (copper-zinc) catalyst, and CO in shift gas coming out of a shift system is less than or equal to 0.1% (dry basis). In the process, CO is subject to deep conversion, the feed gas (containing water gas, semi-water gas, natural gas conversion gas or coke-oven gas conversion gas) utilization rate is high, the shift catalyst is not overheated, and the catalyst has a long service life; meanwhile, by-product saturated steam with the pressure of 0.5 to 9.0 MPa is generated, sensible heat and latent heat in the shift gas are further recovered by deoxygenated water and desalted water, low-grade heat energy is converted into high-grade heat energy, cooling water consumption is reduced, the temperature of` the shift gas coming out of a process system is lower than or equal to 40 DEG C, equipment is few, the flow is short, the investment is small, and the resistance is low (less than or equal to 0.05MPa).

Owner:NANJING DUNXIAN CHEM TECH

Method for preparing solid fuel by mixing sludge and biomass

InactiveCN103060044AOvercoming prone to crackingOvercome strengthBiofuelsSolid fuelsSludgeSolid fuel

The invention discloses a method for preparing a solid fuel by mixing sludge and biomass. The method comprises the following steps: (1) pretreating: adding additive accounting for 1-5% of the dry basis quantity of the sludge to the sludge; dewatering and drying the obtained mixture until the water content is 10-25%; crushing and sieving to form dried sludge raw material; dewatering and drying the biomass until the water content is 10-25%; crushing and sieving the biomass so as to obtain dried biomass raw material; (2) mixing and forming: mixing and stirring the dried sludge raw material and the dried biomass raw material to obtain a raw material mixture, wherein the mass fraction of the dried sludge raw material is 30-70%; the mass fraction of the dried biomass raw material is 70-30%; and extruding and forming the raw material mixture so as to obtain the solid fuel. The method disclosed by the invention is low in cost, energy-saving and environment-friendly, realizes the recycle of the solid waste and the biomass and effectively solves the treatment problem of the solid waste and the biomass.

Owner:东莞市图美环保科技有限公司

Agricultural fibre fuel pellets

A method of preparing fuel pellets includes the steps of providing a feedstock in the form of agricultural hull fibres having a moisture content of about 10 to about 16%; and compressing and extruding the agricultural fibre feedstock through a die to obtain fuel pellets in the form of small cylinders having a diameter of about ⅜ inch to ¾ inch or more, said pellets having an ash content of about 1.1% to about 20% by weight and a calorific value of about 7,000 BTUs per pound of fuel on a dry basis. The agricultural hull fibres may be derived from all whole grains and seeds. For example, are comprised of at least one of corn bran fibre, rye bran fibre; oat bran fibre, rice bran fibre, soy bran fibre, canola bran fibre and wheat bran fibre. The method may include the step of pre-treating the agricultural whole grain and seed hull fibre feedstock with high temperature steam before being formed into pellets at a sufficient temperature and sufficient time to activate hemicellulose within the fibre as a binding agent. The method may include the step of mixing the agricultural whole grain and seed hull fibre feedstock with a sequestering agent before being formed into pellets for sequestering alkali metal vapors and raising the fusion point of the inorganic elements during combustion of the pellets. The sequestering agent may be calcium carbonate added in amounts up to about 0.5% by weight. The pellets contain additives comprised of ammonium nitrate, calcium, manganese, magnesium, aluminum, barium, iron, potassium and amorphous silicate, which sequester potassium and chlorides and alter the fusion point of the inorganic elements present in the fuel.

Owner:EVERGREEN BIOFUELS

Method for preparing furan chemical by catalytic pyrolysis of biomass

InactiveCN101475544AHigh selectivityHighly selective outputPhysical/chemical process catalystsOrganic chemistryLiquid productFuran

The invention relates to a method for preparing a liquid product rich in furfural and other furan chemicals by biomass. The method comprises the following steps: a catalyst is added into particles of a biomass raw material by a dry method or a wet method; the mixture is dried after the mixture is sufficiently mixed; the mixture is placed in a drying cabinet to remove free moisture for standby; the obtained material is filled into a quartz reactor, the reactor is placed in a microwave purolyzer, and oxygen in the quartz reactor and a condenser pipeline is driven off by inert gas; and microwave is started, power of the microwave is adjusted to pyrolyze the material in the quartz reactor, and the pyrolyzed steam is condensed into a pyrolysis liquid through a two stage water-cooled condenser. The method has the advantages that the yield of the pyrolysis liquid reaches over 50 percent (dry base), the furfural in a liquid product is over 60 percent of the content of organic compositions, which is far higher than the content of quickly pyrolzed furfural by the biomass (below 10 percent), and the time of a pyrolyzing reaction is obviously shortened. The method has the characteristics of simple process, single product, high furfural selectivity, and the like.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

