Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7606 results about "Grout" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grout is a dense fluid which is used to fill gaps or used as reinforcement in existing structures. Grout is generally a mixture of water, cement, and sand and is employed in pressure grouting, embedding rebar in masonry walls, connecting sections of pre-cast concrete, filling voids, and sealing joints such as those between tiles. Common uses for grout in the household include filling in tiles of shower floors and kitchen tiles. It is often color tinted when it has to be kept visible and sometimes includes fine gravel when being used to fill large spaces (such as the cores of concrete blocks). Unlike other structural pastes such as plaster or joint compound, correctly mixed and applied grout forms a water resistant seal.

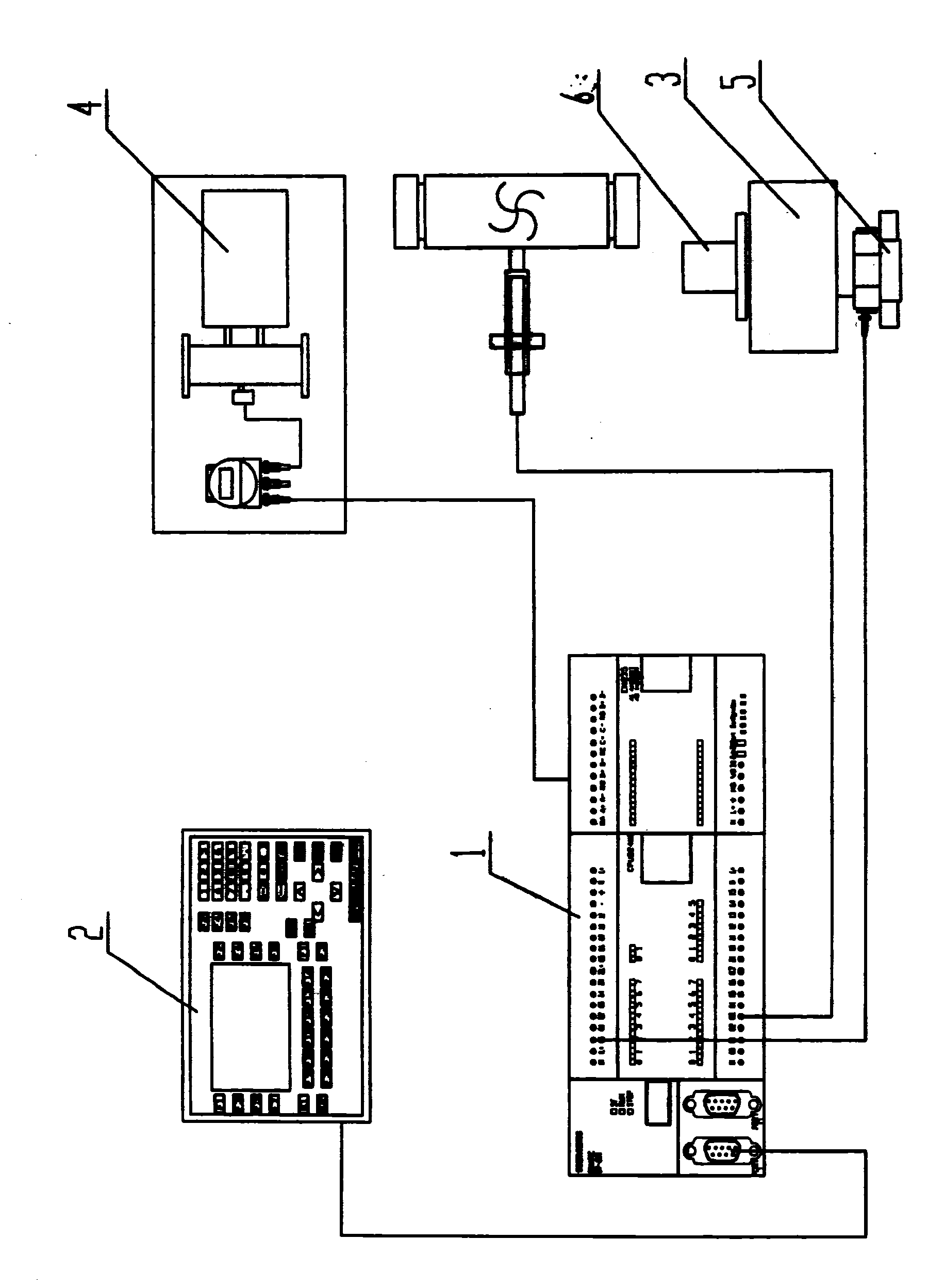

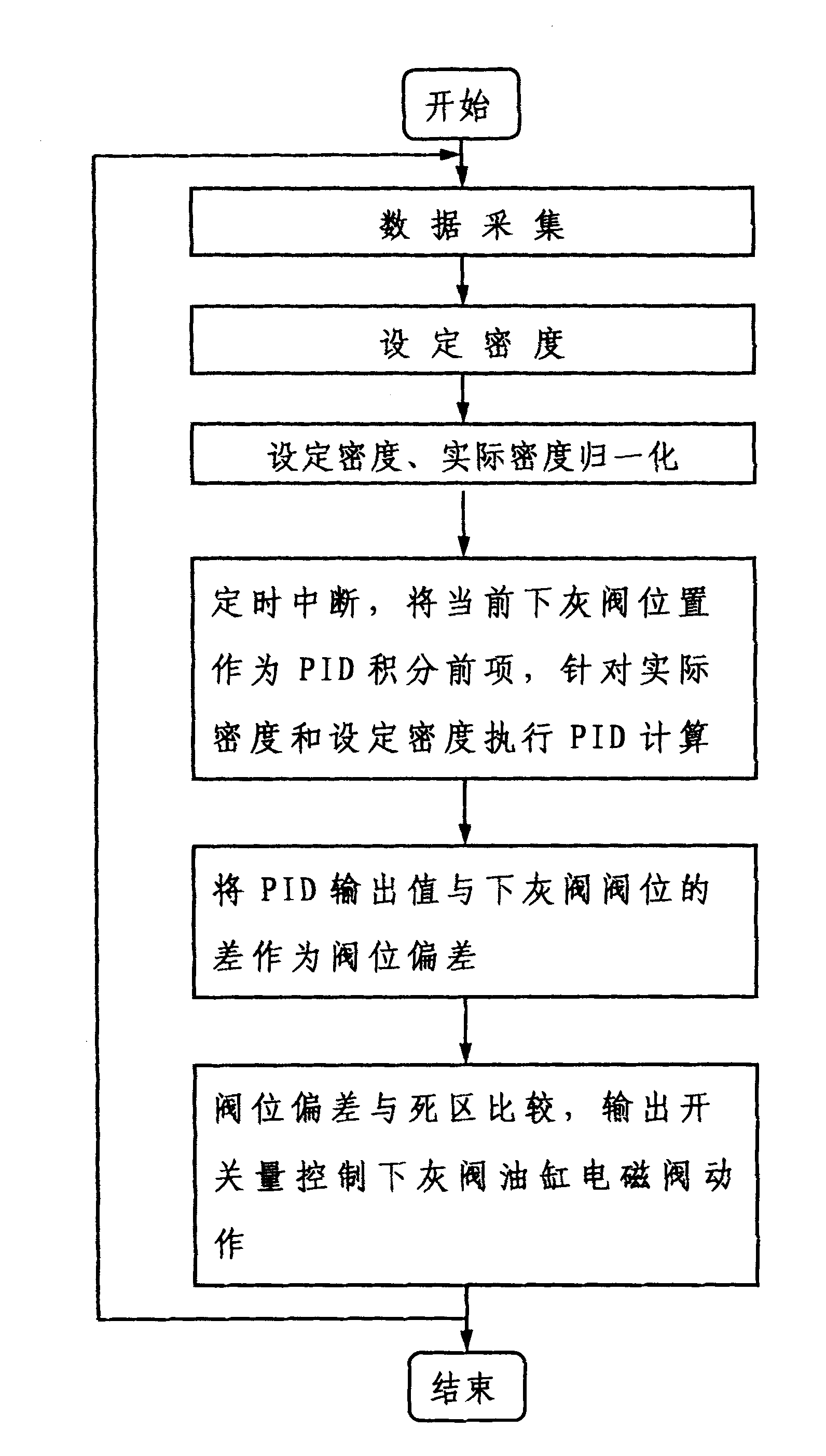

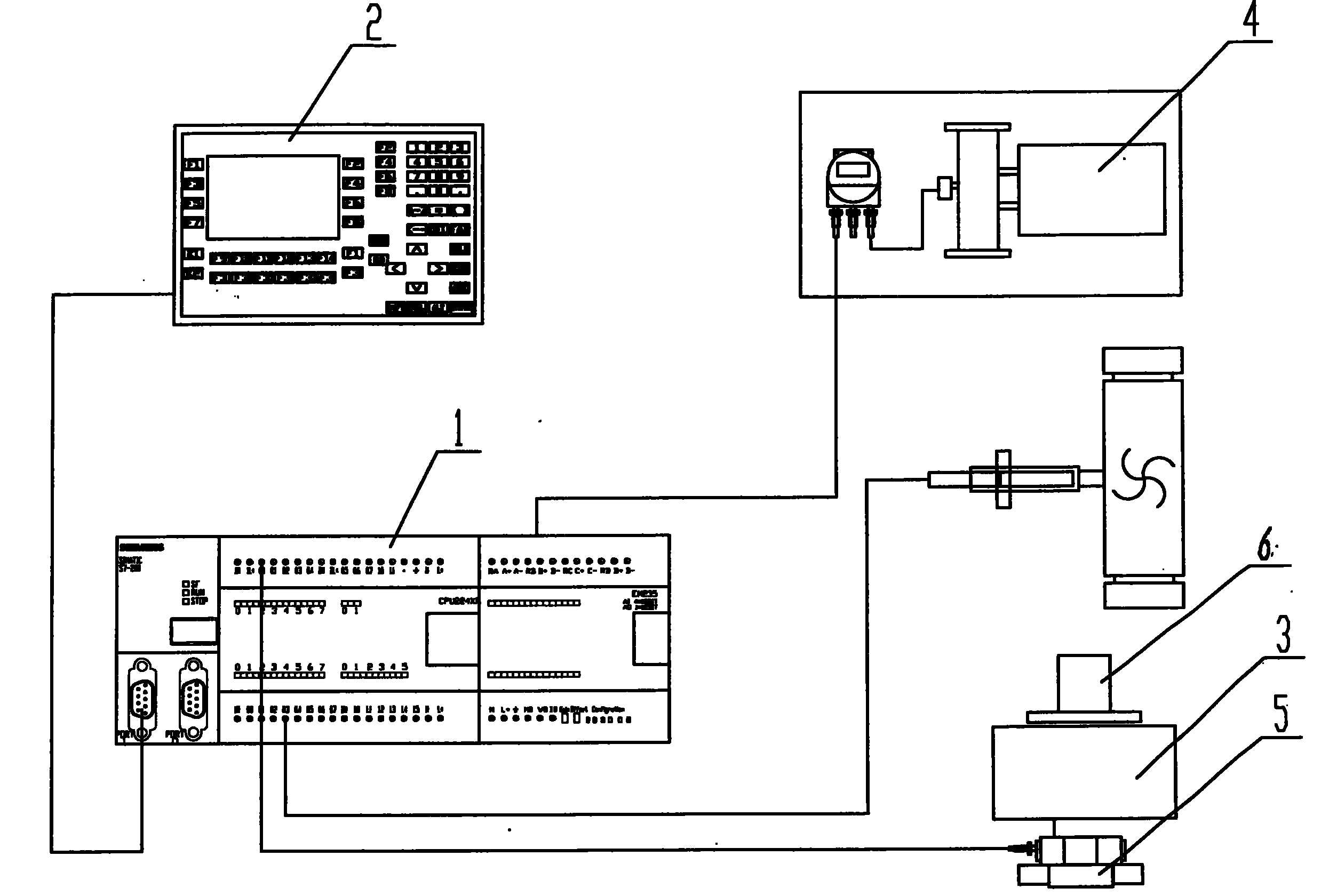

System and control method for automatically compounding cement paste

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

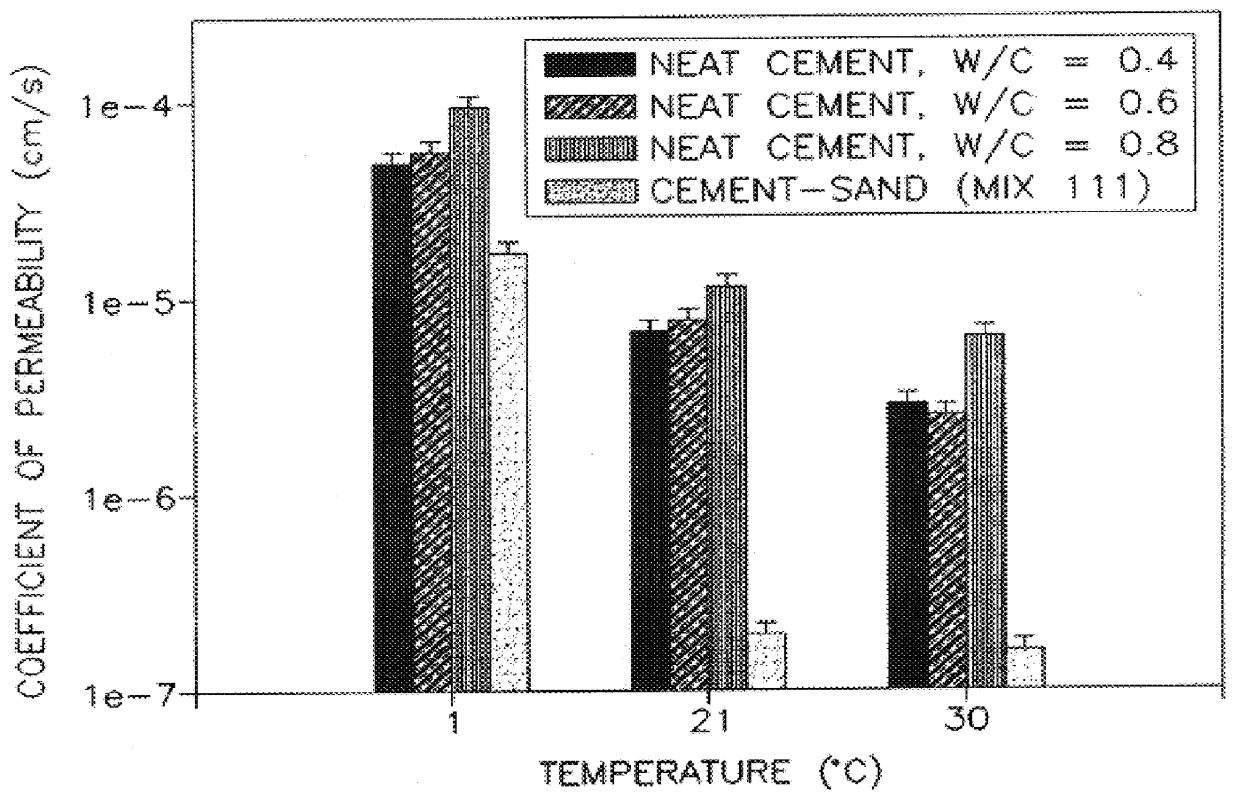

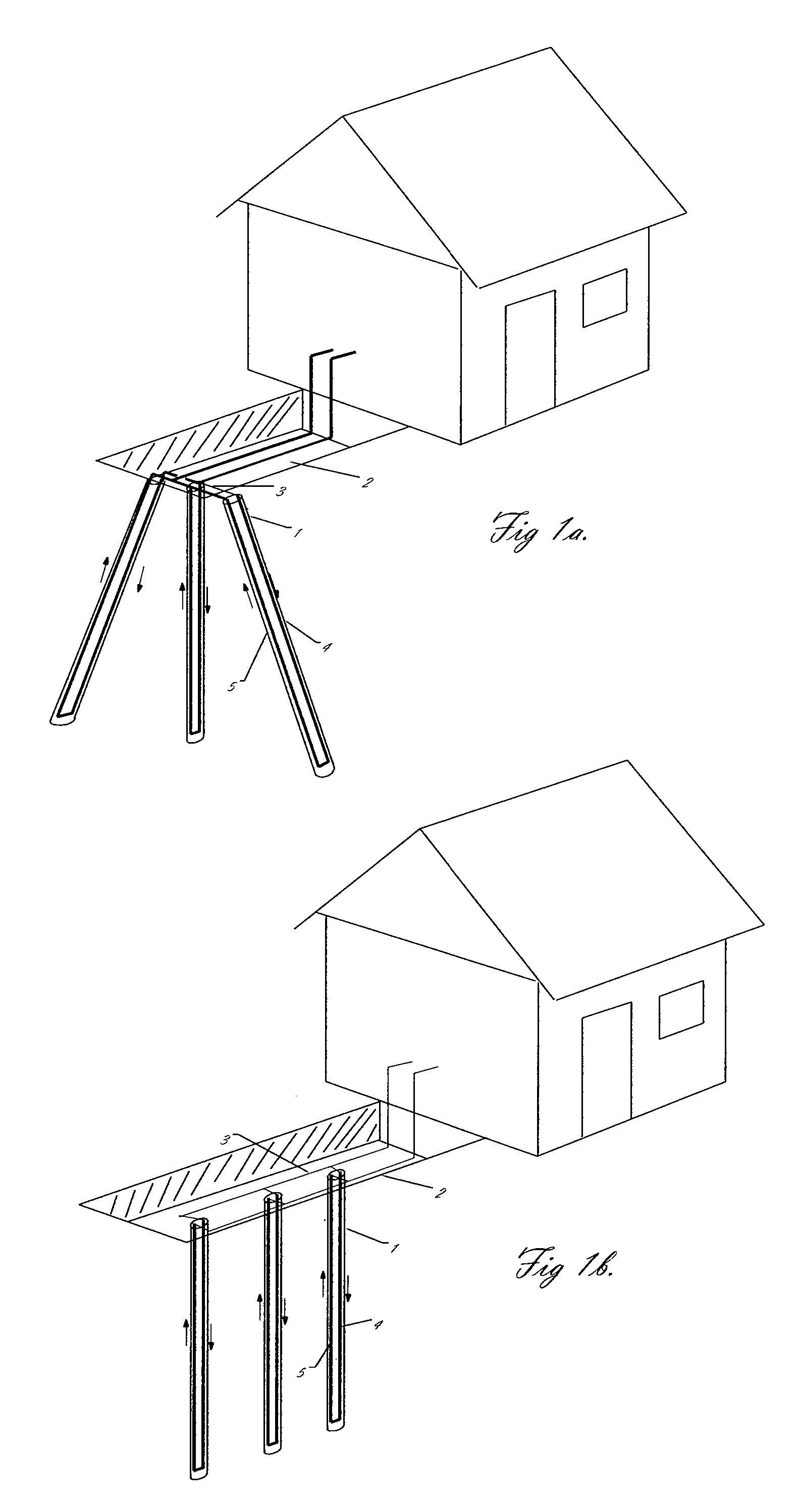

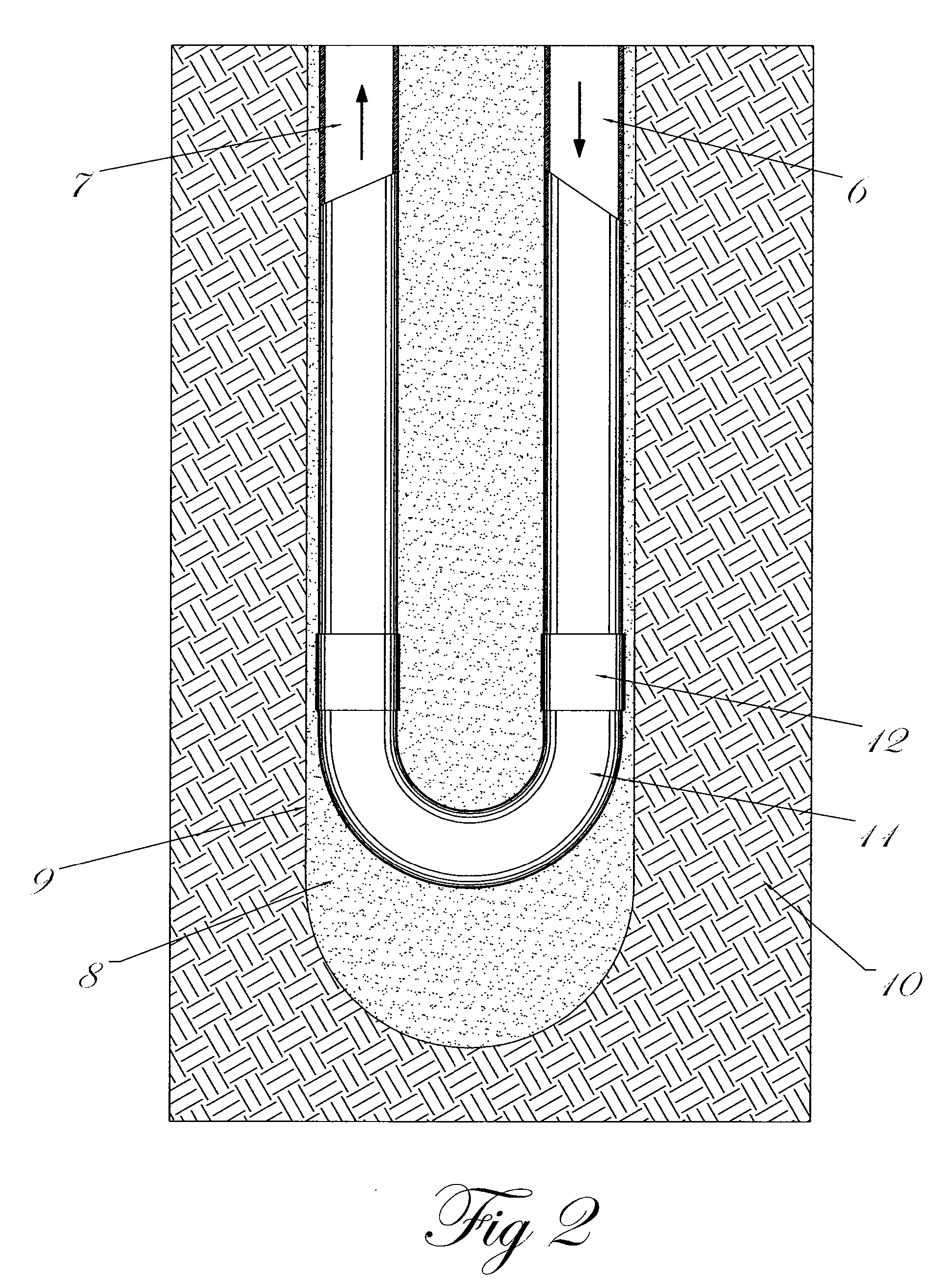

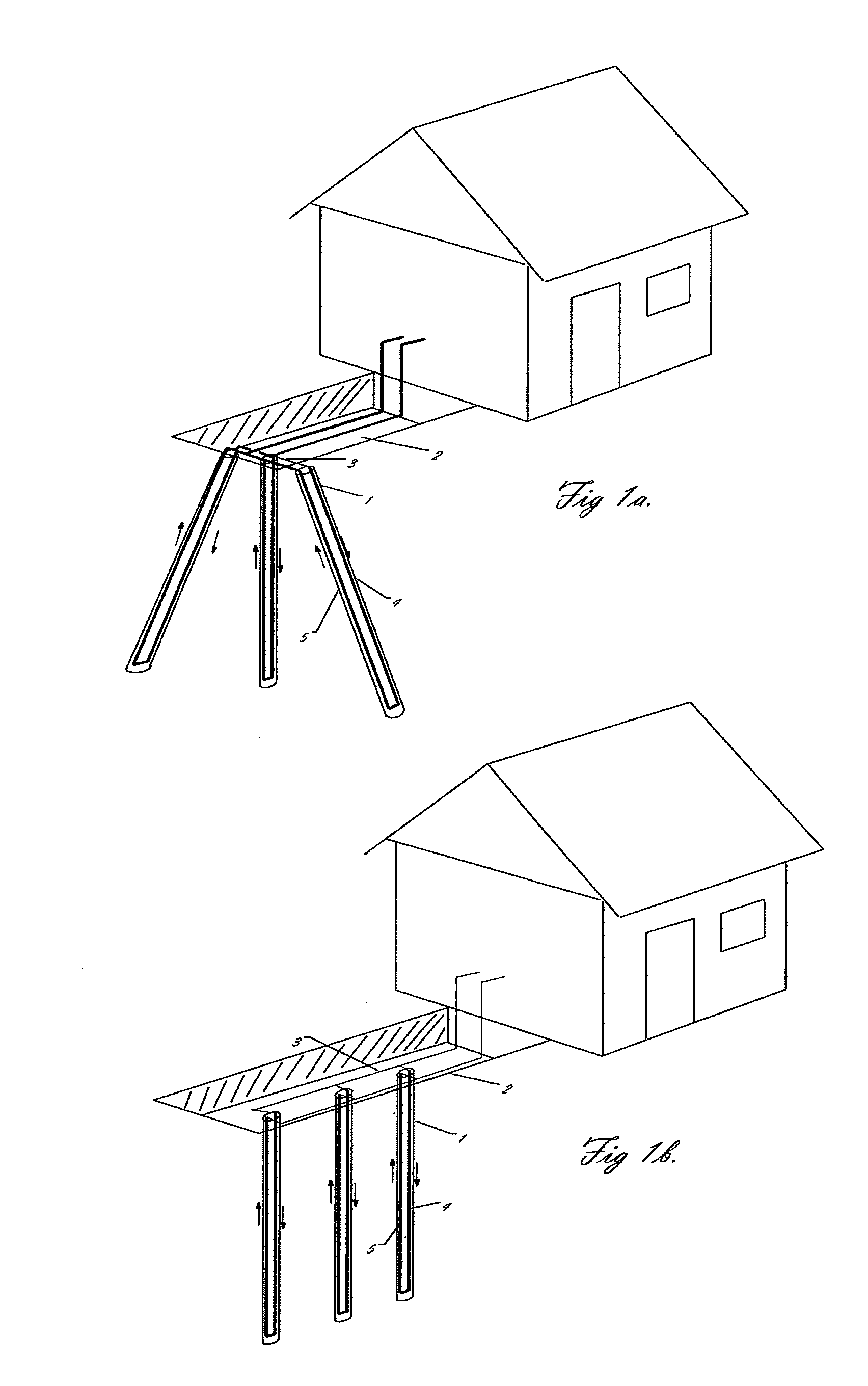

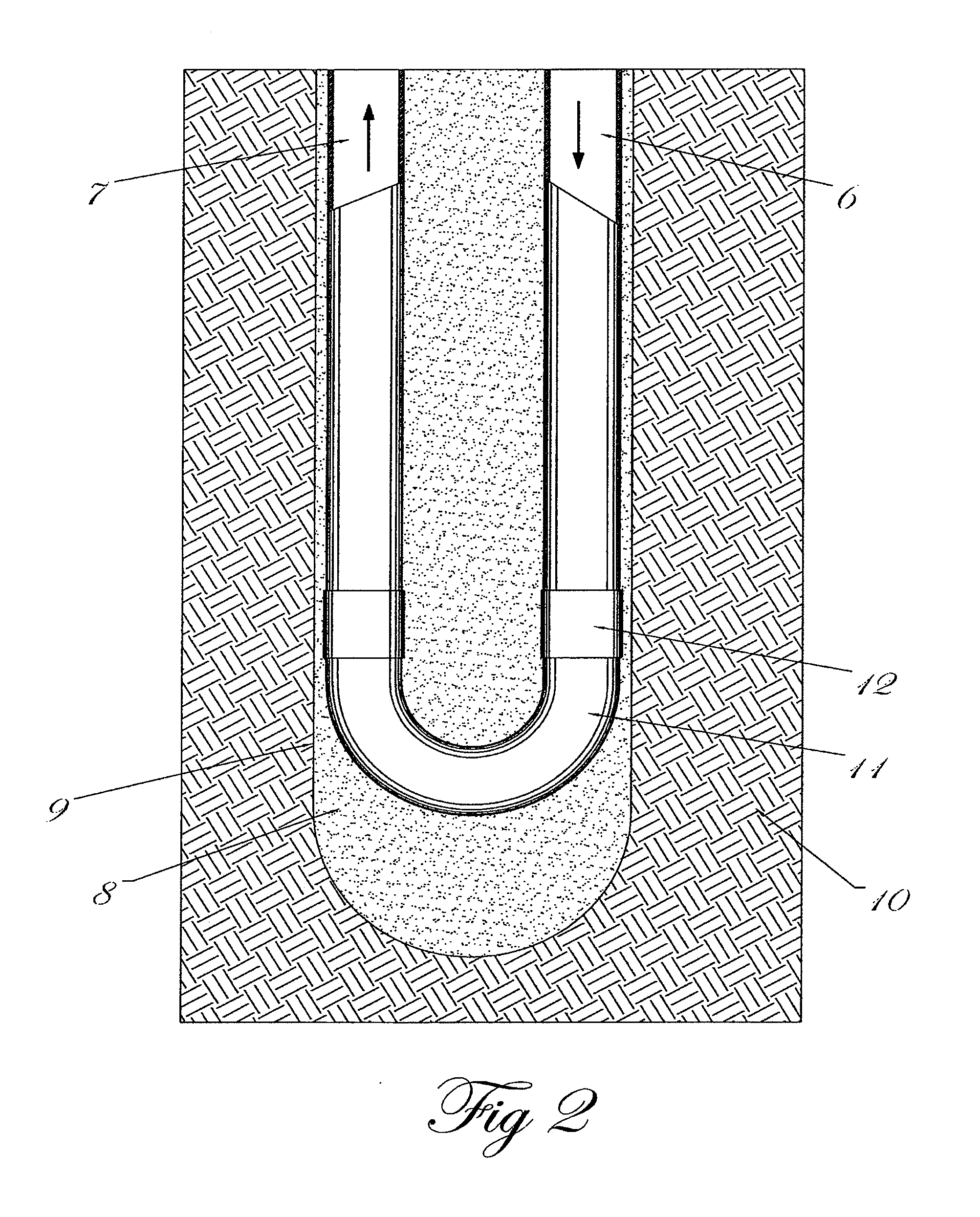

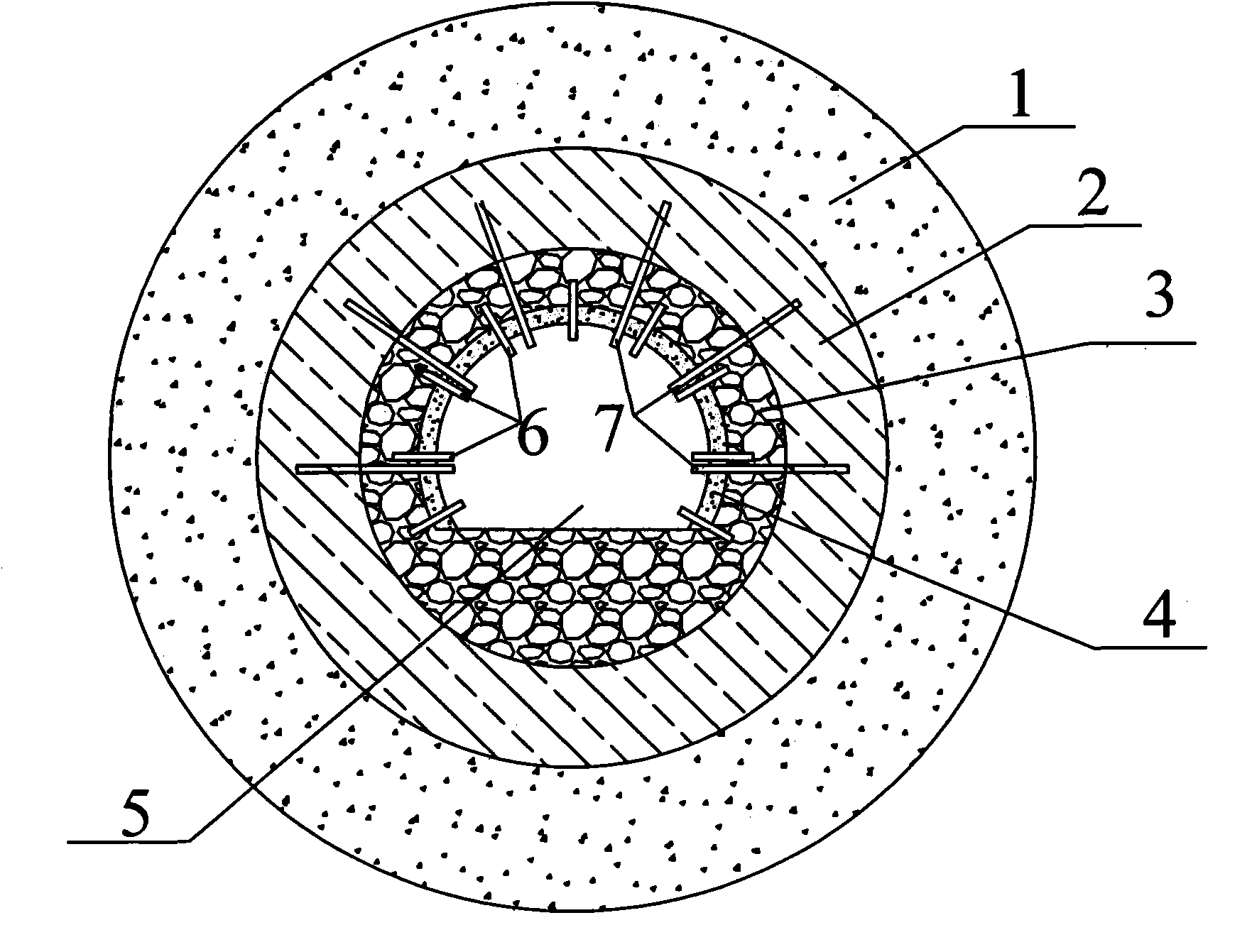

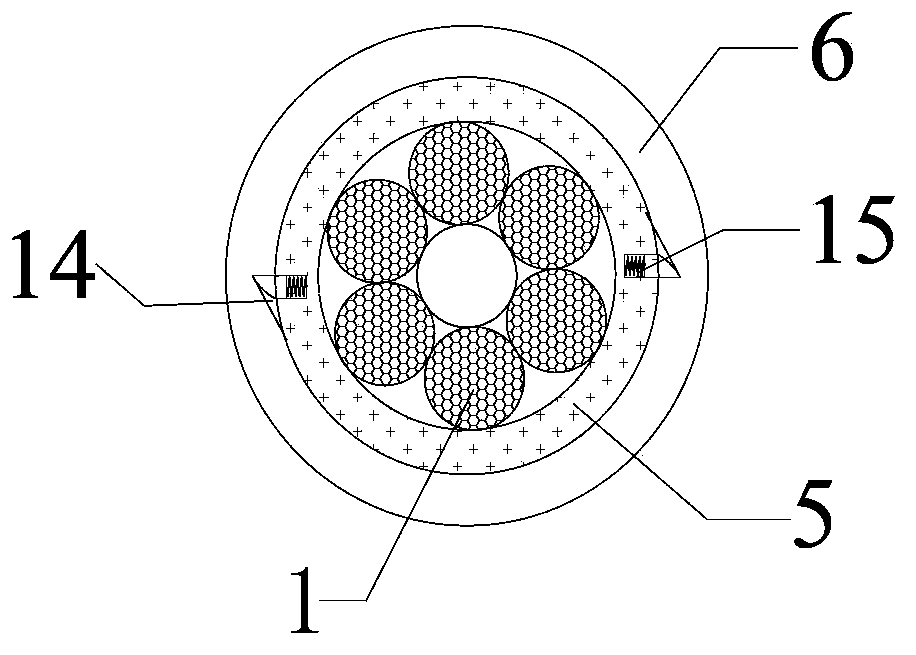

Thermally conductive cementitious grout for geothermal heat pump systems

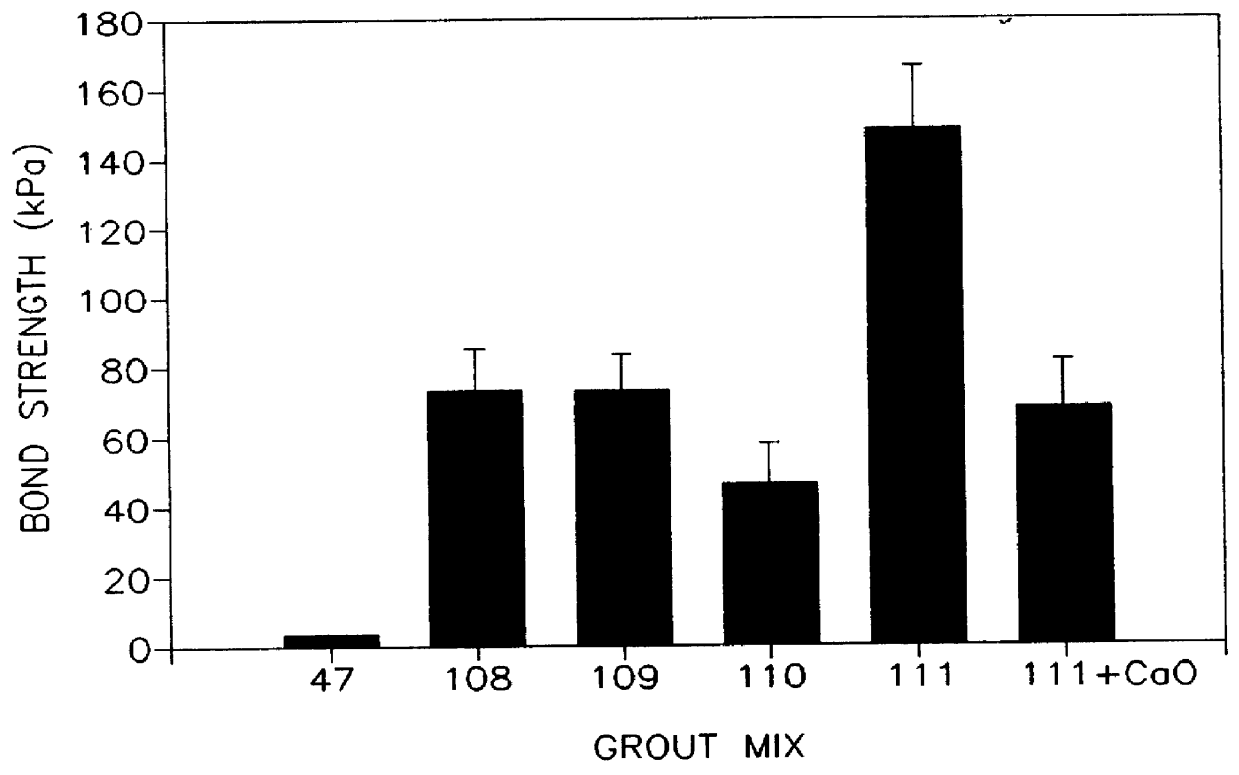

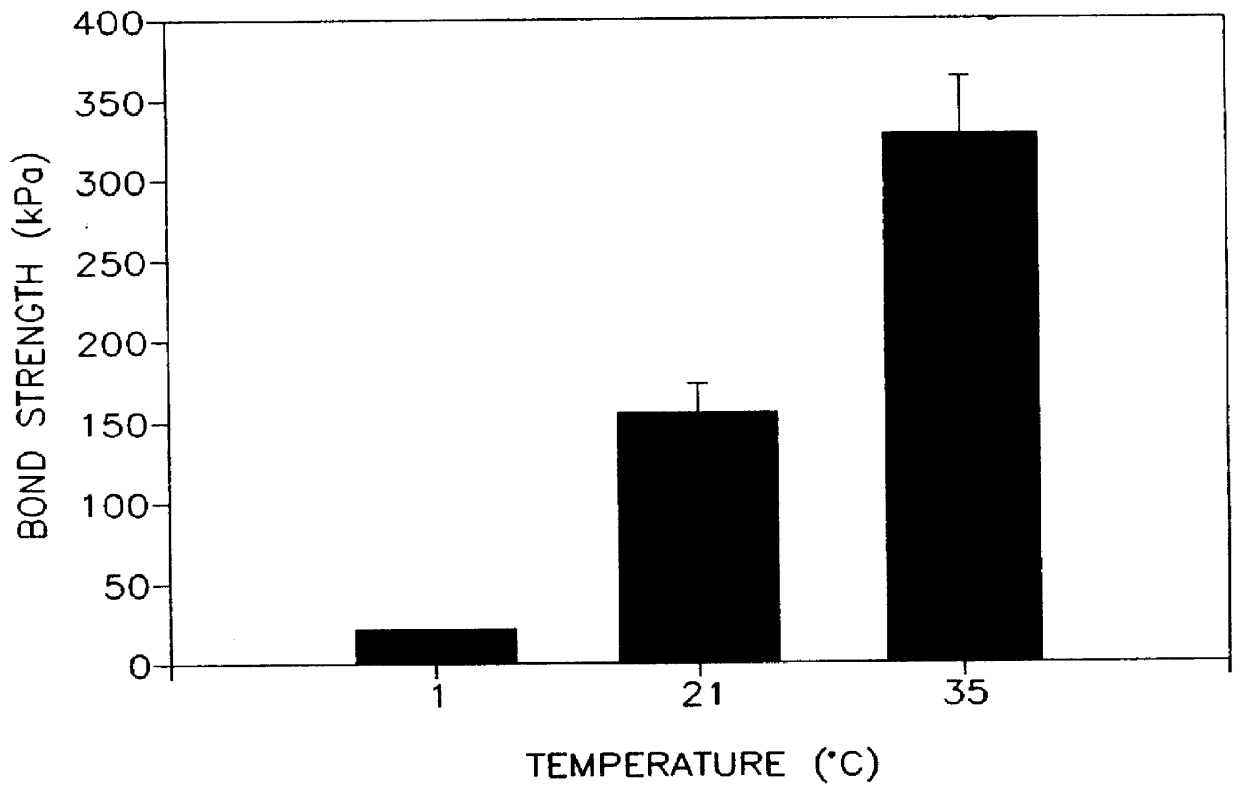

A thermally conductive cement-sand grout for use with a geothermal heat pump system. The cement sand grout contains cement, silica sand, a superplasticizer, water and optionally bentonite. The present invention also includes a method of filling boreholes used for geothermal heat pump systems with the thermally conductive cement-sand grout. The cement-sand grout has improved thermal conductivity over neat cement and bentonite grouts, which allows shallower bore holes to be used to provide an equivalent heat transfer capacity. In addition, the cement-sand grouts of the present invention also provide improved bond strengths and decreased permeabilities. The cement-sand grouts can also contain blast furnace slag, fly ash, a thermoplastic air entraining agent, latex, a shrinkage reducing admixture, calcium oxide and combinations thereof.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

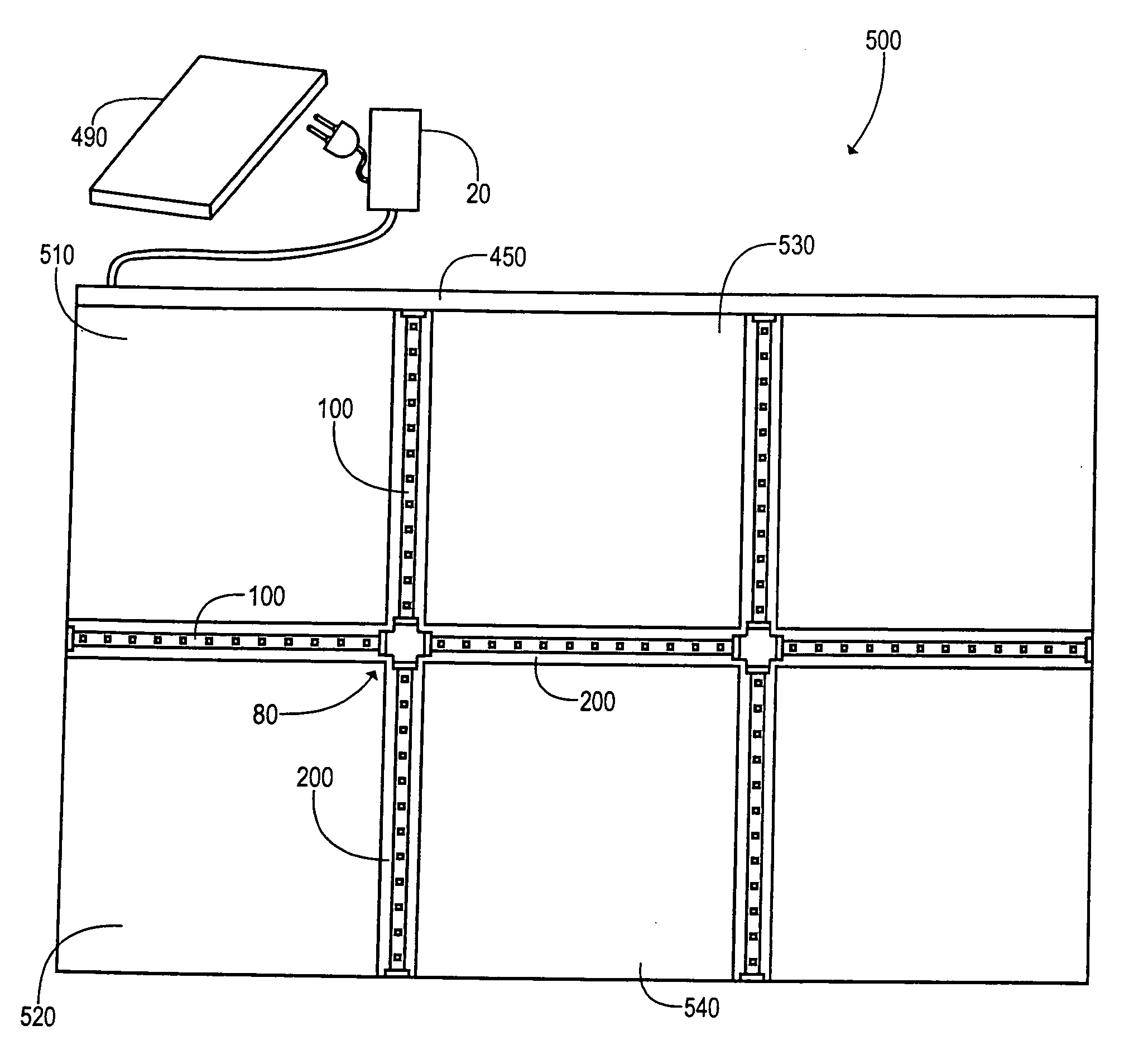

