Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73results about How to "Easy to move out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon nano tube/graphene composite negative pole material, preparation method thereof and lithium battery

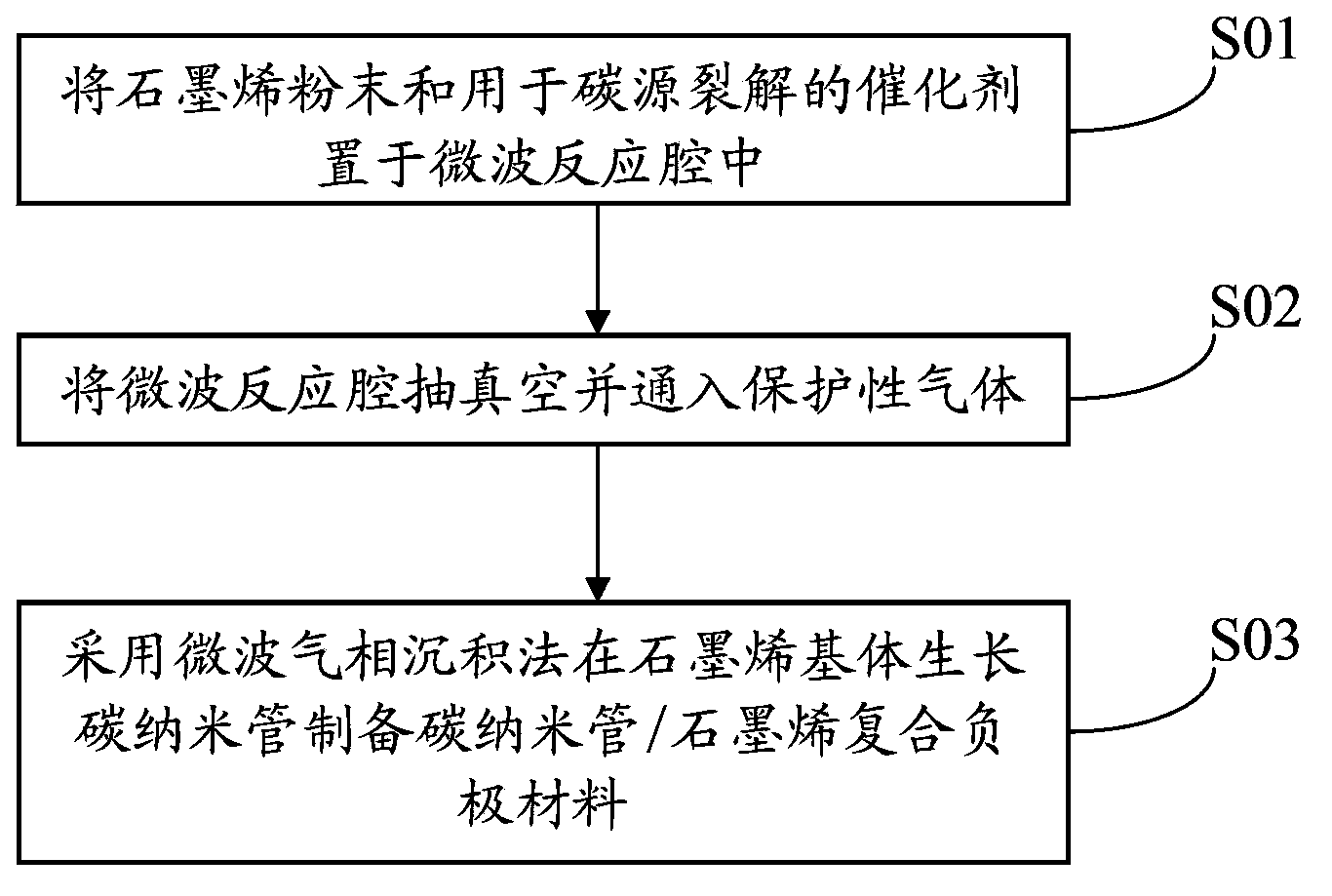

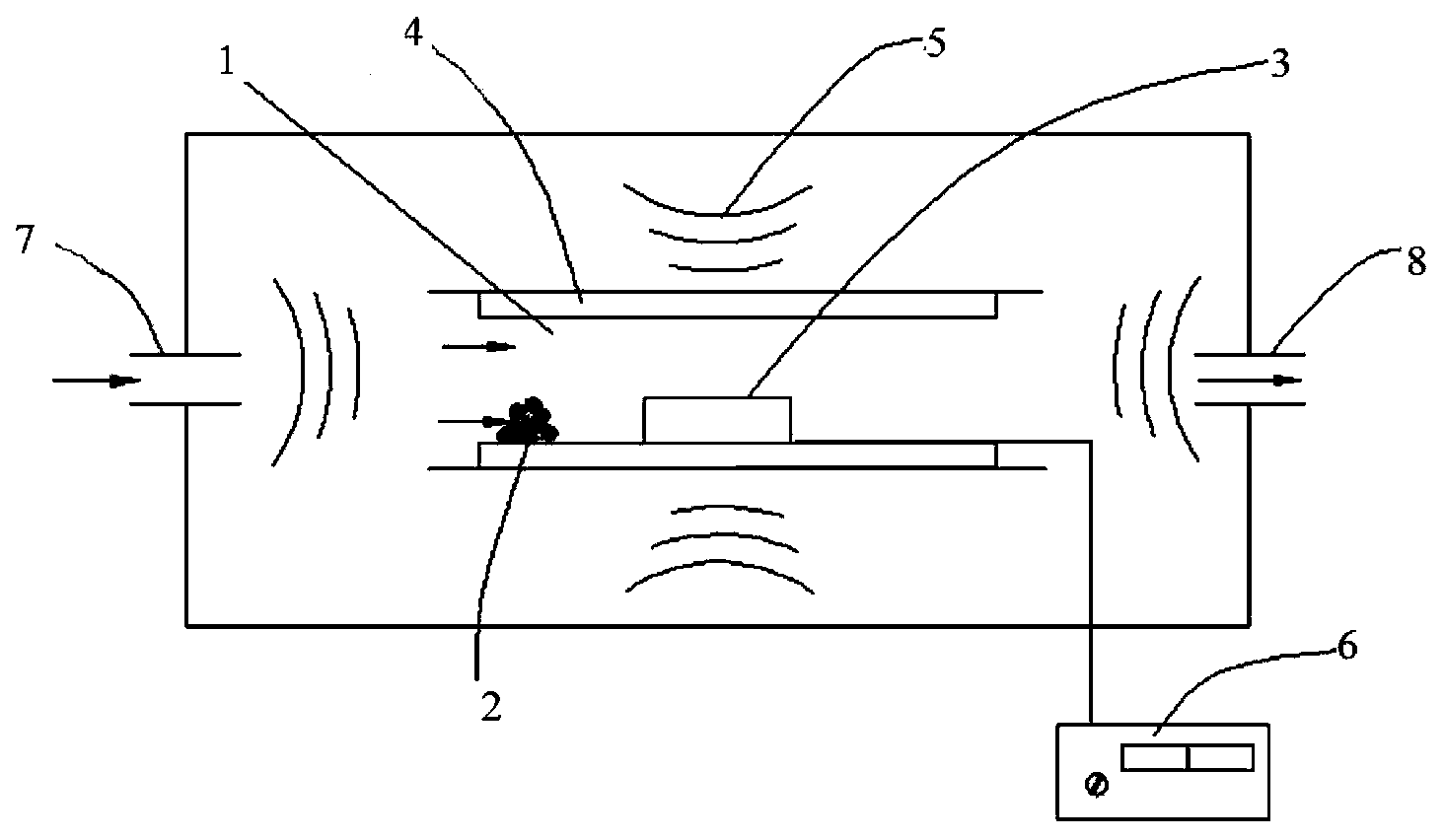

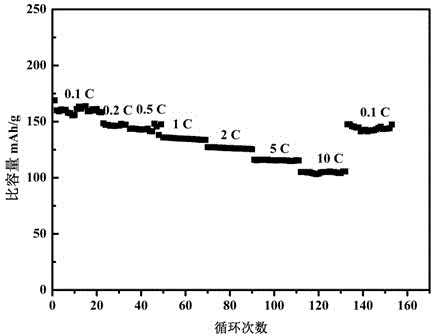

The invention discloses a carbon nano tube / graphene composite negative pole material, a preparation method thereof and a lithium battery. The preparation method of the carbon nano tube / graphene composite negative pole material comprises the steps of placing graphene powder and a catalyst for carbon source splitting decomposition in a microwave reaction cavity, vacuumizing the microwave reaction cavity and leading protective gas into the microwave reaction cavity and using a microwave vapor deposition method to prepare the carbon nano tube / graphene composite negative pole material on a graphene base body growing carbon nano tube. A negative pole of the lithium battery contains the carbon nano tube / graphene composite negative pole material. The preparation method of the carbon nano tube / graphene composite negative pole material adopts the microwave vapor deposition method to perform in-situ preparation of the carbon nano tube / graphene composite negative pole material, does not needs a pre-synthesis process, reduces the production cost, adopts microwave heating and is efficient, low in energy consumption and short in production period. Due to the fact that the lithium battery contains the carbon nano tube / graphene composite negative pole material, embedding and taking-out of lithium are facilitated, the inreversible capacity of first-time charging and discharging is reduced, and the lithium battery is good in safety and high in power.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

