Alkali treatment modifying method of Y-shaped molecular sieve

A molecular sieve and alkali treatment technology, applied in the field of molecular sieve, achieves good industrial application prospects, improves ion exchange efficiency, and has the effects of fast diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

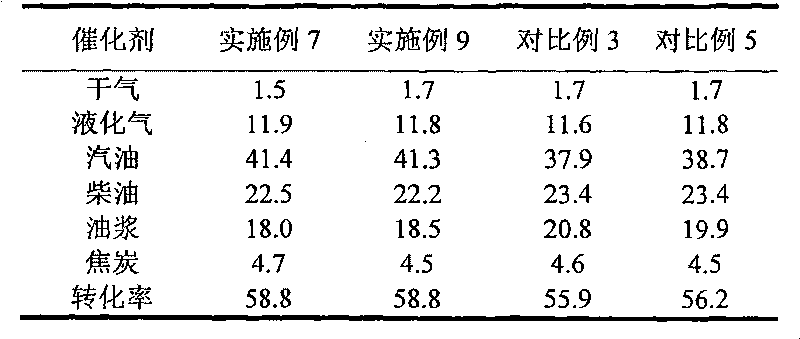

Examples

Embodiment 1

[0039] Weigh 30 grams of sodium hydroxide and dissolve in 970 grams of distilled water, stir evenly and heat up to 85°C. Get 200 grams of NaY molecular sieves (sample name Y-A; crystallinity: 95%; skeleton silicon-aluminum ratio: 6.15; bulk phase silicon-aluminum ratio: 6.24; surface silicon-aluminum ratio: 5.12; Na 2 O: 12.1% by weight; N 2 Adsorption capacity: 295.01cc / g; water adsorption capacity 295mg / g; self-synthesized according to the method described in patent CN 1785808), added to the above alkali solution, stirred at 85°C for 2 hours, filtered, washed, and dried. Obtain alkali treatment sample (measurement result is: crystallinity: 92%; Skeleton silicon-aluminum ratio: 5.43; Bulk phase silicon-aluminum ratio: 5.56; Surface silicon-aluminum ratio: 4.72; Na 2 O: 12.0% by weight; N 2 Molecular adsorption: 323.08cc / g; water adsorption: 320mg / g).

[0040] Under the same conditions, the water adsorption capacity of ordinary NaY molecular sieves with a skeleton silicon-a...

Embodiment 2

[0043] Take 30 grams of the alkali-treated product in Example 1, add it into 300 grams of distilled water together with 30 grams of ammonium chloride, stir evenly, and then stir and exchange at 90° C. for 1 hour. During the exchange process, 1mol / L hydrochloric acid solution was used to adjust the pH value of the exchange slurry to 3.0 and maintain it. After the exchange is completed, filter and wash, the Na in the obtained ammonium exchange product 2 O residual amount was 4.3% by weight.

Embodiment 3

[0048] Weigh 40 grams of sodium hydroxide and dissolve it in 960 grams of distilled water. Stir evenly and heat up to 65°C. Take 150 grams of NaY molecular sieve Y-A described in Example 1 and add it to the above prepared alkali solution, and stir at 65°C. After 3 hours, filter, wash with deionized water until the pH of the filtrate = 10, collect the obtained filter cake, and dry it for future use.

[0049] Take 30 grams of the NaY molecular sieve sample that has been treated with the above alkali and add 30 grams of ammonium chloride to 300 grams of distilled water and stir evenly, then stir and exchange at 90°C for 1 hour, filter, repeat the above exchange process twice, and filter the sample And fully washed with water, the Na in the obtained ammonium ion exchange sample 2 O residual amount was 2.0% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water adsorption | aaaaa | aaaaa |

| Water adsorption | aaaaa | aaaaa |

| Cell constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com