Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5976 results about "Rock bolt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A rock bolt is a long anchor bolt, for stabilizing rock excavations, which may be used in tunnels or rock cuts. It transfers load from the unstable exterior to the confined (and much stronger) interior of the rock mass.

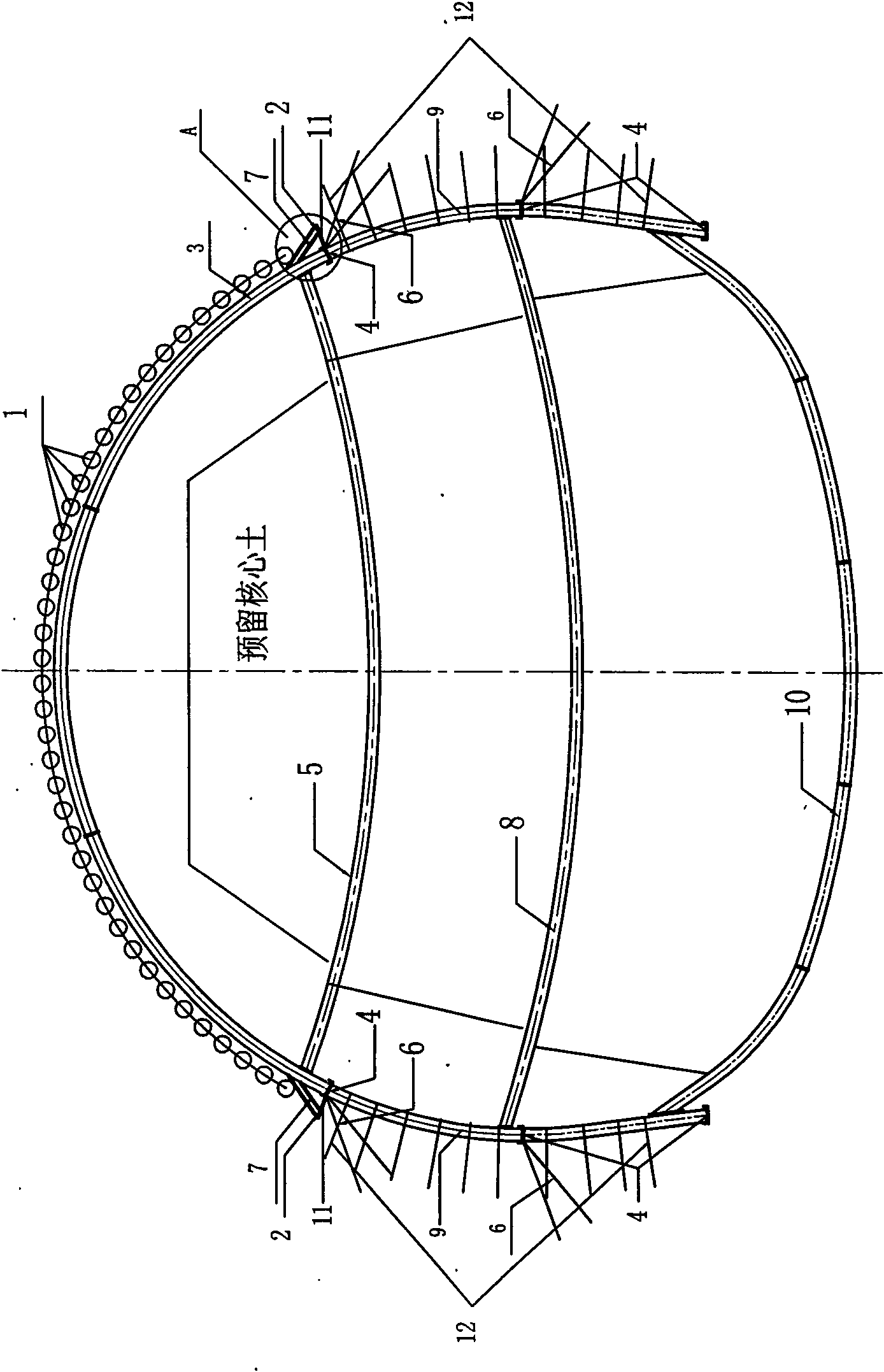

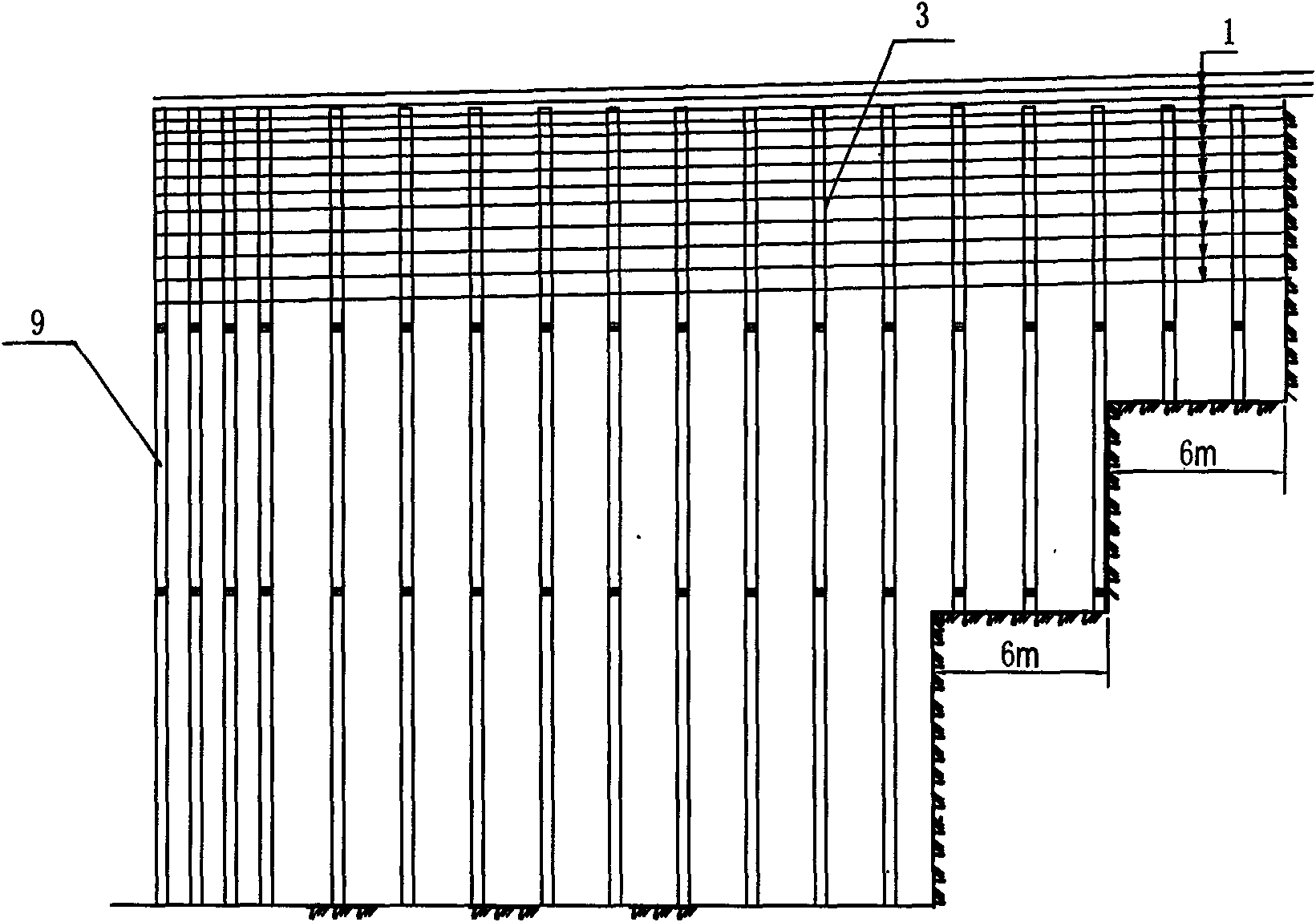

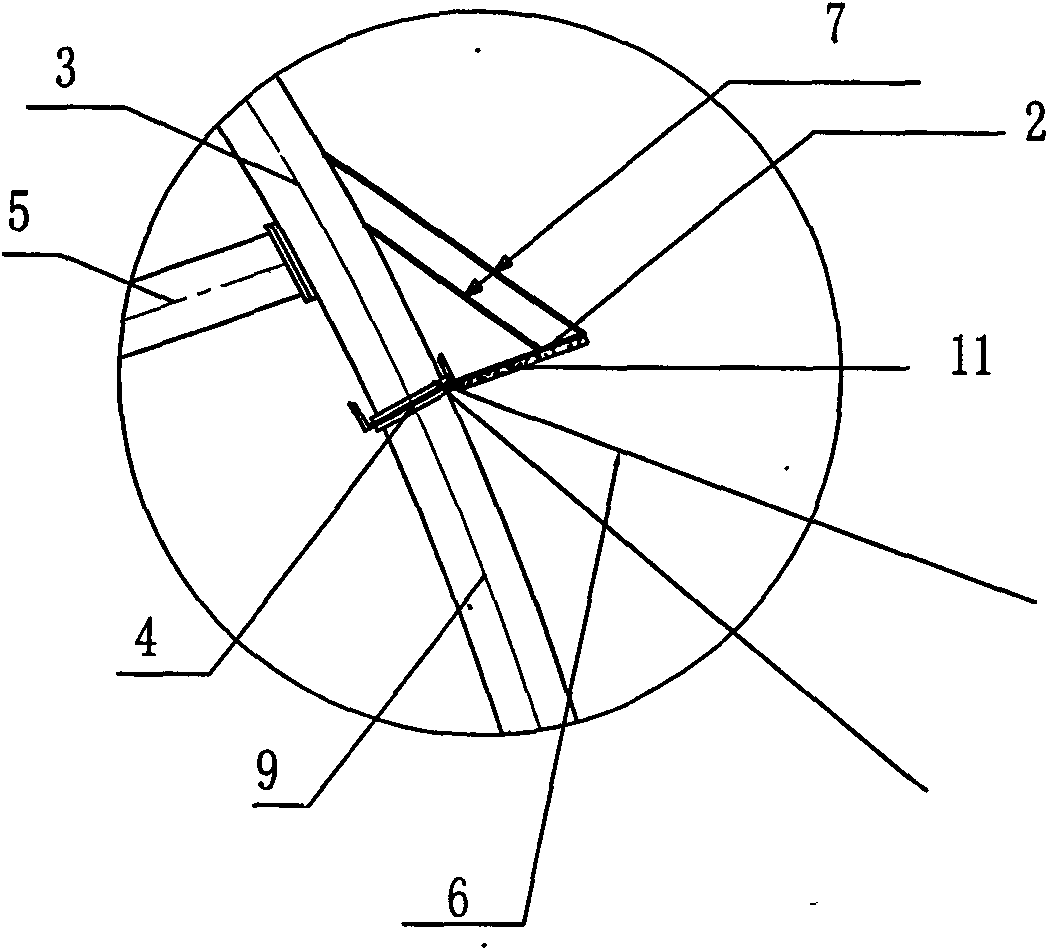

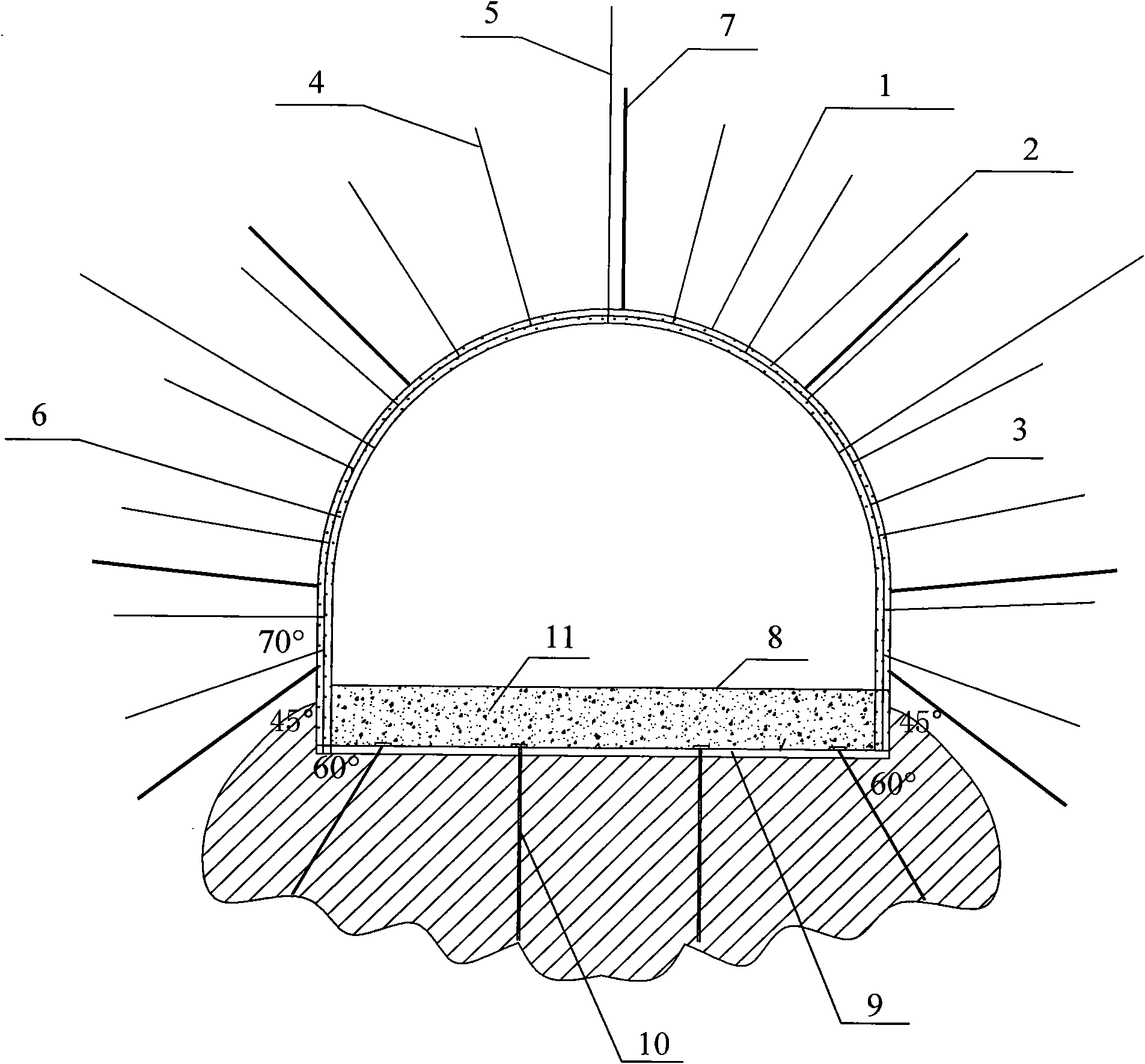

Construction method of V-level surrounding rock tunnel

InactiveCN101614125AAvoid defects such as cavity collapseRealize safe constructionUnderground chambersTunnel liningRock tunnelTunnel wall

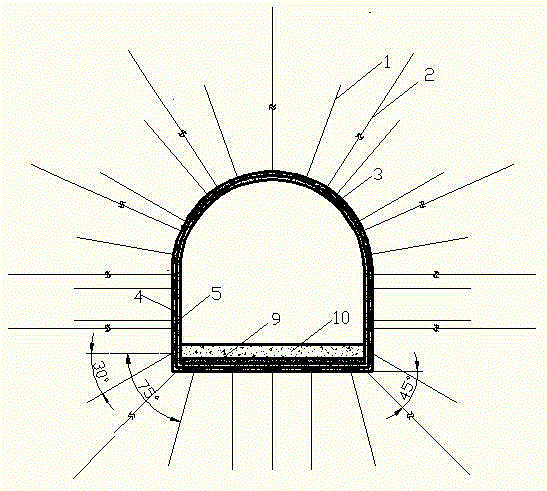

The invention relates to a construction method of a V-level surrounding rock tunnel, comprising the following steps: (1) making a drill guiding I-beam steel lagging jack, i.e. mounting an I-beam steel lagging jack, a groove steel trimming beam, a lock pin anchor rod, a guiding steel pipe, a longitudinal connection steel rib and face injecting concrete in sequence; and (2) construction and support in the tunnel, i.e. drilling pipe shelter steel pipe holes, mounting pipe shelter steel pipes, filling slurry inwards. The earthwork construction of a pilot tunnel comprises earthwork construction, primary support, injecting concrete on a pilot tunnel wall, suspending steel bar nets, casting concrete basis, mounting I-beam steel lagging jack, groove steel trimming beam, steel pads, I-shaped steel inclined strut and lock pin anchor rods, welding longitudinal connection steel bar, injecting concrete on the face and removing core soils; mounting a first-level step temporary inverted arch comprises: constructing lower-level earthwork, performing primary support in the pivot tunnel, mounting the second-level step temporary inverted arch, constructing the following level of earthwork, performing primary support, casting and filling inverted arch, and casting lining concrete at a time inside the pivot tunnel. The invention has the advantage of rapid penetration speed and safe construction.

Owner:CHINA RAILWAY NO 9 GRP

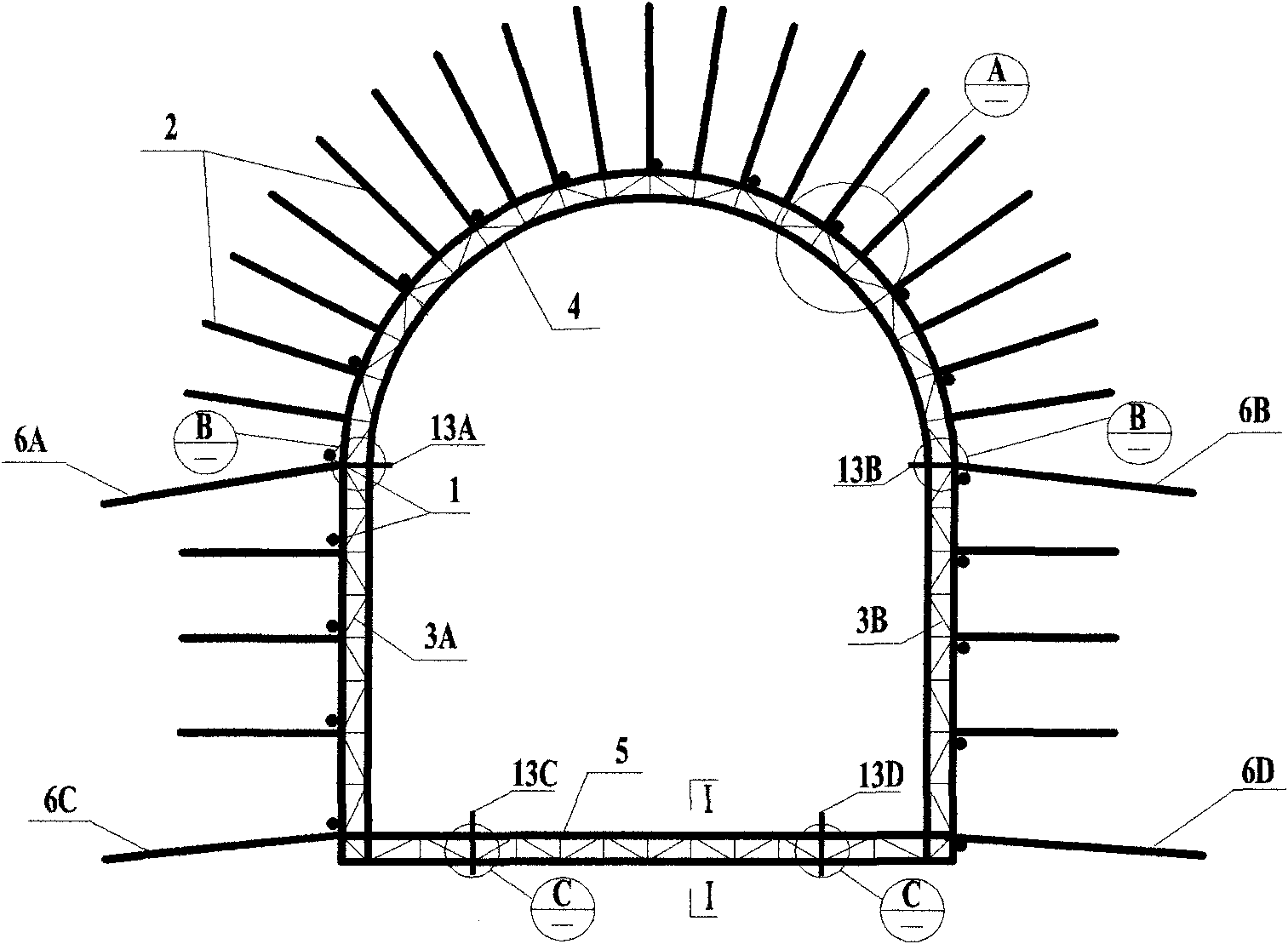

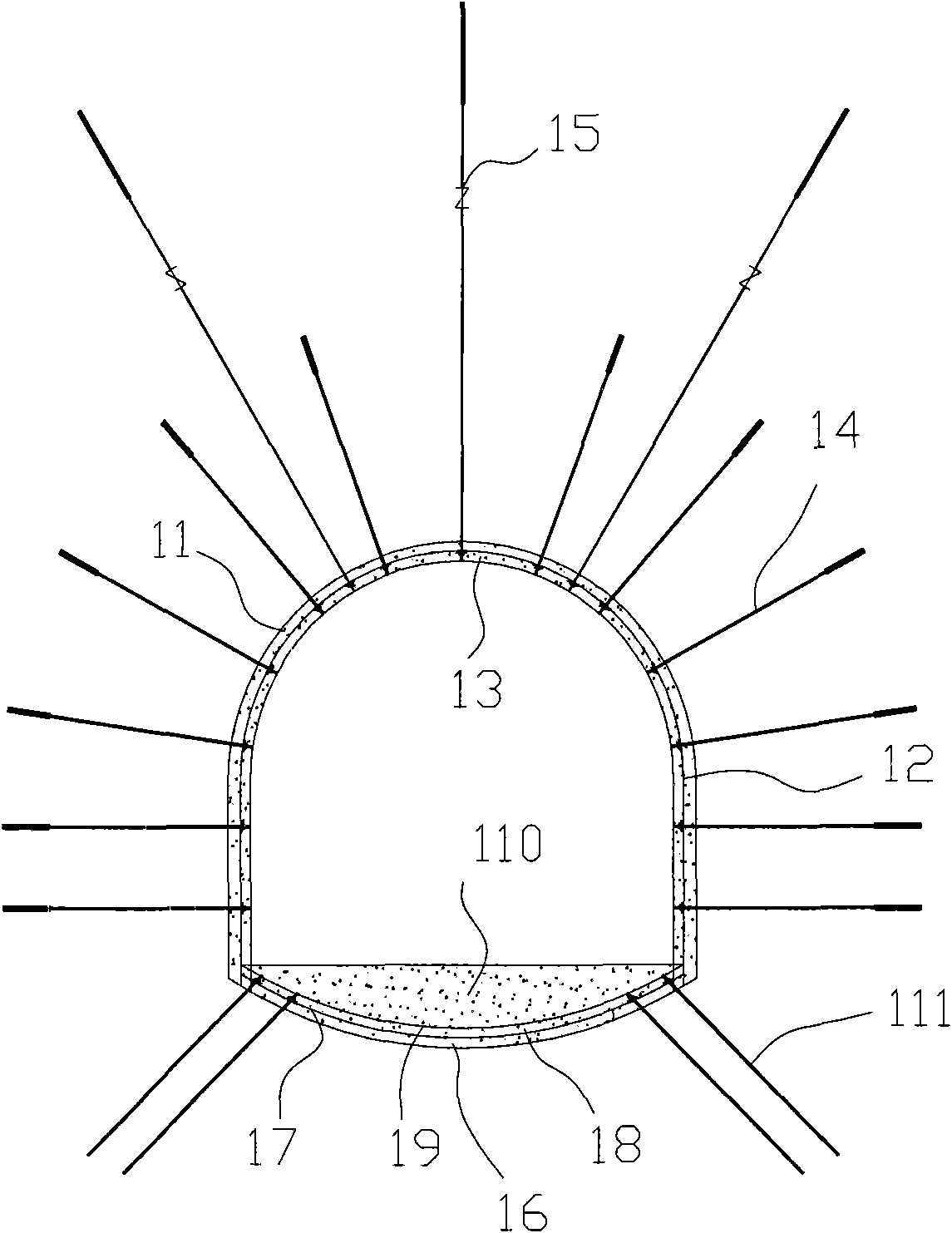

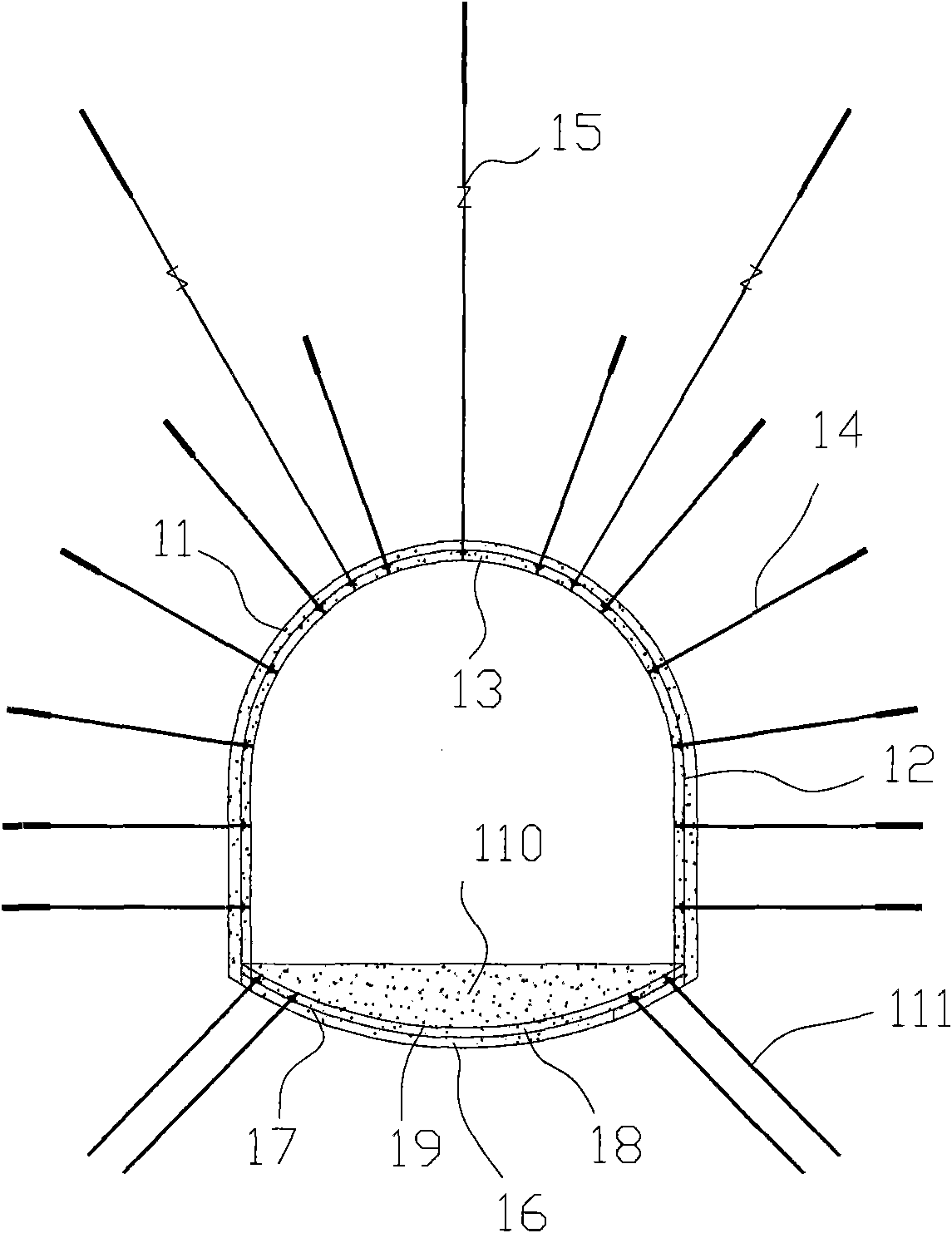

Quick supporting method for large-deformation roadway easy to fall, break and loosen and apparatus thereof