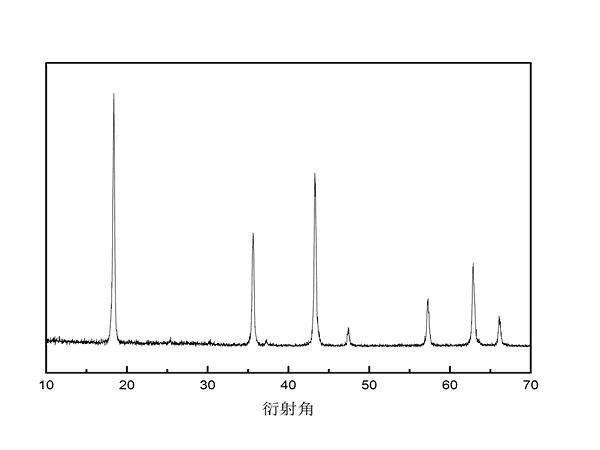

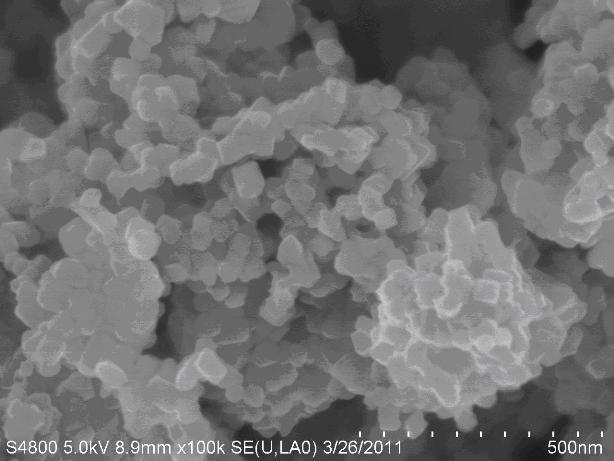

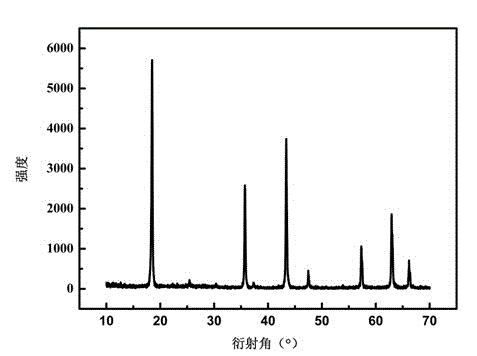

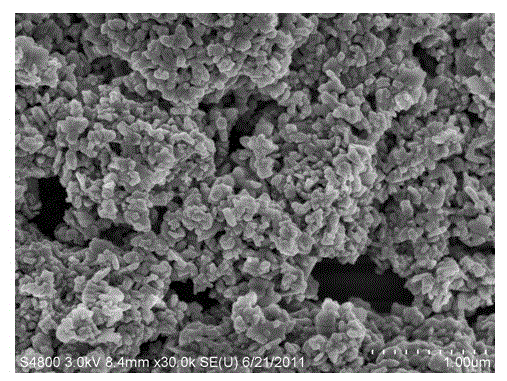

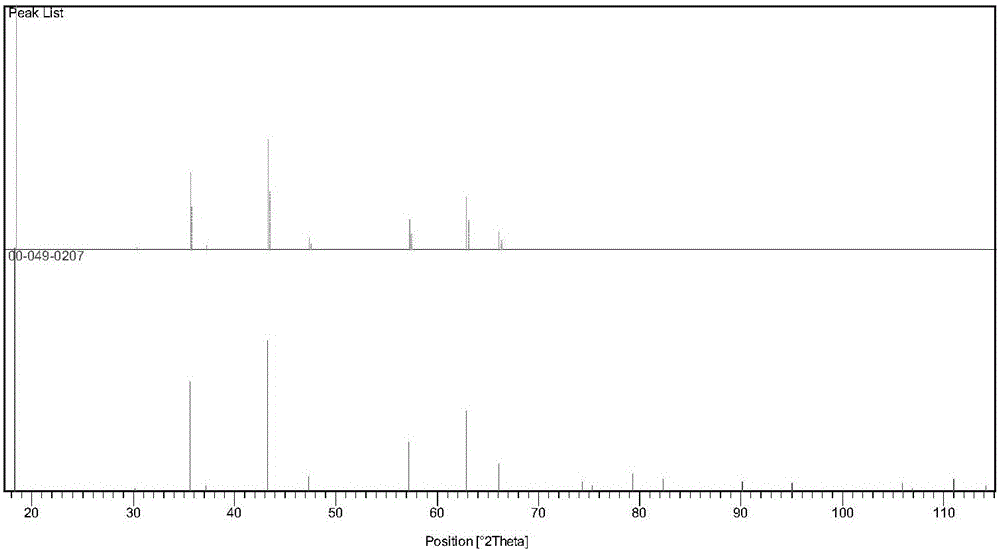

Preparation method of lithium titanate (Li4Ti5O12)/Ag composite lithium-ion negative electrode materials

InactiveCN102610824AEvenly distributedReduce consumptionCell electrodesElectric carsElectric vehicle

The invention discloses a preparation method of nanometer lithium titanate (Li4Ti5O12) / Ag composite lithium-ion negative electrode materials. The Ag doping modification is simultaneously carried out on the nanometer Li4Ti5O12. The chemical ingredients and the grain diameters of the Li4Ti5O12 are effectively controlled through hydrothermal treatment, the temperature during the subsequent treatment is greatly shortened, the grain agglomeration is prevented, and the industrial implementation is easier. In the preparation process, the Ag is doped, the conductivity of the materials is greatly improved, and meanwhile, the high-power charging and discharging performance and the cyclic times of the materials are effectively improved. The high-power specific capacity of the prepared materials is high, and the materials can be used for batteries required by various kinds of portable electronic equipment and various electric vehicles.

Owner:SHANGHAI UNIV

Preparation method for nanoscale lithium titanate material with high specific capacity

ActiveCN103682296AEvenly distributedReduce consumptionMaterial nanotechnologyAlkali titanatesAlcoholRoom temperature

The invention discloses a preparation method for a nanoscale lithium titanate material with high specific capacity. The preparation method comprises the following steps: (1) preparing a liquid A; (2) preparing a liquid B; (3) under a condition of magnetic stirring, slowly adding the liquid B into the liquid A, so as to obtain a mixed dispersion liquid; (4) putting the mixed dispersion liquid into a high-temperature reaction still, then placing the high-temperature reaction still in a drying oven for reaction, after the reaction, naturally cooling to room temperature, leaching, washing with deionized water and absolute ethyl alcohol, and then drying under a condition that the temperature is 60-120 DEG C so as to obtain a precursor; (5) sintering the precursor for 1-5 hours in anitrogen atmosphere under a condition that the temperature is between 400-1000 DEG C, so as to obtain the nanoscale lithium titanate material; (6) immersing the nanoscale lithium titanate material in an acid solution with the hydrogen ion concentration of 0.01-14mol / L under a condition that the temperature is 20-200 DEG C, then leaching, washing with deionized water and absolute ethyl alcohol, and then drying, so as to obtain the nanoscale lithium titanate material with high specific capacity.

Owner:上海大学浙江嘉兴新兴产业研究院

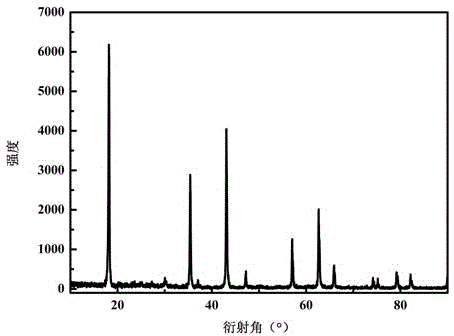

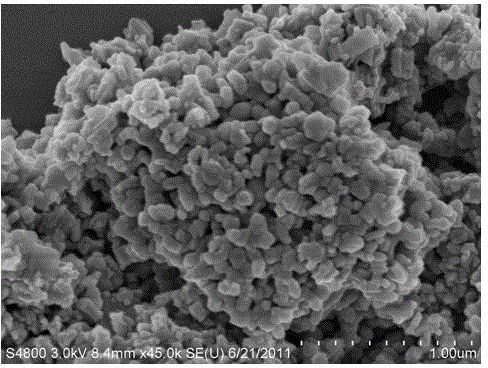

Lanthanum lithium titanate doped composite negative electrode material of lithium ion battery and preparation method thereof

ActiveCN103151508AParticles are evenly distributedAdequate responseCell electrodesComposite materialElectric devices

The invention discloses a lanthanum lithium titanate doped composite negative electrode material of a lithium ion battery and a preparation method thereof. Lithium titanate in nanoscale is prepared and meanwhile lanthanum doping modification is performed on lithium titanate according to the method. Chemical components and grain size of lithium titanate are effectively controlled by hydro-thermal treatment, so that subsequent treatment temperature is greatly reduced, particle conglomeration is prevented, and the method is more prone to industrial implementation. In preparation, lanthanum is doped, so that the discharge specific capacity of the material is improved. The material prepared according to the invention is great in multiplying power and high in specific capacity, and can be used for batteries required by various portable electronic devices and various electromobiles.

Owner:SHANGHAI UNIV

Preparation method of nanoscale zirconium-doped lithium titanate material

InactiveCN103151506AEvenly distributedGrain refinementCell electrodesElectrical batteryElectric cars

The invention discloses a preparation method of a nanoscale zirconium-doped lithium titanate material. Nanoscale lithium titanate is prepared by the method, and simultaneously is modified through doping zirconium. According to the preparation method, chemical components and grain sizes of the lithium titanate are effectively controlled by using hydro-thermal treatment, the temperature during subsequent treatment is greatly reduced, and grains are prevented from being agglomerated; and the preparation method is easy to implement in industry. The lithium titanate is doped with the zirconium in a preparation process, so that the specific discharge capacity of the material is increased at high magnification. Simultaneously, the gas expansion problem existing in the charge-discharge process of lithium titanate batteries is solved to a certain extent. The material prepared by the method has high magnification and high specific capacity and can be applied to the batteries needed for various portable electronic equipment and various electric vehicles.

Owner:SHANGHAI UNIV

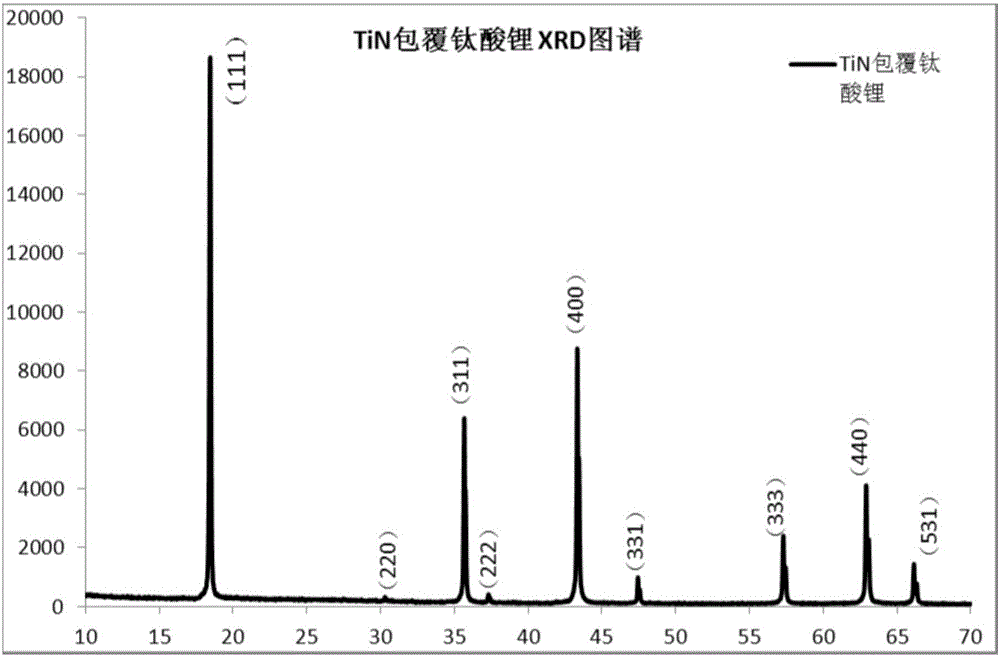

Titanium nitride coated lithium titanate material preparation method

The present invention relates to the technical field of battery materials, particularly to a titanium nitride coated lithium titanate material preparation method, which sequentially comprises: preparing a precursor solution, evaporating a solvent, sintering in an atmosphere containing oxygen, and sintering in an atmosphere containing reduction gas nitrogen. According to the present invention, the titanium nitride coated lithium titanate material prepared by using the preparation method has characteristics of high titanium nitride coating uniformity, good coating effect and good conductivity, and the conductivity problem of application of titanium nitride in electrode materials is solved; and titanium nitride is adopted to separate tetravalent titanium ions and an electrolyte, such that catalysis cracking of the electrolyte by the tetravalent titanium ions can be effectively prevented so as to prevent phenomenon of gas generation. In addition, the preparation process is simple and controllable, and process parameters of the lithium titanate material coated through titanium nitride can be controlled so as to control the coating degree of titanium nitride.

Owner:SHENZHEN DYNANONIC

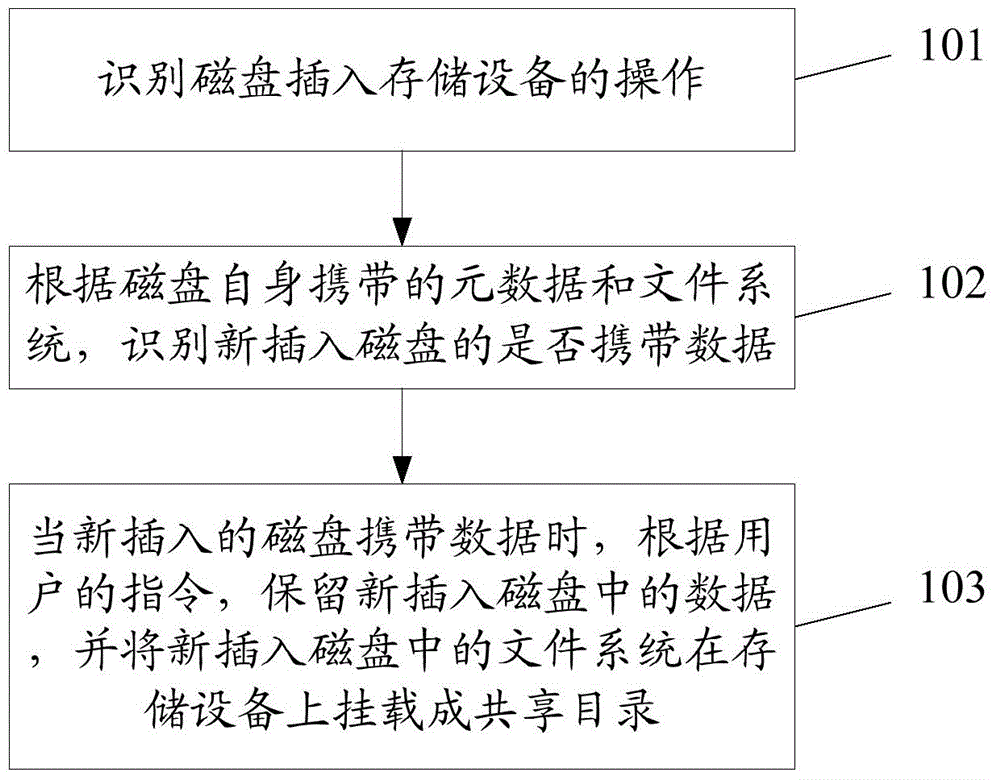

Disk storage space managing method, apparatus and storage device

The invention discloses a disk storage space managing method, apparatus and storage device. The method comprises the following steps of identifying an operation that a disk is inserted into the storage device, identifying whether a newly-inserted disk carries data according to metadata and file systems carried by the disk, and preserving data of the newly-inserted disk according to a user instruction and mounting the file systems of the newly-inserted disk into a shared catalogue in the storage device or mounting file systems of a disk array RAID of the newly-inserted disk into a shared catalogue in the storage device when the newly-inserted data carries data. The apparatus comprises a data identifying module, a data reserving module and a catalogue mounting module. By the use of the method, the device and the storage device, changes of the disk of the storage device can be sensed, so the user can preserve original data of the disk.