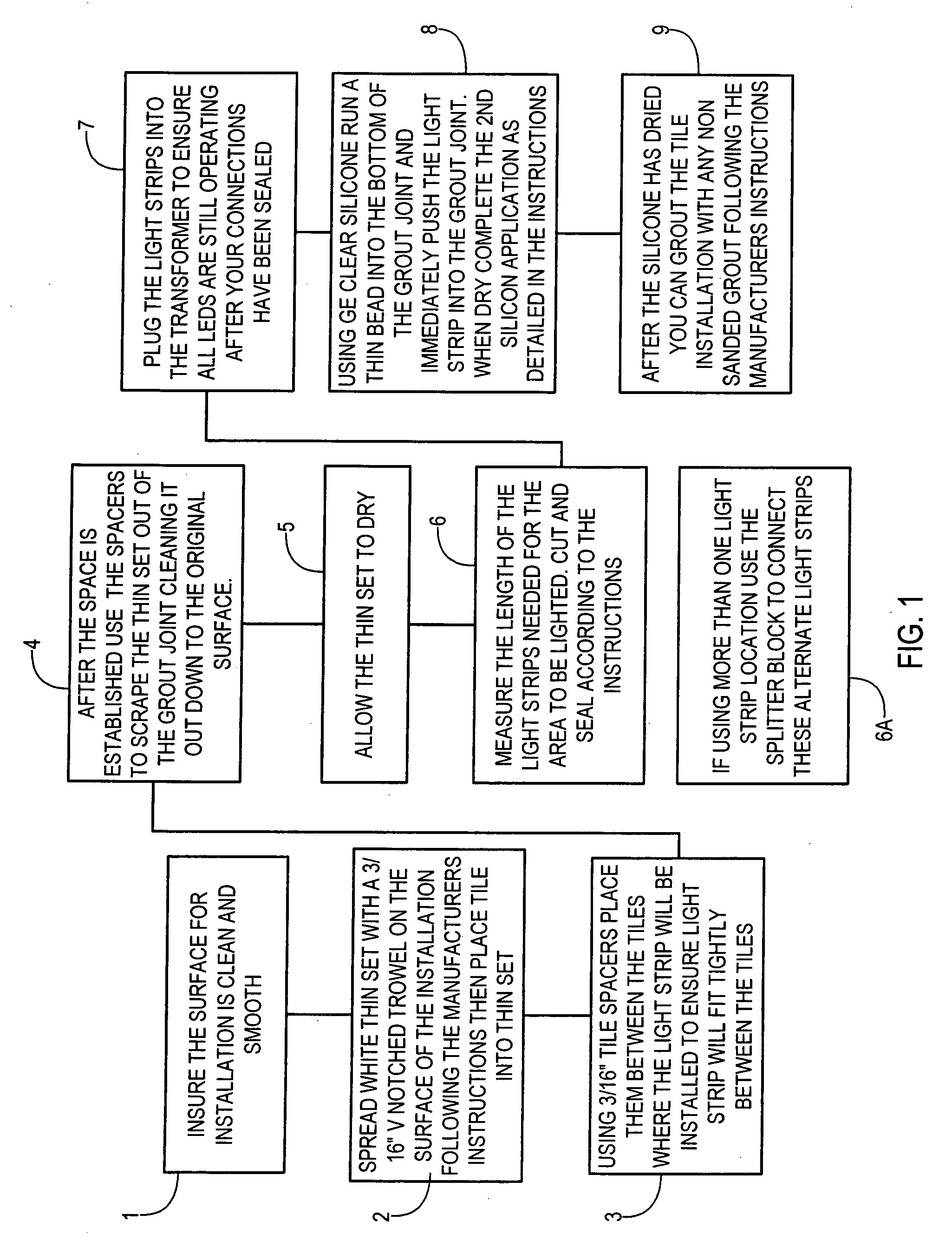

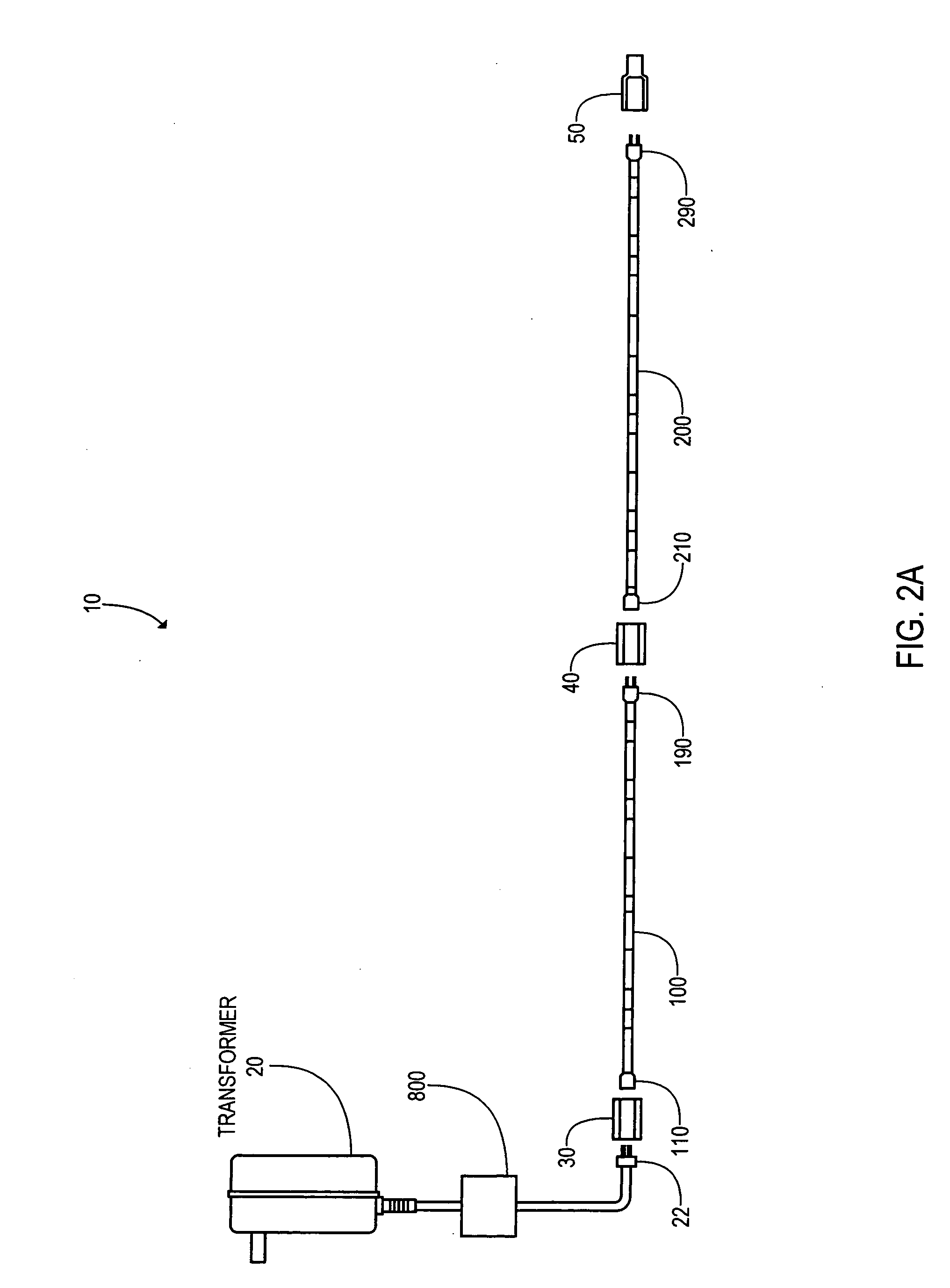

LED lighting for glass tiles

InactiveUS20090147504A1Easy to removeEasy to replaceCovering/liningsPoint-like light sourceBrickSurface layer

Devices, apparatus, systems, and methods of installing LED (light emitting diodes) for glass tiles and glass blocks. The LEDs can be housed in flexible strips having flexible bendable transparent housing sleeves with ends that can interconnect by male and female ends to one another with various types of interconnectors. Each separate sleeve can house up to 33 LEDs in a transparent plastic sleeve. A transparent connector sleeve can be slid over the interconnected ends and heat shrunk in place. The glass tiles can be laid out to uniform joints spacings between the glass tiles of approximately 3 / 16 of an inch. The LED strips can be placed on a surface layer of transparent grout that has been laid in the joint spacing, followed by a top layer of transparent grout. The transparent grout can be removable grout and include clear Silicon. The LED strips can have peel and stick back layers with adhesive backing that allows mounting to the lower surface. The LED strips can be placed with glass tiles, and other types of tiles such as but not limited to ceramic tiles, stone tiles and the like, as well as with glass blocks. Splitter(s) can be used to run parallel runs of LED strips at different spaced apart locations.

Owner:NEW HORIZON DESIGNS

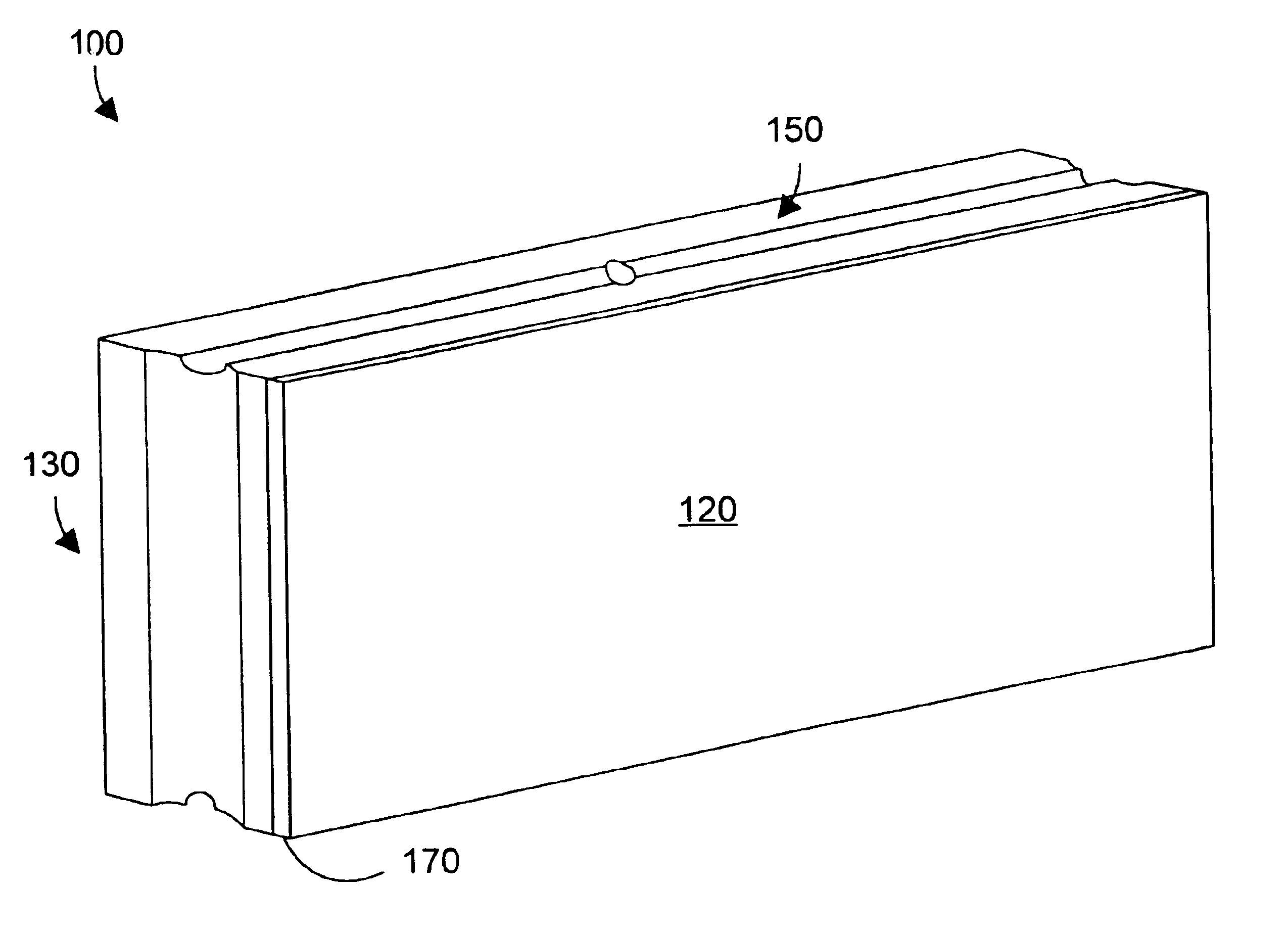

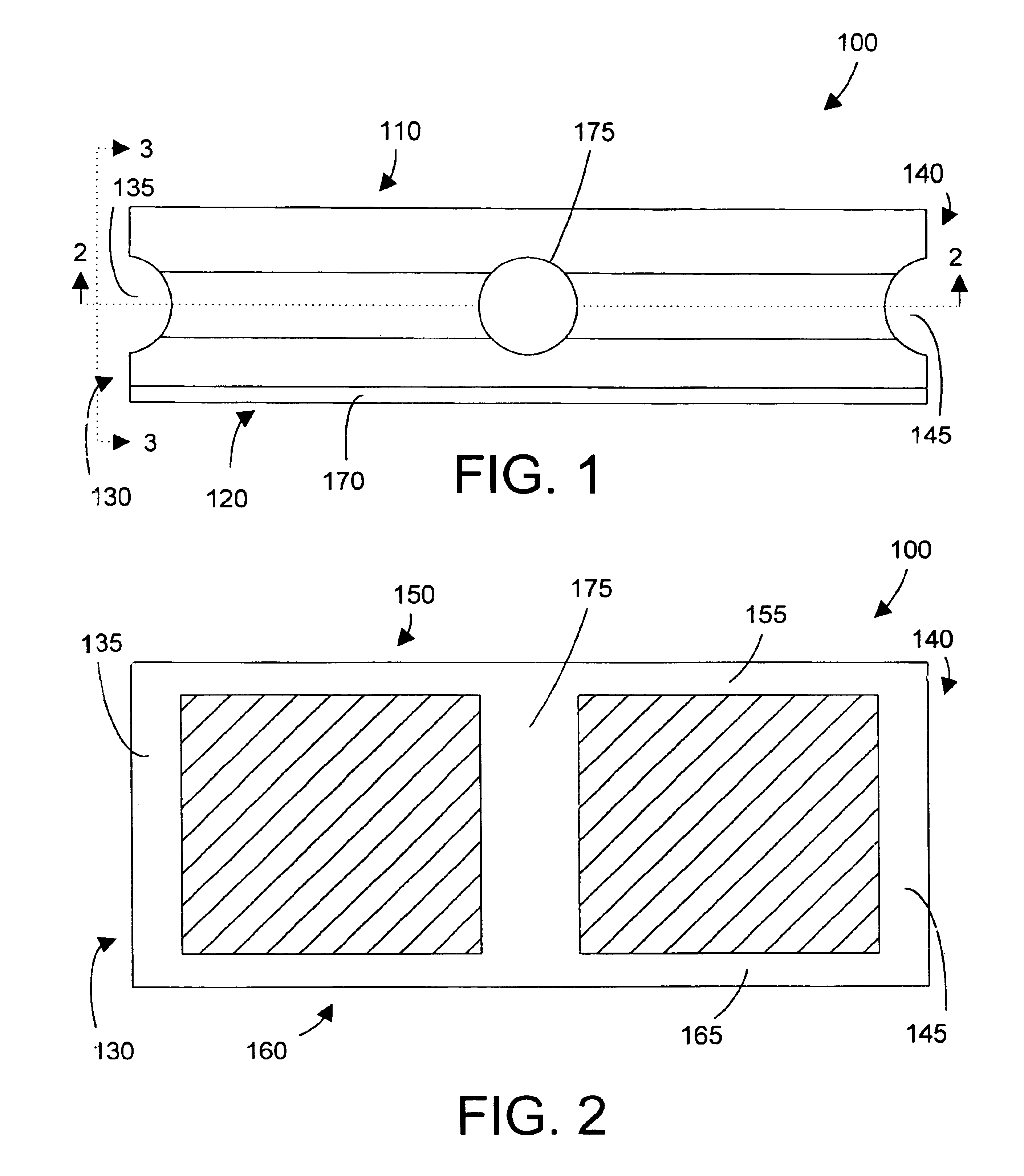

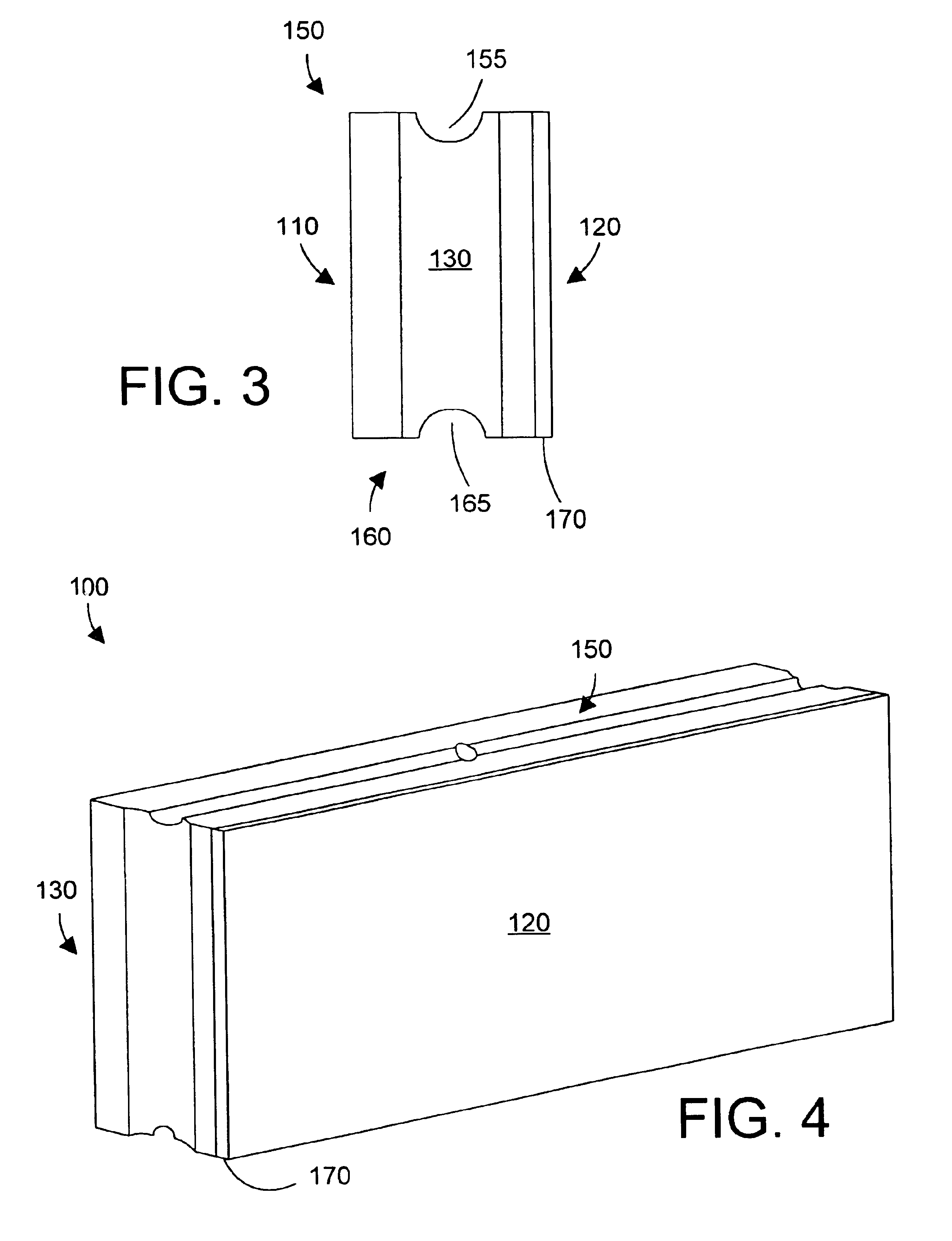

Building block with a cement-based attachment layer

A building block has a cement-based attachment layer on one or both exterior surfaces of the block that can receive and hold a penetrating fastener such as a nail, screw, staple, or the like. This allows surficial coverings such as wallboard, siding or other materials to be easily attached to a block wall made of the building blocks. The block includes substantially semi-cylindrical concave portions that form a cross-linked structure of channels when the blocks are assembled into a wall. Once the blocks have been stacked in place in a wall, grout or other suitable filling material is poured into the cross-linked structure of channels. When the filling material hardens, the blocks are locked together. Surficial covering materials may then be nailed, screwed, or stapled directly to the attachment layer.