InactiveCN101852083AImprove stress statusStop looseningUnderground chambersMine roof supportsFiberSupporting system

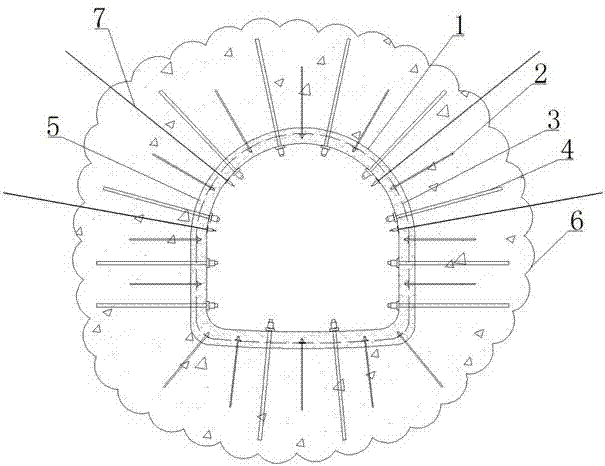

The invention discloses a quick supporting method for large-deformation roadway easy to fall, break and loosen and an apparatus thereof. The method comprises the following steps of: (1) clearing away the loose stones on the wall of the surrounding rock of the roadway; (2) hanging a reinforcing steel bar mesh along the digging outline of the roadway and initially spraying one thin concrete layer; (3) arranging an anchor rod in the drill hole of the roadway wall; (4) arranging a side-wall steel grating arch to support the surrounding rock of the side wall; (5) arranging a top-supporting steel grating arch, touching the top and supporting the upper surrounding rock; (6) clearing away the floating slag at the bottom of the roadway, arranging a steel grating arch of the inverted arch, supporting and sealing the system into a ring; (7) carrying out the cement injection construction on the anchor rod; (8) welding the exposed part of the cement injected anchor rod on the steel grating arch to form a whole structure; and (9) multi-spraying concrete or steel fiber concrete along the roadway wall. The apparatus comprises an anchor rod, a side-wall steel grating arch, a steel grating arch of top arch, a steel grating arch of inverted arch, and a concrete spray layer of reinforcing steel bar. The invention has the advantage of remarkable support effect, simple method and convenient operation and solves the problem that the bracket and the surrounding rock are not adhered tightly.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

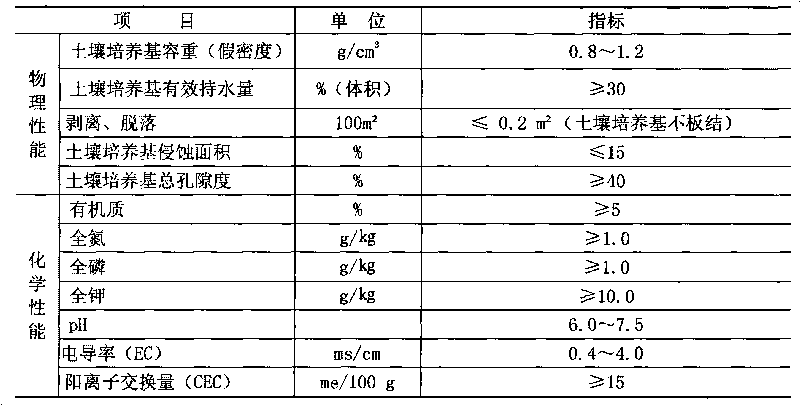

Ecological protection method for high steep side slope

The invention relates to an ecological protection method for a high steep side slope. The method mainly comprises the steps of slope surface treatment, concrete shotcrete and rock bolt support, vegetating hole arrangement, net spreading, spray material preparation, granule spray sowing, maintenance, management, and the like. In the method, guest soil materials such as humus loam rich in organic matters and clay are utilized to undergo a granule reaction after mixed with a granule agent at the moment of spray sowing so as to form a greening template which has the same high order granule structure as natural soil and strong erosion resistance and can suppress water and soil loss. After a diversified mature plant community which is in harmony with surrounding vegetation environment is formed, the slope surface can be protected, which can effectively resist diseases and insect pests and maintain the ecological balance. Post maintenance management and expenses can be saved. All used materials can be naturally degraded, have no pollution to the environment and can purify air and beautify the environment. Equipment of the method does not need to be hung on the slope surface for construction, and spray sowing operations are carried out only below the slope surface, thus the method has high construction speed and safety. The method is suitable for slope surfaces which are difficult to green, and the like, such as various high steep and unstable slope surfaces, bare slope surfaces having high greening expected values, and the like.

Owner:河南国网宝泉抽水蓄能有限公司

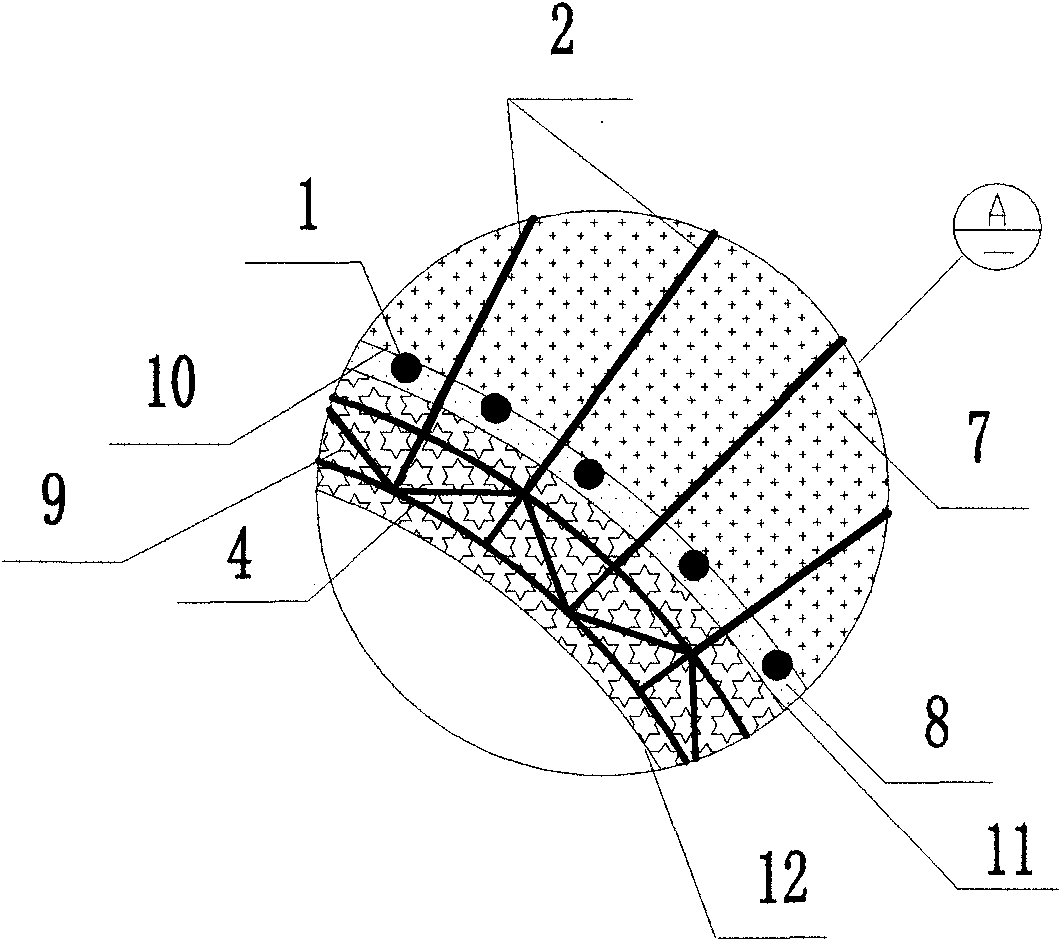

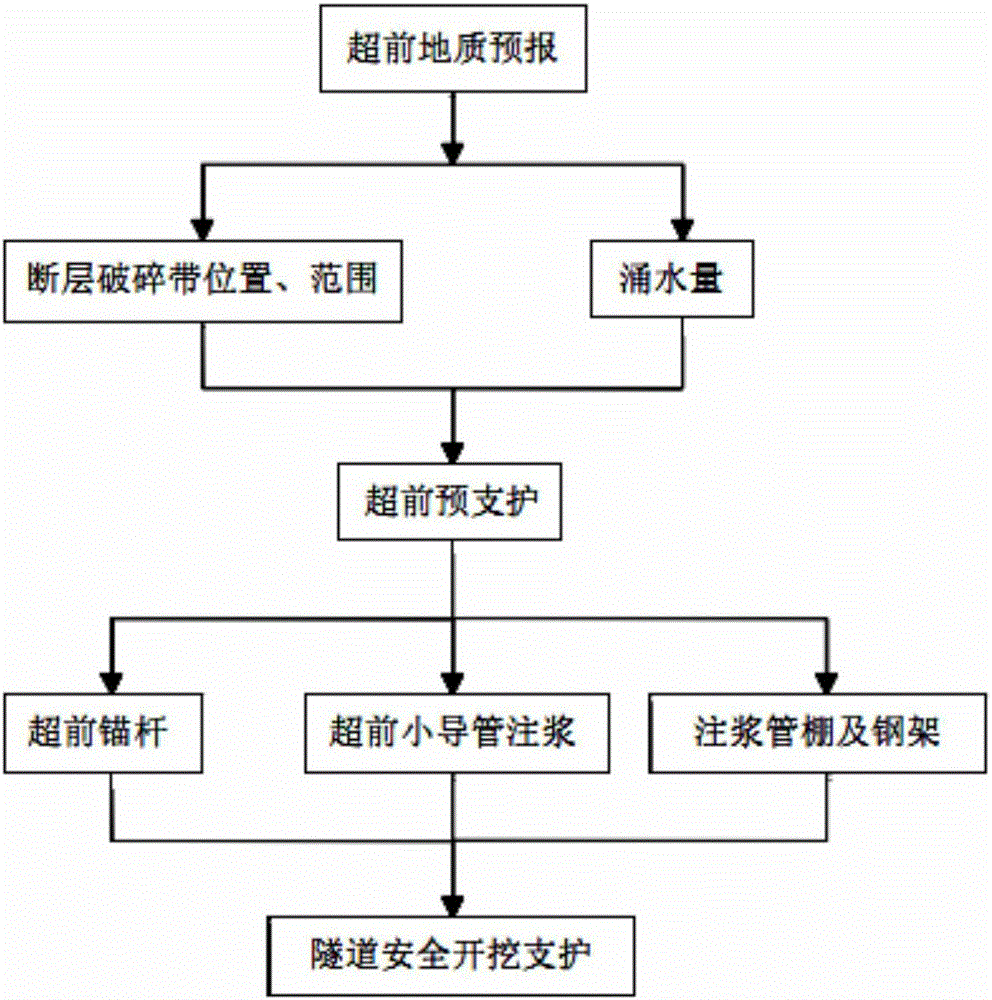

Construction method for fault fracture zone surrounding rock tunnel

InactiveCN106837352AEnsure safetyImprove applicabilityUnderground chambersTunnel liningGeomorphologyShortest distance

The invention discloses a tunnel construction method in a fault fracture zone, which comprises the following steps: a. adopting the method of combining geophysical prospecting and drilling and combining long-distance and short-distance to ascertain the geological situation in front, and carry out advanced geological prediction; b. adopting advanced Anchor construction, pre-grouting construction of the surrounding walls of small conduits in advance, and advance support construction of grouting pipe shed and steel frame, and advance pre-support; c. Tunnel excavation and support. It provides a theoretical basis for detecting the specific location, range and water inflow of the fault fracture zone; ensures the safety of tunnel construction; on the basis of analyzing the specific location and scope of the fault fracture zone and adopting a reasonable advanced pre-support method, comprehensive and specific According to the geological conditions, choose a reasonable tunnel excavation method. It has strong applicability for the construction of expressway tunnels crossing fault fracture zones; at the same time, it has reference and reference significance for the construction of railway, municipal and water conservancy tunnels (holes) with similar geological conditions.

Owner:CENT SOUTH UNIV +2

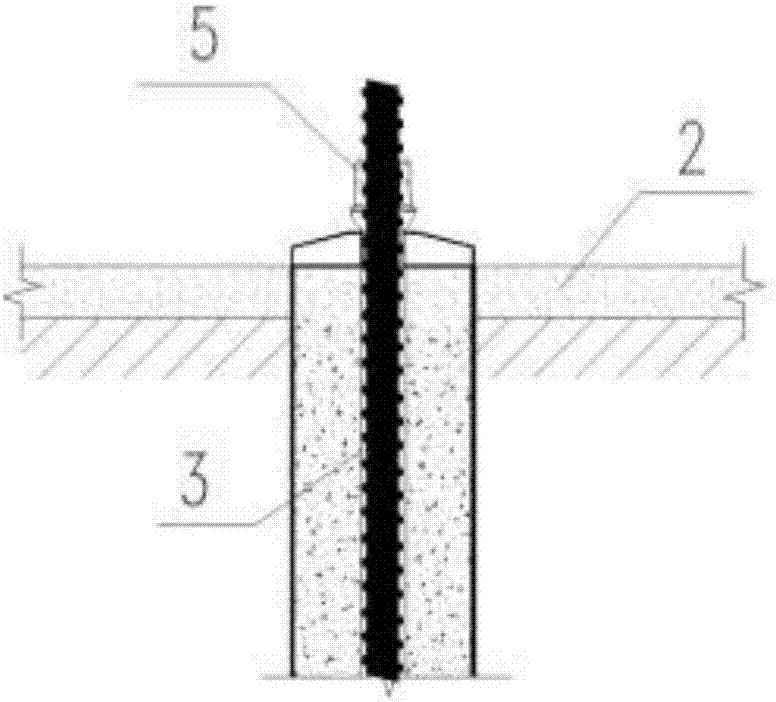

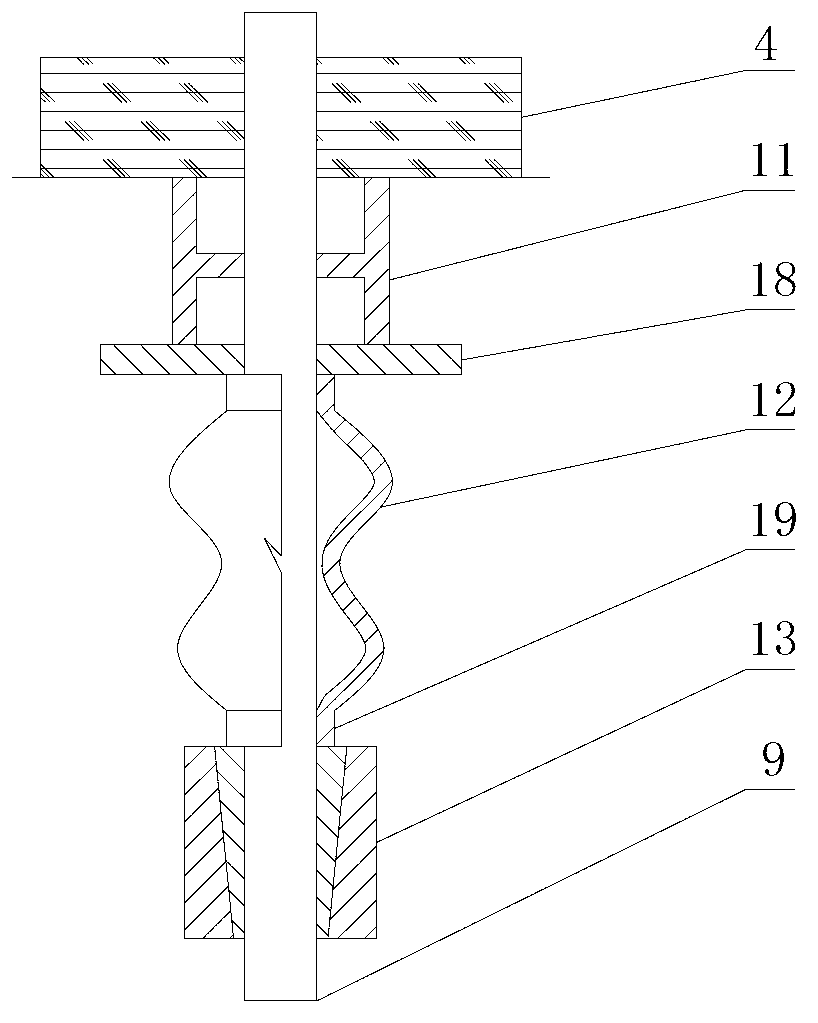

Composite support device of dynamic pressure softrock tunnel based on steel pipe concrete bracket

InactiveCN101725362AControl deformationSimple structureProps/chocksAnchoring boltsSupporting systemHardness

The invention relates to a composite support device of a dynamic pressure softrock tunnel based on a steel pipe concrete bracket, which comprises a steel pipe concrete bracket, wherein a flexible pressure sharing and releasing layer is arranged between the steel pipe concrete bracket and supported surrounding rock. The composite support device also comprises a surrounding rock grouting and reinforcing device, wherein the surrounding rock grouting and reinforcing device comprises a plurality of hollow surrounding rock grouting anchor rods, and the surrounding rock is grouted by the hollow anchor rods; after being injected with a concrete layer, the surrounding rock is covered by a flexible seal layer; and the steel pipe concrete bracket is provided with a vertical column shaped or Y-shaped or T-shaped high-strength steel pipe concrete strut. The high-strength steel pipe concrete bracket and the flexible pressure sharing and releasing layer are two necessary technologies; and the flexible seal layer, the surrounding rock grouting and reinforcement and the high-strength steel pipe concrete strut are three optional technologies. The flexible pressure sharing and releasing layer is combined with the steel pipe concrete bracket so that the whole support system combines hardness with softness, has simple structure, low cost and high support resistance and can effectively control the stability of large deformed tunnels of deep well softrock dynamic pressure, and the like.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

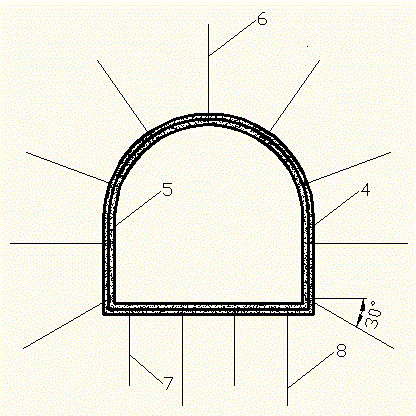

Total-section closed type deep-shallow coupling yielding, bolting-grouting and supporting method for incompact and fractured soft-rock roadway

InactiveCN105178981AImprove support strengthWatch protection effect is goodUnderground chambersTunnel liningCouplingStructure of the Earth

The invention relates to a total-section closed type deep-shallow coupling yielding, bolting-grouting and supporting method for an incompact and fractured soft-rock roadway. On the basis of a multilayered cooperative supporting principle, a spraying net combined isolating arch, an anchor rod extruding reinforcing arch, a total-section closed type grouting reinforcing ring and a deep slurry diffusion reinforcing arch are respectively formed on surrounding rock of the roadway from shallow to deep finally, and are combined to form a multilayered effective combined arch by a suspension effect of a high-strength grouting anchor cable, advantages of yielding supporting, bolting-grouting supporting and deep-shallow coupling supporting are combined organically, bearing range, integrity and bearing capability of a supporting structure are improved obviously, a control effect on deformation characteristics of large deformation, high speed, long duration, wide destroying range, peripheral pressing, obvious floor heaves and the like of the surrounding rock of the incompact and fractured soft-rock roadway is excellent, and various deformations of the surrounding rock of the incompact and fractured soft-rock roadway are controlled effectively. The total-section closed type deep-shallow coupling yielding, bolting-grouting and supporting method is particularly suitable for a large-section incompact and fractured soft-rock roadway of a deep well, is simple in work procedures and low in cost, and has high field promotion and application value; and parallel operation can be realized.

Owner:CHINA UNIV OF MINING & TECH

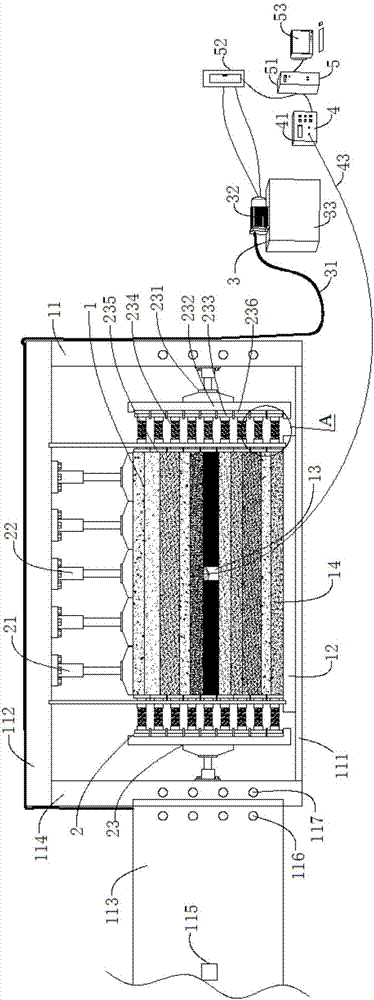

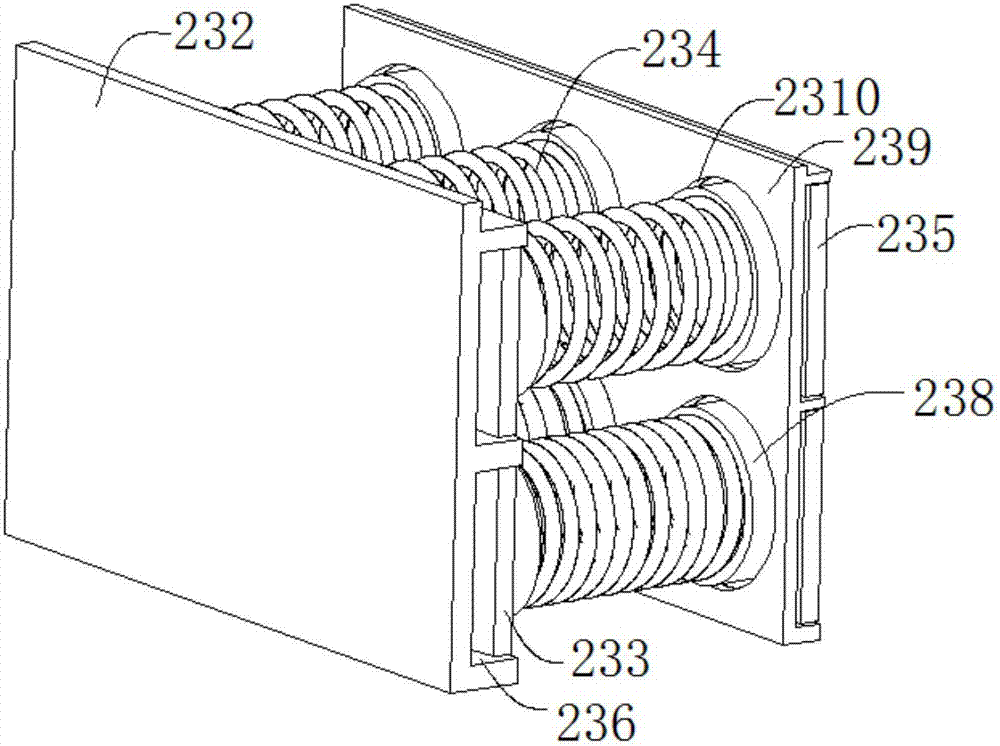

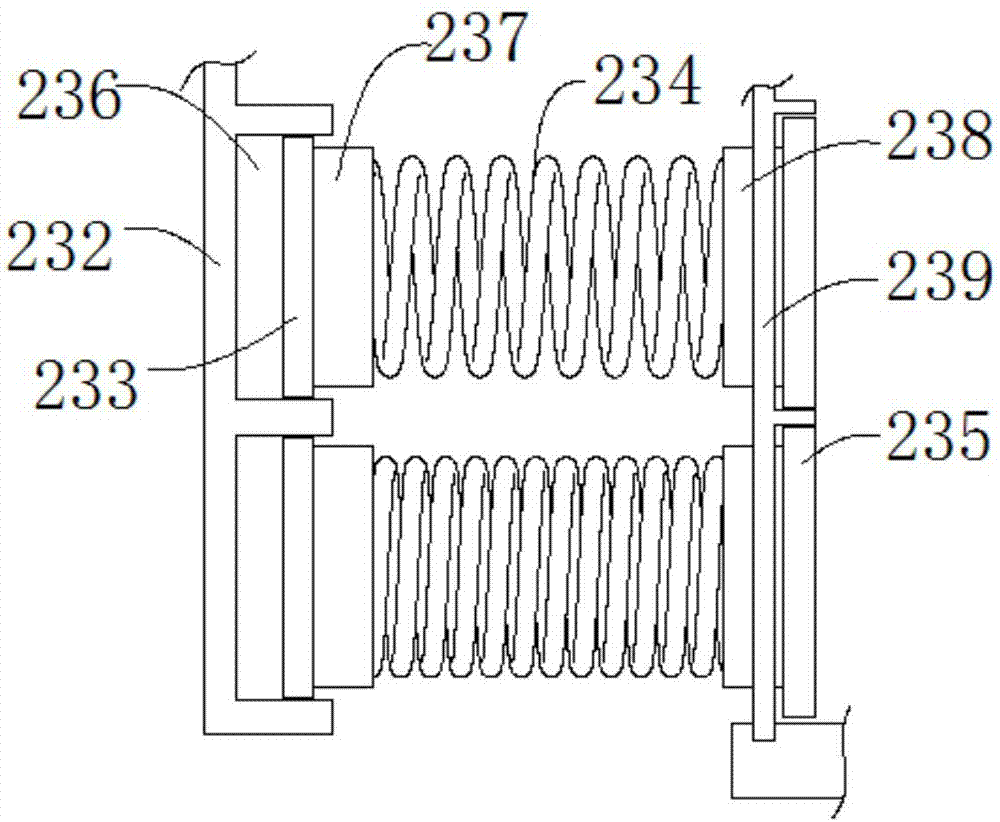

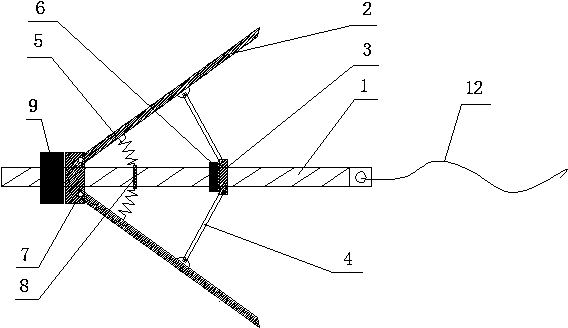

Roadway support mechanics simulation test system under dynamic-static combined loads and method of roadway support mechanics simulation test system

ActiveCN108007781AConsistent forceThe test result is accurateMaterial strength using tensile/compressive forcesControl systemMonitoring system

The invention discloses a roadway support mechanics simulation test system under dynamic-static combined loads and a method of the roadway support mechanics simulation test system. The system comprises a similar material laying system, a hydraulic loading system, a dynamical system, a monitoring system and a control system, wherein the similar material laying system comprises a connecting bracket,a laying platform and a reserved anchor rod model; the laying platform is placed in the connecting bracket; a coal rock similar layer is arranged on the laying platform; the coal rock similar layer is obtained by laying coal rock similar materials sequentially layer by layer; the reserved anchor rod model is arranged in the middle of the coal rock similar layer. According to the roadway support mechanics simulation test system, an adjustable static load and an adjustable dynamic load are simultaneously exerted on the coal rock similar layer, so that the force on a surrounding rock and a support of a roadway can be consistent with actual force; therefore, a test result is more accurate. Meanwhile, the roadway support mechanics simulation test system is simple in operation and is stable andreliable; therefore, the roadway support mechanics simulation test system has great significance in support designs of deep mines, tunnels and the like.

