Method for preparing core-shell silicon dioxide-coated ammonium polyphosphate (APP)

A technology for coating ammonium polyphosphate and silicon dioxide, which is applied in the direction of silicon dioxide, silicon oxide, chemical instruments and methods, etc., can solve the problems of frosting strength, insufficient, unsuitable ammonium polyphosphate coating, etc., and reduce the dosage , low water solubility, excellent hydrophobic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) 100 grams of ammonium polyphosphate are added to an aqueous ethanol solution prepared from 100 grams of ethanol and 200 grams of water. The average particle size of the added ammonium polyphosphate particles is about 12 microns.

[0028] (2) Under sufficient stirring, add ammoniacal liquor to the solution of step (1) to adjust the pH value of the solution to 10, then add dropwise 200ml of ethanol solution of tetraethyl orthosilicate with a molar concentration of 0.1mol / L, drop Then stir well for 3 hours. Control the reaction temperature of step (1) and step (2) in the range of 15-35°C.

[0029] (3) Add 2 grams of titanate coupling agent TC-311 to the slurry obtained in step (2) for surface treatment, the surface treatment temperature is 90°C, the treatment time is 2 hours, and then filtered, washed and dried , to obtain silica-coated ammonium polyphosphate.

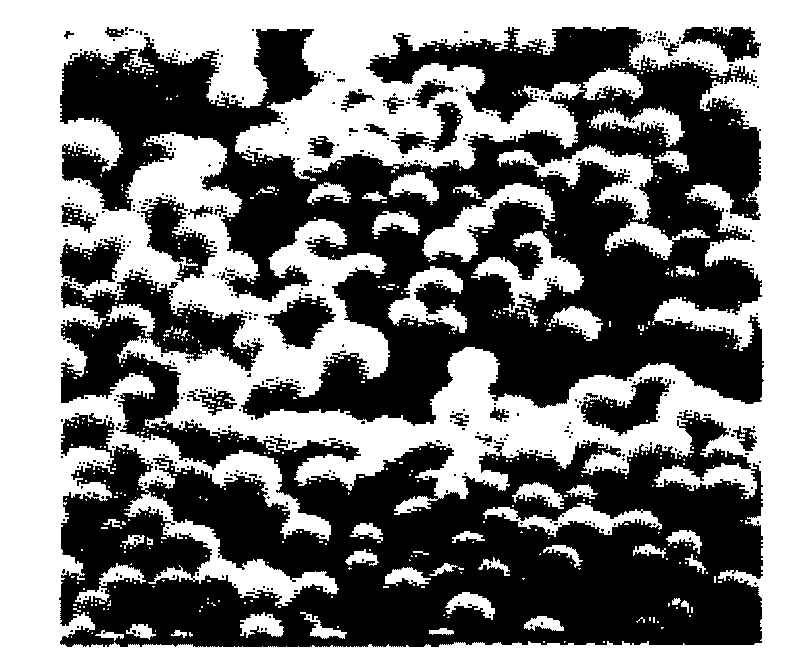

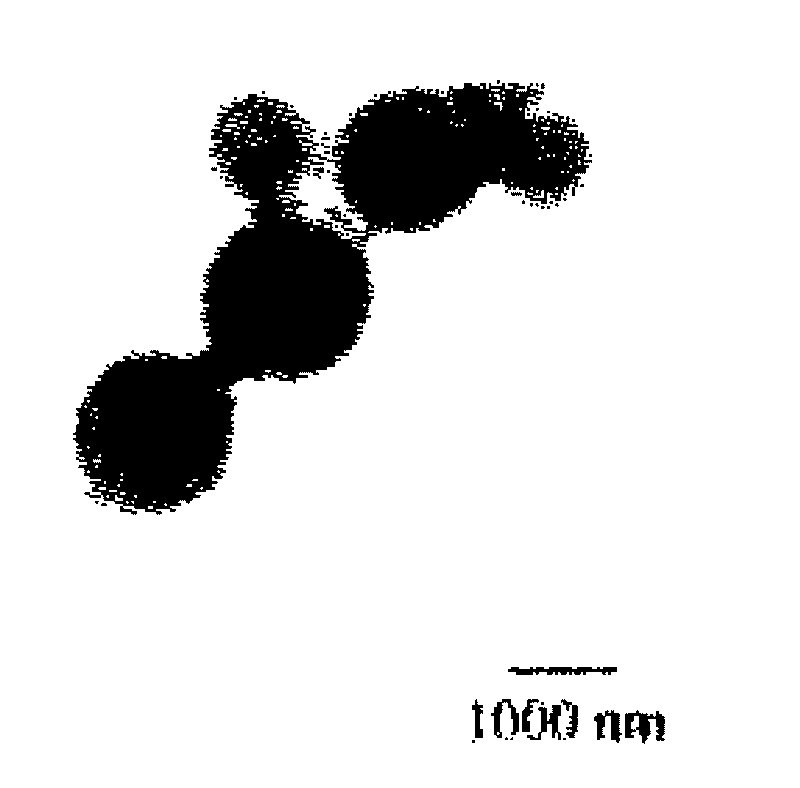

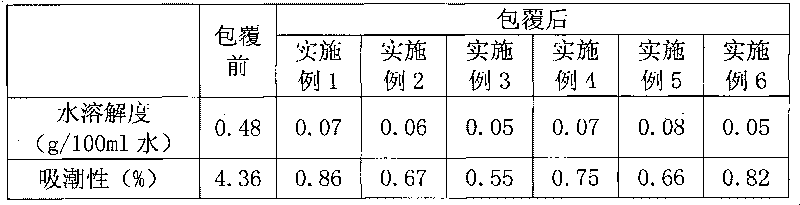

[0030] The ammonium polyphosphate obtained above is analyzed by scanning electron microscope and transmis...

Embodiment 2

[0032] (1) 200 grams of ammonium polyphosphate are added to an aqueous ethanol solution prepared from 100 grams of ethanol and 200 grams of water. The average particle size of the added ammonium polyphosphate particles is about 25 microns.

[0033] (2) under sufficient stirring, add ammoniacal liquor to the solution of step (1) to adjust the pH value of the solution to 9, then add dropwise the ethanol solution 48ml of tetraethyl orthosilicate whose molar concentration is 1mol / L, dropwise Stir well for another 4 hours. Control the reaction temperature of step (1) and step (2) in the range of 15-35°C.

[0034] (3) Add 2 grams of titanate coupling agent TC-311 to the slurry obtained in step (2) for surface treatment, the surface treatment temperature is 90°C, the treatment time is 2 hours, and then filtered, washed and dried , to obtain silica-coated ammonium polyphosphate.

Embodiment 3

[0036] (1) 150 grams of ammonium polyphosphate are added to the aqueous ethanol solution prepared by 120 grams of ethanol and 180 grams of water. The average particle size of the added ammonium polyphosphate particles is about 8 microns.

[0037] (2) under sufficient stirring, add ammoniacal liquor to the solution of step (1) to adjust the pH value of the solution to 11, then add dropwise the ethanol solution 720ml of tetraethyl orthosilicate whose molar concentration is 0.05mol / L, drop Then stir well for 3 hours. Control the reaction temperature of step (1) and step (2) in the range of 15-35°C.

[0038] (3) Add 2 grams of titanate coupling agent TC-311 to the slurry obtained in step (2) for surface treatment, the surface treatment temperature is 90°C, the treatment time is 2 hours, and then filtered, washed and dried , to obtain silica-coated ammonium polyphosphate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com