Owner:PACIFIC COAST BUILDING PRODS

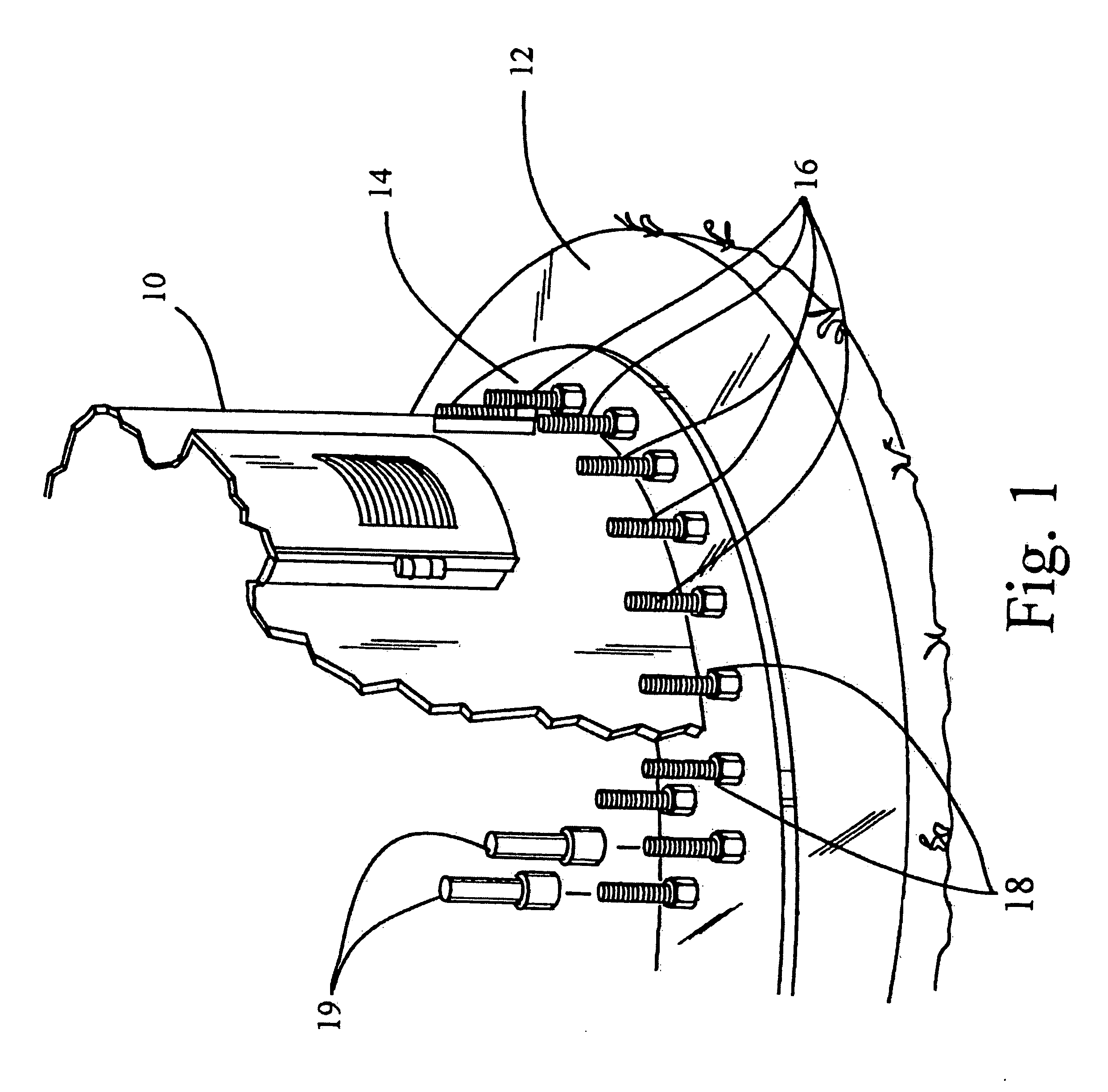

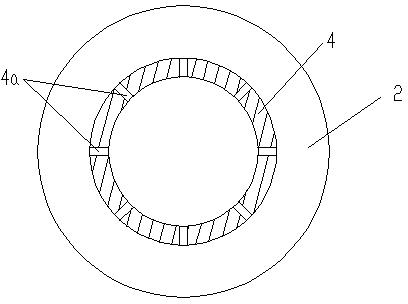

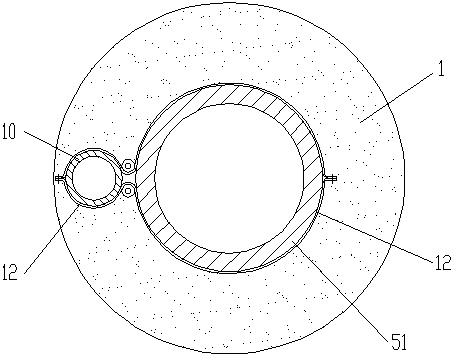

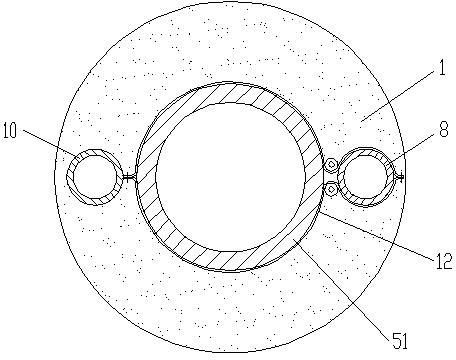

Wind turbine installation comprising an apparatus for protection of anchor bolts and method of installation

InactiveUS20090044482A1Preventing greatly limiting axial migrationAvoid stickingBuilding repairsWind motor supports/mountsEngineeringTower

An apparatus for use in providing a level grout surface for placement of a wind turbine tower flange, the apparatus comprising a template member levelly suspended on the anchor bolts above the grout trough, wherein the template member comprises a surface to which grout will not adhere. The template member can comprise an upper layer and a lower grout engagement layer, wherein the grout engagement layer comprises a surface to which grout will not adhere. The upper layer can comprise a metallic layer, and the lower layer can comprise a plastic layer, wherein the upper layer and the lower layer are bonded together. The lower layer can comprise polypropylene. The means of bonding are selected from the group consisting of mechanical bonding, thermal bonding and chemical bonding. The grout can comprise an epoxy grout. The template member can be suspended through the use of magnetic nuts or the use of a rotating sleeve. The template member can comprise a plurality of sections, and can comprise a circular form.

Owner:TOOMAN NORMAN L

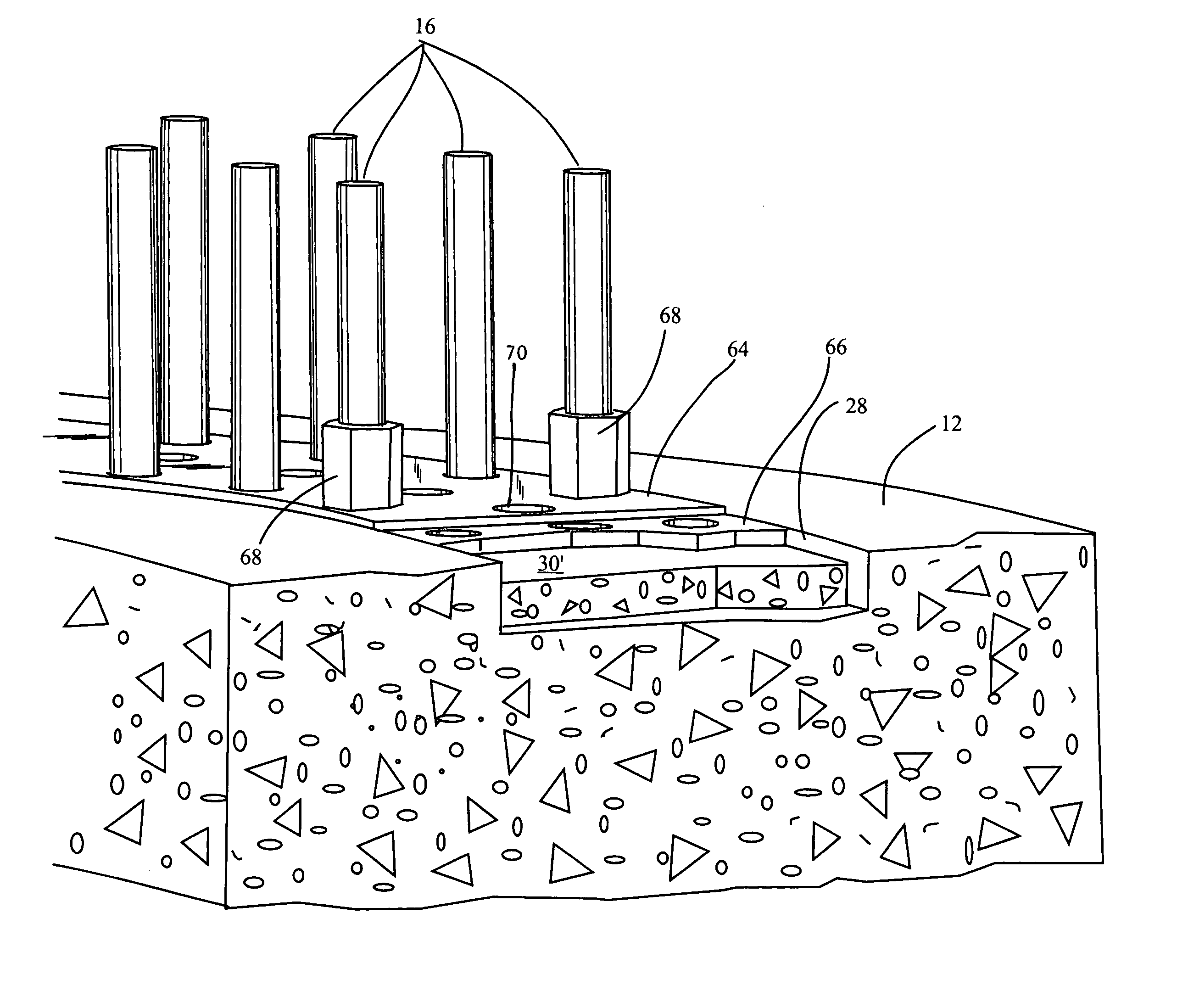

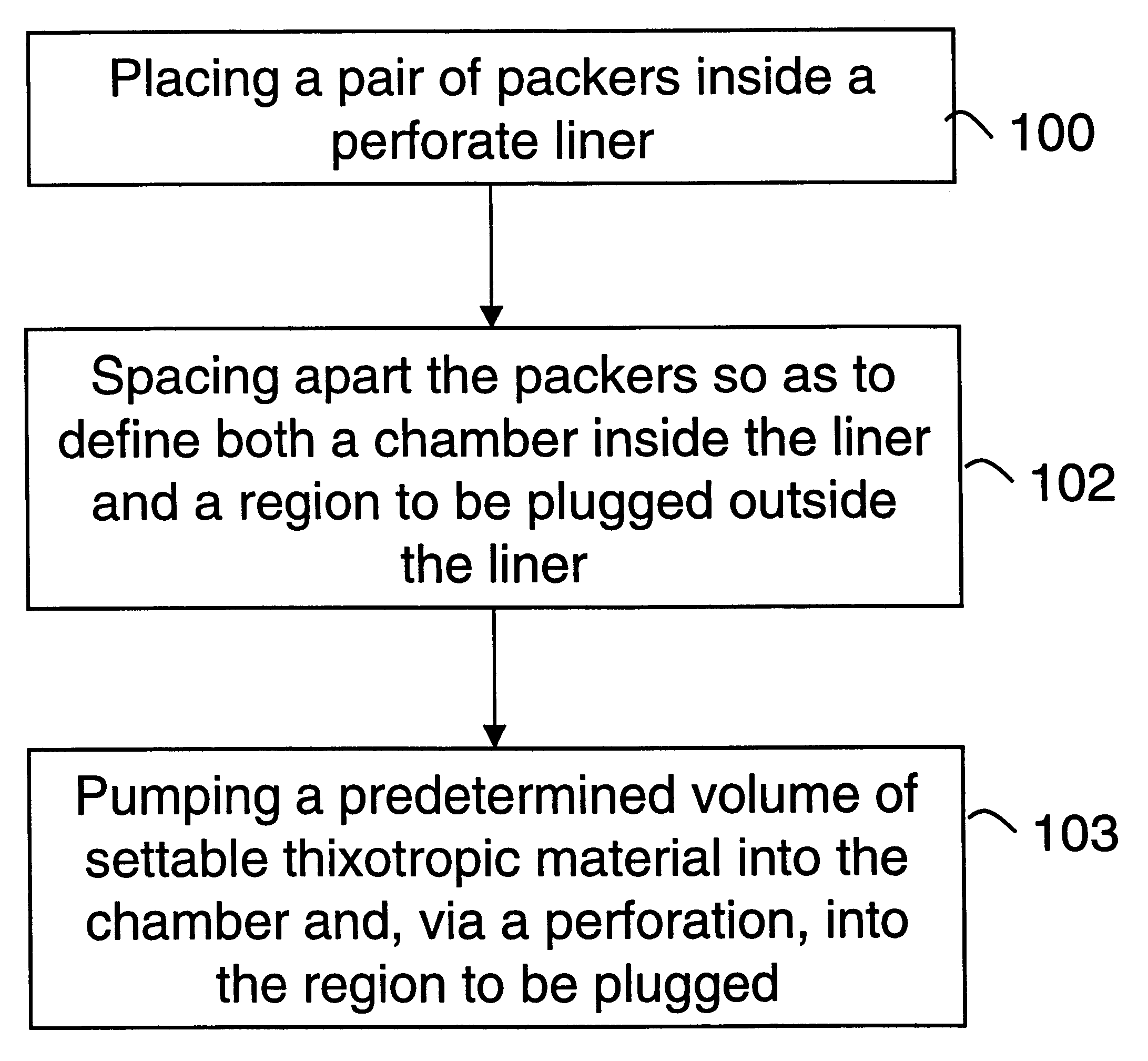

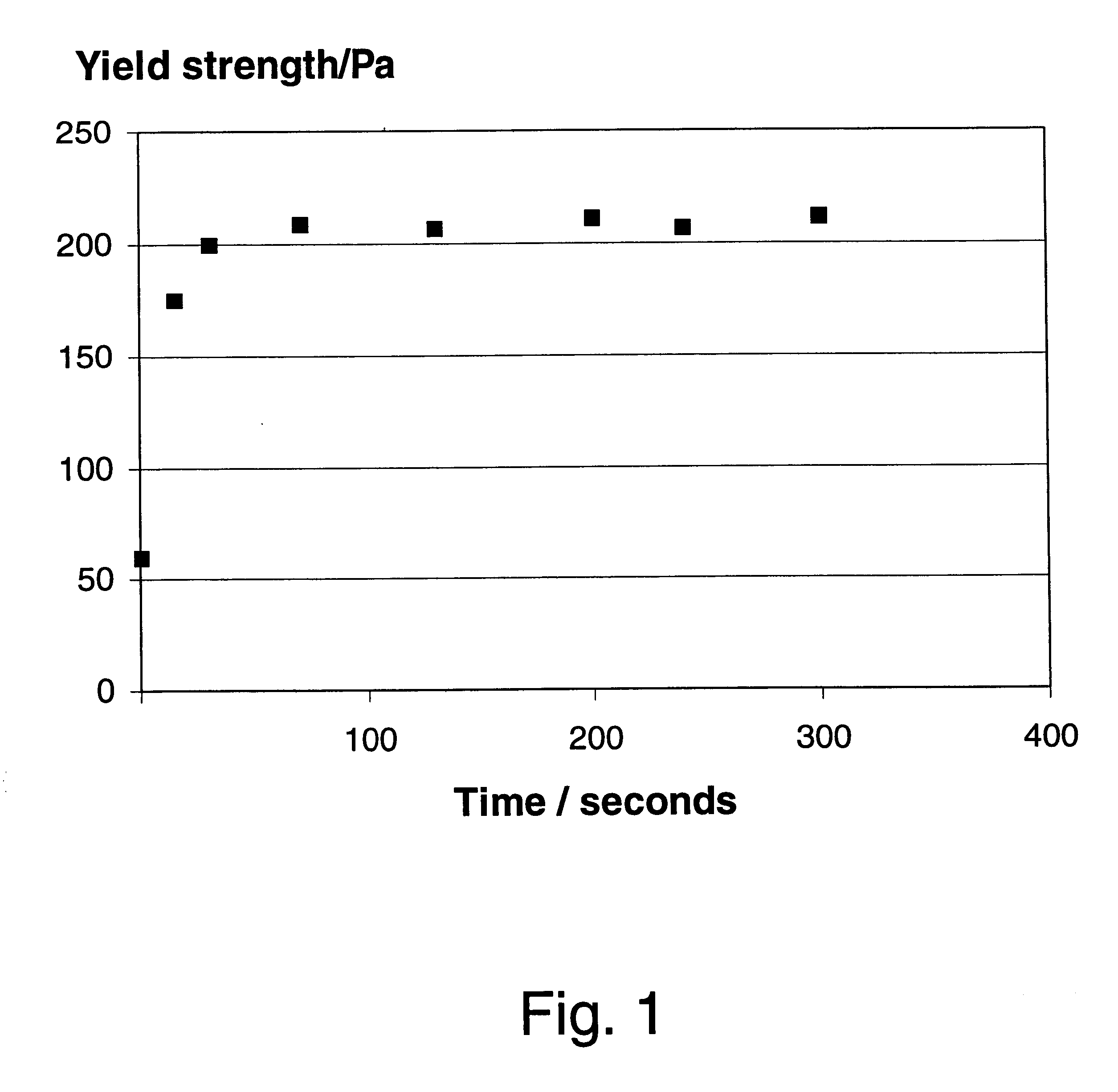

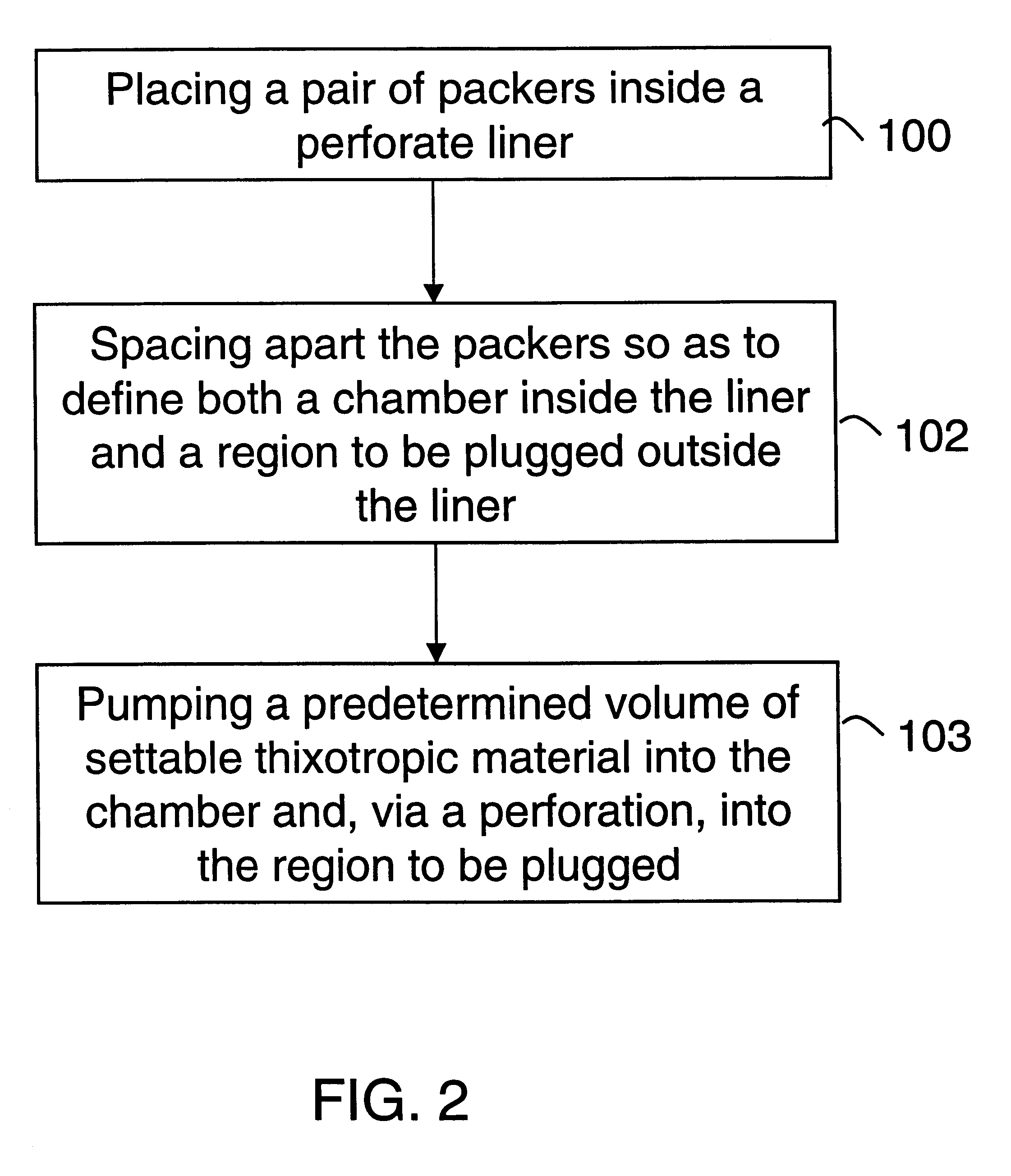

Thixotropic materials

A settable thixotropic material comprises a thixotrope and a settable substance, the material being capable of gelling reversibly in a gelling time of less than 60 seconds. The thixotrope conveniently comprises a fine grained clay, especially smectite clays, e.g. hectorites. It is preferred to use synthetic smectite type clay colloids, and goods results have been obtained with the synthetic clay known as Laponite RDS. The settable material conveniently comprises cement, particularly Portland cement. The thixotropic material finds use generally in oilwell applications, e.g. to plug lost circulation zones, to repair damaged or corroded casing, as grouts, and to limit annular gas migration. The material also finds particular application in techniques for completion of horizontal wells completed with slotted or pre-drilled liners.

Owner:SCHLUMBERGER TECH CORP

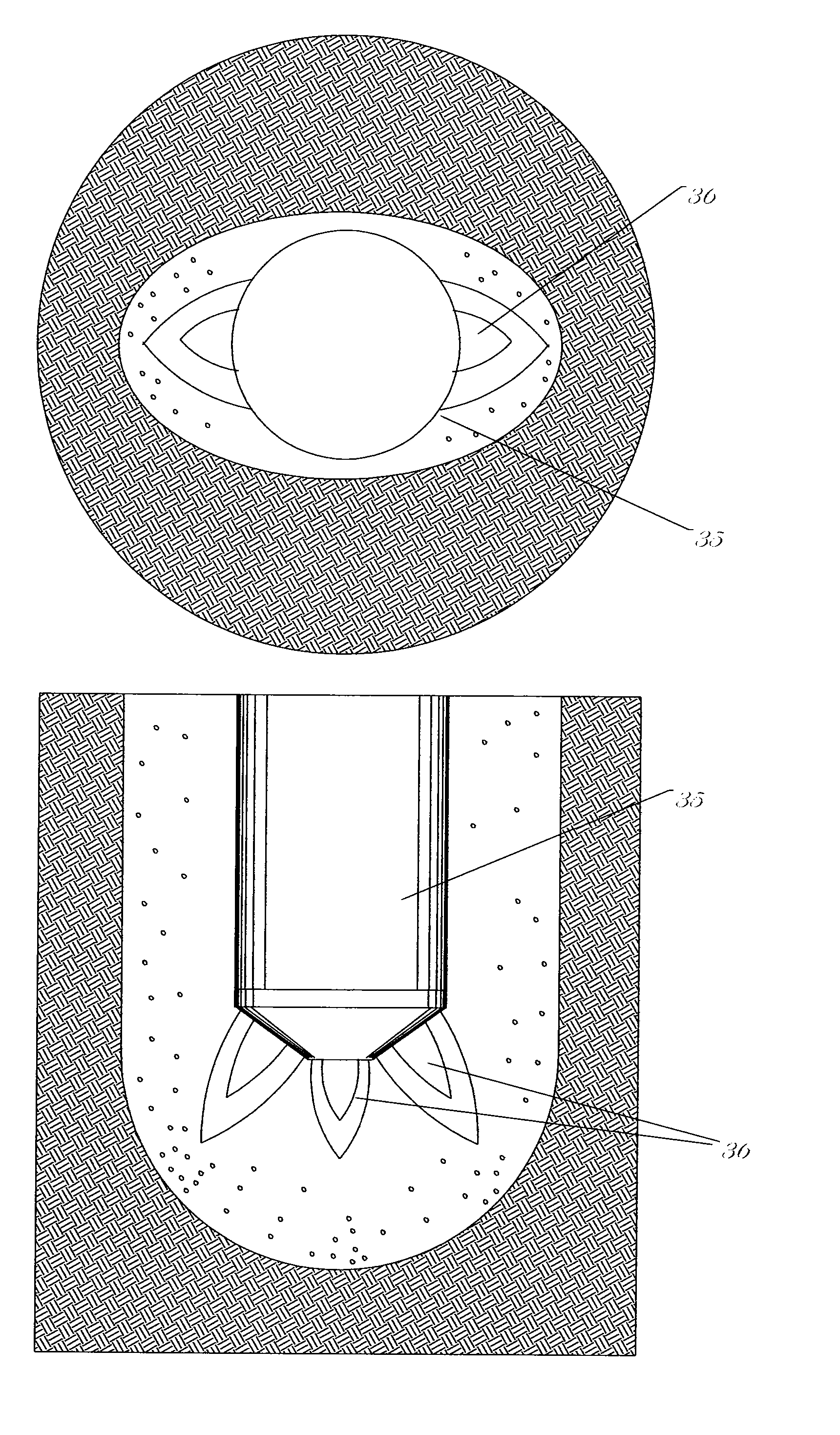

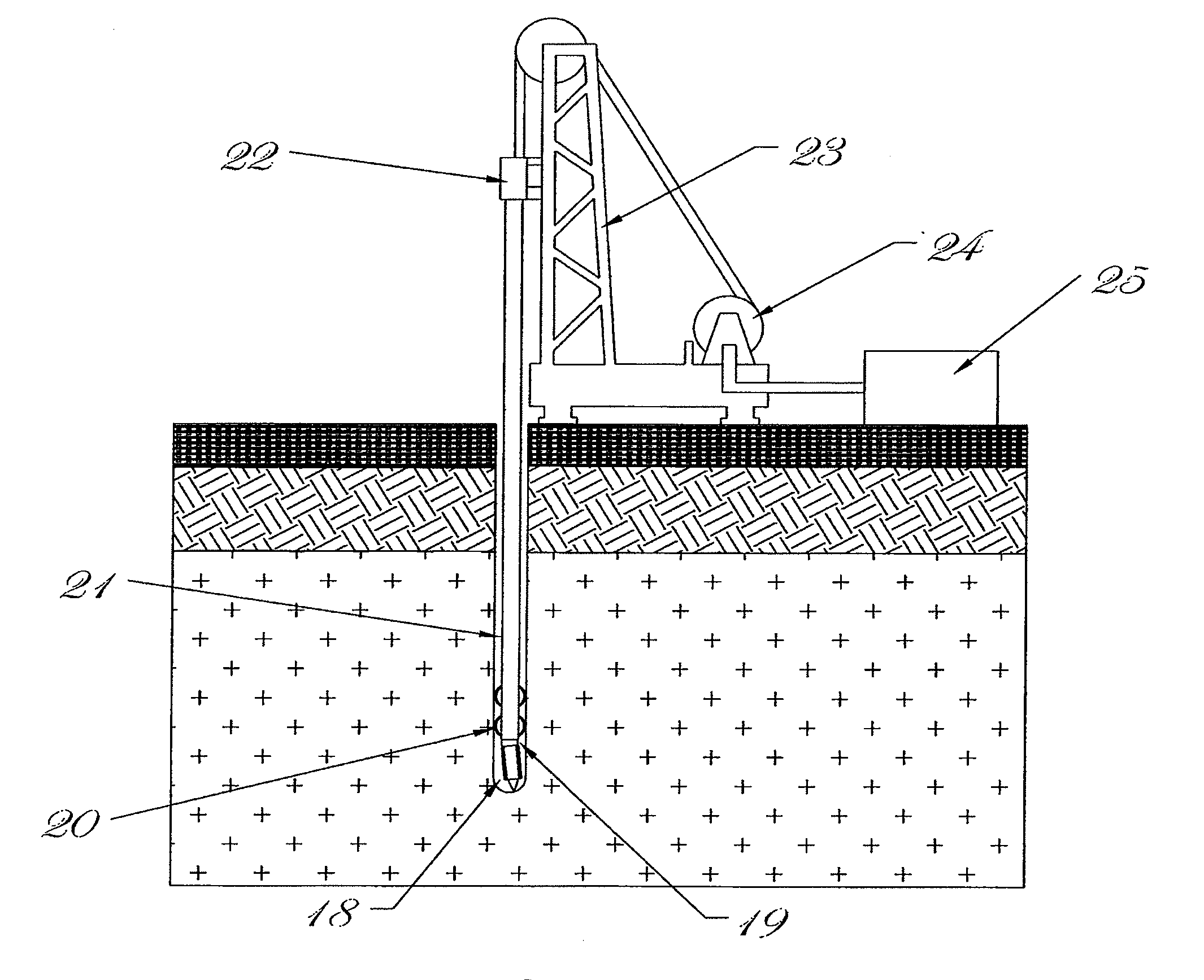

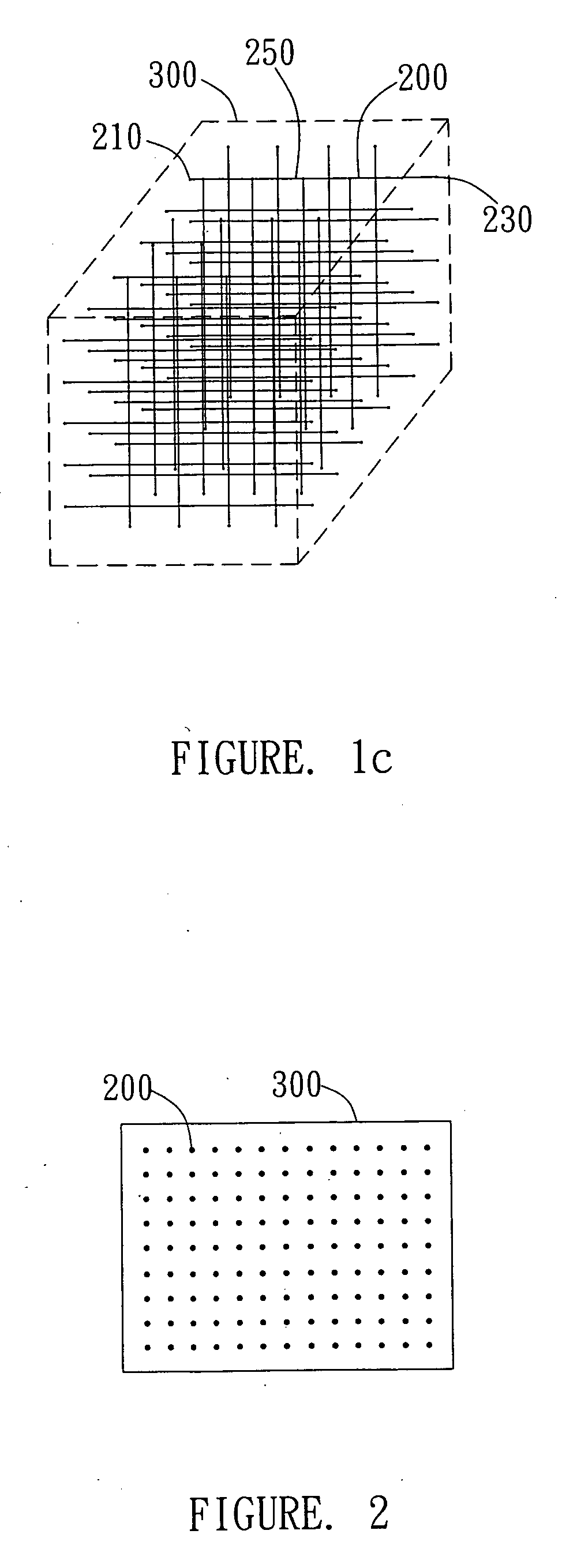

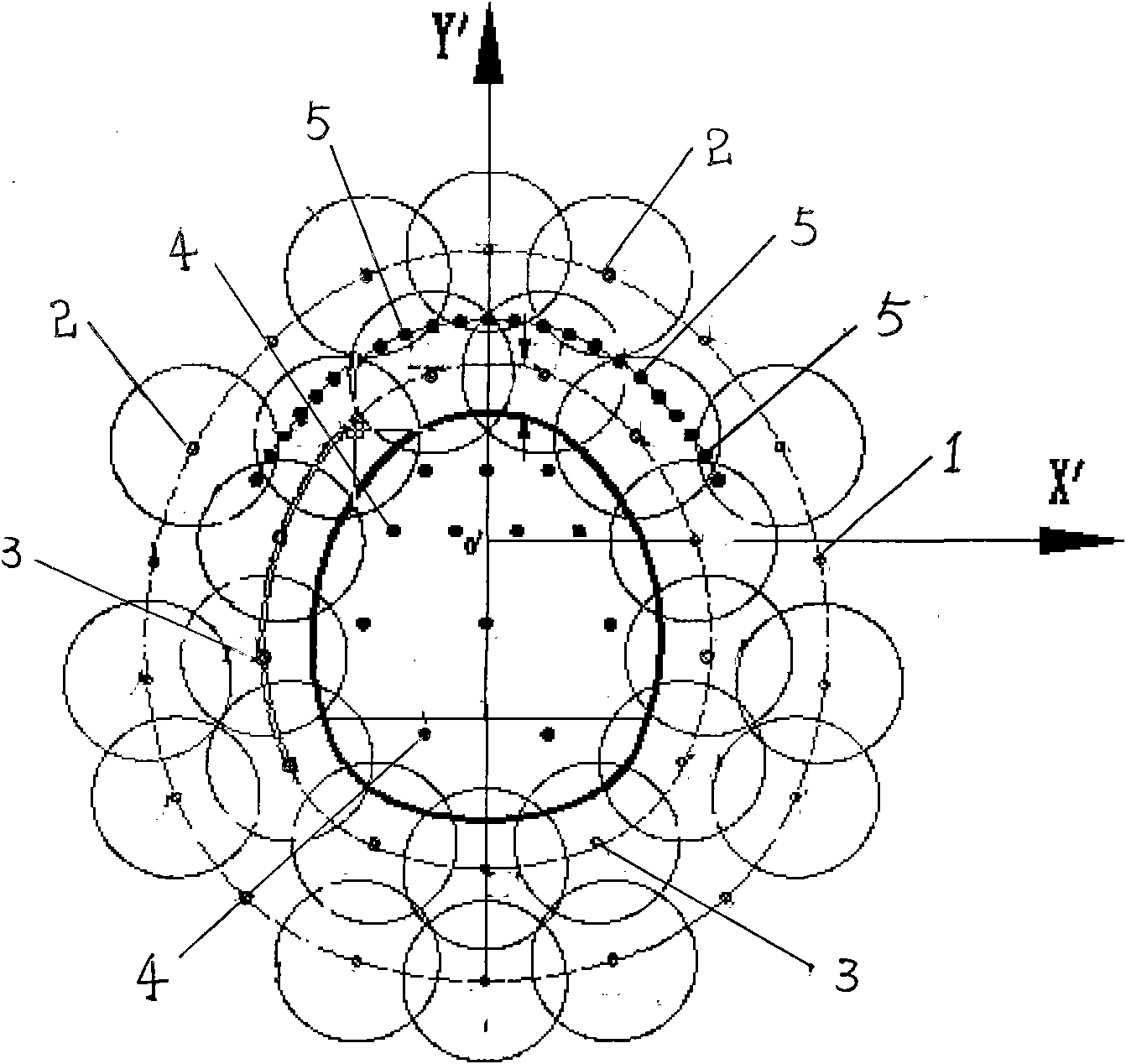

Method and System for Forming a Non-Circular Borehole

InactiveUS20080093125A1Prevent outbreakEasy to installEarth drilling toolsDrill bitsDissolutionGeothermal heat pump

System and methods for creating shaped, non-circular boreholes in rocks especially for use with geothermal heat pump applications and for increasing wellbore support in applications such as horizontal oil and gas drilling are described. The systems and methods when applied to geothermal heat pumps create an elliptical shaped hole that is optimized for placing heat transfer tubes with a minimum of grout used. The significantly reduced cross-sectional area of the elliptical borehole also increases the overall drilling rate in rock and especially in hard rocks. In horizontal hard-rock drilling, creation of a horizontal non-circular borehole or modification of a circular borehole to a non-circular geometry is used to stabilize the borehole prior to casing insertion, and may also allow the use of lower mud pressures improving drilling rates. The system uses a non-contacting drilling system which in one embodiment uses a supersonic flame jet drilling system with a movable nozzle that swings between pivot points. In a second embodiment the elliptical shaped hole is created by an abrasive fluid or particle bearing-fluid or air jet drill that moves between pivot points. In another embodiment a non-contacting drill can use dual parallel nutating nozzles that create a pair of overlapping circular holes. The non-circular shaped hole is created by either the high temperature flame or water-particle jet or chemically active fluid jet as it removes rock material by erosion, dissolution and or thermal spalling. Modifications of circular boreholes to a generally elliptical shape can also be done using milling or jetting techniques.

