Outdoor high-weather-resistance bamboo scrimber and manufacturing method thereof

A manufacturing method and technology of recombined wood, applied in the field of outdoor bamboo recombined wood and its manufacture, outdoor high weather-resistant bamboo recombined wood and its manufacturing field, can solve poor permeability, loss of bamboo, decay, mildew, etc. problems, achieve uniform distribution and long-term fixation, improve weather resistance and durability, and eliminate microbial nutrient sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A kind of manufacture method of outdoor high-weather-resistant bamboo quality reconstituted material of the present invention, such as figure 1 shown, including the following steps:

[0047] S1, biological pretreatment

[0048] S1.1, preparation of bamboo bundles: sawing fresh moso bamboo into bamboo tubes with a length of 2.15m, using a bamboo tube splitting machine to split it into bamboo strips with a width of 30mm, after removing the green and yellowing treatment, and then using the bamboo chip disintegrating machine The bamboo strips are processed into bamboo bundles to obtain a horizontally loose and longitudinally connected bamboo bundle unit.

[0049] S1.2. High-temperature steam sterilization treatment: put the bamboo bundle unit in an autoclave with a temperature of 115°C, sterilize it with high-temperature steam for 30 minutes, take it out, and immediately transfer it to a sterilized constant temperature and humidity room for use. The high temperature stea...

Embodiment 2

[0070] A manufacturing method of outdoor high-weather-resistant bamboo quality reconstituted material of the present invention, comprising the following steps:

[0071] S1, biological pretreatment

[0072] S1.1. Preparation of bamboo stalks: sawing fresh moso bamboo into bamboo tubes with a length of 1.55m, using a bamboo tube splitting machine to split it into bamboo strips with a width of 15mm, and then using a bamboo splitting machine to cut the bamboo strips along the radial direction. The direction is divided into thin bamboos with a thickness of 1-2 mm, and bamboos are obtained.

[0073] S1.2, high-temperature steam sterilization treatment: place the above-mentioned bamboo stalk unit in an autoclave with a temperature of 120 ° C, take out after 20min of high-temperature steam sterilization, and immediately transfer to a sterilized constant temperature and humidity room in standby. The high temperature sterilization treatment is to kill other miscellaneous bacteria carr...

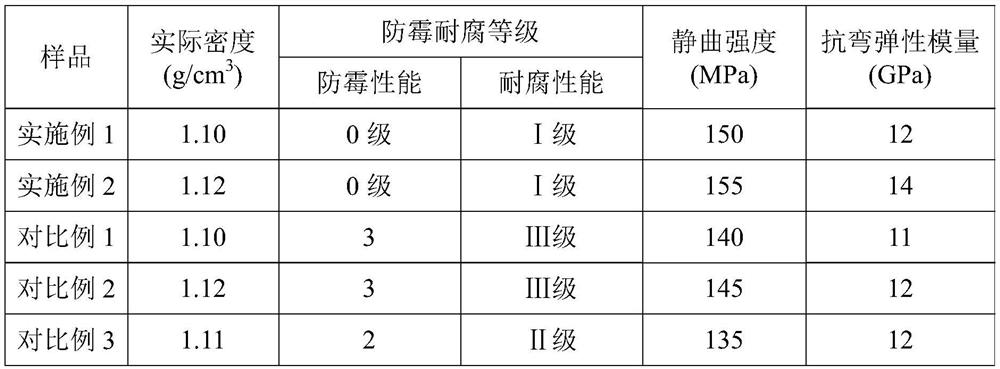

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Static bending strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com