Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3551 results about "Ammonium polyphosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonium polyphosphate commercially produced by Clariant, (former business area of Hoechst AG), Budenheim and other sources is an inorganic salt of polyphosphoric acid and ammonia containing both chains and possibly branching. Its chemical formula is [NH₄ PO₃]ₙ(OH)₂ showing that each monomer consists of an orthophosphate radical of a phosphorus atom with three oxygens and one negative charge neutralized by an ammonium cation leaving two bonds free to polymerize. In the branched cases some monomers are missing the ammonium anion and instead link to three other monomers.

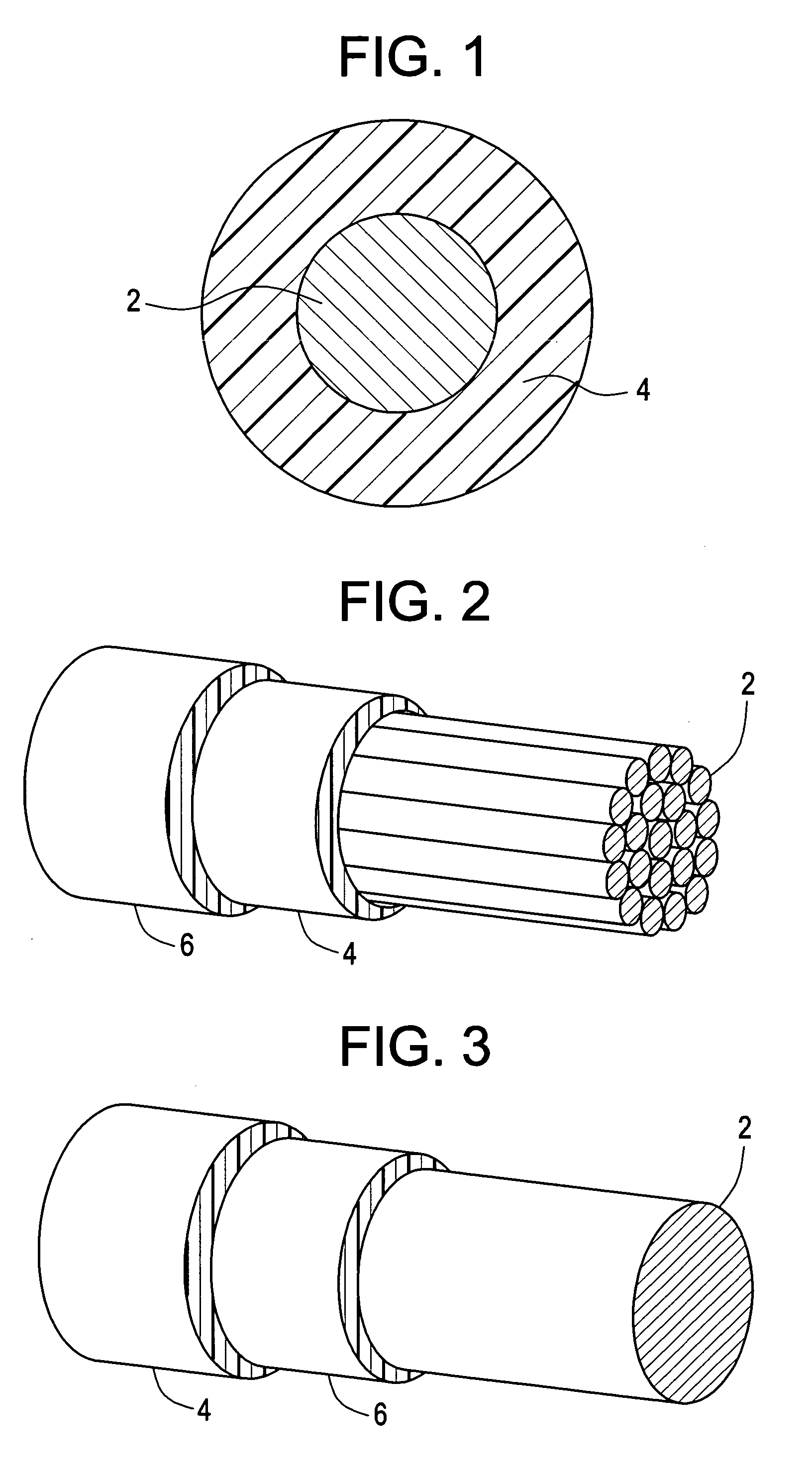

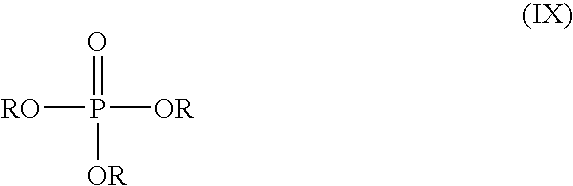

Flame retardant thermoplastic composition and articles comprising the same

A flame retardant thermoplastic composition comprises: a poly(arylene ether); an impact modifier; a polyolefin; a phosphoric acid salt selected from the group consisting of melamine phosphate, melamine pyrophosphate, melamine orthophosphate, diammonium phosphate, monoammonium phosphate, phosphoric acid amide, melamine polyphosphate, ammonium polyphosphate, polyphosphoric acid amide, and combinations of two or more of the foregoing; a metal hydroxide; and an organic phosphate wherein the amount of phosphoric acid salt by weight is greater than or equal to the amount of organic phosphate by weight. The flame retardant composition is may be used in the production of electrical wires.

Owner:SHPP GLOBAL TECH BV

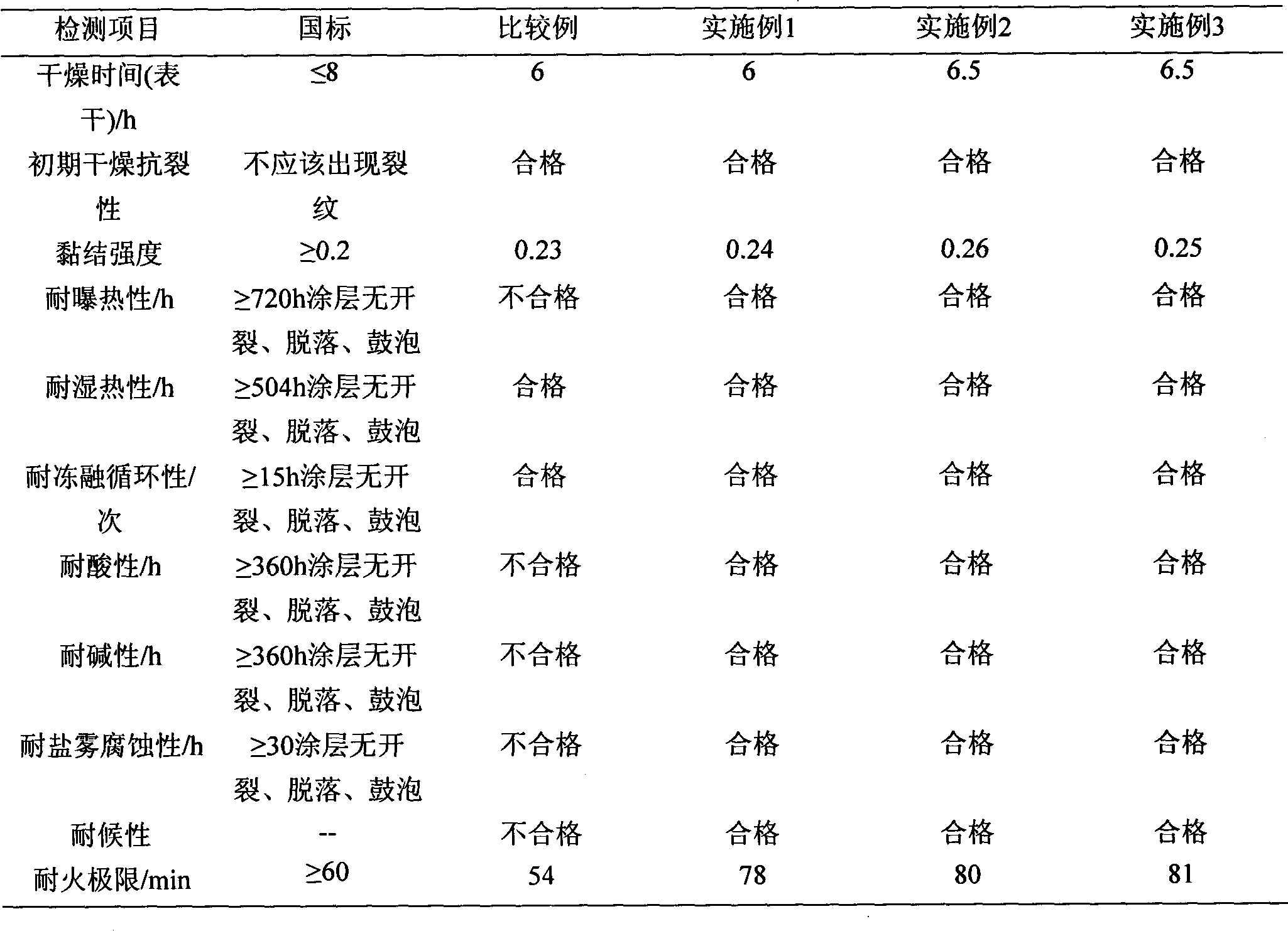

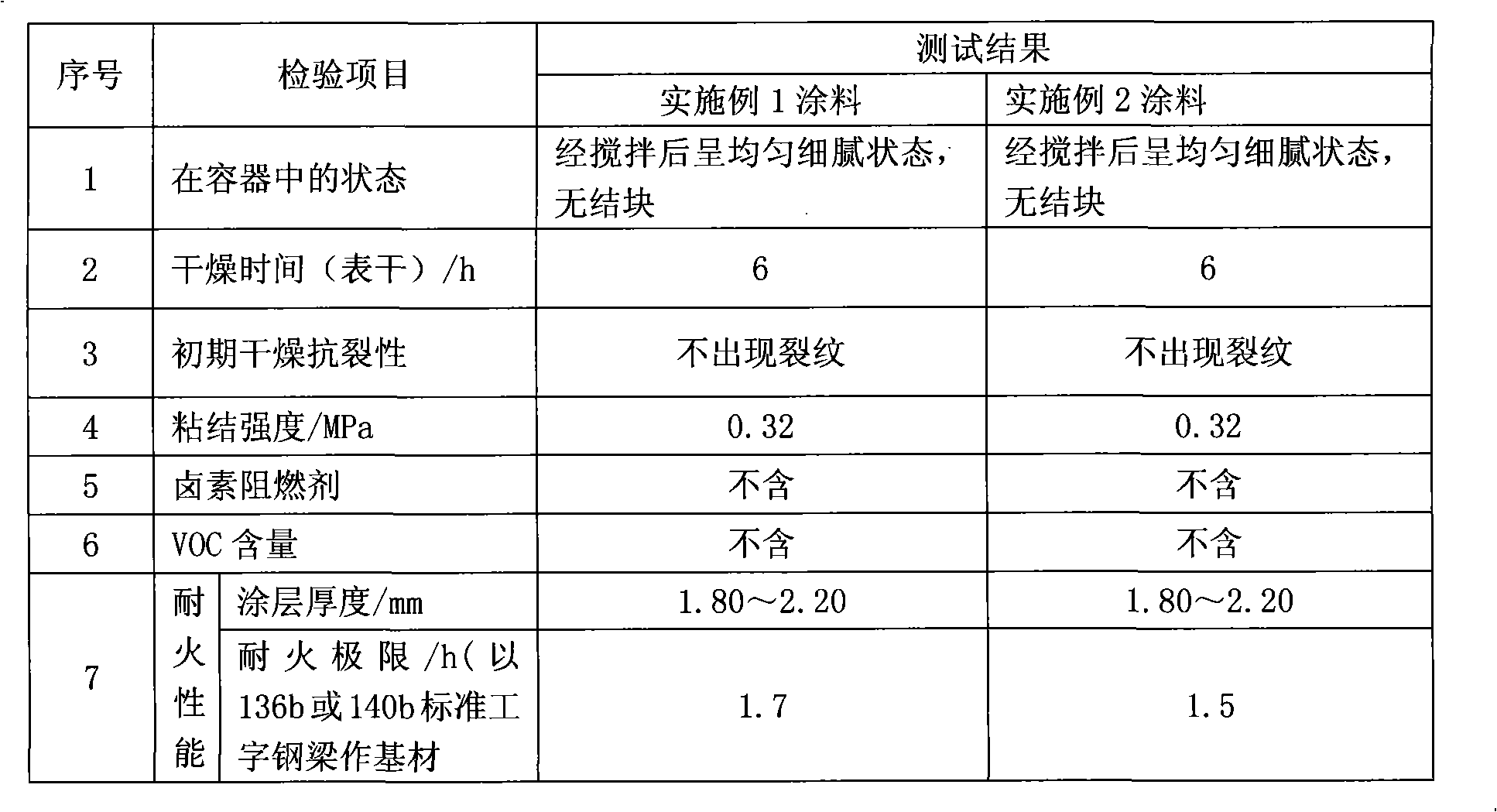

Waterborne ultra-thin steel structure fire retardant coating and preparation method thereof