Owner:POTTER DRILLING

Method and System for Forming a Non-Circular Borehole

InactiveUS20100032207A1Easy to installEasy to operateCollector components/accessoriesLighting and heating apparatusEngineeringDissolution

System and methods for creating shaped, non-circular boreholes in rocks especially for use with geothermal heat pump applications and for increasing wellbore support in applications such as horizontal oil and gas drilling are described. The systems and methods when applied to geothermal heat pumps create an elliptical shaped hole that is optimized for placing heat transfer tubes with a minimum of grout used. The significantly reduced cross-sectional area of the elliptical borehole also increases the overall drilling rate in rock and especially in hard rocks. In horizontal hard-rock drilling, creation of a horizontal non-circular borehole or modification of a circular borehole to a non-circular geometry is used to stabilize the borehole prior to casing insertion, and may also allow the use of lower mud pressures improving drilling rates. The system uses a non-contacting drilling system which in one embodiment uses a supersonic flame jet drilling system with a movable nozzle that swings between pivot points. In a second embodiment the elliptical shaped hole is created by an abrasive fluid or particle bearing-fluid or air jet drill that moves between pivot points. In another embodiment a non-contacting drill can use dual parallel nutating nozzles that create a pair of overlapping circular holes. The non-circular shaped hole is created by either the high temperature flame or water-particle jet or chemically active fluid jet as it removes rock material by erosion, dissolution and or thermal spalling. Modifications of circular boreholes to a generally elliptical shape can also be done using milling or jetting techniques.

Owner:POTTER JARED MICHAEL +3

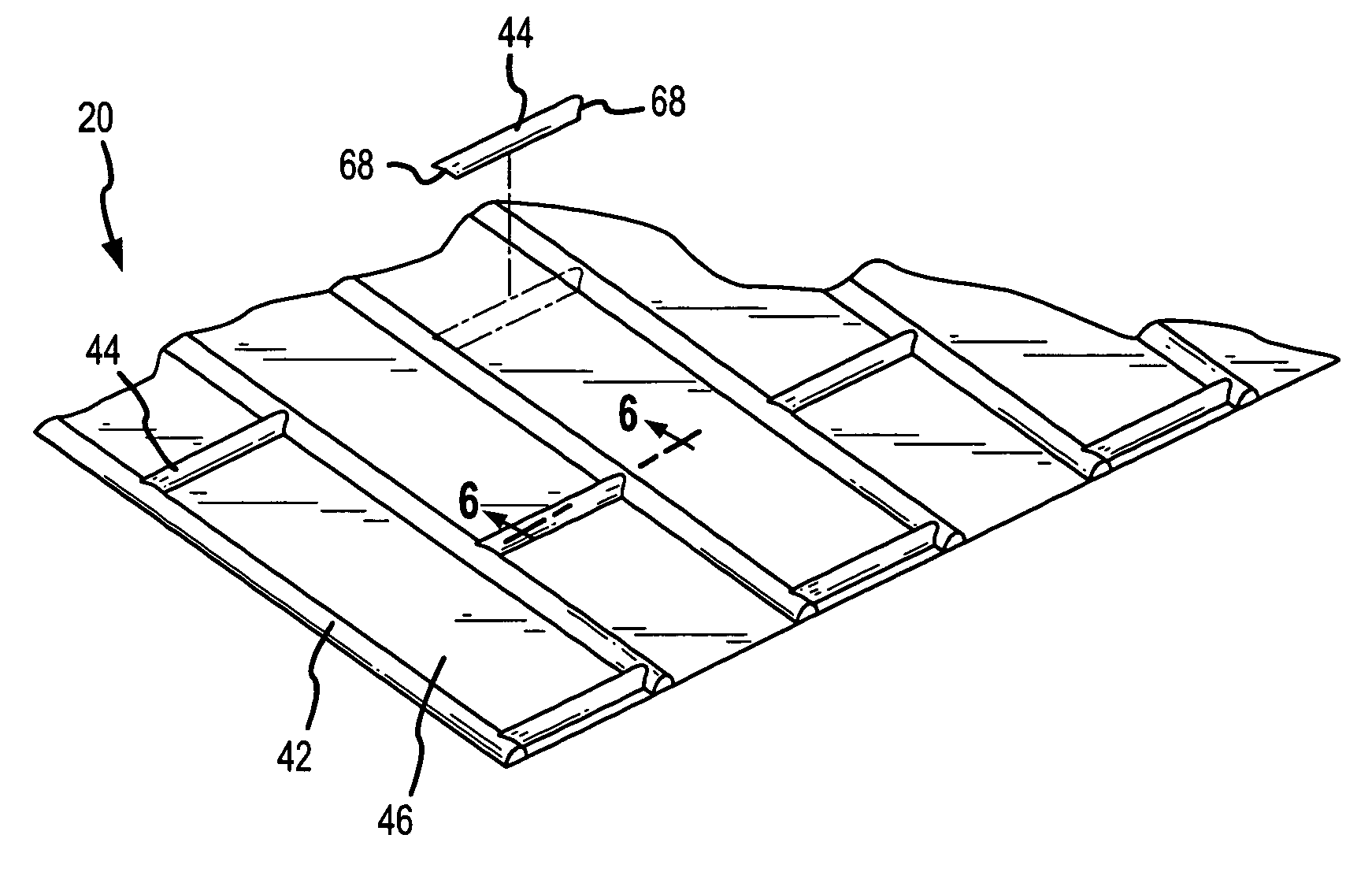

Modular flooring assemblies

Owner:COMC

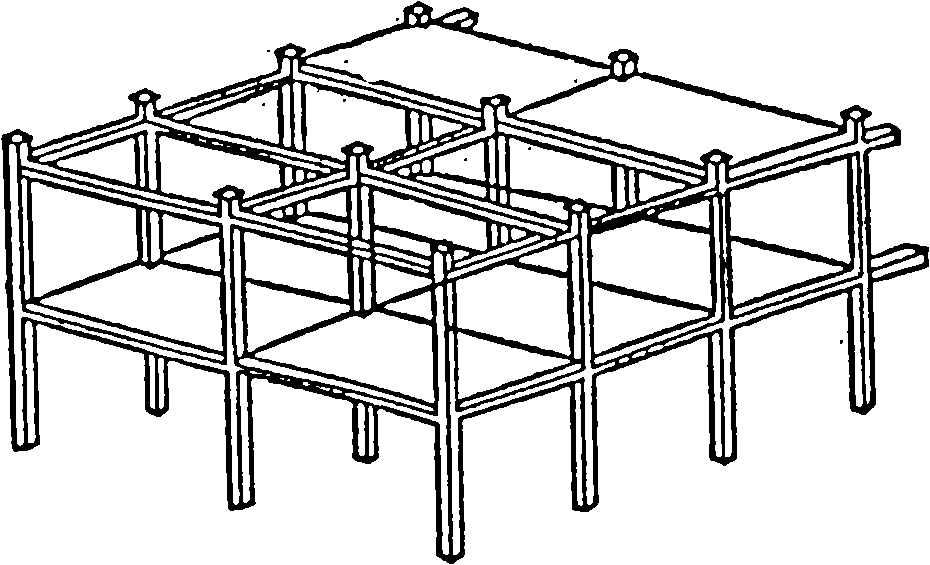

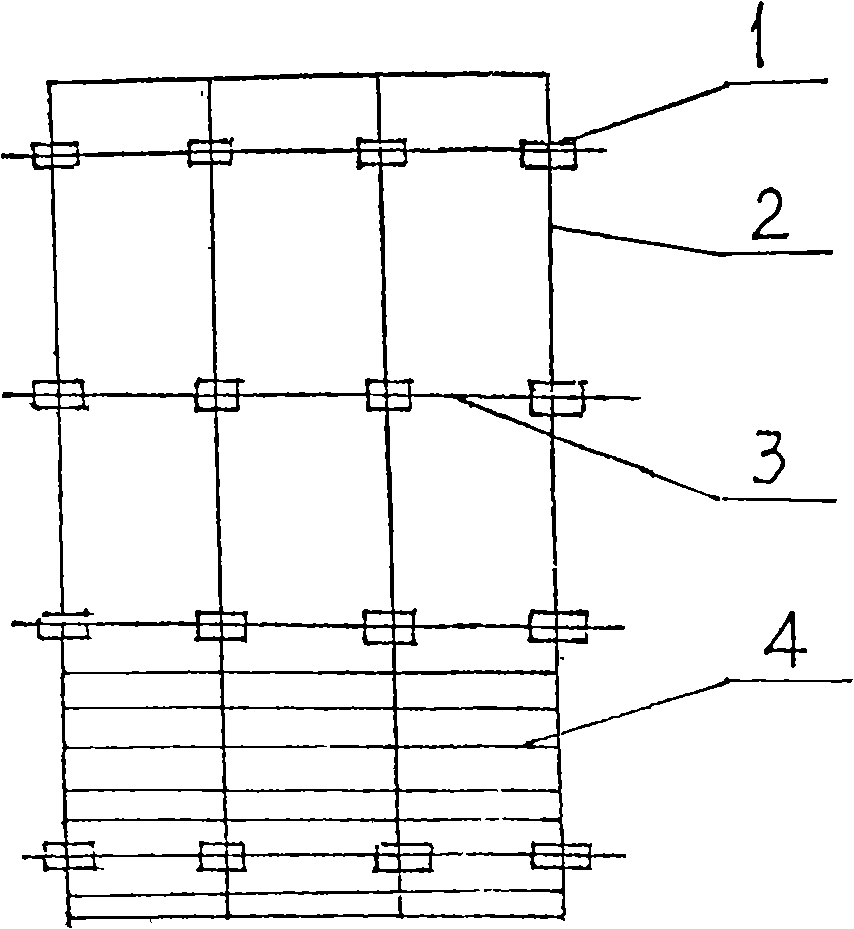

Novel method for quickly assembling low-cost energy-saving house with prefabricated pole, beam, plate

InactiveCN101294419ANo wasteReduce the amount of manual laborBuilding constructionsReinforced concrete columnHigh density

A novel method for rapidly assembling a low-cost energy-saving house with precast columns, beams and slabs comprises the steps of preparing house columns, beam molds and built-in reinforcing steel bars or profiled steel bars, pouring concrete grout into the molds, high-speed rotating in a centrifuge, curing, and demolding to obtain precast reinforced concrete columns and beam components; and inserting the precast columns on a cup foundation element, passing the precast beams through the preformed pores on the precast column, lapping precast floor slabs on the precast beams, and embedding wall slabs inside the embedding grooves of the precast beams, so as to form the major structure of the rapidly assembled low-cost energy-saving house. The inventive method has the advantages of application to industrial production, no air holes in components, high density, high strength, long service life, standardized production, low production cost, low time and raw materials consumption, rapid house construction speed, and high quality; and is a novel energy-saving house construction method in the construction field.

Owner:丁公权 +1

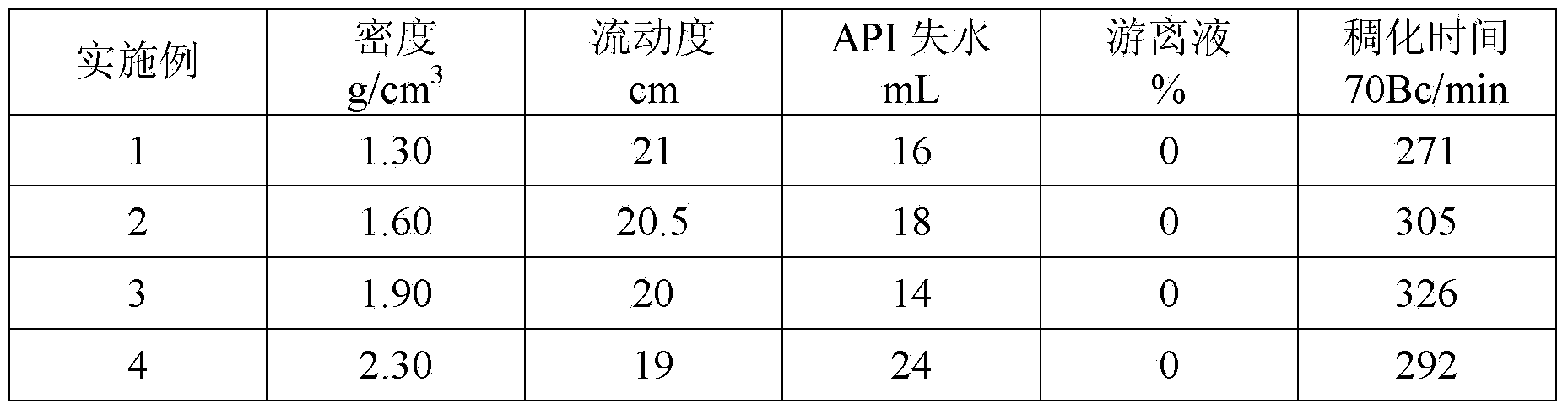

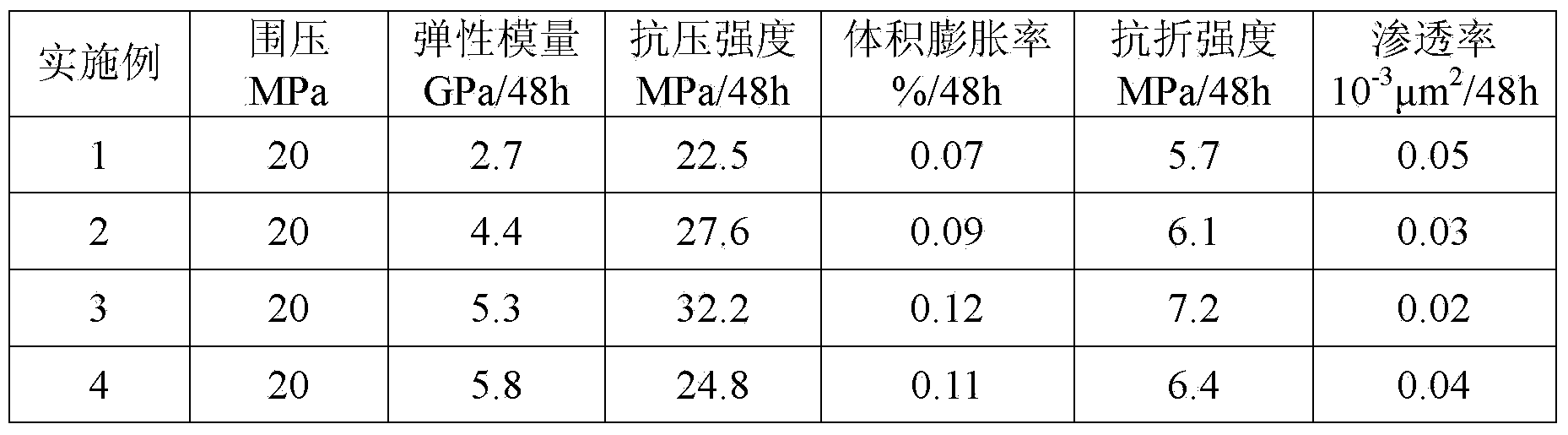

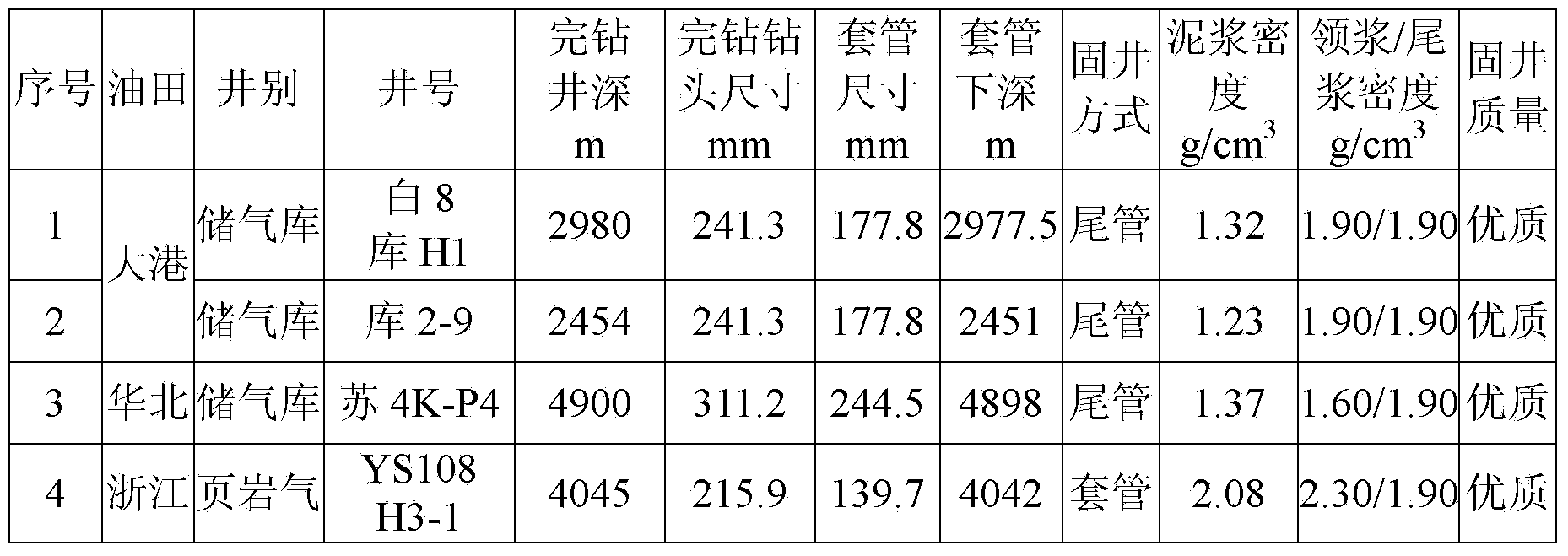

Expanded flexible well cementing grout and preparation method thereof

ActiveCN104371678ALow elastic modulusLower transfer coefficientDrilling compositionHorizontal wellsVolumetric Mass Density

The invention provides an expanded flexible well cementing grout and a preparation method thereof. The grout comprises the following components in parts by weight: 100 parts of cement, 6-14 parts of toughening material, 3-80 parts of reinforcing material, 8-120 parts of density modifier, 0.5-2.5 parts of suspension stabilizer, 20-40 parts of high-temperature stabilizer, 35-100 parts of distilled water, 0.5-2 parts of dispersant, 0.5-4 parts of fluid loss agent, 0.3-4 parts of retarder, 0.1-2 parts of foam inhibitor and 0.1-2 parts of defoamer. The invention further provides a preparation method of the expanded flexible well cementing grout. The grout has good sedimentation stability; and the set cement has the characteristics of micro expansion, high strength and low elasticity modulus, and can avoid the phenomena of micro cracks, micro annuluses, even fracture and the like caused by cement sheaths in subsequent operation of gas storage wells, shale gas wells, dense oil-gas horizontal wells and the like, thus realizing good zonal isolation and providing a technical support for long-term, safe and effective operation of oil-gas wells.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

