Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2834results about How to "Small amount of deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

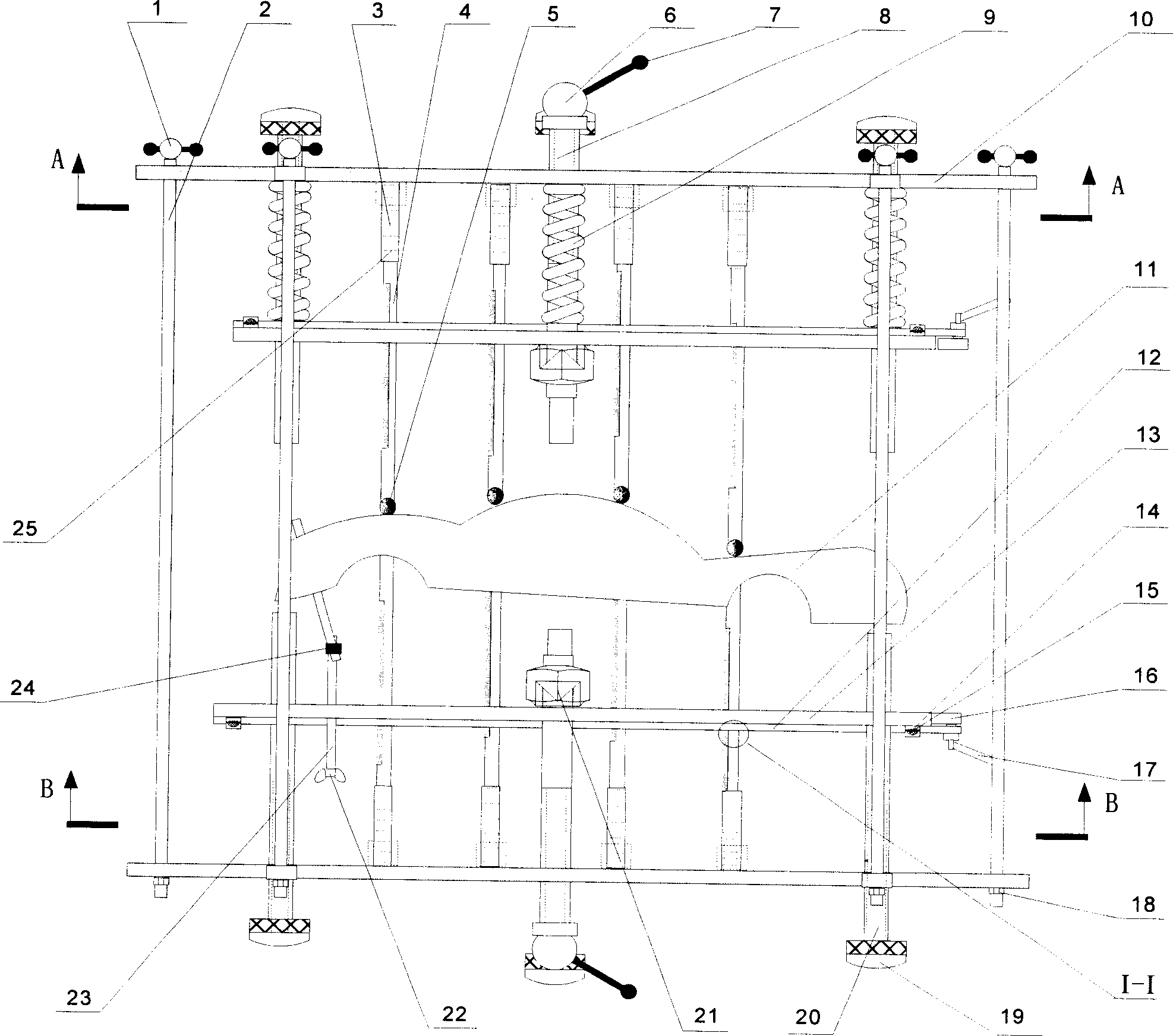

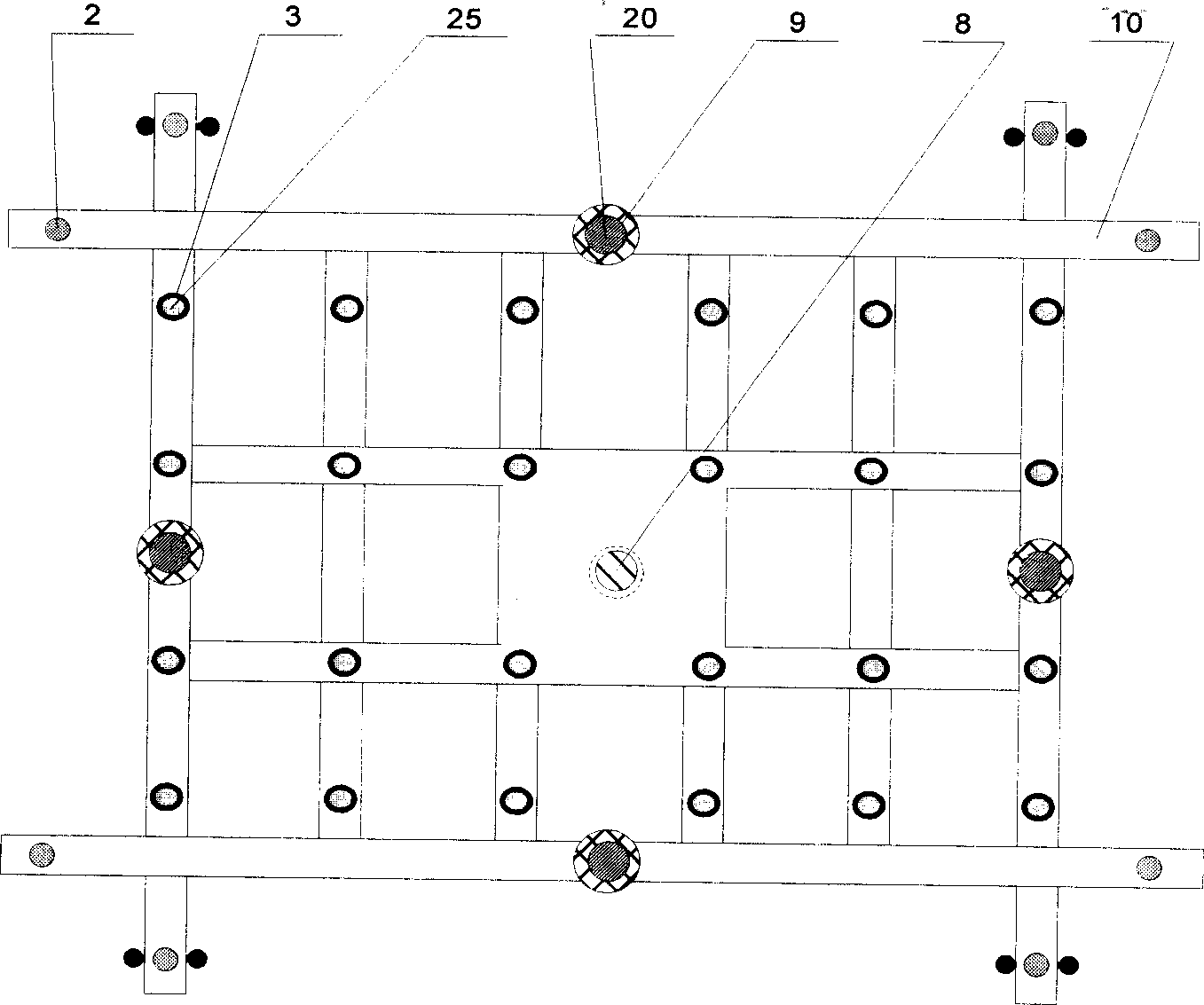

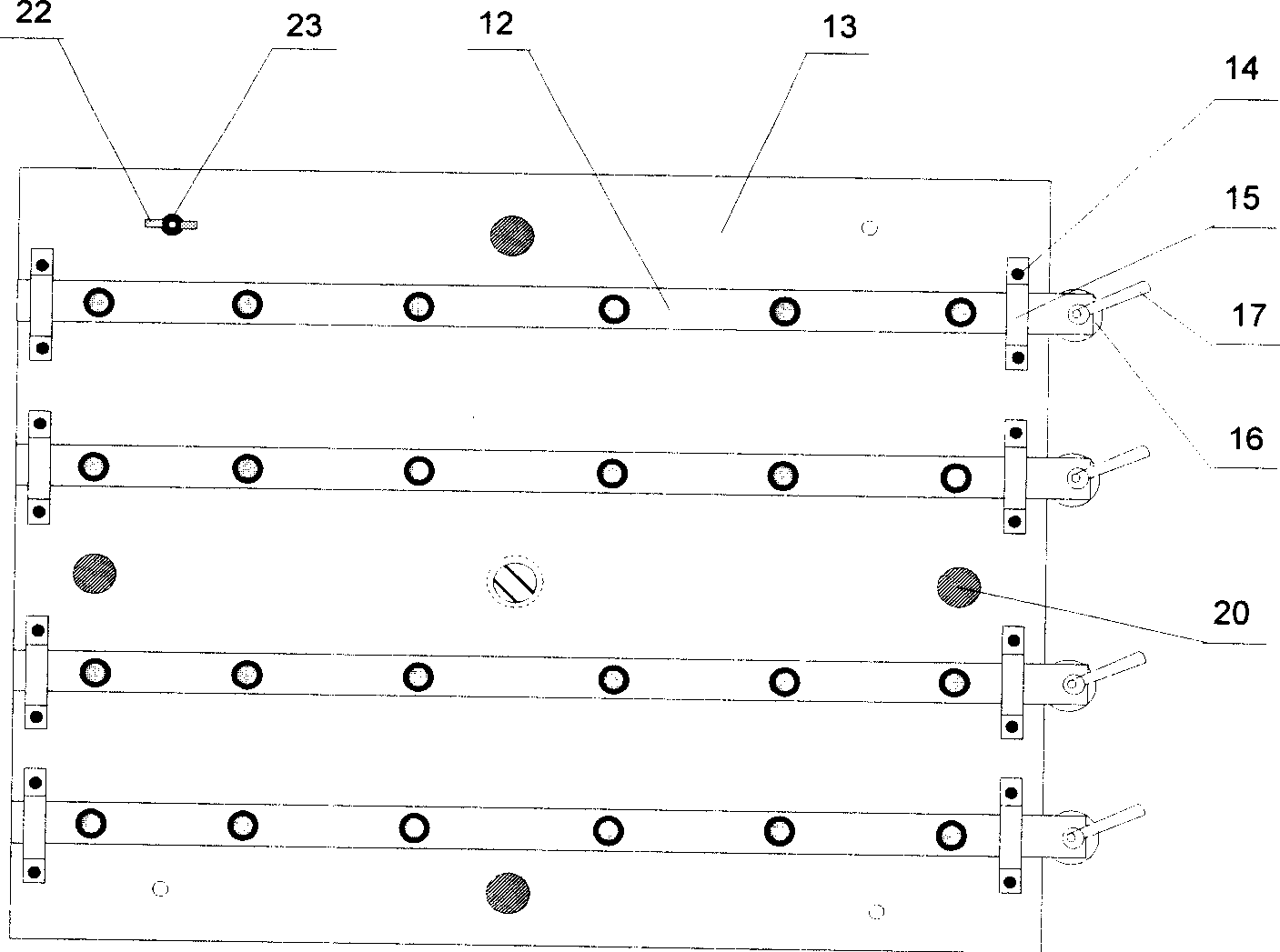

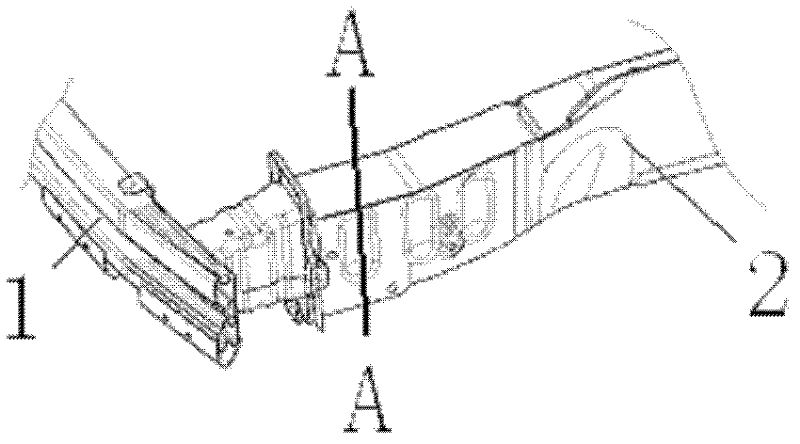

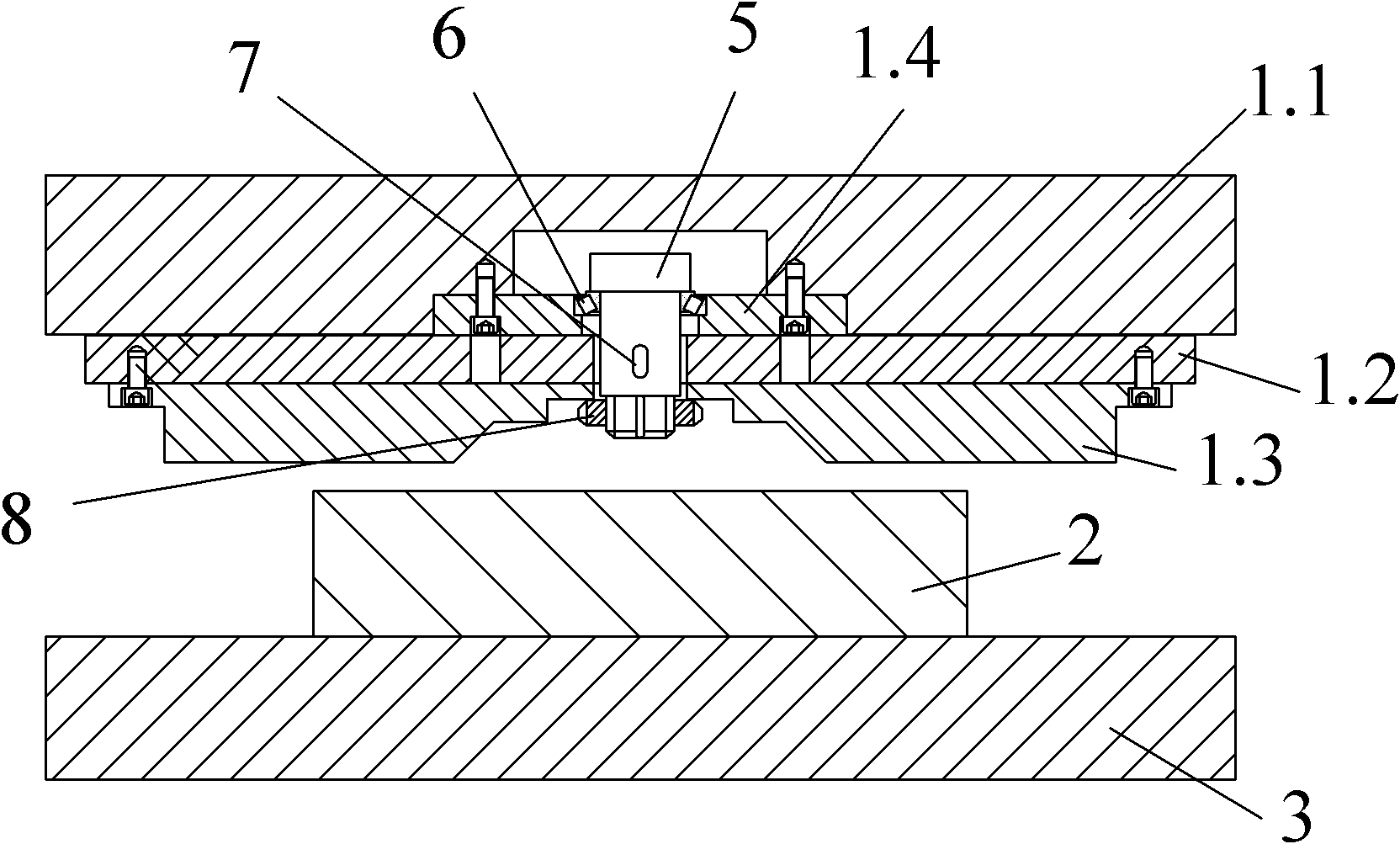

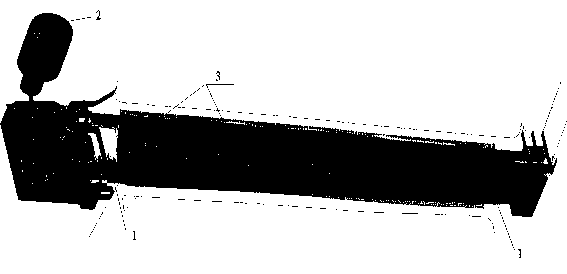

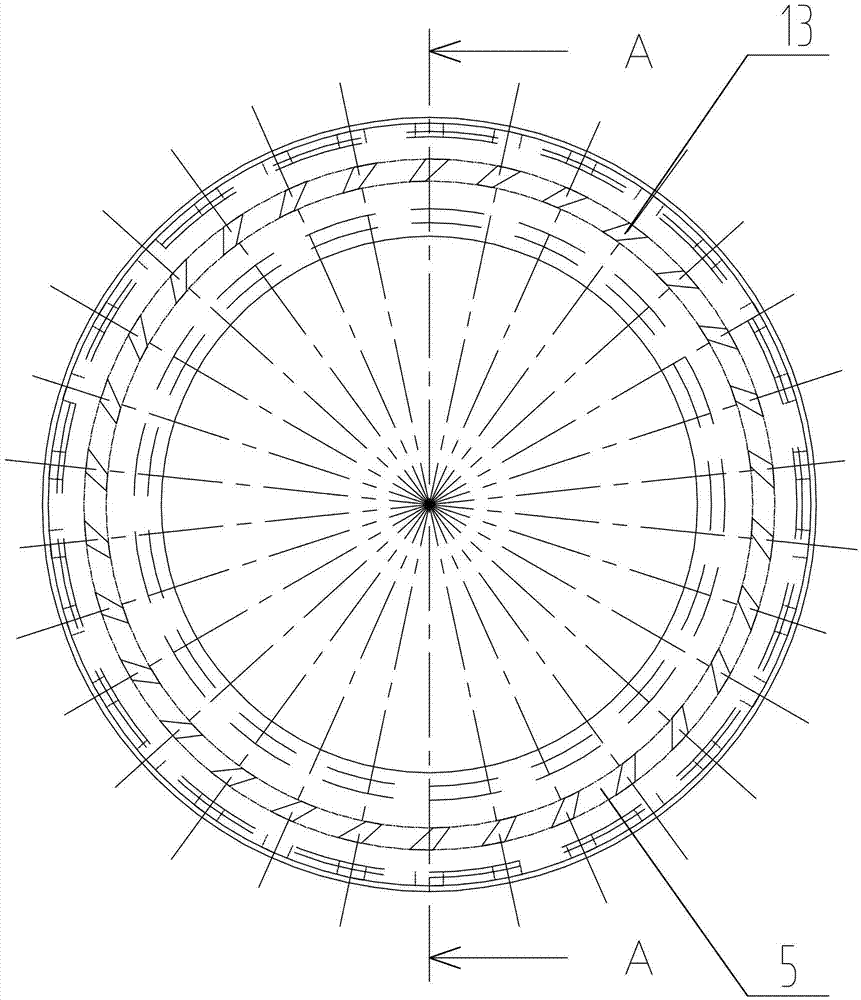

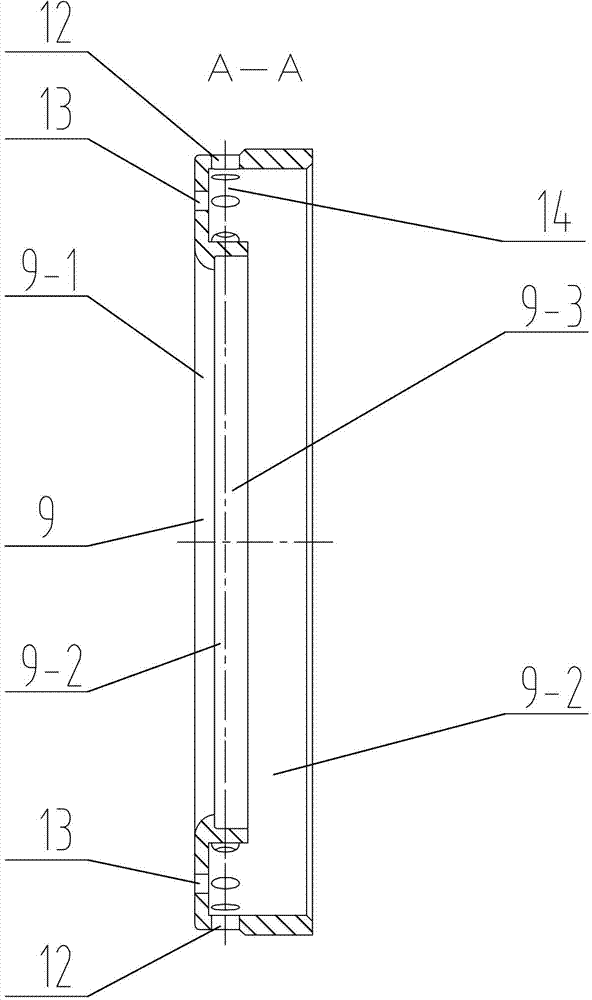

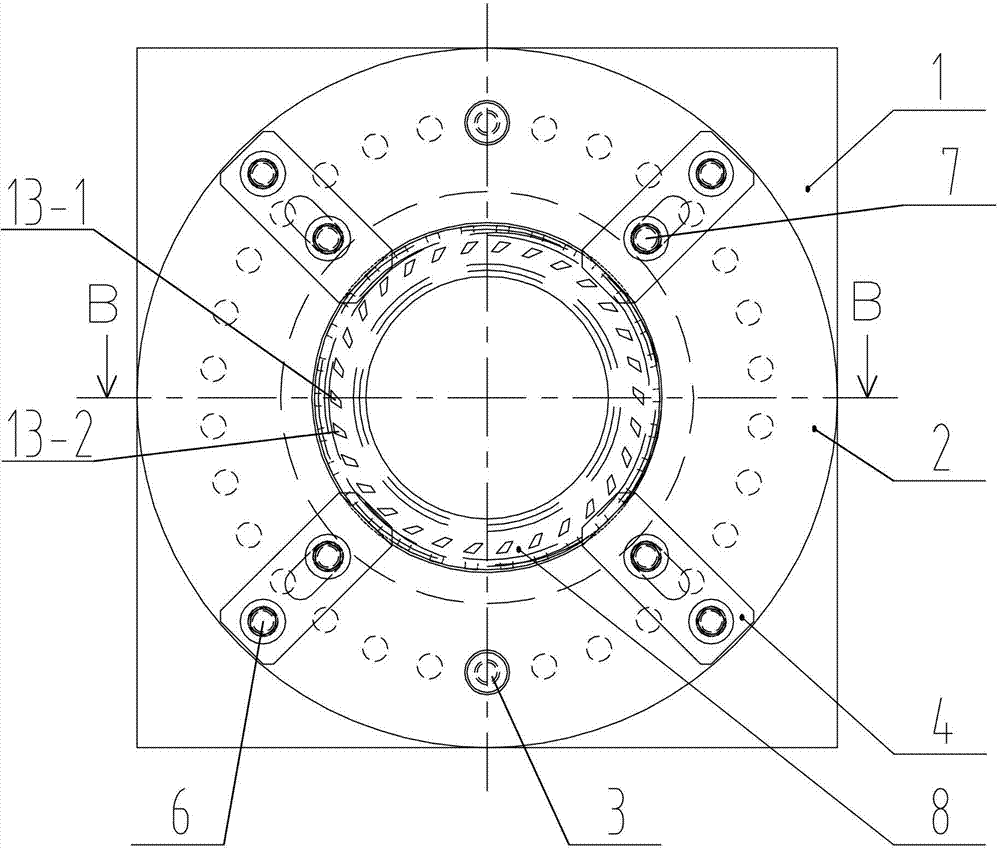

Flexible device for multipoint clamping and positioning spatial 3D thin wall part

InactiveCN1695896APrecise liftingConvenient location changeWelding/cutting auxillary devicesWork holdersCircular discMultiple point

Owner:SHANGHAI JIAO TONG UNIV

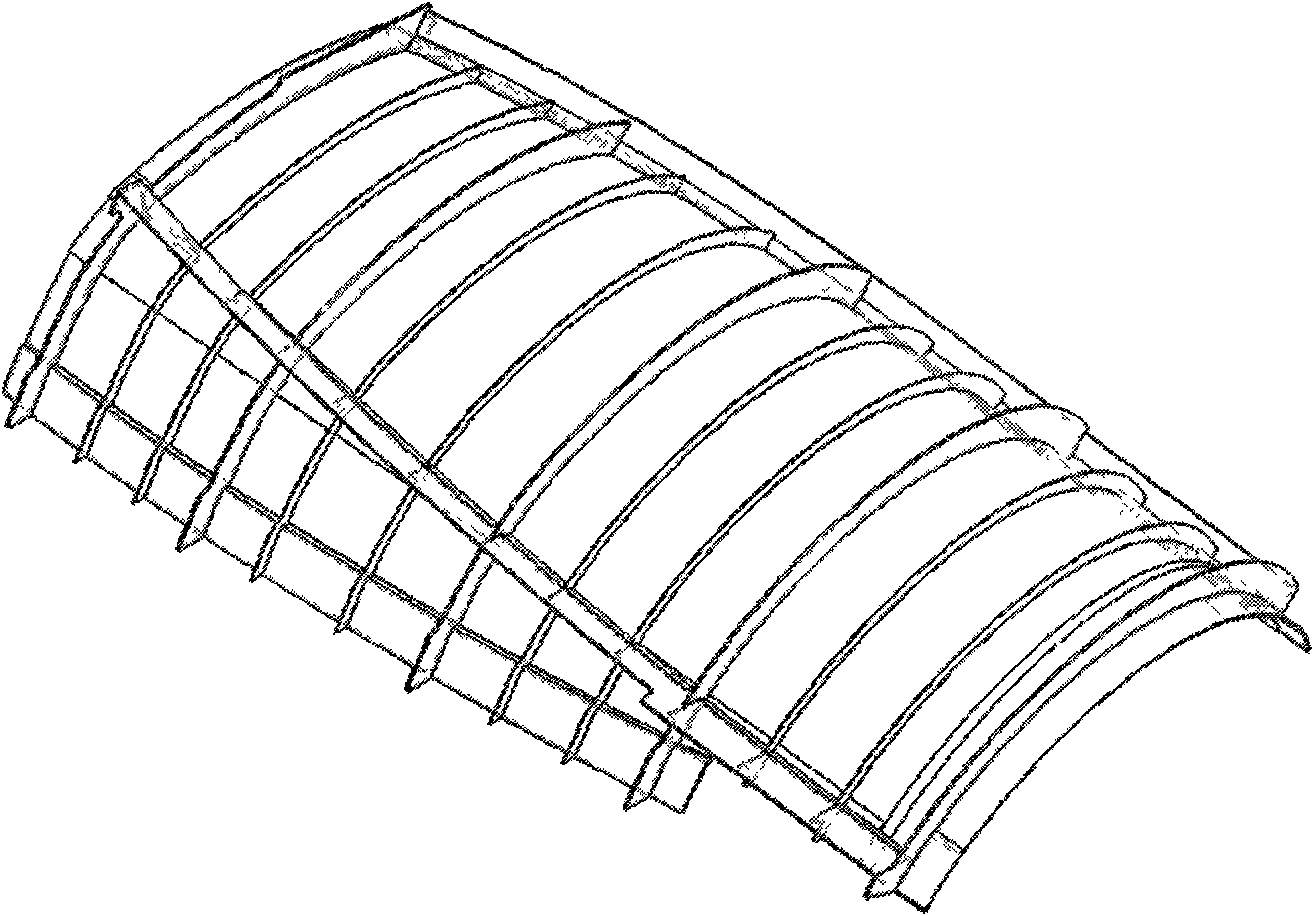

Wall plate processing technology for hyperboloid thin wall

ActiveCN101670462ASmall amount of deformationGuaranteed correctnessMilling equipment detailsThin walledWall plate

The invention relates to a wall plate processing technology for hyperboloid thin wall, belonging to the field of the mechanical processing technology. The process of producing the thin-wall wall boardwith double curved surfaces comprises the steps of rough finishing by a three-coordinate numerically controlled milling machine, heat-treating, semifinishing by a five-coordinate numerically controlled milling machine, natural aging, finishing by the five-coordinate numerically controlled milling machine, finishing on a vacuum platform and process boss cutting. The margin of the parts can be eliminated evenly and the deformation of the parts can be reduced to the maximum extent by adjusting the parameters including the processing allowance, the processing speed, the milling mode and the likein each numerically controlled procedure. The difficult problem of part clamping and positioning is solved by adopting the vacuum absorbing platform integrally having a cambered surface to absorb andprocess the parts.