Owner:SHANDONG UNIV OF SCI & TECH

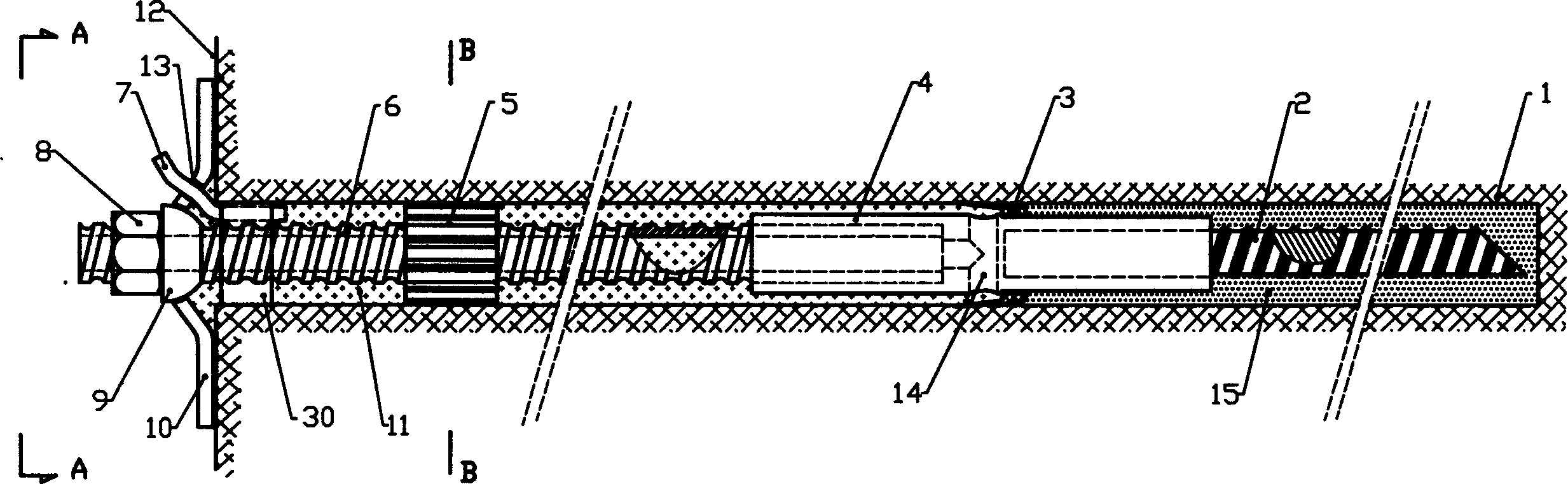

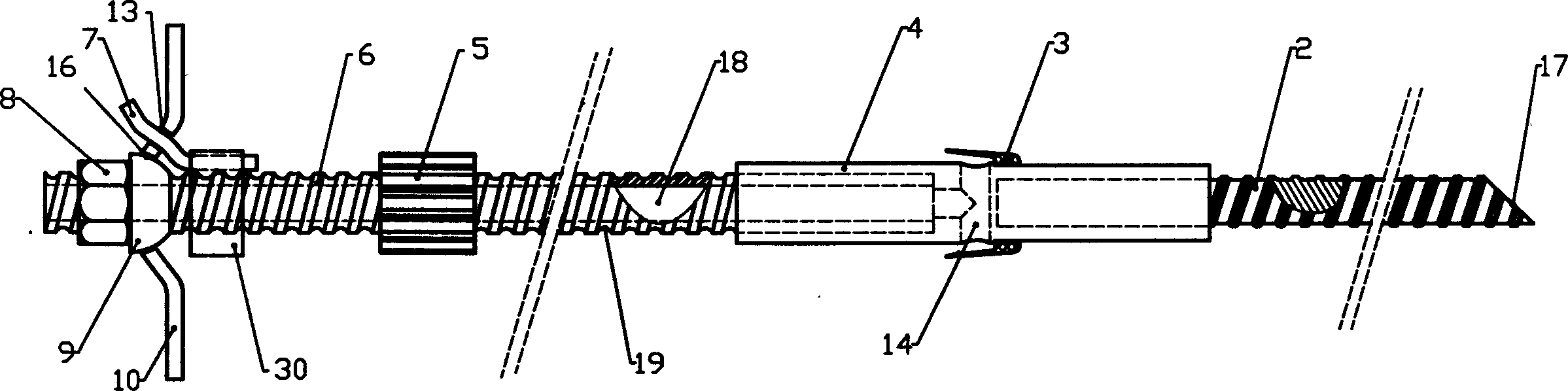

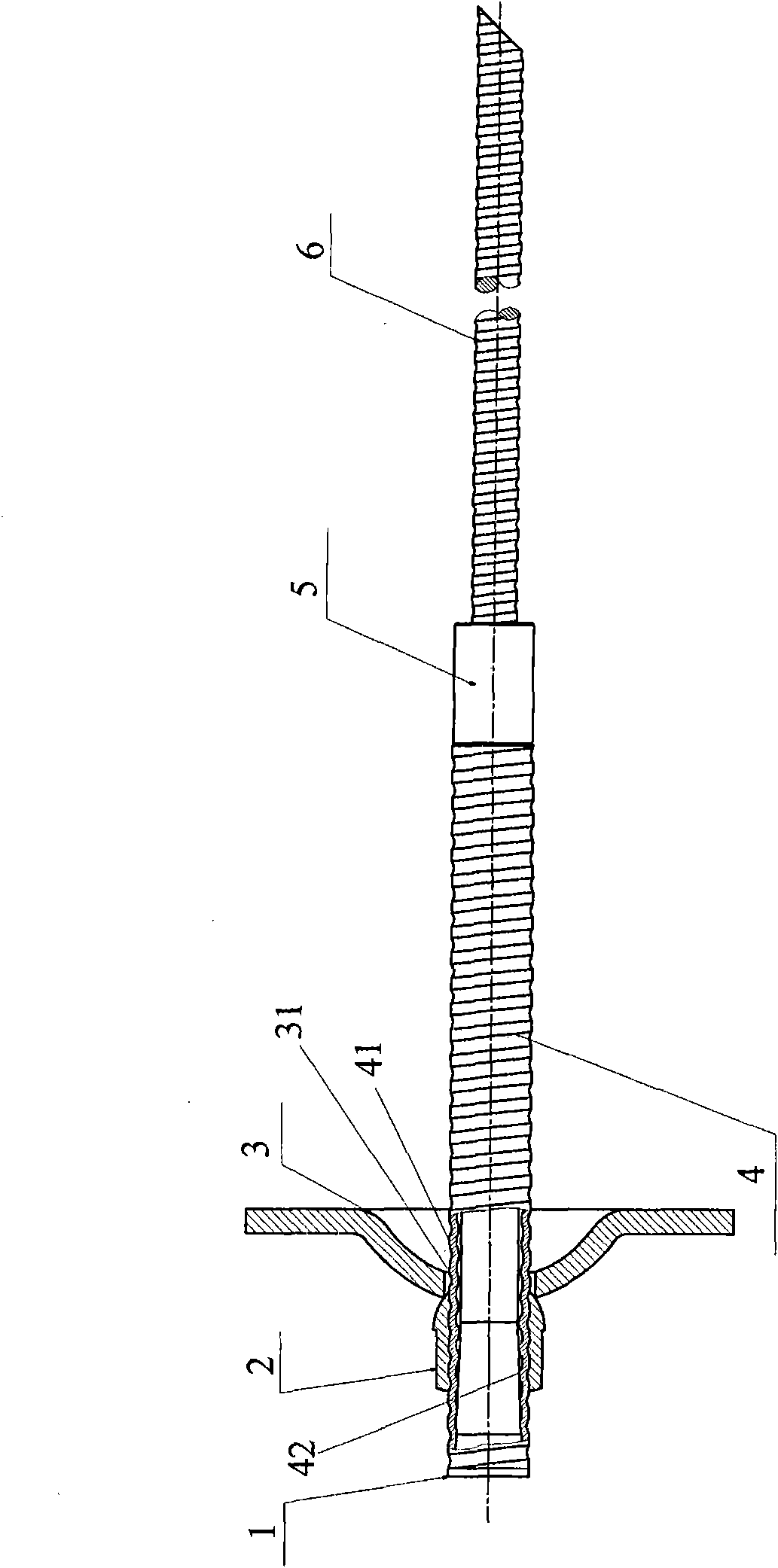

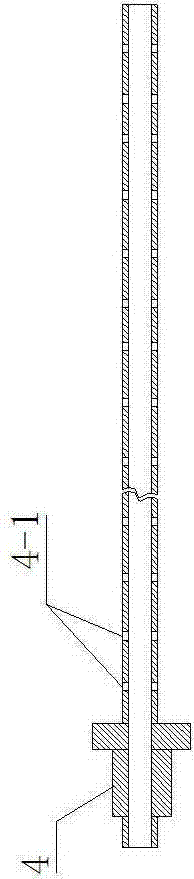

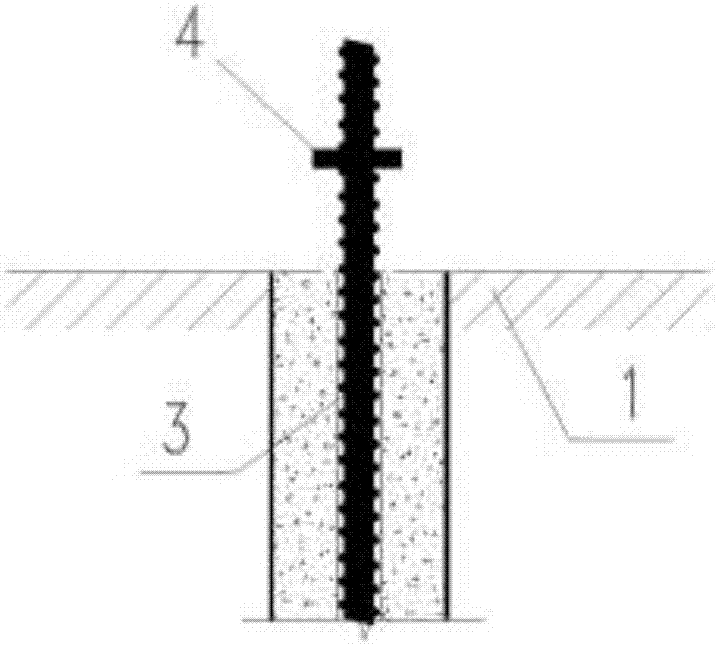

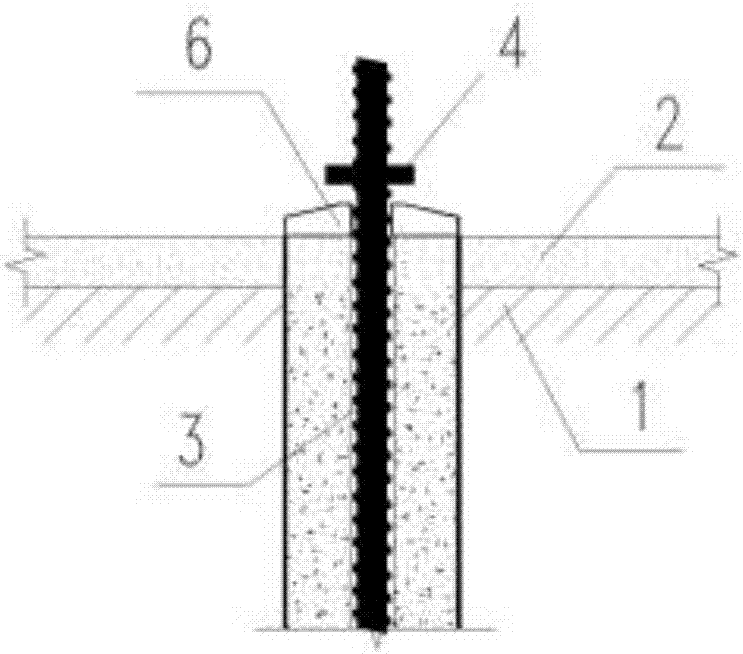

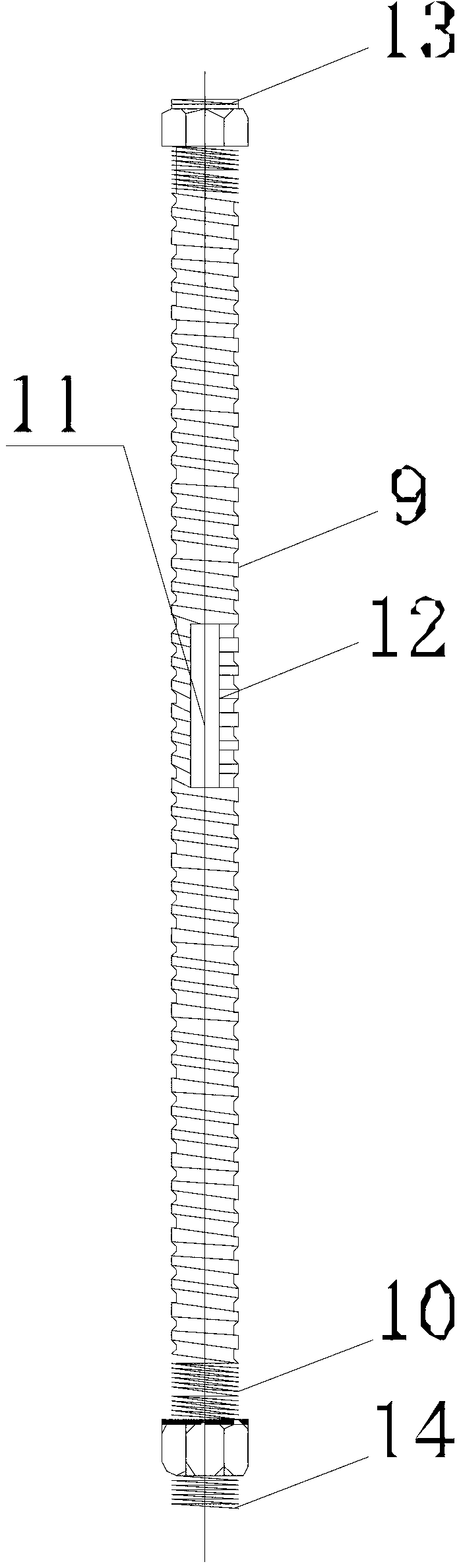

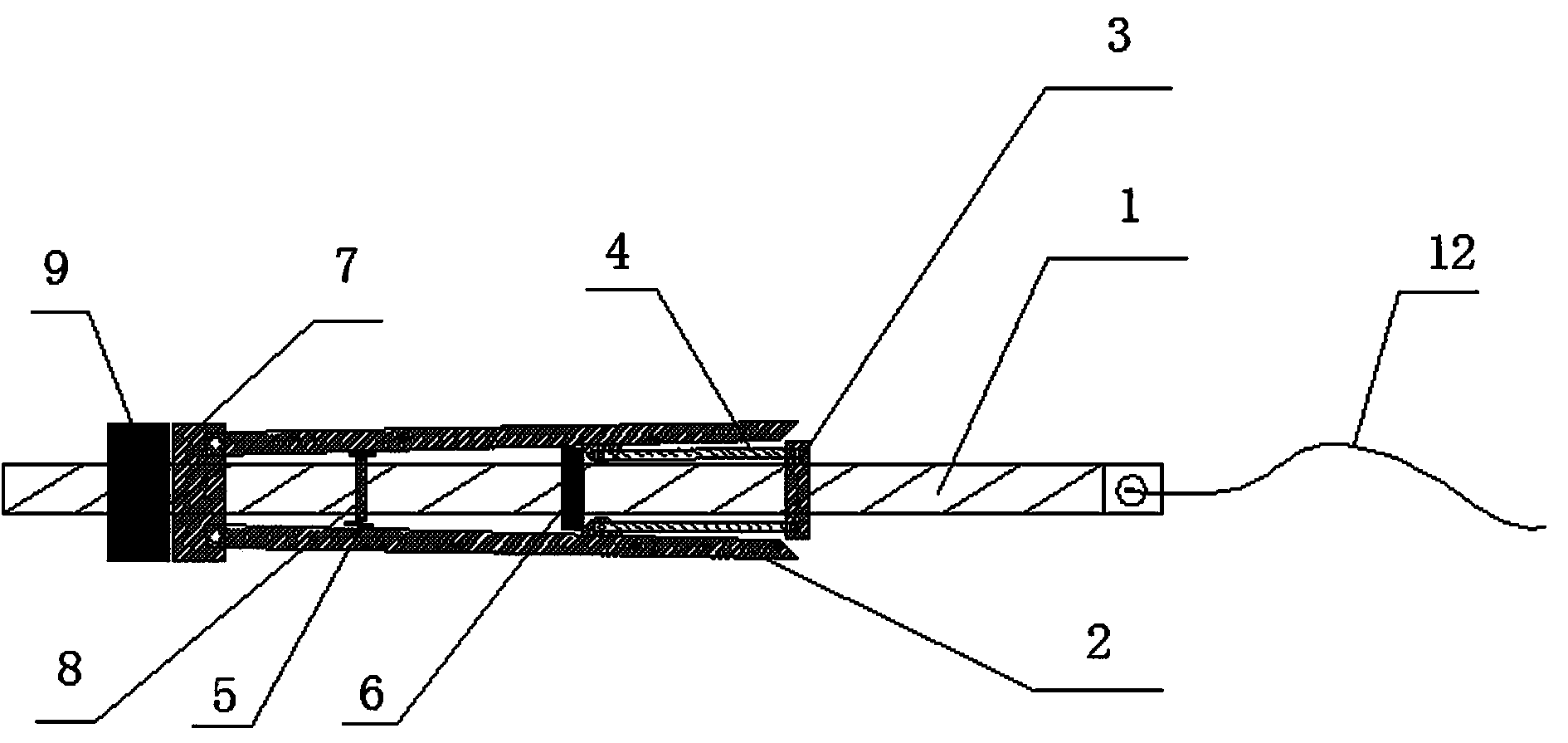

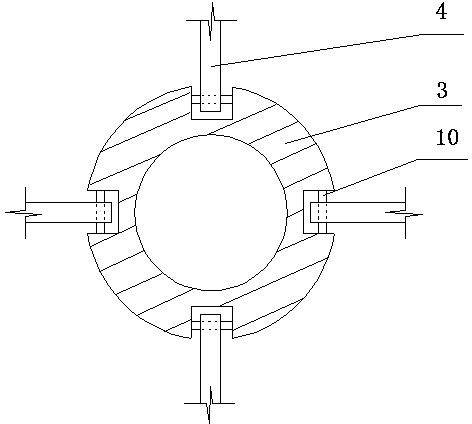

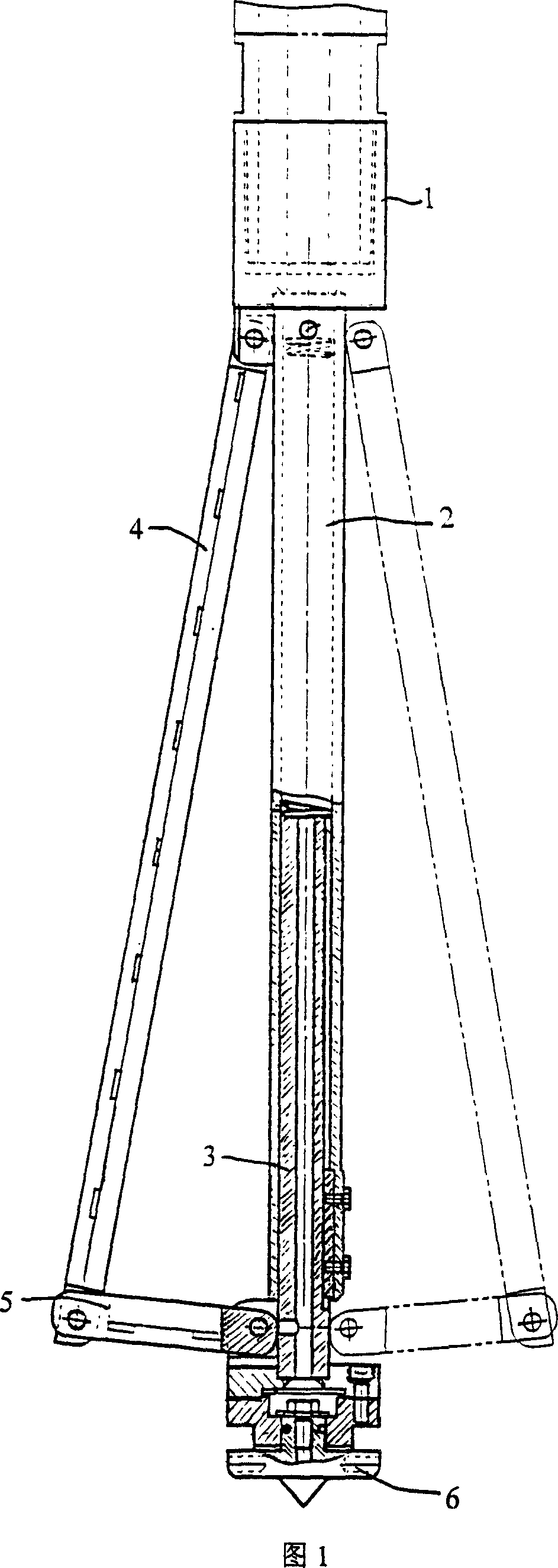

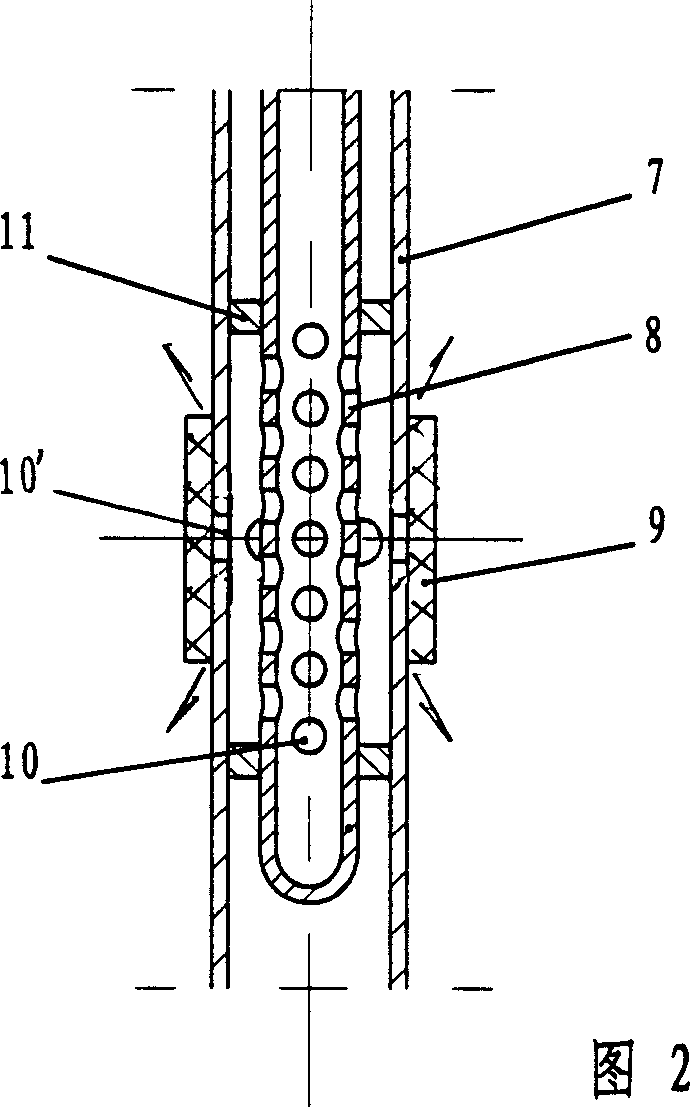

A pin timbering process and sectionalized hollow mud injecting stay bolt thereof

InactiveCN1464176AImprovement of Bolt Support MethodImproved support methodAnchoring boltsPre stressEngineering

The present invention is anchor support method and one kind of sectional hollow grouted anchor and has the features of first early strengthening locking and then grouting protection and prestressing. The sectional hollow grouted anchor consists of two sections including front solid rod and back hollow rod connected via connecting sleeve, the connecting sleeve has mortar blocking unit and hollow rod section has several centralizing units. There are side hole canal in the joint of the connecting sleeve and the hollow rod and hole canal in the support cushion for some pipe to pass through. The said anchor support method of the present invention is used for temporary and permanent fast support in both hard and weak rock formation conditions.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +3

Method for preventing and treating large deformation and collapse of softrock tunnel

ActiveCN101906977AImprove pullout resistanceGuaranteed stabilityUnderground chambersTunnel liningLarge deformationRock bolt

The invention relates to a method for preventing and treating large deformation and collapse of a softrock tunnel, which comprises the following steps: tunneling molding or enlarging a tunnel; primarily spraying the first layer of concrete, and hanging a side net and a top net at the first layer of concrete; arranging a constant-resistance large deformation rock bolt; multiply spraying the second layer of concrete; arranging a constant-resistance large deformation anchor cable on the top plate; digging and laying the first layer of base plate concrete; hanging a layer of backing screen on the first layer of base plate concrete, and arranging a base angle anchor rod at the base angle; laying the second layer of base plate concrete onto the grade level; setting a long-term ground pressure monitoring point, if the tunnel deforms to a certain preset valve, carrying out secondary support at the key position of the tunnel and carrying out pressurization and slip casting on surrounding rock. The invention can well ensure the stability of softrock tunnel under the condition of large deformation, in addition, the invention has the advantages of simple and practicable implement and lower cost.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Deep well tunnel cable anchor rigid-flexible coupling support and surrounding rock overall reinforced support method