Owner:ZTE CORP

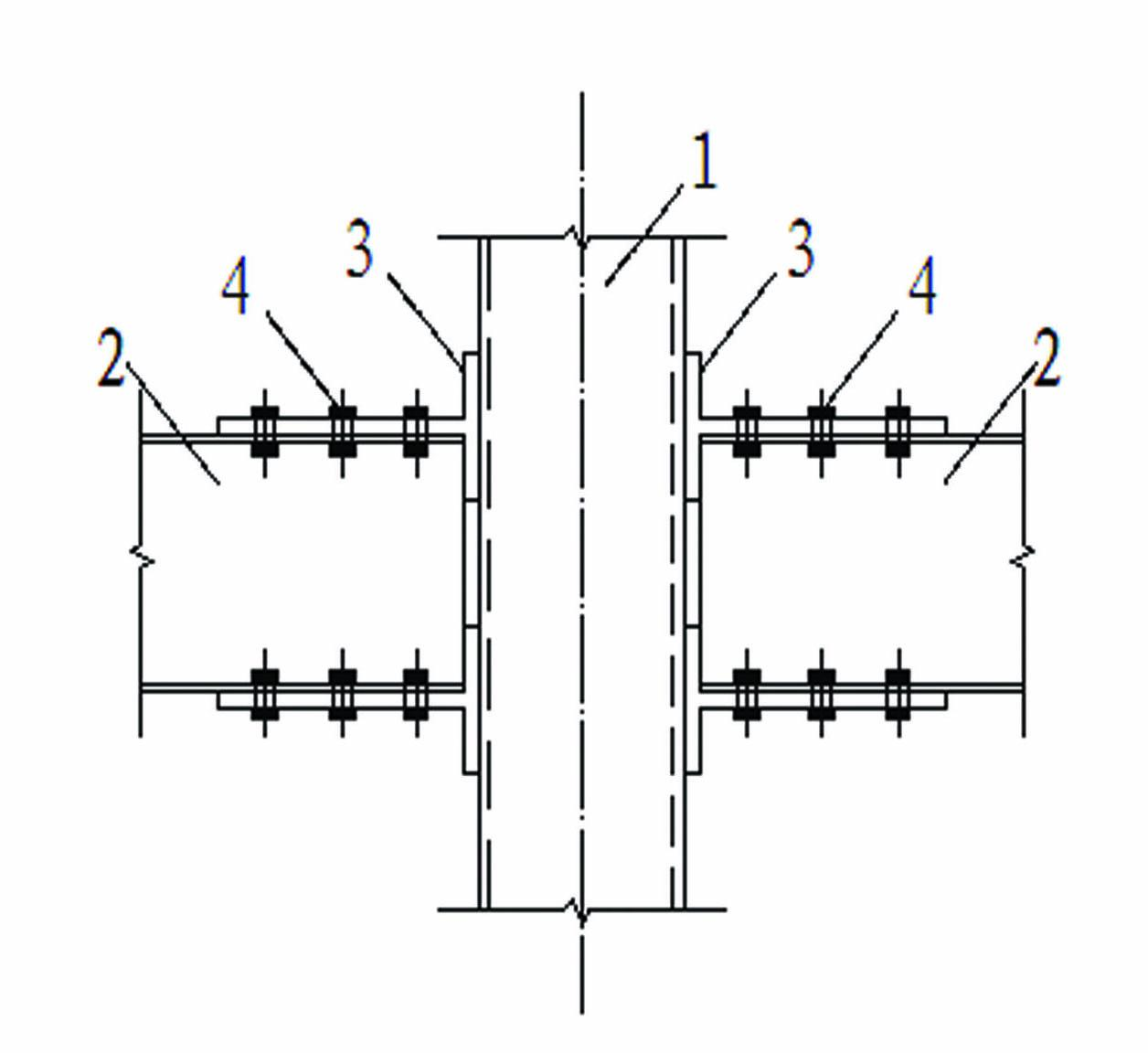

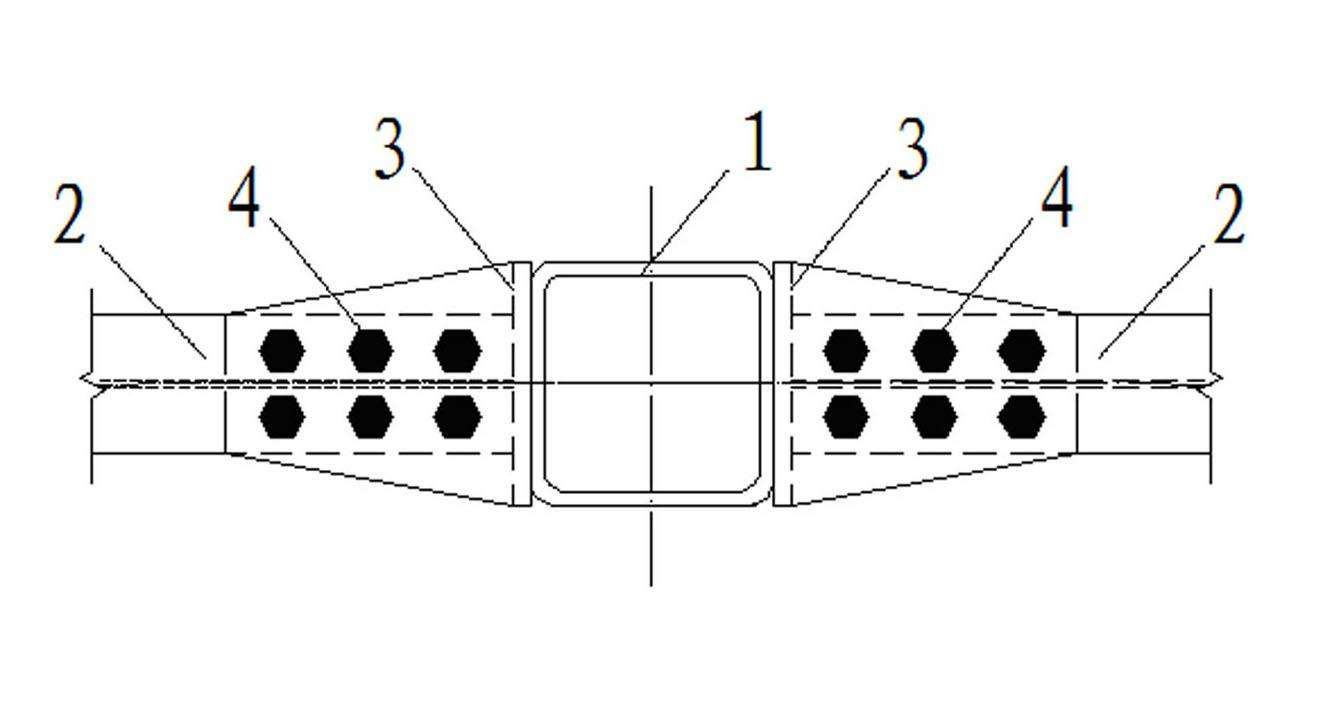

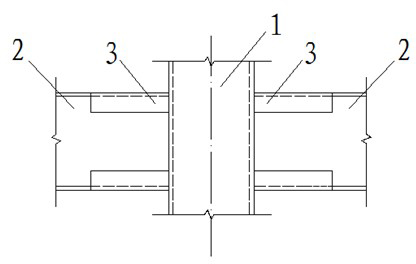

Connecting node of square steel pipe column and H-shaped steel beams

InactiveCN102635166APrevent local bucklingImprove the shortcomings of insufficient stiffnessBuilding constructionsFloor slabShock resistance

The invention relates to a connecting node of a beam and a column of building steel structures, in particular to a connecting node of a square steel pipe column and H-shaped steel beams for multi-layer and high-rise steel structures. The connecting node comprises a square steel pipe column, H-shaped steel beams and T-shaped steels; the T-shaped steels are arranged on the lateral wall of the square steel pipe column and the upper and lower wing edges of the H-shaped steels; webs of the T-shaped steels are connected with the wing edges of the H-shaped steel beams; and the wing edges of the T-shaped steels are fixedly connected with the lateral walls of the square steel pipe column. According to the connecting node of the square steel pipe column and the H-shaped steel beams, the connecting node is simple in structure, and the problem of construction difficulty in installing an internal separating plate is solved; a plastic hinge shifts outwards and better shock-absorbing property is achieved; the construction of an upper floor and the casting of concrete in the square steel pipe are not influenced; and the steel consumption is low. Therefore, the connecting node has high economic and social benefits.

Owner:SHENYANG JIANZHU UNIVERSITY

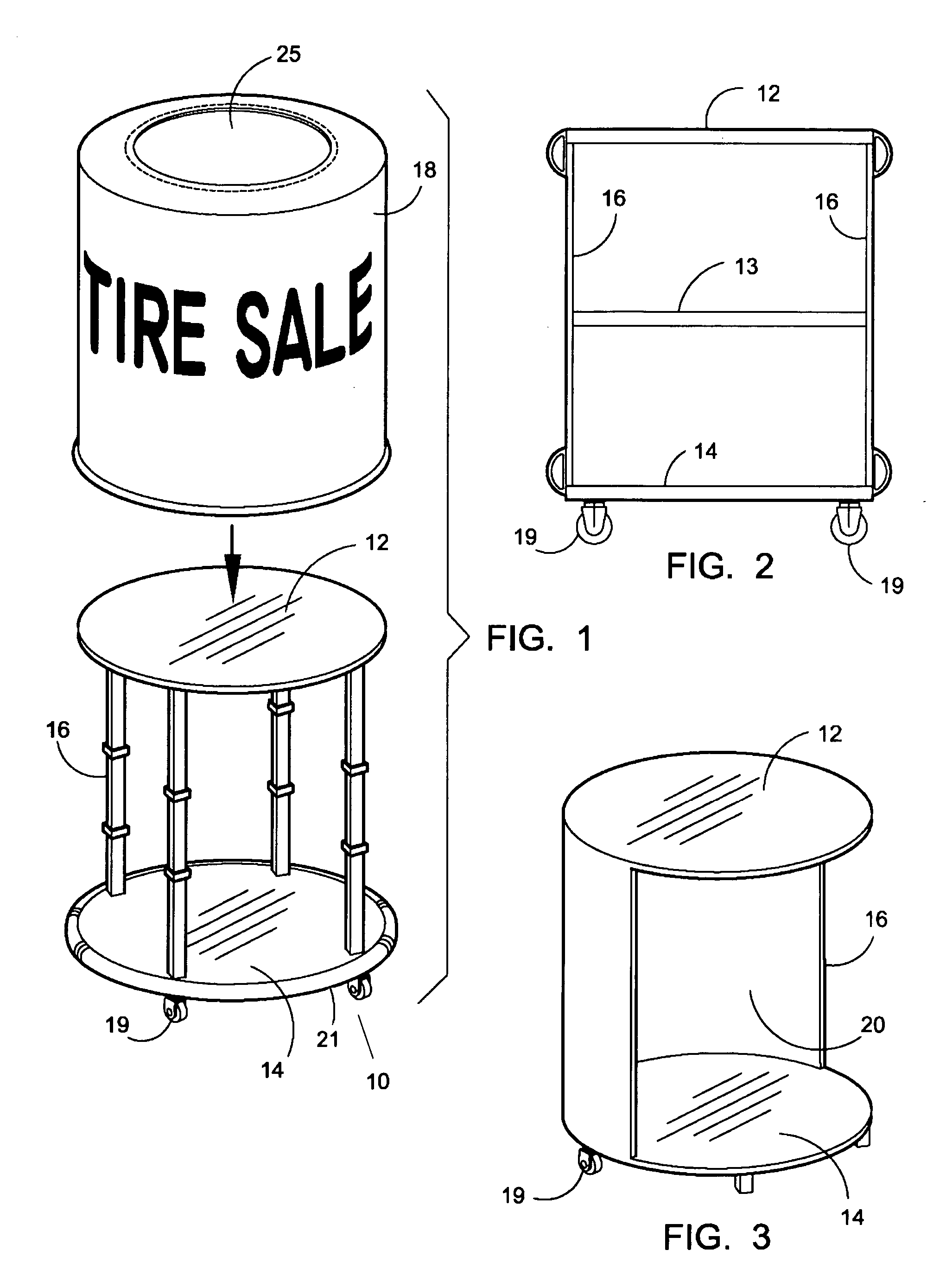

Rack simulating tire stack for signage mount

An engaging rack for engagement with a cylindrical banner adapted for mounting on a tire stack. The rack features top and bottom components having a circular perimeter edge substantially the diameter of a tire. At least one elongated member engages between the top component and the bottom component with the resulting rack dimensioned to provide a mount for said cylindrical banner conventionally engaged over stacks of tires. Rollers may be engaged for easy transport and the elongated members may be telescopic to adjust height. The device may be provided in kit form with different diameters for the top and bottom components to adjust the rack for ultimate dimension to accommodate various sized tire stack banners.