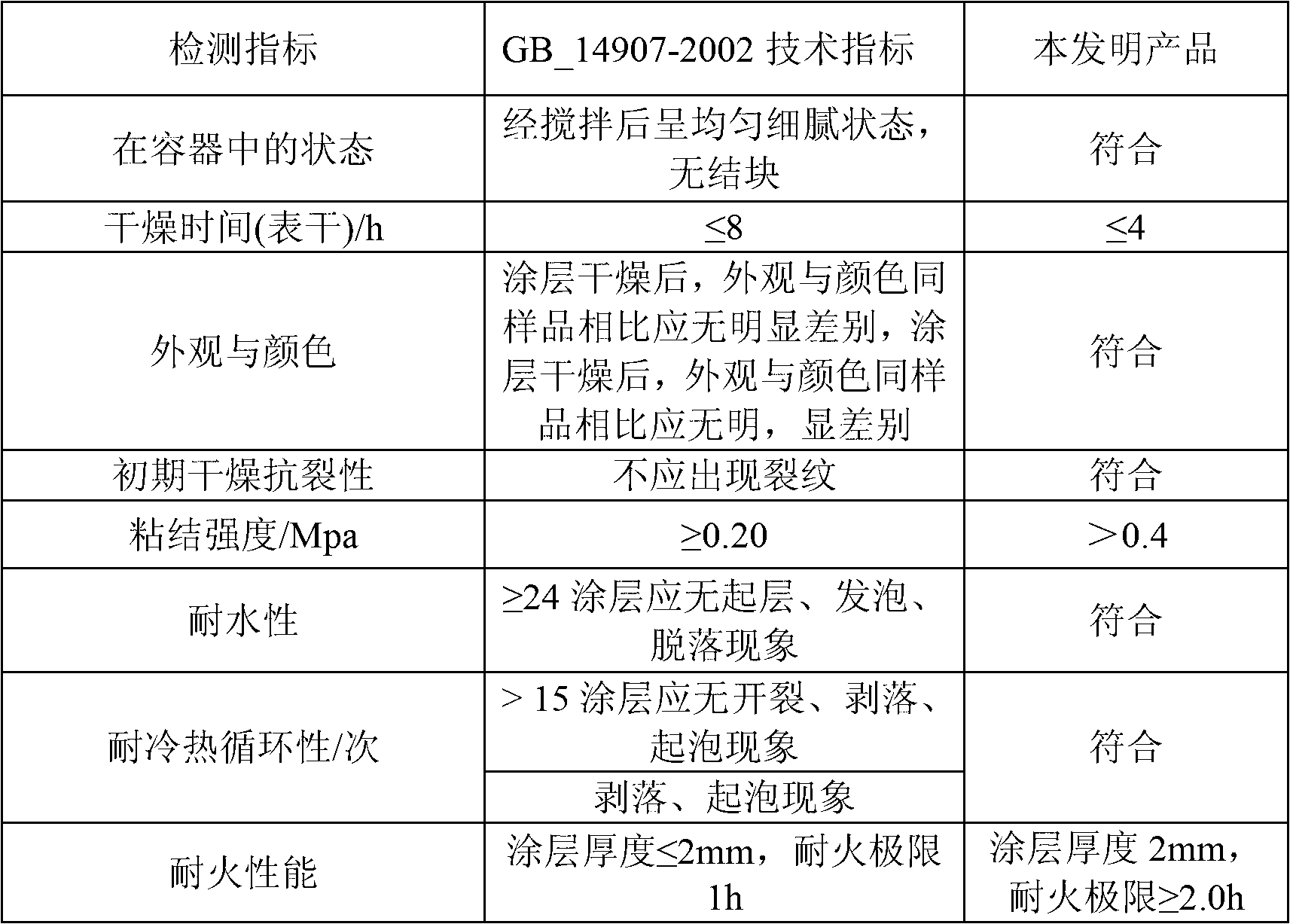

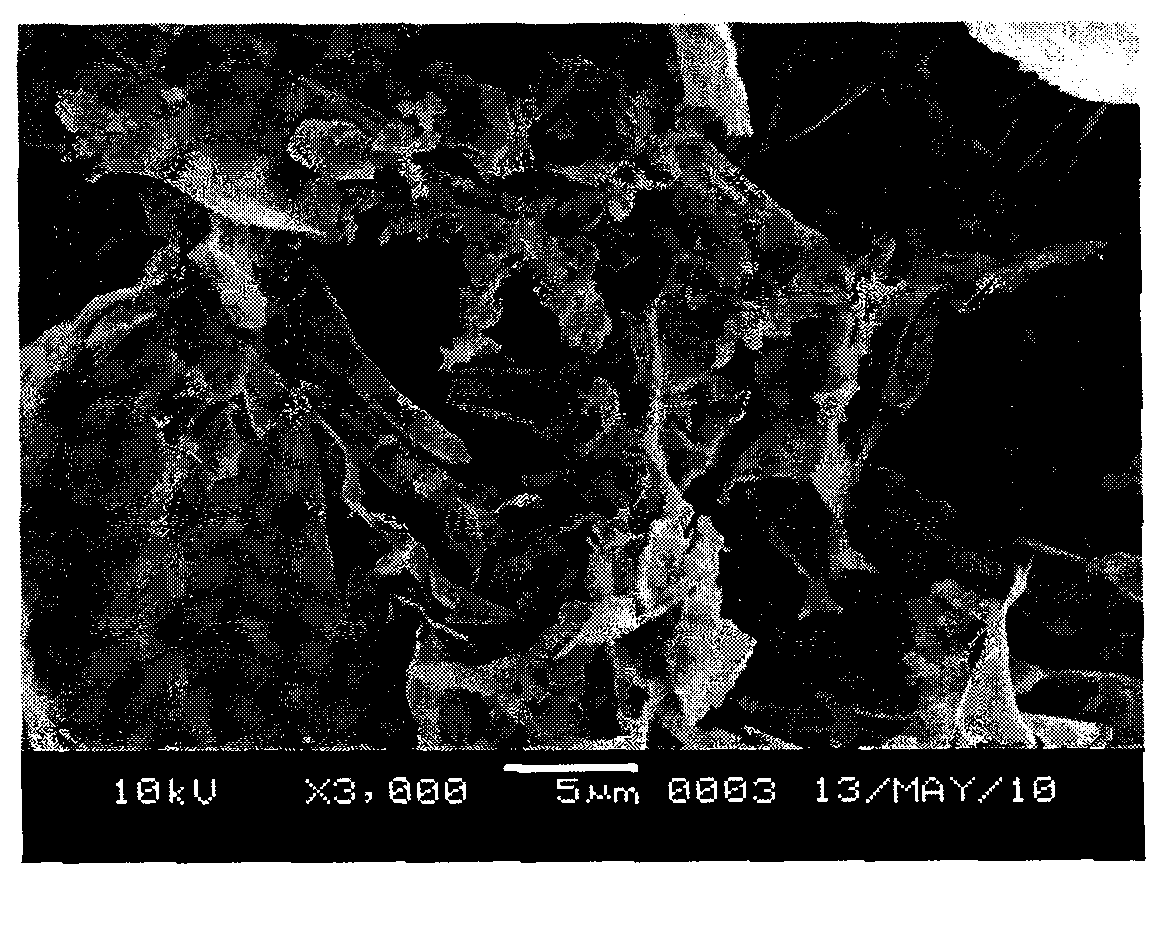

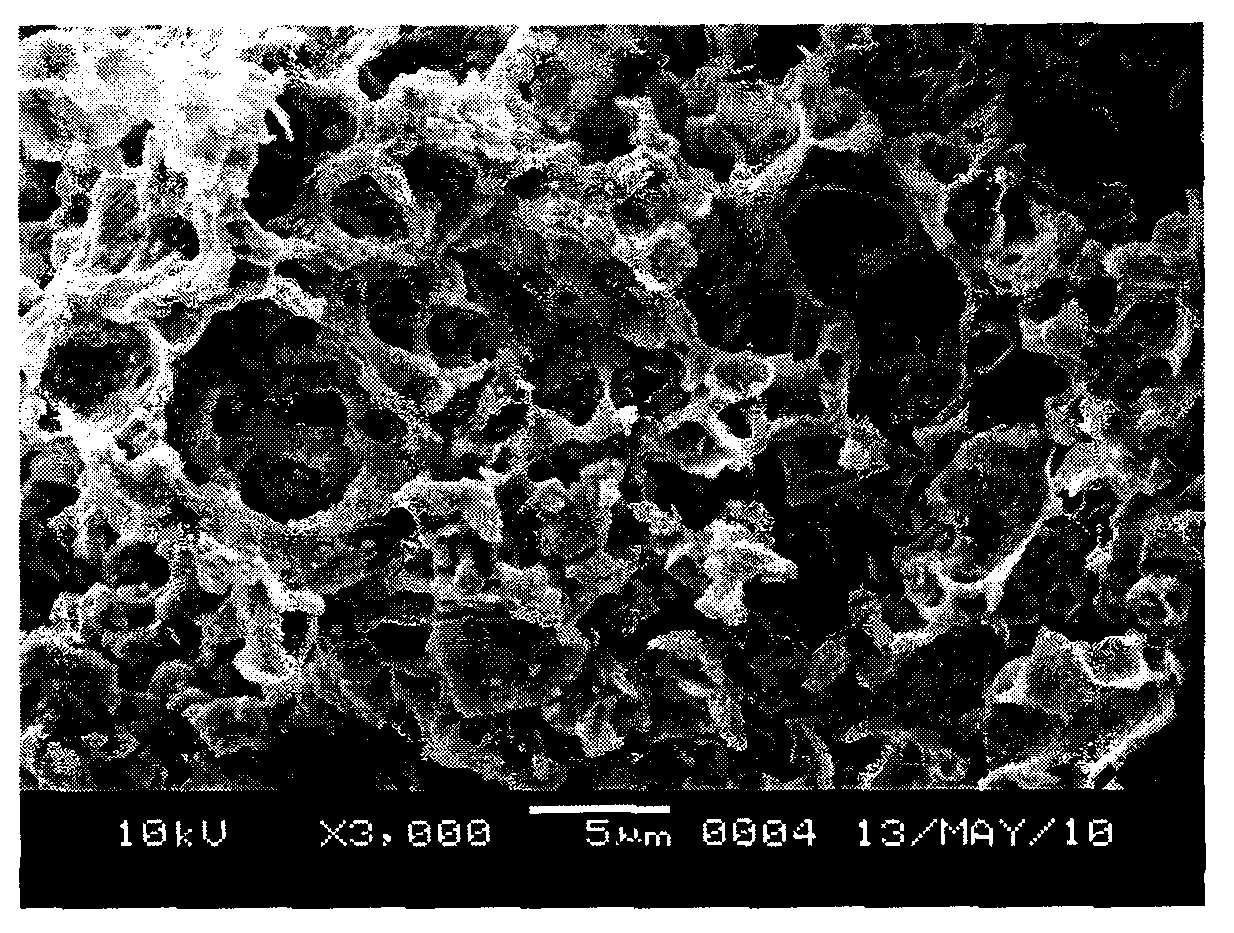

ActiveCN102838907AGood foaming effectThe pores are small and uniformFireproof paintsCarbonizationMaterials science