InactiveCN101967984AImprove carrying capacityPrevent shear deformationUnderground chambersTunnel liningPre stressCoupling

Owner:ANHUI UNIV OF SCI & TECH

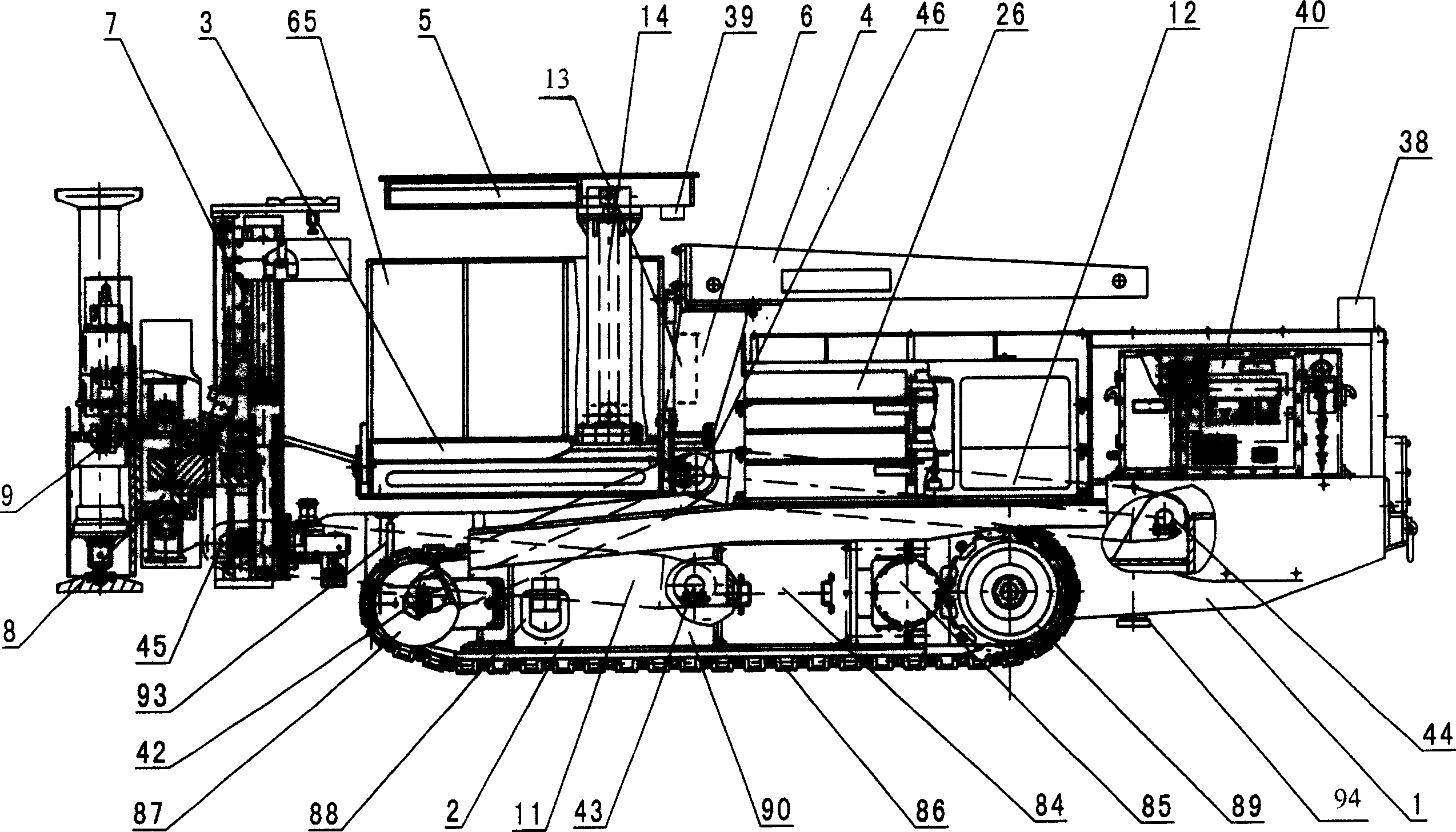

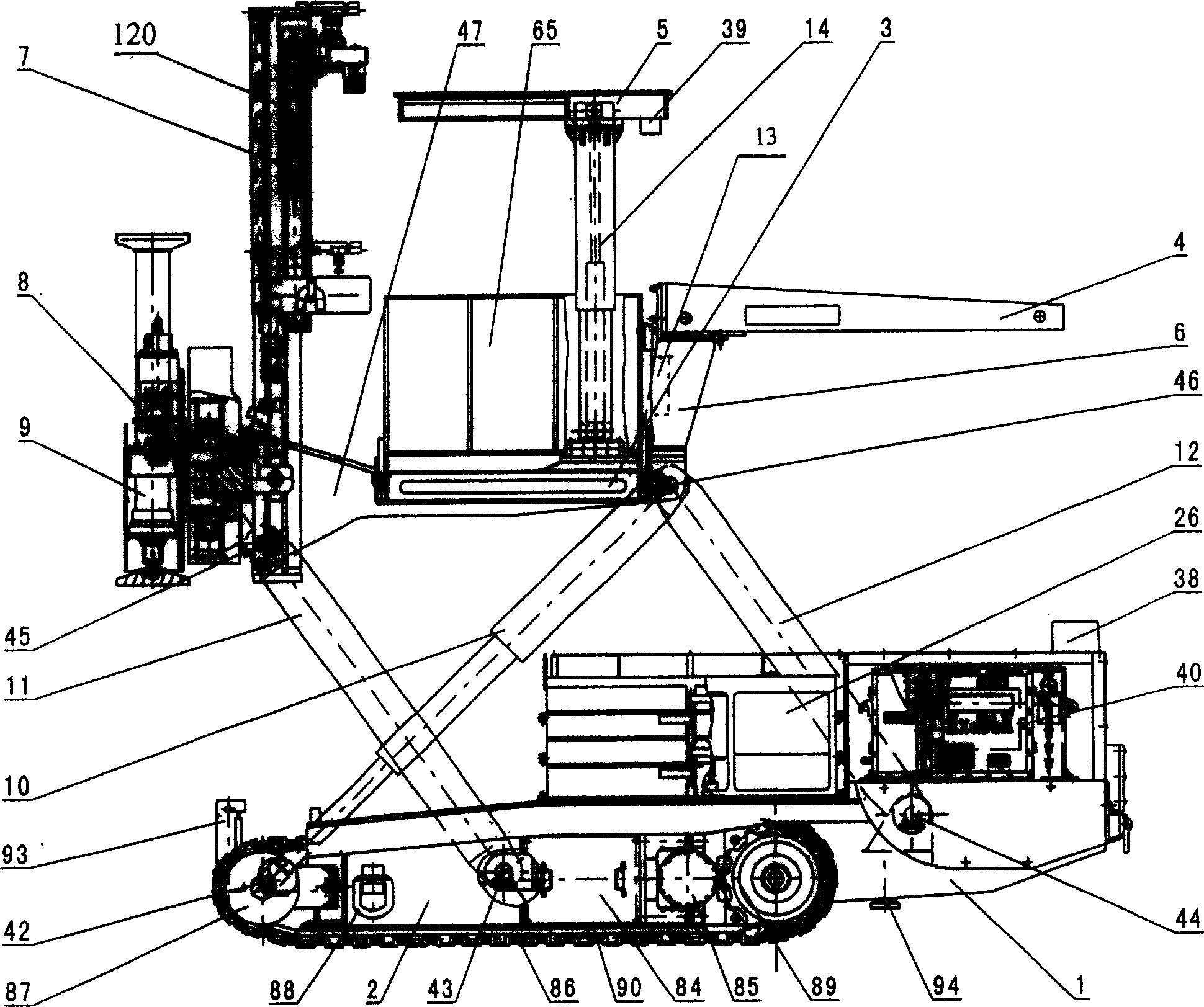

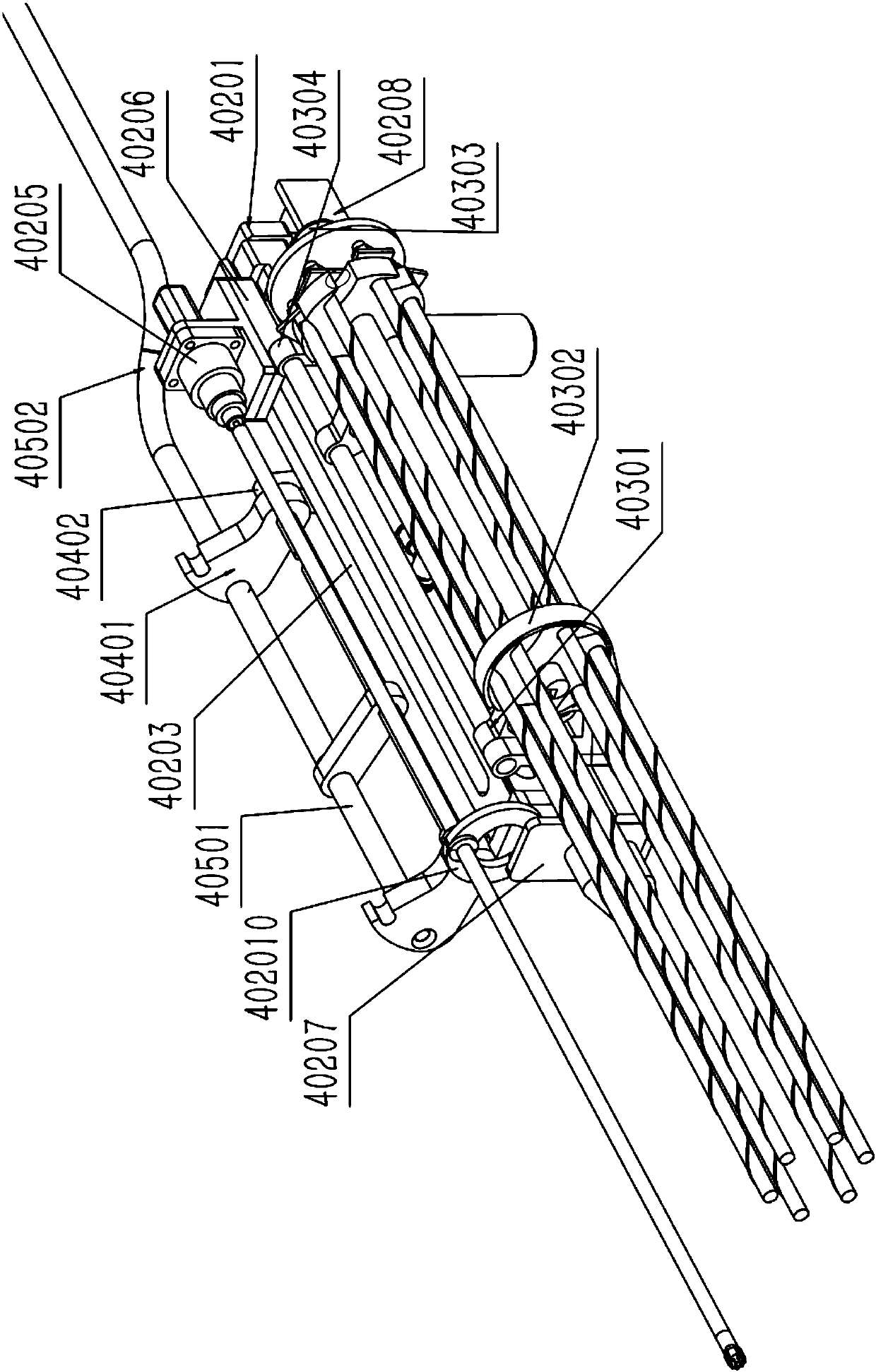

Crawler-type walking rockbolt drilling carriages

ActiveCN1584292AThe mechanical relationship is reasonableMechanizationAnchoring boltsDrilling machines and methodsElectric controlRock bolt

The present invention relates to a crawler running roof-bolting jumbo for coal extraction in the pit. It mainly includes machine seat, working table, running mechanism, lifting mechanism, hydraulic mechanism, dust-removing mechanism, cable-rolling mechanism, drilling cramp component, slideway component, support component and electric control box, said whole machine adopts hydraulic transmission, automatic dust-removing, automatic cable-rolling and crawler running modes, and utilizes the hydraulic oil cylinder to control parallelogram lifting movement and can make moving, lifting and multi-arm roof-bolt drilling works in the excavating tunnel. Said invention is reasonable in structure, large in load-bearing capacity, reliable and high in working efficiency.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP

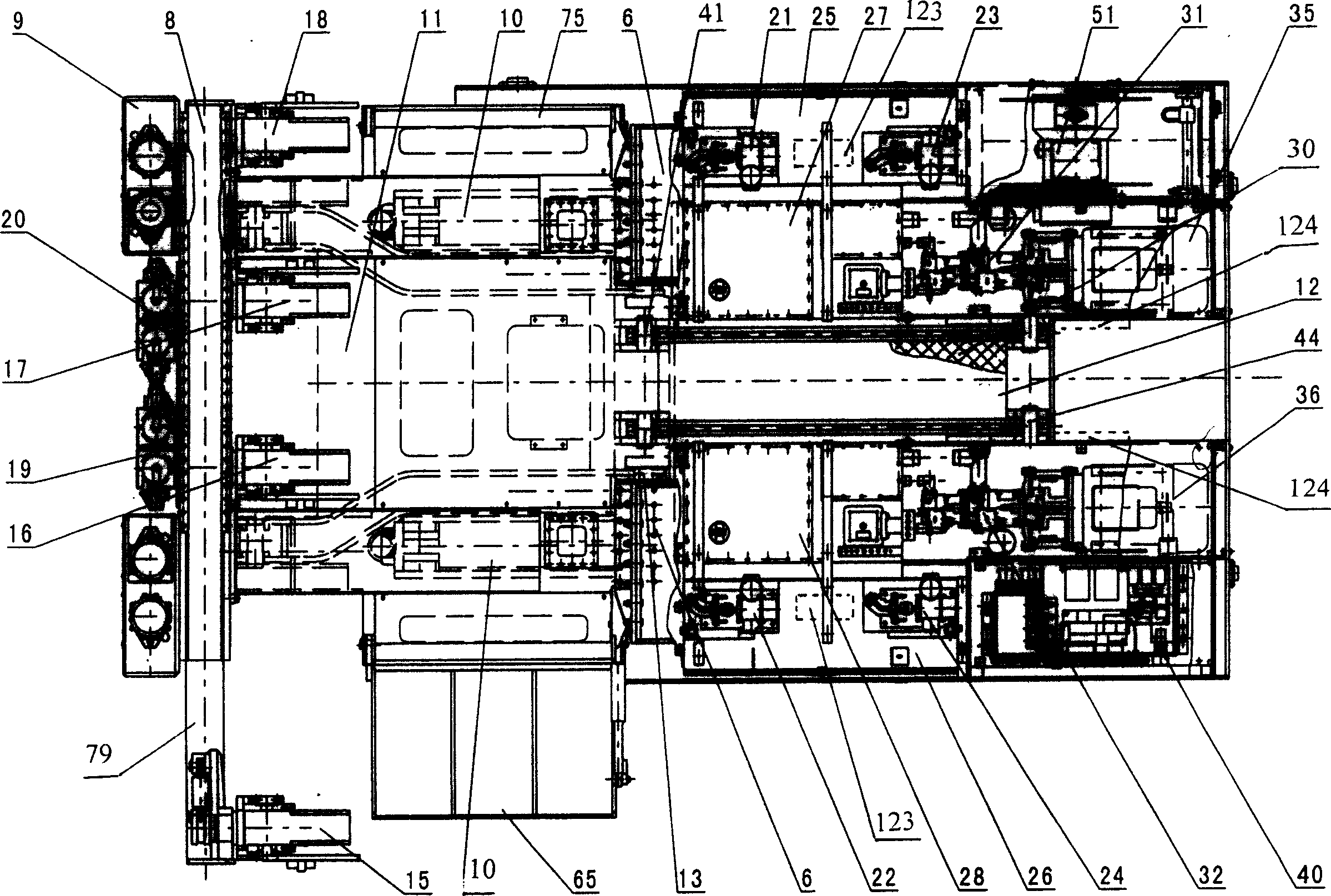

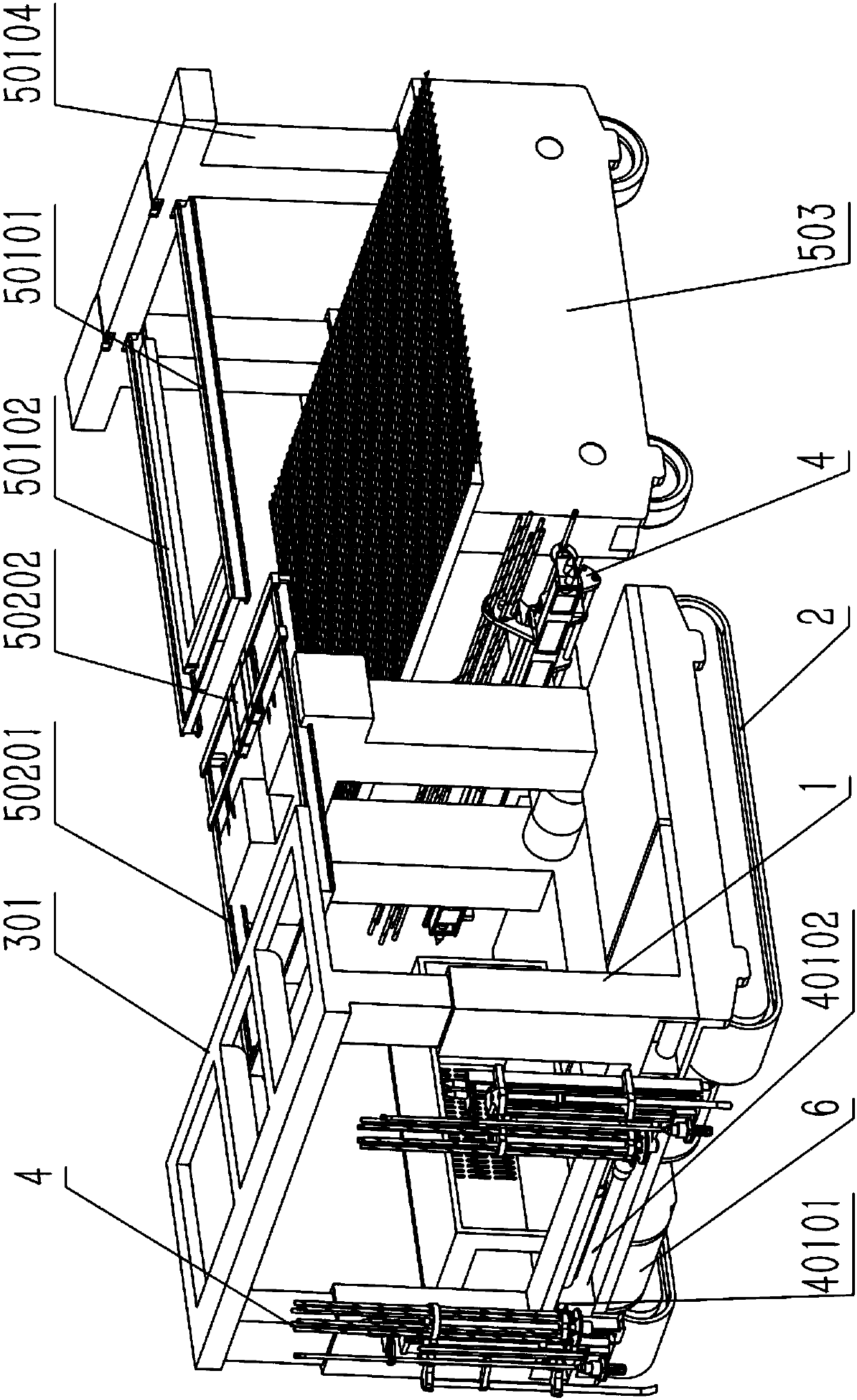

Fully automatic drilling anchor work vehicle

ActiveCN108104853AReduce volumeLess interferenceDrilling rodsConstructionsHydraulic cylinderEngineering

The invention discloses a fully automatic drilling anchor work vehicle integrating processes of anchor net paving, anchor hole drilling, anchoring agent injecting and installing of anchor bolt, and relates to the field of coal mine downhole tunnel support. The fully automatic drilling anchor work vehicle solves the existing problem of misalignment of digging and supporting caused by complicated process and low efficiency of tunnel support operation. The fully automatic drilling anchor work vehicle is characterized by comprising a vehicle body, a self-walking mechanism, a temporary support mechanism, an anchor drilling automation device, and an anchor net storing and a conveying mechanism. The anchor net is grabbed and conveyed to a temporary support frame by the anchor net conveying mechanism from an anchor net storage vehicle, and is supported by the temporary support frame to complete the anchor net laying work; and the anchor drilling automation device realizes the left-right and up-down displacement by the double-acting hydraulic cylinder in a car body sliding slot, and the rotation of the anchor drilling automation device is realized by a swing motor. According to the fully automatic drilling anchor work vehicle, the automatic laying of a back anchor net can be completed, mechanized support and automatic support of a top anchor rod and a side anchor rod can be realized, and the fully automatic drilling anchor work vehicle is matched with tunneling equipment to realize the parallel operation of digging and supporting anchor.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