Owner:JIANGXI HONGDU AVIATION IND GRP

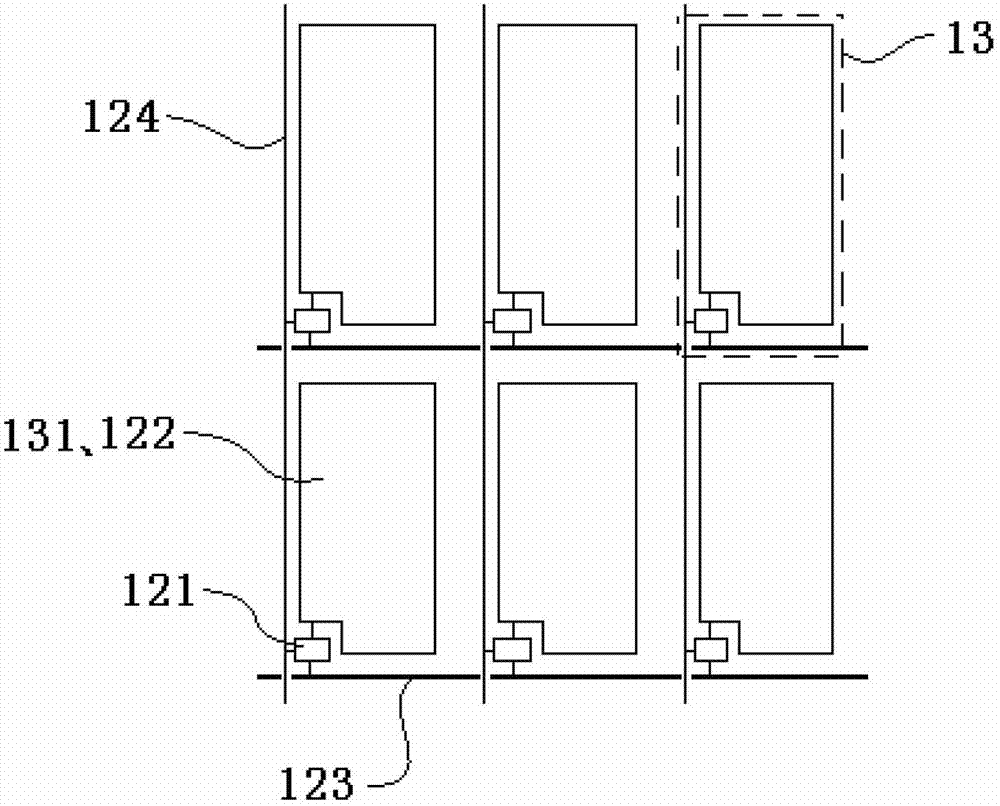

Flexible display substrate and preparation method thereof as well as flexible display device

ActiveCN102969320ANot easy to damageSmall amount of deformationFinal product manufactureSolid-state devicesLiquid-crystal displayOrganic electroluminescence

The invention provides a flexible display substrate and a preparation method thereof as well as a flexible display device, belongs to the technical field of flexible display, and can solve the problem that the conventional flexible display substrate is easily damaged during deformation, small in deformation quantity, low in display performance, high in cost, or difficult in preparation. The flexible display substrate comprises a hard material layer which is arranged at a vulnerable position of the flexible display substrate. The preparation method of the flexible display substrate comprises a step of forming a graph of the hard material layer. The flexible display device comprises the flexible display substrate. The flexible display substrate can be used in the flexible display devices such as an organic electroluminescent display device, a flexible electrophoretic display device and a flexible liquid crystal display device.

Owner:BOE TECH GRP CO LTD

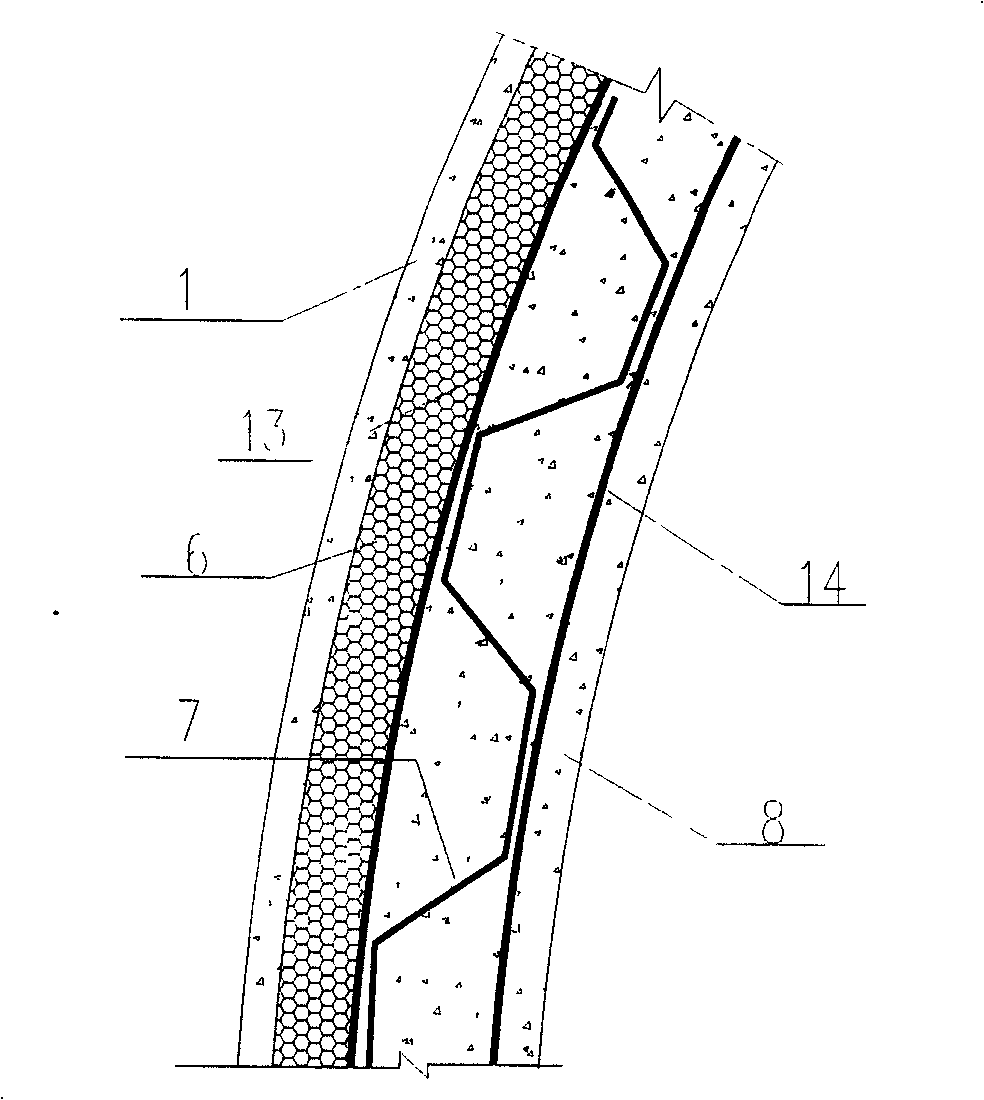

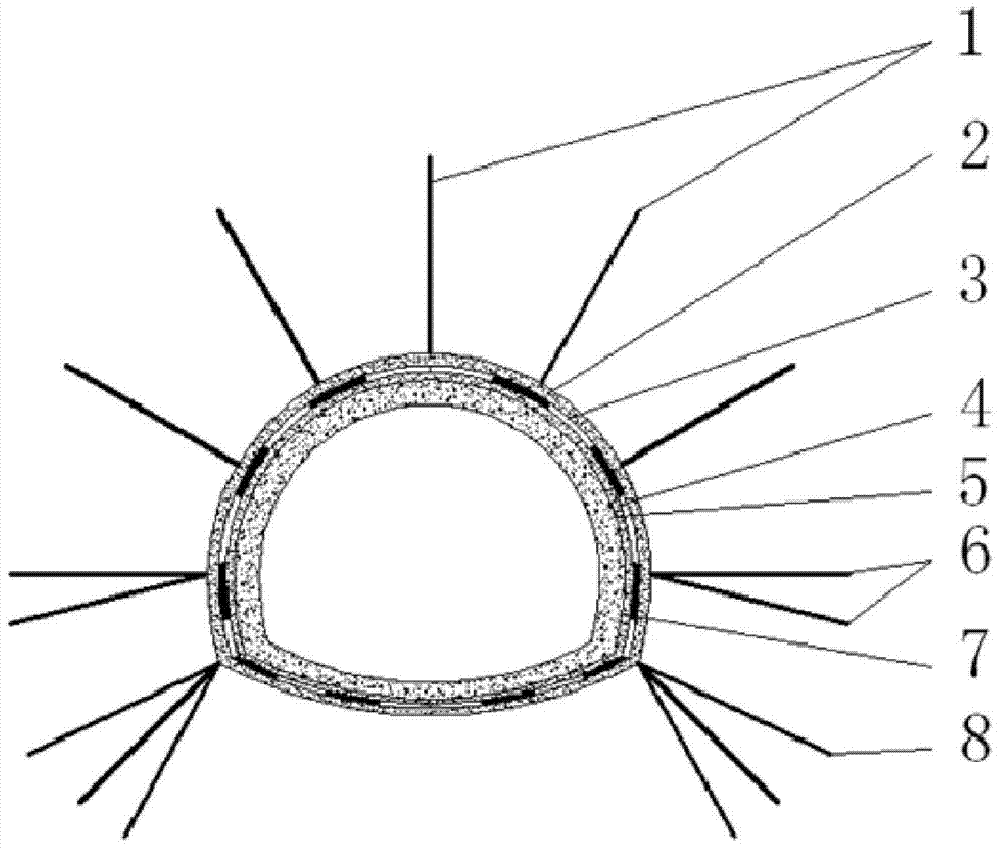

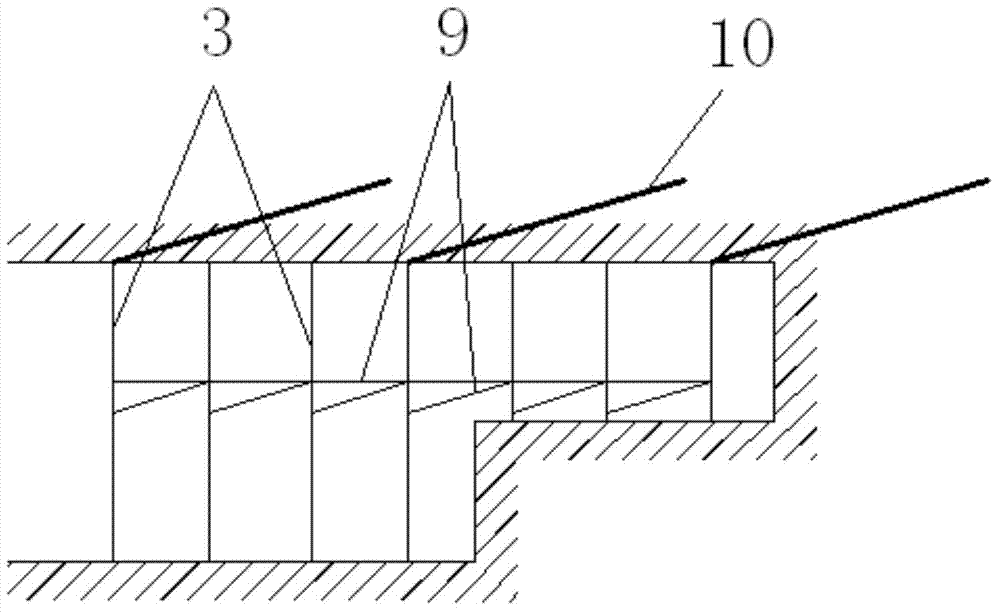

Soft expansion type wall rock tunnel support method

InactiveCN101493011AIncreased shear strengthImprove stabilityUnderground chambersTunnel liningCushionLower intensity

The invention discloses a support method of a weak expansion type surrounding rock laneway, comrprising the following steps: A. the laneway is excavated according to the sectional form, an arc pit is excavated on a bottom board of the laneway, and full face injection of a thick concrete leveling course is carried out; B. high-strength prestressed anchor and prestressed anchor cable are used for supporting the surrounding rock, an anchor rod and an anchor cable are constructed, a high-strength prestressed anchor rod uses a laevo rod body without longitudinal bar and is arranged in plum blossom shape; C. a foam cushion is laid, and the full face of the laneway is tightly stuck and paved with an initial ejection leveling course, and a gap is added and preserved in case of laneway deformation; D. a first layer of reinforcement mat is hung and tightly stuck to the foam cushion, a full face sealed type steel bar grid arching is constructed, the main bar inside the grid is bonded with the first layer of reinforcement mat, and the second layer of reinforcement mat is hung on the sealed type steel bar grid arching; E. the bottom board is constructed, a cast-in-place concrete gutter is constructed at the center part of a positive arching, and rubbles are paved at the both sides of the gutter. The method solves the problems of low intensity of surrounding rock laneway, water expansion and floor heave, thereby avoiding reclamation work of the laneway and having low cost.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

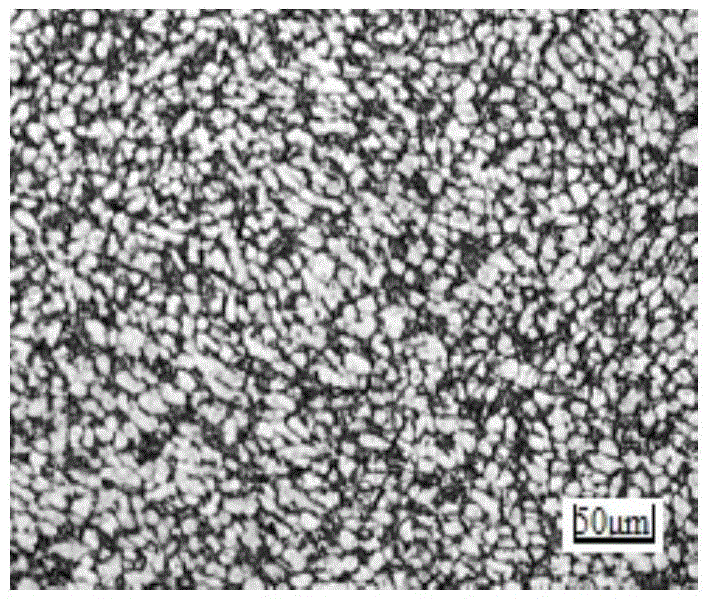

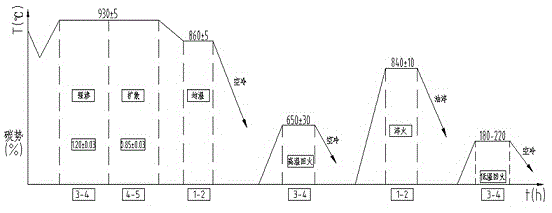

Forging machining method of large-sized bar materials of TC4 (Ti-6Al-4V) titanium alloy

InactiveCN104070125ALess investmentSave energyForging/hammering/pressing machinesElectric arc furnaceIngot casting

The invention relates to bar material forging machining method of titanium alloy, particularly to a forging machining method of large-sized bar materials of TC4 (Ti-6Al-4V) titanium alloy. The forging machining method is characterized by comprising the following steps of step 1, performing cogging forging, step 2, performing intermediate forging above a phase transformation point, step 3, performing intermediate forging below the phase transformation point, step 4 and step 5, performing finished product forging and obtaining the phi 200 to 300 mm and 2000 to 3000 mm length of large-sized bar materials of the TC4 titanium alloy finally. Compared with the prior art, a large-sized ingot casting and a large-tonnage forging device are not required and the industrialized production can be achieved through an ordinary industrial 3 ton ingot and a small-tonnage forging press and the equipment investment is small, only a 3 tons of electric arc furnace and a 3000 tons of forming oil press which is matched with the electric arc furnace need to be invested in the phi 600 of 3 ton ingot, the small-tonnage forging press such as a 1600 tons of forging press needs to be invested in the forging process, and accordingly the equipment investment is significantly reduced.

Owner:宁夏中色金航钛业有限公司

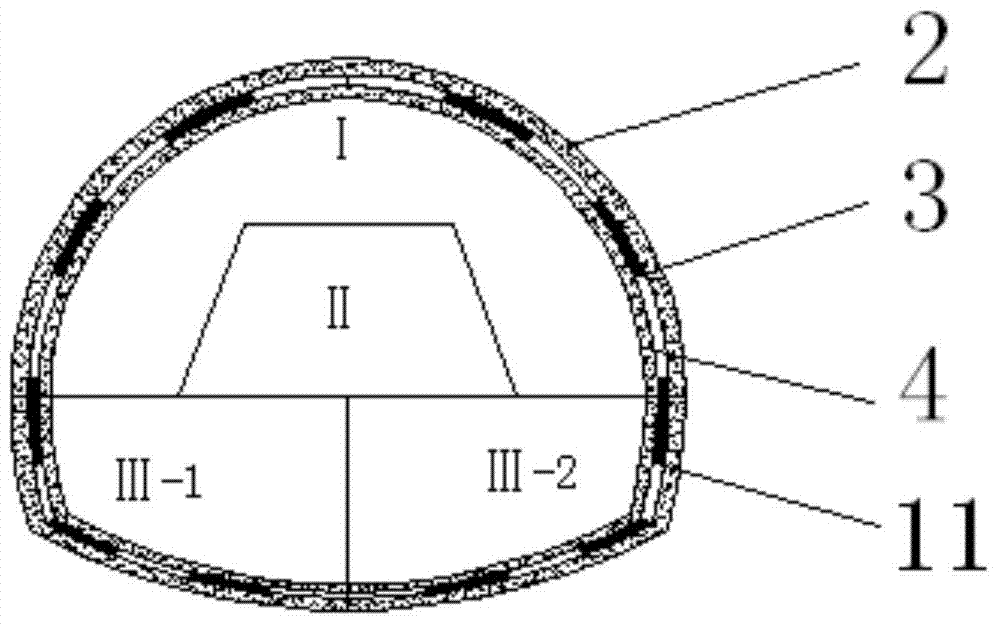

Soft rock large-deformation tunnel supporting system and construction method thereof

InactiveCN104847374AEnsure safetySmall overall deformationUnderground chambersTunnel liningSupporting systemLarge deformation

The invention discloses a soft rock large-deformation tunnel supporting system and a construction method thereof. The system comprises a forepoling, a preliminary bracing, a waterproof layer, a secondary lining and other main structures, wherein the structures are constructed in sequence according to construction procedures. Surrounding rock is reinforced through advanced small pipe grouting by means of the forepoling, the preliminary bracing comprises lengthened anchor rods, a primary spraying layer, steel arches and a re-jetting layer, feet-lock bolts are further arranged at the positions of an upper bench and arch feet to be welded to the steel arches, the adjacent steel arches are connected through longitudinal connecting ribs, and the secondary lining is constructed at last to form the supporting system. The steps are simple and linked with one another, supporting lag caused by idling of labor force is avoided, and large-deformation of tunnels is well controlled.

Owner:CHANGAN UNIV

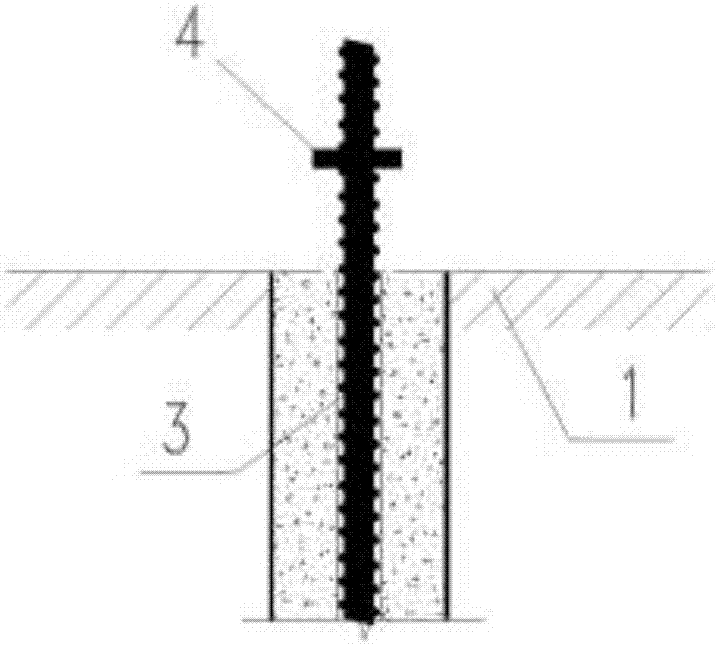

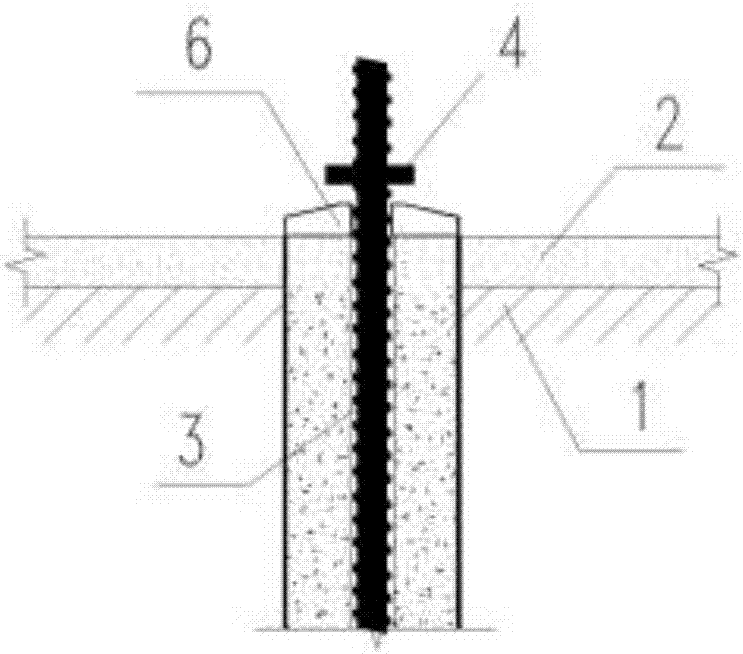

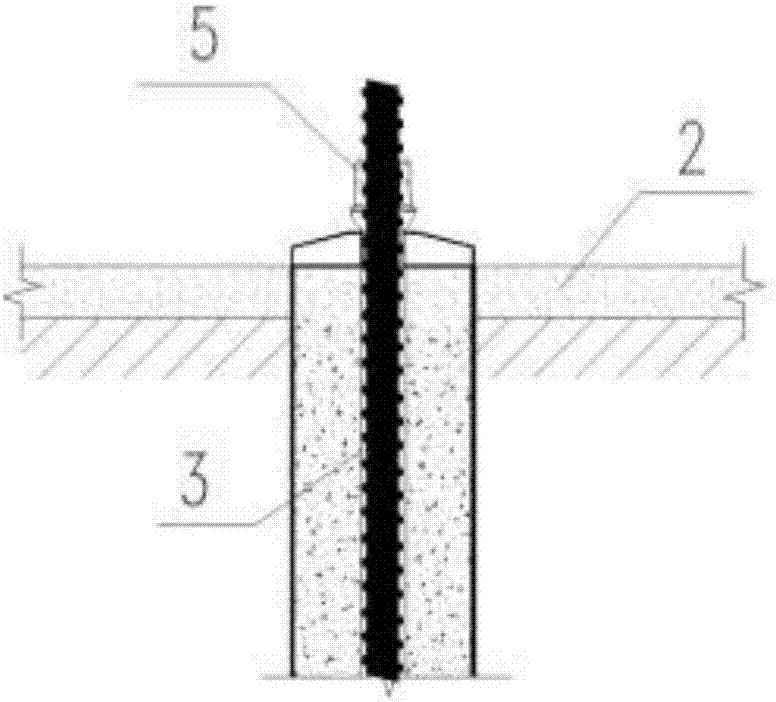

Construction method for overcoming deformation of anti-floating fixed diameter anchor head or expanded head anchor rod system

ActiveCN107044122AEliminate deformationSmall amount of deformationProtective foundationBulkheads/pilesPre stressRebar

The invention discloses a pressure bearing type fixed diameter anchor head or expanded head anchor rod prestress application method. Drilling is conducted to the design depth till rotary jet grouting or mechanical chambering construction can be developed, a pull rod of an anchor rod and a fixed diameter anchor head or an expanded head are placed, after the expanded head is arranged in place, the expanded head is expanded to the design size through an expanding mechanism, then, high-pressure grouting or concrete pouring is conducted, and pile forming is achieved in an expanded body section and a whole free section. Threaded steel bars to which prestress can be applied are adopted in the pull rod in the anchor rod, spiral stirrups and base bottom plate steel bars on a base are bundled, and collisions of the prestress steel bars are avoided in the bundling process. Lastly, a base concrete base bottom plate is poured by erecting a template.