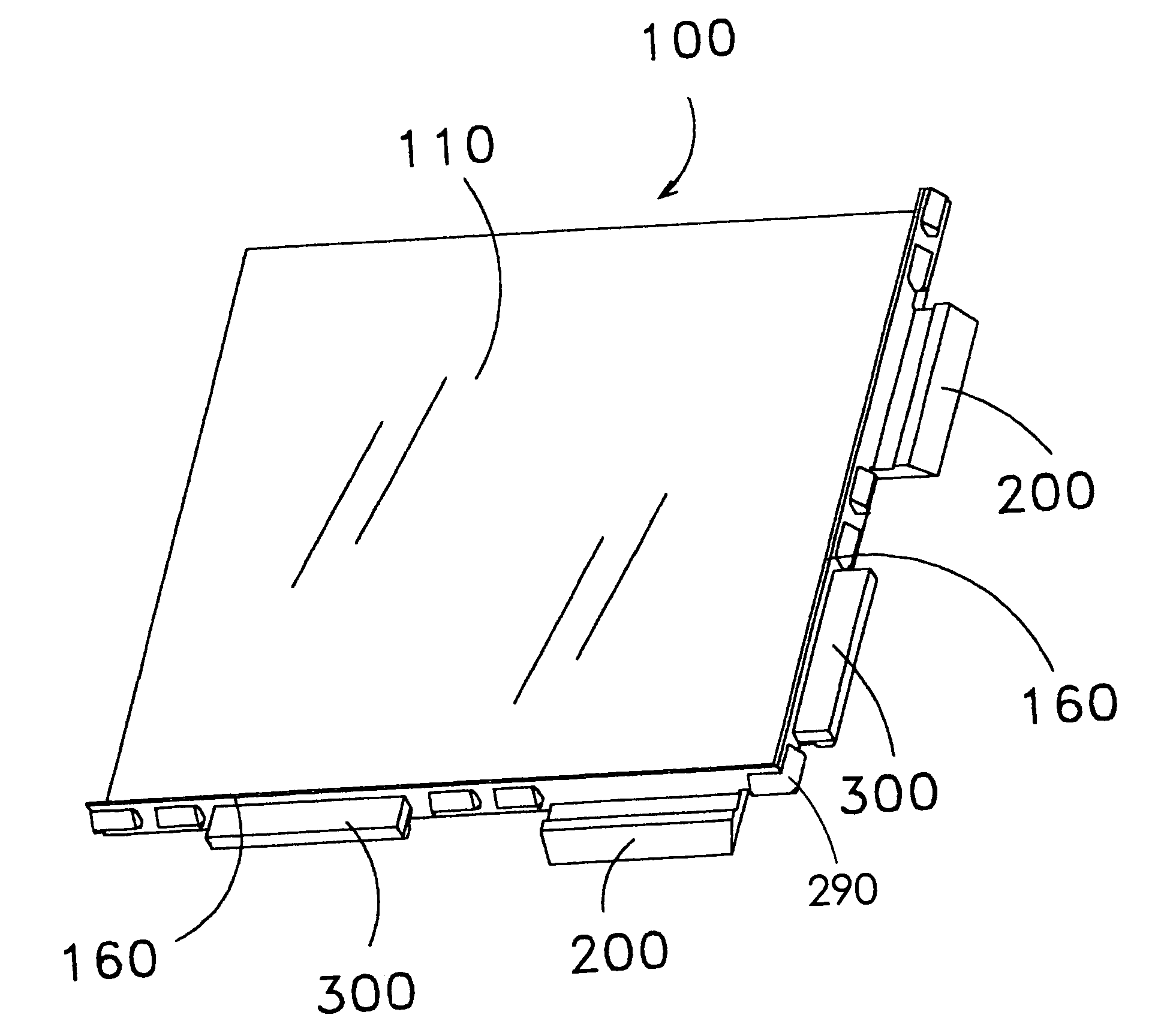

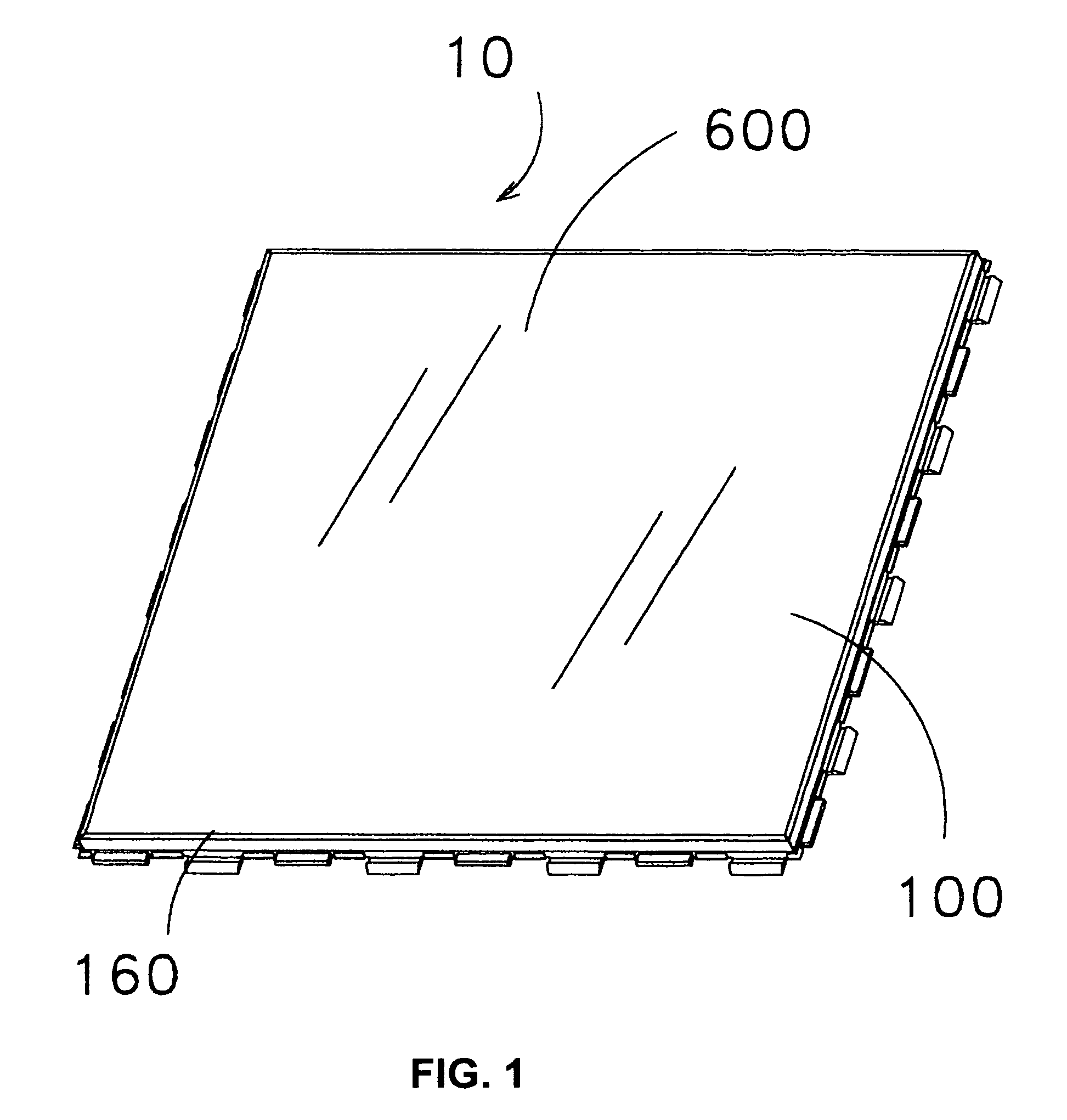

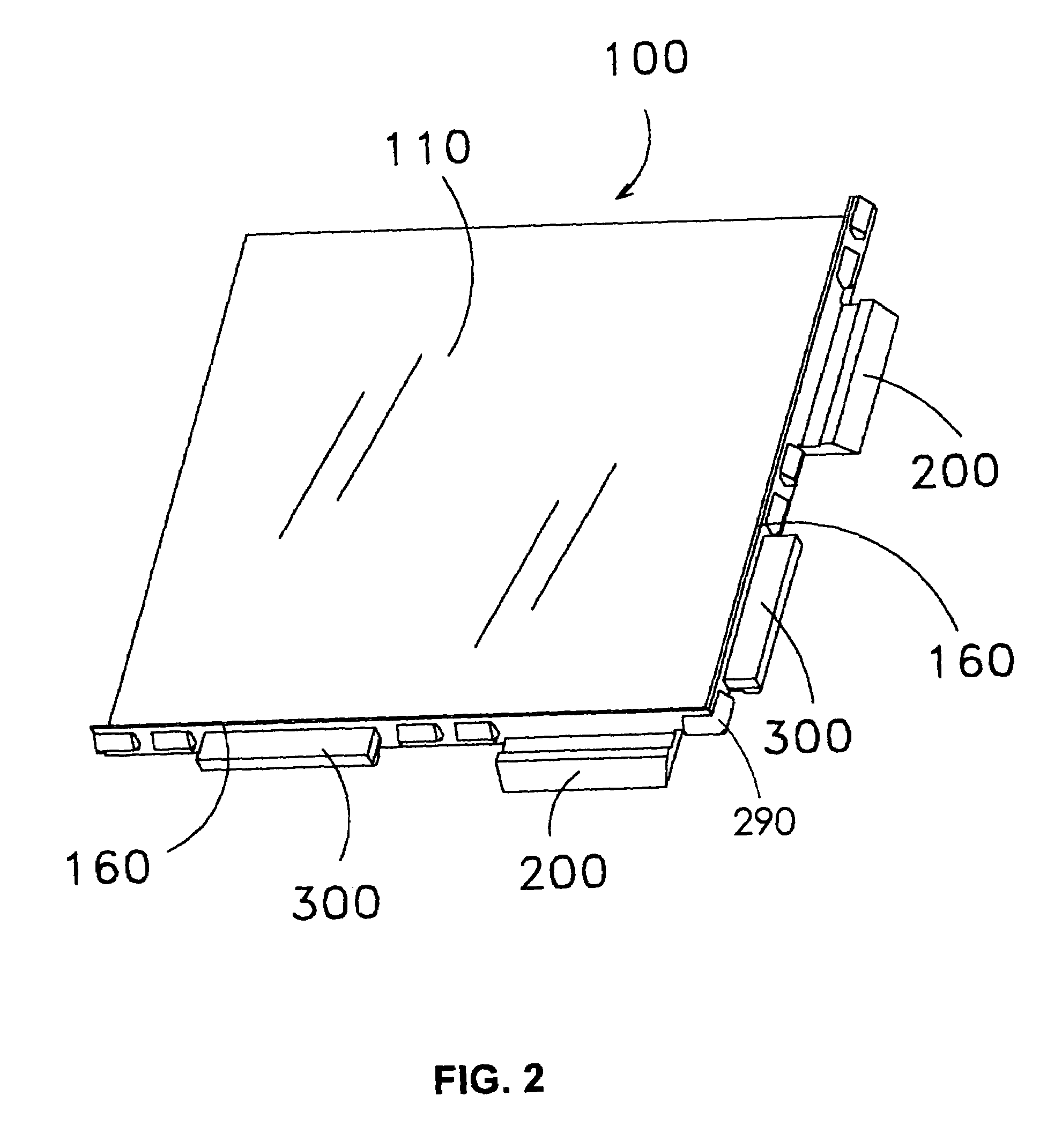

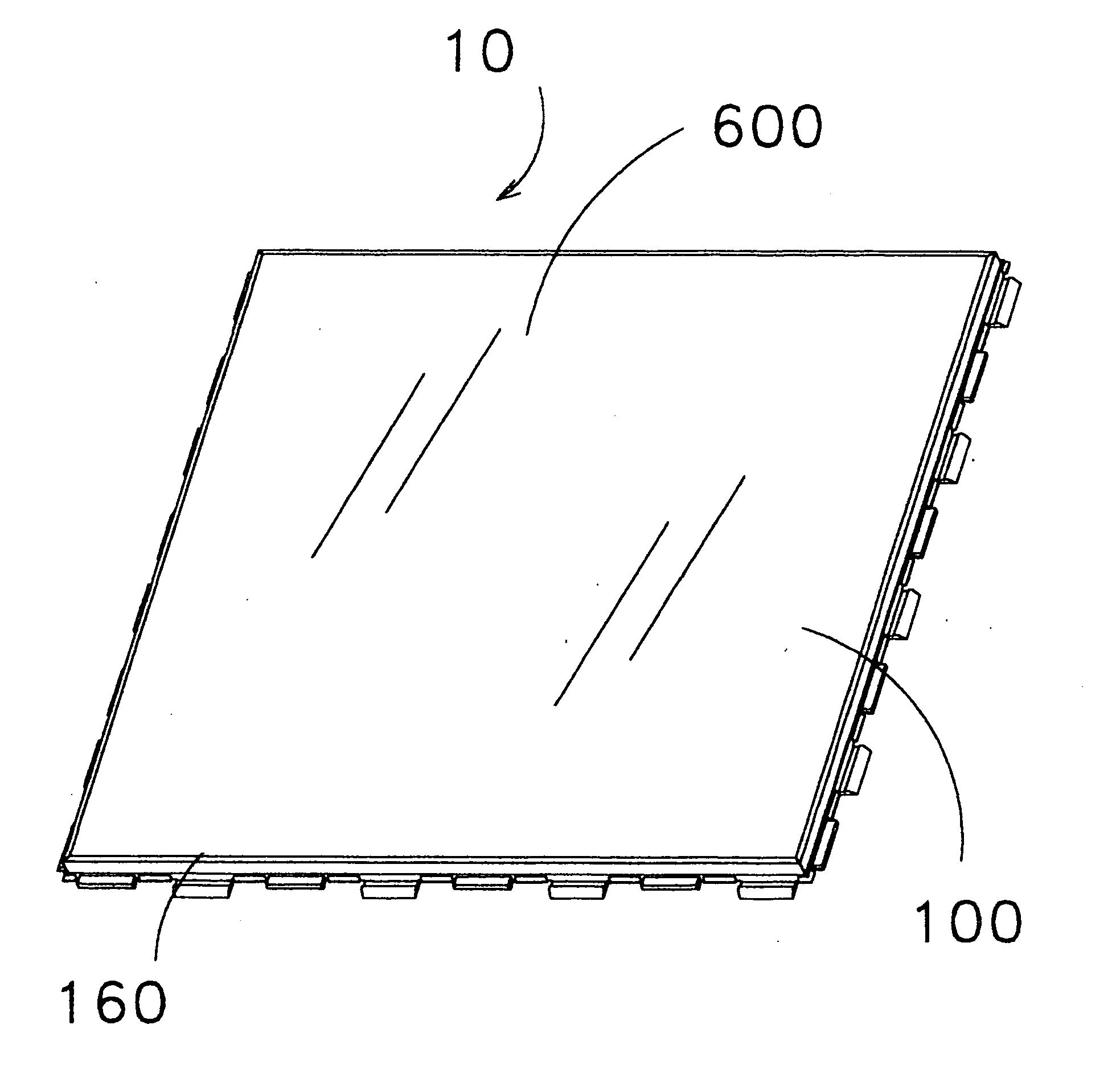

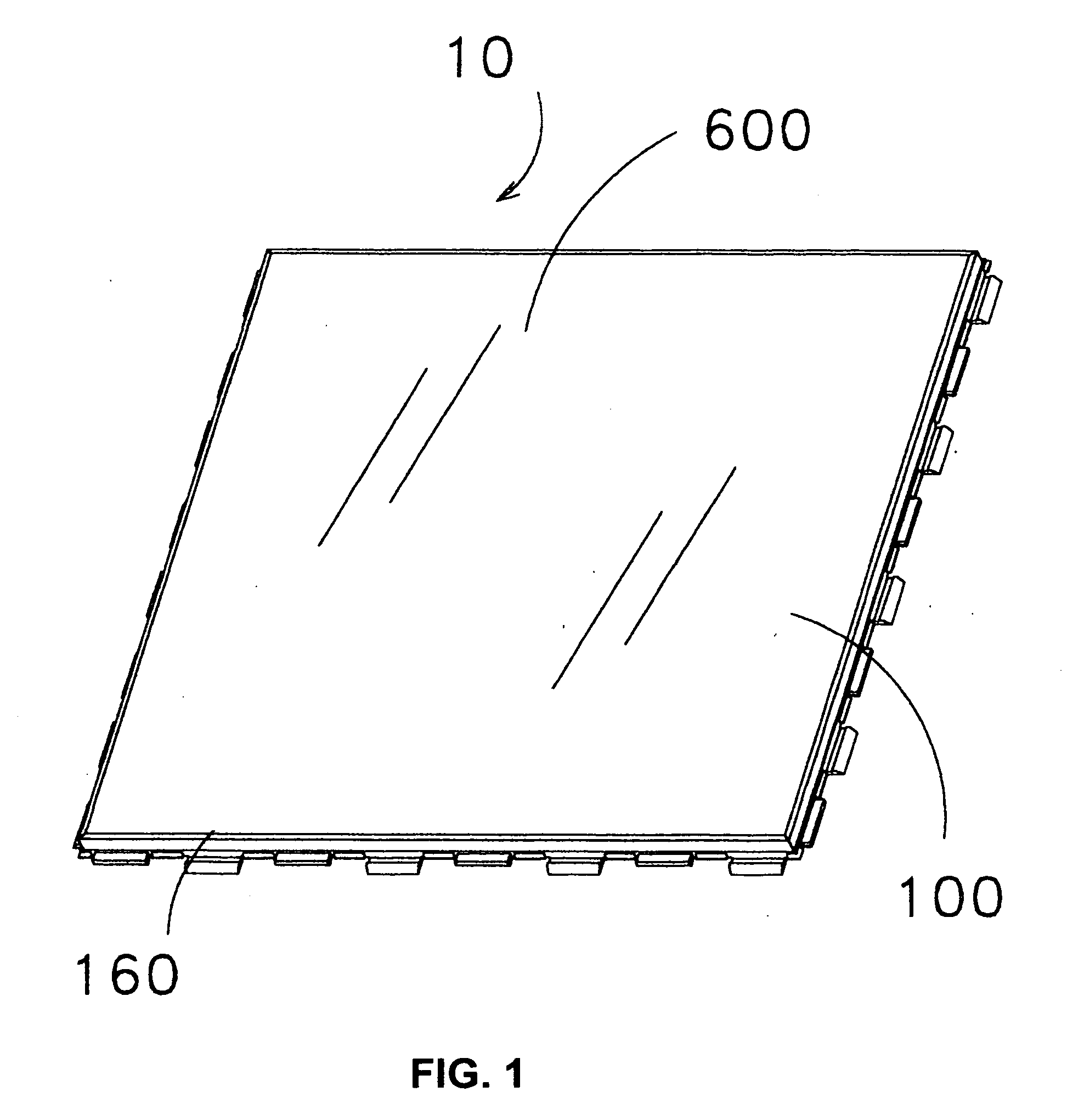

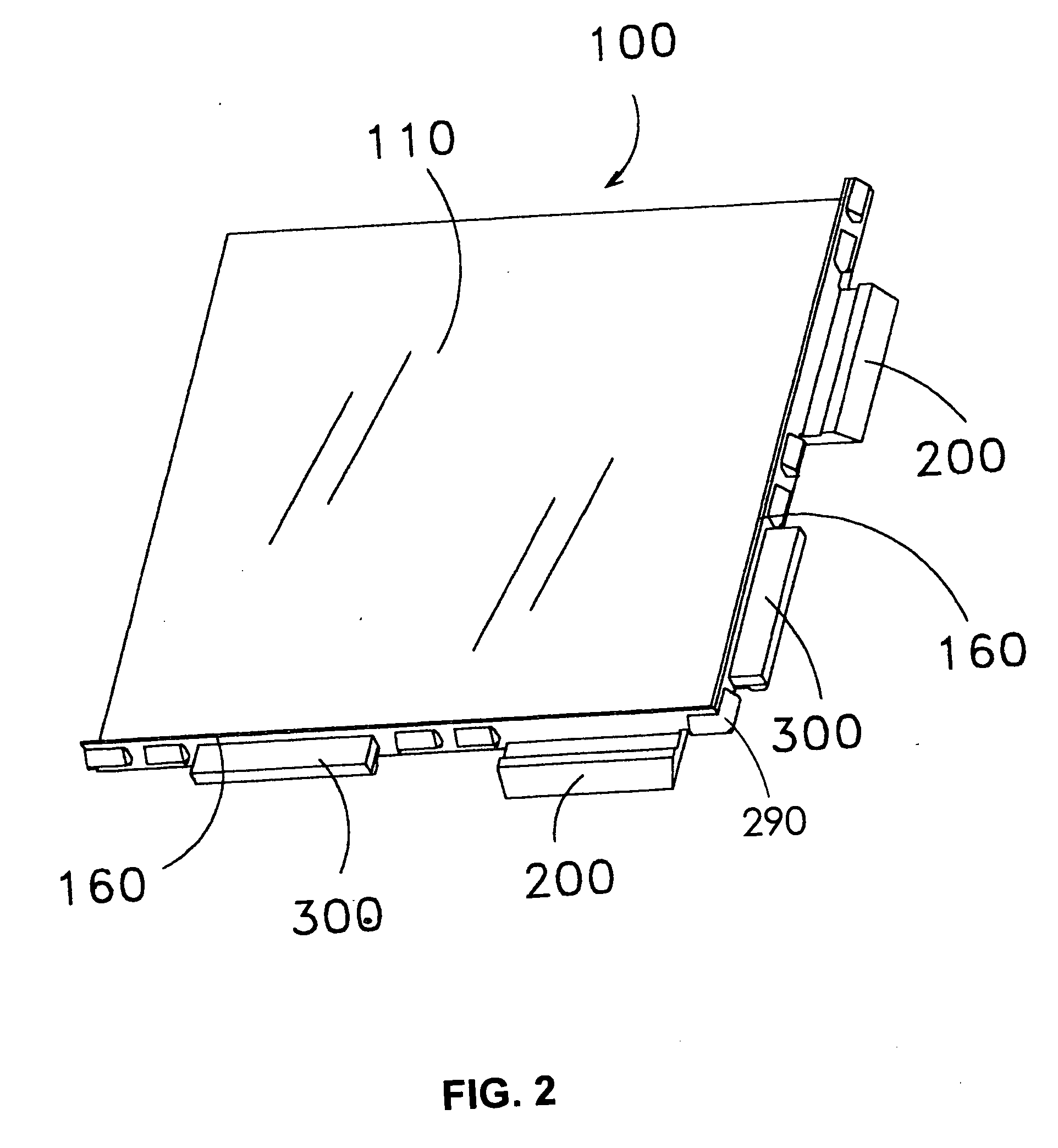

Modular flooring assemblies

A modular flooring assembly including a flooring component adhered to a tray substrate is described. The modular flooring assembly may be interconnected with additional modular flooring assemblies to form a modular floor suitable for most flooring applications. The flooring component may be tile or wood or other materials commonly used in flooring applications. Convention fill-in grout or a snap-in grout may be used with the modular flooring assemblies. One suitable snap-in grout is a right angle grout member.

Owner:COMC

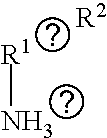

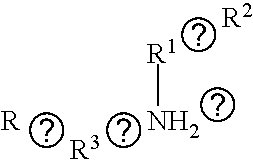

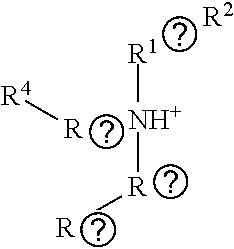

Chemical Admixtures for Hydraulic Cements

InactiveUS20130074736A1Improve propertiesImprove economySolid waste managementChemical admixtureHardness

This invention relates to a new class of chemical admixtures for hydraulic cement compositions such as pastes, mortars, grouts and concretes. The cement compositions are comprised of ordinary Portland cement, blended cements, or non-Portland cements made with Supplementary Cementitious Materials. The admixtures contain complexes of metals with derivatives of hydroxycarboxylic acids, and improve properties of cement compositions, including setting, hardness, compressive strength, shrinkage, and freeze-thaw resistance. The invention discloses a method for improving the properties of hydraulic cements by adding the disclosed chemical admixtures to cement compositions, and also discloses methods of preparing said admixtures.

Owner:GILL IQBAL

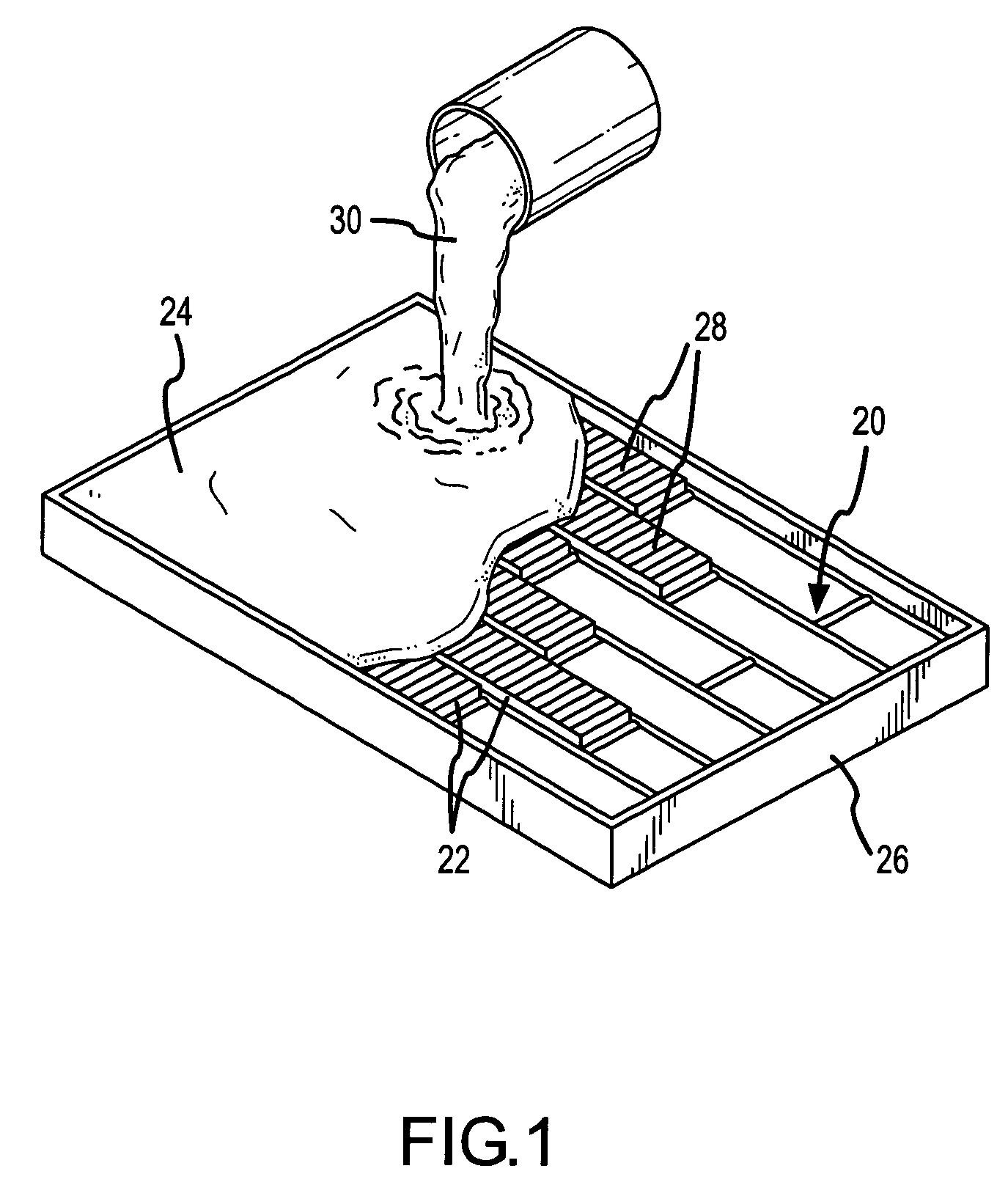

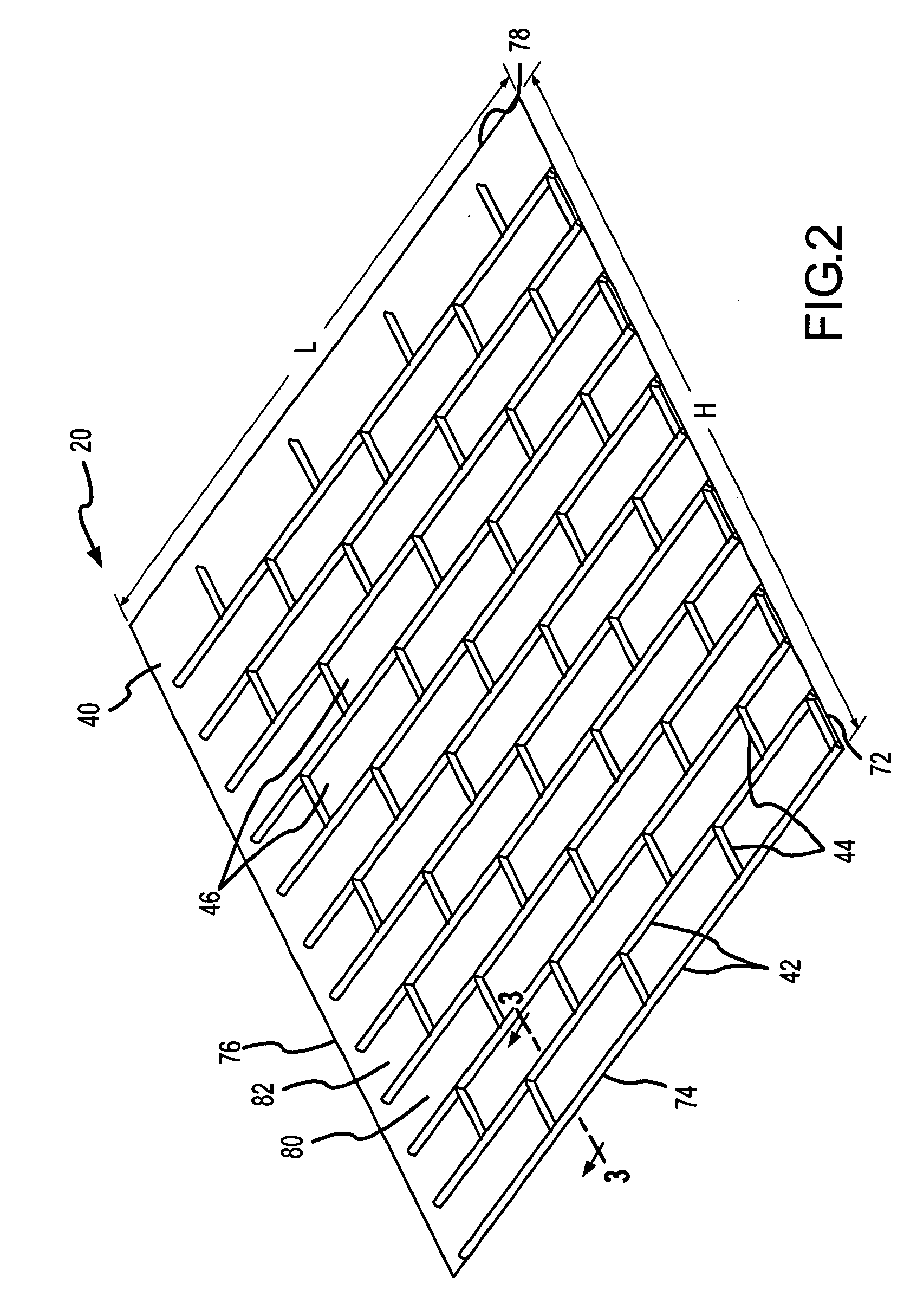

Foam liner for casting objects in poured walls

A liner holds objects in place within a form for a poured wall. The liner includes a backing sheet and a plurality of foam bed joints arranged in a substantially parallel fashion along a length dimension. A plurality of separate foam head joints are attached along a height dimension, wherein opposing ends of the foam head joints engage adjacent bed joints to define a plurality of regions on the backing sheet for receiving the objects to be cast in the poured wall. Each foam joint has a rounded cross section to form a curved grout line between the objects cast in the poured wall. The foam joints include an outer protective skin to prevent the poured wall material from bonding with the foam cells. A method of forming the liner includes aligning the separate foam bed joints and head joints in a grid and then pressing an adhesive-backed paper sheet against the foam joints.

Owner:SCOTT WILLIAM CLARE +1

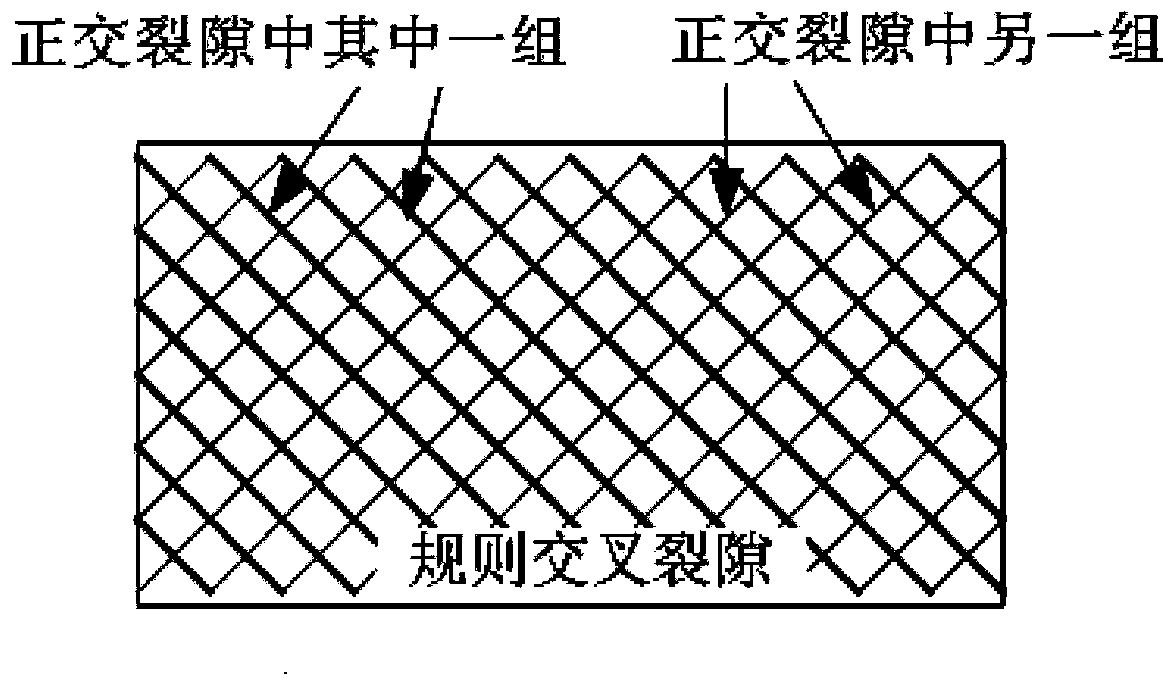

Visual intersected fracture flowing water grouting test device and method

ActiveCN103411751ARealize grouting simulation testRealize analysisHydrodynamic testingSlurryAtmospheric pressure

The invention discloses a visual intersected fracture flowing water grouting test device and method. The visual intersected fracture flowing water grouting test device comprises a grout collection device and further comprises an intersected fracture platform. The intersected fracture platform comprises supporting frames, an intersected fracture test room arranged on the supporting frames, intersected fractures arranged on the inner wall of the intersected fracture test room, flow sensors arranged inside the intersected fracture test room, and pressure sensors arranged inside the intersected fracture test room. The visual intersected fracture flowing water grouting test device further comprises a flowing water supply device used for injecting water for the intersected fracture test room and an air pressure grouting device used for grouting for the intersected fracture test room, and the intersected fracture test room is connected with the grout collection device. The visual intersected fracture flowing water grouting test device and method can achieve grouting simulation test and analysis under the conditions of the intersected fractures and flowing water.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

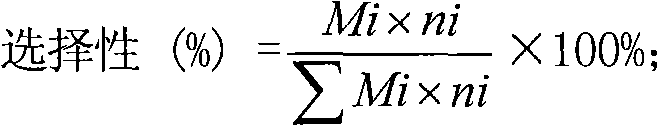

Propane dehydrogenation to propylene catalyst and preparation and applications thereof

InactiveCN102019178ALow costSimple methodCatalyst activation/preparationHydrocarbonsAir atmosphereAlkaline earth metal

The invention relates to a propane dehydrogenation to propylene catalyst and preparation and applications thereof. The propane dehydrogenation to propylene catalyst is characterized by being a composition prepared from Gamma-Al2O3, a kind or many kinds of chromium oxides, a kind or many kinds of rare earth oxides and a kind or many kinds of alkali metal oxides, wherein the Gamma-Al2O3 accounts for 30-95%, the chromium oxides account for 1-50%, the rare earth oxides account for 0-30%, and the alkali metal oxides account for 0-10%. The preparation process comprises the following steps of: adding active components, such as chromium, rare earth, alkali metal and the like into aluminum oxide grout, regulating the pH value of 1-5 to form gelatum with concentrated nitric acid, and spraying and drying to form microballoons; then roasting for 0-5 hours at 250-750 DEG C in a nitrogen atmosphere; and roasting for 0.1-20 hours at 250-1000 DEG C in an air atmosphere. The obtained catalyst is in a fluid bed reactor, and reaction conditions comprise 400-700 DEG C of temperature, 0.01-3MPa of absolute pressure and 10-10000 h-1 of volume hourly space velocity.

Owner:卓润生

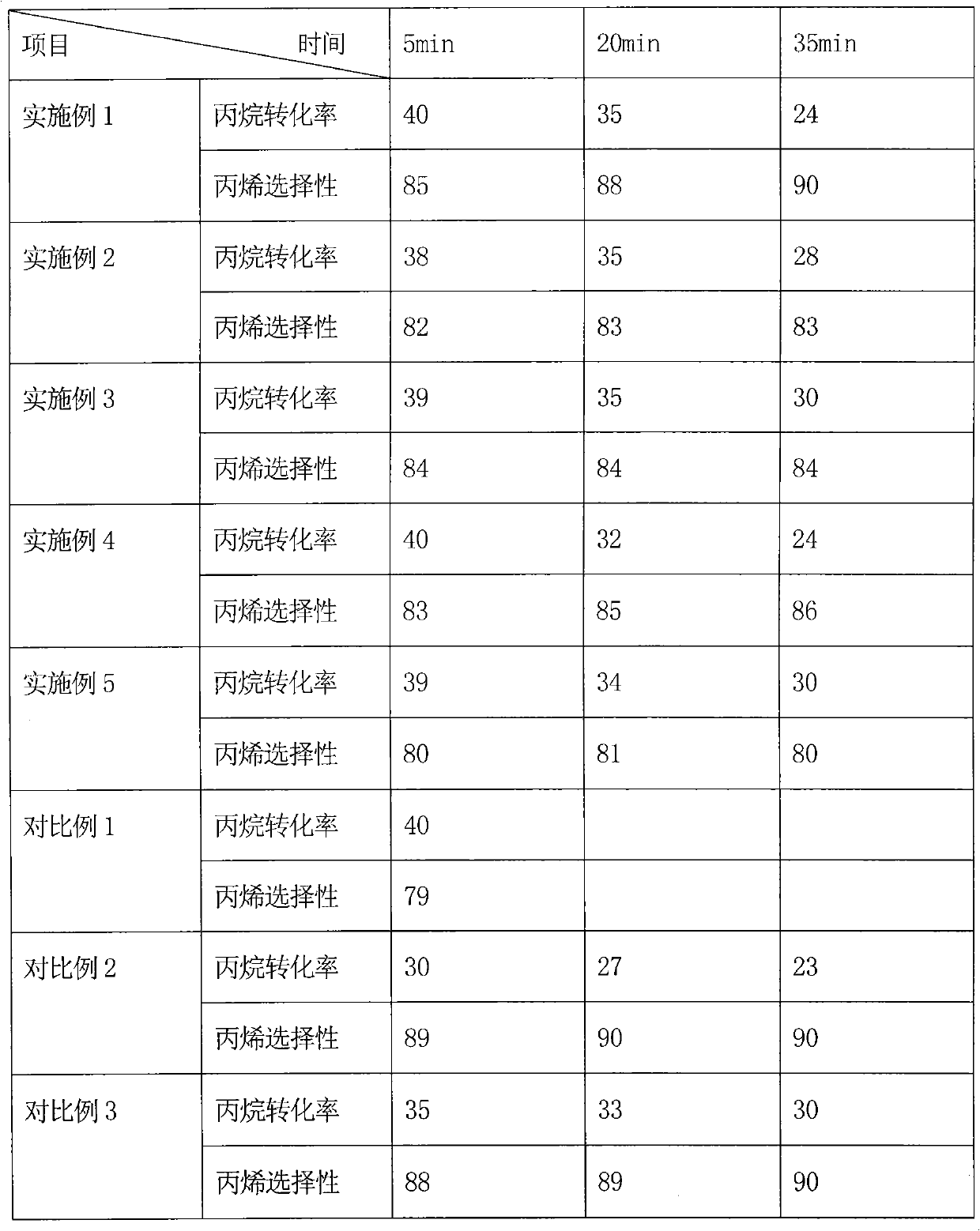

Precast concrete post tensioned segmented wind turbine tower

ActiveUS20140033628A1Easy constructionEliminate needWind motor supports/mountsMachines/enginesTowerTurbine

A post-tensioned precast segmental concrete tower has a stack of annular segments with uniform cross-sections which varies over the tower height. The transition between tower segments occurs in stages and is achieved using annular members or segments which support and anchor post-tensioning tendons that transfer loads passing through the tower as a result of a change in tower geometry. The tower segments are match cast against one another in fabrication to create tight matching opposing surfaces when placed into the tower and to create tight joints. The match casting eliminates the need for grout between precast segments, resulting in a faster tower erection time and high durability of the joints. All annular segments have horizontal joints and no vertical joints. The tower geometry simplifies the formwork system used to precast the segments, and the post-tensioning tendons tie all segments together and to the foundation.

Owner:WIND TOWER TECH

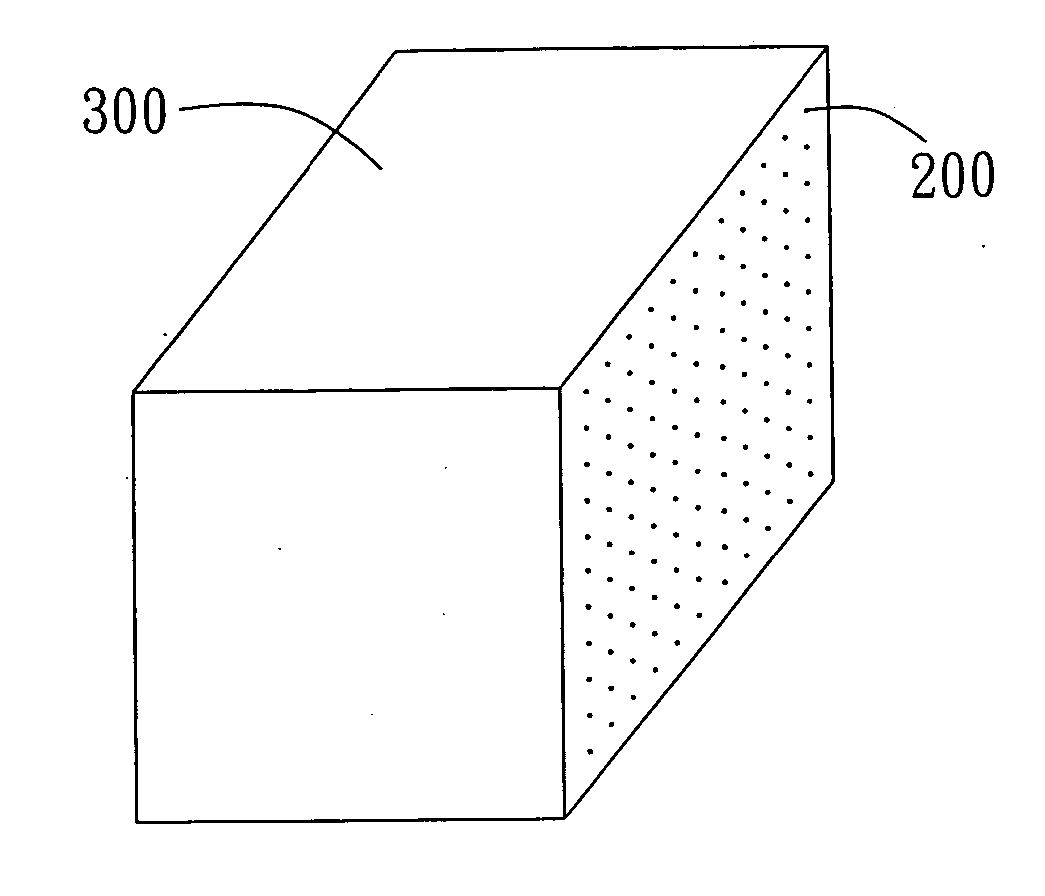

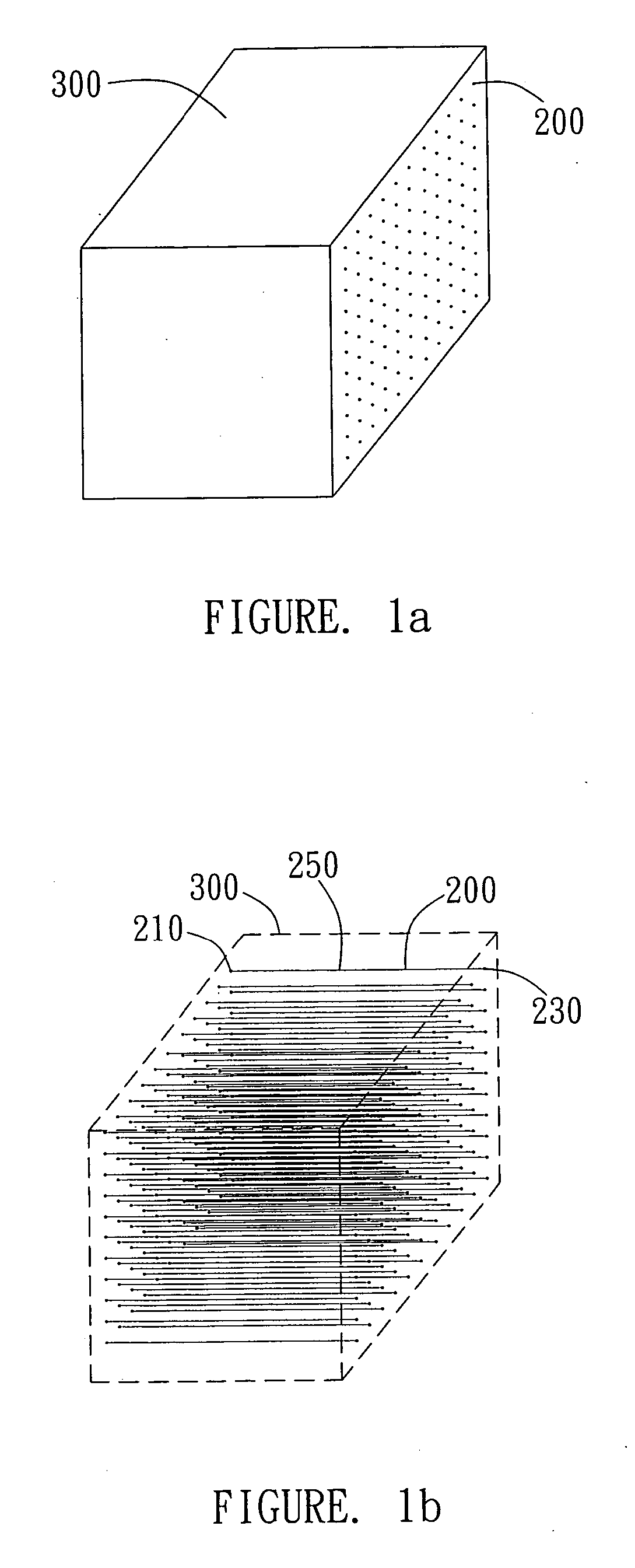

Light-transmissible construction material and manufacturing method for the same

InactiveUS20070074484A1Increase varietyEfficient preparationBuilding repairsCeramic shaping apparatusEngineeringGrout

A light-transmissible construction material and manufacturing method for the same. The light-transmissible construction material comprises at least a light-transmitting unit and a concrete unit. The light-transmitting unit has a light entrance end, a light exit end, and a lateral wall between both ends. The lateral wall of the light-transmitting unit is enclosed and surrounded with the concrete unit. The light entrance and exit end of the light-transmitting unit are exposed from two opposite surfaces of the concrete unit. A method for manufacturing the same light-transmissible construction material comprises: placing at least one light-transmitting unit between two side formworks; filling the concrete grout between above two side formworks; and drying the concrete grout to form the light-transmissible construction material.