Owner:EDWARDS KELLY CHRISTOPHER

Method for manufacturing copper wire rod and winding device

InactiveCN1833813ANo damageSave spaceData processing applicationsFilament handlingWinding machineCopper wire

The invention relates to a method for producing line copper mother metal of coil, and relative winding machine, which can improve the quality and the efficiency, and coil present line copper mother metal whose diameter is more than 25mm, to improve the operational property. The winding machine continuously winds the line copper mother metal the guided out from the continuous casting machine and compressed extend in the compress extend process. It is characterized in that: it has a cooling reduction groove (10) which can keep the reduction solution that dipping said line copper mother metal; and a winding axle (2) inside said cooling reduction groove (10).

Owner:MITSUBISHI MATERIALS CORP

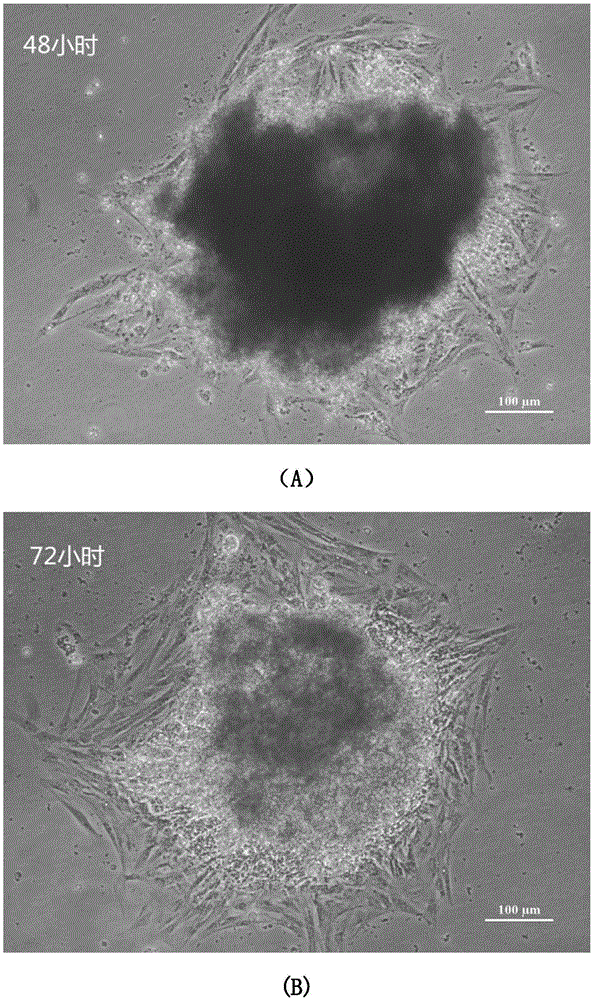

Turbot liver tissue cell in-vitro establishing method and application thereof

InactiveCN105255817AMove out quicklyEasy to move outVertebrate cellsArtificial cell constructsNutritionCulture mediums

The invention provides a turbot liver tissue cell in-vitro establishing method and application thereof. The method is characterized in that turbot liver tissue serves as the experimental material, the type-II collagenase enzymolysis approach is used for starting the primary culture of fish liver cells, and a novel L-15 compound culture medium where fetal calf serum of certain concentration, various growth factors and other nutritional components are added is used for cultivation in a biochemical incubator at a temperature of 24 DEG C. It is found through lipidosome transfer dyeing that transfer dyeing can be successfully conducted on turbot liver tissue primary culture cells through reporter plasmids such as pIRES2-EGFP. The method is easy and convenient to implement, high in repeatability, low in cost and rapid in cell growth, and an effective in-vitro cell model can be provided for research on the molecular cell biology of fish nutrition metabolism.

Owner:OCEAN UNIV OF CHINA

Plain trolley for logistics transportation

PendingCN109334743APlay the role of limit and prevent falling outPrevent tippingHand carts with multiple axesRolloverLogistics management

The invention discloses a plain trolley for logistics transportation. The plain trolley comprises a base, locking universal wheels are arranged at the bottom of the base, the middle position of the upper surface of the base is fixedly connected with a mounting block, a mounting groove is formed in the upper surface of the mounting block, an opening of the mounting groove faces upwards, a telescopic mechanism is arranged at the inner bottom of the mounting groove, and a bottom plate is connected to the telescopic mechanism; and the telescopic mechanism comprises a plurality of telescopic rods fixedly mounted at the inner bottom of the mounting groove, the ends, away from the base, of the multiple telescopic rods are all fixedly connected with the bottom of the bottom plate, and a spring isarranged on each telescopic rod in a sleeving mode. According to the plain trolley for logistics transportation, the effects of limiting and disengaging prevention on cargos stacked on the bottom plate can be achieved through a surround formed by the mounting groove formed in the mounting block and two limiting blocking discs, accidental falling-off and rollover of the cargos are avoided when thetrolley passes through a jolting road section, and integrity in the cargo transporting process is ensured.

Owner:湖州平坦物流有限公司

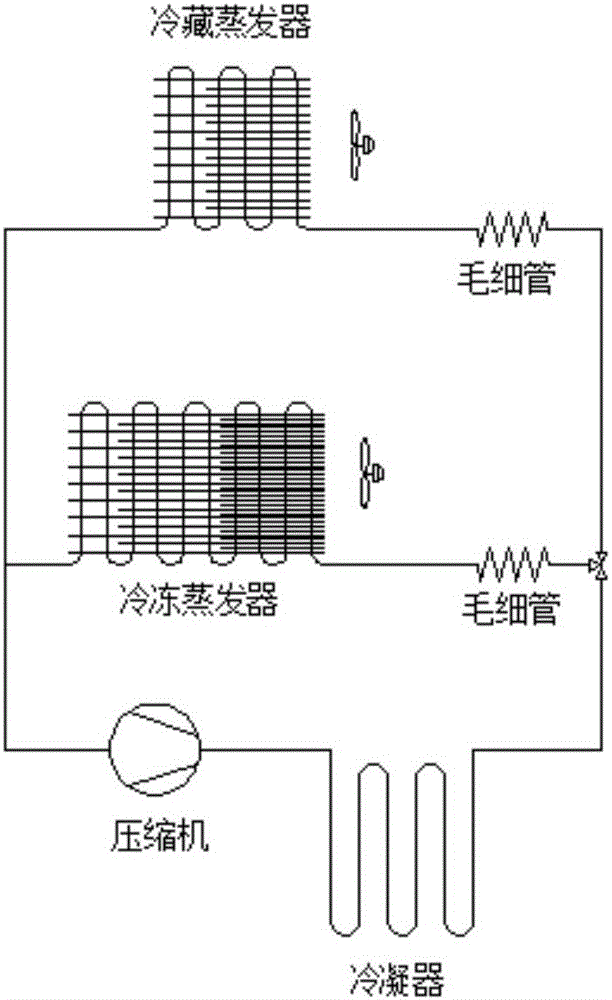

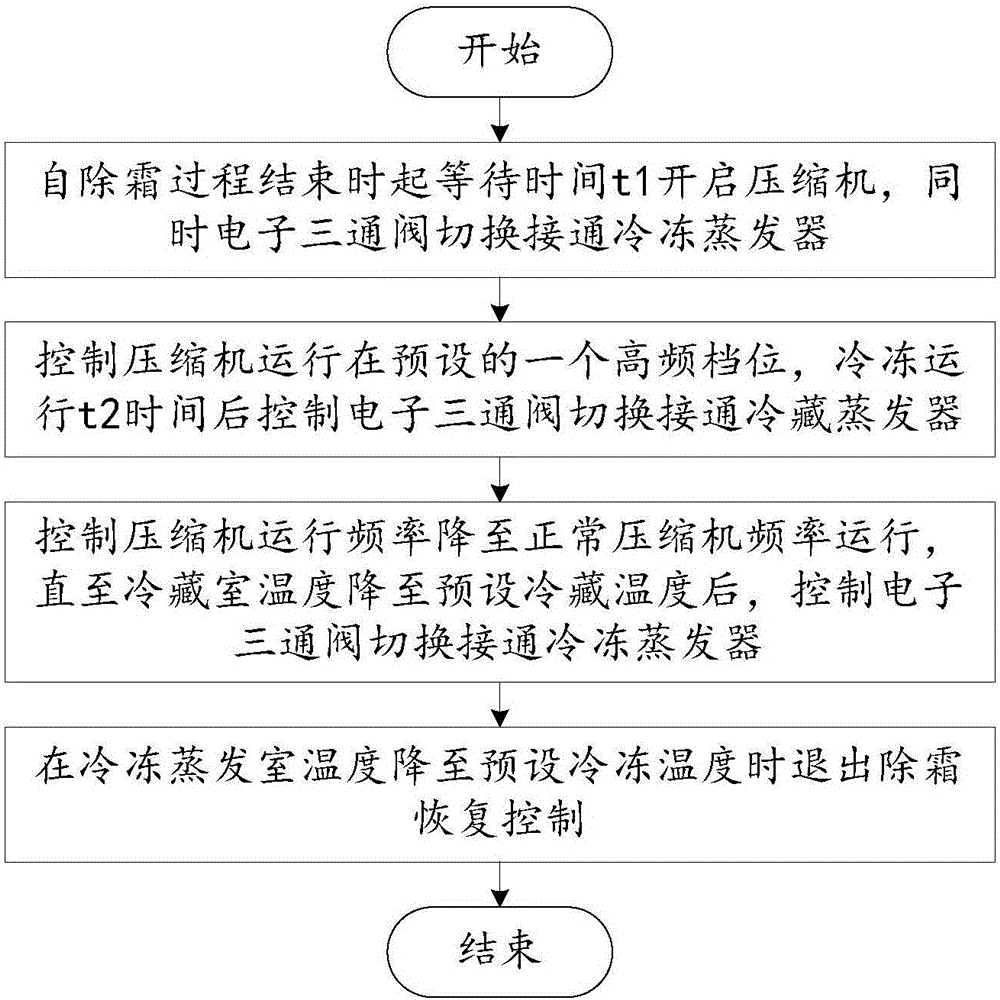

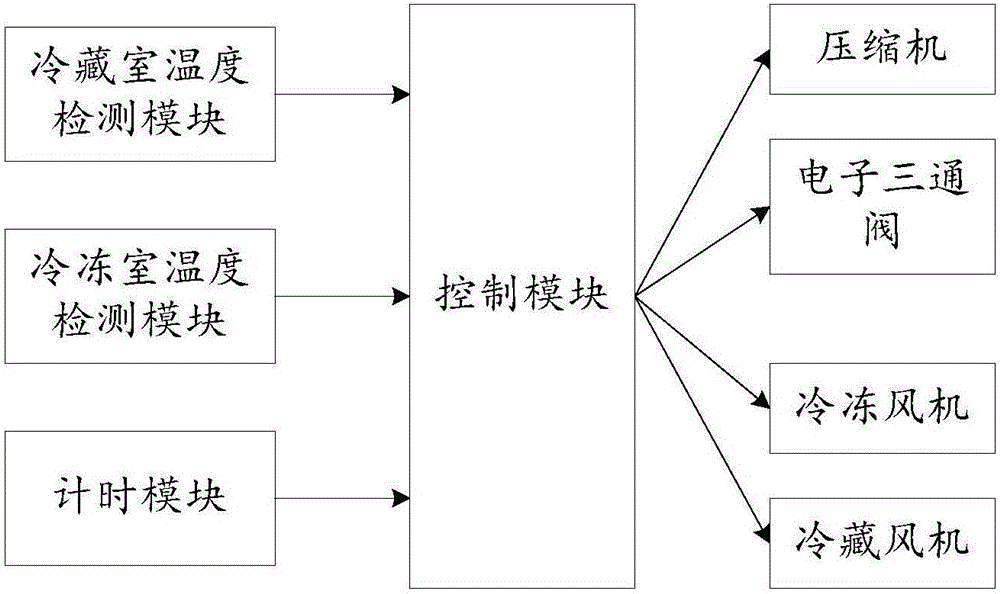

Control method and system for dual system refrigerator and dual system refrigerator