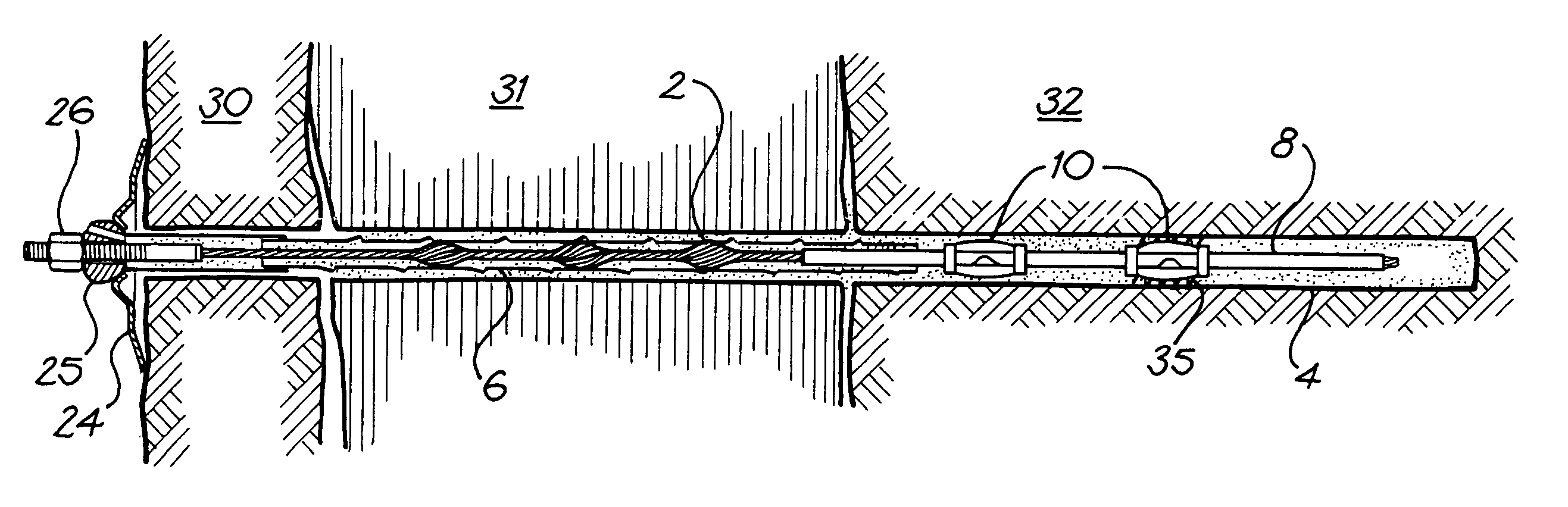

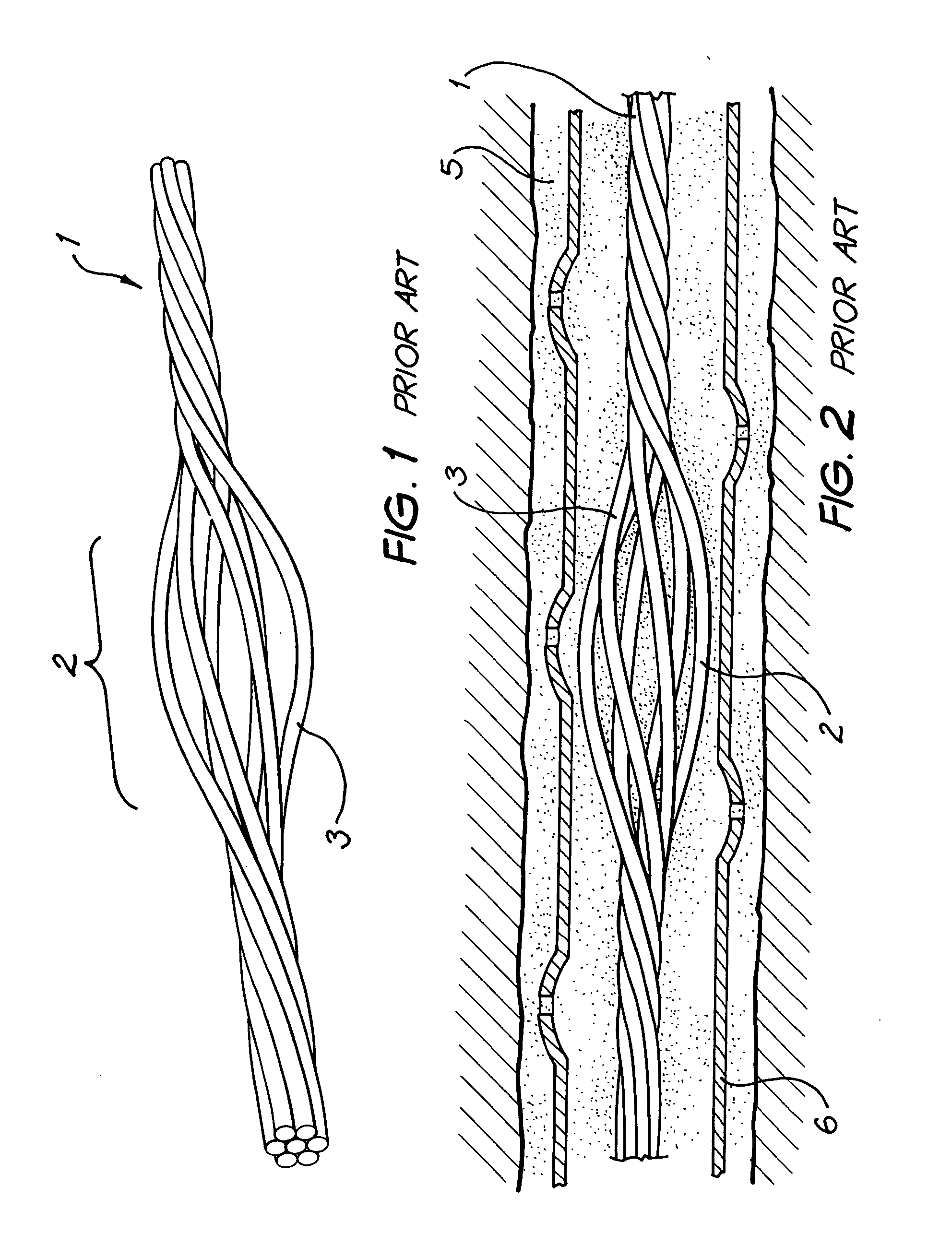

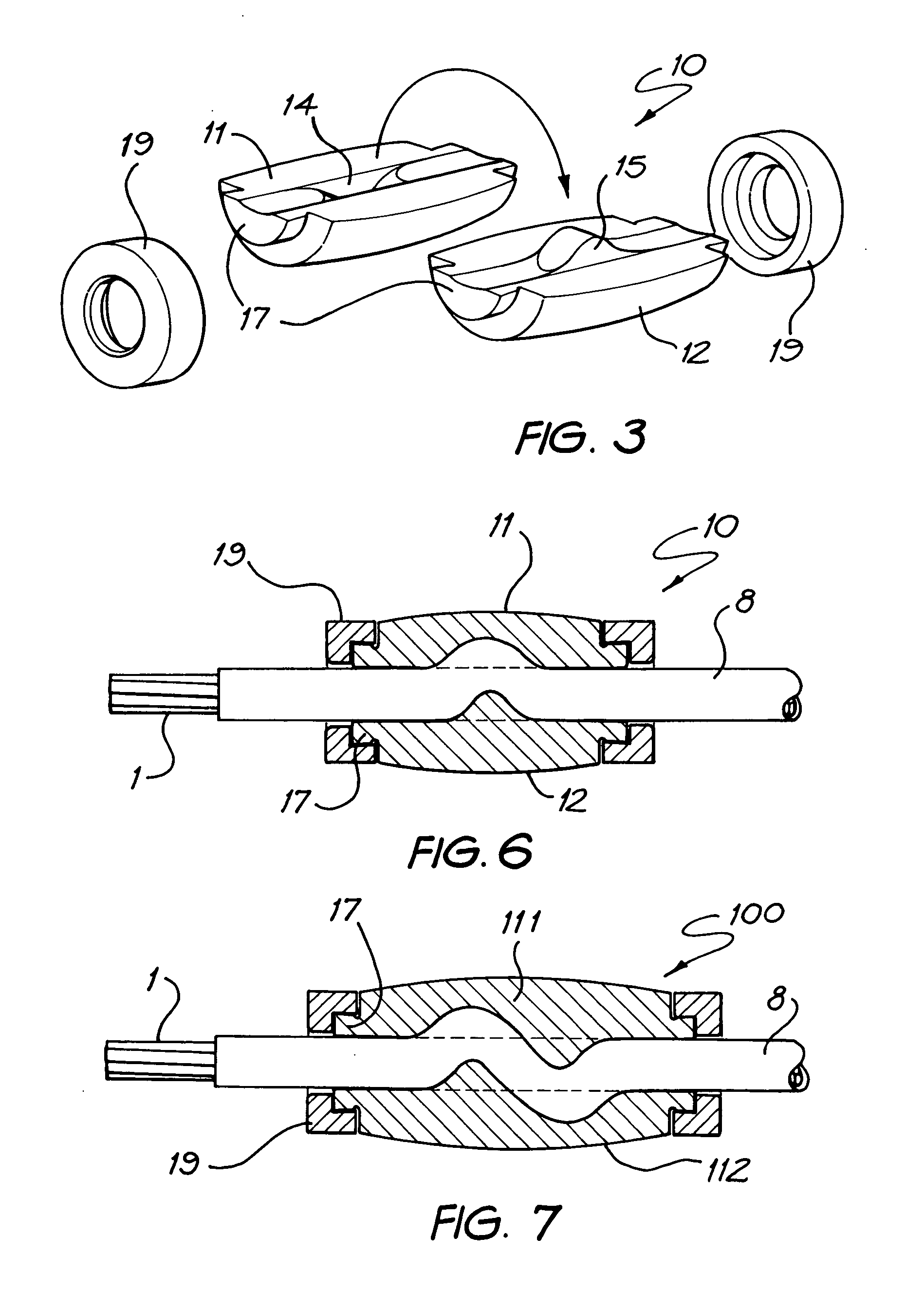

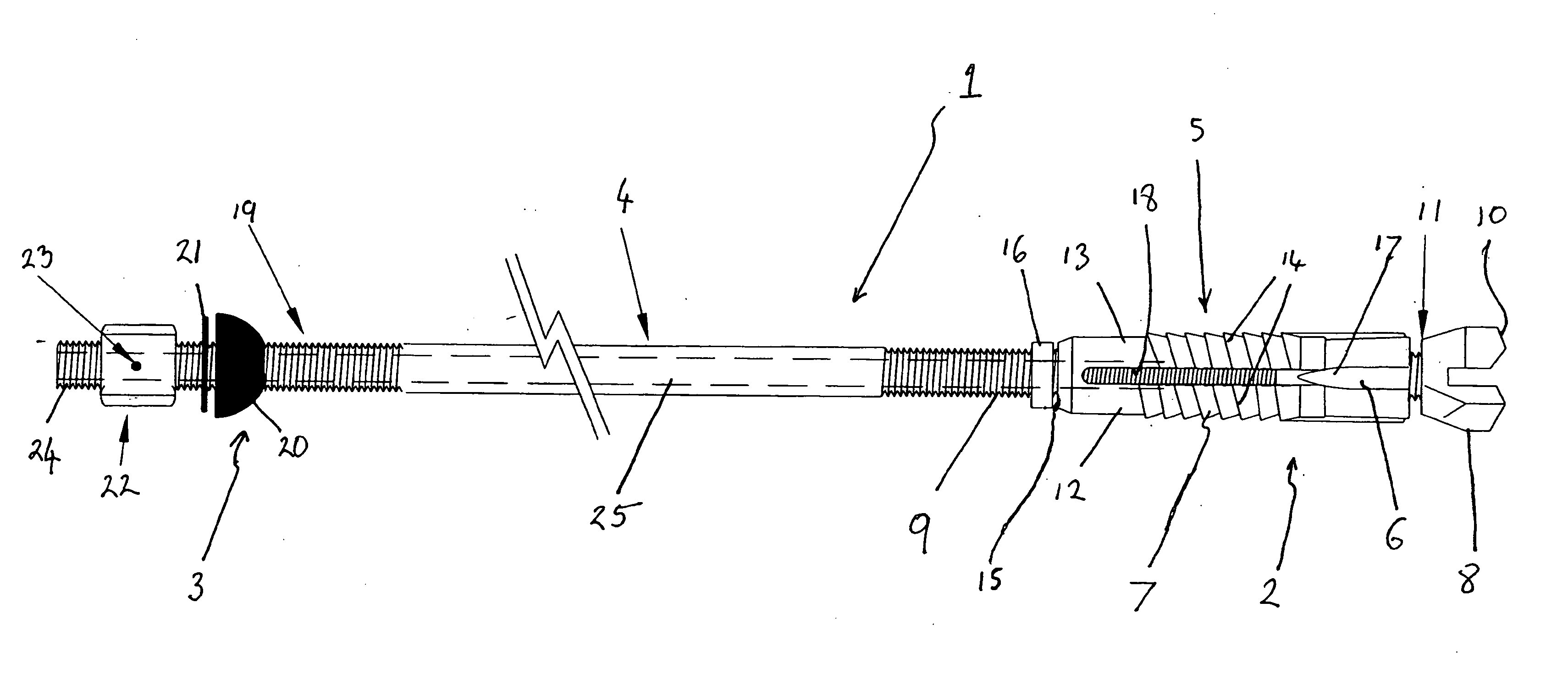

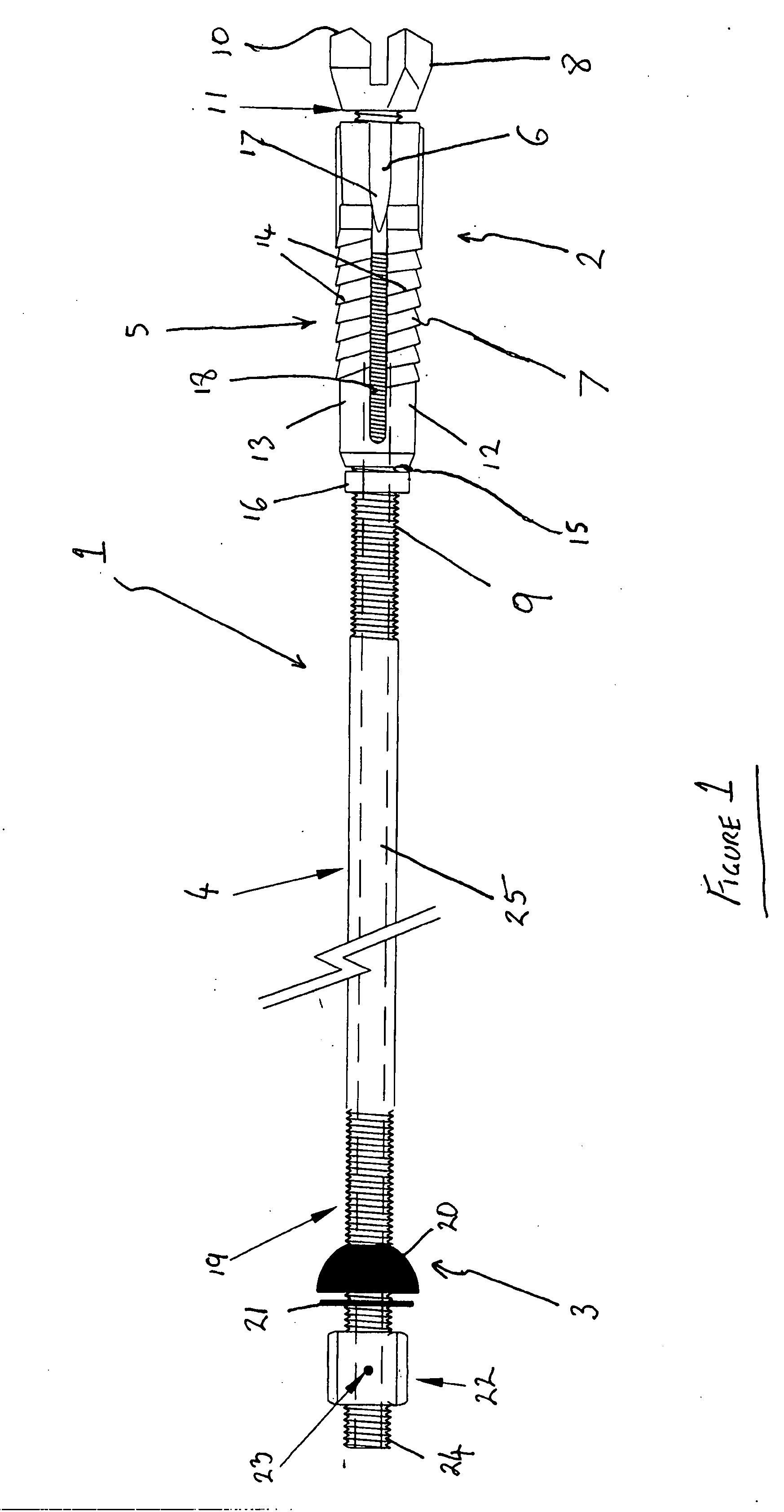

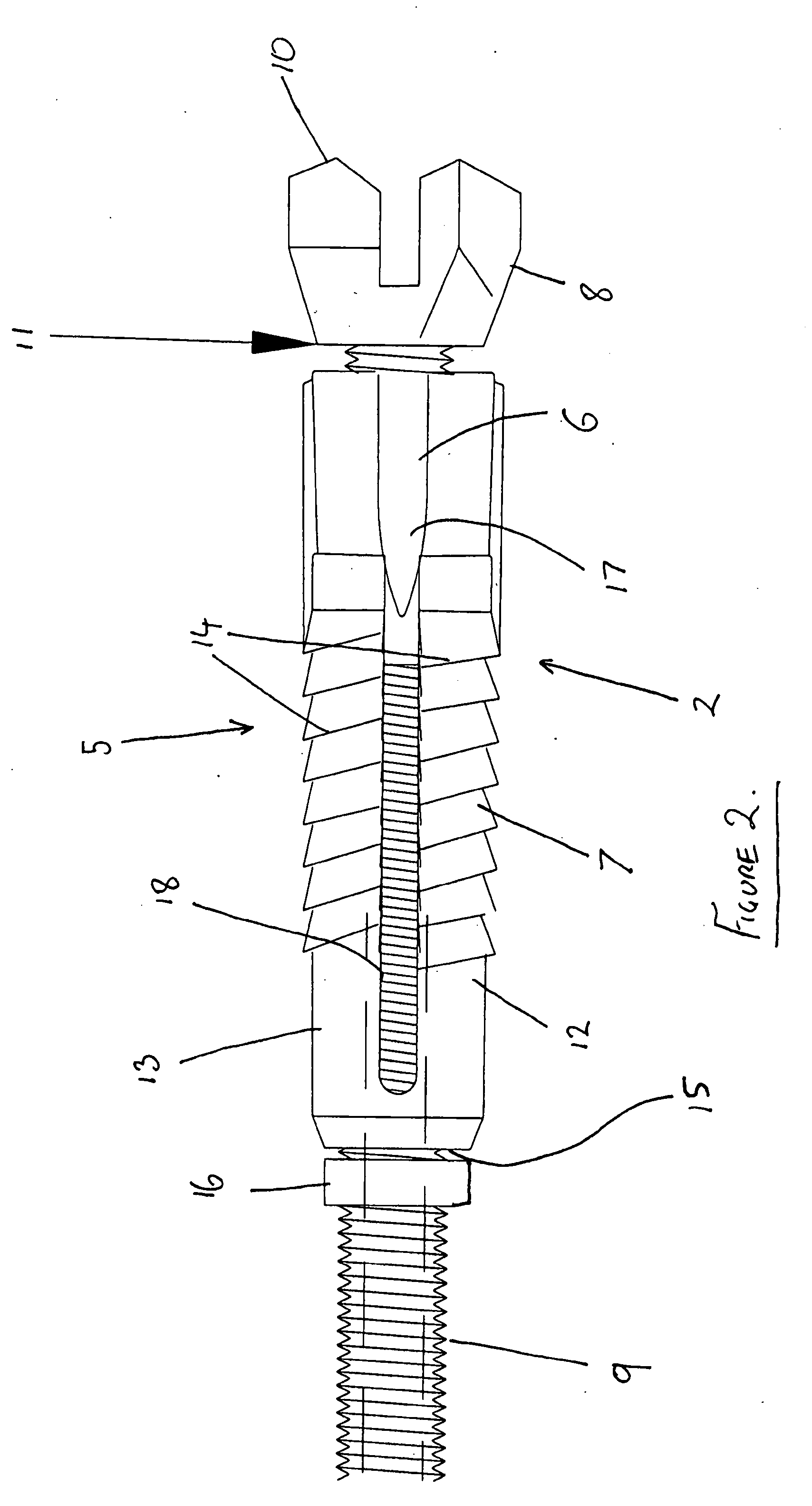

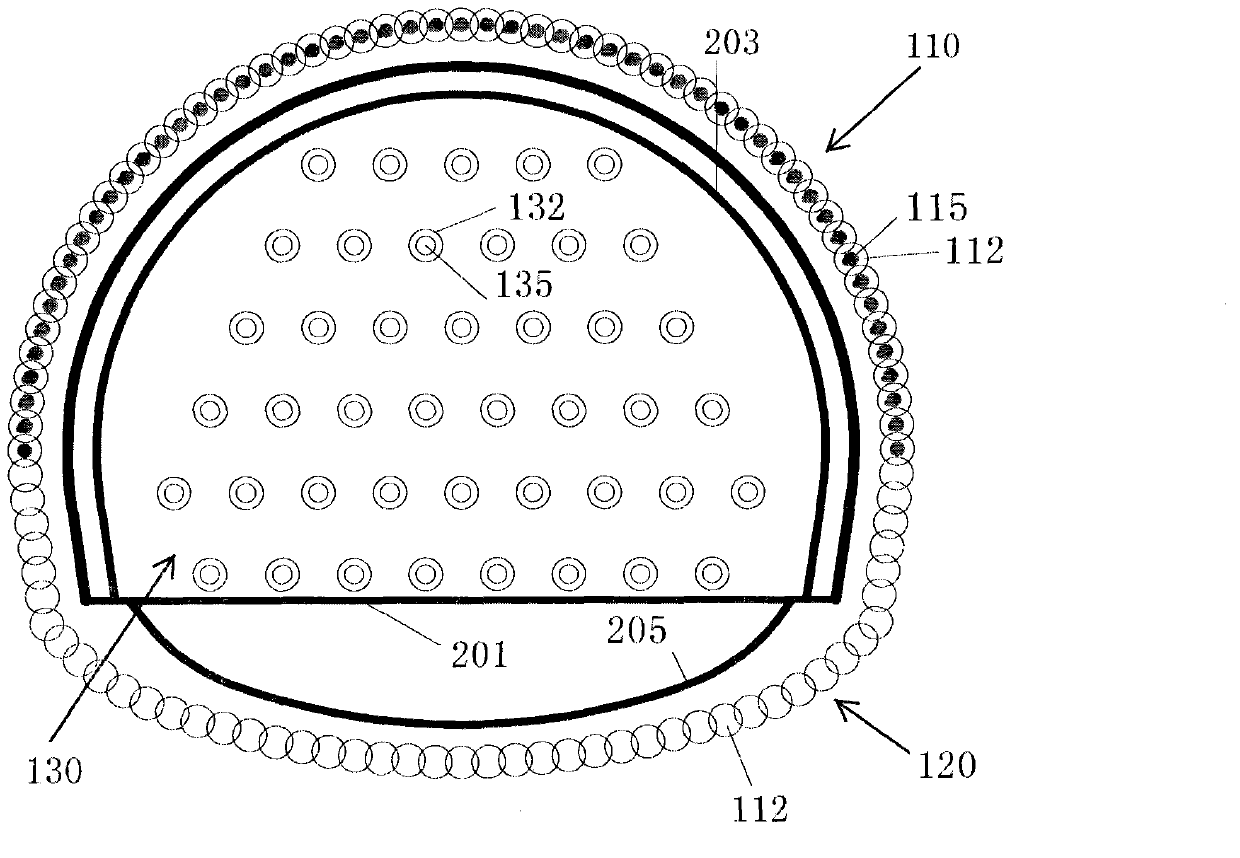

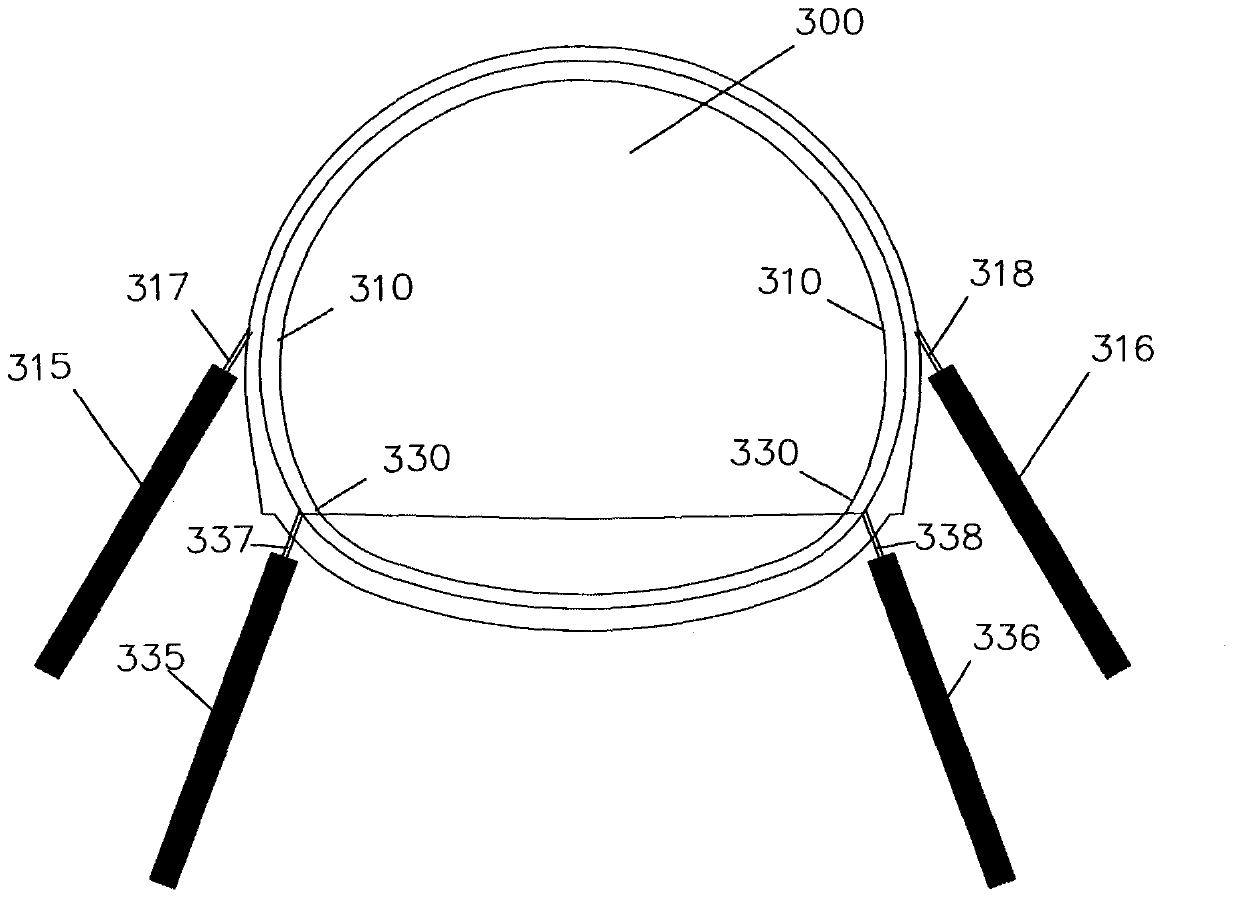

Yielding strata bolt

The present invention discloses a rock bolt having a tendon (1, 201) which is able to yield and thereby control movement of unstable rock strata into which the bolt is installed. The tendon has a portion which is provided with a grout slippage mechanism, preferably in the form of a tube (8) which surrounds the tendon. A two part grout anchor (10, 100, 200) is clamped to the tendon. The grout anchor is embedded in grout and is therefore essentially immovable. The tendon passing through the anchor is worked and thereby dissipates energy. The tendon can be either a multi-strand cable (1) or a solid bar (200). Various forms of anchor (10, 200) are disclosed with either complementary recess(es) (14) and protrusion(s) (15) or opposed protrusions (115) which form pinch point(s). A one piece grout anchor (300) is also disclosed.

Owner:FERGUSSON JEFFREY ROBERT

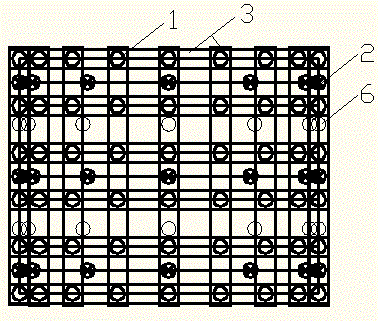

Supporting and reinforcing structure of coal mine tunnel and construction technology thereof

InactiveCN103195441AEven by forcePrevent weatheringUnderground chambersTunnel liningPre stressArchitectural engineering

The invention discloses a supporting and reinforcing structure of a coal mine tunnel and a construction technology thereof. The supporting and reinforcing structure of the coal mine tunnel comprises a lane, wherein a grid-shaped reinforced layer is arranged on the inner wall of the lane, an anchor rod is arranged on the grid node portion of the reinforced layer, the inner end of the anchor rod is anchored in surrounding rock of the lane, and an anchor plate and a nut of the anchor reinforced layer are arranged at the outer end of the anchor rod. A concrete spraying layer covered on the reinforced layer and arranged at the outer end of the anchor rod is further arranged on the inner wall of the lane, a grouting anchor rod is arranged in the surrounding rock of the lane, an anchor cable is further arranged in the surrounding rock of the lane, the inner end of the anchor cable is anchored in the surrounding rock of the lane, and the outer end of the anchor cable is anchored on the outer side of the concrete spraying layer through a tray and a tensioning lock. The supporting and reinforcing structure of the coal mine tunnel integrates the surrounding rock of the lane in cementing mode with the initiative supporting theory as the guidance, prestress is reserved in the rock body, and stress is released and superimposed slowly, so that self integral strength and stability of soft rock and coal body are improved, the surrounding rock in a release ring of the lane can form a structure relatively homogenous and stable, and the aim of reinforcing and protecting the soft rock lane can be achieved within a long time.