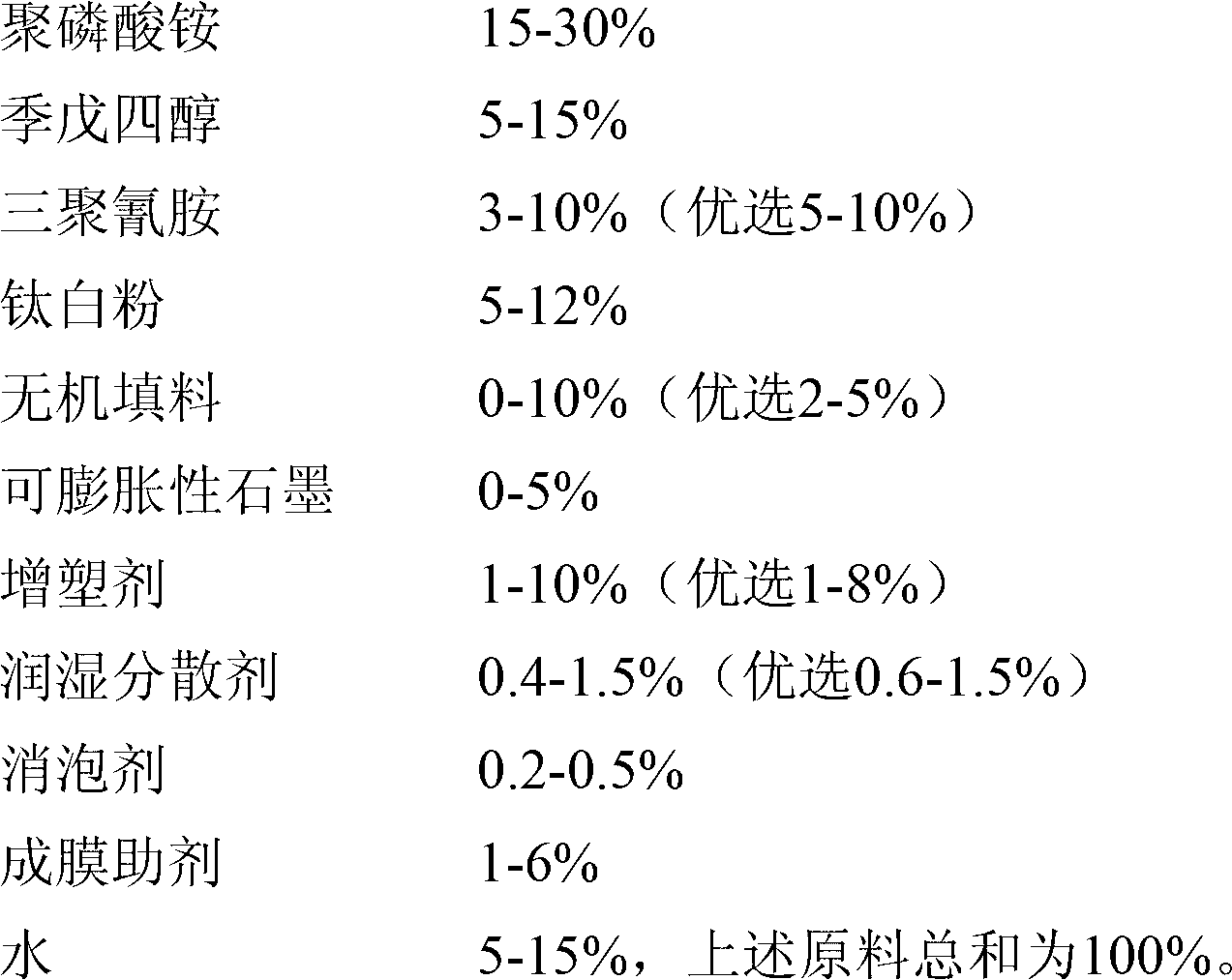

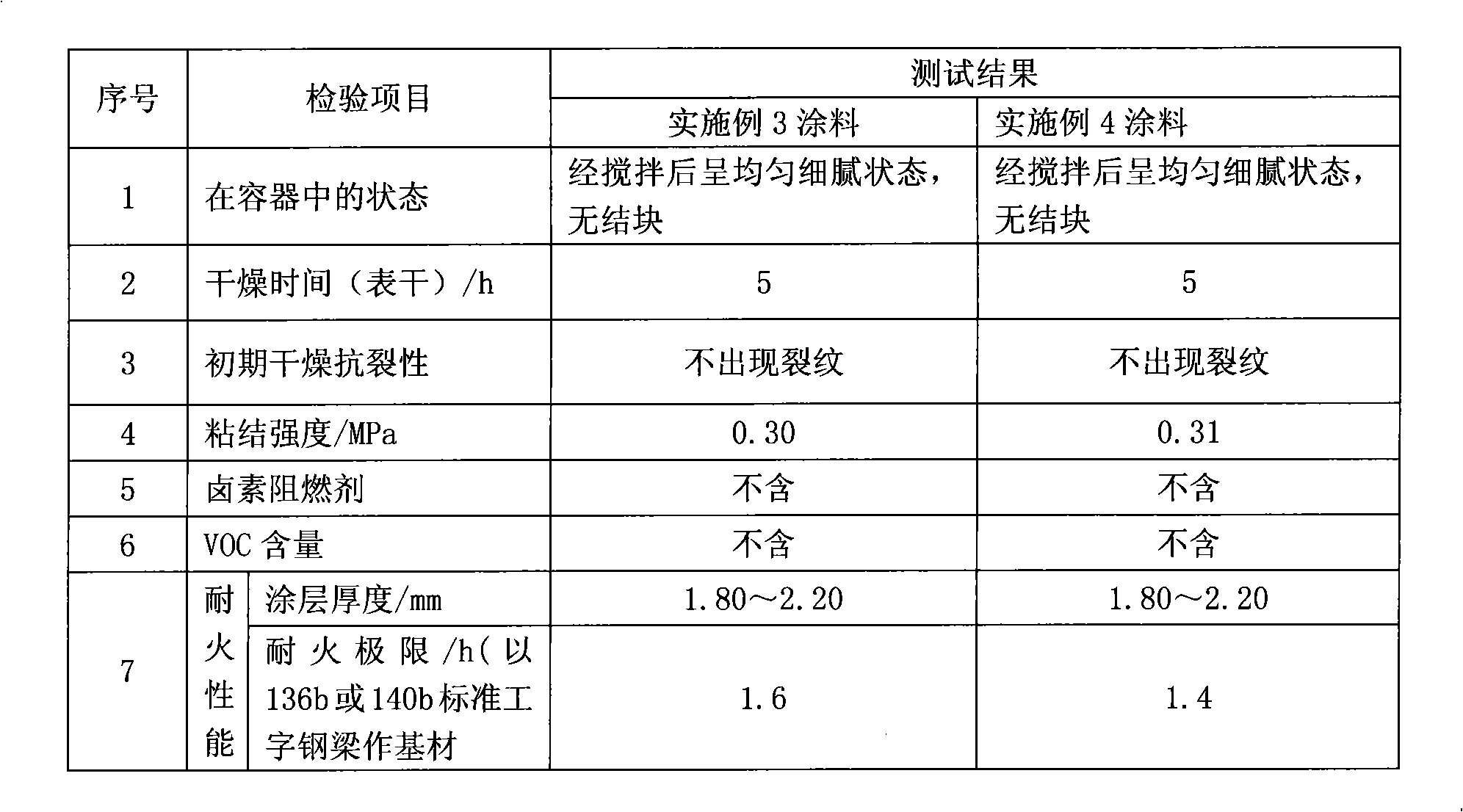

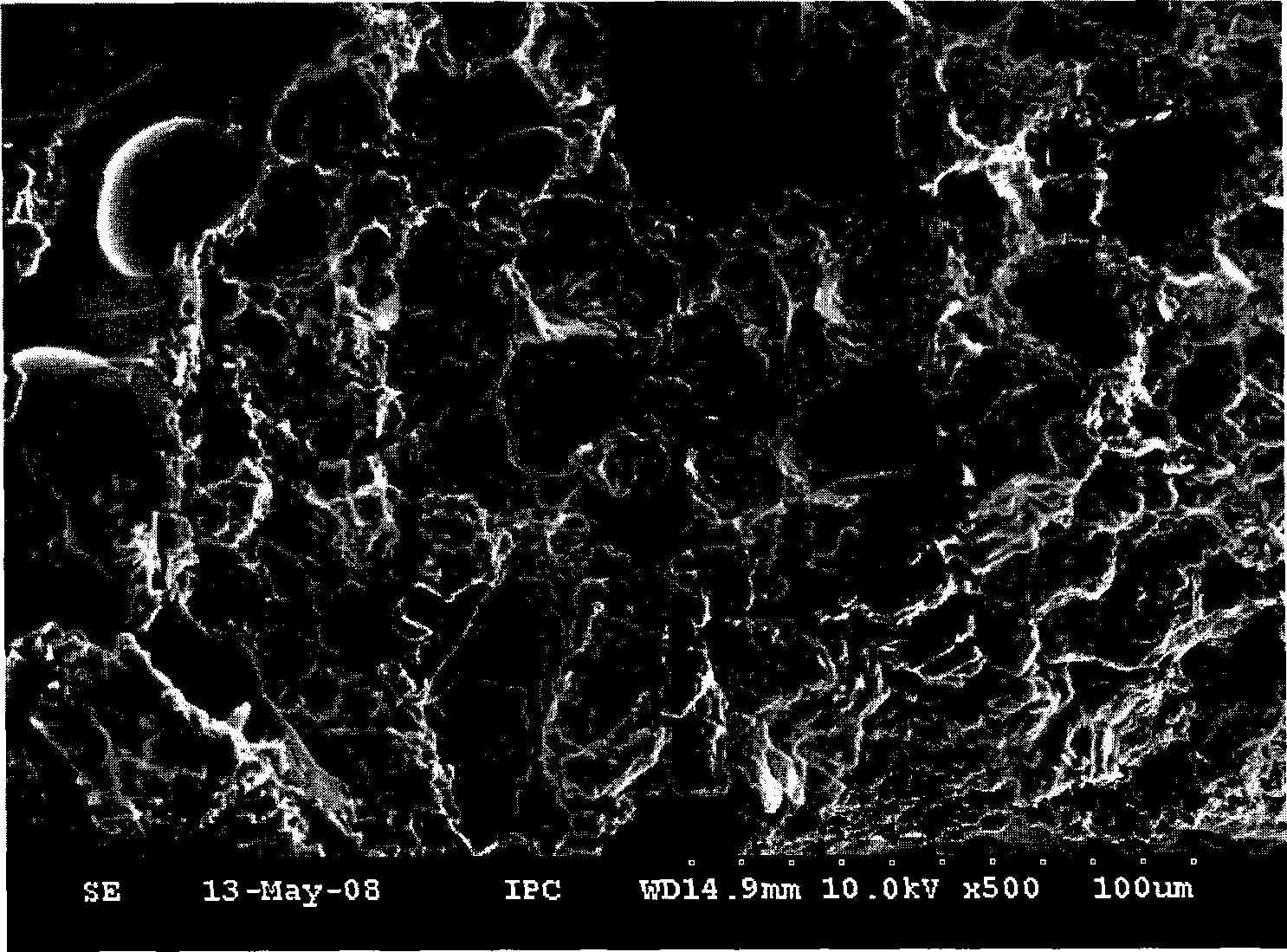

Provided is a waterborne ultra-thin steel structure fire retardant coating and a preparation method thereof. The raw material ratio of the coating includes 15-50% by weight of polymer latex, 15-30% by weight of ammonium polyphosphate, 5-15% by weight of pentaerythritol, 3-10% by weight of cyanurtriamide, 5-12% by weight of titanium dioxide, 2-13% inorganic filler, 0-5% by weight of expansiveness graphite, 1-10% by weight of plasticizer, 0.4-1.5% by weight of wetting dispersant, 0.2-0.5% by weight of defoamer, 1-6% by weight of coalescing agents and 5-15% by weight of water, and total raw material ratio is 100%. A high-speed dispersion method or a grinding dispersion method is adopted in preparation of the coating. A coating layer of the fire retardant coating can form a carbonization layer which is good in foaming effect, small and uniform in air holes and high in expansion times when in heating. The final fire retardant performance of the coating is far higher than technical requirements of a national standard. The waterborne ultra-thin steel structure fire retardant coating is a waterborne coating product, is non-poisonous and odorless and environment-friendly, and can be coated in a mode of brushing or spraying or roller coating.

Owner:SOUTH CHINA UNIV OF TECH +1

Aqueous ultra-thin expansion type steel structure fire-proof anti-corrosive paint and preparation method thereof

InactiveCN101857760AGuaranteed expansion heightHas anti-rustFireproof paintsAnti-corrosive paintsAcrylic resinRust

The invention relates to an aqueous ultra-thin expansion type steel structure fire-proof anti-corrosive paint and a preparation method thereof. The fire-proof anti-corrosive paint is prepared by adding ammonium polyphosphate, pentaerythritol, melamine, titanium white, expandable graphite, a preservative, a ceramic filler, an antifoaming agent, a dispersing agent, a plasticizer and the like into organic silicon-modified acrylic resin emulsion serving as a film forming base material. The paint has the advantages of high fire-proof performance, anti-corrosion and anti-rust function, and high water resistance, acid-alkali resistance and corrosion resistance, capability of meeting the requirements of various steel structures on the fire-proof and anti-corrosion performance, environmental friendliness, low cost, and readily available raw materials, so the paint can be widely applied to fire-proof protection of various steel structures.

Owner:EAST CHINA UNIV OF SCI & TECH

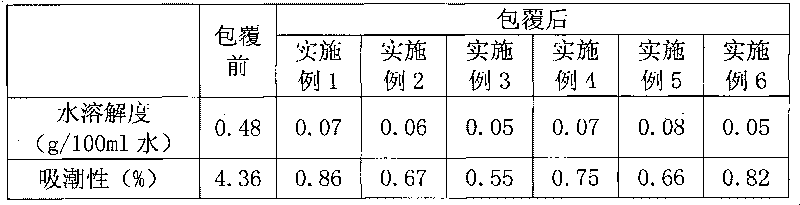

Method for preparing aminosilane coupling agent modifying ammonium polyphosphate

InactiveCN101235221AHigh flame retardant efficiencyReduce solubilityFireproof paintsFibre treatmentSolubilityPolyolefin