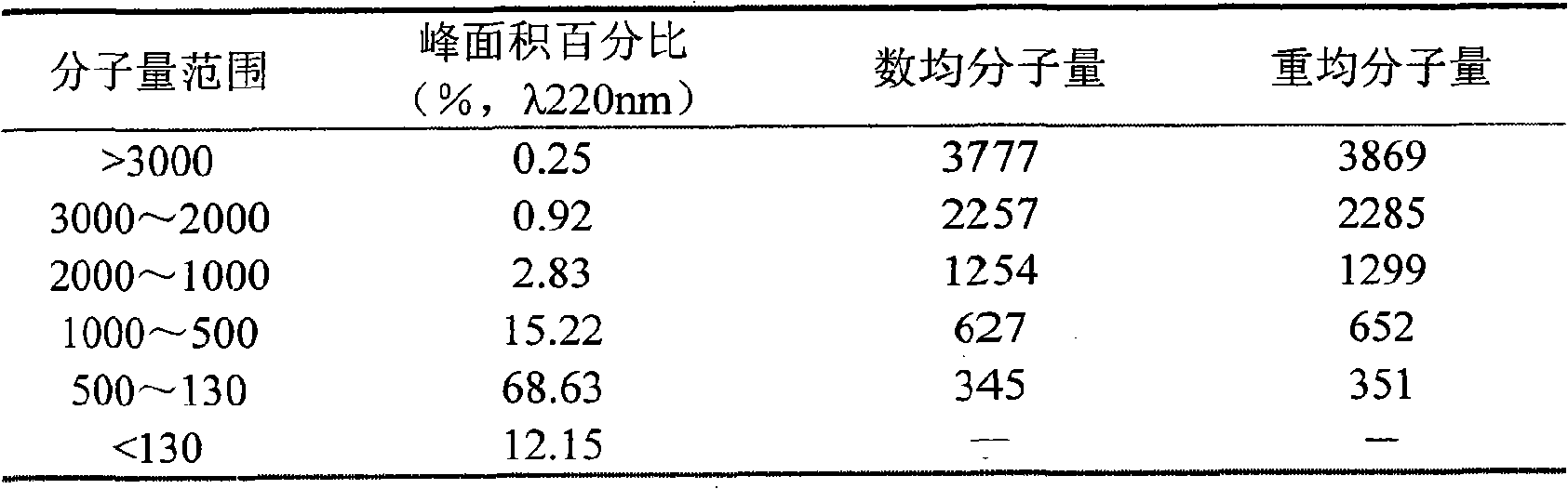

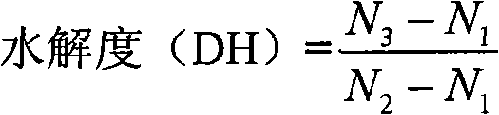

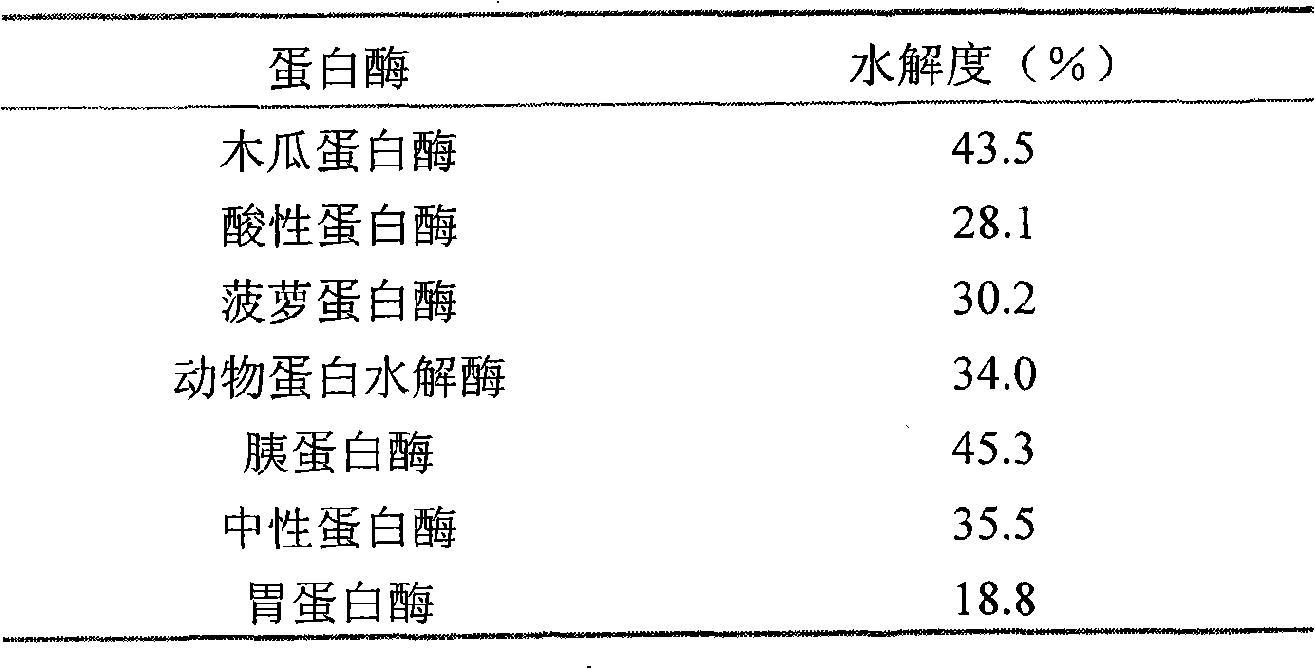

Method for preparing whey protein peptide by composite protease hydrolysis

InactiveCN101260421AIncrease profitExcellent molecular weight distribution rangeFermentationLactalbuminChemistry

The invention discloses a method for preparing lactalbumin peptides, comprising the following steps: (1) adding compound protease into lactalbumin solution to carry out enzymatic hydrolysis; (2) inactivating the compound protease; (3) depositing the enzyme solution and selecting supernatant fluid to carry out centrifugation; (4) carrying out decoloring processing on the centrifugalized supernatant fluid and then carrying out desalting processing; (5) carrying out nanofiltration on the desalted enzyme solution; (6)concentrating; (7) embedding the concentrated product into wall material; (8) spray drying, then the product is obtained. By applying compound protease in the invention, the lactalbumin is zymohydrolyzed with effectively improving enzyme hydrolysis degree, prominently improving usage factor of the lactalbumin, high product yield, good distribution range of molecular weight of the lactalbumin peptides, high peptide content and good product quality. By detecting, the content (counted by dry basis) of the lactalbumin peptides prepared by the method in the invention is up to 75.15 percent, the molecular weight distribution range of the peptide smaller than 2258 dalton can reach 98.83 percent.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Method for producing air entrapping building block by utilizing red mud

InactiveCN101648402ALight weightHigh strengthSolid waste managementCeramic shaping apparatusNatural resourceRed mud

The invention provides a method for producing an air entrapping building block by utilizing red mud, comprising the following steps: mixing the following raw materials (dry basis) by weight part: 50-70 parts of red mud, 5-10 parts of calcium oxide and 20-40 parts of active gelled material; adding water according to 85-100 percent of the dry basis mass of the mixture, adding aluminium powder according to 0.04-0.06 percent of the dry basis mass of the mixture and adding an auxiliary agent according to 0.5-0.8 percent of the dry basis mass of the mixture; mixing to prepare a sizing agent; and finally obtaining the air entrapping building block through foaming, standing and steam curing. The air entrapping building block has the advantages of stable physical properties, light weight, good heat-insulation property, high waste use ratio, simple process, low cost, environmental protection, natural resource saving and the like, and can be used as non-load bearing partitions of urban high-risebuildings and as heat-insulation building blocks of low-temperature warehouses, heat-insulation warehouses and cold storage warehouses of industrial equipment.