Owner:PINGDINGSHAN TIANAN COAL MINING

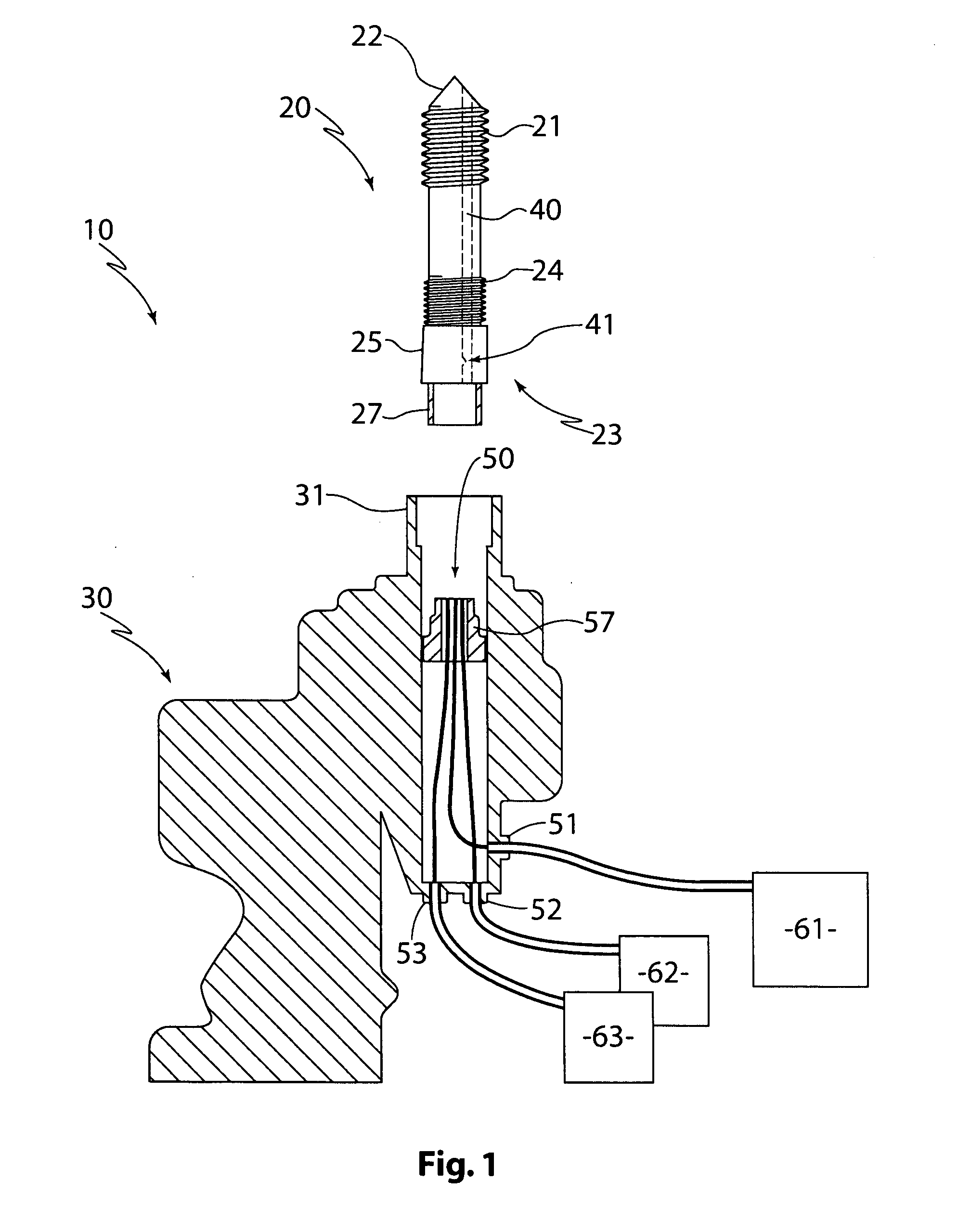

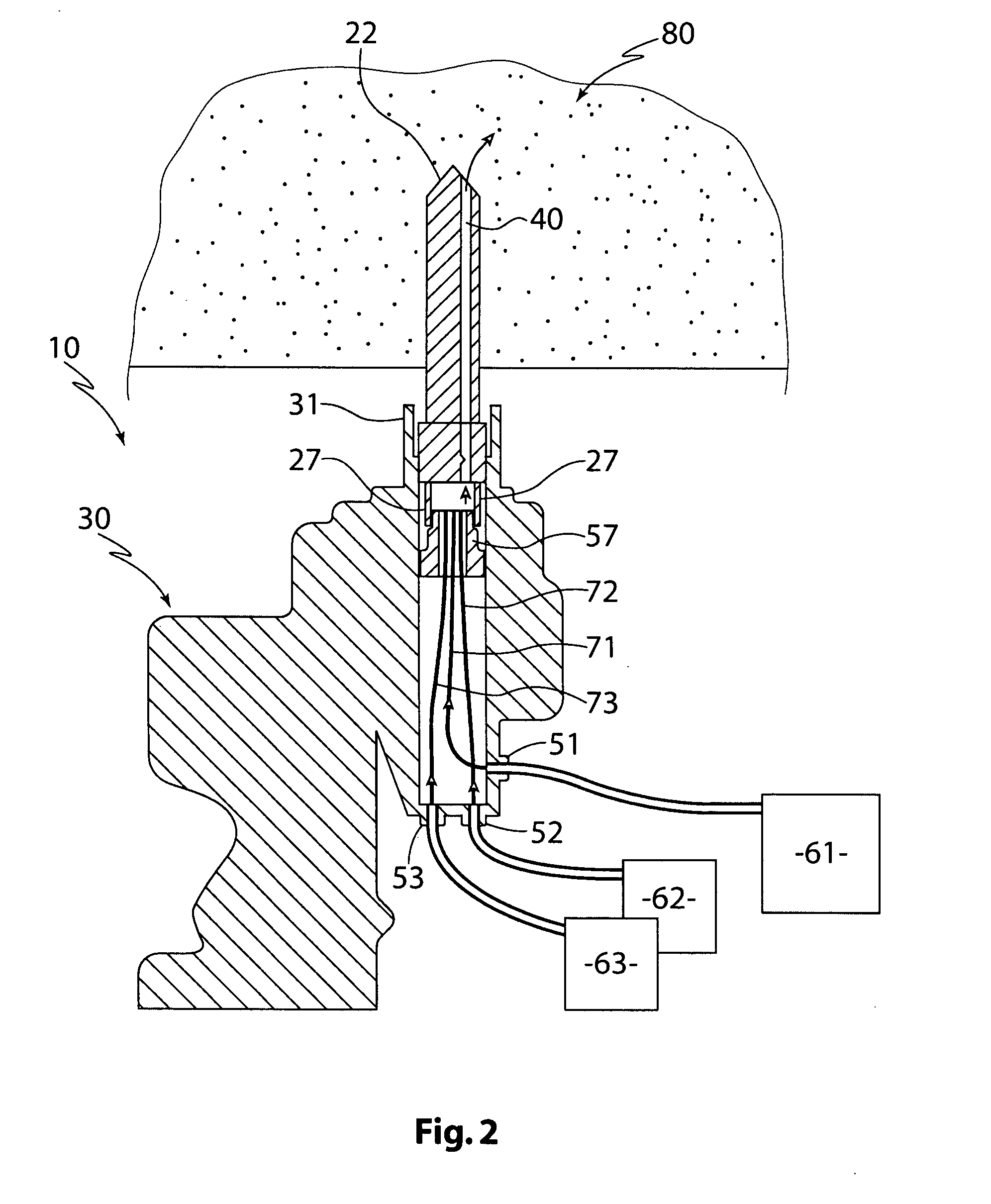

Self drilling rock bolting

The present invention relates to self drilling rock bolting. In particular, the invention concerns both a drilling apparatus for rock bolting, and a rock bolt for use with the drilling apparatus. The drilling apparatus comprises within it a fluid injector having an upper part that mates with a self-drilling rock bolt for boring a hole. The injector includes three fluid inlets, three fluid outlets in the upper part, and three fluid conduits extending from respective inlets to respective outlets. The self drilling rock bolt comprises an elongate body having a leading end with a cutting tip, and around the tip a thread with a coarse pitch. The bolt also has a trailing end with an integral collar for fluid connection to a channel that extends axially through the body of the rock bolt to the leading end. Above the collar is a thread with a fine pitch. In other aspects the invention concerns a system comprising the drilling apparatus in combination with a rock bolt and a method for rock bolting using the system. The invention has application, but not exclusively, to rock bolting to stabilise the roof and walls of underground coal mines.

Owner:ALMINCO

Construction method for overcoming deformation of anti-floating fixed diameter anchor head or expanded head anchor rod system

ActiveCN107044122AEliminate deformationSmall amount of deformationProtective foundationBulkheads/pilesPre stressRebar

The invention discloses a pressure bearing type fixed diameter anchor head or expanded head anchor rod prestress application method. Drilling is conducted to the design depth till rotary jet grouting or mechanical chambering construction can be developed, a pull rod of an anchor rod and a fixed diameter anchor head or an expanded head are placed, after the expanded head is arranged in place, the expanded head is expanded to the design size through an expanding mechanism, then, high-pressure grouting or concrete pouring is conducted, and pile forming is achieved in an expanded body section and a whole free section. Threaded steel bars to which prestress can be applied are adopted in the pull rod in the anchor rod, spiral stirrups and base bottom plate steel bars on a base are bundled, and collisions of the prestress steel bars are avoided in the bundling process. Lastly, a base concrete base bottom plate is poured by erecting a template.

Owner:JIANGSU GREEN RIVER ENVIRONMENTAL TECH CO LTD

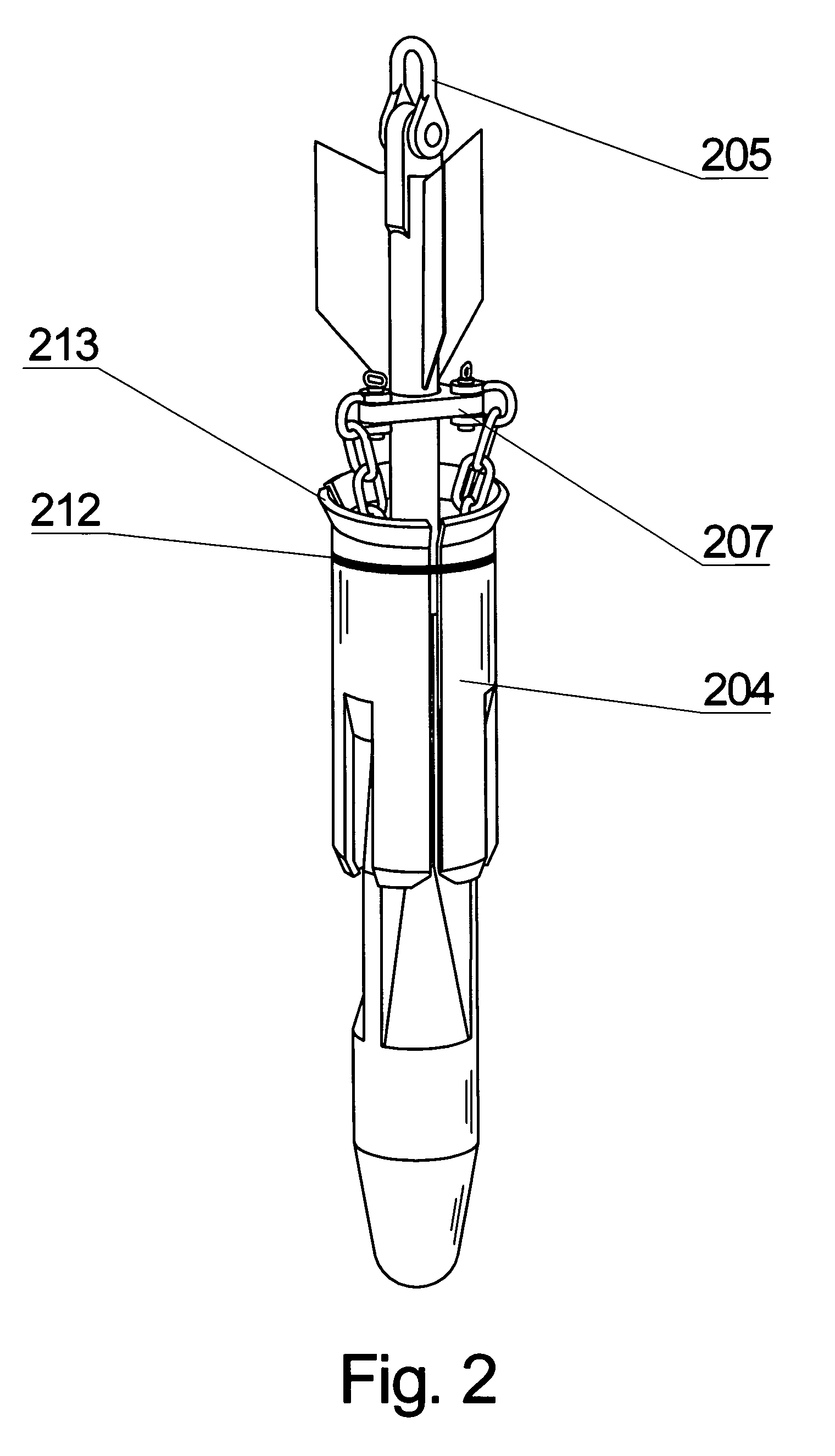

Rock bolt

The present invention relates to rock bolts which may be used in mining applications. The rock bolt of this invention includes a mechanical anchoring arrangement to facilitate retaining the rock bolt in a borehole, and also a drill bit to enable self drilling of the rock bolt. Rotation of the rock bolt about an axis of the rock bolt in a first direction causes the drill bit to drill into rock and to create a borehole to receive the rock bolt. Subsequently, rotation in the opposite direction actuates a mechanical anchoring arrangement to anchor rock bolt.

Owner:FCI HLDG DELAWARE

Top-cutting roadway coal-pillar-free mining method of close-range thin coal seam

ActiveCN103233740AAvoid destructionDoes not cause prominenceUnderground miningSurface miningShotcreteCoal pillar

The invention discloses a top-cutting roadway coal-pillar-free mining method of a close-range thin coal seam. The method comprises the following steps of: (1), excavating an upper crossheading roadway and a lower crossheading roadway; (2), mounting a grouting constant-resistance anchor rope and a grouting constant-resistance anchor rod without grouting at first, and a monomer hydraulic pillar, machining energy-accumulation presplitting top-cutting holes, and blasting to obtain presplitting cutting joints; (3), extracting an upper coal seam till unavailable; (4), allowing a mining field ejection plate to collapse along the shallow energy-accumulation presplitting cutting joints; (5), spraying a concrete spray layer to the rise side wall of the lower crossheading roadway, and grouting the grouting constant-resistance anchor rope and the grouting constant-resistance anchor rod; (6), extracting a lower coal seam till unavailable, and allowing the mining field ejection plate to collapse along the deep energy-accumulation presplitting cutting joints; (7), taking a roadway automatically formed at the original lower crossheading roadway as the upper crossheading roadway of a next mining surface; and (8), repeating steps (2) to (7). According to the method, by using the cutting joints formed by the energy-accumulation presplitting top-cutting holes for blasting the ejection plate, shallow breakage and deep breakage can be performed twice, and twice collapse of the mining field ejection plate is achieved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

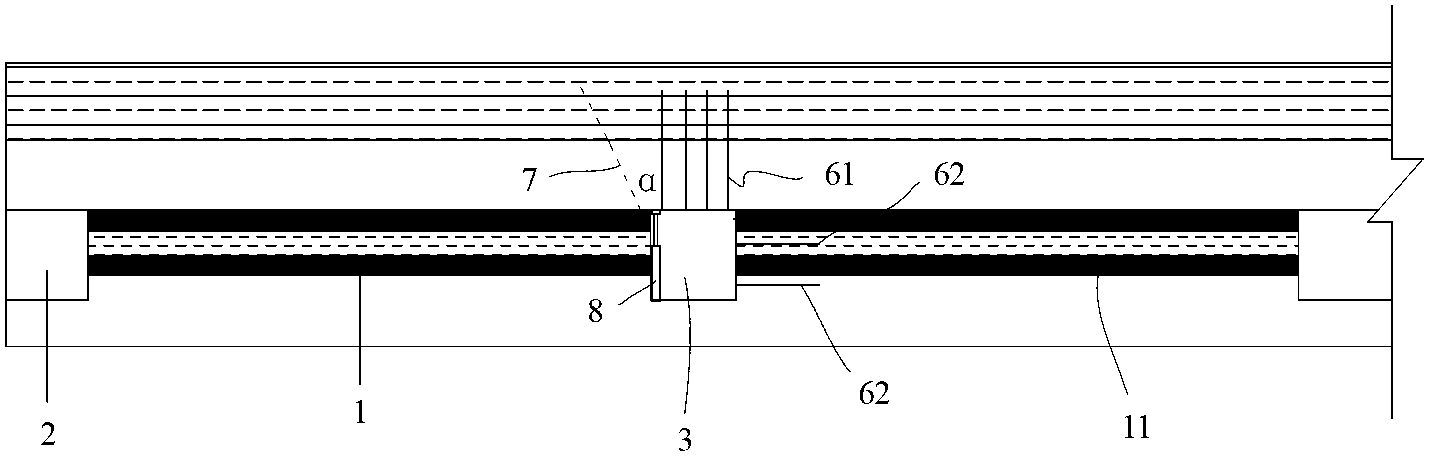

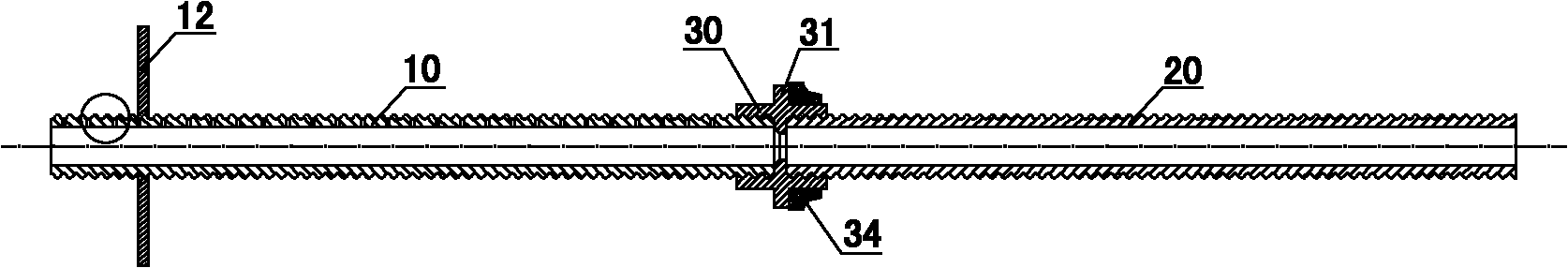

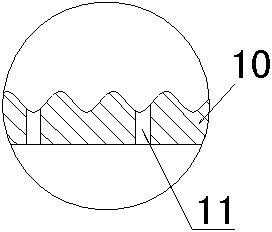

Drainage anchor rod, side slope protection engineering repairing and reinforcing structure and construction method

InactiveCN102155016AEfficient repairThe effect is long-lasting and stableFoundation repairExcavationsFiltrationStructural engineering

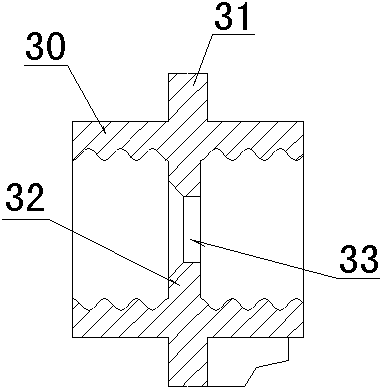

The invention discloses a drainage anchor rod, a side slope protection engineering repairing and reinforcing structure and a construction method; the side slope protection engineering repairing and reinforcing structure can reinforce the side slope protection engineering, also can effectively repair an inverted filtration system of the side slope protection engineering, obtains lasting and stable effect, has a simple structure and is easy to construct. The drainage anchor rod comprises a drain pipe (10) and an anchoring pipe (20), wherein the drain pipe (10) and the anchoring pipe can be axially detached or butted by a connecting member (30); small drain holes (11) are dispersedly arranged on the wall pipe of the drain pipe (10); and the external end part of the drain pipe (10) is connected with an external anchoring steel plate (12).

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Prefabricated shearwall having improved structural characteristics

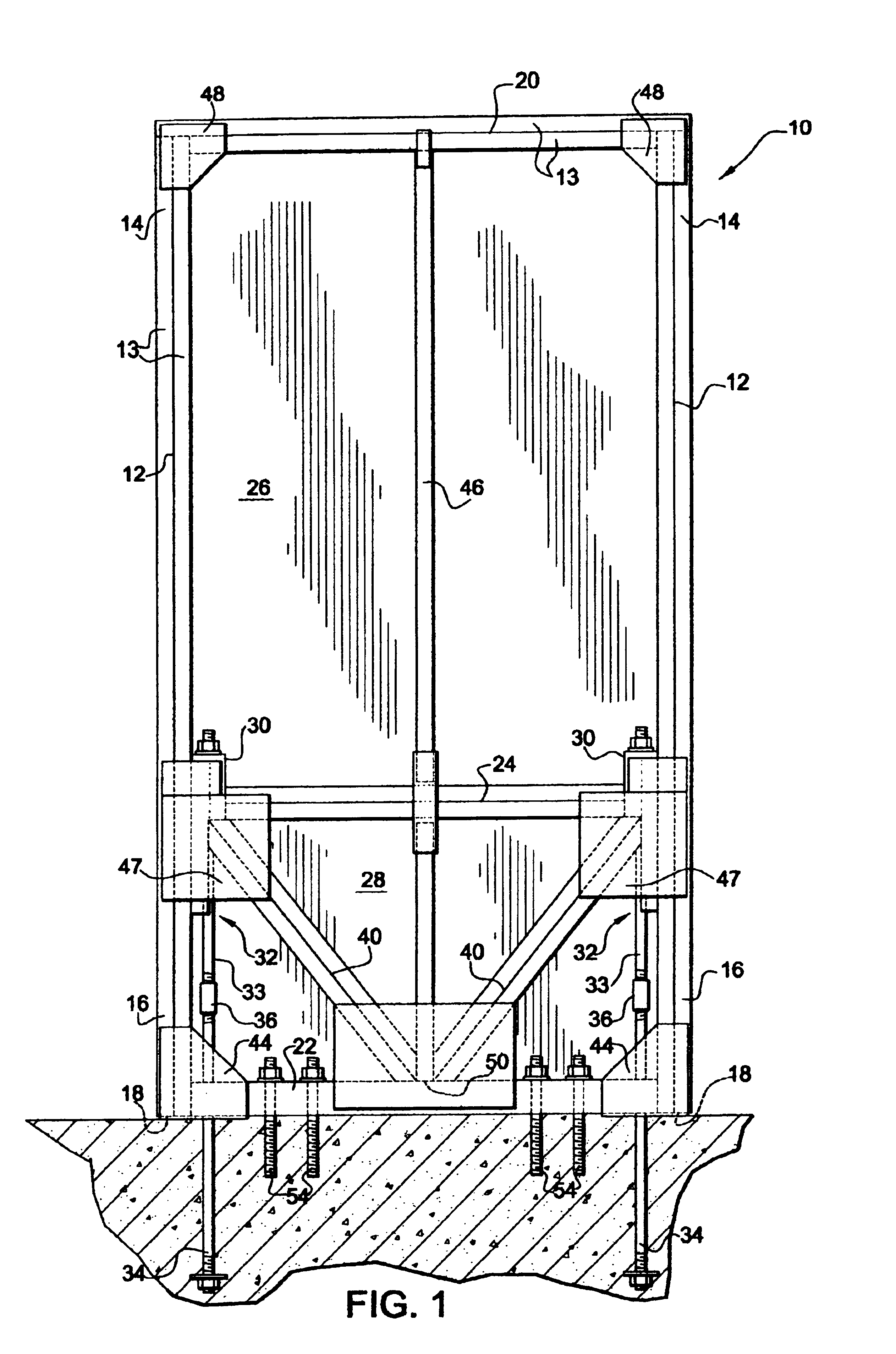

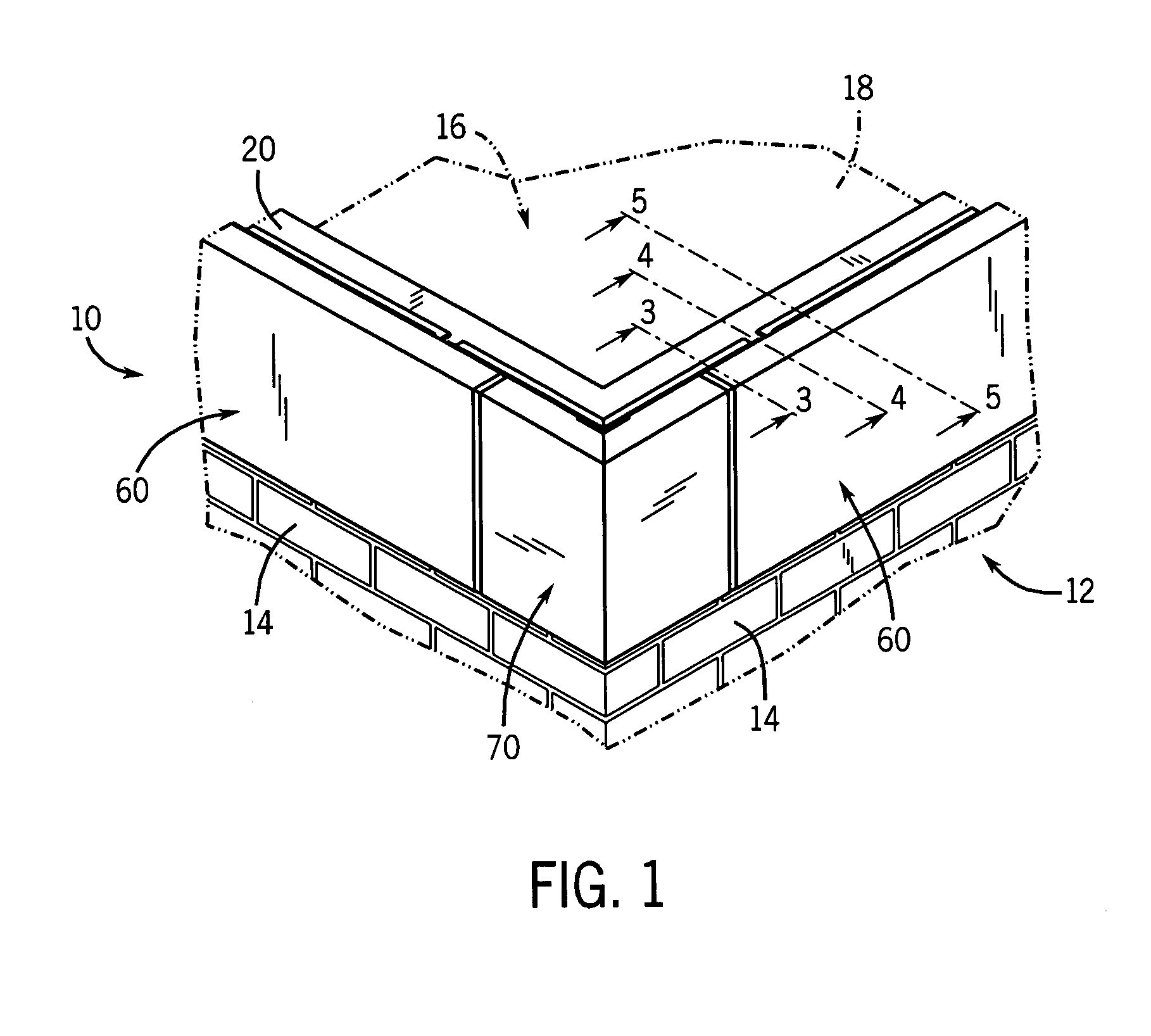

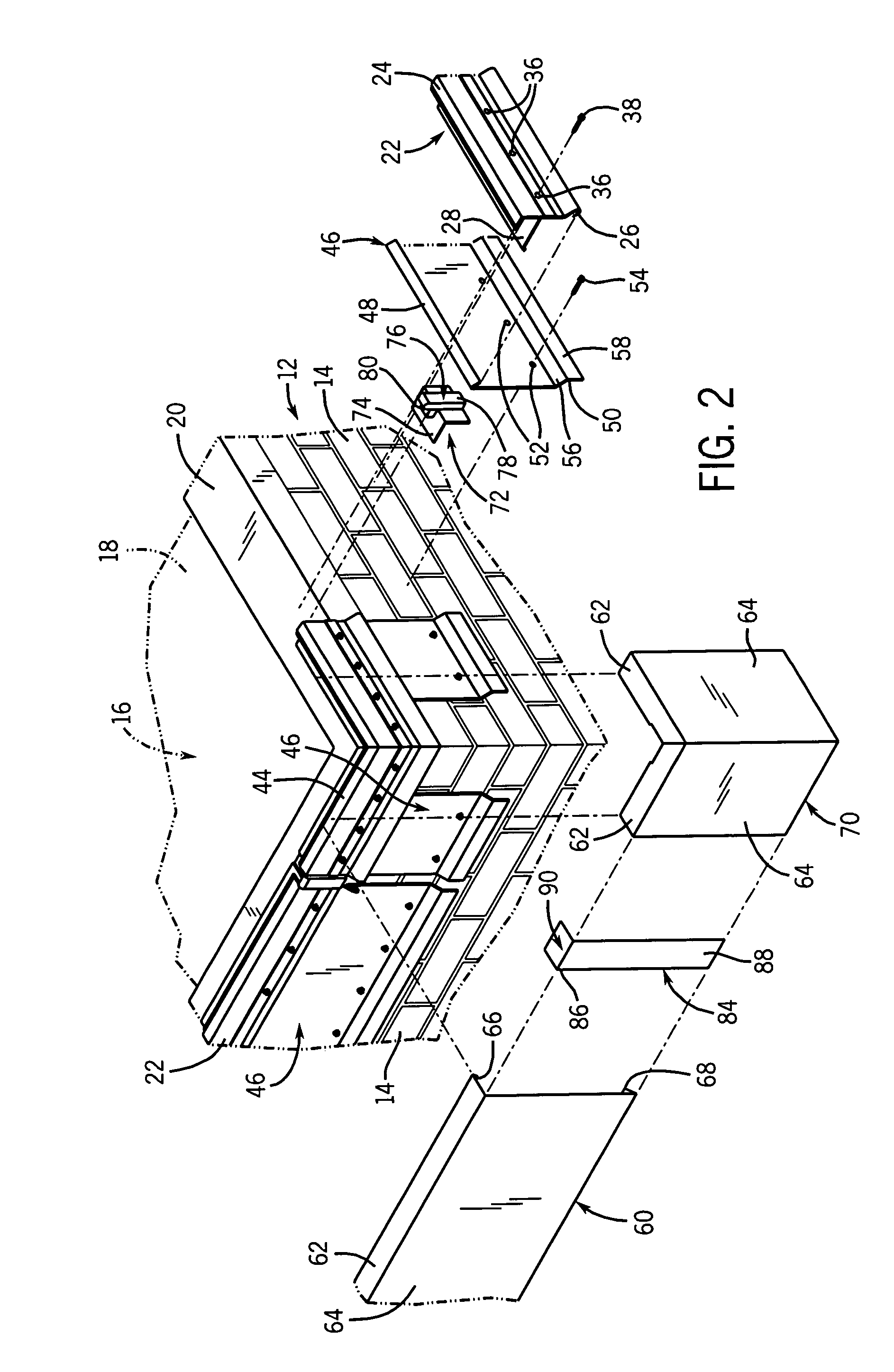

InactiveUS6931804B2Improve structural performanceVariable stiffnessBuilding roofsWallsEngineeringUltimate tensile strength

A novel prefabricated shearwall is disclosed with improved structural characteristics in terms of its ability to 1) transfer lateral loads to the foundation, 2) resist bending moments normally arising in conventional shearwalls between hold-down hardware and end posts or vertical framing members, 3) effectively diffuse stresses known to result in nail fatigue, and 4) reduce slippage between the bottom of the end posts and base in response to cyclic loadings. These superior properties result partly from its geometry in lower, or shear force transfer region, accompanied by thrust block / anchor rod assemblies to provide stiffness and strength over the lower portion of the end posts. Furthermore, specialized wrap-around connector plates that cover a portion of the bottom surface of these end posts also contribute to the enhanced prefabricated shearwall design.

