A nano-zirconium phosphate-coated modified ammonium polyphosphate and an intumescent fireproof coating prepared therefrom

A technology of ammonium polyphosphate and zirconium phosphate package is applied in the field of flame retardant materials, which can solve the problems of poor compatibility, easy migration, easy hydrolysis, etc., and achieves improved thermal stability and barrier performance, simple preparation method, and flame retardant effect. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

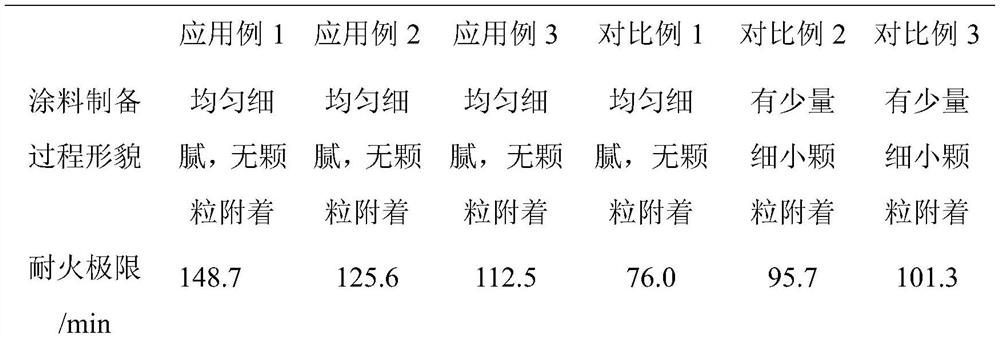

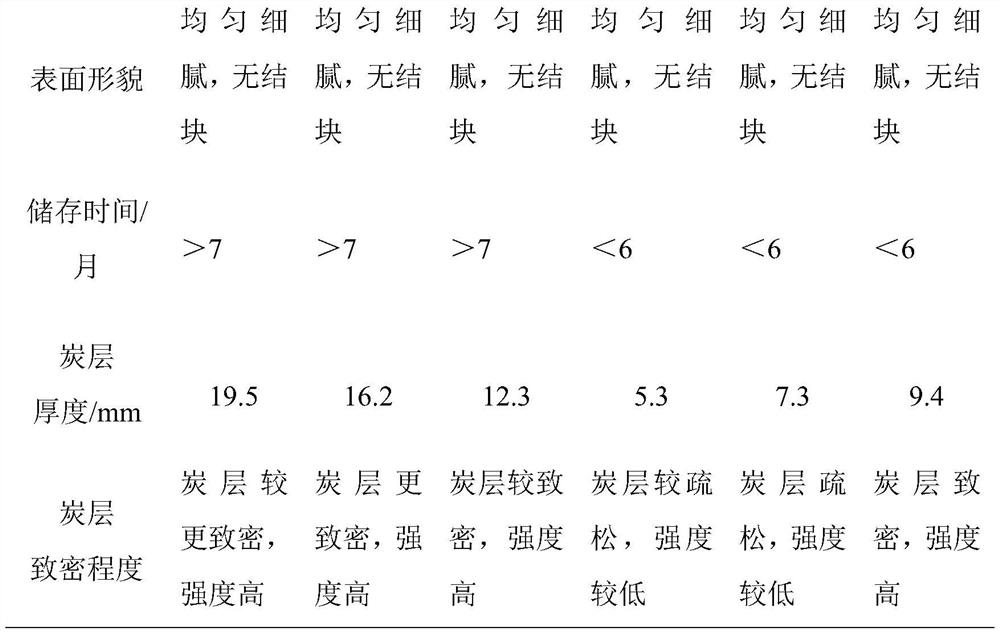

Examples

Embodiment 1

[0042] A kind of nano zirconium phosphate coated modified ammonium polyphosphate, its preparation method comprises the steps:

[0043] 1) TBA exfoliation of zirconium phosphate: In a 500ml four-neck flask, 0.01mol zirconium phosphate and 300ml deionized water were fully dispersed by mechanical stirring and ultrasonication. Tetrabutylammonium hydroxide solution (TBA concentration is 0.1mol / L), dropwise in the four-necked flask within 30min at a constant speed, continue to react for 2h after dropping, then add 20ml of 4mol / L concentrated phosphoric acid dropwise at a constant speed within 30min In the flask, after the reaction (2h), the resulting mixed solution was centrifuged for solid-liquid separation to obtain a translucent gel precipitate and washed with distilled water;

[0044] 2) PEI-coated APP: Disperse 3 g of ammonium polyphosphate in deionized water by mechanical stirring and ultrasonic action to form a suspension, then add 6 g of polyethyleneimine PEI to the resultin...

Embodiment 2

[0047] A kind of nano zirconium phosphate coated modified ammonium polyphosphate, its preparation method comprises the steps:

[0048] 1) TBA exfoliation of zirconium phosphate: In a 500ml four-neck flask, 0.01mol zirconium phosphate and 300ml deionized water were fully dispersed by mechanical stirring and ultrasonication. Tetrabutylammonium hydroxide solution (TBA concentration is 0.1mol / L), dropwise in the four-necked flask within 30min at a constant speed, continue to react for 2h after dropping, then add 20ml of 4mol / L concentrated phosphoric acid dropwise at a constant speed within 30min In the flask, after the reaction (2h), the resulting mixed solution was centrifuged for solid-liquid separation to obtain a translucent gel precipitate and washed with distilled water;

[0049] 2) PEI-coated APP: Disperse 2g of ammonium polyphosphate in deionized water by mechanical stirring and ultrasonic action to form a suspension, then add 4g of polyethyleneimine PEI to the resulting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com