Owner:JIANGSU GREEN RIVER ENVIRONMENTAL TECH CO LTD

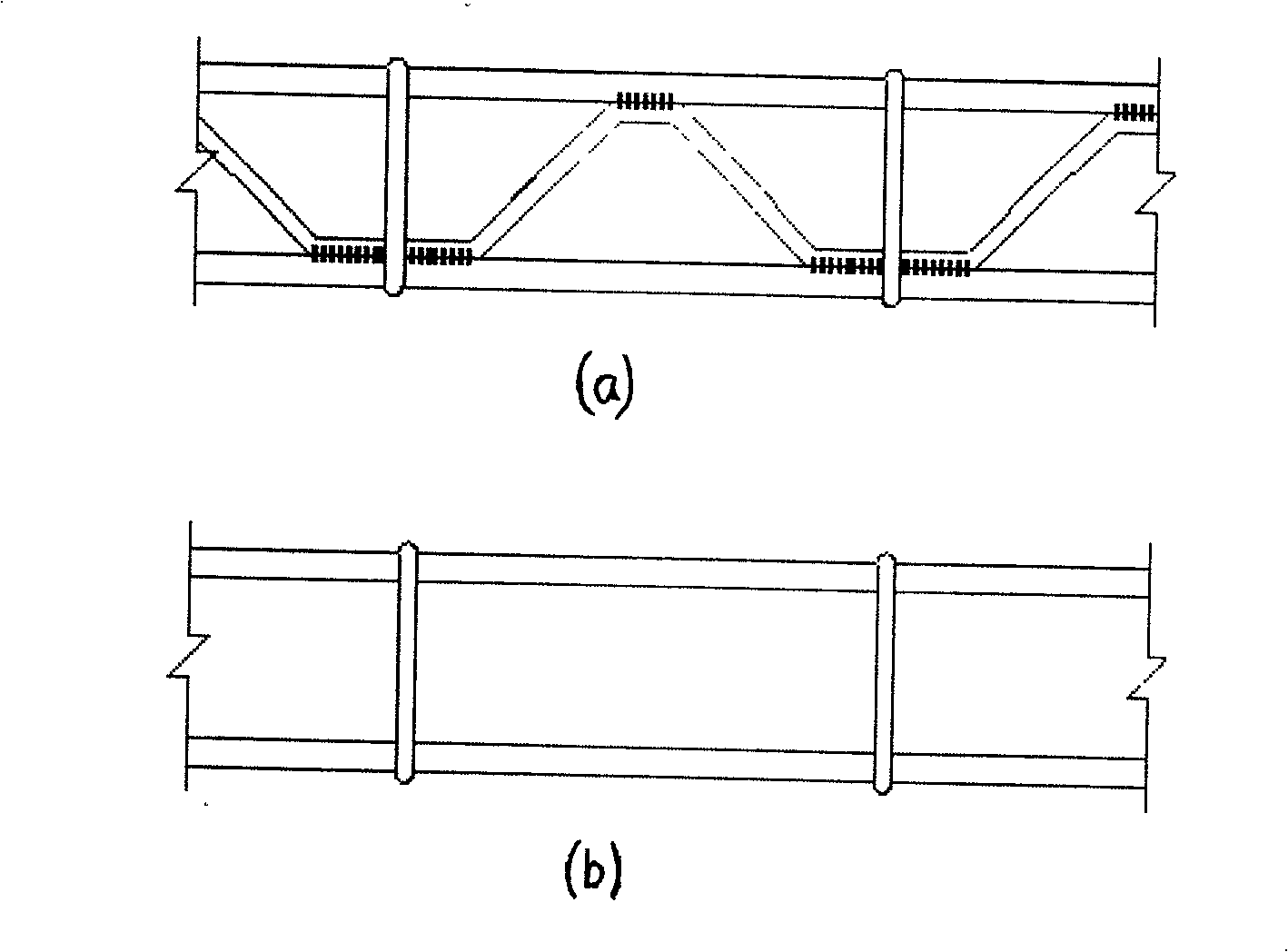

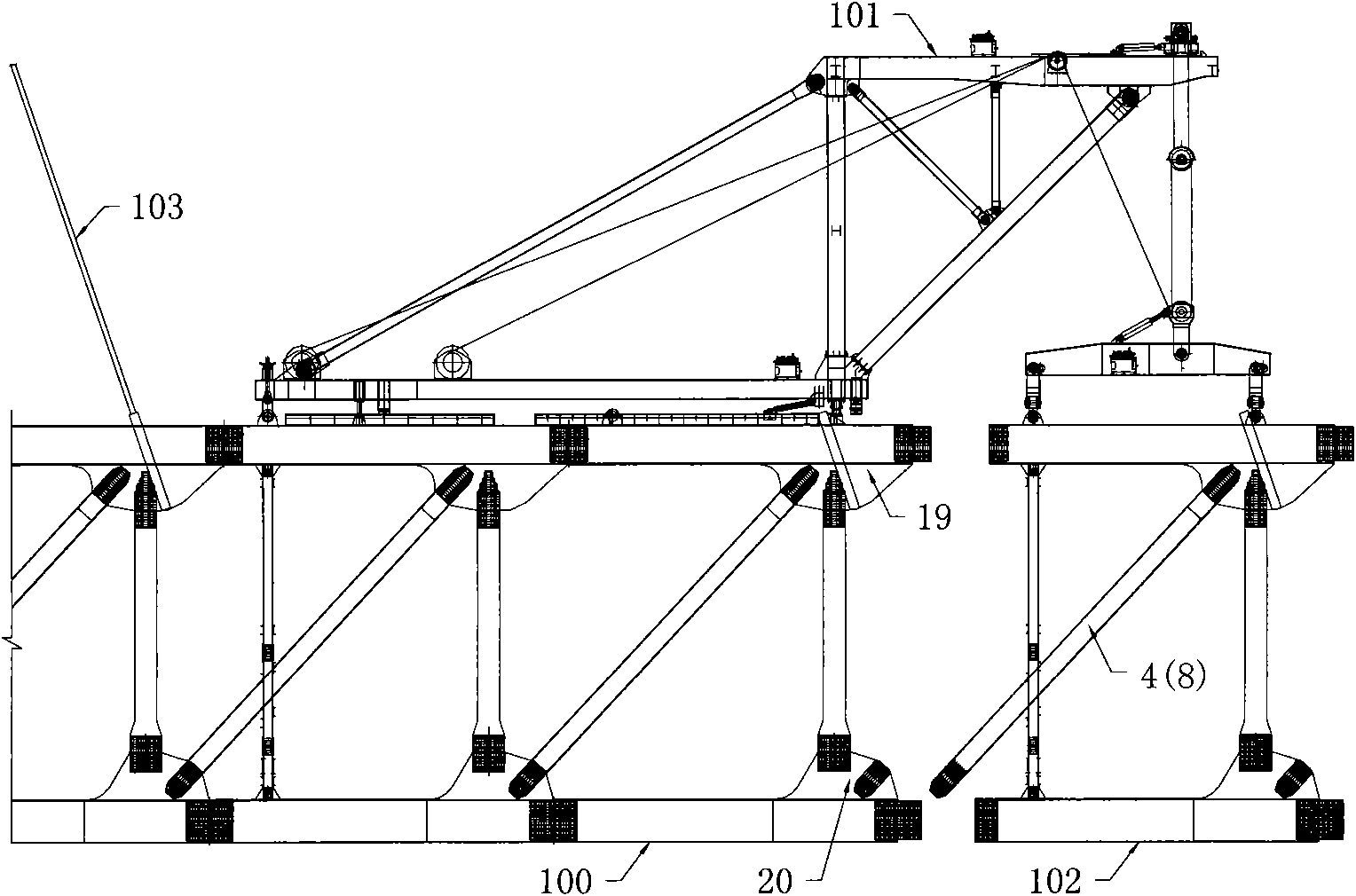

Three-truss main girder structure of highway and railway bi-purpose cable-stayed bridge and installation method thereof

ActiveCN101603288AImprove installation efficiencySave installation timeBridge erection/assemblyLoad-engaging elementsButt jointCable stayed

The invention relates to a three-truss main girder structure of a highway and railway bi-purpose cable-stayed bridge and an installation method thereof, relating to the technologies of designing and constructing a heavy load and long span highway and railway bi-purpose cable-stayed bridge. The structure of three main trusses comprises a middle truss piece and side truss pieces arranged on both sides of the middle truss piece, wherein an orthotropic slab and a transverse bracing truss are arranged between the upper edges of the middle truss piece and each side truss piece, and a railroad transverse girder, a railroad longitudinal girder and a horizontal bracing cross bridging are arranged between the lower edges of the middle truss piece and each side truss piece; and the invention provides the installation method adopting adaptive pre-splicing of multiple truss-sections, arrangement of temporary constructional rod pieces, integral lifting of each truss section and multi-node simultaneous alignment. The invention has the beneficial effects of: 1. pushing the highway and railway bi-purpose cable-stayed bridge to develop towards the direction of large span and heavy loading, 2. improving the installation efficiency and quality, 3. reducing the quantity of welding lines of construction sites, 4. innovatively practicing the multi-point simultaneous butt joint technology, 5. adopting the temporary rod pieces for solving the problems of unstability and large deformation in the processes of delivering and lifting the truss sections, 6. strengthening the adaptability of adjacent truss sections, and 7. solving the problems of inconsistent deformation of the middle and the side trusses and inconsistent centre-of-gravity positions of the truss sections.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD +1

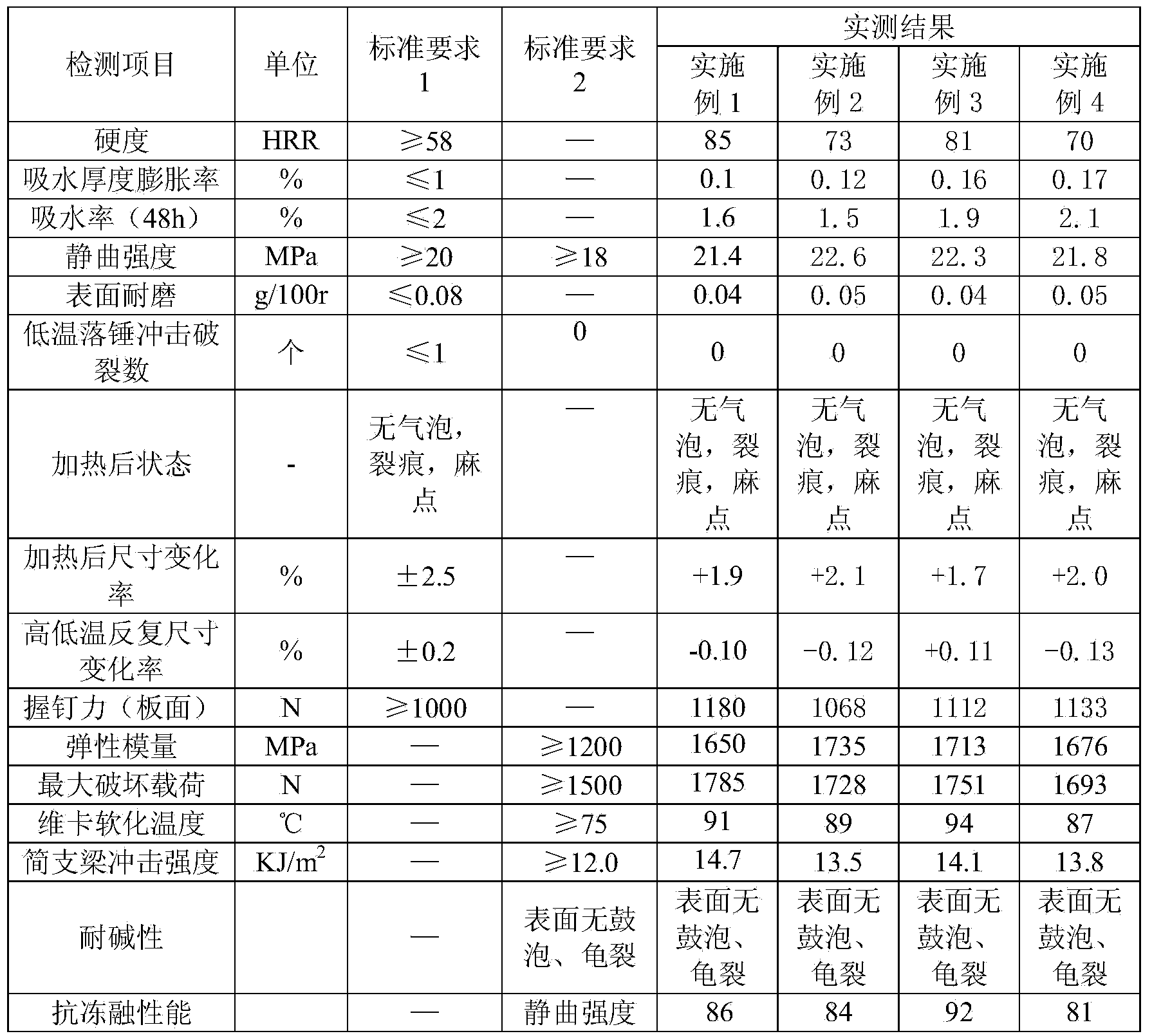

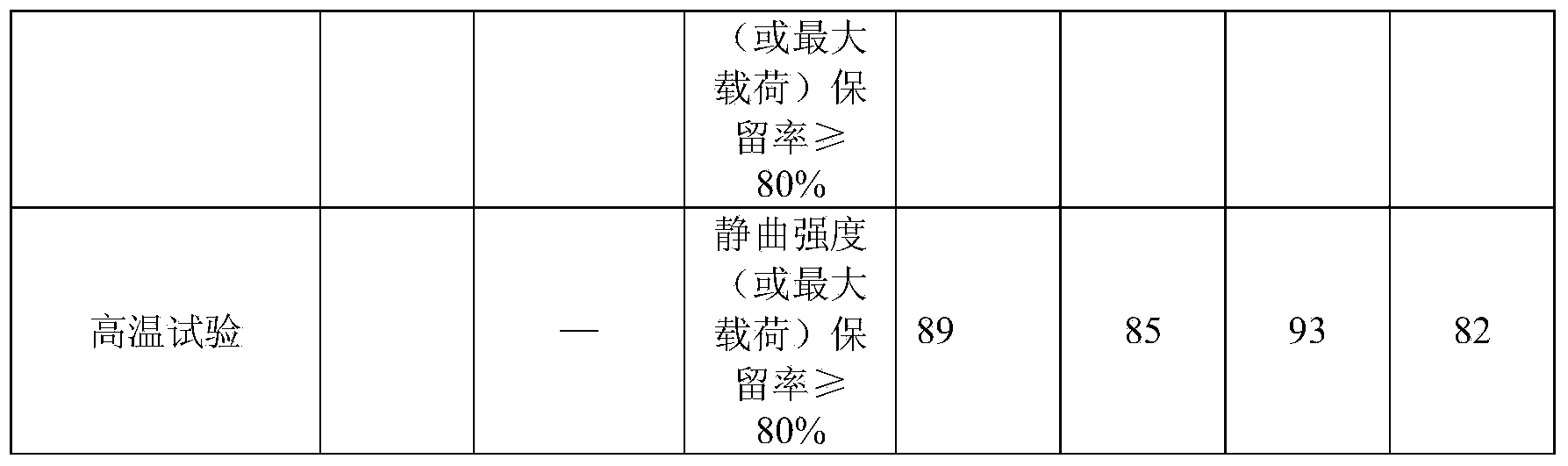

Environment-friendly single-layer microcellular foam PVC (polyvinyl chloride) wood-plastic composite board and preparation method thereof

The invention discloses an environment-friendly single-layer microcellular foamPVC (polyvinyl chloride) wood-plastic composite board and a preparation method thereof. According to an adopted raw material formula,the board comprises the components in percentage by mass as follows: 20%-60% of a PVC reclaimed material, 15%-45% of PVC resin, 5.6%-10% of wood fiber powder, 5%-8.9% of filler, 4%-4.4% of a foaming conditioning agent, 1%-1.5% of a compound stabilizer, 0.7%-0.9% of a foaming agent, 2%-2.5% of a reinforcing agent, 2.2%-2.4% of an impact modifier, 0.3%-0.45% of a lubricating agent, 0.1%-0.15% of a coupling agent and 3%-5% of a functional additive, and the functional additive is an anti-aging agent, a fire retardant or a coloring agent. The composite board has the processability similar to that of wood, can substitute for a wood board and also has thecharacteristics of fireproof property, moistureproof property, smooth and attractive appearance and the like, and the wood does not have the characteristics; according to the preparation method of the composite board, waste PVC can be used for performing cycle production, waste materials can be changed into things of value, waste of wood resources can be reduced, and the pollution caused by plastic products to the environment can also be avoided.

Owner:JIANGSU RUNJU ENVIRONMENTAL TECH CO LTD +1

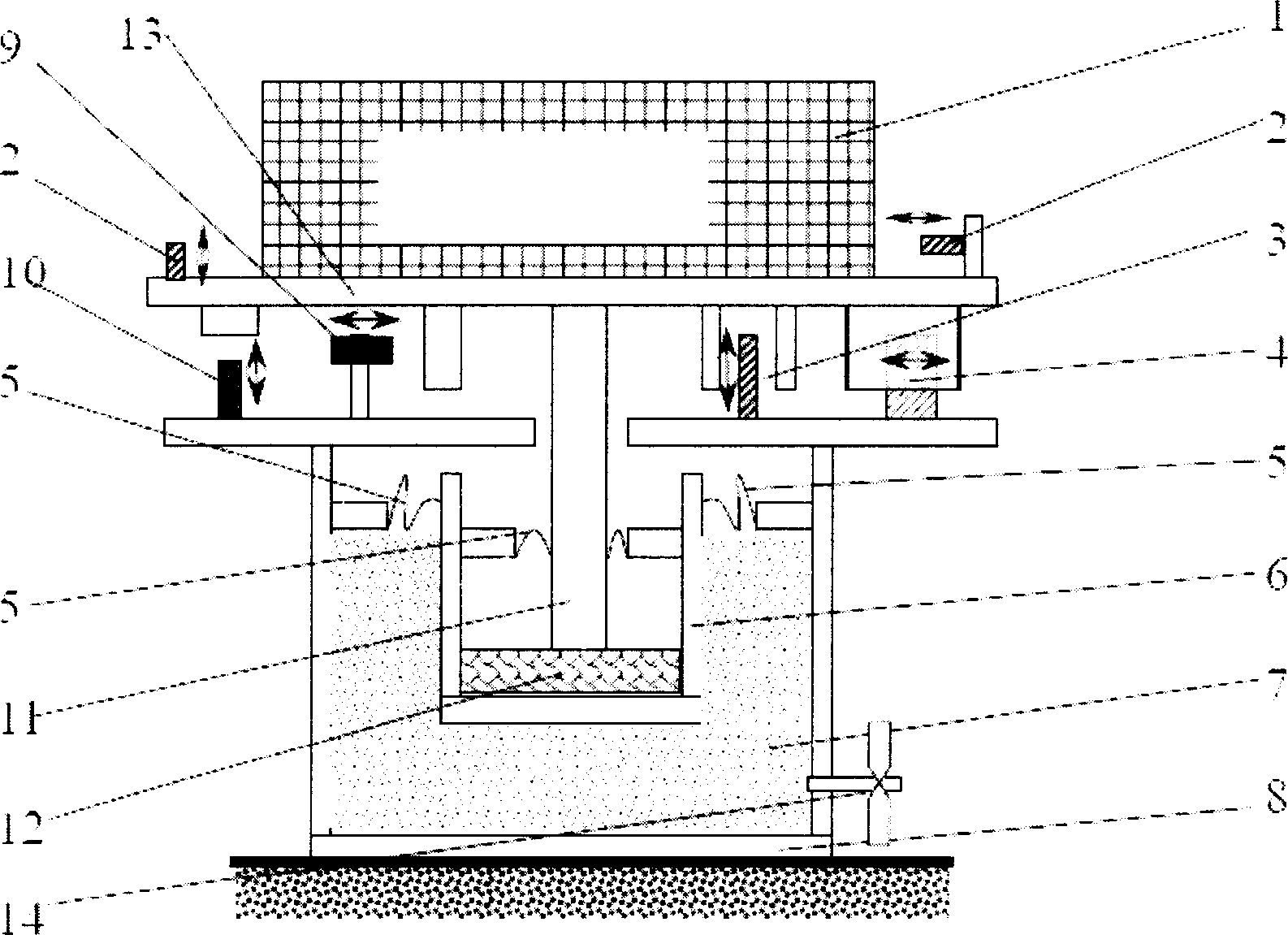

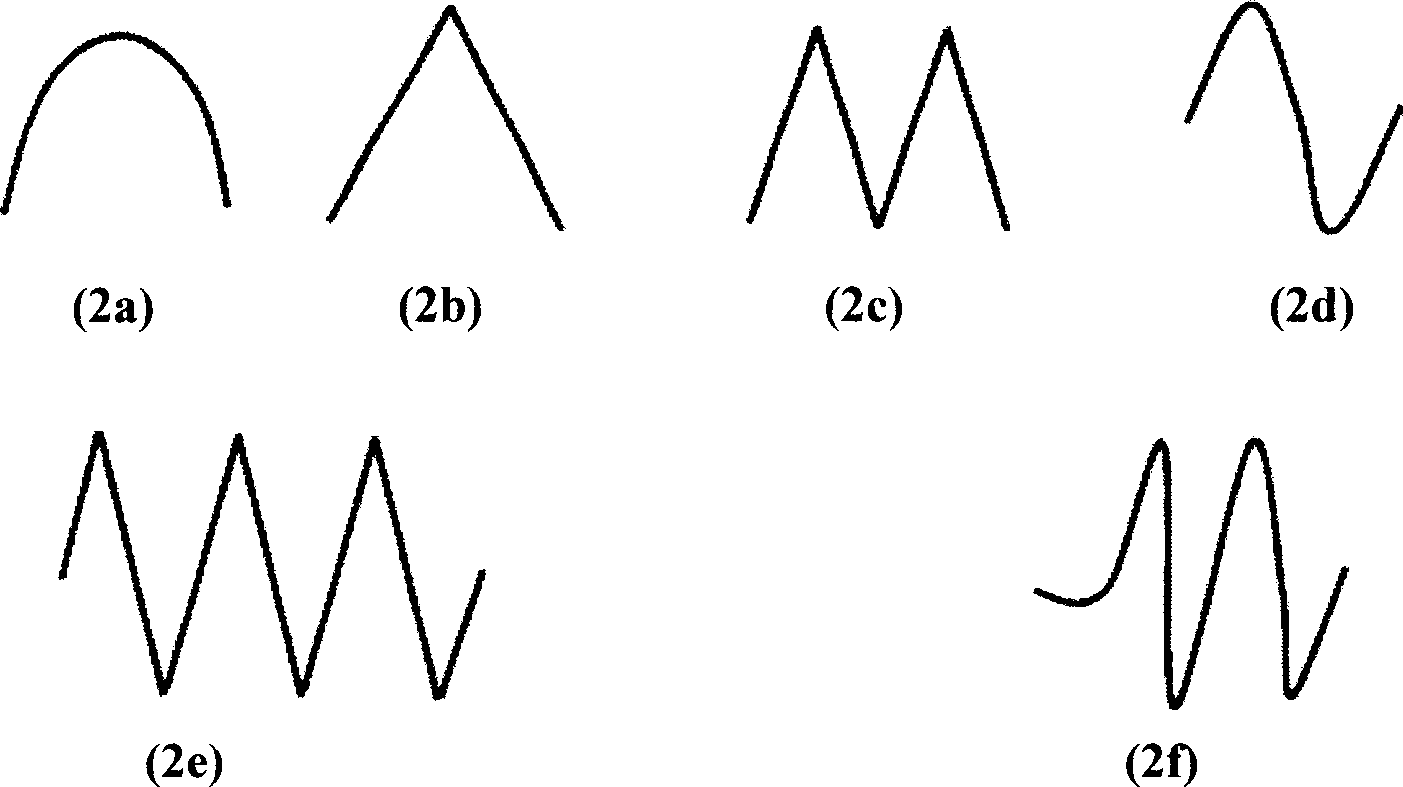

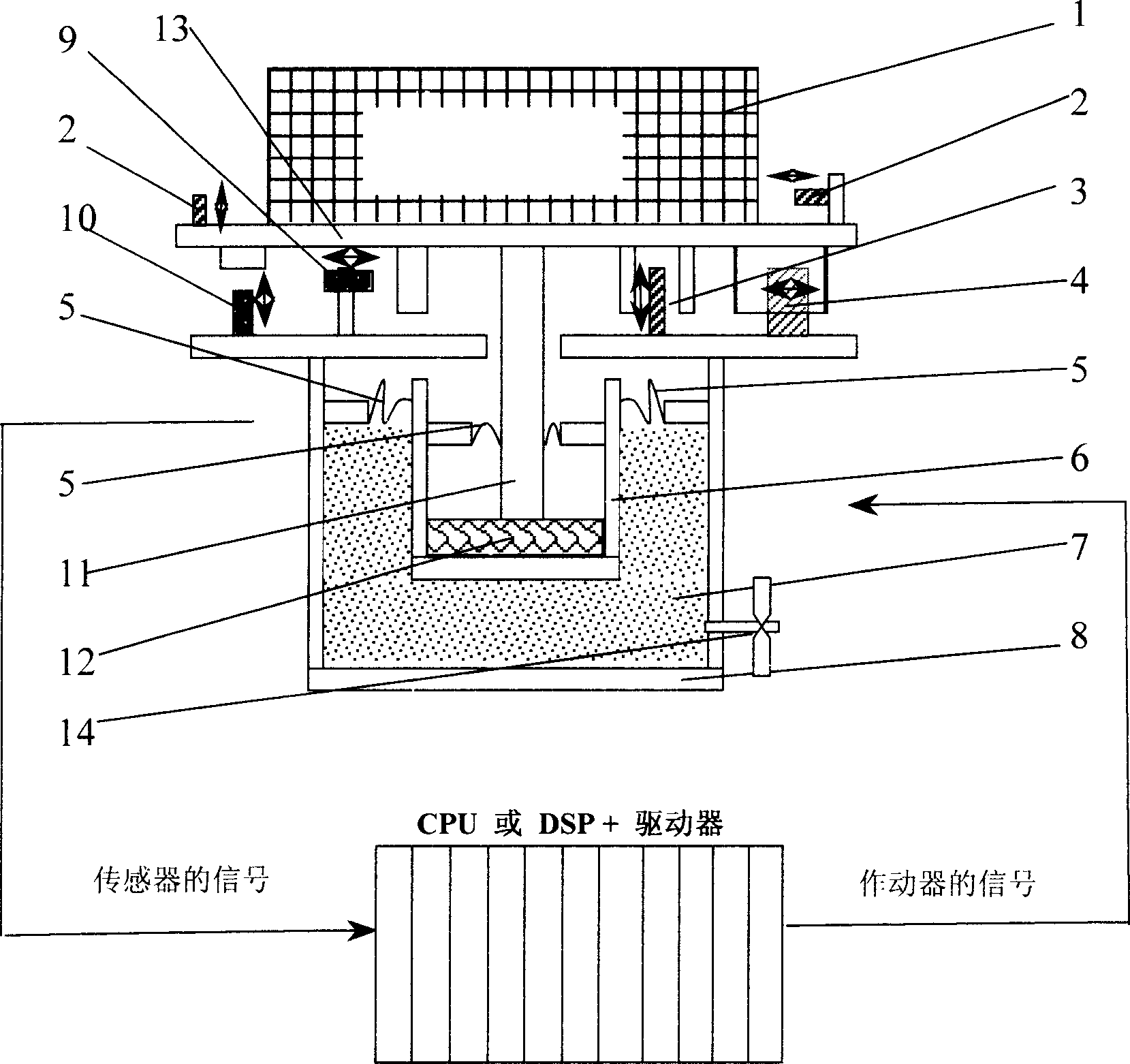

Precision vibration damping and locating device

InactiveCN1724892AAccurate positioningCompact structureNon-rotating vibration suppressionSemiconductor/solid-state device manufacturingPolicy makerRoom temperature