Owner:RUNHORN PRETECH ENG CO LTD

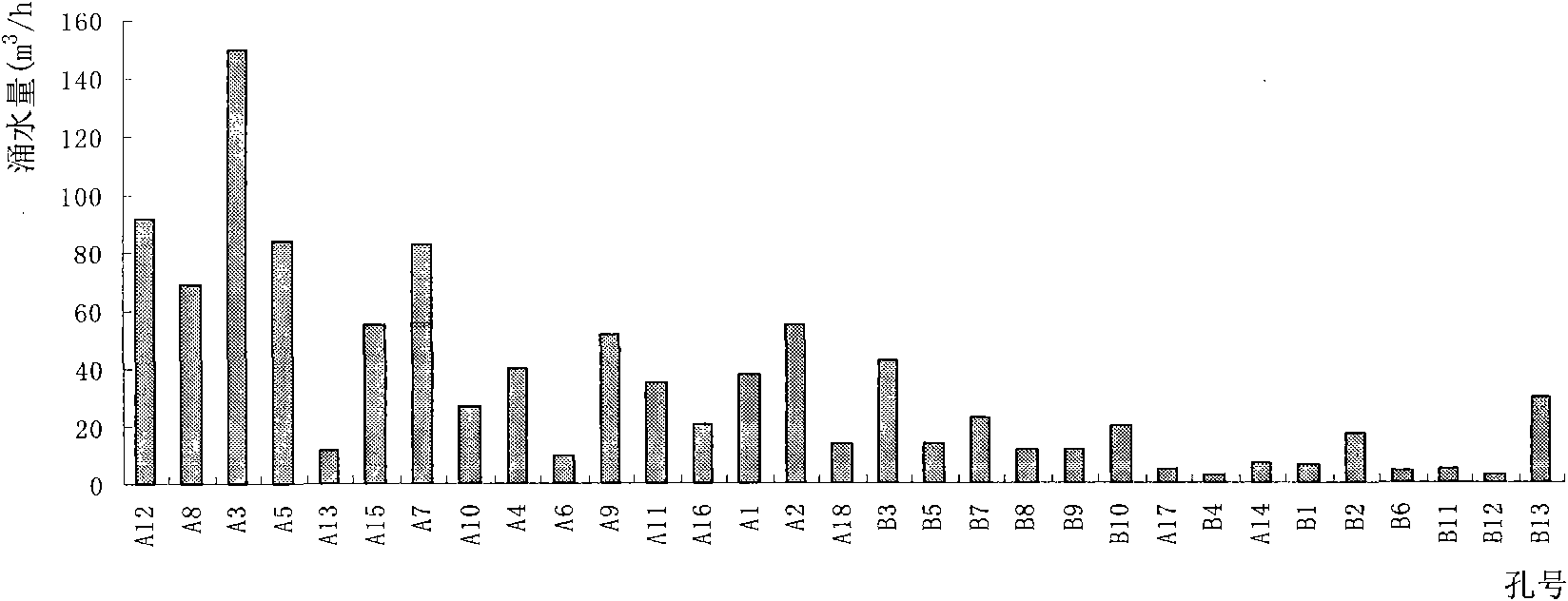

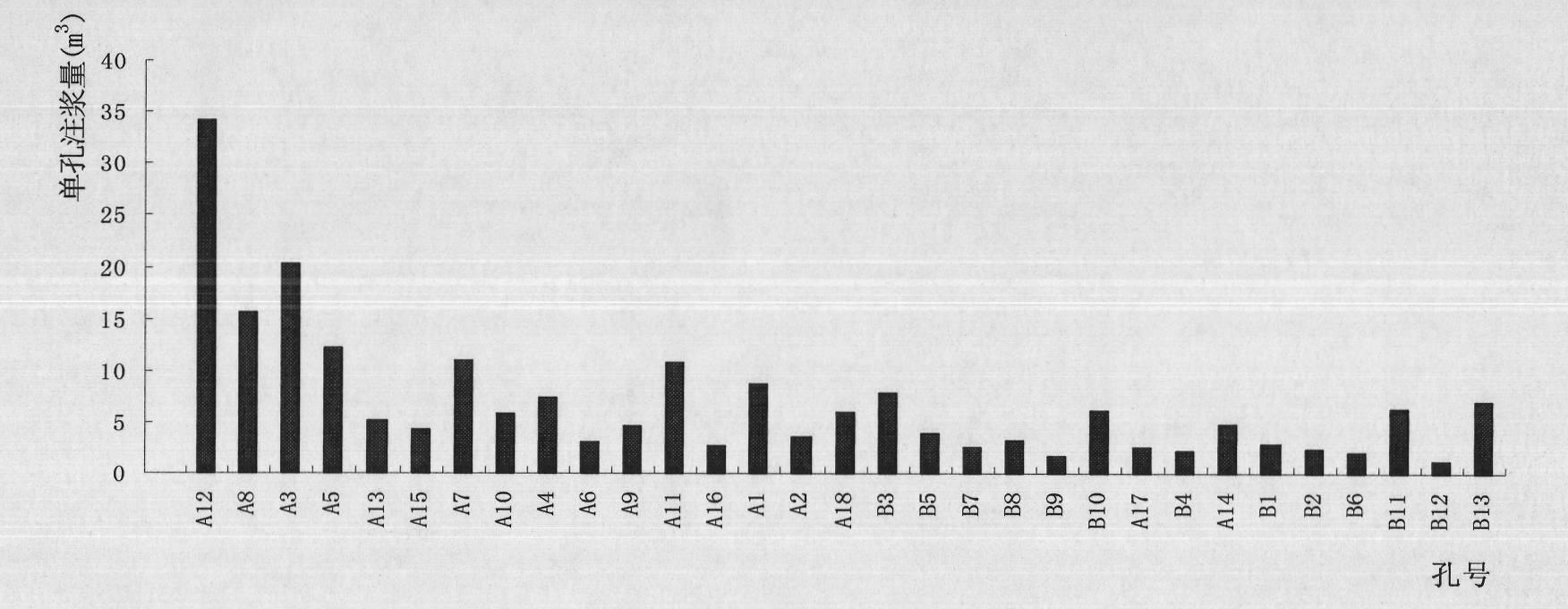

Tunnel information tracing accurate grouting method

ActiveCN101832142AOptimizing the Number of Grouting HolesReduce the amount of waterUnderground chambersTunnel liningGlass fiberGeomorphology

The invention relates to the field of tunnel grouting, in particular to a tunnel information tracing accurate grouting method, which solves the problems of thick reinforcing ring, large number of drilled holes, long construction period and the like of the traditional curtain grouting method adopted in current tunnel grouting. The method comprises the processes of grout stopping wall building, arrangement of orifice tubes and grouting tubes, measurement of the water burst of a drill hole, packer test, hole arrangement, drilling operation and grouting, wherein the hole arrangement and the grouting are performed according to the sequence from an advance geological drill hole to other outer ring holes to an inner ring hole to a working surface stabilizing hole to an access hole to a pipe-shed hole; and steps such as advance big pipe-shed construction of a working chamber and working surface stabilization by using a glass fiber anchor rod are saved. In the invention, a break through is made in the conventional construction philosophy, grouting design and geological change are tightly combined together, a grouting mechanism of 'crack blocking, water reduction, surrounding rock fixation and stratum stabilization' is adopted, the grouting holes are reduced by 30 to 40 percent, grouting quality is improved, the safe and quick construction is guaranteed, major water burst and mud burst accidents are eliminated, and the environment is protected maximally.

Owner:CHINA RAILWAY 12TH BUREAU GRP

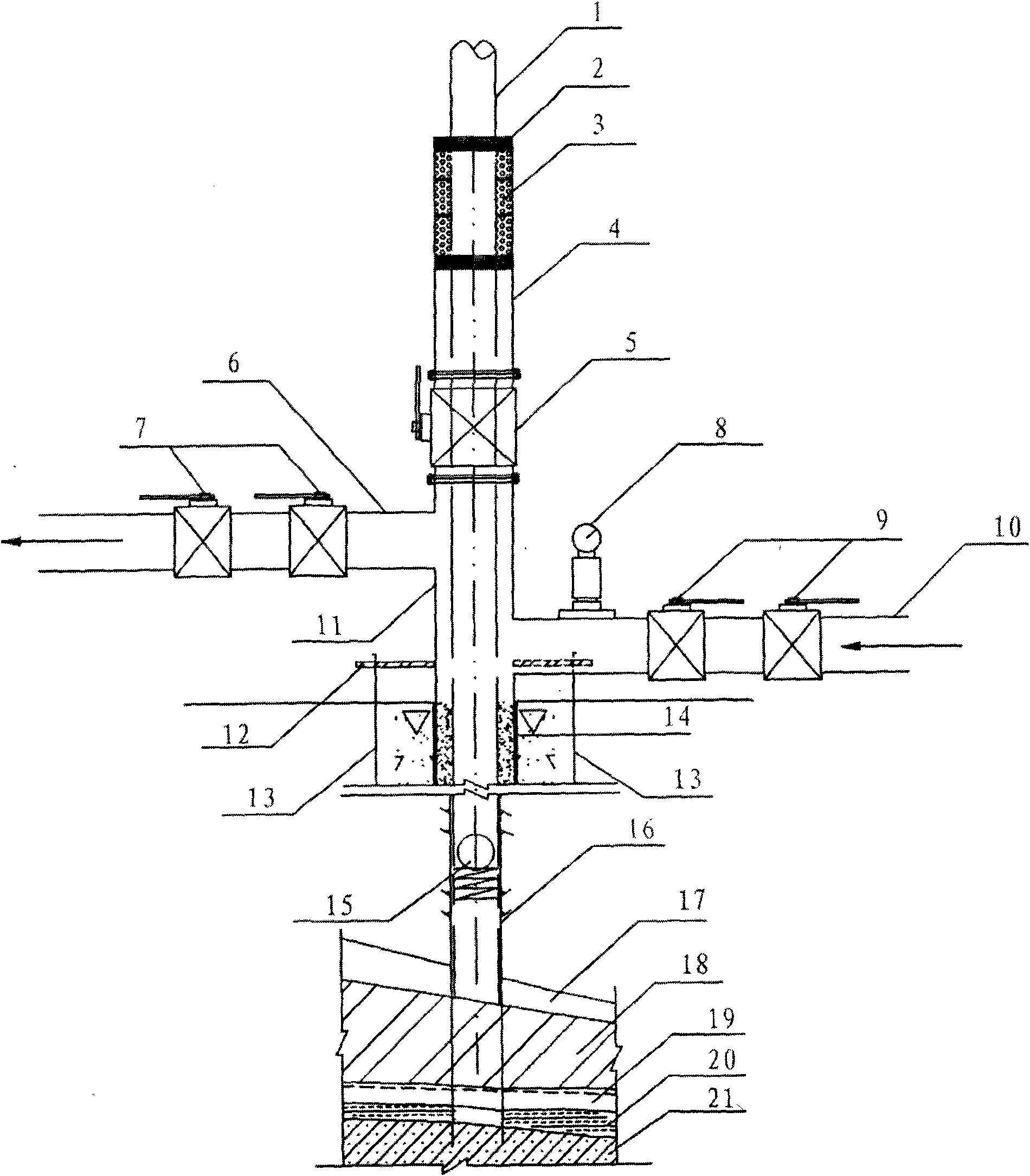

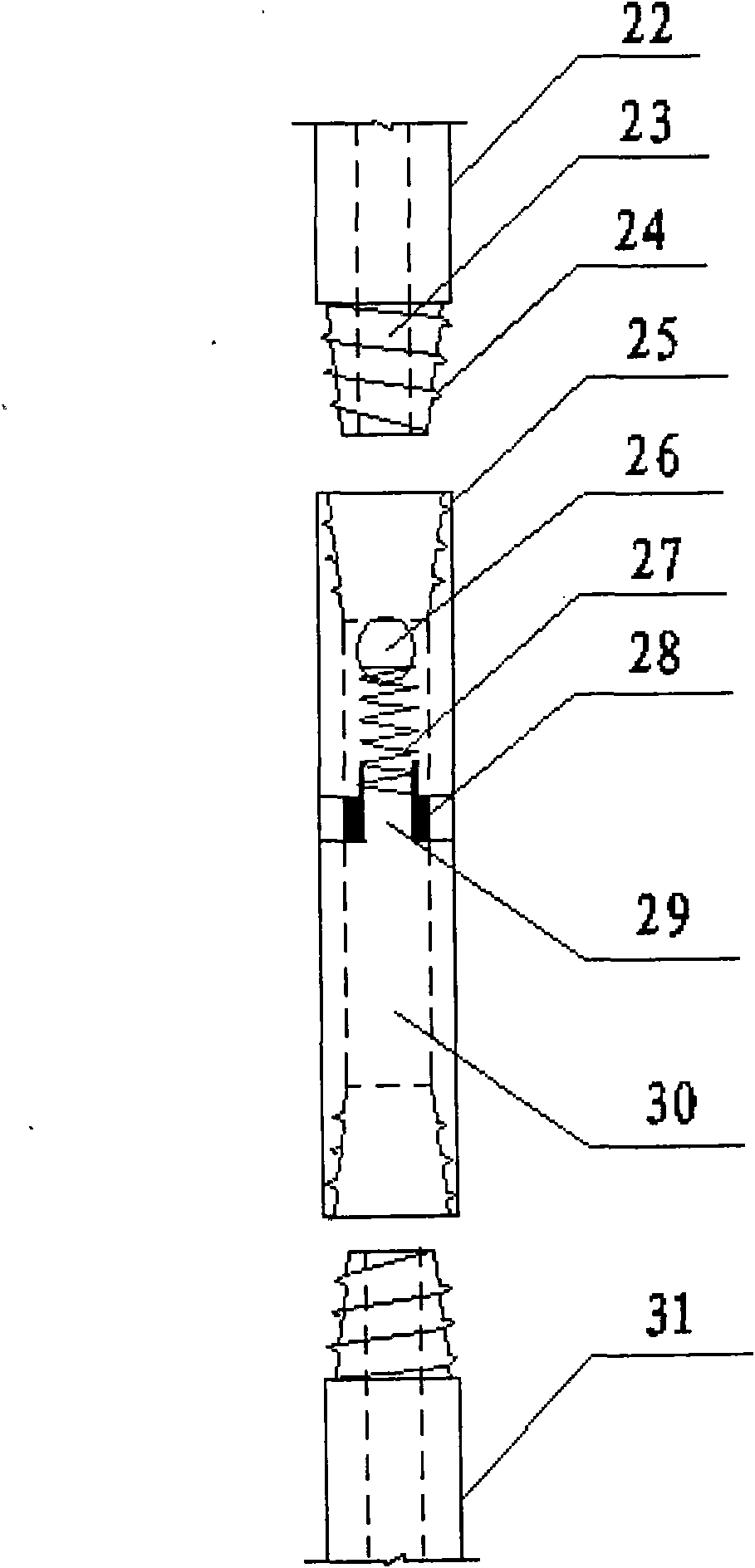

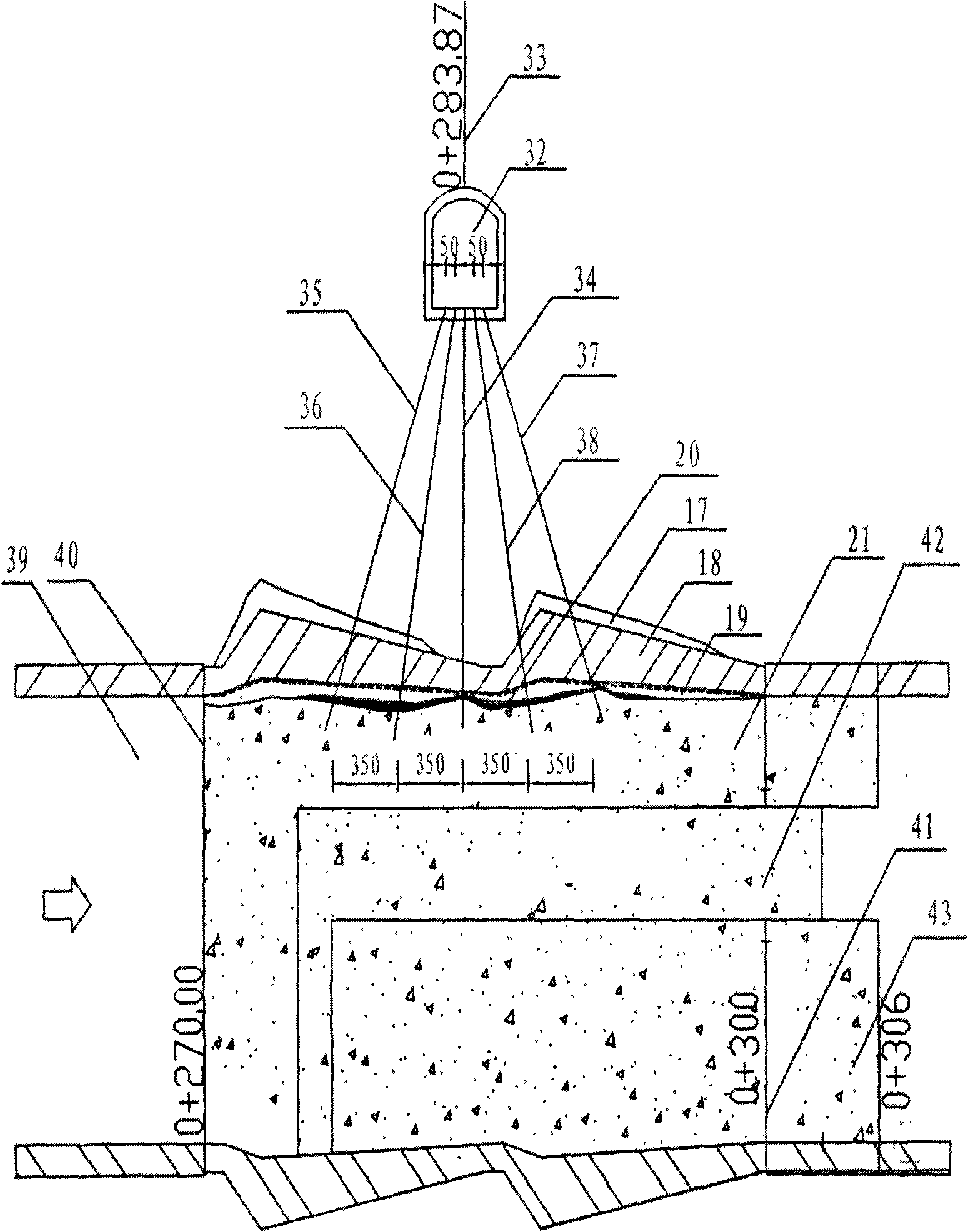

High-flow high-speed jet plugging grouting technique under high-pressure water head of hydropower station

InactiveCN101654907ASafe Drilling and Irrigation ConstructionSolve unreported problemsLiquid/gas jet drillingFoundation engineeringHydropower engineeringEngineering

The invention relates to a high-flow high-speed jet plugging grouting technique under a high-pressure water head of a hydropower station. For water permeability and water seepage of flow guide holes under pressure of the high water head of 50m to 130m, the technique adopts a 'high-flow high-speed jet plugging drilling orifice safety control device under the high-pressure water head' and a 'high-pressure-resisting water-returning safety control device in a drilling rod under the high-pressure water head' which integrate multiple functions of water stopping in the drilling rod, water drainage, pressure relieving, orifice closing, safe drilling construction and the like, solves the construction of safe drilling and grouting under the working condition of water burst of the high water head inthe orifice and completes plugging under the condition of the high water head, which is a difficulty without being recorded in world hydropower engineering construction. The high-flow high-speed jet plugging grouting technique reduces direct and indirect economic losses of over ** and has good economic benefit, simultaneously creates a new way for the plugging difficulties of water permeability and water seepage of flow guide holes under pressure of the high water head of 130m of the hydropower station in China.

Owner:SINOHYDRO BUREAU 9

Strengthening and reinforcing method of high-ground-pressure soft rock laneway by hierarchical grouting

InactiveCN101864967AImprove the strengthening effectWill not blockUnderground chambersTunnel liningSlurryHigh pressure

The invention relates to a strengthening and reinforcing method of a high-ground-pressure soft rock laneway by hierarchical grouting. Aiming at the deformation damage and crack distribution rules of laneway wall rock of high-ground-pressure soft rock, a hierarchical grouting mode for a shallow layer and a deep layer is adopted to hierarchically and emphatically strengthen and reinforce the shallow layer and the deep layer by grouting. The method comprises the following steps of: firstly, carrying out shallow-hole low-pressure grouting to a laneway shallow-layer gap development zone and then carrying out deep-hole high-pressure grouting to deep rock bodies; constructing shallow-hole grouting with small grouting pressure so that grout is scarcely diffused into the deep part, and grouting passages, such as a deep gap of the deep part and the like, are well preserved without blockage; and adopting a double-component chemical grout malisan with easy dispersion and strong permeability in constructing deep-hole grouting to realize deep high-pressure grouting on the basis of a formed grout-stopping shielding shell formed by former-period shallow-hole grouting so that the distribution compactness and the dispersion evenness of the grout in the deep grouting are improved, and the strengthening effect of the deep grouting on the wall rock is effectively improved. The method is simple and easy to implement.

Owner:CHINA UNIV OF MINING & TECH

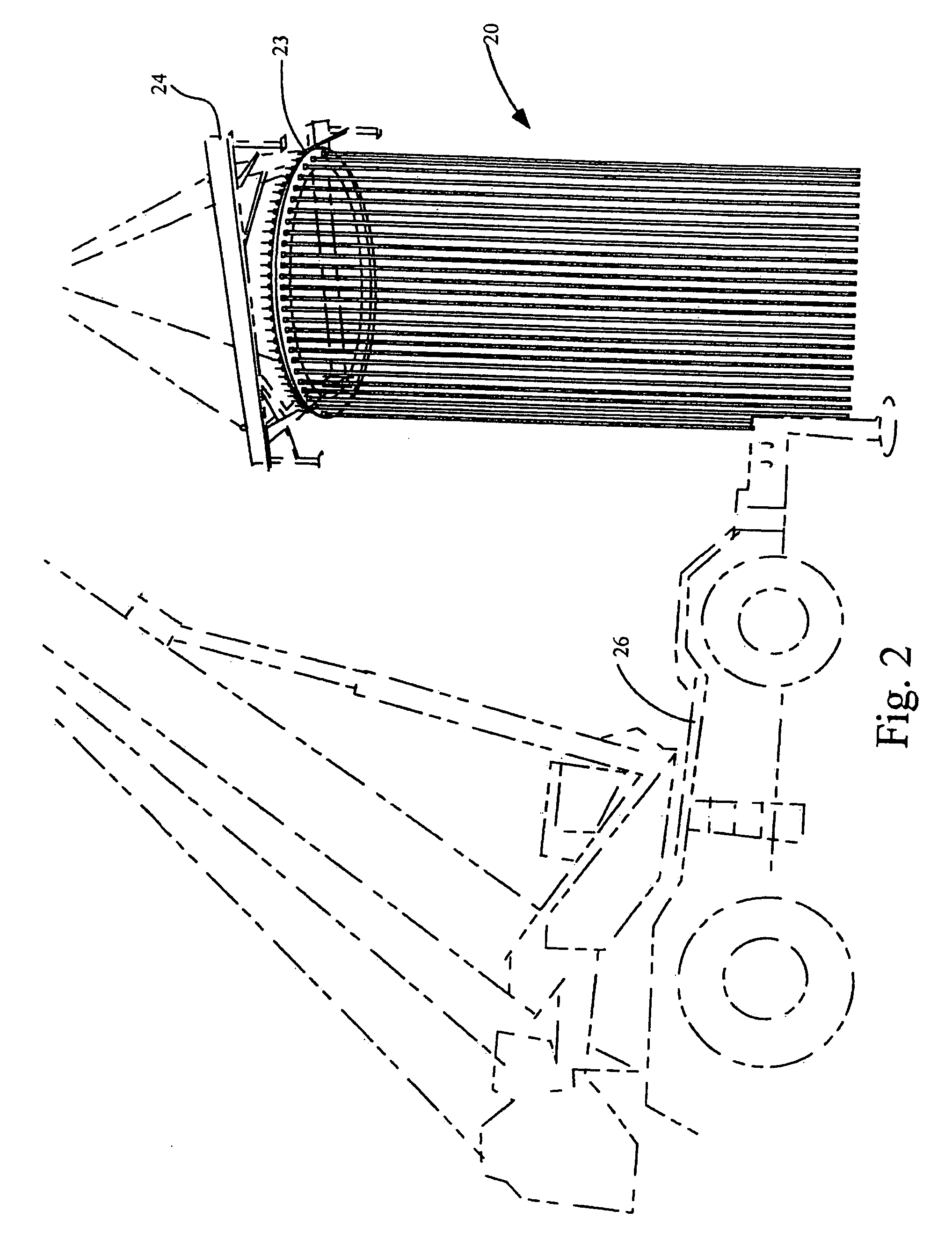

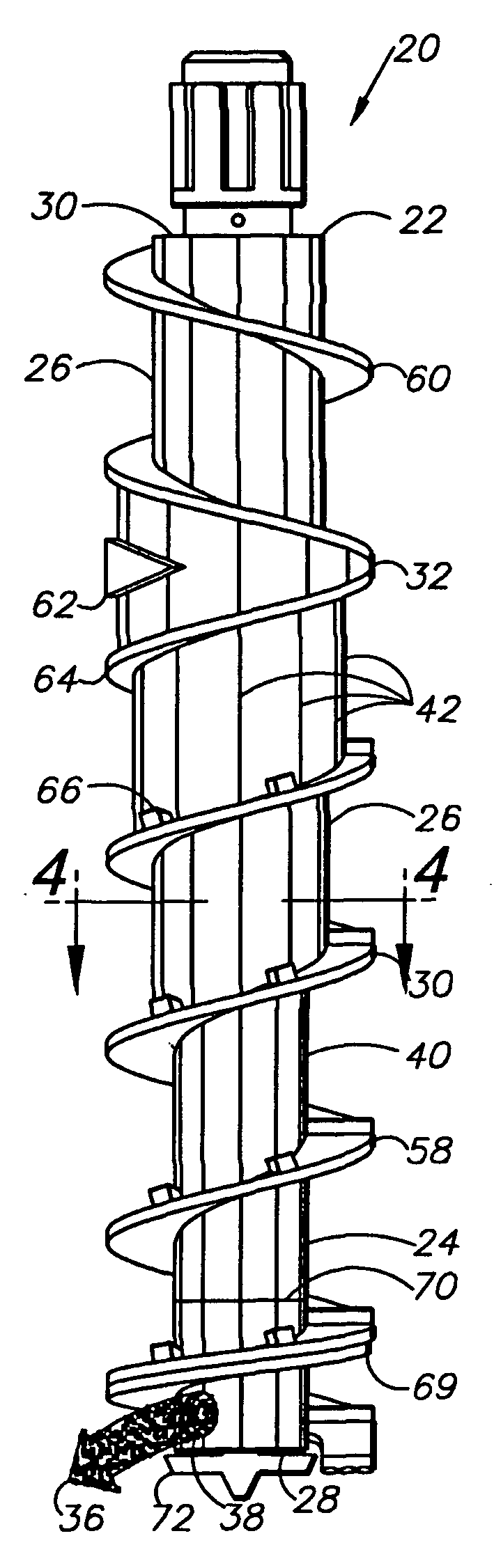

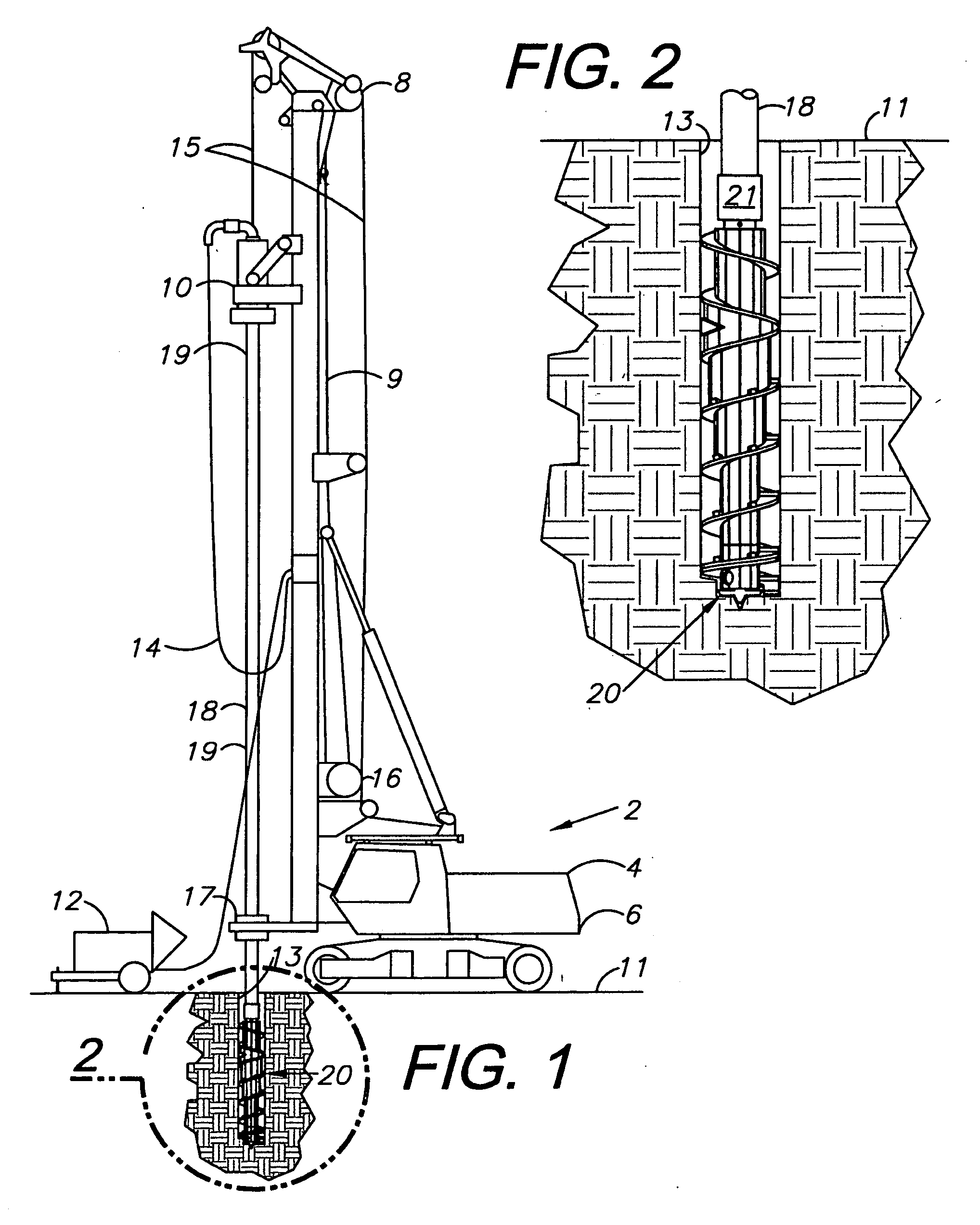

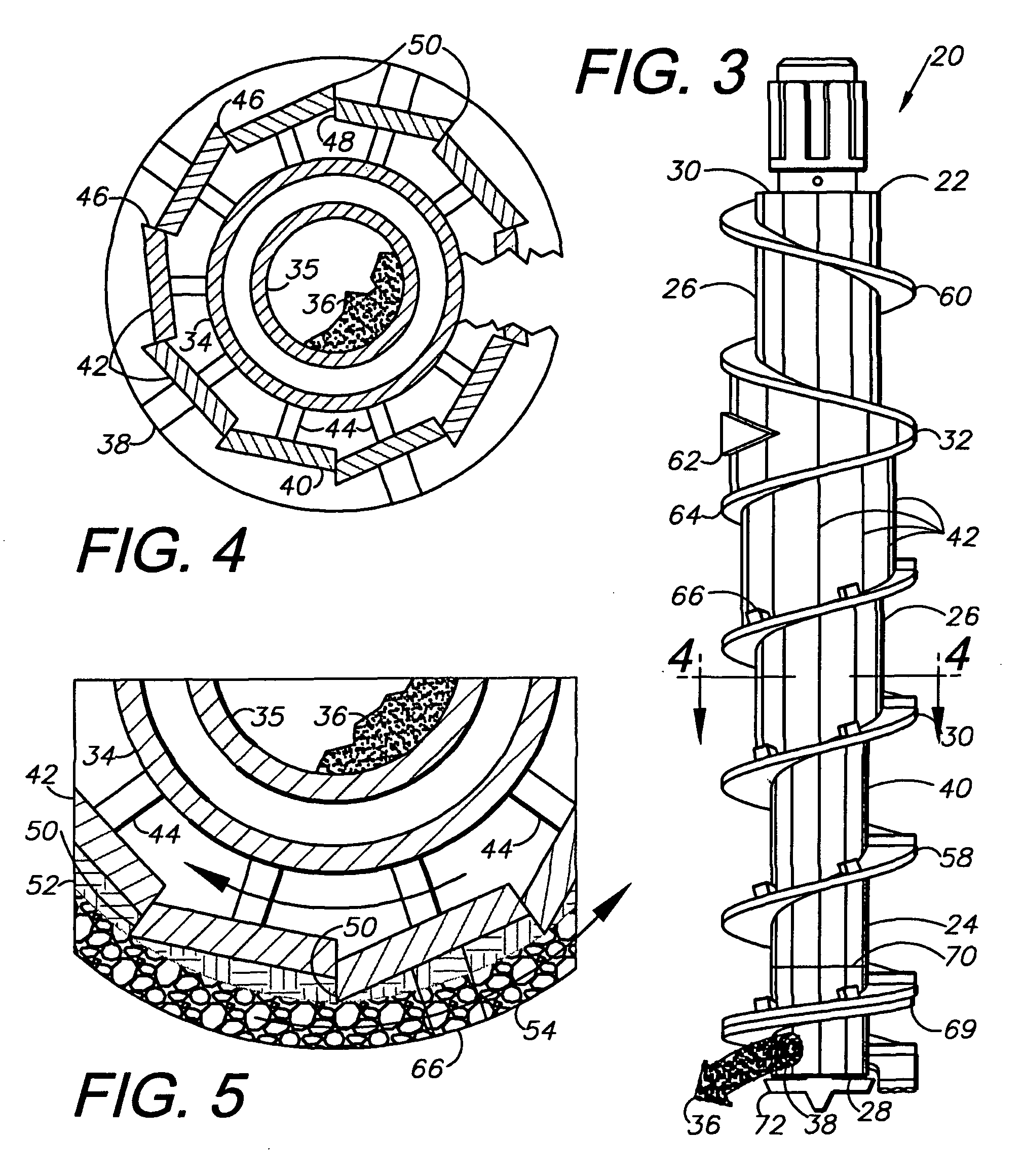

Full-displacement pressure grouted pile system and method

An auger bit is provided for a foundation pile system including a drilling rig adapted for mounting and rotating a grout pipe connected to the auger bit to form an auger. The auger bit includes a stem with lower and upper sections, which taper towards a transition whereat the stem has a maximum diameter. Right-hand flighting is mounted on the stem lower section and converges with left-hand flighting mounted on the stem upper section at a transition. The stem and the flighting have substantially equal diameters at the transition whereby soil is displaced laterally and compacted at the borehole perimeter during drilling of same. A pile foundation forming method includes the steps of providing a drilling rig, forming an auger with a grout pipe coupled to an auger bit, rotating the auger with the rig, forming a borehole with laterally displaced soil, pumping pressurized grout through the auger and into the borehole, placing a reinforcing cage in the wet grout and curing same.