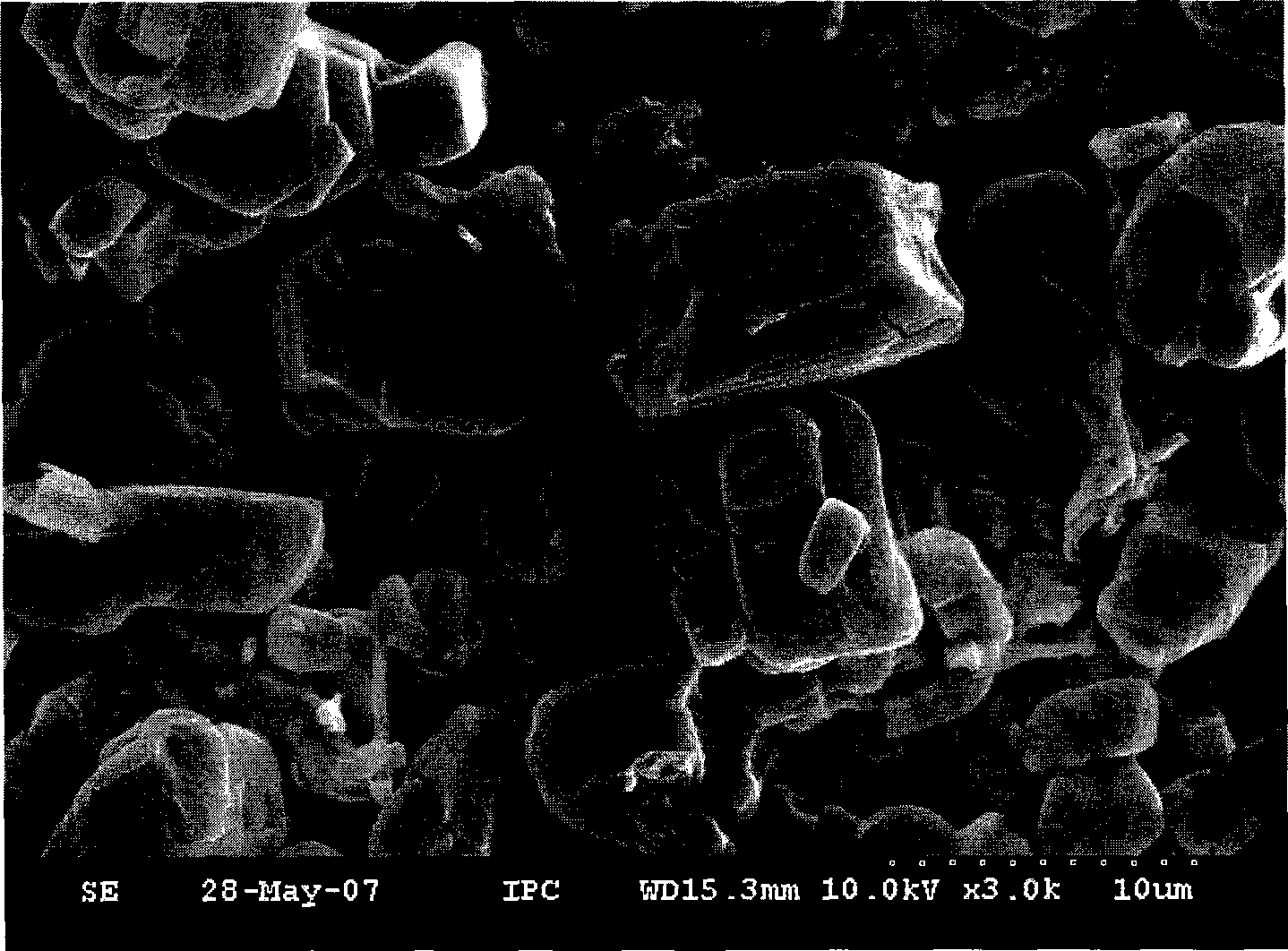

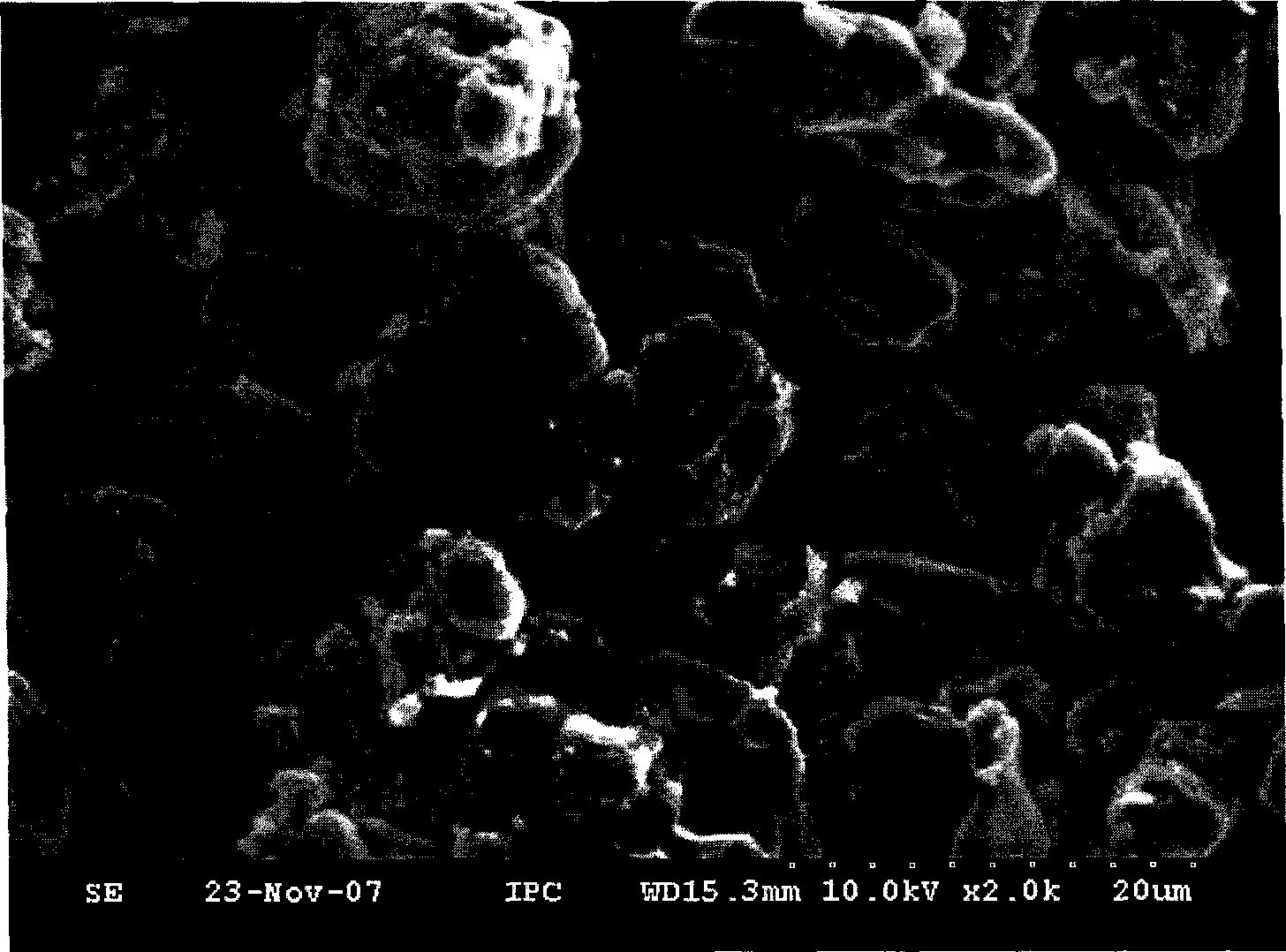

The invention discloses a preparation process of modifying ammonium polyphosphate with amino silane coupling agent, relating to the flame-retardant technology in chemical field. The invention provides a surface organic modified technology which can significantly reduce the water-solubility of ammonium polyphosphate, increases the compatibility of ammonium polyphosphate expansion flame-proof macromolecule material and the flame-proof efficiency, aiming to the problems existing the current ammonium polyphosphate flame-retardant that the current ammonium polyphosphate flame-retardant has higher dissolvability in water, and serious mechanical loss after applied on flame-proof plastic. The invention is conducted through two steps that firstly mixing amino silane coupling agent with deionized water according to weight ratio to hydrolyze, and secondly conducting surface organic modifying processing for ammonium polyphosphate (II type) with hydrolyzed amino silane coupling agent, which makes the dissolvability of II type ammonium polyphosphate in water be reduced to 0.43g / 100mL H2O from 1.101g / 100mL H2O, and respectively increases elongation at break and tension strength by 39.4% and 8.0% through applying modified ammonium polyphosphate on expansion flame-proof polypropylene. The modified ammonium polyphosphate can be extensively applied on the expansion flame-proof of polyolefins plastic, textile, lumber, paper and painting.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