ActiveCN106123478AShorten defrost cycle timeSpend less timeLighting and heating apparatusDomestic refrigeratorsTime controlControl theory

The invention relates to the technical field of refrigerators, in particular to a control method and system for a dual system refrigerator and the dual system refrigerator. The control method for the dual system refrigerator comprises the steps that after the defrosting process is completed, high-frequency operation freezing time control is conducted firstly, and then low-frequency operation temperature control is conducted. According to the control method for the dual system refrigerator, the defrosting recovery phase duration can be shortened, power consumption in the recovery phase can be reduced, and the refrigerating and freezing modes are rapidly recovered to the normal and stable operation states.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

Technology for extracting lithium from seawater

InactiveCN108793203AEasy to move outAct as selective separationLithium carbonates/bicarbonatesLithium carbonateDesorption

The invention discloses a method for extracting lithium from seawater by utilizing a lithium adsorbent. The invention in particular relates to the method comprising the following steps: adsorbing thelithium in the seawater by utilizing the lithium adsorbent; then desorbing by adopting a desorption agent to prepare a lithium-enriched solution; carrying out re-concentration, purification and lithium sedimentation on the lithium-enriched solution to obtain lithium carbonate. The technology provided by the invention provides a new raw material source for the production of the lithium carbonate and dependence on minerals and bittern is reduced, so that the production cost is greatly reduced and the technology is suitable for industrialization.

Owner:南通四度化工贸易有限公司 +1

Method for oxidizing cultural relics in ironware

This invention describes a process for the dechlorination of iron antiquities, comprising the steps of: adding a cleaning agent and an amine inhibitor to an alkaline solution to prepare an alkaline dechlorination cleaning solution, and carrying out the cathode polarization dechlorination of iron antiquities in the said solution at a constant electric potential. This invention overcomes such problems as a certain degree of corrosion existing in the traditional dechlorination processes for iron antiquities or the damage to the intrinsic appearances of iron antiquities led by the abscission of the rusty layer resulting from hydrogen evolution caused by high local current in the electrochemical reduction method, and provides a rapid, effective and more protective process for the dechlorination of iron antiquities.

Owner:BEIJING UNIV OF CHEM TECH

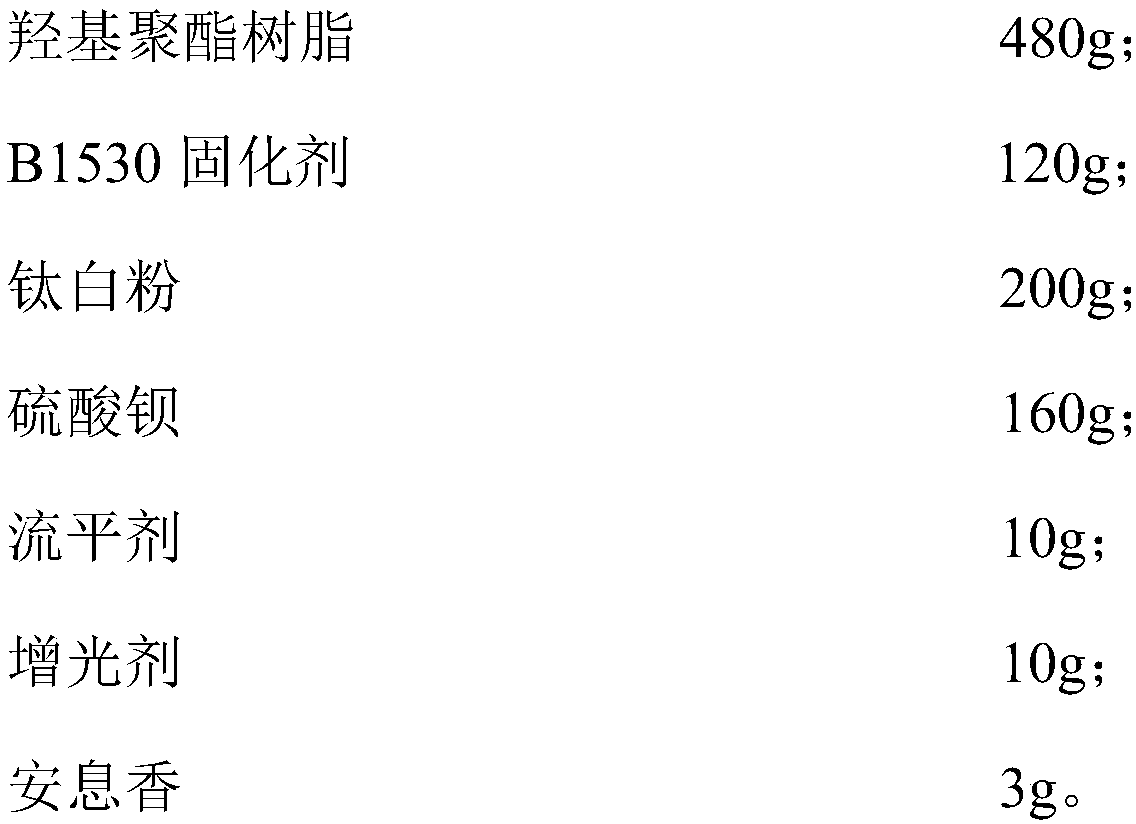

Hydroxyl polyester resin for high-gloss powder coating, and preparation method and application thereof

ActiveCN109180925AImprove melt fluidityReduce melt viscosityPowdery paintsPolyester coatingsSilanesTert butyl

The invention specifically relates to hydroxy polyester resin for a high-gloss powder coating, a preparation method thereof and application of the hydroxy polyester resin to powder coatings, belongingto the technical field of powder coatings. The hydroxy polyester resin for the high-gloss powder coating is prepared through polymerization of the following raw materials: terephthalic acid, 6-aminocaproic acid, domoic acid, 3,6-dithia-1,8-octanediol, 2-propenoic acid-2,18-dihydroxy-4,7,10,13,16-pentaoxanonadecane-1,19-diyl ester, neopentyl glycol, 3-(2,3-epoxypropoxy)propyl trimethoxy silane and3,5-di-tert-butyl-4-hydroxybenzyl alcohol. It has been determined that the obtained hydroxy polyester resin has good melt fluidity at 200 DEG C, low melt viscosity and long leveling time, and allowsa film to have high gloss. The hydroxy polyester resin is eventually applied to the powder coating cured by polyurethane B1530, can improve the surface gloss of the coating, and allows a coated boardsurface with high gloss to be obtained.

Owner:安徽恒隆新材料有限公司

Environmentally-friendly and energy-saving repairing agent for polyester dyeing, and application thereof

The invention discloses an environmentally-friendly and energy-saving repairing agent for polyester dyeing, and an application thereof. The repairing agent comprises, by weight, 1-4 parts of plant extract, 2-8 parts of fish gelatin proteins, 25-39 parts of modified benzyl benzoate, 8-15 parts of aromatic diol phthalate, 1-3 parts of a nonionic surfactant and 1-3 parts of citric acid. Benzyl benzoate is modified, and then is loaded with copper foam, so the compatibility between the benzyl benzoate and fibers is increased, and the outward movement of a dye in the fibers is effectively promoted;the synergistic effects of the modified benzyl benzoate and fish gelatin proteins promote the uniform distribution of the dye; and the addition of the plant extract reduces the addition of an antibacterial agent and a reducing agent and effectively protects the use field and the service life of the fabric. Additionally, the repairing agent has a strong transferability, and reduces the temperaturerequired by level dyeing, so color spots, color flowers, off color and other problems of clothes are repaired.

Owner:常州依丝特纺织服饰有限公司

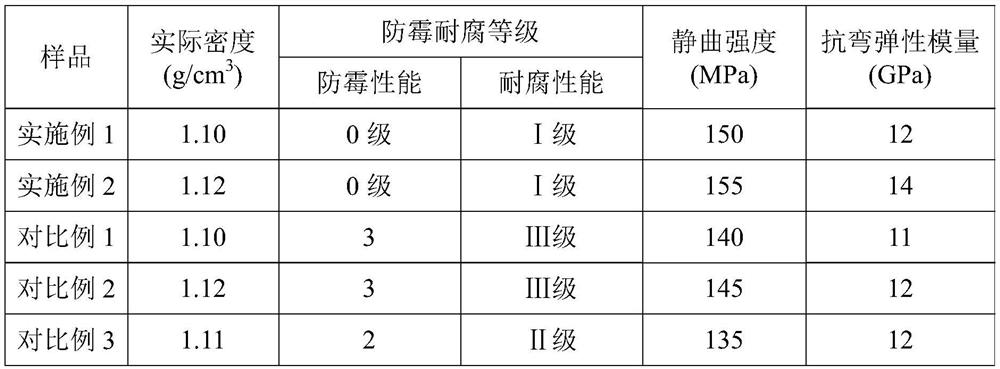

Outdoor high-weather-resistance bamboo scrimber and manufacturing method thereof

ActiveCN114714459AImprove weather durabilityMaintain the tint colorClimate change adaptationWood treatment detailsPulp and paper industryIndustrial engineering

The invention discloses an outdoor high-weather-resistance bamboo scrimber and a manufacturing method thereof.The manufacturing method comprises the steps that bamboo units are sequentially subjected to high-temperature steam sterilization treatment, biological pretreatment, primary cooking treatment, saturated steam carbonization treatment and secondary cooking treatment, and then the mildew-proof and corrosion-proof bamboo units are obtained; and carrying out gum dipping treatment, drying and balancing treatment, assembling, hot-pressing forming and post-treatment to obtain the outdoor high-weather-resistance bamboo scrimber. The outdoor high-weather-resistance bamboo scrimber has the advantages of being high in weather resistance, high in strength, close to the color of bamboo wood and the like, can meet the requirements for production and manufacturing of outdoor bamboo engineering materials and engineering components, and can be widely applied to the field of modern bamboo structure building engineering.

Owner:HUNAN TAOHUAJIANG BAMBOO SCI & TECH CO LTD +1

Potato planting equipment

InactiveCN105850311ACompact structureRealize lightweight structurePotato plantersFurrow making/coveringEngineeringSlide plate

The invention relates to potato planting equipment. The potato planting equipment comprises a soil breaking mechanism, a soil covering mechanism, a seed potato box, a material dropping-off mechanism, a rack, a travelling wheel and a sliding plate, wherein the soil breaking mechanism is provided with two oblique surfaces, a knife-edge arete for breaking soil is formed at the intersected position of the two oblique surfaces, the knife-edge arete is obliquely and downwardly extended to a knife-edge point, during planting, the knife-edge point of the soil breaking mechanism is positioned in a soil layer, and is at a depth same as the depth required by the planted potato, the soil layer is broken by the knife-edge point and the knife-edge arete, the soil is pushed to two sides by the oblique surfaces, so that a trench required by the potato planting is formed; a material dropping-off gap is left between the soil covering mechanism and the soil breaking mechanism, the soil covering mechanism is provided with an opened front part and closed sides and rear part, and the width of the opening in the front part of the soil covering mechanism is more than that of the soil breaking mechanism. The potato planting equipment has small and light structure, can be pulled or pushed by a person or livestock due to low broken soil amount, can realize soil breaking, seeding, and soil filling in once travelling, does not require additional power and thus has lightweight structure.