Owner:BERKEL & CONTRACTORS

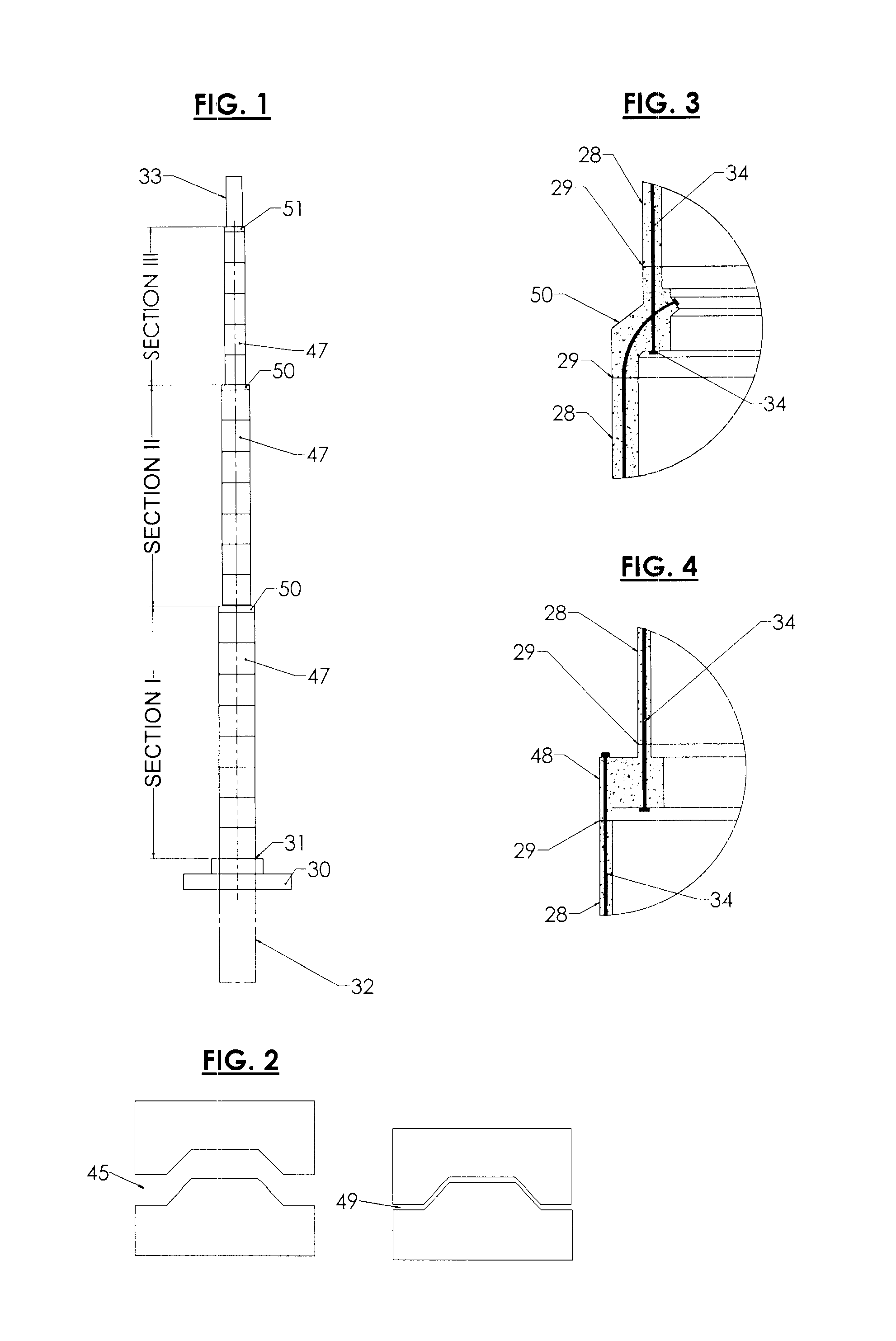

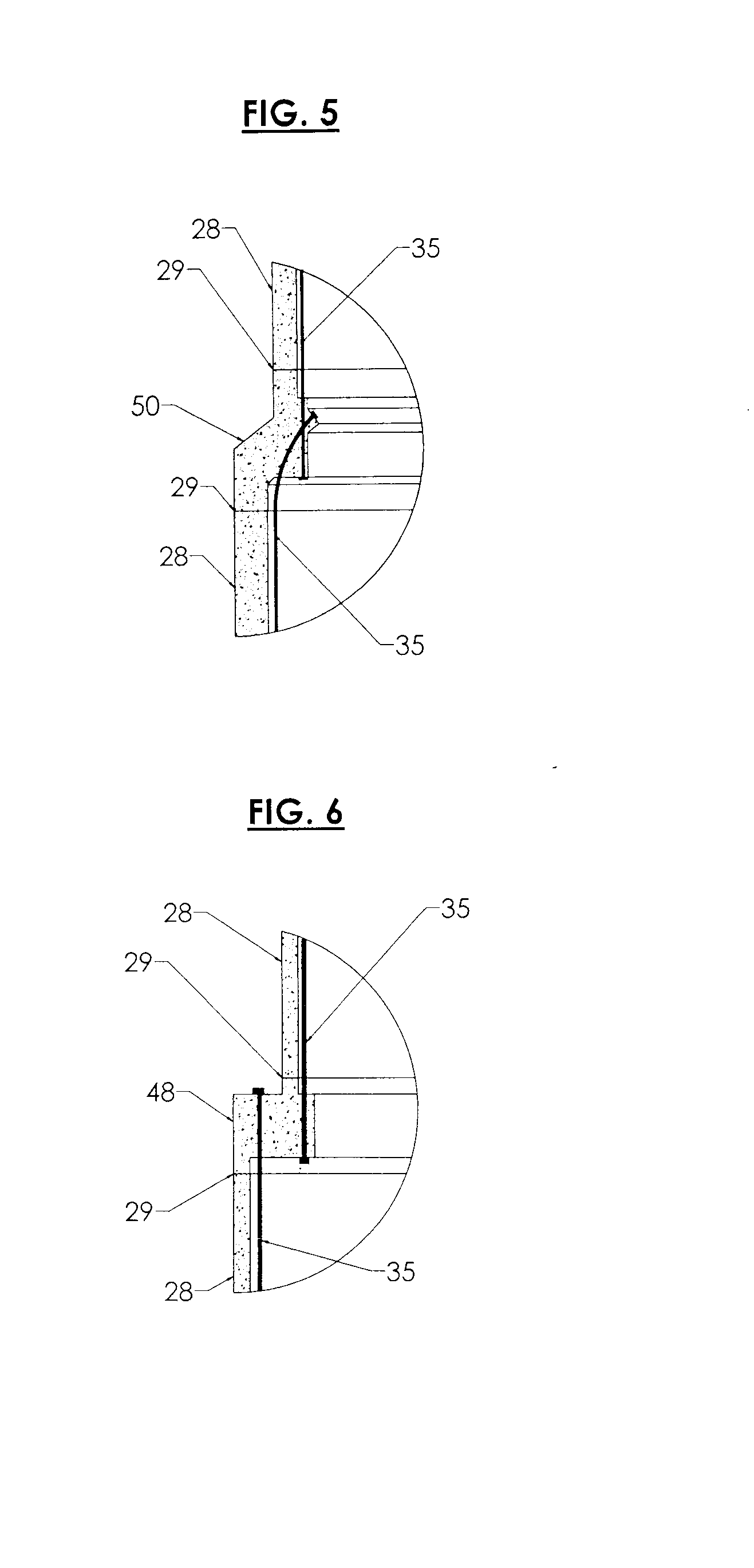

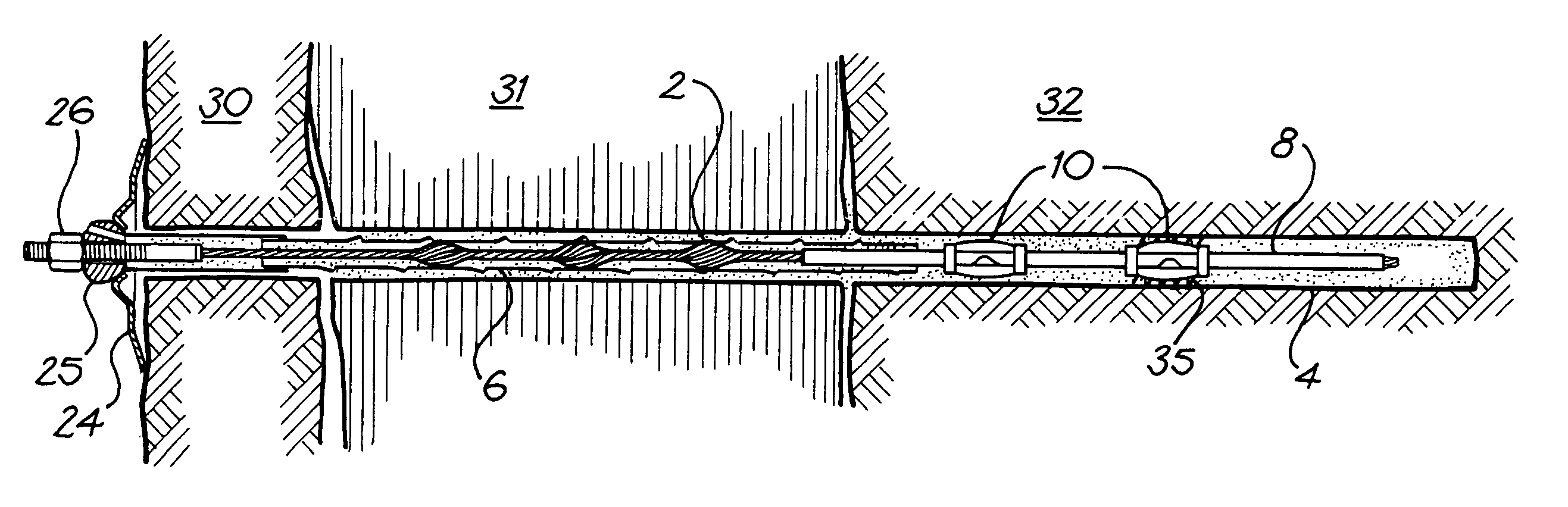

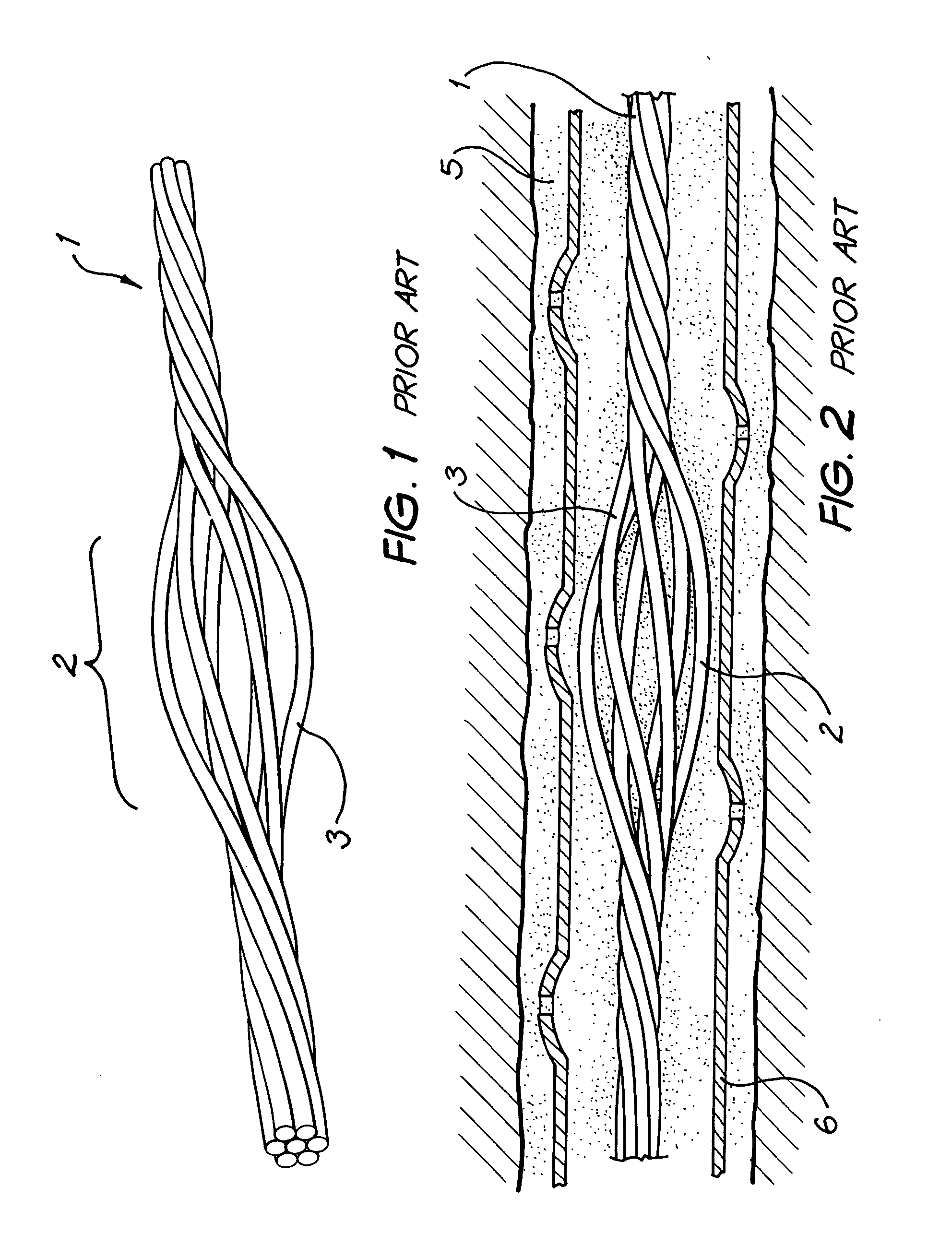

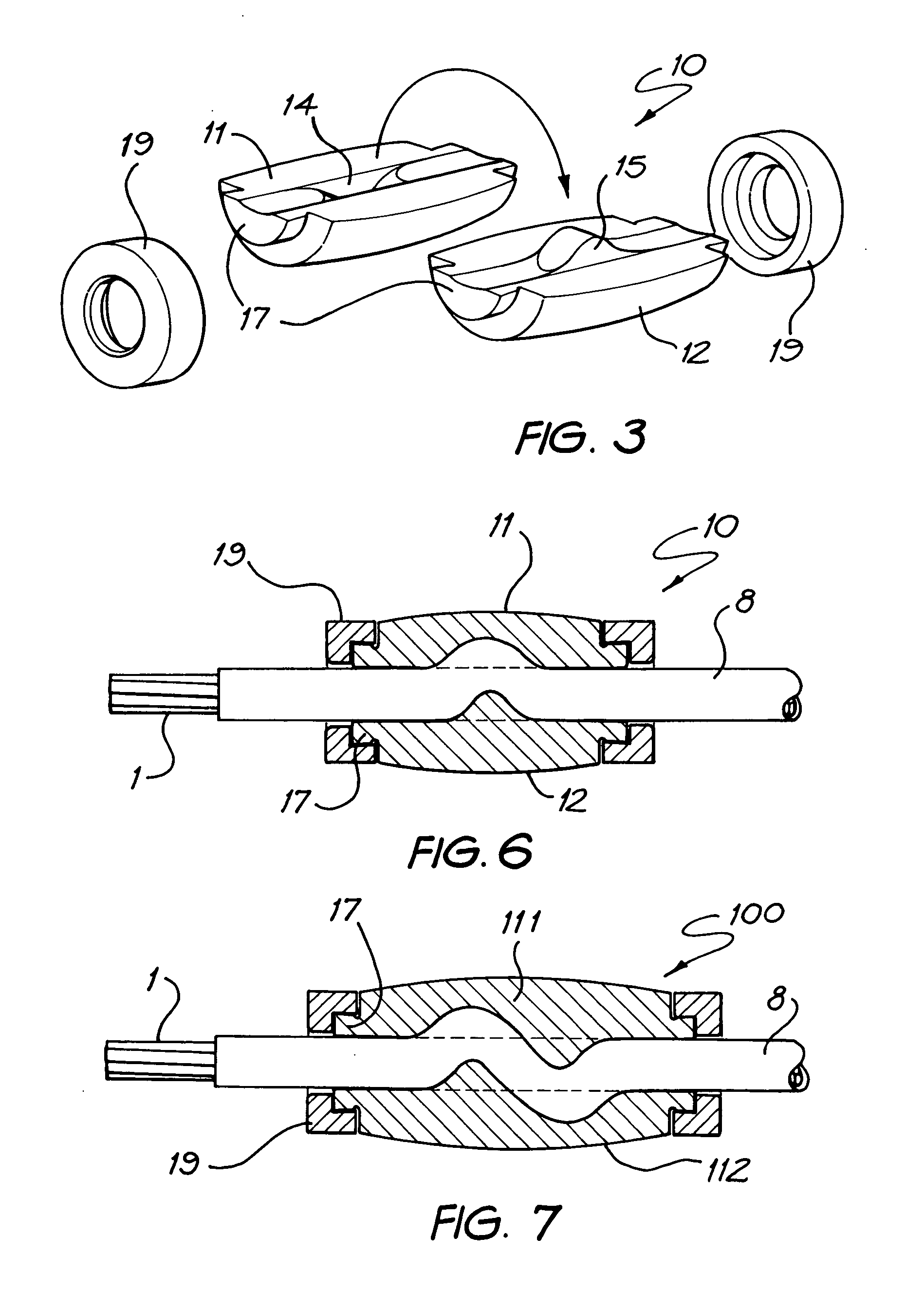

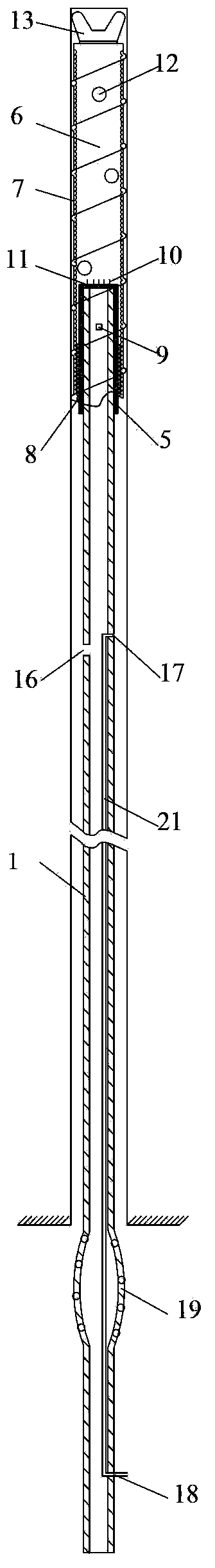

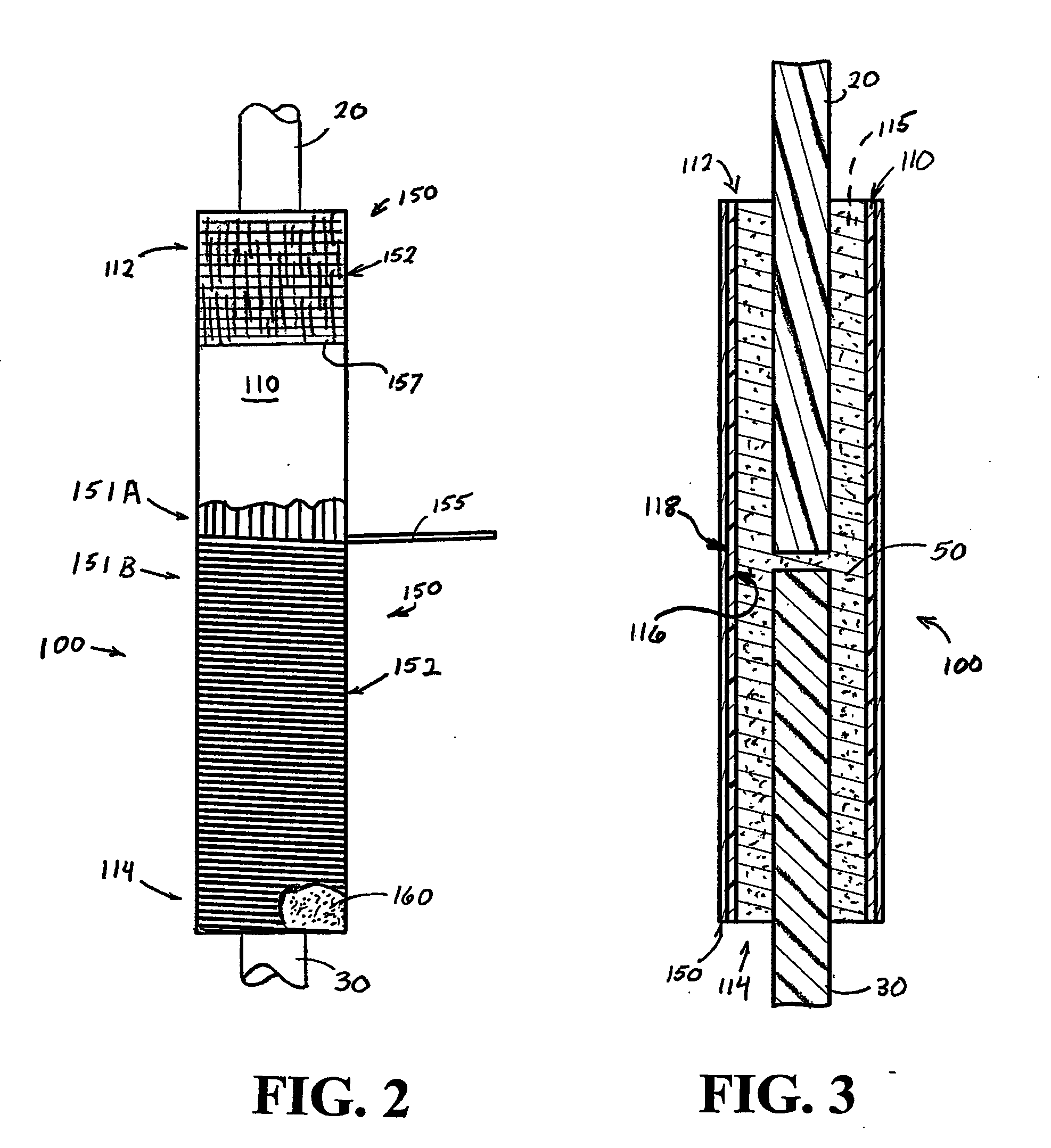

Yielding strata bolt

The present invention discloses a rock bolt having a tendon (1, 201) which is able to yield and thereby control movement of unstable rock strata into which the bolt is installed. The tendon has a portion which is provided with a grout slippage mechanism, preferably in the form of a tube (8) which surrounds the tendon. A two part grout anchor (10, 100, 200) is clamped to the tendon. The grout anchor is embedded in grout and is therefore essentially immovable. The tendon passing through the anchor is worked and thereby dissipates energy. The tendon can be either a multi-strand cable (1) or a solid bar (200). Various forms of anchor (10, 200) are disclosed with either complementary recess(es) (14) and protrusion(s) (15) or opposed protrusions (115) which form pinch point(s). A one piece grout anchor (300) is also disclosed.

Owner:FERGUSSON JEFFREY ROBERT

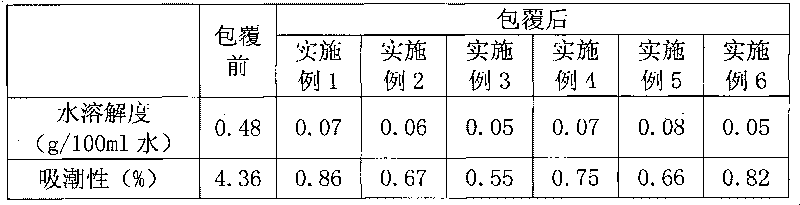

Method for preparing core-shell silicon dioxide-coated ammonium polyphosphate (APP)

ActiveCN101760049ALow water solubilityHigh strengthSilicaPigment treatment with non-polymer organic compoundsMass ratioSilicon dioxide

The invention relates to a method for preparing core-shell silicon dioxide-coated ammonium polyphosphate (APP), which is characterized by comprising the following steps successively: (1) adding ammonium polyphosphate into ethanol water solution, stirring and dispersing well; (2) adding silicate ester ethanol solution into the solution obtained in the step (1) while the mass ratio of silicate ester to ammonium polyphosphate is 0.05-10:1, adjusting the pH value of the solution to 9-12 by adding alkaline solution, and then performing complete reaction at room temperature; and (3) adding couplingagent into the grout obtained in the step (2) to carry out surface treatment, and then filtrating, washing and drying to obtain the silicon dioxide-coated ammonium polyphosphate. On one hand, the ammonium polyphosphate flame retardant utilizes the synergistic flame retardance of silicon and phosphorus elements to increase retardant effectiveness and reduce dosage, thereby bringing down the negative effects of APP; on the other hand, the ammonium polyphosphate flame retardant utilizes the advantages of silicon dioxide, such as excellent hydrophobicity, heat resistance, high strength and the like, to further solve the problems of APP such as infiltration and migration, influence on product strength, insufficient heat resistance and the like.