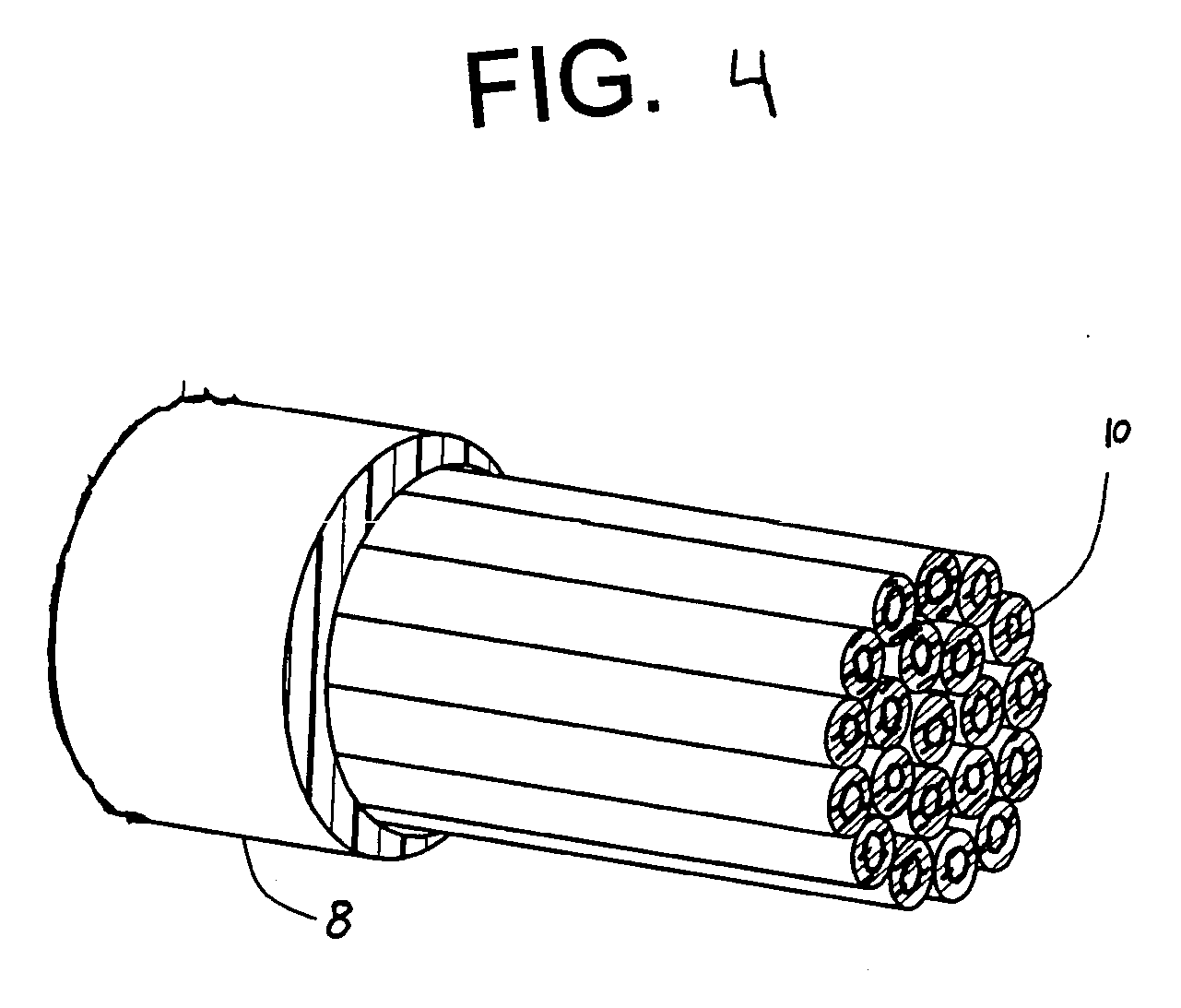

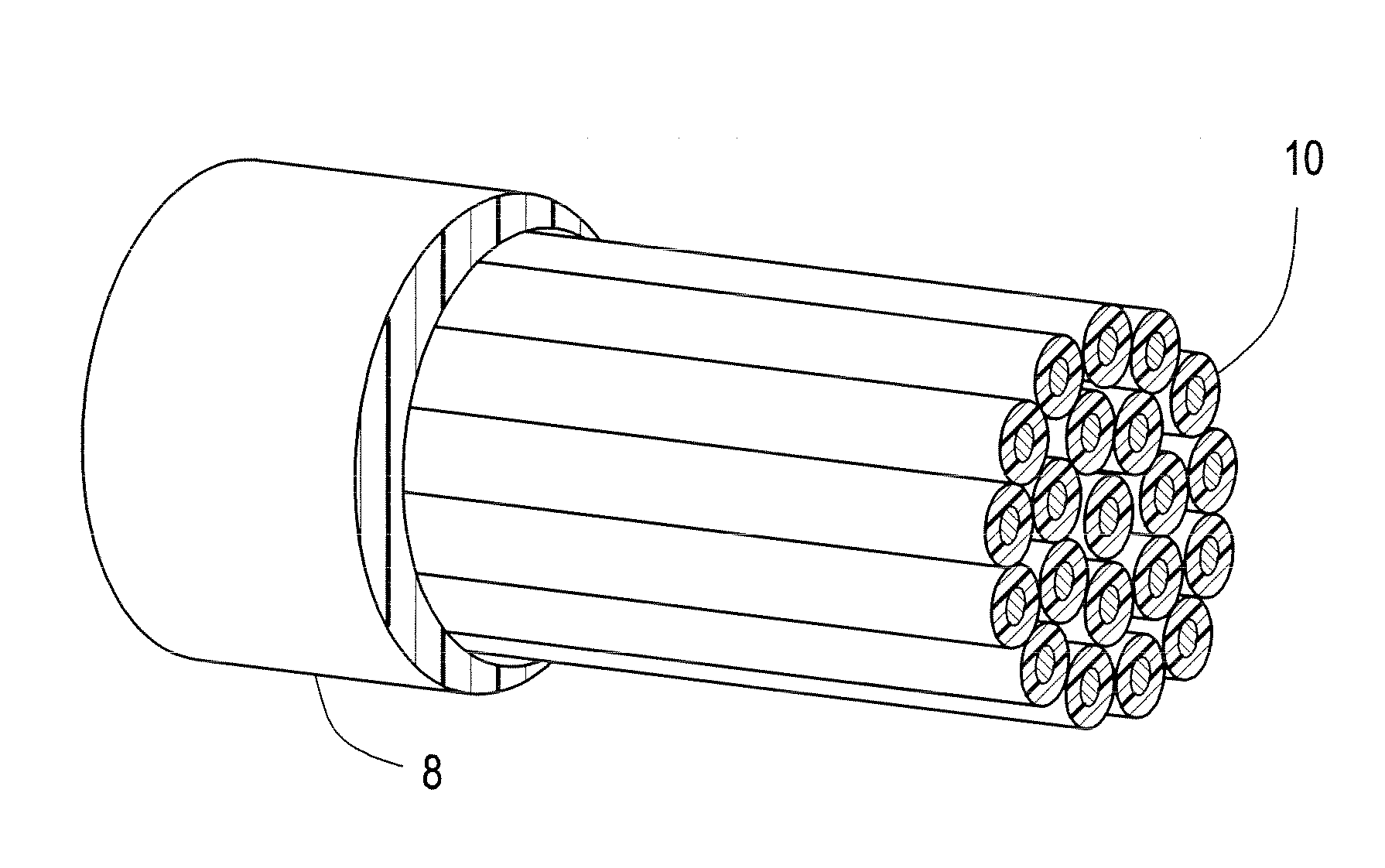

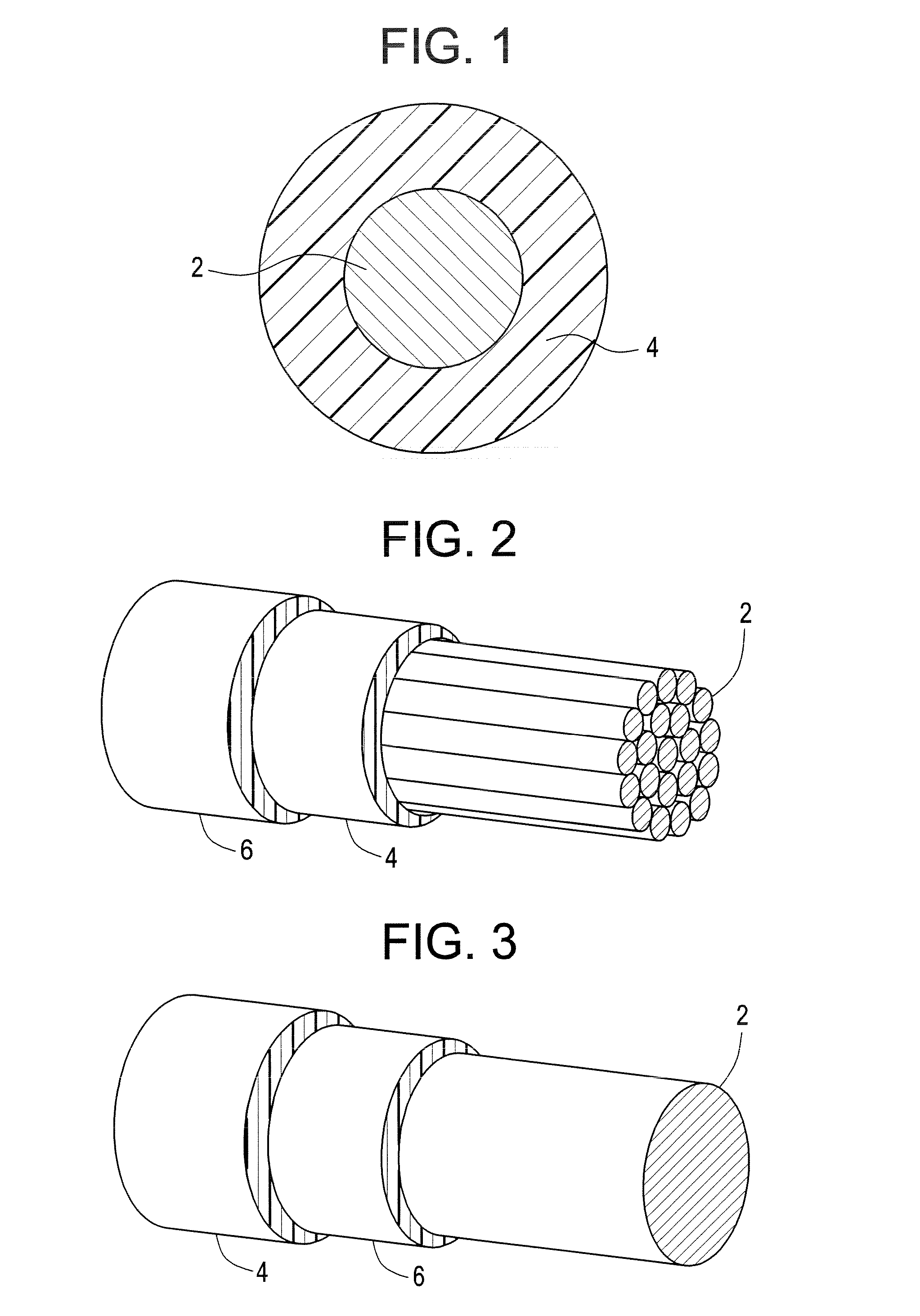

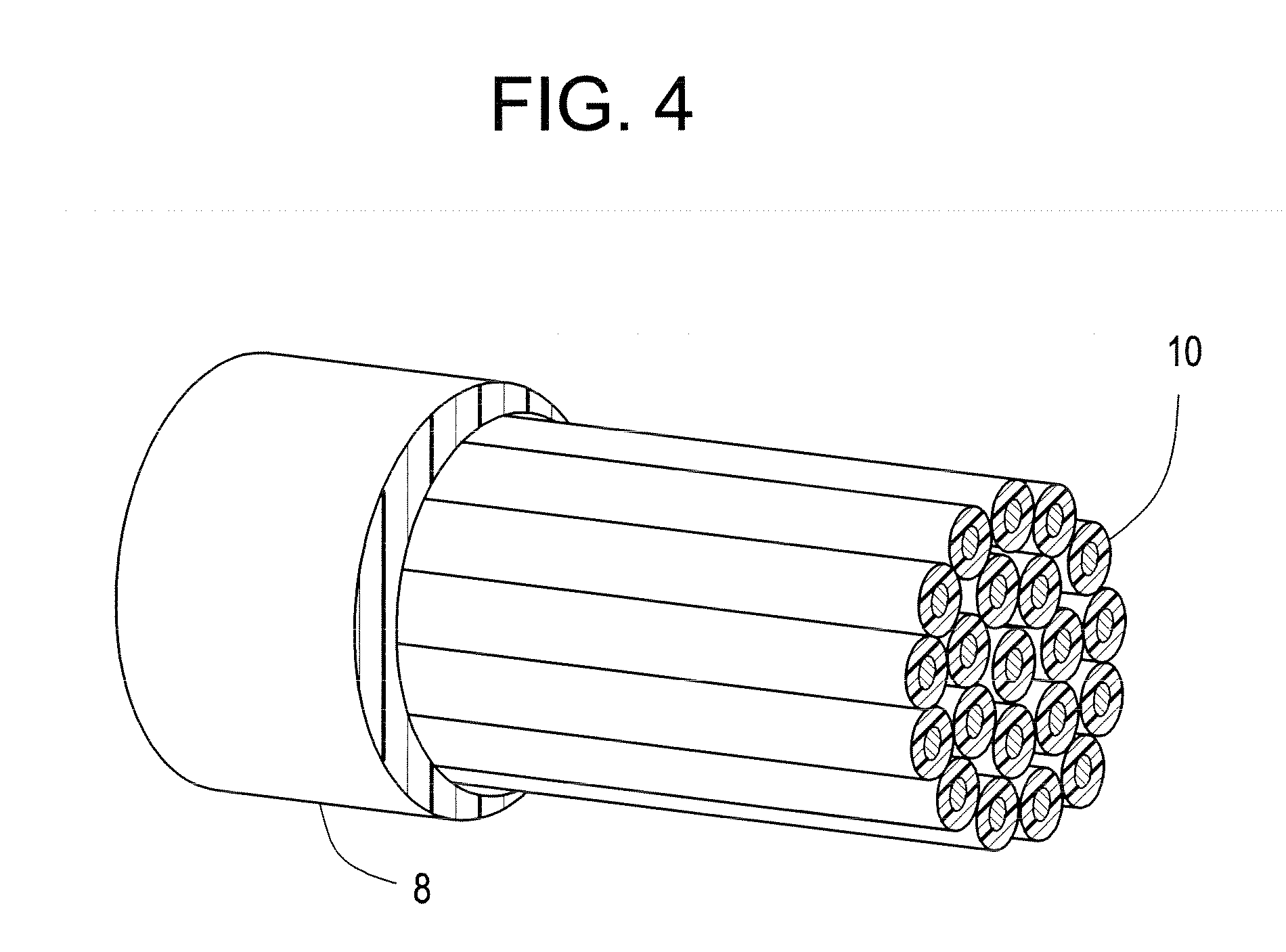

Flame retardant thermoplastic composition and articles comprising the same

ActiveUS20070261878A1Decreasing and eliminating plate-outDecreasing and eliminating and migrationPlastic/resin/waxes insulatorsDyeing processElectrical conductorPolyolefin

A flame retardant thermoplastic composition comprising a poly(arylene ether), a block copolymer, a liquid polyolefin, and a flame retardant additive composition. The flame retardant additive composition comprises a metal hydroxide, an organic phosphate, and a phosphoric acid salt selected from the group consisting of melamine phosphate, melamine pyrophosphate, melamine orthophosphate, melem polyphosphate, melam polyphosphate, diammonium phosphate, monoammonium phosphate, phosphoric acid amide, melamine polyphosphate, ammonium polyphosphate, polyphosphoric acid amide, and combinations of two or more of the foregoing. The block copolymer comprises a block that is a controlled distribution copolymer having terminal regions that are rich in alkylene units and a center region that is rich in aryl alkylene units. The flame retardant composition may be used in the production of covered conductors.

Owner:SHPP GLOBAL TECH BV

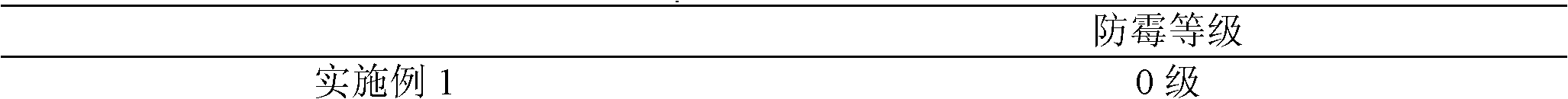

Anti-mildew halogen-free flame-retardant smoke-suppression wood-plastic composite material and preparation method thereof

The invention discloses an anti-mildew halogen-free flame-retardant smoke-suppression wood-plastic composite material, which comprises the following components in parts by mass: 25-70 parts of plastic resin, 10-50 parts of plant fiber powder, 5-10 parts of camphor wood powder, 0.5-20 parts of a compatibilizer, 0-15 parts of a toughening agent, 10-35 parts of a flame retardant and a synergist, 2-5 parts of a thermal stabilizer, 0-1 part of an antioxidant and 1-4 parts of a lubricating agent. According to a method for preparing the wood-plastic composite material with a two-step fusion method disclosed by the invention, the interfacial compatibility can be improved effectively, and the flame retardance of the wood-plastic composite material is enhanced on the premise of keeping high mechanical property; and moreover, the using amount of ammonium polyphosphate serving as a major flame retardant is reduced. Compared with the conventional wood-plastic composite material, the wood-plastic composite material disclosed by the invention has a simple production flow, has the technical effects of flame retardance, smoke suppression and mildew resistance, and is widely applied to occasions such as indoor and outdoor architectural decoration, and the like.

Owner:ANHUI GUOFENG WOOD PLASTIC COMPOSITE +1

Method for producing flame-retardant glued board

ActiveCN101412231AReduce releaseImprove flame retardant performanceOther plywood/veneer working apparatusWood treatment detailsAdhesivePyrophosphate

The invention discloses a method for producing a flame-retardant veneer plywood, which comprises the following steps: placing wood veneers into a flame retardant aqueous solution to perform dipping treatment, applying the mixed adhesive to the upper surfaces and the lower surfaces of the veneers after the veneers are dried, assembling the veneers into a plate blank according to the principle that odd layers are crossed and symmetrical with even layers, and then performing the processes of cold pressing, hot pressing, cutting edge, sanding, surface treating and the like to obtain the flame-retardant veneer plywood product the thickness of which is between 2.7 and 20 millimeters. The flame retardant in the method is a mixture of low ammonium polyphosphate, ammonium phosphate, ammonium pyrophosphate, urea phosphate, boric acid and pentaerythritol, and the mixed adhesive is a uniform mixture of wood adhesive, filler, and a curing agent. The flame-retardant decorative veneer plywood prepared by the method has the advantages of excellent flame-retardant and fireproof performance, environmental prevention performance, and good mechanical properties.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Aqueous environmental protection ultration expansion type steel structure fireproof paint and its preparation method

InactiveCN1824716ADecorativeReduce dosageFireproof paintsLiquid spraying apparatusAdditive ingredientPhosphate

The present invention provides a water environment-protecting superthin expanded type steel structure fire-retardant coating. Said fire-retardant coating uses water as dispersion medium, uses flake expandable graphite as expansion reinforcing material, uses one or several kinds of emulsions of acrylic emulsion and others as film-forming material, and its expansion system adopts the ingredients of polyammonium phosphate, pentaerythritol and tripolycyanamide. Said invention also provides its preparation method and concrete steps.