The invention relates to an effectively damping multi-freedom locating device with the passive control as the principal and the active control as the auxiliary, used to realize accurate horizontal and height location, and comprising passive damping component and active damping component, where the passive damping component is of a cavity structure able to have a certain horizontal and vertical moving range and is connected through the cavity-supported piston mechanism to a damped platform for isolating or attenuating the vibrating source in a wider frequency band by a large margin; an active control component joins the damped vibrating components, and is composed of vibration sensor, signal processor, data collector, operation policy maker, electric machine driver, and two linear electric machines in the vertical and horizontal directions, so as to make accuracy location. The invention has compact structure, high reliability, high repeated locating accuracy, strong adaptability, small device deformation, moving stability and meets the strict requirements of the precision devices, such as photo-etcher, etc. at normal temperature.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

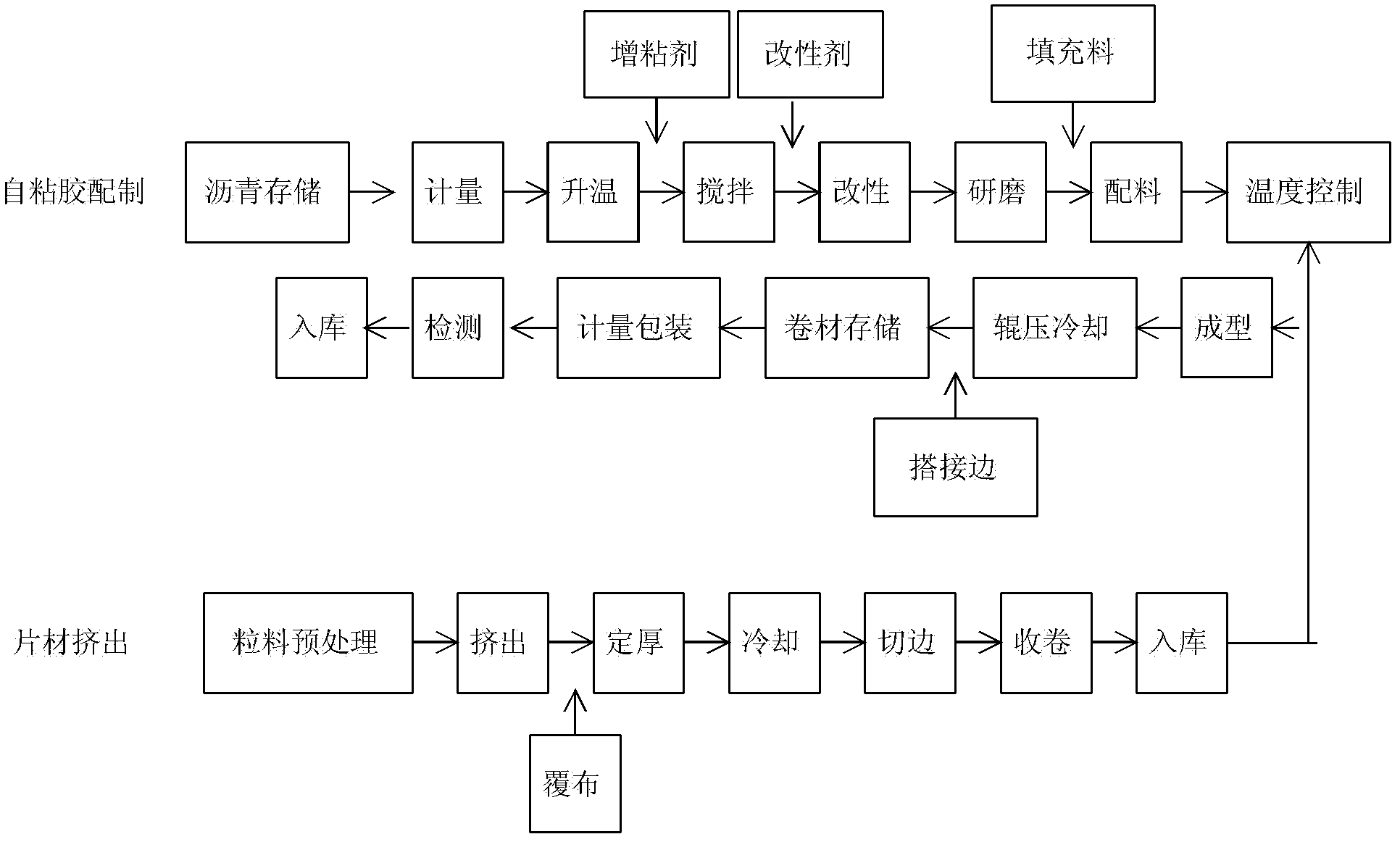

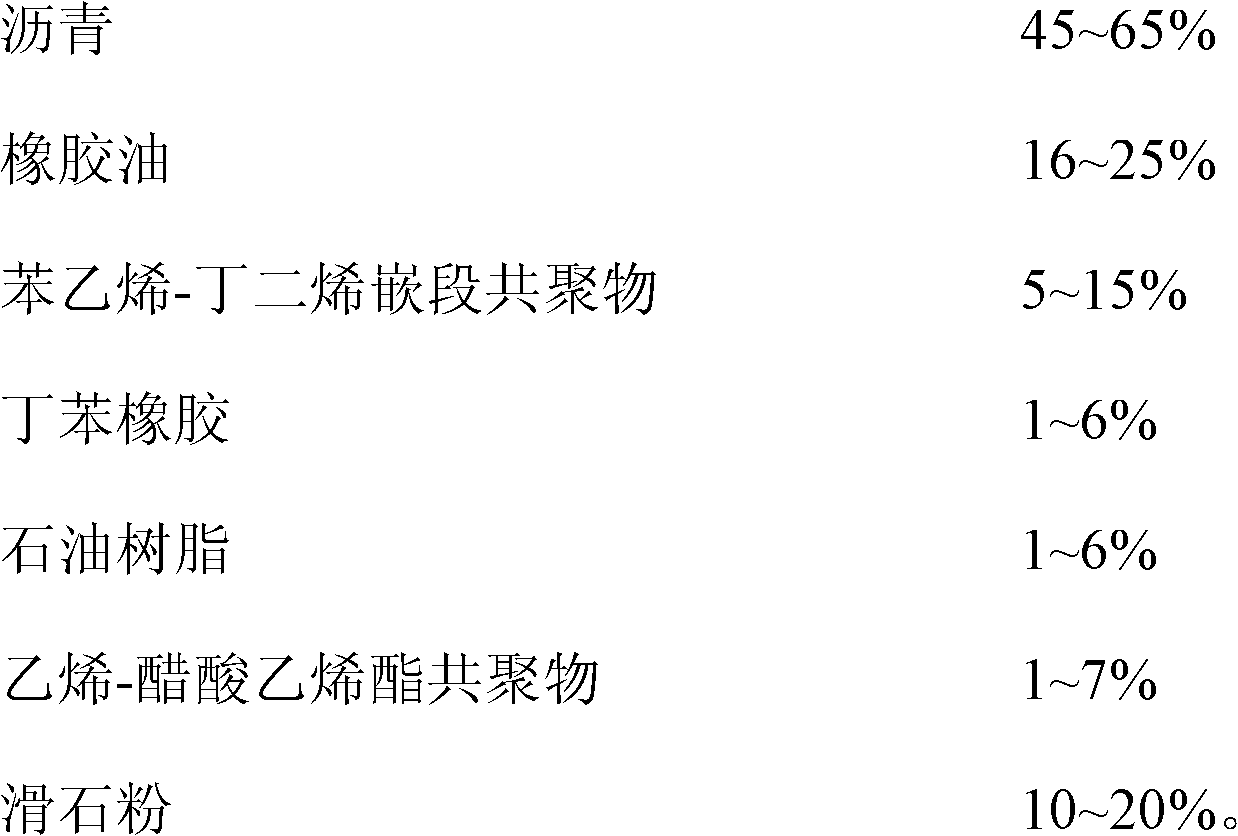

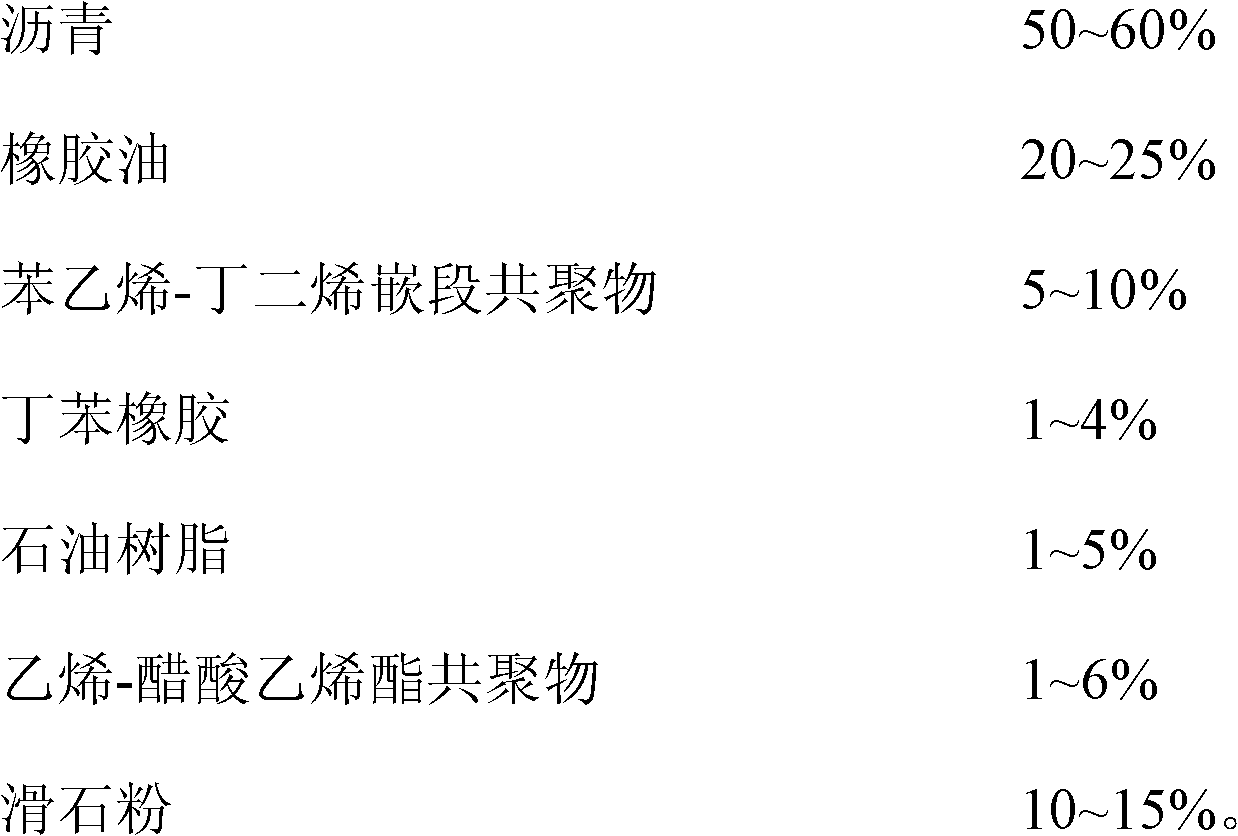

Asphalt self-adhesive and high-polymer self-adhesion rubber waterproof coiled material prepared from asphalt self-adhesive

InactiveCN102559135AGood compatibilityHigh composite strengthMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesUltimate tensile strengthButadiene-styrene rubber

The invention discloses asphalt self-adhesive. The asphalt self-adhesive comprises the following components in percentage by weight: 45 to 65 percent of asphalt, 16 to 25 percent of rubber oil, 5 to 15 percent of styrene butadiene styrene (SBS), 1 to 6 percent of styrene butadiene rubber (SBR), 1 to 6 percent of petroleum resin, 1 to 7 percent of ethylene vinyl acetate (EVA), and 10 to 20 percent of talcpowder. The invention also provides a high-polymer self-adhesion rubber waterproof coiled material which comprises a non-woven fabric coating, a high-polymer sheet coating, and an asphalt self-adhesive coating which consists of the asphalt self-adhesive from bottom to top. Two ends of the waterproof coiled material are provided with joint sides. The asphalt self-adhesive contains EVA, so the compatibility of the self-adhesive and a high-polymer sheet is improved, and compounding intensity of the high-polymer sheet coating is improved. The problem that the high-polymer sheets cannot be jointed reliably in a self-adhesion joint process is solved, so the coiled materials are jointed by the adhesive; and the coiled materials can be adhered firmly and reliably, and adjusted freely and flexibly.

Owner:SHENZHEN ZHUOBAO TECH

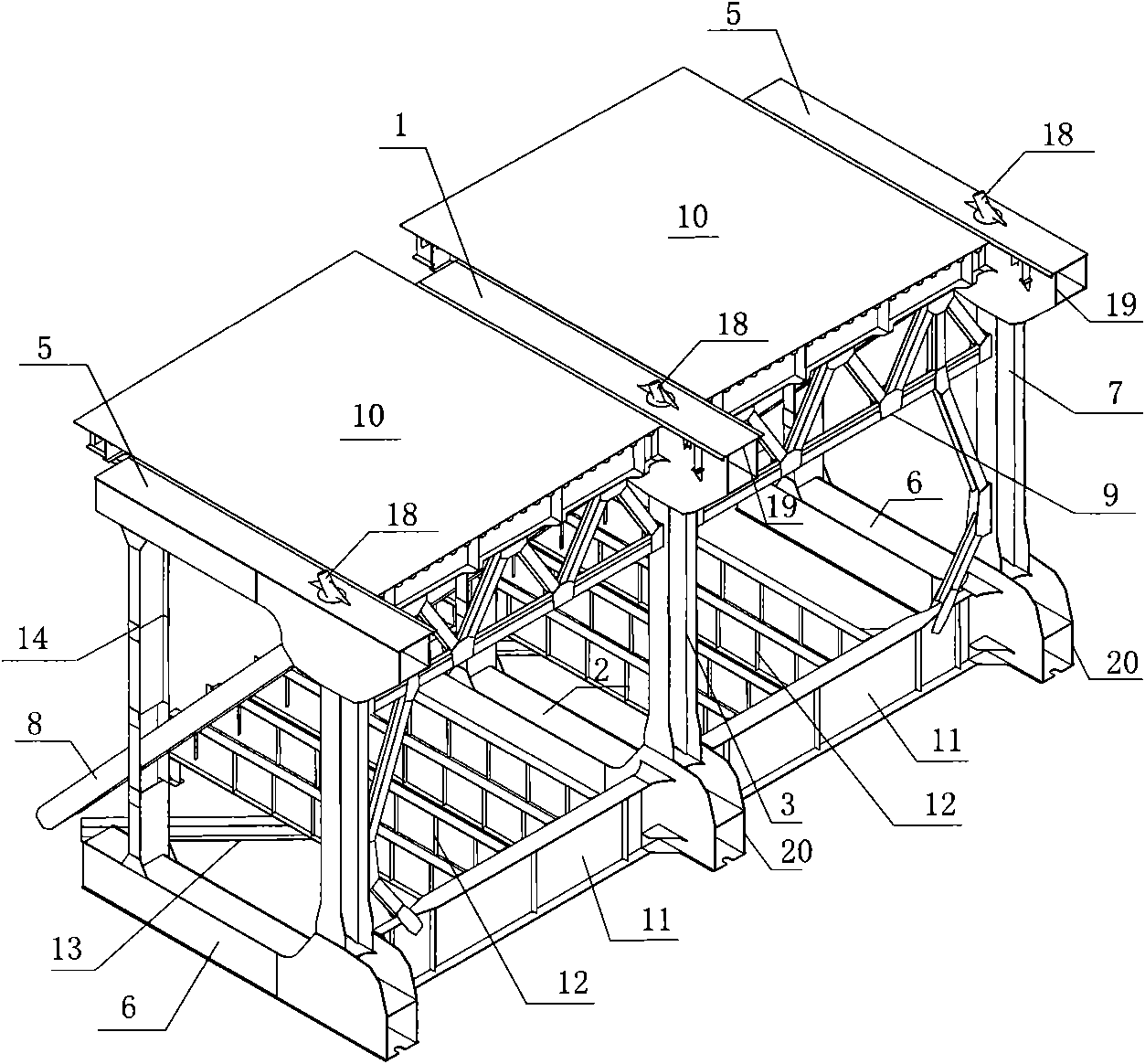

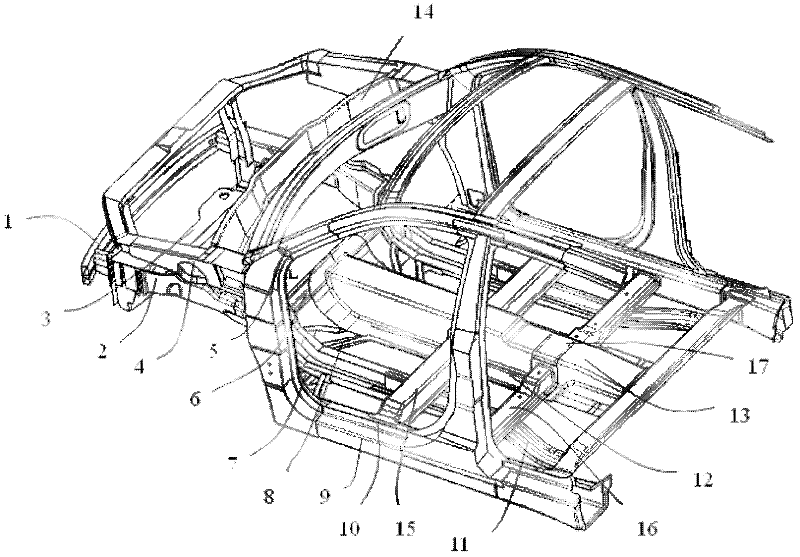

Front body framework structure of automobile

ActiveCN102358349AAbsorb in timeReasonable dispersionMonocoque constructionsAbsorbed energyEngineering

The invention discloses a front body framework structure of an automobile. The front body framework structure of the automobile comprises an automobile body A post, a front protective cross beam, a front engine room framework assembly and a front floor framework assembly, wherein the front engine room framework assembly comprises a front engine room longitudinal beam, and a plurality of longitudinal beams and cross beams, which are connected with the front engine room longitudinal beam and are used for dispersing and transferring collision energy; and the front floor framework assembly comprises a front floor longitudinal beam, a lower door sill, and a plurality of longitudinal beams and cross beams, which are connected with the front floor longitudinal beam and the lower door sill and are used for dispersing and transferring collision energy. Through the technical scheme, a plurality of structural beams are welded to form a closed annular body framework structure; the plurality of longitudinal beams and cross beams are used for absorbing and transferring the collision impact load, so that the front part is deformed and absorbs energy sufficiently; the number of impact energy transfer passages is large; the energy is reasonably dispersed; the energy is absorbed in time; the invasion amount of a front baffle plate is small; the deformation of the floor and a middle passage is small; the deformation of a cab is reduced; and thus, the damage to a passenger in the collision, and the maintenance cost of the automobile are reduced.

Owner:CHERY AUTOMOBILE CO LTD

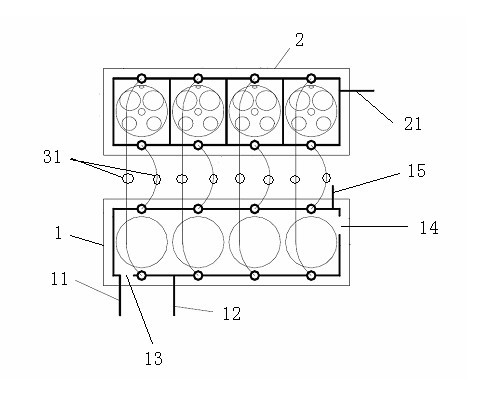

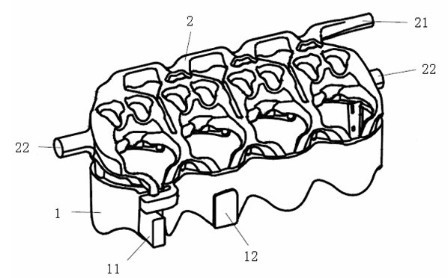

Engine cooling water jacket

InactiveCN102042116AImprove powerImprove performanceLiquid coolingCylinder headsThermal stateEngineering

The invention provides an engine cooling water jacket which has the advantages of simple structure, small volume, uniform flow rate and low pressure loss. The engine cooling water jacket comprises a cylinder body water jacket and a cylinder cover water jacket, wherein the cylinder body water jacket is separated by two baffle plates to form a first flow channel and a second flow channel, and the first flow channel and the second flow channel are communicated with the cylinder cover water jacket through water holes in a cylinder gasket; and coolant mainly flows into the first flow channel from a water inlet and flows through an air exhaust side, then flows into the cylinder cover water jacket through the water holes at one side of the cylinder gasket, subsequently flows into the second flow channel through the water holes at the other side of the cylinder gasket and flows through an air admission side, and finally flows out from a water outlet. Thus, the invention enables the flow rate of the coolant in the whole engine cooling water jacket to be more uniform, reduces the thermal-state deformation of the cylinder holes and improves the dynamic performance of the engine; and the water holes in the cylinder gasket can be arranged as required without being influenced by the design of traditional water jacket cylinder holes, thereby integrally increasing the flow areas of the water holes in the cylinder gasket, reducing the pressure loss of the whole water jacket and lowering the performance requirements for water pumps.