Owner:KUNMING UNIV OF SCI & TECH

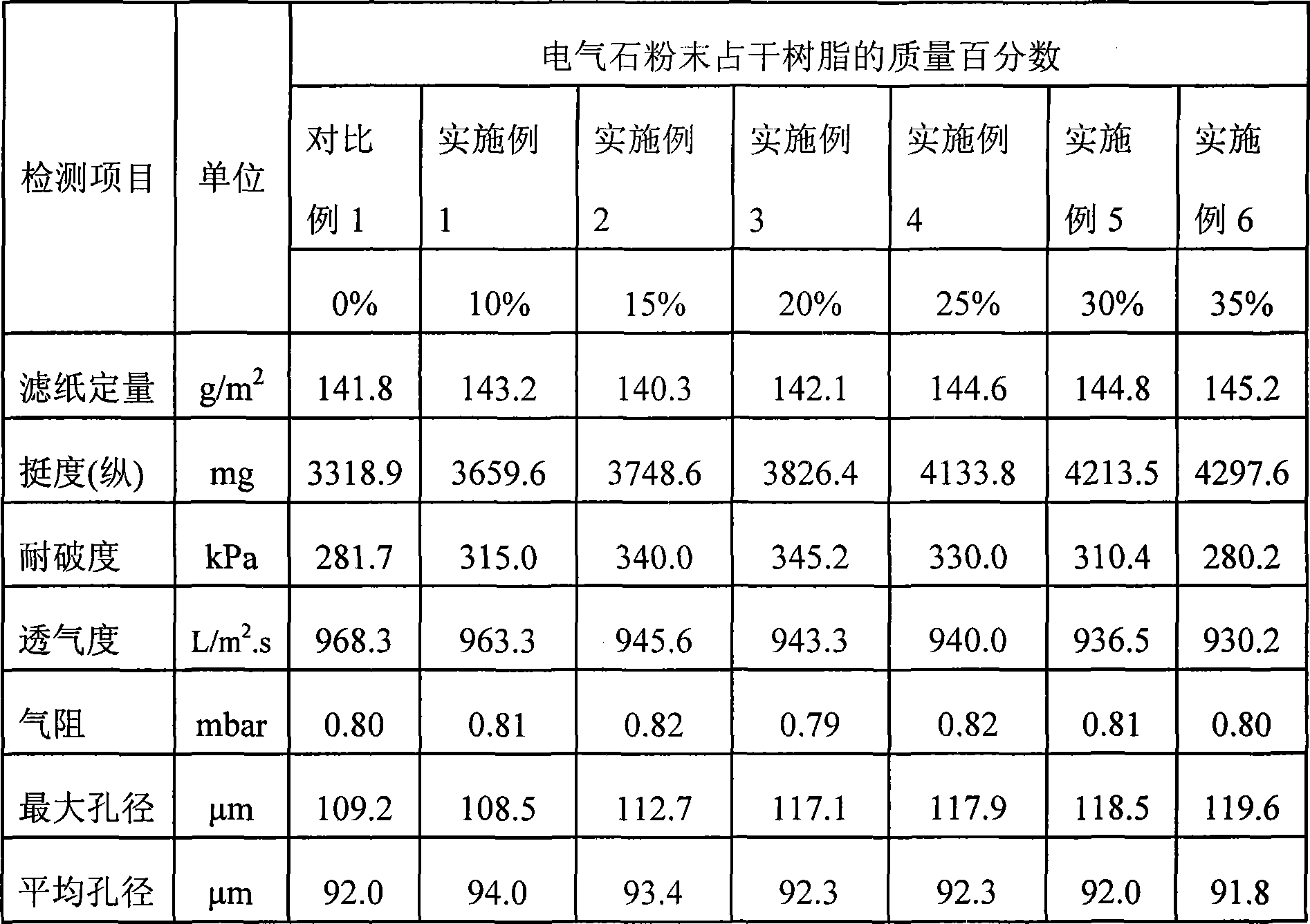

Filter paper of air filter for saving fuel and method for manufacturing same

ActiveCN101392703AReduce resistanceEasy to useWater-repelling agents additionMachines/enginesWater basedFuel conservation

The invention provides filter paper of an air filter of fuel conservation and a manufacture method thereof. The filter paper consists of base paper and a sizing agent which is coated on a single side or double sides of the base paper gram weight of between 110 and 160 gram / meter<2>, and water-base resin (butt) is 5 to 30 percent of mass of the base paper. The sizing agent comprises the following components in weight percentage: 2 to 20 percent of the water-base resin (butt), 1 to 20 percent of powder functional material, and 60 to 80 percent of water. The powder functional material is more than one of tourmaline ore powder with far infrared emitting property and releasing anion property, molten mass powder of rare-earth zirconium oxide and alumina, molten mass powder of rare-earth zirconium oxide, titanium oxide or rare-earth zirconium oxide, zinc oxide and the like. With the filter paper, fuel can be saved by 3 to 10 percent, but power of the engine is increased by 5 to 20 percent; noise of the engine is reduced by over 10 decibels, and exhaust emission pollutants are reduced by over 10 to 30 percent.

Owner:湖北国鼎华明纳米新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com