Owner:北京首纳东方科技有限公司

Fireproof coating

The invention relates to a fireproof coating. The fireproof coating is composed of, by weight, 15-25 parts of dicyandiamide, 15-30 parts of silicate, 10-18 parts of pentaerythritol, 8-15 parts of titanium dioxide, 7-10 parts of chlorcosane, 6-8 parts of ammonium polyphosphate, 15-20 parts of acrylic emulsion and the balance auxiliaries. The fireproof coating is free of poison and irritation; when the surface of steel is coated with the fireproof coating, the caking property is good and the coated steel is attractive and good in flame retardant efficiency.

Owner:娄志

Method for preparing core-shell silicon dioxide-coated ammonium polyphosphate (APP)

ActiveCN101760049ALow water solubilityHigh strengthSilicaPigment treatment with non-polymer organic compoundsMass ratioSilicon dioxide

The invention relates to a method for preparing core-shell silicon dioxide-coated ammonium polyphosphate (APP), which is characterized by comprising the following steps successively: (1) adding ammonium polyphosphate into ethanol water solution, stirring and dispersing well; (2) adding silicate ester ethanol solution into the solution obtained in the step (1) while the mass ratio of silicate ester to ammonium polyphosphate is 0.05-10:1, adjusting the pH value of the solution to 9-12 by adding alkaline solution, and then performing complete reaction at room temperature; and (3) adding couplingagent into the grout obtained in the step (2) to carry out surface treatment, and then filtrating, washing and drying to obtain the silicon dioxide-coated ammonium polyphosphate. On one hand, the ammonium polyphosphate flame retardant utilizes the synergistic flame retardance of silicon and phosphorus elements to increase retardant effectiveness and reduce dosage, thereby bringing down the negative effects of APP; on the other hand, the ammonium polyphosphate flame retardant utilizes the advantages of silicon dioxide, such as excellent hydrophobicity, heat resistance, high strength and the like, to further solve the problems of APP such as infiltration and migration, influence on product strength, insufficient heat resistance and the like.

Owner:浙江富锦新材料有限公司

Radiation cross-linked low-smoke halogen-free red phosphorus-free flame retardant material and its application

ActiveCN102766293AImprove flame retardant performanceAvoid it happening againInsulated cablesCable/conductor manufactureCross-linkAluminium hydroxide

The invention discloses a radiation cross-linked low-smoke halogen-free red phosphorus-free flame retardant material, which comprises the following components of: by weight, 10-80 parts of ethene-vinyl acetate copolymer, 5-30 parts of ethylene-octene copolymer and / or ethene-butene copolymer and / or terpolymer EP rubber, 0-100 parts of polyethylene, 1-20 parts of a polymer compatilizer, 0.5-10 parts of organosilicon polymer, 1-10 parts of a composite anti-oxidant, 0-200 parts of aluminium hydroxide and / or magnesium hydroxide and / or modified aluminium hydroxide and / or modified magnesium hydroxide, 0.1-100 parts of high molecular weight ammonium polyphosphate and / or 0.1-50 parts of a phosphate ester fire retardant and / or 0.1-50 parts of MCA. The material provided by the invention reaches American UL224VW-1 standard when applied in thermal shrinkable tubes, reaches American UL1581VW-1 standard when applied in electric wires and cables, contains no halogen or red phosphorus, and is environmentally friendly.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL

Water thin type expanding steel structure fire-resisting paint and its preparation method

The present invention relates to a water thin expanding steel structure fire-resisting coating material and its preparation method. Said ivnention adopts a self-synthesized high melting temp. acrylate emulsion as main film-forming substance, adding proper quantity of chlorometaemulsion to raise fibre resistance of film-forming substance self-body, and on the basis of convertional ammonium polyphosphate fire-resistant adjuvant an expandable graphite as foaming material is added so as to form the invented fire-resisting coating material. Said invention can greatly raise forming rate to coating layer, the thickness of foamed layer can be up to 30-50 times that of original coating layer, and its fire-resisting limit can be up to 75 min (thickness of coating layer is 3 mm).

Owner:TONGJI UNIV

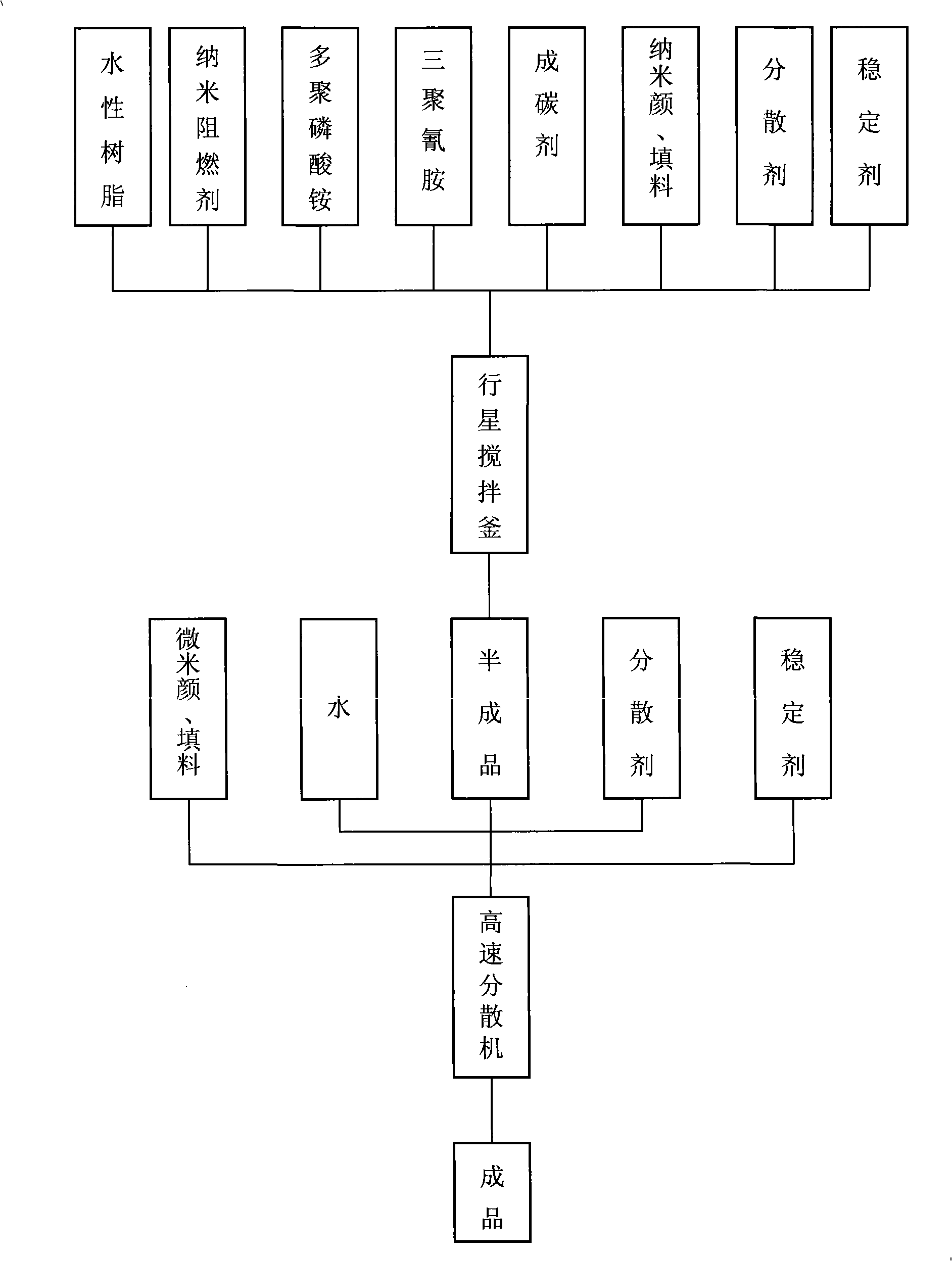

Environment-friendly aqueous nanometer fireproof flame-retardant coating and preparation thereof

InactiveCN101280142AImprove fire performanceLow VOC contentFireproof paintsEmulsion paintsPolymerStabilizing Agents

The invention is environmental-friendly waterborne nanometer fireproof flame-retardant coating and the preparation method, which belong to the fireproof flame-retardant coating manufacturing industry. The flame-retardant coating is obtained through the compounding of two types of flame-retardant agents, waterborne resin, ammonium polyphosphate, melamine, carbon-forming agent, nanometer pigment and filler, micrometer pigment and filler and other auxiliary agent; the flame-retardant coating contains no organic agent and halogen flame retardant, low VOC content, good fireproof property, good physical and chemical properties; the composition of the flame-retardant coating is as follows: the content of waterborne resin is 10-90%; the content of phyllo-silicate nanometer flame retardant which contains phosphor, nitrogen organic intercalation is 1-50%; the content of nanometer magnesium hydroxide flame retardant wrapped by polymer is 1-50%; the content of ammonium polyphosphate is 1-30%; the content of melamine is 1-20%; the content of carbon-forming agent is 1-30%; the content of nanometer pigment and filler is 0.1 to 30%; the content of micrometer filler is 0.1 to 60%; the content of dispersant is 0.1 to 10%; the content of stabilizer is 0.1 to 10%; the content of water is 0.1 to 50%; the content of micrometer pigment is proper; firstly, waterborne resin, nanometer flame retardant, ammonium polyphosphate, melamine, carbon-forming agent, nanometer pigment and fillers, dispersant and stabilizer are put into a planet stirring reactor for stirring and even dispersion; micrometer pigment and filler, water, dispersant and stabilizer are added to the discharged mixture and then put into a high-speed dispersion machine for even dispersion so that the product is obtained.

Owner:中山市孙大化工科技有限公司

Expansion type flame-retardant coatings glue and use thereof in textile finishing

ActiveCN101498100AImprove washing resistanceResistance to Mechanical ImprovementVegetal fibresCross-linkPolymer science

The invention discloses an intumescent flame retardant coating gum and the application thereof on fabric finishing. When the traditional intumescent flame retardant is applied to fabric, the fabric is not resistant to water rinse, water immersion or transfer, the flame retardant can lose or degrade under the action of luminous rays, heat, moisture and mechanical external force, and the flame retardant properties are reduced. The intumescent flame retardant coating gum comprises a flame retardant coating base gum and a carbon source, and is characterized in that the flame retardant coating base gum is prepared by mixing ammonium polyphosphate, melamine and 4A zeolite, adding organic alcohol, coating the mixture by more than two silane coupling agents for modification, drying the mixture after removing the organic alcohol to obtain a composite flame retardant, adding water, a non-ionic surface active agent, a binding agent and a cross-linking agent to the composite flame retardant, and grinding and dispersing the mixture; the carbon source is aqueous polyacrylic ester containing hydroxyl groups or aqueous polyurethane containing hydroxyl groups or a modifier of the former two. The invention obviously improves the performance of the flame retardant coating gum on flame retardant fabric for resistance to water rinse, transfer, light, heat and friction.

Owner:传化智联股份有限公司 +2

Dual components foaming system and products in use for fireproof plugging

This invention discloses a bi-component foaming system and its product used for fireproof plugging of buildings. The bi-component foaming system is a fireproof plugging material, and is prepared by mixing components A and B at a ratio of (1-4):2, and reacting. Compoent A is composed of polyester polyol, polyether polyol, catalyst, foaming agent, foaming stabilizer and composite flame retardant. Component B is composed of polyisocyanates. The basic component of the bi-component foaming system and its product is flame retardant bi-component polyurethane foam plastic. The flame retardancy technique in this invention is much different from traditional flame retardancy technique using polyurethane foam plastic as the fireproof plugging material. Firstly, hollow microbeads are added during the preparation of polyurethane foam plastic, which can improve flame retardant effect, reduce the material viscosity, improve processability, and reduce the heat conductivity of polyurethane foam plastic. Thus polyurethane foam plastic with good heat insulation effect can be obtained. Secondly, polyisocyanurate is used to modify polyurethane foam plastic, which can improve the flame retardancy of polyurethane foam plastic. Thirdly, the synergistic flame retardant effect of polyisocyanurate, ammonium polyphosphate and expandable graphite can largely improve the flame retardancy of polyurethane foam plastic, and can largely reduce the addition amount of flame retardant with the same flame retardant effect.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