Owner:CHERY AUTOMOBILE CO LTD

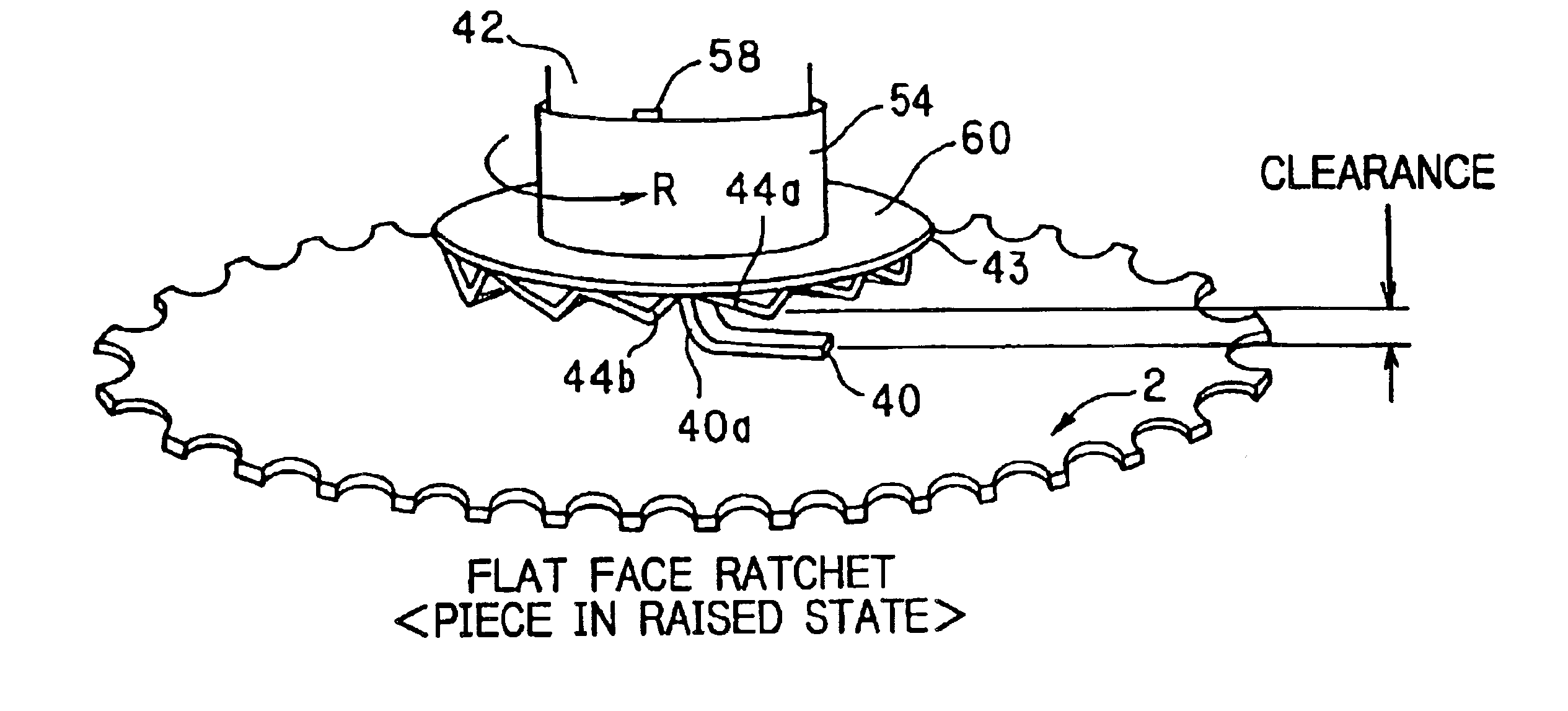

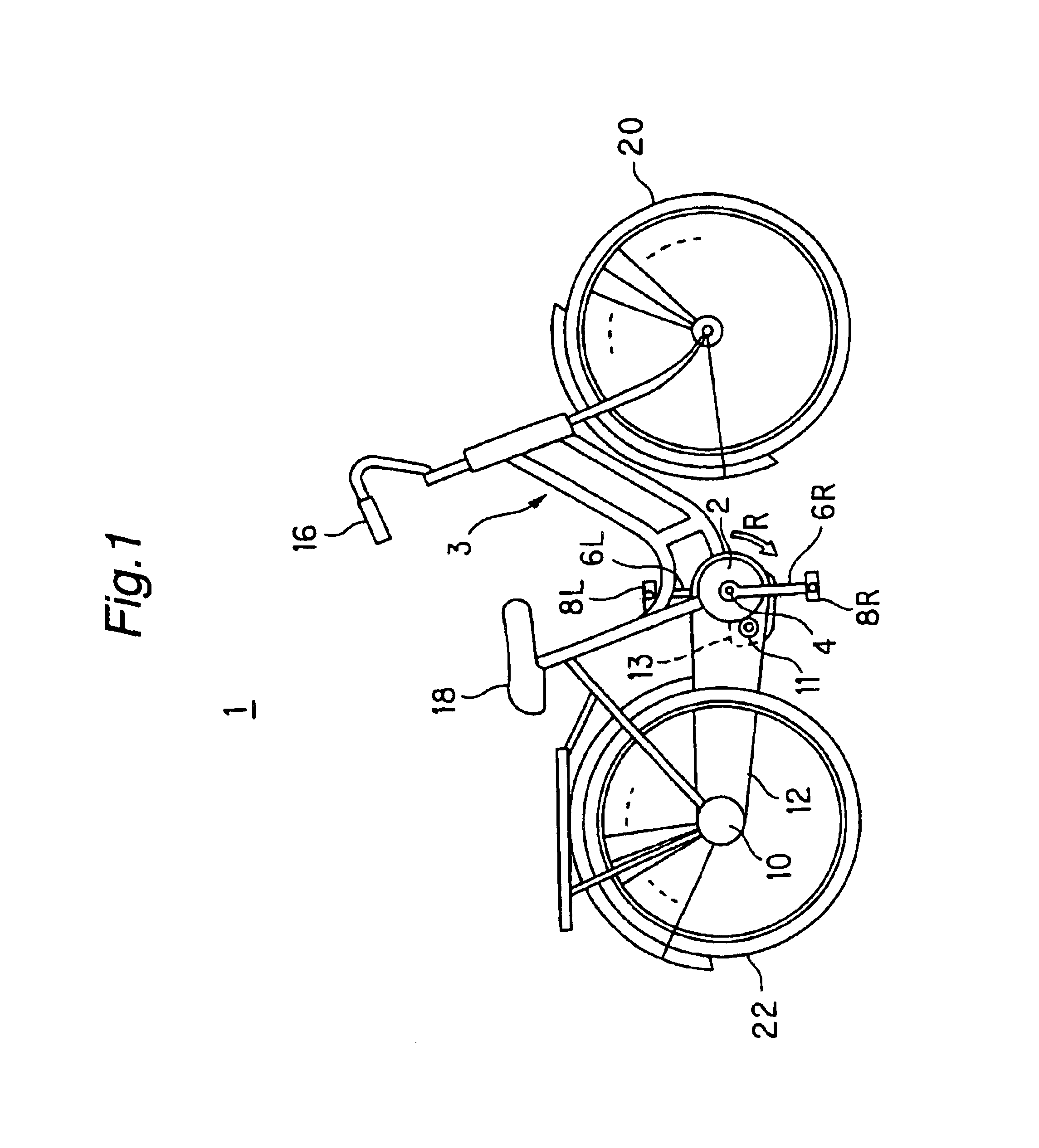

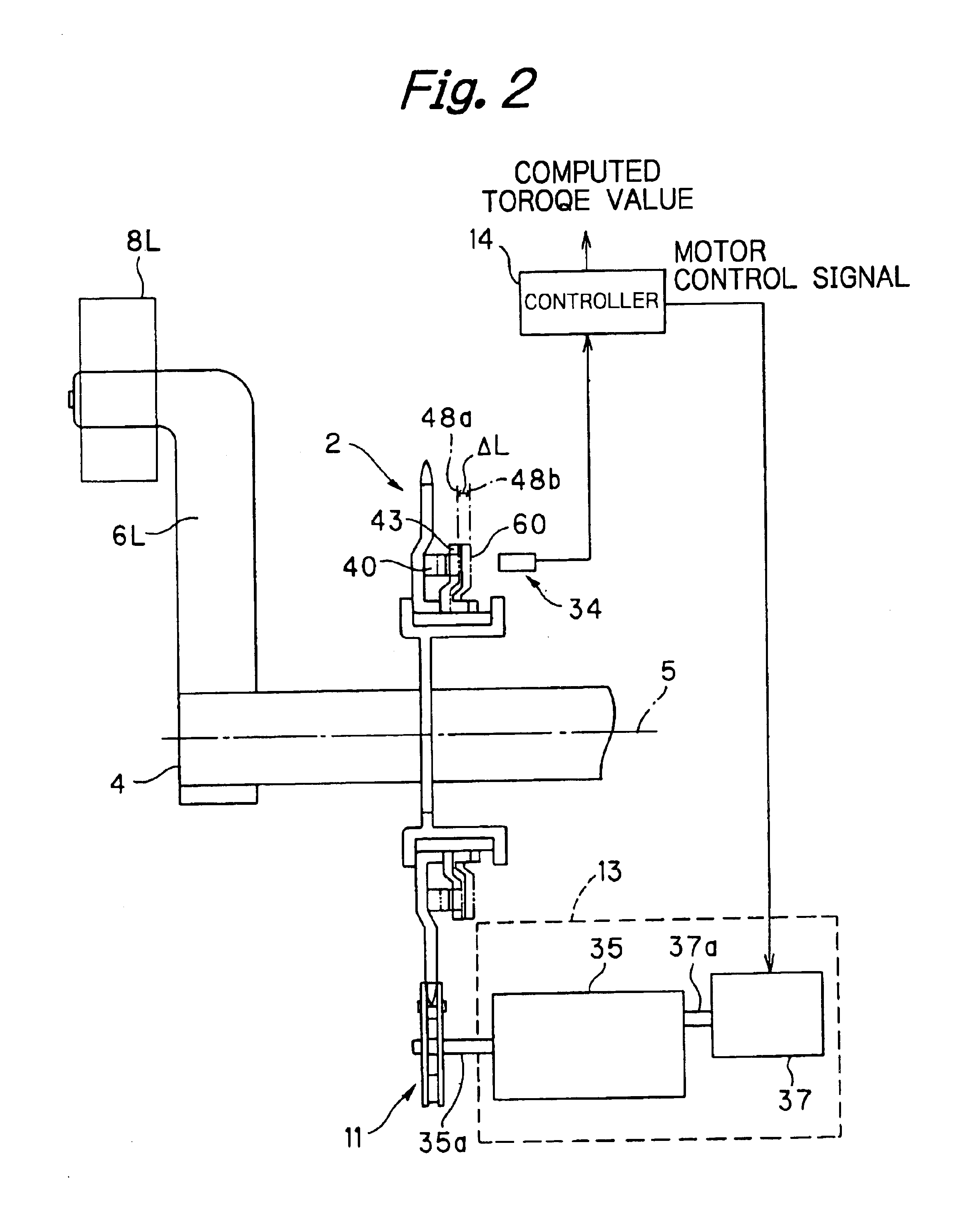

Power-assisted bicycle

InactiveUS6851497B1Simple and light structureProcess economyMechanical actuated clutchesVehicle transmissionDrive shaftSprocket

A power-assisted bicycle includes a torque detection mechanism system that is simple in structure, saves space, and is lightweight. A one-way clutch (72) for transmitting only rotation of the drive shaft (4) to the sprocket (70) in the direction in which the bicycle proceeds is disposed inside a hollow cylindrical portion (82) of the sprocket (70). On the sprocket face opposite thereto, a bearing (74) is engaged with an outer periphery of the cylindrical portion (82), and an elastic disc spring (76) holds the sprocket (70) with the aid of the bearing. The disc spring (76) is fixed to the bicycle body and a strain gauge (80) for detecting a stress deformation of the disc spring (76) is mounted on the surface thereof. As the drive shaft (4) is rotated by the aid of the pedaling torque, the one-way clutch (72) exerts an axially pressing force onto the sprocket (70) to deform the disc spring (76), and the strain gauge (80) detects the stress deformation of the disc spring (76) (that is, a physical parameter associated with the pedaling torque).

Owner:SUNSTAR GIKEN KK +1

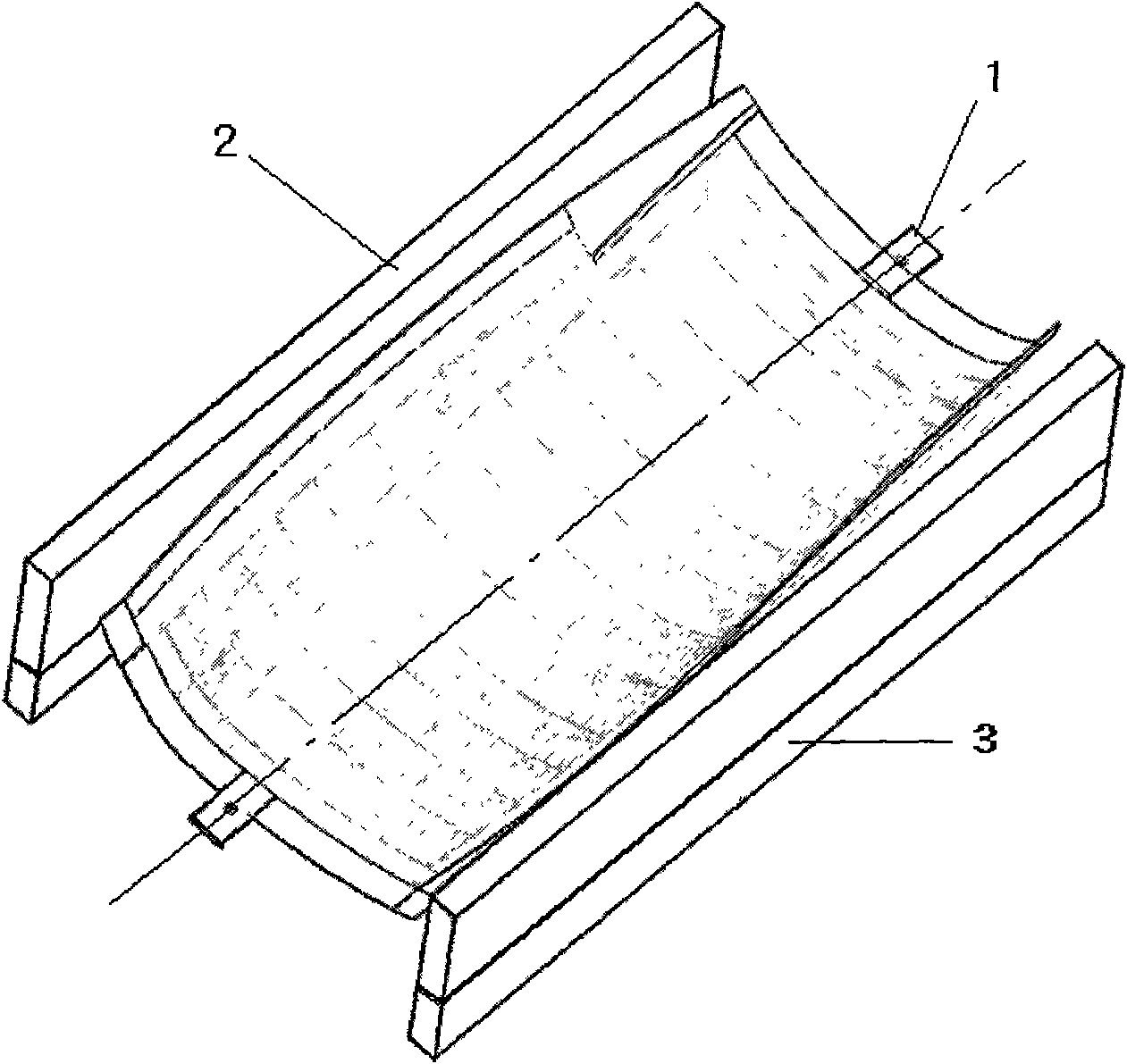

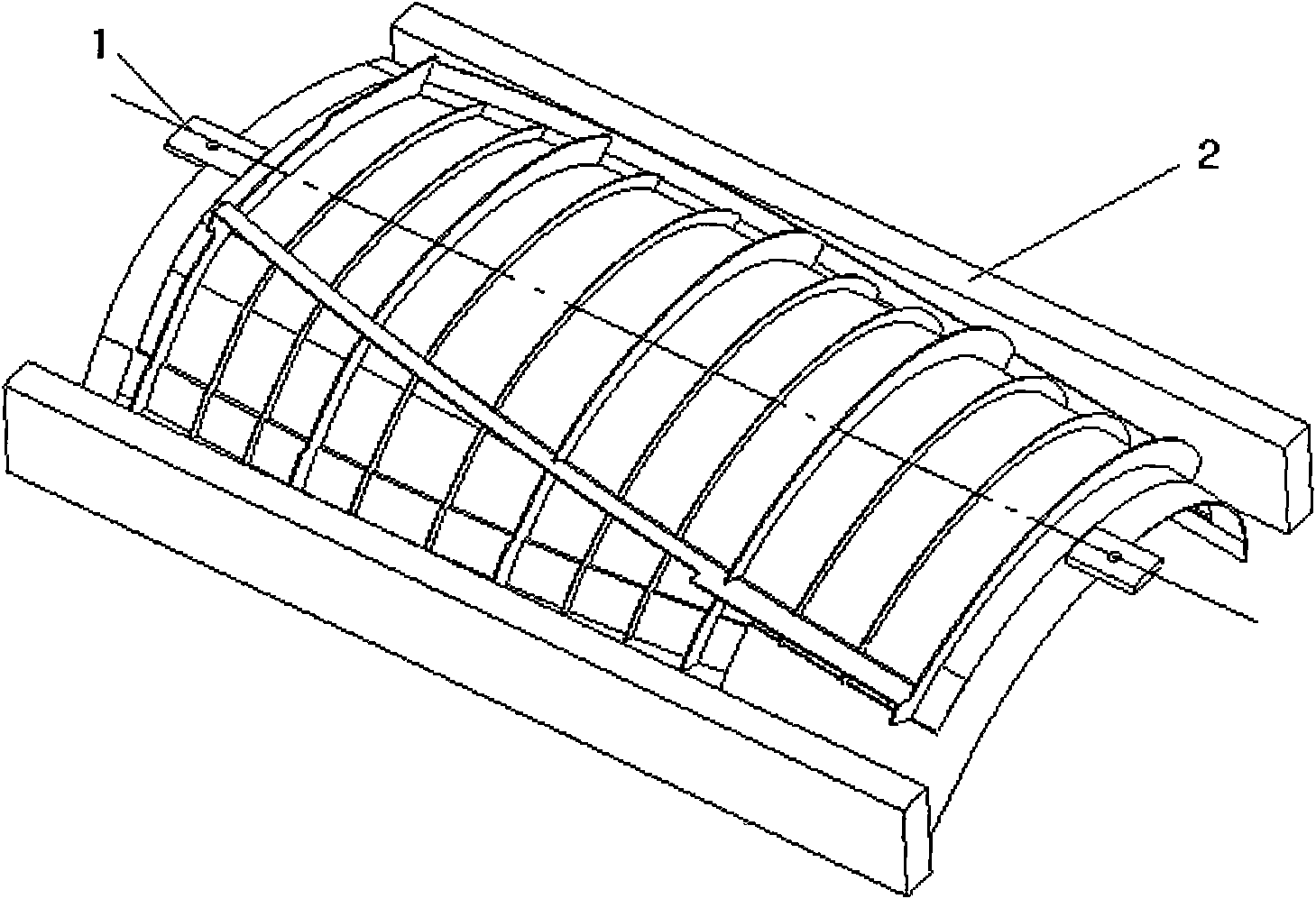

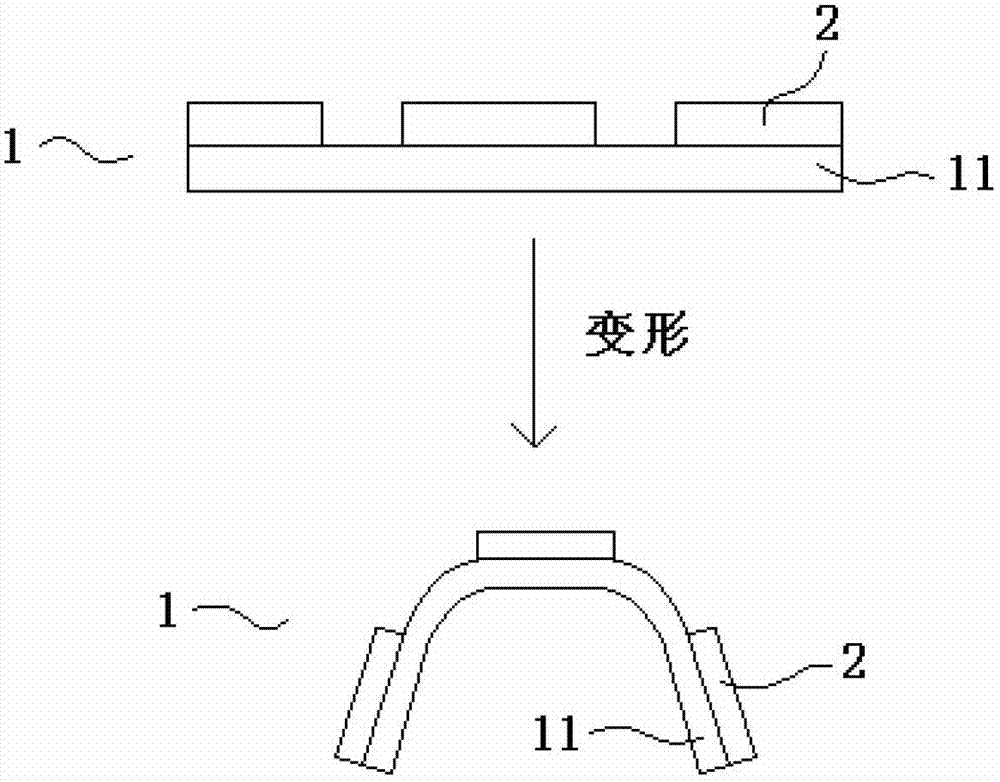

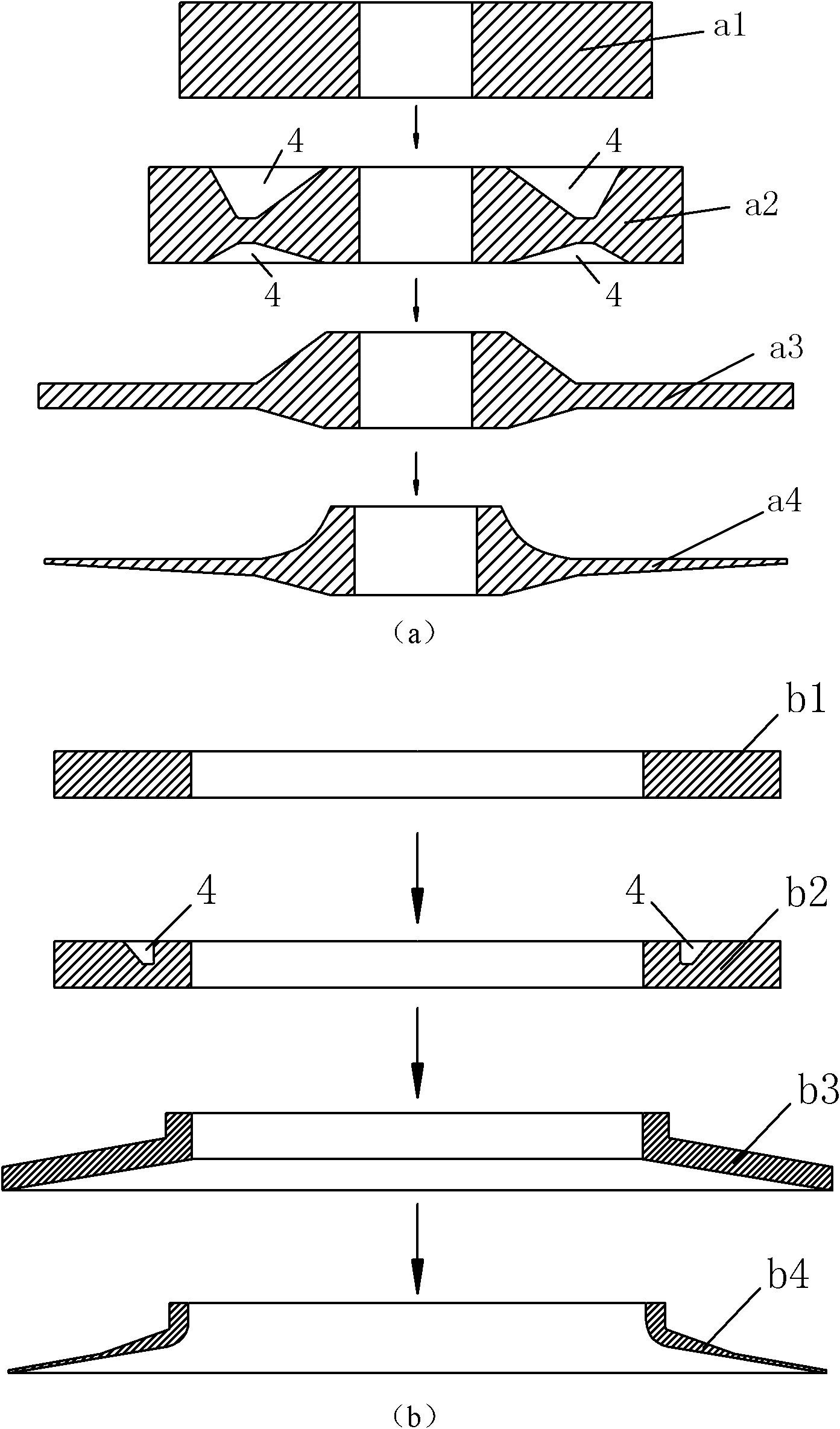

Integral forming method for thin-walled titanium alloy part with irregularly-shaped curved surface and die

InactiveCN102672435AOvercoming shape constraintsOvercome the processShaping toolsLaser beam welding apparatusTitanium alloyMetal

The invention belongs to the field of sheet metal and welding processing, and relates to an integral forming method for a thin-walled titanium alloy part with an irregularly-shaped curved surface. The integral forming method aims at overcoming the defects that the shape of parts processed through the prior art is limited or the procedure and the cost are higher, and effectively ensuring the precision forming of a thin-walled component with an irregular shape. The integral forming method comprises the steps as follows: a parting surface is determined; blanking is carried out; in the preforming step, a plate is bent from a flat into a circular arc through a bending die or a bending machine; welding is carried out; in the hot shaping step, a hot shaping die is put in the inner part of a part that is processed through the assembly welding under the ordinary temperature, and the part is supported tightly due to the dead weight of the die and is heated in a hot shaping machine; and in addition, a pressing machine applies pressure to the hot shaping die when the part is heated until material is softened, so as to enable the part to reach the needed size. The integral forming method comprehensively utilizes the advantages of various processes, can obtain the large-sized thin-walled titanium alloy part with the irregularly-shaped curved surface through only two weld joints, and achieves higher surface quality of the part.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Super plastic forming method for plate type heat converter special titanium plate

InactiveCN101121178AHigh yield strengthEasy to processRoll mill control devicesFurnace typesPlate heat exchangerTitanium

The present invention relates to a superplastic forming method for the titanium plate specially used for the plate type heat exchanger, which belongs to the field of mechanical processing technology. The present invention comprises the following steps that spongy titanium is chosen to be the melted raw material; the spongy titanium is placed in a vacuum plasma smelting furnace to be directly cast into plate base; the plate base forms a plate of a thickness of 2.0 to 2.4 mm after the process of heating, hot rolling, acid and alkali washing; second heating, hot rolling and acid and alkali washing and annealing; the plate of a thickness of 2.0 to 2.4 mm after the annealing in the vacuum smelting furnace forms a titanium plate of a thickness of 0.5 to 0.6 mm after the process of cold rolling, cleaning, second annealing and cold rolling, acid and alkali washing and third annealing. The present invention adopts the process that the spongy titanium which contains oxygen, iron and nitrogen of comparatively high content is directly processed into the titanium plate base in the plasma smelting furnace and directly rolled into the plate without forging and pressing.