Owner:SHEAR FORCE WALL SYST

Roof fascia with extension cleat

InactiveUS7451572B1Extend length of edgeIncrease the lengthRoof covering using slabs/sheetsRoof covering using tiles/slatesEngineeringRock bolt

A roof edging system includes an anchor bar, an extension cleat attachable to the anchor bar, and a cover plate applied over the anchor bar and extension cleat. The anchor bar may be of a generally uniform size and shape and the extension cleat may be of varying sizes. The anchor bar and extension cleat are secured to the exterior of the building using fasteners inserted through a number of apertures in each member. The engagement of the anchor bar with the roof provides a waterproof seal between a roofing membrane placed on the roof and the anchor bar. The extension cleat provides a means to vary the overall length of the assembly. A durable cover plate may then be attached over the anchor bar and extension cleat to provide an aesthetically pleasing appearance to the periphery of the roof of the building.

Owner:METAL ERA LLC

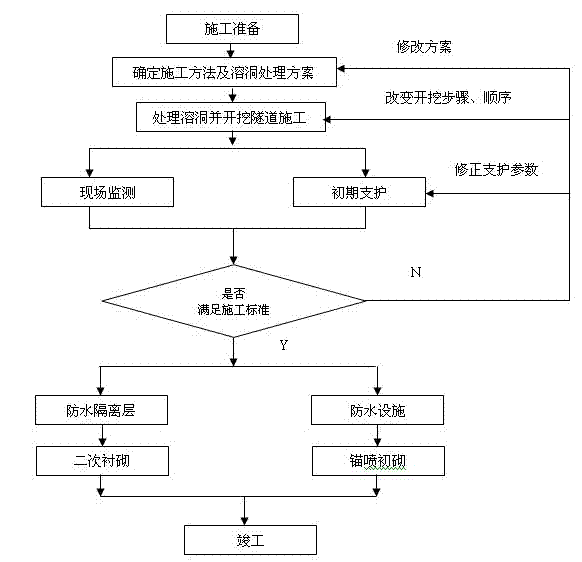

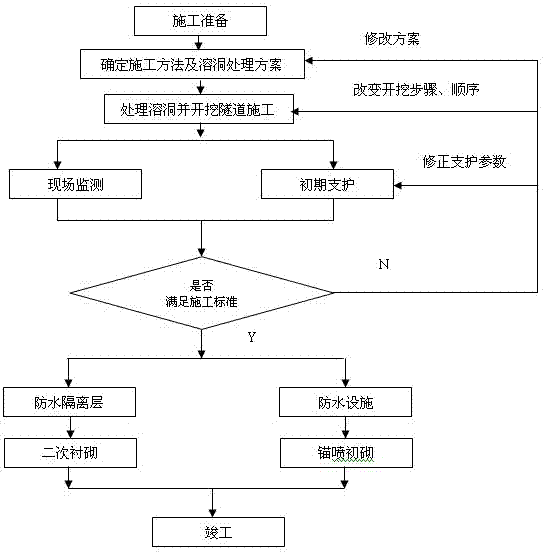

Construction technology for allowing tunnel to pass through ultra-large karst cave

ActiveCN102383806ADo not delay the construction periodQuality assuranceUnderground chambersFoundation engineeringShotcreteMesh reinforcement

The invention relates to a construction technology for allowing a tunnel to pass through a karst cave, and in particular relates to a construction technology for allowing a tunnel to pass through an ultra-large karst cave. The technology at least comprises the following steps of: 1) performing simple bridge treatment on the underground part of the karst cave; 2) performing primary support, namelyarranging a support wall at one side of the karst cave; 3) forming parallel guide holes; 4) performing bottom treatment; 5) treating the tunnel hole body at the inlet section of the karst cave; 6) filling C25 early strength sprayed concrete within 1 meter at the top of the support wall, and arranging phi 50 small grouting conduits with the lengths of 3 meters in the concrete, wherein the distancebetween the small conduits is 1.5 meters; 7) supporting the arch part and the side wall surrounding rock of the karst cave by adopting phi 22 cartridge anchor rods arranged in a plum blossom shape and at a distance of 150cm*150cm, hanging phi6 reinforcing meshes at a distance of 15cm*15cm, and spraying C25 early strength concrete with the thickness of 15 centimeters; 8) treating the accumulation of the karst cave; and 9) monitoring and measuring when the tunnel passes through the ultra-large karst cave. The construction technology for allowing the tunnel to pass through the ultra-large karst cave is simple in process, convenient for construction, low in cost, scientific, effective, energy-saving and environmentally-friendly.

Owner:CCCC SHEC DONGMENG ENG CO LTD

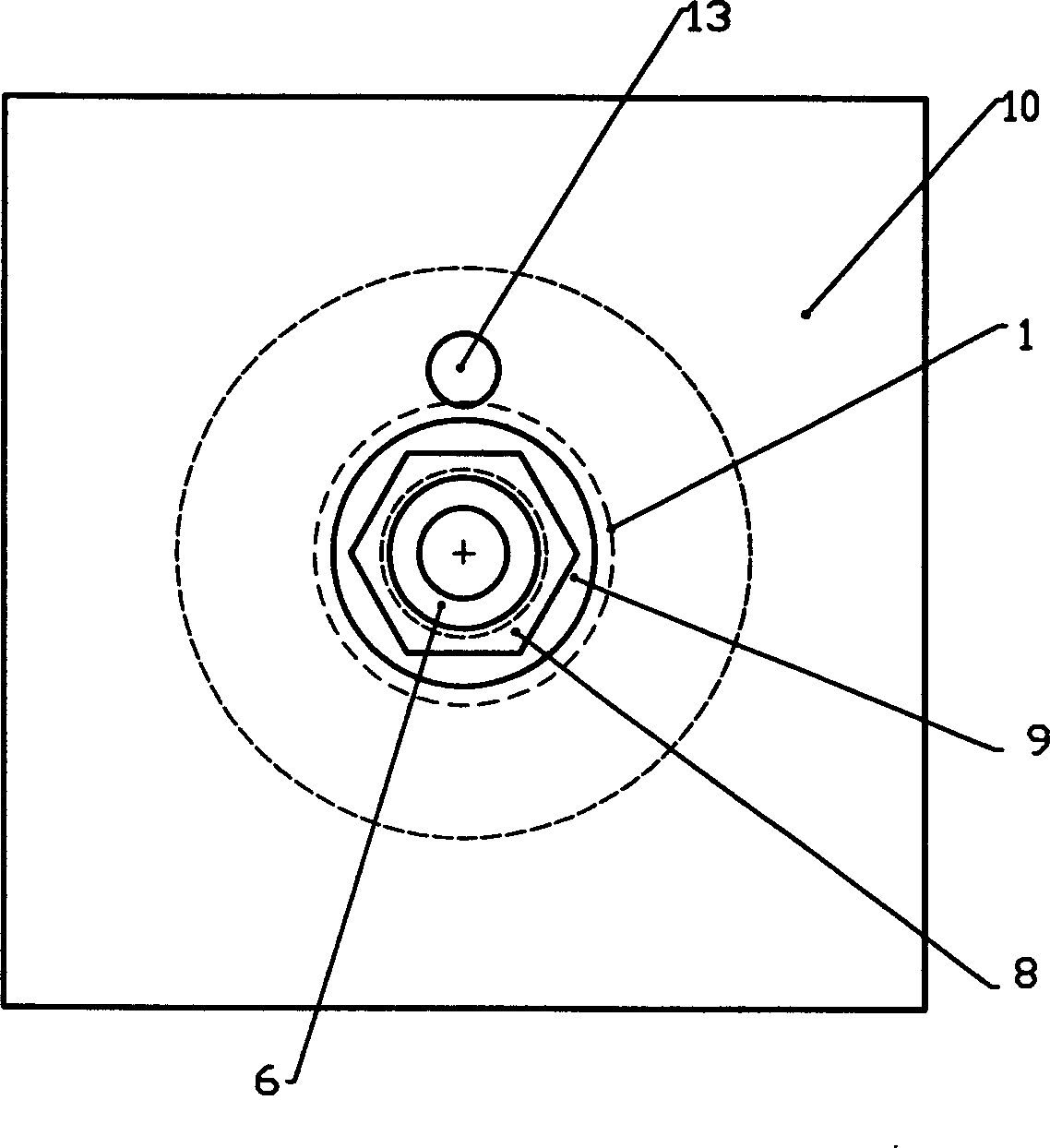

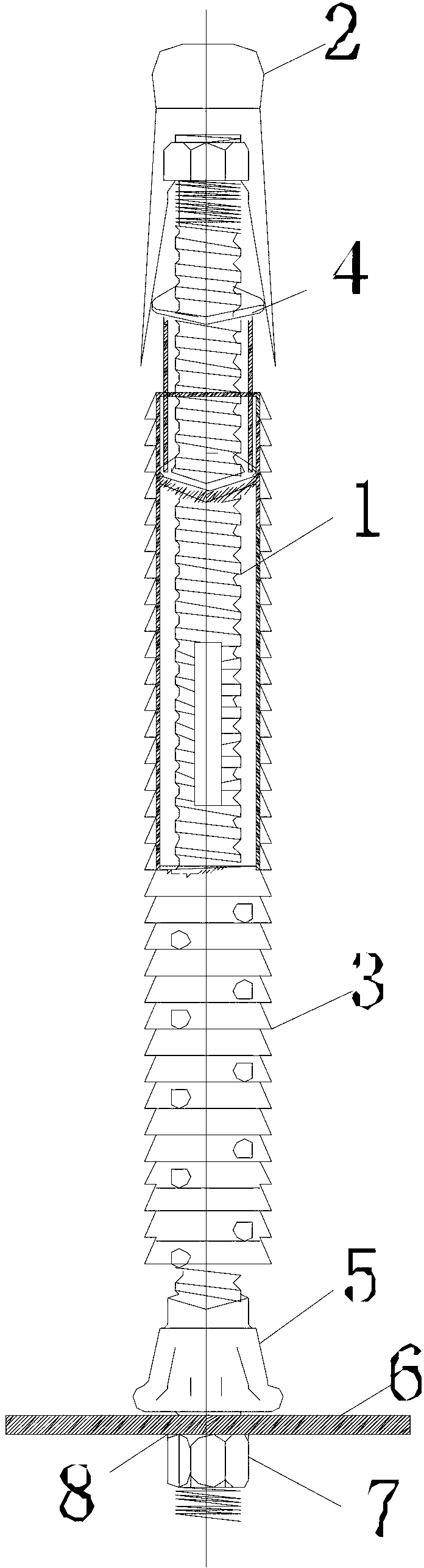

Novel expansion shell inverted wedge type grouting anchor rod

InactiveCN103133026ATo achieve unityControl deformationAnchoring boltsScrew threadMechanical construction

The invention provides a novel expansion shell inverted wedge type grouting anchor rod comprising an anchor rod body, an expansion shell type anchoring head, an inverted wedge type outer sleeve, a transmission ring, a grouting blocking plug, an anchoring base plate and nuts. The anchor rod is characterized in that the expansion shell type anchoring head and the anchoring base plate are located at two ends of the anchor rod body and are fixed through the nuts, the inverted wedge type outer sleeve is sleeved outside of the anchor rod body, the bottom of the transmission ring is arranged in the inverted wedge type outer sleeve, and the top end of the transmission ring contacts the expansion shell type anchoring head. The anchor rod body is a hollow metal rod element provided with left-hand threads. The expansion shell type anchoring head is small-end-up and provided with a flap-shaped structure which can open at a certain angle in an expansion mode, and can form barbs invertedly piercing in a rock body when stressed and expanded. The surface of the inverted wedge type outer sleeve is provided with inverted wedge type grooves in the annular direction. The novel expansion shell inverted wedge type grouting anchor rod has the advantages of being fast in anchoring, easy to install, capable of grouting and the like, facilitates mechanical construction, and has good anchoring effects on soft, expanded and cracked surrounding rock.

Owner:ANHUI UNIV OF SCI & TECH

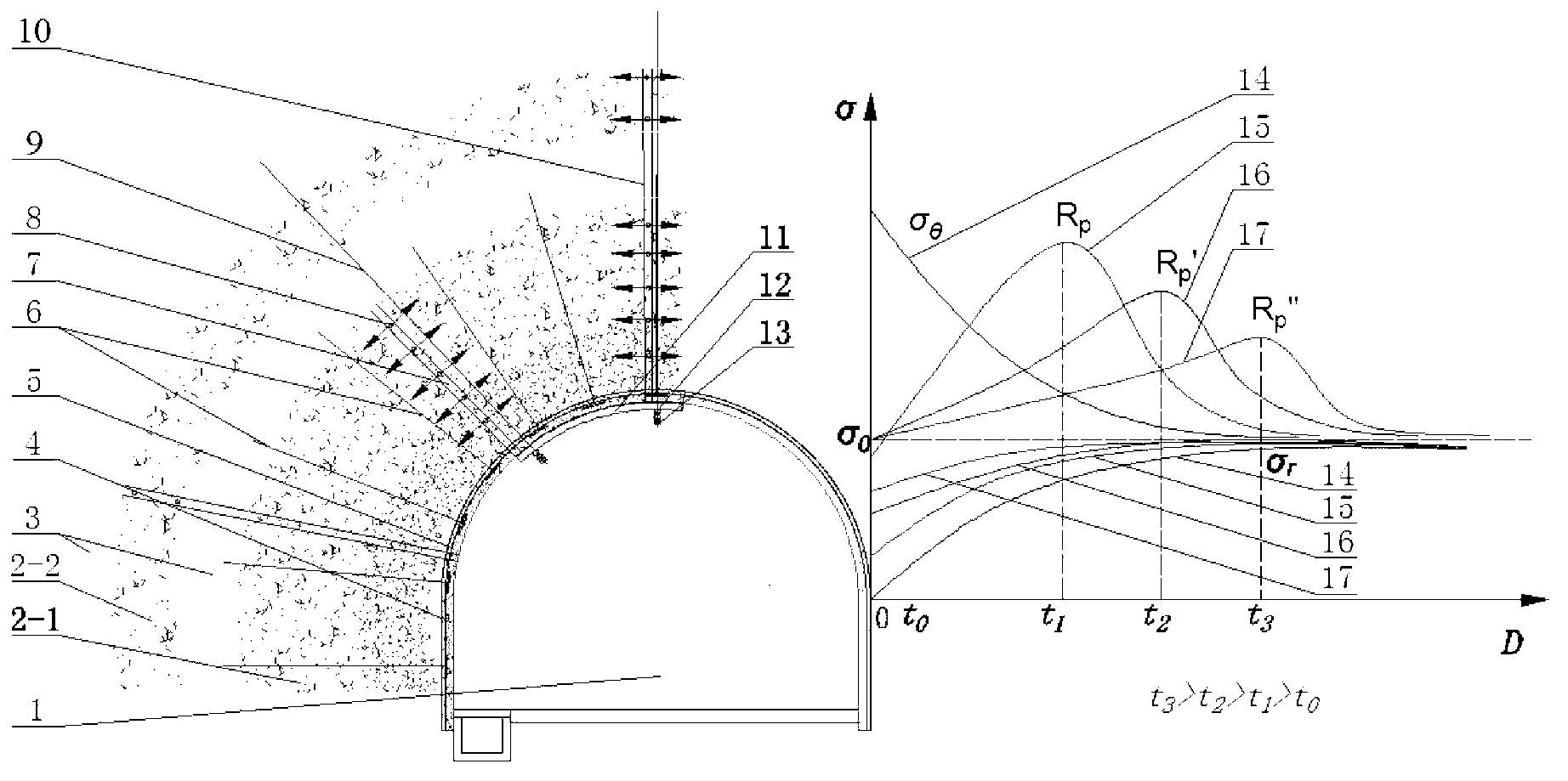

Bolting-grouting integrated support method for zonal disintegration of deep roadway surrounding rock

The invention specifically discloses a bolting-grouting integrated support method for zonal disintegration of deep roadway surrounding rock, and the method comprises the following steps of: (1) after the roadway is excavated, immediately shotting concrete to close the surrounding rock, employing a high-pretightening force overstrength anchor bolt for supporting in the first disintegration zone, and arranging a steel bar net on the inner wall of the roadway surrounding rock and shotting concrete again; (2) applying a pretightening force anchor cable on the top plate of the roadway surrounding rock such that the anchoring end of the anchor cable is located in the deep intact rock mass, arranging a steel I-beam closely to the surrounding rock, passing the anchor cable through the shotcrete, the steel I-beam and a yielding ring and fixing the anchor cable on the inner wall of the roadway surrounding rock by using an anchor cable lock, thereby realizing coupling and supporting of the anchor bolt and the anchor cable; and (3) according to the monitoring result of the zonal disintegration of the surrounding rock, performing the delayed anchor bolt support for about 20-30 days, and performing grouting reinforcement on each disintegration zone by virtue of long and short combined injection pipes or a hollow sectional spiral grouting anchor bolt. The bolting-grouting integrated support method is capable of effectively performing bolting-grouting integrated reinforcement on the disintegrated surrounding rock of the deep roadway and thereby obviously enhancing the stability of the roadway.

Owner:SHANDONG UNIV

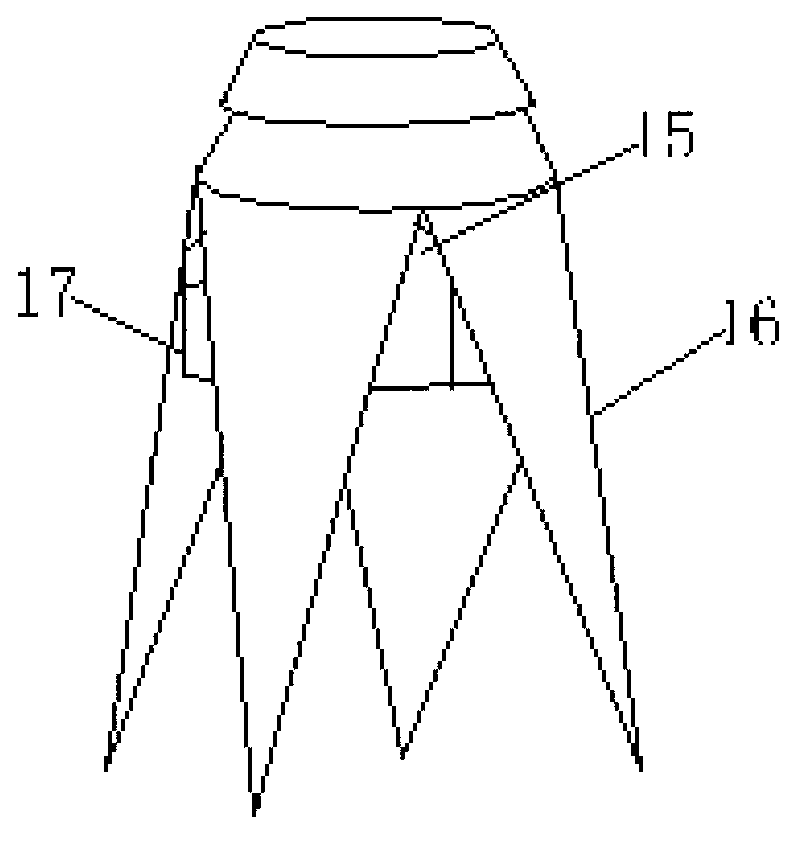

Flexible umbrella supporting anchor bolt and method for supporting soil slope thereby

ActiveCN104179178AIncrease anchoring forceConstruction quality is easy to ensureExcavationsBulkheads/pilesGeogridRock bolt

The invention relates to a flexible umbrella supporting anchor bolt and a method for supporting a soil slope thereby. An end ring and an end circular connector are fixedly disposed at one end of a round anchor bolt. A spring circular connector and a middle ring are fixedly disposed in the middle of the round anchor bolt. A lower circular connector adjacent to the right side of the middle ring movably sleeves the round anchor bolt. A drag umbrella surrounding the round anchor bolt comprises reacting plates evenly arranged, pull rods and compression springs. One end of a flexible pull rope is fixed to a round hole arranged in the other end of the round anchor bolt. More than one flexible umbrella supporting anchor bolt is connected with a soil high slope protective structure, composed of a geogrid mesh, a vegetation protective layer and a retaining wall, through the flexible pull ropes, and a whole for firmly and reliably anchoring and protecting the soil high slope is formed. The umbrella reacting plates are connected with the protective structural mesh through the flexible pull rope, anchoring force is greatly higher than that of a traditional anchor bolt, anchoring effect is more reliable, and engineering cost can be decreased by 50-60%.

Owner:NANCHANG INST OF TECH

Even-grouting structure of coal mine tunnel and construction technology thereof

InactiveCN103195442AChange cohesionChanging the internal friction angleUnderground chambersTunnel liningSlurryRock bolt

The invention discloses an even-grouting structure of a coal mine tunnel and a construction technology thereof. The even-grouting structure of the coal mine tunnel comprises a lane, wherein a concrete spraying layer is arranged on the inner wall of the lane, a grouting anchor rod for filling reinforcing slurry into surrounding rock so as to form a reinforcing assembly arch on the outer side of the lane is arranged in the surrounding rock of the lane, the inner end of the grouting anchor rod is communicated with a crack in the surrounding rock of the lane, the outer end of the grouting anchor rod protrudes out of the concrete spraying layer, grouting anchor cables are further arranged at the top of the lane and in the surrounding rock on two sides of the lane, one end of each grouting anchor cable is anchored in the surrounding rock, and the other end of the grouting anchor cable is anchored on the outer side of the concrete spraying layer. Slurry is filled in cracks in the surrounding rock of the lane for reinforcing, the grouting is performed according to the softness and broken degree and the crack development degree of the rock, and repeated reinforcing and cementing are performed, so that cohesion and inner friction angles of the surrounding rock can be fundamentally changed, the surrounding rock in a broken rock zone of the lane can be in a relatively homogeneous and stable state, and the reinforcing assembly arch even in stress is formed on the outer side of the lane.