Owner:XIJI COUNTY POTATO IND SERVICE CENT

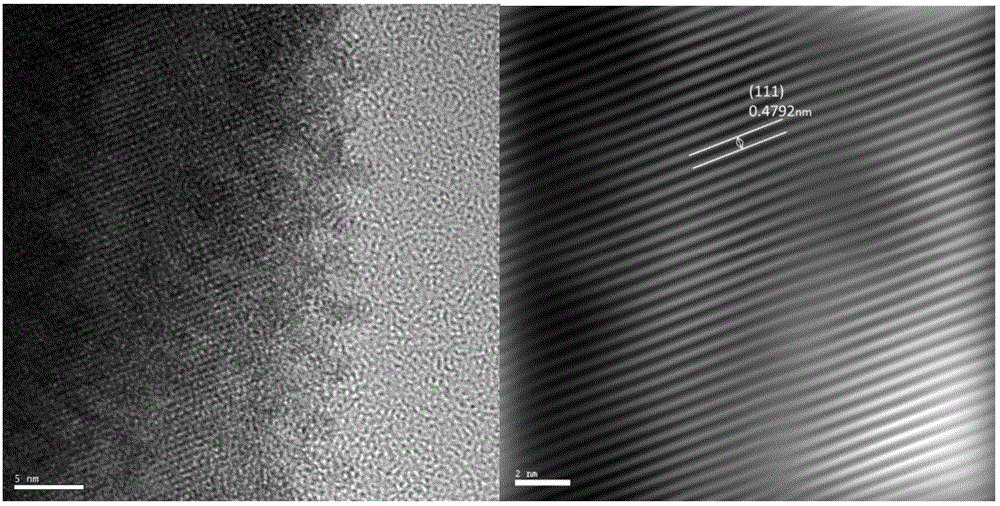

A kind of preparation method of titanium nitride coated lithium titanate material

ActiveCN103400976BGood coating effectImprove uniformityCell electrodesMaterials preparationTitanium nitride

The present invention relates to the technical field of battery materials, particularly to a titanium nitride coated lithium titanate material preparation method, which sequentially comprises: preparing a precursor solution, evaporating a solvent, sintering in an atmosphere containing oxygen, and sintering in an atmosphere containing reduction gas nitrogen. According to the present invention, the titanium nitride coated lithium titanate material prepared by using the preparation method has characteristics of high titanium nitride coating uniformity, good coating effect and good conductivity, and the conductivity problem of application of titanium nitride in electrode materials is solved; and titanium nitride is adopted to separate tetravalent titanium ions and an electrolyte, such that catalysis cracking of the electrolyte by the tetravalent titanium ions can be effectively prevented so as to prevent phenomenon of gas generation. In addition, the preparation process is simple and controllable, and process parameters of the lithium titanate material coated through titanium nitride can be controlled so as to control the coating degree of titanium nitride.

Owner:SHENZHEN DYNANONIC

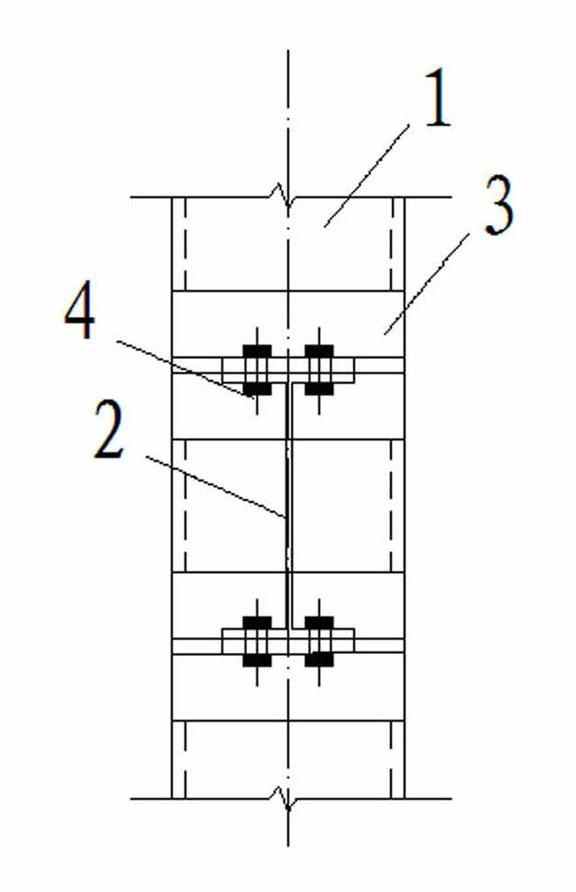

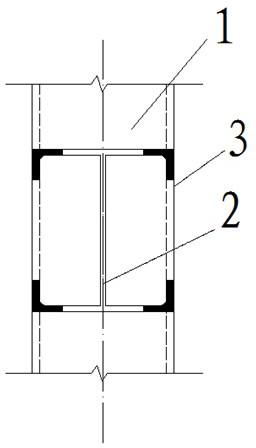

Connecting node of square steel pipe column, H-shaped steel beam and L-shaped ribbed plate

InactiveCN102359192AAdd out-of-plane deformationSimple structureBuilding constructionsSheet steelButt joint

The invention relates to a connecting node of a square steel pipe column, an H-shaped steel beam and an L-shaped ribbed plate. The node is simple in structure, convenient to construct and is free of affecting to pour concrete in the square steel pipe column. The connecting node comprises the square steel pipe column, the H-shaped steel beam and the L-shaped ribbed plate, wherein two limbs of the L-shaped ribbed plate are respectively in butted joint with the upper flange and the lower flange of the H-shaped steel beam and connected with a wall plate of the square steel pipe column. The width B of the flange of the H-shaped steel beam 1 is twice the sum of the lengths b1 of the limbs of the L-shaped ribbed plate in butted joint with the H-shaped steel beam 1. The square steel pipe column comprises a cold bending rectangular square steel pipe column and a hot rolled square column; and the H-shaped steel beam comprises an H-shaped hot rolled steel beam and an H-shaped welded steel beam. The connecting node of the square steel pipe column, the H-shaped steel beam and the L-shaped ribbed plate in the invention adopts a measure of additionally arranging stiffening ribs outside to replace inner partition plates, and the L-shaped ribbed plate can transfer tension and pressure of the flanges of the beam to the wall of the square steel pipe column, so that the deformation outside a plane of the node is increased. Meanwhile, the problem of construction difficulty in installing the inner partition plates can also be avoided.

Owner:SHENYANG JIANZHU UNIVERSITY

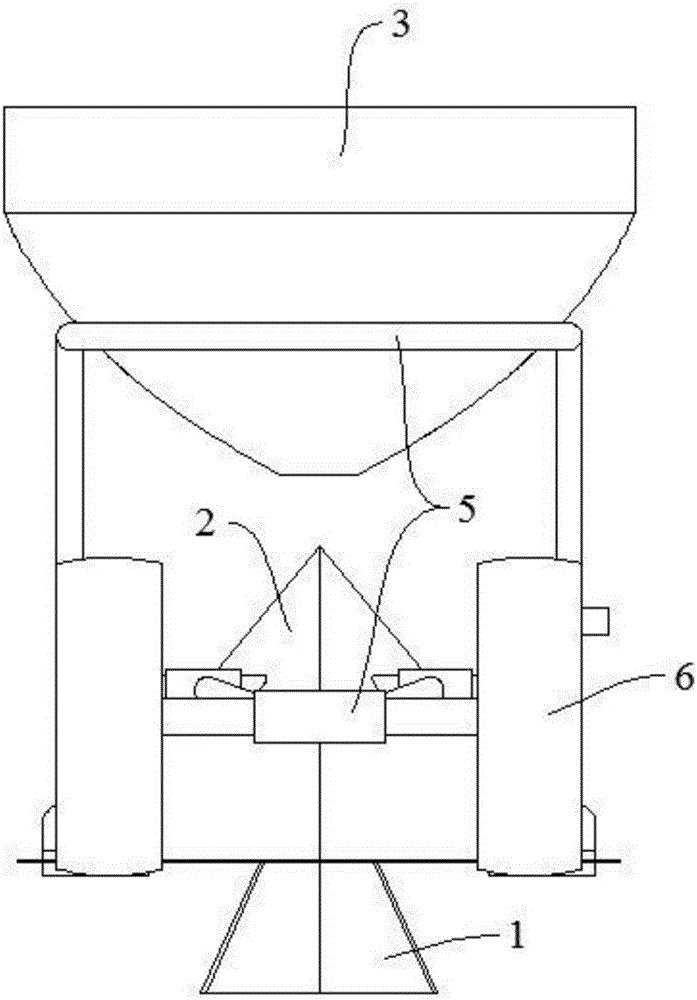

Orius minutus releasing device and method

The invention discloses an orius minutus releasing device, comprising a glass container (1), wherein a pothook (5) and a moving plate (2) are mounted on an upper cover of the glass container (1), one protection plate of protection plates around the glass container (1) is provided with at least one small hole (4), and a side plate (3) is mounted at a hole part of the small hole (4). The orius minutus releasing device and an orius minutus releasing method are used to solve the problem that in an orius minutus releasing process by science researchers, a great amount of time and labor need to be consumed as a region for releasing the orius minutus in a large area is often dispersed in production, and releasing is performed without a simple and practical device and method, so that the orius minutus cannot be quickly released to target crops to timely control pests.

Owner:GUIZHOU UNIV

Carbon nanotube/graphene composite negative electrode material and preparation method thereof, lithium battery

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

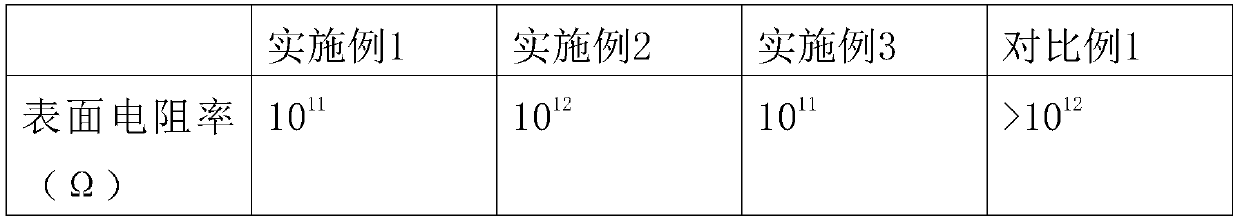

Antistatic recyclable PE film for powder packaging

ActiveCN111572147AChemically activeLow thermal conductivityPackage recyclingFlexible coversAnti oxidantZirconium dioxide

The invention discloses an antistatic recyclable PE packaging film for powder packaging. The PE packaging film is a three-layer co-extrusion blown-molded film and comprises a PE surface layer, a PE middle layer and a PE heat-sealing layer which are sequentially overlapped, wherein the PE heat-sealing layer comprises PE resin and porous heat insulation ceramic microspheres adsorbed with a cationicantistatic agent, and the porous heat insulation ceramic microspheres are porous zirconium dioxide microspheres modified by allyl trimethylsiloxane. According to the invention, the cationic antistaticagent is adsorbed by the zirconium dioxide porous microspheres which are inactive in chemical property but good in heat-insulating property, so the decomposition effect of high temperature on the cationic antioxidant in the film processing process is inhibited; and the porous structures of the zirconium dioxide microspheres are utilized to adsorb water vapor in an environment, so the antistatic agent is easy to migrate out to reach the surface of the film at low humidity, and an efficient and stable electrostatic effect is formed.