Owner:上海桦厦实业有限公司

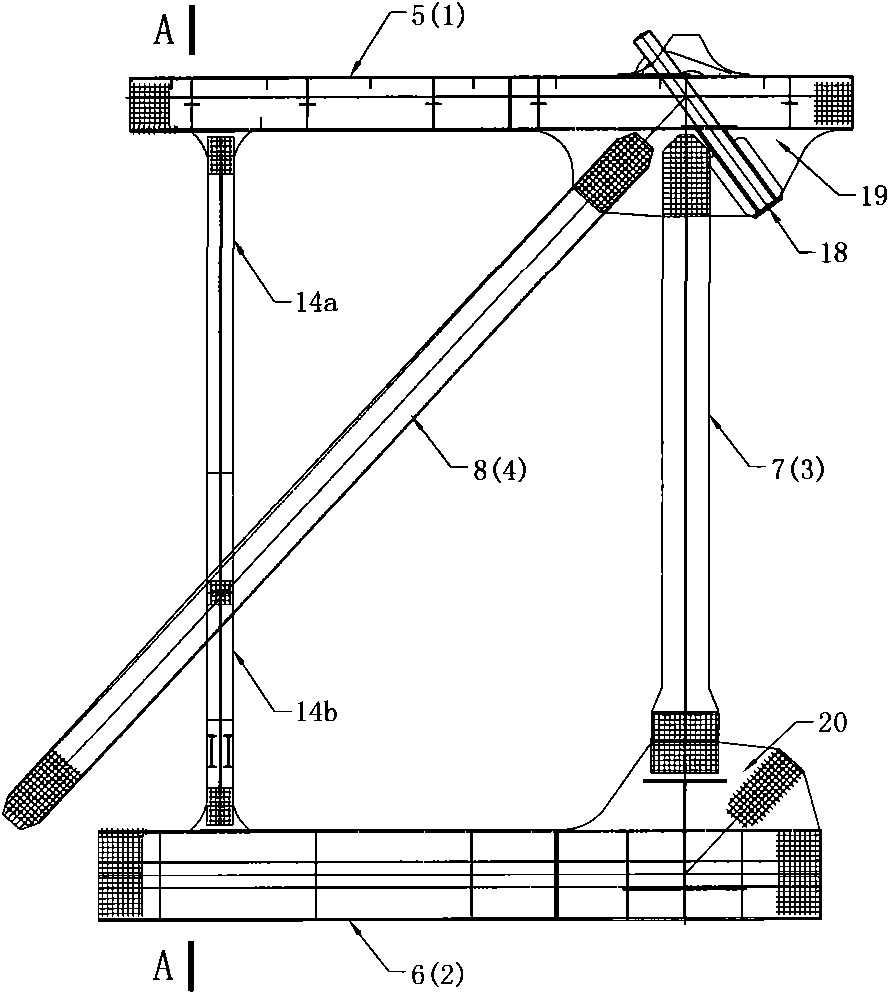

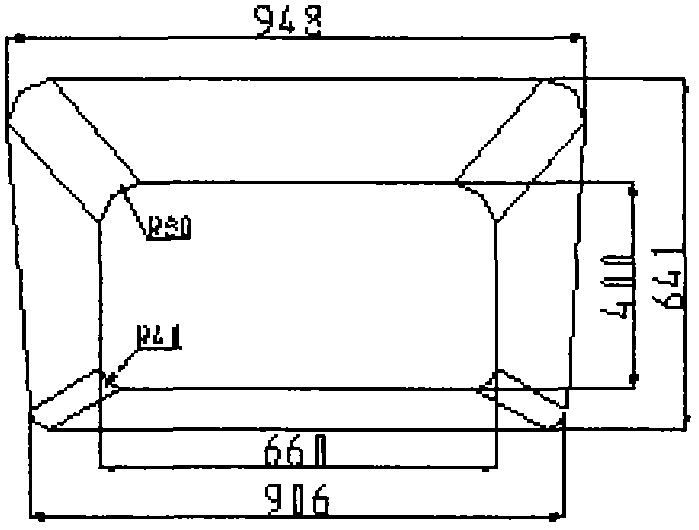

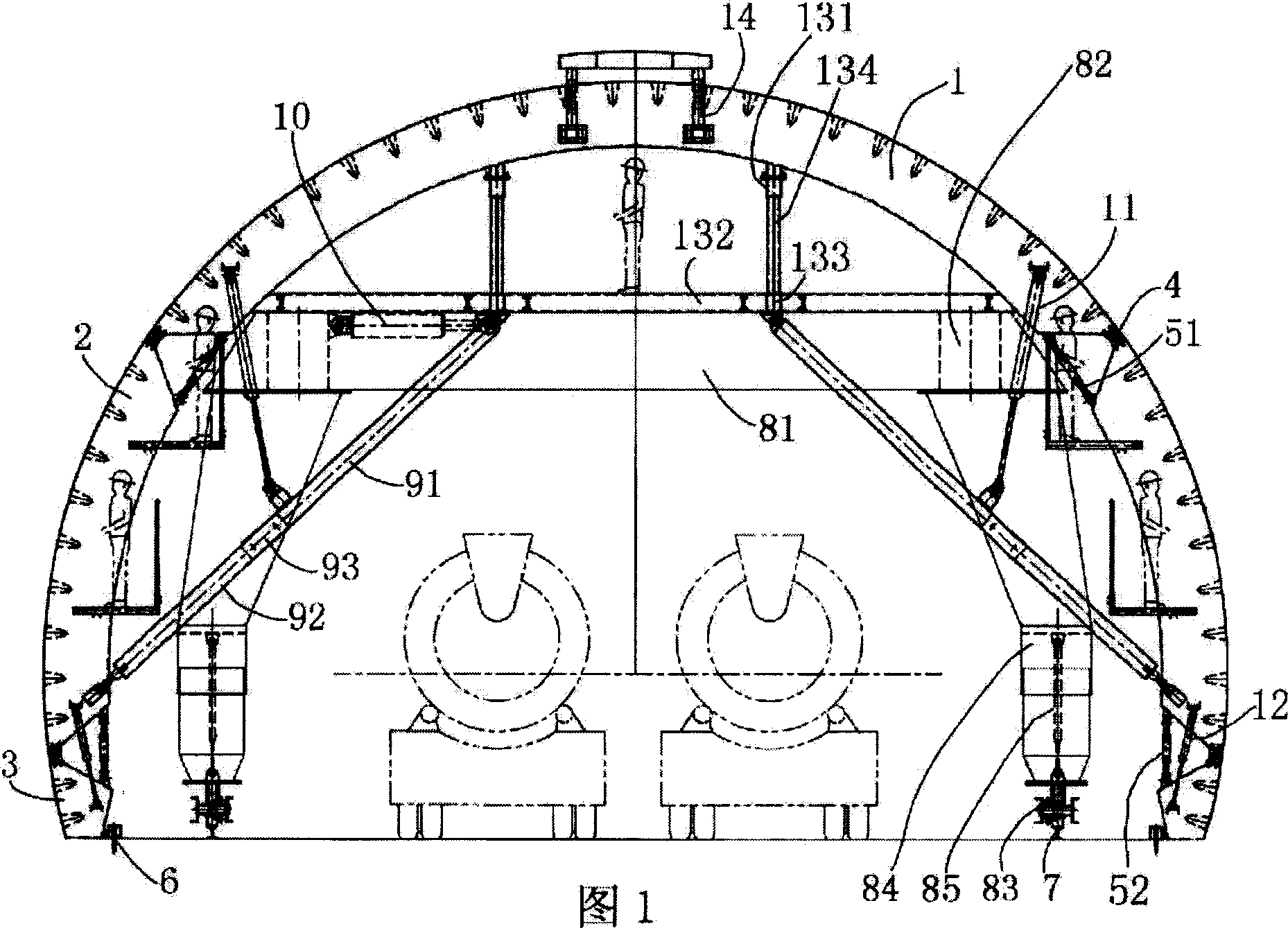

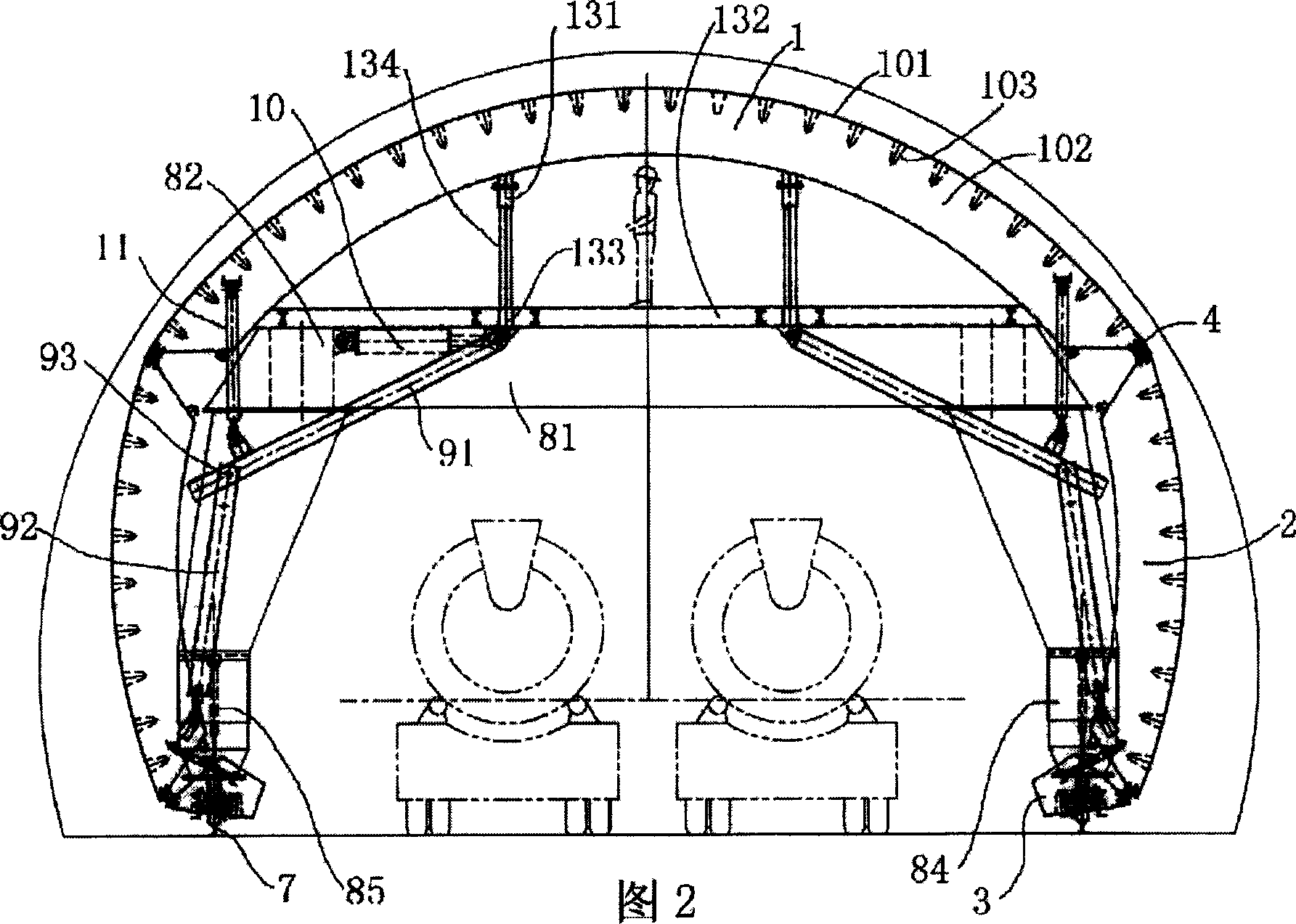

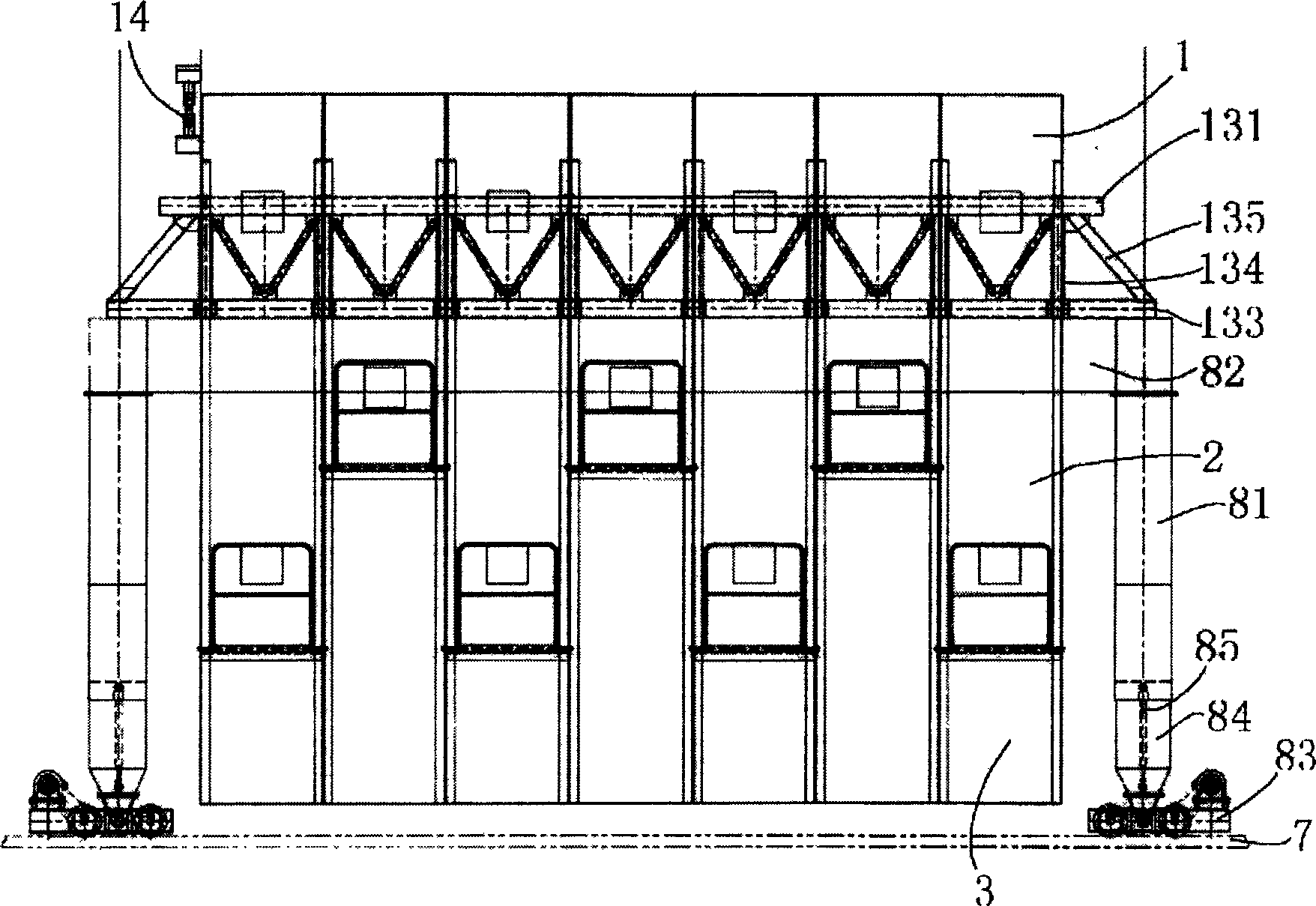

Tunnel lining trolley

InactiveCN1851233AFrame widthIncrease stiffnessUnderground chambersTunnel liningEngineeringMechanical engineering

The invention is a tunnel lining carrier, where a group of templates comprises top plate, two side templates and two bottom templates, the cross sections at the interfaces between the top template and the two side templates and between the two side templates and the two bottom templates are horn-shaped, and their outer edges are hinged with flat top hinge and their inner edges are connected with regulating screws; a template bracket comprises top longitudinal beam, cross beam, bottom longitudinal beam, column and inclined strut. And the carrier comprises door frame, girder summer and moving system; folding supports arms are connected between the bottom surface of the crossbeam and the bottom ends of the two side templates, side moving hydraulic oil cylinder is connected between the bottom longitudinal beam and the girder summer, expanding hydraulic oil cylinders are connected between the large arms of the folding support arms and the two bottom ends of the top template, and opening hydraulic oil cylinders are connected in the horn-shaped positions between the side and bottom templates.

Owner:杨秋利

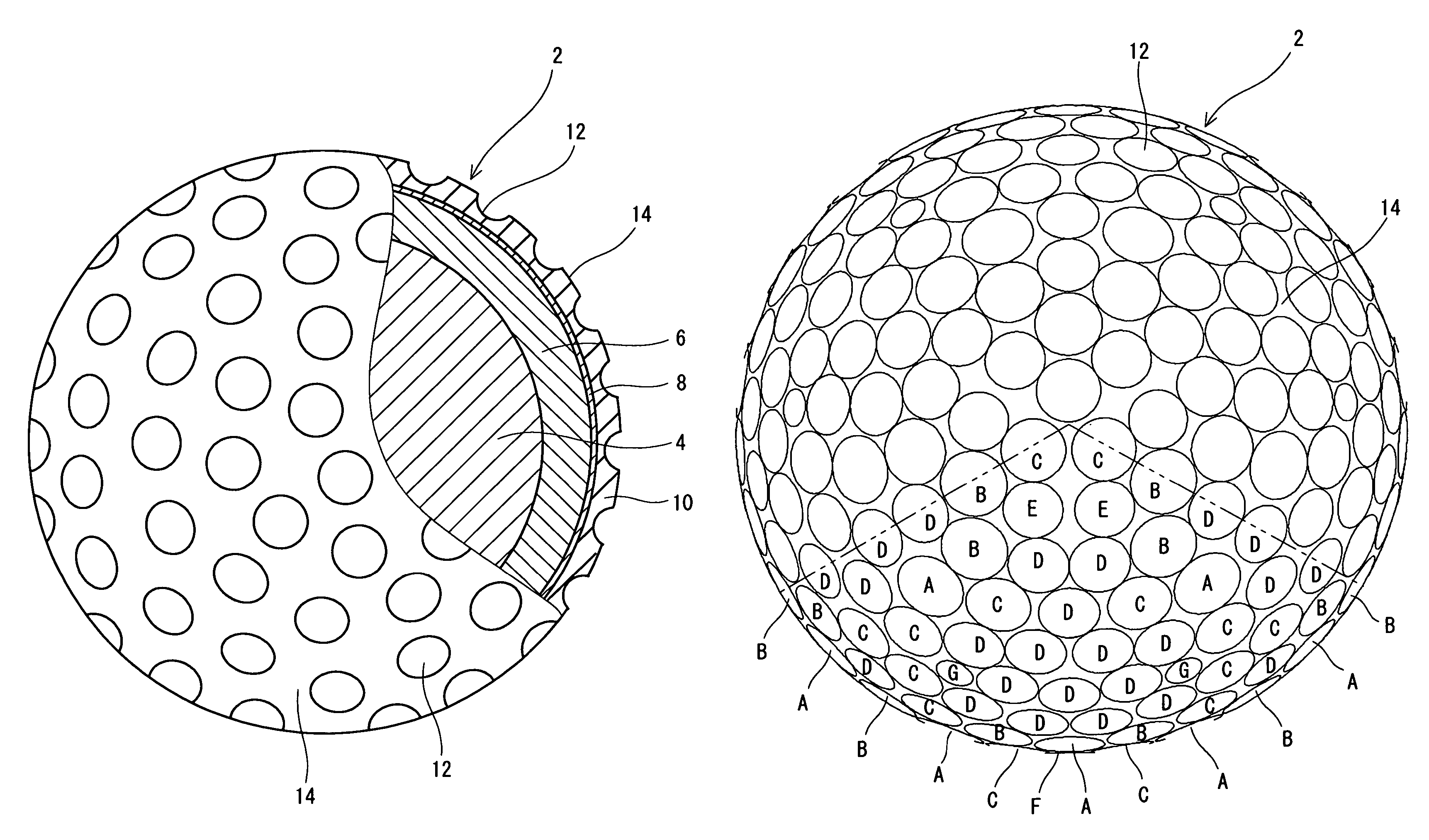

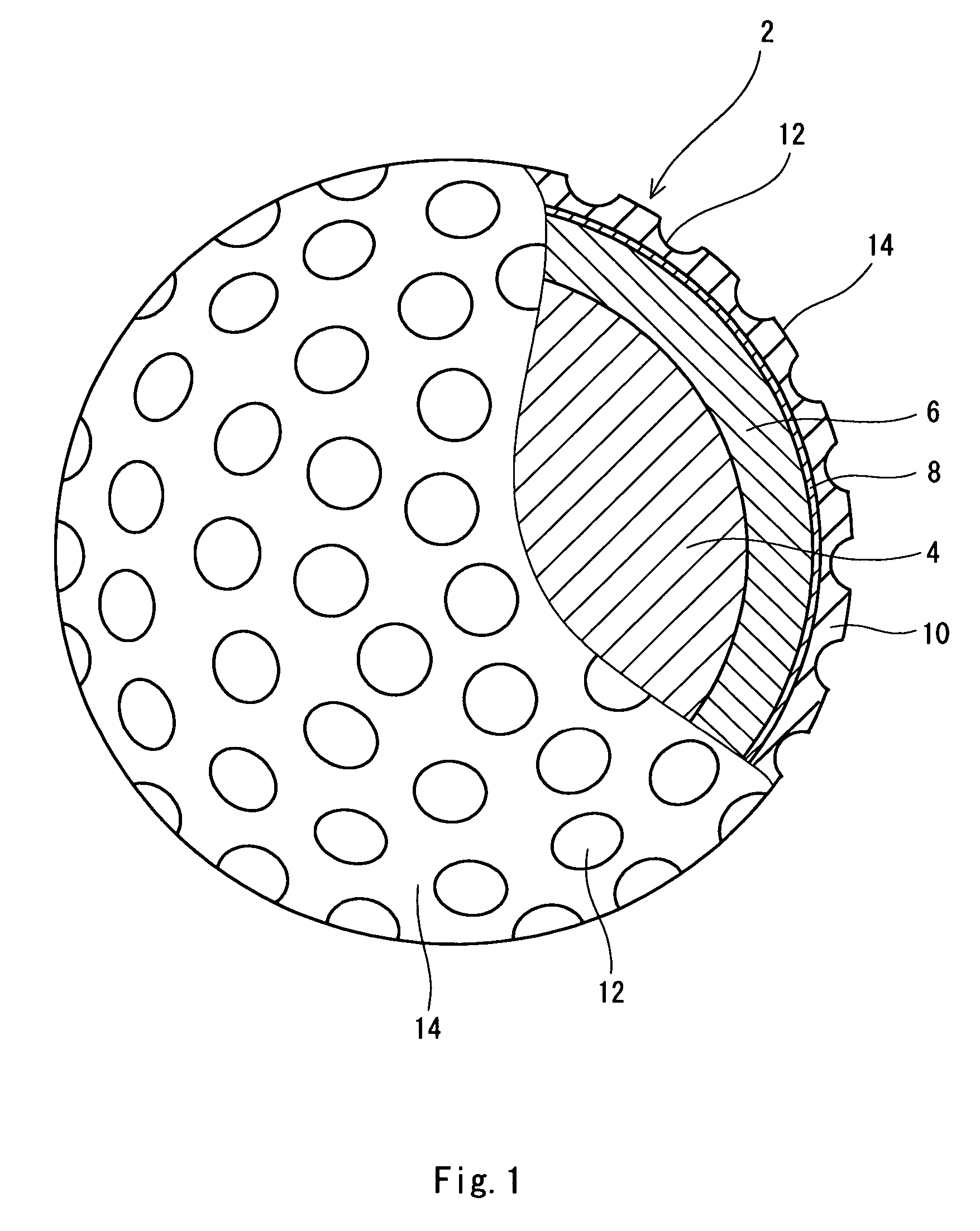

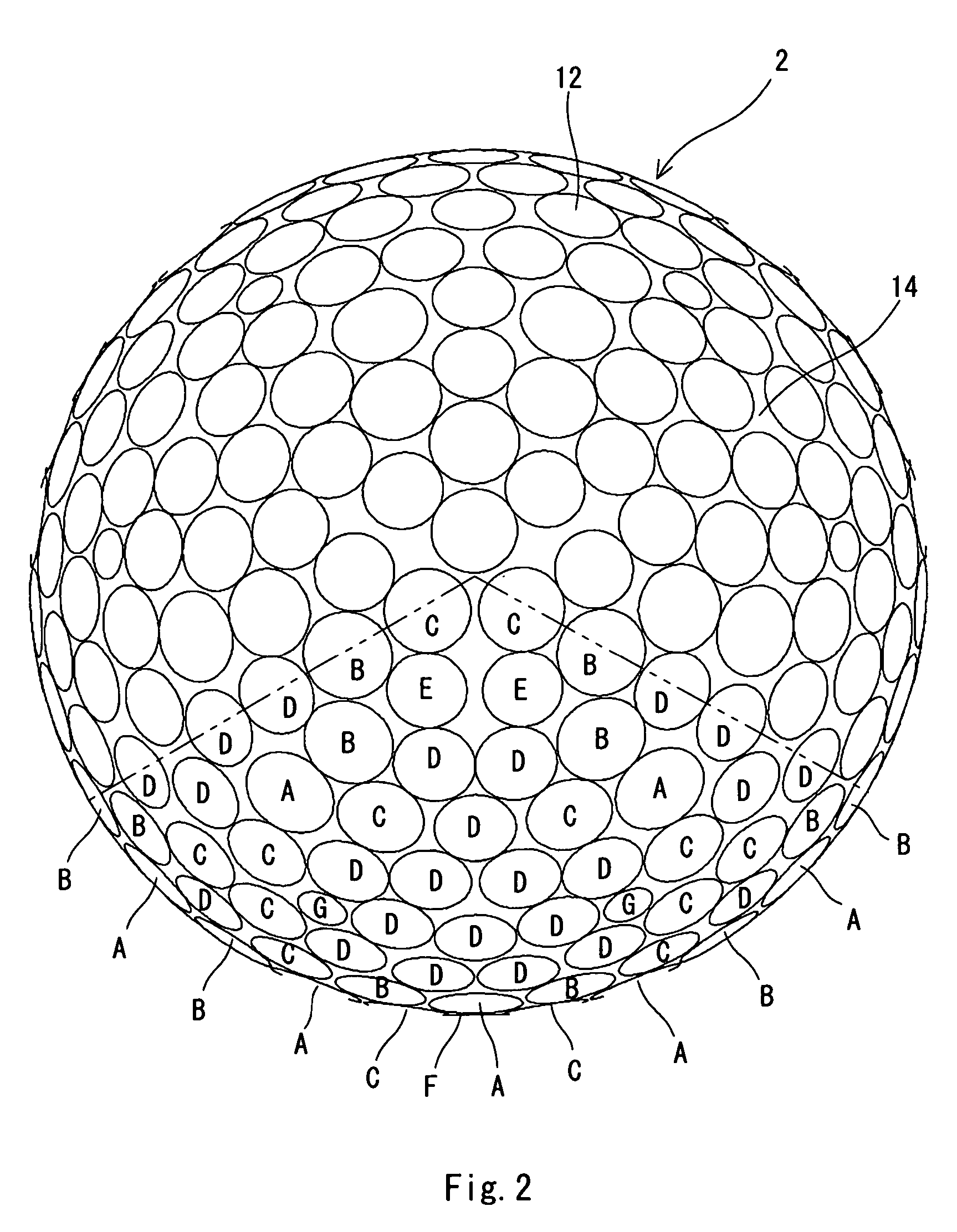

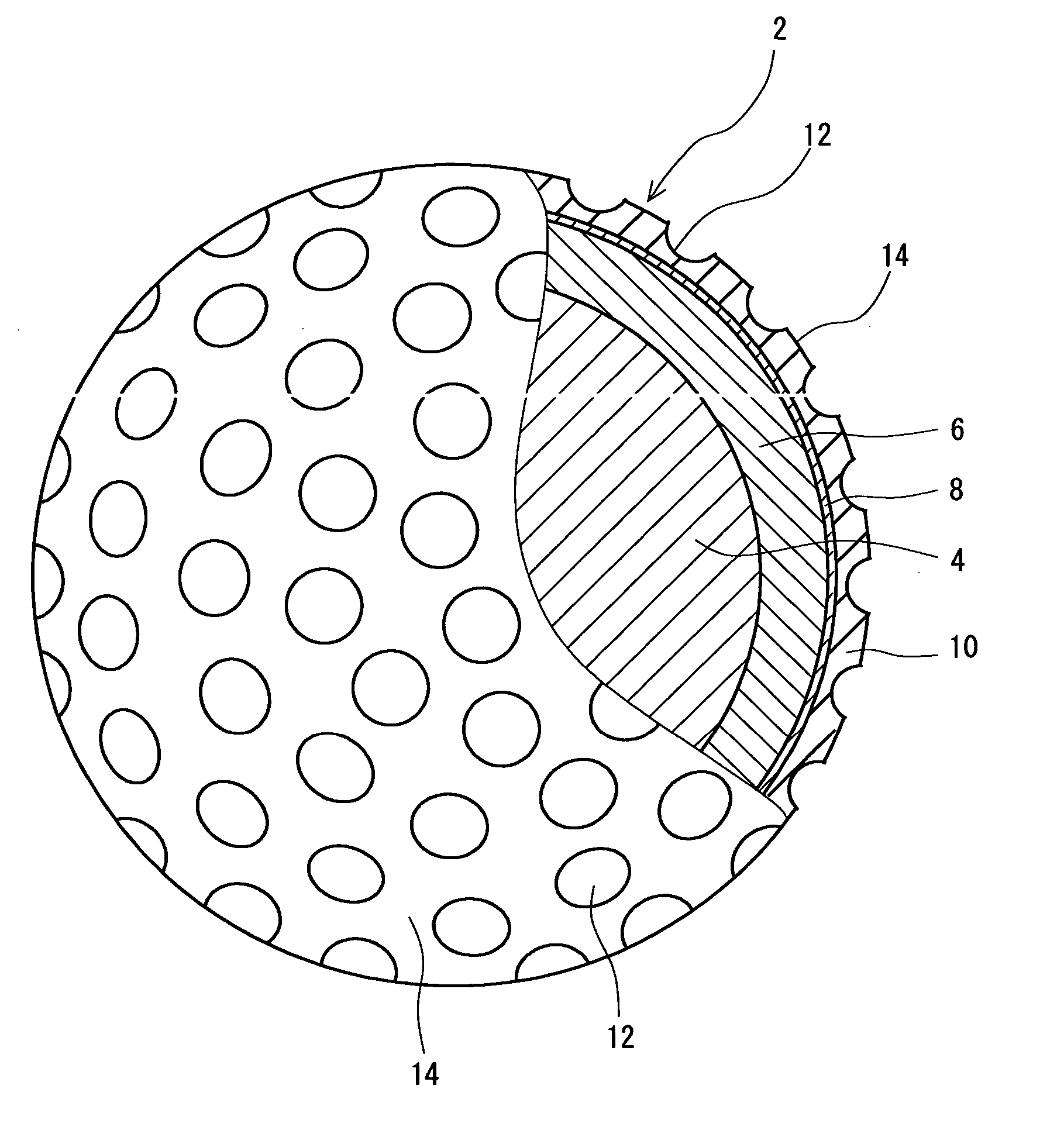

Golf ball

InactiveUS7278930B2Improve control effectSmall amount of deformationGolf ballsSolid ballsMean diameterThermoplastic polyurethane

Golf ball 2 has a core 4, a mid layer 6, a reinforcing layer 8, a cover 10 and dimples 12. Base polymer of the mid layer 6 includes an ionomer resin as a principal component. The reinforcing layer 8 includes a thermosetting resin as a base polymer. Base polymer of the cover 10 includes a thermoplastic polyurethane elastomer as a principal component. The cover 10 has a thickness Tc of equal to or less than 0.6 mm. The cover has a hardness Hc of equal to or less than 54. The cover has a volume V of equal to or less than 3.0 cm3. Product obtained by multiplying the thickness Tc, the hardness Hc and the volume V is equal to or less than 90. Ratio (Dx / Dn), which is a ratio of a mean diameter of the dimples ranking in the top 10% Dx to a mean diameter of the dimples ranking in the bottom 10% Dn when all the dimples are arranged in decreasing order of the diameter is equal to or greater than 1.30. Standard deviation η of the diameter of all the dimples is equal to or less than 0.52.