Owner:PINGDINGSHAN TIANAN COAL MINING

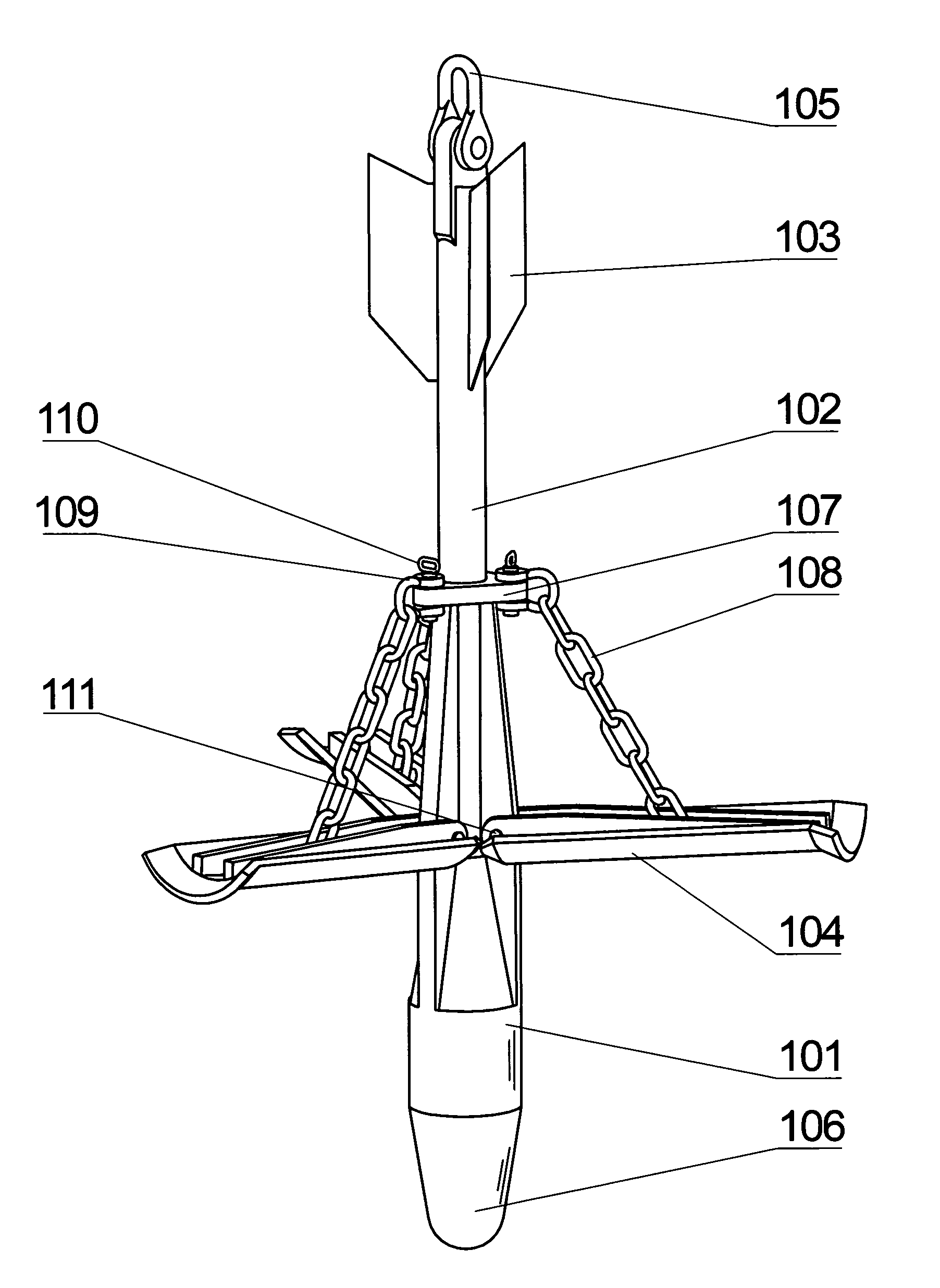

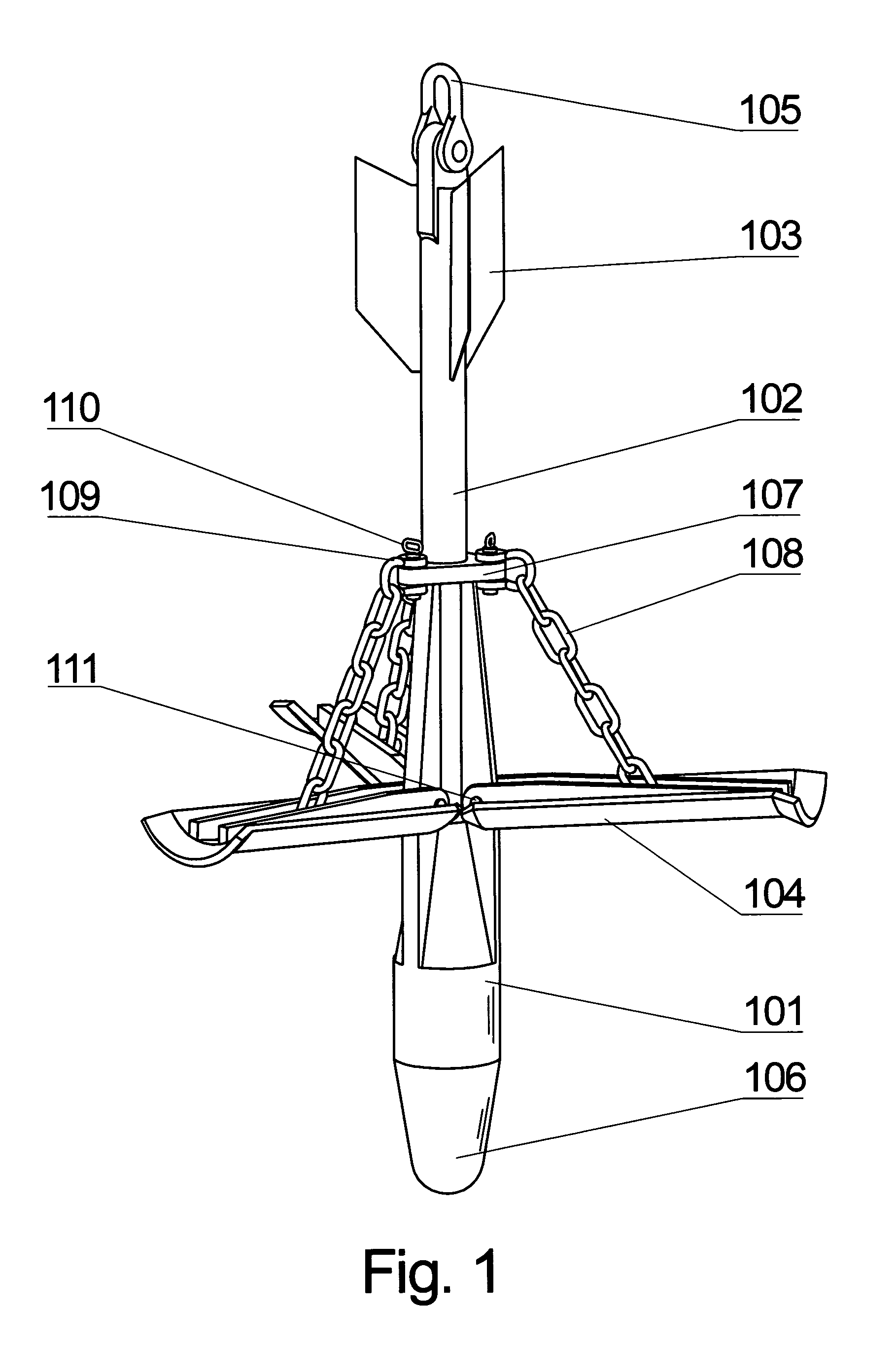

Folding torpedo anchor for marine moorings

The present invention comprises a deepwater anchor that combines the high holding capacity of a plate anchor with the simple installation procedures associated with torpedo anchors. The complex embedding procedure typical for plate anchors is avoided. Instead, the anchor is installed by allowing it to free-fall through the water and then impact into the seabed. After penetrating the seabed, a pull on the anchor line causes the deployment of initially folded flukes. In their deployed positions, one or more flukes or plate-like structures extend perpendicularly toward the anchor shank, and function similar to conventional plate anchors. As a result of the fluke deployment, the holding capacity of the anchor against uplift loads is significantly greater than with a conventional torpedo anchor. Another aspect of the invention relates to the modular construction of a torpedo anchor, wherein the properties of an anchor can be adapted to the specific conditions determined at the deployment site. Still another aspect of the invention relates to fast, inexpensive procedures for installing a torpedo anchor in a desired operational environment.

Owner:MUEHLNER EDMUND

Construction method for mechanical hole reaming of anchor rod

InactiveCN1963043AShorten the lengthImprove carrying capacityBulkheads/pilesDrilling machines and methodsCarrying capacityPre stress

The invention involves an anchorage method to reinforcing and maintaining the layer of rock and soil, namely the construction method of producing the prestress anchor bolt using the mechanical reaming reamer. It includes drilling, reaming, washing and slip casting, the slurries are wrapped with the prestress dabber together and are solidified to forming the anchor bolt. The second slip casting is needed after the first slip casting according the design requirements; the second slip casting adopts high pressure splitting casting pipe or many pipes. The construction method of the invention applies to ground layers with different soil strata, it can work in the direction of horizontal angle is 0~90degree, it is equipped with cylinderin volumes and conical reaming volumes along the length of the anchor bar; it can ream only once, and can ream many times or for many volumes, and they are connected with each other for a whole to increasing the contact area between the anchor bolt and the rock or soil. Because of the combination of the effect of anchor bolt end bearing and the effect of friction, it doubles the carrying capacity of anchor bolt and correspondingly shortens the length of the anchor bolt, so it has significant economic benefits.

Owner:CHINA JINGYE ENG

Construction method for deformation control via horizontal whirling jet grouting of long cantilever in soft-rock tunnel

InactiveCN103306687AImprove stabilityControl deformationUnderground chambersTunnel liningGlass fiberEngineering

The invention discloses a construction method for deformation control via the horizontal whirling jet grouting of a long cantilever in a soft-rock tunnel. The method comprises the following steps of: (1) drilling on the periphery of a dug outline, carrying out the whirling jet grouting while retreating a drill stem, and lowering a first profile component after the whirling jet grouting to form a first profile pile body; (2) repeating the step (1) to construct a first curtain system; (3) drilling on a tunnel face designed in a tunnel, carrying out the whirling jet grouting while retreating the drill stem, lowering a second profile component after the whirling jet grouting to form a second profile pile body; (4) repeating the step (3) to construct a second core earth reinforcing system; (5) carrying out the mechanical digging and initial supporting on a large section; (6) drilling in the arch springing position of middle and lower steps obliquely towards the lower direction of the tunnel at 30-45 degrees, lowering a third profile component to form a third profile pile body; and (7) repeating the step (6) to construct a locking whirling jet grouting pile stabilization system. According to the construction method, the advanced reinforcement of a horizontal whirling jet grouting pile with a highly strong tunnel outline, the binding and deforming effect of a tunnel face glass fiber anchor stem, and the anchoring of the locking whirling jet grouting pile are utilized, and the deformation of rock-soil is effectively controlled.

Owner:北京中铁瑞威基础工程有限公司

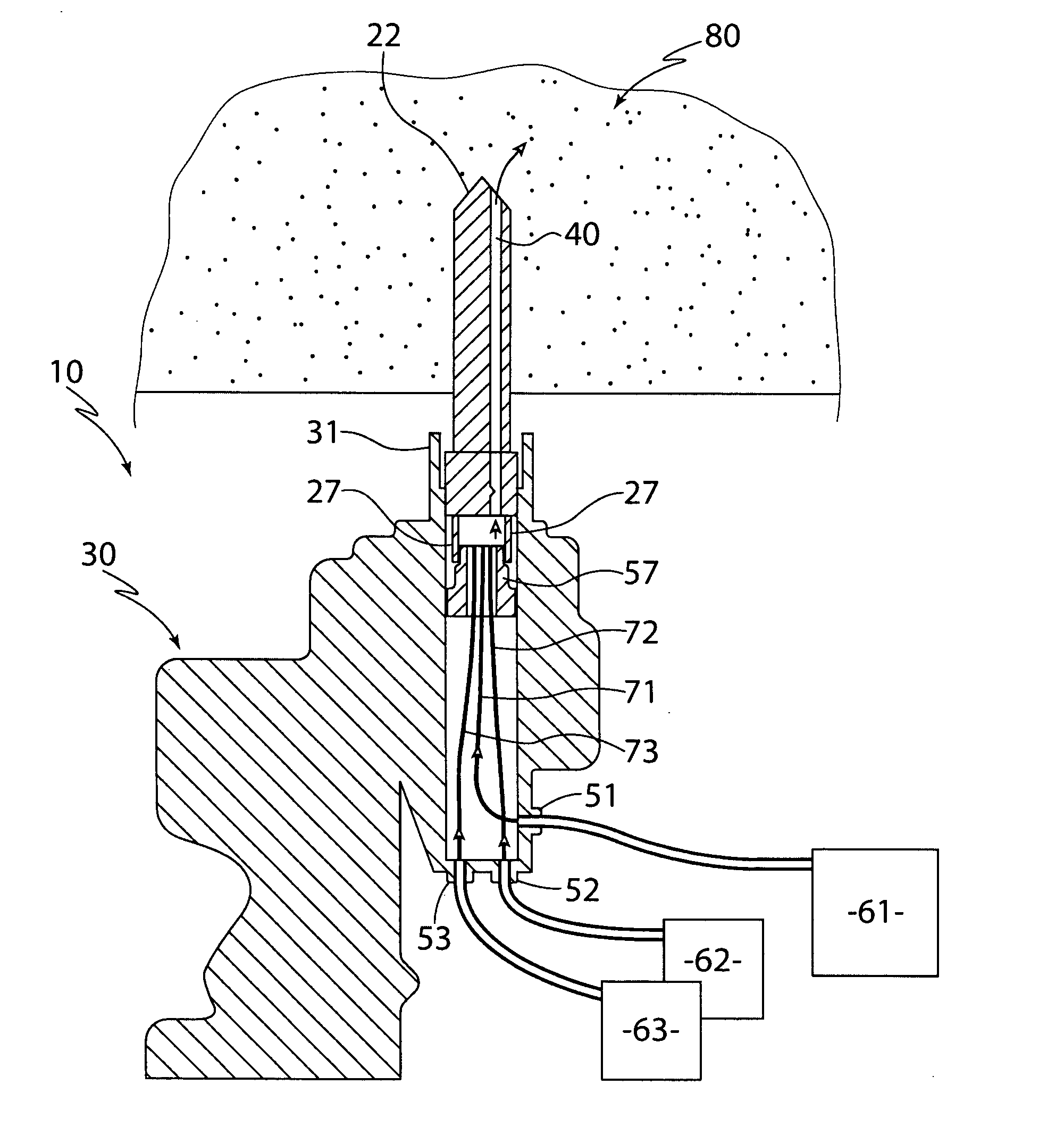

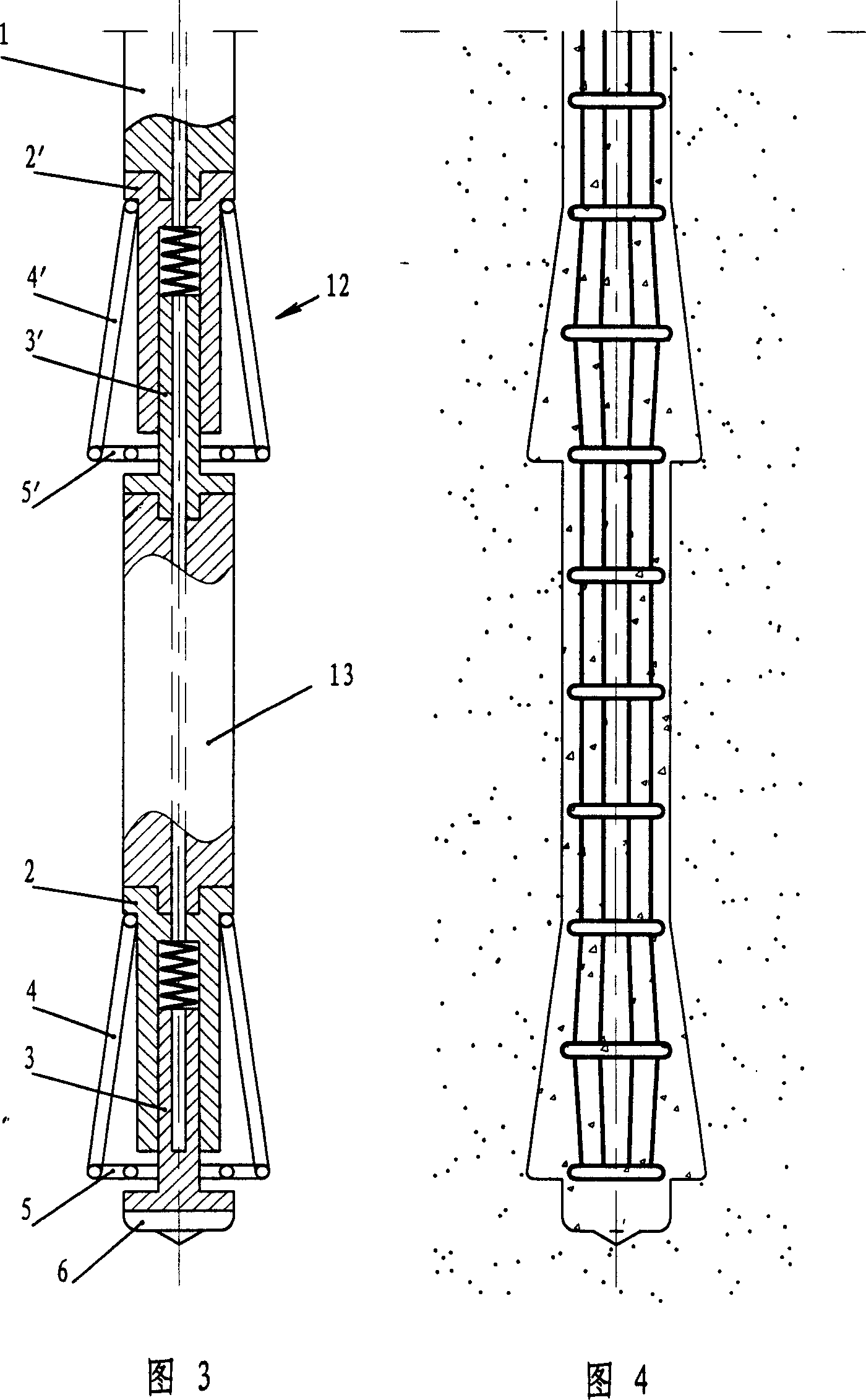

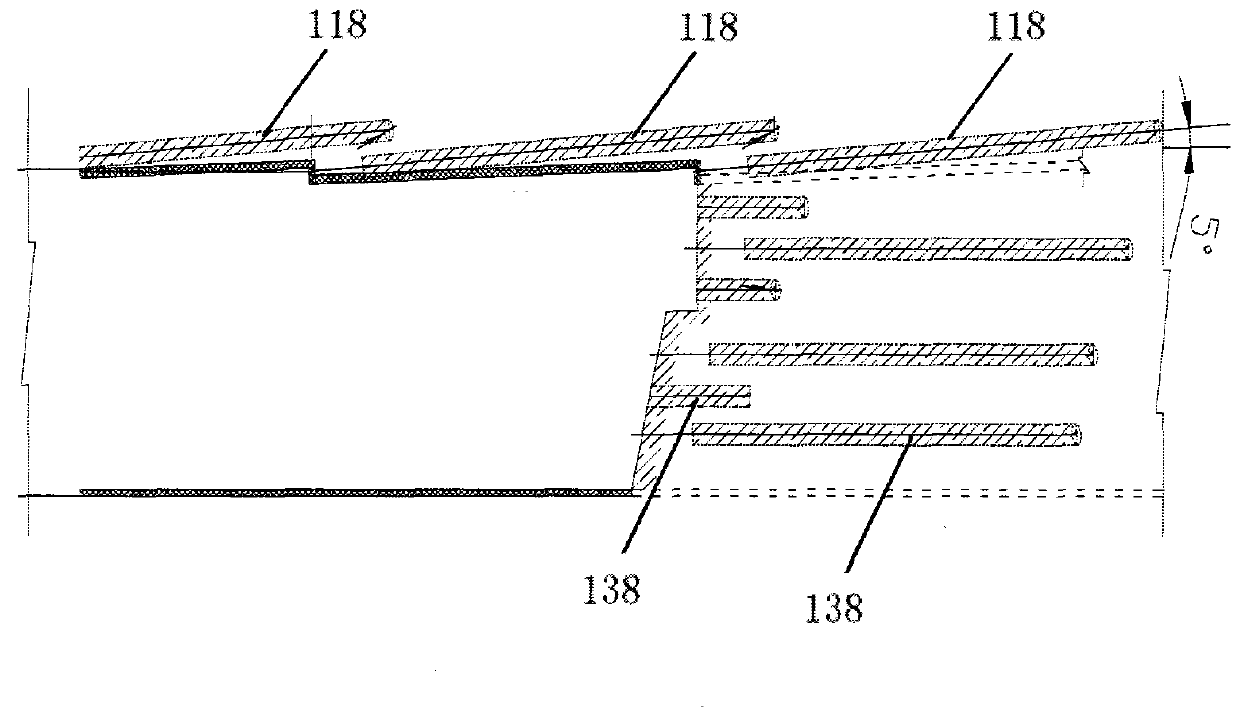

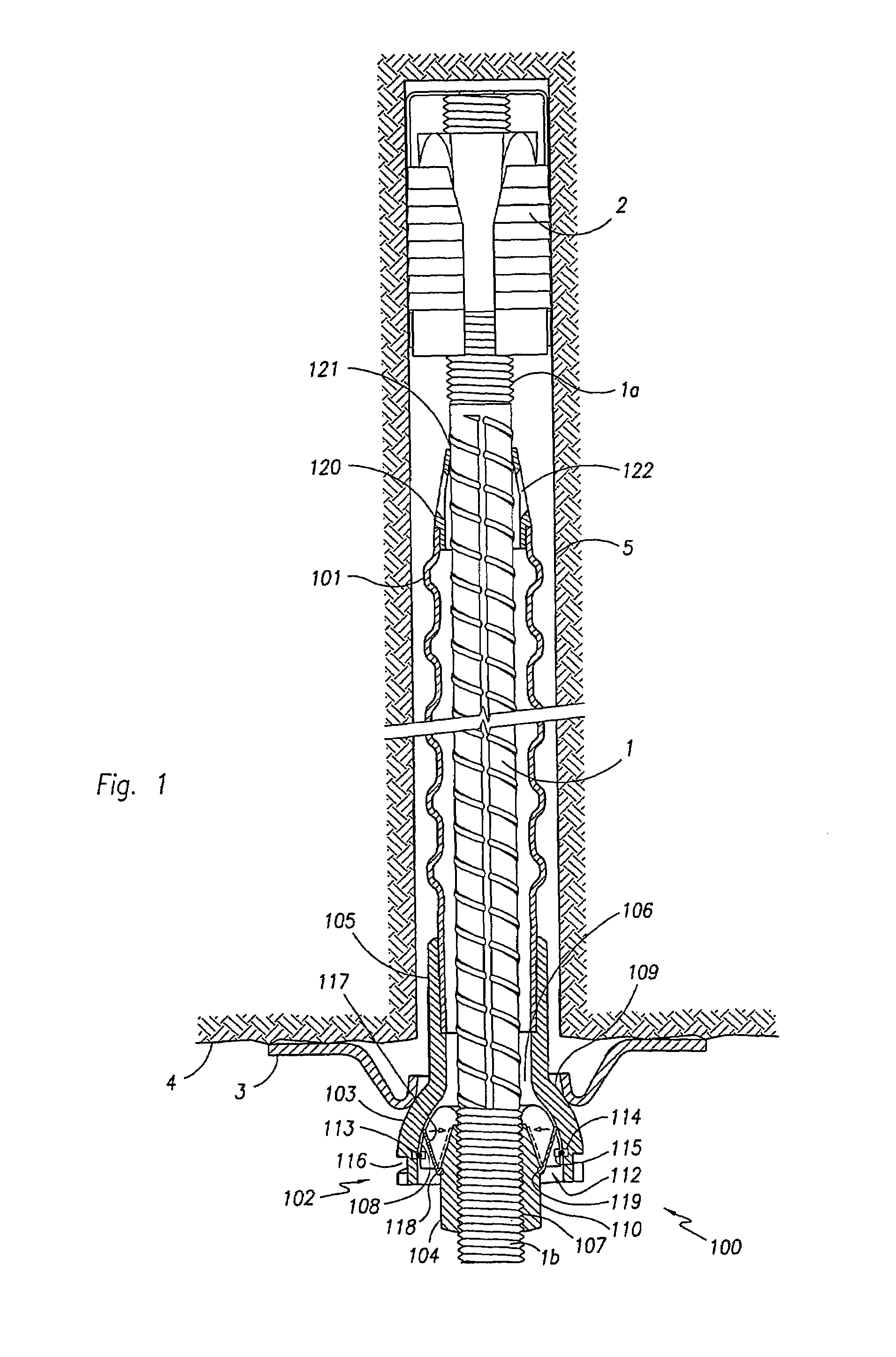

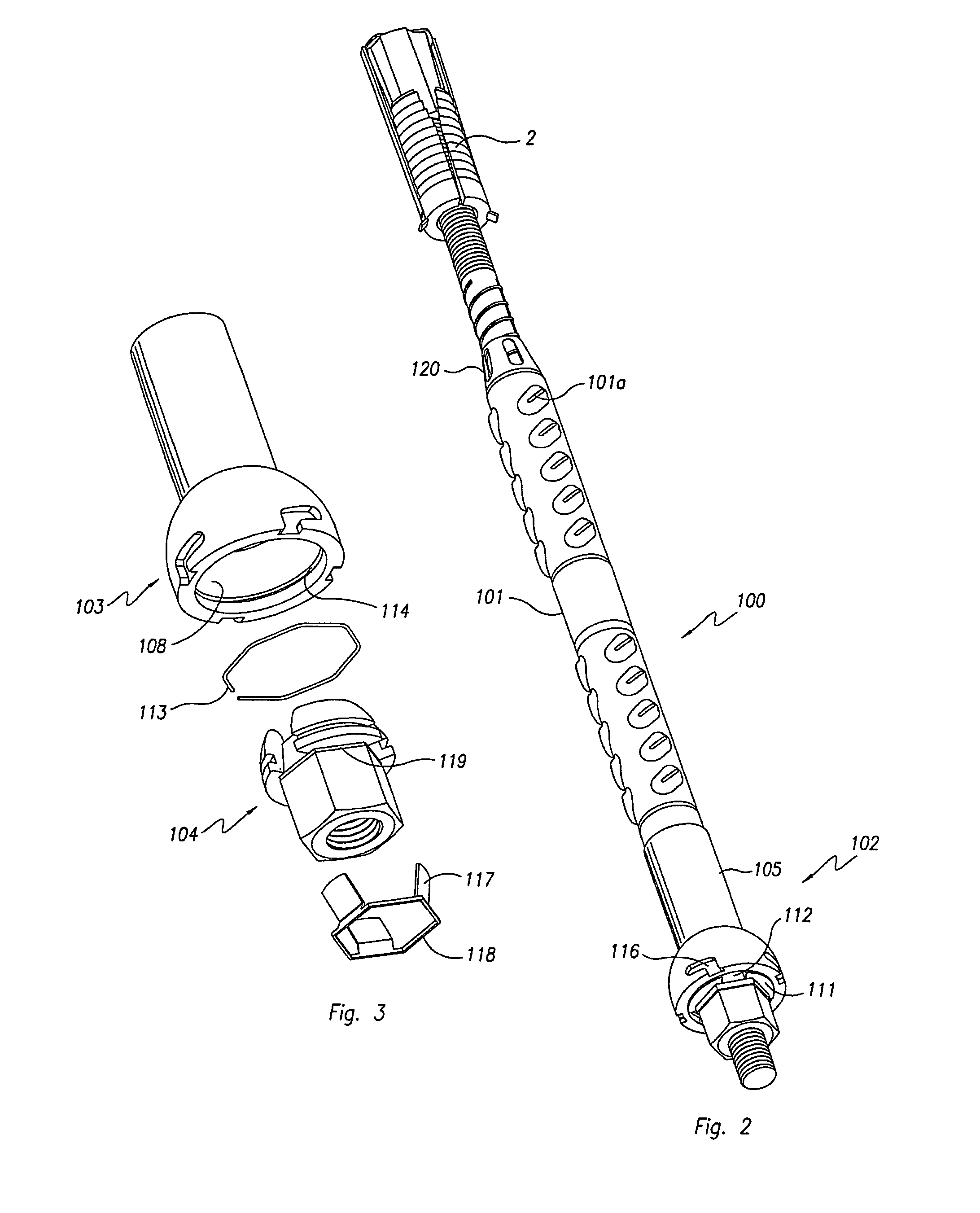

Rock bolt post grouting apparatus

An apparatus (100) for post-grouting a rock bolt (1) has an elongate sleeve (101) adapted to receive a rock bolt (1) with a first end (1a) thereof extending beyond the sleeve first end (101a) and a second end (1b) thereof extending beyond the sleeve second end (101b). An end fitting (102) is attached to the sleeve second end (101b) and has a central aperture (106, 107) for receiving the rock bolt (1). Grout passages (112) communicate the exterior of the end fitting (102) with the interior of the sleeve (101). A seal means (117) is displaceable between open and closed positions so as to seal the grout passages (112). The seal means (117) is biased towards the closed position at which the grout passages (112) are substantially sealed. Injection of grout into the end fitting (102) via the passages (112) deflects the seal means (117) to the open position enabling flow of grout through the passages (112) and into the sleeve (101).

Owner:DYWIDAG SYST INT GMBH (DE)

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com