Owner:JIANGYIN SHENLONG PACKAGING MATERIALS CO LTD

Transport arrangement and container for transporting objects in building

ActiveCN109153541AMove in easilyEasy to move outElevatorsBuilding material handlingEngineeringMechanical engineering

Owner:FALK INVENTIONS AB

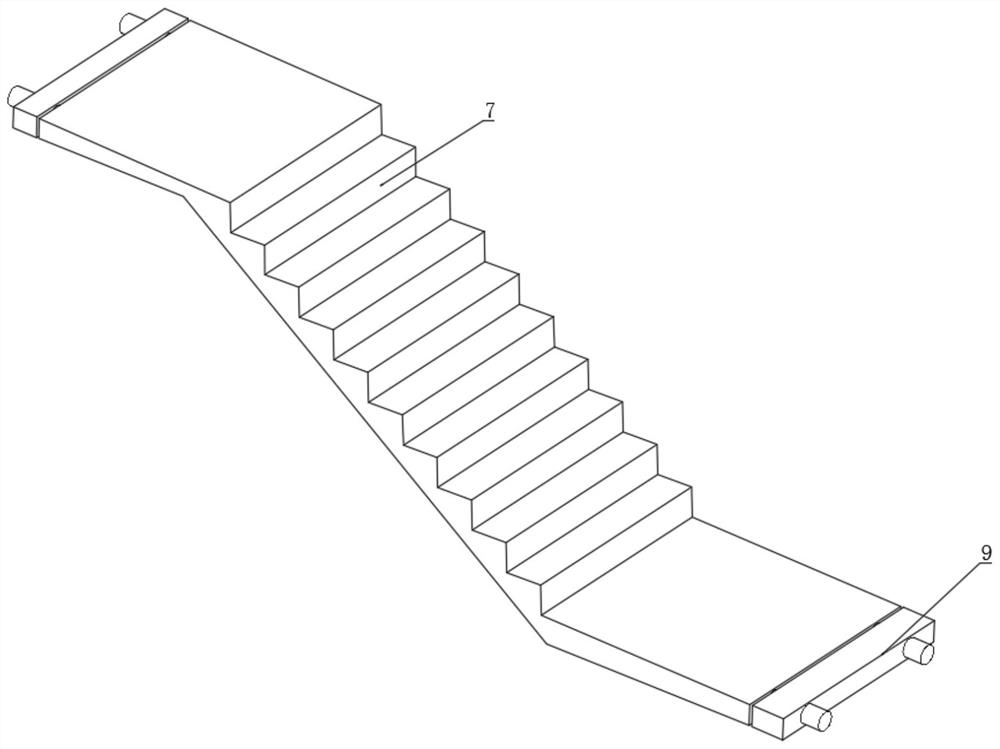

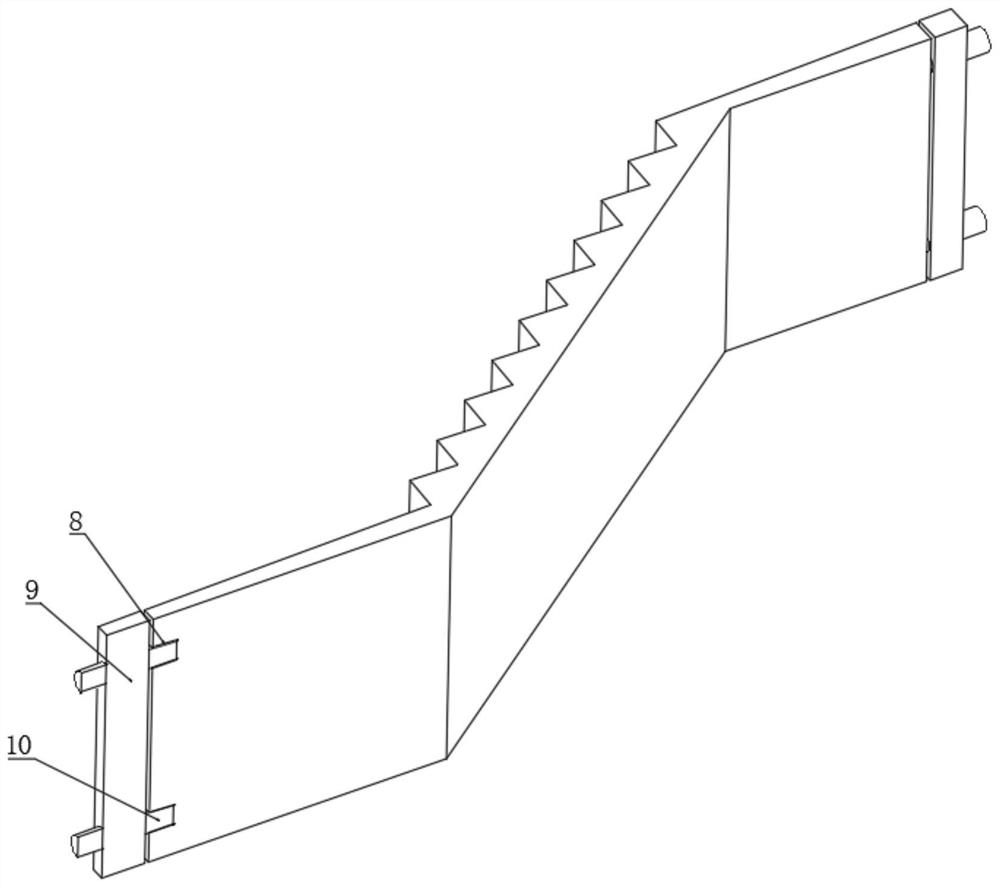

Assembled prefabricated stair and preparation device thereof

ActiveCN113001710AEasy to demouldEasy to disassembleDischarging arrangementMould separation apparatusSlide plateMaterials science

The invention discloses an assembled prefabricated stair and a preparation device thereof. The assembled prefabricated stair comprises a base, wherein a demolding mechanism is arranged in the middle position of the top end of the base, and the demolding mechanism comprises step plates, ventilation cavities, air guide pipes, sliding plates, mounting frames, guide rods, connecting frames, placement grooves, a sliding groove, sliding blocks, ejector rods and sealing films; and the step plates are symmetrically welded to the middle position of the top end of the base, and the ventilation cavities are formed in the opposite ends of the two step plates. According to the assembled prefabricated stair and the preparation device thereof, hot steam can be conveniently injected into the ventilation cavities through the air guide pipes, and therefore, the step plates can be conveniently heated; through the cooperation of the placement grooves and the sliding groove, the sliding blocks can conveniently slide, so that the two mounting frames are conveniently spliced, and the two sliding plates are combined; and meanwhile, through the ejector rods and the sealing films, air is conveniently injected into the ventilation cavities, so that contact parts of concrete and the step plates are separated through thermal expansion and cold contraction, and the inner sides of two stair base bodies are conveniently demolded.