Owner:SUMITOMO RUBBER IND LTD

Rotary forging method for large disc type work piece and forging device

InactiveCN101862807ALow manufacturing costReduce the amount of machiningForging/hammering/pressing machinesWheelsForgingMaterials science

The invention provides a rotary forging method for large disc type work pieces and a forging device. The method comprises preparing a forging die, preparing blanks, pre-forging a shunt slot, positioning the blanks and carrying out rotary forging in steps. Based on the method, the invention also provides a forging device which can realize relative rotation of an upper forging die and a lower die, and the local forming process for the disc type work pieces can be carried out through rotary forging of the upper forging die and the lower die. In order to control metal flow in the forging process, the procedure of pre-forging the shunt slot is added prior to the rotary forging. Moreover, the upper forging die with a special structure is adopted to overcome the warpage of the work pieces during rotary forging. The forming method has the advantages of low forming load, simple dies and low processing cost, and can greatly reduce the manufacturing cost of existing large disc type work pieces.

Owner:XI AN JIAOTONG UNIV +1

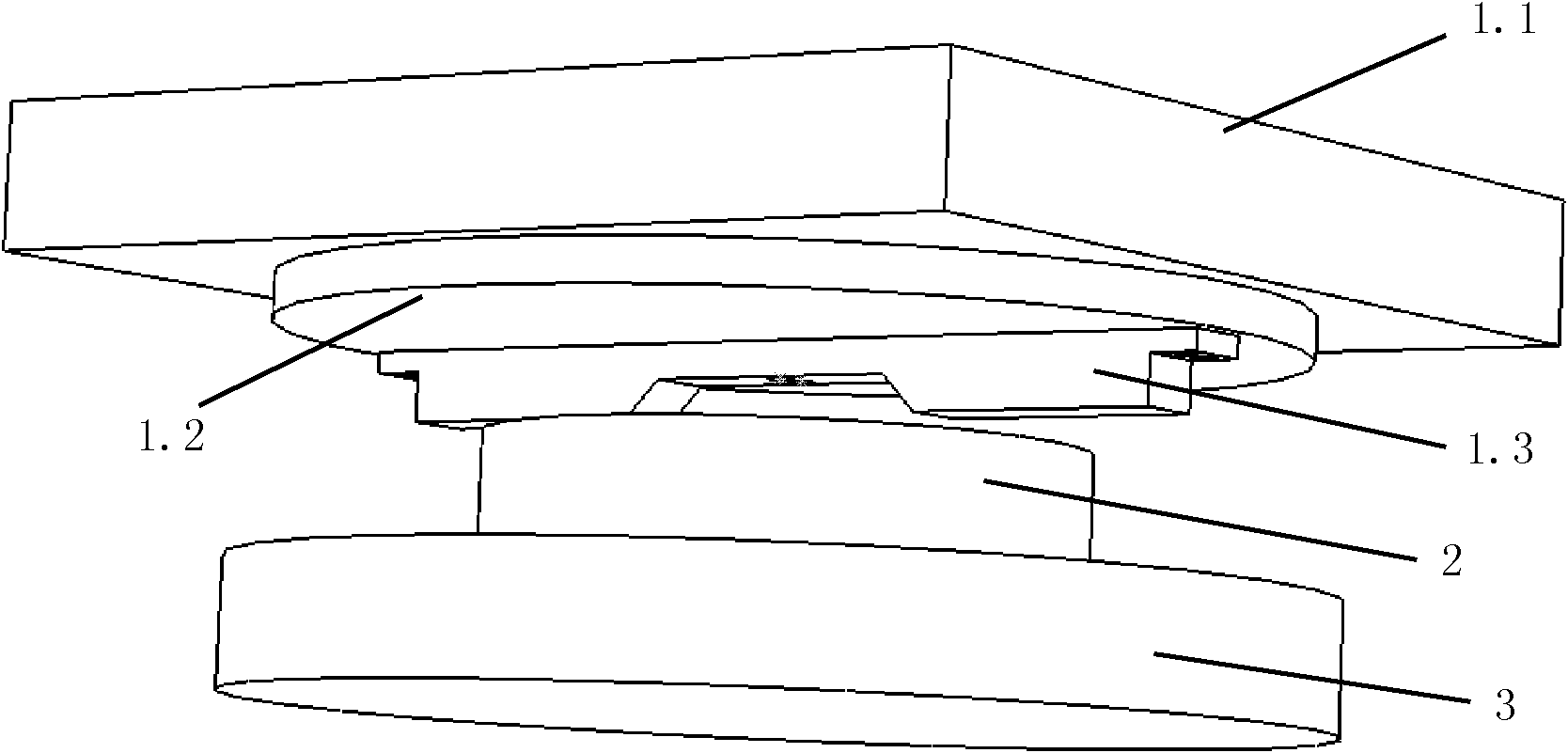

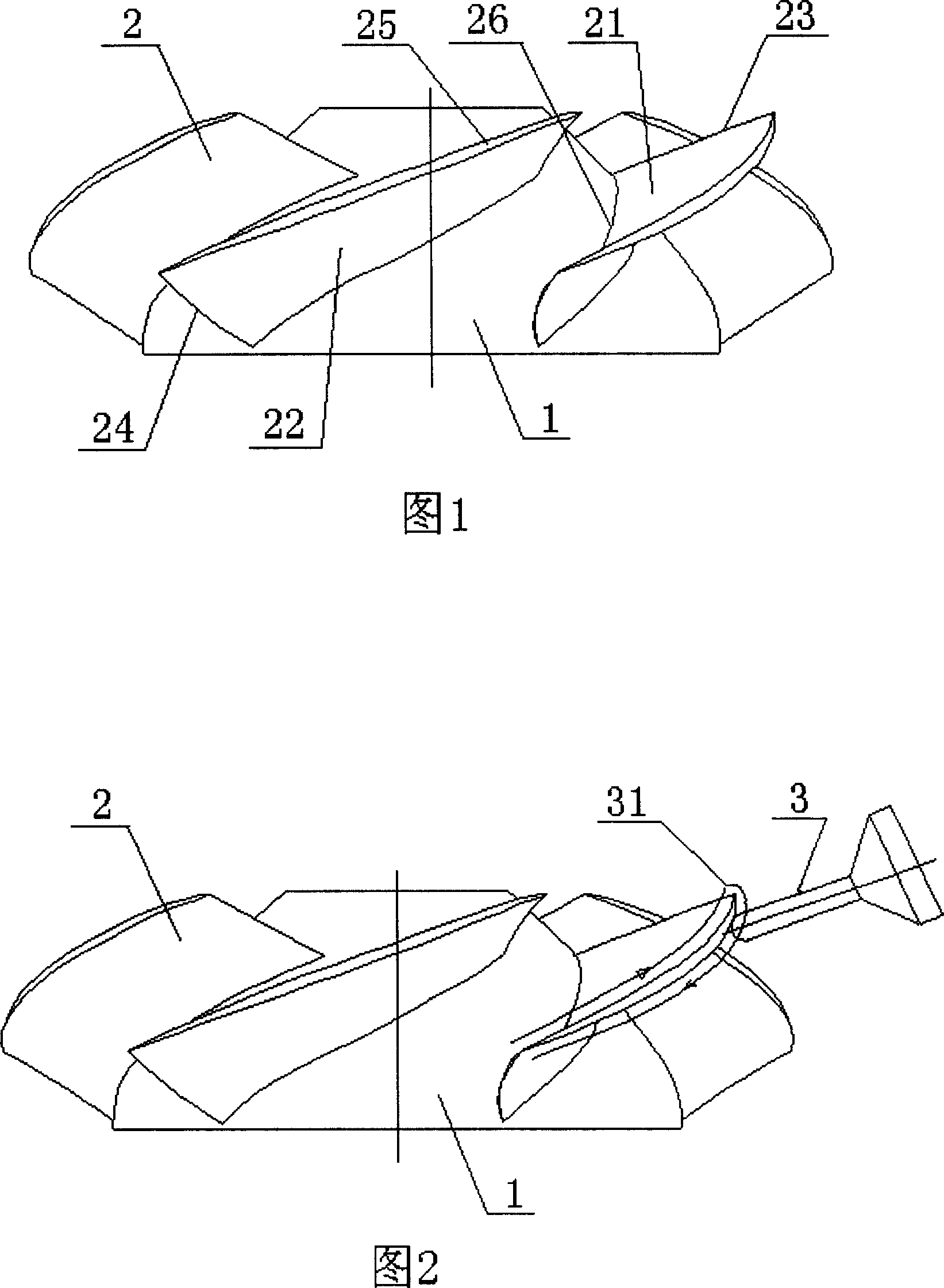

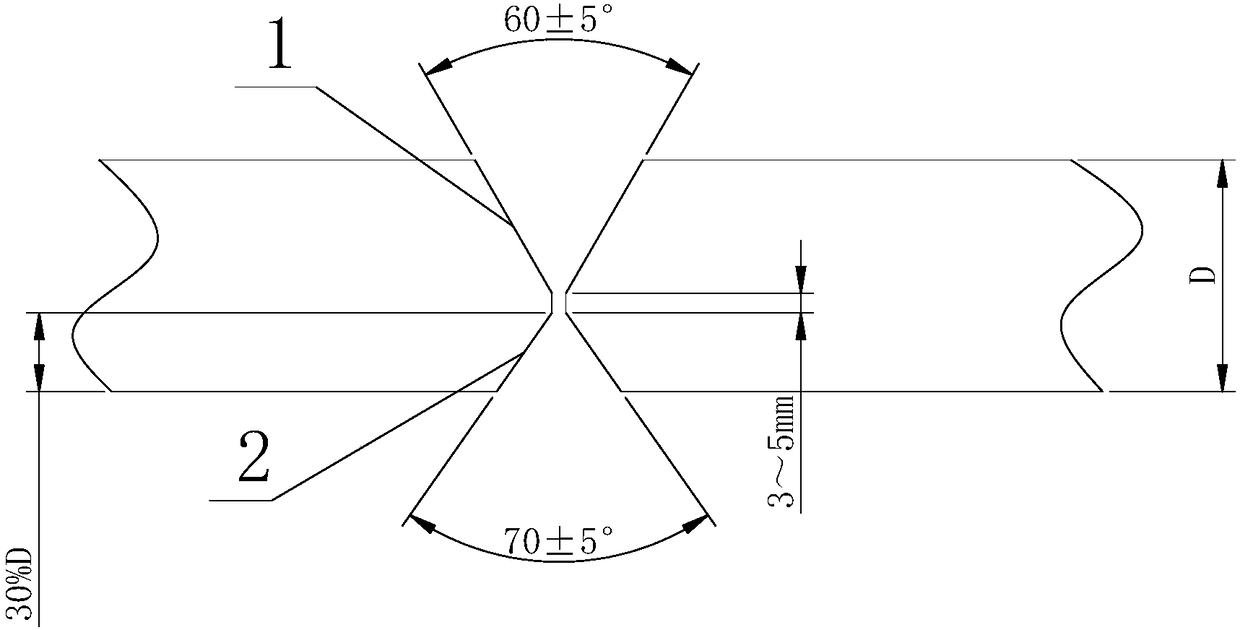

Slotting and milling process for vane of integral vane wheel

InactiveCN1986127ASmall radial componentSmall amount of deformationMilling cuttersImpellerNumerical control

The slotting and milling cutter process for vane of integral vane wheel is completed in a numerically controlled machine tool with slotting and milling cutter advancing in the radial direction of the vane wheel and axial direction of the cutter. It has small radial force component caused by cutting, less vibration of the workpiece and the cutter, smooth cutting, small and controllable vane deformation, high machining quality and high machining efficiency. The present invention can meet the requirement of machining great diameter and high precision vane wheel product.

Owner:WUHAN MARINE MACHINERY PLANT

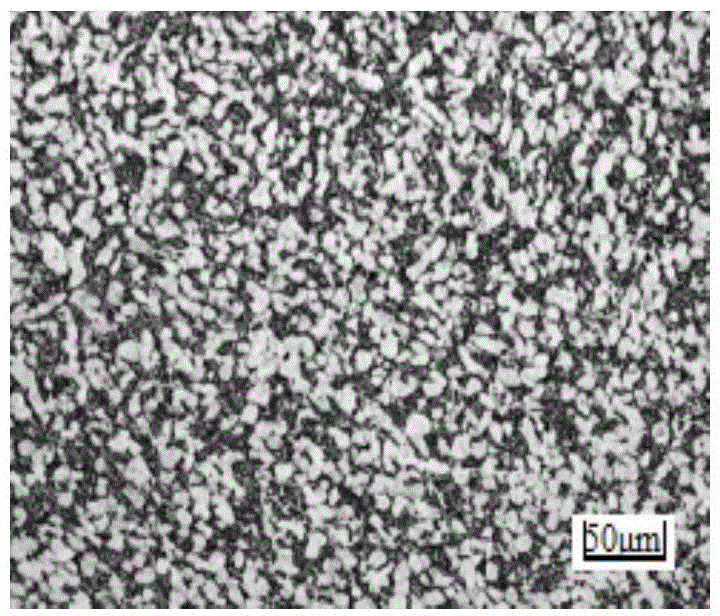

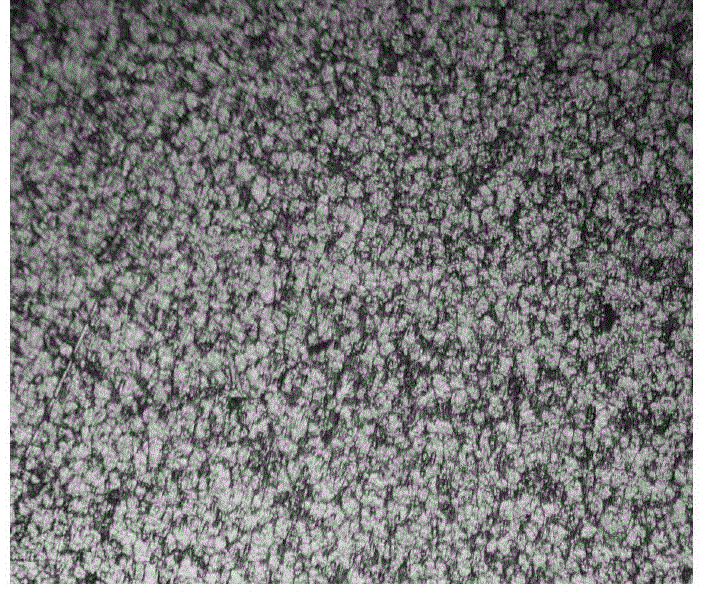

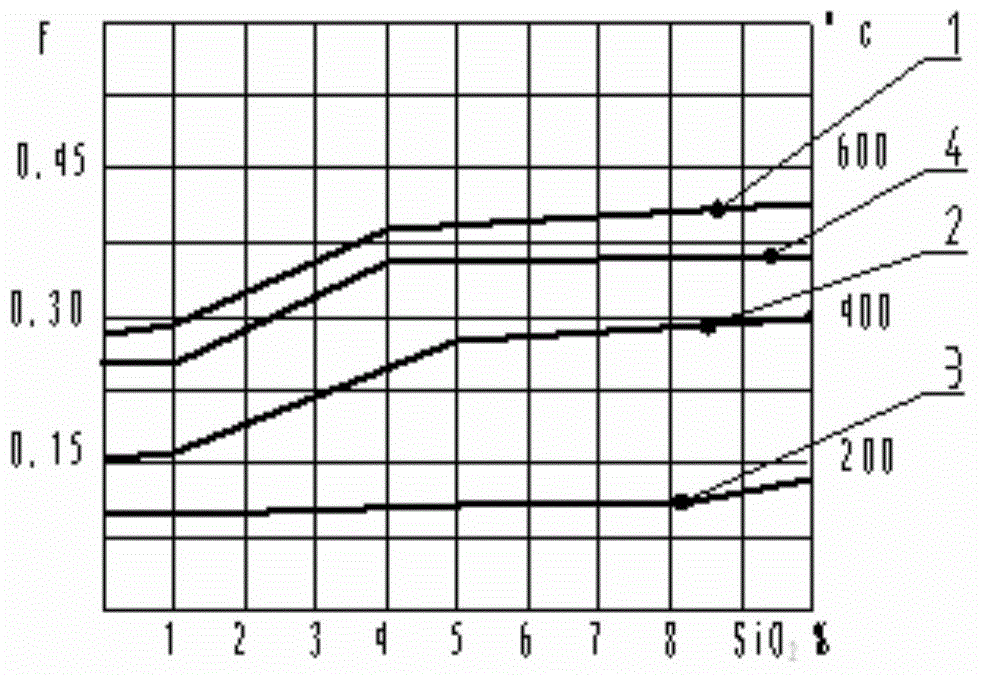

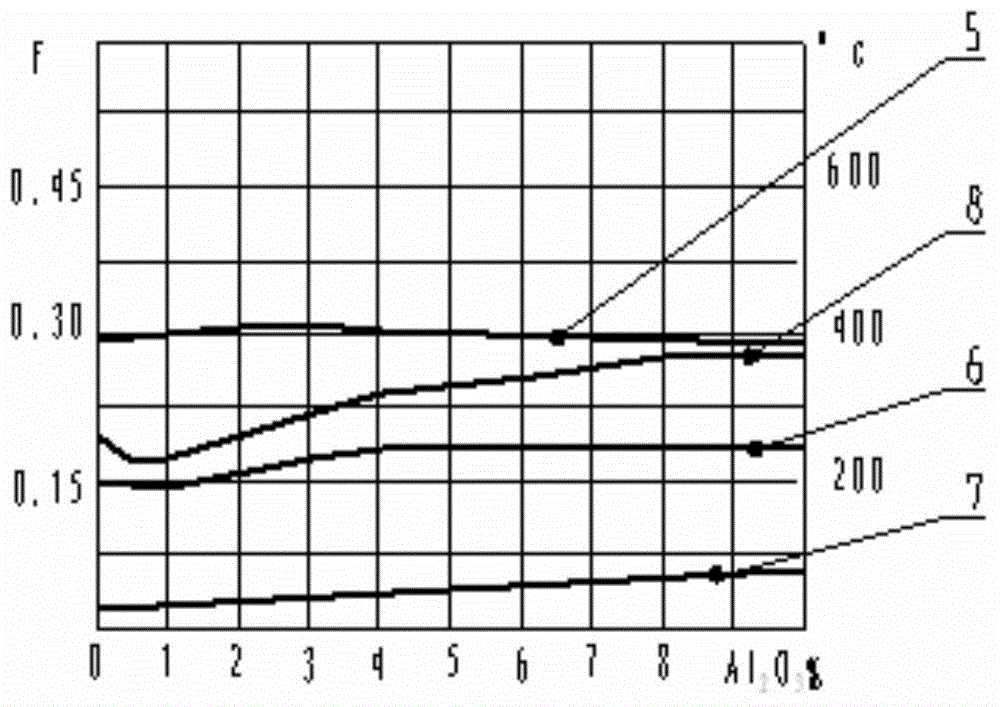

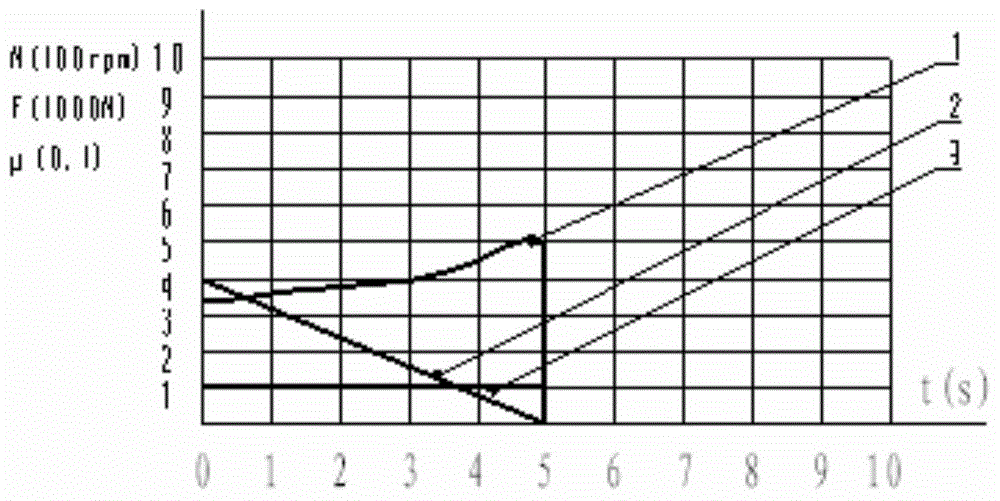

Iron-based powder metallurgy friction material and preparation method thereof

The invention provides an iron-based powder metallurgy friction material and a preparation method thereof. The iron-based powder metallurgy friction material is prepared from iron powder, copper powder, manganese powder, graphite powder, silicon carbide powder, molybdenum disulfide powder, silicon dioxide powder, aluminum oxide powder and precipitated barium sulfate powder; the system matching effects of an iron alloy matrix, a lubricating component, a solid friction component and the like are developed, and the high-performance iron-based powder metallurgy friction material which has excellent mechanical strength and can be used at a low speed and within a wide pressure range can be obtained. The friction coefficient of the iron-based powder metallurgy friction material is greater than 0.32, while the abrasion loss of the same is less than or equal to 0.0005mm per face at each time.

Owner:XIAN AVIATION BRAKE TECH

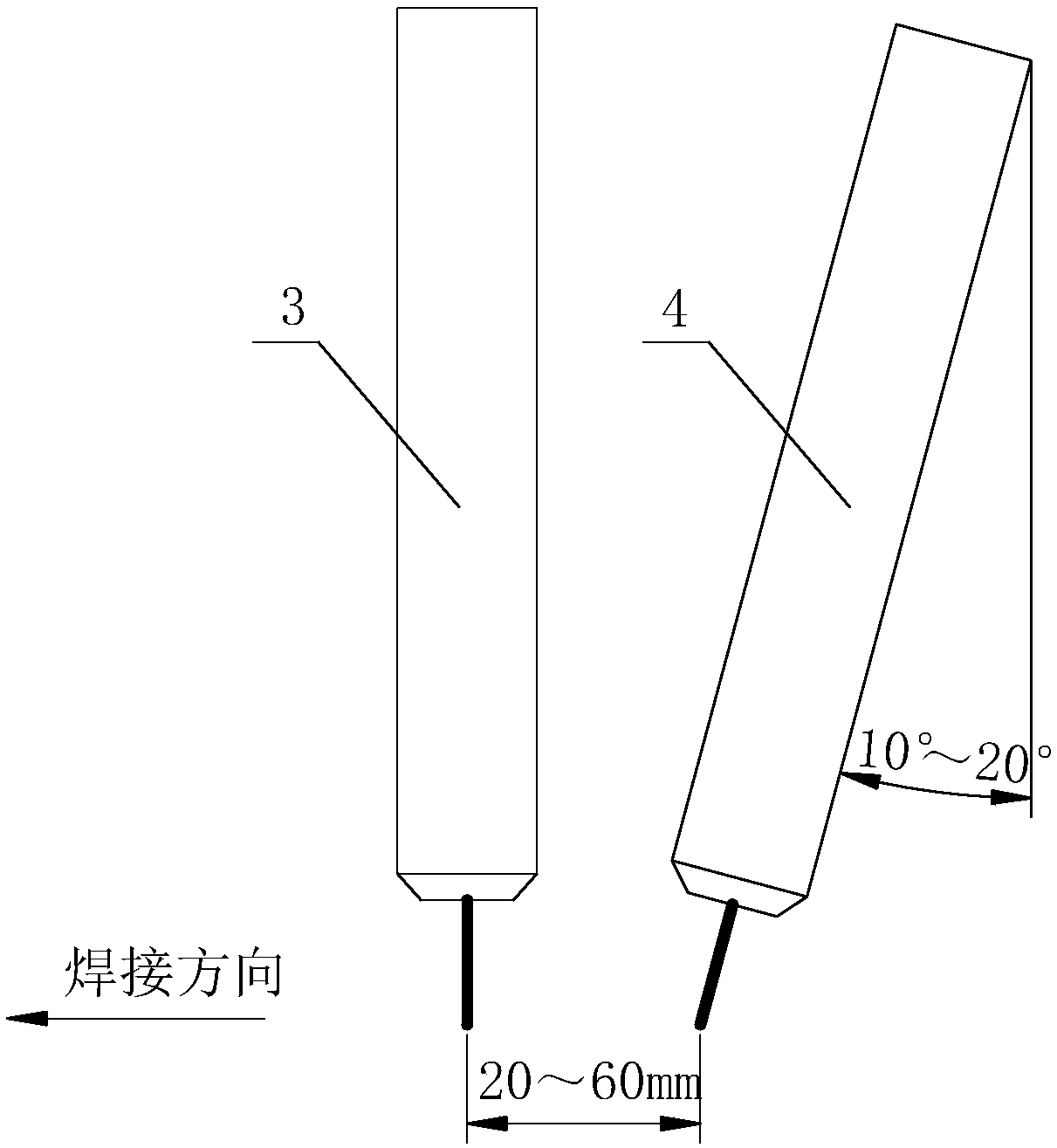

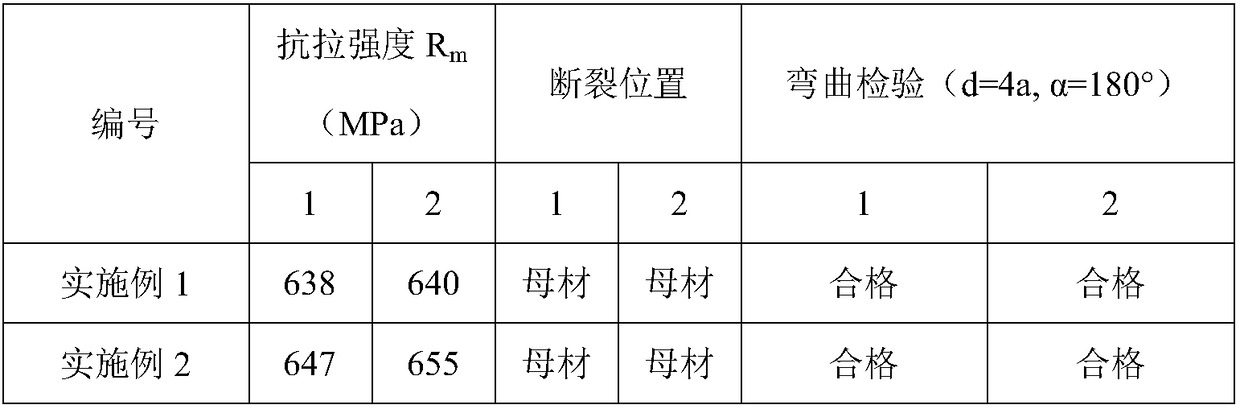

Double-wire submerged arc welding method for high heat input energy welding of high-strength super-thick steel plates

InactiveCN109014513AImprove performanceSimple methodArc welding apparatusWelding/cutting media/materialsSheet steelEngineering

The invention relates to a double-wire submerged arc welding method for the high heat input energy welding of high-strength super-thick steel plates. Double-wire submerged arc welding is carried out on the steel plates of which the thickness is larger than 50mm without carrying out preheating before welding or carrying out heat treatment after welding. The total welding heat input energy of double-wire submerged arc welding is controlled at 100+ / -5kJ / cm, interlayer temperature is controlled between 100DEG C and 150DEG C, and the welding groove type belongs to a non-symmetrical X type. The double-wire submerged arc welding method has the advantages that the method is simple, easy to operate and efficient, saves energy and is particularly suitable for guiding the building construction of a large steel structure; and the quality of welding joints is excellent, the deformation degree of the welded plates is very small, welding defects are effectively avoided, welding deformation is controlled, the welding efficiency is increased, and the welding operation intensity is reduced.