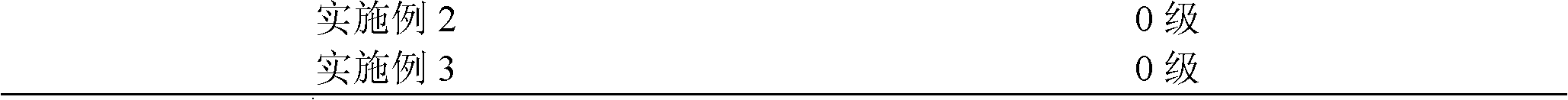

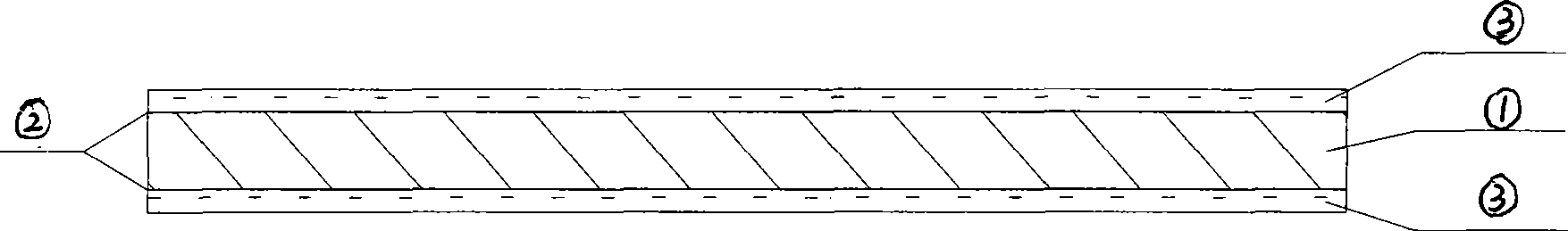

Low-smoke halogen-free inflaming-retarding cable material and preparation method thereof

InactiveCN101597395AHigh strengthHigh elongationRubber insulatorsPlastic/resin/waxes insulatorsLow-density polyethyleneLinear low-density polyethylene

The invention provides a low-smoke halogen-free inflaming-retarding cable material and preparation method thereof. The cable material comprises 5 to 15 parts (part by weight) of compatilizer that comprises maleic anhydride functional group grafted ethylene-vinyl acetate copolymer and maleic anhydride functional group grafted ethylene propylene terpolymer; 85 to 95 parts of base material formed by blending two or more than two of linear low-density polyethylene, ethylene-vinyl acetate copolymer and ethylene propylene terpolymer granular materials; 2 to 6 parts of composite antioxidant composed of the following antioxidants in terms of weight ratio: hindered phenol antioxidants : thiol ester antioxidants = 1 : (2 to 6); 20 to 40 parts of ammonium polyphosphate; 10 to 20 parts of pentaerythritol; 8 to 15 parts of melamine; 50 to 100 parts of composite inorganic fire retardant composed of the following fire retardants: magnesium hydroxide : zinc borate = (2 to 4) : 1; 2 to 6 parts of lubricant; 0 to 0.5 parts of metal passivator; 0 to 3 parts of crosslinking assistant agent; and 0 to 5 parts of halogen-free master batch. The invention has provided a harmless halogen-free inflaming-retarding cable material having high temperature tolerance, high tension, high elongation and high fire resistance.

Owner:ORIGIANL DOW ADVANCED COMPOUNDS SHANGHAI +2

Expanded type aqueous facing fireproof coating and preparation method thereof

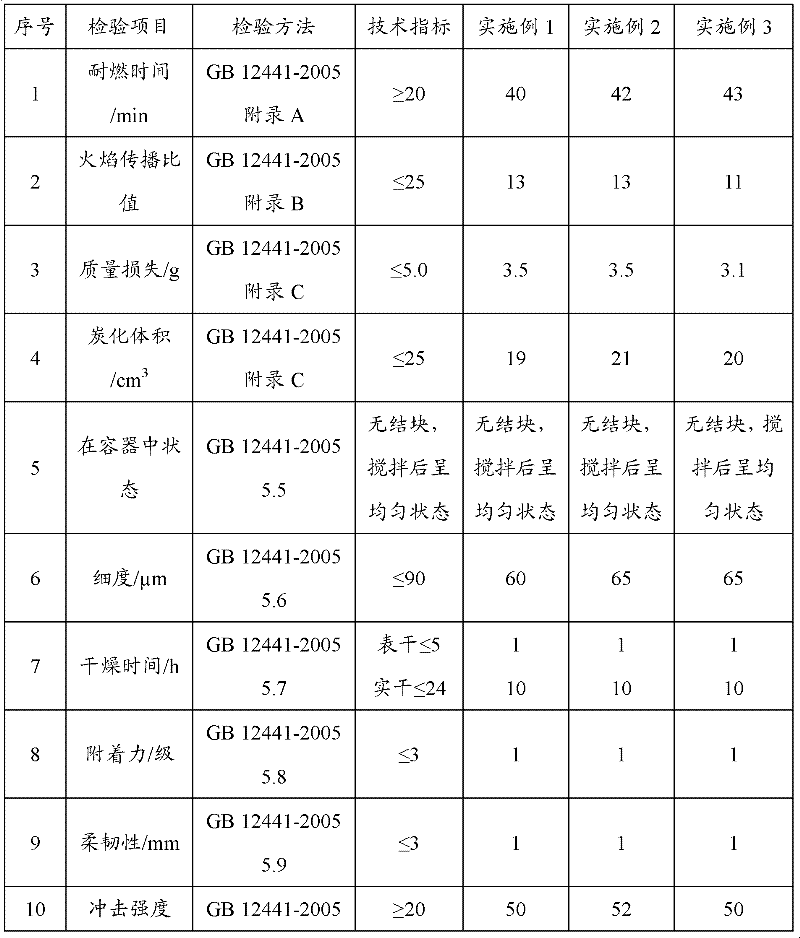

ActiveCN102675992AImprove fire resistanceImprove water resistanceFireproof paintsCelluloseChlorinated paraffins

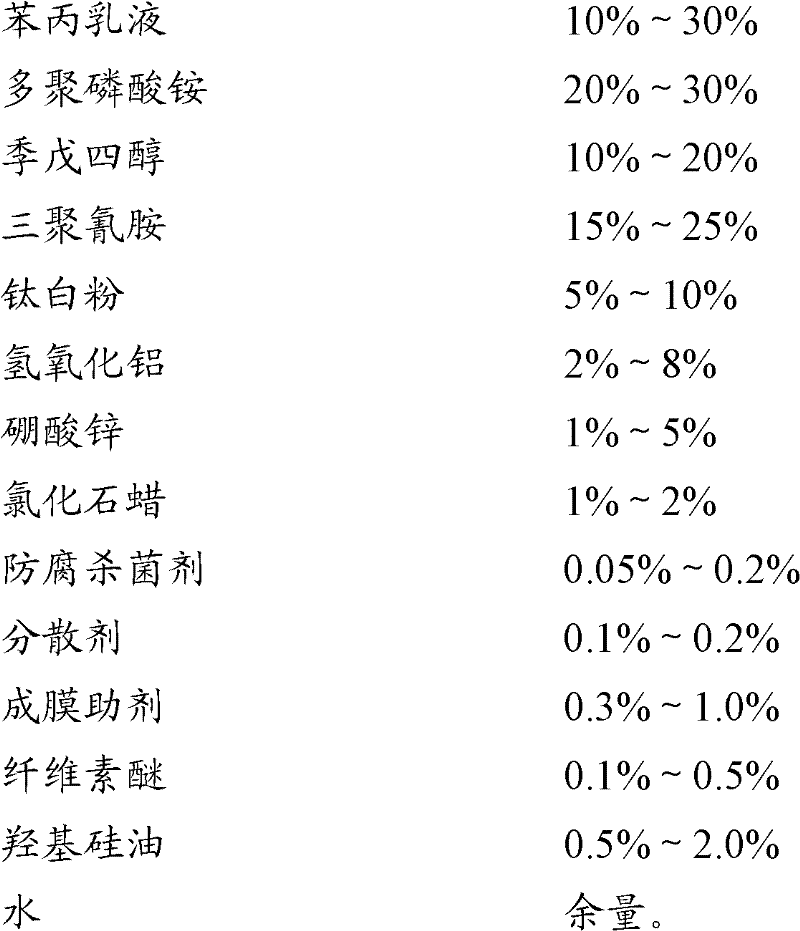

The invention provides an expanded type aqueous facing fireproof coating, which comprises the following components by weight: 10% to 30% of styrene-acrylic emulsion, 20% to 30% of ammonium polyphosphate, 10% to 20% of pentaerythritol, 15% to 25% of melamine, 5% to 10% of titanium dioxide, 2% to 8% of aluminum hydroxide, 1% to 5% of zinc borate, 1% to 2% of chlorinated paraffin, 0.05% to 0.2% of antiseptic, 0.1% to 0.2% of dispersing agent, 0.3% to 1.0% of film-forming auxiliary, 0.1% to 0.5% of cellulose ether, 0.5% to 2.0% of hydroxy silicone oil and the balance of water. The expanded type aqueous facing fireproof coating, provided by the invention, has the advantages of excellent water resistance and salt mist resistance, excellent adhesion and flexibility, good storage stability, no layering, no fineness change and no packing phenomenon, excellent waterproof resistance, smooth and fine coating film, no toxicity and pollution, and environment-friendliness.

Owner:CARPOLY CHEM GRP

Flame retardant composition

A flame retardant additive composition comprising a phosphoric acid salt selected from the group consisting of melamine phosphate, melamine pyrophosphate, melamine orthophosphate, ammonium phosphate, ammonium phosphate amide, phosphoric acid amide, melamine polyphosphate, ammonium polyphosphate, ammonium polyphosphate amide, polyphosphoric acid amide and combinations of two or more of the foregoing; a metal hydroxide; and an organic phosphate. The flame retardant additive is useful in a wide range of thermoplastic compositions.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Core-shell type ammonium polyphosphate synergetic flame-retardant polyurethane elastic composite material and preparation method thereof

ActiveCN101608060AHigh flame retardant efficiencyImprove efficiencyPolyurethane elastomerFire protection

The invention discloses a core-shell type ammonium polyphosphate synergetic flame-retardant polyurethane elastic composite material and a preparation method thereof, which is characterized in that the polyurethane elastic composite material containing core-shell type ammonium polyphosphate can be obtained by melting and co-mixing 75-94.9% of polyurethane, 5-25% of core-shell type ammonium polyphosphate and 0.1-5% of synergistic agent at the temperature of 160-220 DEG C for 5-30 minutes by weight percentage. The composite material can ensure that the adding amount of flame retardant is reduced while ensuring the flame retardance effect, and the composite material has good resistance of melt drip, simultaneously improves the shortcoming of poor water resistance of the flame-retardant composite material containing the ammonium polyphosphate, enhances the compatibility of the flame retardant and a polyurethane elastomer and improves the mechanical properties of the material, such as tensile strength, fracture strength and flame retardance performance, thereby meeting the requirements of fire protection safety and engineering applications.

Owner:UNIV OF SCI & TECH OF CHINA

Fire-retardant paint with steel structure

ActiveCN101857756AExtend fire resistance timeImprove fire resistanceFireproof paintsPolyurea/polyurethane coatingsPhosphoric acidComposite substrate

The invention relates to fire-retardant paint with a steel structure, which is prepared from the following raw materials proportioning by weight: 45 to 60 of composite substrate resin, 6 to 8 of melamine, 6 to 8 of pentaerythritol, 16 to 20 of ammonium polyphosphate, 4 to 10 of expansible graphite, 2 to 5 of nano magnesium hydroxide, 1 to 3 of zinc phosphate, 1 to 3 of zinc borate, 2 to 5 of aluminum hydroxide, 3 to 5 of aluminum polyphosphate, 6 to 9 of titanium dioxide, 0.5 to 0.8 of flatting agent and 15 to 20 of acetone. The paint has excellent capabilities of fire prevention and corrosion prevention.

Owner:INNER MONGOLIA XINGTAI CONSTRAL GRP CO LTD

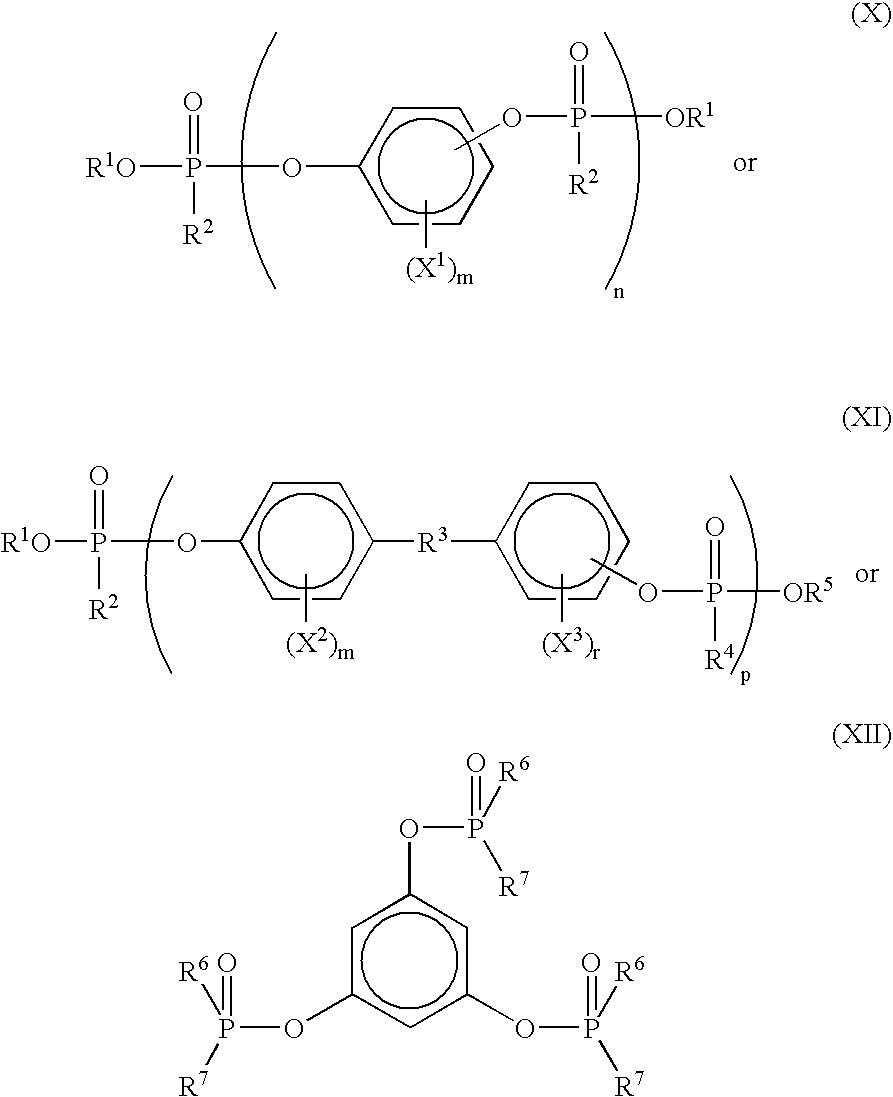

Flame retardant composition

A flame retardant additive composition comprising a phosphoric acid salt selected from the group consisting of melamine phosphate, melamine pyrophosphate, melamine orthophosphate, diammonium phosphate, monoammonium phosphate, phosphoric acid amide, melamine polyphosphate, ammonium polyphosphate, polyphosphoric acid amide and combinations of two or more of the foregoing; a metal hydroxide; and an organic phosphate. The flame retardant additive is useful in a wide range of thermoplastic compositions.