Owner:泰华远大装配式建筑(廊坊)有限公司

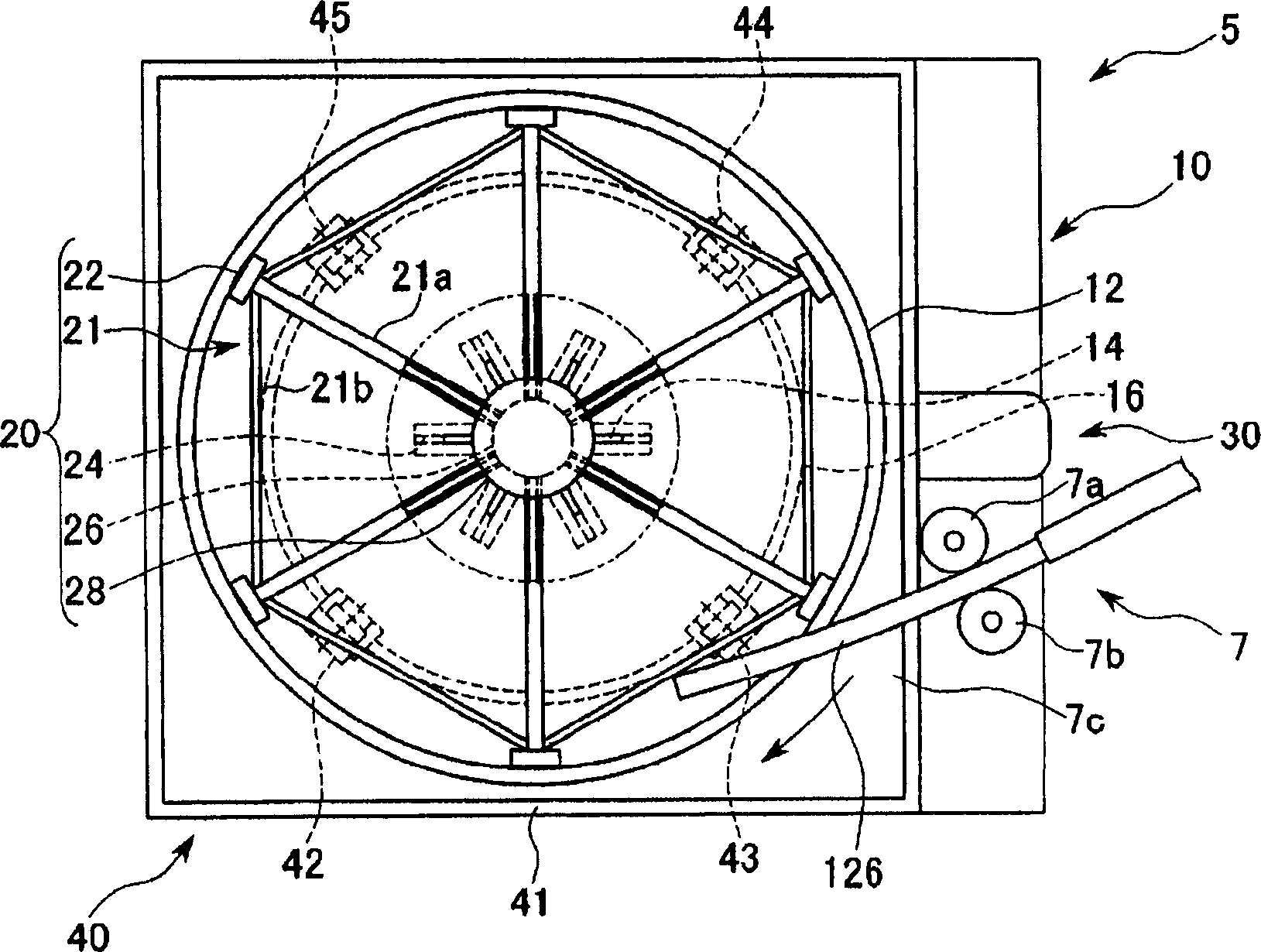

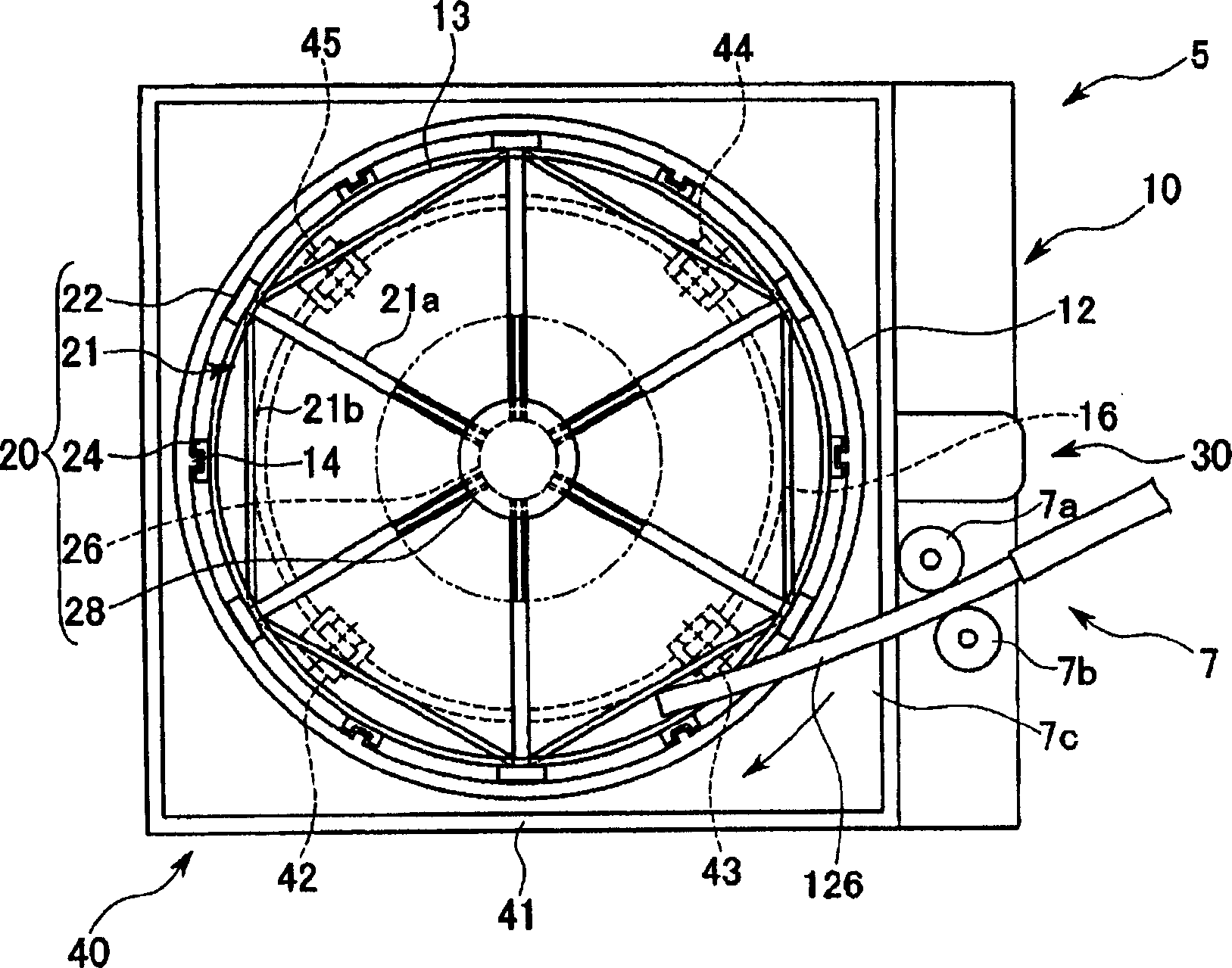

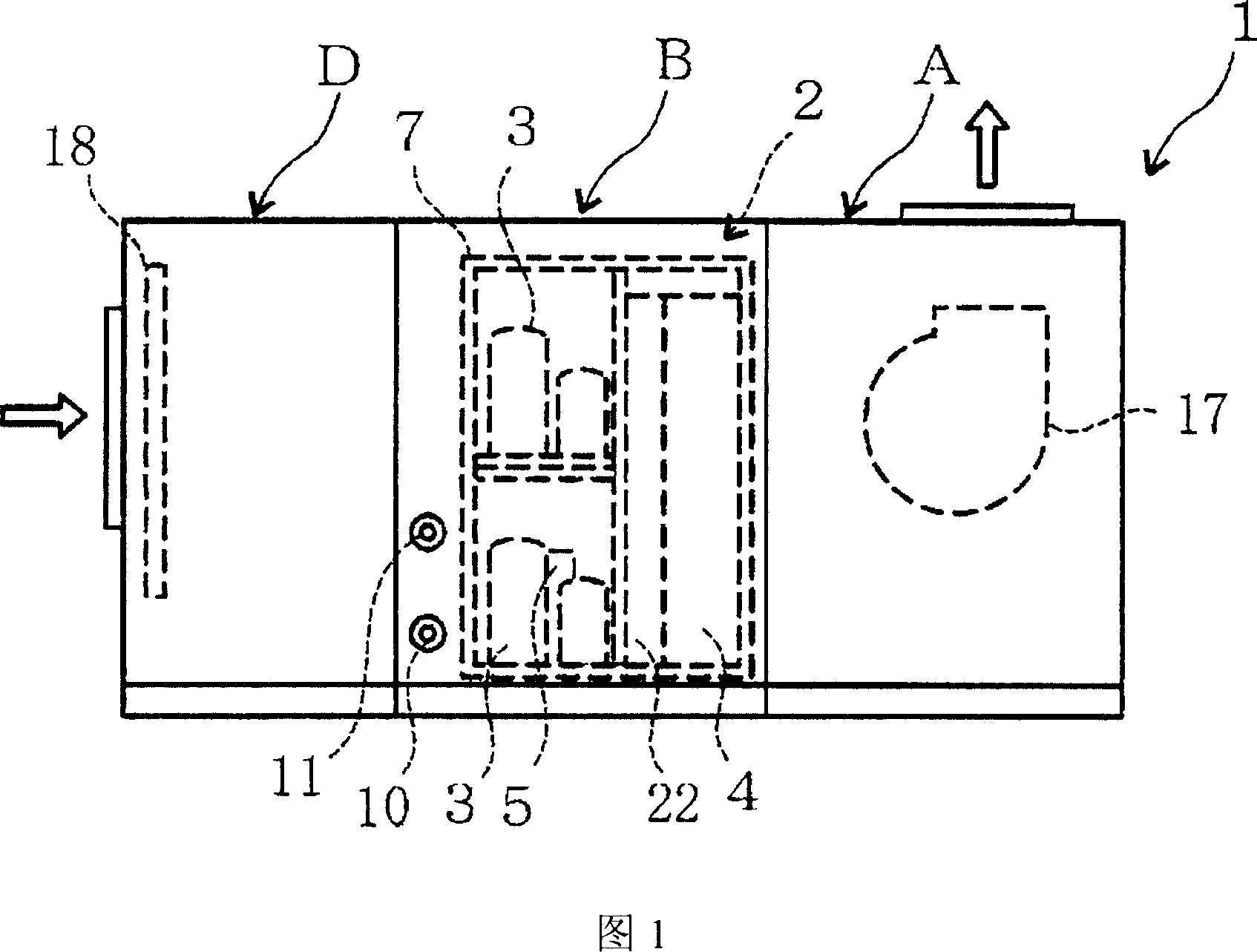

Water-cooling type air conditioner

InactiveCN1967093AReduce in quantityGuaranteed large air volumeHeat pumpsAir conditioning systemsEngineeringHeat pump

A water-cooling heat pump type air conditioner comprises a housing (1) and a plurality of water-cooling heat pump units (2) which is opposite to the housing (1) and can be taken out or received freely. The water-cooling heat pump units (2) at least comprises a plurality of compressors (3), an air heat exchanger (4) and a water heat exchanger (5) for a plurality of compressors (3), a decompressor, and a frame (7) for arranging the parts. The compressors (3) arranged on the air entrance of the air heat exchanger (4) are arranged up-and-down separated. The thermal source water passageway of the water heat exchanger (5) can connect or separate freely with enter pipe (10) and discharge pipe (11) of the thermal source water arranged in the housing (1).

Owner:KIMURA KOHKI CO LTD

LED display module with interface protection structure and LED display device

ActiveCN112271492ARealize automatic extensionEasy to move outCouplings bases/casesSemiconductor lamp usageRatchetLED display

The invention discloses an LED display module with an interface protection structure and an LED display device. The LED display module comprises an LED display screen, a protection outer frame is fixedly connected to the right side of the LED display screen, a butt joint groove is formed in the right side of the protection outer frame, a data line butt joint mechanism is connected into the butt joint groove, and a sealing mechanism for sealing the butt joint groove is arranged at an opening of the butt joint groove; through arrangement of an extrusion plate, a movable plate and a sealing door,the problem that a data interface is exposed outside and is easily damaged by external problems to cause failure in normal operation is avoided, and through arrangement of a rotary vertical plate, arotary transverse plate and a waterproof plate, the problem of unstable data transmission caused by rainwater infiltration contact due to severe weather is avoided; and by arranging a ratchet wheel, alimiting block and a pressing plate, the problem that normal work of the LED screen is influenced by looseness between a data interface and a butt joint wire head due to severe weather is avoided.

Owner:深圳市同一方光电技术有限公司

A kind of preparation method of high specific capacity nanoscale lithium titanate material

ActiveCN103682296BEvenly distributedReduce consumptionMaterial nanotechnologyAlkali titanatesAlcoholRoom temperature

Owner:上海大学浙江嘉兴新兴产业研究院

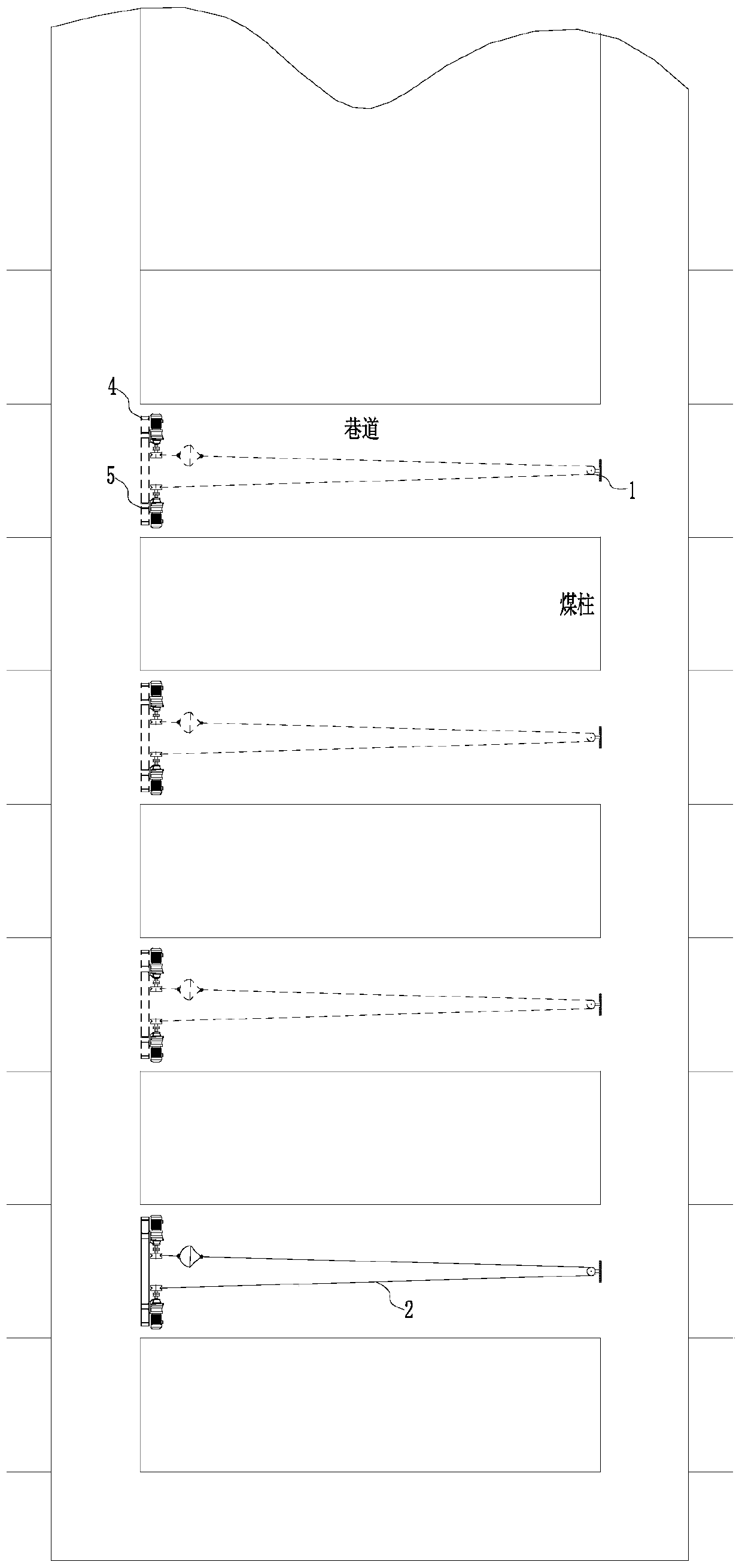

Roadway intelligent gangue filling machine and filling method

PendingCN110145360AGuaranteed filling efficiencyPrevent overwindingMaterial fill-upFilling materialsPosition sensor

The invention provides a roadway intelligent gangue filling machine and a filling method and relates to the technical field of gangue filling. The filling machine comprises a top plate fixing device,a hauling rope, a filling round-bottomed bucket, a first electric drum, a second electric drum and a position sensor. The top plate fixing device is arranged on a top plate and comprises a pulley anda tensioning device. The hauling rope is wound around the pulley. The filling round-bottomed bucket is arranged on the hauling rope. The two ends of the hauling rope are fixed to the first electric drum and the second electric drum correspondingly. The position sensor determines the distance between the round-bottomed bucket and the pulley as well as between the round-bottomed bucket and the firstelectric drum. In the gangue filling process, by means of the filling round-bottomed bucket, filling materials in a roadway are directly piled, the first electric drum and the second electric drum are utilized for pulling the filling bottom-round bucket to achieve automatic piling and discharging, and then piling of the filling materials within a certain distance is achieved. The technical problem that in a wall type exploiting system, especially in the short roadway, construction of a large filling tool is inconvenient is solved. In addition, the machine has the advantages of being flexibleto use, high in working efficiency and the like.

Owner:山东威斯特矿山工程科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com