Owner:ANGANG STEEL CO LTD

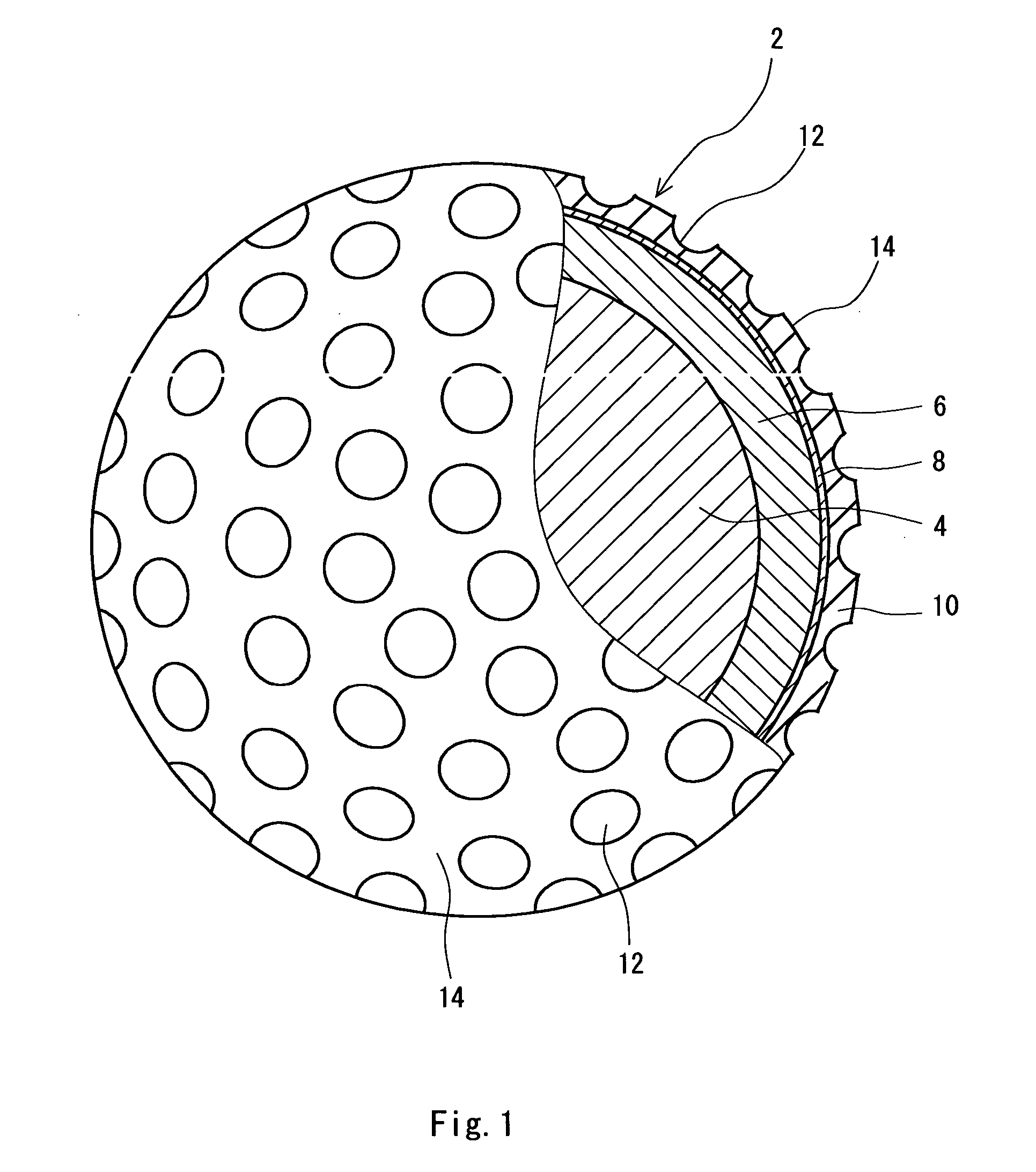

Golf ball

InactiveUS20060025238A1Great spin rateExcellent in control performanceGolf ballsSolid ballsEngineeringThermoplastic polyurethane

Golf ball 2 has a spherical core 4, a mid layer 6 covering this core 4, a reinforcing layer 8 covering this mid layer 6, and a cover 10 covering this reinforcing layer 8. Base polymer of this mid layer 6 includes an ionomer resin as a principal component. Base polymer of this cover 10 includes a thermoplastic polyurethane elastomer as a principal component. The cover 10 has a thickness Tc of equal to or less than 0.6 mm. The cover 10 has a hardness Hc as measured with a Shore D type hardness scale of equal to or less than 54. The cover 10 has a volume V of equal to or less than 3.0 cm3. A product obtained by multiplying the thickness Tc, the hardness Hc and the volume V is equal to or less than 90. The reinforcing layer 8 includes a thermosetting resin as a base polymer. The reinforcing layer has a thickness of 3 μm or greater and 50 μm or less.

Owner:SUMITOMO RUBBER IND LTD

Machining process of middle-long thin-wall blades

ActiveCN103008741AReduce cumulative errorReduce processing stress deformationMilling equipment detailsEngineeringMachining process

The invention discloses a machining process of middle-long thin-wall blades, which belongs to the technical field of machining of blades. The machining process is implemented by a detailed process of integrated rough machining and integrated fine machining, wherein the integrated rough machining comprise the specific steps of rough machining of each surface of a blade tip, each surface of a blade root and a molded surface of a steam passage; and the integrated fine machining comprises the specific steps: semifinishing of each surface of the blade tip and each surface of the blade root, fine machining of each surface of the blade tip, each surface of the blade root and each residue, semifinishing of the steam passage and fine machining of the steam passage. According to the machining process of the middle-long thin-wall blades, the operation is simple and convenient, the use is convenient and fast, the cost is low, the machining efficiency is high, and the operation is easy and labor-saving; and the deformation of the middle-long thin-wall blades is controlled within 0 to 0.8mm, the normal machining of a subsequent mold correction process is facilitated, and the machining of each blade is finished once.

Owner:SICHUAN MIANZHU XINKUN MACHINERY MAKING

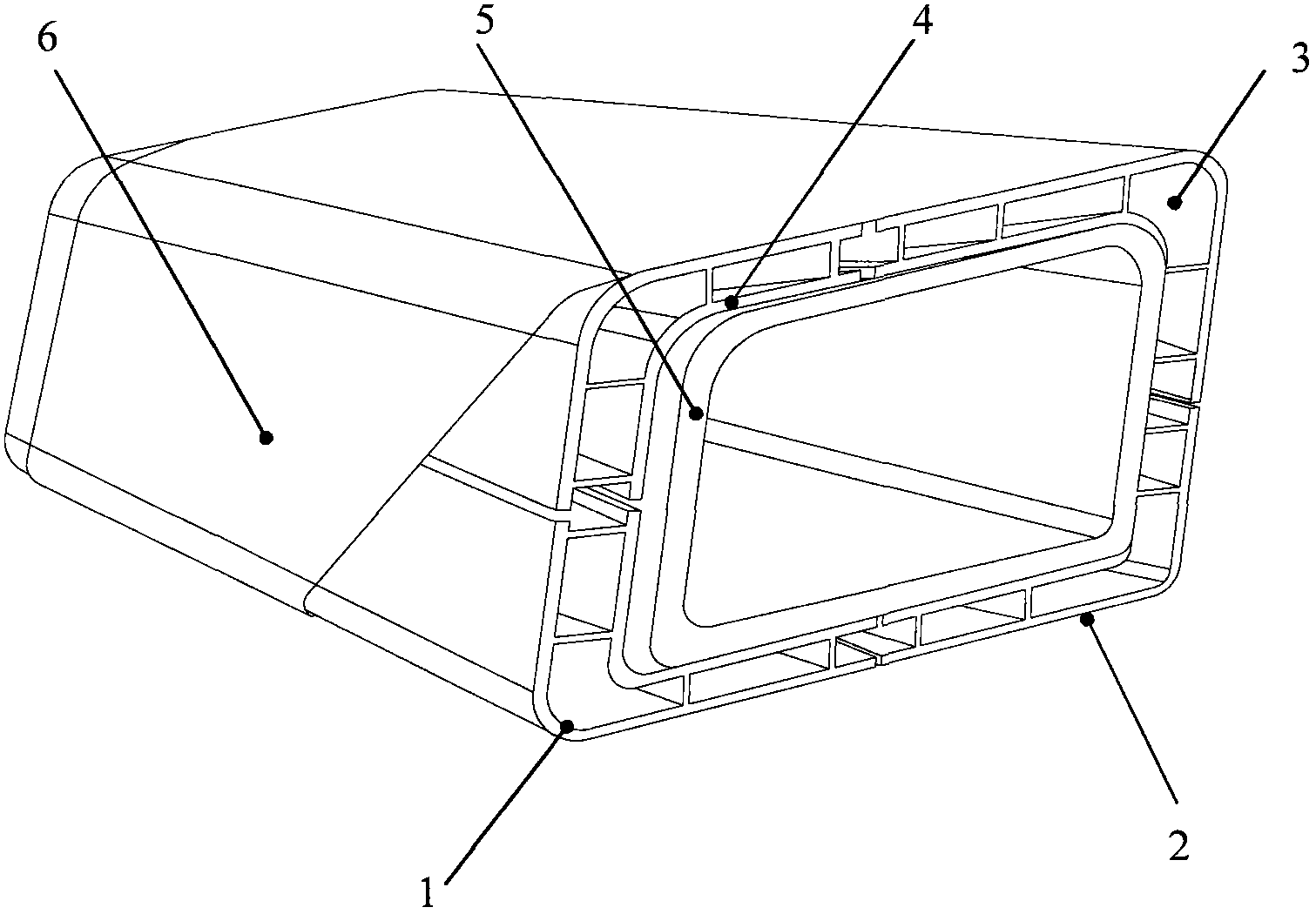

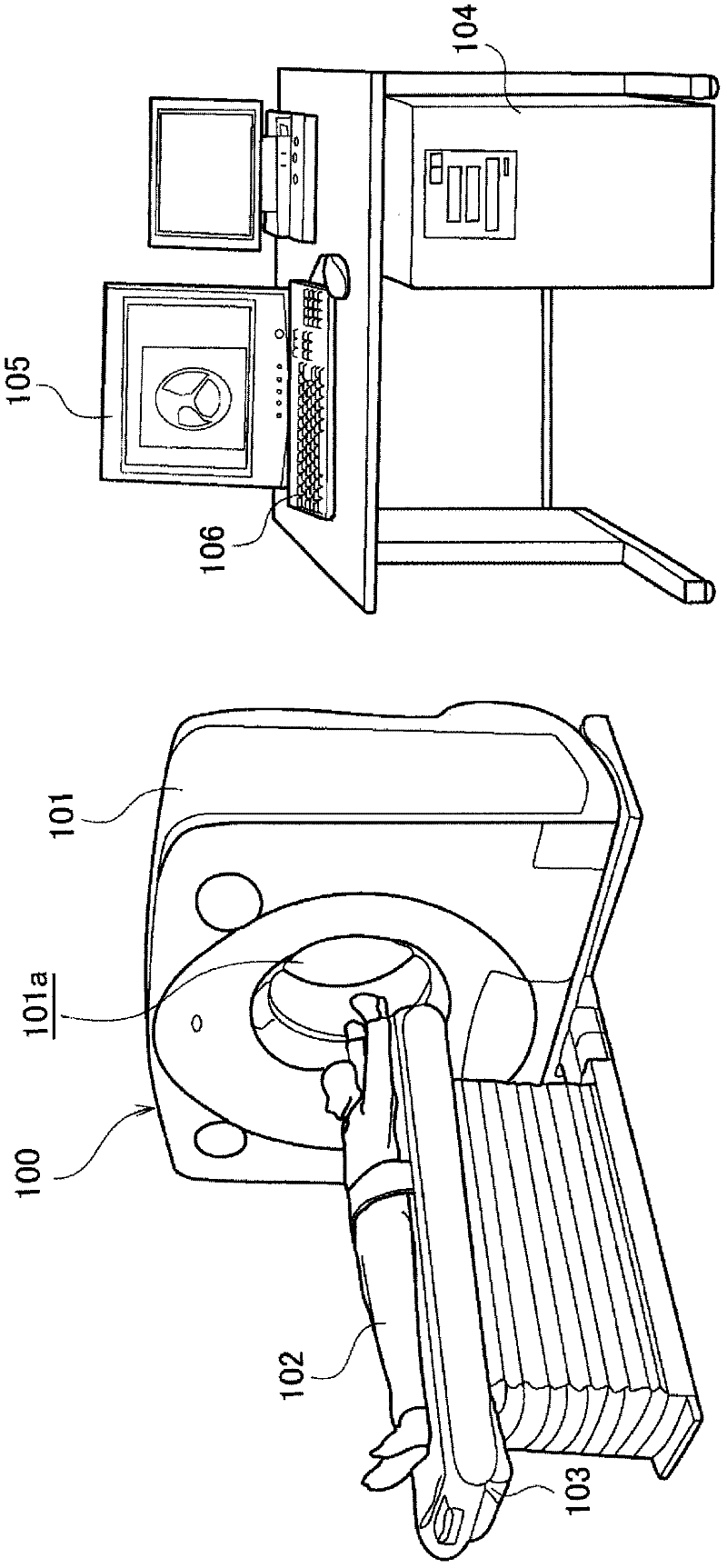

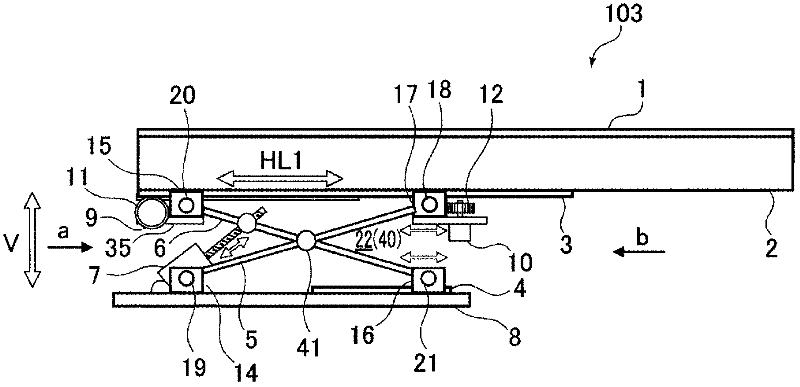

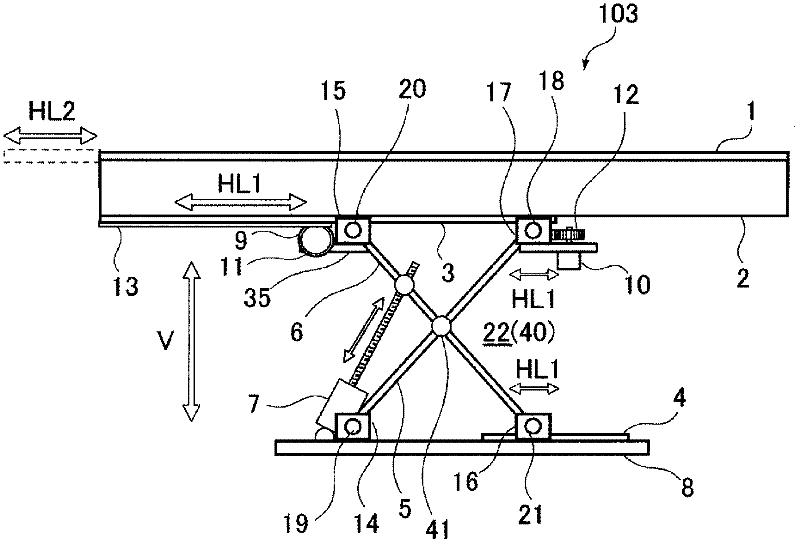

Bed for medical imaging apparatus

ActiveCN102413768ALight in massSmall amount of deformationPatient positioning for diagnosticsComputerised tomographsEngineeringMedical imaging

Provided is a bed for a medical imaging apparatus equipped with a lightweight lateral motion device in which the deformation amount is reduced while limiting the height of the bed at the bottom of a top board. The bed for the medical imaging apparatus comprises a base (8), an upper frame (2) which supports a top board (1), and a lifting and lowering device (40) located between the base (8) and the upper frame (2) and lifting and lowering the upper frame (2), wherein the lifting and lowering device (40) is equipped with a lateral motion device (a motor (10), a pinion gear (12), a rack (23)) which moves at least two members (a rail receiving block (17) and a rotating shaft (18), and a rail receiving block (15) and a rotating shaft (20)) constituting the lifting and lowering device (40) relatively along the direction perpendicular to the longitudinal direction of the upper frame (2) in the top board plane of the top board.

Owner:HITACHI HEALTHCARE MFG LTD

Automobile transmission gear heat treatment method

ActiveCN104894506AAvoid early crackingAlleviate the problem of bulky carbidesSolid state diffusion coatingFatigue IntensityHigh carbon

The invention discloses an automobile transmission gear heat treatment method. The method includes the steps of carburization, carbonitriding, quenching, cleaning, low temperature tempering and air cooling. The carburization technique is combined with the carbonitriding technique, abrasion resistance, fatigue strength and corrosive resistance are improved by a layer of highly hard nitride layer obtained on the carburized layer on the surface of a gear, and comprehensive performance of a product is good; meanwhile, the problems of massive carbide appearing under the high carbon potential state and network carbide appearing in the cooling process are avoided, and early-age cracking of the surface of the gear is avoided; moreover, by the method, the technological process is simplified, heating and cooling links and discharge links are reduced, carburization deformation and quenching deformation are reduced, generation of black structures is reduced as well, and anti-fatigue performance is guaranteed; finally, by the method, production cycle is shortened greatly, energy consumption is lowered, and production efficiency is improved highly.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Process of obtaining composite brazed seam with ultrasonic brazed aluminium-base composite material

InactiveCN101088691ARealize weld compoundingRealize the structureWelding/cutting media/materialsWelding/soldering/cutting articlesBraze alloyUltrasonic vibration

The present invention relates to relates to welding method, and is especially ultrasonic brazing process of obtain composite brazed seam in aluminum-base composite material. The process includes the following steps: 1. filling brazing alloy; 2. primary brazing; and 3. ultrasonic vibration treatment to obtain composite brazed seam in aluminum-base composite material. The said brazing process can obtain brazed joint with greatly improved mechanical performance and heat expansion performance, low heat expansion coefficient, and high strength near that of the mother material.

Owner:HARBIN INST OF TECH

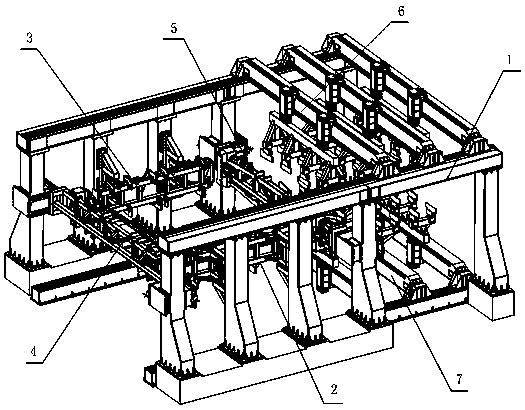

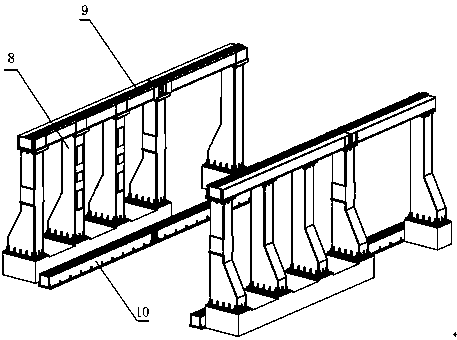

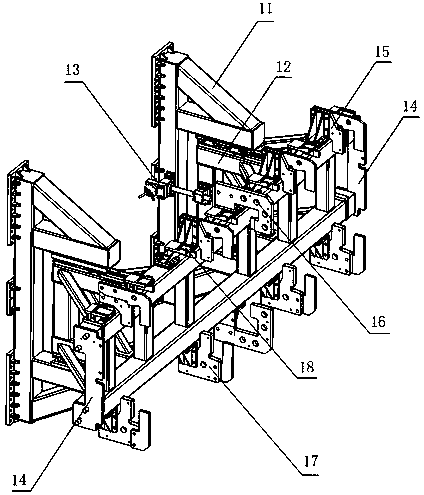

Aircraft center wing box digital assembly positioning system and positioning method

ActiveCN109204873AAchieve precise positioningIncreased versatilityAircraft assemblyAutomatic controlPositioning system

An aircraft center wing box digital assembly positioning system and positioning method are provided. A digital flexible positioning tool is divided into a bed body unit, a front spar positioning unit,a rear spar positioning unit, a left wing rib conformal unit, a right wing rib conformal unit, an upper tooling positioning pressing unit and a lower tooling positioning pressing unit according to functional modules. At first, an automatic positioning method is performed with the skeleton as the reference; skeleton parts such as the front spar, the rear spar and the wing rib of the large-scale central wing box are accurately positioned, and then the upper panel, the low panel and the longitudinal spar are positioned with the skeleton as a reference until the whole positioning process of the central wing box is completed. The digital assembly positioning system and positioning method are capable of accurate positioning, automatic control, multi-functional integration, and flexible design of large-scale center wing boxes.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Method for realizing machining of combustion-compression ring bushes by using combustion-compression ring bush cutting clamp

ActiveCN102950479ASmall amount of deformationGuaranteed machining accuracyPositioning apparatusMetal-working holdersCombustionWork in process

The invention discloses a method for realizing the machining of combustion-compression ring bushes by using a combustion-compression ring bush cutting clamp, relating to a machining method for ring parts. The invention aims to solve the problems that because the existing combustion-compression ring bush is a thin-walled workpiece, the existing combustion-compression ring bush is easy to deform in the process of machining, so that the machining quality of the combustion-compression ring bush is affected, and meanwhile, the 30-equated positions of 30 molded holes of a combustion-compression ring bush machined by using the existing machining method are poor in accuracy. The clamp used in the invention comprises a base plate, a turntable, two positioning pins and four pressing plates. The method disclosed by the invention comprises the following steps of: 1, roughly turning an inner hole, an outer circumferential surface and two planes of a blank; 2, relieving stress of a semi-finished combustion-compression ring bush product; 3, carrying out finish turning on an inner hole, an outer circumferential surface and two planes of the semi-finished combustion-compression ring bush product; 4, drawing center position lines of radial holes and molded holes; 5, drilling 30 radial holes with a diameter of 5 mm; and 6, cutting and machining 30 molded holes. The method disclosed by the invention is used for machining combustion-compression ring bushes.

Owner:HARBIN TURBINE +1

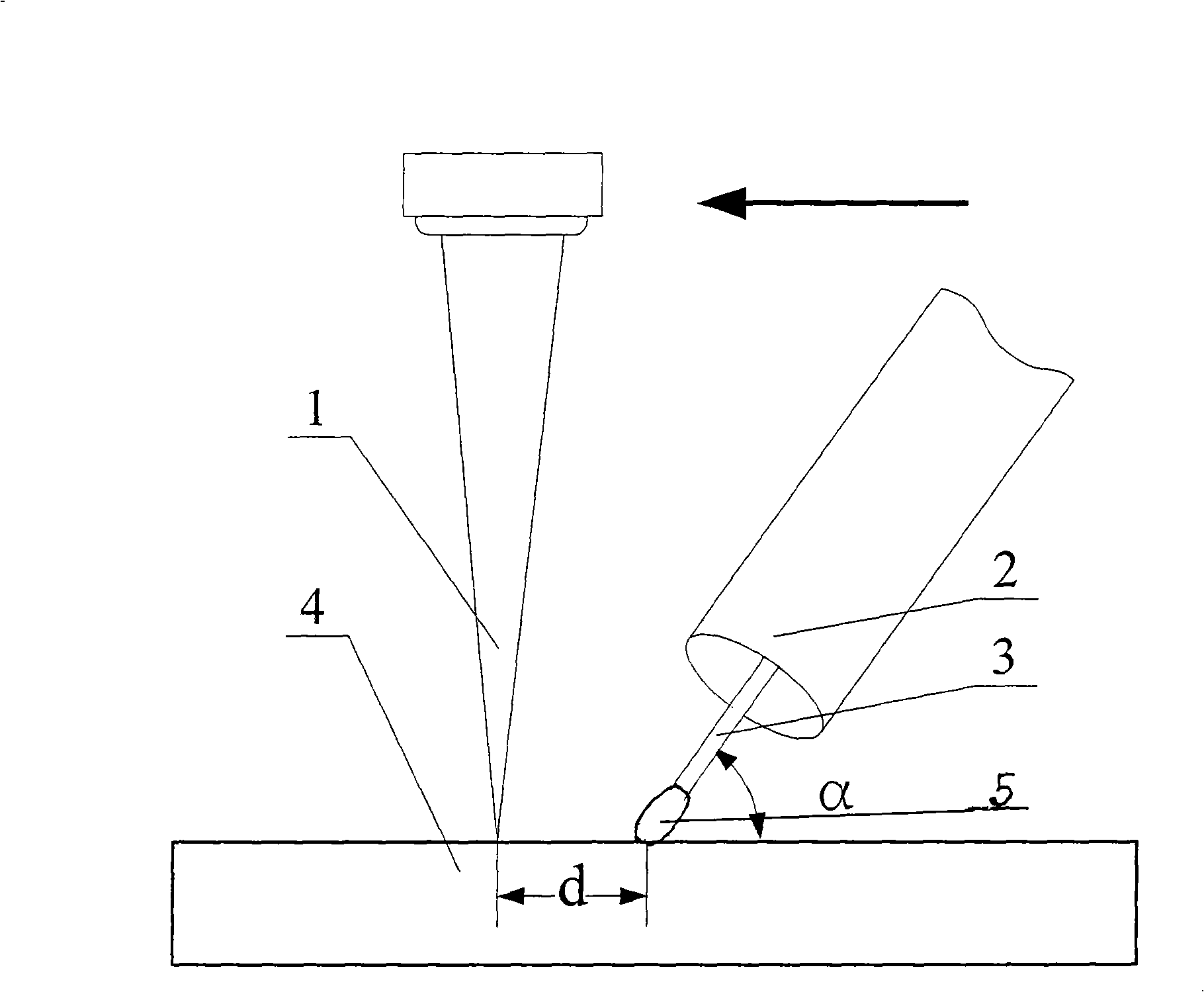

Laser-ultrasmall current GMA compound heat power supply welding method

InactiveCN101347870ASmall amount of deformationImprove mechanical propertiesLaser beam welding apparatusAverage currentLaser beams

The invention discloses a welding method of a laser-ultra-small current GMA composite heat source; the welding method can solve the technical problem of large deformation when a metal thin plate is welded; the invention mainly comprises the following steps; in composite heat source welding, the adopted average current of a GMA arc (5) is 15A to 30A; when the steel material is welded, the power of the laser (1) is more than 800W, and when the aluminium alloy is welded, the power of the laser (1) is more than 1,600W; a laser beam (1) is at the front and the GMA arc is at the back; and the distance of chevilled silk is 0mm to 3mm and the two molten pools are connected together. The welding method is applicable to the welding of thin metal plates with the thickness to be 0.5mm to 4mm such as aluminium alloy, carbon steel, low alloy and more than two dissimilar metals.

Owner:HARBIN WELDING INST LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com