Owner:浙江富锦新材料有限公司

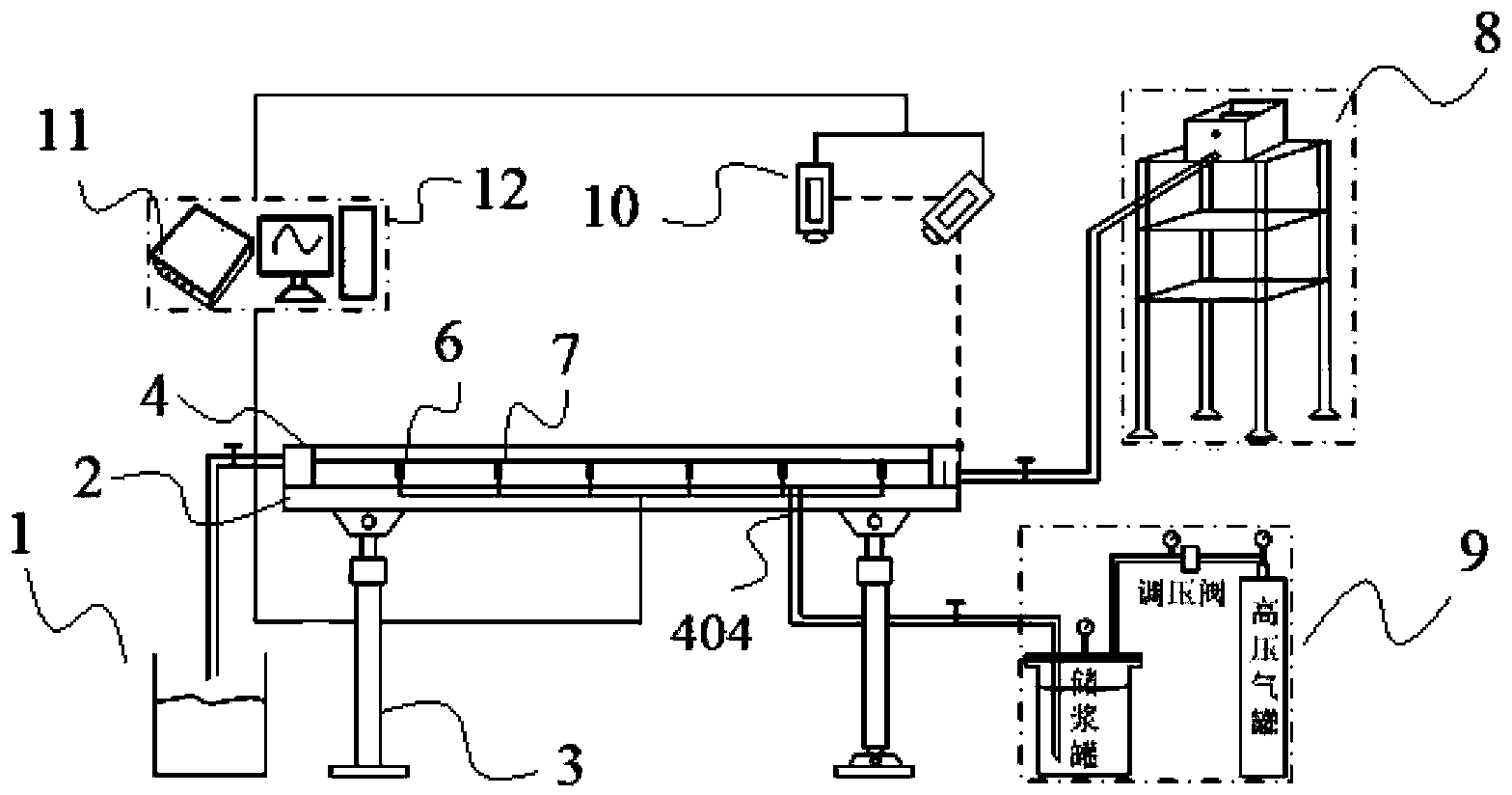

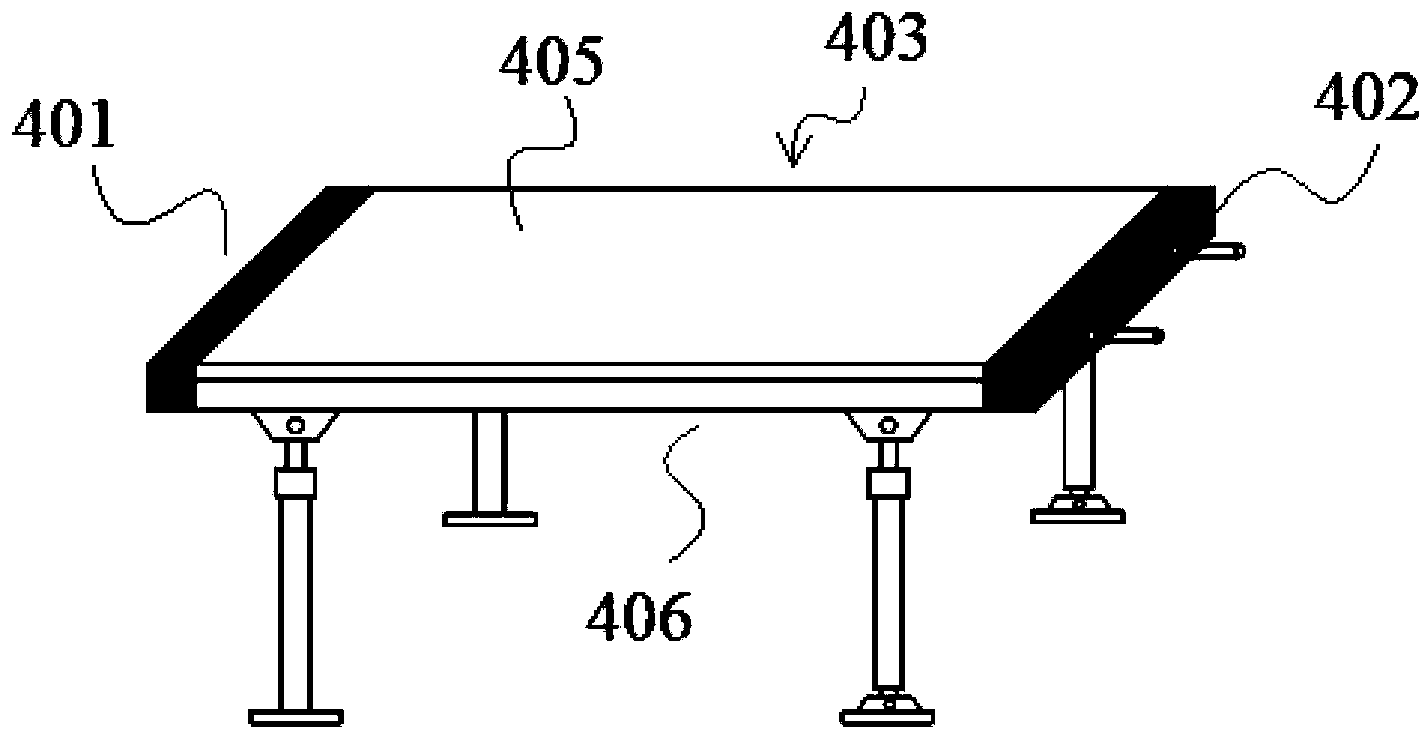

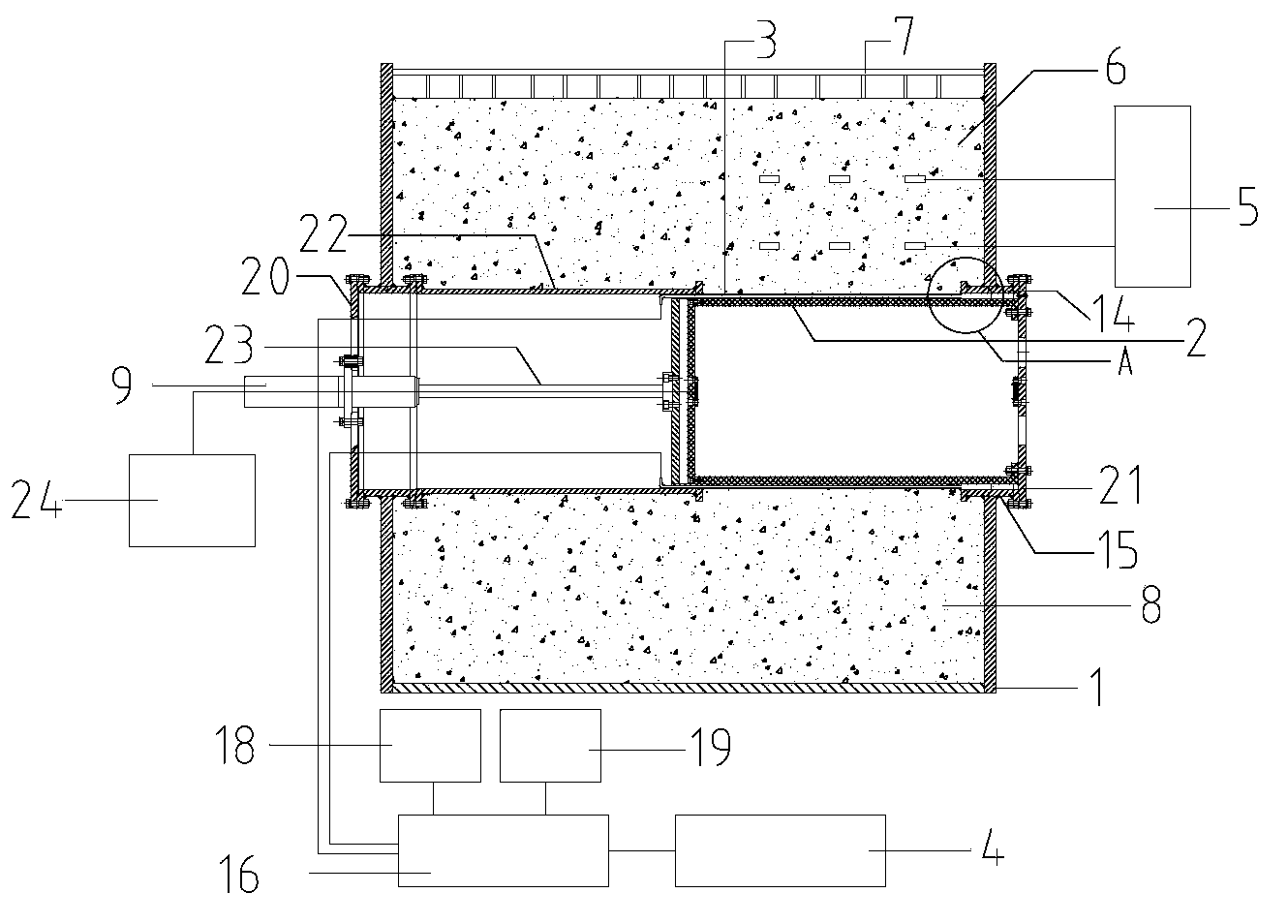

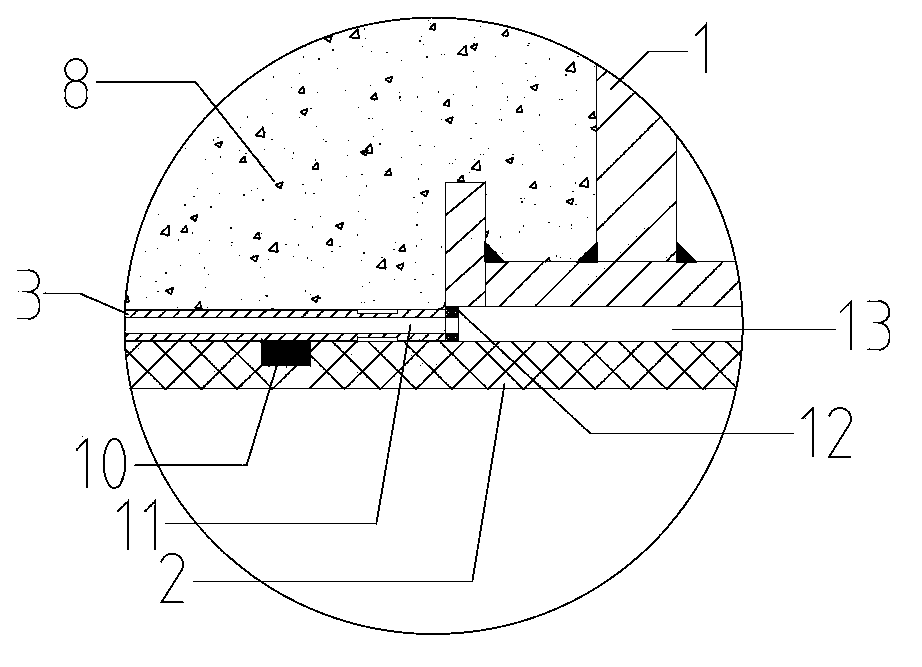

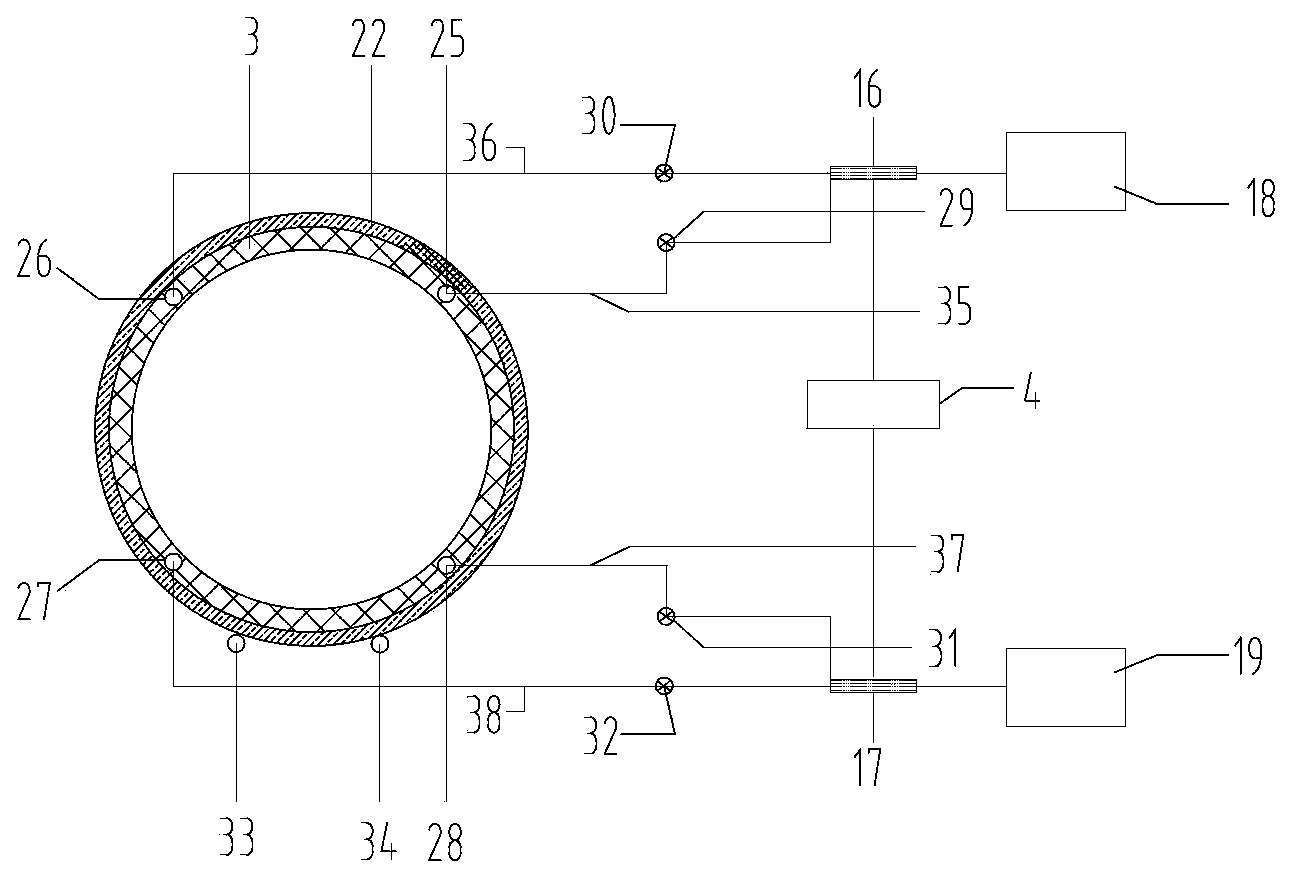

Simulating system used for shield tunnel synchronous grouting test and test method thereof

InactiveCN103913289AMonitor changes in real timeMonitor real-time changesHydrodynamic testingSoil scienceControl system

Disclosed is a simulating system used for a shield tunnel synchronous grouting test. The system includes model soil, model grout and a synchronous grouting simulating test platform. The model grout is injected into the model soil through the synchronous grouting simulating test platform. The synchronous grouting simulating test platform includes a soil box, a data acquisition system, a loading system, a shield propulsion control system, a simulating shield tunneling machine, pressure sensors and a grouting system. The simulating shield tunneling machine and the model soil are arranged in the soil box. The invention also discloses a test method which uses the simulating system used for the shield tunnel synchronous grouting test. The method includes: 1) preparing the model soil; 2) preparing the model grout; 3) constructing a shield-soil-grout similar system to carry out synchronous grouting tests of different grouting positions, different grouting holes and different grouting quantity allocation proportions.

Owner:TONGJI UNIV +1

Drilling and sealing method and sealing device for ultra-high pressure fracturing holes in underground coal mines

The invention discloses a drilling-sealing method and a sealing device of a coal mine underground ultrahigh pressure fracturing hole. The drilling-sealing method comprises the following steps: drilling a plugging hole on coal rock body; going on drilling a fracturing hole forward in the plugging hole; transmitting the sealing device into the plugging hole, enabling a water outlet hole of a fracturing pipe to stretch into the fracturing hole and enabling a taper sleeve sleeved on the fracturing pipe and made of soft material to plug on a hole opening of the fracturing hole; sealing by using polyurethane and solidifying for 30 minutes for 1 m length section at the hole opening of the plugging hole; and grouting cement slurry greater than 425 into the plugging hole with pressure by a grouting pipe, and solidifying for 48 hours after finishing grouting. The device comprises a grouting pipe and a slurry returning pipe and a fracturing pipe. The grouting pipe and the slurry returning pipe are arranged in the plugging hole. The grouting pipe, the slurry returning pipe and the fracturing pipe are connected integrally. A soft taper sleeve is arranged on the fracturing pipe. The soft taper sleeve is plugged at the hole opening of the fracturing hole. The invention has the advantages that the sealing method has high sealing success rate, good effect and wide application range; and the sealing device has simple structure and convenient operation.

Owner:重庆市能源投资集团科技有限责任公司 +1

Geothermal grout, and methods of preparing and utilizing same

A thermally enhanced, single component, geothermal grout from recycled materials, such as class F fly ash and cement kiln dust. Additional components can include a mid-range water reducer and a dry caustic.

Owner:KONCZAK JEFFREY J

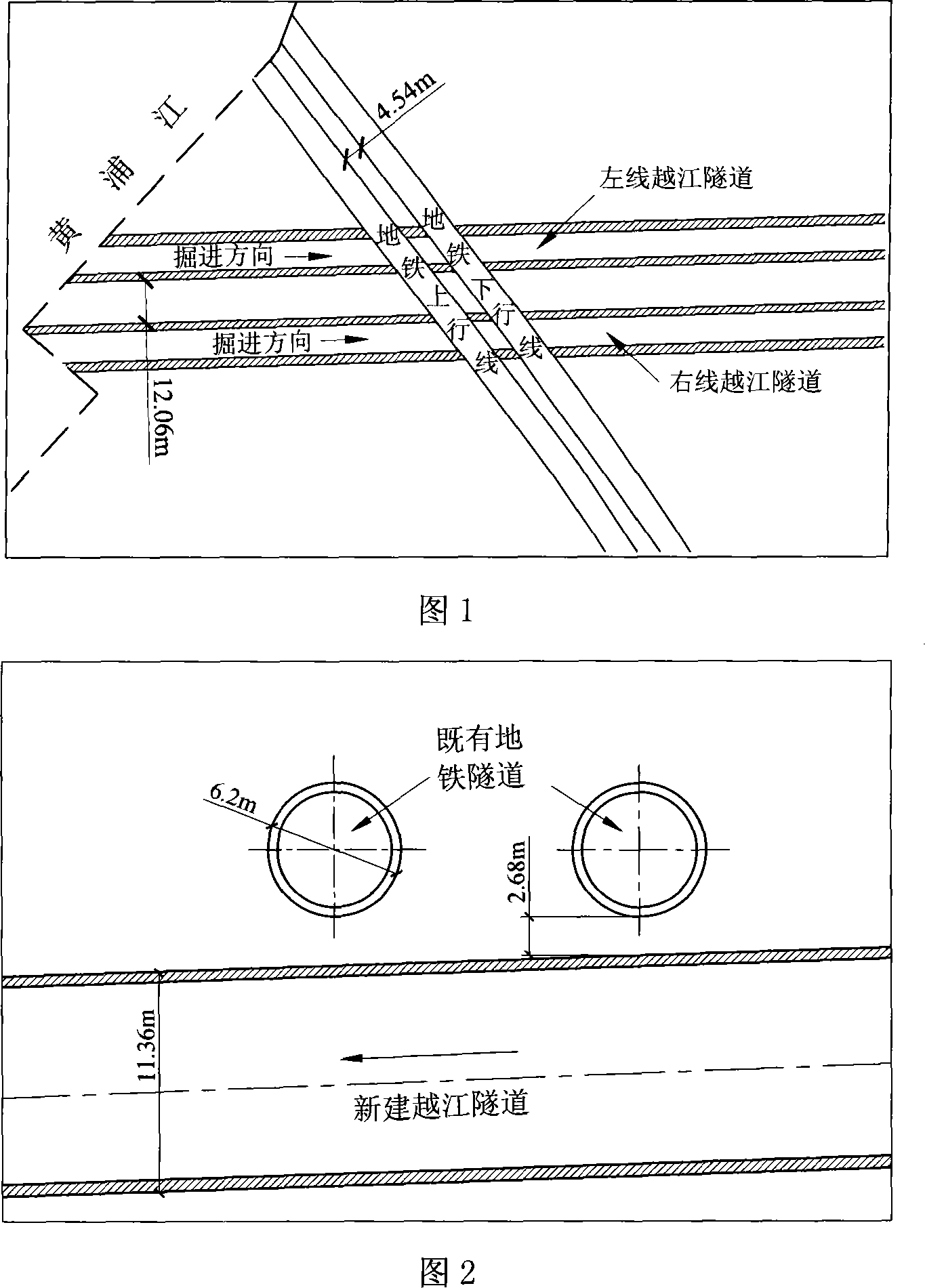

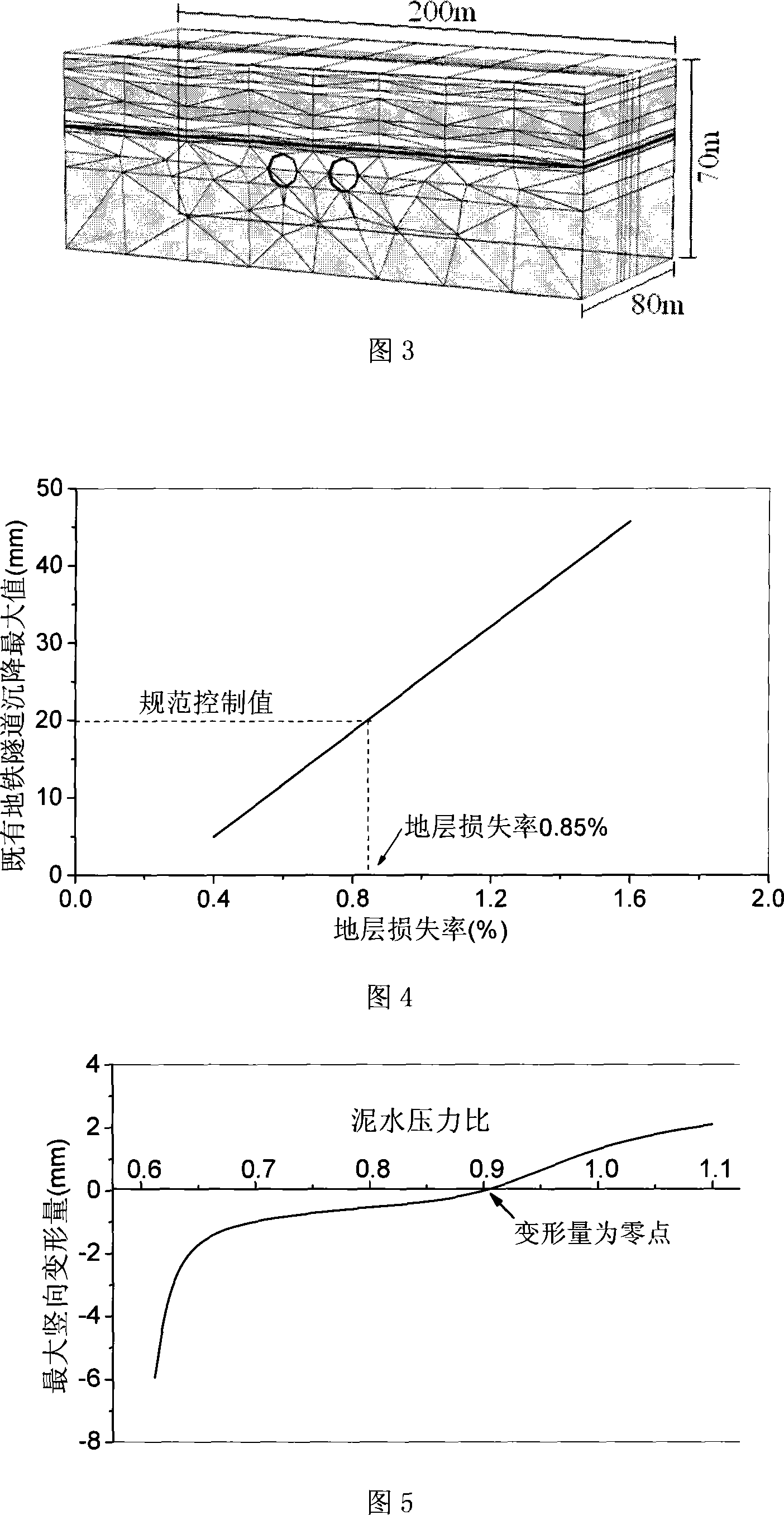

Large diameter tunneling close range down-traversing small diameter subway tunnel distortion control method

InactiveCN101215969AGuarantee smooth constructionEnsure safetyTunnelsUnderground tunnelFinite element method

The invention discloses a method for controlling distortion for deep large diameter shield tunnels to under-pass small diameter tunnels, which pertains to the technical field of tunnel engineering. According to the method, the control range of the stratum loss ratio of newly established tunnels and the optimum value of the support pressure of the shield cut surface are acquired by using the finite-element method; soil pressure in front of the shield cut surface is kept relatively balanced by setting the optimal value of the support pressure, and the support pressure fluctuation range of the cut surface is controlled to range from minus 10kPa to plus 10kPa; the stratum loss ratio of the newly established tunnels is controlled within the allowed range. According to the construction technique measures, a test propelling area is arranged before the shield reaches a cross position. In the area, construction is carried out according to the situation of the existing underground tunnels above; and construction parameters are controlled and regulated to adjust the support pressure, the propulsive velocity and the amount of the grout to be injected in time; the shield passes through the cross position in combination with the optimal values of the construction parameters of the test propelling area. The invention can not only ensure the construction of tunnels to be carried out safely and smoothly, but also minimize the influence of construction on ambient environment.

Owner:SHANGHAI JIAO TONG UNIV

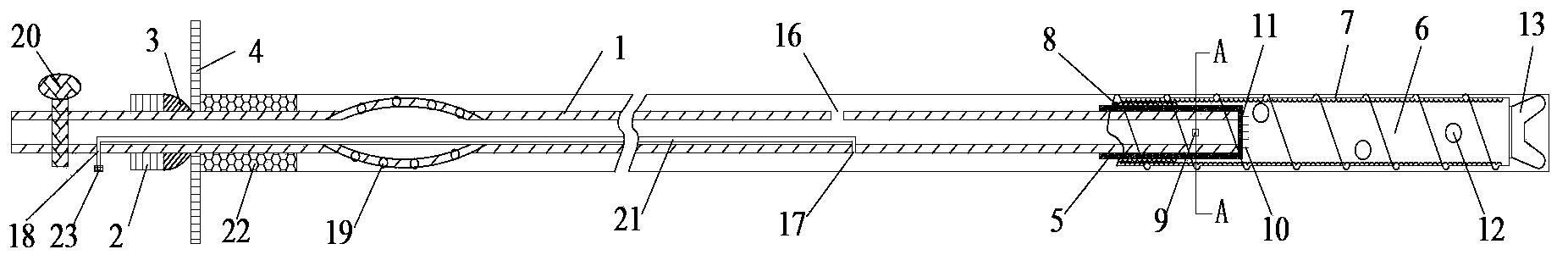

Prestressed drilling, anchoring and grouting anchor cable and support method

ActiveCN103382847AImprove stabilitySolve difficult access problemsAnchoring boltsUltimate tensile strengthMetal nail

Disclosed are a prestressed drilling, anchoring and grouting anchor cable and a support method. The prestressed drilling, anchoring and grouting anchor cable comprises a hollow grouting anchor cable, a sleeve, a lock, a washer and a tray, the hollow grouting anchor cable is provided with a sleeve head, a drill bit is arranged at the front end of the sleeve, and the sleeve is provided with an anchoring hole and a thread. The hollow grouting anchor cable drives the sleeve to drill holes and advances inwards through the thread in reverse rotation, a metal nail at the front end of the sleeve head punctures an anchoring agent package inside the sleeve, anchoring agents are mixed and then discharged through the anchoring hole in the sleeve, the gap between the sleeve and a drill hole wall is filled with the anchoring agents, and the anchoring function is achieved. An exhaust pipe is arranged in the anchor cable, the anchor cable is provided with a plurality of lantern-shaped grouting sections, and grout vent holes are formed in the lantern-shaped grouting sections. The prestressed drilling, anchoring and grouting anchor cable integrates drilling, exhausting, grouting and anchoring, the tail of the grouting anchor cable is firstly tensioned and fastened, grouting is then performed, an anchored body becomes reinforced pre-tightening force concrete, loose coal rocks are drilled, anchored, grouted and supported once, the problem that the anchor cable does not easily enter drilled holes in the loose coal rocks due to sticking and hole collapse is solved, the support strength of surrounding rocks of a roadway is enhanced, and the carrying capacity of a rock mass is improved. The prestressed drilling, anchoring and grouting anchor cable is simple in structure, low in cost, easy in construction and fine in support effect.

Owner:CHINA UNIV OF MINING & TECH

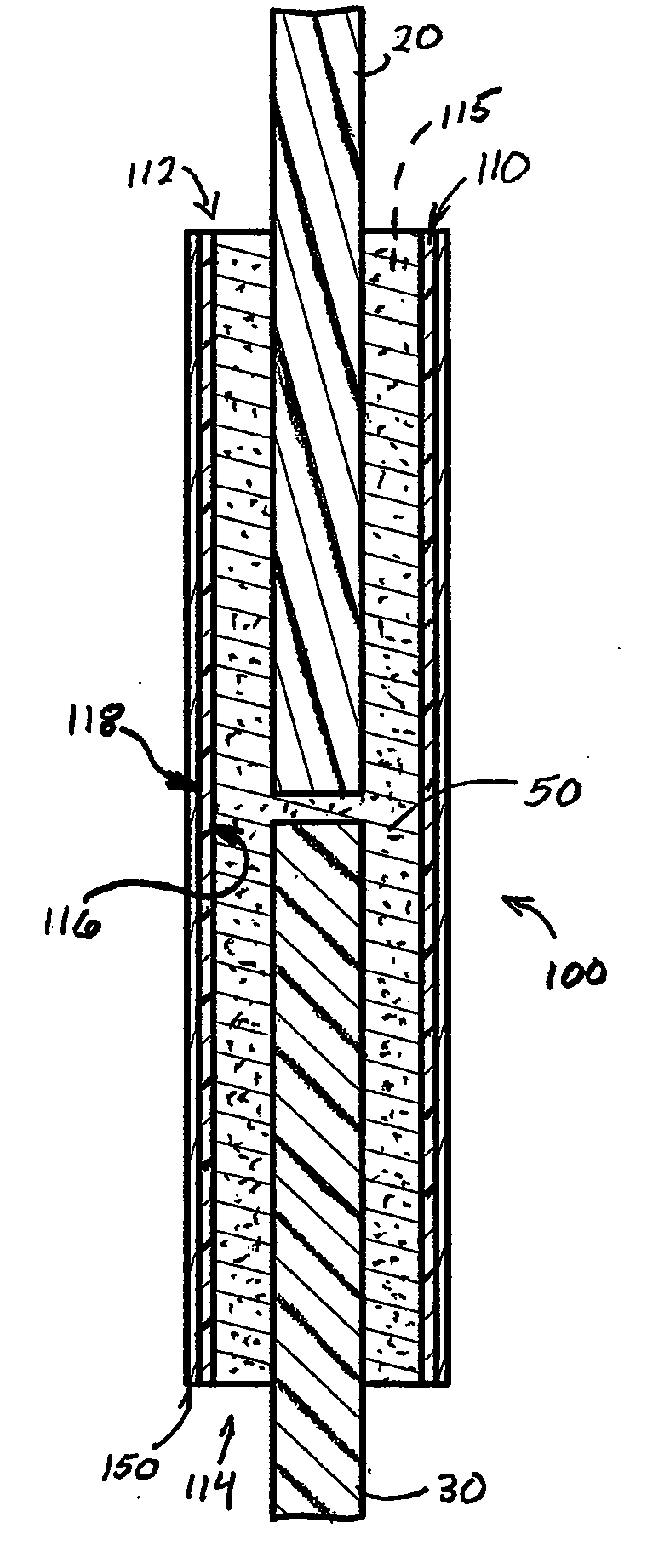

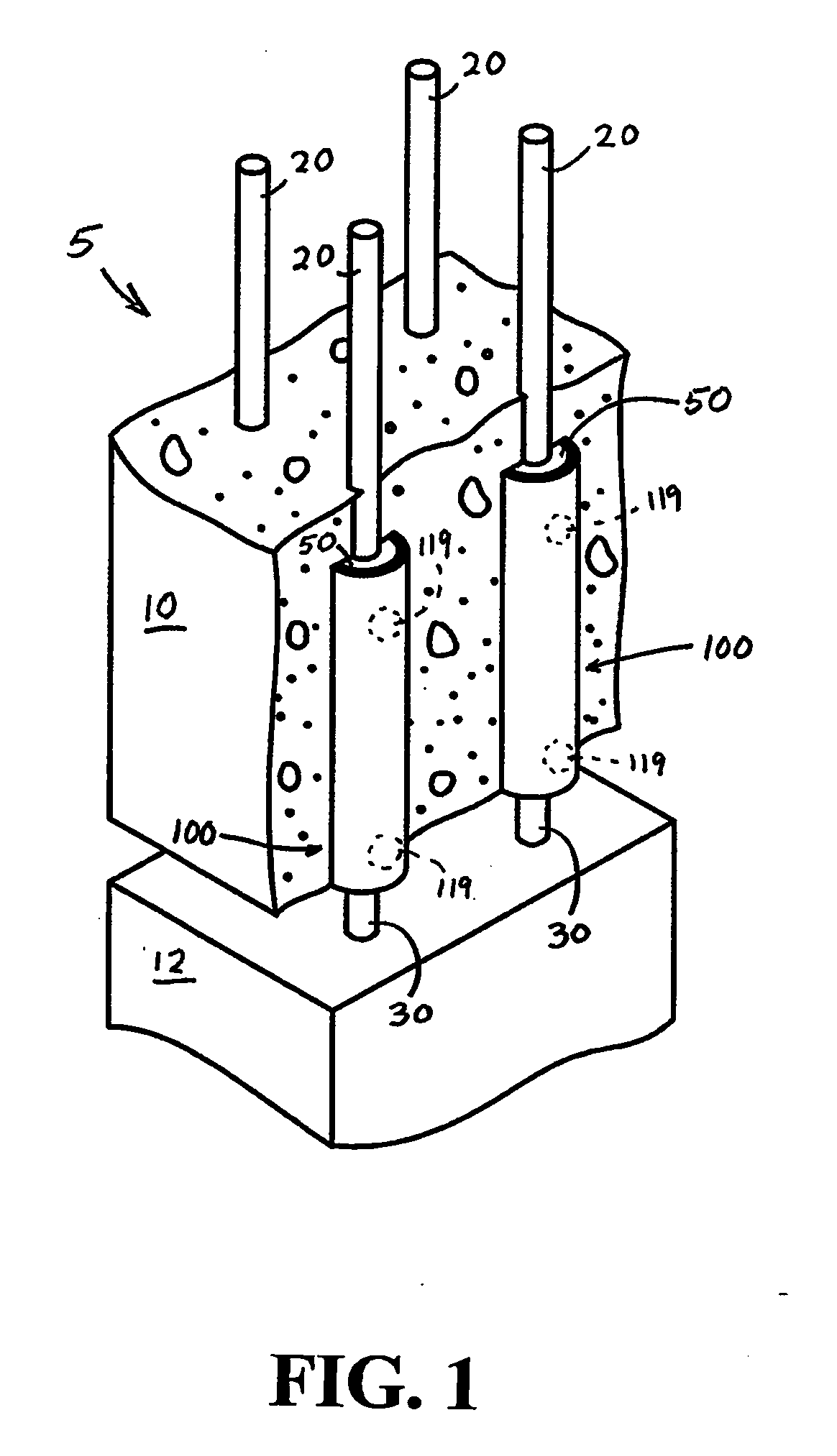

Splice System for Fiber-Reinforced Polymer Rebars

InactiveUS20100031607A1Highly corrosive environmentLong useful lifeRopes and cables for vehicles/pulleyBuilding repairsEngineeringRebar

A splice assembly and corresponding system for connecting multiple fiber-reinforced polymer rebars include a polymeric tube that is externally covered by a reinforcing layer to control radial expansion of grout within the polymeric tube and of the polymeric tube itself, and the polymeric tube may be internally provided with locking structures for mechanically interlocking with the grout, ensuring that the splice assembly functions as a unit for transferring loads from a first rebar, extending from a first end of the polymeric tube, to a second rebar, extending from a second end of the polymeric tube.

Owner:WISCONSIN ALUMNI RES FOUND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com