Owner:SHPP GLOBAL TECH BV

Three-source integrated microcapsule intumescent flame retardant and preparation method thereof

InactiveCN101812305AImprove toughnessHas a flame retardant synergistic effectMicroballoon preparationMicrocapsule preparationPolymer scienceMelamine formaldehyde

The invention discloses a three-source integrated microcapsule intumescent flame retardant and a preparation method thereof. The flame retardant integrates an acid source, a carbon source and a gas source; and the preparation method comprises the following steps of: reacting polyethylene glycol, melamine, aqueous solution of formaldehyde, a promoter with distilled water to prepare polyethylene glycol modified melamine-formaldehyde prepolymer; suspending ammonium polyphosphate powder particles in a dispersing agent; and adding the prepolymer and a hardener to finally obtain the three-source integrated microcapsule intumescent flame retardant powder particles. The flame retardant has good compatibility, flame retardancy and waterproofness.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

High-temperature resistant fiber filter paper for engine oil filter and preparation method of high-temperature resistant fiber filter paper

ActiveCN102912680AImprove high temperature resistanceImprove toughnessNon-macromolecular organic additionPaper/cardboardBursting strengthFiber

The invention discloses high-temperature resistant fiber filter paper for an engine oil filter and a preparation method of the high-temperature resistant fiber filter paper. The high-temperature resistant fiber filter paper comprises, by weight, 60-70 parts of coniferous wood pulp, 20-30 parts of cotton pulp, 20-30 parts of modified polyimide fiber, 2-5 parts of kaoline, 1-3 parts of lithopone, 2-4 parts of silica gel, 1-2 parts of nanometer titania, 0.5-0.8 part of ammonium polyphosphate, 1-2 parts of modified acrylic emulsion, 2-4 parts of acetic styrene-acrylic emulsion, 0.5-1 part of stearic acid monoglyceride, 0.5-1 part of silane coupling agent KH590, 0.4-0.8 part of sodium lauryl sulfate, and 2-5 parts of urea resin. The high-temperature resistant fiber filter paper prepared is good in water permeability, large in filtering area, small in maximum hole diameter, high in filtering precision, strong in bursting strength, high in temperature resistance and the like, has stable performance index under normal-temperature and high-temperature working conditions and is provided with good temperature resistance and filtering effects, and filtering efficiency of the high-temperature resistant fiber filter paper can reach 99.97%.

Owner:ANHUI PHOENIX INT CO LTD

Swell type combustion-proof glass fiber reinforced polypropylene composite material and its preparation method

InactiveCN1807497AImprove flame retardant performanceImprove mechanical propertiesSynthetic resin layered productsAmmonium polyphosphatePhosphate

This invention discloses a composite material which is non-halogen, environment-friendly, inflatable flame-resistant, glass fiber polypropylene reinforced and method for making same. This invention compounds the inflatableaa (IFR) composed by polyammonium phosphate(APP), melamine(MEL) and pentaerythrite(PER) with polypropylene, so as to entitle polypropylene material good flame-resistant, The mechanics behaviour of the material could be reinforced largely through composition with long glass fiber, glass fiber felt and after interface modifying. This material contains no halogen constituent; it generates little smoke and smoketoxicity is small. Through controlling the content of flame-resistant in composite material, we can get polypropylene composite material whose limited oxygen index over 45 and has good mechanics behaviour. This material has good application foreground in the fields of electric, ship making, orbit and building materials, which is very sensible to expand the application range of PP.

Owner:EAST CHINA UNIV OF SCI & TECH

Environment-friendly efficient filter filtering paper and preparation method thereof

ActiveCN102888784AImprove efficiencyImprove filtration efficiencyNon-fibrous pulp additionPaper/cardboardSolubilityGlycerol

The invention discloses an environment-friendly efficient filter filtering paper. The environment-friendly efficient filter filtering paper is prepared by the following raw materials in part by weight: 40-50 parts of softwood pulp, 30-40 parts of waste paper pulp, 20-30 parts of high-silica glass fiber, 2-5 parts of modified vermiculite, 1-3 parts of zeolite molecular sieve, 2-4 parts of nanometer calcium, 1-2 parts of modified pulverized fuel ash, 2-3 parts of water-solubility organic silicon resin emulsion, 1-2 parts of water-solubility polytetrafluoroethylene emulsion, 0.5-0.8 parts of ammonium polyphosphate, 3-4 parts of glycerol triacetate, 0.5-1 parts of diethanolamide, 0.5-1 parts of silane coupling agent KH560, 0.4-0.8 parts of sodium dodecyl sulfate, 0.5-1 parts of antioxidant DSTP, and 4-6 parts of polyethylenimine. The filtering paper prepared by the method provided by the invention has the advantages of being good in water permeability, large in filtering area, small in maximum diameter of hole, high in filtering precision, strong in bursting strength, high-temperature-resistant, good in water resistance and the like, can achieve the filtering efficiency by 99.98%, has stable performance index at atmospheric and high-temperature working conditions, as well as better temperature resistance and filtering effects.

Owner:ANHUI PHOENIX INT CO LTD

Polypropylene halogen-free intumescent flame retardant

InactiveCN104448560ASolve easy precipitationHigh flame retardant efficiencyPolymer scienceThermal stability

The invention discloses a polypropylene halogen-free intumescent flame retardant, and relates to a flame retardant, for solving the problems that the flame retardancy is degraded and a flame retardant is easily separated out from a material as a conventional polypropylene halogen-free intumescent flame retardant is low in flame retardancy efficiency, low in thermal stability, low in water resistance and poor in compatibility with polypropylene. The polypropylene halogen-free intumescent flame retardant is prepared from a carbonizing agent, ammonium polyphosphate, an auxiliary fire retardant, a processing additive and a modification additive. The invention discloses the polypropylene halogen-free intumescent flame retardant.

Owner:HONGLONGJIANG ORIENT SCI & TECH

Flame-retardant wood-plastic composite and preparation method thereof

The invention provides a flame-retardant wood-plastic composite and a preparation method thereof, which relates to a wood-plastic composite and the preparation method thereof. The invention solves the problems that the halogen-containing flame retardant in the existing flame-retardant wood-plastic composite releases a great amount of smoke, ammonium polyphosphate as the main body of the flame retardant is unsuitable for preparing the wood-plastic composite with the requirement of high temperature for contour machining, and the wood-plastic composite prepared has poor mechanical properties. The flame-retardant wood-plastic composite is made of modified waste plastic, wood fiber, intumescent flame retardant, lubricant and auxiliary agent. The preparation method of the flame-retardant wood-plastic composite comprises the following steps of: 1. weighing raw materials; 2. pretreating the wood fiber; 3. obtaining premix compound by mixing the raw materials; 4. preparing wood-plastic composite fusant by the melting compounding of the premix compound; 5. obtaining the flame-retardant wood-plastic composite by extrusion, injection, and thermocompression or compression molding. The intumescent flame retardant of the invention is suitable for preparing the wood-plastic composite with the requirement of high machining temperature. The flame-retardant wood-plastic composite has the advantages of good flame retardancy and mechanical properties, and little smoke release.

Owner:JIANGSU KENTIER WOOD

Halon-free intumescent fire-retardant epoxy resin compound

A halogen-free expansion flame-retardant epoxy resin combination mainly includes the following components (in terms of weight portion) 45 to 85 portions of epoxy resin, 4 to 40 portions of ammonium polyphosphate, 2 to 30 portions of melamine or the derivatives, 1 to 20 portions of phosphonate ester, 1 to 13 portions of solidified agent, 0.1 to 8 portions of diluting agent and 0.1 to 4 portions of filling agent. The combination with no halogen, strong moisture resistance and good flame retardance can reach V-0 standard in UL-94; therefore, the combination is used as the substrate of manufacturing spare parts and fittings in the electronic and electric field.

Owner:SHANGHAI RES INST OF CHEM IND

Material used for halogen-free flame retardant heat shrinkable sheathing and cross-linking cable wire and preparation method thereof

The invention relates to a material used for a halogen-free, flame retardant and thermal shrinkage sleeve and crosslinked wires and cables as well as the preparation method, aiming to provide a material and the preparation preparation method for halogen-free, flame retardant and thermal shrinkage sleeve and crosslinked wires and cables in diversified colors. The preparation method comprises the following steps: first, evenly mixing the compound formed by polyolefin copolymer, silicon rubber, halogen-free ammonium polyphosphate composite fire retardant, lubricant, colorant color master batch and antioxidant in specific proportions through a high speed mixer, then extruding and granulating the compound by means of the mechanical blending, finally turning out the material for producing the halogen-free flame retardant and thermal shrinkage sleeve and crosslinked wires and cables.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL

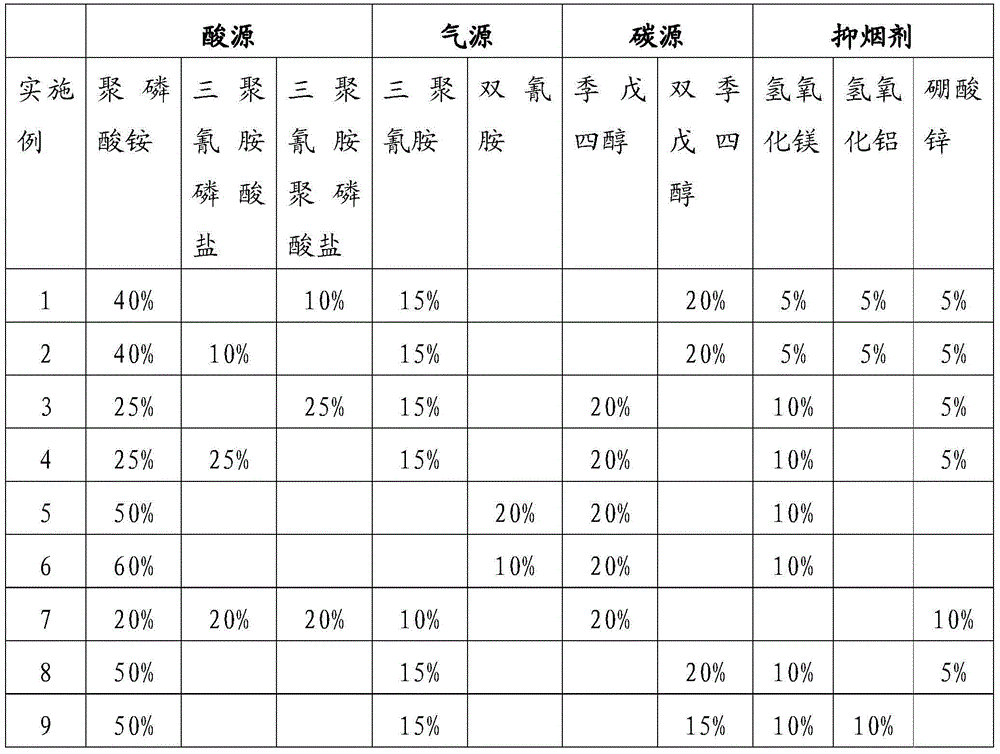

Composite intumescent flame retardant and preparation method thereof

InactiveCN104532588AReduce generationImprove flame retardant performanceFibre typesMelamine phosphateAluminium hydroxide

The invention discloses a composite intumescent flame retardant which is composed of the following components in percentage by weight: 50-65% of acid source, 10-20% of gas source, 15-20% of carbon source and 10-20% of smoke inhibitor. The acid source is composed of at least one of ammonium polyphosphate, melamine phosphate and melamine polyphosphate, wherein the ammonium polyphosphate is crystal II ammonium polyphosphate with the average degree of polymerization of greater than 1000; the gas source is composed of at least one of melamine and dicyandiamide; the carbon source is composed of at least one of pentaerythritol and bis pentaerythritol; and the smoke inhibitor is composed of at least one of magnesium hydroxide, aluminum hydroxide and zinc borate. The invention also discloses a preparation method of the composite intumescent flame retardant.

Owner:SHIFANG TAIFENG NEW FLAME RETARDANT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com